Abstract

In order to understand the diffusion behavior of polyurethane (PU) in asphalt and the adhesion between modified asphalt and aggregate, the diffusion system of PU-modified asphalt was studied by molecular dynamics simulation software. Asphalt molecular model, PU molecular model, and PU-modified asphalt molecular model were established, respectively, and were geometrically optimized. The interface model between original asphalt molecule and aggregate, modified asphalt molecule and aggregate, PU molecule and asphalt molecule are established. The diffusion coefficient is calculated from the mean square displacement curve of asphalt and PU, so as to characterize the diffusion ability of asphalt and PU. The adhesion between modified asphalt and aggregate is characterized the interface energy between modified asphalt and aggregate. The results show that the molecular movement of the two substances is relatively active, and the micro-holes in the system structure can be filled in a short time. The interface energy between PU-modified asphalt and aggregate is more significant than that between original asphalt and aggregate. PU-modified asphalt has good diffusion ability and better adhesion with aggregate.

1 Introduction

Under the influence of traffic load and environmental factors (water, temperature, etc.), the pavement performance decreases gradually with the passage of time. Pavement performance can be improved by using polymer-modified asphalt. Common polymers include ethylene vinyl acetate copolymer, low-density polyethylene, styrene butadiene styrene, high-density polyethylene, styrene butadiene rubber, natural rubber, etc. Polymer-modified asphalt is usually physically modified. Although the high temperature deformation resistance of asphalt can be improved to a certain extent, due to the polarity difference of molecular structure and poor compatibility, the water resistance, aging resistance, and compatibility of polymer-modified asphalt need to be improved [1–3]. At present, the materials used in traditional polymer-modified asphalt mixture will degrade under the action of heat, light, and oxygen [4–6]. However, in addition to polymers, chemically modified asphalt can also be used to improve the performance [7]. These asphalts are added with chemical modifiers under specific conditions to form new functional groups and change their structure [8].

Polyurethane (PU) is a polymer containing carbamate group (−NHCOO−) in its molecular structure. It is usually obtained by the reaction of isocyanate with polyol. PU has excellent mechanical strength, oxidation resistance, chemical stability, high elasticity, and other excellent properties. Since its invention by O. Bay in 1937, PU has been widely used in adhesive, synthetic leather, rubber, civil engineering, petroleum engineering, and other industries because of its flexible formulation, excellent product performance, and various forms. For example, PU foam has the characteristics of low density and high energy absorption capacity. It is widely used in insulation board, including wall, roof insulation, and filled space around doors and windows [9–11]. Synthetic PUs have been widely used in recent 10 years. PU has excellent heat resistance and mechanical properties. It is widely used in foam plastics to improve the thermal insulation performance of buildings, paints, coatings, and synthetic leather [12–14]. PU-modified asphalt has been widely studied in the field of road engineering. Liu et al. [15] conducted a molecular simulation study on the compatibility of PU and polyvinyl chloride and the performance of the blend film, and found that when the mass ratio of PU and polyvinyl chloride was 9:1, the phase between the two was capacitive and was the best.

Fu et al. [16] studied the aging protection mechanism of three amine antioxidants on hydroxyl-terminated polybutadiene PU, calculated its diffusion coefficient, solubility parameter, and permeability coefficient, and obtained the advantages and disadvantages of its aging performance. Wang et al. [17] and He et al. [18] studied the effect of aging on the performance of rubber powder-modified asphalt and found that thermal oxygen aging has a great impact on the rheological properties of rubber powder-modified asphalt. Short-term aging has little effect on the aging of rubber powder-modified asphalt, and long-term aging is the main aging form of rubber powder-modified asphalt. Xiao et al. [19] and Ding et al. [20] studied the interaction between asphalt mixture and regenerated by using molecular dynamics (MD) and found that regenerant has obvious effect on asphalt after long-term aging, but limited effect on asphalt after short-term aging. Xu et al. [21] studied the effects of time, temperature, and four components on the diffusion behavior of regenerant in aged asphalt by using Materials Studio software, and characterized its diffusion ability by the calculated diffusion coefficient. The simulation results show that the diffusion coefficient of recycled asphalt increases gradually with the prolongation of aging time; with the increase of temperature, the increase rate of diffusion coefficient gradually slows down; the diffusion coefficients of aromatic and saturated components are greater than those of resin and asphaltene. Wang et al. [22] analyzed the basic principle of asphalt mixture molecular simulation technology, summarized the asphaltene structure model in different periods and aggregate model in different applications, and discussed the asphalt diffusion phenomenon and the influence mechanism of additives on asphalt performance, and put forward the application prospect of simulation technology. In terms of the application prospect of simulation technology, improving the asphalt aggregate interface model is still the focus of MD simulation research. The subsequent research should focus on accurately expressing the asphalt aggregate interface under the coupling action of external factors such as water, temperature, and load, and explore the attenuation law of asphalt mixture performance. The soft section in PU structure covers a large area. In the PU-modified asphalt currently studied, polyester polyols and polyether polyols are commonly used in soft segments. The molecular structures of polyester polyol and polyether polyol contain a large number of ester bonds and ether bonds, respectively, which make PU modifiers have greater polarity than asphalt binders. Therefore, the interaction between PU and asphalt components (especially light components) is weak, which ultimately limits the modification effect of asphalt [23]. In this article, Materials Studio will be used to study the diffusion behavior of PU in asphalt and the interface between PU-modified asphalt and aggregate, and the microscopic effect of mutual diffusion of PU–asphalt and the adhesion between -modified asphalt and aggregate will be characterized. First, the asphalt molecular model, PU molecular model, and modified asphalt molecular model are established, respectively, based on the molecular model of four components of asphalt and the molecular model of main components of PU. Then, the diffusion behavior of PU in asphalt and the interface between modified asphalt and aggregate are simulated by Materials Studio. Finally, the diffusion coefficients of asphalt and PU are calculated according to the mean square displacement (MSD) curve, and the adhesion between modified asphalt and aggregate is analyzed according to the interface energy. It provides a research idea for the research of PU-modified asphalt. It is also expected to be applied to the regeneration of waste porous asphalt mixture.

2 Model building

2.1 Asphalt

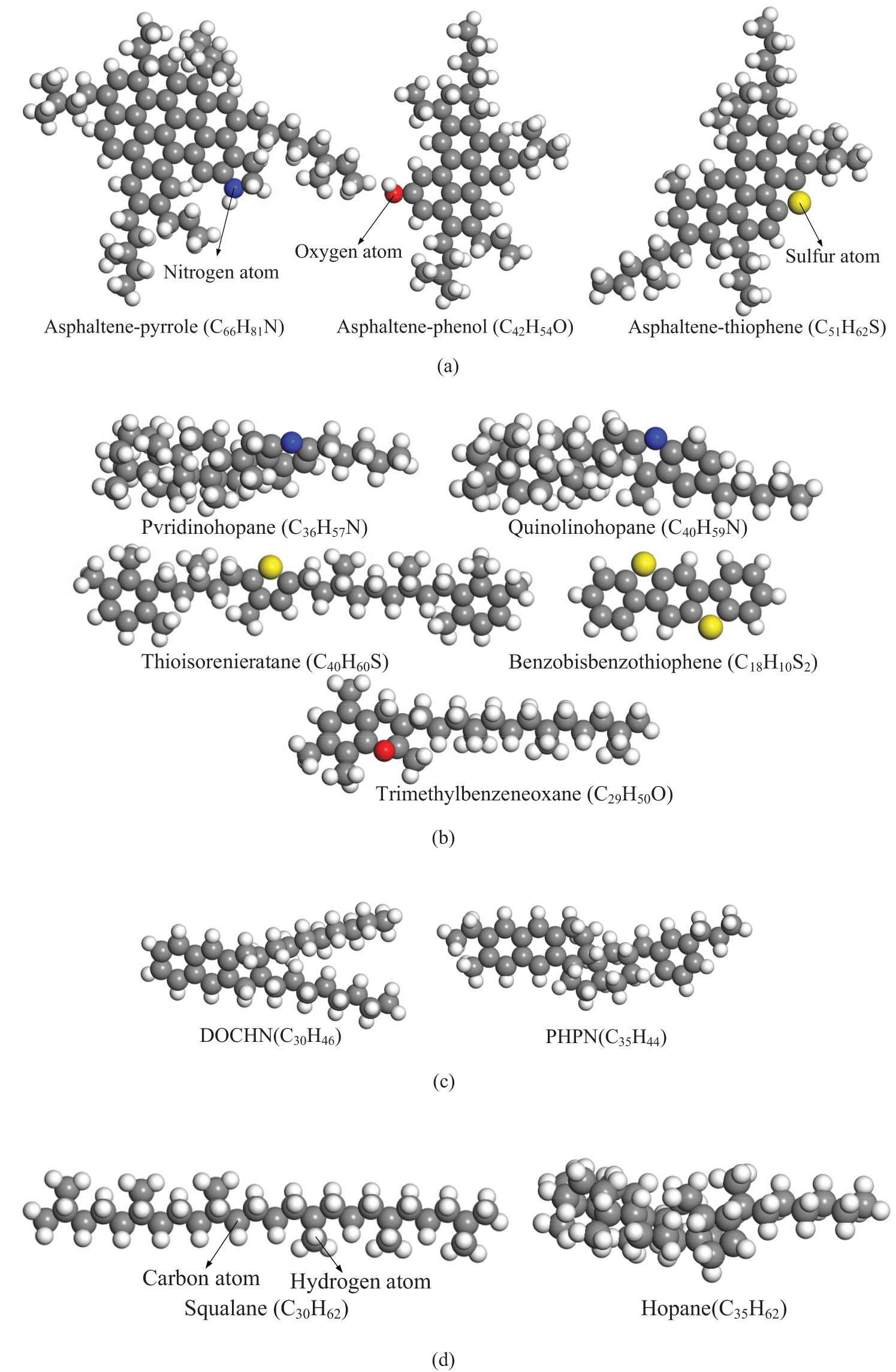

Asphalt is a complex mixture of millions of molecules, so it is difficult to obtain detailed chemical composition. According to the molecular size, solubility parameters, and selective adsorption desorption behavior of asphalt [24], asphalt is divided into four different components: SARA (saturation, asphaltene, resin, and aromatic). MD simulations are based on SARA classification. Representative molecules are selected to build asphalt molecular model and its physical and chemical behavior is simulated [25,26]. Li and Greenfield [27] proposed a 12-component AAA-1 asphalt molecular model according to the Strategic Highway Research Program, and the density and coefficient of thermal expansion are verified by experimental data. In the 12 component asphalt model, asphalt is divided into three types of asphaltenes (asphaltene-phenol, asphaltene-pyrrole, and asphaltene-thiophene), five resin molecules (quinolinohopane, thioisorenieratane, benzobisbenzothiophene, pyridinohopane, and trimethylbenzeneoxane), two types of aromatics (PHPN and DOCHN) and two types of saturation (squalane and hopane) (as shown in Figure 1). The 12 component asphalt model was adopted in this study. The detailed molecular information such as molecular formula and mass ratio are shown in Table 1. The molecular models of asphalt were established according to the molecular number of the 12 components of asphalt in Table 1 (as shown in Figure 2).

Twelve components of asphalt: (a) asphaltene, (b) resin, (c) aromatics, and (d) saturation.

Model composition of 12 components of asphalt

| Molecular components | Molecular formula | Molecular number | Molecular mass (g·mol−1) | Mass ratio (%) |

|---|---|---|---|---|

| Asphaltene-pyrrole | C66H81N | 2 | 888.4 | 5.5 |

| Asphaltene-phenol | C42H54O | 3 | 574.9 | 5.3 |

| Asphaltene-thiophene | C51H62S | 3 | 707.1 | 6.5 |

| Pyridinohopane | C36H57N | 4 | 503.9 | 6.2 |

| Quinolinohopane | C40H59N | 4 | 553.9 | 6.8 |

| Thioisorenieratane | C40H60S | 4 | 573.0 | 7.0 |

| Benzobisbenzothiophene | C18H10S2 | 15 | 290.4 | 13.4 |

| Trimethylbenzeneoxane | C29H50O | 5 | 414.7 | 6.4 |

| DOCHN | C30H46 | 13 | 406.7 | 16.2 |

| PHPN | C35H44 | 11 | 464.7 | 15.7 |

| Squalane | C30H62 | 4 | 422.8 | 5.2 |

| Hopane | C35H62 | 4 | 482.9 | 5.9 |

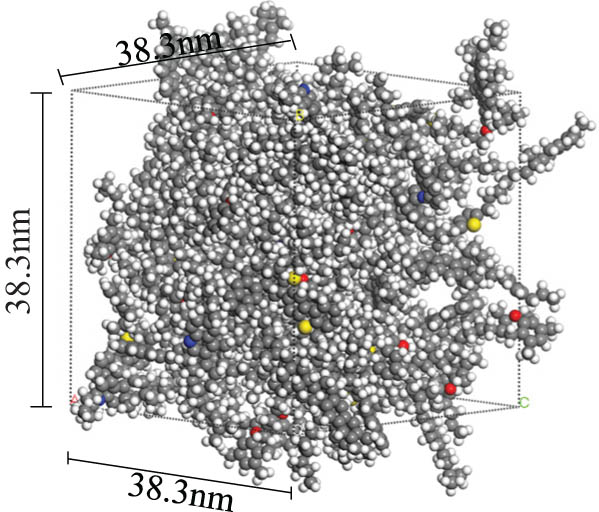

Asphalt molecular model.

2.2 PU

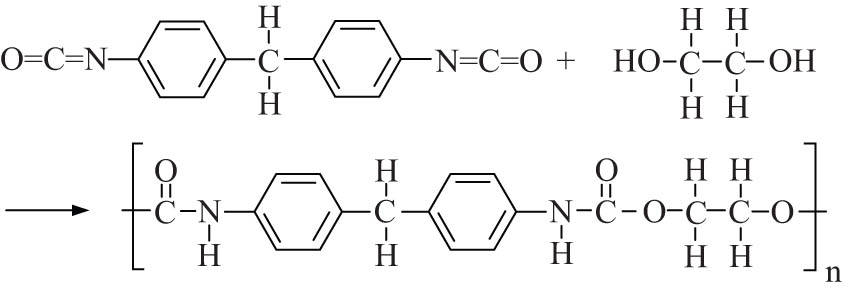

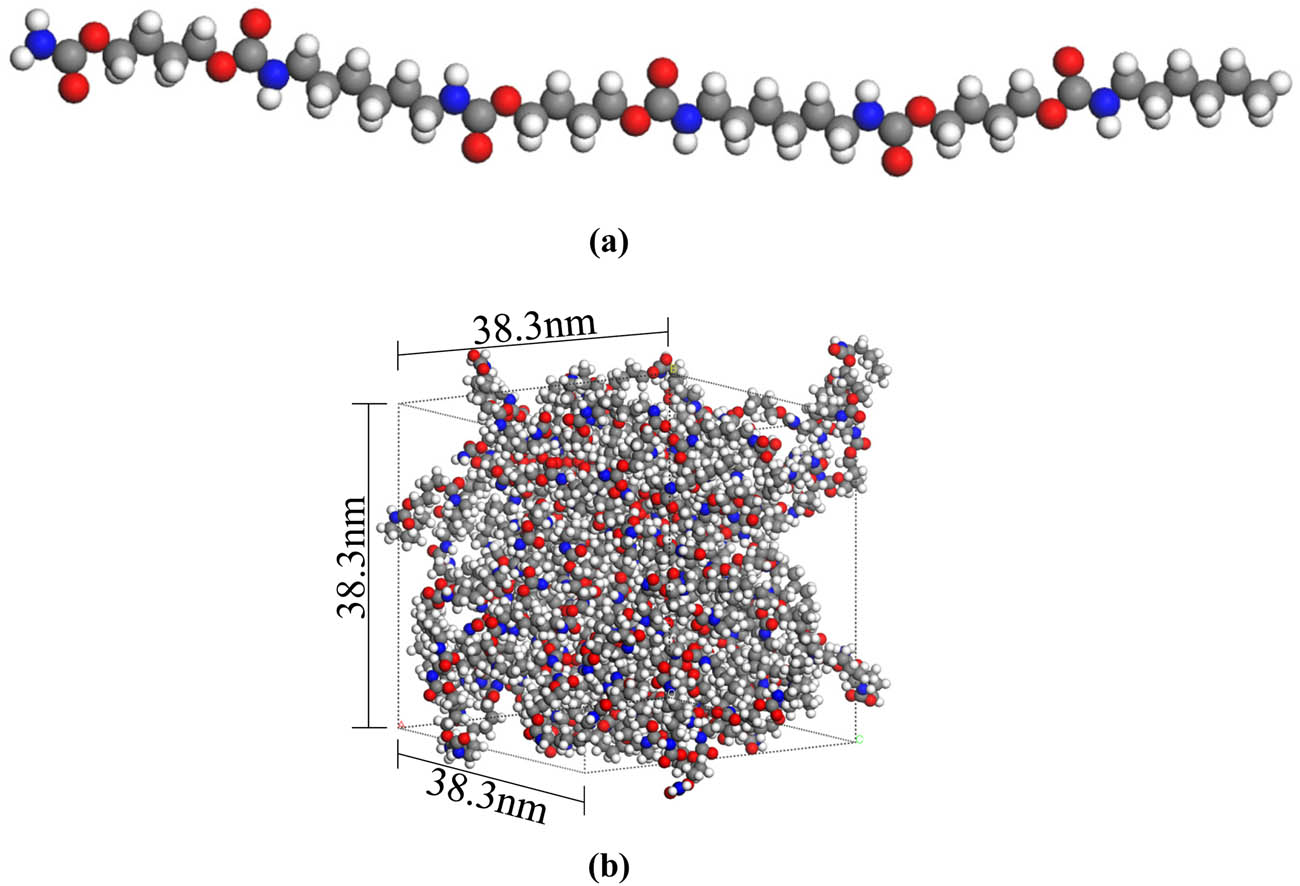

PU polymers are traditionally and most commonly polymerized by the reaction of dimerized or trimerized isocyanates with polyols. PUs are classified as alternating copolymers because they contain two monomers that are polymerized alternately with each other. Isocyanates and polyols used to prepare PU contain two or more functional groups per molecule. The synthesis process is shown in Figure 3. PU belongs to the category of reactive polymer compounds, which include epoxy resin, unsaturated polyester, and phenolic resin [28–30]. PUs are synthesized from isocyanates (R–(n═C═O)n) and polyols (R′–(OH)n) under catalyst or UV irradiation, and each molecule contains more than two isocyanate groups [31]. The PU molecular model is shown in Figure 4.

PU molecular synthesis process.

PU molecular model: (a) PU monomer molecular model (n = 3) and (b) PU macromolecular model.

2.3 Asphalt-PU

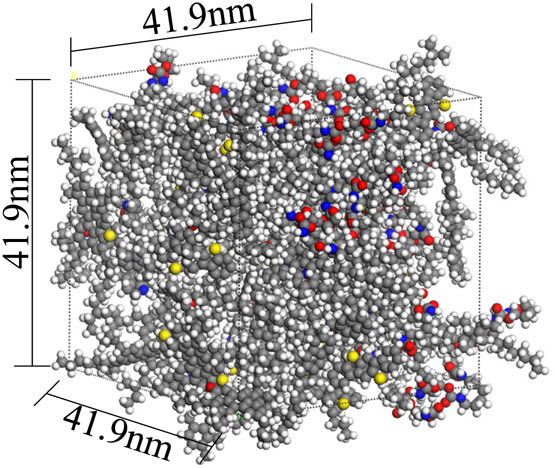

Ying and Xing [32] determined that the best content of PU is 35% through tensile test by selecting five kinds of PU with 30, 35, 40, 45, and 50% of asphalt quality. In view of the above, 15 PU monomer molecules should be added on the basis of Table 1 to form the final PU-modified asphalt molecule (as shown in Figure 5).

Molecular model of PU-modified asphalt.

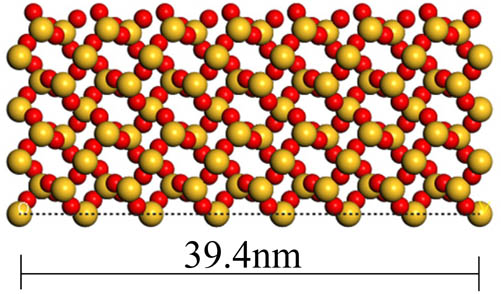

2.4 Aggregate

For the construction of aggregate model, the relevant crystal cells are mainly constructed according to the chemical composition of aggregate, so as to represent the characteristics of aggregate. In order to explore the friction characteristics of wheeled asphalt pavement, Sun et al. [33] constructed SiO2 cell plane to represent asphalt pavement. In this article, SiO2 cell plane is used to represent the aggregate model. The crystal structure of the stone, namely the crystal structure of SiO2, is introduced into the system, and the slice calculation is performed to determine the (1 –1 0) plane with the lowest energy and the most stable crystal plane, and relax the most stable crystal plane (as shown in Figure 6).

Section of SiO2 molecular crystal.

3 MD simulations

3.1 Force field and ensemble

3.1.1 Force field

In the calculation of MD, the selection of force field plays a key role, which determines the rationality and reliability of the calculation results. In the system, the position type and energy expression of each atom together constitute the force field. Once the force field in the system is determined, the position type of each atom is also determined. At present, hundreds of force field types have been researched and developed. Generally, a force field is developed through a specific system, so the application scope of the force field is different, but they are popularized and used after strict verification, so they have high reliability. The force fields commonly used in molecular simulation include Universal, Cvff, PCFF, COMPASS, and so on. In this article, COMPASS force field is used in MD simulation. The compass force field is based on the basic theory of CFF911. The force field can accurately predict the structure and properties of gaseous and condensed matter in a large range of temperature and pressure. The force field covers most of the covalently bonded molecular systems, and later covers various inorganic materials. The atoms and functional groups covered by the force field are relatively complete and have high precision. In terms of coverage of the range of atomic types, Universal force field is the most extensive, but the calculation accuracy of this force field is relatively low. The coverage and calculation accuracy of Cvff and Pcff are general, so COMPASS force field is selected for the MD calculation involved in this article.

3.1.2 Ensemble

Ensemble refers to a collection of a large number of independent systems with exactly the same nature and structure, in various motion states and under certain macro-conditions, which is called statistical ensemble. In the process of simulation, all microstates of the system appear successively, and each microstate is assigned to a system. This system has exactly the same macro-thermodynamic quantity as the experimental system, but the microscopic quantity is the same as the microscopic state. Therefore, a set of systems is obtained, which is called ensemble. From a macroscopic perspective, all systems in the ensemble are identical, which are copies of the experimental system; from the microscopic perspective, each system is different and has its own microscopic state. The ensemble used in this article has the following two aspects:

Canonical ensemble (NVT), in which the number of particles (N), volume (V), and temperature (T) remain constant. The canonical ensemble is a typical representative of the MD ensemble. Assuming that the number of particles in a box of volume V is N, which are embedded in a hot bath with constant temperature T, the volume of the whole system does not change, there is no material exchange with the environment, and the total energy E and pressure P of the system may fluctuate near a certain average value.

Constant pressure, constant temperature (NPT), the number of particles (N), pressure (P), and temperature (T) of the ensemble remain unchanged. The NPT ensemble is realized by a freely movable piston, a container with good thermal conductivity, and a vessel in contact with a huge constant temperature thermal bath. The volume of the ensemble can vary freely, and the total energy may also fluctuate.

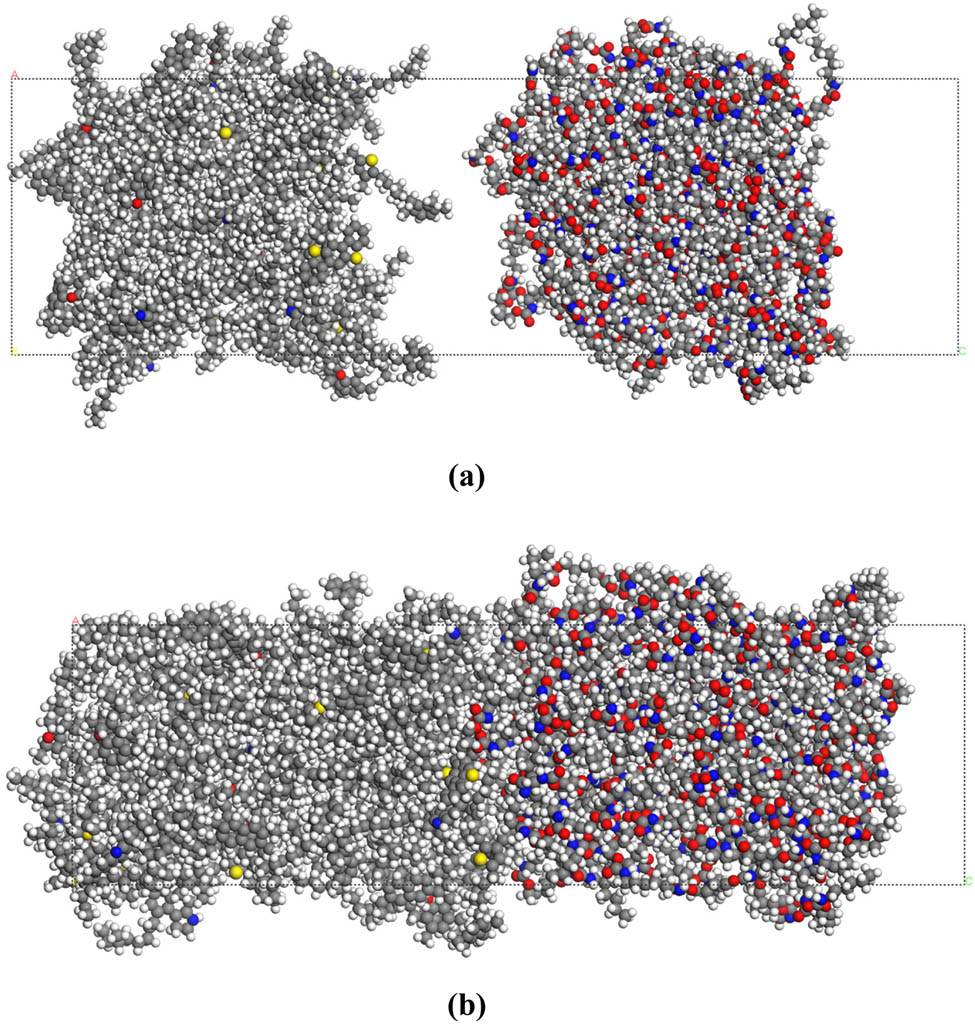

3.2 Diffusion model

In order to reflect the interface diffusion behavior of asphalt and PU, the diffusion model of asphalt and PU was constructed by using the Build Layers command of Materials Studio 8.0 software. In order to ensure that the system and structure of the established model are similar to the actual situation, the model needs to be optimized with Forcite module before it can be used for MD calculation. Model optimization is mainly divided into two steps: geometric optimization, which mainly uses Geometry Optimization in Forcite in Materials Studio software to optimize the molecular structure under the COMPASS force field and annealing which uses the Anneal module in the Forcite module to anneal the optimized molecular structure. In the experiment, the interaction between the modifier and the asphalt is usually carried out at room temperature. Therefore, the NPT ensemble is selected and the temperature range is 300–500 K for five consecutive simulated annealing treatments, so as to find a stable molecular structure model with minimum global energy. Finally, molecular dynamic calculation are performed on the molecular model that has been annealed.

At 298 K, the setting conditions of constant pressure and constant temperature (NPT ensemble) were selected, the total time was set to 100 ps, and a configuration was output every 5,000 steps, so that the energy of the molecular model was further released, and finally a stable equilibrium was achieved. The interface models of asphalt and PU before and after dynamic calculation are shown in Figure 7.

Interface model of asphalt and PU before and after calculation: (a) interface model between original asphalt and PU and (b) interface model of original asphalt and PU after diffusion.

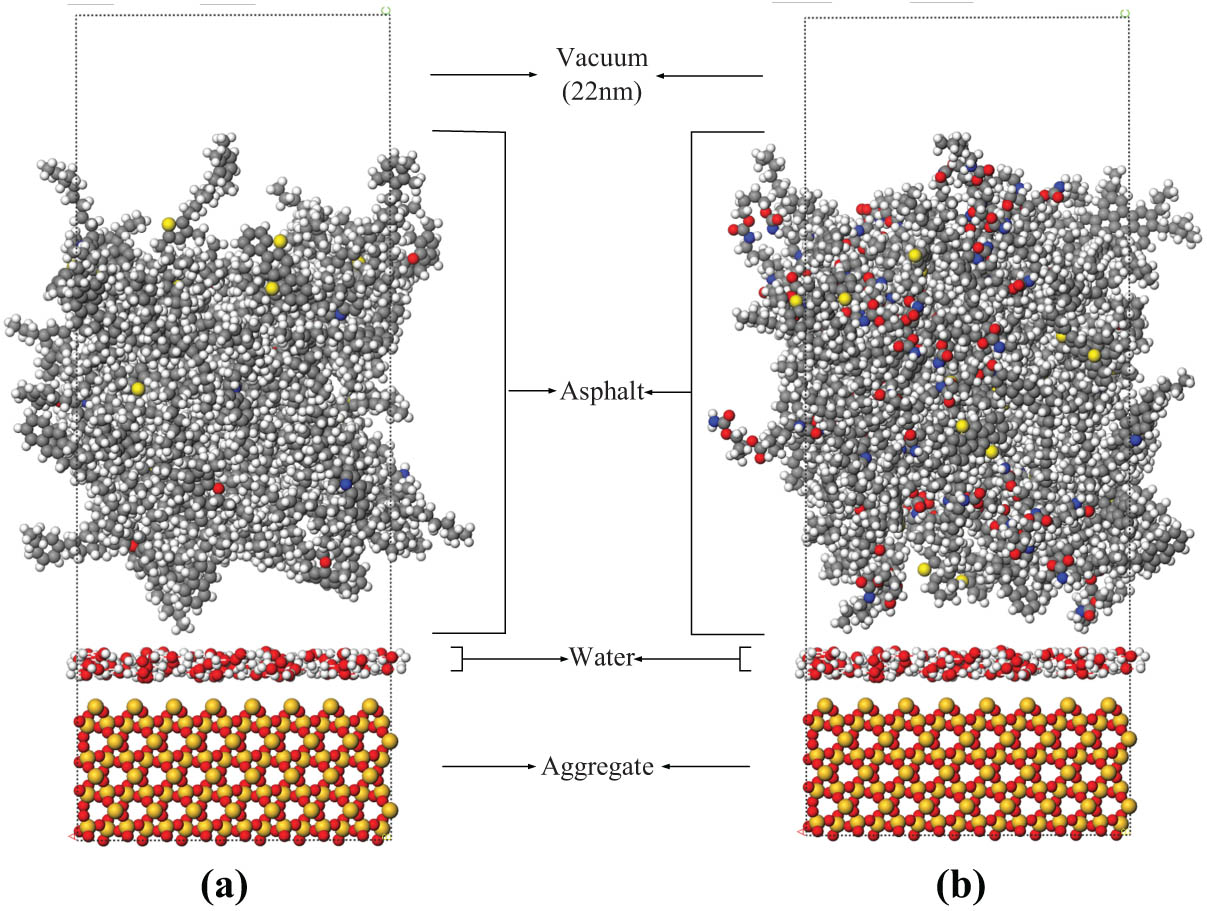

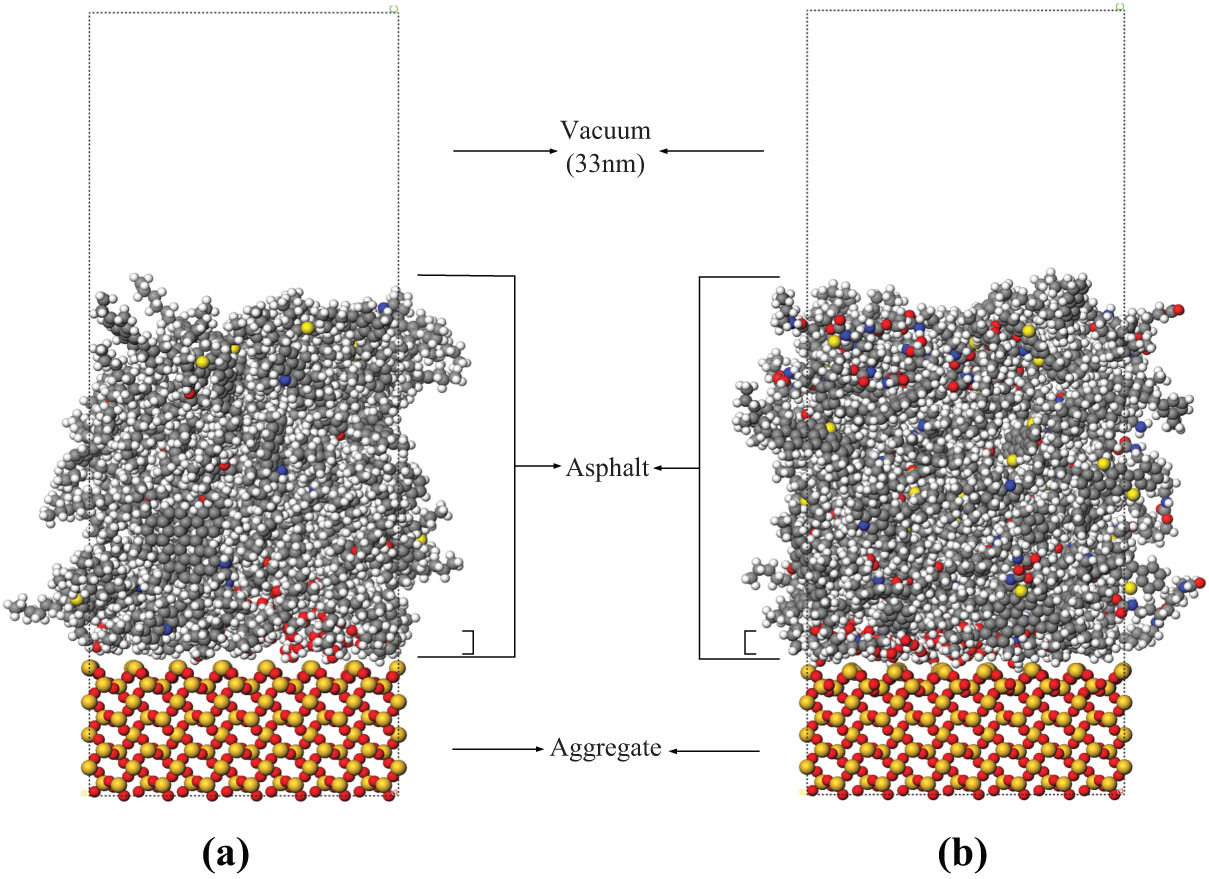

3.3 Interface energy model

In order to characterize the adhesion between modified asphalt and aggregates, the original asphalt–aggregate and PU-modified asphalt–aggregate interface models were constructed using the Build Layers command of Materials Studio software. Geometric optimization and dynamic calculation are also required. At 298 K, the setting condition of constant volume and constant temperature (NVT) are selected, the total time is set at 100 ps, and a configuration is output every 5,000 steps.

The interface models between asphalt and aggregate before and after dynamic calculation are shown in Figures 8 and 9.

Interface model of asphalt and aggregate: (a) original asphalt–water–aggregate and (b) PU-modified asphalt–water–aggregate.

Interface model of asphalt and aggregate after dynamic calculation: (a) original asphalt–water–aggregate and (b) PU-modified asphalt–water–aggregate.

4 Results and analysis

4.1 Interfacial diffusion behavior

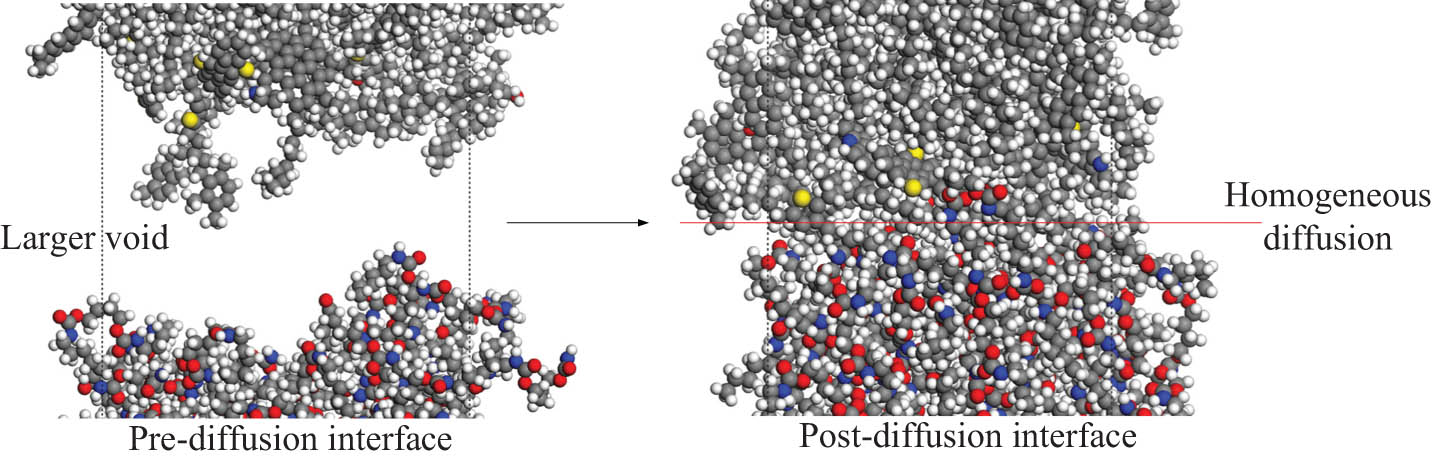

4.1.1 Visual amplification analysis

After 100 ps dynamic calculation, the system is stable. The enlarged view of the diffusion interface between asphalt and PU before and after diffusion is shown in Figure 10.

Diffusion interface model of asphalt and PU.

It can be seen from Figure 10 that the asphalt and PU are closely combined without gaps after the dynamic calculation, indicating that the asphalt molecules diffuse into the PU molecules and the PU molecules also diffuse into the asphalt molecules. These two molecules diffuse into each other and have good compatibility. Therefore, when the PU modifier is added to the asphalt, the two can be well miscible together, thereby showing better physical and chemical properties.

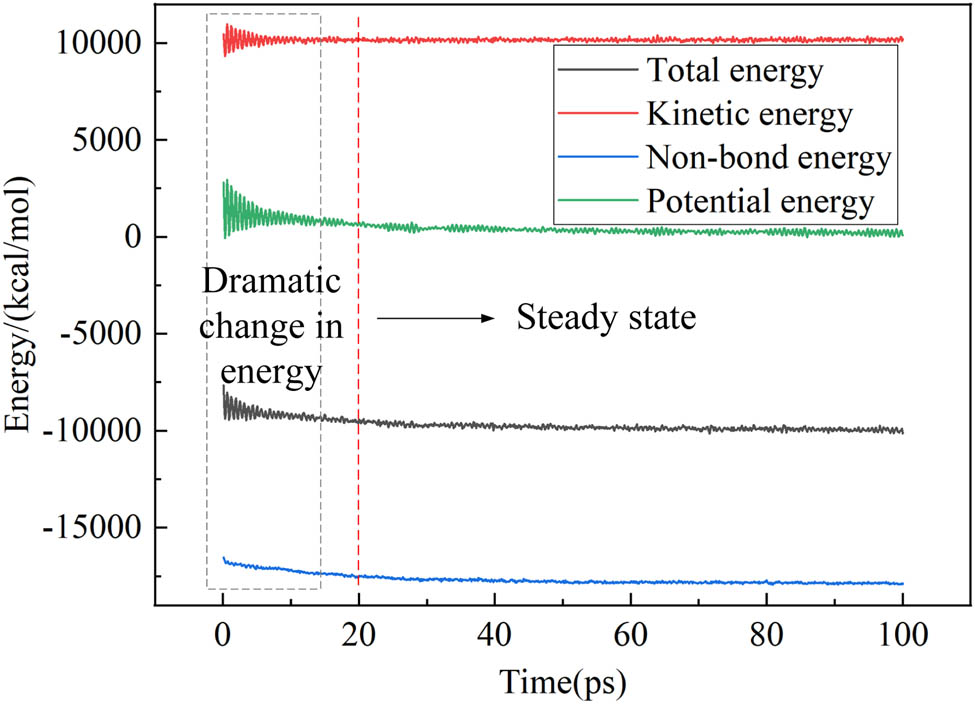

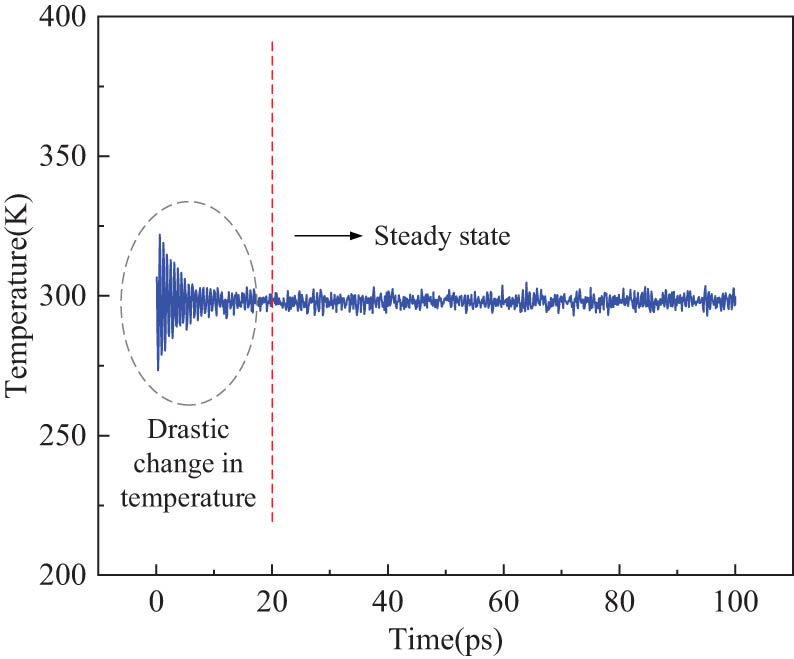

4.1.2 Verification of diffusion system

The total energy of the system includes potential energy, kinetic energy, and bond energy. Among them, the chemical bond energy is relatively stable from beginning to end, indicating that the internal energy of the molecules in the system has no obvious change, and there is no obvious resistance in the process of MD simulation. It is a spontaneous diffusion process. When the system is heated, the energy and temperature in the system will gradually change. Therefore, two indicators of energy and temperature are used to characterize the change law of the system in this article. The dynamic simulation of asphalt and PU was carried out by Materials Studio software, the interface model diffuses and the system reaches a stable state. The changes of energy and temperature are shown in Figures 11 and 12. It can be seen from Figures 11 and 12 that after 20 ps MD simulation, the system basically reaches a stable state, and its energy and temperature spontaneously reach a stable state.

Forcite dynamics energy.

Forcite dynamics temperature.

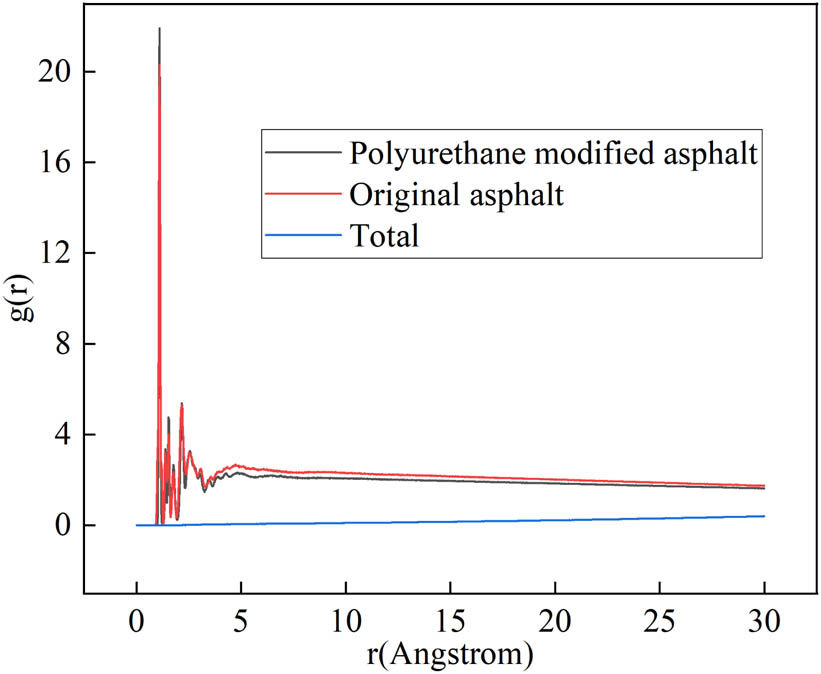

The radial distribution function of the average molecular configuration of asphalt is shown in Figure 13. It can be seen from Figure 13 that g(r) generally exhibits the characteristics of intense and scattered fluctuations in the short range, and gentle and dense fluctuations in the long range. When r < 5 nm, g(r) shows strong regularity and peak appears, which indicate that the probability of particles appearing from the reference particle to this position is much higher than the other positions. The position of the main peak generally marks the emergence of aggregated structure. When r > 5 nm, the function value of g(r) approaches constant 1, indicating that the distribution of particles is irregular and disordered.

Radial distribution function.

4.1.3 MSD

For models in MD simulation-controlled systems, molecules always tend to move and diffuse away from their initial positions. During the simulated diffusion process, the molecules in the system are continuously embedded. MSD can be used to characterize the movement and activity of asphalt molecules and PU molecules in the system, so that the law of molecular diffusion can be studied. The calculation formula is shown in the formula below:

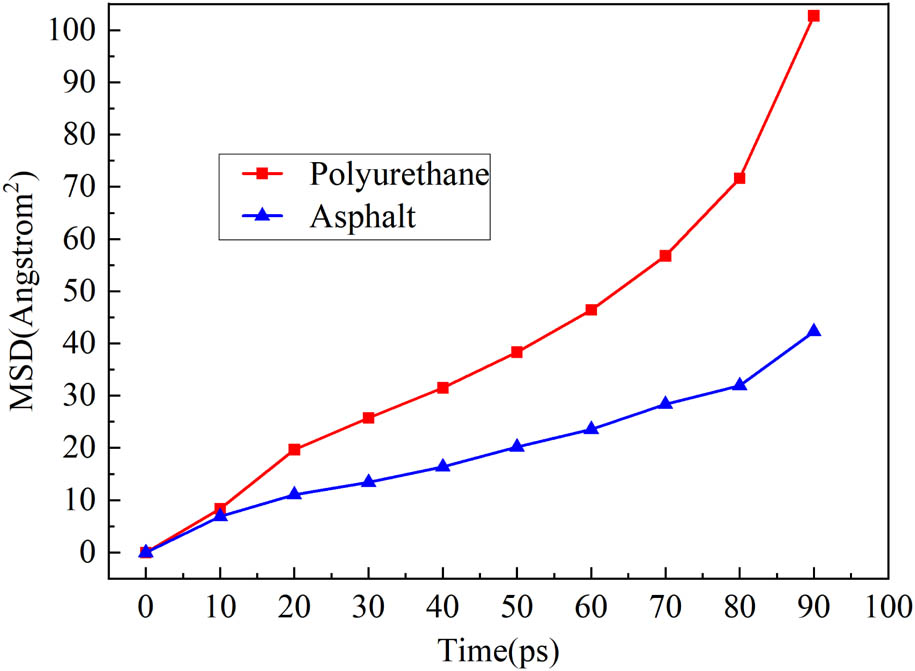

The analysis is carried out through the MSD option of the analysis module, and the results obtained are shown in Figure 14, where r i (t) is the position vector of particle i at time t.

MSD fitting results of interfacial diffusion between asphalt and PU.

It can be seen from Figure 14 that the curve shows a rapid upward trend in the initial stage of simulation, and then the rate reaches a stable state. The first stage is the close contact stage. At this stage, asphalt molecule and PU molecule approach rapidly, the gaps between them are filled rapidly, some components enter into the micro-gap inside the material, and the volume of the model decreases rapidly. Therefore, the MSD of the molecules inside the system changes greatly with time at this stage. The second stage is the continuous diffusion stage. In this stage, molecules continue to diffuse into each other under the action of van der Waals force and electric field force. In this simulation, the critical time corresponding to the stage division is about 20 ps, when the trend of the curve changes significantly, that is, the critical point of diffusion. Furthermore, it can be seen that the distance the PU molecules move is “larger.” The reason for this phenomenon has a certain correlation with the results of molecular recombination. Due to the uncertainty of diffusion, the difference in the atomic displacement of asphalt and PU from non-contact to contact state is caused. As for whether there are other reasons, it is difficult to determine, so further research is needed.

4.1.4 Diffusion coefficient

The term diffusion coefficient was proposed by von Smoluchowski [34]. It can also be simplified to the limiting slope of the MSD curve as a function of time, which can be used to estimate the diffusion coefficient of particles. By averaging the MSD of all atoms, it is made linearly dependent on time, which can intuitively reflect the relative speed of material diffusion. The commonly used relationship between MSD and diffusion coefficient is shown in the formula below:

In formula (2), MSD(t) is the diffusion coefficient corresponding to a certain time point and k(MSD) is the slope of the diffusion coefficient curve. The formula shows that the diffusion coefficient is 1/6 of the MSD curve k, where k should be the slope of the interdiffusion phase of the two substances after contact. According to the results in Figure 14, the slopes of the trend lines of the MSD curves of asphalt and PU are 0.410 and 0.983, respectively, in which the fitting degree of asphalt is R 2 = 0.9965 and the fitting degree of PU is R 2 = 0.9986, indicating that the obtained slopes can meet the accuracy of calculating the diffusion coefficient. Therefore, the diffusion coefficient of asphalt is 6.83 × 10−9 m2·s−1 and that of PU is 1.64 × 10−8 m2·s−1. It can be seen from the calculation results that the diffusion coefficient of asphalt is smaller than that of PU, so the molecular motion of PU in the system is faster. Asphalt and PU in the system interact during the diffusion process, and the two substances penetrate each other. Therefore, when asphalt diffuses into PU, PU also diffuses into asphalt. Previously, Li et al. [35] studied the diffusion behavior of waste edible oil and aged asphalt and concluded that the diffusion coefficient of aged asphalt was 4.31 × 10−9 m2·s−1, the diffusion coefficient of waste edible oil is 2.12 × 10–9 m2·s−1, so the asphalt regenerator based on waste edible oil has good diffusion ability. So in this study, the diffusion coefficient of PU in the system is greater than that of asphalt, which can fill the microscopic voids in the system structure in a short time. Therefore, the modified asphalt based on PU has good diffusion ability.

4.2 Adhesion calculation

4.2.1 Intuitive amplification

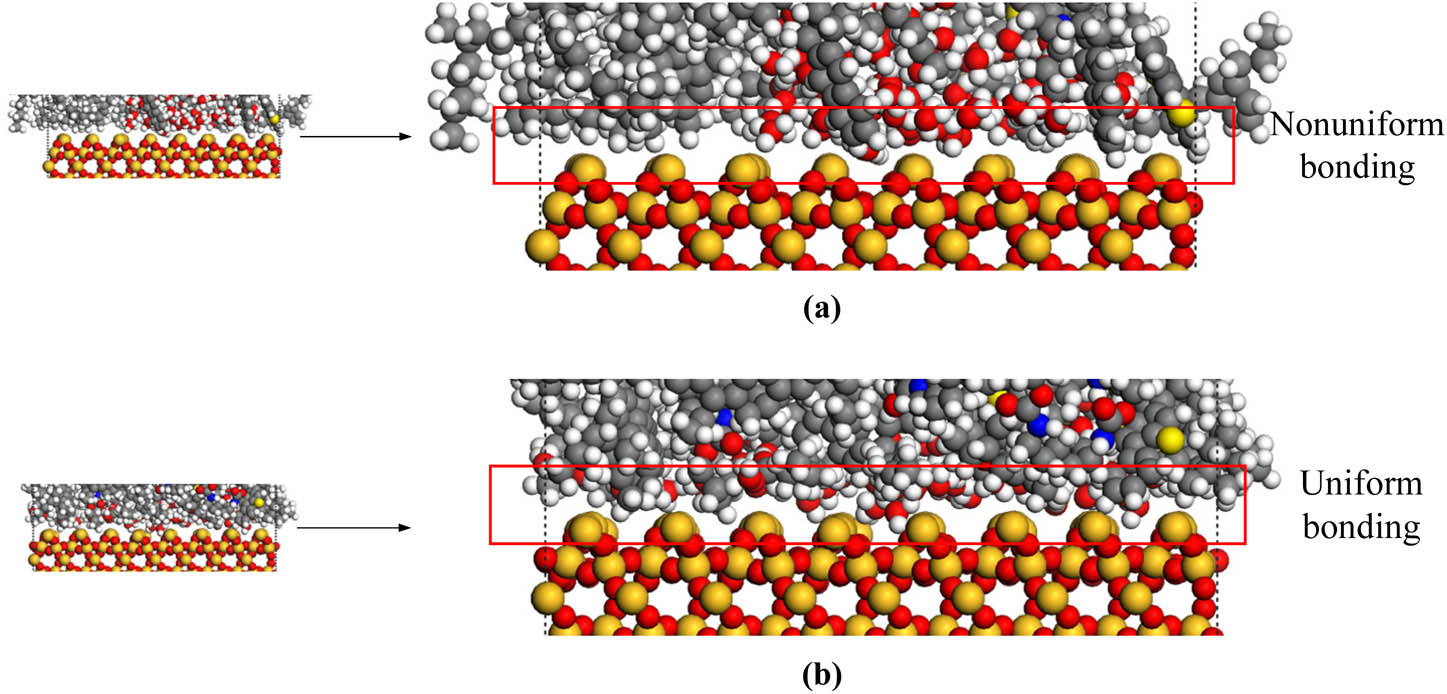

After 100 ps dynamic calculation, the system reached stability, and the enlarged interface of the original asphalt and aggregate, modified asphalt and aggregate is shown in Figure 15.

Contact surface between different asphalt and aggregate: (a) original asphalt–aggregate and (b) PU-modified asphalt–aggregate.

It can be seen from Figure 15 that the modified asphalt is in uniform contact and tightly combined with the aggregate. Most of the water molecules enter the asphalt molecules or recombine with some atoms in the asphalt molecules, and only a small part is exposed. However, the binding of the original asphalt and aggregate is not as good as that of modified asphalt and aggregate. Water molecules are mostly exposed and are not uniformly bound to the aggregate layer. Therefore, under the observation of microscopic visual magnification, it can be seen that the adhesion between the PU-modified asphalt and the aggregate is greater than that of the original asphalt and the aggregate.

4.2.2 Interface energy

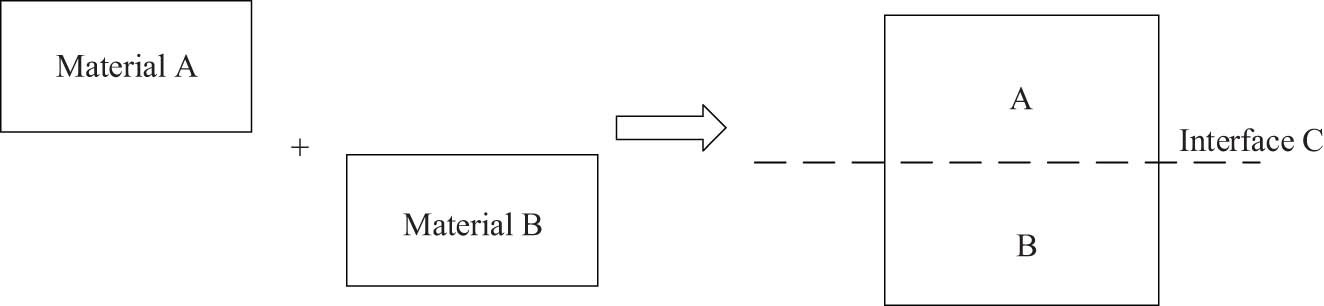

Interfacial energy, also known as interaction energy, is an important parameter to study the interaction of two materials. A schematic diagram of the interfacial energy between different materials is shown in Figure 16.

Diagram of interaction energy.

When two different materials A and B are in contact at a specific temperature and pressure, the two materials have coplanar C. At this point, the molecules on the interface of the two materials begin to move until the whole system reaches a stable state.

At this time, the total energy of systems A and B is E AB, while the energies of materials A and B at steady state is E A and E B, respectively, then the interface energy is as shown in the formula below:

In formula (3), E interaction is the interaction energy of the interface between materials A and B (kJ·mol−1), E AB is the total energy of the system at steady state (kJ·mol−1), E A is the energy of material A at steady state (kJ·mol−1), and E B is the energy of material B at steady state (kJ·mol−1). The measurement of the interface energy reflects the strength of the adhesion between asphalt and aggregate. The greater the interfacial energy, the easier it is to form an interface between them, or the more stable the formed interface, that is, the better the adhesion. The simulation results of interface energy between asphalt and aggregate are shown in Table 2.

Simulation results of interfacial energy between asphalt and aggregate (kJ·mol−1)

| Molecular model system | E Total | E Asphalt | E Water | E Aggregate | E interaction |

|---|---|---|---|---|---|

| Original asphalt–aggregate | −26229.31 | 34664.20 | −2666.52 | −57120.04 | −1106.95 |

| Modified asphalt–aggregate | −62084.07 | 22779.49 | −2440.67 | −80889.97 | −1532.91 |

Molecular potential energy is a quantity that considers direction. When molecules attract each other, the molecular potential energy is negative; when molecules repel each other, the molecular potential energy is positive. Therefore, when comparing the strength of the action, only its absolute value is considered. It can be seen from Table 2 that the interface energy between the modified asphalt and aggregate is greater than that between the original asphalt and aggregate. The greater interaction energy between the molecules of the two polymers, it indicates that the stronger the interaction between the molecules, the more difficult the molecules are to be destroyed or separated, which shows that the better the adhesion between the two materials. Chen et al. [36] studied the interface energy between algae biological-modified asphalt and aggregate. The results show that the interface energy between modified asphalt and aggregate is less than that between original asphalt and aggregate. However, in this study, the interface energy between PU-modified asphalt and aggregate is improved than that between the original asphalt and aggregate. Therefore, PU-modified asphalt and aggregates have better adhesion.

5 Macro experiment

5.1 Basic properties of asphalt

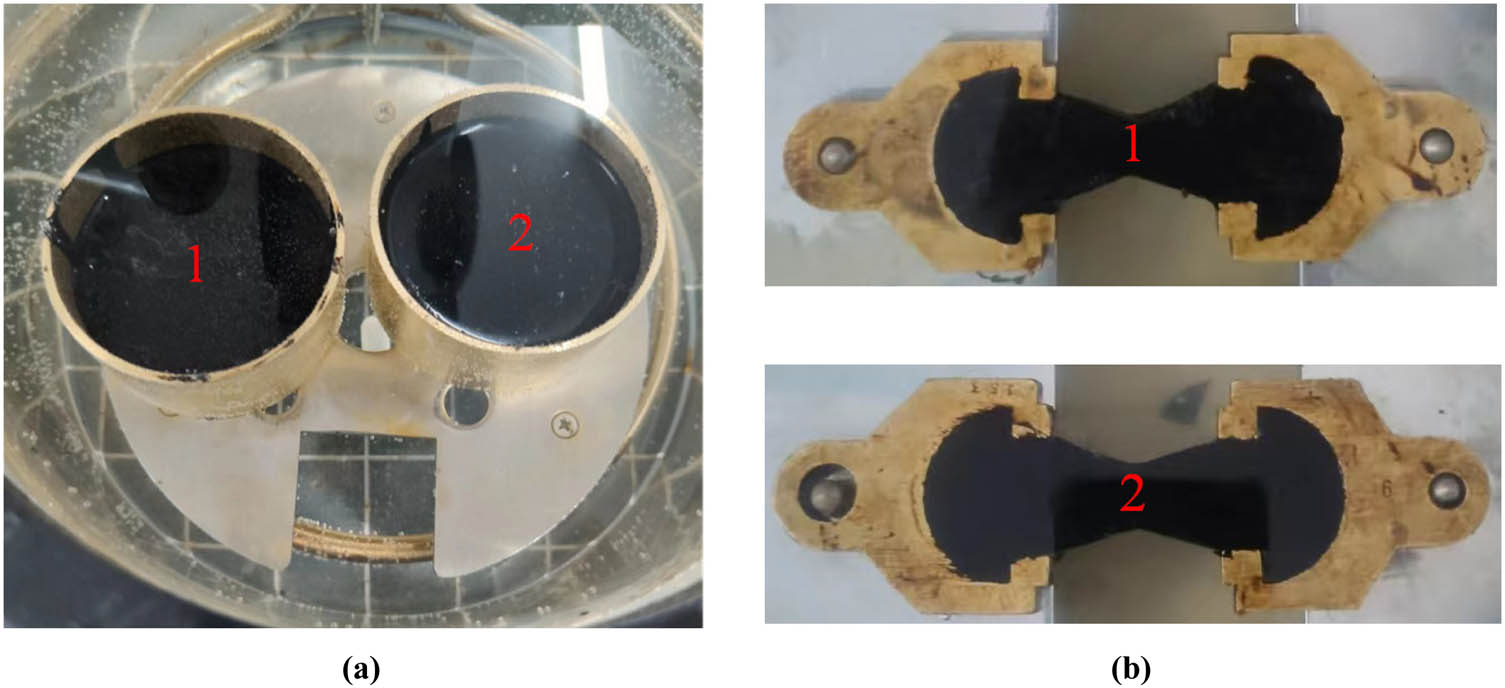

By preparing different asphalt samples, the original asphalt and the PU-modified asphalt were evaluated in terms of penetration at 25°C and ductility at 5°C. The depth of the free fall of the pointer is the penetration, and the length when stretching to fracture at the speed of 1 cm per minute as the ductility (0.1 mm). The test processes are shown in Figure 17. The test results are shown in Table 3.

Experiment of basic indexes of asphalt: (a) penetration test and (b) ductility test. Note: 1. Original asphalt; 2. PU-modified asphalt.

Comparison of indexes before and after asphalt modification

| Detection index | Original asphalt | Modified asphalt |

|---|---|---|

| Penetration at 25°C/0.1 mm | 78.7 | 23.4 |

| Ductility at 5°C·mm−1 | 139 | 131 |

It can be seen from Table 3 that the penetration of PU-modified asphalt is less than that of the original asphalt, indicating that the hardness and shear failure resistance of PU-modified asphalt are better than that of the original asphalt. The ductility of PU-modified asphalt is slightly less than that of the original asphalt, indicating that the plastic properties of PU-modified asphalt are slightly better than that of the original asphalt.

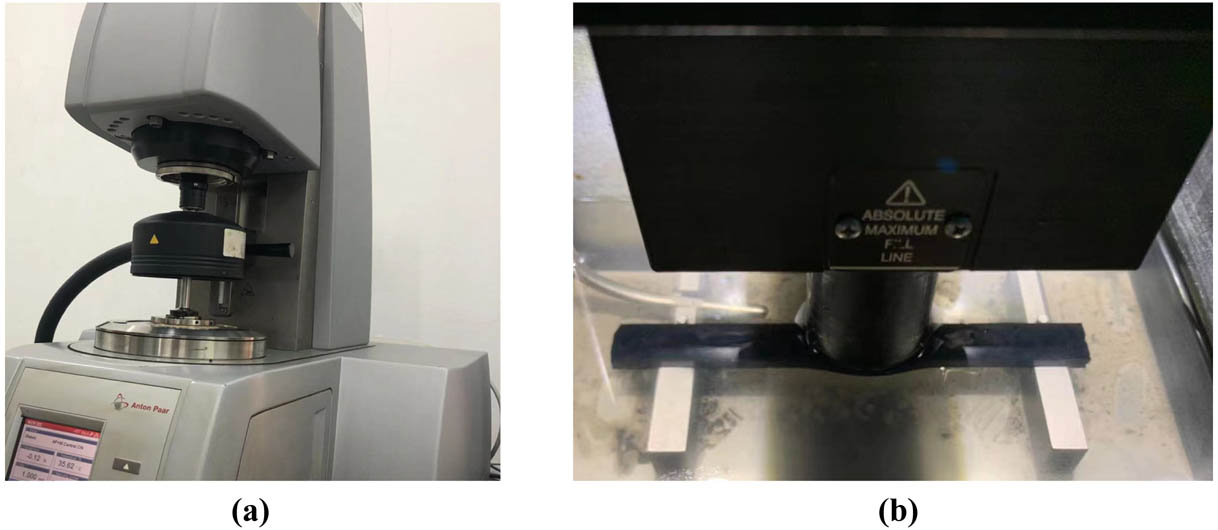

5.2 Dynamic shear rheometer (DSR) test

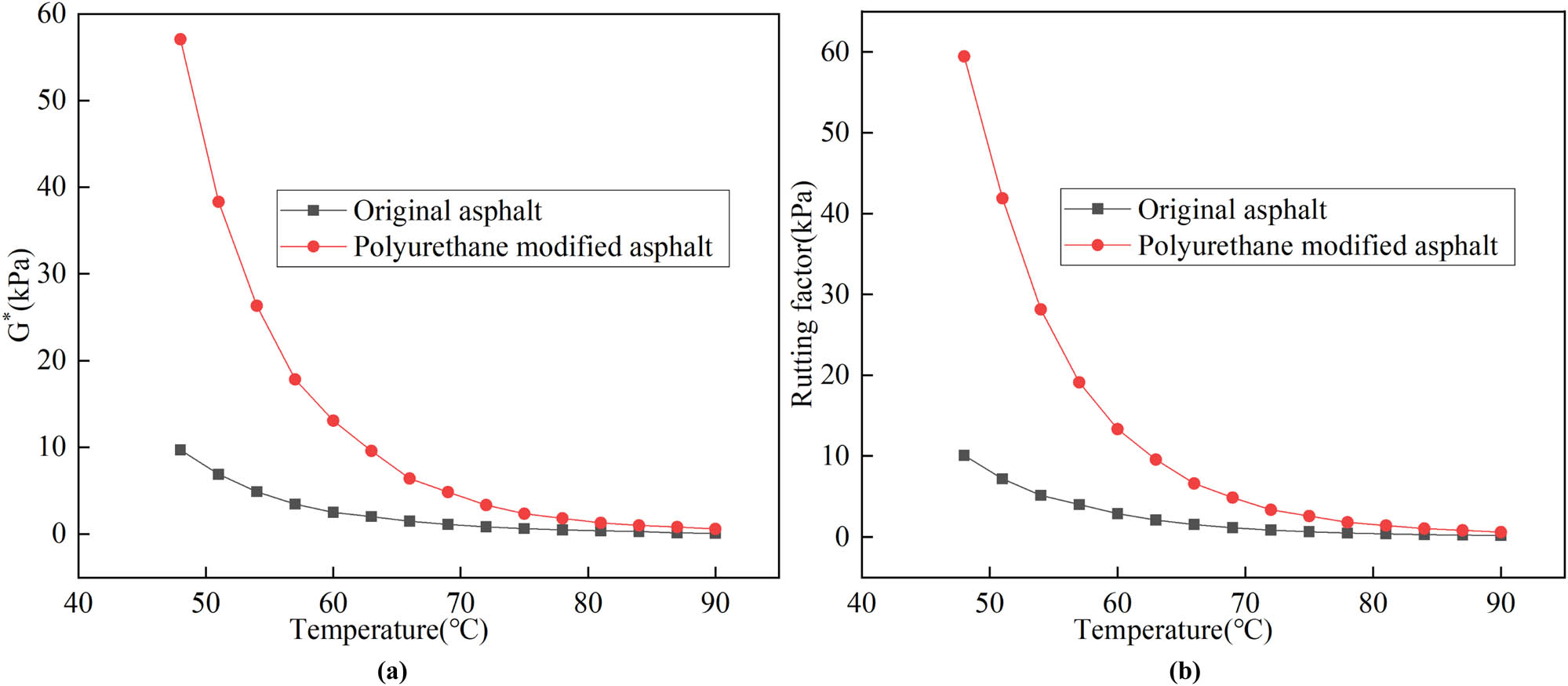

The DSR test was carried out according to the method in AASHTO T312-2008, and the original asphalt and PU-modified asphalt were tested, respectively, in the temperature scanning mode. The loading frequency was 10 rad·s−1, and the experimental temperature was from 48 to 90°C. The damage form at high temperature is mainly rutting deformation. As the temperature increases, the fluidity of the asphalt increases, and the rutting phenomenon of asphalt pavement is caused. Therefore, the rutting factor is used to evaluate the high temperature performance of asphalt. The numerical value of the rutting factor can indicate the strength of the rutting resistance of the asphalt mixture. At high temperature, the larger the value of the rutting factor, the smaller the rheological properties of the asphalt binder and better the rutting resistance. The test process is shown in Figure 18(a). The test results are shown in Figure 19.

DSR and bending beam rheometer (BBR) test: (a) dynamic shear rheological test and (b) flexural creep stiffness test.

DSR test result of two asphalts: (a) complex modulus S and (b) rutting factor.

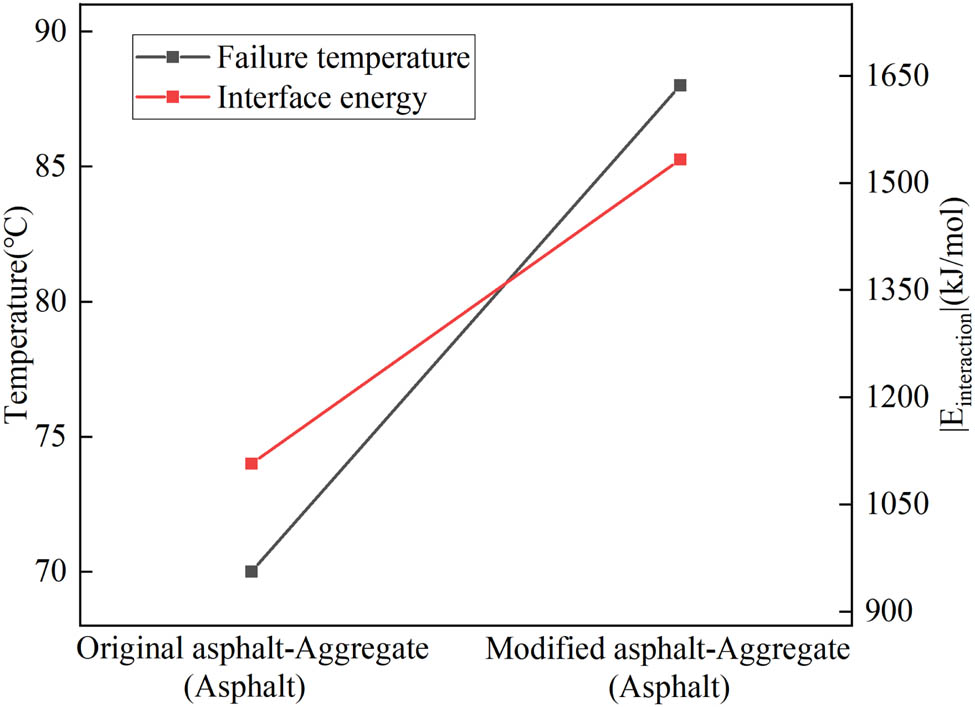

Figure 19 shows the DSR test results of the three asphalts, Figure 19(a) shows the variation of the complex modulus of the two asphalts with temperature, and Figure 19(b) shows the variation curve of the rutting resistance factor of the two asphalts with temperature. It can be seen from Figure 19(a) that the complex modulus of the two asphalts decrease continuously with the increase of temperature. The analysis shows that when the temperature of asphalt increases, the molecules accelerate, resulting in its volume expansion. So far, the state of asphalt changes from high elastic state to viscous flow state. The shear stress of asphalt decreases, so the shear strain increases, and finally the complex shear modulus decreases when the temperature increases, and the change is very obvious in the range of 45–60°C. When the temperature is higher than 60°C, the complex modulus of PU-modified asphalt and original asphalt decreases, indicating that the influence on it decreases gradually with the increase of temperature. In Figure 19(b), the rutting resistance ability of asphalt mixture is analyzed by using the anti-rutting factor, in which the rutting factor is G*/sin δ express. At high temperature, the greater the rutting factor, the smaller the rheological property and better the rutting resistance. It can be seen from Figure 19(b) that the rutting factors of the two asphalts gradually decrease with the increase of temperature, indicating that the higher the temperature, the worse the anti-rutting performance. Compared with the original asphalt, the PU-modified asphalt improves the rutting resistance of the asphalt, and the effect is remarkable. Through the overall analysis of the experimental results in Figure 19, it can be seen that the failure temperatures of the original asphalt and the PU-modified asphalt are 70–88°C, respectively, indicating that the high temperature performance of the PU-modified asphalt is excellent. The complex modulus and rutting factor of the two asphalts gradually decreased with the increase of temperature, and the PU-modified asphalt changed significantly from 52 to 82°C, indicating that the PU-modified asphalt has the best high temperature performance in this temperature range.

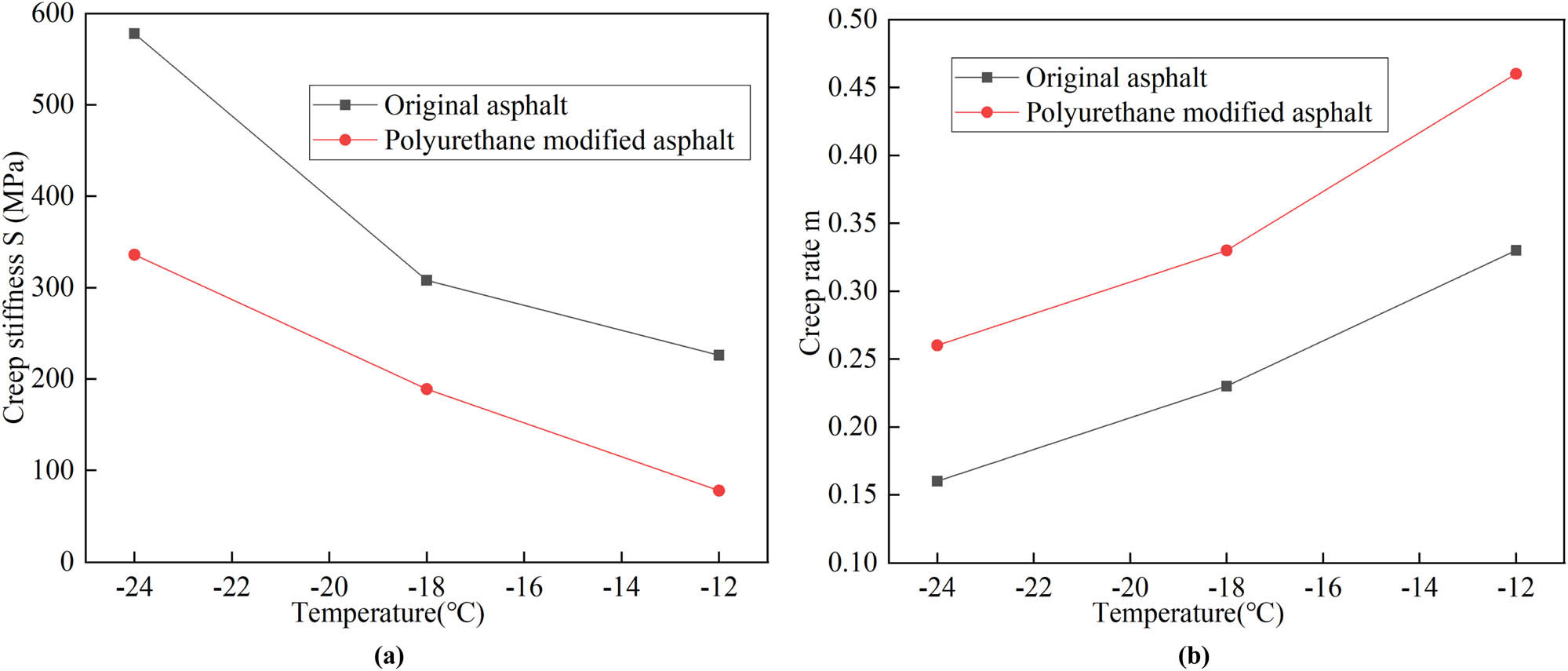

5.3 BBR test

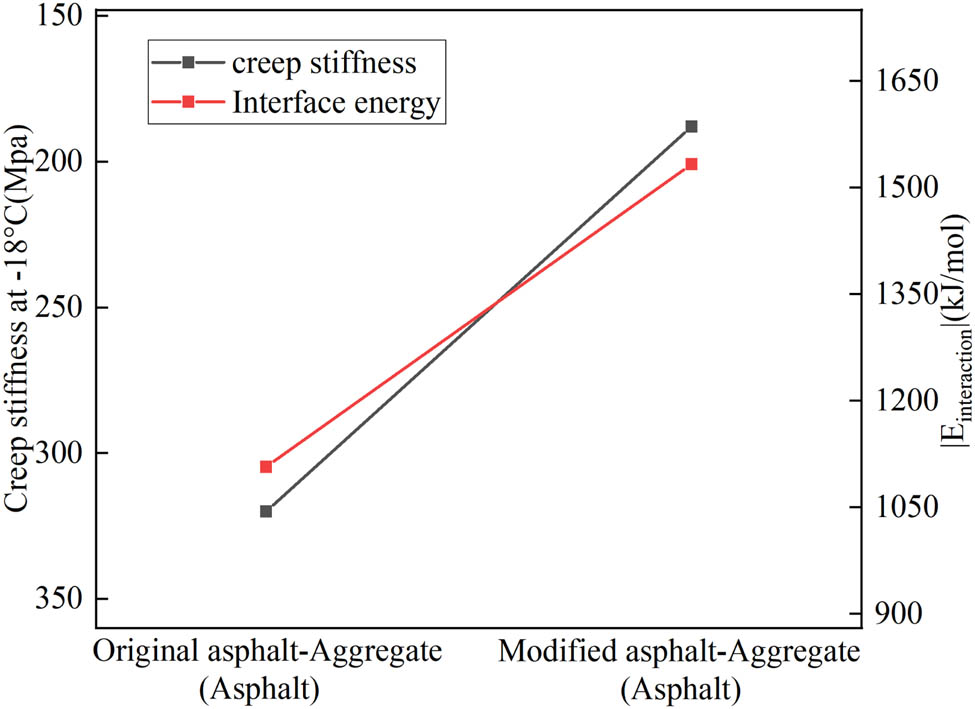

The stiffness of asphalt beam under creep load was measured by BBR test. The low temperature rheological behavior of the original asphalt and the PU-modified asphalt at −12, −18, and −24°C for 60 s were analyzed, respectively, using the creep stiffness modulus S and the creep rate m of asphalt as evaluation indicators, which reflects the low temperature bending rheological properties of asphalt. The test process is shown in Figure 18(b). The measurement results are shown in Figure 20.

BBR test result of two asphalts: (a) creep stiffness modulus S and (b) creep rate m.

It can be seen from Figure 20 that the creep stiffness modulus S of the two asphalts gradually decreases with the increase of temperature, which indicates that under the load condition, the material is more prone to brittle fracture with the decrease of temperature. Therefore, the lower the creep stiffness is, the better the low temperature performance is. It can be seen from Figure 20(a) that for these two asphalts, the creep stiffness of the PU-modified asphalt is greater than that of the original asphalt. Contrary to the creep stiffness S, the creep rate m increases gradually with the increase of temperature. This shows that the brittle components in the asphalt gradually increase, and the stress relaxation ability gradually deteriorates, which leads to the decrease of the low temperature rheological properties of the asphalt. It can be seen from Figure 20(b) that the low-temperature rheology of the PU-modified asphalt is greater than that of the original asphalt. At the same time, this also shows that the addition of PU modifier reduces the stiffness modulus of asphalt, increases the creep rate, and improves the low temperature rheological properties of asphalt.

5.4 Adhesion test

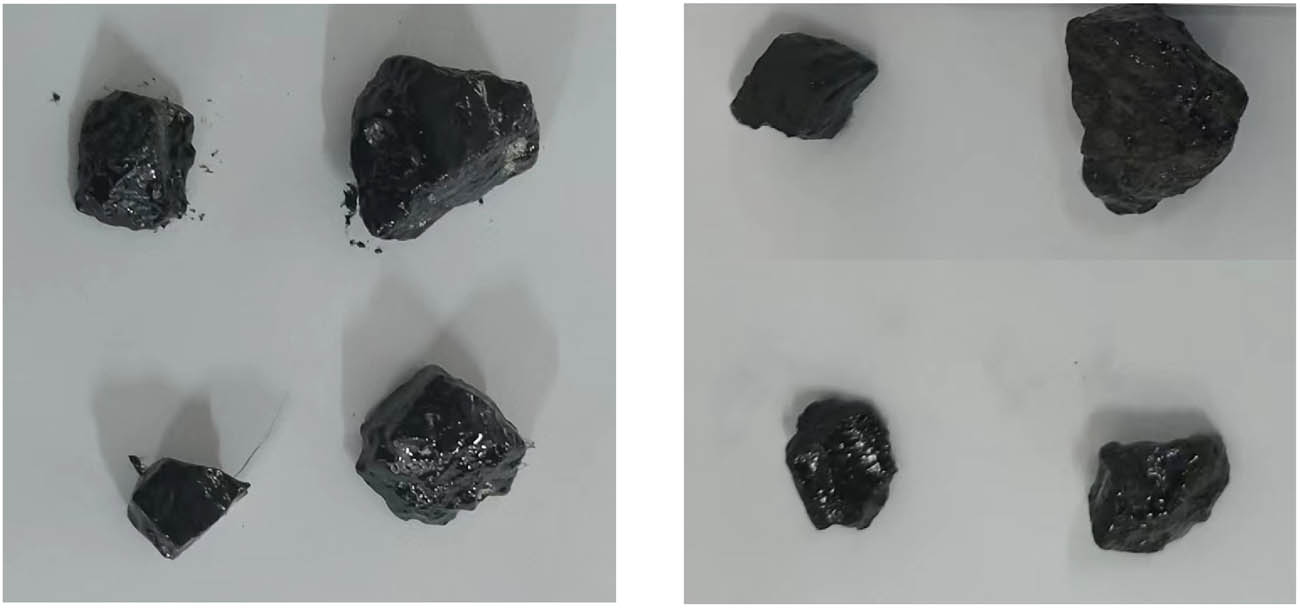

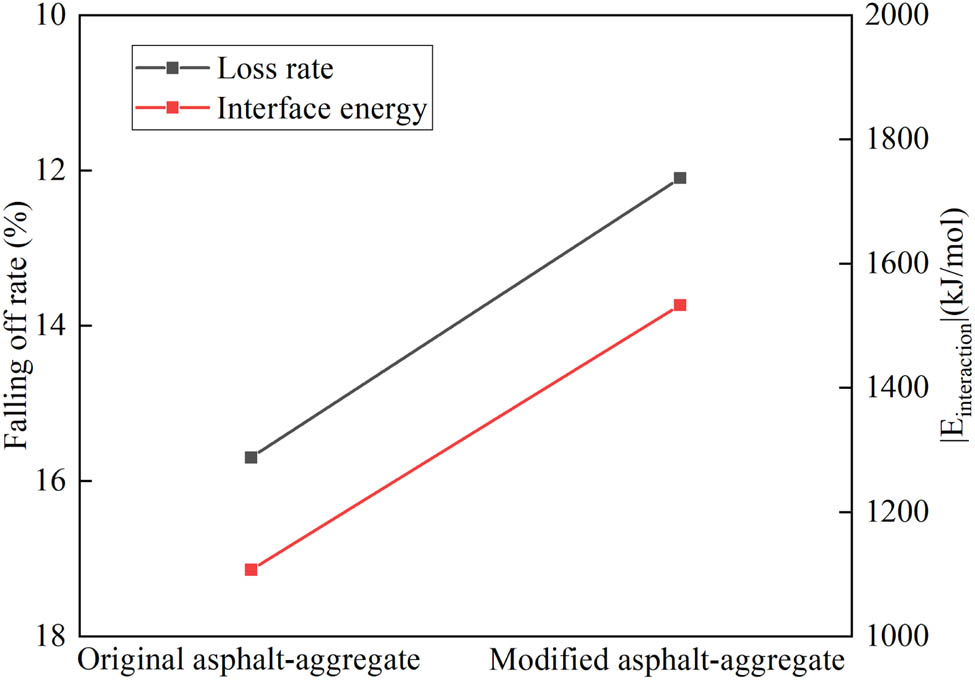

Coarse aggregates with a particle size larger than 13.2 mm are used, and the aggregates are coated with asphalt, soaked with asphalt at about 150°C, taken out and cooled and boiled in boiling water for 5 min. After being boiled in water, the peeling rate of asphalt from the aggregate surface was calculated to evaluate its adhesion. In this article, a water boiling method is proposed to observe the content of asphalt falling off after boiling. The lower the falling off rate is, the better the adhesion between asphalt and aggregate is. The samples before and after boiling are shown in Figure 21. The adhesion test results of the original asphalt and aggregate, modified asphalt and aggregate are shown in Table 4.

Boiling test: (a) before boiling and (b) after boiling.

Adhesion test results of two kinds of asphalt and aggregate

| Detection index (%) | Original asphalt (%) | Modified asphalt (%) |

|---|---|---|

| Falling off rate | 15.7 | 12.1 |

5.5 Macro-test verification of simulation results

The results of the DSR, BBR, and adhesion test are compared with the simulation results. The macro-test results and simulation results are shown in Figures 22–24.

Verification of DSR test results and simulation results.

Validation of BBR test results and simulation results.

Verification of boiled test results and simulation results.

It can be seen from Figures 22 to 24 that the failure temperature of PU-modified asphalt is higher than that of the original asphalt, and the stiffness modulus of PU-modified asphalt is lower than that of the original asphalt at a temperature of −18°C. It shows that the PU-modified asphalt has better rheological properties than the original asphalt, and the two have better compatibility. The interfacial energy of PU-modified asphalt and aggregate is greater than that of original asphalt and aggregate, while the shedding rate of modified asphalt-coated aggregate is smaller than that of original asphalt-coated aggregate. Therefore, the adhesion between the modified asphalt and the aggregate is greater than that of the original asphalt and the aggregate, and the mechanical properties of the asphalt mixture can also meet the requirements.

6 Conclusions

The diffusion behavior of asphalt and PU and the interface between PU-modified asphalt and aggregate are studied by MD simulation method. The adhesion between asphalt and aggregate is characterized by the interfacial energy of asphalt and aggregate, and is verified by macroscopic test. The following conclusions can be drawn:

The molecular models of asphalt and PU, asphalt and aggregate are established by using Materials Studio software, and the established molecular models are optimized to minimize the global energy, so as to better characterize the characteristics of materials. The diffusion coefficients of asphalt and PU are calculated by MSD curve, which were 0.683 × 10−9 and 1.638 × 10−9 m2·s−1, respectively. It can be concluded that during the diffusion process, the molecular movement of the two substances is very active, and the PU molecules are relatively more active. Combined with the mechanism of diffusion process, it shows that PU as a modifier of asphalt can fill each other’s internal microscopic voids with asphalt in a relatively short time, and can continue to move along the voids. Therefore, the asphalt modifier based on PU has good diffusion ability.

In this article, Materials Studio is used to verify that PU has good diffusion ability in asphalt, and the R 2 of diffusion coefficients of asphalt and PU are 0.9965 and 0.9986, respectively, indicating that it is reliable to simulate the diffusion behavior of asphalt and PU by MD. From the results of the interface energy, it can be seen that the interface energy between the PU-modified asphalt and the aggregate is 1883.60 kJ·mol−1, which is greater than the interface energy between the original asphalt and the aggregate, which is 1106.95 kJ·mol−1, indicating that PU can also play a very good role in road engineering as an asphalt modifier.

Through the macroscopic test results of penetration, ductility, DSR, BBR, and water boiling methods, it is shown that the PU-modified asphalt has excellent high temperature rheological properties and low temperature rheological properties and has better bonding properties with aggregates. By comparing the penetration, boiling, and simulation results, the rationality of the simulation results is more fully demonstrated, providing strong evidence for the research and application of PU in road materials.

Acknowledgments

The author thanks the special funds of the basic scientific research business expenses of central universities and the support of key projects in Heilongjiang Province.

-

Funding information: The authors are grateful for the support of the special fund for basic scientific research business expenses of central universities (2572022AW56) and the research project of the Department of Transportation of Heilongjiang Province (JTT-2019).

-

Author contributions: Song Zhao: writing review and editing; Haitao Zhang: conceptualization, project administration, and funding acquisition; Yuping Feng: conceptualization formal analysis; and Yutong Hang: software and investigation.

-

Conflict of interest: The authors declare that there are no competing interests or personal relationships that could have appeared to influence the work reported in this article.

-

Data availability statement: The data used to support the findings of this study have not been made available because they also form part of an ongoing study.

References

[1] Al-Hadidy, A. L. and Y. Tan. Mechanistic approach for polypropylene-modified flexible pavements. Materials and Design, Vol. 430, 2009, pp. 1133–1140.10.1016/j.matdes.2008.06.021Search in Google Scholar

[2] Tan, Y., M. Guo, L. Cao, and L. Zhang. Performance optimization of composite modified asphalt sealant based on rheological behavior. Construction and Building Materials, Vol. 47, 2013, pp. 799–805.10.1016/j.conbuildmat.2013.05.015Search in Google Scholar

[3] Fernandez-Gomez, W. D., H. A. R. Quintana, C. E. Daza, and F. Liz. The effects of environmental aging on colombian asphalts. Fuel, Vol. 115, 2014, pp. 321–328.10.1016/j.fuel.2013.07.009Search in Google Scholar

[4] Khodaii, A. and A. Mehrara. Evaluation of permanent deformation of unmodified and sbs modified asphalt mixtures using dynamic creep test. Construction and Building Materials, Vol. 7, No. 23, 2009, pp. 2586–2592.10.1016/j.conbuildmat.2009.02.015Search in Google Scholar

[5] Cong, P., N. Liu, Y. Tian, and Y. Zhang. Effects of long-term aging on the properties of asphalt binder containing diatoms. Construction and Building Materials, Vol. 123, 2016, pp. 534–540.10.1016/j.conbuildmat.2016.07.073Search in Google Scholar

[6] Chen, J. S., T. Wang, and C. T. L. Ee. Evaluation of a highly-modified asphalt binder for field performance. Construction and Building Materials, Vol. 171, 2018, pp. 539–545.10.1016/j.conbuildmat.2018.03.188Search in Google Scholar

[7] Fu, L. Q., Z. Wang, X. Huang, and R. Zhang. Performance research of polyphosphoric acid modified asphalt. Journal of Highway and Transportation Research and Development, Vol. 143, No. 2, 2008, pp. 16–19.Search in Google Scholar

[8] Cao, X. J., Z. Zhang, P. Hao, and L. Dong. Effect of polyphosphoric acid on the high- and-low temperature property of matrix asphalt mixture. Journal of Wuhan University of Technology, Vol. 6, No. 36, 2014, pp. 47–53.Search in Google Scholar

[9] Li, P., Y. Guo, M. Zhou, and V. P. W. Shim. Response of anisotropic polyurethane foam to compression at different loading angles and strain rates. International Journal of Impact Engineering, Vol. 127, 2018, pp. 154–168.10.1016/j.ijimpeng.2018.12.009Search in Google Scholar

[10] Demirel, S. and B. E. Tuna. Evaluation of the cyclic fatigue performance of polyurethane foam in different density and category. Polymer Testing, Vol. 127, 2019, pp. 146–153.10.1016/j.polymertesting.2019.03.019Search in Google Scholar

[11] Swinton, M. C., W. Maref, M. T. Bomberg, M. K. Kumaran, and N. Normandin. In situ performance evaluation of spray polyurethane foam in the exterior insulation basement system (EIBS). Building and Environment, Vol. 12, No. 41, 2006, pp. 1872–1880.10.1016/j.buildenv.2005.06.028Search in Google Scholar

[12] Wang, Q., S. Chen, T. Wang, and X. Zhang. Damping, thermal, and mechanical properties of polyurethane based on poly(tetramethylene glycol)/epoxy interpenetrating polymer networks: effects of composition and isocyanate index. Applied Physics A, Vol. 1, No. 104, 2011, pp. 375–382.10.1007/s00339-010-6153-7Search in Google Scholar

[13] Yoon, K. H., J. Kim, and D. Bang. Damping properties and transmission loss of polyurethane. Ⅱ. PU layer and copolymer effect. Fibers and Polymers, Vol. 2, No. 4, 2003, pp. 49–53.10.1007/BF02875436Search in Google Scholar

[14] Chern, Y. C., S. M. Tseng, and K. H. Hsieh. Damping properties of interpenetrating polymer networks of polyurethane-modified epoxy and polyurethanes. Journal of Applied Polymer Science, Vol. 2, No. 74, 1999, pp. 328–335.10.1002/(SICI)1097-4628(19991010)74:2<328::AID-APP14>3.0.CO;2-WSearch in Google Scholar

[15] Liu, M., H. Shen, X. Li, and S. Wang. Molecular simulation on compatibility of polyurethane and polyvinyl chloride and properties of PU/PVC blend membranes. Gaofenzi Cailiao Kexue Yu Gongcheng/Polymeric Materials Science and Engineering, Vol. 7, No. 34, 2018, pp. 114–120.Search in Google Scholar

[16] Fu, Y. Z., Y. Liu, and Y. Lan. Molecular dynamics simulation on compatibility of hydroxyl-terminated polybutadiene/plasticizer blends. Acta Physico-Chimica Sinica, Vol. 7, No. 25, 2009, pp. 1267–1272.10.3866/PKU.WHXB20090710Search in Google Scholar

[17] Wang, L., G. Chen, Y. Xing, H. Jiangsan, and B. Leng. Effect of aging on rheological properties of crumb rubber and SBS modified asphalt. Journal of Building Materials, Vol. 3, No. 18, 2015, pp. 499–504.Search in Google Scholar

[18] He, L., Y. Ma, T. Ling, M. Tao, and X. Huang. Analysis on crumb rubber modified asphalt and its aging characteristics on microscale. Journal of Functional Materials, Vol. 21, No. 46, 2015, pp. 21093–21098.Search in Google Scholar

[19] Xiao, Y., C. Li, M. Wan, X. Zhou, Y. Wang, and S. Wu. Study of the diffusion of rejuvenators and its effect on aged bitumen binder. Applied Sciences, Vol. 7, No. 4, 2017, id. 397.10.3390/app7040397Search in Google Scholar

[20] Ding, Y., B. Huang, S. Xiang, Y. Zhang, and M. Woods. Use of molecular dynamics to investigate diffusion between virgin and aged asphalt binders. Fuel, Vol. 174, 2016, pp. 267–273.10.1016/j.fuel.2016.02.022Search in Google Scholar

[21] Xu, M., J. Yi, D. Feng, and Y. Huang. Diffusion characteristics of asphalt rejuvenators based on molecular dynamics simulation. The International Journal of Pavement Engineering, Vol. 5, No. 20, 2019, pp. 615–627.10.1080/10298436.2017.1321412Search in Google Scholar

[22] Wang, H. N., H. Ding, P. Feng, L. Shao, and Z. You. Advances on molecular simulation technique in asphalt mixture. Journal of Traffic and Transportation Engineering, Vol. 2, No. 20, 2020, pp. 1–14.Search in Google Scholar

[23] Cong, L., F. Yang, G. Guo, M. Ren, and L. Tan. The use of polyurethane for asphalt pavement engineering applications: a state-of-the-art review. Construction and Building Materials, Vol. 225, 2019, pp. 1012–1025.10.1016/j.conbuildmat.2019.07.213Search in Google Scholar

[24] Corbett, L. W. Composition of asphalt based on generic fractionation, using solvent deasphaltening, elution-adsorption chromatography, and densimetric characterization. Analytical Chemistry, Vol. 4, No. 41, 1969, pp. 576–579.10.1021/ac60273a004Search in Google Scholar

[25] Hansen, J. S., C. A. Lemarchand, E. Nielsen, J. C. Dyre, and T. Schroder. Four-component united-atom model of bitumen. The Journal of Chemical Physics, Vol. 9, No. 138, 2013, id. 094508.10.1063/1.4792045Search in Google Scholar

[26] Zhang, L. and M. L. Greenfield. Analyzing properties of model asphalts using molecular simulation. Energy and Fuels, Vol. 3, No. 21, 2007, pp. 1712–1716.10.1021/ef060658jSearch in Google Scholar

[27] Li, D. D. and M. L. Greenfield. Chemical compositions of improved model asphalt systems for molecular simulations. Fuel, Vol. 1, No. 115, 2014, pp. 347–356.10.1016/j.fuel.2013.07.012Search in Google Scholar

[28] Schweiger, C. W. Method of preparing flexible flame retardant polyether based one-shot polyurethane foams and compositions therefore. U.S. Patent and Trademark Office, Washington, DC, 1979.Search in Google Scholar

[29] Ulrich, H. Chemistry and technology of isocyanates, Wiley-Blackwell, Chichester, UK, 1996.Search in Google Scholar

[30] Woods, G. The ICI Polyurethanes Book, published jointly by ICI Polyurethanes and John Wiley and Sons: Polyols and Case Polyurethan Elastomers (CPU), USA, 1990, pp. 182–187.Search in Google Scholar

[31] Soto, M., R. M. Sebastián, and J. Marquet. Photochemical activation of extremely weak nucleophiles: highly fluorinated urethanes and polyurethanes from polyfluoro alcohols. Journal of Organic Chemistry, Vol. 11, No. 79, pp. 5019–5027.10.1021/jo5005789Search in Google Scholar PubMed

[32] Ying, L. and X. Xing. Study on performance of polyurethane modified asphalt for pavement. Petroleum Asphalt, Vol. 29, No. 1, 2015, pp. 48–53.Search in Google Scholar

[33] Sun, F. Y., L. Huang, and L. Wang. Molecular dynamics simulation of micro frictional contact characteristics between tires and asphalt pavement. Chinese Journal of Engineering, Vol. 6, No. 11, 2016, pp. 847–852.Search in Google Scholar

[34] von Smoluchowski, M. Zur kinetischen theorie der brownschen molekularbewegung und der suspensionen. Annalen der physik, Vol. 326, No. 14, 1906, pp. 756–780 (In German).10.1002/andp.19063261405Search in Google Scholar

[35] Li, L., C. Xin, M. Guan, and M. Guo. Using molecular dynamics simulation to analyze the feasibility of using waste cooking oil as an alternative rejuvenator for aged asphalt. Sustainability, Vol. 8, No. 13, 2021, id. 4373.10.3390/su13084373Search in Google Scholar

[36] Chen, W., S. Chen, and C. Zheng. Analysis of micromechanical properties of algae bio-based bio-asphalt–mineral interface based on molecular simulation technology. Construction and Building Materials, Vol. 306, 2021, id. 124888.10.1016/j.conbuildmat.2021.124888Search in Google Scholar

© 2022 Song Zhao et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers

- A review on the properties of concrete reinforced with recycled steel fiber from waste tires

- Copper ternary oxides as photocathodes for solar-driven CO2 reduction

- Properties of fresh and hardened self-compacting concrete incorporating rice husk ash: A review

- Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey

- Research progress on durability of marine concrete under the combined action of Cl− erosion, carbonation, and dry–wet cycles

- Delivery systems in nanocosmeceuticals

- Study on the preparation process and sintering performance of doped nano-silver paste

- Analysis of the interactions between nonoxide reinforcements and Al–Si–Cu–Mg matrices

- Research Articles

- Study on the influence of structural form and parameters on vibration characteristics of typical ship structures

- Deterioration characteristics of recycled aggregate concrete subjected to coupling effect with salt and frost

- Novel approach to improve shale stability using super-amphiphobic nanoscale materials in water-based drilling fluids and its field application

- Research on the low-frequency multiline spectrum vibration control of offshore platforms

- Multiple wide band gaps in a convex-like holey phononic crystal strip

- Response analysis and optimization of the air spring with epistemic uncertainties

- Molecular dynamics of C–S–H production in graphene oxide environment

- Residual stress relief mechanisms of 2219 Al–Cu alloy by thermal stress relief method

- Characteristics and microstructures of the GFRP waste powder/GGBS-based geopolymer paste and concrete

- Development and performance evaluation of a novel environmentally friendly adsorbent for waste water-based drilling fluids

- Determination of shear stresses in the measurement area of a modified wood sample

- Influence of ettringite on the crack self-repairing of cement-based materials in a hydraulic environment

- Multiple load recognition and fatigue assessment on longitudinal stop of railway freight car

- Synthesis and characterization of nano-SiO2@octadecylbisimidazoline quaternary ammonium salt used as acidizing corrosion inhibitor

- Perforated steel for realizing extraordinary ductility under compression: Testing and finite element modeling

- The influence of oiled fiber, freeze-thawing cycle, and sulfate attack on strain hardening cement-based composites

- Perforated steel block of realizing large ductility under compression: Parametric study and stress–strain modeling

- Study on dynamic viscoelastic constitutive model of nonwater reacted polyurethane grouting materials based on DMA

- Mechanical behavior and mechanism investigation on the optimized and novel bio-inspired nonpneumatic composite tires

- Effect of cooling rate on the microstructure and thermal expansion properties of Al–Mn–Fe alloy

- Research on process optimization and rapid prediction method of thermal vibration stress relief for 2219 aluminum alloy rings

- Failure prevention of seafloor composite pipelines using enhanced strain-based design

- Deterioration of concrete under the coupling action of freeze–thaw cycles and salt solution erosion

- Creep rupture behavior of 2.25Cr1Mo0.25V steel and weld for hydrogenation reactors under different stress levels

- Statistical damage constitutive model for the two-component foaming polymer grouting material

- Nano-structural and nano-constraint behavior of mortar containing silica aggregates

- Influence of recycled clay brick aggregate on the mechanical properties of concrete

- Effect of LDH on the dissolution and adsorption behaviors of sulfate in Portland cement early hydration process

- Comparison of properties of colorless and transparent polyimide films using various diamine monomers

- Study in the parameter influence on underwater acoustic radiation characteristics of cylindrical shells

- Experimental study on basic mechanical properties of recycled steel fiber reinforced concrete

- Dynamic characteristic analysis of acoustic black hole in typical raft structure

- A semi-analytical method for dynamic analysis of a rectangular plate with general boundary conditions based on FSDT

- Research on modification of mechanical properties of recycled aggregate concrete by replacing sand with graphite tailings

- Dynamic response of Voronoi structures with gradient perpendicular to the impact direction

- Deposition mechanisms and characteristics of nano-modified multimodal Cr3C2–NiCr coatings sprayed by HVOF

- Effect of excitation type on vibration characteristics of typical ship grillage structure

- Study on the nanoscale mechanical properties of graphene oxide–enhanced shear resisting cement

- Experimental investigation on static compressive toughness of steel fiber rubber concrete

- Study on the stress field concentration at the tip of elliptical cracks

- Corrosion resistance of 6061-T6 aluminium alloy and its feasibility of near-surface reinforcements in concrete structure

- Effect of the synthesis method on the MnCo2O4 towards the photocatalytic production of H2

- Experimental study of the shear strength criterion of rock structural plane based on three-dimensional surface description

- Evaluation of wear and corrosion properties of FSWed aluminum alloy plates of AA2020-T4 with heat treatment under different aging periods

- Thermal–mechanical coupling deformation difference analysis for the flexspline of a harmonic drive

- Frost resistance of fiber-reinforced self-compacting recycled concrete

- High-temperature treated TiO2 modified with 3-aminopropyltriethoxysilane as photoactive nanomaterials

- Effect of nano Al2O3 particles on the mechanical and wear properties of Al/Al2O3 composites manufactured via ARB

- Co3O4 nanoparticles embedded in electrospun carbon nanofibers as free-standing nanocomposite electrodes as highly sensitive enzyme-free glucose biosensors

- Effect of freeze–thaw cycles on deformation properties of deep foundation pit supported by pile-anchor in Harbin

- Temperature-porosity-dependent elastic modulus model for metallic materials

- Effect of diffusion on interfacial properties of polyurethane-modified asphalt–aggregate using molecular dynamic simulation

- Experimental study on comprehensive improvement of shear strength and erosion resistance of yellow mud in Qiang Village

- A novel method for low-cost and rapid preparation of nanoporous phenolic aerogels and its performance regulation mechanism

- In situ bow reduction during sublimation growth of cubic silicon carbide

- Adhesion behaviour of 3D printed polyamide–carbon fibre composite filament

- An experimental investigation and machine learning-based prediction for seismic performance of steel tubular column filled with recycled aggregate concrete

- Effects of rare earth metals on microstructure, mechanical properties, and pitting corrosion of 27% Cr hyper duplex stainless steel

- Application research of acoustic black hole in floating raft vibration isolation system

- Multi-objective parametric optimization on the EDM machining of hybrid SiCp/Grp/aluminum nanocomposites using Non-dominating Sorting Genetic Algorithm (NSGA-II): Fabrication and microstructural characterizations

- Estimating of cutting force and surface roughness in turning of GFRP composites with different orientation angles using artificial neural network

- Displacement recovery and energy dissipation of crimped NiTi SMA fibers during cyclic pullout tests

Articles in the same Issue

- Review Articles

- State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers

- A review on the properties of concrete reinforced with recycled steel fiber from waste tires

- Copper ternary oxides as photocathodes for solar-driven CO2 reduction

- Properties of fresh and hardened self-compacting concrete incorporating rice husk ash: A review

- Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey

- Research progress on durability of marine concrete under the combined action of Cl− erosion, carbonation, and dry–wet cycles

- Delivery systems in nanocosmeceuticals

- Study on the preparation process and sintering performance of doped nano-silver paste

- Analysis of the interactions between nonoxide reinforcements and Al–Si–Cu–Mg matrices

- Research Articles

- Study on the influence of structural form and parameters on vibration characteristics of typical ship structures

- Deterioration characteristics of recycled aggregate concrete subjected to coupling effect with salt and frost

- Novel approach to improve shale stability using super-amphiphobic nanoscale materials in water-based drilling fluids and its field application

- Research on the low-frequency multiline spectrum vibration control of offshore platforms

- Multiple wide band gaps in a convex-like holey phononic crystal strip

- Response analysis and optimization of the air spring with epistemic uncertainties

- Molecular dynamics of C–S–H production in graphene oxide environment

- Residual stress relief mechanisms of 2219 Al–Cu alloy by thermal stress relief method

- Characteristics and microstructures of the GFRP waste powder/GGBS-based geopolymer paste and concrete

- Development and performance evaluation of a novel environmentally friendly adsorbent for waste water-based drilling fluids

- Determination of shear stresses in the measurement area of a modified wood sample

- Influence of ettringite on the crack self-repairing of cement-based materials in a hydraulic environment

- Multiple load recognition and fatigue assessment on longitudinal stop of railway freight car

- Synthesis and characterization of nano-SiO2@octadecylbisimidazoline quaternary ammonium salt used as acidizing corrosion inhibitor

- Perforated steel for realizing extraordinary ductility under compression: Testing and finite element modeling

- The influence of oiled fiber, freeze-thawing cycle, and sulfate attack on strain hardening cement-based composites

- Perforated steel block of realizing large ductility under compression: Parametric study and stress–strain modeling

- Study on dynamic viscoelastic constitutive model of nonwater reacted polyurethane grouting materials based on DMA

- Mechanical behavior and mechanism investigation on the optimized and novel bio-inspired nonpneumatic composite tires

- Effect of cooling rate on the microstructure and thermal expansion properties of Al–Mn–Fe alloy

- Research on process optimization and rapid prediction method of thermal vibration stress relief for 2219 aluminum alloy rings

- Failure prevention of seafloor composite pipelines using enhanced strain-based design

- Deterioration of concrete under the coupling action of freeze–thaw cycles and salt solution erosion

- Creep rupture behavior of 2.25Cr1Mo0.25V steel and weld for hydrogenation reactors under different stress levels

- Statistical damage constitutive model for the two-component foaming polymer grouting material

- Nano-structural and nano-constraint behavior of mortar containing silica aggregates

- Influence of recycled clay brick aggregate on the mechanical properties of concrete

- Effect of LDH on the dissolution and adsorption behaviors of sulfate in Portland cement early hydration process

- Comparison of properties of colorless and transparent polyimide films using various diamine monomers

- Study in the parameter influence on underwater acoustic radiation characteristics of cylindrical shells

- Experimental study on basic mechanical properties of recycled steel fiber reinforced concrete

- Dynamic characteristic analysis of acoustic black hole in typical raft structure

- A semi-analytical method for dynamic analysis of a rectangular plate with general boundary conditions based on FSDT

- Research on modification of mechanical properties of recycled aggregate concrete by replacing sand with graphite tailings

- Dynamic response of Voronoi structures with gradient perpendicular to the impact direction

- Deposition mechanisms and characteristics of nano-modified multimodal Cr3C2–NiCr coatings sprayed by HVOF

- Effect of excitation type on vibration characteristics of typical ship grillage structure

- Study on the nanoscale mechanical properties of graphene oxide–enhanced shear resisting cement

- Experimental investigation on static compressive toughness of steel fiber rubber concrete

- Study on the stress field concentration at the tip of elliptical cracks

- Corrosion resistance of 6061-T6 aluminium alloy and its feasibility of near-surface reinforcements in concrete structure

- Effect of the synthesis method on the MnCo2O4 towards the photocatalytic production of H2

- Experimental study of the shear strength criterion of rock structural plane based on three-dimensional surface description

- Evaluation of wear and corrosion properties of FSWed aluminum alloy plates of AA2020-T4 with heat treatment under different aging periods

- Thermal–mechanical coupling deformation difference analysis for the flexspline of a harmonic drive

- Frost resistance of fiber-reinforced self-compacting recycled concrete

- High-temperature treated TiO2 modified with 3-aminopropyltriethoxysilane as photoactive nanomaterials

- Effect of nano Al2O3 particles on the mechanical and wear properties of Al/Al2O3 composites manufactured via ARB

- Co3O4 nanoparticles embedded in electrospun carbon nanofibers as free-standing nanocomposite electrodes as highly sensitive enzyme-free glucose biosensors

- Effect of freeze–thaw cycles on deformation properties of deep foundation pit supported by pile-anchor in Harbin

- Temperature-porosity-dependent elastic modulus model for metallic materials

- Effect of diffusion on interfacial properties of polyurethane-modified asphalt–aggregate using molecular dynamic simulation

- Experimental study on comprehensive improvement of shear strength and erosion resistance of yellow mud in Qiang Village

- A novel method for low-cost and rapid preparation of nanoporous phenolic aerogels and its performance regulation mechanism

- In situ bow reduction during sublimation growth of cubic silicon carbide

- Adhesion behaviour of 3D printed polyamide–carbon fibre composite filament

- An experimental investigation and machine learning-based prediction for seismic performance of steel tubular column filled with recycled aggregate concrete

- Effects of rare earth metals on microstructure, mechanical properties, and pitting corrosion of 27% Cr hyper duplex stainless steel

- Application research of acoustic black hole in floating raft vibration isolation system

- Multi-objective parametric optimization on the EDM machining of hybrid SiCp/Grp/aluminum nanocomposites using Non-dominating Sorting Genetic Algorithm (NSGA-II): Fabrication and microstructural characterizations

- Estimating of cutting force and surface roughness in turning of GFRP composites with different orientation angles using artificial neural network

- Displacement recovery and energy dissipation of crimped NiTi SMA fibers during cyclic pullout tests