Abstract

To investigate the impact and flexure behavior of carbon fiber reinforced polymers/aluminum-honeycomb sandwich panel, low-velocity impact, compression-after-impact (CAI), and three-point flexure tests are conducted carefully. Four kinds of carbon fiber prepregs are selected to make face sheets by hot press preparation. Further, the digital image correlation technique is employed to record the damage evolution under the compression and flexure loads. The results show that the sandwich structure has two stages of impact response, first, the brittle behavior of the upper panel, and then the resistance of both sandwich and lower panel to absorb energy. In the CAI test, the failure position shifts from the ends to the impact cross section, and the compressive strength can be reduced by 40% only by 1 J impact. The strength of in-plane flexure is at least twice greater than that of out-of-plane flexure. The damage and deformation of in-plane flexure are found mainly in the upper panel and sandwich core, and the lower panel bends significantly.

1 Introduction

Owing to the superior specific bending stiffness, thermal insulation, and acoustic damping capacity, composite sandwich structures have met the special requirements in today’s engineering fields, involving automotive, marine, aerospace, and wind power (1–7). Carbon fiber reinforced polymers (CFRP) face sheets, characterized by exceptional mechanical performances, such as light weight, high strength, as well as excellent fatigue property and structural designability, have promoted the application of sandwich structures (8–11). Aluminum honeycomb stands out among a variety of core materials, including metal foam, corrugation, and Y-frame core (12–16), because of its outstanding energy absorption. Therefore, the mechanical properties of CFRP/aluminum-honeycomb sandwich (AHS) structures need to be investigated further.

Many investigations have been carried out on the failure behavior of sandwich beams with CFRP face-sheets and aluminum-honeycomb core under quasi-static loading (17–20). Zhang et al. (21) conducted three-point bending tests of AHS panels. A variety of methods, including increasing the face-sheet thickness, honeycomb wall-thickness, the ratio of the core height to span length, and the elasticity effect of metal materials, can improve the load-carrying capacity and energy absorption. Besides, the debonding between face sheets and core of sandwich structures subjected to flexure loading is often found (22–24).

The mechanical behavior of sandwich structures under high-speed impact and quasi-static loading are concerned mainly by the current studies, while few investigations focus on low-velocity impact (LVI) (24–27). After LVI, the invisible internal damage is a huge hidden danger of structural failure. Many researchers found from experiments and finite element simulations that CFRP face sheets play a leading role in the impact resistance of sandwich structures (28). Sun et al. (29) investigated the effect of the adhesive geometry on the impact damage of adhesively bonded aluminum sandwich panels. The results showed that the variation of the adhesive fillet height between different cell walls has a significant influence on the core damage depth, which cannot be ignored when predicting the range of the core damage depth. Zhang et al. (30) focused on repeated impact loads, and drew some important conclusion. With the increase of the repeated impact numbers, the bending deflections of both top and bottom face sheets of sandwich panel accumulate gradually, the compressive deformations of the honeycomb cores enlarge gradually, and finally the densification phenomenon appears.

Further, impact damage may greatly reduce the residual strength of sandwich structures, involving the strength and stiffness in flexure and compression tests (31,32). Zhu and Pan (33) use mirror-assisted MV-DIC to study the deformation behaviors of AHS panels with artificial defects of different sizes under in-panel compression. He et al. (34) found that residual flexural strength almost reduces 20–30% even though superficial impact damage remains barely visible. In Daniele’s report (35), an increase in impact strength of 25% is observed in the aluminum–flax hybrid sandwich structures compared to the unreinforced AHS structures, and an increase of 50% in specific energy absorption is seen compared to conventional AHS constructions.

However, few studies have involved simultaneously static and dynamic response, as well as post-impact residual strength. Therefore, we manufactured four types of CFRP face sheets, and LVI, compression-after-impact (CAI), and three-point bonding tests are conducted carefully. Further, their failure behaviors are compared and analyzed.

2 Materials and methods

2.1 Raw materials and fabrication

The specimens are composed of AHS and CFRP hybrid face sheets, which are fabricated by four kinds of unidirectional fiber prepreg as shown in Table 1, including T300, M55J, BHM, and BHM3. The honeycomb cell of AHS is 5 mm in side length, 0.03 mm in thickness, and 4 mm in height.

Mechanical properties of four kinds of fiber prepreg

| Type of fiber prepreg | Tensile strength (MPa) | Tensile modulus (GPa) | Extensibility of fiber (%) | Density of fiber (g·cm−3) |

|---|---|---|---|---|

| T300 | 3,530 | 230 | 1.5 | 1.76 |

| M55J | 4,020 | 540 | 0.8 | 1.91 |

| BHM | 1,680 | 206 | 0.9 | 1.85 |

| BHM3 | 3,100 | 400 | 0.7 | 1.63 |

The fabrication process is shown in Figure 1. The prepreg, a single layer of 0.15 mm thickness, is stacked sequentially in 0° and 90° directions with total four layers ([0/90]2), and finally is used to manufacture laminates by hot press machine. The CFRP face sheets are put in a mold and heated up to 145°C, then pressurized to 5 kPa and held for 60 min in the hot press machine, finally cooled to 90°C in the room-temperature environment. AHS and four kinds of CFRP face sheets are bonded, respectively, by the adhesive film N6492N0-20 made of thermosetting epoxy resin. Finally, four specimens made of face sheets of T300, M55J, BHM, and BHM3 carbon fiber prepreg are named Ⅰ, Ⅱ, Ⅲ, and Ⅳ, respectively. For LVI and CAI tests, the length, width, and height of sandwich panels are 150, 100, and 42 mm, respectively, and those are 180, 100, and 42 mm in three-point flexure loading. Besides, the case after LVI is named as F-E, where F is the type of fiber prepreg and E represents the incident energy.

Fabrication process.

2.2 LVI tests

Instron CEAST 9340, meeting ASTM D7136, is employed to implement the LVI testing, in which the history including absorbed energy, displacement as well as contact force on the surface of the impactor, 4.5 kg of mass, and nose of 16 mm diameter, are recorded as shown in Figure 2(a). It is worth noting that, to investigate the effect of the incident energy, the specimens are fixed by four toggle clamps on the impact support fixture base and are subjected to 1/2/3 J LVI loading (at a speed of 0.37/0.75/1.12 m·s−1).

Setup of testing: (a) LVI, (b) CAI, (c) in-plane and out-of-plane three-point bending tests.

2.3 CAI tests

According to ASTM-D7137, CAI testing is conducted at a speed of 1.25 mm·min−1 on the universal testing machine. The two circular platforms with 100 mm diameter are installed in the testers as shown in Figure 2(b). During the compressive test, in addition to the history of force and displacement, the strain-contour evolution of post-impact samples is presented with the help of 3-D digital image correlation.

2.4 Three-point flexure tests

To study the flexure behavior of sandwich panel, the in-plane and out-of-plane flexure tests at a speed of 1.5 mm·min−1, as shown in Figure 2(c), is carried out according to ASTM D790. The standard fixture of the three-point flexure test with a 130 mm span is installed in the testers. Therefore, in Figure 2(c), L 1 is the span length of 130 mm and L 2 is the cantilever length of 25 mm. Besides, in the above three tests, at least three parallel tests of the specimen under each operating condition are performed carefully.

3 Results and discussion

3.1 LVI

3.1.1 Damage morphology

Before the LVI test, all specimens are visually inspected to ensure that there is no initial damage, and their upper and lower surfaces are photographed after the tests. The comparison of all kinds of cases subjected to the impact of three incident energies on damage morphology is shown in Figure 3. Clearly, according to the diameter and depth of the impact dent, the impact damage of all cases is more serious with the increase of incident energy. For the cases subjected to 1 J impact, the upper face sheet of case I-2 is penetrated, and a significant fiber breaking is observed in case IV, but specimens I and III have minor impact damage. Further, with the increase of impact energy, the sandwich core of specimen Ⅱ is exposed to outside.

Damage morphology of all kinds of specimens.

3.1.2 Impact response history

The impact response history, including force–time and force–displacement curves, of all cases is shown in Figure 4. In the initial stage of all the curves, the contact force rises with a constant velocity, and then different trends are found in four kinds of sandwich panel. However, a certain bearing capacity with fluctuation is kept after the force reaches the peak in all cases. The peak force of all specimens is listed in Table 2.

Force–time and force–displacement curves of four types of sandwich panel under three incident energies: (a) and (b) specimen I, (c) and (d) specimen II, (e) and (f) specimen III, and (g) and (h) specimen IV.

Comparison of all cases on peak force

| Impact energy (J) | Peak force under LVI loading (N) | |||

|---|---|---|---|---|

| Ⅰ | Ⅱ | Ⅲ | Ⅳ | |

| 1 | 501.98 | 280.98 | 476.36 | 390.26 |

| 2 | 585.35 | 306.14 | 454.75 | 354.68 |

| 3 | 595.12 | 300.78 | 420.37 | 334.54 |

For specimen I, the peak force is the largest among the four kinds of sandwich panel at all incident energies, and it increases with the increase of incident energy. When the oscillation occurs after the displacement at the peak force of 1.8 mm, the upper face sheet has suffered ultimate elastic force.

For specimen II, the peak force is the smallest among the four kinds of sandwich panel at all incident energies and no changes with the increase of incident energy. Compared with the damage morphology, when the vibration occurs after the displacement at the peak force of 1.2 mm, the upper face sheet has penetrated and the AHS is bearing.

Compared with other types of specimens, the curves of specimens III and IV show a sharp decline after the peak force, and then keep a low level of contact force with fluctuation. Likewise, the upper panel has penetrated and the sandwich core is bearing.

Combined with the above, the face panel of latter three specimens show brittle behavior under LVI load. Therefore, considering the bearing capacity, the impact performance of specimen I is the best, followed by specimen III and IV, and specimen II is the worst.

3.2 CAI

3.2.1 Damage evolution

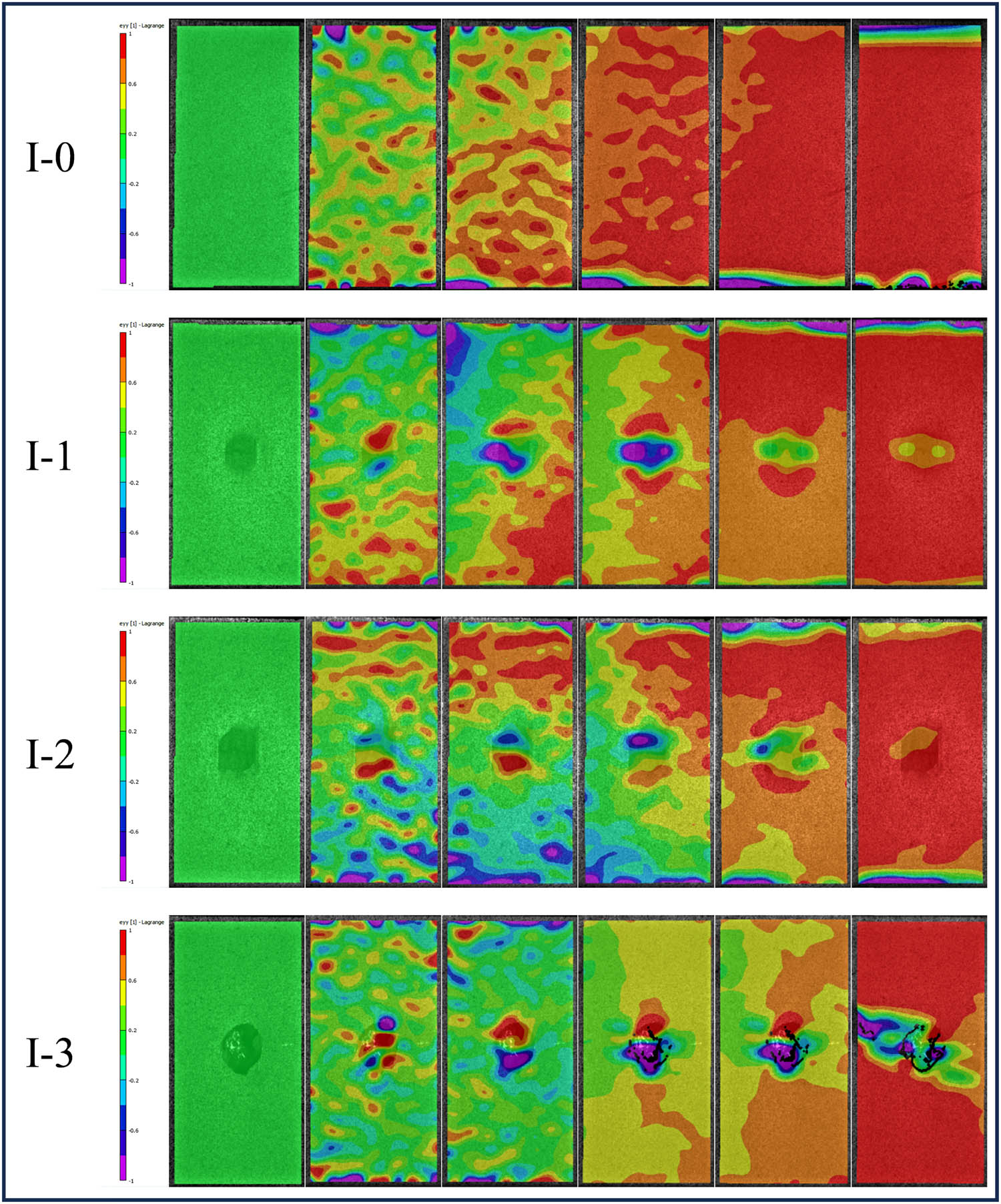

The CAI tests of all specimens are conducted carefully, and there is no difference in their evolution trend of strain contour. Especially, specimen I is the most representative case, and the damage evolution is shown in Figure 5. During the compressive process, the specimen is uniformly stressed without large out-of-plane deformation in the initial stage.

Stain contour of specimen I in compressive tests after impact with various incident energies.

For no impact specimens, stress concentration is gradually observed at their both ends, and the ends are crushed when the loading exceeds their bearing capacity. However, for the impacted specimens, stress concentration is found at the impact point with the increase of compressive displacement. Then, the region of stress concentration propagates to the whole cross section, where the specimen is broken.

3.2.2 Mechanical response

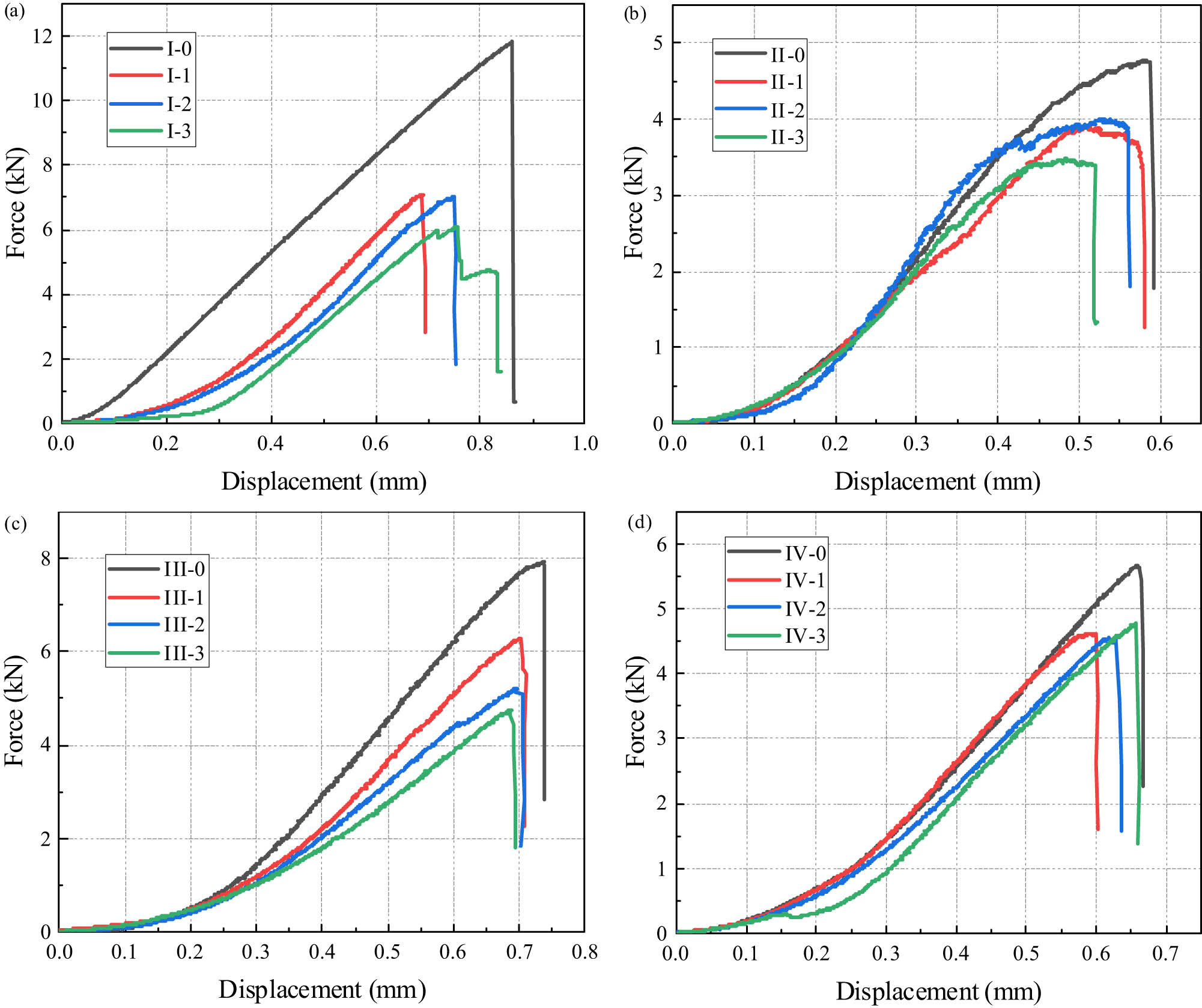

The typical contact force–displacement curves of the specimens under CAI testing are compared in Figure 6, and the key formation, including the peak force and decline ratio of impacted cases to virgin cases in residual strength, is summarized in Table 3. Compared with no impact specimens, the peak force of the impacted specimens has a significant decline. Owing to this specimen suffers more severe damage and out-plane deformation, the residual compressive strength of specimens decreases generally with the increase of impact energy. For no impact specimens, the virgin compressive strength of specimen I is the largest. Compared with other types of specimens, although there is the most significant decline in residual compressive strength of specimen I, the compressive strength of specimen I is also the largest after the impact with various incident energies.

Comparison of all cases under compression loading on the force–displacement curves: (a) specimen I, (b) specimen II, (c) specimen III, and (d) specimen IV.

Key information of all cases in CAI tests

| Impact energy (J) | Peak force under CAI loading (kN) | Decline ratio of impacted cases to virgin cases in residual strength (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| Ⅰ | Ⅱ | Ⅲ | Ⅳ | Ⅰ | Ⅱ | Ⅲ | Ⅳ | |

| 0 | 11.82 | 4.76 | 7.94 | 5.67 | 0 | 0 | 0 | 0 |

| 1 | 7.06 | 3.90 | 6.29 | 4.63 | 40.20 | 18.20 | 20.74 | 18.44 |

| 2 | 7.00 | 4.01 | 5.21 | 4.56 | 40.73 | 15.85 | 34.38 | 19.62 |

| 3 | 6.10 | 3.50 | 4.77 | 4.77 | 48.37 | 26.85 | 39.95 | 15.85 |

3.3 Three-point flexure

3.3.1 Mechanical response

The force–displacement curve of all kinds of specimens subjected to in-plane and out-of-plane flexure loading is shown in Figure 7. In their force–displacement curve, the contact force first rises briefly and linearly. Then, in the last stage of force–displacement curve of the specimens under in-plane flexure, the contact force oscillates dramatically, which is because both CFRP face sheets and sandwich core bear load together. However, a long and gentle ascent is found in that of the specimens under out-of-plane flexure. The best in-plane flexure property belongs to specimen I due to the highest resistance in the oscillation stage of curves. Besides, specimen II shows the best out-of-plane flexure performance and the worst in-plane flexibility. However, in-plane flexure performance is more valued because of wider application. Significantly, the bearing capacity and failure displacement of specimens under in-plane flexure are much greater than those of out-of-plane.

Comparison of all cases under (a) in-plane and (b) out-plane flexure loading on the force–displacement curves.

3.3.2 Damage evolution

The damage evolution of specimen I with the best flexure performance subjected to in-plane and out-of-plane flexure loading is shown in Figure 8. Moreover, they are presented as images of damage process and strain contour, respectively. For in-plane flexure process, the compressive load is transferred from the upper panel to the sandwich and then to the lower panel. The upper panel and the sandwich are extruded and depressed gradually, but the lower panel is only bent slowly. In the strain contour of out-of-plane flexure, there is the fan-shaped diffusion of strain in the x–y plane from among a compression point and two support rollers as well as the obvious strain dividing region in the middle of the specimen. Finally, the whole specimen is compressed, and the panel fails due to brittle failure at the compression point. Obviously, the deformation and damage of specimens under in-plane flexure are much greater than those of out-of-plane.

Damage evolution of specimen I under (a) in-plane and (b) out-of-plane flexure loading.

4 Conclusion

In the LVI, CAI, and three-point flexure loading, the damage mechanism and failure mode of sandwich panels composed of AHS and CFRP face sheets are investigated based on the typical response history, damage morphology, and strain contour. Therefore, the following conclusions can be drawn:

The brittle behavior is caused by both thin face sheet and hot press technology. Therefore, the drop rise and decline are found around the peak force of the sandwich panel made of BHM and BHM3, where fiber breaking, penetrated panel, and exposed sandwich are observed. However, in the last stage of curves, contact force keeps a long and fluctuating rise because of cushion and energy absorption of AHS.

Because of the damage and out-of-plane deformation caused by LVI, the failure position shifts from the ends to the cross section of the impact point in CAI. The residual compressive strength decreases with the increase of incident energy. The sandwich panel made of T300 prepreg is the best CAI property, but its decline ratio of impacted cases to virgin cases is also the largest, exceeding 40%.

The in-plane flexure strength is at least twice greater than the out-of-plane strength. The damage and deformation of in-plane flexure are found mainly in the upper panel and sandwich core, and the lower panel finally bends significantly. The failure mode of out-of-plane flexure is brittle extrusion failure in the side of face sheets, and the failure displacement is small.

The sandwich panel made of T300 prepreg is the best LVI, CAI, and in-plane flexure performance compared with those of M55J, BHM, and BHM3. Therefore, it is reasonable to believe that suitable face sheet can improve these properties at the same time.

Acknowledgements

This work was sponsored by the Foundation of Jiangxi Province of China Educational Committee (GJJ201907, GJJ2201503) and the Innovative Projects of NIT (YC2023-S997, YC2023-S1004).

-

Author contributions: Shicheng Zhao: Conceptualization, Methodology, Software Validation, Formal analysis, Investigation, Resources, Data Curation, Writing – Original Draft, Writing – Review & Editing, Visualization, Supervision, Project administration, Funding acquisition. Xuan Gao: Formal analysis, Investigation, Resources, Data Curation, Writing - Original Draft, Writing – Review & Editing, Visualization, Supervision, Project administration. Ye Wu: Conceptualization, Methodology, Investigation, Resources, Data Curation, Writing - Review & Editing, Visualization, Supervision, Project administration, Funding acquisition. Jiajun Lou, Cuilong Liu, and Youping Liu: Data Curation, Writing – Original Draft, Writing – Review & Editing, Visualization.

-

Conflict of interest: Authors state no conflict of interest.

References

(1) Feng H, Liu L, Zhao Q. Experimental and numerical investigation of the effect of entrapped air on the mechanical response of Nomex honeycomb under flatwise compression. Compos Struct. 2017;182:617–27.10.1016/j.compstruct.2017.09.080Search in Google Scholar

(2) Ma S, He Y, Hui L, Xu L. Effects of hygrothermal and thermal aging on the low-velocity impact properties of carbon fiber composites. Adv Compos Mater. 2020;29(1):55–72.10.1080/09243046.2019.1630054Search in Google Scholar

(3) Ramnath BV, Alagarraja K, Elanchezhian C. Review on sandwich composite and their applications. Mater Today: Proc. 2019;16:859–64.10.1016/j.matpr.2019.05.169Search in Google Scholar

(4) Choe J, Huang Q, Yang J, Hu H. An efficient approach to investigate the post-buckling behaviors of sandwich structures. Compos Struct. 2018;201:377–88.10.1016/j.compstruct.2018.06.025Search in Google Scholar

(5) Zhang J, Qin Q, Xiang C, Wang T. Dynamic response of slender multilayer sandwich beams with metal foam cores subjected to low-velocity impact. Compos Struct. 2016;153:614–23.10.1016/j.compstruct.2016.06.059Search in Google Scholar

(6) Dogan A, Arikan V. Low-velocity impact response of E-glass reinforced thermoset and thermoplastic based sandwich composites. Compos Part B: Eng. 2017;127:63–9.10.1016/j.compositesb.2017.06.027Search in Google Scholar

(7) Liu Y, Wu Y. Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact. Sci Eng Compos Mater. 2022;29(1):9–22.10.1515/secm-2022-0003Search in Google Scholar

(8) Wan Y, Liu Y, Hu C, Yao J, Wang F, Yang B. The failure mechanism of curved composite laminates subjected to low-velocity impact. Acta Mech Sin. 2023;39(12):423113.10.1007/s10409-023-23113-xSearch in Google Scholar

(9) Zhang L, Wang X, Lu S, Jiang X, Ma C, Lin L, et al. Fatigue damage monitoring of repaired composite wind turbine blades using high-stability buckypaper sensors. Compos Sci Technol. 2022;227:109592.10.1016/j.compscitech.2022.109592Search in Google Scholar

(10) Liu Y, Wan Y, Zhou S, Huang M, Zhao Z, Wang Y, et al. Experimental investigation on the compression-after-double-impact behaviors of GF/epoxy laminates embedded with/without metal wire nets. Case Stud Constr Mater. 2023;18:e01783.10.1016/j.cscm.2022.e01783Search in Google Scholar

(11) Zhang L, Xie Y, Lu S, Zhang B, Wang X, Li X, et al. Mechanical behavior monitoring of composite hybrid bonded-riveted joints using high-stability MXene sensors. Polym Compos. 2024;45(8):7316–28.10.1002/pc.28267Search in Google Scholar

(12) Li H, Jiang C, Wu Y, Huang Y, Wan Y, Chen R. Experimental study on the low-velocity impact failure mechanism of foam core sandwich panels with shape memory alloy hybrid face-sheets. Sci Eng Compos Mater. 2021;28(1):592–604.10.1515/secm-2021-0059Search in Google Scholar

(13) Birman V, Kardomateas GA. Review of current trends in research and applications of sandwich structures. Compos Part B: Eng. 2018;142:221–40.10.1016/j.compositesb.2018.01.027Search in Google Scholar

(14) Zhang J, Ye Y, Qin Q, Wang T. Low-velocity impact of sandwich beams with fibre-metal laminate face-sheets. Compos Sci Technol. 2018;168:152–9.10.1016/j.compscitech.2018.09.018Search in Google Scholar

(15) Wu X, Li Y, Cai W, Guo K, Zhu L. Dynamic responses and energy absorption of sandwich panel with aluminium honeycomb core under ice wedge impact. Int J Impact Eng. 2022;162:104137.10.1016/j.ijimpeng.2021.104137Search in Google Scholar

(16) Rajkumar S. Strength and stiffness characteristics of A3003 aluminum honeycomb core sandwich panels. Mater Today: Proc. 2021;37:1140–5.10.1016/j.matpr.2020.06.348Search in Google Scholar

(17) Zhang J, Yuan H, Li J, Meng J, Huang W. Dynamic response of multilayer curved aluminum honeycomb sandwich beams under low-velocity impact. Thin-Walled Struct. 2022;177:109446.10.1016/j.tws.2022.109446Search in Google Scholar

(18) Kobayashi M, Ogino H, Burman M, Wada D, Igawa H, Murayama H. Shape sensing for CFRP and aluminum honeycomb sandwich panel using inverse finite element method with distributed fiber-optic sensors. Compos Struct. 2023;308:116648.10.1016/j.compstruct.2022.116648Search in Google Scholar

(19) Wan Y, Wang L, Liu Y, Wu Y. Experimental investigation on the low-velocity impact response and the residual strength of CFRP tubes. Polym Compos. 2024;1–17.10.1002/pc.28368Search in Google Scholar

(20) Wan Y, Liu Y, Li H, Yao J, Yu Y, Zhao Z. Low-velocity impact and interlaminar damage mechanism of carbon fiber-metal mesh reinforced composites. Acta Mater Compos Sin. 2023;40(11):6351–62 (in Chinese).Search in Google Scholar

(21) Zhang J, Zhu Y, Yuan H, Huang W. Failure behavior of sandwich beams with glass fiber-reinforced epoxy/aluminum laminates face-sheets and aluminum honeycomb core under three-point bending. Thin-Walled Struct. 2022;177:109476.10.1016/j.tws.2022.109476Search in Google Scholar

(22) Funari MF, Greco F, Lonetti P. Sandwich panels under interfacial debonding mechanisms. Compos Struct. 2018;203:310–20.10.1016/j.compstruct.2018.06.113Search in Google Scholar

(23) Yang P, Shams SS, Slay A, Brokate B, Elhajjar R. Evaluation of temperature effects on low velocity impact damage in composite sandwich panels with polymeric foam cores. Compos Struct. 2015;129:213–23.10.1016/j.compstruct.2015.03.065Search in Google Scholar

(24) Gilioli A, Sbarufatti C, Manes A, Giglio M. Compression after impact test (CAI) on NOMEX™ honeycomb sandwich panels with thin aluminum skins. Compos Part B: Eng. 2014;67:313–25.10.1016/j.compositesb.2014.07.015Search in Google Scholar

(25) Yang B, Wang Z, Zhou L, Zhang J, Tong L, Liang W. Study on the low-velocity impact response and CAI behavior of foam-filled sandwich panels with hybrid facesheet. Compos Struct. 2015;132:1129–40.10.1016/j.compstruct.2015.07.058Search in Google Scholar

(26) Wu Y, Wan Y. The low-velocity impact and compression after impact (CAI) behavior of foam core sandwich panels with shape memory alloy hybrid face-sheets. Sci Eng Compos Mater. 2019;26(1):517–30.10.1515/secm-2019-0034Search in Google Scholar

(27) You P, Chen C, Wu Y, Zhang B, Tang X, Zhu D, et al. An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading. Sci Eng Compos Mater. 2022;29(1):466–72.10.1515/secm-2022-0169Search in Google Scholar

(28) Yuan K, Shen L, Xiong W, Yao S, He J, Wang Z. The impact and post-impact flexural behaviors of CFRP/aluminum-honeycomb sandwich. Int J Impact Eng. 2023;174:104507.10.1016/j.ijimpeng.2023.104507Search in Google Scholar

(29) Sun M, Wowk D, Mechefske C, Alexander E, Kim I. Surface and honeycomb core damage in adhesively bonded aluminum sandwich panels subjected to low-velocity impact. Compos Part B: Eng. 2022;230:109506.10.1016/j.compositesb.2021.109506Search in Google Scholar

(30) Zhang Y, Li Y, Guo K, Zhu L. Dynamic mechanical behaviour and energy absorption of aluminium honeycomb sandwich panels under repeated impact loads. Ocean Eng. 2021;219:108344.10.1016/j.oceaneng.2020.108344Search in Google Scholar

(31) Wan Y, Tang C, Jiang Z, Wang F, Hu C, Yang B. Structural enhancement and repair of CFRP T-joint by the cross-embedded SMA wire. Compos Commun. 2023;41:101634.10.1016/j.coco.2023.101634Search in Google Scholar

(32) Wan Y, Lu W, Li H, Huang Y, Lei Z, Yang B. Tensile behavior of the bolt-jointed GFRP after low-velocity impact. Polym Compos. 2023;44(5):2645–55.10.1002/pc.27267Search in Google Scholar

(33) Zhu K, Pan B. Deformation behaviors of defective aluminum honeycomb sandwich panels subjected to in-panel compressive loading: an experimental study with mirror-assisted multi-view DIC. Thin-Walled Struct. 2024;197:111592.10.1016/j.tws.2024.111592Search in Google Scholar

(34) He W, Lu S, Yi K, Wang S, Sun G, Hu Z. Residual flexural properties of CFRP sandwich structures with aluminum honeycomb cores after low-velocity impact. Int J Mech Sci. 2019;161–162:105026.10.1016/j.ijmecsci.2019.105026Search in Google Scholar

(35) Rizzo D, Epasto G, Valente T, Russo P. Mechanical behaviour of hybrid FFRP/aluminium honeycomb sandwich structures. Eng Fail Anal. 2023;154:107655.10.1016/j.engfailanal.2023.107655Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Flame-retardant thermoelectric responsive coating based on poly(3,4-ethylenedioxythiphene) modified metal–organic frameworks

- Highly stretchable, durable, and reversibly thermochromic wrapped yarns induced by Joule heating: With an emphasis on parametric study of elastane drafts

- Molecular dynamics simulation and experimental study on the mechanical properties of PET nanocomposites filled with CaCO3, SiO2, and POE-g-GMA

- Multifunctional hydrogel based on silk fibroin/thermosensitive polymers supporting implant biomaterials in osteomyelitis

- Marine antifouling coating based on fluorescent-modified poly(ethylene-co-tetrafluoroethylene) resin

- Preparation and application of profiled luminescent polyester fiber with reversible photochromism materials

- Determination of pesticide residue in soil samples by molecularly imprinted solid-phase extraction method

- The die swell eliminating mechanism of hot air assisted 3D printing of GF/PP and its influence on the product performance

- Rheological behavior of particle-filled polymer suspensions and its influence on surface structure of the coated electrodes

- The effects of property variation on the dripping behaviour of polymers during UL94 test simulated by particle finite element method

- Experimental evaluation on compression-after-impact behavior of perforated sandwich panel comprised of foam core and glass fiber reinforced epoxy hybrid facesheets

- Synthesis, characterization and evaluation of a pH-responsive molecular imprinted polymer for Matrine as an intelligent drug delivery system

- Twist-related parametric optimization of Joule heating-triggered highly stretchable thermochromic wrapped yarns using technique for order preference by similarity to ideal solution

- Comparative analysis of flow factors and crystallinity in conventional extrusion and gas-assisted extrusion

- Simulation approach to study kinetic heterogeneity of gadolinium catalytic system in the 1,4-cis-polyisoprene production

- Properties of kenaf fiber-reinforced polyamide 6 composites

- Cellulose acetate filter rods tuned by surface engineering modification for typical smoke components adsorption

- A blue fluorescent waterborne polyurethane-based Zn(ii) complex with antibacterial activity

- Experimental investigation on damage mechanism of GFRP laminates embedded with/without steel wire mesh under low-velocity-impact and post-impact tensile loading

- Preparation and application research of composites with low vacuum outgassing and excellent electromagnetic sealing performance

- Assessing the recycling potential of thermosetting polymer waste in high-density polyethylene composites for safety helmet applications

- Mesoscale mechanics investigation of multi-component solid propellant systems

- Preparation of HTV silicone rubber with hydrophobic–uvioresistant composite coating and the aging research

- Experimental investigation on tensile behavior of CFRP bolted joints subjected to hydrothermal aging

- Structure and transition behavior of crosslinked poly(2-(2-methoxyethoxy) ethylmethacrylate-co-(ethyleneglycol) methacrylate) gel film on cellulosic-based flat substrate

- Mechanical properties and thermal stability of high-temperature (cooking temperature)-resistant PP/HDPE/POE composites

- Preparation of itaconic acid-modified epoxy resins and comparative study on the properties of it and epoxy acrylates

- Synthesis and properties of novel degradable polyglycolide-based polyurethanes

- Fatigue life prediction method of carbon fiber-reinforced composites

- Thermal, morphological, and structural characterization of starch-based bio-polymers for melt spinnability

- Robust biaxially stretchable polylactic acid films based on the highly oriented chain network and “nano-walls” containing zinc phenylphosphonate and calcium sulfate whisker: Superior mechanical, barrier, and optical properties

- ARGET ATRP of styrene with low catalyst usage in bio-based solvent γ-valerolactone

- New PMMA-InP/ZnS nanohybrid coatings for improving the performance of c-Si photovoltaic cells

- Impacts of the calcinated clay on structure and gamma-ray shielding capacity of epoxy-based composites

- Preparation of cardanol-based curing agent for underwater drainage pipeline repairs

- Preparation of lightweight PBS foams with high ductility and impact toughness by foam injection molding

- Gamma-ray shielding investigation of nano- and microstructures of SnO on polyester resin composites: Experimental and theoretical study

- Experimental study on impact and flexural behaviors of CFRP/aluminum-honeycomb sandwich panel

- Normal-hexane treatment on PET-based waste fiber depolymerization process

- Effect of tannic acid chelating treatment on thermo-oxidative aging property of natural rubber

- Design, synthesis, and characterization of novel copolymer gel particles for water-plugging applications

- Influence of 1,1′-Azobis(cyclohexanezonitrile) on the thermo-oxidative aging performance of diolefin elastomers

- Characteristics of cellulose nanofibril films prepared by liquid- and gas-phase esterification processes

- Investigation on the biaxial stretching deformation mechanism of PA6 film based on finite element method

- Simultaneous effects of temperature and backbone length on static and dynamic properties of high-density polyethylene-1-butene copolymer melt: Equilibrium molecular dynamics approach

- Research on microscopic structure–activity relationship of AP particle–matrix interface in HTPB propellant

- Three-layered films enable efficient passive radiation cooling of buildings

- Electrospun nanofibers membranes of La(OH)3/PAN as a versatile adsorbent for fluoride remediation: Performance and mechanisms

- Preparation and characterization of biodegradable polyester fibers enhanced with antibacterial and antiviral organic composites

- Preparation of hydrophobic silicone rubber composite insulators and the research of anti-aging performance

- Surface modification of sepiolite and its application in one-component silicone potting adhesive

- Study on hydrophobicity and aging characteristics of epoxy resin modified with nano-MgO

- Optimization of baffle’s height in an asymmetric twin-screw extruder using the response surface model

- Effect of surface treatment of nickel-coated graphite on conductive rubber

- Experimental investigation on low-velocity impact and compression after impact behaviors of GFRP laminates with steel mesh reinforced

- Development and characterization of acetylated and acetylated surface-modified tapioca starches as a carrier material for linalool

- Investigation of the compaction density of electromagnetic moulding of poly(ether-ketone-ketone) polymer powder

- Experimental investigation on low-velocity-impact and post-impact-tension behaviors of GFRP T-joints after hydrothermal aging

- The repeated low-velocity impact response and damage accumulation of shape memory alloy hybrid composite laminates

- Exploring a new method for high-performance TPSiV preparation through innovative Si–H/Pt curing system in VSR/TPU blends

- Large-scale production of highly responsive, stretchable, and conductive wrapped yarns for wearable strain sensors

- Preparation of natural raw rubber and silica/NR composites with low generation heat through aqueous silane flocculation

- Molecular dynamics simulation of the interaction between polybutylene terephthalate and A3 during thermal-oxidative aging

- Crashworthiness of GFRP/aluminum hybrid square tubes under quasi-static compression and single/repeated impact

- Review Articles

- Recent advancements in multinuclear early transition metal catalysts for olefin polymerization through cooperative effects

- Impact of ionic liquids on the thermal properties of polymer composites

- Recent progress in properties and application of antibacterial food packaging materials based on polyvinyl alcohol

- Additive manufacturing (3D printing) technologies for fiber-reinforced polymer composite materials: A review on fabrication methods and process parameters

- Rapid Communication

- Design, synthesis, characterization, and adsorption capacities of novel superabsorbent polymers derived from poly (potato starch xanthate-graft-acrylamide)

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Development of smart core–shell nanoparticles-based sensors for diagnostics of salivary alpha-amylase in biomedical and forensics

- Thermoplastic-polymer matrix composite of banana/betel nut husk fiber reinforcement: Physico-mechanical properties evaluation

- Special Issue: Electrospun Functional Materials

- Electrospun polyacrylonitrile/regenerated cellulose/citral nanofibers as active food packagings

Articles in the same Issue

- Research Articles

- Flame-retardant thermoelectric responsive coating based on poly(3,4-ethylenedioxythiphene) modified metal–organic frameworks

- Highly stretchable, durable, and reversibly thermochromic wrapped yarns induced by Joule heating: With an emphasis on parametric study of elastane drafts

- Molecular dynamics simulation and experimental study on the mechanical properties of PET nanocomposites filled with CaCO3, SiO2, and POE-g-GMA

- Multifunctional hydrogel based on silk fibroin/thermosensitive polymers supporting implant biomaterials in osteomyelitis

- Marine antifouling coating based on fluorescent-modified poly(ethylene-co-tetrafluoroethylene) resin

- Preparation and application of profiled luminescent polyester fiber with reversible photochromism materials

- Determination of pesticide residue in soil samples by molecularly imprinted solid-phase extraction method

- The die swell eliminating mechanism of hot air assisted 3D printing of GF/PP and its influence on the product performance

- Rheological behavior of particle-filled polymer suspensions and its influence on surface structure of the coated electrodes

- The effects of property variation on the dripping behaviour of polymers during UL94 test simulated by particle finite element method

- Experimental evaluation on compression-after-impact behavior of perforated sandwich panel comprised of foam core and glass fiber reinforced epoxy hybrid facesheets

- Synthesis, characterization and evaluation of a pH-responsive molecular imprinted polymer for Matrine as an intelligent drug delivery system

- Twist-related parametric optimization of Joule heating-triggered highly stretchable thermochromic wrapped yarns using technique for order preference by similarity to ideal solution

- Comparative analysis of flow factors and crystallinity in conventional extrusion and gas-assisted extrusion

- Simulation approach to study kinetic heterogeneity of gadolinium catalytic system in the 1,4-cis-polyisoprene production

- Properties of kenaf fiber-reinforced polyamide 6 composites

- Cellulose acetate filter rods tuned by surface engineering modification for typical smoke components adsorption

- A blue fluorescent waterborne polyurethane-based Zn(ii) complex with antibacterial activity

- Experimental investigation on damage mechanism of GFRP laminates embedded with/without steel wire mesh under low-velocity-impact and post-impact tensile loading

- Preparation and application research of composites with low vacuum outgassing and excellent electromagnetic sealing performance

- Assessing the recycling potential of thermosetting polymer waste in high-density polyethylene composites for safety helmet applications

- Mesoscale mechanics investigation of multi-component solid propellant systems

- Preparation of HTV silicone rubber with hydrophobic–uvioresistant composite coating and the aging research

- Experimental investigation on tensile behavior of CFRP bolted joints subjected to hydrothermal aging

- Structure and transition behavior of crosslinked poly(2-(2-methoxyethoxy) ethylmethacrylate-co-(ethyleneglycol) methacrylate) gel film on cellulosic-based flat substrate

- Mechanical properties and thermal stability of high-temperature (cooking temperature)-resistant PP/HDPE/POE composites

- Preparation of itaconic acid-modified epoxy resins and comparative study on the properties of it and epoxy acrylates

- Synthesis and properties of novel degradable polyglycolide-based polyurethanes

- Fatigue life prediction method of carbon fiber-reinforced composites

- Thermal, morphological, and structural characterization of starch-based bio-polymers for melt spinnability

- Robust biaxially stretchable polylactic acid films based on the highly oriented chain network and “nano-walls” containing zinc phenylphosphonate and calcium sulfate whisker: Superior mechanical, barrier, and optical properties

- ARGET ATRP of styrene with low catalyst usage in bio-based solvent γ-valerolactone

- New PMMA-InP/ZnS nanohybrid coatings for improving the performance of c-Si photovoltaic cells

- Impacts of the calcinated clay on structure and gamma-ray shielding capacity of epoxy-based composites

- Preparation of cardanol-based curing agent for underwater drainage pipeline repairs

- Preparation of lightweight PBS foams with high ductility and impact toughness by foam injection molding

- Gamma-ray shielding investigation of nano- and microstructures of SnO on polyester resin composites: Experimental and theoretical study

- Experimental study on impact and flexural behaviors of CFRP/aluminum-honeycomb sandwich panel

- Normal-hexane treatment on PET-based waste fiber depolymerization process

- Effect of tannic acid chelating treatment on thermo-oxidative aging property of natural rubber

- Design, synthesis, and characterization of novel copolymer gel particles for water-plugging applications

- Influence of 1,1′-Azobis(cyclohexanezonitrile) on the thermo-oxidative aging performance of diolefin elastomers

- Characteristics of cellulose nanofibril films prepared by liquid- and gas-phase esterification processes

- Investigation on the biaxial stretching deformation mechanism of PA6 film based on finite element method

- Simultaneous effects of temperature and backbone length on static and dynamic properties of high-density polyethylene-1-butene copolymer melt: Equilibrium molecular dynamics approach

- Research on microscopic structure–activity relationship of AP particle–matrix interface in HTPB propellant

- Three-layered films enable efficient passive radiation cooling of buildings

- Electrospun nanofibers membranes of La(OH)3/PAN as a versatile adsorbent for fluoride remediation: Performance and mechanisms

- Preparation and characterization of biodegradable polyester fibers enhanced with antibacterial and antiviral organic composites

- Preparation of hydrophobic silicone rubber composite insulators and the research of anti-aging performance

- Surface modification of sepiolite and its application in one-component silicone potting adhesive

- Study on hydrophobicity and aging characteristics of epoxy resin modified with nano-MgO

- Optimization of baffle’s height in an asymmetric twin-screw extruder using the response surface model

- Effect of surface treatment of nickel-coated graphite on conductive rubber

- Experimental investigation on low-velocity impact and compression after impact behaviors of GFRP laminates with steel mesh reinforced

- Development and characterization of acetylated and acetylated surface-modified tapioca starches as a carrier material for linalool

- Investigation of the compaction density of electromagnetic moulding of poly(ether-ketone-ketone) polymer powder

- Experimental investigation on low-velocity-impact and post-impact-tension behaviors of GFRP T-joints after hydrothermal aging

- The repeated low-velocity impact response and damage accumulation of shape memory alloy hybrid composite laminates

- Exploring a new method for high-performance TPSiV preparation through innovative Si–H/Pt curing system in VSR/TPU blends

- Large-scale production of highly responsive, stretchable, and conductive wrapped yarns for wearable strain sensors

- Preparation of natural raw rubber and silica/NR composites with low generation heat through aqueous silane flocculation

- Molecular dynamics simulation of the interaction between polybutylene terephthalate and A3 during thermal-oxidative aging

- Crashworthiness of GFRP/aluminum hybrid square tubes under quasi-static compression and single/repeated impact

- Review Articles

- Recent advancements in multinuclear early transition metal catalysts for olefin polymerization through cooperative effects

- Impact of ionic liquids on the thermal properties of polymer composites

- Recent progress in properties and application of antibacterial food packaging materials based on polyvinyl alcohol

- Additive manufacturing (3D printing) technologies for fiber-reinforced polymer composite materials: A review on fabrication methods and process parameters

- Rapid Communication

- Design, synthesis, characterization, and adsorption capacities of novel superabsorbent polymers derived from poly (potato starch xanthate-graft-acrylamide)

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Development of smart core–shell nanoparticles-based sensors for diagnostics of salivary alpha-amylase in biomedical and forensics

- Thermoplastic-polymer matrix composite of banana/betel nut husk fiber reinforcement: Physico-mechanical properties evaluation

- Special Issue: Electrospun Functional Materials

- Electrospun polyacrylonitrile/regenerated cellulose/citral nanofibers as active food packagings