Abstract

Industrial processes are the main generator of littering agents, and the growing environmental awareness has contributed to a focus on the issue of littering. One of the biggest environmental issues in the world is how to manage this waste given the limited space available, the high cost of remediation, and the need for landfilling. However, the idea of reusing some of this waste is an alternative solution to decreasing the process of landfilling, and reducing the increase of waste. In this research, three different waste materials were used, namely plastic waste, aluminum waste, and silica sand. Each of these materials was mixed in a ratio of 1, 3, and 5%, with silty sand soil. The consistency limits of maximum dry density and the optimal ratio for the preferred materials were determined by examining and comparing cohesiveness and angle of internal friction. Research results showed that the maximum unit weight decreased after adding the waste materials: it decreased by 9.35 and 11.69% when 5% each of aluminum and plastic waste was added, respectively. At the same time, the increase in the inner angle of internal friction reached 26.41% at the highest percentage of plastic waste. The addition of 3% of silica sand gave the highest value of cohesion, and the increase reached 218.7% for soils not treated with silica. It also showed the effect of adding 1% of silica sand on the plasticity, reducing it by 72.7% from its original value.

1 Introduction

The aim of modification, which is one of the uses of engineering soil, whether by the chemical or mechanical method, is for the purpose of improving the soil such as the soil of sedimentary plain south of Iraq [1,2]. Furthermore, one of the aims of improvement is to improve and boost the soil’s bearing capacity. On the other hand, it may help in reducing the amount of waste and its risks to the environment, in an environment-friendly and inexpensive manner, compared to the cost of materials previously used for soil stabilization. The most popular technique for stabilizing soil is to add chemicals to it. The mechanical qualities of soil have been improved by researchers using cement, lime, and other binders, but in recent years, the utilization of solid wastes including plastic, glass, metal, rubber, and fabric fibers has received attention. This was done to increase these qualities, make them easier to mix with the soil, increase the soil’s shear strength due to their non-interaction and tensile strength, as well as to get rid of the waste in a helpful and healthy way because it is currently an issue for all countries. The reed fibers and industrial glass fibers were used as soil reinforcement fibers. Also fabrics, commercially available materials, were used for floor coverings. The results showed an increase in soil strength commensurate with the amount of fiber used, but this increase reached a specific value and did not exceed it [3]. The effect of adding polyethylene fibers (waste plastic bottles) was studied, randomly distributed, to fine sand, and subjected to an unconfined compression test and saturated drained tests. The results showed an increase in soil resistance by increasing the percentage of fibers [4]. A direct shear test on soil that contained plastic fibers was carried out by Naeini and Sadjadi (2008). The findings revealed an improvement in the shear coefficients (c and φ) as well as an increase in the shear strength [5]. In order to study the impact of industrial aluminum scraps on clay soil, Zuheir et al. [6] performed altered compaction and unconfined compression tests for five different additive percentages. The test findings revealed a rise in the dry density, an increase in the compression strength, and a drop in the optimal water content by increasing the proportion of aluminum added up to 10%; however, this strength reduced by raising the percentage beyond that threshold [7]. Wang et al. (2017) developed a technique to produce new, porous and permeable sandy soil from recycled glass waste and sand (glass sandy soil). The permeability of glass sandy soil was investigated using various glass waste percentages, smoothing value, and glass particle size. Research revealed that the best permeability was obtained when 20% of glass trash was recycled with sand [8]. Syed and Sudipta [9] looked into how glass powder affected cohesive soils. A significant portion of the original soil was combined with the glass powder, and the mixture was then tested for geotechnical stability. As a result of lower liquid limit (LL) and plastic limit (PL) values and higher maximum dry densities (MDDs), the plasticity index (PI) decreased. This was accomplished by raising the value of California bearing ratio and the unconfined compressive strength of the glass powder, up to 8%, while lowering the ideal moisture content. When the additive percentage was raised, though, it fell [10]. Therefore, the main objective of this study was to demonstrate the effect of adding the used waste on the properties of the soil because it is available in large quantities in the environment and is chemically inert and does not interact with the water in the soil.

2 Materials and methods

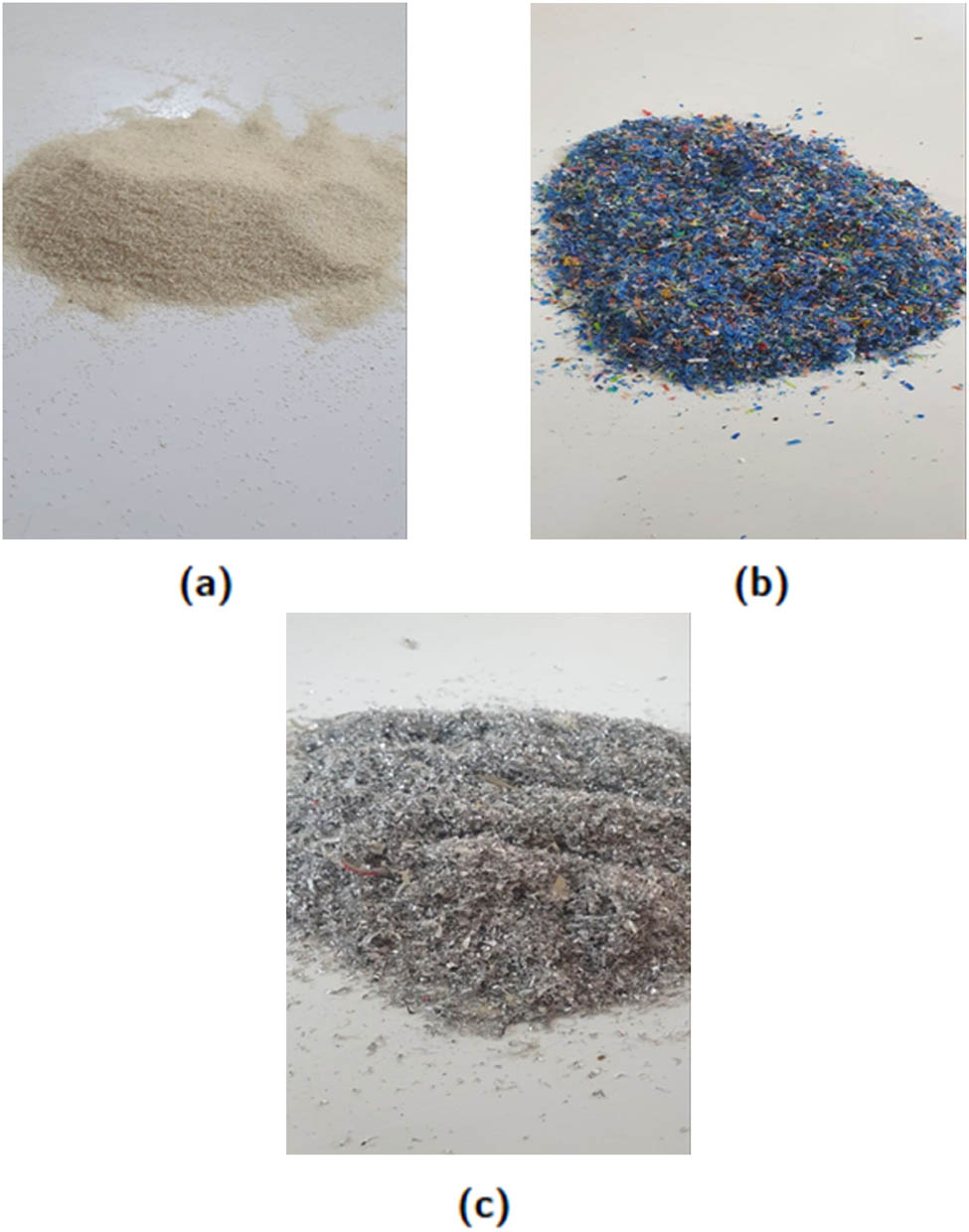

Soil: Silty sand soil from the Wasit Governorate in western Iraq was transported for use in this investigation. The physical characteristics of the soils utilized were determined through “standard tests,” as indicated in Table 1. Three different forms of solid waste were used in this study. Plastic garbage was transported from Baghdad’s Organization for Plastic Industries. This was divided into pieces with a thickness of 0.5 mm and a length of 1–3 mm. The substance was made of polyethylene and had a specific gravity of 0.93. Pieces of aluminum (0.3–0.6 mm in size) were collected from the waste of factories that used aluminum in the manufacture of windows, doors, and others. The soil was well dried by air, and then each of these materials was mixed in a ratio of 0, 1, 3, and 5% with the soil, and then a modified compaction test and a direct shear test were performed for the examination of the Atterberg limits. It was conducted only on the soil mixed with glass powder, due to its smoothness, because only soil that had passed through sieve no. 40 in accordance with the specifications was used for the examination. Due to the smoothness of the mixed soil – the texture check was only performed on soil passing through sieve no. 40 – the American Society for Testing and Materials’ (ASTM) standards were checked for each of the additives and for each ratio with silica sand powder. This was done in accordance with the requirements of “ASTM:D 4318-00” (Figures 1 and 2).

Physical properties of the silty sand soil

| Physical properties | Index value | Standards |

|---|---|---|

| Specific gravity (G s) | 2.69 | ASTM: D854-02 |

| LL% | 47 | ASTM: D4318-00 |

| PL% | 28 | ASTM: D4318-00 |

| PI% | 19 | ASTM: D4318-00 |

| Sand% | 69 | |

| Fine particles% | 31 | |

| Maximum dry unit weight (kN/m3) | 17.1 | ASTM: D698 |

| Optimum moisture content% | 22.63 | ASTM: D698 |

| Soil classification (USCS) | SM | ASTM: D698ASTM: D2487-00 |

| Angle of internal friction Φ | 36.8 | ASTM: D2435 |

| Cohesion C (kPa) | 11.053 | ASTM: D2435 |

The waste materials used in the study. (a) Silica sand, (b) plastic waste, and (c) aluminum waste.

The grain size distribution of the soil sample.

3 Results and discussion

3.1 Compaction test

The dry soil and solid waste were combined separately for this test in conformance with ASTM D:698 in order to determine the MDD and optimal moisture content (OMC), respectively, in order to take advantage of the latter and prepare samples for “the direct shear test.” However, soil samples with various water contents were prepared for Proctor Test and the size of the mold is 4 inch diameter with 3 layers and each layer was compacted 25 blows (as shown in Figure 3). The outcomes of these tests are shown in Figures 4–8.

Proctor mold.

Compaction curves for various percentages of aluminum waste.

Compaction curves for various percentages of plastic waste.

Compaction curves for various percentages of silica sand.

Variation in OMC% at various percentages of three waste materials.

Soil samples maximum dry density and waste material percentage relationship.

As shown in the previous figures and Table 2, we see a drop in the dry unit weight of the soil with just a rise in waste materials. This is helpful while constructing dams, which call for using light materials. These findings concur with those made by many previous studies [11–15]. The results show that MDD was decreased 11.69 and 9.35% for each of the plastic and aluminum waste, respectively, when adding 5% for each of them, compared to that decrease that occurred when adding silica sand waste, as the percentage of reduction was (4.67, 4.03, and 1.75)% when adding silica sand by (1, 3, and 5)%, respectively. We also noticed a decrease in the optimum water content percentage only when adding 1% of the plastic waste, as it was 28.46%. Adding 1 and 5% of silica sand, it was 28.46%, whereas when adding 1 and 5% of silica sand, it was 20.46 and 12.95%, respectively. Also, adding 3% silica sand shows that the percentage of increase was not noticeable as it was 3.4%. It could be the reason for the low specific gravity of plastic and aluminum waste; while silica sand has a similar composition to the original soil, there is a slight difference in value for this addition compared to the other additions. Also, we can notice a 28.45% decrease in OMC for 1% of plastic waste; at 1 and 5% of silica sand, the decrease was 20.45 and 12.94%, respectively. The optimum moisture content increases for the rest in the percentage of waste materials. This result may be that the water in the soil needs to be hydrated, which is similar to the result by Kadhim et at. [16].

Test results of the soil sample incorporated with waste material for maximum dry density and optimum moisture content

| Waste material | Soil description | MDD (cm3/g) | OMC% |

|---|---|---|---|

| Plastic waste | Soil without additive | 1.71 | 22.63 |

| Soil with 1% plastic | 1.70 | 16.19 | |

| Soil with 3% plastic | 1.54 | 26.10 | |

| Soil with 5% plastic | 1.51 | 14.10 | |

| Aluminum waste | Soil without additive | 1.71 | 22.63 |

| Soil with 1% aluminum | 1.59 | 26.10 | |

| Soil with 3% aluminum | 1.61 | 26.40 | |

| Soil with 5% aluminum | 1.55 | 27.90 | |

| Silica sand | Soil without additive | 1.71 | 22.63 |

| Soil with 1% silica sand | 1.63 | 18.00 | |

| Soil with 3% silica sand | 1.64 | 23.40 | |

| Soil with 5% silica sand | 1.68 | 19.70 |

3.2 Direct shear test

Direct shear test was employed on soil samples having various ratios of soild waste. As the MDD and optimum water content were used for each of the previously used samples in the compaction test in preparing the sample for this test, samples having a volume of 60 mm × 60 mm × 20 mm were prepared, and the applied stress was 1.25 mm per minute; Figure 9 shows a picture of the direct shear test device used. Figures 10–13 show the results of this test.

Direct shear test device.

Friction angle (Φ) and percentages of waste relationship.

Cohesion (C) and various percentages of waste relationship.

Variation of angle of friction due to various percentages of three waste materials.

Variation of soil cohesion due to percentages of three waste materials.

Through the previous figures and Table 3, after applying plastic and silica sand, we observed a rise in the value of the interior friction angle and a rise in the percentage, and this was close to what was found in the research of Nsaif [13]. From this research, we noticed an increase in the angle of internal friction of the soil when adding plastic and aluminum wastes in most of the added percentages, as it increased by 11.34 and 26.41% when adding 3 and 5% of the plastic waste material, respectively. In addition, the rate of increase was 22.09 and 9.23% for the ratios of 1 and 5, respectively, for aluminum waste. However, the increase was 6.84% for the silica sand when adding 5% of the plastic waste material. As a result, the aluminum and plastic waste materials had more influence on the friction angle, perhaps due to the increase in surface area of these two materials, which is more than the surface area of the soil particle, compared with the silica sand material, which has a similar size to the soil particle. As for cohesion, it is also possible to notice an increase in cohesion when 1 to 3% plastic material is added: the increases in cohesion were 146.35 and 9.47%, respectively. When adding aluminum and silica sand, the increase was clear at a ratio of 3 and 5% for both materials: for aluminum, it was 175.94 and 152.42% for each of the 3 and 5%, respectively, and for silica sand the increase was 218.7 and 138.4% for each of the 3 and 5%, respectively. This test’s outline was similar to what Hamid [15] discovered in his research. According to the aforementioned results, the best percentage for each of the additives is plastic material at 3%, aluminum at 4%, and silica sand material at 5%, which is affected by increasing cohesion and angle of friction and thus increasing the shear resistance of the soil.

Results of direct shear test on the soil mixes with waste materials

| Waste material | Soil description | Angle friction Φ | Cohesion C (kPa) |

|---|---|---|---|

| Plastic waste | Soil without additive | 32.60 | 11.053 |

| Soil with 1% plastic | 20.20 | 27.23 | |

| Soil with 3% plastic | 36.30 | 12.10 | |

| Soil with 5% plastic | 41.21 | 3.13 | |

| Aluminum waste | Soil without additive | 32.60 | 11.053 |

| Soil with 1% aluminum | 39.80 | 9.10 | |

| Soil with 3% aluminum | 32.20 | 30.50 | |

| Soil with 5% aluminum | 35.61 | 27.90 | |

| Silica sand | Soil without additive | 32.60 | 11.053 |

| Soil with 1% silica sand | 22.98 | 6.00 | |

| Soil with 3% silica sand | 23.00 | 35.23 | |

| Soil with 5% silica sand | 34.83 | 26.38 |

3.3 Consistency limits

The results of LL, PL, and PI with varying percentages of silica sand are shown in Figure 14. It can be seen from this figure that LL was decreased with the increase in the percentage of silica sand. On the other hand, PL was slightly increased when 1% of silica sand was added; the values were gradually decreased when the percentage of silica sand was increased. This affects the value of PI, transforming the soil from high plasticity to medium plastic soil [17]. The decrease in the value of PI was 42.11, 21.05, and 15.78% for each of the 1, 3, and 5%, respectively. This could be due to the activity of silica sand during hydration. This decrease leads to a decrease in the compressibility and swelling of the soil; hence, this soil can be used to improve the soil subgrade.

Effect of silica sand on consistency limits.

4 Conclusions

The test findings presented in this study demonstrate how silty sand reacts to different amounts of waste materials.

MDD decreases with the increase in percentage of all waste materials (plastic waste, aluminum waste, and silica sand) that were added to the silty sand soil and the maximum value of decrease was at 5% additive from plastic waste material.

OMC decreases by 28.45% due to 1% plastic waste addition. While OMC decreases by 20.45% and 12.45% due to 1% and 5% silica sand addition respectively.

The amount of additional material increases as the specified maximum weight decreases.

In general, as the amount of additive material increases, the degree of frictional resistance also increases.

The best percentage for plastic waste, aluminum and silica sand additives for soil cohesion and soil friction angle improvement were 3%, 5% and 5% respectively.

Increasing the addition of silica sand waste led to a decrease in the plasticity (PI) and this decrease leads to a decrease in the compressibility and swelling of the soil; hence, this soil can be used to improve the soil subgrade.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: Most datasets generated and analyzed in this study are comprised in this submitted manuscript. The other datasets are available on reasonable request from the corresponding author with the attached information.

References

[1] Imariq SM, Abdul-Sahib AA, Saleem HD, Shamkhi MS. Quantify distribution of topsoil erodibility factor for watersheds that feed the Al-Shewicha trough–Iraq using GIS. Open Eng. 2022;12(1):769–77.10.1515/eng-2022-0328Search in Google Scholar

[2] Shamkhi MS, Al-Badry HJ. Soil texture distribution for east wasit province, Iraq. In IOP Conference Series: Earth and Environmental Science. Vol. 961. IOP Publishing; 2022. p. 012073.10.1088/1755-1315/961/1/012073Search in Google Scholar

[3] Hassan HJA, Rasul J, Samin M. Effects of plastic waste materials on geotechnical properties of clayey soil. Transp Infrastruct Geotechnol. 2021;8(3):390–413.Search in Google Scholar

[4] Consoli NC, Montardo JP, Prietto PDM, Pasa GS. Engineering behavior of a sand reinforced with plastic waste. J Geotech Geoenviron Eng. 2002;128(6):462–72.10.1061/(ASCE)1090-0241(2002)128:6(462)Search in Google Scholar

[5] Naeini SA, Sadjadi SM. Effect of waste polymer materials on shear strength of unsaturated clays. Electron J Geotech Eng. 2008;13(Bund. K):1–12.Search in Google Scholar

[6] Zuheir K, Ali FC, Nurullah A. The Behavior of Clayey Reinforced with Waste Aluminum Pieces. Procedia Earth and Planet. Sci. 2015;15:353–8.Search in Google Scholar

[7] Karabash Z, Çabalar AF, Akbulut N. The behavior of clayey soil reinforced with waste aluminium pieces. Procedia Earth Planet Sci. 2015;15:353–8.10.1016/j.proeps.2015.08.088Search in Google Scholar

[8] Wang F, Feng X, Gong H, Zhao H. Study of permeability of glass-sand soil. Arch Civ Eng. 2017;63(3):175–90.10.1515/ace-2017-0036Search in Google Scholar

[9] Syed AJ, Sudipta C. Effect of Waste Glass Powder on Subgrade Soil Improvement. Int. Sci. J. 2020;144:30–42.Search in Google Scholar

[10] Javed SA, Chakraborty S. Effects of waste glass powder on subgrade soil improvement. World Sci News. 2020;144:30–42.Search in Google Scholar

[11] Małek M, Łasica W, Jackowski M, Kadela M. Effect of waste glass addition as a replacement for fine aggregate on properties of mortar. Materials. 2020;13(14):3189.10.3390/ma13143189Search in Google Scholar PubMed PubMed Central

[12] Hassan H, Rasul J, Samin M. Effects of plastic waste materials on geotechnical properties of clayey soil. Transp Infrastruct Geotechnol. 2021;9(8):390–413.10.1007/s40515-020-00145-4Search in Google Scholar

[13] Nsaif MH. Behavior of soils strengthened by plastic waste materials. J Eng Sustain Dev. 2013;17(4):182–94.Search in Google Scholar

[14] Dixit S. Effect of waste plastic on the strength characteristics of the subgrade for the flexible pavement. GRD J-Global Res Dev J Eng. 2017;2(11):19–33.Search in Google Scholar

[15] Hamid A. Use of waste plastics for the enhancement of soil properties: a recent advancement in geotechnical engineering. Int J Eng Res Technol. 2017;6(7):102–11.10.17577/IJERTV6IS070079Search in Google Scholar

[16] Kadhim YM, Al-Adhamii RA, Fattah MY. Geotechnical properties of clayey soil improved by sewage sludge ash. J Air Waste Manag Assoc. 2022;72(1):34–47.10.1080/10962247.2020.1862939Search in Google Scholar PubMed

[17] Murthy V. Textbook of soil mechanics and foundation engineering-geotechnical engineering series. New Delhi: Pvt: Statish Kumar Jain; 2007.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Design optimization of a 4-bar exoskeleton with natural trajectories using unique gait-based synthesis approach

- Technical review of supervised machine learning studies and potential implementation to identify herbal plant dataset

- Effect of ECAP die angle and route type on the experimental evolution, crystallographic texture, and mechanical properties of pure magnesium

- Design and characteristics of two-dimensional piezoelectric nanogenerators

- Hybrid and cognitive digital twins for the process industry

- Discharge predicted in compound channels using adaptive neuro-fuzzy inference system (ANFIS)

- Human factors in aviation: Fatigue management in ramp workers

- LLDPE matrix with LDPE and UV stabilizer additive to evaluate the interface adhesion impact on the thermal and mechanical degradation

- Dislocated time sequences – deep neural network for broken bearing diagnosis

- Estimation method of corrosion current density of RC elements

- A computational iterative design method for bend-twist deformation in composite ship propeller blades for thrusters

- Compressive forces influence on the vibrations of double beams

- Research on dynamical properties of a three-wheeled electric vehicle from the point of view of driving safety

- Risk management based on the best value approach and its application in conditions of the Czech Republic

- Effect of openings on simply supported reinforced concrete skew slabs using finite element method

- Experimental and simulation study on a rooftop vertical-axis wind turbine

- Rehabilitation of overload-damaged reinforced concrete columns using ultra-high-performance fiber-reinforced concrete

- Performance of a horizontal well in a bounded anisotropic reservoir: Part II: Performance analysis of well length and reservoir geometry

- Effect of chloride concentration on the corrosion resistance of pure Zn metal in a 0.0626 M H2SO4 solution

- Numerical and experimental analysis of the heat transfer process in a railway disc brake tested on a dynamometer stand

- Design parameters and mechanical efficiency of jet wind turbine under high wind speed conditions

- Architectural modeling of data warehouse and analytic business intelligence for Bedstead manufacturers

- Influence of nano chromium addition on the corrosion and erosion–corrosion behavior of cupronickel 70/30 alloy in seawater

- Evaluating hydraulic parameters in clays based on in situ tests

- Optimization of railway entry and exit transition curves

- Daily load curve prediction for Jordan based on statistical techniques

- Review Articles

- A review of rutting in asphalt concrete pavement

- Powered education based on Metaverse: Pre- and post-COVID comprehensive review

- A review of safety test methods for new car assessment program in Southeast Asian countries

- Communication

- StarCrete: A starch-based biocomposite for off-world construction

- Special Issue: Transport 2022 - Part I

- Analysis and assessment of the human factor as a cause of occurrence of selected railway accidents and incidents

- Testing the way of driving a vehicle in real road conditions

- Research of dynamic phenomena in a model engine stand

- Testing the relationship between the technical condition of motorcycle shock absorbers determined on the diagnostic line and their characteristics

- Retrospective analysis of the data concerning inspections of vehicles with adaptive devices

- Analysis of the operating parameters of electric, hybrid, and conventional vehicles on different types of roads

- Special Issue: 49th KKBN - Part II

- Influence of a thin dielectric layer on resonance frequencies of square SRR metasurface operating in THz band

- Influence of the presence of a nitrided layer on changes in the ultrasonic wave parameters

- Special Issue: ICRTEEC - 2021 - Part III

- Reverse droop control strategy with virtual resistance for low-voltage microgrid with multiple distributed generation sources

- Special Issue: AESMT-2 - Part II

- Waste ceramic as partial replacement for sand in integral waterproof concrete: The durability against sulfate attack of certain properties

- Assessment of Manning coefficient for Dujila Canal, Wasit/-Iraq

- Special Issue: AESMT-3 - Part I

- Modulation and performance of synchronous demodulation for speech signal detection and dialect intelligibility

- Seismic evaluation cylindrical concrete shells

- Investigating the role of different stabilizers of PVCs by using a torque rheometer

- Investigation of high-turbidity tap water problem in Najaf governorate/middle of Iraq

- Experimental and numerical evaluation of tire rubber powder effectiveness for reducing seepage rate in earth dams

- Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation

- Assessment for behavior of axially loaded reinforced concrete columns strengthened by different patterns of steel-framed jacket

- Novel graph for an appropriate cross section and length for cantilever RC beams

- Discharge coefficient and energy dissipation on stepped weir

- Numerical study of the fluid flow and heat transfer in a finned heat sink using Ansys Icepak

- Integration of numerical models to simulate 2D hydrodynamic/water quality model of contaminant concentration in Shatt Al-Arab River with WRDB calibration tools

- Study of the behavior of reactive powder concrete RC deep beams by strengthening shear using near-surface mounted CFRP bars

- The nonlinear analysis of reactive powder concrete effectiveness in shear for reinforced concrete deep beams

- Activated carbon from sugarcane as an efficient adsorbent for phenol from petroleum refinery wastewater: Equilibrium, kinetic, and thermodynamic study

- Structural behavior of concrete filled double-skin PVC tubular columns confined by plain PVC sockets

- Probabilistic derivation of droplet velocity using quadrature method of moments

- A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar

- Effect of waste materials on soil properties

- Experimental investigation of electrode wear assessment in the EDM process using image processing technique

- Punching shear of reinforced concrete slabs bonded with reactive powder after exposure to fire

- Deep learning model for intrusion detection system utilizing convolution neural network

- Improvement of CBR of gypsum subgrade soil by cement kiln dust and granulated blast-furnace slag

- Investigation of effect lengths and angles of the control devices below the hydraulic structure

- Finite element analysis for built-up steel beam with extended plate connected by bolts

- Finite element analysis and retrofit of the existing reinforced concrete columns in Iraqi schools by using CFRP as confining technique

- Performing laboratory study of the behavior of reactive powder concrete on the shear of RC deep beams by the drilling core test

- Special Issue: AESMT-4 - Part I

- Depletion zones of groundwater resources in the Southwest Desert of Iraq

- A case study of T-beams with hybrid section shear characteristics of reactive powder concrete

- Feasibility studies and their effects on the success or failure of investment projects. “Najaf governorate as a model”

- Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

- Effect of the 40-PPI copper foam layer height on the solar cooker performance

- Identification and investigation of corrosion behavior of electroless composite coating on steel substrate

- Improvement in the California bearing ratio of subbase soil by recycled asphalt pavement and cement

- Some properties of thermal insulating cement mortar using Ponza aggregate

- Assessment of the impacts of land use/land cover change on water resources in the Diyala River, Iraq

- Effect of varied waste concrete ratios on the mechanical properties of polymer concrete

- Effect of adverse slope on performance of USBR II stilling basin

- Shear capacity of reinforced concrete beams with recycled steel fibers

- Extracting oil from oil shale using internal distillation (in situ retorting)

- Influence of recycling waste hardened mortar and ceramic rubbish on the properties of flowable fill material

- Rehabilitation of reinforced concrete deep beams by near-surface-mounted steel reinforcement

- Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

- Studying pandemic effects and mitigation measures on management of construction projects: Najaf City as a case study

- Design and implementation of a frequency reconfigurable antenna using PIN switch for sub-6 GHz applications

- Average monthly recharge, surface runoff, and actual evapotranspiration estimation using WetSpass-M model in Low Folded Zone, Iraq

- Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads

- Assessment of ALINEA method performance at different loop detector locations using field data and micro-simulation modeling via AIMSUN

- Special Issue: AESMT-5 - Part I

- Experimental and theoretical investigation of the structural behavior of reinforced glulam wooden members by NSM steel bars and shear reinforcement CFRP sheet

- Improving the fatigue life of composite by using multiwall carbon nanotubes

- A comparative study to solve fractional initial value problems in discrete domain

- Assessing strength properties of stabilized soils using dynamic cone penetrometer test

- Investigating traffic characteristics for merging sections in Iraq

- Enhancement of flexural behavior of hybrid flat slab by using SIFCON

- The main impacts of a managed aquifer recharge using AHP-weighted overlay analysis based on GIS in the eastern Wasit province, Iraq

Articles in the same Issue

- Regular Articles

- Design optimization of a 4-bar exoskeleton with natural trajectories using unique gait-based synthesis approach

- Technical review of supervised machine learning studies and potential implementation to identify herbal plant dataset

- Effect of ECAP die angle and route type on the experimental evolution, crystallographic texture, and mechanical properties of pure magnesium

- Design and characteristics of two-dimensional piezoelectric nanogenerators

- Hybrid and cognitive digital twins for the process industry

- Discharge predicted in compound channels using adaptive neuro-fuzzy inference system (ANFIS)

- Human factors in aviation: Fatigue management in ramp workers

- LLDPE matrix with LDPE and UV stabilizer additive to evaluate the interface adhesion impact on the thermal and mechanical degradation

- Dislocated time sequences – deep neural network for broken bearing diagnosis

- Estimation method of corrosion current density of RC elements

- A computational iterative design method for bend-twist deformation in composite ship propeller blades for thrusters

- Compressive forces influence on the vibrations of double beams

- Research on dynamical properties of a three-wheeled electric vehicle from the point of view of driving safety

- Risk management based on the best value approach and its application in conditions of the Czech Republic

- Effect of openings on simply supported reinforced concrete skew slabs using finite element method

- Experimental and simulation study on a rooftop vertical-axis wind turbine

- Rehabilitation of overload-damaged reinforced concrete columns using ultra-high-performance fiber-reinforced concrete

- Performance of a horizontal well in a bounded anisotropic reservoir: Part II: Performance analysis of well length and reservoir geometry

- Effect of chloride concentration on the corrosion resistance of pure Zn metal in a 0.0626 M H2SO4 solution

- Numerical and experimental analysis of the heat transfer process in a railway disc brake tested on a dynamometer stand

- Design parameters and mechanical efficiency of jet wind turbine under high wind speed conditions

- Architectural modeling of data warehouse and analytic business intelligence for Bedstead manufacturers

- Influence of nano chromium addition on the corrosion and erosion–corrosion behavior of cupronickel 70/30 alloy in seawater

- Evaluating hydraulic parameters in clays based on in situ tests

- Optimization of railway entry and exit transition curves

- Daily load curve prediction for Jordan based on statistical techniques

- Review Articles

- A review of rutting in asphalt concrete pavement

- Powered education based on Metaverse: Pre- and post-COVID comprehensive review

- A review of safety test methods for new car assessment program in Southeast Asian countries

- Communication

- StarCrete: A starch-based biocomposite for off-world construction

- Special Issue: Transport 2022 - Part I

- Analysis and assessment of the human factor as a cause of occurrence of selected railway accidents and incidents

- Testing the way of driving a vehicle in real road conditions

- Research of dynamic phenomena in a model engine stand

- Testing the relationship between the technical condition of motorcycle shock absorbers determined on the diagnostic line and their characteristics

- Retrospective analysis of the data concerning inspections of vehicles with adaptive devices

- Analysis of the operating parameters of electric, hybrid, and conventional vehicles on different types of roads

- Special Issue: 49th KKBN - Part II

- Influence of a thin dielectric layer on resonance frequencies of square SRR metasurface operating in THz band

- Influence of the presence of a nitrided layer on changes in the ultrasonic wave parameters

- Special Issue: ICRTEEC - 2021 - Part III

- Reverse droop control strategy with virtual resistance for low-voltage microgrid with multiple distributed generation sources

- Special Issue: AESMT-2 - Part II

- Waste ceramic as partial replacement for sand in integral waterproof concrete: The durability against sulfate attack of certain properties

- Assessment of Manning coefficient for Dujila Canal, Wasit/-Iraq

- Special Issue: AESMT-3 - Part I

- Modulation and performance of synchronous demodulation for speech signal detection and dialect intelligibility

- Seismic evaluation cylindrical concrete shells

- Investigating the role of different stabilizers of PVCs by using a torque rheometer

- Investigation of high-turbidity tap water problem in Najaf governorate/middle of Iraq

- Experimental and numerical evaluation of tire rubber powder effectiveness for reducing seepage rate in earth dams

- Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation

- Assessment for behavior of axially loaded reinforced concrete columns strengthened by different patterns of steel-framed jacket

- Novel graph for an appropriate cross section and length for cantilever RC beams

- Discharge coefficient and energy dissipation on stepped weir

- Numerical study of the fluid flow and heat transfer in a finned heat sink using Ansys Icepak

- Integration of numerical models to simulate 2D hydrodynamic/water quality model of contaminant concentration in Shatt Al-Arab River with WRDB calibration tools

- Study of the behavior of reactive powder concrete RC deep beams by strengthening shear using near-surface mounted CFRP bars

- The nonlinear analysis of reactive powder concrete effectiveness in shear for reinforced concrete deep beams

- Activated carbon from sugarcane as an efficient adsorbent for phenol from petroleum refinery wastewater: Equilibrium, kinetic, and thermodynamic study

- Structural behavior of concrete filled double-skin PVC tubular columns confined by plain PVC sockets

- Probabilistic derivation of droplet velocity using quadrature method of moments

- A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar

- Effect of waste materials on soil properties

- Experimental investigation of electrode wear assessment in the EDM process using image processing technique

- Punching shear of reinforced concrete slabs bonded with reactive powder after exposure to fire

- Deep learning model for intrusion detection system utilizing convolution neural network

- Improvement of CBR of gypsum subgrade soil by cement kiln dust and granulated blast-furnace slag

- Investigation of effect lengths and angles of the control devices below the hydraulic structure

- Finite element analysis for built-up steel beam with extended plate connected by bolts

- Finite element analysis and retrofit of the existing reinforced concrete columns in Iraqi schools by using CFRP as confining technique

- Performing laboratory study of the behavior of reactive powder concrete on the shear of RC deep beams by the drilling core test

- Special Issue: AESMT-4 - Part I

- Depletion zones of groundwater resources in the Southwest Desert of Iraq

- A case study of T-beams with hybrid section shear characteristics of reactive powder concrete

- Feasibility studies and their effects on the success or failure of investment projects. “Najaf governorate as a model”

- Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

- Effect of the 40-PPI copper foam layer height on the solar cooker performance

- Identification and investigation of corrosion behavior of electroless composite coating on steel substrate

- Improvement in the California bearing ratio of subbase soil by recycled asphalt pavement and cement

- Some properties of thermal insulating cement mortar using Ponza aggregate

- Assessment of the impacts of land use/land cover change on water resources in the Diyala River, Iraq

- Effect of varied waste concrete ratios on the mechanical properties of polymer concrete

- Effect of adverse slope on performance of USBR II stilling basin

- Shear capacity of reinforced concrete beams with recycled steel fibers

- Extracting oil from oil shale using internal distillation (in situ retorting)

- Influence of recycling waste hardened mortar and ceramic rubbish on the properties of flowable fill material

- Rehabilitation of reinforced concrete deep beams by near-surface-mounted steel reinforcement

- Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

- Studying pandemic effects and mitigation measures on management of construction projects: Najaf City as a case study

- Design and implementation of a frequency reconfigurable antenna using PIN switch for sub-6 GHz applications

- Average monthly recharge, surface runoff, and actual evapotranspiration estimation using WetSpass-M model in Low Folded Zone, Iraq

- Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads

- Assessment of ALINEA method performance at different loop detector locations using field data and micro-simulation modeling via AIMSUN

- Special Issue: AESMT-5 - Part I

- Experimental and theoretical investigation of the structural behavior of reinforced glulam wooden members by NSM steel bars and shear reinforcement CFRP sheet

- Improving the fatigue life of composite by using multiwall carbon nanotubes

- A comparative study to solve fractional initial value problems in discrete domain

- Assessing strength properties of stabilized soils using dynamic cone penetrometer test

- Investigating traffic characteristics for merging sections in Iraq

- Enhancement of flexural behavior of hybrid flat slab by using SIFCON

- The main impacts of a managed aquifer recharge using AHP-weighted overlay analysis based on GIS in the eastern Wasit province, Iraq