Abstract

In this study, the comprehensive performance and material properties of recycled aggregate concrete (RAC) under the coupled effect of salt-frost cycles were investigated to simulate the effect of complex environmental effects on the durability and deterioration of RAC. The tests on mass loss, relative dynamic modulus of elasticity (RDME), and compressive strength of RAC were conducted after 0, 25, 50, 75, and 100 standard salt-frost cycles. The results show that the mass loss, RDME, and compressive strength of RAC develop in a bad direction with the increase of the number of salt-frost cycles and the amount of recycled aggregate admixture. The concrete damage is particularly severe at more than 40% recycled aggregate admixture. This phenomenon is explained by the changes in the microscopic morphology, distribution of the pore structure, and functional groups of RAC.

1 Introduction

As an indispensable building material, concrete plays a pivotal role in the development of the construction industry [1,2]. However, with the continuous expansion of urbanization and rural urbanization in China, a large amount of natural resources such as sand and gravel are becoming depleted [3]. Meanwhile, the total amount of construction waste generated from the demolition of abandoned houses, road renovation, and major natural disasters is about 1.85 billion tons per year, accounting for 80–90% of the total urban waste, but the utilization rate is less than 10% [4,5,6,7,8]. This set of problems is causing the conventional concrete industry to struggle [9,10,11]. To compensate for the lack of sustainability potential of conventional concrete, an increasing amount of construction waste is being used to produce recycled aggregates, including recycled fine aggregate (FA) and recycled coarse aggregate (RCA). In addition, recycled aggregates can be used to prepare recycled aggregate concrete (RAC) by replacing natural aggregates in concrete [12,13]. At this stage, many researchers are using recycled aggregates to replace some of the natural aggregates in concrete pavements, road construction, and other civil engineering applications. They found that the low dose of recycled aggregates can make the structure with better mechanical properties and durability performance. However, the modification of recycled aggregates by dipping and adding nanomaterials allows recycled aggregates to achieve the same effect as natural aggregates [14,15,16]. Compared with the traditional aggregates, the application of recycled aggregates has more economic and environmental benefits.

Simultaneously, the architectural structure of the salt lake area and coastal ports in northern China has been in a complex service environment coupled with salt erosion and freezing and thawing for a long time. Buildings often suffer severe damage before reaching their normal service life. The harsh environmental conditions in the northern China pose severe challenges to the normal service of RAC. The research results on the resistance of recycled aggregates to salt-frost coupling erosion have shown that (1) The mechanical and durability performance of RAC is generally lower than that of natural aggregate concrete and decreases with the increase of RCA substitution rate [17,18,19,20,21,22,23,24,25,26,27]. (2) As the replacement rate of recycled aggregates increases, the frost resistance and chloride ion corrosion resistance of concrete decrease [28,29,30]. (3) The performance of recycled concrete with the same replacement rate in salt solution is worse than that in water freezing. This can be attributed to the complex microstructures in the old cement mortar adhering to the surface of the RAC, such as aggregate cracks and voids [30]. In summary, the current research on the durability of RAC under severe service environment mainly focuses on the degradation performance of recycled aggregate in a single environment. Research on related degradation characteristics under coupled conditions is insufficient, and the lack of relevant research hinders recycled aggregate. The lack of relevant studies hinders the development of regenerated aggregates and the application of concrete in cold, high latitude coastal or salt lake areas.

Therefore, it is necessary to investigate the deterioration characteristics of recycled concrete under the coupling effect of chloride salt and freeze–thaw cycles. The purpose of this study is to investigate the effects of salt-frost cycles on the surface damage, mass loss rate (MLR), relative dynamic modulus of elasticity (RDME), and cubic compressive strength of RAC with different RCA substitution rates. At the same time, the internal microscopic damage of the recycled concrete after salt-frost cycles is investigated to explain the deterioration of macroscopic mechanical properties and to elaborate the damage mechanism for future practical engineering applications.

2 Materials and experimental methods

2.1 Raw materials and mixing proportions

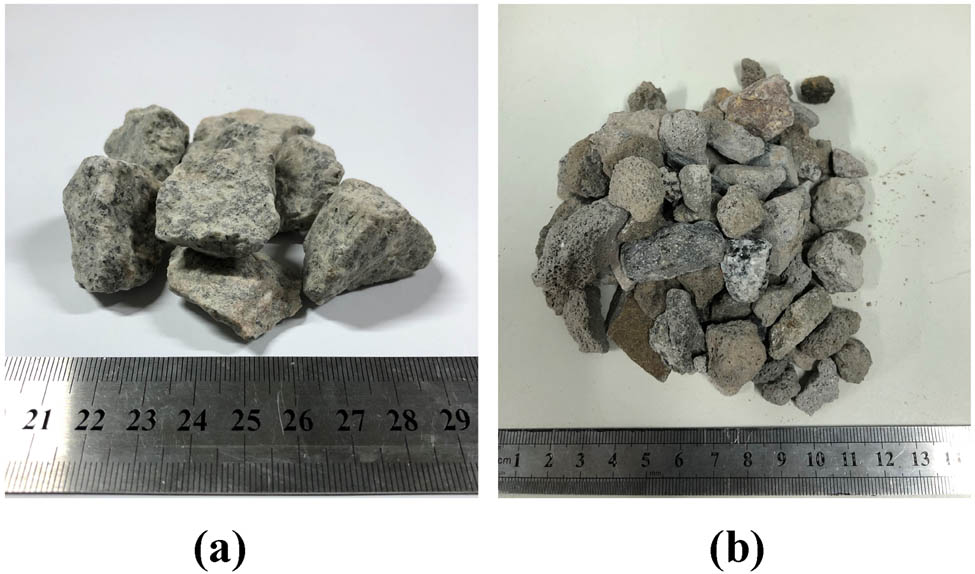

The cement was made of ordinary silicate cement (P·O42.5N) produced by Foshan Conch Cement Co. Ltd., and the mechanical properties of the cement are shown in Table 1. The aggregates in the concrete mix include natural coarse aggregate (NCA), RCA, and natural FA. NCA was made of crushed limestone with particle size of 5–20 mm. The RCA was produced from a demolished building in Foshan, China, with a particle size of 5–20 mm. The coarse aggregate was crushed, screened, and cleaned to comply with Chinese standards GB/T25177-2010 [32]. The appearance and particle gradation of coarse aggregate are shown in Figures 1 and 2. Natural FA is medium sand with a fineness modulus of 2.76. The basic physical indexes of NCA, RCA, and FA were tested with reference to Chinese standards GB/T14685-2011 [33] and GB/T14684-2011 [34], and their physical properties are shown in Table 2. A high-efficiency polycarboxylic acid water reducing agent was used as admixture.

Mechanical properties of Portland cement

| Flexural strength (MPa) | Compressive strength (MPa) | Fineness | Setting time (min) | |||

|---|---|---|---|---|---|---|

| 3 days | 28 days | 3 days | 28 days | 1.2 | Initial setting | Final setting |

| 4.0 | 7.2 | 20.4 | 43.5 | 174 | 269 | |

Particle gradation of coarse aggregates.

Appearance of coarse aggregates: (a) NCA and (b) RCA.

Physical properties of aggregates

| Physical properties | Coarse aggregate | FA | |

|---|---|---|---|

| Type | Natural stone | Recycle stone | Natural sand |

| Bulk density (kg·m−3) | 1,650 | 1,450 | 2,050 |

| Apparent density (kg·m−3) | 2,550 | 2,360 | 2,512 |

| Water content (%) | 0.12 | 2.51 | 0.81 |

| Mass water absorption (%) | 1.21 | 12 | 7.58 |

| Crushing value (%) | 5.32 | 27.6 | — |

In this study, the presaturation method [35,36,37,38] was referred for the design of the RAC ratio, and the ratio is shown in Table 3. The mixture was compensated with saturated RCA to offset the moisture absorbed by RCA. In this study, five concrete mixes were designed with 0, 20, 40, 60, 80, and 100% replacement rates, which were labeled as RAC-0, RAC-20, RAC-40, RAC-60, RAC-80, and RAC-100, using RCA replacement rate as the main parameter and choosing w/c = 0.5.

Mix proportion of RAC (kg·m−3)

| Specimens | Water | Cement | Sand | NCA | RCA | SP |

|---|---|---|---|---|---|---|

| RAC-0 | 189 | 378 | 712 | 1162.2 | 0 | 1.9 |

| RAC-20 | 189 | 378 | 712 | 929.8 | 232.4 | 1.9 |

| RAC-40 | 189 | 378 | 712 | 697.3 | 464.9 | 1.9 |

| RAC-60 | 189 | 378 | 712 | 464.9 | 697.3 | 1.9 |

| RAC-80 | 189 | 378 | 712 | 232.4 | 928.8 | 1.9 |

| RAC-100 | 189 | 378 | 712 | 0 | 1162.2 | 1.9 |

2.2 Specimen casting and curing conditions

According to Chinese standards GB/T50476-2008 [38], 60 groups of cubic specimens with dimensions of 100 mm × 100 mm × 100 mm (180 pieces) were designed and fabricated, with three pieces in each group. After 24 h of casting, the specimens were demolded and maintained in a standard maintenance room at 20 ± 2°C and 95% relative humidity for 24 days. For 24 days, the specimens were immersed in a solution of sodium chloride with a mass fraction of 3.5% for 4 days. The finished specimens were used for cubic compressive strength test, mass loss test, and elastic modulus test, respectively.

2.3 Experimental methods

2.3.1 Salt-frost cycles test

According to the fast freezing method in Chinese standards GB/T 50082-2009 [40], the salt-frost cycles test was carried out using a rapid freeze–thaw testing machine for concrete with model number TDR-10. The number of salt-frost cycles were 0, 25, 50, 75, and 100, and the test procedure is shown in Figure 3.

Test flow chart of salt-frost cycles.

2.3.2 Dynamic modulus of elasticity and mass loss tests

To obtain data on the RDME, this study used the HMP-13 bdynamic elastometer to nondestructively test the dynamic modulus of elasticity of the collected specimens. The RDME of concrete was determined by equation (1).

The specimens were removed from the brine with different number of salt-frost cycles and dried the surface water, and their MLR was determined, and the MLR was determined by equation (2).

2.3.3 Compressive strength test

According to Chinese standards GB/T50081-2019 [41], an electro-hydraulic pressure tester of model NYL was used to test the compressive strength of the specimens under different salt-frost cycles. All test specimens were grouped in groups of three, and the arithmetic mean of their measured values was taken as the final result.

2.3.4 Material properties testing

To further investigate the effect of RCA on the freezing and corrosion disturbance of recycled concrete under the action of salt-frost cycles, the microscopic morphology, pore structure distribution, enhancement mechanism, and damage characteristics of hydration products and chemical bonds or molecules of recycled concrete specimens under different numbers of salt-frost cycles were analyzed using scanning electron microscopy (SEM), Fourier-transform infrared spectroscopy (FTIR), and mercury-pressure porosimetry (MIP). For microscopic performance, the test procedures were as follows. First, the specimens that reached the number of salt-freezing cycles were broken into 2–5 mm pellets. Second, these pellets were immersed in alcohol for 24 h to terminate the reaction. Then, the pellets were dried at 60°C for 48 h. Finally, the treated pellets were stored in a desiccator. The specimens were sprayed with gold and subjected to SEM analysis. The pellets were ground together with potassium bromide and pressed into thin slices for FTIR analysis. In addition, samples of 0.5–1 g were weighed and put into swellers, sealed with vacuum grease, and then subjected to MIP analysis using low and high pressure. The drying and preparation conditions of the samples were in accordance with Chinese standards GB/T 16594-2008 [42], ISO 19618-2017 [43], and GB/T 21650-2008 [44].

3 Results and discussion

3.1 Effect of salt-frost cycles on RAC

3.1.1 Surface damage pattern of RAC specimens

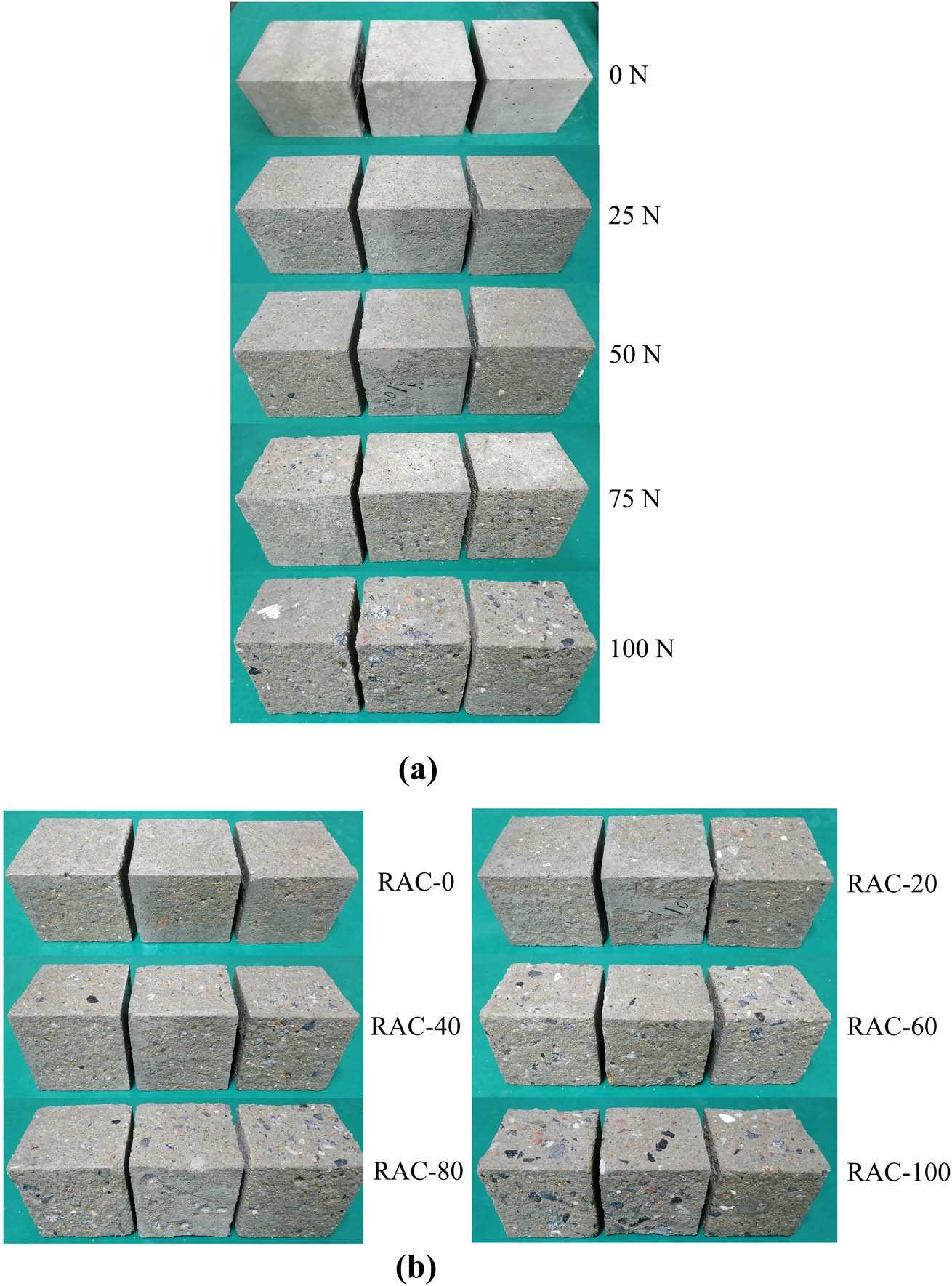

Figure 4(a) shows the damage pattern of RAC-60 specimens under different number of salt-frost cycles. With the increase of the number of salt-frost cycles, the surface of the specimens become increasingly rougher. Before the salt-frost cycles, the surface of each group of specimens is flat and smooth with a dense cement mortar package. After 25N salt-frost cycles, many pits appear on the surface of the specimens due to the spalling of the surface mortar. With the further increase of the number of salt-frost cycles, holes begin to appear on the surface of the specimens and the coarse aggregate is gradually exposed. In addition, the increase of RCA would aggravate the damage of the specimens. As shown in Figure 4(b), at reaching 100N salt-frost cycles, mortar spalling and exposed coarse aggregate soon appear on the surface of the specimens with the increase of RCA content. At 60% of RCA content, the surface of the specimen have mortar completely spalled off, aggregate exposed, and the edges collapsed because the strength of the old mortar attached to the aggregate is lower than that of the new mortar. Therefore, it is less sensitive to the osmotic pressure and resistance to crystallization pressure induced by salt-frost cycles than natural coarse concrete (NC) samples, leading to further damage. This result is similar to that reported by many researchers [45,46,47].

Damage morphology of specimens after salt-frost cycles: (a) RAC-60 and (b) 100N.

3.1.2 RDME and mass loss of RAC

The results of dynamic modulus of elasticity of RAC for different number of salt-frost cycles are shown in Figure 5. With the increase of the number of salt-frost cycles, the RDME of the RAC decreases more than that of the normal concrete. After 75N salt-frost cycles, the RDME of RAC-100 specimens decreases to 57.6%, which is lower than the critical value of RDME (60%). Meanwhile, the salt-frost cycles is more likely to negatively affect the RDME of the RAC compares with the normal concrete. 25N salt-frost cycles of the RAC specimens show a severe loss of RDME. In the final stage, the loss of RDME is significantly reduced. In addition, the incorporation of RCA contributes to produce a more significant reduction in RDME of RAC. This may be attributed to the poor bonding of the old mortar to the new mortar on the RCA surface, which is more prone to internal cracking under crystallization pressure, resulting in a reduction in RDME.

The RDME of concrete after salt-frost cycles.

The MLR of RAC under different number of salt-frost cycles is shown in Figure 6. For the RAC specimens with less than 40% RCA admixture, the MLR of RAC only changes by about 0.4% under 25N salt-frost cycles. This may be due to the presence of brine crystals in the internal pores of the concrete, which offset part of the spalling of the cement mortar. The MLR of the concrete gradually increases with the number of salt-frost cycles. Similarly, the incorporation of RCA intensifies the deterioration of the concrete specimens. Specimens of RAC-80 and RAC-100 are elevated to 5.1 and 6.8% mass loss after 100N salt-frost cycles, which exceed the MLR threshold (5%). As analyzed by Zhu et al. [48], the mass change of concrete under freeze–thaw cycles is the result of a combination of water intrusion mass increase and surface scaling mass loss. When the number of salt-frost cycles is low, the specimens have less freeze damage, and the mass gained by the specimens from solution crystallization can mitigate mass loss due to spalling. With the increase of the number of salt-frost cycles and RCA content, the frost damage of the specimens becomes more and more serious, the cracks increase, the aggregate and mortar fall off, and the mass gain from solution crystallization is smaller than the mass loss from specimen spalling, which leads to a substantial loss of the overall mass of the specimens.

The MLR of concrete after salt-frost cycles.

3.1.3 Changes in compressive strength of RAC

Figure 7 shows the change law of compressive strength of RAC under different number of salt-frost cycles. It can be seen that the compressive strength of RAC decreases with the increase of the number of salt-frost cycles and the amount of RCA content. After more than 75N salt-frost cycles, the compressive strength loss of RAC-0, RAC-20, and RAC-40 is relatively moderate, whereas the compressive strength loss of RAC-60, RAC-80, and RAC-100 increase steeply, and their strength loss rates reach 20, 21.9, and 17.5%, respectively. This indicates that the large amount of RCA is very detrimental to RAC at the late stage of salt-frost cycles. The reason is that the number of original microcracks of RCA is high and the bond between the old mortar and the aggregate or the old mortar and the new mortar is poor, which leads to the high frost swelling force generated during the salt-frost cycles. At the same time, the NaCl crystals are formed by the salt entering the concrete interior with the cracks further strengthen the extrusion and swelling damage to the internal capillaries and microcracks of the concrete, which severely damages its internal structure; however, the crushing index and the needle-like content of the RCA are greater than those of the natural aggregate, which also leads to a lower strength of RAC than ordinary concrete and an increased rate of compressive strength loss after the salt-frost cycles [49].

The compressive strength of concrete after salt-frost cycles.

3.2 Material properties of RAC after salt-frost cycles

3.2.1 Material morphology changes of RAC

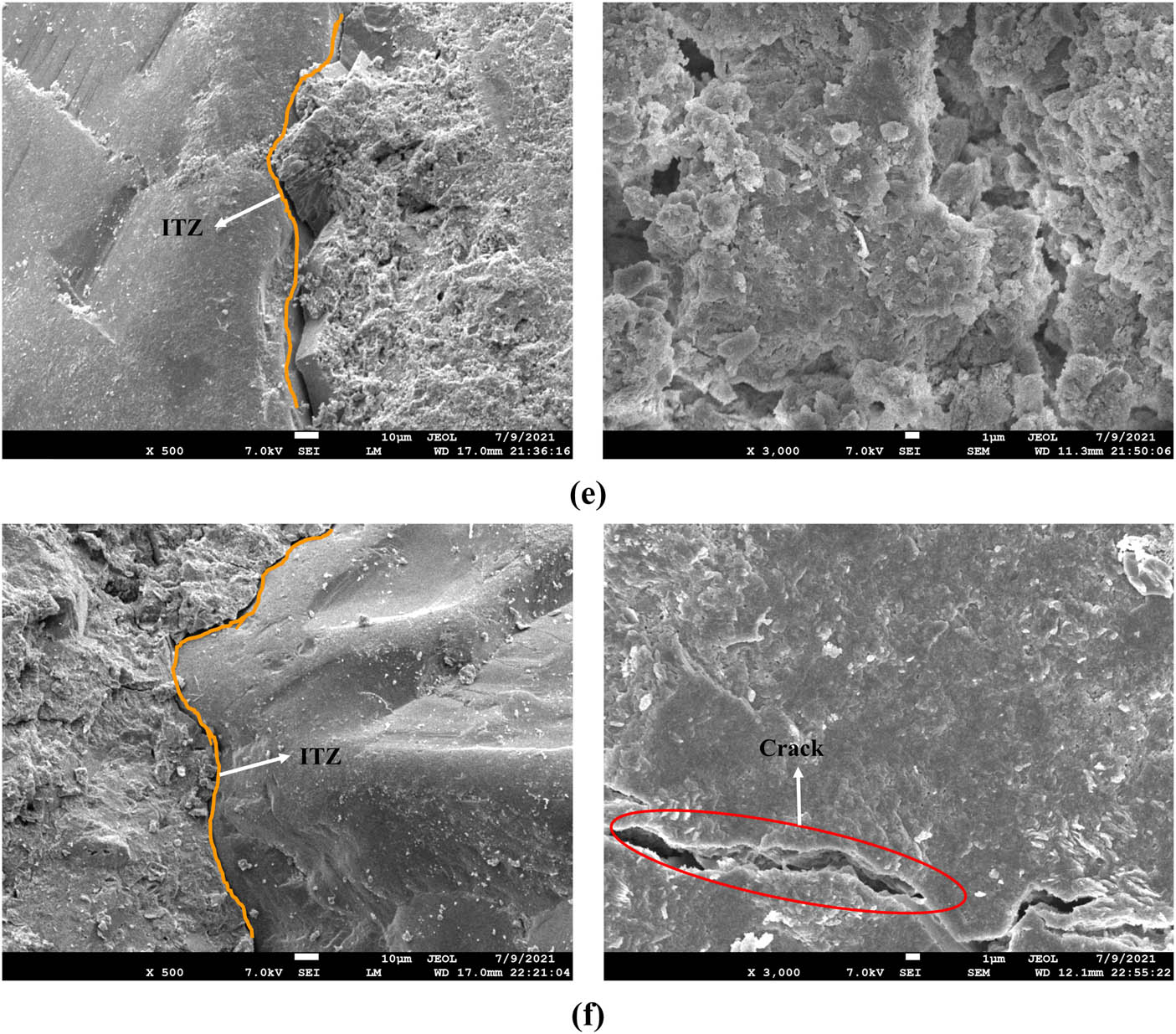

The microscopic morphological changes of the materials under 0N and 100N salt-frost cycles are determined by SEM for RAC-0, RAC-40, and RAC-100, as shown in Figure 8. It can be seen that all the concrete internal structures are relatively dense in the initial state, with only a few micropores and microcracks. However, the interface transition zone (ITZ) of conventional concrete is more compact than RAC-100, which is due to the old mortar attached to the surface of RCA. After 100N salt-frost cycles, the cement matrix is extruded to form wider cracks and poorer pore structure. With the increase of RCA admixture, the micropores develop into large pore size holes, and the microcracks gradually develop into cracks, showing a loose porous state. Meanwhile, the loose internal structure makes the poorly bonded ITZ further deteriorated. The results clearly show that the degradation of RAC under the coupling action of RCA and salt freezing is more severe than that under the action of single factor, which is attributed to the increase of pore size and microcracks during freeze–thawing. These pores and microcracks provide more pathways for subsequent chloride ion infiltration and promote structural damage, which leads to more severe deterioration of the complex environment.

Micromorphology of the RAC: (a) RAC-0-0N, (b) RAC-0-100N, (c) RAC-40-0N, (d) RAC-40-100N, (e) RAC-100-0N, and (f) RAC-100-100N.

3.2.2 Pore structure distribution of RAC

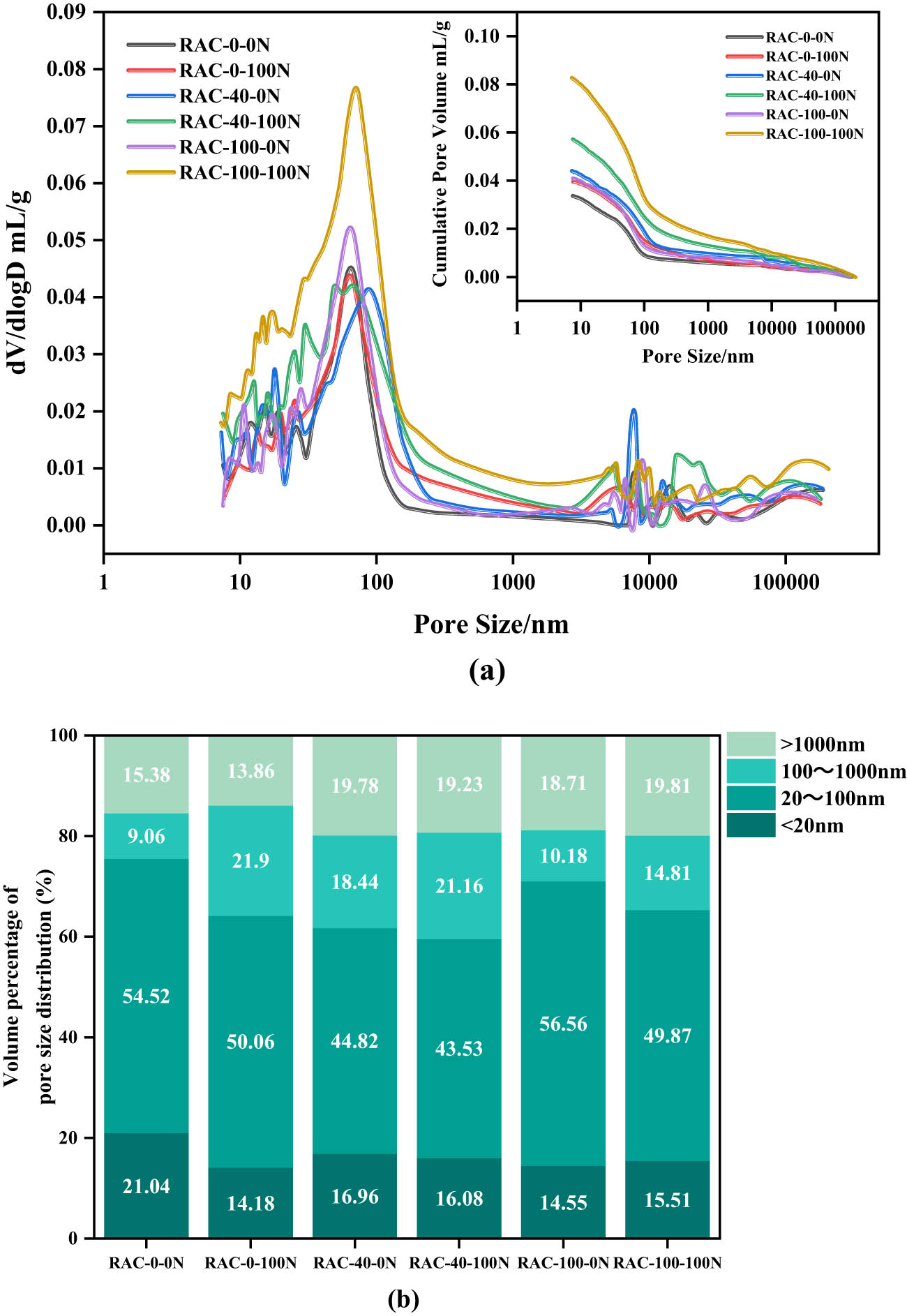

Figure 9(a) and Table 4 show the pore size distribution, porosity, total pore volume, and total pore area of RAC under different salt-frost cycles. At 0N, the curve of RAC shift significantly upward with the incorporation of RCA and the porosity increased, and the porosity of RAC-100 increased by 45.1% compares with that of RAC-0. This indicates that RCA has a negative effect on the pore structure of concrete. As the number of salt-frost cycles increased, the cumulative damage of salt-frost cycles and the collapse and blockage of some large pores eventually lead to the deterioration of the pore structure and densification inside the concrete. The porosity of RAC-100-100N reach 26.5%, which is 134.5% higher than that of RAC-0-0N. The cumulative pore volume percentages are shown in Figure 10(b). The cumulative pore volume percentages are classified according to the principles of harmless pores (<20 nm), less harmful pores (20–100 nm), harmful pores (100–1,000 nm) and very harmful pores (>1,000 nm). The salt-frost cycles can significantly increase the volume fraction of harmful pores (100–1,000 nm) and decrease the volume fraction of less harmful pores (20–100 nm). In summary, the salt-frost cycling effect accelerates the degradation of RAC. This result is attributed to the fact that RCA itself has certain pores, and when the material is in the process of salt-frost cycling, the space in the pore structure is favorable for the migration of water molecules to the interior and promotes the development of ice crystals. Under hydrostatic pressure the pores are opened up to each other and large pores are formed [50].

Pore structure distribution of RC for after salt-frost cycles: (a) pore size distribution; (b) cumulative pore volume percentage.

Porosity, total pore size, and area of RAC

| Specimen | Porosity (%) | Total intruded volume (mL·g−1) | Total surface area (m2·g−1) |

|---|---|---|---|

| RAC-0-0N | 11.3 | 0.0339 | 3.7807 |

| RAC-0-100N | 13.6 | 0.0398 | 3.5640 |

| RAC-40-0N | 14.9 | 0.0442 | 4.1532 |

| RAC-40-100N | 18.8 | 0.0576 | 5.5077 |

| RAC-100-0N | 16.4 | 0.0410 | 3.8949 |

| RAC-100-100N | 26.5 | 0.0828 | 7.7558 |

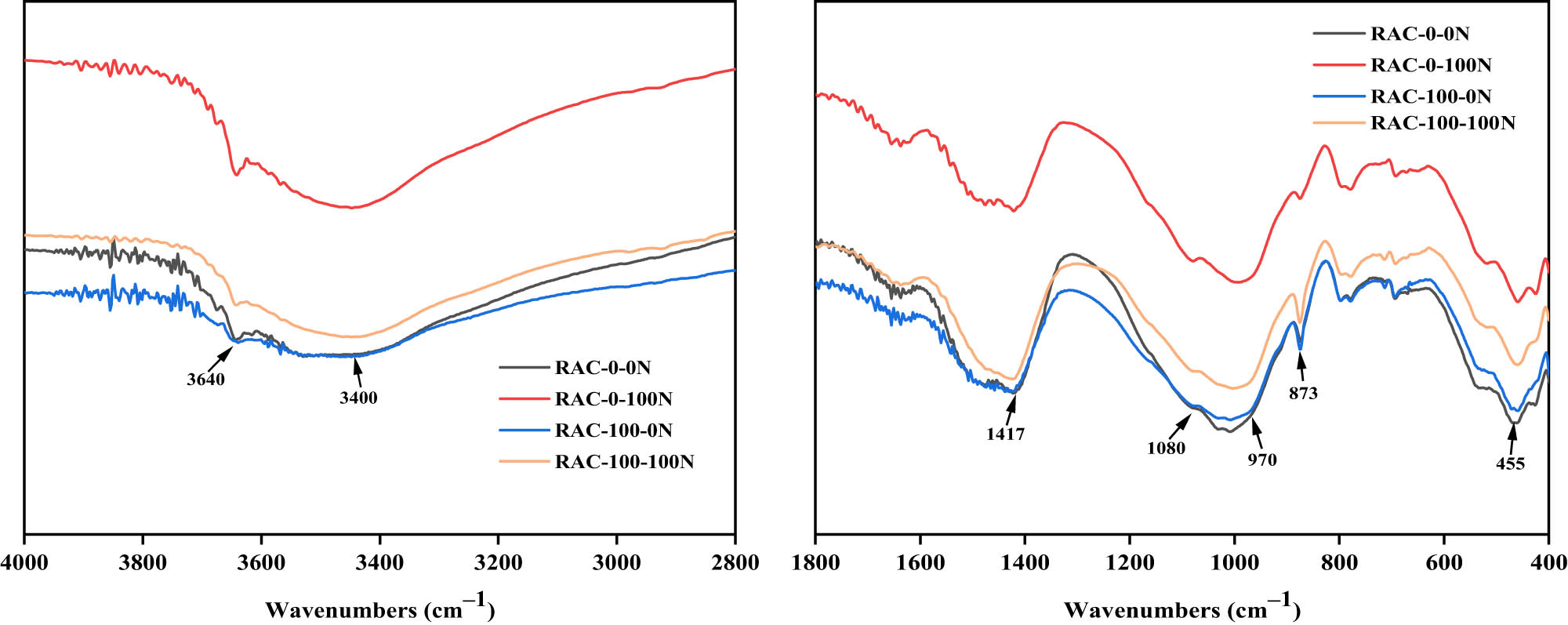

Function groups analysis on RAC subjected to salt-frost cycles.

3.2.3 Functional group changes of RAC

The changes in the functional groups of the RAC during the salt-frost cycles are determined based on FTIR and are shown in Figure 10. With the increase of the number of salt-frost cycles, the intensity of the contraction vibration of the H–O–H functional group (3,400) increased, and the expansion of the internal space lead to the extrusion and bending of water molecules raising the degree of aqueous phase deformation. In addition, the contraction vibration of Si–O functional group (970) in Q2 tetrahedra is obvious, indicating that the enhanced polymerization of this functional group produces absorption peaks [51,52,53]. Meanwhile, the incorporation of RCA makes the absorption peak of the –OH functional group (3,640) weaker, which affects the proportion of functional group –OH in CH [54,55]. In conclusion, the salt-frost cycles and the incorporation of recycled aggregates affect the Si–O and –OH groups of the concrete materials, thus altering their mechanical and durability properties.

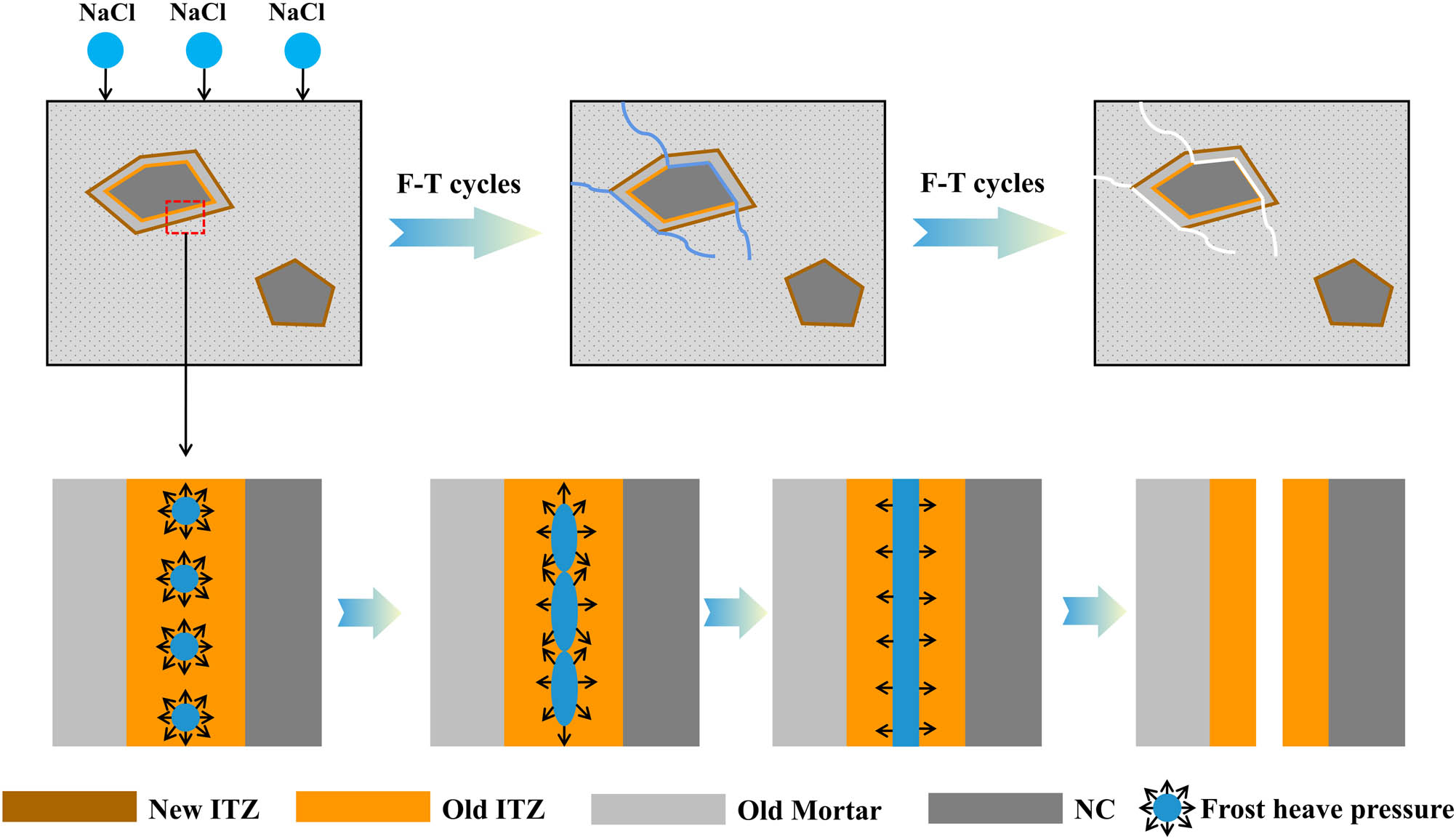

3.2.4 Damage mechanism of RAC

In this study, a large amount of mortar spalling and exposed aggregates are observed on the surface of the RAC specimens after 100N salt-frost cycles. However, the internal crack width of the concrete increased, the number of holes increases, and the ITZ is weak. However, no significant changes are observed in the plain concrete specimens after 100N salt-frost cycles. According to a previous study [56], the damage to the internal structure of concrete exposes to salt-frost cycles may be due to water migration and crystallization expansion resulting in water pressure and frost swelling pressure. The frost swelling pressure may accelerate the development of microcracks and macrocracks when the tensile strength of concrete that can withstand is exceeded. As shown in Figure 11, as salt-frost erosion proceeds, the ITZ around the RCA is gradually filled with salt solution and further expansion of the crystals can lead to separation of the old mortar from the aggregate or the old mortar from the new mortar. Therefore, after 100N salt-frost cycles, large holes and exposed RCA appear on the surface of the specimens. This indicates that the ITZ between the RCA and the old mortar is the weak link. Compared with the RAC with multi-interface structure, the tensile strength of the ITZ with internal structure of NC is higher than that of the old ITZ. Also, the NC samples have lower porosity than the RAC samples, which limits the frost swelling due to internal pressure. Therefore, RAC is more sensitive to salt-frost cycles than natural aggregate concrete. Therefore, the use of RAC in cold coastal areas must be considered in concert to reduce the damage caused by salt-frost cycles.

Damage mechanism of salt-frost cycles on RAC.

4 Conclusion

This study analyzed the mechanism of the effect of salt-frost cycles on RAC based on the results of the study on the effect of RAC performance under salt-frost cycles conditions, and concludes as follows:

The incorporation of RCA accelerates the spalling of concrete under salt-frost cycles conditions. After 100 salt-frost cycles, a large number of holes and exposed aggregates appear in RAC-100 specimens.

The relative dynamic modulus, MLR, and compressive strength decrease with the increase of the number of salt-frost cycles. The RDME of RAC-100 specimens is lower than 60% after 100N salt-frost cycles, and the mass loss is more than 5%. The compressive strength of specimens with more than 60% RCA admixture decreases significantly, and the compressive strength of RAC-100 after 100 salt-frost cycles is lower than that of RAC-0 by 51.6%.

The damage of specimens caused by salt-frost cycles is different from that of ordinary concrete. The main damage location tend to occur in the ITZ of old mortar and coarse aggregate or old mortar and new mortar, and then the cracks extend along the surface of old mortar. Moreover, the deterioration of pore size and the effect on Si–O and –OH groups caused by salt-frost cycles are factors that cannot be ignored in reducing their mechanical and durability properties.

Acknowledgements

The authors thank the team members from ASIM Group, China, the support from Foshan Intelligent Land and Ocean Engineering Materials Engineering Technology Research and Development Center, Foshan, China.

-

Funding information: The Science and Technology Innovation Platform of Foshan City (Grant No. 2016AG100341, Guangdong Province, China). 2021 Guangdong Provincial Department of Education, Guangdong University Scientific Research Project-Special Project for Young Innovative Talents (2021KQNCX083)

-

Author contributions: Ying Yu: formal analysis, writing – original draft, and project administration; Ben Li: conceptualization – ideas, funding acquisition, and resources; Chen Zhang: investigation and visualization; and Yu Zhang: investigation and software.

-

Conflict of interest: We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service, and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled, “Deterioration characteristics of recycled aggregate concrete under the effect of salt-frost cycles.”

-

Data availability statement: Data available on request due to restrictions, for example, privacy or ethical.

References

[1] Li, W. G., Z. Y. Luo, C. Long, C. Q. Wu, W. H. Duan, and S. P. Shah. Effects of nanoparticle on the dynamic behaviors of recycled aggregate concrete under impact loading. Materials & Design, Vol. 112, 2016, pp. 58–66.10.1016/j.matdes.2016.09.045Search in Google Scholar

[2] Radonjanin, V., M. Malešev, S. Marinković, and A. E. S. Al Malty. Green recycled aggregate concrete. Construction and Building Materials, Vol. 47, 2013, pp. 1503–1511.10.1016/j.conbuildmat.2013.06.076Search in Google Scholar

[3] Xiao, J., W. Li, Y. Fan, and X. Huang. An overview of study on recycled aggregate concrete in China (1996–2011). Construction and Building Materials, Vol. 31, 2012, pp. 364–383.10.1016/j.conbuildmat.2011.12.074Search in Google Scholar

[4] Liu, J., Z. Hua, Y. Pang, and X. Wang. Risk sharing for PPP project in construction waste recycling industry in China. Environmental Science and Pollution Research, Vol. 29, 2021, pp. 1–15.10.1007/s11356-021-15816-zSearch in Google Scholar PubMed

[5] Lu, N., S. Feng, and H. Lu. Te tempo-spatial difference of urbanization on construction sector carbon emissions in China. Journal of Beijing Institute of Technology (Social Sciences Edition), Vol. 20, 2018, pp. 8–17 (in Chinese).Search in Google Scholar

[6] National Bureau of Statistics Net, Beijing, China. http://www.stats.gov.cn/.Search in Google Scholar

[7] Xiao, J., Z. Ma, T. Sui, A. Akbarnezhad, and Z. Duan. Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste. Journal of Cleaner Production, Vol. 188, 2018, pp. 720–731.10.1016/j.jclepro.2018.03.277Search in Google Scholar

[8] Chinese Know Net, Tsinghua University, Beijing, China. http://www.cnki.net/.Search in Google Scholar

[9] Mercader-Moyano, P. and A. Ramırez-de-Arellano-Agudo. Selective classification and quantification model of C&D waste from material resources consumed in residential building construction. Waste Management and Research, Vol. 31, No. 5, 2013, pp. 458–474.10.1177/0734242X13477719Search in Google Scholar PubMed

[10] Seror, N., S. Hareli, and B.A. Portnov. Evaluating the effect of vehicle impoundment policy on illegal construction and demolition waste dumping: Israel as a case study. Waste Management, Vol. 34, No. 8, 2014, pp. 1436–1445.10.1016/j.wasman.2014.03.026Search in Google Scholar PubMed

[11] Gálvez-Martos, J.-L., D. Styles, H. Schoenberger, and B. Zeschmar-Lahl. Construction and demolition waste best management practice in Europe. Resources, Conservation And Recycling, Vol. 136, 2018, pp. 166–178.10.1016/j.resconrec.2018.04.016Search in Google Scholar

[12] Zhang, J., J. Wang, X. Li, T. Zhou, and Y. Guo. Rapid-hardening controlled low strength materials made of recycled fine aggregate from construction anddemolition waste. Construction and Building Materials, Vol. 173, 2018, pp. 81–89.10.1016/j.conbuildmat.2018.04.023Search in Google Scholar

[13] Velay-Lizancos, M., P. Vazquez-Burgo, D. Restrepo, and I. Martinez-Lage. Effect of fine and coarse recycled concrete aggregate on the mechanical behavior of precast reinforced beams: comparison of FE simulations, theoretical, and experimental results on real scale beams. Construction and Building Materials, Vol. 191, 2018, pp. 1109–1119.10.1016/j.conbuildmat.2018.10.075Search in Google Scholar

[14] Xiao, J., D. Lu, and J. Ying. Durability of recycled aggregate concrete: an overview. Journal of Advanced Concrete Technology, Vol. 11, No. 12, 2013, pp. 347–359.10.3151/jact.11.347Search in Google Scholar

[15] Xiao, J., D. Lu, and J. Ying. Durability of recycled aggregate concrete-a review. Cement and Concrete Composites, Vol. 89, 2018, pp. 251–259.10.1016/j.cemconcomp.2018.03.008Search in Google Scholar

[16] Evangelista, L. and J. De Brito. Durability performance of concrete made with fine recycled concrete aggregates. Cement and Concrete Composites, Vol. 32, No. 1, 2010, pp. 9–14.10.1016/j.cemconcomp.2009.09.005Search in Google Scholar

[17] Chen, H., Z. Peng, W. Zeng, and J. Wu. Salt movement during soil freezing events in inner Mongolia, China. Journal of Coastal Research, Vol. 82, No. 10082, 2018, pp. 55–63.10.2112/SI82-007.1Search in Google Scholar

[18] Yi J., Comprehensive experimental study of compressive and anti-chloride ion erosion ability of recycled high performance concrete. Journal of Shijiazhuang Institute of Railway Technology, Vol. 13, 2014, pp. 81–86 (in Chinese).Search in Google Scholar

[19] Ye, T., Y. Xu, and J. Zhang. Experimental study on chloride penetration resistance performance of recycled concrete. Journal of Changchun University of Technology (Natural Science Edition), Vol. 35, No. 5, 2014, pp. 567–571 (in Chinese).Search in Google Scholar

[20] Han, S., Q. Y. Li, G. B. Yue, J. Mo, and X. F. Wang. Influence of quality and substitution rate of recycled coarse aggregate on coefficient of the chloride migration of recycled concrete. Concrete, Vol. 314, No. 12, 2015, pp. 80–83 (in Chinese).Search in Google Scholar

[21] Qin, H. and H. Tang. Experimental study on influence of coarse aggregate content on chloride penetration resistance of recycled aggregate concrete. Journal of China and Foreign Highway, Vol. 35, No. 6, 2015, pp. 286–290 (in Chinese).Search in Google Scholar

[22] Ouyang, Z. and Y. Chen. Study on chloride permeability of recycled concrete after repeated compressive stress. Concrete, Vol. 327, No. 1, 2017, pp. 31–33 (in Chinese).Search in Google Scholar

[23] Adessina, A., A. B. Fraj, J. F. Barthélémy, C. Chateau, and D. Garnier. Experimental and micromechanical investigation on the mechanical and durability properties of recycled aggregates concrete. Cement and Concrete Research, Vol. 126, 2019, id. 105900.10.1016/j.cemconres.2019.105900Search in Google Scholar

[24] Abbas, A., G. Fathifazl, O. B. Isgor, A. G. Razaqpur, B. Fournier, and S. Foo. Durability of recycled aggregate concrete designed with equivalent mortar volume method. Cement and Concrete Composites, Vol. 31, 2009, pp. 555–563.10.1016/j.cemconcomp.2009.02.012Search in Google Scholar

[25] Yildirim, S. T., C. Meyer, and S. Herfellner. Effects of internal curing on the strength, drying shrinkage and freeze-thaw resistance of concrete containing recycled concrete aggregate. Construction and Building Materials, Vol. 91, 2015, pp. 288–296.10.1016/j.conbuildmat.2015.05.045Search in Google Scholar

[26] Bogas, J. A., J. Brito, and D. Ramos. Freeze-thaw resistance of concrete produced with fine recycled concrete aggregates. Journal of Cleaner Production, Vol. 115, 2016, pp. 294–306.10.1016/j.jclepro.2015.12.065Search in Google Scholar

[27] Huda, S. B. and M. S. Alam. Mechanical and freeze-thaw durability properties of recycled aggregate concrete made with recycled coarse aggregate. Journal of Materials in Civil Engineering, Vol. 27, No. 10, 2015, id. 04015003.10.1061/(ASCE)MT.1943-5533.0001237Search in Google Scholar

[28] Vázquez, E., M. Barra, D. Aponte, C. Jiménez, and S. Valls. Improvement of the durability of concrete with recycled aggregates in chloride exposed environment. Construction and Building Materials, Vol. 67, Part A, 2014, pp. 61–67.10.1016/j.conbuildmat.2013.11.028Search in Google Scholar

[29] Ying, J., J. Xiao, and V. W. Tam. On the variability of chloride diffusion in modelled recycled aggregate concrete. Construction and Building Materials, Vol. 41, 2013, pp. 732–741.10.1016/j.conbuildmat.2012.12.031Search in Google Scholar

[30] Hu, B., S. Zheng, and G. Ren. The experimental study on the frost resistance of different recycled coarse aggregate replacement rate of recycled concrete. DEStech Transactions on Materials Science and Engineering, Vol. 15816, 2017, pp. 21–37.10.12783/dtmse/ictim2017/9898Search in Google Scholar

[31] Mehta, P. K. Durability-critical issues for the future. Concrete International, Vol. 20, No. 7, 1997, pp. 27–33.Search in Google Scholar

[32] GB/T 25177-2010. Regenerated coarse aggregate for concrete, Ministry of Housing and Urban-Rural Construction of the People’s Republic of China, 2010.Search in Google Scholar

[33] GB/T 14685-2011. Construction pebbles and gravels, China Federation of Building Materials, 2011.Search in Google Scholar

[34] GB/T 14684-2001. Construction Sand, State Bureau of Construction Materials Industry, 2001.Search in Google Scholar

[35] Wang, Q., Y. Wang, G. Yue, and Z. Huan. Influence of mixing methods on mechanical behaviors of recycled aggregate concrete. Journal of Building Structure, Vol. 37, No. s2, 2016, pp. 79–87 (in Chinese).Search in Google Scholar

[36] Yildirim, S. T., C. Meyer, and S. Herfellner. Effects of internal curing on the strength, drying shrinkage and freeze-thaw resistance of concrete containing recycled concrete aggregates. Construction and Building Materials, Vol. 91, 2015, pp. 288–296.10.1016/j.conbuildmat.2015.05.045Search in Google Scholar

[37] Richardson, A., K. Coventry, and J. Bacon. Freeze/thaw durability of concrete with recycled demolition aggregate compared to virgin aggregate concrete. Journal of Cleaner Production, Vol. 19, No. 2–3, 2011, pp. 272–277.10.1016/j.jclepro.2010.09.014Search in Google Scholar

[38] Xuan, D., B. Zhan, and C. S. Poon. Assessment of mechanical properties of concrete incorporating carbonated recycled concrete aggregates. Cement and Concrete Composites, Vol. 65, 2016, pp. 67–74.10.1016/j.cemconcomp.2015.10.018Search in Google Scholar

[39] GB/T 50476-2008. Design Specification for Durability of Concrete Structures, China, 2009.Search in Google Scholar

[40] GB/T 50082-2009. Standard for Testing Methods for Long-Term and Durability of Common Concrete, China, 2009.Search in Google Scholar

[41] GB/T 50081-2019. Standard for Testing Methods of Mechanical Properties of Normal Concrete, China, 2019.Search in Google Scholar

[42] GB/T 16594-2008. General Rules for Measurement of Length in Micron Scale by SEM, ISO, Geneva, Switzerland, 2008.Search in Google Scholar

[43] ISO 19618-2017. Measurement Method for Normal Spectral Emissivity Using Blackbody Reference with an FTIR Spectrometer, ISO, Geneva, Switzerland, 2017.Search in Google Scholar

[44] GB/T 21650-2008. Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas adsorption. Part 1: Mercury Porosimetry, ISO, Geneva, Switzerland, 2008.Search in Google Scholar

[45] Powers, T. C. A working hypothesis for further studies of frost resistance of concrete. ACI Journal Proceedings, Vol. 16, No. 4, 1945, pp. 245–272.Search in Google Scholar

[46] Álava, H. E., E. Tsangouri, N. De Belie, and G. De Schutter. Chloride interaction with concretes subjected to a permanent splitting tensile stress level of 65%. Construction and Building Materials, Vol. 127, 2016, pp. 527–538.10.1016/j.conbuildmat.2016.10.009Search in Google Scholar

[47] Powers, T. C. and R. A. Helmuth. Theory of volume changes in hardened Portland cement paste during freezing. Proceedings of Highway Research Board, Vol. 32, 1953, pp. 285–297.Search in Google Scholar

[48] Zhu, P., Y. Hao, H. Liu, X. Wang, and L. Gu. Durability evaluation of recycled aggregate concrete in a complex environment. Journal of Cleaner Production, Vol. 273, 2020, id. 122569.10.1016/j.jclepro.2020.122569Search in Google Scholar

[49] Júnior, N. A., G. A. O. Silva, and D. V. Ribeiro. Effects of the incorporation of recycled aggregate in the durability of the concrete submitted to freeze-thaw cycles. Construction and Building Materials, Vol. 161, 2018, pp. 723–730.10.1016/j.conbuildmat.2017.12.076Search in Google Scholar

[50] Wang, Y., Z. Liu, K. Fu, Q. Li, and Y. Wang. Experimental studies on the chloride ion permeability of concrete considering the effect of freeze–thaw damage. Construction and Building Materials, Vol. 236, 2020, id. 117556.10.1016/j.conbuildmat.2019.117556Search in Google Scholar

[51] Richard, T., L. Mercury, F. Poulet, and L. d’Hendecourt. Diffuse reflectance infrared Fourier transform spectroscopy as a tool to characterise water in adsorption/confinement situations. Journal of Colloid and Interface Science, Vol. 304, No. 1, 2006, pp. 125–136.10.1016/j.jcis.2006.08.036Search in Google Scholar PubMed

[52] Yu, P., R. J. Kirkpatrick, B. Poe, P. F. McMillan, and X. Cong. Structure of calcium silicate hydrate (C–S–H): Near-, Mid-, and Far-infrared spectroscopy. Journal of the American Ceramic Society, Vol. 82, No. 3, 1999, pp. 742–748.10.1111/j.1151-2916.1999.tb01826.xSearch in Google Scholar

[53] Lodeiro, I. G., D. E. Macphee, A. Palomo, and A. Fernández-Jiménez. Effect of alkalis on fresh C-S-H gels. FTIR analysis. Cement and Concrete Research, Vol. 39, No. 3, 2009, pp. 147–153.10.1016/j.cemconres.2009.01.003Search in Google Scholar

[54] Silva, D. A. D., H. R. Roman, and P. J. P. Gleize. Evidences of chemical interaction between EVA and hydrating Portland cement. Cement and Concrete Research, Vol. 32, No. 9, 2002, pp. 1383–1390.10.1016/S0008-8846(02)00805-0Search in Google Scholar

[55] Ridi, F., E. Fratini, S. Milani, and P. Baglioni. Near-infrared spectroscopy investigation of the water confined in tricalcium silicate pastes. The Journal of Physical Chemistry B, Vol. 110, No. 33, 2006, pp. 16326–16331.10.1021/jp060026ySearch in Google Scholar PubMed

[56] Sidorova, A., E. Vazquez-Ramonich, M. Barra-Bizinotto, J. J. Roa-Rovira, and E. Jimenez-Pique. Study of the recycled aggregates nature’s influence on the aggregate–cement paste interface and ITZ. Construction and Building Materials, Vol. 68, 2014, pp. 677–684.10.1016/j.conbuildmat.2014.06.076Search in Google Scholar

© 2022 Ying Yu et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers

- A review on the properties of concrete reinforced with recycled steel fiber from waste tires

- Copper ternary oxides as photocathodes for solar-driven CO2 reduction

- Properties of fresh and hardened self-compacting concrete incorporating rice husk ash: A review

- Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey

- Research progress on durability of marine concrete under the combined action of Cl− erosion, carbonation, and dry–wet cycles

- Delivery systems in nanocosmeceuticals

- Study on the preparation process and sintering performance of doped nano-silver paste

- Analysis of the interactions between nonoxide reinforcements and Al–Si–Cu–Mg matrices

- Research Articles

- Study on the influence of structural form and parameters on vibration characteristics of typical ship structures

- Deterioration characteristics of recycled aggregate concrete subjected to coupling effect with salt and frost

- Novel approach to improve shale stability using super-amphiphobic nanoscale materials in water-based drilling fluids and its field application

- Research on the low-frequency multiline spectrum vibration control of offshore platforms

- Multiple wide band gaps in a convex-like holey phononic crystal strip

- Response analysis and optimization of the air spring with epistemic uncertainties

- Molecular dynamics of C–S–H production in graphene oxide environment

- Residual stress relief mechanisms of 2219 Al–Cu alloy by thermal stress relief method

- Characteristics and microstructures of the GFRP waste powder/GGBS-based geopolymer paste and concrete

- Development and performance evaluation of a novel environmentally friendly adsorbent for waste water-based drilling fluids

- Determination of shear stresses in the measurement area of a modified wood sample

- Influence of ettringite on the crack self-repairing of cement-based materials in a hydraulic environment

- Multiple load recognition and fatigue assessment on longitudinal stop of railway freight car

- Synthesis and characterization of nano-SiO2@octadecylbisimidazoline quaternary ammonium salt used as acidizing corrosion inhibitor

- Perforated steel for realizing extraordinary ductility under compression: Testing and finite element modeling

- The influence of oiled fiber, freeze-thawing cycle, and sulfate attack on strain hardening cement-based composites

- Perforated steel block of realizing large ductility under compression: Parametric study and stress–strain modeling

- Study on dynamic viscoelastic constitutive model of nonwater reacted polyurethane grouting materials based on DMA

- Mechanical behavior and mechanism investigation on the optimized and novel bio-inspired nonpneumatic composite tires

- Effect of cooling rate on the microstructure and thermal expansion properties of Al–Mn–Fe alloy

- Research on process optimization and rapid prediction method of thermal vibration stress relief for 2219 aluminum alloy rings

- Failure prevention of seafloor composite pipelines using enhanced strain-based design

- Deterioration of concrete under the coupling action of freeze–thaw cycles and salt solution erosion

- Creep rupture behavior of 2.25Cr1Mo0.25V steel and weld for hydrogenation reactors under different stress levels

- Statistical damage constitutive model for the two-component foaming polymer grouting material

- Nano-structural and nano-constraint behavior of mortar containing silica aggregates

- Influence of recycled clay brick aggregate on the mechanical properties of concrete

- Effect of LDH on the dissolution and adsorption behaviors of sulfate in Portland cement early hydration process

- Comparison of properties of colorless and transparent polyimide films using various diamine monomers

- Study in the parameter influence on underwater acoustic radiation characteristics of cylindrical shells

- Experimental study on basic mechanical properties of recycled steel fiber reinforced concrete

- Dynamic characteristic analysis of acoustic black hole in typical raft structure

- A semi-analytical method for dynamic analysis of a rectangular plate with general boundary conditions based on FSDT

- Research on modification of mechanical properties of recycled aggregate concrete by replacing sand with graphite tailings

- Dynamic response of Voronoi structures with gradient perpendicular to the impact direction

- Deposition mechanisms and characteristics of nano-modified multimodal Cr3C2–NiCr coatings sprayed by HVOF

- Effect of excitation type on vibration characteristics of typical ship grillage structure

- Study on the nanoscale mechanical properties of graphene oxide–enhanced shear resisting cement

- Experimental investigation on static compressive toughness of steel fiber rubber concrete

- Study on the stress field concentration at the tip of elliptical cracks

- Corrosion resistance of 6061-T6 aluminium alloy and its feasibility of near-surface reinforcements in concrete structure

- Effect of the synthesis method on the MnCo2O4 towards the photocatalytic production of H2

- Experimental study of the shear strength criterion of rock structural plane based on three-dimensional surface description

- Evaluation of wear and corrosion properties of FSWed aluminum alloy plates of AA2020-T4 with heat treatment under different aging periods

- Thermal–mechanical coupling deformation difference analysis for the flexspline of a harmonic drive

- Frost resistance of fiber-reinforced self-compacting recycled concrete

- High-temperature treated TiO2 modified with 3-aminopropyltriethoxysilane as photoactive nanomaterials

- Effect of nano Al2O3 particles on the mechanical and wear properties of Al/Al2O3 composites manufactured via ARB

- Co3O4 nanoparticles embedded in electrospun carbon nanofibers as free-standing nanocomposite electrodes as highly sensitive enzyme-free glucose biosensors

- Effect of freeze–thaw cycles on deformation properties of deep foundation pit supported by pile-anchor in Harbin

- Temperature-porosity-dependent elastic modulus model for metallic materials

- Effect of diffusion on interfacial properties of polyurethane-modified asphalt–aggregate using molecular dynamic simulation

- Experimental study on comprehensive improvement of shear strength and erosion resistance of yellow mud in Qiang Village

- A novel method for low-cost and rapid preparation of nanoporous phenolic aerogels and its performance regulation mechanism

- In situ bow reduction during sublimation growth of cubic silicon carbide

- Adhesion behaviour of 3D printed polyamide–carbon fibre composite filament

- An experimental investigation and machine learning-based prediction for seismic performance of steel tubular column filled with recycled aggregate concrete

- Effects of rare earth metals on microstructure, mechanical properties, and pitting corrosion of 27% Cr hyper duplex stainless steel

- Application research of acoustic black hole in floating raft vibration isolation system

- Multi-objective parametric optimization on the EDM machining of hybrid SiCp/Grp/aluminum nanocomposites using Non-dominating Sorting Genetic Algorithm (NSGA-II): Fabrication and microstructural characterizations

- Estimating of cutting force and surface roughness in turning of GFRP composites with different orientation angles using artificial neural network

- Displacement recovery and energy dissipation of crimped NiTi SMA fibers during cyclic pullout tests

Articles in the same Issue

- Review Articles

- State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers

- A review on the properties of concrete reinforced with recycled steel fiber from waste tires

- Copper ternary oxides as photocathodes for solar-driven CO2 reduction

- Properties of fresh and hardened self-compacting concrete incorporating rice husk ash: A review

- Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey

- Research progress on durability of marine concrete under the combined action of Cl− erosion, carbonation, and dry–wet cycles

- Delivery systems in nanocosmeceuticals

- Study on the preparation process and sintering performance of doped nano-silver paste

- Analysis of the interactions between nonoxide reinforcements and Al–Si–Cu–Mg matrices

- Research Articles

- Study on the influence of structural form and parameters on vibration characteristics of typical ship structures

- Deterioration characteristics of recycled aggregate concrete subjected to coupling effect with salt and frost

- Novel approach to improve shale stability using super-amphiphobic nanoscale materials in water-based drilling fluids and its field application

- Research on the low-frequency multiline spectrum vibration control of offshore platforms

- Multiple wide band gaps in a convex-like holey phononic crystal strip

- Response analysis and optimization of the air spring with epistemic uncertainties

- Molecular dynamics of C–S–H production in graphene oxide environment

- Residual stress relief mechanisms of 2219 Al–Cu alloy by thermal stress relief method

- Characteristics and microstructures of the GFRP waste powder/GGBS-based geopolymer paste and concrete

- Development and performance evaluation of a novel environmentally friendly adsorbent for waste water-based drilling fluids

- Determination of shear stresses in the measurement area of a modified wood sample

- Influence of ettringite on the crack self-repairing of cement-based materials in a hydraulic environment

- Multiple load recognition and fatigue assessment on longitudinal stop of railway freight car

- Synthesis and characterization of nano-SiO2@octadecylbisimidazoline quaternary ammonium salt used as acidizing corrosion inhibitor

- Perforated steel for realizing extraordinary ductility under compression: Testing and finite element modeling

- The influence of oiled fiber, freeze-thawing cycle, and sulfate attack on strain hardening cement-based composites

- Perforated steel block of realizing large ductility under compression: Parametric study and stress–strain modeling

- Study on dynamic viscoelastic constitutive model of nonwater reacted polyurethane grouting materials based on DMA

- Mechanical behavior and mechanism investigation on the optimized and novel bio-inspired nonpneumatic composite tires

- Effect of cooling rate on the microstructure and thermal expansion properties of Al–Mn–Fe alloy

- Research on process optimization and rapid prediction method of thermal vibration stress relief for 2219 aluminum alloy rings

- Failure prevention of seafloor composite pipelines using enhanced strain-based design

- Deterioration of concrete under the coupling action of freeze–thaw cycles and salt solution erosion

- Creep rupture behavior of 2.25Cr1Mo0.25V steel and weld for hydrogenation reactors under different stress levels

- Statistical damage constitutive model for the two-component foaming polymer grouting material

- Nano-structural and nano-constraint behavior of mortar containing silica aggregates

- Influence of recycled clay brick aggregate on the mechanical properties of concrete

- Effect of LDH on the dissolution and adsorption behaviors of sulfate in Portland cement early hydration process

- Comparison of properties of colorless and transparent polyimide films using various diamine monomers

- Study in the parameter influence on underwater acoustic radiation characteristics of cylindrical shells

- Experimental study on basic mechanical properties of recycled steel fiber reinforced concrete

- Dynamic characteristic analysis of acoustic black hole in typical raft structure

- A semi-analytical method for dynamic analysis of a rectangular plate with general boundary conditions based on FSDT

- Research on modification of mechanical properties of recycled aggregate concrete by replacing sand with graphite tailings

- Dynamic response of Voronoi structures with gradient perpendicular to the impact direction

- Deposition mechanisms and characteristics of nano-modified multimodal Cr3C2–NiCr coatings sprayed by HVOF

- Effect of excitation type on vibration characteristics of typical ship grillage structure

- Study on the nanoscale mechanical properties of graphene oxide–enhanced shear resisting cement

- Experimental investigation on static compressive toughness of steel fiber rubber concrete

- Study on the stress field concentration at the tip of elliptical cracks

- Corrosion resistance of 6061-T6 aluminium alloy and its feasibility of near-surface reinforcements in concrete structure

- Effect of the synthesis method on the MnCo2O4 towards the photocatalytic production of H2

- Experimental study of the shear strength criterion of rock structural plane based on three-dimensional surface description

- Evaluation of wear and corrosion properties of FSWed aluminum alloy plates of AA2020-T4 with heat treatment under different aging periods

- Thermal–mechanical coupling deformation difference analysis for the flexspline of a harmonic drive

- Frost resistance of fiber-reinforced self-compacting recycled concrete

- High-temperature treated TiO2 modified with 3-aminopropyltriethoxysilane as photoactive nanomaterials

- Effect of nano Al2O3 particles on the mechanical and wear properties of Al/Al2O3 composites manufactured via ARB

- Co3O4 nanoparticles embedded in electrospun carbon nanofibers as free-standing nanocomposite electrodes as highly sensitive enzyme-free glucose biosensors

- Effect of freeze–thaw cycles on deformation properties of deep foundation pit supported by pile-anchor in Harbin

- Temperature-porosity-dependent elastic modulus model for metallic materials

- Effect of diffusion on interfacial properties of polyurethane-modified asphalt–aggregate using molecular dynamic simulation

- Experimental study on comprehensive improvement of shear strength and erosion resistance of yellow mud in Qiang Village

- A novel method for low-cost and rapid preparation of nanoporous phenolic aerogels and its performance regulation mechanism

- In situ bow reduction during sublimation growth of cubic silicon carbide

- Adhesion behaviour of 3D printed polyamide–carbon fibre composite filament

- An experimental investigation and machine learning-based prediction for seismic performance of steel tubular column filled with recycled aggregate concrete

- Effects of rare earth metals on microstructure, mechanical properties, and pitting corrosion of 27% Cr hyper duplex stainless steel

- Application research of acoustic black hole in floating raft vibration isolation system

- Multi-objective parametric optimization on the EDM machining of hybrid SiCp/Grp/aluminum nanocomposites using Non-dominating Sorting Genetic Algorithm (NSGA-II): Fabrication and microstructural characterizations

- Estimating of cutting force and surface roughness in turning of GFRP composites with different orientation angles using artificial neural network

- Displacement recovery and energy dissipation of crimped NiTi SMA fibers during cyclic pullout tests