Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

-

Samir Saify

and Fatimah Al-Husseinawi

Abstract

Pozzolanic materials, glass powder, and silica fume (SF) have all been used in concrete recently as a partial cement substitution to increase the strength of the concrete. The aim of this study is to analyze the impact of waste glass powder (WGP) and SF combination on high-strength concrete (HSC) characteristics. The working methodology of the current research consists of using SF passed through sieve No. 200, and WGP particles that passed through sieve No. 400 (particle size less than 38 µm), maximum size of aggregate (14, 20) mm and W/C + p (0.25, 0.35, and 0.45). The used waste materials were in three different amounts of SF and WGP (5, 10, and 15%) by weight of cement. HSC was tested for compressive strength, density, and ultrasonic pulse velocity (UPV) with various glass powder and SF contents. The obtained results show that after 7 and 28 days, concrete specimens containing 15% glass powder and SF demonstrated an increase in density, UPV, and compressive strength, depending on the test results. Conversely, concrete specimens with 5% SF and WGP had decreased compressive strength, UPV, and density. It was detected that WGP gave high mechanical (compressive strength) and physical properties (density and UPV) than SF with a ratio of 15% and lower properties with a ratio of 5%. In HSC manufacturing, glass powder may be used instead of SF.

1 Introduction

The main environmental concerns brought on by releasing carbon dioxide (CO2) were climate change and global warming [1,2,3]. A considerable portion of CO2 emissions is caused by the building industry, which negatively influences the environment [4,5]. Studies from the past suggest that cement production emits 522 million metric tons of CO2, or around 0.8 tons of CO2 each ton of cement produced [6]. With an annual growth rate of 2.5% and a total output of 4.6 billion tons in 2015 [7], cement production is accelerating rapidly worldwide. The “Getting the Numbers Right” project, run by the International Council for Sustainable Development and its sustainability initiative, offers a CO2 and energy performance database. Researchers from all around the globe are always searching for a new material that might either completely or partly replace cement [8]. Throughout the past 10 years, attention has been focused on using supplemental cementitious materials, including silica fume (SF), rice husk ash, metakaolin, ground granulated blast-furnace slag, and fly ash, as cement replacements [9,10,11]. Additional cementitious components react in pore solution by hydrating cement hydraulically or pozzolanic ally [12]. In the United States, cementitious elements are typically added during concrete manufacturing; ready-mixed plants use 60% of supplemental cementitious materials [13]. The reactivity of additives or pozzolans is often lower than that of cement; hence, using supplemental cementitious materials has drawbacks [14,15]. Recent studies revealed that the two most often used supplemental cementitious materials worldwide – fly ash, with an annual output of one billion tons, and ground-granulated blast-furnace slag, with a yearly production of 360 billion tons – can only partially meet expanding demand. Finding other materials that might be used instead of cement has thus become a need on a worldwide scale [13].

Even when used as a fine aggregate in white cement mortars [16], waste glass powder (WGP) as an active additive to concrete has been proven in prior works to have positive environmental and economic effects [17]. Glass was used as an additional cementitious material in numerous other studies [18,19,20], but most of them suggested using 10–20 wt% WGP as a cement substitution with a steady decline in compressive strength. However, Carsana [21] found that mortars of ground glass submerged in water for 7 years had not degraded and had higher compressive strengths. Glass has a significant alkali content. Still, according to the study by Schwarz [22], it only discharged a little sodium into the pore solution, making it a safer addition.

The outcomes of three concrete mixtures, namely, SF, fly ash, and ordinary Portland cement (OPC), were reported by Ibrahim [23]. WGP was substituted for 0, 5, 10, 15, and 20% of the cement in the three mixtures. The findings of tests demonstrated that WGP might partly substitute OPC in concrete with tensile and compressive strengths higher than fly-ash- and silica-fume-based concrete when used up to 5 wt%. The compressive and tensile strengths might also be reduced by 13–14%, respectively, with a greater substitution of up to 20 wt% WGP. Notwithstanding the aforementioned results, there are certain drawbacks to using glass in concrete, including low early strength that might be problematic, particularly when early formwork stripping is necessary for building practice [24].

SF is a waste material produced due to ferrosilicon alloy and silicon manufacturing. Environmental solid waste that includes approximately 75% silica [25,26] has contributed to the strength and minimized the bleeding and permeability of concrete owing to its pozzolanic impacts [27,28,29]. It, nonetheless, has certain drawbacks, including reducing the setting time and workability [30,31] of the concrete mix [32], once the necessary amount is not used. The amount of SF for an efficient performance is stated to be in the range of 10–15 wt% [33]. WGP may be contributed to the concrete mix consistency [34], owing to its glassy surface with minimal water absorption. SF and glass waste up to 10–25 wt% were separately stated to contribute to compressive strength over a time beyond 90 days [20]. Rakhimova and Rakhimov [35] examined glass compositions with a noticeable improvement in workability (flowability) and a reduction in setting time. A similar discovery was observed by Rahma et al. [36], while Sadati and Khayat [37] found a drop in structural networks build-up from (0.118333–0.0133333 Pa/s) 7.1 to 0.8 Pa/min with a rise in viscosity from 0.118 to 0.013 Pa/s. A further advantage of using glass waste was also gained when using cullet glass waste as a replacement for natural sand throughout the synthesis of an alkaline binder by using fly ash and ground granulated blast furnace slag as precursors. Good findings of durability performance have also been obtained for substitute for sand by glass waste at the level of 25–100 wt% within the temperature range of 200–800°C [38,39].

To enhance the compressive strength of concrete, the incorporation of supplementary cementitious materials such as SF has been widely adopted. SF can be used as a filler or as a partial substitute for cement in concrete. The addition of SF has been found to enhance the strength characteristics of concrete; however, a marginal reduction in its workability was noted in a research investigation. The study found that the substitution of SF at levels ranging from 0 to 15% in m25 concrete did not significantly affect the elastic modulus. The observed enhancement in concrete strength can be attributed to a reduction in voids, while the decrease in slump value can be explained by an increase in surface area, which results in greater water absorption during the mixing process [40]. In a comparable manner, the use of WGP in concrete was partially substituted with cement, ranging from 0 to 25% replacement, while maintaining an identical water/cement ratio. At the 90-day mark, there was an observed increase in compressive strength when 10% of cement was replaced with glass powder. The study reported an upward trend in the observed values up to a 20% substitution, followed by a decline thereafter, as indicated [41]. Grinys et al. conducted a study on rubberized concrete that was modified with WGP. Their findings indicated a notable enhancement in the properties of the concrete. The pozzolanic properties of the glass powder exhibited superior performance during the latter phase as compared to the 28th day. According to Grinys [41], the cement is activated by the glass powder, which facilitates the continuation of the hydration process into subsequent stages and ultimately contributes to the attainment of greater strength. Due to its high silica dioxide content, glass powder exhibits pozzolanic properties. The compressive strength of concrete containing glass powder exhibits a decrease during the early stages of curing, followed by an increase in strength during later stages. This phenomenon can be attributed to the pozzolanic activity of glass powder, which becomes more pronounced over time. A decrease in unit weight is observed because of a lower specific gravity in comparison with cement, as reported in Khan et al. [42]. An experimental investigation was carried out by Manikandan and Vasugi [43] to examine the effects of incorporating 25–40% WGP into ground granulated blast furnace slag, in combination with metakaolin, on the mechanical and fresh properties of the resultant concrete. The study found that the ideal substitution rate for WGP was 35%. Nevertheless, the augmentation in the concentration of WGP results in a reduction of the mechanical characteristics.

Regarding the advantages and disadvantages of using SF and glass waste separately, there is little information in the literature on how combining the two substances might affect how the binder is created with regular Portland cement in ternary mixed concrete. To better understand their synergy in concrete manufacturing, this research tries to close this gap. The aim of this research is to open the possibility of using inorganic solid wastes in mortar and concrete manufacturing more often. The current investigation compares how WGP and SF affect high-strength concrete (HSC). Also, this investigation analyze the impact of WGP on the mechanical and physical characteristics of HSC.

2 Experimental work

2.1 Materials

2.1.1 Cement

Commercially available OPC, confirming to ISO 9001:2015, was used in the mixes. The chemical and physical characteristics of OPC are displayed in Table 1.

Physical and chemical characteristics of cement

| Test name | Contents (by wt%) |

|---|---|

| Specific surface (m2/kg) | 310 |

| Specific gravity | 3.15 |

| SiO2 | 20.39 |

| CaO | 62.20 |

| MgO | 2.36 |

| L.O.I | 2.41 |

| Fe2O3 | 3.81 |

| SO3 | 1.97 |

| Al2O3 | 4.55 |

2.1.2 Fine aggregate

Locally available natural sand is applied as fine aggregate conforming to the requirements of No [44]. The fine modulus of 2.42 sulfate content is 0.1% with a density of fine aggregate of 1,600 kg/m3. The grading of fine aggregate is demonstrated in Table 2.

Fine aggregate grading

| Sieve size (mm) | Percent passing (%) |

|---|---|

| 10 | 100 |

| 4.75 | 93.5 |

| 2.36 | 84 |

| 1.18 | 75.5 |

| 0.6 | 50 |

| 0.3 | 20 |

| 0.15 | 4 |

2.1.3 Coarse aggregate

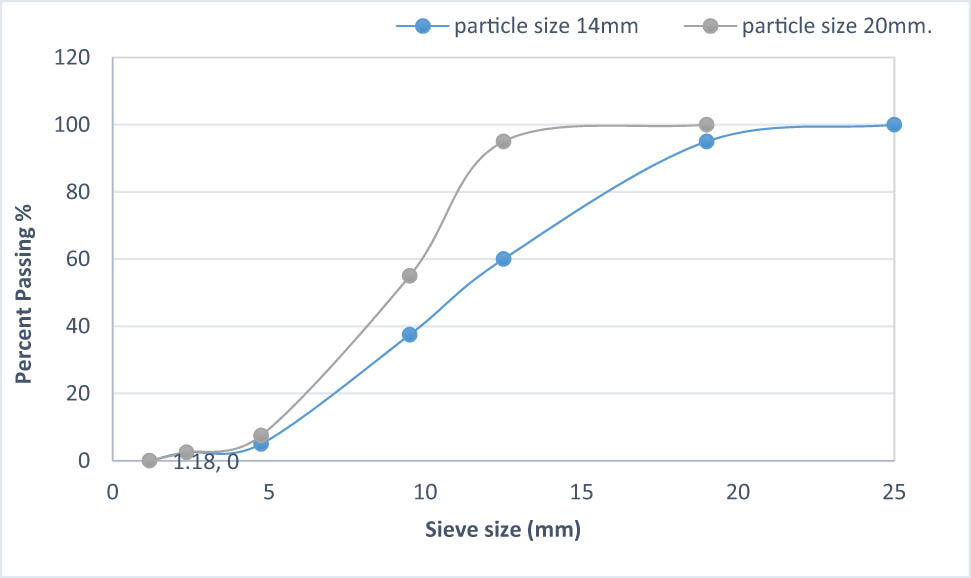

The coarse aggregate used was crushed gravel with maximum sizes (14, 20 mm), and with a sulfate content of 0.08%, with a density of coarse aggregate of 1,600 kg/m3. It conforms to the requirements of ASTM 33 [45]. The grading of coarse aggregate is demonstrated in Table 3 (Figures 1 and 2).

Grading of coarse aggregate for a different size

| Sieve size (mm) | Particle size (20 mm) | Particle size (14 mm) |

|---|---|---|

| 25 | 100 | — |

| 19 | 95 | 100 |

| 12.5 | 60 | 95 |

| 9.5 | 37.5 | 55 |

| 4.75 | 5 | 7.5 |

| 2.36 | 2.5 | 2.5 |

| 1.18 | 0 | 0 |

Fine aggregate grading.

Coarse aggregate grading.

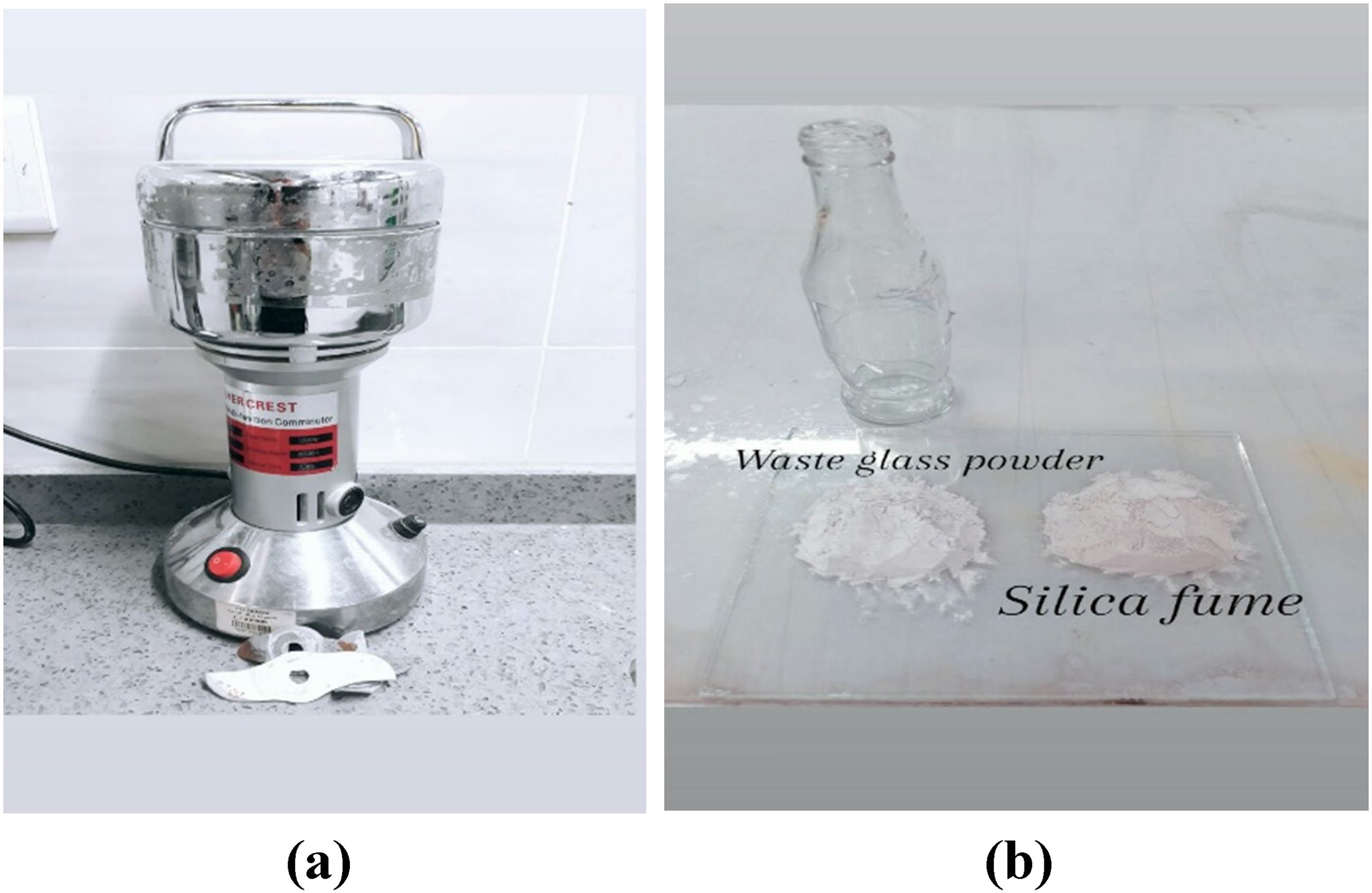

2.1.4 SF

The SF was German production in powder form, with a SiO2 content of 90%, a loss density of 1.1 g/cm3, a compacted density of 1.6 g/cm3, and a specific gravity of 2.28. It passed sieve No. 200 and the rest of sieve No. 400. It is a light to dark gray, as demonstrated in Figure 3, and Figure 4(a) shows the scanning electron microscope (SEM) images for SF that is used in this study.

(a) Small mill and (b) WGP and SF.

SEM images for (a) SF and (b) glass powder waste.

2.1.5 WGP

Waste glass is available locally, and it was collected, washed, crushed, and milled with small milling for 10 min, resulting in particle size less than 38 µm, and the passed sieved No. 400 was used. The loss density of WGP is 0.91 g/cm3, a compacted density is 1.33 g/cm3, and specific gravity is 2.22. The chemical composition of WGP and the small mill is demonstrated in Table 4, and Figure 3(a) and (b) and Figure 4(b) show the SEM images for WGP that are used in this study.

Chemical composition of WGP

| Composition | Glass powder (%) |

|---|---|

| SiO2 | 73.6 |

| CaO | 8.04 |

| SO3 | 0.23 |

| Na2O | 12.6 |

| MgO | 2.78 |

| K2O | 0.3 |

| Fe2O3 | 0.7 |

| Cr2O3 | 0.04 |

| TiO2 | 0.025 |

| AL2O3 | 1.4 |

Superplasticizer: Euniflow 612i was used in mixes. It was produced in a light brown color in Germany; the properties of the superplasticizer are demonstrated in Table 5 and Figure 4.

Typical properties of EU NIFLOW 612i

| Properties* | Value |

|---|---|

| Addition rate range | 1 – 3 L per 100 kg cement (1.0–3%) v/w by weight of cement |

| Appearance | Light brown |

| Specific gravity | 1.09 ± 0.02 at 20®C |

*From the catalog of manufacture.

2.1.6 Water

It was distilled water used through this work for both mixing and curing.

2.2 Mixing procedure

Two blends were designed to produce HSC using SF and WGP, according to research by Samir A. Al Mashhad and Dalya Hekmat Hameed [46]. In one blend, concrete prepared with mixed cement was replaced with SF (A, B, and C); in the other, concrete was prepared with WGP instead of SF (A1, B1, and C1). It used three ratios of 5, 10, and 15% by weight of cement with W\C + P for two blends (0.45, 0.35, and 0.25), respectively. The slump was in the range of 5, 10, and 15 mm for SF mix and 1, 5, and 10 mm for waste glass mix. The laboratory mixing procedure was the cement mixed with SF by hand until a homogeneous mixture was obtained. The dry materials (fine and coarse aggregate) were mixed using a portable cement mixer with a drum capacity of 140 L. Then, water and plasticizer were added for 4 min. Cubes with size 100 mm × 100 mm × 100 mm were used for the compressive strength test. The molds were cleaned and lubricated for test specimens before being used to create test specimens. Two layers of concrete were formed in molds, and each layer was crushed with a tamping rod to release any trapped air. The samples were covered with nylon sheets to stop water evaporation for 1 day after the concrete surface had been troweled into a smooth finish. On the second day, the samples were opened and placed in a water tank for curing to the day of testing after 7 and 28 days. In total, 18 cubes were examined for compressive strength and density at 7 and 28 days, while ultrasonic pulse velocity (UPV) was tested at 28 days. The information on the concrete mix types and designations is presented in Table 6 and Figure 5.

Proportion of mixtures

| Mix symbol | Cement (kg/m3) | SF (kg/m3) | WGP (kg/m3) | Sand (kg/m3) | Gravel (kg/m3) | Water (kg/m3) | HRWR (L/m3) | HRWR (wt% of cementitious) | W/C + p |

|---|---|---|---|---|---|---|---|---|---|

| A | 442 | 78 (15%) | 665.6 | 1,144 | 130.0 | 10.30 | 1.5 | 0.25 | |

| B | 468 | 52 (10%) | 665.6 | 1,144 | 182.8 | 2.29 | 0.4 | 0.35 | |

| C | 494 | 26 (5%) | 665.6 | 1,144 | 234.0 | 0.57 | 0.1 | 0.45 | |

| A1 | 442 | 78 (15%) | 665.6 | 1,144 | 130.0 | 10.30 | 1.8 | 0.25 | |

| B1 | 468 | 52 (10%) | 665.6 | 1,144 | 182.8 | 2.29 | 0.4 | 0.35 | |

| C1 | 494 | 26 (5%) | 665.6 | 1,144 | 234.0 | 0.57 | 0.1 | 0.45 |

Where (A, B, and C) concrete is prepared by mix cement replaced with SF (A1, B1, and C1). Concrete is prepared by WGP.

EUNIFLOW 612i.

3 Testing of concrete specimens

3.1 Compressive strength test

The compressive strength test has been performed depending on B.S: 1881 [47]. It used a machine of 2,000 kN maximum capacity, as demonstrated in Figure 6.

(a) Portable cement mixer and (b) different specimen cubes.

3.2 UPV

The UPV was measured using Pundit Lab+ according to BS:12504 [36] requirements for HSC. It had a bandwidth between 24 and 500 Hz [48]. The UPV (Pundit Lab+) is demonstrated in Figure 7.

Compressive strength machine.

4 Results and discussion

The influence of SF and WGP on features of concrete, including compressive strength, UPV, and density, are demonstrated in Figures 8–11.

UPV (Pundit Lab+).

Compressive strength for various replacement materials and ratios.

UPV for different replacement materials and ratios.

Density for different replacement materials and ratios.

Figure 8 shows that compressive strength increased with different cement replacements by SF and WGP of 5, 10, and 15% by weight of cement. When there was a substitution of cement with SF with 5, 10, and 15%, the compressive strength was 43, 52, and 73.5 MPa after 7 days and was 52, 60, and 84 MPa, respectively, after 28 days. When replacing SF with WGP with 5, 10, and 15%, the compressive strength was 43, 54, and 78 MPa after 7 days and 55, 63, and 88 MPa, respectively, after 28 days. The maximum magnitudes of compressive strength were found at 15% during the replacement of cement with WGP instead of SF. The WGP gave the higher values of compressive strength than the SF after 7 and 28 days, which might result from the WGP pozzolanic materials’ high activity being the cause of the increased compressive strength of concrete. Additionally, the silica present in WGP reacted with calcium hydrate formed throughout the hydration process to form calcium silicate hydrate gel, which provides additional binding characteristics and contributes to the increased compressive strength of concrete [49].

The UPV in HSC was detected after 28 days of curing values in concrete samples having 5, 10, and 15% SF was 4,870, 4,984, and 5,200 m/s, respectively, while concrete specimens containing WGP (5, 10, and 15%) were 4,984, 5,245, and 5,300 m/s, as demonstrated in Figure 9. The UPV increased in concrete specimens containing 15% of WGP and SF, while 5% in concrete specimens containing WGP and SF caused UPV values to decrease.

Impact of replacing WGP and SF cement by on the density of concrete after replacement of SF with 5, 10, and 15%, the density values were found 2,395, 2,388, and 2,440 kg/m3 at 7 days, while at 28 days, the density was 2,390, 2,432, and 2,456 kg/m3 respectively; however, during the replacement of SF by WGP with 5, 10, and 15%, the density values were 2,375, 2,420, and 2,489 kg/m3 after 7 days and 2,422, 2,455, and 2,481 kg/m3 after 28 days, as demonstrated in Figure 10. Adesina and Das [50] discovered that the substitution of 25% fly ash with glass powder improved the performance of designed cementitious composite mixes using glass powder, reducing concrete voids and improving concrete density.

When 15% cement was changed with WGP instead of SF, the density and UPV values rose. Nonetheless, the WGP provided greater values than the SF because the WGP was finer than the SF and had high activity led to fill the gaps, increasing both UPV and leading to denser concrete, as seen in Figure 10. Figure 11 demonstrates the relationship between UPV and density after using different replacement ratios of both SF and WGP; however, WGP gives higher density and UPV comparison with similar replacement ratios of SF. Based on Aldeeky and Al Hattamleh [51], there is a good coefficient of correlation (ranged 0.832 and 0.929) between UPV and dry density, where in current research the authors obtained similar coefficients of correlation range (Figure 12).

Relationship between UPV and density for different replacement materials and ratios.

5 Conclusion

To enhance the development sustainability goals, most of industrial wastes have been reused or recycled based on the composite of the selected materials; in the current study, glass powder and SF waste were recycled to improve the concrete strength. Depending on the findings of the experimental work of this research, it has been reached:

The highest compressive strength values were discovered when cement was replaced with 15% SF and SF was replaced with WGP. After 7 and 28 days, the compressive strength was 78 and 88 MPa, respectively. UPV values in concrete specimens containing 15% powder glass, on the other hand, are higher than in specimens containing 15% SF. However, 5% WGP in the concrete mix reduced UPV readings.

The density values increased as the percentage of WGP in the mix increased, with up to 15% of the WGP instead of SF. The density level was 2,482 and 2,481 kg/m3 after 7 and 28 days, respectively. Partial replacement of SF with WGP at a ratio of 15% was observed. Therefore, WGP gave higher mechanical (compressive strength) and physical properties (density and UPV) than SF with a ratio of 15% and lower properties with a ratio of 5%. WGP can be used instead of SF in HSC production.

Acknowledgments

The Ministry of Higher Education, University of Babylon, and Al-Mustaqbal University are gratefully acknowledged (Grant number: MUC-E-0122). This research was carried out in the laboratory at the University of Babylon.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: Most datasets generated and analyzed in this study are in this submitted manuscript. The other datasets are available on a reasonable request from the corresponding author with the attached information.

References

[1] Wilberforce T, Baroutaji A, Soudan B, Al-Alami AH, Olabi AG. Outlook of carbon capture technology and challenges. Sci Total Environ. 2019;657:56–72.10.1016/j.scitotenv.2018.11.424Search in Google Scholar PubMed

[2] Shubbar A, Nasr M, Falah M, Al-Khafaji Z. Towards net zero carbon economy: Improving the sustainability of existing industrial infrastructures in the UK. Energies. 2021;14:5896.10.3390/en14185896Search in Google Scholar

[3] Hamad MA, Nasr M, Shubbar A, Al-Khafaji Z, Al Masoodi Z, Al-Hashimi O, et al. Production of ultra-high-performance concrete with low energy consumption and carbon footprint using supplementary cementitious materials instead of silica fume: A review. Energies. 2021;14:8291.10.3390/en14248291Search in Google Scholar

[4] Drissi S, Ling T-C, Mo KH, Eddhahak A. A review of microencapsulated and composite phase change materials: Alteration of strength and thermal properties of cement-based materials. Renew Sustain Energy Rev. 2019;110:467–84.10.1016/j.rser.2019.04.072Search in Google Scholar

[5] Al-Khafaji ZS, Falah MW. Applications of high density concrete in preventing the impact of radiation on human health. J Adv Res Dyn Control Syst. 2020;12:666–70. 10.5373/JARDCS/V12SP1/20201115.Search in Google Scholar

[6] Meng Y, Ling T-C, Mo KH, Tian W. Enhancement of high temperature performance of cement blocks via CO2 curing. Sci Total Environ. 2019;671:827–37.10.1016/j.scitotenv.2019.03.411Search in Google Scholar PubMed

[7] Kaliyavaradhan SK, Ling T-C. Potential of CO2 sequestration through construction and demolition (C&D) waste – an overview. J CO2 Util. 2017;20:234–42.10.1016/j.jcou.2017.05.014Search in Google Scholar

[8] Schneider M, Romer M, Tschudin M, Bolio H. Sustainable cement production-present and future. Cem Concr Res. 2011;41(7):642–50.10.1016/j.cemconres.2011.03.019Search in Google Scholar

[9] Ashish DK. Concrete made with waste marble powder and supplementary cementitious material for sustainable development. J Clean Prod. 2019;211:716–29.10.1016/j.jclepro.2018.11.245Search in Google Scholar

[10] Ashish DK, Verma SK. Determination of optimum mixture design method for self-compacting concrete: Validation of method with experimental results. Constr Build Mater. 2019;217:664–78.10.1016/j.conbuildmat.2019.05.034Search in Google Scholar

[11] Luukkonen T, Abdollahnejad Z, Yliniemi J, Kinnunen P, Illikainen M. Comparison of alkali and silica sources in one-part alkali-activated blast furnace slag mortar. J Clean Prod. 2018;187:171–9.10.1016/j.jclepro.2018.03.202Search in Google Scholar

[12] Federico L. Waste glass-a supplementary cementitious material; 2013.Search in Google Scholar

[13] Juenger MCG, Siddique R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem Concr Res. 2015;78:71–80.10.1016/j.cemconres.2015.03.018Search in Google Scholar

[14] Snellings R. Assessing, understanding and unlocking supplementary cementitious materials. RILEM Tech Lett. 2016;1:50–5.10.21809/rilemtechlett.2016.12Search in Google Scholar

[15] Thanon Dawood E, Hani Abdullah M. Behavior of non-reinforced and reinforced green mortar with fibers. Open Eng. 2020;11:67–84. 10.1515/eng-2021-0006.Search in Google Scholar

[16] Maraghechi H, Maraghechi M, Rajabipour F, Pantano CG. Pozzolanic reactivity of recycled glass powder at elevated temperatures: Reaction stoichiometry, reaction products and effect of alkali activation. Cem Concr Compos. 2014;53:105–14.10.1016/j.cemconcomp.2014.06.015Search in Google Scholar

[17] Ling T-C, Poon C-S, Kou S-C. Feasibility of using recycled glass in architectural cement mortars. Cem Concr Compos. 2011;33:848–54.10.1016/j.cemconcomp.2011.05.006Search in Google Scholar

[18] Patel D, Tiwari RP, Shrivastava R, Yadav RK. Effective utilization of waste glass powder as the substitution of cement in making paste and mortar. Constr Build Mater. 2019;199:406–15.10.1016/j.conbuildmat.2018.12.017Search in Google Scholar

[19] He Z, Zhan P, Du S, Liu B, Yuan W. Creep behavior of concrete containing glass powder. Compos Part B Eng. 2019;166:13–20.10.1016/j.compositesb.2018.11.133Search in Google Scholar

[20] Islam GMS, Rahman M, Kazi N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int J Sustain Built Environ. 2017;6:37–44.10.1016/j.ijsbe.2016.10.005Search in Google Scholar

[21] Carsana M, Frassoni M, Bertolini L. Comparison of ground waste glass with other supplementary cementitious materials. Cem Concr Compos. 2014;45:39–45.10.1016/j.cemconcomp.2013.09.005Search in Google Scholar

[22] Schwarz N, Neithalath N. Influence of a fine glass powder on cement hydration: Comparison to fly ash and modeling the degree of hydration. Cem Concr Res. 2008;38:429–36.10.1016/j.cemconres.2007.12.001Search in Google Scholar

[23] Ibrahim KIM. Recycled waste glass powder as a partial replacement of cement in concrete containing silica fume and fly ash. Case Stud Constr Mater. 2021;15:e00630.10.1016/j.cscm.2021.e00630Search in Google Scholar

[24] ASTM C192 C. Standard practice for making and curing concrete test specimens in the laboratory. West Conshohocken: ASTM Int; 2006.Search in Google Scholar

[25] Falah MW, Hafedh AA, Hussein SA, Al-Khafaji ZS, Shubbar AA, Nasr MS. The combined effect of CKD and silica fume on the mechanical and durability performance of cement mortar. Key Engineering Materials. Vol. 895. Switzerland: Trans Tech Publ; 2021. p. 59–67.10.4028/www.scientific.net/KEM.895.59Search in Google Scholar

[26] Al-Khafaji ZS, Jafer H, Dulaimi AF, Atherton W, Al Masoodi Z. The soft soil stabilisation using binary blending of ordinary portland cement and high alumina silica waste material. The 3rd BUiD Doctoral Research Conference, the British University in Dubai. UAE, Dubai: 13th May 2017.Search in Google Scholar

[27] Bagheri AR, Zanganeh H, Moalemi MM. Mechanical and durability properties of ternary concretes containing silica fume and low reactivity blast furnace slag. Cem Concr Compos. 2012;34:663–70.10.1016/j.cemconcomp.2012.01.007Search in Google Scholar

[28] Al-Masoodi ZO, Al-Khafaji Z, Jafer HM, Dulaimi A, Atherton W. The effect of a high alumina silica waste material on the engineering properties of a cement-stabilised soft soil. The 3rd BUiD Doctoral Research Conference. Dubai, UAE: The British University in Dubai; 2017.Search in Google Scholar

[29] Salman AJ, Jawad ZF, Ghayyib RJ, Kareem FA, Al-khafaji Z. Verification of utilizing nanowaste (glass waste and fly ash) as an alternative to nanosilica in epoxy. Energies. 2022;15:6808. 10.3390/en15186808.Search in Google Scholar

[30] Hasan-Nattaj F, Nematzadeh M. The effect of forta-ferro and steel fibers on mechanical properties of high-strength concrete with and without silica fume and nano-silica. Constr Build Mater. 2017;137:557–72.10.1016/j.conbuildmat.2017.01.078Search in Google Scholar

[31] Fallah S, Nematzadeh M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr Build Mater. 2017;132:170–87.10.1016/j.conbuildmat.2016.11.100Search in Google Scholar

[32] Justice JM, Kennison LH, Mohr BJ, Beckwith SL, McCormick LE, Wiggins B, et al. Comparison of two metakaolins and a silica fume used as supplementary cementitious materials. Farmingt Hills, Mich: SP-228, ACI; 2005. p. 213–36.Search in Google Scholar

[33] Khayat KH, Aitcin PC. Silica fume-a unique supplementary cementitious material. Rozdział W, Ghosh SN, editor. In: Progress in Cement and Concrete. Mineral Admixtures in Cement and Concrete. New Delhi, India: ABI Books Private Limited; 1995.Search in Google Scholar

[34] Aliabdo AA, Abd Elmoaty M, Aboshama AY. Utilization of waste glass powder in the production of cement and concrete. Constr Build Mater. 2016;124:866–77.10.1016/j.conbuildmat.2016.08.016Search in Google Scholar

[35] Rakhimova NR, Rakhimov RZ. Alkali-activated cements and mortars based on blast furnace slag and red clay brick waste. Mater Des. 2015;85:324–31. 10.1016/j.matdes.2015.06.182.Search in Google Scholar

[36] Rahma A, El Naber N, Issa Ismail S. Effect of glass powder on the compression strength and the workability of concrete. Cogent Eng. 2017;4:1373415.10.1080/23311916.2017.1373415Search in Google Scholar

[37] Sadati S, Khayat KH. Rheological and hardened properties of mortar incorporating high-volume ground glass fiber. Constr Build Mater. 2017;152:978–89.10.1016/j.conbuildmat.2017.07.065Search in Google Scholar

[38] Sasui S, Kim G, Nam J, van Riessen A, Hadzima-Nyarko M. Effects of waste glass as a sand replacement on the strength and durability of fly ash/GGBS based alkali activated mortar. Ceram Int. 2021;47:21175–96.10.1016/j.ceramint.2021.04.121Search in Google Scholar

[39] Khan MNN, Sarker PK. Effect of waste glass fine aggregate on the strength, durability and high temperature resistance of alkali-activated fly ash and GGBFS blended mortar. Constr Build Mater. 2020;263:120177.10.1016/j.conbuildmat.2020.120177Search in Google Scholar

[40] Jagan S, Neelakantan TR. Effect of silica fume on the hardened and durability properties of concrete. Int Rev Appl Sci Eng. 2021;12:44–9.10.1556/1848.2020.00129Search in Google Scholar

[41] Grinys A, Balamurugan M, Augonis A, Ivanauskas E. Mechanical properties and durability of rubberized and glass powder modified rubberized concrete for whitetopping structures. Materials (Basel). 2021;14:2321.10.3390/ma14092321Search in Google Scholar PubMed PubMed Central

[42] Khan FA, Shahzada K, Ullah QS, Fahim M, Khan SW, Badrashi YI. Development of environment-friendly concrete through partial addition of waste glass powder (WGP) as cement replacement. Civ Eng J. 2020;6:2332–43.10.28991/cej-2020-03091620Search in Google Scholar

[43] Manikandan P, Vasugi V. Potential utilization of waste glass powder as a precursor material in synthesizing ecofriendly ternary blended geopolymer matrix. J Clean Prod. 2022;355:131860.10.1016/j.jclepro.2022.131860Search in Google Scholar

[44] No A. Specification for aggregates from natural sources for concrete. Bs. Vol. 882. London, UK: Standard – British Standard Institution; 1992. p. 1–14.Search in Google Scholar

[45] ASTM C. Standard specification for concrete aggregates. Philadelphia, PA: Am Soc Test Mater; 2003.Search in Google Scholar

[46] Al-Mashhadi SA, Hameed DH. Mix design for high strength concrete with portland cement and silica fume. Int J Civ Eng Technol. 2014;5(3):132–50.Search in Google Scholar

[47] Standard B. Testing concrete-Part 116: method for determination of compressive strength of concrete cubes. BS. Vol. 116. London, UK: Standard – British Standard Institution; 1881. p. 36.Search in Google Scholar

[48] Al-Baghdadi HM, Mahan HM, Shubbar AAF, Al-Khafaji ZS. Studying the impact of imposed actual loads on the non-destructive test results for evaluating the compressive strength and other properties of concrete. Int Rev Civ Eng. 2022;13:1–12. 10.15866/irece.v13i3.20880.Search in Google Scholar

[49] Ahmad J, Aslam F, Martinez-Garcia R, de-Prado-Gil J, Qaidi SMA, Brahmia A. Effects of waste glass and waste marble on mechanical and durability performance of concrete. Sci Rep. 2021;11:21525.10.1038/s41598-021-00994-0Search in Google Scholar PubMed PubMed Central

[50] Adesina A, Das S. Influence of glass powder on the durability properties of engineered cementitious composites. Constr Build Mater. 2020;242:118199. 10.1016/j.conbuildmat.2020.118199.Search in Google Scholar

[51] Aldeeky H, Al Hattamleh O. Prediction of engineering properties of basalt rock in Jordan using ultrasonic pulse velocity test. Geotech Geol Eng. 2018;36:3511–25.10.1007/s10706-018-0551-6Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Design optimization of a 4-bar exoskeleton with natural trajectories using unique gait-based synthesis approach

- Technical review of supervised machine learning studies and potential implementation to identify herbal plant dataset

- Effect of ECAP die angle and route type on the experimental evolution, crystallographic texture, and mechanical properties of pure magnesium

- Design and characteristics of two-dimensional piezoelectric nanogenerators

- Hybrid and cognitive digital twins for the process industry

- Discharge predicted in compound channels using adaptive neuro-fuzzy inference system (ANFIS)

- Human factors in aviation: Fatigue management in ramp workers

- LLDPE matrix with LDPE and UV stabilizer additive to evaluate the interface adhesion impact on the thermal and mechanical degradation

- Dislocated time sequences – deep neural network for broken bearing diagnosis

- Estimation method of corrosion current density of RC elements

- A computational iterative design method for bend-twist deformation in composite ship propeller blades for thrusters

- Compressive forces influence on the vibrations of double beams

- Research on dynamical properties of a three-wheeled electric vehicle from the point of view of driving safety

- Risk management based on the best value approach and its application in conditions of the Czech Republic

- Effect of openings on simply supported reinforced concrete skew slabs using finite element method

- Experimental and simulation study on a rooftop vertical-axis wind turbine

- Rehabilitation of overload-damaged reinforced concrete columns using ultra-high-performance fiber-reinforced concrete

- Performance of a horizontal well in a bounded anisotropic reservoir: Part II: Performance analysis of well length and reservoir geometry

- Effect of chloride concentration on the corrosion resistance of pure Zn metal in a 0.0626 M H2SO4 solution

- Numerical and experimental analysis of the heat transfer process in a railway disc brake tested on a dynamometer stand

- Design parameters and mechanical efficiency of jet wind turbine under high wind speed conditions

- Architectural modeling of data warehouse and analytic business intelligence for Bedstead manufacturers

- Influence of nano chromium addition on the corrosion and erosion–corrosion behavior of cupronickel 70/30 alloy in seawater

- Evaluating hydraulic parameters in clays based on in situ tests

- Optimization of railway entry and exit transition curves

- Daily load curve prediction for Jordan based on statistical techniques

- Review Articles

- A review of rutting in asphalt concrete pavement

- Powered education based on Metaverse: Pre- and post-COVID comprehensive review

- A review of safety test methods for new car assessment program in Southeast Asian countries

- Communication

- StarCrete: A starch-based biocomposite for off-world construction

- Special Issue: Transport 2022 - Part I

- Analysis and assessment of the human factor as a cause of occurrence of selected railway accidents and incidents

- Testing the way of driving a vehicle in real road conditions

- Research of dynamic phenomena in a model engine stand

- Testing the relationship between the technical condition of motorcycle shock absorbers determined on the diagnostic line and their characteristics

- Retrospective analysis of the data concerning inspections of vehicles with adaptive devices

- Analysis of the operating parameters of electric, hybrid, and conventional vehicles on different types of roads

- Special Issue: 49th KKBN - Part II

- Influence of a thin dielectric layer on resonance frequencies of square SRR metasurface operating in THz band

- Influence of the presence of a nitrided layer on changes in the ultrasonic wave parameters

- Special Issue: ICRTEEC - 2021 - Part III

- Reverse droop control strategy with virtual resistance for low-voltage microgrid with multiple distributed generation sources

- Special Issue: AESMT-2 - Part II

- Waste ceramic as partial replacement for sand in integral waterproof concrete: The durability against sulfate attack of certain properties

- Assessment of Manning coefficient for Dujila Canal, Wasit/-Iraq

- Special Issue: AESMT-3 - Part I

- Modulation and performance of synchronous demodulation for speech signal detection and dialect intelligibility

- Seismic evaluation cylindrical concrete shells

- Investigating the role of different stabilizers of PVCs by using a torque rheometer

- Investigation of high-turbidity tap water problem in Najaf governorate/middle of Iraq

- Experimental and numerical evaluation of tire rubber powder effectiveness for reducing seepage rate in earth dams

- Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation

- Assessment for behavior of axially loaded reinforced concrete columns strengthened by different patterns of steel-framed jacket

- Novel graph for an appropriate cross section and length for cantilever RC beams

- Discharge coefficient and energy dissipation on stepped weir

- Numerical study of the fluid flow and heat transfer in a finned heat sink using Ansys Icepak

- Integration of numerical models to simulate 2D hydrodynamic/water quality model of contaminant concentration in Shatt Al-Arab River with WRDB calibration tools

- Study of the behavior of reactive powder concrete RC deep beams by strengthening shear using near-surface mounted CFRP bars

- The nonlinear analysis of reactive powder concrete effectiveness in shear for reinforced concrete deep beams

- Activated carbon from sugarcane as an efficient adsorbent for phenol from petroleum refinery wastewater: Equilibrium, kinetic, and thermodynamic study

- Structural behavior of concrete filled double-skin PVC tubular columns confined by plain PVC sockets

- Probabilistic derivation of droplet velocity using quadrature method of moments

- A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar

- Effect of waste materials on soil properties

- Experimental investigation of electrode wear assessment in the EDM process using image processing technique

- Punching shear of reinforced concrete slabs bonded with reactive powder after exposure to fire

- Deep learning model for intrusion detection system utilizing convolution neural network

- Improvement of CBR of gypsum subgrade soil by cement kiln dust and granulated blast-furnace slag

- Investigation of effect lengths and angles of the control devices below the hydraulic structure

- Finite element analysis for built-up steel beam with extended plate connected by bolts

- Finite element analysis and retrofit of the existing reinforced concrete columns in Iraqi schools by using CFRP as confining technique

- Performing laboratory study of the behavior of reactive powder concrete on the shear of RC deep beams by the drilling core test

- Special Issue: AESMT-4 - Part I

- Depletion zones of groundwater resources in the Southwest Desert of Iraq

- A case study of T-beams with hybrid section shear characteristics of reactive powder concrete

- Feasibility studies and their effects on the success or failure of investment projects. “Najaf governorate as a model”

- Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

- Effect of the 40-PPI copper foam layer height on the solar cooker performance

- Identification and investigation of corrosion behavior of electroless composite coating on steel substrate

- Improvement in the California bearing ratio of subbase soil by recycled asphalt pavement and cement

- Some properties of thermal insulating cement mortar using Ponza aggregate

- Assessment of the impacts of land use/land cover change on water resources in the Diyala River, Iraq

- Effect of varied waste concrete ratios on the mechanical properties of polymer concrete

- Effect of adverse slope on performance of USBR II stilling basin

- Shear capacity of reinforced concrete beams with recycled steel fibers

- Extracting oil from oil shale using internal distillation (in situ retorting)

- Influence of recycling waste hardened mortar and ceramic rubbish on the properties of flowable fill material

- Rehabilitation of reinforced concrete deep beams by near-surface-mounted steel reinforcement

- Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

- Studying pandemic effects and mitigation measures on management of construction projects: Najaf City as a case study

- Design and implementation of a frequency reconfigurable antenna using PIN switch for sub-6 GHz applications

- Average monthly recharge, surface runoff, and actual evapotranspiration estimation using WetSpass-M model in Low Folded Zone, Iraq

- Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads

- Assessment of ALINEA method performance at different loop detector locations using field data and micro-simulation modeling via AIMSUN

- Special Issue: AESMT-5 - Part I

- Experimental and theoretical investigation of the structural behavior of reinforced glulam wooden members by NSM steel bars and shear reinforcement CFRP sheet

- Improving the fatigue life of composite by using multiwall carbon nanotubes

- A comparative study to solve fractional initial value problems in discrete domain

- Assessing strength properties of stabilized soils using dynamic cone penetrometer test

- Investigating traffic characteristics for merging sections in Iraq

- Enhancement of flexural behavior of hybrid flat slab by using SIFCON

- The main impacts of a managed aquifer recharge using AHP-weighted overlay analysis based on GIS in the eastern Wasit province, Iraq

Articles in the same Issue

- Regular Articles

- Design optimization of a 4-bar exoskeleton with natural trajectories using unique gait-based synthesis approach

- Technical review of supervised machine learning studies and potential implementation to identify herbal plant dataset

- Effect of ECAP die angle and route type on the experimental evolution, crystallographic texture, and mechanical properties of pure magnesium

- Design and characteristics of two-dimensional piezoelectric nanogenerators

- Hybrid and cognitive digital twins for the process industry

- Discharge predicted in compound channels using adaptive neuro-fuzzy inference system (ANFIS)

- Human factors in aviation: Fatigue management in ramp workers

- LLDPE matrix with LDPE and UV stabilizer additive to evaluate the interface adhesion impact on the thermal and mechanical degradation

- Dislocated time sequences – deep neural network for broken bearing diagnosis

- Estimation method of corrosion current density of RC elements

- A computational iterative design method for bend-twist deformation in composite ship propeller blades for thrusters

- Compressive forces influence on the vibrations of double beams

- Research on dynamical properties of a three-wheeled electric vehicle from the point of view of driving safety

- Risk management based on the best value approach and its application in conditions of the Czech Republic

- Effect of openings on simply supported reinforced concrete skew slabs using finite element method

- Experimental and simulation study on a rooftop vertical-axis wind turbine

- Rehabilitation of overload-damaged reinforced concrete columns using ultra-high-performance fiber-reinforced concrete

- Performance of a horizontal well in a bounded anisotropic reservoir: Part II: Performance analysis of well length and reservoir geometry

- Effect of chloride concentration on the corrosion resistance of pure Zn metal in a 0.0626 M H2SO4 solution

- Numerical and experimental analysis of the heat transfer process in a railway disc brake tested on a dynamometer stand

- Design parameters and mechanical efficiency of jet wind turbine under high wind speed conditions

- Architectural modeling of data warehouse and analytic business intelligence for Bedstead manufacturers

- Influence of nano chromium addition on the corrosion and erosion–corrosion behavior of cupronickel 70/30 alloy in seawater

- Evaluating hydraulic parameters in clays based on in situ tests

- Optimization of railway entry and exit transition curves

- Daily load curve prediction for Jordan based on statistical techniques

- Review Articles

- A review of rutting in asphalt concrete pavement

- Powered education based on Metaverse: Pre- and post-COVID comprehensive review

- A review of safety test methods for new car assessment program in Southeast Asian countries

- Communication

- StarCrete: A starch-based biocomposite for off-world construction

- Special Issue: Transport 2022 - Part I

- Analysis and assessment of the human factor as a cause of occurrence of selected railway accidents and incidents

- Testing the way of driving a vehicle in real road conditions

- Research of dynamic phenomena in a model engine stand

- Testing the relationship between the technical condition of motorcycle shock absorbers determined on the diagnostic line and their characteristics

- Retrospective analysis of the data concerning inspections of vehicles with adaptive devices

- Analysis of the operating parameters of electric, hybrid, and conventional vehicles on different types of roads

- Special Issue: 49th KKBN - Part II

- Influence of a thin dielectric layer on resonance frequencies of square SRR metasurface operating in THz band

- Influence of the presence of a nitrided layer on changes in the ultrasonic wave parameters

- Special Issue: ICRTEEC - 2021 - Part III

- Reverse droop control strategy with virtual resistance for low-voltage microgrid with multiple distributed generation sources

- Special Issue: AESMT-2 - Part II

- Waste ceramic as partial replacement for sand in integral waterproof concrete: The durability against sulfate attack of certain properties

- Assessment of Manning coefficient for Dujila Canal, Wasit/-Iraq

- Special Issue: AESMT-3 - Part I

- Modulation and performance of synchronous demodulation for speech signal detection and dialect intelligibility

- Seismic evaluation cylindrical concrete shells

- Investigating the role of different stabilizers of PVCs by using a torque rheometer

- Investigation of high-turbidity tap water problem in Najaf governorate/middle of Iraq

- Experimental and numerical evaluation of tire rubber powder effectiveness for reducing seepage rate in earth dams

- Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation

- Assessment for behavior of axially loaded reinforced concrete columns strengthened by different patterns of steel-framed jacket

- Novel graph for an appropriate cross section and length for cantilever RC beams

- Discharge coefficient and energy dissipation on stepped weir

- Numerical study of the fluid flow and heat transfer in a finned heat sink using Ansys Icepak

- Integration of numerical models to simulate 2D hydrodynamic/water quality model of contaminant concentration in Shatt Al-Arab River with WRDB calibration tools

- Study of the behavior of reactive powder concrete RC deep beams by strengthening shear using near-surface mounted CFRP bars

- The nonlinear analysis of reactive powder concrete effectiveness in shear for reinforced concrete deep beams

- Activated carbon from sugarcane as an efficient adsorbent for phenol from petroleum refinery wastewater: Equilibrium, kinetic, and thermodynamic study

- Structural behavior of concrete filled double-skin PVC tubular columns confined by plain PVC sockets

- Probabilistic derivation of droplet velocity using quadrature method of moments

- A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar

- Effect of waste materials on soil properties

- Experimental investigation of electrode wear assessment in the EDM process using image processing technique

- Punching shear of reinforced concrete slabs bonded with reactive powder after exposure to fire

- Deep learning model for intrusion detection system utilizing convolution neural network

- Improvement of CBR of gypsum subgrade soil by cement kiln dust and granulated blast-furnace slag

- Investigation of effect lengths and angles of the control devices below the hydraulic structure

- Finite element analysis for built-up steel beam with extended plate connected by bolts

- Finite element analysis and retrofit of the existing reinforced concrete columns in Iraqi schools by using CFRP as confining technique

- Performing laboratory study of the behavior of reactive powder concrete on the shear of RC deep beams by the drilling core test

- Special Issue: AESMT-4 - Part I

- Depletion zones of groundwater resources in the Southwest Desert of Iraq

- A case study of T-beams with hybrid section shear characteristics of reactive powder concrete

- Feasibility studies and their effects on the success or failure of investment projects. “Najaf governorate as a model”

- Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

- Effect of the 40-PPI copper foam layer height on the solar cooker performance

- Identification and investigation of corrosion behavior of electroless composite coating on steel substrate

- Improvement in the California bearing ratio of subbase soil by recycled asphalt pavement and cement

- Some properties of thermal insulating cement mortar using Ponza aggregate

- Assessment of the impacts of land use/land cover change on water resources in the Diyala River, Iraq

- Effect of varied waste concrete ratios on the mechanical properties of polymer concrete

- Effect of adverse slope on performance of USBR II stilling basin

- Shear capacity of reinforced concrete beams with recycled steel fibers

- Extracting oil from oil shale using internal distillation (in situ retorting)

- Influence of recycling waste hardened mortar and ceramic rubbish on the properties of flowable fill material

- Rehabilitation of reinforced concrete deep beams by near-surface-mounted steel reinforcement

- Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

- Studying pandemic effects and mitigation measures on management of construction projects: Najaf City as a case study

- Design and implementation of a frequency reconfigurable antenna using PIN switch for sub-6 GHz applications

- Average monthly recharge, surface runoff, and actual evapotranspiration estimation using WetSpass-M model in Low Folded Zone, Iraq

- Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads

- Assessment of ALINEA method performance at different loop detector locations using field data and micro-simulation modeling via AIMSUN

- Special Issue: AESMT-5 - Part I

- Experimental and theoretical investigation of the structural behavior of reinforced glulam wooden members by NSM steel bars and shear reinforcement CFRP sheet

- Improving the fatigue life of composite by using multiwall carbon nanotubes

- A comparative study to solve fractional initial value problems in discrete domain

- Assessing strength properties of stabilized soils using dynamic cone penetrometer test

- Investigating traffic characteristics for merging sections in Iraq

- Enhancement of flexural behavior of hybrid flat slab by using SIFCON

- The main impacts of a managed aquifer recharge using AHP-weighted overlay analysis based on GIS in the eastern Wasit province, Iraq