Abstract

Linear low-density polyethylene (LLDPE) is a commodity material that has been increasingly used in various open environments owing to its versatile properties. The mechanical and thermal degradation and processability properties can be enhanced by blending with other polymers or using different types of fillers to adjust such properties to fit the required applications. The objective of this work is to investigate the polymer–polymer interface and compare it with the polymer–additive (microparticles) interface in terms of structural changes and the impact on the polymer environmental properties. The novelty of this work is how to control the adhesion at the interface to enhance selected properties of the polymer without compromising other properties. LLDPE dried resins were compounded with UV additive and different wt% content of LDPE resin separately in a twin-screw extruder at 180–200°C and 150 rpm rotating speed with a die head to produce 1 mm thickness sheets. Then the prepared specimens were cooled to ambient temperature for testing. The nuclear magnetic resonance results showed that LLDPE with microparticles has good phase adhesion compared to the blended samples with LDPE. Moreover, thermal gravimetric analysis showed that the blends decompose in two steps at high LDPE content. The morphological images revealed cavities in the microstructure of low weight percent blends inductive of the relatively weak interaction between the components. The present study conclusively demonstrates that the polymer matrix is more stable with microparticle fillers (UV stabilizer) additive than with LDPE, which impacts the environment durability for outdoor application.

1 Introduction

Polyethylene (PE) or polythene is the most common plastic and has the highest share of global production [1]. It has wide usages in packaging, plastic bags, plastic films, geomembranes, bottles, etc. The most important polyethylene grades are low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and high-density polyethylene (HDPE). LLDPE is currently a fast-growing polymer used in packaging. Globally, around 80% of LLDPE goes into film applications for food and non-food packaging, shrink/stretch film, and non-packaging uses [2–4]. LDPE has lower tensile strength and higher resilience than LLDPE. Moreover, it is less crystalline since its molecules are less tightly packed [5]. The trend in food packaging films is toward high-performance film structures that are less permeable to increase the shelf life and enhance the flavour. However, such desirable performance cannot be achieved with a single polymer. Therefore, many research activities were directed to select a blend of polymers or use additives for specific applications, including those for packaging and food packaging. A polymer blend is a mixture of two or more polymers that have been blended to create a new material with different physical properties [6,7]. There are three categories of polymer blends: immiscible polymer blends, compatible polymer blends, and miscible polymer blends [8]. These categories indirectly describe the behaviour of the polymers at the interface, which impacts the properties of the blends and is adjusted according to the usage by the correct selection of the component polymers [9]. In comparison, the use of special additives is also considered an attractive technique to produce enhanced polymeric materials with specific properties. Additives can impact polymer processing by four primary mechanisms – adsorption, abrasion, site competition, and chemical reaction. Light stabilizers, in particular, are growing faster than fillers and other additives at over 7% per year [10,11].

Consequently, it becomes mandatory to assess the efficiency of additives or blending with respect to the polymer matrix and the interface changes [12,13]. For example, polyethylene linear low-density blend with to alter certain properties such as improved mechanical and thermal properties. When blending, although the densities of LDPE and LLDPE (0.921–0.926 g/cc) are similar, LLDPE displays better tear and impact film properties than LDPE [14]. Therefore, adding LLDPE to LDPE is expected to improve thermal as well as good barrier properties. In producing polymers with desirable final properties, it is essential to study the interface adhesion; this demands characterizing and understanding the interfacial reaction under processing conditions. Such deviations critically determine the final physical properties of materials prepared from multicomponent macromolecules. In the literature, numerous articles can be found about the role of interfacial adhesion in altering the polymer properties [15–17]. To evade interfacial failure in the presence of filler and miscible blend, it is essential to ensure good adhesion properties at the interfaces. In the industry, the manufacturer needs to ensure that the composite parts are properly bonded together and that this bond will endure. Nuclear magnetic resonance (NMR) is an outstanding experimental tool to understand whether certain polymeric chains are miscible or phase separate and to define the final state of mixing in solid materials. The end-use physical properties depend on the state of mixing [18,19].

Understanding this structural change is crucial in material science to correlate structural parameters with the final properties of a material. This article focused on investigating the influence of the structural changes at the interface of different enhancement techniques for LLDPE outdoor application. Samples of LLDPE were blended with different contents of LDPE and UV stabilizer (as microparticles). The prepared samples were evaluated for structural changes, thermal stability, mechanical properties, and morphology.

2 Materials and methods

2.1 Samples collection

The LLDPE and LDPE were received from a local manufacturing company and Qapco. The material properties of each sample are given in Table 1. The stabilizer additive was UV additives (Tinuvin 494FB, Tinuvin NOR 371, and Chimasorb 81) acquired from “Aldrige” chemical company.

Polymers material properties

| Name | Grade | Melt flow index (g/10 min) | Density (g/cm3) | Melting point (°C) | Haze (%) | Gloss (GU) |

|---|---|---|---|---|---|---|

| LDPE | FB3003 | 0.30 | 0.920 | 109 | 13 | 40 |

| LLDPE | EFDC-7050 | 2.00 | 0.918 | 124 | 14 | 50 |

2.2 Sample preparation and testing

The polymer pellets were dried at 80°C in a hot air oven for blending. Then the materials were sealed in plastic bags and kept in desiccators prior to blending. The samples were compounded by simultaneously adding both components to the twin-screw extruder at the selected wt% content. During the compounding of all blends, the barrel temperature profiles varied from 180 to 200°C over the six zones at the rotating speed of 40 rpm (to allow more residence time for the blend). For UV additive, the masterbatch that contained LLDPE and UV additive was prepared in a mixer, and then compounded in a twin extruder at 180–200°C at a rotating speed of 150 rpm. All test samples were rested under ambient conditions for a period of 24 h.

Mechanical and thermal properties were tested according to ASTM D 638 and ASTM D 3850-200, respectively [20,21].

2.3 NMR

NMR 400 MHz was used under the solution technique in which the polymer is partially dissolved in acetone to ensure the solution state so that NMR can detect it. The samples were ground and then mixed with acetone-d6. Proton one-degree NMR pulse sequence was applied for each sample separately (90-degree pulse sequence; proton is the name of the pulse in topspin; one-degree pulse sequence; duration time, 26 s; relaxation time, 2 s; power, 18.911 W; several scans, 100 scans). The NMR spectra were obtained for the samples and analysed using BRUKER software.

Morphological: Morphology of the samples was examined using a scanning electron microscope (SEM), a TESCAN TS5135MM model. The specimens were sputter-coated with a thin layer of gold by using vapour deposition techniques to avoid electrostatic charging during sample examination.

2.4 Thermogravimetric analysis (TGA)

TGA (TGA-50H from Japan, Shimadzu) was used under air at 40 mL/min flow rate. This test determines the changes in the sample weight with an increase in temperature, as the onset temperature is directly calculated from the TGA traces corresponding to the temperature at which the weight loss begins. The experimental temperatures varied from ambient temperature to 700°C with a heating rate of 10°C/min.

2.5 Statistical analysis

The experiments were conducted with five replicates per condition. The results were analysed statistically using the average of three techniques with less than 1% error in the final results for each condition.

3 Discussion of results

3.1 NMR

The research on the characterization of LLDPE and the prepared samples based on the H-NMR technique is scarce. However, the protons of the methylene (CH2) and methyl (CH3) chemical groups appear in separate chemical shifts in the H-NMR spectra, and thus H-NMR was used to characterize these chemical groups. Different categories of interfaces are examined systematically by NMR to isolate the role of the interface in the enhancement of different properties for a specific application [22]. This section discusses the separation and dynamic behaviour of the prepared samples.

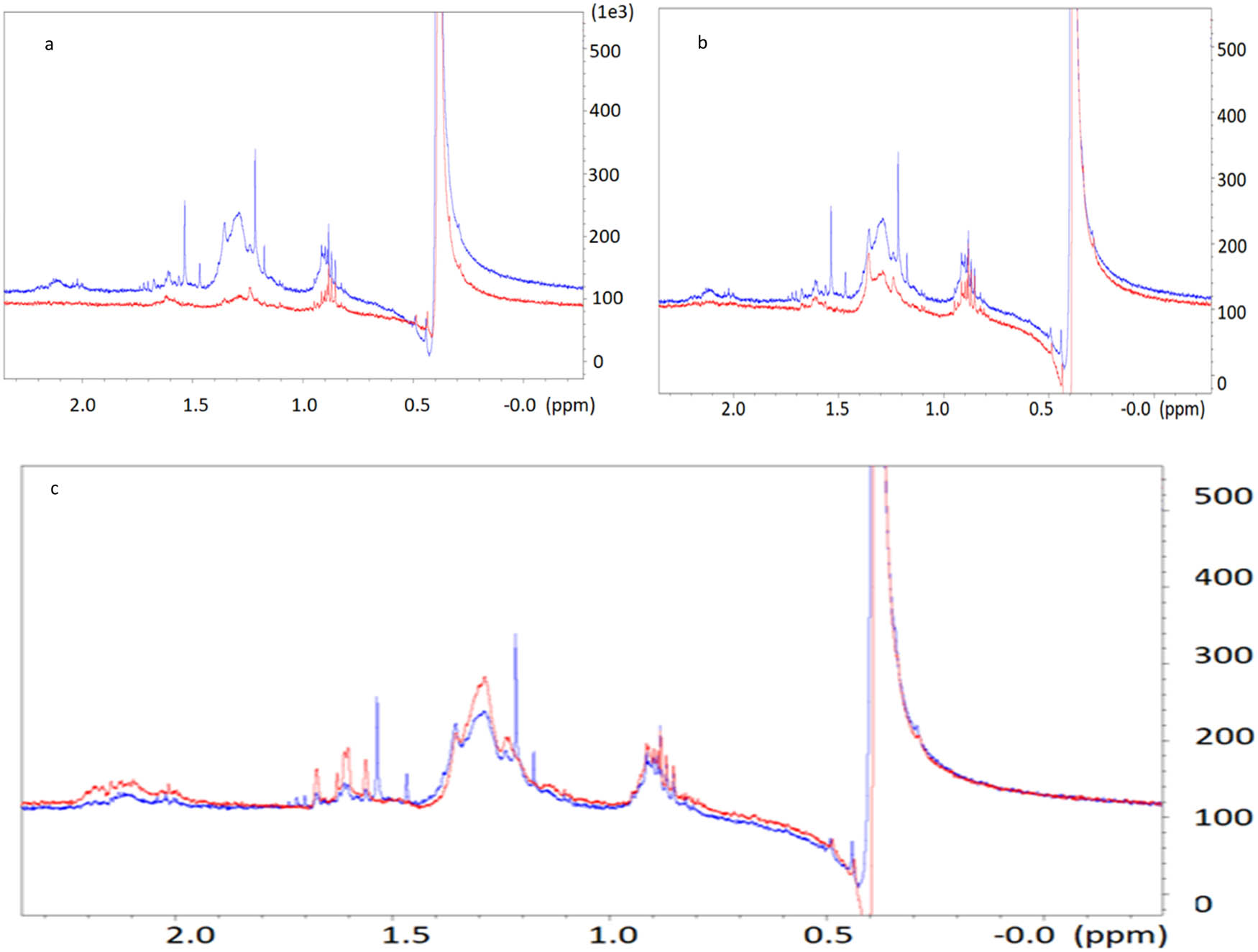

Figure 1a and b shows that the blends were immiscible in the melt. Moreover, the peaks at 1.4–1.55 ppm were not observed in the case of 50/50% LLDPE/LDPE, which indicates the weak interfacial stability of the blend matrix. In the case of Figure 1b, at higher LLDPE content, the blend showed less chemical shifts indicating a better adhesion at the interface, this could be attributed to the high side branching nature of LDPE. The chemical shift is most often used for structure determination through the shield patterns. In Figure 1c, the chemical shield shift is almost negligible, indicating a strong bonding of the UV stabilizer microparticles at the interface without causing a restructuring of the lamella. Moreover, NMR analysis shows as in Table 2 a breakdown of the functional group at the interface of the LLDPE, which affects the phase stability of the blend.

H-NMR spectra of LLDPE in blue: (a) 80/20 LDPE/LLDPE in red, (b) 50/50% LLDPE; LDPE in red, and (c) LLDPE with UV 0.3% in red.

NMR functional group peaks along with the interface for LLDPE

| Peak | ν(F1) (ppm) | Chemical molecule |

|---|---|---|

| 1 | 2.131 | CH3COR |

| 2 | 1.6101 | CH |

| 3 | 1.5358 | CH |

| 4 | 1.4672 | CH |

| 5 | 1.3555 | CH2 |

| 6 | 1.289 | CH2 |

| 7 | 1.2162 | CH2 |

| 8 | 1.1749 | CH2 |

| 9 | 0.9157 | CH3 |

| 10 | 0.8891 | CH3 |

| 11 | 0.8827 | CH3 |

| 12 | 0.8696 | CH3 |

| 13 | 0.8531 | CH3 |

Therefore, samples with microparticle additives showed more interfacial stability in the polymer matrix, keeping the lamella structure intact without changes; this will be reflected in the polymer properties. On the other hand, the behaviour at the LLDPE/LDPE blend interface was affected by the nature of the individual polymer, such as the weak intermolecular forces of LDPE and the considerable short branch LLDPE indicated by the chemical shield shift.

3.2 SEM

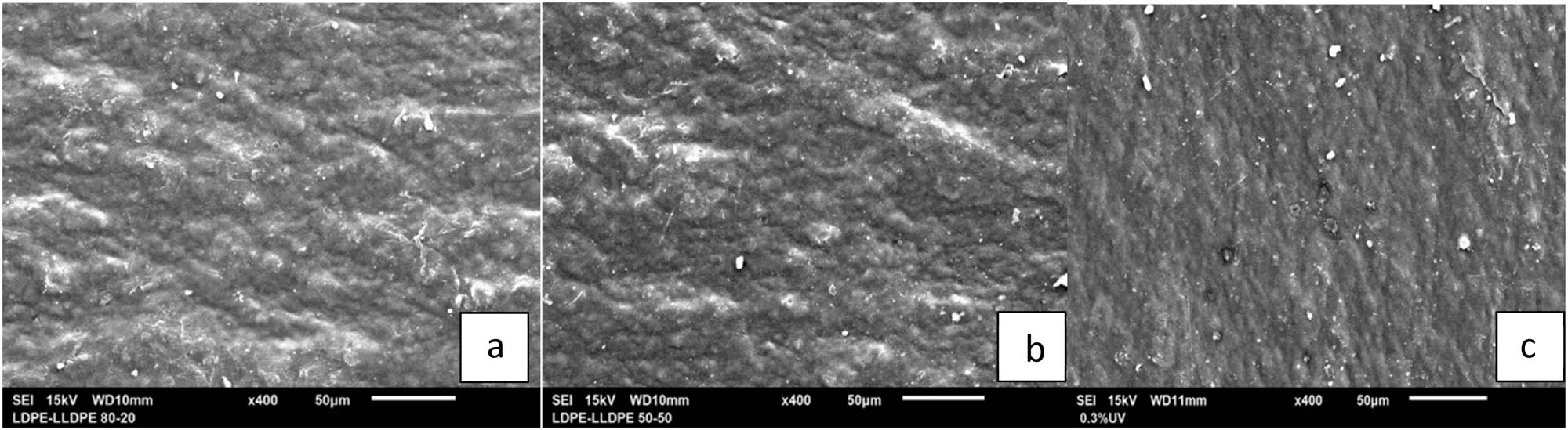

SEM was used to study the differences in morphological and interfacial properties between the two enhancement methods of LLDPE and to confirm the findings from NMR. The visual examination of the matrix through SEM was not practically very clear because the blend materials have almost the same density, which directly affects the contrast in SEM. The light colour (light grey and white) represents the contrast between the different phases. In Figure 2a, the blend of low content of LLDPE (20%) with LDPE demonstrates the worst adhesion of the whole sample. A clear white interface can be noticed, indicating detachment between the phases; thus, the light patches are predominantly due to compositional contrast. Furthermore, in Figure 2b, the low adhesion at the interface is also noticed with less amount due to the higher content of LLDPE (50%). This indicates that LDPE spherulites disappeared, and LDPE became the continuous phase. Moreover, the obtained morphology indicated the absence of miscibility between the two polymers. The surface morphology of the LLDPE sample with UV stabilizer microparticles is shown in Figure 2c. The micrograph shows the continuous phase of LLDPE with uniform distribution of the microparticles with no dark patches that represent structural changes due to particle agglomeration.

Surface morphology of (a) LDPE/LLDPE blend (80/20), (b) LDPE/LLDPE blend (50/50), and (c) LLDPE with UV stabilized microparticles.

In general, the micrograph image synergies with NMR results show the stability of the polymer matrix for LLDPE samples with microparticles and interfacial unsteadiness for the blend samples even for LLDPE 50% content.

3.3 Thermal stability

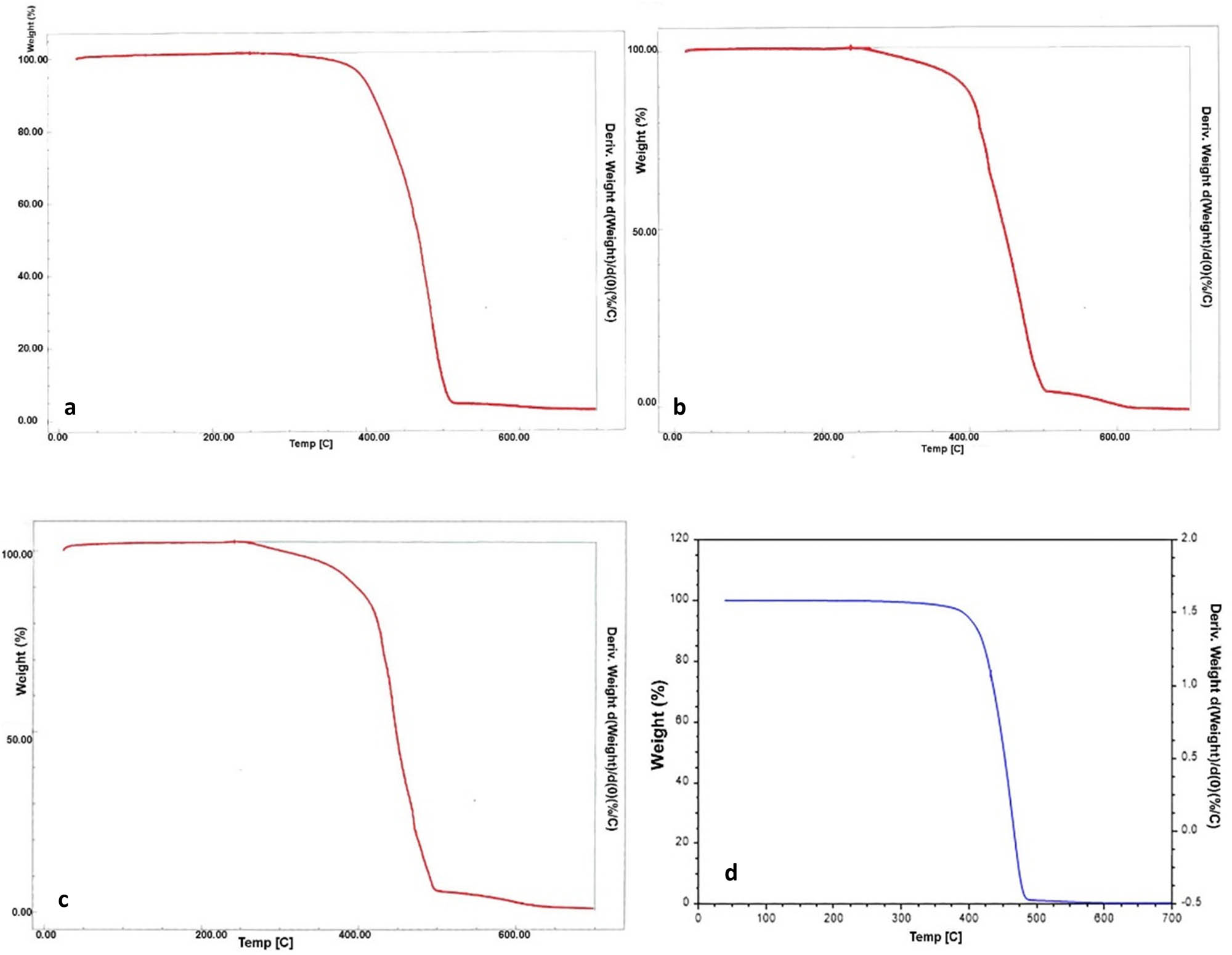

TGA was carried out for the prepared samples to investigate the thermal degradation of the prepared films. It is essential to realize that when a proper interface interaction exists, the particles can restrain/ease the movement of a polymer chain, making it less difficult to break the polymer chains occurring at a lower temperature. Therefore, the prepared blend showed an earlier degradation temperature than pure LLDPE.

TGA analysis of the prepared samples is provided in Figure 3. The thermogram suggests that the onset of degradation started around 240–250°C for most of the blend compositions. On the other hand, the temperature at maximum degradation commenced after 400°C. Once the temperature rises above 250°C, the epoxy resin starts to decompose rapidly. The single degradation step for the polymer blend confirms the stability of the blend and that the polymers are composed of carbon–carbon bonds in the main chain, thereby allowing a temperature increase to promote random scission. Associated thermal degradation and thermal depolymerization occur at a weak part of the polymer’s main chain [23,24]. Moreover, for LDPE in Figure 3a, a smooth degradation is noticed as it is a decomposition of pure material, wherein in Figure 3b it is noticed that samples with high LDPE content of 80% experience an unstable double stage at 500°C before complete decomposition which can be attributed to the breaking of the chain due to the high concentration of the LDPE in the blend. However, in Figure 3c, at high LLDPE content (50%), the blends decompose in two steps, first slowly, then rapidly, as it reaches 400°C; this could be attributed to the incompatibility behaviour of the blend at high LLDPE content, which synergies with the results produced from the NMR and SEM. In addition, there was a visible influence of the individual polymer components on the thermal stability of each blend, indicating that LLDPE dominated the structural changes at the interface.

(a) TGA of LDPE pure, (b) TGA of 20/80 contents of LLDPE/LDPE blend, (c) TGA of 50/50 contents of LLDPE/LDPE blend, and (d) TGA of LLDPE with microparticles (UV stabilizer).

For the samples with microparticles UV stabilizer Figure 3d, the delay in starting decomposition temperature for the high LLDPE content could be attributed to the decrease in the additional strength of the LLDPE interface and the UV stabilizer particles [25,26]. This forms distinct lamellae morphologies and thicknesses, the layers of the lamella are expected in the shape as shown in Figure 4. The smooth one-stage decomposition that started at 490°C indicates a thermally stable polymer matrix due to the uniform adhesion of the microparticles at the interface of the LLDPE.

Expected distribution of microparticles in the lamella phase of LLDPE.

3.4 Mechanical impact

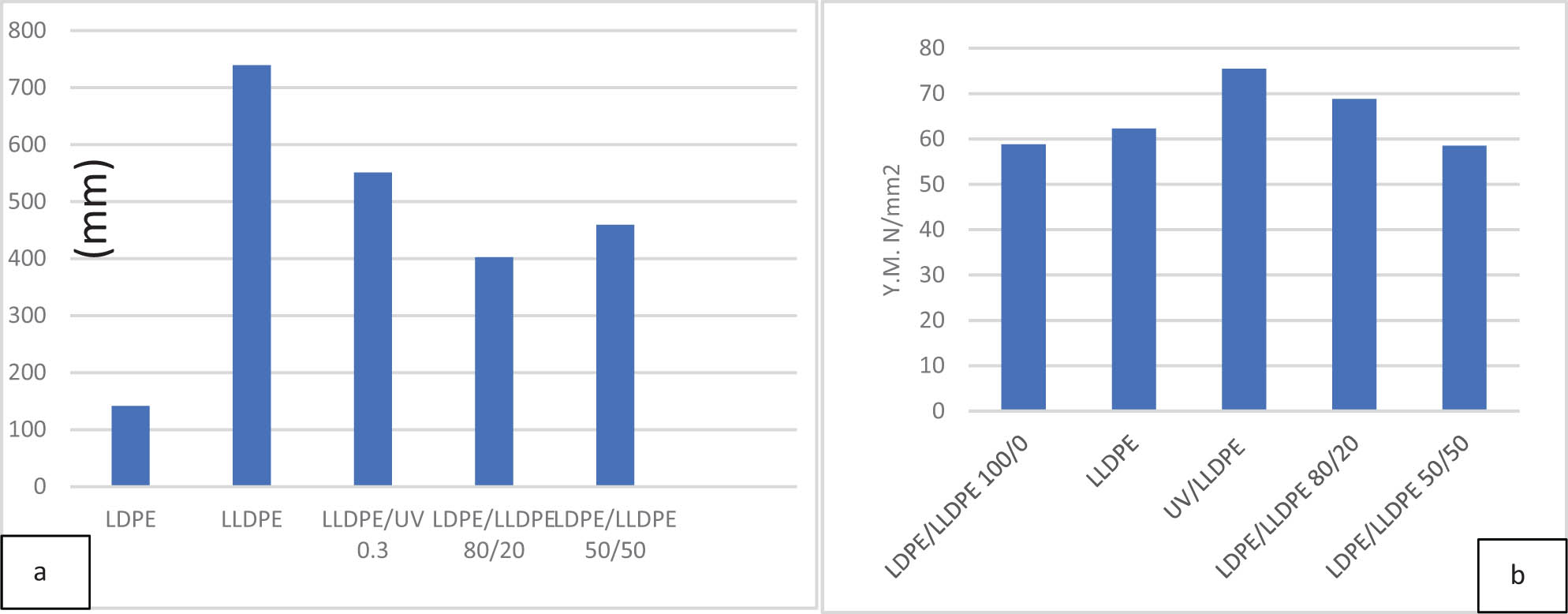

The impact of the structural changes and the level of adhesion at the interface can always be detected by altering the mechanical properties of the composites. In this section, the mechanical properties of the prepared samples are investigated and compared to the changes reported in the NMR and SEM. The matrix interfaces of LLDPE and LDPE have the same monomer repeating unit, but with the side branching of LDPE that resulted in forming an immiscible mixture, which was noticed from the NMR graphs (Figures 1 and 2). A comprehensive description of the tensile and modulus values for the blend and enhanced samples with microparticle additives is provided in Table 3.

Mechanical properties of the prepared samples

| Sample | Elong. @ peak (mm) | Stress @ break (N/mm²) | Strain @ break (%) | Stress @ peak (N/mm²) |

|---|---|---|---|---|

| LDPE/LLDPE 100/0 | 138.3 | 16.7 | 282.8 | 19.1 |

| LDPE/LLDPE 0/100 | 721 | 19 | 1481.2 | 19.4 |

| UV/LLDPE 0.3% | 498.3 | 21.7 | 951.4 | 29.1 |

| LDPE/LLDPE 80/20 | 400.128 | 17.703 | 805.585 | 20.51 |

| LDPE/LLDPE 50/50 | 447.928 | 20.903 | 918.651 | 21.524 |

The elongation results of the breakpoint measurements and Young’s modulus are presented in Figure 5. It is clear that the incorporation of microparticles has a noticeable negative effect on the elongation at the breaking point, with a decrease reaching up to 32% compared to pure LLDPE (Figure 5a). This is due to the minor restructuring of the lamella due to the adhesion of the UV stabilizer particles on the polymer matrix [27]. For the blend at low LLPDE concentrations of 20%, the elongation at the break decreases with an increasing amount of LDPE, which is expected as the LDPE dominates the structure at the interface and the short branches form more stiffness of the matrix. Furthermore, the blend interface behaves like physical crosslinking point, which restricts the movement of polymer chains and has this property in the final material [28]. As a result, they inhibit the mechanical properties of the blend, making it less flexible. It is important to mention that the interfacial forces on solid interfaces are not located on the interface itself but are distributed in their vicinity and appear as body forces.

Comparison of the (a) elongation @ break and (b) Young’s modulus for the tested samples of LLDPE.

Similarly, in Figure 5b, when the LLDPE mechanical properties are subjected to enhancement by using microfillers (UV stabilizers), Young’s modulus increases over the values for LLDPE/LDPE blend samples, as shown in Figure 5b. This is because the changes in the lamella formed in the matrix due to LDPE resulted in a profoundly deleterious effect on the properties of the blend samples; such phenomena do not exist at the interface of the LLDPE with UV stabilizer microparticles. LDPE has excessive branching leading to a less tight molecular structure which causes the low density of the material. On the other hand, LLDPE has a significant number of short branches leading to less entanglement during elongation, consequently giving LLDPE higher tensile strength.

In general, weak adhesion would result in poor mechanical properties in the blends. The inferior properties of the LDPE/LLDPE blend can be confirmed from the SEM images of the blend (Figure 4a), which shows incompatibility. However, a mixed amorphous interphase is expected to present, meaning that the chains of both polymers in the blend are mixed in the amorphous phase, resulting in a stronger interphase.

4 Conclusion

Different polymer outdoor properties enhancing techniques were examined in this work in terms of structural changes and behaviour at the interface, and also the impact of these changes on the thermal and mechanical properties were examined for desert environment durability. The comparison was made between blending LLDPE with LDPE at different ratios and using microparticles (UV stabilizers) as a property-enhancing method. The NMR analysis showed a noticeable change in the blended structure compared to the microparticle additive. Using SEM, a morphology study of the selected samples revealed a reasonably weak interaction between the blend components. Moreover, the compatibility issues of the blend with higher LLDPE content were realized. Correspondingly, at low LLDPE content in the blend, the mechanical characteristics of the LDPE were dominant, whereas the TGA test for thermal property evaluation showed that the blend composition LLDPE/LDPE is thermally more stable at low LDPE content. Moreover, analysis of the mechanical properties of elongation at break and Young’s modulus gave a clear picture that the microparticle additives technique can produce good properties of the matrix due to the adhesion and stability of both lamella and amorphous structures of the polymer. Wherein the blend, the immiscible characteristic of the blend, can dictate the structural changes and consequently show instability in the thermal properties and undermine some mechanical properties. The improved properties are commonly attributed to the improved adhesion at the interface of the dispersed phase and the matrix. In terms of cost and processability, the use of UV microparticles is more effective and less complex when compared with polymer blending.

-

Conflict of interest: Authors state no conflict of interest.

References

[1] Al-Samhan M, Al-Attar F, Al-Fadhli J, Abraham G. Thermal and rheological response to ultraviolet stabilizers additive in linear low density polyethylene under sever environmental conditions. J Environ Sci Technol. 2019;12:213–20. 10.3923/jest.2019.213.220.Search in Google Scholar

[2] Noorunnisa P, AlMaadeed M. Processing and characterization of polyethylene-based composites. Adv Manuf Polym Compos Sci. 2015;1(2):63–79. 10.1179/2055035915Y.0000000002.Search in Google Scholar

[3] Huang X, Ke Q, Kim C, Zhong H, Wei P, Wang G, et al. Polym Eng Sci. 2007;47(7):1052–61.10.1002/pen.20784Search in Google Scholar

[4] Basfar A, Ali K. Natural weathering for films of various formulations of low density polyethylene and linear low density polyethylene. Polym Degrad Stab J. 2006;91:437–43.10.1016/j.polymdegradstab.2004.11.027Search in Google Scholar

[5] Cho K, Lee BH, Hwang K, Lee H, Choe S. Rheological and mechanical properties in polyethylene blends. Polym Eng Sci. 1998;38:1969–75.10.1002/pen.10366Search in Google Scholar

[6] Yamaguchi M, Abe S. LLDPE/LDPE blends. I. Rheological, thermal, and mechanical properties. J Appl Polym Sci. 1999;74:3153–9.10.1002/(SICI)1097-4628(19991220)74:13<3153::AID-APP18>3.0.CO;2-TSearch in Google Scholar

[7] Hussein IA. Melt miscibility and mechanical properties of metallocene linear low-density polyethylene blends with high-density polyethylene: influence of comonomer type. Polym Int. 2005;54:1330–6.10.1002/pi.1860Search in Google Scholar

[8] Gupta AK, Rana SK, Deopura BL. Mechanical properties and morphology of high-density polyethylene/linear low-density polyethylene blend. J Appl Polym Sci. 1992;46:99–108.10.1002/app.1992.070460110Search in Google Scholar

[9] Tashiro K, Stein RS, Hsu SL. Cocrystallization and phase segregation of polyethylene blends. 1. Thermal and vibrational spectroscopic study by utilizing the deuteration technique. Macromolecules. 1992;25:1801–8.10.1021/ma00032a029Search in Google Scholar

[10] Liauw CM, Quadir A, Allen NS, Edge M, Wagner A. Effect of hindered piperidine light stabilizer molecular structure and UV-absorber addition on the oxidation of HDPE. Part 1: long-term thermal and photo-oxidation studies. J Vinyl Addit Technol. 2004;10(2):79–87.10.1002/vnl.20011Search in Google Scholar

[11] Andradey L, Hamid S. Effect of climate change and UV on materials. Photochem Photobio Sci. 2013;2:68–72.10.1039/b211085gSearch in Google Scholar PubMed

[12] Xu J, Xu X, Chen L, Feng L, Chen W. Effect of composition distribution on miscibility and co-crystallization phenomena in the blends of low density polyethylene with conventional and metallocene-based ethylene-butene copolymers. Polymer. 2001;42:3867–74. 10.1016/S0032-3861(00)00756-4.Search in Google Scholar

[13] Martuscelli R, Palumbo A, Kryszwski M. Polymer blends. New York: Plenum Press; 1980.10.1007/978-1-4613-3177-3Search in Google Scholar

[14] Mohammed NA. The mechanical properties and morphology of ternary blends of polyethylene. Eng Tech J. 2009;27(6):1197–202.10.30684/etj.27.6.17Search in Google Scholar

[15] Sui G, Fuqua MA, Ulven CA, Zhong WH. A plant fiber reinforced polymer composite prepared by a twin-screw extruder. Bioresour Technol. 2009;100:1246–51. 10.1016/j.biortech.2008.03.065.Search in Google Scholar PubMed

[16] Salasinska K, Ryszkowska J. The effect of filler chemical constitution and morphological properties on the mechanical properties of natural fiber composites. Compos Interface. 2015;22:39–50. 10.1080/15685543.2015.984521.Search in Google Scholar

[17] Flinn B, Clark B, Satterwhite J, Voast P. Influence of peel ply type on adhesion bonding of composites. In SAMPE 2008 Proceedings. Long Beach, CA; Society for the Advancement of Material and Process Engineering. 2008 June 3–7. p. 1–26.Search in Google Scholar

[18] Al-Samhan M, Al-Attar F, Al-Fadhli J, Al-Shamali M. The influence of nano CaCO3 on nucleation and interface of PP nanocomposite: matrix processability and impact resistance. Polymers. 2021;13:1389. 10.3390/polym13091389.Search in Google Scholar PubMed PubMed Central

[19] Hassan A, Wahit U, Chee CY. Mechanical and morphological properties of PP/NR/LLDPE ternary blend-Effect of HVA-2. Polym Test. 2003;22:281–90.10.1016/S0142-9418(02)00100-9Search in Google Scholar

[20] American Society for Testing and Materials, ASTM test method D-638, Standard Test Method for Tensile Properties of Plastics. 2003.Search in Google Scholar

[21] American Society for Testing and Materials, ASTM test method D-3850, Standard Test Method for Rapid Thermal Degradation of Solid Electrical Insulating Materials By Thermogravimetric Method (TGA); 2019.Search in Google Scholar

[22] Masud M, Yu Y. Determination of the composition of LDPE/LLDPE blends via 13C NMR. Macromolecular Symposia. Vol. 390; 2020. p. 1. 10.1002/masy.201900013.Search in Google Scholar

[23] Ishigaki T, Sugano W, Nakanishi A, Tateda M, Ike M, Fujita M. The degradability of biodegradable plastics in aerobic and anaerobic waste landfill model reactors. Chemosphere. 2004 January;54(3):225–33.10.1016/S0045-6535(03)00750-1Search in Google Scholar PubMed

[24] Miao Y, von Jouanne A, Yokochi A. Current technologies in depolymerization process and the road ahead. Polymers (Basel). 2021 Jan 30;13(3):449. 10.3390/polym13030449. PMID: 33573290; PMCID: PMC7866858.Search in Google Scholar PubMed PubMed Central

[25] Zhang F, Liu J, Xie F, Fu Q, He T. Polydispersity of ethylene sequence length in metallocene ethylene/α-olefin copolymers. II. Influence on crystallization and melting behavior. Polym Sci Polym Phys Ed. 2002;40:822–30.10.1002/polb.10146Search in Google Scholar

[26] Arnal ML, Sánchez JJ, Müller AJ. Miscibility of linear and branched polyethylene by thermal fractionation: use of the successive self-nucleation and annealing (SSA) technique. Polymer. 2001;42:6877–90.10.1016/S0032-3861(01)00177-XSearch in Google Scholar

[27] La Mantia FP, Morreale M, Botta L, Mistretta MC, Ceraulo M, Scaffaro R. Degradation of polymer blends: a brief review. Polym Degrad Stab. 2017;145:79–92.10.1016/j.polymdegradstab.2017.07.011Search in Google Scholar

[28] Spiechowicz J, Łuczka J. Arcsine law and multistable Brownian dynamics in a tilted periodic potential. Phys Rev E. 2021;104:024132.10.1103/PhysRevE.104.024132Search in Google Scholar PubMed

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Design optimization of a 4-bar exoskeleton with natural trajectories using unique gait-based synthesis approach

- Technical review of supervised machine learning studies and potential implementation to identify herbal plant dataset

- Effect of ECAP die angle and route type on the experimental evolution, crystallographic texture, and mechanical properties of pure magnesium

- Design and characteristics of two-dimensional piezoelectric nanogenerators

- Hybrid and cognitive digital twins for the process industry

- Discharge predicted in compound channels using adaptive neuro-fuzzy inference system (ANFIS)

- Human factors in aviation: Fatigue management in ramp workers

- LLDPE matrix with LDPE and UV stabilizer additive to evaluate the interface adhesion impact on the thermal and mechanical degradation

- Dislocated time sequences – deep neural network for broken bearing diagnosis

- Estimation method of corrosion current density of RC elements

- A computational iterative design method for bend-twist deformation in composite ship propeller blades for thrusters

- Compressive forces influence on the vibrations of double beams

- Research on dynamical properties of a three-wheeled electric vehicle from the point of view of driving safety

- Risk management based on the best value approach and its application in conditions of the Czech Republic

- Effect of openings on simply supported reinforced concrete skew slabs using finite element method

- Experimental and simulation study on a rooftop vertical-axis wind turbine

- Rehabilitation of overload-damaged reinforced concrete columns using ultra-high-performance fiber-reinforced concrete

- Performance of a horizontal well in a bounded anisotropic reservoir: Part II: Performance analysis of well length and reservoir geometry

- Effect of chloride concentration on the corrosion resistance of pure Zn metal in a 0.0626 M H2SO4 solution

- Numerical and experimental analysis of the heat transfer process in a railway disc brake tested on a dynamometer stand

- Design parameters and mechanical efficiency of jet wind turbine under high wind speed conditions

- Architectural modeling of data warehouse and analytic business intelligence for Bedstead manufacturers

- Influence of nano chromium addition on the corrosion and erosion–corrosion behavior of cupronickel 70/30 alloy in seawater

- Evaluating hydraulic parameters in clays based on in situ tests

- Optimization of railway entry and exit transition curves

- Daily load curve prediction for Jordan based on statistical techniques

- Review Articles

- A review of rutting in asphalt concrete pavement

- Powered education based on Metaverse: Pre- and post-COVID comprehensive review

- A review of safety test methods for new car assessment program in Southeast Asian countries

- Communication

- StarCrete: A starch-based biocomposite for off-world construction

- Special Issue: Transport 2022 - Part I

- Analysis and assessment of the human factor as a cause of occurrence of selected railway accidents and incidents

- Testing the way of driving a vehicle in real road conditions

- Research of dynamic phenomena in a model engine stand

- Testing the relationship between the technical condition of motorcycle shock absorbers determined on the diagnostic line and their characteristics

- Retrospective analysis of the data concerning inspections of vehicles with adaptive devices

- Analysis of the operating parameters of electric, hybrid, and conventional vehicles on different types of roads

- Special Issue: 49th KKBN - Part II

- Influence of a thin dielectric layer on resonance frequencies of square SRR metasurface operating in THz band

- Influence of the presence of a nitrided layer on changes in the ultrasonic wave parameters

- Special Issue: ICRTEEC - 2021 - Part III

- Reverse droop control strategy with virtual resistance for low-voltage microgrid with multiple distributed generation sources

- Special Issue: AESMT-2 - Part II

- Waste ceramic as partial replacement for sand in integral waterproof concrete: The durability against sulfate attack of certain properties

- Assessment of Manning coefficient for Dujila Canal, Wasit/-Iraq

- Special Issue: AESMT-3 - Part I

- Modulation and performance of synchronous demodulation for speech signal detection and dialect intelligibility

- Seismic evaluation cylindrical concrete shells

- Investigating the role of different stabilizers of PVCs by using a torque rheometer

- Investigation of high-turbidity tap water problem in Najaf governorate/middle of Iraq

- Experimental and numerical evaluation of tire rubber powder effectiveness for reducing seepage rate in earth dams

- Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation

- Assessment for behavior of axially loaded reinforced concrete columns strengthened by different patterns of steel-framed jacket

- Novel graph for an appropriate cross section and length for cantilever RC beams

- Discharge coefficient and energy dissipation on stepped weir

- Numerical study of the fluid flow and heat transfer in a finned heat sink using Ansys Icepak

- Integration of numerical models to simulate 2D hydrodynamic/water quality model of contaminant concentration in Shatt Al-Arab River with WRDB calibration tools

- Study of the behavior of reactive powder concrete RC deep beams by strengthening shear using near-surface mounted CFRP bars

- The nonlinear analysis of reactive powder concrete effectiveness in shear for reinforced concrete deep beams

- Activated carbon from sugarcane as an efficient adsorbent for phenol from petroleum refinery wastewater: Equilibrium, kinetic, and thermodynamic study

- Structural behavior of concrete filled double-skin PVC tubular columns confined by plain PVC sockets

- Probabilistic derivation of droplet velocity using quadrature method of moments

- A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar

- Effect of waste materials on soil properties

- Experimental investigation of electrode wear assessment in the EDM process using image processing technique

- Punching shear of reinforced concrete slabs bonded with reactive powder after exposure to fire

- Deep learning model for intrusion detection system utilizing convolution neural network

- Improvement of CBR of gypsum subgrade soil by cement kiln dust and granulated blast-furnace slag

- Investigation of effect lengths and angles of the control devices below the hydraulic structure

- Finite element analysis for built-up steel beam with extended plate connected by bolts

- Finite element analysis and retrofit of the existing reinforced concrete columns in Iraqi schools by using CFRP as confining technique

- Performing laboratory study of the behavior of reactive powder concrete on the shear of RC deep beams by the drilling core test

- Special Issue: AESMT-4 - Part I

- Depletion zones of groundwater resources in the Southwest Desert of Iraq

- A case study of T-beams with hybrid section shear characteristics of reactive powder concrete

- Feasibility studies and their effects on the success or failure of investment projects. “Najaf governorate as a model”

- Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

- Effect of the 40-PPI copper foam layer height on the solar cooker performance

- Identification and investigation of corrosion behavior of electroless composite coating on steel substrate

- Improvement in the California bearing ratio of subbase soil by recycled asphalt pavement and cement

- Some properties of thermal insulating cement mortar using Ponza aggregate

- Assessment of the impacts of land use/land cover change on water resources in the Diyala River, Iraq

- Effect of varied waste concrete ratios on the mechanical properties of polymer concrete

- Effect of adverse slope on performance of USBR II stilling basin

- Shear capacity of reinforced concrete beams with recycled steel fibers

- Extracting oil from oil shale using internal distillation (in situ retorting)

- Influence of recycling waste hardened mortar and ceramic rubbish on the properties of flowable fill material

- Rehabilitation of reinforced concrete deep beams by near-surface-mounted steel reinforcement

- Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

- Studying pandemic effects and mitigation measures on management of construction projects: Najaf City as a case study

- Design and implementation of a frequency reconfigurable antenna using PIN switch for sub-6 GHz applications

- Average monthly recharge, surface runoff, and actual evapotranspiration estimation using WetSpass-M model in Low Folded Zone, Iraq

- Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads

- Assessment of ALINEA method performance at different loop detector locations using field data and micro-simulation modeling via AIMSUN

- Special Issue: AESMT-5 - Part I

- Experimental and theoretical investigation of the structural behavior of reinforced glulam wooden members by NSM steel bars and shear reinforcement CFRP sheet

- Improving the fatigue life of composite by using multiwall carbon nanotubes

- A comparative study to solve fractional initial value problems in discrete domain

- Assessing strength properties of stabilized soils using dynamic cone penetrometer test

- Investigating traffic characteristics for merging sections in Iraq

- Enhancement of flexural behavior of hybrid flat slab by using SIFCON

- The main impacts of a managed aquifer recharge using AHP-weighted overlay analysis based on GIS in the eastern Wasit province, Iraq

Articles in the same Issue

- Regular Articles

- Design optimization of a 4-bar exoskeleton with natural trajectories using unique gait-based synthesis approach

- Technical review of supervised machine learning studies and potential implementation to identify herbal plant dataset

- Effect of ECAP die angle and route type on the experimental evolution, crystallographic texture, and mechanical properties of pure magnesium

- Design and characteristics of two-dimensional piezoelectric nanogenerators

- Hybrid and cognitive digital twins for the process industry

- Discharge predicted in compound channels using adaptive neuro-fuzzy inference system (ANFIS)

- Human factors in aviation: Fatigue management in ramp workers

- LLDPE matrix with LDPE and UV stabilizer additive to evaluate the interface adhesion impact on the thermal and mechanical degradation

- Dislocated time sequences – deep neural network for broken bearing diagnosis

- Estimation method of corrosion current density of RC elements

- A computational iterative design method for bend-twist deformation in composite ship propeller blades for thrusters

- Compressive forces influence on the vibrations of double beams

- Research on dynamical properties of a three-wheeled electric vehicle from the point of view of driving safety

- Risk management based on the best value approach and its application in conditions of the Czech Republic

- Effect of openings on simply supported reinforced concrete skew slabs using finite element method

- Experimental and simulation study on a rooftop vertical-axis wind turbine

- Rehabilitation of overload-damaged reinforced concrete columns using ultra-high-performance fiber-reinforced concrete

- Performance of a horizontal well in a bounded anisotropic reservoir: Part II: Performance analysis of well length and reservoir geometry

- Effect of chloride concentration on the corrosion resistance of pure Zn metal in a 0.0626 M H2SO4 solution

- Numerical and experimental analysis of the heat transfer process in a railway disc brake tested on a dynamometer stand

- Design parameters and mechanical efficiency of jet wind turbine under high wind speed conditions

- Architectural modeling of data warehouse and analytic business intelligence for Bedstead manufacturers

- Influence of nano chromium addition on the corrosion and erosion–corrosion behavior of cupronickel 70/30 alloy in seawater

- Evaluating hydraulic parameters in clays based on in situ tests

- Optimization of railway entry and exit transition curves

- Daily load curve prediction for Jordan based on statistical techniques

- Review Articles

- A review of rutting in asphalt concrete pavement

- Powered education based on Metaverse: Pre- and post-COVID comprehensive review

- A review of safety test methods for new car assessment program in Southeast Asian countries

- Communication

- StarCrete: A starch-based biocomposite for off-world construction

- Special Issue: Transport 2022 - Part I

- Analysis and assessment of the human factor as a cause of occurrence of selected railway accidents and incidents

- Testing the way of driving a vehicle in real road conditions

- Research of dynamic phenomena in a model engine stand

- Testing the relationship between the technical condition of motorcycle shock absorbers determined on the diagnostic line and their characteristics

- Retrospective analysis of the data concerning inspections of vehicles with adaptive devices

- Analysis of the operating parameters of electric, hybrid, and conventional vehicles on different types of roads

- Special Issue: 49th KKBN - Part II

- Influence of a thin dielectric layer on resonance frequencies of square SRR metasurface operating in THz band

- Influence of the presence of a nitrided layer on changes in the ultrasonic wave parameters

- Special Issue: ICRTEEC - 2021 - Part III

- Reverse droop control strategy with virtual resistance for low-voltage microgrid with multiple distributed generation sources

- Special Issue: AESMT-2 - Part II

- Waste ceramic as partial replacement for sand in integral waterproof concrete: The durability against sulfate attack of certain properties

- Assessment of Manning coefficient for Dujila Canal, Wasit/-Iraq

- Special Issue: AESMT-3 - Part I

- Modulation and performance of synchronous demodulation for speech signal detection and dialect intelligibility

- Seismic evaluation cylindrical concrete shells

- Investigating the role of different stabilizers of PVCs by using a torque rheometer

- Investigation of high-turbidity tap water problem in Najaf governorate/middle of Iraq

- Experimental and numerical evaluation of tire rubber powder effectiveness for reducing seepage rate in earth dams

- Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation

- Assessment for behavior of axially loaded reinforced concrete columns strengthened by different patterns of steel-framed jacket

- Novel graph for an appropriate cross section and length for cantilever RC beams

- Discharge coefficient and energy dissipation on stepped weir

- Numerical study of the fluid flow and heat transfer in a finned heat sink using Ansys Icepak

- Integration of numerical models to simulate 2D hydrodynamic/water quality model of contaminant concentration in Shatt Al-Arab River with WRDB calibration tools

- Study of the behavior of reactive powder concrete RC deep beams by strengthening shear using near-surface mounted CFRP bars

- The nonlinear analysis of reactive powder concrete effectiveness in shear for reinforced concrete deep beams

- Activated carbon from sugarcane as an efficient adsorbent for phenol from petroleum refinery wastewater: Equilibrium, kinetic, and thermodynamic study

- Structural behavior of concrete filled double-skin PVC tubular columns confined by plain PVC sockets

- Probabilistic derivation of droplet velocity using quadrature method of moments

- A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar

- Effect of waste materials on soil properties

- Experimental investigation of electrode wear assessment in the EDM process using image processing technique

- Punching shear of reinforced concrete slabs bonded with reactive powder after exposure to fire

- Deep learning model for intrusion detection system utilizing convolution neural network

- Improvement of CBR of gypsum subgrade soil by cement kiln dust and granulated blast-furnace slag

- Investigation of effect lengths and angles of the control devices below the hydraulic structure

- Finite element analysis for built-up steel beam with extended plate connected by bolts

- Finite element analysis and retrofit of the existing reinforced concrete columns in Iraqi schools by using CFRP as confining technique

- Performing laboratory study of the behavior of reactive powder concrete on the shear of RC deep beams by the drilling core test

- Special Issue: AESMT-4 - Part I

- Depletion zones of groundwater resources in the Southwest Desert of Iraq

- A case study of T-beams with hybrid section shear characteristics of reactive powder concrete

- Feasibility studies and their effects on the success or failure of investment projects. “Najaf governorate as a model”

- Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

- Effect of the 40-PPI copper foam layer height on the solar cooker performance

- Identification and investigation of corrosion behavior of electroless composite coating on steel substrate

- Improvement in the California bearing ratio of subbase soil by recycled asphalt pavement and cement

- Some properties of thermal insulating cement mortar using Ponza aggregate

- Assessment of the impacts of land use/land cover change on water resources in the Diyala River, Iraq

- Effect of varied waste concrete ratios on the mechanical properties of polymer concrete

- Effect of adverse slope on performance of USBR II stilling basin

- Shear capacity of reinforced concrete beams with recycled steel fibers

- Extracting oil from oil shale using internal distillation (in situ retorting)

- Influence of recycling waste hardened mortar and ceramic rubbish on the properties of flowable fill material

- Rehabilitation of reinforced concrete deep beams by near-surface-mounted steel reinforcement

- Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

- Studying pandemic effects and mitigation measures on management of construction projects: Najaf City as a case study

- Design and implementation of a frequency reconfigurable antenna using PIN switch for sub-6 GHz applications

- Average monthly recharge, surface runoff, and actual evapotranspiration estimation using WetSpass-M model in Low Folded Zone, Iraq

- Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads

- Assessment of ALINEA method performance at different loop detector locations using field data and micro-simulation modeling via AIMSUN

- Special Issue: AESMT-5 - Part I

- Experimental and theoretical investigation of the structural behavior of reinforced glulam wooden members by NSM steel bars and shear reinforcement CFRP sheet

- Improving the fatigue life of composite by using multiwall carbon nanotubes

- A comparative study to solve fractional initial value problems in discrete domain

- Assessing strength properties of stabilized soils using dynamic cone penetrometer test

- Investigating traffic characteristics for merging sections in Iraq

- Enhancement of flexural behavior of hybrid flat slab by using SIFCON

- The main impacts of a managed aquifer recharge using AHP-weighted overlay analysis based on GIS in the eastern Wasit province, Iraq