Abstract

This study investigates the corrosion and erosion-corrosion performance of HVOF-sprayed WC-10Co-4Cr coatings for offshore hydraulic applications. By tuning kerosene (18.1–25.3 l·h−1) and oxygen (820–990 l·min−1) flow rates, coatings with optimal hardness (1200 HV0.3), porosity (0.35%), carbide retention (90%), and polarization resistance (15.2 kΩ·cm−2) are attained. In-flight diagnostics reveal that particle temperatures and velocities peak at 1,842°C and 799 m·s−1, respectively, at stoichiometric combustion. Higher temperatures degrade electrochemical stability due to enriched binders when 30% of carbides decompose. The localized attack is mitigated as splatting from high-velocity particles eliminates 25% more porosity. With exposure to sulfate-reducing bacteria for 15 days, polarization resistance reduces to 12.4 kΩ·cm−2 owing to biofilm formation, indicating self-healing effects from protective corrosion films. The optimized WC-CoCr coatings reduce corrosion rates under combined erosion and bacterial conditions by 86% compared to untreated steel substrates. This research provides a framework to customize HVOF coatings for demanding offshore conditions.

1 Introduction

Hard chromium plating has been widely used to provide wear and corrosion protection for components in hydraulic systems used in offshore oil and gas operations [1]. However, the hexavalent chromium used in the plating process poses environmental and health hazards [2]. There has been increasing motivation to identify chrome-replacement coatings that can withstand the demanding offshore conditions without the toxic effects of chromium [3]. High-velocity oxy-fuel (HVOF) thermal spraying is considered one of the most promising alternatives for producing protective coatings on offshore hydraulic machinery [4]. Compared to other thermal spray methods, HVOF produces very dense and well-adhered metallic, ceramic, and cermet coatings due to the high kinetic energy imparted by the hypersonic spray jet.

WC-CoCr coatings have shown excellent combined wear and corrosion resistance and are emerging as a leading candidate to replace hard chrome coatings in multiple applications [5,6,7]. The wear resistance stems from the hard tungsten carbide (WC) phase embedded in a tougher cobalt-chrome (CoCr) binder, while the alloyed CoCr matrix provides corrosion protection [8]. In recent years, several studies have investigated the corrosion properties of tungsten carbide coatings. Lekatou et al. [9] compared the corrosion and wear behavior of nanostructured and conventional WC-10Co-4Cr coatings deposited by HVOF on Al7075-T6 substrates. Kumar et al. [10] analyzed the effect of graphene nanoplatelets on the performance of WC-10Co-4Cr coatings applied to HSLA DH-36 steel using HVOF. Zhao et al. [11] investigated the influence of post-heat treatment on the wear and corrosion behavior of HVOF-sprayed WC-10Co-4Cr coatings. Kumar and Upadhyaya [12] evaluated the corrosion and wear performance of HVOLF-sprayed WC-10CO-4Cr coatings on geothermal turbine blades. Cao et al. [13] studied the low-temperature corrosion behavior of plasma transferred arc deposited WC-Co coatings on EH40 steel. While these studies provide valuable insights, there remains a need for systematic investigation focused on the combined effects of erosion, corrosion, and microbial activity, specifically in offshore environments. The corrosion behavior depends strongly on the coating microstructure, such as the carbide distribution, porosity levels, dissolution of W and C in the binder, and the presence of detrimental phases [14]. Optimizing the HVOF process parameters tailors the thermal and kinetic histories of the in-flight particles, enabling control of the coating properties. Prolonged exposure to saline environments leads to general dissolution attack, while wear processes during hydraulic component operation expose fresh reactive surfaces. Offshore platforms and pipelines also face threats from biological influences such as sulfate-reducing bacteria [15,16]. It is therefore critical to systematically analyze the corrosion mechanisms affecting HVOF coatings across a range of anticipated offshore conditions.

This article aims to elucidate the slurry-erosion-corrosion and microbial corrosion performance of HVOF-sprayed WC-10Co-4Cr coatings in marine environments containing sand particles and sulfate-reducing bacteria. The specific influence of HVOF parameters including kerosene and oxygen flow rates on the in-flight particle characteristics and resulting coating properties are quantified. Detailed microstructural examination combined with electrochemical testing techniques provides insights into coating degradation mechanisms when subjected to erosion-corrosion in saline solutions and immersion in seawater inoculated with SRB cultures. The corrosion behavior metrics are benchmarked against stainless steel to quantify the performance advantages offered by optimized HVOF coatings. The comprehensive study will facilitate science-based design strategies for chrome-free protective coatings tailored to resist complex offshore operation conditions. Enhancing component durability and service life translates to significant cost reductions over the lifecycle of offshore hydraulic systems. Eliminating toxic hexavalent chrome also minimizes ecological impact to benefit marine life in offshore waters.

2 Materials and methods

2.1 Coating deposition

The protective coating studied in this work was a conventional WC-10wt%Co-4wt%Cr agglomerated and sintered cermet powder provided by Ding Hong Material Technology Co., LTD. The powder particles had a spherical morphology with sizes ranging from 10 to 38 μm. The powder feedstock was deposited onto rectangular substrates of AISI 4340 low alloy steel using a Praxair JP-8000 HVOF thermal spray system. The 100 mm × 50 mm × 6 mm steel substrates were grit-blasted with Al2O3 particles to attain a 4–6 μm surface roughness profile prior to coating deposition. The steel substrates were selected based on the recommendations provided in ASTM C633 – Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings. These dimensions ensure sufficient surface area for coating adhesion while maintaining compatibility with the sample holders used in our corrosion testing setup. For each combination of HVOF spray parameters, a set of five identical samples were deposited to ensure repeatability and to provide specimens for the various characterization techniques employed in this study.

A kerosene–oxygen combustion flame was utilized for the HVOF process with kerosene flow rates ranging from 18.1 to 25.3 l·h−1 and oxygen flow rates from 820 to 990 l·min−1. The powders were injected into the combustor at a feed rate of 5 rpm using argon as the carrier gas. A robotic arm controlling the spray gun executed a raster pattern transverse to the 100 mm dimension of the substrates during coating deposition. The spray gun was maintained perpendicular to the substrates at a standoff distance of 300 mm. The number of passes and traverse speeds were adjusted to achieve a final coating thickness of 400 ± 20 μm. The in-flight particle diagnostics during spraying were captured using an Accuraspray-g3 sensor fixed at 200 mm from the spray plume centerline. Cross-correlation of dual photodetector signals assessed particle velocities, while two-color optical pyrometry measured the average particle temperatures.

2.2 Coating characterization

The phase composition of the as-received feedstock powder and the deposited HVOF coatings were analyzed using X-ray diffraction (XRD) with a Siemens D500 instrument and Cu-Kα radiation. Scanning electron microscopy (SEM) in backscattered electron imaging mode enabled the examination of powder morphology and detailed microstructural features of the coating cross-sections. The specimens were metallographically prepared and polished to a 0.02 μm surface finish before microscopy. Image analysis of optical micrographs was utilized to quantify the porosity levels in the coatings by setting an appropriate threshold to differentiate between pores and coating material. Microhardness testing using a 300 gf Vickers indenter evaluated the mechanical properties of the as-sprayed coatings.

2.3 Corrosion testing

The electrochemical characteristics of the WC-CoCr coatings were measured using a Princeton Applied Research VMP3 Potentiostat/Galvanostat controlled by a computer interface. A typical three-electrode setup was employed, with the coating sample serving as the 1 cm2 working electrode while a platinum mesh acted as the counter electrode. A saturated calomel electrode provided the reference potential. 0.1 N hydrochloric acid (HCl) was selected as an aggressive test solution to accelerate the corrosion reactions. Potentiodynamic polarization tests were conducted by sweeping the applied potential on the samples at a scan rate of 1 mV·s−1 after allowing adequate time for open circuit stabilization. Corrosion current density (i corr) and potential (E corr) values were extracted from the measured polarization curves by Tafel analysis. Electrochemical impedance spectroscopy (EIS) analyzed the coating response under open circuit conditions across frequencies from 100 kHz to 10 mHz at 10 mV AC amplitude. Subsequent modeling via equivalent circuits provided insights into the corrosion mechanisms.

Immersion testing assessed the biocorrosion behavior in the presence of sulfate-reducing bacteria (SRB), which are commonly observed in offshore marine sediments. SRB cultures were enriched from marine mud samples in modified Postgate’s medium C containing sodium lactate as the electron donor. The pH was adjusted to 7 prior to autoclaving the medium. Sterile agar plating generated an isolated SRB strain that was inoculated into sterile seawater obtained offshore from the test region. Coupon samples of the WC-CoCr coatings and stainless steel control samples were immersed in the SRB-containing actual seawater at 30°C for different durations of up to 15 days. The extent of bacterial colonization and biofilm formation on the sample surfaces was monitored using SEM.

3 Results and discussion

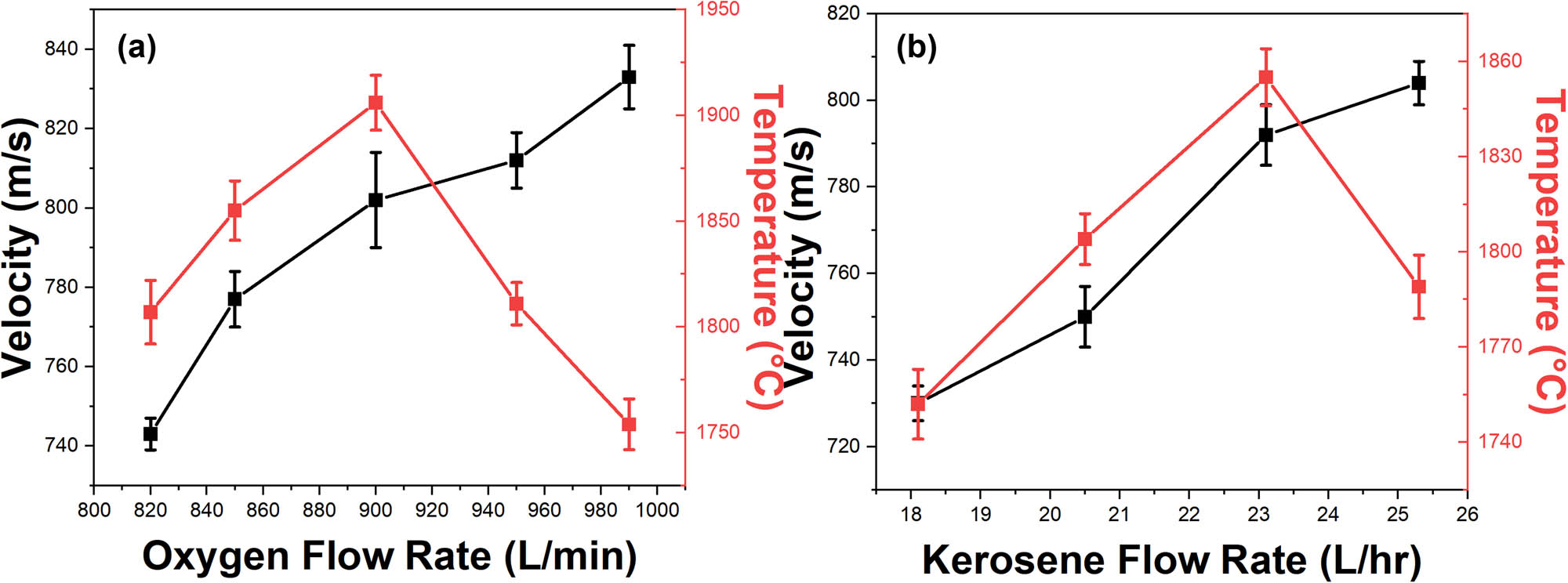

The effect of HVOF parameters on in-flight particle velocity/temperature is shown in Figure 1. The in-flight particle state during HVOF spraying plays a crucial role in determining the properties of the deposited coating. Key particle characteristics are the impact velocity and temperature, which were measured using the Accuraspray sensor for the range of kerosene and oxygen flow rates explored. As shown in Figure 1a, both particle velocity and temperature exhibit an increasing trend with a higher oxygen flow rate when maintaining the kerosene flow constant at 23.1 l·h−1. The particle temperature reaches a maximum value of 1,842°C at an oxygen flow of 850 l·min−1, corresponding to a stoichiometric combustion ratio (SCR) of 1.08. This indicates optimal combustion conditions, while excessive oxygen at higher flows has a cooling effect, thereby decreasing the flame and particle temperature. In contrast, continually increasing oxygen flow boosts the total gas volume passing through the torch nozzle [17]. This elevates the gas velocity, explaining the rise in particle velocities up to 793 m·s−1 for the maximum tested oxygen flow rate of 990 l·min−1.

In-flight particle velocity and temperature during HVOF spraying at (a) fixed kerosene flow with varying oxygen flow and (b) fixed oxygen flow with varying kerosene flow.

The influence of kerosene flow rate at a constant oxygen rate reveals similar trends, as presented in Figure 1b. The particle temperature peaks at an intermediate kerosene value of 23.1 l·h−1, equivalent to the optimal SCR of 1.14. Lower quantities of kerosene result in incomplete combustion and insufficient thermal input to the particles [18]. Higher flows provide excess fuel that must vaporize to participate in combustion, thereby absorbing heat and reducing flame temperatures [19]. The velocity profile shows a nearly linear rise with increasing kerosene flows, wherein higher fuel quantities boost the total gas volume. The maximum tested flow of 25.3 l·h−1 yielded a velocity of 779 m·s−1. Thus, balancing the oxygen and kerosene inputs is necessary to achieve suitably high velocities without compromising particle heating [20].

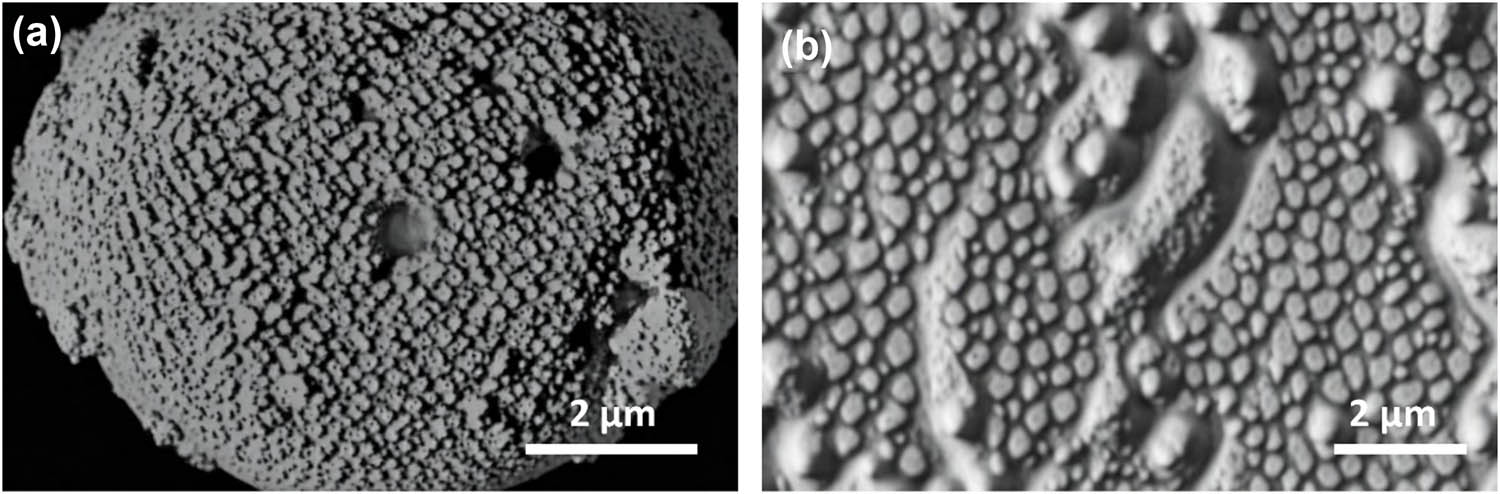

The distinctive two-phase microstructure of HVOF-sprayed WC-CoCr cermet coatings comprises hard WC particles dispersed in a softer CoCr alloy matrix. The backscattered electron micrographs in Figures 2 and 3 highlight the carbide distribution and dissolution characteristics as a function of particle temperature during spraying. Figure 2a shows the SEM image of the 10 wt%Co-4wt%Cr powders. The size of WC-10wt%Co-4wt%Cr agglomerates is about 20 μm in diameter. Figure 2b shows negligible alteration of the angular carbide morphology for the coating sprayed at a lower temperature of 1,741°C. However, evidence of WC dissolution is clearly discernible in Figure 3 for the high temperature (1,842°C) condition, wherein the carbide particles develop rounded edges because of partial melting [21]. This phenomenon enriches the binder with W and C atoms dissolved from the decomposed carbide phase [22].

Backscattered SEM micrographs of (a) WC-10wt%Co-4wt%Cr agglomerates and (b) carbide dissolution at particle temperatures of 1,741°C.

Backscattered SEM micrographs of carbide dissolution at particle temperatures of 1,842°C.

Despite microstructural differences, both coatings in Figures 2 and 3 manifest remarkably low porosity levels below 0.8%, which exceeds most porosity specifications for thermal spray coatings. This substantiates the capability of HVOF parameters to produce highly dense coatings. The rapid solidification and flattening of impinging particles aids pore elimination between successive coating layers [23]. Moreover, the high particle velocities minimize the loss of carbides during spraying by reducing dwell times in the torch flame [24]. This mitigates the formation of binder-rich regions with high shrinkage that ordinarily introduce coating porosity.

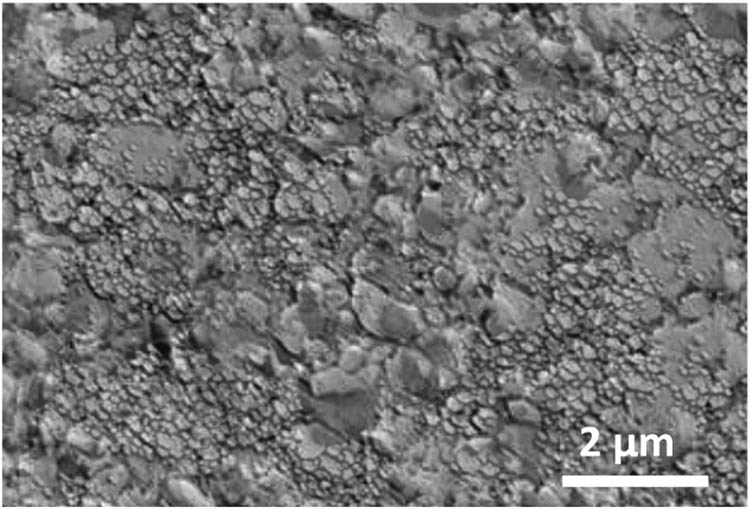

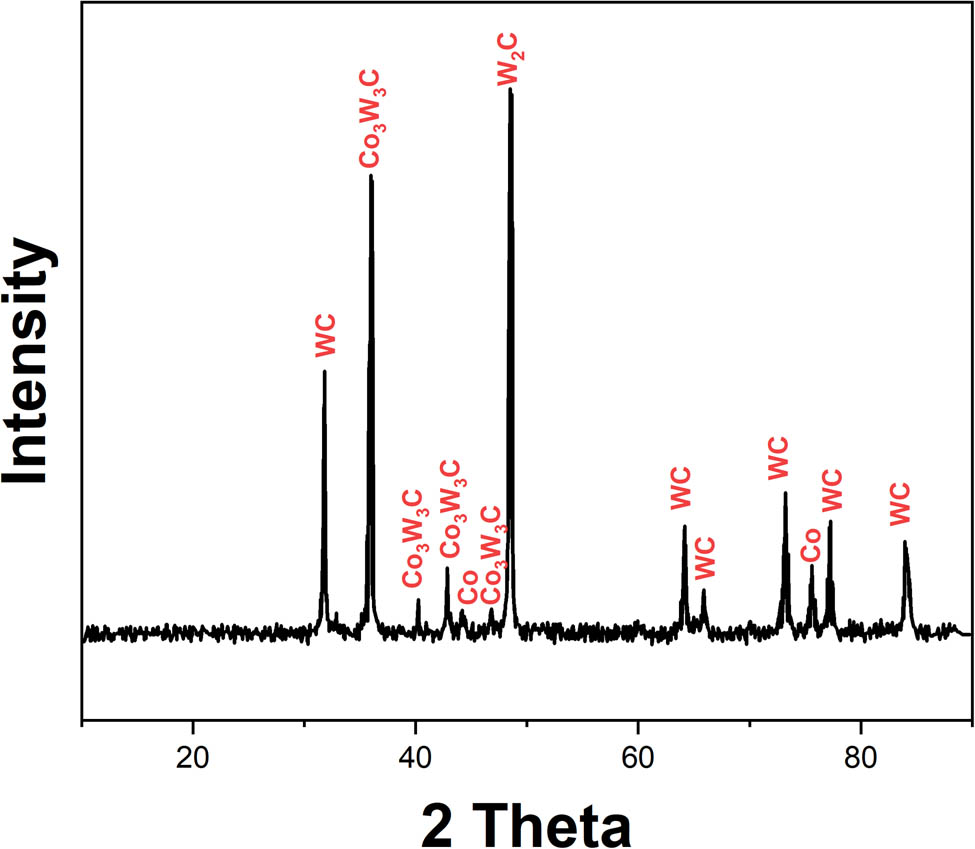

Figure 4 compiles the X-ray diffractograms obtained from the WC-CoCr powders and the as-sprayed coatings. The broad humps between 37° and 45° 2θ indicate an amorphous structure for the metallic CoCr binder resulting from its extremely high quenching rate during spraying [25]. Based on the carbide peaks, the index of retention compares dissolution across coatings, while the emerging W2C phase highlights the decomposition of WC at elevated temperatures [26]. The data suggests that strategically limiting particle heating during spraying balances dense deposition and retention of the beneficial hard carbide phases.

XRD patterns illustrating phases in feedstock powder and HVOF coatings.

The lamellar microstructure of HVOF coatings generates properties distinct from conventional bulk materials, wherein the splat boundaries and carbide distribution govern the mechanical performance. Table 1 documents the microhardness values alongside key microstructural metrics for the various WC-CoCr coatings produced in this study. The hardnesses correlate strongly with the index of carbide retention, as coatings sprayed under higher particle temperatures suffer from enhanced WC dissolution. This enriches the binder with W and C, increasing hardness through solid solution strengthening. Moreover, the presence of nano-crystalline W2C particles from WC decomposition also escalates hardness. However, simultaneously intensifying galvanic interactions and chemical dissolution negate the benefits of the minor hardness increment. An intermediate temperature of 1,835°C achieves near-complete carbide retention with adequate particle melting to yield a hardness exceeding 1200 HV0.3. The low porosity eliminates potential fatigue crack initiation sites that would undermine mechanical integrity. Overall, the data verifies that a compromise between particle heating and velocity is essential during HVOF spraying of cermet coatings to obtain optimal combinations of hardness, wear resistance, and electrochemical stability.

Quantitative correlation between HVOF particle conditions, microstructure, and properties

| Test | Particle temperature (°C) | Particle velocity (m·s−1) | Index of carbide retention | Porosity (%) | Hardness (HV0.3) |

|---|---|---|---|---|---|

| 1 | 1,741 ± 11 | 722 ± 4 | 0.94 ± 0.01 | 0.60 ± 0.05 | 1,141 ± 79 |

| 2 | 1,792 ± 8 | 743 ± 3 | 0.93 ± 0.01 | 0.55 ± 0.04 | 1,157 ± 102 |

| 3 | 1,842 ± 10 | 799 ± 6 | 0.90 ± 0.02 | 0.35 ± 0.05 | 1,214 ± 65 |

| 4 | 1,904 ± 7 | 804 ± 5 | 0.90 ± 0.01 | 0.27 ± 0.05 | 1,195 ± 121 |

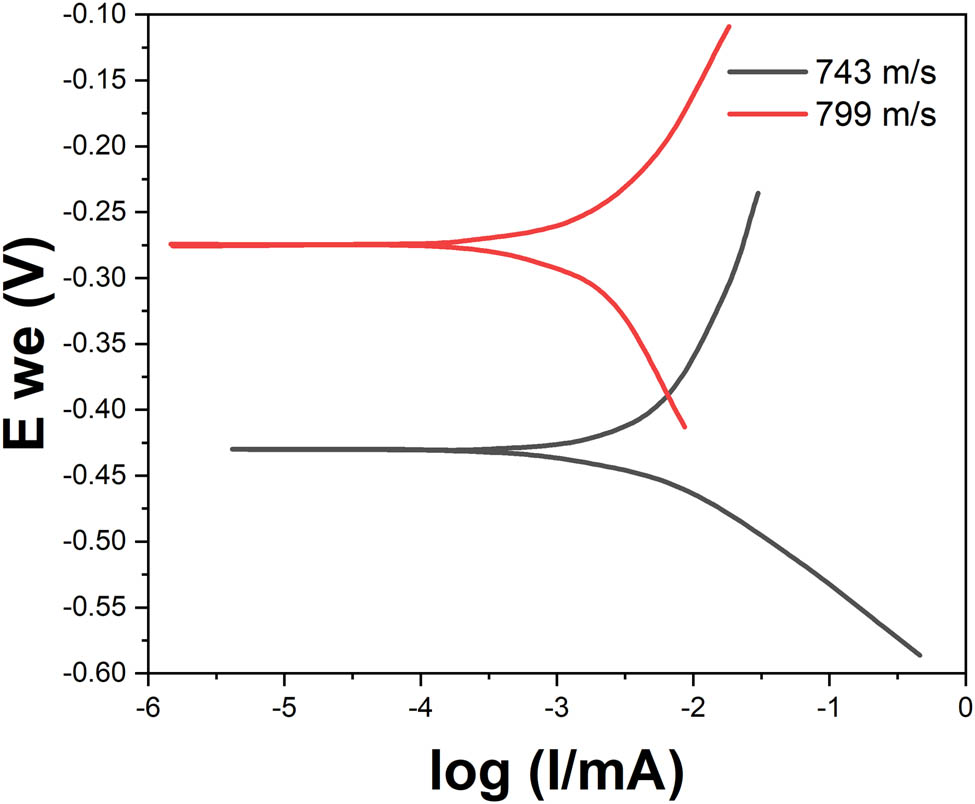

Potentiodynamic polarization tests are widely utilized for quantitatively evaluating electrochemical corrosion resistance. Figures 5 and 6 illustrate the measured polarization curves for the HVOF sprayed WC-CoCr coatings tested in aggressive 0.1 N HCl solution. The characteristic passive region spanning several hundred millivolts confirms the integrity of the protective oxide films, succeeded by transpassive dissolution at extreme anodic overpotentials [27]. Comparing the polarization curves in Figure 5 for coatings deposited under the same particle temperature (1,842°C) but different velocities of 799 and 743 m·s−1, respectively, the faster velocity manifests lower i corr and higher polarization resistance [28]. This highlights the role of particle deformation and adhesive stacking in mitigating galvanic effects associated with binder enrichment from carbide dissolution.

Potentiodynamic polarization curves showing the effect of particle velocity.

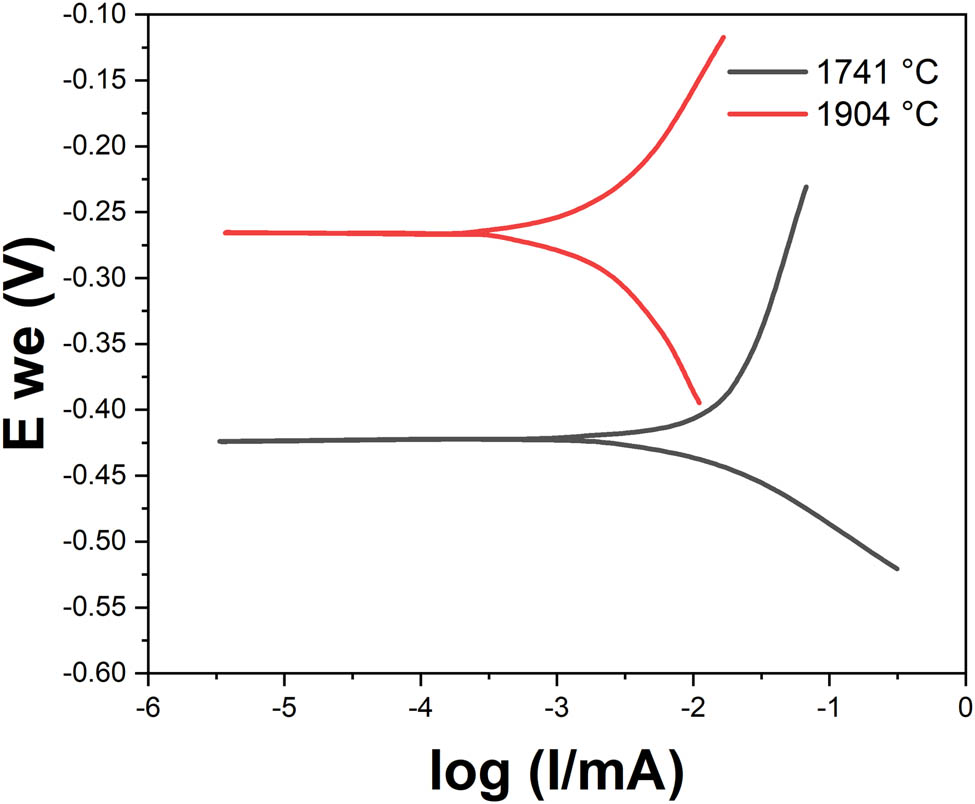

Potentiodynamic polarization curves showing the effect of particle temperature.

Figure 6 presents the polarization response for two coatings with identical particle velocities but different temperatures. The lower temperature condition again demonstrates superior behavior, substantiating that minimizing WC decarburization is vital for electrochemical stability in corrosive environments [29]. Table 2 compiles the quantitative electrochemical parameters along with the particle state during spraying. An intermediate temperature of 1,842°C balanced with a high velocity above 799 m·s−1 optimizes the corrosion resistance. This validates conclusions from the microstructural characterization, emphasizing that suitable particle heating enables coating consolidation while extensive carbide dissolution degrades electrochemical properties [30]. The results verify that corrosion is initiated at the carbide–matrix interfaces or splat boundaries, wherein localized attack causes carbide debonding [31]. Strategies for improving corrosion performance include reducing porosity to below 0.5% while restricting carbide dissolution to over 90% retention. The data signifies that corrosion protection must be holistically co-optimized during spraying along with conventional metrics for wear protection like hardness.

Compilation of particle states during HVOF spraying and resultant corrosion parameters

| Test | Particle temperature (°C) | Particle velocity (m·s−1) | i corr (μA·cm−2) | E corr (mV) | Rp (Ω·cm2) |

|---|---|---|---|---|---|

| 1 | 1,741 | 722 | 4.7 | −455 | 1,699 |

| 2 | 1,792 | 743 | 3.8 | −433 | 6,301 |

| 3 | 1,842 | 799 | 3.1 | −272 | 15,224 |

| 4 | 1,904 | 804 | 3.2 | −274 | 16,877 |

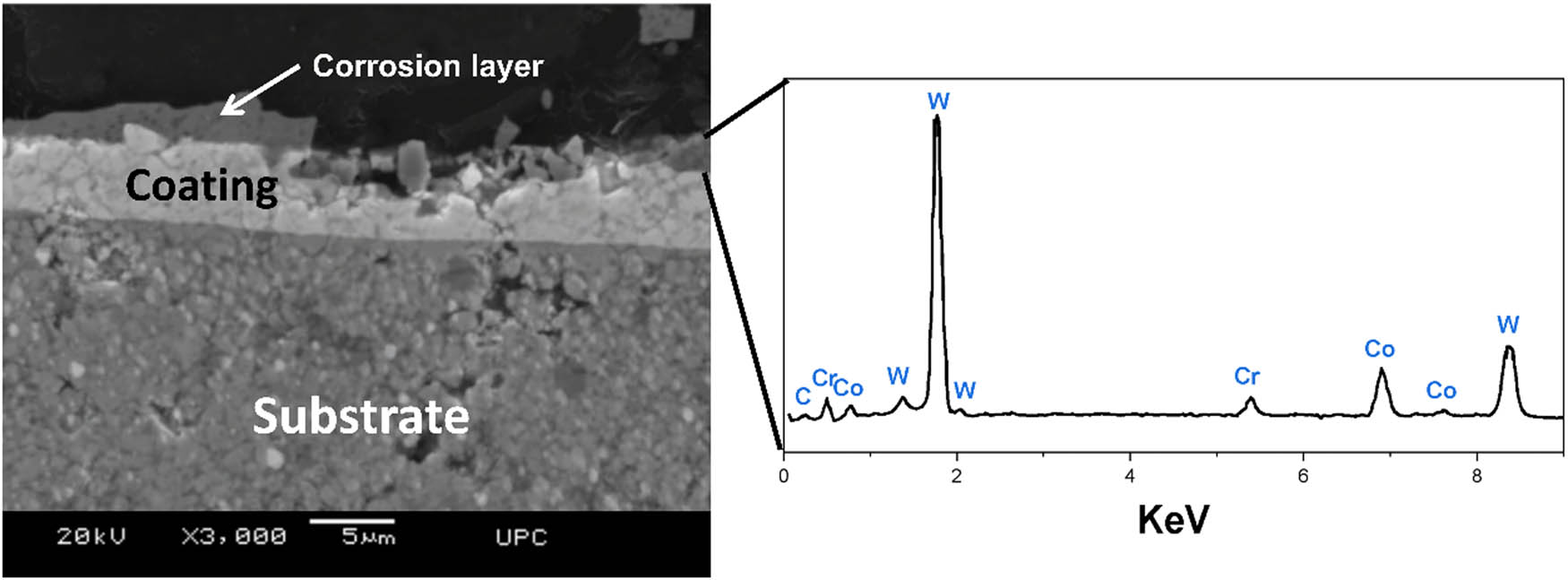

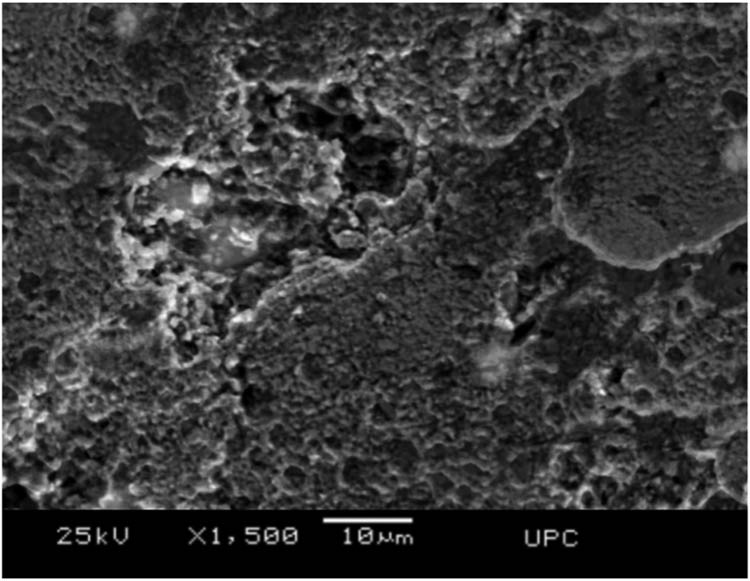

The distinctive splat-based architecture makes HVOF coatings susceptible to localized corrosion phenomena compared to conventional monolithic materials [32]. Detailed analysis of potentiodynamically tested samples provides vital insights into the associated mechanisms. The secondary electron images in Figures 7 and 8 reveal characteristic features of crevice corrosion along inter-splat zones. This arises from fluid ingression into pores or imperfect interfaces, creating localized electrochemical cells. The acidic environment so produced accelerates metal dissolution, eventually dislodging entire splats from the coating surface. Energy dispersive spectroscopy confirmed dealloying of the CoCr matrix occurring at these crevices.

SEM image showing crevice corrosion along splat boundary.

Pitting corrosion induced by carbide–matrix galvanic couples.

The corrosion resistance of HVOF-sprayed cermet coatings is governed by a complex interplay of microstructural features, including the extent of carbide dissolution, porosity levels, and the formation of galvanic couples between the carbide and matrix phases. Our results demonstrate that these microstructural attributes are directly influenced by the in-flight particle temperature and velocity during the HVOF process. Higher particle temperatures, as shown in Figure 6, lead to increased dissolution of the WC particles in the CoCr matrix. This occurs due to the partial melting of the carbide phase, which results in the enrichment of the binder with tungsten and carbon atoms. The presence of these dissolved species alters the electrochemical behavior of the matrix, making it more susceptible to corrosion attack. Additionally, the formation of eta-phases due to carbide decomposition can create localized galvanic cells that accelerate corrosion. On the other hand, higher particle velocities promote the formation of denser and more cohesive coatings. The increased kinetic energy of the impacting particles results in improved inter-splat bonding and reduces the overall porosity of the coating. This is evident from the data in Table 1, where coatings deposited at higher velocities exhibit lower porosity levels. Minimizing porosity is crucial for corrosion resistance, as it limits the ingress of corrosive media and prevents the formation of localized corrosion cells at splat boundaries. The optimal corrosion resistance is achieved by striking a balance between particle temperature and velocity. In our study, the best-performing coating was obtained at an intermediate temperature of 1,842°C and a high velocity of 799 m·s−1. This combination allows for sufficient particle melting and deformation to produce a dense coating while minimizing the detrimental effects of excessive carbide dissolution.

Figure 8 also elucidates the pitting corrosion mechanism initiated by the debonding of WC particles. This triggers the formation of intense galvanic couples between the electrically conductive carbides and the oxidized metal matrix [33]. Unmitigated dissolution subsequent to pit nucleation leads to extensive subsurface attack and loss of coating integrity. Minimizing porosity levels to below 0.5% through HVOF parametric optimization suppresses such localized degradation phenomena [9]. Nonetheless, evidence from the current and previous studies proves that optimally limiting carbide dissolution is equally vital to mitigate coating damage from corrosion.

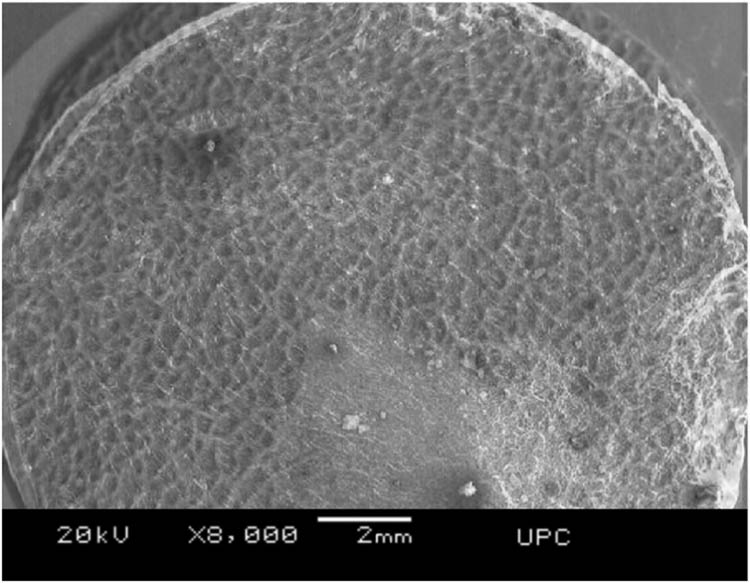

The protective oxide structure responsible for electrochemical stability is illustrated in the fractograph–micrograph in Figure 9. The entire coating surface is engulfed by an adherent chromium-enriched oxide film, confirmed by compositional analysis. This layer forms spontaneously upon exposure to aqueous environments and impedes charge transfer reactions [34]. However, breakdown of its passivity occurs at localized imperfections like pores or carbide–matrix interfaces. The nodular morphology visible in Figure 9 resembles reported structures of cobalt/tungsten oxide phases generated on WC-CoCr surfaces due to anodic polarization. Unfortunately, the acidic conditions diminish their protectiveness against sustained corrosion attacks. Yet, rational tuning of HVOF process parameters aids the growth of more resilient surface films.

Surface oxide morphology and composition after polarization test.

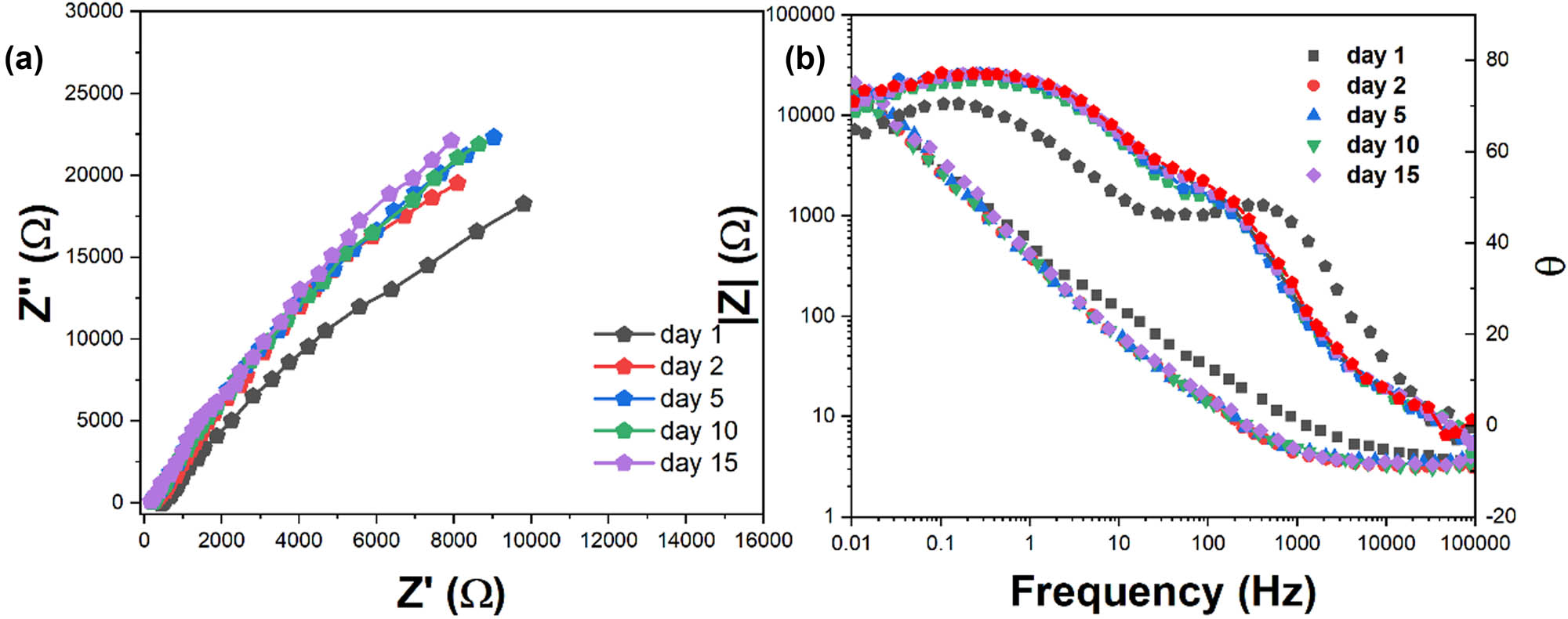

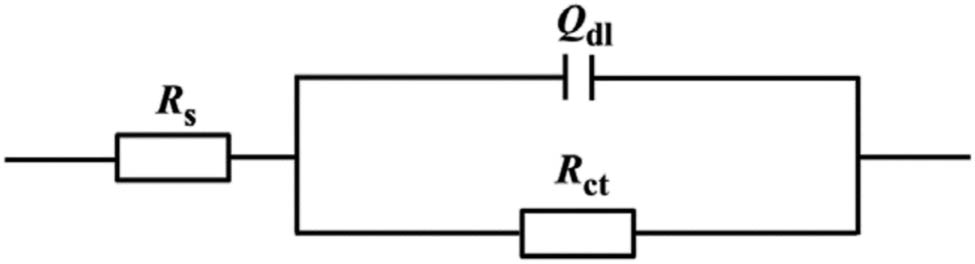

EIS enables detailed analysis of coatings’ corrosion mechanisms by appropriate modeling using equivalent circuit representations. The Nyquist and Bode phase plots in Figure 10a and b, respectively, compile the EIS response of the optimized WC-CoCr coating upon prolonged exposure to SRB-inoculated actual seawater over 15 days. The sequential evolution of the spectra suggests active surface colonization by the SRBs, which alter charge transfer pathways [35]. Equivalent circuit models presented in Figure 11 decipher the physical significance behind the measured EIS response.

(a) Nyquist and (b) Bode phase plots showing EIS response with time.

Equivalent circuits modeling corrosion mechanisms.

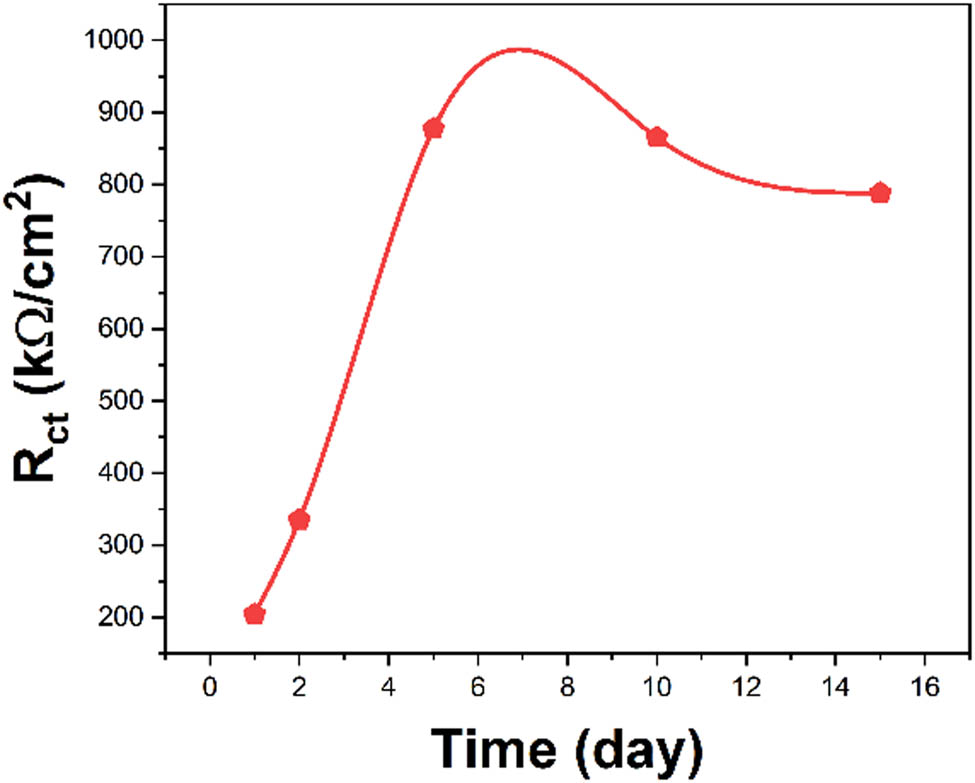

The excellent conformity between experimental data and the modeled plots validates the proposed equivalent circuits. The core elements in all cases are the polarization resistance (R ct) and double layer capacitance (C dl), which quantify the kinetics of electrochemical reactions occurring at the coating surface [36]. Their time-dependence presented in Figure 12 confirms that R ct decreases during the initial period as the coating surface gets activated upon interaction with corrosive species and SRB metabolites. However, protective surface film formation by the corrosion products subsequently increases R ct. The final reduction is attributable to localized film breakdown, which accelerates charge transfer [37]. Overall, the EIS results verify that the HVOF coatings offer adequate electrochemical stability even after prolonged bacterial exposure, suggesting suitability for maritime applications.

Extracted R ct values demonstrating time dependence.

Sulfate-reducing bacteria pose a concern for offshore hydraulic components owing to accelerated corrosion resulting from their metabolic activity. The EIS results showcase noticeable variation upon inoculation with SRBs compared to as-prepared conditions. This confirms that the biofilms alter corrosion mechanisms involving charge transfer and mass transport processes [38]. Interestingly, trends in R ct values noted earlier indicate self-healing behavior wherein corrosion products deposit on defects, thereby resisting further attack [39]. Such quantitative electrochemical interrogation of coating's performance in representative operating conditions is invaluable for science-guided coating customization and parameter optimization.

4 Conclusion

In conclusion, this comprehensive study provides vital insights into corrosion and biocorrosion phenomena affecting HVOF-sprayed WC-10Co-4Cr coatings, enabling science-based strategies to obtain optimal protection specifications sought in demanding offshore hydraulic applications. By balancing particle velocity and temperature through parametric control of the kerosene and oxygen flow rates, coatings with hardness exceeding 1,200 HV0.3 are attained alongside properties such as 0.35% porosity, over 90% carbide retention, and corrosion rates below 4 μA·cm−2 in acidic media. Localized attack is mitigated by the lamellar cohesion from particles impacting at velocities upwards of 799 m·s−1. Prolonged marine exposure introduces complex electrochemical interactions, with sulfate-reducing bacterial biofilms on coating surfaces causing the polarization resistance to decrease from 15.2 to 12.4 kΩ·cm−2 over 15 days. Nonetheless, self-healing effects are noted as corrosion products deposit on defects, resisting sustained biocorrosion. The quantitative corrosion characterization techniques substantiate HVOF coatings as effective and eco-friendly replacements for toxic chromate platings currently used in offshore hydraulics. The research provides a framework enabling science-guided customization of thermally sprayed coatings for combined wear and corrosion specifications in corrosive applications spanning maritime, aerospace, and chemical sectors. This offers vital economic benefits and ecosystem preservation.

-

Funding information: The authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The data that support the findings of this study are available on request from the corresponding author.

References

[1] Xu, L., L. Pi, Y. Dou, Y. Cui, X. Mao, A. Lin, et al. Electroplating of thick hard chromium coating from a trivalent chromium bath containing a ternary complexing agent: A methodological and mechanistic study. ACS Sustainable Chemistry & Engineering, Vol. 8, No. 41, 2020, pp. 15540–15549.10.1021/acssuschemeng.0c04529Search in Google Scholar

[2] Wang, S., C. Ma, and F. Walsh. Alternative tribological coatings to electrodeposited hard chromium: a critical review. Transactions of the IMF, Vol. 98, No. 4, 2020, pp. 173–185.10.1080/00202967.2020.1776962Search in Google Scholar

[3] Garcia Nieto, P. J., E. García Gonzalo, F. Sanchez Lasheras, and A. Bernardo Sánchez. A hybrid predictive approach for chromium layer thickness in the hard chromium plating process based on the differential evolution/gradient boosted regression tree methodology. Mathematics, Vol. 8, No. 6, 2020 Jun, id. 959.10.3390/math8060959Search in Google Scholar

[4] Nguyen, V. P., T. N. Dang, C. C. Le, and D. A. Wang. Effect of coating thickness on fatigue behavior of AISI 1045 steel with HVOF thermal spray and hard chrome electroplating. Journal of Thermal Spray Technology, Vol. 29, No. 8, 2020, pp. 1968–1981.10.1007/s11666-020-01090-xSearch in Google Scholar

[5] Singh, J. and J. P. Singh. Performance analysis of erosion resistant Mo2C reinforced WC-CoCr coating for pump impeller with Taguchi’s method. Industrial Lubrication and Tribology, Vol. 74, No. 4, 2022, pp. 431–441.10.1108/ILT-05-2020-0155Search in Google Scholar

[6] Thakur, L. and N. Arora. An investigation on the development and wear performance of chromium-MWCNTs transformed HVOF sprayed nano-WC-CoCr coatings. Surface and Coatings Technology, Vol. 388, 2020 Apr, id. 125610.10.1016/j.surfcoat.2020.125610Search in Google Scholar

[7] Torkashvand, K., M. Gupta, S. Björklund, F. Marra, L. Baiamonte, and S. Joshi. Influence of nozzle configuration and particle size on characteristics and sliding wear behaviour of HVAF-sprayed WC-CoCr coatings. Surface and Coatings Technology, Vol. 423, 2021 Oct, id. 127585.10.1016/j.surfcoat.2021.127585Search in Google Scholar

[8] Russell, Z., M. Gaier, M. J. Froning, and K. P. Plucknett. The aqueous corrosion and wear responses of HVOF-deposited TiC-Ni3Al, WC-Co, and WC-CoCr coatings on AISI 4130 steel substrates. Surface and Coatings Technology, Vol. 473, 2023 Nov, id. 130018.10.1016/j.surfcoat.2023.130018Search in Google Scholar

[9] Lekatou, A. G., D. Sioulas, and D. Grimanelis. Corrosion and wear of coatings fabricated by HVOF-spraying of nanostructured and conventional WC–10Co-4Cr powders on Al7075-T6. International Journal of Refractory Metals and Hard Materials, Vol. 112, 2023 Apr, id. 106164.10.1016/j.ijrmhm.2023.106164Search in Google Scholar

[10] Kumar, V., R. Verma, and R. Kumar. Analysis of the corrosion and wear of WC-10Co-4Cr + GNPs coating applied to HSLA DH-36 steel using HVOF. Surface Topography: Metrology and Properties, Vol. 10, No. 4, 2022 Oct, id. 045007.10.1088/2051-672X/ac998eSearch in Google Scholar

[11] Zhao, L., H. Sun, S. Li, C. Si, and S. Xu. An investigation of the effect of post heat treatment on the wear and corrosion behavior of HVOF-sprayed WC-10Co4Cr coatings. Journal of Thermal Spray Technology, Vol. 32, No. 8, 2023 Dec, pp. 2394–2410.10.1007/s11666-023-01661-8Search in Google Scholar

[12] Kumar, M. and R. Upadhyaya. Corrosion and wear analysis of HVOLF sprayed WC-10CO-4Cr coating on geothermal turbine blade. World Journal of Engineering, Vol. 16, No. 6, 2019 Jan, pp. 768–774.10.1108/WJE-03-2019-0089Search in Google Scholar

[13] Cao, Q., L. Fan, H. Chen, Y. Xu, and L. Dong. Corrosion behavior of WC–Co coating by plasma transferred arc on EH40 steel in low-temperature. High Temperature Materials and Processes, Vol. 41, No. 1, 2022 Jan, pp. 191–205.10.1515/htmp-2022-0010Search in Google Scholar

[14] Moghaddasi, M., M. Bozorg, E. Aghaie, H. Bakhtiyari, and H. Torbati-Sarraf. Corrosion and wear analysis of high-velocity oxy-fuel sprayed WC-10Co-4Cr and colmonoy-6 coatings on nickel-aluminum bronze alloy substrate. Journal of Materials Engineering and Performance, Vol. 30, No. 10, 2021 Oct, pp. 7564–7576.10.1007/s11665-021-05965-0Search in Google Scholar

[15] Zhou, Y. K., X. B. Liu, J. J. Kang, W. Yue, W. B. Qin, G. Z. Ma, et al. Corrosion behavior of HVOF sprayed WC-10Co4Cr coatings in the simulated seawater drilling fluid under the high pressure. Engineering Failure Analysis, Vol. 109, 2020 Jan, id. 104338.10.1016/j.engfailanal.2019.104338Search in Google Scholar

[16] Tian, Y., H. Zhang, X. Chen, A. McDonald, S. Wu, T. Xiao, et al. Effect of cavitation on corrosion behavior of HVOF-sprayed WC-10Co4Cr coating with post-sealing in artificial seawater. Surface and Coatings Technology, Vol. 397, 2020 Sep, id. 126012.10.1016/j.surfcoat.2020.126012Search in Google Scholar

[17] Zhao, X., C. Li, H. Jiang, S. Li, and X. Han. Mechanistic study on the influence of hydrogen fuel in high-velocity oxygen-fuel (HVOF) thermal spraying process. JOM, Vol. 76, No. 1, 2024 Jan, pp. 57–70.10.1007/s11837-023-06254-ySearch in Google Scholar

[18] Legros, S., C. Brunet, P. Domingo-Alvarez, P. Malbois, E. Salaun, G. Godard, et al. Combustion for aircraft propulsion: Progress in advanced laser-based diagnostics on high-pressure kerosene/air flames produced with low-NOx fuel injection systems. Combustion and Flame, Vol. 224, 2021 Feb, pp. 273–294.10.1016/j.combustflame.2020.12.036Search in Google Scholar

[19] Zhao, X., C. Li, S. Li, X. Han, and P. Liu. Mechanism evaluations of conventional and suspended HVOF thermal spraying based on EDC and EDM combustion models. Applied Thermal Engineering, Vol. 241, 2024 Mar, id. 122405.10.1016/j.applthermaleng.2024.122405Search in Google Scholar

[20] Kannan, S., T. Ba, S. Wan, C. W. Kang, J. Pan, and Z. Zhang. Numerical and experimental investigations of CoNiCrAlY particle suspension dynamics in kerosene-oxygen high velocity oxygen fuel spraying. Coatings, Vol. 13, No. 4, 2023 Apr, id. 668.10.3390/coatings13040668Search in Google Scholar

[21] Yang, G., W. Song, N. Wang, Y. Li, and Y. Ma. Fabrication and formation mechanism of vacuum cladding Ni/WC/GO composite fusion coatings. Materials Today Communications, Vol. 25, 2020 Dec, id. 101342.10.1016/j.mtcomm.2020.101342Search in Google Scholar

[22] Qian, C., Y. Liu, H. Cheng, K. Li, and B. Liu. Effect of the carbon content on the morphology evolution of the η phase in cemented carbides with the CoNiFeCr high entropy alloy binder. International Journal of Refractory Metals and Hard Materials, Vol. 102, 2022 Jan, id. 105731.10.1016/j.ijrmhm.2021.105731Search in Google Scholar

[23] Mittal, G. and S. Paul. Suspension and solution precursor plasma and HVOF spray: A review. Journal of Thermal Spray Technology, Vol. 31, No. 5, 2022 Jun, pp. 1443–1475.10.1007/s11666-022-01360-wSearch in Google Scholar

[24] Baumann, I., L. Hagen, W. Tillmann, P. Hollingsworth, D. Stangier, G. Schmidtmann, et al. Process characteristics, particle behavior and coating properties during HVOF spraying of conventional, fine and nanostructured WC-12Co powders. Surface and Coatings Technology, Vol. 405, 2021 Jan, id. 126716.10.1016/j.surfcoat.2020.126716Search in Google Scholar

[25] Berget, J., T. Rogne, and E. Bardal. Erosion–corrosion properties of different WC–Co–Cr coatings deposited by the HVOF process—influence of metallic matrix composition and spray powder size distribution. Surface and Coatings Technology, Vol. 201, No. 18, 2007 Jun, pp. 7619–7625.10.1016/j.surfcoat.2007.02.032Search in Google Scholar

[26] Maiti, A. K., N. Mukhopadhyay, and R. Raman. Improving the wear behavior of WC-CoCr-based HVOF coating by surface grinding. Journal of Materials Engineering and Performance, Vol. 18, No. 8, 2009 Nov, pp. 1060–1066.10.1007/s11665-009-9354-5Search in Google Scholar

[27] Yang, X., X. Dong, W. Li, W. Feng, and Y. Xu. Effect of solution and aging treatments on corrosion performance of laser solid formed Ti-6Al-4V alloy in a 3.5 wt. % NaCl solution. Journal of Materials Research and Technology, Vol. 9, No. 2, 2020 Mar, pp. 1559–1568.10.1016/j.jmrt.2019.11.082Search in Google Scholar

[28] Meghwal, A., A. Anupam, C. Schulz, C. Hall, B. S. Murty, R. S. Kottada, et al. Tribological and corrosion performance of an atmospheric plasma sprayed AlCoCr0.5Ni high-entropy alloy coating. Wear, Vol. 506–507, 2022 Oct, id. 204443.10.1016/j.wear.2022.204443Search in Google Scholar

[29] Wang, D., Q. Zhao, T. Yang, X. Chang, S. Qu, S. Sun, et al. Influences of thermomechanical conditions on corrosion behavior of low-carbon steels in artificial seawater. International Journal of Electrochemical Science, Vol. 14, No. 3, 2019 Mar, pp. 2509–2525.10.20964/2019.03.65Search in Google Scholar

[30] Heakal, F. E. T. and A. M. Bakry. Corrosion degradation of AXJ530 magnesium alloy in simulated pysiological fluid and its mitigation by fluoride and chitosan coatings for osteosynthetic applications. International Journal of Electrochemical Science, Vol. 13, No. 8, 2018 Aug, pp. 7724–7747.10.20964/2018.08.67Search in Google Scholar

[31] Luo, T., P. Xu, and C. Guo. Controllable construction and corrosion resistance mechanism of durable superhydrophobic micro-nano structure on aluminum alloy surface. Sustainability, Vol. 15, No. 13, 2023 Jan, id. 10550.10.3390/su151310550Search in Google Scholar

[32] Abbas, M., G. M. Smith, and P. R. Munroe. Microstructural characterization of HVOF-sprayed ni on polished and oxidized stainless steel substrates. Journal of Thermal Spray Technology, Vol. 29, No. 5, 2020 Jun, pp. 1093–1110.10.1007/s11666-020-01031-8Search in Google Scholar

[33] Katiyar, P. K. A comprehensive review on synergy effect between corrosion and wear of cemented tungsten carbide tool bits: A mechanistic approach. International Journal of Refractory Metals and Hard Materials, Vol. 92, 2020 Nov, id. 105315.10.1016/j.ijrmhm.2020.105315Search in Google Scholar

[34] Kihn, Y., G. E. Thompson, G. Galaup, P. Skeldon, X. Zhou, K. Shimizu, et al. Morphology, composition and structure of anodic films on Al–Cr alloys. Corrosion Science, Vol. 42, No. 3, 2000 Mar, pp. 533–544.10.1016/S0010-938X(99)00063-3Search in Google Scholar

[35] Sun, C., J. Xu, F. H. Wang, and C. K. Yu. Effect of sulfate reducing bacteria on corrosion of stainless steel 1Cr18Ni9Ti in soils containing chloride ions. Materials Chemistry and Physics, Vol. 126, No. 1, 2011 Mar, pp. 330–336.10.1016/j.matchemphys.2010.11.017Search in Google Scholar

[36] Xu, J., K. Wang, C. Sun, F. Wang, X. Li, J. Yang, et al. The effects of sulfate reducing bacteria on corrosion of carbon steel Q235 under simulated disbonded coating by using electrochemical impedance spectroscopy. Corrosion Science, Vol. 53, No. 4, 2011 Apr, pp. 1554–1562.10.1016/j.corsci.2011.01.037Search in Google Scholar

[37] AlAbbas, F. M., C. Williamson, S. M. Bhola, J. R. Spear, D. L. Olson, B. Mishra, et al. Influence of sulfate reducing bacterial biofilm on corrosion behavior of low-alloy, high-strength steel (API-5L X80). International Biodeterioration & Biodegradation, Vol. 78, 2013 Mar, pp. 34–42.10.1016/j.ibiod.2012.10.014Search in Google Scholar

[38] Tran, T. T. T., K. Kannoorpatti, A. Padovan, and S. Thennadil. Effect of pH regulation by sulfate-reducing bacteria on corrosion behaviour of duplex stainless steel 2205 in acidic artificial seawater. Royal Society Open Science, Vol. 8, No. 1, 2021 Jan, id. 200639.10.1098/rsos.200639Search in Google Scholar PubMed PubMed Central

[39] Chen, L., B. Wei, and X. Xu. Effect of sulfate-reducing bacteria (SRB) on the corrosion of buried pipe steel in acidic soil solution. Coatings, Vol. 11, No. 6, 2021 Jun, id. 625.10.3390/coatings11060625Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research progress on rubidium and cesium separation and extraction

- A step towards sustainable concrete with the utilization of M-sand in concrete production: A review

- Studying the effect of nanofillers in civil applications: A review

- Studies on the anticorrosive effect of phytochemicals on mild steel, carbon steel, and stainless-steel surfaces in acid and alkali medium: A review

- Nanotechnology for calcium aluminate cement: thematic analysis

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites

- Analyzing the compressive strength, eco-strength, and cost–strength ratio of agro-waste-derived concrete using advanced machine learning methods

- Tensile behavior evaluation of two-stage concrete using an innovative model optimization approach

- Tailoring the mechanical and degradation properties of 3DP PLA/PCL scaffolds for biomedical applications

- Optimizing compressive strength prediction in glass powder-modified concrete: A comprehensive study on silicon dioxide and calcium oxide influence across varied sample dimensions and strength ranges

- Experimental study on solid particle erosion of protective aircraft coatings at different impact angles

- Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters

- Fe-containing nominal wollastonite (CaSiO3)–Na2O glass-ceramic: Characterization and biocompatibility

- Relevance of pore network connectivity in tannin-derived carbons for rapid detection of BTEX traces in indoor air

- A life cycle and environmental impact analysis of sustainable concrete incorporating date palm ash and eggshell powder as supplementary cementitious materials

- Eco-friendly utilisation of agricultural waste: Assessing mixture performance and physical properties of asphalt modified with peanut husk ash using response surface methodology

- Benefits and limitations of N2 addition with Ar as shielding gas on microstructure change and their effect on hardness and corrosion resistance of duplex stainless steel weldments

- Effect of selective laser sintering processing parameters on the mechanical properties of peanut shell powder/polyether sulfone composite

- Impact and mechanism of improving the UV aging resistance performance of modified asphalt binder

- AI-based prediction for the strength, cost, and sustainability of eggshell and date palm ash-blended concrete

- Investigating the sulfonated ZnO–PVA membrane for improved MFC performance

- Strontium coupling with sulphur in mouse bone apatites

- Transforming waste into value: Advancing sustainable construction materials with treated plastic waste and foundry sand in lightweight foamed concrete for a greener future

- Evaluating the use of recycled sawdust in porous foam mortar for improved performance

- Improvement and predictive modeling of the mechanical performance of waste fire clay blended concrete

- Polyvinyl alcohol/alginate/gelatin hydrogel-based CaSiO3 designed for accelerating wound healing

- Research on assembly stress and deformation of thin-walled composite material power cabin fairings

- Effect of volcanic pumice powder on the properties of fiber-reinforced cement mortars in aggressive environments

- Analyzing the compressive performance of lightweight foamcrete and parameter interdependencies using machine intelligence strategies

- Selected materials techniques for evaluation of attributes of sourdough bread with Kombucha SCOBY

- Establishing strength prediction models for low-carbon rubberized cementitious mortar using advanced AI tools

- Investigating the strength performance of 3D printed fiber-reinforced concrete using applicable predictive models

- An eco-friendly synthesis of ZnO nanoparticles with jamun seed extract and their multi-applications

- The application of convolutional neural networks, LF-NMR, and texture for microparticle analysis in assessing the quality of fruit powders: Case study – blackcurrant powders

- Study of feasibility of using copper mining tailings in mortar production

- Shear and flexural performance of reinforced concrete beams with recycled concrete aggregates

- Advancing GGBS geopolymer concrete with nano-alumina: A study on strength and durability in aggressive environments

- Leveraging waste-based additives and machine learning for sustainable mortar development in construction

- Study on the modification effects and mechanisms of organic–inorganic composite anti-aging agents on asphalt across multiple scales

- Morphological and microstructural analysis of sustainable concrete with crumb rubber and SCMs

- Structural, physical, and luminescence properties of sodium–aluminum–zinc borophosphate glass embedded with Nd3+ ions for optical applications

- Eco-friendly waste plastic-based mortar incorporating industrial waste powders: Interpretable models for flexural strength

- Bioactive potential of marine Aspergillus niger AMG31: Metabolite profiling and green synthesis of copper/zinc oxide nanocomposites – An insight into biomedical applications

- Preparation of geopolymer cementitious materials by combining industrial waste and municipal dewatering sludge: Stabilization, microscopic analysis and water seepage

- Seismic behavior and shear capacity calculation of a new type of self-centering steel-concrete composite joint

- Sustainable utilization of aluminum waste in geopolymer concrete: Influence of alkaline activation on microstructure and mechanical properties

- Optimization of oil palm boiler ash waste and zinc oxide as antibacterial fabric coating

- Tailoring ZX30 alloy’s microstructural evolution, electrochemical and mechanical behavior via ECAP processing parameters

- Comparative study on the effect of natural and synthetic fibers on the production of sustainable concrete

- Microemulsion synthesis of zinc-containing mesoporous bioactive silicate glass nanoparticles: In vitro bioactivity and drug release studies

- On the interaction of shear bands with nanoparticles in ZrCu-based metallic glass: In situ TEM investigation

- Developing low carbon molybdenum tailing self-consolidating concrete: Workability, shrinkage, strength, and pore structure

- Experimental and computational analyses of eco-friendly concrete using recycled crushed brick

- High-performance WC–Co coatings via HVOF: Mechanical properties of steel surfaces

- Mechanical properties and fatigue analysis of rubber concrete under uniaxial compression modified by a combination of mineral admixture

- Experimental study of flexural performance of solid wood beams strengthened with CFRP fibers

- Eco-friendly green synthesis of silver nanoparticles with Syzygium aromaticum extract: characterization and evaluation against Schistosoma haematobium

- Predictive modeling assessment of advanced concrete materials incorporating plastic waste as sand replacement

- Self-compacting mortar overlays using expanded polystyrene beads for thermal performance and energy efficiency in buildings

- Enhancing frost resistance of alkali-activated slag concrete using surfactants: sodium dodecyl sulfate, sodium abietate, and triterpenoid saponins

- Equation-driven strength prediction of GGBS concrete: a symbolic machine learning approach for sustainable development

- Empowering 3D printed concrete: discovering the impact of steel fiber reinforcement on mechanical performance

- Advanced hybrid machine learning models for estimating chloride penetration resistance of concrete structures for durability assessment: optimization and hyperparameter tuning

- Influence of diamine structure on the properties of colorless and transparent polyimides

- Post-heating strength prediction in concrete with Wadi Gyada Alkharj fine aggregate using thermal conductivity and ultrasonic pulse velocity

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part II

- Investigating the effect of locally available volcanic ash on mechanical and microstructure properties of concrete

- Flexural performance evaluation using computational tools for plastic-derived mortar modified with blends of industrial waste powders

- Foamed geopolymers as low carbon materials for fire-resistant and lightweight applications in construction: A review

- Autogenous shrinkage of cementitious composites incorporating red mud

- Mechanical, durability, and microstructure analysis of concrete made with metakaolin and copper slag for sustainable construction

- Special Issue on AI-Driven Advances for Nano-Enhanced Sustainable Construction Materials

- Advanced explainable models for strength evaluation of self-compacting concrete modified with supplementary glass and marble powders

- Analyzing the viability of agro-waste for sustainable concrete: Expression-based formulation and validation of predictive models for strength performance

- Special Issue on Advanced Materials for Energy Storage and Conversion

- Innovative optimization of seashell ash-based lightweight foamed concrete: Enhancing physicomechanical properties through ANN-GA hybrid approach

- Production of novel reinforcing rods of waste polyester, polypropylene, and cotton as alternatives to reinforcement steel rods

Articles in the same Issue

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research progress on rubidium and cesium separation and extraction

- A step towards sustainable concrete with the utilization of M-sand in concrete production: A review

- Studying the effect of nanofillers in civil applications: A review

- Studies on the anticorrosive effect of phytochemicals on mild steel, carbon steel, and stainless-steel surfaces in acid and alkali medium: A review

- Nanotechnology for calcium aluminate cement: thematic analysis

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites

- Analyzing the compressive strength, eco-strength, and cost–strength ratio of agro-waste-derived concrete using advanced machine learning methods

- Tensile behavior evaluation of two-stage concrete using an innovative model optimization approach

- Tailoring the mechanical and degradation properties of 3DP PLA/PCL scaffolds for biomedical applications

- Optimizing compressive strength prediction in glass powder-modified concrete: A comprehensive study on silicon dioxide and calcium oxide influence across varied sample dimensions and strength ranges

- Experimental study on solid particle erosion of protective aircraft coatings at different impact angles

- Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters

- Fe-containing nominal wollastonite (CaSiO3)–Na2O glass-ceramic: Characterization and biocompatibility

- Relevance of pore network connectivity in tannin-derived carbons for rapid detection of BTEX traces in indoor air

- A life cycle and environmental impact analysis of sustainable concrete incorporating date palm ash and eggshell powder as supplementary cementitious materials

- Eco-friendly utilisation of agricultural waste: Assessing mixture performance and physical properties of asphalt modified with peanut husk ash using response surface methodology

- Benefits and limitations of N2 addition with Ar as shielding gas on microstructure change and their effect on hardness and corrosion resistance of duplex stainless steel weldments

- Effect of selective laser sintering processing parameters on the mechanical properties of peanut shell powder/polyether sulfone composite

- Impact and mechanism of improving the UV aging resistance performance of modified asphalt binder

- AI-based prediction for the strength, cost, and sustainability of eggshell and date palm ash-blended concrete

- Investigating the sulfonated ZnO–PVA membrane for improved MFC performance

- Strontium coupling with sulphur in mouse bone apatites

- Transforming waste into value: Advancing sustainable construction materials with treated plastic waste and foundry sand in lightweight foamed concrete for a greener future

- Evaluating the use of recycled sawdust in porous foam mortar for improved performance

- Improvement and predictive modeling of the mechanical performance of waste fire clay blended concrete

- Polyvinyl alcohol/alginate/gelatin hydrogel-based CaSiO3 designed for accelerating wound healing

- Research on assembly stress and deformation of thin-walled composite material power cabin fairings

- Effect of volcanic pumice powder on the properties of fiber-reinforced cement mortars in aggressive environments

- Analyzing the compressive performance of lightweight foamcrete and parameter interdependencies using machine intelligence strategies

- Selected materials techniques for evaluation of attributes of sourdough bread with Kombucha SCOBY

- Establishing strength prediction models for low-carbon rubberized cementitious mortar using advanced AI tools

- Investigating the strength performance of 3D printed fiber-reinforced concrete using applicable predictive models

- An eco-friendly synthesis of ZnO nanoparticles with jamun seed extract and their multi-applications

- The application of convolutional neural networks, LF-NMR, and texture for microparticle analysis in assessing the quality of fruit powders: Case study – blackcurrant powders

- Study of feasibility of using copper mining tailings in mortar production

- Shear and flexural performance of reinforced concrete beams with recycled concrete aggregates

- Advancing GGBS geopolymer concrete with nano-alumina: A study on strength and durability in aggressive environments

- Leveraging waste-based additives and machine learning for sustainable mortar development in construction

- Study on the modification effects and mechanisms of organic–inorganic composite anti-aging agents on asphalt across multiple scales

- Morphological and microstructural analysis of sustainable concrete with crumb rubber and SCMs

- Structural, physical, and luminescence properties of sodium–aluminum–zinc borophosphate glass embedded with Nd3+ ions for optical applications

- Eco-friendly waste plastic-based mortar incorporating industrial waste powders: Interpretable models for flexural strength

- Bioactive potential of marine Aspergillus niger AMG31: Metabolite profiling and green synthesis of copper/zinc oxide nanocomposites – An insight into biomedical applications

- Preparation of geopolymer cementitious materials by combining industrial waste and municipal dewatering sludge: Stabilization, microscopic analysis and water seepage

- Seismic behavior and shear capacity calculation of a new type of self-centering steel-concrete composite joint

- Sustainable utilization of aluminum waste in geopolymer concrete: Influence of alkaline activation on microstructure and mechanical properties

- Optimization of oil palm boiler ash waste and zinc oxide as antibacterial fabric coating

- Tailoring ZX30 alloy’s microstructural evolution, electrochemical and mechanical behavior via ECAP processing parameters

- Comparative study on the effect of natural and synthetic fibers on the production of sustainable concrete

- Microemulsion synthesis of zinc-containing mesoporous bioactive silicate glass nanoparticles: In vitro bioactivity and drug release studies

- On the interaction of shear bands with nanoparticles in ZrCu-based metallic glass: In situ TEM investigation

- Developing low carbon molybdenum tailing self-consolidating concrete: Workability, shrinkage, strength, and pore structure

- Experimental and computational analyses of eco-friendly concrete using recycled crushed brick

- High-performance WC–Co coatings via HVOF: Mechanical properties of steel surfaces

- Mechanical properties and fatigue analysis of rubber concrete under uniaxial compression modified by a combination of mineral admixture

- Experimental study of flexural performance of solid wood beams strengthened with CFRP fibers

- Eco-friendly green synthesis of silver nanoparticles with Syzygium aromaticum extract: characterization and evaluation against Schistosoma haematobium

- Predictive modeling assessment of advanced concrete materials incorporating plastic waste as sand replacement

- Self-compacting mortar overlays using expanded polystyrene beads for thermal performance and energy efficiency in buildings

- Enhancing frost resistance of alkali-activated slag concrete using surfactants: sodium dodecyl sulfate, sodium abietate, and triterpenoid saponins

- Equation-driven strength prediction of GGBS concrete: a symbolic machine learning approach for sustainable development

- Empowering 3D printed concrete: discovering the impact of steel fiber reinforcement on mechanical performance

- Advanced hybrid machine learning models for estimating chloride penetration resistance of concrete structures for durability assessment: optimization and hyperparameter tuning

- Influence of diamine structure on the properties of colorless and transparent polyimides

- Post-heating strength prediction in concrete with Wadi Gyada Alkharj fine aggregate using thermal conductivity and ultrasonic pulse velocity

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part II

- Investigating the effect of locally available volcanic ash on mechanical and microstructure properties of concrete

- Flexural performance evaluation using computational tools for plastic-derived mortar modified with blends of industrial waste powders

- Foamed geopolymers as low carbon materials for fire-resistant and lightweight applications in construction: A review

- Autogenous shrinkage of cementitious composites incorporating red mud

- Mechanical, durability, and microstructure analysis of concrete made with metakaolin and copper slag for sustainable construction

- Special Issue on AI-Driven Advances for Nano-Enhanced Sustainable Construction Materials

- Advanced explainable models for strength evaluation of self-compacting concrete modified with supplementary glass and marble powders

- Analyzing the viability of agro-waste for sustainable concrete: Expression-based formulation and validation of predictive models for strength performance

- Special Issue on Advanced Materials for Energy Storage and Conversion

- Innovative optimization of seashell ash-based lightweight foamed concrete: Enhancing physicomechanical properties through ANN-GA hybrid approach

- Production of novel reinforcing rods of waste polyester, polypropylene, and cotton as alternatives to reinforcement steel rods