Abstract

In this study, different processes are performed for the preparation of natural rubber latex (NRL)/silica composites. A novel approach is to use spray sputtering technology combined with in situ method to improve the dispersion of silica in rubber latex matrix and further improve the properties of vulcanizates. Results show that in situ silica in rubber matrix prepared from NH4Cl and Na2SiO3 has better Payen effect than other processes. Meanwhile, when the in situ silica reached 10 phr in the rubber matrix, the dosage can suitably match the dispersion capacity of the spray sputtering process with superior comprehensive mechanical properties. Compared with the traditional precipitation method, the tensile strength and tear strength of the silica/NR composites prepared by spray sputtering technology combined with in situ method were increased by 34.7% and 19.7%.

1 Introduction

As an important reinforcing agent for rubber, silica has advantages in improving the wet-skid resistance of tires and reduce the rolling resistance of semi-steel radial tires (1,2,3). Silica mixed with rubber-carbon black systems is widely used in tread rubber, especially in all rigid radial tires. Actually, filler dispersion has become a trending topic for researchers from the whole world. However, the traditional dry mixing process (4,5,6), which mixed rubber and fillers in a mixer with strong shear action, consumes a lot of energy (more than 50% of the consumption in the whole processing) (7). The quality between different batches of rubber is uneven in the ordinary dry mixing process, which not only decreases the quality control of the subsequent process, but also causes dust pollution (8). Therefore, in recent years, the wet mixing process of rubber (9,10,11,12,13,14) has been developed, which can improve the dispersion of inorganic fillers in rubber and reduce dust pollution. During wet mixing, the fillers are added into latex, and the compounded rubber will be obtained when the filler is evenly mixed, but the filler is difficult to coprecipitate completely (15,16,17,18). Others add the precursor of inorganic fillers to the latex to generate inorganic fillers in situ (19,20,21,22) by a chemical reaction, thus making latex solidified to prepare compounded rubber (23,24).

Sodium silicate or solution of water glass is added into latex to obtain the mixture for the preparation of silica in situ. When the mixture is well mixed, the acid solution is added into the latex to produce silica in situ and solidify the latex, which can improve the dispersion of silica-filled. However, the partial acid concentration can be strong if the silica in situ reaction speed performs fast in the process of adding acid, which can influence the dispersion of fillers in suspension. Especially, the particle size is not easy to control in the case of higher filling degrees and the agglomeration of silica cannot be avoided (25).

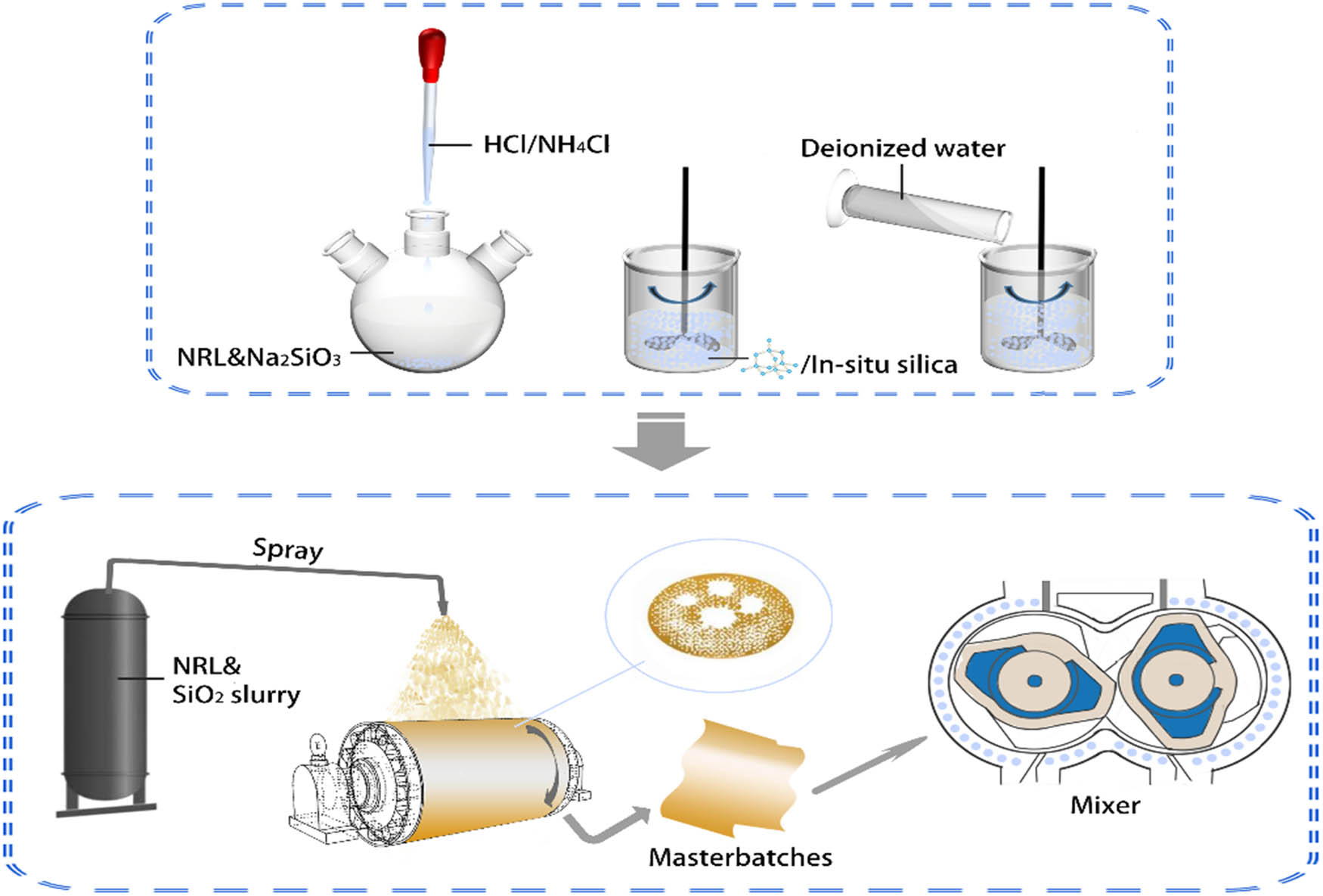

The reinforcing effect of silica in the NRL matrix is mainly related to the dispersion state of silica and the interfacial interaction between them. The spray sputtering technology combined with in situ method is very efficient in increasing the dispersion and mechanical properties of NR/silica composites. Tang et al. studied the properties of spherical natural rubber/silica composite powders via spray drying (26). Xing et al. combined in situ organic modification of montmorillonite and the latex compounding method in SBR latex (27). The in situ silica formation has a small particle size while spraying and sputtering processes can lead to a uniform distribution, which both increase the contact area between the rubber hydrocarbon and the silica particles (28,29,30,31). Besides, there is the velocity difference between the material liquid column and the compressed air at the nozzle during high-pressure spraying. Meanwhile, the material liquid column is splitting and broken due to the disturbance of the compressed air, making the mixed liquid atomized (31,32,33,34,35). Under the high pressure, the SiO2 agglomerates will be fully dispersed, and the protective film on the surface of the latex particles will be destroyed by the gas vibration waves and the friction from gas, so that the filler will be mixed with the rubber hydrocarbon into the rubber for crushing, dispersing, and mixing, thus avoiding a series of problems caused by traditional acid flocculation and improving the dispersion of fillers in rubber matrix (36,37,38,39). Therefore, silica can reinforce the rubber well and improve the physical properties of the compound. Figure 1 shows the schematic of the preparation of silica/NR composites by spray sputtering technology combined with in situ method. In summary, spray sputtering technology can instantly dehydrate and prevent secondary agglomeration of in situ silica after stirring. Once dry and agglomerate, the mechanical mixing in the following process can hardly disperse evenly. The participation of the spray sputtering method greatly enhances the dispersion effect of in situ silica.

Schematic of preparation of silica/NR composite by spray sputtering combined with in situ method.

In this study, an attempt was made to prepare NRL/silica composites by in situ combined with the spray sputtering method. Na2SiO3 is first introduced into the NRL matrix. After that, HCL or NH4CL solution with Si69 suspension is titrated for the preparation of silica in situ. Compared with wet mixing with commercial silica-filled, some interesting results in mechanical properties are achieved. In addition, micromorphology and Payne effect are investigated among three methods with different amounts of silica loading.

2 Experimental

2.1 Materials

Natural rubber latex (NRL) (60 wt% solids) was imported from Thailand. Silica was purchased from Qingdao Croatia Ltd Co. (China). Na2SiO3 was provided by Tianjin Hengxing Chemical Reagent Manufacturing Ltd Co. (China). HCl (analytical purity) was obtained from Jinan Shenghe Chemical Ltd Co. (China). NH4Cl was purchased from Tianjin Beichen-Fangzheng Reagent Factory. Zink oxide, stearic acid, accelerator D (diphenyl guanidine), accelerator DM (2,2′-dibenzothiazoledisulfde), and sulfur were all commercially available industrial-grade products. All investigated silica/NR compounds were based on basic formulation according to Table 1.

Formulation of silica/NR composites

| Component | Contents (phr)a | Component | Contents (phr)a |

|---|---|---|---|

| NR | 100.0 | Carbon black N660 | Variable from 23.5 to 38.5 |

| Silica | Variable from 0–15.0 | Si69 | 2.0 |

| Accelerator Db | 0.5 | Zink oxide | 3.0 |

| Accelerator DMc | 1.5 | Stearic acid | 2.0 |

| Sulfur | Variable from 0–3.0 |

- a

Parts per hundred rubbers.

- b

Diphenyl guanidine.

- c

Dibenzothiazole disulfide.

2.2 Preparation of NRL/silica slurry in three different ways

2.2.1 In situ method from HCl

HCl solution with a mass fraction of 0.05 was prepared. The dissolved Na2SiO3 was added to the flask with three necks filled with NRL. Then, the HCl solution (0.05 wt%) was titrated slowly into the latex solution until the pH of the solution reached about 7. The process was then carried out under the condition of stirring by a paddle mixer (Shanghai Yikong Company, China) at 1,500 rpm and 25°C for 30 min. At the same time, suspension of SiO2 could be obtained in situ and Na2SiO3 was completely converted to SiO2. Deionized water was added to the cased nozzle clogging when spraying. Finally, NRL/silica slurry by in situ method from HCl was obtained for spray drying.

2.2.2 In situ method from NH4Cl

NH4Cl solution with the mass fraction of 0.2 was prepared. The dissolved Na2SiO3 was added to the flask with NRL. Then the NH4Cl solution (0.2 wt%) was titrated slowly into the solution under the same condition until the pH of the solution reached about 6–7. At this time, SiO2 could be generated suspending in the slurry. Deionized water was added and mixed with slurry vigorously stirring. Finally, NRL/silica slurry by in situ method from NH4Cl was obtained for spray drying.

2.2.3 Traditional latex precipitation method

Silica from Qingdao Croatia Ltd Co. (China) was added into NRL suspension at the same processing of other two methods to obtain NRL/silica suspension for traditional wet mixing by precipitation drying.

2.3 Preparation of NRL/silica masterbatches by spray sputtering method

The amount of silica varied from 5 to 15 to replace carbon black in the rubber matrix, as shown in Table 2. For every 5 phr of silica increased, carbon black decreased by 5 phr and Si69 increase by 1 phr.

Silica/NR composites experimental program

| Experiment number | Amount of the silica (phr) | Type of the silica |

|---|---|---|

| 1 | 0 | No |

| 2 | 5 | Precipitated silica from commercial available |

| 3 | 5 | Preparation by HCl with in situ method |

| 4 | 5 | Preparation by NH4Cl with in situ method |

| 5 | 10 | Precipitated silica from commercial availability |

| 6 | 10 | Preparation by HCl with in situ method |

| 7 | 10 | Preparation by NH4Cl with in situ method |

| 8 | 15 | Precipitated silica from commercial availability |

| 9 | 15 | Preparation by HCl with in situ method |

| 10 | 15 | Preparation by NH4Cl with in situ method |

The NRL/silica slurry was poured into a container tank. The mixture was atomized by a gas-assisted spray gun under the pressure of 0.5–1.5 MPa. The mixture was sprayed onto a self-designed high-temperature mill roller at 150°C with a scraper. Then, the mixture was atomized into small droplets. After contacting the Teflon coating on a high-temperature mill roll, the moisture contained in droplets rapidly evaporated to produce dry masterbatches. At the same time, the masterbatches with a certain thickness could be scraped and placed aside for further processing.

2.4 Preparation of NRL/silica composites

The obtained masterbatches were refined in an internal mixer (Qingdao University of Science and Technology, China). The process parameters of the mixer were set as follows: filling coefficient 0.7, initial temperature 80°C, rotor speed 80 rpm, and mixing time 6 min. The masterbatches, N660, zink oxide, stearic acid, accelerator D, and accelerator DM were added to the internal mixer, respectively. The mixing cycle time was 5 min. Sulfur was finally added into rubber masterbatches via an open mill (SK-168 from Shanghai Double Wing Rubber Machinery Factory). The process parameters of the open mill were set as follows: roller spacing 3 mm and roll temperature 50°C. And the shear ratio of front and rear rolls was: 1:4. At last, the rubber compound was vulcanized by a QLB-400X2 flat vulcanizing machine (Qingdao Yadong Rubber Machinery Factory) after resting for 16 h.

2.5 Characterization

Vulcanization characteristics were carried out according to GB/T16584-1996. The conditions of vulcanization were at 150°C/10 MPa × T90 (min).

The Payne effect was tested by the RPA2000 Rubber Dynamic Processing Analyzer (Alpha Technologies Co of USA) with a strain of 0.28–50% and a frequency of 60 rpm.

The vulcanizate samples were subjected to brittle fracture in liquid nitrogen and subjected to gold-spray treatment and then analyzed by scanning electron microscopy (JEOL, Japan).

The dynamic mechanical properties were characterized by the Dynamic Mechanical Analyzer (GABO Company of Germany). The samples were measured in the fixed frequency mode, at an operating frequency of 10 Hz and a heating rate of 2°C per min. The samples were evaluated in the temperature range from –65°C to 65°C.

The tensile strength and tear strength were tested by TS2005b type Tensile Testing Machine from U-CAN Technology Co. (China) according to GB/T528-1999.

For tensile tests, the sample was dumb-bell-shaped according to GB/T528-2009 Type 1, and for tear tests, GB/T 529-2008 Type B. Shore A hardness was carried out according to GB/T531-1999.

3 Results and discussion

3.1 Mechanical properties

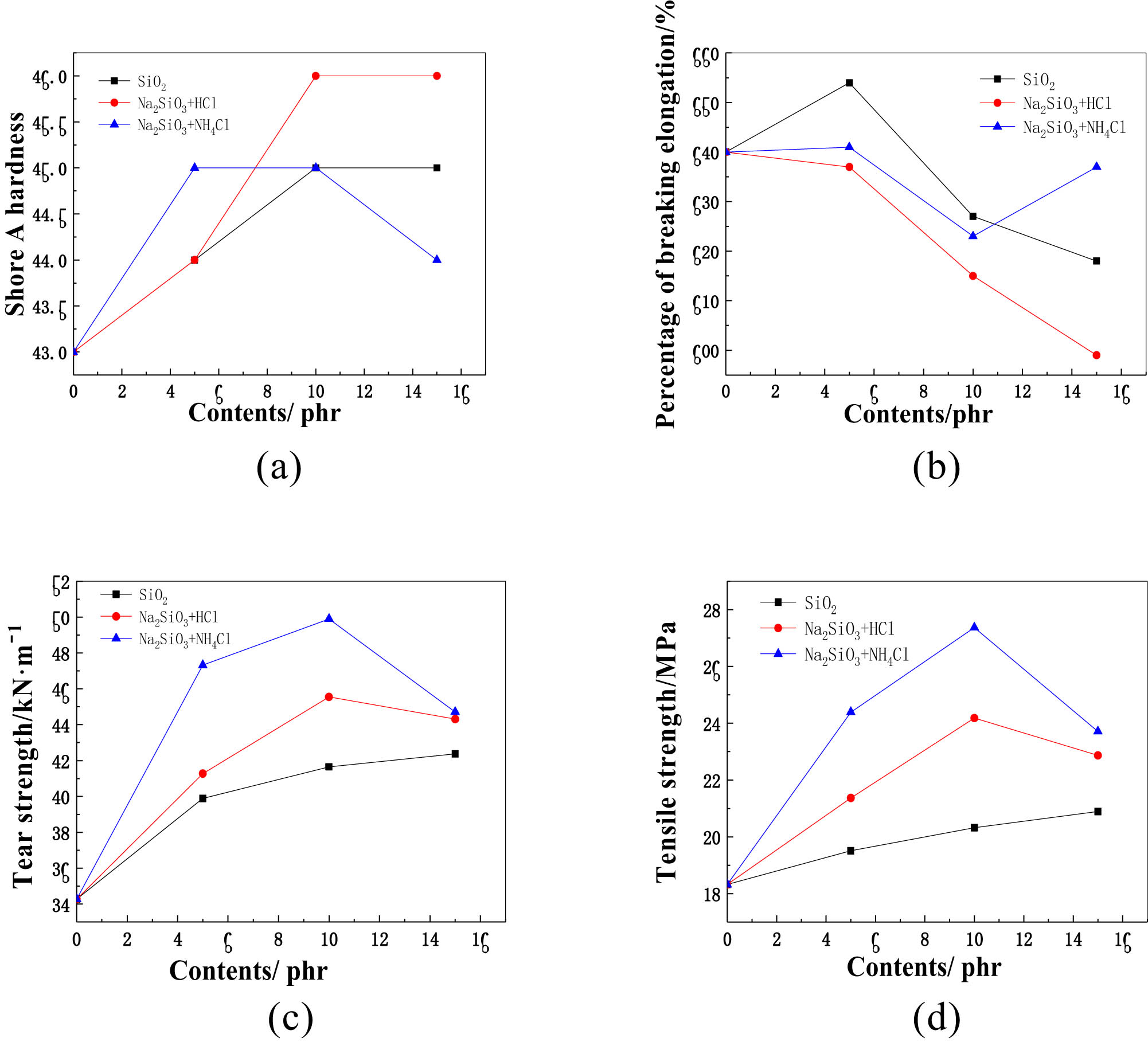

The mechanical properties amount of silica for NR/silica composites with different processes is shown in Figure 2. From the experiment of variable dosage, the tensile strength and tear strength of the vulcanized rubber prepared by in situ method increase first and then decrease with the increase of the dosage which is different from that of the traditional wet mixing method. The threshold value of in situ preparation of silica appears at 10 phr, while the threshold value of the wet mixing method does not appear in the whole range of variables curve. The reason might be that the silica generated by the in situ method has a smaller particle size of filler agglomeration and is dispersed well with appropriate interaction fillers and rubber matrix via spray sputtering method when 10 phr loading. Thus, the interfacial interaction in silica/NRL composites is improved which forming a regular filler network than wet mixing without in situ silica at 10 phr. Especially, the tensile strength and tear strength of NH4Cl treated vulcanizates are 34.7% and 19.8% higher than those of ordinary silica vulcanizates, respectively. When the dosage exceeds 10 phr, the properties of the vulcanized composites prepared by the in situ method combined with spray sputtering method are decreased because of the enhancement of the filler network effect (Payne effect) formed among nanoparticles and the reduction of reinforcement effect. This phenomenon will be verified in Section 3.2 with further efforts.

The mechanical properties amount of silica for NR/silica composites with different processes: (a) shore A hardness, (b) percentage of breaking elongation, (c) tear strength, and (d) tensile strength.

It can be concluded from Figure 2 that the tensile strength and tear strength of the vulcanizates obtained by in situ method are significantly higher than those of the wet mixing with commercial silica-filled, while the hardness and elongation at break have no obvious change. In addition, the mechanical properties of vulcanized composites treated by the NH4Cl method are the most ideal among them. Above all, within a certain range, the mechanical properties of vulcanizates increase as the dosage of silica increases. When silica exceeds a certain amount, the mechanical properties of vulcanizate composites prepared by spray sputtering technology combined with in situ method decrease with the increase of silica content, which reduces the reinforcing effect of fillers on the compound. The reason might be that the silica particles produced in situ have a smaller size of aggregates and uniform distribution, which increases the contact area between rubber hydrocarbons and silica particles. The good adsorption and bonding effect between fillers and rubber composites make the silica-filled in situ combined with spray sputtering method reinforce rubber well and improve the mechanical properties of rubber composites. However, with the increase of silica production, the interaction between filler and filler is greater than that between rubber and filler, and agglomeration occurs to a certain extent which affects the dispersion of silica, thus decreasing the physical and mechanical properties of NRL/silica composites.

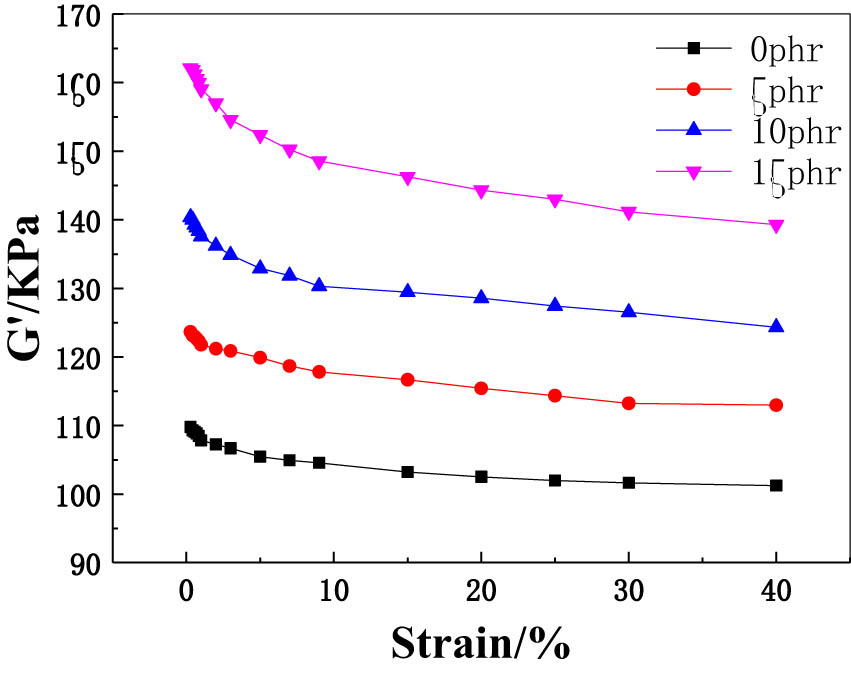

3.2 Payne effect of NR/silica composites with different silica dosages

Payne effect (40,41) is a phenomenon in which the shear storage modules G′ of the rubber nonlinear decrease with the increase of strain. Within a certain range, the elastic modulus decreases rapidly with the increase of strain, and the viscoelasticity reaches its maximum value in the region where the elastic modulus decreases. The dynamic modulus of filled rubber decreases sharply with the increase of strain due to the failure of the interaction force between fillers. Therefore, the value of ΔG′ = G′0 − G′∞ can indicate the interaction between filler-filler and filler-rubber matrix to some extent. In this section, controlling the same condition via spray sputtering technology combined with the in situ method with NH4Cl treated, Figure 3 shows the data of 0 phr (ΔG′ = 8.04), 5 phr (ΔG′ = 10.15), 10 phr (ΔG′ = 15.66), and 15 phr (ΔG′ = 22.6) by rubber process analyzer (RPA) test.

The effect of different amounts of silica on Payne effect of NH4Cl process.

Regularly, the lower the Payne effect is, the better the dispersion of the filler in the rubber matrix and the weaker the network structure of the filler will be. As can be seen from Figure 3, the value of ΔG′ is low with 0 and 5 phr silica which means the interaction force between filler aggregates is not serious, and a less large-scale filler network has been formed. The ΔG′ increased obviously beyond 15 phr silica loaded. As the dosage of silica increases, the distance between fillers and fillers decreases, and the interaction between silica and rubber matrix increases. Therefore, a greater external force is needed to overcome the interaction between silica in the dynamic strain process. However, the degree of filler network is excessive and the reinforcing between rubber and fillers is declined, leading to a lower mechanical property of composites. That might be because the specific surface area of in situ silica is larger, which is more liable to agglomeration. In addition, the interaction between silica and the natural rubber matrix is inherently weak and the developed three-dimensional filler network structure will be decreased under giant dynamic strain. When the filler agglomeration is serious, the filler network has a stronger tendency to collapse under the action of strain, resulting in a larger value of ΔG′. The comprehensive mechanical properties of the compound reach the best with 10 phr silica loaded mainly because 10 phr loading of silica is more compatible with the dispersion capability of this process. Meanwhile, the interfacial interaction between rubber-filler and filler-filler can be beneficial for reinforcing comprehensive properties appropriately.

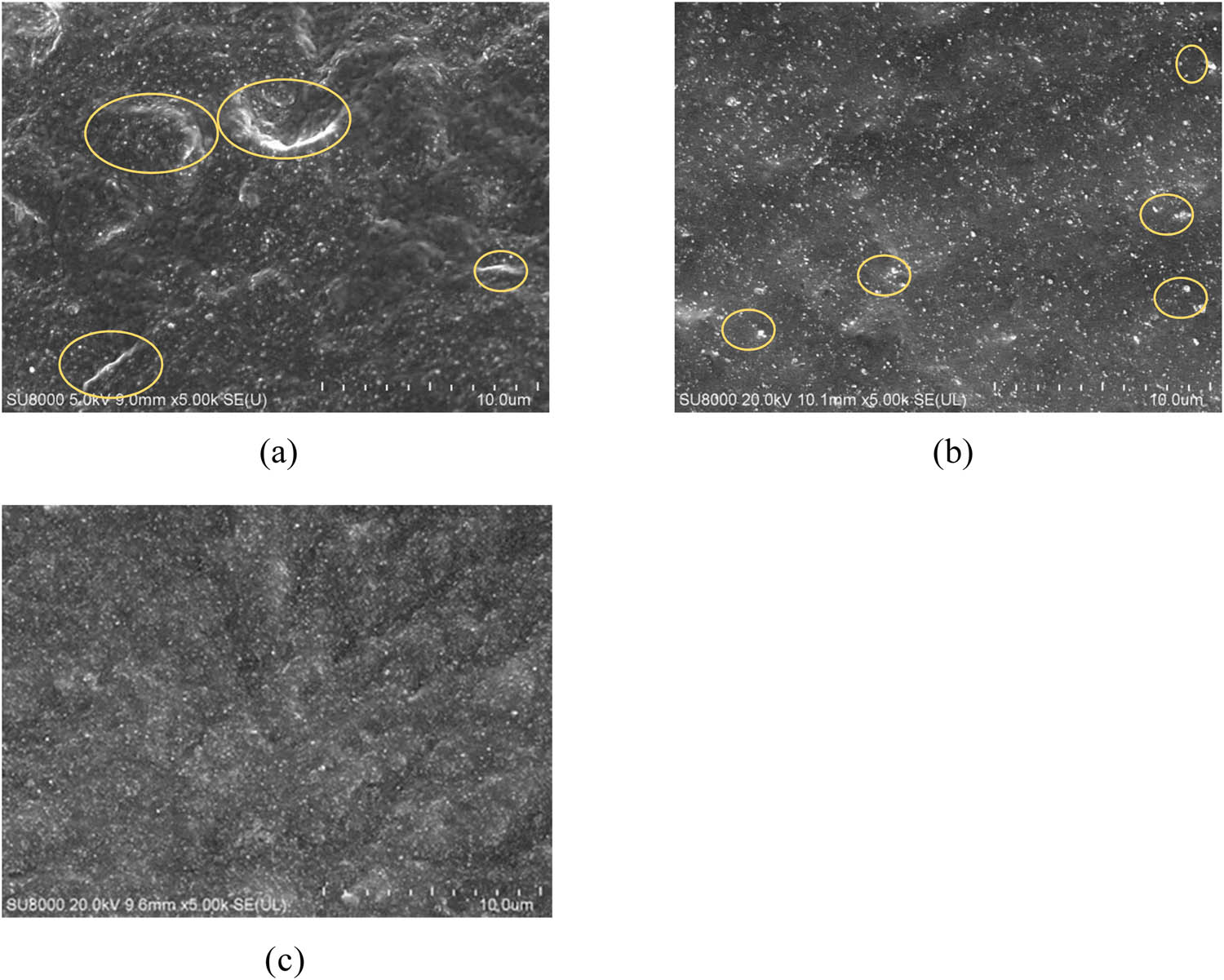

3.3 Microscopic appearance

Scanning electron microscopes (SEM) tests were conducted on JSM-7500F from JEOL (Japan) with surface gold-spray treatment. In order to compare the particle size of silica generated by different preparation methods and its dispersion in composites, we selected rubber composites filled with different preparation methods under 10 phr dosage for scanning electron microscope observation. When 10 phr of silica is added, the SEM images of rubber composites are shown in Figure 4.

SEM images of composite preparation by spray sputtering method with a different type of silica: (a) silica commercially available, (b) in situ preparation from HCl solution, and (c) in situ preparation from NH4Cl solution.

It can be concluded from Figure 4a that silica unevenly disperses in vulcanizates obtained by preparation of silica commercially and the local agglomeration is obvious, which decreases the reinforcing effect of rubber. In Figure 4b and c, silica disperses better than the conventional wet mixing method and the aggregate size of fillers is relatively smaller, which verifies the advancement of reinforcement for rubber composites by in situ combined with a spray sputtering method. In case of traditional drying, it is possible for well-dispersed silica to again flocculate which leads to agglomerates. During in situ combined with spray sputtering method, the droplets enfolded in situ silica with appropriate spraying pressure hit the high-temperature roller and then sputter into smaller-grade droplets onto the surface of the roller with instantaneous evaporation of water, which can efficiently improve the dispersion and further enhance the interfacial bonding strength of in situ silica for rubber matrix. However, some aggregates of silica can also be observed by in situ methods from HCl in Figure 4b. That might be because the HCl solution belongs to strong acid and reacts more intensely with Na2SiO3 than NH4Cl with aggregates generation, which leads to worse mechanical properties than in situ preparation from NH4Cl by spray sputtering process.

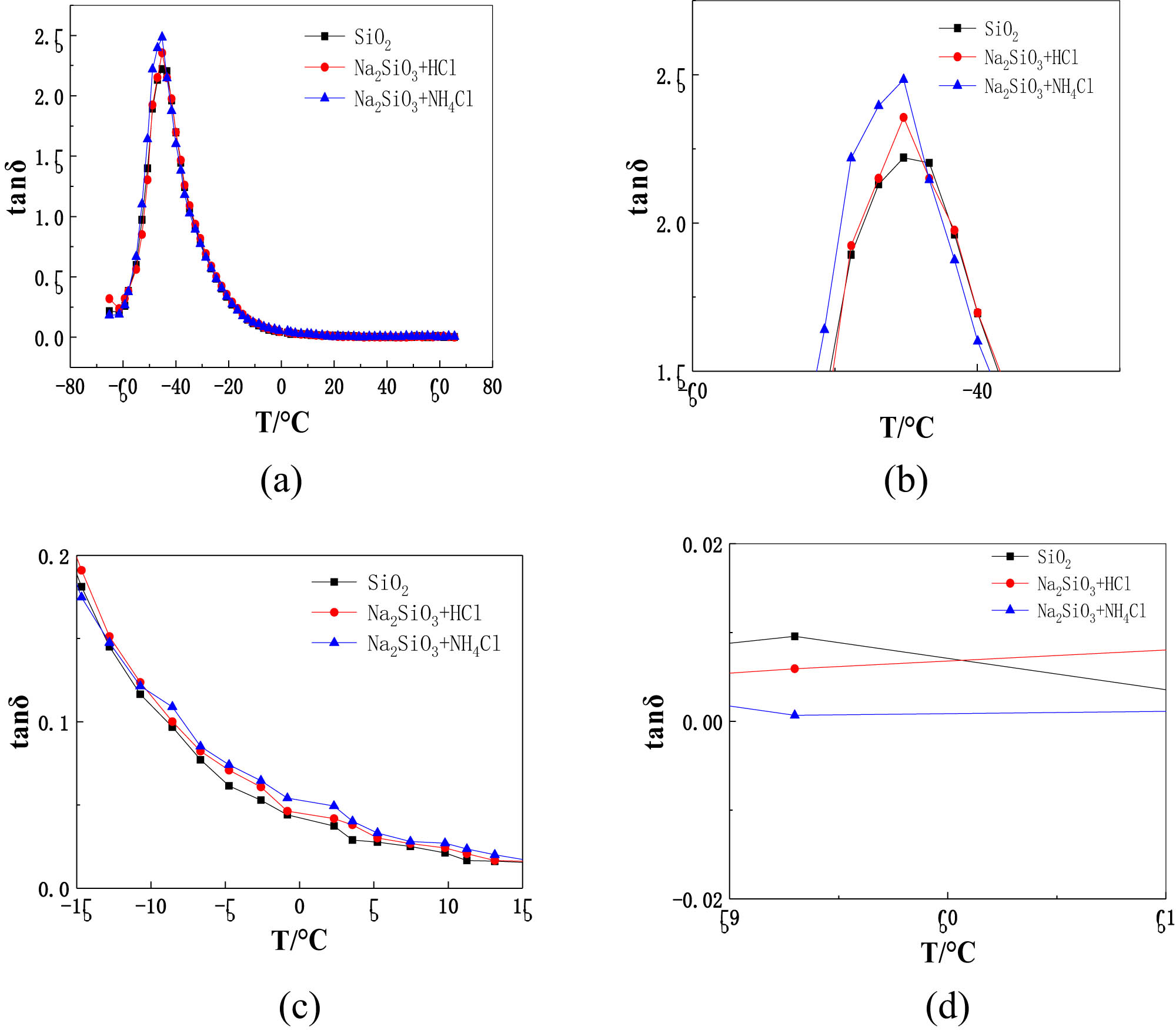

3.4 Dynamic mechanical performance analysis

Dynamic mechanics analyzer (DMA) can measure the response of vibration deformation and temperature function of a given material under the action of cyclic stress-strain. Controlling 10 phr silica loading in NR-carbon black matrix, Figure 5 shows the results of loss factor-temperature of NR/silica composites with different processes from −65°C to 65°C. To some degree, the loss factor-temperature curve can reflect filler dispersion, the strength of filler network, wet traction, and rolling resistance of composites with fillers.

Loss factor-temperature of NR/silica composites with different processes (subfigures (b–d) are partially enlarged drawings of subfigure (a)).

In the tire industry, it is difficult to coordinate the relationship among rolling resistance, wet-skid resistance, and wear resistance of traditional tires. These three indexes have become important indexes to evaluate the performance of automobile tires in the modern tire industry. Especially, the loss factor (tan δ) values at two important temperatures of 0°C and 60°C can measure the wet slip resistance and rolling resistance of tires to a certain extent. The value of tan δ near 0°C is used to indicate the anti-skid performance of the tread compound. The larger the tan δ value is, the stronger the holding ability of the tread compound is. The rolling resistance of tread rubber is characterized by the value of tan δ between 40°C and 60°C; the lower value of tan δ indicates the lower rolling resistance and the less heat generated by the friction of the tire on the road surface.

In the glass transition zone, the internal friction of the material mainly comes from the internal friction among the rubber macromolecular chains. The conventional silica-filled method has the lowest peak value which indicates that more rubber molecular chains are trapped in the filler network structure. As a result, a small number of rubber molecular chains participate in the chain segment relaxation process. In other words, the dispersion of fillers in the rubber matrix and the interaction between filler and rubber interface will affect the value of the loss factor tan δ. The peak value of loss factor (tan δ) of in situ silica from the NH4Cl method is the largest among them because the silica produced by the in situ method has a large contact area and good compatibility with rubber latex. Thus, the agglomerate effect is difficult to achieve, and the strength of the network of composite fillers is weak. There are relatively few rubber molecules retained in the filler network structure, which means that more rubber molecules are involved in the chain segment movement to increase tan δ.

With the increase in temperature, the activity of the rubber molecular chain is enhanced. When the temperature reaches about 60°C, the breaking and reconstruction of the filler network structure in the process of dynamic mechanics is the main reason for the energy loss of the rubber system. The uniform dispersion of silica and the strong adhesion between filler and natural rubber matrix can restrict the movement of rubber molecular chains. Therefore, the energy consumption of breaking and rebuilding the filler network structure is reduced, which leads to the low value of loss factor and nice rolling resistance.

4 Conclusion

Different processes are performed in this work to disperse silica into NRL-carbon black matrix. When a load of silica reached 10 phr, the capacity of filler dispersion can be suitably matched with spray sputtering technology combined with an in situ process. In this case, NR/silica composites obtained from the NH4Cl solution can reach better mechanical behavior. Meanwhile, the microscopic appearance shows that the NR/silica composites prepared by in situ silica from the NH4Cl method combined with spray sputtering technology at 10 phr have better dispersion compared with other processes. Moreover, the NR/silica composites prepared by in situ silica from the NH4Cl method combined with spray sputtering technology perform well in dynamic mechanical properties.

-

Funding information: The work was supported by the Key Research and Development Program of Shandong: research on new method and new process for the preparation of carbon-rubber composites by latex compounding technology (2019GGX102018), Young innovator science and technology plan of Shandong: polymer materials intelligent manufacturing innovation team/functional Nano-filler/technology and equipment for preparation of high-performance composites by latex compounding technology (2019KJB007). The work was supported by the National Natural Science Foundation of China (No. 50775116 and No. 51875297).

-

Author contributions: Tianhao Chang: conceptualization, methodology, writing – original draft, writing – review and editing; Huiguang Bian: methodology, validation, data curation; Yao Xiao: validation, formal analysis; Junxiu Xue: visualization, formal analysis; Chuansheng Wang: conceptualization, methodology.

-

Conflict of interest: Authors declare no conflict of interest.

References

(1) Nematollahi M, Jalali-Arani A, Modarress H. Effect of nanoparticle localization on the rheology, morphology and toughness of nanocomposites based on poly(lactic acid)/natural rubber/nanosilica. Polym Int. 2019;68(4):779–84.10.1002/pi.5767Search in Google Scholar

(2) Ozaki Y, Hayashi H. Tire having low rolling resistance. U.S. Patent 5896904; 1999 April 27.Search in Google Scholar

(3) Greiner M, Unrau HJ, Gauterin F. A model for prediction of the transient rolling resistance of tyres based on inner-liner temperatures. Veh Syst Dyn. 2018;56(1):78–94.10.1080/00423114.2017.1343955Search in Google Scholar

(4) Inui N, Yamamoto K, Nagasaki H, Sasaki M, Yachigo S. Rubber composition having excellent gripping power and rolling resistance, and production thereof. U.S. Patent 5362794; 1994 Nov 8.Search in Google Scholar

(5) Choi SS, Kwon HM, Kim Y, Ko E, Lee KS. Hybrid factors influencing wet grip and rolling resistance properties of solution styrene-butadiene rubber composites. Polym Int. 2018;67(3):340–6.10.1002/pi.5515Search in Google Scholar

(6) Rasyid MF, Ahmad, Salim MS, Akil HM. Non-woven flax fibre reinforced acrylic based polyester composites: the effect of sodium silicate on mechanical, flammability and acoustic properties. Exp Polym Lett. 2019;13(6):553–64.10.3144/expresspolymlett.2019.47Search in Google Scholar

(7) Zhang LQ, Wang YZ, Wang YQ, Sui Y, Yu DS. Morphology and mechanical properties of clay/styrene-butadiene rubber nanocomposite. J Appl Polym Sci. 2000;78(11):1873–8.10.1002/1097-4628(20001209)78:11<1873::AID-APP40>3.0.CO;2-8Search in Google Scholar

(8) Yang Q, Mai QL. Preliminary study on the preparation process and properties of Silica/NR wet mixtures. China Rubber. 2014;30(23):36–42.Search in Google Scholar

(9) Le HH, Abhijeet S, Ilisch S, Klehm J, Henning S, Beiner M, et al. The role of linked phospholipids in the rubber-filler interaction in carbon nanotube (CNT) filled natural rubber (NR) composites. Polymer. 2014;55(18):4738–47.10.1016/j.polymer.2014.07.043Search in Google Scholar

(10) Xun W, Duoli C, Wensheng Z, Zhang L, Fan XQ, Cai ZB, et al. Experimental and theoretical evaluations of the interfacial interaction between carbon nanotubes and carboxylated butadiene nitrile rubber. Mater Des. 2020;186(15):108318.10.1016/j.matdes.2019.108318Search in Google Scholar

(11) Subramaniam K, Das A, Steinhauser D, Kluppel M, Heinrich G. Effect of ionic liquid on dielectric, mechanical and dynamic mechanical properties of multi-walled carbon nanotubes/polychloroprene rubber composites. Eur Polym J. 2011;47(12):2234–43.10.1016/j.eurpolymj.2011.09.021Search in Google Scholar

(12) Kalkornsurapranee E, Koedthip D, Songtipya P, Prodpran T, Johns J, Nakaramontri Y, et al. Influence of modified natural rubbers as compatibilizers on the properties of flexible food contact materials based on NR/PBAT blends. Mater Des. 2020;196:109134.10.1016/j.matdes.2020.109134Search in Google Scholar

(13) Le HH, Sriharish MN, Henning S, Klehm J, Menzel M, Frank W, et al. Dispersion and distribution of carbon nanotubes in ternary rubber blends. Compos Sci Technol. 2014;90:180–6.10.1016/j.compscitech.2013.11.008Search in Google Scholar

(14) Kaiqiang L, Guohua Y, Xiuying Z. Synergistic effects of antioxidant and silica on enhancing thermo-oxidative resistance of natural rubber: insights from experiments and molecular simulations. Mater & Des. 2019;181(5):107944.10.1016/j.matdes.2019.107944Search in Google Scholar

(15) Song Y, Yu J, Dai D, Song LX, Jiang N. Effect of silica particles modified by in-situ and ex-situ methods on the reinforcement of silicone rubber. Mater Des. 2014;64:687–93.10.1016/j.matdes.2014.08.051Search in Google Scholar

(16) Scotti R, Wahba L, Crippa M, D'Arienzo M, Donetti R, Santo N, et al. Rubber–silica nanocomposites obtained by in situ sol–gel method: particle shape influence on the filler–filler and filler–rubber interactions. Soft Matter. 2012;8(7):2131–43.10.1039/c1sm06716hSearch in Google Scholar

(17) Pouya R, Faramarz AG, Mohammad F, Saberian M. Effect of styrene-butadiene rubber and fumed silica nano-filler on the microstructure and mechanical properties of glass fiber reinforced unsaturated polyester resin. Compos Part B Eng. 2019;173(15):106803.10.1016/j.compositesb.2019.05.014Search in Google Scholar

(18) Liu X, Kuang W, Guo B. Preparation of rubber/graphene oxide composites with in-situ interfacial design. Polymer. 2015;56:553–62.10.1016/j.polymer.2014.11.048Search in Google Scholar

(19) Wahba L, D'Arienzo M, Donetti R, Hanel T, Scotti R, Tadiello L, et al. In situ sol–gel obtained silica–rubber nanocomposites: influence of the filler precursors on the improvement of the mechanical properties. RSC Adv. 2013;3(17):5832–44.10.1039/c3ra22706eSearch in Google Scholar

(20) Ikeda Y, Kohjiya S. In situ formed silica particles in rubber vulcanizate by the sol–gel method. Polymer. 1997;38(17):4417–23.10.1016/S0032-3861(96)01037-3Search in Google Scholar

(21) Wisutiratanamanee A, Poochinda K, Poompradub S. Low-temperature particle synthesis of titania/silica/natural rubber composites for antibacterial properties. Adv Powder Technol. 2017;28(4):1263–9.10.1016/j.apt.2017.02.014Search in Google Scholar

(22) Bansod ND, Das C. Studies on mechanical, rheological, thermal and morphological properties of in situ silica-filled butadiene rubber composites. Plastics Rubber Compos. 2018;47(8):345–51.10.1080/14658011.2018.1492272Search in Google Scholar

(23) Yan G, Junchi Z, Xin Y, Han DL, Xi MM, Zhang LQ. Preparation and performance of silica/SBR masterbatches with high silica loading by latex compounding method. Compos Part B Eng. 2016;85:130–9.10.1016/j.compositesb.2015.07.001Search in Google Scholar

(24) Bose R, Roychoudhury P, Pal R. In-situ green synthesis of fluorescent silica-silver conjugate nanodendrites using nanoporous frustules of diatoms: an unprecedented approach. Bioprocess Biosyst Eng. 2021;44:1263–73. 10.1007/s00449-021-02536-4.Search in Google Scholar PubMed

(25) Chuansheng W, Tianhao C, Huiguang B, Zhang LQ. Study on the preparation of graphene oxide/silica/natural rubber latex composites by different processes. Polym Polym Compos. 2019;27(3):135–42.10.1177/0967391118819710Search in Google Scholar

(26) Tang SY, Sopanon P, Tanthapanichakoon W, Soottitantawat A. Preparation and properties of spherical natural rubber/silica composite powders via spray drying. KONA Powder Part J. 2020;37:214–23.10.14356/kona.2020009Search in Google Scholar

(27) Xing W, Li LT, Wu JR, Tang MZ, Fu X, Li HY, et al. Study on the microstructure of grapheme/natural rubber nanocomposites prepared by latex compounding method. China Sci Paper. 2014;9(6):669–72.Search in Google Scholar

(28) Cui GJ, Wang SW, Yin PG, Guo L. Study of viscoelastic properties of white carbon black reinforced synthetic polyisoprene. Chin J Polym Sci. 2016;34(4):457–65.10.1007/s10118-016-1765-9Search in Google Scholar

(29) Ma Z, Chen YP, Gao Z, Liao JH. Properties of in-situ synthysized nano-silica/NR composites. China Sci Paper. 2016;11(16):1912–6.Search in Google Scholar

(30) Li Y, Chen Z, Li X, Zeng HW. A new surface modification method to improve the dispersity of nano-silica in organic solvents. J Sol–Gel Sci Technol. 2011;58(1):290–5.10.1007/s10971-010-2389-0Search in Google Scholar

(31) Das A, Jurk R, Stockelhuber KW. Silica‐ethylene propylene diene monomer rubber networking by in situ sol–gel method. J Macromol Sci Part A Pure Appl Chem. 2007;45(1):101–6.10.1080/10601320701683447Search in Google Scholar

(32) Neng Y, Junchi Z, Xin Y, Xue JJ, Han DL, Xu HS, et al. Performance enhancement of rubber composites using VOC-Free interfacial silica coupling agent. Compos Part B Eng. 2020;202(1):108301.10.1016/j.compositesb.2020.108301Search in Google Scholar

(33) Kapgate BP, Das C, Basu D, Das A, Heinrich G. Rubber composites based on silane-treated stöber silica and nitrile rubber: interaction of treated silica with rubber matrix. J Elastomers Plast. 2015;47(3):248–61.10.1177/0095244313507807Search in Google Scholar

(34) Perera SJ, Egodage SM, Walpalage S. Enhancement of mechanical properties of natural rubber–clay nanocomposites through incorporation of silanated organoclay into natural rubber latex. e-Polymers. 2020;20(1):144–53.10.1515/epoly-2020-0017Search in Google Scholar

(35) Peng Z, Qin Y, Song J, Zhu D, Chen S, Ren J, et al. Structuring of hydroxy-terminated polydimethylsiloxane filled by fumed silica. e-Polymers. 2021;21(1):131–9.10.1515/epoly-2021-0012Search in Google Scholar

(36) Bumyong Y, Yeon K, Uiseok H, Oh MK, Kim M, Han SB, et al. Dynamic viscoelasticity of silica-filled styrene-butadiene rubber/polybutadiene rubber (SBR/BR) elastomer composites. Compos Part B Eng. 2020;187(15):107865.10.1016/j.compositesb.2020.107865Search in Google Scholar

(37) Lan C, Tridib K, Lei T, Li H, Zong CZ, Kim JK. Synergistic reinforcement of silanized silica-graphene oxide hybrid in natural rubber for tire-tread fabrication: a latex based facile approach. Compos Part B Eng. 2019;161(15):667–76.10.1016/j.compositesb.2019.01.024Search in Google Scholar

(38) Wang X, Wu L, Yu H, Xiao TL, Li HM, Yang J. Analysis of effect of modification of silica and carbon black co-filled rubber composite on mechanical properties. e-Polymers. 2021;21(1):279–88.10.1515/epoly-2021-0034Search in Google Scholar

(39) Hu B, Zhou Y, Luo MC, Wei YC, Liu GX, Liao S, et al. Influence of l-quebrachitol on the properties of centrifuged natural rubber. e-Polymers. 2021;21(1):420–7.10.1515/epoly-2021-0042Search in Google Scholar

(40) Payne AR. The dynamic properties of carbon black-loaded natural rubber vulcanizates. Part I. J Appl Polym Sci. 1962;6(19):57–63.10.1002/app.1962.070061906Search in Google Scholar

(41) Payne AR, Whittaker RE. Low strain dynamic properties of filled rubbers. Rubber Chem Technol. 1971;44(2):440–78.10.5254/1.3547375Search in Google Scholar

© 2021 Tianhao Chang et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Research on the mechanism of gel accelerator on gel transition of PAN solution by rheology and dynamic light scattering

- Gel point determination of gellan biopolymer gel from DC electrical conductivity

- Composite of polylactic acid and microcellulose from kombucha membranes

- Synthesis of highly branched water-soluble polyester and its surface sizing agent strengthening mechanism

- Fabrication and characterization of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) modified with nano-montmorillonite biocomposite

- Fabrication of N-halamine polyurethane films with excellent antibacterial properties

- Formulation and optimization of gastroretentive bilayer tablets of calcium carbonate using D-optimal mixture design

- Sustainable nanocomposite films based on SiO2 and biodegradable poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH) for food packaging

- Evaluation of physicochemical properties of film-based alginate for food packing applications

- Electrically conductive and light-weight branched polylactic acid-based carbon nanotube foams

- Structuring of hydroxy-terminated polydimethylsiloxane filled by fumed silica

- Surface functionalization of nanostructured Cu/Ag-deposited polypropylene fiber by magnetron sputtering

- Influence of composite structure design on the ablation performance of ethylene propylene diene monomer composites

- MOFs/PVA hybrid membranes with enhanced mechanical and ion-conductive properties

- Improvement of the electromechanical properties of thermoplastic polyurethane composite by ionic liquid modified multiwall carbon nanotubes

- Natural rubber latex/MXene foam with robust and multifunctional properties

- Rheological properties of two high polymers suspended in an abrasive slurry jet

- Two-step polyaniline loading in polyelectrolyte complex membranes for improved pseudo-capacitor electrodes

- Preparation and application of carbon and hollow TiO2 microspheres by microwave heating at a low temperature

- Properties of a bovine collagen type I membrane for guided bone regeneration applications

- Fabrication and characterization of thermoresponsive composite carriers: PNIPAAm-grafted glass spheres

- Effect of talc and diatomite on compatible, morphological, and mechanical behavior of PLA/PBAT blends

- Multifunctional graphene nanofiller in flame retarded polybutadiene/chloroprene/carbon black composites

- Strain-dependent wicking behavior of cotton/lycra elastic woven fabric for sportswear

- Enhanced dielectric properties and breakdown strength of polymer/carbon nanotube composites by coating an SrTiO3 layer

- Analysis of effect of modification of silica and carbon black co-filled rubber composite on mechanical properties

- Polytriazole resins toughened by an azide-terminated polyhedral oligomeric silsesquioxane (OADTP)

- Phosphine oxide for reducing flammability of ethylene-vinyl-acetate copolymer

- Study on preparation and properties of bentonite-modified epoxy sheet molding compound

- Polyhedral oligomeric silsesquioxane (POSS)-modified phenolic resin: Synthesis and anti-oxidation properties

- Study on structure and properties of natural indigo spun-dyed viscose fiber

- Biodegradable thermoplastic copolyester elastomers: Methyl branched PBAmT

- Investigations of polyethylene of raised temperature resistance service performance using autoclave test under sour medium conditions

- Investigation of corrosion and thermal behavior of PU–PDMS-coated AISI 316L

- Modification of sodium bicarbonate and its effect on foaming behavior of polypropylene

- Effect of coupling agents on the olive pomace-filled polypropylene composite

- High strength and conductive hydrogel with fully interpenetrated structure from alginate and acrylamide

- Removal of methylene blue in water by electrospun PAN/β-CD nanofibre membrane

- Theoretical and experimental studies on the fabrication of cylindrical-electrode-assisted solution blowing spinning nanofibers

- Influence of l-quebrachitol on the properties of centrifuged natural rubber

- Ultrasonic-modified montmorillonite uniting ethylene glycol diglycidyl ether to reinforce protein-based composite films

- Experimental study on the dissolution of supercritical CO2 in PS under different agitators

- Experimental research on the performance of the thermal-reflective coatings with liquid silicone rubber for pavement applications

- Study on controlling nicotine release from snus by the SIPN membranes

- Catalase biosensor based on the PAni/cMWCNT support for peroxide sensing

- Synthesis and characterization of different soybean oil-based polyols with fatty alcohol and aromatic alcohol

- Molecularly imprinted electrospun fiber membrane for colorimetric detection of hexanoic acid

- Poly(propylene carbonate) networks with excellent properties: Terpolymerization of carbon dioxide, propylene oxide, and 4,4ʹ-(hexafluoroisopropylidene) diphthalic anhydride

- Polypropylene/graphene nanoplatelets nanocomposites with high conductivity via solid-state shear mixing

- Mechanical properties of fiber-reinforced asphalt concrete: Finite element simulation and experimental study

- Applying design of experiments (DoE) on the properties of buccal film for nicotine delivery

- Preparation and characterizations of antibacterial–antioxidant film from soy protein isolate incorporated with mangosteen peel extract

- Preparation and adsorption properties of Ni(ii) ion-imprinted polymers based on synthesized novel functional monomer

- Rare-earth doped radioluminescent hydrogel as a potential phantom material for 3D gel dosimeter

- Effects of cryogenic treatment and interface modifications of basalt fibre on the mechanical properties of hybrid fibre-reinforced composites

- Stable super-hydrophobic and comfort PDMS-coated polyester fabric

- Impact of a nanomixture of carbon black and clay on the mechanical properties of a series of irradiated natural rubber/butyl rubber blend

- Preparation and characterization of a novel composite membrane of natural silk fiber/nano-hydroxyapatite/chitosan for guided bone tissue regeneration

- Study on the thermal properties and insulation resistance of epoxy resin modified by hexagonal boron nitride

- A new method for plugging the dominant seepage channel after polymer flooding and its mechanism: Fracturing–seepage–plugging

- Analysis of the rheological property and crystallization behavior of polylactic acid (Ingeo™ Biopolymer 4032D) at different process temperatures

- Hybrid green organic/inorganic filler polypropylene composites: Morphological study and mechanical performance investigations

- In situ polymerization of PEDOT:PSS films based on EMI-TFSI and the analysis of electrochromic performance

- Effect of laser irradiation on morphology and dielectric properties of quartz fiber reinforced epoxy resin composite

- The optimization of Carreau model and rheological behavior of alumina/linear low-density polyethylene composites with different alumina content and diameter

- Properties of polyurethane foam with fourth-generation blowing agent

- Hydrophobicity and corrosion resistance of waterborne fluorinated acrylate/silica nanocomposite coatings

- Investigation on in situ silica dispersed in natural rubber latex matrix combined with spray sputtering technology

- The degradable time evaluation of degradable polymer film in agriculture based on polyethylene film experiments

- Improving mechanical and water vapor barrier properties of the parylene C film by UV-curable polyurethane acrylate coating

- Thermal conductivity of silicone elastomer with a porous alumina continuum

- Copolymerization of CO2, propylene oxide, and itaconic anhydride with double metal cyanide complex catalyst to form crosslinked polypropylene carbonate

- Combining good dispersion with tailored charge trapping in nanodielectrics by hybrid functionalization of silica

- Thermosensitive hydrogel for in situ-controlled methotrexate delivery

- Analysis of the aging mechanism and life evaluation of elastomers in simulated proton exchange membrane fuel cell environments

- The crystallization and mechanical properties of poly(4-methyl-1-pentene) hard elastic film with different melt draw ratios

- Review Articles

- Aromatic polyamide nonporous membranes for gas separation application

- Optical elements from 3D printed polymers

- Evidence for bicomponent fibers: A review

- Mapping the scientific research on the ionizing radiation impacts on polymers (1975–2019)

- Recent advances in compatibility and toughness of poly(lactic acid)/poly(butylene succinate) blends

- Topical Issue: (Micro)plastics pollution - Knowns and unknows (Guest Editor: João Pinto da Costa)

- Simple pyrolysis of polystyrene into valuable chemicals

- Topical Issue: Recent advances of chitosan- and cellulose-based materials: From production to application (Guest Editor: Marc Delgado-Aguilar)

- In situ photo-crosslinking hydrogel with rapid healing, antibacterial, and hemostatic activities

- A novel CT contrast agent for intestinal-targeted imaging through rectal administration

- Properties and applications of cellulose regenerated from cellulose/imidazolium-based ionic liquid/co-solvent solutions: A short review

- Towards the use of acrylic acid graft-copolymerized plant biofiber in sustainable fortified composites: Manufacturing and characterization

Articles in the same Issue

- Research Articles

- Research on the mechanism of gel accelerator on gel transition of PAN solution by rheology and dynamic light scattering

- Gel point determination of gellan biopolymer gel from DC electrical conductivity

- Composite of polylactic acid and microcellulose from kombucha membranes

- Synthesis of highly branched water-soluble polyester and its surface sizing agent strengthening mechanism

- Fabrication and characterization of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) modified with nano-montmorillonite biocomposite

- Fabrication of N-halamine polyurethane films with excellent antibacterial properties

- Formulation and optimization of gastroretentive bilayer tablets of calcium carbonate using D-optimal mixture design

- Sustainable nanocomposite films based on SiO2 and biodegradable poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH) for food packaging

- Evaluation of physicochemical properties of film-based alginate for food packing applications

- Electrically conductive and light-weight branched polylactic acid-based carbon nanotube foams

- Structuring of hydroxy-terminated polydimethylsiloxane filled by fumed silica

- Surface functionalization of nanostructured Cu/Ag-deposited polypropylene fiber by magnetron sputtering

- Influence of composite structure design on the ablation performance of ethylene propylene diene monomer composites

- MOFs/PVA hybrid membranes with enhanced mechanical and ion-conductive properties

- Improvement of the electromechanical properties of thermoplastic polyurethane composite by ionic liquid modified multiwall carbon nanotubes

- Natural rubber latex/MXene foam with robust and multifunctional properties

- Rheological properties of two high polymers suspended in an abrasive slurry jet

- Two-step polyaniline loading in polyelectrolyte complex membranes for improved pseudo-capacitor electrodes

- Preparation and application of carbon and hollow TiO2 microspheres by microwave heating at a low temperature

- Properties of a bovine collagen type I membrane for guided bone regeneration applications

- Fabrication and characterization of thermoresponsive composite carriers: PNIPAAm-grafted glass spheres

- Effect of talc and diatomite on compatible, morphological, and mechanical behavior of PLA/PBAT blends

- Multifunctional graphene nanofiller in flame retarded polybutadiene/chloroprene/carbon black composites

- Strain-dependent wicking behavior of cotton/lycra elastic woven fabric for sportswear

- Enhanced dielectric properties and breakdown strength of polymer/carbon nanotube composites by coating an SrTiO3 layer

- Analysis of effect of modification of silica and carbon black co-filled rubber composite on mechanical properties

- Polytriazole resins toughened by an azide-terminated polyhedral oligomeric silsesquioxane (OADTP)

- Phosphine oxide for reducing flammability of ethylene-vinyl-acetate copolymer

- Study on preparation and properties of bentonite-modified epoxy sheet molding compound

- Polyhedral oligomeric silsesquioxane (POSS)-modified phenolic resin: Synthesis and anti-oxidation properties

- Study on structure and properties of natural indigo spun-dyed viscose fiber

- Biodegradable thermoplastic copolyester elastomers: Methyl branched PBAmT

- Investigations of polyethylene of raised temperature resistance service performance using autoclave test under sour medium conditions

- Investigation of corrosion and thermal behavior of PU–PDMS-coated AISI 316L

- Modification of sodium bicarbonate and its effect on foaming behavior of polypropylene

- Effect of coupling agents on the olive pomace-filled polypropylene composite

- High strength and conductive hydrogel with fully interpenetrated structure from alginate and acrylamide

- Removal of methylene blue in water by electrospun PAN/β-CD nanofibre membrane

- Theoretical and experimental studies on the fabrication of cylindrical-electrode-assisted solution blowing spinning nanofibers

- Influence of l-quebrachitol on the properties of centrifuged natural rubber

- Ultrasonic-modified montmorillonite uniting ethylene glycol diglycidyl ether to reinforce protein-based composite films

- Experimental study on the dissolution of supercritical CO2 in PS under different agitators

- Experimental research on the performance of the thermal-reflective coatings with liquid silicone rubber for pavement applications

- Study on controlling nicotine release from snus by the SIPN membranes

- Catalase biosensor based on the PAni/cMWCNT support for peroxide sensing

- Synthesis and characterization of different soybean oil-based polyols with fatty alcohol and aromatic alcohol

- Molecularly imprinted electrospun fiber membrane for colorimetric detection of hexanoic acid

- Poly(propylene carbonate) networks with excellent properties: Terpolymerization of carbon dioxide, propylene oxide, and 4,4ʹ-(hexafluoroisopropylidene) diphthalic anhydride

- Polypropylene/graphene nanoplatelets nanocomposites with high conductivity via solid-state shear mixing

- Mechanical properties of fiber-reinforced asphalt concrete: Finite element simulation and experimental study

- Applying design of experiments (DoE) on the properties of buccal film for nicotine delivery

- Preparation and characterizations of antibacterial–antioxidant film from soy protein isolate incorporated with mangosteen peel extract

- Preparation and adsorption properties of Ni(ii) ion-imprinted polymers based on synthesized novel functional monomer

- Rare-earth doped radioluminescent hydrogel as a potential phantom material for 3D gel dosimeter

- Effects of cryogenic treatment and interface modifications of basalt fibre on the mechanical properties of hybrid fibre-reinforced composites

- Stable super-hydrophobic and comfort PDMS-coated polyester fabric

- Impact of a nanomixture of carbon black and clay on the mechanical properties of a series of irradiated natural rubber/butyl rubber blend

- Preparation and characterization of a novel composite membrane of natural silk fiber/nano-hydroxyapatite/chitosan for guided bone tissue regeneration

- Study on the thermal properties and insulation resistance of epoxy resin modified by hexagonal boron nitride

- A new method for plugging the dominant seepage channel after polymer flooding and its mechanism: Fracturing–seepage–plugging

- Analysis of the rheological property and crystallization behavior of polylactic acid (Ingeo™ Biopolymer 4032D) at different process temperatures

- Hybrid green organic/inorganic filler polypropylene composites: Morphological study and mechanical performance investigations

- In situ polymerization of PEDOT:PSS films based on EMI-TFSI and the analysis of electrochromic performance

- Effect of laser irradiation on morphology and dielectric properties of quartz fiber reinforced epoxy resin composite

- The optimization of Carreau model and rheological behavior of alumina/linear low-density polyethylene composites with different alumina content and diameter

- Properties of polyurethane foam with fourth-generation blowing agent

- Hydrophobicity and corrosion resistance of waterborne fluorinated acrylate/silica nanocomposite coatings

- Investigation on in situ silica dispersed in natural rubber latex matrix combined with spray sputtering technology

- The degradable time evaluation of degradable polymer film in agriculture based on polyethylene film experiments

- Improving mechanical and water vapor barrier properties of the parylene C film by UV-curable polyurethane acrylate coating

- Thermal conductivity of silicone elastomer with a porous alumina continuum

- Copolymerization of CO2, propylene oxide, and itaconic anhydride with double metal cyanide complex catalyst to form crosslinked polypropylene carbonate

- Combining good dispersion with tailored charge trapping in nanodielectrics by hybrid functionalization of silica

- Thermosensitive hydrogel for in situ-controlled methotrexate delivery

- Analysis of the aging mechanism and life evaluation of elastomers in simulated proton exchange membrane fuel cell environments

- The crystallization and mechanical properties of poly(4-methyl-1-pentene) hard elastic film with different melt draw ratios

- Review Articles

- Aromatic polyamide nonporous membranes for gas separation application

- Optical elements from 3D printed polymers

- Evidence for bicomponent fibers: A review

- Mapping the scientific research on the ionizing radiation impacts on polymers (1975–2019)

- Recent advances in compatibility and toughness of poly(lactic acid)/poly(butylene succinate) blends

- Topical Issue: (Micro)plastics pollution - Knowns and unknows (Guest Editor: João Pinto da Costa)

- Simple pyrolysis of polystyrene into valuable chemicals

- Topical Issue: Recent advances of chitosan- and cellulose-based materials: From production to application (Guest Editor: Marc Delgado-Aguilar)

- In situ photo-crosslinking hydrogel with rapid healing, antibacterial, and hemostatic activities

- A novel CT contrast agent for intestinal-targeted imaging through rectal administration

- Properties and applications of cellulose regenerated from cellulose/imidazolium-based ionic liquid/co-solvent solutions: A short review

- Towards the use of acrylic acid graft-copolymerized plant biofiber in sustainable fortified composites: Manufacturing and characterization