Abstract

In this study, bentonite/epoxy sheet molding compound composites (BS/ESMC) were prepared with different bentonite contents (0.5, 1, 1.5, 2, 2.5, 5, and 10 wt%) by hot compression molding. The effects of BS content on the mechanical properties, thermal stability, and fire-retardant properties of samples were investigated. When the BS addition amount is 1.5%, the tensile strength, flexural strength, and impact strength reach the maximum, increasing by 24.15%, 26.56%, and 51.33%, respectively. The measurement of mechanical properties showed that the fracture toughness of BS/ESMC composite has been greatly improved from 71.41 to 108.07 MPa. As the content of the bentonite increases, the heat resistance of the sample increases, and the residual carbon content of the system increases by 61.54% when the amount of the bentonite added is 10%. In addition, the value of LOI increased from 25.6 to 27.9 with the addition of the bentonite.

1 Introduction

Sheet molding compound (SMC) is a sheet molding material, which is mainly composed of resin, fiber-reinforced materials, fillers, and various additives. The demand for SMC is gradually increasing due to its excellent dimensional stability, corrosion resistance, short molding cycle, and low price (1,2,3,4,5,6). Types of resins include unsaturated polyester, epoxy resin, and phenolic resin (7,8). Epoxy resin used in this study has excellent electrical, mechanical, and adhesive properties, which makes it the most widely used matrix resin for resin-based composites (9,10).

Generally, fillers can be divided into organic fillers and inorganic fillers based on their chemical composition. Inorganic fillers are mainly granular fillers made from natural minerals through mining and processing. Naturally occurring calcium carbonate is of low cost and easily available, with large size distribution and high stiffness, and so it is the most widely used filler in composite materials. However, the high surface energy of CaCO3 will cause the mechanical properties of the composite to decrease (11).

Therefore, it is urgent to find new alternative fillers. Kadir and Mahmut (12) studied the reinforcement effect of different particle fillers in SMC composites formed by compression molding. Studies have shown that compared with SMC composites reinforced by CaCO3 particles, basalt particles can effectively bond glass fibers and resin matrix together, thereby the tensile strength increased by approximately 15%, whereas the flexural strength was enhanced by 8% in SMC composites prepared by basalt particles. Noh et al. (13) optimized the content of glass fibers and hollow glass beads mixed in SMC to reduce the density of SMC products while maintaining their mechanical properties, which is of great significance to the realization of lightweight automobiles. In addition, some people added magnesium oxychloride crystal double salt to SMC to obtain composite materials with excellent flame retardant properties (14).

Goswami et al. (15) studied fiber composite sheets reinforced with natural shellac. The results showed that with the introduction of 10% shellac, the tensile strength and the flexural strength of the sheet were improved by 13.94% and 30.00%, whereas the impact strength was reduced by 3.11%. The continued addition of shellac would hinder the rigid three-dimensional structure, resulting in deterioration of mechanical properties. Asadi et al. (16) introduced 0.9 wt% cellulose nanocrystals into sheet molding compound composite and found that the resin matrix became hard, the interphase area changed, and the apparent modulus of the interface increased, which resulted in increases in the tensile strength by 30% and in the flexural strength by 33%.

Although there are many fillers currently in use, the addition of bentonite as a filler for ESMC has not been studied. Bentonite (BS) is a nanolevel (10−9 to 10−7 m) aluminosilicate clay mineral. Its main component is montmorillonite that consists of two layers of silicon–oxygen tetrahedron and one layer of aluminum–oxygen octahedron to form a unit crystal layer. Atoms are connected, and the crystal layers are connected by the oxygen layer, stacked along the C-axis, so that it has rigidity and does not slip between layers (17,18). The prepared material can improve the strength, heat, electricity, and other properties of the matrix due to the special structure of the silicate material. Brown et al. (19) used modified montmorillonite dispersed in thermosetting resin to prepare nanocomposites to obtain exfoliated and partially exfoliated epoxy/diamine nanocomposites with high heat distortion temperature and excellent flame-retardant properties. Takashi et al. (20) studied biodegradable resin/clay composite-modified materials, tested the mechanical properties of the materials, and found that the elastic properties and three-point bending properties have been significantly improved.

In this study, BS was introduced in ESMC as a filler, and the effect of BS concentration on the mechanical properties and thermal stability of BS/ESMC composites was determined. The property enhancement of ESMC composites as a result of BS additions are discussed in the context of two mechanisms:

matrix stiffening due to the presence of the BS, and

a three-dimensional woven network structure enhances the interface bonding between EP and GF, which helps to improve the mechanical properties of composite materials (21).

2 Materials and methods

2.1 Materials

All the materials used in this study are commercially available. Epoxy resin (LY1564) was purchased from Huntsman Company (USA) and was selected as a matrix material. Glass fiber with a diameter of 25–30 mm was purchased from Hubei Senxin Auto Parts Co., Ltd (China). CaCO3 (400 mesh) was purchased from Sichuan Baoxing. Bentonite (DK-NF) with a diameter of 5–20 μm was obtained from Zhejiang Fenghong New Materials Co., Ltd. (China). Polyethylene polyamine (Chemically pure) provided by Wuhan Hongda Chemical Reagent Factory (China) was used as a curing agent.

2.2 Sample preparation

There are two steps in the production of ESMC composites. The first step is to prepare a prepreg formulation according to the given formula (Table 1) and incubated for a maturation period, which plays an important role in the adhesion between matrix and fiber. In addition, ultrasonic for 20 min during the process facilitates the dispersion of bentonite in the matrix. In the second step, under the effect of a constant pressure of 10 MPa, the ESMC plates were placed in a 200 × 200 × 4 mm sheet mold for about 30 min at a temperature of 80–90°C.

The formulation of ESMC prepreg

| Compound | Weight ratio |

|---|---|

| Glass fiber | 24 |

| Epoxy resin | 100 |

| Curing agent | 10 |

| Thickening agent | 8 |

| CaCO3 | 120 |

| bentonite | 0–10 |

| Other additives | 4 |

The equipment used in the experimental process included electronic balance, flat vulcanizing machine, and oven.

2.3 Characterization

The morphological features of the broken composite surfaces are characterized by SEM (JSM-5610LV, Japan) with the accelerating voltage of 20 kV. The infrared image of ESMC composite was measured by the Intelligent Fourier transform infrared spectrometer (Nexus, USA)

According to the ASTM D7264M-15 (22) and ASTM D3039M-17 (23), a three-point bending test and a tensile test were conducted on the composite specimens by a hydraulic testing machine (CTM001, England). The impact strength was measured according to the ASTM standards (24). The duration of the impact test process is very short, but it is a complex failure process, and generally, there are three main energy absorption stages: (1) initial stage, including material compression, bending, internal friction, and the initiation of crack crazing; (2) crack growth stage, which may be accompanied by behaviors such as neck formation, interface debonding, torsion, and drafting; and (3) end stage, including splitting, separation, and fragmentation (25). The plates were cut into rectangular splines according to the standard. All the mechanical properties measurements were carried out at room temperature (23°C), and the average values obtained from at least five specimens were reported.

The German NETZSCH STA449C/3/G synchronous thermal analyzer was used to observe the thermal stability of ESMC composites. The heating process is carried out in N2 atmosphere, and the temperature is increased from room temperature to 1,000°C at a rate of 10°C min−1. The limiting oxygen index (LOI) was tested by the JF-3 oxygen index tester (Nanjing Jiangning Analytical Instrument Factory) according to ASTM D2863-2017 (26).

3 Results and discussion

3.1 Microstructure

The morphologies of the samples were characterized using SEM, and the results are shown in Figure 1. For samples without added bentonite, a smooth impact failure surface can be observed (Figure 1a). The glass fiber is easily separated from the matrix when subjected to external force due to the insufficient strength of the interface between the fiber and the matrix. Therefore, interface peeling leads to a decrease in mechanical properties. As shown in Figure 1b and c, the fracture surface of the bentonite/ESMC composites with 1.5 wt% added was uneven and very rough, and obvious laminar microcracks appeared after failure. With the increase of the bentonite content, there is a resin matrix covering the fiber surface in the impact section of the sample (Figure 1d), indicating that the glass fiber and the matrix are well bonded. When the composite material is subjected to external force, due to the strong interfacial adhesion, the effect of the external force is transferred to the fiber. Hence, the mechanical properties of the ESMC plates are remarkably improved. When the content of bentonite reaches 10%, bentonite has a large amount of agglomeration (Figure 2b) due to its high surface energy (27,28). The resin cannot completely infiltrate all the bentonite, which reduces the interface strength between the fiber and the matrix. Therefore, the sample showed a decrease in mechanical properties.

SEM images of the fractured surfaces of the impact samples. (a) 0 wt% BS, (b) 1.5 wt% BS, (c) the enlarged observation SEM image when 1.5 wt% BS is added, (d) 2 wt% BS.

SEM images of the representative BS/ESMC composites samples. (a) 1.5 wt% BS, (b) 10 wt% BS.

3.2 Mechanical properties

Figures 3 and 4 show the change curve of the mechanical properties of the BS/ESMC composite material when the added amount of bentonite is changed from 0 to 10 wt%. The image shows that the mechanical properties of the sample increase with the amount of BS introduced, and the tensile strength, flexural strength, and impact strength reach the maximum when the BS addition amount is 1.5%, increasing by 24.15%, 26.56%, and 51.33%, respectively. However, all the strengths showed a clear downward trend as the content of bentonite continued to increase, which is consistent with the conclusion obtained by SEM.

Effect of the content of the bentonite on the sample’s tensile strength and flexural strength.

Effect of the content of the bentonite on the sample’s impact strength.

The reason for the aforementioned results may be that bentonite is an inorganic clay mineral, which has greater rigidity and strength, playing a reinforcing role. In addition, the bentonite has a layered silicate structure, and the epoxy resin can easily enter the lamellar structure during the curing process to realize the intercalation of the bentonite, which is beneficial to the formation of a three-dimensional woven network structure. Therefore, it helps to improve the mechanical properties of composite materials. When the epoxy resin system is affected by an external force, the external force must overcome the strength of the matrix and the adhesion between the GF and the EP and break the bond between the BS and the matrix. In addition, the bentonite layer can not only cause silver streaks but also shift, turn, or terminate the silver streaks or cracks as a stress concentrator, which dissipates most of the energy to achieve toughening effects.

However, when the content of bentonite is too high, the epoxy resin cannot completely penetrate all the bentonite. Bentonite particles tend to agglomerate and form larger agglomerates due to their high surface energy. The agglomerates introduce defects in the resin matrix, which greatly reduces the mechanical properties of the composite material. In general, adding BS appropriately can improve the mechanical properties of ESMC composites.

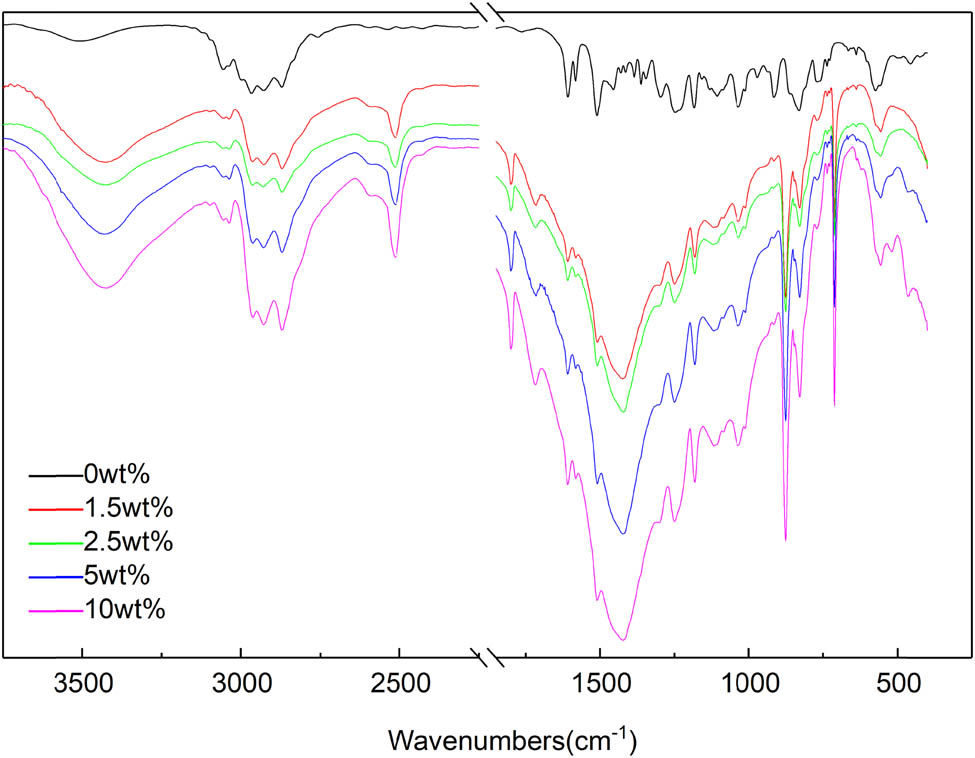

3.3 FTIR of BS/ESMC composites

The infrared spectrum of the BS/ESMC composite is shown in Figure 5. The characteristic absorption peaks of epoxy groups in the “fingerprint area” are 830, 913, and 1,250 cm−1 (29). As the curing reaction of the epoxy resin progresses, the epoxy group gradually opens up, and the intensity of the band at 913 cm−1 gradually weakens. Moreover, the energy band is almost undisturbed during the curing process, so the content of epoxy groups can be sensitively reflected. In the infrared spectrum of the sample with bentonite, the vibration peaks of Si–O bond, Mg–Al–OH bond, and Si–O–Mg bond can be observed at 1,040, 797, and 522 cm−1, respectively. It shows that the skeleton structure of layered silicate is not destroyed during the curing process of epoxy resin.

FTIR spectrum of the representative BS/ESMC composites samples.

3.4 Thermal stability

The effect of bentonite on the heat resistance of samples can be compared and analyzed by thermal weight loss experiments on BS/ESMC composites with different mass fractions of BS. From the curve shown in Figure 6 and the data presented in Table 2, it can be seen that as the content of bentonite increases, the heat resistance of the sample material is improved, which can be concluded by the obvious increase of the initial thermal decomposition temperature and the residual amount of the system at 1,000°C. The improvement in heat resistance may be explained as follows: first, there is a strong interaction between the epoxy resin macromolecular chain and the bentonite layer. The strong interface bonding limits the thermal movement of the molecular chain and increases its thermal decomposition temperature. Second, as an inorganic material, the elements such as Si and Al contained in the bentonite composition have excellent thermal conductivity, which can radiate heat in time and protect the internal structure of the material from damage. Finally, the bentonite layer has a barrier effect. It can not only block the conduction of external heat to the inside of the material but also prevent the degradation of epoxy resin from spreading out, which can also lead to an increase in its thermal decomposition temperature. All in all, bentonite can improve the heat resistance of composite materials.

The TG curves of the representative BS/ESMC composites samples.

The TG data of the representative BS/ESMC composites samples

| Content of BS | θ i (°C) | θ max (°C) | θ f (°C) | ω(C·R) (%) | |

|---|---|---|---|---|---|

| Peak 1 | Peak 2 | ||||

| 0 | 344 | 378 | 745 | 795 | 39 |

| 1.5 | 345 | 370 | 743 | 789 | 47 |

| 2.5 | 346 | 371 | 746 | 785 | 49 |

| 5 | 349 | 375 | 745 | 782 | 52 |

| 10 | 355 | 370 | 744 | 782 | 63 |

θ i – initial decomposition temperature (system weight loss 5%); θ max – temperature of maximum weight loss rate; θ f – termination temperature; ω(C·R) – residual carbon at 1,000°C.

3.5 Fire-retardant properties

As shown in Figure 7, the LOI value of the sample measured in the experiment was 25.6 when the bentonite sample was not added. Under the same test conditions, the greater the oxygen index, the greater the amount of oxygen required for the sample to burn. Moreover, under the same oxygen concentration, the worse the burning degree, the better the flame-retardant performance of the sample. With the increase of the content of bentonite, the LOI showed an upward trend, indicating that BS has a flame-retardant effect on ESMC composites. However, when the added content of BS reached 2.5 wt%, the increase in LOI of the system gradually became flat, indicating that the flame-retardant effect of BS on the system is limited.

Effect of the content of the bentonite on oxygen index of samples.

4 Conclusion

The BS/ESMC composites were successfully prepared. Compared with ESMC composites reinforced by CaCO3 particles, mechanical properties, thermal stability, and fire-retardant properties of BS-reinforced composites have been significantly improved. In this article, the optimal bentonite content determined is 1.5%. The following are the major observations of this study:

The increase in the bentonite content improves the tensile strength, flexural strength, and impact strength of the composite, but the excessive BS content leads to a decrease. When the BS content is 1.5%, the BS/ESMC composite reaches the highest tensile strength, flexural strength, and impact strength of 77.68, 230.75, and 108.07 MPa, respectively. Compared with 0% bentonite/ESMC composite, the tensile strength, flexural strength, and impact strength were increased by 24.15%, 26.56%, and 51.33%, respectively.

Through the thermal weight loss experiment, it can be seen that with the increase of the bentonite content, the heat resistance of the sample material has been improved. As the amount of bentonite added is 10%, the residual carbon content of the system increases by 61.54%. This is because elements (Si, Al) contained in the bentonite component can dissipate heat in time. In addition, bentonite restricts the movement of resin molecular chains, which also leads to an increase in the thermal decomposition temperature.

BS has a flame-retardant effect on ESMC composite materials. As the content of bentonite in the system increases, the LOI increased from 25.6 to 27.9. However, excessive BS has limited flame-retardant effect on the system.

-

Author contributions: Jingke Wang: writing – original draft, writing – review and editing, formal analysis; Zongyi Deng: conceptualization – ideas; Zhixiong Huang: funding acquisition, supervision; Zhuangzhuang Li: writing – review and editing, investigation; Jianglai Yue: investigation.

-

Funding information: The authors state no funding involved.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The data used to support the findings of this study are available from the first author upon request.

References

(1) Chen MF, Liu YH. Preparation and properties of unsaturated polyester resin sheet molding compound. J Appl Chem. 2018;35(10):1222–6.Search in Google Scholar

(2) Tatsuya O. Sheet molding compound for compression molding. JP2002338712. Kitahata; 2002.Search in Google Scholar

(3) Atkins KE. New developments in low pressure SMC. Modern plastics international, 51th annual SPI-RP conference, session 2-D; 1996.Search in Google Scholar

(4) Neat JA. Low cost molding with low pressure molding compound. 49th Annual SPI-RP conference, session 13-D.Search in Google Scholar

(5) Lisa M, Abrams MS. Processing studies in sheet molding compound compression molding. USA: The Ohio State University; 2001.Search in Google Scholar

(6) Butler KI. Low pressure sheet molding compounds. US Patent 5998510. Kingsville, OH; 1999 Dec 7.Search in Google Scholar

(7) Silva-Nieto RJ, Fisher BC, Birley AW. Rheological characterization of unsaturated polyester resin sheet molding compound. Polym Eng Sci. 1981;21(8):499–506.10.1002/pen.760210810Search in Google Scholar

(8) Shinohara H. Approach on practical applications of phenolic sheet molding compound (SMC). J Netw Polym Jpn. 2010;32(1):43–8.Search in Google Scholar

(9) Gafarova VA, Bazrova JV, Teltsova LZ. Formation of the structure and properties of epoxy-based composite materials. Mater Sci Forum. 2020;992:336–40.10.4028/www.scientific.net/MSF.992.336Search in Google Scholar

(10) Verma V. Tensile and fracture properties of epoxy alumina composite: role of particle size and morphology. J Polym Res. 2020;27(12):1–14.10.1007/s10965-020-02359-zSearch in Google Scholar

(11) Manh TV, Woon JD, Joon YH, Kang SY, Nguyen VG, Thai H, et al. Using rutile TiO2 nanoparticles reinforcing high density polyethylene resin. Int J Polym Sci. 2015;2014:1–7.10.1155/2014/758351Search in Google Scholar

(12) Kadir C, Mahmut B. Investigation of mechanical properties of basalt particle-filled SMC composites. Int J Polym Sci. 2016;2016:1–6.10.1155/2016/1231606Search in Google Scholar

(13) Noh YJ, Lee YC, Hwang T. Synergistic effect in mechanical properties of sheet molding compound via simultaneous incorporation of glass fiber and glass bubble fillers. Compos Res. 2018;31(1):8–11.Search in Google Scholar

(14) Li J, Huang ZX, Zhao Y. Study on flame-retardance of sheet molding compounds and its preparing. J Funct Mater. 2008;10:39.Search in Google Scholar

(15) Goswami DN, Jha PC, Mahato K. Shellac as filler in sheet moulding compound. Indian J Chem Technol. 2004;11(1):67–73.Search in Google Scholar

(16) Asadi A, Miller M, Sultana S, Moon RJ, Kalaitzidou K. Introducing cellulose nanocrystals in sheet molding compounds (SMC). Compos Part A-Appl S. 2016;88:206–15.10.1016/j.compositesa.2016.05.033Search in Google Scholar

(17) Hasegawa N. Preparation and mechanical properties of polypropylene-clay hybrids using a maleic anhydride-modified polypropylene oligomer. J Appl Polym Sci. 1998;67(1):87–92.10.1002/(SICI)1097-4628(19980103)67:1<87::AID-APP10>3.0.CO;2-2Search in Google Scholar

(18) Carrado KA. Synthetic organo- and polymer–clays: preparation, characterization, and materials applications. Appl Clay Sci. 2000;17(1/2):1–23.10.1016/S0169-1317(00)00005-3Search in Google Scholar

(19) Brown JM, Curliss D, Vaia RA. Thermoset-layered silicate nanocomposites. Quaternary ammonium montmorillonite with primary diamine cured epoxies. Chem Mater. 2000;12(11):3376–84.10.1021/cm000477+Search in Google Scholar

(20) Takashi M, Kenji O, Youichi N, Teruo K. Modification of biodegradable resin by clay nanocomposite. Seikei-Kako. 2002;14(9):604–10.10.4325/seikeikakou.14.604Search in Google Scholar

(21) Sabaa MW, Abdelhakim M, Soliman SMA. Characterization and application of cured epoxy resin reinforced with montmorillonite. B Mater Sci. 2020;43:1.10.1007/s12034-020-02100-ySearch in Google Scholar

(22) ASTM D7264M-15. Standard test method for flexural properties of polymer matrix composite materials; 2010.Search in Google Scholar

(23) ASTM D3039M-17. Standard test method for tensile properties of polymer matrix composite materials; 2008.Search in Google Scholar

(24) ASTM D7136M-20. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event; 2007.Search in Google Scholar

(25) Cai LF, Yang J, Lin ZY. Interface of filled polymer/glass bead composites. Eng Plast Appl. 2003;31(3):66–9.Search in Google Scholar

(26) ASTM D2863-2017. Standard test method for measuring the minimum oxygen concentration to support candle-like combustion of plastics (oxygen index).Search in Google Scholar

(27) Alsaadi M, Erkliğ A. A comparative study on mode I and mode II interlaminar behavior of borax and SiC particles toughened S-glass fabric/epoxy composite. Arab J Sci Eng. 2017;42(13):1–11.10.1007/s13369-017-2649-1Search in Google Scholar

(28) Alsaadi M, Erkliğ A. Effect of perlite particle contents on delamination toughness of S-glass fiber reinforced epoxy matrix composites. Compos Part B-Eng. 2018;141:182–90.10.1016/j.compositesb.2017.12.059Search in Google Scholar

(29) Zhao JQ, Wang SQ. A study on curing characteristics of epoxy resin as matrix for FRP with infrared spectrum method. Acta Mater Compos Sin. 1989;1:26–31.Search in Google Scholar

© 2021 Jingke Wang et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Research on the mechanism of gel accelerator on gel transition of PAN solution by rheology and dynamic light scattering

- Gel point determination of gellan biopolymer gel from DC electrical conductivity

- Composite of polylactic acid and microcellulose from kombucha membranes

- Synthesis of highly branched water-soluble polyester and its surface sizing agent strengthening mechanism

- Fabrication and characterization of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) modified with nano-montmorillonite biocomposite

- Fabrication of N-halamine polyurethane films with excellent antibacterial properties

- Formulation and optimization of gastroretentive bilayer tablets of calcium carbonate using D-optimal mixture design

- Sustainable nanocomposite films based on SiO2 and biodegradable poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH) for food packaging

- Evaluation of physicochemical properties of film-based alginate for food packing applications

- Electrically conductive and light-weight branched polylactic acid-based carbon nanotube foams

- Structuring of hydroxy-terminated polydimethylsiloxane filled by fumed silica

- Surface functionalization of nanostructured Cu/Ag-deposited polypropylene fiber by magnetron sputtering

- Influence of composite structure design on the ablation performance of ethylene propylene diene monomer composites

- MOFs/PVA hybrid membranes with enhanced mechanical and ion-conductive properties

- Improvement of the electromechanical properties of thermoplastic polyurethane composite by ionic liquid modified multiwall carbon nanotubes

- Natural rubber latex/MXene foam with robust and multifunctional properties

- Rheological properties of two high polymers suspended in an abrasive slurry jet

- Two-step polyaniline loading in polyelectrolyte complex membranes for improved pseudo-capacitor electrodes

- Preparation and application of carbon and hollow TiO2 microspheres by microwave heating at a low temperature

- Properties of a bovine collagen type I membrane for guided bone regeneration applications

- Fabrication and characterization of thermoresponsive composite carriers: PNIPAAm-grafted glass spheres

- Effect of talc and diatomite on compatible, morphological, and mechanical behavior of PLA/PBAT blends

- Multifunctional graphene nanofiller in flame retarded polybutadiene/chloroprene/carbon black composites

- Strain-dependent wicking behavior of cotton/lycra elastic woven fabric for sportswear

- Enhanced dielectric properties and breakdown strength of polymer/carbon nanotube composites by coating an SrTiO3 layer

- Analysis of effect of modification of silica and carbon black co-filled rubber composite on mechanical properties

- Polytriazole resins toughened by an azide-terminated polyhedral oligomeric silsesquioxane (OADTP)

- Phosphine oxide for reducing flammability of ethylene-vinyl-acetate copolymer

- Study on preparation and properties of bentonite-modified epoxy sheet molding compound

- Polyhedral oligomeric silsesquioxane (POSS)-modified phenolic resin: Synthesis and anti-oxidation properties

- Study on structure and properties of natural indigo spun-dyed viscose fiber

- Biodegradable thermoplastic copolyester elastomers: Methyl branched PBAmT

- Investigations of polyethylene of raised temperature resistance service performance using autoclave test under sour medium conditions

- Investigation of corrosion and thermal behavior of PU–PDMS-coated AISI 316L

- Modification of sodium bicarbonate and its effect on foaming behavior of polypropylene

- Effect of coupling agents on the olive pomace-filled polypropylene composite

- High strength and conductive hydrogel with fully interpenetrated structure from alginate and acrylamide

- Removal of methylene blue in water by electrospun PAN/β-CD nanofibre membrane

- Theoretical and experimental studies on the fabrication of cylindrical-electrode-assisted solution blowing spinning nanofibers

- Influence of l-quebrachitol on the properties of centrifuged natural rubber

- Ultrasonic-modified montmorillonite uniting ethylene glycol diglycidyl ether to reinforce protein-based composite films

- Experimental study on the dissolution of supercritical CO2 in PS under different agitators

- Experimental research on the performance of the thermal-reflective coatings with liquid silicone rubber for pavement applications

- Study on controlling nicotine release from snus by the SIPN membranes

- Catalase biosensor based on the PAni/cMWCNT support for peroxide sensing

- Synthesis and characterization of different soybean oil-based polyols with fatty alcohol and aromatic alcohol

- Molecularly imprinted electrospun fiber membrane for colorimetric detection of hexanoic acid

- Poly(propylene carbonate) networks with excellent properties: Terpolymerization of carbon dioxide, propylene oxide, and 4,4ʹ-(hexafluoroisopropylidene) diphthalic anhydride

- Polypropylene/graphene nanoplatelets nanocomposites with high conductivity via solid-state shear mixing

- Mechanical properties of fiber-reinforced asphalt concrete: Finite element simulation and experimental study

- Applying design of experiments (DoE) on the properties of buccal film for nicotine delivery

- Preparation and characterizations of antibacterial–antioxidant film from soy protein isolate incorporated with mangosteen peel extract

- Preparation and adsorption properties of Ni(ii) ion-imprinted polymers based on synthesized novel functional monomer

- Rare-earth doped radioluminescent hydrogel as a potential phantom material for 3D gel dosimeter

- Effects of cryogenic treatment and interface modifications of basalt fibre on the mechanical properties of hybrid fibre-reinforced composites

- Stable super-hydrophobic and comfort PDMS-coated polyester fabric

- Impact of a nanomixture of carbon black and clay on the mechanical properties of a series of irradiated natural rubber/butyl rubber blend

- Preparation and characterization of a novel composite membrane of natural silk fiber/nano-hydroxyapatite/chitosan for guided bone tissue regeneration

- Study on the thermal properties and insulation resistance of epoxy resin modified by hexagonal boron nitride

- A new method for plugging the dominant seepage channel after polymer flooding and its mechanism: Fracturing–seepage–plugging

- Analysis of the rheological property and crystallization behavior of polylactic acid (Ingeo™ Biopolymer 4032D) at different process temperatures

- Hybrid green organic/inorganic filler polypropylene composites: Morphological study and mechanical performance investigations

- In situ polymerization of PEDOT:PSS films based on EMI-TFSI and the analysis of electrochromic performance

- Effect of laser irradiation on morphology and dielectric properties of quartz fiber reinforced epoxy resin composite

- The optimization of Carreau model and rheological behavior of alumina/linear low-density polyethylene composites with different alumina content and diameter

- Properties of polyurethane foam with fourth-generation blowing agent

- Hydrophobicity and corrosion resistance of waterborne fluorinated acrylate/silica nanocomposite coatings

- Investigation on in situ silica dispersed in natural rubber latex matrix combined with spray sputtering technology

- The degradable time evaluation of degradable polymer film in agriculture based on polyethylene film experiments

- Improving mechanical and water vapor barrier properties of the parylene C film by UV-curable polyurethane acrylate coating

- Thermal conductivity of silicone elastomer with a porous alumina continuum

- Copolymerization of CO2, propylene oxide, and itaconic anhydride with double metal cyanide complex catalyst to form crosslinked polypropylene carbonate

- Combining good dispersion with tailored charge trapping in nanodielectrics by hybrid functionalization of silica

- Thermosensitive hydrogel for in situ-controlled methotrexate delivery

- Analysis of the aging mechanism and life evaluation of elastomers in simulated proton exchange membrane fuel cell environments

- The crystallization and mechanical properties of poly(4-methyl-1-pentene) hard elastic film with different melt draw ratios

- Review Articles

- Aromatic polyamide nonporous membranes for gas separation application

- Optical elements from 3D printed polymers

- Evidence for bicomponent fibers: A review

- Mapping the scientific research on the ionizing radiation impacts on polymers (1975–2019)

- Recent advances in compatibility and toughness of poly(lactic acid)/poly(butylene succinate) blends

- Topical Issue: (Micro)plastics pollution - Knowns and unknows (Guest Editor: João Pinto da Costa)

- Simple pyrolysis of polystyrene into valuable chemicals

- Topical Issue: Recent advances of chitosan- and cellulose-based materials: From production to application (Guest Editor: Marc Delgado-Aguilar)

- In situ photo-crosslinking hydrogel with rapid healing, antibacterial, and hemostatic activities

- A novel CT contrast agent for intestinal-targeted imaging through rectal administration

- Properties and applications of cellulose regenerated from cellulose/imidazolium-based ionic liquid/co-solvent solutions: A short review

- Towards the use of acrylic acid graft-copolymerized plant biofiber in sustainable fortified composites: Manufacturing and characterization

Articles in the same Issue

- Research Articles

- Research on the mechanism of gel accelerator on gel transition of PAN solution by rheology and dynamic light scattering

- Gel point determination of gellan biopolymer gel from DC electrical conductivity

- Composite of polylactic acid and microcellulose from kombucha membranes

- Synthesis of highly branched water-soluble polyester and its surface sizing agent strengthening mechanism

- Fabrication and characterization of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) modified with nano-montmorillonite biocomposite

- Fabrication of N-halamine polyurethane films with excellent antibacterial properties

- Formulation and optimization of gastroretentive bilayer tablets of calcium carbonate using D-optimal mixture design

- Sustainable nanocomposite films based on SiO2 and biodegradable poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH) for food packaging

- Evaluation of physicochemical properties of film-based alginate for food packing applications

- Electrically conductive and light-weight branched polylactic acid-based carbon nanotube foams

- Structuring of hydroxy-terminated polydimethylsiloxane filled by fumed silica

- Surface functionalization of nanostructured Cu/Ag-deposited polypropylene fiber by magnetron sputtering

- Influence of composite structure design on the ablation performance of ethylene propylene diene monomer composites

- MOFs/PVA hybrid membranes with enhanced mechanical and ion-conductive properties

- Improvement of the electromechanical properties of thermoplastic polyurethane composite by ionic liquid modified multiwall carbon nanotubes

- Natural rubber latex/MXene foam with robust and multifunctional properties

- Rheological properties of two high polymers suspended in an abrasive slurry jet

- Two-step polyaniline loading in polyelectrolyte complex membranes for improved pseudo-capacitor electrodes

- Preparation and application of carbon and hollow TiO2 microspheres by microwave heating at a low temperature

- Properties of a bovine collagen type I membrane for guided bone regeneration applications

- Fabrication and characterization of thermoresponsive composite carriers: PNIPAAm-grafted glass spheres

- Effect of talc and diatomite on compatible, morphological, and mechanical behavior of PLA/PBAT blends

- Multifunctional graphene nanofiller in flame retarded polybutadiene/chloroprene/carbon black composites

- Strain-dependent wicking behavior of cotton/lycra elastic woven fabric for sportswear

- Enhanced dielectric properties and breakdown strength of polymer/carbon nanotube composites by coating an SrTiO3 layer

- Analysis of effect of modification of silica and carbon black co-filled rubber composite on mechanical properties

- Polytriazole resins toughened by an azide-terminated polyhedral oligomeric silsesquioxane (OADTP)

- Phosphine oxide for reducing flammability of ethylene-vinyl-acetate copolymer

- Study on preparation and properties of bentonite-modified epoxy sheet molding compound

- Polyhedral oligomeric silsesquioxane (POSS)-modified phenolic resin: Synthesis and anti-oxidation properties

- Study on structure and properties of natural indigo spun-dyed viscose fiber

- Biodegradable thermoplastic copolyester elastomers: Methyl branched PBAmT

- Investigations of polyethylene of raised temperature resistance service performance using autoclave test under sour medium conditions

- Investigation of corrosion and thermal behavior of PU–PDMS-coated AISI 316L

- Modification of sodium bicarbonate and its effect on foaming behavior of polypropylene

- Effect of coupling agents on the olive pomace-filled polypropylene composite

- High strength and conductive hydrogel with fully interpenetrated structure from alginate and acrylamide

- Removal of methylene blue in water by electrospun PAN/β-CD nanofibre membrane

- Theoretical and experimental studies on the fabrication of cylindrical-electrode-assisted solution blowing spinning nanofibers

- Influence of l-quebrachitol on the properties of centrifuged natural rubber

- Ultrasonic-modified montmorillonite uniting ethylene glycol diglycidyl ether to reinforce protein-based composite films

- Experimental study on the dissolution of supercritical CO2 in PS under different agitators

- Experimental research on the performance of the thermal-reflective coatings with liquid silicone rubber for pavement applications

- Study on controlling nicotine release from snus by the SIPN membranes

- Catalase biosensor based on the PAni/cMWCNT support for peroxide sensing

- Synthesis and characterization of different soybean oil-based polyols with fatty alcohol and aromatic alcohol

- Molecularly imprinted electrospun fiber membrane for colorimetric detection of hexanoic acid

- Poly(propylene carbonate) networks with excellent properties: Terpolymerization of carbon dioxide, propylene oxide, and 4,4ʹ-(hexafluoroisopropylidene) diphthalic anhydride

- Polypropylene/graphene nanoplatelets nanocomposites with high conductivity via solid-state shear mixing

- Mechanical properties of fiber-reinforced asphalt concrete: Finite element simulation and experimental study

- Applying design of experiments (DoE) on the properties of buccal film for nicotine delivery

- Preparation and characterizations of antibacterial–antioxidant film from soy protein isolate incorporated with mangosteen peel extract

- Preparation and adsorption properties of Ni(ii) ion-imprinted polymers based on synthesized novel functional monomer

- Rare-earth doped radioluminescent hydrogel as a potential phantom material for 3D gel dosimeter

- Effects of cryogenic treatment and interface modifications of basalt fibre on the mechanical properties of hybrid fibre-reinforced composites

- Stable super-hydrophobic and comfort PDMS-coated polyester fabric

- Impact of a nanomixture of carbon black and clay on the mechanical properties of a series of irradiated natural rubber/butyl rubber blend

- Preparation and characterization of a novel composite membrane of natural silk fiber/nano-hydroxyapatite/chitosan for guided bone tissue regeneration

- Study on the thermal properties and insulation resistance of epoxy resin modified by hexagonal boron nitride

- A new method for plugging the dominant seepage channel after polymer flooding and its mechanism: Fracturing–seepage–plugging

- Analysis of the rheological property and crystallization behavior of polylactic acid (Ingeo™ Biopolymer 4032D) at different process temperatures

- Hybrid green organic/inorganic filler polypropylene composites: Morphological study and mechanical performance investigations

- In situ polymerization of PEDOT:PSS films based on EMI-TFSI and the analysis of electrochromic performance

- Effect of laser irradiation on morphology and dielectric properties of quartz fiber reinforced epoxy resin composite

- The optimization of Carreau model and rheological behavior of alumina/linear low-density polyethylene composites with different alumina content and diameter

- Properties of polyurethane foam with fourth-generation blowing agent

- Hydrophobicity and corrosion resistance of waterborne fluorinated acrylate/silica nanocomposite coatings

- Investigation on in situ silica dispersed in natural rubber latex matrix combined with spray sputtering technology

- The degradable time evaluation of degradable polymer film in agriculture based on polyethylene film experiments

- Improving mechanical and water vapor barrier properties of the parylene C film by UV-curable polyurethane acrylate coating

- Thermal conductivity of silicone elastomer with a porous alumina continuum

- Copolymerization of CO2, propylene oxide, and itaconic anhydride with double metal cyanide complex catalyst to form crosslinked polypropylene carbonate

- Combining good dispersion with tailored charge trapping in nanodielectrics by hybrid functionalization of silica

- Thermosensitive hydrogel for in situ-controlled methotrexate delivery

- Analysis of the aging mechanism and life evaluation of elastomers in simulated proton exchange membrane fuel cell environments

- The crystallization and mechanical properties of poly(4-methyl-1-pentene) hard elastic film with different melt draw ratios

- Review Articles

- Aromatic polyamide nonporous membranes for gas separation application

- Optical elements from 3D printed polymers

- Evidence for bicomponent fibers: A review

- Mapping the scientific research on the ionizing radiation impacts on polymers (1975–2019)

- Recent advances in compatibility and toughness of poly(lactic acid)/poly(butylene succinate) blends

- Topical Issue: (Micro)plastics pollution - Knowns and unknows (Guest Editor: João Pinto da Costa)

- Simple pyrolysis of polystyrene into valuable chemicals

- Topical Issue: Recent advances of chitosan- and cellulose-based materials: From production to application (Guest Editor: Marc Delgado-Aguilar)

- In situ photo-crosslinking hydrogel with rapid healing, antibacterial, and hemostatic activities

- A novel CT contrast agent for intestinal-targeted imaging through rectal administration

- Properties and applications of cellulose regenerated from cellulose/imidazolium-based ionic liquid/co-solvent solutions: A short review

- Towards the use of acrylic acid graft-copolymerized plant biofiber in sustainable fortified composites: Manufacturing and characterization