Abstract

The quartz fiber-reinforced epoxy resin-based composites (QFRECs) were fabricated by resin transfer molding (RTM), and then the effect of laser ablation on the structure and dielectric properties of the prepared composite was investigated. The FTIR, XRD, and SEM analyses show that the thermal decomposition, pyrolysis, carbonization, graphitization, and ablation occurred on the surface of the epoxy resin under laser irradiation. The in situ produced carbon endows the QFREC with an improved dielectric constant, which increases maximally from 3.3 to 4.5 in the range of 7–17 GHz under the energy intensity of 226 W·cm−2. Compared with short-time irradiation (5 s), long-time irradiation (10 s) exhibits a greater impact on the dielectric constant due to the formation of crystal graphite at prolonged high temperature. Meanwhile, the rough and deep pits are inclined to form onthe surface of the long-time irradiative composite. These findings provide guidance for the practical application of QFREC as wave-transmitting materials.

1 Introduction

Polymer-based composite has been widely used in the fields of communication and telemetry due to its characteristic merits of process efficiency, excellent dielectric properties, good environmental resistance, and low cost (1,2,3). The wave permeability, an important parameter of wave-transmitting composite, not only depended on the inherent characteristics of raw materials but also mainly affected by the service environment. In practical use, the wave-transmitting material may be subjected to long-term high-temperature service caused by high-speed air flow, strong electronic confrontation, and laser ablation (4,5,6). The microstructure and the composition of polymer inevitably change in some extreme cases on account of its poor intrinsic thermal property, which will result in serious deterioration of wave permeability. This severely harmed the stability and reliability of polymer-based composites and may cause unacceptable performance degradation of wave-transmitting materials (6,7). In consideration that the wave permeability is often determined by electromagnetic parameters of materials, the effect of application environments on the functional parameters of polymer-based wave-transmitting composite is necessary to be investigated systematically.

As the wave permeability is directly related to the dielectric parameters (dielectric constant ε and dielectric loss δ) of the material, the dielectric property is considered as one of the most important criteria for evaluating the wave transmission (8). In general, low ε and δ of wave-transmitting material often result in good wave transmission due to weak interfacial polarization, electron polarization, and dipole polarization (9). So, the quartz fiber-reinforced polymer resin composite (QFRPC) has attracted great attention owing to its low ε and tg δ (loss angle tangent), as well as good mechanical and thermal properties (10). However, the polymer matrix can easily decompose into gas volatile and produce carbonization zone under high-temperature ablation process (11,12,13,14,15,16). Although the wave-transmitting variation of QFRPC under high temperature caused by rapid speed air flow has been investigated in depth and systematically, few researches focused on the effect of laser ablation on its dielectric property. In fact, the laser ablation might be the most probably encountered destruction for composite in the future. Under the laser ablation, the surface temperature of composite in the local region abruptly increases and results in oxidation of the organic compound matrix (11,12,13). The ablated surface can turn into carbon compounds, including the formation of splitting carbon residue (17,18,19), and simultaneously eject carbon monoxide, carbon dioxide, and water vapor. The produced carbon compounds can form crystalline graphite under continuous laser ablation (20,21,22,23). The power intensity and time of laser ablation inevitable determine the graphitization degree and microstructure of ablated surface, which mainly affect the conductivity and electromagnetic wave attenuation capacities of wave-transmitting material (24). However, it is a great challenge to clearly understand the relationship between laser ablation and wave permeability of QFRPC due to the complex ablative mechanism and rigorous conditions.

Herein, quartz/epoxy composite, the most commonly used wave-transmitting material, was first fabricated via resin transfer molding (RTM) (25,26). Then, the laser ablation experiment was carried out on the prepared composite under two conditions of the same laser energy, i.e., the power intensity of 226 W·cm−2 for 10 s irradiation and the power intensity of 452 W·cm−2 for 5 s irradiation. The analysis of morphology shows that the epoxy resin undergoes ablation, and in situ formed the graphitized carbon with “sea-island” structure on the ablated surface, resulting in the increased dielectric constant of the material. Compared with the ablation of 452 W·cm−2 for 5 s, the ablation of 226 W·cm−2 for 10 s results in higher graphitization degree and dielectric constant.

2 Experimental section

2.1 Materials

JC/T 2244-2014 Quartz fiber cloth woven from C-type Quartz fiber with the average diameter of 7.5 μm, linear density of 190 tex, and density of 2.2 g·cm−3 was provided by Hubei Feilihua Quartz glass Co. Ltd. (Jingzhou, China). The poly CC135 epoxy resin with the epoxy equivalent of 0.48–0.54 mol·100 g−1 and W-93 acted as a curing agent were supplied by Guangzhou Jiuying Chemical Materials Co., Ltd. (Guangzhou, China).

2.2 Preparation of the quartz/epoxy composite

Quartz/epoxy composite was prepared by the resin transfer molding (RTM), and according to the shape of the finished product, a certain size of quartz fiber cloth was cut for manual layering. To obtain the total height of the composite of 7 cm, the stacked layers are set about 50. The quartz fiber was put in the mold and the resin of 20 mPa·s was injected. After the resin infiltrates the quartz fiber completely, the composites were cured at 130°C for 24 h. The mass fraction of the fiber in the composites was 65 ± 2 wt%.

2.3 Laser ablation

The ablative carbonization experiment of quartz/epoxy composite was carried out by 2 kW near-infrared commercial solid laser device (homemade instrument, Nd: YAG, wavelength 1,064 nm), which has uniform laser intensity in the 20 mm diameter beam area. To realize full ablative carbonization of the material surface, the laser beam acting on the material surface is 20 mm in diameter, slightly larger than 18 mm in diameter of the material. To obtain the effects of laser parameters on the dielectric constant after ablative carbonization of materials, different laser heat flux and irradiation time were selected in the experiment under the same laser energy applied on the surface of materials, as shown in Table 1.

Experimental laser parameters

| No. | Laser energy (kJ) | Laser power (W) | Energy intensity (kJ·cm−2) | Power intensity (W·cm−2) | Irradiation time (s) | Spot size (mm) |

|---|---|---|---|---|---|---|

| 1 | 14.2 | 1,420 | 2.26 | 452 | 5 | 20 |

| 2 | 7.1 | 710 | 2.26 | 226 | 10 | 20 |

2.4 Characterization

The thermogravimetric analysis (TGA) was performed on a thermogravimetric analyzer (Pyris1, Perkin-Elmer, USA). The dielectric property of composites was obtained by the precision impedance analyzer (HDMS-1000). The surface morphologies of the ablated composite were observed by using a field emission scanning electron microscope (SEM) (JSM-6700F) at an accelerating voltage of 5.0 kV. The samples were coated with a thin layer of gold beforehand. Wide angel X-ray diffraction (XRD) measurements were performed on a Y-2000X diffractometer (40 kV, 40 mA) with Cu (wavelength = 0.1542 nm). The recorded region went from 10° to 70° with the scanning speed of 5°·min−1. The ablated composites were prepared with KBr by pressing and tested on a Nicolet 6700 Fourier-transform infrared spectroscopy analyzer (Thermo Fisher Scientific). The spectra were obtained in the wave number range of 4,000–700 cm−1 by averaging 16 scans with a resolution of 2 cm−1. The dielectric constant and loss were measured by a high Q cylindrical resonant cavity test set at the frequency range from 7 to 17 GHz. The testing was conducted on a cylindrical specimen with a diameter of 50 mm and a thickness of 3 mm.

3 Results and discussion

3.1 Morphology analysis

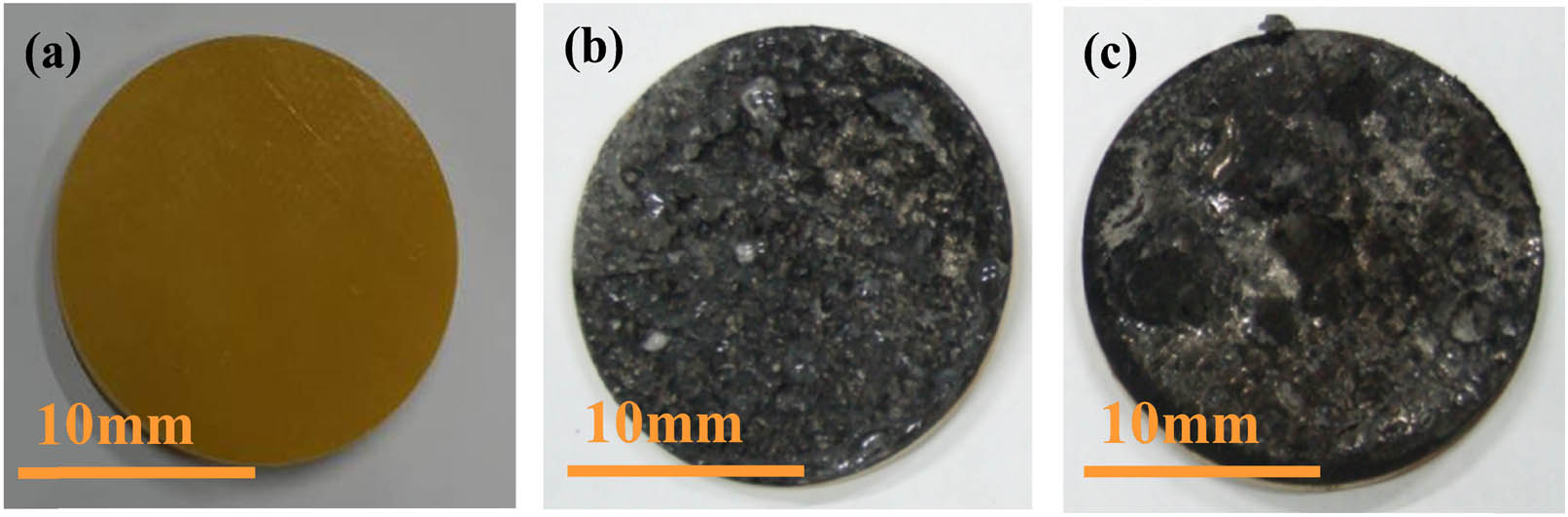

The digital photographs of the prepared quartz/epoxy composite before and after laser ablation are shown in Figure 1. The quartz/epoxy sample exhibits a uniform surface with light yellow, which is the characteristic of cured epoxy matrix composite. The black appearance of the samples after laser ablation indicates that serious carbonization occurs on the ablative surface. Closer observation reveals the carbonization layer is rough, bulging, and nondense, and lots of potholes existed in the surface of the ablated samples. This is due to the nondensification of the ablative products formed by laser heat flow, as well as the thermal decomposition and pyrolysis of resin matrix during the process to produce gas, so that the quartz fiber layer is no longer glued between layers. Although the laser intensity in the beam area is uniformity, the temperatures of the sample in center and edge position are actually different due to the heat conduction. In spite of this, nearly uniform morphologies of the samples in SEM images suggest that the difference of temperature can be neglected, which may be attributed to the short irradiation time (5–10 s). Compared with that of the ablation under 452 W·cm−2 for 5 s, the ablated sample of 226 W·cm−2 for 10 s exhibits a deeper pit and rougher surface. It indicates that the carbonization of epoxy resin is influenced not only by the energy intensity of the laser but also by the ablation mode. For the case of the same laser energy intensity of 2.26 kJ·cm−2, the damage of quartz/epoxy composite under long-time ablation is more serious than that of short-time ablation. This may be related to the combination of the low thermal conductivity of the epoxy resin and the high thermal stability of the quartz fiber.

Digital photographs of the prepared quartz/epoxy composite before (a) and after laser ablation with 452 W·cm−2 power intensity for 5 s (b) and 226 W·cm−2 for 10 s (c).

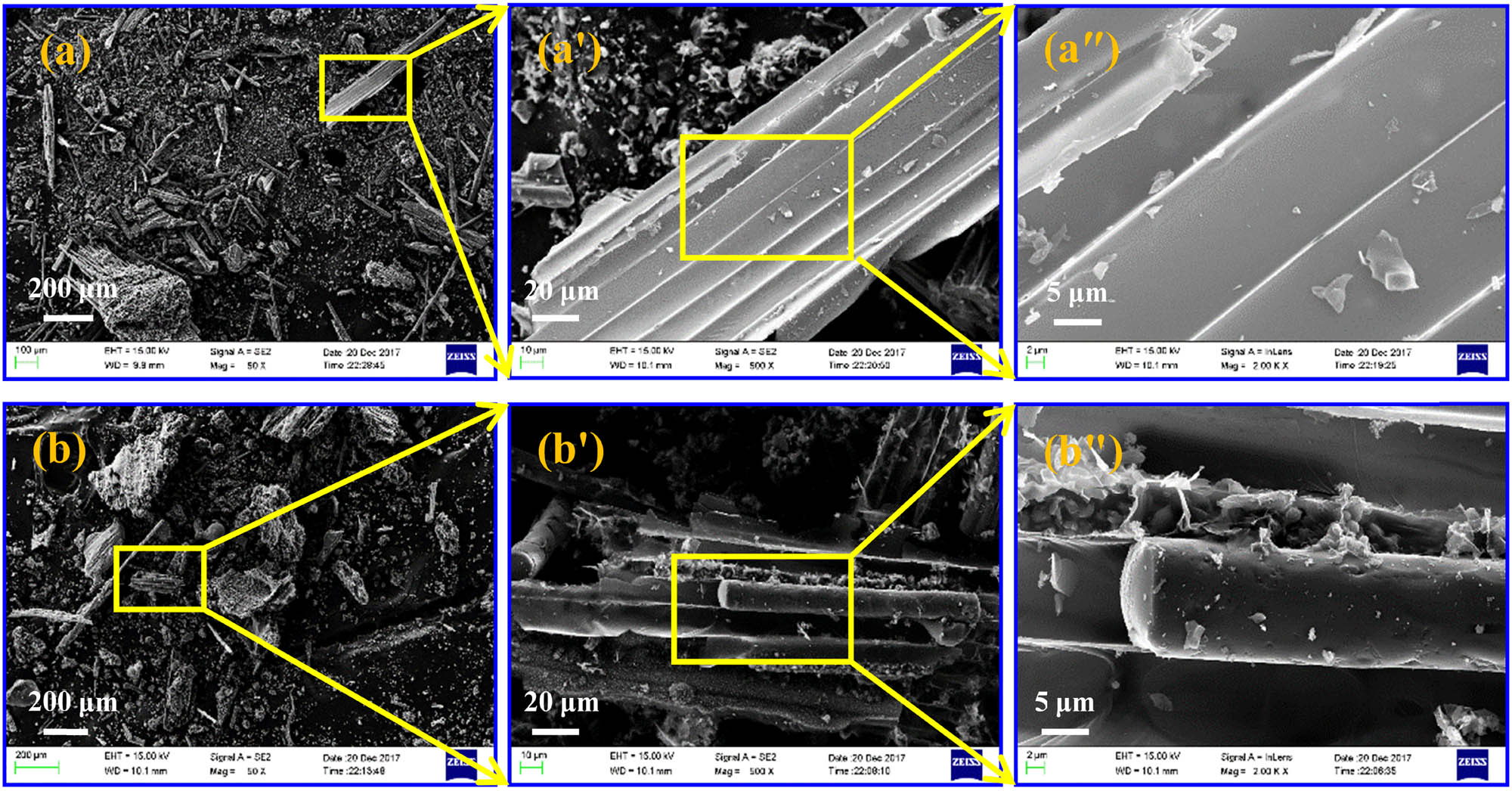

To better understand the morphologic difference of quartz/epoxy composite under the two ablative models, the scanning electron microscopy (SEM) of quartz/epoxy composite surface after laser ablation was carried out and the corresponding results are shown in Figure 2. Lots of little bits and pieces are observed in the ablated surface of quartz/epoxy composite, which is attributed to the ablative products from epoxy resin. By comparing Figure 2a with Figure 2b, it can be seen that the ablative fragments under 226 W·cm−2 power intensity for 10 s are larger and looser than that of 452 W·cm−2 for 5 s. This indicates long-time ablative action at low energy is more detrimental to the quartz/epoxy composite than high-power intensity but short-time ablation, which is consistent with the macro-observation from Figure 1. Although the large number of ablative debris appeared in the enlarged images of both samples (Figure 2a’, a”, b’, and b”) are attached to the quartz fibers, the fibers are separated from each other. It manifests that the quartz fiber cloth has been obviously broken due to the thermal damage and rapid melting under laser irradiation.

SEM images of sample under different the ablative conditions: (a) 452 W·cm−2 for 5 s and (b) 226 W·cm−2 for 10 s.

3.2 Structure analysis

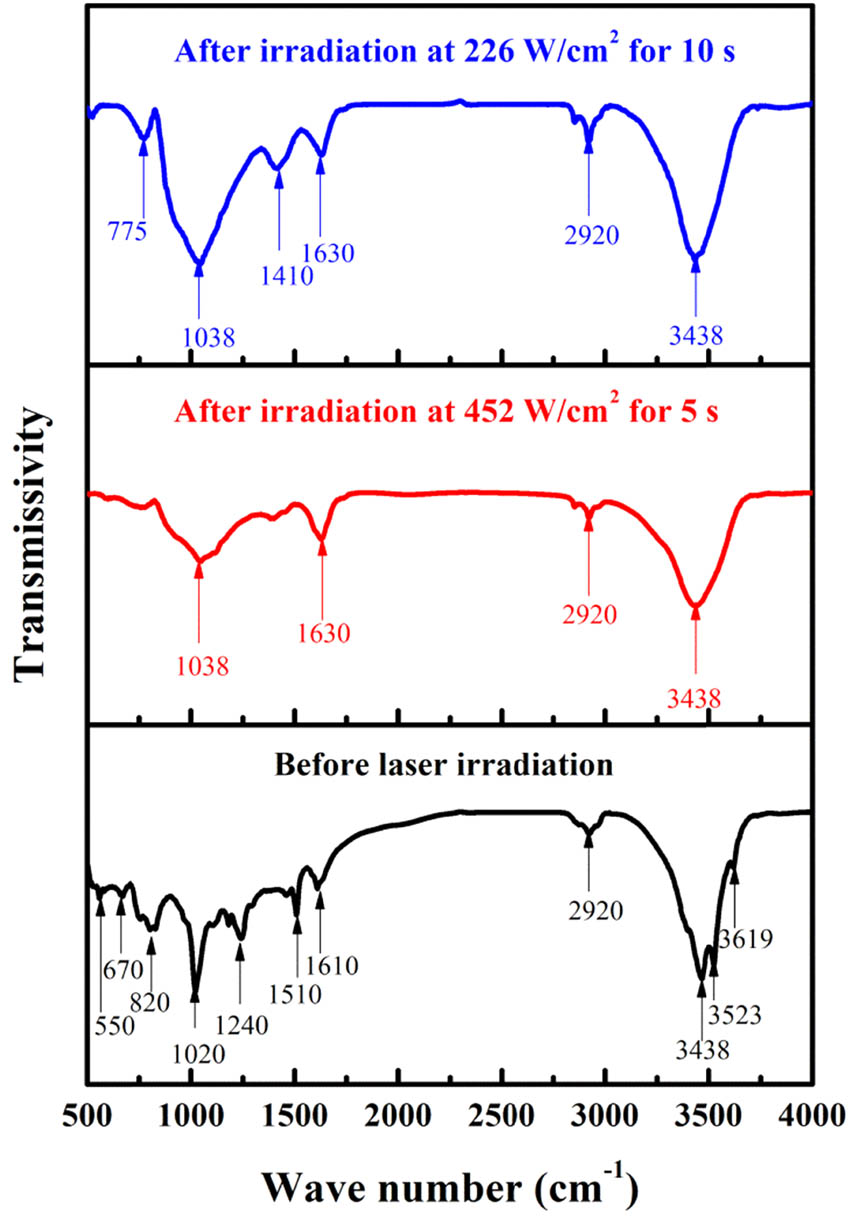

The Fourier-transform infrared (FTIR) spectra of the quartz/epoxy composite before and after laser ablation are shown in Figure 3. The presence of numerous absorption peaks in the original composite sample, especially in the fingerprint region, suggests the existence of a large number of organic groups in epoxy resin. However, most of these peaks including C–O–C group (absorption peak at 1,020 cm−1), tertiary alcohol (1,240 cm−1), and benzene ring (1,510 cm−1) completely disappeared after laser ablation. Nevertheless, the absorption peaks at 3,438, 2,920, and 1,630 cm−1 still existed in the spectra of the ablated samples, which are assigned to –OH, –CH2, and C═C groups. This indicates that most oxygen-containing groups are eliminated from epoxy resin after laser ablation, and the ablation product contains C═C, C–OH, and C–H groups. Compared with that of laser irradiation under 452 W·cm−2 for 5 s, the composite irradiated under 226 W·cm−2 for 10 s exhibits strong absorption at 1,410 and 775 cm−1, assigning to stretching vibration and bending vibration outside benzene ring surface of C–H. The difference in spectra between various laser ablative conditions displays that more organic-functional groups existed in the sample of 5 s irradiation compared with that of 10 s irradiation. It implies the surface ablation at high power intensity is more serious than that of low power intensity. This may be explained by the fact that high-power intensity of laser irradiation results in high temperate on the sample surface, which leads to complete decomposition of epoxy resin. Therefore, it may conclude that high-power intensity leads to sufficient ablation on the surface, but the irradiation is relatively shallow. The ablation under low-power intensity is just the opposite and exhibits inadequate decomposition on the surface, but deeper irradiation pit.

FTIR spectra of the quartz/epoxy composite before and after laser ablation.

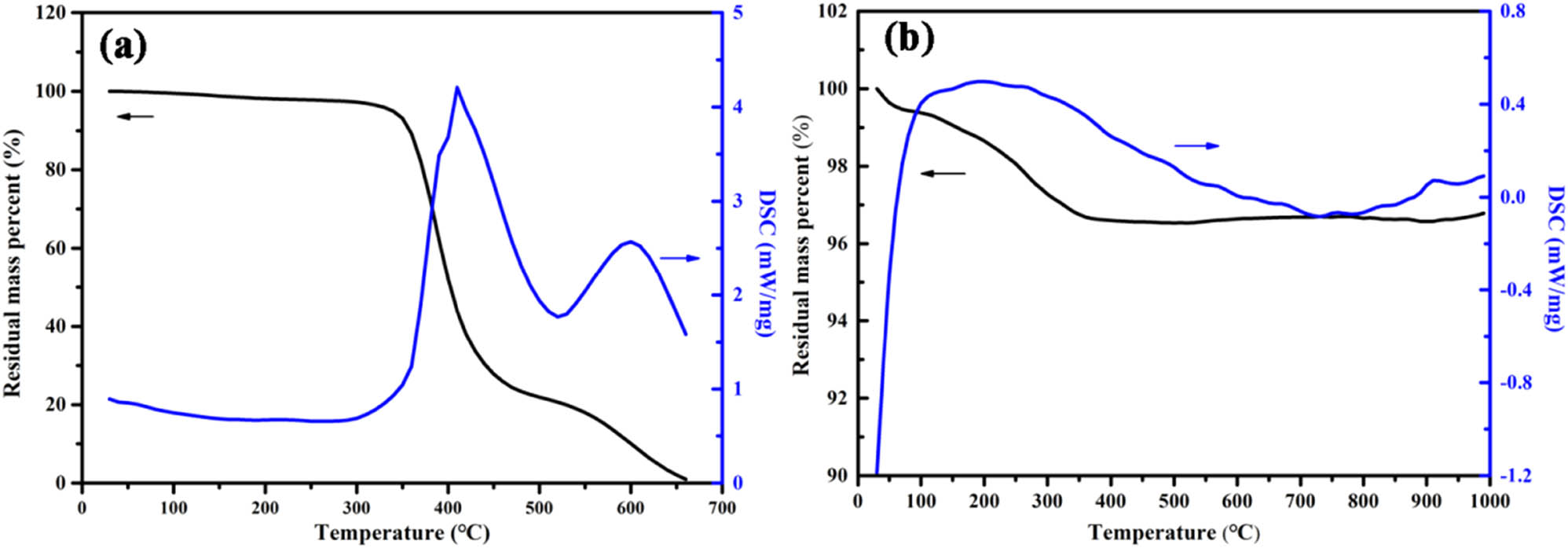

To better explore the ablative mechanism of the prepared composite, the thermal analysis of epoxy resin and quartz fiber was carried out under air conditions by using a simultaneous thermal analyzer, and the corresponding TG and DSC curves are shown in Figure 4. Three mass loss stages are observed in the TG curve of epoxy resin. The mass loss of the first stage from room temperature to 310°C is about 2.9%, while no obvious absorption peak exists on the DSC curve within this range. This suggests that the mass loss in the first stage is attributed to the volatilization of annex such as absorbed water and other small molecules in epoxy resin. Rapid mass loss of epoxy resin occur in the second stage. The mass residual rate declines from 97.1% to 27.8% when the temperature rises further to 450°C. Combining with the obvious exothermic peak that appeared in the DSC curve at 410°C, the mass loss at this stage is mainly ascribed to the thermal degradation and decomposition. In this stage, the chemical bond of epoxy resin breaks gradually as the temperature increases, forming the volatile matter including H2O (gaseous), CO, and CO2. The third stage from 450°C to 660°C exhibits the moderate mass loss rate, and the final mass residual is only 1%. Meanwhile, the medium exothermic peak also appears on the curve of DSC. This may be attributed to the further decomposition of material with high chemical bonds and oxidation of the residual carbon. Compared with the second stage, the mass loss rate of this stage is relatively low. This indicates that the serious ablation and maximum mass loss of epoxy resin occurs near 400°C. Unlike epoxy resin, the quartz fiber shows excellent thermal stability. Only 3% mass loss is observed below 300°C, which may be attributed to the volatilization of absorbed water. Thereafter, almost no mass loss has been detected until 1,000°C. This is because the decomposition temperatures of SiO2, the main ingredient of quartz fiber, exceed 2,000°C. Combining with the small exothermic and endothermic fluctuations in the DSC curve, it implies that the quartz fiber has hardly changed during the laser ablation. In conclusion, the laser ablation mainly affects the composition of epoxy resin rather than quartz fiber, although the quartz fiber may rapidly melt during the laser irradiation.

TG and DSC curves of epoxy resin (a) and quartz fiber (b).

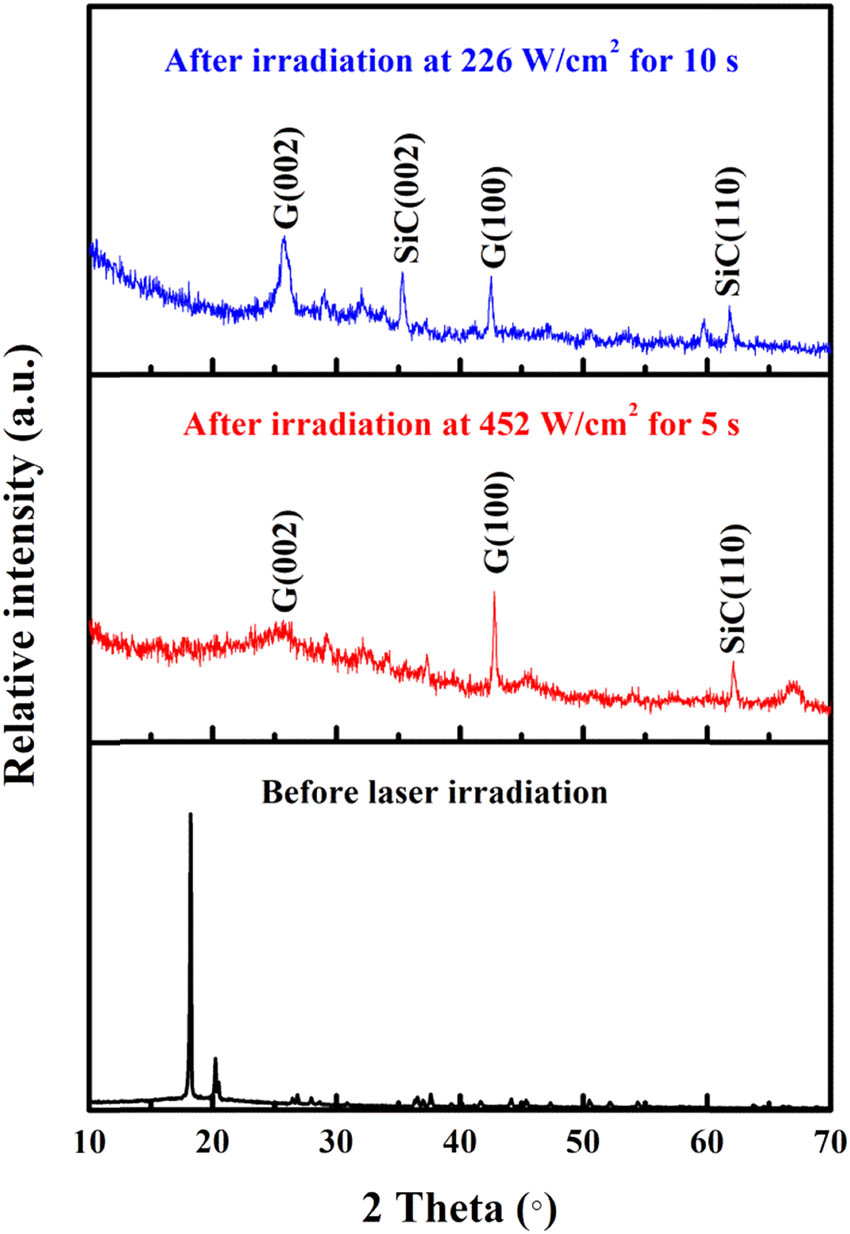

X-ray diffraction (XRD) is a universal method to test the microcrystalline structure of substances, such as grain size and crystallization degree. The XRD diffraction pattern of quartz/epoxy composite before and after laser irradiation is shown in Figure 5. The obvious difference exists in the XRD diffraction pattern between the initial composite and the ablated samples. Two sharp diffraction peaks at 2θ = 18° and 21° can be observed in the initial composite. However, these peaks disappeared from the diffraction spectra of the ablated samples, and some new peaks appeared at 2θ = 26.6° and 44.6°, assigning to graphite (002) (G (002)) and graphite (100) (G (100)) lattice plane (XRD PDF standard card No. 75-1621). This indicates that the carbonization reaction occurred in the prepared composites under laser irradiation. The relatively wide diffraction peak of G (002) lattice plane under the condition of 5 s irradiation exhibits the characteristics of a typical bread peak and “disorderly layer structure” microcrystal. However, the corresponding peak under the condition of 10 s irradiation is relatively narrow, showing a higher degree of crystallization. The degree of graphitization (G) is often used to describe the crystallization degree of carbon materials. The corresponding expression is shown in Eq. 1:

where d 002 (nm) is the layer spacing calculated by the main characteristic peak of G (002) lattice plane in the XRD spectrum.

The surface XRD spectra of quartz/epoxy composite.

By means of the XRD spectrum analysis software JADE6.0, the crystal plane diffraction peak spacing under the laser irradiation of 5 s and irradiation of 10 s is 0.3401 and 0.33918 nm, respectively, and the corresponding graphitization degrees calculated from the formula is 45.3% and 56.0%. It suggests that under the same laser energy intensity, long-time irradiation tends to form the high graphitization degree in the quartz/epoxy composite. The epoxy resin in quartz/epoxy composite is first decomposed to produce carbon materials under high temperature caused by laser irradiation. With the ablation time prolonging, the produced carbon material with the amorphous structure gradually turns into crystalline graphite. Because the dielectric properties and electrical conductivity of carbon materials are determined by their microstructure, the wave permeability of quartz/epoxy composite therefore mainly depends on laser irritation conditions.

In addition, the peak appeared at 2θ = 62.5° in composite after 5 s irradiation is assigned to SiC (110) (SiC (110)) (XRD PDF standard card No. 73-1749), which indicates the carbon can react with quartz fiber to form SiC crystal under the laser irritation condition. Compared with that of the 5 s laser irradiation, a relatively narrow and intensive peak appeared at 2θ = 35.6° in the composite after 10 s irradiation is assigned to SiC (002) lattice plane (SiC (002)). This further suggests that the perfect graphite and SiC crystals are formatted at high temperature for a long time.

3.3 Dielectric performance analysis

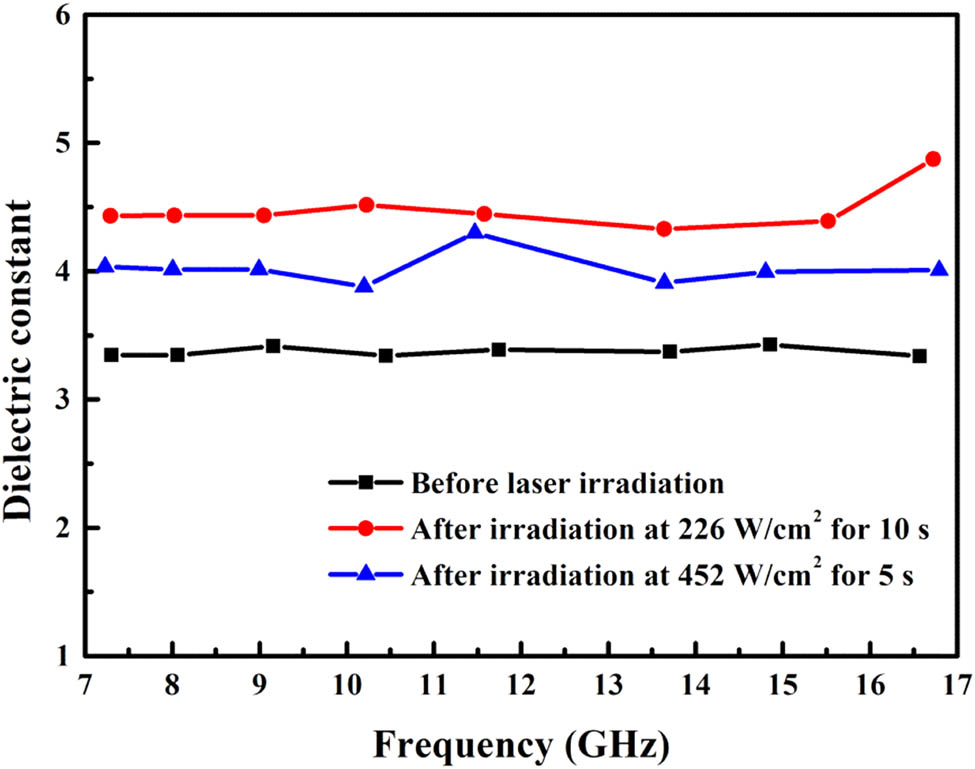

The dielectric constants of quartz/epoxy composites before and after laser ablation are shown in Figure 6. The initial quartz/epoxy composite exhibits a relatively low and stable dielectric constant of 3.3–3.4 in the range of 7–17 GHz, thanks to the excellent performance of quartz fiber and epoxy resin. However, the dielectric constant of the ablated composites increases obviously and shows some fluctuations. The average dielectric constants of both ablated composites are 4.0–4.5, which is about 21–36% higher than that of the initial composite. The improvement in the dielectric constant is attributed to the formation of highly conductive carbon/graphite materials after laser ablation. Compared with laser irradiation of 5 s, the dielectric constant under 10 s irradiation increases greatly. The maximum dielectric constant of the latter reaches 4.87 at 16.6 GHz, almost 20% increasing than that of the former. This phenomenon can be explained by the difference in graphitization degree between ablated composites. Because the electric conductivity of crystal graphite is superior to that of amorphous carbon, the quartz/epoxy composite ablated for 10 s displays a higher dielectric constant due to its relatively complete graphitization compared with that of 5 s irradiation.

The dielectric constant of the quartz/epoxy composites before and after ablation.

Overall, the quartz/epoxy composite is suitable to be used as a wave-transmitting material on account of its low and invariable dielectric constant. However, the surface structure and composition of the composite change significantly under the laser irradiation with high energy, resulting in the obvious improvement of the dielectric constant. In the case of constant energy intensity, amorphous carbonation is liable to form on the surface of ablated composite with short-time laser irradiation, while crystal graphite structure is easily formed under long-time laser irradiation, which is more harmful to wave-transmitting material.

4 Conclusion

Although low and invariable dielectric performance endows quartz/epoxy composite with extensive application in the fields of communication and telemetry, obvious improvement in dielectric performance was observed in laser ablated composite due to the existence of thermal decomposition, pyrolysis, carbonization, graphitization, and ablation on the surface of epoxy resin. Rougher and deeper pits are easier to form on the surface of composite under long-time irradiation, rather than short-time irradiation. In addition, short-time laser irradiation tends to produce amorphous carbonation on the surface of ablated composite, while crystal graphite structure is easily formed under long-time laser irradiation, which is more harmful to wave-transmitting material due to its high electrical conductivity and dielectric constant. Under the 226 W·cm−2 energy intensity of the laser irradiation, the dielectric constant of the quartz/epoxy composite ablated for 5 and 10 s increased from 3.3 to 4.0 and 4.5, respectively.

Acknowledgement

The authors thank Dr Yi Yong from Southwest University of Science for some performance testing.

-

Funding information: The authors state no funding involved.

-

Author contributions: Yongqiang Zhang: writing – original draft, methodology, formal analysis; Li Zhang: writing – review and editing, visualization; Fuli Tan: resources, formal analysis; Zhichao Xiao: writing – original draft, writing – review and editing, project administration.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article. The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

(1) Wu BY, Liu HB, Fu RL, Song XL, Su XQ, Liu XH. Epoxy-matrix composite with low dielectric constant and high thermal conductivity fabricated by HGMs/Al2O3 co-continuous skeleton. J Alloy Compd. 2021;869:159332.10.1016/j.jallcom.2021.159332Search in Google Scholar

(2) Lee DH, Lee N, Park H. Role of silica nanoparticle in multi-component epoxy composites for electrical insulation with high thermal conductivity. J Ceram Soc. 2018;101:2450–8.10.1111/jace.15395Search in Google Scholar

(3) Yang GQ, Cui JD, Ohki Y, Wang DY, Li Y, Tao K. Dielectric and relaxation properties of composites of epoxy resin and hyper branched-polyester treated nanosilica. RSC Adv. 2018;8:30669–77.10.1039/C8RA05846FSearch in Google Scholar

(4) Wang JK, Deng ZY, Huang ZX, Li ZZ, Yue JL. Study on preparation and properties of bentonite-modified epoxy sheet molding compound. e-Polymers. 2021;21:309–15.10.1515/epoly-2021-0025Search in Google Scholar

(5) Wei CH, Ma ZL, Zhu YX, Wang JW, Liu WP. Laser ablation properties of glass fiber reinforced epoxy composite under obliquely impinging air jet. Proc SPIE. 2018;11046:110462U-1–5.10.1117/12.2524440Search in Google Scholar

(6) Freeman RK, Rigby FA. Temperature-dependent reflectance of plated metals and composite materials under laser irradiation. J Thermophys Heat Transf. 2000;14:305–15.10.2514/6.1998-2482Search in Google Scholar

(7) Liu XL, Yang HX, Liu JG, Yang SY, Li YF. Preparation and characterization of quartz-fiber-cloth-reinforced,polymerization-of-monomer-reactant-type polyimide substrates with a high impact strength. J Appl Polym Sci. 2015;132(36):42358.10.1002/app.42358Search in Google Scholar

(8) Gao K, Sun BG, Yang ZY, Pan LY, Shang CY. Improvement research progress in the dielectric properties of resin matrix for wave-transparent composites. J Funct Mater. 2015;46:44–8.Search in Google Scholar

(9) Sergolle M, Castel X, Himidi M, Besnier P, Parneix P. Structural composite laminate materials with low dielectric loss: theoretical model towards dielectric characterization. Compos Part C Open Access. 2020;3:100050.10.1016/j.jcomc.2020.100050Search in Google Scholar

(10) Fu HD, Qin Y, He X, Meng XY, Zhong YY, Zou ZY. Effect of curing degree on mechanical and thermal properties of 2.5D quartz fiber reinforced boron phenolic composites. e-Polymers. 2019;19:462–9.10.1515/epoly-2019-0048Search in Google Scholar

(11) Chen JK, Perea A, Allahdadi FA. A study of laser/composite material interactions. Compos Sci Technol. 1995;54:35–44.10.1016/0266-3538(95)00034-8Search in Google Scholar

(12) Morgan RJ, Kong FM, Lepper JK. Laser-induced damage mechanisms of kevlar 49-epoxy composites. J Composite Mater. 1988;22:1026–44.10.1177/002199838802201102Search in Google Scholar

(13) Zhang JL, Wang WP, Li ZN. Laser ablation experiments of composites in vacuum and atmospheric environment. Laser Infraned. 2016;46:1134–9.Search in Google Scholar

(14) Young TO, Driscoll D. Impact of Nd-YAG laser drilled holes on the strength and stiffness of laminar flow carbon fibre reinforced composite panels. Compos Part A Appl Sci Manuf. 2002;33:1–9.10.1016/S1359-835X(01)00081-1Search in Google Scholar

(15) Benard Q, Fois M, Grisel M, Laurens P. Surface treatment of carbon/epoxy and glass/epoxy composites with an excimer laser beam. Int J Adhes Adhes. 2006;26:543–9.10.1016/j.ijadhadh.2005.07.008Search in Google Scholar

(16) Cozzens RF, Walter P, Snow AW. Laser pyrolysis of characterized cyanuratenet work polymers. J Appl Polym Sci. 1987;34:601–16.10.1002/app.1987.070340215Search in Google Scholar

(17) Yi XS, Feng Y, Pan Y, Shu XZ. Laser etching of polymer compounds. J Appl Polym Sci. 1998;67:2119–23.10.1002/(SICI)1097-4628(19980328)67:13<2119::AID-APP1>3.0.CO;2-HSearch in Google Scholar

(18) Ono S, Nakaoka S, Wang J, Niino H, Yabe A. Surface modification of carbon blackrelastomer composite by excimer laser ablation. Appl Surf Sci. 2003;127–129:821–5.10.1016/S0169-4332(97)00749-6Search in Google Scholar

(19) Feng Y, Liu ZQ, Yi XS. Marking carbon black/polypropylene compounds using a Nd:YAG laser. J Mater Sci Lett. 2001;20:517–9.10.1023/A:1010968214597Search in Google Scholar

(20) Inagaki M, Fujita K, Takeuchi Y, Oshida K, Iwata H, Konno H. Formation of graphite crystals at 1000–1200oC from mixtures of vinyl polymers with metal oxides. Carbon. 2001;39:921–9.10.1016/S0008-6223(00)00210-4Search in Google Scholar

(21) Lloyd CT, Jensen SD, Cozzens RF. Formation of graphite-containing char upon high energy laser irradiation of composite materials. Polym Mater Sci Eng. 2004;91:615–6.Search in Google Scholar

(22) Ohkawara Y, Shinada T, Fukada S, Ohshio S, Saitoh H. Synthesis of graphite using laser decomposition of SiC. J Mater Sci. 2003;38:2447–53.10.1023/A:1023909203003Search in Google Scholar

(23) Pantea D, Darmstadt H, Kaliaguine S, Roy C. Electrical conductivity of conductive carbon blacks:influence of surface chemistry and topology. Appl Surf Sci. 2003;217:181–93.10.1016/S0169-4332(03)00550-6Search in Google Scholar

(24) Li ZQ, Lu CJ, Xia ZP, Zhou Y, Luo Z. X-ray diffraction patterns of graphite and turbostratic carbon. Carbon. 2007;45:1686–95.10.1016/j.carbon.2007.03.038Search in Google Scholar

(25) Yoo HM, Kim MS, Kim BS, Kwon DJ, Choi SW. Impact and shear properties of carbon fabric/poly-dicyclopentadiene composites manufactured by vacuum‐assisted resin transfer molding. e-Polymers. 2019;19:437–43.10.1515/epoly-2019-0045Search in Google Scholar

(26) Song JH. Manufacturing method of carbon and glass fabric composites with dispersed nanofibers using vacuum-assisted resin transfer molding. e-Polymers. 2014;14:345–52.10.1515/epoly-2014-0091Search in Google Scholar

© 2021 Yongqiang Zhang et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Research on the mechanism of gel accelerator on gel transition of PAN solution by rheology and dynamic light scattering

- Gel point determination of gellan biopolymer gel from DC electrical conductivity

- Composite of polylactic acid and microcellulose from kombucha membranes

- Synthesis of highly branched water-soluble polyester and its surface sizing agent strengthening mechanism

- Fabrication and characterization of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) modified with nano-montmorillonite biocomposite

- Fabrication of N-halamine polyurethane films with excellent antibacterial properties

- Formulation and optimization of gastroretentive bilayer tablets of calcium carbonate using D-optimal mixture design

- Sustainable nanocomposite films based on SiO2 and biodegradable poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH) for food packaging

- Evaluation of physicochemical properties of film-based alginate for food packing applications

- Electrically conductive and light-weight branched polylactic acid-based carbon nanotube foams

- Structuring of hydroxy-terminated polydimethylsiloxane filled by fumed silica

- Surface functionalization of nanostructured Cu/Ag-deposited polypropylene fiber by magnetron sputtering

- Influence of composite structure design on the ablation performance of ethylene propylene diene monomer composites

- MOFs/PVA hybrid membranes with enhanced mechanical and ion-conductive properties

- Improvement of the electromechanical properties of thermoplastic polyurethane composite by ionic liquid modified multiwall carbon nanotubes

- Natural rubber latex/MXene foam with robust and multifunctional properties

- Rheological properties of two high polymers suspended in an abrasive slurry jet

- Two-step polyaniline loading in polyelectrolyte complex membranes for improved pseudo-capacitor electrodes

- Preparation and application of carbon and hollow TiO2 microspheres by microwave heating at a low temperature

- Properties of a bovine collagen type I membrane for guided bone regeneration applications

- Fabrication and characterization of thermoresponsive composite carriers: PNIPAAm-grafted glass spheres

- Effect of talc and diatomite on compatible, morphological, and mechanical behavior of PLA/PBAT blends

- Multifunctional graphene nanofiller in flame retarded polybutadiene/chloroprene/carbon black composites

- Strain-dependent wicking behavior of cotton/lycra elastic woven fabric for sportswear

- Enhanced dielectric properties and breakdown strength of polymer/carbon nanotube composites by coating an SrTiO3 layer

- Analysis of effect of modification of silica and carbon black co-filled rubber composite on mechanical properties

- Polytriazole resins toughened by an azide-terminated polyhedral oligomeric silsesquioxane (OADTP)

- Phosphine oxide for reducing flammability of ethylene-vinyl-acetate copolymer

- Study on preparation and properties of bentonite-modified epoxy sheet molding compound

- Polyhedral oligomeric silsesquioxane (POSS)-modified phenolic resin: Synthesis and anti-oxidation properties

- Study on structure and properties of natural indigo spun-dyed viscose fiber

- Biodegradable thermoplastic copolyester elastomers: Methyl branched PBAmT

- Investigations of polyethylene of raised temperature resistance service performance using autoclave test under sour medium conditions

- Investigation of corrosion and thermal behavior of PU–PDMS-coated AISI 316L

- Modification of sodium bicarbonate and its effect on foaming behavior of polypropylene

- Effect of coupling agents on the olive pomace-filled polypropylene composite

- High strength and conductive hydrogel with fully interpenetrated structure from alginate and acrylamide

- Removal of methylene blue in water by electrospun PAN/β-CD nanofibre membrane

- Theoretical and experimental studies on the fabrication of cylindrical-electrode-assisted solution blowing spinning nanofibers

- Influence of l-quebrachitol on the properties of centrifuged natural rubber

- Ultrasonic-modified montmorillonite uniting ethylene glycol diglycidyl ether to reinforce protein-based composite films

- Experimental study on the dissolution of supercritical CO2 in PS under different agitators

- Experimental research on the performance of the thermal-reflective coatings with liquid silicone rubber for pavement applications

- Study on controlling nicotine release from snus by the SIPN membranes

- Catalase biosensor based on the PAni/cMWCNT support for peroxide sensing

- Synthesis and characterization of different soybean oil-based polyols with fatty alcohol and aromatic alcohol

- Molecularly imprinted electrospun fiber membrane for colorimetric detection of hexanoic acid

- Poly(propylene carbonate) networks with excellent properties: Terpolymerization of carbon dioxide, propylene oxide, and 4,4ʹ-(hexafluoroisopropylidene) diphthalic anhydride

- Polypropylene/graphene nanoplatelets nanocomposites with high conductivity via solid-state shear mixing

- Mechanical properties of fiber-reinforced asphalt concrete: Finite element simulation and experimental study

- Applying design of experiments (DoE) on the properties of buccal film for nicotine delivery

- Preparation and characterizations of antibacterial–antioxidant film from soy protein isolate incorporated with mangosteen peel extract

- Preparation and adsorption properties of Ni(ii) ion-imprinted polymers based on synthesized novel functional monomer

- Rare-earth doped radioluminescent hydrogel as a potential phantom material for 3D gel dosimeter

- Effects of cryogenic treatment and interface modifications of basalt fibre on the mechanical properties of hybrid fibre-reinforced composites

- Stable super-hydrophobic and comfort PDMS-coated polyester fabric

- Impact of a nanomixture of carbon black and clay on the mechanical properties of a series of irradiated natural rubber/butyl rubber blend

- Preparation and characterization of a novel composite membrane of natural silk fiber/nano-hydroxyapatite/chitosan for guided bone tissue regeneration

- Study on the thermal properties and insulation resistance of epoxy resin modified by hexagonal boron nitride

- A new method for plugging the dominant seepage channel after polymer flooding and its mechanism: Fracturing–seepage–plugging

- Analysis of the rheological property and crystallization behavior of polylactic acid (Ingeo™ Biopolymer 4032D) at different process temperatures

- Hybrid green organic/inorganic filler polypropylene composites: Morphological study and mechanical performance investigations

- In situ polymerization of PEDOT:PSS films based on EMI-TFSI and the analysis of electrochromic performance

- Effect of laser irradiation on morphology and dielectric properties of quartz fiber reinforced epoxy resin composite

- The optimization of Carreau model and rheological behavior of alumina/linear low-density polyethylene composites with different alumina content and diameter

- Properties of polyurethane foam with fourth-generation blowing agent

- Hydrophobicity and corrosion resistance of waterborne fluorinated acrylate/silica nanocomposite coatings

- Investigation on in situ silica dispersed in natural rubber latex matrix combined with spray sputtering technology

- The degradable time evaluation of degradable polymer film in agriculture based on polyethylene film experiments

- Improving mechanical and water vapor barrier properties of the parylene C film by UV-curable polyurethane acrylate coating

- Thermal conductivity of silicone elastomer with a porous alumina continuum

- Copolymerization of CO2, propylene oxide, and itaconic anhydride with double metal cyanide complex catalyst to form crosslinked polypropylene carbonate

- Combining good dispersion with tailored charge trapping in nanodielectrics by hybrid functionalization of silica

- Thermosensitive hydrogel for in situ-controlled methotrexate delivery

- Analysis of the aging mechanism and life evaluation of elastomers in simulated proton exchange membrane fuel cell environments

- The crystallization and mechanical properties of poly(4-methyl-1-pentene) hard elastic film with different melt draw ratios

- Review Articles

- Aromatic polyamide nonporous membranes for gas separation application

- Optical elements from 3D printed polymers

- Evidence for bicomponent fibers: A review

- Mapping the scientific research on the ionizing radiation impacts on polymers (1975–2019)

- Recent advances in compatibility and toughness of poly(lactic acid)/poly(butylene succinate) blends

- Topical Issue: (Micro)plastics pollution - Knowns and unknows (Guest Editor: João Pinto da Costa)

- Simple pyrolysis of polystyrene into valuable chemicals

- Topical Issue: Recent advances of chitosan- and cellulose-based materials: From production to application (Guest Editor: Marc Delgado-Aguilar)

- In situ photo-crosslinking hydrogel with rapid healing, antibacterial, and hemostatic activities

- A novel CT contrast agent for intestinal-targeted imaging through rectal administration

- Properties and applications of cellulose regenerated from cellulose/imidazolium-based ionic liquid/co-solvent solutions: A short review

- Towards the use of acrylic acid graft-copolymerized plant biofiber in sustainable fortified composites: Manufacturing and characterization

Articles in the same Issue

- Research Articles

- Research on the mechanism of gel accelerator on gel transition of PAN solution by rheology and dynamic light scattering

- Gel point determination of gellan biopolymer gel from DC electrical conductivity

- Composite of polylactic acid and microcellulose from kombucha membranes

- Synthesis of highly branched water-soluble polyester and its surface sizing agent strengthening mechanism

- Fabrication and characterization of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) modified with nano-montmorillonite biocomposite

- Fabrication of N-halamine polyurethane films with excellent antibacterial properties

- Formulation and optimization of gastroretentive bilayer tablets of calcium carbonate using D-optimal mixture design

- Sustainable nanocomposite films based on SiO2 and biodegradable poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH) for food packaging

- Evaluation of physicochemical properties of film-based alginate for food packing applications

- Electrically conductive and light-weight branched polylactic acid-based carbon nanotube foams

- Structuring of hydroxy-terminated polydimethylsiloxane filled by fumed silica

- Surface functionalization of nanostructured Cu/Ag-deposited polypropylene fiber by magnetron sputtering

- Influence of composite structure design on the ablation performance of ethylene propylene diene monomer composites

- MOFs/PVA hybrid membranes with enhanced mechanical and ion-conductive properties

- Improvement of the electromechanical properties of thermoplastic polyurethane composite by ionic liquid modified multiwall carbon nanotubes

- Natural rubber latex/MXene foam with robust and multifunctional properties

- Rheological properties of two high polymers suspended in an abrasive slurry jet

- Two-step polyaniline loading in polyelectrolyte complex membranes for improved pseudo-capacitor electrodes

- Preparation and application of carbon and hollow TiO2 microspheres by microwave heating at a low temperature

- Properties of a bovine collagen type I membrane for guided bone regeneration applications

- Fabrication and characterization of thermoresponsive composite carriers: PNIPAAm-grafted glass spheres

- Effect of talc and diatomite on compatible, morphological, and mechanical behavior of PLA/PBAT blends

- Multifunctional graphene nanofiller in flame retarded polybutadiene/chloroprene/carbon black composites

- Strain-dependent wicking behavior of cotton/lycra elastic woven fabric for sportswear

- Enhanced dielectric properties and breakdown strength of polymer/carbon nanotube composites by coating an SrTiO3 layer

- Analysis of effect of modification of silica and carbon black co-filled rubber composite on mechanical properties

- Polytriazole resins toughened by an azide-terminated polyhedral oligomeric silsesquioxane (OADTP)

- Phosphine oxide for reducing flammability of ethylene-vinyl-acetate copolymer

- Study on preparation and properties of bentonite-modified epoxy sheet molding compound

- Polyhedral oligomeric silsesquioxane (POSS)-modified phenolic resin: Synthesis and anti-oxidation properties

- Study on structure and properties of natural indigo spun-dyed viscose fiber

- Biodegradable thermoplastic copolyester elastomers: Methyl branched PBAmT

- Investigations of polyethylene of raised temperature resistance service performance using autoclave test under sour medium conditions

- Investigation of corrosion and thermal behavior of PU–PDMS-coated AISI 316L

- Modification of sodium bicarbonate and its effect on foaming behavior of polypropylene

- Effect of coupling agents on the olive pomace-filled polypropylene composite

- High strength and conductive hydrogel with fully interpenetrated structure from alginate and acrylamide

- Removal of methylene blue in water by electrospun PAN/β-CD nanofibre membrane

- Theoretical and experimental studies on the fabrication of cylindrical-electrode-assisted solution blowing spinning nanofibers

- Influence of l-quebrachitol on the properties of centrifuged natural rubber

- Ultrasonic-modified montmorillonite uniting ethylene glycol diglycidyl ether to reinforce protein-based composite films

- Experimental study on the dissolution of supercritical CO2 in PS under different agitators

- Experimental research on the performance of the thermal-reflective coatings with liquid silicone rubber for pavement applications

- Study on controlling nicotine release from snus by the SIPN membranes

- Catalase biosensor based on the PAni/cMWCNT support for peroxide sensing

- Synthesis and characterization of different soybean oil-based polyols with fatty alcohol and aromatic alcohol

- Molecularly imprinted electrospun fiber membrane for colorimetric detection of hexanoic acid

- Poly(propylene carbonate) networks with excellent properties: Terpolymerization of carbon dioxide, propylene oxide, and 4,4ʹ-(hexafluoroisopropylidene) diphthalic anhydride

- Polypropylene/graphene nanoplatelets nanocomposites with high conductivity via solid-state shear mixing

- Mechanical properties of fiber-reinforced asphalt concrete: Finite element simulation and experimental study

- Applying design of experiments (DoE) on the properties of buccal film for nicotine delivery

- Preparation and characterizations of antibacterial–antioxidant film from soy protein isolate incorporated with mangosteen peel extract

- Preparation and adsorption properties of Ni(ii) ion-imprinted polymers based on synthesized novel functional monomer

- Rare-earth doped radioluminescent hydrogel as a potential phantom material for 3D gel dosimeter

- Effects of cryogenic treatment and interface modifications of basalt fibre on the mechanical properties of hybrid fibre-reinforced composites

- Stable super-hydrophobic and comfort PDMS-coated polyester fabric

- Impact of a nanomixture of carbon black and clay on the mechanical properties of a series of irradiated natural rubber/butyl rubber blend

- Preparation and characterization of a novel composite membrane of natural silk fiber/nano-hydroxyapatite/chitosan for guided bone tissue regeneration

- Study on the thermal properties and insulation resistance of epoxy resin modified by hexagonal boron nitride

- A new method for plugging the dominant seepage channel after polymer flooding and its mechanism: Fracturing–seepage–plugging

- Analysis of the rheological property and crystallization behavior of polylactic acid (Ingeo™ Biopolymer 4032D) at different process temperatures

- Hybrid green organic/inorganic filler polypropylene composites: Morphological study and mechanical performance investigations

- In situ polymerization of PEDOT:PSS films based on EMI-TFSI and the analysis of electrochromic performance

- Effect of laser irradiation on morphology and dielectric properties of quartz fiber reinforced epoxy resin composite

- The optimization of Carreau model and rheological behavior of alumina/linear low-density polyethylene composites with different alumina content and diameter

- Properties of polyurethane foam with fourth-generation blowing agent

- Hydrophobicity and corrosion resistance of waterborne fluorinated acrylate/silica nanocomposite coatings

- Investigation on in situ silica dispersed in natural rubber latex matrix combined with spray sputtering technology

- The degradable time evaluation of degradable polymer film in agriculture based on polyethylene film experiments

- Improving mechanical and water vapor barrier properties of the parylene C film by UV-curable polyurethane acrylate coating

- Thermal conductivity of silicone elastomer with a porous alumina continuum

- Copolymerization of CO2, propylene oxide, and itaconic anhydride with double metal cyanide complex catalyst to form crosslinked polypropylene carbonate

- Combining good dispersion with tailored charge trapping in nanodielectrics by hybrid functionalization of silica

- Thermosensitive hydrogel for in situ-controlled methotrexate delivery

- Analysis of the aging mechanism and life evaluation of elastomers in simulated proton exchange membrane fuel cell environments

- The crystallization and mechanical properties of poly(4-methyl-1-pentene) hard elastic film with different melt draw ratios

- Review Articles

- Aromatic polyamide nonporous membranes for gas separation application

- Optical elements from 3D printed polymers

- Evidence for bicomponent fibers: A review

- Mapping the scientific research on the ionizing radiation impacts on polymers (1975–2019)

- Recent advances in compatibility and toughness of poly(lactic acid)/poly(butylene succinate) blends

- Topical Issue: (Micro)plastics pollution - Knowns and unknows (Guest Editor: João Pinto da Costa)

- Simple pyrolysis of polystyrene into valuable chemicals

- Topical Issue: Recent advances of chitosan- and cellulose-based materials: From production to application (Guest Editor: Marc Delgado-Aguilar)

- In situ photo-crosslinking hydrogel with rapid healing, antibacterial, and hemostatic activities

- A novel CT contrast agent for intestinal-targeted imaging through rectal administration

- Properties and applications of cellulose regenerated from cellulose/imidazolium-based ionic liquid/co-solvent solutions: A short review

- Towards the use of acrylic acid graft-copolymerized plant biofiber in sustainable fortified composites: Manufacturing and characterization