Abstract

Polymer fiber reinforcement can elevate the pavement performance indicators of asphalt concrete, including low temperature crack resistance, high temperature stability, and water stability. Fiber-reinforced asphalt concrete (FRAC) is a suitable solution to improve the road performance of asphalt concrete. However, the mechanism of the fiber parameters in asphalt concrete has still not been introduced. Herein we studied the influence of fiber geometry characteristics on improving the mechanical properties of asphalt concrete through numerical simulation. The finite element method (FEM) was used to establish an elastoplastic mesoscopic model for indirect tensile test of the asphalt mixtures via ABAQUS. The best fiber length, volume ratio, diameter, and modulus were confirmed based on the simulated results. Furthermore, the indirect tensile tests were undertaken to prove the influence of polyacrylonitrile (PAN) and polyvinyl alcohol (PVA) fiber parameters on the FRAC’s splitting stability. This study fills the gap between theoretical simulations and laboratory experiments, and it is a promising solution to improve engineered FRAC road performance.

Graphical abstract

The research objectives, modeling, and tensile test strategy of fiber-reinforced asphalt concrete.

1 Introduction

As the main component of public infrastructure, road transportation construction provides efficient and convenient personnel, goods, and capital flows for modern countries (1). This has attracted wide attention to road construction and maintenance from both developing and developed societies (2). Compared with other pavement materials such as cement, sand, and gravel, asphalt pavement has the advantages of convenient construction, convenient maintenance, good driving comfort, and longer vehicle’s tire life (3). It has been widely used in high-grade pavements, especially highways or motorways. In recent years, the huge boom in traffic volume and the increase in vehicle weight have caused asphalt pavements to often exhibit cracks, rutting, water damage, and other problems (4). As time goes by, the road performance drops significantly, threatening driving safety (5).

Fiber-reinforced asphalt concrete (FRAC) is one solution to improve the performance of asphalt pavements (6). Fiber reinforcement is a technology that adds reinforcement fibers to the concrete mixture to improve its physical and mechanical properties (7,8). Relatively speaking, the other two solutions, which are perfecting the aggregate gradation and improving the asphalt performance, have shown limited improvement in the performance indicators of asphalt concrete (9,10). Since the 1950s, fiber-reinforced Portland cement concrete mixtures have been widely researched and commercialized (11). The addition of fibers to concretes has the effect of delaying concrete cracks and increasing its strength (12). It is a relatively new research topic that uses fibers to reinforce asphalt mixtures. Furthermore, current studies usually focused on experimental tests (13,14). Laboratory tests have revealed that fibers improve a series of road performance indicators, such as the rutting and fatigue resistance of asphalt mixtures (15). Previous works have demonstrated that the mechanical response mainly depends on the process of pulling out fiber from the asphalt mixture and fiber breaking performance. However, research on fiber reinforcement mechanism is insufficient, especially for asphalt concrete (16,17). Further study on fiber impact parameters is even rarer (18).

Research on the various properties of composite materials usually requires massive experiments to investigate. For the purpose of obtaining more accurate scientific data, experimental study often takes a lot of time and effort to produce a large number of samples and to characterize them. When the behavior of the material is complex, numerical methods are usually used. It is feasible, economical, and efficient to use computers for numerical simulations. The finite element method (FEM) is an effective method for developing numerical solutions to constitutive relationships or models (19). In FEM, the composite structure, i.e., FRAC, is divided into an equivalent system (20). This equivalent system contains many smaller elements, which are interconnected via boundary lines or curved surfaces at nodes (21,22). These elements have physical properties including density, Young’s modulus, Poisson’s ratio, etc. (23,24). FEM simulation can also be used to study the improvement of the mechanical properties of asphalt concrete due to parameters such as fiber length volume rate, diameter, and modulus to verify the rationality of the model against actual test results (25). Polyacrylonitrile (PAN) fiber has a more significant enhancement effect on FRAC specimens compared with other polymer fibers such as polypropylene (PP) and polyvinyl alcohol (PVA) (26). Moreover, the heat resistance of PAN is much better than that of PP and PVA fibers (27,28).

ABAQUS was used to simulate the mechanical behavior of FRAC with different fiber parameters in indirect tensile test. A two-phase material model composed of fiber and asphalt concrete matrix was used (29). The influence of fiber parameters on the maximum tensile stress at the center of the asphalt concrete was reflected by generating stress distribution cloud diagrams, extracting stress peaks, fitting stress curves, etc. Consequently, indirect tensile experiments for PAN and PVA fibers demonstrated the reasonability and accuracy of the model.

2 Experimental methods

2.1 Geometric modeling of FRAC

In order to ensure consistency between the simulation and experimental verification, MATLAB (R2018a, MathWorks, USA) was used to simulate the generation of a three-dimensional random fiber distribution in asphalt concrete when modeling. It was assumed that the cross section of the fiber was circular, and each fiber was a uniform slender cylinder, without crimping or other special shape. According to fiber length (l), diameter (d), fiber volume content (n), and sample volume (V), the total number of fibers N could be calculated. The equation for fiber number is given as:

Fibers were randomly generated in MATLAB software. The position of each fiber was composed of two endpoint coordinates. An INP file containing the coordinates and node numbers was generated. This INP file could successfully import model data into ABAQUS for the sequent numerical simulation. The size of the simulated asphalt concrete sample was a cylindrical Marshall specimen with a diameter of 101.6 mm and a height of 63.5 mm. The investigated volume ratios of fibers were 0.1%, 0.3%, and 0.5% (v/v). The fiber lengths were set as 3, 6, 9, 12, 15, and 18 mm as examples for simulated placement. The fiber diameters were set as 10, 20, 30, 40, 60, 80, 100, 120, 140, and 160 μm. The fiber modulus was set as 5,000, 10,000, 20,000, 30,000, 40,000, and 50,000 MPa.

2.2 Finite element modeling of the mechanical properties of FRAC

ABAQUS (Dassault, France) was used to simulate the mechanical behavior of FRAC with different fiber parameters in the indirect tensile test. The simulation was undertaken by a workstation with an Intel® Xeon® CPU E5-2603 @1.70 GHz and a 64 GB RAM. The size of the finite element mesh is 6 mm × 6 mm × 6 mm and its number is 2,992.

For the model, a two-phase material composed of fiber and asphalt concrete matrix was used. An elastoplastic model was used to simulate the asphalt mixture in this work. Taking PAN fibers (density of 1.12 g/cm3) with a length of 9 mm and a diameter of 20 μm as an example, assuming that each fiber was a uniform slender cylindrical structure, at a volume of 0.3% (v/v) of the standard Marshall specimen size, the calculated number of fibers was 1,885,200. Regarding the computer capability and actual experimental status, this work adopts the method of “bundling” the fibers to reduce time and cost.

In this work, 100 fibers were bundled, which reduced the required computer calculations and allowed easier convergence. The INP files from MATLAB were archived and the fiber was generated. For the matrix, the standard Marshall specimen size was adopted. The fiber used beam elements, and the matrix used C3D8R elements. The width of the upper and lower loading beads was 12.5 mm, and the inner surface was the same arc as the test piece. The contact condition used between the upper and lower loading beads and the cylindrical specimen was interaction constrain tie to limit the relative displacement. The lower loading bead was fixed in simulation. A downward displacement load was applied to the upper loading bead in Direction 2. The boundary of all other directions was also fixed. The fiber and the matrix were bound by tie, and the parts were assembled.

Among the three failure modes of the asphalt matrix, split failure belongs to I-shaped failure (30), which is also regarded as brittle zone failure. So, the elastoplastic model was used for simulation. The matrix model parameters which were obtained from the stress–strain curve of the uniaxial compression test are shown in Table 1. The loading bead was set as a rigid body and the fiber was set as an elastomer, with elastic modulus of 17 GPa.

Material properties of the fiber-reinforced asphalt concrete (FRAC) matrix

| Material model | Model item | Parameter | |

|---|---|---|---|

| Elastomer | Elastic modulus (MPa) | 1,200 | |

| Poisson ratio | 0.3 | ||

| Stress (MPa) | Strain | ||

| Plastomer | Concrete cracks in dispersion | 1.879 | 0 |

| 2.171 | 0.0005 | ||

| 2.389 | 0.0022 | ||

| 2.512 | 0.0052 | ||

| 2.541 | 0.0101 | ||

| 2.501 | 0.0163 | ||

| 2.398 | 0.0225 | ||

| 2.259 | 0.0301 | ||

| 2.007 | 0.0381 | ||

| 1.861 | 0.0454 | ||

| 1.151 | 0.0628 | ||

| Stress ratio | Strain difference | ||

| Tension stiffness | 1.0 | 0 | |

| 0 | 0.05 | ||

Following indirect tensile test (31), a loading rate of 50 mm/min was set. The load was in the displacement mode. Since the loading bead was a rigid body, a displacement load was applied at the reference point of the loading bead rigid body instead. As the boundary conditions, all degrees of freedom were restricted to the lower loading bead, and all rotational degrees of freedom and translational degrees of freedom in directions 1 and 3 were restricted to the upper loading bead. All rotational degrees of freedom were restricted for the fibers.

2.3 Experimental materials

The 70# asphalt concrete (specific compositions are shown in supporting Tables A1–A3 in Appendix) was purchased from Weilong Petroleum & Chemical Corporation, China, under the JTG E20-2011 Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering in China. The coarse aggregates were limestone, under the standard JTG E42-2005 Test Methods of Aggregate for Highway Engineering in China. All aggregates were sifted by grade to a single particle size before testing. Fibers were 1.2 dtex monofilament chopped PAN purchased from Zhongfu Shenying Carbon Fiber Co., Ltd., China and 1.7 dtex PVA fibers were purchased from Wanwei High-tech Materials Co., Ltd., China.

2.4 FRAC sample preparation

Three volume ratios (0.1%, 0.3%, and 0.5%) were selected as the fiber volume content. The fiber lengths were chosen as 6, 9, and 12 mm. With reference to T0702-2011 in standard JTG E20-2011, the Marshall specimen made by the standard compaction method was used for the test. The specimen size met the requirements of (101.6 ± 0.25 mm) × (63.5 ± 1.3 mm). Each specimen group had 3 samples. The asphalt consumption volume was 5.8%. Specifically, appropriate amounts of mineral material, asphalt, and fibers were weighed according to the ratio and heated in an oven at 145°C for 1 h. The shear mixer was preheated at about 120°C. Then, the heated materials were sequentially added to an automatic asphalt mixing machine (BH-10, Luda Construction Equipment Co., China), as shown in Figure 1a, at 145°C. Each Marshall specimen weighed about 1,180 g to meet the size requirement as the Figure A1 in Appendix presented.

The optical photos of (a) asphalt mixer, (b) Marshall electric compactor, (c) indirect tensile test machine, and (d) FRAC samples in tensile tests.

As Figure 1b demonstrates, a Marshall electric compactor (MJ-IZ, Luda Construction Equipment Co., China) was used to strike specimens 75 times per side. After the test specimens were compacted, they were measured to ensure that the height met the size of 63.5 ± 1.3 mm.

2.5 FRAC sample mechanical tests

The indirect tensile test was conducted according to T0716 in standard JTG E20-2011. As shown in Figure 1c and d, the WDW-T200 microcomputer-controlled electronic universal testing machine (Tianchen Instruments, China) was turned on, and the test piece was split on the testing machine with a loading rate of 50 mm/min. The test temperature was room temperature (25°C).

3 Results and discussions

3.1 Fiber distribution simulation

The distribution of the fibers in asphalt concrete composite material can be regarded as a random distribution in the real situation. The focus of this research was the improvement in asphalt mixture performance characteristics by fiber reinforcement and determining the influence of the fiber parameters via mechanical experiments and numerical simulation of FRAC composites (32). However, ABAQUS is unable to complete the three-dimensional random fiber formation and to realize three-dimensional random distribution model establishment, due to this software sketches for the XY plane; its built-in modules and programming languages can only be put in the direction of random fibers. Based on the Monte Carlo method and pseudo-random number generation method (33), the Rand () function in MATLAB software was used to generate fibers through random numbers. Specifically, the total number of required fibers, N, was calculated according to Eq. 1. Then, the random function Rand () of MATLAB was used to generate the starting coordinates (X 0, Y 0, and Z 0) of the fiber in the simulated specimen geometry as shown in supporting information Figure A2 in Appendix. The random functions “rand (1) × 2π” and “rand (1) × π” in the intervals [0, 2π] and [0, π] were used to generate θ and φ. Eq. 2 was used to generate the fiber’s another endpoint coordinates (X 1, Y 1, and Z 1) (34). The term θ refers to the angle between the fiber and the Z-axis, while φ refers to the angle between the fiber’s projection on the XY plane and the X-axis.

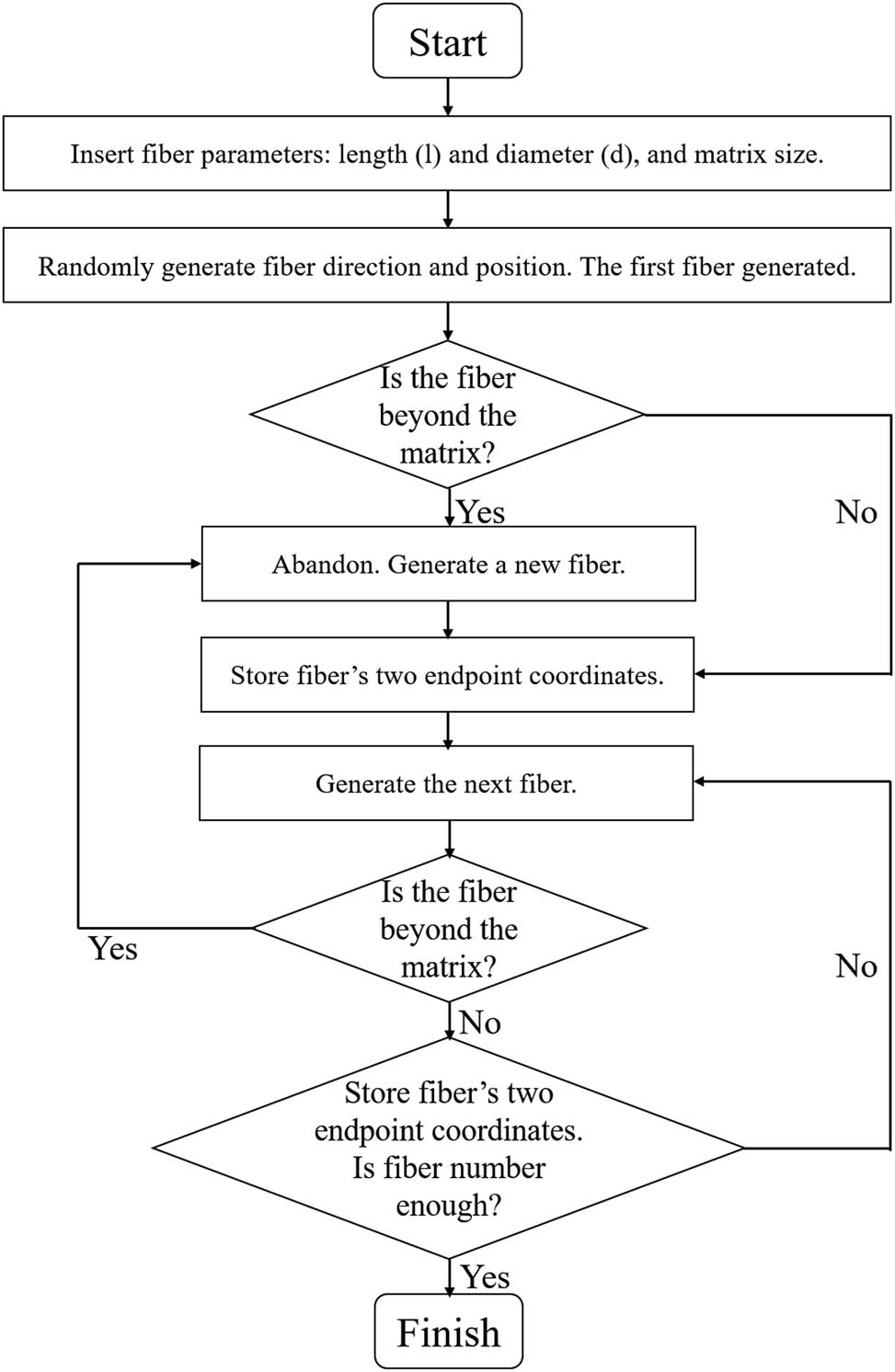

The fibers were generated one by one to ensure that both ends of each fiber were in the model interior. The specific process was as follows: The first cylindrical fiber was generated according to the determined boundary conditions and the random algorithm and then each fiber was generated in turn to determine whether it was in the model interior. If the fiber met the requirements, it was stored. Otherwise, the fiber was regenerated until the required number of fibers was generated. A flow chart of the model implemented in MATLAB is demonstrated in Figure 2. Finally, the data of both coordinates of all randomly distributed fibers were derived as INP files.

A flow chart of the model implemented in MATLAB.

The final coordinates realize a random and messy distribution of fibers in the matrix in the numerical model. The MATLAB simulated model with randomly distributed fibers is shown in Figure 3.

Random fiber distribution models with different fiber lengths. (a) 3 mm, (b) 6 mm, (c) 9 mm, (d) 12 mm, (e) 15 mm, and (f) 18 mm.

3.2 Finite element numerical modeling

In order to simplify the model to a certain extent and make the calculation more convenient and feasible, this study adopts the method of “bundling” the fibers to reduce the computational capability cost. For instance, when 100 pieces of fibers were bundled, 10 fibers

3.2.1 Numerical simulation of the mechanical properties of asphalt concrete

According to the indirect tensile test, ABAQUS software was used to establish the elastoplastic mesoscopic model of the mixture. All simulation conditions are set according to the actual indirect tensile test requirements and parameters including the sizes of cylindrical Marshall test piece and loading beads and tensile loading rate (50 mm/min). The parameters in Table 1 are determined by the stress–strain curve obtained from the uniaxial compression tests of the asphalt mixture without fiber-reinforcement. By adjusting the fiber parameters, the stress distribution cloud diagram from the model could be extracted, along with the influence of fiber parameters on the von Mises stress at the center of the asphalt concrete matrix and the average von Mises stress at the midpoint of fibers. Figure 4a demonstrates the Mises stress cloud of the model without fibers. These simulated results in Figure 4 were consistent with the previous reported experiments (34).

(a) Simulation results of von Mises stress without fibers, (b) stress in Direction 1, (c) stress in Direction 2, and (d) stress in Direction 3.

A positive value of stress is tensile stress, which is shown as red in Figure 4b–d. A negative value is compressive stress, which is shown as blue in Figure 4. It can be seen from the cloud diagram in Figure 4 that the stresses were distributed symmetrically. The central point of the vertical stress along the Direction 1 was tensile stress, the two ends were compressive stress, and the largest tensile stress point was the center of the specimen. The horizontal stress in the Direction 1 was tensile stress, and the largest tensile stress point was the center of the specimen. The vertical stress along the Direction 2 was compressive stress, while the weakest compressive stress point was at the center of the specimen. For the Direction 2, the middle of the horizontal stress was compressive stress, the two ends were tensile stress, and the weakest compressive stress point was at the center point of the specimen. For the Direction 3, the stress of all parts was tensile stress, except for compressive stress in contact with the loading bead. Therefore, the maximum stress appeared in the center of the specimen and was tensile stress, which was consistent with the theoretical situation. The value of stress at the center point of the matrix is 0.7676 MPa.

This work studies the influence of fiber length and fiber volume ratio on the stress at the center of the matrix and the average value of the fiber stress at the center point. The fiber parameters could be determined in the model based on the actual situation. The pressing speed of 50 mm/min was kept consistent with the action time of each test specimen. Test results from the finite element software could be collected through the numerical simulation results.

3.2.2 Influence of fiber length on the mechanical properties of asphalt concrete

Following the bundling method, the six fiber lengths were set from 3 to 18 mm. The polymer fiber added volume ratio was 0.3%, the fiber modulus was 17,000 MPa, the fiber diameter was 20 μm, and 100 fibers were bundled to establish a model. The calculation of the number of fibers are shown in Table 2.

Conversion of fiber numbers of different lengths under the bundling method

| Fiber length (mm) | Fiber number |

|---|---|

| 3 | 15,698 |

| 6 | 7,849 |

| 9 | 5,232 |

| 12 | 3,925 |

| 15 | 3,139 |

| 18 | 2,616 |

The modulus based on the actual fiber is usually at the GPa level (35), and the average stress at the center of the fiber is much lower than the fiber stress at failure. So, the fiber would not break and fail in FRAC. Following from Table 2, the trend diagram is shown in Figure 5a. As the fiber length increased from 0 to 6 mm, the stress at the center of the matrix decreased continuously. From 6 to 18 mm, the stress at the center of the matrix continued to ascend. In finite element analysis, the greater the von Mises stress to the specimen, the closer the stress to its failure and the smaller the residual stress (36). Thus, the material is more likely to be damaged under the same load. Therefore, according to the simulation results, when the fiber length is 6 mm, the reinforcement effect on the matrix is the best. According to the theory of the toughening mechanics model (37), the greater the stress when the fiber has not failed, the greater the energy absorbed, and better the toughening effect of the fiber on asphalt concrete. From analyzing the average value of fiber stress at the center point of different lengths, it can be concluded that the 3 and 9 mm fibers had a more obvious toughening effect. From the simulation results combined with the fitted curve, it can be seen that the fiber length in mixed concrete should not be too long, preferably from 3 to 9 mm.

(a) The stress for center point of matrix and fibers in different length fibers, and (b) the stress at the center points of the matrix and fibers for different fiber volume ratios.

The fitting curves are shown in Figure 6a and b, and the fitting equations are as follows:

where

Simulation results and non-linear fitting of fiber length against (a) the stress at the center of the matrix, (b) the average value of fiber stress at the center point, and fiber volume ratio against (c) the stress at the center of the matrix, and (d) the average value of fiber stress at the center point.

3.2.3 Influence of fiber volume ratio on the mechanical properties of asphalt concrete

The fiber volume ratio ranged from 0.1% to 0.9%, increasing in steps of 0.2%. The uniform length was fixed at 6 mm, the fiber modulus was 17,000 MPa, the fiber diameter was 20 μm, and 100 pieces were bundled to establish a model. The calculated number of fibers is shown in Table 3.

Conversion of fiber numbers with different fiber volume ratios

| Fiber volume ratio (%) | Fiber number |

|---|---|

| 0.1 | 2,616 |

| 0.3 | 7,849 |

| 0.5 | 13,080 |

| 0.7 | 18,312 |

| 0.9 | 23,544 |

Following from Table 3, the trend chart in Figure 5b shows that as the fiber volume is increased, the stress at the center of the matrix decreased first and then increased. At 0.3%, the stress at the center of the matrix was the smallest. At this time, the residual stress of the matrix was the largest, with farthest damage value which means that the specimen is the least likely to be damaged (38). Therefore, there is an optimal content value. When the content was 0.3%, the fiber had the most obvious reinforcement effect on the specimen. The average stress value of the fiber at the center point decreased first and then increases. The greater the fiber content, the greater the average stress of the fiber at the center point. According to the theory of the toughening mechanics model, the greater the stress is when the fiber has not failed, the greater the absorbed energy, and better the toughening effect of fiber on asphalt concrete (39). Therefore, when the content was 0.1%, the fiber had the effect of strengthening and toughening. When the content was 0.3%, the fiber had the best reinforcement effect on the specimen. The effect of fiber with content of more than 0.3% on the specimen was mainly toughening.

The fitting curves are shown in Figure 6c and d, and the fitting equations are as follows:

where

3.2.4 Influence of fiber diameter on the mechanical properties of asphalt concrete

In FEM, the fiber diameter increased from 10 to 200 μm with the length of 6 mm and the fiber modulus of 17,000 MPa. The number was set as 7,849 based on Tables 2 and 3.

The trend chart shown in Figure 7a demonstrated that as the fiber diameter increased, the stress at the center of the matrix decreased continuously, and the stress value decreased compared with the specimens without fiber. Average fiber stress at the center point dropped sharply when the fiber diameter increased from 10 to 40 μm. The average fiber stress at the center point dropped slowly after fiber diameter exceeded 60 μm. According to the toughening mechanics model (40), the simulated results demonstrated that coarse fibers above 60 μm played a major reinforcement role, while finer fibers below 40 μm played a toughening role.

(a) The stress at the center points of the matrix and fibers for different fiber diameters and (b) the stress for center point of matrix and fibers in different fiber modulus.

The fitting curves are shown in Figure 8a and b, and the fitting equations are as follows:

where d is the fiber diameter (μm),

Simulation results and nonlinear fitting of fiber diameters against (a) the stress at the center of the matrix, (b) the average value of fiber stress at the center point, and fiber modulus against (c) the stress at the center of the matrix, and (d) the average value of fiber stress at the center point.

3.2.5 Influence of fiber modulus on the mechanical properties of asphalt concrete

The fiber modulus was set between 1,000 and 50,000 MPa. The fiber length was fixed as 6 mm, and the fiber diameter was fixed at 20 μm. The fiber number was set as 7,849 based on Tables 2 and 3.

As the modulus increased, the stress for center point of matrix decreased sharply and then tended to increase gently. The stress value of the matrix was lower than that of the specimen without fibers. The stress for center point of matrix was the smallest when the fiber modulus was 20 GPa, which means that the specimen is least likely to be damaged. The fiber stress at the center point increased continuously, which means that the fibers play a significant role in toughening. The high modulus fiber had the best effect in improving the toughness of concrete when the average value of fiber stress increased to 50 GPa. Under this circumstance, the simulated result demonstrated that the fiber reinforcement would be the most efficient to asphalt concrete when the fiber modulus is 20–30 GPa. Furthermore, the high modulus had a more obvious effect in improving its toughness.

The fitting curves are shown in Figure 8c and d, and the fitting equations are as follows:

where E is the fiber modulus (mm),

3.3 Indirect tensile tests

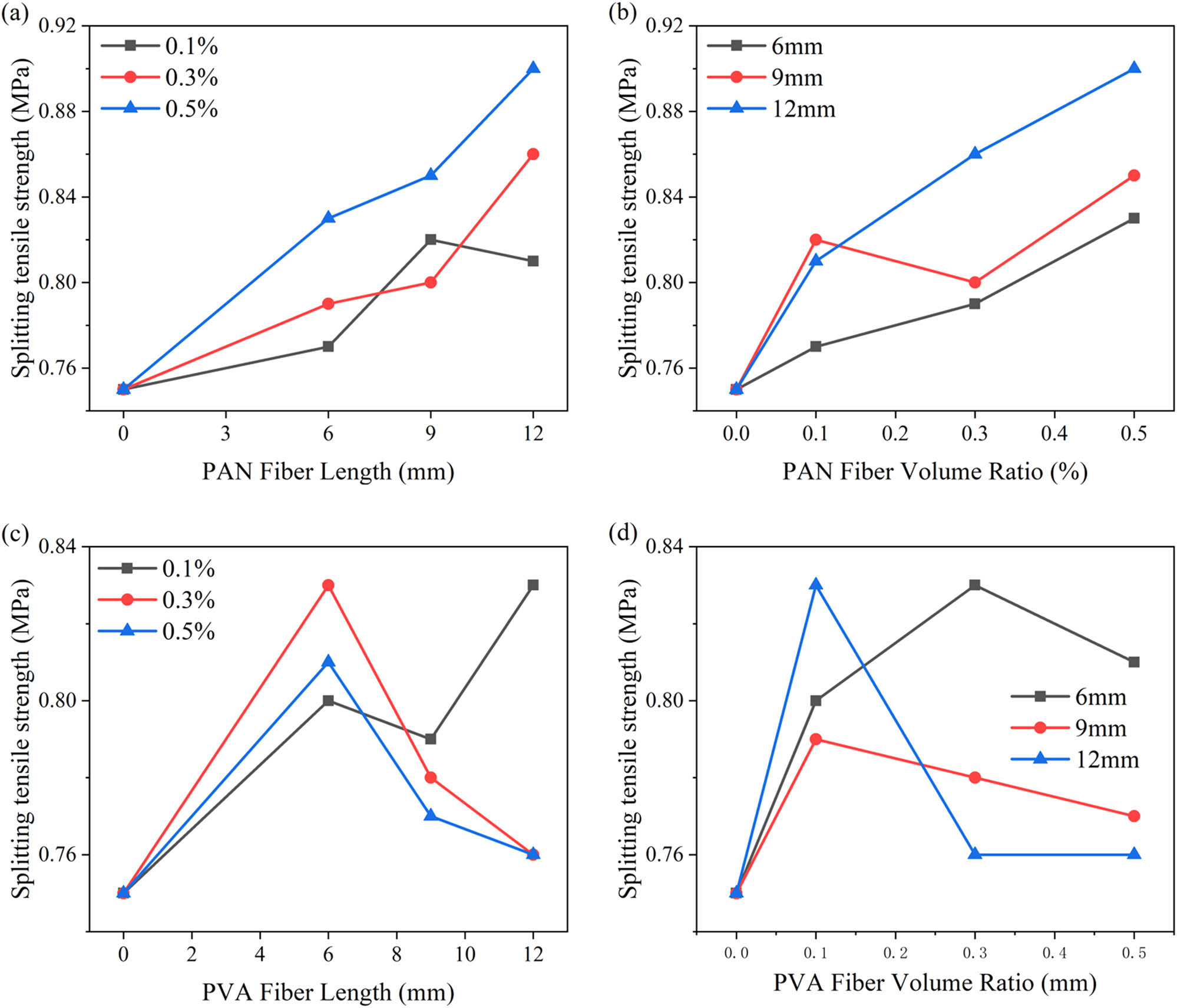

3.3.1 The influence of fiber length on the splitting tensile strength of FRAC specimens

As shown in Figure 9a and c, after adding fibers to the asphalt concrete mixture within a certain volume, the splitting tensile strength was higher than that of the specimen without fibers. This result indicates that the addition of fibers will enhance the asphalt concrete mixture to a required extent. The bonding performance among the fiber and the asphalt plays a major role in this enhancement. Furthermore, the three-dimensional distribution of the fiber prevents the generation and expansion of cracks in the asphalt concrete. The fibers that cross the crack bear the tensile force when the matrix cracks. According to the theory of composite material mechanics, it takes energy to pull out the fiber to slow down the occurrence and propagation of cracks. In addition, the fiber has a high elastic modulus, and a large quantity of fibers bridge the crack to withstand higher loads.

The influence of (a) PAN fiber length, (b) PAN fiber volume ratio, (c) PVA fiber length, and (d) PVA fiber volume ratio on the splitting tensile strength of FRAC specimens.

Compared with PVA specimens, PAN specimens had a better enhancement for asphalt concrete tensile strength. As the length of PAN fiber increased, its splitting tensile strength basically showed an upward trend. For the 0.1% fiber volume group, the splitting tensile strength boosted first and then decreased with the increase in length. For smaller fiber volume, the fiber length reached the peak at 9 mm. For 0.5% fiber volume, the 12 mm fiber length showed the greatest degree of improvement, and the improvement effect weakened as the length increased. The improvement effect gradually weakens to insignificance when the fiber volume was too large, and the fiber length was too long. The reason for this is that it is easy to self-bond under the action of asphalt due to the fiber being too long, and it is easier to produce agglomeration when the content is high. So, the improvement in the mechanical properties is weak under this scenario (41). For PVA fibers, the mechanical properties’ improvement of the 6 mm fiber length specimens was most obvious when the fiber volume was relatively high. The improvement effect weakened with the increase in the length. In the case of fiber volume at a small dose, the mechanical properties of the specimen were continuously improved with the increase in the fiber length. The 12 mm fiber specimens with 0.1% of fiber volume and 6 mm fiber specimens with 0.3% of fiber volume had the best tensile strength enhancement. The reason is that obvious shrinkage and deformation will occur when PVA monofilament exceeds 110–115°C. Asphalt mixing temperature is always far above 110°C. Second, the self-binding and agglomeration of fibers is another significant reason.

3.3.2 The influence of fiber volume on the splitting tensile strength of FRAC specimens

As shown in Figure 9b and d, 12 mm PAN fiber had the most obvious reinforcement effect on FRAC specimens. With an increase in PAN fiber volume ratio, the splitting tensile strength basically showed an upward trend. When the length was 6 mm, the improvement effect was strengthened with the increased volume, the volume reaching the peak at 0.5%. For the PVA fiber specimens, the mechanical properties increased first and then decreased with an increase in the volume. The peak was reached when the volume ratio was 0.3% for 6 mm group and the volume ratio was 0.1% for 12 mm group. The reason for this is that the fibers themselves bond and form agglomerates, so for different fiber types, the appropriate volume and fiber length should be carefully considered.

The fiber volume ratio could affect the performance of the asphalt mixture. If the fiber volume is too low, the performance of the asphalt mixture will be limited. However, it may cause uneven fiber dispersion and agglomeration if too much fiber is used, thereby affecting the performance of the asphalt mixture. If the fiber length is too short, it cannot fully reflect the “bridging effect” (42) of the fiber, while if the length is too long, the soft fiber will easily bond to itself under the asphalt coating.

4 Conclusion

Based on the simulation model of the asphalt concrete matrix center point stress and the average value of the fiber stress at the center point, fiber with a 6 mm length or with a diameter over 60 μm had the best reinforcement effect on the matrix. The fibers with lengths 3 and 9 mm or with a diameter below 40 μm had more obvious toughening effects. It could also be seen that fiber reinforcement provided a balance between the effects of strengthening and toughening when the fiber volume was 0.1%. When the fiber volume was 0.3% or the fiber modulus was 20–30 GPa, the fiber reinforcement effect on the specimen was the best. This effect was mainly toughening when the fiber volume was over 0.3% or the fiber modulus was over 30 GPa in the asphalt concrete specimen. Furthermore, the influence of fiber length, volume ratio, diameter, and modulus on the mechanical properties of FRAC was studied through indirect tensile test. The splitting tensile strength of the specimen after adding fiber was higher than that of the original asphalt concrete. PAN specimens have a better elevation than that of PVA specimens. These results prove that adding fiber has a reinforcing effect on the asphalt mixture. Considering the von Mises stress distribution diagram simulation, it was found that the distribution of tensile and compressive stresses was consistent with the theoretical situation. The error of the experimental and simulated data was within an acceptable range. The elastic–plastic model used in this work is thus reasonable and effective.

-

Funding information: This research was funded by National Key Research and Development Program from Ministry of Science and Technology of the People’s Republic of China (Grant No. 2016YFB0303104) (Sub-program 4: Preparation and Engineered Application Key Technology: Advanced Fibers and Geomaterials for Constructions).

-

Author contributions: Huan Gao: software, validation, formal analysis, investigation, resources, writing – original draft preparation, visualization; Lizhe Zhang: investigation, resources, data curation; Dongbo Zhang: validation, data curation; Tao Ji: conceptualization, project administration, funding acquisition; Jun Song: conceptualization, methodology, writing – review and editing, visualization, supervision. All authors have read and agreed to the published version of the manuscript.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The MATLAB code used in this manuscript is freely available at: https://github.com/Airslashcn/Fiber-Reinforced-Asphalt-Concrete

Appendix

FRAC specimens with different lengths and volume ratios of PAN fibers.

Schematic diagram for fiber randomly generated in MATLAB.

The 70# asphalt concrete technical index

| Materials | Penetration (25°C, 0.1 mm) | Softening point (°C) | 15°C ductility (cm) | Density (g/cm3) | Thin-film sample heating (165°C, 5 h) | |

|---|---|---|---|---|---|---|

| Weight loss (%) | Penetration ratio (%) | |||||

| Standard requirement | 60–80 | ≥46 | ≥100 | 1.01–1.05 | ≤0.8 | ≥61 |

| The 70# asphalt concrete | 67.00 | 48.50 | >100 | 1.04 | 0.28 | 86.60 |

Fine aggregate technical index for 70# asphalt concrete

| Technology index | Standard requirement | Experimental data |

|---|---|---|

| Apparent density (t/m3) |

|

26.4 |

| Durability (%) |

|

6.1 |

| Mud content (<0.075) (%) | ≤3 | 0.6 |

Coarse aggregate technical index for 70# asphalt concrete

| Technology index | Standard requirement | Experimental data |

|---|---|---|

| Apparent density (g/cm3) | ≥2.5 | 2.89 |

| Crushing value (%) | ≤26 | 19.50 |

| Attrition rate (%) | ≤28 | 22.30 |

| Water absorption (%) | ≤2 | 0.65 |

| Lamellar flake (%) | ≤10 | 8.20 |

| Adhesion to asphalt (level) | ≥5 | 5.00 |

References

(1) Colon C , Hallegatte S , Rozenberg J . Criticality analysis of a country’s transport network via an agent-based supply chain model. Nat Sustain. 2020;4:209–15. 10.1038/s41893-020-00649-4.Search in Google Scholar

(2) Pablo-Martí F , Sánchez A . Improving transportation networks: effects of population structure and decision making policies. Sci Rep. 2017;7(1):4498. 10.1038/s41598-017-04892-2.Search in Google Scholar PubMed PubMed Central

(3) vYue H , Wenjuan S , Yucheng H , Ayatollahi M , Linbing W , Jiong Z . J Cold Reg Eng. 2017;31(2):4016009. 10.1061/(ASCE)CR.1943-5495.0000116.Search in Google Scholar

(4) Van Dinh C . Anticorrosion behavior of the SiO2/Epoxy nanocomposite-concrete lining system under H2SO4 acid aqueous environment. ACS Omega. 2020;5(18):10533–42. 10.1021/acsomega.0c00828.Search in Google Scholar PubMed PubMed Central

(5) Yao A , Yu S , Li J , Di H , Wang Y . Fiber-reinforced asphalt macadam sealing with rubber particles and its ice-breaking and snow-melting properties. CICTP 2020, Proceedings. Reston, VA: American Society of Civil Engineers; 2020. p. 1485–97. 10.1061/9780784482933.127.Search in Google Scholar

(6) Souliman MI , Ashish T , Mayzan I . Mechanistic analysis and economic benefits of fiber-reinforced asphalt mixtures. J Mater Civ Eng. 2019;31(8):4019142. 10.1061/(ASCE)MT.1943-5533.0002755.Search in Google Scholar

(7) Ríos JD , Leiva C , Ariza MP , Seitl S , Cifuentes H . Analysis of the tensile fracture properties of ultra-high-strength fiber-reinforced concrete with different types of steel fibers by X-ray tomography. Mater Des. 2019;165:107582. 10.1016/j.matdes.2019.107582.Search in Google Scholar

(8) Abtahi SM , Sheikhzadeh M , Hejazi SM . Fiber-reinforced asphalt-concrete – a review. Constr Build Mater. 2010;24(6):871–7. 10.1016/j.conbuildmat.2009.11.009.Search in Google Scholar

(9) Kilić Pamuković J , Rogulj K , Dumanić D , Jajac N . A sustainable approach for the maintenance of asphalt pavement construction. Sustainability. 2020;13(1):109. 10.3390/su13010109.Search in Google Scholar

(10) Patel P . Helping concrete heal itself. C&EN Glob Enterp. 2016;94(6):29–30. 10.1021/cen-09406-scitech2.Search in Google Scholar

(11) Wu J , Liu X , Zhou H , Li L , Liu Z . Experimental and numerical study on soft-hard-soft (SHS) cement based composite system under multiple impact loads. Mater Des. 2018;139:234–57. 10.1016/j.matdes.2017.10.073.Search in Google Scholar

(12) Kekez S , Kubica J . Connecting concrete technology and machine learning: proposal for application of ANNs and CNT/concrete composites in structural health monitoring. RSC Adv. 2020;10(39):23038–48. 10.1039/D0RA03450A.Search in Google Scholar PubMed PubMed Central

(13) Noorvand H , Castro S , Underwood BS , Kaloush KE . Evaluating interaction of fibre reinforcement mechanism with mesostructure of asphalt concrete. Int J Pavement Eng. 2020;1–18. 10.1080/10298436.2020.1813286.Search in Google Scholar

(14) Haido JH , Tayeh BA , Majeed SS , Karpuzcu M . Effect of high temperature on the mechanical properties of basalt fibre self-compacting concrete as an overlay material. Constr Build Mater. 2021;268:121725. 10.1016/j.conbuildmat.2020.121725.Search in Google Scholar

(15) Lu S , Wang X , Meng Z , Deng Q , Peng F , Yu C , et al. The mechanical properties, microstructures and mechanism of carbon nanotube-reinforced oil well cement-based nanocomposites. RSC Adv. 2019;9(46):26691–702. 10.1039/C9RA04723A.Search in Google Scholar PubMed PubMed Central

(16) Shalchy F , Rahbar N . Nanostructural characteristics and interfacial properties of polymer fibers in cement matrix. ACS Appl Mater Interfaces. 2015;7(31):17278–86. 10.1021/acsami.5b04344.Search in Google Scholar PubMed

(17) Beroll P , Schmalzl S , Volkmer D . Influence of surface-modification, length and volume fraction of carbon short fibers on the mechanical properties of calcium aluminate cement systems. Mater Today Commun. 2020;25:101704. 10.1016/j.mtcomm.2020.101704.Search in Google Scholar

(18) Zhang X , Gu X , Lv J , Zhu Z , Zou X . Numerical analysis of the rheological behaviors of basalt fiber reinforced asphalt mortar using ABAQUS. Constr Build Mater. 2017;157:392–401. 10.1016/j.conbuildmat.2017.09.044.Search in Google Scholar

(19) Haido JH . Flexural behavior of basalt fiber-reinforced concrete beams: finite element simulation with new constitutive relationships. Structures. 2020;27:1876–89. 10.1016/j.istruc.2020.08.005.Search in Google Scholar

(20) Arsenie IM , Chazallon C , Duchez J-L , Mouhoubi S . Modelling of the fatigue damage of a geogrid-reinforced asphalt concrete. Road Mater Pavement Des. 2017;18(1):250–62. 10.1080/14680629.2016.1159973.Search in Google Scholar

(21) Yaman IO , Akbay Z , Aktan H . Numerical modelling and finite element analysis of stress wave propagation for ultrasonic pulse velocity testing of concrete. Comput Concr. 2006;3(6):423–37. 10.12989/cac.2006.3.6.423.Search in Google Scholar

(22) Henann DL , Bertoldi K . Modeling of elasto-capillary phenomena. Soft Matter. 2014;10(5):709–17. 10.1039/C3SM52583J.Search in Google Scholar

(23) Stempihar JJ , Souliman MI , Kaloush KE . Fiber-reinforced asphalt concrete as sustainable paving material for airfields. Transp Res Rec J Transp Res Board. 2012;2266(1):60–8. 10.3141/2266-07.Search in Google Scholar

(24) Sharan Gupta U , Dharkar A , Dhamarikar M , Choudhary A , Wasnik D , Chouhan P , et al. Study on the effects of fiber orientation on the mechanical properties of natural fiber reinforced epoxy composite by finite element method. Mater Today Proc. 2021;45:7885–93. 10.1016/j.matpr.2020.12.614.Search in Google Scholar

(25) Noorvand H , Salim R , Medina J , Stempihar J , Underwood BS . Effect of synthetic fiber state on mechanical performance of fiber reinforced asphalt concrete. Transp Res Rec J Transp Res Board. 2018;2672(28):42–51. 10.1177/0361198118787975.Search in Google Scholar

(26) Liu Y , Kumar S . Polymer/carbon nanotube nanocomposite fibers–a review. ACS Appl Mater Interfaces. 2014;6(9):6069–87. 10.1021/am405136s.Search in Google Scholar PubMed

(27) Sarvaranta L . Shrinkage of short PP and PAN fibers under hot-stage microscope. J Appl Polym Sci. 1995;56(9):1085–91. 10.1002/app.1995.070560908.Search in Google Scholar

(28) Tlaiji T , Vu XH , Michel M , Ferrier E , Larbi AS . Physical, chemical and thermomechanical characterisation of glass textile-reinforced concretes (TRC): effect of elevated temperature and of cementitious matrix nature on properties of TRC. Mater Today Commun. 2020;25:101580. 10.1016/j.mtcomm.2020.101580.Search in Google Scholar

(29) Chen F , Huang C , Wang J , Gao D . Experimental analysis on flexural-tensile performance of polyester fiber asphalt concrete. Ann Chim - Sci des Matériaux. 2019;43(2):81–8. 10.18280/acsm.430203.Search in Google Scholar

(30) Liang C , Ma J , Zhou P , Ma G , Xu X . Fracture damage properties of SBS-modified asphalt mixtures reinforced with basalt fiber after freeze-thaw cycles using the acoustic emission approach. Appl Sci. 2020;10(9):3301. 10.3390/app10093301.Search in Google Scholar

(31) Su Y-M , Hossiney N , Tia M , Bergin M . Mechanical properties assessment of concrete containing reclaimed asphalt pavement using the superpave indirect tensile strength test. J Test Eval. 2014;42(4):20130093. 10.1520/JTE20130093.Search in Google Scholar

(32) Fang Q , Zhang J . Three-dimensional modelling of steel fiber reinforced concrete material under intense dynamic loading. Constr Build Mater. 2013;44:118–32. 10.1016/j.conbuildmat.2013.02.067.Search in Google Scholar

(33) Głodkowska W , Kobaka J . Modelling of properties and distribution of steel fibres within a fine aggregate concrete. Constr Build Mater. 2013;44:645–53. 10.1016/j.conbuildmat.2013.02.037.Search in Google Scholar

(34) Zhang X , Wan C , Wang D , He L . Numerical simulation of asphalt mixture based on three-dimensional heterogeneous specimen. J Cent South Univ Technol. 2011;18(6):2201–6. 10.1007/s11771-011-0963-4.Search in Google Scholar

(35) Punith VS , Veeraragavan A . Behavior of asphalt concrete mixtures with reclaimed polyethylene as additive. J Mater Civ Eng. 2007;19(6):500–7. 10.1061/(ASCE)0899-1561(2007)19:6(500).Search in Google Scholar

(36) Chakraborty S , Kundu SP , Roy A , Adhikari B , Majumder SB . Effect of jute as fiber reinforcement controlling the hydration characteristics of cement matrix. Ind Eng Chem Res. 2013;52(3):1252–60. 10.1021/ie300607r.Search in Google Scholar

(37) Yanase K , Ju J . Toughening behavior of unidirectional fiber reinforced composites containing a crack-like flaw: matrix crack without fiber break. Int J Damage Mech. 2013;22(3):336–55. 10.1177/1056789512446519.Search in Google Scholar

(38) Sukontasukkul P , Nimityongskul P , Mindess S . Effect of loading rate on damage of concrete. Cem Concr Res. 2004;34(11):2127–34. 10.1016/j.cemconres.2004.03.022.Search in Google Scholar

(39) Niu D , Li D , Fu Q . A 3D-IFU model for characterising the pore structure of hybrid fibre-reinforced concrete. Mater Des. 2020;188:108473. 10.1016/j.matdes.2020.108473.Search in Google Scholar

(40) Liao L , Wang X , Fang P , Liew KM , Pan C . Interface enhancement of glass fiber reinforced vinyl ester composites with flame-synthesized carbon nanotubes and its enhancing mechanism. ACS Appl Mater Interfaces. 2011;3(2):534–8. 10.1021/am101114t.Search in Google Scholar PubMed

(41) Liu Y-F , Masuda C , Yuuki R . Effect of microstructural parameters on the fracture behavior of fiber-reinforced ceramics. Mech Mater. 1998;29(2):111–21. 10.1016/S0167-6636(98)00009-X.Search in Google Scholar

(42) Kawashima K , Zafra R , Sasaki T , Kajiwara K , Nakayama M . Effect of polypropylene fiber-reinforced cement composite and steel fiber-reinforced concrete for enhancing the seismic performance of bridge columns. J Earthq Eng. 2011;15(8):1194–211. 10.1080/13632469.2011.569051.Search in Google Scholar

© 2021 Huan Gao et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Research on the mechanism of gel accelerator on gel transition of PAN solution by rheology and dynamic light scattering

- Gel point determination of gellan biopolymer gel from DC electrical conductivity

- Composite of polylactic acid and microcellulose from kombucha membranes

- Synthesis of highly branched water-soluble polyester and its surface sizing agent strengthening mechanism

- Fabrication and characterization of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) modified with nano-montmorillonite biocomposite

- Fabrication of N-halamine polyurethane films with excellent antibacterial properties

- Formulation and optimization of gastroretentive bilayer tablets of calcium carbonate using D-optimal mixture design

- Sustainable nanocomposite films based on SiO2 and biodegradable poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH) for food packaging

- Evaluation of physicochemical properties of film-based alginate for food packing applications

- Electrically conductive and light-weight branched polylactic acid-based carbon nanotube foams

- Structuring of hydroxy-terminated polydimethylsiloxane filled by fumed silica

- Surface functionalization of nanostructured Cu/Ag-deposited polypropylene fiber by magnetron sputtering

- Influence of composite structure design on the ablation performance of ethylene propylene diene monomer composites

- MOFs/PVA hybrid membranes with enhanced mechanical and ion-conductive properties

- Improvement of the electromechanical properties of thermoplastic polyurethane composite by ionic liquid modified multiwall carbon nanotubes

- Natural rubber latex/MXene foam with robust and multifunctional properties

- Rheological properties of two high polymers suspended in an abrasive slurry jet

- Two-step polyaniline loading in polyelectrolyte complex membranes for improved pseudo-capacitor electrodes

- Preparation and application of carbon and hollow TiO2 microspheres by microwave heating at a low temperature

- Properties of a bovine collagen type I membrane for guided bone regeneration applications

- Fabrication and characterization of thermoresponsive composite carriers: PNIPAAm-grafted glass spheres

- Effect of talc and diatomite on compatible, morphological, and mechanical behavior of PLA/PBAT blends

- Multifunctional graphene nanofiller in flame retarded polybutadiene/chloroprene/carbon black composites

- Strain-dependent wicking behavior of cotton/lycra elastic woven fabric for sportswear

- Enhanced dielectric properties and breakdown strength of polymer/carbon nanotube composites by coating an SrTiO3 layer

- Analysis of effect of modification of silica and carbon black co-filled rubber composite on mechanical properties

- Polytriazole resins toughened by an azide-terminated polyhedral oligomeric silsesquioxane (OADTP)

- Phosphine oxide for reducing flammability of ethylene-vinyl-acetate copolymer

- Study on preparation and properties of bentonite-modified epoxy sheet molding compound

- Polyhedral oligomeric silsesquioxane (POSS)-modified phenolic resin: Synthesis and anti-oxidation properties

- Study on structure and properties of natural indigo spun-dyed viscose fiber

- Biodegradable thermoplastic copolyester elastomers: Methyl branched PBAmT

- Investigations of polyethylene of raised temperature resistance service performance using autoclave test under sour medium conditions

- Investigation of corrosion and thermal behavior of PU–PDMS-coated AISI 316L

- Modification of sodium bicarbonate and its effect on foaming behavior of polypropylene

- Effect of coupling agents on the olive pomace-filled polypropylene composite

- High strength and conductive hydrogel with fully interpenetrated structure from alginate and acrylamide

- Removal of methylene blue in water by electrospun PAN/β-CD nanofibre membrane

- Theoretical and experimental studies on the fabrication of cylindrical-electrode-assisted solution blowing spinning nanofibers

- Influence of l-quebrachitol on the properties of centrifuged natural rubber

- Ultrasonic-modified montmorillonite uniting ethylene glycol diglycidyl ether to reinforce protein-based composite films

- Experimental study on the dissolution of supercritical CO2 in PS under different agitators

- Experimental research on the performance of the thermal-reflective coatings with liquid silicone rubber for pavement applications

- Study on controlling nicotine release from snus by the SIPN membranes

- Catalase biosensor based on the PAni/cMWCNT support for peroxide sensing

- Synthesis and characterization of different soybean oil-based polyols with fatty alcohol and aromatic alcohol

- Molecularly imprinted electrospun fiber membrane for colorimetric detection of hexanoic acid

- Poly(propylene carbonate) networks with excellent properties: Terpolymerization of carbon dioxide, propylene oxide, and 4,4ʹ-(hexafluoroisopropylidene) diphthalic anhydride

- Polypropylene/graphene nanoplatelets nanocomposites with high conductivity via solid-state shear mixing

- Mechanical properties of fiber-reinforced asphalt concrete: Finite element simulation and experimental study

- Applying design of experiments (DoE) on the properties of buccal film for nicotine delivery

- Preparation and characterizations of antibacterial–antioxidant film from soy protein isolate incorporated with mangosteen peel extract

- Preparation and adsorption properties of Ni(ii) ion-imprinted polymers based on synthesized novel functional monomer

- Rare-earth doped radioluminescent hydrogel as a potential phantom material for 3D gel dosimeter

- Effects of cryogenic treatment and interface modifications of basalt fibre on the mechanical properties of hybrid fibre-reinforced composites

- Stable super-hydrophobic and comfort PDMS-coated polyester fabric

- Impact of a nanomixture of carbon black and clay on the mechanical properties of a series of irradiated natural rubber/butyl rubber blend

- Preparation and characterization of a novel composite membrane of natural silk fiber/nano-hydroxyapatite/chitosan for guided bone tissue regeneration

- Study on the thermal properties and insulation resistance of epoxy resin modified by hexagonal boron nitride

- A new method for plugging the dominant seepage channel after polymer flooding and its mechanism: Fracturing–seepage–plugging

- Analysis of the rheological property and crystallization behavior of polylactic acid (Ingeo™ Biopolymer 4032D) at different process temperatures

- Hybrid green organic/inorganic filler polypropylene composites: Morphological study and mechanical performance investigations

- In situ polymerization of PEDOT:PSS films based on EMI-TFSI and the analysis of electrochromic performance

- Effect of laser irradiation on morphology and dielectric properties of quartz fiber reinforced epoxy resin composite

- The optimization of Carreau model and rheological behavior of alumina/linear low-density polyethylene composites with different alumina content and diameter

- Properties of polyurethane foam with fourth-generation blowing agent

- Hydrophobicity and corrosion resistance of waterborne fluorinated acrylate/silica nanocomposite coatings

- Investigation on in situ silica dispersed in natural rubber latex matrix combined with spray sputtering technology

- The degradable time evaluation of degradable polymer film in agriculture based on polyethylene film experiments

- Improving mechanical and water vapor barrier properties of the parylene C film by UV-curable polyurethane acrylate coating

- Thermal conductivity of silicone elastomer with a porous alumina continuum

- Copolymerization of CO2, propylene oxide, and itaconic anhydride with double metal cyanide complex catalyst to form crosslinked polypropylene carbonate

- Combining good dispersion with tailored charge trapping in nanodielectrics by hybrid functionalization of silica

- Thermosensitive hydrogel for in situ-controlled methotrexate delivery

- Analysis of the aging mechanism and life evaluation of elastomers in simulated proton exchange membrane fuel cell environments

- The crystallization and mechanical properties of poly(4-methyl-1-pentene) hard elastic film with different melt draw ratios

- Review Articles

- Aromatic polyamide nonporous membranes for gas separation application

- Optical elements from 3D printed polymers

- Evidence for bicomponent fibers: A review

- Mapping the scientific research on the ionizing radiation impacts on polymers (1975–2019)

- Recent advances in compatibility and toughness of poly(lactic acid)/poly(butylene succinate) blends

- Topical Issue: (Micro)plastics pollution - Knowns and unknows (Guest Editor: João Pinto da Costa)

- Simple pyrolysis of polystyrene into valuable chemicals

- Topical Issue: Recent advances of chitosan- and cellulose-based materials: From production to application (Guest Editor: Marc Delgado-Aguilar)

- In situ photo-crosslinking hydrogel with rapid healing, antibacterial, and hemostatic activities

- A novel CT contrast agent for intestinal-targeted imaging through rectal administration

- Properties and applications of cellulose regenerated from cellulose/imidazolium-based ionic liquid/co-solvent solutions: A short review

- Towards the use of acrylic acid graft-copolymerized plant biofiber in sustainable fortified composites: Manufacturing and characterization

Articles in the same Issue

- Research Articles

- Research on the mechanism of gel accelerator on gel transition of PAN solution by rheology and dynamic light scattering

- Gel point determination of gellan biopolymer gel from DC electrical conductivity

- Composite of polylactic acid and microcellulose from kombucha membranes

- Synthesis of highly branched water-soluble polyester and its surface sizing agent strengthening mechanism

- Fabrication and characterization of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) modified with nano-montmorillonite biocomposite

- Fabrication of N-halamine polyurethane films with excellent antibacterial properties

- Formulation and optimization of gastroretentive bilayer tablets of calcium carbonate using D-optimal mixture design

- Sustainable nanocomposite films based on SiO2 and biodegradable poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH) for food packaging

- Evaluation of physicochemical properties of film-based alginate for food packing applications

- Electrically conductive and light-weight branched polylactic acid-based carbon nanotube foams

- Structuring of hydroxy-terminated polydimethylsiloxane filled by fumed silica

- Surface functionalization of nanostructured Cu/Ag-deposited polypropylene fiber by magnetron sputtering

- Influence of composite structure design on the ablation performance of ethylene propylene diene monomer composites

- MOFs/PVA hybrid membranes with enhanced mechanical and ion-conductive properties

- Improvement of the electromechanical properties of thermoplastic polyurethane composite by ionic liquid modified multiwall carbon nanotubes

- Natural rubber latex/MXene foam with robust and multifunctional properties

- Rheological properties of two high polymers suspended in an abrasive slurry jet

- Two-step polyaniline loading in polyelectrolyte complex membranes for improved pseudo-capacitor electrodes

- Preparation and application of carbon and hollow TiO2 microspheres by microwave heating at a low temperature

- Properties of a bovine collagen type I membrane for guided bone regeneration applications

- Fabrication and characterization of thermoresponsive composite carriers: PNIPAAm-grafted glass spheres

- Effect of talc and diatomite on compatible, morphological, and mechanical behavior of PLA/PBAT blends

- Multifunctional graphene nanofiller in flame retarded polybutadiene/chloroprene/carbon black composites

- Strain-dependent wicking behavior of cotton/lycra elastic woven fabric for sportswear

- Enhanced dielectric properties and breakdown strength of polymer/carbon nanotube composites by coating an SrTiO3 layer

- Analysis of effect of modification of silica and carbon black co-filled rubber composite on mechanical properties

- Polytriazole resins toughened by an azide-terminated polyhedral oligomeric silsesquioxane (OADTP)

- Phosphine oxide for reducing flammability of ethylene-vinyl-acetate copolymer

- Study on preparation and properties of bentonite-modified epoxy sheet molding compound

- Polyhedral oligomeric silsesquioxane (POSS)-modified phenolic resin: Synthesis and anti-oxidation properties

- Study on structure and properties of natural indigo spun-dyed viscose fiber

- Biodegradable thermoplastic copolyester elastomers: Methyl branched PBAmT

- Investigations of polyethylene of raised temperature resistance service performance using autoclave test under sour medium conditions

- Investigation of corrosion and thermal behavior of PU–PDMS-coated AISI 316L

- Modification of sodium bicarbonate and its effect on foaming behavior of polypropylene

- Effect of coupling agents on the olive pomace-filled polypropylene composite

- High strength and conductive hydrogel with fully interpenetrated structure from alginate and acrylamide

- Removal of methylene blue in water by electrospun PAN/β-CD nanofibre membrane

- Theoretical and experimental studies on the fabrication of cylindrical-electrode-assisted solution blowing spinning nanofibers

- Influence of l-quebrachitol on the properties of centrifuged natural rubber

- Ultrasonic-modified montmorillonite uniting ethylene glycol diglycidyl ether to reinforce protein-based composite films

- Experimental study on the dissolution of supercritical CO2 in PS under different agitators

- Experimental research on the performance of the thermal-reflective coatings with liquid silicone rubber for pavement applications

- Study on controlling nicotine release from snus by the SIPN membranes

- Catalase biosensor based on the PAni/cMWCNT support for peroxide sensing

- Synthesis and characterization of different soybean oil-based polyols with fatty alcohol and aromatic alcohol

- Molecularly imprinted electrospun fiber membrane for colorimetric detection of hexanoic acid

- Poly(propylene carbonate) networks with excellent properties: Terpolymerization of carbon dioxide, propylene oxide, and 4,4ʹ-(hexafluoroisopropylidene) diphthalic anhydride

- Polypropylene/graphene nanoplatelets nanocomposites with high conductivity via solid-state shear mixing

- Mechanical properties of fiber-reinforced asphalt concrete: Finite element simulation and experimental study

- Applying design of experiments (DoE) on the properties of buccal film for nicotine delivery

- Preparation and characterizations of antibacterial–antioxidant film from soy protein isolate incorporated with mangosteen peel extract

- Preparation and adsorption properties of Ni(ii) ion-imprinted polymers based on synthesized novel functional monomer

- Rare-earth doped radioluminescent hydrogel as a potential phantom material for 3D gel dosimeter

- Effects of cryogenic treatment and interface modifications of basalt fibre on the mechanical properties of hybrid fibre-reinforced composites

- Stable super-hydrophobic and comfort PDMS-coated polyester fabric

- Impact of a nanomixture of carbon black and clay on the mechanical properties of a series of irradiated natural rubber/butyl rubber blend

- Preparation and characterization of a novel composite membrane of natural silk fiber/nano-hydroxyapatite/chitosan for guided bone tissue regeneration

- Study on the thermal properties and insulation resistance of epoxy resin modified by hexagonal boron nitride

- A new method for plugging the dominant seepage channel after polymer flooding and its mechanism: Fracturing–seepage–plugging

- Analysis of the rheological property and crystallization behavior of polylactic acid (Ingeo™ Biopolymer 4032D) at different process temperatures

- Hybrid green organic/inorganic filler polypropylene composites: Morphological study and mechanical performance investigations

- In situ polymerization of PEDOT:PSS films based on EMI-TFSI and the analysis of electrochromic performance

- Effect of laser irradiation on morphology and dielectric properties of quartz fiber reinforced epoxy resin composite

- The optimization of Carreau model and rheological behavior of alumina/linear low-density polyethylene composites with different alumina content and diameter

- Properties of polyurethane foam with fourth-generation blowing agent

- Hydrophobicity and corrosion resistance of waterborne fluorinated acrylate/silica nanocomposite coatings

- Investigation on in situ silica dispersed in natural rubber latex matrix combined with spray sputtering technology

- The degradable time evaluation of degradable polymer film in agriculture based on polyethylene film experiments

- Improving mechanical and water vapor barrier properties of the parylene C film by UV-curable polyurethane acrylate coating

- Thermal conductivity of silicone elastomer with a porous alumina continuum

- Copolymerization of CO2, propylene oxide, and itaconic anhydride with double metal cyanide complex catalyst to form crosslinked polypropylene carbonate

- Combining good dispersion with tailored charge trapping in nanodielectrics by hybrid functionalization of silica

- Thermosensitive hydrogel for in situ-controlled methotrexate delivery

- Analysis of the aging mechanism and life evaluation of elastomers in simulated proton exchange membrane fuel cell environments

- The crystallization and mechanical properties of poly(4-methyl-1-pentene) hard elastic film with different melt draw ratios

- Review Articles

- Aromatic polyamide nonporous membranes for gas separation application

- Optical elements from 3D printed polymers

- Evidence for bicomponent fibers: A review

- Mapping the scientific research on the ionizing radiation impacts on polymers (1975–2019)

- Recent advances in compatibility and toughness of poly(lactic acid)/poly(butylene succinate) blends

- Topical Issue: (Micro)plastics pollution - Knowns and unknows (Guest Editor: João Pinto da Costa)

- Simple pyrolysis of polystyrene into valuable chemicals

- Topical Issue: Recent advances of chitosan- and cellulose-based materials: From production to application (Guest Editor: Marc Delgado-Aguilar)

- In situ photo-crosslinking hydrogel with rapid healing, antibacterial, and hemostatic activities

- A novel CT contrast agent for intestinal-targeted imaging through rectal administration

- Properties and applications of cellulose regenerated from cellulose/imidazolium-based ionic liquid/co-solvent solutions: A short review

- Towards the use of acrylic acid graft-copolymerized plant biofiber in sustainable fortified composites: Manufacturing and characterization