Abstract

The aim of this study was to simulate olive oil use and to monitor changes in the profile of fatty acids in home-made preparations using olive oil, which involve repeated heat treatment cycles. The material used in the experiment consisted of extra virgin and refined olive oil samples. Fatty acid profiles of olive oil samples were monitored after each heating cycle (10 min). The outcomes showed that cycles of heat treatment cause significant (p < 0.05) differences in the fatty acid profile of olive oil. A similar trend of differences (p < 0.05) was found between fatty acid profiles in extra virgin and refined olive oils. As expected, the main differences occurred in monounsaturated fatty acids (MUFAs) and polyunsaturated fatty acids (PUFAs). Cross-correlation analysis also showed differences between the fatty acid profiles. The most prolific changes were observed between the control samples and the heated (at 180°C) samples of refined olive oil in PUFAs, though a heating temperature of 220°C resulted in similar decrease in MUFAs and PUFAs, in both extra virgin and refined olive oil samples. The study showed differences in fatty acid profiles that can occur during the culinary heating of olive oil. Furthermore, the study indicated that culinary heating of extra virgin olive oil produced results similar to those of the refined olive oil heating at a lower temperature below 180°C.

1 Introduction

Olive oil, especially extra virgin olive oil, is the major source of fat in the so-called Mediterranean diet that very often has positive health benefits. The reason for this attribute is mainly the lower content of saturated fatty acids (SFAs) and the higher content of polyphenolic compounds. The fatty acid profile is important for the quality and stability of oils. Oleic acid (C18:1) is a monounsaturated fatty acid (MUFA), and it is more stable than polyunsaturated fatty acids (PUFAs). PUFAs are usually present in lower percentages in olive oil [1,2,3,4]. Cold-pressed edible plant oils, such as extra virgin olive oil, are usually added to different salads. This may mean that they are consumed without heat treatment. Recently, these types of edible plant oils have been used for cooking, as part of different culinary techniques and recipes. In this case, even cold-pressed edible plant oils are heated at high temperatures. Such heating processes can affect the fatty acid profile of these oils, for instance, heating increases the trans fatty acids, which have potentially harmful health effects [5].

Different culinary conditions, especially the temperature and the time of heat processing, can influence the fatty acid composition of oils [6,7]. The type of oil also influences the changes in oil and its stability during heat treatment due to difference in fatty acid profiles. SFAs are more stable than unsaturated fatty acids, and similarly MUFAs are more stable when compared to PUFAs [8]. The advantage of olive oil is the higher content of MUFA (oleic acid), and this property gives olive oil a higher level of oxidative stability than that of other edible plant oils with a higher content of PUFAs. Cold-pressed olive oil or extra virgin olive oil has the additional advantage of high levels of polyphenols, tocopherols, and carotenoids [4,9,10]. The fatty acid profile of olive oil is influenced by olive variety, weather, environment, and harvest conditions, as well as agronomic and technologic factors [11,12].

Olive oil, especially extra virgin olive oil (cold-pressed olive oil), is considered beneficial for the health of consumers due to the presence of phenolic compounds, such as hydroxytyrosol (which improves radical stability) and oleuropein. Such compounds are involved in inhibiting inflammatory processes. They additionally prevent liver damage by reducing oxidative stress, mitochondrial dysfunction, endoplasmic reticulum stress, and insulin resistance [13,14].

Deep frying is a frequently used culinary practice. The temperature during deep frying is usually around 180°C. This practice is popular among consumers since deep fried food usually have attractive sensory properties [15,16]. The legislation concerning the fatty acid profile of different olive oils is given in percentages, with a key emphasis on oleic fatty acid (C18:1) [17].

This study aimed to simulate home-based heat treatment of olive oil and to measure the changes in the profile of fatty acids due to repeated heating cycles.

2 Materials and methods

2.1 Heat treatment of olive oil samples

The samples (n = 10) used in the experiment consisted of refined olive oils (n = 4) and multivariate extra virgin olive oils (n = 6; olive oil purchased in retail markets in the Czech Republic, originating from Spain and Greece). Each purchased olive oil had around 18 months for the expiration date. The purchased olive oil samples were packed in glass bottles (volume: from 0.5 to 1 L). The labeling of the olive oil samples indicated that they had peroxide value (PV) and free fatty acid (FFA) content below the allowed limits proposed by Codex Alimentarius (refined olive oil: PV < 5 mEq of active oxygen/kg oil, FFAs < 0.3 mg KOH/g oil; cold-pressed olive oil: PV < 20 mEq of active oxygen/kg oil, FFAs < 0.8 mg KOH/g oil; the standard limits were written on the labeling of extra virgin olive oil samples). Part of the olive oil sample was taken to serve as a control sample without heat treatment. The remainder of the olive oil sample (300 mL) was heated in open glass tubes (250 mL glass tubes used for Kjeltec 2300 digestion) at 180°C and 220°C, in an oven (Professional Ovens GARB-IN, Model:23 GM). The heat treatment lasted for 10 min and was repeated for three cycles (3 × 10 min). Between each cycle, part of the olive oil sample (100 mL) was taken for analysis (of fatty acid composition) and the remainder was heated again. Between heat cycles, the samples were allowed to cool for 20 min.

2.2 Fatty acid composition

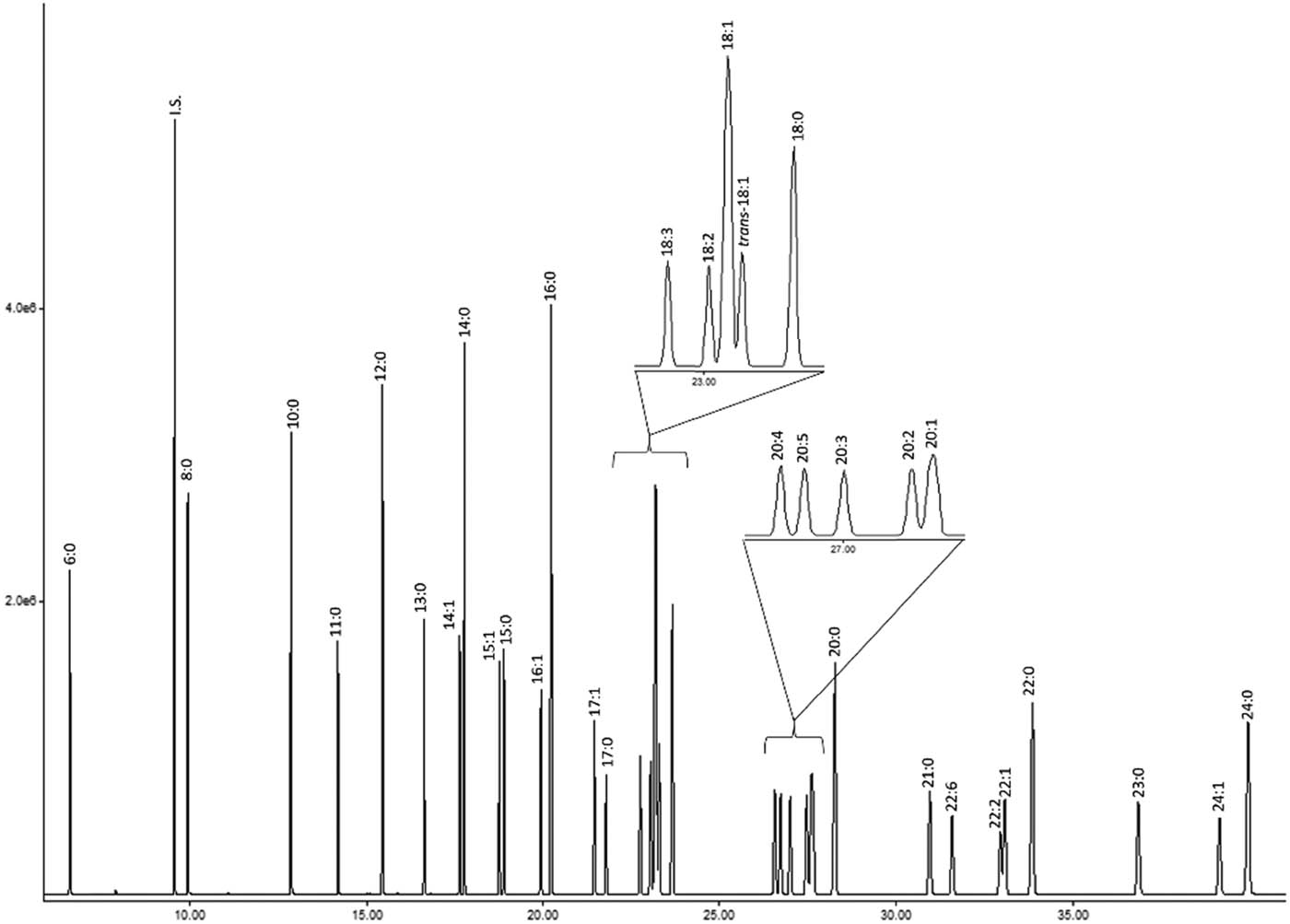

Fatty acids were methylated with 0.5 M NaOMe/MeOH solution and extracted into n-hexane. The resulting fatty acid methyl esters (FAMEs) were analyzed by the gas chromatography–mass spectrometry method on the Agilent system (GC 7890 A; MSD 5975C series II) on a fused silica HP-5MS UI column (30 m × 0.25 mm × 0.25 mm) and carrier gas He (1.1 mL/min). The temperature was programmed at 40°C for 2 min, 10°C/min to 200°C, and finally 2°C/min to 250°C for 2 min. Post run of 15 min was set at 310°C. The temperature of the injection port was 250°C and that of the detector was 280°C. Ionization was performed in the EI mode (70 eV). Identification was performed by comparison of retention times and mass spectra with authentic standards (Supelco. Merck KGaA, Darmstadt, Germany), and the results were presented as mg/mL. The results were calculated according to the official method for fatty acid profile determination [18,19,20]. The successful separation of the evaluated FAMEs, including n-undecane that was used as an internal standard, is shown in Figure 1.

Chromatogram of FAME standards (Supelco).

2.3 Antioxidant profile

Chlorophyll, carotenoid, and polyphenol contents were measured in the samples of olive oil before (control samples) and after three heating cycles at 180°C and 220°C. All the samples were measured in triplicates to reduce the possibility of error.

Carotenoid, polyphenol, and chlorophyll contents were evaluated on a Cecil Instrument spectrophotometer (CE7210). The wavelength for calculating carotenoids was 445 nm. The cuvettes were rinsed with n-hexane to avoid mixing of samples. The carotenoid contents were expressed as β-carotene. The quantification was done according to the extinction coefficient and the results were expressed as mg/kg [21].

The polyphenol contents were determined by a standard method using the Folin–Ciocalteu reagent at a reading absorbance of 765 nm. The procedure included the use of the Folin–Ciocalteu reagent previously diluted with distilled water (1:10) and sodium carbonate. The incubation of the sample (1 g), mentioned chemicals, and distilled water was done in the dark and lasted for 30 min. Results were expressed as gallic acid equivalents (mg/kg) [22].

Chlorophyll contents were measured and calculated at the wavelengths of 630, 670, and 710 nm. The samples were not diluted, and the cuvettes were rinsed with n-hexane. Results were expressed as pheophytin (mg/kg) [23].

2.4 Statistical analysis

The results were calculated (mean ± SD) in the program Microsoft Office Excel 2007 (Microsoft Corp., Redmond, WA, USA). Triplicate sampling was used in all data calculations. Statistical significance (p < 0.05) was estimated by the analysis of variance. The Shapiro–Wilk test was used to determine the results’ normality, whereas Levene’s test was used to estimate the homogeneity of variances. The results with normal distribution, homogenous variances, and significant differences between independent variances were found by Tukey’s post hoc test. The Games–Howell test was used for the results without normal distribution and unequal variances. Correlations between heating cycles and fatty acid profile changes were measured by Pearson’s correlation analysis. The overall differences between independent variances were checked by principal component analysis (PCA). SPSS 20 statistical software (IBM Corporation, Armonk, USA) was used for the mentioned statistical analysis.

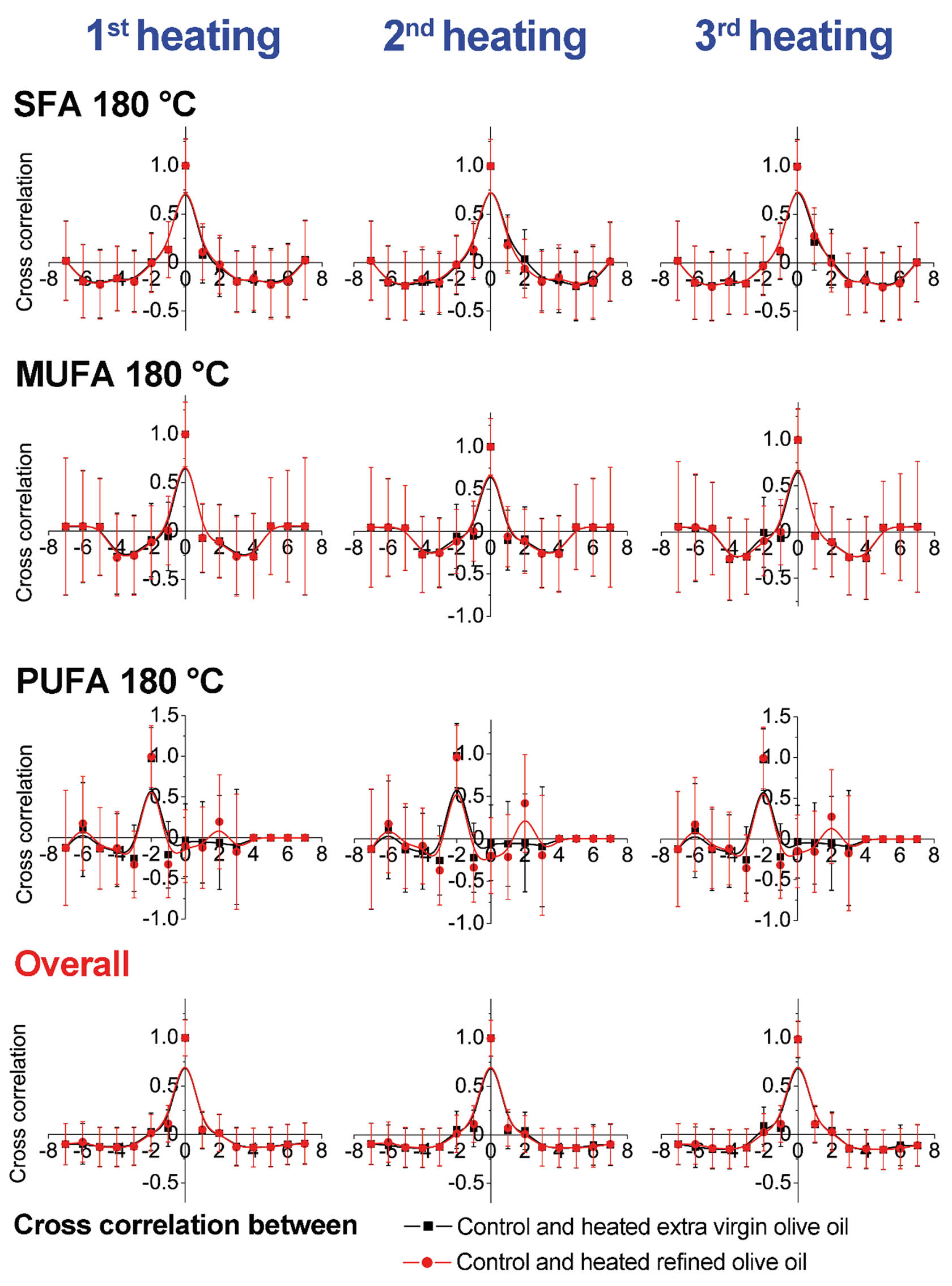

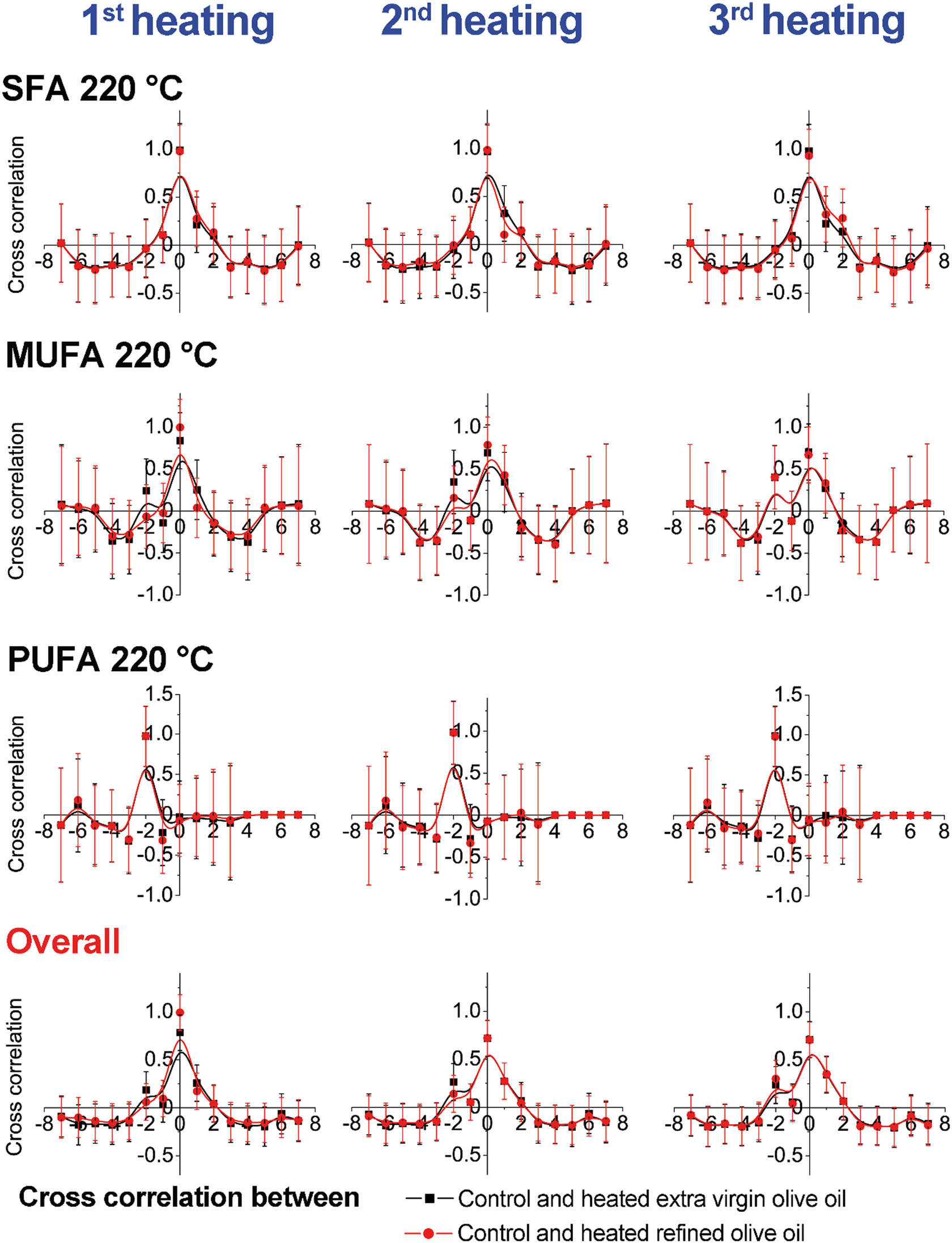

The correlation analysis was carried out to study the temporal correlations between the control, first heating cycle, second heating cycle, and third heating cycle for both temperature regimes of 180°C and 220°C for extra virgin and refined olive oil samples. The values of the defined function parameters (namely, SFAs, MUFAs, and PUFAs) were used in the correlation study. Cross-correlation plots were built by software package Origin7, based on the cross-correlation results obtained using SPSS 20 statistical software (IBM Corporation, Armonk, USA).

3 Results and discussion

Fatty acid profile changes, during the three heating cycles, in extra virgin and refined olive oil samples are shown in Tables 1–4 and Tables S1–S4. Statistical significant (p < 0.05) differences were not found in concentrations of the following SFAs: caproic (C6:0), caprylic (C8:0), capric (C10:0), lauric (C12:0), palmitic (C16:0), stearic (C18:0), heneicosanoic (C21:0), tricosanoic (C23:0), and lignoceric (C24:0) fatty acids in the samples of extra virgin olive oil heated in three cycles at 180°C. Although caproic acid was under detectable limits after three cycles of heating, myristic acid (C14:0) increased (p < 0.05) after three cycles of heating. The same trend occurred with pentadecylic acid (C15:0), where the content increased statistically significantly (p < 0.05). Berasategi et al. [24] also found increased concentrations of myristic fatty acids after heat treatment. The fluctuation (p < 0.05) in the content of arachidic (C20:0) and behenic (C22:0) fatty acids was also measured. The overall significant changes in the total content of SFAs were not monitored. Negative significant (p < 0.05) correlations between heating cycles and fatty acid contents (extra virgin olive oil heated at 180°C) were measured for the following fatty acids: oleic acid (C18:1), trans oleic acid (C18:1), erucic acid (C22:1), mead acid (C20:3), eicosadienoic acid (C20:2), and docosadienoic acid (C22:2). In contrast, a positive significant (p < 0.05) correlation was monitored for the following fatty acids: myristic acid (C14:0), pentadecylic acid (C15:0), stearic acid (C18:0), arachidic acid (C20:0), behenic acid (C22:0), myristoleic acid (C14:1), pentadecenoic acid (C15:1), palmitoleic acid (C16:1), and heptadecenoic acid (C17:1). A statistically significant (p < 0.05) decrease occurred in MUFAs and PUFAs after three cycles of heating. It was stated by previous studies that temperatures of deep frying (>180°C) led to changes in fatty acid composition [18]. In contrast, higher concentrations of oleic acid make olive oil more stable during heating, and also olive oil as a representative of cold-pressed plant oils is one of the most stable oils during the storage period [25]. It can also be explained by the fact that olive oil contains lower amounts of PUFAs, such as linoleic (C18:2) and linolenic (C18:3) acids that oxidize rapidly during storage and heating.

Fatty acid profile of virgin olive oil heated in three cycles at 180°C

| Virgin olive oil 180°C | ||||

|---|---|---|---|---|

| Control | First heating | Second heating | Third heating | |

| Mean ± SD (mg/mL) | Mean ± SD (mg/mL) | Mean ± SD (mg/mL) | Mean ± SD (mg/mL) | |

| Ʃ SFA | 26.62 ± 4.91 | 24.15 ± 4.89 | 25.62 ± 7.59 | 26.08 ± 8.28 |

| Ʃ MUFA | 46.01 ± 6.36a | 42.62 ± 4.19ab | 40.08 ± 6.94ab | 32.31 ± 10.98b |

| Ʃ PUFA | 3.56 ± 1.36a | 2.64 ± 1.10b | 2.86 ± 0.73b | 2.82 ± 0.89b |

Different superscript letters (a, b, c) indicate significance (p < 0.05) between columns.

Fatty acid profile of virgin olive oil heated in three cycles at 220°C

| Virgin olive oil 220°C | ||||

|---|---|---|---|---|

| Control | First heating | Second heating | Third heating | |

| Mean ± SD (mg/mL) | Mean ± SD (mg/mL) | Mean ± SD (mg/mL) | Mean ± SD (mg/mL) | |

| Ʃ SFA | 26.68 ± 4.91 | 22.82 ± 6.26 | 22.22 ± 8.09 | 22.06 ± 6.70 |

| Ʃ MUFA | 46.01 ± 6.36a | 19.14 ± 9.00b | 18.63 ± 6.90b | 18.72 ± 7.38b |

| Ʃ PUFA | 3.56 ± 1.36a | 3.27 ± 1.71ab | 2.74 ± 0.62b | 2.97 ± 0.47b |

Different superscript letters (a, b, c) indicate significance (p < 0.05) between columns.

Fatty acid profile of refined olive oil heated in three cycles at 180°C

| Refined olive oil 180°C | ||||

|---|---|---|---|---|

| Control | First heating | Second heating | Third heating | |

| Mean ± SD (mg/mL) | Mean ± SD (mg/mL) | Mean ± SD (mg/mL) | Mean ± SD (mg/mL) | |

| Ʃ SFA | 25.82 ± 1.90 | 24.76 ± 3.86 | 24.12 ± 4.44 | 31.32 ± 5.06 |

| Ʃ MUFA | 47.18 ± 3.78 | 43.04 ± 4.26 | 41.50 ± 7.50 | 40.54 ± 4.87 |

| Ʃ PUFA | 5.34 ± 0.94a | 3.23 ± 1.62a | 2.41 ± 0.60a | 2.18 ± 0.38b |

Different superscript letters (a, b, c) indicate significance (p < 0.05) between columns.

Fatty acid profile of refined olive oil heated in three cycles at 220°C

| Refined olive oil 220°C | ||||

|---|---|---|---|---|

| Control | First heating | Second heating | Third heating | |

| Mean ± SD (mg/mL) | Mean ± SD (mg/mL) | Mean ± SD (mg/mL) | Mean ± SD (mg/mL) | |

| Ʃ SFA | 25.81 ± 1.90 | 22.42 ± 4.98 | 21.21 ± 7.86 | 19.20 ± 4.83 |

| Ʃ MUFA | 47.18 ± 3.78b | 36.87 ± 5.47a | 16.44 ± 7.30a | 17.34 ± 4.90a |

| Ʃ PUFA | 5.34 ± 0.94a | 2.58 ± 0.44ab | 2.38 ± 1.22b | 2.36 ± 0.21b |

Different superscript letters (a, b, c) indicate significance (p < 0.05) between columns.

That is the reason why olive oil is often marked as an oil with properties of better resistance toward thermal treatment. Certainly, heating period and heating time affect differently the fatty acid profiles of cooking oils, since heating for 5 min is considered short term and heating for 40 min and more is considered long term. Previous studies indicated that especially these long-term heating resulted in increments of SFA contents [25,26]. In contrast, other studies are also indicating that the fatty acid profile is more affected by cooking temperatures than the heating time [16,27]. On the other hand, the study of Allouche et al. [28] indicated that olive oil samples heated at 180°C for 6 h demonstrated changes in palmitoleic, linoleic, and linolenic acids, but changes in oleic acid contents were not monitored.

It can be observed from Table 2 that heat treatment at 220°C resulted in more significant (p < 0.05) decrease in MUFAs and PUFAs in extra virgin olive oils. The difference between heat treatments (180°C and 220°C) is clearly visible since the second cycle of heat treatment at 220°C resulted in a content of omega-3 fatty acid (C18:3 – linolenic fatty acid) under the detectable limit. In contrast, the content of lauric fatty acid (C12:0) stayed almost intact during the three heating cycles at both 180°C and 220°C in the samples of extra virgin olive oil. Lauric fatty acid is a medium chain fatty acid and studies have showed that it has a strong antimicrobial activity [29].

Myristic acid (C14:0) content increased significantly (p < 0.05) during heating cycles, and it also showed statistically significant (p < 0.01) positive correlations (r = 0.374) among three heating cycles. During heating cycles, the same trends were found for pentadecylic acid (C15:0), stearic acid (C18:0), behenic acid (C22:0), and for arachidic acid (C20:0), with significant (p < 0.01) positive correlation factor (r = 0.658), which is similar to tricosylic acid (C23:0) and lignoceric (C24:0) acid.

The content of palmitic acid (C16:0) also demonstrated statistically significant decrease (p < 0.05), with a negative correlation (p < 0.01) factor of −0.512. Statistically significant (p < 0.01) negative correlation (r = −0.850) was calculated from decreased amounts of oleic acid (C18:1) during three heating cycles. After three repeated heating cycles, the following PUFAs were under the detection limit: linolenic acid (C18:3), arachidonic acid (C20:4), and eicosapentaenoic acid (C20:5). Statistical (p < 0.05) decreases and negative correlations (p < 0.05) were also found during the three heating cycles for eicosadienoic acid (C20:2) and docosadienoic acid (C22:2; Table 2). These changes are at the lower rate among the samples of extra virgin olive oil samples heated during three cycles at 180°C (Table 1). Heat treatments significantly affect the fatty acid profiles of olive oil, which is similar to other plant oils. Plant oils containing higher contents of MUFAs, especially oleic acid (C18:1) are considered more heat stable. Extra virgin olive oil with its higher content of polyphenolic compounds is also, according to studies, considered more stable during heating [9,10,22]. On the other hand, higher concentrations of SFAs in oils make them more resistant toward oxidation. The health benefits of MUFAs are also reflected in the findings, that is, their consumption reduced the level of bad cholesterol in blood, and therefore, PUFAs are essential for the proper functioning of the human organs [30].

Palmitic acid (C16:0) content increased only in the samples of refined olive oil after three cycles of heating at 180°C (Table 3). In the study of Giuffrè et al. [30], an increase in palmitic acid was also observed (C16:0), at 240°C, for 120 min. The total content of SFAs in the same study [30] also increased at the same temperature regime, while in our study SFAs increased only in the samples of refined olive oil after three heating cycles at 180°C, and this was not statistically significant (p > 0.05; Table 3).

Linoleic acid (C18:2) showed a decreased trend in almost all investigated samples (Tables 1, 3, and 4), which is similar to the findings of Giuffrè et al. [30]. The samples of extra virgin olive oil that passed through three heating cycles at 220°C had a slightly increased content of linoleic acid (C18:2), which was not statistically significant (p > 0.05). Positive correlations were observed mainly among SFAs, especially stearic acid (C18:0; r = 0.655; p < 0.05; Table 3).

The content of oleic fatty acid decreased statistically significantly (p < 0.05) with significant (p < 0.01) negative correlation (r = −0.675).

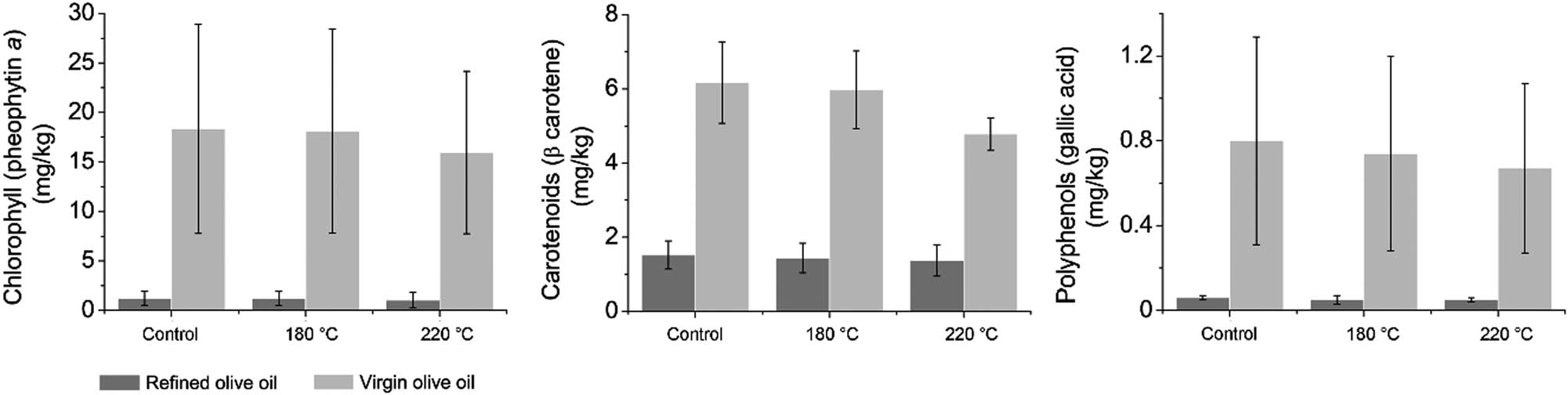

In the refined olive oil samples, PUFA is lost after three heating cycles at 180°C and this occurred at a higher rate (p < 0.05) compared to that in extra virgin olive oil samples; while the three heating cycles at 220°C also resulted in significant (p < 0.01) decrease in MUFA. Heat processing reflects changes in the fatty acid profile of plant oils, and the same holds good for cold pressed and refined oils. It also reflects the sensory properties of oils due to hydrolysis, oxidation, and polymerization. These processes affect the oil unfavorably, especially the extra virgin olive oil [18]. The differences between the extra virgin olive oil and the refined olive oil can be observed based on their antioxidant profiles. Various studies differently declare the role of antioxidants in extra virgin olive oil during its heat treatment.

Certain studies are also stating that compared to refined plant oils, cold-pressed plant oils are less stable during heating [30,31]. The heating at 220°C during three heating cycles resulted in a decrease (p < 0.05) in amount of palmitic acid (C16:0) with negative significant (p < 0.01) correlation (r = −0.821). The same trend was observed with the amounts of oleic acid (C18:1) and linoleic acid (C18:2) that decreased (p < 0.05) with negative correlations (p < 0.01; r = −0.957 and r = −0.725, respectively; Table 4). Fatty acids represent a very important indicator of nutritional profile and quality of each oil. This profile is influenced differently according to the type of storage and especially based on the processing types that include heat treatments. Combinations of temperatures and application time affect differently the fatty acid profile changes [32,33]. Linoleic (C18:2) and linolenic (C18:3) fatty acids belong to fatty acids that degrade more rapidly during heating processes. Certainly, the results can vary based on the different olive cultivars [25].

The results gained from the experiment are in accordance with Gharby et al. [25] since the authors also found more changes in MUFA and PUFA in the samples of refined olive oil compared to the extra virgin olive oil. It can be explained by the fact that extra virgin olive oil contains higher amounts of antioxidant compounds (chlorophylls, carotenoids, and especially polyphenols) that protect unsaturated fatty acids, especially PUFA from deterioration, though the processes around polyphenol behaviors during heating in different food matrixes are still not fully understood [25,34].

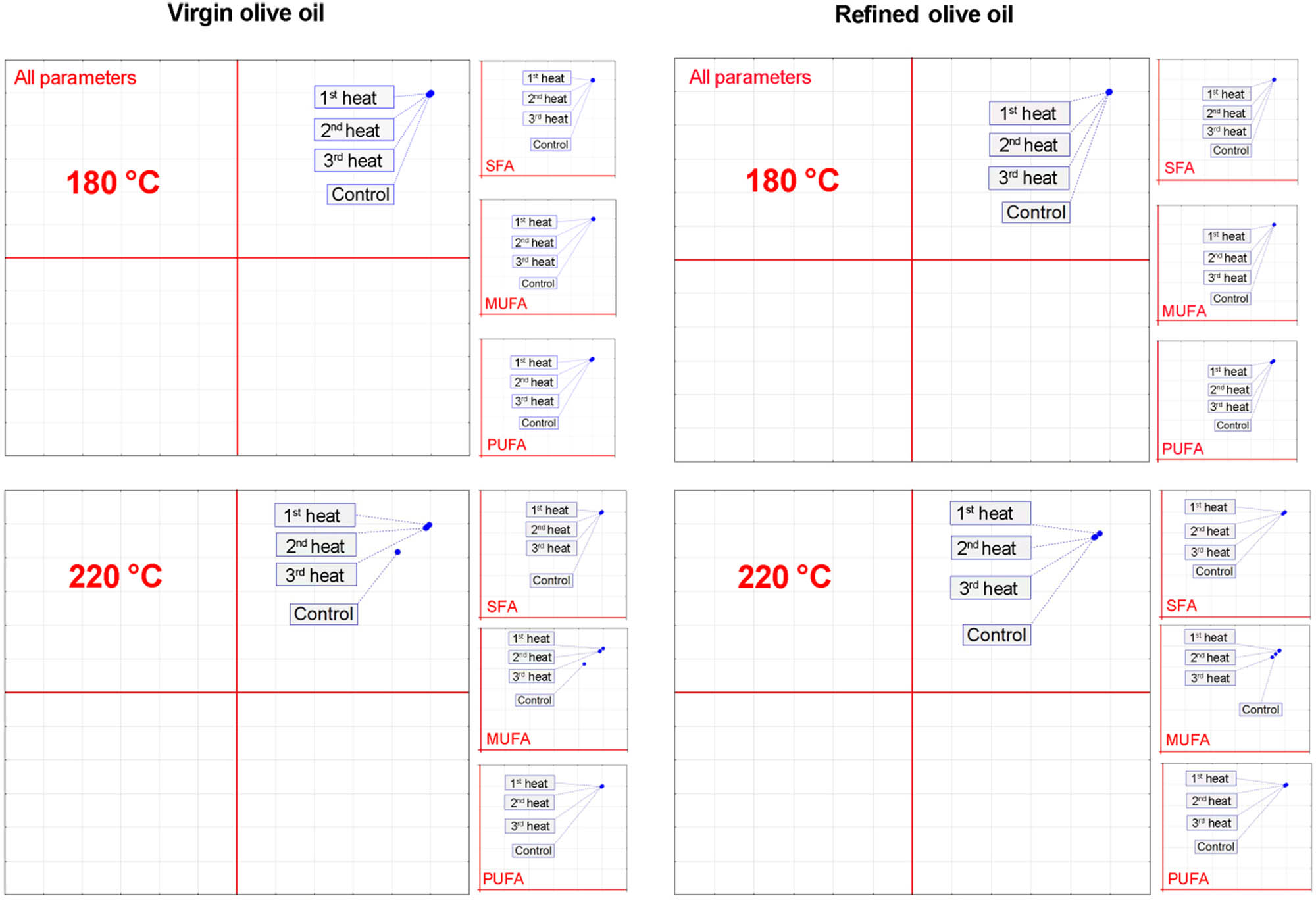

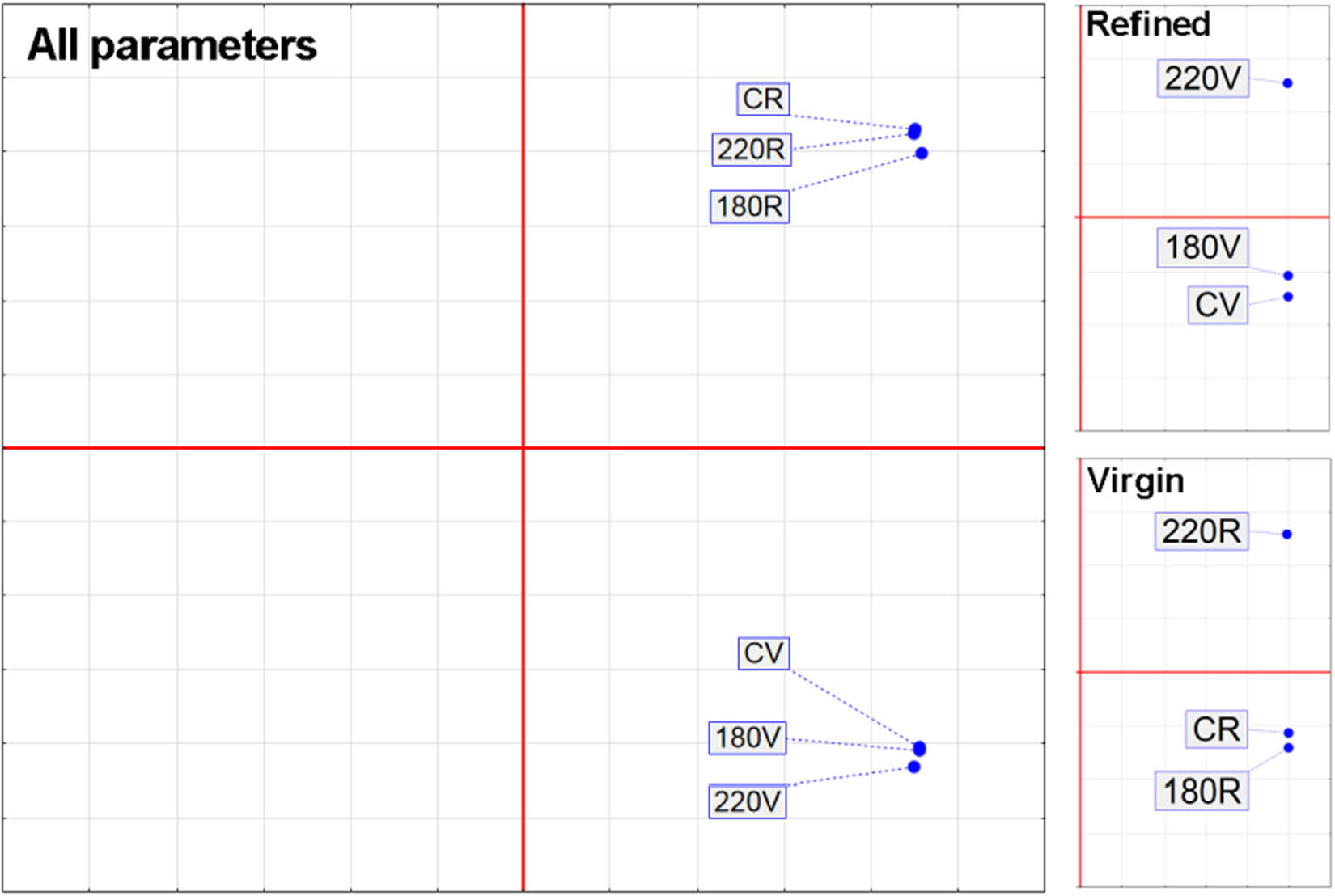

The results obtained by PCA are shown in Figure 2. The PCA results indicate that the biggest changes in fatty acid profiles were observed among extra virgin olive oil samples heated at 220°C, far more than the differences observed between refined olive oil samples undergoing three repeated heating cycles at 220°C (Figure 2).

PCA of fatty acid profiles changes during heating treatment of extra virgin and refined olive oils.

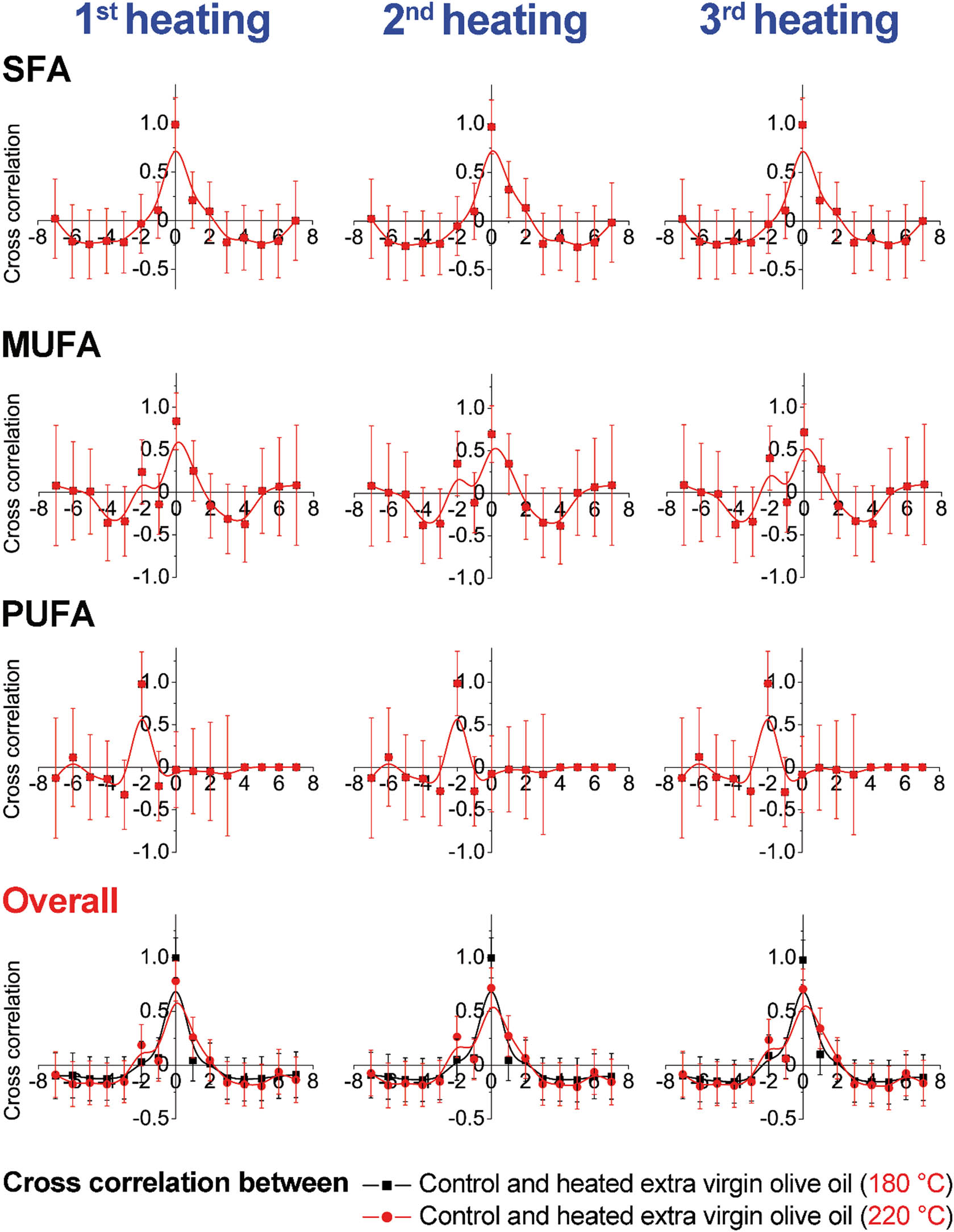

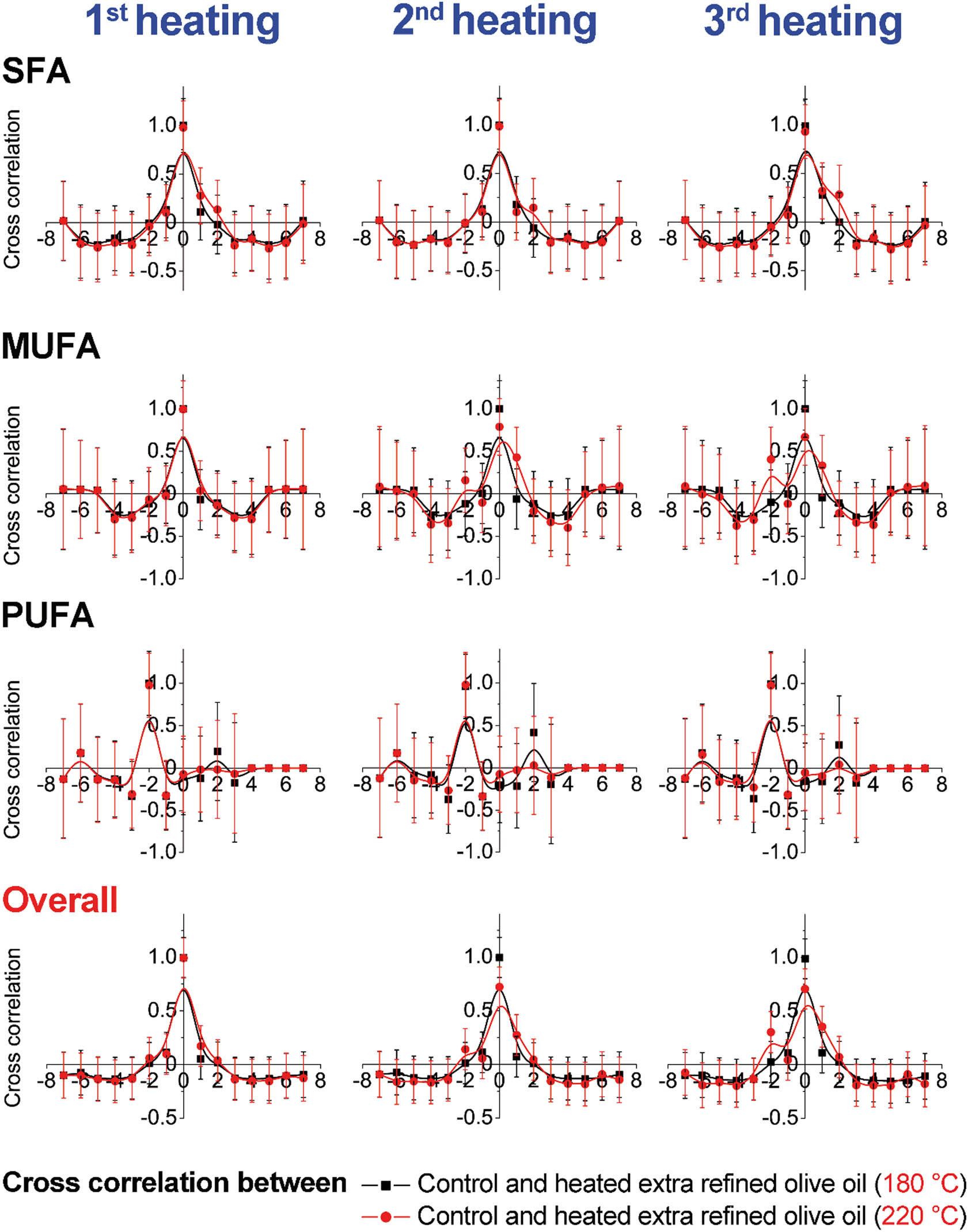

Cross-correlation results presented graphically are shown in Figures 3–6. The obtained results emphasize changes within the same group and between two examined olive oil groups (extra virgin and refined olive oils). The results indicate higher changes in MUFAs at 220°C in comparison with the results of samples heated at 180°C, within the refined olive oil samples. In contrast, cross-correlation results of extra virgin olive oil heated at 180°C and 220°C indicated higher changes among PUFAs (Figures 3 and 4). According to cross-correlation results, higher differences were observed in the content of MUFAs and PUFAs between refined olive oil samples heated at 180°C and 220°C. The overall differences were not observed between the examined two types of olive oil (Figures 5 and 6).

Cross-correlation analysis of olive oil samples within same groups (extra virgin and refined olive oils) heated during three repeated cycles at 180°C.

Cross-correlation analysis of olive oil samples within same groups (extra virgin and refined olive oils) heated during three repeated cycles at 220°C.

Cross-correlation analysis of olive oil samples between groups (extra virgin olive oils) heated during three repeated cycles at 180°C and 220°C.

Cross-correlation analysis of olive oil samples between groups (extra refined olive oils) heated during three repeated cycles at 180°C and 220°C.

Antioxidant profile changes in olive oil samples (both refined and virgin olive oils) before and after three cycles of heating are shown in Figures 7 and 8. The trend of reducing chlorophyll, carotenoids, and polyphenols contents can be clearly seen in Figure 7. The differences between the three heating cycles can also be observed between olive oil samples heated at 180°C and 220°C (Figure 8).

Chlorophyll, carotenoid, and polyphenolic compound contents in olive oil before and after three cycles of heating at 180°C and 220°C.

PCA of antioxidant contents in olive oil before and after three cycles of heating at 180°C and 220°C. CR – control samples; 180R – refined oils heated at 180°C; 220R – refined oils heated at 220°C; 180V – virgin oils heated at 180°C; 220V – virgin oils heated at 220°C.

PCA formed separate groups of olive oil samples heated at 220°C. The olive oil, especially cold-pressed olive oil, has a unique flavor due to the polyphenol content that positively affects the oxidative stability of olive oil [25]. It is known that polyphenols are the most affected due to heat treatment, though the reductions differ based on the olive cultivar [28].

4 Conclusions

The experiments showed that the cycles of heating temperatures at 180°C and at 220°C affect the fatty acid profile of olive oils. Certainly, our results unambiguously emphasized how relatively small differences in heating temperatures result in totally different fatty acid profiles. The study also indicated that extra virgin olive oil can be used for culinary heating in the same way as refined olive oil, though only at a lower temperature below 180°C. Refined olive oil also did not show high stability during heating at 220°C. Cross-correlation analysis emphasized the differences between extra virgin and refined olive oil during heating, i.e., both between them and within the same olive oil group. MUFAs, according to cross-correlation analysis, changed more rapidly in refined olive oil, while PUFAs changed more rapidly in extra virgin olive oil. The changes in antioxidant compounds (chlorophyll, carotenoids, and polyphenols) after and before the three heating cycles also showed statistical reduction, especially among samples heated at 220°C (in both refined and virgin olive samples).

Acknowledgments

The research was done by financial support of Internal Grant Agency IGA VFU Brno 215/2019/FVHE. This work was funded by the project no. RO0418 (sustainable systems and technologies, improving crop production for higher quality of production of food, feed, and raw materials, under conditions of changing climate) funded by the Ministry of Agriculture, Czech Republic. This study was supported by Grant Agency of the Masaryk University (MUNI/A/0947/2019).

Conflict of interest: The authors state no conflict of interest.

Data availability statement: All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

[1] Kulišić T, Berković K, Pavić S, Šustra A. The processing of turning colour olives of Oblica cultivar. Agriculturae Conspectus Scientificus. 2004;69:103–7.Search in Google Scholar

[2] Šindrak Z, Benčić Đ, Voća S, Berberić A. Total phenols in varietal olive oils from Istria. Pomologia Croatica: Glasilo Hrvatskog agronomskog društva. 2007;13:17–29.Search in Google Scholar

[3] Abdalla AEM, El-Difrawy EA, Abdelneem YF. A study on the effect of harvest time on quality of Egyptian olive oil. In: Alex J, editor. Fd. Sci. & Technol. Special volume conference; 2008. p. 61–74.10.21608/ajfs.2008.19646Search in Google Scholar

[4] Perona JS, Botham KM. Olive oil as a functional food: nutritional and health benefits. In: Aparicio R, Harwood J, editors. Handbook of Olive Oil. The United States of America: Springer US; 2013. p. 677–771.10.1007/978-1-4614-7777-8_18Search in Google Scholar

[5] Soupas L, Juntunen L, Säynäjoki S, Lampi AM, Piironen V. GC-MS method for characterization and quantification of sitostanol oxidation products. J Am Oil Chem Soc. 2004;81:135–41.10.1007/s11746-004-0871-1Search in Google Scholar

[6] Rudziñska M, Korczak J, Wasowicz E. Changes in phytosterols and their oxidation products during frying of French fries in rapeseed oil. Pol J Food Nutr Sci. 2005;14:381.Search in Google Scholar

[7] Kmiecik D, Korczak J, Rudzińska M, Michałowska AG, Hęś M. Stabilization of phytosterols in rapeseed oil by natural antioxidants during heating. Eur J Lipid Sci Technol. 2009;111:1124–32.10.1002/ejlt.200800304Search in Google Scholar

[8] Choe E, Min DB. Chemistry of deep‐fat frying oils. J Food Sci. 2007;72:77–86.10.1111/j.1750-3841.2007.00352.xSearch in Google Scholar

[9] Teissedre PL, Waterhouse AL. Inhibition of oxidation of human low-density lipoproteins by phenolic substances in different essential oils varieties. J Agric Food Chem. 2000;48:3801–5.10.1021/jf990921xSearch in Google Scholar

[10] Koski A, Psomiadou E, Tsimidou M, Hopia A, Kefalas P, Wahala K, et al. Oxidative stability and minor constituents of virgin olive oil and cold-pressed rapeseed oil. Eur Food Res Technol. 2002;214:294–8.10.1007/s00217-001-0479-5Search in Google Scholar

[11] Angerosa F, Servili M, Selvaggini R, Taticchi A, Esposto S, Montedoro G. Volatile compounds in virgin olive oil: Occurrence and their relationship with the quality. J Chromatogr A. 2004;m1054:17–31.10.1016/S0021-9673(04)01298-1Search in Google Scholar

[12] Kalogeropoulos N, Tsimidou MZ. Antioxidants in Greek virgin olive oils. Antioxidants. 2014;3:387–413.10.3390/antiox3020387Search in Google Scholar PubMed PubMed Central

[13] Echeverría F, Ortiz M, Valenzuela R, Videla LA. Hydroxytyrosol and cytoprotection: a projection for clinical interventions. Int J Mol Sci. 2017;18:930.10.3390/ijms18050930Search in Google Scholar PubMed PubMed Central

[14] Soto-Alarcon SA, Valenzuela R, Valenzuela A, Videla LA. Liver protective effects of extra virgin olive oil: interaction between its chemical composition and the cell-signaling pathways involved in protection. Endocr Metab Immune Disord-Drug Targets (Former Curr Drug Targets-Immune, Endocrine & Metab Disorders). 2018;18:75–84.10.2174/1871530317666171114120552Search in Google Scholar PubMed

[15] Rani AKS, Reddy SY, Chetana R. Quality changes in trans and trans free fats/oils and products during frying. Eur Food Res Technol. 2010;230:803–11.10.1007/s00217-010-1225-7Search in Google Scholar

[16] Liu Y, Wang Y, Cao P, Liu Y. Combination of gas chromatography-mass spectrometry and electron spin resonance spectroscopy for analysis of oxidative stability in soybean oil during deep-frying process. Food Anal Methods. 2018;11:1485–92.10.1007/s12161-017-1132-7Search in Google Scholar

[17] Codex Alimentarius International Food Standards (CAIFS). Standard for olive oils and olive pomace oils codex stan 33–1981. Adopted in 1981. Revision: 1989, 2003, 2015. Amendment: 2009, 2013.Search in Google Scholar

[18] Multari S, Marsol-Vall A, Heponiemi P, Suomela JP, Yang B. Changes in the volatile profile, fatty acid composition and other markers of lipid oxidation of six different vegetable oils during short-term deep-frying. Food Res Int. 2019;122:318–29.10.1016/j.foodres.2019.04.026Search in Google Scholar PubMed

[19] Härtig C. Rapid identification of fatty acid methyl esters using a multidimensional gas chromatography – mass spectrometry database. J Chromatogr A. 2008;1177:159–69.10.1016/j.chroma.2007.10.089Search in Google Scholar PubMed

[20] Official Methods and Recommended Practices of the AOCS 7th Ed. American Oil Chemists’ Society, Champaign, IL, Method Ce 2-66. Preparation of Methyl Esters of LongChain Fatty Acids. 2018.Search in Google Scholar

[21] Munasinghe M, Wansapala J. B-Carotene content of M. Longifolia seed oil in different agro-climatic zones in Sri Lanka, the effect of heat on its stability and the composition of seed cake. Potravinarstvo. 2015;9(1):474–9.10.5219/502Search in Google Scholar

[22] Singleton V, Rossi J. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Viticult. 1965;16:144–58.Search in Google Scholar

[23] Kiritsakis A, Christie W. Handbook of Olive Oil. Boston, MA: Springer US; 2000. p. 138.Search in Google Scholar

[24] Berasategi I, Barriuso B, Ansorena D, Astiasarán I. Stability of avocado oil during heating: comparative study to olive oil. Food Chem. 2012;132:439–46.10.1016/j.foodchem.2011.11.018Search in Google Scholar PubMed

[25] Gharby S, Harhar H, Matthäus B, Bouzoubaa Z, Charrouf Z. The chemical parameters and oxidative resistance to heat treatment of refined and extra virgin Moroccan Picholine olive oil. J Taibah Univ Sci. 2016;10:100–6.10.1016/j.jtusci.2015.05.004Search in Google Scholar

[26] Li X, Li J, Wang Y, Cao P, Liu Y. Effects of frying oils’ fatty acids profile on the formation of polar lipids components and their retention in French fries over deep-frying process. Food Chem. 2017;237:98–105.10.1016/j.foodchem.2017.05.100Search in Google Scholar PubMed

[27] Wang SN, Sui XN, Wang ZJ, Qi BK, Jiang LZ, Li Y, et al. Improvement in thermal stability of soybean oil by blending with camellia oil during deep fat frying. Eur J Lipid Sci Technol. 2016;118:524–31.10.1002/ejlt.201500085Search in Google Scholar

[28] Allouche Y, Jiménez A, Gaforio JJ, Uceda M, Beltrán G. How heating affects extra virgin olive oil quality indexes and chemical composition. J Agric Food Chem. 2007;55:9646–54.10.1021/jf070628uSearch in Google Scholar PubMed

[29] Park KM, Lee SJ, Yu H, Park JY, Jung HS, Kim K, et al. Hydrophilic and lipophilic characteristics of non-fatty acid moieties: significant factors affecting antibacterial activity of lauric acid esters. Food Sci Biotechnol. 2018;27:401–9.10.1007/s10068-018-0353-xSearch in Google Scholar PubMed PubMed Central

[30] Giuffrè AM, Zappia C, Capocasale M. Effects of high temperatures and duration of heating on olive oil properties for food use and biodiesel production. J Am Oil Chem Soc. 2017;94:819–30.10.1007/s11746-017-2988-9Search in Google Scholar

[31] Santos CS, García LM, Cruz R, Cunha SC, Fernandes JO, Casal S. Impact of potatoes deep-frying on common monounsaturated-rich vegetable oils: a comparative study. J Food Sci Technol. 2019;56:290–301.10.1007/s13197-018-3489-zSearch in Google Scholar PubMed PubMed Central

[32] Charrouf Z, Guillaume D. Argan oil: occurrence, composition and impact on human health. Eur J Lipid Sci Technol. 2008;110:632–6.10.1002/ejlt.200700220Search in Google Scholar

[33] Harhar H, Gharby S, Kartah B, El Monfalouti H, Guillaume D, Charrouf Z. Influence of argan kernel roasting-time on virgin argan oil composition and oxidative stability. Plant Foods Hum Nutr. 2011;66:163–8.10.1007/s11130-011-0220-xSearch in Google Scholar PubMed

[34] Dordevic D, Janickova S, Tremlova B. Antioxidant profile of mulled wine. Potravinarstvo Slovak J Food Sci. 2019;13:415–21.10.5219/1070Search in Google Scholar

© 2020 Dani Dordevic et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Plant Sciences

- Dependence of the heterosis effect on genetic distance, determined using various molecular markers

- Plant Growth Promoting Rhizobacteria (PGPR) Regulated Phyto and Microbial Beneficial Protein Interactions

- Role of strigolactones: Signalling and crosstalk with other phytohormones

- An efficient protocol for regenerating shoots from paper mulberry (Broussonetia papyrifera) leaf explants

- Functional divergence and adaptive selection of KNOX gene family in plants

- In silico identification of Capsicum type III polyketide synthase genes and expression patterns in Capsicum annuum

- In vitro induction and characterisation of tetraploid drumstick tree (Moringa oleifera Lam.)

- CRISPR/Cas9 or prime editing? – It depends on…

- Study on the optimal antagonistic effect of a bacterial complex against Monilinia fructicola in peach

- Natural variation in stress response induced by low CO2 in Arabidopsis thaliana

- The complete mitogenome sequence of the coral lily (Lilium pumilum) and the Lanzhou lily (Lilium davidii) in China

- Ecology and Environmental Sciences

- Use of phosphatase and dehydrogenase activities in the assessment of calcium peroxide and citric acid effects in soil contaminated with petrol

- Analysis of ethanol dehydration using membrane separation processes

- Activity of Vip3Aa1 against Periplaneta americana

- Thermostable cellulase biosynthesis from Paenibacillus alvei and its utilization in lactic acid production by simultaneous saccharification and fermentation

- Spatiotemporal dynamics of terrestrial invertebrate assemblages in the riparian zone of the Wewe river, Ashanti region, Ghana

- Antifungal activity of selected volatile essential oils against Penicillium sp.

- Toxic effect of three imidazole ionic liquids on two terrestrial plants

- Biosurfactant production by a Bacillus megaterium strain

- Distribution and density of Lutraria rhynchaena Jonas, 1844 relate to sediment while reproduction shows multiple peaks per year in Cat Ba-Ha Long Bay, Vietnam

- Biomedical Sciences

- Treatment of Epilepsy Associated with Common Chromosomal Developmental Diseases

- A Mouse Model for Studying Stem Cell Effects on Regeneration of Hair Follicle Outer Root Sheaths

- Morphine modulates hippocampal neurogenesis and contextual memory extinction via miR-34c/Notch1 pathway in male ICR mice

- Composition, Anticholinesterase and Antipedicular Activities of Satureja capitata L. Volatile Oil

- Weight loss may be unrelated to dietary intake in the imiquimod-induced plaque psoriasis mice model

- Construction of recombinant lentiviral vector containing human stem cell leukemia gene and its expression in interstitial cells of cajal

- Knockdown of lncRNA KCNQ1OT1 inhibits glioma progression by regulating miR-338-3p/RRM2

- Protective effect of asiaticoside on radiation-induced proliferation inhibition and DNA damage of fibroblasts and mice death

- Prevalence of dyslipidemia in Tibetan monks from Gansu Province, Northwest China

- Sevoflurane inhibits proliferation, invasion, but enhances apoptosis of lung cancer cells by Wnt/β-catenin signaling via regulating lncRNA PCAT6/ miR-326 axis

- MiR-542-3p suppresses neuroblastoma cell proliferation and invasion by downregulation of KDM1A and ZNF346

- Calcium Phosphate Cement Causes Nucleus Pulposus Cell Degeneration Through the ERK Signaling Pathway

- Human Dental Pulp Stem Cells Exhibit Osteogenic Differentiation Potential

- MiR-489-3p inhibits cell proliferation, migration, and invasion, and induces apoptosis, by targeting the BDNF-mediated PI3K/AKT pathway in glioblastoma

- Long non-coding RNA TUG1 knockdown hinders the tumorigenesis of multiple myeloma by regulating the microRNA-34a-5p/NOTCH1 signaling pathway

- Large Brunner’s gland adenoma of the duodenum for almost 10 years

- Neurotrophin-3 accelerates reendothelialization through inducing EPC mobilization and homing

- Hepatoprotective effects of chamazulene against alcohol-induced liver damage by alleviation of oxidative stress in rat models

- FXYD6 overexpression in HBV-related hepatocellular carcinoma with cirrhosis

- Risk factors for elevated serum colorectal cancer markers in patients with type 2 diabetes mellitus

- Effect of hepatic sympathetic nerve removal on energy metabolism in an animal model of cognitive impairment and its relationship to Glut2 expression

- Progress in research on the role of fibrinogen in lung cancer

- Advanced glycation end product levels were correlated with inflammation and carotid atherosclerosis in type 2 diabetes patients

- MiR-223-3p regulates cell viability, migration, invasion, and apoptosis of non-small cell lung cancer cells by targeting RHOB

- Knockdown of DDX46 inhibits trophoblast cell proliferation and migration through the PI3K/Akt/mTOR signaling pathway in preeclampsia

- Buformin suppresses osteosarcoma via targeting AMPK signaling pathway

- Effect of FibroScan test in antiviral therapy for HBV-infected patients with ALT <2 upper limit of normal

- LncRNA SNHG15 regulates osteosarcoma progression in vitro and in vivo via sponging miR-346 and regulating TRAF4 expression

- LINC00202 promotes retinoblastoma progression by regulating cell proliferation, apoptosis, and aerobic glycolysis through miR-204-5p/HMGCR axis

- Coexisting flavonoids and administration route effect on pharmacokinetics of Puerarin in MCAO rats

- GeneXpert Technology for the diagnosis of HIV-associated tuberculosis: Is scale-up worth it?

- Circ_001569 regulates FLOT2 expression to promote the proliferation, migration, invasion and EMT of osteosarcoma cells through sponging miR-185-5p

- Lnc-PICSAR contributes to cisplatin resistance by miR-485-5p/REV3L axis in cutaneous squamous cell carcinoma

- BRCA1 subcellular localization regulated by PI3K signaling pathway in triple-negative breast cancer MDA-MB-231 cells and hormone-sensitive T47D cells

- MYL6B drives the capabilities of proliferation, invasion, and migration in rectal adenocarcinoma through the EMT process

- Inhibition of lncRNA LINC00461/miR-216a/aquaporin 4 pathway suppresses cell proliferation, migration, invasion, and chemoresistance in glioma

- Upregulation of miR-150-5p alleviates LPS-induced inflammatory response and apoptosis of RAW264.7 macrophages by targeting Notch1

- Long non-coding RNA LINC00704 promotes cell proliferation, migration, and invasion in papillary thyroid carcinoma via miR-204-5p/HMGB1 axis

- Neuroanatomy of melanocortin-4 receptor pathway in the mouse brain

- Lipopolysaccharides promote pulmonary fibrosis in silicosis through the aggravation of apoptosis and inflammation in alveolar macrophages

- Influences of advanced glycosylation end products on the inner blood–retinal barrier in a co-culture cell model in vitro

- MiR-4328 inhibits proliferation, metastasis and induces apoptosis in keloid fibroblasts by targeting BCL2 expression

- Aberrant expression of microRNA-132-3p and microRNA-146a-5p in Parkinson’s disease patients

- Long non-coding RNA SNHG3 accelerates progression in glioma by modulating miR-384/HDGF axis

- Long non-coding RNA NEAT1 mediates MPTP/MPP+-induced apoptosis via regulating the miR-124/KLF4 axis in Parkinson’s disease

- PCR-detectable Candida DNA exists a short period in the blood of systemic candidiasis murine model

- CircHIPK3/miR-381-3p axis modulates proliferation, migration, and glycolysis of lung cancer cells by regulating the AKT/mTOR signaling pathway

- Reversine and herbal Xiang–Sha–Liu–Jun–Zi decoction ameliorate thioacetamide-induced hepatic injury by regulating the RelA/NF-κB/caspase signaling pathway

- Therapeutic effects of coronary granulocyte colony-stimulating factor on rats with chronic ischemic heart disease

- The effects of yam gruel on lowering fasted blood glucose in T2DM rats

- Circ_0084043 promotes cell proliferation and glycolysis but blocks cell apoptosis in melanoma via circ_0084043-miR-31-KLF3 axis

- CircSAMD4A contributes to cell doxorubicin resistance in osteosarcoma by regulating the miR-218-5p/KLF8 axis

- Relationship of FTO gene variations with NAFLD risk in Chinese men

- The prognostic and predictive value of platelet parameters in diabetic and nondiabetic patients with sudden sensorineural hearing loss

- LncRNA SNHG15 contributes to doxorubicin resistance of osteosarcoma cells through targeting the miR-381-3p/GFRA1 axis

- miR-339-3p regulated acute pancreatitis induced by caerulein through targeting TNF receptor-associated factor 3 in AR42J cells

- LncRNA RP1-85F18.6 affects osteoblast cells by regulating the cell cycle

- MiR-203-3p inhibits the oxidative stress, inflammatory responses and apoptosis of mice podocytes induced by high glucose through regulating Sema3A expression

- MiR-30c-5p/ROCK2 axis regulates cell proliferation, apoptosis and EMT via the PI3K/AKT signaling pathway in HG-induced HK-2 cells

- CTRP9 protects against MIA-induced inflammation and knee cartilage damage by deactivating the MAPK/NF-κB pathway in rats with osteoarthritis

- Relationship between hemodynamic parameters and portal venous pressure in cirrhosis patients with portal hypertension

- Long noncoding RNA FTX ameliorates hydrogen peroxide-induced cardiomyocyte injury by regulating the miR-150/KLF13 axis

- Ropivacaine inhibits proliferation, migration, and invasion while inducing apoptosis of glioma cells by regulating the SNHG16/miR-424-5p axis

- CD11b is involved in coxsackievirus B3-induced viral myocarditis in mice by inducing Th17 cells

- Decitabine shows anti-acute myeloid leukemia potential via regulating the miR-212-5p/CCNT2 axis

- Testosterone aggravates cerebral vascular injury by reducing plasma HDL levels

- Bioengineering and Biotechnology

- PL/Vancomycin/Nano-hydroxyapatite Sustained-release Material to Treat Infectious Bone Defect

- The thickness of surface grafting layer on bio-materials directly mediates the immuno-reacitivity of macrophages in vitro

- Silver nanoparticles: synthesis, characterisation and biomedical applications

- Food Science

- Bread making potential of Triticum aestivum and Triticum spelta species

- Modeling the effect of heat treatment on fatty acid composition in home-made olive oil preparations

- Effect of addition of dried potato pulp on selected quality characteristics of shortcrust pastry cookies

- Preparation of konjac oligoglucomannans with different molecular weights and their in vitro and in vivo antioxidant activities

- Animal Sciences

- Changes in the fecal microbiome of the Yangtze finless porpoise during a short-term therapeutic treatment

- Agriculture

- Influence of inoculation with Lactobacillus on fermentation, production of 1,2-propanediol and 1-propanol as well as Maize silage aerobic stability

- Application of extrusion-cooking technology in hatchery waste management

- In-field screening for host plant resistance to Delia radicum and Brevicoryne brassicae within selected rapeseed cultivars and new interspecific hybrids

- Studying of the promotion mechanism of Bacillus subtilis QM3 on wheat seed germination based on β-amylase

- Rapid visual detection of FecB gene expression in sheep

- Effects of Bacillus megaterium on growth performance, serum biochemical parameters, antioxidant capacity, and immune function in suckling calves

- Effects of center pivot sprinkler fertigation on the yield of continuously cropped soybean

- Special Issue On New Approach To Obtain Bioactive Compounds And New Metabolites From Agro-Industrial By-Products

- Technological and antioxidant properties of proteins obtained from waste potato juice

- The aspects of microbial biomass use in the utilization of selected waste from the agro-food industry

- Special Issue on Computing and Artificial Techniques for Life Science Applications - Part I

- Automatic detection and segmentation of adenomatous colorectal polyps during colonoscopy using Mask R-CNN

- The impedance analysis of small intestine fusion by pulse source

- Errata

- Erratum to “Diagnostic performance of serum CK-MB, TNF-α and hs-CRP in children with viral myocarditis”

- Erratum to “MYL6B drives the capabilities of proliferation, invasion, and migration in rectal adenocarcinoma through the EMT process”

- Erratum to “Thermostable cellulase biosynthesis from Paenibacillus alvei and its utilization in lactic acid production by simultaneous saccharification and fermentation”

Articles in the same Issue

- Plant Sciences

- Dependence of the heterosis effect on genetic distance, determined using various molecular markers

- Plant Growth Promoting Rhizobacteria (PGPR) Regulated Phyto and Microbial Beneficial Protein Interactions

- Role of strigolactones: Signalling and crosstalk with other phytohormones

- An efficient protocol for regenerating shoots from paper mulberry (Broussonetia papyrifera) leaf explants

- Functional divergence and adaptive selection of KNOX gene family in plants

- In silico identification of Capsicum type III polyketide synthase genes and expression patterns in Capsicum annuum

- In vitro induction and characterisation of tetraploid drumstick tree (Moringa oleifera Lam.)

- CRISPR/Cas9 or prime editing? – It depends on…

- Study on the optimal antagonistic effect of a bacterial complex against Monilinia fructicola in peach

- Natural variation in stress response induced by low CO2 in Arabidopsis thaliana

- The complete mitogenome sequence of the coral lily (Lilium pumilum) and the Lanzhou lily (Lilium davidii) in China

- Ecology and Environmental Sciences

- Use of phosphatase and dehydrogenase activities in the assessment of calcium peroxide and citric acid effects in soil contaminated with petrol

- Analysis of ethanol dehydration using membrane separation processes

- Activity of Vip3Aa1 against Periplaneta americana

- Thermostable cellulase biosynthesis from Paenibacillus alvei and its utilization in lactic acid production by simultaneous saccharification and fermentation

- Spatiotemporal dynamics of terrestrial invertebrate assemblages in the riparian zone of the Wewe river, Ashanti region, Ghana

- Antifungal activity of selected volatile essential oils against Penicillium sp.

- Toxic effect of three imidazole ionic liquids on two terrestrial plants

- Biosurfactant production by a Bacillus megaterium strain

- Distribution and density of Lutraria rhynchaena Jonas, 1844 relate to sediment while reproduction shows multiple peaks per year in Cat Ba-Ha Long Bay, Vietnam

- Biomedical Sciences

- Treatment of Epilepsy Associated with Common Chromosomal Developmental Diseases

- A Mouse Model for Studying Stem Cell Effects on Regeneration of Hair Follicle Outer Root Sheaths

- Morphine modulates hippocampal neurogenesis and contextual memory extinction via miR-34c/Notch1 pathway in male ICR mice

- Composition, Anticholinesterase and Antipedicular Activities of Satureja capitata L. Volatile Oil

- Weight loss may be unrelated to dietary intake in the imiquimod-induced plaque psoriasis mice model

- Construction of recombinant lentiviral vector containing human stem cell leukemia gene and its expression in interstitial cells of cajal

- Knockdown of lncRNA KCNQ1OT1 inhibits glioma progression by regulating miR-338-3p/RRM2

- Protective effect of asiaticoside on radiation-induced proliferation inhibition and DNA damage of fibroblasts and mice death

- Prevalence of dyslipidemia in Tibetan monks from Gansu Province, Northwest China

- Sevoflurane inhibits proliferation, invasion, but enhances apoptosis of lung cancer cells by Wnt/β-catenin signaling via regulating lncRNA PCAT6/ miR-326 axis

- MiR-542-3p suppresses neuroblastoma cell proliferation and invasion by downregulation of KDM1A and ZNF346

- Calcium Phosphate Cement Causes Nucleus Pulposus Cell Degeneration Through the ERK Signaling Pathway

- Human Dental Pulp Stem Cells Exhibit Osteogenic Differentiation Potential

- MiR-489-3p inhibits cell proliferation, migration, and invasion, and induces apoptosis, by targeting the BDNF-mediated PI3K/AKT pathway in glioblastoma

- Long non-coding RNA TUG1 knockdown hinders the tumorigenesis of multiple myeloma by regulating the microRNA-34a-5p/NOTCH1 signaling pathway

- Large Brunner’s gland adenoma of the duodenum for almost 10 years

- Neurotrophin-3 accelerates reendothelialization through inducing EPC mobilization and homing

- Hepatoprotective effects of chamazulene against alcohol-induced liver damage by alleviation of oxidative stress in rat models

- FXYD6 overexpression in HBV-related hepatocellular carcinoma with cirrhosis

- Risk factors for elevated serum colorectal cancer markers in patients with type 2 diabetes mellitus

- Effect of hepatic sympathetic nerve removal on energy metabolism in an animal model of cognitive impairment and its relationship to Glut2 expression

- Progress in research on the role of fibrinogen in lung cancer

- Advanced glycation end product levels were correlated with inflammation and carotid atherosclerosis in type 2 diabetes patients

- MiR-223-3p regulates cell viability, migration, invasion, and apoptosis of non-small cell lung cancer cells by targeting RHOB

- Knockdown of DDX46 inhibits trophoblast cell proliferation and migration through the PI3K/Akt/mTOR signaling pathway in preeclampsia

- Buformin suppresses osteosarcoma via targeting AMPK signaling pathway

- Effect of FibroScan test in antiviral therapy for HBV-infected patients with ALT <2 upper limit of normal

- LncRNA SNHG15 regulates osteosarcoma progression in vitro and in vivo via sponging miR-346 and regulating TRAF4 expression

- LINC00202 promotes retinoblastoma progression by regulating cell proliferation, apoptosis, and aerobic glycolysis through miR-204-5p/HMGCR axis

- Coexisting flavonoids and administration route effect on pharmacokinetics of Puerarin in MCAO rats

- GeneXpert Technology for the diagnosis of HIV-associated tuberculosis: Is scale-up worth it?

- Circ_001569 regulates FLOT2 expression to promote the proliferation, migration, invasion and EMT of osteosarcoma cells through sponging miR-185-5p

- Lnc-PICSAR contributes to cisplatin resistance by miR-485-5p/REV3L axis in cutaneous squamous cell carcinoma

- BRCA1 subcellular localization regulated by PI3K signaling pathway in triple-negative breast cancer MDA-MB-231 cells and hormone-sensitive T47D cells

- MYL6B drives the capabilities of proliferation, invasion, and migration in rectal adenocarcinoma through the EMT process

- Inhibition of lncRNA LINC00461/miR-216a/aquaporin 4 pathway suppresses cell proliferation, migration, invasion, and chemoresistance in glioma

- Upregulation of miR-150-5p alleviates LPS-induced inflammatory response and apoptosis of RAW264.7 macrophages by targeting Notch1

- Long non-coding RNA LINC00704 promotes cell proliferation, migration, and invasion in papillary thyroid carcinoma via miR-204-5p/HMGB1 axis

- Neuroanatomy of melanocortin-4 receptor pathway in the mouse brain

- Lipopolysaccharides promote pulmonary fibrosis in silicosis through the aggravation of apoptosis and inflammation in alveolar macrophages

- Influences of advanced glycosylation end products on the inner blood–retinal barrier in a co-culture cell model in vitro

- MiR-4328 inhibits proliferation, metastasis and induces apoptosis in keloid fibroblasts by targeting BCL2 expression

- Aberrant expression of microRNA-132-3p and microRNA-146a-5p in Parkinson’s disease patients

- Long non-coding RNA SNHG3 accelerates progression in glioma by modulating miR-384/HDGF axis

- Long non-coding RNA NEAT1 mediates MPTP/MPP+-induced apoptosis via regulating the miR-124/KLF4 axis in Parkinson’s disease

- PCR-detectable Candida DNA exists a short period in the blood of systemic candidiasis murine model

- CircHIPK3/miR-381-3p axis modulates proliferation, migration, and glycolysis of lung cancer cells by regulating the AKT/mTOR signaling pathway

- Reversine and herbal Xiang–Sha–Liu–Jun–Zi decoction ameliorate thioacetamide-induced hepatic injury by regulating the RelA/NF-κB/caspase signaling pathway

- Therapeutic effects of coronary granulocyte colony-stimulating factor on rats with chronic ischemic heart disease

- The effects of yam gruel on lowering fasted blood glucose in T2DM rats

- Circ_0084043 promotes cell proliferation and glycolysis but blocks cell apoptosis in melanoma via circ_0084043-miR-31-KLF3 axis

- CircSAMD4A contributes to cell doxorubicin resistance in osteosarcoma by regulating the miR-218-5p/KLF8 axis

- Relationship of FTO gene variations with NAFLD risk in Chinese men

- The prognostic and predictive value of platelet parameters in diabetic and nondiabetic patients with sudden sensorineural hearing loss

- LncRNA SNHG15 contributes to doxorubicin resistance of osteosarcoma cells through targeting the miR-381-3p/GFRA1 axis

- miR-339-3p regulated acute pancreatitis induced by caerulein through targeting TNF receptor-associated factor 3 in AR42J cells

- LncRNA RP1-85F18.6 affects osteoblast cells by regulating the cell cycle

- MiR-203-3p inhibits the oxidative stress, inflammatory responses and apoptosis of mice podocytes induced by high glucose through regulating Sema3A expression

- MiR-30c-5p/ROCK2 axis regulates cell proliferation, apoptosis and EMT via the PI3K/AKT signaling pathway in HG-induced HK-2 cells

- CTRP9 protects against MIA-induced inflammation and knee cartilage damage by deactivating the MAPK/NF-κB pathway in rats with osteoarthritis

- Relationship between hemodynamic parameters and portal venous pressure in cirrhosis patients with portal hypertension

- Long noncoding RNA FTX ameliorates hydrogen peroxide-induced cardiomyocyte injury by regulating the miR-150/KLF13 axis

- Ropivacaine inhibits proliferation, migration, and invasion while inducing apoptosis of glioma cells by regulating the SNHG16/miR-424-5p axis

- CD11b is involved in coxsackievirus B3-induced viral myocarditis in mice by inducing Th17 cells

- Decitabine shows anti-acute myeloid leukemia potential via regulating the miR-212-5p/CCNT2 axis

- Testosterone aggravates cerebral vascular injury by reducing plasma HDL levels

- Bioengineering and Biotechnology

- PL/Vancomycin/Nano-hydroxyapatite Sustained-release Material to Treat Infectious Bone Defect

- The thickness of surface grafting layer on bio-materials directly mediates the immuno-reacitivity of macrophages in vitro

- Silver nanoparticles: synthesis, characterisation and biomedical applications

- Food Science

- Bread making potential of Triticum aestivum and Triticum spelta species

- Modeling the effect of heat treatment on fatty acid composition in home-made olive oil preparations

- Effect of addition of dried potato pulp on selected quality characteristics of shortcrust pastry cookies

- Preparation of konjac oligoglucomannans with different molecular weights and their in vitro and in vivo antioxidant activities

- Animal Sciences

- Changes in the fecal microbiome of the Yangtze finless porpoise during a short-term therapeutic treatment

- Agriculture

- Influence of inoculation with Lactobacillus on fermentation, production of 1,2-propanediol and 1-propanol as well as Maize silage aerobic stability

- Application of extrusion-cooking technology in hatchery waste management

- In-field screening for host plant resistance to Delia radicum and Brevicoryne brassicae within selected rapeseed cultivars and new interspecific hybrids

- Studying of the promotion mechanism of Bacillus subtilis QM3 on wheat seed germination based on β-amylase

- Rapid visual detection of FecB gene expression in sheep

- Effects of Bacillus megaterium on growth performance, serum biochemical parameters, antioxidant capacity, and immune function in suckling calves

- Effects of center pivot sprinkler fertigation on the yield of continuously cropped soybean

- Special Issue On New Approach To Obtain Bioactive Compounds And New Metabolites From Agro-Industrial By-Products

- Technological and antioxidant properties of proteins obtained from waste potato juice

- The aspects of microbial biomass use in the utilization of selected waste from the agro-food industry

- Special Issue on Computing and Artificial Techniques for Life Science Applications - Part I

- Automatic detection and segmentation of adenomatous colorectal polyps during colonoscopy using Mask R-CNN

- The impedance analysis of small intestine fusion by pulse source

- Errata

- Erratum to “Diagnostic performance of serum CK-MB, TNF-α and hs-CRP in children with viral myocarditis”

- Erratum to “MYL6B drives the capabilities of proliferation, invasion, and migration in rectal adenocarcinoma through the EMT process”

- Erratum to “Thermostable cellulase biosynthesis from Paenibacillus alvei and its utilization in lactic acid production by simultaneous saccharification and fermentation”