Abstract

The rheological and mechanical properties of bituminous binders vary significantly depending on the crude oil source. Consequently, the response of binders from different sources to polymer modification also differs. This study compares the rheological performance of B160/220 penetration-grade binders sourced from the Turkey-Batman and Iraq-Lanaz refineries, modified with styrene-butadiene-styrene (SBS), the most widely used polymer additive. To evaluate high-temperature performance, performance grade and frequency sweep tests were conducted using a dynamic shear rheometer. In addition to experimental assessments, the rheological behavior of the binders was analyzed using the Christensen–Anderson, Cross, and Carreau-Yasuda models. Time-temperature superposition principle master curves were generated to characterize their viscoelastic behavior. Zero shear viscosity (ZSV) values were determined using the Cross and Carreau-Yasuda models to examine the impact of polymer modification on binder viscosity. The findings indicate that the initial rheological properties of bitumen significantly influence its response to SBS modification. For instance, the G*/sin δ value increased by up to 199% at 64°C with 4% SBS addition, while the softening point rose by 9.5°C compared to unmodified binders. Modelled ZSV values showed more than a sevenfold increase in some cases, especially in Iraqi binders. On the other hand, at −18°C, the m-value dropped to 0.282 in the B-SBS4 binder, indicating a potential risk of low-temperature cracking. While polymer modification improved the rheological properties of both bitumen types, its effectiveness varied depending on the source.

Graphical abstract

1 Introduction

With the rapid growth of population, industrialization, and globalization, modern transportation has also evolved significantly. Hot mix asphalt (HMA) has become one of the most widely used construction materials due to its advantages, such as driving comfort, quick traffic reopening, and durability [1,2]. HMA is a composite material composed of bitumen as the binder and aggregates as the structural framework, exhibiting viscoelastic and thermoplastic behavior. The temperature- and time-dependent viscoelastic nature of bitumen is one of its most distinctive properties [3,4], as its behavior ranges between that of a viscous fluid and an elastic solid. During its service life, bitumen is exposed to a wide range of temperatures and loading conditions. At high temperatures and long loading durations, it behaves as a viscous fluid, making it more prone to permanent deformation. Conversely, at low temperatures and short loading durations, it behaves like an elastic solid, increasing the risk of brittle fracture [5,6]. For this reason, there has been a need to research additives with practical application potential, and very successful studies have been carried out for this purpose [7,8]. For decades, multidisciplinary research has sought to clarify this complex behavior, with polymer modification emerging as the most common approach to optimizing binder properties [9]. A wide variety of polymer materials are used for asphalt as well as for other engineering structures [10,11]. One of the most widely used polymer additives in bitumen is styrene-butadiene-styrene (SBS) block copolymer, which belongs to the elastomer family [12]. SBS enhances the rheological properties of bitumen by increasing its elasticity and improving performance across a wide temperature range. The effectiveness of SBS modification depends on several factors, including polymer concentration, the chemical and colloidal structure of bitumen, and mixing conditions such as temperature and duration [13]. Extensive research has demonstrated that SBS modification enhances rutting resistance at high temperatures and fatigue resistance at low temperatures [14,15]. Some cost disadvantages of SBS should not be overlooked as well. Recent studies have explored alternative binder modification strategies such as bio-oils and polymer blends to enhance sustainability. These approaches may offer environmental and economic advantages, though SBS remains the benchmark for high-performance applications due to its superior rheological properties [16].

Despite its low proportion in asphalt mixtures, bitumen plays a critical role in pavement performance by binding aggregates and other materials [17]. Consequently, the quality of the binder directly influences pavement durability and service life [18]. Bitumen, a byproduct of petroleum refining, has a complex chemical structure that varies depending on the crude oil source and refining method (e.g., straight-run or blown processes) [19]. These variations result in significant differences in bitumen properties [20,21]. Given this complexity, bitumen is commonly analyzed using SARA fractionation, a standard method that categorizes bitumen into saturates, aromatics, resins, and asphaltenes based on solubility in solvents of different polarities [22,23]. Studies have shown that SARA fractions influence key rheological properties, such as dynamic modulus, viscosity, and temperature sensitivity, which are closely linked to bitumen’s colloidal structure and composition [24,25,26,27]. Understanding the relationship between chemical composition, microstructure, and rheology is essential for optimizing bitumen performance.

Several studies have highlighted the impact of crude oil source on bitumen properties. Pei et al. [28] analyzed binders from four petroleum sources and found significant variations in chemical composition, thermal properties, and aging behavior. Similarly, Michalica et al. [20] examined bitumen from Cold Lake (Canada) and the Urals (Russia), revealing substantial differences in asphaltene content, heteroatom concentration, and temperature performance. Cold Lake bitumen exhibited superior resistance to both low-temperature cracking and high-temperature rutting, whereas Urals bitumen was more brittle at low temperatures and less durable at high temperatures due to its higher wax content. Cold Lake bitumen also demonstrated greater resistance to oxidative aging and lower temperature sensitivity. Wu et al. [29] explored the chemical and microstructural factors affecting viscosity in binders from three different sources. Their study developed predictive models based on molecular weight, carbonyl and sulfoxide indices, showing that bitumen viscosity changes significantly with aging, particularly in high-sulfur samples. Another study [30] investigated the variations in short- and long-term performance and moisture damage resistance of Indian bitumen. The results underscored the strong influence of crude oil source on binder durability and suggested that conventional quality control measures may be insufficient. Additionally, research has shown that binders from different crude sources respond differently to antioxidants, further influencing their chemical and rheological properties [31]. Zhai et al. [32] analyzed the physicochemical and thermodynamic properties of nine bitumen samples from different refineries, demonstrating that crude oil source significantly affects cohesion properties. Similarly, Djimasbe et al. [33] found that refining processes also influence bitumen characteristics. These findings highlight the importance of considering crude oil origin and refining methods when evaluating binder performance.

As discussed, the chemical and rheological properties of bitumen vary significantly based on crude oil source and refining process [34]. Even within the same penetration grade, bitumen from different refineries may differ in chemical composition, aromatic and saturate content, and rheological response. These variations are particularly pronounced during polymer modification, directly affecting the efficiency of SBS-bitumen interactions. While some bitumens exhibit good compatibility with SBS, others hinder polymer dispersion and swelling, limiting modification effectiveness [35]. Higher concentrations of unsaturated and aromatic components enhance polymer solubility and improve modification efficiency, whereas high saturate content may inhibit polymer swelling, leading to phase separation issues [36,37,38].

Moreover, oxidation resistance, thermal stability, and aging behavior differ across bitumen sources, significantly influencing long-term pavement performance [39]. Understanding these refinery-dependent variations is essential for optimizing polymer modification strategies. Even within the same penetration grade, differences in modified bitumen behavior are critical for asphalt pavement durability and must be considered in road engineering applications.

Although numerous studies have explored the effects of SBS on bitumen properties, most have overlooked the influence of crude oil source on polymer modification efficiency. Moreover, advanced rheological modeling approaches and comparative analyses across different binder sources remain limited. These gaps hinder the development of source-specific binder design strategies, highlighting the need for more comprehensive and performance-oriented investigations.

1.1 Study overview

Although polymer modification is a well-established technique for improving bitumen performance, the variability in base bitumen properties – particularly due to differences in crude oil source – can lead to significant inconsistencies in the modification outcome. This study is motivated by the need to understand how binders from different origins, yet with similar grade specifications, respond to SBS modification under identical conditions. Gaining such insight is essential for improving binder selection strategies and ensuring consistent pavement performance.

This study examines SBS-modified bituminous binders of the same penetration grade sourced from Batman (Turkey) and Lanaz (Iraq). The rheological properties of SBS-modified binders were analyzed in detail, providing insights into the fundamental differences between binders from these two regions. Additionally, this research offers a novel perspective by comprehensively evaluating the polymer modification process through rheological modeling. Conventional binder tests, rotational viscometer (RV) analysis, and dynamic shear rheometer (DSR) tests, including performance grade and frequency sweep (FS) tests, were conducted. The FS results were further analyzed using numerical and mechanistic rheological models to investigate the viscoelastic response and flow properties of both pure and modified binders.

2 Materials and method

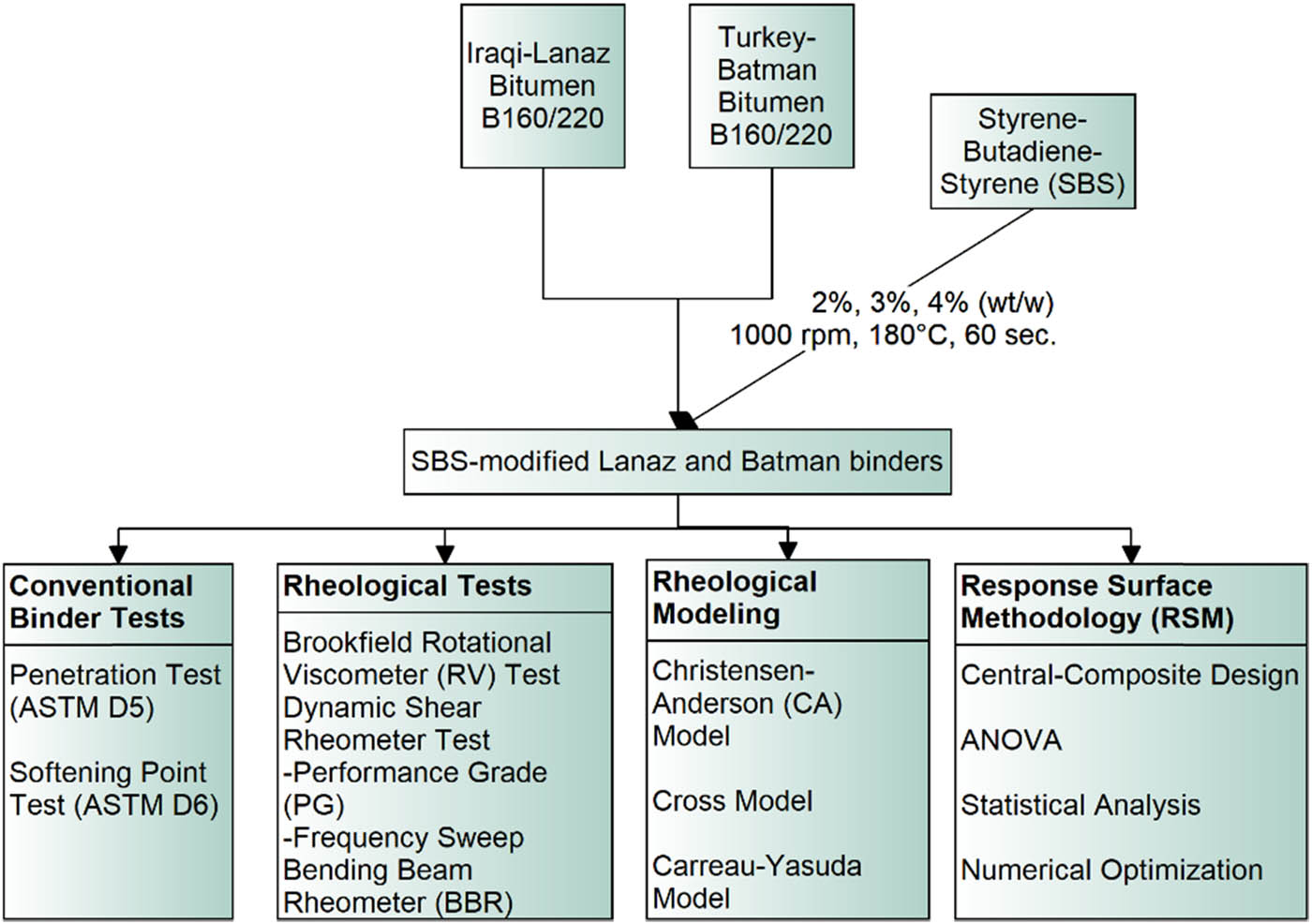

A schematic representation of the experimental procedure followed in the study is given in Figure 1.

Experimental flowchart of the study.

2.1 Bitumen supplied from different refineries

In this study, bituminous binders from two different refineries with different crude oil sources were used. These binders, supplied from Batman refinery in Turkey and Lanaz refinery in Iraq, have a penetration grade of B160/220 and are among the medium hardness binders. The penetration grade of the selected binders is in a range widely preferred for asphalt pavements and is particularly suitable for use in HMA production and applications. Considering that bitumen obtained from different refineries may differ in terms of chemical composition and rheological properties, the analyses carried out within the scope of this study aim to determine the viscoelastic behavior of the binders and to investigate their responses to the modification process comparatively.

2.2 SBS

SBS (SBS-MD-243), the most widely used bitumen additive, was preferred as the additive in the study. The basic properties of SBS are given in Table 1.

Properties of elastomer additives

| Features | SBS |

|---|---|

| Molecule structure | Linear |

| Styrene/butadiene ratio | 31/69 |

| Density (cm/m3) | 0.94 |

| Fat content | N/A |

| Viscosity (% 5, cps) | — |

| Melting index (190℃/kgw) | <1 |

| Tensile strength (kgw/cm2) | 324 |

| Hardness | 70 |

| Ash content | — |

| Elongation at break (%) | 880 |

2.3 Preparation of SBS-modified bitumen

After the pure binders were fluidized by heating in an oven, a certain amount of bitumen (400 g) was transferred to the mixing vessel. Then, SBS was added at the ratios of 2, 3, and 4% by weight of bitumen and mixed at 180°C at 1,000 rpm for 60 min [40,41,42]. It is known that 180°C is the recommended temperature for SBS modification [43,44]. Both bituminous binders were subjected to the same modification conditions. The appearance of the mechanical mixer with additive and temperature controlled bitumen vessel is given in Figure 2.

SBS polymer and mechanical mixer.

2.4 Conventional binder tests

According to ASTM D5, the penetration test is performed by measuring the depth, in decimillimeters (dmm), to which a standard needle penetrates the asphalt binder in 5 s under a load of 100 g at 25°C. This value is an indirect measure of the binder’s viscosity at 25°C. Typical penetration values range from 15 to 200 dmm; lower values indicate harder binders, which are preferred for use in hot regions. The softening point test, performed according to ASTM D36, is conducted to determine the temperature at which the binder begins to flow. The binder is placed in a brass ring, topped with a steel ball, and the samples are heated in a water or glycerin bath, with the temperature increasing by 5°C/min. The temperature at which the binder contacts the base plate is the softening point. Typical values range from 35 to 65°C, with higher values indicating harder binders.

2.5 Brookfield RV test

RV test is performed to determine the pumpability, mixability, and workability properties (high temperature properties) of bitumen. The viscosity values found as a result of this test are used to determine the mixing and compression temperature values of bitumen. The viscosity value is calculated by measuring the torque (moment of force) required to rotate the roller shaft in the bitumen sample with constant temperature in order to maintain its speed. In this study, viscosity measurements were carried out using the SC4-29 spindle-equipped Brookfield DV-III device at 135 and 165°C, following the ASTM D4402 standard.

2.6 DSR test

The DSR test was conducted using a Bohlin DSRII rheometer to assess the rheological behavior of Iraqi Lanaz and Turkey Batman binders under controlled-stress conditions within a temperature range of 52–70°C. This test was performed in accordance with the ASTM D7175 standard, which is widely used for evaluating the viscoelastic properties of asphalt binders, particularly their resistance to permanent deformation at high service temperatures. During testing, a 25 mm diameter parallel plate geometry was utilized with a 1 mm gap between the upper and lower plates. The applied oscillatory shear frequency was set to 1.59 Hz, which corresponds to a loading time of approximately 0.63 s, simulating the shear stresses experienced by the binder in real-world traffic conditions. The rutting resistance parameter (G*/sin δ) was determined for each binder, providing insights into their stiffness and ability to resist deformation under repeated loading. Additionally, phase angle (δ) values were measured to characterize the balance between elastic and viscous responses of the binders, aiding in the identification of modifications that enhance elasticity and delay permanent deformation. The results of this study contribute to a comprehensive understanding of the high-temperature performance of both unmodified and modified binders, allowing for a comparative evaluation of their suitability for asphalt pavement applications. By analyzing the rheological responses, it becomes possible to determine the effectiveness of polymer modification strategies in improving the stiffness, elasticity, and overall rutting resistance of the binders, ensuring enhanced durability and long-term pavement performance under varying climatic and traffic conditions.

2.7 FS test

The FS test for asphalt binders using a DSR is a critical method for evaluating the viscoelastic properties of asphalt materials under varying conditions. This test is designed to assess the complex shear modulus (G*) and phase angle (δ) of asphalt binders, which are essential for predicting their performance in pavement applications. The FS test is particularly valuable as it allows for the examination of the material’s behavior across a range of frequencies, simulating the conditions that asphalt pavements experience under traffic loads [45]. In conducting the FS test, asphalt binder samples are subjected to oscillatory shear loading at different frequencies, typically ranging from 0.01 to 10 Hz, while maintaining a constant temperature. The temperature is often set at elevated levels, such as 40, 50, 60, and 70°C, to replicate the high-temperature conditions that asphalt pavements encounter during service [46].

With the FS test, the asphalt binder can oscillate at different frequencies under a constant tension and the differentiation of the oscillation frequency allows the viscoelastic properties of the asphalt binder to be evaluated. With this test, the speed of a vehicle travelling on the asphalt pavement is simulated and it is assumed that a loading frequency of 10 Hz corresponds to a speed of 60–65 km/h [47]. Frequency-sweep test was conducted within the linear viscoelastic range of the binder. Asphalt binders, to which the test temperature was applied with 10°C increments between 40 and 70°C, were loaded at a frequency in the range of 0.01–10 Hz.

2.8 Rheological assessment of dynamical-mechanical behavior

2.8.1 Christensen–Anderson (CA) model

The analysis of FS master curves, particularly those constructed using the time-temperature superposition principle (TTSP), allows for a comprehensive understanding of the rheological behavior of asphalt binders [48,49]. By horizontally shifting the data obtained from DSR tests at various temperatures, master curves can be generated at a reference temperature, facilitating the comparison of viscoelastic properties across different conditions [50,51]. These master curves can then be analyzed using various rheological models, which provide insights into the material’s performance characteristics under different loading and temperature conditions [52].

One such model is the CA model, which is widely used for characterizing the viscoelastic properties of asphalt binders [53]. The CA model is based on the assumption that the complex shear modulus (G*) can be expressed as a function of frequency (ω) and temperature (T) (Figure 3). The model incorporates parameters that account for the material’s behavior in both the linear and nonlinear viscoelastic regions, making it suitable for predicting the performance of asphalt under various conditions [54,55].

Christensen and Anderson developed an empirical analytical model in 1992 as part of the strategic highway research program to describe the rheological behavior of asphalt binders. In this model, presented in equation (1), the rheological behavior is described in terms of G* values as a function of the frequency applied to the bituminous binder. Although the original purpose of the model was to characterize pure bitumen, it has recently been used to describe the behavior of modified bitumen. Numerous studies have been carried out with the CA model [55,56,57]. A typical curve of the CA model is given in Figure 3.

Definition of CA model.

ωc represents the frequency at which the viscous and elastic modulus values are the same. This is also the point where the viscous asymptote and the glassy asymptote overlap. ωc characterizes the overall hardness of the asphalt binder. R is defined as the difference between the complex modulus at ωc and the intercept asymptotes, also called shape factor. An increase in R indicates a decrease in the viscous properties of the asphalt binder at intermediate loading times and temperatures, and an improvement in its elastic properties, and gives the idea that it will show wider relaxation spectra.

2.8.2 Cross model

One of the key outputs of the FS test is complex viscosity, which represents the material’s resistance to flow and significantly influences the workability of asphalt mixtures [58]. As a result, the viscosity properties of modified bitumen have been widely studied and can be evaluated using various methods. The viscosity of viscoelastic materials, such as bituminous binders, can be determined through dynamic shear measurements, where the viscosity measured in the dynamic domain is referred to as “complex viscosity.”

Complex viscosity values can be interpreted as shear viscosity and modeled using various nonlinear flow models. The nonlinear shear viscosity characteristics and shear-thinning behavior of bitumen can be effectively described using generalized Newtonian models [59]. In particular, the Cross and Carreau-Yasuda models have been developed to analyze the viscoelastic properties of asphalt binders, focusing on how complex viscosity varies with frequency or shear rate. These models provide valuable insights into the rheological behavior of asphalt under different temperature and loading conditions, capturing essential viscosity-related properties such as shear-thinning effects and stiffness at specific temperatures.

The Cross model is widely employed to characterize the shear-thinning behavior of non-Newtonian fluids, including asphalt binders. The Cross model is given in equation (2) [59,60].

where n is the viscosity value and

2.8.3 Carreau-Yasuda model

The Carreau-Yasuda model is an enhanced version of the Carreau model, incorporating an additional parameter to provide a more flexible representation of shear-thinning behavior. This modification enables a more precise characterization of the viscosity-shear rate relationship over a broader range, making it particularly suitable for bituminous binders [61,62]. The Carreau-Yasuda model is given in equation (3) [63].

The parameter a in this model controls the transition region of the viscosity-shear rate curve and is used when the binder exhibits a more flexible transition to shear rate. Lower values indicate that the transition region of the curve is more pronounced and sharp, while higher values indicate a smoother transition. Compared to the Carreau Model, the Carreau-Yasuda model is capable of characterizing the viscosity behavior at both low and high shear rates. In this study, the complex viscosity master curves of pure and modified binders were analyzed with the Carreau-Yasuda model. In all viscosity models, when the zero shear rate viscosity (η 0) is high, the stiffness of the bitumen under load increases, indicating that it may be more resistant to permanent deformation at high temperatures. In the study, the error rates were determined by comparing the zero shear viscosity (ZSV) values obtained from both models.

2.9 Bending beam rheometer (BBR) test

The BBR test was conducted to evaluate the low-temperature performance of the modified and unmodified binders by determining their creep stiffness (St) and m-value in accordance with ASTM D6648-08 standard. The test was performed using a ATS BBR device under controlled environmental conditions at −12, −18, and −24°C. For the experiment, rectangular bitumen beams with dimensions of 125 mm (length) × 12.5 mm (width) × 6.25 mm (thickness) were prepared and conditioned in a temperature-controlled chamber for 1 h before testing. The beams were subjected to a constant load of 980 mN (100 g) for 240 s (4 min) while being submerged in a low-temperature fluid bath to maintain the desired test temperature.

The primary parameters obtained from the BBR test are creep stiffness (St) and the stiffness curve slope (m-value), which characterize the binder’s resistance to thermal cracking. To ensure sufficient flexibility and stress relaxation at low temperatures, the creep stiffness should not exceed 300 MPa, while the m-value should be greater than 0.300.

In this study, BBR test results were used to evaluate the low-temperature performance of the Turkey-Batman and Iraq-Lanaz binders, both in their unmodified and SBS-modified forms. The findings provided insights into the effectiveness of SBS modification in enhancing the thermal cracking resistance of the binders. The test was conducted on pressure aging vessel residual specimens after rotational thin-film oven test aging and was specifically applied to the I-SBS4 and B-SBS4 binders, which exhibited the highest risk of thermal cracking at low temperatures.

2.10 Analysis of SBS-modification via response surface methodology (RSM)

RSM is a statistical technique used in experimental design, modeling, analysis and optimization processes. This method builds mathematical models with experimental data to examine the effects of one or more variables on one or more outputs [64]. It is often used to determine the optimal conditions in complex systems. RSM is a powerful tool for understanding the interactions of variables and improving the response of the system. Thus, it is aimed to obtain maximum information with minimum experimentation. Within the scope of the study, RSM analysis was performed to analyze the effect of SBS modification on the rheological behavior of different bituminous binders and the analysis was applied with Design Expert software.

Although SBS significantly improves the rheological performance of bitumen, it has certain economic drawbacks. The high cost of SBS polymer and the additional energy required for high-temperature mixing increase the overall production cost of modified binders. These factors may limit its widespread adoption, especially in cost-sensitive projects or regions with limited access to polymer materials [65]. For this reason, determining the optimum SBS rate is important. The central composite design approach was used to systematically evaluate the effect of three different variables. Factors and responses are given in Table 2.

Factors and responses for RSM analysis

| Factor | Name | Unit | Type | Subtype | Min. | Max. | Coded low | Coded high | Mean value | Std. dev. |

|---|---|---|---|---|---|---|---|---|---|---|

| A | Frequency | Hz | Numeric | Continuous | 0.01 | 10 | −1 ↔ 0.01 | +1 ↔ 10.00 | 5.11 | 3.17 |

| B | SBS ratio | % | Numeric | Continuous | 0 | 4 | −1 ↔ 2.00 | +1 ↔ 4.00 | 2.22 | 1.49 |

| C | Temperature | °C | Numeric | Continuous | 40 | 70 | −1 ↔ 40.00 | +1 ↔ 70.00 | 55.48 | 11.06 |

| Response | Name | Units | Observations | Minimum | Maximum | Mean value | Std. dev. | Ratio | ||

| Iraq-Lanaz | G* | Pa | 155 | 2 | 182,000 | 24,384 | 38316.71 | 91,000 | ||

| Turkey-Batman | G* | Pa | 157 | 1.492 | 163,500 | 24,307 | 38247.16 | 109,584 | ||

The adequacy and significance of the developed model were assessed through statistical analysis, including the coefficient of determination (R 2), analysis of variance (ANOVA), and lack-of-fit tests. Additionally, three-dimensional response surface plots and contour plots were generated to visualize the interaction effects between the variables and identify the optimal SBS content and temperature conditions for enhanced rheological performance.

3 Results and discussion

3.1 Conventional binder tests results

Figure 4 shows the penetration test results of bitumen with two different origins and modified with SBS at different ratios.

Penetration values of SBS-modified Iraqi and Batman bitumen.

The penetration test results highlight the impact of SBS modification on the hardness and consistency of bituminous binders. Unmodified binders exhibit the highest penetration values, indicating lower viscosity and a softer binder structure. With the addition of SBS, penetration values decrease significantly, reflecting an increase in stiffness. This trend suggests that polymer modification strengthens the elastic network within the binder, limiting molecular mobility and enhancing resistance to deformation. At the same modification levels, Iraqi bitumen exhibit lower penetration values than Turkish bitumen, likely due to differences in their base bitumen properties. These findings confirm that SBS modification substantially increases binder stiffness, which is beneficial for high-temperature performance. The softening point values of both pure and modified binders are presented in Figure 5.

Softening point values of SBS-modified Iraqi and Batman bitumen.

The softening point values in the graph show the differences in the thermal resistance of pure and SBS modified bituminous binders from Iraq (I) and Batman (B). The results show that SBS modification significantly increases the softening point for both bitumen types. Pure bitumens (I-Pure and B-Pure) had the lowest softening points and these values were observed to increase as the degree of modification increased (SBS2, SBS3, and SBS4). The fact that the binders modified with SBS4 have the highest softening points shows that the SBS polymer provides an effect that increases the hardness and viscosity in the binder matrix. It was observed that Iraqi bitumen generally presented a higher softening point compared to Batman bitumen, suggesting that the initial viscosity or component distribution of Iraqi bitumen may be more favorable in terms of thermal stability. In addition, the softening point increased with increasing SBS polymer content, indicating that the modification improved the elastic behavior of the binder and its stability against temperature.

3.2 Brookfield RV test

Viscosity measurements of binders at 135 and 165°C temperatures are given in Figure 6. As seen in Figure 6, viscosity values decreased with increasing temperature in all binder samples. The increase in temperature increases the molecular mobility and the resistance value of the binders against flow, viscosity, decreases. For both binders, the effect of the use of SBS on viscosity is clearly seen. The addition of SBS increased the viscosity values of the binders in a regular manner. The lowest viscosity values were observed in pure binders, Iraqi bitumen presented higher viscosity values compared to Batman bitumen. This was also the case for each SBS ratio. The results of the rotational viscosity test show that Iraqi bitumen will be more resistant to permanent deformations.

Rotational viscosity test results of binders.

Mixing and compression temperature ranges are given in Table 3. The mixing and compaction temperature results obtained from the rotational viscosity test reveal the impact of SBS modification on the workability of the binders. The unmodified binders (I-Pure and B-Pure) exhibit the lowest temperature ranges, indicating their relatively lower viscosity and ease of handling. However, as the SBS content increases, both the mixing and compaction temperatures progressively rise, reflecting the increased viscosity and stiffness of the modified binders. The highest mixing and compression temperatures were found in I-SBS3 and I-SBS4. These findings suggest that while SBS modification improves high-temperature performance by increasing viscosity and stiffness, it also necessitates higher processing temperatures. This increased demand for energy should be considered in practical applications to balance enhanced performance with economic and environmental concerns.

Mixing and compaction temperature ranges of pure and modified binders

| Binder type | Mixing temperature range (°C) | Compaction temperature range (°C) |

|---|---|---|

| I-Pure | 145.8–153.2 | 130.5–137.2 |

| I-SBS-2 | 155.3–162.1 | 141.5–147.5 |

| I-SBS-3 | 164.5–172.1 | 148.7–155.7 |

| I-SBS-4 | 165.2–172.1 | 150.8–157.1 |

| B-Pure | 143.0–150.1 | 128.1–134.6 |

| B-SBS-2 | 151.7–158.5 | 137.5–143.9 |

| B-SBS-3 | 156.9–163.6 | 142.9–149.1 |

| B-SBS-4 | 162.9–169.3 | 149.6–155.4 |

3.3 DSR test results

DSR test results of Iraq-Lanaz and Turkey-Batman bitumen modified with SBS are given in Figure 7.

DSR results of SBS-modified Iraqi and Batman binders.

DSR results provide critical insights into the viscoelastic behavior of the SBS-modified bitumen, as reflected by the complex shear modulus (G*) and phase angle (δ). G* represents the material’s resistance to deformation under shear stress, with higher values indicating greater stiffness and better resistance to rutting at high temperatures. The phase angle (δ) reflects the balance between elastic (solid-like) and viscous (liquid-like) behavior, where lower values indicate more elastic and less viscous response, which is desirable for improved fatigue resistance. The results show that both Iraqi (I) and Batman (B) bitumen exhibit increased G* and reduced δ with higher SBS content, indicating enhanced stiffness and elasticity. Notably, Batman bitumen demonstrates a more significant improvement in G* and a greater reduction in δ compared to Iraqi bitumen at equivalent SBS concentrations, suggesting better compatibility and performance enhancement with SBS modification. These improvements correlate with superior high-temperature performance, reduced rutting, and enhanced fatigue resistance in asphalt pavements, highlighting the importance of bitumen source and SBS content in optimizing asphalt performance. The highest rutting parameter and the lowest phase angle values were observed in I-SBS4 specimen. It is not correct to comment only on phase angle values. This value is an important viscoelastic parameter, but the G*/sin δ value provides more consistent results. When Figure 7 is analyzed, while there is a significant phase angle difference between B-SBS4 and I-SBS3, G*/sin δ results show that I-SBS3 is more resistant to rutting. However, from another point of view, it can be concluded that SBS modified Iraqi bitumen offers higher performance in terms of rutting, while Batman bitumen is more successful according to the SBS modification effect. Modification index (MI) values calculated according to G*/sin δ values are given in Table 4. When Table 4 is analyzed, these results are confirmed. The highest MI values at each temperature and additive ratio were found in Batman bitumen. In this case, it can be said that the level of interaction with SBS varies according to the source of bitumen. The MI value was obtained by dividing the rutting parameter of the modified binder by that of the pure binder.

MI values of binders

| Temp. (°C) | I-SBS2 | I-SBS3 | I-SBS4 | B-SBS2 | B-SBS3 | B-SBS4 |

|---|---|---|---|---|---|---|

| 52 | 1.26 | 1.93 | 2.14 | 2.41 | 2.55 | 2.84 |

| 58 | 1.25 | 1.98 | 2.19 | 2.29 | 2.58 | 2.91 |

| 64 | 1.22 | 1.99 | 2.27 | 2.29 | 2.60 | 2.99 |

FS test was performed on pure and SBS-modified Iraqi and Batman bituminous binders at ten different frequencies (0.01–10 Hz) and four different temperatures (40, 50, 60, and 70°C) and the results are given in Figure 8.

FS test results of binders under 0.01–10 Hz and 40–70°C.

Bituminous binders exhibit viscoelastic and thermoplastic behavior, with their mechanical properties being highly dependent on both time and temperature. The FS test, which systematically evaluates these two critical variables over a broad range, is therefore a fundamental method for characterizing bituminous materials. At low temperatures or high loading rates, elastic properties tend to dominate, whereas at elevated temperatures and extended loading durations, viscous behavior becomes more pronounced [66]. An analysis of Figure 8 reveals that the complex modulus (G*) decreases with increasing temperature. Additionally, G* increases with frequency; however, beyond a low frequency threshold such as 0.01 Hz, the rate of increase slows down. Based on these observations, high temperatures combined with low frequencies (i.e., prolonged loading times) represent the most critical conditions for bituminous binders. From this perspective, constructing a master curve based on the TTSP emerges as the most appropriate approach. Figure 9 presents the TTSP master curves for Iraqi and Batman bitumen modified with varying ratios of SBS.

TTSP master curves of binders.

The master curves presented in Figure 9 were constructed by shifting the data to a reference temperature of 40°C. These curves were generated by consolidating data from different temperatures into a single curve using appropriate shift factors, enabling the evaluation of material behavior at frequencies significantly lower than the minimum test frequency of 0.01 Hz. An analysis of Figure 9 indicates that the highest shear deformation resistance was observed in the I-SBS4 binder across all frequency values. This was followed by I-SBS3, B-SBS4, B-SBS3, B-SBS2, and I-SBS2, in descending order. While the complex modulus values of the binders tend to converge at higher frequencies, the effect of modification becomes more pronounced at lower frequencies. When comparing the G* values of unmodified Iraq and Batman bitumen, it is evident that Batman bitumen exhibits lower resistance values than Iraq bitumen. However, this difference diminishes with increasing frequency, and at high frequencies, both binders exhibit nearly similar resistance characteristics. SBS modification significantly enhances the resistance of unmodified binders to permanent deformation. This effect is particularly evident under high loading durations and elevated temperatures, which are identified as the most critical conditions. It has been determined that as the SBS content increases, elastic behavior becomes more dominant, contributing to the development of flexible pavements with improved resistance to permanent deformation. Additionally, the master curves in Figure 9 appear smooth and thermo-rheologically simple, indicating the reliability and consistency of the experimental data. To further investigate the rheological differences observed in the master curves, the CA model was applied for analysis. As an example, the CA model curves for the two unmodified bitumens are illustrated in Figure 10, while the corresponding CA model parameters are presented in Table 5.

CA model fit curves of I-Pure and B-Pure binders.

CA model parameters of pure and modified Iraqi-Batman binders

| Binder | Parameter | Value | R 2 |

|---|---|---|---|

| I-Pure | G | 1 × 1009 | 0.998 |

| ωc | 327 | ||

| R | 1.38 | ||

| B-Pure | G | 1 × 1009 | 0.996 |

| ωc | 788 | ||

| R | 1.2 | ||

| I-SBS2 | G | 1 × 1009 | 0.998 |

| ωc | 42.38 | ||

| R | 1.59 | ||

| I-SBS3 | G | 1 × 1009 | 0.996 |

| ωc | 34.63 | ||

| R | 1.97 | ||

| I-SBS4 | G | 1 × 1009 | 0.995 |

| ωc | 31.74 | ||

| R | 2.01 | ||

| B-SBS2 | G | 1 × 1009 | 0.996 |

| ωc | 40.65 | ||

| R | 1.67 | ||

| B-SBS3 | G | 1 × 1009 | 0.999 |

| ωc | 37.52 | ||

| R | 1.83 | ||

| B-SBS4 | G | 1 × 1009 | 0.998 |

| ωc | 35.46 | ||

| R | 1.88 |

An examination of Figure 10 reveals that the CA model allows for a broader evaluation of complex modulus behavior. Up to the experimental maximum frequency (10 Hz), the I-Pure binder exhibits higher complex modulus values. However, at very high frequencies, the B-Pure binder demonstrates superior performance. These findings suggest that Batman bitumen may be more suitable for applications involving high-frequency loading, such as heavy traffic conditions. The complex viscosity test results, presented in this study, further support these conclusions.

Figure 10 shows that the CA model was successfully applied on both Iraqi and Batman bitumen. It is seen that the curves of the binders are flattened at very high frequencies. Flattening of the master curve, i.e., becoming flatter and more horizontal, indicates that the binder gains a more stable structure in its viscoelastic behavior under different temperature and frequency conditions. It can be said that the sensitivity of a flattened master curve to frequency decreases [51,67,68]. It has been determined that the rheological behavior of bitumen can be successfully monitored at very high and very low frequencies with the CA model.

An examination of Table 5 reveals that the experimental master curves exhibit an excellent fit to the CA model, with R 2 values exceeding 0.99. Various studies have investigated the assumption of a glassy modulus (G g) of 1 GPa in shear strength assessments, concluding that most binders conform to this value. Previous research has recommended fixing the glassy modulus (G g) at 109 Pa, and it has been determined that the majority of binders exhibit this value [69]. In this study, the G g value was fixed at 109 Pa, while the other parameters (ωc and R) were left as free variables. According to Table 5, the highest ωc value was observed in Batman bitumen, whereas Iraqi bitumen exhibited a lower ωc value. A reduction in ωc corresponds to a decrease in the frequency at which the elastic and viscous modulus values are equal. The shift of this equality point toward lower frequencies indicates that the master curve is moving toward the elastic region. The incorporation of SBS significantly reduced ωc values, suggesting that SBS modification enhances the binder’s ability to maintain its elasticity under low-frequency and high-temperature conditions. Among the modified binders, the lowest ωc value was recorded for I-SBS4, followed by I-SBS3, B-SBS4, B-SBS3, B-SBS2, and I-SBS2. Except for the 2% SBS modification, Iraqi bitumen exhibited superior elastic performance compared to Batman bitumen. These findings are consistent with the DSR test results.

The parameter “R,” defined as the rheological index, characterizes the shape of the master curve and is associated with the width of the relaxation spectrum [70]. Additionally, R is a valuable tool for assessing the sensitivity of asphalt hardness to loading time and frequency variations. Even minor changes in asphalt hardness due to aging or chemical alterations can lead to significant variations in R values [71]. An increase in R indicates a broader relaxation spectrum, which corresponds to increased stiffness and a reduction in viscous behavior. As shown in Table 5, the lowest R value was observed in unmodified Batman bitumen, while R values consistently increased with the incorporation of SBS. In addition to enhancing the stiffness of the bitumen, SBS modification improved its ability to maintain a non-Newtonian behavior under low-frequency and high-temperature conditions.

The ANOVA results of the curve fitting process performed using the CA model (Table 6) show that the model is highly significant in explaining the rheological behavior of the binders. The regression-derived sum of squares values for all binders are quite close to the corrected sum of squares values, indicating that the explanatory power of the model is high. The F values are quite high for all binders, indicating that the regression is highly statistically significant (p < 0.0001). Compared to the unmodified (pure) binders, the explanatory power of the regression is significantly increased in the SBS-modified binders; especially the regression sum of squares reached the highest levels for the I-SBS4 and B-SBS3 formulations. However, it was observed that the residual error sum of squares increased as the modification rate increased, suggesting that the model may contain some uncertainty in explaining the rheological behavior of binders with high polymer content. However, the rather low p-values indicate that the model provides a generally reliable prediction for all binder types and that the CA model is a powerful tool for evaluating the viscoelastic properties of bitumen binders with different modification levels.

ANOVA results for CA model analysis

| Binder | Data | DF | Sum of squares | Mean square | F value | Prob > F | R 2 |

|---|---|---|---|---|---|---|---|

| I-Pure | Regression | 2 | 1.52 × 1010 | 7.59 × 1009 | 1,529,313 | 6.18 × 10−94 | 0.99 |

| Residual | 38 | 188655.592 | 4964.62084 | ||||

| Uncorrected total | 40 | 1.52 × 1010 | |||||

| Corrected total | 39 | 1.06 × 1010 | |||||

| B-Pure | Regression | 2 | 1.93 × 1010 | 9.67 × 1009 | 418813.2 | 3.00 × 10−83 | 0.99 |

| Residual | 38 | 877617.0919 | 23095.18663 | ||||

| Uncorrected total | 40 | 1.93 × 1010 | |||||

| Corrected total | 39 | 1.31 × 1010 | |||||

| I-SBS2 | Regression | 2 | 9.52 × 1010 | 4.76 × 1010 | 108389.3 | 4.27 × 10−72 | 0.99 |

| Residual | 38 | 1.67 × 1007 | 439362.0531 | ||||

| Uncorrected total | 40 | 9.53 × 1010 | |||||

| Corrected total | 39 | 6.45 × 1010 | |||||

| I-SBS3 | Regression | 2 | 1.23 × 1011 | 6.15 × 1010 | 18156.4 | 4.39 × 10−56 | 0.99 |

| Residual | 37 | 1.25 × 1008 | 3385136.202 | ||||

| Uncorrected total | 39 | 1.23 × 1011 | |||||

| Corrected total | 38 | 8.42 × 1010 | |||||

| I-SBS4 | Regression | 2 | 1.52 × 1011 | 7.59 × 1010 | 11581.08 | 1.78 × 10−52 | 0.99 |

| Residual | 37 | 2.43 × 1008 | 6556846.787 | ||||

| Uncorrected total | 39 | 1.52 × 1011 | |||||

| Corrected total | 38 | 1.04 × 1011 | |||||

| B-SBS2 | Regression | 2 | 9.44 × 1010 | 4.72 × 1010 | 69417.14 | 7.47 × 10−67 | 0.99 |

| Residual | 37 | 2.52 × 1007 | 679813.0998 | ||||

| Uncorrected total | 39 | 9.44 × 1010 | |||||

| Corrected total | 38 | 6.49 × 1010 | |||||

| B-SBS3 | Regression | 2 | 1.16 × 1011 | 5.81 × 1010 | 274373.5 | 6.80 × 10−78 | 0.99 |

| Residual | 37 | 7839789.303 | 211886.1974 | ||||

| Uncorrected total | 39 | 1.16 × 1011 | |||||

| Corrected total | 38 | 7.88 × 1010 | |||||

| B-SBS4 | Regression | 2 | 9.03 × 1010 | 4.51 × 1010 | 117693.5 | 4.29 × 10−71 | 0.99 |

| Residual | 37 | 1.42 × 1007 | 383621.663 | ||||

| Uncorrected total | 39 | 9.03 × 1010 | |||||

| Corrected total | 38 | 6.25 × 1010 |

Similar to the binders, complex viscosity values were determined through DSR tests conducted at four different temperatures (40, 50, 60, and 70°C) and ten different frequencies (ranging from 0.01 to 10 Hz). The results are presented in Figure 11. It was observed that complex viscosity values decreased significantly with increasing temperature, and at 70°C, all binder samples exhibited behavior characteristic of a Newtonian fluid. An analysis of the complex viscosity values at 40°C revealed a sharp decline in viscosity with increasing frequency, particularly at the initial frequency range. This behavior indicates that the bitumen exhibits shear-thinning properties under these conditions. Furthermore, as the temperature increased, the shear-thinning behavior of the binders diminished, suggesting a transition toward more Newtonian-like flow characteristics at elevated temperatures.

Complex viscosity values of SBS-modified Iraqi and Batman binders.

To better achieve the objectives of this study, it would be more effective to present the complex viscosity values on a single curve, similar to the complex modulus values. For this purpose, the TTSP master curves for complex viscosity are provided in Figure 12. These master curves were constructed using a reference temperature of 60°C, as 60°C is commonly used for viscosity measurements and evaluations of bituminous materials [63,72]. Additionally, previous studies have indicated that an experimental frequency scan temperature of 60°C is representative of high road surface temperatures [61]. An analysis of Figure 12 reveals that the behavioral differences between the binders are more pronounced compared to Figure 11. At low frequencies, the binders exhibit Newtonian fluid behavior, whereas at higher frequencies, they transition to non-Newtonian behavior. It is observed that Newtonian behavior ceases at a critical frequency, beyond which the viscosity of the binder decreases significantly with increasing frequency. The highest complex viscosity values were recorded for the I-SBS4 binder across all frequency ranges. Another notable observation in Figure 12 is the difference in complex viscosity values between unmodified Iraqi and Batman bitumen. Up to a certain frequency, Iraqi bitumen exhibits higher viscosity values than Batman bitumen; however, beyond this threshold, the trend reverses. This suggests that Batman bitumen is capable of maintaining its elasticity for a longer duration under heavy traffic conditions compared to Iraqi bitumen.

Complex viscosity master curves of binders.

When plotting the master curves, shift factors as a function of the temperature used are fitted to the Arrhenius model and then the activation energy E a is obtained. The Arrhenius model is given in equation (4) [73].

where

In order to obtain viscosity as a function of temperature, through E a, equation (5) was developed by mathematically editing equation (4).

where T is the absolute temperature, T ref is the reference temperature (absolute), η (T ref) is the viscosity at T ref, and E a is the activation energy, C 1 and C 2 are two material coefficients and are obtained by the Williams–Landel–Ferry equation. Activation energy values obtained from Arrhenius equation are given in Figure 13.

Activation energy values of binders.

Activation energy is the minimum amount of energy required for bitumen molecules to begin to move by exceeding a certain thermal energy level. During the HMA production, the binder material must pass into the liquid phase in order to be effectively coated with aggregates and to obtain a homogeneous mixture. The higher the energy barrier required for this liquefaction process to occur, the higher the amount of energy spent during production [74]. While high energy requirements create an economic disadvantage by increasing fuel consumption and production costs, they can also have negative consequences in terms of carbon emissions and environmental impacts caused by working at high temperatures. Therefore, activation energy is considered a critical parameter that directly affects both energy efficiency and environmental sustainability in the production process of asphalt pavements. In particular, the development of binder formulations that provide sufficient workability at low production temperatures can offer both economic and environmental advantages by minimizing energy consumption. When Figure 13 is examined, the lowest activation energy value is seen in the B-Pure binder, and the highest value is seen in the I-SBS4 binder. With the use of SBS, the activation energy values increased regularly. After SBS modification, there was no significant difference in activation energy between Iraq and Batman binders. However, when pure Iraq and pure Batman bitumen were compared, Iraq bitumen had 10% more activation energy value than Batman bitumen. The increase in activation energy means that the amount of energy required for flow deformation increased [75].

The complex viscosity master curves of pure and modified binders were fitted to the Cross model to obtain model parameters for in-depth analysis of frequency-dependent flow behavior. Cross model parameters are presented in Table 7 and ANOVA analysis is presented in Table 8.

Cross model parameters of SBS-modified Iraqi and Batman binders

| Binder | Parameter | Value | R 2 |

|---|---|---|---|

| I-Pure | n 0 | 106.2074 | 0.860 |

| n ∞ | 15.99047 | 0.973 | |

| λ | 0.03366 | 0.966 | |

| CSR (s−1) | 29.71 | — | |

| B-Pure | n 0 | 75.10691 | 0.876 |

| n ∞ | 35.67318 | 0.991 | |

| λ | 0.01481 | 0.993 | |

| CSR (s−1) | 67.52194 | — | |

| I-SBS2 | n 0 | 280.0279 | 0.943 |

| n ∞ | 8.81385 | 0.993 | |

| λ | 0.03399 | 0.990 | |

| CSR (s−1) | 29.42 | — | |

| I-SBS3 | n 0 | 370.1186 | 0.983 |

| n ∞ | 0.00 × 1000 | 0.996 | |

| λ | 0.1813 | 0.991 | |

| CSR (s−1) | 5.52 | — | |

| I-SBS4 | n 0 | 821.1263 | 0.990 |

| n ∞ | 0 | 0 | |

| λ | 0.58854 | 0.994 | |

| CSR (s−1) | 1.70 | — | |

| B-SBS2 | n 0 | 291.1724 | 0.993 |

| n ∞ | 0.00 × 1000 | 0.998 | |

| λ | 0.09201 | 0.996 | |

| CSR (s−1) | 10.87 | — | |

| B-SBS3 | n 0 | 375.4077 | 0.984 |

| n ∞ | 0.00 × 1000 | 0.995 | |

| λ | 0.12524 | 0.987 | |

| CSR (s−1) | 7.98 | — | |

| B-SBS4 | n 0 | 488.7712 | 0.893 |

| n ∞ | 47.42112 | 0.983 | |

| λ | 0.12087 | 0.981 | |

| CSR (s−1) | 8.27 | — |

ANOVA results for Cross model analysis

| Binder | Data | DF | Sum of squares | Mean square | F value | Prob > F | R 2 |

|---|---|---|---|---|---|---|---|

| I-Pure | Regression | 4 | 240766.1 | 60191.53 | 35294.46 | 3.93 × 10−64 | 0.99 |

| Residual | 36 | 61.39475 | 1.70541 | ||||

| Uncorrected total | 40 | 240827.5 | |||||

| Corrected total | 39 | 20254.5 | |||||

| B-Pure | Regression | 4 | 171771.8 | 42942.96 | 191,482 | 2.38 × 10−77 | 0.99 |

| Residual | 36 | 8.07359 | 0.22427 | ||||

| Uncorrected total | 40 | 171779.9 | |||||

| Corrected total | 39 | 2377.978 | |||||

| I-SBS2 | Regression | 4 | 1,366,665 | 341666.3 | 32769.42 | 1.49 × 10−63 | 0.99 |

| Residual | 36 | 375.3496 | 10.42638 | ||||

| Uncorrected total | 40 | 1,367,041 | |||||

| Corrected total | 39 | 108387.7 | |||||

| I-SBS3 | Regression | 4 | 1,593,555 | 398388.7 | 19278.58 | 2.09 × 10−59 | 0.99 |

| Residual | 36 | 743.9341 | 20.66484 | ||||

| Uncorrected total | 40 | 1,594,299 | |||||

| Corrected total | 39 | 158809.5 | |||||

| I-SBS4 | Regression | 3 | 2,306,890 | 768963.3 | 10685.59 | 2.17 × 10−54 | 0.99 |

| Residual | 37 | 2662.619 | 71.96267 | ||||

| Uncorrected total | 40 | 2,309,552 | |||||

| Corrected total | 39 | 407223.2 | |||||

| B-SBS2 | Regression | 4 | 971531.4 | 242882.8 | 11451.59 | 2.45 × 10−55 | 0.99 |

| Residual | 36 | 763.543 | 21.20953 | ||||

| Uncorrected total | 40 | 972294.9 | |||||

| Corrected total | 39 | 75184.62 | |||||

| B-SBS3 | Regression | 4 | 1,488,010 | 372002.4 | 30962.74 | 4.15 × 10−63 | 0.99 |

| Residual | 36 | 432.5226 | 12.01452 | ||||

| Uncorrected total | 40 | 1,488,442 | |||||

| Corrected total | 39 | 165905.2 | |||||

| B-SBS4 | Regression | 4 | 778949.7 | 194737.4 | 50385.05 | 6.49 × 10−67 | 0.99 |

| Residual | 36 | 139.1394 | 3.86498 | ||||

| Uncorrected total | 40 | 779088.8 | |||||

| Corrected total | 39 | 39936.81 |

Table 7 presents the Cross model parameters for SBS-modified Iraqi and Batman binders. The Cross model enables comprehensive rheological evaluations by determining key parameters, including η 0 (ZSV), λ, m, and critical shear rate (CSR). ZSV represents the quasi-static or Newtonian fluid-like behavior of the bituminous binder as the shear rate approaches zero. At very low shear rates, the alignment of microstructures due to flow is minimal, allowing the intrinsic viscosity of the bitumen to be accurately determined through ZSV. This parameter is directly related to the binder’s resistance to permanent deformation, with higher ZSV values indicating improved rutting resistance. In other words, a higher ZSV value suggests a bitumen that is more resistant to permanent deformation (rutting), particularly in hot climates and under heavy traffic conditions [76,77,78]. An examination of Table 7 reveals that pure Batman bitumen exhibited the lowest ZSV value, whereas the highest ZSV value was observed in I-SBS4 bitumen. The ZSV values increased consistently with SBS modification, confirming that SBS enhances resistance to permanent deformation. Additionally, λ values also increased with the incorporation of SBS, with the highest λ value recorded for the I-SBS4 binder. The λ parameter represents the transition time from Newtonian to shear-thinning behavior and is indicative of the overall consistency of the system [79]. CSR (s⁻¹) is defined as the shear rate at which non-Newtonian behavior begins and is calculated as 1/λ. This parameter marks the transition of the bituminous binder from the Newtonian plateau (constant viscosity) to the shear-thinning region (where viscosity decreases with increasing shear rate). The transition point is considered a critical indicator of bituminous binder performance. A reduction in CSR implies that the binder reaches shear-thinning behavior more rapidly, making it more resistant to traffic-induced stresses, which encompass varying loading speeds. According to Table 7, the lowest CSR value (1.70 Hz) was recorded for the I-SBS4 binder. The Cross model CSR values indicate that the I-SBS4 binder transitions to non-Newtonian behavior at a very low frequency of 1.70 Hz. CSR values consistently decreased with SBS modification, signifying that the use of additives enhances shear-thinning behavior. This improvement suggests that the material can sustain viscosity levels necessary to withstand traffic loads at high frequencies (under heavy traffic conditions).

Furthermore, Table 7 clearly demonstrates that the curve-fitting process was performed with exceptionally high accuracy, as evidenced by the high R 2 values.

The ANOVA analysis results provide a comprehensive evaluation of the statistical significance of the regression models for each binder type, including pure and SBS-modified bitumen from Iraqi (I) and Batman (B) sources. The F-value and Prob > F (p-value) are key indicators of the model’s validity. High F-values and extremely low p-values (e.g., <0.05) suggest that the regression models are highly significant and effectively explain the variability in the data. For I-Pure and B-Pure, the F-values are 35294.46 and 191,482, respectively, with p-values close to zero, indicating that the models for pure bitumen are statistically robust. The sum of squares and mean square values for regression are significantly higher than those for residuals, further confirming the models’ explanatory power. For SBS-modified binders, the F-values remain exceptionally high (e.g., 32769.42 for I-SBS2 and 50385.05 for B-SBS4), with p-values approaching zero, demonstrating that the addition of SBS significantly improves the model’s ability to predict the behavior of the modified bitumen. Notably, B-SBS4 exhibits the highest F-value (50385.05) and the lowest residual mean square (3.86498), indicating that Batman bitumen with 4% SBS has the most statistically significant and precise model among all samples. The corrected total sum of squares reflects the total variability in the data, and the relatively small residual sum of squares across all samples suggest that the models account for most of the variability. This implies that the regression models are well-fitted and reliable for predicting the performance of both pure and SBS-modified bitumen. Complex viscosity master curves were analyzed by Carreau-Yasuda Model and model parameters are given in Table 9.

Carreau-Yasuda model parameters of binders

| Binder | Parameter | Value | R 2 |

|---|---|---|---|

| I-Pure | n 0 | 105.7384 | 0.8843 |

| n ∞ | 0 | 0 | |

| λ | 0.11309 | 0.99469 | |

| a | 0.69062 | 0.97892 | |

| n | 0.6832 | 0.98931 | |

| B-Pure | n 0 | 74.9645 | 0.90802 |

| n ∞ | 0 | 0 | |

| λ | 0.09167 | 0.99682 | |

| a | 0.69543 | 0.98418 | |

| n | 0.86193 | 0.99407 | |

| I-SBS2 | n 0 | 279.8357 | 0.95682 |

| n ∞ | 0 | 0 | |

| λ | 0.4768 | 0.99936 | |

| a | 0.41661 | 0.99658 | |

| n | 0.64049 | 0.99866 | |

| I-SBS3 | n 0 | 395.8237 | 0.99545 |

| n ∞ | 0 | 0 | |

| λ | 0.5117 | 0.99998 | |

| a | 0.22155 | 0.99984 | |

| n | 0.33168 | 0.99996 | |

| I-SBS4 | n 0 | 1376.657 | 0.99994 |

| n ∞ | 0 | 0 | |

| λ | 0.61038 | 1 | |

| a | 0.10021 | 1 | |

| n | 0.1017 | 1 | |

| B-SBS2 | n 0 | 316.3108 | 0.99839 |

| n ∞ | 0 | 0 | |

| λ | 0.1894 | 1 | |

| a | 0.17548 | 0.99997 | |

| n | 0.58694 | 1 | |

| B-SBS3 | n 0 | 415.2749 | 0.99692 |

| n ∞ | 0 | 0 | |

| λ | 0.2347 | 0.99999 | |

| a | 0.19829 | 0.99992 | |

| n | 0.52617 | 0.99999 | |

| B-SBS4 | n 0 | 1016.254 | 0.91828 |

| n ∞ | 0 | 0 | |

| λ | 0.2949 | 0.99543 | |

| a | 0.61941 | 0.98155 | |

| n | 0.37603 | 0.99131 |

The Carreau-Yasuda model parameters provide a comprehensive understanding of the rheological behavior of both pure and SBS-modified bitumen, with the updated values further highlighting the impact of SBS modification. The zero-shear viscosity (η 0) increases significantly with SBS content, particularly in I-SBS4 and B-SBS4, indicating a substantial improvement in resistance to deformation at low shear rates. This enhancement is crucial for high-temperature performance and rutting resistance. Similarly, the relaxation time (λ) increases with SBS modification, with I-SBS4 and B-SBS4 exhibiting longer relaxation times. This suggests improved elastic behavior and enhanced fatigue resistance. The Yasuda parameter (a) decreases with the addition of SBS, as observed in I-SBS4 and B-SBS4, indicating a more abrupt transition between Newtonian and power-law behavior. This is a characteristic feature of pronounced shear-thinning behavior. The power-law index (n) also decreases with increasing SBS content, with I-SBS4 and B-SBS4 showing the lowest values, further confirming the enhanced shear-thinning behavior. The value of “n” approaching 1 indicates that the bituminous material exhibits more Newtonian behavior, whereas a value deviating further from 1 signifies more pronounced shear-thinning and non-Newtonian characteristics [80]. In other words, viscosity decreases as the “n” value increases [81]. According to the Carreau-Yasuda model, I-SBS4 is the binder most prone to shear-thinning behavior.

The high R 2 values (close to 1) for most parameters indicate an excellent model fit, validating the reliability of the Carreau-Yasuda model in capturing the rheological behavior of the binders. Overall, the results demonstrate that SBS modification significantly enhances the rheological properties of bitumen, with I-SBS4 and B-SBS4 exhibiting the most notable improvements in viscosity, elasticity, and shear-thinning behavior. These enhancements collectively contribute to superior performance in terms of high-temperature stability, rutting resistance, and fatigue resistance. Furthermore, Batman bitumen (B) generally shows better compatibility with SBS, as evidenced by its higher η 0 and λ values at equivalent SBS concentrations, further underscoring the importance of bitumen source in optimizing bitumen performance.

Figure 14 shows the comparison of ZSV values for two different viscosity models (Cross and Carreau-Yasuda). According to Figure 14, quite close results are obtained for all binders except I-SBS4 and B-SBS4 binders. In these two binders, Carreau-Yasuda model is presented high ZSV values. This may be due to the fact that the model is more sensitive to flow properties in low shear rates.

Comparison of ZSV values calculated for Cross and Carreau-Yasuda models.

3.4 BBR test results

BBR test was applied to I-Pure, B-Pure, I-SBS4, and B-SBS4 binders and the results are given in Table 10.

BBR test results

| Binders | Test temperature (°C) | Creep stiffness (St, mPa) | Creep rate (m-value) |

|---|---|---|---|

| I-Pure | −18 | 95.7697 | 0.358385 |

| I-Pure | −24 | 249.7732 | 0.276174 |

| B-Pure | −18 | 80.2374 | 0.359002 |

| B-Pure | −24 | 236.9738 | 0.283499 |

| I-SBS4 | −12 | 115.6762 | 0.351914 |

| I-SBS4 | −18 | 207.1083 | 0.299646 |

| B-SBS4 | −12 | 93.5368 | 0.337615 |

| B-SBS4 | −18 | 215.0576 | 0.282774 |

The BBR test results provide critical insights into the low-temperature performance of both unmodified and SBS-modified binders. The creep stiffness (St) values indicate the binder’s resistance to deformation under low-temperature loading conditions, while the m-value represents its ability to relax stresses and mitigate thermal cracking. For unmodified binders, I-Pure and B-Pure, the results reveal that at −18°C, both binders exhibit relatively low creep stiffness values, suggesting acceptable flexibility. However, as the temperature decreases to −24°C, stiffness values increase significantly, indicating a reduction in flexibility and an increased risk of thermal cracking. The corresponding m-values also decline, which confirms the binders’ reduced stress relaxation ability at lower temperatures. For SBS-modified binders (I-SBS4 and B-SBS4), the influence of polymer modification is evident. At −12°C, the creep stiffness of I-SBS4 (115.68 MPa) and B-SBS4 (93.54 MPa) remains within an acceptable range, though slightly higher than the corresponding unmodified binders. However, at −18°C, the stiffness values rise to 207.11 MPa for I-SBS4 and 215.06 MPa for B-SBS4, which are significantly higher than the values observed for the pure binders at the same temperature. This suggests that while SBS modification improves high-temperature performance, it also leads to increased stiffness at lower temperatures, potentially making the binder more prone to low-temperature cracking if not properly balanced. Additionally, the m-values for the modified binders further highlight this effect. At −18°C, I-SBS4 shows an m-value of 0.299, which remains close to the critical threshold of 0.300, while B-SBS4 drops to 0.283, indicating a further reduction in stress relaxation capability. This suggests that the modification with SBS, while beneficial in enhancing rutting resistance, may slightly compromise the low-temperature cracking resistance, particularly at very low temperatures. Overall, the results demonstrate that SBS modification increases stiffness at low temperatures, which may require further optimization to ensure a balanced rheological performance across a wide temperature range. The findings emphasize the importance of selecting an optimal polymer dosage and bitumen source to achieve a binder with both superior high-temperature stability and adequate flexibility at low temperatures. ΔTc results are given in Table 11.

ΔTc results

| Binder | Tc_s (°C) | Tc_m (°C) | ΔTc (°C) |

|---|---|---|---|

| I-Pure | −35.15 | −32.26 | −2.89 |

| B-Pure | −35.31 | −32.69 | −2.62 |

| I-SBS4 | −31.82 | −27.96 | −3.86 |

| B-SBS4 | −30.40 | −26.12 | −4.28 |

The calculated ΔTc values (Table 11) revealed important insights into the low-temperature performance balance of the binders. Neat binders (I-Pure and B-Pure) showed relatively moderate ΔTc values (−2.89 and −2.62°C), indicating a reasonable balance between stiffness and relaxation capacity. However, SBS-modified binders (I-SBS4 and B-SBS4) exhibited more negative ΔTc values (−3.86 and −4.28°C), suggesting an increased tendency toward low-temperature cracking. This implies that while SBS enhances high-temperature performance, it may lead to an imbalance at low temperatures by increasing stiffness more than relaxation ability. The highest ΔTc observed in B-SBS4 indicates that the interaction between Turkish bitumen and SBS could result in more rigid structures with limited stress dissipation at low temperatures. Therefore, ΔTc analysis underscores the importance of evaluating cold climate suitability when using SBS modifiers, and suggests that complementary additives may be required to ensure thermal cracking resistance.

3.5 RSM analysis results

3.5.1 RSM analysis of Iraq-Lanaz bitumen

Figure 15 shows the response surface graphs obtained as a result of RSM analysis applied to Iraqi bitumen.

RSM plots of Iraqi bitumen.

RSM results reveal how the complex shear modulus (G*) value of bitumen changes with both temperature and the independent variables frequency and SBS ratio. The surface plot on the left shows the effect of temperature and frequency on G*, and it is seen that the G* value decreases with increasing temperature, but this decrease is less pronounced at high frequencies. This confirms the viscoelastic structure of the binder and shows that the elastic component becomes dominant especially at high frequencies. On the other hand, the surface plot on the right shows that there is a significant increase in the G* value with increasing SBS ratio, which proves that the polymer modification increases the stiffness and elasticity of the binder. It is observed that as the SBS ratio increases, the temperature sensitivity decreases and the binder performance improves especially at high temperatures. RSM analyses are important in terms of determining the optimum performance conditions by quantitatively modeling the interaction of both variables on the rheological properties of bitumen. These models, which are created in line with the combinations of temperature, frequency and polymer ratio, are an important guide in engineering designs in terms of increasing the resistance of bitumen to deformation at high temperatures and providing sufficient flexibility at low temperatures. In this context, RSM-based surface analyses provide a reliable methodology for optimizing the mechanical behavior of bitumen depending on temperature and loading conditions, and stand out as an effective decision support tool especially in the performance evaluation and design process of modified binders. Perturbation curve, prediction performance curve, and cubic model explaining the effect of each variable on the response are given in Figure 16 for Iraqi bitumen.

RSM analysis results of Iraq bitumen: (a) Perturbation curves, (b) predicted vs actual values, and (c) cubic model illustration.

Perturbation graph shows the effect of independent variables on G* comparatively at the same reference point. Three different curves on the graph express the effect of temperature (C), SBS ratio (B), and frequency (A) on G*. Frequency (A – Green curve): It is observed that G* value slightly increases with the increase in frequency in the graph. This situation shows that high frequencies dominate the elastic component of the asphalt binder and increase its stiffness. SBS Ratio (B – Blue curve): A significant increase is observed in G* value with the increase in SBS ratio. It is known that this trend increases the elasticity of the asphalt binder and increases its stiffness. Considering that SBS additive improves the rheological properties of the binder, this result is expected. Temperature (C – Gray curve): It is seen that the effect of temperature change on G* is quite significant. Increasing temperature significantly decreases the G* value by increasing the viscous properties of the binder. This situation shows that asphalt becomes more fluid and loses its stiffness at high temperatures. These results show that SBS rate and temperature have a more significant effect on G* than frequency, especially the effect of temperature on G* value is much higher. Table 12 shows the variance analysis (ANOVA) results for the RSM model for Iraq-Lanaz bitumen.

ANOVA results for Iraqi-Lanaz bitumen

| Source | Sum of squares | df | Mean square | F-value | p-value | ||

|---|---|---|---|---|---|---|---|

| Model | 1.61 × 1006 | 17 | 94738.23 | 2470.01 | <0.0001 | Significant | |

| A – frequency | 12152.88 | 1 | 12152.88 | 316.85 | <0.0001 | ||

| B – SBS ratio | 1811.05 | 1 | 1811.05 | 47.22 | <0.0001 | ||

| C – temperature | 68403.12 | 1 | 68403.12 | 1783.4 | <0.0001 | ||

| AB | 494.57 | 1 | 494.57 | 12.89 | 0.0005 | ||

| AC | 75407.17 | 1 | 75407.17 | 1966.01 | <0.0001 | ||

| BC | 1920.18 | 1 | 1920.18 | 50.06 | <0.0001 | ||

| A 2 | 18769.85 | 1 | 18769.85 | 489.37 | <0.0001 | ||

| B 2 | 2144.05 | 1 | 2144.05 | 55.9 | <0.0001 | ||

| C 2 | 1.09 × 1005 | 1 | 1.09 × 1005 | 2841.04 | <0.0001 | ||

| ABC | 1757.68 | 1 | 1757.68 | 45.83 | <0.0001 | ||

| A 2 C | 4788.24 | 1 | 4788.24 | 124.84 | <0.0001 | ||

| AB 2 | 358.68 | 1 | 358.68 | 9.35 | 0.0027 | ||

| AC 2 | 6743.99 | 1 | 6743.99 | 175.83 | <0.0001 | ||

| B 2 C | 2489.05 | 1 | 2489.05 | 64.89 | <0.0001 | ||

| BC 2 | 4530.72 | 1 | 4530.72 | 118.12 | <0.0001 | ||

| A 3 | 3511.6 | 1 | 3511.6 | 91.55 | <0.0001 | ||

| C 3 | 4808.62 | 1 | 4808.62 | 125.37 | <0.0001 | ||

| Residual | 5254.69 | 137 | 38.36 | ||||

| Cor Total | 1.62 × 1006 | 154 | |||||

| Statistical values | |||||||

| Std. dev. | 6.19 | R 2 | 0.9967 | ||||

| Mean value | 118.15 | Adjusted R 2 | 0.9963 | ||||

| C.V.% | 5.24 | Predicted R 2 | 0.9952 | ||||

| Adeq. precision | 206.6089 | ||||||

According to ANOVA analysis, the model has a very high explanatory power (R 2 = 0.996, adjusted R 2 = 0.9963), which shows that the independent variables largely explain the G* value. The total sum of squares of the model is 1.61 × 1006, and it is statistically strong with a high F-value (2470.01) and a significant p-value (<0.0001). When the main effects are examined, temperature (C) is the most determining factor, has the highest F-value (1783.4) and shows a dominant effect on G*. Frequency (A) is also a significant variable (F = 316.85, p < 0.0001), but it does not have as significant an effect as temperature. SBS ratio (B) has a relatively lower effect compared to the other two variables (F = 47.22, p < 0.0001). When the interaction terms are examined, it is seen that temperature and frequency (AC) have the highest interaction (F = 1966.01), which shows that the effect of frequency changes as the temperature increases. The triple interaction (ABC) is also significant (F = 45.83, p < 0.0001), which shows that when all variables are evaluated together, they create a complex and nonlinear effect on G*. When the square terms are examined, the quadratic effect of temperature (C 2) is quite high (F = 2841.04), which proves that the sensitivity of G* to temperature is not linear and shows a quadratic trend. The residual sum of squares of the model (5254.69) is low, and the mean square value (38.36) shows that the model makes predictions with high precision. As a result, it was determined that the model has sufficient predictive power (R 2 pred = 0.9952), the interactions between the variables are significant, and temperature is the most dominant factor on G*. Equation (6) provides the numerical estimation equation that allows G* estimation using frequency (A), temperature SBS rate (B), and temperature (C) inputs.

3.5.2 RSM analysis of Turkey-Batman bitumen

Figure 17 shows the response surface graphs obtained after RSM analysis for Batman bitumen.

RSM plots of Batman bitumen.

It is observed that the RSM surface graphs of Batman bitumen are similar in general form to the graphs obtained for Iraqi bitumen; for both bitumen types, the complex modulus G* shows a significant decrease tendency as the temperature increases. When the left graph showing the frequency-temperature relationship is examined, it is seen that the G* value is higher at high frequencies and exhibits a more pronounced viscoelastic behavior at low temperatures; however, it is noteworthy that the G* value is relatively lower in the high frequency region in Batman bitumen compared to Iraqi bitumen. When the interaction between the SBS ratio and temperature is analyzed in the right graph, a significant improvement is observed in the G* value with the increase in the SBS ratio; however, it is seen that this increase is more limited in Batman bitumen compared to Iraqi bitumen. As a result, it was determined that temperature is a dominant variable in Batman bitumen, frequency and SBS contribution are effective, but the increase in G* values is more limited compared to Iraqi bitumen; this situation shows that Batman bitumen has a rheologically different structure and that the modification efficiency may vary depending on the bitumen type. In Figure 18, the perturbation curve, the forecast performance curve, and the cubic model explaining the effect of each variable on the response are given for Batman bitumen.

RSM analysis results of Batman bitumen: (a) Perturbation curves, (b) predicted vs actual values, and (c) cubic model illustration.

When the perturbation graph of Batman bitumen is examined, it is seen that the dominant effect of the temperature variable (C) on the complex modulus G* is similar to Iraqi bitumen; however, the effect of temperature exhibits a sharper decreasing trend in Batman bitumen compared to Iraqi bitumen. The effect of the frequency (A) and SBS ratio (B) variables is relatively lower and follows a more horizontal course compared to Iraqi bitumen. The predicted vs actual graph shows that the model makes predictions with a very high accuracy, confirming that the model developed for Batman bitumen also has a strong predictive ability. Table 13 shows the variance analysis (ANOVA) results for the RSM model created for Iraqi-Lanaz bitumen.

ANOVA results for Turkey-Batman bitumen

| Source | Sum of squares | df | Mean square | F-value | p-value | |

|---|---|---|---|---|---|---|

| Model | 1.65 × 1006 | 19 | 86999.1 | 2291.97 | <0.0001 | Significant |

| A – frequency | 11808.19 | 1 | 11808.19 | 311.08 | <0.0001 | |

| B – SBS ratio | 0.4677 | 1 | 0.4677 | 0.0123 | 0.9118 | |

| C – temperature | 66698.78 | 1 | 66698.78 | 1757.17 | <0.0001 | |

| AB | 171.96 | 1 | 171.96 | 4.53 | 0.0351 | |

| AC | 74566.17 | 1 | 74566.17 | 1964.43 | <0.0001 | |

| BC | 642.05 | 1 | 642.05 | 16.91 | <0.0001 | |

| A 2 | 14751.49 | 1 | 14751.49 | 388.63 | <0.0001 | |

| B 2 | 7.48 | 1 | 7.48 | 0.1971 | 0.6577 | |

| C 2 | 98404.41 | 1 | 98404.41 | 2592.44 | <0.0001 | |

| ABC | 1027.59 | 1 | 1027.59 | 27.07 | <0.0001 | |

| A 2 B | 239.59 | 1 | 239.59 | 6.31 | 0.0132 | |

| A 2 C | 4172.15 | 1 | 4172.15 | 109.91 | <0.0001 | |

| AB 2 | 593.93 | 1 | 593.93 | 15.65 | 0.0001 | |

| AC 2 | 6469.91 | 1 | 6469.91 | 170.45 | <0.0001 | |

| B 2 C | 4922.43 | 1 | 4922.43 | 129.68 | <0.0001 | |

| BC 2 | 3540.43 | 1 | 3540.43 | 93.27 | <0.0001 | |

| A 3 | 3297.48 | 1 | 3297.48 | 86.87 | <0.0001 | |

| B 3 | 392.36 | 1 | 392.36 | 10.34 | 0.0016 | |

| C 3 | 3801.09 | 1 | 3801.09 | 100.14 | <0.0001 | |

| Residual | 5200.27 | 137 | 37.96 | |||

| Cor total | 1.66 × 1006 | 156 | ||||

| Statistical values | ||||||

| Std. dev. | 6.16 | R 2 | 0.9969 | |||

| Mean value | 117.24 | Adjusted R 2 | 0.9964 | |||

| C.V.% | 5.25 | Predicted R 2 | 0.9954 | |||

| Adeq Precision | 185.2227 | |||||

Equation (7) gives the numerical prediction equation for G* prediction using frequency (A), temperature SBS ratio (B), and temperature (C) factors.

4 Conclusion