Abstract

Twin-screw extrusion of plant proteins for meat analogue production has gained significant attention. However, understanding the underlying mechanisms remains challenging due to the complex flow behavior of protein doughs and limited measurement techniques. This study investigates the temperature-dependent flow behavior of a soy protein isolate dough (55 wt% water) under extrusion-relevant conditions. Apparent shear viscosity was measured between 95 and 140°C using a capillary rheometer and, for the first time in protein doughs, by performing a ramp test in a closed cavity rheometer (CCR). The Bagley correction was applied, and the resulting correction factors were analyzed and discussed. Flow curves from both methods were fitted with a power-law model. The ramp test resulted in higher consistency indices (K = 3,412–32,237 Pa s n ) and lower flow behavior indices (n = 0–0.43) at all temperatures than the uncorrected data from the capillary rheometer (K = 708–13,013 Pa s n , n = 0.1–0.48). Visual analysis of extruded strands and CCR samples revealed ongoing reactions, stick-slip-like surface patterns, and melt-fracture-like appearances in the extruded strands. In the CCR samples, bulk fracture was evident at 95 and 110°C. At 125°C, deformations of the sample were visible, which could be attributed to partial flow, limited relaxation, or rearrangements within the protein network. Both methods were affected by protein reactions and water evaporation at 140°C, which partially falsified the measurements. Thus, this publication presents two methods for examining viscosity under extrusion-relevant conditions, demonstrating their potential and challenges, and discusses how they contribute to understanding high moisture extrusion for meat analogue production.

1 Introduction

High moisture extrusion of plant proteins to produce meat analogues is considered a promising technology for providing alternatives to meat. The growing demand for sustainable and animal-free meat analogues is driving research in this area. While the products available on the market are satisfactory to a degree, many lack the textural variability that meat products offer. Flavor also remains a major challenge, especially when it comes to meeting consumer demand for less processed or locally available protein sources. Therefore, a more detailed understanding of the high moisture extrusion process is crucial to achieve improved control and targeted enhancements, both in the technology and the products. A recent review summarizing the current understanding of the mechanism of formation of fiber-like structures and related hypotheses can be found in the work of van der Sman and van der Goot [1].

During the production of meat analogues via high moisture extrusion, protein-rich powder formulations are mixed with water, and the resulting protein dough is subjected to thermomechanical treatment in the screw section, before being pushed through a cooling die, where the protein dough is structured and cooled. Protein doughs used for manufacturing meat analogues can be viewed as biopolymer gels [2]. Thus, depending on the milieu (temperature, pH, water content, shear rate, and others), these systems behave somewhere between solid and liquid-like. To complicate matters, the protein doughs are heterogeneous, leading to multiphase systems that include filled networks (lipid droplets, fibers, and others), phase-separated networks (different protein types, water-rich, and water-pour phases), and co-gelled networks [2,3,4,5,6,7]. Consequently, the heterogeneity of the protein dough can be regarded as a multiphase system, composed of domains with varying degrees of compatibility, which ultimately influence the overall flow behavior. In general for gels, depending on the applied shear stress and temperature, bulk fracture can occur, leading to separated gel pieces that slide past each other [8,9]. Van der Sman and van der Goot hypothesize that the protein dough, depending on the temperature and shear stress, can be described as a transient network in which intermolecular bonds can break and rearrange [1]. Thus, understanding the structuring mechanisms of the protein doughs during high moisture extrusion remains challenging. Nevertheless, extensive experimental [3,10,11,12] and numerical [13,14,15,16] studies have significantly improved process-level understanding. However, despite these advances, the flow behavior of protein doughs under extrusion-relevant conditions (steady shear, 25–150°C, 40–70 wt% water, 5–40 bar) remains insufficiently characterized, which limits experimental control and predictive modeling.

While changes in the flow behavior can be influenced by complex biopolymer interactions, this study does not seek to resolve the underlying molecular mechanisms. Instead, the focus is on evaluating and comparing rheological methods that are suitable for measuring shear viscosity under extrusion-relevant conditions, in order to assess the flow behavior within an extruder. A soy protein isolate (SPI) dough was used as the model protein system, as it is assumed to behave as a physical gel [17] (no covalent bonds formed) with a transient network structure as described by van der Sman and van der Goot [1]. As it is unclear how the transient network responds to steady shear, the terms apparent shear viscosity and apparent flow behavior are used throughout this study.

In general, conventional rotational rheometers are not particularly suitable for investigating protein doughs under extrusion-relevant conditions, as the required torque is often insufficient to quantify these highly viscous systems at relevant shear rates. Additionally, issues such as water loss, pressure effects, wall slippage, edge fracture, and sample loss may complicate the measurements. Nevertheless, such rheometers are used to obtain information about doughs for meat analogues, for example, they can be used to measure at lower temperatures [18], to measure at higher water contents and then extrapolate to relevant extrusion conditions [19], or to measure by using pressure cells [20].

Closed cavity rheometers (CCR), also known as rubber process analyzers (RPA), are made for such challenging measurements. They are designed with a sealed, pressurized measuring chamber (preventing water evaporation, edge fracture, and sample loss), grooved geometries (preventing slippage), and a motor capable of providing high torque. This enables the measurement of protein doughs closer to extrusion-like conditions, which is why the instrument is widely used by researchers in the field of meat analogues [4,21,22,23]. However, due to inherent construction limitations, the maximum strain of many of these instruments is restricted to a single rotation, and thereby precluding the performance of steady-rotational tests. Furthermore, the potential impact of the grooves on a steady flow is not accounted for in their theoretical framework. Recently, researchers have demonstrated that a start-up shear test of CCRs up to one rotation (referred to as ramp test) is sufficient to achieve a steady-state for the flow of polyolefin polymers and rubber compounds, thereby enabling the reliable acquisition of data for shear viscosity [24,25,26,27].

In addition to rotational rheometers, capillary rheometers provide the capability to assess shear viscosity under conditions relevant to extrusion. Such rheometers may be attached inline to the extruder or used as offline instruments. To obtain true shear viscosity data, corrections for entrance effects [28], non-Newtonian flow profiles [29], and wall slippage [30] must be made. An additional challenge is that the temperature control is less precise and slower than in rotational rheometers, which makes it more difficult to examine reactive protein doughs accurately.

SPI is commonly used to produce meat analogues. Compared to other protein sources, such as wheat gluten, SPI is expected to have a lower reactivity [17]. Depending on the processing conditions, the effects of time and temperature on the properties of SPI may appear negligible [3]. However, at temperatures of 140°C, it has been demonstrated that the time-temperature history influences SPI doughs, potentially due to thermal degradation [31]. As the measurement of the apparent flow behavior is challenging, only limited data on shear viscosity are available in the literature. In addition, protein isolates and concentrates from different manufacturers [32], and even different batches from the same manufacturer, can vary in composition and functionality, further complicating the comparability of rheological data. In the early 1990s, Fujio et al. and Hayashi et al. used a customized capillary rheometer to investigate SPI doughs with water contents between 17 and 70 wt% at a temperature of 140°C [33,34,35]. The data may be described with the Herschel–Bulkley model, and it was found that with decreasing water content, the yield stress, the consistency coefficient, and the flow behavior index decrease. The visual appearance of the samples is not provided in this study, meaning that no conclusions can be drawn regarding flow instabilities and wall slip phenomena, which can be of significant importance and represent a research gap.

In this study, we investigate the apparent flow behavior, with a specific focus on the apparent shear viscosity of a SPI dough containing 55 wt% water at temperatures ranging from 95 to 140°C. We compare data obtained from a conventional capillary rheometer and the ramp test, applied for the first time to protein doughs, using a CCR. Additionally, samples collected during rheological measurements are visualized for the first time to identify potential volume instabilities. Observed flow irregularities are examined and discussed, with speculative insights into their possible relevance for structure formation in meat analogues. This work aims to provide a methodological contribution by evaluating and contrasting rheological techniques suitable for extrusion-relevant conditions.

2 Material and methods

2.1 Materials

SPI Supro ST from Solae LLC (St. Louis, Mo, USA) was used for this study. According to the manufacturer, the protein content of SPI was >90%, the fat content <1%, and the ash content <5%. The water content was determined gravimetrically and was 3%.

2.2 Sample preparation

In order to produce homogeneous protein doughs that are easy to handle (insertable, no air pockets) for the capillary rheometer and CCR, a twin screw extruder (Brabender TwinLab F 20/40, Duisburg, Germany) with an attached 13 mm diameter cylindrical die was used. An SPI dough with a gravimetrically determined water content of 55 wt% was produced at a set barrel temperature of 30°C and a total mass flow of 4 kg/h. The extruded samples with an average length of 20 cm were vacuum-sealed and kept at −32°C until further usage. To thaw the sample, the material was removed from the freezer and allowed to thaw in its sealed form at 20°C room temperature.

2.3 Capillary rheometry

To investigate the apparent flow behavior, a Göttfert RG 20 capillary rheometer (Buchen, Germany) was used. The apparent shear viscosity

where

Thus, the Bagley corrected apparent shear viscosity

The prepared doughs were inserted into the rheometers reservoir and compressed by the piston as fast as possible to a pressure of 5 bar to minimize potential water loss/drying effects. Subsequently, the sample was held 300 s at the investigation temperature (95, 110, 125, and 140°C), to ensure uniform material temperature. We note that all three temperature zones of the capillary rheometer were set at the same temperature. The doughs were extruded from apparent shear rates of 1,000–10 s−1 in 11 steps with 120 s for 1,000 s−1 and 60 s for the other shear rates. The pressure to calculate the shear stress was determined as last 15 s of each shear rate step. To investigate possible time-temperature effects, a measurement was performed with a 300 s preheating step, a 120 s and 1,000 s−1 step, followed by a 480 s step at a constant shear rate of 150 s−1.

The time–temperature effect was investigated once using the 20/1 die, whereas all other measurements were performed in triplicate, and the deviation of the average value was calculated and is shown in the figures.

2.4 Ramp test in CCR

To perform the ramp test (in literature, well-known as step shear rate test [36]) a rubber process analyzer (RPA flex, TA Instruments, Inc., New Castle, DE, USA), also called CCR was used. To obtain the apparent shear viscosity, the lower cone of the CCR deflects by a maximum of γ = 5,000% (almost 1 rotation) at a constant rotational speed while the torque is measured at the upper cone. More information about the ramp test can be found in our previous publication, where the method was validated for polyolefin polymers [24]. For each deflection and thus each individual shear rate, a new sample piece weighing approximately 5 g was taken for measurement. After the dough was inserted into the rheometer, the measurement was started as fast as possible. Before the actual ramp starts, the dough is held for 90 s at the selected temperature (95, 110, 125, and 140°C) in the basic position to ensure uniform material temperature.

All measurements were performed in triplicate, and the deviation of the average value was calculated and is shown in the figures.

2.5 Sample optical visualization

To visualize the surface of the extrudate strands and the samples from the CCR, a visualization system consisting of a Canon EOS 90D DSLR camera (Tokyo, Japan) equipped with a Canon L-series 100 mm macro lens and an LED (Kaiser slimlite plano 5000K, Buchen, Germany) was used. Before visualization, the extrudates and CCR samples were air dried at room temperature.

3 Results

3.1 Capillary rheometry measurements

The effect of time-temperature history in the capillary rheometer reservoir on the stability of SPI doughs is shown in Figure 1, where measured pressure is plotted against time at different temperatures under constant shear rate in isothermal conditions. The pressure fluctuates at 95, 110, 125, and 140°C, but the fluctuation decreases as the temperature increases. The pressure decreases as the temperature rises between 110 and 140°C. However, at 95°C, the pressure lies between the values for 110 and 125°C. At 140°C, the pressure decreases with increasing time.

Measured pressure at constant apparent shear rate of

Figure 2 shows the apparent viscosity for different dies at various temperatures. At all temperatures, shear thinning behavior is found and the apparent viscosity increases as die length decreases. The apparent viscosity values at a temperature of 95°C are within the same range as at a temperature of 110°C (also refer Figure 9a). With further increase in the temperature, the apparent viscosity decreases. After applying the Bagley correction [28] (Figure 3), the Bagley-corrected apparent viscosities for each temperature largely overlap; however, there are a few exceptions. The shear thinning behavior is observed at all temperatures; however, at 140°C, it only occurs between 250 and 1,000 s−1, while at lower shear rates, it appears as a plateau.

Apparent viscosity plotted over apparent shear rate for dies with the same diameter and different lengths for a temperature of 95°C (a), 110°C (b), 125°C (c), and 140°C (d).

Bagley-corrected apparent shear viscosity plotted over apparent shear rate for dies with the same diameter and different length for a temperature of 95°C (a), 110°C (b), 125°C (c), and 140°C (d).

The found (Bagley) pressure correction factors are plotted in Figure 4 over apparent shear rates for different temperatures. At 95°C, the factor remains constant at approximately 17 bar across all apparent shear rates. At 110°C, it stays constant at around 27 bar up to 100 s⁻¹, then rises to 39 bar. At 125°C, it rises across the entire apparent shear rate range, increasing from 6 bar to 20 bar, while at 140°C, it remains constant at 3 bar, except for a slight increase at 1,000 s⁻¹.

Pressure (Bagley) correction factor plotted over apparent shear rate for temperatures of 95, 110, 125, and 140°C.

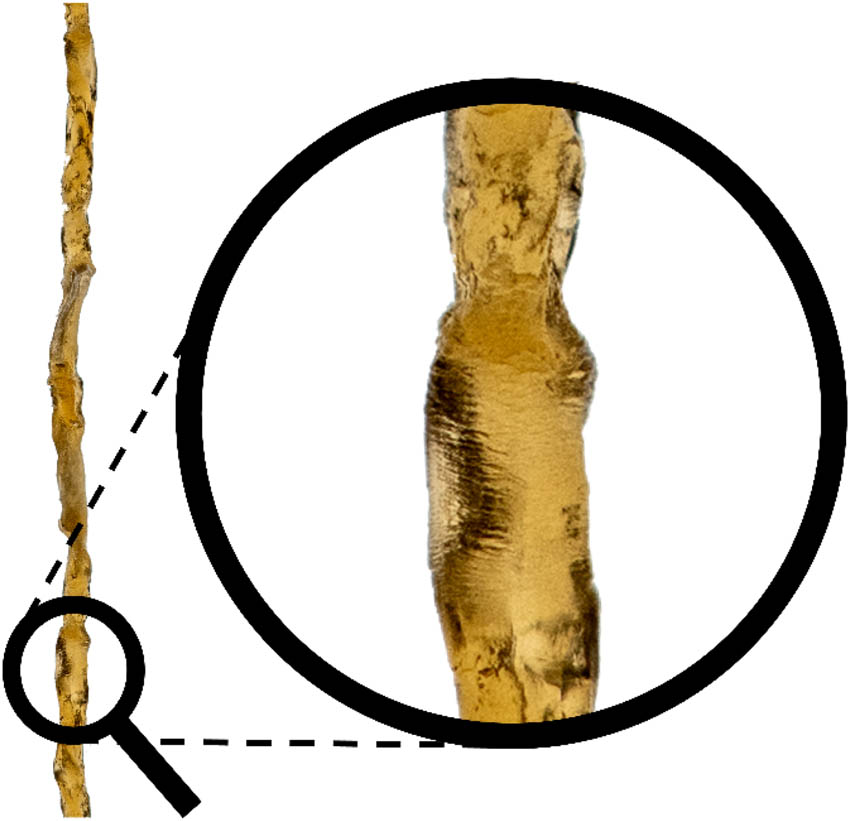

Samples were taken during the capillary rheometer measurements to visually examine whether flow instabilities or wall slip phenomena could be observed. Figure 5 shows the capillary extruded strands produced at different temperatures and subsequently air-dried. For temperatures of 95, 110, and 125°C across all shear rates, no smooth surfaces over the entire strand length are observed. Instead, the shapes are mainly random and discontinuous, appearing most similar to melt fracture or spurt in synthetic polymers [37,38]. At 125°C, a stick-slip-like behavior is evident at apparent shear rates of 10 and 15 s−1, as detailed in Figure 6 for an apparent shear rate of 10 s−1 [39]. At 140°C, the strand is not smooth at higher apparent shear rates, but it appears partially smooth at a shear rate of 150 s−1. At lower shear rates, bubble formation at the surface is clearly visible. A browning of the extruded strands with decreasing apparent shear rate (and increasing residence time in the reservoir) at 140°C is also observed.

Offline visualization of the extrudate strands extruded at different apparent shear rates using the L = 40 mm, D = 1 mm die at a temperature of 95°C (a), 110°C (b), 125°C (c), and 140°C (d).

Offline visualization of the possible stick-slip effect at an apparent shear rate of 10 s−1 at a temperature of 125°C.

3.2 Ramp test method

The apparent shear viscosity measured during a full rotation with the CCR is shown in Figure 7 for different apparent shear rates at all temperatures. The apparent viscosity increases up to an overshoot, which can be seen as yielding point of a fluid, after which it decreases toward a lower “post-yield” value [40,41]. The overshoot slightly shifts toward higher strains with increasing shear rate and temperature.

Apparent viscosity plotted over strain while performing the ramp test (start shear experiment) with a CCR at a temperature of 95°C (a), 110°C (b), 125°C (c), and 140°C (d).

At all temperatures, shear-thinning behavior is evident, except for the measurement at 140°C and 1 s−1. At 95 and 110°C, the apparent viscosity tends to stabilize to an almost steady value in the post-yield area. As already observed in the capillary rheometer measurements, the apparent viscosity values at 95 and 110°C are within the same range (also refer Figure 9c). At 125°C, the apparent viscosity decreases compared to lower temperatures and reaches a steady state, though it oscillates around this value. Similarly, at 140°C, apparent viscosity decreases further, with oscillations still present, while showing a slight decline with increasing strain. Comparing the number of oscillations to the number of grooves in the cone of the CCR reveals a match.

The visualization of the CCR samples after performing the ramp tests is shown in Figure 8. The bottom view displays the CCRs rotating cone while the top view reveals the surface of the CCRs fixed cone.

Offline visualization of the CCR pellets at different apparent shear rates using the ramp test at a temperature of 95°C (a), 110°C (b), 125°C (c), and 140°C (d).

At 95°C, the bottom view reveals bulk fracture. It looks like fracture is happening near the grooves, causing some gel pieces to remain stuck in the instrument and therefore not being visualized. The top view of the samples reflects the grooved surface of the fixed cone.

Irregular, deformed samples are presented at 110°C. The bottom view shows that the gel that was previously in the grooves appears to have detached from the surrounding sample matrix, but no gel pieces have adhered to the grooves of the instrument. The top view shows that the gel that was in the grooves still adheres to the sample but is partially deformed.

At 125°C, it does not appear as if bulk fracture was happening, but the samples are deformed. At apparent shear rates of 50, 25, and 10 s−1, the material that was in the grooves is deformed. At apparent shear rates of 5, 2.5, and 1 s−1, the view from below shows that the material in the grooves has been pressed flat.

At 140°C, the shape of the sample reflects the intact shape of the grooved measuring geometry, but holes and bubbles due to water expansion are visible on the surface.

4 Discussion

To further compare and discuss the differences in viscosity measurements, the results from the different techniques were compiled and plotted in Figure 9. The measured viscosity data at various temperatures were fitted using a power law model, and the corresponding fitting parameters, including the consistency index and flow behavior index, are provided in Table 1. However, these flow curves and fits should be interpreted with caution, as the previously presented results indicate significant influences of ongoing reactions, bulk fracture, and potential flow instabilities on the measurements.

Comparison and power law fitting of the measured viscosities at different temperatures for (a) the apparent viscosity measured with the capillary, (b) the Bagley corrected apparent viscosity measured with the capillary, and (c) the apparent viscosity measured with the closed cavity.

Consistency index and flow behavior index of the fitted viscosity data obtained with different methods at different temperatures

|

|

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 95°C | 110°C | 125°C | 140°C | |||||||||

| K/Pa s n | n/− | R 2 | K/Pa s n | n/− | R 2 | K/Pa s n | n/− | R 2 | K/Pa s n | n/− | R 2 | |

| Capillary | ||||||||||||

|

|

13,013 | 0.19 | 0.98 | 7,303 | 0.32 | 0.98 | 1,794 | 0.48 | 0.99 | 708 | 0.48 | 0.97 |

|

|

6,985 | 0.2 | 0.99 | 890 | 0.55 | 0.98 | 752 | 0.54 | 0.99 | 70 | 0.88 | 0.57 |

| CCR | ||||||||||||

|

|

32,337 | 0 | 0.88 | 27,928 | 0.12 | 0.99 | 8,441 | 0.39 | 0.95 | 3,412 | 0.43 | 0.88 |

4.1 Method-specific observations

Both rheometers confirmed shear-thinning behavior across the temperature range (95–140°C); however, substantial differences in the resulting flow curves and fitted parameters were observed depending on the measurement technique.

Capillary rheometry data indicated lower apparent viscosity values at higher temperatures but also exhibited strong signs of flow instabilities, including melt fracture and stick-slip patterns (Figures 5 and 6). These instabilities complicate data interpretation and may arise from interactions between the protein matrix and capillary wall, potentially intensified by water evaporation or bulk fracture near the die entrance. Further, the Bagley correction (Figure 4) revealed atypical behavior at 95, 110, and 140°C. While the nearly constant correction factors at 140°C may be attributed to proximity to the water vapor pressure, the trends at 95°C (approximately constant correction factors) and 110°C (approximately constant up to a shear rate of 100 s−1) remain difficult to explain. It is particularly unclear why the apparent viscosity data before Bagley correction partly overlap at these two temperatures, while the Bagley correction factor at 110°C is noticeably higher. One possible contributing factor could be temperature-dependent changes in network formation or intermolecular bonding, though this remains speculative and requires further investigation.

In contrast, the CCR method yielded higher apparent viscosity values and displayed a yield-like overshoot followed by viscosity decay, consistent with stress-induced bulk fracture. This overshoot could indicate a structural transition, possibly related to bond breakage in the protein network, as has been observed in other complex biopolymer systems [41,42]. Notably, at 95 and 110°C, bulk fracture was observed in CCR samples, as evidenced by detachment from the groove structures (Figure 8). Once bulk fracture has occurred, it is conceivable that the lower cone will simply slip down the rest of the sample. This would result in a slipping measurement between the two surfaces rather than a measurement of stationary flow.

At 125 and 140°C, an oscillating torque signal was observed, the origin of which remains unclear. One possible explanation is that the material within the grooves does not fracture under stress; instead, the cone may slip over the sample surface. This would be consistent with the fact that the number of oscillations matches the number of grooves in the geometry.

The discrepancies between the capillary and CCR methods are not merely methodological artifacts but reflect the inherent challenges of measuring how SPI dough responds to thermomechanical stress. While capillary rheometry approximates extrusion flow more directly, it is prone to water evaporation, entrance effects, and flow instabilities, even when applying Bagley corrections. CCR, on the other hand, offers better control over evaporation but is limited by its strain range and the potential for geometry-induced flow distortions.

4.2 Influence of temperature on flow behavior

Investigation of the influence of temperature on the stability of SPI doughs (Figure 1) revealed that between 95 and 125°C, the pressure signal remained relatively stable over time, with fluctuations decreasing as temperature increased. This reduction in fluctuations could also be related to changes in the transient network structure, which was suggested by the atypical trends seen in the Bagley correction factors. However, at 140°C, a clear decrease in pressure over time was observed, indicating ongoing reactions. These reactions were also visually evident through the browning of the samples. These findings align with previously reported results, demonstrating that SPI remains stable up to 120°C but becomes unstable at 140°C [3,31].

The temperature dependence of material behavior became clearly evident in both measurement methods. At 95 and 110°C, the transient protein network responded to shear stress more like a solid, as evidenced by the bulk fracture observed in the CCR measurements.

At 125°C, transitional behavior was observed, with capillary data suggesting emerging wall slip and stick-slip effects. CCR measurements revealed that the material reaches a state where bond breaking and rearranging could play a crucial role, as evidenced by the deformed and flattened appearance of the samples, indicating partial flow but limited relaxation. This temperature range may represent a critical processing window for fine-tuning meat-like structure formation during extrusion.

Notably, signs of water expansion were only observed at a temperature of 140°C, despite the expectation that expansion would occur at temperatures above 100°C. This may be because the water is bound in the protein network and is therefore not freely available in the sample. The formation of bubbles and sample browning at 140°C indicate chemical and physical transformations that likely alter the network structure and thus the flow behavior.

Interestingly, the flow behavior index at 125 and 140°C changes only slightly between the apparent viscosities obtained by the capillary method without Bagley correction (n = 0.48 at 125 and 140°C) and the CCR ramp test (n = 0.39 at 125°C and n = 0.43 at 140°C). Additionally, the relative decrease in the consistency index

4.3 Potential for meat analogues structuring

Flow instabilities such as intermittent slippage and bulk fracture were observed across both methods and temperature ranges. Notably, these instabilities occurred within the same temperature range (95–140°C) in which the SPI used here has previously been shown to form fibrous structures at comparable moisture contents [13,17]. While these phenomena are typically regarded as undesirable artifacts in polymer processing, they may provide important insights into the mechanisms underlying fibrous structure formation during high moisture extrusion of meat analogues. The interplay between localized stress, shear deformation, and transient network structure (breaking and rearranging) could be a prerequisite for the development of anisotropic structures in meat analogues.

Moreover, Guan et al. recently proposed that flow instabilities, including sharkskin and melt fracture, may actually facilitate fiber formation [43]. In our study, we observed sharkskin-like surface patterns in the capillary rheometer and signs of bulk fracture in the CCR, lending support to this hypothesis even though a different protein dough was used.

Finally, the overshoot observed in the CCR ramp test, which may be interpreted as the fracturing point of the protein network, could serve as a useful marker for the onset of structural transitions. It could potentially act as a fingerprint for predicting fibrous structure formation or be used for material screening.

4.4 Future directions

Future work should focus on understanding the presented artefacts and minimizing measurement inaccuracies by adapting rheological measurement techniques. This could enable flow instabilities and bulk fracture to be linked more directly to structure formation mechanisms in meat analogues, and set these in correlation with the underlying biopolymer mechanics and the multiphase nature of the system. Particular attention should be given to identifying the relaxation dynamics and critical shear rates that determine whether the material undergoes bulk fracture. Additionally, understanding how thermomechanical history influences rheological behavior and protein conformation will be essential for optimizing processing conditions. Another key area is the identification of viscosity measures that are most relevant for experimental control, prediction of product characteristics, and improvement of predictive modeling.

5 Conclusion

This study examined the apparent flow behavior of SPI dough (55 wt% water) between 95 and 140°C using a capillary rheometer and by performing a ramp test in a CCR. The two methods showed clear differences, mainly due to flow instabilities, and material-specific behavior like bulk fracture and protein reactions, which were not analyzed in detail. Visual inspection of the samples helped to interpret the measurement results. The capillary extrudates showed irregular surface patterns resembling melt fracture, stick-slip-like behavior at 125°C and low shear rates (10 and 15 s−1) and signs of browning reactions and water evaporation at 140°C. Bagley correction factors showed atypical behavior at 95, 110, and 140°C, possibly linked to the transient network and vapor pressure, but yet could not be fully explained. In the CCR, bulk fracture occurred at 95 and 110°C, while at 125°C, deformed and flattened samples pointed to bond breaking and rearrangement in the protein network.

While both rheological methods have limitations, they provide complementary insights into the apparent flow behavior of protein doughs under extrusion-relevant conditions. The capillary rheometer better mimics flow in the extrusion process, while the CCR ramp test may serve as a useful tool for material screening and potentially offer a fingerprinting approach for structuring protein doughs. Future work should aim to link these flow behaviors to structure formation and improve methods for predicting extrusion outcomes.

Acknowledgments

The authors acknowledge support from the KIT Publication Fund of the Karlsruhe Institute of Technology. Felix Ellwanger would like to thank Sajjad Pashazadeh and Ases Mishra for assistance with capillary measurements and fruitful discussions of the results. Felix Ellwanger would also like to thank Matheus Mendes for assistance with sample visualization. The authors thank Bahiru Tsegaye for his help with sample preparation. Felix Ellwanger would also like to thank Nina Weis for her support with the closed-cavity rheometer measurements in Karlsruhe. The authors thank Laurids Pernice and Laura Riedel for proofreading the manuscript.

-

Funding information: The data of this work were obtained during a research stay at the Department of Industrial and Materials Science, Rheology and Processing of Soft Matters at Chalmers University of Technology. The research stay was funded by the Karlsruhe House of Young Scientists (KHYS).

-

Author contributions: F.E.: conceptualization (lead), data curation (lead), formal analysis (lead), investigation (lead), and writing – original draft (lead). R.K.: conceptualization (supporting), supervision (supporting), and writing – original draft (supporting). M.A.E.: conceptualization (supporting) and supervision (lead).

-

Conflict of interest: The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

-

Ethical approval: The conducted research is not related to either human or animal use.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available with the corresponding author on reasonable request.

References

[1] van der Sman RGM, van der Goot AJ. Hypotheses concerning structuring of extruded meat analogs. Curr Res Food Sci. 2023;6:100510.10.1016/j.crfs.2023.100510Search in Google Scholar PubMed PubMed Central

[2] McClements DJ. Soft matter physics approaches for creating plant-based meat analogs. Curr Opin Food Sci. 2024;55:101120.10.1016/j.cofs.2023.101120Search in Google Scholar

[3] Wittek P, Zeiler N, Karbstein HP, Emin MA. High moisture extrusion of soy protein: Investigations on the formation of anisotropic product structure. Foods. 2021;10:102.10.3390/foods10010102Search in Google Scholar PubMed PubMed Central

[4] Opaluwa C, Deskovski S, Karbstein HP, Emin MA. Effect of oil on the rheological properties and reaction behavior of highly concentrated wheat gluten under conditions relevant to high moisture extrusion. Future Foods. 2024;34:100307.10.1016/j.fufo.2024.100307Search in Google Scholar

[5] Wittek P, Karbstein HP, Emin MA. Blending proteins in high moisture extrusion to design meat analogues: Rheological properties, morphology development and product properties. Foods. 2021;10:1509.10.3390/foods10071509Search in Google Scholar PubMed PubMed Central

[6] Saavedra Isusi GI, Pietsch V, Beutler P, Hoehne S, Leister N. Influence of rapeseed oil on extruded plant-based meat analogues: Assessing mechanical and rheological properties. Processes. 2023;11:1871.10.3390/pr11071871Search in Google Scholar

[7] Wagner CE, Ganjyal GM. Impact of functional dietary fiber incorporation on the appearance and mechanical properties of extruded high moisture meat analogs. J Food Sci. 2024;89:4953.10.1111/1750-3841.17164Search in Google Scholar PubMed

[8] Skrzeszewska PJ, Sprakel J, de Wolf FA, Fokkink R, Cohen Stuart MA, van der Gucht J. Fracture and self-healing in a well-defined self-assembled polymer network. Macromolecules. 2010;43(7):3542–8.10.1021/ma1000173Search in Google Scholar

[9] Thornell TL, Helfrecht BA, Mullen SA, Bawiskar A, Erk KA. Fracture-healing kinetics of thermoreversible physical gels quantified by shear rheophysical experiments. ACS Macro Lett. 2014;3:1069.10.1021/mz500524dSearch in Google Scholar PubMed

[10] Pietsch VL, Emin MA, Schuchmann HP. Process conditions influencing wheat gluten polymerization during high moisture extrusion of meat analog products. J Food Eng. 2017;198:28.10.1016/j.jfoodeng.2016.10.027Search in Google Scholar

[11] Pietsch VL, Schöffel F, Rädle M, Karbstein HP, Emin MA. High moisture extrusion of wheat gluten: Modeling of the polymerization behavior in the screw section of the extrusion process. J Food Eng. 2019;246:67.10.1016/j.jfoodeng.2018.10.031Search in Google Scholar

[12] Kendler C, Duchardt A, Karbstein HP, Emin MA. Effect of oil content and oil addition point on the extrusion processing of wheat gluten-based meat analogues. Foods. 2021;10:697.10.3390/foods10040697Search in Google Scholar PubMed PubMed Central

[13] Wittek P, Ellwanger F, Karbstein HP, Emin MA. Morphology development and flow characteristics during high moisture extrusion of a plant-based meat analogue. Foods. 2021;10:1753.10.3390/foods10081753Search in Google Scholar PubMed PubMed Central

[14] Ellwanger F, Pernice L, Karbstein HP, Emin MA. Investigating local residence time and thermomechanical stress profile in twin-screw extrusion of plant proteins by using the moving particle semi-implicit simulation method. J Food Eng. 2023;359:111665.10.1016/j.jfoodeng.2023.111665Search in Google Scholar

[15] Kaunisto E, Wassén S, Stading M. A thermodynamical finite element model of the fibre formation process during extrusion of high-moisture meat analogues. J Food Eng. 2024;362:111760.10.1016/j.jfoodeng.2023.111760Search in Google Scholar

[16] Li D, Zhang T, Gao F, Zhou C, Sun D, Gao Y, et al. The study of numerical simulation and texture of soybean protein based on high moisture extrusion with different screw elements. Innov Food Sci Emerg Technol. 2024;92:103560.10.1016/j.ifset.2023.103560Search in Google Scholar

[17] Ellwanger F, Fuhrmann M, Karbstein HP, Saavedra Isusi GI. Influence of lowering the pH value on the generation of fibrous structures of protein gels with different network types. Gels. 2024;10:173.10.3390/gels10030173Search in Google Scholar PubMed PubMed Central

[18] Tsegaye B, Barman S, Bovagne L, Ellwanger F, Kaunisto E, Lorén N, et al. Rheological properties of pea protein melts used for producing meat analogues. Appl Rheol. 2025;35:20250036.10.1515/arh-2025-0036Search in Google Scholar

[19] van der Sman RGM, Voudouris P, Hamoen JR. Extrapolation of classical rheometry of plant protein pastes to extrusion conditions. Food Hydrocoll. 2024;150:109663.10.1016/j.foodhyd.2023.109663Search in Google Scholar

[20] Sägesser C, Mair T, Braun A, Dumpler J, Fischer P, Mathys A. Application of a shear cell for the simulation of extrusion to test the structurability of raw materials. Food Hydrocoll. 2025;160:110736.10.1016/j.foodhyd.2024.110736Search in Google Scholar

[21] Emin MA, Quevedo M, Wilhelm M, Karbstein HP. Analysis of the reaction behavior of highly concentrated plant proteins in extrusion-like conditions. Innov Food Sci Emerg Technol. 2017;44:15.10.1016/j.ifset.2017.09.013Search in Google Scholar

[22] Wittek P, Zeiler N, Karbstein HP, Emin MA. Analysis of the complex rheological properties of highly concentrated proteins with a closed cavity rheometer. Appl Rheol. 2020;30:64.10.1515/arh-2020-0107Search in Google Scholar

[23] Schreuders F, Sagis L, Bodnár I, Erni P, Boom RM, van der Goot A-J. Mapping the texture of plant protein blends for meat analogues. Food Hydrocoll. 2021;118:106753.10.1016/j.foodhyd.2021.106753Search in Google Scholar

[24] Ellwanger F, Georgantopoulos CK, Karbstein HP, Wilhelm M, Azad Emin M. Application of the ramp test from a closed cavity rheometer to obtain the steady-state shear viscosity η (γ̇). Appl Rheol. 2023;33:20220149.10.1515/arh-2022-0149Search in Google Scholar

[25] Buhrin HG, Rauschmann T. Viscosity measurement of filled rubber compounds – New insight for error free measurements. Kautsch Gummi Kunstst. 2021;74:39.Search in Google Scholar

[26] Buhrin HG, Rauschmann T, Graf HJ. Wall slip in processing rubber compound revisited. Kautsch Gummi Kunstst. 2021;74:61.Search in Google Scholar

[27] Kleinschmidt D, Brüning F, Petzke J. Wall slip-free viscosity determination of filled rubber compounds using steady-state shear measurements. Polymers (Basel). 2023;15:4406.10.3390/polym15224406Search in Google Scholar PubMed PubMed Central

[28] Bagley EB. End corrections in the capillary flow of polyethylene. J Appl Phys. 1957;28:624.10.1063/1.1722814Search in Google Scholar

[29] Rabinowitsch B. Über die viskosität und elastizität von solen. Z Phys Chem. 1929;145:1.10.1515/zpch-1929-14502Search in Google Scholar

[30] Mooney M. Explicit formulas for slip and fluidity. J Rheol. 1931;2:210.10.1122/1.2116364Search in Google Scholar

[31] Hayashi N, Noma K, Hayakawa I, Fujio Y. Influence of time‐temperature history and strain history on the melt rheology of soy protein isolate at an elevated temperature. IJFST. 1992;27:297.10.1111/j.1365-2621.1992.tb02031.xSearch in Google Scholar

[32] Wittek P, Walther G, Karbstein HP, Emin MA. Comparison of the rheological properties of plant proteins from various sources for extrusion applications. Foods. 2021;10:1700.10.3390/foods10081700Search in Google Scholar PubMed PubMed Central

[33] Hayashi N, Hayakawa I, Fujio Y. Entrance effect correction on the flow of moisturized soy protein isolate melt in an extrusion viscometer. IJFST. 1991;26:567.10.1111/j.1365-2621.1991.tb02002.xSearch in Google Scholar

[34] Fujio Y, Hayashi N, Hayakawa I. Effect of moisture content on flow behaviour of molten soy‐protein isolate under an elevated temperature. IJFST. 1991;26:45.10.1111/j.1365-2621.1991.tb01140.xSearch in Google Scholar

[35] Hayashi N, Hayakawa I, Fujio Y. Flow behaviour of soy protein isolate melt with low and intermediate moisture levels at an elevated temperature. J Food Eng. 1993;18:1.10.1016/0260-8774(93)90072-RSearch in Google Scholar

[36] Stokes JR, Telford JH. Measuring the yield behaviour of structured fluids. J Non-Newtonian Fluid Mech. 2004;124:137.10.1016/j.jnnfm.2004.09.001Search in Google Scholar

[37] Koopmans R, Den Doelder J, Molenaar J. Polymer melt fracture. Boca Raton: CRC Press; 2010.10.1201/9781420018288Search in Google Scholar

[38] Georgantopoulos CK, Esfahani MK, Botha C, Naue IFC, Dingenouts N, Causa A, et al. Mechano‐optical characterization of extrusion flow instabilities in styrene‐butadiene rubbers: Investigating the influence of molecular properties and die geometry. Macro Mater Eng. 2021;306:6.10.1002/mame.202000801Search in Google Scholar

[39] Burghelea TI, Griess HJ, Muenstedt H. Comparative investigations of surface instabilities (“sharkskin”) of a linear and a long-chain branched polyethylene. J Non-Newtonian Fluid Mech. 2010;165(19–20):1093–104.10.1016/j.jnnfm.2010.05.007Search in Google Scholar

[40] Skadsem HJ, Leulseged A, Cayeux E. Measurement of drilling fluid rheology and modeling of thixotropic behavior. Appl Rheol. 2019;29:1.10.1515/arh-2019-0001Search in Google Scholar

[41] Mujumdar A, Beris AN, Metzner AB. Transient phenomena in thixotropic systems. J Non-Newtonian Fluid Mech. 2002;102:157.10.1016/S0377-0257(01)00176-8Search in Google Scholar

[42] Hicks CI, See H. The rheological characterisation of bread dough using capillary rheometry. Rheol Acta. 2010;49:719.10.1007/s00397-010-0441-1Search in Google Scholar

[43] Guan T, Sägesser C, Villiger R, Zychowski L, Kohlbrecher J, Dumpler J et al. In situ studies of plant-based meat analog texturization. Food Hydrocoll. 2024;155:110215.10.1016/j.foodhyd.2024.110215Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Lie symmetry analysis of bio-nano-slip flow in a conical gap between a rotating disk and cone with Stefan blowing

- Mathematical modelling of MHD hybrid nanofluid flow in a convergent and divergent channel under variable thermal conductivity effect

- Advanced ANN computational procedure for thermal transport prediction in polymer-based ternary radiative Carreau nanofluid with extreme shear rates over bullet surface

- Effects of Ca(OH)2 on mechanical damage and energy evolution characteristics of limestone adsorbed with H2S

- Effect of plasticizer content on the rheological behavior of LTCC casting slurry under large amplitude oscillating shear

- Studying the role of fine materials characteristics on the packing density and rheological properties of blended cement pastes

- Deep learning-based image analysis for confirming segregation in fresh self-consolidating concrete

- MHD Casson nanofluid flow over a three-dimensional exponentially stretching surface with waste discharge concentration: A revised Buongiorno’s model

- Rheological behavior of fire-fighting foams during their application – a new experimental set-up and protocol for foam performance qualification

- Viscoelastic characterization of corn starch paste: (II) The first normal stress difference of a cross-linked waxy corn starch paste

- An innovative rheometric tool to study chemorheology

- Effect of polymer modification on bitumen rheology: A comparative study of bitumens obtained from different sources

- Rheological and irreversibility analysis of ternary nanofluid flow over an inclined radiative MHD cylinder with porous media and couple stress

- Rheological analysis of saliva samples in the context of phonation in ectodermal dysplasia

- Analytical study of the hybrid nanofluid for the porosity flowing through an accelerated plate: Laplace transform for the rheological behavior

- Brief Report

- Correlations for friction factor of Carreau fluids in a laminar tube flow

- Special Issue on the Rheological Properties of Low-carbon Cementitious Materials for Conventional and 3D Printing Applications

- Rheological and mechanical properties of self-compacting concrete with recycled coarse aggregate from the demolition of large panel system buildings

- Effect of the combined use of polyacrylamide and accelerators on the static yield stress evolution of cement paste and its mechanisms

- Special Issue on The rheological test, modeling and numerical simulation of rock material - Part II

- Revealing the interfacial dynamics of Escherichia coli growth and biofilm formation with integrated micro- and macro-scale approaches

- Construction of a model for predicting sensory attributes of cosmetic creams using instrumental parameters based on machine learning

- Effect of flaw inclination angle and crack arrest holes on mechanical behavior and failure mechanism of pre-cracked granite under uniaxial compression

- Special Issue on The rheology of emerging plant-based food systems

- Rheological properties of pea protein melts used for producing meat analogues

- Understanding the large deformation response of paste-like 3D food printing inks

- Seeing the unseen: Laser speckles as a tool for coagulation tracking

- Composition, structure, and interfacial rheological properties of walnut glutelin

- Microstructure and rheology of heated foams stabilized by faba bean isolate and their comparison to egg white foams

- Rheological analysis of swelling food soils for optimized cleaning in plant-based food production

- Multiscale monitoring of oleogels during thermal transition

- Influence of pea protein on alginate gelation behaviour: Implications for plant-based inks in 3D printing

- Observations from capillary and closed cavity rheometry on the apparent flow behavior of a soy protein isolate dough used in meat analogues

- Special Issue on Hydromechanical coupling and rheological mechanism of geomaterials

- Rheological behavior of geopolymer dope solution activated by alkaline activator at different temperature

- Special Issue on Rheology of Petroleum, Bitumen, and Building Materials

- Rheological investigation and optimization of crumb rubber-modified bitumen production conditions in the plant and laboratory

Articles in the same Issue

- Research Articles

- Lie symmetry analysis of bio-nano-slip flow in a conical gap between a rotating disk and cone with Stefan blowing

- Mathematical modelling of MHD hybrid nanofluid flow in a convergent and divergent channel under variable thermal conductivity effect

- Advanced ANN computational procedure for thermal transport prediction in polymer-based ternary radiative Carreau nanofluid with extreme shear rates over bullet surface

- Effects of Ca(OH)2 on mechanical damage and energy evolution characteristics of limestone adsorbed with H2S

- Effect of plasticizer content on the rheological behavior of LTCC casting slurry under large amplitude oscillating shear

- Studying the role of fine materials characteristics on the packing density and rheological properties of blended cement pastes

- Deep learning-based image analysis for confirming segregation in fresh self-consolidating concrete

- MHD Casson nanofluid flow over a three-dimensional exponentially stretching surface with waste discharge concentration: A revised Buongiorno’s model

- Rheological behavior of fire-fighting foams during their application – a new experimental set-up and protocol for foam performance qualification

- Viscoelastic characterization of corn starch paste: (II) The first normal stress difference of a cross-linked waxy corn starch paste

- An innovative rheometric tool to study chemorheology

- Effect of polymer modification on bitumen rheology: A comparative study of bitumens obtained from different sources

- Rheological and irreversibility analysis of ternary nanofluid flow over an inclined radiative MHD cylinder with porous media and couple stress

- Rheological analysis of saliva samples in the context of phonation in ectodermal dysplasia

- Analytical study of the hybrid nanofluid for the porosity flowing through an accelerated plate: Laplace transform for the rheological behavior

- Brief Report

- Correlations for friction factor of Carreau fluids in a laminar tube flow

- Special Issue on the Rheological Properties of Low-carbon Cementitious Materials for Conventional and 3D Printing Applications

- Rheological and mechanical properties of self-compacting concrete with recycled coarse aggregate from the demolition of large panel system buildings

- Effect of the combined use of polyacrylamide and accelerators on the static yield stress evolution of cement paste and its mechanisms

- Special Issue on The rheological test, modeling and numerical simulation of rock material - Part II

- Revealing the interfacial dynamics of Escherichia coli growth and biofilm formation with integrated micro- and macro-scale approaches

- Construction of a model for predicting sensory attributes of cosmetic creams using instrumental parameters based on machine learning

- Effect of flaw inclination angle and crack arrest holes on mechanical behavior and failure mechanism of pre-cracked granite under uniaxial compression

- Special Issue on The rheology of emerging plant-based food systems

- Rheological properties of pea protein melts used for producing meat analogues

- Understanding the large deformation response of paste-like 3D food printing inks

- Seeing the unseen: Laser speckles as a tool for coagulation tracking

- Composition, structure, and interfacial rheological properties of walnut glutelin

- Microstructure and rheology of heated foams stabilized by faba bean isolate and their comparison to egg white foams

- Rheological analysis of swelling food soils for optimized cleaning in plant-based food production

- Multiscale monitoring of oleogels during thermal transition

- Influence of pea protein on alginate gelation behaviour: Implications for plant-based inks in 3D printing

- Observations from capillary and closed cavity rheometry on the apparent flow behavior of a soy protein isolate dough used in meat analogues

- Special Issue on Hydromechanical coupling and rheological mechanism of geomaterials

- Rheological behavior of geopolymer dope solution activated by alkaline activator at different temperature

- Special Issue on Rheology of Petroleum, Bitumen, and Building Materials

- Rheological investigation and optimization of crumb rubber-modified bitumen production conditions in the plant and laboratory