Abstract

The main purpose of this research is to examine the performance of lightweight concrete (LWC) that contains palm oil clinker (POC) as a replacement for aggregate by either 50 or 100% of volume. Also, the use of palm oil ash (POA) and silica fume (SF) as a 10 and 20% weight replacement for cement, respectively, was examined. This research involved designing 20 mixtures. The performance of the fresh mixed LWC was assessed using a slump test. A variety of experiments were used to assess the performance of hardened concrete, including a dry density test, a compressive strength (CS) test, a split tensile strength test, a flexural strength test, and a modulus of elasticity test. In addition, the performance of concrete exposed to high temperatures on CS is evaluated. The transport properties were evaluated by applying tests including water permeability, chloride permeability, and water absorption. Finally, microstructure analysis was performed. The findings revealed that employing cementitious materials, such as SF and POA, as cement replacements or POC as an aggregate substitute reduced workability. The usage of POC as an alternative to aggregate also reduced CS. The mixture containing 100% POC showed the highest reduction, with a rate of 52% lower than the reference mixture. Furthermore, the applied temperature increased to 600°C, resulting in a significant decrease in CS, ranging from 34.6 to 42.6%.

Notations

- CS

-

compressive strength

- FS

-

flexural strength

- LWC

-

lightweight concrete

- MOE

-

modulus of elasticity

- POA

-

palm oil ash

- POC

-

palm oil clinker

- PC

-

Portland cement

- SF

-

silica fume

- STS

-

splitting tensile strength

- SP

-

superplasticizer

1 Introduction

Numerous countries are using enormous quantities of non-renewable natural resources due to the growing requirement for building materials to support rapid development. Therefore, it is evident that the growing demand has led to a rise in the expenses associated with acquiring raw materials and a persistent scarcity of natural resources [1]. The base of the building sector is concrete, which consumes huge quantities of non-renewable natural materials such as limestone and fossil fuels during the manufacturing process [2]. In addition to the pollution caused by carbon dioxide emissions during Portland cement (PC) manufacturing processes [3,4], the releases of CO2 related to the manufacturing of PC typically varies between 0.73 and 0.99 tons of CO2 per ton of PC, on average [5]. According to the findings of the World PC and Concrete Association, it is noted that PC manufacturing contributed to approximately 7% of world CO2 emissions in the year 2020 [6]. As a result, it is very important to look for a full or sectional substitute for PC in the building field to reduce consumption. In previous years, concrete was made using industrial or agricultural residue as a potential alternative for PC, a topic that attracted a lot of scientific interest [7,8]. One of the most important factors in preserving natural resources and making concrete manufacturing economically viable is the incorporation of industrial and agricultural waste [9]. The suitable treatment processes for industrial and agricultural wastes have demonstrated remarkable efficacy as partial alternatives to PC or as supplementary components for the creation of environmentally conscious and sustainable concrete [10]. The process of managing agricultural or industrial waste involves preparing it to potentially serve as a sectional replacement for construction materials while ensuring it meets standard specifications with ease [11]. Concrete is extensively utilized as a construction material due to its distinctive characteristics, ease of design, and controllable properties. Furthermore, it considers the possibility of managing fresh and hardened properties related to density, strength, and durability [12]. Density control has a positive impact on a variety of factors, including reduced loads, improved thermal and acoustic insulation, and lower transportation and handling costs [13]. It is imperative that the dry density of structural lightweight concrete (LWC) does not exceed 2,000 kg·m−3, based on British standard (BS EN 206) [14]. The dry density of LWC, as specified by the American Concrete Institute (ACI 213R), may not exceed 1,920 kg·m−3 [15]. LWC can be made by incorporating different elements, including (1) gaseous agents such as aluminum powder or foaming agents [16]; (2) light particles like expanded clay, pumice, oil shale, and slate [17]; (3) using farm trash, such as coconut or palm oil leaves, as a partial or full substitute for aggregate [18]; and (4) incorporating granules of plastic, rubber, or other polymeric materials [19]. In the past decades, researchers have also directed their focus toward the exploration of various agricultural wastes as potential building materials in the field of concrete [20,21]. One potential alternative that could be considered is palm oil clinker (POC), which is a prevalent agricultural solid waste in numerous tropical countries [22]. The POC is made when oil palm stalks are completely burned, as husks and fibers are. Its physical properties consist of being gray in color, having a porous structure, irregular form, and being lightweight. The majority of palm oil processing plants dispose POC in landfills, which is detrimental to the environment. Therefore, using it as a sectional substitution for aggregates in the manufacture of LWC reduces the environmental impact and consumption of natural resources. Furthermore, palm oil ash (POA) is an ashy byproduct created when palm oil is treated. Several studies suggest that the POA might be utilized as a sectional substitute for PC or as supplemental PC material. Several studies demonstrate that sectional substitute of POA for PC has a beneficial influence on concrete characteristics. The researchers proposed heat treatment at temperatures ranging between 500 and 600°C, as well as an increase in fineness by grinding, to improve the efficiency of the POA [10,23]. The thermal and physical treatment techniques resulted in POA with improved microstructure and increased reactivity, allowing it to act as a more effective pozzolanic [24,25]. Hamada et al. [26] utilized POC as a primary component for the creation of LWC. Reports indicate that using it as a whole substitute for coarse aggregate resulted in a decrease in density from 2,380 to 2,020 kg·m−3. Furthermore, the compressive strength (CS) of LWC samples using POC100% and nano-POA as a sectional replacement for PC at 30% by weight was 58.3 MPa. Ahmmad et al. [27] substituted POC for coarse aggregate at a rate ranging from 25 to 100% for LWC production, and the study obtained dried concrete densities between 1,833 and 1,971 kg·mm−3 and CSs between 27 and 31.3 MPa at 289 days. The research prepared by Abutaha et al. [28] emphasized the utilization of POC as a fine as well as coarse aggregate in LWC. The density exhibited was 2,074–2,358 kg·m−3, while the CS demonstrated was 33–49 MPa after 28 days.

1.1 Research significance

There is a shortage of previous research on the impact of using POC as a substitute for coarse and fine aggregates, as well as using POA as a partial replacement for PC in conjunction with silica fume (SF). In addition, based on previous literature reviews, few studies have been done on the utilization of binary mixes of PC and POA or PC and SF as a substitute for coarse and fine aggregates in POC-based LWC. The importance of this research lies in its focus on investigating the impact of substituting natural aggregate with POC at levels of 50 and 100% of the aggregate volume, in addition to using POA or SF as a sectional substitute for PC at levels of 10 and 20% by weight. The slump test was used to study the properties of fresh LWC. The hardening properties were investigated using the dry density test, CS, splitting tensile strength (STS), flexural strength (FS), and modulus of elasticity (MOE). In addition to evaluating the durability of LWC by examining the effect of elevated temperatures on CS, chloride permeability, water absorption, water permeability, and microstructures.

2 Experimental program

2.1 Materials

2.1.1 PC

In this study, PC type (CEM I 52.5N) was used, which complies with BS EN 197/1 2011. The physical and chemical characteristics of the PC used are delineated in Table 1.

Characteristics of binder materials

| Properties | PC | SF | POA |

|---|---|---|---|

| Physical | |||

| Specific gravity | 3.14 | 2.14 | 2.25 |

| Initial setting time (min) | 72 | — | — |

| Final setting time (min) | 327 | — | — |

| Specific area (cm2·g−1) | 3,525 | 19,950 | 10,640 |

| Color | Gray | Light gray | Light gray |

| Chemical composition (%) | |||

| SiO2 | 21.93 | 98.71 | 63.97 |

| Al2O3 | 3.65 | 0.27 | 4.74 |

| Fe2O3 | 3.07 | 0.34 | 5.95 |

| CaO | 63.32 | 0.17 | 6.10 |

| MgO | 2.88 | 0.11 | 4.92 |

| SO3 | 2.94 | 0.16 | 1.10 |

| K2O | 0.89 | 0.14 | 9.83 |

| Na2O | 0.67 | 0.10 | 0.15 |

| LOI | 0.65 | — | 3.24 |

2.1.2 SF

In this work, SF is a secondary material from a ferrosilicon alloy factory. The SF utilized was locally obtained and is in accordance with ASTM C1240-20 standards. The physical characteristics and chemical attributes of SF from the manufacturer are tabulated in Table 1.

2.1.3 POA

The waste of palm oil comes from companies that make palm oil. The POA for this work came from a palm oil mill in Marsa Matrouh, Egypt. The POA was air-dried in an electrical oven set to 110 ± 5°C for 1 day. It was then put through a 150 mm sieve to get rid of any big or odd particles. The POA that had been sieved was then ground on a grinding machine from Los Angeles to make the particles very small [29]. An electric furnace was used to heat the POA to temperatures of up to 600°C for around 2 h to boost the effectiveness of the POA by eliminating any unburned carbon [24,30]. The equipment that was used in Los Angeles to make POA was also employed in the second step of grinding for the POA that was produced there, and the same method was used in the production of previous studies [29,31]. And finally, the very fine POA was gathered. It meets the standards of BS 3892: Part 1. The POA generated may be classified as classes C and F, in accordance with the ASTM C618-19 standard specifications. Table 1 provides a concise summary of the physical attributes and chemical makeup of POA.

2.1.4 Aggregates

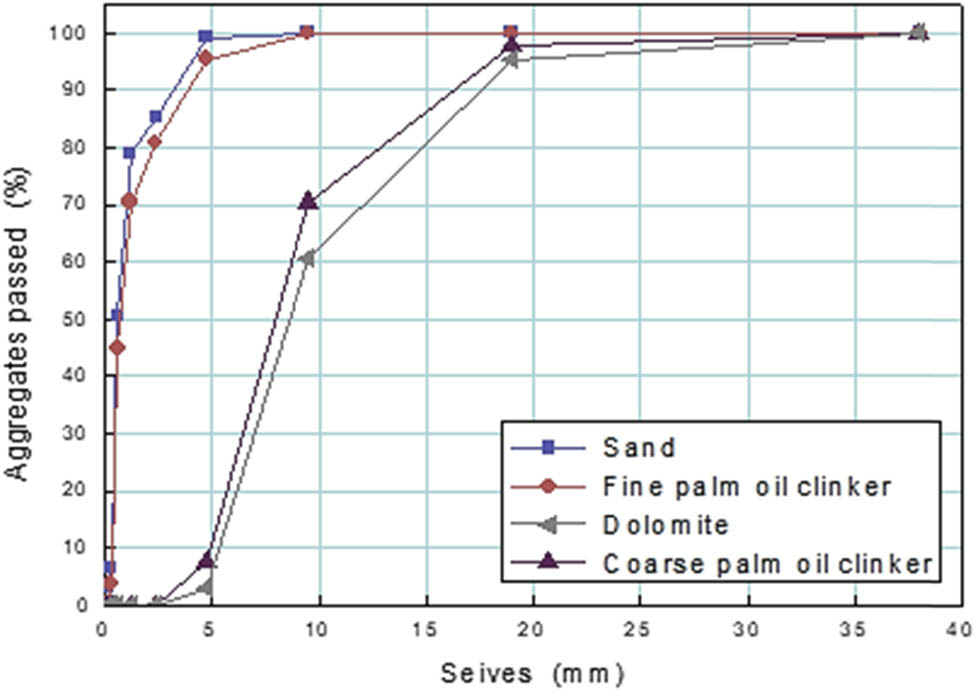

This research used two basic types of fine particles. Concerning the sand, it was used to cast the reference mixtures, while POC wastes as fine aggregates were used to produce LWC mixtures. The utilized fine aggregate (sand or POC) with dimensions varying between 0.15 and 4.75 mm is from the Belbes zone and the Marsa Matrouh zone in Egypt, respectively. Also, two main coarse aggregates (dolomite and POC as lightweight aggregates) were utilized in this work with a maximum particle dimension of 19 mm, and they were obtained from the Attaka zone, Suez, and Marsa Matrouh zone, Egypt, respectively. Some of the previous works investigated the influence of POC on the properties of LWC [32,33]. The properties of aggregates were determined as per ASTM C33/C33M-18. Table 2 presents the outcomes of the physical and mechanical characteristics of the aggregates. Figure 1 displays the gradation shape of the aggregates used.

Mechanical and physical properties of the utilized aggregate

| Property | Sand | Fine POC | Dolomite | Coarse POC |

|---|---|---|---|---|

| Specific gravity | 2.65 | 1.55 | 2.62 | 1.42 |

| Unit weight (kg·m−3) | 1,697 | 1,043 | 1,663 | 887 |

| Fineness modulus | 2.763 | 3.043 | 6.411 | 6.241 |

| Water absorption (%) | 0.79 | 11.85 | 1.13 | 4.89 |

| Clay and fine materials (%) | 0.84 | 0.93 | 0.74 | 0.38 |

| Impact value (%) | — | — | 12.23 | 20.65 |

| Crushing value (%) | — | — | 11.72 | 17.92 |

| Los Angles abrasion loss (%) | — | — | 13.88 | 25.96 |

Gradation shape of aggregates used.

2.1.5 Superplasticizer (SP)

SP (Viscocrete-3425) was used with the aim of obtaining the required workability [34,35]. About 2.9% of SP was utilized in the binder materials. It complies with the specifications for SP as outlined in ASTM-C-494 Type G and BS EN 934 Part 2:2001, with 1.1 specific gravity.

2.2 Mixtures proportion

The used design method for all poured mixtures in this research was the absolute volume method. The study was conducted on four primary series, consisting of a total of 20 LWC mixtures, to accomplish the goals of this research. The details of the mix portions for LWC are illustrated in Table 3. The following ranges were chosen for the components of the mixtures: The control mix contains PC (CEM I 52.5N) with a PC concentration of 500 kg·m−3. The other mixes have PC contents ranging from 450 to 400 kg·m−3. SF and POA are used as a partial substitute for PC, with SF comprising 10% and POA comprising 20% of the total weight of PC. POC is utilized as a substitute for natural fine aggregate (sand) at volumes of 50 and 100%. Similarly, coarse POC is used as a replacement for natural coarse aggregate (dolomite) at volumes of 50 and 100%. The dose of SP is 2.9%, as per the binder materials. The ratio of water to binder is 0.25.

LWC mixture proportions (kg·m−3)

| Mix. ID | CEM I | Fine aggregates | Coarse aggregates | SF | POA | SP | Water | ||

|---|---|---|---|---|---|---|---|---|---|

| Sand | POC | Dolomite | POC | ||||||

| CEM-S-D | 500 | 925.7 | 0 | 925.7 | 0 | 0 | 0 | 14.5 | 125 |

| SF10-S-D | 450 | 915.9 | 0 | 915.9 | 0 | 50 | 0 | 14.5 | 125 |

| SF20-S-D | 400 | 906.1 | 0 | 906.1 | 0 | 100 | 0 | 14.5 | 125 |

| PA10-S-D | 450 | 917.4 | 0 | 917.4 | 0 | 0 | 50 | 14.5 | 125 |

| PA20-S-D | 400 | 909.1 | 0 | 909.1 | 0 | 0 | 100 | 14.5 | 125 |

| CEM-FP-D | 500 | 0 | 684.1 | 684.1 | 0 | 0 | 0 | 14.5 | 125 |

| SF10-FP-D | 450 | 0 | 676.9 | 676.9 | 0 | 50 | 0 | 14.5 | 125 |

| SF20-FP-D | 400 | 0 | 669.6 | 669.6 | 0 | 100 | 0 | 14.5 | 125 |

| PA10-FP-D | 450 | 0 | 678.0 | 678.0 | 0 | 0 | 50 | 14.5 | 125 |

| PA20-FP-D | 400 | 0 | 671.9 | 671.9 | 0 | 0 | 100 | 14.5 | 125 |

| CEM-S-FP-D-CP | 500 | 333.3 | 333.3 | 333.3 | 333.3 | 0 | 0 | 14.5 | 125 |

| SF10-S-FP-D-CP | 450 | 329.8 | 329.8 | 329.8 | 329.8 | 50 | 0 | 14.5 | 125 |

| SF20-S-FP-D-CP | 400 | 326.2 | 326.2 | 326.2 | 326.2 | 100 | 0 | 14.5 | 125 |

| PA10-S-FP-D-CP | 450 | 330.3 | 330.3 | 330.3 | 330.3 | 0 | 50 | 14.5 | 125 |

| PA20-S-FP-D-CP | 400 | 327.3 | 327.3 | 327.3 | 327.3 | 0 | 100 | 14.5 | 125 |

| CEM-FP-CP | 500 | 0 | 520.8 | 0 | 520.8 | 0 | 0 | 14.5 | 125 |

| SF10-FP-CP | 450 | 0 | 515.3 | 0 | 515.3 | 50 | 0 | 14.5 | 125 |

| SF20-FP-CP | 400 | 0 | 509.8 | 0 | 509.8 | 100 | 0 | 14.5 | 125 |

| PA10-FP-CP | 450 | 0 | 516.2 | 0 | 516.2 | 0 | 50 | 14.5 | 125 |

| PA20-FP-CP | 400 | 0 | 511.5 | 0 | 511.5 | 0 | 100 | 14.5 | 125 |

There are four groups of LWC mixtures, each including four different kinds of aggregates (sand, fine POC, dolomite, and coarse POC). The mixes consisted of four distinct groups, each representing the variables in this research. The first group with 50% sand and 50% dolomite was prepared with 400–500 kg·m−3 CEM I (control group), while the other three groups contained 50 and 100% fine POC and 50 and 100% coarse POC as a partial substitution of nature’s aggregate (sand or dolomite). Each group consists of five mixtures, as demonstrated in Table 3.

2.3 Sample preparation

All the dry ingredients (aggregates and binder materials) were put into the mixer, and it was mixed for about 3 min, or until the mix was uniform. Half of the water was added slowly while the mixture was being mixed, and then the remaining water with SP was added. All the mixes were poured into molds and left in the casting room with the lid on for 24 h. As per ASTM C192, the samples were taken out of the mold 24 h after they were made and put in the drying tank to cure in water.

2.4 Test procedure

Slump, density, CS, STS, FS, MOE, chloride penetration resistance, water sorptivity, water permeability, and elevated temperature are the fresh and hardened properties of LWC mixtures that were investigated in this work, in addition to microstructure characteristics. The slump test, as per ASTM C 143, was utilized to evaluate the workability of the LWC in its fresh form. The density of LWC mixes was calculated in accordance with the specifications stated in ASTM C642-13. Referring to BS EN 12390-3, nine 100 mm × 100 mm × 100 mm cube samples were utilized to measure CS at 7, 28, and 91 days of LWC mixing. The STS was evaluated based on ASTM C 496. In this test, three cylindrical samples measuring 150 mm × 300 mm were utilized for the STS test at 28 days for each mixture. The FS at 28 days of LWC was calculated in accordance with ASTM C 78. The prism samples of 100 mm × 100 mm × 500 mm for this test were utilized. The MOE was calculated utilizing the methodology outlined in ASTM C 469. Three 150 mm × 300 mm cylinder samples for each mix were tested for the MOE at 28 days. Disc specimens with a diameter of 100 mm and a thickness of 50 mm were employed to assess the resistance of chloride penetration after 28 days, applying the procedure outlined in ASTM C1202-17. The sorptivity at 28 days, which measures the rates at which water is absorbed, was measured according to the guidelines of ASTM C1585-13 on 100 mm × 50 mm cylinder. The water permeability at 28 days was assessed by executing the test outlined in BS EN 12390-8 on cylindrical specimens with dimensions of 150 mm × 150 mm. In this study, the residual CS characteristics of high-temperature LWC are evaluated by exposing them to high elevated temperatures up to 800°C. The samples employed in this work are 100 mm cubes based on EN 2390-3. LWC mixes were subjected to temperatures of 22, 200, 400, 600, and 800°C for about 2 h in the oven.

The specimens were exposed to elevated temperatures using a temperature furnace that was regulated. The furnace was heated at a rate of 10°C·min−1. After maintaining a constant temperature for 2 h, the desired temperature was reached. After that, the furnace was cooled at a rate of 1.67°C·min−1 to prevent any thermal shock to the specimens. The samples were cooled before testing by leaving them in the laboratory hall for 24 h until their temperature dropped to 22°C (laboratory temperature). The heating protocol used was concurrent with the method used in previous studies [34,36–41]. The concrete samples were exposed to high temperatures according to the European specification EN 1992-1 (2010). The samples were cooled before testing by leaving them in the laboratory hall for 24 h until their temperature dropped to 22°C (laboratory temperature).

The samples casted with the variables were subjected to the CS test. Finally, microstructure tests using scanning electron microscope (SEM) analysis were performed to validate the obtained results.

3 Obtained outcomes

3.1 Fresh characteristics

3.1.1 Slump

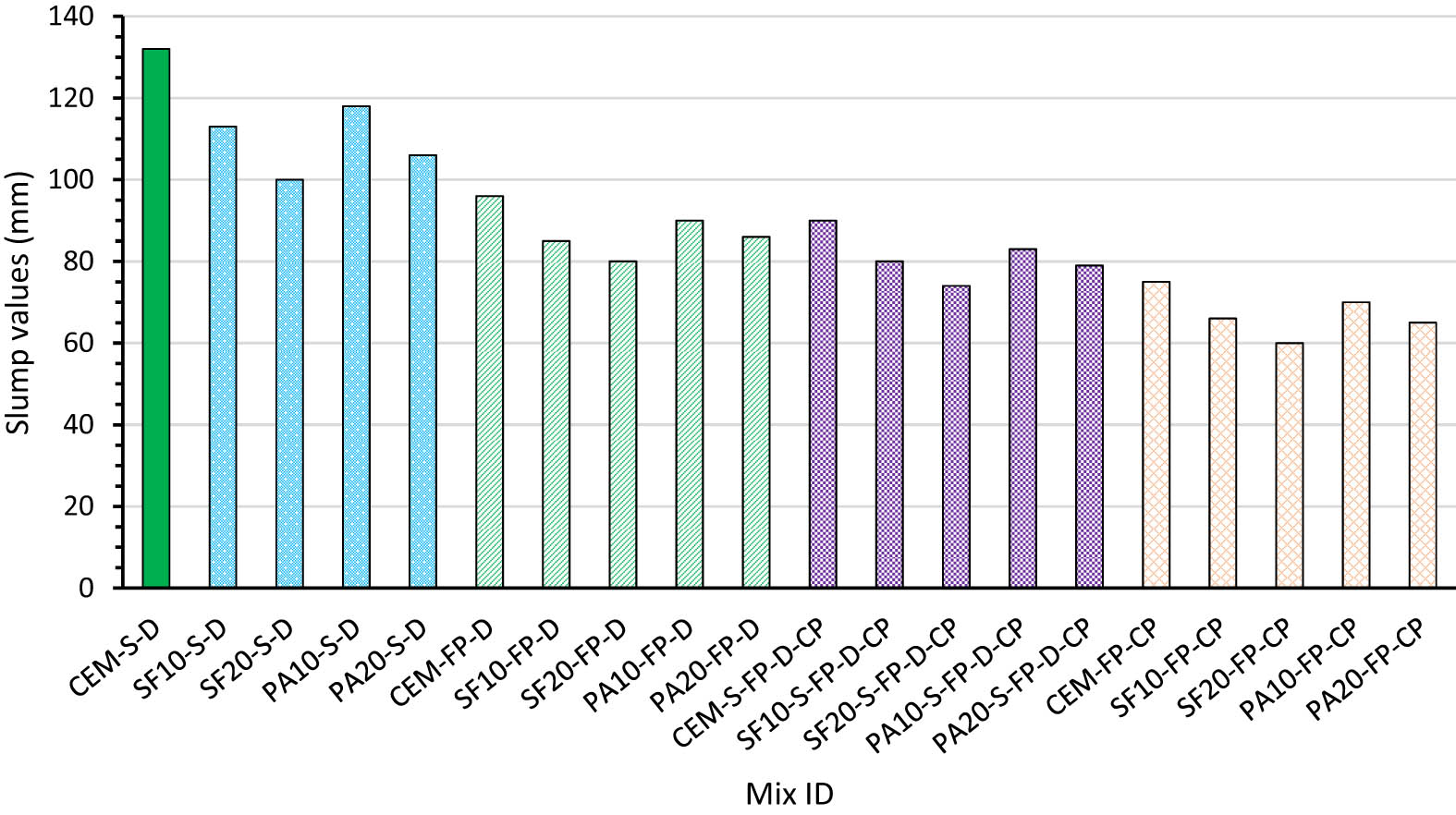

Figure 2 presents the obtained slump values of full poured LWC mixes. It can be seen that, for CEM-S-D and SF20-FP-CP, the greatest and lowest recorded slump values were, respectively, 132 and 60 mm. The slump values for each group decreased gradually up to a certain point, after which they increased. To give an example, for mixes CEM-S-D, SF10-S-D, SF20-S-D, PA10-S-D, and PA20-S-D, the recorded slump values were 132, 113, 100, 118, and 106 mm. This may be related to the use of a great replacement ratio of SF “20%” by mass from PC, which has a high specific area of 19,995 cm2·g−1” in comparison to the specific area of the used PC, which is 3,525 cm2·g−1. This indicates that a high amount of mixing water was absorbed due to the fineness of the SF particles, which decreased the quantity of free water and reduced the slump values. The reference mix is also shown to have the highest slump value across all groups. Additionally, mixtures with POA have slump values higher than mixtures with SF, where the slump values for mixes CEM-FP-D, SF10-FP-D, SF20-FP-D, PA10-FP-D, and PA20-FP-D were 96, 85, 80, 90, and 86 mm, respectively. This might be related to the material characterization (Table 1) in which the SF-specific area is larger than the POA specific area. Finally, increasing the replacement of sand or dolomite with POC, respectively, at a constant ratio of POA resulted in poor workability, as demonstrated by mixtures PA10-S-D, PA10-FP-D, PA10-S-FP-D-CP, and PA10-FP-CP with associated slump values of 118, 90, 83, and 70 mm, which may occur as a result of increased water absorption (%) of POC than used aggregate, and also the % of clay and fine materials in POC is greater than the utilized aggregate (Table 2). From the preceding discussion, it is obvious that utilizing POA as a replacement for PC in addition to employing POC as a substitute for sand or dolomite creates a negative effect on the workability of LWC, which is consistent with previous studies [42,43].

Outcomes of slump values of LWC.

3.2 Mechanical characteristics

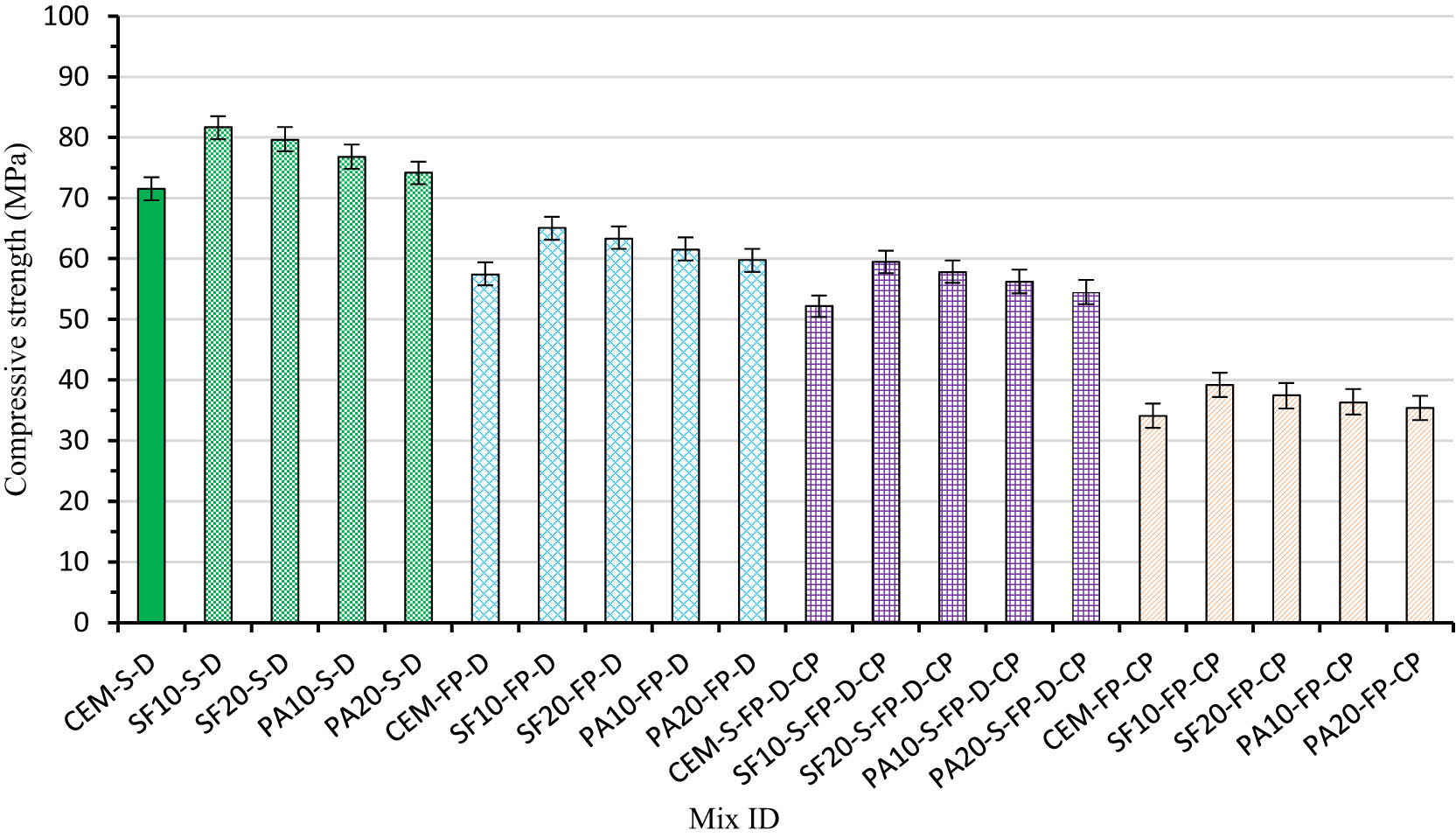

3.2.1 Dry density

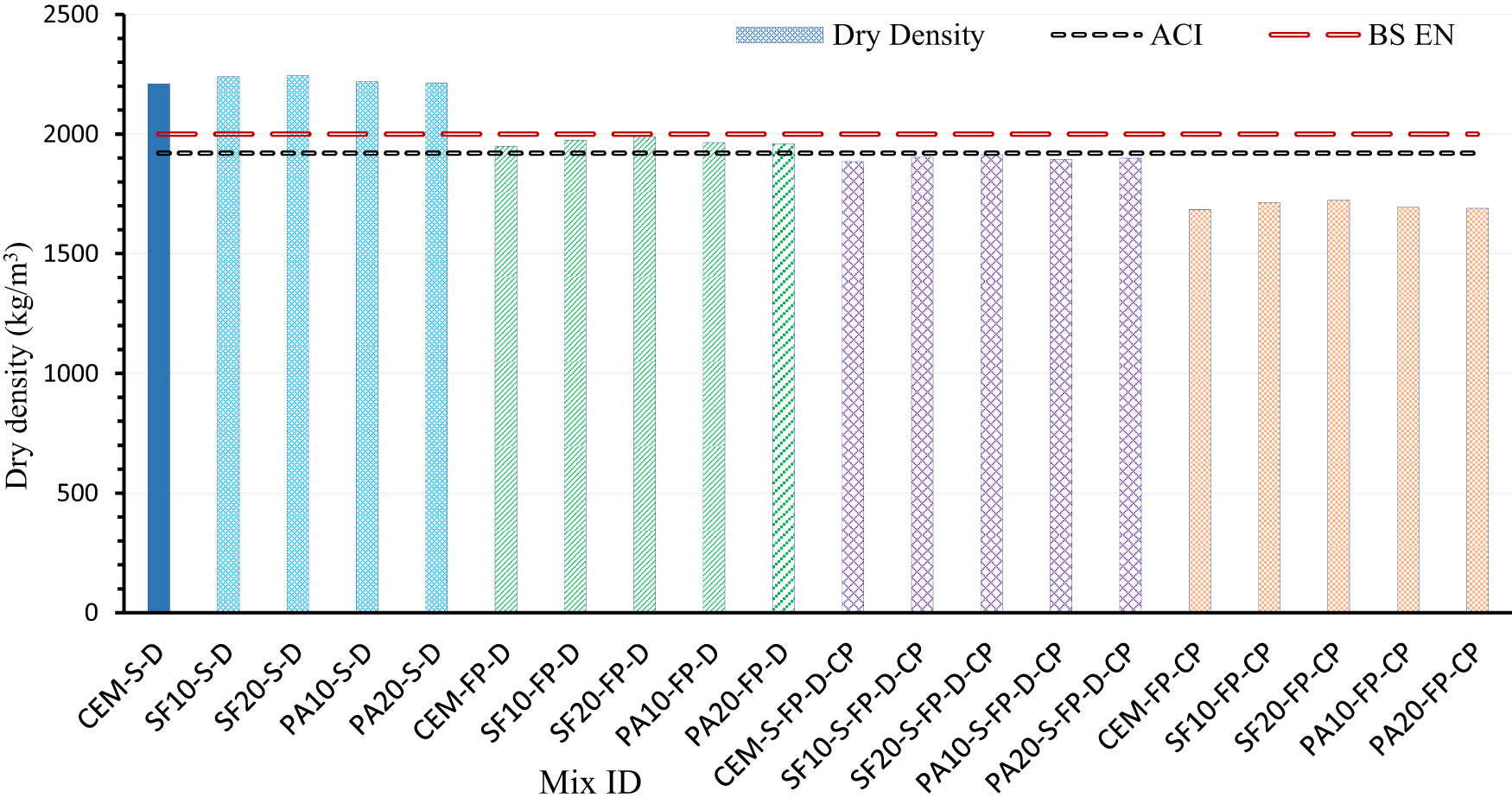

Figure 3 displays the dry density test outcomes for combined clinker and palm oil samples as a replacement for fine and coarse aggregates, as well as the use of POA as a sectional replacement for PC at 28 days. It is noted that the production of LWC using POA or SF at replacement rates of 0, 10, and 20% by mass of PC resulted in an average dry density of 2,245–2,210 kg·m−3 at 28 days. In contrast, the CS ranged between 71.5 and 81.7 MPa at a test age of 28 days. It is noticed that utilizing POA or SF as a sectional replacement for PC did not change much in the density of LWC; on the contrary, it led to a slight enhancement in the dry density of LWC compared to the reference mixture, whereas replacing 50% of the sand with POC causes a decrease in the dry density of the LWC. The dry density of LWC ranged from 1,950, 1,975, 1,990, 1,965, and 1,960 kg·m−3 for CEM-FP-D, SF10-FP-D, SF20-FP-D, PA10-FP-D, and PA20-FP-D kg·m−3, respectively. It is noted that this decrease in dry density meets the requirements of LWC based on the BS EN specifications, which require that the dry density of LWC be lower than 2,000 kg·m−3. In addition, replacing 25% sand and 25% coarse aggregate with POC creates a more pronounced decrease in dry LWC density than when replacing 50% sand with POC alone. In this case, the density of dry LWC conforms to the basic requirements for LWC in BS EN and ACI specifications. The results for the dry density of the LWC were less than 1,920 kg·m−3 at 28 days. In the case of substituting 50% sand and 50% coarse aggregate by POC, it resulted in a decrease in the dry density of LWC by 23.7, 22.3, 21.9, 23.3, and 23.5% for CEM-FP-CP, SF10-FP-CP, SF20-FP-CP, PA10-FP-CP, and PA20-FP-CP mixtures compared to CEM-S-D (reference mixture). Therefore, the density of dry LWC, which includes the replacement of 50% sand and 50% coarse aggregate by POC, meets the LWC requirements of BS EN and ACI specifications. The dry density results for LWC in this case ranged between 1,685 and 1,725 kg·m−3 at 28 days.

Outcomes of the dry density of LWC.

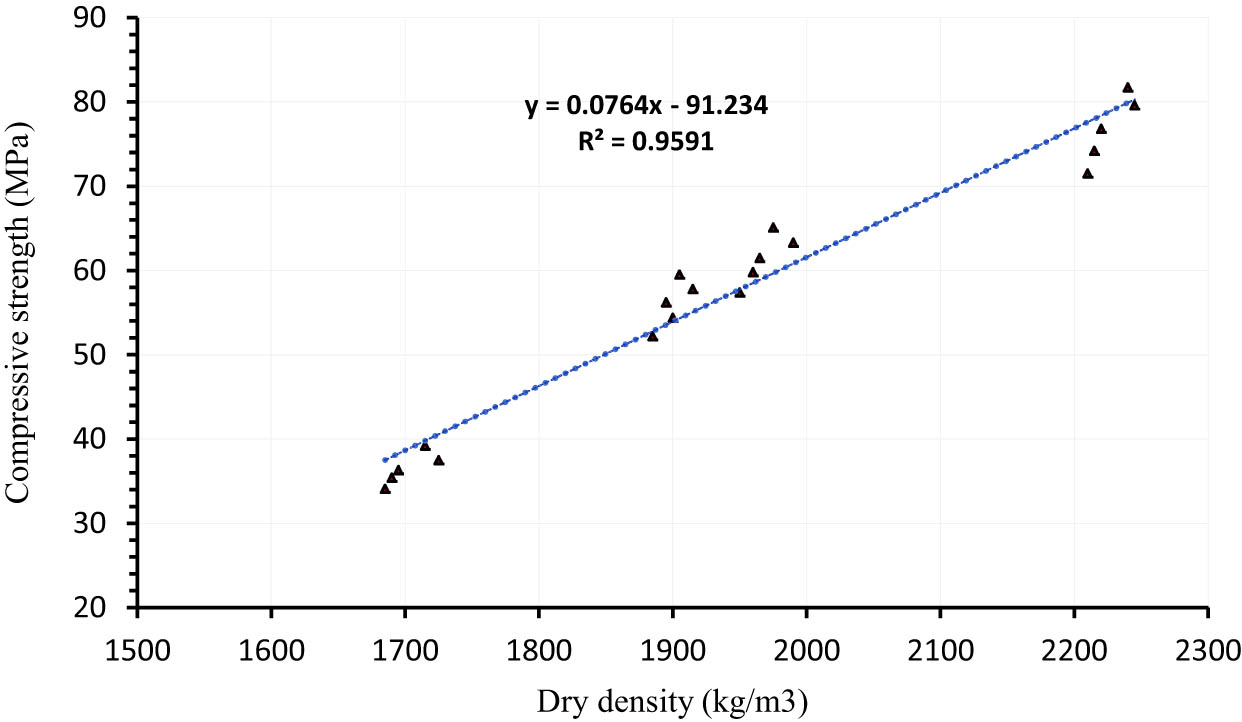

Figure 4 illustrates the relationship between the dry density and CS of LWC at 28 days. The relationship shows a strong correlation (R = 0.95) between the dry density and CS of the LWC at 28 days. The lower the drying density, the lower the CS. The CEM-FP-CP mixture showed the lowest dry density of 1,685 kg·m−3 and the lowest CS of 34.1 MPa among all the mixtures applied in this work. Generally, the outcomes are consistent with the results of prior investigations that studied the impact of low dry density on CS. The utilization of lightweight materials as a sectional replacement for aggregates has a positive influence on reducing density and, on the other hand, a harmful impact on strength, transport, and durability properties. On the other hand, the utilization of POA and SF as a sectional substitute for PC contributed to the preservation of better engineering properties compared to the control mix [44,45].

Relationship between dry density and CS of LWC.

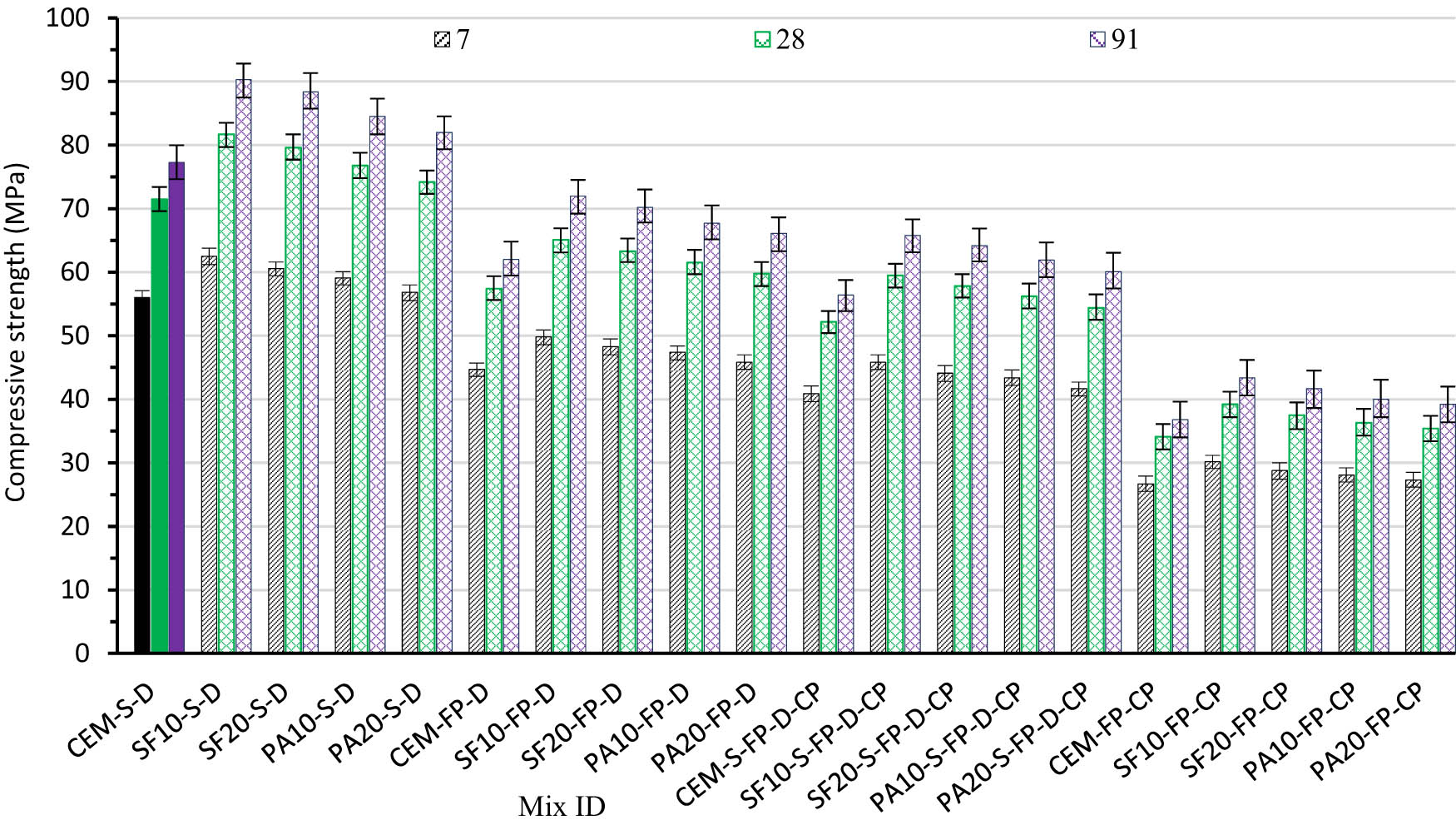

3.2.2 CS

Figure 5 shows the results of the CS test of LWC including the substitution of PC with SF and POA, in addition to the replacement of sand and coarse aggregate with POC at 7, 28, and 91 days. SF and POA were used as partial replacements at a ratio of 10 and 20% by weight of PC, and POC was employed as a substitute for both sand and coarse aggregates at rates of 50 and 100% by volume. The findings indicate that incorporating SF and POA as partial substitutes for PC yielded positive results, as evidenced by an improvement in CS compared to the reference mix. The substitution of 10 and 20% PC with SF resulted in a 14.3 and 11.3% increase in CS, respectively. Similarly, substituting 10 and 20% PC with POA led to a 7.4 and 3.8% increase in CS, respectively, when compared to the reference mixture. Referring to Table 1, POA has pozzolanic properties with a chemical structure of SiO2, Al2O3, and Fe2O3 of 74.6% and a loss of ignition (LOI) of 3.2% by weight. Therefore, the incorporation of POA as a sectional substitute for PC enhanced the CS of LWC because of the interaction of pozzolanic with Ca(OH)2, which generated an extra additional calcium silicate hydrate (C–S–H) gel. This is consistent with the investigation by Tangchirapat et al. [46], which states that replacing 10–30% of the PC weight with fine POA increases CS compared to the reference mix. POA’s high SiO2 content and high fineness increased the response between SiO2 and calcium hydroxide to generate more C–S–H, which increased CS. On the other hand, POC utilization as an alternative for sand and coarse aggregates caused a decrease in CS. There is an inverse relationship between the replacement rate and the CS, whereby an enhancement in the substitution rate leads to a reduction in the CS. The substitution of 100% sand and 100% coarse aggregates with POC resulted in the greatest reduction in the CS of the CEM-FP-CP mixture by 52.3% compared to the reference mixture. While the rates of reduction in CS varied according to the rate of substitution of sand and coarse aggregate with POC and the level of substitution of PC by SF or POA, they ranged from 8.9 to 52.3%, with an age of 28 days. It is also observed that the utilization of SF or POA as a sectional replacement for PC contributed to reducing the damage to the CS as a result of the utilization of POC as a substitute for coarse aggregate and sand. The findings align with the research investigated by Ibrahim et al. [47], which indicates that substituting aggregates with POC for the manufacture of LWC creates a decrease in CS. Furthermore, the reduction in CS is observed to increase as the rate of aggregate replacement increases.

Outcomes of CS of LWC.

Figure 6 presents the amount of change in the CS of LWC because of utilizing SF and POA as a sectional substitution for PC and using POC as a replacement for coarse aggregate and sand with a test age of 28 days.

Outcomes of CS of LWC at 28 days.

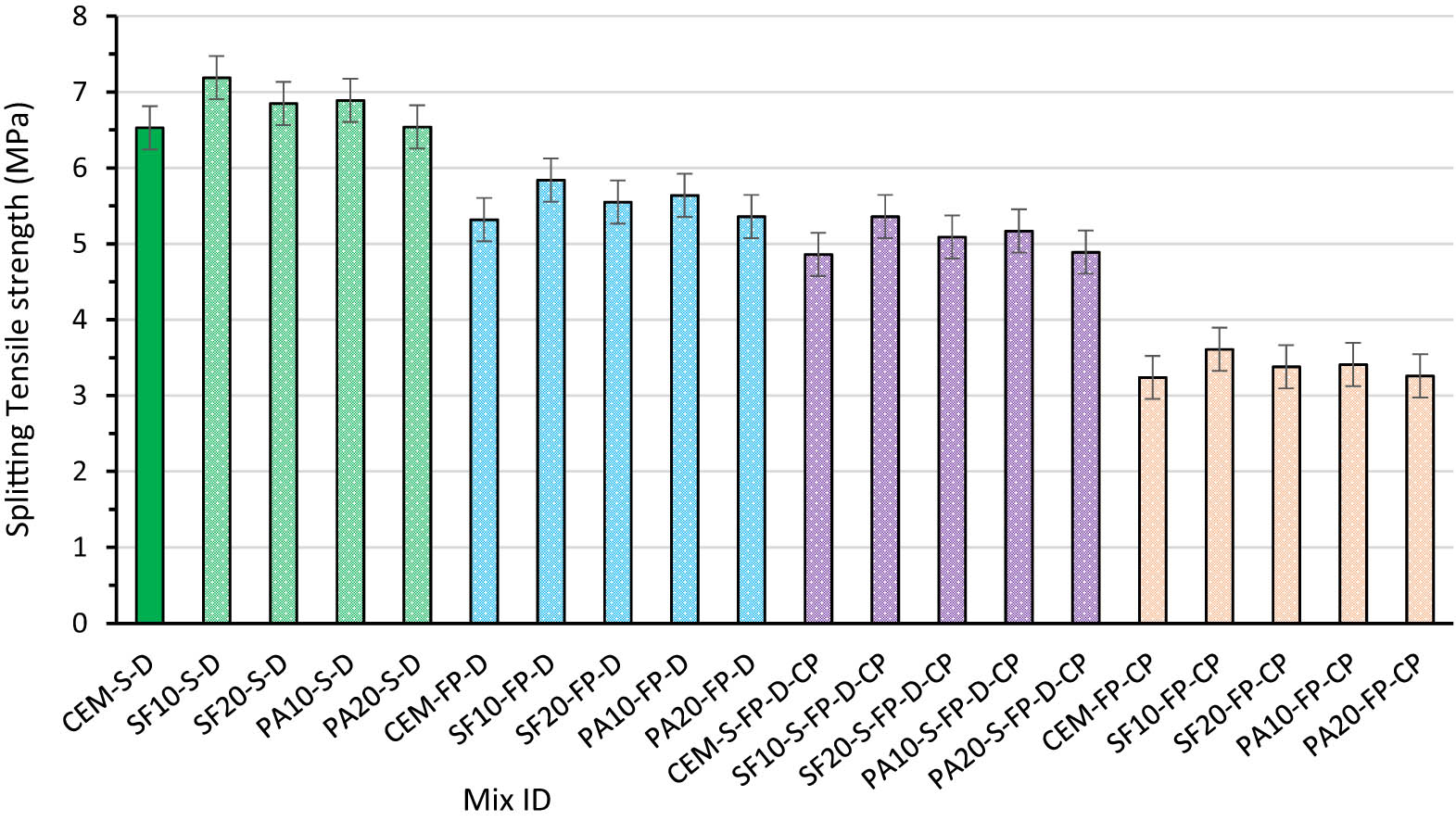

3.2.3 STS

The STS results at 28 days are delineated in Figure 7 for all LWC mixtures. The effect of replacing PC with SF or POA at levels of 10, 20% by weight, and sand and coarse aggregate with POC at rates of 50 and 100% by volume on the STS is investigated. By referring to Figure 7, the STS for the reference mix was 6.53 MPa; in addition, the maximum and minimum splitting tensile values were 7.19 and 3.24 MPa for mixtures SF10-S-D and CEM-FP-CP, respectively. The best results for STS were achieved in each group at a replacement ratio of 10% using SF, which means using SF as a replacement for PC is preferable to using POA, where the STS for SF10-S-D and PA10-S-D increased by about 10.1 and 5.51%, respectively. That may refer to the SF particles being finer than POA particles based on the material characteristics shown in Table 1. Furthermore, adding 20% SF or 10% POA to LWC mixes gives very similar results for STS values, e.g., the STS values for mixes SF20-FP-D and PA10-FP-D were 7.85 and 7.87 MPa, respectively. On the other side, replacing sand and dolomite with POC at different levels at the same level of replacement of PC by SF or POA has an adverse impact on splitting tensile values; increasing the replacement ratios increase the reduction in STS values. For example, the splitting tensile values for mixes SF20-S-D, SF20-FP-D, SF20-S-FP-D-CP, and SF20-FP-CP were 6.85, 5.55, 5.09, and 3.38 MPa, respectively. These outcomes may be related to the crushing value (%) and Los Angles abrasion loss (%) of coarse particles of POC, which are higher than their counterparts in the used dolomite (Table 2). The obtained outcomes agree with the research conducted by Ibrahim et al. [47], which indicates that when POC was used in place of aggregates in the manufacturing of LWC, there was a decrease in the STS of the material. Furthermore, the rate of aggregate replacement significantly contributes to the material’s STS decline.

Outcomes of STS of LWC at 28 days.

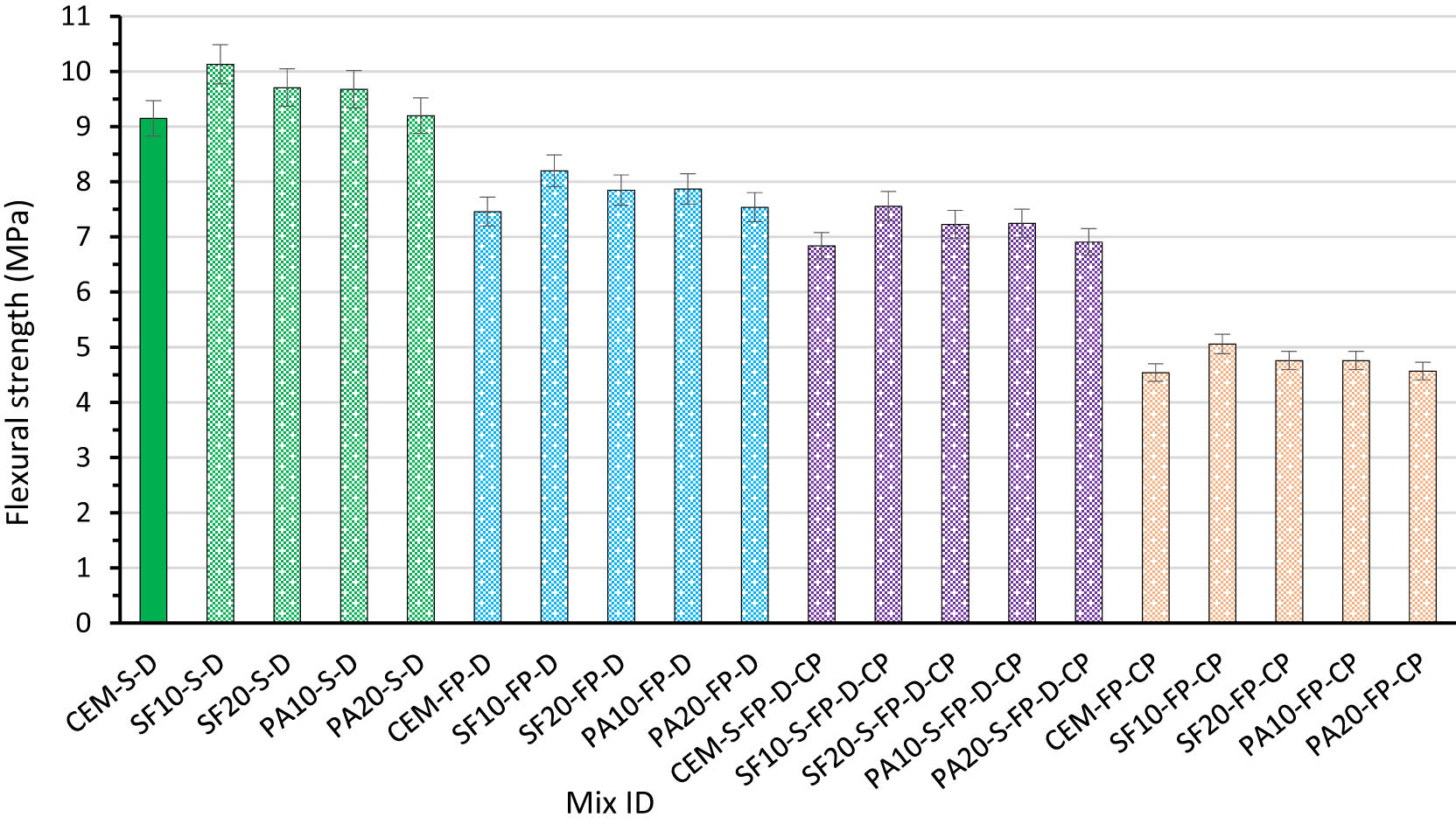

3.2.4 FS

Figure 8 illustrates the outcomes obtained from the FS test conducted on LWC specimens. The test included the substitution of PC with supplementary cementitious materials, namely, SF and POA, as well as the replacement of sand and coarse aggregate with POC. The samples were tested at 28 days. In the study, the researchers used SF and POA as partial substitutes for PC, with a weight ratio of 10 and 20%, respectively. Additionally, POC was utilized as a substitute for both sand and coarse aggregates, with volume ratios of 50 and 100%, respectively. The findings indicate that the presence of supplementary materials such as SF and POA as sectional replacements for PC yields a favorable outcome. This is supported by an observed improvement in FS when compared to the reference mixture. The incorporation of SF as a substitution for 10 and 20% of PC led to a respective increase of 10.7 and 6.12% in FS. Furthermore, the substitution of 10 and 20% of PC with POA resulted in a corresponding rise of 5.7 and 0.5% in FS, as compared to the control mixture. Referring to the data illustrated in Table 1, POA has pozzolanic characteristics, as indicated by its chemical composition, which includes SiO2, Al2O3, and Fe2O3, which together account for 74.6% of its total weight. Additionally, POA shows a LOI of 3.2% by weight. As a result, the inclusion of POA as a sectional replacement for PC led to an increase in the CS of LWC due to the pozzolanic reaction with Ca(OH)2, resulting in the formation of an extra C–S–H gel. This agrees with the study by Tangchirapat et al. [46]. The elevated SiO2 concentration and small particle size of POA facilitated the interaction between SiO2 and calcium hydroxide, resulting in the augmented formation of calcium silicate hydrate. This, in turn, led to an increment in FS. Conversely, the presence of POC as a substitute for sand and coarse aggregates creates a decrease in FS. A negative correlation exists between the replacement rate and the FS, whereby an increase in the replacement rate results in a drop in the FS. The replacement of 100% sand and 100% coarse aggregates with POC resulted in the most significant decrease in the FS of the CEM-FP-CP, exhibiting a loss of 25.24% when compared to the CEM-S-D mixture. The rates of decline in STS exhibited variability depending on the extent of sand and coarse aggregate substitution with POC, as well as the extent of PC substitution with SF or POA. These rates ranged from 10.38 to 25.24% at an age of 28 days. Additionally, it should be acknowledged that including supplementary materials such as SF or POA as a sectional replacement for PC has been shown to have a role in mitigating the adverse impact on FS. This is particularly evident when utilizing POC as an alternative for coarse aggregate. Finally, the FS outcomes follow the same trend as the CS findings, and the FS outcomes agree with the results obtained by Ibrahim et al. [47].

Outcomes of FS of LWC at 28 days.

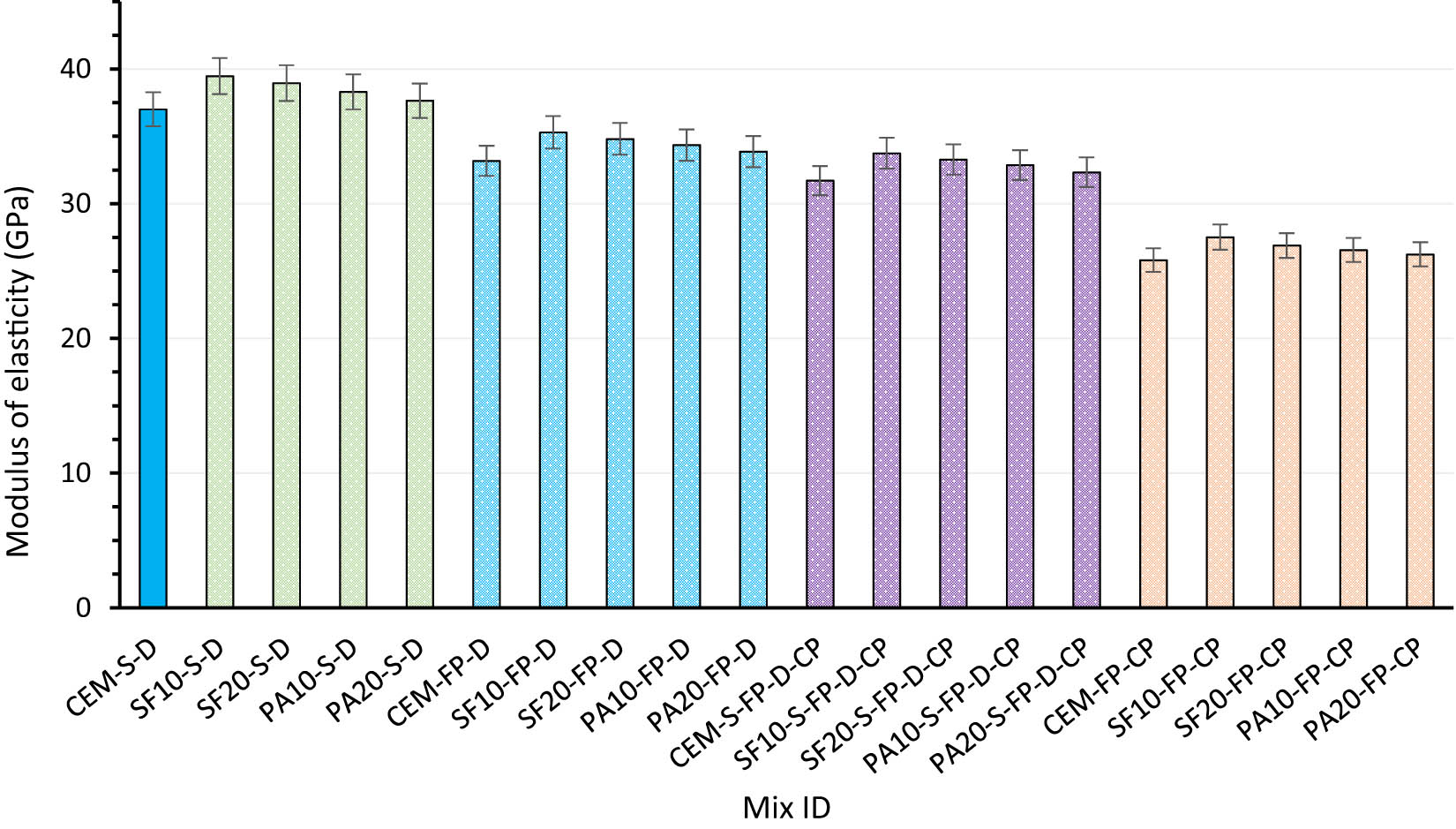

3.2.5 MOE

MOE is evaluated at 28 days by testing three 150 mm × 300 mm cylinder specimens for each LWC mixture. Figure 9 demonstrates the outcomes of MOE for entire LWC mixtures at 28 days due to the effect of utilizing SF and POA as a substitute for PC with levels of 10 and 20% by weight in addition to replacing aggregates by volume with ratios of 50 and 100% using POC. The obtained findings have the same trend as the CS findings. The reference mix recorded MOE values of 37.01 GPa, while the best and worst values of MOE occurred at mixtures SF10-S-D and CEM-FP-CP, respectively, whereas the MOE values were 39.47 and 25.81 GPa, respectively. It is observed that using SF is better than using POA as a substitution for PC, and that may relate to the good particle characteristics of SF compared with the properties of POA particles, where SF particles are finer than POA particles, and from chemical composition, the SiO2 content of SF is higher than the SiO2 content of POA. That increased the reaction between SiO2 and calcium hydroxide to produce more calcium silicate hydrate, which increased MOE. Furthermore, a 10% SF percentage is considered to be the optimal ratio for achieving high MOE results. For clarification, the recorded MOE results were 10.13, 9.71, 9.68, and 9.20 GPa for mixes SF10-S-D, SF20-S-D, PA10-S-D, and PA20-S-D, respectively. On the other side, the presence of POC as a replacement for aggregates resulted in a decline in MOE values due to the bad characteristics of the used POC compared to the utilized aggregates (Table 2). The MOE values decreased by about 4.62, 8.8, and 25.6% for mixes SF10-FP-D, SF10-S-FP-D-CP, and SF10-FP-CP, respectively, compared to CEM-S-D. In addition, it is seen that using POC as a full substitution for sand is better than utilizing POC as a sectional substitution for sand or dolomite, where the obtained results for mixes CEM-FP-D, CEM-S-FP-D-CP, and CEM-FP-CP were 33.18, 31.72, and 25.81 GPa, respectively. These results agree with that reported by Ibrahim et al. [47].

Outcomes of MOE of LWC at 28 days.

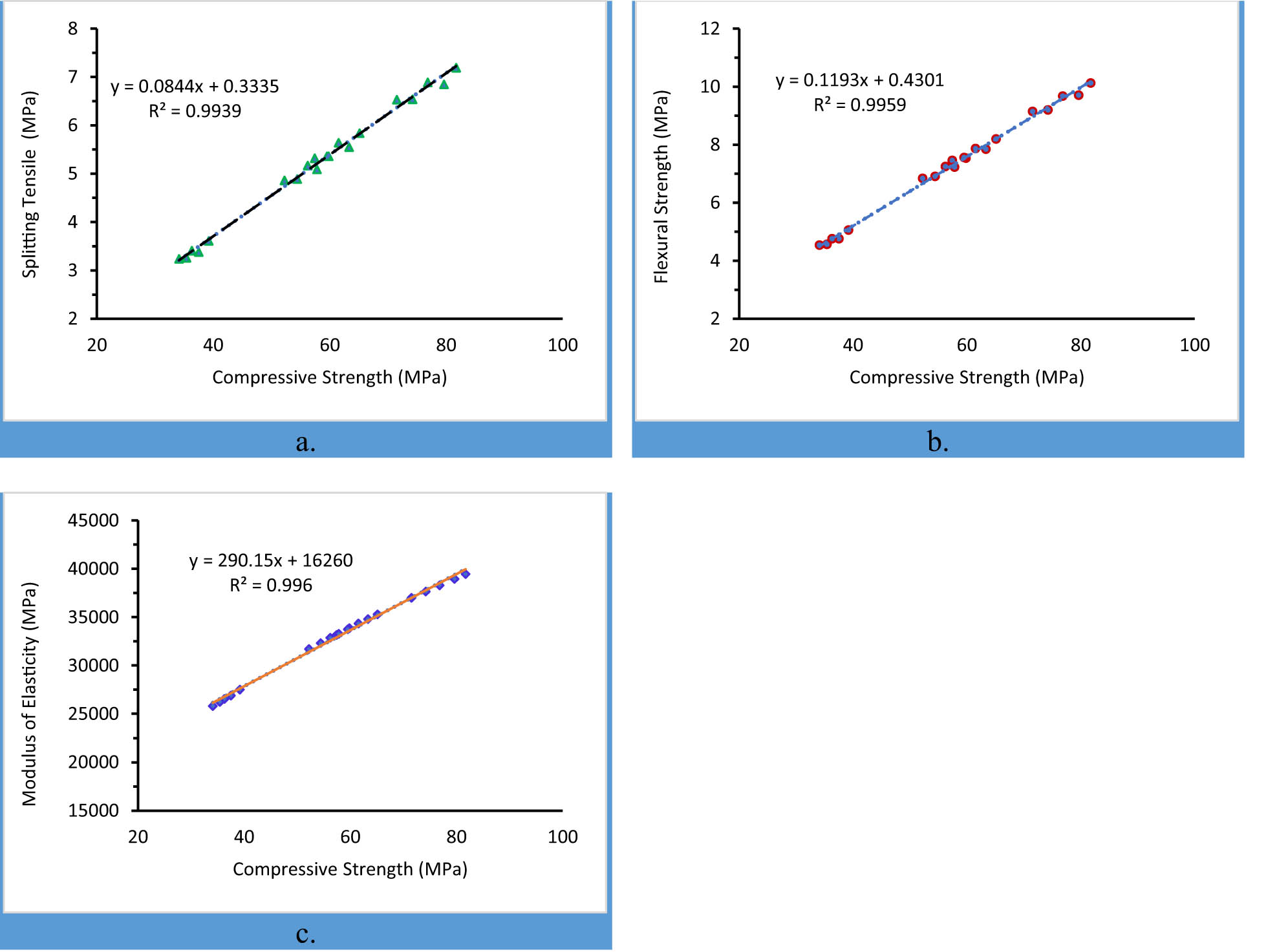

3.2.6 Relationship of mechanical properties with CS

Figure 10(a)–(c) shows the relationship between CS and tensile strength (TS), FS, and MOE, respectively. The correlation strength between the mechanical properties of concrete is exceptional, remaining above 99% for all relationships, including those between CS and TS, FS, and MOE. This confirms that CS expresses other properties in a percentage that exceeds 99% of the results. The American Concrete Institute’s (ACI 318-11) code also supports this, which is consistent with most of the prior research [48,49]. The following relationships serve as evidence that the ACI 318-11 affirms a strong correlation between CS and other mechanical properties.

The relationship between CS and TS, FS, and MOE. (a) The relationship between CS and TS. (b) The relationship between CS and FS. (c) The relationship between CS and MOE.

This study estimated that the TS of concrete samples is directly proportional to their CS, as shown in Eq. (1).

The FS of concrete samples was also estimated to be directly proportional to their CS as shown in Eq. (2).

The MOE of concrete samples was also estimated to be directly proportional to their CS as shown in Eq. (3).

3.3 Physical characteristics

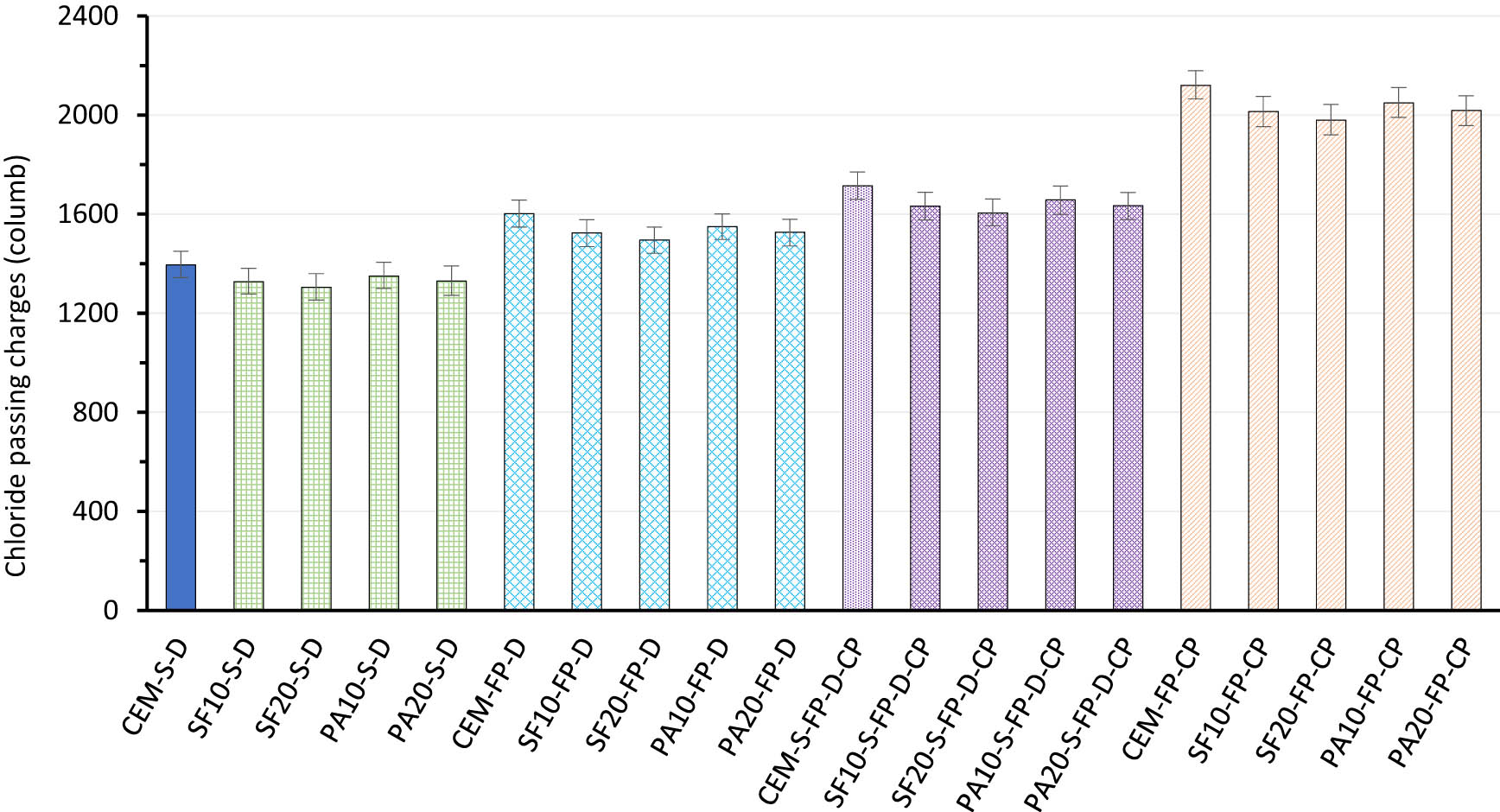

3.3.1 Chloride permeability

Figure 11 illustrates the chloride permeability test outcomes for LWC specimens at 28 days. The samples were prepared with partial substitutions of SF and POA for PC and POC as a replacement for coarse aggregate and sand. The results clearly fall into three categories. First, the use of SF and POA as partial substitutes at levels of 10 and 20% of the PC mass. In this case, the results showed a slight improvement in the transport characteristics, as the chloride permeability values decreased by 3–6% compared to the reference mixture. The chloride permeability values of the SF10-S-D, SF20-S-D, PA10-S-D, and PA20-S-D mixtures were lower by 4.8, 6.4, 3.2, and 4.6%, respectively, when fine pozzolanic materials like SF and POA were used. The enhancement in transport characteristics may be attributed to the role of pozzolanic materials (SF and POA) in interaction with Ca(OH)2 and the presence of extra gel C–S–H. In addition to filling efficiency, both effects contributed to closing the pores and increasing the density of the LWC matrix, which impeded the chloride permeability inside the LWC. This agrees with most of the prior investigations that confirmed the role of soft and ultra-fine pozzolanic materials in reducing chloride permeability through LWC [50,51].

Outcomes of chloride permeability of LWC at 28 days.

Second, using POC as an alternative to fine aggregate and coarse aggregate at rates of 50 and 100% of the aggregate volume. In this case, the results showed damage to the transport properties, as the chloride permeability values increased by 14.8–51.9% compared to the reference mixture. Compared to the control mixture, using POC as substitutes for fine aggregate and coarse aggregate raised the chloride permeability values of the CEM-FP-D, CEM-S-FP-D-CP, and CEM-FP-CP mixtures by 14.8, 22.9, and 51.9%, respectively. POC’s porous structure, which allowed for higher chloride permeability compared to natural aggregates, may have contributed to the decline in transport properties. This agrees with most of the prior research, which confirms that the use of lightweight aggregates as a replacement for natural aggregates leads to worse transport properties and increases the permeability of chloride and water through LWC [52,53].

Third, using POC as an alternative for fine and coarse aggregates in proportions of 50 and 100% by volume, as well as using SF and POA as partial substitutes in proportions of 10 and 20% by mass of PC. In this case, the outcomes showed a very slight improvement in transport properties, with chloride permeability values decreasing by 3.2–6.6% compared to mixtures that included only POC as a substitute for the normal aggregate. The observed phenomenon can be attributed to the effects of filling efficiency and the pozzolanic reactivity of supplementary cementitious materials such as SF and POA. However, the porous structure of POC limits these two effects. Hence, in this particular case, the influence of POC outweighed the influence of pozzolanic materials, resulting in a greater degree of chloride permeability compared to the reference mixture [53,54].

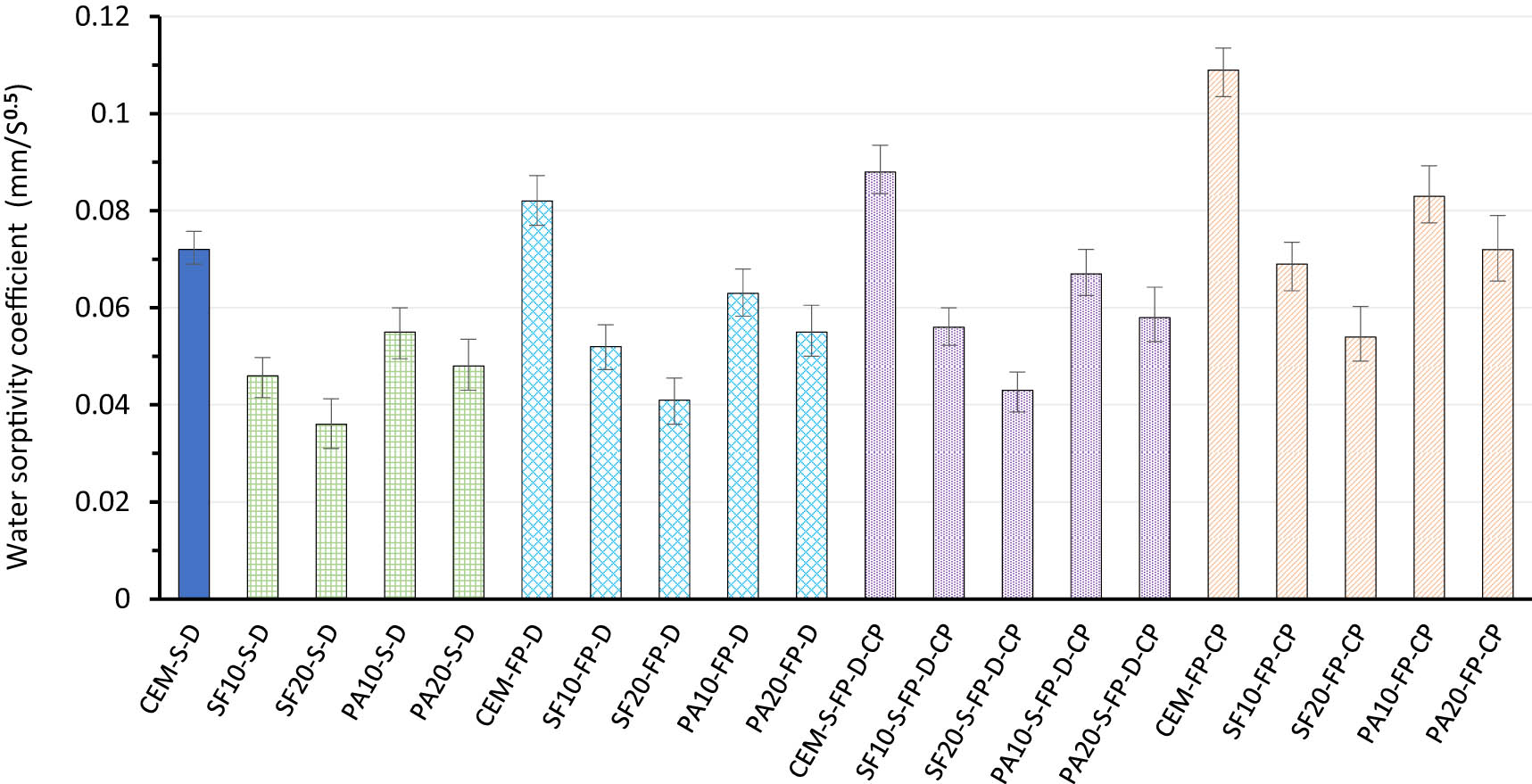

3.3.2 Water sorptivity

Figure 12 illustrates the results of the water sorptivity test for the LWC samples at 28 days. The specimens were prepared by using SF and POA as substitutes for PC, while POC was utilized as a substitute for both coarse aggregate and sand. According to the research findings, the presence of POA and SF resulted in a significant reduction in water sorptivity in LWC specimens. Furthermore, as the substitution rate increased, the reduction in water sorptivity became more noticeable. The mixture incorporating 20% SF as a partial PC substitute demonstrated superior transport properties compared to all other mixtures examined in this study. The mixtures SF10-S-D, SF20-S-D, PA10-S-D, and PA20-S-D showed water sorptivity values of 0.046, 0.036, 0.055, and 0.048 × 10−4 (mm·s−0.5), respectively. While the reference mixture (CEM-S-D) showed water sorptivity value of 0.072 × 10−4 (mm·s−0.5). It is also observed that the substitution of sand and coarse aggregate by POC in volume ratios of 50 and 100% led to an enhancement in the water sorptivity values in the LWC specimens. The higher the replacement rate of aggregate, the higher the water sorptivity values. Therefore, the CEM-FP-D, CEM-S-FP-D-CP, and CEM-FP-CP mixtures achieved water sorptivity values of 0.082, 0.088, and 0.109 × 10−4 (mm·s−0.5), respectively. On the other hand, adding POA and SF to the LWC samples containing POC as a replacement for aggregate led to a slight enhancement in the transport characteristics. The results that included POA and SF showed a reduction in water sorptivity compared to the samples that only included POC as a substitute for aggregate. The decrease in water sorptivity in LWC samples may be attributed to the positive effects of the pozzolanic reaction and filling efficiency. The efficiency of pozzolanic materials depends on the proportion of amorphous SiO2 (effective) and the fineness of the material used. The higher the fineness and effective SiO2 content, the better the transport properties. It also appears from the outcomes of this research that the SF-containing specimens had a higher sorptivity of water than the POA-containing samples. Accordingly, higher efficiency can be achieved by improving ash treatment to achieve higher efficiency, as mentioned in previous research [10,55].

Outcomes of water sorptivity of LWC at 28 days.

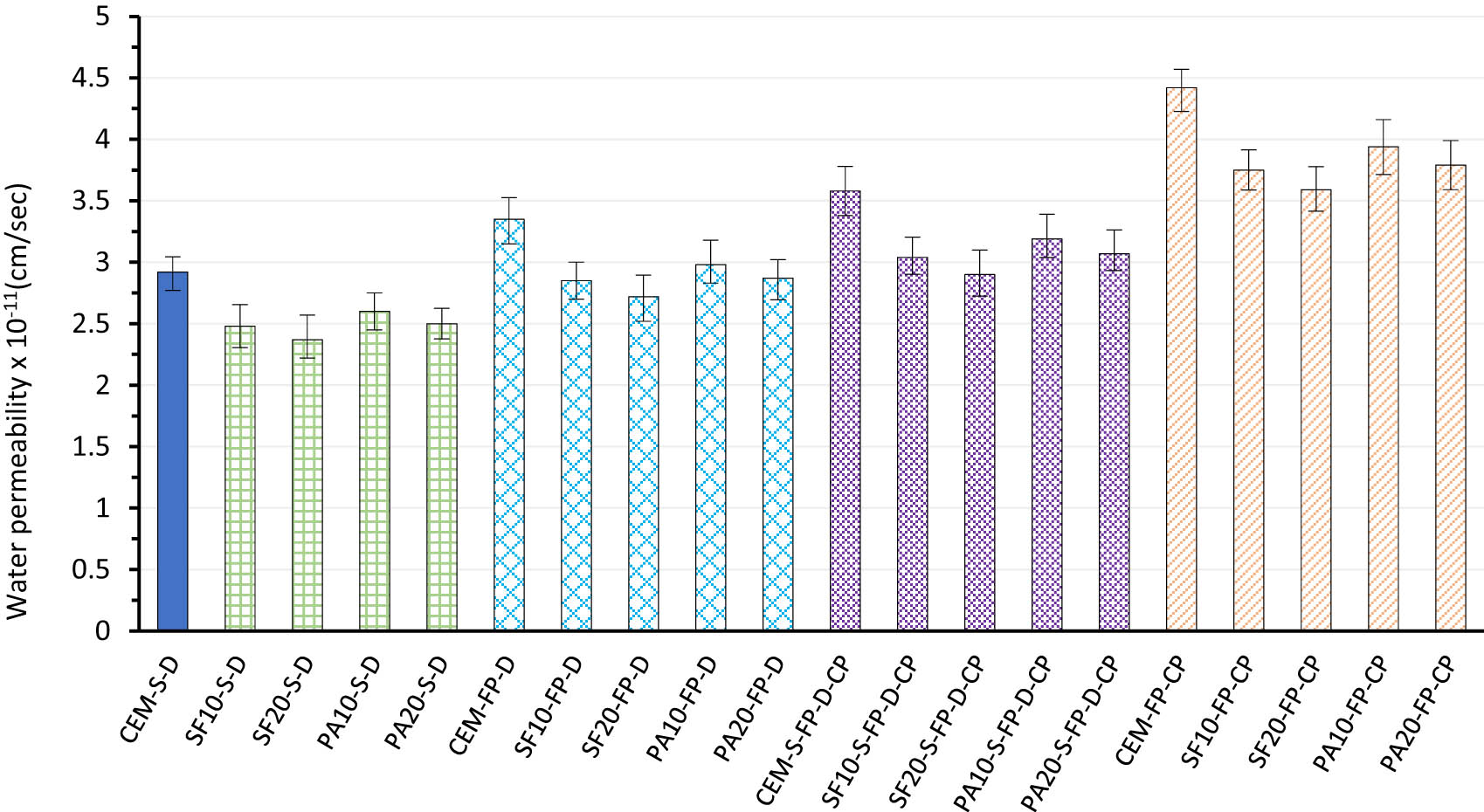

3.3.3 Water permeability

Figure 13 demonstrates the outcomes of the water permeability test for LWC samples prepared by combining SF and POA as partial PC substitutes at a rate of 10 and 20% by weight. In addition, POC was utilized as a replacement for both coarse aggregate and sand at 50 and 100% by volume at 28 days. The study’s findings demonstrate that employing POA and SF resulted in a notable decrease in water permeability in the LWC specimens. Furthermore, the decrease in water permeability became more noticeable as the substitution rate increased. The mixture containing 20% SF as a partial PC replacement demonstrated higher transport properties in comparison to all other mixtures studied in this research. The water permeability values of the mixtures SF10-S-D, SF20-S-D, PA10-S-D, and PA20-S-D were 2.48, 2.37, 2.6, and 2.5 × 10–11 (cm·s−1), respectively. While the water permeability value of the reference mixture (CEM-S-D) was 2.92 × 10–11 (cm·s−1). Moreover, substituting fine and coarse aggregates with POC at volume ratios of 50 and 100% had an adverse impact on the transport characteristics of the LWC. This was evidenced by an increase in the water permeability values observed in the LWC samples. As the rate of aggregate replacement by the POC increases, the water permeability values also increase. The water permeability values of the LWC samples CEM-FP-D, CEM-S-FP-D-CP, and CEM-FP-CP were measured to be 3.35, 3.58, and 4.24 × 10−11 (cm·s−1), respectively. In contrast, incorporating POA and SF into LWC samples containing POC as a substitution for aggregate resulted in a modest enhancement of the transport properties. In addition, the findings indicated that incorporating POA and SF as partial replacements for PC in LWC specimens containing POC as an alternative for aggregate resulted in a minor increase in transport properties, as evidenced by a decrease in water permeability values. The decrease in water permeability rate of the LWC samples was due to the pozzolanic reaction and the filling efficiency of the materials (SF and POA) used as partial PC substitutes. Prior investigations have shown that the effectiveness of pozzolanic materials is influenced by their chemical composition, the percentage of amorphous SiO2, and the particle size. The efficiency of the pozzolanic reaction increases with decreasing particle size (higher fineness) and higher active SiO2 content. Consequently, the pozzolanic reaction leads to an increase in gel production, density of the PC matrix, and impermeability of LWC. The study’s findings indicate that the samples containing SF exhibited superior strength and transport properties in comparison to the samples containing POA. Prior investigations have reported that the effectiveness of ash can be enhanced through heat treatment and grinding [55,56]. On the other hand, the outcomes of this work are consistent with prior research, according to which utilizing lightweight aggregates as a substitute for coarse or fine natural aggregates leads to a reduction in strength and an improvement in permeability. The reason for the deterioration of the engineering properties of LWC is its weak and mostly porous structure [52,57]. This required conducting many studies to try to enhance the characteristics of LWC, including this research.

Outcomes of water permeability of LWC at 28 days.

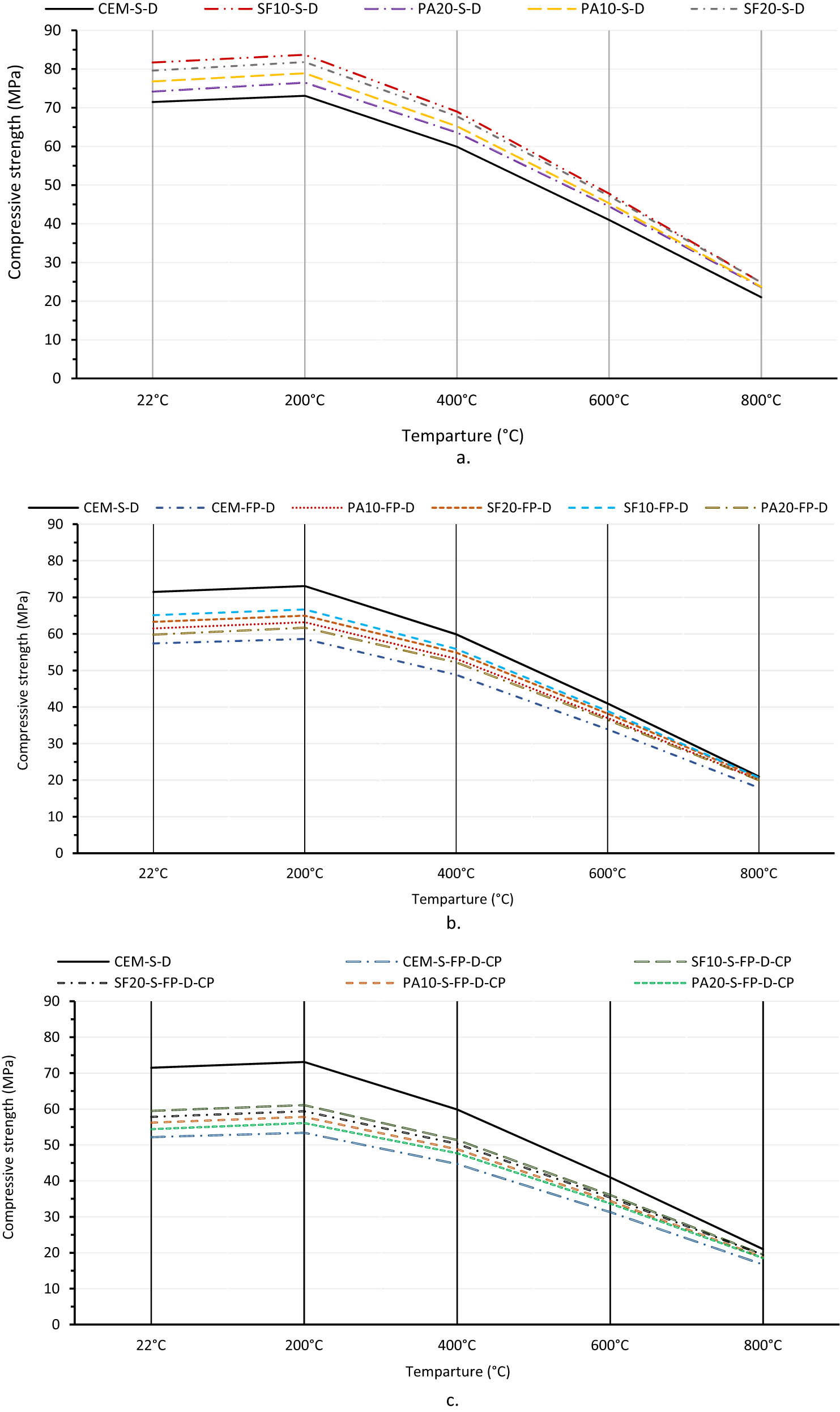

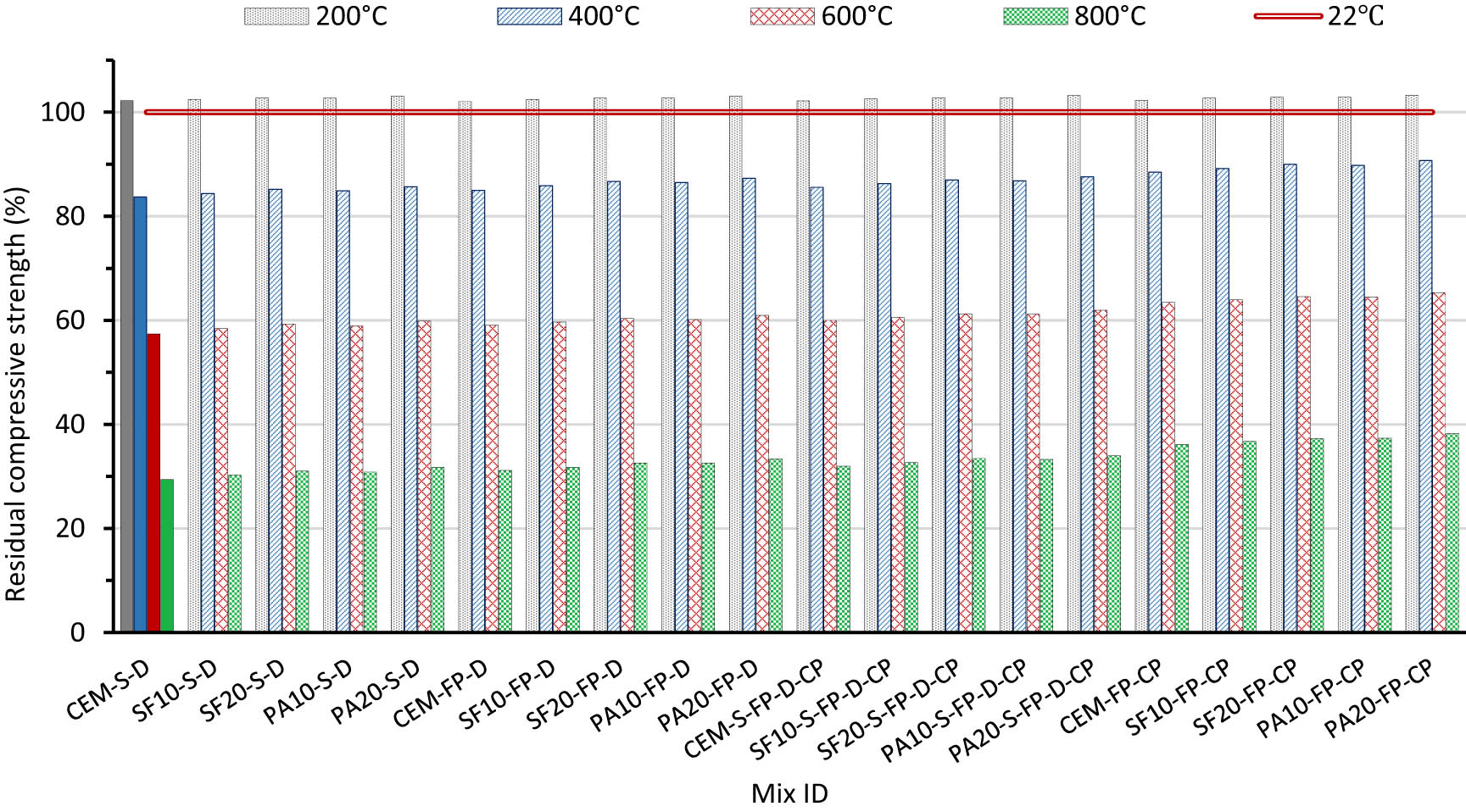

3.4 Temperature studies

Figure 14(a)–(d) displays the CS results of unheated and heated LWC at 200, 400, 600, and 800°C after 28 days. The presented outcomes illustrate the influence of high temperatures on LWC containing POA and SF as a as partial replacement for PC at levels of 10 and 20% by weight. In addition, the results of the effect of high temperature on LWC containing POC as replacement of fine and coarse aggregate at 50 and 100 wt% are shown. Figure 14 presents the residual CS ratio of LWC samples exposed to elevated temperatures. The effect of high temperatures on the CS of LWC can be divided into four stages. The first stage is when the temperature applied to the LWC is raised from 22 to 200°C. At this stage, a slight increase in the CS of LWC for all specimens is observed, ranging between 2 and 3%, compared to unheated LWC (at a temperature of 22°C). The slight increase in CS can be attributed to the drying effect of the LWC samples and the increase in forces between the gel particles due to the removal of the water content. In addition to the effect of catalyzing the reaction between the non-aqueous PC particles and lime at the first stages of the evaporation process, this outcome agrees with the hypothesis of a number of researchers that the first stage of raising the temperature of the LWC from 100 to 300°C may contribute to increasing the CS of the LWC as a result of the rehydration of the paste due to the migration of water in the pores [58,59].

CS results for LWC specimens exposed to elevated temperatures. (a) LWC samples include SF and POA. (b) LWC samples containing 100% sand replacement with POC. (c) LWC samples containing 50% sand and 50% coarse aggregate replacement with POC. (d) LWC samples containing 100% coarse aggregate replacement with POC.

The second stage is to raise the heating temperature of LWC samples from 200 to 400°C. A slight reduction in the CS of the LWC samples was noted, ranging from 9.3 to 16.3% compared to the CS of the reference samples (at a temperature of 22°C). As suggested by various authors, the decrease in question may potentially be attributed to the loss of water from the hydrate pores, as well as the initial stage of desiccation and dissociation of the gel [60,61]. In contrast, the mixtures containing pozzolanic materials of POA and SF additives showed improved performance and exhibited higher residual strength in comparison to the reference mixture.

The third stage is to raise the preheating temperature of the LWC samples from 400 to 600°C. At this point, there is a significant reduction in CS, ranging from 34.6 to 42.6%. It is noteworthy that mixtures incorporating pozzolanic materials such as POA and SF showed relatively higher CSs when compared to the control mixture. The decrease in the CS of the LWC samples can be attributed to the damage to the microstructures of the PC matrix and the structure of the LWC. Therefore, the dense microstructures of the PC matrix contributed to the accumulation of high internal pressure when exposed to high temperatures [62]. Furthermore, it causes the breakdown of calcium hydroxide, which occurs in the temperature range of 450–500°C [59]. In addition, at higher temperatures, the bond between the aggregate and the PC paste is weakened due to the difference in their thermal expansion factor [63]. On the other hand, high temperatures lead to shrinkage of the PC paste due to the loss of water, and in turn, high temperatures lead to expansion of the aggregates, thus destroying the structure of the LWC matrix [64]. In addition, the high temperature of 573°C led to the transformation of α-quartz into quartz causing it to expand [65].

The fourth stage is to raise the preheating temperature of LWC samples from 600 to 800°C. All LWC samples showed severe deterioration in CS, with a loss of 61.7–70.6% compared to unheated LWC samples. Some researchers suggest that the reduction in CS at temperatures exceeding 600°C is caused by the breakdown of the residual gels C–S–H and C–A–S–H, the decomposition of calcium hydroxide, and the transformation of quartz’s crystalline structure. Furthermore, the expansion of the aggregate and the contraction of the PC paste result in increased stress concentrations within the LWC matrix and the transition zone [66]. On the other hand, the outcomes revealed that the LWC samples containing pozzolanic materials of POA and SF had higher residual CS than the other samples. This may be attributed to its role in terms of pozzolanic interaction and filling efficiency [67].

Based on the above analysis of the impact of high-temperature exposure on concrete, it is observed that it reveals varying effects on CS. Exposure to 200°C at 28 days of age positively affected all samples. The CS of the reference mixture at standard temperature (22°C) was 71.5 MPa. Exposure to 200°C led to a minor increase to 73.1 MPa. On the other hand, the CS decreased to 59.9, 41, and 21 MPa when exposed to temperatures of 400, 600, and 800°C, respectively. In addition, it is worth mentioning that exposing concrete samples to a temperature of 200°C resulted in slight improvements in CS by 2.2, 2.4, 2.8, 2.7, and 3.1% for CEM-S-D, SF10-S-D, SF20-S-D, PA10-S-D, and PA20-S-D, respectively.

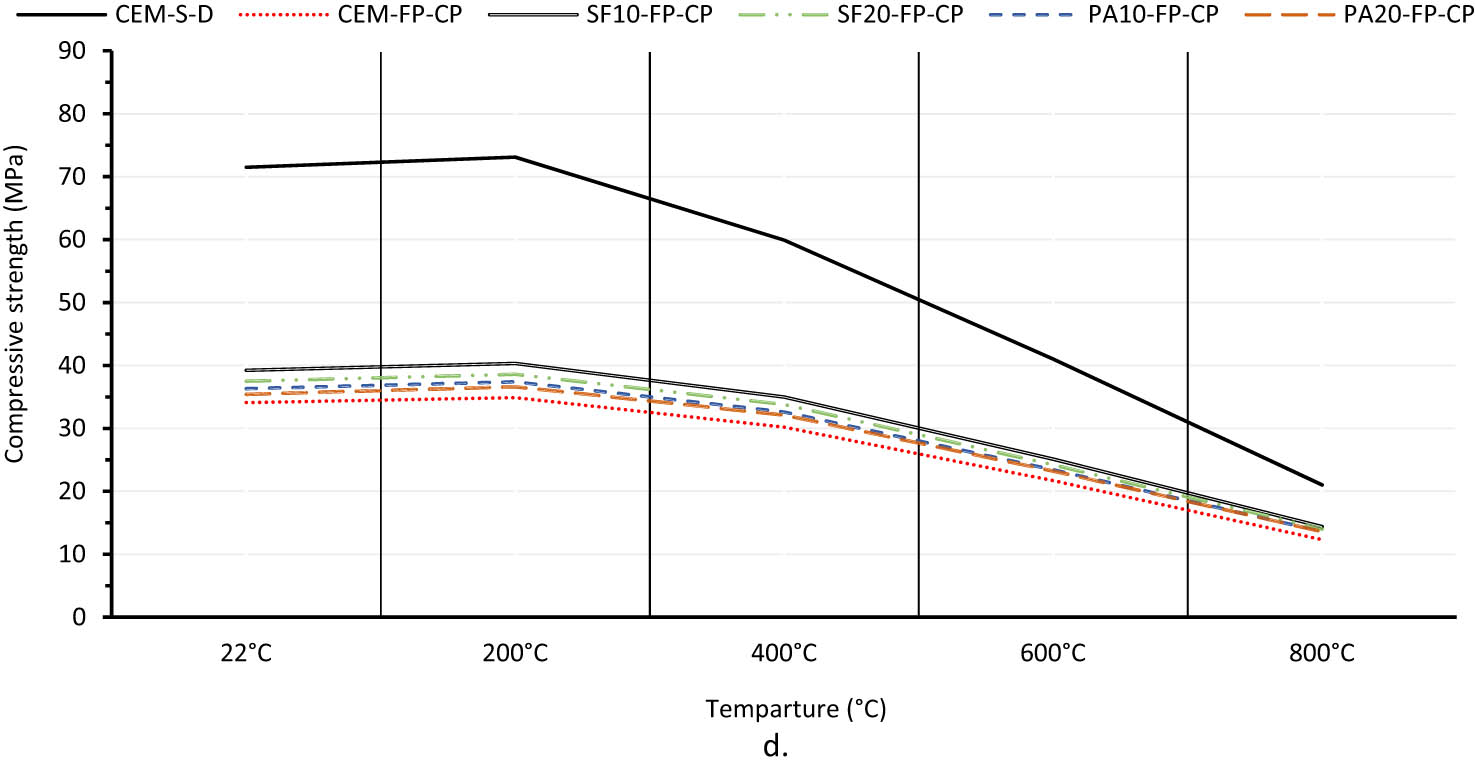

Figure 15 presents the relative values of residual CS for heated and unheated LWC samples after 28 days. Samples were heated in an electric oven at 22, 200, 400, 600, and 800°C. The study clearly shows that when the samples were heated to 400, 600, and 800°C, the CS dropped between 9 and 16%, 35 and 43%, and 62 and 71%, respectively. Additionally, rising temperatures have less adverse effect on concrete samples containing POC compared to samples containing natural aggregate.

Residual CS for LWC specimens exposed to elevated temperatures.

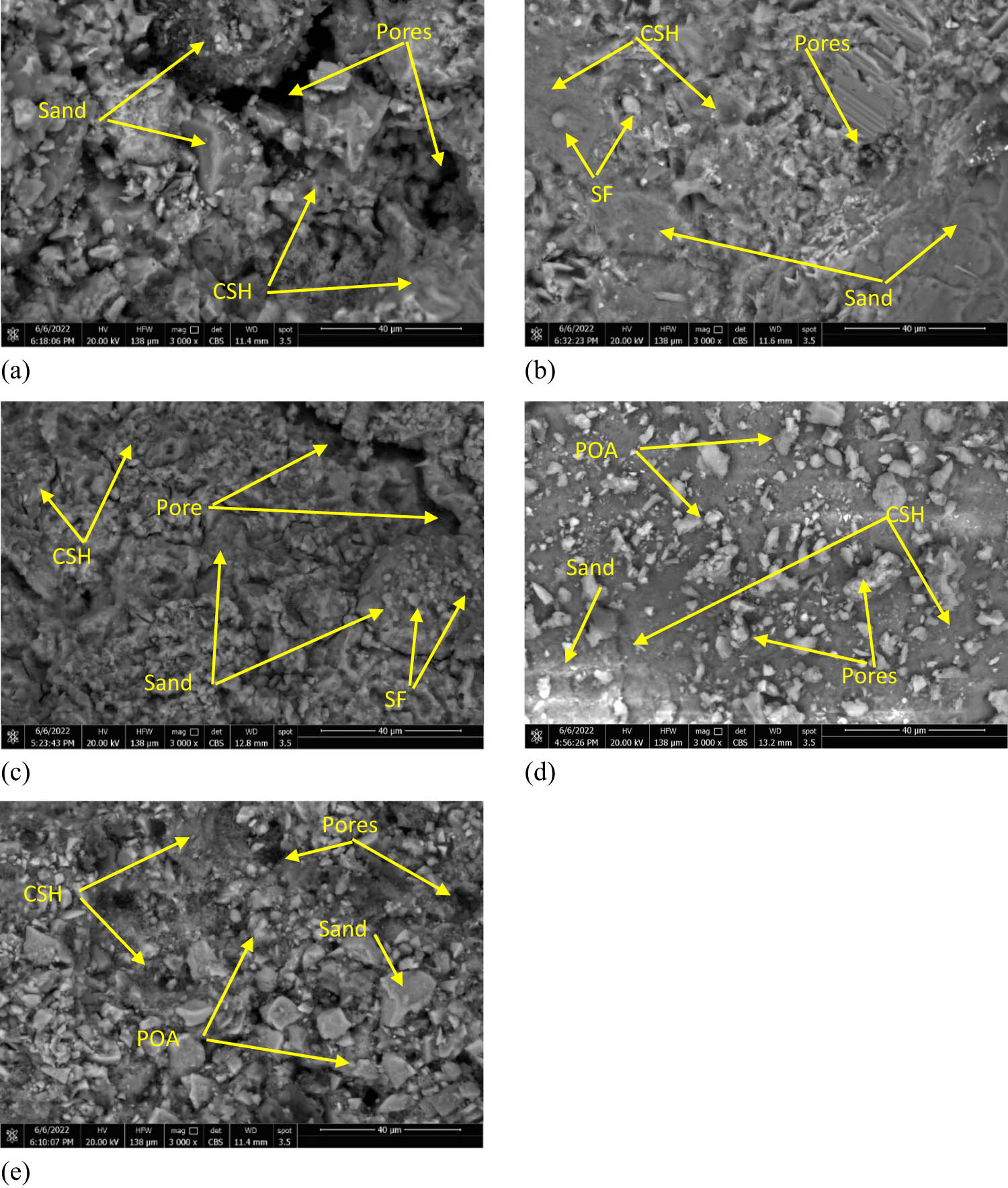

4 Cement paste microstructure analysis

The SEM pictures in Figure 16(a)–(e) illustrate the changes in the microstructure of cement pastes when SF or POA replace 10 and 20% of the cement by weight. Figure 16(a) displays the morphology of the control mixture (CEM), revealing diffuse pores. These pores, likely due to the heterogeneity or dispersion of C–S–H, are unable to completely fill the concrete microstructure. The heterogeneity was a major factor contributing to the occurrence of internal cracks and the prevalence of numerous macropores in the reference concrete. Moreover, the cement paste contained distinct CH precipitates with large crystals, which further contributed to the observed cracks and macropores. The dry density test results show that the reference mixture had a lower density than the mixture containing SF or POA. The results of tests for CS, TS, FS, and MOE also show an improvement in mechanical properties when SF or POA replaces cement. Several studies indicate that replacing cement with cementitious materials such as SF or agricultural waste ash can improve the microstructure, strength, and durability of concrete. The best results suggest using replacement ratios between 10 and 20% by weight of cement [37,68].

SEM images of cement paste. (a) CEM, (b) SF10, (c) SF20, (d) PA10, and (e) PA20.

Figure 16(b) and (c) shows the microstructure of hydration products in cement pastes containing 10% SF and 20% SF, respectively, showing a significantly more homogeneous, dense, and pore-free structure. It was also clear that there was a C–S–H gel with microscopic properties. This gel probably forms because of the pozzolanic interaction between SF and CH. The SF substitute’s higher SiO2 content significantly reduced microvoids, as SF reacted with CH to compensate for the decrease in C–S–H. Consequently, the distribution of C–S–H gel was more diffuse in these mixtures, resulting in superior strength compared to the reference mixture. This supports the interpretation of previous results, which showed that replacing cement with SF contributed to improving the mechanical properties of concrete, along with a slight increase in the dry density of concrete. Previous research indicated the positive role of using SF as a partial cement replacement at levels up to 20% by weight of cement [69].

Figure 16(d) and (e) shows the morphology of cement paste containing 10 and 20% POA, respectively. POA, which is rich in silica and alumina, reacts with calcium hydroxide produced during cement hydration. This reaction promotes the formation of additional C–S–H gel, thereby enhancing the concrete density and reducing pore space. The pozzolanic properties of POA contribute to increased strength and durability by forming complementary binders within the concrete matrix, thereby enhancing its mechanical properties. Concrete mixes containing POA exhibit tighter concrete structure and mechanical superiority, which helps to enhance strength and durability through additional C–S–H gel formation. The mechanical test results in this study demonstrate an improvement when POA serves as a partial cement substitute.

5 Conclusion

The aim of the present research was to evaluate the performance of LWC including POC as a substitute for aggregate at replacement levels of 50 or 100% by volume. The study investigated the use of POA and SF as 10 and 20% weight substitutes for cement, respectively. This study included a design of 20 mixtures. The efficacy of the freshly mixed LWC was evaluated by a slump test. A variety of tests was conducted to evaluate the performance of hardened concrete, including a dry density test, a CS test, an STS test, an FS test, and an MOE test. The performance of concrete subjected to elevated temperatures on CS is assessed. The findings of this research may be presented as follows:

POC and POA generate LWC with lower slump values than the reference mixture. The slump test showed the greatest drop (54% for SF20-FP-CP).

Using POC as partial or full aggregate substitute yields LWC with 1,685 kg·m−3 density and 34.1 MPa CS at 28 days. In addition, using POC as a partial or full substitute to aggregate may improve CS by decreasing the impact of high temperatures up to 800°C.

POA as a partial cement substitution in LWC improved strength compared to 0% POA. The PA20-FP-CP combination had the greatest CS retention of all mixes, with 38.3% of the reference mixture.

The efficacy of LWC in resisting chloride permeability, water permeability, and water sorptivity decreases when POC replaces aggregate. However, light concrete transport qualities increase when SF or POA partially replaces cement.

All LWC mixtures in this investigation had higher CSs than the reference mixture after being heated to 200°C.

The use of POA or SF as partial cement substitution enhances the microstructure of the LWC matrix.

6 Limitations and future works

The results obtained from this research are validated to use in the range of this study. Also, it is recommended for future studies to study the dynamic effect or cyclic load effect on the properties of LWC which have POC. In addition, the finite element analysis can be used to study the structural behavior of LWC structural elements incorporating POC. Finally, adding agricultural or industrial waste to POC to enhance the characteristics of LWC can also be studied.

Acknowledgments

The authors are thankful to the Deanship of Graduate Studies and Scientific Research at the University of Bisha for supporting this work through the Fast-Track Research Support Program.

-

Funding information: This work was supported by the Deanship of Graduate Studies and Scientific Research at the University of Bisha through the Fast-Track Research Support Program.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

References

[1] Ding, G. K. C. Life cycle assessment (LCA) of sustainable building materials: An overview. In: Eco-Efficient Construction and Building Materials, Wood Head Publishing, 2014, pp. 38–62.10.1533/9780857097729.1.38Suche in Google Scholar

[2] Esparham, A., N. I. Vatin, M. Kharun, and M. Hematibahar. A study of modern eco-friendly composite (geopolymer) based on blast furnace slag compared to conventional concrete using the life cycle assessment approach. Infrastructures, Vol. 8, No. 3, 2023, id. 58.10.3390/infrastructures8030058Suche in Google Scholar

[3] Hakeem, I. Y., M. Alharthai, M. Amin, A. M. Zeyad, B. A. Tayeh, and I. S. Agwa. Properties of sustainable high-strength concrete containing large quantities of industrial wastes, nanosilica and recycled aggregates. Journal of Materials Research and Technology, Vol. 24, 2023, pp. 7444–7461.10.1016/j.jmrt.2023.05.050Suche in Google Scholar

[4] Adesina, A. Recent advances in the concrete industry to reduce its carbon dioxide emissions. Environmental Challenges, Vol. 1, 2020, id. 100004.10.1016/j.envc.2020.100004Suche in Google Scholar

[5] Hasanbeigi, A., C. Menke, and L. Price. The CO2 abatement cost curve for the Thailand cement industry. Journal of Cleaner Production, Vol. 18, No. 15, 2010, pp. 1509–1518.10.1016/j.jclepro.2010.06.005Suche in Google Scholar

[6] Mossie, A. T., D. Khatiwada, B. Palm, and G. Bekele. Investigating energy saving and climate mitigation potentials in cement production–A case study in Ethiopia. Energy Conversion and Management, Vol. 287, 2023, id. 117111.10.1016/j.enconman.2023.117111Suche in Google Scholar

[7] Raheem, A. A. and B. D. Ikotun. Incorporation of agricultural residues as partial substitution for cement in concrete and mortar–A review. Journal of Building Engineering, Vol. 31, 2020, id. 101428.10.1016/j.jobe.2020.101428Suche in Google Scholar

[8] Zeyad, A. M., M. Shubaili, and A. Abutaleb. Using volcanic pumice dust to produce high-strength self-curing concrete in hot weather regions. Case Studies in Construction Materials, Vol. 18, 2023, id. e01927.10.1016/j.cscm.2023.e01927Suche in Google Scholar

[9] Sangmesh, B., N. Patil, K. K. Jaiswal, T. P. Gowrishankar, K. K. Selvakumar, M. S. Jyothi, et al. Development of sustainable alternative materials for the construction of green buildings using agricultural residues: A review. Construction and Building Materials, Vol. 368, 2023, id. 130457.10.1016/j.conbuildmat.2023.130457Suche in Google Scholar

[10] Zeyad, A. M., M. A. M. Johari, B. A. Tayeh, and M. O. Yusuf. Efficiency of treated and untreated palm oil fuel ash as a supplementary binder on engineering and fluid transport properties of high-strength concrete. Construction and Building Materials, Vol. 125, 2016, pp. 1066–1079.10.1016/j.conbuildmat.2016.08.065Suche in Google Scholar

[11] Maraveas, C. Production of sustainable construction materials using agro-wastes. Materials, Vol. 13, No. 2, 2020, id. 262.10.3390/ma13020262Suche in Google Scholar PubMed PubMed Central

[12] Bahij, S., S. Omary, F. Feugeas, and A. Faqiri. Fresh and hardened properties of concrete containing different forms of plastic waste–A review. Waste Management, Vol. 113, 2020, pp. 157–175.10.1016/j.wasman.2020.05.048Suche in Google Scholar PubMed

[13] Latha, P. K., Y. Darshana, and V. Venugopal. Role of building material in thermal comfort in tropical climates–A review. Journal of Building Engineering, Vol. 3, 2015, pp. 104–113.10.1016/j.jobe.2015.06.003Suche in Google Scholar

[14] Tanyıldızı, M. and İ. Gökalp. Utilization of pumice as aggregate in the concrete: A state of art. Construction and Building Materials, Vol. 377, 2023, id. 131102.10.1016/j.conbuildmat.2023.131102Suche in Google Scholar

[15] Institute, A. C. Guide for structural lightweight-aggregate concrete. ACI213R Farmington Hills, American Concrete Institute, MI, USA, 2014, id. 38.Suche in Google Scholar

[16] Serelis, E. and V. Vaitkevicius. Utilization of glass shards from municipal solid waste in aluminium-based ultra-lightweight concrete. Construction and Building Materials, Vol. 350, 2022, id. 128396.10.1016/j.conbuildmat.2022.128396Suche in Google Scholar

[17] Jafari, S. and S. S. Mahini. Lightweight concrete design using gene expression programing. Construction and Building Materials, Vol. 139, 2017, pp. 93–100.10.1016/j.conbuildmat.2017.01.120Suche in Google Scholar

[18] Shafigh, P., H. B. Mahmud, M. Z. Jumaat, and M. Zargar. Agricultural wastes as aggregate in concrete mixtures–A review. Construction and Building Materials, Vol. 53, 2014, pp. 110–117.10.1016/j.conbuildmat.2013.11.074Suche in Google Scholar

[19] D’Alessandro, F., F. Asdrubali, and G. Baldinelli. Multi-parametric characterization of a sustainable lightweight concrete containing polymers derived from electric wires. Construction and Building Materials, Vol. 68, 2014, pp. 277–284.10.1016/j.conbuildmat.2014.06.075Suche in Google Scholar

[20] Olanipekun, E. A., K. O. Olusola, and O. Ata. A comparative study of concrete properties using coconut shell and palm kernel shell as coarse aggregates. Building and Environment, Vol. 41, No. 3, 2006, pp. 297–301.10.1016/j.buildenv.2005.01.029Suche in Google Scholar

[21] Kanadasan, J. and H. Abdul Razak. Utilization of palm oil clinker as cement replacement material. Materials, Vol. 8, No. 12, 2015, pp. 8817–8838.10.3390/ma8125494Suche in Google Scholar PubMed PubMed Central

[22] Hosen, M. A., M. I. Shammas, S. K. Shill, M. Z. Jumaat, U. J. Alengaram, R. Ahmmad, et al. Investigation of structural characteristics of palm oil clinker based high-strength lightweight concrete comprising steel fibers. Journal of Materials Research and Technology, Vol. 15, 2021, pp. 6736–6746.10.1016/j.jmrt.2021.11.105Suche in Google Scholar

[23] Kolovos, K. G., P. G. Asteris, D. Cotsovos, E. Badogiannis, and S. Tsivilis. Mechanical properties of soilcrete mixtures modified with metakaolin. Construction and Building Materials, Vol. 47, 2013, pp. 1026–1036.10.1016/j.conbuildmat.2013.06.008Suche in Google Scholar

[24] Johari, M. A. M., A. M. Zeyad, N. M. Bunnori, and K. S. Ariffin. Engineering and transport properties of high-strength green concrete containing high volume of ultrafine palm oil fuel ash. Construction and Building Materials, Vol. 30, 2012, pp. 281–288.10.1016/j.conbuildmat.2011.12.007Suche in Google Scholar

[25] Bashar, I. I., U. J. Alengaram, and M. Z. Jumaat. Enunciation of embryonic palm oil clinker based geopolymer concrete and its engineering properties. Construction and Building Materials, Vol. 318, 2022, id. 125975.10.1016/j.conbuildmat.2021.125975Suche in Google Scholar

[26] Hamada, H. M., F. M. Yahaya, K. Muthusamy, G. A. Jokhio, and A. M. Humada. Fresh and hardened properties of palm oil clinker lightweight aggregate concrete incorporating nano-palm oil fuel ash. Construction and Building Materials, Vol. 214, 2019, pp. 344–354.10.1016/j.conbuildmat.2019.04.101Suche in Google Scholar

[27] Ahmmad, R., M. Z. Jumaat, U. J. Alengaram, S. Bahri, M. A. Rehman, and H. bin Hashim. Performance evaluation of palm oil clinker as coarse aggregate in high strength lightweight concrete. Journal of Cleaner Production, Vol. 112, 2016, pp. 566–574.10.1016/j.jclepro.2015.08.043Suche in Google Scholar

[28] Abutaha, F., H. A. Razak, and J. Kanadasan. Effect of palm oil clinker (POC) aggregates on fresh and hardened properties of concrete. Construction and Building Materials, Vol. 112, 2016, pp. 416–423.10.1016/j.conbuildmat.2016.02.172Suche in Google Scholar

[29] Hamada, H., B. Tayeh, F. Yahaya, K. Muthusamy, and A. Al-Attar. Effects of nano-palm oil fuel ash and nano-eggshell powder on concrete. Construction and Building Materials, Vol. 261, 2020, id. 119790.10.1016/j.conbuildmat.2020.119790Suche in Google Scholar

[30] Zeyad, A. M., M. A. M. Johari, B. A. Tayeh, and M. O. Yusuf. Pozzolanic reactivity of ultrafine palm oil fuel ash waste on strength and durability performances of high strength concrete. Journal of Cleaner Production, Vol. 144, 2017, pp. 511–522.10.1016/j.jclepro.2016.12.121Suche in Google Scholar

[31] Alabduljabbar, H., H. Mohammadhosseini, M. M. Tahir, and R. Alyousef. Green and sustainable concrete production using carpet fibers waste and palm oil fuel ash. Materials Today: Proceedings, Vol. 39, 2021, pp. 929–934.10.1016/j.matpr.2020.04.047Suche in Google Scholar

[32] Zawawi, M. N. A. A., K. Muthusamy, A. P. A. Majeed, R. M. Musa, and A. M. A. Budiea. Mechanical properties of oil palm waste lightweight aggregate concrete with fly ash as fine aggregate replacement. Journal of Building Engineering, Vol. 27, 2020, id. 100924.10.1016/j.jobe.2019.100924Suche in Google Scholar

[33] Ting, T. Z. H., M. E. Rahman, and H. H. Lau. Sustainable lightweight self-compacting concrete using oil palm shell and fly ash. Construction and Building Materials, Vol. 264, 2020, id. 120590.10.1016/j.conbuildmat.2020.120590Suche in Google Scholar

[34] Amin, M., I. Y. Hakeem, A. M. Zeyad, B. A. Tayeh, A. M. Maglad, and I. S. Agwa. Influence of recycled aggregates and carbon nanofibres on properties of ultra-high-performance concrete under elevated temperatures. Case Studies in Construction Materials, Vol. 16, 2022, id. e01063.10.1016/j.cscm.2022.e01063Suche in Google Scholar

[35] Tahwia, A. M., G. M. Elgendy, and M. Amin. Effect of environmentally friendly materials on steel corrosion resistance of sustainable UHPC in marine environment. Structural Engineering and Mechanics, Vol. 82, No. 2, 2022, pp. 133–149.Suche in Google Scholar

[36] Amin, M., A. M. Zeyad, I. S. Agwa, and M. S. Rizk. Effect of industrial wastes on the properties of sustainable ultra-high-performance concrete: Ganite, ceramic, and glass. Construction and Building Materials, Vol. 428, 2024, id. 136292.10.1016/j.conbuildmat.2024.136292Suche in Google Scholar

[37] Hakeem, I. Y., M. Amin, I. S. Agwa, M. H. Abd-Elrahman, and M. F. Abdelmagied. Using a combination of industrial and agricultural wastes to manufacture sustainable ultra-high-performance concrete. Case Studies in Construction Materials, Vol. 19, 2023, id. e02323.10.1016/j.cscm.2023.e02323Suche in Google Scholar

[38] Zeyad, A. M., I. Y. Hakeem, M. Amin, B. A. Tayeh, and I. S. Agwa. Effect of aggregate and fibre types on ultra-high-performance concrete designed for radiation shielding. Journal of Building Engineering, Vol. 58, 2022, id. 104960.10.1016/j.jobe.2022.104960Suche in Google Scholar

[39] Agwa, I. S., A. M. Zeyad, B. A. Tayeh, and M. Amin. Effect of different burning degrees of sugarcane leaf ash on the properties of ultrahigh-strength concrete. Journal of Building Engineering, Vol. 56, 2022, id. 104773.10.1016/j.jobe.2022.104773Suche in Google Scholar

[40] Tayeh, B. A., A. Hakamy, M. Amin, A. M. Zeyad, and I. S. Agwa. Effect of air agent on mechanical properties and microstructure of lightweight geopolymer concrete under high temperature. Case Studies in Construction Materials, Vol. 16, 2022, id. e00951.10.1016/j.cscm.2022.e00951Suche in Google Scholar

[41] Amin, M., A. M. Zeyad, B. A. Tayeh, and I. S. Agwa. Engineering properties of self-cured normal and high strength concrete produced using polyethylene glycol and porous ceramic waste as coarse aggregate. Construction and Building Materials, Vol. 299, 2021, id. 124243.10.1016/j.conbuildmat.2021.124243Suche in Google Scholar

[42] Abd-Elrahman, M. H., I. S. Agwa, S. A. Mostafa, and O. Youssf. Effect of utilizing peanut husk ash on the properties of ultra-high strength concrete. Construction and Building Materials, Vol. 384, 2023, id. 131398.10.1016/j.conbuildmat.2023.131398Suche in Google Scholar

[43] Hakeem, I. Y., I. S. Agwa, B. A. Tayeh, and M. H. Abd-Elrahman. Effect of using a combination of rice husk and olive waste ashes on high-strength concrete properties. Case Studies in Construction Materials, Vol. 17, 2022, id. e01486.10.1016/j.cscm.2022.e01486Suche in Google Scholar

[44] Islam, M. J. and M. Shahjalal. Effect of polypropylene plastic on concrete properties as a partial replacement of stone and brick aggregate. Case Studies in Construction Materials, Vol. 15, 2021, id. e00627.10.1016/j.cscm.2021.e00627Suche in Google Scholar

[45] Kanadasan, J. and H. A. Razak. Engineering and sustainability performance of self-compacting palm oil mill incinerated waste concrete. Journal of Cleaner Production, Vol. 89, 2015, pp. 78–86.10.1016/j.jclepro.2014.11.002Suche in Google Scholar

[46] Tangchirapat, W., C. Jaturapitakkul, and P. Chindaprasirt. Use of palm oil fuel ash as a supplementary cementitious material for producing high-strength concrete. Construction and Building Materials, Vol. 23, No. 7, 2009, pp. 2641–2646.10.1016/j.conbuildmat.2009.01.008Suche in Google Scholar

[47] Ibrahim, H. A., H. A. Razak, and F. Abutaha. Strength and abrasion resistance of palm oil clinker pervious concrete under different curing method. Construction and Building Materials, Vol. 147, 2017, pp. 576–587.10.1016/j.conbuildmat.2017.04.072Suche in Google Scholar

[48] Craeye, B., P. Van Itterbeeck, P. Desnerck, V. Boel, and G. De Schutter. Modulus of elasticity and tensile strength of self-compacting concrete: Survey of experimental data and structural design codes. Cement and Concrete Composites, Vol. 54, 2014, pp. 53–61.10.1016/j.cemconcomp.2014.03.011Suche in Google Scholar

[49] Nguyen, K. T., N. Ahn, T. A. Le, and K. Lee. Theoretical and experimental study on mechanical properties and flexural strength of fly ash-geopolymer concrete. Construction and Building Materials, Vol. 106, 2016, pp. 65–77.10.1016/j.conbuildmat.2015.12.033Suche in Google Scholar

[50] Al-mulali, M. Z., H. Awang, H. P. S. A. Khalil, and Z. S. Aljoumaily. The incorporation of oil palm ash in concrete as a means of recycling: A review. Cement and Concrete Composites, Vol. 55, 2015, pp. 129–138.10.1016/j.cemconcomp.2014.09.007Suche in Google Scholar

[51] Zeyad, A. M., M. A. M. Johari, N. M. Bunnori, K. S. Ariffin, and N. M. Altwair. Characteristics of treated palm oil fuel ash and its effects on properties of high strength concrete. Advanced Materials Research, Vol. 626, 2013, pp. 152–156.10.4028/www.scientific.net/AMR.626.152Suche in Google Scholar

[52] Zhang, B. and C. S. Poon. Use of furnace bottom ash for producing lightweight aggregate concrete with thermal insulation properties. Journal of Cleaner Production, Vol. 99, 2015, pp. 94–100.10.1016/j.jclepro.2015.03.007Suche in Google Scholar

[53] Alengaram, U. J., B. A. Al Muhit, and M. Z. bin Jumaat. Utilization of oil palm kernel shell as lightweight aggregate in concrete–A review. Construction and Building Materials, Vol. 38, 2013, pp. 161–172.10.1016/j.conbuildmat.2012.08.026Suche in Google Scholar

[54] Lau, P. C., D. C. L. Teo, and M. A. Mannan. Mechanical, durability and microstructure properties of lightweight concrete using aggregate made from lime-treated sewage sludge and palm oil fuel ash. Construction and Building Materials, Vol. 176, 2018, pp. 24–34.10.1016/j.conbuildmat.2018.04.179Suche in Google Scholar

[55] Hamada, H. M., A. Alya’a, F. M. Yahaya, K. Muthusamy, B. A. Tayeh, and A. M. Humada. Effect of high-volume ultrafine palm oil fuel ash on the engineering and transport properties of concrete. Case Studies in Construction Materials, Vol. 12, 2020, id. e00318.10.1016/j.cscm.2019.e00318Suche in Google Scholar

[56] Alsubari, B., P. Shafigh, Z. Ibrahim, and M. Z. Jumaat. Heat-treated palm oil fuel ash as an effective supplementary cementitious material originating from agriculture waste. Construction and Building Materials, Vol. 167, 2018, pp. 44–54.10.1016/j.conbuildmat.2018.01.134Suche in Google Scholar

[57] Atmaca, N., M. L. Abbas, and A. Atmaca. Effects of nano-silica on the gas permeability, durability and mechanical properties of high-strength lightweight concrete. Construction and Building Materials, Vol. 147, 2017, pp. 17–26.10.1016/j.conbuildmat.2017.04.156Suche in Google Scholar

[58] Elalaoui, O., E. Ghorbel, V. Mignot, and M. B. Ouezdou. Mechanical and physical properties of epoxy polymer concrete after exposure to temperatures up to 250°C. Construction and Building Materials, Vol. 27, No. 1, 2012, pp. 415–424.10.1016/j.conbuildmat.2011.07.027Suche in Google Scholar

[59] Behnood, A. and H. Ziari. Effects of silica fume addition and water to cement ratio on the properties of high-strength concrete after exposure to high temperatures. Cement and Concrete Composites, Vol. 30, No. 2, 2008, pp. 106–112.10.1016/j.cemconcomp.2007.06.003Suche in Google Scholar

[60] Uysal, M. and H. Tanyildizi. Estimation of compressive strength of self compacting concrete containing polypropylene fiber and mineral additives exposed to high temperature using artificial neural network. Construction and Building Materials, Vol. 27, No. 1, 2012, pp. 404–414.10.1016/j.conbuildmat.2011.07.028Suche in Google Scholar

[61] Ye, G., X. Liu, G. De Schutter, L. Taerwe, and P. Vandevelde. Phase distribution and microstructural changes of self-compacting cement paste at elevated temperature. Cement and Concrete Research, Vol. 37, No. 6, 2007, pp. 978–987.10.1016/j.cemconres.2007.02.011Suche in Google Scholar

[62] Şahmaran, M., E. Özbay, H. E. Yücel, M. Lachemi, and V. C. Li. Effect of fly ash and PVA fiber on microstructural damage and residual properties of engineered cementitious composites exposed to high temperatures. Journal of Materials in Civil Engineering, Vol. 23, No. 12, 2011, pp. 1735–1745.10.1061/(ASCE)MT.1943-5533.0000335Suche in Google Scholar

[63] Malik, M., S. K. Bhattacharyya, and S. V. Barai. Thermal and mechanical properties of concrete and its constituents at elevated temperatures: A review. Construction and Building Materials, Vol. 270, 2021, id. 121398.10.1016/j.conbuildmat.2020.121398Suche in Google Scholar

[64] Wang, W., X. Liu, L. Guo, and P. Duan. Evaluation of properties and microstructure of cement paste blended with metakaolin subjected to high temperatures. Materials, Vol. 12, No. 6, 2019, id. 941.10.3390/ma12060941Suche in Google Scholar PubMed PubMed Central

[65] Fares, H., S. Remond, A. Noumowe, and A. Cousture. High temperature behaviour of self-consolidating concrete: microstructure and physicochemical properties. Cement and Concrete Research, Vol. 40, No. 3, 2010, pp. 488–496.10.1016/j.cemconres.2009.10.006Suche in Google Scholar

[66] Moghadam, M. J., R. Ajalloeian, and A. Hajiannia. Preparation and application of alkali-activated materials based on waste glass and coal gangue: A review. Construction and Building Materials, Vol. 221, 2019, pp. 84–98.10.1016/j.conbuildmat.2019.06.071Suche in Google Scholar

[67] Poon, C.-S., S. Azhar, M. Anson, and Y.-L. Wong. Comparison of the strength and durability performance of normal-and high-strength pozzolanic concretes at elevated temperatures. Cement and Concrete Research, Vol. 31, No. 9, 2001, pp. 1291–1300.10.1016/S0008-8846(01)00580-4Suche in Google Scholar

[68] Aprianti, E., P. Shafigh, S. Bahri, and J. N. Farahani. Supplementary cementitious materials origin from agricultural wastes–A review. Construction and Building Materials, Vol. 74, 2015, pp. 176–187.10.1016/j.conbuildmat.2014.10.010Suche in Google Scholar

[69] Heikal, M., H. El-Didamony, T. M. Sokkary, and I. A. Ahmed. Behavior of composite cement pastes containing microsilica and fly ash at elevated temperature. Construction and Building Materials, Vol. 38, 2013, pp. 1180–1190.10.1016/j.conbuildmat.2012.09.069Suche in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Review Articles

- Effect of superplasticizer in geopolymer and alkali-activated cement mortar/concrete: A review

- Experimenting the influence of corncob ash on the mechanical strength of slag-based geopolymer concrete

- Powder metallurgy processing of high entropy alloys: Bibliometric analysis and systematic review

- Exploring the potential of agricultural waste as an additive in ultra-high-performance concrete for sustainable construction: A comprehensive review

- A review on partial substitution of nanosilica in concrete

- Foam concrete for lightweight construction applications: A comprehensive review of the research development and material characteristics

- Modification of PEEK for implants: Strategies to improve mechanical, antibacterial, and osteogenic properties

- Interfacing the IoT in composite manufacturing: An overview

- Advances in processing and ablation properties of carbon fiber reinforced ultra-high temperature ceramic composites

- Advancing auxetic materials: Emerging development and innovative applications

- Revolutionizing energy harvesting: A comprehensive review of thermoelectric devices

- Exploring polyetheretherketone in dental implants and abutments: A focus on biomechanics and finite element methods

- Smart technologies and textiles and their potential use and application in the care and support of elderly individuals: A systematic review

- Reinforcement mechanisms and current research status of silicon carbide whisker-reinforced composites: A comprehensive review

- Innovative eco-friendly bio-composites: A comprehensive review of the fabrication, characterization, and applications

- Review on geopolymer concrete incorporating Alccofine-1203

- Advancements in surface treatments for aluminum alloys in sports equipment

- Ionic liquid-modified carbon-based fillers and their polymer composites – A Raman spectroscopy analysis

- Emerging boron nitride nanosheets: A review on synthesis, corrosion resistance coatings, and their impacts on the environment and health

- Mechanism, models, and influence of heterogeneous factors of the microarc oxidation process: A comprehensive review

- Synthesizing sustainable construction paradigms: A comprehensive review and bibliometric analysis of granite waste powder utilization and moisture correction in concrete

- 10.1515/rams-2025-0086

- Research Articles

- Coverage and reliability improvement of copper metallization layer in through hole at BGA area during load board manufacture

- Study on dynamic response of cushion layer-reinforced concrete slab under rockfall impact based on smoothed particle hydrodynamics and finite-element method coupling