Abstract

Geopolymers have emerged as promising alternatives to traditional cement-based composites, offering enhanced sustainability and opportunities for recycling industrial waste. The incorporation of waste materials into the binding matrix of geopolymer concrete not only promotes environmental benefits but also significantly improves the overall performance, including mechanical strength, durability, and microstructural integrity of the matrix. This study explores the impact of incorporating varying dosages of nano-basic oxygen furnace slag (NBOFS) and nano-banded iron formation (NBIF) on the properties of high-performance geopolymer concrete (HPGC) that utilizes waste glass as 50% fine aggregate. The research focuses on evaluating both the fresh and mechanical properties, including compressive strength, splitting tensile strength, modulus of elasticity, and flexural strength. Additionally, this study investigated the transport properties of concrete under aggressive environments, such as resistance to chloride penetration, sulfate attack, and sorptivity. The microstructure was examined using scanning electron microscopy. The results demonstrated that the addition of 3% NBOFS and 2.5% NBIF significantly improved the fresh, mechanical, and transport properties of HPGC. These nanomaterials also enhance the splitting tensile strength, flexural strength, and elastic modulus under highly aggressive environmental conditions. The contribution of these nanomaterials to the strength and durability of concrete is particularly relevant in the construction of both substructures and superstructures. Additionally, geopolymer concrete significantly reduces CO2 emissions by eliminating the requirement for ordinary Portland cement and promoting the recycling of waste products, contributing to more environmentally friendly construction practices.

1 Introduction

In recent years, global crude steel production has increased significantly, with particularly impressive results observed in 2021 when the world produced 1,960 million tons of steel [1]. The Brazilian steel industry continues to rank among the top ten global steel producers, accounting for approximately 34 million metric tons of crude steel in 2022 [2,3]. The steel industry, along with iron and steel, generates substantial quantities of by-products. Consequently, the primary by-product of steel manufacturing is slag, which accounts for 90% of the total mass. Furthermore, as steel production increases, slag production also increases [4]. When comparing the production of by-products, the basic oxygen furnace (BOF) production line produces an average of 400 kg of by-products per ton of steel. In contrast, an electric arc furnace (EAF) slag production line produces 200 kg of by-products per ton of steel. Although both materials have certain characteristics, such as the presence of free oxides and a chemical composition based on iron oxides, aluminum, silicon, and calcium, they also exhibit significant differences. For example, (1) the levels of CaO and free CaO in BOF slag are elevated, (2) the FeO content in EAF slag is reduced; (3) EAF slag exhibits a higher SiO2 content; and (4) BOF slag contains a larger quantity of hydraulic silicate minerals [5]. These qualities pertain to the expanding nature of the slag and the interactions between the slag and the cementitious matrix. These facts establish BOF slag as a unique material, necessitating a detailed examination of its properties and the effects of its utilization [6]. Various efforts are underway to reduce the dependence on cement for construction activities by developing alternative binders that can substitute the traditional Portland cement. To mitigate the environmental impact and reduce the consumption of nonrenewable natural resources, it is necessary to decrease the production of ordinary Portland cement [7,8]. Various efforts are underway to utilize pozzolanic waste and materials as partial substitutes for cement to improve performance and reduce consumption. Recently, the focus has been on the development of alternative binders by employing alkaline-activated bond systems, also known as geopolymer bonding [9]. Silica (Si) and alumina (Al) react in a strong alkaline solution to form a three-dimensional polymer chain. This occurred because alumina and silica polycondensate created Si–O–Al–O linkages [10]. Metakaolin, fly ash (FA), and granulated blast furnace slag (GBFS) are commonly used precursors for manufacturing geopolymer concrete (GC) via alkaline activation [11,12]. The specific activators used, their concentrations, types of aluminosilicate materials employed, mixing ratios, and curing processes primarily influence the efficiency of GC [13]. GC has the potential to serve as a viable substitute for cement-based concretes. GC is characterized by its low permeability, strong early compressive strength (CS), and high resilience to fire and extreme environmental conditions [14].

High-performance geopolymer concrete (HPGC) is one type of GC that incorporates waste as a primary binder, resulting in improved mechanical strength, durability, and sustainability compared to traditional cement-based materials [15,16]. The rapid development of HPGC has enabled the effective adoption of alkaline-activated technology as a viable alternative for structural applications that offers enhanced sustainability and durability [17]. The production of HPGC depends on several factors: (1) the use of silica fume (SF) and ground granulated blast furnace slag (GGBS) to improve the flow characteristics while maintaining low water-to-binder ratios and high alkali activation potentials [18] and (2) adding nanomaterials or increasing the surface area of the binder particles [19]. To achieve this, they mixed SF and hydroxide fiber with GGBS to produce concrete with a CS and flexural 28-day strength (FS) of 175 and 13.5 MPa, respectively. This finding is supported by Aydın and Baradan [20], who demonstrated that adding SF to GGBS to create HPGC increased the CS by more than 150 MPa compared with adding SF only. A study by Li et al. [21] found that adding 10–15 vol% GGBS to HPGC led to a maximum CS of 178.6 MPa. However, these studies have shown that 20–30% SF dosages make geopolymer concrete less flowable, but with significant contributions to mechanical and rheological properties at higher substitution rates. Previous studies [22,23,24,25] showed that increasing the amount of 10–30% SF improved the mechanical properties and made it easier for the fibers to bond with the matrix. Furthermore, the implementation of HPGC steel fibers enhances the ability of the material to deform without cracking. It also exhibited good resistance to cracking under stress and impact forces.

Nanomaterials are crucial for enhancing the microstructure [26,27], minimizing the porosity, and augmenting the mechanical strength of GC. The aim of this study is to investigate the influence of different dosages of nano-basic oxygen furnace slag (NBOFS) and nano-banded iron formations (NBIFs) on the properties of HPGC produced by GBFS, FA, and SF as environmental solutions for CO2 emissions, in addition to recycling the by-products of the steel manufacturing process. This investigation contributes to the development of sustainable construction materials and paves the way for future innovations in eco-friendly building technologies. The study could significantly impact the construction industry by providing a greener alternative to traditional concrete, with reduced environmental pollution that causes landfills.

2 Experimental program

2.1 Materials

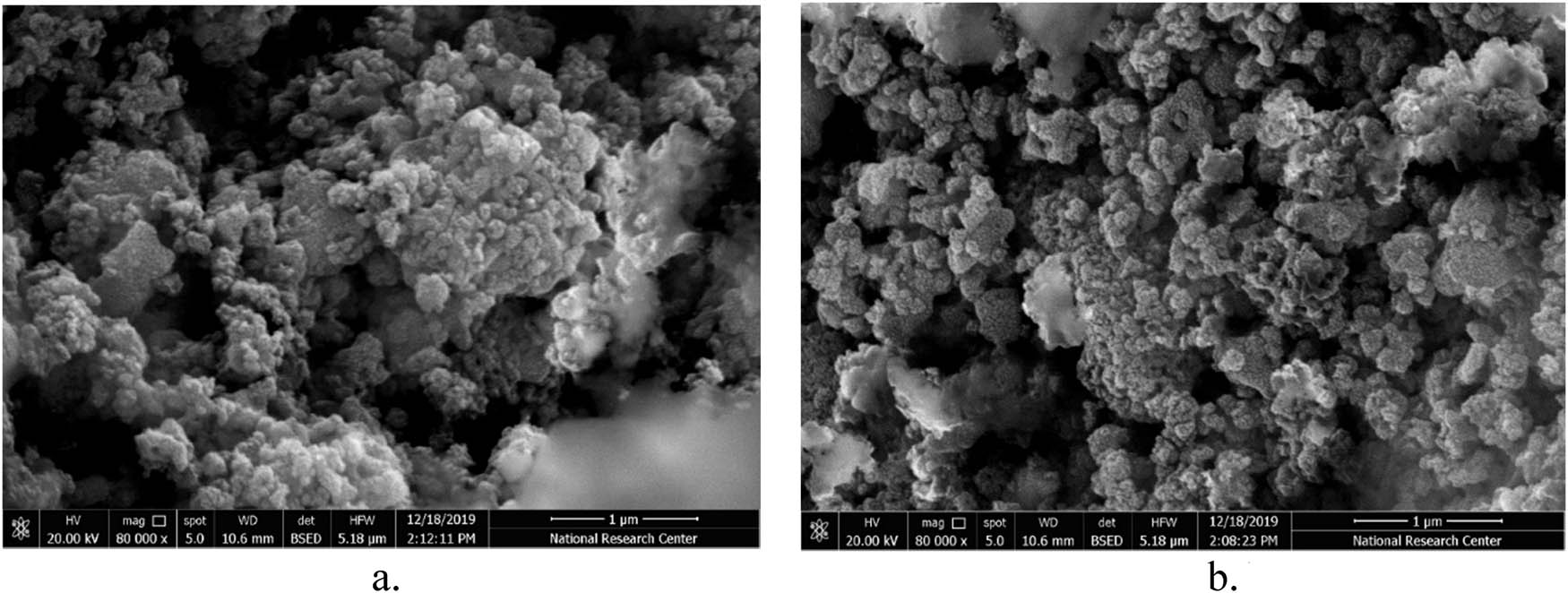

GBFS is a by-product of iron manufacturing. Slag formation occurs when an iron foundry uses water to cool it. GBFS is used in the production of HPGC. GBFS was synthesized with a uniform density of 730 kg·m−3 for all mixes analyzed in this study. Table 1 presents the chemical and physical properties of the GBFS. FA is a by-product of coal-fired power plants in Cairo, Egypt. The ASTM C618 Class F [36] requirements were classified as Class F fly ash, whose oxide composition is shown in Table 1, together with SF and GBFS. SF is a by-product obtained from the manufacturing of ferrosilicon alloy. It meets the requirements set by ASTM C1240 [28] and SF has been employed for its pozzolanic action [29,30,31]. This study involved the synthesis of two types of nanomaterial powders: NBIFs with silica, iron oxide, and lime contents, as shown in Table 1. The steps of the milling process are illustrated in Figure 1. The additives, NBIFs, and NBOFS varied from 0.5 to 3.0 wt% of the total powder content (GBFS, FA, and SF) [9–11]. The physical properties of NBIFs and NBOFS are listed in Table 2. Scanning electron microscopy (SEM) figures are shown in Figure 2. The filler employed in this study was quartz powder (QP) with particle sizes ranging from 10 to 25 µm [32,33]. Table 3 summarizes the characteristics of the QP. To enhance its consistency, quartz sand (fine aggregates) with a mean particle size of 4.75 mm was added to the mixture, with the grading curve shown in Figure 4. The fine aggregate characteristics were assessed in accordance with ES 1109/2008 and ASTM C33/C33M-18. Table 4 provides information regarding the physical parameters of the fine aggregates. Table 5 provides mixed proportions. The alkaline activator solutions used in the experiment included potassium hydroxide (KOH) with a purity of 98% and sodium silicate (Na2SiO3). NaOH was prepared 24 h before use. The experimental study employed a constant alkaline liquid ratio (SH:SS) of 1:3 and a consistent ratio of alkaline solution to binder materials (AA/total binder = 0.37 for all mixtures) [34,35,36]. High-range water-reducing agent (1.5 wt% of the precursor) was added to the mixture to improve the workability of HPGC. The material complies with the standards for SP (Viscocrete-5930) with a specific gravity of 1.09, according to ASTM-C-494 Type G and F [37] and the British Standard EN 934 Part 2:2001.

Chemical composition and physical properties of binder materials

| Chemical component (%) | Physical characteristics | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Characteristics | SiO2 | Al2O3 | Fe2O3 | CaO | SO3 | Na2O | K2O | MgO | TiO2 | Specific gravity | Specific surface area (cm2·g−1) |

| GBFS | 37.98 | 12.55 | 1.51 | 39.95 | 2.69 | 0.76 | 0.7 | 3.86 | — | 2.55 | 6,175 |

| FA | 59.45 | 21.42 | 5.91 | 6.73 | 0.15 | 1.5 | 1.66 | 1.78 | 1.4 | 2.34 | 6,840 |

| SF | 98.9 | 0.25 | 0.13 | 0.27 | — | 0.17 | 0.12 | 0.16 | — | 2.15 | 19,750 |

| NBIF | 15.3 | — | 16.2 | 52.3 | |||||||

| NBOFS | 15.5 | — | 28.2 | 37.9 | |||||||

Appearance of BOF slag.

The physical properties of nanomaterials

| Properties | Form | Particle size (nm) | Color | Molecular Weight (g·mol−1) | Melting point (°C) | Boiling point (°C) | Density (g·cm−3) | Specific gravity | Water solubility |

|---|---|---|---|---|---|---|---|---|---|

| NBIF | Powder | 20 ± 5 | Black | 80.08 | 1,600 | 2,230 | 2.2–2.6 | 3.2 | Insoluble |

| NBOFS | Powder | 5 | Black | 89.88 | 1,825 | 2,500–3,000 | 3.79 | 3.7 | Insoluble |

SEM images of the nanomaterials. (a) NBIFs. (b) NBOF.

Physical and chemical properties of the QP

| Properties | Physical properties | Chemical compositions (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| Specific gravity | Specific area (cm2·g−1) | Color | SiO2 | Al2O3 | Fe2O3 | CaO | SO3 | |

| Quartz powder | 2.56 | 4,090 | White | 98.68 | 0.16 | 0.1 | 0.1 | 1.11 |

Fine aggregates physical properties

| Property | Specific gravity | Unit weight (kg·m−3) | Fineness modulus | Water absorption (%) | Clay and fine materials (%) |

|---|---|---|---|---|---|

| Sand | 2.68 | 1,695 | 2.727 | 1.2 | 0.79 |

| Waste glass | 2.63 | 1,712 | 2.6 | 0.95 | 0.1 |

Mix proportions for HPGC mixtures

| Mixture ID | GBFS | FA | SF | NBIF | NBOFS | Waste glass | Sand | KHS | SSS | ASMA | SP | Curing | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg·m−3 | kg·m−3 | kg·m−3 | % | % | kg·m−3 | kg·m−3 | Ratio | Mol. | Ratio | Ratio | % | Time Hour | Temp. °C | |

| Control | 200 | 200 | 40 | 0 | 0 | 750 | 750 | 1 | 14 | 3 | 0.4 | 1 | 48 | 70 |

| NBIF 0.5 | 200 | 200 | 40 | 0.5 | 0 | 750 | 750 | 1 | 14 | 3 | 0.4 | 1 | 48 | 70 |

| NBIF 1.0 | 200 | 200 | 40 | 1 | 0 | 750 | 750 | 1 | 14 | 3 | 0.4 | 1 | 48 | 70 |

| NBIF 1.5 | 200 | 200 | 40 | 1.5 | 0 | 750 | 750 | 1 | 14 | 3 | 0.4 | 1 | 48 | 70 |

| NBIF 2.0 | 200 | 200 | 40 | 2 | 0 | 750 | 750 | 1 | 14 | 3 | 0.4 | 1 | 48 | 70 |

| NBIF 2.5 | 200 | 200 | 40 | 2.5 | 0 | 750 | 750 | 1 | 14 | 3 | 0.4 | 1 | 48 | 70 |

| NBIF 3.0 | 200 | 200 | 40 | 3 | 0 | 750 | 750 | 1 | 14 | 3 | 0.4 | 1 | 48 | 70 |

| NBOFS 0.5 | 200 | 200 | 40 | 0 | 0.5 | 750 | 750 | 1 | 14 | 3 | 0.4 | 1 | 48 | 70 |

| NBOFS 1.0 | 200 | 200 | 40 | 0 | 1 | 750 | 750 | 1 | 14 | 3 | 0.4 | 1 | 48 | 70 |

| NBOFS 1.5 | 200 | 200 | 40 | 0 | 1.5 | 750 | 750 | 1 | 14 | 3 | 0.4 | 1 | 48 | 70 |

| NBOFS 2.0 | 200 | 200 | 40 | 0 | 2 | 750 | 750 | 1 | 14 | 3 | 0.4 | 1 | 48 | 70 |

| NBOFS 2.5 | 200 | 200 | 40 | 0 | 2.5 | 750 | 750 | 1 | 14 | 3 | 0.4 | 1 | 48 | 70 |

| NBOFS 3.0 | 200 | 200 | 40 | 0 | 3 | 750 | 750 | 1 | 14 | 3 | 0.4 | 1 | 48 | 70 |

GBFS: granulated blast furnace slag; FA: fly ash; SF: silica fume; KHS: potassium hydroxide solution; SSS: sodium silicate solution; Mol: molarity; AS/MA: alkaline solution to mineral additives; SP: superplasticizer; w/b: water–binder ratio.

2.2 Mixing procedures

This study used a paddle mixer to provide a consistent homogenous mixture for the HPGC. The alkali and sodium silicate solution were mixed in separate containers, and raw materials (GBFS, FA, and SF) were mixed with sand and glass waste for 3 min. After that, a homogenous solution was added and mixed for 3 min. A magnetic stirrer was used for full dispersion of nanoparticles, and then, nanosolution was added and mixed. All constituent materials were homogenously mixed for the next 3–5 min and then poured into molds. Finally, the specimens and molds were thermally cured in an oven at 80°C for 48 h and then demolded to produce HPGC. The demolded samples were cured at ambient temperature before being tested for their mechanical properties.

2.3 Test procedure

2.3.1 Fresh properties

The influence of different nanomaterial compositions on the ease of handling fresh HPGC composites was assessed by quantifying the flow diameter and air content percentage, following the guidelines provided by ASTM-C-143-15a and ASTM-C-231-17a.

2.3.2 Mechanical properties

The CSs at 3, 7, 28, and 90 days were determined by conducting tests on cubic specimens with dimensions of 100 mm × 100 mm × 100 mm, in accordance with the specifications outlined in BS-1881: part-116-2004. The tensile strength and elasticity modulus were determined by tests conducted on cylindrical specimens with a diameter of 150 mm and height of 300 mm, in accordance with the ASTM-C496-11 and ASTM-C469-14 standards, respectively. The 28-day flexural strength was evaluated by conducting tests on prism specimens with dimensions of 100 mm × 100 mm × 500 mm (ASTM-C78-16). The results were recorded as the average of the three specimens.

2.3.3 Physical properties

A water permeability test was performed on cylindrical specimens of 150 mm × 150 mm after 28 days, following the guidelines of BS EN 12390-8. The chloride penetration resistance was assessed by employing disc specimens with a diameter of 100 mm and thickness of 50 mm, in accordance with the guidelines specified in ASTM C1202-17 [38]. The water sorptivity test conducted after 28 days quantified the level of water absorption. The test was performed in accordance with the specifications provided in ASTM C1585-13 [39], using a cylindrical sample with dimensions of 50 mm × 100 mm.

2.3.4 Sulfate attack

The ability of the specimens to resist sulfate attack was assessed using the procedures described in ASTM C1012 and BS 8500-2. Sodium sulfate solutions with concentrations of 0, 5, 50, 75, and 100 g·L−1 were prepared for sample (70 mm × 70 mm × 70 mm) immersion, and the residual strengths were measured and recorded at 28, 90, and 180 days to examine the effects of short-, medium-, and long-term attacks, respectively.

3 Results and discussion

3.1 Workability

This study rigorously assessed the impact of varying the concentration of nano-banded iron NBIF (0.5–3%) on the slump flow of HPGC. Figure 3 shows a negative correlation with an increasing proportion of NBIFs usage. The unique interaction between the NBIF particles and geopolymer matrix caused a steady decline in the slump flow from 598 to 534.6 mm. The slump flow exhibited a distinct decreasing trend as the concentration of the NBOFS increased. The specific interactions between the nanoparticles of the NBOFS and geopolymer matrix account for the observed behavior. The results suggest that the incorporation of NBOFS influences the rheological properties of HPGC, leading to an increase in viscosity and a subsequent decrease in flowability [40,41,42], with values decreasing from 598.4 in the control mix to 537.9 when NBOFS was 3%. The addition of NBOFS resulted in the formation of more compact and less flexible geopolymer structures [43,44,45].

Flowability of HPGC incorporating NBIFS and NBOF.

3.2 Mechanical properties

3.2.1 Compressive strength

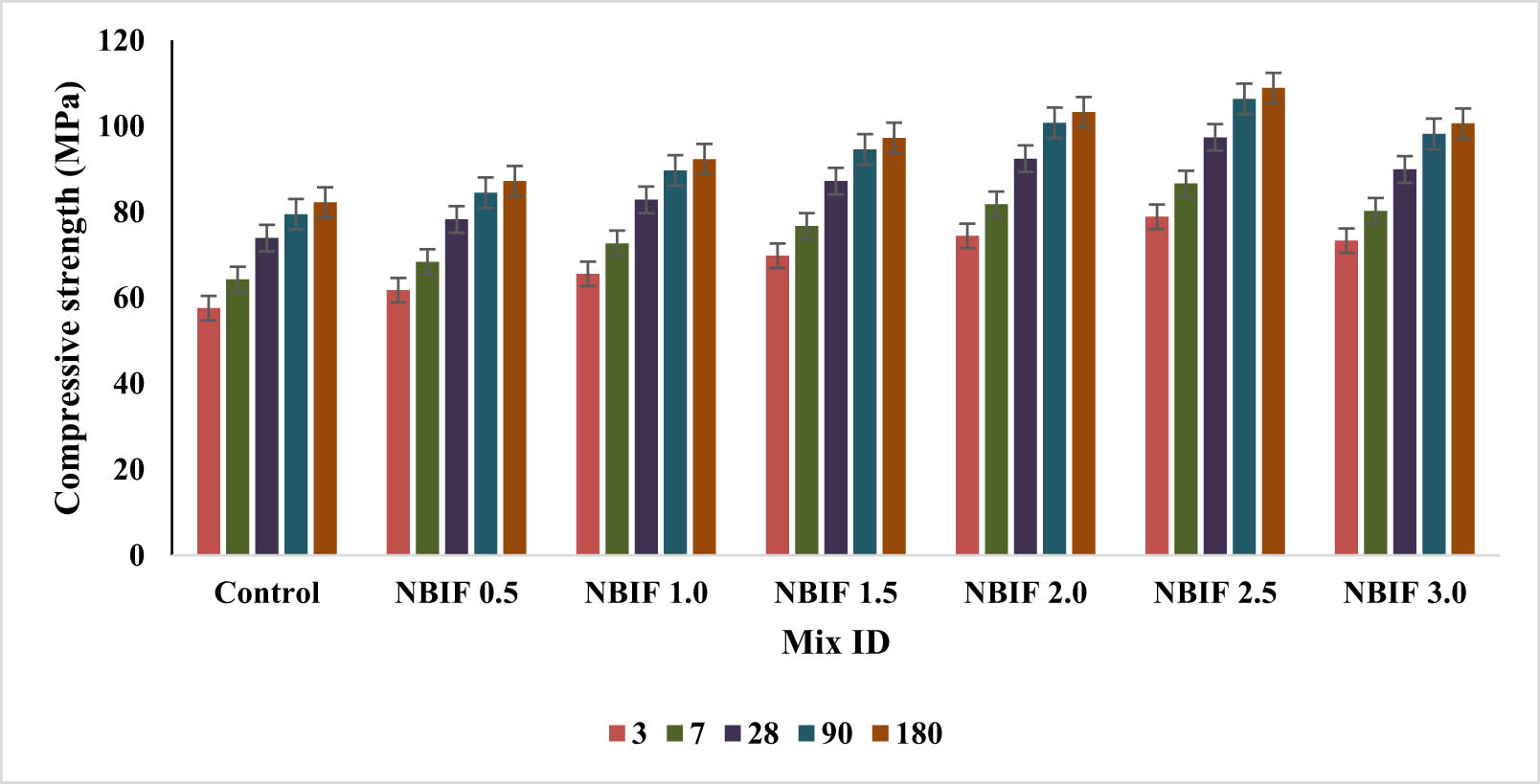

Figures 4 and 5 show the CSs of HPGC samples, including NBIFs and NBOFS. The samples were tested at various percentages (0, 0.5, 1.0, 1.5, 2.0, 2.5, and 3.0) as additives from binder mass at various ages (3, 7, 28, 90, and 180 days). The mechanical properties are discussed in detail below.

Results of CS test of HPGC containing NBIFs at different test ages.

Results of CS test of HPGC containing NBOFS at different curing ages.

3.2.1.1 Compressive strength for HSGC containing NBIFs

The inclusion of nanomaterials (specifically NBIFs) enhances the CS of HPGC. The results indicated that the 28-day CS values for 0–3% NBIF ranged between 73.8 and 98.9 MPa, respectively. Furthermore, 2.5% NBIFs were incorporated into the mixture to achieve the maximum static friction coefficient. The CS values were 161.0, 176.8, 198.7, 217.0, and 222.2 MPa for the ages of 3, 7, 28, 90, and 180 days, respectively. Consequently, increasing the proportion of NBIFs led to an improvement in CS, with a positive correlation between 0.5 and 2.5%. However, the use of quantities greater than 2.5% led to a decline in CS. Nevertheless, all percentages of NBIF added (ranging from 0.5 to 3.0%) resulted in higher CS values than those of the NBIF-free control mixtures. The results illustrated that adding nanomaterials, specifically NBIF, could strengthen the nanostructure of the sample [46]. The presence of NBIFs primarily affects the breakdown process during dissolution and potentially results in a faster geopolymerization rate. A previous study [47] has observed that the presence of slag positively affects the formation of reaction products and the extent of geopolymerization, leading to a more uniform and compact matrix.

3.2.1.2 Compressive strength for HSGC containing nano-basic iron formations

The results indicated that the inclusion of NBOF in HPGC enhanced the CS of concrete at various rates of addition (0.5, 1.0, 1.5, 2.0, 2.5, and 3.0% of NBOFS) for all test ages compared with the reference control mixtures. The results demonstrated a positive correlation between the rate of NBOF addition and the CS increase in the presence of basalt fiber. Mixture NBOFS 3.0, with an addition rate of 3% NBOFS, achieved the highest CS compared to other mixtures containing NBOFS. The CS values were 75.46, 83.93, 94.32, 102.3, and 105.35 MPa at test ages of 3, 7, 28, 90, and 180 days, respectively. The advantageous impact of the NBOF on the microstructure could reduce CS. These effects include filling tiny pores within the geopolymer matrix with nanoparticles and fibers [48,49]. This process not only improves nucleation during the formation of crystal nuclei or the seeding effect but also results in a more uniform distribution of hydration products. The addition of NBOFS enhances the CS of graphene composites (GC) by approximately 2% [6,50]. Nanomaterials (NBOF and NBIF) affect the formation of reaction products and the extent of geopolymerization, leading to a more uniform and compact matrix [30].

3.2.2 Splitting tensile strength

Impact of varying the NBIF (0.5–3%) on the splitting tensile strength of HPGC. Notable patterns were observed in the experiments. The results in Figure 6 show a constant increase in the strength of the NBIF to 2.5%. The observed pattern indicates that a lower NBIF content enhances microstructural bonding within the geopolymer matrix, thereby resulting in a higher splitting tensile strength [51]. However, at a higher substitution of 3%, a change in the observed pattern occurred as the splitting tensile strength decreased [52,53]. Impact of NBOFS content on splitting tensile strength of HPGC at addition ratios ranging from 0.5 to 3%. An incremental improvement in splitting tensile strength was observed up to an addition ratio of 3%. This upward trajectory can be ascribed to the enhancement of pozzolanic reactivity and interfacial bonding in the geopolymer matrix [43]. The addition of NBOFS results in a more durable material when subjected to tensile stress, which is more significant in the presence of fibers [54,55].

Splitting tensile strength of HPGC incorporating NBIFs and NBOFS.

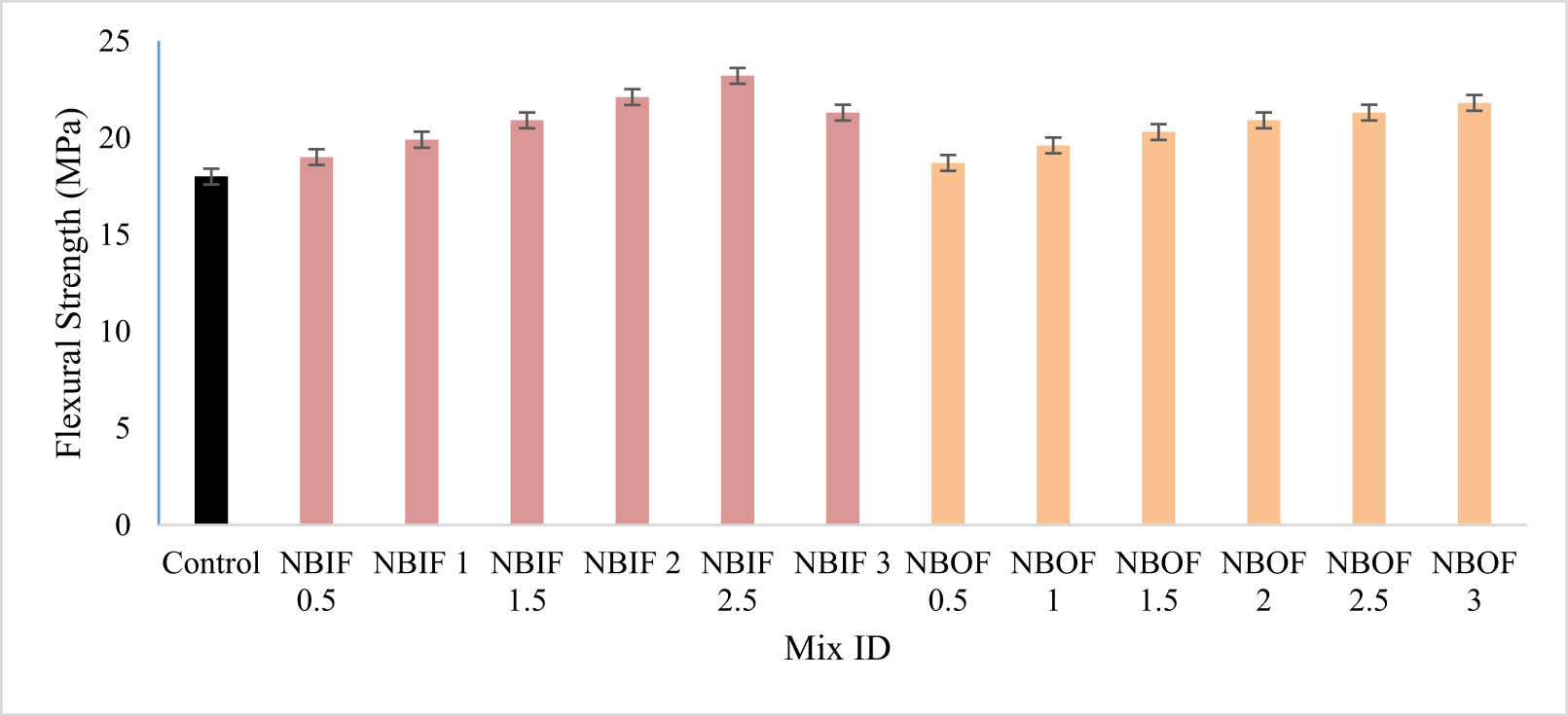

3.2.3 Flexural strength

This study examined the effect of varying the NBIF content from 0.5 to 3% on the flexural strength of HPGC. The analysis showed a continuous pattern, where an increase in the ratio of NBIF of up to 2.5% was associated with a decrease in the flexural strength. The initial drop in flexural strength is related to the reactivity of NBIF, which improves the bonding within the geopolymer matrix. However, when the addition ratio exceeded 2%, a reverse trend was observed, indicating a decrease in flexural strength. The observed discrepancy may be ascribed to the possible agglomeration or excessive inclusion of NBIF, which disrupts the uniformity of the geopolymer structure and consequently undermines the flexural performance of the material [56]. These results emphasize the importance of carefully choosing the addition ratio of nano-banded iron in HPGC formulations to achieve a balance between enhanced mechanical quality and potential negative consequences.

This study found a continuous and favorable relationship between a higher proportion of NBOFS used as a substitute and the flexural strength of HPGC. The flexural strength of the geopolymer matrices increased proportionally with a gradual increase in the amount of NBOFS and fibers [57,58], demonstrating the potential of NBOFS as a reinforcing agent. The increase in flexural strength can be attributed to the pozzolanic reactivity of NBOFS with the surrounding matrix [4,43,44]. This leads to an increase in the resistance of the sample to the bending stress. These results emphasize the positive impact of NBOFS in enhancing the bending strength of HPGC, showing their potential use in the development of strong and long-lasting construction materials. NBIFs showed higher strength at all levels compared to all levels of NBOF (Figure 7).

Flexure strength of HPGC incorporating NBIFs and NBOF.

3.2.4 Modulus of elasticity

The findings in Figure 8 indicate a complex correlation between NBIF concentrations and material parameters. This study demonstrated a gradual increase in the modulus of elasticity that peaked at an addition ratio of 2.5%. The first improvement is due to the pozzolanic properties of NBIFs, which enhance the microstructure and strengthen the bonding between geopolymeric materials. These characteristics enhance the rigidity and flexibility of materials. However, when the addition ratio exceeded 2.5%, this trend was reversed, leading to a subsequent decrease in the modulus of elasticity. This can be ascribed to the possible clumping or excessive integration of NBIFs, resulting in uneven dispersion within the geopolymer framework and the subsequent impairment of the elasticity of the material. These results highlight the significance of tailoring the addition ratios of nano-banded iron within a specified range to attain the required equilibrium between the enhanced modulus of elasticity and potential negative consequences [46,59]. Therefore, it is crucial to conduct additional research on microstructural changes and durability factors related to the formation of different concentrations of NBIFs. This will provide a thorough knowledge of the complex connection between the NBIF content and the modulus of elasticity in HPGC.

Modulus of elasticity of HPGC incorporating NBIFs and NBOF.

3.3 Physical properties

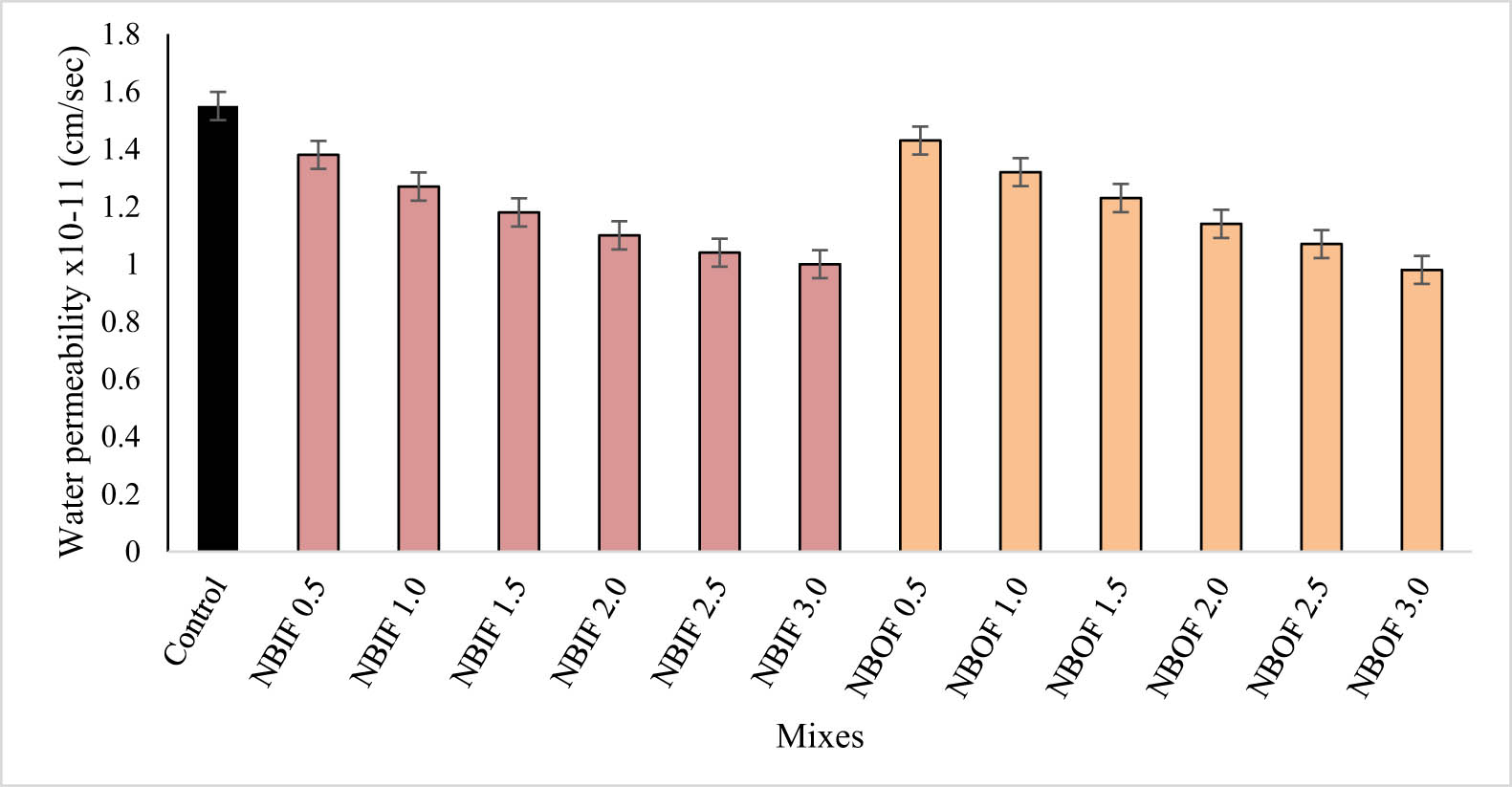

3.3.1 Water permeability

The results of the water permeability tests of the HPGC samples at a test age of 28 days are shown in Figure 9. Overall, the study indicated that the water permeability values of the HPGC samples varied between 0.90 × 10−11 and 1.38 × 10−11 (cm·s−1) for mixtures that included NBIFs. The water permeability values for HPGC samples varied between 0.5 × 10 and 1.43 × 10−11 (cm·s−1) when mixed with NBOFS. The control mixture without nanomaterials (NBIFs and NBOFS) had a water permeability value of 1.55 × 10−11 (cm·s−1). The results show that the inclusion of NBIFs in HPGC production significantly reduced the water permeability compared to the reference control mixture, and the results were 1.38, 1.27, 1.18, 1.10, 1.04, and 1.0 × 10−11 (cm·s−1) for NBIFs, for 0.5, 1.0, 1.5, 2.0, 2.5, and 3% NBIFs. The inclusion of nanoparticles improved the permeability resistance of the HPGC with an increase in the rate of addition. This is consistent with many previous studies that have confirmed that the use of nanomaterials plays an important role in filling micropores in addition to improving the density of the geopolymer paste matrix [60,61]. The incorporation of NBIFs has a positive impact on the porosity and pore structure of the matrix by reducing the number of macropores [62]. These findings indicate that incorporating NBIFs in the production of HPGC led to a significant reduction in the water permeability values compared to the reference mixture. The recorded values were 1.43, 1.32, 1.23, 1.14, 1.07, and 0.98 × 10−11 cm·s−1 for the NBOF 0.5, NBOF 1.0, NBOF 1.5, NBOF 2.0, NBOF 2.5, and NBOF 3.0, respectively. This observation indicated that the incorporation of NBOFS enhanced the impermeability resistance of HPGC. The results obtained from this study support the theory of previous research, confirming the positive role of adding nanoparticles to concrete to achieve lower permeability, and higher durability [15,43,46,54,63]. In general, NBIFs have lower water permeability than NBOF and, thus, have better resistance in this aspect.

Results of water permeability test of HPGC containing NBIFs and NBOF.

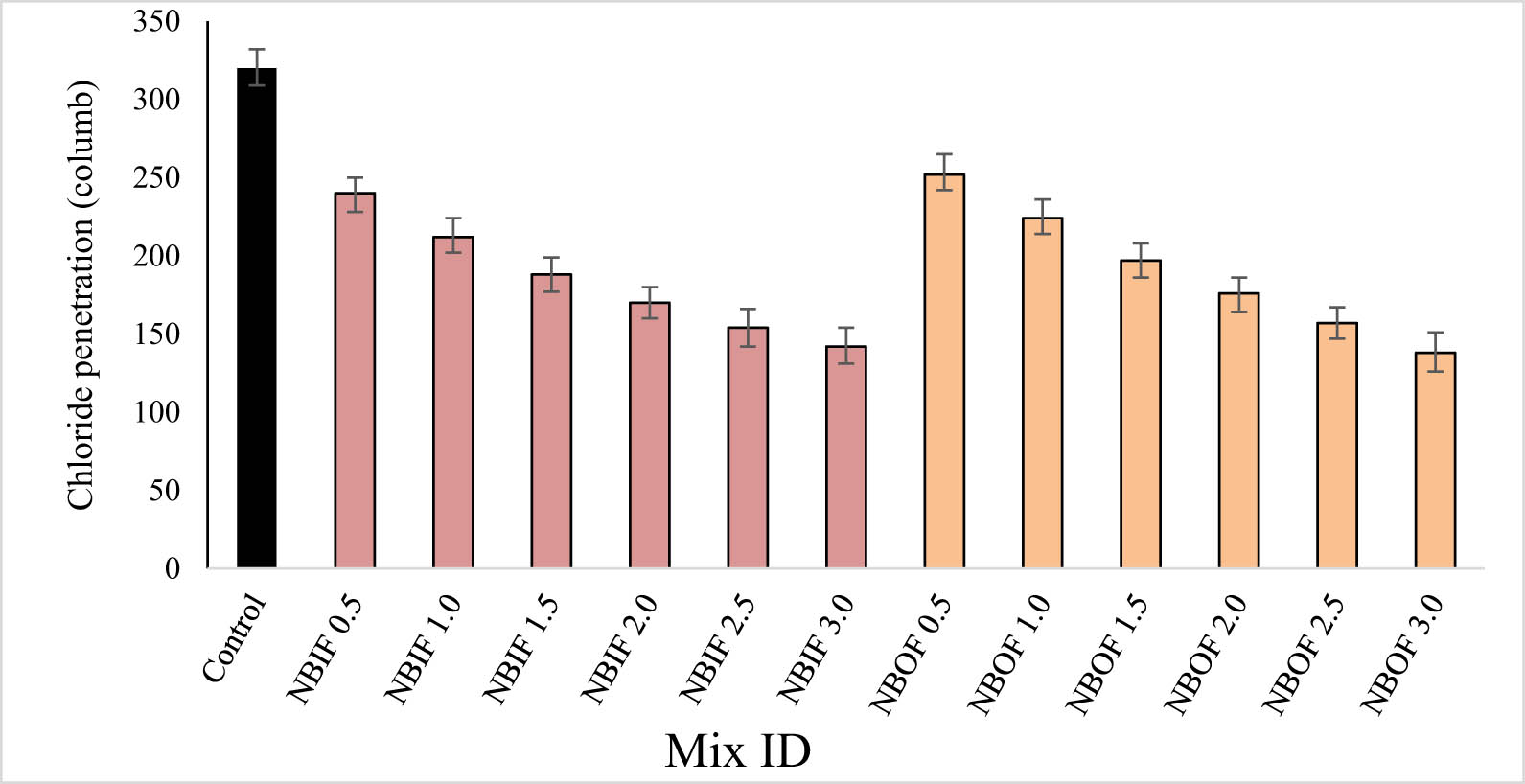

3.3.2 Chloride penetration resistance

Figure 10 shows the results of the chloride penetration test for the HPGC samples at a test age of 28 days. Notably, the chloride penetration resistance of the HPGC samples containing nanomaterials improved. The chloride penetration values of the HPGC samples containing NBIFs ranged from 138 to 260 (coulombs). The chloride penetration test results for the HPGC samples that included NBOFS were between 272 and 130 (coulombs). For the control mixture without nanomaterials (NBIFs and NBOFS), the chloride penetration value is 340 (column b). Accordingly, the NBOFS 3.0 mixture achieved the lowest chloride permeability at 158 (column b), followed by the NBIFs 3.0 mixture at 163 (column b). From the presented results, it can be concluded that the addition of nanoparticles improves the impermeability of concrete. The permeability progressively decreases with an increase in the rate of nanomaterial addition [26]. This is attributed to the role of nanomaterials in improving the polymerization process and reducing pore size [44,64].

Results of chloride penetration test of HPGC containing NBIFs and NBOF.

3.3.3 Sorptivity

The data presented in Figure 11 display the water sorptivity coefficient values for the HPGC samples after 28 days of testing. Based on these findings, it appears that the inclusion of NBIFs and NBOFS in HPGC samples leads to a reduction in water sorptivity coefficient values. The water sorptivity coefficient values for HPGC samples containing NBIFs were observed to range between 2.36 and 1.16 (10–4 mm·s−0.5). The water sorptivity coefficients of the HPGC samples containing NBOFS ranged from 2.36 to 1.18 (10–4 mm·s−0.5). In the case of the control mixture without NBIFs and NBOFS, the water sorptivity coefficient was measured to be 2.95 (10–4 mm·s−0.5). Based on the results, it appears that the NBOF 3.0 mixture demonstrated the most favorable water sorptivity coefficient value of 1.18 (10–4 mm·s−0.5), while the NBIFs 3.0 mixture exhibited a slightly higher water diffusion coefficient value of 1.16 (10–4 mm·s−0.5). Based on the presented findings, it appears that the inclusion of nanoparticles has a positive effect on the impermeability of concrete [65,66]. The results showed a clear correlation between the increase in the rate of nanomaterial addition and a gradual decrease in the water absorption coefficient. The water sorptivity in the case of NBOF showed a smaller decrease than the similar percentages in the case of NBIFs.

Results of water sorptivity test of HPGC containing NBIFs and NBOF.

3.3.4 Correlation between physical properties and durability

Figures 12–14 show that according to previous studies, it has been suggested that geopolymer mixtures incorporating FA and GBFS with NBIFs or NBOFS can enhance the characteristics of GC, subject to the addition rate. The effectiveness of nanomaterials added to geopolymer mixtures depends on their chemical composition and fineness [43,46,64]. Based on the available results, the findings of previous studies on the mechanisms of action of nanomaterials were supported. These findings suggest that nanomaterials tend to focus on the following three aspects. This study primarily focused on the framework of nanomaterials (NBIFs and NBOFS) in HPGC. The unique properties of nanoparticles, such as (1) effect of small particle size, significant surface area, and high surface energy, have a significant impact on the potential impact of nanomaterials on the geopolymer matrix [61]; (2) in the phenomenon of nucleation, nanoparticles have significant surface area and surface energy, which serve as nucleation sites for a less porous geopolymer matrix. This accelerates the geopolymerization process [67]. (3) The effect of nanopore filling, which involves the incorporation of nanoparticles into the geopolymer matrix with the potential to improve the pore structure by filling nanopores [62]. Figures 14–16 show high correlations of more than 0.98 between the durability results, which is in agreement with similar relations presented in the literature [68,69].

The correlation between water permeability and water sorptivity coefficient.

The correlation between water permeability and water chloride penetration.

The correlation between sorptivity coefficient and chloride penetration.

Residual CS after exposure of concrete to the concentration of sodium sulfate of 100 gm·L−1 for 180 days.

Microstructural morphology of HPGC. (a) Control mix. (b) 2.5 NBIFs. (c) 3 NBOFs.

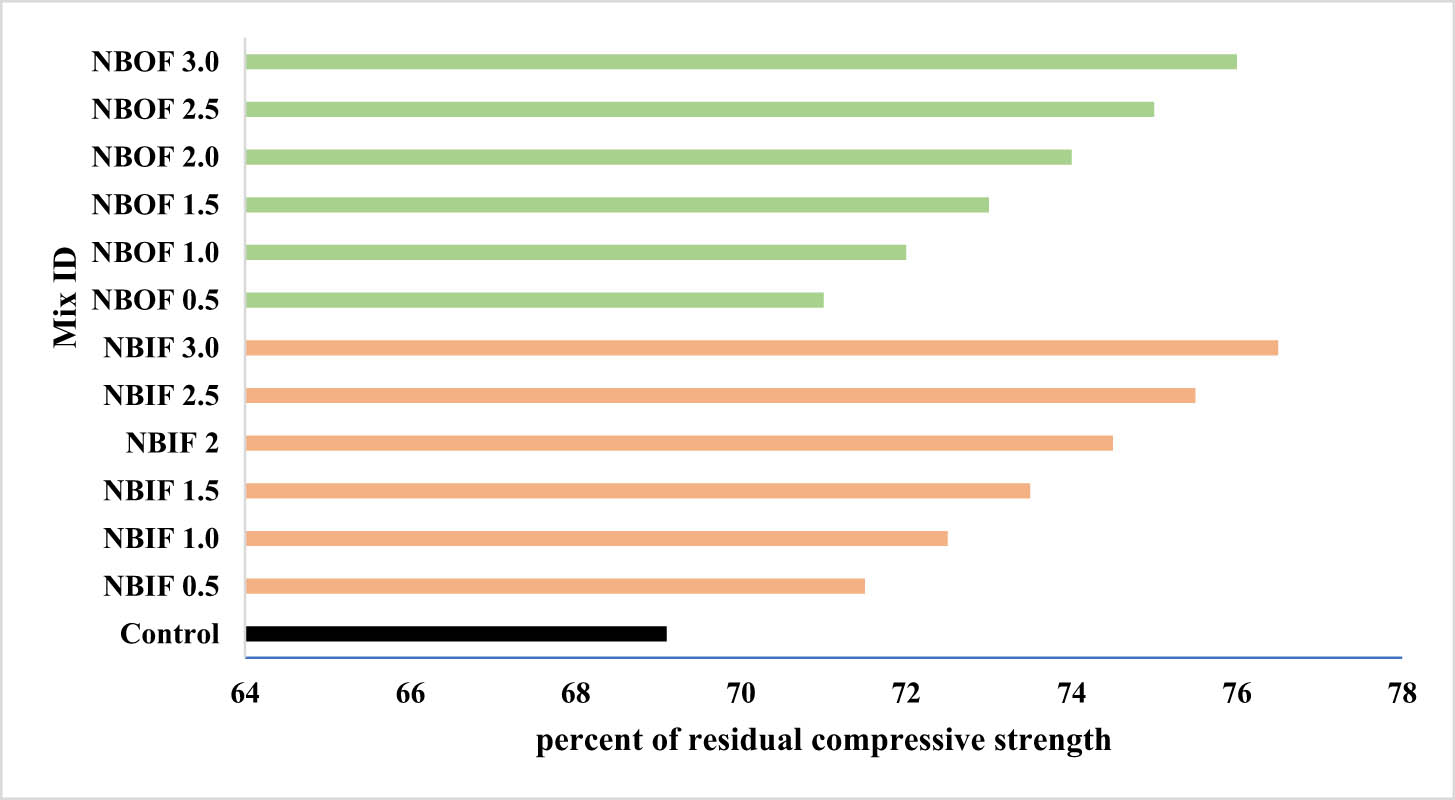

3.4 Sulfate attack

Results of sulfate attack (Na2SO4) on HPGC at varying concentrations of 0.0–100.0 gm·L−1 over periods of 28, 90, and 180 days are shown. Figure 15 illustrates the CS of no sulfate-attacked HPGC, where 0.0 mg·L−1 (no attack) is the reference mixture for calculating a loss in CS upon sulfate attack exposure. As shown in Figure 15, the CS of HPGC was not significantly affected by sulfate attack at concentrations as low as 5 mg·L−1 (low attack) over 180 days. The reduction in CS was between 1.7 and 3.9% for CS without sulfate attack. In addition, as shown in Figure 15c and d, the CS decreased more rapidly when the sulfate attack exposure at the concentration increased by 50 mg·L−1 (medium attack) and 75 mg·L−1 (high attack) over 180 days. When subjected to a sulfate attack at a concentration of 50 mg·L−1, the decrease in the CS of the HPGC ranged from 4.6 to 11.3% compared to the reference mixture. The decrease in CS ranged from 11.8 to 20.0% after exposure to 75 mg·L−1. Moreover, Figure 15 shows a significant decrease in the CS of the HPGC samples subjected to 100 mg·L−1 sulfate attack owing to severe deterioration (extreme attack), with the level of severity being more pronounced with age (worst at 180 days). The decrease in the CS of HPGC ranged from 21.5 to 30.8% compared with that of the control.

3.5 Microstructure

Figure 16 shows the SEM micrographs of the three HPGC mixtures. The addition of 2% nano-banded iron to HPGC has a substantial impact on the microstructure of the material. The utilization of NBIF particles enhances the geopolymer matrix owing to their substantial surface area and pozzolanic properties. The SEM study demonstrated a denser and more compact microstructure with a decreased porosity. The interfacial bonding between the geopolymer gel and aggregates was also enhanced. The formation of nano-banded iron facilitates the generation of supplementary reaction products, thereby augmenting the total crystalline architecture. The enhanced microstructure was associated with enhanced mechanical qualities, including CS and durability, making the HPGC with 2% NBIF a highly promising option for high-performance construction applications. In contrast, the microstructure of the HPGC containing 3% NBOFS exhibited different alterations compared to those of the NBOF-free samples. SEM revealed a distinct morphology characterized by evenly distributed NBOFS particles within the geopolymer matrix. The inclusion of NBOFs enhanced the microstructure, resulting in more consistent and even dispersion of the particles. Owing to this modification, there was an enhancement in the bonding between the interfaces and an increase in the packing density, resulting in a greater strength and endurance. Nevertheless, when using larger addition ratios such as 3%, it is crucial to carefully consider the possible occurrence of agglomeration effects [8]. Analysis of the microstructure revealed the complex function of NBOFS in enhancing the internal structure of HPGC, underscoring the need for the careful incorporation of nano-additives to attain exceptional material performance [3]. Comparative evaluations demonstrated that the changes in the microstructure caused by the addition of 3% NBOFS had a beneficial impact on the mechanical and durability characteristics of HPGC, thereby providing valuable information for the development of durable construction materials.

4 Discussion

The observed decrease in slump flow highlights the need for a thorough understanding of the role of NBOFS in HPGC mixtures. In conclusion, using NBIFs decreases the slump more than using NBOF, but both nanomaterials decrease the slump owing to their composition, fineness, and chemical reactions. In addition, in studies [34,70], the addition of iron to the products enhanced the CS of the GPC. These studies demonstrated that a precise dosage of NBIFs can result in an increase in CS based on the results of a previous study [61]. Precise dosages of NBIFs can increase the CS [15,71]. Finally, adding 2.5% NBIFs has a significant effect in improving CS than 3% NBOF at all ages. This study found a reliable and favorable relationship between the increasing ratio of NBOFS substitution and the elastic modulus of HPGC. With an increase in NBOFS content, there was a proportional and gradual increase in the elastic modulus of the material. The observed improvement indicated that the presence of NBOFS nanoparticles had a positive effect on the rigidity and elasticity of the geopolymer matrix [67]. The pozzolanic reactivity of NBOF is likely responsible for the enhanced microstructure, thus facilitating better interfacial bonding inside the HPGC. A higher modulus of elasticity indicates stronger resistance to deformation and enhanced structural integrity, making NBOFS a potential enhancer of the elastic properties of HPGC [43,44]. The results illustrate the deterioration in the CS of concrete after exposure to Na2SO4 for 180 days, with the lowest values recorded for 3% NBIFs and NBOFS, with retentions of 78.5 and 78%, respectively. Using nanomaterials like NBOFS and NBIFs in HPGC improves mechanical strength, durability, and microstructural integrity while reducing porosity. NBOFS and NBIFs in HPGC also support sustainability by recycling industrial by-products, contributing to waste reduction. Furthermore, NBOFS and NBIFs in HPGC inclusion help lower carbon emissions, offering a more environmentally friendly alternative to traditional cement-based concrete. Investigating new nanomaterials and studying the radiation resistance of BOFS and BIFs are recommended for future work. Also, future studies could optimize the dosages of NBOFS and NBIFs in HPGC to achieve long-term performance, including exposure to environmental factors such as freeze–thaw cycles and chemical attacks. Life cycle assessments and economic evaluations should also be conducted to determine the sustainability and cost-effectiveness of NBOFS and NBIFs in HPGC compared to conventional HPGC.

5 Conclusions

This study investigates the effects of utilizing different amounts of NBOFS and NBIF ranging from 0.5 to 3% on HPGC. Slump and mechanical properties, including compression, splitting, modulus of elasticity, and flexural strength, are studied. In addition, durability tests such as chloride penetration, sulfate attack, and sorptivity were investigated. Moreover, microstructural analysis was conducted, and the results are presented below.

The addition of NBIFs and NBOFS resulted in a slight decrease in workability by 17 and 13%, respectively, because the nanoparticles caused a steady decline in the rheology of the sample at the 3% replacement level.

The optimum replacement levels in the NBIFs and NBOFS for the optimum 180-day CS were 2.5 and 3% to achieve 222.2 and 215 MPa, respectively.

The splitting tensile strength improved at all levels of 2.5% NBOFS and 3% NBOFS increased by 23% compared to the reference (control) mix.

The flexural strengths at all levels of NBOFS, especially at 2.5% NBIFs and 3% NBOF, increased by 22 and 27%, respectively, compared to the control.

The inclusion of NBIFs significantly reduced the water permeability values compared with the reference control mixture. The control mixture recorded a water permeability value of 1.55 × 10−11 (cm·s−1) reduced to 1.0 × 10−11 (cm·s−1) and 0.98 × 10−11 (cm·s−1) in 2.5% NBIFs and 3% NBOF, respectively.

A higher quantity of added nanomaterials enhances transport properties such as chloride penetration, sorptivity, and water absorption. Sorptivity and water absorption decreased by 59 and 61.7% in NBIFs and NBOFS, respectively.

NBIFs and NBOFS induce crystalline microstructural densities or networks by generating additional reaction products.

Acknowledgments

The author acknowledges the facilities and support provided by the University of Hafr Al Batin, Saudi Arabia.

-

Funding information: The author states no funding involved.

-

Author contribution: The author has accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The author states no conflict of interest.

-

Data availability statement: The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Amran, M., G. Murali, N. H. A. Khalid, R. Fediuk, T. Ozbakkaloglu, Y. H. Lee, et al. Slag uses in making an ecofriendly and sustainable concrete: A review. Construction and Building Materials, Vol. 272, 2021, id. 121942.10.1016/j.conbuildmat.2020.121942Search in Google Scholar

[2] Zago, S. C., F. Vernilli, and O. Cascudo. The reuse of basic oxygen furnace slag as concrete aggregate to achieve sustainable development: Characteristics and limitations. Buildings, Vol. 13, No. 5, 2023, id. 1193.10.3390/buildings13051193Search in Google Scholar

[3] Zeyad, A. M., K. H. Bayagoob, M. Amin, B. A. Tayeh, S. A. Mostafa, and I. S. Agwa. Effect of olive waste ash on the properties of high‐strength geopolymer concrete. Structural Concrete, 2024, id. 140539.10.1002/suco.202400035Search in Google Scholar

[4] Ahmed, M. J., S. Durand, M. Antoun, F. Gauvin, S. Amziane, and H. J. H. Brouwers. Utilization of air granulated basic oxygen furnace slag as a binder in belite calcium sulfoaluminate cement: A sustainable alternative. Journal of Cleaner Production, Vol. 436, 2024, id. 140539.10.1016/j.jclepro.2023.140539Search in Google Scholar

[5] Zhou, X., Q. Yuan, L. Chen, K. Zheng, S. Wei, and Y. Iftikhar. Sulfate resistance of carbonated basic oxygen furnace slag-metakaolin-Portland cement blends. Journal of Building Engineering, Vol. 87, 2024, id. 109098.10.1016/j.jobe.2024.109098Search in Google Scholar

[6] Li, Y., H. Mehdizadeh, K. H. Mo, and T.-C. Ling. Co-utilization of aqueous carbonated basic oxygen furnace slag (BOFS) and carbonated filtrate in cement pastes considering reaction duration effect. Cement and Concrete Composites, Vol. 138, 2023, id. 104988.10.1016/j.cemconcomp.2023.104988Search in Google Scholar

[7] Liu, M. Y. J., U. J. Alengaram, M. Santhanam, M. Z. Jumaat, and K. H. Mo. Microstructural investigations of palm oil fuel ash and fly ash based binders in lightweight aggregate foamed geopolymer concrete. Construction and Building Materials, Vol. 120, 2016, pp. 112–122.10.1016/j.conbuildmat.2016.05.076Search in Google Scholar

[8] Yuan, X., W. Xu, A. H. AlAteah, and S. A. Mostafa. Evaluation of the performance of high-strength geopolymer concrete prepared with recycled coarse aggregate containing eggshell powder and rice husk ash cured at different curing regimes. Construction and Building Materials, Vol. 434, 2024, id. 136722.10.1016/j.conbuildmat.2024.136722Search in Google Scholar

[9] Nurruddin, M. F., H. Sani, B. S. Mohammed, and I. Shaaban. Methods of curing geopolymer concrete: A review. International Journal of Advanced and Applied Sciences, Vol. 5, No. 1, 2018, pp. 31–36.10.21833/ijaas.2018.01.005Search in Google Scholar

[10] Ma, C.-K., A. Z. Awang, and W. Omar. Structural and material performance of geopolymer concrete: A review. Construction and Building Materials, Vol. 186, 2018, pp. 90–102.10.1016/j.conbuildmat.2018.07.111Search in Google Scholar

[11] Junior, J. A. L., A. R. G. de Azevedo, M. T. Marvila, S. R. Teixeira, R. Fediuk, and C. M. F. Vieira. Influence of processing parameters variation on the development of geopolymeric ceramic blocks with calcined kaolinite clay. Case Studies in Construction Materials, Vol. 16, 2022, id. e00897.10.1016/j.cscm.2022.e00897Search in Google Scholar

[12] Sayed, D., S. El-Gamal, F. El-Hosiny, M. Hazem, and M. Ramadan. Promoting the performance of green slag-based geopolymer using eskolaite nanoparticles for bio-mechanical, thermal, and shielding applications. Construction and Building Materials, Vol. 433, 2024, id. 136706.10.1016/j.conbuildmat.2024.136706Search in Google Scholar

[13] Singh, B., G. Ishwarya, M. Gupta, and S. K. Bhattacharyya. Geopolymer concrete: A review of some recent developments. Construction and Building Materials, Vol. 85, 2015, pp. 78–90.10.1016/j.conbuildmat.2015.03.036Search in Google Scholar

[14] Li, C., H. Sun, and L. Li. A review: The comparison between alkali-activated slag (Si+ Ca) and metakaolin (Si+ Al) cements. Cement and Concrete Research, Vol. 40, No. 9, 2010, pp. 1341–1349.10.1016/j.cemconres.2010.03.020Search in Google Scholar

[15] Lin, Y., W. Zhou, A. H. AlAteah, and S. A. Mostafa. Recycling and reuse of waste banded iron formation as fine aggregate in the production of lightweight foamed concrete: Fresh-state, mechanical, thermal, microstructure and durability properties assessment. Construction and Building Materials, Vol. 439, 2024, id. 137369.10.1016/j.conbuildmat.2024.137369Search in Google Scholar

[16] Bayrak, B., S. A. Mostafa, A. Öz, B. A. Tayeh, G. Kaplan, and A. C. Aydın. The effect of clinker aggregate on acid resistance in prepacked geopolymers containing metakaolin and quartz powder in the presence of ground blast furnace slag. Journal of Building Engineering, Vol. 69, 2023, id. 106290.10.1016/j.jobe.2023.106290Search in Google Scholar

[17] Ranjbar, N., A. Kashefi, G. Ye, and M. Mehrali. Effects of heat and pressure on hot-pressed geopolymer. Construction and Building Materials, Vol. 231, 2020, id. 117106.10.1016/j.conbuildmat.2019.117106Search in Google Scholar

[18] Wetzel, A. and B. Middendorf. Influence of silica fume on properties of fresh and hardened ultra-high performance concrete based on alkali-activated slag. Cement and Concrete Composites, Vol. 100, 2019, pp. 53–59.10.1016/j.cemconcomp.2019.03.023Search in Google Scholar

[19] Du, B., F. Xu, A. H. AlAteah, and S. A. Mostafa. Sustainable development of ultra high-performance concrete using basil plant waste: Investigation at normal and extreme conditions. Journal of Building Engineering, Vol. 80, 2023, id. 107997.10.1016/j.jobe.2023.107997Search in Google Scholar

[20] Aydın, S. and B. Baradan. The effect of fiber properties on high performance alkali-activated slag/silica fume mortars. Composites Part B: Engineering, Vol. 45, No. 1, 2013, pp. 63–69.10.1016/j.compositesb.2012.09.080Search in Google Scholar

[21] Li, L., C. Yan, N. Zhang, M. U. Farooqi, S. Xu, A. F. Deifalla, et al. Flexural fracture parameters of polypropylene fiber reinforced geopolymer. Journal of Materials Research and Technology, Vol. 24, 2023, pp. 1839–1855.10.1016/j.jmrt.2023.03.035Search in Google Scholar

[22] Liu, J., N. Farzadnia, and C. Shi. Effects of superabsorbent polymer on interfacial transition zone and mechanical properties of ultra-high performance concrete. Construction and Building Materials, Vol. 231, 2020, id. 117142.10.1016/j.conbuildmat.2019.117142Search in Google Scholar

[23] Li, L., H. X. Sun, Y. Zhang, and Z. Li. Dynamic evolution of crack fractal of polypropylene fiber reinforced geopolymer during flexural process. Engineering Fracture Mechanics, Vol. 300, 2024, id. 109992.10.1016/j.engfracmech.2024.109992Search in Google Scholar

[24] Li, L., J. C. Tao, Y. Zhang, H. X. Sun, K. V. Yuen, and P. B. You. Crack fractal analysis of fractured polyethylene fiber reinforced alkali activated mortar under flexural load. Construction and Building Materials, Vol. 345, 2022, id. 128428.10.1016/j.conbuildmat.2022.128428Search in Google Scholar

[25] Tayeh, B. A., A. A. Hakamy, M. S. Fattouh, and S. A. Mostafa. The effect of using nano agriculture wastes on microstructure and electrochemical performance of ultra-high-performance fiber reinforced self-compacting concrete under normal and acceleration conditions. Case Studies in Construction Materials, Vol. 18, 2023, id. e01721.10.1016/j.cscm.2022.e01721Search in Google Scholar

[26] Zheng, D., A. H. AlAteah, A. Alsubeai, and S. A. Mostafa. Integrating micro-and nanowaste glass with waste foundry sand in ultra-high-performance concrete to enhance material performance and sustainability. Reviews on Advanced Materials Science, Vol. 63, No. 1, 2024, id. 20240012.10.1515/rams-2024-0012Search in Google Scholar

[27] Yusuf, M. O., K. A. A. Al-Sodani, A. H. AlAteah, M. M. Al-Tholaia, A. A. Adewumi, A. O. Bakare, et al. Performances of the synergy of silica fume and waste glass powder in ternary blended concrete. Applied Sciences, Vol. 12, No. 13, 2022, id. 6637.10.3390/app12136637Search in Google Scholar

[28] Hassan, M. S. Adequacy of the ASTM C1240 specifications for nanosilica pozzolans. The Open Civil Engineering Journal, Vol. 13, No. 1, 2019.10.2174/1874149501913010042Search in Google Scholar

[29] Choudhary, R., R. Gupta, and R. Nagar. Impact on fresh, mechanical, and microstructural properties of high strength self-compacting concrete by marble cutting slurry waste, fly ash, and silica fume. Construction and Building Materials, Vol. 239, 2020, id. 117888.10.1016/j.conbuildmat.2019.117888Search in Google Scholar

[30] Gupta, A. Investigation of the strength of ground granulated blast furnace slag based geopolymer composite with silica fume. Materials Today: Proceedings, Vol. 44, 2021, pp. 23–28.10.1016/j.matpr.2020.06.010Search in Google Scholar

[31] Kansal, C. M. and R. Goyal. Effect of nano silica, silica fume and steel slag on concrete properties. Materials Today: Proceedings, Vol. 45, 2021, pp. 4535–4540.10.1016/j.matpr.2020.12.1162Search in Google Scholar

[32] Kaplan, G., A. Öz, B. Bayrak, H. G. Alcan, O. Çelebi, and A. C. Aydın. Effect of quartz powder on mid-strength fly ash geopolymers at short curing time and low curing temperature. Construction and Building Materials, Vol. 329, 2022, id. 127153.10.1016/j.conbuildmat.2022.127153Search in Google Scholar

[33] Rashad, A. M., A. A. Hassan, and S. R. Zeedan. An investigation on alkali-activated Egyptian metakaolin pastes blended with quartz powder subjected to elevated temperatures. Applied Clay Science, Vol. 132, 2016, pp. 366–376.10.1016/j.clay.2016.07.002Search in Google Scholar

[34] Hattaf, R., M. Benchikhi, A. Azzouzi, R. El Ouatib, M. Gomina, A. Samdi, et al. Preparation of cement clinker from geopolymer-based wastes. Materials (Basel), Vol. 14, No. 21, 2021.10.3390/ma14216534Search in Google Scholar PubMed PubMed Central

[35] Ramasamy, S., K. Hussin, M. M. A. B. Abdullah, C. M. R. Ghazali, M. Binhussain, and A. V. Sandu. Interrelationship of kaolin, alkaline liquid ratio and strength of kaolin geopolymer. IOP Conference Series: Materials Science and Engineering, Vol. 133, No. 1, 2016, id. 012004.10.1088/1757-899X/133/1/012004Search in Google Scholar

[36] Wong, L. S. Durability performance of geopolymer concrete: A review. Polymers (Basel), Vol. 14, No. 5, 2022, id. 868.10.3390/polym14050868Search in Google Scholar PubMed PubMed Central

[37] Stacey, S. M. Evaluation of ASTM C 494 procedures for polycarboxylate admixtures used in precast concrete elements. Doctoral dissertation, 2016.Search in Google Scholar

[38] Noushini, A. and A. Castel. Performance-based criteria to assess the suitability of geopolymer concrete in marine environments using modified ASTM C1202 and ASTM C1556 methods. Materials and Structures, Vol. 51, No. 6, 2018, id. 146.10.1617/s11527-018-1267-zSearch in Google Scholar

[39] Mujkanović, A., A. Ključanin, M. Jovanović, A. Zahirović, A. Karić, N. Merdić, et al. Effect of nanosilica addition on concrete porosity and sorptivity. Conference at 13th Scientific/Research Symposium with International Participation “Metallic and nonmetallic materials” B&H, 27th May 2021.Search in Google Scholar

[40] Tahwia, A. M., K. A. Helal, and O. Youssf. Chopped basalt fiber-reinforced high-performance concrete: an experimental and analytical study. Journal of Composites Science, Vol. 7, No. 6, 2023, id. 250.10.3390/jcs7060250Search in Google Scholar

[41] Al-Kharabsheh, B. N., M. M. Arbili, A. Majdi, S. M. Alogla, A. Hakamy, J. Ahmad, et al. Basalt fiber reinforced concrete: A compressive review on durability aspects. Materials, Vol. 16, No. 1, 2023, id. 429.10.3390/ma16010429Search in Google Scholar PubMed PubMed Central

[42] Hassani Niaki, M., A. Fereidoon, and M. Ghorbanzadeh Ahangari. Experimental study on the mechanical and thermal properties of basalt fiber and nanoclay reinforced polymer concrete. Composite Structures, Vol. 191, 2018, pp. 231–238.10.1016/j.compstruct.2018.02.063Search in Google Scholar

[43] Sastry, K. G., P. Sahitya, and A. Ravitheja. Influence of nano TiO2 on strength and durability properties of geopolymer concrete. Materials Today: Proceedings, Vol. 45, 2021, pp. 1017–1025.10.1016/j.matpr.2020.03.139Search in Google Scholar

[44] Duan, P., C. Yan, W. Luo, and W. Zhou. Effects of adding nano-TiO2 on compressive strength, drying shrinkage, carbonation and microstructure of fluidized bed fly ash based geopolymer paste. Construction and Building Materials, Vol. 106, 2016, pp. 115–125.10.1016/j.conbuildmat.2015.12.095Search in Google Scholar

[45] Jagadesh, P. and V. Nagarajan. Effect of nano titanium di oxide on mechanical properties of fly ash and ground granulated blast furnace slag based geopolymer concrete. Journal of Building Engineering, Vol. 61, 2022, id. 105235.10.1016/j.jobe.2022.105235Search in Google Scholar

[46] Dheyaaldin, M. H., M. A. Mosaberpanah, and J. Shi. The effects of nanomaterials on the characteristics of aluminosilicate-based geopolymer composites: A critical review. Journal of Building Engineering, Vol. 73, 2023, id. 106713.10.1016/j.jobe.2023.106713Search in Google Scholar

[47] Aziz, I. H., M. M. A. B. Abdullah, M. A. A. Mohd Salleh, E. A. Azimi, J. Chaiprapa, and A. V. Sandu. Strength development of solely ground granulated blast furnace slag geopolymers. Construction and Building Materials, Vol. 250, 2020, id. 118720.10.1016/j.conbuildmat.2020.118720Search in Google Scholar

[48] Lu, Z., L. Su, G. Xian, B. Lu, and J. Xie. Durability study of concrete-covered basalt fiber-reinforced polymer (BFRP) bars in marine environment. Composite Structures, Vol. 234, 2020, id. 111650.10.1016/j.compstruct.2019.111650Search in Google Scholar

[49] Wang, Y., S. Zhang, D. Niu, L. Su, and D. Luo. Strength and chloride ion distribution brought by aggregate of basalt fiber reinforced coral aggregate concrete. Construction and Building Materials, Vol. 234, 2020, id. 117390.10.1016/j.conbuildmat.2019.117390Search in Google Scholar

[50] Li, M., R. Luo, L. Qin, H. Liu, P. Duan, W. Jing, et al. High temperature properties of graphene oxide modified metakaolin based geopolymer paste. Cement and Concrete Composites, Vol. 125, 2022, id. 104318.10.1016/j.cemconcomp.2021.104318Search in Google Scholar

[51] Xu, Z., Q. Liu, H. Long, H. Deng, Z. Chen, and D. Hui. Influence of nano-SiO2 and steel fiber on mechanical and microstructural properties of red mud-based geopolymer concrete. Construction and Building Materials, Vol. 364, 2023, id. 129990.10.1016/j.conbuildmat.2022.129990Search in Google Scholar

[52] Gülşan, M. E., R. Alzeebaree, A. A. Rasheed, A. Niş, and A. E. Kurtoğlu. Development of fly ash/slag based self-compacting geopolymer concrete using nano-silica and steel fiber. Construction and Building Materials, Vol. 211, 2019, pp. 271–83.10.1016/j.conbuildmat.2019.03.228Search in Google Scholar

[53] Mustapha, I. B., M. Abdulkareem, T. M. Jassam, A. H. AlAteah, K. A. A. Al-Sodani, M. M. Al-Tholaia, et al. Comparative analysis of gradient-boosting ensembles for estimation of compressive strength of quaternary blend concrete. International Journal of Concrete Structures and Materials, Vol. 18, No. 1, 2024, id. 20.10.1186/s40069-023-00653-wSearch in Google Scholar

[54] Tran, T. T., T. M. Pham, and H. Hao. Effect of hybrid fibers on shear behaviour of geopolymer concrete beams reinforced by basalt fiber reinforced polymer (BFRP) bars without stirrups. Composite Structures, Vol. 243, 2020, id. 112236.10.1016/j.compstruct.2020.112236Search in Google Scholar

[55] Yusuf, M. O., K. A. A. Al-Sodani, A. A. Adewumi, A. H. Alateah, M. M. Al-Tholaia, S. M. I. Shamsah, et al. Microstructural characteristics, modeling of mechanical strength and thermal performance of industrial waste glass blended concrete. Applied Sciences, Vol. 12, No. 17, 2022, id. 8600.10.3390/app12178600Search in Google Scholar

[56] Althoey, F., O. Zaid, F. Alsharari, A. Yosri, and H. F. Isleem. Evaluating the impact of nano-silica on characteristics of self-compacting geopolymer concrete with waste tire steel fiber. Archives of Civil and Mechanical Engineering, Vol. 23, No. 1, 2023, pp. 1–17.10.1007/s43452-022-00587-2Search in Google Scholar

[57] Zhang, C., Y. Wang, X. Zhang, Y. Ding, and P. Xu. Mechanical properties and microstructure of basalt fiber-reinforced recycled concrete. Journal of Cleaner Production, Vol. 278, 2021, id. 123252.10.1016/j.jclepro.2020.123252Search in Google Scholar

[58] Mostafa, S. A., B. A. Tayeh, and I. Almeshal. Investigation the properties of sustainable ultra-high-performance basalt fibre self-compacting concrete incorporating nano agricultural waste under normal and elevated temperatures. Case Studies in Construction Materials, Vol. 17, 2022, id. e01453.10.1016/j.cscm.2022.e01453Search in Google Scholar

[59] Alvee, A. R., R. Malinda, A. M. Akbar, R. D. Ashar, C. Rahmawati, T. Alomayri, et al. Experimental study of the mechanical properties and microstructure of geopolymer paste containing nano-silica from agricultural waste and crystalline admixtures. Case Studies in Construction Materials, Vol. 16, 2022, id. e00792.10.1016/j.cscm.2021.e00792Search in Google Scholar

[60] Provis, J. L., R. J. Myers, C. E. White, V. Rose, and J. S. J. Van Deventer. X-ray microtomography shows pore structure and tortuosity in alkali-activated binders. Cement and Concrete Research, Vol. 42, No. 6, 2012, pp. 855–864.10.1016/j.cemconres.2012.03.004Search in Google Scholar

[61] Huo, W., Z. Zhu, H. Sun, Q. Gao, J. Zhang, Y. Wan, et al. Reaction kinetics, mechanical properties, and microstructure of nano-modified recycled concrete fine powder/slag based geopolymers. Journal of Cleaner Production, Vol. 372, 2022, id. 133715.10.1016/j.jclepro.2022.133715Search in Google Scholar

[62] Ibrahim, M., M. A. M. Johari, M. Maslehuddin, and M. K. Rahman. Influence of nano-SiO2 on the strength and microstructure of natural pozzolan based alkali activated concrete. Construction and Building Materials, Vol. 173, 2018, pp. 573–585.10.1016/j.conbuildmat.2018.04.051Search in Google Scholar

[63] Yu, X., B. Zhou, F. Hu, Y. Zhang, X. Xu, C. Fan, et al. Experimental investigation of basalt fiber-reinforced polymer (BFRP) bar reinforced concrete slabs under contact explosions. International Journal of Impact Engineering, Vol. 144, 2020, id. 103632.10.1016/j.ijimpeng.2020.103632Search in Google Scholar

[64] Deb, P. S., P. K. Sarker, and S. Barbhuiya. Sorptivity and acid resistance of ambient-cured geopolymer mortars containing nano-silica. Cement and Concrete Composites, Vol. 72, 2016, pp. 235–245.10.1016/j.cemconcomp.2016.06.017Search in Google Scholar

[65] Ghafari, E., M. Arezoumandi, H. Costa, and E. Júlio. Influence of nano-silica addition on durability of UHPC. Construction and Building Materials, Vol. 94, 2015, pp. 181–188.10.1016/j.conbuildmat.2015.07.009Search in Google Scholar

[66] Ghafari, E., H. Costa, and E. Júlio. Critical review on eco-efficient ultra high performance concrete enhanced with nano-materials. Construction and Building Materials, Vol. 101, 2015, pp. 201–208.10.1016/j.conbuildmat.2015.10.066Search in Google Scholar

[67] Jindal, B. B. and R. Sharma. The effect of nanomaterials on properties of geopolymers derived from industrial by-products: A state-of-the-art review. Construction and Building Materials, Vol. 252, 2020, id. 119028.10.1016/j.conbuildmat.2020.119028Search in Google Scholar

[68] Wolfs, R. J. M., F. P. Bos, and T. A. M. Salet. Correlation between destructive compression tests and non-destructive ultrasonic measurements on early age 3D printed concrete. Construction and Building Materials, Vol. 181, 2018, pp. 447–454.10.1016/j.conbuildmat.2018.06.060Search in Google Scholar

[69] Dao, D. V., H. B. Ly, H. T. Vu, T. T. Le, and B. T. Pham. Investigation and optimization of the C-ANN structure in predicting the compressive strength of foamed concrete. Materials (Basel), Vol. 13, No. 5, 2020, id. 1072.10.3390/ma13051072Search in Google Scholar PubMed PubMed Central

[70] Baral, A., C. Pesce, A. S. Yorkshire, Z. Zhakiyeva, R. Snellings, T. Hanein, et al. Characterisation of iron-rich cementitious materials. Cement and Concrete Research, Vol. 177, 2024, id. 107419.10.1016/j.cemconres.2023.107419Search in Google Scholar

[71] Thunuguntla, C. S. and T. D. Gunneswara Rao. Effect of mix design parameters on mechanical and durability properties of alkali activated slag concrete. Construction and Building Materials, Vol. 193, 2018, pp. 173–188.10.1016/j.conbuildmat.2018.10.189Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Effect of superplasticizer in geopolymer and alkali-activated cement mortar/concrete: A review

- Experimenting the influence of corncob ash on the mechanical strength of slag-based geopolymer concrete

- Powder metallurgy processing of high entropy alloys: Bibliometric analysis and systematic review

- Exploring the potential of agricultural waste as an additive in ultra-high-performance concrete for sustainable construction: A comprehensive review

- A review on partial substitution of nanosilica in concrete

- Foam concrete for lightweight construction applications: A comprehensive review of the research development and material characteristics

- Modification of PEEK for implants: Strategies to improve mechanical, antibacterial, and osteogenic properties

- Interfacing the IoT in composite manufacturing: An overview

- Advances in processing and ablation properties of carbon fiber reinforced ultra-high temperature ceramic composites

- Advancing auxetic materials: Emerging development and innovative applications

- Revolutionizing energy harvesting: A comprehensive review of thermoelectric devices

- Exploring polyetheretherketone in dental implants and abutments: A focus on biomechanics and finite element methods

- Smart technologies and textiles and their potential use and application in the care and support of elderly individuals: A systematic review

- Reinforcement mechanisms and current research status of silicon carbide whisker-reinforced composites: A comprehensive review

- Innovative eco-friendly bio-composites: A comprehensive review of the fabrication, characterization, and applications

- Review on geopolymer concrete incorporating Alccofine-1203

- Advancements in surface treatments for aluminum alloys in sports equipment

- Ionic liquid-modified carbon-based fillers and their polymer composites – A Raman spectroscopy analysis

- Emerging boron nitride nanosheets: A review on synthesis, corrosion resistance coatings, and their impacts on the environment and health

- Mechanism, models, and influence of heterogeneous factors of the microarc oxidation process: A comprehensive review

- Synthesizing sustainable construction paradigms: A comprehensive review and bibliometric analysis of granite waste powder utilization and moisture correction in concrete

- 10.1515/rams-2025-0086

- Research Articles

- Coverage and reliability improvement of copper metallization layer in through hole at BGA area during load board manufacture

- Study on dynamic response of cushion layer-reinforced concrete slab under rockfall impact based on smoothed particle hydrodynamics and finite-element method coupling

- Study on the mechanical properties and microstructure of recycled brick aggregate concrete with waste fiber

- Multiscale characterization of the UV aging resistance and mechanism of light stabilizer-modified asphalt

- Characterization of sandwich materials – Nomex-Aramid carbon fiber performances under mechanical loadings: Nonlinear FE and convergence studies

- Effect of grain boundary segregation and oxygen vacancy annihilation on aging resistance of cobalt oxide-doped 3Y-TZP ceramics for biomedical applications

- Mechanical damage mechanism investigation on CFRP strengthened recycled red brick concrete

- Finite element analysis of deterioration of axial compression behavior of corroded steel-reinforced concrete middle-length columns

- Grinding force model for ultrasonic assisted grinding of γ-TiAl intermetallic compounds and experimental validation

- Enhancement of hardness and wear strength of pure Cu and Cu–TiO2 composites via a friction stir process while maintaining electrical resistivity

- Effect of sand–precursor ratio on mechanical properties and durability of geopolymer mortar with manufactured sand

- Research on the strength prediction for pervious concrete based on design porosity and water-to-cement ratio

- Development of a new damping ratio prediction model for recycled aggregate concrete: Incorporating modified admixtures and carbonation effects

- Exploring the viability of AI-aided genetic algorithms in estimating the crack repair rate of self-healing concrete

- Modification of methacrylate bone cement with eugenol – A new material with antibacterial properties

- Numerical investigations on constitutive model parameters of HRB400 and HTRB600 steel bars based on tensile and fatigue tests

- Research progress on Fe3+-activated near-infrared phosphor

- Discrete element simulation study on effects of grain preferred orientation on micro-cracking and macro-mechanical behavior of crystalline rocks

- Ultrasonic resonance evaluation method for deep interfacial debonding defects of multilayer adhesive bonded materials

- Effect of impurity components in titanium gypsum on the setting time and mechanical properties of gypsum-slag cementitious materials

- Bending energy absorption performance of composite fender piles with different winding angles

- Theoretical study of the effect of orientations and fibre volume on the thermal insulation capability of reinforced polymer composites

- Synthesis and characterization of a novel ternary magnetic composite for the enhanced adsorption capacity to remove organic dyes

- Couple effects of multi-impact damage and CAI capability on NCF composites

- Mechanical testing and engineering applicability analysis of SAP concrete used in buffer layer design for tunnels in active fault zones

- Investigating the rheological characteristics of alkali-activated concrete using contemporary artificial intelligence approaches

- Integrating micro- and nanowaste glass with waste foundry sand in ultra-high-performance concrete to enhance material performance and sustainability

- Effect of water immersion on shear strength of epoxy adhesive filled with graphene nanoplatelets

- Impact of carbon content on the phase structure and mechanical properties of TiBCN coatings via direct current magnetron sputtering

- Investigating the anti-aging properties of asphalt modified with polyphosphoric acid and tire pyrolysis oil

- Biomedical and therapeutic potential of marine-derived Pseudomonas sp. strain AHG22 exopolysaccharide: A novel bioactive microbial metabolite

- Effect of basalt fiber length on the behavior of natural hydraulic lime-based mortars

- Optimizing the performance of TPCB/SCA composite-modified asphalt using improved response surface methodology

- Compressive strength of waste-derived cementitious composites using machine learning

- Melting phenomenon of thermally stratified MHD Powell–Eyring nanofluid with variable porosity past a stretching Riga plate

- Development and characterization of a coaxial strain-sensing cable integrated steel strand for wide-range stress monitoring

- Compressive and tensile strength estimation of sustainable geopolymer concrete using contemporary boosting ensemble techniques

- Customized 3D printed porous titanium scaffolds with nanotubes loading antibacterial drugs for bone tissue engineering

- Facile design of PTFE-kaolin-based ternary nanocomposite as a hydrophobic and high corrosion-barrier coating

- Effects of C and heat treatment on microstructure, mechanical, and tribo-corrosion properties of VAlTiMoSi high-entropy alloy coating

- Study on the damage mechanism and evolution model of preloaded sandstone subjected to freezing–thawing action based on the NMR technology

- Promoting low carbon construction using alkali-activated materials: A modeling study for strength prediction and feature interaction

- Entropy generation analysis of MHD convection flow of hybrid nanofluid in a wavy enclosure with heat generation and thermal radiation

- Friction stir welding of dissimilar Al–Mg alloys for aerospace applications: Prospects and future potential

- Fe nanoparticle-functionalized ordered mesoporous carbon with tailored mesostructures and their applications in magnetic removal of Ag(i)

- Study on physical and mechanical properties of complex-phase conductive fiber cementitious materials

- Evaluating the strength loss and the effectiveness of glass and eggshell powder for cement mortar under acidic conditions

- Effect of fly ash on properties and hydration of calcium sulphoaluminate cement-based materials with high water content

- Analyzing the efficacy of waste marble and glass powder for the compressive strength of self-compacting concrete using machine learning strategies

- Experimental study on municipal solid waste incineration ash micro-powder as concrete admixture

- Parameter optimization for ultrasonic-assisted grinding of γ-TiAl intermetallics: A gray relational analysis approach with surface integrity evaluation

- Producing sustainable binding materials using marble waste blended with fly ash and rice husk ash for building materials

- Effect of steam curing system on compressive strength of recycled aggregate concrete

- A sawtooth constitutive model describing strain hardening and multiple cracking of ECC under uniaxial tension

- Predicting mechanical properties of sustainable green concrete using novel machine learning: Stacking and gene expression programming

- Toward sustainability: Integrating experimental study and data-driven modeling for eco-friendly paver blocks containing plastic waste

- A numerical analysis of the rotational flow of a hybrid nanofluid past a unidirectional extending surface with velocity and thermal slip conditions

- A magnetohydrodynamic flow of a water-based hybrid nanofluid past a convectively heated rotating disk surface: A passive control of nanoparticles

- Prediction of flexural strength of concrete with eggshell and glass powders: Advanced cutting-edge approach for sustainable materials

- Efficacy of sustainable cementitious materials on concrete porosity for enhancing the durability of building materials

- Phase and microstructural characterization of swat soapstone (Mg3Si4O10(OH)2)

- Effect of waste crab shell powder on matrix asphalt

- Improving effect and mechanism on service performance of asphalt binder modified by PW polymer

- Influence of pH on the synthesis of carbon spheres and the application of carbon sphere-based solid catalysts in esterification

- Experimenting the compressive performance of low-carbon alkali-activated materials using advanced modeling techniques

- Thermogravimetric (TG/DTG) characterization of cold-pressed oil blends and Saccharomyces cerevisiae-based microcapsules obtained with them

- Investigation of temperature effect on thermo-mechanical property of carbon fiber/PEEK composites

- Computational approaches for structural analysis of wood specimens

- Integrated structure–function design of 3D-printed porous polydimethylsiloxane for superhydrophobic engineering

- Exploring the impact of seashell powder and nano-silica on ultra-high-performance self-curing concrete: Insights into mechanical strength, durability, and high-temperature resilience

- Axial compression damage constitutive model and damage characteristics of fly ash/silica fume modified magnesium phosphate cement after being treated at different temperatures

- Integrating testing and modeling methods to examine the feasibility of blended waste materials for the compressive strength of rubberized mortar

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part II

- Energy absorption of gradient triply periodic minimal surface structure manufactured by stereolithography

- Marine polymers in tissue bioprinting: Current achievements and challenges

- Quick insight into the dynamic dimensions of 4D printing in polymeric composite mechanics

- Recent advances in 4D printing of hydrogels

- Mechanically sustainable and primary recycled thermo-responsive ABS–PLA polymer composites for 4D printing applications: Fabrication and studies

- Special Issue on Materials and Technologies for Low-carbon Biomass Processing and Upgrading

- Low-carbon embodied alkali-activated materials for sustainable construction: A comparative study of single and ensemble learners

- Study on bending performance of prefabricated glulam-cross laminated timber composite floor

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part I

- Supplementary cementitious materials-based concrete porosity estimation using modeling approaches: A comparative study of GEP and MEP

- Modeling the strength parameters of agro waste-derived geopolymer concrete using advanced machine intelligence techniques

- Promoting the sustainable construction: A scientometric review on the utilization of waste glass in concrete

- Incorporating geranium plant waste into ultra-high performance concrete prepared with crumb rubber as fine aggregate in the presence of polypropylene fibers

- Investigation of nano-basic oxygen furnace slag and nano-banded iron formation on properties of high-performance geopolymer concrete

- Effect of incorporating ultrafine palm oil fuel ash on the resistance to corrosion of steel bars embedded in high-strength green concrete

- Influence of nanomaterials on properties and durability of ultra-high-performance geopolymer concrete

- Influence of palm oil ash and palm oil clinker on the properties of lightweight concrete

Articles in the same Issue

- Review Articles

- Effect of superplasticizer in geopolymer and alkali-activated cement mortar/concrete: A review

- Experimenting the influence of corncob ash on the mechanical strength of slag-based geopolymer concrete

- Powder metallurgy processing of high entropy alloys: Bibliometric analysis and systematic review

- Exploring the potential of agricultural waste as an additive in ultra-high-performance concrete for sustainable construction: A comprehensive review

- A review on partial substitution of nanosilica in concrete

- Foam concrete for lightweight construction applications: A comprehensive review of the research development and material characteristics

- Modification of PEEK for implants: Strategies to improve mechanical, antibacterial, and osteogenic properties

- Interfacing the IoT in composite manufacturing: An overview

- Advances in processing and ablation properties of carbon fiber reinforced ultra-high temperature ceramic composites

- Advancing auxetic materials: Emerging development and innovative applications

- Revolutionizing energy harvesting: A comprehensive review of thermoelectric devices

- Exploring polyetheretherketone in dental implants and abutments: A focus on biomechanics and finite element methods

- Smart technologies and textiles and their potential use and application in the care and support of elderly individuals: A systematic review

- Reinforcement mechanisms and current research status of silicon carbide whisker-reinforced composites: A comprehensive review

- Innovative eco-friendly bio-composites: A comprehensive review of the fabrication, characterization, and applications

- Review on geopolymer concrete incorporating Alccofine-1203

- Advancements in surface treatments for aluminum alloys in sports equipment

- Ionic liquid-modified carbon-based fillers and their polymer composites – A Raman spectroscopy analysis

- Emerging boron nitride nanosheets: A review on synthesis, corrosion resistance coatings, and their impacts on the environment and health

- Mechanism, models, and influence of heterogeneous factors of the microarc oxidation process: A comprehensive review

- Synthesizing sustainable construction paradigms: A comprehensive review and bibliometric analysis of granite waste powder utilization and moisture correction in concrete

- 10.1515/rams-2025-0086

- Research Articles

- Coverage and reliability improvement of copper metallization layer in through hole at BGA area during load board manufacture

- Study on dynamic response of cushion layer-reinforced concrete slab under rockfall impact based on smoothed particle hydrodynamics and finite-element method coupling

- Study on the mechanical properties and microstructure of recycled brick aggregate concrete with waste fiber

- Multiscale characterization of the UV aging resistance and mechanism of light stabilizer-modified asphalt

- Characterization of sandwich materials – Nomex-Aramid carbon fiber performances under mechanical loadings: Nonlinear FE and convergence studies

- Effect of grain boundary segregation and oxygen vacancy annihilation on aging resistance of cobalt oxide-doped 3Y-TZP ceramics for biomedical applications

- Mechanical damage mechanism investigation on CFRP strengthened recycled red brick concrete

- Finite element analysis of deterioration of axial compression behavior of corroded steel-reinforced concrete middle-length columns

- Grinding force model for ultrasonic assisted grinding of γ-TiAl intermetallic compounds and experimental validation

- Enhancement of hardness and wear strength of pure Cu and Cu–TiO2 composites via a friction stir process while maintaining electrical resistivity

- Effect of sand–precursor ratio on mechanical properties and durability of geopolymer mortar with manufactured sand

- Research on the strength prediction for pervious concrete based on design porosity and water-to-cement ratio

- Development of a new damping ratio prediction model for recycled aggregate concrete: Incorporating modified admixtures and carbonation effects

- Exploring the viability of AI-aided genetic algorithms in estimating the crack repair rate of self-healing concrete

- Modification of methacrylate bone cement with eugenol – A new material with antibacterial properties