Abstract

A composite-modified asphalt was developed by incorporating tire pyrolytic carbon black (TPCB) with a silane coupling agent (SCA) to enhance its ductility and storage stability. The functional binding between asphalt and TPCB was improved by the addition of SCA. The gray correlation comprehensive evaluation method is incorporated into the response surface methodology (RSM), leading to an improved RSM. The improved RSM was employed to optimize the content of the modifier and the preparation process to enhance overall performance. A central composite design-based experiment was conducted to optimize the penetration, softening point, 10°C ductility, Brookfield rotational viscosity, and storage stability indicators of modified asphalt. The response surface of the gray comprehensive evaluation value of the evaluation indicators was calculated using the gray correlation analysis method, and a second-order regression model was established between independent variables such as TPCB, SCA content, and shear time factor and the gray comprehensive evaluation value. This model analyzed the impact of a single variable and variable interaction on the performance of the TPCB/SCA composite-modified asphalt. The optimized model results showed that the preparation parameters that optimize the expected comprehensive performance of the composite-modified asphalt are 9.2% TPCB content, 2.1% SCA content, and a shear time of 56.3 min. Finally, the TPCB/SCA composite-modified asphalt prepared with the improved RSM exhibited the highest gray comprehensive evaluation value and the best overall performance, indicating the feasibility of the optimized preparation parameters with the improved RSM.

1 Introduction

Due to the rapid growth of the transportation industry and the increase in the number of vehicles, waste tires have become one of the largest types of waste worldwide. As a result, recycling and reuse of waste tires have become urgent issues that need to be addressed [1]. There are two main ways to recycle waste tires: direct utilization, such as reuse and rubber product remanufacturing, and indirect utilization, such as powder utilization, desulfurization regeneration, material modification, pyrolysis distillation, and alternative fuels [1,2,3]. Pyrolysis is a process that degrades the organic components in rubber powder; generates volatile substances and solid coke; and produces carbon black, pyrolysis oil, combustible gas, and steel wire from waste tires under anaerobic conditions [4]. This process is mainly divided into two parts: natural rubber pyrolysis and synthetic rubber pyrolysis and has the advantage of large processing capacity, no secondary pollution, and multiple resource recycling and utilization [1,5]. Carbon black is an important byproduct of the pyrolysis method for treating tires, with a production yield of usually 30–40% [6]. Since the emergence of waste tire pyrolysis technology in the 1980s, the application of waste tire pyrolysis carbon black (TPCB) has gained significant attention. In 1995, Lesueur et al. found that with increasing amounts of TPCB, the high-temperature performance of asphalt gradually improved, and TPCB had rheological properties similar to those of mineral powder [7]. In 2016, Feng et al. found that TPCB improved the high-temperature performance of asphalt and significantly improved the thermal, light, and oxygen aging of matrix asphalt [8]. Kumar et al. studied the storage stability performance of tire pyrolysis carbon (TPC)-modified adhesives for waste tires with and without the addition of crosslinking agents. The TPC-modified binder exhibits good storage stability in sulfur (optimal dosage of 0.3%) and PPA (optimal dosage of 1%). In addition, waste plastic pyrolysis carbon-modified sulfur-containing binder can provide a stable storage formula [9,10]. In 2018, Li et al. confirmed that TPCB improved the anti-rutting performance of asphalt mixtures [11]. In 2021, Feng et al. found that TPCB weakened the interfacial interaction force between aggregate and asphalt, leading to poor low-temperature crack resistance, and the characteristics of TPCB insoluble in asphalt and organic solvents resulted in its poor storage stability [12]. In 2022, Li et al. proposed a process for preparing asphalt mixtures modified by TPCB through dry mixing [1]. Chen et al. revealed the modification mechanism of TPCB/TPO-MB. They showed that using TPCB and TPO composite materials to modify asphalt is feasible [13]. TPCB-modified asphalt significantly improves the high-temperature performance of asphalt and asphalt mixtures; enhances resistance to heat, light, and oxygen aging; and provides a new choice for green road construction materials with good economic and environmental performance. TPCB-modified asphalt has attracted significant attention and has been applied in real engineering projects in China [14].

Silane coupling agent (SCA) is an organic compound that simultaneously possesses a hydrophilic inorganic group and a hydrophobic organic group [15]. It is of great significance for bonding materials of different types and properties, which can improve the interfacial conditions and combine with various materials, such as glass fiber, adhesive, coating, textile, and filler. It improves the interaction between matrix materials and functionalized silicon compounds by forming “molecular bridges.” Some road researchers used SCA as intermediate materials to surface-treat the existing road materials. In 2009, Guo et al. [16] used SCA to pretreat oil shale waste powder and then remade composite-modified asphalt. It was found that the addition of SCA significantly improved the high-temperature rheological properties and storage stability of the asphalt and effectively improved the temperature sensitivity of the asphalt. In 2012, Chen and Tang [17] used SCA to surface treat asphalt flame retardants, and the two underwent chemical reactions to form new chemical bonds, improving the dispersibility and compatibility of the flame retardants in the asphalt and improving the thermal stability of the asphalt flame retardants. In 2012, Liang et al. [18] found that increasing the coupling agent content gradually increased the contact angle of the asphalt, indicating that the surface tension of the asphalt decreased, the hydrophobicity increased, and the surface activity increased. Compared with the matrix asphalt, the bonding properties between modified asphalt and aggregates are excellent. In 2020, Hui [19] used SCA to treat coal liquefaction residue-modified asphalt, which effectively improved the low-temperature performance of the coal liquefaction residue-modified asphalt. In 2021, Lv et al. [20] studied the composite-modified asphalt of fish scale powder and KH-560 SCA and found that the addition of coupling agents could increase the storage modulus and loss modulus of asphalt binders. It was confirmed that there was a chemical reaction between fish scale powder, SCA, and asphalt. In 2022, Hao et al. studied the effect of SCA on a new thermosetting polyurethane asphalt binder (PUAB). The study showed that SCA can improve the thermal and storage stability of PUAB [21]. Numerous road researchers have attempted to use coupling agents to link different road materials, thereby improving the physical and chemical properties and contact effects of asphalt, aggregates, and modifiers, and thus improving the high- and low-temperature properties and water stability of asphalt mixtures.

In order to scientifically determine the optimal modification formula and preparation process of composite-modified asphalt, it is necessary to study the comprehensive effects of multi-level and multiple factors on multi-objective and use response surface methodology (RSM) to model and analyze the problems under the influence of multiple factors by combining mathematical and statistical methods. RSM is an experimental design methodology that combines mathematical methods with statistical analysis. It is commonly used to optimize experimental processes, predict experimental results, and quantitatively describe the functional relationship between multiple independent variables and response variables. Due to its small experimental size and ability to accurately reflect significant effects of interaction between multiple independent variables, RSM has been increasingly introduced into road engineering experimental design. Tang et al. used RSM central composite design (CCD) to study the effect of areca fiber content, shear time, and oil-to-stone ratio on the water stability of areca fiber-modified asphalt mixture [22]. Gong et al. used the Box–Behnken design method in RSM to conduct a three-factor three-level design, studying the response variables of Marshall stability, flow value, VFA, VMA, and other multiple indicators of the mixture, and verified the optimal nano-TiO2/CaCO3, basalt fiber composite content, and optimal oil-to-stone ratio through experiments, with maximum and minimum errors of 6.96 and 0.096%, respectively [23]. Li et al. used RSM based on CCD to conduct experiments on the formed Marshall specimens, studying and analyzing the effects of asphalt content and TPCB content on the volumetric parameters, strength, and high-temperature road performance of the asphalt mixture [24]. Bala et al. used CCD to analyze the interaction effects of two independent variable factors, nanosilica and binder content, on nanocomposite strength, volumetric, and performance properties and developed a model to fit experimental results to predict the response [25]. Adnan et al. used RSM to study the influence of graphite oxide (GO) and asphalt content on the volume and strength characteristics of asphalt mixture and the interaction effect of temperature, GO content, and loading frequency on the rutting performance of GO-modified asphalt and established a prediction mathematical model [26,27]. Yuan et al. adopted a comparison matrix method to evaluate the comprehensive performance of NAM, BAM, RAM, and RABAM [28]. The results of the above research demonstrate that RSM can be used to optimize the content of road materials and process parameters with good prediction accuracy. In this study, the RSM is introduced into the optimization design of composite modified asphalt, which can comprehensively investigate the interaction between different modifier dosages and preparation processes and balance its multiple evaluation indicators to prepare the composite modified asphalt with the best comprehensive performance.

Since Professor Deng proposed the gray correlation model, it has gradually become one of the important theoretical methods for studying uncertain systems. The basic idea of gray correlation analysis theory is based on the geometric similarity of behavioral factor sequences. It converts the discrete points of observation sequences into continuous piecewise lines and constructs a gray correlation model by extracting the geometric characteristic differences of the lines [29]. Gray correlation degree comprehensive evaluation is one of the important branches of gray system theory. It is an analytical evaluation method proposed to measure the degree of influence between factors or the contribution of factors to the main behavior. Compared with traditional mathematical and statistical analysis methods, it is better at dealing with data with the characteristics of “limited effective data and incomplete information.” In 2015, Tian used the gray correlation analysis evaluation method to obtain the optimal preparation parameters for preparing carbon black-modified asphalt [30]. In 2021, Zhou found the relationship between the length of glass fiber and the enhancement effect on the road performance of asphalt mixture through a comprehensive gray correlation evaluation analysis and recommended the optimal length of glass fiber for application in the mixture [31]. The gray correlation degree comprehensive evaluation method can assign values to various evaluation indicators of the evaluation object and thus make a comprehensive judgment on the evaluation object under the joint action of multiple independent variable factors.

In summary, the incorporation of TPCB into asphalt has been found to be effective in improving its high-temperature shear deformation resistance and aging resistance. However, TPCB does not improve the low-temperature performance and resistance to water damage of asphalt and may even reduce them. To address this issue, the use of SCA has been proposed to improve the dispersibility and adhesion of TPCB in asphalt. This is expected to prevent TPCB agglomeration and low-temperature cracking in asphalt and enhance the adhesion between asphalt and stone, effectively improving the low-temperature performance and water stability of asphalt and asphalt mixtures. However, research studies on TPCB and SCA as composite modifiers for asphalt are relatively rare. Therefore, this article aims to investigate the composite modification of asphalt using TPCB and SCA. It is expected that TPCB-modified asphalt will have better high-temperature performance and anti-aging performance, while its low-temperature performance and storage stability will also be improved. The independent variables are TPCB and SCA content, and the key process parameter for preparing composite-modified asphalt is shear time. Other process parameters, such as temperature, shear rate, stirring time, and static development time, will be set according to Guo et al. [16]. The evaluation of composite asphalt’s performance is crucial in assessing its quality. To improve the high and low-temperature performance of asphalt while considering other properties, various performance evaluation indicators such as penetration, softening point, 10℃ ductility, Brookfield viscosity, and storage stability are employed. In this study, the gray correlation comprehensive evaluation method is introduced to the response surface design to evaluate the five performance parameters for each group of design experiments. The gray comprehensive evaluation value is calculated based on this method, and an improved RSM is developed. A quadratic regression model is established using the independent variables of TPCB, SCA content, and shear time, and the gray comprehensive evaluation value. This model helps to determine the optimal TPCB content, SCA content, and shear time for composite modified asphalt, leading to the best comprehensive performance and maximum gray comprehensive evaluation value. Ultimately, this study aims to identify the optimal preparation parameters for TPCB/SCA composite asphalt to improve its comprehensive performance and enhance the pavement performance of the TPCB-modified asphalt mixture.

2 Experimental materials and methods

2.1 Asphalt

The matrix asphalt used in this study is Grade A 70# road petroleum asphalt. The performance indicators of the asphalt were tested according to the methods outlined in “Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering JTG E20-2011.” The test results are shown in Table 1.

Technical indicators of matrix asphalt

| Detect items | Unit | Technical requirement | Test result | Test method | |

|---|---|---|---|---|---|

| Penetration (25℃, 100 g, 5 s) | 0.1 mm | 60–80 | 67 | T0604-2011 | |

| Softening point | ℃ | ≥46 | 48.4 | T0606-2011 | |

| Ductility (15℃) | cm | ≥100 | >100 | T0605-2011 | |

| Dynamic viscosity (60℃) | Pa·s | ≥180 | 215.2 | T0620-2000 | |

| RTFOT | Mass change | % | ±0.8 | +0.4 | T0610-2011 |

| Penetration ratio | % | ≥61 | 69.8 | T0604-2011 | |

| Residual ductility | cm | ≥15 | 18.5 | T0605-2011 | |

2.2 TPCB from waste tire pyrolysis

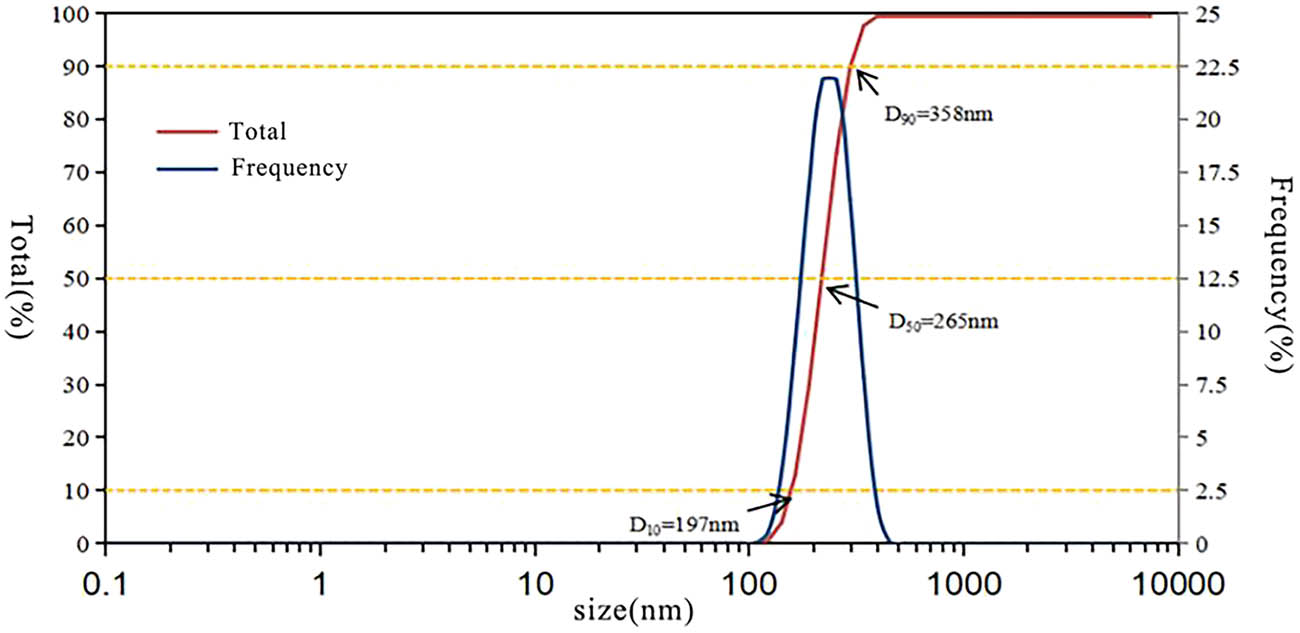

Domestically produced TPCB was selected for this study. TPCB is a mixture of various industrial carbon blacks with varying sizes and aggregates. The particle size distribution of the TPCB used in the experiment is shown in Figure 1 [32].

TPCB particle size distribution diagram.

As shown in Figure 1, the particle size of TPCB mainly ranges from 0 to 10,000 nm in diameter. The D10, D50, and D90 of TPCB are 197, 265, and 358 nm, respectively, with an average particle size of 307.3 nm. TPCB was tested according to the specifications outlined in “Additives for Asphalt Mixtures – Part 7: Waste Tire Pyrolysis Carbon Black JT/T 860.7-2017,” and the results are shown in Table 2, which meets the technical requirements of the standard.

Technical indicators of TPCB

| Detect items | Unit | Technical requirement | Test result | Test method |

|---|---|---|---|---|

| Appearance | — | Black powder | Black powder | Visual inspection |

| Ash content | % | ≤18.5 | 15.02 | JTG E20/T 0614 |

| Iodine absorption | mg·g−1 | ≥80 | 85.1 | GB/T 3780.1 |

| Water content | % | ≤2.0 | 1.5 | JTG E20/T 0103 |

| Oil absorption | 10−2 mL·g−1 | ≥70 | 87.1 | GB/T 3780.2 |

| Hydrogen ion concentration | — | ≥6 | 7.68 | GB/T 3780.7 |

| Granularity (the rate of passed 0.045 mm) | % | 100 | 100 | JTG E42/T 0302 |

2.3 SCA

The SCA used in this study is KH550, with a chemical name of γ-amino propyl trimethoxy silane. It can be used in the surface treatment of inorganic fillers such as carbon black, silica, and clay to enhance the wettability and dispersibility of the fillers in the polymer. The main physical and chemical properties of KH550 are shown in Table 3.

Physicochemical properties of SCA

| Items | Physical and chemical properties |

|---|---|

| Chemical formula | NH2(CH2)3Si (OCH2CH5)3 |

| Relative molecular mass | 221.4 |

| Appearance | Colorless, transparent liquid |

| Refractive index | 1.421 |

| Flash point (℃) | 96 |

| 25℃ Density (g·cm−3) | 0.946 |

| Boiling point (℃) | 217 |

| Solubility | It can be miscible with organic solvents such as ethanol, ether, toluene, and xylene, react with CCl4, and hydrolyze into silicanols in the presence of water, presenting an alkaline state |

| Matters needing attention | Strictly seal and store in a dry, cool, and dark room |

2.4 Improved RSM

To establish a quadratic response surface equation for composite-modified asphalt, a sequential methodology was employed in the response surface design. Each factor that affects the response variable was analyzed separately, followed by multi-factor and multi-level experiments conducted using the CCD method. The optimal solution was found using mathematical methods. By using this method, the optimal values of different asphalt performance evaluation indicators can be predicted under different influencing factors. However, the optimal solution for composite-modified asphalt varies for different evaluation indicators. Therefore, it is crucial to assign weights to multiple evaluation indicators based on different application conditions to determine the total evaluation value characterizing the comprehensive performance of the composite-modified asphalt.

To achieve this, the gray correlation analysis comprehensive evaluation method was introduced into the response surface design. This method assigns an evaluation value to each evaluation indicator of the evaluated object based on the given application conditions, enabling a comprehensive evaluation of the evaluated object under the interaction of multiple factors. In this study, qualitative and quantitative analyses were combined to calculate the total gray comprehensive evaluation value for the comprehensive evaluation of the researched object. An improved response surface design method was developed by establishing a quadratic response surface equation between the total gray comprehensive evaluation value and each influencing factor to determine the optimal content of each modifier and shearing time for composite-modified asphalt with the best comprehensive performance. The main calculation steps of the gray correlation comprehensive evaluation method are as follows:

(1) Determine the reference sequence X 0 and the comparison sequence X i , and perform non-dimensional processing.

Reference sequence (also known as the parent sequence):

Comparison sequence (also known as the sub-sequence):

(2) Calculate the correlation coefficient ζ i (k)

where |x o(k) – x i (k)| is the absolute difference between x 0 sequence and x i sequence at point k:

Let

ρ ∈ (0, ∞) is called the resolution coefficient. The smaller the ρ, the higher the resolution. The general ρ value range is (0,1), and the actual value can vary depending on the situation. When ρ ≤ 0.5463, the resolution is best, and ρ is usually taken as 0.5.

(3) Calculate the correlation degree R i

Since the correlation coefficient is a measure of the degree of association between the comparison sequence and the reference sequence at each preparation parameter condition (i.e., each point on the curve), it has multiple values, and the information is too dispersed to facilitate overall comparison. Therefore, it is necessary to consolidate the correlation coefficients of each preparation parameter condition (i.e., each point on the curve) into one value, namely, the average value, as a quantitative representation of the degree of correlation between the comparison sequence and the reference sequence, called the correlation degree R i . The correlation degree R i is calculated according to formula (3):

i = 1, 2, …, m; k = 1, 2, …, n,

where R i is the correlation degree of the ith group of experiments, ζ i (k) is the correlation coefficient; k is the evaluation index, n is the number of experimental groups, and m is the number of evaluation indexes.

(4) Calculate the proportion P i and the gray comprehensive evaluation value GC(k) for each evaluation index.

where P i is the proportion of evaluation index, i = 0, 1, 2, … m

where GC(k) is the gray comprehensive evaluation value, i = 1, 2, …,m; k = 1, 2, …, n.

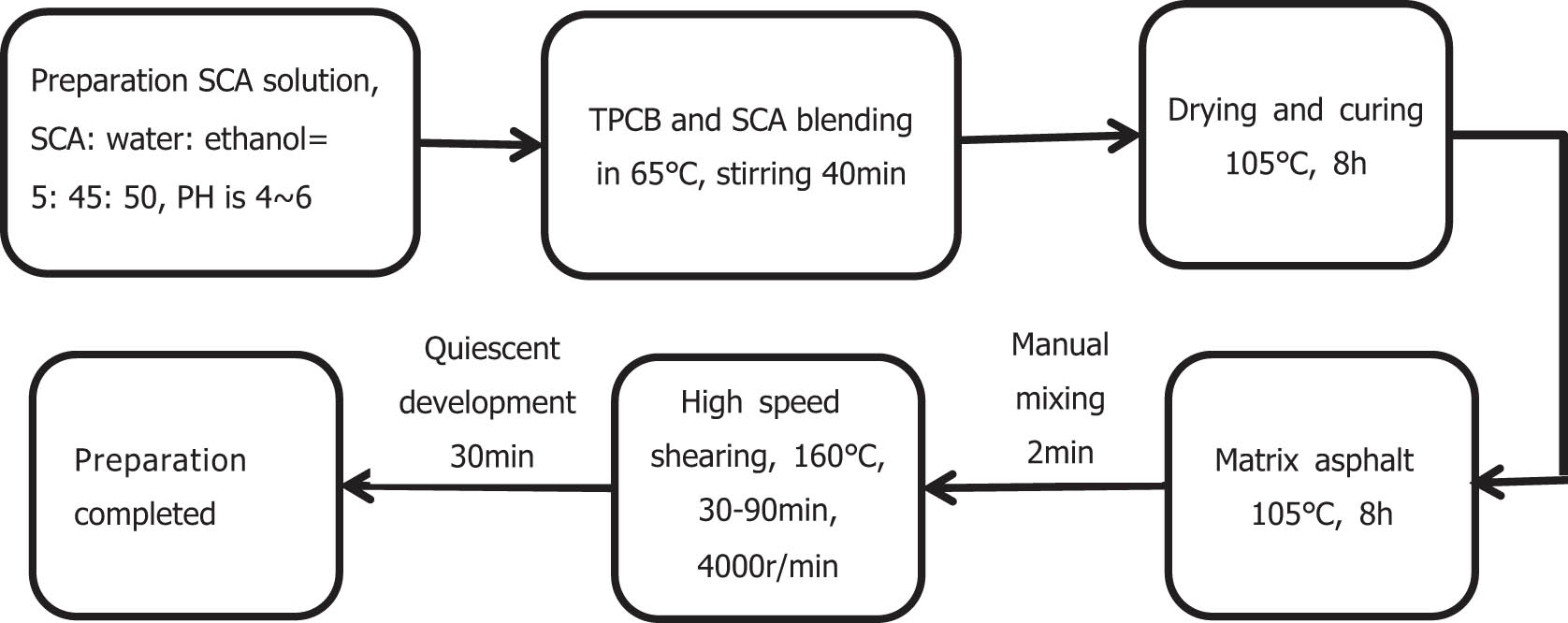

2.5 Preparation process of the composite-modified asphalt

To ensure the quality of the composite-modified asphalt, it is necessary to comprehensively consider the characteristics of each modifier and determine the appropriate feeding sequence and processing conditions. The surface pre-treatment method can make SCA fully contact with inorganic materials, resulting in better results. Based on relevant research [16], the following preparation process steps are determined:

Hydrolysis. Before surface modification, a certain proportion of water and ethanol solution is added, and the pH of the solution is adjusted to 4–6 with a small amount of cold acetic acid. Then, SCA is added to the prepared hydrolysis solution and mixed for 30 min to achieve sufficient hydrolysis. The hydrolyzed SCA solution is then immersed in the surface of TPCB and stirred evenly in a constant temperature water bath at 65℃. The hydroxyl groups formed by the hydrolysis reaction of the silanol groups first form hydrogen bonds on the surface of TPCB and then form a coating film on the surface of TPCB through a dehydration reaction. The degree of hydrolysis of SCA affects the surface modification of TPCB. According to relevant research [15], the ratio of SCA to water and ethanol is 5:45:50.

Curing. The surface of TPCB treated with SCA solution also needs to undergo a curing reaction, i.e., thermal drying. After the curing reaction, some hydrogen bonds form covalent bonds due to dehydration, and SCA will be in a solid or fixed state on the surface of TPCB. When TPCB is coated on the substrate, a chemical reaction occurs between SCA and TPCB, making their bonding tighter, thus improving the adhesion performance of the coating. The curing time and curing temperature affect the bonding strength. The purpose of thermal drying is mainly to remove water and ethanol solution during the hydrolysis process. According to the actual preheating requirements, the curing temperature is selected as 105℃ and the curing time is 8 h to prepare SCA surface-modified TPCB.

Shear mixing. After the curing process, TPCB treated with SCA should be shear mixed with the matrix asphalt to create TPCB/SCA composite-modified asphalt. First, preheat the matrix asphalt to 150°C in an oven, then add the SCA-treated TPCB according to the desired mixing ratio. Stir the mixture by hand for 2 min and then shear it using an asphalt shear apparatus at a speed of 4,000 rpm for a shearing time of 30–90 min. After shearing, let the asphalt stand at 150°C for 30 min to develop, and the TPCB/SCA composite modified asphalt is obtained. Figure 2 shows the process flow for preparing TPCB/SCA composite-modified asphalt.

Preparation process of the TPCB/SCA composite-modified asphalt.

2.6 Experimental design and results

Based on the relevant literature [8,11,12,24], this study proposed comprehensive evaluation indices and expected targets for composite-modified asphalt. Penetration, softening point, 10℃ ductility, Brookfield viscosity, and storage stability were used as evaluation indices for analysis. The penetration was used as the consistency index, as it reflects the consistency and grading of the asphalt. The expected penetration value should be moderate to ensure proper construction and ductility performance. The softening point was used as the high-temperature index, as it has a relatively small parallel error, and the experimental steps are relatively simple. A higher softening point indicates better high-temperature performance of the asphalt. The 10℃ ductility test was used as the low-temperature index, as it measures the ductility of the asphalt at low temperatures and reflects its low-temperature performance. A higher ductility value indicates better low-temperature ductility. The 135℃ Brookfield viscosity was used as the construction and workability index, as it characterizes the construction and workability of asphalt. The storage stability index, softening point difference, was used to measure the degree of separation of modified asphalt under heat and the quality stability of modified asphalt in actual use.

According to previous studies [4,7,8,12,14,19,24,30], the optimal TPCB content is 15%, and the shear time is 60 min. When the TPCB content is less than 10%, it has excellent storage stability, but when it is greater than 15%, its low-temperature performance will be affected. In order to ensure the rigor of this experiment and test the performance of composite modified asphalt, the TPCB content of 0–20% and the shear time of 30–90 min were selected. According to Lv et al.’s research and previous experiments, the optimal dosage of SCA for modification is 1% [20,33]. To meet the requirements of this experiment, a dosage of 1–3% was selected for SCA. To comprehensively consider the interaction between different influencing factors and effectively estimate the primary and secondary terms, CCD was adopted in this study as a 3-factor, 5-level experimental plan. The corresponding values of each factor code are shown in Table 4. In order to examine the comprehensive performance of the test experiments, the optimal value of the evaluation index was assumed to be the “ideal performance” as the reference performance X 0, and the various performance indicators of each test group constituted a comparative sequence X ij. The gray system analysis method was used to calculate the gray comprehensive evaluation value (GC) of each group of tests and rank the comprehensive characteristics of each group of experiments according to the size of the GC. The preparation parameters corresponding to the highest gray comprehensive evaluation value are optimal. Excel 2016 was used for data processing. The results of the segregation test are shown in Table 5. The experimental results, the correlation coefficient of the experimental group, and the gray comprehensive evaluation values are shown in Table 6.

Corresponding values of each factor code

| Factor code | −1.682 | −1 | 0 | 1 | 1.682 |

|---|---|---|---|---|---|

| TPCB content (%) | 0 | 4.1 | 10 | 15.9 | 20 |

| SCA content (%) | 1 | 1.4 | 2 | 2.6 | 3 |

| Shearing time (min−1) | 30 | 42 | 60 | 78 | 90 |

Results of the segregation test

| Number | Lower softening point | Upper softening point | Softening point difference |

|---|---|---|---|

| 0 | 54 | 53.7 | 0.3 |

| 1 | 46 | 45.3 | 0.7 |

| 2 | 48.4 | 45.5 | 2.9 |

| 3 | 52 | 50.8 | 1.2 |

| 4 | 48.6 | 46.2 | 2.4 |

| 5 | 52.5 | 51.9 | 0.6 |

| 6 | 49 | 46.2 | 2.8 |

| 7 | 54 | 53.5 | 0.5 |

| 8 | 49.2 | 47.2 | 2 |

| 9 | 46.3 | 46 | 0.3 |

| 10 | 53.5 | 50.2 | 3.3 |

| 11 | 53.9 | 51.5 | 2.4 |

| 12 | 50.8 | 49.7 | 1.1 |

| 13 | 51 | 49.6 | 1.4 |

| 14 | 50.2 | 48.9 | 1.3 |

| 15–20 | 51.6 ± 0.5 | 50.5 ± 0.5 | 1.1 ± 0.5 |

Response surface test and data analysis results

| Serial number | A | B | C | 25℃ Penetration/0.1 mm | Softening point (℃) | 10℃ Ductility (cm) | 135℃ Brookfield rotational viscosity (Pa·s) | Storage stability (℃) | Gray comprehensive evaluation value (%) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measured value | Correlation coefficient

|

Measured value | Correlation coefficient

|

Measured value | Correlation coefficient

|

Measured value | Correlation coefficient

|

Measured value | Correlation coefficient

|

|||||

| 0 | Reference performance | 57.3 | 1 | 53.7 | 1 | 23.4 | 1 | 0.219 | 1 | 0.3 | 1 | 100 | ||

| 1 | −1 | −1 | −1 | 60.8 | 0.78 | 46.1 | 0.46 | 22.3 | 0.73 | 0.329 | 0.60 | 0.7 | 0.47 | 62.55 |

| 2 | 1 | −1 | −1 | 54.9 | 0.70 | 48.4 | 0.32 | 13.8 | 0.39 | 0.446 | 0.50 | 2.9 | 0.36 | 47.03 |

| 3 | −1 | 1 | −1 | 52.1 | 0.52 | 52.4 | 0.69 | 23.4 | 1.00 | 0.332 | 0.59 | 1.2 | 0.40 | 65.28 |

| 4 | 1 | 1 | −1 | 55.0 | 0.71 | 48.5 | 0.41 | 15.9 | 0.41 | 0.45 | 0.49 | 2.4 | 0.36 | 49.43 |

| 5 | −1 | −1 | 1 | 59.6 | 0.71 | 52.7 | 0.62 | 21 | 0.67 | 0.321 | 0.61 | 0.6 | 0.50 | 63.38 |

| 6 | 1 | −1 | 1 | 54.5 | 0.67 | 48.9 | 0.42 | 13.6 | 0.34 | 0.438 | 0.50 | 2.8 | 0.36 | 47.13 |

| 7 | −1 | 1 | 1 | 60.2 | 0.66 | 53.3 | 0.66 | 23.2 | 0.87 | 0.368 | 0.55 | 0.5 | 0.56 | 66.92 |

| 8 | 1 | 1 | 1 | 54.3 | 0.66 | 49 | 0.37 | 15.7 | 0.52 | 0.432 | 0.50 | 2 | 0.37 | 49.85 |

| 9 | −1.682 | 0 | 0 | 68.7 | 0.33 | 46.1 | 0.62 | 23.2 | 0.87 | 0.219 | 1.00 | 0.3 | 1.00 | 63.00 |

| 10 | 1.682 | 0 | 0 | 53.9 | 0.63 | 53.5 | 0.68 | 12.1 | 0.31 | 0.428 | 0.51 | 3.3 | 0.35 | 50.36 |

| 11 | 0 | −1.682 | 0 | 56.4 | 0.86 | 53.7 | 1.00 | 19.8 | 0.42 | 0.399 | 0.53 | 2.4 | 0.36 | 65.16 |

| 12 | 0 | 1.682 | 0 | 57.1 | 0.97 | 50.7 | 0.42 | 23.4 | 1.00 | 0.411 | 0.52 | 1.1 | 0.41 | 69.76 |

| 13 | 0 | 0 | −1.682 | 58.4 | 0.84 | 50.9 | 0.38 | 22.1 | 0.76 | 0.413 | 0.52 | 1.4 | 0.39 | 60.43 |

| 14 | 0 | 0 | 1.682 | 56.9 | 0.93 | 50.4 | 0.29 | 20.8 | 0.69 | 0.423 | 0.51 | 1.3 | 0.39 | 59.47 |

| 15–20 | 0 | 0 | 0 | 56.7 ± 1.8 | 0.90 | 51.4 ± 0.6 | 0.95 | 21.4 ± 1.6 | 0.92 | 0.402 ± 0.012 | 0.52 | 1.1 ± 0.5 | 0.41 | 76.76 |

| Relevance | 0.73 | 0.55 | 0.63 | 0.56 | 0.45 | — | ||||||||

| Proportion of evaluation indicators | 0.25 | 0.19 | 0.22 | 0.19 | 0.15 | — | ||||||||

Note: A – TPCB content; B – SCA content; and C – shearing time.

In order to test the rheological properties of TPCB/SCA composite-modified asphalt, this study used dynamic shear rheological tests to compare 70# matrix asphalt (BA-70), TPCB-modified asphalt (TMA), and their short-term thermal oxidative aging samples (TSMA), and verify the rheological properties and applicability of TPCB/SCA composite-modified asphalt. The test results are shown in Table 7.

Dynamic shear rheological test results

| Type | Rutting factor (kPa) | Critical temperature (℃) | ||||||

|---|---|---|---|---|---|---|---|---|

| 54℃ | 58℃ | 62℃ | 66℃ | 70℃ | 74℃ | 78℃ | ||

| BA-70 | 6.25 | 4.37 | 3.28 | 2.43 | 1.19 | 0.86 | 0.44 | 71.2 |

| TMA | 24.78 | 14.58 | 7.82 | 4.11 | 2.27 | 1.16 | 0.56 | 75.1 |

| TSMA | 27.02 | 16.36 | 9.04 | 4.84 | 2.32 | 1.19 | 0.57 | 75.4 |

According to Table 7, as the temperature increases, the G*/sin δ of BA-70, TMA, and TSMA gradually decrease. Asphalt is a temperature-sensitive material, so its ability to resist permanent deformation will decrease with increasing temperature. The critical temperatures of BA-70, TMA, and TSMA asphalt are 71.2, 75.1, and 75.4°C. The addition of TPCB significantly increased the rutting factor of asphalt, resulting in a critical temperature increase of 3.9 and 4.2°C for TMA and TSMA compared to BA-70. With the continuous increase of temperature, the difference in high-temperature performance of these three types of asphalt gradually narrows. At 58°C, their G*/sin δ difference is more obvious, and after 70°C, the difference between the three types of asphalt is no longer significant. Therefore, the addition of pyrolysis carbon black from waste tires can effectively improve the rheological properties of asphalt.

3 Data processing and analysis

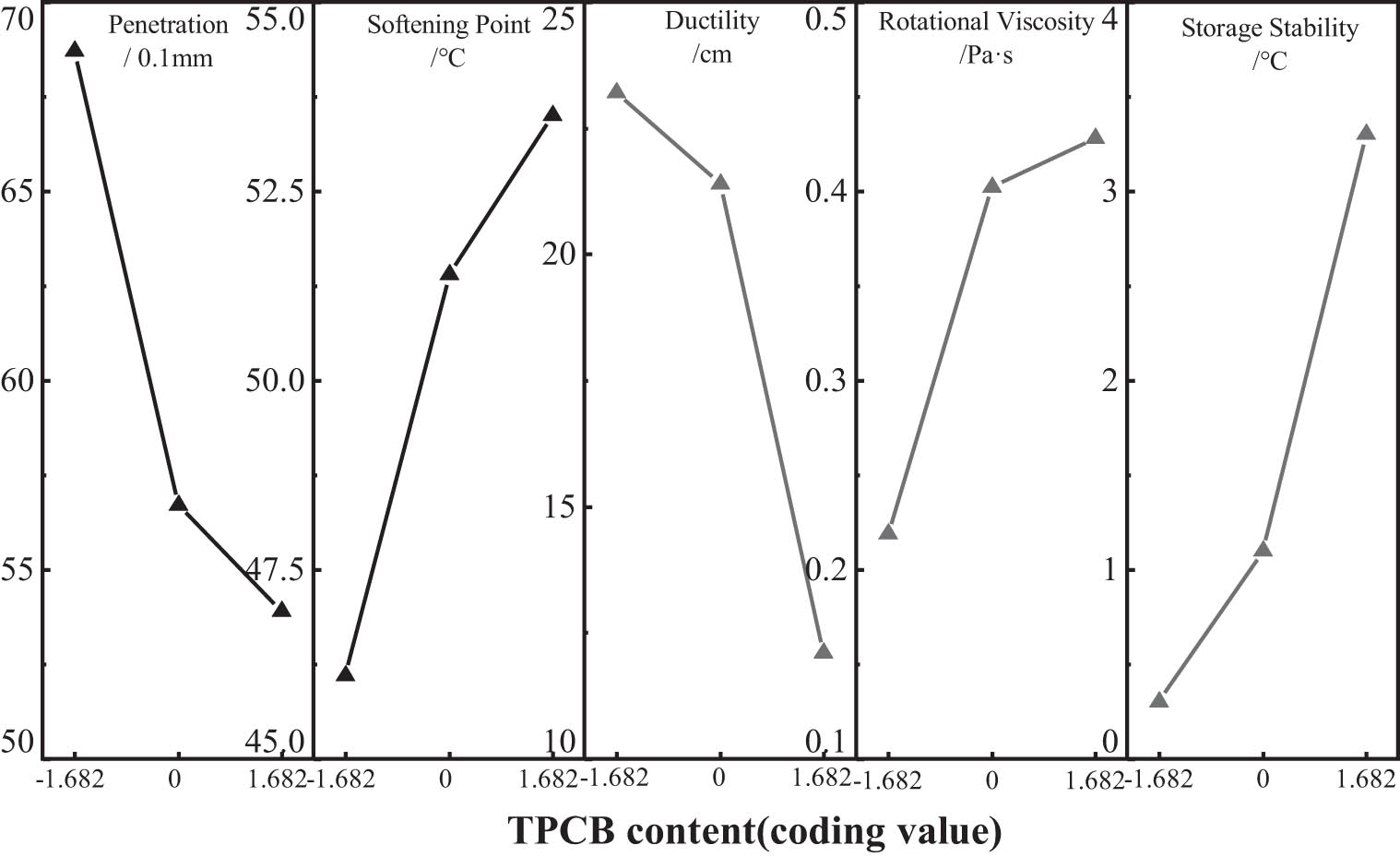

3.1 Analysis of single-factor effects

By analyzing the experimental results of eight test points (namely, 9 (−1.682, 0, 0), 15–20 (0, 0, 0), and 10 (1.682, 0, 0)), we can obtain the variation pattern of asphalt performance with TPCB content. To simplify the analysis, the experimental results of points 15–20 are averaged for calculation. Figure 3 shows that as the TPCB content increases from code −1.682 to code 0, the penetration value of asphalt decreases from 68.7 to 56.7. If the asphalt is categorized by grade number, the modified asphalt has changed from 70# to 50#. The decreasing trend of penetration value slows down as the TPCB content continues to increase. The changes in softening point and rotational viscosity are strongly correlated with the changes in the penetration value. When the TPCB content increases from code −1.682 to code 0, the softening point and viscosity increase significantly by 11.5 and 83.6%, respectively. However, as the TPCB content continues to increase, the increments of softening point and viscosity decrease to 4.1 and 6.5%, respectively.

Effect of TPCB content on asphalt performance.

At a low TPCB content level, its influence on the ductility and storage stability of asphalt is not significant, but at a higher level, the ductility of asphalt decreases significantly. At the same time, the storage stability of asphalt decreases significantly, and the difference in softening point reaches 3.3℃, which exceeds the maximum value of 2.5℃ specified in the “Technical Specifications for Construction of Highway Asphalt Pavements.” TPCB has a larger specific surface area and a developed pore structure, which leads to a certain adsorption effect on the light components in asphalt, increasing the viscosity, consistency, and stiffness of asphalt. The reduction of light components also weakens the extensibility of asphalt and reduces its ductility. Moreover, excessive TPCB will cause agglomeration in asphalt, making it prone to settling and segregation. Therefore, it is essential to optimize the TPCB content to minimize its negative effects on the viscosity, ductility, and storage stability of asphalt.

Similarly, by analyzing the results of the eight test points, namely 11 (0, −1.682, 0), 15–20 (0, 0, 0), and 12 (0, 1.682, 0), under the condition of other factors being constant, the influence curve of SCA content on asphalt performance can be obtained, as shown in Figure 4. It can be seen that compared with the TPCB content, the influence of SCA content on asphalt performance is significantly weaker. Changes in the SCA content have almost no effect on asphalt penetration and rotational viscosity. When SCA content increases from code −1.682 to code 1.682, the softening point of asphalt decreases by 3°C, and the elongation increases by 3.6 cm. This indicates that SCA has a certain improvement effect on the low-temperature performance of asphalt. This can be attributed to the lower molecular weight of SCA, which has a certain regulatory effect on the components of asphalt. However, compared with the enhancement effect of TPCB, this effect is very limited. In addition, as SCA content increases from code −1.862 to code 0, the softening point difference of asphalt decreases from 2.4 to 1.1°C, with a decrease of 54.2%. This indicates that SCA plays a good bridging role between TPCB and asphalt and can significantly improve the compatibility of TPCB-modified asphalt. However, when the SCA content continues to increase to code 1.682, the softening point difference of asphalt does not continue to decrease but remains at 1.1°C. This indicates that there is an optimal SCA content to fully ensure the compatibility between TPCB and asphalt. To avoid wasting resources, the optimal SCA content should be further determined through a predictive equation.

Effect of SCA content on asphalt performance.

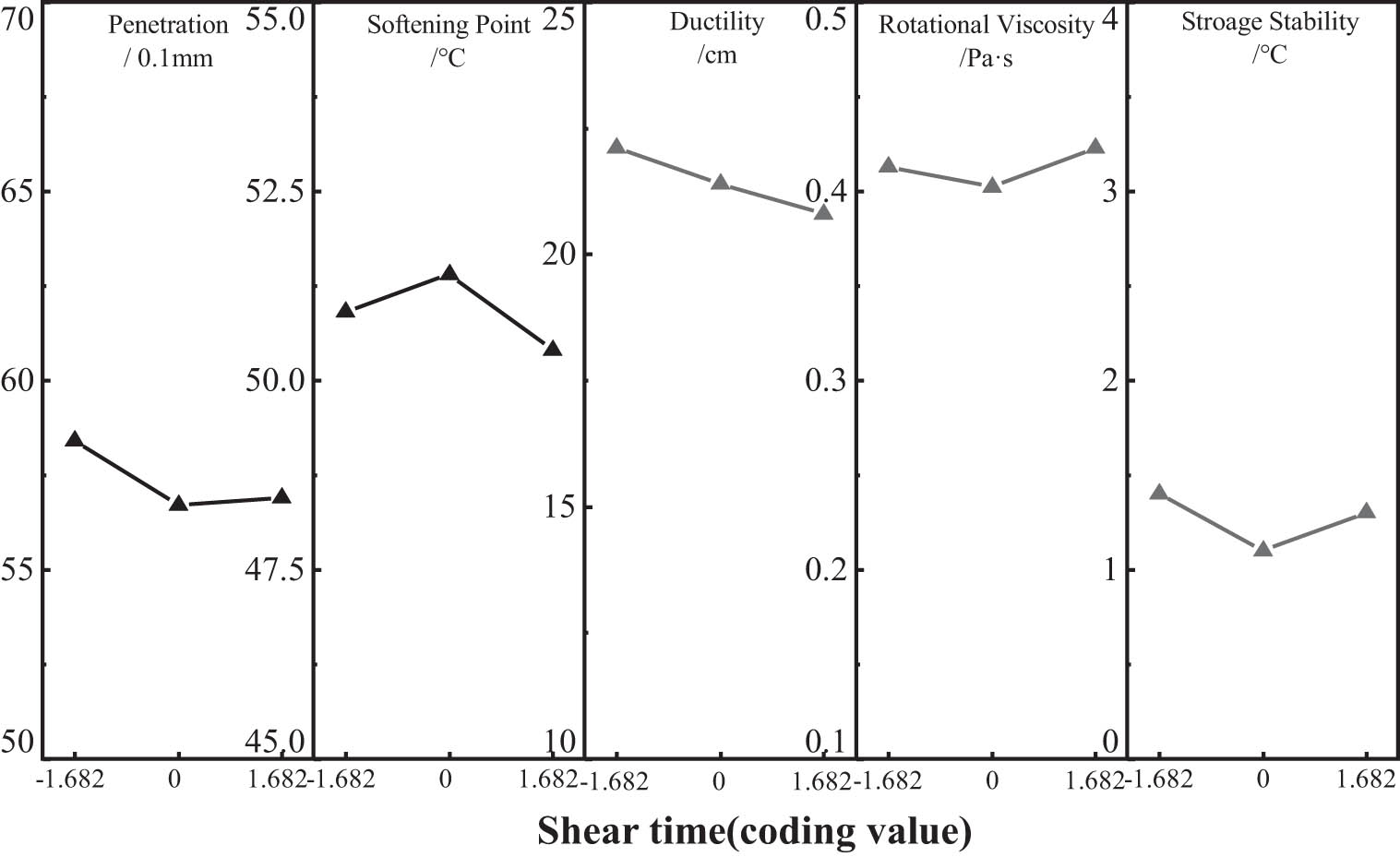

By analyzing the results of eight testing points, namely 13 (0, 0, −1.682), 15–20 (0, 0, 0), and 14 (0, 0, 1.682), under other constant conditions, the curve of the influence of shear time on the performance of asphalt can be obtained, as shown in Figure 5. Compared with the changes in TPCB and SCA contents, the influence of shear time on the performance of asphalt is less significant. As the shear time increases from the coding of −1.682 to 0 and finally to 1.682, there is a turning point in the penetration and softening point of asphalt. This may be because asphalt undergoes some aging during the long-term shearing process, resulting in increased viscosity and high-temperature performance. As the shear continues to deepen, the crosslinking degree of SCA and TPCB increases and the reinforcing effect of TPCB is partially neutralized by the plasticizing effect of SCA, resulting in the recovery of asphalt performance. However, this process does not significantly affect the ductility of asphalt. Dominated by the aging of asphalt, the ductility of asphalt continues to decrease slowly with the prolongation of shear time. The changes in rotational viscosity and storage stability are not significant, and their numerical fluctuations remain within the range of experimental errors. Therefore, it can be considered that shear time does not significantly affect the viscosity and storage performance of asphalt.

Effect of shearing time on asphalt performance.

3.2 Interaction analysis

In order to quantitatively analyze the effects of TPCB content, SCA content, and shear time on the gray comprehensive evaluation value and to determine the optimal ratio, a quadratic polynomial equation was fitted to the experimental data using MINITAB19 software. A quadratic function of A, B, and C was established to describe the relationship between the gray comprehensive evaluation value GC and A, B, and C. The regression equation is shown in Eq. (6):

Checking the reliability of the model is an important part of data analysis. If the fit is insufficient, the model function will give incorrect responses. In order to evaluate the significance of the model, a variance test analysis was performed, and the results are listed in Table 8.

Analysis of variance of the fitting equation

| Source | Degree of freedom | Adj SS | Adj MS | F value | P value |

|---|---|---|---|---|---|

| Model | 9 | 1032.78 | 114.753 | 5.04 | 0.045 |

| Linear | 3 | 567.81 | 189.268 | 8.31 | 0.022 |

| A | 1 | 540.88 | 540.881 | 23.75 | 0.005 |

| B | 1 | 26.79 | 26.786 | 1.18 | 0.328 |

| C | 1 | 0.14 | 0.138 | 0.01 | 0.941 |

| Square | 3 | 464.17 | 154.724 | 6.79 | 0.033 |

| A × A | 1 | 402.62 | 402.618 | 17.68 | 0.008 |

| B × B | 1 | 114.27 | 114.275 | 5.02 | 0.035 |

| C × C | 1 | 296.58 | 296.577 | 13.02 | 0.015 |

| Two-factor interaction | 3 | 0.8 | 0.267 | 0.01 | 0.998 |

| A × B | 1 | 0.17 | 0.165 | 0.01 | 0.935 |

| A × C | 1 | 0.48 | 0.475 | 0.02 | 0.891 |

| B × C | 1 | 0.16 | 0.160 | 0.01 | 0.937 |

| Error | 5 | 113.88 | 22.777 | — | — |

| Total | 14 | — | — | — | — |

According to the variance analysis data in Table 8, the F-value of the fitted variance model is 5.04. After removing five items of B, C, A × B, A × C, and B × C from the model, all other items have P ≤ 0.05. According to the relevant research results [34,35], the smaller the P value, the better the fitting effect and the more credible the regression equation. Therefore, the fitting degree of the model in this article is high, and it can accurately reflect the relationship between the gray comprehensive evaluation value and the various influencing factors. On the basis of the overall significance test of this model, the significance test was conducted on each sub coefficient of the model to analyze the effects of three influencing factors, as shown in Table 9.

Quadratic polynomial coefficients and their significance analysis

| Term | Coefficient | Coefficient standard deviation | T value | P value |

|---|---|---|---|---|

| Constant | 78.969 | 0.874 | 90.4 | 0 |

| A | 1.905 | 0.238 | 8.01 | 0 |

| B | 0.828 | 0.238 | 3.48 | 0.008 |

| C | 0.319 | 0.238 | 1.34 | 0.238 |

| A × A | −15.661 | 0.357 | −43.85 | 0 |

| B × B | −8.3 | 0.357 | −23.24 | 0 |

| C × C | −2.586 | 0.357 | −7.24 | 0.001 |

| A × B | 2.097 | 0.311 | 6.75 | 0.001 |

| A × C | 0.087 | 0.311 | 0.28 | 0.789 |

| B × C | −1.257 | 0.311 | −4.05 | 0.010 |

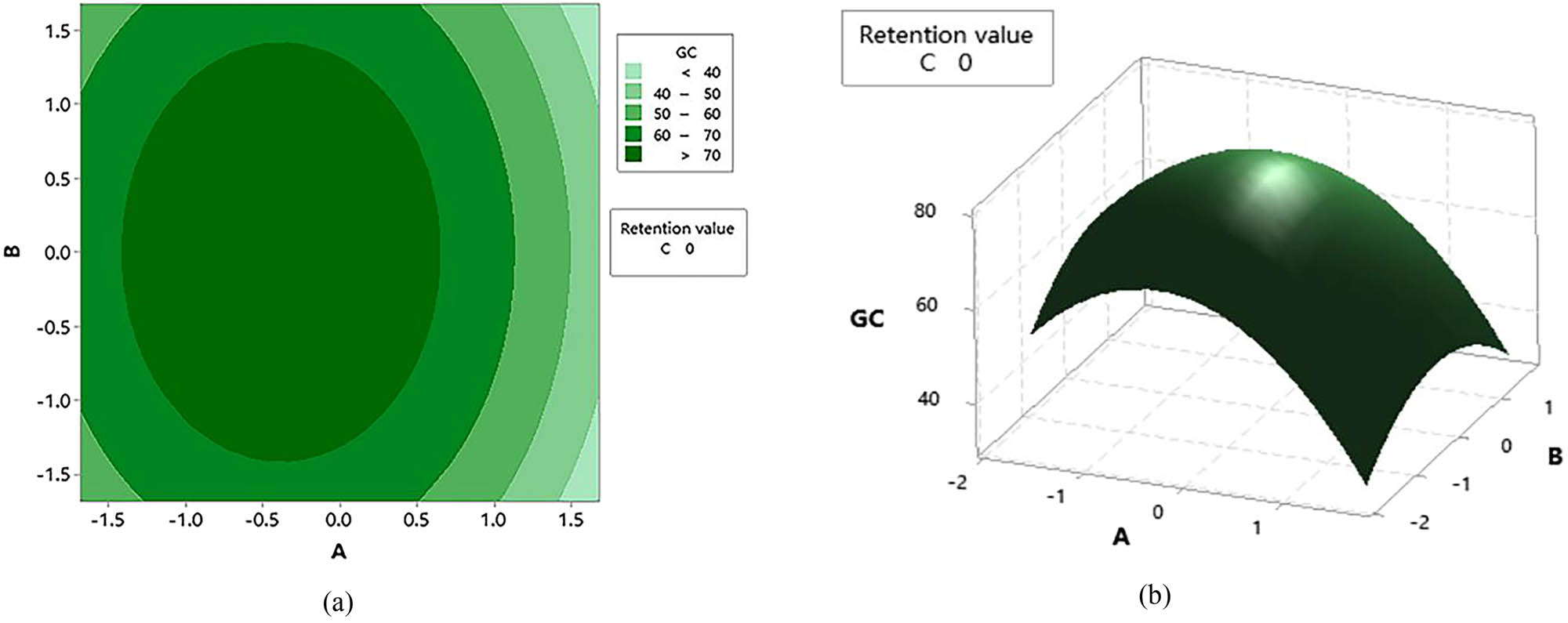

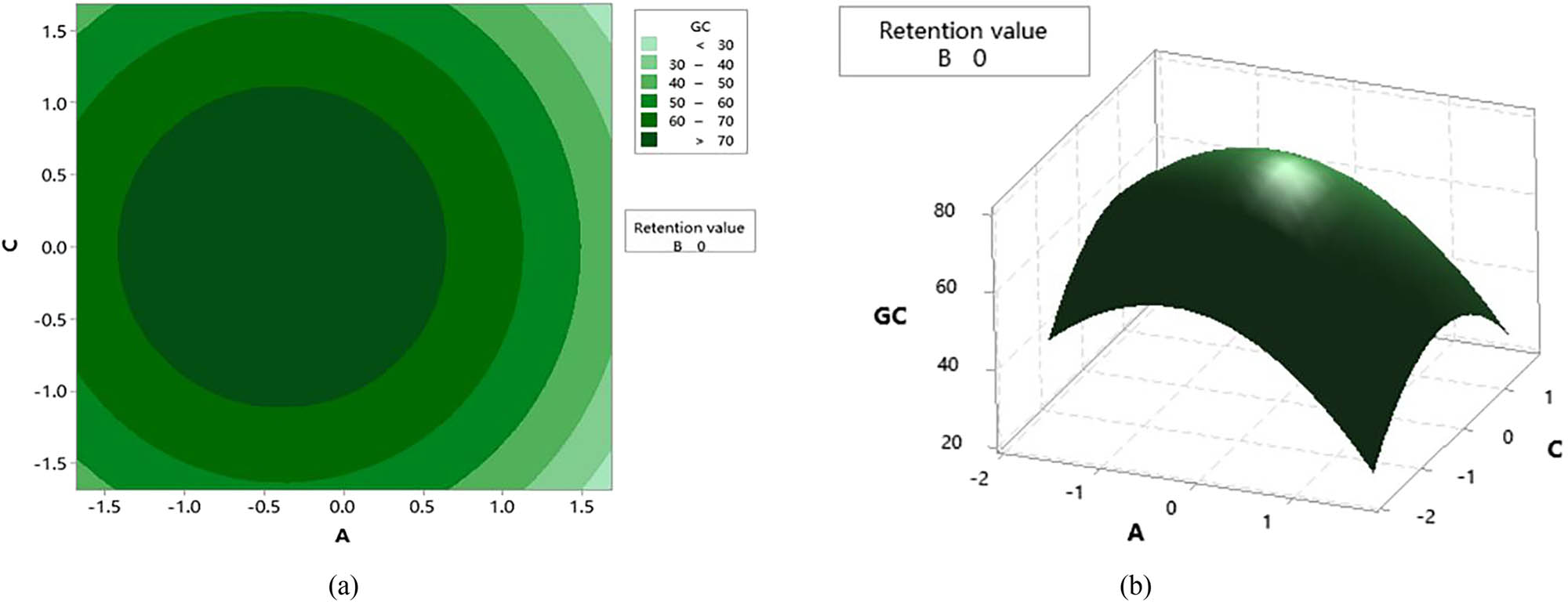

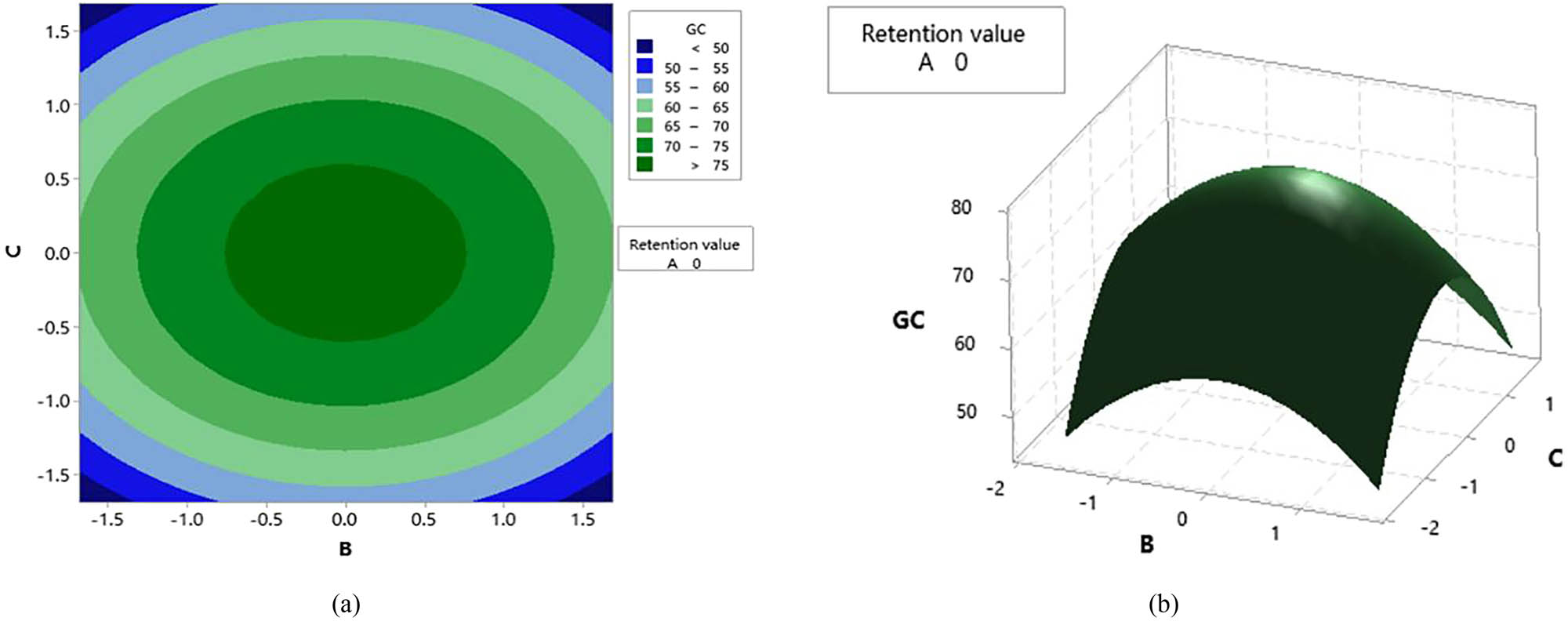

It can be seen from Table 9 that the coefficients of some primary, secondary, and interaction terms of the three influencing factors A, B, and C are all greater than 1, which indicates that there is a strong interaction between the influencing factors, and also verifies the applicability of the improved RSM for optimizing the preparation of modified asphalt. To more intuitively analyze the degree of interaction between various factors and the influence on the performance of asphalt, a two-dimensional contour plot and a three-dimensional response surface plot of the factors A, B, and C, and the comprehensive evaluation value were generated based on the regression model (6) established according to the experimental data in Table 6. The contour plot is a projection of the response surface plot on the horizontal plane for more intuitive observation and analysis of the relationship between the comprehensive evaluation value and various factors, as shown in Figures 6–8.

Contour and response surface diagrams of A and B. (a) Contour map and (b) response surface graph.

Contour and response surface diagrams of A and C. (a) Contour map and (b) response surface graph.

Contour and response surface diagrams of B and C. (a) Contour map and (b) response surface graph.

Figure 6 shows the contour map and response surface map of the influence of A and B on the gray comprehensive evaluation value, which indicates the interactive effect of TPCB content and SCA content on the gray comprehensive evaluation value of asphalt when C is at the central level, i.e., the shearing time is 60 min. From the contour map formed by TPCB content and shearing time in Figure 6(a), the graph shows an elliptical shape, indicating that the interaction between TPCB content and shearing time is more significant than other factors. In Figure 6(b), when the encoding value of A is around −0.2 and the content of B is around 0.1, the response variable can reach the maximum value. This indirectly proves that a small amount of SCA can undergo a branching reaction with TPCB, making TPCB stable and evenly distributed in the asphalt and promoting the modification effect of TPCB. However, excessive SCA has no significant effect on the asphalt and may even have a negative effect, leading to a decrease in the gray comprehensive evaluation value of the asphalt.

Figure 7 shows the contour map and response surface map of the influence of A and C on the comprehensive evaluation value. From the contour map in Figure 7(a), the shape of the graph is circular. Combined with Figure 7(b), it can be seen that irrespective of the value set for factor A, the response variable can reach a maximum value when factor B takes the encoding value of 0. Similarly, when factor B takes the encoding value of −0.4, the response variable can reach a relative maximum value within the process, regardless of the specific value of factor A. This indicates that the interaction between A and C is not significant, and when A and C, respectively, take the optimal solutions under single-factor action, the response variable, i.e., the optimal value in the global response process, is also obtained. The model does not have the characteristic of a quadratic bending response.

Figure 8 shows the interaction effect of SCA content and shearing time on the gray comprehensive evaluation value of asphalt when A is at the central level, i.e., TPCB content is 10%. From the contour map in Figure 8(a), it can be seen that the interaction between B and C is relatively significant, and when the encoding value of B is −0.1, and the encoding value of C is −0.1, i.e., SCA content is 1.9% and shearing time is 58.2 min, the comprehensive evaluation value of asphalt is the maximum. The main reason may be that when the shearing time is too short, TPCB/SCA is not uniformly mixed in the asphalt, affecting its modification effect; however, when the shearing time is too long, the asphalt will undergo thermal oxidation aging, leading to a decrease in its overall performance.

3.3 Determination of optimal parameters

In Table 7, a p-value < 0.05 indicates the significance of the model and parameters in evaluating the response variable. However, some unimportant interactions were analyzed for each formula model with variance (p-value >0.01). From the response surface plots of the interaction terms, it can also be seen that the interaction effects of the factors achieve the optimal value when the values of each factor are at their optimal level during the single-factor variation process. Therefore, the interaction terms in the model are not significant enough to predict the accuracy of the model. To improve the model and optimize the results, these unimportant terms can be eliminated from the model. The optimized model is shown as follows:

Eq. (7) shows that there is quadratic bending in the gray comprehensive evaluation value with the three influencing factors A, B, and C. According to the variance analysis data in Table 7, the F-value of the fitted variance model is 5.04. After removing five items of B C, A × B, A × C, and B × C from the model, all other items have P ≤ 0.05. Therefore, the fitting degree of the model in this article is high, and it can accurately reflect the relationship between the gray comprehensive evaluation value and the various influencing factors. The adjusted R

2, predicted R

2, and signal-to-noise ratio (SN) after adjustment through variance analysis using MINITAB19 are shown in Table 10. The signal-to-noise ratio represents the ratio of signal to noise and is generally ideal when it is greater than 4. The fitness of the model is evaluated by the value of R

2. Models with R

2 > 0.8 are considered to be well-fitting [36]. The higher correlation coefficients R

2 and adjusted

Indicators of model adequacy

| Signal-to-noise ratio (SN) | R 2 |

|

|

|---|---|---|---|

| 8.73 | 82.71% | 87.65% | 83.47% |

Based on the analysis of response surface experimental data and variance significance, it is known that the established mathematical model has a high degree of fitting, and on this basis, predictive research has been carried out, which can effectively approach the actual situation. The response value optimization was carried out using MINITAB19 software, and the expected value of the gray comprehensive evaluation value was set to the maximum value. The results showed that the optimal proportional code values of the pyrolysis carbon black content (A), SCA content (B), and shearing time (C) were -0.14, 0.19, and −0.21, respectively, and the corresponding data were 9.2%, 2.1%, and 56.3 min. The predicted comprehensive evaluation value was 77.14%. Then, TPCB/SCA composite-modified asphalt was prepared according to the optimal formula and preferred process for related tests to verify the optimization results and the accuracy of the response, and the experimental results are shown in Table 11.

Test data for optimal content and process

| Optimal formula and process | 25℃ Penetration/0.1 mm | Softening point (℃) | 10℃ ductility (cm) | 135℃ Brookfield viscosity (Pa·s) | Storage stability (℃) | Gray comprehensive evaluation value (%) |

|---|---|---|---|---|---|---|

| 9.2% TPCB + 2.1% SCA, Cutting time 56.3 min | 56.9 | 51.4 | 21.4 | 0.413 | 0.6 | 78.92 |

| Test value range | 52.1–68.7 | 46.1–53.7 | 12.1–23.4 | 0.219–0.450 | 0.3–2.9 | — |

| Target expectations | Median | Bigger | Bigger | Smaller | Smaller | — |

Based on the test results of the modified asphalt prepared with the selected content and shear time, as shown in Table 11, the correlation coefficients and weightings of the evaluation indicators corresponding to the test values were calculated according to Table 6, and the comprehensive evaluation value was calculated as 78.92% using Formula (5). Compared with the predicted result, the error is 2.31%, indicating a close agreement between the predicted and measured gray comprehensive evaluation values. Thus, the tires’ pyrolysis carbon black can effectively improve the rheological properties of asphalt. From the test results, it can be seen that the TPCB/SCA composite-modified asphalt prepared using the improved RSM is the closest to the reference performance in Table 6, with superior high-temperature performance, qualified low-temperature ductility, good workability, and strong anti-segregation ability of the asphalt. Economic analysis needs to be carried out in the future for further promotion and application.

4 Conclusions

The present study explores the potential of waste TPCB as a reinforcing filler for asphalt modification. Additionally, SCA) has both inorganic and organic groups, which can improve the adhesion between asphalt and aggregates and achieve the characteristic of improving asphalt performance. A basic preparation process of composite-modified asphalt is proposed, and a novel TPCB/SCA composite-modified asphalt formulation is developed through systematic experimentation and analysis, ensuring the reliability of its preparation process.

To address the technical challenge of comprehensive evaluation involving multiple indexes, the gray correlation comprehensive evaluation method is incorporated into the RSM, leading to an improved RSM. By using this method, the comprehensive properties of asphalt, such as penetration, softening point, 10℃ ductility, 135℃ Brinell rotation viscosity, and storage stability were taken as response values to determine the optimal comprehensive performance indicators for composite-modified asphalt: the content of TPCB was 14.2%, the content of SCA was 2.1%, and the shear time was 56.3 min.

A highly accurate and reliable mathematical model is established for predicting and optimizing asphalt formulations. Performance verification tests reveal that the TPCB/SCA composite-modified asphalt exhibits significantly improved high-temperature shear deformation resistance, low-temperature cracking resistance, and storage stability, resulting in the highest gray comprehensive evaluation value among multiple indicators. This study sheds light on the potential of TPCB/SCA composite-modified asphalt for sustainable and high-performance road construction materials.

Acknowledgments

The authors would like to acknowledge the support of Changsha University of Science and technology for paying the Article Processing Charges (APC) of this publication.

-

Funding information: The Science and Technology Project of the Department of Transportation of Jiangxi Province (2023H0025).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Li, C. M., B. Peng, and X. Z. Gan. Indoor test research on road performance of TPCB modified asphalt mixture prepared by dry and wet method. Journal of Changsha University of Science and Technology (Natural Science Edition), Vol. 19, No. 2, 2022, pp. 49–60.Search in Google Scholar

[2] Lin, H. and B. Zhang. Application of thermal cracking technology in recycling of waste tires. China Tire Resources Recycling, Vol. 4, 2020, pp. 45–48.Search in Google Scholar

[3] Ruijing, S., J. Guan, and B. Liang. Research progress in recycling of waste tyre. Journal of Shanghai Polytechnic University, Vol. 33, No. 1, 2016, pp. 20–26.Search in Google Scholar

[4] Dong, R. and M. Zhao. Research on the pyrolysis process of crumb tire rubber in waste cooking oil. Renewable Energy, Vol. 125, 2018, pp. 557–567.10.1016/j.renene.2018.02.133Search in Google Scholar

[5] Xu, J., J. Yu, J. Xu, C. Sun, W. He, J. Huang, et al. High-value utilization of waste tires: A review with focus on modified carbon black from pyrolysis. Science of The Total Environment, Vol. 742, 2020, id. 140235.10.1016/j.scitotenv.2020.140235Search in Google Scholar PubMed

[6] Wang, F., N. Gao, and C. Quancui. Progress on pyrolysis technology of waste tires and upgrade and recycle utilization of carbon black product. Journal of Chemical Industry, Vol. 70, No. 8, 2019, pp. 2864–2875.Search in Google Scholar

[7] Lesueur, D., D. L. Dekker, and J. P. Planche. Comparison of carbon black from pyrolysis tires to other fillers as asphalt rheology modifiers. Transportation Research Record, Vol. 1515, 1995, pp. 47–55.Search in Google Scholar

[8] Feng, Z., W. Rao, C. Chen, B. Tian, X. J. Li, P. L. Li, et al. Performance evaluation of bitumen modified with pyrolysis carbon black made from waste tires. Construction and Building Materials, Vol. 111, 2016, pp. 495–501.10.1016/j.conbuildmat.2016.02.143Search in Google Scholar

[9] Kumar, A., R. Choudhary, and A. Kumar. Storage stability of waste tire pyrolytic char–modified asphalt binders: Rheological and chemical characterization. Journal of Materials in Civil Engineering, Vol. 34, No. 3, 2022, id. 04021489.10.1061/(ASCE)MT.1943-5533.0004129Search in Google Scholar

[10] Kumar, A., R. Choudhary, and A. Kumar. Characterization of thermal storage stability of waste plastic pyrolytic char modified asphalt binders with sulfur. Plos One, Vol. 16, No. 3, 2021, id. e0248465.10.1371/journal.pone.0248465Search in Google Scholar PubMed PubMed Central

[11] Li, C., Z. Fan, S. Wu, Y. Li, Y. Gan, and A. Zhang. Effect of carbon black nanoparticles from the pyrolysis of discarded tires on the performance of asphalt and its mixtures. Applied Sciences, Vol. 8, No. 4, 2018, id. 8040624.10.3390/app8040624Search in Google Scholar

[12] Feng, Z., P. Zhao, X. Li, and L. Zhu. Preparation and properties of bitumen modified with waste rubber pyrolytic carbon black. Construction and Building Materials, Vol. 282, 2021, id. 122697.10.1016/j.conbuildmat.2021.122697Search in Google Scholar

[13] Chen, A., Q. Deng, Y. Li, T. Bai, Z. Chen, J. Li, et al. Harmless treatment and environmentally friendly application of waste tires—TPCB/TPO composite-modified bitumen. Construction and Building Materials, Vol. 325, 2022, id. 126785.10.1016/j.conbuildmat.2022.126785Search in Google Scholar

[14] Yu, H., X. Meng, and X. Gan. Research on the first piece engineering process of the surface layer of TPCB modified asphalt made from waste tires by dry-casting method. Highway, Vol. 67, No. 2, 2022, pp. 7–15.Search in Google Scholar

[15] Yao, C., G. S. Gao, X. P. Lin, X. J. Yang, L. D. Lu and X. Wang. Surface modification of Nanosized TiO2 with silane coupling Reagent. Journal of Inorganic Materials, Vol. 21, No. 2, 2006, pp. 315–321.Search in Google Scholar

[16] Guo, X., X. Chen, Y. Li, Z. Li, and W. Guo. Using sustainable oil shale waste powder treated with silane coupling agent for enriching the performance of asphalt and asphalt mixture. Sustainability, Vol. 11, No. 18, 2019, id. 4857.10.3390/su11184857Search in Google Scholar

[17] Chen, H. and B. Tang. Surface modification of fire-retardant asphalt with silane coupling agent. Journal of Wuhan University of Technology-Material Science Ed, Vol. 27, No. 2, 2012, pp. 310–315.10.1007/s11595-012-0458-7Search in Google Scholar

[18] Liang, X., X. D. Guo, H. Wang, et al. The effect and characterization of modified asphalt by coupling agent. Applied Mechanics and Materials, Vol. 105, 2012, pp. 1773–1778. Trans Tech Publications Ltd.10.4028/www.scientific.net/AMM.105-107.1773Search in Google Scholar

[19] Hui, L. I. Study on low-temperature performance of direct coal liquefaction residue modified asphalt, Beijing University of Architecture, Beijing, 2020.Search in Google Scholar

[20] Hu, P., B. Lv, K. Yang, Z. Lu, and J. Ma. Surface-treated fish scale powder with silane coupling agent in asphalt for performance improvement: conventional properties, rheology, and morphology. Journal of Cleaner Production, Vol. 311, 2021, id. 127772.10.1016/j.jclepro.2021.127772Search in Google Scholar

[21] Hao, H., A. Zhang, Y. Cheng, and P. Cong. The modification mechanisms of silane coupling agent (SCA) on the physical properties of thermosetting polyurethane asphalt binder (PUAB). Construction and Building Materials, Vol. 350, 2022, id. 128836.10.1016/j.conbuildmat.2022.128836Search in Google Scholar

[22] Tang, Z., Y. Gan, T. Yu, and C. Li. Study on betel nut fiber enhancing water stability of asphalt mixture based on response surface method. Case Studies in Construction Materials, 2022, Vol. 16, id. e870.10.1016/j.cscm.2022.e00870Search in Google Scholar

[23] Gong, Y., J. Song, H. Bi, and Z. Tian. Optimization design of the mix ratio of a Nano-TiO2/CaCO3-basalt fiber composite modified asphalt mixture based on response surface methodology. Applied Sciences, Vol. 10, No. 13, 2020, id. 4596.10.3390/app10134596Search in Google Scholar

[24] Li, C. M., Z. Y. Hu, Y. W. Gan, W. S. Yang, and X. Z. Gan. Experimental study on optimum additive content of pyrolytic carbon black asphalt mixture. Journal of Changsha University of Science & Technology (Natural Science), Vol. 19, No. 4, 2022, pp. 161–170.Search in Google Scholar

[25] Bala, N., M. Napiah, and I. Kamaruddin. Nanosilica composite asphalt mixtures performance-based design and optimisation using response surface methodology. International Journal of Pavement Engineering, Vol. 21, No. 1, 2020, pp. 29–40.10.1080/10298436.2018.1435881Search in Google Scholar

[26] Adnan, A. M., X. Luo, C. Lü, J. Wang, and Z. Huang. Physical properties of graphene-oxide modified asphalt and performance analysis of its mixtures using response surface methodology. International Journal of Pavement Engineering, Vol. 23, No. 5, 2022, pp. 1378–1392.10.1080/10298436.2020.1804061Search in Google Scholar

[27] Adnan, A. M., C. Lü, X. Luo, and J. Wang. High-temperature rheological characteristics of asphalt binder incorporated with graphene oxide and predicting its rutting potential using response surface method. Journal of Materials in Civil Engineering, Vol. 33, No. 11, 2021, id. 04021331.10.1061/(ASCE)MT.1943-5533.0003957Search in Google Scholar

[28] Yuan J, Lv S, Peng X, Liu K. Comprehensive Properties Evaluation of Modified Bio-Asphalt Mixture Based on Comparison Matrix. Journal of Materials in Civil Engineering, Vol. 36, No. 3, 2024, id. 04023616.10.1061/JMCEE7.MTENG-16740Search in Google Scholar

[29] Deng, J. L. The elements of gray system, Press of Huazhong University of Science and Technology, Wuhan, 2002, pp. 63–170.Search in Google Scholar

[30] Tian, Q. The research on preparation for pyrolytic carbon black from used tire asphalt and performance for the mixture. Changsha University of Technology, Changsha, 2015.Search in Google Scholar

[31] Zhou, Q. Study on influence of glass fiber length on road performance of different grade asphalt mixtures with various grades. China Foreign Highway, Vol. 41, No. 1, 2021, pp. 284–289.Search in Google Scholar

[32] Li, C, Li Z., Gan Y., and Deng Q. Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber. Reviews on Advanced Materials Science, Vol. 62, No. 1, 2023, id. 20230143.10.1515/rams-2023-0143Search in Google Scholar

[33] Peng, C., P. Chen, Z. You, S. Lv, R. Zhang, F. Xu, et al. Effect of silane coupling agent on improving the adhesive properties between asphalt binder and aggregates. Construction and Building Materials, Vol. 169, 2018, pp. 591–600.10.1016/j.conbuildmat.2018.02.186Search in Google Scholar

[34] Lu, P., S. Huang, Y. Shen, Y. Wu, and D. Li. Mix design of asphalt plug joint based on response surface method and grey relational analysis. International Journal of Pavement Engineering, Vol. 24, No. 2, 2022, pp. 1–11.10.1080/10298436.2022.2032699Search in Google Scholar

[35] Zhang, M., H. Zhao, L. Fan, and J. Yi. Dynamic modulus prediction model and analysis of factors influencing asphalt mixtures using gray relational analysis methods. Journal of Materials Research and Technology, Vol. 19, 2022, pp. 1312–1321.10.1016/j.jmrt.2022.05.120Search in Google Scholar

[36] Baghaee Moghaddam, T., M. Soltani, M. R. Karim, and H. Baaj. Optimization of asphalt and modifier contents for polyethylene terephthalate modified asphalt mixtures using response surface methodology. Measurement, Vol. 74, 2015, pp. 159–169.10.1016/j.measurement.2015.07.012Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Effect of superplasticizer in geopolymer and alkali-activated cement mortar/concrete: A review

- Experimenting the influence of corncob ash on the mechanical strength of slag-based geopolymer concrete

- Powder metallurgy processing of high entropy alloys: Bibliometric analysis and systematic review

- Exploring the potential of agricultural waste as an additive in ultra-high-performance concrete for sustainable construction: A comprehensive review

- A review on partial substitution of nanosilica in concrete

- Foam concrete for lightweight construction applications: A comprehensive review of the research development and material characteristics

- Modification of PEEK for implants: Strategies to improve mechanical, antibacterial, and osteogenic properties

- Interfacing the IoT in composite manufacturing: An overview

- Advances in processing and ablation properties of carbon fiber reinforced ultra-high temperature ceramic composites

- Advancing auxetic materials: Emerging development and innovative applications

- Revolutionizing energy harvesting: A comprehensive review of thermoelectric devices

- Exploring polyetheretherketone in dental implants and abutments: A focus on biomechanics and finite element methods

- Smart technologies and textiles and their potential use and application in the care and support of elderly individuals: A systematic review

- Reinforcement mechanisms and current research status of silicon carbide whisker-reinforced composites: A comprehensive review

- Innovative eco-friendly bio-composites: A comprehensive review of the fabrication, characterization, and applications

- Review on geopolymer concrete incorporating Alccofine-1203

- Advancements in surface treatments for aluminum alloys in sports equipment

- Ionic liquid-modified carbon-based fillers and their polymer composites – A Raman spectroscopy analysis

- Emerging boron nitride nanosheets: A review on synthesis, corrosion resistance coatings, and their impacts on the environment and health

- Mechanism, models, and influence of heterogeneous factors of the microarc oxidation process: A comprehensive review

- Synthesizing sustainable construction paradigms: A comprehensive review and bibliometric analysis of granite waste powder utilization and moisture correction in concrete

- 10.1515/rams-2025-0086

- Research Articles

- Coverage and reliability improvement of copper metallization layer in through hole at BGA area during load board manufacture

- Study on dynamic response of cushion layer-reinforced concrete slab under rockfall impact based on smoothed particle hydrodynamics and finite-element method coupling

- Study on the mechanical properties and microstructure of recycled brick aggregate concrete with waste fiber

- Multiscale characterization of the UV aging resistance and mechanism of light stabilizer-modified asphalt

- Characterization of sandwich materials – Nomex-Aramid carbon fiber performances under mechanical loadings: Nonlinear FE and convergence studies

- Effect of grain boundary segregation and oxygen vacancy annihilation on aging resistance of cobalt oxide-doped 3Y-TZP ceramics for biomedical applications

- Mechanical damage mechanism investigation on CFRP strengthened recycled red brick concrete

- Finite element analysis of deterioration of axial compression behavior of corroded steel-reinforced concrete middle-length columns

- Grinding force model for ultrasonic assisted grinding of γ-TiAl intermetallic compounds and experimental validation

- Enhancement of hardness and wear strength of pure Cu and Cu–TiO2 composites via a friction stir process while maintaining electrical resistivity

- Effect of sand–precursor ratio on mechanical properties and durability of geopolymer mortar with manufactured sand

- Research on the strength prediction for pervious concrete based on design porosity and water-to-cement ratio

- Development of a new damping ratio prediction model for recycled aggregate concrete: Incorporating modified admixtures and carbonation effects

- Exploring the viability of AI-aided genetic algorithms in estimating the crack repair rate of self-healing concrete

- Modification of methacrylate bone cement with eugenol – A new material with antibacterial properties

- Numerical investigations on constitutive model parameters of HRB400 and HTRB600 steel bars based on tensile and fatigue tests

- Research progress on Fe3+-activated near-infrared phosphor

- Discrete element simulation study on effects of grain preferred orientation on micro-cracking and macro-mechanical behavior of crystalline rocks

- Ultrasonic resonance evaluation method for deep interfacial debonding defects of multilayer adhesive bonded materials

- Effect of impurity components in titanium gypsum on the setting time and mechanical properties of gypsum-slag cementitious materials

- Bending energy absorption performance of composite fender piles with different winding angles

- Theoretical study of the effect of orientations and fibre volume on the thermal insulation capability of reinforced polymer composites

- Synthesis and characterization of a novel ternary magnetic composite for the enhanced adsorption capacity to remove organic dyes

- Couple effects of multi-impact damage and CAI capability on NCF composites

- Mechanical testing and engineering applicability analysis of SAP concrete used in buffer layer design for tunnels in active fault zones

- Investigating the rheological characteristics of alkali-activated concrete using contemporary artificial intelligence approaches

- Integrating micro- and nanowaste glass with waste foundry sand in ultra-high-performance concrete to enhance material performance and sustainability

- Effect of water immersion on shear strength of epoxy adhesive filled with graphene nanoplatelets

- Impact of carbon content on the phase structure and mechanical properties of TiBCN coatings via direct current magnetron sputtering

- Investigating the anti-aging properties of asphalt modified with polyphosphoric acid and tire pyrolysis oil

- Biomedical and therapeutic potential of marine-derived Pseudomonas sp. strain AHG22 exopolysaccharide: A novel bioactive microbial metabolite

- Effect of basalt fiber length on the behavior of natural hydraulic lime-based mortars

- Optimizing the performance of TPCB/SCA composite-modified asphalt using improved response surface methodology

- Compressive strength of waste-derived cementitious composites using machine learning

- Melting phenomenon of thermally stratified MHD Powell–Eyring nanofluid with variable porosity past a stretching Riga plate

- Development and characterization of a coaxial strain-sensing cable integrated steel strand for wide-range stress monitoring

- Compressive and tensile strength estimation of sustainable geopolymer concrete using contemporary boosting ensemble techniques

- Customized 3D printed porous titanium scaffolds with nanotubes loading antibacterial drugs for bone tissue engineering

- Facile design of PTFE-kaolin-based ternary nanocomposite as a hydrophobic and high corrosion-barrier coating

- Effects of C and heat treatment on microstructure, mechanical, and tribo-corrosion properties of VAlTiMoSi high-entropy alloy coating

- Study on the damage mechanism and evolution model of preloaded sandstone subjected to freezing–thawing action based on the NMR technology

- Promoting low carbon construction using alkali-activated materials: A modeling study for strength prediction and feature interaction

- Entropy generation analysis of MHD convection flow of hybrid nanofluid in a wavy enclosure with heat generation and thermal radiation

- Friction stir welding of dissimilar Al–Mg alloys for aerospace applications: Prospects and future potential

- Fe nanoparticle-functionalized ordered mesoporous carbon with tailored mesostructures and their applications in magnetic removal of Ag(i)

- Study on physical and mechanical properties of complex-phase conductive fiber cementitious materials

- Evaluating the strength loss and the effectiveness of glass and eggshell powder for cement mortar under acidic conditions

- Effect of fly ash on properties and hydration of calcium sulphoaluminate cement-based materials with high water content

- Analyzing the efficacy of waste marble and glass powder for the compressive strength of self-compacting concrete using machine learning strategies

- Experimental study on municipal solid waste incineration ash micro-powder as concrete admixture

- Parameter optimization for ultrasonic-assisted grinding of γ-TiAl intermetallics: A gray relational analysis approach with surface integrity evaluation

- Producing sustainable binding materials using marble waste blended with fly ash and rice husk ash for building materials

- Effect of steam curing system on compressive strength of recycled aggregate concrete

- A sawtooth constitutive model describing strain hardening and multiple cracking of ECC under uniaxial tension

- Predicting mechanical properties of sustainable green concrete using novel machine learning: Stacking and gene expression programming

- Toward sustainability: Integrating experimental study and data-driven modeling for eco-friendly paver blocks containing plastic waste

- A numerical analysis of the rotational flow of a hybrid nanofluid past a unidirectional extending surface with velocity and thermal slip conditions

- A magnetohydrodynamic flow of a water-based hybrid nanofluid past a convectively heated rotating disk surface: A passive control of nanoparticles

- Prediction of flexural strength of concrete with eggshell and glass powders: Advanced cutting-edge approach for sustainable materials

- Efficacy of sustainable cementitious materials on concrete porosity for enhancing the durability of building materials

- Phase and microstructural characterization of swat soapstone (Mg3Si4O10(OH)2)

- Effect of waste crab shell powder on matrix asphalt

- Improving effect and mechanism on service performance of asphalt binder modified by PW polymer

- Influence of pH on the synthesis of carbon spheres and the application of carbon sphere-based solid catalysts in esterification

- Experimenting the compressive performance of low-carbon alkali-activated materials using advanced modeling techniques

- Thermogravimetric (TG/DTG) characterization of cold-pressed oil blends and Saccharomyces cerevisiae-based microcapsules obtained with them

- Investigation of temperature effect on thermo-mechanical property of carbon fiber/PEEK composites

- Computational approaches for structural analysis of wood specimens

- Integrated structure–function design of 3D-printed porous polydimethylsiloxane for superhydrophobic engineering

- Exploring the impact of seashell powder and nano-silica on ultra-high-performance self-curing concrete: Insights into mechanical strength, durability, and high-temperature resilience

- Axial compression damage constitutive model and damage characteristics of fly ash/silica fume modified magnesium phosphate cement after being treated at different temperatures

- Integrating testing and modeling methods to examine the feasibility of blended waste materials for the compressive strength of rubberized mortar

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part II

- Energy absorption of gradient triply periodic minimal surface structure manufactured by stereolithography

- Marine polymers in tissue bioprinting: Current achievements and challenges

- Quick insight into the dynamic dimensions of 4D printing in polymeric composite mechanics

- Recent advances in 4D printing of hydrogels

- Mechanically sustainable and primary recycled thermo-responsive ABS–PLA polymer composites for 4D printing applications: Fabrication and studies

- Special Issue on Materials and Technologies for Low-carbon Biomass Processing and Upgrading

- Low-carbon embodied alkali-activated materials for sustainable construction: A comparative study of single and ensemble learners

- Study on bending performance of prefabricated glulam-cross laminated timber composite floor

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part I

- Supplementary cementitious materials-based concrete porosity estimation using modeling approaches: A comparative study of GEP and MEP

- Modeling the strength parameters of agro waste-derived geopolymer concrete using advanced machine intelligence techniques

- Promoting the sustainable construction: A scientometric review on the utilization of waste glass in concrete

- Incorporating geranium plant waste into ultra-high performance concrete prepared with crumb rubber as fine aggregate in the presence of polypropylene fibers

- Investigation of nano-basic oxygen furnace slag and nano-banded iron formation on properties of high-performance geopolymer concrete

- Effect of incorporating ultrafine palm oil fuel ash on the resistance to corrosion of steel bars embedded in high-strength green concrete

- Influence of nanomaterials on properties and durability of ultra-high-performance geopolymer concrete

- Influence of palm oil ash and palm oil clinker on the properties of lightweight concrete

Articles in the same Issue

- Review Articles

- Effect of superplasticizer in geopolymer and alkali-activated cement mortar/concrete: A review

- Experimenting the influence of corncob ash on the mechanical strength of slag-based geopolymer concrete

- Powder metallurgy processing of high entropy alloys: Bibliometric analysis and systematic review

- Exploring the potential of agricultural waste as an additive in ultra-high-performance concrete for sustainable construction: A comprehensive review

- A review on partial substitution of nanosilica in concrete

- Foam concrete for lightweight construction applications: A comprehensive review of the research development and material characteristics

- Modification of PEEK for implants: Strategies to improve mechanical, antibacterial, and osteogenic properties

- Interfacing the IoT in composite manufacturing: An overview

- Advances in processing and ablation properties of carbon fiber reinforced ultra-high temperature ceramic composites

- Advancing auxetic materials: Emerging development and innovative applications

- Revolutionizing energy harvesting: A comprehensive review of thermoelectric devices

- Exploring polyetheretherketone in dental implants and abutments: A focus on biomechanics and finite element methods

- Smart technologies and textiles and their potential use and application in the care and support of elderly individuals: A systematic review

- Reinforcement mechanisms and current research status of silicon carbide whisker-reinforced composites: A comprehensive review

- Innovative eco-friendly bio-composites: A comprehensive review of the fabrication, characterization, and applications

- Review on geopolymer concrete incorporating Alccofine-1203

- Advancements in surface treatments for aluminum alloys in sports equipment

- Ionic liquid-modified carbon-based fillers and their polymer composites – A Raman spectroscopy analysis

- Emerging boron nitride nanosheets: A review on synthesis, corrosion resistance coatings, and their impacts on the environment and health

- Mechanism, models, and influence of heterogeneous factors of the microarc oxidation process: A comprehensive review

- Synthesizing sustainable construction paradigms: A comprehensive review and bibliometric analysis of granite waste powder utilization and moisture correction in concrete

- 10.1515/rams-2025-0086

- Research Articles

- Coverage and reliability improvement of copper metallization layer in through hole at BGA area during load board manufacture

- Study on dynamic response of cushion layer-reinforced concrete slab under rockfall impact based on smoothed particle hydrodynamics and finite-element method coupling

- Study on the mechanical properties and microstructure of recycled brick aggregate concrete with waste fiber

- Multiscale characterization of the UV aging resistance and mechanism of light stabilizer-modified asphalt

- Characterization of sandwich materials – Nomex-Aramid carbon fiber performances under mechanical loadings: Nonlinear FE and convergence studies

- Effect of grain boundary segregation and oxygen vacancy annihilation on aging resistance of cobalt oxide-doped 3Y-TZP ceramics for biomedical applications

- Mechanical damage mechanism investigation on CFRP strengthened recycled red brick concrete