Abstract

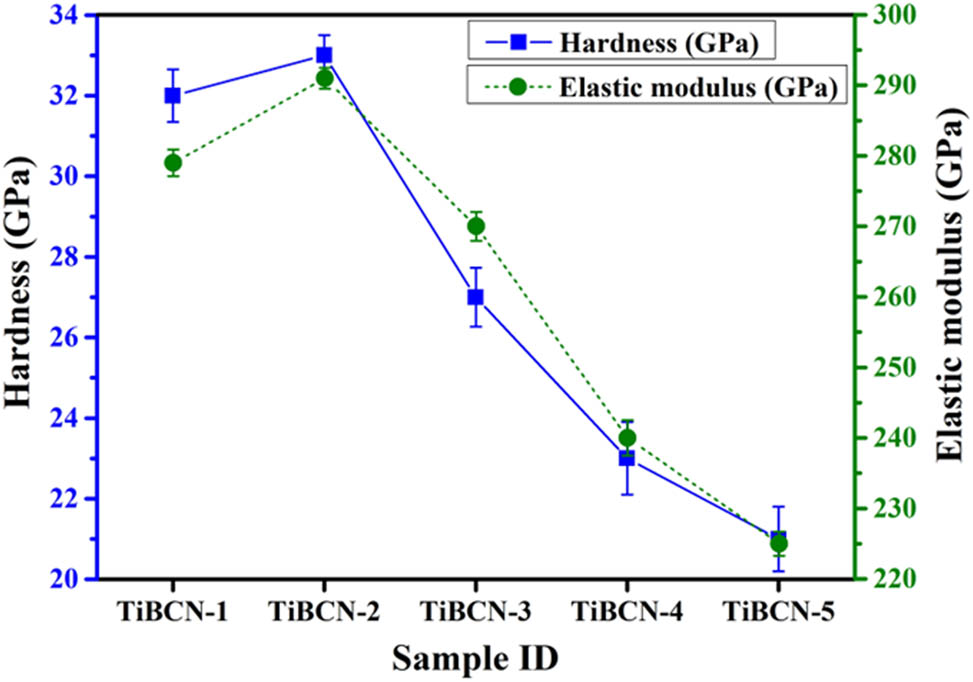

In this study, unbalanced direct current magnetron sputtering was employed to develop TiBCN coatings on Si (100) wafers. The carbon (C) concentration was varied to manipulate the phase structure and mechanical properties of the coatings. The coatings were analyzed using Raman spectroscopy, scanning electron microscopy, X-ray diffraction, X-ray photoelectron spectroscopy, and nanoindentation. The results revealed that the TiBCN-2 coating, with a C concentration of 4.4 at.%, exhibited optimal hardness and elastic modulus values of 33 and 291 GPa, respectively. On the other hand, as the C content increased from 4.4 to 24.4 at.%, the hardness and elastic modulus values of the coatings decreased to 21 and 225 GPa, respectively, due to the formation of boron nitride and carbon phases within the coating matrix. Therefore, the inclusion of an ideal C concentration can considerably improve the properties of TiBCN coatings, thus rendering the coating a desirable material for cutting tools.

1 Introduction

The engineering sector has grown quickly, resulting in an increase in the number of machine parts that can operate under various circumstances. Coatings that are based on borides, carbides, and nitrides, specifically TiB, TiC, TiN, TiB2, TiBC, TiCN, TiBN, and TiBCN, are of great importance in determining the functional properties of machining tools [1,2,3]. These coatings are carefully selected to optimize performance and longevity of the tool. For cutting tools, the T(C, N) ceramic component in cermet is particularly valuable due to its high refractoriness, wear and corrosion resistance, hardness, edge strength, edge sharpness, low density, and conductivity [4,5,6,7,8,9]. Similar to this, Ti(C, N)-based cermet is also utilized in automotive parts, bearings, and gas turbine components [10]. TiB2 ultra-high temperature ceramic is used for high-temperature structural components due to its high specific strength and endurance [11,12]. Research has shown that combining TiB2 and Ti(CN) compounds in ceramic composites can be used for a variety of applications due to their superior mechanical capabilities to those of individual ceramic components [13,14,15,16]. Other comparable nanocomposite hard coating systems that combine improved hardness, toughness, and reduced coefficient of friction have proven to be significant [3,17]. These systems, such as TiB, TiC, TiN, and TiB2 compounds, do this by adding various materials gradually and intelligently to a hard single-component phase.

To further enhance the quality of these ceramic compounds, a novel and intriguing material based on the TiBCN composite has been developed [2]. As in the Ti(C, N) ceramic phase [2,18], these nanocomposites exhibit a face-centered cubic structure, where boron (B) is positioned in the same crystallographic position as carbon (C) and nitrogen (N). The unique properties of the TiBCN composite are mostly based on solid solution hardening. It is envisaged that nanometric TiCN and TiB2 would embed during this solid solution hardening process as amorphous boron nitride (BN) and carbon matrix are formed. The change in the C contents within the coating matrix is anticipated to significantly influence the phase structure and mechanical properties of TiBCN coatings. In order to correlate the structure of the phase with the mechanical properties of the resulting TiBCN coatings, the current work aims to investigate the effect of C concentration (ranging from 0.0 to 24.4 at.%) in an unbalanced direct current (DC) magnetron sputtering of TiBCN coatings onto Si (100) substrates. Raman spectroscopy, X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), and optical microscopy methods were used to investigate the phase structure of the TiBCN coatings. However, the nanoindentation method was used to determine the mechanical properties.

2 Experiment

2.1 TiBCN coating deposition on wafers

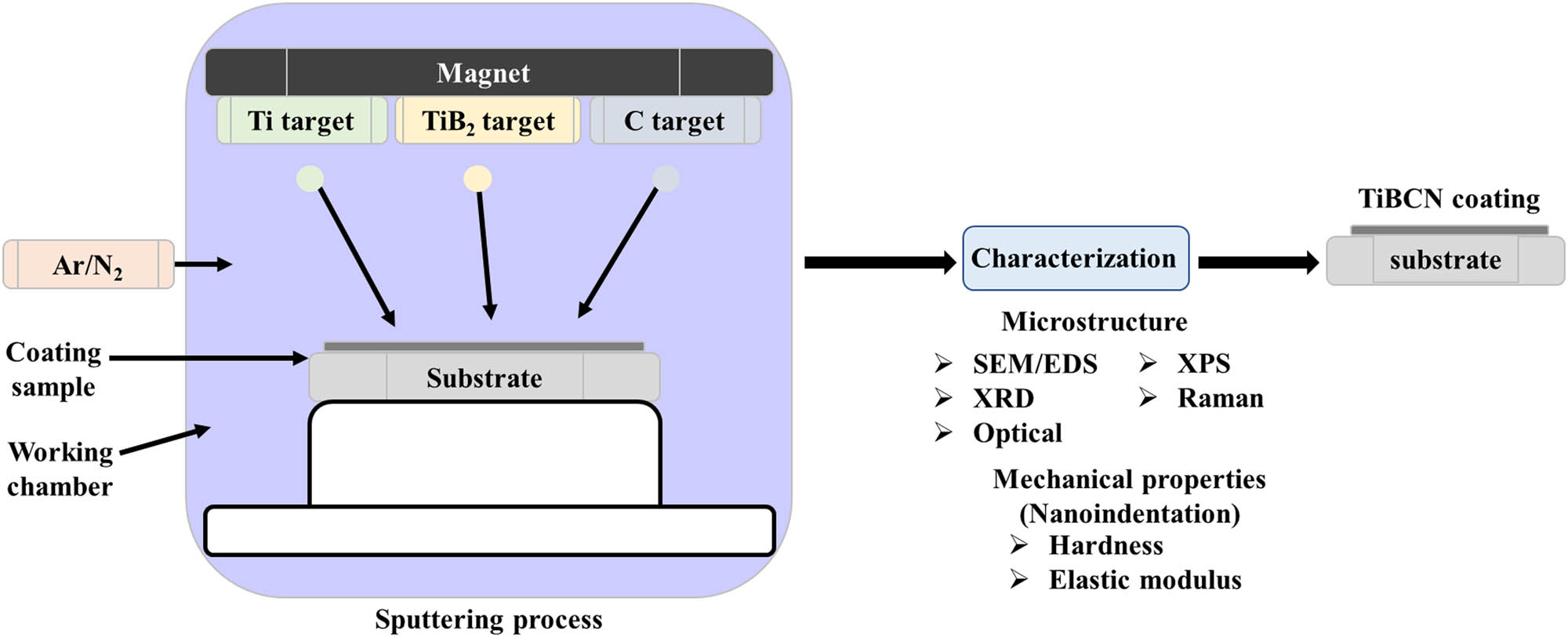

Thin films of TiBCN were deposited onto Si(100) substrates using unbalanced DC-magnetron sputtering equipment (UDP450, Teer Coating Limited). The deposition process involved the use of one Ti, one TiB2, and two C targets. To achieve coatings with different carbon content, the C target current was varied from 0.0 to 2.0 A, while the Ti target current and TiB2 target current were held constant at 6.0 and 3.0 A, respectively. The process enabled the deposition of TiBCN coatings that differed in their carbon content. The coatings were designated as TiBCN-1 (0 at.% C), TiBCN-2 (4.4 at.% C), TiBCN-3 (12.4 at.% C), TiBCN-4 (19.2 at.% C), and TiBCN-5 (24.4 at.% C). The substrate rotation speed was maintained at 15 rpm, while the substrate bias voltage was −60 V. The process was carried out under an operating pressure of 0.26 Pa, and the amount of nitrogen added to the chamber was measured using a computer-controlled optical emission spectroscopy instrument set at 80%. Prior to the deposition, the surface of the substrate was maintained at a negative bias voltage of 500 V for 30 min with Ar plasma. Next, a Ti buffer layer of 100 nm in thickness was deposited. The objective of depositing this Ti buffer layer was to not only increase the coating adhesion but also decrease the stress at the interface with the Si (100) substrate. Due to plasma heating, the substrate temperature was estimated to be around 200°C during deposition. The schematic diagram depicting the experimental set-up, followed by the characterization technique, is presented in Figure 1.

Schematic diagram of DC magnetron sputtering deposition of TiBCN coatings.

2.2 Characterization

X-ray photoelectron spectroscopy (XPS, PHI 5802 system) with a monochromatic Al Kα X-ray source (h = 1486.6 eV) was used to investigate elemental concentration and the bonding status in the coatings. The surface morphology and composition of the coatings were analyzed using the scanning electron microscope (ESEM Quanta 200 SEM) equipped with an energy-dispersive X-ray spectroscopy (EDS) detector at 25 kV. LABRAM HR-800 Raman spectroscope was used to examine the chemical substance and structure of the coatings. Using a Rigaku MiniFlex diffractometer, operating at 40 kV and 30 mA, XRD was used to determine the crystalline structure of the coatings. Cu Kα radiation was used for the experiments, and an Ni filter was used to cut off Cu Kα reflections. Using a trigonal Berkovich diamond tip indenter with a maximum load of 1,000 mN, nanoindentation studies were used to determine the elastic modulus and nano-hardness. For calibration reasons, the hardness value of a fused silica sample was routinely verified. Ten different measurements were made for each sample to calculate the mean. By employing a Teer 3001 scratch tester, the cohesive and adhesive strengths of the coatings were evaluated. A diamond indenter with a 0.2 mm radius was moved across the coatings at a sliding velocity of 10 nm·min−1 and a loading rate of 100 N·min−1.

3 Results and discussion

Figure 2 displays the elemental concentration of TiBCN coatings (atomic percentage (at.%)). According to Figure 2, the C concentration increases linearly as the C target current increases from 0.0 to 2.0 A, whereas the Ti and N atomic concentrations within the coating matrix show the reverse trend. It was determined that B’s atomic concentration in the coating matrix is between 10.5 and 14.4 at.%. The observed differences in the concentration of the elements in Figure 2 can be attributed to the various phase formations within the coatings matrix, as detailed later in the Raman and XRD results, which may have an impact on the mechanical properties of the coatings. Figure 3 shows the observed scanning electron microscopy (SEM) images of the cross-sectional morphology of the TiBCN coatings. According to the cross-section SEM images of the TiBCN film, the overall coating thickness is around ∼1 μm for all coating conditions, with the exception of TiBCN-5, which shows a thickness of 0.68 μm. Additionally, the cross-sectional view of the coatings appears to be uniform across all coatings conditions.

Elemental composition of TiBCN coatings at different C concentrations.

SEM cross-sectional images of TiBCN coatings at different C concentrations.

The Raman spectra were obtained to compare the C–C bonding structure present in different TiBCN coatings. The coatings were tested at varying C concentrations, ranging from 0 to 24.4 at.% in the wave range of 1,000–2,000 cm−1 (as shown in Figures 4 and 5). The inset figures in Figure 4 illustrate the spectra fitting using the Gaussian function to determine the peak area and the full-width half maximum (FWHM). The G peak, representing sp²-C (sp²-bond), and the D peaks, representing sp³-C (sp³-bond), are depicted in Figure 5(a)–(e) at approximately 1,581 and 1,385 cm−1, respectively [19,20]. Figure 5(a) illustrates the peak area ratio (I D/I G) as a function of the C target current, which represents the ratio of sp3 and sp2 in the coating. The I D/I G ratio falls from 1.0079 to 0.9681 as the C concentration increases from 0 to 4.4 at.%, indicating a minor increase in the sp3 content due to the additional B and N atoms that prevent the formation of a graphite-like structure. As the C concentration increases from 4.4 to 24.4 at.%, the ratio increases to 1.0240, indicating an increase in the sp2-C concentration and the graphitic characteristics of the coatings after C incorporation. The position and peak width (FWHM) of the G and D peaks change with the C concentration, as shown in Figure 5(b) and (c). The G peak width (FWHM) measures the bond length and bond angle disorder in sp2 clusters. The size and strain of the sp2 clusters inside the sp3 network increase as the sp3 content decreases, leading to lower length and bond angle disorder and reducing G peak width [21]. As the C concentration increases in Figure 5(b), the G peak position shows only minor fluctuations in the limited range of 1583.64 to 1582.24 cm−1, indicating a slight change in the coatings’ sp2 and sp3 content. The little shift in the G peak width is similarly accompanied by an increase in the sp2 contents in the 120.59–121.41 cm−1 range.

Raman spectra of TiBCN coatings at (a) 0 at.% C, (b) 4.4 at.% C, (c) 12.4 at.% C, (d) 19.2 at.% C, and (e) 24.4 at.% C concentration.

Raman parameters determined by Gaussian curve-fitting of TiBCN coatings (a) I D/I G ratio, (b) G peak position and width, and (c) D peak position and width.

The XRD patterns of TiBCN coatings at various C concentrations are depicted in Figure 6. The TiBCN coating displayed an intensity peak at 32.99° that corresponds to a hexagonal TiB2-type (100) at 0 at.% C. The orientation of the coating to TiB-type (111) after adding C to the film, along with the disappearance/low intensity of the TiB2-type (100) and the coating’s broadness, points to the possibility that the C in the coating matrix exists as either interstitial or substitutional atoms in the TiB2 lattice [22]. It is important to note that both TiN and TiC possess NaCl structures in which, at the corners of the face center cubic structure, Ti atoms are distributed, whereas C or N atoms exist at the interstitial sites of the octahedron. Additionally, the Scherrer formula was used to determine the crystallite size of the TiBCN coatings [23]. The calculated crystallite sizes are 39.70, 34.9, 27.5, 31.8, and 19.5 nm for the coating with C concentrations ranging from 0 to 24.4 at.%, respectively. This suggests that the inclusion of C into the TiBCN matrix will affect how the coating grows.

XRD patterns of TiBCN coatings at different C concentrations.

XPS was used to characterize the chemical binding states of the TiBCN coatings at various C concentrations between 0 and 24.4 at.%. Figure 7 displays the Ti 2p, B 1s, C 1s, and N 1s XPS core level spectra. The coatings showed identical Ti 2p3/2 and Ti 2p1/2 peaks in the Ti 2p spectra shown in Figures 7(a), 8(a), 9(a), 10(a) and 11(a) at energies of 454.5 and 460.25 eV, respectively. Due to the near binding energies of TiC (454.5/460.5 eV), TiN (455.5/462 eV), and Ti(C, N) (457/463.9), the Ti atoms might be bound to both B, C, and N atoms, as shown by these binding energies (i.e., 454.5 and 460.25 eV) [24]. The Ti 2p3/2 and Ti 2p1/2 peaks gradually move towards the higher binding energy as the C content in the coatings rises, which is a sign of a decline in the TiB and an increase in the TiN bonds in the coatings.

XPS spectra of (a) Ti 2p, (b) B 1s, (c) C 1s, and (d) N 1s energy regions of TiBCN-1 coatings at 0 at.% C concentrations.

XPS spectra of Ti 2p, B 1s, C 1s, and N 1s energy regions of TiBCN-2 coatings at 4.4 at.% C concentrations.

XPS spectra of Ti 2p, B 1s, C 1s, and N 1s energy regions of TiBCN-3 coatings at 12.4 at.% C concentrations.

XPS spectra of Ti 2p, B 1s, C 1s, and N 1s energy regions of TiBCN-4 coatings at 19.2 at.% C concentrations.

XPS spectra of Ti 2p, B 1s, C 1s, and N 1s energy regions of TiBCN-5 coatings at 24.4 at.% C concentrations.

Figures 7(b), 8(b), 9(b), 10(b) and 11(b) B 1s spectra demonstrate the presence of B (189.3 eV) and BN (190.6 eV) bonding states. The intensity of the BN component inside the coatings matrix dramatically rises with an increase in the C contents. It is assumed that the BN phase in the coatings is in the amorphous condition because the XRD patterns showed no sign of crystalline h-BN. The N–(Ti, C) (396.7 eV), N–Ti (397.1 eV), and B–N (398.2 eV) bonding states made up the three primary species of the N 1s spectra in Figures 7(d), 8(d), 9(d), 10(d) and 11(d). As the coatings’ C concentrations rise, the N–(Ti, C) component’s intensity also rises.

The low C concentration in the TiBCN-1 coating is the reason why Figure 7(c) does not display a significant spectra component, but Figures 8(c), 9(c), 10(c) and 11(c) all show three substantial components in the C 1s spectra at the binding energies of 281.5, 282, and 284 eV. The component at the binding energy 281.5 eV indicates the potential formation of a metal carbide in the form of Ti–(B, C), while the component at the binding energy 282.5 eV is attributed to the sp2 amorphous C–C bonding and the component at the binding energy of 284 eV is a possible indication of the formation of the CN phase. Although a gradual chemical shift of the Ti–(B, C) peak with increasing C contents has been detected, this suggests that there were fewer B atoms linked to C atoms in the T–(B, C) solid solution.

Figure 12 displays the elastic modulus and hardness of TiBCN coatings with various C concentrations. When C with a concentration of 4.4 at.% is added, the hardness changes from 32 to 33 GPa, and the elastic modulus rises from 279 to 291 GPa. The coating’s hardness and elastic modulus drop to 21 and 225 GPa, respectively, as the C concentration is raised to 24.4 at.% in the coating. The observed alterations in the coating’s phase structure, as determined by XRD (Figure 6), can be used to explain these changes. An indicator that the compressive stress and micro-hardness are decreasing, for instance, is a shift in the diffraction peak to a higher 2θ angle [20,25]. The production of an amorphous graphitic structure in the coatings is explained by the D and G peaks in the Raman spectra, but this structure can reduce the hardness of the coating due to its poor shear strength [1]. This study found that the TiBCN-2 coating’s amorphous C content, particularly the sp2 content, had decreased. This finding was supported by a decline in the I D/I G ratio from 1.0079 to 0.9681 (Figure 5(a)). The I D/I G ratio rises to 1.0240 when the C concentration rises from 4.4 to 24.4 at.%. Consequently, the elastic modulus and hardness both drop (Figure 12).

Hardness and elastic modulus of TiBCN coatings at different C concentrations.

The cohesive and adhesive properties of the TiBCN coatings at different C concentrations were evaluated using scratch adhesion tests with increasing loads ranging from 10 to 80 N. Table 1 shows the calculated critical load values for cohesive (L C1) and adhesive (L C2) failure. The critical load is influenced by testing parameters used, like loading rate, indenter radius, scratching speed, coating thickness, friction coefficient, and residual stress [1]. The information on the frictional and plastic deformation of the coating system is contained in the friction coefficient (Ft/Fn). The critical loads were ascertained from the acquired friction plots (Friction [N] versus load [N]) shown in Figure 13 by examining the first and second onsets of significantly abrupt fluctuation in the friction forces. The TiBCN-1 micrograph in Figure 12 shows chipping, conformal buckling, or interfacial spallation at a critical load, L C1 = 39 N (i.e., C-free coating). Chipping results from a surface or internal crack. Furthermore, the second start of the increased frictional force curve that yields adhesive failure values comes at critical load LC2, which is a point of inflection. The TiBCN-1 coating has an LC2 greater than 65 N. Additionally, the acoustic emission (AE) signal is used to determine the L C values since the crack detected by the AE transducer produces an AE signal. All of the coating samples had distinct AE events that provided details on the extent of coating damage, which is shown in Figure 13. Critical load levels and frictional curves match up nicely. The outcome was identical, with L C1 equaling 42 N when the C concentration increased from 0 to 4.4 at.%. The beginning of cracking at the edges of the scratch track, which is plainly evident, is indicated by L C1 in accordance with the AE signal curves of TiBCN-3, TiBCN-4, and TiBCN-5 coatings.

Scratch test measurements of TiBCN coatings with different C concentrations

| Sample | TiBCN-1 | TiBCN-2 | TiBCN-3 | TiBCN-4 | TiBCN-5 |

|---|---|---|---|---|---|

| L C1 a (N) | 39 | 42 | 27 | 27 | 17 |

| L C2 b (N) | >65 | >75 | >75 | >75 | >75 |

L C1 a (N) is the critical load for cohesive failure and defined as the load at which the coating shows first chipping on the scratch track. L C2 b (N) is the critical load for adhesive failure and defined as the load at which the substrate is showed on the scratch track.

Frictional and AE signal versus load of TiBCN coatings at different C concentrations.

However, the first abrupt rise of the acoustic signal cannot be used alone to understand the L C values [1]. The straightforward acoustic signal is insufficient to assess the coating strength due to the intricacy of the contact and failure mechanism. As a result, all the coating samples were subjected to a scratch examination in order to assess the adhesion strength of coatings. The optical micrographs of all the TiBCN coating failure behaviors are displayed in Figure 14 as a result. However, when the C concentration increased, the scratch track underwent plastic deformation without spallation or chipping, as shown by the optical micrograph of TiBCN-3, TiBCN-4, and TiBCN-5 in Figure 14. The critical loads have been established and are shown in Table 1 after accounting for the frictional plots, AE signal, and optical observations.

Optical micrographs displaying the scratch trails on TiBCN coatings at different C concentrations.

4 Conclusion

TiBCN coatings were deposited onto Si (100) wafer substrates using an unbalanced DC magnetron sputtering approach, with a range of C concentrations from 0 to 24.4 at.%. XRD analysis determined that the coatings contained crystalline phases of TiB2/Ti(B, C), TN/Ti(C, N), and Ti2B5 within the amorphous phase of the coating matrix. XPS spectrum analysis showed the presence of Ti(B, C), Ti(C, N), TiN, BN, B–C, Ti–N, sp2C–C, and sp3C in the TiBCN coatings. Among the coatings, the TiBCN-2 (4.4 at.% C) demonstrated the optimal hardness and elastic modulus of 33 and 291 GPa, respectively. As the C concentration increased in the TiBCN coatings, the nano-hardness and elastic modulus decreased. The increased nano-hardness and elastic modulus of the TiBCN-2 coatings were attributed to the low amorphous phase fraction and declining sp3/sp2 ratio.

Acknowledgments

The authors are grateful to Dr. Z.F. Zhou from the Department of Mechanical Engineering, City University of Hong Kong for aiding with the laboratory facilities. The authors also would like to thank for the funding support to the State Key Laboratories in Hong Kong from the Innovation and Technology Commission (ITC) of the Government of the Hong Kong Special Administrative Region (HKSAR), China (Project code: BBX5, BBXC).

-

Funding information: The research activities were supported by the Innovation and Technology Commission (ITC) of the Government of the Hong Kong Special Administrative Region (HKSAR), China (Project code: BBX5, BBXC).

-

Author contributions: Anand Vyas: conceived and designed the experiments; performed the experiments; contributed reagents, materials, analysis tools, or data; wrote the article. Ahmed Aliyu: analyzed and interpreted the data; wrote the article. Gary Chi-Pong Tsui: analyzed and reviewed. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Cheng, Y. H., T. Browne, B. Heckerman, and E. I. Meletis. Influence of the C content on the mechanical and tribological properties of the TiCN coatings deposited by LAFAD technique. Surface and Coatings Technology, Vol. 205, 2011, pp. 4024–4029.10.1016/j.surfcoat.2011.02.032Search in Google Scholar

[2] Lin, J. L., J. J. Moore, B. Mishra, M. Pinkas, and W. D. Sproul. The structure and mechanical and tribological properties of TiBCN nanocomposite coatings. Acta Materialia, Vol. 58, 2010, pp. 1554–1564.10.1016/j.actamat.2009.10.063Search in Google Scholar

[3] Mishra, S. K. Toughening of nanocomposite hard coatings. Reviews on Advanced Materials Science, Vol. 59, 2020, pp. 553–585.10.1515/rams-2020-0049Search in Google Scholar

[4] Zhang, H., J. Yan, X. Zhang, and S. Tang. Properties of titanium carbonitride matrix cermets. International Journal of Refractory Metals and Hard Materials, Vol. 24, 2006, pp. 236–239.10.1016/j.ijrmhm.2005.05.009Search in Google Scholar

[5] Chicardi, E., J. M. Cordoba, and F. J. Gotor. High temperature oxidation resistance of (Ti, Ta)(C,N)-based cermets. Corrosion Science, Vol. 102, 2016, pp. 125–136.10.1016/j.corsci.2015.10.001Search in Google Scholar

[6] Zhang, S. Titanium carbonitride-based cermets: Processes and properties. Materials Science & Engineering, A: Structural Materials: Properties, Microstructure and Processing, Vol. 163, 1993, pp. 141–148.10.1016/0921-5093(93)90588-6Search in Google Scholar

[7] Li, Y., K. Su, P. Bar, L. Wu, H. Liu, H. Su, et al. Effect of TiBCN content on microstructure and properties of laser cladding Ti/TiBCN composite coatings. Metals And Materials International, Vol. 25, 2019, pp. 1366–1377.10.1007/s12540-019-00287-2Search in Google Scholar

[8] Levi, G., W. D. Kaplan, and M. Bamberger. Structure refinement of titanium carbonitride (TiCN). Materials Letters, Vol. 35, 1998, pp. 344–350.10.1016/S0167-577X(97)00276-0Search in Google Scholar

[9] Angerer, P., L. G. Yu, K. A. Khor, G. Korb, and I. Zalite. Spark-plasma-sintering (SPS) of nanostructured titanium carbonitride powders. Journal of the European Ceramic Society, Vol. 25, 2005, pp. 1919–1927.10.1016/j.jeurceramsoc.2004.06.008Search in Google Scholar

[10] Clark, E. B. and B. Roebuck. Extending the application areas for titanium carbonitride cermets. International Journal of Refractory Metals and Hard Materials, Vol. 11, 1992, pp. 23–33.10.1016/0263-4368(92)90081-CSearch in Google Scholar

[11] Sulima, I. Tribological properties of steel/TiB2 composites prepared by spark plasma sintering. Archives of Metallurgy and Materials, Vol. 59, 2014, pp. 1263–1268.10.2478/amm-2014-0216Search in Google Scholar

[12] Munro, R. G. Material properties of titanium diboride. Journal of Research of the National institute of standards and Technology, Vol. 105, 2000, pp. 709–720.10.6028/jres.105.057Search in Google Scholar PubMed PubMed Central

[13] Zhao, X. R., D. W. Zuo, M. X. Zhang, F. Xu, and S. S. Feng. In situ production of ultra-fine Ti(C,N)-TiB2-Co cermets by reactive hot processing from the Co-Ti-C-BN system. International Journal of Refractory Metals and Hard Materials, Vol. 55, 2016, pp. 1–10.10.1016/j.ijrmhm.2015.11.003Search in Google Scholar

[14] Zhang, G. J., Z. Z. Jin, and X. M. Yue. TiB2-Ti(C,N)-SiC composites prepared by reactive hot pressing. Journal of Materials Science Letters, Vol. 15, 1996, pp. 26–28.10.1007/BF01855600Search in Google Scholar

[15] Shankar, E., S. B. Prabu, and K. A. Padmanabhan. Mechanical properties and microstructures of TiCN/nano-TiB2/TiN cermets prepared by spark plasma sintering. Ceramics International, Vol. 44, 2018, pp. 9384–9394.10.1016/j.ceramint.2018.02.154Search in Google Scholar

[16] Shimada, S., A. Takahashi, H. Kiyono, and J. Tsujino. Coatings and microstructures of monolithic TiB2 films and double layer and composite TiCN/TiB2 films from alkoxide solutions by thermal plasma CVD. Thin Solid Films, Vol. 516, 2008, pp. 6616–6621.10.1016/j.tsf.2007.11.093Search in Google Scholar

[17] Bahce, E. and N. Cakir. Tribological investigation of multilayer CrN/CrCN/TaN films deposited by close field unbalanced magnetron sputtering. Reviews on Advanced Materials Science, Vol. 58, 2019, pp. 271–279.10.1515/rams-2019-0036Search in Google Scholar

[18] Wolfe, D. E. and J. Singh. Synthesis and characterization of TiBCN coatings deposited by ion beam assisted, co-evaporation electron beam-physical vapor deposition (EB-PVD). Journal of Materials Science, Vol. 37, 2002, pp. 3777–3787.Search in Google Scholar

[19] Ferrari, A. C. and J. Robertson. Resonant Raman spectroscopy of disordered, amorphous, and diamondlike carbon. Physical Review B, Vol. 64, 2000, id. 075414.10.1103/PhysRevB.64.075414Search in Google Scholar

[20] Gilkes, K. W. R., S. Prawer, K. W. Nugent, J. Robertson, H. S. Sands, Y. Lifshitz, et al. Direct quantitative detection of the sp3 bonding in diamond-like carbon films using ultraviolet and visible Raman spectroscopy. Journal of Applied Physics, Vol. 87, 2000, pp. 7283–7289.10.1063/1.372981Search in Google Scholar

[21] Oshiro, T., M. Yamazato, A. Higa, and M. Toguchi. Raman analysis of trans-polyacetylene chains in hydrogenated amorphous carbon films. Japanese Journal of Applied Physics, Vol. 46, 2007, id. 756.10.1143/JJAP.46.756Search in Google Scholar

[22] O., Knotek, R., Breidenbach, F., Jungblut, et al. Ti-B-C-N coatings. Surface and Coatings Technology, Vol. 43, 1990, pp. 107–115.10.1016/0257-8972(90)90065-KSearch in Google Scholar

[23] Aliyu, A. and C. Srivastava. Correlation between growth texture, crystallite size, lattice strain and corrosion behavior of copper-carbon nanotubes composite coatings. Surface and Coatings Technology, Vol. 405, 2021, id. 126596.10.1016/j.surfcoat.2020.126596Search in Google Scholar

[24] Wagner, C. D., J. F. Moulder, L. E. Davis, and W. M. Riggs. Physical electronics. Handbook of X-ray photoelectron spectroscopy, Vol. 20, Perkin–Elmer Corporation, 1979.Search in Google Scholar

[25] Zeng, Q. and Z. Ning. High-temperature tribological properties of diamond-like carbon films: A review. Reviews on Advanced Materials Science, Eden Prairie, Minnesota, USA, Vol. 60, 2021, pp. 276–292.10.1515/rams-2021-0028Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Effect of superplasticizer in geopolymer and alkali-activated cement mortar/concrete: A review

- Experimenting the influence of corncob ash on the mechanical strength of slag-based geopolymer concrete

- Powder metallurgy processing of high entropy alloys: Bibliometric analysis and systematic review

- Exploring the potential of agricultural waste as an additive in ultra-high-performance concrete for sustainable construction: A comprehensive review

- A review on partial substitution of nanosilica in concrete

- Foam concrete for lightweight construction applications: A comprehensive review of the research development and material characteristics

- Modification of PEEK for implants: Strategies to improve mechanical, antibacterial, and osteogenic properties

- Interfacing the IoT in composite manufacturing: An overview

- Advances in processing and ablation properties of carbon fiber reinforced ultra-high temperature ceramic composites

- Advancing auxetic materials: Emerging development and innovative applications

- Revolutionizing energy harvesting: A comprehensive review of thermoelectric devices

- Exploring polyetheretherketone in dental implants and abutments: A focus on biomechanics and finite element methods

- Smart technologies and textiles and their potential use and application in the care and support of elderly individuals: A systematic review

- Reinforcement mechanisms and current research status of silicon carbide whisker-reinforced composites: A comprehensive review

- Innovative eco-friendly bio-composites: A comprehensive review of the fabrication, characterization, and applications

- Review on geopolymer concrete incorporating Alccofine-1203

- Advancements in surface treatments for aluminum alloys in sports equipment

- Ionic liquid-modified carbon-based fillers and their polymer composites – A Raman spectroscopy analysis

- Emerging boron nitride nanosheets: A review on synthesis, corrosion resistance coatings, and their impacts on the environment and health

- Mechanism, models, and influence of heterogeneous factors of the microarc oxidation process: A comprehensive review

- Synthesizing sustainable construction paradigms: A comprehensive review and bibliometric analysis of granite waste powder utilization and moisture correction in concrete

- 10.1515/rams-2025-0086

- Research Articles

- Coverage and reliability improvement of copper metallization layer in through hole at BGA area during load board manufacture

- Study on dynamic response of cushion layer-reinforced concrete slab under rockfall impact based on smoothed particle hydrodynamics and finite-element method coupling

- Study on the mechanical properties and microstructure of recycled brick aggregate concrete with waste fiber

- Multiscale characterization of the UV aging resistance and mechanism of light stabilizer-modified asphalt

- Characterization of sandwich materials – Nomex-Aramid carbon fiber performances under mechanical loadings: Nonlinear FE and convergence studies

- Effect of grain boundary segregation and oxygen vacancy annihilation on aging resistance of cobalt oxide-doped 3Y-TZP ceramics for biomedical applications

- Mechanical damage mechanism investigation on CFRP strengthened recycled red brick concrete

- Finite element analysis of deterioration of axial compression behavior of corroded steel-reinforced concrete middle-length columns

- Grinding force model for ultrasonic assisted grinding of γ-TiAl intermetallic compounds and experimental validation

- Enhancement of hardness and wear strength of pure Cu and Cu–TiO2 composites via a friction stir process while maintaining electrical resistivity

- Effect of sand–precursor ratio on mechanical properties and durability of geopolymer mortar with manufactured sand

- Research on the strength prediction for pervious concrete based on design porosity and water-to-cement ratio

- Development of a new damping ratio prediction model for recycled aggregate concrete: Incorporating modified admixtures and carbonation effects

- Exploring the viability of AI-aided genetic algorithms in estimating the crack repair rate of self-healing concrete

- Modification of methacrylate bone cement with eugenol – A new material with antibacterial properties

- Numerical investigations on constitutive model parameters of HRB400 and HTRB600 steel bars based on tensile and fatigue tests

- Research progress on Fe3+-activated near-infrared phosphor

- Discrete element simulation study on effects of grain preferred orientation on micro-cracking and macro-mechanical behavior of crystalline rocks

- Ultrasonic resonance evaluation method for deep interfacial debonding defects of multilayer adhesive bonded materials

- Effect of impurity components in titanium gypsum on the setting time and mechanical properties of gypsum-slag cementitious materials

- Bending energy absorption performance of composite fender piles with different winding angles

- Theoretical study of the effect of orientations and fibre volume on the thermal insulation capability of reinforced polymer composites

- Synthesis and characterization of a novel ternary magnetic composite for the enhanced adsorption capacity to remove organic dyes

- Couple effects of multi-impact damage and CAI capability on NCF composites

- Mechanical testing and engineering applicability analysis of SAP concrete used in buffer layer design for tunnels in active fault zones

- Investigating the rheological characteristics of alkali-activated concrete using contemporary artificial intelligence approaches

- Integrating micro- and nanowaste glass with waste foundry sand in ultra-high-performance concrete to enhance material performance and sustainability

- Effect of water immersion on shear strength of epoxy adhesive filled with graphene nanoplatelets

- Impact of carbon content on the phase structure and mechanical properties of TiBCN coatings via direct current magnetron sputtering

- Investigating the anti-aging properties of asphalt modified with polyphosphoric acid and tire pyrolysis oil

- Biomedical and therapeutic potential of marine-derived Pseudomonas sp. strain AHG22 exopolysaccharide: A novel bioactive microbial metabolite

- Effect of basalt fiber length on the behavior of natural hydraulic lime-based mortars

- Optimizing the performance of TPCB/SCA composite-modified asphalt using improved response surface methodology

- Compressive strength of waste-derived cementitious composites using machine learning

- Melting phenomenon of thermally stratified MHD Powell–Eyring nanofluid with variable porosity past a stretching Riga plate

- Development and characterization of a coaxial strain-sensing cable integrated steel strand for wide-range stress monitoring

- Compressive and tensile strength estimation of sustainable geopolymer concrete using contemporary boosting ensemble techniques

- Customized 3D printed porous titanium scaffolds with nanotubes loading antibacterial drugs for bone tissue engineering

- Facile design of PTFE-kaolin-based ternary nanocomposite as a hydrophobic and high corrosion-barrier coating

- Effects of C and heat treatment on microstructure, mechanical, and tribo-corrosion properties of VAlTiMoSi high-entropy alloy coating

- Study on the damage mechanism and evolution model of preloaded sandstone subjected to freezing–thawing action based on the NMR technology

- Promoting low carbon construction using alkali-activated materials: A modeling study for strength prediction and feature interaction

- Entropy generation analysis of MHD convection flow of hybrid nanofluid in a wavy enclosure with heat generation and thermal radiation

- Friction stir welding of dissimilar Al–Mg alloys for aerospace applications: Prospects and future potential

- Fe nanoparticle-functionalized ordered mesoporous carbon with tailored mesostructures and their applications in magnetic removal of Ag(i)

- Study on physical and mechanical properties of complex-phase conductive fiber cementitious materials

- Evaluating the strength loss and the effectiveness of glass and eggshell powder for cement mortar under acidic conditions

- Effect of fly ash on properties and hydration of calcium sulphoaluminate cement-based materials with high water content

- Analyzing the efficacy of waste marble and glass powder for the compressive strength of self-compacting concrete using machine learning strategies

- Experimental study on municipal solid waste incineration ash micro-powder as concrete admixture

- Parameter optimization for ultrasonic-assisted grinding of γ-TiAl intermetallics: A gray relational analysis approach with surface integrity evaluation

- Producing sustainable binding materials using marble waste blended with fly ash and rice husk ash for building materials

- Effect of steam curing system on compressive strength of recycled aggregate concrete

- A sawtooth constitutive model describing strain hardening and multiple cracking of ECC under uniaxial tension

- Predicting mechanical properties of sustainable green concrete using novel machine learning: Stacking and gene expression programming

- Toward sustainability: Integrating experimental study and data-driven modeling for eco-friendly paver blocks containing plastic waste

- A numerical analysis of the rotational flow of a hybrid nanofluid past a unidirectional extending surface with velocity and thermal slip conditions

- A magnetohydrodynamic flow of a water-based hybrid nanofluid past a convectively heated rotating disk surface: A passive control of nanoparticles

- Prediction of flexural strength of concrete with eggshell and glass powders: Advanced cutting-edge approach for sustainable materials

- Efficacy of sustainable cementitious materials on concrete porosity for enhancing the durability of building materials

- Phase and microstructural characterization of swat soapstone (Mg3Si4O10(OH)2)

- Effect of waste crab shell powder on matrix asphalt

- Improving effect and mechanism on service performance of asphalt binder modified by PW polymer

- Influence of pH on the synthesis of carbon spheres and the application of carbon sphere-based solid catalysts in esterification

- Experimenting the compressive performance of low-carbon alkali-activated materials using advanced modeling techniques

- Thermogravimetric (TG/DTG) characterization of cold-pressed oil blends and Saccharomyces cerevisiae-based microcapsules obtained with them

- Investigation of temperature effect on thermo-mechanical property of carbon fiber/PEEK composites

- Computational approaches for structural analysis of wood specimens

- Integrated structure–function design of 3D-printed porous polydimethylsiloxane for superhydrophobic engineering

- Exploring the impact of seashell powder and nano-silica on ultra-high-performance self-curing concrete: Insights into mechanical strength, durability, and high-temperature resilience

- Axial compression damage constitutive model and damage characteristics of fly ash/silica fume modified magnesium phosphate cement after being treated at different temperatures

- Integrating testing and modeling methods to examine the feasibility of blended waste materials for the compressive strength of rubberized mortar

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part II

- Energy absorption of gradient triply periodic minimal surface structure manufactured by stereolithography

- Marine polymers in tissue bioprinting: Current achievements and challenges

- Quick insight into the dynamic dimensions of 4D printing in polymeric composite mechanics

- Recent advances in 4D printing of hydrogels

- Mechanically sustainable and primary recycled thermo-responsive ABS–PLA polymer composites for 4D printing applications: Fabrication and studies

- Special Issue on Materials and Technologies for Low-carbon Biomass Processing and Upgrading

- Low-carbon embodied alkali-activated materials for sustainable construction: A comparative study of single and ensemble learners

- Study on bending performance of prefabricated glulam-cross laminated timber composite floor

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part I

- Supplementary cementitious materials-based concrete porosity estimation using modeling approaches: A comparative study of GEP and MEP

- Modeling the strength parameters of agro waste-derived geopolymer concrete using advanced machine intelligence techniques

- Promoting the sustainable construction: A scientometric review on the utilization of waste glass in concrete

- Incorporating geranium plant waste into ultra-high performance concrete prepared with crumb rubber as fine aggregate in the presence of polypropylene fibers

- Investigation of nano-basic oxygen furnace slag and nano-banded iron formation on properties of high-performance geopolymer concrete

- Effect of incorporating ultrafine palm oil fuel ash on the resistance to corrosion of steel bars embedded in high-strength green concrete

- Influence of nanomaterials on properties and durability of ultra-high-performance geopolymer concrete

- Influence of palm oil ash and palm oil clinker on the properties of lightweight concrete

Articles in the same Issue

- Review Articles

- Effect of superplasticizer in geopolymer and alkali-activated cement mortar/concrete: A review

- Experimenting the influence of corncob ash on the mechanical strength of slag-based geopolymer concrete

- Powder metallurgy processing of high entropy alloys: Bibliometric analysis and systematic review

- Exploring the potential of agricultural waste as an additive in ultra-high-performance concrete for sustainable construction: A comprehensive review

- A review on partial substitution of nanosilica in concrete

- Foam concrete for lightweight construction applications: A comprehensive review of the research development and material characteristics

- Modification of PEEK for implants: Strategies to improve mechanical, antibacterial, and osteogenic properties

- Interfacing the IoT in composite manufacturing: An overview

- Advances in processing and ablation properties of carbon fiber reinforced ultra-high temperature ceramic composites

- Advancing auxetic materials: Emerging development and innovative applications

- Revolutionizing energy harvesting: A comprehensive review of thermoelectric devices

- Exploring polyetheretherketone in dental implants and abutments: A focus on biomechanics and finite element methods

- Smart technologies and textiles and their potential use and application in the care and support of elderly individuals: A systematic review

- Reinforcement mechanisms and current research status of silicon carbide whisker-reinforced composites: A comprehensive review

- Innovative eco-friendly bio-composites: A comprehensive review of the fabrication, characterization, and applications

- Review on geopolymer concrete incorporating Alccofine-1203

- Advancements in surface treatments for aluminum alloys in sports equipment

- Ionic liquid-modified carbon-based fillers and their polymer composites – A Raman spectroscopy analysis

- Emerging boron nitride nanosheets: A review on synthesis, corrosion resistance coatings, and their impacts on the environment and health

- Mechanism, models, and influence of heterogeneous factors of the microarc oxidation process: A comprehensive review

- Synthesizing sustainable construction paradigms: A comprehensive review and bibliometric analysis of granite waste powder utilization and moisture correction in concrete

- 10.1515/rams-2025-0086

- Research Articles

- Coverage and reliability improvement of copper metallization layer in through hole at BGA area during load board manufacture

- Study on dynamic response of cushion layer-reinforced concrete slab under rockfall impact based on smoothed particle hydrodynamics and finite-element method coupling

- Study on the mechanical properties and microstructure of recycled brick aggregate concrete with waste fiber

- Multiscale characterization of the UV aging resistance and mechanism of light stabilizer-modified asphalt

- Characterization of sandwich materials – Nomex-Aramid carbon fiber performances under mechanical loadings: Nonlinear FE and convergence studies

- Effect of grain boundary segregation and oxygen vacancy annihilation on aging resistance of cobalt oxide-doped 3Y-TZP ceramics for biomedical applications

- Mechanical damage mechanism investigation on CFRP strengthened recycled red brick concrete

- Finite element analysis of deterioration of axial compression behavior of corroded steel-reinforced concrete middle-length columns

- Grinding force model for ultrasonic assisted grinding of γ-TiAl intermetallic compounds and experimental validation

- Enhancement of hardness and wear strength of pure Cu and Cu–TiO2 composites via a friction stir process while maintaining electrical resistivity

- Effect of sand–precursor ratio on mechanical properties and durability of geopolymer mortar with manufactured sand

- Research on the strength prediction for pervious concrete based on design porosity and water-to-cement ratio

- Development of a new damping ratio prediction model for recycled aggregate concrete: Incorporating modified admixtures and carbonation effects

- Exploring the viability of AI-aided genetic algorithms in estimating the crack repair rate of self-healing concrete

- Modification of methacrylate bone cement with eugenol – A new material with antibacterial properties

- Numerical investigations on constitutive model parameters of HRB400 and HTRB600 steel bars based on tensile and fatigue tests

- Research progress on Fe3+-activated near-infrared phosphor

- Discrete element simulation study on effects of grain preferred orientation on micro-cracking and macro-mechanical behavior of crystalline rocks

- Ultrasonic resonance evaluation method for deep interfacial debonding defects of multilayer adhesive bonded materials

- Effect of impurity components in titanium gypsum on the setting time and mechanical properties of gypsum-slag cementitious materials

- Bending energy absorption performance of composite fender piles with different winding angles

- Theoretical study of the effect of orientations and fibre volume on the thermal insulation capability of reinforced polymer composites

- Synthesis and characterization of a novel ternary magnetic composite for the enhanced adsorption capacity to remove organic dyes

- Couple effects of multi-impact damage and CAI capability on NCF composites

- Mechanical testing and engineering applicability analysis of SAP concrete used in buffer layer design for tunnels in active fault zones

- Investigating the rheological characteristics of alkali-activated concrete using contemporary artificial intelligence approaches

- Integrating micro- and nanowaste glass with waste foundry sand in ultra-high-performance concrete to enhance material performance and sustainability

- Effect of water immersion on shear strength of epoxy adhesive filled with graphene nanoplatelets

- Impact of carbon content on the phase structure and mechanical properties of TiBCN coatings via direct current magnetron sputtering

- Investigating the anti-aging properties of asphalt modified with polyphosphoric acid and tire pyrolysis oil

- Biomedical and therapeutic potential of marine-derived Pseudomonas sp. strain AHG22 exopolysaccharide: A novel bioactive microbial metabolite

- Effect of basalt fiber length on the behavior of natural hydraulic lime-based mortars

- Optimizing the performance of TPCB/SCA composite-modified asphalt using improved response surface methodology

- Compressive strength of waste-derived cementitious composites using machine learning

- Melting phenomenon of thermally stratified MHD Powell–Eyring nanofluid with variable porosity past a stretching Riga plate

- Development and characterization of a coaxial strain-sensing cable integrated steel strand for wide-range stress monitoring

- Compressive and tensile strength estimation of sustainable geopolymer concrete using contemporary boosting ensemble techniques

- Customized 3D printed porous titanium scaffolds with nanotubes loading antibacterial drugs for bone tissue engineering

- Facile design of PTFE-kaolin-based ternary nanocomposite as a hydrophobic and high corrosion-barrier coating

- Effects of C and heat treatment on microstructure, mechanical, and tribo-corrosion properties of VAlTiMoSi high-entropy alloy coating

- Study on the damage mechanism and evolution model of preloaded sandstone subjected to freezing–thawing action based on the NMR technology

- Promoting low carbon construction using alkali-activated materials: A modeling study for strength prediction and feature interaction

- Entropy generation analysis of MHD convection flow of hybrid nanofluid in a wavy enclosure with heat generation and thermal radiation

- Friction stir welding of dissimilar Al–Mg alloys for aerospace applications: Prospects and future potential

- Fe nanoparticle-functionalized ordered mesoporous carbon with tailored mesostructures and their applications in magnetic removal of Ag(i)

- Study on physical and mechanical properties of complex-phase conductive fiber cementitious materials

- Evaluating the strength loss and the effectiveness of glass and eggshell powder for cement mortar under acidic conditions

- Effect of fly ash on properties and hydration of calcium sulphoaluminate cement-based materials with high water content

- Analyzing the efficacy of waste marble and glass powder for the compressive strength of self-compacting concrete using machine learning strategies

- Experimental study on municipal solid waste incineration ash micro-powder as concrete admixture

- Parameter optimization for ultrasonic-assisted grinding of γ-TiAl intermetallics: A gray relational analysis approach with surface integrity evaluation

- Producing sustainable binding materials using marble waste blended with fly ash and rice husk ash for building materials

- Effect of steam curing system on compressive strength of recycled aggregate concrete

- A sawtooth constitutive model describing strain hardening and multiple cracking of ECC under uniaxial tension

- Predicting mechanical properties of sustainable green concrete using novel machine learning: Stacking and gene expression programming

- Toward sustainability: Integrating experimental study and data-driven modeling for eco-friendly paver blocks containing plastic waste

- A numerical analysis of the rotational flow of a hybrid nanofluid past a unidirectional extending surface with velocity and thermal slip conditions

- A magnetohydrodynamic flow of a water-based hybrid nanofluid past a convectively heated rotating disk surface: A passive control of nanoparticles

- Prediction of flexural strength of concrete with eggshell and glass powders: Advanced cutting-edge approach for sustainable materials

- Efficacy of sustainable cementitious materials on concrete porosity for enhancing the durability of building materials

- Phase and microstructural characterization of swat soapstone (Mg3Si4O10(OH)2)

- Effect of waste crab shell powder on matrix asphalt

- Improving effect and mechanism on service performance of asphalt binder modified by PW polymer

- Influence of pH on the synthesis of carbon spheres and the application of carbon sphere-based solid catalysts in esterification

- Experimenting the compressive performance of low-carbon alkali-activated materials using advanced modeling techniques

- Thermogravimetric (TG/DTG) characterization of cold-pressed oil blends and Saccharomyces cerevisiae-based microcapsules obtained with them

- Investigation of temperature effect on thermo-mechanical property of carbon fiber/PEEK composites

- Computational approaches for structural analysis of wood specimens

- Integrated structure–function design of 3D-printed porous polydimethylsiloxane for superhydrophobic engineering

- Exploring the impact of seashell powder and nano-silica on ultra-high-performance self-curing concrete: Insights into mechanical strength, durability, and high-temperature resilience

- Axial compression damage constitutive model and damage characteristics of fly ash/silica fume modified magnesium phosphate cement after being treated at different temperatures

- Integrating testing and modeling methods to examine the feasibility of blended waste materials for the compressive strength of rubberized mortar

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part II

- Energy absorption of gradient triply periodic minimal surface structure manufactured by stereolithography

- Marine polymers in tissue bioprinting: Current achievements and challenges

- Quick insight into the dynamic dimensions of 4D printing in polymeric composite mechanics

- Recent advances in 4D printing of hydrogels

- Mechanically sustainable and primary recycled thermo-responsive ABS–PLA polymer composites for 4D printing applications: Fabrication and studies

- Special Issue on Materials and Technologies for Low-carbon Biomass Processing and Upgrading

- Low-carbon embodied alkali-activated materials for sustainable construction: A comparative study of single and ensemble learners

- Study on bending performance of prefabricated glulam-cross laminated timber composite floor

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part I

- Supplementary cementitious materials-based concrete porosity estimation using modeling approaches: A comparative study of GEP and MEP

- Modeling the strength parameters of agro waste-derived geopolymer concrete using advanced machine intelligence techniques

- Promoting the sustainable construction: A scientometric review on the utilization of waste glass in concrete

- Incorporating geranium plant waste into ultra-high performance concrete prepared with crumb rubber as fine aggregate in the presence of polypropylene fibers

- Investigation of nano-basic oxygen furnace slag and nano-banded iron formation on properties of high-performance geopolymer concrete

- Effect of incorporating ultrafine palm oil fuel ash on the resistance to corrosion of steel bars embedded in high-strength green concrete

- Influence of nanomaterials on properties and durability of ultra-high-performance geopolymer concrete

- Influence of palm oil ash and palm oil clinker on the properties of lightweight concrete