Foam concrete for lightweight construction applications: A comprehensive review of the research development and material characteristics

-

Yajun Liu

, Muhammad Nasir Amin

und Fadi Althoey

Abstract

Foam concrete or foamcrete is a lightweight, porous material with a wide range of applications in the construction domain. This article focused on reviewing porosity, thermal conductivity, acoustic properties, compressive strength (f c′), elastic modulus (E), flexural strength (f y), stability, resistance to hostile environments, density, and fire resistance of foam concrete. A systematic literature analysis was conducted to identify relevant research trends on foam concrete. The challenges and limitations of foam concrete research were highlighted, including the lack of standardized testing methods and the need for more research on the long-term durability and structural performance of foam concrete. The analysis of the literature data revealed that there had been a growing interest in foamcrete research over the past decade. Foam concrete may be utilized in several construction applications due to its adaptability and wide range of uses. Its potential uses can be increased by developing new manufacturing methods and the inclusion of certain admixtures. The present research has the potential to be advantageous for scholars interested in collaborative advancement and the exchange of novel tactics and concepts, owing to the visual and statistical representation of the regions/countries and researchers that have contributed.

1 Introduction

The word “cellular concrete,” “foamed concrete,” or “foamcrete” denotes cement pastes or mortars in which air voids have been intentionally trapped. It has good thermal insulating qualities, high flowability, little aggregate use, low self-weight, and controlled low strength. By carefully controlling the foam dosage for partition, lining, structural, and post-grading, foamcrete with a broad range of densities (400–1,850 kg·m−3) can be produced [1,2]. Its uses as a lightweight semi- or non-structural element in the building industry are becoming increasingly popular due to its lightweight and affordable nature.

Axel Eriksson invented the first foamcrete made with Portland cement in 1923 [3]. Additionally, Valore [4] performed the initial comprehensive review of cellular concrete. Foamcrete has been used extensively in the past 20 years because of significant advancements in production instruments and procedures, better superplasticizers (SPs), and foam agents. Many attempts have been made to thoroughly study the properties and behavior of foamcrete to make it easier to use in structural applications. According to some researchers, foamed concrete has superior qualities. Foamcrete is frequently utilized in construction for uses such as blocks, sandwich panels, facades, wall sheets, and floor slabs due to its popularity and outstanding performance. The primary reason for foam concrete’s rise in popularity in the current era has correspondingly been ascribed to its adaptability for viable building designs, such as environmental protection (i.e., reducing CO2 emissions, conserving energy), financial savings (i.e., minimizing dead loads for structures, requiring fewer men force to operate, and limiting energy losses), and console of living (i.e., maintaining the absolute interior warmth, reducing noise) [5,6,7,8]. According to reports, exterior walls of lightweight foam embedded in concrete can save up to 50% of the building’s total heat capacity [9].

Aerated concrete is divided into two categories: air-entrained concrete and foamcrete, depending on how the pores are formed [10]. Air bubbles make chemicals blended into the mortar when using the air-entraining technique. Chemical reactions will occur during mixing, and the resulting vapors will form a porous structure. Hydrogen peroxide, calcium carbide, and aluminum powder are frequently employed as aerating substances. There are two mechanical methods for creating pores in foam concrete by a foaming agent. The first method is called the pre-foaming process, where the foaming agent is blended with the water prior to being put into the mortar. The second procedure is the blended foaming process, where the foaming agent is blended directly with the mortar. Both these methods result in the formation of voids in the foamcrete, which contribute to its lightweight and porous properties. Additionally, it can also be categorized based on density. For insulation and filling, densities between 300 and 600 kg·m−3 are frequently utilized, while between 600 and 1,200 kg·m−3 are used to produce non-load bearing assemblies (precast blocks, panels for buildings, divider walls, and soundproofing screeds). For producing load-bearing composites, high-density foamcrete (1,200–1,600 kg·m−3) is frequently used [2]. Based on the compressive strength (f c′) of concrete, foamcrete is categorized into three groups: low strength (f c′ < 10 MPa), medium strength (f c′ between 10 and 20 MPa), and high strength (f c′ > 20 MPa). Figure 1 displays the flow chart of types of foam concretes.

Types of foam concretes.

Considerable research has been conducted on the foamcrete [6,11,12,13]. Reviewing the current studies on foam concrete is therefore essential. On the subject of the current research, a few review studies have also been published [1,2,14,15,16,17]. For example, Yang et al. [16] and Shah et al. [17] reviewed the potential of waste materials in producing sustainable foamed concrete. However, no study has been identified that used the advanced scientometric approach for reviewing the foamed concrete research. This research used a scientometric-based evaluation approach, which highlights the various facets of the relevant literature. In the current research, bibliometric data from the Scopus database were used to oversee a scientometric literature review to analyze multiple aspects of the published papers using the software. Specifically, during the scientometric assessment phase, documents, publishing sources, states, and authors were examined. The goal of the scientometric analysis was to assess the various bibliometric data parameters quantitatively. In addition, the various properties of foam concrete such as mechanical properties (flexural strength, elastic modulus, and compressive strength) [18,19], physical properties (density, dry shrinkage, and porosity) [20], fresh properties (consistency, workability, and stability), durability properties (permeability and resistance to the hostile environment) [21,22], and functional properties (fire resistance, acoustic insulation resistance, and thermal conductivity [TC]) [23,24] were also discussed in this article. In order to better focus future research, this article will help find current research gaps on foam concrete.

2 Review methods

The objective of the scientometric study is to quantitatively evaluate the multiple components of the current literature on foamcrete. The systematic mapping technique is utilized in the scientometric analysis, a method acquired by academics for evaluating multiple aspects of the literature [25,26,27]. The first stage in the literature search process is to choose a credible database. Two extremely popular and credible sources are Scopus and Web of Science [28,29]. The Scopus data corpus was utilized to gather the bibliographic data for the analysis because it is highly suggested by academics [30,31]. The Scopus database was created by searching keywords of foam concrete, cellular lightweight concrete, and foamcrete in February 2023, and the results show 2,932, 328, and 14 documents, respectively. Figure 2 shows the list of various filters that were employed in the raw dataset in order to remove unnecessary documents.

Filters employed on Scopus data.

After the application of filters mentioned in Figure 2, the number of documents was reduced to 1,847, 246, and 11 for foam concrete, cellular lightweight concrete, and foamcrete, respectively. This dataset is downloaded in a comma-separated value file for a more thorough assessment in VOSviewer (version: 1.6.19) software. Many academics in different fields of study have adopted the same methodology [32,33,34,35]. Open-source visualization software called VOSviewer is conventionally used in diverse fields and frequently recommended by scholars [36,37,38,39,40]. While preserving data reliability and consistency, the collected bibliometric data were uploaded and analyzed in the VOSviewer. The scientometric research evaluated the publishing journal, the most common keywords, the participation of countries, and the authors and publications with the maximum citations. Maps were created to show multiple variables, their connections, and co-occurrences, and tables were utilized to enumerate their statistical values.

3 Results and discussion on scientometric analysis

The most pertinent study areas for this evaluation were obtained using Scopus. Engineering and materials science were found to be the two areas that produced the majority of papers, accounting for about 42 and 26% of all articles and 68% of all documents in the study of foamcrete, as disclosed in Figure 3. Additionally, materials relevant to the subject of the research were searched for on Scopus (Figure 4). According to the analysis, full-length articles and conference papers made up 61 and 33%, respectively, of the total data, whereas article reviews and conference reviews made up 3 and 3%, respectively. Figure 5 shows the annual growth of publications from 1958 to Feb 2023. The first document on the topic of foam concrete was published in 1958; then, with just two papers per year from 1973 until 1983, foam-concrete research publications made only modest success. Following that, the publication rate accelerated, with a mean of 7 publications per year from 1984 to 2002 and an average of over 45 papers published annually between 2006 and 2016. Between 2017 and 2022, there were significantly more publications, with an average of 178 pieces per year and 206 publications in 2021. Every year, there are more publications on the topic of study, and in the current year, till Feb 2023, 46 publications have been made.

Graph for the document’s source.

Document type published on the topic of foam concrete.

Year-wise distribution of publications.

3.1 Publication sources

The minimum criterion for a single source document was set as 10, which resulted in 27 of 583 documents lying under this threshold. Table 1 contains a list of the top papers, ranked by publications and citations, that contain information on foam concrete from the VOSviewer analysis. Construction and building materials, the IOP Conference Series: Materials Science and Engineering, and Materials with 129, 104, and 43 publications, respectively, are the highest three journals in terms of the number of publications. Construction and Building Materials, Cement and Concrete Composites, and Cement and Concrete Research, with 6,153, 2,626, and 2,005 citations, respectively, are the top three journals in terms of the number of citations. Figure 6 shows a scientific mapping of the journal sources for publications with links based on citations. The frame size reflects how many articles a journal has contributed to the field of study; a bigger frame dimension denotes a more substantial addition. The construction and building materials, for instance, have larger frame dimensions than the other sources, demonstrating that this journal has a publication with enormous influence in this study area. The result was the creation of six clusters, each of which is depicted in the image by a different hue. The scope of the research sources or how frequently they are combined in references causes groups or clusters to develop [38]. Furthermore, frames close to one another have stronger linkage than frames that are dispersed broadly. For instance, Composite Structures is less directly related to Construction and Building Materials than ASTM Special Technical Publications.

Top 15 publishing sources list

| S/N | Source | Documents | Citations |

|---|---|---|---|

| 1 | Construction and building materials | 129 | 6,153 |

| 2 | IOP conference series: materials science and engineering | 104 | 288 |

| 3 | Materials | 43 | 471 |

| 4 | Journal of building engineering | 40 | 573 |

| 5 | Matec web of conferences | 39 | 183 |

| 6 | IOP conference series: earth and environmental science | 37 | 115 |

| 7 | Cement and concrete composites | 34 | 2,626 |

| 8 | Procedia engineering | 26 | 495 |

| 9 | Materials today: proceedings | 25 | 172 |

| 10 | Geotechnical special publication | 24 | 61 |

| 11 | Composite structures | 23 | 783 |

| 12 | Journal of cleaner production | 21 | 700 |

| 13 | Cement and concrete research | 20 | 2,005 |

| 14 | Engineering structures | 20 | 412 |

| 15 | Fib symposium | 20 | 1 |

Visualization of the publishing source using scientific mapping.

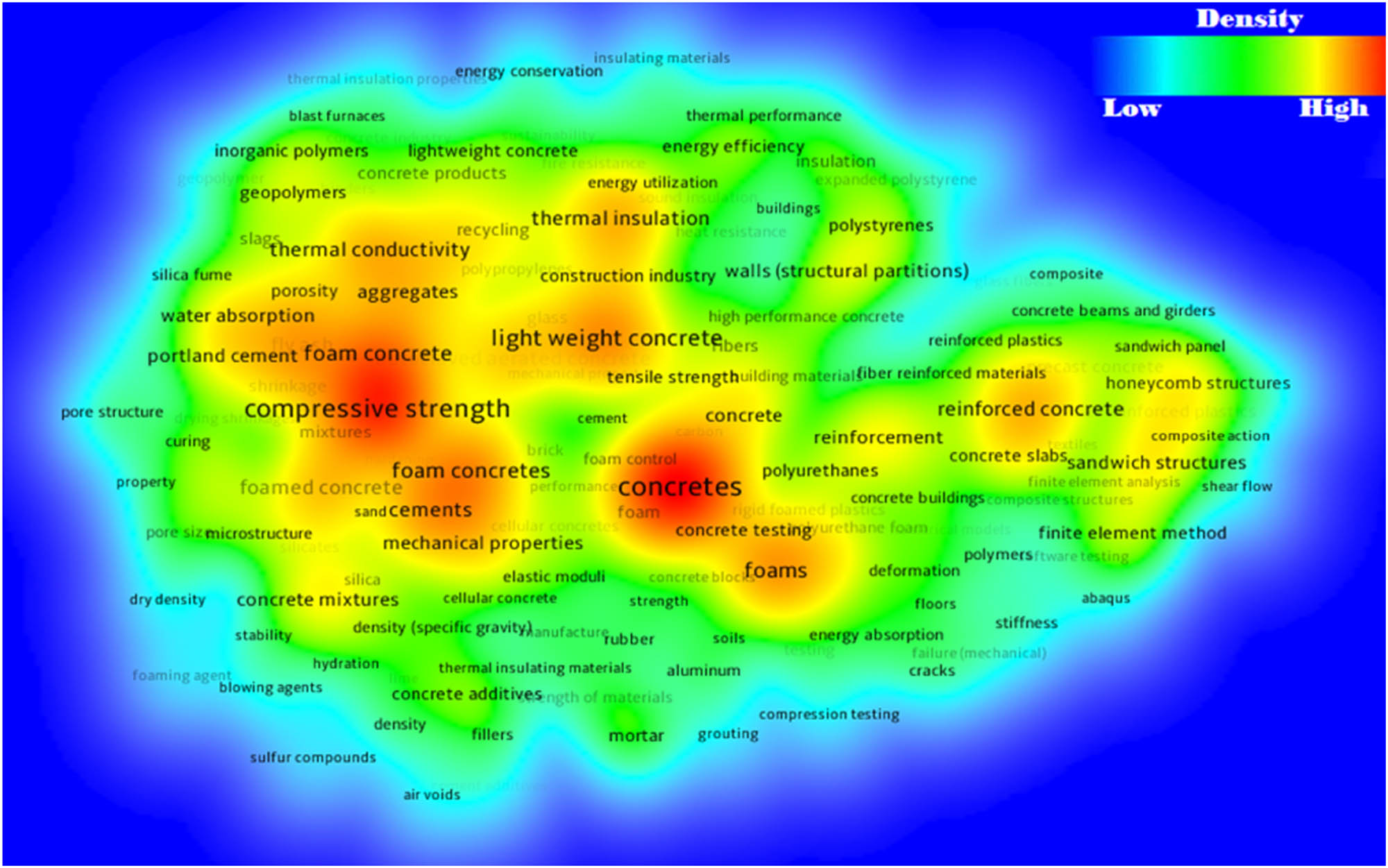

3.2 Keywords

Table 2 lists the topmost 20 terms that were frequently utilized in articles that have been published in the subject area. Concrete, compressive strength, lightweight concrete, foam concretes, and foam concrete are the top five terms associated with foam-concrete research. In relation to their co-occurrences, links between them, and density in correlation to their recurrence rate, keywords are visualized in Figure 7 as an image. The map in Figure 7 shows groups of keywords that reflect the co-occurrence of these terms across different publications. Distinct hues resemble different degrees of keyword density, as shown in Figure 7. Based on their relative densities, the colors green, blue, red, and yellow are arranged, with red denoting the greatest density and blue denoting the least. As shown in Figure 7, the most frequent keywords have red marks, which denote a significant density. This study will help future researchers choose keywords that will make finding previously published content in a particular area effortless.

Top 20 most repeated keywords in papers

| S/N | Keyword | Occurrences |

|---|---|---|

| 1 | Concretes | 559 |

| 2 | Compressive strength | 417 |

| 3 | Light weight concrete | 245 |

| 4 | Foam concretes | 236 |

| 5 | Foam concrete | 225 |

| 6 | Foams | 220 |

| 7 | Cements | 178 |

| 8 | Thermal insulation | 178 |

| 9 | TC | 176 |

| 10 | Reinforced concrete | 174 |

| 11 | FA | 171 |

| 12 | Foamed concrete | 166 |

| 13 | Autoclaved aerated concrete | 151 |

| 14 | Mechanical properties | 119 |

| 15 | Concrete | 112 |

| 16 | Reinforcement | 110 |

| 17 | Sandwich structures | 108 |

| 18 | Concrete aggregates | 105 |

| 19 | Concrete mixtures | 99 |

| 20 | Walls (structural partitions) | 95 |

Density of most occurring keywords.

4 Findings and discussions

Foam concrete has the ability to provide thermal insulation. The low density and high porosity make it an excellent insulating material, which can help to reduce energy utilization and costs correlated with warming up and cooling the buildings. In addition, using foamcrete in walls and roofs can improve the energy efficiency of buildings, leading to a reduction in greenhouse gas emissions and environmental impact. Traditional concrete is a heavy and dense material, which can limit its use in certain applications, such as in precast panels or roofing systems. The use of foamcrete, with its low density, can reduce the weight of these structures, making them easier to transport, install, and support while still maintaining the necessary strength and durability. Foam concrete also has potential applications in the remediation of contaminated soils and brownfield sites. The low permeability of foamcrete can limit the migration of contaminants, while its lightweight properties can help to reduce the load on underlying soils, minimizing the risk of further soil degradation. The following subsections briefly discuss the most crucial subjects in the current study area, which were determined through a scientometric-based review of the bibliographic data. The evaluation of all keywords and a study of the most relevant publications served as the foundation for this identification. Other academics have used comparable methods in earlier research [29,41].

4.1 Components of foam concrete

Both essential and optional components make up foamcrete. Concrete comprises aggregates, water, sand, and cement as fundamental materials, whereas fly ash (FA), plasticizers, and fibers are added as supplements. Figure 8 presents the ingredients used to form foam concrete.

![Figure 8

Supplementary ingredients of foamcrete [2].](/document/doi/10.1515/rams-2024-0022/asset/graphic/j_rams-2024-0022_fig_008.jpg)

Supplementary ingredients of foamcrete [2].

In distinction to ordinary Portland cement, foam concrete can be made with calcium sufflaminate cement, alkali-activated cement, accelerated hardening Portland cement, and high alumina cement. These cements were used to shorten the foamcrete’s setting time and boost its early strength. Conversely, other auxiliary materials like lime, FA, silica fume (SF), and incinerator bottom ash can also be substituted to an extent with cement, varying from 10 to 75% [42,43,44,45]. Typically, foam concrete was not made with coarse aggregate. A summary of the various research studies that have been carried out on the subject of utilizing finer compounds as substitutes for ordinary sand is given in Table 3. Through a succession of air cavities produced in the concrete matrix combination, foam agents regulate the density of the concrete. In most cases, manufactured, protein-based foaming agents include glue polymers, hydrolyzed proteins, resin soaps, and saponin [46,47]. Synthetic and protein-based foaming additives are frequently utilized in construction. According to reports, a large amount of foam causes the flow to decrease [48,49]. Additionally, chemical admixtures that reduce water are likely to lead to foam volatility and are rarely used. According to ASTM C869-91 and ASTM C796-97 test procedures, the steadiness of the foaming reactant should be verified [50,51]. In most foamcrete applications, the air voids make up 6%–35% of the total volume of the final matrix [52].

Materials used as a substitute for fine aggregate

| Source | Material utilized in place of sand | Observation |

|---|---|---|

| Hajimohammadi et al. [53] | Glass fines | There was less material shrinkage. Significant gains in strength were seen at modest densities |

| Akhund et al. [54] | Biomass aggregates | When compared to regular sand in an indoor setting, they noticed that the biomass aggregate foamcrete had the greatest f c′ after 91 days of air curing |

| Lim et al. [55] | Quarry waste | The bonds were strengthened by the finer quarry dust, which also decreased the amount of foam needed for the required density of lightweight concrete. Consequently, greater f c′ and TC were seen |

| Ikponmwosa et al. [56] | Polyvinyl waste | C–S–H gel could be created when the combined alumina–silica and ferrite concentration of polyvinyl waste was higher than 51.45%. Greater flexing capability and f c′ |

| Yuvaraj et al. [57] | Manufactured sand | f c′ improved when sand was replaced with M-sand up to 60%, after which it decreased |

| Sharipudin et al. [58] | Recycled concrete aggregate | Increased f c′ with a sand bulk replacement of no more than 10%. Additionally, it was stated that recycled sand had higher water absorption and porosity than calcareous sand was utilized |

| Balasundaram et al. [59] | River sand, sea sand, and quarry dust | In comparison to other specimens, specimens filled with quarry dust had higher densities and f c′, and specimens filled with marine sand had densities and f c′ almost identical to those of river sand |

| Hadipramana et al. [60] | Rice husk ash (RHA) | Due to its pozzolanic impact, RHA’s f c′ expanded with increased RHA |

| Lim et al. [61] | Multiple gradations of sand | The fineness of the sand improved the f y, f c′, and ductility of the material |

For the fabrication of foamcrete, potable water with a pH reaching 7 is ideal. To avoid the cement pulling water from the foam, a minimum W/C of 0.35 is necessary. The British Cement Association’s recommended foamcrete blend creation can adversely influence organic infectivity when protein-based foaming reactants are utilized [62]. However, undrinkable water may also be used when foamcrete achieves 90% of its strength in 7–28 days, comparable to samples produced with water from a public supply [63]. The plasticizers are heavily used in foamed concrete to increase workability and maintain compatibility [64,65]. However, no appreciable influences on concrete segregation have been reported [66,67]. Fluor-surfactant is one of the widely used plasticizers in the manufacture of foamcrete. The plasticizers make up roughly 0.45–5% of the amount of the foaming agent. Alkali-resistant glass fiber, polypropylene fiber (PP), palm, and steel fibers are some of the manufactured or natural fibers used in foamcrete [47,52,68,69]. These fibers make up between 0.25 and 0.4% of the overall volume of the mix design’s ingredients [70]. Figure 9 presents the visual of foam concrete samples and its practical application in civil engineering.

4.2 Fresh properties of foamcrete

Fresh-state characteristics of foamcrete include workability, consistency, and stability. The ratio of either W/C, supplemental materials, fine- or course-grained gravel, plasticizers, and the quantity and type of foaming reagent added all significantly impact these parameters [73].

4.2.1 Workability

Due to the incorporation of a stable foaming reagent, the workability of foamcrete exhibits outstanding performance through air bubbles in the fresh blend [74]. Low-density fresh concrete, as defined by BS EN 12350: Part 2 [75], does not apply to the workability test, which is typically carried out by a slump test for normal concrete. To achieve a suitable mix viscosity, the workability of foamed concrete is visually assessed. Additionally, Brewer [76] used a technique termed spreadability to gauge the workability of foamcrete. Brewer suggested performing this test on a freshly mixed low-strength material (such as foamcrete) by quantifying the spread of a sample inside a 75 mm in diameter by 150 mm in length open-ended cylinder after the cylinder had been elevated vertically. To the nearest 5 mm, the median of the two recorded diameters was computed and reported [76].

For appropriate workability of foamcrete, Dhir et al. [77] advised that the base mix’s flowability must be approximately 85–125 mm for a mortar mix and have between 115 and 140 mm if FA was added [76]. Few studies have been carried out to identify the minimal workability needed for the ideal mix. For instance, blends with ground-granulated blast-furnace slag (GGBS) were found to have high workability of foamcrete, though segregation was also noted. To enhance workability in a situation with a low W/C ratio, it was stated that plasticizers should not be frequently used in foamcrete unless the amount is restricted to less than 0.2% of the weight of cement [78].

4.2.2 Consistency

It was discovered that foamcrete with flow times under 20 s and flow values ranging between 40 and 60% had acceptable consistency [79]. The consistency of the mix was said to have increased with the inclusion of an SP and declined considerably with the inclusion of foam because of greater cohesion and lower self-weight [79]. W/C ratios improved the consistency of foamcrete, but too much water resulted in segregation. According to experimental research on the properties of foamcrete in its fresh state when GGBS and FA were used as fine aggregate and partial replacements for cement, the mixtures remained workable even after the additament of ultrafine GGBS, while the inclusion of FA reduced consistency because of the greater fines and increased water demand [80]. Another factor that impacted the uniformity of the blend was the aggregate density; low-density aggregate has decreased consistency, which was then improved by the inclusion of FA. The consistency of foamcrete is divided into five groups utilizing the Modified Marsh Cone test, as displayed in Table 4 [81].

Classes of foamcrete based on flow time [81]

| S. No | Time period of flow | Description |

|---|---|---|

| 1 | 1 Lit ≤ 1 min | Constant flow |

| 2 | 1 Lit ≥ 1 min | Interrupted flow |

| 3 | 0.5 Lit ≤ Ei ≤ 1 Lit | Completion of flow after tamping gently |

| 4 | Ei ≤ 0.5 Lit | Limited flow |

| 5 | Ei = 0 Lit | No flow |

-

Ei, Efflux, Lit, Liter.

4.2.3 Stability

The adhesive behavior, cohesiveness, and consistency of the foam-concrete mixture ingredients as a system all contribute to stability [82]. The blends are categorized as homogeneous foamed concrete when they have a pourable, creamy, and closely fluid consistency that produces a fresh blend without any bleeding or segregation [83]. If the observed plastic density of a mixture does not differ from the desired plastic density by more than 2–7%, it is deemed to have been prepared correctly using an appropriate mix design method and accurate calculation process [78,84]. Additionally, it was stated that a spread flow of 45% was a suitable range of workability to verify the satisfactory stability of the foamcrete mixture [79]. To date, various tests have been suggested by experts to evaluate the mix’s stability. For example, Nambiar and Ramamurthy [48,79] measured the density of freshly foamcrete supplied in containers and contrasted it to the proportion of the target density to evaluate the stability of the foamed concrete. Another methodology to assess the stability of foamcrete blend is to evaluate the variation between the actual and computed W/C ratio, which should ideally be less than 2% [49].

The stability of the mixture may be affected by a variety of variables, such as the addition of mineral admixtures. For instance, because cement paste had a higher packing density than GGBS paste under the same pressure, using GGBS in the blend decreased its stability and led to segregation and bleeding of the blends [78]. Additionally, it was claimed that SPs increased durability by 43% and allowed W/C ratios to be reduced to less than 0.3. Additionally, it was demonstrated that adding too much foam ingredient decreased stability [85]. Furthermore, it was noted that blends made from protein-based composites were susceptible to segregation, likely owing to the SP’s unsuitability with the surfactant-type additive [86]. Figure 10 shows the water-to-solid (W/S) ratios needed to obtain a density ratio of one for different densities and the corresponding foam volume requirements. Foam concrete mixes containing FA need slightly greater W/S ratios than mixes containing sand because they have a larger surface area. In addition, since FA has a lower specific gravity (2.09) than fine sand (2.52), mixtures with it require less foam volume. With a rise in density, the W/S ratio requirement only slightly decreases, but the foam requirement drastically decreases. The findings mentioned above demonstrate that the consistency demand is primarily influenced by the type of filler, with the amount of foam to be added to the mixture having a much smaller impact.

![Figure 10

Stability requirement for foam concrete against various water–solid ratios [48].](/document/doi/10.1515/rams-2024-0022/asset/graphic/j_rams-2024-0022_fig_010.jpg)

Stability requirement for foam concrete against various water–solid ratios [48].

4.3 Physical properties of foamcrete

The crucial physical characteristics of foamcrete that affect its viability and effectiveness are porosity, density, and drying shrinkage (DS).

4.3.1 Porosity

The porosity of foamcrete is a critical factor to consider because it affects other substantial qualities like f y and f c′ as well as durability. In foamed-concrete and mortar, Kearsley and Wainwright [87] investigated the connection between water vapor permeability and porosity. Studies, however, indicated that larger capillary voids, rather than overall porosity, more closely correspond to the permeability and extent of flowing liquids through the concrete matrix [88]. According to a report, the pore tortuosity, diameter, continuity, and distribution all affect how water moves through concrete rather than just being a straightforward function of porosity [79]. Mercury intrusion porosimeter (MIP) and apparent total vacuum saturation (TVS) techniques are utilized to calculate the porosity of foamcrete. The TVS technique, however, is the most important methodology for determining the porosity of foamcrete because the findings are said to be more accurate than apparent and MIP techniques by 66 and 13%, respectively [89,90].

The foamed concrete’s porosity makes it anxious for aggressive fluids to move through its hardened structure. Infusion properties such as permeability, sorption, and water absorption influence porosity. The mixture design compositions, foaming agents, and curing methods are just a few examples of the many variables that can influence the porosity of concrete structures. As per the reports, an elevated W/C ratio substantially negatively influences foamed concrete and increases porosity [87]. The porosity and pore volume distribution of Portland cement composite was found to rise when the W/C ratio raised from 0.3 to 0.9, at which point substantial volumes of larger voids with greater diameter were found [88,91].

4.3.2 Density

The blend’s fresh (γ f) and dry (γ d) densities can be used to determine its density. Both the γ f and γ d of the mix can be tested. It is advised to keep the difference between γ f and γ d levels between 100 and 120 kg·m−3 [92]. The real fresh mixture density is typically determined by filling and measuring a pre-weighted typical container of a specific amount with the created foamcrete. The highest allowable tolerance for γ d is only 50 kg·m−3, although high-density foamcrete mixtures (i.e., 1,600 kg·m−3) may experience a variation of approximately 100 kg·m−3 [47]. BS EN 12350 [75] describes the process. While the γ d precisely controls the mechanical, physical, and durability characteristics of hardened foamcrete, the γ f is utilized to produce the actual volume for blend proportion and the casting [93,94].

The sources have described the impact of blend ingredients, like the amount of the foaming reagent and ancillary cementitious substance on density. For example, it has been recorded that the γ f of foamcrete usually declines as the volume of foam increases [47]. However, the fluctuations in density caused by ash incorporation could be controlled with foaming reagent volume [48]. Alternatively, the inclusion of FA is said to have raised γ d of the foamcrete at a given foaming reagent volume (10%). Usually, lightweight foamcrete can attain strength up to 50 MPa with a new volumetric density of only 65% that of normal concrete (the surfactant solutions are foaming reagents with a unit weight between 20 and 90 kg·m−3) [47]. The kinds of foundry sand and aggregate size distribution may also have an influence on density. According to McCormick [95], density would increase as the percentage of aggregates arose.

4.3.3 DS

One of the drawbacks of foamcrete is DS, which usually occurs within the initial 20 days after pouring [86]. The typical limit of DS for foamcrete ranges between 0.1 and 0.35% of the overall volume of the hardened concrete [96]. Because of the aggregate type in the blend design, the greater W/C contents, and the mineral admixture in foamcrete, the DS of foamcrete is also assumed to be 4–10 times larger than that of regular concrete.

In reality, there is less understanding about the impact of Portland cement on the DS of foamcrete, but some investigators have claimed that cement amount had adverse effects on the performance of foamcrete concerning DS, which could be stunned by partially substituting Portland cement with other ancillary materials like SF, FA, and lime because of a lesser heat of hydration [97]. Additionally, it is reported that the restrictive impact of higher aggregate and water contents decreases DS [98,99]. Higher water content substances would lose moisture through comparatively larger pores, which do not pointedly shrink.

4.4 Mechanical properties of foamcrete

The most crucial criteria for assessing the applicability of foamcrete in its hardened form are its mechanical characteristics. This article reviews the compressive strength (f c′), flexural strengths (f y), and elastic modulus (E) to give the reader an overview of the current status of foamed concrete.

4.4.1 Compressive strength

Experimental findings show that f c′ and density are directly correlated, with compressive strength being negatively affected exponentially by a decrease in density. As can be seen from Table 5, prior studies applied dry densities between 280 and 1,800 kg·m−3, which led to a striking variation in f c′. The f c′ is generally influenced by a number of factors, comprising the rate of the foaming reagent, the W/C ratio, the type of sand, the curing process, the cement-to-sand ratio, and the dispersal of other components [4,100,101]. The volume/density of the foaming reagent, which affects the number of air voids in the hardened foamcrete, is one of the main determining variables in the mix’s f c′ [93,94]. For instance, the corresponding f c′ at 28 days was 43 and 0.6 MPa, respectively, when plastic densities of foamcrete were 1,800 and 280 kg·m−3, respectively [102,103]. Because of the larger volume of foam agent’s frequent creation of air voids and lower density, the overzealous addition of foaming agent reduced the f c′ [48,104].

Relationship between γ and f c′ of foamcrete

| Density (kg·m−3) | 28-days strength (MPa) | W/C ratio | FA/C ratio | Ref. |

|---|---|---|---|---|

| 982–1,185 (DD) | 1.0–6.0 | 0.61–0.81 | — | [42] |

| 1,000–1,500 (TD) | ≥85.4 365 d | 0.60–1.17 | 0.29–0.4 | [116] |

| 280–1,200 (TD) | 0.6–1,091 d | 0.45–0.6 | — | [100] |

| 800–1,500 (TD) | 10–50 | (Fi/C) | 0.2–0.76 | [47] |

| (SF/C) | ||||

| 800–1,500 (TD) | 39.6–91.3 | 0.30–0.60 | — | [7,47] |

| 800–1,350 (DD) | 1.0–7.0 | (0–100%) | 1–3 | [79] |

| 1,150 (TD) | ≥4.73 | 0.40–1.25 | — | [117] |

| 1,400–1,800 (TD) | 10–26 | 0.3 | — | [102] |

| 1,200–1,600(TD) | ≥25 | 0.40–0.55 | 0.43 | [118] |

| 650–1,200 (DD) | 2.0–11 | (0–100%) | 1–3 | [93,94] |

| 1,000–1,500 (TD) | 2.0–18 | 0.60–1.17 | — | [87] |

| 1,000–1,400 (TD) | 4.0–7.37 d | 1.11–1.56 | 1.22–2.11 | [102] |

| 1.0–2.07 d | 0.5 | |||

| 400–1,800 | 0.5–107 d | 0.35–0.63 | — | [119] |

| 650–1,200 (DD) | 4.0–19 | Fi/C (1–3) | 1–3 | [94] |

| 1,710 (DD) | ≥44,180 d | S/C (1–3) | 1–3 | [84] |

| 1,400–1,800 (TD) | 20–43 | 0.63–0.83 | 1.15–1.78 | [102] |

| 541–1,003 (DD) | 15–3,077 d | 0.48–0.71 | 1.48–2.3 | [42] |

| 1,400–1,000 (TD) | 1.6–4.6180 d | 0.45–1.0 | — | [96] |

| 1,500–1,800 (DD) | 3.9–10.5 | 0.3 | ≥0.25 | [8] |

| 1,837 (DD) | ≥25 | 0.5 | — | [43] |

| 1,400–1,800 (PD) | 25–58 | 0.3–0.5 | 0.25–0.5 (pp) | [73] |

| 1,300–1,900 (PD) | 1.82–16.73 | 0.60–0.81 | — | [105] |

| 1,000–1,500 (TD) | ≥40 | 0.3–1.17 | 0.29–0.60 | [120] |

| 800–1,800 (PD) | 1.8–17.9 | 0.35–0.57 | — | [95] |

| 1,800 (PD) | ≥28 | 0.3–0.4 | — | [73] |

| 1,400–1,800 (PD) | 13.8–48 | 0.5–0.6 | — | [121] |

DD, dry density; TD, target density; PD, plastic density; d, days; Fi (filler).

Another controlling element that affects the f c′ of the foamcrete is the W/C ratio. Appropriate water content improves the mix’s stability and consistency and decreases large foam bubbles, which increases f c′ [46,105]. When 0.19 and 0.17 of the W/C ratio were used, high-strength foamcrete was found to be produced [106]. The quantity of sand in relation to the binder influences the f c′ of foamcrete, in addition to the W/C ratio, which affects f c′. In Europe, foamcrete is typically created using sand/binder ratios of 1:1 to 4:1. When a sand/cement ratio of 1.0–2.0 was used, McCormick [95] reported that the impact of the sand particle seemed negligible as comparable to f c′. Figure 11 illustrates the relation between the dry density and f c′ for foamcrete mixtures containing fine sand and FA as infill. The mixture with fine sand produced greater strength than the mixture with coarse sand for a particular density, and the variation is greater at higher densities. The rise in FA content yields greater strength for a given density. Additionally, too much coarse sand reduces the strength of the solidified concrete because it changes the pore dimensions in the paste, reducing the foamcrete’s strength. Additionally, cement substitutes like FA and SF alter the mix’s f c′ over time. FA has been used to substitute a high volume of concrete, up to 65%, without affecting f c′ [87,92]. The reported replacement for SF had a reduced content, but its pozzolanic behavior increased strength gain over time. According to reports, up to 25% more FA and SF were applied, increasing the tensile strength [47].

![Figure 11

f

c′ and γ relation with respect to various mix proportions [48].](/document/doi/10.1515/rams-2024-0022/asset/graphic/j_rams-2024-0022_fig_011.jpg)

f c′ and γ relation with respect to various mix proportions [48].

The curing process is another important element that influences the f c′ of foamcrete. In accordance with ASTM C 796 [107], cellular and lightweight concrete mixtures that will be used in compression tests need to dry for at least 3 days in a moist space with 100% relative humidity (RH). Take the samples out of the curing chamber and dry them in an oven for 72 h at 60°C. According to Fujiwara et al. [106], the specimens should be cured in a typical moist condition for 1 day before being placed in steam, at which temperature should rise at a rate of 20°C·h−1 to maintain at 65°C for 4 h before being cooled in air. According to Kearsley and Visagie [108], when cement was substituted with 50% FA, a curing temperature of 40°C was probably the best for the greater ultimate strength of foamcrete.

By preventing microcracks and accelerating energy absorption, fibers may also enhance the f c′ of foamcrete [109,110]. The use of glass fibers and manufactured fibers (polyamide, polypropylene, and polyvinyl alcohol fibers) is advised by ACI committee 544 [111,112,113,114]. The ideal fiber volume percentage typically ranges from 3 to 5%. However, the impact of restraint on shrinkage cracking increased whenever the fiber volume fraction fell between 0.1 and 1% [115].

4.4.2 Flexural strength

Foamcrete has an inferior flexural strength (f y) than comparable normal weight and LWC. According to reports, foam concrete has a greater ratio of f y to f c′ (0.2–0.4) than regular concrete (0.08–0.11) [82]. According to Narayanan and Ramamurthy [122], foamcrete with a mass of less than 300 kg·m−3 has a ratio of almost 0 for f y to f c′, ranging from 0.15 to 0.35. The addition of appropriate fibers with the right length, size, and high E-value can lessen the early-age cracking of foam concretes. When fibers were added to foam concrete, the fundamental material’s brittle behavior changed to ductile behavior, and the f y was increased [51,123,124,125]. Table 6 summarizes the coloration of flexural strength and density of foamcrete across different foaming agents and binding materials.

Relationship between γ and f y of foamcrete

| Density (kg·m−3) | Curing temperature | Foaming agent | Binding materials | Flexural strength (MPa) | Ref. |

|---|---|---|---|---|---|

| 1,600–1,750 | Ambient | Conplast F292 (M) | FA, waste materials | 3.5–4.5 | [129] |

| 350–410 | Ambient | H2O2 | GGBS, FA, cenospheres | 0.5–1.1 | [130] |

| 350–650 | Ambient | H2O2 | FA, Metakaolin | 1–1.5 | [131] |

In comparison to synthetic foaming agents, natural foaming reagents are more readily accessible and have higher f y, according to research [59]. Depending on the failure mechanism, SF, FA, and LWA produced foam concrete mixtures with greater ductility than those without SPs for a given density. Additionally, it was discovered that the critical pressure increased with density in foam concrete with additives, and the crack in horizontal deformation before failure was larger [124]. Reinforcement rebar in foamcrete prematurely failed due to poor shear strength. The shear mechanism of foam was enhanced by the utilization of shredded PP and carbon fiber [126]. Water content was another element that affected f y. Foam concrete with constant cement content lost strength when it contained too much water [127,128].

The f y of foamcrete is influenced by the fiber reinforcement. Figure 12 displays the f y of various mixtures after 7 and 28 days. This number indicates that the f y of foamcrete varied from 4.30 MPa for B0SF15F40 to 6.91 MPa for B3SF15F20 on the 28th day of curing. The inclusion of SF (0–15%) improved the f y by 5 and 12% at the 7th and 28th days of curing, respectively. Additionally, basalt fiber addition (0–3%) increased the 7-day f y of foam concrete containing 20, 30, and 40 kg·m−3 foaming agent by 18, 10, and 29%, and the 28-day f y by 25, 6, and 23%, respectively, at 0% SF concentration.

![Figure 12

Effect of basalt fibers on the f

y of foamcrete (a) with 0% silica (b) with 15% silica [24].](/document/doi/10.1515/rams-2024-0022/asset/graphic/j_rams-2024-0022_fig_012.jpg)

Effect of basalt fibers on the f y of foamcrete (a) with 0% silica (b) with 15% silica [24].

4.4.3 Elastic modulus

The density of the foamcrete is related to the modulus of elasticity (E). According to a review of past research, the E-value of foamed concrete with γ d between 500 and 1,600 kg·m−3 lies between 1.0 and 12 kN·m−2, respectively [73]. The E-value of foamcrete is four times lower than that of regular concrete [102], but there are ways to make up for this difference by adding PP fibers to the mix. According to Jones and McCarthy [102], the most noticeable increases were at a rate of 0.50% (by volume) and 1,400 kg·m−3 density. Due to its light weight, which does not affect the consistency of foam bubbles, PP fibers (0.50% by volume) are regarded as flexible fibers for use in foamed concrete uses.

Additionally, according to Jones and McCarthy [76,102], the aggregate variety and content affected the elastic modulus. They investigated that the E-value of foamcrete with coarse pebbles was lower than that of foamcrete with FA. Additionally, Brady et al. [73] noted that the use of fine sand in greater proportions than coarse aggregates at 28 days raised the E-value. Because of the strengthened correlation between paste and the porous aggregates, it was also noticed that adding lightweight FA aggregates sustained better E-value results than adding fine sand [78]. The relationships between the three variables f c′, E, and γ are shown in Table 7. According to the empirical formulas, foamcrete with a high γ d has a greater f c′ as well as an increased E-value.

Relation between f c′, E-value, and γ of foamcrete

| Equation | Description | Ref. |

|---|---|---|

| E = 33W 1.5(f c′)0.5 | Pauw’s formula | [95,102] |

| E = 0.99(f c′)0.67 | FA is utilized as FA | [95] |

| E = 0.42(f c′)1.18 | Sand is utilized as FA | [95] |

| E = 5.31 × W – 853 | Density between 200 and 800 kg·m−3 | [132] |

| E = 6,326(γ c)1.5(f c′)0.5 | γ c = Concrete’s unit weightPoisson’s ratio = 0.2 | [82] |

| E = 57,000(f c′)0.5 | Density between 2,200 and 2,400 kg·m−3 replacement with 80 kg·m−3 for steel | [133] |

| E = 1.70 × 10−6 P 2(f c′)0.33 | P = plastic density (kg·m−3) | [134] |

| E = 9.10(f c′)0.33 | — | [134] |

4.5 Durability characteristics of foamcrete

The capability of concrete to withstand external intervention that could impact or cause deterioration and shorten its lifespan is referred to as the durability characteristic of foamcrete. The following section summarizes and discusses the study’s findings on permeability and resistance to hostile environments.

4.5.1 Permeability

Permeability is the term used to describe the amount of water that flows under pressure through a saturated porous material. In general, foamcrete absorbs water at a rate that is nearly twice that of regular concrete when the W/C ratio is the same [87,135]. Research has so far focused on how aggregates and mineral additives affect the foamed concrete’s porosity. According to Nyame [136], the addition of aggregates limits the porosity of concrete mortars, which in turn causes a drop in permeability. Additionally, he claimed that raising the bulk volume in the mixture raised the permeability. Furthermore, the cement paste created discrete, almost sphere-like bubbles that were only about 50 μm in diameter, resulting in very few water-channeling pathways and a negligible rise in permeability [137]. On account of their pozzolanic action, filling particles and mineral admixtures like FA have also been documented to have an impact on the pore structure attributes and the permeability of grout [138]. It was found that, particularly at lower densities, increasing the ash/cement ratio in foamcrete mixtures proportionally improved the water vapor permeability [120].

4.5.2 Resistance to hostile environments

Experimental research regarding the carbonation of foamcrete was conducted by Loon et al. [139]. It was assessed that specimens with densities of 1,800 and 1,300 kg·m−3 had carbonation depths of 4.63 and 16.3 mm per year, respectively, and it was noted that foamcrete had greater carbonation than regular concrete. The samples with the lowest densities and the greatest W/C ratios yielded the highest values [140]. The numerous open holes in low-density foam concrete hastened the carbonation processes. It was claimed that the molecular make-up and crystalline structure of foamcrete were changed by atmospheric CO2. A small amount of chemically bound water was released, and calcium hydrosilicate formed refined silica gel and CaCO3. After carbonation, a larger crystal with a mostly closed hole was found [141].

In foam concrete, water flow under pressure does not result in expansive pressure [142]. The endurance characteristics of high-performance foamed concrete were researched by Namsone et al. [143]. Due to open porosity and an inadequate number of closed (reserve) pores, gas silicate concrete had the lowest value of frost resistance, while higher-density foamcrete with SF and fibers of carbon had the greatest value. The foam concrete’s thawing and freezing resilience were higher than what was predicted based solely on porosity. Since foamcrete is employed as an exterior decoration for masonry or frame walls under typical circumstances, its pores should not be filled with water [4].

4.6 Functional characteristics of foamcrete

Functional characteristics, such as acoustic and TC, as well as fire resistance, describe the actual behavior of foamcrete throughout its lifetime. Although more study is required, this portion reviews the most recently published research on the functional characteristics of foamed concrete.

4.6.1 Acoustic proofing

Recent research indicates that foamed concrete exhibits greater sound insulation than regular concrete because of its microstructure, which resembles a cell [100,144]. However, the real stiffness of concrete mass determines how well sound is insulated or how much sound is reflected. According to the concept of solid wall acoustic resistance, the width of the wall and its overall density are thought to influence the amplitude of sound reflection [145]. As a result, a concrete wall that is very stiff can reflect sound more effectively than a cellular structure that can only receive it [146]. The foamcrete cellular wall emits sound at a frequency that is likely 3% higher than a regular concrete wall. In contrast to dense concrete, foamcrete has a 10 times greater rate of sound absorption [4,147]. The quantity of foam present, the number, size, and distribution of pores, along with the consistency of the concrete, can all affect how well it absorbs sound [76,102]. Table 8 presents a comprehensive overview of the sound absorption coefficient (α) for foamcrete at different densities. According to the data presented in the table, foamcrete exhibits a significantly low density, measuring below 1,310 kg·m−3. Additionally, it has been observed that foamcrete possesses favorable sound absorption properties, as indicated by its noise reduction coefficient (NRC) surpassing 0.1.

Acoustic properties of foamcrete

| Type of concrete | Density (kg·m−3) | Foam dosage (%) | α for varying frequency (Hz) | NRC | Ref. | |||

|---|---|---|---|---|---|---|---|---|

| 250 | 500 | 1,000 | 2,000 | |||||

| Alkali-activated foamcrete | 1,050 | 5 | 0.05 | 0.1 | 0.15 | — | 0.1 | [148] |

| 960 | 10 | 0.06 | 0.1 | 0.2 | — | 0.12 | ||

| Alkali-activated foamcrete | 820 | 25 | 0.03 | 0.12 | 0.43 | 0.85 | 0.36 | [149] |

| 720 | 30 | 0.18 | 0.16 | 0.54 | 0.78 | 0.42 | ||

| 600 | 35 | 0.2 | 0.1 | 0.4 | 0.94 | 0.41 | ||

| Alkali-activated foamcrete | 940 | Sufficient foam is introduced to attain the desired density. | — | — | — | — | 0.19 | [150] |

| 1,130 | – | – | – | — | 0.24 | |||

| 1,310 | – | – | – | — | 0.11 | |||

4.6.2 TC

During the construction of the building, it is crucial to ensure adequate TC. Foam concrete’s cellular microstructure gives it excellent heat insulation capabilities. The pore size, density, existence of fibers, and admixtures all affect the TC of foam concrete.

Density influence: According to the density of foam concrete, thermal resistance is inversely proportionate. With 20% less weight and 10% fewer raw materials, foam concrete achieved the same insulation qualities as regular concrete [100]. A 20% of entrained air in the concrete reduced the γ d by 100 kg·m−3 and raised thermal resistance by 25%, which decreased its TC by 0.04 W·m−1·K−1 [98]. The TC characteristic of concrete is enhanced with a decrease in temperature because the degree of a rise in TC alongside density declines at lower temperatures [151]. Ganesan et al. [152] investigated the thermal behavior of foamcrete with various densities and admixtures and concluded that, due to the abundance of voids, a density variation (700–1,400 kg·m−3) correlates with a fluctuation in TC in the interval of 0.24–0.74 W·m−1·K−1.

Impact of fibers: Experimental research on the thermal resilience of oil palm-shell foamcrete (OPSFC) was conducted by Liu et al. [153] and contrasted with that of more traditional building materials like clay bricks and concrete blocks. They discovered that the TC rose with concrete’s density, peaking at 0.40 W·m−1·K−1, which is 33 and 56% less than block and brick, respectively. The heat conductivity of OPSFC with densities (1,100–1,300 kg·m−3) was comparable to that of blotted perlite aggregate concrete and pumice-based concrete. Awang et al. [154] attempted to compare the foamed concrete’s durability qualities to those of synthetic and natural fibers like PP, steel, oil palm, and AR-glass fiber. The outcome showed that PP fibers significantly decreased shrinkage and TC.

Impact of pore-structure: The impact of expanded perlite material on the characteristics of aerated concrete was examined by Różycka and Pichór [155]. About 10% of perlite was added, which resulted in a 15% reduction in TC without impacting f c′. TC further decreased with a strength drop of about 20% after the inclusion of perlite waste up to 30%. The 40% substitution showed the greatest strength loss and the lowest TC. The mechanical characteristics and TC of blotted polystyrene foamcrete were empirically examined by Chen and Liu [156]. The test findings demonstrated that adding foam significantly improved the workability, TC, and strength of the expanded polystyrene blend, and the stress-strain relationship demonstrated the ductile nature of the blotted polystyrene foamcrete. TC will be lower the more porous the material is, but occasionally, it will rise because of the tighter pore connections.

Impact of admixtures: Mineral admixtures have an impact on the mechanical properties of foam concrete, but Hilal et al.‘s [89] research shows that SF and FA additions only slightly boost TC. Table 9 provides a summary of how different admixtures affect the temperature characteristics of foam concrete.

4.6.3 Fire resistance

According to the existing study, foamcrete offers an admissible level of fire resistance when contrasted with regular concrete, even though it experiences excessive shrinkage due to substantial evaporation when exposed to high temperatures [160]. The ratios, components, and constituents of the foamcrete mixture affect its ability to withstand flames. In general, the fire resistance of foamcrete rises proportionately as its density decreases. Concrete that has been foamed has a spectrum of fire resistance comparable to regular concrete. Around 950 and 1,200 kg·m−3 of concrete are said to be able to resist fire for 3.5 and 2 h, respectively. According to Vilches et al. [160], foamcrete with an average γ of 400 kg·m−3 demonstrated three times poorer fire resistance than concrete with an average γ d of 150 kg·m−3.

4.7 Microstructure of foamcrete

The impact of foamcrete’s components on its microstructure will be demonstrated in this part. The impacts of the added additives and the W/C ratios are compared in the SEM pictures shown in Figure 13(a) and (b). The foamcrete in the left-hand picture is pure, with a W/C ratio of 0.60. The image on the right depicts a sample that was produced using foam concrete with a W/C ratio of 0.35, which was prepared by incorporating microsilica and an SP into the mixture. A stronger construction was made possible by the use of microsilica and SP [161].

![Figure 13

SEM image of foamcrete (a) with a W/C ratio of 0.3 and no micro-silica and (b) with 0.6 W/C ratio and 10% micro-silica [161].](/document/doi/10.1515/rams-2024-0022/asset/graphic/j_rams-2024-0022_fig_013.jpg)

SEM image of foamcrete (a) with a W/C ratio of 0.3 and no micro-silica and (b) with 0.6 W/C ratio and 10% micro-silica [161].

Figure 14(a)–(e) shows the impact of a higher W/C ratio on the porous structure of foamcrete. The pores became rounder and had a larger diameter as the W/C ratio increased. This can be explained by the difficulty in maintaining the bubbles due to the viscosity decreasing with a rise in water content. Consequently, larger pores can develop, and bubbles can easily consolidate [162].

![Figure 14

W/C ratio impact on pore structure. (a) W/C = 0.40, (b) W/C = 0.45, (c) W/C = 0.50, (d) W/C = 0.55, and (e) W/C = 0.60 [162].](/document/doi/10.1515/rams-2024-0022/asset/graphic/j_rams-2024-0022_fig_014.jpg)

W/C ratio impact on pore structure. (a) W/C = 0.40, (b) W/C = 0.45, (c) W/C = 0.50, (d) W/C = 0.55, and (e) W/C = 0.60 [162].

With densities (500 and 1,000 kg·m−3), foamcrete is shown in Figure 15 as SEM pictures. High air content concretes often have bigger air pockets because the air pockets tend to get closer to one another. Since there was not enough grout to avoid the joining of the voids, which were created by the drop in grout content and the rise in foam, the size of the air voids grew. Because of the proximity of air pockets, concrete with a greater air content frequently results in larger air pockets. As a result, void fusing occurs more frequently, increasing the size of irregular air pockets. Concrete with a plastic density of less than 900 kg·m−3, where the appropriate foam content is 52%, this finding is more significant. Since cement paste content is insufficient to stop voids from coalescing when less than 48%, the average air bubble size considerably increases [163].

![Figure 15

SEM pictures of foamcrete: (a) with 500 kg·m−3 and (b) with 1,000 kg·m−3 [163].](/document/doi/10.1515/rams-2024-0022/asset/graphic/j_rams-2024-0022_fig_015.jpg)

SEM pictures of foamcrete: (a) with 500 kg·m−3 and (b) with 1,000 kg·m−3 [163].

4.8 Applications and challenges

Foamed concrete has been used in various civil and structural engineering fields because of its unique characteristics, including density diminution, poor TC, self-compacting concrete, and high flowability. For instance, low-density foamcrete has been applied for structural uses, while high-density foamcrete has been employed for insulation and cavity filling [161]. Some popular uses of foamed concrete include manufacturing lightweight blocks, precast panels, and trench reinstatement. Additionally, foamed concrete is used for soil stabilization, road sub-base, and shock-absorbing obstacles for airports and regular traffic [64]. Additionally, its flowability makes it a superior substance for voids like those under roads caused by a cliff of severe rains, old sewage lines, storage tanks, basements, and ducts [3]. Figure 16 displays some common applications of foam concrete.

Applications of foam concrete.

The use of foamcrete has gained popularity all over the globe, particularly in areas with a shortage of housing or where earthquakes and hurricanes are frequent [3]. A substantial rise in the price of other lightweight construction components like drywall and wood and environmental concerns appear to be contributing factors to this growing interest [64,164]. Due to the high manufacturing and environmental costs of producing cement, foamed concrete also had the added benefit of being suitable for large amounts of supplemental cementing admixtures [3]. Foamcrete finds various applications, such as insulation of shallow foundation structures, avoidance of frost heave in roads, backfill under buried oil field modules, and as grout to fill abandoned pipelines. It is also utilized in the filling of voids under slabs, reduction of thermal stress and grazing, as well as to hinder frost heave under pile caps and shallow piles. Although foamcrete has many benefits, there are some drawbacks to using it as well. Several of these difficulties include:

Strength: The comparatively low strength of foam concrete in comparison with regular concrete is one of the main problems. This may restrict its use in load-bearing applications and necessitate extra support or reinforcement.

Cost: If foam concrete is not produced locally or in large quantities, it may be more expensive than traditional concrete. For some uses, it might become less cost-effective as a result. The cost of foam concrete depends on the desired density of concrete and the type of foaming agent. The bulk quantity of foams can reduce the overall cost, but for small-scale construction, the cost of the foam increases foamed concrete cost. However, the utilization of waste like industrial, chemical, and agricultural waste as a substitute for cement or fine aggregates can reduce the cost of foamed concrete [17].

Standardization: Foam concrete is not presently standardized, making it challenging to compare different products and guarantee quality control. This has raised questions about the consistency and dependability of foam concrete goods.

4.9 Future research directions

Future studies on foam concrete can focus on several areas, including the following.

Improved strength: As was already stated, one of the main issues preventing foam concrete from being used in load-bearing applications is its lack of strength. Future studies can concentrate on creating new formulas and manufacturing processes that boost the strength of foam concrete.

Durability: Foam concrete is prone to damp damage, which, over time, can reduce its toughness. Future studies can concentrate on creating new substances and processes that increase the resilience of foam concrete and lower the risk of harm.

Standardization: The production, testing, and application of foam concrete all require the creation of standards and guidelines. Standardization of foam concrete is still a difficult task. Future studies could concentrate on creating these norms and regulations to guarantee the reliability and consistency of foamcrete goods.

Environmental impact: Due to its lightweight and thermal insulating qualities, foam concrete has the potential to be an ecologically friendly material. Future studies could examine how foam concrete affects the environment throughout its lifetime and find additional methods to lessen it.

5 Conclusions

This article has highlighted the unique properties and potential applications of foam concrete, challenges that need to be addressed for its widespread use, as well as the scientometric analysis of published data on foamcrete. The following judgments have been reached:

The findings of the scientometric-based analysis showed that, with 129 and 104, the Construction and Building Materials and IOP Conference Series: Material Science and Engineering, respectively, are the top publication sources for documents on foam concrete. The top five most employed keywords in the published work are concrete, compressive strength, lightweight concrete, foam concrete, and foams.

An important factor that significantly influences foam concrete’s strength is foam stability. Many variables, including the technique of foam preparation, the type of foaming agent, the type of agents, the perfection of the mix and additives used, mix design, etc., affect the creation of stable foamed concrete. For designing foam concrete, there are no known standards-based techniques. For foamcrete, a minimum W/C ratio of 0.3 is recommended because it should meet the material’s requirements for consistency and stability. Concrete’s consistency rises when more water is present and falls when there is more foam.

The major factor that affected the foam concrete’s durability was pore connectivity as a percentage of overall pore size. As the connected pore concentration is elevated, the influx of contaminants will be greater. A homogeneous concrete circulated in a closed circular air cavity demonstrated excellent thermal and mechanical quality. There was a rise in f c′ with the rise in density value. However, foamcrete uses admixtures like FA and SF, demonstrating a high strength-to-density ratio. It can be used in weight-bearing structures because it lowers the dead load, which results in a smaller base.

The specified materials’ TC coefficients impact the foam concrete’s TC. Studies have shown that the TC of foamcrete can range from 0.07 to 0.5 W·m−1·K−1, depending on the density of the material. Additionally, using different types of foaming agents and admixtures can affect the TC of foam concrete. For instance, adding SF has been found to reduce the TC of foamcrete by up to 20%.

The acoustic performance of foamcrete depends on several factors, such as density, thickness, and frequency. Lower-density foam concrete is generally more effective at absorbing low-frequency sounds, while higher-density foam concrete is more effective at absorbing high-frequency sounds.

Foam concrete generally has good fire resistance due to its low TC and high porosity. The thermal insulation properties of foam concrete can help limit heat transfer during a fire, reducing the risk of structural damage or collapse. Additionally, the high porosity of foam concrete allows it to absorb a significant amount of heat energy, further limiting heat transfer and reducing the spread of fire.

Overall, the wide range of applications for foam concrete highlights its versatility and potential to be used in various construction applications. The development of new production techniques and the addition of specific admixtures can further expand its potential applications.

Acknowledgments

The authors acknowledge the Deanship of Scientific Research, Vice Presidency for Graduate Studies and Scientific Research, King Faisal University, Saudi Arabia (Project No. GRANT5610). The authors are thankful to the Deanship of Graduate Studies and Scientific Research at Najran University for funding this work under the Growth Funding Program grant code NU/GP/SERC/13/109-1. The authors extend their appreciation for the financial support that made this study possible.

-

Funding information: This work was supported by the Deanship of Scientific Research, Vice Presidency for Graduate Studies and Scientific Research, King Faisal University, Saudi Arabia (Project No. GRANT5610) and the Deanship of Graduate Studies and Scientific Research at Najran University for funding this work under the Growth Funding Program grant code NU/GP/SERC/13/109-1.

-

Author contributions: Y.L.: conceptualization, formal analysis, data acquisition, visualization, writing-original draft. Z.Z.: investigation, resources, supervision, methodology, writing, reviewing, and editing. M.N.A.: funding acquisition, investigation, project administration, supervision, writing, reviewing, and editing. B.A.: formal analysis, methodology, writing, reviewing, and editing. K.K.: investigation, resources, validation, writing, reviewing, and editing. S.U.A.: conceptualization, data acquisition, software, methodology, writing-original draft. F.A.: resources, visualization, writing, reviewing, and editing. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

[1] Amran, Y. H. M., N. Farzadnia, and A. A. A. Ali. Properties and applications of foamed concrete: a review. Construction and Building Materials, Vol. 101, 2015, pp. 990–1005.10.1016/j.conbuildmat.2015.10.112Suche in Google Scholar

[2] Raj, A., D. Sathyan, and K. M. Mini. Physical and functional characteristics of foam concrete: A review. Construction and Building Materials, Vol. 221, 2019, pp. 787–799.10.1016/j.conbuildmat.2019.06.052Suche in Google Scholar

[3] Mindess, S. Developments in the formulation and reinforcement of concrete, Woodhead Publishing, 2019.Suche in Google Scholar

[4] Valore, R. C. Cellular concretes part 2 physical properties, International Concrete Abstracts Portal, American Concrete Institute, 1954, pp. 817–836.Suche in Google Scholar

[5] Ricciotti, L., A. Occhicone, A. Petrillo, C. Ferone, R. Cioffi, and G. Roviello. Geopolymer-based hybrid foams: Lightweight materials from a sustainable production process. Journal of cleaner production, Vol. 250, 2020, id. 119588.10.1016/j.jclepro.2019.119588Suche in Google Scholar

[6] Kunhanandan Nambiar, E. K. and K. Ramamurthy. Fresh state characteristics of foam concrete. Journal of Materials in Civil Engineering, Vol. 20, 2008, pp. 111–117.10.1061/(ASCE)0899-1561(2008)20:2(111)Suche in Google Scholar

[7] Kolias, S. and C. Georgiou. The effect of paste volume and of water content on the strength and water absorption of concrete. Cement and Concrete Composites, Vol. 27, 2005, pp. 211–216.10.1016/j.cemconcomp.2004.02.009Suche in Google Scholar

[8] Richard, A. O. and M. Ramli. Experimental production of sustainable lightweight foamed concrete. British Journal of Applied Science and Technology, Vol. 3, 2013, id. 994.10.9734/BJAST/2014/4242Suche in Google Scholar

[9] Zhang, J., G. Pan, X. Zheng, and C. Chen. Preparation and characterization of ultra-lightweight fly ash-based cement foams incorporating ethylene-vinyl acetate emulsion and waste-derived CSH seeds. Construction and Building Materials, Vol. 274, 2021, id. 122027.10.1016/j.conbuildmat.2020.122027Suche in Google Scholar

[10] Hamad, A. J. Materials, production, properties and application of aerated lightweight concrete. International Journal of Materials Science and Engineering, Vol. 2, 2014, pp. 152–157.10.12720/ijmse.2.2.152-157Suche in Google Scholar

[11] Jalal, M. D. , A. Tanveer, K. Jagdeesh, and F. Ahmed. Foam concrete. International Journal of Civil Engineering Research, Vol. 8, 2017, pp. 1–14.Suche in Google Scholar

[12] Bayraktar, O. Y., G. Kaplan, O. Gencel, A. Benli, and M. Sutcu. Physico-mechanical, durability and thermal properties of basalt fiber reinforced foamed concrete containing waste marble powder and slag. Construction and Building Materials, Vol. 288, 2021, id. 123128.10.1016/j.conbuildmat.2021.123128Suche in Google Scholar

[13] Gencel, O., O. Y. Bayraktar, G. Kaplan, A. Benli, G. Martinez-Barrera, Brostow, et al. Characteristics of hemp fibre reinforced foam concretes with fly ash and Taguchi optimization. Construction and Building Materials, Vol. 294, 2021, id. 123607.10.1016/j.conbuildmat.2021.123607Suche in Google Scholar

[14] Fu, Y., X. Wang, L. Wang, and Y. Li. Foam concrete: A state-of-the-art and state-of-the-practice review. Advances in Materials Science and Engineering, Vol. 2020, 2020, pp. 1–25.10.1155/2020/6153602Suche in Google Scholar

[15] Gencel, O., T. Bilir, Z. Bademler, and T. Ozbakkaloglu. A detailed review on foam concrete composites: Ingredients, properties, and microstructure. Applied Sciences, Vol. 12, 2022, id. 5752.10.3390/app12115752Suche in Google Scholar

[16] Yang, S., X. Wang, Z. Hu, J. Li, X. Yao, C. Zhang, et al. Recent advances in sustainable lightweight foamed concrete incorporating recycled waste and byproducts: A review. Construction and Building Materials, Vol. 403, 2023, id. 133083.10.1016/j.conbuildmat.2023.133083Suche in Google Scholar

[17] Shah, S. N., K. H. Mo, S. P. Yap, J. Yang, and T.-C. Ling. Lightweight foamed concrete as a promising avenue for incorporating waste materials: A review. Resources, Conservation and Recycling, Vol. 164, 2021, id. 105103.10.1016/j.resconrec.2020.105103Suche in Google Scholar

[18] Bayraktar, O. Y., G. Yarar, A. Benli, G. Kaplan, O. Gencel, M. Sutcu, et al. Basalt fiber reinforced foam concrete with marble waste and calcium aluminate cement. Structural Concrete, Vol. 24, 2023, pp. 1152–1178.10.1002/suco.202200142Suche in Google Scholar

[19] Gencel, O., B. Balci, O. Y. Bayraktar, M. Nodehi, A. Sarı, G. Kaplan, et al. The effect of limestone and bottom ash sand with recycled fine aggregate in foam concrete. Journal of Building Engineering, Vol. 54, 2022, id. 104689.10.1016/j.jobe.2022.104689Suche in Google Scholar

[20] Gencel, O., A. Ustaoglu, A. Benli, G. Hekimoğlu, A. Sarı, E. Erdogmus, et al. Investigation of physico-mechanical, thermal properties and solar thermoregulation performance of shape-stable attapulgite based composite phase change material in foam concrete. Solar Energy, Vol. 236, 2022, pp. 51–62.10.1016/j.solener.2022.02.042Suche in Google Scholar

[21] Bayraktar, O. Y., H. Soylemez, G. Kaplan, A. Benli, O. Gencel, and M. Turkoglu. Effect of cement dosage and waste tire rubber on the mechanical, transport and abrasion characteristics of foam concretes subjected to H2SO4 and freeze–thaw. Construction and Building Materials, Vol. 302, 2021, id. 124229.10.1016/j.conbuildmat.2021.124229Suche in Google Scholar

[22] Gencel, O., A. Benli, O. Y. Bayraktar, G. Kaplan, M. Sutcu, and W. A. T. Elabade. Effect of waste marble powder and rice husk ash on the microstructural, physico-mechanical and transport properties of foam concretes exposed to high temperatures and freeze–thaw cycles. Construction and Building Materials, Vol. 291, 2021, id. 123374.10.1016/j.conbuildmat.2021.123374Suche in Google Scholar

[23] Gencel, O., O. Y. Bayraktar, G. Kaplan, O. Arslan, M. Nodehi, A. Benli, et al. Lightweight foam concrete containing expanded perlite and glass sand: Physico-mechanical, durability, and insulation properties. Construction and Building Materials, Vol. 320, 2022, id. 126187.10.1016/j.conbuildmat.2021.126187Suche in Google Scholar

[24] Gencel, O., M. Nodehi, O. Y. Bayraktar, G. Kaplan, A. Benli, A. Gholampour, et al. Basalt fiber-reinforced foam concrete containing silica fume: An experimental study. Construction and Building Materials, Vol. 326, 2022, id. 126861.10.1016/j.conbuildmat.2022.126861Suche in Google Scholar

[25] Markoulli, M. P., C. I. S. G. Lee, E. Byington, and W. A. Felps. Mapping Human Resource Management: Reviewing the field and charting future directions. Human Resource Management Review, Vol. 27, 2017, pp. 367–396.10.1016/j.hrmr.2016.10.001Suche in Google Scholar

[26] Yang, D., J. Zhao, W. Ahmad, M. N. Amin, F. Aslam, K. Khan, et al. Potential use of waste eggshells in cement-based materials: A bibliographic analysis and review of the material properties. Construction and Building Materials, Vol. 344, 2022, id. 128143.10.1016/j.conbuildmat.2022.128143Suche in Google Scholar

[27] Li, G., C. Zhou, W. Ahmad, K. I. Usanova, M. Karelina, A. M. Mohamed, et al. Fly ash application as supplementary cementitious material: a review. Materials, Vol. 15, 2022, id. 2664.10.3390/ma15072664Suche in Google Scholar PubMed PubMed Central

[28] Chadegani, A. A., H. Salehi, M. M. Yunus, H. Farhadi, M. Fooladi, M. Farhadi, et al. A comparison between two main academic literature collections: Web of Science and Scopus databases arXiv preprint arXiv, Vol. 1305, 2013, p. 0377.10.5539/ass.v9n5p18Suche in Google Scholar

[29] Afgan, S. and C. Bing. Scientometric review of international research trends on thermal energy storage cement based composites via integration of phase change materials from 1993 to 2020. Construction and Building Materials, Vol. 278, 2021, id. 122344.10.1016/j.conbuildmat.2021.122344Suche in Google Scholar

[30] Bergman, E. M. L. Finding citations to social work literature: The relative benefits of using Web of Science, Scopus, or Google Scholar. The Journal of Academic Librarianship, Vol. 38, 2012, pp. 370–379.10.1016/j.acalib.2012.08.002Suche in Google Scholar

[31] Meho, L. I. Using Scopus’s CiteScore for assessing the quality of computer science conferences. Journal of Informetrics, Vol. 13, 2019, pp. 419–433.10.1016/j.joi.2019.02.006Suche in Google Scholar

[32] Li, X., D. Qin, Y. Hu, W. Ahmad, A. Ahmad, F. Aslam, et al. A systematic review of waste materials in cement-based composites for construction applications. Journal of Building Engineering, Vol. 45, 2022, id. 103447.10.1016/j.jobe.2021.103447Suche in Google Scholar

[33] Zuo, J. and Z.-Y. Zhao. Green building research–current status and future agenda: A review. Renewable and Sustainable Energy Reviews, Vol. 30, 2014, pp. 271–281.10.1016/j.rser.2013.10.021Suche in Google Scholar

[34] Darko, A., C. Zhang, and A. P. C. Chan. Drivers for green building: A review of empirical studies. Habitat International, Vol. 60, 2017, pp. 34–49.10.1016/j.habitatint.2016.12.007Suche in Google Scholar

[35] Ahmad, W., M. Khan, and P. Smarzewski. Effect of short fiber reinforcements on fracture performance of cement-based materials: A systematic review approach. Materials, Vol. 14, 2021, id. 1745.10.3390/ma14071745Suche in Google Scholar PubMed PubMed Central

[36] Goulden, S., E. Erell, Y. Garb, and D. Pearlmutter. Green building standards as socio-technical actors in municipal environmental policy. Building Research & Information, Vol. 45, 2017, pp. 414–425.10.1080/09613218.2015.1116844Suche in Google Scholar

[37] Jin, R., S. Gao, A. Cheshmehzangi, and E. Aboagye-Nimo. A holistic review of off-site construction literature published between 2008 and 2018. Journal of Cleaner Production, Vol. 202, 2018, pp. 1202–1219.10.1016/j.jclepro.2018.08.195Suche in Google Scholar

[38] Park, J. Y. and Z. Nagy. Comprehensive analysis of the relationship between thermal comfort and building control research-A data-driven literature review. Renewable and Sustainable Energy Reviews, Vol. 82, 2018, pp. 2664–2679.10.1016/j.rser.2017.09.102Suche in Google Scholar

[39] Oraee, M., M. R. Hosseini, E. Papadonikolaki, R. Palliyaguru, and M. Arashpour. Collaboration in BIM-based construction networks: A bibliometric-qualitative literature review. International Journal of Project Management, Vol. 35, 2017, pp. 1288–1301.10.1016/j.ijproman.2017.07.001Suche in Google Scholar

[40] Van Eck, N. and L. Waltman. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics, Vol. 84, 2010, pp. 523–538.10.1007/s11192-009-0146-3Suche in Google Scholar PubMed PubMed Central

[41] Zakka, W. P., N. H. A. S. Lim, and M. C. Khun. A scientometric review of geopolymer concrete. Journal of Cleaner Production, Vol. 280, 2021, id. 124353.10.1016/j.jclepro.2020.124353Suche in Google Scholar

[42] Durack, J. M. and L. Weiqing. The properties of foamed air cured fly ash based concrete for masonry production, Gladstone, The Queensland, Australia, 1998, pp. 129–138.Suche in Google Scholar

[43] Ibrahim, N. M., R. Che Amat, N. L. Rahim, and S. Sallehuddin. Performance of lightweight foamed concrete with replacement of concrete sludge aggregate as coarse aggregate, Advanced Materials Research, Vol. 689, 2013, pp. 265–268.10.4028/www.scientific.net/AMR.689.265Suche in Google Scholar

[44] Pickford, C. and S. Crompton. Foamed concrete in bridge construction. Concrete, Vol. 30, 1996, id. 30.Suche in Google Scholar

[45] Wee, T.-H., D. S. Babu, T. Tamilselvan, and H.-S. Lim. Air-void system of foamed concrete and its effect on mechanical properties. ACI Materials Journal, Vol. 103, 2006, id. 45.10.14359/15126Suche in Google Scholar

[46] De Rose, L. and J. Morris. The influence of mix design on the properties of microcellular concrete, Thomas Telford, London, UK, 1999.Suche in Google Scholar

[47] Bing, C., W. Zhen, and L. Ning. Experimental research on properties of high-strength foamed concrete. Journal of Materials in Civil Engineering, Vol. 24, 2012, pp. 113–118.10.1061/(ASCE)MT.1943-5533.0000353Suche in Google Scholar

[48] Nambiar, E. K. K. and K. Ramamurthy. Influence of filler type on the properties of foam concrete. Cement and Concrete Composites, Vol. 28, 2006, pp. 475–480.10.1016/j.cemconcomp.2005.12.001Suche in Google Scholar

[49] Jones, M. R. and A. McCarthy. Heat of hydration in foamed concrete: Effect of mix constituents and plastic density. Cement and Concrete Research, Vol. 36, 2006, pp. 1032–1041.10.1016/j.cemconres.2006.01.011Suche in Google Scholar

[50] Standard specification for foaming agents used in making preformed foam for cellular concrete, ASTM, 2016.Suche in Google Scholar