Abstract

This study examines the impact of using seashell powder, shells mixed with nano-silica, and basic oxygen furnace slag as sand substitutes in addition to the internal curing regime. This study focuses on important factors related to material sustainability and the efficient use of resources. The comprehensive evaluation of mechanical properties, including compressive and tensile strength at different stages, provides a significant understanding of the performance improvements achieved with these innovative additives. Durability tests, which evaluate the absorption, water permeability, salt penetration, and sulfate resistance, advance our understanding of how these materials enhance the long-term durability of ultra-high-performance concrete (UHPC) under extreme environmental conditions. In addition, examining UHPC samples at high temperatures (350 and 700°C) and applying scanning electron microscopy. The improved mechanical strength and toughness achieved using seashells and nano-silica demonstrated the potential of these additives to create UHPC that is more sustainable and environmentally friendly. The results indicate that the addition of seashell powder slightly reduced the compressive strength. However, replacing cement with a blend of seashells and nano-silica led to an improvement ranging from 5 to 6% in compressive strength across various replacement ratios at 7, 28, and 90 days. The optimum strength is obtained at a 5% replacement ratio. Tensile strength also increased from 1.6 to 1.8 MPa when seashells were pre-mixed with nano-silica. The incorporation of nano-silica significantly enhanced the thermal stability of the seashells, resulting in a better residual strength of 84–93% at 350°C and ranged from 68 to 82% at 700°C. Furthermore, the combination of seashells and seashell powder with nano-silica notably improved durability by reducing the water permeability, sorptivity, and chloride penetration depth. The residual strength of UHPC showed greater improvement after exposure to a sulfate environment when the seashells were combined with nano-silica than when seashells alone were used and achieved 81 MPa compared to 69.1 MPa for the control mix and 74 MPa for seashells only. Overall, the inclusion of seashells pre-mixed with nano-silica in UHPC enhanced the microstructure at both normal and elevated temperatures.

1 Introduction

Ultra-high-performance concrete (UHPC) is a modern type of material based on cement. Concrete is a fundamental component of the building sector, and its utilization can be regarded as a cost-effective solution. Nevertheless, concrete has certain drawbacks owing to its substantial weight. For instance, it occupies a substantial amount of space throughout the construction process and has significant dimensions as its components. In light of these limitations, researchers have directed their efforts toward enhancing conventional concrete or developing novel variants with exceptional attributes, such as toughness, durability, and remarkable strength, using the principles of packing theory. UHPC possesses advantageous characteristics that can satisfy infrastructure demands [1,2,3]. Initial investigations into the production of UHPC necessitated specific requirements for the treatment, mixing procedure, and use of high-quality compositions while also excluding coarse materials [4,5,6,7,8,9]. Nevertheless, it is crucial to thoroughly evaluate rigorous protocols and exceptional management practices before selecting UHPC [10,11,12,13,14,15]. The production involves a series of critical processes, including the selection of highly specialized raw materials, including high-quality cement, fine silica fume, quartz powder, and steel fibers; precise proportioning using packing theory for design [14]; and stringent quality control measures during mixing, casting, and curing to achieve UHPC’s exceptional properties of UHPC, such as high compressive strength and enhanced durability [16], adherence to rigorous protocols, and effective management practices [17]. Thus, the “selection” of UHPC refers to the decision to implement these specialized production techniques and materials, ensuring that the intended performance criteria are met [18].

The formulations of UHPC can be modified to meet all the criteria and purposes. As an illustration, the road bridge in Bourg-les-Valence, France, using UHPC, was built in 2005, in addition to the Mars Hill Bridge in the United States (US), which was built in 2006 using UHPC, resulting in a 66% reduction in weight compared to the use of traditional concrete. A reduction in the reinforcement of up to 90% was achieved. This effectively eliminated the need for shear reinforcement. UHPC has been utilized in various applications globally owing to its advantageous features such as distinctive design, simple fabrication, intricate forms, lightweight, and resilience under harsh conditions [19,20,21,22].

UHPC has been employed in numerous global projects and has attracted significant attention for its use in complex applications [3]. These applications include the construction of vertical components such as overlay materials, offshore structures, hydraulic structures, windmill towers, and oil industries, in addition to repair, rehabilitation, bridges, and architectural features. The most prevalent use of UHPC is in the construction of bridges and roadways. UHPC has been utilized in bridge construction in several countries, such as Slovenia, the Netherlands, Malaysia, Germany, China, Italy, Canada, New Zealand, France, the Czech Republic, South Korea, Switzerland, the US, and Australia [21,23]. The concrete industry faces significant challenges in implementing effective curing regimes. Wu et al. [24] showed that heat curing has a significant impact on early-age shrinkage when using a double-treatment approach. Exposing the concrete to a temperature of 55°C for 70 min resulted in a significant enhancement of its quality compared to curing it at 48°C for 60 min. Steam curing is the preferred method of curing compared to standard curing (SC) and autoclave curing [4,6,25,26,27,28,29,30,31]. In addition, there have been advancements in the development of novel hybrid regimes [5]. To summarize, although SC may be the most cost-effective and practical method, it is not the optimal choice. ACI 308 [32] found that internal curing (IC) of concrete can be accomplished by employing certain agents, such as admixtures, which have the ability to retain water within the mix while saving the initial amount of water included in the mixture [6,33,34]. Hydration necessitates the utilization of water from the external surface to sustain the process and achieve full response to delicate substances. Self-curing technology relies on the provision of internal moisture to facilitate the hydration process and improve concrete characteristics. An important limitation of this technology is the formation of empty spaces in concrete. However, this issue can be managed by carefully selecting the optimal dosage to minimize shrinkage [34,35]. For example, the recommended dosage for liquids is 1% polyethylene glycol (PEG) [33,34,36]. Therefore, nanoparticles (NPs) are used to enhance the performance of UHPC.

Nanotechnology has sparked a revolution in several domains. The use of silica-reinforced NPs optimizes mechanical qualities, leading to higher performance and increased resistance to corrosion. The addition of 1% nano-meta-clay to UHPC improves its resistance to electrochemical processes [37,38,39]. Basic oxygen furnace (BOF) slag is a highly abundant byproduct of the steel-making process, with 90–150 kg of slag produced per ton of basic steel [40]. Europe produces approximately 10 million metric tons of BOF slag per year, with approximately 23% of this slag being physically deposited in piles, thus occupying land resources. The utilization of BOF slag as a supplemental cementitious material in construction materials has received significant attention [41]. Previous study [42] investigated the use of BOFs as a cement replacement material for low-carbon-content cement by examining the hydration products in standard mortar. The reactivity of the new binder was determined by analyzing its thermal properties, mineral composition, and microstructure, which in turn affected its workability and mechanical performance. As a result, replacing 10–30% of the material causes a delay in the final setting time by preventing the development of ettringite, which leads to a decline in mechanical performance until 28 days. Between the ages of 28 and 180 days, the substitution of 30–50% showed a synergistic effect on the mechanical performance. This effect can be linked to the development of hydrogarnets, calcium silicate hydrates, and stratlingite. Furthermore, all the mortar samples demonstrated leaching of heavy metals and drying shrinkage that fell below the allowable limit. Steel-making slag is classified as an alkaline residue and accounts for approximately 15–20% of the entire steel production [43]. Approximately 70% of the slag produced was attributed to BOFS. BOFS exhibits limited hydration reactivity as a result of its minimal tricalcium silicate content [44]. Nevertheless, BOFS has high reactivity toward carbonation because of its abundance of free-CaO/MgO, dicalcium silicate (β-C2S and γ-C2S) phases, and portlandite concentration. These components readily react with CO2 to produce calcium [45]. Previous investigations have shown that BOF slag can be used in concrete for many purposes and has positive effects, indicating its ability to significantly enhance the performance of concrete [42]. Studies have suggested that including BOF slag as a substitute for natural aggregates or as an additional cementitious material can improve the durability, strength, and lifespan of concrete. The thermal characteristics of BOF slag additionally enhance the fire resistance of the concrete. Furthermore, the recycling of industrial leftovers not only reduces the environmental impact but also minimizes the usage of landfills and preserves natural resources. The various characteristics of BOF slag make it an appealing option for a diverse array of construction applications, ranging from large-scale infrastructure projects to specific high-performance building applications [46,47].

This research is of great interest because it investigates new methods to improve UHPC by incorporating sustainable and modern waste materials. This study examines the impact of using seashell powder, shells mixed with nano-silica, and BOF slag as sand substitutes in addition to the IC regime. This study focuses on important factors related to material sustainability and the efficient use of resources. The comprehensive evaluation of mechanical properties, including compressive and tensile strengths at different stages, provides a significant understanding of the performance improvements achieved with these innovative additives. Durability tests, which evaluate the absorption, water permeability, salt penetration, and sulfate resistance, advance our understanding of how these materials enhance the long-term durability of UHPC under extreme environmental conditions. In addition, examining UHPC samples at high temperatures (350 and 700°C) and applying scanning electron microscopy (SEM) to evaluate changes in the microstructure provide essential information regarding thermal durability and residual strength. The improved mechanical strength and toughness achieved using seashells and nano-silica demonstrated the potential of these additives to create UHPC that is more sustainable and environmentally friendly. This research not only advances the field of building materials but also advocates the use of waste products and nanotechnology to create high-performance, environmentally friendly concrete solutions for construction and building applications.

2 Experimental program

2.1 Raw materials

This section provides an analysis of the primary components used and necessary preparation procedures. The investigation utilized (52.5 grade) Type I Ordinary Portland cement obtained from the Al Arish Cement Factory, following the specifications of ASTM C150 [48]. In this study, silica fume with a specific surface area of 17.4 × 103 (m2·kg−1) and a specific gravity of 2.15 is used. Table 1 presents the precise chemical compositions of both SF and cement. BOF slag was obtained, crushed, sieved, and used as a fine aggregate with a fineness modulus of 2.13 mm. Polycarboxylates called Sika® ViscoCrete®-3425 are used for high workability and to reduce the water content in UHPC. Tap water was consumed. PEG 400 was selected as a shelf-curing additive. The chemical compositions of cementitious materials and nanomaterials are listed in Table 1.

Chemical composition for binder materials (%)

| Oxides (%) | Cement | Silica fume | Seashell powder | Seashell-pre-mixed with nano-silica |

|---|---|---|---|---|

| SiO2 | 23.9 | 96.55 | 2.4 | 62.36 |

| Al2O3 | 7.45 | 0.19 | 0.42 | 3.33 |

| Fe2O3 | 3.02 | 0.32 | 0.22 | 2.34 |

| CaO | 57.3 | 0.98 | 96.69 | 39.71 |

| MgO | 3.94 | 0.73 | 0.67 | 1.95 |

| SO3 | 3.23 | — | 0.09 | 0.19 |

| Na2O | 0.29 | 0.38 | 0.4 | 5.54 |

| K2O | 0.87 | 0.85 | 0.1 | 0.11 |

| Cl | — | — | 0.09 | 0.66 |

All chemical elements are expressed in percentage (%).

2.1.1 Seashell preparation

The seashell was obtained locally, washed, dried, crushed to small particles, milled, and sieved with a sieve no 170. For pre-mixing with nano-silica, seashell powder was added to sodium silicate, and the powder and solution were mixed, followed by the addition of hydrochloric acid. The next step was to remove sodium chlorides by mixing them several times until they were fully dissolved in water. The water was changed until pure water was obtained, and the new composite was dried to obtain a powder, as shown in Figure 1.

The preparation procedures of pre-mixed seashell powder.

2.2 Concrete mix design

The mix percentages for creating the UHPC mixes based on multiple trials are listed in Table 2 relative to the weight of cement until the best results were obtained [38,42]. Table 2 lists the proportions of these mixtures. A fixed water-to-binder ratio (w/b) of 0.18, a silica fume of 15%, and a consistent BOF slag were used. Multiple trial mixes were conducted to achieve the desired strength of UHPC. Table 2 shows the details of mix proportions.

Mix proportions in kg·m−3

| Mixes | Binders | BOFS | SP | Water | |||

|---|---|---|---|---|---|---|---|

| Cement | SS | ss-NS | Silica fume | ||||

| Ref | 800 | 0 | — | 240 | 1,200 | 82 | 142 |

| 1 SS | 792 | 8 | — | 240 | 1,200 | 82 | 142 |

| 3 SS | 776 | 24 | — | 240 | 1,200 | 82 | 142 |

| 5 SS | 760 | 40 | — | 240 | 1,200 | 82 | 142 |

| 7 SS | 735 | 65 | — | 240 | 1,200 | 82 | 142 |

| 9 SS | 728 | 72 | — | 240 | 1,200 | 82 | 142 |

| 1 SS-NSC | 792 | — | 8 | 240 | 1,200 | 82 | 142 |

| 3 SS-NSC | 776 | — | 24 | 240 | 1,200 | 82 | 142 |

| 5 SS-NSC | 760 | — | 40 | 240 | 1,200 | 82 | 142 |

| 7 SS-NSC | 735 | — | 65 | 240 | 1,200 | 82 | 142 |

| 9 SS-NSC | 728 | — | 72 | 240 | 1,200 | 82 | 142 |

2.3 Mixing procedures

The mixing techniques are briefly outlined as follows. The mixer was filled with BOF in addition to the binder materials (cement and SF). The mixture was then blended for 2 min to ensure even distribution. Subsequently, half the volume of water was added to the self-curing agent. Concurrently, superplasticizers were introduced and blended using a magnetic stirrer for full dispersion to half-water and seashell powder, whereas the NPs were gradually added to achieve a well-dispersed and uniform solution, as described in ref. [49]. Subsequently, the solution that remained and the duration of mixing varied between 5 and 10 min for the combination of NPs, superplasticizers, and half of the water content, and the specimens were removed from the mold until the testing date. Figure 2 shows mixing procedures of UHPC.

Mixing procedures of UHPC.

2.4 Casting

For the mixing process, a 10-l forced concrete mixer was used. The components of the mixture, including cement, crushed glass, and silica fume, were weighed before blending to produce a homogeneous blend. Water was added to the dry materials of the mixer drum after mixing the superplasticizer and water in a different container. The substance was carefully mixed to achieve appropriate consistency for casting. The various components of each mixture required different quantities of time to blend. For each concrete mixture, 100 mm diameter and 200 mm height cylindrical specimens and 100 mm diameter and 100 mm diameter cubic specimens were cast. The three layers of concrete that were poured into the molds were each slightly vibrated to allow any trapped air to be released. Following the completion of the concrete surface, the specimens were covered with plastic sheets to prevent water evaporation. The samples were demolded and placed in the air at 25°C/2°C until testing, which included evaluations at 7, 28, and 90 days.

2.5 Testing

Several test procedures were performed to ensure compressive strength. This was in accordance with ASTM C109 [50]. Three 100 × 100 × 100 mm3 cubes were investigated for each concrete mix, and the specimens were subjected to compressive strength testing at ages 7, 28, and 90 days using an ELE crushing machine with a 3,000 kN capacity. In accordance with ASTM C496 [51], cylindrical specimens with dimensions of 100 mm × 200 mm were analyzed to identify the splitting tensile strength, and the average value was determined for each test. After drying the samples at 105°C and isolating them from all other parameters, in addition to the base, SS underwent sorptivity tests for 100 × 50 mm cylinders to ensure durability in accordance with ASTM C1585 [52]. Water permeability was measured for cubes measuring 15 cm × 15 cm × 15 cm. Chloride penetration was assessed 28 days after immersing the samples in solution with 3.5% sodium chloride, in addition to measuring the strength loss due to subjecting samples to sodium sulfates at 5% concentration, and the effect of elevated temperature was investigated by subjecting the samples to 350 and 700°C. SEM was performed to analyze the microstructure of thin sections of the material approximately 1 cm × 1 cm in size from the crushed cube core. The study was performed using a Philips XL 30. Figure 3 shows experimental work procedures.

Experimental work.

3 Results and discussion

3.1 Compressive strength

3.1.1 Compressive strength for mixes with seashell powder

Figure 4 shows the compressive strength when seashell powder is used at various concentrations (1, 3, 5, 7, and 9%) in UHPC containing BOF slag as a fine aggregate exerts a good influence on compressive strength, especially with regard to IC. The results showed that at low concentrations of 1 and 3%, the shell powder resulted in a slight decrease in compressive strength from 115 to 107 MPa at 7 days, from 133 to 131 at 28 days, and from 139 to 138 MPa at 90 days, likely owing to the role of calcium carbonate as a filler that enhances the microstructure of concrete without significantly compromising the hydration process. However, as the concentration increased to 5, 7, and 9%, the decrease in the compressive strength became more obvious as the strength decreased to 98, 129.9, and 136.68 MPa at 7, 28, and 90 days compared to 115.188, 133.59, and 139.5 MPa for reference mix. High doses of seashell powder increase the overall water demand and reduce the effective water–cement ratio, thereby weakening the cement matrix [53]. Furthermore, an excessive amount of nonreactive fillers may hinder the formation of strong bonds within concrete, thereby reducing its structural integrity [54]. Thus, although small amounts of seashell powder may have minimal adverse effects or even potential benefits for internal processing [55], higher amounts significantly reduce compressive strength.

Compressive strength for UHPC contains seashell powder.

3.1.2 Compressive strength for mixes with seashell powder pre-mixed with nano-silica

Figure 5 shows the compressive strength when seashell powder pre-mixed with nano-silica at doses of 1, 3, 5, 7, and 9% was incorporated into concrete containing BOF slag, where the fine aggregate significantly enhanced the compressive strength across all mixtures at 7, 28, and 90 days. This improvement is attributed to the synergistic effects of seashell powder and nano-silica [56], which collectively contribute to improved internal processing and a finer microstructure [57]. At lower doses of 1 and 3%, the mixture began to moderately increase in strength owing to the filler effect and pozzolanic activity of nano-silica, which improved the compressive strength from 115 to 119 MPa, 133 to 137.93 MPa, and 139.5 to 145.49 MPa at 7, 28, and 90 days, respectively, which promoted the formation of additional calcium silicate hydrate (C–S–H) [58]. The best dosage was achieved at 5% at ages ranging from 7 to 90 days, where the compressive force reached its peak, demonstrating the most efficient balance between enhancing filling and accelerating hydration. At this concentration, concrete exhibits maximum densification and reduced porosity, resulting in superior structural integrity [59]. Higher doses of 7–9% improved the strength to 118.23, 134.87, and 141.23 at 7, 28, and 90 days, respectively. At a 9% replacement ratio, but at a decreasing rate, indicating that the optimal interaction between seashell powder and nano-silica was best achieved at the 5% dose. Overall, the combined addition of seashell powder and nano-silica effectively enhanced the compressive strength, with the 5% dose providing the most obvious enhancement.

Compressive strength for UHPC contains seashell powder pre-mixed with nano-silica.

3.1.3 Comparison between compressive strength for UHPC with seashell powders and seashells pre-mixed with nano-silica

Figure 6 shows the compressive strength when seashell powder was added and seashells pre-mixed with nano-silica with doses were utilized. The use of shell powder at doses of 1, 3, 5, 7, and 9% in concrete with BOF slag as a fine aggregate generally results in a slight decrease in compressive strength, with a particularly noticeable dose increase. At low concentrations (1 and 3%), the reduction is minimal, most likely owing to the filler effect of calcium carbonate, which enhances the microstructure without severely affecting hydration. However, higher doses (5, 7, and 9%) significantly weakened the cement matrix by increasing the water demand and incorporating excess nonreactive fillers, thus reducing the structural integrity. In contrast, when the seashell powder was pre-mixed with nano-silica at the same doses, the compressive strength of concrete improved across all test ages (7, 28, and 90 days). This enhancement is due to the combined effects of the filler and the pozzolanic properties of nano-silica, which promote the formation of additional calcium silicate hydrate (C–S–H) and improve the IC [36]. The optimum strength was achieved at a dosage of 5%, at which point the concrete exhibited maximum densification and reduced porosity [60]. Higher doses (7 and 9%) continued to enhance strength but with weakening proceeds, suggesting that 5% is the most effective concentration to balance the benefits of shell powder and nano-silica [61]. In summary, while seashell powder alone tends to slightly reduce compressive strength at high doses, combining it with nano-silica significantly increases strength, with a 5% dose providing optimal enhancement. This demonstrates the importance of composite admixtures in improving concrete performance, particularly in IC applications that include BOF slag as a fine aggregate [46].

Compressive strength for UHPC contains seashell powder and seashells pre-mixed with nano-silica.

3.2 Split tensile strength

Figure 7 shows the splitting tensile strength results for seashell powder and seashells pre-mixed with nano-silica at doses of 1, 3, 5, 7, and 9% in concrete with BOF slag as a fine aggregate demonstrating that the tensile strength tends to be reduced slightly, especially in IC applications. At low doses of 1 and 3%, the decrease in the tensile strength was minimal from 1.64 to 1.61 MPa, likely because of the limited disruption caused by the seashell powder in the cement matrix. However, as the dosage increased to 5, 7, and 9%, the tensile strength decreased further to reach 1.58 MPa, mainly because the higher content of the nonreactive filler increased the water demand and weakened the bond within the cement matrix [54,62]. Conversely, when the seashell powder was pre-mixed with nano-silica at the same doses, there was a significant increase in tensile strength across all mixtures at 28 days. This improvement is attributed to the synergistic effect of nano-silica [63,64], which enhances the pozzolanic reaction, leading to the formation of additional calcium silicate hydrate (C–S–H) and improved microstructural integrity. The optimal tensile strength was achieved at a dosage of 5% by increasing the splitting tensile strength from 1.6 to 1.8 MPa, as the composite mixture increased densification and reduced porosity, resulting in superior bond strength and overall concrete performance. Higher doses of 7 and 9% continued to increase the tensile strength but at a reduced rate, indicating that the 5% dose provides the most effective balance between the benefits of seashell powder and nano-silica. In summary, while SS powder alone slightly reduced the tensile strength at high doses owing to the increased water demand and decreased bond strength, its combination with nano-silica significantly enhanced the cleavage tensile strength, particularly at the 5% dose. This comparison highlights the advantages of using composite admixtures to improve the tensile strength of concrete with BOF slag as a fine aggregate.

Splitting tensile strength for UHPC contains seashell powder and seashells pre-mixed with nano-silica.

3.3 Compressive strength at elevated temperature

Figure 8(a) and (b) show the residual strength when UHPC containing seashell powder and shells mixed with nano-silica in varying amounts between 1 and 9% were exposed to high temperatures of up to 350 and 700°C, respectively. This effect is particularly noticeable when UHPC is subjected to self-curing conditions and when BOF slag is used as a fine aggregate. Shell-derived admixtures have the potential to improve the heat resistance and mechanical properties of UHPC at elevated temperatures [65]. Seashell powder, which contains calcium carbonate, acts as a filler in concrete, rendering it denser and less permeable, with strength reduction from 7.6 to 16% at 350°C and from 25.8 to 32.7% at 700°C. This is important for maintaining the structural integrity of concrete when exposed to high temperatures [42,65]. In addition, the performance of UHPC is further enhanced when seashells are combined with nano-silica due to synergistic effects. Nano-silica promotes the production of more C–S–H gel, which improves the cohesion of the cement matrix and mitigates the negative effects of thermal expansion and spalling. Doses ranging from 5 to 7% showed the most favorable results in terms of maintaining UHPC performance under high-temperature conditions, with residual strength ranging from 92 to 95.4% at 350°C. The lowest strength loss was obtained at 5% SS-NS relative to all mixes, with residual strength ranging from 72 to 77% at 700°C. This highlights the potential of seashell-based additives, especially when combined with nano-silica, to improve the durability of UHPC when exposed to BOF slag as a fine aggregate.

Residual strength for UHPC (a) contains seashell powder and (b) contains seashells pre-mixed with nano-silica.

3.4 Sorptivity

Figure 9 shows the sorptivity results for seashell powder and seashells pre-mixed with nano-silica at doses of 1, 3, 5, 7, and 9% in UHPC using BOF slag as a fine aggregate, which has a beneficial effect on reducing absorbency. This is particularly true in the context of internal processing. At low doses of 1 and 3%, the decrease in absorption is modest but noticeable and is due to the filler effect of the calcium carbonate in the shell powder, which improves the pore structure and reduces capillary action. As the dose increased to 5, 7, and 9%, the decrease in absorbance became more significant. This is owing to the increased presence of fine particles filling voids within the concrete matrix, further impeding water ingress and enhancing the durability of UHPC. However, although higher doses effectively reduce absorption, they must be carefully balanced to avoid adverse effects on other mechanical properties. Adding nano-silica to seashell powder at the same doses resulted in a greater decrease in absorbance than the use of seashell powder alone. The inclusion of nano-silica initiated the pozzolanic reaction, resulting in the formation of more calcium silicate hydrate (C–S–H) and significantly improving the pore structure of UHPC. The combined use of seashell powder and nano-silica improves hull compaction, resulting in a significant reduction in absorbency at all application levels. At a 5% dose, the combination mixture achieves an ideal balance, resulting in a significant reduction in absorption while maintaining the other crucial qualities of UHPC. Increasing the dose to 7 and 9% resulted in a slight improvement in absorption, but the benefits were small compared to using the 5% dose. The comparison shows that the combination of seashell powder and silica nanocomposite is more effective than seashell powder alone in improving the durability and water resistance of UHPC.

Sorptivity for UHPC contains seashell powder and seashells pre-mixed with nano-silica.

3.5 Water permeability

The addition of shell powder to UHPC at different dosages (1, 3, 5, 7, and 9%) and the use of BOF slag as a fine aggregate have a beneficial effect on reducing water permeability, especially with regard to curing. Interior. When doses below 1 and 3% were used, the decrease in water permeability was not noticeable [66]. This was mainly due to the presence of calcium carbonate in the seashell powder [55]. Figure 10 shows that calcium carbonate improves the pore structure and restricts the entry of water; when the concentration increases to 5, 7, and 9%, the decrease in water permeability becomes more significant [67]. The increased concentration of small shell particles effectively fills small empty spaces within the concrete structure, significantly obstructing the routes through which water can enter and improving the overall strength and water resistance of UHPC. However, the decrease in water permeability was more pronounced when the seashell powder was mixed with nano-silica at the same dose as when seashell powder was used alone. The pozzolanic reaction resulting from the addition of nano-silica produces more C–S–H [68]. This process improved the densification of the UHPC matrix and the pore structure. Seashell powder and nano-silica worked together to reduce the water permeability more effectively at all doses [69]. The combination mixture finds its sweet spot at a 5% dosage, which minimizes the water permeability while maintaining the UHPC integrity and other important features. Although the effects of the 5% dose were more pronounced, water resistance continued to improve with higher doses of 7 and 9%. This comparison highlights the effectiveness of the combination of seashell powder and silica nanocomposites of seashell powder alone in improving the water resistance and durability of UHPC.

Water permeability for UHPC contains seashell powder and seashells pre-mixed with nano-silica.

3.6 Chloride penetration

When shell powder is added to UHPC with BOF slag as a fine aggregate, using doses of 1, 3, 5, 7, and 9%, chloride is effectively reduced. This effect was particularly noticeable when combined with internal processing. Figure 11 shows that when seashell powder was used at lower doses of 1 and 3%, seashell powder had a slight effect on reducing chloride penetration from to the 340–174 coulomb. This is because the powder acts as a filler, refining the pore structure and restricting the entry of the chloride ions. As the dose increased to 5, 7, and 9%, the decrease in chloride penetration became more pronounced in 208–174 coulomb, with the 5% dose exhibiting the best performance. The small particles of the shell powder effectively cover small empty spaces and create a more compact structure, thus blocking the paths through which chloride ions can pass. The addition of nano-silica to seashell powder significantly reduced chloride penetration at all doses [70,71]. The presence of nano-silica triggers a pozzolanic reaction, resulting in the formation of more C–S–H. This process further improves the pore structure of the concrete and enhances its impermeability. The combination of these factors resulted in a significant reduction in chloride penetration. Of the many compound doses tested, the 5% dose demonstrated the highest level of performance, providing the strongest resistance against chloride ingress while maintaining the overall integrity of UHPC.

Chloride penetration for UHPC contains seashell powder and seashells pre-mixed with nano-silica.

3.7 Sulfate attack

The negative impact was reduced by adding different amounts of shell powder (1, 3, 5, 7, and 9%) to UHPC containing BOF slag as a fine aggregate. The force generated by the sulfate attack was greatly reduced. This reduction is particularly important when internal processing is used. When used at lower doses of 1 and 3%, seashell powder improved the microstructure of concrete and reduced permeability. As a result, it limits the penetration of sulfate ions and modestly reduces the strength loss [72]. As the dose increased to 5, 7, and 9%, the reduction in strength degradation became more noticeable, with the 5% dose achieving optimal performance and the highest residual strength of 81 MPa compared to 69.1 MPa for the control mix, as shown in Figure 12. The presence of tiny shell particles in the concrete matrix fills the small empty spaces [73], resulting in a more compact and less porous structure [47]. These NPs provided increased protection against the penetration of sulfate ions. The addition of nano-silica to seashell powder significantly reduced the strength loss due to sulfate attack in all mixtures. Nano-silica undergoes a pozzolanic reaction that leads to the formation of more C–S–H [73].

Residual strength for UHPC contains seashell powder and seashells pre-mixed with nano-silica after subjecting to sulfates.

4 Microstructural assessment

4.1 SEM in case of ambient temperature

Figure 13 shows SEM micrographs of UHPC. The incorporation of seashell powder and shells mixed with nano-silica achieved the highest compressive strength at 1% SS and 5% SS-NS and had a significant effect on the microstructural properties, as observed by electron microscopy. The inclusion of smaller particles improves the particle arrangement and reduces the porosity [58,59,74]. This improvement is characterized by the production of a denser matrix and a reduction in the empty spaces between the different materials. The figure shows a denser microstructure in the case of SS-NS than in the reference mix, whereas the mix of seashells with the lowest strength showed microcracks without voids. This could be due to the effective filling of small empty spaces with seashell components and the additional chemical reaction generated by nano-silica. These improvements significantly improve the mechanical properties and longevity of UHPC even under normal conditions [53]. The high Ca/Si in the case of the seashell pre-mixed with NPs owing to the pozzolanic effect over Ca/Si in the case of the reference mix being lower than those of the seashell mix owing to the high calcium carbonate content and only the filling effect.

SEM micrograph for UHPC (a) Ref mix, (b) 1 SS, and (c) 1 SS-NS.

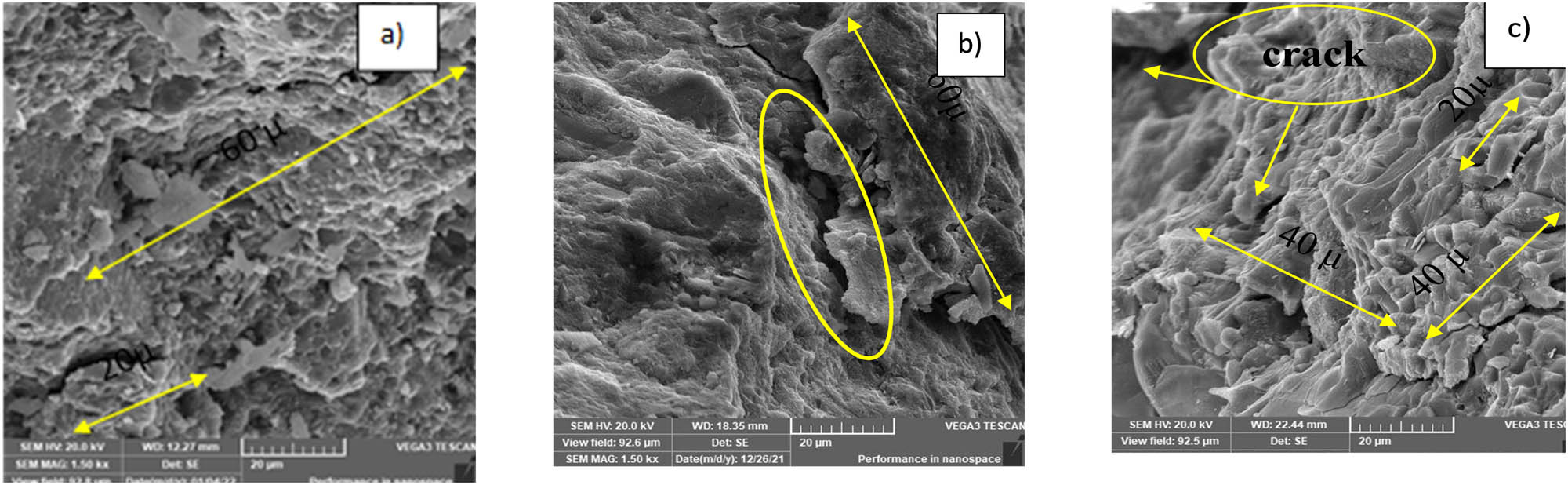

4.2 SEM in the case of elevated temperature

The incorporation of seashell powder and shells mixed with nano-silica achieved the highest compressive strength at 1% ss and 5% SS-NS at an elevated temperature of 700°C. At elevated temperatures, SEM showed a significant change in the microstructural properties of UHPC incorporating admixtures made from seashells, as shown in Figure 14. The inclusion of seashell and nano-silica components helped reduce the heat-induced deterioration in UHPC. This is demonstrated by the preservation of the fine microstructure and limited expansion of pores [75], which showed minimal evidence of heat damage, including minor microcracks and decreased connectivity between pores with smaller crack depths and lengths. The exceptional performance of this material is due to the combined effects of seashell-based additives and nano-silica. These admixtures improve the ability of high-performance concrete to withstand thermal stress and maintain its structural integrity [57,58,76], even under extremely high- or low-temperature conditions. SEM investigation demonstrated that seashell-based additives, especially when used with nano-silica, effectively increased the microstructural properties and thermal stability of UHPC.

SEM micrograph for UHPC (a) Ref mix, (b) 1-SS, and (c) 1SS-NS 700C.

5 Discussion

This study examines the effect of introducing seashell and seashell powder pre-mixed with nano-silica into UHPC, incorporating BOF slag as a fine aggregate. The concrete was also subjected to IC using PEG 400. The results indicated that the use of shell powder resulted in a marginal reduction in the compressive strength [55]. However, replacing cement with seashells mixed with nano-silica resulted in enhanced compressive strength at all replacement ratios (1, 3, 5, 7, and 9%) owing to the particle size effect and pozzolanic reaction [60]. The most significant improvement of 5–6% was observed when the replacement rate was 5% after 7, 28, and 90 days. In addition, the cleavage tensile strength increased by 9.5% when the seashells were pre-mixed with nano-silica at a dose of 5%. Adding nano-silica to seashells significantly improves thermal stability [75], resulting in increased residual strength at temperatures of 350 and 700°C compared to the use of seashells alone. Furthermore, the combination of seashell powder and seashells infused with nano-silica resulted in a significant reduction in water permeability and absorption across all replacement levels [77,78,79]. The incorporation of shell powder into UHPC significantly reduced the extent of chloride penetration. This reduction was more pronounced when the seashells were combined with nano-silica before use. The residual strength of UHPC was greater when the seashells were pre-mixed with nano-silica than when using the seashells alone after being immersed in sulfate [73,80]. Furthermore, by incorporating nano-silica into seashells, a more condensed microstructure and increased Ca/Si ratio were obtained, as well as internal processing advantages in improving the durability and microstructure via curing continuity [33,34,36,81].

6 Conclusion

This study comprehensively evaluates the mechanical properties, including compressive and tensile strengths at different stages, and provides a significant understanding of the performance improvements achieved with innovative additives (seashell powder and BOF). Durability tests, such as sorptivity, water permeability, salt penetration, and sulfate resistance tests under extreme environmental conditions, were performed for UHPC. In addition, SEM was used to evaluate changes in the microstructure. The following conclusions are made:

Replacing cement with seashells pre-mixed with nano-silica enhanced compressive strength at all replacement ratios of 1, 3, 5, 7, and 9% at all curing ages.

Using seashells as cement replacement material slightly decreased compressive strength.

The optimum compressive strength in the case of seashells pre-mixed with nano-silica is achieved at 5% dosage as cement replacement material with an improvement of 5–6% compared to the control mix at 7, 28, and 90 days.

The use of seashells pre-mixed with nano-silica with a content of 5% in UHPC resulted in a 9.5% improvement in tensile strength compared to the control mix.

Replacing cement with seashells pre-mixed with nano-silica resulted in increased residual strength at 350 and 700°C.

The water permeability and absorption capacity of UHPC were significantly reduced at all replacement levels 1, 3, 5, 7, and 9% when using seashell and shell powders pre-mixed with nano-silica.

The incorporation of sea shell powder into UHPC resulted in a significant reduction in the depth of chloride penetration.

Residual strength of UHPC after immersing in sulfates increased in the case of seashells pre-mixed with nano-silica more than in the case of seashells only.

Compact microstructure and higher Ca/Si content are obtained in the case of seashells pre-mixed with nano-silica in addition to IC with a positive effect.

Low microcracks and high thermal stability are obtained when UHPC mixes are subjected to high temperatures, and seashell powder pre-mixed with nano-silica shows fewer cracks in number, length, and width than the control mix and seashell powder mix.

Acknowledgments

The authors extend their appreciation to Taif University, Saudi Arabia, for supporting this work through project number (TU-DSPP-2024-248).

-

Funding information: This research was funded by Taif University, Saudi Arabia, Project No. TU-DSPP-2024-248.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

References

[1] Bahmani, H. and D. Mostofinejad. Microstructure of ultra-high-performance concrete (UHPC) – A review study. Journal of Building Engineering, Vol. 50, 2022, id. 104118.10.1016/j.jobe.2022.104118Search in Google Scholar

[2] Huang, B. T., J. X. Zhu, K. F. Weng, J. Q. Huang, and J. G. Dai. Prefabricated UHPC-concrete-ECC underground utility tunnel reinforced by perforated steel plate: Experimental and numerical investigations. Case Studies in Construction Materials, Vol. 16, 2022, id. e00856.10.1016/j.cscm.2021.e00856Search in Google Scholar

[3] Khan, M., J. Lao, and J. G. Dai. Comparative study of advanced computational techniques for estimating the compressive strength of UHPC. Journal of Asian Concrete Federation, Vol. 8, No. 1, 2022, pp. 51–68.10.18702/acf.2022.6.8.1.51Search in Google Scholar

[4] Ozawa, M., S. Subedi Parajuli, Y. Uchida, and B. Zhou. Preventive effects of polypropylene and jute fibers on spalling of UHPC at high temperatures in combination with waste porous ceramic fine aggregate as an internal curing material. Construction and Building Materials, Vol. 206, 2019, pp. 219–225.10.1016/j.conbuildmat.2019.02.056Search in Google Scholar

[5] Peng, G.-F., X. J. Niu, Y. J. Shang, D. P. Zhang, X. W. Chen, and H. Ding. Combined curing as a novel approach to improve resistance of ultra-high performance concrete to explosive spalling under high temperature and its mechanical properties. Cement and Concrete Research, Vol. 109, 2018, pp. 147–158.10.1016/j.cemconres.2018.04.011Search in Google Scholar

[6] Shen, P., L. Lu, Y. He, F. Wang, and S. Hu. The effect of curing regimes on the mechanical properties, nano-mechanical properties and microstructure of ultra-high performance concrete. Cement and Concrete Research, Vol. 118, 2019, pp. 1–13.10.1016/j.cemconres.2019.01.004Search in Google Scholar

[7] Tayeh, B. A., A. S. Aadi, N. N. Hilal, B. H. Bakar, M. M. Al-Tayeb, and W. N. Mansour. Properties of ultra-high-performance fiber-reinforced concrete (UHPFRC) – a review paper. In AIP Conference Proceedings, AIP Publishing LLC, 2019.10.1063/1.5126575Search in Google Scholar

[8] Schröfl, C., M. Gruber, and J. Plank. Preferential adsorption of polycarboxylate superplasticizers on cement and silica fume in ultra-high performance concrete (UHPC). Cement and Concrete Research, Vol. 42, No. 11, 2012, pp. 1401–1408.10.1016/j.cemconres.2012.08.013Search in Google Scholar

[9] Courtial, M., M. N. de Noirfontaine, F. Dunstetter, M. Signes-Frehel, P. Mounanga, K. Cherkaoui, et al. Effect of polycarboxylate and crushed quartz in UHPC: Microstructural investigation. Construction and Building Materials, Vol. 44, 2013, pp. 699–705.10.1016/j.conbuildmat.2013.03.077Search in Google Scholar

[10] Su, Y., J. Li, C. Wu, P. Wu, and Z. X. Li. Influences of nano-particles on dynamic strength of ultra-high performance concrete. Composites Part B: Engineering, Vol. 91, 2016, pp. 595–609.10.1016/j.compositesb.2016.01.044Search in Google Scholar

[11] Wu, Z., C. Shi, K. H. Khayat, and L. Xie. Effect of SCM and nano-particles on static and dynamic mechanical properties of UHPC. Construction and Building Materials, Vol. 182, 2018, pp. 118–125.10.1016/j.conbuildmat.2018.06.126Search in Google Scholar

[12] Tayeh, B. A., B. H. A. Bakar, M. A. M. Johari, and Y. L. Voo. Utilization of ultra-high performance fibre concrete (UHPFC) for rehabilitation–a review. Procedia Engineering, Vol. 54, 2013, pp. 525–538.10.1016/j.proeng.2013.03.048Search in Google Scholar

[13] Baharuddin, N. K., F. Mohamed Nazri, B. H. Abu Bakar, S. Beddu, and B. A. Tayeh. Potential use of ultra high-performance fibre-reinforced concrete as a repair material for fire-damaged concrete in terms of bond strength. International Journal of Integrated Engineering, Vol. 12, No. 9, 2020, pp. 87–95.Search in Google Scholar

[14] Yu, R., P. H. Spiesz, and H. J. Brouwers. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cement and Concrete Composites, Vol. 55, 2015, pp. 383–394.10.1016/j.cemconcomp.2014.09.024Search in Google Scholar

[15] Muhd Norhasri, M. S., M. S. Hamidah, A. Mohd Fadzil, and O. Megawati. Inclusion of nano metakaolin as additive in ultra high performance concrete (UHPC). Construction and Building Materials, Vol. 127, 2016, pp. 167–175.10.1016/j.conbuildmat.2016.09.127Search in Google Scholar

[16] Ghafari, E., M. Arezoumandi, H. Costa, and E. Júlio. Influence of nano-silica addition on durability of UHPC. Construction and Building Materials, Vol. 94, 2015, pp. 181–188.10.1016/j.conbuildmat.2015.07.009Search in Google Scholar

[17] Abdulkareem, O. M., A. Ben Fraj, M. Bouasker, and A. Khelidj. Mixture design and early age investigations of more sustainable UHPC. Construction and Building Materials, Vol. 163, 2018, pp. 235–246.10.1016/j.conbuildmat.2017.12.107Search in Google Scholar

[18] Alsalman, A., C. N. Dang, J. R. Martí-Vargas, and W. Micah Hale. Mixture-proportioning of economical UHPC mixtures. Journal of Building Engineering, Vol. 27, 2020, id. 100970.10.1016/j.jobe.2019.100970Search in Google Scholar

[19] Chen, Y., R. Yu, X. Wang, J. Chen, and Z. Shui. Evaluation and optimization of Ultra-High Performance Concrete (UHPC) subjected to harsh ocean environment: Towards an application of Layered Double Hydroxides (LDHs). Construction and Building Materials, Vol. 177, 2018, pp. 51–62.10.1016/j.conbuildmat.2018.03.210Search in Google Scholar

[20] Zhou, M., W. Lu, J. Song, and G. C. Lee. Application of Ultra-High Performance Concrete in bridge engineering. Construction and Building Materials, Vol. 186, 2018, pp. 1256–1267.10.1016/j.conbuildmat.2018.08.036Search in Google Scholar

[21] Liu, K., R. Yu, Z. Shui, X. Li, C. Guo, B. Yu, et al. Optimization of autogenous shrinkage and microstructure for Ultra-High Performance Concrete (UHPC) based on appropriate application of porous pumice. Construction and Building Materials, Vol. 214, 2019, pp. 369–381.10.1016/j.conbuildmat.2019.04.089Search in Google Scholar

[22] Yu, Z., L. Wu, Z. Yuan, C. Zhang, and T. Bangi. Mechanical properties, durability and application of ultra-high-performance concrete containing coarse aggregate (UHPC-CA): A review. Construction and Building Materials, Vol. 334, 2022, id. 127360.10.1016/j.conbuildmat.2022.127360Search in Google Scholar

[23] Azmee, N. M. and N. Shafiq. Ultra-high performance concrete: From fundamental to applications. Case Studies in Construction Materials, Vol. 9, 2018, id. e00197.10.1016/j.cscm.2018.e00197Search in Google Scholar

[24] Wu, D., X. Li, X. Guo, J. Qin, and S. Li. Early-age shrinkage development of ultra-high-performance concrete under heat curing treatment. Construction and Building Materials, Vol. 131, 2017, pp. 767–774.10.1016/j.conbuildmat.2016.11.024Search in Google Scholar

[25] Demiss, B. A., W. O. Oyawa, and S. M. Shitote. Mechanical and microstructural properties of recycled reactive powder concrete containing waste glass powder and fly ash at standard curing. Cogent Engineering, Vol. 5, No. 1, 2018, id. 1464877.10.1080/23311916.2018.1464877Search in Google Scholar

[26] Zhang, H., T. Ji, B. He, and L. He. Performance of ultra-high performance concrete (UHPC) with cement partially replaced by ground granite powder (GGP) under different curing conditions. Construction and Building Materials, Vol. 213, 2019, pp. 469–482.10.1016/j.conbuildmat.2019.04.058Search in Google Scholar

[27] Zhang, H., T. Ji, and X. Lin. Pullout behavior of steel fibers with different shapes from ultra-high performance concrete (UHPC) prepared with granite powder under different curing conditions. Construction and Building Materials, Vol. 211, 2019, pp. 688–702.10.1016/j.conbuildmat.2019.03.274Search in Google Scholar

[28] Tayeh, B. A., B. H. A. Bakar, M. A. M. Johari, and M. M. Ratnam. The relationship between substrate roughness parameters and bond strength of ultra high-performance fiber concrete. Journal of Adhesion Science and Technology, Vol. 27, No. 16, 2013, pp. 1790–1810.10.1080/01694243.2012.761543Search in Google Scholar

[29] Tayeh, B. A., B. H. Abu Bakar, M. A. Megat Johari, and A. M. Zeyad. Microstructural analysis of the adhesion mechanism between old concrete substrate and UHPFC. Journal of Adhesion Science and Technology, Vol. 28, No. 18, 2014, pp. 1846–1864.10.1080/01694243.2014.925386Search in Google Scholar

[30] Tayeh, B. A., B. A. Bakar, and M. M. Johari. Mechanical properties of old concrete – UHPFC interface. In Concrete Repair, Rehabilitation and Retrofitting III: 3rd International Conference on Concrete Repair, Rehabilitation and Retrofitting, ICCRRR-3, CRC Press, Cape Town, South Africa, September 2012.Search in Google Scholar

[31] Askar, L. K., B. A. Tayeh, and B. Abu Bakar. Effect of different curing conditions on the mechanical properties of UHPFC. Iranian (Iranica) Journal of Energy & Environment, Vol. 4, No. 3, 2013, pp. 299–303.10.5829/idosi.ijee.2013.04.03.18Search in Google Scholar

[32] ACI H. “308R-Guide to Curing Concrete.” American Concrete Institute International, 2001.Search in Google Scholar

[33] Vijayan, D. S., S. Arvindan, D. Parthiban, R. S. Kumar, B. Saravanan, and Y. Robert. An experimental study on mechanical and durable properties of self-curing concrete by adding admixture. Materials Today: Proceedings, Vol. 33, 2020, pp. 496–501.10.1016/j.matpr.2020.05.071Search in Google Scholar

[34] Kamal, M. M., M. A. Safan, A. A. Bashandy, and A. M. Khalil. Experimental investigation on the behavior of normal strength and high strength self-curing self-compacting concrete. Journal of Building Engineering, Vol. 16, 2018, pp. 79–93.10.1016/j.jobe.2017.12.012Search in Google Scholar

[35] Van, V.-T.-A., C. Rößler, D. D. Bui, and H. M. Ludwig. Rice husk ash as both pozzolanic admixture and internal curing agent in ultra-high performance concrete. Cement and Concrete Composites, Vol. 53, 2014, pp. 270–278.10.1016/j.cemconcomp.2014.07.015Search in Google Scholar

[36] Singh, K. Mechanical properties of self curing concrete studied using polyethylene glycol-400: A-review. Materials Today: Proceedings, Vol. 37, 2020, pp. 2318–2320.10.1016/j.matpr.2020.08.662Search in Google Scholar

[37] Md Jaafar, M. F., H. Mohd Saman, N. F. Ariffin, K. Muthusamy, S. Wan Ahmad, and N. Ismail. Corrosion monitoring on steel reinforced nano metaclayed-UHPC towards strain modulation using fiber Bragg grating sensor. IOP Conference Series: Materials Science and Engineering, Vol. 431, 2018, id. 122006.10.1088/1757-899X/431/12/122006Search in Google Scholar

[38] Xiaoyu, G., F. Yingfang, and L. Haiyang. The compressive behavior of cement mortar with the addition of nano metakaolin. Nanomaterials and Nanotechnology, Vol. 8, 2018, id. 184798041875559.10.1177/1847980418755599Search in Google Scholar

[39] Abo-El-Enein, S. A., M. S. Amin, F. I. El-Hosiny, S. Hanafi, T. M. ElSokkary, and M. M. Hazem. Pozzolanic and hydraulic activity of nano-metakaolin. HBRC Journal, Vol. 10, No. 1, 2019, pp. 64–72.10.1016/j.hbrcj.2013.09.006Search in Google Scholar

[40] Guo, J., Y. Bao, and M. Wang. Steel slag in China: Treatment, recycling, and management. Waste Management, Vol. 78, 2018, pp. 318–330.10.1016/j.wasman.2018.04.045Search in Google Scholar PubMed

[41] Horii, K., N. Tsutsumi, Y. Kitano, and T. Kato. Processing and reusing technologies for steelmaking slag. Nippon Steel Technical Report, Vol. 104, 2013, pp. 123–129.Search in Google Scholar

[42] Ahmed, M. J., S. Durand, M. Antoun, F. Gauvin, S. Amziane, and H. J. H. Brouwers. Utilization of air granulated basic oxygen furnace slag as a binder in belite calcium sulfoaluminate cement: A sustainable alternative. Journal of Cleaner Production, Vol. 436, 2024, id. 140539.10.1016/j.jclepro.2023.140539Search in Google Scholar

[43] Humbert, P. S. and J. Castro-Gomes. CO2 activated steel slag-based materials: A review. Journal of Cleaner Production, Vol. 208, 2019, pp. 448–457.10.1016/j.jclepro.2018.10.058Search in Google Scholar

[44] Song, Q., M. Z. Guo, L. Wang, and T. C. Ling. Use of steel slag as sustainable construction materials: A review of accelerated carbonation treatment. Resources, Conservation and Recycling, Vol. 173, 2021, id. 105740.10.1016/j.resconrec.2021.105740Search in Google Scholar

[45] Jiang, Y.-Q., Y. C. Lin, X. Y. Zhang, C. Chen, Q. W. Wang, and G. D. Pang. Isothermal tensile deformation behaviors and fracture mechanism of Ti-5Al-5Mo-5V-1Cr-1Fe alloy in β phase field. Vacuum, Vol. 156, 2018, pp. 187–197.10.1016/j.vacuum.2018.07.034Search in Google Scholar

[46] Zago, S. C., F. Vernilli, and O. Cascudo. The reuse of basic oxygen furnace slag as concrete aggregate to achieve sustainable development: Characteristics and limitations. Buildings, Vol. 13, No. 5, 2023, id. 1193.10.3390/buildings13051193Search in Google Scholar

[47] Zhou, X., Q. Yuan, L. Chen, K. Zheng, S. Wei, and Y. Iftikhar. Sulfate resistance of carbonated basic oxygen furnace slag-metakaolin-Portland cement blends. Journal of Building Engineering, Vol. 87, 2024, id. 109098.10.1016/j.jobe.2024.109098Search in Google Scholar

[48] A. ASTM, C150/C150M-17. Standard Specifcation for Portland Cement, American Society for Testing and Materials, West Conshohocken, PA, USA, 2017.Search in Google Scholar

[49] Meng, W. and K. H. Khayat. Effect of graphite nanoplatelets and carbon nanofibers on rheology, hydration, shrinkage, mechanical properties, and microstructure of UHPC. Cement and Concrete Research, Vol. 105, 2018, pp. 64–71.10.1016/j.cemconres.2018.01.001Search in Google Scholar

[50] Concrete, A.I.C.C.o. and C. Aggregates. Standard test method for compressive strength of cylindrical concrete specimens, ASTM international, 2014.Search in Google Scholar

[51] Concrete, A.I.C.C.o. and C. Aggregates. Standard test method for splitting tensile strength of cylindrical concrete specimens1, ASTM international, 2017.Search in Google Scholar

[52] Ali, N., O. Canpolat, Y. Aygörmez, and M. M. Al-Mashhadani. Evaluation of the 12–24 mm basalt fibers and boron waste on reinforced metakaolin-based geopolymer. Construction and Building Materials, Vol. 251, 2020, id. 118976.10.1016/j.conbuildmat.2020.118976Search in Google Scholar

[53] Wu, Y., J. Lu, Y. Nie, and W. He. Effect of seashell powder as binder material on the performance and microstructure of low-carbon sustainable alkali-activated concrete. Journal of Building Engineering, Vol. 90, 2024, id. 109442.10.1016/j.jobe.2024.109442Search in Google Scholar

[54] Olivia, M., A. A. Mifshella, and L. Darmayanti. Mechanical properties of seashell concrete. Procedia Engineering, Vol. 125, 2015, pp. 760–764.10.1016/j.proeng.2015.11.127Search in Google Scholar

[55] Bamigboye, G. O., A. T. Nworgu, A. O. Odetoyan, M. Kareem, D. O. Enabulele, and D. E. Bassey. Sustainable use of seashells as binder in concrete production: Prospect and challenges. Journal of Building Engineering, Vol. 34, 2021, id. 101864.10.1016/j.jobe.2020.101864Search in Google Scholar

[56] Ma, B., J. Wang, H. Tan, X. Li, L. Cai, Y. Zhou, et al. Utilization of waste marble powder in cement-based materials by incorporating nano silica. Construction and Building Materials, Vol. 211, 2019, pp. 139–149.10.1016/j.conbuildmat.2019.03.248Search in Google Scholar

[57] Yu, R., P. Spiesz, and H. J. H. Brouwers. Effect of nano-silica on the hydration and microstructure development of Ultra-High Performance Concrete (UHPC) with a low binder amount. Construction and Building Materials, Vol. 65, 2014, pp. 140–150.10.1016/j.conbuildmat.2014.04.063Search in Google Scholar

[58] Xu, W., T. Y. Lo, W. Wang, D. Ouyang, P. Wang, and F. Xing. Pozzolanic reactivity of silica fume and ground rice husk ash as reactive silica in a cementitious system: a comparative study. Materials (Basel), Vol. 9, No. 3, 2016, id. 146.10.3390/ma9030146Search in Google Scholar PubMed PubMed Central

[59] Alvee, A. R., R. Malinda, A. M. Akbar, R. D. Ashar, C. Rahmawati, T. Alomayri, et al. Experimental study of the mechanical properties and microstructure of geopolymer paste containing nano-silica from agricultural waste and crystalline admixtures. Case Studies in Construction Materials, Vol. 16, 2022, id. e00792.10.1016/j.cscm.2021.e00792Search in Google Scholar

[60] Hakeem, I. Y., M. Amin, B. A. Abdelsalam, B. A. Tayeh, F. Althoey, and I. S. Agwa. Effects of nano-silica and micro-steel fiber on the engineering properties of ultra-high performance concrete. Structural Engineering and Mechanics, Vol. 82, No. 3, 2022, pp. 295–312.Search in Google Scholar

[61] Ashrafian, A., M. J. Taheri Amiri, M. Rezaie-Balf, T. Ozbakkaloglu, and O. Lotfi-Omran. Prediction of compressive strength and ultrasonic pulse velocity of fiber reinforced concrete incorporating nano silica using heuristic regression methods. Construction and Building Materials, Vol. 190, 2018, pp. 479–494.10.1016/j.conbuildmat.2018.09.047Search in Google Scholar

[62] Hamada, H. M., F. Abed, B. Tayeh, M. S. Al Jawahery, A. Majdi, and S. T. Yousif. Effect of recycled seashells on concrete properties: A comprehensive review of the recent studies. Construction and Building Materials, Vol. 376, 2023, id. 376.10.1016/j.conbuildmat.2023.131036Search in Google Scholar

[63] Tchakouté, H. K., D. E. Tchinda Mabah, C. Henning Rüscher, E. Kamseu, F. Andreola, M. C. Bignozzi, et al. Preparation of low-cost nano and microcomposites from chicken eggshell, nano-silica and rice husk ash and their utilisations as additives for producing geopolymer cements. Journal of Asian Ceramic Societies, Vol. 8, No. 1, 2020, pp. 149–161.10.1080/21870764.2020.1718860Search in Google Scholar

[64] Mostafa, S. A., M. M. El-Deeb, A. A. Farghali, and A. S. Faried. Evaluation of the nano silica and nano waste materials on the corrosion protection of high strength steel embedded in ultra-high performance concrete. Scientific Reports, Vol. 11, No. 1, 2021, id. 2617.10.1038/s41598-021-82322-0Search in Google Scholar PubMed PubMed Central

[65] Ahsan, M. H., M. S. Siddique, S. H. Farooq, M. Usman, M. A. Ul Aleem, M. Hussain, et al. Mechanical behavior of high-strength concrete incorporating seashell powder at elevated temperatures. Journal of Building Engineering, Vol. 50, 2022, id. 104226.10.1016/j.jobe.2022.104226Search in Google Scholar

[66] Zhang, Y., D. Chen, Y. Liang, K. Qu, K. Lu, S. Chen, et al. Study on engineering properties of foam concrete containing waste seashell. Construction and Building Materials, Vol. 260, 2020, id. 119896.10.1016/j.conbuildmat.2020.119896Search in Google Scholar

[67] Sangeetha, P., V. E. Annamalai, and P. Kaythry. Durability studies on concrete with partial replacement of cement and coarse aggregate by seashell waste. Materials Today: Proceedings, 2023.10.1016/j.matpr.2023.12.009Search in Google Scholar

[68] Abhilash, P. P., D. K. Nayak, B. Sangoju, R. Kumar, and V. Kumar. Effect of nano-silica in concrete; a review. Construction and Building Materials, Vol. 278, 2021, id. 122347.10.1016/j.conbuildmat.2021.122347Search in Google Scholar

[69] Heikal, M., H. A. Abdel-Gawwad, and F. A. Ababneh. Positive impact performance of hybrid effect of nano-clay and silica nano-particles on composite cements. Construction and Building Materials, Vol. 190, 2018, pp. 508–516.10.1016/j.conbuildmat.2018.09.163Search in Google Scholar

[70] Harilal, M., V. R. Rathish, B. Anandkumar, R. P. George, M. S. H. S. Mohammed, J. Philip, et al. High performance green concrete (HPGC) with improved strength and chloride ion penetration resistance by synergistic action of fly ash, nanoparticles and corrosion inhibitor. Construction and Building Materials, Vol. 198, 2019, pp. 299–312.10.1016/j.conbuildmat.2018.11.266Search in Google Scholar

[71] Amorim Júnior, N. S., J. S. Andrade Neto, H. A. Santana, M. S. Cilla, and D. V. Ribeiro. Durability and service life analysis of metakaolin-based geopolymer concretes with respect to chloride penetration using chloride migration test and corrosion potential. Construction and Building Materials, Vol. 287, 2021, id. 122970.10.1016/j.conbuildmat.2021.122970Search in Google Scholar

[72] Das, J. K. and B. Pradhan. Long term effect of corrosion inhibitor and associated cation type of chloride ions on chloride profile of concrete exposed to composite chloride-sulfate environment. Materials Today: Proceedings, Vol. 32, 2020, pp. 803–809.10.1016/j.matpr.2020.04.014Search in Google Scholar

[73] Diab, A. M., H. E. Elyamany, A. E. M. Abd Elmoaty, and M. M. Sreh. Effect of nanomaterials additives on performance of concrete resistance against magnesium sulfate and acids. Construction and Building Materials, Vol. 210, 2019, pp. 210–231.10.1016/j.conbuildmat.2019.03.099Search in Google Scholar

[74] He, Z. H., S. G. Du, and D. Chen. Microstructure of ultra high performance concrete containing lithium slag. Journal of Hazardous Materials, Vol. 353, 2018, pp. 35–43.10.1016/j.jhazmat.2018.03.063Search in Google Scholar PubMed

[75] Yonggui, W., L. Shuaipeng, P. Hughes, and F. Yuhui. Mechanical properties and microstructure of basalt fibre and nano-silica reinforced recycled concrete after exposure to elevated temperatures. Construction and Building Materials, Vol. 247, 2020, id. 118561.10.1016/j.conbuildmat.2020.118561Search in Google Scholar

[76] Mostafa, S. A., A. S. Faried, A. A. Farghali, M. M. El-Deeb, T. A. Tawfik, S. Majer, et al. Influence of nanoparticles from waste materials on mechanical properties, durability and microstructure of UHPC. Materials (Basel), Vol. 13, No. 20, 2020, id. 4530.10.3390/ma13204530Search in Google Scholar PubMed PubMed Central

[77] Li, Y., H. Mehdizadeh, K. H. Mo, and T. C. Ling. Co-utilization of aqueous carbonated basic oxygen furnace slag (BOFS) and carbonated filtrate in cement pastes considering reaction duration effect. Cement and Concrete Composites, Vol. 138, 2023, id. 104988.10.1016/j.cemconcomp.2023.104988Search in Google Scholar

[78] Mo, K. H., U. J. Alengaram, M. Z. Jumaat, S. C. Lee, W. I. Goh, and C. W. Yuen. Recycling of seashell waste in concrete: A review. Construction and Building Materials, Vol. 162, 2018, pp. 751–764.10.1016/j.conbuildmat.2017.12.009Search in Google Scholar

[79] Tayeh, B. A., M. W. Hasaniyah, A. M. Zeyad, and M. O. Yusuf. Properties of concrete containing recycled seashells as cement partial replacement: A review. Journal of Cleaner Production, Vol. 237, 2019, id. 117723.10.1016/j.jclepro.2019.117723Search in Google Scholar

[80] Abdel-Gawwad, H. A., M. Heikal, M. S. Mohammed, S. A. El-Aleem, H. S. Hassan, S. R. V. García, et al. Evaluating the impact of nano-magnesium calcite waste on the performance of cement mortar in normal and sulfate-rich media. Construction and Building Materials, Vol. 203, 2019, pp. 392–400.10.1016/j.conbuildmat.2019.01.108Search in Google Scholar

[81] Pourchet, S., S. Liautaud, D. Rinaldi, and I. Pochard. Effect of the repartition of the PEG side chains on the adsorption and dispersion behaviors of PCP in presence of sulfate. Cement and Concrete Research, Vol. 42, No. 2, 2012, pp. 431–439.10.1016/j.cemconres.2011.11.011Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Effect of superplasticizer in geopolymer and alkali-activated cement mortar/concrete: A review

- Experimenting the influence of corncob ash on the mechanical strength of slag-based geopolymer concrete

- Powder metallurgy processing of high entropy alloys: Bibliometric analysis and systematic review

- Exploring the potential of agricultural waste as an additive in ultra-high-performance concrete for sustainable construction: A comprehensive review

- A review on partial substitution of nanosilica in concrete

- Foam concrete for lightweight construction applications: A comprehensive review of the research development and material characteristics

- Modification of PEEK for implants: Strategies to improve mechanical, antibacterial, and osteogenic properties

- Interfacing the IoT in composite manufacturing: An overview

- Advances in processing and ablation properties of carbon fiber reinforced ultra-high temperature ceramic composites

- Advancing auxetic materials: Emerging development and innovative applications

- Revolutionizing energy harvesting: A comprehensive review of thermoelectric devices

- Exploring polyetheretherketone in dental implants and abutments: A focus on biomechanics and finite element methods

- Smart technologies and textiles and their potential use and application in the care and support of elderly individuals: A systematic review

- Reinforcement mechanisms and current research status of silicon carbide whisker-reinforced composites: A comprehensive review

- Innovative eco-friendly bio-composites: A comprehensive review of the fabrication, characterization, and applications

- Review on geopolymer concrete incorporating Alccofine-1203

- Advancements in surface treatments for aluminum alloys in sports equipment

- Ionic liquid-modified carbon-based fillers and their polymer composites – A Raman spectroscopy analysis

- Emerging boron nitride nanosheets: A review on synthesis, corrosion resistance coatings, and their impacts on the environment and health

- Mechanism, models, and influence of heterogeneous factors of the microarc oxidation process: A comprehensive review

- Synthesizing sustainable construction paradigms: A comprehensive review and bibliometric analysis of granite waste powder utilization and moisture correction in concrete

- 10.1515/rams-2025-0086

- Research Articles

- Coverage and reliability improvement of copper metallization layer in through hole at BGA area during load board manufacture

- Study on dynamic response of cushion layer-reinforced concrete slab under rockfall impact based on smoothed particle hydrodynamics and finite-element method coupling

- Study on the mechanical properties and microstructure of recycled brick aggregate concrete with waste fiber

- Multiscale characterization of the UV aging resistance and mechanism of light stabilizer-modified asphalt

- Characterization of sandwich materials – Nomex-Aramid carbon fiber performances under mechanical loadings: Nonlinear FE and convergence studies

- Effect of grain boundary segregation and oxygen vacancy annihilation on aging resistance of cobalt oxide-doped 3Y-TZP ceramics for biomedical applications

- Mechanical damage mechanism investigation on CFRP strengthened recycled red brick concrete

- Finite element analysis of deterioration of axial compression behavior of corroded steel-reinforced concrete middle-length columns

- Grinding force model for ultrasonic assisted grinding of γ-TiAl intermetallic compounds and experimental validation

- Enhancement of hardness and wear strength of pure Cu and Cu–TiO2 composites via a friction stir process while maintaining electrical resistivity

- Effect of sand–precursor ratio on mechanical properties and durability of geopolymer mortar with manufactured sand

- Research on the strength prediction for pervious concrete based on design porosity and water-to-cement ratio

- Development of a new damping ratio prediction model for recycled aggregate concrete: Incorporating modified admixtures and carbonation effects

- Exploring the viability of AI-aided genetic algorithms in estimating the crack repair rate of self-healing concrete

- Modification of methacrylate bone cement with eugenol – A new material with antibacterial properties

- Numerical investigations on constitutive model parameters of HRB400 and HTRB600 steel bars based on tensile and fatigue tests

- Research progress on Fe3+-activated near-infrared phosphor

- Discrete element simulation study on effects of grain preferred orientation on micro-cracking and macro-mechanical behavior of crystalline rocks

- Ultrasonic resonance evaluation method for deep interfacial debonding defects of multilayer adhesive bonded materials

- Effect of impurity components in titanium gypsum on the setting time and mechanical properties of gypsum-slag cementitious materials

- Bending energy absorption performance of composite fender piles with different winding angles

- Theoretical study of the effect of orientations and fibre volume on the thermal insulation capability of reinforced polymer composites

- Synthesis and characterization of a novel ternary magnetic composite for the enhanced adsorption capacity to remove organic dyes

- Couple effects of multi-impact damage and CAI capability on NCF composites

- Mechanical testing and engineering applicability analysis of SAP concrete used in buffer layer design for tunnels in active fault zones

- Investigating the rheological characteristics of alkali-activated concrete using contemporary artificial intelligence approaches

- Integrating micro- and nanowaste glass with waste foundry sand in ultra-high-performance concrete to enhance material performance and sustainability

- Effect of water immersion on shear strength of epoxy adhesive filled with graphene nanoplatelets

- Impact of carbon content on the phase structure and mechanical properties of TiBCN coatings via direct current magnetron sputtering

- Investigating the anti-aging properties of asphalt modified with polyphosphoric acid and tire pyrolysis oil

- Biomedical and therapeutic potential of marine-derived Pseudomonas sp. strain AHG22 exopolysaccharide: A novel bioactive microbial metabolite

- Effect of basalt fiber length on the behavior of natural hydraulic lime-based mortars

- Optimizing the performance of TPCB/SCA composite-modified asphalt using improved response surface methodology

- Compressive strength of waste-derived cementitious composites using machine learning

- Melting phenomenon of thermally stratified MHD Powell–Eyring nanofluid with variable porosity past a stretching Riga plate

- Development and characterization of a coaxial strain-sensing cable integrated steel strand for wide-range stress monitoring

- Compressive and tensile strength estimation of sustainable geopolymer concrete using contemporary boosting ensemble techniques

- Customized 3D printed porous titanium scaffolds with nanotubes loading antibacterial drugs for bone tissue engineering

- Facile design of PTFE-kaolin-based ternary nanocomposite as a hydrophobic and high corrosion-barrier coating

- Effects of C and heat treatment on microstructure, mechanical, and tribo-corrosion properties of VAlTiMoSi high-entropy alloy coating

- Study on the damage mechanism and evolution model of preloaded sandstone subjected to freezing–thawing action based on the NMR technology

- Promoting low carbon construction using alkali-activated materials: A modeling study for strength prediction and feature interaction

- Entropy generation analysis of MHD convection flow of hybrid nanofluid in a wavy enclosure with heat generation and thermal radiation

- Friction stir welding of dissimilar Al–Mg alloys for aerospace applications: Prospects and future potential

- Fe nanoparticle-functionalized ordered mesoporous carbon with tailored mesostructures and their applications in magnetic removal of Ag(i)

- Study on physical and mechanical properties of complex-phase conductive fiber cementitious materials

- Evaluating the strength loss and the effectiveness of glass and eggshell powder for cement mortar under acidic conditions

- Effect of fly ash on properties and hydration of calcium sulphoaluminate cement-based materials with high water content

- Analyzing the efficacy of waste marble and glass powder for the compressive strength of self-compacting concrete using machine learning strategies

- Experimental study on municipal solid waste incineration ash micro-powder as concrete admixture

- Parameter optimization for ultrasonic-assisted grinding of γ-TiAl intermetallics: A gray relational analysis approach with surface integrity evaluation

- Producing sustainable binding materials using marble waste blended with fly ash and rice husk ash for building materials

- Effect of steam curing system on compressive strength of recycled aggregate concrete

- A sawtooth constitutive model describing strain hardening and multiple cracking of ECC under uniaxial tension

- Predicting mechanical properties of sustainable green concrete using novel machine learning: Stacking and gene expression programming

- Toward sustainability: Integrating experimental study and data-driven modeling for eco-friendly paver blocks containing plastic waste

- A numerical analysis of the rotational flow of a hybrid nanofluid past a unidirectional extending surface with velocity and thermal slip conditions

- A magnetohydrodynamic flow of a water-based hybrid nanofluid past a convectively heated rotating disk surface: A passive control of nanoparticles

- Prediction of flexural strength of concrete with eggshell and glass powders: Advanced cutting-edge approach for sustainable materials

- Efficacy of sustainable cementitious materials on concrete porosity for enhancing the durability of building materials

- Phase and microstructural characterization of swat soapstone (Mg3Si4O10(OH)2)

- Effect of waste crab shell powder on matrix asphalt

- Improving effect and mechanism on service performance of asphalt binder modified by PW polymer

- Influence of pH on the synthesis of carbon spheres and the application of carbon sphere-based solid catalysts in esterification

- Experimenting the compressive performance of low-carbon alkali-activated materials using advanced modeling techniques

- Thermogravimetric (TG/DTG) characterization of cold-pressed oil blends and Saccharomyces cerevisiae-based microcapsules obtained with them

- Investigation of temperature effect on thermo-mechanical property of carbon fiber/PEEK composites

- Computational approaches for structural analysis of wood specimens

- Integrated structure–function design of 3D-printed porous polydimethylsiloxane for superhydrophobic engineering

- Exploring the impact of seashell powder and nano-silica on ultra-high-performance self-curing concrete: Insights into mechanical strength, durability, and high-temperature resilience

- Axial compression damage constitutive model and damage characteristics of fly ash/silica fume modified magnesium phosphate cement after being treated at different temperatures

- Integrating testing and modeling methods to examine the feasibility of blended waste materials for the compressive strength of rubberized mortar

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part II

- Energy absorption of gradient triply periodic minimal surface structure manufactured by stereolithography

- Marine polymers in tissue bioprinting: Current achievements and challenges

- Quick insight into the dynamic dimensions of 4D printing in polymeric composite mechanics

- Recent advances in 4D printing of hydrogels

- Mechanically sustainable and primary recycled thermo-responsive ABS–PLA polymer composites for 4D printing applications: Fabrication and studies

- Special Issue on Materials and Technologies for Low-carbon Biomass Processing and Upgrading

- Low-carbon embodied alkali-activated materials for sustainable construction: A comparative study of single and ensemble learners

- Study on bending performance of prefabricated glulam-cross laminated timber composite floor

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part I

- Supplementary cementitious materials-based concrete porosity estimation using modeling approaches: A comparative study of GEP and MEP

- Modeling the strength parameters of agro waste-derived geopolymer concrete using advanced machine intelligence techniques

- Promoting the sustainable construction: A scientometric review on the utilization of waste glass in concrete

- Incorporating geranium plant waste into ultra-high performance concrete prepared with crumb rubber as fine aggregate in the presence of polypropylene fibers

- Investigation of nano-basic oxygen furnace slag and nano-banded iron formation on properties of high-performance geopolymer concrete

- Effect of incorporating ultrafine palm oil fuel ash on the resistance to corrosion of steel bars embedded in high-strength green concrete