Exploring the potential of agricultural waste as an additive in ultra-high-performance concrete for sustainable construction: A comprehensive review

Abstract

This study thoroughly reviews the recent design methods for ultra-high-performance concrete (UHPC) with agricultural waste. The goal is to identify UHPC composites that meets environmental sustainability requirements while fulfilling workability, durability, and mechanical properties. The capacity of typical review studies is limited in bridging the various literature aspects systematically. The article includes comparative analyses identifying these methods’ intrinsic connections and current trends. The analysis indicates that 71% of documents on incorporating agricultural waste into UHPC are in the “Engineering” and “Materials Science” disciplines, with 69% being journal articles, and 27% conference documents. Significant research keywords involve “Ultra-High-Performance Concrete,” “Cements,” “Sustainable Development,” and “Agricultural Wastes,” highlighting the extensive exploration of agricultural waste in UHPC. It has been discovered that agricultural waste can replace silica fume in UHPC, improving strength and durability by reducing pore volume and enhancing microstructure. Substituting 5–30% of cement with rice husk ash significantly boosts compressive strength, enhancing cement hydration, pore structure, and pozzolanic reaction, offering substantial environmental benefits and supporting the construction industry’s contribution to low-carbon sustainable development. This article provides guidance and recommendations for developing sustainable UHPC to meet diverse design specifications, promoting environmentally friendly construction practices.

Abbreviations

- ASTM

-

American Standard for Testing Materials

- BSE

-

backscattered electron

- Ca(OH)2

-

calcium hydroxide

- C–S–H

-

calcium-silicate-hydrate

- CO2

-

carbon dioxide

- CSV

-

comma-sapertaed values

- EDX

-

energy-dispersive X-ray

- HSC

-

high-strength concrete

- MPa

-

mega Pascal

- MS

-

micro-silica

- NCSA

-

nano cotton stack ash

- OWA

-

olive waste ash

- PLA

-

palm leaf ash

- POFA

-

palm oil fuel ash

- RHA

-

rice husk ash

- RSA

-

rice straw ash

- RSM

-

response surface methodology

- SBA

-

sugarcane bagasse ash

- SCMs

-

supplementary cementitious materials

- SEM

-

scanning electron micrograph

- SF

-

silica fume

- SLA

-

sugarcane leaf ash

- SUHPC

-

sustainable ultra-high-performance concrete

- UHPC

-

ultra-high-performance concrete

- w/c

-

water cement ratio

- WSA

-

wheat straw ash

- XRD

-

X-ray diffraction pattern

1 Introduction

Concrete is extensively used in construction due to its versatility, abundant raw materials, and affordable maintenance expenses [1,2]. Ultra-high-performance concrete (UHPC) has been developed to improve its performance. UHPC, a cement-based material, exhibits exceptional mechanical properties, such as a compressive strength surpassing 150 MPa [3,4,5] and superior durability, as evidenced by its substantial reduction in chloride ion diffusion compared to normal concrete [5,6]. Consequently, UHPC has emerged as an ideal material for use in a range of applications, including thin-shell structures [7], highway bridges [8], repair work [9], marine structures [10], nuclear power plants [11], and military engineering projects [12]. However, UHPC typically contains more cement (900–1,100 kg·m−3) than normal concrete or high-performance concrete, resulting in a higher carbon footprint [13,14,15]. Ahmed et al. [16] reported that advancements in concrete technology have given rise to an innovative material termed reactive powder concrete. Reactive powder concrete, classified as UHPC, offers exceptional strength and impressive ductility by employing techniques that enhance its microstructure. Notably, it stands out as the frequently employed form of UHPC. As depicted in Figure 1, a noticeable pattern emerges where the proportion of coarse aggregates steadily decreases from normal concrete to high-strength and UHPC. This results in a corresponding increase in the percentage of fines, incorporating both quartz sand and binder, with the primary aim of achieving heightened strengths, particularly evident in high-strength concrete (HSC) and UHPC. Notably, UHPC exhibits 3–4 times more predominant cement binder compared to normal and high-performance concrete. The heightened reliance on UHPC has, however, been limited due to challenges related to cement carbon emissions and the significant energy consumption associated with extracting non-renewable resources like quartz sand, posing risks of dust lung disease. As a result, there is a growing interest in researching alternatives for cement, quartz sand, and other components with high energy requirements in the development of UHPC, necessitating the establishment of a mature strategy that simultaneously reduces carbon emissions and ensures safety benefits.

![Figure 1

Ingredients of different concrete types. (a) natural concrete (NC), (b) high-performance concrete (HPC), (c) ultra-high-performance concrete (UHPC) [17].](/document/doi/10.1515/rams-2023-0181/asset/graphic/j_rams-2023-0181_fig_001.jpg)

Ingredients of different concrete types. (a) natural concrete (NC), (b) high-performance concrete (HPC), (c) ultra-high-performance concrete (UHPC) [17].

Using agricultural and industrial waste as substitutes for cement, aggregate, and reinforcing materials in sustainable UHPC (SUHPC) production holds promise as a potential solution to the issue. SUHPC can be defined as having fresh and hardened-state properties that fulfill design specifications while integrating sustainability principles. Advanced design strategies may be adopted to achieve SUHPC while enhancing durability without replacing energy-rich individual constituents [18]. In this study, SUHPC refers to UHPC that exhibits lower energy consumption and facilitates the recovery and utilization of agricultural and industrial waste, thus reducing waste pollution. Hakeem et al. [19] explored the application of a blend of industrial and agricultural residues to produce environmentally SUHPC. The outcomes of their experimental inquiry demonstrated enhanced characteristics in SUHPC by incorporating glass powder and wheat straw ash (WSA). Hamada et al. [20] explored the existing literature on potential palm oil fuel ash (POFA) as a supplementary cementitious material (SCM) in cementitious composites to promote sustainable development through the construction industry. Moreover, Hamada et al. [21] conducted a study to explore how POFA impacts HSC and UHPC. The research explored the effects of POFA on the properties of HSC and UHPC in their fresh and hardened states, emphasizing durability and microstructure characteristics. Utilizing ultrafine POFA successfully reduced the rapid chloride permeability and water absorption of HSC, thereby improving its structural integrity. Several alternatives with reduced embedded energy have been employed, including fly ash [22,23], ground-granulated blast furnace slag [24], tailings [25], waste glass [26], and copper slag [27]. Nevertheless, previous studies on SUHPC design have primarily concentrated on comprehending the influence of substitutions on UHPC performance. During the development of SUHPC, varying or even contradictory effects can be observed when utilizing the same substitution, primarily due to alterations in the physicochemical properties of raw materials. As a result, the mixture proportions documented in the literature may not offer direct and precise guidance for practical implementation. Hence, designing SUHPC with optimized performance remains challenging for most designers. The emphasis should be on the design of SUHPC, establishing the framework for producing UHPC that meets specific requirements for a given application rather than replicating traditional mixture proportions. However, there is a scarcity of research conducted regarding the design of SUHPC.

This research aims to perform a thorough review of SUHPC design. The review considers each method’s benefits, limitations, interrelationships, and practical recommendations and systematically compares them to offer guidance for designing SUHPC that fulfills diverse design specifications. Given the diverse mix compositions of UHPC that incorporate agricultural waste materials, their complex mechanical properties, and varying material testing methods, it is crucial to review existing research on UHPC with agricultural waste thoroughly. This systematic review aims to categorize and condense research findings, offering a dependable and comprehensive resource for scholars in this area. Pursuing SUHPC through agricultural waste research has prompted a need for more comprehensive and accessible information, which can pose challenges for researchers seeking to undertake novel studies and collaborations. As such, it is crucial to establish a framework that enables scholars to access high-quality, essential materials from reliable sources to facilitate their work. A scientometric approach utilizing software tools can be employed to address this issue. This study conducts a scientometric analysis of bibliographic data on UHPC with agricultural waste up to 2023. Conventional review-based studies may encounter difficulties in accurately and comprehensively linking various aspects of literature. Advanced features such as co-occurrence, scientific visualization, and co-citations have been particularly complex in recent research [28,29]. Through the scientometric analysis, this study has identified the top publication sources and authors based on the number of articles and related citations, keywords co-occurrence, the most significant contributing countries, and the most cited articles in the field of UHPC with agricultural waste. The Scopus search engine extracts relevant data from related documents, including the abstract, bibliography, keywords, funding, citations, and other information. Subsequently, the VOS viewer tool is utilized to analyze the collected data. The statistical and graphical representation of the countries and academics identified in this study can facilitate knowledge exchange among young scientists, enabling them to share cutting-edge concepts and methods and develop collaborative ventures. This study highlights the utilization of agricultural waste in achieving SUHPC. It provides insight into its prospects through a scientometric analysis of research area-related keywords and a relevant literature review.

2 Review significance

Through an inventive and comprehensive technique, this research considerably advances the field of sustainable UHPC design. Unlike conventional literature reviews, it evaluates the benefits, drawbacks, and relationships between UHPC design techniques while methodically contrasting them to provide useful advice for satisfying various design requirements. A new aspect of UHPC is incorporating agricultural waste materials, which effectively negotiate the complexities of various mix compositions and mechanical properties. Furthermore, the research presents a unique perspective on the UHPC research field using agricultural waste by pioneering a scientometric analysis utilizing advanced technologies such as Scopus and VOS viewer. This system actively fosters researcher collaboration and knowledge exchange by identifying important publications, authors, contributing countries, and important articles. Moreover, this review is closely linked to multiple sustainable development goals. The exploration of using agricultural waste in UHPC aligns with the goal of responsible consumption, which is to reduce reliance on non-renewable resources and repurpose waste materials. By addressing the carbon emissions associated with the manufacturing of conventional concrete, the study on SUHPC aims to promote climate action by reducing the environmental impact of construction materials. Incorporating agricultural waste into UHPC contributes to biodiversity preservation and lessens the environmental impact of landfills. The need for thorough and freely obtainable data in agricultural waste research for UHPC highlights the value of cooperative collaborations, which promote knowledge-sharing and collaboration between academics, businesses, and organizations. By easing the transmission of knowledge, igniting learning, and encouraging the adoption of sustainable practices within the field, information accessibility supports quality education. The continuous research and development projects in SUHPC that make use of agricultural waste represent a unique approach to construction materials and hence progress in sustainable infrastructure development. To sum up, this study advances our understanding of SUHPC and presents a new approach that can shape future research direction, making it a noteworthy and significant contribution to sustainable development.

3 Methodology

This study involves scientometric analysis of bibliographic data to measure its properties [29]. The scientometric analysis employs scientific mapping, a method developed by researchers to examine bibliometric data [29,30]. Given the abundance of articles available in the relatively unexplored research area, using a reliable search engine is essential. Scopus and Web of Science are highly recommended databases to help achieve the study objective [31]. To collect bibliographic data on the research area of UHPC with agricultural waste, Scopus is utilized. Additionally, several filters are employed to exclude irrelevant data. Figure 2 provides a comprehensive flowchart outlining the various methodological steps involved, including data retrieval, analysis, and application of different filters. Within the realm of literature, various research studies have utilized similar methodologies [32,33]. The Scopus database is stocked in CSV format to allow additional evaluation through appropriate software. To conduct quantitative assessment and scientific visualization of the collected data, an open-source mapping tool, VOS viewer (version 1.6.18), is freely accessible [34]. The study’s objectives are attained by utilizing the VOS viewer tool, updating the CSV file, and conducting further assessments to verify data consistency and dependability. The scientometric analysis encompasses the evaluation of frequently used keywords, publication sources, highly cited authors and articles, the contribution of various countries, as well as highly cited papers. Maps represent the features, their co-occurrences, and interconnectivity visually. Relevant and concrete statistics are presented using tables. The groups are distinguished by allocating colors to identify specific elements in the map. Additionally, density mapping is depicted through the use of specific colors, such as rainbow, plasma, and Viridis.

Flowchart of the research methodology.

4 Findings and interpretation

4.1 Pertinent research domains and yearly publications

To determine the most pertinent research areas, a Scopus analyzer is employed. The analysis, as shown in Figure 3, indicates that a majority of the documents, approximately 42%, belong to the field of Engineering, followed by Materials Science, which comprises almost 29% of the documents. Combined, these two disciplines account for 71% of the total papers. In addition, the Scopus database is also analyzed to investigate the types of publications found in the research area under consideration (as shown in Figure 4). It is revealed from the analysis that the majority of the publications, approximately 69%, are journal articles. Conference review articles and conference papers accounted for 16 and 11% of the publications, respectively. These results imply that conferences come in second to journals as the main venues for research in this area. Researchers looking to publish their work or find pertinent publications may find this material beneficial. Researchers may be able to boost the visibility and influence of their study and support the continued development of knowledge in this field by focusing on high-impact publications or conferences. The annual trend of publications on UHPC using agricultural waste from 2013 to 2023 is shown in Figure 5. The graph demonstrates that, with some fluctuations, the number of papers pertaining to this field of study has typically increased. There have been 11 publications in this area as of 2023. These findings imply that using agricultural waste in UHPC is a developing topic of interest for scientists working to create more environmentally friendly building materials. The growing number of papers in this field suggests that it is a subject of ongoing study and innovation with prospects for growth. Overall, this analysis offers insightful information on the current state of the field’s research, assisting researchers in better understanding the most crucial research areas and identifying possibilities for future investigation and collaboration. Researchers can help advance knowledge and promote their discipline by concentrating on these important areas.

Areas of research covered by articles.

Published materials in the researched field of study.

Annual publication trend of articles.

4.2 Publication sources

Bibliographic data were analyzed using a VOS reader to identify the primary published sources in the pertinent study topic. The number of articles in various journals from 2014 to 2023 are shown in Figure 6. According to the data, “Case Studies in Construction Materials” had the most articles published, and “Journal of Cleaner Production” was the second most popular journal. In the field of UHPC with agricultural waste, “Construction and Building Materials” was found to be the third most important publication source, after “Cement and Concrete Composites” and “Journal of Building Engineering.” The subsequent scientometric evaluation of research on UHPC with agricultural waste will be based largely on this assessment. In order to identify the primary sources of publications in the pertinent research field, bibliographic data must be analyzed using a VOSviewer. This analysis is important because it gives a clear picture of the most prestigious journals in the field of UHPC using agricultural waste. Researchers can prioritize their reading and publishing in these high-impact journals by accessing these reliable sources, boosting the visibility and effect of their work. The analysis also provides a basis for the upcoming scientometric assessment of this field of research, enabling a more thorough understanding of research patterns, growth, and prospective future advances.

Annual documents in top five journals.

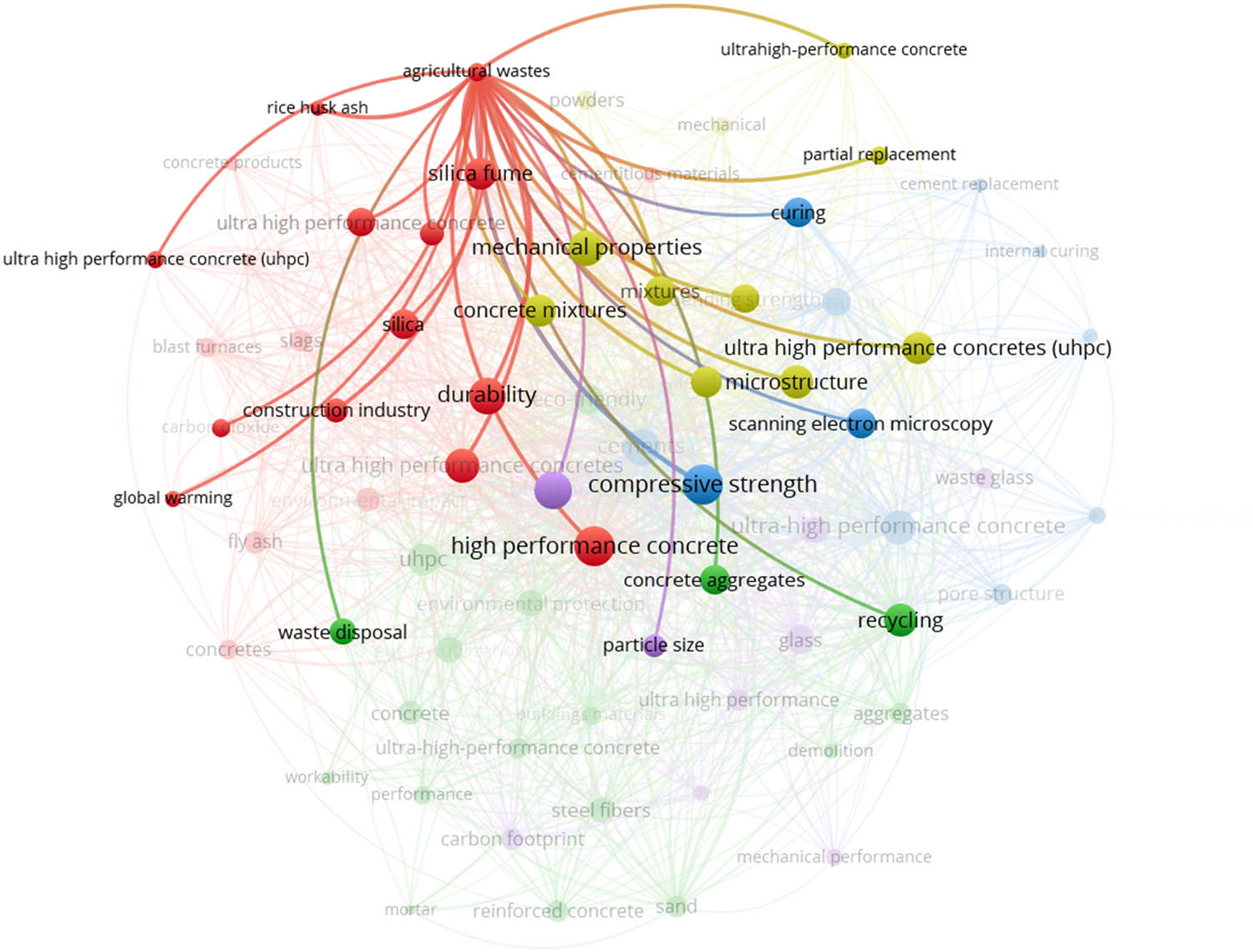

4.3 Co-occurring keywords

In order to define and emphasize a specific research study’s main subject, keywords are crucial in research [35]. To ensure variety in the selection of keywords, a threshold of ten is established for keyword repetition. Table 1 shows the examination of 20 keywords. Among these, “Ultra-High-Performance Concrete,” “Compressive Strength,” “Cements,” “Sustainable Development,” and “Agricultural Wastes” are the most commonly used keywords in the research domain of UHPC with agricultural waste. The analysis of the keywords reveals that the use of waste materials in UHPC has been investigated to achieve sustainable development. Figure 7 provides a detailed frequency map, illustrating the occurrence patterns based on density and connections. Specifically, in Figure 7(a), individual keywords are graphically represented by circles. The size of each circle corresponds to the frequency of occurrence of the respective keyword, conveying the term’s prevalence in the examined articles. Additionally, the position of each circle within the map reflects the degree of co-occurrence of the keyword with others in the articles under consideration. The significance of certain keywords is emphasized by the presence of larger circles, particularly those encircling the most frequently used terms. These larger circles serve as visual indicators of the paramount importance of these keywords within the literature review focused on UHPC incorporating agricultural waste. The visualization highlights key areas and the interconnectedness of terms in the scholarly discourse, providing a comprehensive overview of the prevailing trends and focal points in the examined literature.

Top 20 commonly used keywords

| S/N | Keyword | Occurrences |

|---|---|---|

| 1 | Ultra-high-performance concrete | 136 |

| 2 | Compressive strength | 63 |

| 3 | Cement | 28 |

| 4 | Sustainable development | 25 |

| 5 | Agricultural wastes | 25 |

| 6 | Recycling | 23 |

| 7 | Ultra-high-performance concretes (UHPC) | 23 |

| 8 | Durability | 21 |

| 9 | Silica fume | 21 |

| 10 | Eco-friendly | 21 |

| 11 | Mechanical properties | 20 |

| 12 | Microstructure | 19 |

| 13 | Glass | 18 |

| 14 | Tensile strength | 17 |

| 15 | Rice husk ash | 15 |

| 16 | Curing | 13 |

| 17 | Steel fibers | 13 |

| 18 | Sustainability | 13 |

| 19 | Construction industry | 12 |

| 20 | Waste disposal | 10 |

Keyword analysis: (a) scientific visualization and (b) density visualization.

To represent the co-occurrence of keywords in diverse publications, groupings are established. Each category is given a distinctive color to represent the co-occurrence of keywords in published documents. Different colors identify and depict the four distinct groupings (Figure 7a). In Figure 7b, the keyword density is displayed using a variety of distinctive colors. According to density, the color schemes are arranged with green indicating the highest density and blue, red, yellow, and purple indicating progressively decreasing densities. The keywords “Ultra High-Performance Concrete” and “Concrete” are depicted in green, indicating their higher frequency of occurrence. The analysis underscores the significance of keywords in research, identifies the frequently used keywords in UHPC research, illustrates a map of keyword co-occurrence and density, and offers valuable insight into research trends and focus areas. Furthermore, it establishes a foundation for future evaluations of UHPC research. This finding can be helpful for researchers in selecting keywords that can facilitate the process of exploring relevant publications in this particular research domain.

Figure 8 visually represents the interconnectivity between the keyword “agricultural waste” and other relevant keywords in the research field of UHPC with agricultural waste. The colors used in the figure are organized based on the level of connectivity, with red indicating the highest connectivity, followed by yellow, blue, green, and purple representing progressively lower connectivity. Upon observing Figure 8, it becomes evident that the keyword “agricultural waste” is closely associated with several other keywords, namely, “Rice Husk Ash,” “Silica Fume,” “Ultra-High-Performance Concrete,” “Construction Industry,” and “Global Warming.” These terms are represented by the color red, which signifies their proximity and strong interconnection. The presence of red indicates that these keywords are highly relevant and extensively linked to the concept of “agricultural waste” within the research domain of UHPC. Furthermore, the figure also displays additional linkages of “agricultural waste” with keywords such as “Concrete Mixtures,” “Microstructure,” and “Mechanical Properties.” These connections are depicted in green color, indicating a secondary level of linkage. While not as strong as the red connections, these green links signify a notable association between “agricultural waste” and the mentioned keywords regarding their relationship within the UHPC research field.

Linkage of agricultural waste with other keywords.

4.4 Authors

Within academic inquiry, the quantity of citations garnered by an author is frequently regarded as a measure of their impact or sway within a specific domain [36]. To conduct a comprehensive analysis, it is important to focus on authors who have contributed significantly. By studying their work and analyzing their impact within the research area, valuable insights can be gained regarding their contributions and influence in the field. Determining the overall standing of an author based on various parameters, such as the number of publications and citations, can be a complex task. To address this challenge, assessing an author’s ranking separately for each parameter is often beneficial. By doing so, a more comprehensive understanding of their performance can be gained. Upon conducting the analysis, it becomes evident that Dai is the leading author. Notably, Zhang and Cai closely follow, showcasing their significant contributions to the field. When examining the citations within the specific realm of research on UHPC having agricultural waste, Nematollahi B. and Sanjayan J. stand out with remarkable citations, indicating the widespread impact of their work. Following these two, Dai and Li secure the second and third positions, respectively. In the fourth position, Shaikh F.U.A further affirmed their influence in incorporating agricultural waste in UHPC. To visually represent the interconnections among these authors, Figure 9 provides a comprehensive view. This visualization demonstrates the relationships formed through citations, emphasizing the substantial interconnectivity observed among authors involved in the research domain of UHPC with agricultural waste. This analysis provides valuable insights regarding the research domain’s collaborative nature and knowledge sharing.

Scientific visualization by authors within the research domain under consideration.

4.5 Documents

The importance of citations in evaluating the significance of research papers within a specific field cannot be overstated. Pioneering articles in a given domain typically garner the highest number of citations. This study presents an advanced depiction of citation patterns of interrelated articles in UHPC having agricultural waste. Figure 10 consists of two distinct elements: Figure 10a visually represents the interconnectedness among articles based on citations extracted from the VOS viewer. The size of each circle in this visualization corresponds to the impact of the respective article within the research domain, thereby providing a summary of article connections and emphasizing the most influential contributions in the field. On the other hand, Figure 10b demonstrates a compelling trend that indicates a progressive increase in the number of research articles authored over time. This portrayal serves as empirical evidence that exploring UHPC with agricultural waste has emerged as an engaging and actively pursued area of interest among research scholars.

Documents’ scientific mapping: (a) density of connected articles derived from citation density and (b) rising trend of research articles authored by researchers.

4.6 Countries

The extent of research contributions in UHPC having agricultural waste exhibits variations across different countries, with certain countries exhibiting more engagement than others. A systematic mapping approach has been developed for avid readers and researchers to assess the significant countries’ leading research efforts on this subject and gain insights into its anticipated characteristics. This approach facilitates a comprehensive evaluation of the research landscape, enabling a deeper understanding of the key contributors and the overall trajectory of UHPC research with agricultural waste. The mapping methodology is anticipated to encompass the classification and comparative analysis of research endeavors across diverse regions, elucidating the extent of involvement in disparate global locales. This evaluative process aids in discerning the nations that spearhead research in this domain, thereby illuminating potential domains of expertise or focal points. China has emerged as the foremost contributor in the research on UHPC utilizing agricultural waste. Figure 11 presents a citation mapping that vividly illustrates the interconnectedness and concentration of research activities among various countries. Notably, the size of each circle in Figure 11a reflects the impact of a specific country in this research domain. Additionally, Figure 11b reveals that countries with more publications exhibit greater research density. The provision of statistical and graphical representations highlighting the contributions of different countries would be highly beneficial for young researchers, enabling them to foster scientific collaborations, establish joint ventures, and exchange innovative concepts and techniques. Researchers from diverse nations interested in exploring UHPC with agricultural waste can seize the opportunity to collaborate with experts in related fields and leverage their invaluable expertise.

Scientific visualization of countries in the research domain under consideration until 2022: (a) network visualization and (b) temporal growth trend.

5 Agricultural waste in UHPC

The production of concrete relies predominantly on the utilization of cement as a component [37]. In certain specialized concrete variants like UHPC, the cement content can reach up to 1,200 kg·m−3. As a result, the escalating requirement for concrete, with an estimated yearly growth rate of around 10 billion m3, has led to a corresponding rise in annual cement production, reaching 4.1 gigatons in 2018 [38,39]. Environmental studies have revealed that cement manufacturing contributes approximately 5–8% of global carbon dioxide emissions [40]. The increasing occurrence of global warming and the depletion of natural resources have prompted researchers and scientists to actively explore environmentally friendly and sustainable alternatives for concrete production. To attain this objective, researchers and scientists are actively examining the feasibility of employing agricultural waste as partial substitutes for cement, integrating SCMs into the mix, and making notable strides in developing zero-cement concrete technology [41,42]. The production of sustainable and eco-friendly concrete yields several environmental benefits, including using industrial and agricultural waste, reduced cement consumption, and enhanced structural durability, thus resulting in a more environmentally responsible construction approach. Recent research has uncovered novel types of industrial and agricultural waste materials that exhibit cementitious or pozzolanic properties, thereby enabling their incorporation as partial substitutes for up to 75% of the cement content [43,44,45,46]. The rise in global warming rates attributed to carbon dioxide emissions and the exhaustion of natural resources has spurred researchers and scientists to seek eco-friendly and sustainable concrete alternatives. This approach involves expanding the utilization of agricultural waste and industrial waste materials as partial substitutes for cement, incorporating supplementary cement materials, and exploring the development of zero-cement concrete [41,42]. Incorporating agricultural waste in UHPC production can reduce cement consumption and improve respective properties due to agricultural waste’s unique physical and chemical attributes [47,48]. Moreover, applying agricultural waste as a supplementary material or partial replacement in UHPC exhibits significant promise in addressing environmental risks associated with air, water, and soil pollution, both at the surface level and within groundwater systems [49]. Hence, creating environmentally sustainable concrete offers numerous environmental advantages, such as the assimilation of industrial and agricultural waste, decreased cement usage, and the attainment of extended structural durability. Scholars have introduced novel industrial and agricultural waste varieties possessing cementitious or pozzolanic properties, serving as partial substitutes for up to 75% of the cement weight [50,51,52].

Numerous researchers have demonstrated the feasibility of utilizing various types of agricultural waste in the concrete industry, including rice husk ash (RHA) [53], rice straw ash [54], sugarcane leaf ash (SLA) [55], sugarcane ash [56,57], POFA [58], bamboo leaf ash [59], olive waste ash (OWA) [60], WSA [61], peanut husk ash [62], and nut shell ash [63]. Pandey and Kumar [64] examined rice straw ash (RSA) produced through the open-air combustion of rice straw and micro-silica (MS) as a pozzolanic material for rigid pavements. Substituting 15% of cement with a blend of RSA and MS did not influence the air content of the fresh composite. The impact of incorporating nano cotton stack ash (NCSA) and palm leaf ash (PLA) as ultrafine pozzolanic materials in UHPC was explored by Amin et al. [65]. Microstructure analyses indicated that the mineral structure of NCSA remained unaffected by burning temperatures. However, a slight modification in the crystalline structure of PLA was observed due to the presence of SiO2, which exhibited changes at 600°C. Incorporating 20% PLA and up to 5% NCSA in UHPC, serving as a partial substitute for cement, positively influenced compressive strength. Moreover, the optimal blend of the two materials may constitute up to 40% of the total cement content [65]. However, optimal strategies should strive for waste prevention and minimization, as highlighted in Figure 12. It is well known that to achieve the necessary bond strength, high compressive strength, and durability, UHPC relies on substantial quantities of cement (800–1,100 kg·m−3) to form a dense cement matrix [65,66]. Consequently, integrating a significant proportion of agricultural waste as partial replacements for cement in the production of SUHPC offers notable environmental and economic benefits while improving its properties [67]. Achieving a minimum compressive strength of 120 MPa and a tensile strength of approximately 8 MPa is imperative for UHPC, as these values are significantly higher than those observed in traditional concrete [68,69]. Researchers have acknowledged the importance of harnessing agricultural waste’s potential and have focused on its integration into UHPC.

![Figure 12

Ranking of agricultural waste options from least to most preferred [67].](/document/doi/10.1515/rams-2023-0181/asset/graphic/j_rams-2023-0181_fig_012.jpg)

Ranking of agricultural waste options from least to most preferred [67].

6 Design of SUHPC

UHPC is now considered a cutting-edge advancement in concrete technology due to its enhanced mechanical and durability characteristics, notably a compressive strength surpassing 150 MPa [70,71,72]. UHPC is commonly composed of fine aggregate, fiber reinforcements, superplasticizers, admixture, and a substantial amount of cement, all meticulously mixed at a reduced w/c ratio [73,74]. The formulation of UHPC arises from blending multiple components, resulting in a highly intricate material when in its hardened state. The increased number of constituents compared to conventional concrete, coupled with a greater range of potential combinations and relative proportions, renders the behavior of this concrete type notably challenging to anticipate [13]. Moreover, the expenses associated with UHPC constituents are considerably higher than those of regular concrete. Consequently, optimizing their dosages holds paramount importance. In recent years, numerous studies have been conducted to refine the mixture proportions of UHPC. Richard and Cheyrezy [75] formulated a UHPC mixture by optimizing the granular composition through compressible packing models (CPM). Fennis et al. [76] elaborated on the impact of surface forces, such as van der Waals forces, electrical charges, and steric forces, on packing density with small particles. Consequently, for particles of micro- and nano-size, predictions of particle packing by the “compressible packing model” (CPM) significantly deviate from experimental data, indicating that the current CPM model lacks accuracy in predicting the behavior of mixtures containing such particles. Park et al. [77] investigated to achieve UHPC with a compressive strength of 180 MPa. The study considered various variables, including the water-to-binder ratio and the type and proportion of replacement for filling powder. Teichmann and Schmidt [78] introduced a technique designed to maximize the packing density of cement and fillers in UHPC, specifically optimized to achieve a compressive strength surpassing 200 MPa. Talebinejad et al. [79] developed an optimized mixture proportion with a density of approximately 2,400 kg·m−3 and a compressive strength exceeding 250 MPa. Notably, the final mixture included a cement dosage of more than 1,500 kg·m−3. More recently, Wille et al. [4] introduced a straightforward mixture design approach for UHPC. This method relies on the rheological properties of the paste, where high spread values of the paste, determined through mini-slump measurements, indicate elevated packing density and, consequently, higher compressive strength.

The compressive strength of UHPC can vary between 150 and 800 MPa, depending on factors such as the specific composition of materials and the techniques utilized during the handling process [80]. UHPC is characterized by a substantial cement content, typically ranging from 900 to 1,000 kg·m−3, and a significant proportion of silica fume (SF) in the range of 150–250 kg·m−3, which serves as a cement substitute. This substitution reduces the cost of UHPC production and reduces CO2 emissions associated with cement manufacturing, thereby mitigating its impact on global warming [70,81,82,83,84]. Metakaolin is produced through the calcination of natural clay, with its pozzolanic reactivity primarily influenced by the calcining temperature [13]. The incorporation of metakaolin powder has been shown to decrease autogenous shrinkage, enhance pore structure refinement, and improve concrete’s early strength and durability [85]. Shi et al. [14] conducted studies where metakaolin was used as a substitute for SF in the preparation of UHPC. Being a non-pozzolanic mineral admixture, incorporating limestone powder (LP) can enhance the fluidity of UHPC [86]. Wang et al. [87] observed that UHPC containing cement, SF, ground granulated blast-furnace slag (GGBS), and LP exhibited outstanding fluidity. Specifically, the concrete comprising 20% LP, 10% SF, and 20% GGBS displayed higher strength than that without LP at 28 days, attributing to the accelerated hydration of cement and SF. This acceleration favored the improved structure and performance of the UHPC [88]. In addition to binding materials, the constituents of UHPC encompass quartz powder, quartz sand, superplasticizer, and fibers. Initially, finely ground quartz sand with a diameter of less than 0.6 mm was employed in early UHPC to enhance performance, but its cost is relatively high. To mitigate the expense of UHPC, substitutions for refined quartz sand, such as recycled glass cullet, natural sands, dune sand, and artificial aggregates, have been explored [89,90,91,92]. Typically, quartz sand exhibits particle sizes ranging from 150 to 600 μm, representing the largest granular material dimensionally. Powdered quartz (PQ), with a particle size distribution spanning from 0.1 to 100 μm, is commonly regarded as an inert filler. Microsteel fibers, measuring 13 mm in length and 0.2 mm in diameter, are frequently employed in UHPC. The optimization of these raw materials is essential for achieving the desired performance characteristics of UHPC [13].

Figure 13 illustrates the overall procedures involved in the experimental optimization for UHPC and SUHPC. Comparing Figure 13a, representing the design strategy for typical UHPC, with Figure 13b, representing the design strategy for SUHPC, it becomes apparent that they share similar approaches except for the screening experiment. For example, a screening experiment is carried out to evaluate the influence of alternatives on the performance of UHPC and ascertain the optimal addition or replacement ratio. This is achieved by formulating a relationship using a fundamental linear model, quantifying the association between the dosage (or type) of alternatives, such as agricultural waste, and the performance of the corresponding SUHPC. After comprehending the substitution impacts, specific ranges or values for factors like water-to-binder ratio, aggregate content, and superplasticizer dosage can be ascertained. This determination is grounded in established principles, standards, or extant literature. After this, by conducting trial batches employing a one-factor-at-a-time approach, a satisfactory UHPC formulation can be attained. This process entails selecting a baseline set of levels for each factor and methodically altering them within their respective ranges while maintaining the constancy of other factors. Iteration of this process continues until the UHPC performance aligns with the stipulated requirements [17].

![Figure 13

The general process for optimizing (a) UHPC and (b) SUHPC [17].](/document/doi/10.1515/rams-2023-0181/asset/graphic/j_rams-2023-0181_fig_013.jpg)

The general process for optimizing (a) UHPC and (b) SUHPC [17].

Adding agricultural waste to UHPC can substantially improve its mechanical strength and durability properties [93,94,95,96]. This is particularly beneficial in regions facing limited availability challenges and high SF costs, especially in developing countries [97]. Researchers and individuals involved in construction activities are currently focused on identifying alternative materials that possess similar properties to substitute in the production of UHPC. Agricultural waste, such as RHA, sugarcane bagasse ash (SBA), etc., demonstrates great potential as a promising alternative material of SF for UHPC, offering advantageous technical and environmental characteristics at a lower cost. Notably, agricultural waste exhibits a chemical composition similar to SF [98]. Agricultural residues like RHA and SBA represent natural pozzolanic substances distinguished by a significant content of amorphous silica and finely divided particles. This composition establishes them as feasible mineral additives for UHPC, similar to the role played by SF [99,100,101,102,103,104,105,106]. RHA, acquired through the incineration of rice husk, is an agricultural byproduct. Upon controlled incineration of the husk, the resulting residue, RHA, consists of 90–96% amorphous silica. Typically, the average particle size of RHA falls within the range of 5–10 μm, accompanied by an exceptionally high specific surface area exceeding 250 m2·g−1 [107]. The increased surface area is a consequence of the porous configuration of RHA [108,109]. In contrast, the specific surface area of SF ranges from 18–20 m2·g−1, primarily attributed to the presence of exceedingly fine particles [110]. SF and RHA are classified as “highly active pozzolans” [111]. Their introduction into cement impacts both the rate and extent of hydration [112,113]. Incorporating RHA into concrete, similar to SF, can decrease porosity and Ca(OH)2 content within the interfacial transition zone (ITZ) connecting the aggregate and cement paste. Additionally, the width of the ITZ is reduced compared to the control sample [114]. Moreover, research has explored the substitution of SF with RHA to attain high-strength/high-performance concrete [115,116]. Rajasekar et al. [117] subjected the raw bagasse ash obtained from the industry to a drying process at 110°C for 24 h to eliminate inherent moisture content. Subsequently, following moisture removal, the bagasse ash underwent controlled incineration in a furnace, varying temperatures from 450 to 650°C in 50°C increments, with a heat rate of 13°C per minute. The residence time in the furnace ranged from 1 to 3 h. Following incineration, the samples underwent dry grinding in a 5 L capacity vibratory ball mill for 120 min, following the procedures outlined by Cordeiro et al. [118]. Moreover, the X-ray diffraction pattern (XRD) and Energy-dispersive X-ray spectroscopy (EDX) tests were also performed to determine the chemical composition of SBA [117]. Based on the XRD patterns, it was evident that ashes subjected to combustion within the temperature range of 450–600°C displayed an amorphous nature, characterized by limited crystal growth of SiO2 in a hexagonal crystal system with a primitive structure in distinct space groups. Beyond 600°C, these ashes manifested the crystallization of silica in the same hexagonal phase, featuring a primitive lattice structure akin to cristobalite. The EDX spectrum revealed the exclusive presence of Silicon as the primary compound, accompanied by minor compound elements such as Al, Ca, Fe, Mg, and K. Furthermore, the contrasting particle sizes of agricultural waste and SF present distinct benefits, particularly in terms of the hydration process and the improvement of the microstructure of cement paste [114,119].

Incorporating agricultural waste as SCMs exhibits the potential to enhance the UHPC’s mechanical properties and durability. This improvement arises from agricultural waste’s physical and chemical properties, which contribute to reducing pore volume in concrete. As a result, the microstructure becomes denser and more uniform, thereby enhancing resistance against water and chloride ion penetration. The effectiveness of agricultural waste in achieving these benefits depends on factors such as the w/c ratio and the specific mixture composition [119,120,121,122]. Incorporating granular blended content is a fundamental approach for enhancing the density of UHPC, leading to improved durability. Specifically, the addition of crystalline blended RHA contributes to the increased UHPC density, resulting in enhanced resistance to applied loads. However, it is worth noting that UHPC formulated with SF outperforms RHA-blended UHPC regarding compressive strength [123]. The porous texture of RHA allows the infiltration of Ca2+ ions into its inner particles, thereby promoting the pozzolanic reaction. As a result, RHA functions as an internal curing material by mitigating the autogenous shrinkage of UHPC. Additionally, incorporating agricultural waste such as SBA and RHA into the cement mixture enhances the extent of cement hydration, as evidenced by increased hydration levels compared to those mixed with SF over an extended curing period [124,125]. In addition, Response surface methodology (RSM) is a commonly used statistical design approach for modeling and analyzing problems with multiple variables that impact response of interest. RSM provides advantages such as assessing factor interactions, identifying optimal responses based on priorities, and establishing non-linear relationships [126,127]. As depicted in Figure 14, the RSM process involves five main steps: problem formulation, design approach selection, experimental runs, statistical data analysis, and determination of optimized solutions.

![Figure 14

Flowchart illustrating the computational design optimization process for SUHPC [17].](/document/doi/10.1515/rams-2023-0181/asset/graphic/j_rams-2023-0181_fig_014.jpg)

Flowchart illustrating the computational design optimization process for SUHPC [17].

A substantial body of research consistently indicates that substituting RHA for cement in UHPC within the range of 5–30% yields significant improvements in compressive strength. These improvements are primarily attributed to the considerable presence of amorphous silica in RHA, which facilitates a pozzolanic reaction [128]. It is worth noting that the effectiveness of the pozzolanic reactivity in cementitious materials blended with RHA is influenced by various factors, including the content of amorphous crystalline silica and the specific surface area [128,129,130]. RHA can serve as either a partial or complete substitute for SF in the production of UHPC. According to ASTM C595, RHA is classified as a highly pozzolanic material with a composition similar to SF. However, RHA and SF differ in their physical properties, including mean particle size, specific surface area, and specific gravity [131]. Considering the limited availability and high cost of SF, particularly in developing countries where substantial amounts of agricultural waste are generated from rice processing, substituting SF with RHA offers a viable solution to reduce the production cost of UHPC [125,132]. The pore structures of RHA exhibit a relatively narrow range, typically between 2 and 5 nm, with an approximate radius of 4 nm. Additionally, RHA possesses a specific pore volume of approximately 0.13 cm3·g−1. These characteristics necessitate a higher amount of water to adequately fill the internal surface of RHA during the mixing process. Consequently, including a superplasticizer is essential to maintain the desired workability of the concrete mixture.

7 Mechanical properties of SUHPC

A notable improvement in the long-term development of compressive strength in UHPC can be achieved by incorporating agricultural waste like RHA, surpassing the 28-day or 1-year timeframe. As per a study, adding RHA as a substitute for 20% of the material in UHPC resulted in an approximate enhancement of 12 and 18% in compressive strength at 28 and 91 days, respectively [133]. In a study conducted by Van Breugel and Van Tuan [134], the potential of using RHA in the production of UHPC was investigated. The results demonstrated that UHPC incorporating RHA achieved an impressive compressive strength exceeding 150 MPa when subjected to standard curing conditions. Notably, this surpasses the performance of samples containing SF. Furthermore, incorporating a blend of RHA and SF as a replacement for 10% of the cement in the UHPC specimen yielded an improved compressive strength compared to the control specimen [135]. Park et al. [136] proposed a model that explains the mechanism behind compressive strength development in cementitious materials blended with agricultural waste. According to their theoretical framework, adding agricultural waste promotes forming a gel matrix, influenced by the hydration degree and the water-to-cement ratio. Remarkably, the hydration kinetics of cementitious materials blended with agricultural waste significantly enhance compressive strength, even under a reduced water-to-cement ratio [137], as agricultural waste stimulates cement hydration [138]. The pore structure of agricultural waste absorbs moisture, which is subsequently released to provide sufficient moisture for the surrounding environment. As the relative humidity within the cement matrix decreases during the process of cement hydration, there is an observed improvement in the long-term development of compressive strength and a reduction in the water-to-binder ratio over time [125].

In a study conducted by Bui et al. [123], it was found that concrete incorporating agricultural waste as a replacement for cementitious materials at a lower w/c ratio exhibited superior compressive strength compared to the control concrete. The strength development of cement blended with agricultural waste cannot solely be attributed to the formation of C–S–H. The mesoporous structure of agricultural waste plays a crucial role as it possesses a high water absorption capacity and facilitates the diffusion of Ca2+ ions into the internal pore structure. This, in turn, enhances the hydration rate of cementitious materials and improves the pozzolanic reaction [135,139]. The compressive strength of UHPC is directly influenced by the packing density of its components [134,140,141]. Interestingly, agricultural waste with a smaller mean particle size tends to have higher compressive strength than agricultural waste with a larger mean particle size. To achieve optimal results in UHPC, it is recommended to utilize agricultural waste particles within the mean particle size range of 3.6–9 μm. This particle size range facilitates efficient integration with Portland cement, thereby enhancing the overall performance of the UHPC mixture [125]. Nguyen [125] conducted a study reporting that including agricultural waste in UHPC increased compressive strength when added up to 10% compared to the control sample. However, beyond this threshold, the introduction of agricultural waste resulted in a decline in the compressive strength of UHPC. Figure 15 graphically illustrates this relationship between the percentage of agricultural waste added and the corresponding compressive strength of UHPC.

![Figure 15

Compressive strength of UHPC with RHA as agricultural waste [142].](/document/doi/10.1515/rams-2023-0181/asset/graphic/j_rams-2023-0181_fig_015.jpg)

Compressive strength of UHPC with RHA as agricultural waste [142].

As far as the splitting-tensile strength of UHPC having agricultural waste is concerned, Vigneshwari et al. [88] conducted a study to examine the impact of replacing RHA, an agricultural waste, with SF UHPC in various curing environments. These conditions encompassed both steam curing and conventional curing. The researchers discovered that incorporating agricultural waste enhanced the flexural and splitting tensile strengths of the UHPC significantly. The literature showed that, compared to the control concrete, UHPC with agricultural waste exhibited an increase in splitting tensile strength ranging from 15 to 46% and an increase in flexural strength ranging from 10 to 36%, depending on the replacement content. Importantly, these improvements in strength were observed for both normal curing and steam curing conditions. The results indicate that incorporating agricultural waste as a substitute for SF can potentially enhance the mechanical properties of UHPC.

8 Microstructure of UHPC with agricultural waste

Several agricultural wastes can be utilized in UHPC depending on their properties and suitability for UHPC production. SBA is obtained from sugarcane bagasse combustion and can be used as a partial replacement for cement in UHPC. POFA is a waste of burning palm oil husks and fibers. It can be utilized as a pozzolanic material in UHPC. RHA, an agricultural waste, is a byproduct of rice production that has gained popularity as a replacement for cement in UHPC due to its pozzolanic properties [99–102,143]. Figure 16 presents the Scanning Electron Micrograph (SEM) images showcasing the microstructure of POFA and RHA, as presented by Le and Ludwig [144] and Tangchirapat et al. [145], respectively. Conversely, Figure 17 depicts the SEM images demonstrating the porous structure of SBA at different grinding intervals, as presented by Cordeiro et al. [146]. Incorporating agricultural wastes in UHPC offers several benefits, including reducing environmental costs associated with waste disposal and lowering concrete production expenses [94,95,147,148].

![Figure 17

SEM images of SBAs obtained through vibratory grinding for (a) 8 min and (b) 240 min [146].](/document/doi/10.1515/rams-2023-0181/asset/graphic/j_rams-2023-0181_fig_017.jpg)

SEM images of SBAs obtained through vibratory grinding for (a) 8 min and (b) 240 min [146].

The SEM images of sustainable UHPC compositions, incorporating RHA, SLA, and OWA, along with their combinations, are presented in Figure 18, as reported by Alyami et al. [43]. The study examined the impact of employing these blends as partial replacements for ordinary Portland cement on the properties and microstructure of SUHPC. A magnification of 2,500× was utilized for SEM analysis, and the results were compared with the control mix. The analysis shows that the microstructure of SUHPC blends, as depicted in Figure 18a, exhibits greater density and thickness than the irregular and undulating micrograph of the control mixture. The latter is characterized by unreacted specimens and intermolecular deformations, indicating insufficient hydration and brittleness in microstructural formation. The enhanced microstructure of SUHPC may be attributed to the effective packing facilitated by the high fineness of RHA, SLA, and OWA. The extremely small particle size was crucial in closing minute gaps that the cement could not reach. Upon scrutinizing the micrograph observations, the control mixture exhibited random pores and micro-cracks alongside a dense microstructure. In contrast, RHA, SLA, and OWA revealed a diminished distribution of pores with smaller diameters. The fine composition of particles enhanced both the pozzolanic effect and the filling effect, increasing the production of CSH gel. Additionally, the presence of un-hydrated particles further ensured an effective filling effect. In summary, using RHA demonstrated superior performance compared to OWA and SLA. The control mixture exhibited a lower microstructural performance overall. Similar findings are also reported in the literature [149–151] in terms of mechanical properties.

![Figure 18

SEM of mixes: (a) Control, (b) RHA, (c) SLA, (d) OWA, (e) RHA-SLA, (f) RHA-OWA, and (g) SLA-OWA [43].](/document/doi/10.1515/rams-2023-0181/asset/graphic/j_rams-2023-0181_fig_018.jpg)

SEM of mixes: (a) Control, (b) RHA, (c) SLA, (d) OWA, (e) RHA-SLA, (f) RHA-OWA, and (g) SLA-OWA [43].

When examining the microstructure of UHPC containing RHA as agricultural waste using backscattered electron (BSE) images in Figure 19 [124,152], it becomes evident that the presence of agricultural waste (RHA) leads to a decrease in the hydration rate. This phenomenon can be attributed to the porous nature of RHA, which absorbs free water within the pores of the UHPC matrix. As a result, the availability of water for cement hydration is reduced. Consequently, incorporating RHA in UHPC increases the presence of unhydrated particles, as the demand for free water in UHPC exceeds the available water. This, in turn, leads to a decrease in the production of calcium-silicate-hydrate (C–S–H) in the microstructure of UHPC. In summary, agricultural waste offers valuable pozzolanic properties, making it a suitable substitute for cement in UHPC. Its utilization addresses environmental concerns and waste management and contributes to cost savings. Nevertheless, it is crucial to evaluate the influence of agricultural waste on the hydration rate and microstructure of UHPC. The porous nature of agricultural waste can impact water availability for cement hydration, thus affecting the formation of C–S–H.

![Figure 19

BSE images: (a) UHPC and b) UHPC with RHA as agricultural waste [152].](/document/doi/10.1515/rams-2023-0181/asset/graphic/j_rams-2023-0181_fig_019.jpg)

BSE images: (a) UHPC and b) UHPC with RHA as agricultural waste [152].

The mercury intrusion porosimetry analysis results for specimens incorporating RHA as agricultural waste demonstrate a decrease in the first peak associated with critical pore diameter over time [124]. Additionally, it has been observed that the inclusion of RHA in UHPC leads to a reduction in total porosity. This reduction is influenced by the filler effect of RHA and its pozzolanic reactions. However, it is noteworthy that the decrease in porosity is more significant in specimens containing agricultural waste than those containing SF, emphasizing the greater impact of pozzolanic reactions and the filler effect of SF in reducing porosity. The thermal gravimetric analysis outcomes, presented in Figure 20, demonstrate the temporal variations in calcium hydroxide (Ca(OH)2) content for UHPC samples incorporating agricultural waste, specifically RHA. These findings indicate that adding agricultural waste reduces the Ca(OH)2 content in UHPC; however, the reduction is not as significant as observed with the addition of SF [153]. It is worth noting that, up to a concrete age of 7 days, the Ca(OH)2 content in specimens containing agricultural waste was lower than those containing SF. However, over time, the Ca(OH)2 content in specimens with SF decreased to even lower levels. This discrepancy may be attributed to the varying amounts of amorphous SiO2 and the distinct characteristics of SF particles and RHA.

![Figure 20

Temporal changes in calcium hydroxide content of UHPC with agricultural waste [152].](/document/doi/10.1515/rams-2023-0181/asset/graphic/j_rams-2023-0181_fig_020.jpg)

Temporal changes in calcium hydroxide content of UHPC with agricultural waste [152].

9 Environmental impact of SUHPC having agricultural waste

The escalation of environmentally detrimental activities has led to a significant increase in concerns related to environmental issues, including climate change and the depletion of natural resources. Consequently, there is a growing urgency to prioritize sustainability aspects within the construction industry, specifically focusing on using recycled or waste materials [154]. These materials, including agricultural waste and recycled materials, are commonly referred to as “green materials” due to their lower energy consumption and their ability to facilitate the production of high-performance, environmentally friendly cement and concrete [155]. However, it should be noted that UHPC typically contains a higher cement content compared to conventional concrete, leading to higher energy consumption and CO2 emissions [156]. Nonetheless, SUHPC offers the advantage of being able to withstand harsh and challenging environments, making it a valuable means to enhance building sustainability [157,158]. The benefits of UHPC having agricultural waste are summarized in Figure 21.

Benefits of SUHPC.

Integrating agricultural waste into UHPC presents a promising approach with potential environmental benefits. Using agricultural waste as a supplementary material, UHPC can reduce the environmental impact of traditional UHPC production [43,45,110]. This incorporation of agricultural waste in UHPC brings several environmental advantages. First, it reduces natural resource consumption by substituting a portion of traditional raw materials, such as cement and aggregates, with agricultural waste. This substitution can potentially conserve natural resources and mitigate the environmental depletion associated with their extraction [46,110]. Moreover, including agricultural waste in UHPC can help minimize greenhouse gas emissions [65]. Conventional UHPC production significantly contributes to CO2 emissions due to the high energy consumption during cement production [159,160]. However, by replacing a portion of cement with agricultural waste, the carbon footprint of UHPC can be reduced. Agricultural waste-based materials often have lower embodied carbon than conventional materials, contributing to a more sustainable construction industry [161]. Using agricultural waste in UHPC also promotes waste management and recycling [162]. Agricultural residues, such as ashes of sugarcane bagasse and RHA or straw, can be diverted from landfills and effectively utilized as valuable resources in the production of UHPC [163]. This approach helps divert waste from disposal sites, thereby reducing the strain on landfill capacities and addressing associated environmental concerns. In conclusion, incorporating agricultural waste into UHPC holds significant potential for generating positive environmental impacts. This approach can contribute to the preservation of natural resources, the mitigation of greenhouse gas emissions, and the advancement of waste management and recycling practices. By adopting UHPC containing agricultural waste, the construction industry can actively contribute to sustainable practices and enhance environmental stewardship in the field of concrete production. The integration of agricultural waste aligns with the principles of sustainable development and sustainable construction, emphasizing the efficient use of resources and the reduction in environmental impacts. This approach supports the transition towards a low-carbon and circular economy, fostering a greener and more responsible approach to concrete production in line with sustainable development goals.

10 Discussions and future prospects

Moreover, the existing conventional research studies that rely on reviews cannot establish precise connections between various aspects of literature. Consequently, the systematic review carried out in this present study facilitates the correlation between bibliographic data and the statistical analysis of research focused on UHPC utilizing agricultural waste. Therefore, the present study focuses on the comprehensive identification of frequently employed keywords, the countries that exhibit the highest level of contribution to pertinent articles, the primary sources responsible for producing highly influential articles, and the most esteemed authors in terms of their published articles and citation records, within the specialized research domain of UHPC incorporating agricultural waste. The keyword assessment reveals a substantial emphasis on investigating incorporating agricultural waste into UHPC to enhance compressive strength and promote sustainable development. Moreover, the countries making notable contributions to research in this specific domain are identified through their literature, demonstrating interconnectedness through citations. The mapping methodology is expected to involve the categorization and comparative examination of research undertakings spanning varied regions. This process aims to clarify the degree of engagement in diverse global locations. The evaluative procedure contributes to identifying nations at the forefront of research in this field, shedding light on potential areas of expertise or focal points. This comprehensive analysis holds the potential to facilitate collaborative endeavors among researchers, thereby driving advancements in research within this field. Through the analysis of keywords and interconnected literature, the current study emphasizes the importance of identifying prospects in UHPC research incorporating agricultural waste. Considering this, the study suggests potential avenues for extended investigation within this research domain.

Further research can focus on determining the optimal proportion of agricultural waste (such as ashes of sugarcane bagasse, rice husk, and palm oil fuel) that can be incorporated into UHPC to maximize its mechanical properties, durability, and sustainability.

Numerous studies have explored agricultural waste’s impact on enhancing the strength, permeability, unit weight, and consistency of UHPC. Nevertheless, there is a need for additional research focused on investigating the long-term durability of UHPC incorporating agricultural waste.

It is crucial to explore various environmental conditions as potential subjects for further investigation in future research to advance the understanding of the durability characteristics of UHPC incorporating agricultural waste. The feasibility of employing UHPC that incorporates agricultural waste in challenging environments, such as sewerage treatment plants or industrial effluent settings, necessitates thorough examination to assess its durability performance.

Research can focus on innovative processing techniques, such as high-pressure compaction, nanomaterial reinforcement, or chemical admixtures, to enhance the dispersion and reactivity of agricultural waste particles within the UHPC matrix, thereby improving overall performance.

Combining agricultural waste with other SCMs or reinforcing fibers can develop composite UHPC materials with enhanced mechanical strength, toughness, and crack resistance.

Further microstructural investigations are warranted to delve deeper into the characteristics of UHPC incorporating different particle sizes of agricultural waste.

Investigating the feasibility and structural performance of UHPC with agricultural waste in practical applications, such as precast elements, bridges, or high-rise buildings, can provide valuable insights into its real-world potential and structural behavior.

Assessing the economic feasibility and market acceptance of UHPC incorporating agricultural waste, including cost-effectiveness, availability of raw materials, and production scalability, can promote its adoption in the construction industry.

Conducting comprehensive life cycle assessments to evaluate the environmental impact and sustainability of UHPC incorporating agricultural waste can guide the development of more eco-friendly construction materials.

11 Conclusion

In the past, the scientific community has been greatly influenced by the wealth of scientific information and the emergence of innovative communication networks, which have paved the way for developing advanced bibliometric metrics. These metrics utilize statistical analysis techniques that enable reliable scales of value. Consequently, evaluating publications contributed by research groups, institutions, individuals, and countries becomes feasible, thereby determining their scientific significance. Conducting a review-based study is an appropriate approach to identifying emerging trends in the literature concerning the incorporation of agricultural waste in UHPC. This assessment can be particularly beneficial for young scholars and researchers. The main aim of this study is to conduct a comprehensive analysis of the existing literature on incorporating agricultural waste in UHPC to explore multiple dimensions within this domain. The drawn conclusions are as follows:

The analysis shows that approximately 42% of the documents fall under the “Engineering” discipline, while “Materials Science” represents almost 29%, contributing to 71%. Among these publications, journal articles account for 69%, conference review papers comprise 16%, and conference articles represent 11%. Furthermore, when examining the sources of published literature related to the incorporation of agricultural waste in UHPC, it becomes evident that the top three journals are “Case Studies in Construction Materials,” “Journal of Cleaner Production,” and “Construction and Building Materials.”

The analysis of keywords in the research on UHPC incorporating agricultural waste highlights the frequent utilization of terms such as “Ultra-High-Performance Concrete,” “Compressive Strength,” “Cements,” “Sustainable Development,” and “Agricultural Wastes.” This examination of keywords further signifies that incorporating agricultural waste in UHPC has been extensively explored as a viable approach to attain sustainable development goals.

The outcomes of the author analysis indicate that Dai ranks as the predominant author in the realm of agricultural waste-incorporated UHPC research, closely followed by Zhang and Cai. Furthermore, the analysis highlights significant interrelationships among authors based on their citation networks, thereby suggesting that a comprehensive evaluation of each parameter independently could lead to more effective and insightful outcomes.

It is revealed that research contributions in UHPC incorporating agricultural waste vary across different countries. China is the foremost contributor to the research on UHPC utilizing agricultural waste. Researchers from diverse nations interested in exploring UHPC with agricultural waste can seize the opportunity to collaborate with experts in related fields and leverage their invaluable expertise.

Agricultural waste can substitute SF in UHPC, improving strength and durability by reducing pore volume and enhancing microstructure. It serves as an internal curing material, reducing shrinkage and enhancing cement hydration. Substituting 5–30% of cement with agricultural waste (i.e., RHA) significantly improves compressive strength. Particle size and surface area affect reactivity. Proper water content and superplasticizer maintain workability in agricultural waste incorporated UHPC design.

UHPC with RHA as an agricultural waste achieves higher compressive strength than SF samples, even with low water-to-cement ratios. Agricultural waste enhances cement hydration, pore structure, and pozzolanic reaction. Excessive use of agricultural waste may decrease compressive strength. Additionally, agricultural waste improves splitting tensile and flexural strengths irrespective of curing conditions. These findings highlight the potential of agricultural waste as a substitute for SF, enhancing UHPC’s mechanical performance.

Using agricultural waste in UHPC affects the hydration rate and microstructure, leading to unhydrated particles and decreased C–S–H production. Agricultural waste also reduces porosity significantly over time and contributes to reducing Ca(OH)2 content in UHPC. These findings highlight agricultural waste’s pozzolanic properties and filler effect, underscoring its potential as a cement substitute in UHPC.

The integration of agricultural waste into UHPC offers significant environmental benefits. It conserves natural resources, reduces greenhouse gas emissions, promotes waste management and recycling, and aligns with sustainable development and construction principles. By adopting UHPC with agricultural waste, the construction industry can contribute to sustainable practices and enhance environmental stewardship, supporting a low-carbon and circular economy.

Acknowledgments

The authors are thankful for the sponsorship of this work in part by “The key scientific and technological research project of Science and Technology Department of Henan Province, “Research on seismic performance and design method of fabricated shear wall with section steel/ECC composite connection” (No.: 222102320027)”. The authors are also thankful to “Deanship of Scientific Research and under the supervision of the Science and Engineering Research Centre at Najran University for funding this work under the Research Centers Funding program grant code (NU/RCP/SERC/12/2)”.

-

Funding information: This work was sponsored in part by The key scientific and technological research project of Science and Technology Department of Henan Province, “Research on seismic performance and design method of fabricated shear wall with section steel/ECC composite connection” (No.: 222102320027). The authors are thankful to Deanship of Scientific Research and under the supervision of the Science and Engineering Research Centre at Najran University for funding this work under the Research Centers Funding program grant code (NU/RCP/SERC/12/2).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Van Damme, H. Concrete material science: Past, present, and future innovations. Cement and Concrete Research, Vol. 112, 2018, pp. 5–24.10.1016/j.cemconres.2018.05.002Suche in Google Scholar

[2] Aïtcin, P. C. High performance concrete, CRC Press, London, 1998.10.4324/9780203475034Suche in Google Scholar

[3] Habel, K., M. Viviani, E. Denarié, and E. Brühwiler. Development of the mechanical properties of an Ultra-High Performance Fiber Reinforced Concrete (UHPFRC). Cement and Concrete Research, Vol. 36, No. 7, 2006, pp. 1362–1370.10.1016/j.cemconres.2006.03.009Suche in Google Scholar

[4] Kay Wille, A. E. N. and J. P. M. Gustavo. Ultra-high performance concrete with compressive strength exceeding 150 MPa (22 ksi): A simpler way. ACI Materials Journal, Vol. 108, No. 1, 2011, pp. 46–54.10.14359/51664215Suche in Google Scholar

[5] Rumpf, H. The characteristics of systems and their changes of state disperse. Particle Technology, Chapman and Hall; Springer: Berlin/Heidelberg, Germany, 1990, pp. 8–54.10.1007/978-94-011-7944-7_2Suche in Google Scholar

[6] Amin, M., A. M. Zeyad, B. A. Tayeh, and I. S. Agwa. Effect of glass powder on high-strength self-compacting concrete durability. Key Engineering Materials, Vol. 945, 2023, pp. 117–127.10.4028/p-w4tcjxSuche in Google Scholar

[7] Chow, T. S., P. Eng, V. H. Perry, G. Culham, and D. Zakariasen. First use of UHPFRC in thin precast concrete roof shell for Canadian LRT station. PCI Journal, Vol. 50, No. 5, 2005, pp. 50–67.10.15554/pcij.09012005.50.67Suche in Google Scholar

[8] Xue, J., B. Briseghella, F. Huang, C. Nuti, H. Tabatabai, and B. Chen. Review of ultra-high performance concrete and its application in bridge engineering. Construction and Building Materials, Vol. 260, 2020, id. 119844.10.1016/j.conbuildmat.2020.119844Suche in Google Scholar

[9] Valikhani, A., A. J. Jahromi, I. M. Mantawy, and A. Azizinamini. Experimental evaluation of concrete-to-UHPC bond strength with correlation to surface roughness for repair application. Construction and Building Materials, Vol. 238, 2020, id. 117753.10.1016/j.conbuildmat.2019.117753Suche in Google Scholar

[10] Li, X., Z. Shui, R. Yu, and X. Wang. Magnesium induced hydration kinetics of ultra-high performance concrete (UHPC) served in marine environment: Experiments and modelling. Construction and Building Materials, Vol. 224, 2019, pp. 1056–1068.10.1016/j.conbuildmat.2019.07.273Suche in Google Scholar

[11] Azreen, N. M., R. S. M. Rashid, M. Haniza, Y. L. Voo, and Y. H. Mugahed Amran. Radiation shielding of ultra-high-performance concrete with silica sand, amang and lead glass. Construction and Building Materials, Vol. 172, 2018, pp. 370–377.10.1016/j.conbuildmat.2018.03.243Suche in Google Scholar

[12] Li, P. P., H. J. H. Brouwers, and Q. Yu. Influence of key design parameters of ultra-high performance fibre reinforced concrete on in-service bullet resistance. International Journal of Impact Engineering, Vol. 136, 2020, id. 103434.10.1016/j.ijimpeng.2019.103434Suche in Google Scholar

[13] Ghafari, E., H. Costa, and E. Júlio. Statistical mixture design approach for eco-efficient UHPC. Cement and Concrete Composites, Vol. 55, 2015, pp. 17–25.10.1016/j.cemconcomp.2014.07.016Suche in Google Scholar

[14] Shi, C., Z. Wu, J. Xiao, D. Wang, Z. Huang, and Z. Fang. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Construction and Building Materials, Vol. 101, 2015, pp. 741–751.10.1016/j.conbuildmat.2015.10.088Suche in Google Scholar

[15] Benjamin, A. Material property characterization of ultra-high performance concrete. US Department of Transport, New Jersey Ave., SE Washington, DC, 2006.Suche in Google Scholar

[16] Ahmed, S., Z. Al-Dawood, F. Abed, M. A. Mannan, and M. Al-Samarai. Impact of using different materials, curing regimes, and mixing procedures on compressive strength of reactive powder concrete – A review. Journal of Building Engineering, Vol. 44, 2021, id. 103238.10.1016/j.jobe.2021.103238Suche in Google Scholar