Abstract

Considering the temperature sensitivity and two-phase incompatibility of the fiber matrix interface, carbon fiber-reinforced thermoplastic composites suffer from weak interfacial bonding strength. To investigate the delamination damage and shear failure mechanism of T700/PEEK composites at varying temperatures, interfacial shear strength (IFSS) and interlaminar shear strength (ILSS) were performed by employing micro debonding experiments and three-point bending. The results indicated that at temperatures below the glass transition, the IFSS of T700/PEEK composites was positively correlated with temperature, and the average strength recorded was 52 ± 6 MPa. When the glass transition temperature was exceeded, the bonding state between polyether ether ketone material and fiber surface became tighter, resulting in a slight increase in IFSS, reaching 60 ± 4 MPa. Further, the ILSS of T700/PEEK composites was tested, and the results indicated a negative correlation between ILSS and temperature, with a maximum ILSS of 40 ± 2 MPa observed at 23°C, and a minimum of 11 ± 1 MPa recorded at 230°C. The decline in bending strength observed with increasing temperature was attributed to the separation of the fiber and matrix interface at high temperatures, which reduced the mechanical properties of T700/PEEK composites. By conducting temperature related mechanical performance tests on T700/PEEK composite materials, the obtained test results will help researchers expand the application scenarios of this material, deepen the relationship between the temperature and its performance, and thus more quickly explore the mechanism of temperature action.

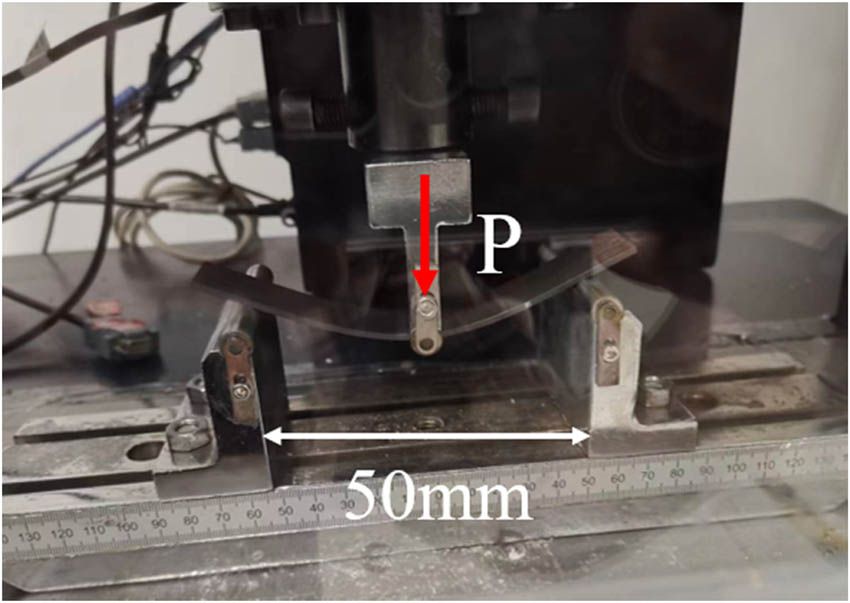

Graphical abstract

1 Introduction

Presently, owing to the swift advancements in the aerospace industry, conventional materials are encountering mounting challenges in fulfilling the performance and dependability stipulations of associated domains. Consequently, composite materials have emerged as a contemporary area of research focus. Within this realm, carbon fiber (CF)- reinforced resin-based composites have garnered significant attention from scholars due to their exceptional mechanical properties, distinctive advantages in terms of heat resistance, lightness, and other attributes [1,2,3,4].

Thermoplastic polyether ether ketone (PEEK) resin exhibits outstanding material properties, such as a high melting point of 343°C, a glass transition temperature of 143°C, and a long-term use temperature of up to 240°C [5]. Furthermore, it possesses exceptional fatigue, wear, and radiation resistance, making it an ideal matrix for CF-reinforced composite materials [6]. The resulting CF/PEEK composites exhibit excellent chemical resistance [7], biocompatibility [8], and radiation resistance, presenting vast prospects in the aerospace, defense industry, and other domains [9]. Lu et al. [10] employed short CF (6 wt%) to reinforce PEEK composites, and utilized varied molding temperatures and pressures to investigate the mechanical properties of CF/PEEK samples, along with associated mechanisms for enhancing these properties. The research findings demonstrated that the maximum tensile strength and bending strength of the material reached 157.3 and 382.0 MPa, respectively. Wu et al. [11] discovered that temperature influences the porosity and crystallinity of CF-laminated composites, thus indirectly affecting the interlaminar shear strength (ILSS) of thermoplastic composites. The ILSS of the composites increased by 32.87% compared to the untreated ILSS when porosity decreased, and crystallinity increased. Di Benedetto et al. [12] designed CF, PEEK, and metal-woven mesh composites to improve the impact resistance of thermoplastic composite structures. The ILSS of the composites improved by 22.7% compared to materials without woven mesh by employing the filament winding process to wind the CF/PEEK mixed tow and five different woven wire meshes together, followed by hot forming. Dai et al. [13] prepared 66 wt% CF-reinforced PEEK-based composites utilizing compression molding techniques and a pre-impregnated layer of 0°/90° to improve their mechanical and wear properties at varying temperatures, especially high temperatures. The results indicate that, at room temperature, the tensile and bending strength of the composites exceeded 1,000 MPa. At 200°C, the tensile strength was 810 MPa, while the bending strength reached 521 MPa. Furthermore, at 300°C, the tensile strength decreased to 458 MPa, with a corresponding bending strength of 290 MPa.

The mechanical properties of CF-reinforced composites are influenced by not only the mechanical properties of the matrix and CFs but also the interface layer between the matrix and fibers [14,15,16]. Under load-bearing conditions, the interface layer transfers the load to the high-strength fibers, thus reducing damage to the composites [17]. However, due to the non-polarity of CFs and low wettability between fibers and resins, the interfacial bonding of composites is limited, resulting in inadequate load transfer and affecting the mechanical properties of the composite materials [18]. In CF/PEEK composites, brittle delamination of the composite material layer occurs, resulting in almost no plastic deformation, and they enter the asymptotic region of the fatigue life map with a lower number of cycles. Cracks develop along the fiber interface, indicating ineffective load transfer by the fibers [19]. These challenges highlight the shortcomings of interfacial shear strength (IFSS) in CF/PEEK composites and ultimately limit their widespread application [20,21,22,23]. Consequently, many researchers have studied the factors that influence the interface performance of composites and have proposed various methods, including the addition of interface reinforcing substances, to improve the interface performance of composites.

The commonly used modification methods currently include chemical grafting, nano reinforcement, sizing process, and electrophoretic deposition (EPD) [24,25,26]. EPD can rapidly deposit a large number of carbon nanotubes (CNTs) on the surface of materials, thereby enhancing surface properties. This method combines advantages such as environmental protection and low cost [27]. Li et al. [28] proposed a feasible method to improve the interfacial strength of CF-reinforced polymers by vertically depositing CNTs on CFs using EPD, and the results showed that the IFSS of the materials was successfully increased by 58.1%. In addition, An et al. [29] found that using EPD to deposit CNTs on the surface of glass fibers exhibited higher interfacial strength in the interface area rich in CNTs. The sizing process [30,31] can effectively improve the wettability of the resin matrix on the fiber surface. Materials such as PEKK oligomer [32,33], sulfonated PEEK [34], polyimide [35], and polyetherimide [36] have excellent solubility and high mechanical properties, and can be used as sizing agents for composites. These soluble modified or inherently soluble polymers, which have lost solvent resistance, often produce defects in harsh environments due to the attack of chemical solvents or water, leading to interfacial phase failure.

Among these methods, the most stable interaction is achieved through nano reinforcement and chemical grafting. In addition, the improvement in interface mechanics is even more evident. Hassan et al. [37] grafted aminated PEEK onto CF surface, increasing ILSS by 33.4%. Liu et al. [38] designed a silica nanoparticle decorated short CF hybrid (SCF-SiO2) to improve interface bonding. CFs and SiO2 were modified with amino and epoxy groups, resulting in a 40.5% increase in IFSS when introduced into PEEK. Wang et al. [39] prepared a novel heterocyclic derivative of PEEK by utilizing it as a linkage between CFs surface and PEEK matrix by a facile and high effective two-step method. Zhang et al. [40] added CNTs to CF/PEEK prepreg, increasing ILSS by 25.21% at 0.1 wt% CNTs. Lyu et al. [41] used a water-based sizing agent, enhancing interfacial bonding with higher shear, flexural, and ILSS. Qin et al. [42] used thermoplastic sizing treatment, increasing tensile strength by 54%. Sharma et al. [43] performed plasma modification on CFs, increasing IFSS by 22% and wear resistance by 26% with decreased single fiber strength. Wang et al. [44] improved interface performance using diazonium salt electrochemical grafting, increasing IFSS by 130.26% through covalent bond connection.

It is evident that the predominant focus of current research endeavors centers on interface modification techniques for enhancing the mechanical properties of CF/PEEK composites. However, investigations into the effects of temperature on the interfacial properties are still inadequate. In an effort to expand upon the understanding of the influence of temperature on the mechanical behavior of T700/PEEK composites, the interfacial properties and delamination damage of T700/PEEK composites were examined. Micro debonding experiments were conducted to evaluate the interfacial shear properties of the composites at various temperatures. Additionally, the ILSS of the laminates was assessed through three-point bending experiments performed under different temperature conditions.

2 Materials and methods

2.1 Experimental materials

The T700 CF (12K per bundle, 400 g·m−2) was purchased from Zhongfu Carbon Fiber Products Co., Ltd. PEEK particles (450G) were purchased from Wiggs, UK. Casting adhesive was purchased from Kafuter office franchise store. The concave iron sheet was provided by Ningbo materials institute of Chinese academy of sciences. The CF/PEEK prepreg with fiber unidirectional 0° distribution purchased from Junhua Special Plastics Company. The CF was content of 60% and density of 1.56 g·cm−3 with layer thickness of 0.13 mm.

2.2 Preparation of T700/PEEK composites samples

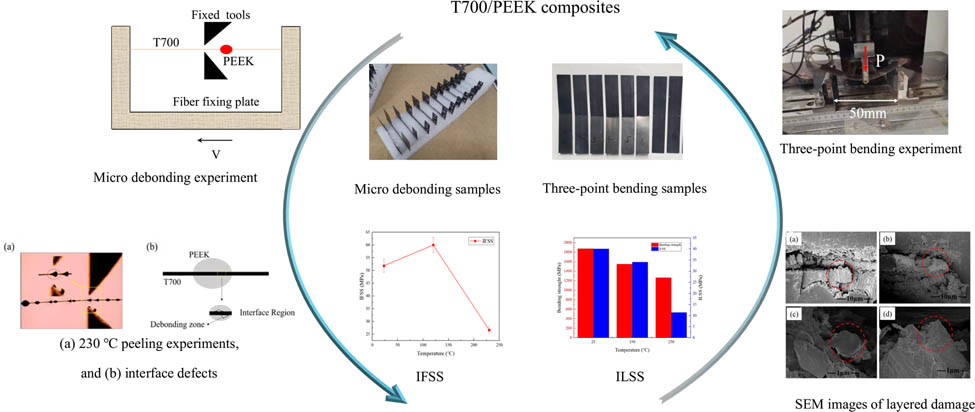

The IFSS between CF monofilament and PEEK resin was measured using the micro debonding method. A single fiber PEEK resin ball sample was prepared before the experiment. First, the single fiber filaments of T700 were separated and fixed onto a specialized fixture using fast drying adhesive. Afterwards, the PEEK particles were placed together in the interface evaluator, heated to the molten state of PEEK, and the loading basket of PEEK in the molten state was controlled by the interface evaluator to contact the fiber filaments, and then the loading basket was raised. The surface of the fibers will be adhered to by the molten droplets of PEEK and condensed into small balls. Afterwards, it was cooled down and protected by a nitrogen atmosphere throughout the entire process to prevent surface oxidation of the material. Finally, the appropriate size of resin balls was selected based on their embedding length, i.e., resin balls with a diameter of 35–55 μm, for peel testing. The three-point bending specimens in this study were fabricated from T700/PEEK composite prepreg with a layer thickness of 0.13 mm. The prepreg was stacked into a 16-layer laminate at an orientation angle of 0° and then consolidated using a flat plate hot pressing technique, resulting in a laminated panel sample with dimensions of 150 mm × 25 mm × 2 mm. The curing procedure involved uniform heating of the sample, followed by the application of a pressure of 12 MPa at 320°C for 0.5 h. This was then held at 370°C for 1 h before cooling to room temperature at a rate of 0.5°C·min−1 [45,46,47]. Finally, the specimens were removed from pressure and machined using a processing center for subsequent use. The resin ball peeling samples and three-point bending samples are shown in Figure 1.

(a) Micro debonding experimental samples and (b) three-point bending samples.

2.3 Characterization

The scanning electron microscope (SEM) (JSM IT800) was employed to conduct microscopic characterization of the damaged part of the T700/PEEK composite samples after three-point bending test, to analyze the internal damage status. In the operational parameters, apply a voltage of 3 kV and the magnification ranges from 500 to 50,000 times.

2.4 Differential scanning calorimetry (DSC) tests

The glass transition temperature (T g) of pure PEEK resin is 143°C, and the addition of fibers can enhance the thermal stability of PEEK to a certain extent. In order to more intuitively and accurately represent the thermal stability of T700/PEEK composite materials, DSC testing was conducted on T700/PEEK composite material samples in this study. The equipment used is DSC2500, which is heated to 400°C at a rate of 10°C·min−1. The time, temperature, and heat flow parameters are recorded, and a nitrogen atmosphere is maintained throughout the process.

2.5 IFSS tests

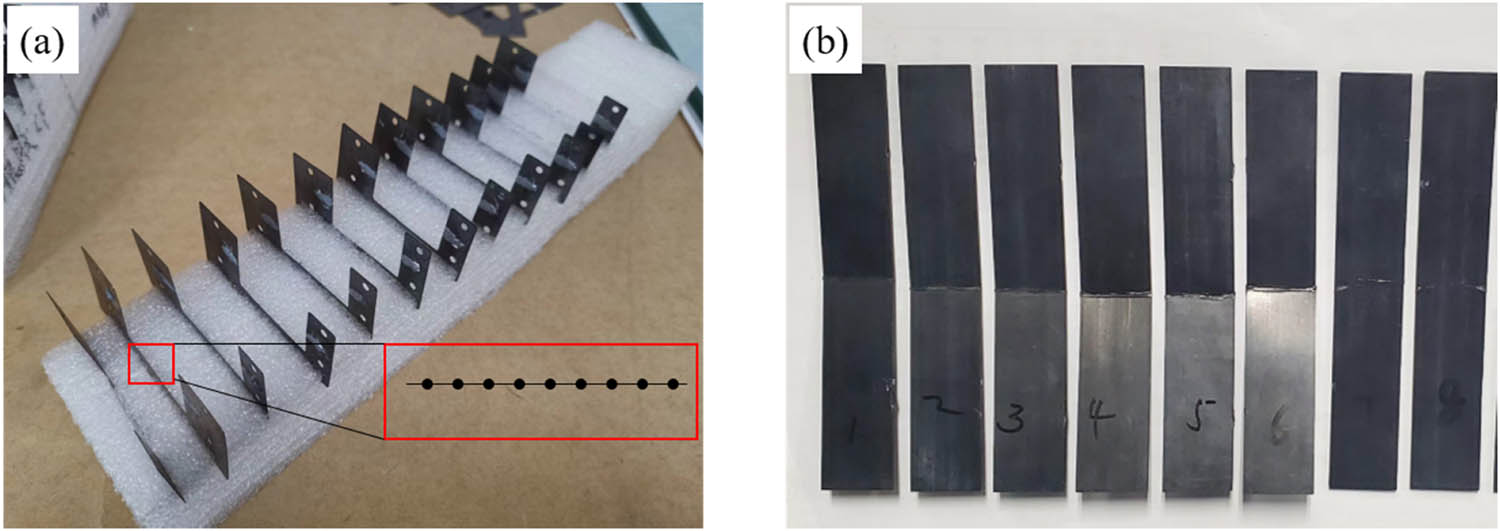

It is crucial to determine the IFSS between the reinforcing material and the matrix to evaluate the mechanical properties of composite materials. The IFSS between CF monofilament and PEEK resin was quantified in this study through microscopic debonding experiments, using a composite material interface performance evaluation instrument (HM410) manufactured by Toyo Industries Co., Ltd in Japan. The force sensor of the testing machine has a testing accuracy of 0.01 N, and the temperature control accuracy of the insulation zone is 0.5°C. During the peeling process, nitrogen atmosphere protection is used throughout the process, and the temperature is maintained at the required temperature for the experiment. Through the movement of fiber filaments and the obstruction of fixed cutting tools, the separation of resin balls and fiber filaments is achieved. Specifically, the IFSS was obtained by measuring the force required to detach the resin ball along the direction of the fiber, as illustrated in Figure 2.

(a) Schematics of micro debonding method and (b) micro debonding experiments.

To investigate the correlation between temperature and IFSS and to obtain accurate and reliable data, the temperatures of 23, 120, and 230°C were chosen for the peel test, given that the glass transition temperature of PEEK was 143°C. The holding time and loading rate were set to 10 min and 0.12 mm·min−1, respectively. The IFSS was determined by Eq. (1).

where F is the maximum force when the ball peels off, mN; d denotes the fiber diameter, μm; L is the diameter of the small ball along the fiber direction, which is the embedding length, μm.

2.6 ILSS tests

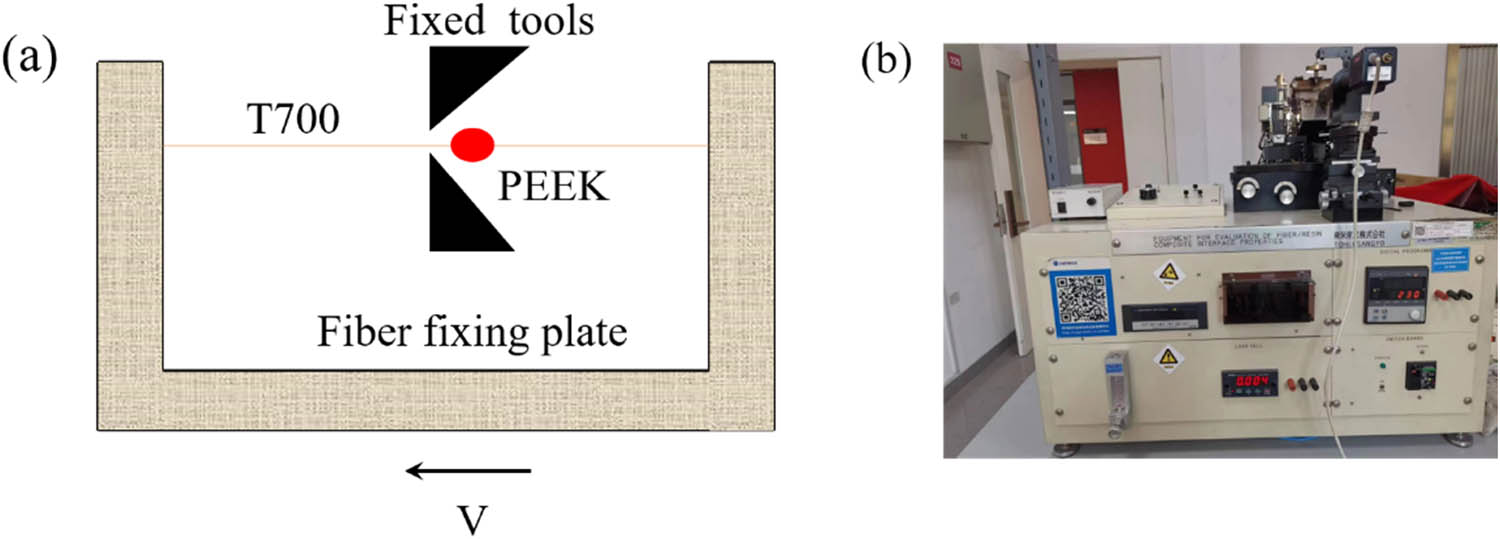

To characterize the interlayer shear strength of the sample, the international testing standard ASTM D7264 for three-point bending test of fiber composite materials was employed. The three-point bending damage test was conducted on T700/PEEK composite material samples using a three-point bending testing machine (UTM5105GD), and the interlayer shear force values were obtained. The testing accuracy of this testing machine is 0.1 N. The force–displacement curve was recorded during the loading process to determine the maximum bending force at the point of laminated board failure, and subsequently, the interlayer shear strength was calculated, as shown in Figure 3.

Three-point bending experiments.

According to the mechanics of composites and classical beam theory, the maximum bending strength formula of composite materials under three-point bending load is shown in Eq. (2).

where M max is the maximum value of the section bending moment, y max denotes the maximum distance from the stress point to the neutral axis, and I z is the moment of inertia of the section to the neutral axis. Due to the rectangular cross-section, the final result was obtained based on a simple derivation of the moment of inertia in material mechanics. P max is the maximum force in the obtained force–displacement curve, l is the span in the three-point bending test, b is the width of the specimen, and h is the thickness of the specimen.

The calculation formula for the ILSS of CF composites in the three-point bending test is shown in Eq. (3).

The definition of the parameters is the same as in Eq. (2). By dividing the two equations, Eq. (4) can be obtained.

For thin plates, l was much greater than h. Therefore, for laminated CF composite materials, the maximum bending normal stress was much greater than its interlayer shear stress. In other words, under three-point bending load, laminated CF composites were more prone to interlayer shear failure, i.e., delamination damage.

3 Results and discussion

The aim of the present study is to investigate the mechanical properties of T700/PEEK composites, with a focus on interfacial debonding and delamination damage. The specimens were prepared for micro debonding and three-point bending experiments. The IFSS and ILSS of the composites were characterized at varying temperatures via micro debonding and three-point bending experiments, and the specimens’ characteristics after delamination damage were examined using SEM analysis.

3.1 Characterization results

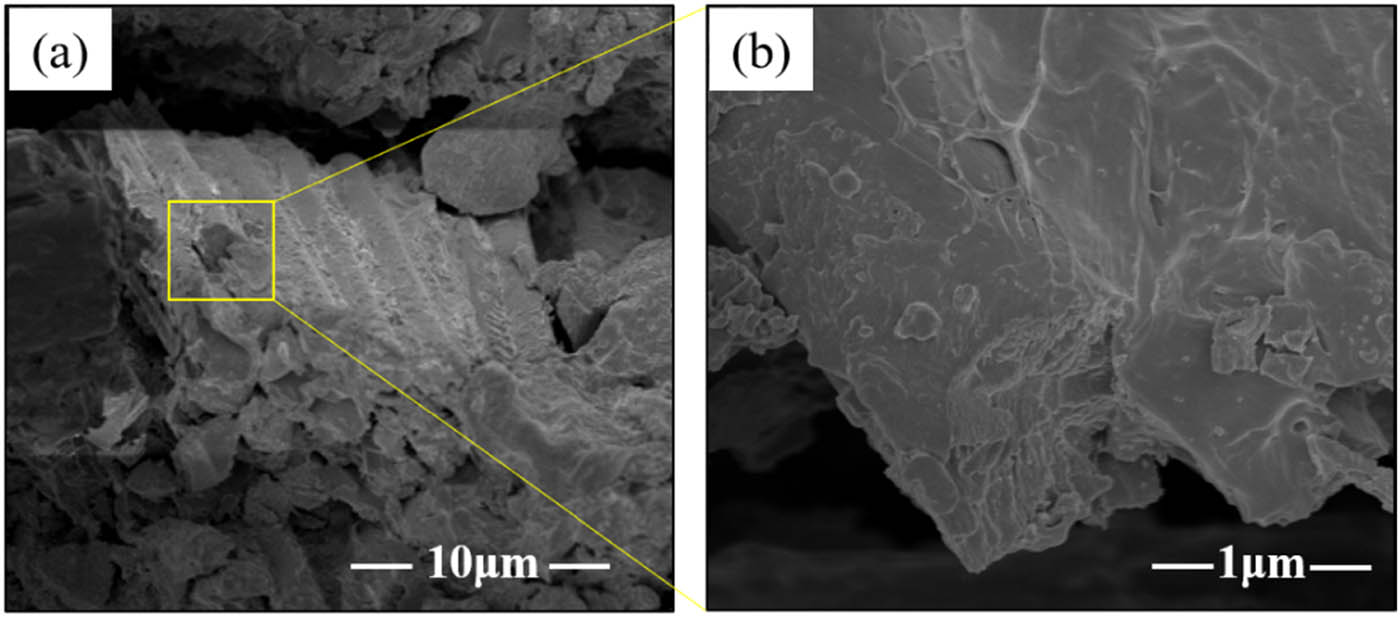

In order to investigate the bonding state and the possible defects arising from the molding process within the T700/PEEK composites, SEM characterization was employed in this study. Accelerated voltage of 3 kV was applied during the analysis. The SEM images, as depicted in Figure 4, were obtained for this purpose.

(a) The SEM and (b) localized magnified images of the T700/PEEK composites.

Based on the SEM images shown in Figure 4, it can be observed that the interfacial bonding between the fibers and the matrix in the T700/PEEK composites was of good quality, with the PEEK resin infiltrating and coating the fibers. The composite material was compact, exhibiting no visible pores or defects. As shown in Figure 4(a), the fibers were uniformly distributed within the matrix, displaying a flat cross-section, indicating that the fibers were well bonded to the matrix, resulting in improved mechanical properties. Figure 4(b) revealed a tightly bonded interfacial region between the fibers and the matrix, with no apparent debonding defects, indicating that the laminated board forming process was highly mature and reliable.

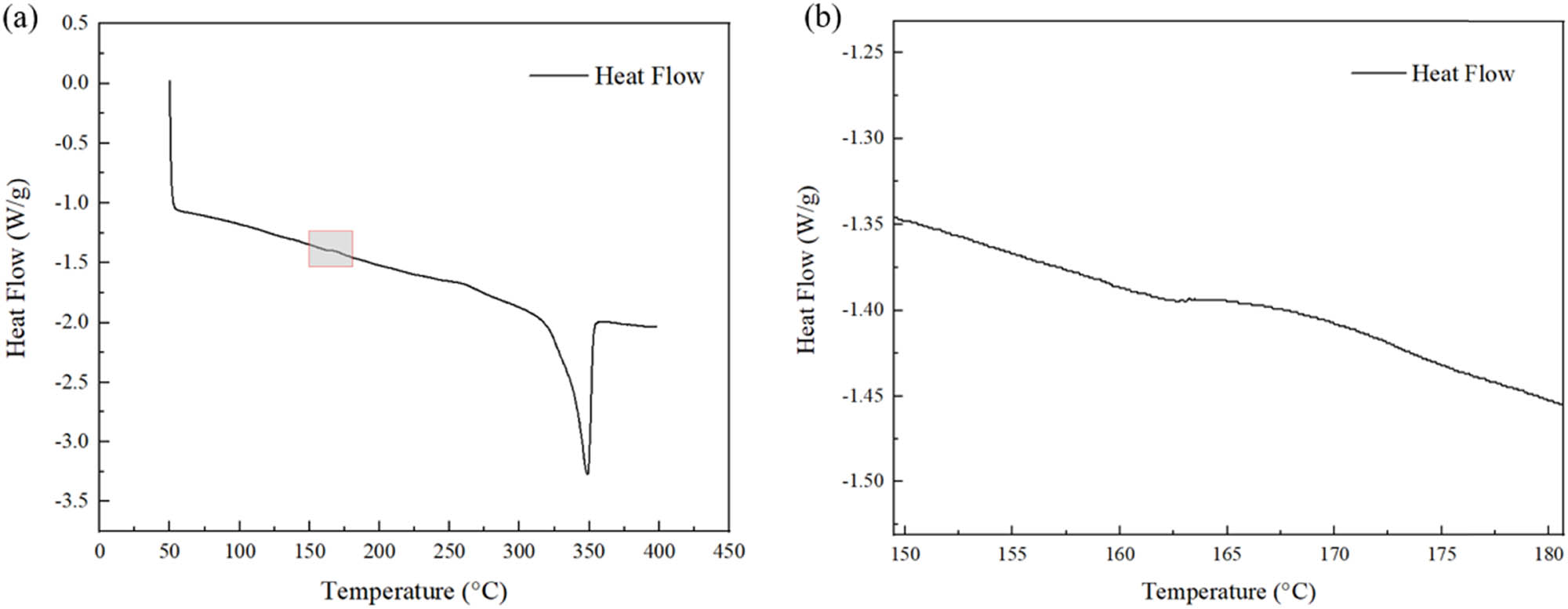

3.2 DSC test results

T g is an important factor affecting the performance of PEEK materials. Based on the T g of T700/PEEK composite materials, three experimental temperatures were designed in this study. Therefore, it is very important to determine the T g of T700/PEEK composite materials. The DSC test results show that the melting peak of T700/PEEK composite material is around 350°C, while T g is around 163°C, which is slightly higher than the T g (143°C) of pure PEEK resin. This indicates that the addition of T700 has improved the thermal stability of the composite material to a certain extent, as shown in Figure 5. Therefore, the three temperature test points selected based on T g in this article are correct.

(a) DSC test and (b) localized magnified image of T700/PEEK composites.

3.3 IFSS analysis

Interfacial debonding, which is one of the fundamental types of micro-damage in composites, has a significant impact on the micro and macro mechanical properties of composites. The study of interfacial debonding is crucial for understanding and characterizing the interface performance of composites.

The micro debonding method is a powerful technique for measuring the IFSS of composites. This method involves peeling a resin ball attached to the surface of a single CF using a fixed tool, and recording the maximum force required for peeling using an instrument. In this study, multiple groups of samples were peeled at three different temperatures, and the average IFSS at each temperature was calculated after eliminating any values that were too large or too small. The peeling results obtained at 23°C are displayed in Table 1.

Peeling results at 23°C

| Group | Embedded length (μm) | Maximum shear force (mN) | Shear strength (MPa) |

|---|---|---|---|

| 1 | 45.23 | 35 | 35.19 |

| 2 | 41.23 | 40 | 44.12 |

| 3 | 40.44 | 35 | 39.36 |

| 4 | 54.11 | 51 | 42.87 |

| 5 | 41.74 | 40 | 43.58 |

| 6 | 43.29 | 45 | 47.27 |

| 7 | 41.71 | 42 | 45.88 |

| 8 | 39.39 | 40 | 46.18 |

| 9 | 52.53 | 62 | 53.68 |

| 10 | 46.35 | 62 | 60.83 |

| 11 | 50.98 | 58 | 51.74 |

| 12 | 45.04 | 40 | 40.39 |

| 13 | 47.89 | 61 | 57.92 |

| 14 | 47.92 | 65 | 61.68 |

| 15 | 38.66 | 45 | 52.93 |

| 16 | 41.74 | 47 | 51.20 |

| 17 | 54.07 | 83 | 69.80 |

| 18 | 60.33 | 75 | 56.53 |

| 19 | 57.35 | 85 | 67.40 |

| 20 | 46.58 | 54 | 52.72 |

| 21 | 40.29 | 50 | 56.43 |

| 22 | 41.97 | 63 | 68.26 |

| 23 | 44.91 | 65 | 65.81 |

| 24 | 50.98 | 54 | 48.17 |

| 25 | 43.29 | 57 | 59.88 |

| 26 | 43.26 | 54 | 56.76 |

| 27 | 47.61 | 42 | 40.12 |

| 28 | 52.53 | 52 | 45.01 |

| 29 | 46.38 | 34 | 33.34 |

| 30 | 44.91 | 40 | 40.50 |

| 31 | 56.15 | 55 | 44.54 |

| 32 | 55.96 | 55 | 44.70 |

| 33 | 42.17 | 47 | 50.68 |

| 34 | 41.71 | 50 | 54.51 |

| 35 | 47.99 | 59 | 55.91 |

| 36 | 45.23 | 49 | 49.26 |

| 37 | 37.37 | 50 | 60.84 |

| 38 | 43.26 | 74 | 77.79 |

| 39 | 49.54 | 63 | 57.78 |

| 40 | 46.45 | 61 | 59.72 |

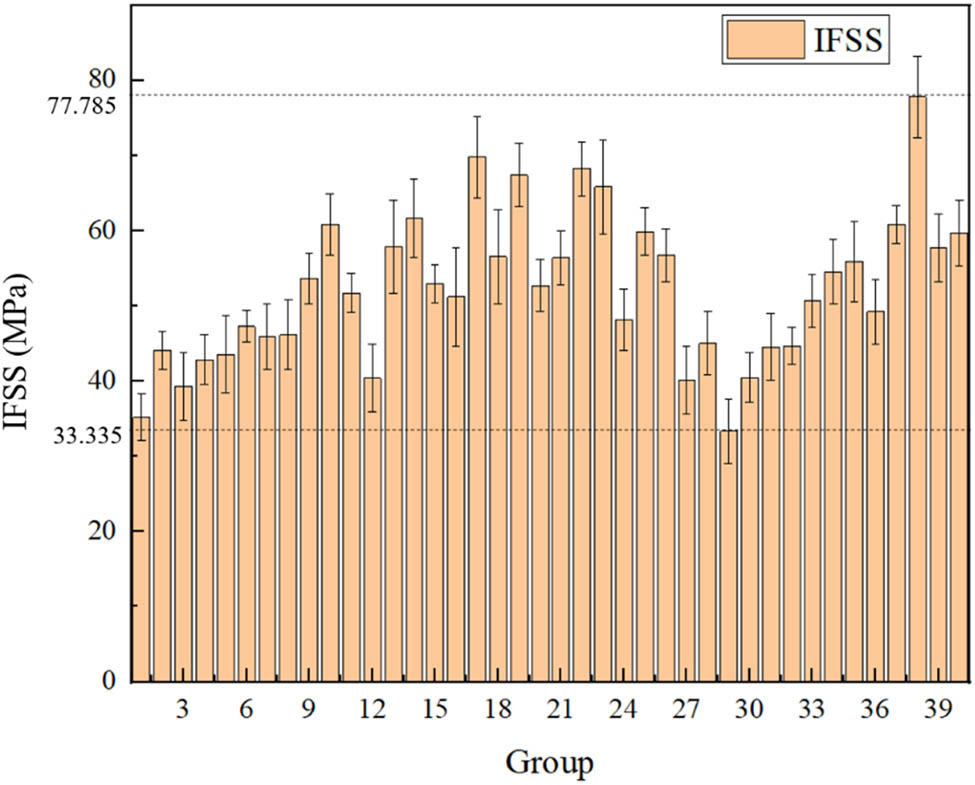

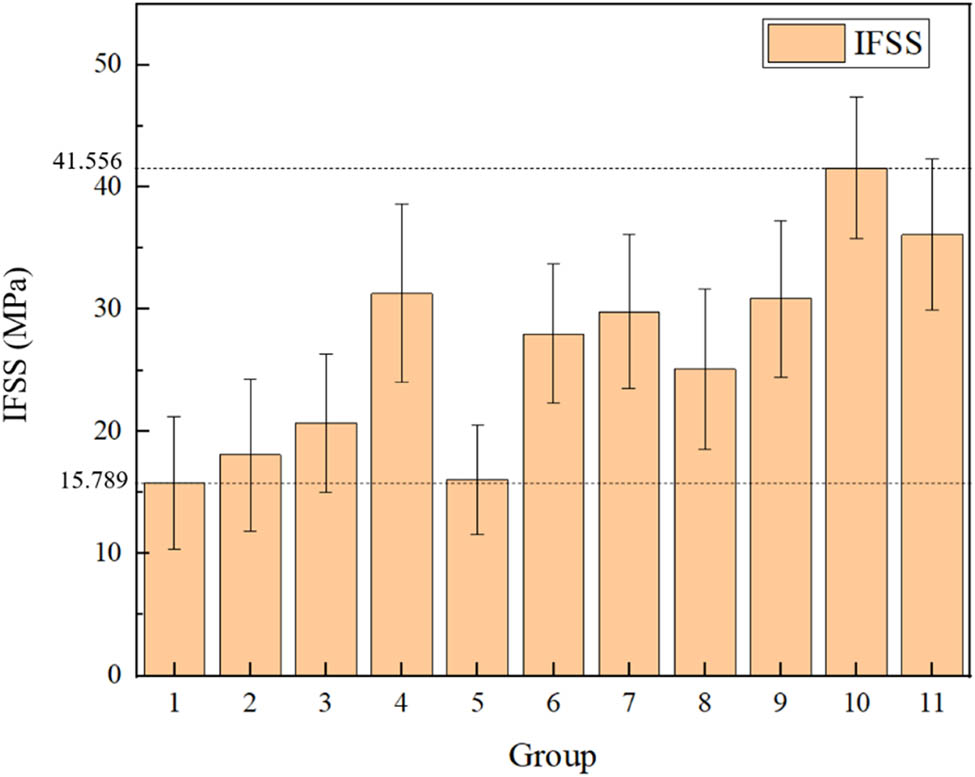

Based on the experimental results presented in Figure 6, it can be observed that the majority of the measured IFSS values ranged from 45 to 60 MPa, with a few values deviating significantly from this range. By analyzing the experimental data, this article calculates that the standard deviation of this group of experimental data is 5.9767. At 23°C, the average value of IFSS is 52 ± 6 MPa.

The peeling IFSS of the composites at 23°C.

This can be attributed to the high viscosity of PEEK during melting, which led to the micro debonding test results being heavily influenced by various factors such as the size, shape, and molding conditions of the resin ball, as well as the texture of the fixture. When such factors were applied to the material, the final result appeared as depicted in Figure 6. When conducting peel tests, low interfacial bonding between microspheres and fibers due to factors such as cooling rate can lead to low IFSS values. When the size of the microbeads was too large, it can cause the experimental data to be too large. Both situations will increase the degree of data dispersion. This study held the view that data that deviated excessively from the average value of all experimental data by more than 10% were significantly affected by external factors and did not provide reliable reference. Therefore, to ensure the reliability of experimental data, this study considered data that exceeded the aforementioned threshold as unacceptable. The remaining experimental data were then averaged to obtain the final IFSS value for the micro debonding experiment conducted at that temperature.

The glass transition temperature is a crucial material property that can significantly affect its behavior beyond this point. Thus, to ensure the experimental results’ accuracy and consider the material’s glass transition temperature effect on its properties, as presented in Table 2, a peel temperature of 120°C was selected for this study.

Peeling results at 120°C

| Group | Embedded length (μm) | Maximum shear force (mN) | Shear strength (MPa) |

|---|---|---|---|

| 1 | 49.44 | 81 | 74.50 |

| 2 | 41.74 | 53 | 57.78 |

| 3 | 43.26 | 50 | 52.56 |

| 4 | 44.81 | 55 | 55.81 |

| 5 | 47.92 | 69 | 65.48 |

| 6 | 38.63 | 49 | 57.68 |

| 7 | 51.01 | 64 | 57.05 |

| 8 | 37.11 | 51 | 62.49 |

| 9 | 37.08 | 56 | 68.68 |

| 10 | 47.89 | 58 | 55.07 |

| 11 | 38.63 | 52 | 61.61 |

| 12 | 44.81 | 63 | 63.93 |

| 13 | 47.92 | 76 | 72.11 |

| 14 | 49.46 | 74 | 68.03 |

| 15 | 38.63 | 61 | 71.81 |

| 16 | 37.08 | 49 | 60.09 |

| 17 | 40.17 | 45 | 50.94 |

| 18 | 38.63 | 43 | 50.62 |

| 19 | 46.35 | 59 | 57.88 |

| 20 | 47.89 | 55 | 52.22 |

| 21 | 46.35 | 59 | 57.88 |

| 22 | 43.26 | 47 | 49.40 |

| 23 | 43.29 | 51 | 53.57 |

| 24 | 52.55 | 67 | 57.98 |

| 25 | 49.46 | 61 | 56.08 |

| 26 | 44.81 | 63 | 63.93 |

| 27 | 43.26 | 50 | 52.56 |

| 28 | 46.35 | 69 | 67.69 |

| 29 | 40.21 | 57 | 64.48 |

| 30 | 49.46 | 74 | 68.03 |

| 31 | 41.74 | 61 | 66.46 |

| 32 | 40.29 | 49 | 55.30 |

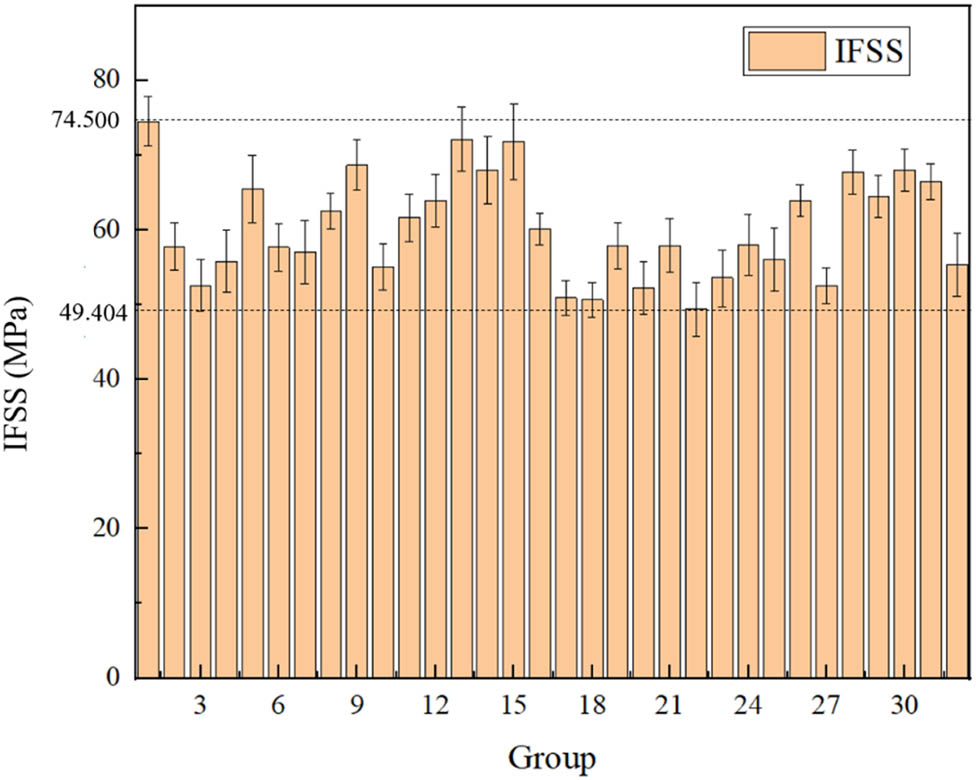

From Figure 7, it is evident that the IFSS values at 120°C exhibited greater dispersion than those at 23°C. While a few data points were outliers, most of the IFSS data ranged between 55 and 65 MPa. The standard deviation of this group of experimental data was calculated to be 3.6495 by analyzing the experimental data in this article. At 120°C, the average value of IFSS is 60 ± 4 MPa. The disparity in data was primarily due to the high viscosity of PEEK and the variability in external conditions during the micro debonding experiments. Moreover, at high temperatures, thermal residual compressive stress at the interface between the fibers and matrix causes increased frictional resistance and energy consumption during interface debonding. This study considered data that deviate from the mean IFSS value by more than 10% as unreliable due to the significant influence of external factors.

The peeling IFSS of the composites at 120°C.

PEEK materials are often utilized in environments below or above T g for a short period. To explore the effect of high temperature on the interfacial properties of composites, peeling experiments were conducted in this study in a high-temperature environment of 230°C. The experimental outcomes are presented in Table 3.

Peeling results at 230°C

| Group | Embedded length (μm) | Maximum shear force (mN) | Shear strength (MPa) |

|---|---|---|---|

| 1 | 63.36 | 22 | 15.79 |

| 2 | 68.01 | 27 | 18.06 |

| 3 | 54.07 | 26 | 20.68 |

| 4 | 116.25 | 80 | 31.29 |

| 5 | 68.05 | 24 | 16.04 |

| 6 | 94.24 | 58 | 27.99 |

| 7 | 97.64 | 64 | 29.81 |

| 8 | 95.99 | 53 | 25.11 |

| 9 | 91.27 | 62 | 30.89 |

| 10 | 89.73 | 82 | 41.56 |

| 11 | 88.08 | 70 | 36.14 |

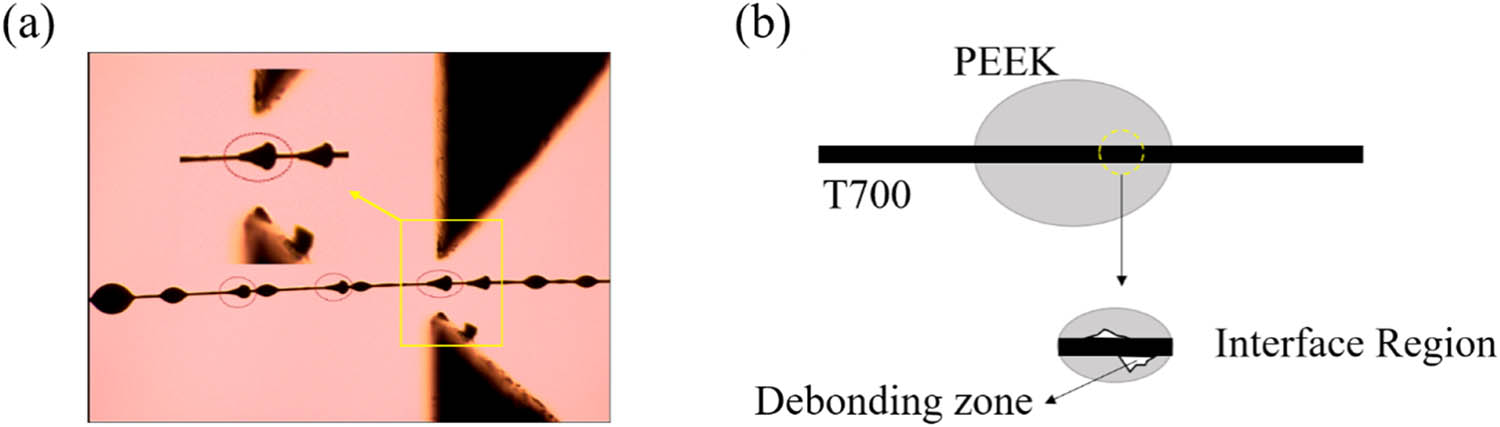

Because the glass transition temperature of PEEK material is 143°C, the material will become soft after exceeding the glass transition temperature. As shown in Figure 8, substantial variability and data inconsistency were exhibited in the IFSS values measured in the experiment at 230°C. The standard deviation of this group of experimental data was calculated to be 15.7165 by analyzing the experimental data in this article. Therefore, the average value at 230°C is 26 ± 20 MPa, indicating a high degree of data dispersion. Therefore, it can be inferred that the peel test method was no longer applicable at this temperature. Nevertheless, the experimental results indicated that the IFSS of composites at high temperature was considerably lower than that at low temperature.

The peeling IFSS of the composites at 230°C.

Based on the observation from the actual photo of the peeling experiment in Figure 9, it was found that at an elevated temperature of 230°C, the resin ball underwent significant deformation before debonding occurred at the fiber interface during the peeling process. The resin ball was extruded from a ball into a cone shape under the action of a fixed tool, and eventually detached from the fiber. This behavior was attributed to the transition of PEEK resin from a glassy state to a rubbery state beyond its glass transition temperature, leading to the magnification of bonding defects between resin and fiber at high temperature, and a subsequent rapid drop in the IFSS. This phenomenon was not limited to specific samples, but a universal behavior. Consequently, the resin ball peeling experiment was deemed unsuitable for investigating interfacial properties under high-temperature environments.

(a) Peeling experiments at 230°C and (b) interface defects.

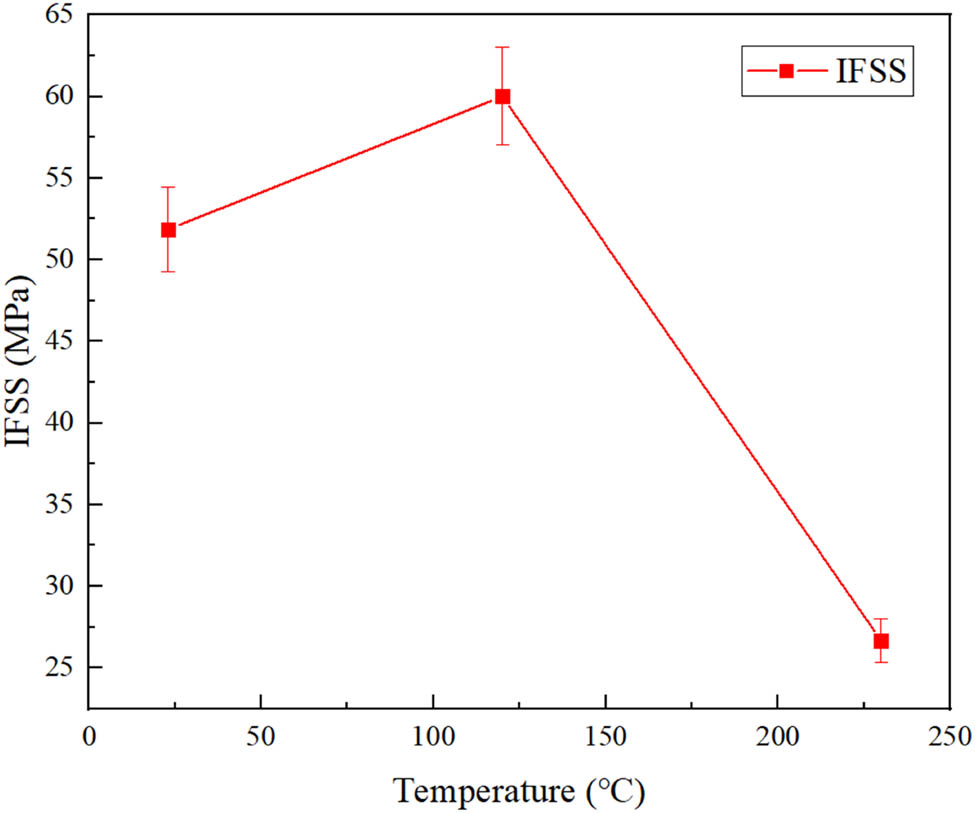

A line chart was plotted to display the average value of IFSS at each temperature, as presented in Figure 10. It is evident from Figure 10 that the IFSS of T700/PEEK composites was significantly influenced by temperature. Below 120°C, when the environmental temperature was lower than the glass transition temperature of PEEK resin, the IFSS of the composite exhibited a positive correlation with temperature. As the temperature surpassed the glass transition temperature, the IFSS exhibited a negative correlation with temperature, and the IFSS declined rapidly.

IFSS values at different temperatures.

The fiber/matrix interface determines the overall mechanical properties of fiber-reinforced composite materials, thereby reducing stress concentration and ensuring stress transfer from matrix to fiber and from fiber to fiber, mainly contributed by the chemical bonding and static friction between fibers and resin matrix. Due to the inherent poor interface bonding, the chemical bonding force can be ignored, which makes the static friction generated by radial compressive stress dominant in the IFSS of thermoplastic polymer matrix composites. However, the radial compressive stress between fibers and polymer matrix that varies with temperature causes IFSS to depend on the ambient temperature, which significantly affects the safety and durability of thermoplastic composites.

3.4 ILSS analysis

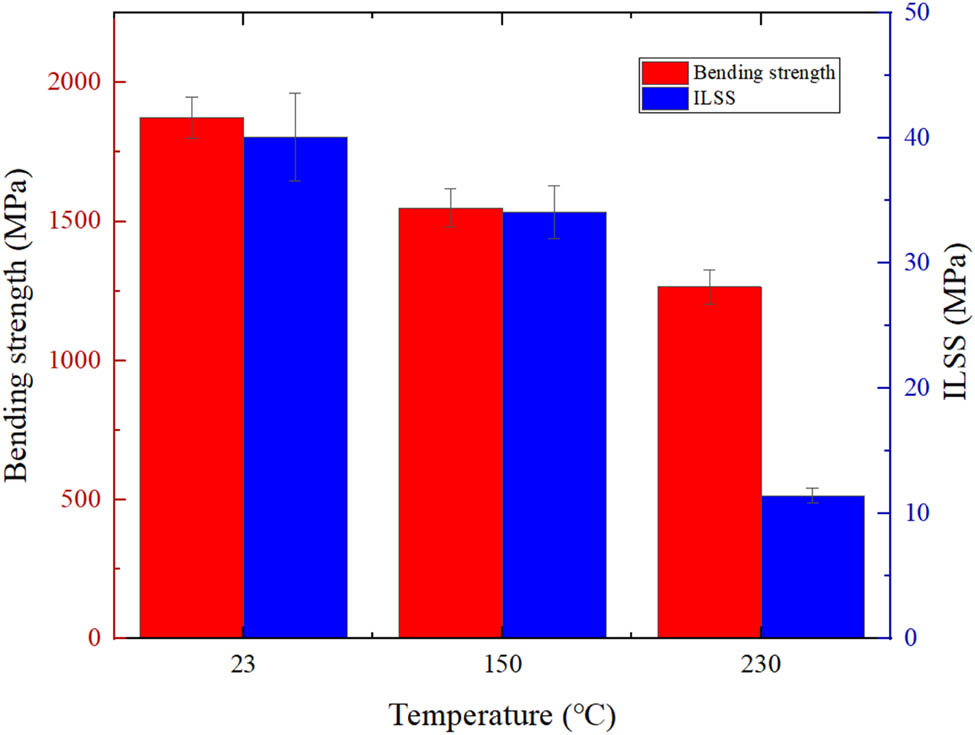

ILSS is a crucial mechanical property index of composite laminates and serves as a key reference for evaluating the hot-pressing process of prepreg. To investigate the effect of temperature on ILSS, delamination failure experiments of T700/PEEK composite laminates were conducted using a three-point bending test at various temperatures in this study. A fundamental basis for exploring the correlation between temperature and ILSS has been established by the results presented in Table 4.

Three-point bending experiment results

| Group | Temperature (°C) | Span (mm) | Maximum bending force (N) | Bending strength (MPa) | ILSS (MPa) |

|---|---|---|---|---|---|

| 1 | 23 | 50 | 2812.40 | 1886.80 | 39.81 |

| 2 | 23 | 50 | 2784.20 | 1783.83 | 38.53 |

| 3 | 23 | 50 | 3027.20 | 1952.16 | 41.97 |

| 4 | 150 | 50 | 2733.20 | 1621.20 | 36.31 |

| 5 | 150 | 50 | 2348.00 | 1478.65 | 32.23 |

| 6 | 150 | 50 | 2458.40 | 1546.32 | 33.71 |

| 7 | 230 | 50 | 790.29 | 1248.40 | 10.86 |

| 8 | 230 | 50 | 840.62 | 1289.40 | 11.73 |

| 9 | 230 | 50 | 834.04 | 1256.00 | 11.74 |

During the three-point bending test, all specimens exhibited a transition from initial linear elastic state to yield state, followed by a sharp drop in loading force, leading to fracture. In the bending process of carbon fiber reinforced polymer (CFRP) composites, the matrix mainly underwent shear deformation, with minor tensile and compressive deformation. The CFRP composites were found to exhibit significant bending deformation of the CFs, with only slight longitudinal deformation, and to have lower longitudinal stress levels and a reduced bending modulus as a result.

As shown in Table 4, at 23°C, the average bending force, bending strength, and ILSS of the composite laminates were 2,874 ± 153 N, 1,874 ± 91 MPa, and 40 ± 2 MPa, respectively. At 150°C, the PEEK material had surpassed its glass transition temperature and appeared in a rubberized state, with the average bending force, bending strength, and ILSS of the composite laminates being 2,513 ± 220 N, 1,548 ± 73 MPa, and 34 ± 2 MPa, respectively. At 230°C, the temperature far exceeded the glass transition temperature of PEEK, and the mechanical properties of the composite laminates significantly decreased, with the average bending force, bending strength, and ILSS being 821 ± 31 N, 1,264 ± 25 MPa, and 11 ± 1 MPa, respectively. The comparison of data at different temperatures is presented in Figure 11. The relationship between temperature and ILSS was revealed by the observed results, providing an important reference for evaluating the hot-pressing process of prepreg.

ILSS and bending strength at different temperatures.

The results presented in Figure 10 demonstrated a positive correlation between ILSS and bending strength of T700/PEEK composite laminates across different temperatures, with both properties decreasing as temperature increases. The sensitivity of the ILSS to temperature was more pronounced, with a 71.47% decrease observed between 23 and 230°C, compared to a 32.53% decrease in flexural strength over the same temperature range. These findings suggested that composite materials processed using the prepreg and molding methods were particularly susceptible to temperature-induced degradation, and thus may experience accelerated material failure. The degradation of the fiber/matrix interface and the thermal softening of the matrix resin are two important aspects that lead to sustained loss of ILSS and shear modulus in composite materials. This yield phenomenon is also caused by the considerable thermal softening of PEEK matrix at temperatures close to or higher than T g.

3.5 Microscopic analysis of damage

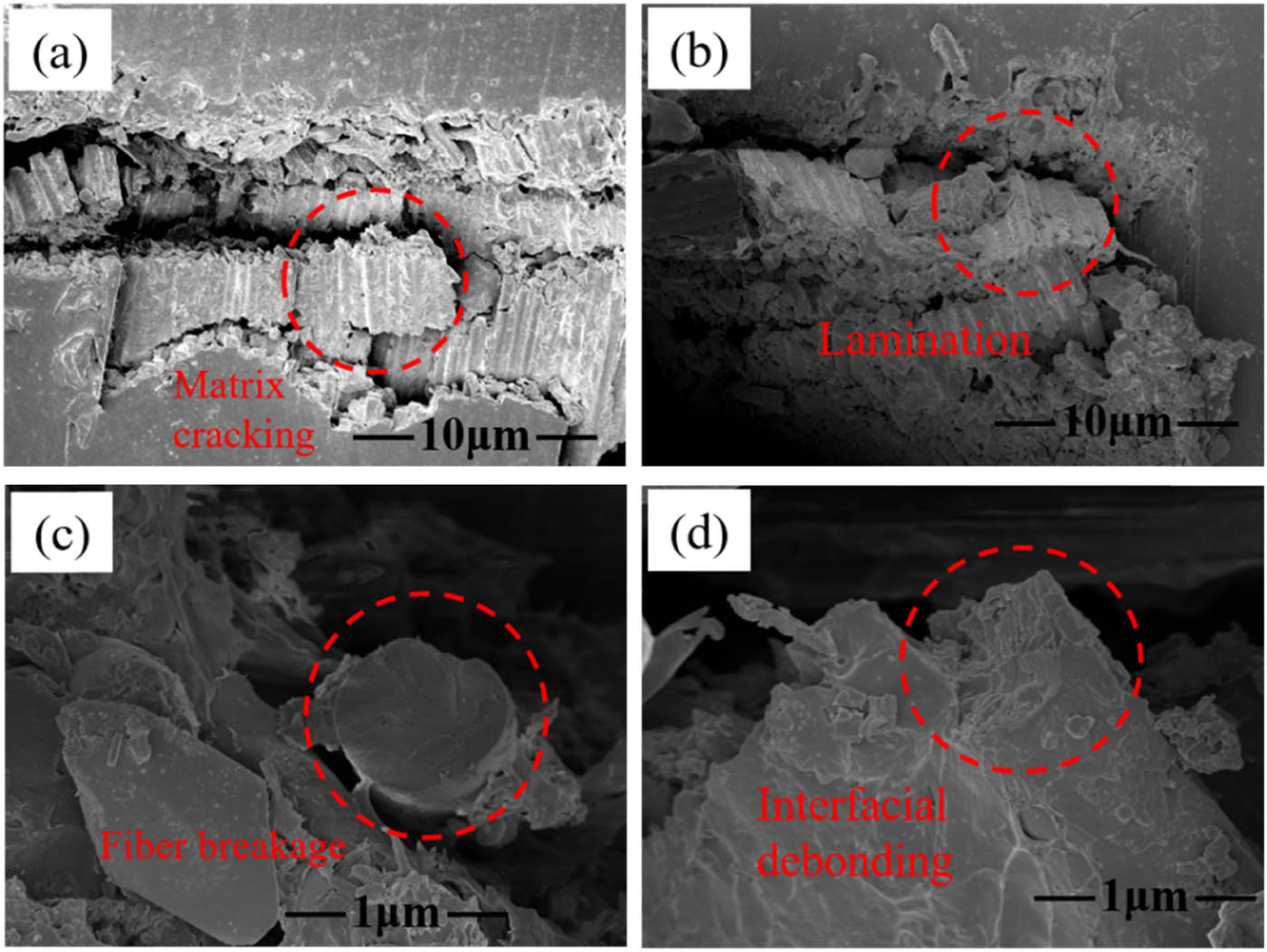

During the three-point bending test of T700/PEEK composite laminates, various failure modes such as matrix cracking, fiber fracture, and delamination were observed. In order to investigate the damage mechanisms of T700/PEEK composites, the SEM images of the selected specimens were obtained at 23°C and subjected them to SEM to observe the internal failure mechanisms at the damage location. The SEM scanning was conducted at an accelerated voltage of 3 kV with magnification factor of 50,000, and images were analyzed at two different scales of 10 and 1 μm, as shown in Figure 12.

The SEM images of (a) matrix cracking, (b) lamination, (c) fiber breakage, and (d) interfacial debending.

The SEM micrographs showed that the region enclosed by the red circle in Figure 12(a) exhibited good bonding between the fiber and matrix, with a compact texture. During the fracture process, a brittle fracture behavior was exhibited by the material, characterized by a relatively flat surface and blocky fragments, consistent with the experimental observation.

Figure 12(b) revealed that the T700/PEEK composite laminates experienced obvious delamination, with significant gaps between layers and matrix cracking and damage. The T700/PEEK composite material exhibits various forms of damage under load, including matrix cracking, fiber fracture, and delamination. From Figure 12(c), after the three-point bending test, the fibers fractured and the cross-section was relatively flat. As shown in Figure 12(d), during the three-point bending test, the deboning occurred between the fibers and the matrix, ultimately leading to delamination of the T700/PEEK composites.

4 Conclusion

The T700/PEEK continuous fiber-reinforced thermoplastic composites possess desirable properties such as high strength, light weight, and fatigue resistance, making them well-suited for applications in fields requiring superior materials. In order to investigate the correlation between interfacial properties of T700/PEEK composites and temperature, the IFSS and ILSS of T700/PEEK composites were measured using micro debonding and three-point bending tests, respectively.

The IFSS of T700/PEEK composites exhibited a positive correlation with temperature when measured below the glass transition temperature. A negative correlation was observed once the glass transition temperature was exceeded, leading to a rapid decline in strength. The ILSS of T700/PEEK composite laminates was negatively correlated with temperature, while the interlayer shear force was positively correlated with bending strength. At 23 and 230°C, the ILSS decreased by 71.47%, while the bending strength decreased by 32.53%. This can be explained by the change in the interface layer under the influence of temperature, resulting in a rapid decrease in the interfacial bonding force.

Acknowledgments

This work was supported by Aviation Science Foundation of China (Grant No. 202400540Q3001), National Natural Science Foundation of China (Grant No. 52475268), China Postdoctoral Science Foundation (Grant No. 2024M751851), Technology project of Jilin electric power science research institute Co., Ltd. (Grant No. KY-GS-23-02-03) and Shandong Province Postdoctoral Innovation Project (Grant No. SDCX-ZG-202400231). The authors thank the referees of this paper for their valuable and very helpful comments.

-

Funding information: This work was supported by National Natural Science Foundation of China (Grant No. 52475268), China Postdoctoral Science Foundation (Grant No. 2024M751851), Technology project of Jilin electric power science research institute Co., Ltd (Grant No. KY-GS-23-02-03), and Shandong Province Postdoctoral Innovation Project (Grant No. SDCX-ZG-202400231). The authors thank the referees of this article for their valuable and very helpful comments.

-

Author contributions: Xiaona Wei: conceptualization and resources. Weishi Chen: formal analysis and methodology. Long Chen: conceptualization, data curation, writing – review and editing, and methodology. Qiong Wu: data curation, formal analysis, and methodology. Yuhan Xin: data curation and writing – review and editing. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Yao, Z., C. Wang, J. Qin, S. Su, Y. Wang, Q. Wang, et al. Interfacial improvement of carbon fiber/epoxy composites using one-step method for grafting carbon nanotubes on the fibers at ultra-low temperatures. Carbon, Vol. 164, 2020, pp. 133–142.10.1016/j.carbon.2020.03.060Suche in Google Scholar

[2] Pu, Y., Z. Ma, L. Liu, Y. Bai, and Y. Huang. Weak hydrogen bonds on CF enhancing interfacial strength and toughness for CFRPs. Composites Science and Technology, Vol. 231, 2023, id. 109826.10.1016/j.compscitech.2022.109826Suche in Google Scholar

[3] Shi, X. H., Y. J. Xu, J. W. Long, Q. Zhao, X. M. Ding, L. Chen, et al. Layer-by-layer assembled flame-retardant architecture toward high-performance carbon fiber composite. Chemical Engineering Journal, Vol. 353, 2018, pp. 550–558.10.1016/j.cej.2018.07.146Suche in Google Scholar

[4] Seyyednourani, M., S. Akgun, H. Ulus, M. Yildiz, and H. S. Sas. Experimental investigation on Compression-After-Impact (CAI) response of aerospace grade thermoset composites under low-temperature conditions assisted with acoustic emission monitoring. Composite Structures, Vol. 231, 2023, id. 117260.10.1016/j.compstruct.2023.117260Suche in Google Scholar

[5] Yildirim, C., H. Ulus, B. Beylergil, A. Al-Nadhari, S. Topal, and M. Yildiz. Effect of atmospheric plasma treatment on Mode-I and Mode-II fracture toughness properties of adhesively bonded carbon fiber/PEKK composite joints. Engineering Fracture Mechanics, Vol. 289, 2023, id. 109463.10.1016/j.engfracmech.2023.109463Suche in Google Scholar

[6] Liu, X., Z. Shan, J. Liu, H. Xia, X. Ao, A. Zou, et al. Mechanical and electrical properties of additive manufactured high-performance continuous glass fiber reinforced PEEK composites. Composites Part B: Engineering, Vol. 247, 2022, id. 110292.10.1016/j.compositesb.2022.110292Suche in Google Scholar

[7] Kiss, P., J. Glinz, W. Stadlbauer, C. Burgstaller, and V. M. Archodoulaki. The effect of thermally desized carbon fibre reinforcement on the flexural and impact properties of PA6, PPS and PEEK composite laminates: A comparative study. Composites Part B: Engineering, Vol. 215, 2021, id. 108844.10.1016/j.compositesb.2021.108844Suche in Google Scholar

[8] Schwitalla, A. D., T. Zimmermann, T. Spintig, M. Abou-Emara, J. Lackmann, W. D. Müller, et al. Maximum insertion torque of a novel implant-abutment-interface design for PEEK dental implants. Journal of the Mechanical Behavior of Biomedical Materials, Vol. 77, 2018, pp. 85–89.10.1016/j.jmbbm.2017.09.005Suche in Google Scholar PubMed

[9] Wang, S., T. Wang, S. Zhang, Z. Dong, V. S. Chevali, Y. Yang, et al. Enhancing fiber-matrix interface in carbon fiber/poly ether ether ketone (CF/PEEK) composites by carbon nanotube reinforcement of crystalline PEEK sizing. Composites Part B: Engineering, Vol. 251, 2023, id. 110470.10.1016/j.compositesb.2022.110470Suche in Google Scholar

[10] Lu, Y., W. Li, J. Zhou, Y. Ren, X. Wang, J. Li, et al. Strengthening and toughening behaviours and mechanisms of carbon fiber reinforced polyetheretherketone composites (CF/PEEK). Composites Communications, Vol. 37, 2023, id. 101397.10.1016/j.coco.2022.101397Suche in Google Scholar

[11] Wu, D., Q. Miao, Z. Dai, F. Niu, and G. Ma. Effect of voids and crystallinity on the interlaminar shear strength of in-situ manufactured CF/PEEK laminates using repass treatment. Composites Science and Technology, Vol. 224, 2022, id. 109448.10.1016/j.compscitech.2022.109448Suche in Google Scholar

[12] Di Benedetto, R. M., A. Janotti, G. F. Gomes, A. C. Junior, and E. C. Botelho. Development of hybrid steel-commingled composites CF/PEEK/BwM by filament winding and thermoforming. Composites Science and Technology, Vol. 218, 2022, id. 109174.10.1016/j.compscitech.2021.109174Suche in Google Scholar

[13] Dai, J. N., S. Q. Kou, H. Y. Yang, Z. B. Xu, S. L. Shu, F. Qiu, et al. High-content continuous carbon fibers reinforced PEEK matrix composite with ultra-high mechanical and wear performance at elevated temperature. Composite Structures, Vol. 295, 2022, id. 115837.10.1016/j.compstruct.2022.115837Suche in Google Scholar

[14] Li, S., D. Chen, Y. Yuan, C. Gao, Y. Cui, H. Wang, et al. Influence of flexible molecular structure on the cryogenic mechanical properties of epoxy matrix and carbon fiber/epoxy composite laminate. Materials Design, Vol. 195, 2020, id. 109028.10.1016/j.matdes.2020.109028Suche in Google Scholar

[15] Hassan, E. A., D. Ge, S. Zhu, L. Yang, J. Zhou, and M. Yu. Enhancing CF/PEEK composites by CF decoration with polyimide and loosely-packed CNT arrays. Composites Part A: Applied Science and Manufacturing, Vol. 127, 2019, id. 105613.10.1016/j.compositesa.2019.105613Suche in Google Scholar

[16] Hassan, E. A., L. Yang, T. H. Elagib, D. Ge, X. Lv, J. Zhou, et al. Synergistic effect of hydrogen bonding and π-π stacking in interface of CF/PEEK composites. Composites Part B: Engineering, Vol. 171, 2019, pp. 70–77.10.1016/j.compositesb.2019.04.015Suche in Google Scholar

[17] Jin, Z., Z. Han, C. Chang, S. Sun, and H. Fu. Review of methods for enhancing interlaminar mechanical properties of fiber-reinforced thermoplastic composites: Interfacial modification, nanofilling and forming technology. Composites Science and Technology, Vol. 228, 2022, id. 109660.10.1016/j.compscitech.2022.109660Suche in Google Scholar

[18] Qiu, X., Y. Gao, X. Wang, S. Tang, A. Gu, M. Xie, et al. Cyclic (phenylene sulfide) treated carbon fiber for facile preparation of high performance PEEK based anti-wear composites. Materials Chemistry and Physics, Vol. 278, 2022, id. 125665.10.1016/j.matchemphys.2021.125665Suche in Google Scholar

[19] Yao, C., Z. Qi, W. Chen, and C. Zhang. Experimental study on CF/PEEK thermoplastic fastener: Effects of fastener matrix crystallinity and fibre content on the strength of single-lap joint. Composites Part B: Engineering, Vol. 213, 2021, id. 108737.10.1016/j.compositesb.2021.108737Suche in Google Scholar

[20] Tan, C., J. Su, Y. Liu, Z. Feng, X. Song, X. Wang, et al. Enhanced interfacial bonding strength of laser bonded titanium alloy/CFRTP joint via hydrogen bonds interaction. Composites Part B: Engineering, Vol. 239, 2022, id. 109966.10.1016/j.compositesb.2022.109966Suche in Google Scholar

[21] Yan, T., F. Yan, S. Li, M. Li, Y. Liu, M. Zhang, et al. Interfacial enhancement of CF/PEEK composites by modifying water-based PEEK-NH2 sizing agent. Composites Part B Engineering, Vol. 199, 2020, id. 108258.10.1016/j.compositesb.2020.108258Suche in Google Scholar

[22] Wu, Q., H. Bai, X. Yang, and J. Zhu. Significantly increasing the interfacial adhesion of carbon fiber composites via constructing a synergistic hydrogen bonding network by vacuum filtration. Composites Part B: Engineering, Vol. 225, 2021, id. 109300.10.1016/j.compositesb.2021.109300Suche in Google Scholar

[23] Hu, J., F. Yan, H. Liu, L. Zhao, Z. Li, Y. Liu, et al. Water-based PEKC-COOH sizing agent for enhancing the interfacial adhesion of carbon fiber/polyether-ether-ketone composites. Composites Part B: Engineering, Vol. 225, 2021, id. 109279.10.1016/j.compositesb.2021.109279Suche in Google Scholar

[24] Mutlu, G., F. Yıldırım, H. Ulus, and V. Eskizeybek. Coating graphene nanoplatelets onto carbon fabric with controlled thickness for improved mechanical performance and EMI shielding effectiveness of carbon/epoxy composites. Engineering Fracture Mechanics, Vol. 284, 2023, id. 109271.10.1016/j.engfracmech.2023.109271Suche in Google Scholar

[25] Ulus, H. and H. B. Kaybal. Out-of-plane static loading performance of lightweight aluminum/composite FML structures for retrofitting applications: Effectiveness of bonded, bolted and hybrid bonded/bolted joining techniques under hydrothermal aging environment. Construction and Building Materials, Vol. 403, 2023, id. 133124.10.1016/j.conbuildmat.2023.133124Suche in Google Scholar

[26] Tınastepe, M. T., H. B. Kaybal, H. Ulus, M. O. Erdal, M. E. Çetin, and A. Avcı. Quasi-Static tensile loading performance of Bonded, Bolted, and hybrid Bonded-Bolted Carbon-to-Carbon composite Joints: Effect of recycled polystyrene nanofiber interleaving. Composite Structures, Vol. 323, 2023, id. 117445.10.1016/j.compstruct.2023.117445Suche in Google Scholar

[27] Schneider, M., M. Weiser, S. Ferl, C. Krasmann, A. Potthoff, K. Voigt, et al. Facile deposition of multiwalled carbon nanotubes via electrophoretic deposition in an environmentally friendly suspension. Surface and Coatings Technology, Vol. 406, 2021, id. 126741.10.1016/j.surfcoat.2020.126741Suche in Google Scholar

[28] Li, L., W. Liu, F. Yang, W. Jiao, L. Hao, and R. Wang. Interfacial reinforcement of hybrid composite by electrophoretic deposition for vertically aligned carbon nanotubes on carbon fiber. Composites Science and Technology, Vol. 187, 2020, id. 107946.10.1016/j.compscitech.2019.107946Suche in Google Scholar

[29] An, Q., S. Tamrakar, J. W. Gillespie Jr, A. N. Rider, and E. T. Thostenson. Tailored glass fiber interphases via electrophoretic deposition of carbon nanotubes: Fiber and interphase characterization. Composites Science and Technology, Vol. 166, 2018, pp. 131–139.10.1016/j.compscitech.2018.01.003Suche in Google Scholar

[30] Wu, Z., H. Cui, L. Chen, D. Jiang, L. Weng, Y. Ma, et al. Interfacially reinforced unsaturated polyester carbon fiber composites with a vinyl ester-carbon nanotube sizing agent. Composites Science and Technology, Vol. 164, 2018, pp. 195–203.10.1016/j.compscitech.2018.05.051Suche in Google Scholar

[31] Yuan, X., J. Jiang, H. Wei, C. Yuan, M. Wang, D. Zhang, et al. PAI/MXene sizing-based dual functional coating for carbon fiber/PEEK composite. Composites Science and Technology, Vol. 201, 2020, id. 108496.10.1016/j.compscitech.2020.108496Suche in Google Scholar

[32] Alexandre, M. A., E. Dantras, C. Lacabanne, E. Perez, S. Franceschi, and D. Coudeyre. Effect of PEKK oligomers sizing on the dynamic mechanical behavior of poly (ether ketone ketone)/carbon fiber composites. Journal of Applied Polymer Science, Vol. 137, 2020, id. 48818.10.1002/app.48818Suche in Google Scholar

[33] Hassan, E. A., D. Ge, L. Yang, J. Zhou, M. Liu, M. Yu, et al. Highly boosting the interlaminar shear strength of CF/PEEK composites via introduction of PEKK onto activated CF. Composites Part A: Applied Science and Manufacturing, Vol. 112, 2018, pp. 155–160.10.1016/j.compositesa.2018.05.029Suche in Google Scholar

[34] Gao, X., Z. Huang, H. Zhou, D. Li, Y. Li, and Y. Wang. Higher mechanical performances of CF/PEEK composite laminates via reducing interlayer porosity based on the affinity of functionals-PEEK. Polymer Composites, Vol. 40, 2019, pp. 3749–3757.10.1002/pc.25236Suche in Google Scholar

[35] Wang, T., Y. Jiao, Z. Mi, J. Li, D. Wang, X. Zhao, et al. PEEK composites with polyimide sizing SCF as reinforcement: Preparation, characterization, and mechanical properties. High Performance Polymers, Vol. 32, 2019, pp. 383–393.10.1177/0954008319867383Suche in Google Scholar

[36] Chen, J., K. Wang, and Y. Zhao. Enhanced interfacial interactions of carbon fiber reinforced PEEK composites by regulating PEI and graphene oxide complex sizing at the interface. Composites Science and Technology, Vol. 154, 2018, pp. 175–186.10.1016/j.compscitech.2017.11.005Suche in Google Scholar

[37] Hassan, E. A., T. H. Elagib, H. Memon, M. Yu, and S. Zhu. Surface modification of carbon fibers by grafting PEEK-NH2 for improving interfacial adhesion with polyetheretherketone. Materials, Vol. 12, 2019, id. 778.10.3390/ma12050778Suche in Google Scholar PubMed PubMed Central

[38] Liu, H., X. Su, J. Tao, R. Fu, C. You, and X. Chen. Effect of SiO2 nanoparticles-decorated SCF on mechanical and tribological properties of cenosphere/SCF/PEEK composites. Journal of Applied Polymer Science, Vol. 137, 2020, id. 48749.10.1002/app.48749Suche in Google Scholar

[39] Wang, X., Z. Huang, M. Lai, L. Jiang, Y. Zhang, and H. Zhou. Highly enhancing the interfacial strength of CF/PEEK composites by introducing PAIK onto diazonium functionalized carbon fibers. Applied Surface Science, Vol. 510, 2020, id. 145400.10.1016/j.apsusc.2020.145400Suche in Google Scholar

[40] Zhang, C., Y. Duan, H. Xiao, B. Wang, Z. Xin, G. Liu, et al. Preparation of MWCNTs/CF/PEEK multi-scale composites with good mechanical and electrical conductivity by a two-step process of AFP and out-of-autoclave tempering. Composites Part C: Open Access, Vol. 9, 2022, id. 100321.10.1016/j.jcomc.2022.100321Suche in Google Scholar

[41] Lyu, H., N. Jiang, J. Hu, Y. Li, N. Zhou, and D. Zhang. Preparing water-based phosphorylated PEEK sizing agent for CF/PEEK interface enhancement. Composites Science and Technology, Vol. 217, 2022, id. 109096.10.1016/j.compscitech.2021.109096Suche in Google Scholar

[42] Qin, Y., G. Ge, J. Yun, X. Tian, X. Liu, J. Han, et al. Enhanced impregnation behavior and interfacial bonding in CF/PEEK prepreg filaments for 3D printing application. Journal of Materials Research and Technology, Vol. 20, 2022, pp. 4608–4623.10.1016/j.jmrt.2022.09.005Suche in Google Scholar

[43] Sharma, M., J. Bijwe, E. Mäder, and K. Kunze. Strengthening of CF/PEEK interface to improve the tribological performance in low amplitude oscillating wear mode. Wear, Vol. 301, 2013, pp. 735–739.10.1016/j.wear.2012.12.006Suche in Google Scholar

[44] Wang, S., S. Zhang, Y. Yang, Z. Dong, and G. Wang. Direct electrochemical grafting of crystalline PAEK macromolecule on carbon fiber to enhance the interfacial properties of PEEK/CF composites. Composites Science and Technology, Vol. 220, 2022, id. 109262.10.1016/j.compscitech.2022.109262Suche in Google Scholar

[45] Fujihara, K., Z. Huang, S. Ramakrishna, and H. Hamada. Influence of processing conditions on bending property of continuous carbon fiber reinforced PEEK composites. Composites Science and Technology, Vol. 64, 2004, pp. 2525–2534.10.1016/j.compscitech.2004.05.014Suche in Google Scholar

[46] Yao, S. S., F. L. Jin, K. Y. Rhee, D. Hui, and S. J. Park. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Composites Part B: Engineering, Vol. 142, 2018, pp. 241–250.10.1016/j.compositesb.2017.12.007Suche in Google Scholar

[47] Wang, X., W. Jiang, Q. He, C. Chen, M. Zhang, Z. Huang, et al. Enhanced interlaminar fracture toughness of CF/PEEK laminates by interleaving CNT-decorated PEEK films. Polymer Testing, Vol. 126, 2023, id. 108159.10.1016/j.polymertesting.2023.108159Suche in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Review Articles

- Effect of superplasticizer in geopolymer and alkali-activated cement mortar/concrete: A review

- Experimenting the influence of corncob ash on the mechanical strength of slag-based geopolymer concrete

- Powder metallurgy processing of high entropy alloys: Bibliometric analysis and systematic review

- Exploring the potential of agricultural waste as an additive in ultra-high-performance concrete for sustainable construction: A comprehensive review

- A review on partial substitution of nanosilica in concrete

- Foam concrete for lightweight construction applications: A comprehensive review of the research development and material characteristics

- Modification of PEEK for implants: Strategies to improve mechanical, antibacterial, and osteogenic properties

- Interfacing the IoT in composite manufacturing: An overview

- Advances in processing and ablation properties of carbon fiber reinforced ultra-high temperature ceramic composites

- Advancing auxetic materials: Emerging development and innovative applications

- Revolutionizing energy harvesting: A comprehensive review of thermoelectric devices

- Exploring polyetheretherketone in dental implants and abutments: A focus on biomechanics and finite element methods

- Smart technologies and textiles and their potential use and application in the care and support of elderly individuals: A systematic review

- Reinforcement mechanisms and current research status of silicon carbide whisker-reinforced composites: A comprehensive review

- Innovative eco-friendly bio-composites: A comprehensive review of the fabrication, characterization, and applications

- Review on geopolymer concrete incorporating Alccofine-1203

- Advancements in surface treatments for aluminum alloys in sports equipment

- Ionic liquid-modified carbon-based fillers and their polymer composites – A Raman spectroscopy analysis

- Emerging boron nitride nanosheets: A review on synthesis, corrosion resistance coatings, and their impacts on the environment and health

- Mechanism, models, and influence of heterogeneous factors of the microarc oxidation process: A comprehensive review

- Synthesizing sustainable construction paradigms: A comprehensive review and bibliometric analysis of granite waste powder utilization and moisture correction in concrete

- 10.1515/rams-2025-0086

- Research Articles

- Coverage and reliability improvement of copper metallization layer in through hole at BGA area during load board manufacture

- Study on dynamic response of cushion layer-reinforced concrete slab under rockfall impact based on smoothed particle hydrodynamics and finite-element method coupling

- Study on the mechanical properties and microstructure of recycled brick aggregate concrete with waste fiber

- Multiscale characterization of the UV aging resistance and mechanism of light stabilizer-modified asphalt

- Characterization of sandwich materials – Nomex-Aramid carbon fiber performances under mechanical loadings: Nonlinear FE and convergence studies

- Effect of grain boundary segregation and oxygen vacancy annihilation on aging resistance of cobalt oxide-doped 3Y-TZP ceramics for biomedical applications

- Mechanical damage mechanism investigation on CFRP strengthened recycled red brick concrete

- Finite element analysis of deterioration of axial compression behavior of corroded steel-reinforced concrete middle-length columns

- Grinding force model for ultrasonic assisted grinding of γ-TiAl intermetallic compounds and experimental validation

- Enhancement of hardness and wear strength of pure Cu and Cu–TiO2 composites via a friction stir process while maintaining electrical resistivity

- Effect of sand–precursor ratio on mechanical properties and durability of geopolymer mortar with manufactured sand

- Research on the strength prediction for pervious concrete based on design porosity and water-to-cement ratio

- Development of a new damping ratio prediction model for recycled aggregate concrete: Incorporating modified admixtures and carbonation effects

- Exploring the viability of AI-aided genetic algorithms in estimating the crack repair rate of self-healing concrete

- Modification of methacrylate bone cement with eugenol – A new material with antibacterial properties

- Numerical investigations on constitutive model parameters of HRB400 and HTRB600 steel bars based on tensile and fatigue tests

- Research progress on Fe3+-activated near-infrared phosphor

- Discrete element simulation study on effects of grain preferred orientation on micro-cracking and macro-mechanical behavior of crystalline rocks

- Ultrasonic resonance evaluation method for deep interfacial debonding defects of multilayer adhesive bonded materials

- Effect of impurity components in titanium gypsum on the setting time and mechanical properties of gypsum-slag cementitious materials

- Bending energy absorption performance of composite fender piles with different winding angles

- Theoretical study of the effect of orientations and fibre volume on the thermal insulation capability of reinforced polymer composites

- Synthesis and characterization of a novel ternary magnetic composite for the enhanced adsorption capacity to remove organic dyes

- Couple effects of multi-impact damage and CAI capability on NCF composites

- Mechanical testing and engineering applicability analysis of SAP concrete used in buffer layer design for tunnels in active fault zones

- Investigating the rheological characteristics of alkali-activated concrete using contemporary artificial intelligence approaches

- Integrating micro- and nanowaste glass with waste foundry sand in ultra-high-performance concrete to enhance material performance and sustainability

- Effect of water immersion on shear strength of epoxy adhesive filled with graphene nanoplatelets

- Impact of carbon content on the phase structure and mechanical properties of TiBCN coatings via direct current magnetron sputtering

- Investigating the anti-aging properties of asphalt modified with polyphosphoric acid and tire pyrolysis oil

- Biomedical and therapeutic potential of marine-derived Pseudomonas sp. strain AHG22 exopolysaccharide: A novel bioactive microbial metabolite

- Effect of basalt fiber length on the behavior of natural hydraulic lime-based mortars

- Optimizing the performance of TPCB/SCA composite-modified asphalt using improved response surface methodology

- Compressive strength of waste-derived cementitious composites using machine learning

- Melting phenomenon of thermally stratified MHD Powell–Eyring nanofluid with variable porosity past a stretching Riga plate

- Development and characterization of a coaxial strain-sensing cable integrated steel strand for wide-range stress monitoring

- Compressive and tensile strength estimation of sustainable geopolymer concrete using contemporary boosting ensemble techniques

- Customized 3D printed porous titanium scaffolds with nanotubes loading antibacterial drugs for bone tissue engineering

- Facile design of PTFE-kaolin-based ternary nanocomposite as a hydrophobic and high corrosion-barrier coating

- Effects of C and heat treatment on microstructure, mechanical, and tribo-corrosion properties of VAlTiMoSi high-entropy alloy coating

- Study on the damage mechanism and evolution model of preloaded sandstone subjected to freezing–thawing action based on the NMR technology

- Promoting low carbon construction using alkali-activated materials: A modeling study for strength prediction and feature interaction

- Entropy generation analysis of MHD convection flow of hybrid nanofluid in a wavy enclosure with heat generation and thermal radiation

- Friction stir welding of dissimilar Al–Mg alloys for aerospace applications: Prospects and future potential

- Fe nanoparticle-functionalized ordered mesoporous carbon with tailored mesostructures and their applications in magnetic removal of Ag(i)

- Study on physical and mechanical properties of complex-phase conductive fiber cementitious materials

- Evaluating the strength loss and the effectiveness of glass and eggshell powder for cement mortar under acidic conditions

- Effect of fly ash on properties and hydration of calcium sulphoaluminate cement-based materials with high water content

- Analyzing the efficacy of waste marble and glass powder for the compressive strength of self-compacting concrete using machine learning strategies

- Experimental study on municipal solid waste incineration ash micro-powder as concrete admixture

- Parameter optimization for ultrasonic-assisted grinding of γ-TiAl intermetallics: A gray relational analysis approach with surface integrity evaluation

- Producing sustainable binding materials using marble waste blended with fly ash and rice husk ash for building materials

- Effect of steam curing system on compressive strength of recycled aggregate concrete

- A sawtooth constitutive model describing strain hardening and multiple cracking of ECC under uniaxial tension

- Predicting mechanical properties of sustainable green concrete using novel machine learning: Stacking and gene expression programming

- Toward sustainability: Integrating experimental study and data-driven modeling for eco-friendly paver blocks containing plastic waste

- A numerical analysis of the rotational flow of a hybrid nanofluid past a unidirectional extending surface with velocity and thermal slip conditions

- A magnetohydrodynamic flow of a water-based hybrid nanofluid past a convectively heated rotating disk surface: A passive control of nanoparticles

- Prediction of flexural strength of concrete with eggshell and glass powders: Advanced cutting-edge approach for sustainable materials

- Efficacy of sustainable cementitious materials on concrete porosity for enhancing the durability of building materials

- Phase and microstructural characterization of swat soapstone (Mg3Si4O10(OH)2)

- Effect of waste crab shell powder on matrix asphalt

- Improving effect and mechanism on service performance of asphalt binder modified by PW polymer

- Influence of pH on the synthesis of carbon spheres and the application of carbon sphere-based solid catalysts in esterification

- Experimenting the compressive performance of low-carbon alkali-activated materials using advanced modeling techniques

- Thermogravimetric (TG/DTG) characterization of cold-pressed oil blends and Saccharomyces cerevisiae-based microcapsules obtained with them

- Investigation of temperature effect on thermo-mechanical property of carbon fiber/PEEK composites

- Computational approaches for structural analysis of wood specimens

- Integrated structure–function design of 3D-printed porous polydimethylsiloxane for superhydrophobic engineering

- Exploring the impact of seashell powder and nano-silica on ultra-high-performance self-curing concrete: Insights into mechanical strength, durability, and high-temperature resilience

- Axial compression damage constitutive model and damage characteristics of fly ash/silica fume modified magnesium phosphate cement after being treated at different temperatures

- Integrating testing and modeling methods to examine the feasibility of blended waste materials for the compressive strength of rubberized mortar

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part II

- Energy absorption of gradient triply periodic minimal surface structure manufactured by stereolithography

- Marine polymers in tissue bioprinting: Current achievements and challenges

- Quick insight into the dynamic dimensions of 4D printing in polymeric composite mechanics

- Recent advances in 4D printing of hydrogels

- Mechanically sustainable and primary recycled thermo-responsive ABS–PLA polymer composites for 4D printing applications: Fabrication and studies

- Special Issue on Materials and Technologies for Low-carbon Biomass Processing and Upgrading

- Low-carbon embodied alkali-activated materials for sustainable construction: A comparative study of single and ensemble learners

- Study on bending performance of prefabricated glulam-cross laminated timber composite floor

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part I

- Supplementary cementitious materials-based concrete porosity estimation using modeling approaches: A comparative study of GEP and MEP

- Modeling the strength parameters of agro waste-derived geopolymer concrete using advanced machine intelligence techniques

- Promoting the sustainable construction: A scientometric review on the utilization of waste glass in concrete

- Incorporating geranium plant waste into ultra-high performance concrete prepared with crumb rubber as fine aggregate in the presence of polypropylene fibers

- Investigation of nano-basic oxygen furnace slag and nano-banded iron formation on properties of high-performance geopolymer concrete

- Effect of incorporating ultrafine palm oil fuel ash on the resistance to corrosion of steel bars embedded in high-strength green concrete

- Influence of nanomaterials on properties and durability of ultra-high-performance geopolymer concrete

- Influence of palm oil ash and palm oil clinker on the properties of lightweight concrete

Artikel in diesem Heft

- Review Articles

- Effect of superplasticizer in geopolymer and alkali-activated cement mortar/concrete: A review

- Experimenting the influence of corncob ash on the mechanical strength of slag-based geopolymer concrete

- Powder metallurgy processing of high entropy alloys: Bibliometric analysis and systematic review

- Exploring the potential of agricultural waste as an additive in ultra-high-performance concrete for sustainable construction: A comprehensive review

- A review on partial substitution of nanosilica in concrete

- Foam concrete for lightweight construction applications: A comprehensive review of the research development and material characteristics

- Modification of PEEK for implants: Strategies to improve mechanical, antibacterial, and osteogenic properties

- Interfacing the IoT in composite manufacturing: An overview

- Advances in processing and ablation properties of carbon fiber reinforced ultra-high temperature ceramic composites

- Advancing auxetic materials: Emerging development and innovative applications

- Revolutionizing energy harvesting: A comprehensive review of thermoelectric devices

- Exploring polyetheretherketone in dental implants and abutments: A focus on biomechanics and finite element methods

- Smart technologies and textiles and their potential use and application in the care and support of elderly individuals: A systematic review

- Reinforcement mechanisms and current research status of silicon carbide whisker-reinforced composites: A comprehensive review

- Innovative eco-friendly bio-composites: A comprehensive review of the fabrication, characterization, and applications

- Review on geopolymer concrete incorporating Alccofine-1203

- Advancements in surface treatments for aluminum alloys in sports equipment

- Ionic liquid-modified carbon-based fillers and their polymer composites – A Raman spectroscopy analysis

- Emerging boron nitride nanosheets: A review on synthesis, corrosion resistance coatings, and their impacts on the environment and health

- Mechanism, models, and influence of heterogeneous factors of the microarc oxidation process: A comprehensive review

- Synthesizing sustainable construction paradigms: A comprehensive review and bibliometric analysis of granite waste powder utilization and moisture correction in concrete

- 10.1515/rams-2025-0086

- Research Articles

- Coverage and reliability improvement of copper metallization layer in through hole at BGA area during load board manufacture

- Study on dynamic response of cushion layer-reinforced concrete slab under rockfall impact based on smoothed particle hydrodynamics and finite-element method coupling

- Study on the mechanical properties and microstructure of recycled brick aggregate concrete with waste fiber

- Multiscale characterization of the UV aging resistance and mechanism of light stabilizer-modified asphalt

- Characterization of sandwich materials – Nomex-Aramid carbon fiber performances under mechanical loadings: Nonlinear FE and convergence studies

- Effect of grain boundary segregation and oxygen vacancy annihilation on aging resistance of cobalt oxide-doped 3Y-TZP ceramics for biomedical applications

- Mechanical damage mechanism investigation on CFRP strengthened recycled red brick concrete

- Finite element analysis of deterioration of axial compression behavior of corroded steel-reinforced concrete middle-length columns

- Grinding force model for ultrasonic assisted grinding of γ-TiAl intermetallic compounds and experimental validation

- Enhancement of hardness and wear strength of pure Cu and Cu–TiO2 composites via a friction stir process while maintaining electrical resistivity

- Effect of sand–precursor ratio on mechanical properties and durability of geopolymer mortar with manufactured sand

- Research on the strength prediction for pervious concrete based on design porosity and water-to-cement ratio

- Development of a new damping ratio prediction model for recycled aggregate concrete: Incorporating modified admixtures and carbonation effects

- Exploring the viability of AI-aided genetic algorithms in estimating the crack repair rate of self-healing concrete

- Modification of methacrylate bone cement with eugenol – A new material with antibacterial properties

- Numerical investigations on constitutive model parameters of HRB400 and HTRB600 steel bars based on tensile and fatigue tests

- Research progress on Fe3+-activated near-infrared phosphor

- Discrete element simulation study on effects of grain preferred orientation on micro-cracking and macro-mechanical behavior of crystalline rocks

- Ultrasonic resonance evaluation method for deep interfacial debonding defects of multilayer adhesive bonded materials

- Effect of impurity components in titanium gypsum on the setting time and mechanical properties of gypsum-slag cementitious materials

- Bending energy absorption performance of composite fender piles with different winding angles

- Theoretical study of the effect of orientations and fibre volume on the thermal insulation capability of reinforced polymer composites

- Synthesis and characterization of a novel ternary magnetic composite for the enhanced adsorption capacity to remove organic dyes

- Couple effects of multi-impact damage and CAI capability on NCF composites

- Mechanical testing and engineering applicability analysis of SAP concrete used in buffer layer design for tunnels in active fault zones

- Investigating the rheological characteristics of alkali-activated concrete using contemporary artificial intelligence approaches

- Integrating micro- and nanowaste glass with waste foundry sand in ultra-high-performance concrete to enhance material performance and sustainability

- Effect of water immersion on shear strength of epoxy adhesive filled with graphene nanoplatelets

- Impact of carbon content on the phase structure and mechanical properties of TiBCN coatings via direct current magnetron sputtering

- Investigating the anti-aging properties of asphalt modified with polyphosphoric acid and tire pyrolysis oil

- Biomedical and therapeutic potential of marine-derived Pseudomonas sp. strain AHG22 exopolysaccharide: A novel bioactive microbial metabolite

- Effect of basalt fiber length on the behavior of natural hydraulic lime-based mortars

- Optimizing the performance of TPCB/SCA composite-modified asphalt using improved response surface methodology

- Compressive strength of waste-derived cementitious composites using machine learning

- Melting phenomenon of thermally stratified MHD Powell–Eyring nanofluid with variable porosity past a stretching Riga plate

- Development and characterization of a coaxial strain-sensing cable integrated steel strand for wide-range stress monitoring

- Compressive and tensile strength estimation of sustainable geopolymer concrete using contemporary boosting ensemble techniques

- Customized 3D printed porous titanium scaffolds with nanotubes loading antibacterial drugs for bone tissue engineering

- Facile design of PTFE-kaolin-based ternary nanocomposite as a hydrophobic and high corrosion-barrier coating

- Effects of C and heat treatment on microstructure, mechanical, and tribo-corrosion properties of VAlTiMoSi high-entropy alloy coating

- Study on the damage mechanism and evolution model of preloaded sandstone subjected to freezing–thawing action based on the NMR technology

- Promoting low carbon construction using alkali-activated materials: A modeling study for strength prediction and feature interaction

- Entropy generation analysis of MHD convection flow of hybrid nanofluid in a wavy enclosure with heat generation and thermal radiation

- Friction stir welding of dissimilar Al–Mg alloys for aerospace applications: Prospects and future potential

- Fe nanoparticle-functionalized ordered mesoporous carbon with tailored mesostructures and their applications in magnetic removal of Ag(i)

- Study on physical and mechanical properties of complex-phase conductive fiber cementitious materials

- Evaluating the strength loss and the effectiveness of glass and eggshell powder for cement mortar under acidic conditions

- Effect of fly ash on properties and hydration of calcium sulphoaluminate cement-based materials with high water content

- Analyzing the efficacy of waste marble and glass powder for the compressive strength of self-compacting concrete using machine learning strategies

- Experimental study on municipal solid waste incineration ash micro-powder as concrete admixture

- Parameter optimization for ultrasonic-assisted grinding of γ-TiAl intermetallics: A gray relational analysis approach with surface integrity evaluation

- Producing sustainable binding materials using marble waste blended with fly ash and rice husk ash for building materials

- Effect of steam curing system on compressive strength of recycled aggregate concrete

- A sawtooth constitutive model describing strain hardening and multiple cracking of ECC under uniaxial tension

- Predicting mechanical properties of sustainable green concrete using novel machine learning: Stacking and gene expression programming

- Toward sustainability: Integrating experimental study and data-driven modeling for eco-friendly paver blocks containing plastic waste

- A numerical analysis of the rotational flow of a hybrid nanofluid past a unidirectional extending surface with velocity and thermal slip conditions

- A magnetohydrodynamic flow of a water-based hybrid nanofluid past a convectively heated rotating disk surface: A passive control of nanoparticles

- Prediction of flexural strength of concrete with eggshell and glass powders: Advanced cutting-edge approach for sustainable materials

- Efficacy of sustainable cementitious materials on concrete porosity for enhancing the durability of building materials

- Phase and microstructural characterization of swat soapstone (Mg3Si4O10(OH)2)

- Effect of waste crab shell powder on matrix asphalt

- Improving effect and mechanism on service performance of asphalt binder modified by PW polymer

- Influence of pH on the synthesis of carbon spheres and the application of carbon sphere-based solid catalysts in esterification

- Experimenting the compressive performance of low-carbon alkali-activated materials using advanced modeling techniques

- Thermogravimetric (TG/DTG) characterization of cold-pressed oil blends and Saccharomyces cerevisiae-based microcapsules obtained with them

- Investigation of temperature effect on thermo-mechanical property of carbon fiber/PEEK composites

- Computational approaches for structural analysis of wood specimens

- Integrated structure–function design of 3D-printed porous polydimethylsiloxane for superhydrophobic engineering

- Exploring the impact of seashell powder and nano-silica on ultra-high-performance self-curing concrete: Insights into mechanical strength, durability, and high-temperature resilience

- Axial compression damage constitutive model and damage characteristics of fly ash/silica fume modified magnesium phosphate cement after being treated at different temperatures

- Integrating testing and modeling methods to examine the feasibility of blended waste materials for the compressive strength of rubberized mortar

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part II

- Energy absorption of gradient triply periodic minimal surface structure manufactured by stereolithography

- Marine polymers in tissue bioprinting: Current achievements and challenges

- Quick insight into the dynamic dimensions of 4D printing in polymeric composite mechanics

- Recent advances in 4D printing of hydrogels

- Mechanically sustainable and primary recycled thermo-responsive ABS–PLA polymer composites for 4D printing applications: Fabrication and studies

- Special Issue on Materials and Technologies for Low-carbon Biomass Processing and Upgrading

- Low-carbon embodied alkali-activated materials for sustainable construction: A comparative study of single and ensemble learners

- Study on bending performance of prefabricated glulam-cross laminated timber composite floor

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part I

- Supplementary cementitious materials-based concrete porosity estimation using modeling approaches: A comparative study of GEP and MEP

- Modeling the strength parameters of agro waste-derived geopolymer concrete using advanced machine intelligence techniques

- Promoting the sustainable construction: A scientometric review on the utilization of waste glass in concrete

- Incorporating geranium plant waste into ultra-high performance concrete prepared with crumb rubber as fine aggregate in the presence of polypropylene fibers

- Investigation of nano-basic oxygen furnace slag and nano-banded iron formation on properties of high-performance geopolymer concrete