Two-phase numerical simulation of thermal and solutal transport exploration of a non-Newtonian nanomaterial flow past a stretching surface with chemical reaction

-

Balaji Vinothkumar

, Ahmad Qazza

Abstract

Non-uniform heat sources and sinks are used to control the temperature of the reaction and ensure that it proceeds at the desired rate. It is worldwide in nature and may be found in all engineering applications such as nuclear reactors, electronic devices, chemical reactors, etc. In food processing, heat is used to cook such as microwave ovens, pasteurize infrared heaters, and sterilize food products. Non-uniform heat sources are mainly used in biomedical applications, such as hyperthermia cancer treatment, to target and kill cancer cells. Because of its ubiquitous nature, the idea is taken as our subject of study. Heat and species transfer analysis of a non-Newtonian fluid flow model under magnetic effects past an extensible moving sheet is modelled and examined. Homogeneous chemical reaction inside the fluid medium is also investigated. This natural phenomenon is framed as a set of Prandtl boundary layer equations under the assumed convective surface boundary constraint. Self-similarity transformation is employed to convert framed boundary layer equations to ordinary differential equations. The resultant system is solved using the efficient finite difference utilized Keller box method with the help of MATLAB programming. The influence of various fluid-affecting parameters on fluid momentum, energy, species diffusion and wall drag, heat, and mass transfer coefficients is studied. Accelerating the Weissenberg number decelerates the fluid velocity. The temperature of the fluid rises due to variations in the non-uniform heat source and sink parameters. Ohmic dissipation affects the temperature profile significantly. Species diffusion reduces when thermophoresis parameter and non-uniform heat source and sink parameters vary. The Eckert number enhances the heat and diffusion transfer rate. Increasing the chemical reaction parameter decreases the shear wall stress and energy transmission rate while improving the diffusion rate. The wall drag coefficient and Sherwood number decrease as the thermophoretic parameter increases whereas the Nusselt number increases. We hope that this work will act as a reference for future scholars who will have to deal with urgent problems related to industrial and technical enclosures.

1 Introduction

Non-Newtonian fluid models have a wide range of applications, spanning various industries and domains. Non-Newtonian models help create these textures by predicting how ingredients interact and contribute to food products like sauces, ice cream, and yogurt; fluids, like emulsions and suspensions, need better stability and longer shelf life. Controlled release of medications often relies on gels, creams, or ointments with specific viscoelastic properties. Creating lotions, shampoos, and other products with optimal spreadability, consistency, and sensory experience often involves non-Newtonian fluids. The Williamson fluid model is one amongst this category that finds applications in various fields due to its ability to capture the shear-thinning behaviour of many real-world fluids. The model can be used to understand the behaviour of shear-thinning lubricants under different operating conditions, leading to improved lubricant design and performance. Formulating cosmetics with desired rheological properties often involves using Williamson fluid models to predict their flow and sensory characteristics. The model can be used to simulate the flow of mudslides, slurries, and other non-Newtonian fluids in the environment, aiding in risk assessment and mitigation strategies. Hamid et al. [1] investigated the MHD Blasius flow across a vertical plate of radiative Williamson nanofluid. Amanulla and Wakif [2] examined the Williamson fluid numerically under convective heating and radiation effects. Jalili et al. [3] explored a thermal study on Williamson fluid over a stretched plate under Lorentz force. Asjad et al. [4] investigated the effect of MHD and activation energy on Williamson fluid flow including bioconvection. Malik et al. [5] studied the impact of Williamson fluid flow across a 3D linear stretching surface. Maaitah et al. [6] analysed the viscous dissipation influence on Williamson fluid over a horizontally saturated porous plate. Sreenivasulu et al. [7] explored internal friction impact on non-Newtonian fluid flow. Ramesh et al. [8] explored radiative analysis of the nano Carreau-fluid model. Mebarek-Oudina et al. [9] investigated the influence of hybrid magneto-convective flow immersed in a porous medium.

The design and analysis of non-uniform heat sources and sinks is a complex topic that requires a good understanding of heat transfer principles. However, the potential benefits of using non-uniform heat sources and sinks are significant, and they are becoming increasingly important in a wide variety of applications. It includes thermal energy storage systems that use non-uniform heat sources and sinks to store and release thermal energy. Concentrated solar power systems use non-uniform heat sources to generate steam for electricity production. In spacecraft, non-uniform heat sources and sinks are used to manage the thermal environment of the spacecraft and its components. This generation concept is to enhance the fluid conductivity while the other reduces fluid energy. Its term is inevitable only when there is a huge temperature difference and has greater importance in MHD flows. These applications were well discussed by the researchers in their early works [10,11,12]. Konda et al. [13] investigated the effects of varied heat sink and source on non-Newtonian fluid. Jyotshna et al. [14] extended the same effect over gallium nitride nanoparticles using the Williamson fluid model. Song et al. [15] investigated the same effects on stretched cylinders. Swain et al. [16] conducted the same investigation on a porous medium. Sajid et al. [17] discussed the effect of an inconstant heat source (sink) on viscous radiative Sutterby nanofluid past the permeable rotative cone. Hussain et al. [18] investigated the effects of a heat source (sink) on hybrid nanoflow over a solid stretchable sheet.

From seemingly ordinary activities such as cooking to groundbreaking advancements in medicine and energy, chemical reactions play an essential role in creating our lives and the world around us. Here are some key areas: Fossil fuels like coal, oil, and natural gas are burned in power plants to generate electricity through combustion reactions. To produce energy, nuclear fission and fusion power plants utilize controlled nuclear reactions. Photovoltaic cells use photochemical reactions. These electrochemical devices utilize chemical reactions to convert chemical energy into electrical energy. Poornima et al. [19,20] discussed the chemical reaction impacts on MHD flow stretchable surfaces and also on a circular cylinder. Malik et al. [21] analysed homogeneous–heterogeneous reactions in the Williamson fluid model across a stretched cylinder. Sarfraz and Masood [22] studied heat transport analysis for nanofluid flows induced by a moving plate with the Cattaneo-Christov double diffusion. Shah et al. [23] examined the effect of homogeneous chemical reactions on mixed convective Williamson fluid passing through a penetrable porous wedge. Alrihieli et al. [24] discussed MHD dissipative Williamson nanofluid flow with chemical reactions caused by a slippery elastic sheet. Gautam et al. [25] considered activation energy and binary chemical reaction impact on MHD flow of Williamson nanofluid in the Darcy–Forchheimer porous medium.

Ohmic dissipation refers to the conversion of electrical energy into thermal energy due to the resistance of a conductor behind heating elements in devices like. The resistance of the wire element converts electrical energy into heat, warming the surrounding environment examples of devices such as toasters, hairdryers, and electric heaters work on the Ohmic dissipation principle. Generating high currents which suffice to melt the fuse is another example. Re-entry vehicles experience significant aerodynamic heating due to friction. This heat can be partially mitigated by using ohmic heating of the vehicle skin to radiate heat away. Ohmic heating is used in some hyperthermia cancer treatment protocols to target and destroy cancer cells. Sreenivasulu et al. [26] examined the Ohmic heating impact on non-Newtonian fluid flow. Rashad et al. [27] described the Joule heating impact on MHD Williamson hybrid nanoflow. Majid et al. [28] investigated the Ohmic heating impact of a mixed convective flow of Williamson fluid with thermal radiations. Dissipation and heat source/sink impact on Williamson fluid with suction was studied by Hussain et al. [29].

With the above research knowledge, no study is focussed on the collective phenomenon of heat and mass transfer analysis of the non-Newtonian Williamson nanofluid model incorporating the asymmetric heat generation/absorption and ohmic dissipation with chemical reactions. Thus, this article focuses on that part of the study considering Williamson nanoflow past a stretching sheet with chemical reaction, non-uniform source of energy, radiation, and Ohmic dissipation, taking into the molecular study of nanoparticles, i.e. Brownian motion and thermophoresis. Williamson nanoflows with Ohmic dissipation and radiation can be utilized for efficient energy conversion and harvesting. Specifically in microfluidic fuel cells where the flow can be designed to enhance the mixing and mass transport of reactants within microfluidic fuel cells, leading to higher power output. In nanogenerators, the conversion of heat generated through Ohmic dissipation or radiation into electrical energy using nanomaterials can be explored for miniaturized power generation applications. A visual representation is provided of how several relevant physical factors affect the temperature, concentration, and fluid velocity. Additionally, the Sherwood Number, Nusselt Number, and skin friction coefficients are calculated numerically and portrayed.

2 Mathematical formulation of the flow problem

The scenario where a time-independent, laminar, two-dimensional, incompressible, and electrically conducting Williamson nanofluid past a stretching surface with stretching velocity U

w is investigated. The Cauchy stress tensor

where

Here,

Furthermore, the sheet is stretched along the x-axis and fluid flow occurs due to stretching and thus occupies the

The geometry of the flow model.

In which:

In addition, the associated physical boundary conditions for the existing model are

In the above equations,

Furthermore, to simplify the scrutiny of the flow, heat, and mass transfer problem, we need to introduce the following similarity transformations [31]:

Here,

The transformed BCs are

In the above equations, the non-dimensional parameters are the magnetic parameter,

The physical quantities are the skin friction coefficient

At the surface of the sheet, the shear stress, heat flux, and mass flux are mathematically expressed as

Utilizing Eq. (8) in Eqs. (14) and (15), the resulting reduced form of the gradients are given by

3 Numerical solution procedure of the given scheme

In this section of the work, we need to discuss the complete procedure of the scheme as well as the authentication of the code for the limiting cases with existing work. Following the mathematical modelling, the next step is to build the answer. We opted the Keller–Box approach (KBM), a hidden finite-difference methodology, for the computational solution of the modelled equations since it combines second-degree validity with the ability of step size adaptation. Since its quicker convergence rate relative to conventional numerical techniques, this approach is best suited for solving boundary layer flow problems rather than other explicit techniques such as the RK method, BVP4c, and the shooting technique. Using this approach, higher-order PDEs are reduced to first-order PDEs, which are then translated into central difference formulas. The decomposition of the LU technique is used to solve the matrix–vector form of transformed solutions. The material domain

Step A: The Nth order partial differential equation system is reduced to N first-order equations.

We add the most recent set of variables listed below to convert higher-order ODEs to first-order ODEs such as

Implementing Eq. (17) in the similarity equations, we obtain

The boundary conditions are

Step B: The finite-difference method.

The rectangular net is in the x and y planes, as shown in Figure 2, and the following are the net points:

where

Keller box method.

The finite-difference form is computed using the central difference technique as follows:

Eqs. (26)–(30) are centred at the

with boundary conditions:

Step C: Newton’s linearization approach.

Using well-known techniques

The collection of equations of central difference is denoted as

We present the iterates below to use Newton’s method to convert to a nonlinear collection of equations approach:

This method results in the following linear system (the superscript [n] has been deleted for clarity):

with the boundary conditions :

Step D: Tridiagonal system of solution.

The block-elimination approach may be used to solve the linearized difference equations (46)–(53), according to Cebeci and Bradshaw [32], because the system is block-tridiagonal in structure. The block-tridiagonal structure is often made of variables or constants, but in this case, an unusual aspect is that it is made of block matrices, Eqs. (46)–(53) may be represented in matrix–vector form as

where

The matrix components are the following:

For the category

The LU decomposition technique may be used to find the solution of a tri-diagonal system. Assuming that matrix A is non-singular, it may be factored into the product of two matrices, denoted by the notation A = LU

where [

Hence, using LU decomposition, the above system is solved.

4 Results and discussion

The obtained numerical results are then plotted for understanding the physical phenomena of various flow affecting parameters on the physical and engineering quantities presented in the form of graphs (Figures 3–20). Here, the effects of dimensionless parameters on the fluid velocity (

Variation of

Variation of

Variation of

Variation of

Variation of

Variation of

Variation of

Variation of

Variation of

Variation of

Variation of

Variation of

Variation of

Streamline for We = 0.1.

Streamline for We = 0.3.

Streamline for We = 0.5.

Streamline for M = 1.0.

Streamline for M = 2.0.

Table 1 shows the values of shear stress, heat, and mass transfer rates for different grid points. It is seen that for grid points above 20, a convergency in the numerical values is noted for all engineering quantities such as wall friction coefficient, energy, and mass gradient. Table 2 is the comparison of our numerical computation with the existing results [33,34]. An excellent agreement is found between our work and them for the limiting cases.

Mesh sensitivity test for

| Grid points | KBM

|

bvp4c

|

KBM

|

bvp4c

|

KBM

|

bvp4c

|

|---|---|---|---|---|---|---|

| 20 | 1.0624 | 1.1026 | 0.4675 | 0.3927 | 0.6847 | 0.7148 |

| 40 | 1.0875 | 1.1026 | 0.4582 | 0.3927 | 0.6957 | 0.7148 |

| 80 | 1.0954 | 1.1026 | 0.4025 | 0.3927 | 0.7200 | 0.7148 |

| 160 | 1.1000 | 1.1026 | 0.3990 | 0.3927 | 0.7286 | 0.7148 |

| 320 | 1.1015 | 1.1026 | 0.3950 | 0.3927 | 0.7325 | 0.7148 |

| 640 | 1.1020 | 1.1026 | 0.3920 | 0.3927 | 0.7420 | 0.7148 |

Comparing the current findings with those of earlier studies for

| Pr | Khan and Pop [33] | Srinivasulu and Goud [34] | Present |

|---|---|---|---|

| 0.2 | 0.1723 | 0.1909 | 0.1900 |

| 0.7 | 0.4539 | 0.4543 | 0.4456 |

| 2.00 | 0.9113 | 0.9121 | 0.9025 |

| 7.00 | 1.8954 | 1.9010 | 1.8952 |

| 20.0 | 3.3539 | 3.3827 | 3.2852 |

| 70.0 | 6.4621 | 6.6473 | 6.4624 |

Figure 3 shows the influence of

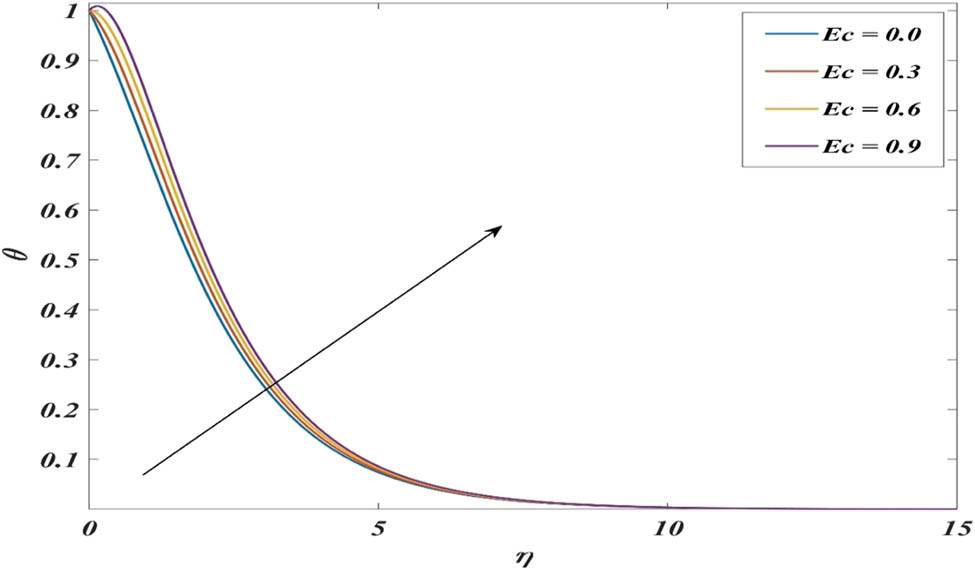

Figures 5–13 show the temperature profiles for different values of Weissenberg number, Eckert number, and Prandtl number, thermophoresis and Brownian motion parameter, Schmidt number, reaction rate parameter, radiation parameter, and non-uniform heat source (sink) parameters, respectively. For simulation purposes, the standard fixed values for these parameters are

Figure 6 describes the temperature profiles for different values for the Weissenberg number. Improving Weissenberg number leads to a rise in the temperature of nanofluids due to the formation of a thicker thermal boundary layer. A thicker boundary layer means the hot fluid layer close to the wall is confined to a smaller region. Figure 7 shows the temperature profiles for different values for radiation parameters. Increasing the radiation parameter (Rd = 0.0, 0.5, 1.0, 1.5) enhances the fluid temperature. The rate of radiative heat transfer increases dramatically with rising temperature. This relationship is governed by the Stefan–Boltzmann Law, which applies to all temperatures above absolute zero. As the temperature of the nanofluid increases, the effect of radiation becomes more dominant compared to conduction.

Figures 8 and 9 show the temperature profiles for different values of the thermophoresis and Brownian motion parameters. Increasing the Nt ( = 0.0, 0.1, 0.2, 0.3) and Nb ( = 1.0, 2.0, 3.0, 4.0) values results in enhancement of the fluid temperature. The zig–zag movement of nanoparticles produces microscopic turbulence, which leads to a temperature rise. The same phenomenon is observed in the nanofluid temperature when thermophoresis transports heat from a hotter to a colder region.

Figures 10 and 11 portray the temperature profiles for different values of a non-uniform heat source and sink parameters (

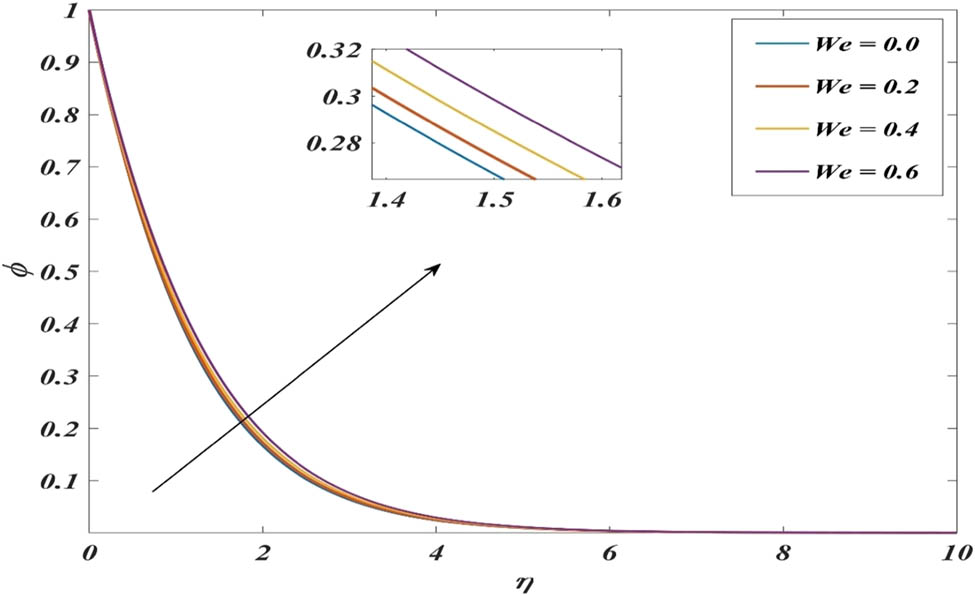

Figure 13 shows the Weissenberg influence on species diffusion. Augmenting We (= 0.0, 0.4, 0.8, 1.2) increases the species diffusion profiles. Figure 14 presents the parameter Nt (0.0, 0.2, 0.4, 0.6) impact on nanoparticle diffusion. It is observed that the diffusion of nanoparticles is decreased as the thermophoresis parameter escalates. As the chemical reaction parameter progresses, the species concentration of reactants decreases. The random movement of nanoparticles can counteract the concentration decrease by causing nanoparticles to move within the fluid, but their effects might be diminished by strong chemical reactions (Figure 15).

Table 3 shows the different engineering quantities affected by the flow parameters. As the Weissenberg number increases, the skin friction coefficient and the Nusselt number increase. But Sherwood's number decreases. The presence of magnetic force reduces the wall friction coefficient and heat transfer coefficient but decreases the concentration gradients. The energy source increases the energy transfer rate while the species diffusion rate decreases. The Eckert number enhances the heat and diffusion transfer rate. Increasing the chemical reaction parameter decreases the shear wall stress and energy transmission rate while the diffusion rate improves. When a species has a lower diffusivity (higher Sc), it is more susceptible to being carried by the flow (convection) rather than relying solely on its random movement (diffusion) to reach its destination. This translates to a more efficient mass transfer process, reflected by a higher Sherwood number. The random motion of nanoparticles decreases all the three engineering quantities. The wall drag coefficient and Sherwood number reduce for increasing thermophoretic parameters, whereas the Nusselt number increases.

List of numerical values for skin friction coefficient, the local Nusselt number and local Sherwood number such as

| We | M | A | B | Ec |

|

Sc | Nt | Nb |

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.0 | 2.14655 | 0.48412 | 1.35455 | ||||||||

| 0.4 | 2.81216 | 0.48652 | 1.34594 | ||||||||

| 0.8 | 2.86745 | 0.48720 | 1.34334 | ||||||||

| 0.0 | 1.40857 | 0.32242 | 1.36996 | ||||||||

| 0.5 | 1.71916 | 0.32356 | 1.36267 | ||||||||

| 1.0 | 1.98263 | 0.33565 | 1.35735 | ||||||||

| 0.0 | 1.33506 | 0.67823 | 1.41617 | ||||||||

| 0.3 | 1.33506 | 0.67956 | 1.47843 | ||||||||

| 0.6 | 1.33506 | 0.67965 | 1.54069 | ||||||||

| 0.0 | 1.33508 | 0.68965 | 1.47898 | ||||||||

| 0.3 | 1.33508 | 0.68985 | 1.46454 | ||||||||

| 0.6 | 1.33508 | 0.68960 | 1.45213 | ||||||||

| 0.1 | 1.40857 | 0.76852 | 1.40290 | ||||||||

| 0.5 | 1.40857 | 0.76952 | 1.47612 | ||||||||

| 1.0 | 1.40857 | 0.76982 | 1.58595 | ||||||||

| 0.1 | 1.33506 | 0.45685 | 1.38037 | ||||||||

| 0.3 | 1.17172 | 0.45582 | 1.44012 | ||||||||

| 0.5 | 1.00838 | 0.45466 | 1.55038 | ||||||||

| 1.0 | 1.98263 | 0.56324 | 1.35735 | ||||||||

| 1.5 | 1.98263 | 0.56325 | 1.48084 | ||||||||

| 2.0 | 1.98263 | 0.56325 | 1.58476 | ||||||||

| 0.2 | 1.65864 | 0.62531 | 1.46521 | ||||||||

| 0.4 | 1.65842 | 0.62542 | 1.46462 | ||||||||

| 0.6 | 1.65625 | 0.62452 | 1.45652 | ||||||||

| 0.2 | 1.58621 | 0.56112 | 1.35621 | ||||||||

| 0.4 | 1.58425 | 0.56021 | 1.35610 | ||||||||

| 0.6 | 1.56822 | 0.54125 | 1.34560 |

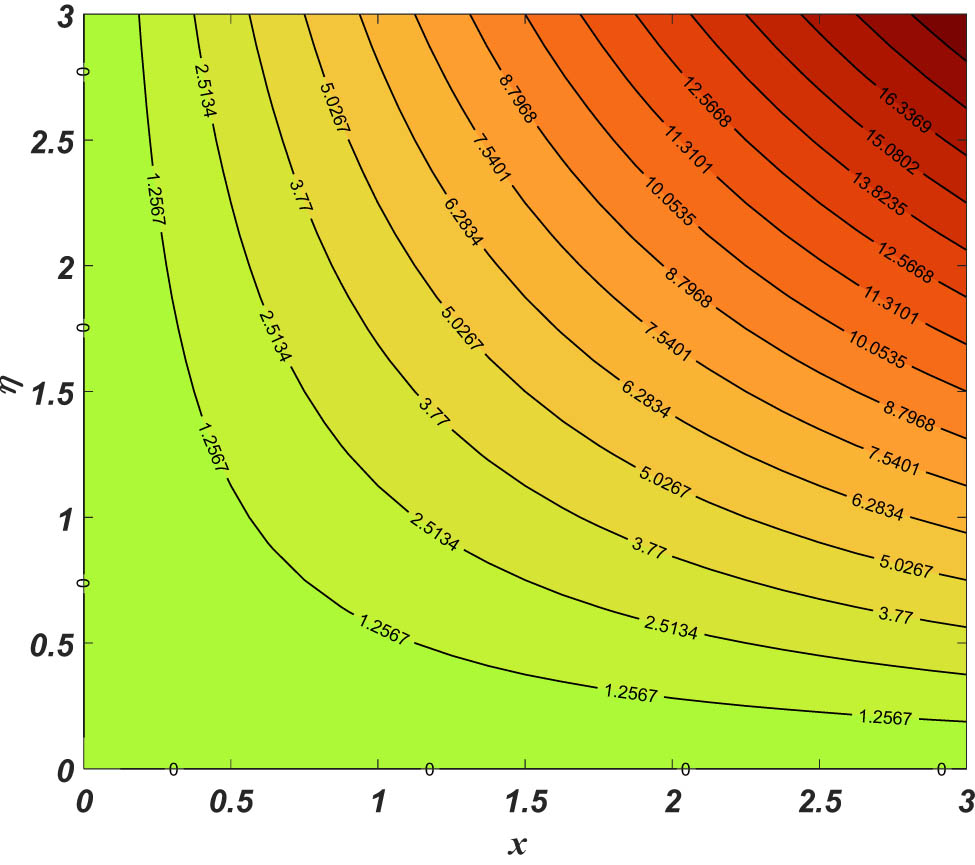

Figures 16–18 show the streamlines for

5 Conclusion

The purpose of this work was to examine the effects of radiation, viscous dissipation, non-uniform heat source and sink, chemical reaction, and heat and mass transfer influences on non-Newtonian nanofluid flow. To solve the formulated boundary layer equations, the Keller box method is utilized. The implications of various pertinent parameters on the flow field are numerically computed using MATLAB and portrayed as graphs and tables. These key findings can be summarized as follows:

Augmenting Weissenberg number and magnetic parameter decelerates the nanofluid velocity.

Incrementing non-uniform heat source parameters accelerates both fluid velocity and temperature. The temperature intensifies as Eckert’s number increases.

Declining species concentration profiles is noticed when thermophoresis parameter and non-uniform heat source parameters boost.

As Weissenberg’s number increases, the skin friction coefficient and Nusselt number increase, but Sherwood’s number decreases.

Enhancing energy source parameters increases the energy transfer rate, while species diffusion rate decreases. Eckert number enhances the energy and diffusion transfer rate.

Increasing chemical reaction parameters decreases the shear wall stress and energy transmission rate while the diffusion rate improves.

This problem can also be extended to add different physical impacts such as nanofluids, hybrid nanofluids, ternary hybrid nanofluids, non-Newtonian models and concentration equations, etc. In addition, we can also apply distinct schemes such as ANN, fractional derivatives, and ARA-Sumudu decomposition method [35,36,37,38,39].

Acknowledgments

The authors extend their appreciation to the Researchers Supporting Project number (RSPD2024R999), King Saud University, Riyadh, Saudi Arabia.

-

Funding information: This research is funded by the Scientific Deanship of Zarqa University, Jordan.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets used and/or analysed during the current study are available from the corresponding author upon reasonable request.

References

[1] Hamid A, Hashim, Khan M, Alghamdi M. MHD Blasius flow of radiative Williamson nanofluid over a vertical plate. Int J Mod Phys B. 2019;33(22):1950245.10.1142/S021797921950245XSearch in Google Scholar

[2] Amanulla CH, Wakif A, Saleem S. Numerical study of a Williamson fluid past a semi-infinite vertical plate with convective heating and radiation effects. Diffus Found. 2020;28:1–15.10.4028/www.scientific.net/DF.28.1Search in Google Scholar

[3] Jalili B, Ganji AD, Jalili P, Nourazar SS, Ganji DD. Thermal analysis of Williamson fluid flow with Lorentz force on the stretching plate. Case Stud Therm Eng. 2022;39:102374.10.1016/j.csite.2022.102374Search in Google Scholar

[4] Asjad MI, Zahid M, Inc M, Baleanu D, Almohsen B. Impact of activation energy and MHD on Williamson fluid flow in the presence of bioconvection. Alex Eng J. 2022;61(11):8715–27.10.1016/j.aej.2022.02.013Search in Google Scholar

[5] Malik MY, Bilal S, Salahuddin T, Rehman KU. Three-dimensional Williamson fluid flow over a linear stretching surface. Math Sci Lett. 2017;6(1):53–61.10.18576/msl/060109Search in Google Scholar

[6] Maaitah H, Olimat AN, Quran O, Duwairi HM. Viscous dissipation analysis of Williamson fluid over a horizontal saturated porous plate at constant wall temperature. Int J Thermofluids. 2023;19:100361.10.1016/j.ijft.2023.100361Search in Google Scholar

[7] Sreenivasulu P, Poornima T, Malleswari B, Reddy NB, Souayeh B. Viscous dissipation impact on electrical resistance heating distributed Carreau nanoliquid along stretching sheet with zero mass flux. Eur Phys J Plus. 2020;135(9):705.10.1140/epjp/s13360-020-00680-6Search in Google Scholar

[8] Ramesh K, Mebarek-Oudina F, Ismail AI, Jaiswal BR, Warke AS, Lodhi RK, et al. Computational analysis on radiative non-Newtonian Carreau nanofluid flow in a microchannel under the magnetic properties. Sci Iran. 2023;30(2):376–90.10.24200/sci.2022.58629.5822Search in Google Scholar

[9] Mebarek-Oudina F, Chabani I, Vaidya H, Ismail AI. Hybrid nanofluid magneto-convective flow and porous media contribution to entropy generation. Int J Numer Methods Heat Fluid Flow. 2024;34(2):809–36. 10.1108/HFF-06-2023-0326.Search in Google Scholar

[10] Sreenivasulu P, Poornima T, Reddy NB, Reddy MG. A numerical analysis on UCM dissipated nanofluid imbedded carbon nanotubes influenced by inclined Lorentzian force along with non-uniform heat source/sink. J Nanofluids. 2019;8(5):1076–84.10.1166/jon.2019.1665Search in Google Scholar

[11] Poornima T, Sreenivasulu P, Souayeh B. Mathematical study of heat transfer in a stagnation flow of a hybrid nanofluid over a stretching/shrinking cylinder. J Eng Phys Thermophys. 2022;95(6):1443–54.10.1007/s10891-022-02613-9Search in Google Scholar

[12] Ragavi M, Poornima T. Enhanced heat transfer analysis on Ag-Al2O3/water hybrid magneto-convective nanoflow. Discov Nano. 2024;19:31. 10.1186/s11671-024-03975-0.Search in Google Scholar PubMed

[13] Konda JR, NP MR, Konijeti R, Dasore A. Effect of non-uniform heat source/sink on MHD boundary layer flow and melting heat transfer of Williamson nanofluid in porous medium. Multidiscipline Modeling Mater Struct. 2019;15(2):452–72.10.1108/MMMS-01-2018-0011Search in Google Scholar

[14] Jyotshna M, Dhanalaxmi V. Impact of Activation energy and heat source/sink on 3D flow of williamson nanofluid with gan nanoparticles over a stretching sheet. Eur J Maths Stat. 2022;3(5):16–29.10.24018/ejmath.2022.3.5.133Search in Google Scholar

[15] Song YQ, Hamid A, Sun TC, Khan MI, Qayyum S, Kumar RN, et al. Unsteady mixed convection flow of magneto-Williamson nanofluid due to stretched cylinder with significant non-uniform heat source/sink features. Alex Eng J. 2022;61(1):195–206.10.1016/j.aej.2021.04.089Search in Google Scholar

[16] Swain K, Parida SK, Dash GC. Effects of non-uniform heat source/sink and viscous dissipation on MHD boundary layer flow of Williamson nanofluid through porous medium. Defect Diffus Forum. 2018;389:110–27. Trans Tech Publications Ltd.10.4028/www.scientific.net/DDF.389.110Search in Google Scholar

[17] Sajid T, Jamshed W, Eid MR, Algarni S, Alqahtani T, Ibrahim RW, et al. Thermal case examination of inconstant heat source (sink) on viscous radiative Sutterby nanofluid flowing via a penetrable rotative cone. Case Stud Therm Eng. 2023;48:103102.10.1016/j.csite.2023.103102Search in Google Scholar

[18] Hussain SM, Eid MR, Prakash M, Jamshed W, Khan A, Alqahtani H. Thermal characterization of heat source (sink) on hybridized (Cu–Ag/EG) nanofluid flow via solid stretchable sheet. Open Phys. 2023;21(1):20220245.10.1515/phys-2022-0245Search in Google Scholar

[19] Poornima T, Sreenivasulu P, Souayeh B. Thermal radiation influence on non-Newtonian nanofluid flow along a stretchable surface with Newton boundary condition. Int J Ambient Energy. 2023;44(1):2469–79.10.1080/01430750.2023.2256329Search in Google Scholar

[20] Poornima T, Sreenivasulu P, Bhaskar Reddy N. Chemical reaction effects on an unsteady MHD mixed convective and radiative boundary layer flow over a circular cylinder. J Appl Fluid Mech. 2016;9(6):2877–85. 10.29252/jafm.09.06.24248.Search in Google Scholar

[21] Malik MY, Salahuddin T, Hussain A, Bilal S, Awais M. Homogeneous-heterogeneous reactions in Williamson fluid model over a stretching cylinder by using Keller box method. AIP Adv. 2015;5(10):107227.10.1063/1.4934937Search in Google Scholar

[22] Mahnoor S, Masood K. Cattaneo-Christov double diffusion based heat transport analysis for nanofluid flows induced by a moving plate. Numer Heat Transfer, Part A: Appl. 2023;85(3):351–63. 10.1080/10407782.2023.2186551.Search in Google Scholar

[23] Shah FA, Hussain M, Akhtar A, Inc M, Sene N, Hussan M. Impacts of chemical reaction and suction/injection on the mixed convective williamson fluid past a penetrable porous wedge. J Mathematics. 2022;2022:Article ID 3233964. 10.1155/2022/3233964.Search in Google Scholar

[24] Alrihieli H, Areshi M, Alali E, Megahed AM. MHD dissipative Williamson nanofluid flow with chemical reaction due to a slippery elastic sheet which was contained within a porous medium. Micromachines (Basel). 2022;13(11):1879. 10.3390/mi13111879.Search in Google Scholar PubMed PubMed Central

[25] Gautam AK, Verma AK, Bhattacharyya K, Mukhopadhyay S, Chamkha AJ. Impacts of activation energy and binary chemical reaction on MHD flow of Williamson nanofluid in Darcy–Forchheimer porous medium: a case of expanding sheet of variable thickness. Waves Random Complex Media. 2021;1–22. 10.1080/17455030.2021.1979274.Search in Google Scholar

[26] Sreenivasulu P, Poornima T, Reddy NB. Influence of joule heating and non-linear radiation on MHD 3D dissipating flow of casson nanofluid past a non-linear stretching sheet. Nonlinear Eng. 2019;8(1):661–72. 10.1515/nleng-2017-0143.Search in Google Scholar

[27] Rashad AM, Nafe MA, Eisa DA. Heat variation on MHD Williamson hybrid nanofluid flow with convective boundary condition and Ohmic heating in a porous material. Sci Rep. 2023;13:6071. 10.1038/s41598-023-33043-z.Search in Google Scholar PubMed PubMed Central

[28] Hussain M, Lubna A, Ashraf M, Anwar MS, Ranjha QA, Akhtar A. Ohmically dissipated MHD mixed convective flow of Williamson fluid over a penetrable stretching convective wedge with thermal radiations. Numer Heat Transfer, Part B: Fundam. 2023;1–15. 10.1080/10407790.2023.2261623.Search in Google Scholar

[29] Hussain M, Jahan S, Ranjha QA, Ahmad J, Jamil MK, Ali A. Suction/blowing impact on magneto-hydrodynamic mixed convection flow of Williamson fluid through stretching porous wedge with viscous dissipation and internal heat generation/absorption. Results Eng. 2022;16:100709. 10.1016/j.rineng.2022.100709.Search in Google Scholar

[30] Hayat T, Shafiq A, Alsaedi A. Hydromagnetic boundary layer flow of Williamson fluid in the presence of thermal radiation and Ohmic dissipation. Alex Eng J. 2016;55(3):2229–40.10.1016/j.aej.2016.06.004Search in Google Scholar

[31] Nayak MM, Mishra SR. Fuzzy parametric behaviour for the Flow of MHD Williamson nanofluid with melting heat transfer boundary condition. Int J Appl Comput Maths. 2023;9(3):18.10.1007/s40819-023-01494-7Search in Google Scholar

[32] Cebeci T, Bradshaw P. Physical and computational aspects of convective heat transfer. New York: Springer; 1984.10.1007/978-3-662-02411-9Search in Google Scholar

[33] Khan WA, Pop I. Boundary-layer flow of a nanofluid past a stretching sheet. Int J heat mass Transf. 2010;53(11–12):2477–83.10.1016/j.ijheatmasstransfer.2010.01.032Search in Google Scholar

[34] Srinivasulu T, Goud BS. Effect of inclined magnetic field on flow, heat, and mass transfer of Williamson nanofluid over a stretching sheet. Case Stud Therm Eng. 2021;23:100819.10.1016/j.csite.2020.100819Search in Google Scholar

[35] Madhu J, Saadeh R, Karthik K, Kumar RV, Kumar RN, Gowda RP, et al. Role of catalytic reactions in a flow-induced due to outer stationary and inner stretched coaxial cylinders: An application of Probabilists’ Hermite collocation method. Case Stud Therm Eng. 2024;56:104218.10.1016/j.csite.2024.104218Search in Google Scholar

[36] Saadeh R, Ahmed SA, Qazza A, Elzaki TM. Adapting partial differential equations via the modified double ARA-Sumudu decomposition method. Partial Differ Equation Appl Maths. 2023;8:100539.10.1016/j.padiff.2023.100539Search in Google Scholar

[37] Saadeh R, Ghazal B, Burqan A. A study of double general transform for solving fractional partial differential equations. Math Methods Appl Sci. 2023;46:17158–76.10.1002/mma.9493Search in Google Scholar

[38] Chandan K, Saadeh R, Qazza A, Karthik K, Varun Kumar RS, Kumar RN, et al. Predicting the thermal distribution in a convective wavy fin using a novel training physics-informed neural network method. Sci Rep. 2024;14(1):7045.10.1038/s41598-024-57772-xSearch in Google Scholar PubMed PubMed Central

[39] Qazza A, Saadeh R, Ahmed SA. ARA-sumudu method for solving volterra partial integro-differential equations. Appl Math. 2023;17(4):727–34.10.18576/amis/170421Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Numerical study of flow and heat transfer in the channel of panel-type radiator with semi-detached inclined trapezoidal wing vortex generators

- Homogeneous–heterogeneous reactions in the colloidal investigation of Casson fluid

- High-speed mid-infrared Mach–Zehnder electro-optical modulators in lithium niobate thin film on sapphire

- Numerical analysis of dengue transmission model using Caputo–Fabrizio fractional derivative

- Mononuclear nanofluids undergoing convective heating across a stretching sheet and undergoing MHD flow in three dimensions: Potential industrial applications

- Heat transfer characteristics of cobalt ferrite nanoparticles scattered in sodium alginate-based non-Newtonian nanofluid over a stretching/shrinking horizontal plane surface

- The electrically conducting water-based nanofluid flow containing titanium and aluminum alloys over a rotating disk surface with nonlinear thermal radiation: A numerical analysis

- Growth, characterization, and anti-bacterial activity of l-methionine supplemented with sulphamic acid single crystals

- A numerical analysis of the blood-based Casson hybrid nanofluid flow past a convectively heated surface embedded in a porous medium

- Optoelectronic–thermomagnetic effect of a microelongated non-local rotating semiconductor heated by pulsed laser with varying thermal conductivity

- Thermal proficiency of magnetized and radiative cross-ternary hybrid nanofluid flow induced by a vertical cylinder

- Enhanced heat transfer and fluid motion in 3D nanofluid with anisotropic slip and magnetic field

- Numerical analysis of thermophoretic particle deposition on 3D Casson nanofluid: Artificial neural networks-based Levenberg–Marquardt algorithm

- Analyzing fuzzy fractional Degasperis–Procesi and Camassa–Holm equations with the Atangana–Baleanu operator

- Bayesian estimation of equipment reliability with normal-type life distribution based on multiple batch tests

- Chaotic control problem of BEC system based on Hartree–Fock mean field theory

- Optimized framework numerical solution for swirling hybrid nanofluid flow with silver/gold nanoparticles on a stretching cylinder with heat source/sink and reactive agents

- Stability analysis and numerical results for some schemes discretising 2D nonconstant coefficient advection–diffusion equations

- Convective flow of a magnetohydrodynamic second-grade fluid past a stretching surface with Cattaneo–Christov heat and mass flux model

- Analysis of the heat transfer enhancement in water-based micropolar hybrid nanofluid flow over a vertical flat surface

- Microscopic seepage simulation of gas and water in shale pores and slits based on VOF

- Model of conversion of flow from confined to unconfined aquifers with stochastic approach

- Study of fractional variable-order lymphatic filariasis infection model

- Soliton, quasi-soliton, and their interaction solutions of a nonlinear (2 + 1)-dimensional ZK–mZK–BBM equation for gravity waves

- Application of conserved quantities using the formal Lagrangian of a nonlinear integro partial differential equation through optimal system of one-dimensional subalgebras in physics and engineering

- Nonlinear fractional-order differential equations: New closed-form traveling-wave solutions

- Sixth-kind Chebyshev polynomials technique to numerically treat the dissipative viscoelastic fluid flow in the rheology of Cattaneo–Christov model

- Some transforms, Riemann–Liouville fractional operators, and applications of newly extended M–L (p, s, k) function

- Magnetohydrodynamic water-based hybrid nanofluid flow comprising diamond and copper nanoparticles on a stretching sheet with slips constraints

- Super-resolution reconstruction method of the optical synthetic aperture image using generative adversarial network

- A two-stage framework for predicting the remaining useful life of bearings

- Influence of variable fluid properties on mixed convective Darcy–Forchheimer flow relation over a surface with Soret and Dufour spectacle

- Inclined surface mixed convection flow of viscous fluid with porous medium and Soret effects

- Exact solutions to vorticity of the fractional nonuniform Poiseuille flows

- In silico modified UV spectrophotometric approaches to resolve overlapped spectra for quality control of rosuvastatin and teneligliptin formulation

- Numerical simulations for fractional Hirota–Satsuma coupled Korteweg–de Vries systems

- Substituent effect on the electronic and optical properties of newly designed pyrrole derivatives using density functional theory

- A comparative analysis of shielding effectiveness in glass and concrete containers

- Numerical analysis of the MHD Williamson nanofluid flow over a nonlinear stretching sheet through a Darcy porous medium: Modeling and simulation

- Analytical and numerical investigation for viscoelastic fluid with heat transfer analysis during rollover-web coating phenomena

- Influence of variable viscosity on existing sheet thickness in the calendering of non-isothermal viscoelastic materials

- Analysis of nonlinear fractional-order Fisher equation using two reliable techniques

- Comparison of plan quality and robustness using VMAT and IMRT for breast cancer

- Radiative nanofluid flow over a slender stretching Riga plate under the impact of exponential heat source/sink

- Numerical investigation of acoustic streaming vortices in cylindrical tube arrays

- Numerical study of blood-based MHD tangent hyperbolic hybrid nanofluid flow over a permeable stretching sheet with variable thermal conductivity and cross-diffusion

- Fractional view analytical analysis of generalized regularized long wave equation

- Dynamic simulation of non-Newtonian boundary layer flow: An enhanced exponential time integrator approach with spatially and temporally variable heat sources

- Inclined magnetized infinite shear rate viscosity of non-Newtonian tetra hybrid nanofluid in stenosed artery with non-uniform heat sink/source

- Estimation of monotone α-quantile of past lifetime function with application

- Numerical simulation for the slip impacts on the radiative nanofluid flow over a stretched surface with nonuniform heat generation and viscous dissipation

- Study of fractional telegraph equation via Shehu homotopy perturbation method

- An investigation into the impact of thermal radiation and chemical reactions on the flow through porous media of a Casson hybrid nanofluid including unstable mixed convection with stretched sheet in the presence of thermophoresis and Brownian motion

- Establishing breather and N-soliton solutions for conformable Klein–Gordon equation

- An electro-optic half subtractor from a silicon-based hybrid surface plasmon polariton waveguide

- CFD analysis of particle shape and Reynolds number on heat transfer characteristics of nanofluid in heated tube

- Abundant exact traveling wave solutions and modulation instability analysis to the generalized Hirota–Satsuma–Ito equation

- A short report on a probability-based interpretation of quantum mechanics

- Study on cavitation and pulsation characteristics of a novel rotor-radial groove hydrodynamic cavitation reactor

- Optimizing heat transport in a permeable cavity with an isothermal solid block: Influence of nanoparticles volume fraction and wall velocity ratio

- Linear instability of the vertical throughflow in a porous layer saturated by a power-law fluid with variable gravity effect

- Thermal analysis of generalized Cattaneo–Christov theories in Burgers nanofluid in the presence of thermo-diffusion effects and variable thermal conductivity

- A new benchmark for camouflaged object detection: RGB-D camouflaged object detection dataset

- Effect of electron temperature and concentration on production of hydroxyl radical and nitric oxide in atmospheric pressure low-temperature helium plasma jet: Swarm analysis and global model investigation

- Double diffusion convection of Maxwell–Cattaneo fluids in a vertical slot

- Thermal analysis of extended surfaces using deep neural networks

- Steady-state thermodynamic process in multilayered heterogeneous cylinder

- Multiresponse optimisation and process capability analysis of chemical vapour jet machining for the acrylonitrile butadiene styrene polymer: Unveiling the morphology

- Modeling monkeypox virus transmission: Stability analysis and comparison of analytical techniques

- Fourier spectral method for the fractional-in-space coupled Whitham–Broer–Kaup equations on unbounded domain

- The chaotic behavior and traveling wave solutions of the conformable extended Korteweg–de-Vries model

- Research on optimization of combustor liner structure based on arc-shaped slot hole

- Construction of M-shaped solitons for a modified regularized long-wave equation via Hirota's bilinear method

- Effectiveness of microwave ablation using two simultaneous antennas for liver malignancy treatment

- Discussion on optical solitons, sensitivity and qualitative analysis to a fractional model of ion sound and Langmuir waves with Atangana Baleanu derivatives

- Reliability of two-dimensional steady magnetized Jeffery fluid over shrinking sheet with chemical effect

- Generalized model of thermoelasticity associated with fractional time-derivative operators and its applications to non-simple elastic materials

- Migration of two rigid spheres translating within an infinite couple stress fluid under the impact of magnetic field

- A comparative investigation of neutron and gamma radiation interaction properties of zircaloy-2 and zircaloy-4 with consideration of mechanical properties

- New optical stochastic solutions for the Schrödinger equation with multiplicative Wiener process/random variable coefficients using two different methods

- Physical aspects of quantile residual lifetime sequence

- Synthesis, structure, I–V characteristics, and optical properties of chromium oxide thin films for optoelectronic applications

- Smart mathematically filtered UV spectroscopic methods for quality assurance of rosuvastatin and valsartan from formulation

- A novel investigation into time-fractional multi-dimensional Navier–Stokes equations within Aboodh transform

- Homotopic dynamic solution of hydrodynamic nonlinear natural convection containing superhydrophobicity and isothermally heated parallel plate with hybrid nanoparticles

- A novel tetra hybrid bio-nanofluid model with stenosed artery

- Propagation of traveling wave solution of the strain wave equation in microcrystalline materials

- Innovative analysis to the time-fractional q-deformed tanh-Gordon equation via modified double Laplace transform method

- A new investigation of the extended Sakovich equation for abundant soliton solution in industrial engineering via two efficient techniques

- New soliton solutions of the conformable time fractional Drinfel'd–Sokolov–Wilson equation based on the complete discriminant system method

- Irradiation of hydrophilic acrylic intraocular lenses by a 365 nm UV lamp

- Inflation and the principle of equivalence

- The use of a supercontinuum light source for the characterization of passive fiber optic components

- Optical solitons to the fractional Kundu–Mukherjee–Naskar equation with time-dependent coefficients

- A promising photocathode for green hydrogen generation from sanitation water without external sacrificing agent: silver-silver oxide/poly(1H-pyrrole) dendritic nanocomposite seeded on poly-1H pyrrole film

- Photon balance in the fiber laser model

- Propagation of optical spatial solitons in nematic liquid crystals with quadruple power law of nonlinearity appears in fluid mechanics

- Theoretical investigation and sensitivity analysis of non-Newtonian fluid during roll coating process by response surface methodology

- Utilizing slip conditions on transport phenomena of heat energy with dust and tiny nanoparticles over a wedge

- Bismuthyl chloride/poly(m-toluidine) nanocomposite seeded on poly-1H pyrrole: Photocathode for green hydrogen generation

- Infrared thermography based fault diagnosis of diesel engines using convolutional neural network and image enhancement

- On some solitary wave solutions of the Estevez--Mansfield--Clarkson equation with conformable fractional derivatives in time

- Impact of permeability and fluid parameters in couple stress media on rotating eccentric spheres

- Review Article

- Transformer-based intelligent fault diagnosis methods of mechanical equipment: A survey

- Special Issue on Predicting pattern alterations in nature - Part II

- A comparative study of Bagley–Torvik equation under nonsingular kernel derivatives using Weeks method

- On the existence and numerical simulation of Cholera epidemic model

- Numerical solutions of generalized Atangana–Baleanu time-fractional FitzHugh–Nagumo equation using cubic B-spline functions

- Dynamic properties of the multimalware attacks in wireless sensor networks: Fractional derivative analysis of wireless sensor networks

- Prediction of COVID-19 spread with models in different patterns: A case study of Russia

- Study of chronic myeloid leukemia with T-cell under fractal-fractional order model

- Accumulation process in the environment for a generalized mass transport system

- Analysis of a generalized proportional fractional stochastic differential equation incorporating Carathéodory's approximation and applications

- Special Issue on Nanomaterial utilization and structural optimization - Part II

- Numerical study on flow and heat transfer performance of a spiral-wound heat exchanger for natural gas

- Study of ultrasonic influence on heat transfer and resistance performance of round tube with twisted belt

- Numerical study on bionic airfoil fins used in printed circuit plate heat exchanger

- Improving heat transfer efficiency via optimization and sensitivity assessment in hybrid nanofluid flow with variable magnetism using the Yamada–Ota model

- Special Issue on Nanofluids: Synthesis, Characterization, and Applications

- Exact solutions of a class of generalized nanofluidic models

- Stability enhancement of Al2O3, ZnO, and TiO2 binary nanofluids for heat transfer applications

- Thermal transport energy performance on tangent hyperbolic hybrid nanofluids and their implementation in concentrated solar aircraft wings

- Studying nonlinear vibration analysis of nanoelectro-mechanical resonators via analytical computational method

- Numerical analysis of non-linear radiative Casson fluids containing CNTs having length and radius over permeable moving plate

- Two-phase numerical simulation of thermal and solutal transport exploration of a non-Newtonian nanomaterial flow past a stretching surface with chemical reaction

- Natural convection and flow patterns of Cu–water nanofluids in hexagonal cavity: A novel thermal case study

- Solitonic solutions and study of nonlinear wave dynamics in a Murnaghan hyperelastic circular pipe

- Comparative study of couple stress fluid flow using OHAM and NIM

- Utilization of OHAM to investigate entropy generation with a temperature-dependent thermal conductivity model in hybrid nanofluid using the radiation phenomenon

- Slip effects on magnetized radiatively hybridized ferrofluid flow with acute magnetic force over shrinking/stretching surface

- Significance of 3D rectangular closed domain filled with charged particles and nanoparticles engaging finite element methodology

- Robustness and dynamical features of fractional difference spacecraft model with Mittag–Leffler stability

- Characterizing magnetohydrodynamic effects on developed nanofluid flow in an obstructed vertical duct under constant pressure gradient

- Study on dynamic and static tensile and puncture-resistant mechanical properties of impregnated STF multi-dimensional structure Kevlar fiber reinforced composites

- Thermosolutal Marangoni convective flow of MHD tangent hyperbolic hybrid nanofluids with elastic deformation and heat source

- Investigation of convective heat transport in a Carreau hybrid nanofluid between two stretchable rotatory disks

- Single-channel cooling system design by using perforated porous insert and modeling with POD for double conductive panel

- Special Issue on Fundamental Physics from Atoms to Cosmos - Part I

- Pulsed excitation of a quantum oscillator: A model accounting for damping

- Review of recent analytical advances in the spectroscopy of hydrogenic lines in plasmas

- Heavy mesons mass spectroscopy under a spin-dependent Cornell potential within the framework of the spinless Salpeter equation

- Coherent manipulation of bright and dark solitons of reflection and transmission pulses through sodium atomic medium

- Effect of the gravitational field strength on the rate of chemical reactions

- The kinetic relativity theory – hiding in plain sight

- Special Issue on Advanced Energy Materials - Part III

- Eco-friendly graphitic carbon nitride–poly(1H pyrrole) nanocomposite: A photocathode for green hydrogen production, paving the way for commercial applications

Articles in the same Issue

- Regular Articles

- Numerical study of flow and heat transfer in the channel of panel-type radiator with semi-detached inclined trapezoidal wing vortex generators

- Homogeneous–heterogeneous reactions in the colloidal investigation of Casson fluid

- High-speed mid-infrared Mach–Zehnder electro-optical modulators in lithium niobate thin film on sapphire

- Numerical analysis of dengue transmission model using Caputo–Fabrizio fractional derivative

- Mononuclear nanofluids undergoing convective heating across a stretching sheet and undergoing MHD flow in three dimensions: Potential industrial applications

- Heat transfer characteristics of cobalt ferrite nanoparticles scattered in sodium alginate-based non-Newtonian nanofluid over a stretching/shrinking horizontal plane surface

- The electrically conducting water-based nanofluid flow containing titanium and aluminum alloys over a rotating disk surface with nonlinear thermal radiation: A numerical analysis

- Growth, characterization, and anti-bacterial activity of l-methionine supplemented with sulphamic acid single crystals

- A numerical analysis of the blood-based Casson hybrid nanofluid flow past a convectively heated surface embedded in a porous medium

- Optoelectronic–thermomagnetic effect of a microelongated non-local rotating semiconductor heated by pulsed laser with varying thermal conductivity

- Thermal proficiency of magnetized and radiative cross-ternary hybrid nanofluid flow induced by a vertical cylinder

- Enhanced heat transfer and fluid motion in 3D nanofluid with anisotropic slip and magnetic field

- Numerical analysis of thermophoretic particle deposition on 3D Casson nanofluid: Artificial neural networks-based Levenberg–Marquardt algorithm

- Analyzing fuzzy fractional Degasperis–Procesi and Camassa–Holm equations with the Atangana–Baleanu operator

- Bayesian estimation of equipment reliability with normal-type life distribution based on multiple batch tests

- Chaotic control problem of BEC system based on Hartree–Fock mean field theory

- Optimized framework numerical solution for swirling hybrid nanofluid flow with silver/gold nanoparticles on a stretching cylinder with heat source/sink and reactive agents

- Stability analysis and numerical results for some schemes discretising 2D nonconstant coefficient advection–diffusion equations

- Convective flow of a magnetohydrodynamic second-grade fluid past a stretching surface with Cattaneo–Christov heat and mass flux model

- Analysis of the heat transfer enhancement in water-based micropolar hybrid nanofluid flow over a vertical flat surface

- Microscopic seepage simulation of gas and water in shale pores and slits based on VOF

- Model of conversion of flow from confined to unconfined aquifers with stochastic approach

- Study of fractional variable-order lymphatic filariasis infection model

- Soliton, quasi-soliton, and their interaction solutions of a nonlinear (2 + 1)-dimensional ZK–mZK–BBM equation for gravity waves

- Application of conserved quantities using the formal Lagrangian of a nonlinear integro partial differential equation through optimal system of one-dimensional subalgebras in physics and engineering

- Nonlinear fractional-order differential equations: New closed-form traveling-wave solutions

- Sixth-kind Chebyshev polynomials technique to numerically treat the dissipative viscoelastic fluid flow in the rheology of Cattaneo–Christov model

- Some transforms, Riemann–Liouville fractional operators, and applications of newly extended M–L (p, s, k) function

- Magnetohydrodynamic water-based hybrid nanofluid flow comprising diamond and copper nanoparticles on a stretching sheet with slips constraints

- Super-resolution reconstruction method of the optical synthetic aperture image using generative adversarial network

- A two-stage framework for predicting the remaining useful life of bearings

- Influence of variable fluid properties on mixed convective Darcy–Forchheimer flow relation over a surface with Soret and Dufour spectacle

- Inclined surface mixed convection flow of viscous fluid with porous medium and Soret effects

- Exact solutions to vorticity of the fractional nonuniform Poiseuille flows

- In silico modified UV spectrophotometric approaches to resolve overlapped spectra for quality control of rosuvastatin and teneligliptin formulation

- Numerical simulations for fractional Hirota–Satsuma coupled Korteweg–de Vries systems

- Substituent effect on the electronic and optical properties of newly designed pyrrole derivatives using density functional theory

- A comparative analysis of shielding effectiveness in glass and concrete containers

- Numerical analysis of the MHD Williamson nanofluid flow over a nonlinear stretching sheet through a Darcy porous medium: Modeling and simulation

- Analytical and numerical investigation for viscoelastic fluid with heat transfer analysis during rollover-web coating phenomena

- Influence of variable viscosity on existing sheet thickness in the calendering of non-isothermal viscoelastic materials

- Analysis of nonlinear fractional-order Fisher equation using two reliable techniques

- Comparison of plan quality and robustness using VMAT and IMRT for breast cancer

- Radiative nanofluid flow over a slender stretching Riga plate under the impact of exponential heat source/sink

- Numerical investigation of acoustic streaming vortices in cylindrical tube arrays

- Numerical study of blood-based MHD tangent hyperbolic hybrid nanofluid flow over a permeable stretching sheet with variable thermal conductivity and cross-diffusion

- Fractional view analytical analysis of generalized regularized long wave equation

- Dynamic simulation of non-Newtonian boundary layer flow: An enhanced exponential time integrator approach with spatially and temporally variable heat sources

- Inclined magnetized infinite shear rate viscosity of non-Newtonian tetra hybrid nanofluid in stenosed artery with non-uniform heat sink/source

- Estimation of monotone α-quantile of past lifetime function with application

- Numerical simulation for the slip impacts on the radiative nanofluid flow over a stretched surface with nonuniform heat generation and viscous dissipation

- Study of fractional telegraph equation via Shehu homotopy perturbation method

- An investigation into the impact of thermal radiation and chemical reactions on the flow through porous media of a Casson hybrid nanofluid including unstable mixed convection with stretched sheet in the presence of thermophoresis and Brownian motion

- Establishing breather and N-soliton solutions for conformable Klein–Gordon equation

- An electro-optic half subtractor from a silicon-based hybrid surface plasmon polariton waveguide

- CFD analysis of particle shape and Reynolds number on heat transfer characteristics of nanofluid in heated tube

- Abundant exact traveling wave solutions and modulation instability analysis to the generalized Hirota–Satsuma–Ito equation

- A short report on a probability-based interpretation of quantum mechanics

- Study on cavitation and pulsation characteristics of a novel rotor-radial groove hydrodynamic cavitation reactor

- Optimizing heat transport in a permeable cavity with an isothermal solid block: Influence of nanoparticles volume fraction and wall velocity ratio

- Linear instability of the vertical throughflow in a porous layer saturated by a power-law fluid with variable gravity effect

- Thermal analysis of generalized Cattaneo–Christov theories in Burgers nanofluid in the presence of thermo-diffusion effects and variable thermal conductivity

- A new benchmark for camouflaged object detection: RGB-D camouflaged object detection dataset

- Effect of electron temperature and concentration on production of hydroxyl radical and nitric oxide in atmospheric pressure low-temperature helium plasma jet: Swarm analysis and global model investigation

- Double diffusion convection of Maxwell–Cattaneo fluids in a vertical slot

- Thermal analysis of extended surfaces using deep neural networks

- Steady-state thermodynamic process in multilayered heterogeneous cylinder

- Multiresponse optimisation and process capability analysis of chemical vapour jet machining for the acrylonitrile butadiene styrene polymer: Unveiling the morphology

- Modeling monkeypox virus transmission: Stability analysis and comparison of analytical techniques

- Fourier spectral method for the fractional-in-space coupled Whitham–Broer–Kaup equations on unbounded domain

- The chaotic behavior and traveling wave solutions of the conformable extended Korteweg–de-Vries model

- Research on optimization of combustor liner structure based on arc-shaped slot hole

- Construction of M-shaped solitons for a modified regularized long-wave equation via Hirota's bilinear method

- Effectiveness of microwave ablation using two simultaneous antennas for liver malignancy treatment

- Discussion on optical solitons, sensitivity and qualitative analysis to a fractional model of ion sound and Langmuir waves with Atangana Baleanu derivatives

- Reliability of two-dimensional steady magnetized Jeffery fluid over shrinking sheet with chemical effect

- Generalized model of thermoelasticity associated with fractional time-derivative operators and its applications to non-simple elastic materials

- Migration of two rigid spheres translating within an infinite couple stress fluid under the impact of magnetic field

- A comparative investigation of neutron and gamma radiation interaction properties of zircaloy-2 and zircaloy-4 with consideration of mechanical properties

- New optical stochastic solutions for the Schrödinger equation with multiplicative Wiener process/random variable coefficients using two different methods

- Physical aspects of quantile residual lifetime sequence

- Synthesis, structure, I–V characteristics, and optical properties of chromium oxide thin films for optoelectronic applications

- Smart mathematically filtered UV spectroscopic methods for quality assurance of rosuvastatin and valsartan from formulation

- A novel investigation into time-fractional multi-dimensional Navier–Stokes equations within Aboodh transform

- Homotopic dynamic solution of hydrodynamic nonlinear natural convection containing superhydrophobicity and isothermally heated parallel plate with hybrid nanoparticles

- A novel tetra hybrid bio-nanofluid model with stenosed artery

- Propagation of traveling wave solution of the strain wave equation in microcrystalline materials

- Innovative analysis to the time-fractional q-deformed tanh-Gordon equation via modified double Laplace transform method

- A new investigation of the extended Sakovich equation for abundant soliton solution in industrial engineering via two efficient techniques

- New soliton solutions of the conformable time fractional Drinfel'd–Sokolov–Wilson equation based on the complete discriminant system method

- Irradiation of hydrophilic acrylic intraocular lenses by a 365 nm UV lamp

- Inflation and the principle of equivalence

- The use of a supercontinuum light source for the characterization of passive fiber optic components

- Optical solitons to the fractional Kundu–Mukherjee–Naskar equation with time-dependent coefficients

- A promising photocathode for green hydrogen generation from sanitation water without external sacrificing agent: silver-silver oxide/poly(1H-pyrrole) dendritic nanocomposite seeded on poly-1H pyrrole film

- Photon balance in the fiber laser model

- Propagation of optical spatial solitons in nematic liquid crystals with quadruple power law of nonlinearity appears in fluid mechanics

- Theoretical investigation and sensitivity analysis of non-Newtonian fluid during roll coating process by response surface methodology

- Utilizing slip conditions on transport phenomena of heat energy with dust and tiny nanoparticles over a wedge

- Bismuthyl chloride/poly(m-toluidine) nanocomposite seeded on poly-1H pyrrole: Photocathode for green hydrogen generation

- Infrared thermography based fault diagnosis of diesel engines using convolutional neural network and image enhancement

- On some solitary wave solutions of the Estevez--Mansfield--Clarkson equation with conformable fractional derivatives in time

- Impact of permeability and fluid parameters in couple stress media on rotating eccentric spheres

- Review Article

- Transformer-based intelligent fault diagnosis methods of mechanical equipment: A survey

- Special Issue on Predicting pattern alterations in nature - Part II

- A comparative study of Bagley–Torvik equation under nonsingular kernel derivatives using Weeks method

- On the existence and numerical simulation of Cholera epidemic model

- Numerical solutions of generalized Atangana–Baleanu time-fractional FitzHugh–Nagumo equation using cubic B-spline functions

- Dynamic properties of the multimalware attacks in wireless sensor networks: Fractional derivative analysis of wireless sensor networks

- Prediction of COVID-19 spread with models in different patterns: A case study of Russia

- Study of chronic myeloid leukemia with T-cell under fractal-fractional order model

- Accumulation process in the environment for a generalized mass transport system

- Analysis of a generalized proportional fractional stochastic differential equation incorporating Carathéodory's approximation and applications

- Special Issue on Nanomaterial utilization and structural optimization - Part II

- Numerical study on flow and heat transfer performance of a spiral-wound heat exchanger for natural gas

- Study of ultrasonic influence on heat transfer and resistance performance of round tube with twisted belt

- Numerical study on bionic airfoil fins used in printed circuit plate heat exchanger

- Improving heat transfer efficiency via optimization and sensitivity assessment in hybrid nanofluid flow with variable magnetism using the Yamada–Ota model

- Special Issue on Nanofluids: Synthesis, Characterization, and Applications

- Exact solutions of a class of generalized nanofluidic models

- Stability enhancement of Al2O3, ZnO, and TiO2 binary nanofluids for heat transfer applications

- Thermal transport energy performance on tangent hyperbolic hybrid nanofluids and their implementation in concentrated solar aircraft wings

- Studying nonlinear vibration analysis of nanoelectro-mechanical resonators via analytical computational method

- Numerical analysis of non-linear radiative Casson fluids containing CNTs having length and radius over permeable moving plate

- Two-phase numerical simulation of thermal and solutal transport exploration of a non-Newtonian nanomaterial flow past a stretching surface with chemical reaction

- Natural convection and flow patterns of Cu–water nanofluids in hexagonal cavity: A novel thermal case study

- Solitonic solutions and study of nonlinear wave dynamics in a Murnaghan hyperelastic circular pipe

- Comparative study of couple stress fluid flow using OHAM and NIM

- Utilization of OHAM to investigate entropy generation with a temperature-dependent thermal conductivity model in hybrid nanofluid using the radiation phenomenon

- Slip effects on magnetized radiatively hybridized ferrofluid flow with acute magnetic force over shrinking/stretching surface

- Significance of 3D rectangular closed domain filled with charged particles and nanoparticles engaging finite element methodology

- Robustness and dynamical features of fractional difference spacecraft model with Mittag–Leffler stability

- Characterizing magnetohydrodynamic effects on developed nanofluid flow in an obstructed vertical duct under constant pressure gradient

- Study on dynamic and static tensile and puncture-resistant mechanical properties of impregnated STF multi-dimensional structure Kevlar fiber reinforced composites

- Thermosolutal Marangoni convective flow of MHD tangent hyperbolic hybrid nanofluids with elastic deformation and heat source

- Investigation of convective heat transport in a Carreau hybrid nanofluid between two stretchable rotatory disks

- Single-channel cooling system design by using perforated porous insert and modeling with POD for double conductive panel

- Special Issue on Fundamental Physics from Atoms to Cosmos - Part I

- Pulsed excitation of a quantum oscillator: A model accounting for damping

- Review of recent analytical advances in the spectroscopy of hydrogenic lines in plasmas

- Heavy mesons mass spectroscopy under a spin-dependent Cornell potential within the framework of the spinless Salpeter equation

- Coherent manipulation of bright and dark solitons of reflection and transmission pulses through sodium atomic medium

- Effect of the gravitational field strength on the rate of chemical reactions

- The kinetic relativity theory – hiding in plain sight

- Special Issue on Advanced Energy Materials - Part III

- Eco-friendly graphitic carbon nitride–poly(1H pyrrole) nanocomposite: A photocathode for green hydrogen production, paving the way for commercial applications