Abstract

Electrostatic adhesion force is analyzed with emphasis on design parameters of the interdigital electrodes, material properties of dielectric layers and its thickness. From these results, two fabrication processes of the electroadhesive foils are studied to reach the highest possible performance. Experimental measurements are carried out to verify the results.

1 Motivation and introduction

The aim of this work is to develop light weight soft-robotic gripper system with emphasis on small size and efficiency for miniature robotic applications. There is no gripper system in use for this kind of application and electrostatic adhesion seems to the be possible solution that will help to solve more complex tasks with miniature robots. A basic idea of discussed gripper utilization is illustrated in Figure 1 in the case of magnetically guided robots with permanent magnets (PMs) [1].

![Figure 1 First ideas of grippers utilization in the case of magnetically guided actuation of miniature robots. Illustration shows three different ideas and also photos of fabricated grippers for developed system MagSnail [2]](/document/doi/10.1515/phys-2018-0059/asset/graphic/j_phys-2018-0059_fig_001.jpg)

First ideas of grippers utilization in the case of magnetically guided actuation of miniature robots. Illustration shows three different ideas and also photos of fabricated grippers for developed system MagSnail [2]

1.1 Theoretical background

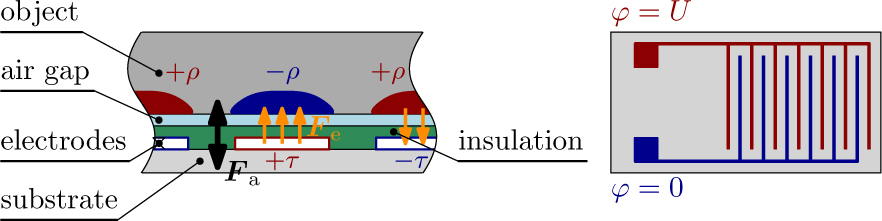

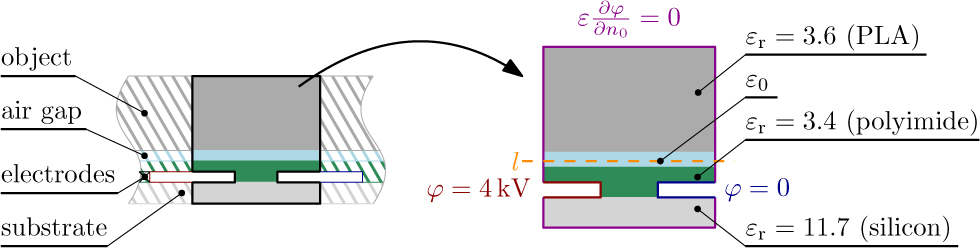

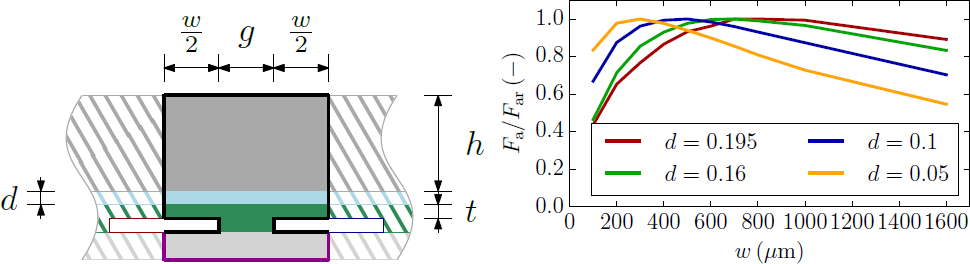

The proposed system uses interdigital electrodes that are placed between two thin dielectric layers (see Figure 2, left). One of the electrodes is connected to the high voltage source U and the other one has potential equal to zero. The electric field that is generated by electrodes can exert adhesive force to various materials. The resulting attractive force Fa is a sum of forces Fe that occur between the region of charges ±ρ in the manipulated materials and electrodes that have opposite charge ±τ. The gripping principle is used without any mechanical damage or chemical reaction [3, 4].

Basic principle of electrostatic adhesion for dielectric object. Left figure shows cross-section of electroadhesive foil with interdigital electodes and right figure top view of the foil

1.2 Design and fabrication

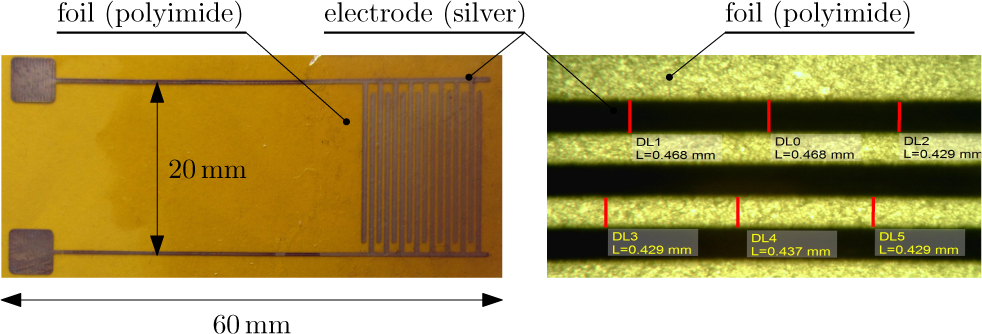

Two different fabrication approaches of electroadhesive foils were studied. The first one is based on Aerosol Jet Printing (AJP)[1]. AJP silver nanoparticle ink is patterned on polyimide (Kapton®, DuPont). Then the nanoparticle ink was cured in the oven. A thin dielectric layer was then applied over electrodes using silicon (Ecoflex 00-30) in the final step. The most advanced prototype has excellent electrical properties (high breakdown voltage, critical electric field Ec = 236 kV ⋅ mm−1), but the mechanical properties lag behind (bending of the sample is limited, not stretchable). The prototype can be seen in Figure 3 together with detail captured by the microscope with optical measurement of precision of the fabrication process. This foil is called flexible.

First prototype of flexible electroadhesive foil fabricated by AJP (left figure shows fabricated foil, right figure shows details captured by microscope)

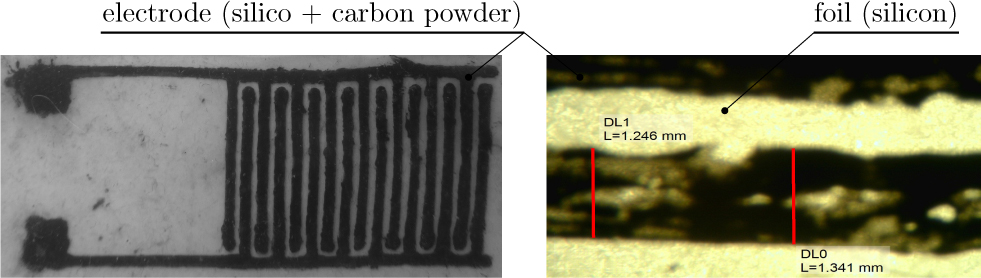

The second method uses only two materials, which are carbon powder (Vulcan XC72, Cabot) and silicon (Ecoflex 00-30, Smooth-On). Material for electrodes must be stretchable as the silicon. This is achieved by mixing the carbon powder and silicon in the weight ratio of 1:5, respectively [5]. Electrodes are patterned on a thin layer of silicon using a simple method of stamping. The stamp was fabricated by 3D printing using PLA material. The final step is to cover the electrodes by a layer of silicon.

This foil has worse electrical properties than the previous one (lower breakdown voltage, critical electric field Ec = 15 kV ⋅ mm−1). On the other hand, mechanical properties of this foil overtake the mechanical properties of the flexible foil (stretchable, able to withstand relative extension up to 200%) [5]. The big advantage of this foil is that both electrodes and insulation layer consist mainly of silicon. This creates strong binding between them. Then, the entire foil acts as one material even during high mechanical extension. This foil is called stretchable.

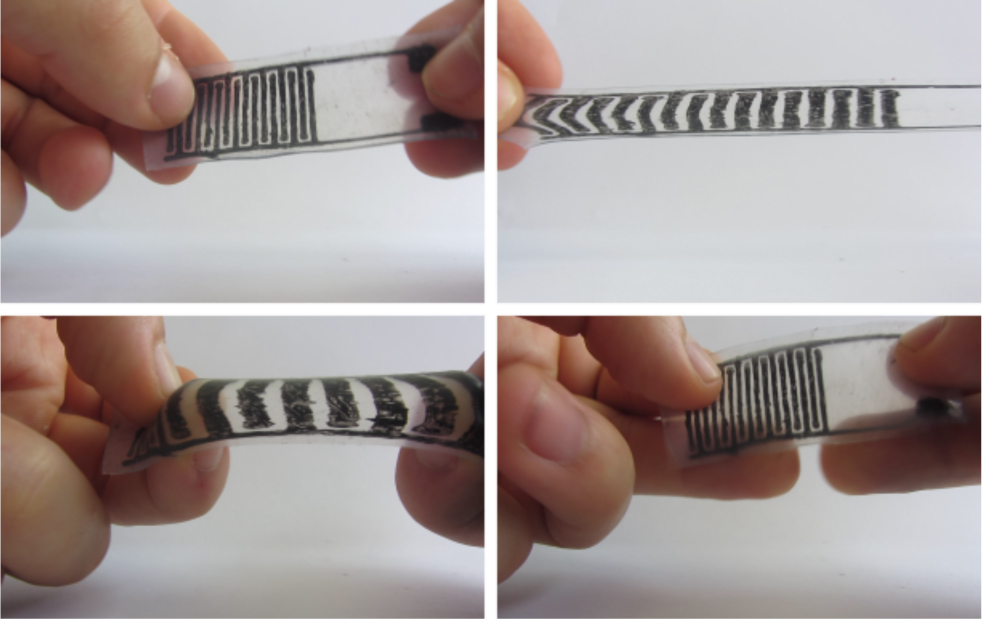

The prototype of elastic electroadhesive foil can be seen in Figure 4 with details captured by microscope with optical measurement of the fabrication precision (scale of the detail in Figure 3 and 4 is the same). It should be noted that the prototype was not fabricated by a machine production and therefore precision and final size of the foil can be significantly improved. Finally, mechanical properties of fabricated foil are shown Figure 5.

First prototype of elastic electroadhesive foil (left figure shows fabricated foil, right figure shows details captured by microscope)

Demonstration of mechanical properties of elastic electroadhesive foil

2 Formulation of mathematical model

The distribution of electric field E within the general electrode system follows from the equation

where ε denotes the permittivity, φ is scalar electric potential (E = −gradφ). Externally generated volume charge density is neglected (attracted material is not previously polarised).

To get results from numerical solution of (1) there is no need to solve the whole surface where the attraction force Fa occurs. The electric field E can be calculated only in one segment that consists of two electrodes with opposite charges. The reason is a repetitive pattern of electrodes [6].

The electrostatic force Fe exerted on the segment can be calculated from the distribution of E using the formula

where T is the Maxwell stress tensor (S being the outward normal to complete boundary of the attracted object). Symbol D represents the dielectric flux density (D = εE), I is unit diagonal matrix and symbol ⊗ denotes the dyadic product [6].

Numerical calculation of (2) can be simplified assuming interdigital electrodes parallel with the surface of attracted object. The Maxwell stress tensor can be then represented as follows

where Ex and Ey are electric field components. Normal direction of electrostatic force Fey acting on the segment with electrodes of length l is then given

Definition area of electroadhesion foil (values of model parameters correspond with fabricated and measured foil)

Let us also mention often used [3] but also rough calculation approach that yields the electrostatic force Fey between the two parallel plates of a capacitor

where We is total energy, Dy is electric displacement field component, V is volume of capacitor, U is applied voltage and t is distance between electrodes.

3 Results and discussions

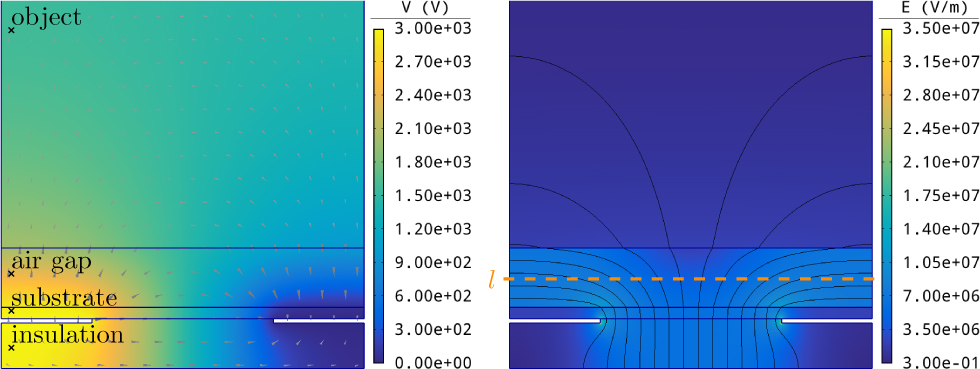

Design analysis of electroadhesive foil was performed by numerical solution of formulated mathematical model (COMSOL Multiphysics and Agros2D was used). Figure 7 shows distribution of scalar electric potential φ and electric field E in the definition area.

Distribution of scalar electric potential φ (left figure) and electric field E (right figure) in the area of electroadhesive foil, air gap and object

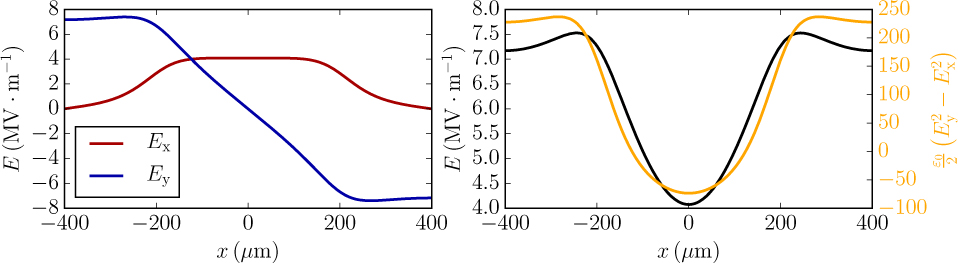

Figure 8 (left figure) shows that on the edge of each electrodes is peak of Maxwell stress tensor component function. Then, the function decreased in the direction to segments axis and reaches minimum there. In opposite direction the function decreased slightly until it reaches electrodes axis and then it rises back to its maximum.

Electric field components Ex, Ey (left figure), electric field E and Mawell stress tensor component

From the experiments, attractive force for U = 3000 V calculated by (2) is Fa = 0.0135 N (Eggshell method), by (3)Fa = 0.0134 N and finally by (4)Fa = 0.4 N. Results are comparable with measurement Fa = 0.0147 N.

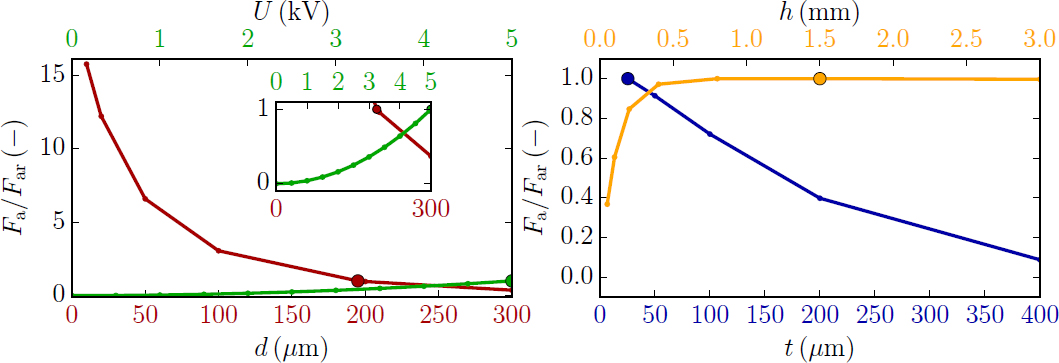

Parameters of the electroadhesive foil with interdigital electrodes are depicted in Figure 9 (bottom left). Figure 9 (top left) shows dependence of electroadhesion force Fa on the air gap d. As can be seen, imperfect contact between the electroadhesive foil and the manipulated object is of huge importance. This implies usage of materials that are strongly stretchable. Influence of air gap can be also slightly reduced by a higher value of applied voltage U but materials with high breakdown voltage have to be used (Figure 9 top left).

Dependency of electroadhesion force on parameter d (red) and U (green) (left figure), t (blue) and h (yellow) (right figure)

Dependencies of electroadhesion force Fa on the thickness of the insulation layer t and height of that manipulated object h are shown in Figure 9 (top right). With higher thickness t, the electroadhesive force rapidly decreases. This also implies usage of insulation materials with high breakdown voltage. If the manipulated object is under 1 mm thick, the adhesion can be reduced to 50% of its full potential. This limits the usage of the electroadhesion to operate on thin films.

Optimization parameters on electroadhesive foil (left figure) and optimization curves of force Fa (right figure)

With fixed width of gap between electrodes g (which is limited by insulation material) ideal width of electrodes w exists (see Figure 9, left). Even though, widening of electrodes increases the electroadhesion force Fa on one segment, this increase cannot compensate the increase in area. This is also true in the opposite direction. If we decrease the width of electrodes w under the optimum width, the saving in length of the segment does not compensate the decrease in the electroadhesion force. The optimum width of electrodes is dependent on air gap d. With thicker air gap the electrode must be wider, because higher values of the electric field are needed.

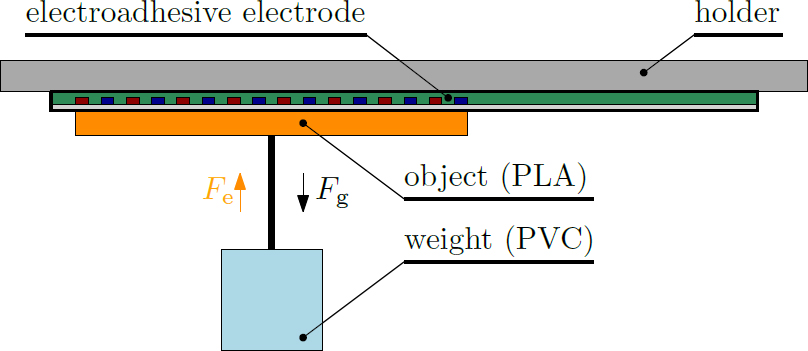

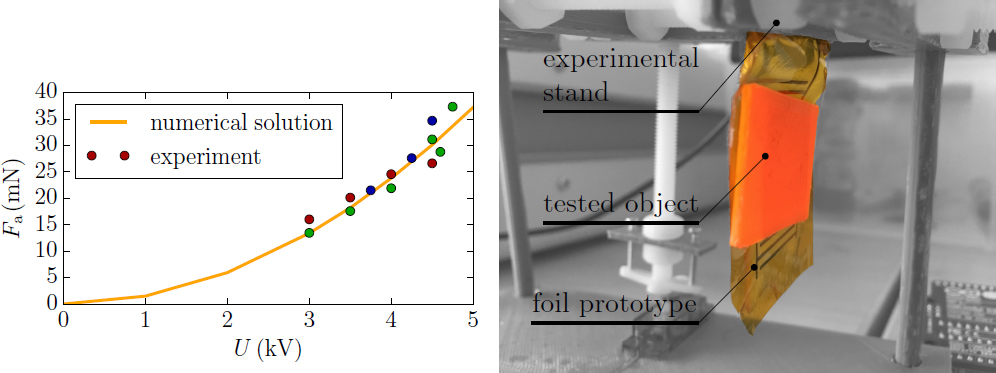

Experimental measurements were done to verify the results of numerical analysis using the electroadhesive foil manufactured by AJP. Figure 11 shows experimental setup for measurement of electrostatic force Fe (horizontal position of the foil minimize adhesion which is not reflected in the formulated mathematical model). Electrostatic force Fe was then measured Fe = Fg.

Arrangement for experimetnal verification

Figure 12 (left) shows results of the measurement and comparison with numerical analysis. The points represent the actual electrostatic forces Fe that were measured. It can be seen that points correspond with the trend of the curve and small differences are caused by air gap d which cannot be measured.

Comparing of experimental measurement and numerical analysis (left figure) and experimental testing of fabricated prototype of electroadhesive foil (right figure)

Finally, Figure 12 (right) shows experimental testing of the electroadhesion prototype (vertical position is shown for better visualization). Experiments were done only with flexible foil. The reason for that is manufacturing precision for stretchable foil which did not meet desired requirements. The width of electrodes was not consistent and voltage breakdown occurred between two opposite electrodes. Therefore the electroadhesive phenomena cannot be seen.

4 Conclusion

The fabrication of the electroadhesive foil demands materials that are stretchable and materials with high breakdown voltage (insulation layer t and air gap d are of huge importance [7]). Materials are subject to future research.

Stretchable electroadhesive foil presented in this paper has big potential in this field of soft robotics. The mechanical properties are on very high level. There is a large space for improvements in electrical properties of silicon. Higher breakdown voltage must be obtained. This can be achieved by using dielectric powders as additives. The identical procedure was used to make conductive silicon by carbon powder. Future investigation for increasing the breakdown voltage of silicon must be made.

Another challenge is the manufacturing process of stretchable foil. Silicon and compounds containing silicon are very tricky to handle. Conventional fabricating method (Screen printing) fail when silicon is used, because of the high surface tension of silicon. This implies that new methods must be developed. Stamping presented in this paper appeared to be the most promising for fabrication of stretchable foil. It is very simple method with relatively high accuracy. As mentioned before there was no machine production and this is the biggest reason why the fabricated foil failed. Quality of patterned electrodes will be increased by using a precise machine production.

By using the most advanced materials and novel fabrication methods, devices using electrostatic electroadhesion effect will perform better and can be used in a variety of applications [8, 9]. One of the examples is space technology (inspection robots, docking system). The main benefits of electroadhesion are the simplicity of mechanism, cheap fabrication and a high ratio of foil weight to object that can handle (1:10 was measured).

Acknowledgement

This research has been supported by the Ministry of Education, Youth and Sports of the Czech Republic under the RICE – New Technologies and Concepts for Smart Industrial Systems, project No. LO1607.

References

[1] Fessl J., Mach F., Navrátil J., Numerical and Experimental Analysis of Electrostatic Adhesion Force Generated by Interdigital Electrodes, 18th International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering, 201710.1109/ISEF.2017.8090706Search in Google Scholar

[2] Kuthan J., Mach F., Magnetically guided actuation of ferromagnetic bodies on the planar surfaces: Numerical modeling and experimental verication, 18th International Conference Computational Problems of Electrical Engineering, 2017Search in Google Scholar

[3] Germann J., Dommer M., Pericet-Camara R., Floreano D., Active connection mechanism for soft modular robots, Advanced Robotics, 26.7, Taylor & Francis, 201210.1163/156855312X626325Search in Google Scholar

[4] Bamber T., Huo J., Singh J., Bigharaz M., Petzing J., Bingham P. A., Justham L., Penders J., Jackson M., Visualization methods for understanding the dynamic electroadhesion phenomenon, Journal of Physics D: Applied Physics, 50.20, 201710.1088/1361-6463/aa6be4Search in Google Scholar

[5] Germann J., Schubert B., Floreano D., Stretchable electroadhesion for soft robots, Intelligent Robots and Systems (IROS 2014), 2014 IEEE/RSJ International Conference on, 201410.1109/IROS.2014.6943115Search in Google Scholar

[6] Cao C., Sun X., Fang Y., Qin Q., Yu A., Feng X., Theoretical model and design of electroadhesive pad with interdigitated electrodes, Materials & Design, 89, Elsevier, 201610.1016/j.matdes.2015.09.162Search in Google Scholar

[7] Huo J., Tailor M., Bamber T., Chamberlain M., Justhamand L., Jackson M., Investigation of relationship between interfacial electroadhesive force and surface texture, Journal of Physics D: Applied Physics, 49.3, 201510.1088/0022-3727/49/3/035303Search in Google Scholar

[8] Chen R., Huang Y., Tang Q., An analytical model for electrostatic adhesive dynamics on dielectric substrates, Journal of Adhesion Science and Technology, 31.11, Elsevier, 201710.1080/01694243.2016.1249689Search in Google Scholar

[9] Chen R., A gecko-inspired electroadhesive wall-climbing robot, IEEE Potentials, 34.2, 201510.1109/MPOT.2014.2360020Search in Google Scholar

[10] Prahlad H., Perline R., Stanford S., Marlow J., Kornbluh R., Electroadhesive robots – wall climbing robots enabled by a novel, robust, and electrically controllable adhesion technology, Robotics and Automation (ICRA), IEEE International Conference on, 200810.1109/ROBOT.2008.4543670Search in Google Scholar

© 2018 Jan Fessl et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 License.

Articles in the same Issue

- Regular Articles

- A modified Fermi-Walker derivative for inextensible flows of binormal spherical image

- Algebraic aspects of evolution partial differential equation arising in the study of constant elasticity of variance model from financial mathematics

- Three-dimensional atom localization via probe absorption in a cascade four-level atomic system

- Determination of the energy transitions and half-lives of Rubidium nuclei

- Three phase heat and mass transfer model for unsaturated soil freezing process: Part 1 - model development

- Three phase heat and mass transfer model for unsaturated soil freezing process: Part 2 - model validation

- Mathematical model for thermal and entropy analysis of thermal solar collectors by using Maxwell nanofluids with slip conditions, thermal radiation and variable thermal conductivity

- Constructing analytic solutions on the Tricomi equation

- Feynman diagrams and rooted maps

- New type of chaos synchronization in discrete-time systems: the F-M synchronization

- Unsteady flow of fractional Oldroyd-B fluids through rotating annulus

- A note on the uniqueness of 2D elastostatic problems formulated by different types of potential functions

- On the conservation laws and solutions of a (2+1) dimensional KdV-mKdV equation of mathematical physics

- Computational methods and traveling wave solutions for the fourth-order nonlinear Ablowitz-Kaup-Newell-Segur water wave dynamical equation via two methods and its applications

- Siewert solutions of transcendental equations, generalized Lambert functions and physical applications

- Numerical solution of mixed convection flow of an MHD Jeffery fluid over an exponentially stretching sheet in the presence of thermal radiation and chemical reaction

- A new three-dimensional chaotic flow with one stable equilibrium: dynamical properties and complexity analysis

- Dynamics of a dry-rebounding drop: observations, simulations, and modeling

- Modeling the initial mechanical response and yielding behavior of gelled crude oil

- Lie symmetry analysis and conservation laws for the time fractional simplified modified Kawahara equation

- Solitary wave solutions of two KdV-type equations

- Applying industrial tomography to control and optimization flow systems

- Reconstructing time series into a complex network to assess the evolution dynamics of the correlations among energy prices

- An optimal solution for software testing case generation based on particle swarm optimization

- Optimal system, nonlinear self-adjointness and conservation laws for generalized shallow water wave equation

- Alternative methods for solving nonlinear two-point boundary value problems

- Global model simulation of OH production in pulsed-DC atmospheric pressure helium-air plasma jets

- Experimental investigation on optical vortex tweezers for microbubble trapping

- Joint measurements of optical parameters by irradiance scintillation and angle-of-arrival fluctuations

- M-polynomials and topological indices of hex-derived networks

- Generalized convergence analysis of the fractional order systems

- Porous flow characteristics of solution-gas drive in tight oil reservoirs

- Complementary wave solutions for the long-short wave resonance model via the extended trial equation method and the generalized Kudryashov method

- A Note on Koide’s Doubly Special Parametrization of Quark Masses

- On right-angled spherical Artin monoid of type Dn

- Gas flow regimes judgement in nanoporous media by digital core analysis

- 4 + n-dimensional water and waves on four and eleven-dimensional manifolds

- Stabilization and Analytic Approximate Solutions of an Optimal Control Problem

- On the equations of electrodynamics in a flat or curved spacetime and a possible interaction energy

- New prediction method for transient productivity of fractured five-spot patterns in low permeability reservoirs at high water cut stages

- The collinear equilibrium points in the restricted three body problem with triaxial primaries

- Detection of the damage threshold of fused silica components and morphologies of repaired damage sites based on the beam deflection method

- On the bivariate spectral quasi-linearization method for solving the two-dimensional Bratu problem

- Ion acoustic quasi-soliton in an electron-positron-ion plasma with superthermal electrons and positrons

- Analysis of projectile motion in view of conformable derivative

- Computing multiple ABC index and multiple GA index of some grid graphs

- Terahertz pulse imaging: A novel denoising method by combing the ant colony algorithm with the compressive sensing

- Characteristics of microscopic pore-throat structure of tight oil reservoirs in Sichuan Basin measured by rate-controlled mercury injection

- An activity window model for social interaction structure on Twitter

- Transient thermal regime trough the constitutive matrix applied to asynchronous electrical machine using the cell method

- On the zagreb polynomials of benzenoid systems

- Integrability analysis of the partial differential equation describing the classical bond-pricing model of mathematical finance

- The Greek parameters of a continuous arithmetic Asian option pricing model via Laplace Adomian decomposition method

- Quantifying the global solar radiation received in Pietermaritzburg, KwaZulu-Natal to motivate the consumption of solar technologies

- Sturm-Liouville difference equations having Bessel and hydrogen atom potential type

- Study on the response characteristics of oil wells after deep profile control in low permeability fractured reservoirs

- Depiction and analysis of a modified theta shaped double negative metamaterial for satellite application

- An attempt to geometrize electromagnetism

- Structure of traveling wave solutions for some nonlinear models via modified mathematical method

- Thermo-convective instability in a rotating ferromagnetic fluid layer with temperature modulation

- Construction of new solitary wave solutions of generalized Zakharov-Kuznetsov-Benjamin-Bona-Mahony and simplified modified form of Camassa-Holm equations

- Effect of magnetic field and heat source on Upper-convected-maxwell fluid in a porous channel

- Physical cues of biomaterials guide stem cell fate of differentiation: The effect of elasticity of cell culture biomaterials

- Shooting method analysis in wire coating withdrawing from a bath of Oldroyd 8-constant fluid with temperature dependent viscosity

- Rank correlation between centrality metrics in complex networks: an empirical study

- Special Issue: The 18th International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering

- Modeling of electric and heat processes in spot resistance welding of cross-wire steel bars

- Dynamic characteristics of triaxial active control magnetic bearing with asymmetric structure

- Design optimization of an axial-field eddy-current magnetic coupling based on magneto-thermal analytical model

- Thermal constitutive matrix applied to asynchronous electrical machine using the cell method

- Temperature distribution around thin electroconductive layers created on composite textile substrates

- Model of the multipolar engine with decreased cogging torque by asymmetrical distribution of the magnets

- Analysis of spatial thermal field in a magnetic bearing

- Use of the mathematical model of the ignition system to analyze the spark discharge, including the destruction of spark plug electrodes

- Assessment of short/long term electric field strength measurements for a pilot district

- Simulation study and experimental results for detection and classification of the transient capacitor inrush current using discrete wavelet transform and artificial intelligence

- Magnetic transmission gear finite element simulation with iron pole hysteresis

- Pulsed excitation terahertz tomography – multiparametric approach

- Low and high frequency model of three phase transformer by frequency response analysis measurement

- Multivariable polynomial fitting of controlled single-phase nonlinear load of input current total harmonic distortion

- Optimal design of a for middle-low-speed maglev trains

- Eddy current modeling in linear and nonlinear multifilamentary composite materials

- The visual attention saliency map for movie retrospection

- AC/DC current ratio in a current superimposition variable flux reluctance machine

- Influence of material uncertainties on the RLC parameters of wound inductors modeled using the finite element method

- Cogging force reduction in linear tubular flux switching permanent-magnet machines

- Modeling hysteresis curves of La(FeCoSi)13 compound near the transition point with the GRUCAD model

- Electro-magneto-hydrodynamic lubrication

- 3-D Electromagnetic field analysis of wireless power transfer system using K computer

- Simplified simulation technique of rotating, induction heated, calender rolls for study of temperature field control

- Design, fabrication and testing of electroadhesive interdigital electrodes

- A method to reduce partial discharges in motor windings fed by PWM inverter

- Reluctance network lumped mechanical & thermal models for the modeling and predesign of concentrated flux synchronous machine

- Special Issue Applications of Nonlinear Dynamics

- Study on dynamic characteristics of silo-stock-foundation interaction system under seismic load

- Microblog topic evolution computing based on LDA algorithm

- Modeling the creep damage effect on the creep crack growth behavior of rotor steel

- Neighborhood condition for all fractional (g, f, n′, m)-critical deleted graphs

- Chinese open information extraction based on DBMCSS in the field of national information resources

- 10.1515/phys-2018-0079

- CPW-fed circularly-polarized antenna array with high front-to-back ratio and low-profile

- Intelligent Monitoring Network Construction based on the utilization of the Internet of things (IoT) in the Metallurgical Coking Process

- Temperature detection technology of power equipment based on Fiber Bragg Grating

- Research on a rotational speed control strategy of the mandrel in a rotary steering system

- Dynamic load balancing algorithm for large data flow in distributed complex networks

- Super-structured photonic crystal fiber Bragg grating biosensor image model based on sparse matrix

- Fractal-based techniques for physiological time series: An updated approach

- Analysis of the Imaging Characteristics of the KB and KBA X-ray Microscopes at Non-coaxial Grazing Incidence

- Application of modified culture Kalman filter in bearing fault diagnosis

- Exact solutions and conservation laws for the modified equal width-Burgers equation

- On topological properties of block shift and hierarchical hypercube networks

- Elastic properties and plane acoustic velocity of cubic Sr2CaMoO6 and Sr2CaWO6 from first-principles calculations

- A note on the transmission feasibility problem in networks

- Ontology learning algorithm using weak functions

- Diagnosis of the power frequency vacuum arc shape based on 2D-PIV

- Parametric simulation analysis and reliability of escalator truss

- A new algorithm for real economy benefit evaluation based on big data analysis

- Synergy analysis of agricultural economic cycle fluctuation based on ant colony algorithm

- Multi-level encryption algorithm for user-related information across social networks

- Multi-target tracking algorithm in intelligent transportation based on wireless sensor network

- Fast recognition method of moving video images based on BP neural networks

- Compressed sensing image restoration algorithm based on improved SURF operator

- Design of load optimal control algorithm for smart grid based on demand response in different scenarios

- Face recognition method based on GA-BP neural network algorithm

- Optimal path selection algorithm for mobile beacons in sensor network under non-dense distribution

- Localization and recognition algorithm for fuzzy anomaly data in big data networks

- Urban road traffic flow control under incidental congestion as a function of accident duration

- Optimization design of reconfiguration algorithm for high voltage power distribution network based on ant colony algorithm

- Feasibility simulation of aseismic structure design for long-span bridges

- Construction of renewable energy supply chain model based on LCA

- The tribological properties study of carbon fabric/ epoxy composites reinforced by nano-TiO2 and MWNTs

- A text-Image feature mapping algorithm based on transfer learning

- Fast recognition algorithm for static traffic sign information

- Topical Issue: Clean Energy: Materials, Processes and Energy Generation

- An investigation of the melting process of RT-35 filled circular thermal energy storage system

- Numerical analysis on the dynamic response of a plate-and-frame membrane humidifier for PEMFC vehicles under various operating conditions

- Energy converting layers for thin-film flexible photovoltaic structures

- Effect of convection heat transfer on thermal energy storage unit

Articles in the same Issue

- Regular Articles

- A modified Fermi-Walker derivative for inextensible flows of binormal spherical image

- Algebraic aspects of evolution partial differential equation arising in the study of constant elasticity of variance model from financial mathematics

- Three-dimensional atom localization via probe absorption in a cascade four-level atomic system

- Determination of the energy transitions and half-lives of Rubidium nuclei

- Three phase heat and mass transfer model for unsaturated soil freezing process: Part 1 - model development

- Three phase heat and mass transfer model for unsaturated soil freezing process: Part 2 - model validation

- Mathematical model for thermal and entropy analysis of thermal solar collectors by using Maxwell nanofluids with slip conditions, thermal radiation and variable thermal conductivity

- Constructing analytic solutions on the Tricomi equation

- Feynman diagrams and rooted maps

- New type of chaos synchronization in discrete-time systems: the F-M synchronization

- Unsteady flow of fractional Oldroyd-B fluids through rotating annulus

- A note on the uniqueness of 2D elastostatic problems formulated by different types of potential functions

- On the conservation laws and solutions of a (2+1) dimensional KdV-mKdV equation of mathematical physics

- Computational methods and traveling wave solutions for the fourth-order nonlinear Ablowitz-Kaup-Newell-Segur water wave dynamical equation via two methods and its applications

- Siewert solutions of transcendental equations, generalized Lambert functions and physical applications

- Numerical solution of mixed convection flow of an MHD Jeffery fluid over an exponentially stretching sheet in the presence of thermal radiation and chemical reaction

- A new three-dimensional chaotic flow with one stable equilibrium: dynamical properties and complexity analysis

- Dynamics of a dry-rebounding drop: observations, simulations, and modeling

- Modeling the initial mechanical response and yielding behavior of gelled crude oil

- Lie symmetry analysis and conservation laws for the time fractional simplified modified Kawahara equation

- Solitary wave solutions of two KdV-type equations

- Applying industrial tomography to control and optimization flow systems

- Reconstructing time series into a complex network to assess the evolution dynamics of the correlations among energy prices

- An optimal solution for software testing case generation based on particle swarm optimization

- Optimal system, nonlinear self-adjointness and conservation laws for generalized shallow water wave equation

- Alternative methods for solving nonlinear two-point boundary value problems

- Global model simulation of OH production in pulsed-DC atmospheric pressure helium-air plasma jets

- Experimental investigation on optical vortex tweezers for microbubble trapping

- Joint measurements of optical parameters by irradiance scintillation and angle-of-arrival fluctuations

- M-polynomials and topological indices of hex-derived networks

- Generalized convergence analysis of the fractional order systems

- Porous flow characteristics of solution-gas drive in tight oil reservoirs

- Complementary wave solutions for the long-short wave resonance model via the extended trial equation method and the generalized Kudryashov method

- A Note on Koide’s Doubly Special Parametrization of Quark Masses

- On right-angled spherical Artin monoid of type Dn

- Gas flow regimes judgement in nanoporous media by digital core analysis

- 4 + n-dimensional water and waves on four and eleven-dimensional manifolds

- Stabilization and Analytic Approximate Solutions of an Optimal Control Problem

- On the equations of electrodynamics in a flat or curved spacetime and a possible interaction energy

- New prediction method for transient productivity of fractured five-spot patterns in low permeability reservoirs at high water cut stages

- The collinear equilibrium points in the restricted three body problem with triaxial primaries

- Detection of the damage threshold of fused silica components and morphologies of repaired damage sites based on the beam deflection method

- On the bivariate spectral quasi-linearization method for solving the two-dimensional Bratu problem

- Ion acoustic quasi-soliton in an electron-positron-ion plasma with superthermal electrons and positrons

- Analysis of projectile motion in view of conformable derivative

- Computing multiple ABC index and multiple GA index of some grid graphs

- Terahertz pulse imaging: A novel denoising method by combing the ant colony algorithm with the compressive sensing

- Characteristics of microscopic pore-throat structure of tight oil reservoirs in Sichuan Basin measured by rate-controlled mercury injection

- An activity window model for social interaction structure on Twitter

- Transient thermal regime trough the constitutive matrix applied to asynchronous electrical machine using the cell method

- On the zagreb polynomials of benzenoid systems

- Integrability analysis of the partial differential equation describing the classical bond-pricing model of mathematical finance

- The Greek parameters of a continuous arithmetic Asian option pricing model via Laplace Adomian decomposition method

- Quantifying the global solar radiation received in Pietermaritzburg, KwaZulu-Natal to motivate the consumption of solar technologies

- Sturm-Liouville difference equations having Bessel and hydrogen atom potential type

- Study on the response characteristics of oil wells after deep profile control in low permeability fractured reservoirs

- Depiction and analysis of a modified theta shaped double negative metamaterial for satellite application

- An attempt to geometrize electromagnetism

- Structure of traveling wave solutions for some nonlinear models via modified mathematical method

- Thermo-convective instability in a rotating ferromagnetic fluid layer with temperature modulation

- Construction of new solitary wave solutions of generalized Zakharov-Kuznetsov-Benjamin-Bona-Mahony and simplified modified form of Camassa-Holm equations

- Effect of magnetic field and heat source on Upper-convected-maxwell fluid in a porous channel

- Physical cues of biomaterials guide stem cell fate of differentiation: The effect of elasticity of cell culture biomaterials

- Shooting method analysis in wire coating withdrawing from a bath of Oldroyd 8-constant fluid with temperature dependent viscosity

- Rank correlation between centrality metrics in complex networks: an empirical study

- Special Issue: The 18th International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering

- Modeling of electric and heat processes in spot resistance welding of cross-wire steel bars

- Dynamic characteristics of triaxial active control magnetic bearing with asymmetric structure

- Design optimization of an axial-field eddy-current magnetic coupling based on magneto-thermal analytical model

- Thermal constitutive matrix applied to asynchronous electrical machine using the cell method

- Temperature distribution around thin electroconductive layers created on composite textile substrates

- Model of the multipolar engine with decreased cogging torque by asymmetrical distribution of the magnets

- Analysis of spatial thermal field in a magnetic bearing

- Use of the mathematical model of the ignition system to analyze the spark discharge, including the destruction of spark plug electrodes

- Assessment of short/long term electric field strength measurements for a pilot district

- Simulation study and experimental results for detection and classification of the transient capacitor inrush current using discrete wavelet transform and artificial intelligence

- Magnetic transmission gear finite element simulation with iron pole hysteresis

- Pulsed excitation terahertz tomography – multiparametric approach

- Low and high frequency model of three phase transformer by frequency response analysis measurement

- Multivariable polynomial fitting of controlled single-phase nonlinear load of input current total harmonic distortion

- Optimal design of a for middle-low-speed maglev trains

- Eddy current modeling in linear and nonlinear multifilamentary composite materials

- The visual attention saliency map for movie retrospection

- AC/DC current ratio in a current superimposition variable flux reluctance machine

- Influence of material uncertainties on the RLC parameters of wound inductors modeled using the finite element method

- Cogging force reduction in linear tubular flux switching permanent-magnet machines

- Modeling hysteresis curves of La(FeCoSi)13 compound near the transition point with the GRUCAD model

- Electro-magneto-hydrodynamic lubrication

- 3-D Electromagnetic field analysis of wireless power transfer system using K computer

- Simplified simulation technique of rotating, induction heated, calender rolls for study of temperature field control

- Design, fabrication and testing of electroadhesive interdigital electrodes

- A method to reduce partial discharges in motor windings fed by PWM inverter

- Reluctance network lumped mechanical & thermal models for the modeling and predesign of concentrated flux synchronous machine

- Special Issue Applications of Nonlinear Dynamics

- Study on dynamic characteristics of silo-stock-foundation interaction system under seismic load

- Microblog topic evolution computing based on LDA algorithm

- Modeling the creep damage effect on the creep crack growth behavior of rotor steel

- Neighborhood condition for all fractional (g, f, n′, m)-critical deleted graphs

- Chinese open information extraction based on DBMCSS in the field of national information resources

- 10.1515/phys-2018-0079

- CPW-fed circularly-polarized antenna array with high front-to-back ratio and low-profile

- Intelligent Monitoring Network Construction based on the utilization of the Internet of things (IoT) in the Metallurgical Coking Process

- Temperature detection technology of power equipment based on Fiber Bragg Grating

- Research on a rotational speed control strategy of the mandrel in a rotary steering system

- Dynamic load balancing algorithm for large data flow in distributed complex networks

- Super-structured photonic crystal fiber Bragg grating biosensor image model based on sparse matrix

- Fractal-based techniques for physiological time series: An updated approach

- Analysis of the Imaging Characteristics of the KB and KBA X-ray Microscopes at Non-coaxial Grazing Incidence

- Application of modified culture Kalman filter in bearing fault diagnosis

- Exact solutions and conservation laws for the modified equal width-Burgers equation

- On topological properties of block shift and hierarchical hypercube networks

- Elastic properties and plane acoustic velocity of cubic Sr2CaMoO6 and Sr2CaWO6 from first-principles calculations

- A note on the transmission feasibility problem in networks

- Ontology learning algorithm using weak functions

- Diagnosis of the power frequency vacuum arc shape based on 2D-PIV

- Parametric simulation analysis and reliability of escalator truss

- A new algorithm for real economy benefit evaluation based on big data analysis

- Synergy analysis of agricultural economic cycle fluctuation based on ant colony algorithm

- Multi-level encryption algorithm for user-related information across social networks

- Multi-target tracking algorithm in intelligent transportation based on wireless sensor network

- Fast recognition method of moving video images based on BP neural networks

- Compressed sensing image restoration algorithm based on improved SURF operator

- Design of load optimal control algorithm for smart grid based on demand response in different scenarios

- Face recognition method based on GA-BP neural network algorithm

- Optimal path selection algorithm for mobile beacons in sensor network under non-dense distribution

- Localization and recognition algorithm for fuzzy anomaly data in big data networks

- Urban road traffic flow control under incidental congestion as a function of accident duration

- Optimization design of reconfiguration algorithm for high voltage power distribution network based on ant colony algorithm

- Feasibility simulation of aseismic structure design for long-span bridges

- Construction of renewable energy supply chain model based on LCA

- The tribological properties study of carbon fabric/ epoxy composites reinforced by nano-TiO2 and MWNTs

- A text-Image feature mapping algorithm based on transfer learning

- Fast recognition algorithm for static traffic sign information

- Topical Issue: Clean Energy: Materials, Processes and Energy Generation

- An investigation of the melting process of RT-35 filled circular thermal energy storage system

- Numerical analysis on the dynamic response of a plate-and-frame membrane humidifier for PEMFC vehicles under various operating conditions

- Energy converting layers for thin-film flexible photovoltaic structures

- Effect of convection heat transfer on thermal energy storage unit