Abstract

A practical examination of the traditional robotic arm (RA) in operation revealed a significant limitation in its ability to control the position of motion. This underscores the urgent need to enhance the current RA’s position control capabilities. Therefore, this study proposes the use of nonlinear differential equations (NDEs) to establish a mathematical model and the design of NDE-based RA motion control algorithms in conjunction with a central pattern generator neural network. A comparison of the control effects showed that the proposed method was highly fitted to the target trajectory. The joint node (JN) motion tracking trajectories of the three RAs were similar, up to 90–85% to the target trajectories of the JNs. In addition, the control of the motion position was similar up to 95–98% to the target motion position trajectories. The motion control algorithm based on NDEs was effective in improving the average execution time of the Pareto optimal frontier of the RA by 58.29%. The joint velocity and angle changes of the three types of RAs under the NDE control algorithm exhibited a high degree of similarity to the fluctuations observed in the expected and predicted curves. These observations contribute to an understanding of the effectiveness of the system observer in observing the joint angle changes. This indicates that the motion control based on NDEs can effectively enhance the tracking effectiveness of the JN positions of the RA, improve the control ability of the RA motion, and increase the joint stability of the RA.

1 Introduction

With the rapid development of modern science and technology, the division of traditional science and research methods continues to innovate, and many natural phenomena in today’s society can be transformed into nonlinear differential equations (NDEs) by the model for solving and description [1,2]. Among them, the research objects in the field of physics are mostly nonlinear systems, and the significance of NDEs in physics research is extremely important [3]. Slyn’ko et al. conducted a multifaceted study of NDE around the stability of Lyapunov functions [4]. The method of applying commutative calculus to linear impulse differential variance was proposed to construct quadratic Lyapunov functions using variable matrices. Moreover, stability was achieved for piecewise constant period matrices [5,6]. A robotic arm (RA) is a type of mechanical device in the robotics industry, which has the advantages of high efficiency and adapting to harsh environments. It gradually becomes the main productive force in the fields of industry and agriculture [7]. However, the current social mechanical devices are updated and iterated at an accelerated rate, and user demand is constantly improving. Furthermore, existing research has demonstrated an inability to control the motion position of robotic RA, which has led to a heightened demand for the control of the motion position of the RA [8,9]. In this context, the study proposes the use of NDE to construct control algorithms on the basis of RA motion, aiming to improve the control efficiency of RA. First, mathematical models (M-M) are designed based on NDE. The control algorithm for utilizing M-M with NDE is constructed according to the model. The aim is to provide a theoretical basis for enhancing the position control capability of M-M motion and strengthening the application research of NDE.

The novelty of the study lies in its use of NDE to establish the M-M of RA, which enhances the precision with which complex dynamic behaviors in RA motion can be captured and described. The study combines the NDE with the central pattern generator (CPG) neural network to develop the RA motion control algorithm (RAMCA), which aims to achieve more natural and efficient control of RA motion by leveraging the CPG neural network’s capacity to simulate biological motion. On this basis, the study achieves a seamless connection from theory to application through the established NDE-based M-M and RAMCA, which improves the theoretical depth of the control algorithm and enhances the effectiveness of the control algorithm in practical applications. Furthermore, the study offers theoretical insight and corroborates the efficacy of the proposed method through empirical RA experimentation, thereby enhancing the overall efficiency and precision of RA, which is of paramount importance for the successful completion of intricate tasks.

Through the NDE-based control algorithm, the motion-tracking accuracy of the RA joint nodes (JNs) is significantly improved. Moreover, the joint stability of the RA is enhanced, which provides a guarantee for the stable operation of the RA in complex environments. The NDE-based RAMCA can significantly improve the execution efficiency of the RA, which is of great significance for improving productivity. This study applies NDE to the field of RA control, which provides new perspectives and methods for the application of NDE to engineering and scientific problems and promotes the development of related theories. Overall, the study demonstrates the potential of multidisciplinary cross-fertilization in solving complex engineering problems by combining mechanical engineering, control theory, and neural network technology and provides new ideas for future research.

The study is divided into four sections. Section 2 summarizes the research findings and limitations on NDE and RA motion both domestically and internationally. In Section 3, the NDE-based RAMCA is examined and developed. In Section 4, experimentation and analysis of the proposed NDE-based RAMCA are conducted. Section 5 summarizes the experimental outcomes while also indicating future research directions.

2 Related works

In recent years, NDEs have played an important role in M-M for science and engineering-related problems, and scholars at home and abroad have conducted relevant studies on the analysis of their algorithms. To obtain solutions for higher-order NDEs, Appalanaidu and Deekshitulu proposed a method to solve the delay and expectation problem for higher-order NDEs. That is, the higher-order differential equations with delay and expectation under mixed conditions are transformed into algebraic equations using polynomials and configuration points and the system of algebraic equations is solved using Newton’s method [10]. To solve the nonlinear Schrödinger equation in isolation by computing the differential form of the new isolated solution, Khan transformed the partial differential equation into a dimensionless nonlinear ordinary differential equation by using an appropriate traveling wave variational. This method realized the variational principle for solving the Schrödinger equation in isolation without the Lagrange multiplier method [11]. In order to realize the M-M construction of semiconductor devices, Chen et al. proposed an efficient dual-mesh method on the Newtonian iteration idea by estimating the solutions of hybrid finite element and eigen-finite element methods, thus obtaining near-optimal solutions to the solved linear equations [12]. In order to optimize the model predictive control algorithms, MarusakPiotr proposed a new set of fuzzy and numerically effective algorithms combining analytical and numerical versions of the model predictive control algorithms. It then proved the control system using two nonlinear control devices that led to a significant increase in the model validity [13]. In order to improve the efficiency of solving differential equations, Jing proposed the use of deep neural networks with oscillating function fitting to solve ordinary differential equations. It led to the establishment of an optimal model for the numerical solution of differential equations and the realization of data simulation to a great extent [14].

With the gradual application of NDE in natural science research, many scholars began to use mathematical tools, such as NDE, to solve physical problems. In order to minimize the error in the parameters of the neural network, Okereke and Maliki proposed a feed-forward inverse layer perceptron neural network based on NDE, which effectively reduces the computational complexity of a given problem [15]. To address the problem of poor stability of the driving system, Chen et al. designed to apply a system of Gray differential equations to the model. Moreover, based on this, the study developed a fuzzy neural network combined with a bat algorithm, thus proving the validity of the system model through the Liapunov-like expression and creating a mathematical framework that can be applied [16]. To obtain the trajectory of the cable motion of the 3D end-effector, Arena et al. proposed to solve it using the total Lagrangian equation as well as the compatibility equation that prescribed the connectivity between the cable and the mass of the end-effector, which revealed that the dynamical representation of the end-effector was realized by the balance of the enhanced linear and angular momentum [17]. In order to solve the controller design and vibration damping problems of the flexible single-link manipulator, Cao and Liu described the flexible single-link manipulator using partial differential equations with Nussbaum-type functions and adaptive laws, which in turn led to efficient control results in simulation experiments [18]. Aiming at the adaptive neural tracking control problem of flexible manipulator systems, Li proposed the use of partial differential equations with boundary conditions to model the flexible manipulator system. Moreover, the study used a neural network technique to deal with the unknown nonlinear function and then realized that the system's full state constraints are satisfied and the closed-loop system signal remains bounded [19].

Taken together, current studies on NDE are focused on equation solving and optimization, while studies on NDEs in physical domains such as RA are mainly focused on achieving efficient control of the operating system. Fewer studies use NDEs for investigating RA motion position control. Therefore, this study proposes to use NDEs to establish RA-related M-M and innovatively combines NDEs with a CPG neural network to construct an NDE-based RAMCA algorithm. Through JN control and joint performance verification, the RA motion position control capability has been further improved, providing theoretical reference for the application of NED in the field of physics.

3 NDE-based M-Ms and their control algorithms

The application fields of NDEs are extremely wide, and the current production puts higher demands on the position control of RA. Using NDEs to improve the RA position control effect or a new way, for this reason, the study utilizes NDEs to establish M-M related to RA, and further attempts to introduce neural network technology combined with NDE. The study proposes that the establishment of NDE-based RAMCA has certain positive significance in improving the RA motion position control, which is conducive to enhancing the value of the application of mathematical tools such as NDEs in physics problems.

3.1 NDE-based M-Ms for RA correlation

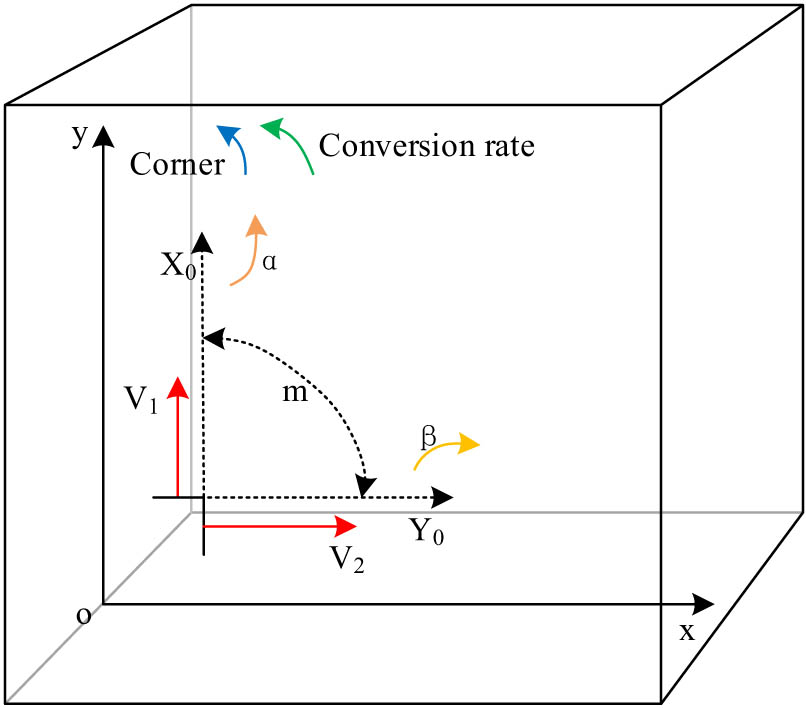

In order to obtain the unit vector angle and rate of rotation in the RA beam unit view, the study utilizes the NDE to establish the M-M. Among them, the setup of the node coordinate positions in the beam unit view is shown in Figure 1.

Layout of node coordinate positions from the perspective of beam elements.

In Figure 1, the choice of node coordinate positions is related to the values taken for the unit vector turn angle and turn rate. Therefore, the study begins with the introduction of Lagrange equations (LE) in order to obtain the geometric stiffness of the unit vector turn angle and turn rate [20,21]. The expression for LE is shown in Eq. (1):

In Eq. (1),

In Eq. (2),

In Eq. (3),

In Eq. (4),

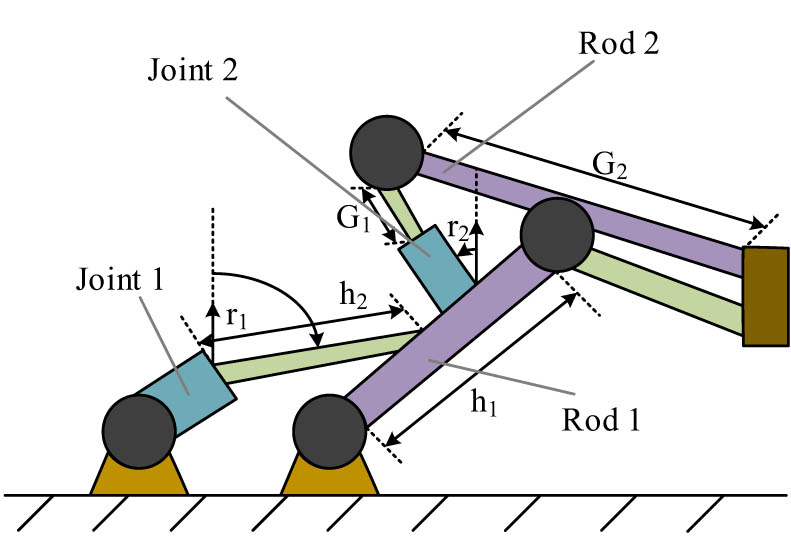

Three-link structure inside the RA.

In Figure 2, the actuation of each joint of the RA is controlled by a hydraulic cylinder at the joint connection. The servo valve of the hydraulic cylinder is closed under normal conditions and opened automatically by the system or manually by hand. The length of the triple link is closely related to the joint angle and the overall motion process of the RA. Therefore, according to the h, G, r motion coordinate system in Figure 2, it is known that the motion trajectory of the random three-link structure inside the RA is shown in Eq. (5):

In Eq. (5),

In Eq. (6),

On this basis, the study takes the kinematic collaboration relationship matrix as the basis, weights the matrix, thus obtaining the dynamic weights of each joint within the RA, and uses the gradient projection method to refine the kinematic weights of the unit joints. The weighted representation is shown in Eq. (8):

In Eq. (8),

In Eq. (9),

In Eq. (10),

In Eq. (11),

In Eq. (12),

3.2 Construction of NDE-based motion control algorithm for RA

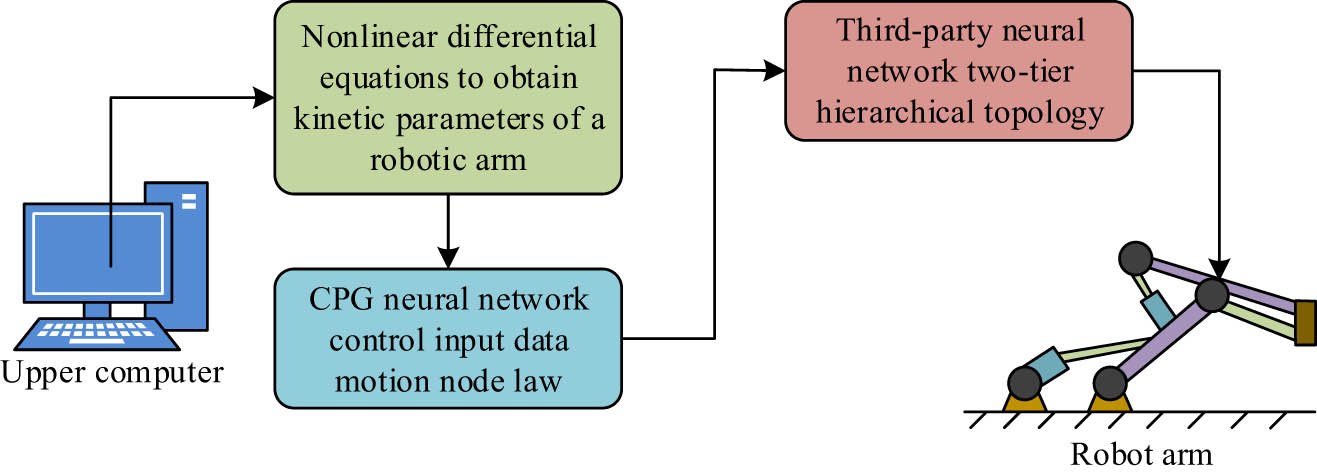

In order to collect the RA motion information of the input data, the study introduces the CPG neural network combined with the M-M of NDEs. The operation of the CPG neural network to control the node regularity of the motion of the input data is determined by the topology of the double-layer level of the third-party neural network [24,25]. In this case, the equation for the topology of the double-layer level of the third-party neural network is shown in Eq. (13):

In Eq. (13)

In Eq. (14),

Algorithmic steps for RA motion control on the basis of NDEs.

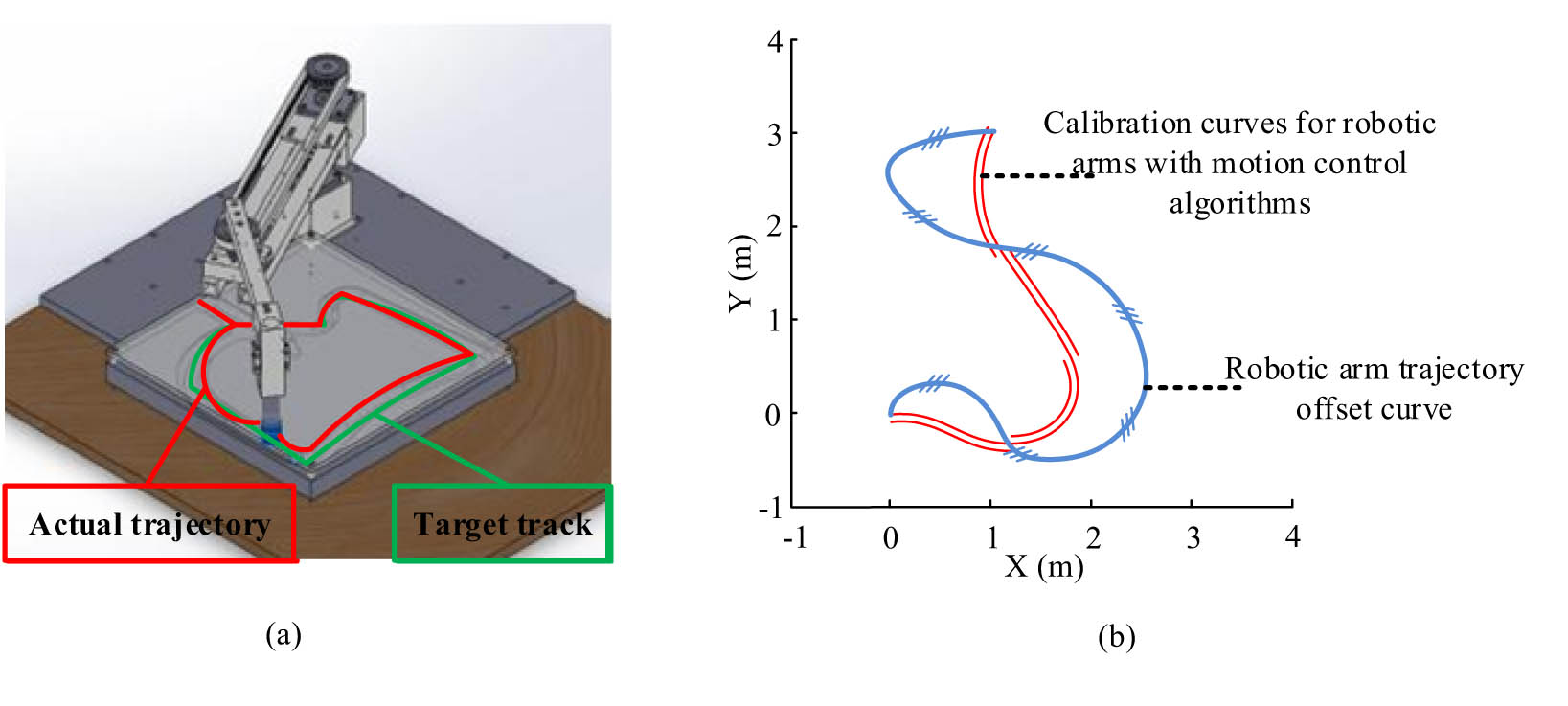

In Figure 3, RAMCA retains the activation and acquisition functions of the CPG neural network and also adds the motion state detection and stabilization performance. It motivates the RA to be able to control the motion profiles more smoothly, thus correcting the RA dynamics error generated by the motion trajectory deviation. In this regard, the calculation equation for the motion control algorithm to correct the RA motion trajectory offset is shown in Eq. (15):

In Eq. (15),

In Figure 4, the CPG-NDE is able to effectively control the motion position of the RA, which in turn improves the productivity of the RA in practical work.

Schematic diagram of motion control algorithm correcting trajectory deviation of RA. (a) Schematic diagram of RA trajectory. (b) Correcting of trajectory deviation using motion control algorithm.

4 Validation of NDE-based motion control algorithm for RA

In order to validate the effectiveness of the proposed NDE-based RAMCA, the study takes three different models of RA as the experimental samples and uses different methods to validate the stability of RA. The main validation contents include the JN of RA, the results of the motion position control as well as the performance of the RA joints, and compares and analyzes the motion control capability of each method based on the validation results.

4.1 Validation of JNs of RA and motion position control results

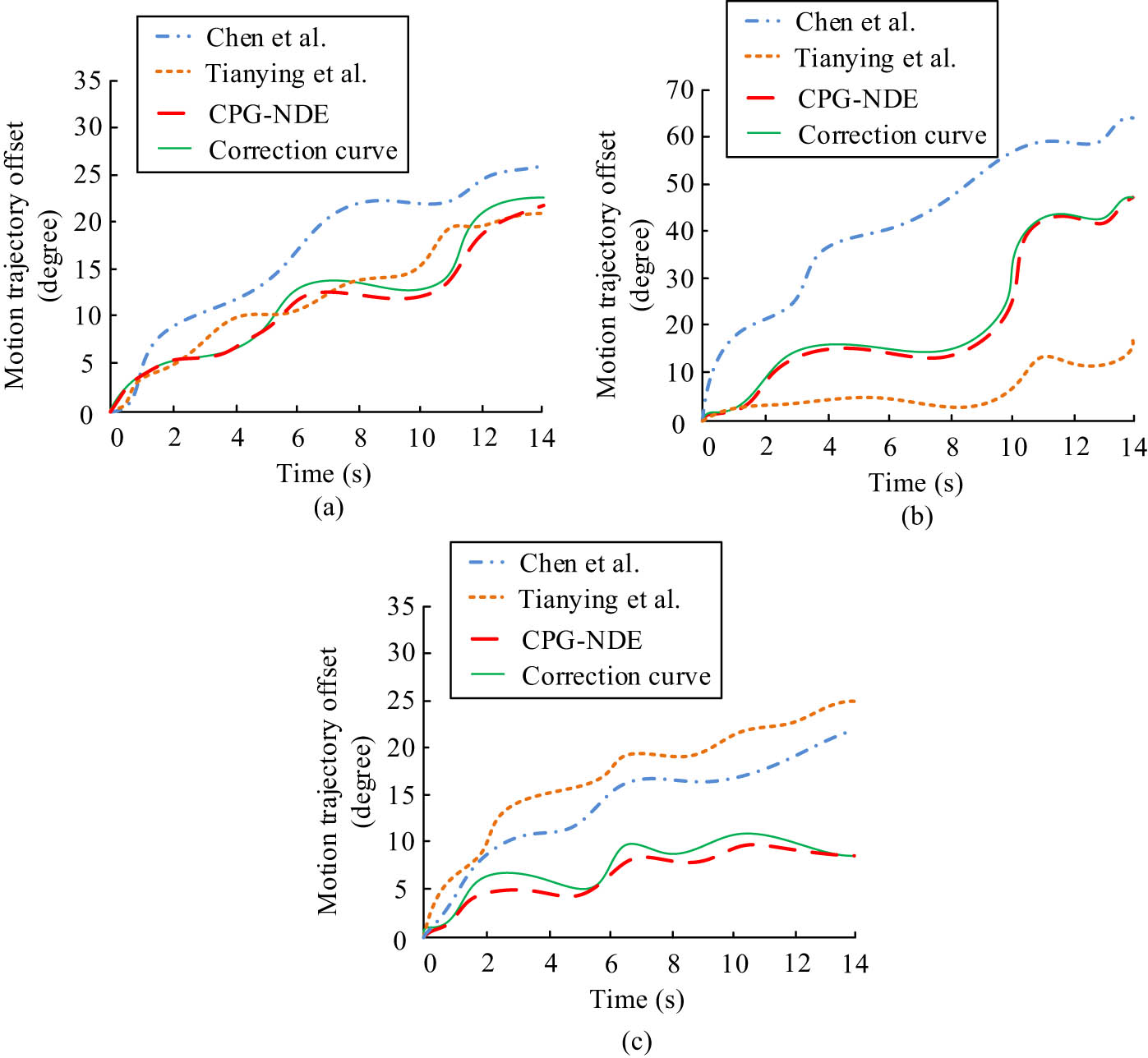

In order to validate the overall effectiveness of the proposed CPG-NDE, the study first validates the JN control and motion position control results of the RA using three different models of RA as samples with different methods. The study used two RA position control methods proposed by Xu et al. and Chen et al. to compare with CPG-NDE, respectively [26,27]. Among them, the JN motion angle tracking results are shown in Figure 5.

Tracking results of different methods for the motion angle of JNs of RA. (a) Tracking results of joint node motion angles of A-type robotic arms using different methods, (b) tracking results of joint node motion angles of B-type robotic arms using different methods, and (c) Tracking results of joint node motion angles of C-type robotic arms using different methods.

In Figure 5, the tracking results of the research-proposed method for the JN motion angles of the three RAs coincide with the JN motion angles of the actual RAs similarly, whereas the tracking results of the motion angles of the JNs of the other two methods show an overall deviation from that of the actual RAs. This indicates that the proposed method of the study is better for JN position tracking and more effective for controlling the JN of RA. Furthermore, the angle of JN motion for different RA models exhibits varying degrees of fluctuating curves, contingent on the specific RA model under consideration. The proposed method of the study incorporates NDE, which is effective in reducing the error of the average tracking results. This may be the reason leading to its better effect on JN control. Meanwhile, the study further compares the control performance of RA motion position under different methods, and the specific results are shown in Figure 6.

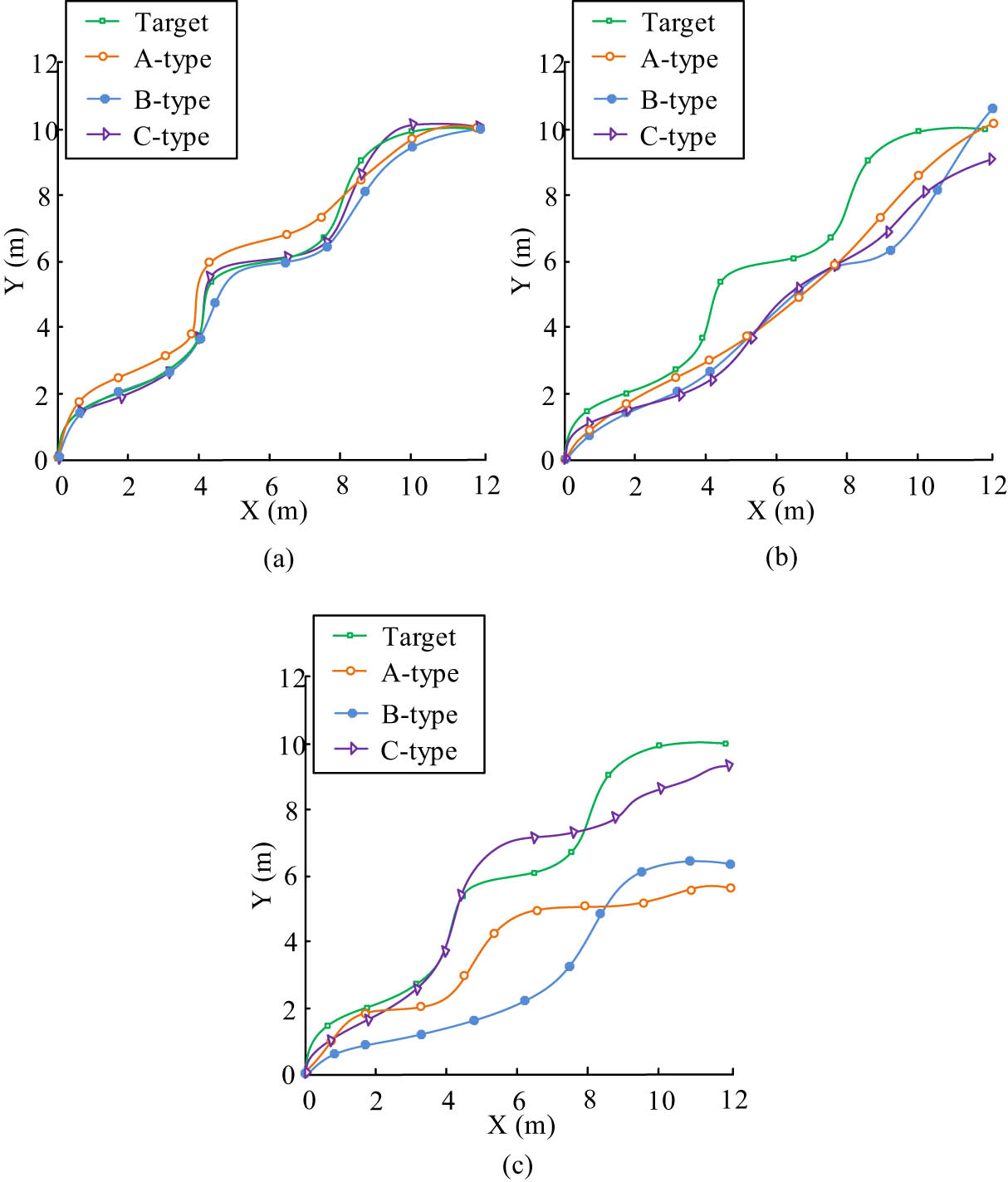

Comparison between the target motion position of the RA and the motion position controlled by three methods. (a) Comparison between the target motion position of the robotic arm and the motion position under CPG-NED control. (b) Comparison between the target motion position of the robotic arm and the motion position under “Tianying et al.” control. (c) Comparison between the target motion position of the robotic arm and the motion position under “Chen et al.” control.

In Figure 6(a), the control of the motion position of the three models of RA under the control of the proposed method of the study is highly consistent with the target motion position, and the motion position of the type C RA is the most effective, which is almost perfectly fitted to the target motion position curve. In Figure 6(b) and (c), the motion positions of the three types of RA under the control of the two methods deviate from the target motion position to a more serious extent, indicating that the effectiveness of the motion position control capability of the two methods is poor. This indicates that the CPG-NDE proposed in the study is more capable of controlling the RA motion position, thus reducing the chance of error in the control system leading to motion trajectory deviation.

4.2 Performance verification of RA joints

In order to verify the joint performance of the RA under CPG-NDE control, we conducted simulation verification experiments in terms of joint velocity variation and joint angle variation. First, the study compares the execution time required to obtain the Pareto-optimal frontier for each of the three types of RA using CPG-NDE and CPG [28]. Moreover, the average execution time curves of the two methods on the three types of RA are obtained by repeating the experiments 30 times with the same desired target position and the attitude of the desired target, and the specific results are shown in Figure 7.

Average execution time curves of different methods on the three types of RAs. (a) CPG-NDE, (b) CPG.

In Figure 7, the execution time of the three RAs under CPG-NDE control to obtain the Pareto-optimal frontier is concentrated in the interval [0.74 s, 0.8 s] and the average execution time is 0.78 s, while the execution time of the three M-Ms under CPG control is concentrated in the interval of [1.8 s, 1.95 s] and the average execution time is 1.87 s, which is higher than the CPG-NBE with a delay of 139.74%. This indicates that RA under CPG-NDE control has a better advantage than CPG in terms of execution time performance. Meanwhile, the study further analyzed the results of CPG-NDE on the three RAs’ joint velocity and angle changes. Among them, the variation of each joint velocity profile of type A RA under CPG-NDE control fed back to the upper computer through the motor is shown in Figure 8.

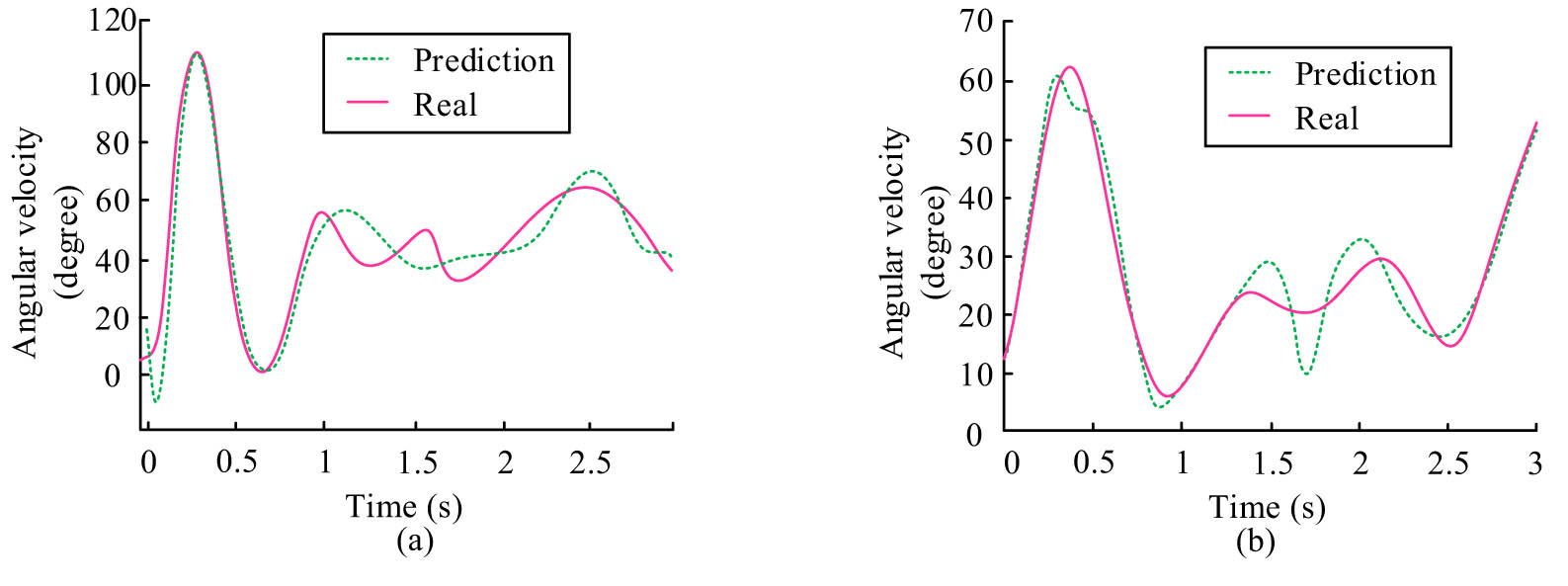

Graph of JN velocity variation of A-type RA. (a) Joint 1 velocity variation diagram. (b) Joint 2 velocity variation diagram.

In Figure 8, the actual change curves of the actual velocities of the two joints of the A-type RA under the control of CPG-NDE fluctuate similarly to the predicted change curves, but there is an error in the range of 0.1–0.5 s. This indicates that the CPG-NDE is effective in controlling the A-type RA. The curve change amplitude of each JN is smooth, and the stability of the RA system is good. The speed change of each joint of the B-type RA under CPG-NDE control is shown in Figure 9.

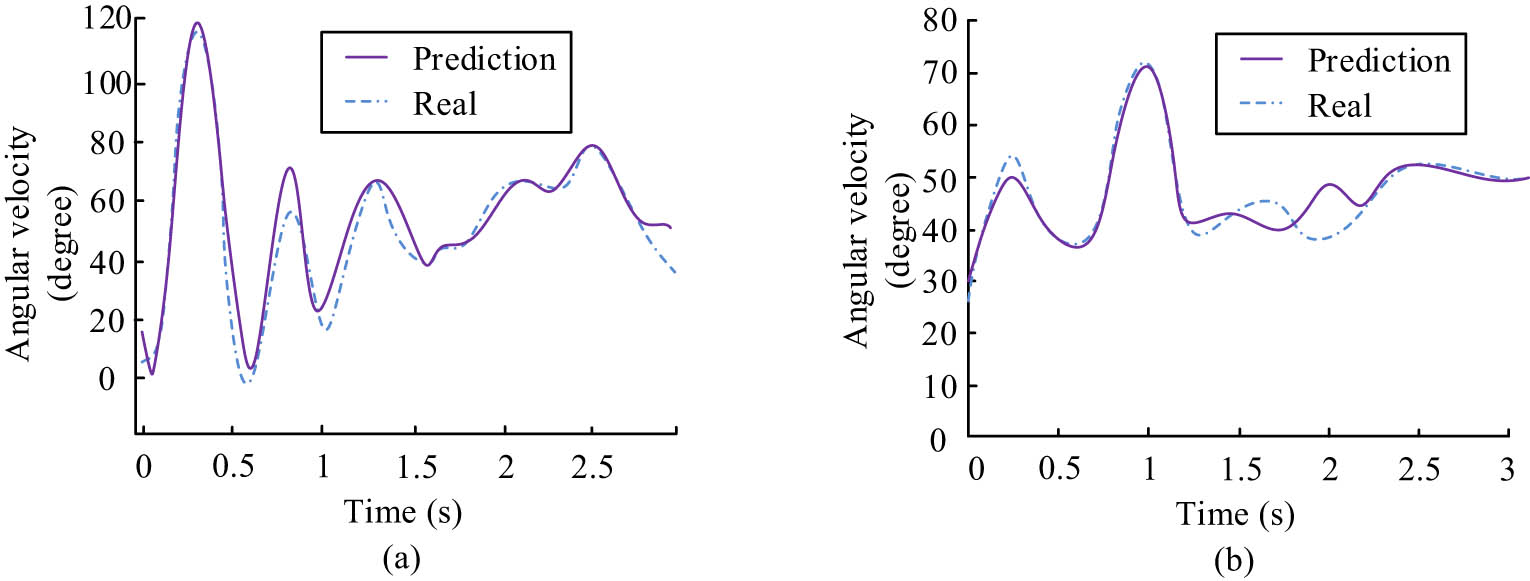

Graph of JN velocity variation of B-type RA. (a) Joint 1 velocity variation diagram. (b) Joint 2 velocity variation diagram.

In Figure 9, the actual change curves of the velocities of the B-type RA joints under CPG-NDE control have more obvious errors with the predicted results, in which the error range of the velocity change of joint 1 is between 0.2 and 1.0 s. However, the actual change curve of joint 2 almost fits the predicted curve, which indicates that the overall performance of the B-type RA joints under CPG-NDE control is better. The velocity change of each joint of the C-type RA under CPG-NDE control is shown in Figure 10.

Graph of JN velocity variation of C-type RA. (a) Joint 1 velocity variation diagram. (b) Joint 2 velocity variation diagram.

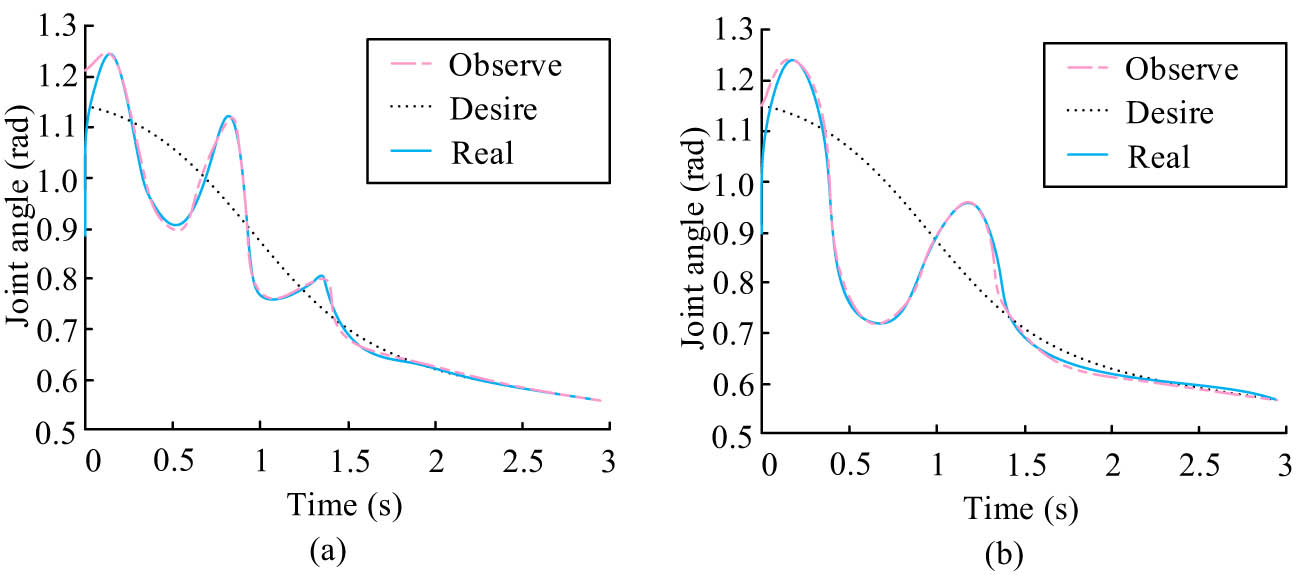

In Figure 10, the error between the actual change and the predicted change of the joint velocity of type C RA is in the range of 0.1–0.3 s, which indicates that the CPG-NDE is more effective in stabilizing the joints of type C RA. Combining the joint velocity changes of the three types of RA, the research-proposed CPG-NDE is more effective in stabilizing the joint points of RA, and all of the change curves show a smooth and steady phenomenon. This indicates that the control algorithm proposed by the study can meet the stability requirements of RA, and the advantages of RA under CPG-NDE control are more obvious. In addition, the joint angle variation of the A-type RA under CPG-NDE control is shown in Figure 11.

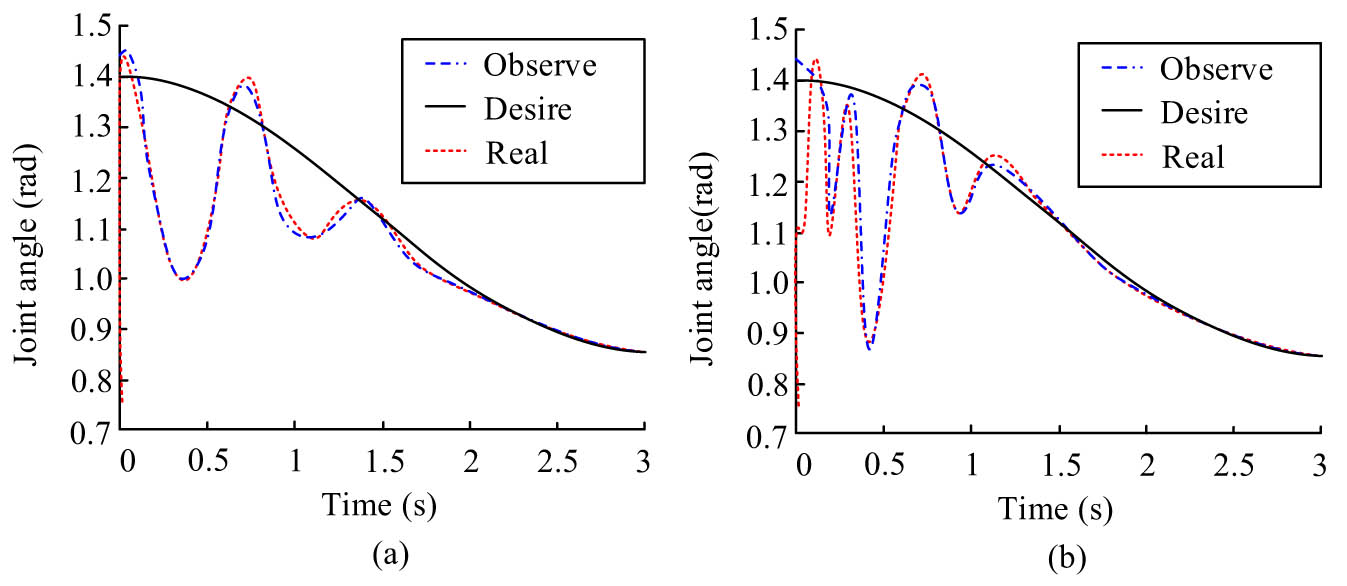

Joint angle changes of A-type RA under CPG-NDE control. (a) Joint 1 angle change curve. (b) Joint 2 angle change curve.

In Figure 11, the joint angle of A-type RA under CPG-NDE control fluctuates significantly in 0–1.5 s, and the fluctuation after 1.5 s almost fits the curve of the desired angle change, which indicates that the stability of the RA joint point is better. Moreover, more than 95% of the curve changes of the actual values have the same trend as the curve changes of the observed values, which indicates that the CPG-NDE is effective in controlling the joints of RA and thus enhances the observation effect of the correlation observer on the changes of the joint angles of RA to a certain extent. The joint angle changes of B-type RA under CPG-NDE control are shown in Figure 12.

Joint angle changes of B-type RA under CPG-NDE control. (a) Joint 1 angle change curve. (b) Joint 2 angle change curve.

In Figure 12, the CPG-NDE proposed in the study is more effective in controlling the B-type RA, and its joint angle change gradually converges to the desired value after 1 s. The joint angle change of the B-type RA under CPG-NDE control is shown in Figure 13, which indicates that the B-type RA is more stable. With the increase of time, the joint angle change decreases, which indicates that the stability of the B-type RA under CPG-NDE control is better. The joint angle change of the C-type RA under CPG-NDE control is shown in Figure 13.

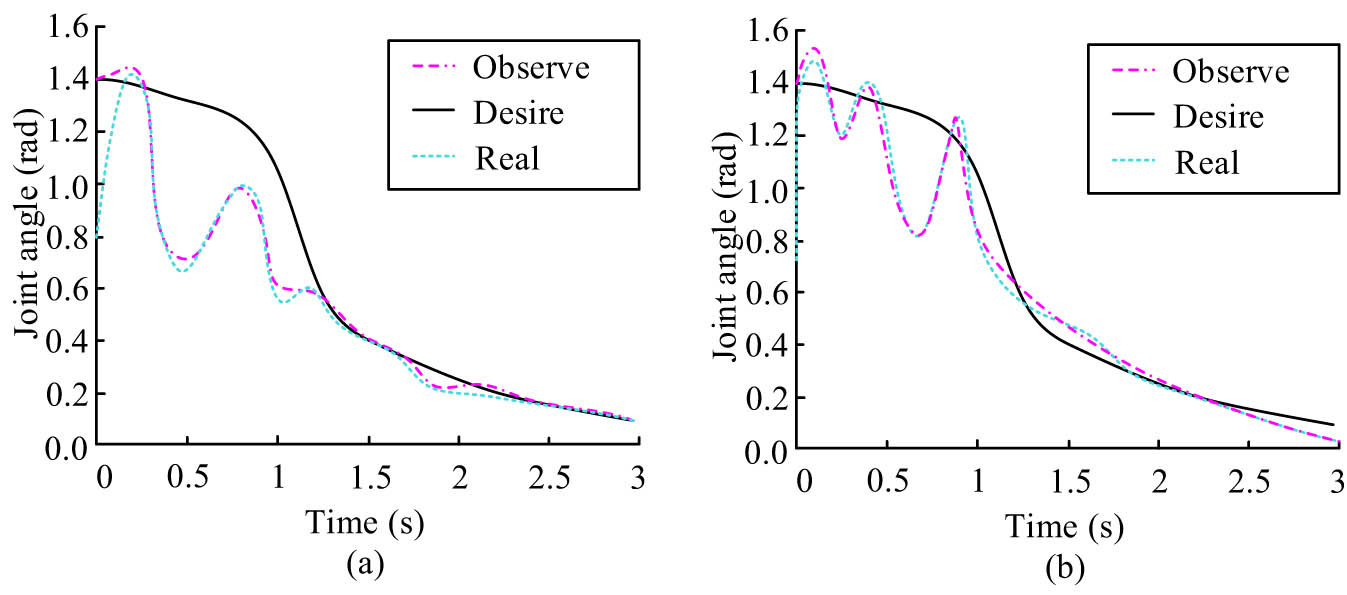

Joint angle changes of B-type RA under CPG-NDE control. (a) Joint 1 angle change curve. (b) Joint 2 angle change curve.

In Figure 13, the joint angle of the C-type RA under CPG-NDE control fluctuates significantly between 0 and 1.3 s compared with the desired value, and the change of its joint angle gradually stabilizes with the increase of time. The above results indicate that the introduction of NDE to control the joint motion position of the RA can effectively enhance the joint stability of the RA, thus obtaining a higher-performance RA operating system.

5 Conclusion

To improve the RA control efficiency, this study designs an algorithm RAMCA for RA motion control by constructing an NDE-based M-M and combining it with a CPG neural network. Experimental validation showed that the algorithm significantly improved the motion control performance of RA in several aspects. The consistency between the JN motion tracking trajectories and the target trajectories of the three types of RAs reached more than 85%, showing good trajectory tracking capability. The motion position control of the RAs had a 98% consistency with the target motion position trajectories. The RAMCA algorithm improved the execution time of the Pareto-optimal frontier of the RAs by 58.29% on average. Under CPG-NDE control, the joint angle and velocity variations of RA of the three robots were highly consistent with the expected and predicted curves. This indicated that the algorithms could effectively enhance the JN position tracking and improve the stability of the robot arm motion control. The above results revealed that the research not only provided a new method for RA motion control but also experimentally verified its effectiveness and superiority in practical applications. In particular, by combining the NDE with the CPG neural network, the study proposed a new control strategy that could improve the motion speed and stability of the robot arm while ensuring position control. Despite the remarkable results of the study, there are still some limitations. For example, the study only analyzes two joints in the structure of a three-link robot arm, and the sample data are analyzed in a narrow range. In the future, the sample data set for the study of RA under CPG-NDE control will be expanded, and the most effective means of increasing the motion speed of the RA machine while maintaining positional control will be investigated. The objective is to enhance the efficiency of production practices.

-

Funding information: This research was supported by 2023 Ordos Vocational College Research Fund Project: “Research on the Integration of Higher Vocational Mathematics Curriculum and Double-creative Talents Training Mode under the Concept of Three Complete Education” (EJSZY2304).

-

Author contributions: Xiaohua Yuan conducted experiments, recorded data, analyzed the results, and wrote the manuscript.

-

Conflict of interest: The author declares no conflict of interest.

-

Data availability statement: The data are provided within the manuscript.

References

[1] Jan A, Boulaaras S, Abdullah FA, Jan R. Dynamical analysis, infections in plants, and preventive policies utilizing the theory of fractional calculus. Eur Phys J Spec Top. 2023;232(14):2497–512.10.1140/epjs/s11734-023-00926-1Search in Google Scholar

[2] Alharbi R, Jan R, Alyobi S, Altayeb Y, Khan Z. Mathematical modeling and stability analysis of the dynamics of monkeypox via fractional-calculus. Fractals. 2022;30(10):2240266.10.1142/S0218348X22402666Search in Google Scholar

[3] Bhatti MM, Sait SM, Ellahi R, Sheremet MA, Oztop H. Thermal analysis and entropy generation of magnetic eyring-powell nanofluid with viscous dissipation in a wavy asymmetric channel. Int J Numer Methods Heat Fluid Flow. 2023;33(5):1609–36.10.1108/HFF-07-2022-0420Search in Google Scholar

[4] Slyn’ko VI, Tunç O, Bivziuk VO. Application of commutator calculus to the study of linear impulsive systems. Syst Control Lett. 2019;123:160–5.10.1016/j.sysconle.2018.10.015Search in Google Scholar

[5] Slyn’ko VI, Tunç C, Bivziuk VO. Robust stabilization of non-linear non-autonomous control systems with periodic linear approximation. IMA J Math Control Inf. 2021;38(1):125–42.10.1093/imamci/dnaa003Search in Google Scholar

[6] Slyn’ko V, Tunç C. Stability of abstract linear switched impulsive differential equations. Automatica. 2019;107:433–41.10.1016/j.automatica.2019.06.001Search in Google Scholar

[7] Xu WH, Cao LJ, Zhong CL. Review of aerial manipulator and its control. Int J Robot Control Syst. 2021;1(3):308–25.10.31763/ijrcs.v1i3.363Search in Google Scholar

[8] Srivastava S. A review on design and fabrication of robotic arm. Int J Robot Autom. 2021;7(2):19–21.Search in Google Scholar

[9] Khan Z, Jawad M, Bonyah E, Khan N, Jan R. Magnetohydrodynamic thin film flow through a porous stretching sheet with the impact of thermal radiation and viscous dissipation. Math Prob Eng. 2022;2022(1):1086847.10.1155/2022/1086847Search in Google Scholar

[10] Appalanaidu V, Deekshitulu GVSR. Bernstein collocation approach for solving nonlinear differential equations with delay and anticipation. Int J Discontinuity Nonlinearity Complex. 2022;11(3):425–34.10.5890/DNC.2022.09.006Search in Google Scholar

[11] Khan Y. Novel solitary wave solution of the nonlinear fractal schrdinger equation and its fractal variational principle. Multidiscip Model Mater Struct. 2021;17(3):630–5.10.1108/MMMS-08-2020-0202Search in Google Scholar

[12] Chen Y, Huang Y, Liu Y, Wang Y. Two-grid method for semiconductor device problem by mixed finite element method and characteristics finite element method. Electron Res Arch. 2021;29(1):1859–80.10.3934/era.2020095Search in Google Scholar

[13] MarusakPiotr MP. A numerically efficient fuzzy mpc algorithm with fast generation of the control signal. Int J Appl Math Comput Sci. 2021;31(1):59–71.10.34768/amcs-2021-0005Search in Google Scholar

[14] Jing L. Data simulation of optimal model for numerical solution of differential equations based on deep learning and genetic algorithm. Soft Comput Fusion Found Methodol App. 2023;27(14):10025–32.10.1007/s00500-023-08208-7Search in Google Scholar

[15] Okereke RN, Maliki OS. Solving riccati-type nonlinear differential equations with novel artificial neural networks. Appl Math. 2021;12(10):919–30.10.4236/am.2021.1210060Search in Google Scholar

[16] Chen ZY, Wang RY, Meng Y, Chen T. Modeling control and forecasting nonlinear systems based on grey signal theory. Int J Uncertain Fuzz Knowl-B Syst. 2023;31(4):649–68.10.1142/S0218488523500307Search in Google Scholar

[17] Arena A, Gattulli V, Ottaviano E. Dynamics of cable-driven parallel manipulators with variable length vibrating cables. Int J Non-Linear Mech. 2023;151(5):1–21.10.1016/j.ijnonlinmec.2023.104382Search in Google Scholar

[18] Cao F, Liu J. Boundary control for pde flexible manipulators: accommodation to both actuator faults and sensor faults. Asian J Control. 2022;24(4):1700–12.10.1002/asjc.2560Search in Google Scholar

[19] Li XY. Adaptive neural boundary control for state constrained flexible manipulators. Int J Adapt Control Signal Process. 2023;37(8):2184–203.10.1002/acs.3633Search in Google Scholar

[20] Sheng X, Quan Q, Yu J, Mao X, Jiang W. Tide-induced lagrangian residual velocity and dynamic analysis based on field observations in the inner xiangshan bay, China. Acta Oceanol Sin. 2022;41(10):32–40.10.1007/s13131-022-2007-3Search in Google Scholar

[21] Yamaguchi T, Takayama K, Hirose N. Quantitative relationships between autumn catches of swordtip squid (uroteuthis edulis) and oceanic conditions to the east of tsushima islands, japan. Am J Mar Sci. 2021;9(1):16–25.Search in Google Scholar

[22] Arnous AH, Hashemi MS, Nisar KS, Shakeel M, Ahmad J, Ahmad I, et al. Investigating solitary wave solutions with enhanced algebraic method for new extended Sakovich equations in fluid dynamics. Results Phys. 2024;57:107369.10.1016/j.rinp.2024.107369Search in Google Scholar

[23] Haiour M, Le Hocine MEAB, Jan R, Himadan A, Boulaaras S. Existence and uniqueness for the evolutionary impulse control problem using an asynchronous algorithms. Partial Differ Equ Appl Math. 2024;11:100766.10.1016/j.padiff.2024.100766Search in Google Scholar

[24] Fu ZT, Wang JY, Liu Y, Xiong JM, Zhang GW. The mechanism of tcm prevention and treatment of heavy covid-19 based on data mining and network pharmacology. Comb Drug Ther. 2023;5(2):30–9.10.53388/DCT20230010Search in Google Scholar

[25] Wei SX, Wu H, Liu L, Zhang YX, Chen J, Li Q. A cpg-based gait planning and motion performance analysis for quadruped robot. Ind Robot. 2022;49(4):779–97.10.1108/IR-08-2021-0181Search in Google Scholar

[26] Xu TY, Zhou HB, Tan SX, Li ZQ, Ju X, Peng YC. Mechanical arm obstacle avoidance path planning based on improved artificial potential field method. Ind Robot. 2022;49(2):271–9.10.1108/IR-06-2021-0120Search in Google Scholar

[27] Chen L, Sun H, Zhao W, Yu T. Ai based gravity compensation algorithm and simulation of load end of robotic arm wrist force. Math Prob Eng. 2021;2021(8):1–11.10.1155/2021/5551544Search in Google Scholar

[28] Guo S, Geng Z, Yuan J. Single-machine pareto-scheduling with multiple weighting vectors for minimizing the total weighted late works. J Ind Manage Optim.2023;19(1):456–71.10.3934/jimo.2021192Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Editorial

- Focus on NLENG 2023 Volume 12 Issue 1

- Research Articles

- Seismic vulnerability signal analysis of low tower cable-stayed bridges method based on convolutional attention network

- Robust passivity-based nonlinear controller design for bilateral teleoperation system under variable time delay and variable load disturbance

- A physically consistent AI-based SPH emulator for computational fluid dynamics

- Asymmetrical novel hyperchaotic system with two exponential functions and an application to image encryption

- A novel framework for effective structural vulnerability assessment of tubular structures using machine learning algorithms (GA and ANN) for hybrid simulations

- Flow and irreversible mechanism of pure and hybridized non-Newtonian nanofluids through elastic surfaces with melting effects

- Stability analysis of the corruption dynamics under fractional-order interventions

- Solutions of certain initial-boundary value problems via a new extended Laplace transform

- Numerical solution of two-dimensional fractional differential equations using Laplace transform with residual power series method

- Fractional-order lead networks to avoid limit cycle in control loops with dead zone and plant servo system

- Modeling anomalous transport in fractal porous media: A study of fractional diffusion PDEs using numerical method

- Analysis of nonlinear dynamics of RC slabs under blast loads: A hybrid machine learning approach

- On theoretical and numerical analysis of fractal--fractional non-linear hybrid differential equations

- Traveling wave solutions, numerical solutions, and stability analysis of the (2+1) conformal time-fractional generalized q-deformed sinh-Gordon equation

- Influence of damage on large displacement buckling analysis of beams

- Approximate numerical procedures for the Navier–Stokes system through the generalized method of lines

- Mathematical analysis of a combustible viscoelastic material in a cylindrical channel taking into account induced electric field: A spectral approach

- A new operational matrix method to solve nonlinear fractional differential equations

- New solutions for the generalized q-deformed wave equation with q-translation symmetry

- Optimize the corrosion behaviour and mechanical properties of AISI 316 stainless steel under heat treatment and previous cold working

- Soliton dynamics of the KdV–mKdV equation using three distinct exact methods in nonlinear phenomena

- Investigation of the lubrication performance of a marine diesel engine crankshaft using a thermo-electrohydrodynamic model

- Modeling credit risk with mixed fractional Brownian motion: An application to barrier options

- Method of feature extraction of abnormal communication signal in network based on nonlinear technology

- An innovative binocular vision-based method for displacement measurement in membrane structures

- An analysis of exponential kernel fractional difference operator for delta positivity

- Novel analytic solutions of strain wave model in micro-structured solids

- Conditions for the existence of soliton solutions: An analysis of coefficients in the generalized Wu–Zhang system and generalized Sawada–Kotera model

- Scale-3 Haar wavelet-based method of fractal-fractional differential equations with power law kernel and exponential decay kernel

- Non-linear influences of track dynamic irregularities on vertical levelling loss of heavy-haul railway track geometry under cyclic loadings

- Fast analysis approach for instability problems of thin shells utilizing ANNs and a Bayesian regularization back-propagation algorithm

- Validity and error analysis of calculating matrix exponential function and vector product

- Optimizing execution time and cost while scheduling scientific workflow in edge data center with fault tolerance awareness

- Estimating the dynamics of the drinking epidemic model with control interventions: A sensitivity analysis

- Online and offline physical education quality assessment based on mobile edge computing

- Discovering optical solutions to a nonlinear Schrödinger equation and its bifurcation and chaos analysis

- New convolved Fibonacci collocation procedure for the Fitzhugh–Nagumo non-linear equation

- Study of weakly nonlinear double-diffusive magneto-convection with throughflow under concentration modulation

- Variable sampling time discrete sliding mode control for a flapping wing micro air vehicle using flapping frequency as the control input

- Error analysis of arbitrarily high-order stepping schemes for fractional integro-differential equations with weakly singular kernels

- Solitary and periodic pattern solutions for time-fractional generalized nonlinear Schrödinger equation

- An unconditionally stable numerical scheme for solving nonlinear Fisher equation

- Effect of modulated boundary on heat and mass transport of Walter-B viscoelastic fluid saturated in porous medium

- Analysis of heat mass transfer in a squeezed Carreau nanofluid flow due to a sensor surface with variable thermal conductivity

- Navigating waves: Advancing ocean dynamics through the nonlinear Schrödinger equation

- Experimental and numerical investigations into torsional-flexural behaviours of railway composite sleepers and bearers

- Novel dynamics of the fractional KFG equation through the unified and unified solver schemes with stability and multistability analysis

- Analysis of the magnetohydrodynamic effects on non-Newtonian fluid flow in an inclined non-uniform channel under long-wavelength, low-Reynolds number conditions

- Convergence analysis of non-matching finite elements for a linear monotone additive Schwarz scheme for semi-linear elliptic problems

- Global well-posedness and exponential decay estimates for semilinear Newell–Whitehead–Segel equation

- Petrov-Galerkin method for small deflections in fourth-order beam equations in civil engineering

- Solution of third-order nonlinear integro-differential equations with parallel computing for intelligent IoT and wireless networks using the Haar wavelet method

- Mathematical modeling and computational analysis of hepatitis B virus transmission using the higher-order Galerkin scheme

- Mathematical model based on nonlinear differential equations and its control algorithm

- Bifurcation and chaos: Unraveling soliton solutions in a couple fractional-order nonlinear evolution equation

- Space–time variable-order carbon nanotube model using modified Atangana–Baleanu–Caputo derivative

- Minimal universal laser network model: Synchronization, extreme events, and multistability

- Valuation of forward start option with mean reverting stock model for uncertain markets

- Geometric nonlinear analysis based on the generalized displacement control method and orthogonal iteration

- Fuzzy neural network with backpropagation for fuzzy quadratic programming problems and portfolio optimization problems

- B-spline curve theory: An overview and applications in real life

- Nonlinearity modeling for online estimation of industrial cooling fan speed subject to model uncertainties and state-dependent measurement noise

- Quantitative analysis and modeling of ride sharing behavior based on internet of vehicles

- Review Article

- Bond performance of recycled coarse aggregate concrete with rebar under freeze–thaw environment: A review

- Retraction

- Retraction of “Convolutional neural network for UAV image processing and navigation in tree plantations based on deep learning”

- Special Issue: Dynamic Engineering and Control Methods for the Nonlinear Systems - Part II

- Improved nonlinear model predictive control with inequality constraints using particle filtering for nonlinear and highly coupled dynamical systems

- Anti-control of Hopf bifurcation for a chaotic system

- Special Issue: Decision and Control in Nonlinear Systems - Part I

- Addressing target loss and actuator saturation in visual servoing of multirotors: A nonrecursive augmented dynamics control approach

- Collaborative control of multi-manipulator systems in intelligent manufacturing based on event-triggered and adaptive strategy

- Greenhouse monitoring system integrating NB-IOT technology and a cloud service framework

- Special Issue: Unleashing the Power of AI and ML in Dynamical System Research

- Computational analysis of the Covid-19 model using the continuous Galerkin–Petrov scheme

- Special Issue: Nonlinear Analysis and Design of Communication Networks for IoT Applications - Part I

- Research on the role of multi-sensor system information fusion in improving hardware control accuracy of intelligent system

- Advanced integration of IoT and AI algorithms for comprehensive smart meter data analysis in smart grids

Articles in the same Issue

- Editorial

- Focus on NLENG 2023 Volume 12 Issue 1

- Research Articles

- Seismic vulnerability signal analysis of low tower cable-stayed bridges method based on convolutional attention network

- Robust passivity-based nonlinear controller design for bilateral teleoperation system under variable time delay and variable load disturbance

- A physically consistent AI-based SPH emulator for computational fluid dynamics

- Asymmetrical novel hyperchaotic system with two exponential functions and an application to image encryption

- A novel framework for effective structural vulnerability assessment of tubular structures using machine learning algorithms (GA and ANN) for hybrid simulations

- Flow and irreversible mechanism of pure and hybridized non-Newtonian nanofluids through elastic surfaces with melting effects

- Stability analysis of the corruption dynamics under fractional-order interventions

- Solutions of certain initial-boundary value problems via a new extended Laplace transform

- Numerical solution of two-dimensional fractional differential equations using Laplace transform with residual power series method

- Fractional-order lead networks to avoid limit cycle in control loops with dead zone and plant servo system

- Modeling anomalous transport in fractal porous media: A study of fractional diffusion PDEs using numerical method

- Analysis of nonlinear dynamics of RC slabs under blast loads: A hybrid machine learning approach

- On theoretical and numerical analysis of fractal--fractional non-linear hybrid differential equations

- Traveling wave solutions, numerical solutions, and stability analysis of the (2+1) conformal time-fractional generalized q-deformed sinh-Gordon equation

- Influence of damage on large displacement buckling analysis of beams

- Approximate numerical procedures for the Navier–Stokes system through the generalized method of lines

- Mathematical analysis of a combustible viscoelastic material in a cylindrical channel taking into account induced electric field: A spectral approach

- A new operational matrix method to solve nonlinear fractional differential equations

- New solutions for the generalized q-deformed wave equation with q-translation symmetry

- Optimize the corrosion behaviour and mechanical properties of AISI 316 stainless steel under heat treatment and previous cold working

- Soliton dynamics of the KdV–mKdV equation using three distinct exact methods in nonlinear phenomena

- Investigation of the lubrication performance of a marine diesel engine crankshaft using a thermo-electrohydrodynamic model

- Modeling credit risk with mixed fractional Brownian motion: An application to barrier options

- Method of feature extraction of abnormal communication signal in network based on nonlinear technology

- An innovative binocular vision-based method for displacement measurement in membrane structures

- An analysis of exponential kernel fractional difference operator for delta positivity

- Novel analytic solutions of strain wave model in micro-structured solids

- Conditions for the existence of soliton solutions: An analysis of coefficients in the generalized Wu–Zhang system and generalized Sawada–Kotera model

- Scale-3 Haar wavelet-based method of fractal-fractional differential equations with power law kernel and exponential decay kernel

- Non-linear influences of track dynamic irregularities on vertical levelling loss of heavy-haul railway track geometry under cyclic loadings

- Fast analysis approach for instability problems of thin shells utilizing ANNs and a Bayesian regularization back-propagation algorithm

- Validity and error analysis of calculating matrix exponential function and vector product

- Optimizing execution time and cost while scheduling scientific workflow in edge data center with fault tolerance awareness

- Estimating the dynamics of the drinking epidemic model with control interventions: A sensitivity analysis

- Online and offline physical education quality assessment based on mobile edge computing

- Discovering optical solutions to a nonlinear Schrödinger equation and its bifurcation and chaos analysis

- New convolved Fibonacci collocation procedure for the Fitzhugh–Nagumo non-linear equation

- Study of weakly nonlinear double-diffusive magneto-convection with throughflow under concentration modulation

- Variable sampling time discrete sliding mode control for a flapping wing micro air vehicle using flapping frequency as the control input

- Error analysis of arbitrarily high-order stepping schemes for fractional integro-differential equations with weakly singular kernels

- Solitary and periodic pattern solutions for time-fractional generalized nonlinear Schrödinger equation

- An unconditionally stable numerical scheme for solving nonlinear Fisher equation

- Effect of modulated boundary on heat and mass transport of Walter-B viscoelastic fluid saturated in porous medium

- Analysis of heat mass transfer in a squeezed Carreau nanofluid flow due to a sensor surface with variable thermal conductivity

- Navigating waves: Advancing ocean dynamics through the nonlinear Schrödinger equation

- Experimental and numerical investigations into torsional-flexural behaviours of railway composite sleepers and bearers

- Novel dynamics of the fractional KFG equation through the unified and unified solver schemes with stability and multistability analysis

- Analysis of the magnetohydrodynamic effects on non-Newtonian fluid flow in an inclined non-uniform channel under long-wavelength, low-Reynolds number conditions

- Convergence analysis of non-matching finite elements for a linear monotone additive Schwarz scheme for semi-linear elliptic problems

- Global well-posedness and exponential decay estimates for semilinear Newell–Whitehead–Segel equation

- Petrov-Galerkin method for small deflections in fourth-order beam equations in civil engineering

- Solution of third-order nonlinear integro-differential equations with parallel computing for intelligent IoT and wireless networks using the Haar wavelet method

- Mathematical modeling and computational analysis of hepatitis B virus transmission using the higher-order Galerkin scheme

- Mathematical model based on nonlinear differential equations and its control algorithm

- Bifurcation and chaos: Unraveling soliton solutions in a couple fractional-order nonlinear evolution equation

- Space–time variable-order carbon nanotube model using modified Atangana–Baleanu–Caputo derivative

- Minimal universal laser network model: Synchronization, extreme events, and multistability

- Valuation of forward start option with mean reverting stock model for uncertain markets

- Geometric nonlinear analysis based on the generalized displacement control method and orthogonal iteration

- Fuzzy neural network with backpropagation for fuzzy quadratic programming problems and portfolio optimization problems

- B-spline curve theory: An overview and applications in real life

- Nonlinearity modeling for online estimation of industrial cooling fan speed subject to model uncertainties and state-dependent measurement noise

- Quantitative analysis and modeling of ride sharing behavior based on internet of vehicles

- Review Article

- Bond performance of recycled coarse aggregate concrete with rebar under freeze–thaw environment: A review

- Retraction

- Retraction of “Convolutional neural network for UAV image processing and navigation in tree plantations based on deep learning”

- Special Issue: Dynamic Engineering and Control Methods for the Nonlinear Systems - Part II

- Improved nonlinear model predictive control with inequality constraints using particle filtering for nonlinear and highly coupled dynamical systems

- Anti-control of Hopf bifurcation for a chaotic system

- Special Issue: Decision and Control in Nonlinear Systems - Part I

- Addressing target loss and actuator saturation in visual servoing of multirotors: A nonrecursive augmented dynamics control approach

- Collaborative control of multi-manipulator systems in intelligent manufacturing based on event-triggered and adaptive strategy

- Greenhouse monitoring system integrating NB-IOT technology and a cloud service framework

- Special Issue: Unleashing the Power of AI and ML in Dynamical System Research

- Computational analysis of the Covid-19 model using the continuous Galerkin–Petrov scheme

- Special Issue: Nonlinear Analysis and Design of Communication Networks for IoT Applications - Part I

- Research on the role of multi-sensor system information fusion in improving hardware control accuracy of intelligent system

- Advanced integration of IoT and AI algorithms for comprehensive smart meter data analysis in smart grids