Abstract

Biopolymer-modified cementitious repair material (CXT) is a composite material designed to enhance the properties of traditional cementitious materials through the incorporation of biopolymers. CXT is formed by blending cement (C) with biopolymers such as xanthan gum (XG) and additives like tartaric acid (TA), which improve the material’s performance characteristics. This study investigates the effects of varying dosages of XG, TA contents, and curing durations on the performance characteristics of CXT. We evaluated key performance indicators, including the flowability, workability, setting time, compressive strength, and shrinkage. The optimal formulation XG 1:2 TA0.6 achieved a maximum compressive strength of 25 N·mm−² and a flexural strength of 9.4 N·mm−², with negligible shrinkage. The results showed rapid early strength development, with the material reaching over 77% of its final compressive strength within the first 14 days. These findings highlight the potential of CXT for crack-repair applications, offering improved workability, accelerated setting times, and reduced environmental impact compared to traditional repair materials. This study provides valuable insights for optimizing the formulation of CXT for enhanced performance in real-world applications.

Nomenclature

- C3S

-

Tricalcium silicate

- C3S2H3, C–S–H

-

Calcium silicate hydrate

- Ca(OH)2

-

Calcium hydroxide

- CXT

-

Cementitious repair material made of cement, xanthan gum, and tartaric acid powder

- SMF

-

Sulfonated melamine formaldehyde

- TA

-

Tartaric acid

- XG

-

Xanthan gum

1 Introduction

Cracks in concrete structures are a common issue that can significantly impact the integrity, safety, and esthetics of buildings. Various types of cracks, such as longitudinal, transverse, and diagonal cracks, can develop due to factors like structural loads, material properties, and construction processes [1,2]. These cracks can lead to corrosion, reduce the load-bearing capacity, and esthetic deterioration, highlighting the importance of timely detection and repair [3]. Advanced methods like image-based crack analysis using photogrammetry and deep learning techniques have been developed to accurately detect, quantify, and reconstruct cracks in concrete surfaces, ensuring precise measurements and assessments for effective maintenance and repair strategies [4]. Understanding the causes and effects of cracking is crucial for implementing appropriate preventive measures and repair techniques to address the diverse types of cracks that can occur in concrete structures [5].

To effectively manage these issues, traditional methods for repairing cracks involve a variety of techniques tailored to the specific type and severity of the crack. Common methods include the filling grouting method, surface repair method, and structural reinforcement method, each chosen based on the intended performance and economic considerations of the structure [6,7]. For instance, epoxy injection is widely used for crack injection due to its effectiveness in restoring the structural integrity and protecting against environmental factors like carbonation and chloride ingress [8]. Additionally, traditional repair techniques have been applied to modern sustainable concretes, such as those containing recycled aggregates, proving their versatility and effectiveness in forming monolithic elements [9]. Electrochemical repair technology, often combined with traditional methods, has shown significant improvements in durability, especially in coastal environments where corrosion is a concern [10]. Moreover, advancements in microbial repair materials, such as those based on sodium alginate, offer promising alternatives by depositing calcium carbonate in situ to seal cracks, thereby enhancing the repair’s durability and environmental friendliness [11]. The use of microbially induced calcite precipitation (MICP) has also been explored for its potential in repairing asphalt concrete cracks, demonstrating significant improvements in mechanical properties and resistance to permanent deformation [12]. For ancient ceramics, improved edge detection algorithms based on cluster analysis have enhanced the accuracy of crack repair, ensuring the preservation of cultural artifacts [13]. Overall, while traditional methods remain effective, integrating new technologies and materials can further enhance the longevity and performance of concrete repairs [14,15].

In the realm of sustainable materials science, the exploration of renewable resources like biopolymers from agro-wastes and aquaculture waste for innovative applications in construction materials is gaining momentum [16]. Biopolymers, such as xanthan gum (XG), have shown promise in enhancing the soil strength, reducing the water permeability, and improving the cohesion in concrete structures, making them a viable alternative for crack repair and sealing in construction materials [17]. Additionally, the development of Eco-Nanoseal, a sealant utilizing composite materials like graphene oxide and chitosan from aquaculture waste, showcases a sustainable approach to healing micro-cracks in concrete without external polymerizing agents, aligning with sustainability indices and offering an eco-friendly alternative to synthetic adhesives [18]. These advancements highlight the potential of biopolymer-modified materials, like CXT, to revolutionize the construction industry by improving the key properties through synergistic effects of biopolymer dosage and tartaric acid (TA) concentration.

Building upon this premise, the present study aims to investigate the synergistic effects of biopolymer dosage (specifically XG) and TA concentration on various key properties of biopolymer-modified cementitious repair materials, referred to as CXT. The specific objectives are as follows:

Quantify the workability and set a time relationship of CXT modified with varying amounts of biopolymer (XG) and TA using the slump cone and Marsh cone tests to determine the optimal mixture.

Evaluate the mechanical properties, such as compressive strength and flexural strength, of the repair material CXT.

2 Materials and methods

The materials utilized in this research include cement, XG, TA powder, superplasticizer, and water. The characteristics of these materials and the reason behind choosing the specific quantities for each component in the presented CXT mix ratios are presented below.

2.1 Cement

The cement used to prepare CXT was Ordinary Portland Cement 43 grade conforming to ASTM C1019 specifications. This cement exhibited a fineness of 225 m²·kg−1, a specific gravity of 3.15, and a soundness of 8 mm, ensuring suitability for its application as a repair material.

2.2 XG

XG was sourced from H R Chemicals, Mumbai – 400019, Maharashtra, India. XG is defined as a biopolymer with unique rheological properties derived from microbial fermentation. It is classified as a polysaccharide, consisting of repeating units of glucose, mannose, and glucuronic acid, and is produced by the bacterium Xanthomonas campestris. The molecular formula of XG is (C35H49O29) n . Its chemical structure consists of a main-chain pentasaccharide repeat of linear β-1,4-d-glucose, with each molecule containing approximately 7,000 pentamers. These repeating units are composed of glucose, mannose, and glucuronic acid. The side chains of XG contain alternating glucose monomers with mannose and glucuronic acid, as well as pyruvic acid (Figure 1). This intricate structure gives XG its unique properties, such as high solubility in both hot and cold water and its ability to form highly viscous solutions at low concentrations [19].

![Figure 1

Chemical structure of XG [20].](/document/doi/10.1515/htmp-2024-0046/asset/graphic/j_htmp-2024-0046_fig_001.jpg)

Chemical structure of XG [20].

The chemical structure of XG also imparts significant stability to the polymer. It remains stable over a wide range of temperatures and pH levels, and its viscosity is not significantly affected by changes in the temperature or pH. Additionally, XG exhibits excellent compatibility with various salts, enabling it to maintain its rheological properties even in the presence of high ionic strength environments.

This complex structure imparts unique rheological properties to XG, such as high viscosity and pseudoplasticity, which make it highly effective in enhancing the flowability and workability of cementitious materials. These properties are particularly advantageous in concrete applications, where XG helps improve the dispersion of particles, reduce the water content, and prevent washout. Additionally, XG remains stable in the presence of acids, alkalis, salts, and high temperatures, making it a robust additive in various industrial applications, including the petroleum sector where it is used extensively as a powerful viscosifier.

Furthermore, XG’s ability to form strong, cohesive matrices with cement hydrates enhances the mechanical strength of the repair material, while its pseudoplastic behavior ensures that the material remains workable during application but becomes highly viscous once applied, reducing the risk of flow and washout.

2.3 TA powder

TA acts as a retarder in CXT by interfering with the early hydration reactions. Careful dosage is essential to prevent strength reduction and potential interactions with other admixtures. This study incorporates TA powder (0.2–0.6% by weight of cement) to explore its potential synergistic interactions with biopolymers. This dosage range was selected to investigate the potential effects of CXT while minimizing risks to the repair material’s ultimate strength and durability.

2.4 Superplasticizer

In this study, sulfonated melamine formaldehyde (SMF) served as a superplasticizer, effectively dispersing cement particles to enhance the workability and flow characteristics of sealant mixes. By reducing the water content while improving the fluidity, it contributes to the enhanced strength and durability of CXT.

2.5 Water

A constant w/c ratio of 0.5 was initially maintained for all mixes to provide a consistent starting point for evaluating the effects of biopolymer and TA.

3 Strengthened properties of biopolymer-modified CXT

The chemical and ionic interactions within this biopolymer-modified CXT influence the key properties, such as the setting time and flowability. Cement hydration plays a fundamental role, with tricalcium silicate (C3S) and dicalcium silicate (C2S) dissolving to release calcium ions (Ca2+) and silicate ions (

TA powder, introduced as a retarder, can dissociate and potentially form complexes with Ca2+, represented as follows:

This interaction likely interferes with the rapid precipitation of solid hydration products, resulting in extended setting times. Simultaneously, SMF acts as a superplasticizer. The negatively charged SMF polymers are electrostatically attracted to positively charged cement particles:

Upon adsorption, SMF creates steric hindrance and repulsion between these particles, significantly improving the dispersion and sealant workability. Understanding these intertwined chemical and ionic mechanisms provides a foundation for optimizing this biopolymer sealant’s formulation and tailoring its performance for specific crack-sealing applications.

3.1 Cement hydration (simplified)

In simplified cement hydration, C3S and C2S react with water to form C3S2H3 and calcium hydroxide (Ca(OH)2).

The equations representing these reactions are the following:

These reactions are crucial for the early stage of cement hydration, where C3S and C2S undergo dissolution and subsequent precipitation of hydration products. C3S2H3 contributes to concrete strength and structure, while Ca(OH)2 provides pore solution alkalinity, aiding in corrosion protection and hydration of supplementary cementitious materials.

3.2 Dissolution of C3S and C2S

In biopolymer-modified CXT, the dissolution of C3S and C2S involves their reaction with water, resulting in the release of Ca2+,

These reactions are essential in the initial stages of cement hydration, where water penetrates the cementitious matrix, interacts with C3S and C2S particles, and triggers their dissolution. The released ions contribute to the formation of pore solution alkalinity and provide the necessary constituents for subsequent hydration reactions, ultimately leading to the development of hydrated cementitious phases and the setting and hardening of the repair material.

3.3 Formation of Ca(OH)2

In the formation of Ca(OH)2, Ca2+ in aqueous solution react with OH− to produce solid Ca(OH)2. The chemical equation representing this reaction is:

This reaction plays a crucial role in cement hydration, as Ca(OH)2 is a key hydration product. It contributes to the strength and durability of CXT.

3.4 TA dissociation

TA, represented as H2T, undergoes dissociation in aqueous solution in two stages. Initially, it dissociates into a hydrogen tartrate ion (HT−) and a hydrogen ion (H+), as shown in the equation:

Subsequently, the HT− further dissociates to yield a tartrate ion (T2−) and another H+:

These dissociation reactions are essential in controlling the pH of solutions containing TA and play a crucial role in various chemical and industrial processes, including food production and pharmaceuticals.

3.5 Calcium–tartrate complex formation

In the formation of a calcium–tartrate complex (CaT), Ca2+ in an aqueous solution react with T2− to produce a soluble CaT. The chemical equation representing this equilibrium reaction is as follows:

This reaction occurs in solution and involves the binding of Ca2+ with T2− to form the complex.

4 Experimental part

To evaluate the initial properties, workability, flowability, and setting time, of a CXT developed for crack repairing applications, preliminary assessments were conducted using slump cone, Marsh cone, and Vicat needle tests. CXT formulations consisted of cement (C), XG, TA, superplasticizer, and water in varying trial mix ratios. The notations “XG” and “TA” will be used throughout, with the number following TA indicating the percentage of TA powder by weight of the total cement.

4.1 Optimization process of CXT

To optimize the formulation of the biopolymer-modified CXT, it is crucial to meticulously adjust the proportions of XG and TA. The concentration of XG was fine-tuned to achieve an optimal balance between workability and strength, as higher concentrations enhanced the viscosity but may impede the flowability. Similarly, the TA dosage was calibrated within a range of 0.2–0.6% by weight of cement to effectively control the setting time without compromising the overall strength. Maintaining a consistent water–cement ratio of approximately 0.5 is essential, and incorporating a superplasticizer, such as SMF, significantly improves the flowability while reducing the water content.

Comprehensive workability tests, including slump cone and Marsh cone tests, were conducted to assess flow characteristics, while Vicat needle tests were performed to determine the initial and final setting times. Mechanical properties were evaluated through compressive and flexural strength tests at 7, 14, and 28 days to ensure long-term durability. Based on these test results, the proportions were iteratively adjusted to minimize the shrinkage and enhance the performance. The optimized formulation was validated through real-world crack repair applications and monitored for long-term performance to ensure its sustainability and robustness.

4.2 Slump cone test

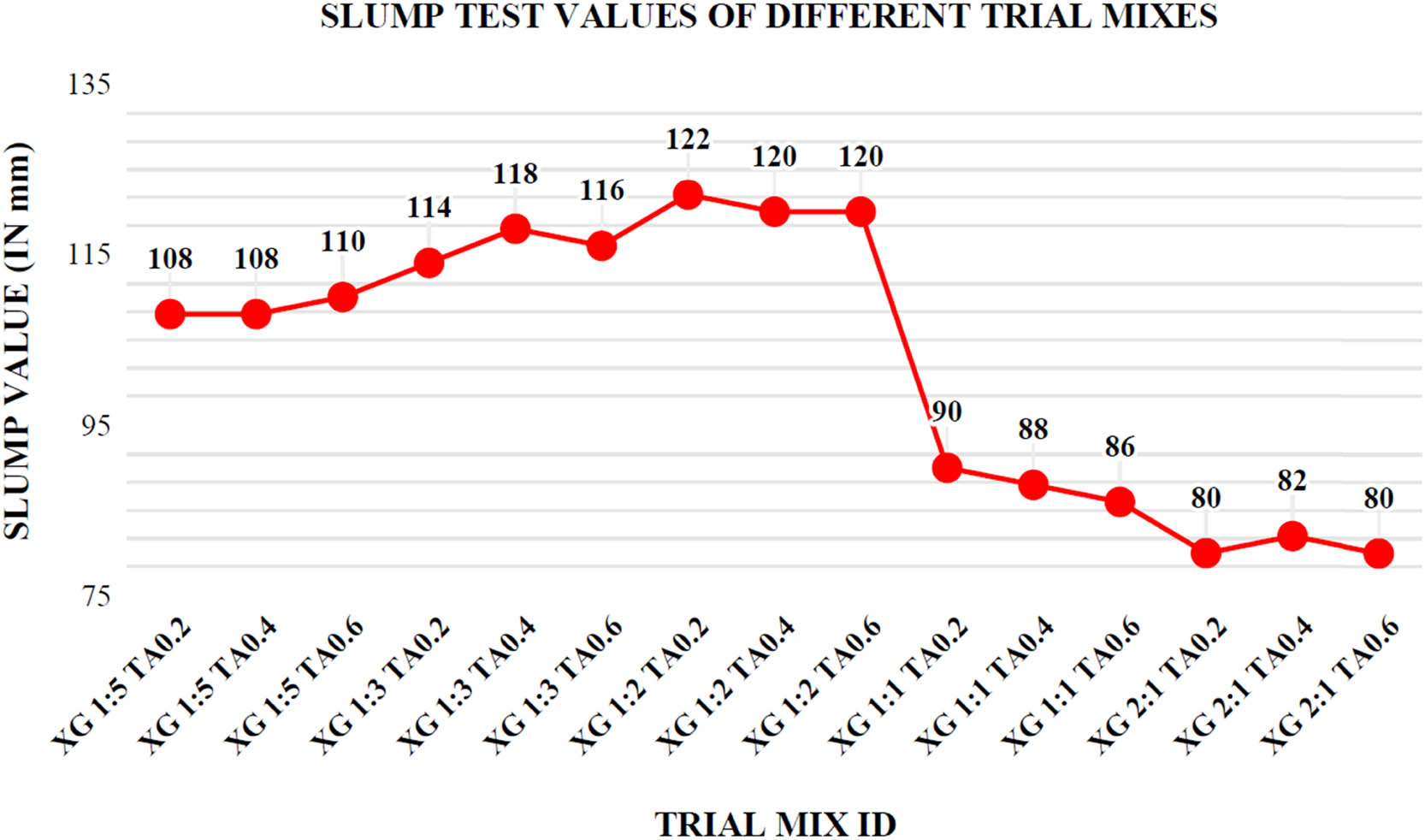

The slump cone test, a widely recognized method for evaluating the workability of fresh concrete, was employed to investigate the effects of varying the XG to cement (XG:C) ratios and TA concentrations on the flow behavior of CXT. The slump values for the different trial mixes of CXT are shown in Figure 2. This test involved filling a metal cone, with a bottom diameter of 20 cm, a top diameter of 10 cm, and a height of 30 cm, with a fresh sealant in three layers. Each layer was tamped 25 times, slightly deviating from the standard practice to ensure thorough compaction. After filling, the cone was carefully lifted vertically, allowing the sealant to slump. The vertical displacement of the sealant, known as the slump, was measured to assess its workability. This process was systematically repeated for each trial mix ratio to accurately determine their respective workability characteristics. By comparing the slump values, the influence of different XG:C ratios and TA concentrations on the flow behavior and workability of the CXT mixtures was comprehensively analyzed.

Graph representing the slump value for each trail.

The results demonstrated a significant positive correlation between the XG:C ratio and the slump value. The 1:2 XG:C ratio consistently exhibited the highest slump values, indicating superior flowability compared to other ratios tested. This enhanced flow can be attributed to the thickening and viscosity-modifying properties of XG. Additionally, the inclusion of moderate amounts of TA (e.g., TA0.4–0.4% weight of cement) exhibited a synergistic effect, further increasing slump values. This is likely due to TA’s retarding action, which delays cement hydration and extends the sealant’s workable time.

While the 1:2 XG:C ratio with moderate TA addition demonstrated significant potential for crack-sealing applications, a comprehensive assessment necessitated further investigations which was performed next to slump tests. Supplementary tests to evaluate the setting time and mechanical strength are essential to ensure that the enhanced workability does not compromise the long-term repair performance. The slump value for each trail is tabulated in Table 1.

Slump value for each trail

| Trial mix ID | Slump value (mm) | Trial mix ID | Slump value (mm) |

|---|---|---|---|

| CM (Control mix) | 95 | XG 1:2 TA0.4 | 130 |

| XG 1:5 TA0.2 | 108 | XG 1:2 TA0.6 | 132 |

| XG 1:5 TA0.4 | 108 | XG 1:1 TA0.2 | 90 |

| XG 1:5 TA0.6 | 110 | XG 1:1 TA0.4 | 88 |

| XG 1:3 TA0.2 | 114 | XG 1:1 TA0.6 | 86 |

| XG 1:3 TA0.4 | 116 | XG 2:1 TA0.2 | 80 |

| XG 1:3 TA0.6 | 118 | XG 2:1 TA0.4 | 82 |

| XG 1:2 TA0.2 | 129 | XG 2:1 TA0.6 | 80 |

4.2.1 Enhanced flow properties

The enhanced flow of CXT can be attributed to the thickening and viscosity-modifying properties of XG. XG, a polysaccharide, is known for its ability to significantly increase the viscosity of aqueous solutions, even at low concentrations. This property is due to its complex molecular structure, which consists of a cellulose backbone with side chains of mannose and glucuronic acid.

When XG was added to the CXT mixture, it increased the viscosity of the water phase, resulting in a more stable and homogenous mixture. This increased viscosity improved the dispersion of cement particles, reducing the likelihood of segregation and bleeding. Additionally, the pseudoplastic (shear-thinning) nature of XG allowed the mixture to flow more easily under shear stress during mixing and application while maintaining its shape and stability when at rest.

By modifying the viscosity and flow properties of the mixture, XG enhanced the workability of the CXT, making it easier to apply and ensuring better penetration into cracks and voids. This results in a more effective and durable repair material.

4.3 Marsh cone test

The Marsh cone is a standardized tool used to measure the flowability of repair material and similar cementitious mixes. It involves filling a metal cone with CXT and measuring the time it takes for a specific volume to flow out as shown in Figure 3.

Images representing the Marsh cone test.

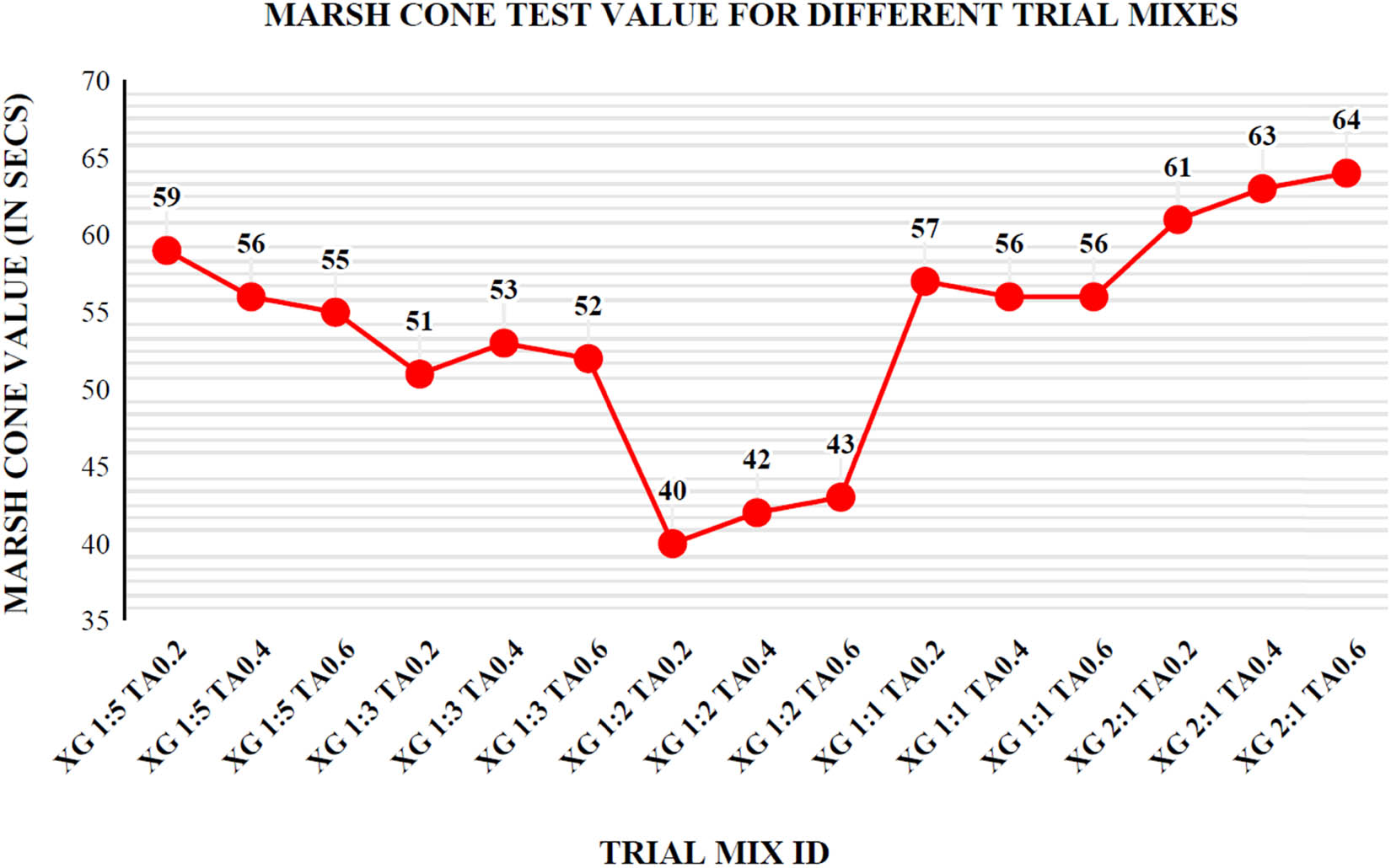

Faster Marsh cone times indicated greater flowability. This simple test provides valuable insights into CXT’s workability, making it relevant for applications like crack sealing where easy flow is essential. The Marsh cone values for different trail mixes of this biopolymer-modified CXT are shown in Figure 4, and the value for each trail is tabulated in Table 2.

Marsh cone test values for each trail.

Marsh cone values for each trail

| Trial mix ID | Marsh cone value (s) | Trial mix ID | Marsh cone value (s) |

|---|---|---|---|

| CM (Control mix) | 60 | XG 1:2 TA0.4 | 42 |

| XG 1:5 TA0.2 | 59 | XG 1:2 TA0.6 | 43 |

| XG 1:5 TA0.4 | 56 | XG 1:1 TA0.2 | 57 |

| XG 1:5 TA0.6 | 55 | XG 1:1 TA0.4 | 56 |

| XG 1:3 TA0.2 | 51 | XG 1:1 TA0.6 | 56 |

| XG 1:3 TA0.4 | 53 | XG 2:1 TA0.2 | 61 |

| XG 1:3 TA0.6 | 52 | XG 2:1 TA0.4 | 63 |

| XG 1:2 TA0.2 | 40 | XG 2:1 TA0.6 | 64 |

The Marsh cone test results reveal a complex interplay between the XG concentration, TA inclusion, and CXT’s flowability. XG emerges as the dominant factor driving flow enhancement, with increasing XG:C ratios consistently yielding lower Marsh cone values (indicating faster flow times). This can be attributed to XG’s ability to thicken the sealant, modifying its viscosity and promoting better flow behavior.

TA demonstrates a synergistic, yet more subtle effect. Within a selected XG:C trail ratio, increasing TA concentrations tend to result in slightly improved flowability. This aligns with TA’s known ability to retard cement hydration, extending the workable time of the repair material CXT and contributing to its flow characteristics. However, there is a crucial caveat: excessive XG concentrations, as demonstrated by the 2:1 ratio, appear to negate these flowability benefits. This highlights the need for a balanced formulation, as overly high XG levels can increase the overall CXT viscosity to the point where the flow is hindered, even with TA present. For crack sealing applications, the 1:2 XG:C ratio, particularly with moderate TA levels, holds significant promise due to their demonstrated superior flow.

4.4 Setting time of CXT

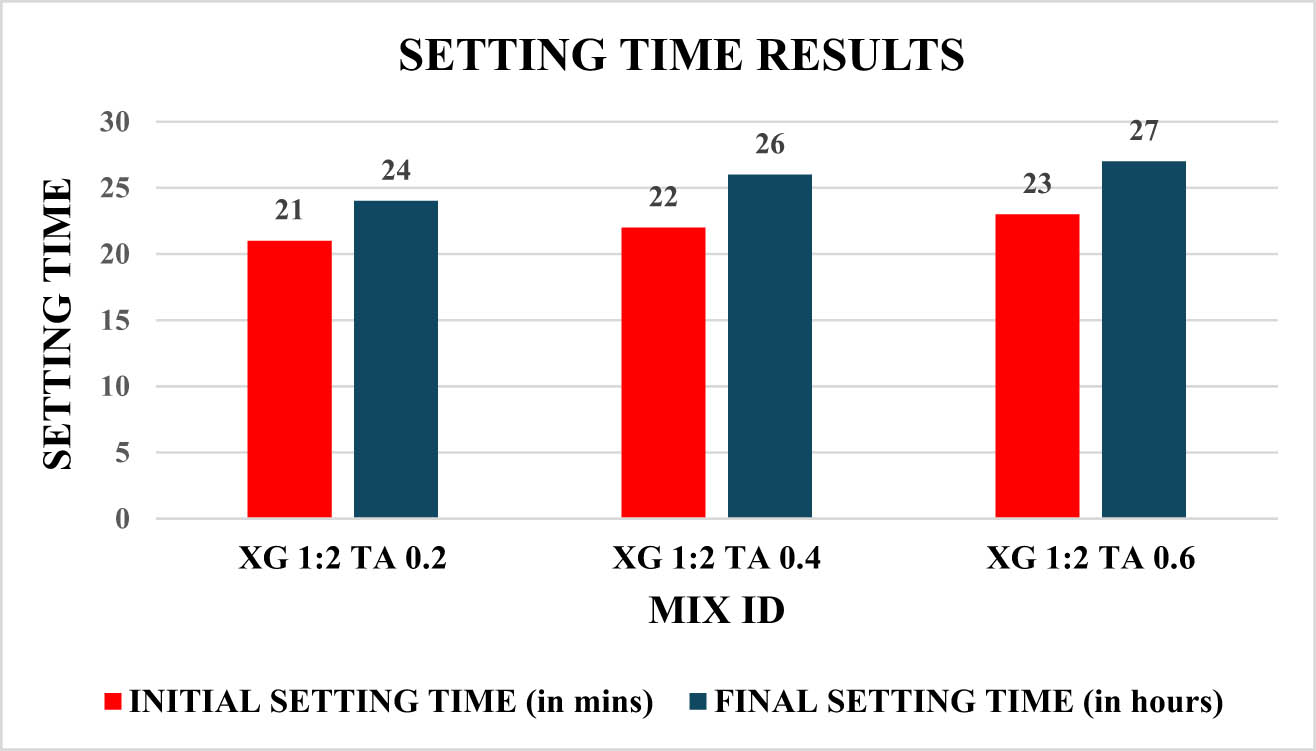

The Vicat needle test (ASTM C191) is a standardized method for evaluating the setting time of cementitious materials. In this study, the Vicat needle test was performed with a load of 300 g to determine the initial setting time of the optimum mix ratio XG 1:2 by varying the TA powder concentration between 0.2 and 0.6% by weight of the cement biopolymer formulation. This test measures the penetration resistance of a standardized needle into the fresh sealant, providing insights into both initial and final setting times.

The initial setting time of the biopolymer-modified CXT was observed to be within the range of 21–23 min. Specifically, the initial setting time for the mix with 0.2% TA was 21 min, for 0.4% TA it was 22 min, and for 0.6% TA it was 23 min. This range indicates that the material remains workable for a sufficient period, allowing for adequate application and adjustments during the repair process.

The final setting time of the repair material CXT was observed between 24 and 27 h. The mix with 0.2% TA had a final setting time of 24 h, the mix with 0.4% TA had a final setting time of 26 h, and the mix with 0.6% TA had a final setting time of 27 h. This extended setting period ensures that the material undergoes a gradual hardening process, reducing the risk of cracking and ensuring a more durable repair. The setting time values for different trail mixes of this biopolymer-modified CXT are shown in Figure 5, and the results are summarized in Table 3.

Setting time values for different trial mixes.

Results of setting time

| Trial mix ID | Initial setting time (min) | Final setting time (h) |

|---|---|---|

| XG 1:2 TA0.2 | 21 | 24 |

| XG 1:2 TA0.4 | 22 | 26 |

| XG 1:2 TA0.6 | 23 | 27 |

These findings indicate that the optimal mix (XG 1:2 with TA0.2/0.4/0.6) provides a balanced performance in terms of workability and setting times. The initial setting times ensure that the material can be easily applied and adjusted, while the final setting times allow for a thorough and gradual hardening process. This balance is essential for the durability of the repair, making the biopolymer-modified CXT with the optimal formulation of XG 1:2 and TA0.2–0.6 a promising solution for effective and durable crack repair in concrete structures.

4.5 Casting of CXT cubes

CXT cubes (5 cm × 5 cm × 5 cm) were prepared using a mix ratio (outlined in Table 4) of XG:C (1:2), as this ratio was identified as optimal in previous experiments. To ensure accuracy, precise quantities of cement, biopolymer (XG), TA, and superplasticizer were calculated to yield the required CXT volume for each cube. The dry components (cement, XG, and TA) were meticulously mixed in a clean container for approximately 2 min to ensure complete homogenization. This mixing was performed using a low-speed mechanical mixer to facilitate consistency.

Details of quantities of material corresponding to the optimum mix ratio

| Mix ID | Cement (g) | Biopolymer (g) | Biopolymer:Cement ratio | TA (g) | Superplasticizer (mL) |

|---|---|---|---|---|---|

| XG 1:2 TA0.2 | 87.5 | 43.75 | 1:2 | 17.5 | 0.125 |

| XG 1:2 TA0.4 | 87.5 | 43.75 | 1:2 | 35 | 0.125 |

| XG 1:2 TA0.6 | 87.5 | 43.75 | 1:2 | 52.5 | 0.125 |

A stepwise addition of water and superplasticizer followed during the mixing process. Initially, roughly 70% of water was added, along with continuous mixing. The superplasticizer was then incorporated, and mixing was continued. The remaining water was gradually added, with adjustments made as necessary to achieve a homogenous mixture with the desired workability. This mixing process typically lasted for 3–5 min, ensuring complete hydration of the cement, a uniform distribution of the biopolymer, and activation of the superplasticizer. This homogenous mixture was placed into cube molds as shown in Figure 6. After molding, the cubes were wrapped with a polythene sheet to prevent moisture loss and ensure proper curing, which is essential for achieving the desired mechanical properties.

Preparation of CXT cubes.

4.6 Compressive strength

The compressive strength of CXT was assessed using standard cubes 5 cm × 5 cm × 5 cm, in accordance with the established procedure outlined in IS 4031 Part 7, and the results are tabulated in Table 5.

Compressive strength values for 7, 14, and 28 days

| Mix ratio | 7 days (N·

|

14 days (N·

|

28 days (N·

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Trial 1 | Trial 2 | Trial 3 | Average | Trial 1 | Trial 2 | Trial 3 | Average | Trial 1 | Trial 2 | Trial 3 | Average | |

| XG 1:2 TA0.2 | 11 | 11.8 | 11.4 | 11.4 | 18.4 | 18.9 | 17.2 | 18.2 | 22.6 | 22.2 | 22.2 | 22.3 |

| XG 1:2 TA0.4 | 11.2 | 12.5 | 10.9 | 11.5 | 17.4 | 16.9 | 18.3 | 17.5 | 23.2 | 23.6 | 24 | 23.6 |

| XG 1:2 TA0.6 | 12.6 | 12.5 | 12 | 12.4 | 18.8 | 19 | 17.2 | 18.3 | 25 | 24.8 | 24.6 | 24.8 |

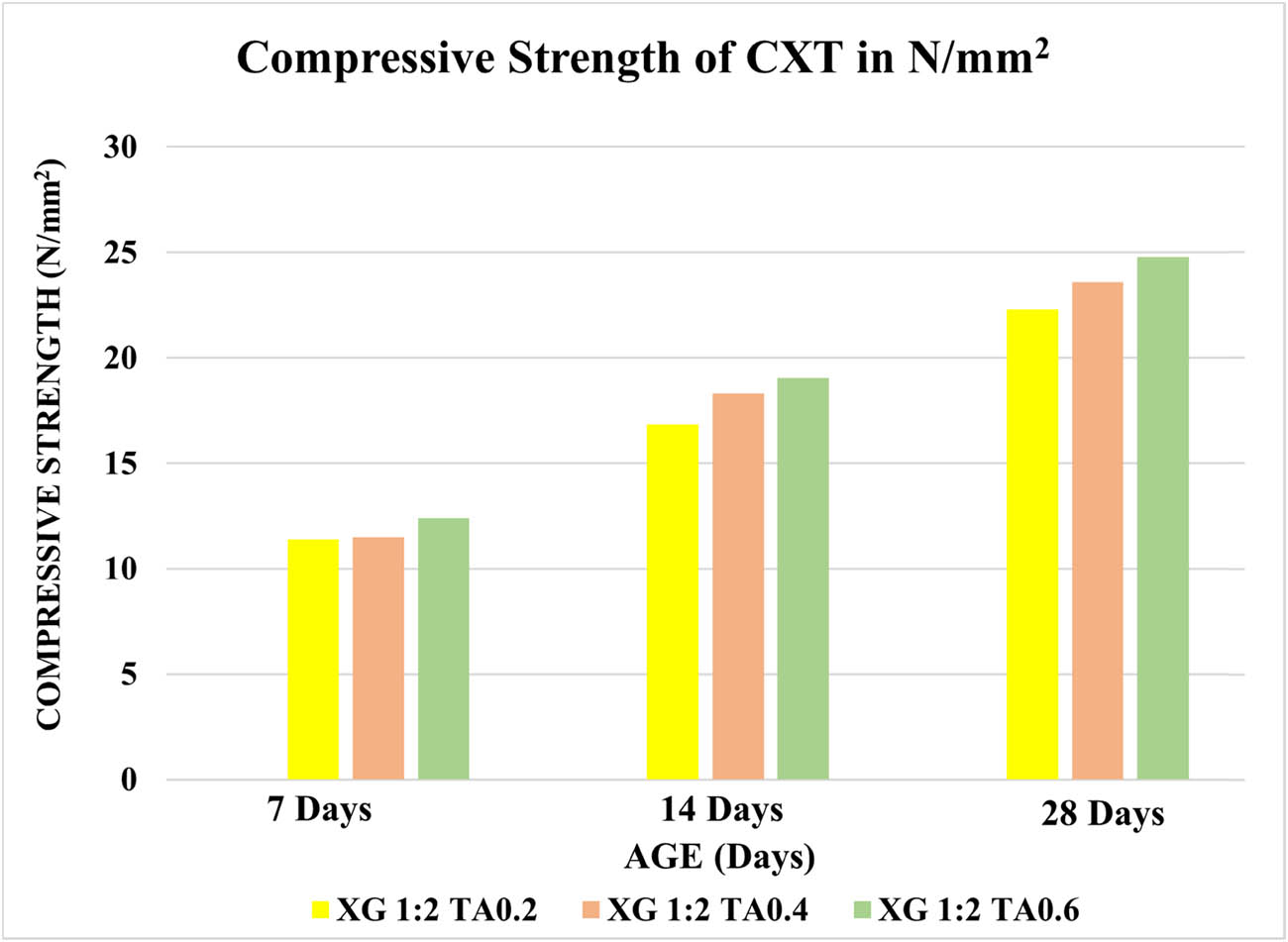

The compressive strength analysis as shown in Figure 7 revealed a significant increase in strength for all CXT mixes over the 28-day curing period. The most rapid strength development occurred between 7 and 14 days, followed by a slower rate of gain from 14 to 28 days. This strength evolution pattern aligns with typical repair material behavior. Notably, mixes incorporating higher TA concentrations (XG 1:2 TA0.6) exhibited slightly greater increases in strength throughout the curing period.

Compressive strength values for 7, 14, and 28 days.

Compressive strength analysis revealed a rapid strength development profile for the CXT formulation. Approximately 50% of its final compressive strength was achieved within the first 7 days. This accelerated early strength gain highlights the formulation’s potential for applications requiring swift material setting. The majority of strength development occurred within the initial 14 days, with the repair material attaining over 77% of its final strength. A slight increase in strength was observed between 14 and 28 days, reaching its final strength; however, the rate of gain decreased progressively throughout this period.

The accelerated early strength gain of the biopolymer-modified CXT is a critical attribute for applications requiring rapid material setting and early load-bearing capacity. The primary mechanism underlying this accelerated early strength gain involves the modification of the hydration process by the biopolymer additives. XG and TA work synergistically to enhance the dispersion of cement particles, improve the hydration efficiency, and control the setting time. XG’s high viscosity and pseudoplastic properties ensure a uniform distribution of cement particles, promoting more effective hydration. TA acts as a retarder, allowing sufficient time for thorough mixing and application before the material begins to set.

As a result, the initial hydration reactions, particularly those involving C3S, proceed more efficiently, leading to the rapid formation of C–S–H, which is the primary strength-giving compound in cementitious materials. This accelerated formation of C–S–H contributed to the early strength development of the repair material. Overall, these results suggest that the incorporation of biopolymer and TA into cement mixtures can positively influence compressive strength development over time. The varying percentages of strength achieved at different curing periods offer valuable insights for optimizing mixture designs tailored to crack sealing project requirements and performance expectations.

4.7 Flexural strength of CXT

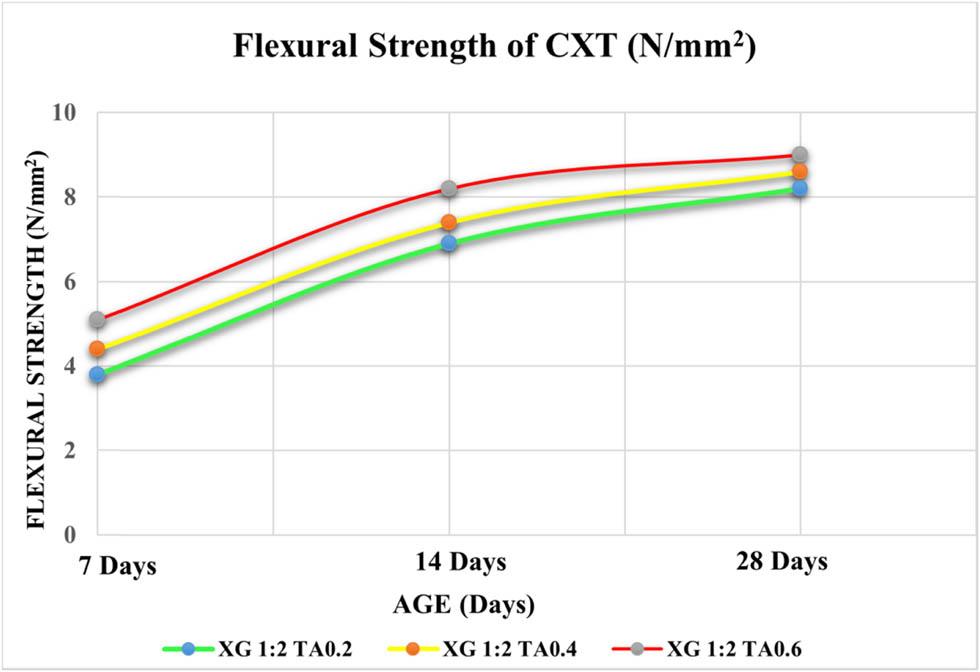

The determination of the flexural strength of CXT followed the protocol outlined in the Indian standard IS:516. This involved studying the flexural strength using beam specimens measuring 40 mm × 40 mm × 160 mm, with an effective span of 120 mm, subjected to three-point loading. The beams were supported by two roller supports, each with a diameter of 10 mm, spaced 120 mm apart. The specimens were positioned on the roller supports on their bottom faces, with the third point loading applied symmetrically on the opposite and top faces using a third roller.

The two support rollers were set up in a simply supportive manner, facilitating unrestricted rotation of the beam around their line of contact to evenly distribute the line load across the width of the beam as a point load. The flexural tensile strength of the cement grout was determined as the average of three beam tests conducted at intervals of 3, 7, and 28 days. The variations in flexural tensile strength of the cement grout at different ages are depicted in Figure 8, and the results are tabulated in Table 6.

Flexural strength values for 7, 14, and 28 days.

Flexural strength values for 7, 14, and 28 days

| Mix ratio | 7 days (N·mm−2) | 14 days (N·mm−2) | 28 days (N·mm−2) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Trial 1 | Trial 2 | Trial 3 | Average | Trial 1 | Trial 2 | Trial 3 | Average | Trial 1 | Trial 2 | Trial 3 | Average | |

| XG 1:2 TA0.2 | 3.6 | 3.8 | 4 | 3.8 | 6.8 | 6.9 | 7.1 | 6.9 | 8.5 | 7.9 | 8.2 | 8.2 |

| XG 1:2 TA0.4 | 4.4 | 4.2 | 4.6 | 4.4 | 7.5 | 7.4 | 7.4 | 7.4 | 8.9 | 8.4 | 8.4 | 8.6 |

| XG 1:2 TA0.6 | 5.2 | 5 | 5.1 | 5.1 | 8.2 | 8.4 | 8 | 8.2 | 8.8 | 8.8 | 9.4 | 9.0 |

Flexural strength analysis demonstrated a rapid strength development profile for the CXT formulation. Within the first 7 days, the material achieved approximately 51% of its ultimate flexural strength. This accelerated early strength development signifies the potential applicability of the CXT formulation for scenarios demanding swift material setting. The majority of strength development transpired within the initial 14 days, with the repair material reaching over 87% of its final strength. Between 14 and 28 days, a slight increase in strength was observed, culminating in the achievement of material’s final flexural strength. However, the rate of strength gain exhibited a progressive decline throughout this period. Overall, these findings indicate that biopolymer-modified CXT can have a beneficial impact on the development of flexural strength over time.

5 Limitations

While this study provides valuable insights into the performance of biopolymer-modified CXT, there are a few limitations that should be considered:

Controlled laboratory conditions: The experiments were performed under controlled laboratory conditions. Variations in environmental factors such as temperature and humidity were not considered. Future studies should investigate the performance of CXT in different environmental conditions to ensure its applicability in real-world scenarios.

Long-term durability: The long-term durability and performance of the biopolymer-modified CXT were not evaluated. Long-term studies are necessary to understand the material’s behavior over extended periods, including its resistance to wear and weathering.

6 Results and discussion

This section presents the findings from various tests conducted on biopolymer-modified CXT, focusing on the workability, setting time, mechanical properties, shrinkage, and environmental impact.

6.1 Workability and flowability

Slump cone test: The slump cone test results (Table 1) demonstrated that the optimal XG ratio was 1:2, with the addition of 0.6% TA, yielding the highest slump values (132 mm). This indicates superior flowability, attributable to the thickening and viscosity-modifying properties of XG. Similar enhancements in flow properties due to biopolymer modifications have been reported, showing significant improvements in the rheological properties of cementitious materials [21].

Marsh cone test: Marsh cone test results (Table 2) corroborated with the slump test findings, with the 1:2 XG ratio and 0.6% TA showing the lowest flow times, indicating improved flowability. This aligns with findings that biopolymers enhance the flow characteristics of cementitious mixtures by reducing the water content and improving the particle dispersion [22].

6.2 Setting time

The Vicat needle test results indicated that the optimal formulation (XG 1:2 TA0.6) maintained an initial setting time within 21–24 min and a final setting time of 24–28 h. This delayed setting time provided sufficient workability without compromising early strength gain, consistent with studies showing that TA effectively extends the setting time of cementitious materials [23].

6.3 Mechanical properties

Compressive strength: The compressive strength results (Table 5) showed a significant increase over the 28-day curing period, with the highest strength recorded for the XG 1:2 TA0.6 mix (24.8 N·mm−²). The rapid early strength gain (77% of final strength within 14 days) observed in this study was supported by research indicating that the inclusion of biopolymers enhanced early-age strength by improving the hydration kinetics and matrix formation [24].

Flexural strength: Flexural strength tests (Table 6) indicated that the XG 1:2 TA0.6 mix achieved a maximum strength of 9.4 N·mm−² at 28 days. This result corroborates with findings that biopolymers improved the flexural performance by forming stronger cohesive matrices within the cement matrix [25].

7 Conclusions and implications

This study investigated the influence of varying dosages of biopolymer (XG) and TA on the performance characteristics of biopolymer-modified CXT. The optimal formulation, identified as XG 1:2 with 0.6% TA, demonstrated superior performance metrics, achieving a maximum compressive strength of 25 N·mm−² and a flexural strength of 9.4 N·mm−², along with minimal shrinkage.

The incorporation of XG significantly enhanced the workability of the CXT by increasing its viscosity and improving the dispersion of cement particles. This resulted in a more stable and homogenous mixture that is easier to apply and better at penetrating cracks. The pseudoplastic nature of XG allowed the mixture to flow under shear stress during application while maintaining its shape and stability when at rest. The formulation exhibited rapid early strength gain, achieving approximately 51% of its ultimate flexural strength within the first 7 days and over 77% of its final compressive strength within 14 days. This accelerated strength development is crucial for applications requiring swift setting and early load-bearing capacity.

Minimal shrinkage in the optimal formulation reduces the risk of crack formation and ensures the longevity of repairs, preventing the propagation of new cracks and maintaining the structural integrity. Additionally, the use of biopolymers in CXTs offers significant environmental benefits. Biopolymers, derived from renewable sources, lower the overall carbon footprint associated with cement production and contribute to more sustainable construction practices. Overall, the findings of this study suggest that the biopolymer-modified CXT, with the optimal formulation of XG 1:2 and TA 0.6, offers a promising solution for effective and durable crack repair in concrete structures, combining desirable mechanical properties with environmental sustainability.

8 Future scope

Building upon these results, future research could involve the following:

Investigating the long-term durability of the XG 1.2 TA0.6 formulation under various environmental conditions relevant to field applications.

Evaluating the performance of this optimized sealant formulation in real-world crack sealing scenarios.

Exploring the potential for further enhancing the properties of biopolymer sealants through the incorporation of additional admixtures or alternative biopolymers.

Conducting a lifecycle assessment of the biopolymer sealant compared to conventional sealants to quantify its environmental impact across production, application, and service life.

Acknowledgements

The authors would like to express their heartfelt gratitude to professors and parents for their unwavering support and encouragement throughout this research.

-

Funding information: The authors received no financial support for the research, authorship, and publication of this article.

-

Author contributions: Sankaranarayanan Asvitha Valli – responsible for the conceptualization of the study, conducting the investigation, and writing the original draft of the manuscript; Muthuswamy Saraswathi Ravi Kumar – provided supervision throughout the study, performed the formal analysis, and contributed to the review and editing of the manuscript.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: Data will be made available on request.

References

[1] Grzegorz, L. and L. Golewski. The phenomenon of cracking in cement concretes and reinforced concrete structures: The mechanism of cracks formation, causes of their initiation, types and places of occurrence, and methods of detection – a review. Buildings, Vol. 13, 2023, pp. 7–10.10.3390/buildings13030765Search in Google Scholar

[2] Payab, M., R. Abbasina, and M. Khanzadi. A brief review and a new graph-based image analysis for concrete crack quantification. Archives of Computational Methods in Engineering, Vol. 26, 2019, pp. 347–365.10.1007/s11831-018-9263-6Search in Google Scholar

[3] Pise, N., T. Meshram, Y. Doijad, R. Gathe, A. Bobade, A. Kutemate, et al. A brief study on causes of cracks, prevention and pattern of cracks on concrete. International Journal of Scientific Research in Science, Engineering and Technology, Vol. 8, No. 3, 2021, pp. 439–443.10.32628/IJSRSET2183194Search in Google Scholar

[4] Shokri, P., M. Shahbazi, D. Lichti, and J. Nielsen. Vision-based approaches for quantifying cracks in concrete structures. ISPRS – International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences, Vol. 43, 2020, pp. 431167–1174.Search in Google Scholar

[5] Dung, T. M. and T. Q. Lam. Cracks in single-layer and multi-layer concrete beams. Transportation Research Procedia, Vol. 62, 2022, pp. 1–4.Search in Google Scholar

[6] Fan, L., J. Zheng, S. Peng, Z. Xun, and G. Chen. Experimental investigation on the influence of crack width of asphalt concrete on the repair effect of microbially induced calcite precipitation. Materials, Vol. 16, 2023, pp. 1–19.10.3390/ma16093576Search in Google Scholar PubMed PubMed Central

[7] Feng, F. Crack repair model of ancient ceramics based on digital image. Scientific Programming, Vol. 2022, 2022, id. 3.10.1155/2022/4932183Search in Google Scholar

[8] Fan, W., J. Mao, W. Jin, J. Zhang, Q. Li, and F. Yuan. Repair effect of cracked reinforced concrete based on electrochemical rehabilitation technology. Journal of Building Engineering, Vol. 57, 2022, pp. 6–10.10.1016/j.jobe.2022.105211Search in Google Scholar

[9] ElKhatib, L. W., A. Elkordi, and J. Khatib. Methods and surface materials repair for concrete structures – a review. BAU Journal – Science and Technology, Vol. 4, No. 2, 2023, id. 7.10.54729/2706-784X.1099Search in Google Scholar

[10] Hu, K., H. Rong, Y. Shi, G. Ma, and X. Zheng. Effect of microbial repair materials based on sodium alginate modification on mortar crack repair. Magazine of Concrete Research, Vol. 74, No. 22, 2022, pp. 4–12.10.2139/ssrn.4130793Search in Google Scholar

[11] Kim, T. K. and J. S. Park. Performance evaluation of concrete structures using crack repair methods. Sustainability, Vol. 13, No. 6, 2021, pp. 4–7.10.3390/su13063217Search in Google Scholar

[12] Bano, S., G. Jaiswal, R. Kumar, A. Tiwari, and M. Karthikeyan. Experimental study on the crack repair techniques of concrete structures: A case study. IOP Conference Series: Materials Science and Engineering, Vol. 1273, 2023, pp. 2–11.10.1088/1757-899X/1273/1/012006Search in Google Scholar

[13] De Belie, N., E. Gruyaert, A. Al‐Tabbaa, P. Antonaci, C. Baera, D. Bajare, et al. A review of self-healing concrete for damage management of structures. Advanced Materials Interfaces, Vol. 5, No. 17, 2018, pp. 4–28.10.1002/admi.201800074Search in Google Scholar

[14] Badr, A. Using standard repair methods on recycled aggregate concrete. Magazine of Concrete Research, Vol. 68, No. 1, 2016, pp. 6–40.Search in Google Scholar

[15] Huang, W. The research progress on cracks repair technology of concrete structure. New Building Materials, Vol. 41, No. 4, 2014, pp. 80–83.Search in Google Scholar

[16] Alaneme, G. U., K. A. Olonade, and E. Esenogho. Eco-friendly agro-waste based geopolymer-concrete: a systematic review. Discover Materials, Vol. 2023, 2023, pp. 1–19.10.1007/s43939-023-00052-8Search in Google Scholar

[17] De Grave, L., J. R. Tenório Filho, D. Snoeck, S. Vynnytska, N. De Belie, K. V. Bernaerts, et al. Poly (aspartic acid) superabsorbent polymers as biobased and biodegradable additives for self-sealing of cementitious mortar. Journal of Sustainable Cement-Based Materials, Vol. 11, No. 6, 2022, pp. 2–16.Search in Google Scholar

[18] Kannan, U., S. A. Gafoor, S. Srivastava, M. Nithyadharan, S. Sen Gupta, and S. M. Maliyekkal. A waste-derived nanocomposite sealant for repairing micro-cracks in concrete. Journal of Building Engineering, Vol. 48, 2022, pp. 1–3.10.1016/j.jobe.2021.103965Search in Google Scholar

[19] Khatami, H. and B. C. O’Kelly. Prevention of bleeding of particulate grouts using biopolymers. Construction and Building Materials, Vol. 192, 2018, pp. 202–209.10.1016/j.conbuildmat.2018.10.131Search in Google Scholar

[20] Tusnim, J., M. E. Hoque, and M. C. Biswas. Biopolymers in building materials. Advanced processing, properties, and applications of starch and other bio-based polymers, Elsevier, Amsterdam, Netherlands, 2020, pp. 185–195.10.1016/B978-0-12-819661-8.00012-3Search in Google Scholar

[21] Ivanov, V. and V. Stabnikov. Basic concepts on biopolymers and biotechnological admixtures for eco-efficient construction materials. In Biopolymers and biotech admixtures for eco-efficient construction materials, Vol. 2016, 2016, pp. 2–21.10.1016/B978-0-08-100214-8.00002-6Search in Google Scholar

[22] Jia, D. X. Q. Incorporation of hybrid biopolymer/silicate-based microcapsules in cementitious mixtures for potential uses in self-healing technology with renewable materials. RILEM Bookseries, Vol. 2023, 2023, pp. 853–864.10.1007/978-3-031-33187-9_78Search in Google Scholar

[23] Bishnoi, P. and K. Scrivener. Role of retarders in cementitious systems. Cement and Concrete Research, Vol. 39, 2009, pp. 849–860.10.1016/j.cemconres.2009.07.004Search in Google Scholar

[24] Khan, R. I., M. I. Haque, W. Ashraf, S. P. Shah, and N. Saleh. Role of biopolymers in enhancing multiscale characteristics of carbonation-cured cementitious composites. Cement & Concrete Composites, Vol. 132, 2022, id. 2022.10.1016/j.cemconcomp.2022.104766Search in Google Scholar

[25] Mignon, A., D. Snoeck, P. Dubruel, L. Balcaen, F. Vanhaecke, S. Van Vlierberghe, et al. Biopolymers for self-sealing and -healing of mortar. Presented at the Magnel Laboratory for Concrete Research, Ghent University, Belgium, 2015.Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- De-chlorination of poly(vinyl) chloride using Fe2O3 and the improvement of chlorine fixing ratio in FeCl2 by SiO2 addition

- Reductive behavior of nickel and iron metallization in magnesian siliceous nickel laterite ores under the action of sulfur-bearing natural gas

- Study on properties of CaF2–CaO–Al2O3–MgO–B2O3 electroslag remelting slag for rack plate steel

- The origin of {113}<361> grains and their impact on secondary recrystallization in producing ultra-thin grain-oriented electrical steel

- Channel parameter optimization of one-strand slab induction heating tundish with double channels

- Effect of rare-earth Ce on the texture of non-oriented silicon steels

- Performance optimization of PERC solar cells based on laser ablation forming local contact on the rear

- Effect of ladle-lining materials on inclusion evolution in Al-killed steel during LF refining

- Analysis of metallurgical defects in enamel steel castings

- Effect of cooling rate and Nb synergistic strengthening on microstructure and mechanical properties of high-strength rebar

- Effect of grain size on fatigue strength of 304 stainless steel

- Analysis and control of surface cracks in a B-bearing continuous casting blooms

- Application of laser surface detection technology in blast furnace gas flow control and optimization

- Preparation of MoO3 powder by hydrothermal method

- The comparative study of Ti-bearing oxides introduced by different methods

- Application of MgO/ZrO2 coating on 309 stainless steel to increase resistance to corrosion at high temperatures and oxidation by an electrochemical method

- Effect of applying a full oxygen blast furnace on carbon emissions based on a carbon metabolism calculation model

- Characterization of low-damage cutting of alfalfa stalks by self-sharpening cutters made of gradient materials

- Thermo-mechanical effects and microstructural evolution-coupled numerical simulation on the hot forming processes of superalloy turbine disk

- Endpoint prediction of BOF steelmaking based on state-of-the-art machine learning and deep learning algorithms

- Effect of calcium treatment on inclusions in 38CrMoAl high aluminum steel

- Effect of isothermal transformation temperature on the microstructure, precipitation behavior, and mechanical properties of anti-seismic rebar

- Evolution of residual stress and microstructure of 2205 duplex stainless steel welded joints during different post-weld heat treatment

- Effect of heating process on the corrosion resistance of zinc iron alloy coatings

- BOF steelmaking endpoint carbon content and temperature soft sensor model based on supervised weighted local structure preserving projection

- Innovative approaches to enhancing crack repair: Performance optimization of biopolymer-infused CXT

- Structural and electrochromic property control of WO3 films through fine-tuning of film-forming parameters

- Influence of non-linear thermal radiation on the dynamics of homogeneous and heterogeneous chemical reactions between the cone and the disk

- Thermodynamic modeling of stacking fault energy in Fe–Mn–C austenitic steels

- Research on the influence of cemented carbide micro-textured structure on tribological properties

- Performance evaluation of fly ash-lime-gypsum-quarry dust (FALGQ) bricks for sustainable construction

- First-principles study on the interfacial interactions between h-BN and Si3N4

- Analysis of carbon emission reduction capacity of hydrogen-rich oxygen blast furnace based on renewable energy hydrogen production

- Just-in-time updated DBN BOF steel-making soft sensor model based on dense connectivity of key features

- Effect of tempering temperature on the microstructure and mechanical properties of Q125 shale gas casing steel

- Review Articles

- A review of emerging trends in Laves phase research: Bibliometric analysis and visualization

- Effect of bottom stirring on bath mixing and transfer behavior during scrap melting in BOF steelmaking: A review

- High-temperature antioxidant silicate coating of low-density Nb–Ti–Al alloy: A review

- Communications

- Experimental investigation on the deterioration of the physical and mechanical properties of autoclaved aerated concrete at elevated temperatures

- Damage evaluation of the austenitic heat-resistance steel subjected to creep by using Kikuchi pattern parameters

- Topical Issue on Focus of Hot Deformation of Metaland High Entropy Alloys - Part II

- Synthesis of aluminium (Al) and alumina (Al2O3)-based graded material by gravity casting

- Experimental investigation into machining performance of magnesium alloy AZ91D under dry, minimum quantity lubrication, and nano minimum quantity lubrication environments

- Numerical simulation of temperature distribution and residual stress in TIG welding of stainless-steel single-pass flange butt joint using finite element analysis

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part I

- Electro-thermal performance evaluation of a prismatic battery pack for an electric vehicle

- Experimental analysis and optimization of machining parameters for Nitinol alloy: A Taguchi and multi-attribute decision-making approach

- Experimental and numerical analysis of temperature distributions in SA 387 pressure vessel steel during submerged arc welding

- Optimization of process parameters in plasma arc cutting of commercial-grade aluminium plate

- Multi-response optimization of friction stir welding using fuzzy-grey system

- Mechanical and micro-structural studies of pulsed and constant current TIG weldments of super duplex stainless steels and Austenitic stainless steels

- Stretch-forming characteristics of austenitic material stainless steel 304 at hot working temperatures

- Work hardening and X-ray diffraction studies on ASS 304 at high temperatures

- Study of phase equilibrium of refractory high-entropy alloys using the atomic size difference concept for turbine blade applications

- A novel intelligent tool wear monitoring system in ball end milling of Ti6Al4V alloy using artificial neural network

- A hybrid approach for the machinability analysis of Incoloy 825 using the entropy-MOORA method

- Special Issue on Recent Developments in 3D Printed Carbon Materials - Part II

- Innovations for sustainable chemical manufacturing and waste minimization through green production practices

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part I

- Characterization of Co–Ni–TiO2 coatings prepared by combined sol-enhanced and pulse current electrodeposition methods

- Hot deformation behaviors and microstructure characteristics of Cr–Mo–Ni–V steel with a banded structure

- Effects of normalizing and tempering temperature on the bainite microstructure and properties of low alloy fire-resistant steel bars

- Dynamic evolution of residual stress upon manufacturing Al-based diesel engine diaphragm

- Study on impact resistance of steel fiber reinforced concrete after exposure to fire

- Bonding behaviour between steel fibre and concrete matrix after experiencing elevated temperature at various loading rates

- Diffusion law of sulfate ions in coral aggregate seawater concrete in the marine environment

- Microstructure evolution and grain refinement mechanism of 316LN steel

- Investigation of the interface and physical properties of a Kovar alloy/Cu composite wire processed by multi-pass drawing

- The investigation of peritectic solidification of high nitrogen stainless steels by in-situ observation

- Microstructure and mechanical properties of submerged arc welded medium-thickness Q690qE high-strength steel plate joints

- Experimental study on the effect of the riveting process on the bending resistance of beams composed of galvanized Q235 steel

- Density functional theory study of Mg–Ho intermetallic phases

- Investigation of electrical properties and PTCR effect in double-donor doping BaTiO3 lead-free ceramics

- Special Issue on Thermal Management and Heat Transfer

- On the thermal performance of a three-dimensional cross-ternary hybrid nanofluid over a wedge using a Bayesian regularization neural network approach

- Time dependent model to analyze the magnetic refrigeration performance of gadolinium near the room temperature

- Heat transfer characteristics in a non-Newtonian (Williamson) hybrid nanofluid with Hall and convective boundary effects

- Computational role of homogeneous–heterogeneous chemical reactions and a mixed convective ternary hybrid nanofluid in a vertical porous microchannel

- Thermal conductivity evaluation of magnetized non-Newtonian nanofluid and dusty particles with thermal radiation

Articles in the same Issue

- Research Articles

- De-chlorination of poly(vinyl) chloride using Fe2O3 and the improvement of chlorine fixing ratio in FeCl2 by SiO2 addition

- Reductive behavior of nickel and iron metallization in magnesian siliceous nickel laterite ores under the action of sulfur-bearing natural gas

- Study on properties of CaF2–CaO–Al2O3–MgO–B2O3 electroslag remelting slag for rack plate steel

- The origin of {113}<361> grains and their impact on secondary recrystallization in producing ultra-thin grain-oriented electrical steel

- Channel parameter optimization of one-strand slab induction heating tundish with double channels

- Effect of rare-earth Ce on the texture of non-oriented silicon steels

- Performance optimization of PERC solar cells based on laser ablation forming local contact on the rear

- Effect of ladle-lining materials on inclusion evolution in Al-killed steel during LF refining

- Analysis of metallurgical defects in enamel steel castings

- Effect of cooling rate and Nb synergistic strengthening on microstructure and mechanical properties of high-strength rebar

- Effect of grain size on fatigue strength of 304 stainless steel

- Analysis and control of surface cracks in a B-bearing continuous casting blooms

- Application of laser surface detection technology in blast furnace gas flow control and optimization

- Preparation of MoO3 powder by hydrothermal method

- The comparative study of Ti-bearing oxides introduced by different methods

- Application of MgO/ZrO2 coating on 309 stainless steel to increase resistance to corrosion at high temperatures and oxidation by an electrochemical method

- Effect of applying a full oxygen blast furnace on carbon emissions based on a carbon metabolism calculation model

- Characterization of low-damage cutting of alfalfa stalks by self-sharpening cutters made of gradient materials

- Thermo-mechanical effects and microstructural evolution-coupled numerical simulation on the hot forming processes of superalloy turbine disk

- Endpoint prediction of BOF steelmaking based on state-of-the-art machine learning and deep learning algorithms

- Effect of calcium treatment on inclusions in 38CrMoAl high aluminum steel

- Effect of isothermal transformation temperature on the microstructure, precipitation behavior, and mechanical properties of anti-seismic rebar

- Evolution of residual stress and microstructure of 2205 duplex stainless steel welded joints during different post-weld heat treatment

- Effect of heating process on the corrosion resistance of zinc iron alloy coatings

- BOF steelmaking endpoint carbon content and temperature soft sensor model based on supervised weighted local structure preserving projection

- Innovative approaches to enhancing crack repair: Performance optimization of biopolymer-infused CXT

- Structural and electrochromic property control of WO3 films through fine-tuning of film-forming parameters

- Influence of non-linear thermal radiation on the dynamics of homogeneous and heterogeneous chemical reactions between the cone and the disk

- Thermodynamic modeling of stacking fault energy in Fe–Mn–C austenitic steels

- Research on the influence of cemented carbide micro-textured structure on tribological properties

- Performance evaluation of fly ash-lime-gypsum-quarry dust (FALGQ) bricks for sustainable construction

- First-principles study on the interfacial interactions between h-BN and Si3N4

- Analysis of carbon emission reduction capacity of hydrogen-rich oxygen blast furnace based on renewable energy hydrogen production

- Just-in-time updated DBN BOF steel-making soft sensor model based on dense connectivity of key features

- Effect of tempering temperature on the microstructure and mechanical properties of Q125 shale gas casing steel

- Review Articles

- A review of emerging trends in Laves phase research: Bibliometric analysis and visualization

- Effect of bottom stirring on bath mixing and transfer behavior during scrap melting in BOF steelmaking: A review

- High-temperature antioxidant silicate coating of low-density Nb–Ti–Al alloy: A review

- Communications

- Experimental investigation on the deterioration of the physical and mechanical properties of autoclaved aerated concrete at elevated temperatures

- Damage evaluation of the austenitic heat-resistance steel subjected to creep by using Kikuchi pattern parameters

- Topical Issue on Focus of Hot Deformation of Metaland High Entropy Alloys - Part II

- Synthesis of aluminium (Al) and alumina (Al2O3)-based graded material by gravity casting

- Experimental investigation into machining performance of magnesium alloy AZ91D under dry, minimum quantity lubrication, and nano minimum quantity lubrication environments

- Numerical simulation of temperature distribution and residual stress in TIG welding of stainless-steel single-pass flange butt joint using finite element analysis

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part I

- Electro-thermal performance evaluation of a prismatic battery pack for an electric vehicle

- Experimental analysis and optimization of machining parameters for Nitinol alloy: A Taguchi and multi-attribute decision-making approach

- Experimental and numerical analysis of temperature distributions in SA 387 pressure vessel steel during submerged arc welding

- Optimization of process parameters in plasma arc cutting of commercial-grade aluminium plate

- Multi-response optimization of friction stir welding using fuzzy-grey system

- Mechanical and micro-structural studies of pulsed and constant current TIG weldments of super duplex stainless steels and Austenitic stainless steels

- Stretch-forming characteristics of austenitic material stainless steel 304 at hot working temperatures

- Work hardening and X-ray diffraction studies on ASS 304 at high temperatures

- Study of phase equilibrium of refractory high-entropy alloys using the atomic size difference concept for turbine blade applications

- A novel intelligent tool wear monitoring system in ball end milling of Ti6Al4V alloy using artificial neural network

- A hybrid approach for the machinability analysis of Incoloy 825 using the entropy-MOORA method

- Special Issue on Recent Developments in 3D Printed Carbon Materials - Part II

- Innovations for sustainable chemical manufacturing and waste minimization through green production practices

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part I

- Characterization of Co–Ni–TiO2 coatings prepared by combined sol-enhanced and pulse current electrodeposition methods

- Hot deformation behaviors and microstructure characteristics of Cr–Mo–Ni–V steel with a banded structure

- Effects of normalizing and tempering temperature on the bainite microstructure and properties of low alloy fire-resistant steel bars

- Dynamic evolution of residual stress upon manufacturing Al-based diesel engine diaphragm

- Study on impact resistance of steel fiber reinforced concrete after exposure to fire

- Bonding behaviour between steel fibre and concrete matrix after experiencing elevated temperature at various loading rates

- Diffusion law of sulfate ions in coral aggregate seawater concrete in the marine environment

- Microstructure evolution and grain refinement mechanism of 316LN steel

- Investigation of the interface and physical properties of a Kovar alloy/Cu composite wire processed by multi-pass drawing

- The investigation of peritectic solidification of high nitrogen stainless steels by in-situ observation

- Microstructure and mechanical properties of submerged arc welded medium-thickness Q690qE high-strength steel plate joints

- Experimental study on the effect of the riveting process on the bending resistance of beams composed of galvanized Q235 steel

- Density functional theory study of Mg–Ho intermetallic phases

- Investigation of electrical properties and PTCR effect in double-donor doping BaTiO3 lead-free ceramics

- Special Issue on Thermal Management and Heat Transfer

- On the thermal performance of a three-dimensional cross-ternary hybrid nanofluid over a wedge using a Bayesian regularization neural network approach

- Time dependent model to analyze the magnetic refrigeration performance of gadolinium near the room temperature

- Heat transfer characteristics in a non-Newtonian (Williamson) hybrid nanofluid with Hall and convective boundary effects

- Computational role of homogeneous–heterogeneous chemical reactions and a mixed convective ternary hybrid nanofluid in a vertical porous microchannel

- Thermal conductivity evaluation of magnetized non-Newtonian nanofluid and dusty particles with thermal radiation