Abstract

This study investigates the effects of tempering temperature on the microstructure and mechanical properties of Q125 grade shale gas casing steel using experimental methods such as optical microscopy, scanning electron microscopy, and transmission electron microscopy. The results show that during the tempering process at 500–560°C, the morphology of the quenched laths gradually disappeared and the microstructure gradually recovered. Carbides precipitate from lamellar structures and gradually transform into short rod-like and fine dispersed spherical shapes, mainly distributed along the prior austenite grain boundaries (PAGB) and lath boundaries, accompanied by a decrease in dislocation density. At a tempering temperature of 530°C, the steel exhibited optimum overall mechanical properties, with a tensile strength of 961 MPa, yield strength of 921 MPa, and impact energy of 138.9 J. Within the tempering range of 500–560°C, the macroscopic tensile fracture surfaces exhibited obvious necking and delamination, with a microscopic morphology characterized by dimples accompanied by secondary cracks and tearing ridges. Both the initiation and propagation zones of the impact fracture surfaces exhibited dimple features, indicating good ductility. Microcracks and micropores observed in the longitudinal section of the tensile fracture are distributed along the PAGB or lath boundaries, with carbides located at the interfaces, reducing the interfacial energy.

1 Introduction

In recent years, the increasing demand for sustainable and low-carbon energy has positioned the United States at the technological forefront of shale gas exploration and production [1,2], changing the global energy supply market share and rapidly making unconventional natural gas stored in rock formations into a hotspot energy source for various countries [3,4]. China has a substantial amount of shale gas reserves, and although its production started later than that of North American countries, it has achieved a higher level of development than other nations. The special Q125 grade casing for shale gas extraction is characterized by high strength and toughness, with superior collapse resistance and bending performance. It plays a key role in deep wells with vertical depths of more than 3,000 m. As China places a greater focus on shale gas extraction, the specialized Q125 grade casing has significant application potential and will be the subject of considerable scientific interest. However, the complex and harsh extraction environment presents a challenge in terms of safety requirements for casing steel [5,6]. In accordance with the American API SPEC 5CT standard, the quenched and tempered Q125 grade casing steel should meet specific performance requirements, including tensile strength ≥931 MPa, yield strength between 862 and 1,034 MPa, elongation after fracture ≥13%, and impact energy at 0°C ≥60 J.

Based on C–Mn–Cr low-carbon steel, appropriate alloying elements are added to meet the strength and toughness requirements of Q125 steel grade casing steel plate. The Mo element is effectively soluble in ferrite, austenite, and carbide, which reduces temper brittleness, stabilizes the microstructure, and promotes the formation of metal carbonitrides. During quenching, Mo atoms concentrated at the grain boundary can pull the boundary, impede its movement, contribute to fine grain strengthening, and increase both strength and plasticity [7,8]. V and Nb elements interact with C and N elements to form carbon nitrides known as M(C, N). These M(C, N) particles pin the grain boundary and the dispersed M(C, N) interacts with dislocations to form a “Cottrell gas group” that hinders dislocation slip. This contributes to fine grain strengthening and precipitation strengthening, improving both strength and toughness. The simultaneous addition of V and Nb elements is more advantageous than the addition of a single element [9–13]. Some studies have shown the addition of Mo can reduce the size of Nb precipitates, making their distribution more dispersed and uniform, thereby enhancing the precipitation-strengthening effect [14]. Additionally, the B element improves the hardenability of the test steel. Some studies also suggest that the B element can strengthen both the grain boundary and the matrix, further improving the mechanical properties [15,16].

It should be noted that until now no heat treatment experiments of Q125 grade steel for casing used in shale gas extraction have been reported. This study aims to investigate the effect of tempering temperature on the microstructure and mechanical properties of the newly designed Q125 casing steel for shale gas application through comprehensive observation and analysis of the precipitate morphology and distribution, microstructural features, dislocation density, mechanical properties, fracture morphology, and crack initiation modes.

2 Materials and methods

The composition of the experimental steel grade Q125, the subject of this study, is presented in Table 1. The whole experimental process of this study is illustrated in Figure 1. The steel was smelted in a vacuum induction furnace with a capacity of 50 kg and cast into a steel ingot measuring 250 mm in length, 150 mm in width and 150 mm in height. The ingot was heated to 1,250°C and maintained at this temperature for 120 min for homogenization treatment. This was followed by multi-pass rolling into a 14 mm-thick plate with the final rolling temperature above 850°C, the material was cooled to room temperature via air cooling for 120–150 min. Metallographic specimens, tensile specimens (along the rolling direction), and impact specimens (perpendicular to the rolling direction) were cut from the hot-rolled steel plate by wire cutting machine. These specimens were then heated in a resistance-heated furnace, quenched in water at 935°C for 25 min to room temperature, and then tempered at 500, 530, and 560°C for 60 min, followed by air cooling to room temperature. For ease of later description, the water-quenched (WQ) specimens were labeled as WQ, and the specimens tempered at different temperatures were labeled as QT-500, QT-530, and QT-560, respectively.

Chemical compositions of experimental steels (wt%)

| C | Si | Mn | Cr | Mo | Nb + V | B | P | S |

|---|---|---|---|---|---|---|---|---|

| 0.23 | 1.25 | 0.80 | 1.0 | 0.70 | 0.10 | 0.05 | 0.008 | 0.01 |

Scheme of the experimental process.

The tempered experimental material was processed into tensile specimens with a gauge length of 50 mm and full plate thickness, as well as standard Charpy-V notch impact specimens (10 × 10 × 55 mm). Room temperature uniaxial tensile tests were conducted using a Z330E tensile testing machine according to ISO 6892-1:2019, with a tensile speed of 1 mm·min−1. To reduce the potential for experimental error, the mean mechanical properties of at least two specimens were employed. Charpy impact tests at 0°C were conducted using a PIT452G-4 pendulum impact testing machine in accordance with ISO 148-1:2016.

The morphologies of the tensile and impact fracture surfaces were observed under a ULTRA 55 field emission scanning electron microscope (SEM). Metallographic specimens, which were mechanically polished and etched with a 4% nitric acid-alcohol solution, and observed using an Axio Observer A1m inverted microscope (OM) and a field emission SEM for microstructure morphology analysis. Thin foils were manually ground to thickness of 50 μm and punched into discs with a diameter of 3 mm and then subjected to double-jet thinning in an 8% perchloric acid-alcohol solution at a temperature of −20°C. The microstructures and precipitates were observed using a Tecnai F30 transmission electron microscope (TEM), and the composition of the precipitates was analyzed using an energy dispersive spectroscopy (EDS) attached to the TEM. Subsequently, electropolishing was performed on mechanically polished samples in a 10% perchloric acid-alcohol solution to remove surface stress. Finally, the microstructure observations were then conducted using an electron back scatter diffraction detector attached to a field emission SEM.

3 Results and discussion

3.1 Microstructures

The microstructures of the WQ specimen were observed by optical microscopy (OM), SEM, and TEM, as illustrated in Figure 2. A modest addition of boron (B) was made to the chemical composition of the experimental steel in order to enhance its hardenability. The WQ microstructure exhibited a typical lath martensite structure, with clearly visible prior austenite grain boundaries (PAGB) and martensite lath boundaries, indicating a uniform structure. As illustrated in Figure 2(a) and (b), martensite blocks were composed of martensite laths with the same orientation, and these blocks with identical habit planes form martensite packets, which collectively constitute a prior austenite grain [17]. As illustrated in Figure 2(c) and (d), the TEM images also confirmed that the WQ specimen exhibited a typical lath martensite structure, with a high density of dislocations distributed throughout the microstructure. These dislocations are intertwined and interact with each other, forming a complex network.

Water quenched microstructure of experimental steel: (a) OM, (b) SEM, (c) and (d) TEM.

Figure 3 illustrates the OM and SEM images of specimens subjected to different tempering heat treatment temperatures. The presence of oversaturated carbon in the lath martensite structure of the WQ specimen leads to a reduction in structural stability. During the tempering process, the material transforms toward stable ferrite and carbide phases. The QT-500 specimen displayed a tempered sorbite structure that retains the lath morphology inherited from the lath martensite. The PAGB and lath boundaries remained visible, indicating insufficient decomposition of the quenched martensite structure. Furthermore, lamellar carbides precipitated with a notable concentration along the PAGB and lamellar boundaries. As the tempering temperature increased, polygonal ferrite began to form in QT-530. The PAGB and lath boundaries become less distinct, and the carbides transition from a lamellar to short rod-like and granular shape. The carbides were primarily located at the lath boundaries, with a notable reduction in their prevalence at the PAGB, most of which adopt a short rod-like shape. Conversely, the number of carbides at the lath boundaries increased. With a further increase in tempering temperature, the grain boundaries and lath boundaries in QT-560 became even less distinct. The ferrite structure continues to expand, and some carbides undergo a higher degree of spheroidization, resulting in fine and dispersed carbides. It is worth noting that during the tempering process from 500 to 560°C, there was no significant change in the microstructural dimensions.

Microstructure of experimental steel at different tempering temperatures: (a) and (b) QT-500, (c) and (d) QT-530, (e) and (f) QT-560.

Figure 4 shows TEM images of the specimens subjected to different tempering temperatures. As the tempering temperature increased, a notable reduction in dislocation density within the specimen’s microstructure was evident. In the QT-500 specimen, lamellar carbide was observed at the boundaries of tempered sorbite laths, evolving from the thin film-like retained austenite between quenched martensite laths. These lamellar gradually broke apart, and a substantial number of short rod-like cementite particles were observed in the matrix of the QT-530 specimen. The carbide showed a greater degree of spheroidization in the matrix and at the phase boundaries in the QT-560 specimen. The different morphologies of carbide are indicated by arrows and correspond to the carbide morphologies observed in the SEM micrographs of the specimens shown in Figure 3. The chemical composition of the second-phase particles was determined by using energy dispersive spectroscopy (EDS) attached to the TEM. The particles were primarily composed of Fe and C, with minor concentrations of Cr, Mn, and Mo. These observations are consistent with those reported by other researchers [18,19]. The addition of trace amounts of V to the experimental steel resulted in the precipitation of elliptical particles with smaller sizes, as shown in Figure 4(c). Previous studies have indicated that these dispersed second-phase particles are essentially alloy cementite (M3C) and secondary hardening carbides (V, X)C, where M represents Fe, Cr, Mn, and X represents Mo and Cr [20–22].

TEM images of experimental steel at different tempering temperatures: (a) QT-500, (b) QT-530, (c) QT-560, and (d) precipitation of VC in QT-560.

Figure 5 illustrates the Kernel Average Misorientation (KAM) maps of the WQ and QT-530 specimens. It can be observed that the WQ specimen exhibited a higher degree of misorientation, which indicated a higher dislocation density within its internal structure. This finding aligns with the observations of abundant dislocations observed in the TEM images presented in Figure 2(c) and (d). In contrast, the QT-530 tempered sample displayed a reduced degree of misorientation, indicating a decrease in dislocation density. During the tempering process, the microstructure undergoes recovery and recrystallization, whereby dislocations slide, rearrange, and cancel each other out, resulting in the gradual disappearance of high-density dislocations [8,23]. This finding is consistent with the TEM images of the tempered specimen shown in Figure 4(b).

KAM diagram of specimens in different states: (a) WQ and (b) QT-530.

3.2 Effect of tempering temperature on mechanical properties

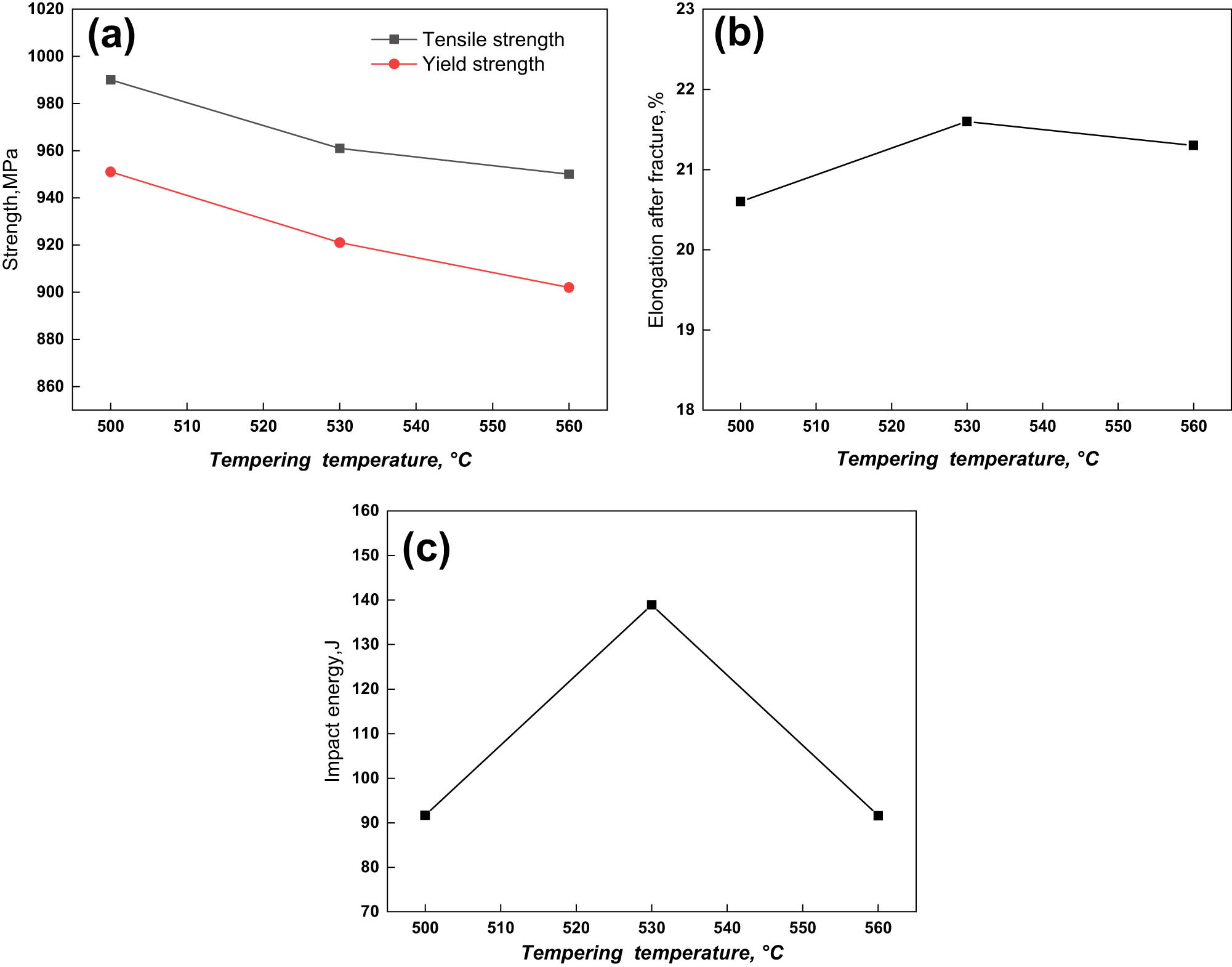

Figure 6 illustrates the trend in mechanical properties of specimens subjected to different tempering temperatures. It can be seen that as the tempering temperature increased, both tensile strength and yield strength gradually decreased, while elongation after fracture showed an increasing trend. These properties meet the standard requirements for tensile strength (≥931 MPa), yield strength (ranging from 862 to 1,034 MPa), and elongation after fracture (≥13%). This indicates that the experimental steel, designed with a customized composition, can satisfy the standard requirements within the tempering temperature range of 500–560°C, demonstrating high feasibility for industrial production. The decline in tensile strength and yield strength of the experimental steel with rising tempering temperature can be attributed to the gradual recovery and softening of the quenched martensite structure during the tempering process. This results in a reduction in dislocation density, which is consistent with the microstructures shown in Figures 4 and 5. In the case of the QT-500 specimen, the lower tempering temperature resulted in insufficient decomposition and transformation of the quenched structure, resulting in a higher dislocation density, as evidenced in Figure 4a. Consequently, the specimen exhibited higher tensile and yield strengths, namely 990 and 951 MPa, respectively. The interaction between higher-density dislocations, the reduction in the number of mobile dislocations, and the increased tendency for dislocation pile-ups collectively promoted the initiation and growth of microcracks. Furthermore, the precipitation and distribution of lamellar carbides along the PAGB contributed to a reduction in the ductility and toughness of the experimental steel. This is evidenced by an elongation after fracture of 20.6% and an impact energy at 0°C of 91.7 J [24]. The QT-530 specimen exhibited a slight reduction in strength, specifically, tensile, and yield strengths of 961 and 921 MPa, respectively. However, it demonstrated superior toughness with an elongation after fracture of 21.6% and an impact energy of 138.9 J, indicating that the steel attained optimal comprehensive mechanical properties at a tempering temperature of 530°C. However, as the tempering temperature was increased further to 560°C, the impact energy of the QT-560 experimental steel decreased to 91.6 J from the peak of 138.9 J exhibited by the QT-530 specimen.

Mechanical properties of specimens at different tempering temperatures: (a) tensile strength and yield strength, (b) elongation after break, and (c) impact energy.

3.3 Tensile fracture behavior of the experimental steel

Figure 7 shows the macroscopic morphologies of tensile fractures of the experimental steel at different tempering temperatures. The experimental steel exhibited clear necking and delamination phenomenon. Many researchers employed the fracture mechanics crack tip of the plastic zone theory to explain the delamination phenomenon. When the yield strength of the tensile specimen in the direction perpendicular to rolling is lower than that along the rolling direction, delamination cracks (crack deflection) are more likely to occur at the interface between the soft and hard phases within the plastic zone at the crack tip [25,26]. This phenomenon has been attributed by some researchers to the flow lines induced by rolling, which are caused by the difference in yield strength between the rolling direction and the direction perpendicular to it [27].

Macroscopic morphology of tensile fractures of specimens: (a) QT-500, (b) QT-530, and (c) QT-560.

Figure 8 illustrates the microstructures of the crack initiation zone and the final fracture zone in the tensile fracture surfaces of the experimental steel specimens tested at different tempering temperatures. The crack initiation zone displayed ductile characteristics, including fine dimples, the presence of secondary microcracks, and tear ridges (indicated by arrows), which collectively formed small facets. In the final facture zone, the dimples were shallower and also featured fine secondary microcracks. The overall tensile fracture surface exhibited shallow and small-sized dimples, which correspond to the evident necking and the high elongation after fracture.

Microscopic morphology of tensile fractures of specimens: (a) and (b) QT-500, (c) and (d) QT-530, (e) and (f) QT-560; (a, c, and e) demonstrates crack initiation zone; (b, d, and f) demonstrates the final fracture zone.

Figure 9 shows the low-magnification longitudinal metallographic images of the tensile fracture surfaces of the experimental steel at different tempering temperatures. A noteworthy phenomenon of necking was observed, which corresponds to the high degree of elongation that occurred subsequent to the fracture of the experimental steel. It is notable that the angle between the fracture direction of the sample and the uniaxial tensile direction was approximately 45°, which is consistent with the fracture characteristics that occur as a result of shear tearing under plane strain conditions. Similar phenomena have also been observed in other studies [28].

Macroscopic morphology of longitudinal section of tensile fracture of specimens: (a) QT-500, (b) QT-530, and (c) QT-560.

SEM images of longitudinal sections near the tensile fracture surfaces of the experimental steel at different tempering temperatures are shown in Figure 10. Micro-voids (indicated by red circles) and micro-cracks (indicated by arrows) can be observed as crack initiation points near the fracture surface. These micro-voids and micro-cracks originated at the PAGB or lath boundaries. As observed in the SEM image of Figure 3, carbides tended to precipitate and segregated at the PAGB and lath boundaries, reducing the grain boundary binding energy and leading to interfacial separation under stress.

Microscopic morphology of longitudinal section of tensile fracture of experimental steel: (a) QT-500, (b) QT-530, and (c) QT-560.

3.4 Morphology of impact fracture surfaces of the experimental steel

Figure 11 depicts the microstructures of the crack initiation zone and the final fracture zone in the impact fracture surfaces of the experimental steel at different tempering temperatures. Both the crack initiation zone and the final fracture zone exhibited ductile dimple morphologies, which are characteristic of ductile failure. Additionally, plastic deformation occurred in the final fracture zone, leading to the formation of small-sized dimples with a parabolic shape. The dimple characteristics across the entire fracture surface contributed to the absorption of impact energy, corresponding to an impact energy of 90 J or higher.

Microscopic morphology of impact fractures of experimental steel: (a) and (b) QT-500, (c) and (d) QT-530, (e) and (f) QT-560; (a, c, and e) demonstrates crack initiation zone; (b, d, and f) demonstrates the final fracture zone.

4 Conclusions

The microstructure obtained through water quenching at 935°C exhibits a typical martensite lath structure, with clearly visible PAGB and martensite lath boundaries. The structure is uniform and exhibits a high density of dislocations. During the tempering process at 500–560°C, the quenched lath morphology gradually disappears, and the microstructure gradually recovers. The carbides transform from lamellar shapes to shorter rod-like and finely dispersed spherical shapes. After tempering, the degree of misorientation and dislocation density in the experimental steel decreases.

At a tempering temperature of 500°C, the high dislocation density within the experimental steel results in an ultimate tensile strength of 990 MPa and a yield strength of 951 MPa. As the tempering temperature gradually increases both the tensile strength and yield strength decrease, while the impact energy initially rises and then decreases. When the tempering temperature reaches 530°C, the experimental steel exhibits the best overall mechanical properties, with a tensile strength of 961 MPa, a yield strength of 921 MPa, and an impact energy of 138.9 J.

Within the tempering temperature range of 500–560°C, the macroscopic fracture surfaces of tensile specimens exhibit significant necking and delamination. Microscopic observations reveal a dimpled morphology accompanied by secondary cracks and tear ridges. These dimples are relatively shallow and small, correlating with the high elongation rate observed after fracture. Furthermore, the impact fracture surfaces exhibit dimple characteristics in both the crack initiation zone and the propagation zone, which correspond to the results of impact energy exceeding 90 J.

Microcracks and micropores observed on the longitudinal section of the tensile fracture are distributed along the PAGB or lath boundaries. Since the carbides are mainly distributed at the PAGB or lath boundaries after tempering, the interfacial bonding energy is reduced.

Given the limitations of the available equipment, a more detailed observation of the microstructural evolution of the experimental steel during heat treatment, including the evolution of second phase particles and dislocation density, using advanced techniques such as three-dimensional atom probe and in situ tensile SEM, was not feasible. Furthermore, while this study has conducted microstructural observations and evaluated the basic mechanical properties of the experimental steel through tensile and impact tests, the evaluation of additional properties tailored to the unique and demanding service conditions of shale gas casing steel remains unaddressed. Future research should therefore focus on conducting a more comprehensive and in-depth study of Q125 grade steel for shale gas casing, taking into account the harsh service environment encountered during shale gas production.

Acknowledgment

The authors would like to thank colleagues from Hansteel for their wonderful collaboration and extend their sincere gratitude for the support provided by HBIS Group and Industry and Information Technology Department of Hebei Province for their financial assistance.

-

Funding information: This research was support by HBIS Group Co., Ltd. and Industry and Information Technology Department of Hebei Province (Project No. JGK231201).

-

Author contributions: Jiaojiao Wang: writing – original draft, writing – review & editing, methodology, formal analysis; Taiyu Guo: writing – review & editing, formal analysis, project administration; Yunzhe Gao: writing – review & editing, experimental guidance, resources; Jian Wang: investigation and visualization; Yuqing Zhou: data curation and resources; Xiaolong Wu: investigation and software; Linlin Zhao: conceptualization and supervision.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The data that support the findings of this study are available on request from the corresponding author, Taiyu Guo, upon reasonable request.

References

[1] Wang, S. Shale gas exploitation: status, problems and prospect. Natural Gas Industry B, Vol. 5, No. 1, 2018, pp. 60–74.10.1016/j.ngib.2017.12.004Search in Google Scholar

[2] Zhang, F. Development of Q125 steel casing for shale gas. Master’s thesis. Inner Mongolia University of Science and Technology, Inner Mongolia, 2019.Search in Google Scholar

[3] Wang, X. and C. Wu. Opportunities of nonferrous metals industry in the shale gas revolution. Non-Ferrous Metals, Vol. 66, No. 3, 2014, pp. 1–5.Search in Google Scholar

[4] Curtis, J. B. Fractured shale-gas systems. AAPG Bulletin, Vol. 86, No. 11, 2002, pp. 1921–1938.10.1306/61EEDDBE-173E-11D7-8645000102C1865DSearch in Google Scholar

[5] Gu, Z. The study on the influence law of tissue and performance of controlled cooling process for V140 oil casin. Master’s thesis. Northeastern University, Shenyang, 2019.Search in Google Scholar

[6] Peng, X. The research on microstructure and mechanical properties of oil casing 100V-Cr-Mo. Master’s thesis. Lanzhou University of Technology, Lanzhou, 2012.Search in Google Scholar

[7] Salemi, A. and A. J. Abdollah-Zadeh. The effect of tempering temperature on the mechanical properties and fracture morphology of a NiCrMoV steel. Materials Characterization, Vol. 59, No. 4, 2008, pp. 484–487.10.1016/j.matchar.2007.02.012Search in Google Scholar

[8] Zhou, C., T. Zhao, Q. Ye, Y. Tian, Z. Dong, and X. Gao. Effect of tempering temperature on microstructure and low-temperature toughness of 1000 MPa grade NiCrMoV low carbon alloyed steel. Acta Metallurgica Sinica, Vol. 58, No. 12, 2022, pp. 1557–1569.Search in Google Scholar

[9] Wang, Z. Study on controlling of microstructure and performance of banintic forging steels. Doctoral dissertation. Beijing Jiaotong University, Beijing, 2021.Search in Google Scholar

[10] Morito, S., X. Huang, T. Furuhara, T. Maki, and N. Hansen. The morphology and crystallography of lath martensite in alloy steels. Acta Materialia, Vol. 54, No. 19, 2006, pp. 5323–5331.10.1016/j.actamat.2006.07.009Search in Google Scholar

[11] Zhang, W., X. He, W. Yu, L. Li, and M. Wang. Effect of Nb microalloying on microstructure and mechanical properties of Cr-Ni-Mo-V high-strength steels. Heat Treatment of Metals, Vol. 48, No. 1, 2023, pp. 29–34.Search in Google Scholar

[12] Ye, X. Effects of vanadium, niobium and nitrogen on the microstructure and properties of N80 grade non-quenched and tempered oil casing. Master’s thesis. Kunming University of Science and Technology, Kunming, 2008.Search in Google Scholar

[13] Zrnı́k, J., T. Kvackaj, A. Pongpaybul, P. Sricharoenchai, J. Vilk, and V. Vrchovinsky. Effect of thermomechanical processing on the microstructure and mechanical properties of Nb–Ti microalloyed steel. Materials Science and Engineering: A, Vol. 319–321, 2001, pp. 321–325.10.1016/S0921-5093(01)01033-4Search in Google Scholar

[14] Wang, M., Y. Ma, and L. Wang. The key technical issues among establishment under the technical conditions of grade X80 pipeline steel and steel pipe. Welded Pipe and Tube, Vol. 28, No. 2, 2005, pp. 15–21.Search in Google Scholar

[15] Fei, Y., J. Hou, S. Gao, C. Wang, and L. Zhou. The effects of boron addition on the microstructure stability and mechanical properties of a Ni-Cr based superalloy. Materials Science and Engineering: A, Vol. 715, 2018, pp. 126–136.10.1016/j.msea.2017.12.082Search in Google Scholar

[16] Liu, Q., S. Huang, F. Liu, Y. Yang, H. Nan, D. Zhang, et al. Effect of boron content on microstructure evolution during solidification and mechanical properties of K417G alloy. Acta Metallurgica Sinica, Vol. 55, No. 6, 2019, pp. 720–728.Search in Google Scholar

[17] Wang, C., M. Wang, J. Shi, W. Hui, and H. Dong. Effect of microstructural refinement on the toughness of low carbon martensitic steel. Scripta Materialia, Vol. 58, No. 6, 2008, pp. 492–495.10.1016/j.scriptamat.2007.10.053Search in Google Scholar

[18] Xv, Z. Research on the hydrogen embrittlement sensitivity of microalloyed medium carbon forging steel. Master’s thesis. Beijing Jiaotong University, Beijing, 2018.Search in Google Scholar

[19] Chen, H. Research of component-process-microstructure-property relationship in 1000 MPa grade low carbon ultra high strength steels. Master’s thesis. University of Science and Technology Beijing, Beijing, 2023.Search in Google Scholar

[20] Hui, W., Y. Zhang, X. Zhao, C. Zhou, K. Wang, W. Sun, et al. Very high cycle fatigue properties of Cr-Mo low alloy steel containing V-rich MC type carbides. Materials Science and Engineering: A, Vol. 651, 2016, pp. 311–320.10.1016/j.msea.2015.10.124Search in Google Scholar

[21] Lei, M. Study of microstructure and mechanical properties of V-alloyed medium Mn steel. Master’s thesis. Beijing Jiaotong University, Beijing, 2019.Search in Google Scholar

[22] Wang, J., H. Liu, Y. Liu, H. Chen, Z. Tian, and H. Zhang. Microstructure and properties of a grade 10.9 bolt steel with wide tempering time window. Heat Treatment of Metals, Vol. 48, No. 9, 2023, pp. 233–237.Search in Google Scholar

[23] Yang, Y., H. Xv, Y. Wang, H. Wu, and X. Mao. Effect of different heat treatment processes on microstructure and properties of large-thickeness bridge steels. Heat Treatment of Metals, Vol. 48, No. 10, 2023, pp. 23–28.Search in Google Scholar

[24] Wang, X. Study on the hardenability and strength & toughness of high strength low alloyed ultra-heavy plate steels for marine engineering. doctoral Dissertation. General Iron and Steel Research Institute, Beijing, 2013.Search in Google Scholar

[25] Nie, Y., Y. Kimura, T. Inoue, F. Yin, E. Akiyama, and K. Tsuzaki. Hydrogen embrittlement of a 1500-MPa tensile strength level steel with an ultrafine elongated grain structure. Metallurgical and Materials Transactions A, Vol. 43, 2012, pp. 1670–1687.10.1007/s11661-011-0974-7Search in Google Scholar

[26] Shao, C. Study on microstructure control and hydrogen embrittlement susceptibility of containing-Al medium Mn steels with high product of strength to ductility. doctoral Disseration. Beijing Jiaotong University, Beijing, 2018.Search in Google Scholar

[27] Kimura, Y., T. Inoue, and K. Tsuzaki. Tempforming in medium-carbon low-alloy steel. Tempforming in Medium-Carbon Low-Alloy Steel, Vol. 577, No. Sup. 1, 2013, pp. S538–S542.10.1016/j.jallcom.2011.12.123Search in Google Scholar

[28] Shao, C., W. Hui, Y. Zhang, X. Zhao, and Y. Weng. Microstructure and mechanical properties of a novel cold rolled medium-Mn steel with superior strength and ductility. Acta Metallurgica Sinica, Vol. 55, No. 2, 2019, pp. 191–201.Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- De-chlorination of poly(vinyl) chloride using Fe2O3 and the improvement of chlorine fixing ratio in FeCl2 by SiO2 addition

- Reductive behavior of nickel and iron metallization in magnesian siliceous nickel laterite ores under the action of sulfur-bearing natural gas

- Study on properties of CaF2–CaO–Al2O3–MgO–B2O3 electroslag remelting slag for rack plate steel

- The origin of {113}<361> grains and their impact on secondary recrystallization in producing ultra-thin grain-oriented electrical steel

- Channel parameter optimization of one-strand slab induction heating tundish with double channels

- Effect of rare-earth Ce on the texture of non-oriented silicon steels

- Performance optimization of PERC solar cells based on laser ablation forming local contact on the rear

- Effect of ladle-lining materials on inclusion evolution in Al-killed steel during LF refining

- Analysis of metallurgical defects in enamel steel castings

- Effect of cooling rate and Nb synergistic strengthening on microstructure and mechanical properties of high-strength rebar

- Effect of grain size on fatigue strength of 304 stainless steel

- Analysis and control of surface cracks in a B-bearing continuous casting blooms

- Application of laser surface detection technology in blast furnace gas flow control and optimization

- Preparation of MoO3 powder by hydrothermal method

- The comparative study of Ti-bearing oxides introduced by different methods

- Application of MgO/ZrO2 coating on 309 stainless steel to increase resistance to corrosion at high temperatures and oxidation by an electrochemical method

- Effect of applying a full oxygen blast furnace on carbon emissions based on a carbon metabolism calculation model

- Characterization of low-damage cutting of alfalfa stalks by self-sharpening cutters made of gradient materials

- Thermo-mechanical effects and microstructural evolution-coupled numerical simulation on the hot forming processes of superalloy turbine disk

- Endpoint prediction of BOF steelmaking based on state-of-the-art machine learning and deep learning algorithms

- Effect of calcium treatment on inclusions in 38CrMoAl high aluminum steel

- Effect of isothermal transformation temperature on the microstructure, precipitation behavior, and mechanical properties of anti-seismic rebar

- Evolution of residual stress and microstructure of 2205 duplex stainless steel welded joints during different post-weld heat treatment

- Effect of heating process on the corrosion resistance of zinc iron alloy coatings

- BOF steelmaking endpoint carbon content and temperature soft sensor model based on supervised weighted local structure preserving projection

- Innovative approaches to enhancing crack repair: Performance optimization of biopolymer-infused CXT

- Structural and electrochromic property control of WO3 films through fine-tuning of film-forming parameters

- Influence of non-linear thermal radiation on the dynamics of homogeneous and heterogeneous chemical reactions between the cone and the disk

- Thermodynamic modeling of stacking fault energy in Fe–Mn–C austenitic steels

- Research on the influence of cemented carbide micro-textured structure on tribological properties

- Performance evaluation of fly ash-lime-gypsum-quarry dust (FALGQ) bricks for sustainable construction

- First-principles study on the interfacial interactions between h-BN and Si3N4

- Analysis of carbon emission reduction capacity of hydrogen-rich oxygen blast furnace based on renewable energy hydrogen production

- Just-in-time updated DBN BOF steel-making soft sensor model based on dense connectivity of key features

- Effect of tempering temperature on the microstructure and mechanical properties of Q125 shale gas casing steel

- Review Articles

- A review of emerging trends in Laves phase research: Bibliometric analysis and visualization

- Effect of bottom stirring on bath mixing and transfer behavior during scrap melting in BOF steelmaking: A review

- High-temperature antioxidant silicate coating of low-density Nb–Ti–Al alloy: A review

- Communications

- Experimental investigation on the deterioration of the physical and mechanical properties of autoclaved aerated concrete at elevated temperatures

- Damage evaluation of the austenitic heat-resistance steel subjected to creep by using Kikuchi pattern parameters

- Topical Issue on Focus of Hot Deformation of Metaland High Entropy Alloys - Part II

- Synthesis of aluminium (Al) and alumina (Al2O3)-based graded material by gravity casting

- Experimental investigation into machining performance of magnesium alloy AZ91D under dry, minimum quantity lubrication, and nano minimum quantity lubrication environments

- Numerical simulation of temperature distribution and residual stress in TIG welding of stainless-steel single-pass flange butt joint using finite element analysis

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part I

- Electro-thermal performance evaluation of a prismatic battery pack for an electric vehicle

- Experimental analysis and optimization of machining parameters for Nitinol alloy: A Taguchi and multi-attribute decision-making approach

- Experimental and numerical analysis of temperature distributions in SA 387 pressure vessel steel during submerged arc welding

- Optimization of process parameters in plasma arc cutting of commercial-grade aluminium plate

- Multi-response optimization of friction stir welding using fuzzy-grey system

- Mechanical and micro-structural studies of pulsed and constant current TIG weldments of super duplex stainless steels and Austenitic stainless steels

- Stretch-forming characteristics of austenitic material stainless steel 304 at hot working temperatures

- Work hardening and X-ray diffraction studies on ASS 304 at high temperatures

- Study of phase equilibrium of refractory high-entropy alloys using the atomic size difference concept for turbine blade applications

- A novel intelligent tool wear monitoring system in ball end milling of Ti6Al4V alloy using artificial neural network

- A hybrid approach for the machinability analysis of Incoloy 825 using the entropy-MOORA method

- Special Issue on Recent Developments in 3D Printed Carbon Materials - Part II

- Innovations for sustainable chemical manufacturing and waste minimization through green production practices

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part I

- Characterization of Co–Ni–TiO2 coatings prepared by combined sol-enhanced and pulse current electrodeposition methods

- Hot deformation behaviors and microstructure characteristics of Cr–Mo–Ni–V steel with a banded structure

- Effects of normalizing and tempering temperature on the bainite microstructure and properties of low alloy fire-resistant steel bars

- Dynamic evolution of residual stress upon manufacturing Al-based diesel engine diaphragm

- Study on impact resistance of steel fiber reinforced concrete after exposure to fire

- Bonding behaviour between steel fibre and concrete matrix after experiencing elevated temperature at various loading rates

- Diffusion law of sulfate ions in coral aggregate seawater concrete in the marine environment

- Microstructure evolution and grain refinement mechanism of 316LN steel

- Investigation of the interface and physical properties of a Kovar alloy/Cu composite wire processed by multi-pass drawing

- The investigation of peritectic solidification of high nitrogen stainless steels by in-situ observation

- Microstructure and mechanical properties of submerged arc welded medium-thickness Q690qE high-strength steel plate joints

- Experimental study on the effect of the riveting process on the bending resistance of beams composed of galvanized Q235 steel

- Density functional theory study of Mg–Ho intermetallic phases

- Investigation of electrical properties and PTCR effect in double-donor doping BaTiO3 lead-free ceramics

- Special Issue on Thermal Management and Heat Transfer

- On the thermal performance of a three-dimensional cross-ternary hybrid nanofluid over a wedge using a Bayesian regularization neural network approach

- Time dependent model to analyze the magnetic refrigeration performance of gadolinium near the room temperature

- Heat transfer characteristics in a non-Newtonian (Williamson) hybrid nanofluid with Hall and convective boundary effects

- Computational role of homogeneous–heterogeneous chemical reactions and a mixed convective ternary hybrid nanofluid in a vertical porous microchannel

- Thermal conductivity evaluation of magnetized non-Newtonian nanofluid and dusty particles with thermal radiation

Articles in the same Issue

- Research Articles

- De-chlorination of poly(vinyl) chloride using Fe2O3 and the improvement of chlorine fixing ratio in FeCl2 by SiO2 addition

- Reductive behavior of nickel and iron metallization in magnesian siliceous nickel laterite ores under the action of sulfur-bearing natural gas

- Study on properties of CaF2–CaO–Al2O3–MgO–B2O3 electroslag remelting slag for rack plate steel

- The origin of {113}<361> grains and their impact on secondary recrystallization in producing ultra-thin grain-oriented electrical steel

- Channel parameter optimization of one-strand slab induction heating tundish with double channels

- Effect of rare-earth Ce on the texture of non-oriented silicon steels

- Performance optimization of PERC solar cells based on laser ablation forming local contact on the rear

- Effect of ladle-lining materials on inclusion evolution in Al-killed steel during LF refining

- Analysis of metallurgical defects in enamel steel castings

- Effect of cooling rate and Nb synergistic strengthening on microstructure and mechanical properties of high-strength rebar

- Effect of grain size on fatigue strength of 304 stainless steel

- Analysis and control of surface cracks in a B-bearing continuous casting blooms

- Application of laser surface detection technology in blast furnace gas flow control and optimization

- Preparation of MoO3 powder by hydrothermal method

- The comparative study of Ti-bearing oxides introduced by different methods

- Application of MgO/ZrO2 coating on 309 stainless steel to increase resistance to corrosion at high temperatures and oxidation by an electrochemical method

- Effect of applying a full oxygen blast furnace on carbon emissions based on a carbon metabolism calculation model

- Characterization of low-damage cutting of alfalfa stalks by self-sharpening cutters made of gradient materials

- Thermo-mechanical effects and microstructural evolution-coupled numerical simulation on the hot forming processes of superalloy turbine disk

- Endpoint prediction of BOF steelmaking based on state-of-the-art machine learning and deep learning algorithms

- Effect of calcium treatment on inclusions in 38CrMoAl high aluminum steel

- Effect of isothermal transformation temperature on the microstructure, precipitation behavior, and mechanical properties of anti-seismic rebar

- Evolution of residual stress and microstructure of 2205 duplex stainless steel welded joints during different post-weld heat treatment

- Effect of heating process on the corrosion resistance of zinc iron alloy coatings

- BOF steelmaking endpoint carbon content and temperature soft sensor model based on supervised weighted local structure preserving projection

- Innovative approaches to enhancing crack repair: Performance optimization of biopolymer-infused CXT

- Structural and electrochromic property control of WO3 films through fine-tuning of film-forming parameters

- Influence of non-linear thermal radiation on the dynamics of homogeneous and heterogeneous chemical reactions between the cone and the disk

- Thermodynamic modeling of stacking fault energy in Fe–Mn–C austenitic steels

- Research on the influence of cemented carbide micro-textured structure on tribological properties

- Performance evaluation of fly ash-lime-gypsum-quarry dust (FALGQ) bricks for sustainable construction

- First-principles study on the interfacial interactions between h-BN and Si3N4

- Analysis of carbon emission reduction capacity of hydrogen-rich oxygen blast furnace based on renewable energy hydrogen production

- Just-in-time updated DBN BOF steel-making soft sensor model based on dense connectivity of key features

- Effect of tempering temperature on the microstructure and mechanical properties of Q125 shale gas casing steel

- Review Articles

- A review of emerging trends in Laves phase research: Bibliometric analysis and visualization

- Effect of bottom stirring on bath mixing and transfer behavior during scrap melting in BOF steelmaking: A review

- High-temperature antioxidant silicate coating of low-density Nb–Ti–Al alloy: A review

- Communications

- Experimental investigation on the deterioration of the physical and mechanical properties of autoclaved aerated concrete at elevated temperatures

- Damage evaluation of the austenitic heat-resistance steel subjected to creep by using Kikuchi pattern parameters

- Topical Issue on Focus of Hot Deformation of Metaland High Entropy Alloys - Part II

- Synthesis of aluminium (Al) and alumina (Al2O3)-based graded material by gravity casting

- Experimental investigation into machining performance of magnesium alloy AZ91D under dry, minimum quantity lubrication, and nano minimum quantity lubrication environments

- Numerical simulation of temperature distribution and residual stress in TIG welding of stainless-steel single-pass flange butt joint using finite element analysis

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part I

- Electro-thermal performance evaluation of a prismatic battery pack for an electric vehicle

- Experimental analysis and optimization of machining parameters for Nitinol alloy: A Taguchi and multi-attribute decision-making approach

- Experimental and numerical analysis of temperature distributions in SA 387 pressure vessel steel during submerged arc welding

- Optimization of process parameters in plasma arc cutting of commercial-grade aluminium plate

- Multi-response optimization of friction stir welding using fuzzy-grey system

- Mechanical and micro-structural studies of pulsed and constant current TIG weldments of super duplex stainless steels and Austenitic stainless steels

- Stretch-forming characteristics of austenitic material stainless steel 304 at hot working temperatures

- Work hardening and X-ray diffraction studies on ASS 304 at high temperatures

- Study of phase equilibrium of refractory high-entropy alloys using the atomic size difference concept for turbine blade applications

- A novel intelligent tool wear monitoring system in ball end milling of Ti6Al4V alloy using artificial neural network

- A hybrid approach for the machinability analysis of Incoloy 825 using the entropy-MOORA method

- Special Issue on Recent Developments in 3D Printed Carbon Materials - Part II

- Innovations for sustainable chemical manufacturing and waste minimization through green production practices

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part I

- Characterization of Co–Ni–TiO2 coatings prepared by combined sol-enhanced and pulse current electrodeposition methods

- Hot deformation behaviors and microstructure characteristics of Cr–Mo–Ni–V steel with a banded structure

- Effects of normalizing and tempering temperature on the bainite microstructure and properties of low alloy fire-resistant steel bars

- Dynamic evolution of residual stress upon manufacturing Al-based diesel engine diaphragm

- Study on impact resistance of steel fiber reinforced concrete after exposure to fire

- Bonding behaviour between steel fibre and concrete matrix after experiencing elevated temperature at various loading rates

- Diffusion law of sulfate ions in coral aggregate seawater concrete in the marine environment

- Microstructure evolution and grain refinement mechanism of 316LN steel

- Investigation of the interface and physical properties of a Kovar alloy/Cu composite wire processed by multi-pass drawing

- The investigation of peritectic solidification of high nitrogen stainless steels by in-situ observation

- Microstructure and mechanical properties of submerged arc welded medium-thickness Q690qE high-strength steel plate joints

- Experimental study on the effect of the riveting process on the bending resistance of beams composed of galvanized Q235 steel

- Density functional theory study of Mg–Ho intermetallic phases

- Investigation of electrical properties and PTCR effect in double-donor doping BaTiO3 lead-free ceramics

- Special Issue on Thermal Management and Heat Transfer

- On the thermal performance of a three-dimensional cross-ternary hybrid nanofluid over a wedge using a Bayesian regularization neural network approach

- Time dependent model to analyze the magnetic refrigeration performance of gadolinium near the room temperature

- Heat transfer characteristics in a non-Newtonian (Williamson) hybrid nanofluid with Hall and convective boundary effects

- Computational role of homogeneous–heterogeneous chemical reactions and a mixed convective ternary hybrid nanofluid in a vertical porous microchannel

- Thermal conductivity evaluation of magnetized non-Newtonian nanofluid and dusty particles with thermal radiation