Abstract

As a thin-walled complex structure, the manufacturing of Al-based diesel engine diaphragms involves casting and heat treatment. Residual stress is introduced during the uneven temperature field in casting and heat treatment, as well as the plastic deformation and cutting heat during mechanical processing. This research investigates the evolution and accumulation models of residual stress in casting and heat treatment for Al-based diesel engine diaphragms using ProCAST and ABAQUS software, combining with the experimental tests. To mitigate residual stress, the optimal parameter combination for casting temperature, knockout temperature, and mold preheating temperature in casting process is explored. The results indicate that the knockout temperature has the most significant influence on casting residual stress, and mold preheating is beneficial for reducing residual stress. Despite improvements, some internal stress concentration areas persist on the knockout casting surface. Furthermore, T6 heat treatment proves to be effective in eliminating more than 50% of the residual stress.

1 Introduction

In the high-precision machining production of diesel engine, stress redistribution can result in deviation between the tool envelope surface and the final shape upon clamp release, leading to the machining deformation [1]. Engine blocks containing residual stresses are susceptible to cracking or expanding during usage, significantly impacting their service life [2,3,4]. The cylinder block spacer, with its complex structure and non-uniform thickness in contact with the main shaft, plays a crucial role in retaining and propagating residual stresses during casting and heat treatment across various segments [5,6]. He et al., in his research on residual stress, used the finite element method to analyze residual stress in diesel engine pistons during manufacturing, demonstrating reduction through sand falling and elimination via heat treatment [7]. Zhang et al. optimized low-pressure casting parameters for ZL205A alloys, employing simulations and experiments to investigate the microstructure-stress interaction, thereby reducing residual stress [8].

In diesel engines, the evolution of residual stress often leads to damage in various parts, negatively impacting the overall service life. The pouring temperature affects the liquid fluidity. High pouring temperature can result in defects, such as porosity and cold segregation, while low pouring temperatures may lead to issues like shrinkage holes [9,10]. Additionally, the sand temperature, which refers to the temperature of the sand box, imposes stress on the casting. Maintaining suitable sand temperature and time is essential, and preheating the sandbox proves beneficial in reducing casting stress.

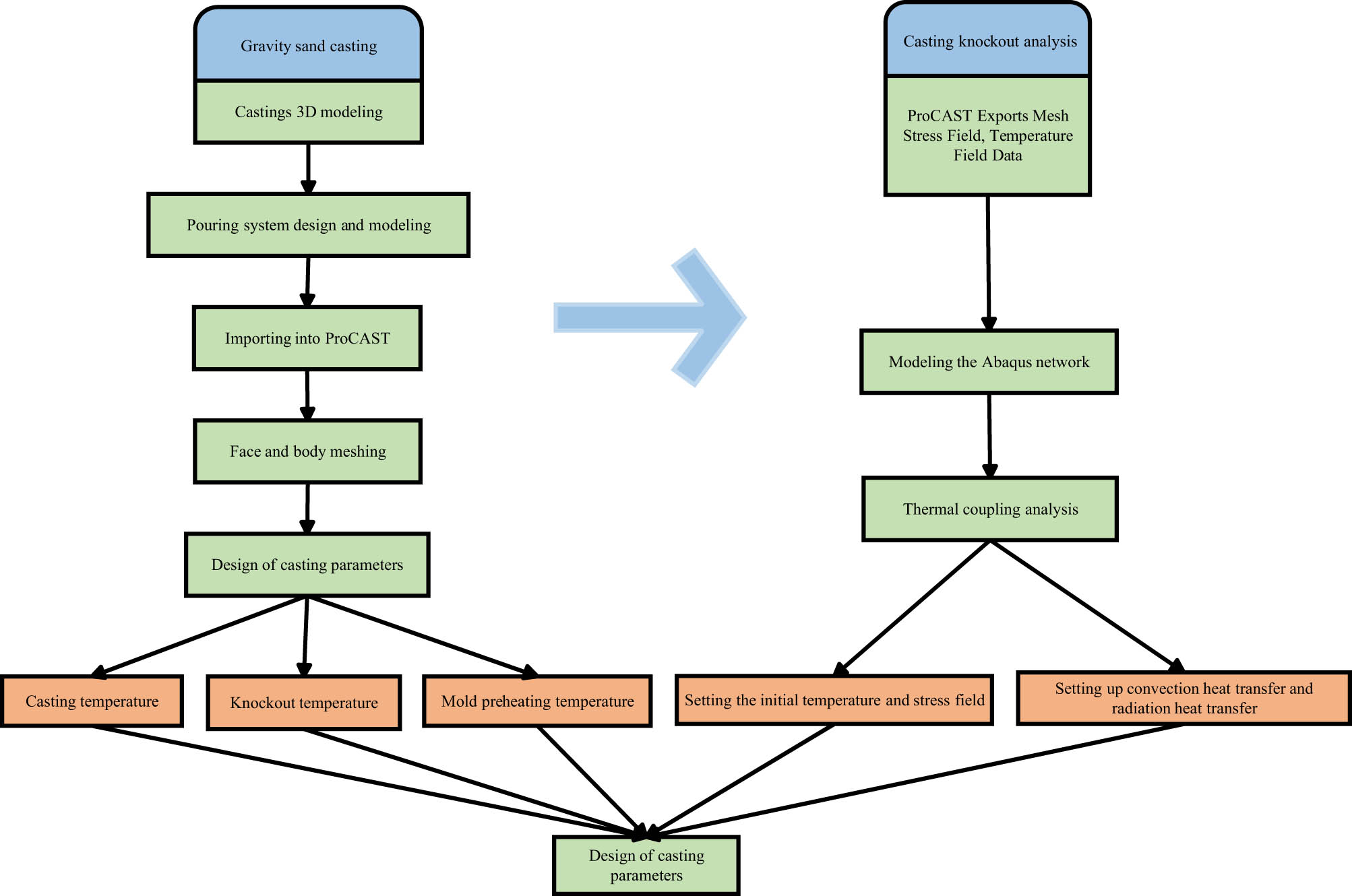

This study utilizes ProCAST software for casting and ABAQUS software for knockout joint simulation. The modeling of the casting process for physical production is combined with experimental studies on residual stresses. The objective is to study the effects of casting process of the spacer plate and the heat treatment on the evolution and accumulation model of residual stresses. The aim is to clarify the distribution of residual stresses and identify potential methods for their elimination. Quantitative analysis is conducted on stress concentration areas in diesel engines. Figure 1 shows the process flow diagram of the diesel engine diaphragm [11,12,13,14,15].

The process flow diagram of the diesel engine diaphragm.

2 Spacer model and sprue design

To meet the specific requirements of a single partition size measuring of 504 mm (length) × 346 mm (width) × 200 mm (height), a modeling ratio of 1:2 was employed in three-dimensional modeling software. The thinnest position was set to a thickness of 7.5 mm. An open casting model was utilized to validate data for the large Al-based casting model. The size of each gate in the gating system was determined using the minimum cross-section method. In this study, the minimum cross-section of components served as the basis, and the areas of other components were determined proportionally. Subsequently, the size of each component was determined based on the structure of casting system. The casting time between each component was set at 7 s. The primary function of the riser is to compensate for shrinkage and prevent shrinkage and porosity during casting. Vertical parting was chosen in the selection of the parting face to maximize compensation for the riser system.

Equation (1) is used to calculate the minimum blocking area.

where

3 Experimental materials and finite element analysis

The accumulation behavior of casting residual stresses is influenced by various factors, including uneven cooling rates, plastic deformation, and phase transformations. These self-equilibrating internal stresses significantly impact the mechanical properties and service life of castings. Modern casting processes often use finite element analysis to predict stress distribution and employ physical testing methods and non-destructive testing techniques to effectively control and enhance product quality by optimizing process parameters.

The studied material in this work is ZAlCu5MnCdVA. The thermophysical properties and mechanical parameters of the material required in model casting are shown in Table 1.

Thermophysical properties and mechanical parameters of materials

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| 20 | 2,830 | 73,934 | 0.367 | 2.3 × 10−5 | 142 | 0.17 |

| 100 | 2,810 | 73,858 | 0.367 | 2.3 × 10−5 | 152 | 0.17 |

| 200 | 2,788 | 68,998 | 0.367 | 2.4 × 10−5 | 160 | 0.33 |

| 300 | 2,766 | 56,010 | 0.367 | 2.5 × 10−5 | 165 | 0.44 |

| 400 | 2,742 | 38,870 | 0.367 | 2.6 × 10−5 | 169 | 0.53 |

| 500 | 2,716 | 22,648 | 0.367 | 2.7 × 10−5 | 172 | 0.60 |

| 600 | 2,641 | 4,388 | 0.385 | 4.7 × 10−5 | 157 | 0.75 |

In Table 1,

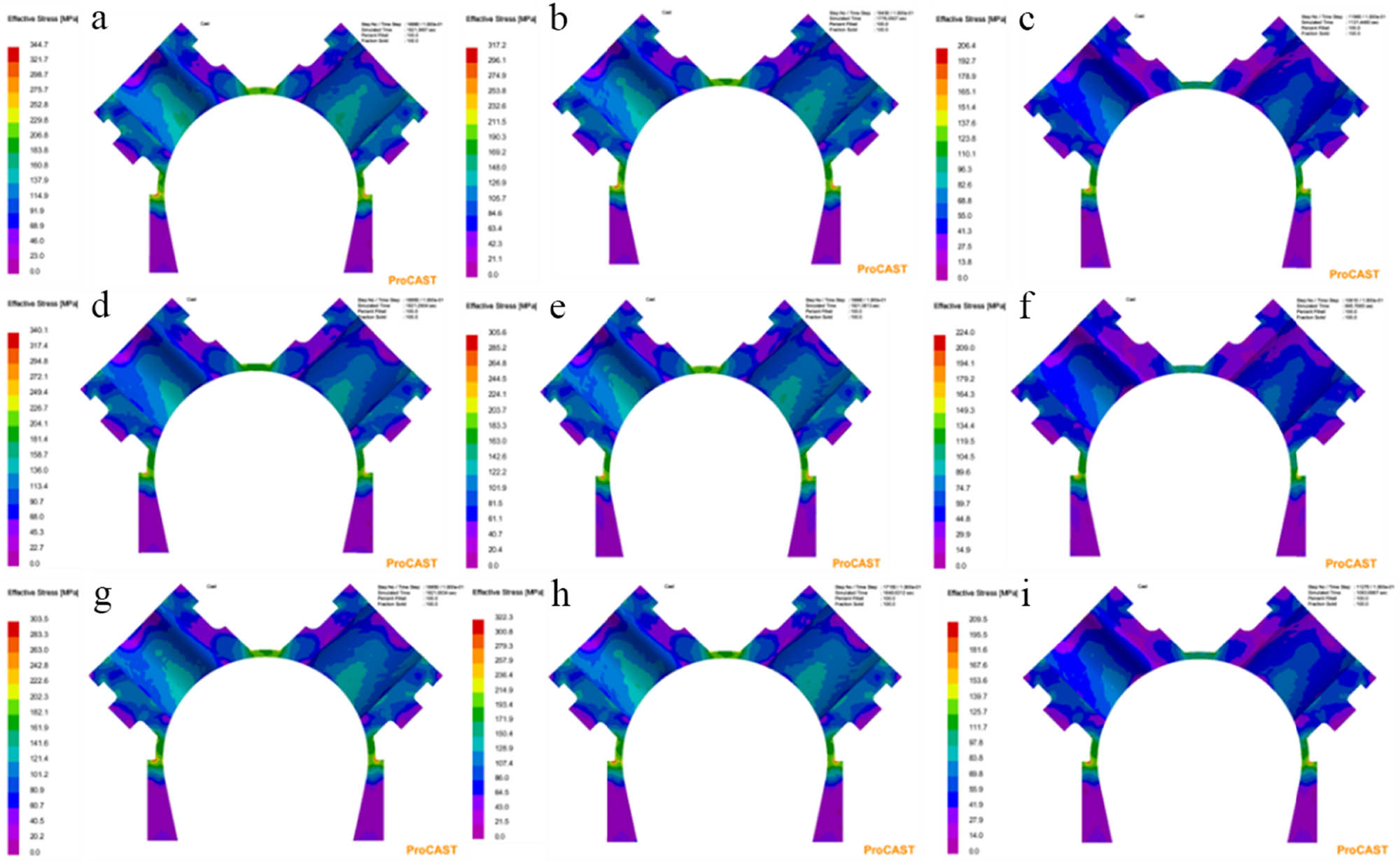

Orthogonal experiments were designed for spacer casting to simulate the casting process, incorporating variables such as casting temperature, knockout temperature, mold preheating temperature, and residual stress. The stress value represents the averaged stress value derived from the stress cloud diagram. Figure 2 shows the stress cloud diagram of the sand falling state. Large stress concentrations are evident in the thin-walled position of the single spacer or the arc part. Stress concentration is also observed at the step corner position with significant thickness, and some stress values approach the yield strength of the material.

Residual stress profile calculated from the parameters listed in Table 2. (a) A1B1C1, (b) A1B2C2, (c) A1B3C3, (d) A2B1C2, (e) A2B2C3, (f) A2B3C1, (g) A3B1C3, (h) A3B2C1, and (i) A3B3C2.

The effects of factors listed in Table 2 on the residual stress were evaluated, where

Orthogonal test parameters of the casting and residual stress values

| Experiment no. | Level combination | Element (°C) | Residual stress (MPa) | ||

|---|---|---|---|---|---|

| Casting temperature | Knockout temperature | Mold preheating temperature | |||

| 1 | A1B1C1 | 680 | 250 | 20 | 96.97 |

| 2 | A1B2C2 | 680 | 350 | 40 | 87.56 |

| 3 | A1B3C3 | 680 | 450 | 60 | 47.21 |

| 4 | A2B1C2 | 710 | 250 | 40 | 89.2 |

| 5 | A2B2C3 | 710 | 350 | 60 | 84.79 |

| 6 | A2B3C1 | 710 | 450 | 20 | 49.13 |

| 7 | A3B1C3 | 740 | 250 | 60 | 82.84 |

| 8 | A3B2C1 | 740 | 350 | 20 | 88.64 |

| 9 | A3B3C2 | 740 | 450 | 40 | 48.01 |

Room temperature stress cloud after the removement of sand box.

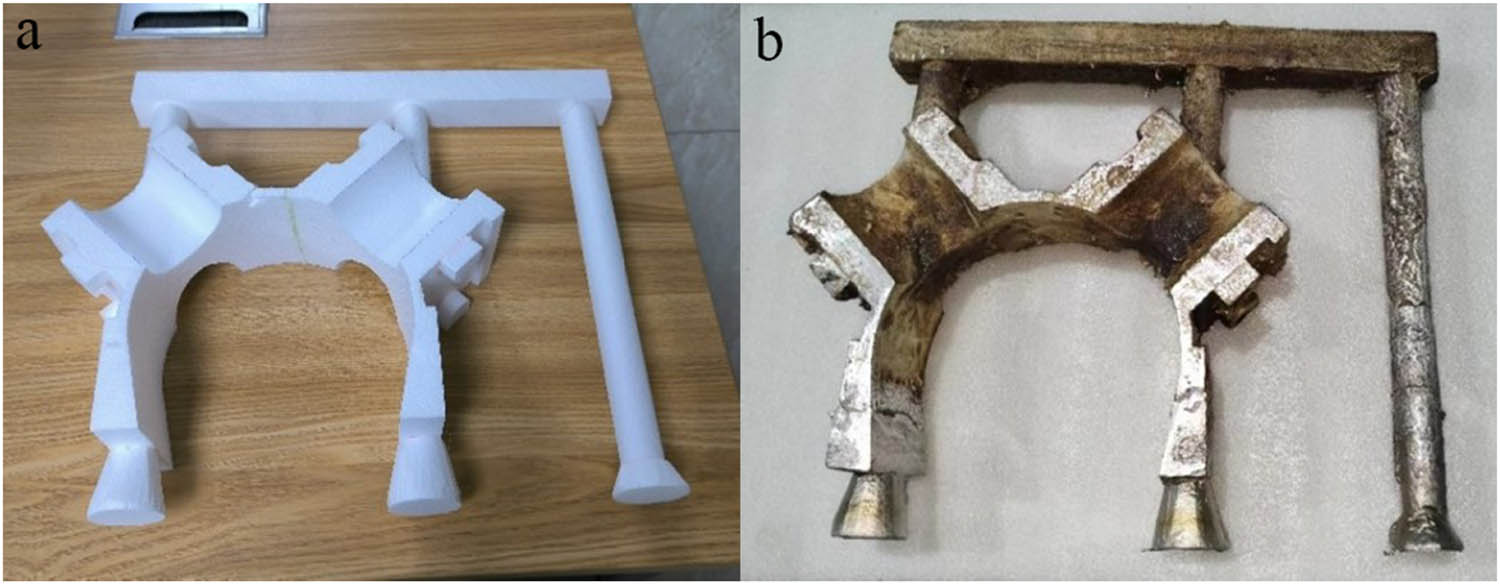

4 Experiment verification for the casting diaphragm

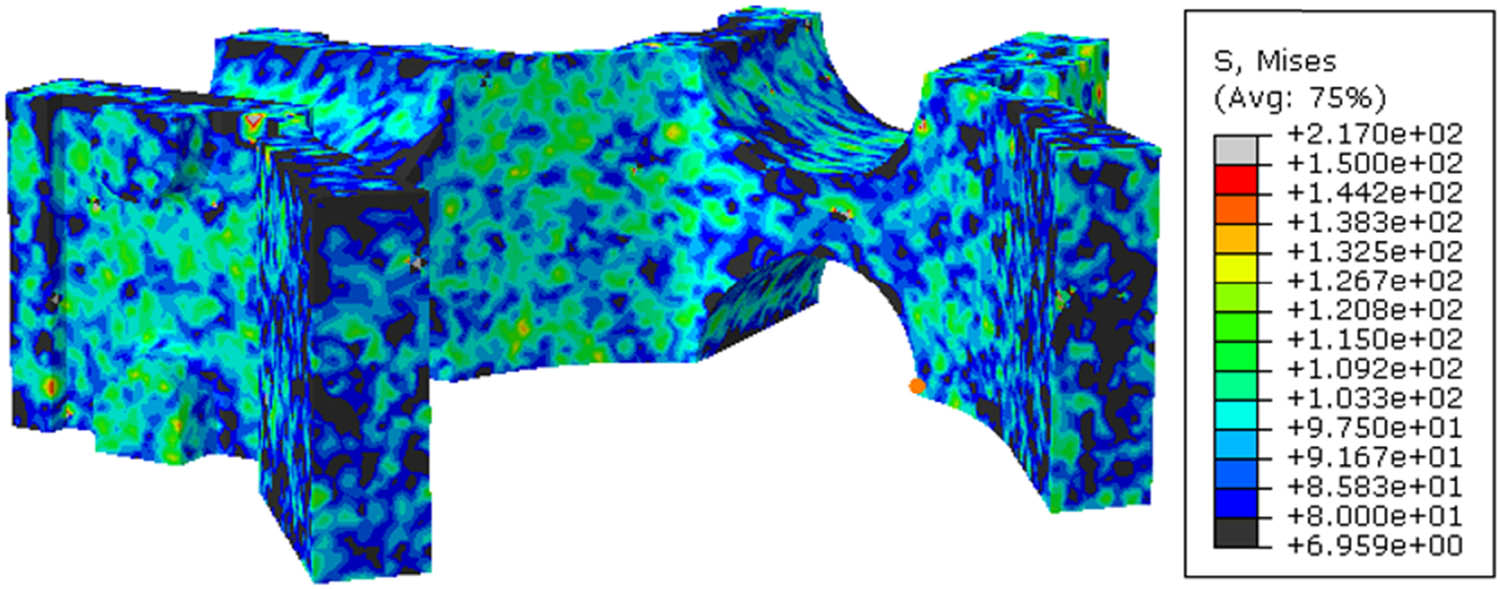

3D printing and disappearing mold casting were used to fabricate the Al-based diesel engine. Due to the challenge of mold removal associated with 3D printing, disappearing mold casting was adopted. The removal of the mold was facilitated by using a drying oven, resulting in the creation of the partition cavity. Figure 4 shows the photographs of the disappearing mold and the fabricated cast. Casting tests were performed with the optimal parameter combination specified in Table 2. The actual residual stress was measured using the blind hole method. The difference between the measured and fitted values falls within the range of 12.5–13.8%, confirming the reliability of the casting modeling in this study. The tensile strength of the cast, prior to the heat treatment, was determined as 217 MPa. After undergoing T6 heat treatment, the strength increased significantly to 423 MPa. Moreover, the residual stress of the cast subjected to T6 heat treatment was notably reduced, as indicated in Table 3.

Photographs showing the disappearing mold (a) and the fabricated cast (b).

Comparison of simulated residual stress buildup model and measured values for single spacers

| Serial number | Accumulation model (MPa) | Measured value in cast state (MPa) | Measured value in heat treatment state (MPa) |

|---|---|---|---|

| Position 1 | 147.74 | 131.28 | 65.68 |

| Position 2 | 154.51 | 135.82 | 46.74 |

| Position 3 | 134.15 | 152.91 | 50.35 |

5 Conclusion

The residual stress accumulation model demonstrated effective prediction of residual stress in Al-based diesel engine. The maximum difference between predicted and measured values was 13.8%.

Casting modeling revealed that a parameter combination of casting temperature at 740°C, knockout temperature of 450°C, and mold preheating temperature at 60°C, would result in reduced stress concentration.

The implementation of T6 heat treatment significantly alleviated residual stress within the cast and concurrently improved tensile strength.

Acknowledgments

The authors gratefully acknowledge the financial support provided by Graduate Student Innovation Program in Shanxi Province (Grant No. 2023KY576).

-

Funding information: This work was supported by Graduate Student Innovation Program in Shanxi Province (Grant No. 2023KY576).

-

Author contributions: Guodong Li: writing – original draft and formal analysis; Xiaosheng Zhou: writing – review and editing; Li Zhang: resources and supervision; YunFei Du: experimental preparation and project administration; and Dong Zhang: methodology and formal analysis.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The data presented in this study are available on request from the corresponding author.

References

[1] Zhang, S. Y., Y. Ran, A. Murphy, G. B. Zhang, and W. Wang. Residual stress analysis of gray cast iron manufacturing processes. Materials and Manufacturing Processes, Vol. 35, No. 15, 2020, pp. 1781–1788.10.1080/10426914.2020.1802035Suche in Google Scholar

[2] Alipooramirabad, H., S. Kianfar, A. Paradowska, and R. Ghomashchi. Residual stress measurement in engine block-an overview. The International Journal of Advanced Manufacturing Technology, Vol. 35, No. 1, 2024, pp. 1–27.10.1007/s00170-024-13071-3Suche in Google Scholar

[3] Zhao, D. H., Z. H. Ai, Y. L. Liu, G. C. Li, H. G. Zhou, X. X. Bai, et al. Evolution analysis of process-induced residual stress during the manufacture of diesel engine block. The International Journal of Advanced Manufacturing Technology, Vol. 120, No. 3–4, 2022, pp. 2655–2669.10.1007/s00170-022-08925-7Suche in Google Scholar

[4] Kianfar, S., E. Aghaie, J. Stroh, D. Sediako, and J. Tjong. Residual stress, microstructure, and mechanical properties analysis of HPDC aluminum engine block with cast-in iron liners. Materials Today Communications, Vol. 26, 2021, id. 101814.10.1016/j.mtcomm.2020.101814Suche in Google Scholar

[5] Salem, S., M. Hamed, A. M. Samuel, F. H. Samuel, Y. Zedan, V. Songmene, et al. Evolution and methods of residual stresses measurement in Al-Si-Cu-Mg castings: role of heat treatment. International Journal of Metalcasting, Vol. 16, No. 3, 2022, pp. 1488–1506.10.1007/s40962-021-00701-9Suche in Google Scholar

[6] Tian, G. Z., Z. Y. Ma, D. H. Zhao, H. G. Zhou, X. W. Jing, Z. C. Xie, et al. Research on the dynamic evolution of residual stress in thermal processing of diesel engine blocks based on FEM. Journal of Mechanical Science and Technology, Vol. 35, No. 6, 2021, pp. 2419–2430.10.1007/s12206-021-0513-4Suche in Google Scholar

[7] He, Q., C. L. Zhou, X. W. Jing, Y. G. Jiang, and H. G. Zhou. Research on residual stress evolution of diesel engine piston manufacturing based on finite element method. Journal of the Brazilian Society of Mechanical Sciences and Engineering, Vol. 44, No. 11, 2022, id. 522.10.1007/s40430-022-03816-0Suche in Google Scholar

[8] Zhang, Z. H., J. H. Liu, J. M. Chen, F. L. Wen, R. Jia, and Q. X. Ma. Optimization of residual stress in low-pressure casting of ZL205A alloys. Journal of Manufacturing Processes, Vol. 99, 2023, pp. 338–350.10.1016/j.jmapro.2023.05.040Suche in Google Scholar

[9] Shi, X. A., C. H. Lv, G. C. Li, K. L. Wang, J. Z. Chen, and J. Tang. Study on induction hardening performance of 34CrNi3MoA steel crankshaft. Frontiers in Materials, Vol. 10, 2023, id. 1240087.10.3389/fmats.2023.1240087Suche in Google Scholar

[10] Cui, Z. X., X. D. Hu, S. Y. Dong, S. X. Yan, and X. Zhao. Numerical simulation and experimental study on residual stress in the curved surface forming of 12CrNi2 alloy steel by laser melting deposition. Materials, Vol. 13, No. 19, 2020, id. 4316.10.3390/ma13194316Suche in Google Scholar PubMed PubMed Central

[11] Xiangdong, J., Z. Yang, and X. Siqi. Effect of heat treatment parameters on mechanical properties of 5052 aluminum alloy. Rare Metal Materials and Engineering, Vol. 50, No. 3, 2021, pp. 963–972.Suche in Google Scholar

[12] Guo, T., Q. Sun, K. Li, D. Huang, J. Wang, and X. Tai. Effect of temperature gradient and cooling rate on solidification structure and properties of ZL205A alloy. Rare Metal Materials and Engineering, Vol. 51, No. 7, 2022, pp. 2400–2408.Suche in Google Scholar

[13] Li, F., Q. T. Hao, and F. C. Xian. Element segregation behavior of aluminum-copper alloy ZL205A. China Foundry, Vol. 11, No. 6, 2014, pp. 510–515.Suche in Google Scholar

[14] Ahmad, A. H., S. Naher, and D. Brabazon. The effect of direct thermal method, temperature and time on microstructure of a cast aluminum alloy. Materials and Manufacturing Processes, Vol. 29, No. 2, 2014, pp. 134–139.10.1080/10426914.2013.822980Suche in Google Scholar

[15] Seydani, M. Z., A. Krimi, S. Khelladi, M. Bedel, and M. El Mansori. 3D numerical simulation and experimental validation of resin-bonded sand gravity casting: Filling, cooling, and solidification with SPH and ProCAST approaches. Thermal Science and Engineering Progress, Vol. 47, 2024, id. 102329.10.1016/j.tsep.2023.102329Suche in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- De-chlorination of poly(vinyl) chloride using Fe2O3 and the improvement of chlorine fixing ratio in FeCl2 by SiO2 addition

- Reductive behavior of nickel and iron metallization in magnesian siliceous nickel laterite ores under the action of sulfur-bearing natural gas

- Study on properties of CaF2–CaO–Al2O3–MgO–B2O3 electroslag remelting slag for rack plate steel

- The origin of {113}<361> grains and their impact on secondary recrystallization in producing ultra-thin grain-oriented electrical steel

- Channel parameter optimization of one-strand slab induction heating tundish with double channels

- Effect of rare-earth Ce on the texture of non-oriented silicon steels

- Performance optimization of PERC solar cells based on laser ablation forming local contact on the rear

- Effect of ladle-lining materials on inclusion evolution in Al-killed steel during LF refining

- Analysis of metallurgical defects in enamel steel castings

- Effect of cooling rate and Nb synergistic strengthening on microstructure and mechanical properties of high-strength rebar

- Effect of grain size on fatigue strength of 304 stainless steel

- Analysis and control of surface cracks in a B-bearing continuous casting blooms

- Application of laser surface detection technology in blast furnace gas flow control and optimization

- Preparation of MoO3 powder by hydrothermal method

- The comparative study of Ti-bearing oxides introduced by different methods

- Application of MgO/ZrO2 coating on 309 stainless steel to increase resistance to corrosion at high temperatures and oxidation by an electrochemical method

- Effect of applying a full oxygen blast furnace on carbon emissions based on a carbon metabolism calculation model

- Characterization of low-damage cutting of alfalfa stalks by self-sharpening cutters made of gradient materials

- Thermo-mechanical effects and microstructural evolution-coupled numerical simulation on the hot forming processes of superalloy turbine disk

- Endpoint prediction of BOF steelmaking based on state-of-the-art machine learning and deep learning algorithms

- Effect of calcium treatment on inclusions in 38CrMoAl high aluminum steel

- Effect of isothermal transformation temperature on the microstructure, precipitation behavior, and mechanical properties of anti-seismic rebar

- Evolution of residual stress and microstructure of 2205 duplex stainless steel welded joints during different post-weld heat treatment

- Effect of heating process on the corrosion resistance of zinc iron alloy coatings

- BOF steelmaking endpoint carbon content and temperature soft sensor model based on supervised weighted local structure preserving projection

- Innovative approaches to enhancing crack repair: Performance optimization of biopolymer-infused CXT

- Structural and electrochromic property control of WO3 films through fine-tuning of film-forming parameters

- Influence of non-linear thermal radiation on the dynamics of homogeneous and heterogeneous chemical reactions between the cone and the disk

- Thermodynamic modeling of stacking fault energy in Fe–Mn–C austenitic steels

- Research on the influence of cemented carbide micro-textured structure on tribological properties

- Performance evaluation of fly ash-lime-gypsum-quarry dust (FALGQ) bricks for sustainable construction

- First-principles study on the interfacial interactions between h-BN and Si3N4

- Analysis of carbon emission reduction capacity of hydrogen-rich oxygen blast furnace based on renewable energy hydrogen production

- Just-in-time updated DBN BOF steel-making soft sensor model based on dense connectivity of key features

- Effect of tempering temperature on the microstructure and mechanical properties of Q125 shale gas casing steel

- Review Articles

- A review of emerging trends in Laves phase research: Bibliometric analysis and visualization

- Effect of bottom stirring on bath mixing and transfer behavior during scrap melting in BOF steelmaking: A review

- High-temperature antioxidant silicate coating of low-density Nb–Ti–Al alloy: A review

- Communications

- Experimental investigation on the deterioration of the physical and mechanical properties of autoclaved aerated concrete at elevated temperatures

- Damage evaluation of the austenitic heat-resistance steel subjected to creep by using Kikuchi pattern parameters

- Topical Issue on Focus of Hot Deformation of Metaland High Entropy Alloys - Part II

- Synthesis of aluminium (Al) and alumina (Al2O3)-based graded material by gravity casting

- Experimental investigation into machining performance of magnesium alloy AZ91D under dry, minimum quantity lubrication, and nano minimum quantity lubrication environments

- Numerical simulation of temperature distribution and residual stress in TIG welding of stainless-steel single-pass flange butt joint using finite element analysis

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part I

- Electro-thermal performance evaluation of a prismatic battery pack for an electric vehicle

- Experimental analysis and optimization of machining parameters for Nitinol alloy: A Taguchi and multi-attribute decision-making approach

- Experimental and numerical analysis of temperature distributions in SA 387 pressure vessel steel during submerged arc welding

- Optimization of process parameters in plasma arc cutting of commercial-grade aluminium plate

- Multi-response optimization of friction stir welding using fuzzy-grey system

- Mechanical and micro-structural studies of pulsed and constant current TIG weldments of super duplex stainless steels and Austenitic stainless steels

- Stretch-forming characteristics of austenitic material stainless steel 304 at hot working temperatures

- Work hardening and X-ray diffraction studies on ASS 304 at high temperatures

- Study of phase equilibrium of refractory high-entropy alloys using the atomic size difference concept for turbine blade applications

- A novel intelligent tool wear monitoring system in ball end milling of Ti6Al4V alloy using artificial neural network

- A hybrid approach for the machinability analysis of Incoloy 825 using the entropy-MOORA method

- Special Issue on Recent Developments in 3D Printed Carbon Materials - Part II

- Innovations for sustainable chemical manufacturing and waste minimization through green production practices

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part I

- Characterization of Co–Ni–TiO2 coatings prepared by combined sol-enhanced and pulse current electrodeposition methods

- Hot deformation behaviors and microstructure characteristics of Cr–Mo–Ni–V steel with a banded structure

- Effects of normalizing and tempering temperature on the bainite microstructure and properties of low alloy fire-resistant steel bars

- Dynamic evolution of residual stress upon manufacturing Al-based diesel engine diaphragm

- Study on impact resistance of steel fiber reinforced concrete after exposure to fire

- Bonding behaviour between steel fibre and concrete matrix after experiencing elevated temperature at various loading rates

- Diffusion law of sulfate ions in coral aggregate seawater concrete in the marine environment

- Microstructure evolution and grain refinement mechanism of 316LN steel

- Investigation of the interface and physical properties of a Kovar alloy/Cu composite wire processed by multi-pass drawing

- The investigation of peritectic solidification of high nitrogen stainless steels by in-situ observation

- Microstructure and mechanical properties of submerged arc welded medium-thickness Q690qE high-strength steel plate joints

- Experimental study on the effect of the riveting process on the bending resistance of beams composed of galvanized Q235 steel

- Density functional theory study of Mg–Ho intermetallic phases

- Investigation of electrical properties and PTCR effect in double-donor doping BaTiO3 lead-free ceramics

- Special Issue on Thermal Management and Heat Transfer

- On the thermal performance of a three-dimensional cross-ternary hybrid nanofluid over a wedge using a Bayesian regularization neural network approach

- Time dependent model to analyze the magnetic refrigeration performance of gadolinium near the room temperature

- Heat transfer characteristics in a non-Newtonian (Williamson) hybrid nanofluid with Hall and convective boundary effects

- Computational role of homogeneous–heterogeneous chemical reactions and a mixed convective ternary hybrid nanofluid in a vertical porous microchannel

- Thermal conductivity evaluation of magnetized non-Newtonian nanofluid and dusty particles with thermal radiation

Artikel in diesem Heft

- Research Articles

- De-chlorination of poly(vinyl) chloride using Fe2O3 and the improvement of chlorine fixing ratio in FeCl2 by SiO2 addition

- Reductive behavior of nickel and iron metallization in magnesian siliceous nickel laterite ores under the action of sulfur-bearing natural gas

- Study on properties of CaF2–CaO–Al2O3–MgO–B2O3 electroslag remelting slag for rack plate steel

- The origin of {113}<361> grains and their impact on secondary recrystallization in producing ultra-thin grain-oriented electrical steel

- Channel parameter optimization of one-strand slab induction heating tundish with double channels

- Effect of rare-earth Ce on the texture of non-oriented silicon steels

- Performance optimization of PERC solar cells based on laser ablation forming local contact on the rear

- Effect of ladle-lining materials on inclusion evolution in Al-killed steel during LF refining

- Analysis of metallurgical defects in enamel steel castings

- Effect of cooling rate and Nb synergistic strengthening on microstructure and mechanical properties of high-strength rebar

- Effect of grain size on fatigue strength of 304 stainless steel

- Analysis and control of surface cracks in a B-bearing continuous casting blooms

- Application of laser surface detection technology in blast furnace gas flow control and optimization

- Preparation of MoO3 powder by hydrothermal method

- The comparative study of Ti-bearing oxides introduced by different methods

- Application of MgO/ZrO2 coating on 309 stainless steel to increase resistance to corrosion at high temperatures and oxidation by an electrochemical method

- Effect of applying a full oxygen blast furnace on carbon emissions based on a carbon metabolism calculation model

- Characterization of low-damage cutting of alfalfa stalks by self-sharpening cutters made of gradient materials

- Thermo-mechanical effects and microstructural evolution-coupled numerical simulation on the hot forming processes of superalloy turbine disk

- Endpoint prediction of BOF steelmaking based on state-of-the-art machine learning and deep learning algorithms

- Effect of calcium treatment on inclusions in 38CrMoAl high aluminum steel

- Effect of isothermal transformation temperature on the microstructure, precipitation behavior, and mechanical properties of anti-seismic rebar

- Evolution of residual stress and microstructure of 2205 duplex stainless steel welded joints during different post-weld heat treatment

- Effect of heating process on the corrosion resistance of zinc iron alloy coatings

- BOF steelmaking endpoint carbon content and temperature soft sensor model based on supervised weighted local structure preserving projection

- Innovative approaches to enhancing crack repair: Performance optimization of biopolymer-infused CXT

- Structural and electrochromic property control of WO3 films through fine-tuning of film-forming parameters

- Influence of non-linear thermal radiation on the dynamics of homogeneous and heterogeneous chemical reactions between the cone and the disk

- Thermodynamic modeling of stacking fault energy in Fe–Mn–C austenitic steels

- Research on the influence of cemented carbide micro-textured structure on tribological properties

- Performance evaluation of fly ash-lime-gypsum-quarry dust (FALGQ) bricks for sustainable construction

- First-principles study on the interfacial interactions between h-BN and Si3N4

- Analysis of carbon emission reduction capacity of hydrogen-rich oxygen blast furnace based on renewable energy hydrogen production

- Just-in-time updated DBN BOF steel-making soft sensor model based on dense connectivity of key features

- Effect of tempering temperature on the microstructure and mechanical properties of Q125 shale gas casing steel

- Review Articles

- A review of emerging trends in Laves phase research: Bibliometric analysis and visualization

- Effect of bottom stirring on bath mixing and transfer behavior during scrap melting in BOF steelmaking: A review

- High-temperature antioxidant silicate coating of low-density Nb–Ti–Al alloy: A review

- Communications

- Experimental investigation on the deterioration of the physical and mechanical properties of autoclaved aerated concrete at elevated temperatures

- Damage evaluation of the austenitic heat-resistance steel subjected to creep by using Kikuchi pattern parameters

- Topical Issue on Focus of Hot Deformation of Metaland High Entropy Alloys - Part II

- Synthesis of aluminium (Al) and alumina (Al2O3)-based graded material by gravity casting

- Experimental investigation into machining performance of magnesium alloy AZ91D under dry, minimum quantity lubrication, and nano minimum quantity lubrication environments

- Numerical simulation of temperature distribution and residual stress in TIG welding of stainless-steel single-pass flange butt joint using finite element analysis

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part I

- Electro-thermal performance evaluation of a prismatic battery pack for an electric vehicle

- Experimental analysis and optimization of machining parameters for Nitinol alloy: A Taguchi and multi-attribute decision-making approach

- Experimental and numerical analysis of temperature distributions in SA 387 pressure vessel steel during submerged arc welding

- Optimization of process parameters in plasma arc cutting of commercial-grade aluminium plate

- Multi-response optimization of friction stir welding using fuzzy-grey system

- Mechanical and micro-structural studies of pulsed and constant current TIG weldments of super duplex stainless steels and Austenitic stainless steels

- Stretch-forming characteristics of austenitic material stainless steel 304 at hot working temperatures

- Work hardening and X-ray diffraction studies on ASS 304 at high temperatures

- Study of phase equilibrium of refractory high-entropy alloys using the atomic size difference concept for turbine blade applications

- A novel intelligent tool wear monitoring system in ball end milling of Ti6Al4V alloy using artificial neural network

- A hybrid approach for the machinability analysis of Incoloy 825 using the entropy-MOORA method

- Special Issue on Recent Developments in 3D Printed Carbon Materials - Part II

- Innovations for sustainable chemical manufacturing and waste minimization through green production practices

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part I

- Characterization of Co–Ni–TiO2 coatings prepared by combined sol-enhanced and pulse current electrodeposition methods

- Hot deformation behaviors and microstructure characteristics of Cr–Mo–Ni–V steel with a banded structure

- Effects of normalizing and tempering temperature on the bainite microstructure and properties of low alloy fire-resistant steel bars

- Dynamic evolution of residual stress upon manufacturing Al-based diesel engine diaphragm

- Study on impact resistance of steel fiber reinforced concrete after exposure to fire

- Bonding behaviour between steel fibre and concrete matrix after experiencing elevated temperature at various loading rates

- Diffusion law of sulfate ions in coral aggregate seawater concrete in the marine environment

- Microstructure evolution and grain refinement mechanism of 316LN steel

- Investigation of the interface and physical properties of a Kovar alloy/Cu composite wire processed by multi-pass drawing

- The investigation of peritectic solidification of high nitrogen stainless steels by in-situ observation

- Microstructure and mechanical properties of submerged arc welded medium-thickness Q690qE high-strength steel plate joints

- Experimental study on the effect of the riveting process on the bending resistance of beams composed of galvanized Q235 steel

- Density functional theory study of Mg–Ho intermetallic phases

- Investigation of electrical properties and PTCR effect in double-donor doping BaTiO3 lead-free ceramics

- Special Issue on Thermal Management and Heat Transfer

- On the thermal performance of a three-dimensional cross-ternary hybrid nanofluid over a wedge using a Bayesian regularization neural network approach

- Time dependent model to analyze the magnetic refrigeration performance of gadolinium near the room temperature

- Heat transfer characteristics in a non-Newtonian (Williamson) hybrid nanofluid with Hall and convective boundary effects

- Computational role of homogeneous–heterogeneous chemical reactions and a mixed convective ternary hybrid nanofluid in a vertical porous microchannel

- Thermal conductivity evaluation of magnetized non-Newtonian nanofluid and dusty particles with thermal radiation