Effects of normalizing and tempering temperature on the bainite microstructure and properties of low alloy fire-resistant steel bars

-

Zhichao Zheng

, Lanfang Guan

, Chengzhi Liu

Abstract

Different combinations of normalizing and tempering were carried out to optimize the microstructure and enhance the high-temperature mechanical properties of HRB400FR fire-resistant steel bars. The results showed that with the increasing of the tempering temperature from 400 to 600°C, the steel bar’s hardness decreases linearly, mainly due to the formation of quasi-polygon ferrite and granular bainite. Besides, the reduced width and the dissolution of the lath bainite also undermine the performance of the tempered steel bars. The highest Vickers hardness of 380 HV is achieved when the steel is normalized at 950°C and then tempered at 400°C, mainly due to precipitation strengthening and bainite strengthening. The hardness of the test steel tempered at 600°C gives the lowest value, only 230 HV since the least amount of bainite is obtained. When the tempering temperature reaches 650°C, the hardness rises to 260 HV due to the formation of the lath bainite. The emergence of needle bainite generally reduces the matrix grain size, and the appearance of lath martensite refines the precipitated carbides.

1 Introduction

With the occurrence of disasters such as fires and earthquakes, steel for high-rise buildings needs to be fire resistant to ensure the safety of the building and people fire resistant steel bar is a type of construction steel that retains 2/3 of its room-temperature yield strength at 600°C [1]. It ensures the safety of the building under fire and other conditions. Bainite is the main reinforcing tissue in fire-resistant steel bar, and the stability of bainite at high temperatures provides a crucial role in the refractory properties of fire-resistant steel bar. The transformation and strengthening mechanism of bainite in refractory steel bar has been a hot topic in the development of high temperature fire-resistant steel bar [2,3,4].

Chen et al. [2] investigated the changes in microstructure and strength of 460 MPa steel at different tempering temperatures. However, the evolution process and strengthening mechanism of bainite were not systematically mentioned. Klemm-Toole et al. [3] found that bainite strengthening and solid solution strengthening supported the refractory properties of fire-resistant steel bars [5]. Currently, there is limited research on the variation of bainite content and ferrite grain size, which have a large influence on the refractory properties of fire-resistant steel bars [6].

In this paper, evolutions of microstructure and strength of fire-resistant steel bars were investigated after different combinations of normalizing and tempering heat treatment. The results of this research serve as a theoretical support reference for the production and handling of fire-resistant steel bars.

2 Materials and methods

HRB400FR fire-resistant steel bars with a diameter of 25 mm were used in this experiment. The chemical composition of HRB400FR was measured by XPS, as shown in Table 1. The metallographic sample was cut 50–60 mm away from the head of the steel bar to avoid the heat-affected zone during rolling. After mechanical grinding and polishing, the sample was etched with 4% nitrate alcohol solution and observed by a LEICADM1750M metallographic microscope and a Siron 200 field emission scanning electron microscope.

Chemical composition (wt%)

| Steel | C | Si | Mn | P | S | Cr | Mo | V | Fe |

|---|---|---|---|---|---|---|---|---|---|

| HRB400FR | 0.1866 | 0.1446 | 1.2009 | 0.0157 | 0.0157 | 0.0181 | 0.4305 | 0.0235 | Balanced |

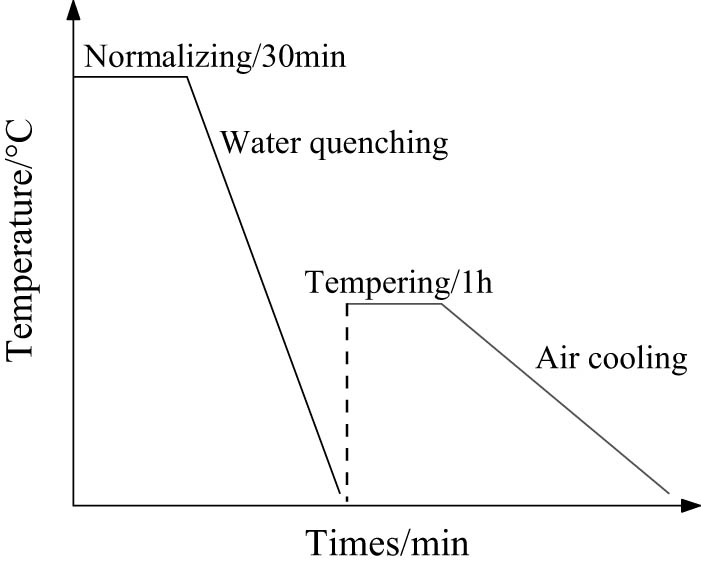

The heat treatment regime is illustrated in Figure 1 and described as follows. Once the muffle burner was heated to the preset normalizing temperature (850, 950, and 1,050°C), the sample was put into the furnace, held for 30 min, and then water quenched. The tempering temperature was designated as 400, 500, 550, 600, and 650°C, and the heating treatment time was 1 h.

Heat treatment diagram.

Samples obtained after different combinations of normalizing and tempering were tested on the Vickers hardness tester at 9.8 N and held for 15 s. Each hardness test data reported is the average value of at least 3 measurements, and the error is less than ±10 HV.

3 Results and discussion

3.1 Evolution of the hardness

The Vickers hardness obtained is shown in Figure 2. The figure shows that as the tempering temperature increases, the hardness of the test steel at different normalizing temperatures decreases linearly to the minimum value at 600°C. Then the hardness increases by 30–50 HV at 650°C. When the tempering temperature is 400°C, the hardness is highest after normalization at 950°C, mainly due to the bainite and precipitation strengthening.

Evolution of Hardness during different combinations of heat treatment.

3.2 Microstructure after normalizing

The initial microstructure of the HRB400FR fire-resistant bar is a typical ferrite + bainite. Besides, a small amount of pearlite can also be observed [2]. Detailed structures of pearlite and bainite are shown in Figure 3b. It is obvious that the lamellar structure of pearlite is nonuniform, which may be attributed to the fact that the Mo-containing phase is segmented into the cementite morphology [7]. The shape of bainite is a mixture of lamellar, coniferous, and feathery, and bainite is evenly distributed in the initial structure of fire-resistant steel bars. The fire-resistant steel bar was insulated at 600°C for 1 h to study the structure stability. It can be seen that bainite structure still exists because bainite has good stability at relatively high temperatures [8].

Microstructure of the HRB400FR: (a) and (b) initial microstructure; (c) microstructure insulated at 600°C for 1 h under OM.

The pearlite structure can still be seen in the normalized fire-resistant steel bar, composed of alternating ferrite and layered cementite phases, as shown in Figure 4. With the increase of normalizing temperature, some cementite in the pearlite disintegrated. Cementite fragmentation in pearlite will result in a decrease in the strength of the test steel [9].

Microstructure of HRB400FR after normalizing: (a) 850°C; (b) 950°C; and (c) 1,050°C.

The microstructure after normalization is composed of alternating bainite, austenite, and M/A island biphase structure [10]. The lath bainite and M/A islands in the microstructure of low alloy fire-resistant steel bars have a certain strengthening effect on the welding performance, high-temperature strength, toughness, and plasticity of this steel grade. The high dislocation density and high frequency of interfaces of bainite provide high strength of fire-resistant steel bar, and the high density of crystalline bainite ferrite clusters and packet boundaries achieve high toughness of fire-resistant steel bars. The microstructural variations of the bainite and the variations in the composition and size of the M/A islands have a great influence on the high-temperature properties of this type of steel. With the increase of normalizing temperature, the precipitates of the sample become coarse, and the hardness decreases.

3.3 Microstructure after tempering

The OM and SEM microstructures of fire-resistant steel test steel at different tempering temperatures are shown in Figures 5 and 6. At normalizing temperatures of 850 and 950°C, granular and plate-like bainite and polygonal ferrite are visible in the test steel [11].

Optical microstructure of fire-resistant steel bars after different combinations of heat treatment.

SEM microstructure of fire-resistant steel bars after different combinations of heat treatment.

At a normalizing temperature of 1,050°C, there are many parallel ferrite needles and flakes in the coarse austenite grains, in which the remaining austenite transforms into pearlite. In the test steel, there is a complex organization in which the pre-eutectic phase is mixed with lamellar pearlite in the form of needles and flakes. The fragile surface formed by a large number of ferrite needles degrades the mechanical properties of this steel bar.

As the tempering temperature gradually increases, the bainite content decreases, the lath bainite becomes rough, the number of M/A islands and dislocations decrease [12], and the polygonal ferrite gradually dominates [13]. At a tempering temperature of 400°C, the bainite lath finer, granular bainite distribution is more uniform, bainite percentage content of about 40%. Tempered to 600°C, the bainite content is significantly reduced, about 10% or so, at this time the fire-resistant steel in the bainite for the coarse lath bainite, visible granular bainite, but the distribution is uneven and the content is small; bainite lath width from 60 to 90 μm varies.

The low carbon content in HRB400FR ([wt] ≤ 0.20%) leads to poor stability of retained austenite, after which the austenite gradually decomposes to polygonal ferrite during the cooling phase. When the temperature reaches the formation temperature of bainite, small amounts of granular bainite and lath bainite are present. At lower tempering temperatures, mixed martensite and austenite (M/A) islands appear. At gradually increasing tempering temperatures up to 600°C, the bainite content is the lowest, the polygonal ferrite content is the highest, and M/A islands decompose at higher temperatures to produce large amounts of carbides and ferrite [14]. When the tempering temperature rises to 650°C, the content of polygonal ferrite decreases, some bainite blocks merge, and the number of lath bainite is refined [10].

Lath bainite still exists at higher temperatures and has good high-temperature stability. Bainite strengthening and Mo precipitation strengthening are the main factors ensuring the mechanical properties of fire-resistant steel bars. This steel sample normalized at 950°C and tempered at 400°C has smaller particles than that normalized at 850 and 1,050°C and tempered at the same temperature. Granular bainite in the form of M/A islands appeared in the ferrite [10], where precipitation strengthening and bainite strengthening increased the hardness of the steel.

In the test steel, the volume fraction of lath bainite excesses ∼15%, which is in the form of slats. Dislocations are aggregated around the lath bainite, and sub-structures are also present in the lath bainite. The strengthening effect of bainite at high temperatures is mainly attributed to these dislocations and substructures. Bainite, as a mechanical mixture, has a microstructural composition that remains stable at elevated temperatures and provides a guarantee for the high strength of fire-resistant steel bars at 600°C. The bainite strengthening effect is a sublimation of the Mo-containing fire-resistant steel bars, and can even give the steel a certain refractory property even after removal of the high-cost Mo element additions. The solid solution strengthening effect of Mo elements in fire-resistant steels is complemented by the increase of the bainite volume fraction through a suitable controlled processing and post-processing treatment.

3.4 Precipitation during heat treatment

The addition of Mo has a significant effect on the high-temperature properties of fire-resistant steel bars. First, the solid solubility of Mo is very high compared to other elements, thus the solid solution strengthening may occur. Second, the interaction of Mo and C elements at high temperatures results in the formation of compounds such as MoC and Mo2C, which are in the form of blocks and round islands as shown in Figure 7 [15]. These precipitates contribute greatly to the high-temperature properties of fire-resistant steel bars due to precipitation-strengthening effect. Third, the addition of Mo element inhibits the formation of ferrite, leading to an enhanced high-temperature strengthening effect by an increased number of bainite.

EDS analysis of precipitated particles within (a) HRB400FR normalized at 850°C and tempered at 400°C and (b) normal 400 MPa steel bar.

4 Conclusions

With the tempering temperature rising to 600°C, the lath bainite in the microstructure of fire-resistant steel bars gradually thickens. The number of M/A islands decreases and decomposes into ferrite and cementite at higher tempering temperatures, with polygonal ferrite dominating.

When the tempering temperature reaches 650°C the bainite blocks appear, and the number of lath bainite is refined. This proves that bainite has good high-temperature stability to ensure the high-temperature mechanical properties of the fire-resistant steel bar.

The steel sample normalized at 950°C and tempered at 400°C has smaller particles than that normalized at 850 and 1,050°C and tempered at the same temperature. Granular bainite and M/A island are mixed, and bainite and precipitation strengthening lead to the highest hardness.

Acknowledgments

The present study was based on North Central University, and we thank all the teachers in the university and the laboratory for their assistance.

-

Funding information: The present study was sponsored by the Fundamental Research Program of Shanxi Province under Grant Nos. 202203021212117 and 202303021212181; the Science and Technology Innovation Project of Colleges and Universities in Shanxi Province under Grant Nos. 2020L0311 and 2020L0320; and Young Elite Scientists Sponsorship Program by CAST under Grant No. 2023QNRC001.

-

Author contributions: Zhichao Zheng: writing – original draft, formal analysis; Jie Ren: formal analysis; Li Zhang: writing – review and editing, resources, supervision; Lanfang Guan: resources, supervision; Chengzhi Liu: project administration; Yanlian Liu: experimental preparation; Shengwei Chen: methodology; Zexing Su: methodology, formal analysis; Fei Yang: methodology, formal analysis.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The data presented in this study are available on request from the corresponding author.

References

[1] Wan, R. C., S. Feng, L. T. Zhang, and A. D. Shan. Development and study of high-strength low-Mo fire-resistant steel. Materials & Design, Vol. 35, 2012, pp. 335–341.10.1016/j.matdes.2011.09.009Search in Google Scholar

[2] Chen, Z. Y., X. J. Zhao, J. J. Qi, W. T. Zhu, Y. Feng, L. Q. Chen, et al. Effect of tempering on the microstructure and properties of a new multi-functional 460 MPa Grade construction structural steel. Journal of Materials Research and Technology-Jmr&T, Vol. 18, 2022, pp. 1092–1104.10.1016/j.jmrt.2022.03.037Search in Google Scholar

[3] Klemm-Toole, J., J. L. Benz, I. Vieira, A. J. Clarke, S. W. Thompson, and K. O. Findley. Strengthening mechanisms influenced by silicon content in high temperature tempered martensite and bainite. Materials Science and Engineering a-Structural Materials Properties Microstructure and Processing, Vol. 786, 2020, id. 139419.10.1016/j.msea.2020.139419Search in Google Scholar

[4] Cong, J. H., J. W. Li, J. J. Fan, R. D. K. Misra, X. Y. Xu, and X. M. Wang. Effect of austenitic state before ferrite transformation on the mechanical behavior at an elevated temperature for seismic-resistant and fire-resistant constructional steel. Journal of Materials Research and Technology-Jmr&T, Vol. 13, 2021, pp. 1220–1229.10.1016/j.jmrt.2021.05.061Search in Google Scholar

[5] Jo, H. H., C. Shin, J. Moon, J. H. Jang, H. Y. Ha, S. J. Park, et al. Mechanisms for improving tensile properties at elevated temperature in fire-resistant steel with Mo and Nb. Materials & Design, Vol. 194, 2020, id. 108882.10.1016/j.matdes.2020.108882Search in Google Scholar

[6] Chen, W., J. C. Cao, Y. H. Yang, Z. Shi, W. Q. Zhang, and M. Huang. Investigation on the strengthening and toughening mechanism of 500 MPa V-Nb microalloyed anti-seismic rebars. Materials Science-Medziagotyra, Vol. 21, No. 4, 2015, pp. 536–542.10.5755/j01.ms.21.4.9710Search in Google Scholar

[7] Tong, M. W., Z. X. Yuan, K. G. Zhang, and X. L. Rui. Influence of Mo content on microstructure and mechanical properties of fire-resistant construction steel. Journal of Iron and Steel Research International, Vol. 18, 2011, pp. 903–907.Search in Google Scholar

[8] Li, Y. D., R. C. Wang, X. Wang, H. Zhao, and X. Gong. Effects of Nb on elevated-temperature properties of fire-resistant steel. Crystals, Vol. 12, No. 12, 2022, id. 1842.10.3390/cryst12121842Search in Google Scholar

[9] Moon, J., C. N. Lee, H. H. Jo, S. D. Kim, H. U. Hong, J. H. Chung, et al. Microstructure and high-temperature strength in the weld coarse-grained heat-affected zone of fire-resistant steels and the effects of Mo and Nb additions. Metals and Materials International, Vol. 28, No. 4, 2022, pp. 966–974.10.1007/s12540-020-00947-8Search in Google Scholar

[10] Zeng, P. Y., C. G. Zuo, X. Y. Zhang, and W. Li. Impact wear properties of dissimilar joints between bainitic frogs and pearlite rails. Journal of Iron and Steel Research International, Vol. 31, No. 1, 2023, pp. 275–287.10.1007/s42243-023-01020-5Search in Google Scholar

[11] Wan, R. C., F. Sun, L. T. Zhang, and A. D. Shan. Development and study of high-strength low-Mo fire-resistant steel. Materials & Design, Vol. 36, 2012, pp. 227–232.10.1016/j.matdes.2011.10.055Search in Google Scholar

[12] Choi, D. J., T. Y. Kim, H. U. Hong, J. Moon, C. H. Lee, D. L. Kim, et al. Effect of Ti addition on yield strength of low-Mo fire-resistant steel at elevated temperatures. Steel Research International, Vol. 94, No. 2, 2023, id. 2200103.10.1002/srin.202200103Search in Google Scholar

[13] Sim, J. H., T. Y. Kim, J. Y. Kim, C. W. Kim, J. H. Chung, J. Moon, et al. On the strengthening effects affecting tensile and low cycle fatigue properties of low-alloyed seismic/fire-resistant structural steels. Metals and Materials International, Vol. 28, No. 2, 2022, pp. 337–345.10.1007/s12540-020-00870-ySearch in Google Scholar

[14] Zhang, Z. H., G. Niu, J. Li, P. C. Zhang, and H. B. Wu. Synergistic effects of Ti and Mo on the microstructure and properties of low-cost fire-resistant and weather-resistant construction steel. Journal of Materials Engineering and Performance, Vol. 32, No. 9, 2023, pp. 3958–3967.10.1007/s11665-022-07388-xSearch in Google Scholar

[15] Zhang, Z. Y., Q. L. Yong, X. J. Sun, Z. D. Li, J. Y. Kang, and G. D. Wang. Microstructure and mechanical properties of precipitation strengthened fire resistant steel containing high Nb and low Mo. Journal of Iron and Steel Research International, Vol. 22, No. 4, 2015, pp. 337–343.10.1016/S1006-706X(15)30009-1Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- De-chlorination of poly(vinyl) chloride using Fe2O3 and the improvement of chlorine fixing ratio in FeCl2 by SiO2 addition

- Reductive behavior of nickel and iron metallization in magnesian siliceous nickel laterite ores under the action of sulfur-bearing natural gas

- Study on properties of CaF2–CaO–Al2O3–MgO–B2O3 electroslag remelting slag for rack plate steel

- The origin of {113}<361> grains and their impact on secondary recrystallization in producing ultra-thin grain-oriented electrical steel

- Channel parameter optimization of one-strand slab induction heating tundish with double channels

- Effect of rare-earth Ce on the texture of non-oriented silicon steels

- Performance optimization of PERC solar cells based on laser ablation forming local contact on the rear

- Effect of ladle-lining materials on inclusion evolution in Al-killed steel during LF refining

- Analysis of metallurgical defects in enamel steel castings

- Effect of cooling rate and Nb synergistic strengthening on microstructure and mechanical properties of high-strength rebar

- Effect of grain size on fatigue strength of 304 stainless steel

- Analysis and control of surface cracks in a B-bearing continuous casting blooms

- Application of laser surface detection technology in blast furnace gas flow control and optimization

- Preparation of MoO3 powder by hydrothermal method

- The comparative study of Ti-bearing oxides introduced by different methods

- Application of MgO/ZrO2 coating on 309 stainless steel to increase resistance to corrosion at high temperatures and oxidation by an electrochemical method

- Effect of applying a full oxygen blast furnace on carbon emissions based on a carbon metabolism calculation model

- Characterization of low-damage cutting of alfalfa stalks by self-sharpening cutters made of gradient materials

- Thermo-mechanical effects and microstructural evolution-coupled numerical simulation on the hot forming processes of superalloy turbine disk

- Endpoint prediction of BOF steelmaking based on state-of-the-art machine learning and deep learning algorithms

- Effect of calcium treatment on inclusions in 38CrMoAl high aluminum steel

- Effect of isothermal transformation temperature on the microstructure, precipitation behavior, and mechanical properties of anti-seismic rebar

- Evolution of residual stress and microstructure of 2205 duplex stainless steel welded joints during different post-weld heat treatment

- Effect of heating process on the corrosion resistance of zinc iron alloy coatings

- BOF steelmaking endpoint carbon content and temperature soft sensor model based on supervised weighted local structure preserving projection

- Innovative approaches to enhancing crack repair: Performance optimization of biopolymer-infused CXT

- Structural and electrochromic property control of WO3 films through fine-tuning of film-forming parameters

- Influence of non-linear thermal radiation on the dynamics of homogeneous and heterogeneous chemical reactions between the cone and the disk

- Thermodynamic modeling of stacking fault energy in Fe–Mn–C austenitic steels

- Research on the influence of cemented carbide micro-textured structure on tribological properties

- Performance evaluation of fly ash-lime-gypsum-quarry dust (FALGQ) bricks for sustainable construction

- First-principles study on the interfacial interactions between h-BN and Si3N4

- Analysis of carbon emission reduction capacity of hydrogen-rich oxygen blast furnace based on renewable energy hydrogen production

- Just-in-time updated DBN BOF steel-making soft sensor model based on dense connectivity of key features

- Effect of tempering temperature on the microstructure and mechanical properties of Q125 shale gas casing steel

- Review Articles

- A review of emerging trends in Laves phase research: Bibliometric analysis and visualization

- Effect of bottom stirring on bath mixing and transfer behavior during scrap melting in BOF steelmaking: A review

- High-temperature antioxidant silicate coating of low-density Nb–Ti–Al alloy: A review

- Communications

- Experimental investigation on the deterioration of the physical and mechanical properties of autoclaved aerated concrete at elevated temperatures

- Damage evaluation of the austenitic heat-resistance steel subjected to creep by using Kikuchi pattern parameters

- Topical Issue on Focus of Hot Deformation of Metaland High Entropy Alloys - Part II

- Synthesis of aluminium (Al) and alumina (Al2O3)-based graded material by gravity casting

- Experimental investigation into machining performance of magnesium alloy AZ91D under dry, minimum quantity lubrication, and nano minimum quantity lubrication environments

- Numerical simulation of temperature distribution and residual stress in TIG welding of stainless-steel single-pass flange butt joint using finite element analysis

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part I

- Electro-thermal performance evaluation of a prismatic battery pack for an electric vehicle

- Experimental analysis and optimization of machining parameters for Nitinol alloy: A Taguchi and multi-attribute decision-making approach

- Experimental and numerical analysis of temperature distributions in SA 387 pressure vessel steel during submerged arc welding

- Optimization of process parameters in plasma arc cutting of commercial-grade aluminium plate

- Multi-response optimization of friction stir welding using fuzzy-grey system

- Mechanical and micro-structural studies of pulsed and constant current TIG weldments of super duplex stainless steels and Austenitic stainless steels

- Stretch-forming characteristics of austenitic material stainless steel 304 at hot working temperatures

- Work hardening and X-ray diffraction studies on ASS 304 at high temperatures

- Study of phase equilibrium of refractory high-entropy alloys using the atomic size difference concept for turbine blade applications

- A novel intelligent tool wear monitoring system in ball end milling of Ti6Al4V alloy using artificial neural network

- A hybrid approach for the machinability analysis of Incoloy 825 using the entropy-MOORA method

- Special Issue on Recent Developments in 3D Printed Carbon Materials - Part II

- Innovations for sustainable chemical manufacturing and waste minimization through green production practices

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part I

- Characterization of Co–Ni–TiO2 coatings prepared by combined sol-enhanced and pulse current electrodeposition methods

- Hot deformation behaviors and microstructure characteristics of Cr–Mo–Ni–V steel with a banded structure

- Effects of normalizing and tempering temperature on the bainite microstructure and properties of low alloy fire-resistant steel bars

- Dynamic evolution of residual stress upon manufacturing Al-based diesel engine diaphragm

- Study on impact resistance of steel fiber reinforced concrete after exposure to fire

- Bonding behaviour between steel fibre and concrete matrix after experiencing elevated temperature at various loading rates

- Diffusion law of sulfate ions in coral aggregate seawater concrete in the marine environment

- Microstructure evolution and grain refinement mechanism of 316LN steel

- Investigation of the interface and physical properties of a Kovar alloy/Cu composite wire processed by multi-pass drawing

- The investigation of peritectic solidification of high nitrogen stainless steels by in-situ observation

- Microstructure and mechanical properties of submerged arc welded medium-thickness Q690qE high-strength steel plate joints

- Experimental study on the effect of the riveting process on the bending resistance of beams composed of galvanized Q235 steel

- Density functional theory study of Mg–Ho intermetallic phases

- Investigation of electrical properties and PTCR effect in double-donor doping BaTiO3 lead-free ceramics

- Special Issue on Thermal Management and Heat Transfer

- On the thermal performance of a three-dimensional cross-ternary hybrid nanofluid over a wedge using a Bayesian regularization neural network approach

- Time dependent model to analyze the magnetic refrigeration performance of gadolinium near the room temperature

- Heat transfer characteristics in a non-Newtonian (Williamson) hybrid nanofluid with Hall and convective boundary effects

- Computational role of homogeneous–heterogeneous chemical reactions and a mixed convective ternary hybrid nanofluid in a vertical porous microchannel

- Thermal conductivity evaluation of magnetized non-Newtonian nanofluid and dusty particles with thermal radiation

Articles in the same Issue

- Research Articles

- De-chlorination of poly(vinyl) chloride using Fe2O3 and the improvement of chlorine fixing ratio in FeCl2 by SiO2 addition

- Reductive behavior of nickel and iron metallization in magnesian siliceous nickel laterite ores under the action of sulfur-bearing natural gas

- Study on properties of CaF2–CaO–Al2O3–MgO–B2O3 electroslag remelting slag for rack plate steel

- The origin of {113}<361> grains and their impact on secondary recrystallization in producing ultra-thin grain-oriented electrical steel

- Channel parameter optimization of one-strand slab induction heating tundish with double channels

- Effect of rare-earth Ce on the texture of non-oriented silicon steels

- Performance optimization of PERC solar cells based on laser ablation forming local contact on the rear

- Effect of ladle-lining materials on inclusion evolution in Al-killed steel during LF refining

- Analysis of metallurgical defects in enamel steel castings

- Effect of cooling rate and Nb synergistic strengthening on microstructure and mechanical properties of high-strength rebar

- Effect of grain size on fatigue strength of 304 stainless steel

- Analysis and control of surface cracks in a B-bearing continuous casting blooms

- Application of laser surface detection technology in blast furnace gas flow control and optimization

- Preparation of MoO3 powder by hydrothermal method

- The comparative study of Ti-bearing oxides introduced by different methods

- Application of MgO/ZrO2 coating on 309 stainless steel to increase resistance to corrosion at high temperatures and oxidation by an electrochemical method

- Effect of applying a full oxygen blast furnace on carbon emissions based on a carbon metabolism calculation model

- Characterization of low-damage cutting of alfalfa stalks by self-sharpening cutters made of gradient materials

- Thermo-mechanical effects and microstructural evolution-coupled numerical simulation on the hot forming processes of superalloy turbine disk

- Endpoint prediction of BOF steelmaking based on state-of-the-art machine learning and deep learning algorithms

- Effect of calcium treatment on inclusions in 38CrMoAl high aluminum steel

- Effect of isothermal transformation temperature on the microstructure, precipitation behavior, and mechanical properties of anti-seismic rebar

- Evolution of residual stress and microstructure of 2205 duplex stainless steel welded joints during different post-weld heat treatment

- Effect of heating process on the corrosion resistance of zinc iron alloy coatings

- BOF steelmaking endpoint carbon content and temperature soft sensor model based on supervised weighted local structure preserving projection

- Innovative approaches to enhancing crack repair: Performance optimization of biopolymer-infused CXT

- Structural and electrochromic property control of WO3 films through fine-tuning of film-forming parameters

- Influence of non-linear thermal radiation on the dynamics of homogeneous and heterogeneous chemical reactions between the cone and the disk

- Thermodynamic modeling of stacking fault energy in Fe–Mn–C austenitic steels

- Research on the influence of cemented carbide micro-textured structure on tribological properties

- Performance evaluation of fly ash-lime-gypsum-quarry dust (FALGQ) bricks for sustainable construction

- First-principles study on the interfacial interactions between h-BN and Si3N4

- Analysis of carbon emission reduction capacity of hydrogen-rich oxygen blast furnace based on renewable energy hydrogen production

- Just-in-time updated DBN BOF steel-making soft sensor model based on dense connectivity of key features

- Effect of tempering temperature on the microstructure and mechanical properties of Q125 shale gas casing steel

- Review Articles

- A review of emerging trends in Laves phase research: Bibliometric analysis and visualization

- Effect of bottom stirring on bath mixing and transfer behavior during scrap melting in BOF steelmaking: A review

- High-temperature antioxidant silicate coating of low-density Nb–Ti–Al alloy: A review

- Communications

- Experimental investigation on the deterioration of the physical and mechanical properties of autoclaved aerated concrete at elevated temperatures

- Damage evaluation of the austenitic heat-resistance steel subjected to creep by using Kikuchi pattern parameters

- Topical Issue on Focus of Hot Deformation of Metaland High Entropy Alloys - Part II

- Synthesis of aluminium (Al) and alumina (Al2O3)-based graded material by gravity casting

- Experimental investigation into machining performance of magnesium alloy AZ91D under dry, minimum quantity lubrication, and nano minimum quantity lubrication environments

- Numerical simulation of temperature distribution and residual stress in TIG welding of stainless-steel single-pass flange butt joint using finite element analysis

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part I

- Electro-thermal performance evaluation of a prismatic battery pack for an electric vehicle

- Experimental analysis and optimization of machining parameters for Nitinol alloy: A Taguchi and multi-attribute decision-making approach

- Experimental and numerical analysis of temperature distributions in SA 387 pressure vessel steel during submerged arc welding

- Optimization of process parameters in plasma arc cutting of commercial-grade aluminium plate

- Multi-response optimization of friction stir welding using fuzzy-grey system

- Mechanical and micro-structural studies of pulsed and constant current TIG weldments of super duplex stainless steels and Austenitic stainless steels

- Stretch-forming characteristics of austenitic material stainless steel 304 at hot working temperatures

- Work hardening and X-ray diffraction studies on ASS 304 at high temperatures

- Study of phase equilibrium of refractory high-entropy alloys using the atomic size difference concept for turbine blade applications

- A novel intelligent tool wear monitoring system in ball end milling of Ti6Al4V alloy using artificial neural network

- A hybrid approach for the machinability analysis of Incoloy 825 using the entropy-MOORA method

- Special Issue on Recent Developments in 3D Printed Carbon Materials - Part II

- Innovations for sustainable chemical manufacturing and waste minimization through green production practices

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part I

- Characterization of Co–Ni–TiO2 coatings prepared by combined sol-enhanced and pulse current electrodeposition methods

- Hot deformation behaviors and microstructure characteristics of Cr–Mo–Ni–V steel with a banded structure

- Effects of normalizing and tempering temperature on the bainite microstructure and properties of low alloy fire-resistant steel bars

- Dynamic evolution of residual stress upon manufacturing Al-based diesel engine diaphragm

- Study on impact resistance of steel fiber reinforced concrete after exposure to fire

- Bonding behaviour between steel fibre and concrete matrix after experiencing elevated temperature at various loading rates

- Diffusion law of sulfate ions in coral aggregate seawater concrete in the marine environment

- Microstructure evolution and grain refinement mechanism of 316LN steel

- Investigation of the interface and physical properties of a Kovar alloy/Cu composite wire processed by multi-pass drawing

- The investigation of peritectic solidification of high nitrogen stainless steels by in-situ observation

- Microstructure and mechanical properties of submerged arc welded medium-thickness Q690qE high-strength steel plate joints

- Experimental study on the effect of the riveting process on the bending resistance of beams composed of galvanized Q235 steel

- Density functional theory study of Mg–Ho intermetallic phases

- Investigation of electrical properties and PTCR effect in double-donor doping BaTiO3 lead-free ceramics

- Special Issue on Thermal Management and Heat Transfer

- On the thermal performance of a three-dimensional cross-ternary hybrid nanofluid over a wedge using a Bayesian regularization neural network approach

- Time dependent model to analyze the magnetic refrigeration performance of gadolinium near the room temperature

- Heat transfer characteristics in a non-Newtonian (Williamson) hybrid nanofluid with Hall and convective boundary effects

- Computational role of homogeneous–heterogeneous chemical reactions and a mixed convective ternary hybrid nanofluid in a vertical porous microchannel

- Thermal conductivity evaluation of magnetized non-Newtonian nanofluid and dusty particles with thermal radiation