Abstract

Duplex stainless steel (DSS) has been widely used in various applications due to the combination of excellent mechanical properties and corrosion resistance. However, shielded manual arc welding (SMAW) always deteriorates its phase balance and further changes its mechanical properties. Therefore, an appropriate post-weld heat treatment (PWHT) is of the essence to gain the superior performance of the DSS SMAW joint. In this article, the effects of PWHT temperature on the microstructure and residual stress of 2205 DSS SMAW joint were investigated by both experimental and simulation methods. The microstructural characteristics including phase ratio, morphology, grain misorientation, and boundary type were analyzed by the electron backscattered diffraction, while the evolution of residual stress was investigated by a thermal–mechanical coupled finite-element simulation and hole drilling method. The results showed that the residual stress decreased significantly after PWHT, particularly under the higher PWHT temperature. The maximum longitudinal residual stress had dropped by 20.4 and 66.8% at the PWHT temperatures 380 and 1,050°C, which were both far below the yield strength. However, the increase in PWHT temperature promoted the phase proportion imbalance due to the excessive precipitation of intragranular austenite and the formation of low-angle grain boundaries. The fraction of austenite had reached 75.5% when the PWHT temperature was 1,050°C. In order to obtain a reasonable distribution of residual stress and microstructure for the 2205 DSS SMAW joint, it is recommended to perform PWHT at 380°C.

1 Introduction

Duplex stainless steel (DSS) is characterized by its high strength and excellent corrosion resistance, making it a suitable choice for various applications, including filter presses, chemical cargo tanks, sulfuric acid evaporators, and heat exchangers handling chloride-containing media [1,2,3]. Shielded manual arc welding (SMAW) is a common welding method for DSS equipment. However, during the welding process, the weld zone and the heat-affected zone (HAZ) undergo complex phase transformations due to the influence of thermal cycling, resulting in an unbalanced phase ratio, which would weaken the mechanical properties. Furthermore, the generation of welding residual stresses is inevitable, which adversely affects the performance of the joint, thereby reducing its service life.

Post-weld heat treatment (PWHT) is a crucial method for reducing residual stresses and modifying the microstructure in the welded joints. Numerous researchers have investigated the reduction of welding residual stress through PWHT. Jabran et al. [4] examined a 2.25Cr–1Mo circumferential butt-welded pipe fabricated using tungsten inert gas (TIG) welding and observed that PWHT could decrease the stress gradient, although stress peaks persisted at the edges of the heated region. Yu et al. [5] explored the impact of PWHT on residual stress relief in SMA490BW steel melt active gas arc welding joints, finding significant stress reduction during the heating stage, with the final residual stress distribution relatively unaffected by the cooling rate. Liu et al. [6] investigated laser beam welding of Ti–45Al–5Nb–0.2C–0.2B alloy and determined that PWHT at 1,260°C for 2 h completely alleviated longitudinal residual stresses. Chao et al. [7] conducted selective laser melting forming on 316L stainless steel powder, analyzing changes in residual stress and microstructure pre- and post-heat treatment. Their findings indicated a decrease in residual stress occurred after heat treatment, changing to a stable state with smaller compressive stresses. Despite numerous studies confirming the efficacy of PWHT in significantly reducing welding residual stress, limited attention has been directed toward the residual stress evolution in DSS SMAW joints due to PWHT.

Muthupandi et al. [8] investigated the optimal microstructure and mechanical properties of joints by controlling the heat input of DSS welds. They found that the proportion of dual phases in DSS often failed to meet the requirements of balance during rapid cooling. Ureña et al. [9] welded 2205 DSS using the plasma arc welding method and observed that at high energy inputs, the ferrite content in the weld and fusion zone exceeded 45%, significantly higher than that in the base material. Cui et al. [10] employed the K-TIG welding method for DSS welding and reported an austenite content of approximately 42% in the weld. These studies suggest that different welding methods employed for DSS welding result in varying phase contents and imbalanced phase proportions in the welds. In order to address the imbalance in phase proportions, Vijayalakshmi et al. [11] investigated the influence of annealing temperature on the microstructure of DSS, revealing that a temperature of 1,350°C results in coarsening of ferrite grains, while rapid quenching promotes the formation of austenite. Zhang et al. [12] studied the evolution of the weld microstructure of 2507 DSS under short-term PWHT at different temperatures. The results indicated a significant increase in the austenite content in the weld zone after a brief heat treatment. Singh et al. [13] examined the effect of isothermal treatment on the microstructure of 2205 DSS gas tungsten arc welded joints, finding a notable decrease in ferrite content after exposure to 850°C isothermal treatment for 2 h. Badji et al. [14] found that the HAZ of 2205 DSS gas tungsten arc welding joints had a higher ferrite content, while the weld center contained more austenite. The ferrite content increased with the increase of annealing temperature, and the rate of formation in the HAZ was higher than that in the base material and fusion zone. Zhang et al. [15] investigated the microstructural evolution of UNS S32750 super DSS TIG welded joints before and after heat treatment. They observed a significant increase in the volume fraction of austenite in the HAZ and weld metal after annealing at 1,080°C. Zhang et al. [16] studied the microstructural evolution of electron beam welded joints of DSS under different heat treatment temperatures. They found that PWHT effectively promoted the formation of austenite. Further investigations by Zhang et al. [17] revealed that heat treatment facilitated the formation of austenite and the dissolution of Cr2N, eliminating dendritic segregation. Shrikrishna and Sathiya [18] performed PWHT on friction-welded joints of DSS. The PWHT involved quenching and water cooling after annealing at 1,080°C, achieving a balanced volume fraction of ferrite and austenite without the precipitation of other phases.

Previous research studies have pointed out that there are significant differences in the austenite content of DSS prepared by different welding methods. However, the effects of PWHT on the formation of austenite in different welding methods are different; some would promote, while some would restrain. Furthermore, there has been no comprehensive study from the perspective of residual stress and microstructure on the effects of PWHT processes on SMAW joints. Therefore, the appropriate heat treatment process for SMAW joints remains unclear. This article focuses on 2205 DSS SMAW welded joints for investigation. The evolution of residual stress was investigated by a thermal–mechanical coupled finite-element simulation and hole drilling method. The microstructural characteristics including phase ratio, morphology, grain misorientation, and boundary type were also analyzed. The optimal PWHT method was then proposed according to the distribution of residual stress and microstructure.

2 Experiment

2.1 Sample preparation

Two SAF2205 DSS plates were butt-welded by SMAW, and the welding consumable is ER2209. The chemical composition of the base metal and welding material is provided in Table 1 [19]. To ensure sufficient penetration, a 60° bevel angle was adopted. In order to match welding performance and avoid welding defects, welding parameters, as shown in Table 2, were selected. As illustrated in Figure 1, the welding joint has a dimension of 400 mm (X) × 10 mm (Y) × 300 mm (Z). The welding joint consists of four welding passes and one root pass.

Chemical composition of the SAF2205 and ER2209 (in wt%)

| Material | C | Mn | Si | Cr | Ni | Mo | N | P | S |

|---|---|---|---|---|---|---|---|---|---|

| SAF2205 | 0.016 | 0.82 | 0.36 | 22.48 | 5.46 | 3.12 | 0.16 | 0.024 | 0.001 |

| ER2209 | 0.013 | 1.54 | 0.49 | 22.92 | 8.61 | 3.18 | 0.17 | 0.018 | 0.0007 |

Welding parameters

| Welding wire diameter φ (mm) | Current I (A) | Volts U (V) | Welding speed ν (cm·min−1) |

|---|---|---|---|

| 3.2 | 100–120 | 14–18 | 10–15 |

| 4.0 | 130–140 | 26–28 | 18–20 |

Geometric dimensions of welding specimens and testing points using drilling method.

The sample was subjected to bulk heat treatment after welding, and the heat treatment temperature profile is shown in Figure 2. The heating time (t 1) is 6 h, the holding time (t 2) is 6 h, and the sample is cooled to room temperature in the furnace. In order to investigate the influence of heat treatment temperatures on residual stress and microstructure, three heat treatment processes were designed: low temperature, medium temperature, and high temperature, in conjunction with the phase transformation of DSS [20,21], as illustrated in Table 3.

PWHT cycle and parameters.

Heat treatment scheme

| Scheme | A | B | C |

|---|---|---|---|

| t 1 (h) | 6 | 6 | 6 |

| t 2 (h) | 12 | 12 | 12 |

| T PWHT (°C) | 380 | 750 | 1,050 |

2.2 Residual stress measurement by the hole drilling method

The principle of the hole drilling method is to paste strain gauges on the surface of the workpiece to be measured and punch holes to relax the stress around the holes and form a new stress/strain field distribution. By calibrating strain release coefficients A and B, the original residual stress and strain of the workpiece can be calculated based on the principle of elastic mechanics. The strain generated on the three strain gauges by drilling is related to the residual principal stress as follows:

where σ 1 and σ 2 represent the principal stresses (MPa); ε 1, ε 2, and ε 3 represent strains in the 0°, 45°, and 90° directions, respectively; A and B are the strain release coefficients; and φ is the angle between σ 1 and the 0° strain gauge [22,23].

In this hole drilling method measurement, an HT101C strain and stress measurement instrument was used with a drill hole diameter of 1 mm and a depth of 2 mm. BX120-3CA three-directional strain gauges were used. The measurement positions are shown in Figure 1.

2.3 Microstructure characterization

For welding and PHWT samples, microstructure analysis was performed at the locations of the first and fourth weld seams. The microstructure of the as-welded sample has been observed in our previous work [24]. The sample size is 15 mm (X) × 10 mm (Y) × 3 mm (Z). The samples were polished with 240#, 400#, 600#, 800#, 1,000#, 1,500#, and 2,000# sandpapers, followed by mechanical polishing with 5, 2.5, and 1 μm diamond polishing agents. After electrolytic corrosion with NaOH solution (40 g NaOH + 200 g H2O), the microstructure observation can be carried out under the optical microscope. The samples were then conducted for the electron backscattered diffraction (EBSD) test after vibratory polishing.

3 Finite-element analysis

3.1 Finite-element model (FEM)

In this study, a three-dimensional FEM was established based on the actual welding sample dimension, as shown in Figure 3. The model consists of 67,200 elements and 74,186 nodes. During the simulation of the temperature field, hexahedral heat transfer elements (DC3D8) were used. For the analysis of the welding stress field, eight-node reduced integration three-dimensional stress elements (C3D8R) were used.

FEM model of the weld joint.

3.2 Welding simulation

3.2.1 Temperature field simulation

A double ellipsoid heat source was adopted to model the heat generation from the moving welding arc [25]. The heat flow density distributions of the front and rear ellipsoids in the heat source are shown in equations (3) and (4), respectively

where Q is the heat input of the arc; a, b, c f, and c r are the shape parameters of the ellipsoid; and m and n represent the energy fractions of the front and rear hemispheres (m + n = 2). In general, m = 0.4, and n = 1.6.

The ambient temperature was 20°C, the convective heat transfer coefficient h was 10 W·m−2·K−1, the emissivity ε was 0.85, and the Boltzmann constant σ was 5.67 × 10−8 W·m−2·K−4). The thermophysical properties of DSS 2205 are shown in Table 4.

Thermophysical properties of SAF2205 steel

| Temperature T (°C) | Thermal conductivity λ (W·m−1·°C−1) | Specific heat capacity C (kJ·kg−1·°C−1) | Density ρ (kg·m−3) |

|---|---|---|---|

| 0 | 19.2 | 400 | 7,886 |

| 100 | 19.2 | 460 | 7,840 |

| 300 | 23.4 | 545 | 7,790 |

| 500 | 25.0 | 720 | 7,772 |

| 600 | 24.1 | 800 | 7,762 |

| 800 | 23.0 | 895 | 7,738 |

| 1,000 | 21.0 | 670 | 7,715 |

| 1,200 | 19.2 | 700 | 7,786 |

| 1,400 | 19.2 | 728 | 7,635 |

| 2,100 | 19.1 | 780 | 7,602 |

3.2.2 Stress field simulation

The sequential coupling method was then carried out, where the results of the temperature field were applied to the stress field as a predefined field. In order to avoid rigid displacement of the specimen, displacement constraints are carried out at the endpoints on the bottom surface. The total strain is decomposed into three components as follows:

where ε e , ε p, and ε th denote elastic strain, plastic strain, and thermal strain, respectively. The elastic strain was calculated using isotropic Hooke’s law with temperature-dependent Young’s modulus and Poisson’s ratio. The plastic strain was calculated using the von Mises yield criterion, temperature-dependent mechanical properties, and isotropic hardening model of the plastic model. Thermal strains were calculated using temperature-dependent thermal expansion coefficients.

The mechanical properties of DSS are calculated by the parameter calculation software JMatPro, including the modulus of elasticity E, the coefficient of linear expansion, Poisson’s ratio μ, and so on, which are shown in Table 5.

Mechanical properties of SAF2205 steel

| Temperature T (°C) | Modulus of elasticity E (GPa) | Poisson’s ratio μ | Yield strength σ y (MPa) | Coefficient of linear expansion A (°C−1) |

|---|---|---|---|---|

| 0 | 222.458 | 0.29 | 441.2 | 1.36 × 10−5 |

| 200 | 217.432 | 0.30 | 322.2 | 1.44 × 10−5 |

| 400 | 194.193 | 0.31 | 278.8 | 1.705 × 10−5 |

| 600 | 166.234 | 0.32 | 218.5 | 1.771 × 10−5 |

| 800 | 140.488 | 0.33 | 170.4 | 1.807 × 10−5 |

| 1,000 | 119.234 | 0.34 | 78.8 | 1.812 × 10−5 |

| 1,200 | 96.543 | 0.34 | 7.4 | 1.828 × 10−5 |

| 1,400 | 70.781 | 0.35 | 7.4 | 1.837 × 10−5 |

3.3 Heat treatment simulation

Heat treatment simulation is also a thermal–mechanical sequential coupled process, which is similar to the welding simulation. The heat treatment temperature simulation would be carried out through the actual process with three PWHT temperatures. The material parameters required for simulation are the same as those in Tables 4 and 5.

4 Results and discussion

4.1 Effect of PWHT temperature on residual stresses

Figure 4 shows the residual stress distribution in the welded component without undergoing heat treatment. Initially, the residual stress is symmetrically distributed, with higher residual stress near the weld seam and the HAZ, approaching the material’s yield strength. In the longitudinal direction, the residual stress exhibits tensile stress in the middle of the weld seam, reaching a maximum value of 530 MPa. To ensure overall stress balance, compressive stress is observed at both ends, with a maximum value of 216 MPa. As further away from the weld seam, the stress values decrease. The transverse residual stress is significantly lower than the longitudinal residual stress. Its highest tensile stress, reaching 262 MPa, is observed at the upper and lower surfaces of the weld toes, and the stress decreases as we move away from the weld seam.

Effect of PWHT temperature on residual stress: transverse stress of as-welded state (a) PWHT at 380°C (c), PWHT at 750°C (e), PWHT at 1,050°C, (g) longitudinal stress of as-welded state (b), PWHT at 380°C (d), PWHT at 750°C (f), and PWHT at 1,050°C (h).

Two paths, P1 and P2, were selected to analyze the distribution and magnitude of welded residual stresses, as shown in Figure 1. P1 is perpendicular to the weld seam, while P2 is in the thickness direction at the center of the weld seam. The transverse and longitudinal stress distributions along these two paths are shown in Figures 5 and 6. It is evident that the maximum tensile stress is observed in the HAZ, with a maximum longitudinal residual stress value of 488 MPa. Transverse residual stress is lower than the longitudinal stress, with a maximum value of 169 MPa. As away from the weld seam, residual stresses gradually decrease and approach 0 MPa. Comparing the data obtained from the hole drilling method experiments with the numerical simulation results, as shown in Figure 6, it is found that, within an acceptable range, there is some deviation, but the distribution is consistent. This, to some extent, validates the accuracy and reliability of the finite-element simulation method. The experimental results show lower values compared to the finite-element simulation. There are several possible reasons for this difference: the hole drilling method involves polishing the specimen surface during the initial preparation, releasing some of the residual stresses, resulting in lower residual stress values during testing compared to the initial state. Additionally, the assumption is made that all residual stresses are released after drilling. Inevitably, there may be some remaining stresses that are not completely released, leading to slightly lower measurement results.

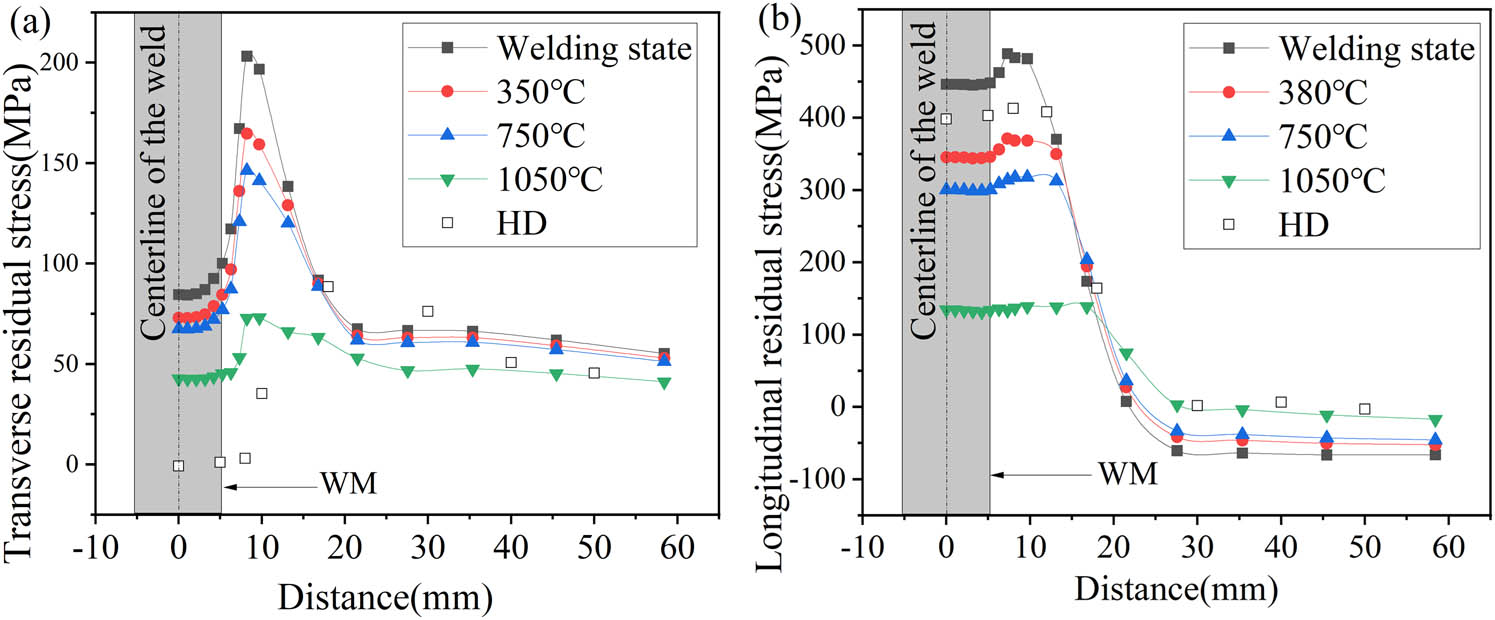

Effect of heating temperature on residual stress perpendicular to the weld seam: (a) transverse stress and (b) longitudinal stress.

Effect of heat treatment on residual stress along the thickness of the weld: (a) transverse residual stress and (b) longitudinal residual stress.

Figure 4(c)–(h) shows the residual stress after heat treatment. The maximum residual stresses in the welded components are reduced after heat treatment, with varying degrees of reduction at different heat treatment temperatures. As shown in Figure 4, after PWHT at 1,050°C, the stress distribution trend is generally the same as that of the as-welded sample. However, the residual stresses are greatly released and the reduction degree is significantly increased with the increase of temperature.

Residual stress distribution curves after heat treatment were plotted perpendicular to the weld path, as shown in Figure 5. It can be observed that at PHWT temperatures ranging from 380 to 1,050°C, the transverse residual stress in the weld seam decreases from 75 to 42 MPa, and the longitudinal residual stress decreases from 345 to 133 MPa. Residual stress peaks still exist in the HAZ after heat treatment. Combining with Figure 4, it can be seen that treatment option A (380°C) has a weaker effect, but the maximum stress is also reduced. After PWHT, the maximum transverse and longitudinal residual stresses are 223.7 and 422.6 MPa, with reductions of 14.8 and 20.4%, respectively. This indicates that although residual stresses are reduced after heat treatment, but for better residual stress distribution, the heat treatment temperature should be increased. Treatment option B (750°C) results in a more effective reduction of residual stresses compared to option A. The transverse and longitudinal residual stress values after heat treatment are 198.0 and 368.0 MPa, respectively, with reductions of 24.6 and 30.7%, making it a more favorable option than option A. After treatment with option C (1,050°C), the reduction in residual stresses in the welded components is quite significant. The maximum transverse and longitudinal residual stresses are 99.3 and 176.1 MPa, respectively, representing a reduction of 62.2 and 66.8% compared to the initial stresses. The effect of high-temperature PWHT at 1,050°C is most pronounced. There is no significant difference in the transverse and longitudinal residual stresses of the base metal at different PHWT temperatures, with transverse residual stresses ranging from 45 to 70 MPa and longitudinal residual stresses ranging from −70 to 10 MPa.

Along the through-thickness direction of the weld seam, stress distribution curves before and after heat treatment are plotted, as shown in Figure 6. The transverse residual stresses gradually decrease from the upper surface to the lower surface, with a slight increase near the lower surface. The stress is lowest at the location of the first weld bead, and due to the tempering effect of subsequent weld passes on the preceding weld bead, the stress is higher at the positions of subsequent weld passes [26]. It can be observed that with higher heat treatment temperatures, the stress curves become smoother and closer to the 0 stress axis. Furthermore, the longitudinal stress does not have an obvious fluctuation along the thickness; its maximum ranges from 465 to 130 MPa from the as-welded condition to the 1,050°C PWHT condition.

4.2 Effect of heat treatment temperature on microstructure

4.2.1 Microstructure morphology

Figure 7 displays the morphology of the weld root region before and after heat treatment at different temperatures. After PWHT at 380°C, the weld’s microstructure remains largely unchanged, resembling the microstructure of the as-welded joint, with minimal changes in phase content. As the temperature is relatively low, which does not reach the temperature of recrystallization. Following PWHT at 750°C, the austenite phase content has a slight increase. Some grains become larger, causing a slight reduction in the ferrite phase content. However, after heat treatment at 1,050°C, the weld’s microstructure appears more uniform, primarily existing in the form of Intragranular austenite, with smaller and evenly distributed grains.

Microstructure of weld root before and after heat treatment: (a) welded state, (b) 380°C, (c) 750°C, and (d) 1,050°C.

Figure 8 illustrates the microstructure morphology on the surface of the weld seam before and after different heat treatment temperatures. As shown in Figure 8(b), after heat treatment at 380°C, there is also no significant change in the microstructure morphology. It remains similar to the as-welded condition, with little difference in the content of austenite and ferrite phases. After heat treatment at 750°C (Figure 8(c)), a noticeable growth in the austenite grain size, an increase in the austenite phase content, a more pronounced dendritic structure, and the formation of a dark precipitate phase between the austenite grains can be observed. As a result, the content of the ferrite phase decreases. Following heat treatment at 1,050°C (Figure 8(d)), the weld’s microstructure becomes more uniform. The coarse dendritic structure disappears, and the higher temperature causes a refinement of the austenite grain size. Austenite continues to form, and the content of the ferrite phase significantly decreases, while the austenite content increases. Observations under an optical microscope indicate that higher-temperature heat treatment promotes further transformation of ferrite into austenite. With increasing heat treatment temperature, the extent of this transformation process becomes more pronounced. To further quantify the impact of heat treatment on microstructure evolution, EBSD experiments were conducted to determine specific phase content and structure types.

Microstructure at the weld surface before and after heat treatment: (a) as-welded state, (b) 380°C, (c) 750°C, and (d) 1,050°C.

After observations using an optical microscope, it was found that the changes in microstructure morphology were more pronounced near the weld seam surface (at the fourth weld pass). Therefore, EBSD tests were conducted at the weld seam surface to analyze and discuss the specific effects. The EBSD results of as-welded states are shown in Figure 9(a). Figure 9 presents the distribution and content of the two phases near the weld seam surface after heat treatments at different temperatures. Following heat treatment at 380°C, the microstructure of the weld seam remains largely unchanged, mainly due to the relatively low temperature. However, some austenite grains show slight growth, resulting in an increase in the austenite content to 67.2%, with the ferrite content at 32.8%. During the holding process at 750°C, intragranular austenite continues to grow within ferrite grains. The ferrite grains become more fragmented, and a significant amount of grain boundary austenite surrounds the ferrite grains. As a result, the austenite content increases significantly to 71.8%, while the ferrite content decreases to 28.2%. When the heat treatment temperature reaches 1,050°C, the transformation of ferrite to austenite becomes more thorough. Austenite grains further refine and exhibit a “wheat-like” shape, distributing more uniformly within the ferrite matrix. At this point, the austenite content reaches 75.5%. Simultaneously, small austenite phases melt away, and alloy elements re-dissolve into both the austenite and ferrite phases [27,28].

Microstructure at the surface of the weld before and after heat treatment: (a) as-welded state, (b) 380°C, (c) 750°C, and (d) 1,050°C.

Based on the above analysis, PWHT induces the formation of more austenite in the weld seam, primarily classified into primary austenite and secondary austenite [29]. Primary austenite solidifies directly from the molten metal, while secondary austenite is generated during the solid-phase transformation from ferrite to austenite, including grain boundary austenite, Widmanstätten austenite, and intragranular austenite. When the post-weld microstructure is reheated, secondary austenite forms within ferrite and at the interface between ferrite and primary austenite [30]. Studies have found that after heat treatment in the range of 1,000–1,100°C, secondary austenite readily precipitates [27]. At 1,050°C, the predominant forms of austenite are primary and secondary austenite [31]. Therefore, the increase in heat treatment temperature promotes the growth of austenite and the generation of intragranular austenite. The increased content of austenite in the weld seam is ultimately attributed to the non-equilibrium nature of the post-weld microstructure [32].

4.2.2 Grain-type distribution

The content of grain types in the weld seam before and after heat treatment is illustrated in Figure 10. After undergoing heat treatment at different temperatures, the predominant grain types at the weld seam surface are recrystallized grains and substructured grains, with a minimal presence of deformed grains. Substructured grains result from lattice distortions, while recrystallized grains require significant stress to induce the recrystallization phenomenon [33]. As the heat treatment temperature increases, the content of deformed grains at the weld seam decreases. The content of deformed grain in the austenite decreases from 12.1 to 0%, while that in the ferrite changes from 21.9 to 2%. This is because there is a large deformation after welding. However, after heat treatment, the plastic deformation is eliminated due to the dislocation rearrangement caused by thermal recovery. Besides, new grains tend to form at pre-existing high-angle boundaries that have a significant density of dislocations. These new grains then grow by absorbing the adjacent deformed grains. Due to the effect of PWHT temperature increase, the driving force of recrystallization also increases, and recrystallization is more prone to occur. Without heat treatment, the recrystallized grain content is 20.30%. However, after heat treatment at 380, 750, and 1,050°C, the recrystallized grain content near the weld seam surface in the two-phase region is 33.25, 32.70, and 46.50%, respectively. The higher the heat treatment temperature, the greater the plastic deformation inside the material, which is closely related to the deformation of the material and the dynamic recrystallization process [34]. When the material deforms, dislocations are generated inside the grains, and a recrystallization process occurs. When this process is not sufficient to offset the dislocations generated, the irregular dislocations on the slip plane redistribute, and the dislocations align vertically to form walls. This distribution releases a large amount of strain energy, and this reorganization of dislocations also leads to the formation of substructures in the microstructure [35]. The formation of these substructures consumes the surrounding sub-grains, ultimately forming substructured grains with relatively low dislocation densities. When recrystallized grains nucleate, these substructured grains are further consumed. In addition, the higher the heat treatment temperature, the more thorough the conversion of elastic deformation to plastic deformation, leading to higher energy storage and the formation of more nucleation sites, effectively reducing the average grain size. In summary, heat treatment increases the content of recrystallized grains and substructured grains. As the heat treatment temperature increases, the weld microstructure still consists mainly of recrystallized grains and substructured grains, with an increase in the content of recrystallized grains and a decrease in the content of substructured grains.

Statistical graph of weld grain-type content before and after heat treatment.

4.2.3 Grain boundaries character distribution

Quantitative analysis of the grain boundary characteristics near the upper surface region of the weld seam after different temperature heat treatments is presented, as shown in Figure 11. The distribution of the misorientation angle in austenite exhibits a bimodal distribution, while the misorientation angle in the ferrite phase is predominantly concentrated at low angles, displaying a unimodal distribution.

Misorientation angle distribution: (a) as-welded state, (b) 380°C, (c) 750°C, and (d) 1,050°C.

The misorientation angle is further calculated to obtain the grain boundary distribution, as shown in Figure 12. The heat treatment temperature of 380°C results in a high content of low-angle grain boundaries (LAGBs) in the ferrite phase, reaching 89.94%, with only 2.04% being high-angle grain boundaries (HAGBs). The medium-angle grain boundaries (MAGBs) have a lower content of about 8.02%. In the austenite phase, both the LAGBs and HAGBs are relatively dominant, with contents of 49.02 and 32.23%, respectively. In the austenite phase, both the LAGBs and HAGBs are relatively dominant, with contents of 49.02 and 32.23%, respectively. When the heat treatment temperature is increased to 750°C, the dominance of LAGBs continues in the ferrite phase, with a content of 93.85%. HAGBs account for only 3.14%. The content of LAGBs in the austenite phase increases compared to the heat treatment at 380°C, reaching approximately 61.00%, while MAGBs and HAGBs are found to be around 9.41 and 29.59%. When the heat treatment temperature reaches 1,050°C, the distribution of austenite phase grain boundaries resembles that at 750°C, with LAGB, MAGB, and HAGB contents of 64.81, 7.57, and 27.62% respectively. Additionally, the presence of HAGBs (5.14%) is observed in the ferrite phase while the content of LAGBs remains as high as 94.50%. Comparing the grain boundary characteristics after PWHT with those of the as-welded state, it is found that heat treatment is conducive to the transformation of LAGBs in two phases. This is due to the large welding residual deformation and a large number of sub-structures generated in the welding process. The sub-grains rotate and the misorientation angle changes during the PHWT process, resulting in the transformation of HABGs to LAGBs. Second, the LAGBs can absorb the motion dislocation and reduce the residual deformation of the weld [36]. If the LAGBs are changed to HAGBs, more energy should be provided by PHWT for the transformation. In addition, due to the reduction of the residual stress in the PHWT process, the grain changes to be in the LAGBs, which is more stable. Therefore, the content of LAGBS increases while that of HAGBs decreases.

Boundary characteristic distribution: (a) welding state, (b) 380°C, (c) 750°C, and (d) 1,050°C.

From the above results of microstructure and residual stress, it can be found that PHWT at lower temperatures would not have a significant influence on the microstructure morphology and phase ratio. However, the PWHT at high temperatures would promote the growth of austenite and result in a severely unbalanced phase ratio, which would weaken the strength of the welded joint [37]. Besides, the content of LAGBs also increases, which would decrease the yield strength because dislocations rearrange themselves to reduce their energy through the rotation and merging of subgrains, as well as the migration of subgrain boundaries [38]. Although the increase of PWHT temperature can lead to an increase in the degree of stress release, the maximum longitudinal stress at PHWT temperature of 380°C has reached only 422.6 MPa, below the yield strength. Therefore, it is recommended to carry out PWHT at a relatively low temperature for the DSS SMAW joint. It then can promote stress relief and avoid the severely unbalanced phase ratio between two phases, which would guarantee excellent mechanical properties [39,40].

5 Conclusion

This study investigated the impact of PWHT temperature on residual stresses and microstructure in DSS SMAW joint, which was expected to provide an appropriate PHWT process to gain excellent mechanical properties. The conclusions are summarized as follows:

In the as-welded joint, large tensile longitudinal residual stress was found in the weld seam and HAZ, which was close to the yield strength of the material. Along the through-thickness direction, the longitudinal residual stress decreases from 465 to 400 MPa. The transverse stress ranges from −48.9 to 126 MPa along the thickness.

PWHT significantly reduced the residual stresses. When the PWHT reached 380°C, the longitudinal and the transverse residual stresses were reduced by 20.4 and 14.8% compared to those of the as-welded joint, respectively. When the PWHT reached 1,050°C, the longitudinal and the transverse residual stresses were reduced by 66.8 and 62.2%, respectively.

After welding, the fraction of austenite was 66.4%. PWHT at 380°C has a slight influence on the phase ratio. However, PWHT at 1,050°C resulted in the fraction of austenite reaching 75.5%. Furthermore, the increase in PWHT temperature would promote the growth of recrystallized grains and LAGBs.

It is recommended to perform PWHT at relatively low temperatures around 380°C to achieve good combination performance of DSS manual arc welding joints.

Acknowledgements

The authors gratefully acknowledge the support provided by the National Natural Science Foundation of China (52105166, 52305172) and the Fundamental Research Funds for the Central Universities (22CX06028A).

-

Funding information: National Natural Science Foundation of China (52105166, 52305172), Fundamental Research Funds for the Central Universities (22CX06028A).

-

Author contributions: Yu Wan: Writing-Original Draft, Validation, Formal analysis, Visualization Software, Methodology Investigation, Conceptualization Data Curation. Laimin Song: Resources, Data Curation, Visualization, Investigation, Formal analysis,Validation. Xuefang Xie: Methodology, Writing-Review and Editing, Funding acquisition, Resources, Supervision. Yue Shi: Software, Data Curation, Visualization.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The raw data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

[1] Moura, V. S., L. D. Lima, J. M. Pardal, A. Y. Kina, R. R. A. Corte, and S. S. M. Tavares. Influence of microstructure on the corrosion resistance of the duplex stainless steel UNS S31803. Materials Characterization, Vol. 59, No. 8, 2008, pp. 1127–1132.10.1016/j.matchar.2007.09.002Search in Google Scholar

[2] Wan, J. An investigation on the metallurgical process and deformation mechanism of a novel resource-saving duplex stainless steel (DSS), Hong Kong Polytechnic University, Hong Kong, China, 2017.Search in Google Scholar

[3] Angella, G., A. Fava, R. Montanari, M. Richetta, and A. Varone. Flat-top cylinder indenter examination of duplex stainless steel 2205 after different heat treatments. Metals, Vol. 7, No. 5, 2017, id. 178.10.3390/met7050178Search in Google Scholar

[4] Jabran, A., C. Peach, Z. Zou, and L. Ren. Finite element analysis of residual stress in 2.25Cr-1Mo steel pipe during welding and heat treatment process. Journal of Manufacturing Processes. Annals of Biomedical Engineering, Vol. 47, 2019, pp. 110–118.10.1016/j.jmapro.2019.09.019Search in Google Scholar

[5] Yu, B., P. Wang, X. Song, and S. Huo. The residual stress relief of post weld heat treatment in SMA490BW welded joints: Simulation and experiment. International Journal of Pressure Vessels and Pi**, Vol. 200, 2022, id. 104852.10.1016/j.ijpvp.2022.104852Search in Google Scholar

[6] Liu, J., V. Ventzke, P. Staron, N. Schell, N. Kashaev, and N. Huber. Investigation of in situ and conventional post‐weld heat treatments on dual‐laser‐beam‐welded γ‐TiAl‐based alloy. Advanced Engineering Materials, Vol. 14, No. 10, 2012, pp. 923–927.10.1002/adem.201200113Search in Google Scholar

[7] Chao, Q., S. Thomas, N. Birbilis, P. Cizek, P. D. Hodgson, and D. Fabijanic. The effect of post-processing heat treatment on the microstructure, residual stress and mechanical properties of selective laser melted 316L stainless steel. Materials Science and Engineering: A, Vol. 821, 2021, id. 141611.10.1016/j.msea.2021.141611Search in Google Scholar

[8] Muthupandi, V., P. Bala Srinivasan, S. K. Seshadri, and S. Sundaresan. Effect of weld metal chemistry and heat input on the structure and properties of duplex stainless steel welds. Materials Science and Engineering a-Structural Materials Properties Microstructure and Processing, Vol. 358, No. 1–2, 2003, pp. 9–16.10.1016/S0921-5093(03)00077-7Search in Google Scholar

[9] Ureña, A., E. Otero, M. V. Utrilla, and C. J. Múnez. Weldability of a 2205 duplex stainless steel using plasma arc welding. Journal of Materials Processing Technology, Vol. 182, No. 1–3, 2007, id. 631.10.1016/j.jmatprotec.2006.08.030Search in Google Scholar

[10] Cui, S., Y. Shi, Y. Cui, and T. Zhu. The impact toughness of novel keyhole TIG welded duplex stainless steel joints. Engineering Failure Analysis, Vol. 94, 2018, pp. 226–231.10.1016/j.engfailanal.2018.08.009Search in Google Scholar

[11] Vijayalakshmi, K., V. Muthupandi, and R. Jayachitra. Influence of heat treatment on the microstructure, ultrasonic attenuation and hardness of SAF 2205 duplex stainless steel. Materials Science & Engineering A, Vol. 529, 2011, pp. 447–451.10.1016/j.msea.2011.09.059Search in Google Scholar

[12] Zhang, Z., H. Zhang, J. Hu, X. Qi, Y. Bian, A. Shen, et al. Microstructure evolution and mechanical properties of briefly heat-treated SAF 2507 super duplex stainless steel welds. Construction and Building Materials, Vol. 168, 2018, pp. 168–345.10.1016/j.conbuildmat.2018.02.143Search in Google Scholar

[13] Singh, S., J. Singh, and A. S. Shahi. Investigation on aging-induced degradation of impact toughness and corrosion performance of duplex stainless steel weldment. Transactions of the Indian Institute of Metals, Vol. 73, 2020, pp. 2747–2765.10.1007/s12666-020-02070-zSearch in Google Scholar

[14] Badji, R., M. Bouabdallah, B. Bacroix, C. Kahloun, B. Belkessa, and H. Maza. Phase transformation and mechanical behavior in annealed 2205 duplex stainless steel welds. Materials Characterization, Vol. 59, No. 4, 2007, pp. 447–453.10.1016/j.matchar.2007.03.004Search in Google Scholar

[15] Zhang, Z., H. Zhao, H. Zhang, J. Hu, and J. Jin. Microstructure evolution and pitting corrosion behavior of UNS S32750 super duplex stainless steel welds after short-time heat treatment. Corrosion Science, Vol. 121, 2017, pp. 22–31.10.1016/j.corsci.2017.02.006Search in Google Scholar

[16] Zhang, Z., Z. Wang, Y. Jiang, H. Tan, D. Han, Y. Guo, et al. Effect of post-weld heat treatment on microstructure evolution and pitting corrosion behavior of UNS S31803 duplex stainless steel welds. Corrosion Science, Vol. 62, 2012, pp. 42–50.10.1016/j.corsci.2012.04.047Search in Google Scholar

[17] Zhang, Z., H. Jing, L. Xu, Y. Han, L. Zhao, and X. Lv. Effect of post-weld heat treatment on microstructure evolution and pitting corrosion resistance of electron beam-welded duplex stainless steel. Corrosion Science, Vol. 141, 2018, pp. 30–45.10.1016/j.corsci.2018.06.030Search in Google Scholar

[18] Shrikrishna, K. A. and P. Sathiya. Effects of post weld heat treatment on friction welded duplex stainless steel joints. Journal of Manufacturing Processes, Vol. 21, 2016, pp. 196–200.10.1016/j.jmapro.2015.10.005Search in Google Scholar

[19] Wang, S., Q. Ma, and Y. Li. Characterization of microstructure, mechanical properties and corrosion resistance of dissimilar welded joint between 2205 duplex stainless steel and 16MnR. Materials and Design, Vol. 32, No. 2, 2011, pp. 831–837.10.1016/j.matdes.2010.07.012Search in Google Scholar

[20] Chan, K. W. and S. C. Tjong. Effect of secondary phase precipitation on the corrosion behavior of duplex stainless steels. Materials, Vol. 7, No. 7, 2014, pp. 5268–5304.10.3390/ma7075268Search in Google Scholar PubMed PubMed Central

[21] Miodownik, A. P. and N. Saunders. Modelling of materials properties in duplex stainless steels. Materials Science and Technology, Vol. 18, No. 8, 2002, pp. 861–868.10.1179/026708302225004694Search in Google Scholar

[22] Schajer, G. S. Advances in hole-drilling residual stress measurements. Experimental mechanics, Vol. 50, 2010. pp. 159–168.10.1007/s11340-009-9228-7Search in Google Scholar

[23] ASTM E837-08. Standard test method for determining residual stresses by the hole-drilling strain-gage method, American Society for Testing and Materials; United States, 2008.Search in Google Scholar

[24] Wan, Y., W. Jiang, M. Song, Y. Huang, J. Li, G. Sun, et al. Distribution and formation mechanism of residual stress in duplex stainless steel weld joint by neutron diffraction and electron backscatter diffraction. Materials and Design, Vol. 181, 2019, id. 108086.10.1016/j.matdes.2019.108086Search in Google Scholar

[25] Taban, E. and E. Kaluc. Welding behaviour of duplex and superduplex stainless steels using laser and plasma ARC welding processes. Welding in the World, Vol. 55, No. 7–8, 2011, pp. 48–57.10.1007/BF03321307Search in Google Scholar

[26] Fu, G., J. Gu, M. I. Lourenco, M. Duan, and S. F. Estefen. Parameter determination of double-ellipsoidal heat source model and its application in the multi-pass welding process. Ships and Offshore Structures, Vol. 10, No. 2, 2015, pp. 204–217.10.1080/17445302.2014.937059Search in Google Scholar

[27] Ramirez, A. J., J. C. Lippold, and S. D. Brandi. The relationship between chromium nitride and secondary austenite precipitation in duplex stainless steels. Metallurgical & Materials Transactions A, Vol. 34, No. 8, 2003, pp. 1575–1597.10.1007/s11661-003-0304-9Search in Google Scholar

[28] Pérez, A. F. M., M. Breda, I. Calliari, G. Y. P. Medina, and R. Sandström. Detrimental Cr-rich phases precipitation on SAF 2205 duplex stainless steels welds after heat treatment. Soldagem & Inspeção, Vol. 21, 2016, pp. 165–171.10.1590/0104-9224/SI2102.06Search in Google Scholar

[29] Eghlimi, A., M. Shamanian, M. Eskandarian, A. Zabolian, M. Nezakat, and J. A. Szpunar. Evaluation of microstructure and texture across the weldedinterface of super duplex stainless steel and high strength low alloy steel. Surface and Coatings Technology, Vol. 264, 2015, pp. 150–162.10.1016/j.surfcoat.2014.12.060Search in Google Scholar

[30] Zhang, Z., H. Jing, L. Xu, Y. Han, and L. Zhao. Investigation on microstructure evolution and properties of duplex stainless steel joint multi-pass welded by using different methods. Materials & Design, Vol. 109, 2016, pp. 670–685.10.1016/j.matdes.2016.07.110Search in Google Scholar

[31] Zhang, Z., H. Jing, L. Xu, Y. Han, L. Zhao, X. Lv, et al. The impact of annealing temperature on improving microstructure and toughness of electron beam welded duplex stainless steel. Journal of Manufacturing Processes, Vol. 31, 2018, pp. 568–582.10.1016/j.jmapro.2017.12.018Search in Google Scholar

[32] Young, M., L. Tsay, C. Shin, and S. Chan. The effect of short time post-weld heat treatment on the fatigue crack growth of 2205 duplex stainless steel welds. International Journal of Fatigue, Vol. 29, No. 12, 2007, pp. 2155–2162.10.1016/j.ijfatigue.2007.01.004Search in Google Scholar

[33] Park, S. J. and S. Muraishi. Influence of residual stress around constituent particles on recrystallization and grain growth in Al-Mn-based alloy during annealing. Materials, Vol. 14, No. 7, 2021, id. 1701.10.3390/ma14071701Search in Google Scholar PubMed PubMed Central

[34] Rout, M., R. Ranjan, S. K. Pal, and S. B. Singh. EBSD study of microstructure evolution during axisymmetric hot compression of 304LN stainless steel. Materials Science & Engineering A, Vol. 711, 2018, pp. 378–388.10.1016/j.msea.2017.11.059Search in Google Scholar

[35] Humphreys, F. J. Review Grain and subgrain characterisation by electron backscatter diffraction. Journal of Materials Science, Vol. 36, No. 16, 2001, pp. 3833–3854.10.1023/A:1017973432592Search in Google Scholar

[36] Badkoobeh, F., H. Mostaan, F. Nematzadeh, and M. Roshanai. Nd: YAG laser beam welding of UNS N07718 superalloy and UNS S32304 duplex stainless steel: Phase transformations and mechanical properties of dissimilar joints. Optics Laser Technology, Vol. 170, 2024, id. 110254.10.1016/j.optlastec.2023.110254Search in Google Scholar

[37] Kurzynowski, T., K. Gruber, W. Stopyra, B. Kuźnicka, and E. Chlebus. Correlation between process parameters, microstructure and properties of 316L stainless steel processed by selective laser melting. Materials Science and Engineering: A, Vol. 718, 2018, pp. 64–73.10.1016/j.msea.2018.01.103Search in Google Scholar

[38] Raabe, D. Recovery and recrystallization: phenomena, physics, models, simulation. Physical Metallurgy, 2014, pp. 2291–2397.10.1016/B978-0-444-53770-6.00023-XSearch in Google Scholar

[39] Jiang, W., Y. Wan, S. T. Tu, H. Wang, Y. Huang, X. Xie, et al. Determination of the through-thickness residual stress in thick duplex stainless steel welded plate by wavelength-dependent neutron diffraction method. International Journal of Pressure Vessels and Piping, Vol. 196, 2022, id. 104603.10.1016/j.ijpvp.2021.104603Search in Google Scholar

[40] Li, S., W. Jiang, X. Xie, and Z. Dong. A comparison of amplitude-and time-dependent cyclic deformation behavior for fully-austenite stainless steel 316L and duplex stainless steel 2205. Materials, Vol. 14, No. 19, 2021, id. 5594.10.3390/ma14195594Search in Google Scholar PubMed PubMed Central

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- De-chlorination of poly(vinyl) chloride using Fe2O3 and the improvement of chlorine fixing ratio in FeCl2 by SiO2 addition

- Reductive behavior of nickel and iron metallization in magnesian siliceous nickel laterite ores under the action of sulfur-bearing natural gas

- Study on properties of CaF2–CaO–Al2O3–MgO–B2O3 electroslag remelting slag for rack plate steel

- The origin of {113}<361> grains and their impact on secondary recrystallization in producing ultra-thin grain-oriented electrical steel

- Channel parameter optimization of one-strand slab induction heating tundish with double channels

- Effect of rare-earth Ce on the texture of non-oriented silicon steels

- Performance optimization of PERC solar cells based on laser ablation forming local contact on the rear

- Effect of ladle-lining materials on inclusion evolution in Al-killed steel during LF refining

- Analysis of metallurgical defects in enamel steel castings

- Effect of cooling rate and Nb synergistic strengthening on microstructure and mechanical properties of high-strength rebar

- Effect of grain size on fatigue strength of 304 stainless steel

- Analysis and control of surface cracks in a B-bearing continuous casting blooms

- Application of laser surface detection technology in blast furnace gas flow control and optimization

- Preparation of MoO3 powder by hydrothermal method

- The comparative study of Ti-bearing oxides introduced by different methods

- Application of MgO/ZrO2 coating on 309 stainless steel to increase resistance to corrosion at high temperatures and oxidation by an electrochemical method

- Effect of applying a full oxygen blast furnace on carbon emissions based on a carbon metabolism calculation model

- Characterization of low-damage cutting of alfalfa stalks by self-sharpening cutters made of gradient materials

- Thermo-mechanical effects and microstructural evolution-coupled numerical simulation on the hot forming processes of superalloy turbine disk

- Endpoint prediction of BOF steelmaking based on state-of-the-art machine learning and deep learning algorithms

- Effect of calcium treatment on inclusions in 38CrMoAl high aluminum steel

- Effect of isothermal transformation temperature on the microstructure, precipitation behavior, and mechanical properties of anti-seismic rebar

- Evolution of residual stress and microstructure of 2205 duplex stainless steel welded joints during different post-weld heat treatment

- Effect of heating process on the corrosion resistance of zinc iron alloy coatings

- BOF steelmaking endpoint carbon content and temperature soft sensor model based on supervised weighted local structure preserving projection

- Innovative approaches to enhancing crack repair: Performance optimization of biopolymer-infused CXT

- Structural and electrochromic property control of WO3 films through fine-tuning of film-forming parameters

- Influence of non-linear thermal radiation on the dynamics of homogeneous and heterogeneous chemical reactions between the cone and the disk

- Thermodynamic modeling of stacking fault energy in Fe–Mn–C austenitic steels

- Research on the influence of cemented carbide micro-textured structure on tribological properties

- Performance evaluation of fly ash-lime-gypsum-quarry dust (FALGQ) bricks for sustainable construction

- First-principles study on the interfacial interactions between h-BN and Si3N4

- Analysis of carbon emission reduction capacity of hydrogen-rich oxygen blast furnace based on renewable energy hydrogen production

- Just-in-time updated DBN BOF steel-making soft sensor model based on dense connectivity of key features

- Effect of tempering temperature on the microstructure and mechanical properties of Q125 shale gas casing steel

- Review Articles

- A review of emerging trends in Laves phase research: Bibliometric analysis and visualization

- Effect of bottom stirring on bath mixing and transfer behavior during scrap melting in BOF steelmaking: A review

- High-temperature antioxidant silicate coating of low-density Nb–Ti–Al alloy: A review

- Communications

- Experimental investigation on the deterioration of the physical and mechanical properties of autoclaved aerated concrete at elevated temperatures

- Damage evaluation of the austenitic heat-resistance steel subjected to creep by using Kikuchi pattern parameters

- Topical Issue on Focus of Hot Deformation of Metaland High Entropy Alloys - Part II

- Synthesis of aluminium (Al) and alumina (Al2O3)-based graded material by gravity casting

- Experimental investigation into machining performance of magnesium alloy AZ91D under dry, minimum quantity lubrication, and nano minimum quantity lubrication environments

- Numerical simulation of temperature distribution and residual stress in TIG welding of stainless-steel single-pass flange butt joint using finite element analysis

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part I

- Electro-thermal performance evaluation of a prismatic battery pack for an electric vehicle

- Experimental analysis and optimization of machining parameters for Nitinol alloy: A Taguchi and multi-attribute decision-making approach

- Experimental and numerical analysis of temperature distributions in SA 387 pressure vessel steel during submerged arc welding

- Optimization of process parameters in plasma arc cutting of commercial-grade aluminium plate

- Multi-response optimization of friction stir welding using fuzzy-grey system

- Mechanical and micro-structural studies of pulsed and constant current TIG weldments of super duplex stainless steels and Austenitic stainless steels

- Stretch-forming characteristics of austenitic material stainless steel 304 at hot working temperatures

- Work hardening and X-ray diffraction studies on ASS 304 at high temperatures

- Study of phase equilibrium of refractory high-entropy alloys using the atomic size difference concept for turbine blade applications

- A novel intelligent tool wear monitoring system in ball end milling of Ti6Al4V alloy using artificial neural network

- A hybrid approach for the machinability analysis of Incoloy 825 using the entropy-MOORA method

- Special Issue on Recent Developments in 3D Printed Carbon Materials - Part II

- Innovations for sustainable chemical manufacturing and waste minimization through green production practices

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part I

- Characterization of Co–Ni–TiO2 coatings prepared by combined sol-enhanced and pulse current electrodeposition methods

- Hot deformation behaviors and microstructure characteristics of Cr–Mo–Ni–V steel with a banded structure

- Effects of normalizing and tempering temperature on the bainite microstructure and properties of low alloy fire-resistant steel bars

- Dynamic evolution of residual stress upon manufacturing Al-based diesel engine diaphragm

- Study on impact resistance of steel fiber reinforced concrete after exposure to fire

- Bonding behaviour between steel fibre and concrete matrix after experiencing elevated temperature at various loading rates

- Diffusion law of sulfate ions in coral aggregate seawater concrete in the marine environment

- Microstructure evolution and grain refinement mechanism of 316LN steel

- Investigation of the interface and physical properties of a Kovar alloy/Cu composite wire processed by multi-pass drawing

- The investigation of peritectic solidification of high nitrogen stainless steels by in-situ observation

- Microstructure and mechanical properties of submerged arc welded medium-thickness Q690qE high-strength steel plate joints

- Experimental study on the effect of the riveting process on the bending resistance of beams composed of galvanized Q235 steel

- Density functional theory study of Mg–Ho intermetallic phases

- Investigation of electrical properties and PTCR effect in double-donor doping BaTiO3 lead-free ceramics

- Special Issue on Thermal Management and Heat Transfer

- On the thermal performance of a three-dimensional cross-ternary hybrid nanofluid over a wedge using a Bayesian regularization neural network approach

- Time dependent model to analyze the magnetic refrigeration performance of gadolinium near the room temperature

- Heat transfer characteristics in a non-Newtonian (Williamson) hybrid nanofluid with Hall and convective boundary effects

- Computational role of homogeneous–heterogeneous chemical reactions and a mixed convective ternary hybrid nanofluid in a vertical porous microchannel

- Thermal conductivity evaluation of magnetized non-Newtonian nanofluid and dusty particles with thermal radiation

Articles in the same Issue

- Research Articles

- De-chlorination of poly(vinyl) chloride using Fe2O3 and the improvement of chlorine fixing ratio in FeCl2 by SiO2 addition

- Reductive behavior of nickel and iron metallization in magnesian siliceous nickel laterite ores under the action of sulfur-bearing natural gas

- Study on properties of CaF2–CaO–Al2O3–MgO–B2O3 electroslag remelting slag for rack plate steel

- The origin of {113}<361> grains and their impact on secondary recrystallization in producing ultra-thin grain-oriented electrical steel

- Channel parameter optimization of one-strand slab induction heating tundish with double channels

- Effect of rare-earth Ce on the texture of non-oriented silicon steels

- Performance optimization of PERC solar cells based on laser ablation forming local contact on the rear

- Effect of ladle-lining materials on inclusion evolution in Al-killed steel during LF refining

- Analysis of metallurgical defects in enamel steel castings

- Effect of cooling rate and Nb synergistic strengthening on microstructure and mechanical properties of high-strength rebar

- Effect of grain size on fatigue strength of 304 stainless steel

- Analysis and control of surface cracks in a B-bearing continuous casting blooms

- Application of laser surface detection technology in blast furnace gas flow control and optimization

- Preparation of MoO3 powder by hydrothermal method

- The comparative study of Ti-bearing oxides introduced by different methods

- Application of MgO/ZrO2 coating on 309 stainless steel to increase resistance to corrosion at high temperatures and oxidation by an electrochemical method

- Effect of applying a full oxygen blast furnace on carbon emissions based on a carbon metabolism calculation model

- Characterization of low-damage cutting of alfalfa stalks by self-sharpening cutters made of gradient materials

- Thermo-mechanical effects and microstructural evolution-coupled numerical simulation on the hot forming processes of superalloy turbine disk

- Endpoint prediction of BOF steelmaking based on state-of-the-art machine learning and deep learning algorithms

- Effect of calcium treatment on inclusions in 38CrMoAl high aluminum steel

- Effect of isothermal transformation temperature on the microstructure, precipitation behavior, and mechanical properties of anti-seismic rebar

- Evolution of residual stress and microstructure of 2205 duplex stainless steel welded joints during different post-weld heat treatment

- Effect of heating process on the corrosion resistance of zinc iron alloy coatings

- BOF steelmaking endpoint carbon content and temperature soft sensor model based on supervised weighted local structure preserving projection

- Innovative approaches to enhancing crack repair: Performance optimization of biopolymer-infused CXT

- Structural and electrochromic property control of WO3 films through fine-tuning of film-forming parameters

- Influence of non-linear thermal radiation on the dynamics of homogeneous and heterogeneous chemical reactions between the cone and the disk

- Thermodynamic modeling of stacking fault energy in Fe–Mn–C austenitic steels

- Research on the influence of cemented carbide micro-textured structure on tribological properties

- Performance evaluation of fly ash-lime-gypsum-quarry dust (FALGQ) bricks for sustainable construction

- First-principles study on the interfacial interactions between h-BN and Si3N4

- Analysis of carbon emission reduction capacity of hydrogen-rich oxygen blast furnace based on renewable energy hydrogen production

- Just-in-time updated DBN BOF steel-making soft sensor model based on dense connectivity of key features

- Effect of tempering temperature on the microstructure and mechanical properties of Q125 shale gas casing steel

- Review Articles

- A review of emerging trends in Laves phase research: Bibliometric analysis and visualization

- Effect of bottom stirring on bath mixing and transfer behavior during scrap melting in BOF steelmaking: A review

- High-temperature antioxidant silicate coating of low-density Nb–Ti–Al alloy: A review

- Communications

- Experimental investigation on the deterioration of the physical and mechanical properties of autoclaved aerated concrete at elevated temperatures

- Damage evaluation of the austenitic heat-resistance steel subjected to creep by using Kikuchi pattern parameters

- Topical Issue on Focus of Hot Deformation of Metaland High Entropy Alloys - Part II

- Synthesis of aluminium (Al) and alumina (Al2O3)-based graded material by gravity casting

- Experimental investigation into machining performance of magnesium alloy AZ91D under dry, minimum quantity lubrication, and nano minimum quantity lubrication environments

- Numerical simulation of temperature distribution and residual stress in TIG welding of stainless-steel single-pass flange butt joint using finite element analysis

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part I

- Electro-thermal performance evaluation of a prismatic battery pack for an electric vehicle

- Experimental analysis and optimization of machining parameters for Nitinol alloy: A Taguchi and multi-attribute decision-making approach

- Experimental and numerical analysis of temperature distributions in SA 387 pressure vessel steel during submerged arc welding

- Optimization of process parameters in plasma arc cutting of commercial-grade aluminium plate

- Multi-response optimization of friction stir welding using fuzzy-grey system

- Mechanical and micro-structural studies of pulsed and constant current TIG weldments of super duplex stainless steels and Austenitic stainless steels

- Stretch-forming characteristics of austenitic material stainless steel 304 at hot working temperatures

- Work hardening and X-ray diffraction studies on ASS 304 at high temperatures

- Study of phase equilibrium of refractory high-entropy alloys using the atomic size difference concept for turbine blade applications

- A novel intelligent tool wear monitoring system in ball end milling of Ti6Al4V alloy using artificial neural network

- A hybrid approach for the machinability analysis of Incoloy 825 using the entropy-MOORA method

- Special Issue on Recent Developments in 3D Printed Carbon Materials - Part II

- Innovations for sustainable chemical manufacturing and waste minimization through green production practices

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part I

- Characterization of Co–Ni–TiO2 coatings prepared by combined sol-enhanced and pulse current electrodeposition methods

- Hot deformation behaviors and microstructure characteristics of Cr–Mo–Ni–V steel with a banded structure

- Effects of normalizing and tempering temperature on the bainite microstructure and properties of low alloy fire-resistant steel bars

- Dynamic evolution of residual stress upon manufacturing Al-based diesel engine diaphragm

- Study on impact resistance of steel fiber reinforced concrete after exposure to fire

- Bonding behaviour between steel fibre and concrete matrix after experiencing elevated temperature at various loading rates

- Diffusion law of sulfate ions in coral aggregate seawater concrete in the marine environment

- Microstructure evolution and grain refinement mechanism of 316LN steel

- Investigation of the interface and physical properties of a Kovar alloy/Cu composite wire processed by multi-pass drawing

- The investigation of peritectic solidification of high nitrogen stainless steels by in-situ observation

- Microstructure and mechanical properties of submerged arc welded medium-thickness Q690qE high-strength steel plate joints

- Experimental study on the effect of the riveting process on the bending resistance of beams composed of galvanized Q235 steel

- Density functional theory study of Mg–Ho intermetallic phases

- Investigation of electrical properties and PTCR effect in double-donor doping BaTiO3 lead-free ceramics

- Special Issue on Thermal Management and Heat Transfer

- On the thermal performance of a three-dimensional cross-ternary hybrid nanofluid over a wedge using a Bayesian regularization neural network approach

- Time dependent model to analyze the magnetic refrigeration performance of gadolinium near the room temperature

- Heat transfer characteristics in a non-Newtonian (Williamson) hybrid nanofluid with Hall and convective boundary effects

- Computational role of homogeneous–heterogeneous chemical reactions and a mixed convective ternary hybrid nanofluid in a vertical porous microchannel

- Thermal conductivity evaluation of magnetized non-Newtonian nanofluid and dusty particles with thermal radiation