Abstract

Highly thermally conductive boron nitride (BN)@ultra-high molecular weight polyethylene (UHMWPE) composites with the segregated structure were fabricated by powder mixing and hot pressing. Scanning electron microscopy and polarizing optical microscopy were used to analyze the dispersion of BN particles in the UHMWPE matrix. The morphology observation shows that BN particles are selectively located at the interfaces of UHMWPE particles and form continuous thermally conductive networks after the compression molding process. As a result, the thermal conductivity of the BN@UHMWPE composite increases to 3.37 W m−1 K−1 with 38.3 vol% BN, which is seven times larger than that of the pure UHMWPE. Furthermore, the incorporation of BN also influences the crystallinity and thermal properties of UHMWPE.

1 Introduction

With the integration and continuous miniaturization of electronic devices, heat dissipation has become the main factor that affects the work stability and lifetime of devices (1,2). However, the thermal conductivity of current polymers is quite low, which can hardly satisfy the efficient heat removal requirements of modern electron devices and electrical equipment. To improve the thermal conductivity of polymers, the incorporation of high thermally conductive fillers is the most effective method.

Recently, carbon materials such as graphite (3,4,5), carbon fiber (6,7,8), carbon nanotube (9,10,11,12), and graphene (13,14,15,16,17) have been widely used as thermal conductive fillers owing to their high thermal conductivity. However, these fillers generally have high electrical conductivity, which may deteriorate the intrinsic insulating properties of the polymer composites and inhibit their usage in microelectronic devices.

Hexagonal boron nitride (h-BN), also called “white graphite,” has a hexagonal lattice structure analogous to graphite (18). It exhibits a thermal conductivity of up to 200 W m−1 K−1 in the planar direction and 1–3 W m−1 K−1 in the perpendicular direction (19,20). Furthermore, BN also shows excellent electrical insulation and high breakdown strength due to a wide bandgap (∼5.9 eV) (21,22), which makes BN as excellent thermal conductive fillers in composite materials.

It is well known that the interfacial thermal resistance exhibits a great role in determining the thermal conductivity of polymer composites (23,24). Generally, the surface modification of filler can be a widespread strategy for reducing the interfacial thermal resistance and enhancing the filler dispersion in the polymer matrix. Wei et al. (25) utilized sulfonated polyarylene ether nitrile to improve the compatibility between BN and polyarylene ether nitrile. Liu et al. (26) utilized ethylcellulose to promote the dispersion of h-BN in polyimide. Thus, the thermal conductivity of the PI composite film with ethyl cellulose could be twice than of PI film without ethyl cellulose. The interfacial thermal resistance is influenced not only by the filler fraction but also by the topological structure of a thermally conductive network, such as the dispersion and orientation of fillers, contact area between fillers, and matrix–filler interaction (27,28). The structure of the thermally conductive network may play a vital role in thermal conductive composites (29,30). To obtain a continuous thermal conduction network, the surface of polymer granules is coated with thermally conductive fillers, and then composites with the segregated structure are constructed by compression molding. Thus, the fillers at the interface of resin particles can form a continuous thermal conduction pathway.

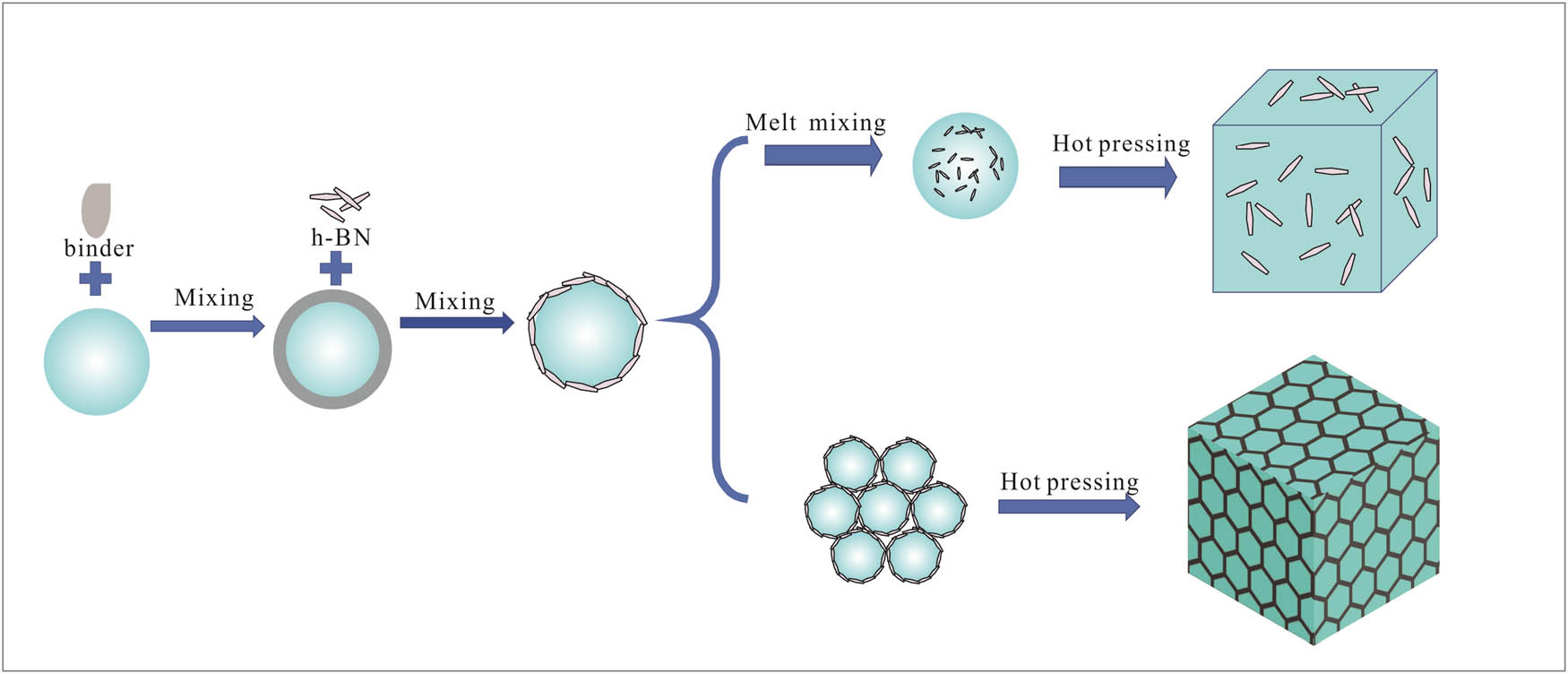

In this study, the method of powder mixing followed by compression molding is introduced to prepare thermally conductive boron nitride (BN)@ultra-high molecular weight polyethylene composites with a segregated structure. Vinyl acetate–ethylene serves as a binder to glue BN platelets to the surface of UHMWPE granules. To optimize the efficiency of the filler, a combination of 4 and 15 μm BN platelets is utilized in the composites (31). The large size BN can form the main thermally conductive pathways in composites, while the smaller size BN will fill the gaps between large sizes of BN to enhance more contact (22,32). Finally, the composites with the segregated structure are constructed in which BN flakes are located at the interface of UHMWPE particles by compression molding. Moreover, the crystallinity and thermal properties of BN@UHMWPE composites are also investigated.

2 Experimental

2.1 Materials

h-BN (average size 4 or 15 μm) was purchased from Yingkou Liaobin Fine Chemicals (Liaoning Province, China). UHMWPE powder was purchased from Beijing No. 2 Auxiliary Agent Factory (Beijing, China). Vinyl acetate-ethylene resin (VAE 707) was provided by Guangzhou Deep Gen Chemical (Guangdong Province, China).

2.2 Fabrication of BN@UHMWPE composites

The fabrication of the BN@UHMWPE composites is illustrated in Figure 1. UHMWPE and VAE 707 (UHMWPE:VAE707 = 6:1, w/w) were mixed by using a high-speed mixer (800Y, Yongkang Boou Hardware Products Co., Ltd) for 5 min at 25°C. Then, BN flakes (4 μm:15 μm = 3:7, w/w (31)) were added into the mixer and mixed for 5 min. After that, the mixtures were dried in an oven at 60°C for 12 h. Lastly, the BN-coated UHMWPE particles were compression molded via a press vulcanizer at 210°C and 10 MPa for 15 min. The obtained samples were labeled as BN@UHMWPE, in which “@” represents the coating process. For comparison, the BN/UHMWPE composites with random distributed BNs were prepared by melt mixing BN-coated UHMWPE particles in a torque rheometer at 220°C for 15 min. The obtained composites were denoted as BN/UHMWPE, in which “/” indicates melt mixing. The loadings of BN in the composites were 2.1 vol% (5 wt%), 4.4 vol% (10 wt%), 9.4 vol% (20 wt%), 15.1 vol% (30 wt%), 21.6 vol% (40 wt%), 29.3 vol% (50 wt%), and 38.3 vol% (60 wt%).

Schematic illustration of the thermally conductive composites fabrication procedure.

2.3 Characterizations

The microstructure and surface morphology of the samples were examined by scanning electron microscopy (FE-SEM; Nova Nano 450, FEI, USA) and polarizing optical microscopy (POM, CX40P; Sunny instruments Co, China). The thermal conductivity of the composites at 25°C was measured by LFA-457 (Netzsch, Germany). The differential scanning calorimetry (DSC) analysis of the samples was carried out in DSC 204 HP (Netzsch, Germany) at a heating rate of 10°C/min. Thermogravimetric analysis (TGA) of samples was performed at a heating rate of 10°C/min under a nitrogen atmosphere by STA449 F3 (NETZSCH, Germany).

3 Results and discussion

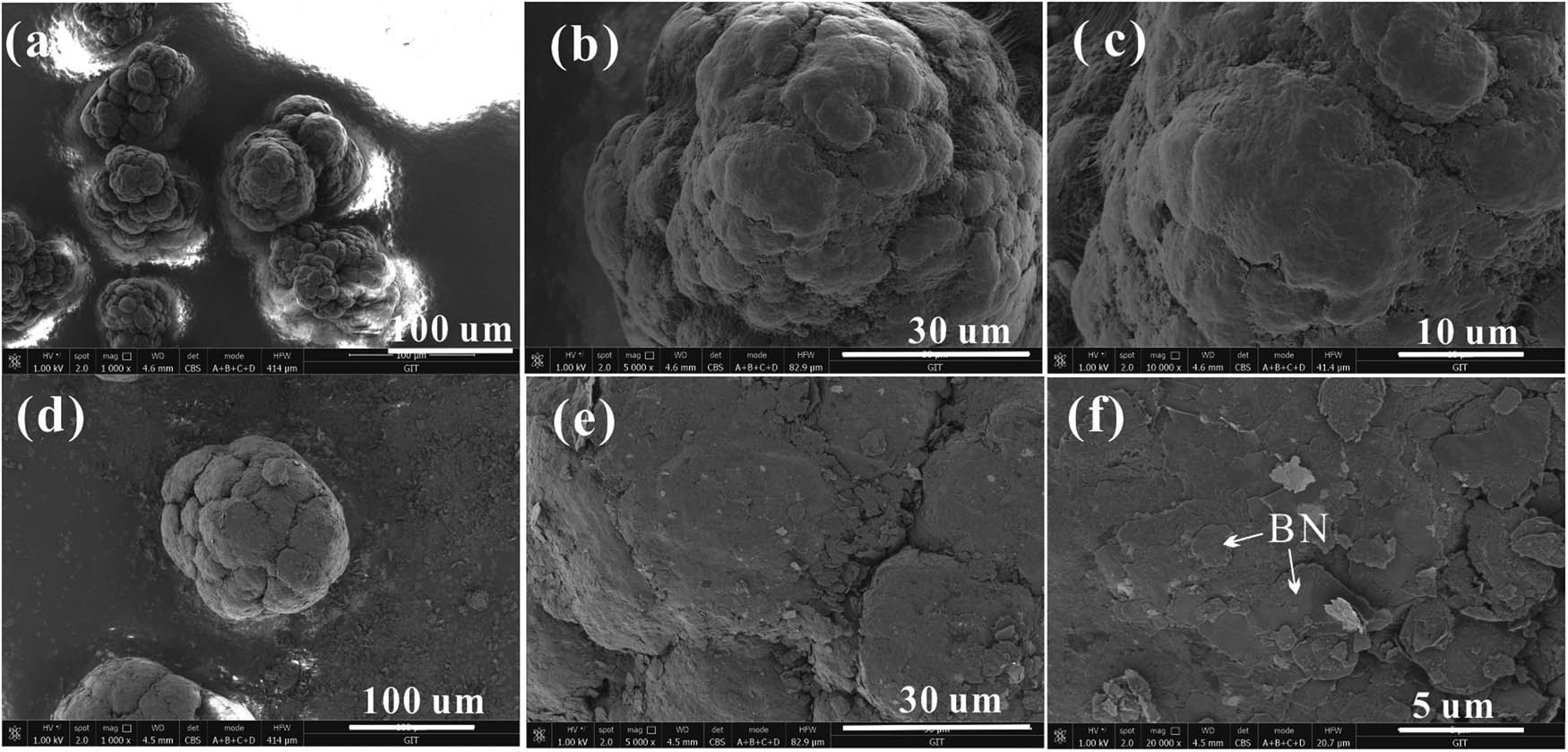

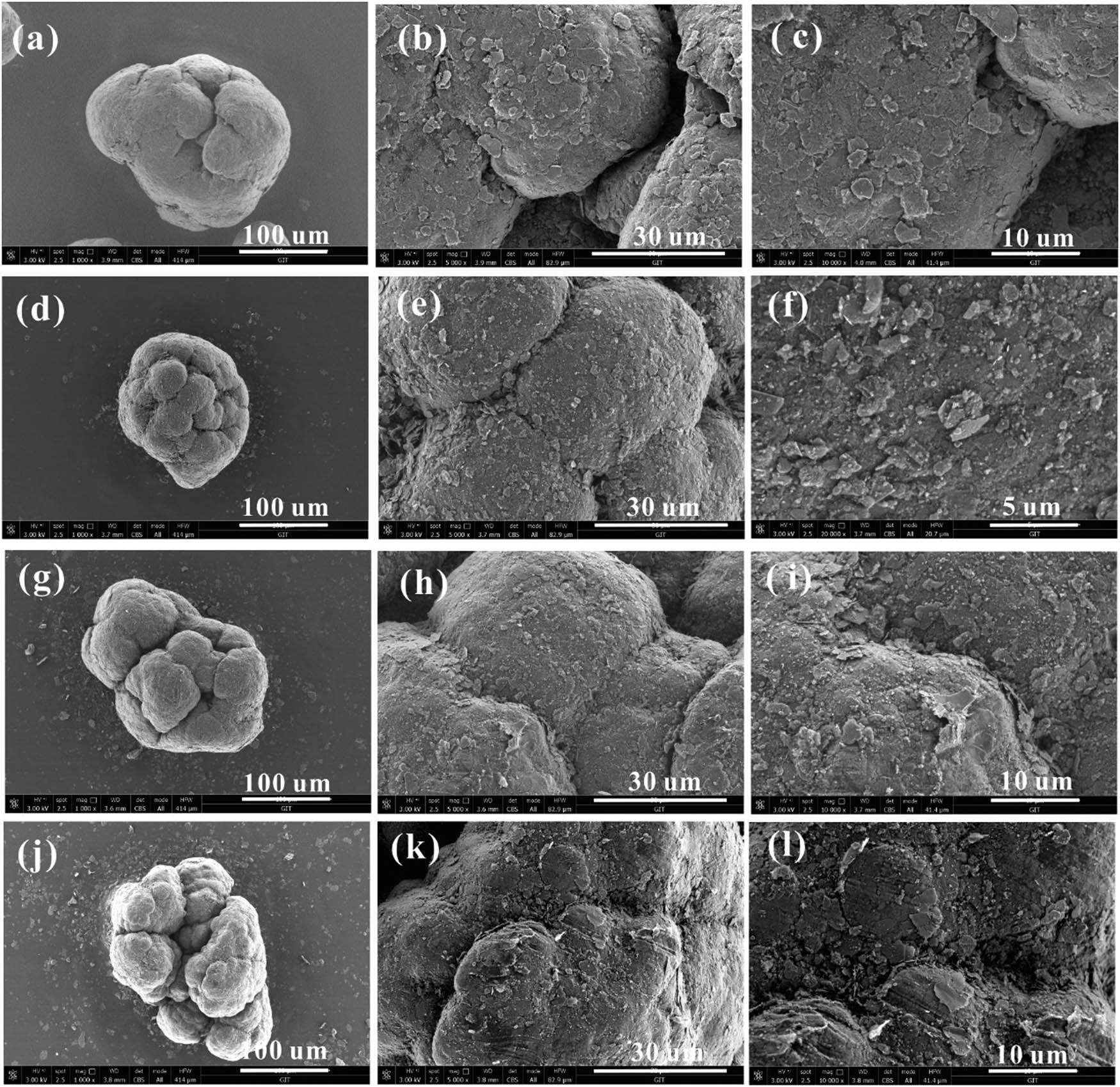

The morphology of UHMWPE and encapsulated UHMWPE granules was observed via SEM. As shown in Figure 2, it is found that the surface of the raw UHMWPE particle is smooth. This morphology changed obviously after coating with BN flakes. One can see that the surface of the UHMWPE particles is tightly covered by the BN sheets. Meanwhile, larger numbers of BN sheets are embedded into the gullies of UHMWPE particles. BN sheets are successfully coated onto the surface of UHMWPE particles with the help of VAE 707 emulsion. This morphology provides the potential for constructing a segregated conductive network of BN in UHMWPE composites. UHMWPE granules with other contents of BN also show similar structures (Figure A1).

Particle morphological SEM images of UHMWPE granules (a–c) and BN-coated UHMWPE granules with 4.4 vol% of BN (d–f).

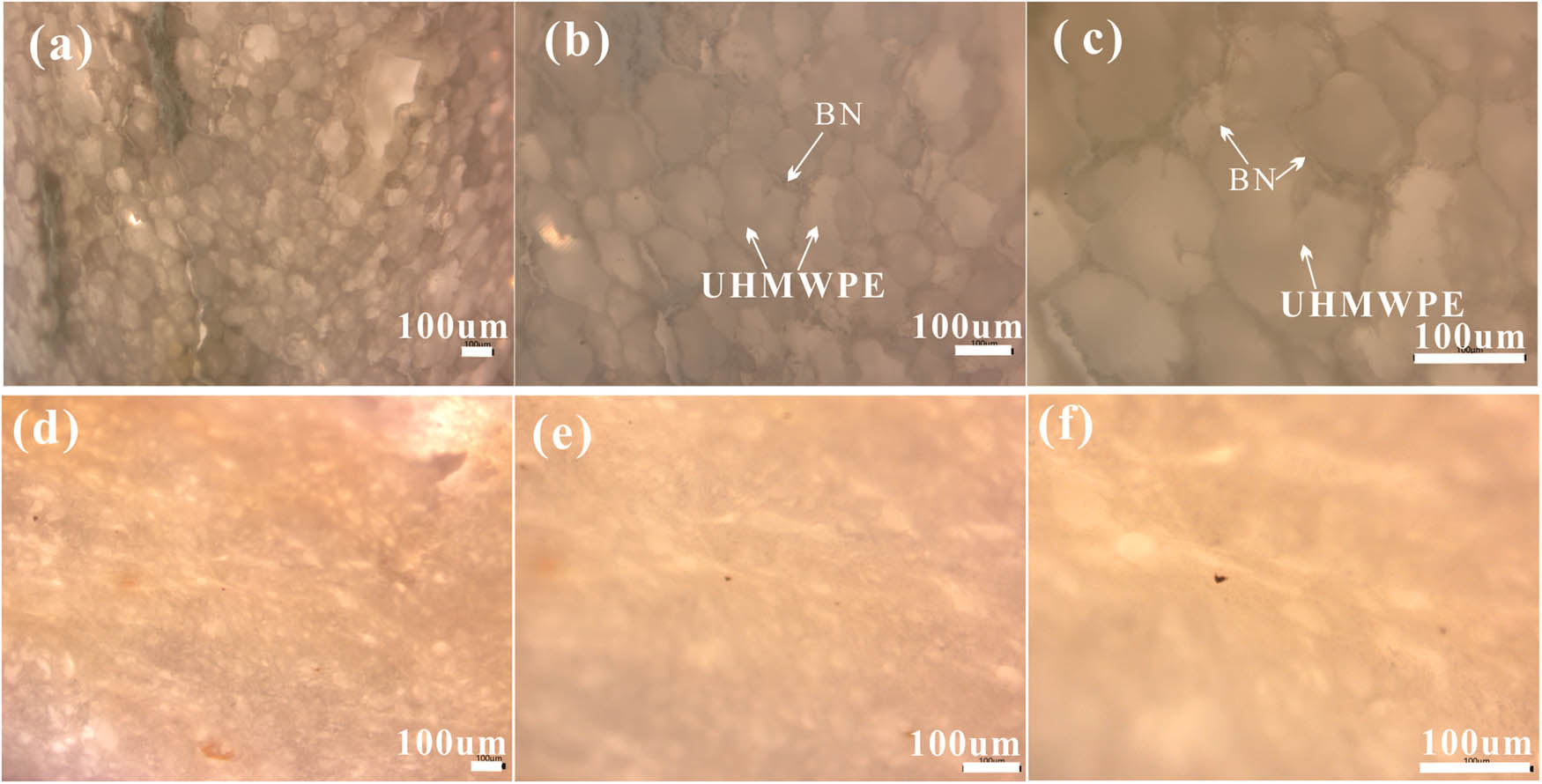

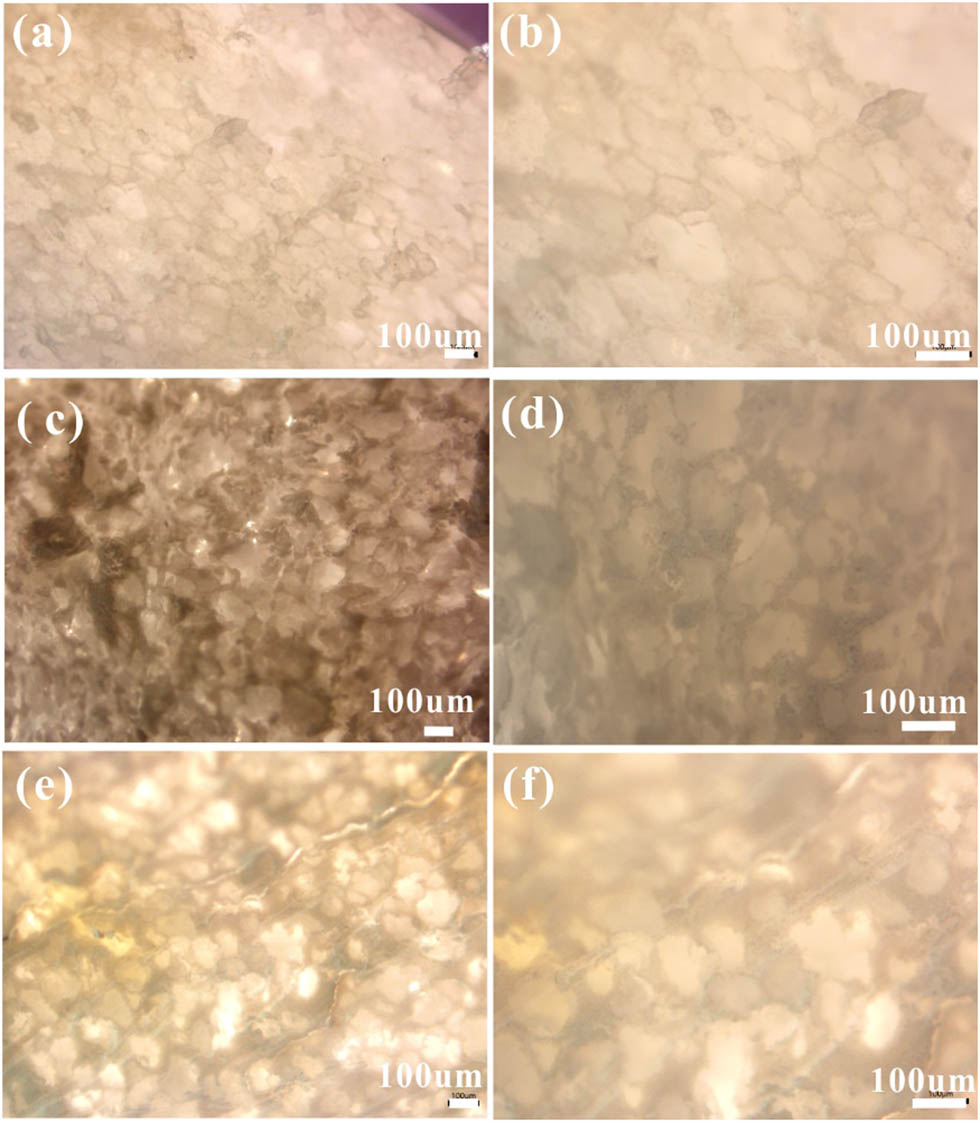

Optical micrographs of BN@UHMWPE (a–c) and BN/UHMWPE composites (d–f) with 9.4 vol% of BN.

POM was used to observe the distribution of BN in the composites that are shown in Figure 3. The BN and UHMWPE present diverse colors under optical microscopy for their different light transmittances. In Figure 3b, the light-colored part is mainly the UHMWPE phase, while the darker part around the polygon is the BN sheets. It indicates that the BN sheets are not homogeneously dispersed within the polymer matrix, but selectively localized at the interfaces of UHMWPE particles. Similar structures are observed in the POM images of BN@UHMWPE composites with other loadings of BN (Figure A2). Compared with the BN@UHMWPE composites, the BN/UHMWPE composites present homogeneous structure and the BN sheets are randomly distributed in the matrix (Figure 3d–f). Based on the POM observations, it can be concluded that continuous BN conductive networks have been successfully formed.

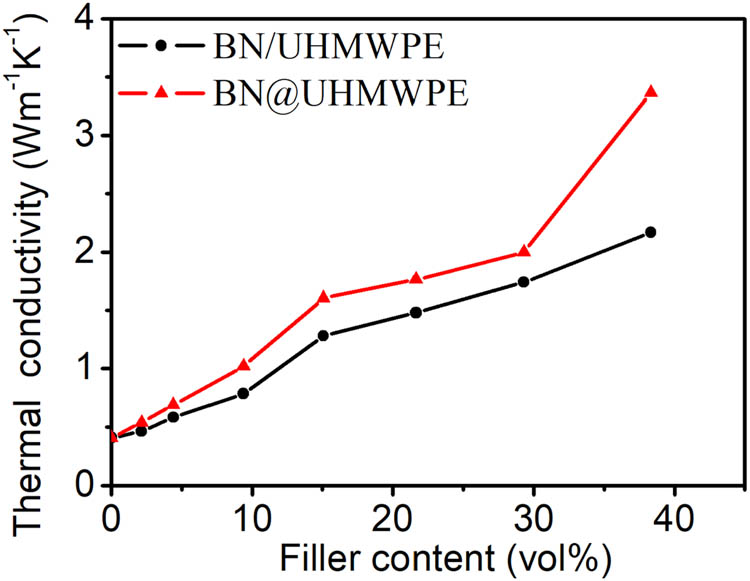

Thermal conductivity of BN/UHMWPE composites made by powder mixing and melt mixing as a function of BN loadings.

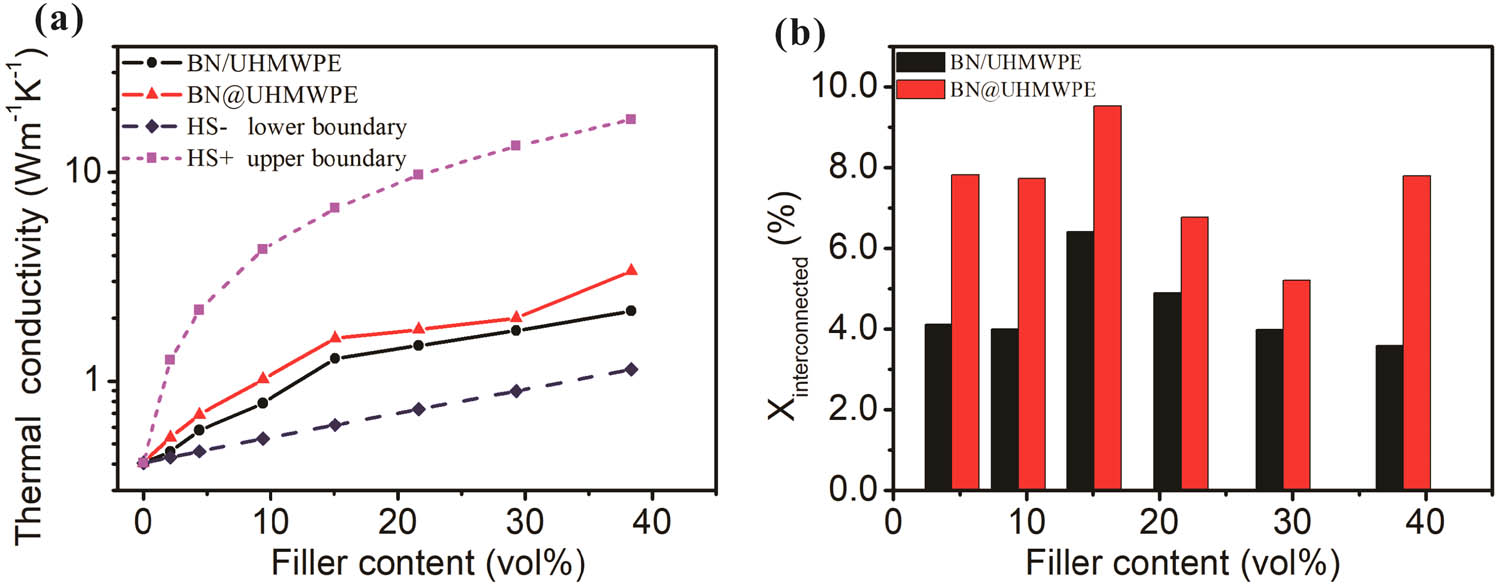

(a) Comparison between experimental data of the composites and HS model and (b) interconnectivity of the filler as a function of filler fraction.

The influence of the volume fraction of BN on the thermal conductivity of BN/UHMWPE composites with different fabricating methods is shown in Figure 4. The thermal conductivity for both BN@UHMWPE composites and BN/UHMWPE composites increases with a growing BN percentage. The BN@UHMWPE composites exhibit the highest thermal conductivity of 3.37 W m−1 K−1 with 38.3 vol% of BN, which is about sevenfold higher than for the original UHMWPE. Moreover, the BN@UHMWPE composites exhibit higher thermal conductivity than BN/UHMWPE composites at the same filler composition. Compared with the thermal conductivity of BN/UHMWPE composites, the thermal conductivity of BN@UHMWPE composites improved 19.2%, 14.8%, and 55.2% when the content of BN is 21.6, 29.3, and 38.3 vol%, and the average thermal conductivity improved by 25.6% at the volume fraction of BN from 2.1 to 38.3 vol%. Segregated structure is much more beneficial to enhance the thermal conductivity of composite compared with the randomly dispersed structure. For the BN@UHMWPE composites, BN is located at the interfaces among UHMWPE particles and formed a continuous thermally conductive network. This tightly stacked structure of BN greatly increases the contact area between the fillers, which reduces the thermal boundary resistance and broadens the heat conduction pathways.

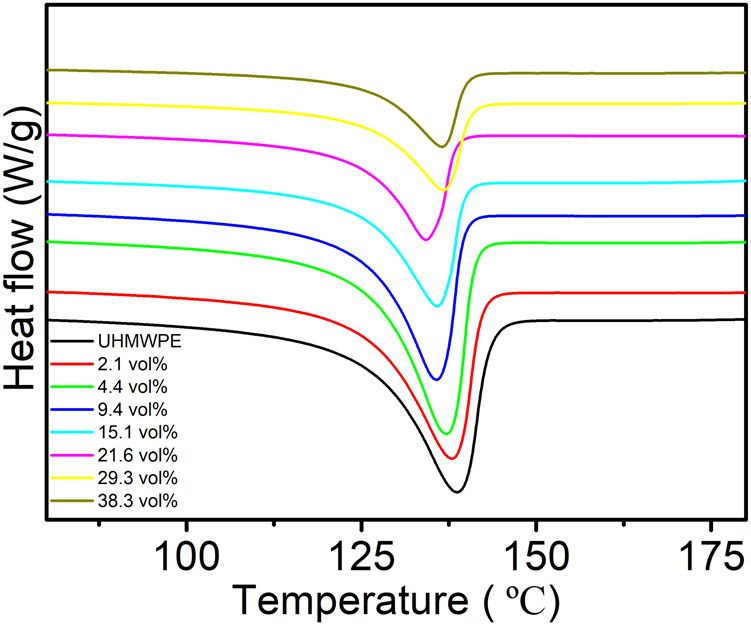

The DSC curves for the UHMWPE and BN@UHMWPE composites with different loadings of BN.

To evaluate the influence of morphology and interconnectivity of fillers on the thermal conductivity of the composites, the Hashin–Shtrikman (HS) model (5,33) is introduced to analyze the thermal conductivity of the composites.

where χf is the particle volume fraction, χp is the volume fraction of the matrix, σf is the thermal conductivity of the particle, and σp is that of the polymer matrix. In the HS model, the lower boundary of the HS model (HS−) assumes thermally conductive phase is surrounded by polymer matrix, while the upper boundary of the HS model (HS+) is an interconnected filler network. Xinterconnected is a relative parameter to measure the interconnectivity of the thermally conducting network. Figure 5a shows that the thermal conductivity of UHMWPE/BN composites with homogeneously dispersed BN flakes is closer to the lower bound, indicating that the BN sheets are well wetted by the polymer matrix. In Figure 5b, the Xinterconnected of BN@UHMWPE composites with segregated structures show much higher interconnectivity than UHMWPE/BN composites. The higher interconnectivity should be attributed to the interconnected conductive network formed in the BN@UHMWPE composites.

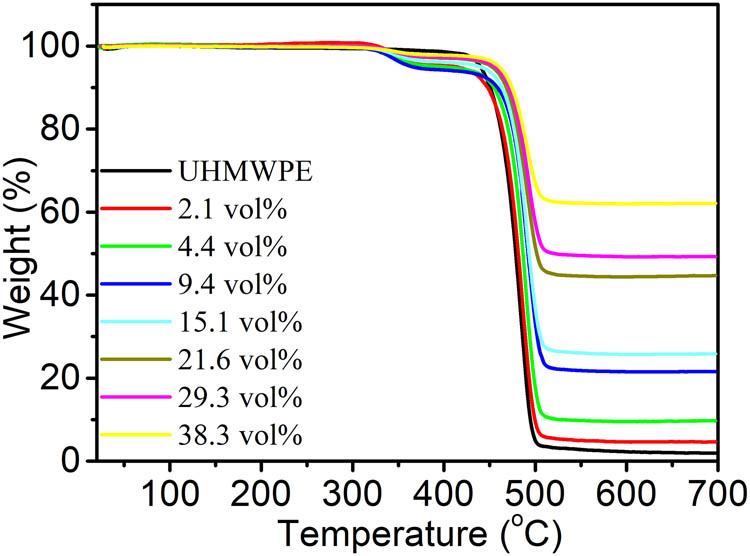

TGA curves of native UHMWPE and BN@UHMWPE composites.

The DSC curves of the UHMWPE and the composites are shown in Figure 6. The thermal parameters obtained from the DSC curves are reported in Table 1. The melting temperature (Tm) of the BN@UHMWPE composites decreased slightly compared with that of neat UHMWPE. This indicates that the lamellar crystallites in the composites are more imperfect than the lamellae in neat UHMWPE, and they will melt at a lower temperature (34).

DSC results for the UHMWPE and BN@UHMWPE composites

| Samples | ΔHf (J/g) | Tm (°C) | X (%) |

|---|---|---|---|

| UHMWPE | 146.7 | 139 | 50 |

| 2.1 vol% BN@UHMWPE | 133.1 | 138 | 48 |

| 4.4 vol% BN@UHMWPE | 142.2 | 137 | 54 |

| 9.4 vol% BN@UHMWPE | 118.5 | 136 | 51 |

| 15.1 vol% BN@UHMWPE | 89.6 | 136 | 44 |

| 21.6 vol% BN@UHMWPE | 74.3 | 134 | 42 |

| 29.3 vol% BN@UHMWPE | 63.9 | 137 | 44 |

| 38.3 vol% BN@UHMWPE | 50.4 | 137 | 43 |

Furthermore, the degree of crystallinity (X, %) of the pure UHMWPE and UHMWPE/BN composites was calculated by:

where ΔHf is the heat fusion of the composites, ΔH0 is the fusion enthalpy of 100% crystalline PE (293 J/g) (35), and ϕ is the weight fraction of the filler in the composites.

According to Table 1, the degree of crystallinity in composites with 4.4 vol% BN is increased by 7.7% compared with that of UHMWPE. Then, the crystallinity reduces to about 43% when the BN content is over 15.1 vol%. Generally, the fillers affect the degree of crystallinity through nucleation and crystal growth. When an appropriate amount of fillers is added into the polymer, the fillers could act as nucleation sites, which might facilitate the nucleation and increase the crystallinity of the composites. However, enhanced amounts of filler decrease the degree of crystallinity because they hinder the mobility of polymer chains from forming highly order arrangements in the crystal growth (36).

The TGA curves of native UHMWPE and BN@UHMWPE composites are presented in Figure 7. The corresponding TGA parameters of the composites are listed in Table 2. As shown in Figure 7, two stages of mass loss can be found from the curves of the composites. The first weight loss, which appears at around 300–390°C, is attributed to the decomposition of the VAE 707 emulsion. The second stage at 410–530°C is due to the degradation of UHMWPE resin. From Table 2, with the increasing content of fillers, the Tmax1 of the composites has no visible change, while the Tmax2 of the composite shifts to higher temperatures. The Tmax2 of the composite with 29.3 vol% BN is 11°C higher than that of original UHMWPE. The phenomenon should be ascribed to the “tortuous path” effect of the BN (37). The lamellar BNs delay the escape of volatile degradation products, resulting in an improvement in the thermal stability of the composites (38). In addition, the char yields at 700°C are also increased with increasing BN content, and these values are very close to the theoretical char yields of the composites.

TGA parameters of BN@UHMWPE composites

| Samples | Tmax1 (°C) | Tmax2 (°C) | Residues (wt%) |

|---|---|---|---|

| UHMWPE | 482.1 | 1.92 | |

| 2.1 vol% BN@UHMWPE | 342.5 | 485.1 | 4.65 |

| 4.4 vol% BN@UHMWPE | 346.4 | 490.2 | 9.74 |

| 9.4 vol% BN@UHMWPE | 344.8 | 485.6 | 21.59 |

| 15.1 vol% BN@UHMWPE | 344.1 | 489.8 | 25.84 |

| 21.6 vol% BN@UHMWPE | 344.7 | 491.5 | 44.67 |

| 29.3 vol% BN@UHMWPE | 342.6 | 493.4 | 49.28 |

| 38.3 vol% BN@UHMWPE | 344.6 | 489.8 | 62.13 |

4 Conclusion

BN@UHMWPE composites with the segregated structure were successfully fabricated by powder mixing and compression molding. The thermal conductivity of the BN@UHMWPE composite with 38.3 vol% BN is greatly improved to 3.37 W m−1 K−1, which was seven times larger than that of the pure UHMWPE. This can be attributed to the formation of an effective conducting pathway, thus leading to the composite with segregated structure exhibits much higher thermal conductivity than BN/UHMWPE composites. The HS model reveals that BN@UHMWPE composites with segregated structure show much higher interconnectivity. Furthermore, the incorporation of BN also influences the crystallinity and thermal properties of UHMWPE.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (grant number 518630003 and 51703039), the Special Project of Cultivating New Academic Seedlings and Exploring Innovation for Guizhou Institute of Technology (grant number QianKeHe [2017]5789-03), the Guizhou Provincial Higher Education Engineering Research Center, China [Qian Jiao He KY (2017) 021], the Action Plan for Scientific Research Institutions Serve Enterprises in Guizhou Province [Qian Ke Fu Qi (2018) 4010], and the Research start-up Foundation for Advanced Talents of Guizhou Institute of Technology (grant number XJGC20190668).

Appendix

Particle morphological SEM images of BN-coated UHMWPE granules with (a–c) 2.1 vol%, (d–f) 9.4 vol%, (g–i) 21.6 vol%, and (j–l) 38.3 vol% BN.

Optical micrographs of BN@UHMWPE with 2.1 vol% (a and b), 21.6 vol% (c and d), and 38.3 vol% (e and f) of BN.

References

(1) An F, Li X, Min P, Liu P, Jiang ZG, Yu ZZ. Vertically aligned high-quality graphene foams for anisotropically conductive polymer composites with ultrahigh through-plane thermal conductivities. ACS Appl Mater Interfaces. 2018;10:17383–92.10.1021/acsami.8b04230Search in Google Scholar PubMed

(2) Wang M, Jiao Z, Chen Y, Hou X, Fu L, Wu Y, et al. Enhanced thermal conductivity of poly(vinylidene fluoride)/boron nitride nanosheet composites at low filler content. Composites Part A. 2018;109:321–9.10.1016/j.compositesa.2018.03.023Search in Google Scholar

(3) Jia Y, He H, Geng Y, Huang B, Peng X. High through-plane thermal conductivity of polymer based product with vertical alignment of graphite flakes achieved via 3D printing. Compos Sci Technol. 2017;145:55–61.10.1016/j.compscitech.2017.03.035Search in Google Scholar

(4) Ren Y, Zhang Y, Fang H, Ding T, Li J, Bai S-L. Simultaneous enhancement on thermal and mechanical properties of polypropylene composites filled with graphite platelets and graphene sheets. Compos Part A: Appl S. 2018;112:57–63.10.1016/j.compositesa.2018.05.017Search in Google Scholar

(5) Feng C, Ni H, Chen J, Yang W. Facile method to fabricate highly thermally conductive graphite/PP composite with network structures. ACS Appl Mater Interfaces. 2016;8:19732–8.10.1021/acsami.6b03723Search in Google Scholar PubMed

(6) Ji T, Feng Y, Qin M, Li S, Zhang F, Lv F, et al. Thermal conductive and flexible silastic composite based on a hierarchical framework of aligned carbon fibers-carbon nanotubes. Carbon. 2018;131:149–59.10.1016/j.carbon.2018.02.002Search in Google Scholar

(7) Hou X, Chen Y, Dai W, Wang Z, Li H, Lin C-T, et al. Highly thermal conductive polymer composites via constructing micro-phragmites communis structured carbon fibers. Chem Eng J. 2019;375:121921.10.1016/j.cej.2019.121921Search in Google Scholar

(8) Zhang S, Gao L, Han J, Li Z, Zu G, Ran X, et al. Through-thickness thermal conductivity enhancement and tensile response of carbon fiber-reinforced polymer composites. Composites Part B. 2019;165:183–92.10.1016/j.compositesb.2018.11.114Search in Google Scholar

(9) Du C, Li M, Cao M, Feng S, Guo H, Li B. Enhanced thermal and mechanical properties of polyvinlydene fluoride composites with magnetic oriented carbon nanotube. Carbon. 2018;126:197–207.10.1016/j.carbon.2017.10.027Search in Google Scholar

(10) Zhang X, Wen R, Huang Z, Tang C, Huang Y, Liu Y, et al. Enhancement of thermal conductivity by the introduction of carbon nanotubes as a filler in paraffin/expanded perlite form-stable phase-change materials. Energy Build. 2017;149:463–70.10.1016/j.enbuild.2017.05.037Search in Google Scholar

(11) Zhang F, Feng Y, Qin M, Ji T, Lv F, Li Z, et al. Stress-sensitive thermally conductive elastic nanocomposite based on interconnected graphite-welded carbon nanotube sponges. Carbon. 2019;145:378–88.10.1016/j.carbon.2019.01.031Search in Google Scholar

(12) Qi X-d, Wang W-y, Xiao Y-j, Huang T, Zhang N, Yang J-h, et al. Tailoring the hybrid network structure of boron nitride/carbon nanotube to achieve thermally conductive poly(vinylidene fluoride) composites. Compos Commun. 2019;13:30–36.10.1016/j.coco.2019.02.004Search in Google Scholar

(13) Chen L, Hou X, Song N, Shi L, Ding P. Cellulose/graphene bioplastic for thermal management: enhanced isotropic thermally conductive property by three-dimensional interconnected graphene aerogel. Composites Part A. 2018;107:189–96.10.1016/j.compositesa.2017.12.014Search in Google Scholar

(14) Liu Z, Chen Y, Li Y, Dai W, Yan Q, Alam FE, et al. Graphene foam-embedded epoxy composites with significant thermal conductivity enhancement. Nanoscale. 2019;11:17600–6.10.1039/C9NR03968FSearch in Google Scholar PubMed

(15) Liu Y, Wu K, Luo F, Lu M, Xiao F, Du X, et al. Significantly enhanced thermal conductivity in polyvinyl alcohol composites enabled by dopamine modified graphene nanoplatelets. Composites Part A. 2019;117:134–43.10.1016/j.compositesa.2018.11.015Search in Google Scholar

(16) Wu X, Li H, Cheng K, Qiu H, Yang J. Modified graphene/polyimide composite films with strongly enhanced thermal conductivity. Nanoscale. 2019;11:8219–25.10.1039/C9NR02117ESearch in Google Scholar PubMed

(17) Rafiee M, Nitzsche F, Laliberte J, Hind S, Robitaille F, Labrosse MR. Thermal properties of doubly reinforced fiberglass/epoxy composites with graphene nanoplatelets, graphene oxide and reduced-graphene oxide. Composites Part B. 2019;164:1–9.10.1016/j.compositesb.2018.11.051Search in Google Scholar

(18) Mittal G, Rhee KY, Park SJ. Processing and characterization of PMMA/PI composites reinforced with surface functionalized hexagonal boron nitride. Appl Surf Sci. 2017;415:49–54.10.1016/j.apsusc.2016.10.029Search in Google Scholar

(19) Partridge G. Inorganic materials V. Ceramic materials possessing high thermal conductivity. Adv Mater. 1992;4:51–54.10.1002/adma.19920040112Search in Google Scholar

(20) Zhang S, Li X, Guan X, Shi Y, Wu K, Liang L, et al. Synthesis of pyridine-containing diamine and properties of its polyimides and polyimide/hexagonal boron nitride composite films. Compos Sci Technol. 2017;152:165–72.10.1016/j.compscitech.2017.09.026Search in Google Scholar

(21) Singh RS, Tay RY, Chow WL, Tsang SH, Mallick G, Teo EHT. Band gap effects of hexagonal boron nitride using oxygen plasma. Appl Phys Lett. 2014;104:163101.10.1063/1.4872318Search in Google Scholar

(22) Yu C, Zhang J, Li Z, Tian W, Wang L, Luo J, et al. Enhanced through-plane thermal conductivity of boron nitride/epoxy composites. Composites Part A. 2017;98:25–31.10.1016/j.compositesa.2017.03.012Search in Google Scholar

(23) Ren P-G, Hou S-Y, Ren F, Zhang Z-P, Sun Z-F, Xu L. The influence of compression molding techniques on thermal conductivity of UHMWPE/BN and UHMWPE/(BN + MWCNT) hybrid composites with segregated structure. Composites Part A. 2016;90:13–21.10.1016/j.compositesa.2016.06.019Search in Google Scholar

(24) Wang Y, Zhan HF, Xiang Y, Yang C, Wang CM, Zhang YY. Effect of covalent functionalization on thermal transport across graphene–polymer interfaces. J Phys Chem C. 2015;119:12731–8.10.1021/acs.jpcc.5b02920Search in Google Scholar

(25) Wei R, Xiao Q, Zhan C, You Y, Zhou X, Liu X. Polyarylene ether nitrile and boron nitride composites: coating with sulfonated polyarylene ether nitrile. e-Polymers. 2019;19:70.10.1515/epoly-2019-0009Search in Google Scholar

(26) Liu L, Shen S, Wang Y. Enhanced thermal conductivity of flexible h-BN/polyimide composites films with ethyl cellulose. e-Polymers. 2019;19:305.10.1515/epoly-2019-0031Search in Google Scholar

(27) Guo Y, Chang C-C, Halada G, Cuiffo MA, Xue Y, Zuo X, et al. Engineering flame retardant biodegradable polymer nanocomposites and their application in 3D printing. Polym Degrad Stab. 2017;137:205–15.10.1016/j.polymdegradstab.2017.01.019Search in Google Scholar

(28) Wang Z-G, Gong F, Yu W-C, Huang Y-F, Zhu L, Lei J, et al. Synergetic enhancement of thermal conductivity by constructing hybrid conductive network in the segregated polymer composites. Compos Sci Technol. 2018;162:7–13.10.1016/j.compscitech.2018.03.016Search in Google Scholar

(29) Zhou W, Wang C, Ai T, Wu K, Zhao F, Gu H. A novel fiber-reinforced polyethylene composite with added silicon nitride particles for enhanced thermal conductivity. Composites Part A. 2009;40:830–6.10.1016/j.compositesa.2009.04.005Search in Google Scholar

(30) Zhou W, Kou Y, Yuan M, Li B, Cai H, Li Z, et al. Polymer composites filled with core@double-shell structured fillers: effects of multiple shells on dielectric and thermal properties. Compos Sci Technol. 2019;181:107686.10.1016/j.compscitech.2019.107686Search in Google Scholar

(31) Tsai M-H, Tseng IH, Chiang J-C, Li J-J. Flexible polyimide films hybrid with functionalized boron nitride and graphene oxide simultaneously to improve thermal conduction and dimensional stability. ACS Appl Mater Interfaces. 2014;6:8639–45.10.1021/am501323mSearch in Google Scholar PubMed

(32) Li TL, Hsu SLC. Enhanced thermal conductivity of polyimide films via a hybrid of micro- and nano-sized boron nitride. J Phys Chem B. 2010;114:6825–9.10.1021/jp101857wSearch in Google Scholar PubMed

(33) Weidenfeller B, Höfer M, Schilling F. Thermal and electrical properties of magnetite filled polymers. Composites Part A. 2002;33:1041–53.10.1016/S1359-835X(02)00085-4Search in Google Scholar

(34) Bartczak Z, Argon AS, Cohen RE, Weinberg M. Toughness mechanism in semi-crystalline polymer blends: II. High-density polyethylene toughened with calcium carbonate filler particles. Polymer. 1999;40:2347–65.10.1016/S0032-3861(98)00444-3Search in Google Scholar

(35) Chen Y, Qi Y, Tai Z, Yan X, Zhu F, Xue Q. Preparation, mechanical properties and biocompatibility of graphene oxide/ultrahigh molecular weight polyethylene composites. Eur Polym J. 2012;48:1026–33.10.1016/j.eurpolymj.2012.03.011Search in Google Scholar

(36) Ren X, Wang XQ, Sui G, Zhong WH, Fuqua MA, Ulven CA. Effects of carbon nanofibers on crystalline structures and properties of ultrahigh molecular weight polyethylene blend fabricated using twin-screw extrusion. J Appl Polym Sci. 2008;107:2837–45.10.1002/app.27354Search in Google Scholar

(37) Zeng X, Yu S, Sun R. Thermal behavior and dielectric property analysis of boron nitride-filled bismaleimide-triazine resin composites. J Appl Polym Sci. 2013;128:1353–9.10.1002/app.38276Search in Google Scholar

(38) Yu B, Xing W, Guo W, Qiu S, Wang X, Lo S, et al. Thermal exfoliation of hexagonal boron nitride for effective enhancements on thermal stability, flame retardancy and smoke suppression of epoxy resin nanocomposites via sol–gel process. J Mater Chem A. 2016;4:7330–40.10.1039/C6TA01565DSearch in Google Scholar

© 2020 Xian Wu et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- The regulatory effects of the number of VP(N-vinylpyrrolidone) function groups on macrostructure and photochromic properties of polyoxometalates/copolymer hybrid films

- How the hindered amines affect the microstructure and mechanical properties of nitrile-butadiene rubber composites

- Novel benzimidazole-based conjugated polyelectrolytes: synthesis, solution photophysics and fluorescent sensing of metal ions

- Study on the variation of rock pore structure after polymer gel flooding

- Investigation on compatibility of PLA/PBAT blends modified by epoxy-terminated branched polymers through chemical micro-crosslinking

- Investigation on degradation mechanism of polymer blockages in unconsolidated sandstone reservoirs

- Investigation on the effect of active-polymers with different functional groups for EOR

- Fabrication and characterization of hexadecyl acrylate cross-linked phase change microspheres

- Surface-induced phase transitions in thin films of dendrimer block copolymers

- ZnO-assisted coating of tetracalcium phosphate/ gelatin on the polyethylene terephthalate woven nets by atomic layer deposition

- Animal fat and glycerol bioconversion to polyhydroxyalkanoate by produced water bacteria

- Effect of microstructure on the properties of polystyrene microporous foaming material

- Synthesis of amphiphilic poly(ethylene glycol)-block-poly(methyl methacrylate) containing trityl ether acid cleavable junction group and its self-assembly into ordered nanoporous thin films

- On-demand optimize design of sound-absorbing porous material based on multi-population genetic algorithm

- Enhancement of mechanical, thermal and water uptake performance of TPU/jute fiber green composites via chemical treatments on fiber surface

- Enhancement of mechanical properties of natural rubber–clay nanocomposites through incorporation of silanated organoclay into natural rubber latex

- Preparation and characterization of corn starch/PVA/glycerol composite films incorporated with ε-polylysine as a novel antimicrobial packaging material

- Preparation of novel amphoteric polyacrylamide and its synergistic retention with cationic polymers

- Effect of montmorillonite on PEBAX® 1074-based mixed matrix membranes to be used in humidifiers in proton exchange membrane fuel cells

- Insight on the effect of a piperonylic acid derivative on the crystallization process, melting behavior, thermal stability, optical and mechanical properties of poly(l-lactic acid)

- Lipase-catalyzed synthesis and post-polymerization modification of new fully bio-based poly(hexamethylene γ-ketopimelate) and poly(hexamethylene γ-ketopimelate-co-hexamethylene adipate) copolyesters

- Dielectric, mechanical and thermal properties of all-organic PI/PSF composite films by in situ polymerization

- Morphological transition of amphiphilic block copolymer/PEGylated phospholipid complexes induced by the dynamic subtle balance interactions in the self-assembled aggregates

- Silica/polymer core–shell particles prepared via soap-free emulsion polymerization

- Antibacterial epoxy composites with addition of natural Artemisia annua waste

- Design and preparation of 3D printing intelligent poly N,N-dimethylacrylamide hydrogel actuators

- Multilayer-structured fibrous membrane with directional moisture transportability and thermal radiation for high-performance air filtration

- Reaction characteristics of polymer expansive jet impact on explosive reactive armour

- Synthesis of a novel modified chitosan as an intumescent flame retardant for epoxy resin

- Synthesis of aminated polystyrene and its self-assembly with nanoparticles at oil/water interface

- The synthesis and characterisation of porous and monodisperse, chemically modified hypercrosslinked poly(acrylonitrile)-based terpolymer as a sorbent for the adsorption of acidic pharmaceuticals

- Crystal transition and thermal behavior of Nylon 12

- All-optical non-conjugated multi-functionalized photorefractive polymers via ring-opening metathesis polymerization

- Fabrication of LDPE/PS interpolymer resin particles through a swelling suspension polymerization approach

- Determination of the carbonyl index of polyethylene and polypropylene using specified area under band methodology with ATR-FTIR spectroscopy

- Synthesis, electropolymerization, and electrochromic performances of two novel tetrathiafulvalene–thiophene assemblies

- Wetting behaviors of fluoroterpolymer fiber films

- Plugging mechanisms of polymer gel used for hydraulic fracture water shutoff

- Synthesis of flexible poly(l-lactide)-b-polyethylene glycol-b-poly(l-lactide) bioplastics by ring-opening polymerization in the presence of chain extender

- Sulfonated poly(arylene ether sulfone) functionalized polysilsesquioxane hybrid membranes with enhanced proton conductivity

- Fmoc-diphenylalanine-based hydrogels as a potential carrier for drug delivery

- Effect of diacylhydrazine as chain extender on microphase separation and performance of energetic polyurethane elastomer

- Improved high-temperature damping performance of nitrile-butadiene rubber/phenolic resin composites by introducing different hindered amine molecules

- Rational synthesis of silicon into polyimide-derived hollow electrospun carbon nanofibers for enhanced lithium storage

- Synthesis, characterization and properties of phthalonitrile-etherified resole resin

- Highly thermally conductive boron nitride@UHMWPE composites with segregated structure

- Synthesis of high-temperature thermally expandable microcapsules and their effects on foaming quality and surface quality of foamed ABS materials

- Tribological and nanomechanical properties of a lignin-based biopolymer

- Hydroxyapatite/polyetheretherketone nanocomposites for selective laser sintering: Thermal and mechanical performances

- Synthesis of a phosphoramidate flame retardant and its flame retardancy on cotton fabrics

- Preparation and characterization of thermoresponsive poly(N-isopropylacrylamide) copolymers with enhanced hydrophilicity

- Fabrication of flexible SiO2 nanofibrous yarn via a conjugate electrospinning process

- Silver-loaded carbon nanofibers for ammonia sensing

- Polar migration behavior of phosphonate groups in phosphonate esterified acrylic grafted epoxy ester composites and their role in substrate protection

- Solubility and diffusion coefficient of supercritical CO2 in polystyrene dynamic melt

- Curcumin-loaded polyvinyl butyral film with antibacterial activity

- Experimental-numerical studies of the effect of cell structure on the mechanical properties of polypropylene foams

- Experimental investigation on the three-dimensional flow field from a meltblowing slot die

- Enhancing tribo-mechanical properties and thermal stability of nylon 6 by hexagonal boron nitride fillers

- Preparation and characterization of electrospun fibrous scaffolds of either PVA or PVP for fast release of sildenafil citrate

- Seawater degradation of PLA accelerated by water-soluble PVA

- Review Article

- Mechanical properties and application analysis of spider silk bionic material

- Additive manufacturing of PLA-based scaffolds intended for bone regeneration and strategies to improve their biological properties

- Structural design toward functional materials by electrospinning: A review

- Special Issue: XXXII National Congress of the Mexican Polymer Society

- Tailoring the morphology of poly(high internal phase emulsions) synthesized by using deep eutectic solvents

- Modification of Ceiba pentandra cellulose for drug release applications

- Redox initiation in semicontinuous polymerization to search for specific mechanical properties of copolymers

- pH-responsive polymer micelles for methotrexate delivery at tumor microenvironments

- Microwave-assisted synthesis of the lipase-catalyzed ring-opening copolymerization of ε-caprolactone and ω-pentadecanolactone: Thermal and FTIR characterization

- Rapid Communications

- Pilot-scale production of polylactic acid nanofibers by melt electrospinning

- Erratum

- Erratum to: Synthesis and characterization of new macromolecule systems for colon-specific drug delivery

Articles in the same Issue

- Regular Articles

- The regulatory effects of the number of VP(N-vinylpyrrolidone) function groups on macrostructure and photochromic properties of polyoxometalates/copolymer hybrid films

- How the hindered amines affect the microstructure and mechanical properties of nitrile-butadiene rubber composites

- Novel benzimidazole-based conjugated polyelectrolytes: synthesis, solution photophysics and fluorescent sensing of metal ions

- Study on the variation of rock pore structure after polymer gel flooding

- Investigation on compatibility of PLA/PBAT blends modified by epoxy-terminated branched polymers through chemical micro-crosslinking

- Investigation on degradation mechanism of polymer blockages in unconsolidated sandstone reservoirs

- Investigation on the effect of active-polymers with different functional groups for EOR

- Fabrication and characterization of hexadecyl acrylate cross-linked phase change microspheres

- Surface-induced phase transitions in thin films of dendrimer block copolymers

- ZnO-assisted coating of tetracalcium phosphate/ gelatin on the polyethylene terephthalate woven nets by atomic layer deposition

- Animal fat and glycerol bioconversion to polyhydroxyalkanoate by produced water bacteria

- Effect of microstructure on the properties of polystyrene microporous foaming material

- Synthesis of amphiphilic poly(ethylene glycol)-block-poly(methyl methacrylate) containing trityl ether acid cleavable junction group and its self-assembly into ordered nanoporous thin films

- On-demand optimize design of sound-absorbing porous material based on multi-population genetic algorithm

- Enhancement of mechanical, thermal and water uptake performance of TPU/jute fiber green composites via chemical treatments on fiber surface

- Enhancement of mechanical properties of natural rubber–clay nanocomposites through incorporation of silanated organoclay into natural rubber latex

- Preparation and characterization of corn starch/PVA/glycerol composite films incorporated with ε-polylysine as a novel antimicrobial packaging material

- Preparation of novel amphoteric polyacrylamide and its synergistic retention with cationic polymers

- Effect of montmorillonite on PEBAX® 1074-based mixed matrix membranes to be used in humidifiers in proton exchange membrane fuel cells

- Insight on the effect of a piperonylic acid derivative on the crystallization process, melting behavior, thermal stability, optical and mechanical properties of poly(l-lactic acid)

- Lipase-catalyzed synthesis and post-polymerization modification of new fully bio-based poly(hexamethylene γ-ketopimelate) and poly(hexamethylene γ-ketopimelate-co-hexamethylene adipate) copolyesters

- Dielectric, mechanical and thermal properties of all-organic PI/PSF composite films by in situ polymerization

- Morphological transition of amphiphilic block copolymer/PEGylated phospholipid complexes induced by the dynamic subtle balance interactions in the self-assembled aggregates

- Silica/polymer core–shell particles prepared via soap-free emulsion polymerization

- Antibacterial epoxy composites with addition of natural Artemisia annua waste

- Design and preparation of 3D printing intelligent poly N,N-dimethylacrylamide hydrogel actuators

- Multilayer-structured fibrous membrane with directional moisture transportability and thermal radiation for high-performance air filtration

- Reaction characteristics of polymer expansive jet impact on explosive reactive armour

- Synthesis of a novel modified chitosan as an intumescent flame retardant for epoxy resin

- Synthesis of aminated polystyrene and its self-assembly with nanoparticles at oil/water interface

- The synthesis and characterisation of porous and monodisperse, chemically modified hypercrosslinked poly(acrylonitrile)-based terpolymer as a sorbent for the adsorption of acidic pharmaceuticals

- Crystal transition and thermal behavior of Nylon 12

- All-optical non-conjugated multi-functionalized photorefractive polymers via ring-opening metathesis polymerization

- Fabrication of LDPE/PS interpolymer resin particles through a swelling suspension polymerization approach

- Determination of the carbonyl index of polyethylene and polypropylene using specified area under band methodology with ATR-FTIR spectroscopy

- Synthesis, electropolymerization, and electrochromic performances of two novel tetrathiafulvalene–thiophene assemblies

- Wetting behaviors of fluoroterpolymer fiber films

- Plugging mechanisms of polymer gel used for hydraulic fracture water shutoff

- Synthesis of flexible poly(l-lactide)-b-polyethylene glycol-b-poly(l-lactide) bioplastics by ring-opening polymerization in the presence of chain extender

- Sulfonated poly(arylene ether sulfone) functionalized polysilsesquioxane hybrid membranes with enhanced proton conductivity

- Fmoc-diphenylalanine-based hydrogels as a potential carrier for drug delivery

- Effect of diacylhydrazine as chain extender on microphase separation and performance of energetic polyurethane elastomer

- Improved high-temperature damping performance of nitrile-butadiene rubber/phenolic resin composites by introducing different hindered amine molecules

- Rational synthesis of silicon into polyimide-derived hollow electrospun carbon nanofibers for enhanced lithium storage

- Synthesis, characterization and properties of phthalonitrile-etherified resole resin

- Highly thermally conductive boron nitride@UHMWPE composites with segregated structure

- Synthesis of high-temperature thermally expandable microcapsules and their effects on foaming quality and surface quality of foamed ABS materials

- Tribological and nanomechanical properties of a lignin-based biopolymer

- Hydroxyapatite/polyetheretherketone nanocomposites for selective laser sintering: Thermal and mechanical performances

- Synthesis of a phosphoramidate flame retardant and its flame retardancy on cotton fabrics

- Preparation and characterization of thermoresponsive poly(N-isopropylacrylamide) copolymers with enhanced hydrophilicity

- Fabrication of flexible SiO2 nanofibrous yarn via a conjugate electrospinning process

- Silver-loaded carbon nanofibers for ammonia sensing

- Polar migration behavior of phosphonate groups in phosphonate esterified acrylic grafted epoxy ester composites and their role in substrate protection

- Solubility and diffusion coefficient of supercritical CO2 in polystyrene dynamic melt

- Curcumin-loaded polyvinyl butyral film with antibacterial activity

- Experimental-numerical studies of the effect of cell structure on the mechanical properties of polypropylene foams

- Experimental investigation on the three-dimensional flow field from a meltblowing slot die

- Enhancing tribo-mechanical properties and thermal stability of nylon 6 by hexagonal boron nitride fillers

- Preparation and characterization of electrospun fibrous scaffolds of either PVA or PVP for fast release of sildenafil citrate

- Seawater degradation of PLA accelerated by water-soluble PVA

- Review Article

- Mechanical properties and application analysis of spider silk bionic material

- Additive manufacturing of PLA-based scaffolds intended for bone regeneration and strategies to improve their biological properties

- Structural design toward functional materials by electrospinning: A review

- Special Issue: XXXII National Congress of the Mexican Polymer Society

- Tailoring the morphology of poly(high internal phase emulsions) synthesized by using deep eutectic solvents

- Modification of Ceiba pentandra cellulose for drug release applications

- Redox initiation in semicontinuous polymerization to search for specific mechanical properties of copolymers

- pH-responsive polymer micelles for methotrexate delivery at tumor microenvironments

- Microwave-assisted synthesis of the lipase-catalyzed ring-opening copolymerization of ε-caprolactone and ω-pentadecanolactone: Thermal and FTIR characterization

- Rapid Communications

- Pilot-scale production of polylactic acid nanofibers by melt electrospinning

- Erratum

- Erratum to: Synthesis and characterization of new macromolecule systems for colon-specific drug delivery