Abstract

The intelligent poly N,N-dimethylacrylamide hydrogel material system with high mechanical strength and the 3D printable property was prepared via in situ free radical polymerization under vacuum successfully. With the increase in nanofibrillated cellulose (NFC) content, stress and strain of hydrogels increased gradually. As the effective reinforcement, NFC enhanced the crosslinking density, which realized the controllable regulation of rheology behaviors including viscosity, storage modulus, and loss modulus of hydrogels. Combined with the swelling rate and the existence of the gel–sol transition point, a hydrogel with 10 mg/mL NFC was treated as the 3D printing ink of hydrogel actuators. Variation of printing parameters significantly affected self-driven deformations. The hydrogel actuators with 90°/0° and 45°/135° configurations owned bending and spiral deformations, respectively. Actuators with a larger length–width ratio owned a lower pitch value. The precise anisotropic swelling property of the printed bilayer structure was the self-driven deformation mechanism of hydrogel actuators, which provided material candidates for the preparation of soft robots and actuators.

1 Introduction

As a kind of typical intelligent soft materials, intelligent hydrogels owned the reversible swelling and deswelling properties under the stimulations of temperature (1,2), pH (3), light (4,5,6), magnetic field (7,8), and electric field (9,10) to realize shape and volume variation. The efficient and repeatable deformation properties expanded the potential application of intelligent hydrogels in fields of soft actuator (11,12,13,14), soft robot (15), artificial muscle (16), and so on.

To realize the functional deformation properties, many kinds of methods were adopted to prepare intelligent hydrogels (17,18). In situ free radical polymerization was the main method to realize the polymerization of intelligent hydrogels. Based on the photopolymerization, a series of temperature-driven intelligent hydrogels were prepared (19,20). In the deformation structures, the bilayer structure was the simplest structure to realize the anisotropic bending property. Via the photothermal conversion function of graphene oxide, the near-infrared laser-driven bilayer intelligent hydrogels were prepared by in situ polymerization (21), exhibiting the multiple deformation patterns. The layered structure constructed by in situ free-radical polymerization and molding provided the effective anisotropic deformation mechanism for intelligent hydrogels. But, the disadvantage of relatively simple structure patterns restricted the potential application of intelligent hydrogels. The 3D printing technology owned the advantages of complex structure construction and accurate sample dimension, which provided effective solvation for the disadvantage of molding. Combined with the ultraviolet light polymerization, the 3D printed hydrogel actuators imitated the deformation patterns of tendrils and flowers to realize the anisotropic swelling deformations (22,23). Based on changing printing parameters, the bilayer intelligent hydrogel actuators were prepared via 3D printing. The relative complex printed structure realized deformations based on swelling and deswelling anisotropy. The deformations of 3D printed intelligent hydrogel actuators were determined by the hydrogel viscosity, printing parameters, and structure design (24). The relative low viscosity enhanced the printable property and restricted the printed structure fixation property of hydrogels. The relative high viscosity enhanced the printed structure fixation property and restricted the printable property of hydrogels. The controllable regulation of rheological behavior built the preparation base of hydrogel actuators. The structure design and printing parameters determined the final deformation patterns. Therefore, optimizing the printing properties was the key point for the 3D printing of intelligent hydrogels (23).

The mechanical strength was the deformation base of intelligent hydrogel actuators. Many kinds of intelligent hydrogels have been used for the preparation of hydrogel actuators. As a typical kind of hydrogel material with high mechanical strength, the poly N,N-dimethylacrylamide (PDMAA) hydrogel was widely used in the preparation of hydrogel actuators. Moreover, the physical crosslinking PDMAA hydrogel was used in 3D printing. As a kind of effective reinforcement, nanofibrillated cellulose (NFC) was adopted to enhance the mechanical strength of intelligent hydrogels. Therefore, changing the rheological behavior to satisfy 3D printing and improving the mechanical strength of PDMAA hydrogel further were the key points for the preparation of 3D printing intelligent hydrogel actuators.

In this study, a series of novel NFC-reinforced PDMAA hydrogels were prepared via physical crosslinking. Combining the design of printing parameters, the intelligent hydrogel actuators realized 3D printing by constructing the relationship between NFC content and rheological behaviors.

2 Experimental

2.1 Materials

The N,N-dimethylacrylamide (DMAA, C5H9NO; Aladdin, Shanghai, China), nanosized synthetic hectorite clay (Laponite XLG, Mg5.34Li0.66Si8O20(OH)4; Rockwood, Ltd, Germany), potassium peroxydisulfate (KPS, K2S2O8; Shanghai Aibi Chemical Reagent Co., Ltd, Shanghai, China), and N,N,N′,N′-tetramethylethylenediamine (TEMED; Tianjin Weiyi Chemical Technology Co., Ltd, Tianjin, China, 98%) were treated as a monomer, a crosslinking agent, an initiator, and a catalyst, respectively. NFC (Guilin Qihong Technology Co., Ltd, Guilin, China, 1,342 nm) was treated as reinforcement to regulate the rheological property of hydrogels. Pure water was obtained by deionization and filtration with a Millipore purification apparatus (resistivity ≥18.2 MΩ cm).

2.2 Synthesis of hydrogel actuators via 3D printing

To investigate whether the addition of NFC affected the synthesis of intelligent hydrogels or not, in situ free-radical polymerization was adopted to prepare PDMAA hydrogels. About 3 mg of methyl blue was added into pure water for dye of hydrogels. Also, the XLG was added into pure water with methyl blue. Then, the mixture was stirred for 1 h and ultrasonically radiated for 30 min. The NFC with various contents was added and stirred for 1 h under the ice–water bath environment. Then, the DMAA was added and stirred for 1 h. After the addition of KPS and TEMED and stirring for 5 min, the prepared hydrogel reaction solution was put into a rubber mold with a dimension of 70 × 20 × 2 mm (length × width × thickness). The mole ratio of monomer, initiator, and catalyst was kept at 100:0.370:0.638. After 24 h of polymerization in 25°C, the prepared intelligent hydrogels were mold unloading. Based on the NFC contents of 0, 10, 11, 12, 13, and 14 mg/mL, the intelligent hydrogels were defined as NFC0, NFC10, NFC11, NFC12, NFC13, and NFC14, respectively. The compositions of intelligent hydrogels with different NFC contents are listed in Table 1.

Compositions of intelligent hydrogels

| Sample | H2O (mL) | DMAA (mL) | XLG (g) | NFC (mg) | KPS (mg) | TEMED (µL) | Methyl blue (mg) |

|---|---|---|---|---|---|---|---|

| NFC0 | 17.5 | 1.97 | 0.65 | 0 | 20 | 30 | 3 |

| NFC10 | 17.5 | 1.97 | 0.65 | 200 | 20 | 30 | 3 |

| NFC11 | 17.5 | 1.97 | 0.65 | 220 | 20 | 30 | 3 |

| NFC-2 | 17.5 | 1.97 | 0.65 | 240 | 20 | 30 | 3 |

| NFC13 | 17.5 | 1.97 | 0.65 | 260 | 20 | 30 | 3 |

| NFC14 | 17.5 | 1.97 | 0.65 | 280 | 20 | 30 | 3 |

The molding preparation provided material reference for 3D printing. To investigate the deformation of 3D printing intelligent hydrogel actuators, the printing structure models were designed. Before 3D printing of intelligent hydrogels, the STL date was produced by SolidWorks. Slic3r software39 offered by Alessandro Ranellucci was used for slicing. The laboratory-made 3D printer with stainless steel needle of 20G (inner diameter of 0.6 mm) was controlled by the open source software of Pronterface. The printed intelligent hydrogels were put into a vacuum dryer at 25°C for 24 h to realize complete polymerization.

2.3 Characteristics

2.3.1 Microstructure

After removing water in hydrogels in a completely swollen state via a freeze-drying oven (LGJ-10C; Beijing Four Ring Scientific Instrument Factory Co., Ltd, Beijing, China), the microstructure of intelligent hydrogel was observed by the scanning electron microscope (Model Evo18 Carl Zeiss, Oberkochen, Germany).

2.3.2 Infrared spectrum analysis

The IR affinity-1 FT-IR spectrometer (Shimadzu Corporation, Kyoto, Japan) was used to analyze the Fourier transform infrared (FT-IR) spectra of intelligent hydrogels. The wavenumber range was 500–4,000 cm−1. Before experiment, samples were ground into powder and pressed with KBr into a disc.

2.3.3 Stress–strain analysis

The effect of NFC content on mechanical strength of intelligent hydrogels was evaluated by stress–strain analysis. The universal testing machine (Model C43; MTS Criterion, America) was employed for testing. The sample dimension was Φ = 6 × 60 mm. The constant loading rate was 100 mm/min. Average values of stress and strain were calculated from three individual measurements.

2.3.4 Rheological behavior analysis

The rotational rheometer (DHR; TA Instruments, USA) was used for rheological behavior analysis. The parallel plate geometry with a diameter of 40 mm and a gap of 0.55 mm was adopted. The linear viscoelastic range of hydrogel reaction solution was carried under the strain sweeps of 0.1–100% and frequencies of 0.1–2 Hz.

2.3.5 Deformations behaviors

The intelligent deformation patterns of 3D printing intelligent hydrogel actuators were conducted in pure water at 25°C. The dynamic deformation process was recorded by a digital camera.

3 Results and discussion

3.1 Microstructure

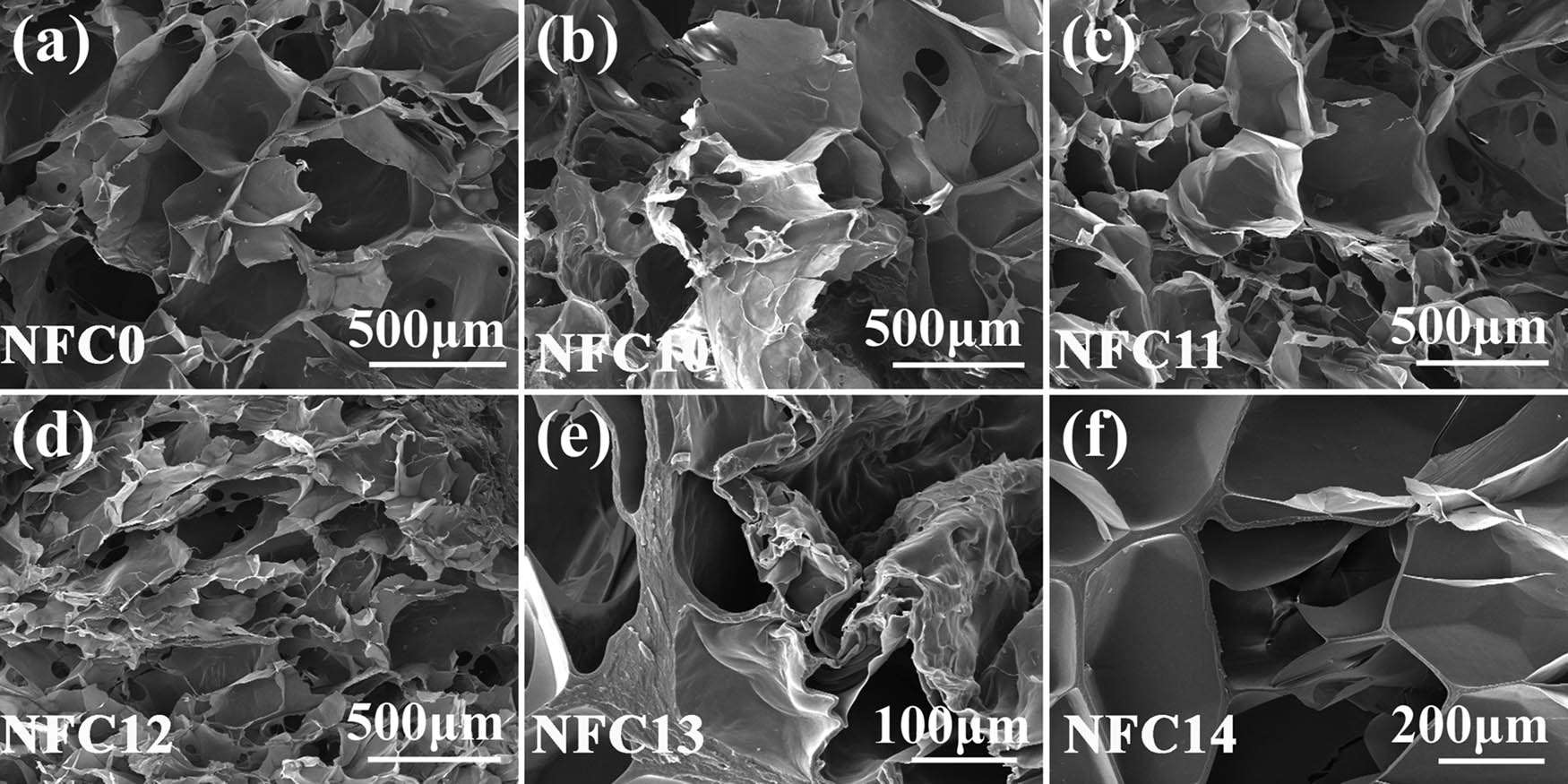

After freeze-drying, the microstructure of hydrogel was maintained integrally. Figure 1 shows the microstructure characteristics of PDMAA hydrogels with different NFC contents via in situ polymerization. The NFC-reinforced intelligent hydrogels exhibited relative harmonious pore sizes in specific sample. From Figure 1a–e, it can be found that NFC contents significantly affected the variation of micropore size. With an increase in NFC contents, the micropore size decreased from about 500 to 100 µm gradually. The reasons can be attributed to the increase in crosslinking density of microstructures, enhancing the compactness of hydrogels. Figure 1 exhibits that the addition of NFC into hydrogel materials maintained the efficient polymerization, proving the feasibility of material composition from point view of microstructure.

Microstructure characteristics of intelligent hydrogels with NFC contents of (a) 0 mg/mL, (b) 10 mg/mL, (c) 11 mg/mL, (d) 12 mg/mL (e) 13 mg/mL, and (f) 14 mg/mL.

3.2 FT-IR spectra and mechanical strength analysis

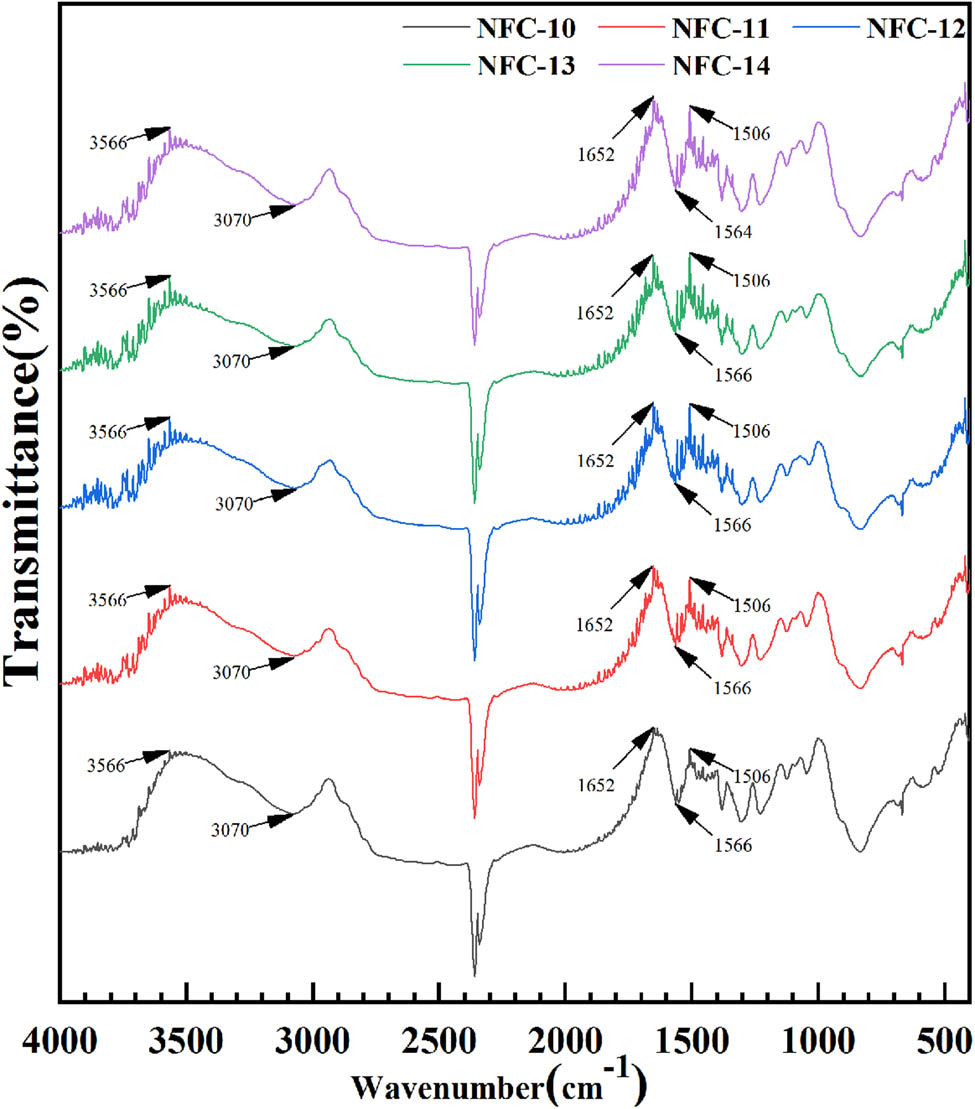

The FT-IR spectra of intelligent PDMAA hydrogels with various NFC contents are exhibited in Figure 2. The variation of NFC contents maintained the positions of typical bands of hydrogels. The band at 3,546 cm−1 was an –OH stretching vibration peak. The bands at 3,070 and 1,380 cm−1 were –CH3 stretching vibration peaks. The band at 1,652 cm−1 was the C═O stretching vibration peak. The band at 1,506 cm−1 was a –C–N– stretching vibration peak. Figure 2 indicates that hydrophilic acylamino existed in the prepared PDMAA intelligent hydrogels. From the point view of functional base, variation of NFC content maintained the original functional chemical bonds of DMAA, which proved the beneficial role of NFC.

FT-IR spectra profiles of intelligent PDMAA hydrogels with various NFC contents.

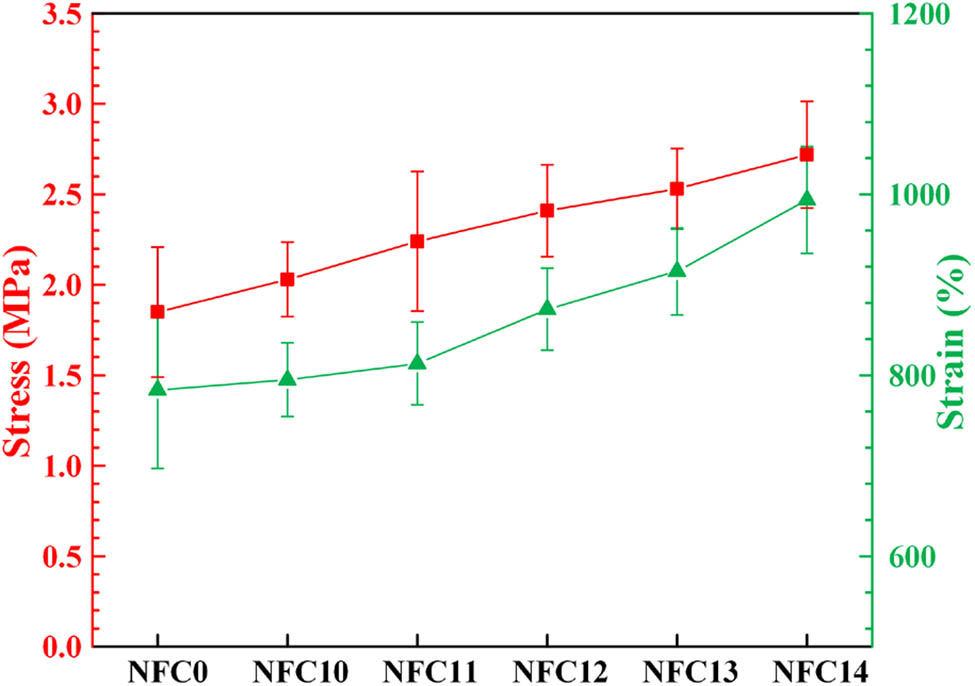

Figure 3 shows the stress–strain profiles of intelligent PDMAA hydrogels with various NFC contents. Variation of NFC content significantly affected the mechanical strength characteristics of hydrogels. With the increase in NFC contents, stress and strain of PDMAA hydrogels with 10, 11, 12, 13, and 14 mg/mL NFC increased. The stress average values of intelligent PDMAA hydrogels were 1.85, 2.03, 2.24, 2.41, 2.53, and 2.72 MPa, respectively. The corresponding strain average values of intelligent PDMAA hydrogels were 784%, 795%, 813%, 873%, 915%, and 994%, respectively. The NFC14 intelligent PDMAA hydrogel owned the highest mechanical strength. Figure 1 indicates the increase in crosslinking density of intelligent hydrogels, which increased the stress and strain values. The material composition of PDMAA hydrogel with different NFC contents exhibited high mechanical property, which provided the mechanical strength base for the application of 3D printing hydrogel actuators.

Stress–strain profiles of intelligent PDMAA hydrogels with various NFC contents.

3.3 Rheology characteristics and 3D printing structure design

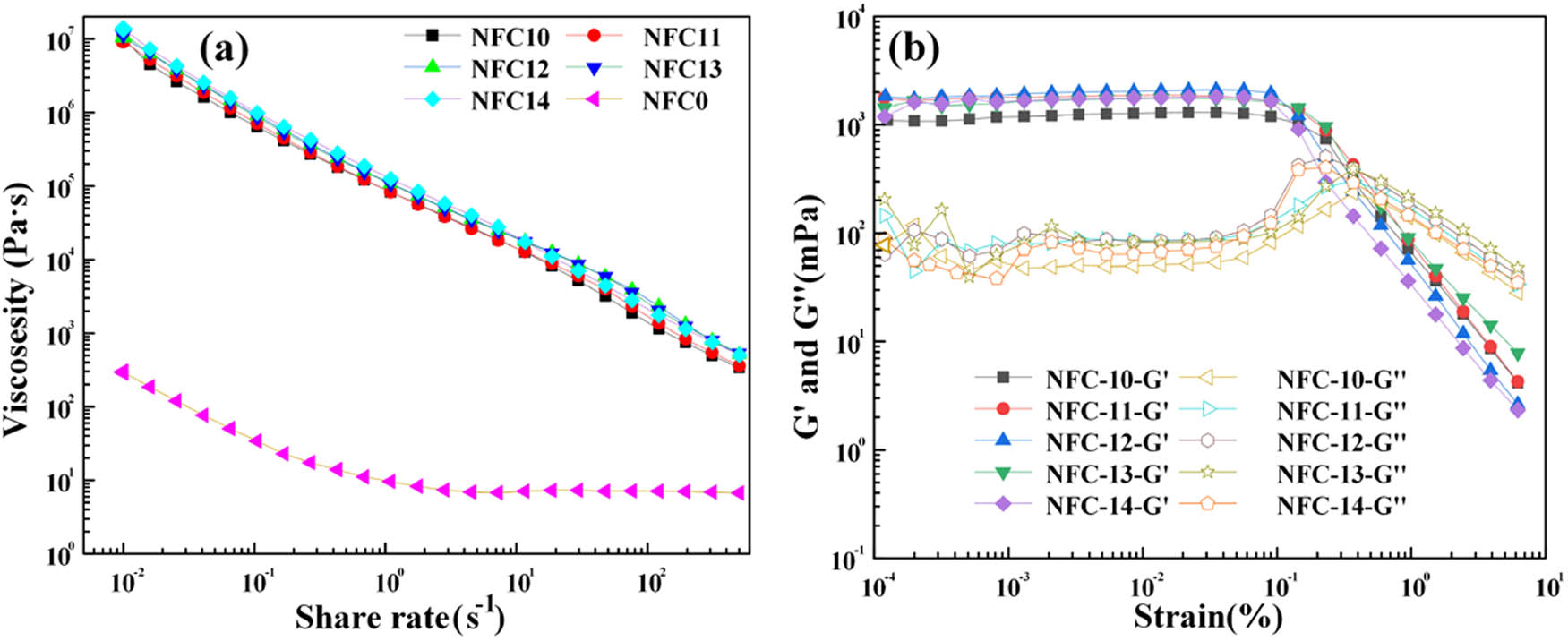

To investigate whether the PDMAA hydrogel reaction solution with various NFC contents was appropriate for 3D printing or not, the rheology characteristics of apparent viscosity, storage modulus, and loss modulus were analyzed, as shown in Figure 4. From Figure 4a, it can be found that the hydrogel reaction solution with and without NFC owned shear thinning phenomenon, exhibiting the non-Newtonian fluid property. The addition of NFC significantly increased the viscosity of hydrogel reaction solution, which enhanced the printable property. With the increase in NFC content, the viscosity of hydrogel reaction solution increased, indicating the controllable regulation property of NFC.

Rheology characteristics of (a) apparent viscosity and (b) storage modulus G′ and loss modulus G″ of intelligent PDMAA hydrogels with various NFC contents.

Figure 4b exhibits the variation of storage modulus and loss modulus of hydrogel reaction solution along with the increase in NFC contents. When strain values exceeded 10−1%, G′ and G″ of intelligent PDMAA hydrogel reaction solution with various NFC contents decreased and increased, respectively, which exhibited the intersection. The intersection indicated the existence of gel–sol transition point of hydrogels. Before the transition point, the hydrogel was in the gel state. After the transition point, the hydrogel was in the liquid state. The prepared PDMAA hydrogel reaction solution owned high rheology characteristics for 3D printing, which proved the feasibility of regulation role of NFC and provided printable ink for 3D printing of hydrogel actuators. Among the NFC contents, besides the perfect viscosity, storage modulus, and loss modulus, NFC10 hydrogel reaction solution owned the high lowest crosslinking density. Based on the printable ability and high swelling property, NFC10 was selected as the NFC content for 3D printing of intelligent hydrogel actuators.

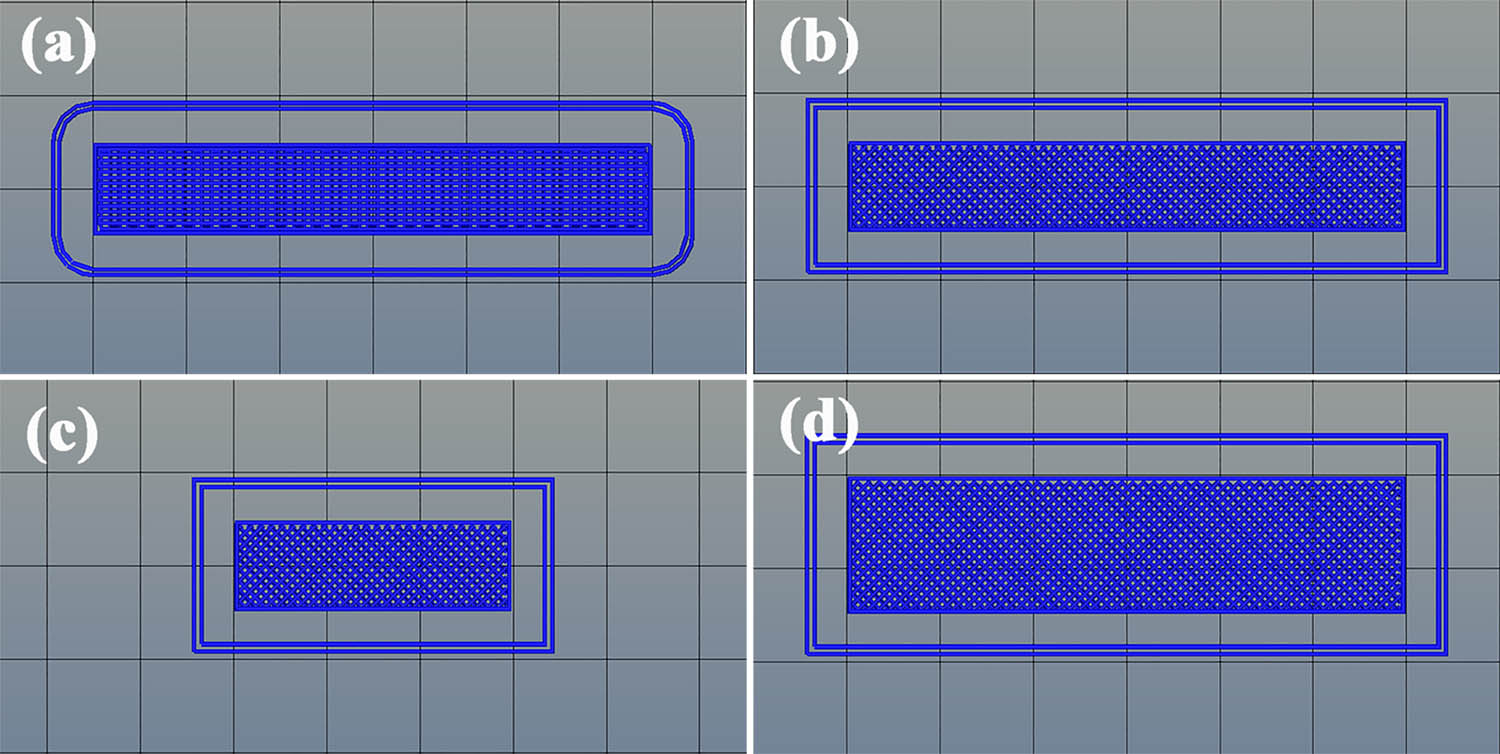

Combined with Figures 1–4, it can be found that besides mechanical strength enhancement, addition of NFC realized the printable property of intelligent hydrogels from the point view of rheology characteristics. Therefore, to realize the 3D printing preparation and investigate the intelligent deformation characteristics, the structure models are built in Figure 5. The printing structures including 90°/0° and 45°/135° configurations and length–width ratios of 3:1, 4:1, and 6:1 were treated as 3D printing parameters. Figure 5a shows the 90°/0° configuration model with sample dimensions of 60 × 10 mm (length × width). Figure 5b shows the 45°/135° configuration model with sample dimensions of 60 × 10 mm (length × width). Figure 5c exhibits the 45°/135° configuration model with sample dimensions of 30 × 10 mm (length × width). Figure 5d shows the 45°/135° configuration model with sample dimensions of 60 × 15 mm (length × width). Figure 5a and b provides the influence of structure model for the deformation of PDMAA hydrogels. Figure 5c and d provides the influence of length–width ratio for the deformation of intelligent PDMAA hydrogels. All structure models were bilayer structure. Attributed to the inner diameter of 6 mm, the thickness of printed bilayer structure was 1.2 mm. To realize the effective polymerization of hydrogel reaction solution, the in situ free radical polymerization under vacuum was adopted on the reference of mold preparation of intelligent hydrogels.

The 3D printing structure models of (a) 60 × 10 mm with 90°/0° configuration, (b) 60 × 10 mm with 45°/135° configuration, (c) 30 × 10 mm with 45°/135° configuration, and (d) 60 × 15 mm with 45°/135° configuration for intelligent PDMAA hydrogels.

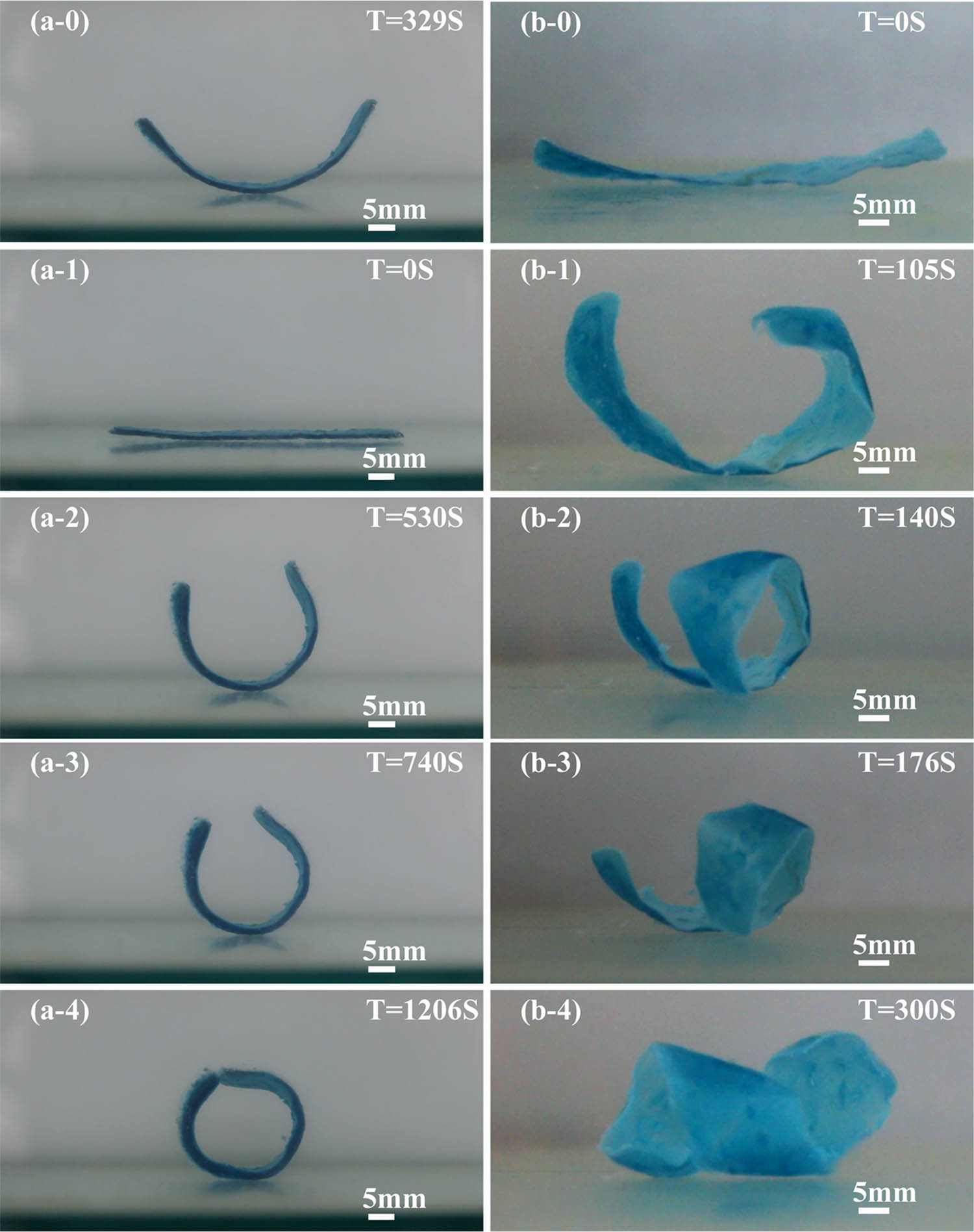

Figure 6 shows the effect of structure models including 90°/0° and 45°/135° configurations on deformation characteristics of intelligent PDMAA hydrogels. At the initial state, the original shape of intelligent hydrogel actuator with 60 × 10 mm and 90°/0° configuration was straight, as shown in Figure 6a-0. When the swelling time reached 329 s, the hydrogel actuator exhibited bending deformation along with the length direction in Figure 6a-1. With the increase in swelling time, the bending degree of hydrogel actuators increased, as shown in Figure 6a-2 and a-3. When the swelling time reached 1,206 s, the hydrogel actuator bent to the final circle state in Figure 6a-4. The initial state of hydrogel actuator with 60 × 10 mm and 45°/135° configuration was also straight in Figure 6b-0. The hydrogel actuator exhibited the torsion deformation at 105 s, which was different from Figure 6a-1. With the increase of swelling time, the spiral degree increased, as shown in Figure 6b-2 and b-3. When the swelling time reached 300 s, the final deformation pattern of hydrogel actuator was the spiral hollow cylinder, as shown in Figure 6b-4. Compared with Figure 6a-4 and b-4, it can be found that the 3D printing structure model significantly affected the intelligent deformation patterns. The 90°/0° and 45°/135° configurations exhibited the bending and spiral deformation, respectively, which indicated the high efficient printable ability of hydrogels and feasibility of 3D printing preparation.

Effect of structure model of (a-0)–(a-4) 90°/0° configuration and (b-0)–(b-4) 45°/135° configuration on deformation characteristics of intelligent PDMAA hydrogels.

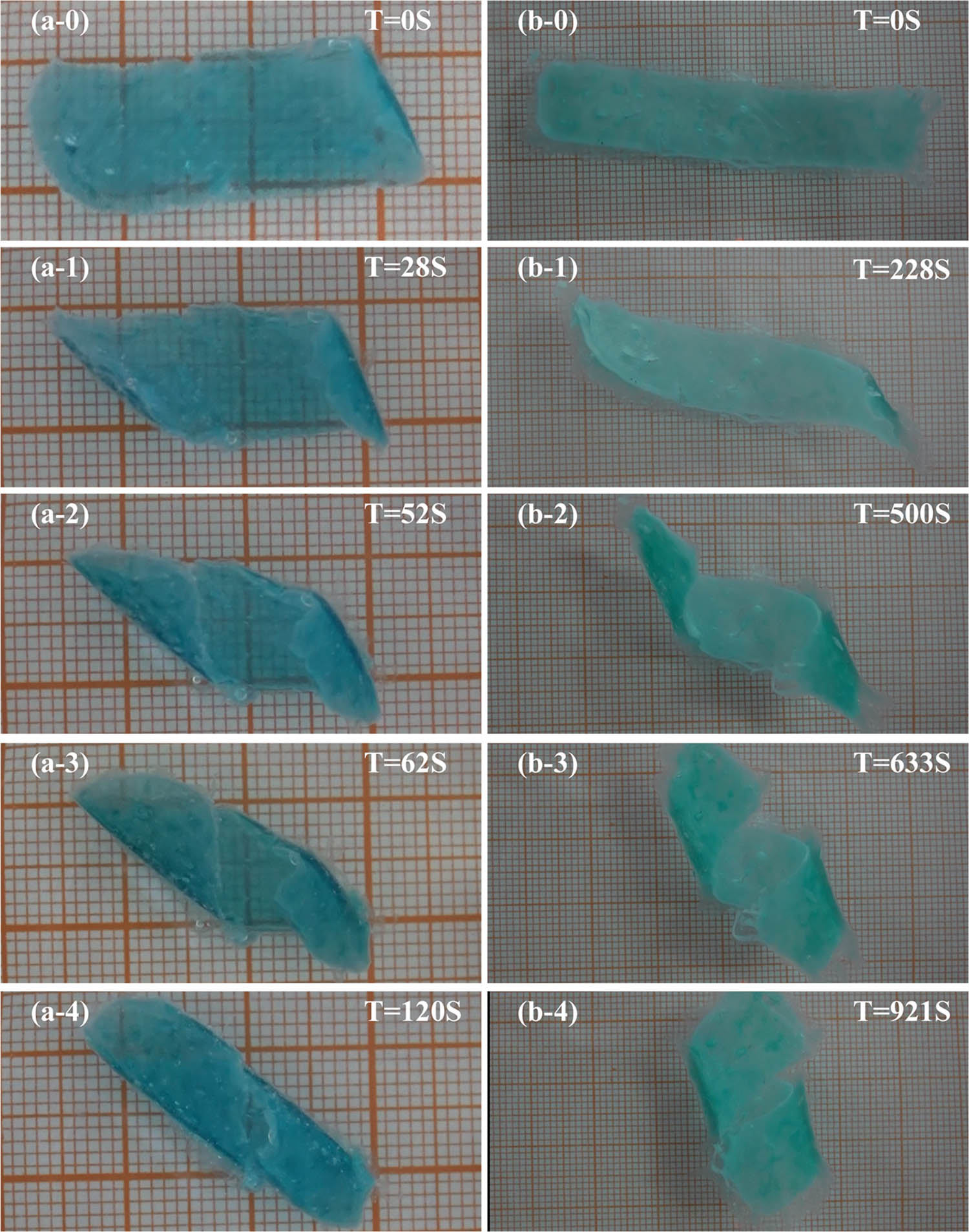

Figure 7 shows the effect of length–width ratios of 3:1 and 4:1 on deformation characteristics of intelligent PDMAA hydrogels. Attributed to the same 45°/135° configuration, the intelligent hydrogels with length–width ratios of 3:1 and 4:1 exhibited the spiral deformations. The initial state of hydrogel actuator was straight, as shown in Figure 7a-0. With an increase in swelling time, both sides of hydrogel actuator twisted together, as shown in Figure 7a-1–a-3. When the swelling time reached 120 s, the spiral hollow cylinder is realized in Figure 7a-4. Both sides of the straight hydrogel actuator with relative high length–width ratio spiraled together, as shown in Figure 7b-0 and b-1. With an increase in swelling time, the spiral degree was enhanced, which can be found in Figure 7b-2–b-4. The variation of length–width ratio also significantly affected the deformation patterns. The pitch that represented the intersection of the same helix and the diameter line can be used to describe the spiral deformation difference between Figure 7a-4 and b-4. The pitch of Figure 7a-4 and b-4 was 2.6 and 3.3 cm, respectively. Namely, the hydrogel actuator with larger length–width ratio owned the lower pitch value, which exhibited higher spiral degree.

Effect of length–width ratio of (a-0)–(a-4) 3:1 and (b-0)–(b-4) 4:1 on deformation characteristics of intelligent PDMAA hydrogels.

Combined with Figures 6 and 7, it can be found that the 3D printed bilayer structure built the swelling deformation base of hydrogel actuators. The anisotropic swelling property of layered structure was the intelligent deformation base of 3D printing hydrogel actuators. The addition of NFC into intelligent PDMAA hydrogels realized the 3D printing of hydrogel actuators, which provided selectable intelligent soft materials for the preparation of intelligent soft actuators with high mechanical strength and self-driven deformations.

4 Conclusion

In this paper, a series of intelligent NFC-reinforced PDMAA hydrogels with high mechanical strength and 3D printable property were prepared. As the reinforcement, NFC changed the crosslinking density and maintained the existence of hydrophilic acylamino, which provided the mechanical strength and swelling function base. With the increase of NFC content, stress and strain values increased. Besides the regulation role of micropore size, the addition of NFC significantly changed the rheology characteristics including apparent viscosity, storage modulus, and loss modulus. With the increase in NFC content, the viscosity of hydrogel reaction solutions with non-Newtonian fluid property increased. The existence of the gel–sol transition point exhibited the printable property of hydrogels. Moreover, combined with the swelling rate, 10 mg/mL was selected as the optimal reinforcement content for 3D printing. To investigate the effect of 3D printing parameters including structure model and length–width ratio on the deformation characteristics of hydrogel actuators, the 90°/0° and 45°/135° configurations and 3:1 and 4:1 were designed. Based on the bilayer structure with precise anisotropic swelling property, the printed hydrogel actuators owned swelling intelligent self-driven deformations. The hydrogel actuators with 90°/0° and 45°/135° configurations exhibited bending and spiral deformations, respectively. The hydrogel actuators with a larger length–width ratio owned the lower pitch value. The self-driven deformation property proved the feasibility of material composition and 3D printing preparation, which provided the selective materials and preparation method candidates for intelligent soft actuators.

Acknowledgments

This work was supported by National Key R&D Program of China (2018YFB1105100).

References

(1) Ma CX, Le XX, Tang XL, He J, Xiao P, Zheng J, et al. A multiresponsive anisotropic hydrogel with macroscopic 3D complex deformations. Adv Funct Mater. 2016;26:8670–6.10.1002/adfm.201603448Search in Google Scholar

(2) Drozdov AD, Christiansen JD. A simplified model for equilibrium and transient swelling of thermo-responsive gels. J Mech Behav Biomed. 2017;75:20–32.10.1016/j.jmbbm.2017.06.034Search in Google Scholar PubMed

(3) Techawanitchai P, Ebara M, Idota N, Asoh TA, Kikuchi A, Aoyagi T. Photo-switchable control of pH-responsive actuators via pH jump reaction. Soft Matter. 2012;8:2844–55.10.1039/c2sm07277gSearch in Google Scholar

(4) Feng YY, Qin MM, Guo HQ, Yoshino K, Wei F. Infrared-actuated recovery of polyurethane filled by reduced graphene oxide/carbon nanotube hybrids with high energy density. ACS Appl Mater Interfaces. 2013;5:10882–8.10.1021/am403071kSearch in Google Scholar PubMed

(5) Zhao Q, Liang YH, Ren L, Yu ZL, Zhang ZH, Ren LQ. Bionic intelligent hydrogel actuators with multimodal deformation and locomotion. Nano Energy. 2018;51:621–31.10.1016/j.nanoen.2018.07.025Search in Google Scholar

(6) Zhao Q, Liang YH, Ren L, Qiu F, Zhang ZH, Ren LQ. Study on temperature and near-infrared driving characteristics of hydrogel actuator fabricated via molding and 3D printing. J Mech Behav Biomed. 2018;78:395–403.10.1016/j.jmbbm.2017.11.043Search in Google Scholar PubMed

(7) Hu W, Lum GZ, Mastrangeli M, Sitti M. Small-scale soft-bodied robot with multimodal locomotion. Nature. 2018;554:81–6.10.1038/nature25443Search in Google Scholar PubMed

(8) Liu TY, Hu SH, Liu TY, Liu DM, Chen SY. Magnetic-sensitive behavior of intelligent ferrogels for controlled release of drug. Langmuir. 2006;22:5974–8.10.1021/la060371eSearch in Google Scholar PubMed

(9) Shao LH, Biener J, Jin HJ, Biener MM, Baumann TF, Weissmüller J. Electrically tunable nanoporous carbon hybrid actuators. Adv Funct Mater. 2012;22:3029–34.10.1002/adfm.201200245Search in Google Scholar

(10) Liang JJ, Huang Y, Oh JY, Kozlov M, Sui D, Fang SL, et al. Electromechanical actuators based on graphene and graphene/Fe3O4 hybrid paper. Adv Funct Mater. 2011;21:3778–84.10.1002/adfm.201101072Search in Google Scholar

(11) Markert CD, Guo XY, Skardal A, Wang Z, Bharadwaj S, Zhang YY, et al. Characterizing the micro-scale elastic modulus of hydrogels for use in regenerative medicine. J Mech Behav Biomed. 2013;27:115–27.10.1016/j.jmbbm.2013.07.008Search in Google Scholar PubMed

(12) Sun ZZ, Yang L, Zhang D, Bian FG, Song WL. High-performance biocompatible nano-biocomposite artificial muscles based on a renewable ionic electrolyte made of cellulose dissolved in ionic liquid. Nanotechnology. 2019;30(28):285503.10.1088/1361-6528/ab0e33Search in Google Scholar PubMed

(13) Sun ZZ, Zhao G, Song WL. A naturally crosslinked chitosan based ionic actuator with cathode deflection phenomenon. Cellulose. 2017;24:441–5.10.1007/s10570-016-1161-1Search in Google Scholar

(14) Sun ZZ, Du SQ, Zhang D, Song WL. Influence of pH and loading of PANI on electrochemical and electromechanical properties for high-performance renewable soft actuator with nano-biocomposite electrode. React Funct Polym. 2019;139:102–11.10.1016/j.reactfunctpolym.2019.03.015Search in Google Scholar

(15) Bassik N, Abebe BT, Laflin KE, Gracias DH. Photolithographically patterned smart hydrogel based bilayer actuators. Polymer. 2010;51:6093–8.10.1016/j.polymer.2010.10.035Search in Google Scholar

(16) Sun ZZ, Li F, Zhang D, Song W. High-performance all-gel-state nano-biopolymer artificial muscles enabled by macromolecularly interconnected conductive microporous chitosan and graphene loaded carbon nanosheet based ionic electrolyte membrane. J Electrochem Soc. 2018;165:H820–30.10.1149/2.0441813jesSearch in Google Scholar

(17) Sun ZZ, Yang L, Zhang D, Song WL. High performance, flexible and renewable nano-biocomposite artificial muscle based on mesoporous cellulose/ionic liquid electrolyte membrane. Sens Actuators B. 2019;283:579–89.10.1016/j.snb.2018.12.073Search in Google Scholar

(18) Song WL, Yang L, Sun ZZ, Li F, Du SQ. Study on actuation enhancement for ionic-induced IL-cellulose based biocompatible composite actuators by glycerol plasticization treatment method. Cellulose. 2018;25(5):2885–99.10.1007/s10570-018-1783-6Search in Google Scholar

(19) Yao C, Liu Z, Yang C, Wang W, Ju XJ, Xie R, et al. Poly(N-isopropylacrylamide)–clay nanocomposite hydrogels with responsive bending property as temperature-controlled manipulators. Adv Funct Mater. 2015;25:2980–91.10.1002/adfm.201500420Search in Google Scholar

(20) Zhang EZ, Wang T, Hong W, Sun WX, Liu XX, Tong Z. Infrared-driving actuation based on bilayer graphene oxide–poly(N-isopropylacrylamide) nanocomposite hydrogels. J Mater Chem A. 2014;2:15633–9.10.1039/C4TA02866JSearch in Google Scholar

(21) Zhao Q, Liang YH, Ren L, Yu ZL, Zhang ZH, Qiu F, et al. Design and fabrication of nanofibrillated cellulose-containing bilayer hydrogel actuators with temperature and near infrared laser responses. J Mater Chem B. 2018;6:1260–72.10.1039/C7TB02853ASearch in Google Scholar

(22) Sydney GA, Matsumoto EA, Nuzzo RG, Mahadevan L, Lewis JA. Biomimetic 4D printing. Nat Mater. 2016;15:413–39.10.1038/nmat4544Search in Google Scholar PubMed

(23) Peng X, Liu TQ, Zhang Q, Shang C, Bai QW, Wang HL. Surface patterning of hydrogels for programmable and complex shape deformations by ion inkjet printing. Adv Funct Mater. 2017;27:1701962–9.10.1002/adfm.201701962Search in Google Scholar

(24) Malda J, Visser J, Melchels FP. 25th anniversary article: engineering hydrogels for biofabrication. Adv Mater. 2013;25:5011–28.10.1002/adma.201302042Search in Google Scholar PubMed

© 2020 Shengzhu Zhou et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- The regulatory effects of the number of VP(N-vinylpyrrolidone) function groups on macrostructure and photochromic properties of polyoxometalates/copolymer hybrid films

- How the hindered amines affect the microstructure and mechanical properties of nitrile-butadiene rubber composites

- Novel benzimidazole-based conjugated polyelectrolytes: synthesis, solution photophysics and fluorescent sensing of metal ions

- Study on the variation of rock pore structure after polymer gel flooding

- Investigation on compatibility of PLA/PBAT blends modified by epoxy-terminated branched polymers through chemical micro-crosslinking

- Investigation on degradation mechanism of polymer blockages in unconsolidated sandstone reservoirs

- Investigation on the effect of active-polymers with different functional groups for EOR

- Fabrication and characterization of hexadecyl acrylate cross-linked phase change microspheres

- Surface-induced phase transitions in thin films of dendrimer block copolymers

- ZnO-assisted coating of tetracalcium phosphate/ gelatin on the polyethylene terephthalate woven nets by atomic layer deposition

- Animal fat and glycerol bioconversion to polyhydroxyalkanoate by produced water bacteria

- Effect of microstructure on the properties of polystyrene microporous foaming material

- Synthesis of amphiphilic poly(ethylene glycol)-block-poly(methyl methacrylate) containing trityl ether acid cleavable junction group and its self-assembly into ordered nanoporous thin films

- On-demand optimize design of sound-absorbing porous material based on multi-population genetic algorithm

- Enhancement of mechanical, thermal and water uptake performance of TPU/jute fiber green composites via chemical treatments on fiber surface

- Enhancement of mechanical properties of natural rubber–clay nanocomposites through incorporation of silanated organoclay into natural rubber latex

- Preparation and characterization of corn starch/PVA/glycerol composite films incorporated with ε-polylysine as a novel antimicrobial packaging material

- Preparation of novel amphoteric polyacrylamide and its synergistic retention with cationic polymers

- Effect of montmorillonite on PEBAX® 1074-based mixed matrix membranes to be used in humidifiers in proton exchange membrane fuel cells

- Insight on the effect of a piperonylic acid derivative on the crystallization process, melting behavior, thermal stability, optical and mechanical properties of poly(l-lactic acid)

- Lipase-catalyzed synthesis and post-polymerization modification of new fully bio-based poly(hexamethylene γ-ketopimelate) and poly(hexamethylene γ-ketopimelate-co-hexamethylene adipate) copolyesters

- Dielectric, mechanical and thermal properties of all-organic PI/PSF composite films by in situ polymerization

- Morphological transition of amphiphilic block copolymer/PEGylated phospholipid complexes induced by the dynamic subtle balance interactions in the self-assembled aggregates

- Silica/polymer core–shell particles prepared via soap-free emulsion polymerization

- Antibacterial epoxy composites with addition of natural Artemisia annua waste

- Design and preparation of 3D printing intelligent poly N,N-dimethylacrylamide hydrogel actuators

- Multilayer-structured fibrous membrane with directional moisture transportability and thermal radiation for high-performance air filtration

- Reaction characteristics of polymer expansive jet impact on explosive reactive armour

- Synthesis of a novel modified chitosan as an intumescent flame retardant for epoxy resin

- Synthesis of aminated polystyrene and its self-assembly with nanoparticles at oil/water interface

- The synthesis and characterisation of porous and monodisperse, chemically modified hypercrosslinked poly(acrylonitrile)-based terpolymer as a sorbent for the adsorption of acidic pharmaceuticals

- Crystal transition and thermal behavior of Nylon 12

- All-optical non-conjugated multi-functionalized photorefractive polymers via ring-opening metathesis polymerization

- Fabrication of LDPE/PS interpolymer resin particles through a swelling suspension polymerization approach

- Determination of the carbonyl index of polyethylene and polypropylene using specified area under band methodology with ATR-FTIR spectroscopy

- Synthesis, electropolymerization, and electrochromic performances of two novel tetrathiafulvalene–thiophene assemblies

- Wetting behaviors of fluoroterpolymer fiber films

- Plugging mechanisms of polymer gel used for hydraulic fracture water shutoff

- Synthesis of flexible poly(l-lactide)-b-polyethylene glycol-b-poly(l-lactide) bioplastics by ring-opening polymerization in the presence of chain extender

- Sulfonated poly(arylene ether sulfone) functionalized polysilsesquioxane hybrid membranes with enhanced proton conductivity

- Fmoc-diphenylalanine-based hydrogels as a potential carrier for drug delivery

- Effect of diacylhydrazine as chain extender on microphase separation and performance of energetic polyurethane elastomer

- Improved high-temperature damping performance of nitrile-butadiene rubber/phenolic resin composites by introducing different hindered amine molecules

- Rational synthesis of silicon into polyimide-derived hollow electrospun carbon nanofibers for enhanced lithium storage

- Synthesis, characterization and properties of phthalonitrile-etherified resole resin

- Highly thermally conductive boron nitride@UHMWPE composites with segregated structure

- Synthesis of high-temperature thermally expandable microcapsules and their effects on foaming quality and surface quality of foamed ABS materials

- Tribological and nanomechanical properties of a lignin-based biopolymer

- Hydroxyapatite/polyetheretherketone nanocomposites for selective laser sintering: Thermal and mechanical performances

- Synthesis of a phosphoramidate flame retardant and its flame retardancy on cotton fabrics

- Preparation and characterization of thermoresponsive poly(N-isopropylacrylamide) copolymers with enhanced hydrophilicity

- Fabrication of flexible SiO2 nanofibrous yarn via a conjugate electrospinning process

- Silver-loaded carbon nanofibers for ammonia sensing

- Polar migration behavior of phosphonate groups in phosphonate esterified acrylic grafted epoxy ester composites and their role in substrate protection

- Solubility and diffusion coefficient of supercritical CO2 in polystyrene dynamic melt

- Curcumin-loaded polyvinyl butyral film with antibacterial activity

- Experimental-numerical studies of the effect of cell structure on the mechanical properties of polypropylene foams

- Experimental investigation on the three-dimensional flow field from a meltblowing slot die

- Enhancing tribo-mechanical properties and thermal stability of nylon 6 by hexagonal boron nitride fillers

- Preparation and characterization of electrospun fibrous scaffolds of either PVA or PVP for fast release of sildenafil citrate

- Seawater degradation of PLA accelerated by water-soluble PVA

- Review Article

- Mechanical properties and application analysis of spider silk bionic material

- Additive manufacturing of PLA-based scaffolds intended for bone regeneration and strategies to improve their biological properties

- Structural design toward functional materials by electrospinning: A review

- Special Issue: XXXII National Congress of the Mexican Polymer Society

- Tailoring the morphology of poly(high internal phase emulsions) synthesized by using deep eutectic solvents

- Modification of Ceiba pentandra cellulose for drug release applications

- Redox initiation in semicontinuous polymerization to search for specific mechanical properties of copolymers

- pH-responsive polymer micelles for methotrexate delivery at tumor microenvironments

- Microwave-assisted synthesis of the lipase-catalyzed ring-opening copolymerization of ε-caprolactone and ω-pentadecanolactone: Thermal and FTIR characterization

- Rapid Communications

- Pilot-scale production of polylactic acid nanofibers by melt electrospinning

- Erratum

- Erratum to: Synthesis and characterization of new macromolecule systems for colon-specific drug delivery

Articles in the same Issue

- Regular Articles

- The regulatory effects of the number of VP(N-vinylpyrrolidone) function groups on macrostructure and photochromic properties of polyoxometalates/copolymer hybrid films

- How the hindered amines affect the microstructure and mechanical properties of nitrile-butadiene rubber composites

- Novel benzimidazole-based conjugated polyelectrolytes: synthesis, solution photophysics and fluorescent sensing of metal ions

- Study on the variation of rock pore structure after polymer gel flooding

- Investigation on compatibility of PLA/PBAT blends modified by epoxy-terminated branched polymers through chemical micro-crosslinking

- Investigation on degradation mechanism of polymer blockages in unconsolidated sandstone reservoirs

- Investigation on the effect of active-polymers with different functional groups for EOR

- Fabrication and characterization of hexadecyl acrylate cross-linked phase change microspheres

- Surface-induced phase transitions in thin films of dendrimer block copolymers

- ZnO-assisted coating of tetracalcium phosphate/ gelatin on the polyethylene terephthalate woven nets by atomic layer deposition

- Animal fat and glycerol bioconversion to polyhydroxyalkanoate by produced water bacteria

- Effect of microstructure on the properties of polystyrene microporous foaming material

- Synthesis of amphiphilic poly(ethylene glycol)-block-poly(methyl methacrylate) containing trityl ether acid cleavable junction group and its self-assembly into ordered nanoporous thin films

- On-demand optimize design of sound-absorbing porous material based on multi-population genetic algorithm

- Enhancement of mechanical, thermal and water uptake performance of TPU/jute fiber green composites via chemical treatments on fiber surface

- Enhancement of mechanical properties of natural rubber–clay nanocomposites through incorporation of silanated organoclay into natural rubber latex

- Preparation and characterization of corn starch/PVA/glycerol composite films incorporated with ε-polylysine as a novel antimicrobial packaging material

- Preparation of novel amphoteric polyacrylamide and its synergistic retention with cationic polymers

- Effect of montmorillonite on PEBAX® 1074-based mixed matrix membranes to be used in humidifiers in proton exchange membrane fuel cells

- Insight on the effect of a piperonylic acid derivative on the crystallization process, melting behavior, thermal stability, optical and mechanical properties of poly(l-lactic acid)

- Lipase-catalyzed synthesis and post-polymerization modification of new fully bio-based poly(hexamethylene γ-ketopimelate) and poly(hexamethylene γ-ketopimelate-co-hexamethylene adipate) copolyesters

- Dielectric, mechanical and thermal properties of all-organic PI/PSF composite films by in situ polymerization

- Morphological transition of amphiphilic block copolymer/PEGylated phospholipid complexes induced by the dynamic subtle balance interactions in the self-assembled aggregates

- Silica/polymer core–shell particles prepared via soap-free emulsion polymerization

- Antibacterial epoxy composites with addition of natural Artemisia annua waste

- Design and preparation of 3D printing intelligent poly N,N-dimethylacrylamide hydrogel actuators

- Multilayer-structured fibrous membrane with directional moisture transportability and thermal radiation for high-performance air filtration

- Reaction characteristics of polymer expansive jet impact on explosive reactive armour

- Synthesis of a novel modified chitosan as an intumescent flame retardant for epoxy resin

- Synthesis of aminated polystyrene and its self-assembly with nanoparticles at oil/water interface

- The synthesis and characterisation of porous and monodisperse, chemically modified hypercrosslinked poly(acrylonitrile)-based terpolymer as a sorbent for the adsorption of acidic pharmaceuticals

- Crystal transition and thermal behavior of Nylon 12

- All-optical non-conjugated multi-functionalized photorefractive polymers via ring-opening metathesis polymerization

- Fabrication of LDPE/PS interpolymer resin particles through a swelling suspension polymerization approach

- Determination of the carbonyl index of polyethylene and polypropylene using specified area under band methodology with ATR-FTIR spectroscopy

- Synthesis, electropolymerization, and electrochromic performances of two novel tetrathiafulvalene–thiophene assemblies

- Wetting behaviors of fluoroterpolymer fiber films

- Plugging mechanisms of polymer gel used for hydraulic fracture water shutoff

- Synthesis of flexible poly(l-lactide)-b-polyethylene glycol-b-poly(l-lactide) bioplastics by ring-opening polymerization in the presence of chain extender

- Sulfonated poly(arylene ether sulfone) functionalized polysilsesquioxane hybrid membranes with enhanced proton conductivity

- Fmoc-diphenylalanine-based hydrogels as a potential carrier for drug delivery

- Effect of diacylhydrazine as chain extender on microphase separation and performance of energetic polyurethane elastomer

- Improved high-temperature damping performance of nitrile-butadiene rubber/phenolic resin composites by introducing different hindered amine molecules

- Rational synthesis of silicon into polyimide-derived hollow electrospun carbon nanofibers for enhanced lithium storage

- Synthesis, characterization and properties of phthalonitrile-etherified resole resin

- Highly thermally conductive boron nitride@UHMWPE composites with segregated structure

- Synthesis of high-temperature thermally expandable microcapsules and their effects on foaming quality and surface quality of foamed ABS materials

- Tribological and nanomechanical properties of a lignin-based biopolymer

- Hydroxyapatite/polyetheretherketone nanocomposites for selective laser sintering: Thermal and mechanical performances

- Synthesis of a phosphoramidate flame retardant and its flame retardancy on cotton fabrics

- Preparation and characterization of thermoresponsive poly(N-isopropylacrylamide) copolymers with enhanced hydrophilicity

- Fabrication of flexible SiO2 nanofibrous yarn via a conjugate electrospinning process

- Silver-loaded carbon nanofibers for ammonia sensing

- Polar migration behavior of phosphonate groups in phosphonate esterified acrylic grafted epoxy ester composites and their role in substrate protection

- Solubility and diffusion coefficient of supercritical CO2 in polystyrene dynamic melt

- Curcumin-loaded polyvinyl butyral film with antibacterial activity

- Experimental-numerical studies of the effect of cell structure on the mechanical properties of polypropylene foams

- Experimental investigation on the three-dimensional flow field from a meltblowing slot die

- Enhancing tribo-mechanical properties and thermal stability of nylon 6 by hexagonal boron nitride fillers

- Preparation and characterization of electrospun fibrous scaffolds of either PVA or PVP for fast release of sildenafil citrate

- Seawater degradation of PLA accelerated by water-soluble PVA

- Review Article

- Mechanical properties and application analysis of spider silk bionic material

- Additive manufacturing of PLA-based scaffolds intended for bone regeneration and strategies to improve their biological properties

- Structural design toward functional materials by electrospinning: A review

- Special Issue: XXXII National Congress of the Mexican Polymer Society

- Tailoring the morphology of poly(high internal phase emulsions) synthesized by using deep eutectic solvents

- Modification of Ceiba pentandra cellulose for drug release applications

- Redox initiation in semicontinuous polymerization to search for specific mechanical properties of copolymers

- pH-responsive polymer micelles for methotrexate delivery at tumor microenvironments

- Microwave-assisted synthesis of the lipase-catalyzed ring-opening copolymerization of ε-caprolactone and ω-pentadecanolactone: Thermal and FTIR characterization

- Rapid Communications

- Pilot-scale production of polylactic acid nanofibers by melt electrospinning

- Erratum

- Erratum to: Synthesis and characterization of new macromolecule systems for colon-specific drug delivery