Abstract

Outer-rotor permanent magnet machines for low-speed and high-torque applications have been used due to their high moment of inertia and torque density. In this paper, the 12-slot/10-pole outer-rotor fractional-slot permanent magnet machine model is established by finite element analysis, the influence of unequal stator tooth width and tooth tip width is investigated for the PM machine, and five different schemes of stator tooth and tip width are designed and analyzed. Detailed comparisons of the performance characteristics of the machines are presented including important issues such as output torque, magnetic field distribution, and tooth flux density. It is shown that the torque density and cogging torque and efficiency can be effectively improved by choosing reasonable tooth and tip width, which lays a foundation for further optimum design and efficiency improvement of the machine.

1 Introduction

Recently, the permanent magnet (PM) machines have been widely used in renewable energy fields, such as wind power generation, because of their wide constant-power speed range, high efficiency, and power density. For some high-precision instruments such as spacecraft and power electronic devices, high-power density and low cogging torque are required. The outer-rotor PM machine has its unique characteristics when compared with the traditional PM machine. To solve the problem of new energy, the outer-rotor fractional-slot permanent magnet (FSPM) machine is widely used in wind power due to its low speed and large torque. It is important for the FSPM machine to effectively improve the performance; there is a large amount of literature on the concept of unequal tooth width. Due to the limitation of equal-tooth winding on line load, magnetic load, and power density [1,2,3,4], the findings of these studies indicated that the FSPM machine not only improves the winding coefficient but also improves the torque density by adopting the structure with different tooth widths, which has a high improvement when compared with the equal tooth. Some studies [5,6,7,8,9] investigated the back electromotive force, output torque, and cogging torque of the machine when it adopts the structure of equal tooth width and unequal tooth width, which found that the unequal tooth structure of the machine has a certain influence on its performance.

However, there are very few experimental statements about the unequal stator tooth width in the outer-rotor FSPM machine, which is described in the previous reference. In view of this, this paper presents a series of analyses to give full play to the advantages of the outer-rotor machine. First, 12-slot/10-pole FSPM machine with a small volume and a high winding coefficient [10] is adopted, and five selected models with different stator tooth widths are designed; then, the output torque, tooth flux density, cogging torque, and speed efficiency are simulated by finite element analysis, which is based on Maxwell’s equation that can simulate and analyze static magnetic fields and dynamic magnetic fields. Finally, the optimal combination of tooth width is determined, which concludes that reasonable setting of stator tooth and tooth tip width can effectively improve the performance of machine, and it is also meaningful to analyze its induced current loss [11,12]. Besides, ref. [13] shows that the stator structure with unequal teeth can effectively improve the electromagnetic vibration of the FSPM.

As shown in Figure 1, an outer-rotor 12-slot/10-pole FSPM machine model with a power of 230 W is built, panel (a) shows the cross-sections of the machine and panel (b) describes the magnetic line distribution of the PM machine, where 1,3,5,7 are armature tooth and 2,4,6 are auxiliary tooth; however, armature tooth are winding tooth and auxiliary tooth are nonwinding tooth.

Cross sections of 12 slot/10 pole outer-rotor machine: (a) model of the machine and (b) magnetic line distribution of the machine.

1.1 Machine design and main parameters

The fractional slot winding is the fraction of slots per pole per phase of the winding. Common N/2P combinations such as 6/4, 6/8, 12/10, 12/14, 18/16, 24/22, and 24/26 have been considered for the study. In order to maximize the winding flux and power density of the FSPM machine, the slot pitch should be approximately equal to the pole pitch. Thus, the number of slots (N) and the number of poles (2P) should differ by a minimum integer. Specifically, a combination of N = 2P ± 2 is adopted instead of N = 2P ± 1, since the latter will increase stator variation and machine noise caused by its asymmetric distribution of winding. Table 1 lists the main parameters of 12-slot/10-pole outer-rotor FSPM machine.

The main parameters of the machine

| Machine parameters | Values | Machine parameters | Values |

|---|---|---|---|

| Rated output power (W) | 230 | Rated speed (rpm) | 400 |

| Stator outer diameter (mm) | 93 | Stator inner diameter (mm) | 36 |

| Rotor outer diameter (mm) | 110 | Rotor inner diameter (mm) | 94.4 |

| Air-gap length (mm) | 0.7 | Magnet thickness (mm) | 2.3 |

| Magnet material | N38SH | Stator/rotor material | D23_50 |

| Turns of each coil | 57 | Winding pitch | 1 |

| Winding connection type | Y | Rated voltage (V) | 50 |

2 Investigation of outer-rotor machine with unequal tooth width

2.1 Model of outer-rotor machine with unequal tooth width

The 12-slot/10-pole outer-rotor FSPM machine with an alternate tooth wound is modeled, which not only realizes the physical isolation between the windings but also improves the fault tolerance of the machine. The stator tooth of alternate tooth wound in the FSPM machine can be divided into armature tooth and auxiliary tooth; equal and unequal tooth widths are formed by the relationship between them. The influence of tooth width on machine performance is studied. Based on the concept that the armature tooth have higher saturation than the auxiliary tooth, the main design idea is to keep the opening of the slot unchanged and ensure that an increase in the armature tooth width equals the decrease in the auxiliary tooth width. The transition from equal tooth to an unequal tooth has been applied to the outer-rotor machine designs shown in Figure 2; in panel (a), the armature tooth tip width T W in outer-rotor machine is equal to the auxiliary tooth tip width T H, where the corresponding tooth body widths are t W and t H, whereas in panel (b), the armature tooth tip width of the machine is not equal to the auxiliary tooth tip width, where a and Δt are the variation value of tooth tip and tooth body width, respectively.

Design principle of unequal tooth width for the outer-rotor machine: (a) T w equal to T H and t W equal to t H and (b) change of tooth width in each part of stator slot.

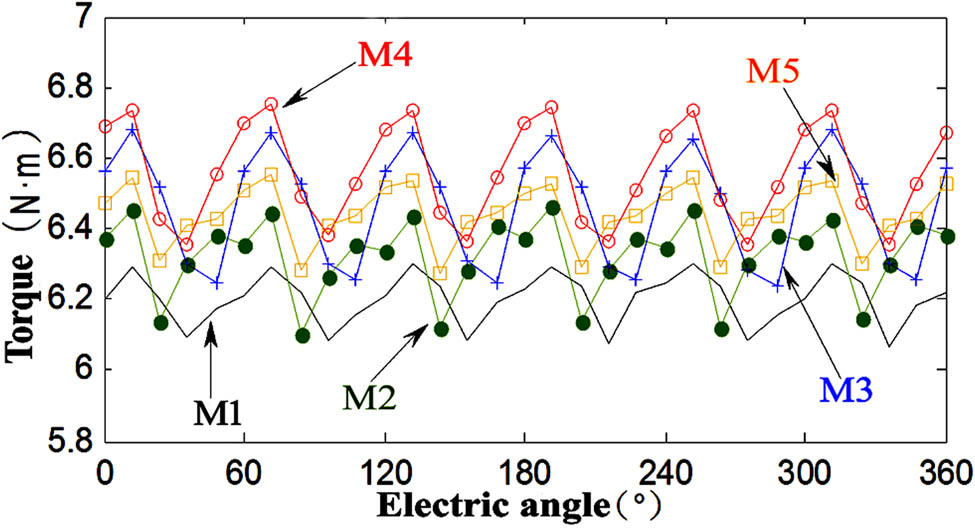

Table 2 lists the structural parameters and the torque of five different tooth widths; the five machine models are referred to as M1, M2, M3, M4, and M5, respectively; M1, M2 and M3–M5 are the two groups of subjects; at the same time, the armature tooth tip width of the second group is larger than that of the first group. Both set of studies ensure that the width of the tooth tip is constant, and the changes in the output torque and ripple torque of the machine are observed by increasing the width of the tooth body gradually.

Tooth width parameters and torque of five models

| Model | Armature tooth (mm) | Auxiliary tooth (mm) | Torque (N m) | |||

|---|---|---|---|---|---|---|

| Tooth width, t w | Tooth tip, T w | Tooth width, t H | Tooth tip, T H | Output torque | Ripple torque | |

| M1 | 9.73 | 19.79 | 9.73 | 19.79 | 6.206 | 0.153 |

| M2 | 11.06 | 19.79 | 8.40 | 19.79 | 6.337 | 0.177 |

| M3 | 12.41 | 25.46 | 7.05 | 14.12 | 6.462 | 0.238 |

| M4 | 13.78 | 25.46 | 5.68 | 14.12 | 6.564 | 0.186 |

| M5 | 14.99 | 25.46 | 4.47 | 14.12 | 6.348 | 0.169 |

Table 3 describes the variation in the tooth width of each model; Δt and a represent the increments in the armature tooth and the tip width of the machine, respectively, which are compared with the equal tooth width machine M1.

Variation of tooth width of each model

| Model | M1 | M2 | M3 | M4 | M5 |

|---|---|---|---|---|---|

| Δt (t w + or t H− ) (mm) | 0 | 1.33 | 2.68 | 4.05 | 5.26 |

| a (T w + or T H− ) (mm) | 0 | 0 | 5.67 | 5.67 | 5.67 |

A comprehensive analysis of the data in Tables 2 and 3 indicates that the output torque is improved with an increase in the tooth width gradually; furthermore, the output torque of second group increases more obviously when compared with the first group; however, the output torque decreases if the tooth width is further larger. At the same time, the output torque and cogging torque waveform of the five machines are shown in Figures 4 and 5, respectively. The variation trend in the output torque is shown in Figure 3.

The variation trend of output torque with an increase in the armature tooth width.

2.2 Simulation results and analysis

Figure 3 shows the output torque that increases first as armature tooth width is increased, and then it decreased, if the width is increased further after a point of value, which means that it has an optimal value of unequal tooth width for maximum output torque. Figure 4 shows the comparison of torque in five models with different tooth widths and the changes in the tooth width of the armature to make the output torque of M4 largest and the M1 smallest; it is worth noting that the decrease in the output torque of M5 when compared with M3 is smaller than M2. Therefore, the output torque is decreased when the increase in the armature tooth width exceeds a certain range. Why the torque increases are that the unequal tooth width structure, on the one hand, makes the tooth tip width of the stator armature equal to the pole distance; at this time, the flux of the winding is the largest, that is to say, K dq is close to 1; thus, the output torque is increased. On the other hand, the flux density amplitude of the armature teeth decreases with an increase in the armature tooth width, which improves the output torque of the machine. Figure 3 shows the data of the output torque in Table 2, and Figure 4 can be understood in conjunction with the torque in Table 2.

Torque comparison of the five models of the machines.

Cogging torque is one of the criteria for measuring the performance of a machine. It mainly causes the machine to generate vibration, noise, and rotational speed fluctuations, which affect the normal operation of the machine. The cogging torque in the five models is shown in Figure 5; the values of the cogging torque in five models are sorted in order of small to large: M1, M2, M5, M4, and M3. Table 4 lists the peak of cogging torque of five machines in Figure 5; although the fluctuation of cogging torque in M3 and M4 is a little bit large, it still satisfies the accuracy requirement of the machine.

Comparison of cogging torque in the five machine models.

Cogging torque amplitude of five machines

| Model | M1 | M2 | M3 | M4 | M5 |

|---|---|---|---|---|---|

| Cogging torque (mN m) | 187 | 262 | 365 | 358 | 279 |

According to the above design idea of unequal tooth width structure and the tip width of the armature, the tooth is equal to the polar distance; at this point, the short-pitch factor K dq is close to 1, and the simplified torque calculation formula [14] is shown as follows:

where T is the output torque of the machine, K α is the waveform coefficient of air gap magnetic field, k dq is the winding factor, α p is the pole-arc coefficient, A is the line load, B δ is the flux density of air gap, D is the armature diameter, and L is the length of effective core. The 12-slot/10-pole FSPM machine can increase the armature tooth width according to Eq. (1), so that the winding factor of the machine is equal to 1, which achieves the maximum purpose of the armature tooth flux. However, if the tooth width of the armature tooth is insufficient when the unequal tooth tip width is used, an excessive increase in the magnetic flux density of the tooth will cause severe saturation of the tooth and a large ripple torque, causing the vibration in the machine. It is generally believed that the tooth flux density of the similar slot number and the equal tooth width machine is about twice the air gap flux density [15], and the air gap magnetic density is generally as large as 1 T. The torque is increased by changing the width of the armature and auxiliary teeth, because the magnetic load of the FSPM machine is too large, leading to saturation of the armature flux. The core material and the performance of the machine are improved by the proximity of the tooth flux density and the auxiliary tooth.

To analyze the effect of unequal tooth width on the machine, the simulation of the torque density is studied. The results of tooth flux density considered structural parameters of the M1 and M4 in the 360° electrical angle, which are shown in Figure 6. It can be observed that the flux density of stator tooth in M1 and M4 shows a downward trend, while the corresponding flux density curves of auxiliary tooth increase with an increase in the armature tooth width and the amplitude of M4 armature tooth is smaller than that of M1 all the time; hence, the saturation of the armature tooth caused by the demagnetization of the PMs can be reduced by the structure of the unequal tooth width. Although the magnetic flux density on the auxiliary teeth increases as the tooth width increases, the coil is not wound on the auxiliary teeth, which will not adversely affect the performance of the machine. Table 5, a further description of Figure 6, lists the amplitude comparison of the magnetic density of M1 and M4 armature teeth with that of auxiliary teeth at two special angles, namely 30 and 200.

Comparison of tooth density between models 1 and 4.

Comparison of tooth flux density of armature teeth and auxiliary teeth in M1 and M4 at 30 and 200 degrees

| Electric angle (°) | M1 armature teeth | M4 armature teeth | M1 auxiliary teeth | M4 auxiliary teeth | Amplitude comparison |

|---|---|---|---|---|---|

| 30 | 1.81 T | 1.49 T | −1.49 T | −1.75 T | M1 armature Teeth > M4 armature teeth |

| 200 | −1.83 T | −1.50 T | 1.51 T | 1.76 T | M1 auxiliary Teeth < M4 auxiliary teeth |

The magnetic field distribution of the above two machines is shown in Figure 7; the panels (a) and (b) are the simulation diagram of the equal tooth and unequal tooth width, respectively. It can be seen from the figure that the flux density of the armature tooth is reduced; hence, the saturation of the armature tooth and the noise will be weakened. The analysis of the magnetic field distribution of the machine is helpful to make a relevant evaluation of the machine performance, which is consistent with the above analysis that the unequal tooth structure has a certain influence on improving the performance of the machine.

Comparison of the distribution of magnetic field lines and magnetic flux density of two kinds of machines: (a) the equal tooth width machine and (b) the unequal tooth width machine.

Figure 8 shows the efficiency of the machine models drawn by Toolkit, the efficiency of M1 at the rated speed is 91%, and the efficiency of M4 at the rated speed is 93%. It can be seen that the maximum efficiency of the unequal tooth width M4 is generally larger than that of the equal tooth width M1 counterpart. Machines with unequal tooth structure are more efficient than the equal tooth; this was because, for unequal tooth width structure, the winding coefficient and the utilization ratio of winding are improved. In conclusion, it is clarified that the optimal model M4 in the five models is formed by the reasonable variation in the stator tooth width, and the rational structure of unequal tooth can effectively improve the operation efficiency of the machine.

Comparison of efficiency for models 1 and 4: (a) the efficiency of machine model 1 and (b) the efficiency of the machine model 4.

3 Conclusion

In this paper, a model of 12-slot/10-pole outer-rotor FSPM machine is established, which is based on the reasonable design of the machine. Due to its unique structure, the output torque of the outer-rotor machine is larger than that of the traditional outer rotor. This paper compares the performance of 12-slot/10-pole FSCW machines with five different teeth and tip width to further optimize machine; a detailed technical description is proposed to describe how the performance of the machine is affected by the unequal stator tooth width, such as output torque, magnetic field distribution, and tooth flux density. The following conclusions are obtained through analysis:

Adjusting the relation between the armature tooth and the auxiliary tooth width has a great influence on the torque of the machine with alternate tooth wounds.

This investigation has confirmed that the performance of the machine can be optimized by adjusting the stator tooth width in an appropriate range.

The reasonable unequal tooth width structure not only improves the winding factor of the machine but also reduces the tooth magnetic density and improves the output torque and working efficiency of the machine. Therefore, the study of unequal tooth width structure plays an important role in the machine.

Abbreviations

- FSPM

-

fractional-slot permanent magnet

- FEA

-

finite element analysis

- PM

-

permanent magnet

- N/2P

-

number of slots of the machine/number of poles

- T W

-

armature tooth tip width

- T H

-

auxiliary tooth tip width

- t w

-

armature tooth body width

- t H

-

auxiliary tooth body width

- a

-

the value variation of stator tooth tip width

- Δt

-

the value variation of stator tooth body width

- M1

-

machine model 1

- M2

-

machine model 2

- M3

-

machine model 3

- M4

-

machine model 4

- M5

-

machine model 5

- T

-

the output torque of the machine

- K dq

-

winding factor

- K α

-

waveform coefficient of air gap magnetic field

- α p

-

pole-arc coefficient

- A

-

line load

- B δ

-

air gap flux density

- D

-

armature diameter

- L

-

length of effective core

Acknowledgments

This study was supported by the Beijing Natural Science Foundation (3172037) and the Natural Science Foundation of Hebei Province (E2017502025).

References

[1] Gu ZY, Wang K, Zhu ZQ, Wu ZZ, Liu C, Cao RW. Torque improvement in five-phase unequal tooth SPM machine by injecting third harmonic current. IEEE Trans Vehicul Technol. Jan 2018;67(1):206–15.10.1109/TVT.2017.2771752Search in Google Scholar

[2] Alberti L, Bianchi N. Theory and design of fractional-slot multilayer windings. IEEE Trans Ind Appl. Mar–Apr 2013;49(2):841–9.10.1109/ECCE.2011.6064188Search in Google Scholar

[3] Xu F, Li T, Tang P. Design of PM synchronous machine with irregular tooth. Micromachines. 2009;42(4):14–6.Search in Google Scholar

[4] Chen P, Chen J, Liao Y, Zhang C, Du J. Vibration and Noise of High Speed Amorphous Alloy Permanent Magnet Synchronous Motor with Different Slot Width. 2019 IEEE 4th International Future Energy Electronics Conference (IFEEC), Singapore, Singapore, 2019. p. 1–5.Search in Google Scholar

[5] Arani MS, Afsari SA. Design of Rotor Structure for Reluctance Magnetic Gear to Improve Torque Characteristic. 2020 11th Power Electronics, Drive Systems, and Technologies Conference (PEDSTC), Tehran, Iran, 2020, p. 1–5.Search in Google Scholar

[6] Chen Q, Liu G, Gong W, Zhao W. A new fault-tolerant permanent-magnet machine for electric vehicle applications. IEEE Trans Magn. Oct 2011;47(10):4183–6.10.1109/TMAG.2011.2146238Search in Google Scholar

[7] Li GJ, Zhu ZQ, Foster M, Stone D. Comparative studies of modular and unequal tooth PM machines either with or without tooth tips. IEEE Trans Magn. July 2014;50(7):1–10.10.1109/TMAG.2014.2310179Search in Google Scholar

[8] Germishuizen JJ, Kamper MJ. IPM traction machine with single layer non-overlapping concentrated windings. IEEE Trans Ind Appl. July–Aug 2009;45(4):1387–94.10.1109/TIA.2009.2023500Search in Google Scholar

[9] Hoffer AE, Petrov I, Pyrhönen JJ, Tapia JA, Bramerdorfer G. Analysis of a tooth-coil winding permanent-magnet synchronous machine with an unequal teeth width. IEEE Access. 2020;8:71512–24.10.1109/ACCESS.2020.2987872Search in Google Scholar

[10] Bianchi N, Bolognani S, Pre MD, Grezzani G. Design considerations for fractional-slot winding configurations of synchronous machines. IEEE Trans Ind Appl. July–Aug 2006;42(4):997–1006.10.1109/TIA.2006.876070Search in Google Scholar

[11] Versaci M. Fuzzy approach and Eddy currents NDT/NDE devices in industrial applications. Electron Lett. 26 May 2016;52(11):943–5.10.1049/el.2015.3409Search in Google Scholar

[12] Schmerr Jr LW, Song SJ. Industrial applications of noncontact ultrasonics techniques. Berlin: Springer Verlag; 2007.Search in Google Scholar

[13] Zhu S, Ji J, Zhao W, Zheng J, Mao Y, Liu G. Unequal teeth design to reduce electromagnetic vibration in fractional-slot concentrated-windings permanent-magnet machine. J Magnet. 2019;24(4):657–67.10.4283/JMAG.2019.24.4.657Search in Google Scholar

[14] Shikun C. Electrical machines design. Beijing: China Machines Press; 2008.Search in Google Scholar

[15] Hwang C, Chang C, Hung S, Liu C. Design of high performance flux switching PM machines with concentrated windings. IEEE Trans Magnet. Jan 2014;50(1):1–4.10.1109/TMAG.2013.2278399Search in Google Scholar

© 2020 Aimeng Wang and Dashuang Li, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Model of electric charge distribution in the trap of a close-contact TENG system

- Dynamics of Online Collective Attention as Hawkes Self-exciting Process

- Enhanced Entanglement in Hybrid Cavity Mediated by a Two-way Coupled Quantum Dot

- The nonlinear integro-differential Ito dynamical equation via three modified mathematical methods and its analytical solutions

- Diagnostic model of low visibility events based on C4.5 algorithm

- Electronic temperature characteristics of laser-induced Fe plasma in fruits

- Comparative study of heat transfer enhancement on liquid-vapor separation plate condenser

- Characterization of the effects of a plasma injector driven by AC dielectric barrier discharge on ethylene-air diffusion flame structure

- Impact of double-diffusive convection and motile gyrotactic microorganisms on magnetohydrodynamics bioconvection tangent hyperbolic nanofluid

- Dependence of the crossover zone on the regularization method in the two-flavor Nambu–Jona-Lasinio model

- Novel numerical analysis for nonlinear advection–reaction–diffusion systems

- Heuristic decision of planned shop visit products based on similar reasoning method: From the perspective of organizational quality-specific immune

- Two-dimensional flow field distribution characteristics of flocking drainage pipes in tunnel

- Dynamic triaxial constitutive model for rock subjected to initial stress

- Automatic target recognition method for multitemporal remote sensing image

- Gaussons: optical solitons with log-law nonlinearity by Laplace–Adomian decomposition method

- Adaptive magnetic suspension anti-rolling device based on frequency modulation

- Dynamic response characteristics of 93W alloy with a spherical structure

- The heuristic model of energy propagation in free space, based on the detection of a current induced in a conductor inside a continuously covered conducting enclosure by an external radio frequency source

- Microchannel filter for air purification

- An explicit representation for the axisymmetric solutions of the free Maxwell equations

- Floquet analysis of linear dynamic RLC circuits

- Subpixel matching method for remote sensing image of ground features based on geographic information

- K-band luminosity–density relation at fixed parameters or for different galaxy families

- Effect of forward expansion angle on film cooling characteristics of shaped holes

- Analysis of the overvoltage cooperative control strategy for the small hydropower distribution network

- Stable walking of biped robot based on center of mass trajectory control

- Modeling and simulation of dynamic recrystallization behavior for Q890 steel plate based on plane strain compression tests

- Edge effect of multi-degree-of-freedom oscillatory actuator driven by vector control

- The effect of guide vane type on performance of multistage energy recovery hydraulic turbine (MERHT)

- Development of a generic framework for lumped parameter modeling

- Optimal control for generating excited state expansion in ring potential

- The phase inversion mechanism of the pH-sensitive reversible invert emulsion from w/o to o/w

- 3D bending simulation and mechanical properties of the OLED bending area

- Resonance overvoltage control algorithms in long cable frequency conversion drive based on discrete mathematics

- The measure of irregularities of nanosheets

- The predicted load balancing algorithm based on the dynamic exponential smoothing

- Influence of different seismic motion input modes on the performance of isolated structures with different seismic measures

- A comparative study of cohesive zone models for predicting delamination fracture behaviors of arterial wall

- Analysis on dynamic feature of cross arm light weighting for photovoltaic panel cleaning device in power station based on power correlation

- Some probability effects in the classical context

- Thermosoluted Marangoni convective flow towards a permeable Riga surface

- Simultaneous measurement of ionizing radiation and heart rate using a smartphone camera

- On the relations between some well-known methods and the projective Riccati equations

- Application of energy dissipation and damping structure in the reinforcement of shear wall in concrete engineering

- On-line detection algorithm of ore grade change in grinding grading system

- Testing algorithm for heat transfer performance of nanofluid-filled heat pipe based on neural network

- New optical solitons of conformable resonant nonlinear Schrödinger’s equation

- Numerical investigations of a new singular second-order nonlinear coupled functional Lane–Emden model

- Circularly symmetric algorithm for UWB RF signal receiving channel based on noise cancellation

- CH4 dissociation on the Pd/Cu(111) surface alloy: A DFT study

- On some novel exact solutions to the time fractional (2 + 1) dimensional Konopelchenko–Dubrovsky system arising in physical science

- An optimal system of group-invariant solutions and conserved quantities of a nonlinear fifth-order integrable equation

- Mining reasonable distance of horizontal concave slope based on variable scale chaotic algorithms

- Mathematical models for information classification and recognition of multi-target optical remote sensing images

- Hopkinson rod test results and constitutive description of TRIP780 steel resistance spot welding material

- Computational exploration for radiative flow of Sutterby nanofluid with variable temperature-dependent thermal conductivity and diffusion coefficient

- Analytical solution of one-dimensional Pennes’ bioheat equation

- MHD squeezed Darcy–Forchheimer nanofluid flow between two h–distance apart horizontal plates

- Analysis of irregularity measures of zigzag, rhombic, and honeycomb benzenoid systems

- A clustering algorithm based on nonuniform partition for WSNs

- An extension of Gronwall inequality in the theory of bodies with voids

- Rheological properties of oil–water Pickering emulsion stabilized by Fe3O4 solid nanoparticles

- Review Article

- Sine Topp-Leone-G family of distributions: Theory and applications

- Review of research, development and application of photovoltaic/thermal water systems

- Special Issue on Fundamental Physics of Thermal Transports and Energy Conversions

- Numerical analysis of sulfur dioxide absorption in water droplets

- Special Issue on Transport phenomena and thermal analysis in micro/nano-scale structure surfaces - Part I

- Random pore structure and REV scale flow analysis of engine particulate filter based on LBM

- Prediction of capillary suction in porous media based on micro-CT technology and B–C model

- Energy equilibrium analysis in the effervescent atomization

- Experimental investigation on steam/nitrogen condensation characteristics inside horizontal enhanced condensation channels

- Experimental analysis and ANN prediction on performances of finned oval-tube heat exchanger under different air inlet angles with limited experimental data

- Investigation on thermal-hydraulic performance prediction of a new parallel-flow shell and tube heat exchanger with different surrogate models

- Comparative study of the thermal performance of four different parallel flow shell and tube heat exchangers with different performance indicators

- Optimization of SCR inflow uniformity based on CFD simulation

- Kinetics and thermodynamics of SO2 adsorption on metal-loaded multiwalled carbon nanotubes

- Effect of the inner-surface baffles on the tangential acoustic mode in the cylindrical combustor

- Special Issue on Future challenges of advanced computational modeling on nonlinear physical phenomena - Part I

- Conserved vectors with conformable derivative for certain systems of partial differential equations with physical applications

- Some new extensions for fractional integral operator having exponential in the kernel and their applications in physical systems

- Exact optical solitons of the perturbed nonlinear Schrödinger–Hirota equation with Kerr law nonlinearity in nonlinear fiber optics

- Analytical mathematical schemes: Circular rod grounded via transverse Poisson’s effect and extensive wave propagation on the surface of water

- Closed-form wave structures of the space-time fractional Hirota–Satsuma coupled KdV equation with nonlinear physical phenomena

- Some misinterpretations and lack of understanding in differential operators with no singular kernels

- Stable solutions to the nonlinear RLC transmission line equation and the Sinh–Poisson equation arising in mathematical physics

- Calculation of focal values for first-order non-autonomous equation with algebraic and trigonometric coefficients

- Influence of interfacial electrokinetic on MHD radiative nanofluid flow in a permeable microchannel with Brownian motion and thermophoresis effects

- Standard routine techniques of modeling of tick-borne encephalitis

- Fractional residual power series method for the analytical and approximate studies of fractional physical phenomena

- Exact solutions of space–time fractional KdV–MKdV equation and Konopelchenko–Dubrovsky equation

- Approximate analytical fractional view of convection–diffusion equations

- Heat and mass transport investigation in radiative and chemically reacting fluid over a differentially heated surface and internal heating

- On solitary wave solutions of a peptide group system with higher order saturable nonlinearity

- Extension of optimal homotopy asymptotic method with use of Daftardar–Jeffery polynomials to Hirota–Satsuma coupled system of Korteweg–de Vries equations

- Unsteady nano-bioconvective channel flow with effect of nth order chemical reaction

- On the flow of MHD generalized maxwell fluid via porous rectangular duct

- Study on the applications of two analytical methods for the construction of traveling wave solutions of the modified equal width equation

- Numerical solution of two-term time-fractional PDE models arising in mathematical physics using local meshless method

- A powerful numerical technique for treating twelfth-order boundary value problems

- Fundamental solutions for the long–short-wave interaction system

- Role of fractal-fractional operators in modeling of rubella epidemic with optimized orders

- Exact solutions of the Laplace fractional boundary value problems via natural decomposition method

- Special Issue on 19th International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering

- Joint use of eddy current imaging and fuzzy similarities to assess the integrity of steel plates

- Uncertainty quantification in the design of wireless power transfer systems

- Influence of unequal stator tooth width on the performance of outer-rotor permanent magnet machines

- New elements within finite element modeling of magnetostriction phenomenon in BLDC motor

- Evaluation of localized heat transfer coefficient for induction heating apparatus by thermal fluid analysis based on the HSMAC method

- Experimental set up for magnetomechanical measurements with a closed flux path sample

- Influence of the earth connections of the PWM drive on the voltage constraints endured by the motor insulation

- High temperature machine: Characterization of materials for the electrical insulation

- Architecture choices for high-temperature synchronous machines

- Analytical study of air-gap surface force – application to electrical machines

- High-power density induction machines with increased windings temperature

- Influence of modern magnetic and insulation materials on dimensions and losses of large induction machines

- New emotional model environment for navigation in a virtual reality

- Performance comparison of axial-flux switched reluctance machines with non-oriented and grain-oriented electrical steel rotors

- Erratum

- Erratum to “Conserved vectors with conformable derivative for certain systems of partial differential equations with physical applications”

Articles in the same Issue

- Regular Articles

- Model of electric charge distribution in the trap of a close-contact TENG system

- Dynamics of Online Collective Attention as Hawkes Self-exciting Process

- Enhanced Entanglement in Hybrid Cavity Mediated by a Two-way Coupled Quantum Dot

- The nonlinear integro-differential Ito dynamical equation via three modified mathematical methods and its analytical solutions

- Diagnostic model of low visibility events based on C4.5 algorithm

- Electronic temperature characteristics of laser-induced Fe plasma in fruits

- Comparative study of heat transfer enhancement on liquid-vapor separation plate condenser

- Characterization of the effects of a plasma injector driven by AC dielectric barrier discharge on ethylene-air diffusion flame structure

- Impact of double-diffusive convection and motile gyrotactic microorganisms on magnetohydrodynamics bioconvection tangent hyperbolic nanofluid

- Dependence of the crossover zone on the regularization method in the two-flavor Nambu–Jona-Lasinio model

- Novel numerical analysis for nonlinear advection–reaction–diffusion systems

- Heuristic decision of planned shop visit products based on similar reasoning method: From the perspective of organizational quality-specific immune

- Two-dimensional flow field distribution characteristics of flocking drainage pipes in tunnel

- Dynamic triaxial constitutive model for rock subjected to initial stress

- Automatic target recognition method for multitemporal remote sensing image

- Gaussons: optical solitons with log-law nonlinearity by Laplace–Adomian decomposition method

- Adaptive magnetic suspension anti-rolling device based on frequency modulation

- Dynamic response characteristics of 93W alloy with a spherical structure

- The heuristic model of energy propagation in free space, based on the detection of a current induced in a conductor inside a continuously covered conducting enclosure by an external radio frequency source

- Microchannel filter for air purification

- An explicit representation for the axisymmetric solutions of the free Maxwell equations

- Floquet analysis of linear dynamic RLC circuits

- Subpixel matching method for remote sensing image of ground features based on geographic information

- K-band luminosity–density relation at fixed parameters or for different galaxy families

- Effect of forward expansion angle on film cooling characteristics of shaped holes

- Analysis of the overvoltage cooperative control strategy for the small hydropower distribution network

- Stable walking of biped robot based on center of mass trajectory control

- Modeling and simulation of dynamic recrystallization behavior for Q890 steel plate based on plane strain compression tests

- Edge effect of multi-degree-of-freedom oscillatory actuator driven by vector control

- The effect of guide vane type on performance of multistage energy recovery hydraulic turbine (MERHT)

- Development of a generic framework for lumped parameter modeling

- Optimal control for generating excited state expansion in ring potential

- The phase inversion mechanism of the pH-sensitive reversible invert emulsion from w/o to o/w

- 3D bending simulation and mechanical properties of the OLED bending area

- Resonance overvoltage control algorithms in long cable frequency conversion drive based on discrete mathematics

- The measure of irregularities of nanosheets

- The predicted load balancing algorithm based on the dynamic exponential smoothing

- Influence of different seismic motion input modes on the performance of isolated structures with different seismic measures

- A comparative study of cohesive zone models for predicting delamination fracture behaviors of arterial wall

- Analysis on dynamic feature of cross arm light weighting for photovoltaic panel cleaning device in power station based on power correlation

- Some probability effects in the classical context

- Thermosoluted Marangoni convective flow towards a permeable Riga surface

- Simultaneous measurement of ionizing radiation and heart rate using a smartphone camera

- On the relations between some well-known methods and the projective Riccati equations

- Application of energy dissipation and damping structure in the reinforcement of shear wall in concrete engineering

- On-line detection algorithm of ore grade change in grinding grading system

- Testing algorithm for heat transfer performance of nanofluid-filled heat pipe based on neural network

- New optical solitons of conformable resonant nonlinear Schrödinger’s equation

- Numerical investigations of a new singular second-order nonlinear coupled functional Lane–Emden model

- Circularly symmetric algorithm for UWB RF signal receiving channel based on noise cancellation

- CH4 dissociation on the Pd/Cu(111) surface alloy: A DFT study

- On some novel exact solutions to the time fractional (2 + 1) dimensional Konopelchenko–Dubrovsky system arising in physical science

- An optimal system of group-invariant solutions and conserved quantities of a nonlinear fifth-order integrable equation

- Mining reasonable distance of horizontal concave slope based on variable scale chaotic algorithms

- Mathematical models for information classification and recognition of multi-target optical remote sensing images

- Hopkinson rod test results and constitutive description of TRIP780 steel resistance spot welding material

- Computational exploration for radiative flow of Sutterby nanofluid with variable temperature-dependent thermal conductivity and diffusion coefficient

- Analytical solution of one-dimensional Pennes’ bioheat equation

- MHD squeezed Darcy–Forchheimer nanofluid flow between two h–distance apart horizontal plates

- Analysis of irregularity measures of zigzag, rhombic, and honeycomb benzenoid systems

- A clustering algorithm based on nonuniform partition for WSNs

- An extension of Gronwall inequality in the theory of bodies with voids

- Rheological properties of oil–water Pickering emulsion stabilized by Fe3O4 solid nanoparticles

- Review Article

- Sine Topp-Leone-G family of distributions: Theory and applications

- Review of research, development and application of photovoltaic/thermal water systems

- Special Issue on Fundamental Physics of Thermal Transports and Energy Conversions

- Numerical analysis of sulfur dioxide absorption in water droplets

- Special Issue on Transport phenomena and thermal analysis in micro/nano-scale structure surfaces - Part I

- Random pore structure and REV scale flow analysis of engine particulate filter based on LBM

- Prediction of capillary suction in porous media based on micro-CT technology and B–C model

- Energy equilibrium analysis in the effervescent atomization

- Experimental investigation on steam/nitrogen condensation characteristics inside horizontal enhanced condensation channels

- Experimental analysis and ANN prediction on performances of finned oval-tube heat exchanger under different air inlet angles with limited experimental data

- Investigation on thermal-hydraulic performance prediction of a new parallel-flow shell and tube heat exchanger with different surrogate models

- Comparative study of the thermal performance of four different parallel flow shell and tube heat exchangers with different performance indicators

- Optimization of SCR inflow uniformity based on CFD simulation

- Kinetics and thermodynamics of SO2 adsorption on metal-loaded multiwalled carbon nanotubes

- Effect of the inner-surface baffles on the tangential acoustic mode in the cylindrical combustor

- Special Issue on Future challenges of advanced computational modeling on nonlinear physical phenomena - Part I

- Conserved vectors with conformable derivative for certain systems of partial differential equations with physical applications

- Some new extensions for fractional integral operator having exponential in the kernel and their applications in physical systems

- Exact optical solitons of the perturbed nonlinear Schrödinger–Hirota equation with Kerr law nonlinearity in nonlinear fiber optics

- Analytical mathematical schemes: Circular rod grounded via transverse Poisson’s effect and extensive wave propagation on the surface of water

- Closed-form wave structures of the space-time fractional Hirota–Satsuma coupled KdV equation with nonlinear physical phenomena

- Some misinterpretations and lack of understanding in differential operators with no singular kernels

- Stable solutions to the nonlinear RLC transmission line equation and the Sinh–Poisson equation arising in mathematical physics

- Calculation of focal values for first-order non-autonomous equation with algebraic and trigonometric coefficients

- Influence of interfacial electrokinetic on MHD radiative nanofluid flow in a permeable microchannel with Brownian motion and thermophoresis effects

- Standard routine techniques of modeling of tick-borne encephalitis

- Fractional residual power series method for the analytical and approximate studies of fractional physical phenomena

- Exact solutions of space–time fractional KdV–MKdV equation and Konopelchenko–Dubrovsky equation

- Approximate analytical fractional view of convection–diffusion equations

- Heat and mass transport investigation in radiative and chemically reacting fluid over a differentially heated surface and internal heating

- On solitary wave solutions of a peptide group system with higher order saturable nonlinearity

- Extension of optimal homotopy asymptotic method with use of Daftardar–Jeffery polynomials to Hirota–Satsuma coupled system of Korteweg–de Vries equations

- Unsteady nano-bioconvective channel flow with effect of nth order chemical reaction

- On the flow of MHD generalized maxwell fluid via porous rectangular duct

- Study on the applications of two analytical methods for the construction of traveling wave solutions of the modified equal width equation

- Numerical solution of two-term time-fractional PDE models arising in mathematical physics using local meshless method

- A powerful numerical technique for treating twelfth-order boundary value problems

- Fundamental solutions for the long–short-wave interaction system

- Role of fractal-fractional operators in modeling of rubella epidemic with optimized orders

- Exact solutions of the Laplace fractional boundary value problems via natural decomposition method

- Special Issue on 19th International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering

- Joint use of eddy current imaging and fuzzy similarities to assess the integrity of steel plates

- Uncertainty quantification in the design of wireless power transfer systems

- Influence of unequal stator tooth width on the performance of outer-rotor permanent magnet machines

- New elements within finite element modeling of magnetostriction phenomenon in BLDC motor

- Evaluation of localized heat transfer coefficient for induction heating apparatus by thermal fluid analysis based on the HSMAC method

- Experimental set up for magnetomechanical measurements with a closed flux path sample

- Influence of the earth connections of the PWM drive on the voltage constraints endured by the motor insulation

- High temperature machine: Characterization of materials for the electrical insulation

- Architecture choices for high-temperature synchronous machines

- Analytical study of air-gap surface force – application to electrical machines

- High-power density induction machines with increased windings temperature

- Influence of modern magnetic and insulation materials on dimensions and losses of large induction machines

- New emotional model environment for navigation in a virtual reality

- Performance comparison of axial-flux switched reluctance machines with non-oriented and grain-oriented electrical steel rotors

- Erratum

- Erratum to “Conserved vectors with conformable derivative for certain systems of partial differential equations with physical applications”