Abstract

In this article, lattice Boltzmann method (LBM) is used to simulate the multi-scale flow characteristics of the engine particulate filter at the pore scale and the representative elementary volume (REV) scale, respectively. Four kinds of random wall-pore structures are considered, which are circular random structure, square random structure, isotropic quartet structure generation set (QSGS), and anisotropic QSGS, with difference analysis done. In terms of the REV scale, the influence of different inlet flow velocities and wall permeabilities on the flow in single channel is analyzed. The result indicates that the internal seepage laws of random structures constructed in this article and single channel are in accordance with Darcy’s law. Circular random structure has better permeability than square random structure. Isotropic QSGS has better fluidity than anisotropic one. The flow in single channel is similar to Poiseuille flow. The flow lines in the channel are complicated and a large number of vortices appear at the ends of channel with high inlet flow rate. With the increase of inlet velocity, the static pressure in channel gradually increases along the axial direction as well as the seepage velocity. The temperature field in the channel becomes more uniform as the flow velocity increases, and the higher temperature distribution appears on the wall of the porous media.

1 Introduction

The particulate matter emitted by the engine will not only cause environmental pollution but also cause serious harm to the human respiratory system [1,2,3,4,5]. Engine particulate filters are currently the most effective and mature post-processing device for reducing particulate emissions [6]. The porous media in the wall-flow particulate filters are mostly made of cordierite or silicon carbide, which has advantages of high temperature resistance, low flow resistance and high mechanical strength, and the filtration efficiency of particulate matter can reach more than 95% [7,8]. Figure 1 shows the structure of wall-flow honeycomb ceramic particulate filter. The channels in the particulate filter are parallel and the adjacent ones are alternately blocked at both ends, forcing the airflow through the wall formed by the porous medium [9]. The particulate matters are collected in and on the surface of porous medium through diffusion deposition, inertial deposition, gravity deposition, and interception deposition to achieve the purpose of reducing particulate matter emission [10,11].

Schematic diagram of a wall-flow honeycomb ceramic particulate filter structure.

Since the operating environment of the particulate filter is very harsh, it is necessary to conduct multi-scale modeling research in different spatial shapes in order to ensure its normal operation [12,13]. The flow of fluid in porous media usually involves three scales, namely, the macro scale, the representative elementary volume (REV), and the pore scale (Pore), as shown in Figure 2. In terms of the pore scale, the research object is the seepage flow through pores of porous media, in which the detailed information of flow can be obtained by studying the transport process through pores of porous media, hence pore scale is often used to explore the mechanism and basic laws of seepage flow. However, there are certain limitations in the application of pore scale since it is often used to simulate the flow of small Reynolds numbers through pores of porous media, and the calculation area is also small, which is difficult to meet the needs of large-scale seepage calculations. Based on the aforementioned reasons, the REV scale is taken into consideration accordingly, which is much larger than the pore scale. REV means a controlled cell of porous medium, which contains enough number of pores, with far large size if compared with single pore, but keeps much smaller than the macro scale.

Three scales of porous media.

The research studies on flow and heat transfer are of great significance [14,15]. Kong et al. [16] established a two-dimensional single channel particulate filter model and used the lattice Boltzmann method (LBM) to calculate the influence of different inlet velocities on the velocity field and pressure field in the channel. Yamamoto et al. [17,18,19,20] used the LBM to study engine particulate filters. By solving the distribution functions of the flow field, temperature field and concentration field, they proposed a conjugate simulation method for gas–solid two-phase flow. According to the temperature change and reaction rate of the particulate filler, the soot combustion process and heat and mass transfer problems during the regeneration of the particulate filler were simulated. Changing the porosity and pore size simulated the filtration and deposition of particulate soot and discussed the flow field and pressure changes during the filtration process. Lee et al. [21] established a stochastic overlapping solid sphere array model, used this model to represent the microstructure of the porous medium in the engine particulate filter, and used the LBM to simulate the flow at the pore scale, and the accuracy of the model was verified.

In this article, the LBM is used to simulate the flow of the porous media wall of the engine particulate filter at the pore scale, and numerical methods of circular random structure, square random structure, isotropic quartet structure generation set (QSGS), and anisotropic QSGS are applied, respectively, for two-dimensional porous media structure modeling, and the differences of flow characteristics are studied. The LBM is used to analyze the flow field distribution, pressure distribution, and temperature distribution inside a single channel at the REV scale.

2 LBM theory

2.1 Introduction to LBM

LBM was originally derived from the lattice gas automata (LGA) theory in the 1980s [22]. LGA simulates the flow of liquid and gas by simulating the basic behavior of gas molecules. First, the fluid and its existence time and space are separated, and then the rules of collision and streaming between discrete fluid particulates are determined. There are three methods for simulating fluid flow and heat transfer, i.e., macroscopic, mesoscopic, and microscopic. LBM is a mesoscopic method between macro and micro. Its core is to build a bridge between macro and micro scale. Unlike molecular dynamics simulation, it no longer considers the motion of individual particulates but considers the motion of all particulates as a whole, which can save a lot of computing resources. And at the mesoscopic level, the fluid is no longer assumed to be a continuous medium, compared with the macroscopic calculation method, accurate results can be obtained. Therefore, the LBM can be used to calculate the small-scale fluid system when the macroscopic model fails. Compared with the commonly used macro methods and micro methods, the LBM has the characteristics of clear physical meaning, simple boundary conditions, and good program parallelism.

2.2 Two-dimensional model of LBM

The lattice Boltzmann model generally includes three parts, i.e., the discrete velocity model, the equilibrium distribution function, and the evolution equation of the distribution function [22]. The key to construct the lattice Boltzmann model is to choose a suitable equilibrium distribution function. In 1992, Qian et al. proposed the classic DdQm model, where d is the space dimension and m is the number of discrete velocities [23]. It is the basic model of the LBM. Among the two-dimensional models, the D2Q9 model is very commonly used in solving fluid flow problems. The evolution of its density distribution function can get the velocity field, and its discrete velocity diagram is shown in Figure 3.

D2Q9 structure discrete speed schematic diagram.

The discrete velocity of the D2Q9 model is as follows:

where

The evolution equation of the density distribution function

The equilibrium distribution function

where

The evolution equation of the internal energy distribution function

The internal energy distribution function

The macro temperature is

2.3 Three-dimensional model of LBM

Among the three-dimensional models, the most commonly used model is the D3Q19 model, and the velocity model diagram is shown in Figure 4. The three-dimensional LBM model uses a dual distribution function model, including a density distribution function and an internal energy distribution function model. The velocity field can be derived from the evolution of the density distribution function, and the temperature field can be derived from the internal energy distribution function [25,26].

D3Q19 structure discrete speed schematic diagram.

The discrete velocity of the D3Q19 model is as follows [27]:

The evolution equation of the density distribution function

The equilibrium distribution function

where

The evolution equation of the internal energy distribution function

where

The internal energy distribution function

where the internal energy

where

2.4 Boundary conditions

When using the LBM to simulate calculations, boundary processing is very critical. After the streaming process, the distribution functions on the internal nodes of the flow field can be obtained, but some distribution functions on the boundary nodes are unknown. Before proceeding to the next calculation, all distribution functions on the boundary nodes must be determined. In numerical simulation, if the flow field changes periodically or infinitely in a certain direction, the periodic boundary should be used. The periodic boundary format is a heuristic format, which means that the unknown distribution function on the boundary node is directly determined by the motion law of the particulate according to the macroscopic physical characteristics of the boundary. For periodic boundaries, when fluid particulates leave the flow field from one side, they will enter the flow field from the other side at the next time step. Periodic boundaries can keep the mass and momentum of the entire system strictly conserved.

The periodic boundary formula is as follows:

2.5 Darcy law

The flow in porous media is usually described by Darcy’s law [29]. Darcy’s law comes from the French engineer Darcy in 1856, which was obtained from a large number of experiments on a cylinder filled with sand [30]. Under laminar flow conditions, without considering the effect of gravity, the following formula is usually used to describe Darcy’s law

where

According to Darcy’s law, the permeability is calculated as [31]:

where

2.6 Unit conversion of LBM

For LBM simulation, it is more convenient to perform calculations by converting dimensioned physical quantities into dimensionless parameters. The calculated governing equation can be decomposed into some dimensionless parameters, and the result obtained can be expressed in a more general form, which has a more universal meaning, and the transformation from macroscopic to mesoscopic is clearer. The flow of fluid in porous media involves three basic physical quantities, namely, length, time, and mass, which are different from the lattice unit used in LBM simulation. The ratio of grid spacing to time step (

The length conversion

The time conversion can be obtained from the hydrodynamic viscosity. For air at 20°C,

The mass conversion

3 Two-dimensional flow analysis of porous media on the wall surface

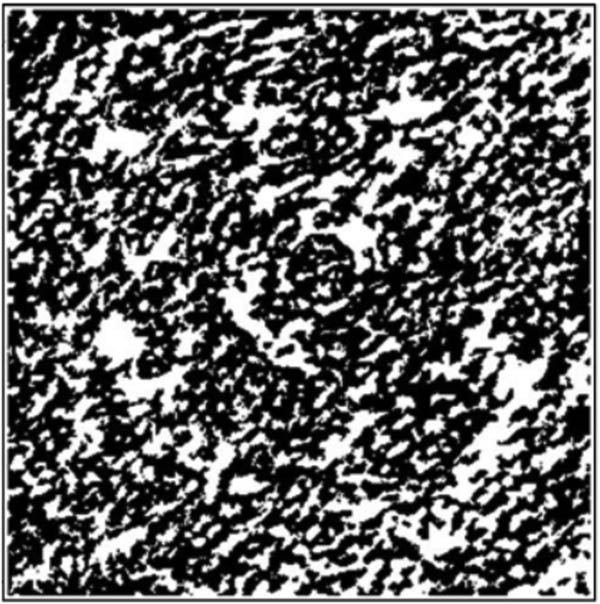

In order to obtain the real internal structure of the porous medium of the engine particulate filter, a Skyscan 1174V2X-CT tomography scanner was used to photograph the porous medium sample. The internal structure is shown in Figure 5. The black part in the figure is the pore through which the fluid moves, and the white area is the pansy Bluestone wall surface. Based on the ratio of the black part to the white part in Figure 5, it can be indicated that the porosity of the sample porous medium is about 0.6. In this article, circular random structure, square random structure, isotropic QSGS, and anisotropic QSGS have been chosen as the numerical methods to model the porous medium structure of the engine particulate filter, and the flow of the models at low and medium Reynolds numbers and the relationship between particle size and filtration efficiency were analyzed. Many scholars have conducted research on particulate matter in fluid flow [32]. Kong et al. [33] have studied the particulate matter distribution of porous media with different porosities in a particulate filter. In 2007, Wang et al. [34,35,36] proposed QSGS closely combined with the LBM to construct a porous medium structure similar to the real porous medium.

Internal structure of porous media.

3.1 Circular and square random structure

A certain number of circles with the same diameter and a number of randomly generated squares with side lengths of random numbers within a certain range are, respectively, placed in a calculation domain with a size of 200 × 200 grids to form a porous medium, and set the porosity of the two structures to be ε = 0.6. Figure 6 shows the schematic diagram of the random structure of the two.

Schematic diagram of circular random structure (a) and square random structure (b).

Figure 7 shows the streamline diagram of the two random structures. The Reynolds number Re is 0.6. It can be found that there is no eddy current in the two random structures, indicating that the flow is mainly determined by the viscous force. At the same stage, it can be found that due to the relatively uneven distribution of the solid framework of the circular random structure, which interferes with the internal fluid flow process, the flow lines inside the circular random structure are relatively winding, with the fluid flowing from the smaller pores into the larger pores. In contrast, the distribution of the solid framework of the square random structure is relatively uniform, and the pore size is relatively uniform, and the fluid basically flows along the nearest pore.

Streamline diagram of circular random structure (a) and square random structure (b).

Figure 8 shows the flow field contour map of two random structures. It can be found that the velocity distribution of the square random structure is relatively concentrated and very uniform, while the velocity distribution of the circular random structure is nonuniform in which there is a velocity peak at the large pores and the velocity at the small pores is almost close to zero.

Contour map of flow field of circular random structure (a) and square random structure (b).

Figure 9 shows the relationship between the dimensionless permeability of two random structures and the Reynolds number. It can be found that the flow inside the two structures conforms to Darcy’s law. The permeability of the circular random structure is greater than that of the square random structure. Figures 7 and 8 show that the distribution of the solid framework of the circular random structure is uneven, and larger pores will be formed to let most of the fluid flow through with relatively better permeability, while the distribution of the solid framework of the square random structure is relatively more uniform so as to make the pore size more consistent and cause greater fluid flow resistance. As a result, the permeability of square random structure is less than that of circular random structure.

The relationship between dimensionless permeability and Reynolds number of circular random structure and square random structure.

3.2 QSGS

3.2.1 Porous media constructed by QSGS

The growth core distribution probability cd represents the density of the growth core number, which reflects the statistical distribution characteristics of the growth phase in the system space. Assuming that there are 400 skeleton units in the calculation area and a 200 × 200 grid is used to construct the porous medium, the value of cd is 400/40,000 = 0.01, which means the probability that each structural node in the area becomes the growth nucleus of the skeleton is 0.01; and cd determines the fine structure characteristics of the porous medium. The larger the value, the smaller the average size of the fiber that produces the structure, and the distribution is more uniform. If the cd value is too small, there will be too few growth core under a certain number of grids, and a more realistic porous media structure cannot be formed. Figure 10 shows the porous media constructed according to different growth core distribution probabilities. The porosity ε of both (a) and (b) is 0.6, and the cd of (b) is smaller. It can be found that the internal framework and pore shape are more refined.

The structure of porous media with different growth core distribution probabilities by QSGS (ε = 0.6). (a) cd = 0.1 and (b) cd = 0.01

The directional growth probability di means the probability that adjacent nodes become the growth phase in the direction i. Choosing the same or different growth probabilities in each direction can construct an isotropic or anisotropic porous medium. For the D2Q9 model, the growth direction is consistent with the discrete velocity direction, and the horizontal growth probability is set to d13, the vertical direction is set to d24, and the two diagonal directions are set to d57 and d68, respectively. Figure 11 shows the pore structure of two-dimensional porous media generated according to different growth probabilities. The black parts in the figure are pores, and the white parts are the solid framework of the growth phase. It can be found that (a) has obvious isotropy, while (b), (c), and (d) have obvious anisotropy.

The structure of porous media with various growth probabilities by QSGS (cd = 0.01, ε = 0.3). (a) d13 = d24 = d57 = d68 = 0.001, (b) d13 = 0.08, d24 = d57 = d68 = 0.001, (c) d24 = 0.08, d13 = d57 = d68 = 0.001, and (d) d57 = 0.08, d13 = d24 = d68 = 0.001.

3.2.2 Flow analysis of QSGS with different directional growth probabilities

The QSGS is used to construct isotropic and anisotropic porous media, the porosity ε is 0.7, the growth core distribution probability cd = 0.01, and the directional growth probability di of isotropic porous media is: d13 = d24 = d57 = d68 = 0.001, the directional growth probability di of anisotropic porous media is: d13 = 0.08, d24 = d57 = d68 = 0.001, Reynolds number Re = 0.6, and the internal flow field is calculated. As shown in Figure 12, the white area is the solid framework and the colored area is the flow area. By comparing the isotropic structure with the anisotropic porous medium, it can be found that although the porosity of the two is the same, in the flow direction, the isotropic porous media structure has fewer effective paths, and most of the pore ends are closed dead ends. Figure 13 shows the average velocity in the y direction of the two. It can be found that the overall average velocity of the isotropic structure is less than the anisotropy. If x/H is smaller than 0.32, the isotropic velocity is greater than the anisotropy. This is because the isotropic structure generated in this article has more pores at the fluid inlet and the flow rate is larger. When the fluid reaches the back section of the structure, it cannot pass through, and its average velocity is lower than the anisotropic structure at the beginning.

Flow field contour map of QSGS with different growth probabilities. (a) d13 = d24 = d57 = d68 = 0.001 and (b) d13 = 0.08, d24 = d57 = d68 = 0.001.

Average velocity in y direction of flow field in porous media with isotropic and anisotropic structure.

Figure 14 shows the pressure distribution contour map of the isotropic structure. Since there are many pores at the left flow inlet, most of the fluid can flow forward, so the pressure gradient of the entire calculation area is small. At the fluid inlet, the pressure in the blue area is lower. If you zoom in on the streamline diagram here, you can find that the fluid cannot continue to flow after entering the pores here, then generate vortices and flow out of the pores. The pressure is lower compared to other areas. The pressure in the red area is significantly higher than other areas. By zooming in on the streamline diagram here, it can be found that after the fluid enters the pores here, there is a sudden narrow “throat” where the flow velocity suddenly increases. According to Darcy’s law, the pressure in the seepage area is linearly correlated with the flow velocity, so the pressure in this area becomes larger.

Pressure distribution contour map of isotropic porous media.

4 Three-dimensional single channel heat transfer analysis

4.1 Three-dimensional channel flow model

Due to the similarity of the internal channels of the particulate filter, a single channel is selected as the calculation domain. Figure 15 shows a schematic diagram of the established three-dimensional and two-dimensional physical model of a single channel of the particulate filter. The main geometric features used in the simulation are shown in Table 1. In order to ensure the stability of the simulation and fully develop the intake air flow, the inlet has increased the calculation area by 0.1 times the length of the channel. The channel is provided with an external flow field as the air outlet, the plug part is set as an adiabatic wall, and the surrounding walls adopt the rebound boundary format. The fluid inlet adopts velocity boundary conditions.

(a) Three-dimensional and (b) two-dimensional schematic diagram of single channel of particulate filter.

Geometric characteristics and working conditions of single channel of particulate filter

| Geometry model features of the channel | Unit | Working conditions | ||

|---|---|---|---|---|

| Length | mm | 20 | ||

| Width | mm | 2 | ||

| Thickness | mm | 0.5 | ||

| Plug thickness | mm | 0.6 | ||

| Wall permeability | m2 | 1 × 10−14 | 1 × 10−13 | 5 × 10−13 |

| Initial pressure | Pa | 0 | ||

| Intake air temperature | K | 600 | ||

| Temperature outside the channel | K | 400 | ||

| Intake speed | m/s | 1 | 5 | 20 |

4.2 Analysis of flow characteristics in the three-dimensional channel

Figure 16 shows the relationship between the wall seepage velocity and the pressure gradient inside and outside the wall when the inlet flow velocity is 1 m/s and the wall permeability is 1 × 10−14 m2. It can be seen from the figure that the seepage velocity of the wall has a linear relationship with the pressure gradient. As the flow velocity increases, the pressure gradient increases, and passing through the origin indicates that the seepage flow through the wall conforms to Darcy’s law.

Relationship between seepage velocity of the wall and pressure gradient inside and outside the wall.

Figure 17 shows the velocity distribution in the x direction at different axial positions when the inlet air velocity is 1 m/s and the wall permeability is 1 × 10−14 m2. It can be found that the air velocity distribution inside the channel is similar to Poiseuille flow. The distribution is parabolic; the farther away from the entrance of the channel, the lower the speed, the lowest air velocity near the wall of the channel, the highest air velocity at the center line, and the minimum seepage velocity in the porous media wall.

Velocity distribution in x direction at different axial positions.

Figure 18 shows the seepage velocity distribution in the porous media wall at different axial positions when the inlet air velocity is 1 m/s and the wall permeability is 1 × 10−14 m2. It can be seen from the figure that the wall seepage at different axial positions the overall velocity is not much different, especially the seepage velocity on the side far from the flow field inside the channel is very close, the seepage velocity in the side wall close to the flow field gradually increases, and the seepage velocity near the channel entrance is relatively large.

Wall seepage velocity distribution at different axial positions.

4.3 Effect of intake speed on flow

Figure 19 shows a three-dimensional streamline diagram at different intake speeds. It can be seen from the figure that when the intake air velocity is low, the streamline passes through the wall and continues to flow in the original velocity direction, while the streamline with higher intake velocity still flows to the rear end of the channel after passing through the wall; when the intake air velocity is low, the streamlines are relatively regular throughout the channel, while the streamlines at high velocities become very complicated, especially at 20 m/s, a large number of vortices appear at the ends of the channel.

Three-dimensional streamline diagram at different intake speeds. (a) u = 1 m/s, (b) u = 5 m/s, and (c) u = 20 m/s.

Figure 20 shows the velocity contour map at different intake air flow rates. It can be found that because the frictional force of the airflow near the wall and the viscous force inside the fluid are greater than the inertial force of the airflow, the uniform flow at the entrance of the channel gradually changes into an uneven flow along the axial direction, and because of the plug at the end of the channel, the airflow cannot directly flow out of the channel, so the flow rate gradually decreases. For the inlet velocity of 1 m/s, the uniformity of the velocity field is significantly lower than that of 5 and 20 m/s, and the velocity near the end of the channel is close to zero, while for the inlet velocity of 5 and 20 m/s cases, the end of the channel has an outward velocity field. Because of its high flow rate, the airflow still has a relatively high velocity near the plug. The fluid is forced to flow through the porous media wall near the plug to the outside of the channel.

Velocity contour map at different intake speeds. (a) u = 1 m/s, (b) u = 5 m/s, and (c) u = 20 m/s.

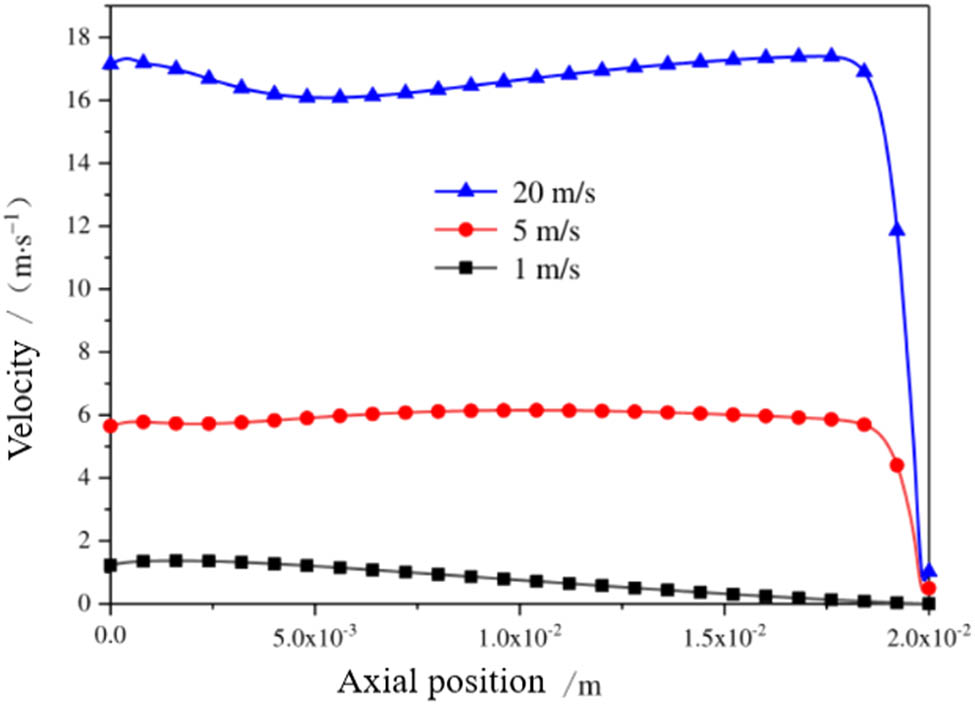

Figure 21 shows the change curve of the channel centerline velocity under different intake speeds in the steady state. From the figure, it can be found that the centerline velocity distribution of the channel with the intake flow velocity of 5 and 20 m/s has similar characteristics. The mainstream velocity does not change much, but the velocity in the area near the plug quickly decreases to zero.

Variation curve of center line velocity of channel under different intake speeds in the steady state.

Figure 22 shows the axial change curve of the wall seepage velocity of the inlet air velocity 1 and 5 m/s, the wall permeability is 1 × 10−14 m2, and the wall thickness is 0.45 mm.

Change curve of wall seepage velocity along the axial direction under different inlet velocities.

It can be seen from Figure 22 that when the intake velocity is 1 m/s, the wall seepage velocity gradually decreases along the axis, and when the intake velocity increases to 5 m/s, it can be found that the wall seepage velocity gradually increases along the axis. It means that more air flows through the wall at the rear end of the channel, which is consistent with the velocity contour maps. When the air inlet velocity is small, the pressure at the end of the channel is also small. The main driving force for the flow from the inside of the channel to the outside, the static pressure of the channel gradually increases along the axial direction, and the seepage velocity increases accordingly. The gas seepage velocity is proportional to the flow rate. The particulates will be filtered out as the gas flows through the wall of the porous medium. When the flow rate is large, it means that the number of particulates passing through the wall is also great, and the more particulates are trapped, so the value of seepage velocity can be used to measure the amount of particulates trapped. It can be inferred that the particulates deposited on the wall at the end of the channel at a higher inlet flow rate are more.

Figure 23 shows the pressure contour map inside the channel at different intake speeds. It can be found that the overall change of static pressure in the channel is small. This is because the resistance in the channel has a small influence on the pressure drop, so the static pressure inside the channel does not change much along the axial direction; as the flow rate increases, the pressure of the channel increases, especially when the air inlet speed is 5 and 20 m/s, the pressure at the end of the channel is significantly higher than the other parts of the channel.

Pressure contour map at different intake speeds. (a) u = 1 m/s, (b) u = 5 m/s, and (c) u = 20 m/s.

Figure 24 shows the temperature contour map inside the channel under different air inlet speeds. It can be found that the temperature field in the channel becomes more uniform as the flow rate increases. The temperature distribution of the porous media wall also appears at higher flow rates. When the flow velocity is 5 and 20 m/s, an outward temperature field appears at the end of the channel, indicating that in the heat transfer process of the channel, part of the heat is transferred to the wall of the porous medium by heat conduction and convection, and the other part flows out of the channel by mass transport. At the same time, it also shows that a larger part of the airflow chooses to pass through the wall of the porous medium at the end of the channel. It can be found that when the air intake velocity is 20 m/s, there is also a temperature distribution outside the inlet and outlet of the channel. This is because the intake air flow is large and contains more heat, so heat accumulation is formed at the inlet.

Temperature contour map at different intake speeds. (a) u = 1 m/s, (b) u = 5 m/s, and (c) u = 20 m/s.

4.4 Effect of wall permeability on heat transfer

Figure 25 shows the change curve of the channel center line velocity under different wall permeabilities when the inlet air flow rate is 5 m/s. It can be found from the figure that when the wall permeability is small, the channel center velocity changes approximately linearly. For larger wall permeability, the channel center velocity shows a nonlinear change. This is because when the wall permeability is low, the flow resistance of the wall is greater, and less air flow from the wall of the channel, and the air flow in the channel is more similar to the pure pipe flow, so the speed change is approximately linear. When the permeability is larger, the wall flow resistance is relatively small, and the airflow flows along the channel while flowing out of the channel through the wall seepage. There are many factors influencing the flow and the flow mechanism is more complicated, so the velocity distribution presents a nonlinear law.

Variation curve of center line velocity of channel under different wall permeabilities.

Figure 26 shows the change curve of the static pressure of the channel centerline under different wall permeabilities at an inlet flow rate of 5 m/s. It can be seen from the figure that as the wall permeability decreases, the static pressure in the channel increases greatly, and when the wall permeability is small, the static pressure change of the channel center is approximately linear. When the wall permeability is large, the static pressure change along the channel is small, and the pressure increases sharply only at the end of the channel.

Variation curve of static pressure at the center line of the channel under different wall permeabilities.

Figure 27 shows the change curve of the temperature of the channel center under different wall permeabilities when the air inlet flow rate is 5 m/s. From the figure, it can be found that the temperature of different wall permeabilities is not much different. This is because the fluid conducts little heat through the wall seepage. And most of the gas flows out of the channel on the wall near the plug. Wall permeability has little effect on the heat transfer of the channel. The heat transfer inside the channel is affected by conduction and convection. Therefore, the temperature curve in the channel is nonlinear changes. The temperature curve near the plug fluctuates. This is due to the accumulation of air flow at the plug, and more gas percolates out of the channel through the wall. The flow situation is more complicated, and the heat transfer mechanism here is also relatively complicated. Therefore, there is a certain fluctuation in temperature at the end of the channel.

Variation curve of center temperature of channel under different wall permeabilities.

5 Conclusions

The internal seepage laws of both the circular random structure and the square random structure constructed in this article conform to Darcy’s law. The flow characteristics of the round and square random structures are affected by the distribution of pores. The solid framework of the round random structure is unevenly distributed and form larger pores, so the permeability is relatively good. The solid framework of the square random structure is uniformly distributed and the pore size is relatively uniform, so the resistance when the fluid flows is relatively large.

The four parameters in the QSGS are the probability of growth core and the probabilities of directional growth in three directions, respectively. The greater the probability of growth core, the finer the structure of the porous media skeleton and pore shape, and the denser the skeleton. Anisotropic and isotropic porous media structure can be realized by changing different directional growth probabilities. The flow capacity of the isotropic QSGS is better than that of the anisotropic one since the flow direction is horizontal in this case.

Based on the REV scale and the flow inside a single channel of the engine particulate filter, it is found that the internal seepage flow in the channel wall conforms to Darcy’s law, and the flow inside the channel is similar to Poiseuille flow when the inlet air velocity is low. Different inlet flow rates have a significant effect on the flow and heat transfer of the channel. That is, the pressure and heat transfer intensity of the channel increase as flow rate goes up. Different wall permeability has a certain influence on the flow in the channel. That is, the smaller the wall permeability, the closer the flow is to pure pipe flow, and the less the influence of wall permeability on the heat transfer inside the channel.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (52005149), Natural Science Foundation of Hebei Province (E2018202064), National Engineering Laboratory for Mobile Source Emission Control Technology (NELMS2017B06), and State Key Laboratory of Engines, Tianjin University (K2020-15).

References

[1] Peters A, von Klot S, Heier M, Trentinaglia I, Hormann A, Wichmann HE, et al. Exposure to traffic and the onset of myocardial infarction. J N Engl J Med. 2004;351(17):1721–30. 10.1056/NEJMoa040203.Search in Google Scholar PubMed

[2] Bernstein JA, Alexis N, Barnes C, Bernstein IL, Williams PB. Health effects of air pollution. J Allergy Clin Immunol. 2004;114(5):1116–23. 10.1016/j.jaci.2004.08.030 Search in Google Scholar PubMed

[3] Franck U, Odeh S, Wiedensohler A, Wehner B, Herbarth O. The effect of particle size on cardiovascular disorders – The smaller the worse. J Sci Total Environ. 2011;409(20):4217–21. 10.1016/j.scitotenv.2011.05.049.Search in Google Scholar PubMed

[4] Han Y, Zhu T, Guan T, Zhu Y, Liu J, Ji Y, et al. Association between size-segregated particles in ambient air and acute respiratory inflammation. J Sci Total Environ. 2016;565:412–9. 10.1016/j.scitotenv.2016.04.196.Search in Google Scholar PubMed

[5] Wang S, Yan Q, Zhang R, Jiang N, Yin S, Ye H, et al. Size-fractionated particulate elements in an inland city of China: Deposition flux in human respiratory, health risks, source apportionment, and dry deposition. J Environ Pollut. 2019;247:515–23. 10.1016/j.envpol.2019.01.051.Search in Google Scholar PubMed

[6] Guan B, Zhan R, Lin H, Huang Z. Review of the state-of-the-art of exhaust particulate filter technology in internal combustion engines. J Environ Manag. 2015;154:225–58. 10.1016/j.jenvman.2015.02.027.Search in Google Scholar PubMed

[7] Eakle S, Avery S, Weber P, Henry C. Comparison of accelerated ash loading methods for gasoline particulate filters. C SAE Technical Paper Series. 2018;2018-01-1703. 10.4271/2018-01-1703.Search in Google Scholar

[8] Yu M, Luss D, Balakotaiah V. Analysis of ignition in a diesel particulate filter. J Catal Today. 2013;216(2013):158–68. 10.1016/j.cattod.2013.05.003.Search in Google Scholar

[9] Wu G, Kuznetsov AV, Jasper WJ. Distribution characteristics of exhaust gases and soot particles in a wall-flow ceramics filter. J Aerosol Sci. 2011;42(7):447–61. 10.1016/j.jaerosci.2011.04.003.Search in Google Scholar

[10] Mizutani T, Kaneda A, Ichikawa S, Miyairi Y, Ohara E, Takahashi A. Filtration behavior of diesel particulate filters (2). C SAE Technical Paper Series. 2007;2007-01-0921. 10.4271/2007-01-0923.Search in Google Scholar

[11] Konstandopoulos AG, Kostoglou M, Housiada P, Vlachos N, Zarvalis D. Simulation of triangular-cell-shaped, fibrous wall-flow filters. C SAE Technical Paper Series. 2003;2003-01-0839. 10.4271/2003-01-0839.Search in Google Scholar

[12] Konstandopoulos AG, Kostoglou M, Vlachos N. The multiscale nature of diesel particulate filter simulation. J Int J Veh Des. 2006;41(1–4):256–84. 10.1504/ijvd.2006.009676.Search in Google Scholar

[13] Fino D, Bensaid S, Piumetti M, Russo N. A review on the catalytic combustion of soot in diesel particulate filters for automotive applications: From powder catalysts to structured reactors. J Appl Catal A: Gen. 2016;509:75–96. 10.1016/j.apcata.2015.10.016.Search in Google Scholar

[14] Zheng D, Wang J, Chen Z, Baleta J, Sundén B. Performance analysis of a plate heat exchanger using various nanofluids. J Int J Heat Mass Transf. 2020;158:119993. 10.1016/j.ijheatmasstransfer.2020.119993.Search in Google Scholar

[15] Chen Z, Zheng D, Wang J, Chen L, Sundén B. Experimental investigation on heat transfer characteristics of various nanofluids in an indoor electric heater. J Renew Energy. 2019;147(1):1011–18. 10.1016/j.renene.2019.09.036.Search in Google Scholar

[16] Kong X, Li Z, Shen B, Wu Y, Zhang Y, Cai D. Simulation of flow and soot particle distribution in wall-flow DPF based on lattice Boltzmann method. J Chem Eng Sci. 2019;202:169–85. 10.1016/j.ces.2019.03.039.Search in Google Scholar

[17] Yamamoto K, Takada N, Misawa M. Combustion simulation with lattice Boltzmann method in a three-dimensional porous structure. J Proc Combust Inst. 2005;30(1):1509–15. 10.1016/j.proci.2004.08.030.Search in Google Scholar

[18] Yamamoto K, Satake S, Yamashita H, Takada N, Misawa M. Lattice Boltzmann simulation on porous structure and soot accumulation. J Math Comp Simul. 2006;72(2–6):257–63. 10.1016/j.matcom.2006.05.021.Search in Google Scholar

[19] Yamamoto K, Takada N. LB simulation on soot combustion in porous media. J Phys A: Stat Mech Its Appl. 2006;362(1):111–7. 10.1016/j.physa.2005.09.033.Search in Google Scholar

[20] Yamamoto K, Satake S, Yamashita H. Microstructure and particle-laden flow in diesel particulate filter. J Int J Therm Sci. 2009;48(2):303–7. 10.1016/j.ijthermalsci.2008.08.009.Search in Google Scholar

[21] Lee DY, Lee GW, Yoon K, Chun B, Jung HW. Lattice Boltzmann simulations for wall-flow dynamics in porous ceramic diesel particulate filters. J Appl Surf Sci. 2018;429:72–80. 10.1016/j.apsusc.2017.08.074.Search in Google Scholar

[22] Wolf-Gladrow DA. Lattice Gas cellular automata and lattice Boltzmann models. New York: Springer; 2000. 10.1007/b72010.Search in Google Scholar

[23] Qian YH, Orszag SA, Lattice BGK. Models for the Navier–Stokes equation: Nonlinear deviation in compressible regimes. Europhys Lett. 1993;21(3):255–9. 10.1209/0295-5075/21/3/001.Search in Google Scholar

[24] Peng Y, Shu C, Chew YT. Simplified thermal lattice Boltzmann model for incompressible thermal flows. J Phys Rev E. 2003;68(2);026701-1–026701-8. 10.1103/physreve.68.026701.Search in Google Scholar PubMed

[25] Shan X. Simulation of Rayleigh–Bénard convection using a lattice Boltzmann method. J Phys Rev. 1997;55:2780–8. 10.1103/physreve.55.2780.Search in Google Scholar

[26] He X, Chen S, Doolen GD, Novel A. Thermal model for the lattice Boltzmann method in incompressible limit. J Comput Phys. 1998;146:282–300. 10.1006/jcph.1998.6057.Search in Google Scholar

[27] Mei R, Shyy W, Yu D, Luo LS. Lattice Boltzmann method for 3-D flows with curved boundary. J Computat Phys. 2000;161(2):680–99. 10.1006/jcph.2000.6522.Search in Google Scholar

[28] He X, Luo LS. Theory of the lattice Boltzmann method: From the Boltzmann equation to the lattice Boltzmann equation. J Phys Rev E. 1997;56(6):6811–7. 10.1103/physreve.56.6811.Search in Google Scholar

[29] Bear J. Dynamics of fluids in porous media. M Soil Sci. 1975;120(2):162–3. 10.1097/00010694-197508000-00022.Search in Google Scholar

[30] Ritzi RW, Bobeck P. Comprehensive principles of quantitative hydrogeology established by Darcy (1856) and Dupuit (1857). J Water Resour Res. 2008;44(10):12–25. 10.1029/2008wr007002.Search in Google Scholar

[31] Zhang M, Ye G, Breugel Kvan. Microstructure-based modeling of permeability of cementitious materials using multiple-relaxation-time lattice Boltzmann method. J Computat Mater Sci. 2013;68:142–51. 10.1016/j.commatsci.2012.09.033.Search in Google Scholar

[32] Wang J, Tian K, Zhu H, Zeng M, Sundén B. Numerical investigation of particle deposition in film-cooled blade leading edge. J Numer Heat Transfer, Part A: Appl. 2020;77(20):579–98. 10.1080/10407782.2020.1713692.Search in Google Scholar

[33] Kong X, Li Z, Cai D, Shen B, Zhang Y. Numerical simulation of the particle filtration process inside porous walls using lattice Boltzmann Method. J Chem Eng Sci. 2019;202:282–99. 10.1016/j.ces.2019.03.040.Search in Google Scholar

[34] Wang M, Wang J, Pan N, Chen S. Mesoscopic predictions of the effective thermal conductivity for microscale random porous media. J Phys Rev E. 2007;75(3):036702. 10.1103/physreve.75.036702.Search in Google Scholar

[35] Wang M, Pan N, Wang J, Chen S. Mesoscopic simulations of phase distribution effects on the effective thermal conductivity of microgranular porous media. J Colloid Interface Sci. 2007;311(2):562–70. 10.1016/j.jcis.2007.03.038.Search in Google Scholar PubMed

[36] Wang M, Pan N. Numerical analyses of effective dielectric constant of multiphase microporous media. J Appl Phys. 2007;101(11):114102. 10.1063/1.274373.Search in Google Scholar

© 2020 Chunrui Wu et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Model of electric charge distribution in the trap of a close-contact TENG system

- Dynamics of Online Collective Attention as Hawkes Self-exciting Process

- Enhanced Entanglement in Hybrid Cavity Mediated by a Two-way Coupled Quantum Dot

- The nonlinear integro-differential Ito dynamical equation via three modified mathematical methods and its analytical solutions

- Diagnostic model of low visibility events based on C4.5 algorithm

- Electronic temperature characteristics of laser-induced Fe plasma in fruits

- Comparative study of heat transfer enhancement on liquid-vapor separation plate condenser

- Characterization of the effects of a plasma injector driven by AC dielectric barrier discharge on ethylene-air diffusion flame structure

- Impact of double-diffusive convection and motile gyrotactic microorganisms on magnetohydrodynamics bioconvection tangent hyperbolic nanofluid

- Dependence of the crossover zone on the regularization method in the two-flavor Nambu–Jona-Lasinio model

- Novel numerical analysis for nonlinear advection–reaction–diffusion systems

- Heuristic decision of planned shop visit products based on similar reasoning method: From the perspective of organizational quality-specific immune

- Two-dimensional flow field distribution characteristics of flocking drainage pipes in tunnel

- Dynamic triaxial constitutive model for rock subjected to initial stress

- Automatic target recognition method for multitemporal remote sensing image

- Gaussons: optical solitons with log-law nonlinearity by Laplace–Adomian decomposition method

- Adaptive magnetic suspension anti-rolling device based on frequency modulation

- Dynamic response characteristics of 93W alloy with a spherical structure

- The heuristic model of energy propagation in free space, based on the detection of a current induced in a conductor inside a continuously covered conducting enclosure by an external radio frequency source

- Microchannel filter for air purification

- An explicit representation for the axisymmetric solutions of the free Maxwell equations

- Floquet analysis of linear dynamic RLC circuits

- Subpixel matching method for remote sensing image of ground features based on geographic information

- K-band luminosity–density relation at fixed parameters or for different galaxy families

- Effect of forward expansion angle on film cooling characteristics of shaped holes

- Analysis of the overvoltage cooperative control strategy for the small hydropower distribution network

- Stable walking of biped robot based on center of mass trajectory control

- Modeling and simulation of dynamic recrystallization behavior for Q890 steel plate based on plane strain compression tests

- Edge effect of multi-degree-of-freedom oscillatory actuator driven by vector control

- The effect of guide vane type on performance of multistage energy recovery hydraulic turbine (MERHT)

- Development of a generic framework for lumped parameter modeling

- Optimal control for generating excited state expansion in ring potential

- The phase inversion mechanism of the pH-sensitive reversible invert emulsion from w/o to o/w

- 3D bending simulation and mechanical properties of the OLED bending area

- Resonance overvoltage control algorithms in long cable frequency conversion drive based on discrete mathematics

- The measure of irregularities of nanosheets

- The predicted load balancing algorithm based on the dynamic exponential smoothing

- Influence of different seismic motion input modes on the performance of isolated structures with different seismic measures

- A comparative study of cohesive zone models for predicting delamination fracture behaviors of arterial wall

- Analysis on dynamic feature of cross arm light weighting for photovoltaic panel cleaning device in power station based on power correlation

- Some probability effects in the classical context

- Thermosoluted Marangoni convective flow towards a permeable Riga surface

- Simultaneous measurement of ionizing radiation and heart rate using a smartphone camera

- On the relations between some well-known methods and the projective Riccati equations

- Application of energy dissipation and damping structure in the reinforcement of shear wall in concrete engineering

- On-line detection algorithm of ore grade change in grinding grading system

- Testing algorithm for heat transfer performance of nanofluid-filled heat pipe based on neural network

- New optical solitons of conformable resonant nonlinear Schrödinger’s equation

- Numerical investigations of a new singular second-order nonlinear coupled functional Lane–Emden model

- Circularly symmetric algorithm for UWB RF signal receiving channel based on noise cancellation

- CH4 dissociation on the Pd/Cu(111) surface alloy: A DFT study

- On some novel exact solutions to the time fractional (2 + 1) dimensional Konopelchenko–Dubrovsky system arising in physical science

- An optimal system of group-invariant solutions and conserved quantities of a nonlinear fifth-order integrable equation

- Mining reasonable distance of horizontal concave slope based on variable scale chaotic algorithms

- Mathematical models for information classification and recognition of multi-target optical remote sensing images

- Hopkinson rod test results and constitutive description of TRIP780 steel resistance spot welding material

- Computational exploration for radiative flow of Sutterby nanofluid with variable temperature-dependent thermal conductivity and diffusion coefficient

- Analytical solution of one-dimensional Pennes’ bioheat equation

- MHD squeezed Darcy–Forchheimer nanofluid flow between two h–distance apart horizontal plates

- Analysis of irregularity measures of zigzag, rhombic, and honeycomb benzenoid systems

- A clustering algorithm based on nonuniform partition for WSNs

- An extension of Gronwall inequality in the theory of bodies with voids

- Rheological properties of oil–water Pickering emulsion stabilized by Fe3O4 solid nanoparticles

- Review Article

- Sine Topp-Leone-G family of distributions: Theory and applications

- Review of research, development and application of photovoltaic/thermal water systems

- Special Issue on Fundamental Physics of Thermal Transports and Energy Conversions

- Numerical analysis of sulfur dioxide absorption in water droplets

- Special Issue on Transport phenomena and thermal analysis in micro/nano-scale structure surfaces - Part I

- Random pore structure and REV scale flow analysis of engine particulate filter based on LBM

- Prediction of capillary suction in porous media based on micro-CT technology and B–C model

- Energy equilibrium analysis in the effervescent atomization

- Experimental investigation on steam/nitrogen condensation characteristics inside horizontal enhanced condensation channels

- Experimental analysis and ANN prediction on performances of finned oval-tube heat exchanger under different air inlet angles with limited experimental data

- Investigation on thermal-hydraulic performance prediction of a new parallel-flow shell and tube heat exchanger with different surrogate models

- Comparative study of the thermal performance of four different parallel flow shell and tube heat exchangers with different performance indicators

- Optimization of SCR inflow uniformity based on CFD simulation

- Kinetics and thermodynamics of SO2 adsorption on metal-loaded multiwalled carbon nanotubes

- Effect of the inner-surface baffles on the tangential acoustic mode in the cylindrical combustor

- Special Issue on Future challenges of advanced computational modeling on nonlinear physical phenomena - Part I

- Conserved vectors with conformable derivative for certain systems of partial differential equations with physical applications

- Some new extensions for fractional integral operator having exponential in the kernel and their applications in physical systems

- Exact optical solitons of the perturbed nonlinear Schrödinger–Hirota equation with Kerr law nonlinearity in nonlinear fiber optics

- Analytical mathematical schemes: Circular rod grounded via transverse Poisson’s effect and extensive wave propagation on the surface of water

- Closed-form wave structures of the space-time fractional Hirota–Satsuma coupled KdV equation with nonlinear physical phenomena

- Some misinterpretations and lack of understanding in differential operators with no singular kernels

- Stable solutions to the nonlinear RLC transmission line equation and the Sinh–Poisson equation arising in mathematical physics

- Calculation of focal values for first-order non-autonomous equation with algebraic and trigonometric coefficients

- Influence of interfacial electrokinetic on MHD radiative nanofluid flow in a permeable microchannel with Brownian motion and thermophoresis effects

- Standard routine techniques of modeling of tick-borne encephalitis

- Fractional residual power series method for the analytical and approximate studies of fractional physical phenomena

- Exact solutions of space–time fractional KdV–MKdV equation and Konopelchenko–Dubrovsky equation

- Approximate analytical fractional view of convection–diffusion equations

- Heat and mass transport investigation in radiative and chemically reacting fluid over a differentially heated surface and internal heating

- On solitary wave solutions of a peptide group system with higher order saturable nonlinearity

- Extension of optimal homotopy asymptotic method with use of Daftardar–Jeffery polynomials to Hirota–Satsuma coupled system of Korteweg–de Vries equations

- Unsteady nano-bioconvective channel flow with effect of nth order chemical reaction

- On the flow of MHD generalized maxwell fluid via porous rectangular duct

- Study on the applications of two analytical methods for the construction of traveling wave solutions of the modified equal width equation

- Numerical solution of two-term time-fractional PDE models arising in mathematical physics using local meshless method

- A powerful numerical technique for treating twelfth-order boundary value problems

- Fundamental solutions for the long–short-wave interaction system

- Role of fractal-fractional operators in modeling of rubella epidemic with optimized orders

- Exact solutions of the Laplace fractional boundary value problems via natural decomposition method

- Special Issue on 19th International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering

- Joint use of eddy current imaging and fuzzy similarities to assess the integrity of steel plates

- Uncertainty quantification in the design of wireless power transfer systems

- Influence of unequal stator tooth width on the performance of outer-rotor permanent magnet machines

- New elements within finite element modeling of magnetostriction phenomenon in BLDC motor

- Evaluation of localized heat transfer coefficient for induction heating apparatus by thermal fluid analysis based on the HSMAC method

- Experimental set up for magnetomechanical measurements with a closed flux path sample

- Influence of the earth connections of the PWM drive on the voltage constraints endured by the motor insulation

- High temperature machine: Characterization of materials for the electrical insulation

- Architecture choices for high-temperature synchronous machines

- Analytical study of air-gap surface force – application to electrical machines

- High-power density induction machines with increased windings temperature

- Influence of modern magnetic and insulation materials on dimensions and losses of large induction machines

- New emotional model environment for navigation in a virtual reality

- Performance comparison of axial-flux switched reluctance machines with non-oriented and grain-oriented electrical steel rotors

- Erratum

- Erratum to “Conserved vectors with conformable derivative for certain systems of partial differential equations with physical applications”

Articles in the same Issue

- Regular Articles

- Model of electric charge distribution in the trap of a close-contact TENG system

- Dynamics of Online Collective Attention as Hawkes Self-exciting Process

- Enhanced Entanglement in Hybrid Cavity Mediated by a Two-way Coupled Quantum Dot

- The nonlinear integro-differential Ito dynamical equation via three modified mathematical methods and its analytical solutions

- Diagnostic model of low visibility events based on C4.5 algorithm

- Electronic temperature characteristics of laser-induced Fe plasma in fruits

- Comparative study of heat transfer enhancement on liquid-vapor separation plate condenser

- Characterization of the effects of a plasma injector driven by AC dielectric barrier discharge on ethylene-air diffusion flame structure

- Impact of double-diffusive convection and motile gyrotactic microorganisms on magnetohydrodynamics bioconvection tangent hyperbolic nanofluid

- Dependence of the crossover zone on the regularization method in the two-flavor Nambu–Jona-Lasinio model

- Novel numerical analysis for nonlinear advection–reaction–diffusion systems

- Heuristic decision of planned shop visit products based on similar reasoning method: From the perspective of organizational quality-specific immune

- Two-dimensional flow field distribution characteristics of flocking drainage pipes in tunnel

- Dynamic triaxial constitutive model for rock subjected to initial stress

- Automatic target recognition method for multitemporal remote sensing image

- Gaussons: optical solitons with log-law nonlinearity by Laplace–Adomian decomposition method

- Adaptive magnetic suspension anti-rolling device based on frequency modulation

- Dynamic response characteristics of 93W alloy with a spherical structure

- The heuristic model of energy propagation in free space, based on the detection of a current induced in a conductor inside a continuously covered conducting enclosure by an external radio frequency source

- Microchannel filter for air purification

- An explicit representation for the axisymmetric solutions of the free Maxwell equations

- Floquet analysis of linear dynamic RLC circuits

- Subpixel matching method for remote sensing image of ground features based on geographic information

- K-band luminosity–density relation at fixed parameters or for different galaxy families

- Effect of forward expansion angle on film cooling characteristics of shaped holes

- Analysis of the overvoltage cooperative control strategy for the small hydropower distribution network

- Stable walking of biped robot based on center of mass trajectory control

- Modeling and simulation of dynamic recrystallization behavior for Q890 steel plate based on plane strain compression tests

- Edge effect of multi-degree-of-freedom oscillatory actuator driven by vector control

- The effect of guide vane type on performance of multistage energy recovery hydraulic turbine (MERHT)

- Development of a generic framework for lumped parameter modeling

- Optimal control for generating excited state expansion in ring potential

- The phase inversion mechanism of the pH-sensitive reversible invert emulsion from w/o to o/w

- 3D bending simulation and mechanical properties of the OLED bending area

- Resonance overvoltage control algorithms in long cable frequency conversion drive based on discrete mathematics

- The measure of irregularities of nanosheets

- The predicted load balancing algorithm based on the dynamic exponential smoothing

- Influence of different seismic motion input modes on the performance of isolated structures with different seismic measures

- A comparative study of cohesive zone models for predicting delamination fracture behaviors of arterial wall

- Analysis on dynamic feature of cross arm light weighting for photovoltaic panel cleaning device in power station based on power correlation

- Some probability effects in the classical context

- Thermosoluted Marangoni convective flow towards a permeable Riga surface

- Simultaneous measurement of ionizing radiation and heart rate using a smartphone camera

- On the relations between some well-known methods and the projective Riccati equations

- Application of energy dissipation and damping structure in the reinforcement of shear wall in concrete engineering

- On-line detection algorithm of ore grade change in grinding grading system

- Testing algorithm for heat transfer performance of nanofluid-filled heat pipe based on neural network

- New optical solitons of conformable resonant nonlinear Schrödinger’s equation

- Numerical investigations of a new singular second-order nonlinear coupled functional Lane–Emden model

- Circularly symmetric algorithm for UWB RF signal receiving channel based on noise cancellation

- CH4 dissociation on the Pd/Cu(111) surface alloy: A DFT study

- On some novel exact solutions to the time fractional (2 + 1) dimensional Konopelchenko–Dubrovsky system arising in physical science

- An optimal system of group-invariant solutions and conserved quantities of a nonlinear fifth-order integrable equation

- Mining reasonable distance of horizontal concave slope based on variable scale chaotic algorithms

- Mathematical models for information classification and recognition of multi-target optical remote sensing images

- Hopkinson rod test results and constitutive description of TRIP780 steel resistance spot welding material

- Computational exploration for radiative flow of Sutterby nanofluid with variable temperature-dependent thermal conductivity and diffusion coefficient

- Analytical solution of one-dimensional Pennes’ bioheat equation

- MHD squeezed Darcy–Forchheimer nanofluid flow between two h–distance apart horizontal plates

- Analysis of irregularity measures of zigzag, rhombic, and honeycomb benzenoid systems

- A clustering algorithm based on nonuniform partition for WSNs

- An extension of Gronwall inequality in the theory of bodies with voids

- Rheological properties of oil–water Pickering emulsion stabilized by Fe3O4 solid nanoparticles

- Review Article

- Sine Topp-Leone-G family of distributions: Theory and applications

- Review of research, development and application of photovoltaic/thermal water systems

- Special Issue on Fundamental Physics of Thermal Transports and Energy Conversions

- Numerical analysis of sulfur dioxide absorption in water droplets

- Special Issue on Transport phenomena and thermal analysis in micro/nano-scale structure surfaces - Part I

- Random pore structure and REV scale flow analysis of engine particulate filter based on LBM

- Prediction of capillary suction in porous media based on micro-CT technology and B–C model

- Energy equilibrium analysis in the effervescent atomization

- Experimental investigation on steam/nitrogen condensation characteristics inside horizontal enhanced condensation channels

- Experimental analysis and ANN prediction on performances of finned oval-tube heat exchanger under different air inlet angles with limited experimental data

- Investigation on thermal-hydraulic performance prediction of a new parallel-flow shell and tube heat exchanger with different surrogate models

- Comparative study of the thermal performance of four different parallel flow shell and tube heat exchangers with different performance indicators

- Optimization of SCR inflow uniformity based on CFD simulation

- Kinetics and thermodynamics of SO2 adsorption on metal-loaded multiwalled carbon nanotubes

- Effect of the inner-surface baffles on the tangential acoustic mode in the cylindrical combustor

- Special Issue on Future challenges of advanced computational modeling on nonlinear physical phenomena - Part I

- Conserved vectors with conformable derivative for certain systems of partial differential equations with physical applications

- Some new extensions for fractional integral operator having exponential in the kernel and their applications in physical systems

- Exact optical solitons of the perturbed nonlinear Schrödinger–Hirota equation with Kerr law nonlinearity in nonlinear fiber optics

- Analytical mathematical schemes: Circular rod grounded via transverse Poisson’s effect and extensive wave propagation on the surface of water

- Closed-form wave structures of the space-time fractional Hirota–Satsuma coupled KdV equation with nonlinear physical phenomena

- Some misinterpretations and lack of understanding in differential operators with no singular kernels

- Stable solutions to the nonlinear RLC transmission line equation and the Sinh–Poisson equation arising in mathematical physics

- Calculation of focal values for first-order non-autonomous equation with algebraic and trigonometric coefficients

- Influence of interfacial electrokinetic on MHD radiative nanofluid flow in a permeable microchannel with Brownian motion and thermophoresis effects

- Standard routine techniques of modeling of tick-borne encephalitis

- Fractional residual power series method for the analytical and approximate studies of fractional physical phenomena

- Exact solutions of space–time fractional KdV–MKdV equation and Konopelchenko–Dubrovsky equation

- Approximate analytical fractional view of convection–diffusion equations

- Heat and mass transport investigation in radiative and chemically reacting fluid over a differentially heated surface and internal heating

- On solitary wave solutions of a peptide group system with higher order saturable nonlinearity

- Extension of optimal homotopy asymptotic method with use of Daftardar–Jeffery polynomials to Hirota–Satsuma coupled system of Korteweg–de Vries equations

- Unsteady nano-bioconvective channel flow with effect of nth order chemical reaction

- On the flow of MHD generalized maxwell fluid via porous rectangular duct

- Study on the applications of two analytical methods for the construction of traveling wave solutions of the modified equal width equation

- Numerical solution of two-term time-fractional PDE models arising in mathematical physics using local meshless method

- A powerful numerical technique for treating twelfth-order boundary value problems

- Fundamental solutions for the long–short-wave interaction system

- Role of fractal-fractional operators in modeling of rubella epidemic with optimized orders

- Exact solutions of the Laplace fractional boundary value problems via natural decomposition method

- Special Issue on 19th International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering

- Joint use of eddy current imaging and fuzzy similarities to assess the integrity of steel plates

- Uncertainty quantification in the design of wireless power transfer systems

- Influence of unequal stator tooth width on the performance of outer-rotor permanent magnet machines

- New elements within finite element modeling of magnetostriction phenomenon in BLDC motor

- Evaluation of localized heat transfer coefficient for induction heating apparatus by thermal fluid analysis based on the HSMAC method

- Experimental set up for magnetomechanical measurements with a closed flux path sample

- Influence of the earth connections of the PWM drive on the voltage constraints endured by the motor insulation

- High temperature machine: Characterization of materials for the electrical insulation

- Architecture choices for high-temperature synchronous machines

- Analytical study of air-gap surface force – application to electrical machines

- High-power density induction machines with increased windings temperature

- Influence of modern magnetic and insulation materials on dimensions and losses of large induction machines

- New emotional model environment for navigation in a virtual reality

- Performance comparison of axial-flux switched reluctance machines with non-oriented and grain-oriented electrical steel rotors

- Erratum

- Erratum to “Conserved vectors with conformable derivative for certain systems of partial differential equations with physical applications”