Abstract

A dielectric barrier discharge plasma controlled diffusion flame experimental system was built based on the designed coaxial swirling plasma injector. The air plasma was generated within the annulus gap of the injector by alternating current dielectric barrier discharge. The discharge characteristics and power of plasma injector under different actuation intensities and air flowrates were measured. Through the measurement techniques, such as schlieren imaging, broadband chemiluminescence image and CH* chemiluminescence, the effect and mechanism of plasma on ethylene-air normal diffusive jet and flame was explored. The results showed that a large number of filamentary discharge channels are formed in air plasma. The increase of air flowrates weakened the intensity of discharge to a certain extent. The induced jet generated by the plasma can short the laminar length of the ethylene-air jet, accelerate the transition of the flow jet, enhance the turbulence and the mixing of the fuel and the oxidizer. The higher the actuation intensity, the shorter distance of the cold jet transition zone, the higher the jet turbulence. Depending on the aerodynamic and kinetic effects, plasma can improve the stability of ethylene-air diffusive flame and reduce the lift height between the flame root and injector. The plasma can also expand the flammability limit of ethylene-air flame and make the flame ignited under some conditions that could not be. In addition, the CH* chemiluminescence shows that, in a certain range of discharge voltage, the heat release distribution can be changed on both sides of the flame, and its representative length are generally reduced as the voltage rises. On the contrary, the overtop voltage could lead to a decrease of flame heat release.

1 Introduction

Rocket engines are widely used in spacecraft, but hydrazine fuels are mostly used as propellants currently, which are highly toxic and pollute the environment. With the rapid development of human space activities, the non-toxicity spacecraft propellants has become an inevitable trend. At present, hydrogen is regarded as an ideal propellant fuels for spacecraft engines due to its easy ignition and non-polluting products [1, 2]. However, hydrogen has a very low boiling point and low density in the case of liquid hydrogen, which in turn leads to an increase in the fuel reserve space required for the aircraft and a reduction in flight payload [3]. As a result, hydrocarbon fuel has become the preferred fuel scheme for active and future new rockets or aircrafts because of its high calorific value, high density, high specific impulse and low pollution [4, 5].

Coaxial injectors are widely used in power system for its simple structure, good chamber compatibility, high combustion safety and stability [6, 7, 8]. However, the fuel and oxidizer are ejected from separated tubes and mixed at the outlet of the injector, which results in a serious deviation of local equivalence ratio from the flammability limit, and the fluctuation of fuel and oxidizer flowrate may seriously affect the flame stability in a practical operating condition. In addition, for reusable aircraft, there is a need for multiple ignition. How to ignite under the lean burn equivalence ratio is also one of the urgent problems to solve. In this case, active or passive control of fuel/oxidizer jet flows generated by coaxial injectors is great significance. Although the control methods are different, they can improve the mixing and spreading of the jet by modify the geometry of the outlet jet. In addition, the active flow control device allows adjustment of control parameters based on real-time operating conditions as compared to passive control devices that modify flow in a permanent manner.

Relying on the particular features of thermal, kinetic, and transport effects, plasma assisted combustion technology can shorten the ignition delay, enhance combustion efficiency and stabilize flame combustion [9, 10, 11, 12, 13]. It is worthwhile to study how to solve the combustion difficulties of hydrocarbon fuel and enhance the mixing of jet by using plasma assisted combustion technology. Several researches have paid attention to the application of plasma to improve the ignition of fuel/air mixtures [14, 15, 16], increase flame propagation speed [17, 18], enhance flame stabilization [19, 20] and extend flammability limits [21, 22].ADBD actuator was designed for the control of a round turbulent air jet [23], the results show that, the electrohydrodynamic forces near to the dielectric wall could cause "electric wind" with the discharge of the DBD actuator,which makes the natural attached turbulent flow separated. In [24], an AC dielectric barrier discharge reactor was designed with quartz as dielectric material. The outer wall of the quartz tube wasmeshed with HV electrode, then the discharge was applied to the propane before it mixed with air. There is a 6 cm long mixing zone above the inner tube and inverse diffusion flame will form after ignition. With the increase of plasma power, propane flame originally adsorbed at the inner ejector gradually inhaled into the mixing zone, and the flame was elongated. The author considers that the phenomenon was related to an increase in the flame propagation rate caused by plasma.The same ACDBDPA and burner geometrical configuration were used by Xu et al. [25], replacing propane with CH4, The above experimental results verified that it is the edge electric field that causes the acceleration of methane-air mixing process. De Giorgi explored the effect of plasma on the stability of CH4-air lean burn flame by intensified CCD imaging technology [26, 27]. Based on the design of ceramic coaxial injector, the influence of plasma control on methane-air combustion flame with AC dielectric barrier discharge was studied by Zhou et al. [28, 29]. It shows that the plasma significantly allows stabilizing the flame under lean conditions. Moreover, the impact of plasma on the flame is strongly dependent on the DBD configuration, in particular on the standoff distance and the flow conditions.

Above all, on the one hand, most plasma assisted jet flame is based on industrial burners configuration, which is relatively rare in spacecraft or aircraft engine system. On the other hand, most plasma controlled diffusion flame experiments mainly use methane and propane as fuel, the focus on ethylene diffusion flame is less. Accordingly, an alternating current dielectric barrier discharge injector is designed and built to reasearch the internal mechanisms of plasma control diffusive flame stabilization. The flame behavior was investigated by photographs and chemiluminescence imaging through a digital camera.

2 Experimental setup

2.1 Plasma injector

The plasma coaxial swirl injector actuator is the core device of the whole flame experiment system. The plasma nozzle is derived from the rocket engine nozzle and redesigned to facilitate the experiment. The injector consists of three parts: the center stainless steel tube, the intermediate quartz tube, and the outer stainless gas collecting chamber. The intermediate quartz tube is connected with the gas collecting chamber by threads and sealant is added to realize sealing.Two ‘O’ shaped sealing rings are also used between the quartz tube flange end and the gas collecting chamber to prevent axial leakage. The center and the quartz tube are fixed by the bottom bolt connection, where a tight fit is adopted.

The center tube has an inner and outer diameter of 5 mm and 7 mm. As the ground electrode, the outlet end has a 30° angle to the axis. For quartz tube, whichworks as the dielectric barrier layer, the inner and outer diameters are 9 mm and 15 mm, respectively. The mixing region, which is the zone between the top ends of the center and quartz tube tubes, is 5 mm long. It is the zone in which the reactants mix themselves and prevent arc formation over the lip of the injector to a certain degree. A 45 mm length copper, which is the high-voltage electrode, surrounds the outlet part of the quartz tube. The plasma injector and its configuration, cross section image are presented in Figure 1. According to the working condition, the swirl number of the injector is 0.11-0.51.

Confguration of plasma injector

2.2 Experimental system

The experimental set-up consists of: a plasma injector device, propellant supply system, high voltage source with discharge control and measure devices, and combustion control and diagnostic system. The whole experimental system are presented in Figure 2. Pure ethylene (99.99%) and dry air (volume ratio of N2 to O2 is 79% : 21%) serve as the gas sources. The fuel and oxidizer flowrates are controlled by the volume flow controllers and are calibrated for air and ethylene with a control accuracy of 2.5%ffl.

Schematic of the plasma injector flame control experiment

The high-pressure fuel and oxidizer are decompressed by specific valve, and then enters into the plasma injector through manual valve, flowmeter, pressure gauge and magnetic valve. The controlling computer sets the working sequence of the magnetic valve to accurately control the supply of air and ethylene. Ethylene is ejected from the center tube directly, while the oxidizer air flow jets out through the annulus gap between the center tube and the quartz tube.

The HV generator was the CPT-2000K plasma generator, which can produce 0–30 kV voltage with actuating frequency of 5–30 kHz. A sinusoidal waveform actuation signal with different voltage amplitudes and a frequency of 10 kHz was applied to the copper foil surrounds the quartz tube. The voltage across the electrodes is measured with a Tektronix (P6015A) high-voltage probe. The current through the electrodes is measured with a Pearson coil (Model 6595). An oscilloscope (Agilent DSO-X 3024A) were used to retrieve the voltage-current characteristic as a function of time and the electrical power dissipation.

The most intuitive display method of flame shape is to take a digital picture through the camera to obtain its visible image. The visible flame appearance was captured using a with a Canon 7D Mark II camera equipped with a Canon EF50mm f/1.8 STM Lens. Since CH radical is an important intermediate reaction product in the combustion process of hydrocarbon fuels, which mainly distributes in the reaction zone, its CH* chemiluminescence has a linear relationship with the heat release rate. Therefore, during the experiment, the CH* chemiluminescence of flame is obtained by camera together with a 430 ± 6 nm bandpass flter (passing 85% of the light emission).

In order to visualize the ethylene-air jet flow, a ‘Z’ shape arrangement schlieren system is established. The schlieren imaging system consists of xenon lamp, adjustable slit, focusing and reflecting mirror, knife edge,and the other instrument bases.

3 Results and discussion

3.1 Electrical characteristics and discharge images

Figure 3 shows the effect of voltages on waveforms with air = 2.0 L/Min, 4.0 L/Min and 6.0 L/Min, respectively. The discharge, produced by plasma injector under the action of AC power supply , formed a large number of pulsed currents.Within each cycle, discharge occurs in the rising and falling edges of the voltage. Irregular tip pulses occurred near the peak of the current, which have the characteristics of typical filamentary discharge.

Characteristics of plasma injector under different flowrates and voltages

For a certain air flowrate, the current peak value and pulse number rise with increasing voltage, and the displacement current increases notably. It can be seen that higher voltage makes the air dielectric ionized more sufficiently, which leads to the increase of micro-discharge channels.

Keeping the actuation voltage, with the increase of air flowrate, the amount of pulse current decreases gradually, which is more obvious at low excitation voltage. When the Ud = 19 kV, the influence of air flowrates on the discharge characteristics is weakened. The reason for this phenomenon is that, under the same outlet cross-sectional area, the higher the air flowrates, the shorter residence time of the air pass through the injector discharge gap, the lower the degree of air ionization.

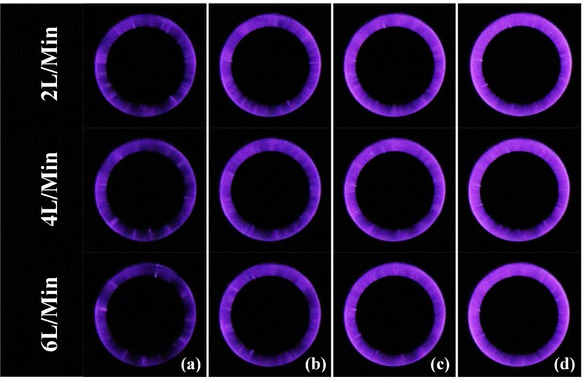

Figure 4 presents the photographs of the discharge captured in the annulus gap of the injector, which correspond to the operation conditions given in Figure 3. The camera parameters are set to 1 ms exposure time, aperture f = 1.8, ISO = 10000.

Discharge image under different air flowrates, (a)-(b): Ud = 13, 15, 17, 19 kV

V̇air = 2.0 L/Min, Ud = 13 kV, at this time, the discharge luminescence of air plasma is not uniform, and the filamentary discharge channel is not completely symmetrical. The discharge area presents dark purple, which means the degree of air ionization is weak. This is mainly due to the fact that, the 13 kV is not much different from the breakdown voltage of about 12.6 kV, and it is difficult to process the designed injector, which results in that the wall of the center tube and quartz tube can not be absolutely smooth, and the annulus gap is not completely symmetrical. In addition, a large number of filamentary discharge channels formed by discharge do not remain stationary in the annular gap,which rotate rapidly counterclockwise.With the increase of excitation voltage, the plasma filaments and discharge brightness in the annular gap area increases. Under Ud = 19 kV, the discharge brightness of the annular gap changes from dark purple to pink purple, and the discharge brightness becomes more uniform.

With the air flowrate increasing to 6.0 L/Min gradually, the overall brightness of the annular gap discharge area decreases, the alternation of light and dark shade increases significantly when the excitation intensity is low. Combined with the analysis above, this is caused by the decrease of pulse discharge channels and current with the increase of air flowrate. Ud = 19 kV, the influence of air flowrate on brightness intensity of annular gap discharge is gradually weakened, the discharge pattern is almost the same at three flowrates.

The average discharge power of swirl plasma injector was measured under different air flowrates. By using the waveform data of voltage and current recorded by oscilloscope, the average plasma power of two half discharge cycles can be obtained by using the following equation.

Where n is the number of recorded data by the oscilloscope; Δt is the time interval of the adjacent data; U and I are the transient discharge voltage and current across the electrodes, respectively. The average power of plasma actuator at different air flowrates is listed in Table 1.

Average power of air discharge in plasma injector, Unit:W

| Voltage (kV) Air Flowrate (L/Min) | 13 | 15 | 17 | 19 |

|---|---|---|---|---|

| 0.0 | 12.66 | 18.37 | 24.73 | 33.09 |

| 2.0 | 13.71 | 19.23 | 25.36 | 32.66 |

| 4.0 | 13.34 | 18.81 | 25.18 | 32.23 |

| 6.0 | 12.63 | 18.26 | 24.56 | 31.79 |

The discharge power of the injector increases notably as the voltage rises. There is a linear relationship between the increase of power and voltage. Compared with Ud = 13 kV, the discharge power at 19 kV increases by nearly 2.6 times at static air. The power is generally lower under a higher flowrate for a certain voltage.

3.2 Gas dynamical effect of plasma injector

To explore the aerodynamic effect of plasma injector in operation condition, schlieren imaging is used to capture the flowfield above the plasma injector. Considering the injection direction of ethylene-air jet, the knife edge of schlieren system is arranged horizontally. The camera exposure time is set to 1/4000 s, aperture f = 1.8, ISO = 100.

The ethylene-air jet mainly consists of three stages: laminar flow, transition and turbulence, which can be seen from Figure 5. Ethylene-air jet is less affected by disturbance in ambient with the increase of air flowrate. The higher the flowrates difference between air and ethylene jet, the shorter laminar zone length of the jet, and the shorter transition time from laminar to turbulence. The morphology of ethylene air jet changed notably with the voltage increase after the actuator turned on. Under various airflow conditions, higher voltage leads to a shorter length of laminar zone, lower height of transition zone from injector outlet, and higher turbulence of the whole jet.

Schlieren image of ethylene-air jet under different voltages

When the excitation voltage is higher than 17 kV, the main distinguishable length of ethylene air jet becomes shorter, and the density gradient of the jet top region decreases obviously. The reason is that the aerodynamic force produced by plasma-induced jet acts on the original jet under high voltage,which makes the turbulence of ethylene air jet increase sharply and causes strong vibration of the main jet. On the one hand, the transition of ethylene air jet has been accelerated, the mixing of ethylene air jet is affected by high turbulence, the large-scale turbulent eddy structure in turbulent region broke up into small-scale quickly, the momentum exchange between vortices so that the energy distribution in the whole region is more uniform, and the turbulent development is more abundant. Finally, the density gradient in the top region of the main stream is smaller. Considering that the schlieren image is a visual reflection of the flow field density gradient, the reduction of the dark portion means the density gradient of ethylene and air in the mixed region decreased, which further indicates that the mixing of ethylene and air has been improved; On the other hand, the jet width at the injector exit increases, which indicates that the tangential velocity caused by plasma-induced jet enhances the transverse diffusion of ethylene air jet and indirectly reduces the penetration ability of the jet in the axial direction.

3.3 Influence of plasma on the shape and heat release of ethylene flame

3.3.1 Conditions for ethylene-air normal diffusive flame

To conduct the plasma flame control experiment, both the air and the ethylene supply valves are opened. By adjusting the air flowrate from 3-7 L/Min, then changing the ethylene flowrate to achieve a specific equivalent ratio. To ignite the mixture jet directly under the designed operation conditions, whether a flame can be formed or not is shown in Table 2. In the table, ‘√’ means that the jet has been successfully ignited directly, while ‘×’ means the opposite. The conditions for successful direct ignition are as follows: three ignition attempts under each working condition, all of which can be successfully ignited and the diffusive flame can be maintained. According to the table above, three typical air flowrates of 3 L/Min, 5 L/Min, and

Direct ignition of ethylene-air jet

| ER Air Flowrate | 0.5 | 0.8 | 1.0 | 1.5 | 2.0 |

|---|---|---|---|---|---|

| (L/Min) | |||||

| 3.0 | × | √ | √ | √ | √ |

| 4.0 | × | √ | √ | √ | √ |

| 5.0 | × | √ | √ | √ | √ |

| 6.0 | × | √ | √ | √ | √ |

| 7.0 | × | × | √ | √ | √ |

7 L/Min were selected as the air reference flowrates, and the plasma controlled ethylene-air normal diffusion flame was tested under different equivalence ratio conditions.

3.3.2 Shape of the ethylene-air flame

Under the condition of V̇air = 3.0 L/Min, the effect of different voltage on flame of ethylene air under five equivalent ratio ER=0.5-2.0 is shown in Figure 6. The camera parameters are set to 1/20 s exposure time, aperture f = 4.5, ISO = 100. The displayed images were the results of average of 20 photographs. The ethylene air diffusive flame is mainly bright yellow but light blue at the root. During the combustion process, a large amount of soot appears at the top of the flame, which accords with the characteristics of ethylene flame.

Effect of different excitation voltage on visible image of ethylene-air flame, V̇air = 3.0 L/Min

When ER = 2.0, the whole flame is slender, the root of the flame is about 16.5 mm away from the injector, with slightly shaken during combustion. After the plasma actuation turned on, the flame mainly undergoes the following two changes: first, the visible length of the flame is shortened; second, the flame lifting height is significantly reduced. Compared with no actuation, the height of the flame root at the Ud = 13 kV, 15 kV is reduced by 78.7% and 84.2%, respectively. Increase the voltage, the root of the flame is attached to the injector. As one of a series of studies, the results of reference 28 showed that the effect of plasma injector on the temperature rise of jet can be negligible. Combined with the analysis of plasma aerodynamic effects, the reason for the above phenomenon is considered to be, on the one hand, the plasma aerodynamic effect decreases the height of ethylene air jet transition and increases its turbulence, which makes ethylene and air mix better and enlarges the flammable area at the bottom of the flame. On the other hand, the air discharge in the annular gap of the actuator can produce a variety of active particles, such as O, O3, which can react directly with ethylene and accelerate the related branching reaction, making ethylene combustion easier. Although the ethylene flame still adsorbs to injector when the voltage is 17 kV under ER = 0.8-1.5, the adsorption capacity decreases with the decrease of the equivalent ratio. When ER = 0.5, the ethylene-air jet cannot be ignited directly without the actuation, while under the 13 kV excitation voltage the jet can be ignited, but the ethylene flame is dark red and blue. The whole flame is weak and unstable, and it is easy to extinguish. Increasing the voltage to 15 kV, 17 kV, the combustion state of has been improved, the visible length of the flame is increased, and the entire flame is more stable. At Ud = 19 kV, the entire flame has been adsorbed at the injector. It can be seen that the plasma actuator can expand the ignition limit of ethylene air jet.

The effect of the excitation voltage on diffusion flame of ethylene air is shown in Figure 7 when the air flowrate is increased to 5 L/Min. The initial height of the flame root from the injector decreases to 12.5 mm under ER = 2.0, the plasma decreases the height of flame root to injector by 55.2% and 56.8% respectively, the degree of height decreases was further reduced. Under ER = 0.8 and 1.0 operation conditions, with the increase of excitation voltage, the visible length of flame increases first and then decreases, and the height of flame root keeps decreasing. However, at Ud = 17 kV, the one side of ethylene flame has been detached from injector, and the lower the equivalence ratio, the higher the detachment height. Despite the increase of air flowrate, the flame root can be stabilized on the injector at Ud = 19 kV. ER = 0.5, the ignition of ethylene air jet cannot be realized under low excitation voltage at this air flowrate. It can be seen that the flame burning intensity at Ud = 19 kV is weaker than other equivalent ratios.

Effect of different excitation voltage on visible image of ethylene-air flame, V̇air = 5.0 L/Min

Finally, increase the air flow to 7L/Min. At this air flow rate, the jet cannot be ignited even with plasma actuation when the equivalent ratio reached 0.5. As shown in Figure 8, ER = 2.0, at Ud = 13 kV, 15 kV, the reduction range is shrunken to 38.4%and 42.3%respectively, which is the smallest reduction range of flame root height under each air flow rate. Ethylene flame cannot be completely adsorbed to the injector even at Ud = 17 kV. ER = 1.5, the visible length of diffusive flame keeps increasing, and the flame root height is almost equal under the excitation voltage of 13 kV and 15 kV. The instability and jump of ethylene flame becomes more and more obvious at Ud = 17 kV with ER = 1.0, and the phenomenon that the height between the flame root and the injector increases instead of decreasing, which has never happened in previous operation conditions. The experimental results show that plasma can improve the stability of ethylene-air diffusive flame. However, under the combined action of plasma-induced aerodynamic and kinetic effect, the overtop discharge voltage at some equivalent ratios may lead to flame instability, the voltage is not need to be as large as possible. The flame stability of ethylene recovers at Ud = 19 kV, and the visible flame length increases greatly.

Effect of different excitation voltage on visible image of ethylene-air flame, V̇air = 7.0 L/Min

3.3.3 CH* chemiluminescence the ethylene-air flame

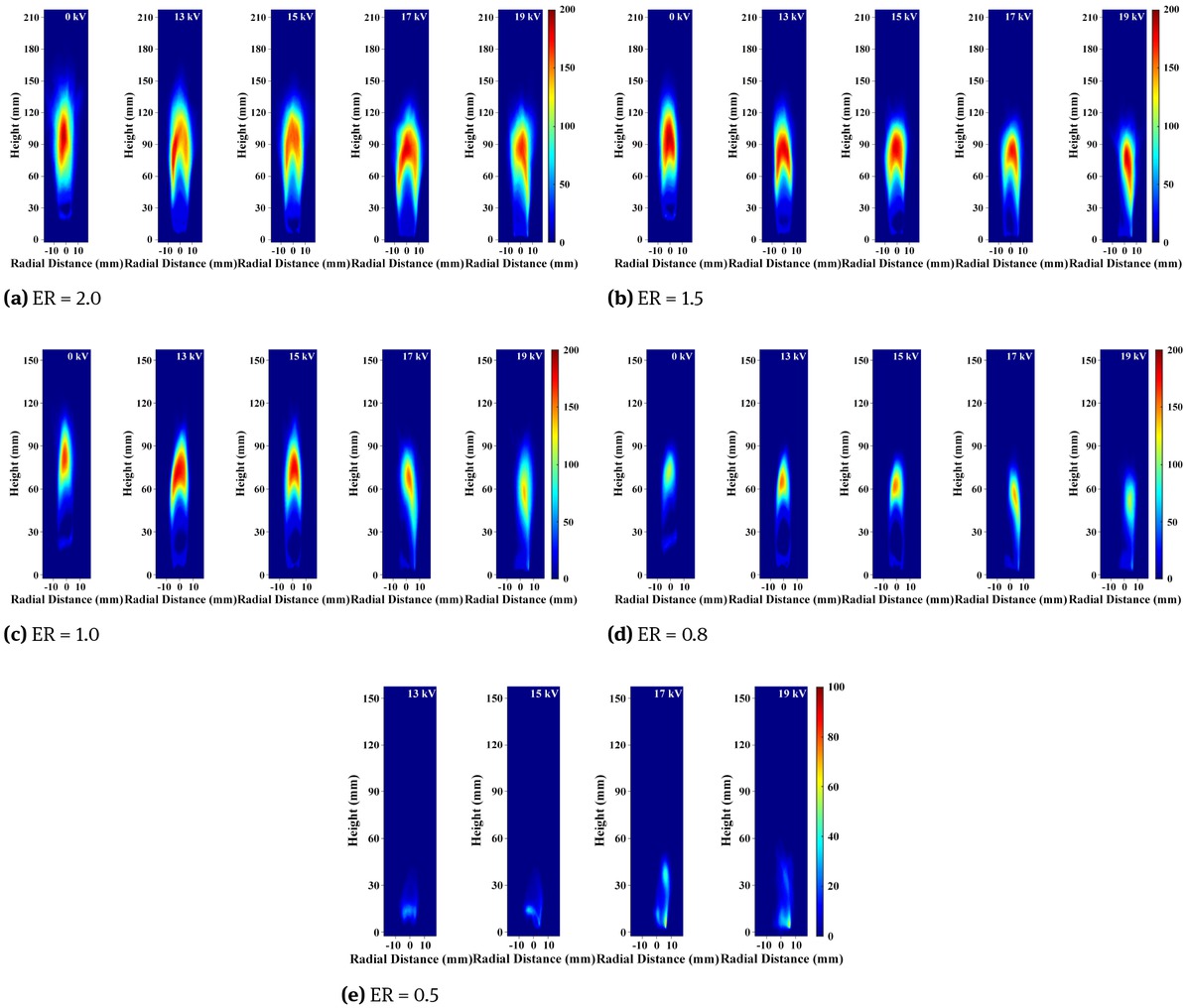

CH* chemiluminescence can clearly distinguish the heat release distribution in ethylene flame. As can be seen from Figure 9, the region with strong CH* emission is the mainly heat release zone of the flame, which concentrates on the upper half of flame.

Effect of different excitation voltage on CH* chemiluminescence of ethylene-air flame, V̇air = 3.0 L/Min

At V̇air = 3.0 L/Min, the area with heat release intensity over 150 is a shape of ellipse under ER = 2.0. When the actuator is turned on to 13 kV, the shape of the heat release zone changes to ’n’ shape. There are two changes, first, the overall height of the flame heat release zone decreases, and second, the heat release from both sides of the ethylene flame increases significantly near the height of 45 mm. This phenomenon indicates that the plasma aerodynamic enhances the mixing of the internal and external jet,which increases the local ethylene concentration in the outer part of the ethylene flame, thus enhancing the combustion heat release of the flame in the region. With the increase of discharge voltage, the heat release zone keeps ’n’ shape, the overall height of the heat release zone decreases continuously, and the heat release on both sides of the flame increases. At Ud = 19 kV, the central heat release zone of the ethylene flame inclines to the right. The possible reason for this phenomenon is that the coaxial degree of the assembled central and the quartz tube may not be completely consistent due to the high processing difficulty. It may result in discharge intensity over an average level in a local area at high voltages, which in turn causes the flame morphology to roll. ER = 1.5, the overall distribution of ethylene flame heat release under different voltage is similar to ER = 2.0.

The equivalent ratio decreases to 0.5-1.0, when the voltage is more than 17 kV, the intensity of the flame heat release begins to attenuate. This phenomenon shows that under certain operating conditions, plasma can enhance flame heat release within a certain range of voltage, but the jet induced by excessive voltage plays a weakening role in flame heat release. For ER = 0.5, the proportion of blue flame increases, and the heat release zone mainly concentrates at the root of the flame. The heat release gets higher with the voltage goes up.

The air flowrate increase to 5 L/Min, it can be seen from Figure 10 that under the action of plasma, the length and height of the ethylene flame heat release zone with a certain extent in the ER = 1.5 and 2.0. Only from the image, the overall height of the heat-dissipating area is almost similar with the increase of the excitation voltage. Ud = 19 kV, the right inclination of the heat release zone decreases. Under this air flowrate, when ER=0.8-1.0, with the voltage increases, the trend of flame heat release distribution increases first and then decreases more clearly. The heat release intensity begins to shrink when the voltage over 17kV. Flame heat release close to the injector at ER = 0.5.

Effect of different excitation voltage on CH* chemiluminescence of ethylene-air flame, V̇air = 5.0 L/Min

As shown in Figure 11, V̇air = 7.0 L/Min and ER = 1.5 and 2.0, the overall height of the main heat release zone of the flame increases gradually with the excitation voltage goes up to 19 kV, which is different from that of the first two groups of air flowrate conditions. ER = 1.0, the unstable combustion status of ethylene flame occurred. Compared with other operation conditions, the main heat release zone of ethylene flame appears at the flame root earlier. However, under Ud = 19 kV, the flame burns steadily and the root of the flame sticks to the injector, the main heat release zone returns to the yellow light region. ER = 0.8, Similar to other operating conditions in ER = 0.5, the heat release under the 19 kV voltage excitation is mainly located on the right half of the flame root.

Effect of different excitation voltage on CH* chemiluminescence of ethylene-air flame, V̇air = 7.0 L/Min

3.3.4 Flame characteristic parameters

According to the relevant definition in [30], height of the flame center HC and the representative flame length LF can be obtained by summing the CH* chemiluminescence intensity within the time-averaged image in the lateral direction. After the calculation, the distribution line of CH* chemiluminescence intensity in the axial direction could be acquired. The HC can be represented by location with maximal CH* chemiluminescence intensity. The full width at half maximum (FWHM) of the heat release distribution line is regarded as the LF.

The influence of plasma on the HC and LF of ethylene-air diffusive flame under different air flow rates is shown in Figure 12. With the increase of air flowrate, there are three kinds of changes in HC under different actuation voltage. V̇air = 3.0 L/Min, in general, the higher the excitation voltage, the lower the height of the flame center. ER = 0.8-2.0, during the plasma actuation, the maximum reduction of HC is 13.8%, 13.3%, 23.6% and 25.7% respectively. The HC of the flame increases first and then decreases with the change of voltage at V̇air = 5.0 L/Min. Compared with the original flame, the reduced flame center position is equal or slightly increased, which indicates that the effect of plasma on the HC begins to fluctuate. Significantly different from the previous operation conditions, V̇air =

Characteristics of plasma injector under different flowrates and voltages

7.0 L/Min, the ethylene and air flowrate ratio is equal to the stoichiometric ratio or above, the plasma excitation increases the value of HC. ER = 0.8, the flame center height reaches 104mm,which is 3.8 times higher than the original flame. This is due to the enhancement of flame top combustion caused by plasma, and the main heat release zone of the flame moves up from the bottom.

Generally, with the increase of the excitation voltage to 19 kV, although the visual length of the whole ethylene flame increases, the representative flame length of the flame decreases compared with the original flame. Based on the analysis of CH* chemiluminescence image, on the one hand, the plasma disturbance on the jet prolongs the non-primary heat release zone in the middle or lower part of the diffusive flame, on the other hand, the combined aerodynamic effect and active particles stimulated by plasma leads to the concentration of the main heat release combustion region of ethylene flame. The decreasing trend of LF is more obvious under the fuel-rich equivalence ratio. In a few cases, the LF of ethylene flame increases after plasma is applied, and this phenomenon mainly occurs above the voltage of 17 kV. In one case, the flame itself is very unstable. After the plasma is applied, the discharge instability and the fluctuation of the flame cause an increase in LF. In another case, a strong discharge causes the stabilized flame to exhibit the ‘oblique’ phenomenon explained above, which lengthens the heat release zone of the flame.

4 Conclusion

A modular plasma injector was designed, and an experimental system of plasma controlled diffusion flame with AC dielectric barrier discharge was built. Through the measurement techniques, such as schlieren imaging, digital camera technology and CH* chemiluminescence, the control effect and mechanism of plasma on ethylene/air normal diffusive jet and flame was explored. The following conclusions were obtained from this research.

Under the action of induced jet generated by plasma, the morphology of ethylene-air normal diffusive jet changes significantly with the increase of actuation voltage. Aerodynamic effect of plasma enhances mixing of ethylene and air jets.Under various air flowrate conditions, the greater the excitation voltage intensity, the shorter the laminar length of the jet, the lower the height of the transition zone from the injector outlet, and the higher the turbulence of the whole jet.

Relying on the aerodynamic and kinetic effects, plasma can improve the stability of ethylene-air diffusion flame and reduce the lift height between the flame root and the injector. The plasma can expand the flammability limit of ethylene-air flame and make the flame formed under some conditions that could not be ignited. However, under the condition of lean burn equivalence ratio with high oxidizer flowrate, overtop excitation voltage may lead to flame instability, so the energy required for plasma combustion is not the greater the better.

According to the analysis of CH* chemiluminescence images, the combined effects of plasma aerodynamics and kinetics can change the heat release distribution of ethylene-air flame, enhance the heat release on both sides of the flame. With the increase of excitation voltage, the heat release intensity of flame increases first and then decreases. The plasma has a certain influence on the height of the flame center and the effects is related to the air flowrate. When the air flow rate is small, the height of the flame center decreases with the increase of the voltage, while the opposite trend appears at the high air flowrate. Generally, plasma can shorten representative flame length and make the combustion area more concentrated.

References

[1] Davis JA, Campbell RL. Advantages of full-Flow staged combustion cycle engine system, 33rd Joint Propulsion Conference and Exhibit. Joint Propulsion Conferences. 1997; 1-13.10.2514/6.1997-3318Search in Google Scholar

[2] Mayer W, Immich H. Cryogenic liquid rocket engine technology developments within the german national technology programme. 33rd Joint Propulsion Conference and Exhibit. 1997; 2882.10.2514/6.1997-2822Search in Google Scholar

[3] Stanley D. NASA’s Exploration Systems Architecture Study. NASA-TM; 2005. pp. 2005–214062.Search in Google Scholar

[4] DeLong D, Greason J, McKee K. Liquid oxygen/liquid methane rocketenginedevelopment. SAETechnicalPaper. 2007; 2007(01):3876.Search in Google Scholar

[5] Huo H, Yang V. Supercritical LOX/methane combustion of a shear coaxial injector. 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition. 2011; AIAA-2011-326.10.2514/6.2011-326Search in Google Scholar

[6] Singla G, Scouflaire P, Rolon C, Candel S. Transcritical oxygen/transcritical or supercritical methane combustion. Proc Combust Inst. 2005;30(2):2921–8.10.1016/j.proci.2004.08.063Search in Google Scholar

[7] Masquelet M, Menon S. Large-eddy simulation of flame- turbulence interactions in a shear coaxial injector. J Propuls Power. 2010;26(5):924–35.10.2514/1.48023Search in Google Scholar

[8] Villermaux E, Rehab H. Mixing in coaxial jets. J Fluid Mech. 2000;425:161–85.10.1017/S002211200000210XSearch in Google Scholar

[9] Starikovskiy A, Aleksandrov N. Plasma-assisted ignition and combustion. Pror Energy Combust Sci. 2013;39(1):61–110.10.5772/17727Search in Google Scholar

[10] Ju Y, Sun W. Plasma assisted combustion: dynamics and chemistry. Pror Energy Combust Sci. 2015;48:21–83.10.1016/j.pecs.2014.12.002Search in Google Scholar

[11] Starikovskaia SM. Plasma-assisted ignition and combustion: nanosecond discharges and development of kinetic mechanisms. J Phys D Appl Phys. 2014;47(35):353001.10.1088/0022-3727/47/35/353001Search in Google Scholar

[12] Wang J, Li G, Zhu H, Luo J, Sundén B. Experimental investigation on convective heat transfer of ferrofluids inside a pipe under various magnet orientations. Int J Heat Mass Transf. 2019;132:407–19.10.1016/j.ijheatmasstransfer.2018.12.023Search in Google Scholar

[13] Li Q, Wang J, Wang J, Baleta J, Min C, Sundén B. Effects of gravity and variable thermal properties on nanofluid convective heat transfer using connected and unconnectedwalls. Energy Convers Manage. 2018;171:1440–8.10.1016/j.enconman.2018.06.097Search in Google Scholar

[14] Nagaraja S, Yang V, Yin Z, Adamovich I. Ignition of hydrogen–air mixtures using pulsed nanosecond dielectric barrier plasma discharges in plane-to-plane geometry. Combust Flame. 2014;161(4):1026–37.10.1016/j.combustflame.2013.10.007Search in Google Scholar

[15] Singleton D, Pendleton SJ, Gundersen MA. The role of non-thermal transient plasma for enhanced flame ignition in C2H4– air. J Phys D Appl Phys. 2010;44(2):022001.10.1088/0022-3727/44/2/022001Search in Google Scholar

[16] Dutta A, Yin Z, Adamovich IV. Cavity ignition and flame- holding of ethylene–air and hydrogen–air flows by a repetitively pulsed nanosecond discharge. Combust Flame. 2011;158(8):1564–76.10.1016/j.combustflame.2010.12.023Search in Google Scholar

[17] Ombrello T, Won SH, Ju Y,Williams S. Flame propagation enhancement by plasma excitation of oxygen. Part II: effects of O2(a1Δg). Combust Flame. 2010;157(10):1916–28.10.1016/j.combustflame.2010.02.004Search in Google Scholar

[18] Ombrello T, Won SH, Ju Y, Williams S. Flame propagation enhancement by plasma excitation of oxygen. Part I: effects of O3. Combust Flame. 2010;157(10):1906–15.10.1016/j.combustflame.2010.02.005Search in Google Scholar

[19] Kim W, Do H, Mungal MG, Cappelli MA. Investigation of NO production and flame structure in plasma enhanced premixed combustion. Proc Combust Inst. 2007;31(2):3319–26.10.1016/j.proci.2006.07.107Search in Google Scholar

[20] Lacoste DA, Moeck JP, Durox D, Laux CO, Schuller T. Effect of nanosecond repetitively pulsed discharges on the dynamics of a swirl- stabilized lean premixed flame. J Eng Gas Turbine Power. 2013;135(10):101501.10.1115/GT2013-94769Search in Google Scholar

[21] Bak MS, Im SK, Mungal MG, Cappelli MA. Studies on the stability limit extension of premixed and jet diffusion flames of methane, ethane, and propane using nanosecond repetitive pulsed discharge plasmas. Combust Flame. 2013;160(11):2396–403.10.1016/j.combustflame.2013.05.023Search in Google Scholar

[22] Pilla G, Galley D, Lacoste DA, Lacas F, Veynante D, Laux CO. Stabilization of a turbulent premixed flame using a nanosecond repetitively pulsed plasma. IEEE Trans Plasma Sci. 2006;34(6):2471–7.10.1109/TPS.2006.886081Search in Google Scholar

[23] Benard N, Braud P, Pons J, et al. Quasi-steady and unsteady actuation by surface non-thermal plasma discharge for control of a turbulent round air jet. Journal of Turbulence. 2007;8(49):1–24.10.1080/14685240701656139Search in Google Scholar

[24] Stange S, Kim YK, Ferreri V, et al. Flame images indicating combustion enhancement by dielectric barrier discharges. IEEE Trans Plasma Sci. 2005;33(2):316–7.10.1109/TPS.2005.845940Search in Google Scholar

[25] Xu CH, Li L. Electric effects on the pre-mixing process in DBD assisted combustions. Appl Mech Mater. 2014;722:235–8.10.4028/www.scientific.net/AMM.722.235Search in Google Scholar

[26] De Giorgi MG, Ficarella A, Sciolti A, Pescini E, Campilongo S, Di Lecce G. Improvement of lean flame stability of inverse methane/air diffusion flame by using coaxial dielectric plasma discharge actuators. Energy. 2017;126:689–706.10.1016/j.energy.2017.03.048Search in Google Scholar

[27] De Giorgi MG, Sciolti A, Campilongo S, et al. Plasma assisted flame stabilization in a non-premixed lean burner. Energy Proce-dia. 2015;82:410–6.10.1016/j.egypro.2015.11.825Search in Google Scholar

[28] Zhou S, Su L, Shi T, Zheng T, Tong Y, Nie W, et al. Experimental study on the diffusive flame stabilization mechanism of plasma injector driven by AC dielectric barrier discharge. J Phys D Appl Phys. 2019;52(26):265202.10.1088/1361-6463/ab15cdSearch in Google Scholar

[29] Nie W, Zhou S, Shi T, Zheng T, Che X. Experimental investigation of CH4/Air inverse diffusion flame stabilization by nonequilib-rium plasma. J Propuls Power. 2019;35(6):1151–62.10.2514/1.B37553Search in Google Scholar

[30] Tong Y, Yu S, Liu X, et al. Experimental study on dynamics of a confined low swirl partially premixed methane- hydrogen-air flame. International Journal of Hydrogen Energy. 2017;42(44):27400-15.10.1016/j.ijhydene.2017.09.066Search in Google Scholar

© 2020 Z. Zheng et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Model of electric charge distribution in the trap of a close-contact TENG system

- Dynamics of Online Collective Attention as Hawkes Self-exciting Process

- Enhanced Entanglement in Hybrid Cavity Mediated by a Two-way Coupled Quantum Dot

- The nonlinear integro-differential Ito dynamical equation via three modified mathematical methods and its analytical solutions

- Diagnostic model of low visibility events based on C4.5 algorithm

- Electronic temperature characteristics of laser-induced Fe plasma in fruits

- Comparative study of heat transfer enhancement on liquid-vapor separation plate condenser

- Characterization of the effects of a plasma injector driven by AC dielectric barrier discharge on ethylene-air diffusion flame structure

- Impact of double-diffusive convection and motile gyrotactic microorganisms on magnetohydrodynamics bioconvection tangent hyperbolic nanofluid

- Dependence of the crossover zone on the regularization method in the two-flavor Nambu–Jona-Lasinio model

- Novel numerical analysis for nonlinear advection–reaction–diffusion systems

- Heuristic decision of planned shop visit products based on similar reasoning method: From the perspective of organizational quality-specific immune

- Two-dimensional flow field distribution characteristics of flocking drainage pipes in tunnel

- Dynamic triaxial constitutive model for rock subjected to initial stress

- Automatic target recognition method for multitemporal remote sensing image

- Gaussons: optical solitons with log-law nonlinearity by Laplace–Adomian decomposition method

- Adaptive magnetic suspension anti-rolling device based on frequency modulation

- Dynamic response characteristics of 93W alloy with a spherical structure

- The heuristic model of energy propagation in free space, based on the detection of a current induced in a conductor inside a continuously covered conducting enclosure by an external radio frequency source

- Microchannel filter for air purification

- An explicit representation for the axisymmetric solutions of the free Maxwell equations

- Floquet analysis of linear dynamic RLC circuits

- Subpixel matching method for remote sensing image of ground features based on geographic information

- K-band luminosity–density relation at fixed parameters or for different galaxy families

- Effect of forward expansion angle on film cooling characteristics of shaped holes

- Analysis of the overvoltage cooperative control strategy for the small hydropower distribution network

- Stable walking of biped robot based on center of mass trajectory control

- Modeling and simulation of dynamic recrystallization behavior for Q890 steel plate based on plane strain compression tests

- Edge effect of multi-degree-of-freedom oscillatory actuator driven by vector control

- The effect of guide vane type on performance of multistage energy recovery hydraulic turbine (MERHT)

- Development of a generic framework for lumped parameter modeling

- Optimal control for generating excited state expansion in ring potential

- The phase inversion mechanism of the pH-sensitive reversible invert emulsion from w/o to o/w

- 3D bending simulation and mechanical properties of the OLED bending area

- Resonance overvoltage control algorithms in long cable frequency conversion drive based on discrete mathematics

- The measure of irregularities of nanosheets

- The predicted load balancing algorithm based on the dynamic exponential smoothing

- Influence of different seismic motion input modes on the performance of isolated structures with different seismic measures

- A comparative study of cohesive zone models for predicting delamination fracture behaviors of arterial wall

- Analysis on dynamic feature of cross arm light weighting for photovoltaic panel cleaning device in power station based on power correlation

- Some probability effects in the classical context

- Thermosoluted Marangoni convective flow towards a permeable Riga surface

- Simultaneous measurement of ionizing radiation and heart rate using a smartphone camera

- On the relations between some well-known methods and the projective Riccati equations

- Application of energy dissipation and damping structure in the reinforcement of shear wall in concrete engineering

- On-line detection algorithm of ore grade change in grinding grading system

- Testing algorithm for heat transfer performance of nanofluid-filled heat pipe based on neural network

- New optical solitons of conformable resonant nonlinear Schrödinger’s equation

- Numerical investigations of a new singular second-order nonlinear coupled functional Lane–Emden model

- Circularly symmetric algorithm for UWB RF signal receiving channel based on noise cancellation

- CH4 dissociation on the Pd/Cu(111) surface alloy: A DFT study

- On some novel exact solutions to the time fractional (2 + 1) dimensional Konopelchenko–Dubrovsky system arising in physical science

- An optimal system of group-invariant solutions and conserved quantities of a nonlinear fifth-order integrable equation

- Mining reasonable distance of horizontal concave slope based on variable scale chaotic algorithms

- Mathematical models for information classification and recognition of multi-target optical remote sensing images

- Hopkinson rod test results and constitutive description of TRIP780 steel resistance spot welding material

- Computational exploration for radiative flow of Sutterby nanofluid with variable temperature-dependent thermal conductivity and diffusion coefficient

- Analytical solution of one-dimensional Pennes’ bioheat equation

- MHD squeezed Darcy–Forchheimer nanofluid flow between two h–distance apart horizontal plates

- Analysis of irregularity measures of zigzag, rhombic, and honeycomb benzenoid systems

- A clustering algorithm based on nonuniform partition for WSNs

- An extension of Gronwall inequality in the theory of bodies with voids

- Rheological properties of oil–water Pickering emulsion stabilized by Fe3O4 solid nanoparticles

- Review Article

- Sine Topp-Leone-G family of distributions: Theory and applications

- Review of research, development and application of photovoltaic/thermal water systems

- Special Issue on Fundamental Physics of Thermal Transports and Energy Conversions

- Numerical analysis of sulfur dioxide absorption in water droplets

- Special Issue on Transport phenomena and thermal analysis in micro/nano-scale structure surfaces - Part I

- Random pore structure and REV scale flow analysis of engine particulate filter based on LBM

- Prediction of capillary suction in porous media based on micro-CT technology and B–C model

- Energy equilibrium analysis in the effervescent atomization

- Experimental investigation on steam/nitrogen condensation characteristics inside horizontal enhanced condensation channels

- Experimental analysis and ANN prediction on performances of finned oval-tube heat exchanger under different air inlet angles with limited experimental data

- Investigation on thermal-hydraulic performance prediction of a new parallel-flow shell and tube heat exchanger with different surrogate models

- Comparative study of the thermal performance of four different parallel flow shell and tube heat exchangers with different performance indicators

- Optimization of SCR inflow uniformity based on CFD simulation

- Kinetics and thermodynamics of SO2 adsorption on metal-loaded multiwalled carbon nanotubes

- Effect of the inner-surface baffles on the tangential acoustic mode in the cylindrical combustor

- Special Issue on Future challenges of advanced computational modeling on nonlinear physical phenomena - Part I

- Conserved vectors with conformable derivative for certain systems of partial differential equations with physical applications

- Some new extensions for fractional integral operator having exponential in the kernel and their applications in physical systems

- Exact optical solitons of the perturbed nonlinear Schrödinger–Hirota equation with Kerr law nonlinearity in nonlinear fiber optics

- Analytical mathematical schemes: Circular rod grounded via transverse Poisson’s effect and extensive wave propagation on the surface of water

- Closed-form wave structures of the space-time fractional Hirota–Satsuma coupled KdV equation with nonlinear physical phenomena

- Some misinterpretations and lack of understanding in differential operators with no singular kernels

- Stable solutions to the nonlinear RLC transmission line equation and the Sinh–Poisson equation arising in mathematical physics

- Calculation of focal values for first-order non-autonomous equation with algebraic and trigonometric coefficients

- Influence of interfacial electrokinetic on MHD radiative nanofluid flow in a permeable microchannel with Brownian motion and thermophoresis effects

- Standard routine techniques of modeling of tick-borne encephalitis

- Fractional residual power series method for the analytical and approximate studies of fractional physical phenomena

- Exact solutions of space–time fractional KdV–MKdV equation and Konopelchenko–Dubrovsky equation

- Approximate analytical fractional view of convection–diffusion equations

- Heat and mass transport investigation in radiative and chemically reacting fluid over a differentially heated surface and internal heating

- On solitary wave solutions of a peptide group system with higher order saturable nonlinearity

- Extension of optimal homotopy asymptotic method with use of Daftardar–Jeffery polynomials to Hirota–Satsuma coupled system of Korteweg–de Vries equations

- Unsteady nano-bioconvective channel flow with effect of nth order chemical reaction

- On the flow of MHD generalized maxwell fluid via porous rectangular duct

- Study on the applications of two analytical methods for the construction of traveling wave solutions of the modified equal width equation

- Numerical solution of two-term time-fractional PDE models arising in mathematical physics using local meshless method

- A powerful numerical technique for treating twelfth-order boundary value problems

- Fundamental solutions for the long–short-wave interaction system

- Role of fractal-fractional operators in modeling of rubella epidemic with optimized orders

- Exact solutions of the Laplace fractional boundary value problems via natural decomposition method

- Special Issue on 19th International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering

- Joint use of eddy current imaging and fuzzy similarities to assess the integrity of steel plates

- Uncertainty quantification in the design of wireless power transfer systems

- Influence of unequal stator tooth width on the performance of outer-rotor permanent magnet machines

- New elements within finite element modeling of magnetostriction phenomenon in BLDC motor

- Evaluation of localized heat transfer coefficient for induction heating apparatus by thermal fluid analysis based on the HSMAC method

- Experimental set up for magnetomechanical measurements with a closed flux path sample

- Influence of the earth connections of the PWM drive on the voltage constraints endured by the motor insulation

- High temperature machine: Characterization of materials for the electrical insulation

- Architecture choices for high-temperature synchronous machines

- Analytical study of air-gap surface force – application to electrical machines

- High-power density induction machines with increased windings temperature

- Influence of modern magnetic and insulation materials on dimensions and losses of large induction machines

- New emotional model environment for navigation in a virtual reality

- Performance comparison of axial-flux switched reluctance machines with non-oriented and grain-oriented electrical steel rotors

- Erratum

- Erratum to “Conserved vectors with conformable derivative for certain systems of partial differential equations with physical applications”

Articles in the same Issue

- Regular Articles

- Model of electric charge distribution in the trap of a close-contact TENG system

- Dynamics of Online Collective Attention as Hawkes Self-exciting Process

- Enhanced Entanglement in Hybrid Cavity Mediated by a Two-way Coupled Quantum Dot

- The nonlinear integro-differential Ito dynamical equation via three modified mathematical methods and its analytical solutions

- Diagnostic model of low visibility events based on C4.5 algorithm

- Electronic temperature characteristics of laser-induced Fe plasma in fruits

- Comparative study of heat transfer enhancement on liquid-vapor separation plate condenser

- Characterization of the effects of a plasma injector driven by AC dielectric barrier discharge on ethylene-air diffusion flame structure

- Impact of double-diffusive convection and motile gyrotactic microorganisms on magnetohydrodynamics bioconvection tangent hyperbolic nanofluid

- Dependence of the crossover zone on the regularization method in the two-flavor Nambu–Jona-Lasinio model

- Novel numerical analysis for nonlinear advection–reaction–diffusion systems

- Heuristic decision of planned shop visit products based on similar reasoning method: From the perspective of organizational quality-specific immune

- Two-dimensional flow field distribution characteristics of flocking drainage pipes in tunnel

- Dynamic triaxial constitutive model for rock subjected to initial stress

- Automatic target recognition method for multitemporal remote sensing image

- Gaussons: optical solitons with log-law nonlinearity by Laplace–Adomian decomposition method

- Adaptive magnetic suspension anti-rolling device based on frequency modulation

- Dynamic response characteristics of 93W alloy with a spherical structure

- The heuristic model of energy propagation in free space, based on the detection of a current induced in a conductor inside a continuously covered conducting enclosure by an external radio frequency source

- Microchannel filter for air purification

- An explicit representation for the axisymmetric solutions of the free Maxwell equations

- Floquet analysis of linear dynamic RLC circuits

- Subpixel matching method for remote sensing image of ground features based on geographic information

- K-band luminosity–density relation at fixed parameters or for different galaxy families

- Effect of forward expansion angle on film cooling characteristics of shaped holes

- Analysis of the overvoltage cooperative control strategy for the small hydropower distribution network

- Stable walking of biped robot based on center of mass trajectory control

- Modeling and simulation of dynamic recrystallization behavior for Q890 steel plate based on plane strain compression tests

- Edge effect of multi-degree-of-freedom oscillatory actuator driven by vector control

- The effect of guide vane type on performance of multistage energy recovery hydraulic turbine (MERHT)

- Development of a generic framework for lumped parameter modeling

- Optimal control for generating excited state expansion in ring potential

- The phase inversion mechanism of the pH-sensitive reversible invert emulsion from w/o to o/w

- 3D bending simulation and mechanical properties of the OLED bending area

- Resonance overvoltage control algorithms in long cable frequency conversion drive based on discrete mathematics

- The measure of irregularities of nanosheets

- The predicted load balancing algorithm based on the dynamic exponential smoothing

- Influence of different seismic motion input modes on the performance of isolated structures with different seismic measures

- A comparative study of cohesive zone models for predicting delamination fracture behaviors of arterial wall

- Analysis on dynamic feature of cross arm light weighting for photovoltaic panel cleaning device in power station based on power correlation

- Some probability effects in the classical context

- Thermosoluted Marangoni convective flow towards a permeable Riga surface

- Simultaneous measurement of ionizing radiation and heart rate using a smartphone camera

- On the relations between some well-known methods and the projective Riccati equations

- Application of energy dissipation and damping structure in the reinforcement of shear wall in concrete engineering

- On-line detection algorithm of ore grade change in grinding grading system

- Testing algorithm for heat transfer performance of nanofluid-filled heat pipe based on neural network

- New optical solitons of conformable resonant nonlinear Schrödinger’s equation

- Numerical investigations of a new singular second-order nonlinear coupled functional Lane–Emden model

- Circularly symmetric algorithm for UWB RF signal receiving channel based on noise cancellation

- CH4 dissociation on the Pd/Cu(111) surface alloy: A DFT study

- On some novel exact solutions to the time fractional (2 + 1) dimensional Konopelchenko–Dubrovsky system arising in physical science

- An optimal system of group-invariant solutions and conserved quantities of a nonlinear fifth-order integrable equation

- Mining reasonable distance of horizontal concave slope based on variable scale chaotic algorithms

- Mathematical models for information classification and recognition of multi-target optical remote sensing images

- Hopkinson rod test results and constitutive description of TRIP780 steel resistance spot welding material

- Computational exploration for radiative flow of Sutterby nanofluid with variable temperature-dependent thermal conductivity and diffusion coefficient

- Analytical solution of one-dimensional Pennes’ bioheat equation

- MHD squeezed Darcy–Forchheimer nanofluid flow between two h–distance apart horizontal plates

- Analysis of irregularity measures of zigzag, rhombic, and honeycomb benzenoid systems

- A clustering algorithm based on nonuniform partition for WSNs

- An extension of Gronwall inequality in the theory of bodies with voids

- Rheological properties of oil–water Pickering emulsion stabilized by Fe3O4 solid nanoparticles

- Review Article

- Sine Topp-Leone-G family of distributions: Theory and applications

- Review of research, development and application of photovoltaic/thermal water systems

- Special Issue on Fundamental Physics of Thermal Transports and Energy Conversions

- Numerical analysis of sulfur dioxide absorption in water droplets

- Special Issue on Transport phenomena and thermal analysis in micro/nano-scale structure surfaces - Part I

- Random pore structure and REV scale flow analysis of engine particulate filter based on LBM

- Prediction of capillary suction in porous media based on micro-CT technology and B–C model

- Energy equilibrium analysis in the effervescent atomization

- Experimental investigation on steam/nitrogen condensation characteristics inside horizontal enhanced condensation channels

- Experimental analysis and ANN prediction on performances of finned oval-tube heat exchanger under different air inlet angles with limited experimental data

- Investigation on thermal-hydraulic performance prediction of a new parallel-flow shell and tube heat exchanger with different surrogate models

- Comparative study of the thermal performance of four different parallel flow shell and tube heat exchangers with different performance indicators

- Optimization of SCR inflow uniformity based on CFD simulation

- Kinetics and thermodynamics of SO2 adsorption on metal-loaded multiwalled carbon nanotubes

- Effect of the inner-surface baffles on the tangential acoustic mode in the cylindrical combustor

- Special Issue on Future challenges of advanced computational modeling on nonlinear physical phenomena - Part I

- Conserved vectors with conformable derivative for certain systems of partial differential equations with physical applications

- Some new extensions for fractional integral operator having exponential in the kernel and their applications in physical systems

- Exact optical solitons of the perturbed nonlinear Schrödinger–Hirota equation with Kerr law nonlinearity in nonlinear fiber optics

- Analytical mathematical schemes: Circular rod grounded via transverse Poisson’s effect and extensive wave propagation on the surface of water

- Closed-form wave structures of the space-time fractional Hirota–Satsuma coupled KdV equation with nonlinear physical phenomena

- Some misinterpretations and lack of understanding in differential operators with no singular kernels

- Stable solutions to the nonlinear RLC transmission line equation and the Sinh–Poisson equation arising in mathematical physics

- Calculation of focal values for first-order non-autonomous equation with algebraic and trigonometric coefficients

- Influence of interfacial electrokinetic on MHD radiative nanofluid flow in a permeable microchannel with Brownian motion and thermophoresis effects

- Standard routine techniques of modeling of tick-borne encephalitis

- Fractional residual power series method for the analytical and approximate studies of fractional physical phenomena

- Exact solutions of space–time fractional KdV–MKdV equation and Konopelchenko–Dubrovsky equation

- Approximate analytical fractional view of convection–diffusion equations

- Heat and mass transport investigation in radiative and chemically reacting fluid over a differentially heated surface and internal heating

- On solitary wave solutions of a peptide group system with higher order saturable nonlinearity

- Extension of optimal homotopy asymptotic method with use of Daftardar–Jeffery polynomials to Hirota–Satsuma coupled system of Korteweg–de Vries equations

- Unsteady nano-bioconvective channel flow with effect of nth order chemical reaction

- On the flow of MHD generalized maxwell fluid via porous rectangular duct

- Study on the applications of two analytical methods for the construction of traveling wave solutions of the modified equal width equation

- Numerical solution of two-term time-fractional PDE models arising in mathematical physics using local meshless method

- A powerful numerical technique for treating twelfth-order boundary value problems

- Fundamental solutions for the long–short-wave interaction system

- Role of fractal-fractional operators in modeling of rubella epidemic with optimized orders

- Exact solutions of the Laplace fractional boundary value problems via natural decomposition method

- Special Issue on 19th International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering

- Joint use of eddy current imaging and fuzzy similarities to assess the integrity of steel plates

- Uncertainty quantification in the design of wireless power transfer systems

- Influence of unequal stator tooth width on the performance of outer-rotor permanent magnet machines

- New elements within finite element modeling of magnetostriction phenomenon in BLDC motor

- Evaluation of localized heat transfer coefficient for induction heating apparatus by thermal fluid analysis based on the HSMAC method

- Experimental set up for magnetomechanical measurements with a closed flux path sample

- Influence of the earth connections of the PWM drive on the voltage constraints endured by the motor insulation

- High temperature machine: Characterization of materials for the electrical insulation

- Architecture choices for high-temperature synchronous machines

- Analytical study of air-gap surface force – application to electrical machines

- High-power density induction machines with increased windings temperature

- Influence of modern magnetic and insulation materials on dimensions and losses of large induction machines

- New emotional model environment for navigation in a virtual reality

- Performance comparison of axial-flux switched reluctance machines with non-oriented and grain-oriented electrical steel rotors

- Erratum

- Erratum to “Conserved vectors with conformable derivative for certain systems of partial differential equations with physical applications”