Abstract

This study investigates the environmental and mechanical performance of eco-friendly concrete using date palm ash (DPA) and eggshell powder (ESP) as cementitious materials. Concrete mixes were made by substituting conventional cement with DPA at varying levels (10, 20, 30, and 40%) and adding ESP in dosages of 1, 2, 3, and 4%. Mechanical strengths and water absorption were evaluated. The optimal mix, comprising 20% DPA and 2% ESP, achieved a compressive strength of 57.53 MPa, demonstrating advancement of 41% over the control mix while reducing water absorption by 22.96%. A life cycle assessment, accomplished using ISO 14040 standards and ReCiPe Midpoint (H) methodology, evaluated environmental impacts across 18 categories for 1 m3 of concrete. The results revealed a significant reduction in global warming potential by up to 15.46%, with Mix M8 (40% DPA) demonstrating the most substantial environmental benefits. Further analysis highlighted reductions in acidification, ozone formation, and resource scarcity. The analytical hierarchy process identified Mix M3 as the optimal design for structural applications due to its superior mechanical performance, while Mix M8 was preferred for non-structural, environmentally sensitive applications. This study demonstrates the dual benefits of DPA and ESP in enhancing sustainability and performance, promoting eco-friendly construction practices.

1 Introduction

Concrete is the most consumed manmade material and the second most consumed material after water. It is the most utilized manmade construction material due to its series of advantages over other construction materials like steel, timber, glass, and asphalt. With infrastructural developments and urbanization on the rise globally, the demand for concrete is increasing progressively, and it is estimated that the average production of concrete has reached 1 m3 per person per annum [1,2]. In terms of quantities, more than 4.4 billion tons of concrete are consumed yearly, and by 2050 this value is expected to project to 5.5 billion tons [3]. The constituent material for making normal concrete includes cement, aggregates, and water. Cement is the main binder material, which, when hardened, solidifies to form the composite (concrete), and it constitutes between 12 and 15% of the total constituent materials [1,4]. Global cement consumption exceeds 3.27 billion tons in 2020, and it is forecasted to surpass 4.83 billion tons by 2030 [5]. However, cement is the most environmentally unsustainable material, as it is the main contributor to the global CO2 linked with concrete production [6]. CO2 emissions over time will concentrate in the environment and intensify the potential of global warming [7]. This raises significant concerns among researchers and scientists about finding a solution or an alternative to cement to promote sustainability. The global CO2 emissions from the cement industry range between 5 and 8%, and these emissions mainly come from the high energy consumed during the process of calcination and formulations. The large volume of greenhouse gas emissions from cement, in addition to the huge volume of natural aggregates used, makes concrete not a sustainable material [3,8]. To address the challenges of cement in concrete, researchers are trying to find an alternative material to be used as supplementary cementitious material (SCM) in concrete. This will lead to a significant reduction in the amount of cement consumed and consequently lower the greenhouse carbon emissions from cement production. Waste-derived materials from industries, such as fly ash, silica fume, and slag, have been utilized as SCMs in concrete and were proven to improve the performance of concrete [9,10]. Agricultural waste is ground into a fine powder and utilized in concrete as SCMs, with date palm ash (DPA) and eggshell powder (ESP) being common examples [11,12,13,14,15]. Recent advancements in sustainable concrete technology, as highlighted by Elfadaly et al. [16], demonstrate innovative approaches to enhancing the eco-friendliness of concrete utilizing rice and other pozzolanic material (pumice powder) as binder sources in geopolymer. Similarly, current research outlined in Abdellatief et al. [17] emphasizes significant improvements in both the mechanical properties and environmental benefits of incorporating SCMs like sawdust ash and ESP into concrete mixes.

Agricultural waste ash has been reported to contain high amounts of silica, which is the main pozzolanic oxide [18]. DPA is an agriculturally based SCM, which contains moderate pozzolanic and little cementing properties [12,19]. DPA is a processed waste product from date palm trees. The waste includes the trunks, branches, leaves, mesh, and fronds of the tree. These wastes are burnt down under high temperatures to obtain ash and further refined into a fine powdered form for use as a substitute material for cement in concrete [12,20,21]. The date palm tree is abundant in the Gulf countries, with Saudi Arabia being the second-highest global date palm producer. Annually, more than 1 million tons of waste are produced from the date palm trees in Saudi Arabia [22,23]. Most of these wastes are discarded into landfills without recycling, with few quantities used together with other biowaste to produce animal feeds. The discarded date tree wastes cause threats to the environment, such as water pollution, leaching, and soil degradation. Therefore, proper management of this waste is vital to prevent these effects and promote environmental sustainability [24]. One of the ways of utilizing the date waste trees is by burning them and use as an SCM to produce sustainable, ecofriendly concrete. This will reduce the overall cost of concrete since cement is the most costly ingredient and also reduce cement-related CO2 emissions indirectly by reducing the amount of cement produced [14,21]. DPA has also been found to be a good pozzolanic material, which, when used as a SCM, improves the mechanical properties and durability performance of concrete and mortar [12,13,19,21,25]. DPA also promotes both the cost and environmental sustainability of concrete; when used as an SCM in concrete, it reduces the cost and embodied CO2 emissions of the concrete [14].

However, the main shortcoming of using DPA in concrete is that only a minimal proportion of cement (not more than 10%) can be replaced without causing a reduction in the mechanical properties and durability performance of the concrete, which might be due to the slower pozzolanic reaction of DPA [11,19]. To address this problem, DPA can be used in conjunction with other strongly reactive SCMs, especially those that contain higher cementitious properties (CaO), such as ESP [12].

ESP is obtained from waste eggshells. Eggs are one of the most consumed foods globally, as they are used in homes, bakeries, poultry farms, restaurants, and factories. Eggshell waste can be collected from any of the mentioned places and recycled [26]. It makes up 11–12% of the total weight of the egg, and a typical egg weighs between 50 and 70 g. These eggshells are mainly dumped into the trash and disposed into landfills, thereby attracting all sorts of insects, snakes, birds, and rodents, which can be harmful to the environment and human health, promoting environmental pollution [27,28]. Eggshell is a great source of calcium, as its main chemical compound is calcium carbonate/calcium oxide (CaCO3/CaO), which makes it a potential material for use in cementitious composites as CaCO3 and aid in the production of more calcium silicate hydrate (CSH) gels. They are the major hydration products for enhancing the durability and strength of cementitious composites [12,29,30]. ESP is reported to contain very high cementitious properties (CaO), even higher than cement, and a specific amount of this compound is required for strength development [30,31,32]. ESP has been reported to strengthen the properties of cementitious composites because of its abundant CaCO3, which helps in balancing ettringite and monocarbonate dosages in the cementitious matrix [26,33]. Usually, ESP, known for its high CaO content, is combined with pozzolanic materials containing moderate to high levels of silica (SiO2) and alumina (Al2O3) to give an excellent CaO–SiO2 reactivity and double the compressive strength at an early age and significantly improve dense gel formulation in the cement matrix [34]. ESP has been blended with pozzolanic materials such as fly ash [35,36], blast furnace slag [37,38], rice husk ash [39], rice straw ash [40,41], silica fume [28], nano silica [26], palm oil fuel ash (POFA), bagasse ash [42], etc., and they all reported significant improvements in both pozzolanic/hydration reactions and enhancements in the properties of the concrete using the materials of the hybrid. Recently, Adamu et al. [12] blended DPA with ESP in cement composite, in which 10–40% of cement was partially substituted with DPA, and ESP was added as an additive to cementitious materials in dosages of 1, 2, 3, and 4% by the weight of the binder. The mechanical strengths improved with the incorporation of up to 20% DPA and 2% ESP, while the durability in terms of pore volume and absorption enhanced with the addition of 30% DPA and 3% ESP.

The development of sustainable construction materials is imperative to address the environmental challenges associated with traditional cement-based concrete. While significant research has been conducted on SCMs, the potential of combining agricultural waste products such as DPA and ESP remains underexplored, particularly regarding their synergistic effects on mechanical performance and environmental sustainability. Previous studies, including the work by Adamu et al. [12], have predominantly concentrated on the mechanical properties of DPA–ESP-based concrete, providing detailed experimental insights but lacking a comprehensive evaluation of its sustainability, such as life cycle assessment (LCA). Thus, some studies have carried out LCA of concrete containing industrial or agro-industrial pozzolanic materials. Onyelowe et al. [43] carried out an LCA for concrete containing silica fume and fly ash as partial substitutes for cement. They found that partially replacing cement with silica fume and fly ash lowered the environmental impact of the concrete due to a reduction in cement usage. Onyelowe et al. [44] reported a reduction in the environmental impact of fly ash and rice husk ash as SCMs due to a reduction in cement use. By adopting a holistic LCA approach, this research seeks to examine the dual impact of DPA and ESP on concrete’s durability, strength, and environmental sustainability, thereby addressing the existing gap. The novelty lies in utilizing a hybrid SCM system that not only optimizes mechanical properties but also minimizes the environmental footprint, offering a sustainable and cost-efficient solution to replace traditional cement. By exploring the optimal mix design of DPA–ESP-based concrete, assessing its mechanical and durability characteristics, and quantifying its life cycle impacts, this research extends the work of Adamu et al. [12], addressing the need for a separate study to focus on sustainability aspects. The findings aim to provide a holistic understanding of the feasibility of DPA and ESP as sustainable construction materials, bridging the gap between performance optimization and environmental responsibility while contributing to the global efforts to counteract the environmental effects of producing concrete.

2 Materials and methods

2.1 Materials

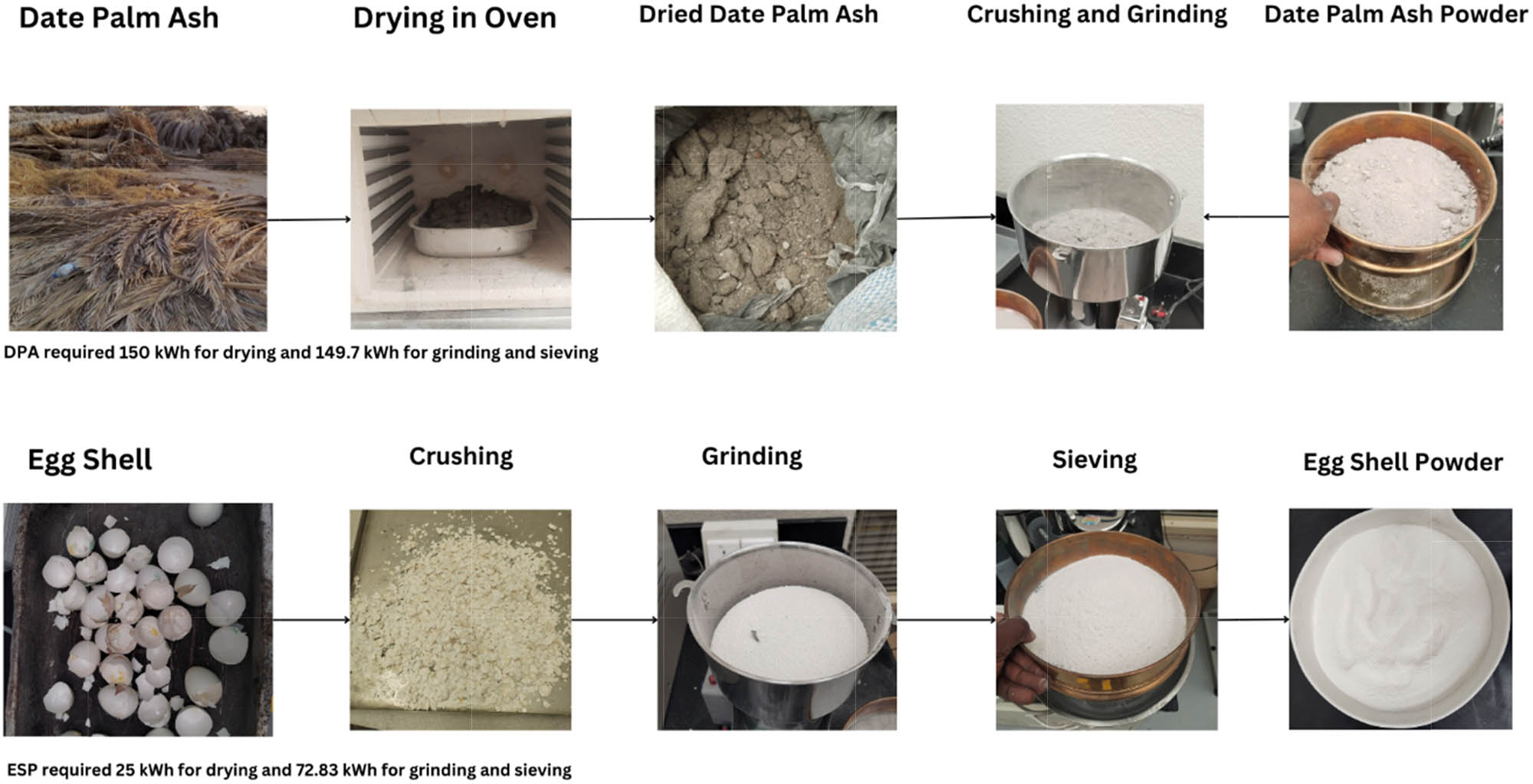

Type I cement was employed as the main binder, with a specific gravity (SG) of 3.15 and a specific surface area of 325 m2·kg−1. DPA was collected from a nearby farm in unprocessed form. On the farm, date palm waste consisting of leaves, trunks, mesh, and branches was burnt in the open. The raw DPA was further processed in the laboratory to obtain the final product for use in concrete. Raw DPA was placed in the furnace at a temperature of 600°C for 2 h to eliminate any moisture and remove unburnt carbon from the ash [45,46]. DPA was ground using a high-powered grinder and subsequently sieved through a 150 μm mesh, and the particles that passed were collected as the processed DPA. DPA has a chemical composition, as shown in Table 1, which met the requirements of ASTM C618 [47] for pozzolanic materials for concrete application. The SG of DPA was found to be 2.14. The eggshell residues were acquired from different sources within Riyadh, Saudi Arabia, which included poultry farms, restaurants, and bakery. After collection, the eggshells were thoroughly washed to eliminate dirt and organic membranes. After washing, the eggshells were ground to smaller particles by hand and oven-dried for 24 h at a temperature of 100 ± 5°C to dry them completely and remove moisture. The eggshells were pulverized into a fine powder and sieved using a 63 μm mesh, and the particles that passed were collected and utilized as ESP, with their properties listed in Table 1. The manufacturing process of DPA and SP waste powder is shown in Figure 1. River sand was obtained from local suppliers and used as a fine aggregate. The aggregate’s SG is 2.63, and its water absorption is 1.26%. The coarse aggregate used was crushed gravel obtained from a nearby quarry. The coarse aggregate has an SG of 2.67, particle size of 19 mm, and water absorption of 0.54%. The particle size gradation of the fine and coarse aggregates is presented in Figure 2, and they fall within the limits specified by ASTM C33/C33M [48] for use in concrete.

Chemical properties of DPA and ESP

| Oxides | Values | ||

|---|---|---|---|

| Cement | DPA | ESP | |

| Calcium oxide (%) | 65.18 | 11.72 | 97.46 |

| Silicon dioxide (%) | 19.17 | 52.35 | 0.03 |

| Ferric oxide (%) | 3.4 | 13.36 | — |

| Aluminum oxide (%) | 5.39 | 6.27 | 0.02 |

| Magnesium oxide (%) | 0.91 | 0.1 | 0.69 |

| Sulfur trioxide (%) | 3.51 | 1.50 | 0.35 |

| SG | 3.15 | 2.14 | 2.39 |

Manufacturing process of DPA and ESP waste.

Particle size gradation of aggregates.

2.2 Mix design and proportioning

In this study, the procedure discussed in ACI 211.1R [49] was followed and implemented for designing the control (100% OPC) cement, which is used as the reference mix for comparison with all other mixes. DPA was used to substitute some fractions of the cement at different proportions (10, 20, and 30%). The replacement procedure used the volume method due to the large variation between the SGs of OPC (3.15) and the DPA (2.14). To enhance the pozzolanic reactivity in concrete, ESP was incorporated as an additive to cementitious materials in several dosages (0, 1, 2, and 3% by weight) of the binders. To optimize the study and lower the number of required mixes, the response surface methodology (RSM) technique was applied. The Design Expert software was utilized for the RSM process, and the central composite design method was selected. A total of ten mixes, including the control, were obtained using various combinations of DPA and ESP by the RSM, as shown in Table 2. This procedure saves time and cost for the experiment and the study [12].

| Mix | Variables (%) | Quantities of each material (kg·m−3) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| DPA | ESP | Cement | DPA | ESP | Fine aggregate | Coarse aggregate | Water | S P | |

| M1 | 0 | 0 | 490 | 0.0 | 0.0 | 750 | 905 | 170 | 4.90 |

| M2 | 30 | 1 | 343 | 113.4 | 4.6 | 750 | 905 | 170 | 4.61 |

| M3* | 20 | 2 | 392 | 75.6 | 9.4 | 750 | 905 | 170 | 4.77 |

| M4 | 0 | 2 | 490 | 0.0 | 9.8 | 750 | 905 | 170 | 5.00 |

| M5* | 20 | 2 | 392 | 75.6 | 9.4 | 750 | 905 | 170 | 4.77 |

| M6 | 10 | 1 | 441 | 37.8 | 4.8 | 750 | 905 | 170 | 4.84 |

| M7 | 20 | 4 | 392 | 75.6 | 18.7 | 750 | 905 | 170 | 4.86 |

| M8 | 40 | 2 | 294 | 151.2 | 8.9 | 750 | 905 | 170 | 4.54 |

| M9* | 20 | 2 | 392 | 75.6 | 9.4 | 750 | 905 | 170 | 4.77 |

| M10 | 10 | 3 | 441 | 37.8 | 14.4 | 750 | 905 | 170 | 4.93 |

| M11* | 20 | 2 | 392 | 75.6 | 9.4 | 750 | 905 | 170 | 4.77 |

| M12 | 20 | 0 | 392 | 75.6 | 0.0 | 750 | 905 | 170 | 4.68 |

| M13 | 30 | 3 | 343 | 113.4 | 13.7 | 750 | 905 | 170 | 4.70 |

*DPA = date palm ash; ESP = eggshell powder.

2.3 Specimen preparation and experimental methodology

In this study, the methodology explained in ASTM C192/C192M [50] for the batching and mixing of the concrete was followed. After mixing, the workability of the fresh concrete was determined. The fresh concrete was cast into the specified molds and allowed to harden in the laboratory. The concrete was extracted from the molds 24 h later and immersed in water for curing prior to testing.

The slump test, conducted in accordance with ASTM C143/C143M [51], was used to evaluate the workability of the freshly prepared concrete. After 28 days of curing in water, the compressive strength of the concrete was determined using 100 mm cubes, as per BS EN 12390-3 [52]. As per the requirements of BS EN 12390-6 [53], split tensile strength testing was conducted on cylindrical concrete samples (200 mm height and 100 mm diameter) cured for 28 days. In line with the ASTM C78/C78M [54] standard, concrete prisms of size 100 mm × 100 mm × 500 mm were prepared and cured for 28 days to determine flexural strength. Finally, in line with ASTM C642 [55], the water absorption of the concrete was tested on 100 mm cubes cured for 28 days.

3 LCA methodology

3.1 Goal and scope definition

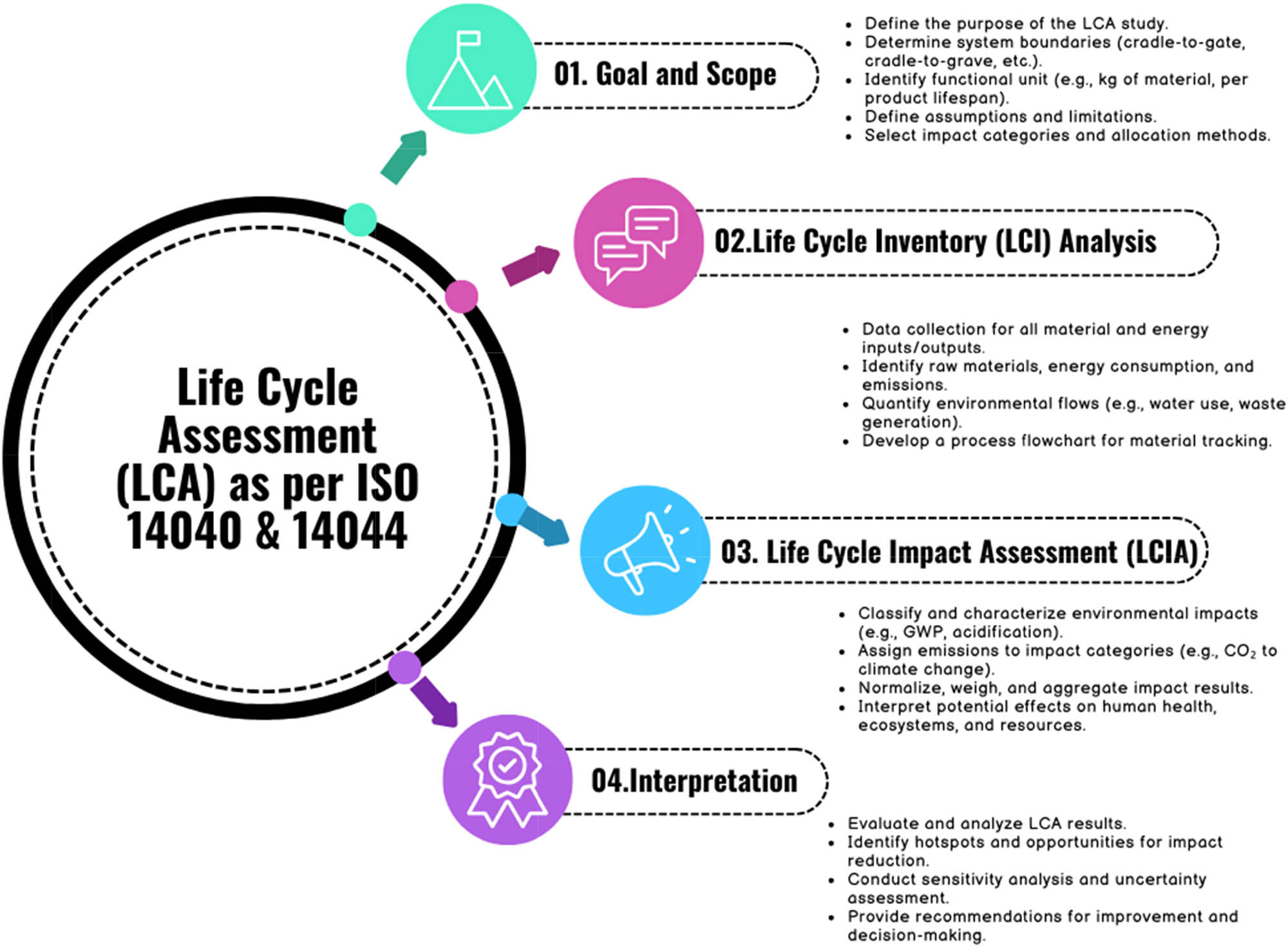

The LCA of DPA–ESP-based concrete was carried out using IS0 14040, which involved four steps, as shown in Figure 3. The primary goal of this LCA was to assess the environmental impacts of producing 1 m3 of DPA–ESP-based concrete and to compare these impacts with conventional concrete mixes. The study aimed to identify the significant impact categories and primary contributors throughout the concrete’s life cycle. The functional unit was defined as 1 m3 of concrete, providing a standard basis for comparing the environmental performance of different materials and processes.

LCA as per ISO 14040.

Figure 4 illustrates the system boundaries, which followed a cradle-to-grave framework, encompassing all life cycle stages: raw material extraction, processing, transportation, mixing, usage, and end-of-life management [56,57,58]. This included acquiring raw materials such as cement, river sand, aggregates, DPA, and ESP; processing DPA and ESP (drying, grinding, and sieving); mixing concrete; and handling end-of-life processes like demolition, waste management, and potential recycling or disposal.

Graphical representation and boundary condition adopted for LCA.

3.2 Life cycle inventory (LCI)

The LCI phase detailed quantifying all inputs and outputs of producing 1 m3 of DPA–ESP-based concrete. The assessment considered various mix designs (M1 to M14) with different percentages of DPA and ESP, replacing portions of conventional cement.

The inventories used in this analysis (Table 3) provide a comprehensive overview of the materials, processing, electricity consumption, and transportation considered in the LCA. The environmental burdens associated with processing DPA and ESP were calculated based on their specific energy consumption: DPA required 150 kW·h for drying and 149.7 kW·h for grinding and sieving. In comparison, ESP required 25 kW·h for drying and 72.83 kW·h for grinding and sieving. These processes were modeled using the “Electricity, high voltage (CN-SA) | Electricity production, hard coal, system S” dataset to account for electricity consumption. Materials were transported using light commercial vehicles over specified distances: DPA was transported 150 km, ESP 50 km, and other materials such as cement, river sand, and aggregates were transported 50 km to the production site. All transportation activities were included in the LCI using the “Light Commercial Vehicle (RoW) | Cut-off, S” dataset.

Inventory for the LCA for the DPA–ESP-based concrete

| Inventory component | Description |

|---|---|

| Cement, Portland {RoW} | Market for cement, Portland |

| Sand {RoW} | Market for sand |

| Gravel, round {RoW} | Market for gravel, round |

| Tap water {RoW} | Market for tap water |

| Plasticizer for concrete | Based on sulfonated melamine formaldehyde {GLO} market for plasticizer |

| DPA | Processed for concrete production |

| ESP | Processed for concrete production |

| Electricity, high voltage (CN-SA) | Electricity production, hard coal, system S |

| Transportation of materials | Light commercial vehicle (RoW) |

3.3 Life cycle impact assessment (LCIA)

The SimaPro v9.6 software and ReCiPe Midpoint (H) methodology were used for the LCIA phase. The ReCIPe midpoint (H) method assesses 18 environmental impacts and offers a detailed evaluation of products or processes. The methodology was selected based on its capacity to conduct an in-depth examination of environmental impacts at midpoints and help point out areas that need improvements in emissions, resource use, and other types of environmental burdens. Some limitations were recognized, such as using Ecoinvent v3.9 data that may not cover regional differences and assumptions that DPA and ESP are considered waste materials with no previous environmental burdens. Additionally, transportation distances and processing of materials could change the results if these parameters vary. The research did not include any potential advantages of recycling concrete at the end-of-life, reusing or reusing it again, which may improve the entire ecological footprint.

3.4 Interpretation

The LCA for DPA–ESP-based concrete, performed by ISO 14040 guidelines, included a complete analysis of the environmental effects to discern relevant factors and ensure data integrity and methodological coherence. By using the ReCiPe Midpoint (H) method analysis, it was found that global warming potential (GWP) was mainly influenced by cement manufacturing. Due to their energy specifications, heavy contributions also came from DPA and ESP processing. Completeness and consistency checks confirmed the proper inclusion of all relevant life cycle stages and inputs. In subsequent sections, LCIA results interpretation and ancillary improvement opportunities are discussed.

3.5 Analytical hierarchy process (AHP) and one-way sensitivity analysis

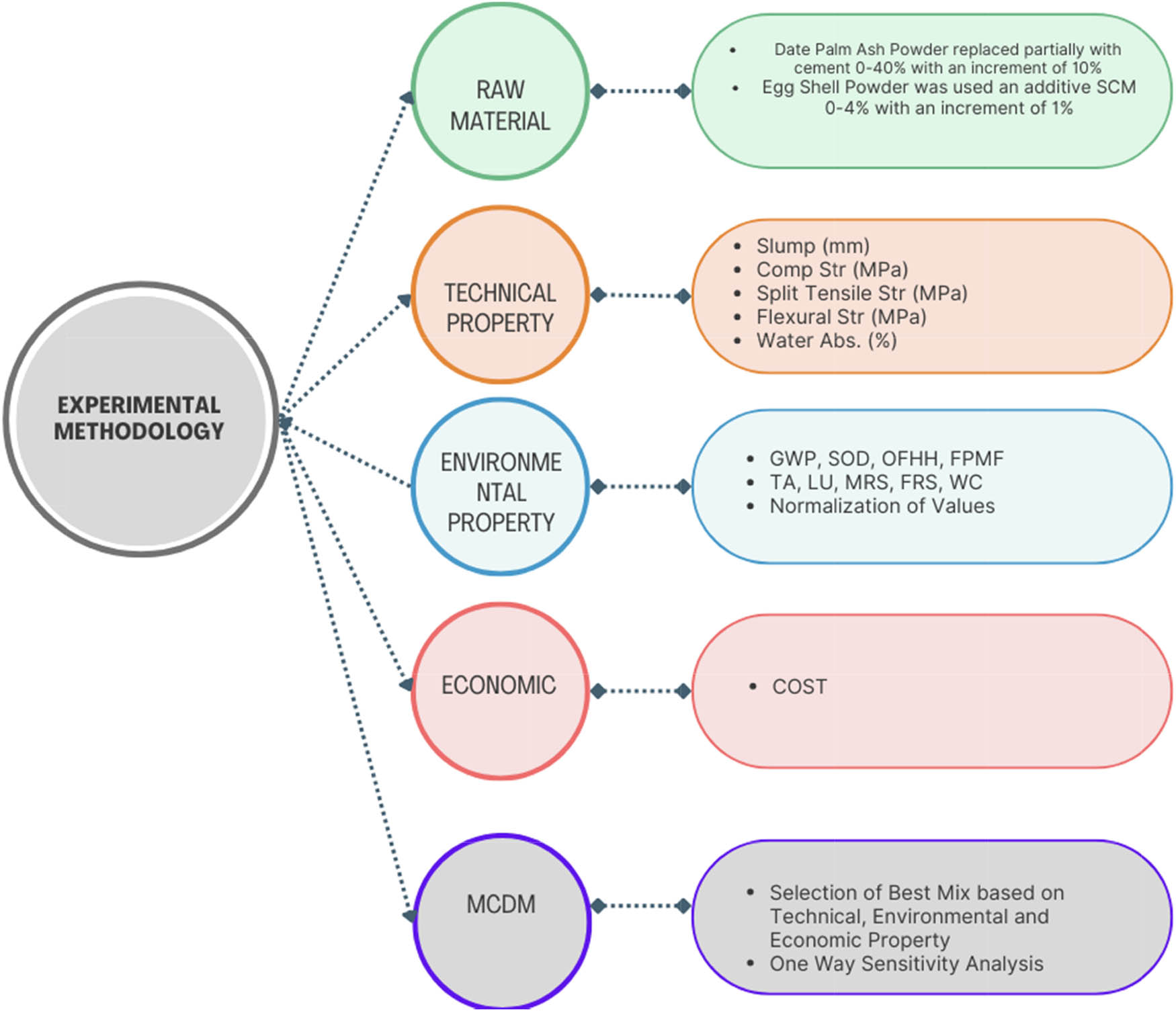

The selection of an optimal mix design for DPA–ESP-based concrete requires a methodical approach to evaluating multiple criteria, including technical performance, environmental impact, and economic feasibility, as shown in Figure 5. The AHP is a widely used multi-criteria decision-making (MCDM) technique that aids in assigning priority weights to these criteria and ranking the available alternatives accordingly. The AHP methodology involves structuring the decision problem into a hierarchy, constructing a pairwise comparison matrix, normalizing the judgments, computing priority vectors, and ensuring consistency in decision-making.

Experimental methodology followed in the present study.

The pairwise comparison matrix is a square matrix A, where each element a ij represents the relative importance of criterion i over criterion j, satisfying the following condition:

Normalization of this matrix is performed to ensure comparability of the elements by dividing each entry by the sum of its respective column:

The priority vector, representing the relative importance weights of each criterion, is obtained by averaging the values across the rows of the normalized matrix:

To ensure the reliability of the judgments, a consistency check is performed by first computing the weighted sum vector:

The principal eigenvalue λ max is estimated using

Using λ max, the consistency index (CI) is calculated as

The consistency ratio (CR) is then computed as

where RI is the random index, a predefined value based on the number of criteria. A CR < 0.1 is considered acceptable; otherwise, the pairwise comparisons need to be revised.

Following the derivation of weights, each mix design (M1 to M13) is evaluated against the technical, environmental, and economic criteria using a decision matrix. The overall score for each mix design is determined using the weighted sum method:

where s ki represents the performance score of the mix. The mix design with the highest score is considered the optimal choice.

To assess the robustness of the rankings, one-way sensitivity analysis is conducted by varying the weight of a selected criterion while proportionally adjusting the others. If the weight of a particular criterion w i is modified, the adjusted weight is given by

The remaining weights are proportionally redistributed as

The recalculated score for each mix design under the new weight distribution is

By analyzing the variation in ranking as a function of ∆w, the sensitivity of the decision model is assessed. If small changes in the criterion weights result in significant rank reversals, the model’s stability is questioned, and adjustments to the decision criteria may be necessary.

4 Results and discussion

4.1 Experimental results

The experimental results discussed in this study were already documented in Adamu et al. [12,13], and a summary is presented in Table 4 for reference and understanding of the LCA. A reduction in concrete slump was observed with higher DPA replacement levels, likely due to the coarse, irregular particle sizes of DPA, leading to increased internal friction and a lower slump. Similarly, adding ESP led to a reduction in the concrete slump caused by the high surface area of ESP that absorbed excess water during mixing and lowered workability. Replacing a portion of the cement with DPA reduced the compressive, flexural, and split tensile strengths, as well as an increase in water absorption. For example, in comparison to mix 1 (0% DPA and 0% ESP), mix M12 (20% DPA and 0% ESP) has lower compressive, split tensile, and flexural strengths by 19.48, 12.3 and 9.05%, respectively, and has higher water absorption by 14.88%. The cause of this effect was related to the slower pozzolanic reaction of DPA during hydration, which hinders C–S–H formation and strength gain and increases porosity in the cement matrix. From Table 4, the addition of ESP to the concrete mixes with or without DPA led to enhancements in its mechanical strengths. For instance, comparing mix M1 (0% DPA and 0% ESP) with M4 (0% DPA and 2% ESP), the latter exhibits higher compressive, split tensile, and flexural strengths by 5.73, 3.6, and 6.98%, respectively, and lower water absorption by 6.08%. The enhancements in the mechanical strengths and reduction in water absorption were linked to the finer sizes and the pore-filling effectiveness of ESP, and the high CaO in the ESP promotes the pozzolanic and hydration reactions and increases C–S–H formation and consequently densified microstructure and higher strengths. From Table 4, blending up to 20% DPA with up to 4% ESP in the concrete led to improvements in mechanical strengths and water absorption due to the combined effects of the DPA in terms of contributing more SiO2 and ESP contributing to the production of more Ca(OH)2, where these two compounds react via pozzolanic reaction to form surplus C–S–H for strength development. The findings in this study were similar to those of Hamada et al. [59], who reported improvement in strengths and reduction in water when POFA was blended with ESP. Rasid et al. [60] also reported significant improvements in the mechanical and durability performance of concrete when blends of POFA and ESP were used to partially substitute cement, where they found that the combination of 15% POFA with 5% ESP yielded the highest strengths.

| Mix | DPA (%) | ESP (%) | Slump (mm) | Comp strength (MPa) | Split tensile strength (MPa) | Flexural strength (MPa) | Water absorption (%) |

|---|---|---|---|---|---|---|---|

| M1 | 0 | 0 | 90 | 40.92 | 3.38 | 5.73 | 3.18 |

| M2 | 30 | 1 | 53 | 41.97 | 3.19 | 5.49 | 3.27 |

| M3 | 20 | 2 | 65 | 57.53 | 4.19 | 7.23 | 2.45 |

| M4 | 0 | 2 | 83 | 46.08 | 3.50 | 6.13 | 2.99 |

| M5 | 20 | 2 | 60 | 59.49 | 4.01 | 6.75 | 2.57 |

| M6 | 10 | 1 | 70 | 49.22 | 3.54 | 6.64 | 2.92 |

| M7 | 20 | 4 | 38 | 44.17 | 3.33 | 5.03 | 3.05 |

| M8 | 40 | 2 | 35 | 32.49 | 2.91 | 4.68 | 4.15 |

| M9 | 20 | 2 | 60 | 58.04 | 3.86 | 7.05 | 2.61 |

| M10 | 10 | 3 | 63 | 55.90 | 4.00 | 6.79 | 2.78 |

| M11 | 20 | 2 | 58 | 63.25 | 3.73 | 6.86 | 2.72 |

| M12 | 20 | 0 | 72 | 35.09 | 2.97 | 5.21 | 3.65 |

| M13 | 30 | 3 | 40 | 44.68 | 3.58 | 5.41 | 3.05 |

| M14 | 20 | 2 | 58 | 51.58 | 4.08 | 6.55 | 2.75 |

4.2 Environmental impact results

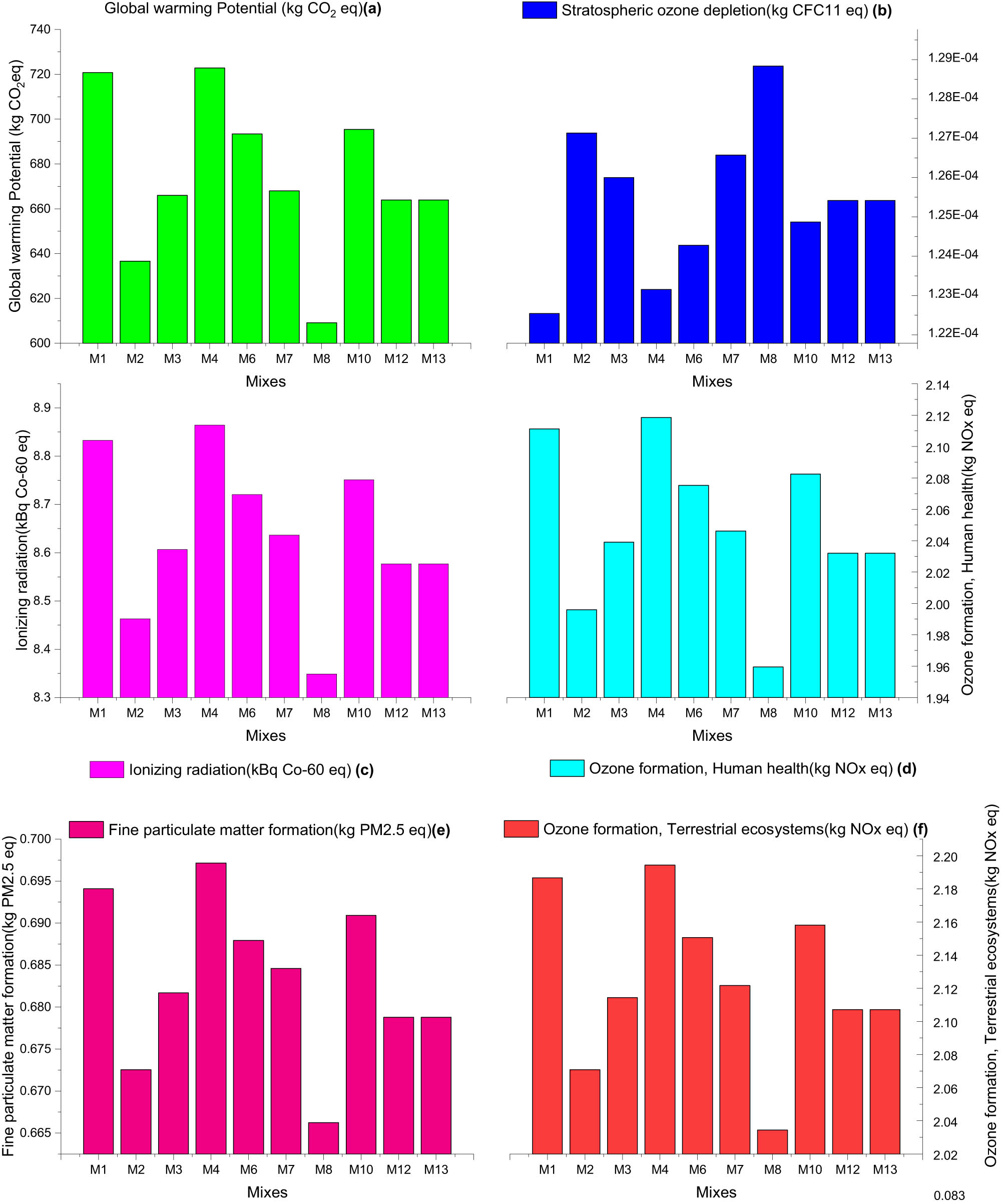

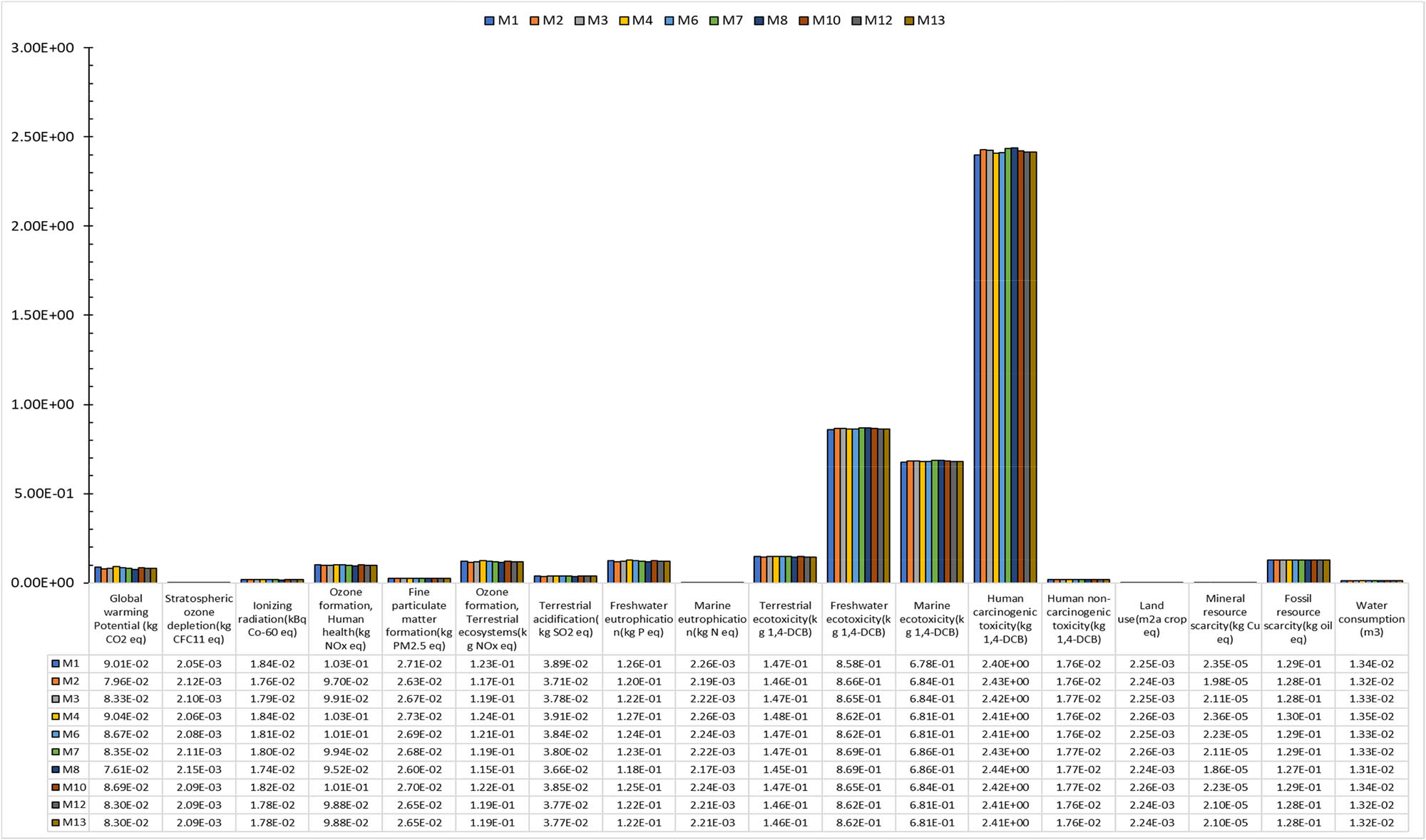

The production and transportation of materials such as cement, Portland, aggregates, and sand significantly drive the environmental impacts of the concrete mixes analyzed in this study. Figure 6(a–r) shows the characterized values of environmental impacts of materials due to the production of various concrete mixes. Across all mixes, cement production is a dominant contributor to the GWP, with contributions ranging from 45.8 to 64.4% of total emissions. For instance, in the M2 mix, cement production accounts for approximately 51.2% (325.79 kg CO2 eq) of the total 636.6 kg CO2 eq emissions, while in the M4 mix, this increases to around 64.4% (465.42 kg CO2 eq) of the total 722.84 kg CO2 eq emissions. The notable impact of cement arises from its high-energy production process, involving limestone calcination and clinker production, which are key contributors to CO2 emissions.

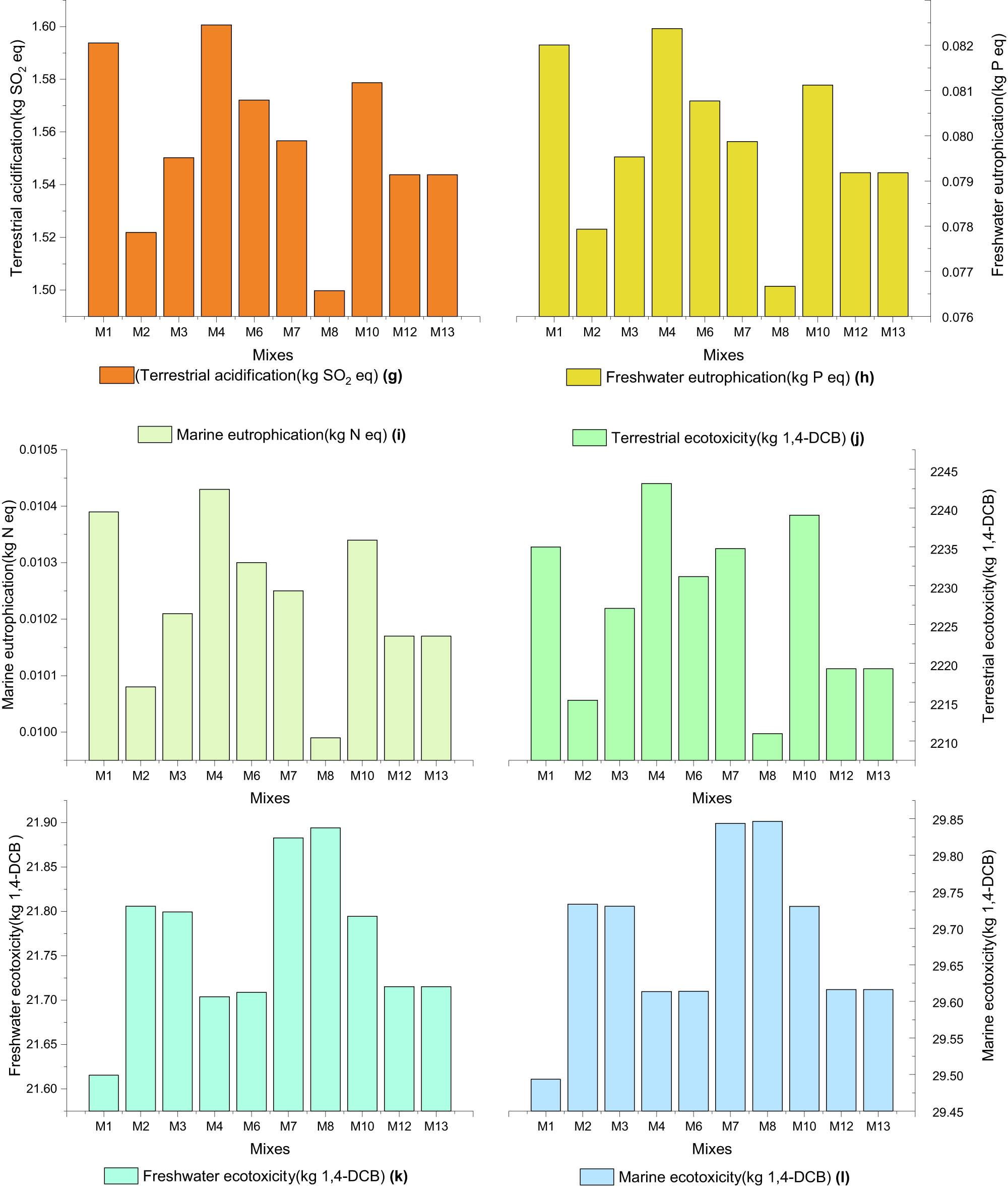

Characterized values of all environmental impacts of DPA–ESP-based concrete.

Transportation also plays a crucial role in the environmental footprint, particularly in GWP, ozone formation, and ecotoxicity categories. For example, in the M6 mix, the transportation of aggregates and sand contributes about 20.2% to the total GWP (139.95 kg CO2 eq out of 693.39 kg CO2 eq). In the M3 mix, aggregate transportation alone accounts for approximately 14.3% of the total GWP (94.05 kg CO2 eq out of 666 kg CO2 eq). Transporting these heavy materials results in substantial fuel consumption and emissions of greenhouse gases (CO2) and air pollutants (NO x , SO2, PM2.5).

Alternative materials such as DPA and ESP show promising potential for reducing environmental impacts. In the M2 mix, the processing of DPA contributes 11.1% (70.54 kg CO2 eq) to the total GWP, whereas the M3 mix has a 7.1% (47.03 kg CO2 eq) contribution from DPA. For the M13 mix, incorporating DPA contributes only 7.1% of the total GWP (47.03 kg CO2 eq out of 663.99 kg CO2 eq). In terms of terrestrial ecotoxicity, cement and aggregate production are significant contributors, accounting for up to 27.3 and 22.5%, respectively, of the total impact in the M6 mix (610 kg 1,4-DCB eq out of 2231.15 kg 1,4-DCB eq).

While less impactful than cement or aggregate transport, plasticizers still contribute to multiple categories. For example, in the M13 mix, plasticizers contribute about 1.0% to the total GWP (6.6 kg CO2 eq out of 663.99 kg CO2 eq) but have a more noticeable impact in toxicity categories, such as contributing 9.5% to the freshwater ecotoxicity impact (0.476 kg 1,4-DCB eq out of 21.71 kg 1,4-DCB eq).

The analysis reveals that conventional materials like cement and aggregates primarily contribute to the environmental impact. Alternative materials like DPA and ESP can reduce these impacts across several categories. For instance, in the M8 mix, including DPA and ESP helps reduce the impact of freshwater eutrophication to 3.1 and 1.2%, respectively, showing a potential for mitigating environmental harm. Optimizing the use of these materials and improving transportation logistics could reduce the environmental footprint.

4.3 Comparison of various mixes with a conventional mix

The LCA results of the DPA–ESP-based concrete mixes highlight variations in environmental impacts across different mix proportions. This discussion compares these mixes (M2, M3, M4, M6, M7, M8, M10, M12, and M13) to identify the optimal mix design regarding environmental performance. Figure 6 shows the comparison of mixes with conventional concrete

4.3.1 GWP

Among all mixes (Figure 6a), M8 shows the lowest GWP (609.15 kg CO2 eq), reflecting a 15.46% decrease compared to the conventional mix M1 (720.73 kg CO2 eq). This substantial decrease results from the higher proportion of DPA (40%), which replaces a considerable amount of cement, the primary contributor to CO2 emissions. Mixes M2 (636.60 kg CO2 eq) and M13 (663.99 kg CO2 eq) also show a notable decrease in GWP, with 11.67 and 7.87% reduction, respectively, compared to M1. Conversely, M4 (722.84 kg CO2 eq) shows a slight 0.29% increase in GWP, primarily due to its lower DPA content (0%) and reliance on traditional cement proportions.

4.3.2 Stratospheric ozone depletion

Stratospheric ozone depletion potential (Figure 6b) is relatively consistent across all mixes, with a slight increase. Mix M8 exhibits a 4.83% increase compared to M1, the highest among the mixes. This suggests that the variations in DPA and ESP content have minimal impact on ozone depletion potential.

4.3.3 Ionizing radiation

Mix M8 shows a 5.48% decrease in ionizing radiation (8.35 kBq Co-60 eq) compared to M1 (8.83 kBq Co-60 eq) (Figure 6c). Other mixes, such as M2 (8.46 kBq Co-60 eq) and M13 (8.58 kBq Co-60 eq), also demonstrate reductions, 4.19 and 2.91%, respectively. Mix M4 has the highest ionizing radiation potential (8.86 kBq Co-60 eq), slightly higher than M1, indicating less environmental benefit in this category.

4.3.4 Ozone formation (human health and terrestrial ecosystems)

Mix M8 again performs best in reducing ozone formation impacts (Figure 6d and f), with a 7.19% decrease in human health impacts (1.96 kg NO x eq) and a 6.96% reduction in terrestrial ecosystem impacts (2.03 kg NO x eq) compared to M1. Mix M2 also shows a significant reduction, with 5.46% (human health) and 5.29% (terrestrial ecosystems). M4, with no DPA, shows a slight increase in both categories, demonstrating the importance of DPA content in minimizing these impacts.

4.3.5 Fine particulate matter formation

Mix M8 achieves a 4.01% reduction in fine particulate matter formation (Figure 6e) (0.67 kg PM2.5 eq) compared to M1 (0.69 kg PM2.5 eq). Other mixes, such as M2 (0.67 kg PM2.5 eq) and M6 (0.69 kg PM2.5 eq), show smaller reductions, with 3.10 and 0.31% decreases, respectively. Mix M4 slightly increases, reinforcing the trend that higher DPA content correlates with reduced particulate matter emissions.

4.3.6 Terrestrial and freshwater acidification

Mix M8 shows the most substantial decrease (Figure 6g and h) in terrestrial acidification (1.50 kg SO2 eq) and freshwater eutrophication (0.0767 kg P eq), with 5.89 and 6.50% reduction, respectively, compared to M1. Mixes with lower DPA content, such as M4, show negligible improvements or slight increases, highlighting the effectiveness of DPA in reducing acidification and eutrophication impacts.

4.3.7 Ecotoxicity (terrestrial, freshwater, and marine)

All mixes show relatively similar impacts on ecotoxicity, with minimal variations (Figure 6j–l). Mix M8 shows slight decreases in terrestrial ecotoxicity (1.07% lower) and marine eutrophication (3.89% lower) compared to M1, while mixes like M4 show a slight increase. The differences in ecotoxicity are less pronounced, suggesting that while DPA and ESP contribute to reduction in some categories, they do not significantly impact ecotoxicity.

4.3.8 Human toxicity (carcinogenic and non-carcinogenic)

Mix M8 has a 1.77% increase in human carcinogenic toxicity (25.13 kg 1,4-DCB) and a 0.81% increase in non-carcinogenic toxicity (553.05 kg 1,4-DCB) compared to M1 (Figure 6m and n). These increases are relatively small but suggest that using DPA and ESP could introduce minor risks that should be further explored. Mixes M2 and M6 show marginally lower increases, indicating a potential trade-off between reducing other environmental impacts and managing human toxicity levels.

4.3.9 Resource use (land use, mineral, and fossil resource scarcity)

Mix M8 shows (Figure 6p and q) the most significant reduction in mineral resource scarcity, with a 21.08% decrease (2.23 kg Cu eq) compared to M1. This is due to reduced reliance on cement, a significant mineral resource use driver. Fossil resource scarcity also shows a 1.45% decrease for M8. Mix M2 shows a 15.85% decrease in mineral resource scarcity, while M4, with no DPA, shows minimal improvements. The land use data (Figure 6o) for different mixes range narrowly from 13.82 to 13.93 m2, indicating minimal variation across the mixes. Thus, land utilization is relatively uniform among all mixes, suggesting that none significantly outperforms the others in minimizing land use impact. These results indicate that higher DPA and ESP contents are associated with more efficient resource use.

4.3.10 Water consumption

Water consumption (Figure 6r) is lowest for mix M8, showing a 2.47% decrease (3.49 m3) compared to M1 (3.58 m3). Mixes M2 (3.51 m3) and M6 (3.56 m3) also show reduction but to a lesser extent (1.90 and 0.38%). The trend demonstrates that increased DPA content can lower water usage in concrete production.

4.4 Summary of LCA results

Mix M8, with the highest DPA content (40%), consistently shows the lowest environmental impacts across most categories, including global warming, ozone formation, acidification, and resource use, demonstrating its potential as the most sustainable mix. Other mixes, such as M2 and M13, also offer significant environmental benefits but to a lesser extent. Mix M4, with no DPA, often shows increases or minimal reductions in impacts, underscoring the importance of DPA and ESP in enhancing the environmental performance of concrete. Although there are slight increases in human toxicity categories, these are relatively minor and may be manageable with proper processing and handling of materials. Overall, DPA–ESP-based mixes, particularly M8, present a promising alternative for reducing the environmental footprint of concrete production.

The characterized environmental impacts presented in Figure 7 were normalized by the world population using the ReCiPe 2016 Midpoint (H) V1.08 method (Figure 8). This normalization allows for a more standardized comparison across different processes by adjusting the impacts relative to the global population. The data reveal that the most significant environmental impacts are seen in categories like “Human carcinogenic toxicity,” “Freshwater ecotoxicity,” and “Marine ecotoxicity.” These high values suggest that the processes analyzed have notable contributions to human health risks and ecosystem toxicity. Lower impact values are noted for categories such as “Global warming” and “Stratospheric ozone depletion,” indicating relatively lesser contributions to these specific impacts.

Characterized values of environmental impacts for all relevant mixes. Note: GWP, terrestrial ecotoxicity, and HNCT are plotted against the primary axis; the rest of the impacts are plotted against the secondary axis.

Normalized values of environmental impacts for relevant mixes.

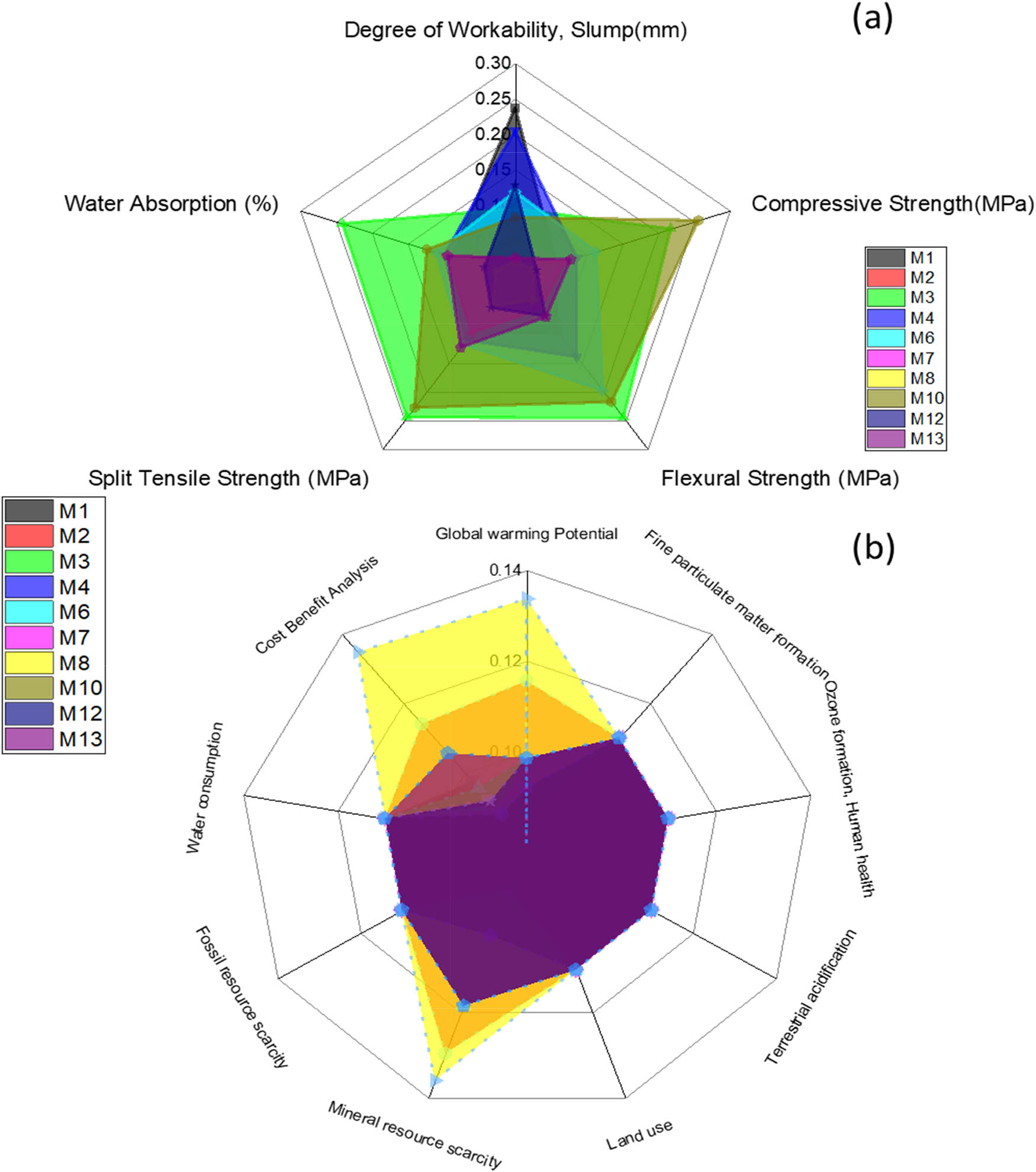

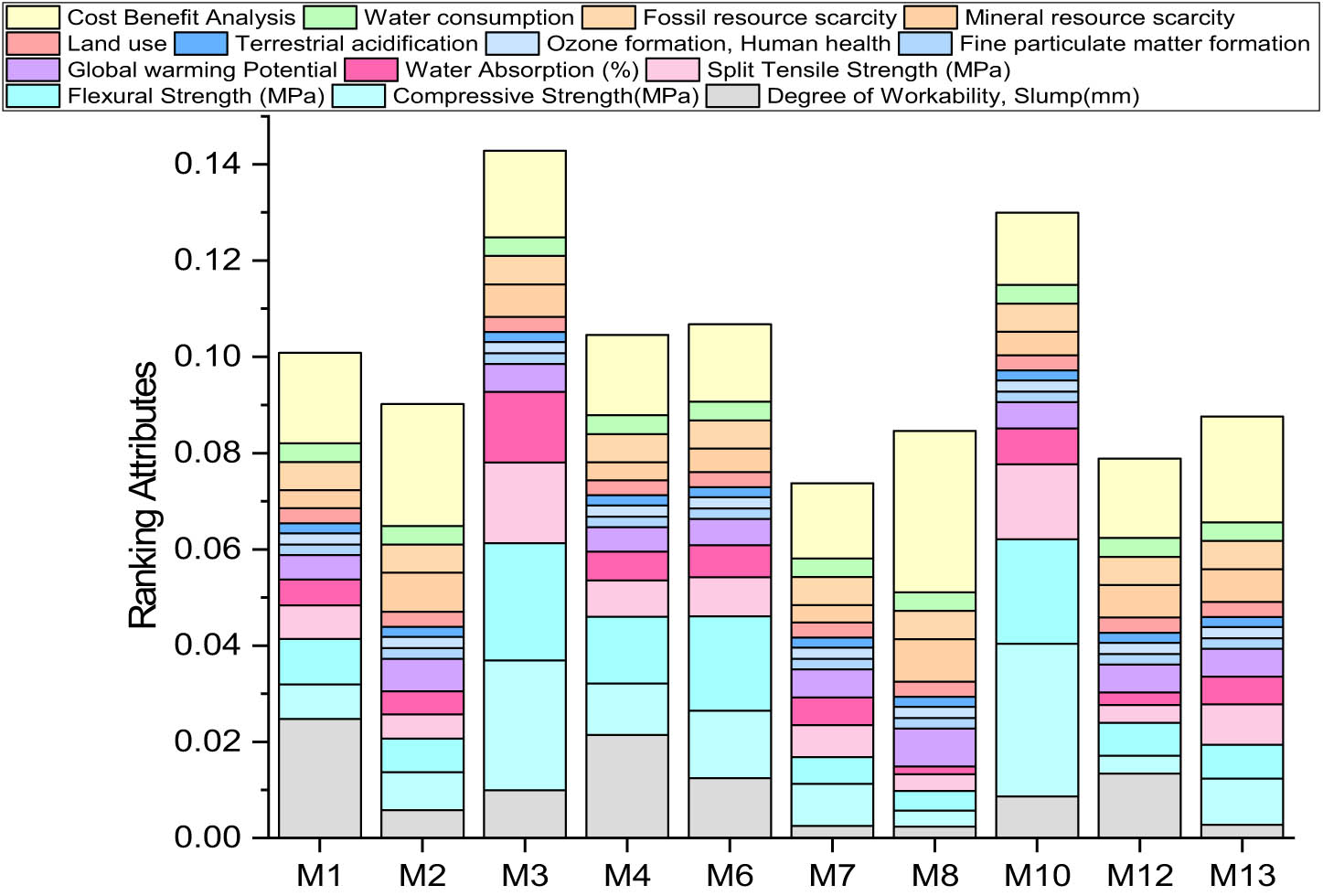

4.5 Discussion on the selection of the best mix

4.5.1 AHP methodology

AHP methodology was used to rank the mix designs (M1–M13) against technical, environmental, and economic criteria. The corresponding weights assigned are shown in Figure 9. AHP framework was used to break down the comparison of mixes into constituent parts and then logically combine them by weighting and aggregating multiple criteria.

Pairwise matrix weights for the selection of best mix.

Using the Saaty scale, which forms the core of the AHP, the technical and environmental properties of several mixes of concrete were then evaluated and compared. Pairs of each mix were compared using the ratios of values for the technical properties of slump, compressive strength, flexural strength, and split tensile strength, where higher values are judged better. The ratio of the higher value to lower value was specifically calculated, and these were subjected to the assignment of preferences using the Saaty scale so that the mixes with the best technical performance had the highest priorities. Conversely, when lower values are desirable (in the case of environmental properties related to GWP, fine particulate matter formation, ozone formation [human health], terrestrial acidification, mineral resource scarcity, and fossil resource scarcity), inverse ratios were chosen. In this case, we determined the ratio of the larger value to the smaller value for a series of mixes with minimal environmental impact. The resulting pairwise comparison matrices were developed using the Saaty scale: Values between 1 and 1.1 were mapped back to 1 (equal preference), between 1.1 and 1.2–2 (slightly preferred), 1.2 and 1.3–3 (moderately preferred), 1.3 and 1.5–4 (strongly preferred), and values higher than 1.5 were mapped back to 5 (very strongly preferred). Figure 10 shows the weighted criteria for the technical, environmental, and economic properties. This structured methodology provided a robust basis for MCDM in concrete mix design since this transparent and consistent evaluation of mixes was based on both technical performance and environmental sustainability.

Weighted attributes assigned based on the pairwise matrix: (a) technical property and (b) environment and economic properties.

The properties that were given higher importance were the technical properties (0.493), such as compressive strength, flexural strength, split tensile strength, and water absorption, since they are directly related to the performance of buildings. Out of the five mixes, M3 was found to have the highest compressive strength, therefore making it the most appropriate mix for the structural member that requires high mechanical and physical properties. Flexural strength and split tensile strength, which are the ability of the concrete to resist bending and cracking, also showed great differences between the mixes. Of all the mixes, M10 presented a very good performance in these attributes, thus showing its overall good technical properties. These include M1 and M4, which, although not very strong in compressive strength, were very good in workability and very crucial in handling and placing concrete during construction. The environmental attributes (0.311) were carefully considered to capture the sustainability aspects of the mixes. Criteria such as GWP, fine particulate matter formation, terrestrial acidification, and resource scarcity were evaluated. Here, M8 emerged as a standout mix with the lowest environmental impact. Its reduced reliance on energy-intensive materials contributed significantly to its performance in this category. However, the adoption of M8 in critical structural applications would require careful deliberation, as its technical scores were not competitive with high-performing mixes like M3 and M10. Mixes such as M12 and M13, which showed moderate environmental benefits, represent viable alternatives for projects prioritizing sustainability without compromising entirely on performance.

From the economic point (0.196) of view, the efficiency of mixes from the perspective of performance versus cost was evaluated using cost–benefit analysis. Mix M8, owing to its composition consisting of economic materials, was the most cost-efficient and is an excellent candidate for cost-sensitive projects. M2 also achieved a high level of economic viability yet appropriate technological attributes. Conversely, mixes such as M3 and M10, though they are more costly, displayed better technical performance and hence could be justified for use in projects where long-term durability and structural integrity are more important. Therefore, identifying the particular priorities of a project makes clear the necessity to align the mix selection to minimize the cost/performance trade‐off.

It was also observed (Figure 11) from the integration of the attributes within the AHP framework that M3 had the highest cumulative weighted attributes (0.143), especially in compressive strength, flexural strength, and split tensile strength. With moderate environmental and economic attributes and possessing technical dominance, it is the most robust choice for structural applications. M10 stood second with a strong performance in compressive strength and flexural strength. Although lagging in technical attributes, M2 was very competitive, with a balanced environmental and economic score. M4 was characterized as having a good balance across workability and moderate compressive strength technical attributes useful for applications demanding moderate structural behavior coupled with ease of handling. Technical attributes like flexural strength and split tensile strength exhibited the competitive performance of M6. It had a moderate environmental and economic score, suggesting that it was a viable option for mid-range applications. M2 exhibited good cost–benefit attributes and tolerable environmental performance. Low on the technical scores than the top performer mixes, its economic viability provided a good value proposition to undertake such a project from the cost perspective. However, due to the lower technical scores of M8, the option was limited in application to only non-structural or environmentally driven projects. Good workability but lower scores in other technical, environmental, and economic attributes were shown by M1. This is a better mix for operations such as handling and placement, where structural strength is not. M12 scored moderately for all attributes and is appropriate for projects that have balanced priorities but do not excel at any one criterion. Compressive and flexural properties were shown for M13, but their cumulative weighted attributes were relatively lower than other mixes.

Ranking of the mixes based on the analytical hierarchical process methodology.

4.5.2 Sensitivity analysis

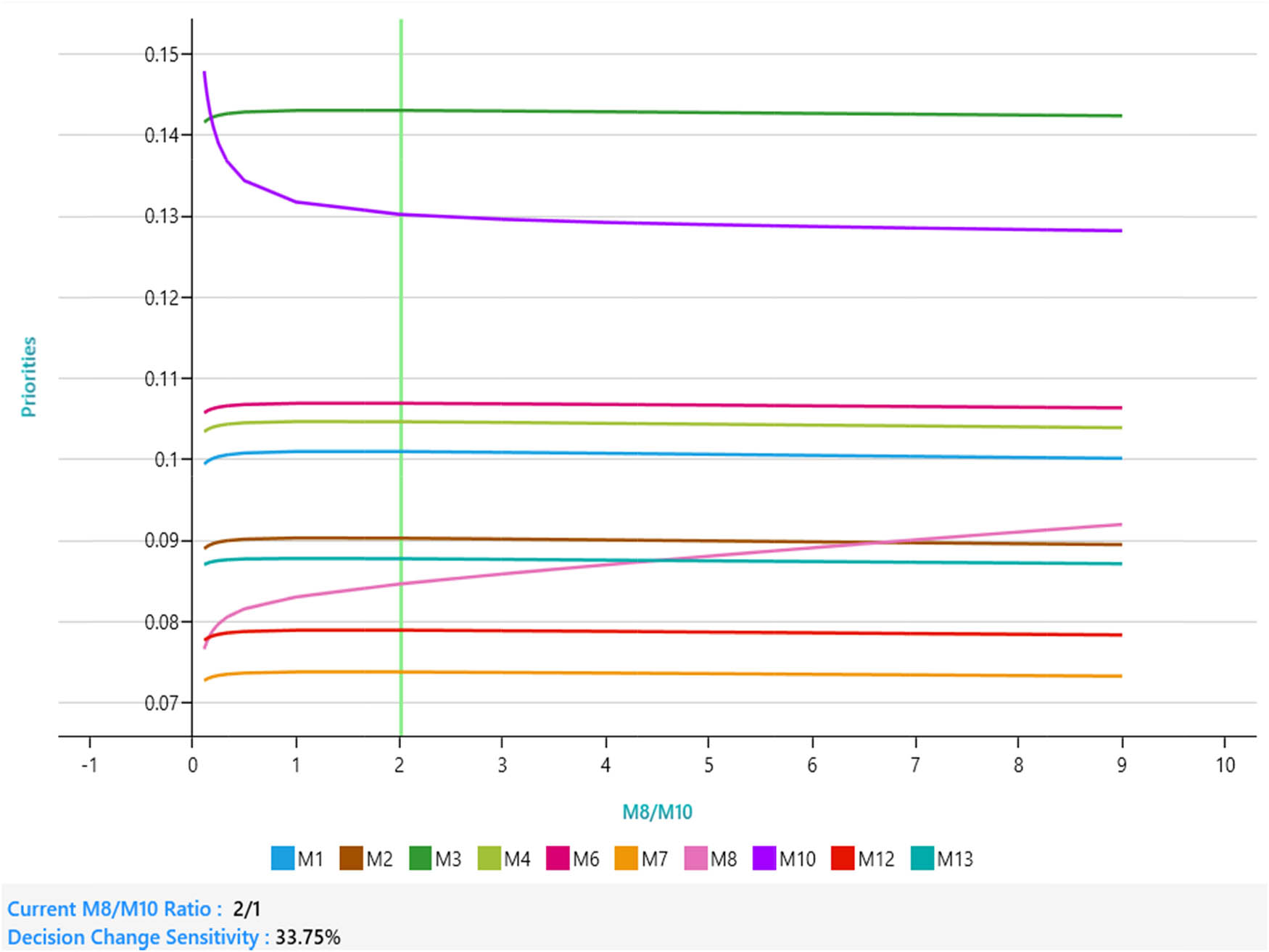

A sensitivity analysis was performed to assess the robustness of the AHP results between five distinct cases by varying the weightage of the criteria or changing the mix pair comparison (uses of study). The priority rankings of the mixes shift as weights and comparisons change, revealing the stability of the decision-making process through this analysis. The sensitivity scenarios considered were based on the compressive strength, flexural strength, cost–benefit analysis (M3 vs M10), technical vs economic trade-offs, and cost–benefit analysis (M8 vs M10).

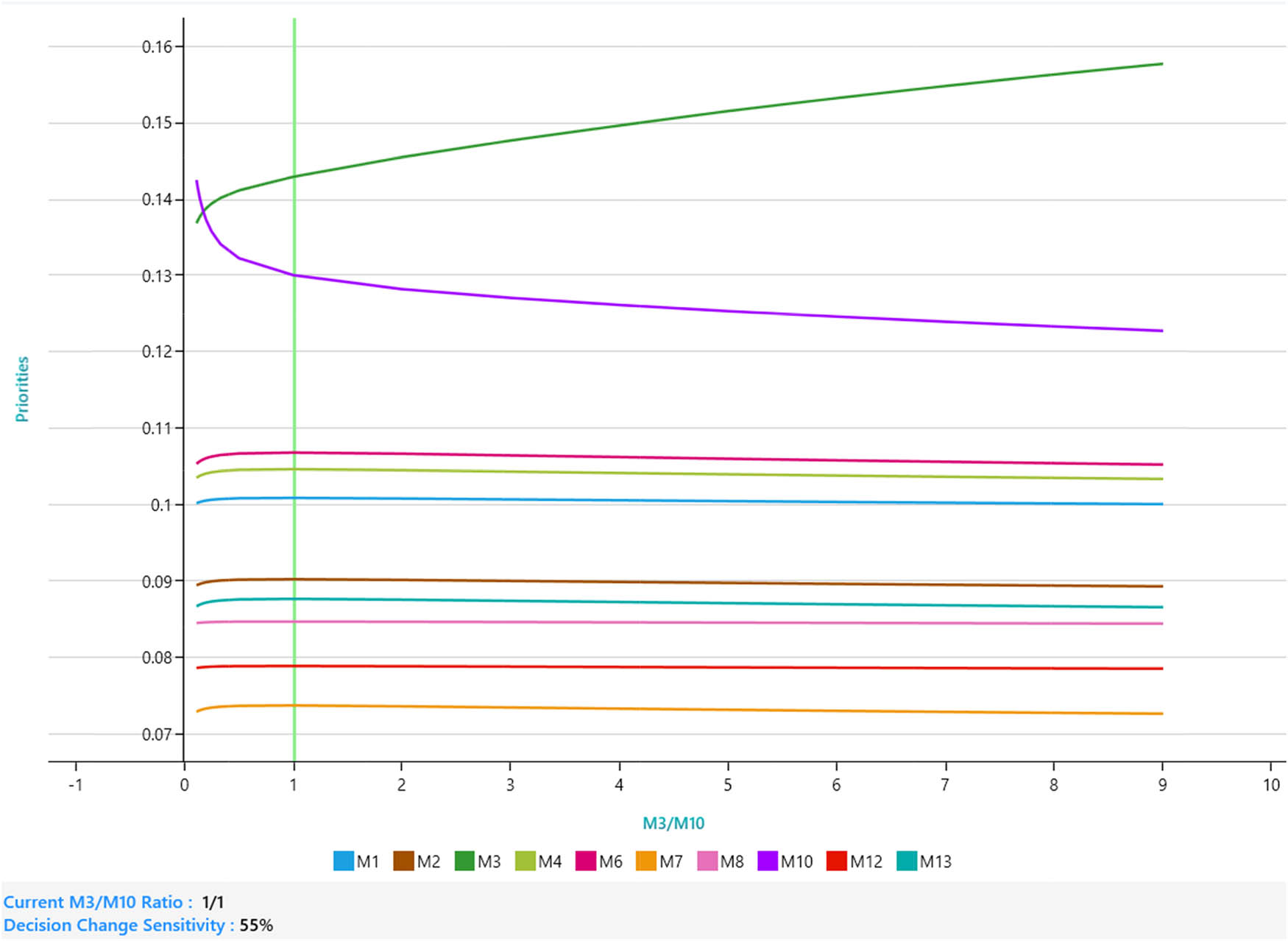

4.5.2.1 Case I: Sensitivity analysis of compressive strength

The most important observation from the compressive sensitivity analysis is the stability of M3 dominance for comparison pairs M3 and M10 (Figure 12). In comparison, by changing the ratio of M3/M10, we always found M3 higher and concluded the higher compressive strength of M3, which is its critical technical attribute. It is also observed that the design change sensitivity of the decision was 55%, i.e., a small change in the weightage made M3 stand inferior to M10 in terms of ranking. The overall hierarchy, however, remained consistent, with its high compressive strength keeping M3 in a top spot.

One-way sensitivity analysis of M3 vs M10 for compressive strength.

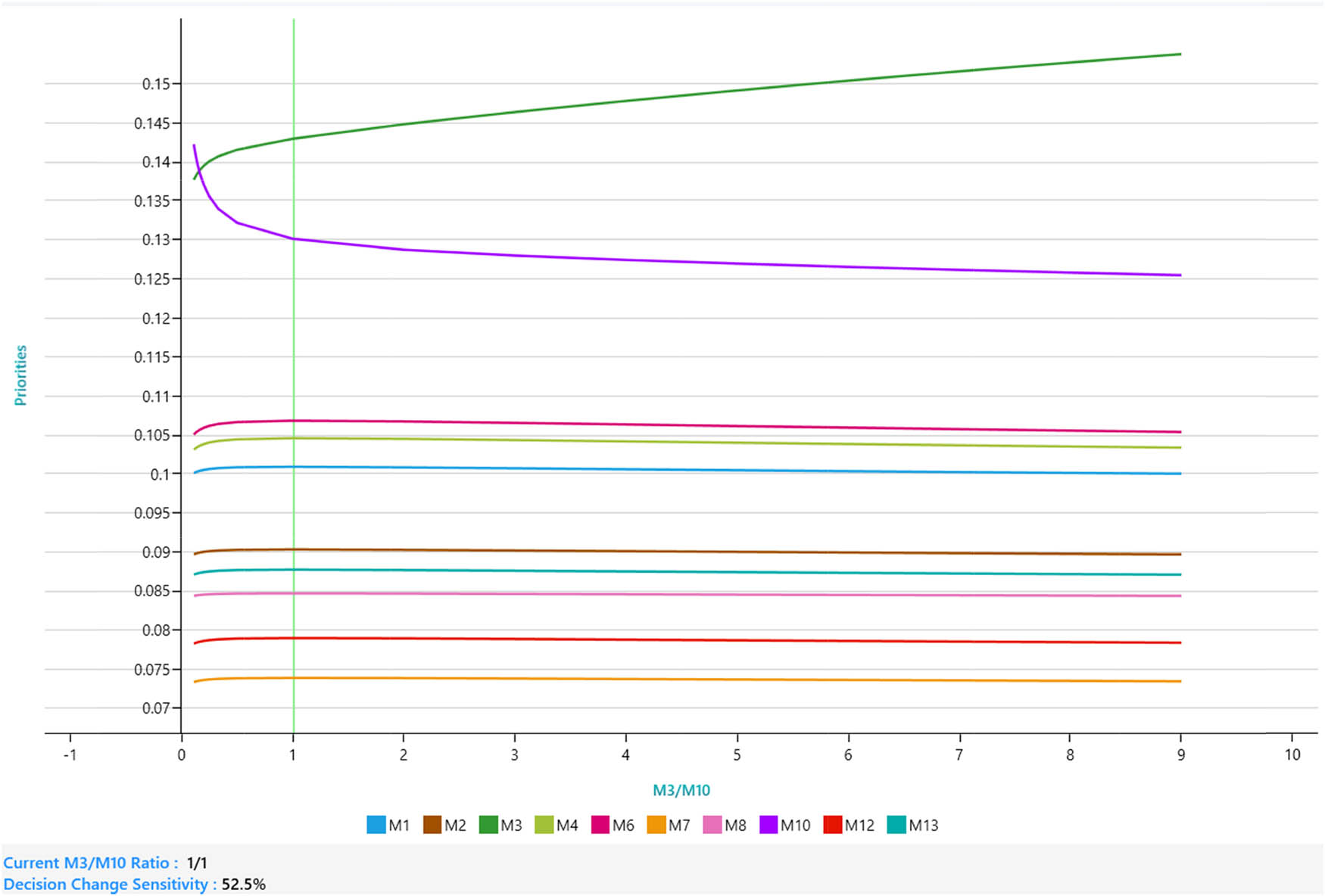

4.5.2.2 Case II: Sensitivity analysis for flexural strength

In this case, M3 vs M10 was varied with a focus on the flexural strength attribute (Figure 13). Its superior technical attributes allowed M3 to once again retain its top position and prove its resilience. Furthermore, the sensitivity analysis indicated that the decision change sensitivity was 53%, meaning that weights to flexural strength greatly affected the overall final rankings. However, M3’s overall dominance was threatened when the weight shifted; however, owing to its technical superiority, it continued to hold its place in the rankings.

One-way sensitivity analysis of M3 vs M10 for flexural strength.

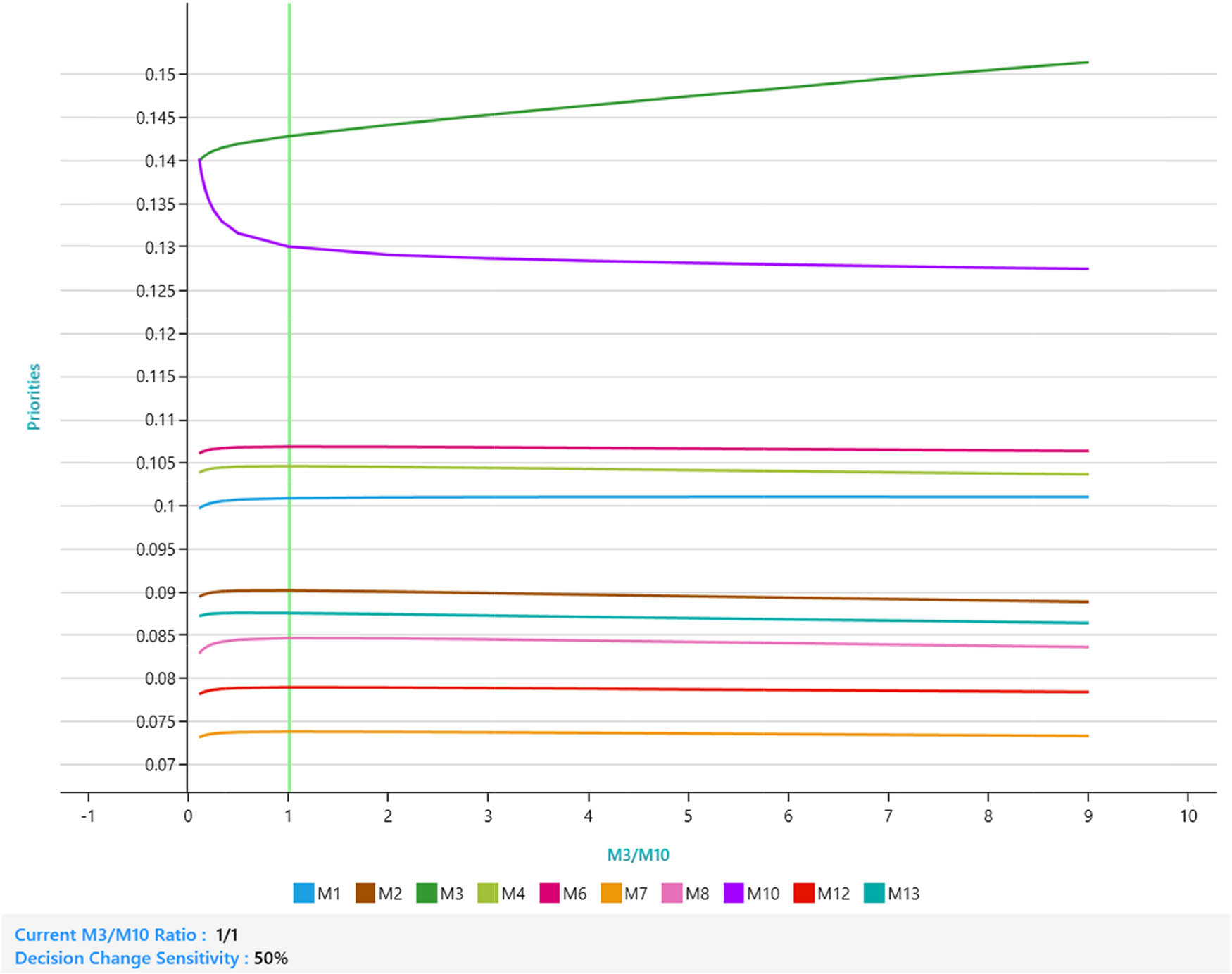

4.5.2.3 Case III: Second analysis: cost–benefit analysis (M3 vs M10)

The cost–benefit of M3 and M10 was in a balanced competitive situation regarding technical performance and economic viability (Figure 14). The analysis showed that with 50% sensitivity, the economic weightage could change M10 toward M3’s rank. Nevertheless, M3’s technical advantages still provided it an edge in cases where attributes of performance were put first. Trade-offs between cost and performance highlighted the importance of matching mix selection to project-specific requirements.

One-way sensitivity analysis of M3 vs M10 for cost–benefit analysis.

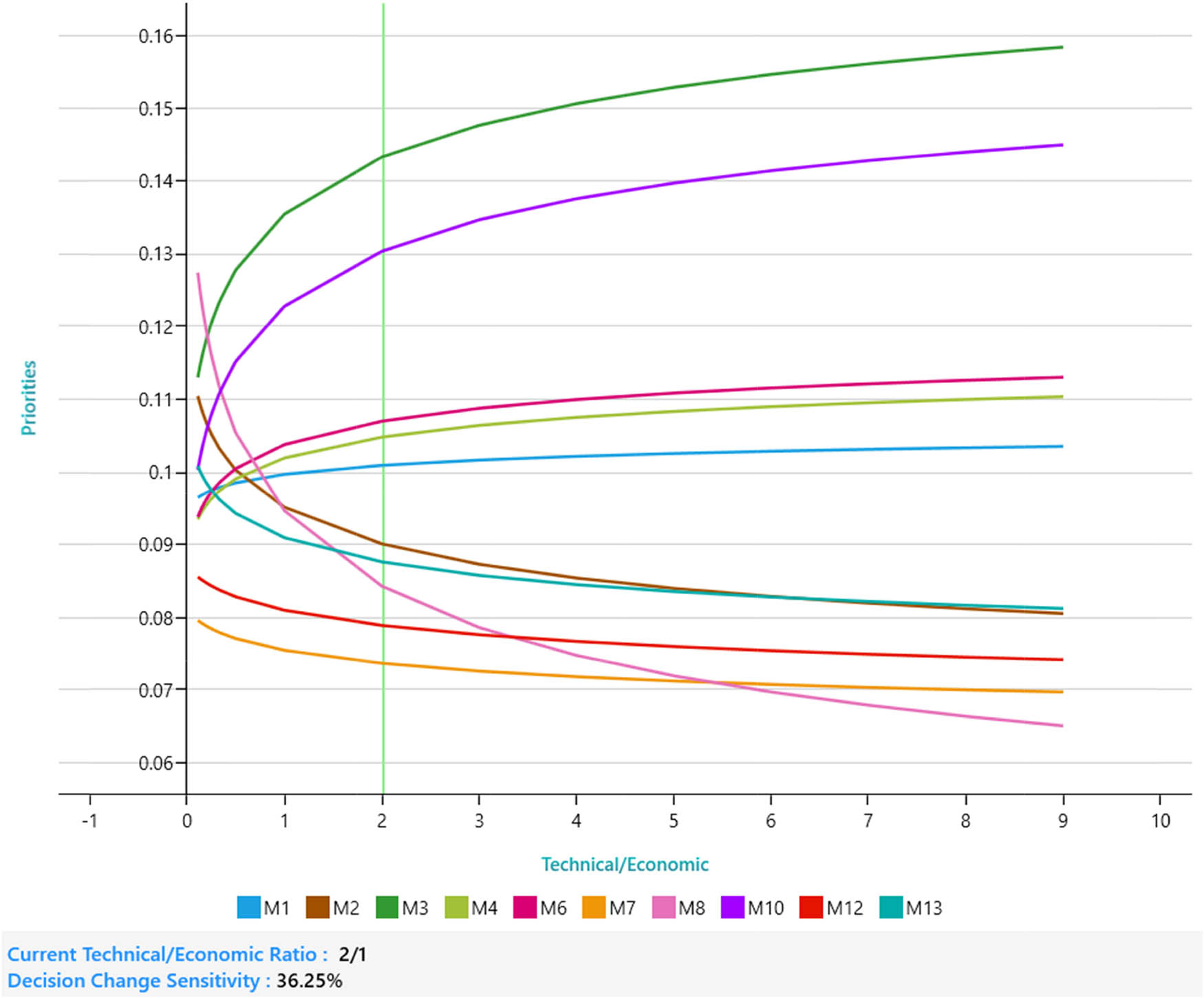

4.5.2.4 Case IV: technical vs economic attributes

The fourth sensitivity evaluated the trade‐offs between technical and economic (Figure 15) attributes by varying the weights between these two criteria. The analysis showed a 36.25% decision change sensitivity, with M3 maintaining superiority in terms of technical consciousness. However, if economic attributes received larger weightage, M10 and M8 were competitive alternatives. A green vertical line was shown in the sensitivity plot for this case, indicating a point when weightage assigned to technical and economic criteria was equal. This inflection point delineated the specific level of concentration at which technical and economic considerations started to revolve around different priorities. Beyond this point, the prominence of cost-efficient mixes such as M8 increased, and M3’s dominance slightly decreased as the technical attributes decreased in importance. The presence of this vertical line acted as a useful reference in making a clear sense of the balance between these technical and economic attributes and, hence, as a guideline for projects that place different emphasis on both.

One-way sensitivity analysis of technical vs economic trade-offs.

4.5.2.5 Case V: Cost–benefit analysis (M10 vs M8)

Sensitivity analysis for cost–benefit comparison between M8 and M10 (Figure 16) showed that each of these mixes inherently excels in certain contexts and where each of these mixes should be used as they are designed. Due to M10’s well-known superior cost efficiency and sustainability attributes, M8 challenged M10 in scenarios where economic and environmental concerns were of greater importance. The relative rankings of M8 and M10 were found to be sensitive to moderate changes in weightage for this case (sensitivity of 33.75%). However, despite its economic benefits, M8 was limited by being a lower-performing technology than M10, which remained strong in scenarios that emphasized structural attributes.

One-way sensitivity analysis of cost–benefit analysis.

5 Conclusion

This study demonstrates the potential of using DPA and ESP as SCMs in concrete to improve sustainability and performance. By optimizing mix designs, it was possible to achieve substantial improvements in mechanical properties while significantly reducing environmental impacts. The findings highlight the value of DPA and ESP as eco-friendly alternatives, suitable for various applications depending on structural and environmental priorities.

Incorporating DPA and ESP into concrete mixes enhances mechanical properties, with 20% DPA and 2% ESP achieving a compressive strength of 57.53 MPa, a 41% improvement over the control mix.

Environmental impacts, including GWP, acidification, and resource scarcity, were substantially reduced, with Mix M8 (40% DPA) showing a 15.46% lower GWP compared to conventional concrete.

Mix designs with higher ESP content improved durability and water resistance due to enhanced hydration and densified microstructure.

The AHP identified Mix M3 as the optimal choice for structural applications and Mix M8 as the most sustainable option for non-structural uses.

The study underscores the scalability and adaptability of DPA and ESP for sustainable concrete production, balancing performance, cost, and environmental sustainability.

This study highlights the potential of DPA and ESP as sustainable alternatives to traditional cement, addressing environmental and cost challenges in construction. By reducing cement reliance and utilizing agricultural waste, it promotes resource efficiency and aligns with circular economy principles. The LCA provides a practical perspective by quantifying environmental benefits, enabling informed decisions on material selection, and identifying the most eco-friendly and cost-effective concrete mixes for specific applications. These findings support policymakers, industry professionals, and researchers in advancing sustainable construction practices. To encourage large-scale adoption, regulatory standards, financial incentives, and public procurement strategies should be implemented. Governments should develop standardized guidelines, offer tax benefits, and integrate SCMs into public infrastructure projects. Awareness programs and industry–academia collaborations can further drive acceptance. By incorporating circular economy policies, policymakers can promote low-carbon, cost-effective, and sustainable construction practices.

Acknowledgments

The authors would like to thank Prince Sultan University for supporting this research through the SEED project with grant number [SEED-2024-CE-174.]. The authors would like to thank the Structures and Materials Research Laboratory at Prince Sultan University for their viable support.

-

Funding information: This work was supported by the research grants [SEED-2024-CE-174], Prince Sultan University, Saudi Arabia.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Pérez, O. F. A., V. S. Arrieta, J. H. G. Ospina, S. H. Herrera, C. F. R. Rojas, and A. M. S. Navarro. Carbon dioxide emissions from traditional and modified concrete. A review. Environmental Development, Vol. 52, 2024, id. 101036.10.1016/j.envdev.2024.101036Search in Google Scholar

[2] Adesina, A. Recent advances in the concrete industry to reduce its carbon dioxide emissions. Environmental Challenges, Vol. 1, 2020, id. 100004.10.1016/j.envc.2020.100004Search in Google Scholar

[3] Munir, Q., M. Abdulkareem, M. Horttanainen, and T. Kärki. A comparative cradle-to-gate life cycle assessment of geopolymer concrete produced from industrial side streams in comparison with traditional concrete. Science of The Total Environment, Vol. 865, 2023, id. 161230.10.1016/j.scitotenv.2022.161230Search in Google Scholar PubMed

[4] Robalo, K., H. Costa, R. do Carmo, and E. Júlio. Experimental development of low cement content and recycled construction and demolition waste aggregates concrete. Construction and Building Materials, Vol. 273, 2021, id. 121680.10.1016/j.conbuildmat.2020.121680Search in Google Scholar

[5] Hamada, H. M., A. Al-Attar, J. Shi, F. Yahaya, M. S. Al Jawahery, and S. T. Yousif. Optimization of sustainable concrete characteristics incorporating palm oil clinker and nano-palm oil fuel ash using response surface methodology. Powder Technology, Vol. 413, 2023, id. 118054.10.1016/j.powtec.2022.118054Search in Google Scholar

[6] Jungclaus, M. A., S. L. Williams, J. H. Arehart, and W. V. Srubar III. Whole-life carbon emissions of concrete mixtures considering maximum CO2 sequestration via carbonation. Resources, Conservation and Recycling, Vol. 206, 2024, id. 107605.10.1016/j.resconrec.2024.107605Search in Google Scholar

[7] Shah, B., M. Shah, V. Shah, and M. Prajapati. An Anatomized study on the progress and prospects of CO2 utilization technology. Case Studies in Chemical and Environmental Engineering, Vol. 8, 2023, id. 100381.10.1016/j.cscee.2023.100381Search in Google Scholar

[8] Munir, Q., S. Afshariantorghabeh, and T. Kärki. Industrial waste pretreatment approach for 3D printing of sustainable building materials. Urban Science, Vol. 6, No. 3, 2022, id. 50.10.3390/urbansci6030050Search in Google Scholar

[9] Papayianni, I. and E. Anastasiou. Production of high-strength concrete using high volume of industrial by-products. Construction and Building Materials, Vol. 24, No. 8, 2010, pp. 1412–1417.10.1016/j.conbuildmat.2010.01.016Search in Google Scholar

[10] Oyejobi, D., A. Firoozi, D. B. Fernandez, and S. Avudaiappan. Integrating circular economy principles into concrete technology: Enhancing sustainability through industrial waste utilization. Results in Engineering, Vol. 24, 2024, id. 102846.10.1016/j.rineng.2024.102846Search in Google Scholar

[11] Nasir, M. and W. Al-Kutti. Performance of date palm ash as a cementitious material by evaluating strength, durability, and characterization. Buildings, Vol. 9, No. 1, 2018, id. 6.10.3390/buildings9010006Search in Google Scholar

[12] Adamu, M., H. Alanazi, Y. E. Ibrahim, and M. Abdellatief. Mechanical, microstructural characteristics and sustainability analysis of concrete incorporating date palm ash and eggshell powder as ternary blends cementitious materials. Construction and Building Materials, Vol. 411, 2024, id. 134753.10.1016/j.conbuildmat.2023.134753Search in Google Scholar

[13] Adamu, M., Y. E. Ibrahim, and H. Alanazi. Optimization of sustainable concrete properties modified with blends of date palm ash and eggshell powder using response surface methodology. Developments in the Built Environment, Vol. 17, 2024, id. 100359.10.1016/j.dibe.2024.100359Search in Google Scholar

[14] Adamu, M. and Y. E. Ibrahim. Environmental sustainability and cost-benefit analysis of concrete containing date palm ash and eggshell powder: A response surface methodology approach. Case Studies in Chemical and Environmental Engineering, Vol. 9, 2024, id. 100636.10.1016/j.cscee.2024.100636Search in Google Scholar

[15] Chong, B., R. Othman, P. Ramadhansyah, S. Doh, and X. Li. Properties of concrete with eggshell powder: A review. Physics and Chemistry of the Earth, Parts A/B/C, Vol. 120, 2020, id. 102951.10.1016/j.pce.2020.102951Search in Google Scholar

[16] Elfadaly, E., A. M. Othman, M. H. Aly, W. A. Elgarhy, and M. Abdellatief. Assessing performance and environmental benefits of high-performance geopolymer mortar incorporating pumice and rice straw ash. Sustainable Chemistry and Pharmacy, Vol. 44, 2025, id. 101918.10.1016/j.scp.2025.101918Search in Google Scholar

[17] Abdellatief, M., Y. M. Ahmed, M. Taman, E. Elfadaly, Y. Tang, and A. A. Abadel. Physico-mechanical, thermal insulation properties, and microstructure of geopolymer foam concrete containing sawdust ash and egg shell. Journal of Building Engineering, Vol. 90, 2024, id. 109374.10.1016/j.jobe.2024.109374Search in Google Scholar

[18] Kuswa, F. M., H. P. Putra, Prabowo, A. Darmawan, M. Aziz, and H. Hariana. Investigation of the combustion and ash deposition characteristics of oil palm waste biomasses. Biomass Conversion and Biorefinery, Vol. 14, No. 19, 2024, pp. 24375–24395.10.1007/s13399-023-04418-zSearch in Google Scholar

[19] Al-Kutti, W., A. S. Islam, and M. Nasir. Potential use of date palm ash in cement-based materials. Journal of King Saud University-Engineering Sciences, Vol. 31, No. 1, 2019, pp. 26–31.10.1016/j.jksues.2017.01.004Search in Google Scholar

[20] Al-Kutti, W., M. Nasir, M. A. M. Johari, A. S. Islam, A. A. Manda, and N. I. Blaisi. An overview and experimental study on hybrid binders containing date palm ash, fly ash, OPC and activator composites. Construction and Building Materials, Vol. 159, 2018, pp. 567–577.10.1016/j.conbuildmat.2017.11.017Search in Google Scholar

[21] Thomas, B. S., J. Yang, K. H. Mo, J. A. Abdalla, R. A. Hawileh, and E. Ariyachandra. Biomass ashes from agricultural wastes as supplementary cementitious materials or aggregate replacement in cement/geopolymer concrete: A comprehensive review. Journal of Building Engineering, Vol. 40, 2021, id. 102332.10.1016/j.jobe.2021.102332Search in Google Scholar

[22] Yearbook, F. S. World food and agriculture. Food and Agriculture Organization of the United Nations, Rome, Vol. 15, 2022.Search in Google Scholar

[23] Akasha, I., L. Campbell, J. Lonchamp, and S. R. Euston. The major proteins of the seed of the fruit of the date palm (Phoenix dactylifera L.): Characterisation and emulsifying properties. Food Chemistry, Vol. 197, 2016, pp. 799–806.10.1016/j.foodchem.2015.11.046Search in Google Scholar PubMed

[24] Faiad, A., M. Alsmari, M. M. Ahmed, M. L. Bouazizi, B. Alzahrani, and H. Alrobei. Date palm tree waste recycling: treatment and processing for potential engineering applications. Sustainability, Vol. 14, No. 3, 2022, id. 1134.10.3390/su14031134Search in Google Scholar

[25] Blaisi, N. I. Environmental assessment of utilizing date palm ash as partial replacement of cement in mortar. Journal of Hazardous Materials, Vol. 357, 2018, pp. 175–179.10.1016/j.jhazmat.2018.06.013Search in Google Scholar PubMed

[26] Zaid, O., S. R. Z. Hashmi, M. H. El Ouni, R. Martínez-García, J. de Prado-Gil, and S. E. A. Yousef. Experimental and analytical study of ultra-high-performance fiber-reinforced concrete modified with egg shell powder and nano-silica. Journal of Materials Research and Technology, Vol. 24, 2023, pp. 7162–7188.10.1016/j.jmrt.2023.04.240Search in Google Scholar

[27] Chen, Y. K., Y. Sun, K. Q. Wang, W. Y. Kuang, S. R. Yan, Z. H. Wang, et al. Utilization of bio-waste eggshell powder as a potential filler material for cement: Analyses of zeta potential, hydration and sustainability. Construction and Building Materials, Vol. 325, 2022, id. 126220.10.1016/j.conbuildmat.2021.126220Search in Google Scholar

[28] Sohu, S., N. Bheel, A. A. Jhatial, A. A. Ansari, and I. A. Shar. Sustainability and mechanical property assessment of concrete incorporating eggshell powder and silica fume as binary and ternary cementitious materials. Environmental Science and Pollution Research, Vol. 29, No. 39, 2022, pp. 58685–58697.10.1007/s11356-022-19894-5Search in Google Scholar PubMed

[29] Nandhini, K. and J. Karthikeyan. Sustainable and greener concrete production by utilizing waste eggshell powder as cementitious material–A review. Construction and Building Materials, Vol. 335, 2022, id. 127482.10.1016/j.conbuildmat.2022.127482Search in Google Scholar

[30] Xuan, M.-Y., R.-S. Lin, T.-B. Min, and X.-Y. Wang. Carbonation treatment of eggshell powder concrete for performance enhancement. Construction and Building Materials, Vol. 377, 2023, id. 130814.10.1016/j.conbuildmat.2023.130814Search in Google Scholar

[31] Maglad, A. M., M. A. O. Mydin, S. S. Majeed, B. A. Tayeh, and D. E. Tobbala. Exploring the influence of calcinated eggshell powder on lightweight foamed concrete: A comprehensive study on freshness, mechanical strength, thermal characteristics and transport properties. Journal of Building Engineering, Vol. 87, 2024, id. 108966.10.1016/j.jobe.2024.108966Search in Google Scholar

[32] Yuan, X., W. Xu, A. H. AlAteah, and S. A. Mostafa. Evaluation of the performance of high-strength geopolymer concrete prepared with recycled coarse aggregate containing eggshell powder and rice husk ash cured at different curing regimes. Construction and Building Materials, Vol. 434, 2024, id. 136722.10.1016/j.conbuildmat.2024.136722Search in Google Scholar

[33] Hamada, H. M., B. A. Tayeh, A. Al-Attar, F. M. Yahaya, K. Muthusamy, and A. M. Humada. The present state of the use of eggshell powder in concrete: A review. Journal of Building Engineering, Vol. 32, 2020, id. 101583.10.1016/j.jobe.2020.101583Search in Google Scholar

[34] Khalid, N. H., N. N. Rasid, A. R. Sam, Z. A. Majid, N. Basar, M. A. Caronge, et al. Evaluation of eggshell lime as green accelerator on palm oil fuel ash concrete production: Effect of thermal treatment. Construction and Building Materials, Vol. 411, 2024, id. 134352.10.1016/j.conbuildmat.2023.134352Search in Google Scholar

[35] Teara, A. and D. S. Ing. Mechanical properties of high strength concrete that replace cement partly by using fly ash and eggshell powder. Physics and Chemistry of the Earth, Parts a/b/c, Vol. 120, 2020, id. 102942.10.1016/j.pce.2020.102942Search in Google Scholar

[36] Kumar, P. C., T. Shanthala, K. Aparna, and S. V. Babu. Experimental investigation on the combined effect of fly ash and eggshell powder as partial replacement of cement. In Sustainable Building Materials and Construction: Select Proceedings of ICSBMC 2021, Springer, 2022, pp. 371–378.10.1007/978-981-16-8496-8_46Search in Google Scholar

[37] Yadav, V. H. and H. Eramma. Experimental studies on concrete for the partial replacement of cement by egg shell powder and GGBS. International Research Journal of Engineering and Technology, Vol. 4, No. 11, 2017, pp. 144–150.Search in Google Scholar

[38] Chong, B. W., R. Othman, R. P. Jaya, X. Li, M. R. M. Hasan, and M. M. A. B. Abdullah. Meta-analysis of studies on eggshell concrete using mixed regression and response surface methodology. Journal of King Saud University-Engineering Sciences, Vol. 35, No. 4, 2023, pp. 279–287.10.1016/j.jksues.2021.03.011Search in Google Scholar

[39] Jhatial, A. A., W. I. Goh, K. H. Mo, S. Sohu, and I. A. Bhatti. Green and sustainable concrete–the potential utilization of rice husk ash and egg shells. Civil Engineering Journal, Vol. 5, No. 1, 2019, pp. 74–81.10.28991/cej-2019-03091226Search in Google Scholar

[40] Hakeem, I. Y., M. Amin, I. S. Agwa, M. H. Abd-Elrahman, O. M. O. Ibrahim, and M. Samy. Ultra-high-performance concrete properties containing rice straw ash and nano eggshell powder. Case Studies in Construction Materials, Vol. 19, 2023, id. e02291.10.1016/j.cscm.2023.e02291Search in Google Scholar

[41] Oliko, C., C. K. Kabubo, and J. N. Mwero. Rice straw and eggshell ash as partial replacements of cement in concrete. Engineering, Technology & Applied Science Research, Vol. 10, No. 6, 2020, pp. 6481–6487.10.48084/etasr.3893Search in Google Scholar

[42] Amin, M., M. M. Attia, I. S. Agwa, Y. Elsakhawy, K. Abu El-hassan, and B. A. Abdelsalam. Effects of sugarcane bagasse ash and nano eggshell powder on high-strength concrete properties. Case Studies in Construction Materials, Vol. 17, 2022, id. e01528.10.1016/j.cscm.2022.e01528Search in Google Scholar

[43] Onyelowe, K. C., A. M. Ebid, A. Riofrio, A. Soleymani, H. Baykara, D. P. Kontoni, et al. Global warming potential-based life cycle assessment and optimization of the compressive strength of fly ash-silica fume concrete; environmental impact consideration. Frontiers in Built Environment, Vol. 8, 2022, id. 992552.10.3389/fbuil.2022.992552Search in Google Scholar

[44] Onyelowe, K. C., A. M. Ebid, H. A. Mahdi, A. Soleymani, H. Jahangir, and F. Dabbaghi. Optimization of green concrete containing fly ash and rice husk ash based on hydro-mechanical properties and life cycle assessment considerations. Civil Engineering Journal, Vol. 8, No. 12, 2022, pp. 3912–3938.10.28991/CEJ-2022-08-12-018Search in Google Scholar

[45] Thomas, B. S., S. Kumar, and H. S. Arel. Sustainable concrete containing palm oil fuel ash as a supplementary cementitious material–A review. Renewable and Sustainable Energy Reviews, Vol. 80, 2017, pp. 550–561.10.1016/j.rser.2017.05.128Search in Google Scholar

[46] Chinnu, S., S. Minnu, A. Bahurudeen, and R. Senthilkumar. Influence of palm oil fuel ash in concrete and a systematic comparison with widely accepted fly ash and slag: A step towards sustainable reuse of agro-waste ashes. Cleaner Materials, Vol. 5, 2022, id. 100122.10.1016/j.clema.2022.100122Search in Google Scholar

[47] American Society for Testing and Materials. Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete, ASTM C618, West Conshohocken, PA, United States, 2015.Search in Google Scholar

[48] American Society for Testing and Materials. Standard specification for concrete aggregates, ASTM C33/C33M, West Conshohocken, PA, USA, 2023.Search in Google Scholar

[49] American Concrete Institute. Standard practice for selecting proportions for normal, heavyweight, and mass concrete, ACI 211.1R, Michigan, USA, 2002.Search in Google Scholar

[50] American Society for Testing and Materials. Standard practice for making and curing concrete test specimens in the laboratory, ASTM C192/C192M, West Conshohocken, USA, 2014.Search in Google Scholar

[51] American Society for Testing and Materials. Standard test method for slump of hydraulic-cement concrete, ASTM C143/C143M, West Conshohocken, PA, USA, 2012.Search in Google Scholar

[52] British Standards European Norm. Testing hardened concrete. Compressive strength of test specimens, BS EN 12390-3, London, United Kingdom, 2009.Search in Google Scholar

[53] British Standards European Norm. Testing hardened concrete - Tensile splitting strength of test specimens, BS EN 12390-6, London, United Kingdom, 2009.Search in Google Scholar

[54] American Society for Testing and Materials. Standard test method for flexural strength of concrete (using simple beam with third-point loading), ASTM C78/C78M, West Conshohocken, PA, USA, 2015.Search in Google Scholar

[55] American Society for Testing and Materials. Standard test method for density, absorption, and voids in hardened concrete, ASTM C642, West Conshohocken, PA, United States, 2013.Search in Google Scholar

[56] Almadhi, A., A. Abdelhadi, and R. Alyamani. Moving from linear to circular economy in Saudi Arabia: life-cycle assessment on plastic waste management. Sustainability, Vol. 15, No. 13, 2023, id. 10450.10.3390/su151310450Search in Google Scholar

[57] Mazzetto, S. Comparative life cycle assessment of traditional and modern materials in heritage building restoration: A case study from Ushaiger Village. Sustainability, Vol. 17, No. 1, 2024, id. 25.10.3390/su17010025Search in Google Scholar

[58] Al Omar, S. and A. Abdelhadi. Comparative life-cycle assessment of steel and GFRP rebars for procurement sustainability in the construction industry. Sustainability, Vol. 16, No. 10, 2024, id. 3899.10.3390/su16103899Search in Google Scholar

[59] Hamada, H., B. Tayeh, F. Yahaya, K. Muthusamy, and A. Al-Attar. Effects of nano-palm oil fuel ash and nano-eggshell powder on concrete. Construction and Building Materials, Vol. 261, 2020, id. 119790.10.1016/j.conbuildmat.2020.119790Search in Google Scholar

[60] Rasid, N. N. A., N. H. A. Khalid, A. Mohamed, A. R. M. Sam, Z. A. Majid, and G. F. Huseien. Ground palm oil fuel ash and calcined eggshell powder as SiO2–CaO based accelerator in green concrete. Journal of Building Engineering, Vol. 65, 2023, id. 105617.10.1016/j.jobe.2022.105617Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites

- Analyzing the compressive strength, eco-strength, and cost–strength ratio of agro-waste-derived concrete using advanced machine learning methods

- Tensile behavior evaluation of two-stage concrete using an innovative model optimization approach

- Tailoring the mechanical and degradation properties of 3DP PLA/PCL scaffolds for biomedical applications

- Optimizing compressive strength prediction in glass powder-modified concrete: A comprehensive study on silicon dioxide and calcium oxide influence across varied sample dimensions and strength ranges

- Experimental study on solid particle erosion of protective aircraft coatings at different impact angles

- Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters

- Fe-containing nominal wollastonite (CaSiO3)–Na2O glass-ceramic: Characterization and biocompatibility

- Relevance of pore network connectivity in tannin-derived carbons for rapid detection of BTEX traces in indoor air

- A life cycle and environmental impact analysis of sustainable concrete incorporating date palm ash and eggshell powder as supplementary cementitious materials

- Eco-friendly utilisation of agricultural waste: Assessing mixture performance and physical properties of asphalt modified with peanut husk ash using response surface methodology

- Benefits and limitations of N2 addition with Ar as shielding gas on microstructure change and their effect on hardness and corrosion resistance of duplex stainless steel weldments

- Effect of selective laser sintering processing parameters on the mechanical properties of peanut shell powder/polyether sulfone composite

- Impact and mechanism of improving the UV aging resistance performance of modified asphalt binder

- AI-based prediction for the strength, cost, and sustainability of eggshell and date palm ash-blended concrete

- Investigating the sulfonated ZnO–PVA membrane for improved MFC performance

- Strontium coupling with sulphur in mouse bone apatites

- Transforming waste into value: Advancing sustainable construction materials with treated plastic waste and foundry sand in lightweight foamed concrete for a greener future

- Evaluating the use of recycled sawdust in porous foam mortar for improved performance

- Improvement and predictive modeling of the mechanical performance of waste fire clay blended concrete

- Polyvinyl alcohol/alginate/gelatin hydrogel-based CaSiO3 designed for accelerating wound healing

- Research on assembly stress and deformation of thin-walled composite material power cabin fairings

- Effect of volcanic pumice powder on the properties of fiber-reinforced cement mortars in aggressive environments

- Analyzing the compressive performance of lightweight foamcrete and parameter interdependencies using machine intelligence strategies

- Selected materials techniques for evaluation of attributes of sourdough bread with Kombucha SCOBY

- Establishing strength prediction models for low-carbon rubberized cementitious mortar using advanced AI tools

- Investigating the strength performance of 3D printed fiber-reinforced concrete using applicable predictive models

- An eco-friendly synthesis of ZnO nanoparticles with jamun seed extract and their multi-applications

- The application of convolutional neural networks, LF-NMR, and texture for microparticle analysis in assessing the quality of fruit powders: Case study – blackcurrant powders

- Study of feasibility of using copper mining tailings in mortar production

- Shear and flexural performance of reinforced concrete beams with recycled concrete aggregates

- Advancing GGBS geopolymer concrete with nano-alumina: A study on strength and durability in aggressive environments

- Leveraging waste-based additives and machine learning for sustainable mortar development in construction

- Study on the modification effects and mechanisms of organic–inorganic composite anti-aging agents on asphalt across multiple scales

- Morphological and microstructural analysis of sustainable concrete with crumb rubber and SCMs

- Structural, physical, and luminescence properties of sodium–aluminum–zinc borophosphate glass embedded with Nd3+ ions for optical applications

- Eco-friendly waste plastic-based mortar incorporating industrial waste powders: Interpretable models for flexural strength

- Bioactive potential of marine Aspergillus niger AMG31: Metabolite profiling and green synthesis of copper/zinc oxide nanocomposites – An insight into biomedical applications