Innovative eco-friendly bio-composites: A comprehensive review of the fabrication, characterization, and applications

-

Nagaraja Santhosh

, Bindiganavile Anand Praveena

Abstract

Sustainability and the need for biodegradable composites are the two new buzzwords finding prominence in recent times. In this regard, there has been a significant increase in interest regarding natural fiber composites (NFCs) due to their potential to address environmental issues and contribution toward the development of sustainable materials. The aim of this extensive review is to thoroughly investigate the current research landscape, advancements, and applications of NFCs. The study covers a range of topics, including the various types of natural fibers commonly used, their processing techniques, reinforcement strategies, mechanical properties, morphological characteristics, biodegradability, and sustainability. It also explores their potential uses across different industries. Furthermore, this article examines the challenges and opportunities associated with NFCs, as well as their environmental impacts and economic viability. By conducting a detailed analysis of existing literature, this review aims to shed light on the advancements achieved so far and the future potential of NFCs as eco-friendly alternatives to conventional materials. Ultimately, it offers insights into how these materials can enhance sustainability in material engineering.

1 Introduction

In the recent decade, increasing global awareness on sustainability has driven global scientific community to take significant steps to protect the environment against various threats of global warming, and the depletion of natural resources [1,2,3]. Consequently, there has been a push for alternative development and behavioral approaches, supported by research outcomes promoting the use of sustainable material. This shift has given rise to the concept of sustainable development [4,5,6,7].

Sustainable development, although widely recognized internationally, lacks a consensus on its precise methods and means [8]. The core idea is to make decisions that benefit both current and future generations. Eco-materials have emerged as a key element in this approach, designed to minimize the environmental impact of human activities. Researchers are focused on developing eco-friendly materials that can significantly contribute to sustainable development [9,10,11,12,13].

Sustainable materials encompass a variety of traditional and innovative materials used across different applications [14]. The development and utilization of these materials are essential for achieving sustainable development and reducing the environmental impact of human activities. Composites, known for their excellent mechanical properties and lightweight nature, are evolving toward more efficient and cost-effective products [11,15–18]. They are extensively used in industries such as automotive, aerospace, marine, and sporting goods. To enhance environmental protection and public health, there is a growing trend to design composites with ecological considerations, reducing reliance on materials derived from fossil resources and aiming to lower carbon emissions by using lighter materials [19–22].

This has led to a shift toward compatible materials like biocomposites, which are replacing traditional composites. Researchers are focusing on composite materials reinforced with natural fibers, as these combine good mechanical properties with low density [23–26]. Natural fiber composites (NFCs) offer advantages such as cost-effectiveness, availability of renewable resources, and biodegradability. Many of these composites also exhibit mechanical properties suitable for various technical applications [27–30]. The use of plant fibers to reinforce composite materials is increasingly popular in sectors like the automotive industry, where textiles have been used for years to reinforce plastics due to their excellent insulation properties [31–34].

However, using natural plant fibers as reinforcement has limitations, including water absorption issues. Plant fibers, being lignocellulosic, contain hydroxyl groups that make them hydrophilic and unsuitable for hydrophobic thermoplastics, leading to poor moisture resistance [35]. Additionally, natural fibers can have low dimensional stability, non-reproducible physical properties, and challenging processing methods, resulting in suboptimal final properties [36–38]. The main challenge is the incompatibility between the polar, hydrophilic natural fibers and the non-polar properties of most commercial polymers [39–41].

External stresses on composite materials lead to various degradation mechanisms, affecting mechanical properties [42]. Factors influencing these mechanisms include the tensile strength of the fibers, the matrix's energy absorption capacity, fiber–matrix interfacial properties, fiber volume fraction, and mechanical stress conditions [43–46]. Therefore, modifying the fiber surface is crucial to enhance matrix adherence and reduce moisture absorption. Physical or chemical treatments can improve fiber compatibility with polymers, enhancing composite performance. Techniques such as alkaline, silane, and other chemical treatments are used to increase fiber–matrix compatibility [47–50].

NFCs, still in the development stage, show great promise for future industries, especially in the automotive and aircraft industries [51–53]. The primary goals of this study are to provide an overview of natural fibers, their physical and chemical characteristics, and mechanical properties. It also explores their compatibility with various matrices, including thermoplastics [51], thermosets [52], ceramic resins [53], biodegradable polymers [54], bioplastics [55], and fossil-derived polymers [56–58]. The study will discuss the performance and potential applications of NFCs in detail.

To better understand fiber–matrix bonding, the review has focused on various treatment methodologies to enhance adhesion, viz., alkaline [59], enzymatic [60], acetylation [61], and physical treatments like heat drying [62] and electric shock treatments [63]. The impact of these treatments and fiber reinforcement types on the mechanical properties of composites will be explored, along with the effects of hygrothermal conditions [64]. A comparison between natural and synthetic fiber composites will highlight their property differences [65]. The potential applications of NFCs in the automotive, construction, and biomedical sectors will be showcased to demonstrate their versatility and future potential [66–70].

Understanding the characteristics and properties of NFCs will enable researchers, engineers, and industries to make informed decisions about material selection and design, promoting sustainable and environmentally friendly solutions [71–74]. The aim of this review is to thoroughly examine NFCs, emphasizing their role in promoting sustainability within material engineering. By evaluating current research and developments, the review seeks to highlight the potential of NFCs in addressing environmental challenges and fostering sustainable practices. Natural fibers, derived from plants, animals, and cellulose-based sources, offer several advantages, such as renewability [75], low density [76], greater specific strengths [77], and biodegradability [78].

The production processes of NFCs are critical for optimizing their properties [79]. Techniques like fiber extraction [80], preparation [81], and modification [82] enhance compatibility between fibers [83] and matrices [84], improving mechanical performance [85] and sustainability [86]. Reinforcement strategies include randomly oriented, aligned, and hybrid composites, tailored to meet specific application needs [87–90]. By skillfully combining different fiber types [91], researchers can balance strength, stiffness, and other desired properties [92–95].

Evaluating the properties of NFCs, such as tensile and flexural strength, impact resistance, thermal conductivity, water absorption, and dimensional stability, is essential for determining their suitability for various applications viz., the automotive [96], construction [97], packaging [98], and aerospace [99], offering pathways to reduce environmental impact [100], increase energy efficiency [101], and enhance sustainability [102].

Challenges to the broader adoption of NFCs include fiber availability [103], moisture sensitivity [104], standardization [105], quality control [106], market acceptance [107], and cost-effectiveness [108]. Overcoming these challenges requires ongoing research, technological innovation, and collaboration among researchers, industry stakeholders, and policymakers.

Ultimately, this review provides a comprehensive overview of NFCs, covering their properties, processing methods, applications, and sustainability aspects. By consolidating current knowledge and identifying future research directions, the review aims to advance the development and broader adoption of NFCs as a sustainable alternative in material engineering.

2 Natural fibers in composite materials

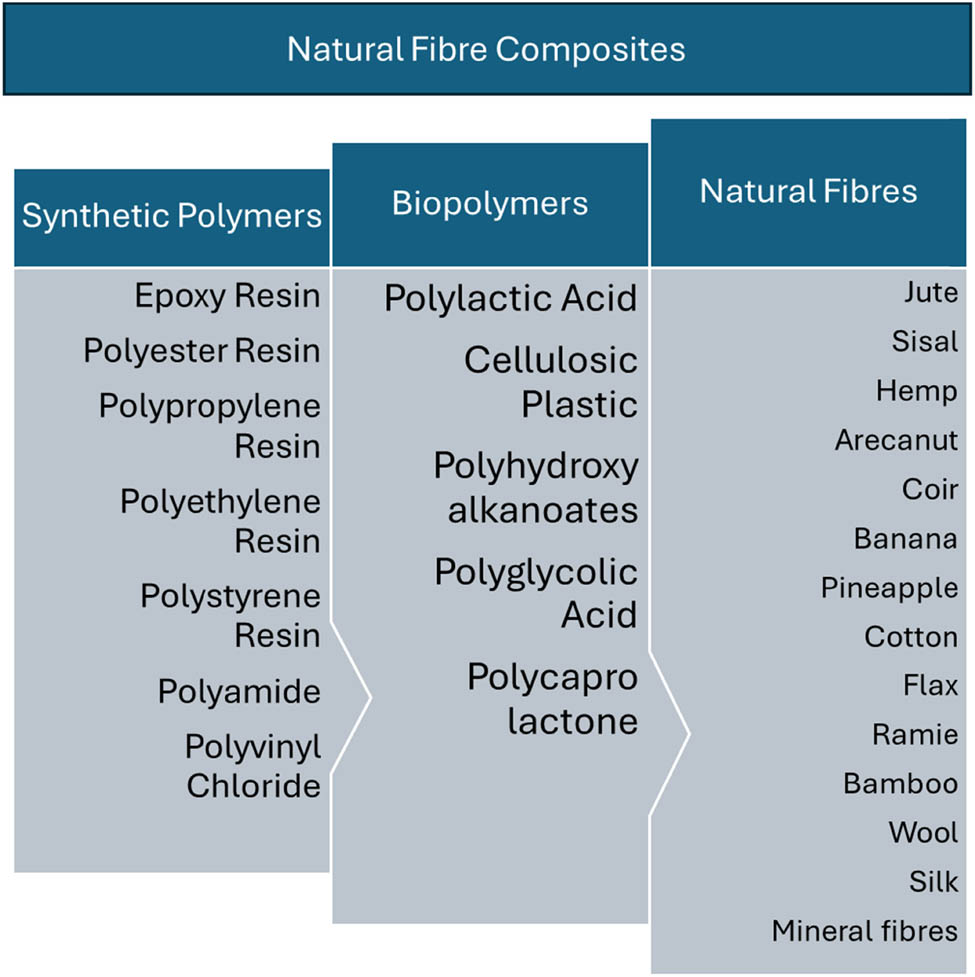

Natural fibers, sourced directly from nature, can be categorized based on their origins: plants, animals, and minerals. These fibers are obtained through various methods such as harvesting, extraction, or processing, and find applications in a wide range of industries. The classification into plant-based, animal-based, and mineral-based categories reflects their diverse origins. Table 1 provides an overview of the different types of natural fibers used in the fabrication of NFCs. The increasing interest among researchers and engineers in natural fiber-reinforced polymeric materials stems from their numerous benefits, such as biodegradability, eco-friendliness, cost-effectiveness, and lightweight nature. This shift from synthetic reinforcements to natural alternatives is driven by the need for sustainable and environmentally friendly materials. Figure 1 gives the detailed classification of NFCs.

| Category of natural fibers | Type | Example |

|---|---|---|

| Plant based (cellulosic/lignocellulosic | Bast | Flax, hemp, jute, kenaf, ramie |

| Leaf | Abaca, pineapple, sisal, banana | |

| Seed | Cotton, kapok | |

| Fruit | Coir | |

| Wood | Hardwood, softwood | |

| Stalk | Wheat, maize, oat, rice | |

| Grass/reed | Bamboo, corn | |

| Animal | Wool/hair | Cashmere, goat hair, horsehair, lamb wool |

| Silk | Mulberry, eri, tussar, muga | |

| Mineral | — | Asbestos, ceramic fibers, metal fibers |

![Figure 1

Classification of natural fibers. Adopted from ref. [113] with permission. Copyright MDPI, 2021 (Open Access CC BY-NC 4.0 Deed).](/document/doi/10.1515/rams-2024-0057/asset/graphic/j_rams-2024-0057_fig_001.jpg)

Classification of natural fibers. Adopted from ref. [113] with permission. Copyright MDPI, 2021 (Open Access CC BY-NC 4.0 Deed).

2.1 Plant-based fibers

Plant-based fibers, sourced from different plants, have a varied composition, including essential elements like cellulose and hemicellulose. These fibers, such as jute, hemp, flax, sisal, coir, kenaf, and ramie, possess a range of beneficial characteristics, making them valuable for use in NFCs [114–118].

Cellulose, a primary constituent in plant-based fibers, provides significant strength and rigidity to the material. Jute, well-known for its high cellulose content, serves as an excellent reinforcement material in composite applications, making it suitable for situations requiring durability [119].

Furthermore, hemicellulose, another important component found alongside cellulose, contributes to the mechanical properties of plant-based fibers. While cellulose offers strength, hemicellulose adds flexibility and resilience. This combination enhances the versatility of these fibers, allowing them to be adapted for various applications across industries [120–122].

For instance, hemp fibers, renowned for their strong mechanical properties, owe their robustness to the interaction between cellulose and hemicellulose. This characteristic makes them suitable for structural applications where reliability is crucial [123].

Similarly, flax fibers strike a balance between flexibility and impact resistance, partly due to their cellulose, and hemicellulose composition. This feature makes flax fibers valuable in industries like automotive and aerospace, where materials must withstand dynamic stresses [124–127].

The widespread availability and renewable nature of plant-based fibers further underscore their appeal for sustainable material engineering initiatives. By harnessing the inherent properties of cellulose and hemicellulose, these fibers continue to offer eco-friendly solutions across various sectors while maintaining performance and quality standards [128–130].

2.2 Animal-based fibers

Animal-based fibers possess unique characteristics that make them suitable for specific applications. Wool and silk are prominent examples of animal-based fibers used in NFCs [131,132]. Wool is renowned for its superb thermal insulation properties, moisture absorption capacity, and inherent flame resistance [133]. These qualities improve the thermal and acoustic properties of composites, making wool ideal for insulation [134]. Silk fibers, on the other hand, are noted for their high tensile strength and elasticity, making them suitable for applications in textiles, medical devices, and high-performance composites [135].

2.3 Mineral-based fibers

Mineral-based fibers, sourced from natural minerals, include asbestos, basalt, and wollastonite. These fibers are extracted from mineral sources and processed for use in various applications. Asbestos fibers, once valued for their high tensile strength and heat resistance, are now largely avoided due to health risks. Basalt fibers, derived from volcanic rock, are gaining popularity due to their excellent mechanical properties, high temperature resistance, and chemical inertness. Wollastonite fibers, composed of calcium silicate, are used for their thermal stability and reinforcement properties in composite materials. These mineral-based fibers offer unique benefits, including non-combustibility, high strength, and durability, making them suitable for critical applications [136–138].

2.4 Summary

Natural fibers, whether plant-based, animal-based, or mineral-based, offer distinct characteristics that can be utilized in composite materials. The choice of fiber type depends on the specific requirements of the intended application, including mechanical performance, sustainability goals, and economic considerations. Understanding the properties and behavior of different natural fibers within composites is essential for achieving optimal performance and enhancing the sustainability of material engineering. As research and development in this field continue, NFCs are expected to play a significant role in promoting sustainable practices across various industries. Table 2 gives an overview of different natural fibers and their properties and applications.

| Natural fiber type | Source | Tensile strength (MPa) | Young's modulus (GPa) | Density (g·cm−³) | Moisture absorption (%) | Applications |

|---|---|---|---|---|---|---|

| Bamboo | Plant | 250–350 | 20–30 | 0.4–0.6 | 0.4–1.2 | Construction, textiles, papermaking |

| Hemp | Plant | 300–700 | 50–80 | 1.3–1.5 | 8–10 | Automotive parts, textiles, paper |

| Jute | Plant | 300–600 | 10–20 | 1.3–1.5 | 12–14 | Textiles, packaging, geotextiles |

| Flax | Plant | 250–700 | 30–70 | 1.4–1.5 | 6–8 | Automotive parts, textiles, paper |

| Coir | Plant | 50–150 | 4–10 | 1.15–1.45 | 15–20 | Geotextiles, erosion control, packaging |

| Wool | Animal | 200–500 | 1–2 | 1.3–1.4 | 13–16 | Textiles, insulation, carpets |

3 Processing of natural fibers

3.1 Natural fiber extraction

The initial step in utilizing natural fibers for composite materials involves extracting and preparing these fibers. The methods for fiber extraction vary depending on the specific type of fiber and its source material. For plant-based fibers, processes like retting, decortication, and mechanical separation are utilized to extract fibers from plant stalks or leaves. Animal-based fibers such as wool or silk undergo shearing or reeling processes to obtain the fibers [145]. In the case of cellulose-based fibers, such as cotton, procedures such as ginning or chemical treatments may be necessary to remove impurities and make the fibers suitable for composite applications. Adhering to appropriate fiber extraction and preparation techniques is essential to ensure the quality, purity, and consistency of the fibers within the composite material. Various techniques are employed to extract natural fibers from plant sources, each method tailored to the specific fiber type and plant species involved [146]. These extraction processes are pivotal steps in preparing fibers for diverse applications.

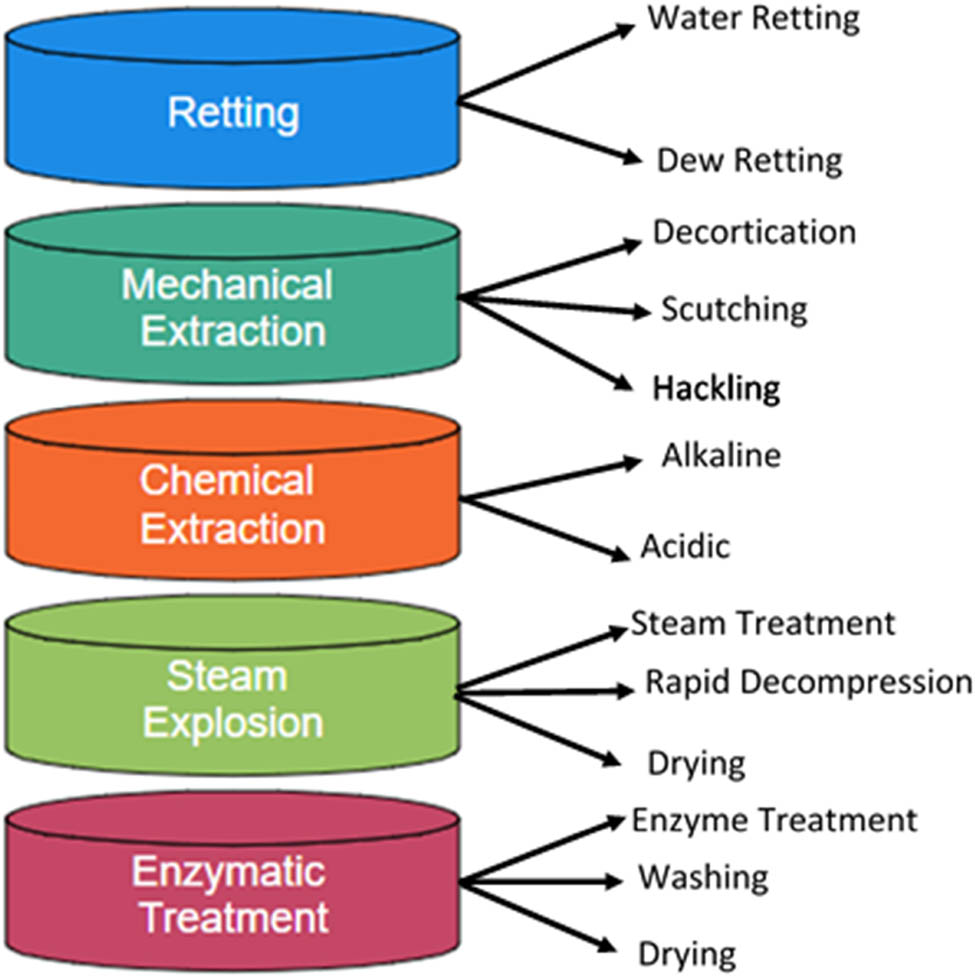

3.1.1 Retting

Retting is a traditional and well-established method for extracting natural fibers from plant stems by breaking down the pectins that bind the fibers to the plant's woody core through microbial activity or chemical agents [147]. There are several retting techniques, each with unique characteristics. In water retting, stems are submerged in water for 1–3 weeks, allowing bacteria and fungi to decompose the pectins; however, this method is time-consuming and water-intensive, with potential pollution risks [90,148–150]. Dew retting spreads stems on the ground, relying on natural moisture to promote microbial activity over 2–6 weeks, making it cost-effective and eco-friendly but weather dependent [151]. Chemical retting uses solutions such as sodium hydroxide or hydrogen peroxide to accelerate pectin breakdown within hours or days, offering speed and control but involving hazardous chemicals that require careful disposal [152]. Enzymatic retting applies specific enzymes to degrade pectins quickly under controlled conditions, producing high-quality fibers in an environmentally friendly manner, albeit at a higher cost due to the enzymes and the need for precise control [153]. Each method provides different benefits and challenges, enabling manufacturers to select the best approach based on their specific requirements for fiber extraction, balancing efficiency, environmental impact, and cost.

3.1.2 Mechanical extraction

Mechanical extraction is a method that employs machinery to separate fibers from plant stems or other parts. This approach is favored for its efficiency and ability to produce high-quality fibers suitable for various industrial applications. The process begins with decortication, where plant stems are crushed mechanically to separate the fibers from the woody core. This is done using decorticators equipped with rotating blades or rollers that break the stems and loosen the fibers [154]. The next step is scutching, which involves beating the stems to further separate the fibers from any remaining woody material and impurities. Scutching machines typically use rotating drums or blades for this purpose. After scutching, the fibers undergo hackling, where they are combed through fine, sharp pins to remove short and tangled fibers, leaving long, straight fibers [155]. Finally, the fibers are subjected to carding, a process that aligns them into a continuous web or sliver, preparing them for spinning. Carding machines utilize rotating drums with fine wire teeth to align the fibers [156]. The main advantages of mechanical extraction include its efficiency, ability to produce high-quality fibers, and scalability for large-scale production. However, it requires significant initial investment in machinery, regular maintenance, and substantial energy consumption.

3.1.3 Chemical extraction

Chemical extraction involves using chemical agents to break down plant materials and isolate fibers, effectively removing lignin, hemicellulose, and other non-cellulosic substances [157]. Alkaline extraction is a common method that uses alkaline substances like sodium hydroxide to dissolve binding materials [158]. The process involves soaking plant pieces in an alkaline solution at elevated temperatures, followed by thorough washing and neutralization. This method produces high-purity fibers but can cause environmental pollution if wastewater is not properly managed [159]. Acid extraction involves using acidic solutions such as sulfuric acid or hydrochloric acid to hydrolyze plant material. This method can produce very fine fibers but involves handling hazardous acids and requires proper disposal to avoid environmental pollution [160]. Oxidative extraction employs oxidizing agents like hydrogen peroxide to break down plant materials. This method is less hazardous than acid extraction but can be costly and requires precise control. Enzymatic extraction is an environmentally friendly approach that uses specific enzymes to break down non-cellulosic components. This method is gentle on fibers and produces high-quality outputs, but the high cost of enzymes and the need for precise control are significant challenges [161].

3.1.4 Steam explosion

Steam explosion is a mechanical–chemical method that treats plant materials with high-pressure steam, followed by rapid decompression, to break down the plant structure and separate the fibers [162]. The process starts with the preparation of plant material, which is cut into manageable pieces and loaded into a steam explosion reactor. High-pressure steam is then injected into the reactor, causing the internal structure of the plant material to soften and partially break down. After the steam treatment, the pressure is rapidly released, causing the plant material to explode outward, effectively separating the fibers from the woody core and other non-fibrous components. The exploded fibers are then collected, washed, and dried. Steam explosion is efficient in fiber separation, enhances fiber properties, and is more environmentally friendly than chemical extraction methods. However, it requires significant initial investment in high-pressure reactors, consumes substantial energy, and, if not carefully controlled, can damage the fibers [163].

3.1.5 Enzymatic treatment

Enzymatic treatment is a sustainable and efficient method that uses specific enzymes to break down non-cellulosic components like pectins, hemicellulose, and lignin, preserving the integrity of cellulose fibers. The process starts with the preparation of plant material, which is cleaned and cut into uniform pieces. Specific enzymes are selected based on the composition of the plant material and the desired fiber properties [164]. The plant material is soaked in water and treated with the enzyme solution under controlled conditions of temperature, pH, enzyme concentration, and incubation time. After the enzyme treatment, the fibers are washed to remove residual enzymes and other impurities, and then dried [165]. Enzymatic treatment is environmentally friendly, operates under mild conditions, and produces high-quality fibers. However, the high cost of enzymes and the need for precise control of the process parameters can be challenging [166]. This method is particularly suitable for producing fibers for the textile industry, composites, non-wovens, and biodegradable products due to the enhanced fiber properties and reduced environmental impact.

These extraction techniques evolve with technological advancements and a growing emphasis on sustainability. By refining these methods, researchers and industry professionals aim to fully utilize natural fibers for various applications, while minimizing environmental impact and maximizing resource efficiency. Figure 2 gives the different treatment procedures for NFCs.

Different treatment procedures for NFCs.

3.2 Treatment procedures for natural fibers

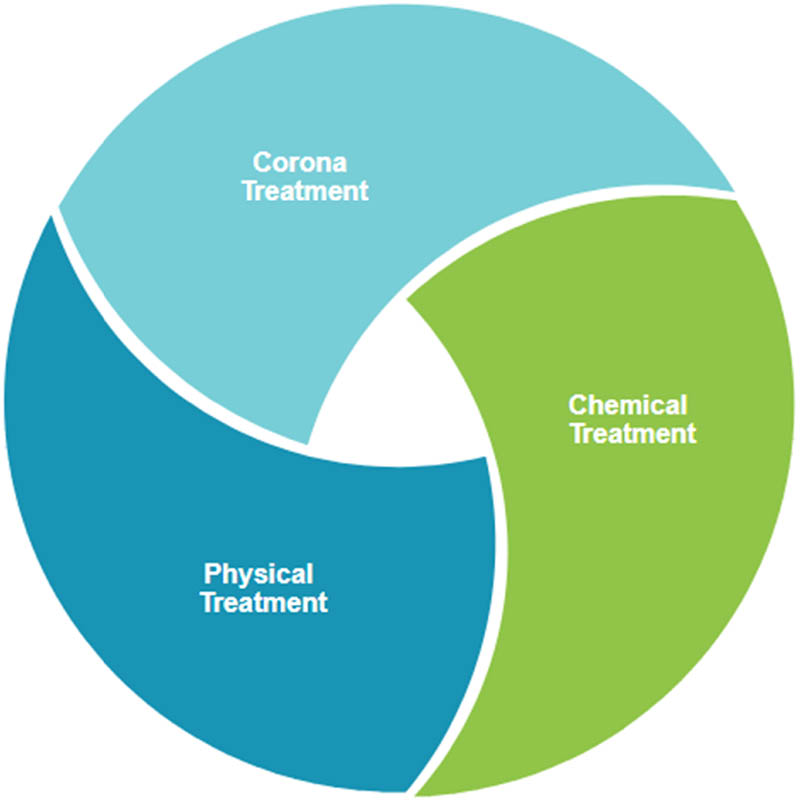

The primary step in utilizing lignocellulosic fibers for high-performance industrial applications necessitates a comprehensive understanding of cell wall segment properties and their correlation with fiber attributes [167]. Natural fibers typically exhibit hydrophilic characteristics, which can limit their engineering applications due to poor chemical resistance, inferior mechanical properties, and a porous structure. This hydrophilicity also restricts the applicability of textile products, especially in transportation and packaging sectors [168]. Various treatments are applied to natural fibers, with physical treatments preceding chemical ones. These physical treatments encompass methods such as corona discharge, plasma treatment, ultraviolet (UV) treatment, fiber beating, and heat treatment [169–172]. Figure 3 gives the schematic of three major types of treatment procedures followed for natural fibers.

Treatment procedures for natural fibers.

Corona treatment is particularly notable for its capacity to activate surface oxidation, thereby altering the surface energy of cellulose strands and enhancing compatibility between hydrophilic matrices and fibers [173]. Plasma treatment effectively removes pollutants and dust particles from fibers, resulting in improved fiber surface characteristics [174]. UV treatment, although relatively novel, is recognized for its ability to eliminate dust particles and enhance the polarity of fiber surfaces, thus improving wettability and ultimately the strength of NFCs [175].

Chemical treatments play a significant role in modifying the mechanical properties of natural-fiber-reinforced polymer composites (NFRPCs) by targeting hydroxyl groups present in cellulose and lignin. These treatments rely on reagent functional groups capable of interacting effectively with natural fiber structures while removing non-cellulosic materials. Chemical modifications introduce or activate hydroxyl groups within cellulose molecules, enhancing bonding potential with the matrix [176]. However, some chemical treatments involve the addition of toxic and reactive chemicals to prevent organic degradation, a common practice in wood preservation.

Various surface treatments, including alkali, silane, acetylation, and benzoylation treatments, have been extensively researched to enhance fiber properties [177]. Alkali treatment, considered cost-effective and efficient, results in surface changes and removal of amorphous hemicelluloses and lignin, thereby improving interfacial bonding between natural fibers and polymer matrices [178–180]. Silane treatment involves several steps, including hydrolysis, self-condensation, adsorption, and chemical grafting, to form a layer on fiber surfaces and promote compound interactions, enhancing adhesion and surface morphology [181].

Acetylation treatment reduces fiber hydrophilicity, improves dimensional stability, and enhances mechanical interlocking with the matrix, while benzoylation treatment alters the fiber surface and promotes epoxy adhesion. Maleated coupling agents, such as polypropylene (PP) combined with maleic anhydride (PP-MAH), are commonly employed to strengthen composites by facilitating esterification reactions and hydrogen bond interactions at the fiber interface [182].

Minor treatments, including potassium permanganate and acrylic acid, can also be utilized to enhance fiber properties. These treatments have specific effects on fiber surfaces, improving adhesion, flexibility, and structural integrity. Overall, understanding and optimizing these treatments are critical for enhancing the performance and applicability of natural fibers in composite materials.

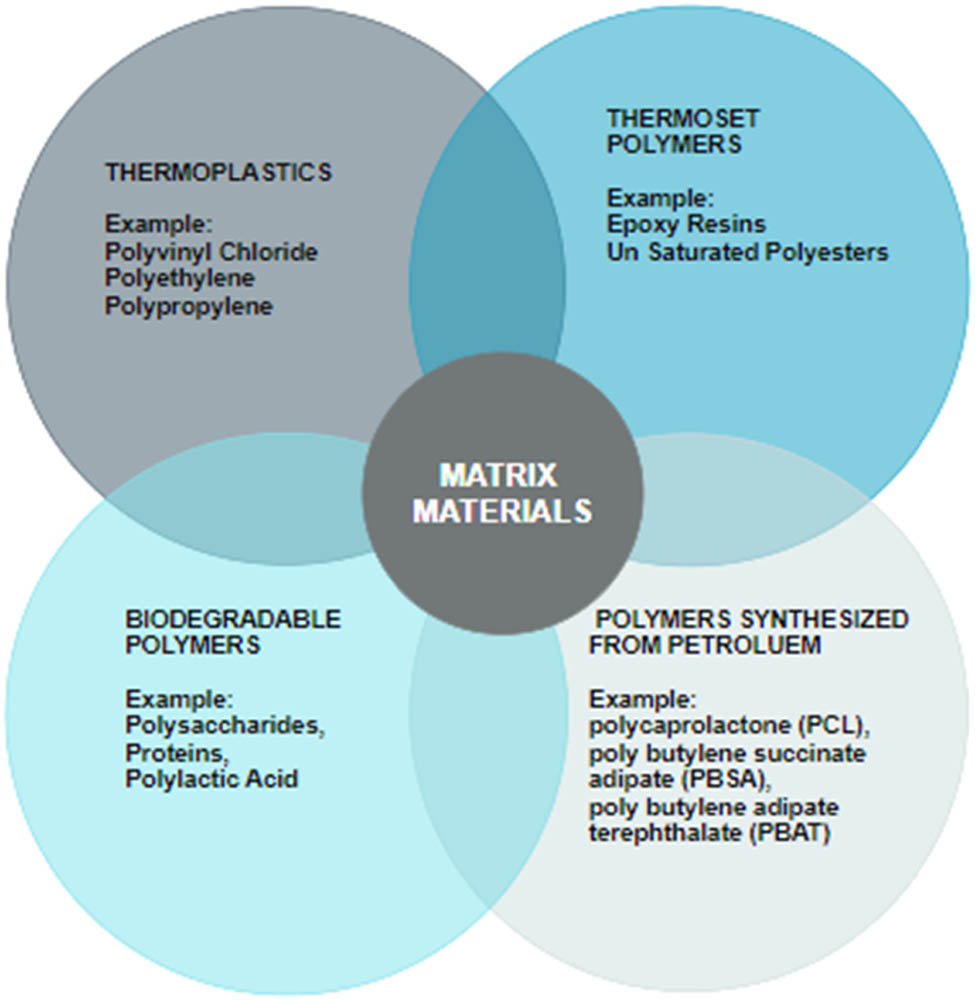

3.3 Matrix materials for NFCs

The matrix material within composite materials serves a multifaceted role, acting as a binder that not only brings together the fibers but also facilitates the transfer of applied stresses while safeguarding the fibers from external damage. It plays a critical role in maintaining the shape and structural integrity of the composite. To fulfill these functions effectively, the matrix must exhibit sufficient deformability and compatibility with the reinforcement fibers, allowing the composite to attain the necessary mechanical properties without impeding the movement of the fibers. Achieving this requires a strong adhesive bond between the matrix and the fibers, enabling optimal stress transfer and minimizing fiber displacement. Typically, polymer resins are the preferred choice of matrix material in composite materials due to their versatility and suitability for various applications [183].

Polymerization, the fundamental process by which monomers combine to form higher molecular weight compounds known as polymers or macromolecules, lies at the heart of matrix material formation. Polymers can exist in two primary forms: homopolymers, composed of identical monomer units, or copolymers, comprised of monomer units of two or more different kinds. These polymers can originate from diverse sources, including natural (e.g., rubber, polysaccharides) or synthetic (e.g., polyethylene (PE), polystyrene) origins [184].

Thermoplastics, characterized by linear chains held together by weak bonds, are widely utilized in composite materials due to their affordability, ease of shaping through heating and cooling cycles, and recyclability. Common thermoplastics such as polyvinyl chloride, PE, and PP find extensive applications in various industries. In contrast, thermosetting polymers form solid networks through chemical polymerization reactions, resulting in materials with high mechanical and thermomechanical properties. Examples of thermosetting polymers include epoxy resins and unsaturated polyesters [185].

Although less common due to their higher cost, ceramic resins are favored for high-temperature applications, offering advantages such as exceptional temperature resistance and chemical stability.

Biodegradable polymers, derived from renewable resources, have gained considerable attention due to their positive environmental impact and recyclability. These polymers, categorized into agro-polymers (e.g., polysaccharides, proteins) and polyesters from biomass (e.g., polyhydroxyalkanoates (PHA), polylactic acid (PLA)), offer properties like biodegradability, biocompatibility, and mechanical strength, making them suitable for various eco-friendly applications [186].

Polymers derived from fossil resources, i.e., mostly synthesized from petroleum, remain widely used, with examples including polycaprolactone (PCL), poly butylene succinate adipate, and poly butylene adipate terephthalate. Despite their advantages such as ductility and ease of shaping, efforts are underway to enhance their properties and biodegradability to align with sustainable practices. A diverse range of polymers, including thermoplastics, thermosets, ceramic resins, biodegradable polymers, and those derived from fossil resources, offer various properties and applications in composite materials [187]. Figure 4 gives the schematic of different matrix materials used for the synthesis of NFCs, while Table 3 gives the different matrix materials, their significant properties, and applications.

Types of matrix materials used for the synthesis of NFCs.

| Matrix material | Source | Properties | Applications |

|---|---|---|---|

| PP | Petrochemical (can be bio-based) | Good impact resistance, low cost, moderate to high strength and stiffness | Automotive components, packaging, consumer goods |

| PE | Petrochemical (can be bio-based) | Flexible, lightweight, good chemical resistance | Packaging, agricultural films, and containers |

| PLA | Biodegradable polymer derived from renewable resources | Biodegradable, good strength and stiffness, and low toxicity | Food packaging, disposable items, 3D printing |

| Epoxy | Synthetic polymer | High strength, excellent adhesion, chemical resistance | Aerospace, marine applications, sporting goods |

| Polyurethane | Petrochemical (can be bio-based) | Flexible, durable, good abrasion resistance | Foams, adhesives, coatings |

| Starch-based polymers | Derived from renewable starch sources | Biodegradable, low cost, good film-forming properties | Packaging, biomedical applications |

3.4 Synthesis of NFCs

Synthesizing NFCs involves a range of methods designed to achieve specific properties and performance attributes. These methods can be broadly divided into physical and chemical synthesis techniques.

3.4.1 Physical synthesis techniques

Hand lay-up: This conventional approach requires manually placing fibers onto a mold, saturating them with resin, and then consolidating the layers to create the composite. While straightforward and cost-effective, it may result in variations in fiber orientation and resin distribution.

Compression molding: Here fiber mats or preforms are positioned in a mold cavity, and pressure and heat are applied to compress and cure the composite. This method is suited for producing large, uniform parts with high fiber content.

Pultrusion: Continuous fibers are pulled through a resin bath and then through a heated die to cure the composite into the desired shape. This continuous process is ideal for making long, uniform profiles with a high fiber content.

Filament winding: Continuous fibers are wrapped around a rotating mandrel and impregnated with resin to form cylindrical or tubular structures. This method is commonly used for manufacturing pressure vessels, pipes, and cylindrical components.

Vacuum bagging: Fiber reinforcements and resin are placed in a mold, covered with a vacuum bag, and vacuum pressure is applied to remove air and consolidate the composite. This method produces parts with excellent surface finish and fiber alignment.

3.4.2 Chemical synthesis techniques

Resin transfer molding (RTM): Liquid resin is injected into a closed mold containing dry fiber reinforcements. The resin infiltrates the fibers under pressure, and the composite is cured to form the final part. RTM enables the production of complex, high-performance components with precise fiber placement and resin control.

Injection molding: Molten resin is injected into a mold cavity containing fiber reinforcements. The resin solidifies, and the part is ejected from the mold. This method is suitable for producing small to medium-sized parts with intricate geometries.

Reaction injection molding (RIM): Liquid resin is combined with a curing agent and injected into a mold containing fiber reinforcements. The reactive mixture reacts and cures in the mold to form the composite part. RIM is advantageous for producing large, complex parts with high strength and dimensional stability.

Solvent casting: Natural fibers are dissolved in a solvent, mixed with a resin solution, and cast into a mold. The solvent evaporates, leaving behind a composite material with uniform fiber dispersion. Solvent casting is suitable for producing films, coatings, and thin-film composites.

These synthesis techniques can be customized based on factors such as fiber type, resin system, desired properties, and production scale. By selecting the appropriate method, manufacturers can create NFCs with the desired performance characteristics for various applications, including automotive, construction, aerospace, and consumer goods. Figure 5 gives the manufacturing techniques used in the synthesis of NFCs.

![Figure 5

Manufacturing techniques used in the synthesis of NFCs. Adopted from ref. [113] with permission. Copyright MDPI 2021. (Open Access CC BY-NC 4.0 Deed).](/document/doi/10.1515/rams-2024-0057/asset/graphic/j_rams-2024-0057_fig_005.jpg)

Manufacturing techniques used in the synthesis of NFCs. Adopted from ref. [113] with permission. Copyright MDPI 2021. (Open Access CC BY-NC 4.0 Deed).

4 NFCs

The addition of natural fibers to biodegradable matrices significantly affects the physical properties of resulting composite materials, encompassing mechanical, thermal, decomposition, and crystallinity aspects. Ongoing advancements in understanding constituent materials enable better control over various design parameters, consequently enhancing composite properties. While these materials find increased efficiency across diverse applications, their preparation encounters a notable limitation due to the maximum forming temperature. Fibers start degrading at temperatures surpassing 200–230°C [188]. Despite shared shaping technologies such as extrusion, injection, and compression, this thermal constraint poses a challenge.

4.1 PP-based composites

PP stands as a popular matrix polymer in biocomposite materials due to its favorable mechanical properties and higher operating temperature compared to polystyrene. Studies have demonstrated the preparation of PP-based biocomposites with bamboo fibers, where untreated fibers initially exhibited promising mechanical properties. However, treatment with alkali NaOH enhanced these properties further, indicating improved fiber–matrix interactions and mechanical capabilities [189].

4.2 PE-based composites

PE, while being cost-effective, has limited mechanical properties. Recent research has shown promising results with PE-based composites reinforced with jute fibers, where chemical treatments like maleic anhydride have been employed to enhance mechanical properties and reduce water absorption [190].

4.3 Polystyrene (PS)-based composites

PS, another thermoplastic matrix, though less studied than PP, has been investigated in composite materials. Studies comparing mechanical properties of hemp and glass fiber-reinforced polystyrene composites have shown differences in behavior, with increasing hemp fiber content enhancing mechanical properties, particularly density and strength [191].

4.4 Biodegradable composites

Biodegradable polymers have emerged as a game-changer in the realm of sustainable materials, offering a viable alternative to traditional plastics. These polymers, characterized by their ability to naturally degrade in the environment, owe their decomposition to the activity of microorganisms such as bacteria and fungi. In stark contrast to conventional plastics, which endure for centuries, biodegradable polymers undergo breakdown into harmless substances like water, carbon dioxide, and biomass. Notable among these polymers are PLA and PHA, derived from renewable sources and synthesized by microorganisms, respectively. Additionally, PCL, another prominent biodegradable polymer, exhibits a low melting point and is utilized in diverse applications such as drug delivery systems and tissue engineering scaffolds. These polymers have found traction across industries, from packaging materials to medical devices, with a shift toward more sustainable practices. Despite their promise, challenges persist, including cost-effectiveness and the need for proper disposal methods to maximize environmental benefits. Nonetheless, ongoing research endeavors aim to address these hurdles, paving the way for a greener future in materials engineering [192]. Figure 6 gives an overview of NFCs that can be fabricated from the combinations of different types of polymer resins and fibers.

NFCs synthesized from different fibers.

5 Evaluation of the properties of NFCs

The properties of composite materials with plant fillers depend on several parameters, including constituents, morphology, orientation, and environmental factors like humidity and temperature. Characterizing natural fiber reinforced polymer composites involves evaluating and understanding their properties and responses, aiding in assessing performance for specific applications. The schematic block diagram in Figure 7 illustrates the various characterization processes, while Table 4 gives the summary of the different testing methodologies and the corresponding ASTM standards [193].

![Figure 7

Testing of natural fiber reinforced composites adopted from ref. [193] with permission. Copyright Springer 2023 (Open Access CC BY-NC 4.0 Deed).](/document/doi/10.1515/rams-2024-0057/asset/graphic/j_rams-2024-0057_fig_007.jpg)

Testing of natural fiber reinforced composites adopted from ref. [193] with permission. Copyright Springer 2023 (Open Access CC BY-NC 4.0 Deed).

| Test type | ASTM standard | Specimen size | Description |

|---|---|---|---|

| Mechanical testing | |||

| Tensile testing | ASTM D3039 | Dogbone-shaped specimens: width = 25.4 mm (1 inch), gauge length = 50–100 mm (2–4 inches), thickness = 2–6 mm | Measures tensile strength, Young's modulus, and elongation at break |

| Flexural testing | ASTM D7264 | Rectangular specimens: width = 12.7 mm (0.5 inch), length = 127 mm (5 inches), thickness = 3–6 mm | Evaluates flexural strength, flexural modulus, and stiffness under bending loads |

| Compression testing | ASTM D695 | Cylindrical specimens: diameter = 12.7 mm (0.5 inch), length = 25.4 mm (1 inch) | Measures compressive strength and modulus under axial loading |

| Impact testing | ASTM D256 | Rectangular specimens: width = 12.7 mm (0.5 inch), length = 63.5 mm (2.5 inches), thickness = 3–6 mm | Assesses the material's resistance to sudden loading or impact |

| Shear testing | ASTM D4255 | Rectangular specimens: width = 12.7 mm (0.5 inch), length = 25.4 mm (1 inch), thickness = 3–6 mm | Measures interlaminar shear strength and resistance to delamination |

| Peel testing | ASTM D1781 | Rectangular specimens: width = 25.4 mm (1 inch), length = 150 mm (6 inches), thickness = 3–6 mm | Evaluates the adhesion strength between layers or interfaces in composite materials |

| Fatigue testing | ASTM D3479 | Depends on specimen geometry and loading conditions | Assess the material's endurance limit and fatigue life under cyclic loading |

| Thermal testing | |||

| Thermogravimetric analysis | ASTM E1131 | Small specimens: typically, a few milligrams | Measures the material's thermal stability and decomposition temperature |

| Differential scanning calorimetry (DSC) | ASTM E1356 | Small specimens: typically, a few milligrams | Analyzes changes in heat flow associated with phase transitions and thermal properties |

| Dynamic mechanical analysis (DMA) | ASTM E1640 | Rectangular specimens: dimensions vary depending on the instrument and mode of testing | Evaluates viscoelastic properties, such as storage modulus and damping behavior, as a function of temperature or frequency |

| Water absorption test | |||

| Water absorption test | ASTM D570 | Rectangular specimens: dimensions depend on material thickness and specific requirements | Determines the amount of water absorbed by the material over time, indicating susceptibility to moisture and environmental degradation |

| Degradation test | |||

| Accelerated weathering test | ASTM G155 | Typically involves exposing specimens to UV radiation, temperature cycling, and moisture | Evaluates material degradation under simulated environmental conditions, including UV exposure, temperature variations, and moisture |

| Soil burial test | ASTM D5988 | Typically involves burying specimens in soil for a specified duration | Assesses material degradation in soil environments, simulating natural degradation processes |

| Composting test | ASTM D5338 | Specimens buried in composting environments under controlled conditions | Evaluates biodegradability and compostability of materials in composting environments |

5.1 Mechanical properties

The mechanical properties of biocomposites with plant fibers have been extensively studied, influenced by production methods, fiber source, form and orientation, fiber volume fraction, fiber–matrix interface strength, load transfer efficiency, and matrix crystallinity. Composite materials are selected based on multifaceted properties, typically exhibiting superior attributes compared to the matrix alone [194]. Although achieving a single composite with all desired properties is impractical, tailored solutions with desired characteristics can be devised.

5.1.1 Tensile properties

Tensile properties of NFCs are crucial indicators of their strength and resilience under tension. ASTM standards such as ASTM D3039 or ASTM D638 provide comprehensive guidelines for testing these properties [195].

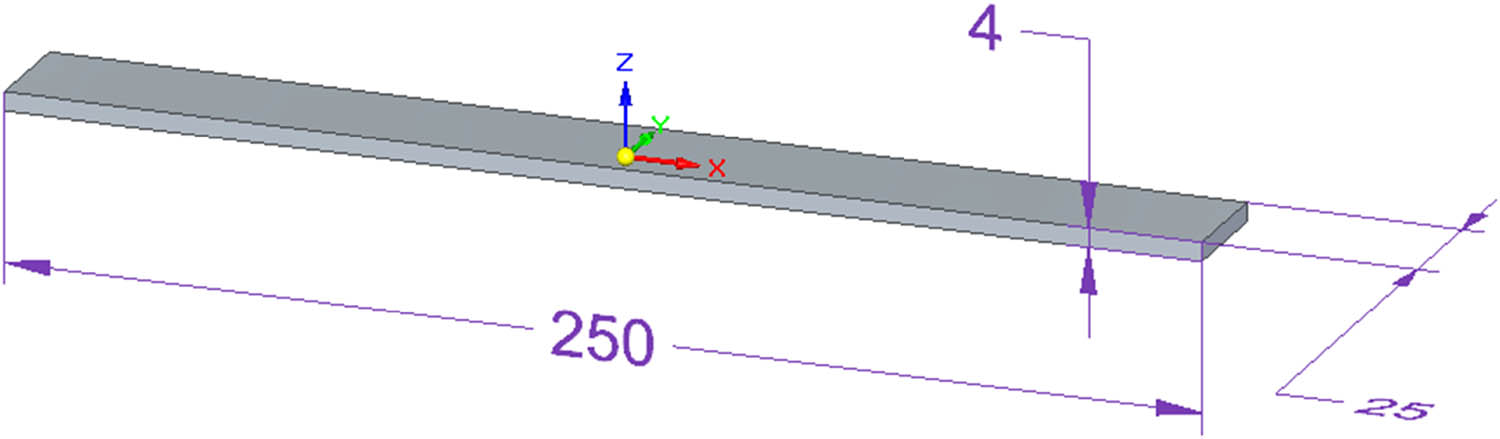

For ASTM D3039, specimens are typically prepared as dog-bone-shaped samples with dimensions of approximately 250 mm in length, 25 mm in width, and a gauge length of 50 mm. The width of the narrower section of the specimen, known as the “grip area,” is usually about 12.5 mm. The thickness of the specimens generally vary between 3 and 6 mm. These dimensions ensure uniform stress distribution and accurate measurement of tensile properties, including tensile strength, modulus, and elongation at break [196]. Figure 8 gives the schematic of the tensile test specimen.

Schematic of the tensile test specimen.

5.1.2 Flexural strength

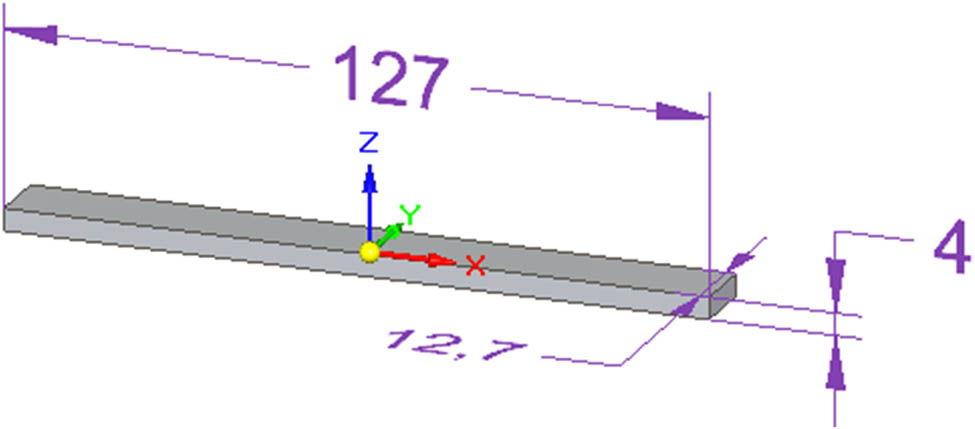

Flexural strength is an essential mechanical property that characterizes a material's ability to withstand bending loads. ASTM D790 outlines the procedures for flexural testing of composite materials.

Specimens for flexural testing are prepared as rectangular bars with dimensions specified by the standard. Typically, the specimen dimensions are 127 mm in length, 12.7 mm in width, and 3–6 mm in thickness. These dimensions ensure consistent testing conditions and allow for accurate determination of flexural properties, including modulus of elasticity and maximum flexural stress [57]. Figure 9 gives the schematic of the flexural test specimen.

Schematic of the flexural test specimen.

5.1.3 Interlaminar shear stress

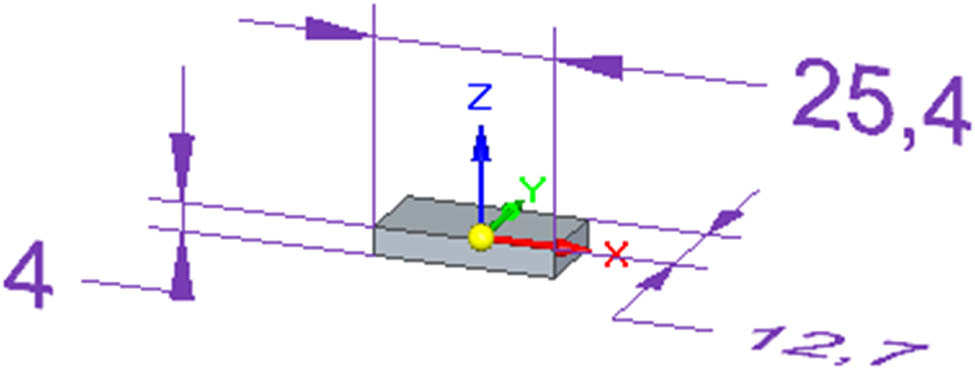

Interlaminar shear stress testing evaluates the shear strength between the layers of a composite material, providing insights into its interlayer bonding and structural integrity. ASTM D2344 provides guidelines for conducting short-beam shear tests on composite materials.

Specimens for interlaminar shear testing are prepared as small rectangular beams with precise dimensions. Typically, the specimen dimensions are 25.4 mm in length, 12.7 mm in width, and 3–6 mm in thickness. These dimensions ensure uniform stress distribution and accurate measurement of interlaminar shear stress (Figure 10) [197].

Schematic of the specimen for short beam shear test.

5.1.4 Impact strength

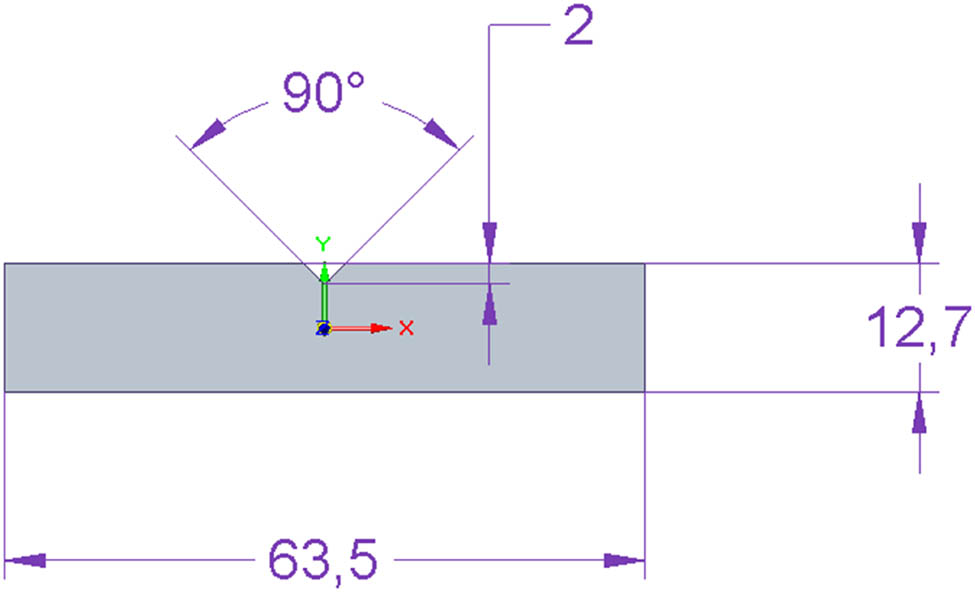

Impact strength testing assesses a material's resistance to sudden loading and is crucial for applications where the material may experience impact or shock. ASTM D256 outlines the procedures for determining the impact resistance of plastics, including composite materials.

Specimens for impact testing are typically prepared as rectangular or notched rectangular bars with specific dimensions. For example, the specimen dimensions for the Izod test are typically 63.5 mm in length, 12.7 mm in width, and 3.2–6 mm in thickness. These dimensions ensure consistent testing conditions and accurate measurement of impact strength (Figure 11) [198].

Schematic of the impact test specimen.

5.1.5 DMA

DMA evaluates the viscoelastic properties of materials under varying temperature and frequency conditions, providing insights into their behavior under dynamic loads. ASTM D4065 provides guidelines for conducting DMA on plastics, including composite materials.

Specimens for DMA testing is prepared as rectangular or cylindrical samples with dimensions specified by the standard. Typically, the specimen dimensions are 50 mm in length, 12.7 mm in width, and 3.2 mm in thickness for rectangular samples, and 12.7 mm in diameter and 3.2 mm in thickness for cylindrical samples. These dimensions ensure consistent testing conditions and accurate characterization of dynamic mechanical properties [199].

By adhering to these ASTM standards and using specimens with precise dimensions, researchers and engineers can conduct accurate and reliable mechanical testing of NFCs, facilitating informed decision-making and advancements in material development and design.

5.2 Thermal properties

Selection of suitable biocomposite materials relies on the criterion of melting temperature (T m), ensuring it remains below the degradation temperature of natural fibers (210°C). This criterion often limits polymer choices, especially polyolefins like PP, low-density polyethylene, and high-density polyethylene (HDPE). HDPE, with its optimal temperature range for shaping NFCs, and PET, modified through copolymerization reactions, are commonly used. Fire retardants and alkaline treatments are employed to enhance fiber thermal stability [200].

Testing the thermal properties of natural fiber polymer composites involves a variety of ASTM standards, each designed to measure specific thermal attributes.

One crucial standard is ASTM E1269, which details the method for determining specific heat capacity using DSC. For this test, a small sample, typically between 10 to 20 mg, is heated at a controlled rate, and the heat flow into the sample is measured. This measurement is essential for understanding how much heat the material can store [201].

Another important standard is ASTM E1131, used for compositional analysis by Thermogravimetry. In this test, a sample weighing between 5 and 20 mg is heated, and the change in weight is recorded as a function of temperature. This technique is pivotal in determining the thermal stability and decomposition characteristics of the composite material [202].

For measuring the glass transition temperature of polymers, ASTM E1356 is employed. This method also uses DSC and typically requires a sample size of 5–10 mg. The test involves heating the sample through its glass transition temperature while monitoring the heat flow, which provides insights into the thermal behavior of the polymer matrix within the composite [203].

ASTM D3418 addresses the determination of transition temperatures and enthalpies of fusion and crystallization of polymers by DSC. Approximately 10 mg of the sample are heated, cooled, and reheated to identify the melting and crystallization temperatures and the enthalpies associated with these transitions. This information is critical for understanding the thermal transitions and stability of the polymer composites, especially during processing and application [204].

When it comes to evaluating thermal conductivity, ASTM D5470 is the standard to follow. This test is conducted on specimens that are 1–3.2 mm thick and about 25 mm in diameter. The standard measures thermal conductivity, thermal impedance, and thermal resistance, which are vital properties for materials used in thermal management applications, such as in electronic packaging or insulation [205].

ASTM E1461 outlines the method for determining thermal diffusivity using the flash method. This test involves using disk-shaped samples, typically 10–12.7 mm in diameter and 1–3 mm thick. An energy pulse is applied to the front face of the sample, and the temperature response on the rear face is measured. This method provides an accurate measurement of the material's thermal diffusivity, which is important for understanding how quickly heat spreads through the material [206].

In addition to these standards, there are other ASTM methods that can be relevant, such as ASTM C518 for measuring thermal conductivity and thermal resistance using the heat flow meter technique. This standard is particularly useful for materials that are used in insulation applications, providing critical data on their thermal insulating properties [207].

Each of these ASTM standards provides comprehensive guidelines for sample preparation, testing procedures, and data analysis, ensuring that the thermal properties of natural fiber polymer composites are accurately and consistently characterized. This information is crucial for developing and optimizing materials for various industrial applications, where thermal performance is a key factor.

5.3 Tribological properties

The tribological properties of NFCs, including friction, wear, and lubrication, are critical for determining their performance in applications where these interactions occur. Friction involves the resistance between sliding surfaces, while wear is the gradual removal of material due to mechanical action, and lubrication refers to the use of substances to reduce friction and wear.

Several ASTM standards are relevant for testing these properties. ASTM G99 specifies the pin-on-disk method, where a pin slides over a rotating disk to assess wear resistance and friction coefficient, with parameters such as normal load, sliding speed, and distance being measured. ASTM D3702 focuses on wear rate and coefficient of friction using a thrust washer testing machine, considering load, speed, and duration. ASTM G133 involves a linearly reciprocating ball-on-flat test to evaluate wear and friction, using parameters like load, stroke length, frequency, and cycles. Additionally, ASTM D6425 measures the friction and wear properties of extreme pressure lubricating oils with disk-on-disk or block-on-ring configurations, considering load, speed, temperature, and lubrication conditions [208].

NFCs are utilized in various industries due to their eco-friendliness and robust mechanical properties. Understanding their tribological properties is crucial for automotive components, industrial machinery, aerospace, and consumer products, where friction and wear are significant factors. For instance, they are used in brake pads, clutches, bearings, gears, and sports equipment.

In summary, accurately characterizing the tribological properties of NFCs according to ASTM standards is essential for their successful application in various industries. Continuous research and development in this field aim to enhance the performance and applicability of these materials in tribology-intensive uses.

In the case of NFCs, many factors influence the tribological behavior of the composites. The type and orientation of natural fibers (such as jute, hemp, and flax), the polymer matrix material (like epoxy or polyester), and the adhesion between fibers and the matrix play crucial roles. Surface treatments of fibers can also improve tribological properties. Environmental conditions, including temperature, humidity, and lubrication presence, can further affect friction and wear behavior [209].

5.4 Water absorption properties of NFCs

Water absorption testing of NFCs is crucial for assessing their durability and performance, especially in environments where they are exposed to moisture. This testing helps in understanding the impact of water absorption on the mechanical properties, dimensional stability, and long-term behavior of the composites. ASTM standards provide structured guidelines for conducting these tests.

5.4.1 ASTM standards for water absorption testing

One of the primary standards for water absorption testing is ASTM D570, which outlines the method for evaluating water absorption in plastics. The procedure involves immersing the specimen in water for a specified duration, removing it, wiping off excess water, and weighing it to determine the absorbed water content. Specimens are typically 3.175 mm (1/8 inch) thick with a surface area of at least 625 mm2, usually in the form of 2 inch diameter or square pieces. Common immersion times include 24 h, 48 h, and 7 days at a standard temperature of 23°C (73.4°F), though these durations can be adjusted as needed.

Another relevant standard is ISO 62, which is similar to ASTM D570. It involves immersing the specimen in water and measuring the weight increase due to water absorption. Typically, the specimens are 60 mm × 60 mm with a thickness ranging from 1 to 4 mm for flat specimens. Standard conditions usually include a 24 h immersion at 23°C, but the test can also accommodate longer durations [210].

5.4.2 Factors influencing water absorption

Several factors influence the water absorption properties of NFCs. The type and content of natural fibers, such as jute, flax, and hemp, play a significant role, with higher fiber content generally leading to increased water absorption. The polymer matrix type, whether epoxy or polyester, also affects water absorption, as thermoset polymers usually absorb less water than thermoplastics. The adhesion between fibers and the matrix is crucial; better interfacial bonding reduces water ingress. Additionally, surface treatments of fibers, like silane treatments, can significantly lower water absorption. The composite processing method and conditions, including curing time and temperature, also impact porosity and water absorption characteristics [211].

5.4.3 Test procedure

The test procedure begins with preparing the composite material into the required specimen size, ensuring smooth and defect-free edges. The specimens are then dried in an oven at 50–60°C until they reach a constant weight, which is recorded as the initial weight. After conditioning, the specimens are submerged in distilled water at 23°C (or another specified temperature) for the required duration. Following immersion, the specimens are removed, surface water is blotted off with a dry cloth, and the specimens are weighed immediately. The water absorption percentage is calculated using the weight difference before and after immersion [212].

5.4.4 Importance of water absorption testing

Understanding the water absorption behavior of NFCs is essential for predicting their performance in practical applications. High water absorption can lead to swelling, reduced mechanical properties, and material degradation, which is particularly important in automotive, construction, and marine environments where moisture exposure is common. By adhering to ASTM and ISO standards, manufacturers and researchers can ensure that NFCs meet the necessary performance criteria for their intended applications [213].

5.5 Degradation tests

Degradation tests play a pivotal role in assessing the long-term performance and environmental impact of NFCs. One commonly employed method is the Accelerated Weathering Test, as outlined by ASTM G155 standards. This procedure involves subjecting composite specimens to a combination of UV radiation, temperature cycling, and moisture, replicating harsh environmental conditions. By doing so, researchers can observe how these composites degrade under simulated scenarios, providing valuable insights into their durability and resistance to environmental stressors such as UV exposure and temperature fluctuations [214].

Another significant degradation test is the Soil Burial Test, guided by ASTM D5988 standards. In this test, specimens are buried in soil for a predetermined period, mimicking natural degradation processes. By monitoring the material's behavior over time in soil environments, researchers can assess its susceptibility to degradation caused by factors like microbial activity, moisture content, and soil pH. This test provides critical data on how NFCs interact with the soil, offering insights into their biodegradability and potential environmental impact when disposed of in natural settings [215].

Additionally, the Composting Test, conducted in accordance with ASTM D5338 standards, offers insights into the biodegradability and compostability of NFCs. Specimens are buried in controlled composting environments, where conditions such as temperature, moisture, and microbial activity are carefully regulated. Through this test, researchers can evaluate how effectively the composites break down into organic matter, contributing to the nutrient cycle without leaving harmful residues. Understanding the compostability of NFCs is vital for assessing their eco-friendliness and suitability for applications where sustainable end-of-life disposal is paramount [216,217].

Degradation tests thus provide invaluable information about the performance, durability, and environmental compatibility of NFCs. By subjecting these materials to accelerated weathering, soil burial, and composting conditions, researchers can gain insights into their behavior under various environmental stressors and make informed decisions regarding material selection, product design, and sustainable waste management practices.

5.6 Microstructure of NFCs

The microstructure of NFCs pertains to the intricate arrangement and interaction of the constituent elements at a microscopic scale. Within these composites, which are crafted from materials like bamboo, hemp, jute, or flax, several key components contribute to their overall structure and properties [194].

First, the fibers themselves constitute a fundamental aspect of the microstructure. These fibers, sourced from plants or animals, serve as the primary reinforcing agents in the composite. Their microscopic characteristics, including shape, size, orientation, and surface properties, vary depending on factors such as the source plant species and processing methods employed. Such diversity in fiber attributes profoundly influences the mechanical behavior and performance of the composite material [195].

Second, the matrix material forms another essential component of the microstructure. This matrix, typically a polymer derived from renewable sources, functions to bind the fibers together and provide structural support. Within the matrix, the arrangement of polymer chains, crystallinity, and intermolecular interactions contribute to the overall microstructural complexity, impacting the composite's mechanical properties and long-term durability [4].

The interphase, serving as the interface between the fibers and the matrix, constitutes a critical region within the microstructure. This interphase plays a pivotal role in facilitating load transfer between the fiber and matrix phases, managing stress distribution, and safeguarding against moisture absorption and degradation. The microstructural characteristics of the interphase, influenced by factors such as fiber surface treatment and interfacial bonding mechanisms, significantly influence the overall performance of the composite material [218].

Moreover, NFCs may incorporate additional components such as fillers and additives to further enhance specific properties or address performance concerns. These additives, which could include nanoparticles, coupling agents, antioxidants, and UV stabilizers, contribute to the composite's overall microstructure. Their microscopic features influence properties such as thermal stability, flame retardancy, and resistance to environmental degradation, underscoring their importance in composite material design and optimization [219].

A thorough understanding of the microstructure of NFCs is essential for tailoring their properties and performance through advanced material design, processing techniques, and composite formulation strategies. Advanced characterization methods, including scanning electron microscopy, atomic force microscopy, and X-ray diffraction, enable the detailed analysis and visualization of the microstructural features, facilitating informed decision-making in composite material development and application. Figure 12 gives the scanning electron (SE) micrographs of different natural fibers [220].

![Figure 12

SE micrographs of natural lignocellulosic fibers: (a) sisal, (b) bamboo, (c) coir, and (d) piassava. Adopted from ref. [220] with permission. Copyright ASM 2011. (Open Access CC by-NC 2.0).](/document/doi/10.1515/rams-2024-0057/asset/graphic/j_rams-2024-0057_fig_012.jpg)

SE micrographs of natural lignocellulosic fibers: (a) sisal, (b) bamboo, (c) coir, and (d) piassava. Adopted from ref. [220] with permission. Copyright ASM 2011. (Open Access CC by-NC 2.0).

6 Scope and challenges of NFCs

The potential scope and challenges surrounding NFCs represent a multifaceted landscape of opportunities and obstacles. Within the automotive sector, these composites offer a compelling solution for manufacturers seeking to enhance the efficiency and sustainability of their vehicles. By utilizing natural fibers in components like dashboards, door trims, and seat backs, automakers can achieve weight reduction, thereby improving fuel efficiency and reducing carbon emissions [7]. Furthermore, the composites' acoustic insulation properties and aesthetic appeal make them an attractive alternative to traditional materials [221].

In the realm of construction and infrastructure [222], NFCs present versatile applications, particularly in reinforcing cementitious materials like fiber-reinforced concrete. These composites bolster crack resistance and flexural strength, making them valuable additions to various construction elements such as roofing materials, wall claddings, and insulation panels. Their lightweight nature and thermal insulation capabilities align well with the growing demand for eco-conscious building practices, offering a sustainable alternative to conventional materials [10].

In packaging and consumer goods, NFCs are increasingly favored for their sustainability and functionality. They serve as viable alternatives to traditional packaging materials, offering strength, moisture resistance, and thermal insulation. From biodegradable containers and trays to household appliances and furniture, these composites are making strides in the consumer goods market, combining durability with environmental friendliness [11].

Despite their potential benefits, NFCs encounter several challenges that hinder their widespread adoption. One critical obstacle is the availability and sourcing of quality fibers. Securing a consistent supply of fibers with the desired attributes poses logistical challenges, as it depends on factors such as geography, agricultural practices, and seasonal variations. Efforts to foster sustainable cultivation methods and establish robust supply chains are underway, but achieving reliable sourcing remains a complex endeavor.

Another challenge lies in addressing the inherent moisture absorption and durability issues associated with natural fibers. Moisture absorption can lead to dimensional changes, mechanical property degradation, and eventual composite deterioration, particularly in applications exposed to outdoor environments. Strategies such as surface treatments and chemical modifications are being explored to mitigate moisture absorption and enhance the long-term durability of NFCs.

Standardization and quality control present additional hurdles in the widespread adoption of NFCs. Variability in fiber attributes, processing techniques, and composite properties complicates efforts to establish consistent testing protocols and performance benchmarks. Initiatives aimed at devising standardized testing methods and quality control procedures specific to these composites are essential to ensure their reliability and market acceptance.

Furthermore, market adoption and cost efficiency pose significant challenges for NFCs. Despite their environmental advantages, perceived performance limitations and higher costs compared to traditional materials can hinder widespread acceptance. However, advancements in production techniques, economies of scale, and increasing recognition of environmental benefits are expected to improve the cost-efficiency of these composites, making them more competitive in the market.

NFCs offer promising avenues for sustainable material innovation across various industries, addressing the challenges they face is crucial for their broader integration. Continued research and development efforts aimed at optimizing their performance, sustainability, and cost-effectiveness will be pivotal in realizing their full potential as eco-friendly alternatives to conventional materials. The schematic of the potential scope of the synthesis, characterization and applications of NFCs is given in Figure 13 [223].

![Figure 13

Potential scope of NFCs. Adopted from ref. [223]. Copyright Sustainable Polymer and Energy 2023. (Open Access CC BY NC 4.0).](/document/doi/10.1515/rams-2024-0057/asset/graphic/j_rams-2024-0057_fig_013.jpg)

Potential scope of NFCs. Adopted from ref. [223]. Copyright Sustainable Polymer and Energy 2023. (Open Access CC BY NC 4.0).

7 Conclusion

The conclusions drawn from this review underscore the pivotal role of NFRPCs in addressing pressing environmental concerns and advancing sustainable material engineering. These composites offer a promising alternative to conventional materials by leveraging renewable resources and biodegradability.

One of the key insights gleaned from this review is the significance of enhancing the mechanical properties of NFRPCs to meet the demands of various applications. Achieving robust adhesion between fibers and polymers, often through treatments like alkali treatment, emerges as a critical strategy in this pursuit.

Moreover, as the field of NFRPCs continues to evolve, there is a pressing need to comprehensively assess the biodegradation behavior of these materials. Understanding the degradation process and timeline is essential for evaluating their long-term environmental impact and ensuring their compatibility with circular economy principles.

The review identifies several areas for future research and development. These include refining processing methods, innovating novel reinforcement techniques, establishing standardized quality control measures, conducting comprehensive life cycle assessments, and advancing recycling technologies specific to composites. Collaboration among academia, industry, and governmental bodies is deemed crucial to drive progress in these areas and expedite the adoption of NFRPCs on a larger scale.

Ultimately, by addressing these research imperatives and fostering widespread dissemination of findings, the potential of NFRPCs to contribute to a greener and more sustainable future can be fully realized. Continued exploration and enhancement of these materials hold the promise of transforming material engineering practices toward greater ecological mindfulness and sustainability.

Acknowledgments

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for funding part of this research work (Project under grant number RGP2/358/45), specifically for data collection and preliminary analysis.

-

Funding information: The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for funding part of this research work (Project under grant number RGP2/358/45), specifically for data collection and preliminary analysis.

-

Author contributions: Nagaraja Santhosh: writing – original draft and writing – review and editing; Bindiganavile Anand Praveena: writing – original draft and writing – review and editing; Ashwin C Gowda: writing – original draft and writing – review and editing; Alaauldeen A. Duhduh: writing – original draft and writing – review and editing; Ali A. Rajhi: writing – original draft and writing – review and editing; Sagr Alamri: writing – original draft and writing – review and editing; Parveen Berwal: writing – original draft and writing – review and editing; Mohammad Amir Khan: writing – original draft and writing – review and editing; and Anteneh Wogasso Wodajo: writing – original draft and writing – review and editing. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Banea, M. D. Natural fibre composites and their mechanical behaviour. Polymers, Vol. 15, 2023, id. 1185.10.3390/polym15051185Search in Google Scholar PubMed PubMed Central

[2] Prasad, V., A. Alliyankal Vijayakumar, T. Jose, and S. C. George. A comprehensive review of sustainability in natural-fiber-reinforced polymers. Sustainability, Vol. 16, 2024, id. 1223.10.3390/su16031223Search in Google Scholar

[3] Hasan, K. M. F., K. N. A. Hasan, T. Ahmed, S.-T. György, M. N. Pervez, L. Bejó, et al. Sustainable bamboo fiber reinforced polymeric composites for structural applications: A mini review of recent advances and future prospects. Case Studies in Chemical and Environmental Engineering, Vol. 8, 2023, id. 100362.10.1016/j.cscee.2023.100362Search in Google Scholar

[4] AL-Oqla, F. M. and M. S. Salit. Material selection of natural fiber composites. In Materials selection for natural fiber composites, Elsevier, Amsterdam, The Netherlands, 2017, pp. 107–168.Search in Google Scholar

[5] Bar, M., R. Alagirusamy, and A. Das. Advances in natural fiber reinforced thermoplastic composite manufacturing: Effect of interface and hybrid yarn structure on composite properties. In Advances in natural fiber composites, Springer International Publishing, Cham, Switzerland, 2018, pp. 99–117.Search in Google Scholar

[6] Shah, D. U., P. J. Schubel, and M. J. Clifford. Modelling the effect of yarn twist on the tensile strength of unidirectional plant fiber yarn composites. Journal of Composite Materials, Vol. 47, 2013, pp. 425–436.Search in Google Scholar

[7] Mallick, P. Fiber-reinforced composites. Dekker mechanical engineering, CRC Press, Boca Raton, FL, USA, 2007, p. 20072757.Search in Google Scholar

[8] Goutianos, S., T. Peijs, B. Nystrom, and M. Skrifvars. Development of flax fiber based textile reinforcements for composite applications. Applied Composite Materials, Vol. 13, 2006, pp. 199–215.Search in Google Scholar

[9] Erden, S. and K. Ho. Fiber reinforced composites. In Fiber technology for fiber-reinforced composites, Elsevier, Amsterdam, The Netherlands, 2017, pp. 51–79.Search in Google Scholar

[10] AL-Oqla, F. M. and S. M. Sapuan. Natural fiber reinforced polymer composites in industrial applications: Feasibility of date palm fibers for sustainable automotive industry. Journal of Cleaner Production, Vol. 66, 2014, pp. 347–354.10.1016/j.jclepro.2013.10.050Search in Google Scholar

[11] Mohammed, L., M. N. M. Ansari, G. Pua, M. Jawaid, and M. S. Islam. A review on natural fiber reinforced polymer composite and its applications. International Journal of Polymer Science, Vol. 2015, 2015, id. 243947.10.1155/2015/243947Search in Google Scholar

[12] Cicala, G., G. Cristaldi, G. Recca, and A. Latteri. Composites based on natural fiber fabrics. In Woven fabric engineering, Dubrovski, P. (Ed.), InTech, London, UK, 2010.10.5772/10465Search in Google Scholar

[13] Keya, K. N., N. A. Kona, F. A. Koly, K. M. Maraz, M. N. Islam, and R. A. Khan. Natural fiber reinforced polymer composites: history, types, advantages and applications. Materials Engineering Research, Vol. 1, No. 2, 2019, pp. 69–87.10.25082/MER.2019.02.006Search in Google Scholar

[14] Jagadeesh, D., K. Kanny, and K. Prashantha. A review on research and development of green composites from plant protein-based polymers. Polymer Composites, Vol. 38, No. 8, 2017, pp. 1504–1518.10.1002/pc.23718Search in Google Scholar

[15] Sahu, P. and M. K. Gupta. A review on the properties of natural fibers and its biocomposites effect of alkali treatment. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, Vol. 234, No. 1, 2020, pp. 198–217.10.1177/1464420719875163Search in Google Scholar

[16] Pickering, K. L., M. G. A. Efendy, and T. M. Le. A review of recent developments in natural fiber composites and their mechanical performance. Composites, Part A: Applied Science and Manufacturing, Vol. 83, 2016, pp. 98–112.Search in Google Scholar

[17] Chermoshentseva, A. S., A. M. Pokrovskiy, and L. A. Bokhoeva. The behavior of delaminations in composite materials – Experimental results. IOP Conference Series: Materials Science and Engineering, Vol. 116, 2016, id. 012005.10.1088/1757-899X/116/1/012005Search in Google Scholar

[18] Stevens, C. V. Series preface, In: Müssig, J. (Ed.), John Wiley & Sons, Ltd., Chichester, UK, 2010.Search in Google Scholar

[19] Praveena, B. A., S. Vijay Kumar, H. N. Manjunath, B. Sachin, S. P. S. Yadav, B. R. Lochan, et al. Investigation of moisture absorption and mechanical properties of natural fiber reinforced polymer hybrid composite. Materials Today: Proceedings, Vol. 45, No. Part 9, 2021, pp. 8219–8223.10.1016/j.matpr.2021.04.254Search in Google Scholar

[20] Imre, B. and B. Pukánszky. Compatibilization in bio-based and biodegradable polymer blends. Eur Polym J, Vol. 49, 2013, pp. 1215–1233.10.1016/j.eurpolymj.2013.01.019Search in Google Scholar

[21] Niaounakis, M. Biopolymers: Processing and Products, Elsevier, Amsterdam, The Netherlands, 2014.Search in Google Scholar

[22] Mattew, A. and R. Bell. Dupont’s renewably sourced high performance polymers. In Proceedings of the SPE ANTEC, Indianapolis, IN, USA, 23–25 May 2016.Search in Google Scholar

[23] Rohan, T., B. Tushar, and G. T. Mahesha. Review of natural fiber composites. IOP Conference Series: Materials Science and Engineering, Vol. 314, 2018, id. 012020.10.1088/1757-899X/314/1/012020Search in Google Scholar

[24] Carus, M. Market study on bio-based polymers in the world. Capacities, production and applications: Status Quo and Trends towards 2020. In Proceedings of the Fifth German WPC Conference, Cologne, Germany, 10–11 December 2013.Search in Google Scholar

[25] Koronis, G., A. Silva, and M. Fontul. Green composites: A review of adequate materials for automotive applications. Composites, Part B: Engineering, Vol. 44, 2013, pp. 120–127.Search in Google Scholar

[26] Smith, G. F. New developments in producing more functional and sustainable composites. In Management, recycling and reuse of waste composites, Elsevier, Amsterdam, The Netherlands, 2010, pp. 425–439.10.1533/9781845697662.4.425Search in Google Scholar

[27] Pickering, S. J. Thermal methods for recycling waste composites. In Management, recycling and reuse of waste composites, Elsevier, Amsterdam, The Netherlands, 2010, pp. 65–101.10.1533/9781845697662.2.65Search in Google Scholar

[28] Thyavihalli Girijappa, Y. G., S. Mavinkere Rangappa, J. Parameswaranpillai, and S. Siengchin. Natural fibers as sustainable and renewable resource for development of eco-friendly composites: a comprehensive review. Frontiers in Materials, Vol. 6, 2019, id. 226.10.3389/fmats.2019.00226Search in Google Scholar

[29] Thakur, V. K. and A. S. Singha. Mechanical and water absorption properties of natural fibers/polymer biocomposites. Polymer-Plastics Technology and Engineering, Vol. 49, 2010, pp. 694–700.10.1080/03602551003682067Search in Google Scholar

[30] Singha, A. S. and V. K. Thakur. Fabrication and characterization of H. sabdariffa fiber-reinforced green polymer composites. Polymer-Plastics Technology and Engineering, Vol. 48, 2009, pp. 482–487.10.1080/03602550902725498Search in Google Scholar