Abstract

Concrete is the second-most used material globally and significantly impacts the environment by emitting a large amount of carbon dioxide (CO2). This scientometric review investigates the sustainable use of waste glass (WG) in concrete. Our study examines the impact of waste glass powder (WGP) on the mechanical and fresh characteristics of concrete and its environmental implications, enhanced by a machine learning prediction model. We observed a progressive increase in research activity on WGP-based concrete since 2000, indicating the growing interest in this area. The primary focus areas are engineering and material science, reflecting the application potential, structural performance, and material properties of WGP-based concrete. Our discussions highlight the significant benefits of WGP in concrete, including its potential to reduce landfill usage, environmental pollution, and enhance properties such as strength, sulfate resistance, alkali–silica reaction resistance, and freeze–thaw resistance. The review also explores the microstructure of glass powder (GP)-based concrete, illuminating the complex interactions between glass particles and the concrete matrix, which influence the material’s overall performance. Environmental impact assessments underscore the necessity for sustainable construction practices and waste reduction. Utilizing machine learning prediction models helps optimize the composition of GP-based concrete, thus enhancing material performance and durability. This review provides a comprehensive analysis of using WG in concrete, contributing to the field’s understanding and informing future research and innovations to optimize WG use in concrete applications.

1 Introduction

Everything in the world is becoming more environmentally friendly and sustainable in recent years. Concrete is the second-most useful material in the world, right behind water [1,2]. Concrete continues to be the substance that is utilized in construction most frequently. Previous researchers [3,4,5] carried out a study and calculated that 11.5 billion tons of concrete are consumed worldwide, or roughly 1.7 tons for every person on the planet. Concrete is one of the largest hurdles to a more friendly environment since it releases the majority of carbon dioxide (CO2) into the atmosphere. Torres-Carrasco et al. [6] have done research, finding a conclusion that 1.7 tons of raw materials are needed to produce 1 ton of cement, and the burning of those raw materials and fuel releases 0.8 tons of CO2 back into the atmosphere. Because there are no concrete eco-friendly alternatives available now in our industry, the usage of concrete is constantly growing. Due to its high compressive strength, the concrete utilization is increasing day by day. China alone has used more concrete than US in the twentieth century. According to Li [7], the results indicated that the amount of waste concrete reached 239 million tonnes in 2010 and is projected to reach 638 million tonnes in 2020, showing an average annual growth rate of 8%. In spite of this, the use of concrete is not slowing down. The usage of concrete in our society is one of the main causes of the extreme rise in the planet’s temperature that the globe is currently experiencing. The generation of greenhouse gases and subsequent climate change are both considerably increased by the construction industry [8]. As mentioned in the study by Ma et al. [9], high temperatures have been recognized as a significant factor in causing severe damage to the micro- and meso-structure of concrete. This results in a decrease in overall mechanical properties and may harm the concrete’s ability to maintain structural integrity, including spalling and exposure of reinforcement bars, particularly in fire situations. Spalling can expose the reinforcement bars to corrosion, which may degrade the bond strength and decrease the concrete structure’s ability to bear weight [10,11]. The concrete absorbs most of the heat coming from the sun and the water absorption of the paved surface also decreases due to this. Water level of the ground also decreases by the paved surfaces like street pathways and other concrete surfaces. The two countries that create the most CO2 globally are the United States and China due to the presence of large industries in these countries. About 60% of the cement produced and consumed globally is in China [12,13], while the USA produces about 86 million metric tons per year [14,15]. Concrete is the main cause for most of the CO2 emission into the atmosphere. While preparing concrete, when its reaction takes place, around 0.93 pound of CO2 is release while preparing 1 pound of concrete which is very high and dangerous for the environment. Concrete emits roughly 8% of world CO2 into the atmosphere. Recycling rate of glass is improving day by day. Some of the countries has up to 90% recycling rate of glass.

Recognizing the urgent need to address these environmental concerns, our scientometric review focuses on the utilization of glass powder (GP) as a sustainable alternative in concrete production. The use of recycled glass has been considered in the construction sector’s circular economy, focusing on its benefits for concrete and addressing challenges and opportunities for sustainable construction [16]. By incorporating waste glass (WG) into concrete mixtures, we can reduce the demand for traditional raw materials, such as sand and gravel, while simultaneously diverting glass waste from landfills and minimizing its harmful impact on the environment. According to Liu et al. [17], due to their non-biodegradable nature, these glass wastes cover vast areas of open space and seriously harm the ecosystem through air, water, and land pollution. Nearly 10 million tons of glass is produced every month for different purposes and the recycle rate of glass is very low. Ruth and DellAnno [18] conducted a study, in which they have concluded that 1.2 tons of nonrenewable raw materials are used to produce one ton of container glass. Glass is mostly recycled by burning in the kiln to mold it for the future use, when the glass is burned, it requires high amount of energy and it pollutes environment as well. In previous research [10,19,20], it is discussed how recycling glass could reduce the energy use and environmental impact of glass production and disposal. Glass is composed of different chemicals and when it is burned, different kinds of chemical smokes are released into the atmosphere which is very dangerous for most of the living things in the world. EID [19] discussed that glass is brittle and can break easily, causing injury or waste. According to Sundaram et al. [21], most glass waste could be periodically recycled without losing any of its chemical or physical characteristics, but the key challenge is the variety in color and quality of the glass collected. There is no completely safe method to recycle glass. In advanced kilns, water is used to clean the smoke, but chemicals from the process mix with the water, which then seeps into the ground and contaminates groundwater, negatively impacting both the land and water quality. Only 60% of the glass is recyclable, due to different colors and chemicals used in glass, it cannot be recycled by only burning the glass. The non-recyclable glass is dumped into landfill and in the ocean. By using GP in concrete, it will not affect environment as much as when glass is burned, which emits most of the CO2 in the atmosphere. According to Jani and Hogland [22], incorporating WG in cement and concrete production offers several benefits such as conservation of natural resources, energy and cost savings, and reduction in CO2 emissions and other greenhouse gases. According to Guo et al. [23], every year, more glass is produced as a result of the rising standard of living and the increasing speed of industrialization, which results in more glass waste ending up in landfills. The natural resources can be preserved, and the glass can be recycled without emitting hazardous chemical smoke into the atmosphere, when the glass replaces in part the cement and fine and coarse aggregates.

Waste glass powder (WGP) concrete has a number of beneficial qualities, as shown in Figure 1. First, it presents an effective cost-saving solution as the GP is a byproduct of glass manufacturing, readily available at a lower cost compared to conventional cementitious materials [24]. Additionally, the inclusion of WGP enhances the hydration process in concrete, leading to improved strength and durability concluded by previous studies [25,26,27]. Acting as a pozzolanic material, it reacts with calcium hydroxide when mixed with water, forming additional cementitious compounds. Another notable benefit is the increased resistance of WGP concrete against chemical attacks. Structures made with this type of concrete exhibit enhanced durability, as they are less susceptible to corrosion caused by chemicals or aggressive substances. By using WGP in concrete, pollution can be reduced as glass waste is diverted from landfills, effectively minimizing the environmental impact associated with glass disposal. Furthermore, WGP concrete is considered environmentally friendly. By partially substituting cement with WGP, the reliance on fresh raw resources is decreased. As a result, the carbon emissions associated with concrete production are lowered, contributing to a reduction in CO2 emissions. This method encourages sustainability and helps in the preservation of natural resources, including clay and limestone, which are commonly utilized in the manufacture of cement. Finally, WGP concrete exhibits improved resistance to freeze and thaw (FT) cycles, making it suitable for colder climates. The incorporation of GP helps minimize the risk of cracking and deterioration caused by repeated FT cycles. Overall, the multiple benefits of WGP concrete, including cost savings [28], improved hydration [29], chemical resistance [30], pollution reduction [31], eco-friendliness [32], CO2 reduction [33], conservation of natural resources [34], and resistance against FT [35], make it a desirable choice for environmentally friendly building techniques.

Benefit of WGP concrete.

The scientometric review for this study is to examine the impacts of incorporating GP into concrete, emphasis on how it affects the environment and how the concrete’s mechanical and fresh properties are affected. GP, when recycled or disposed improperly in water or land, can have detrimental effects on the environment. Burning glass releases harmful chemicals into the atmosphere [8]. However, there are significant environmental advantages of using glass waste in the production of geopolymer concrete. These include conserving natural resources, conversion of landfill waste into useful products, reduction in CO2 and greenhouse gas emissions, promotion of sustainable building practices, and significant energy and cost savings. Traditionally, concrete production relies heavily on cement, fine aggregate, and coarse aggregate, which are obtained by crushing natural resources from the earth. This leads to a rapid depletion of valuable natural resources [36]. By incorporating GP into concrete, the need for burning is eliminated, making it an environmentally friendly alternative. Utilizing WG in concrete not only avoids disposal in landfills but also contributes to resource conservation [37]. In addition, testing the effects of GP on newly formed characteristics is another goal of its use in concrete [38], such as workability [39] and setting time [40], as well as the mechanical properties [39], including compressive [41], tensile [42], and flexural strengths [43]. Understanding how GP affects these properties is crucial for sustainable construction practices. The primary focus is to reduce the reliance on natural aggregates and maximize waste recycling. GP can be used as a cementitious material, substituting both fine and coarse cement in specific applications [44] and coarse aggregates [45] in others. Due to its widespread household usage and disposal in landfills [46], GP is readily available and cost-effective to procure. To use glass in concrete, it is crushed into a fine powder form, ensuring its suitability for concrete applications. The objective of the scientometric review is to assess the environmental effects of utilizing GP in concrete, considering its effects on recycling and incorrect disposal. In order to maximize sustainable construction techniques, the fresh and mechanical qualities of the final concrete are also prioritized. This is done by minimizing the use of natural aggregate and maximizing waste recycling [47]. The availability and cost-effectiveness of GP make it a viable option for incorporating recycled materials into concrete production.

The utilization of WG in concrete represents a pivotal area of research within sustainable construction practices. This review holds substantial importance as it systematically synthesizes and analyzes the application of WGP, a largely underutilized by-product, in concrete, contributing to environmental sustainability and innovation in construction materials. By investigating the integration of WG into concrete, this study addresses a significant gap in current construction practices that often overlook the potential of recycled materials in reducing carbon footprints and enhancing material properties. The primary contribution of this review to the existing body of knowledge lies in its comprehensive analysis of how WGP influences the mechanical and fresh properties of concrete. Through a detailed scientometric analysis, this review highlights emerging trends, evaluates the effectiveness of past and current methodologies, and provides a new perspective on the potential scalability of such practices. This not only aids in advancing academic understanding but also serves as a crucial resource for industry practitioners seeking to implement more sustainable and cost-effective materials. Furthermore, this review tackles the problem of industrial waste, specifically the underutilization of glass waste, which has been a longstanding environmental issue. By mapping out the benefits and challenges associated with using WG in concrete, the review sets a foundation for future research and development in this area. The objectives of this review are to delineate the current state of research on WG in concrete, to identify and fill gaps in the knowledge, and to suggest directions for future research that could lead to wider adoption of this sustainable practice in the construction industry. By achieving these goals, this review intends to foster a deeper understanding of the material’s capabilities and encourage its incorporation into mainstream construction practices, thus promoting greater environmental responsibility and innovation in building materials.

2 Methods

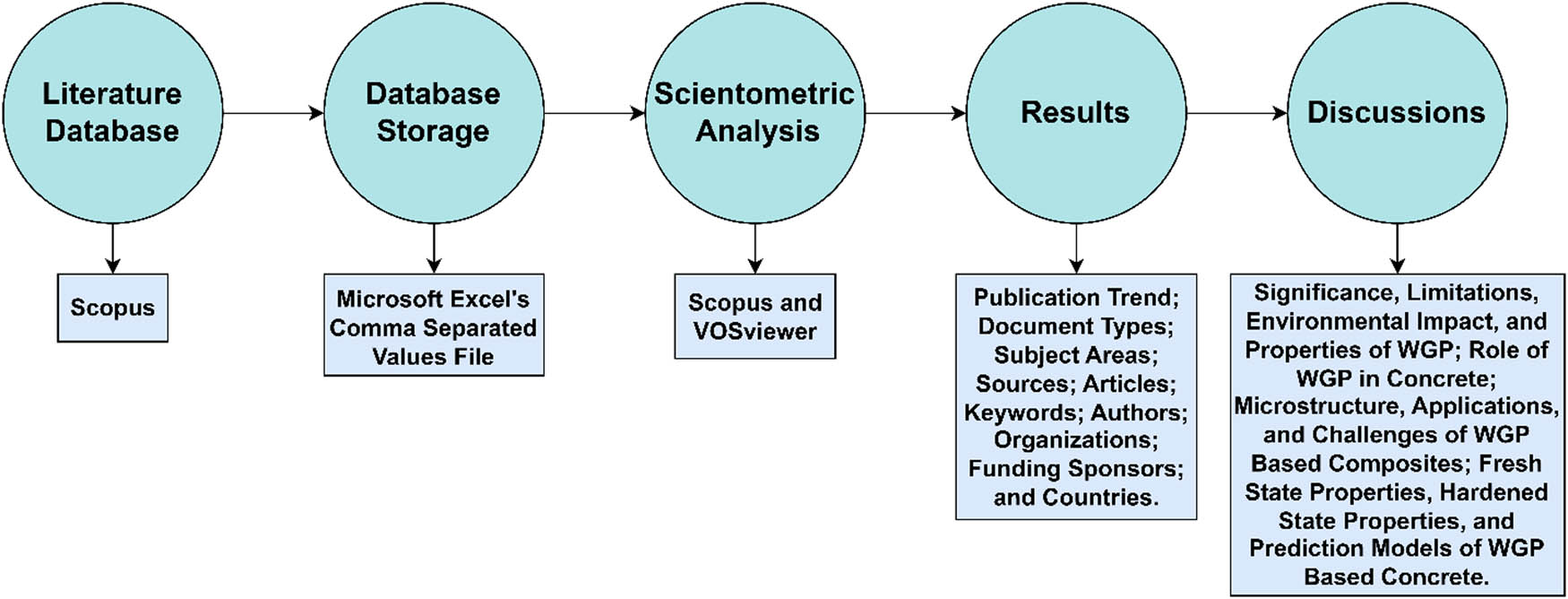

The methodology for reviewing WGP-based concrete, as represented in Figure 2, involves a series of systematic steps. First, a thorough search is conducted in a reputable literature database, such as Scopus, to gather relevant scholarly articles and research papers. The information extracted from the literature database is then stored and organized in a Microsoft Excel comma-separated value file for efficient data management. Subsequently, scientometric analysis is performed using Scopus and VOSviewer, enabling the visualization and examination of publication trends, subject areas, sources, articles, organizations, funding sponsors, and countries associated with WGP-based concrete research. Finally, the obtained results are presented, encompassing various aspects such as publication trends over time, distribution of research across subject areas, prominent literature sources, article counts, contributing organizations, funding sources, and active countries in the field of WGP-based concrete research. The review seeks to provide a thorough knowledge of the research landscape through this rigorous technique, identify key contributors, and shed light on the development and impact of WGP-based concrete.

Review methodology of WGP-based concrete.

3 Results

The findings of the scientometric review on the use of recycled glass in concrete for green building, as part of the aim, encompass a comprehensive analysis of various key aspects. First, publication trends over time are examined, providing insights on the development and evolution of this field’s research. The distribution of research across subject areas helps identify the diverse areas of focus within the domain of WGP-based concrete. The review also highlights prominent literature sources, showcasing the key references and resources that have contributed significantly to the body of knowledge. Additionally, article counts offer a quantitative measure of the research output and productivity in the field. The analysis also encompasses identifying the contributing organizations, shedding light on the institutions and entities actively involved in WGP-based concrete research. Moreover, the review explores funding sources, providing an understanding of the financial support that drives research in this area. Finally, the examination of active countries in WGP-based concrete research highlights the global distribution and participation, offering insights into the geographical spread of research endeavors. These findings add to our understanding of sustainable building techniques in this area by offering a thorough analysis of the use of WG in concrete.

3.1 Publication trend

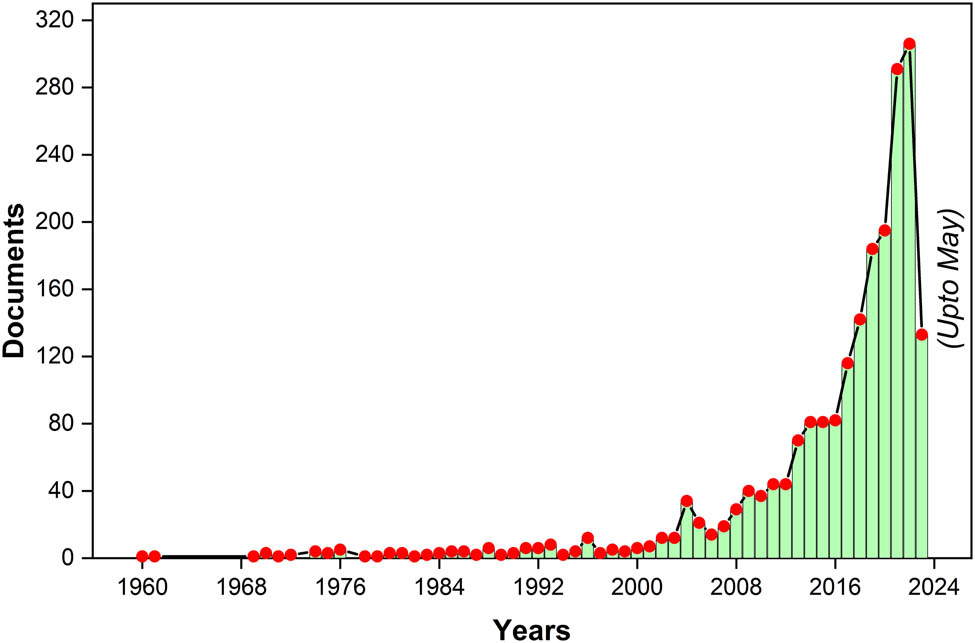

According to Chadegani et al. [48], a thorough comparison of databases such as Web of Science and Scopus, which classify journals based on output and total citations, reveals the latest research on the use of discarded glass in concrete. According to Markoulli et al. [49], science visualization is used in scientometric reviews, a method developed by researchers for analyzing bibliometric data with diverse objectives. The trend of annual publication patterns related to WGP-based concrete, as illustrated in Figure 3, exhibits a remarkable and progressive increase in research activity over time. Upon analyzing the data from 1960 to 2000, it becomes evident that the number of publications per year during this period was relatively low, averaging less than 10. However, a significant shift occurred starting from 2000 to 2008, as the number of publications experienced a notable surge, reaching nearly 30 per year. Subsequently, from 2008 to 2016, there was a substantial improvement in research output, with the number of published documents skyrocketing to approximately 80 per year. This upward trajectory persisted, with a remarkable growth observed from 2016 to 2024, as exemplified by the consistently increasing number of publications each year. The year 2017 witnessed a count of 80 publications, followed by a substantial jump to 120 in 2018, 140 in 2019, 170 in 2020, 290 in 2021, and 300 in 2022. Up until May 2023, approximately 150 additional publications have already been recorded, indicating a continued surge in research activity. It is predicted that this year’s total number of publications will exceed 300 based on current patterns, further reinforcing the escalating interest and engagement in research related to WGP-based concrete. This trend underscores the increasing importance of this innovative material in the field of sustainable construction and highlights its potential for driving positive change.

Annual publication pattern of WGP-based concrete documents.

3.2 Document types

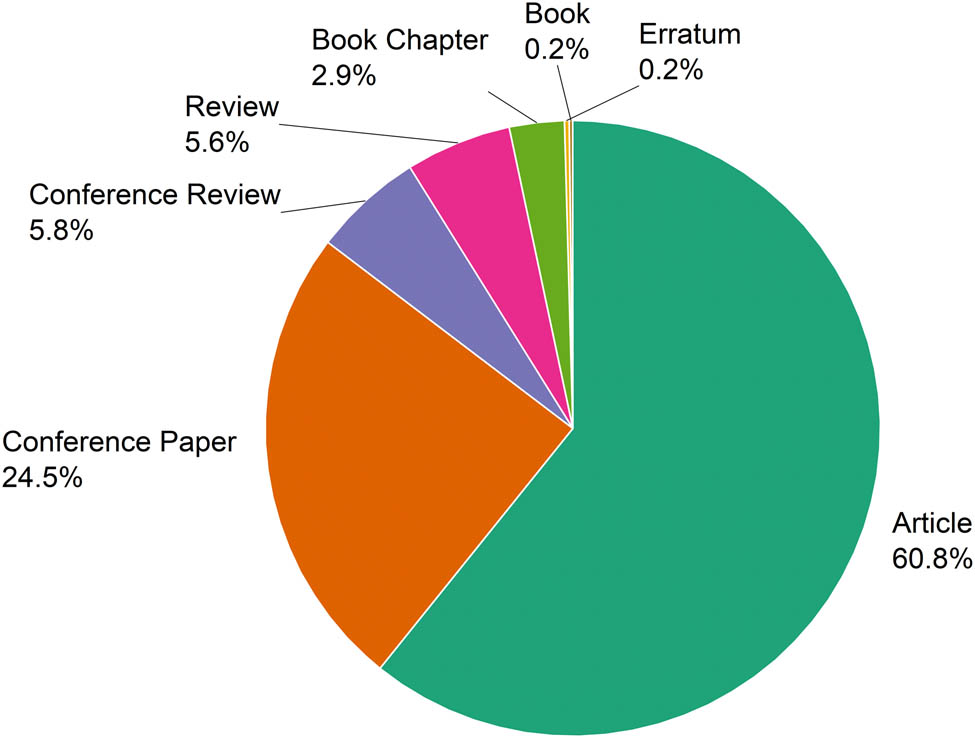

According to Qin et al. [50], the scientific mapping review included analysis of document sources, keyword co-occurrence, citation networks, co-authorship, publications, bibliometric overlap, and country contributions. The distribution of WGP-based concrete records among various categories is shown in Figure 4. The analysis reveals that articles constitute the majority, accounting for 60% of the documents. Conference papers comprise 24.5% of the total, indicating a significant contribution from conference proceedings in disseminating research in this area. Conference review papers make up 5.8% of the documents, reflecting the importance of critical assessments and evaluations within conference settings. Review papers, which provide comprehensive summaries and analyses of existing literature, represent 5.6% of the documents, indicating their role in synthesizing knowledge and highlighting key findings in WGP-based concrete research. Additionally, there are book chapters, comprising 2.9% of the documents, suggesting the inclusion of this topic within book compilations. Books and erratum make up a small fraction, each accounting for 0.2% of the total. This distribution across different document types signifies the diverse range of scholarly outputs, including original research articles, conference contributions, reviews, book chapters, and books, contributing to the knowledge base on WGP-based concrete.

Types of WGP-based concrete documents.

3.3 Subject areas

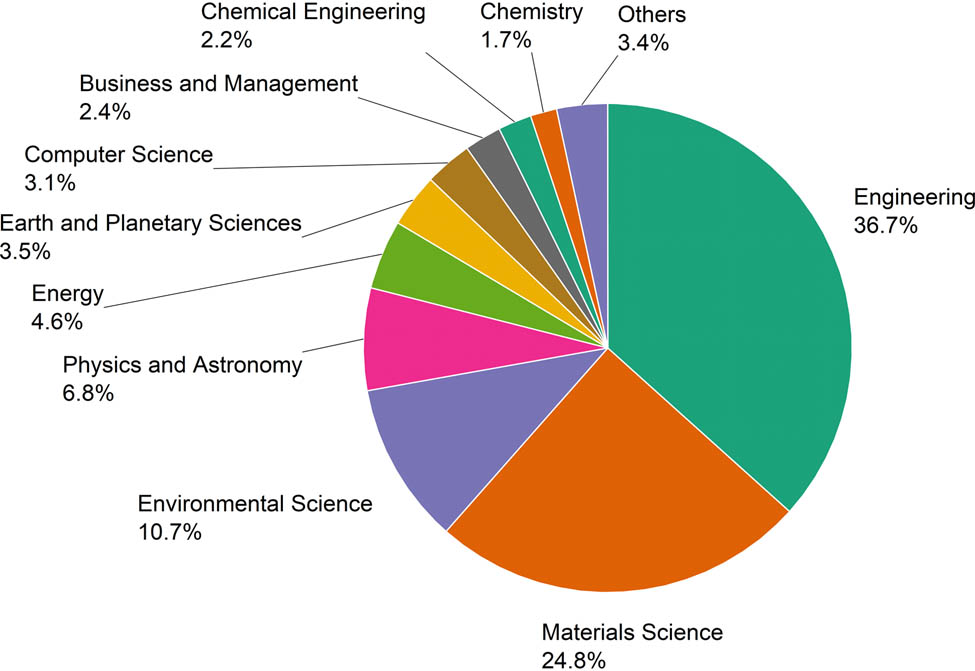

In order to identify the most important study fields, the Scopus database was examined using the Scopus analyzer. Figure 5 presents a pie chart illustrating the distribution of subject areas in WGP-based concrete research. The analysis reveals that engineering represents the largest portion, comprising 36.7% of the chart. This highlights the close relationship between WGP-based concrete and engineering disciplines, emphasizing the engineering-driven approach in exploring its applications, structural performance, and construction techniques. Material science follows closely, accounting for 24.8% of the distribution, indicating the significance of understanding the material properties, durability, and structural behavior of WGP-based concrete. This field of study is essential for maximizing the material’s composition, characteristics, and performance and assuring its compatibility for various construction applications. The presence of environmental science at 10.7% underscores the increasing focus on sustainable construction practices. WGP-based concrete provides advantages for the environment by lowering waste production, conserving natural resources, and minimizing carbon emissions associated with traditional concrete production. The inclusion of physics and astronomy at 6.8% highlights the scientific principles applied to study the physical properties, interactions, and behavior of WGP-based concrete. Energy-related research at 4.6% reflects the growing emphasis on energy efficiency in the construction sector, with WGP-based concrete offering potential benefits in reducing energy consumption and carbon footprint. The presence of earth and planetary science, computer science, business and management, chemical engineering, and chemistry in the chart signifies the interdisciplinary nature of WGP-based concrete research. These subject areas contribute expertise in areas such as geotechnical aspects, computational modeling, sustainability assessment, industrial processes, and chemical interactions, enriching the understanding and development of WGP-based concrete. The diverse subject areas represented in the chart highlight the collaborative and interdisciplinary efforts required for advancing WGP-based concrete as a sustainable construction material.

Subject areas of WGP-based concrete documents.

3.4 Sources

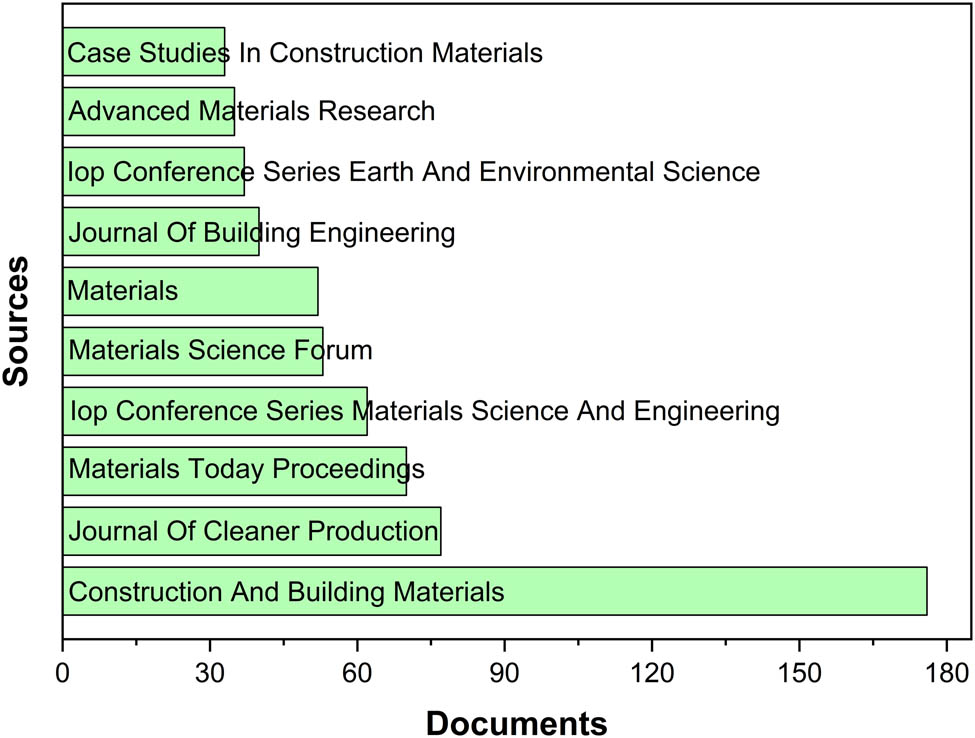

The investigation of growth and innovation may be visualized, thanks to source mapping. These sources provide data within the bounds of particular, predetermined limits. Table 1 presents the sources of literature on WGP-based concrete, along with the corresponding document counts, citation counts, and total link strength. The sources are ranked according to the quantity of papers they contribute to the field. At the top of the list is “Construction and Building Materials,” which accounts for 176 documents. It has received a significant number of citations (7,870) and has a high total link strength (4,825), indicating its influence and impact within the research community. Following closely is the “Journal of Cleaner Production” with 77 documents. It has received a substantial number of citations (3,992) and has a total link strength of 2,710. Other sources, such as “Materials Today: Proceedings,” “IOP Conference Series: Materials Science and Engineering,” “Materials Science Forum,” and “Materials,” also contribute a significant number of documents to the field, with varying citation counts and total link strengths. IOP Conference Series: Materials Science and Engineering, known for publishing conference proceedings, has contributed 62 documents to the field. It has received 232 citations and has a total link strength of 319, indicating its role in disseminating conference-based research on WGP-based concrete. As per Materials Science Forum with 53 published documents, this source has received 179 citations. It has a total link strength of 176, reflecting its contributions to the knowledge base on WGP-based concrete from a materials science perspective. The source “Materials” has contributed 52 documents on WGP-based concrete. It has received 761 citations and demonstrates a total link strength of 1,455, indicating its impact and connectivity within the research field. The “Journal of Building Engineering” has contributed 40 documents on WGP-based concrete, receiving 1,128 citations. With a total link strength of 2,006, it demonstrates strong connections and references within the field of building engineering. The “IOP Conference Series: Earth and Environmental Science” has contributed 37 documents on WGP-based concrete. These publications have received 54 citations, indicating their impact and recognition within the field. With a total link strength of 108, this source demonstrates connections and references to other studies in the realm of earth and environmental science. The source “Advanced Materials Research” has provided 35 documents on WGP-based concrete. These documents have received 38 citations, suggesting a moderate level of recognition. With a total link strength of 4, this source may have fewer connections to other studies in the field. However, it still holds value for exploring specific aspects of WGP-based concrete. The source “Case Studies in Construction Materials” has 33 documents on WGP-based concrete, with 379 citations and a total link strength of 1,563. It offers valuable case studies and practical applications of this material in construction projects. The journal “Resources, Conservation and Recycling” has 31 documents, with 3,514 citations and a total link strength of 1,237, focusing on the sustainable aspects of utilizing waste materials. “Key Engineering Materials” offers 30 documents with 117 citations and a link strength of 129, providing insights into the engineering properties and materials science aspects. “International Journal of Civil Engineering and Technology” features 25 documents, 131 citations, and a link strength of 63, presenting research on civil engineering applications. “Sustainability (Switzerland)” publishes 24 documents, with 266 citations and a link strength of 1,008, emphasizing sustainable practices in WGP-based concrete. “Cement and Concrete Composites” presents 23 documents, with 1,937 citations and a link strength of 1,106, focusing on the composites’ performance and properties. “Waste Management” explores waste management strategies with 21 documents, 2,756 citations, and a link strength of 432. “AIP Conference Proceedings” contains 20 documents, 18 citations, and a link strength of 31, providing conference contributions on the topic. “American Concrete Institute, ACI Special Publication” and “Applied Sciences (Switzerland)” both offer 19 documents, with 24 citations and a link strength of 157, and 172 citations and a link strength of 668, respectively. Finally, “Cement and Concrete Research” presents 19 documents, 3,420 citations, and a link strength of 212, focusing on research in cement and concrete materials. The table presents a diverse range of sources contributing to the literature on WGP-based concrete. These sources address a variety of topics related to the topic, such as engineering, environmental science, materials science, construction and building materials, and cleaner production. The findings suggest a strong emphasis on sustainability, engineering properties, civil engineering applications, and composites’ performance. The high citation counts and total link strengths of certain sources indicate their significant impact and influence within the research community. Overall, these sources collectively contribute to the growing knowledge and understanding of WGP-based concrete, supporting advancements in its applications, properties, and sustainable utilization.

Sources of WGP-based concrete documents

| S. no. | Source | Documents | Citations | Total link strength |

|---|---|---|---|---|

| 1 | Construction and Building Materials | 176 | 7,870 | 4,825 |

| 2 | Journal of Cleaner Production | 77 | 3,992 | 2,710 |

| 3 | Materials Today: Proceedings | 70 | 363 | 1,176 |

| 4 | IOP Conference Series: Materials Science and Engineering | 62 | 232 | 319 |

| 5 | Materials Science Forum | 53 | 179 | 176 |

| 6 | Materials | 52 | 761 | 1,455 |

| 7 | Journal of Building Engineering | 40 | 1,128 | 2,006 |

| 8 | IOP Conference Series: Earth and Environmental Science | 37 | 54 | 108 |

| 9 | Advanced Materials Research | 35 | 38 | 4 |

| 10 | Case Studies in Construction Materials | 33 | 379 | 1,563 |

| 11 | Resources, Conservation, and Recycling | 31 | 3,514 | 1,237 |

| 12 | Key Engineering Materials | 30 | 117 | 129 |

| 13 | International Journal of Civil Engineering and Technology | 25 | 131 | 63 |

| 14 | Sustainability (Switzerland) | 24 | 266 | 1,008 |

| 15 | Cement and Concrete Composites | 23 | 1,937 | 1,106 |

| 16 | Waste Management | 21 | 2,756 | 432 |

| 17 | AIP Conference Proceedings | 20 | 18 | 31 |

| 18 | American Concrete Institute, ACI Special Publication | 19 | 24 | 157 |

| 19 | Applied Sciences (Switzerland) | 19 | 172 | 668 |

| 20 | Cement and Concrete Research | 19 | 3,420 | 212 |

Figure 6 depicts a graphical representation of the sources of WGP-based concrete study. The graph showcases the range of documents contributed by each source, indicating their significance in the field. The source with the minimum number of documents is “Case Studies in Construction Materials,” which accounts for 33 documents. On the other hand, the source with the maximum number of documents is “Construction and Building Materials,” which contributes 176 documents. Other notable sources include “Advanced Materials Research” with 35 documents, “IOP Conference Series: Earth and Environmental Science” with 47 documents, “Journal of Building Engineering” with 40 documents, “Materials” with 52 documents, “Materials Science Forum” with 53 documents, “IOP Conference Series: Materials Science and Engineering” with 62 documents, “Materials Today: Proceedings” with 70 documents, “Journal of Cleaner Production” with 77 documents, and “Construction and Building Materials” with the highest number of 176 documents. The distribution of research efforts among different sources is represented graphically in the graph, which sheds light on the academic contributions made in the area of WGP-based concrete.

Sources of WGP-based concrete documents.

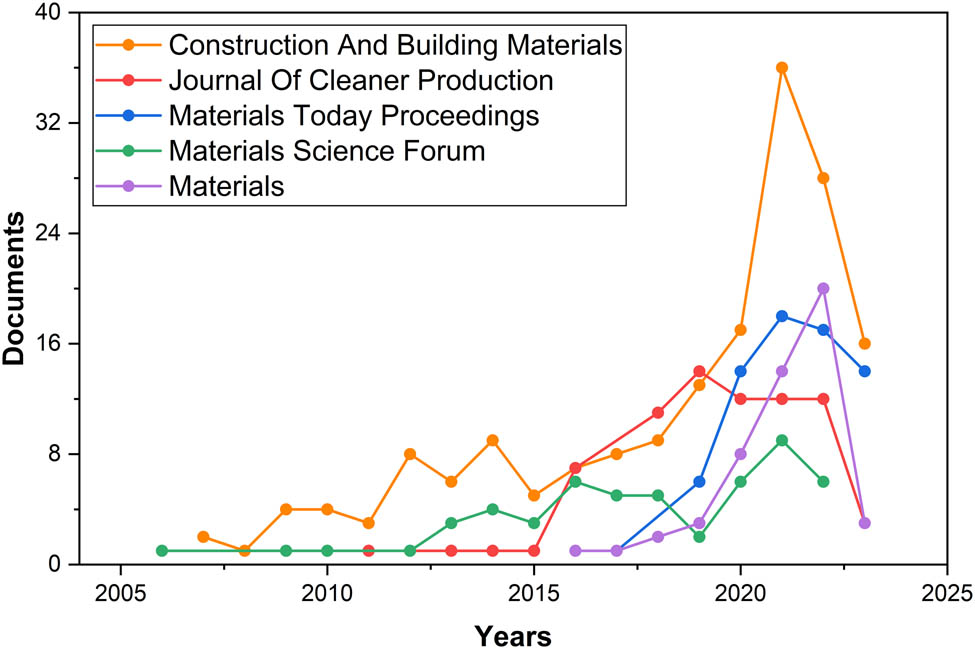

Figure 7 illustrates the publication pattern of sources in WGP-based concrete research over the years. The graph provides insights into the number of publications by each source across different time periods. The source “Construction and Building Materials” shows significant progress, starting with an average of five publications per year from 2005 to 2010. The number of publications increases to around seven per year from 2010 to 2015 and further rises to an average of ten publications per year from 2015 to 2020. Notably, from 2020 to 2023, the average publication rate reaches 26 papers per year, with a peak in 2021 with 36 publications. In contrast, the “Journal of Cleaner Production” initially had around one publication per year from 2005 to 2015, but the average publication rate increases to eight papers per year from 2015 to 2023, with the highest number of publications in 2019. “Materials Today: Proceedings” started its publication in 2017, averaging around 12 papers per year. “Materials Science Forum” began publishing in 2006, with an average of one paper per year from 2006 to 2012, and then increased to around five papers per year from 2012 to 2023. “Materials” published its first paper in 2016, with an average of approximately eight papers per year. The publication pattern graph provides valuable information about the research output and trends of these sources in the field of WGP-based concrete over time.

Publication pattern of the sources of WGP-based concrete documents.

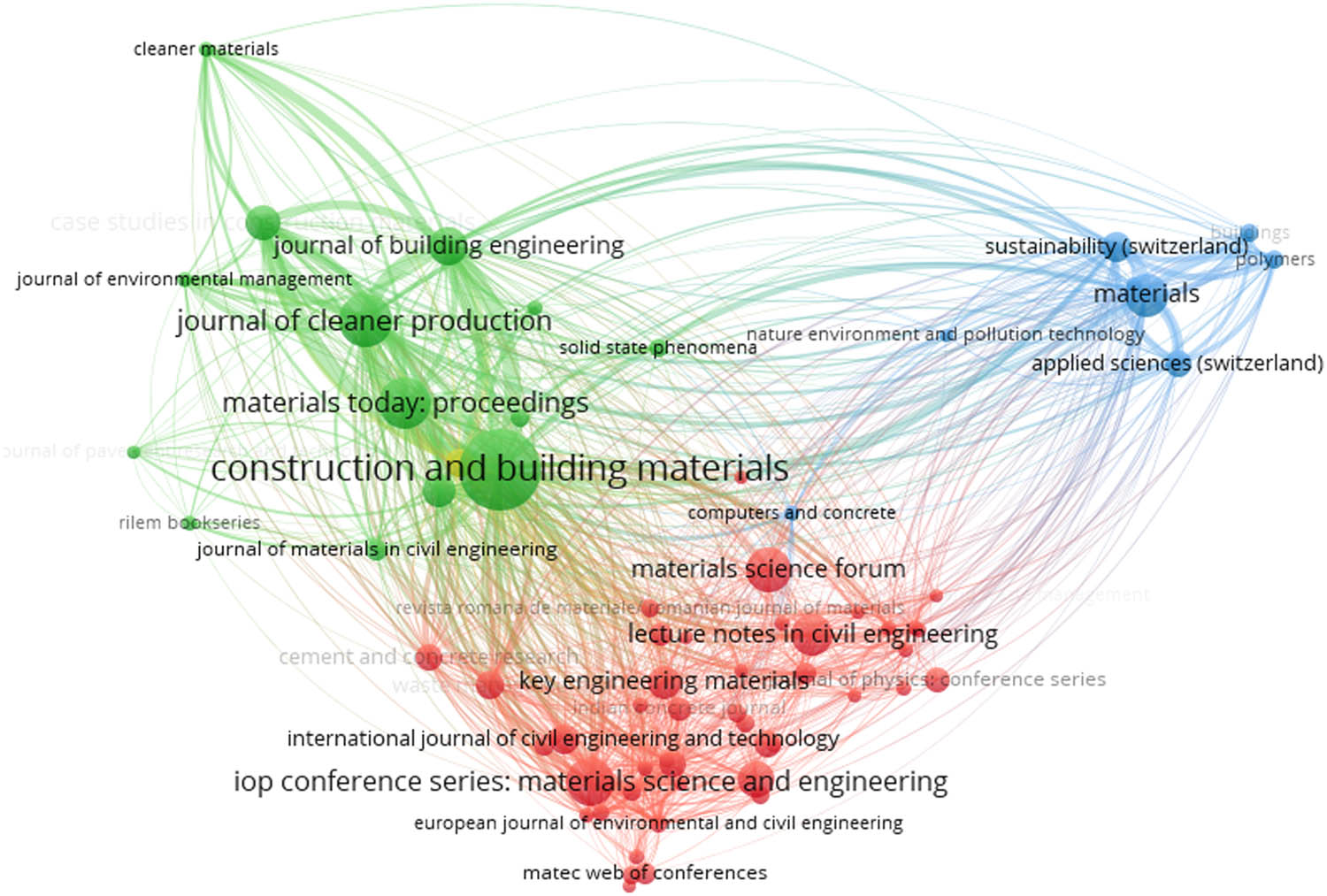

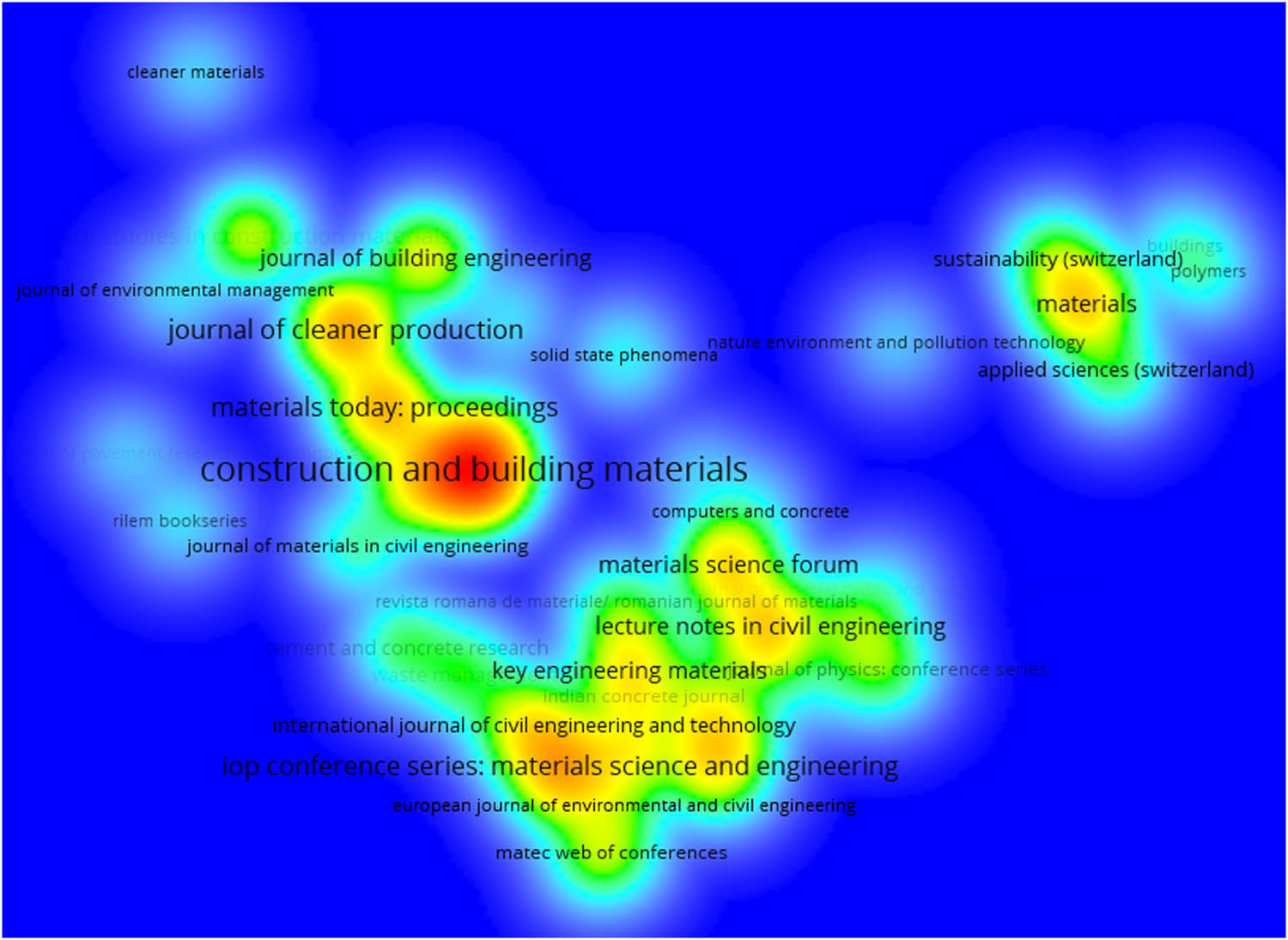

Figures 8 and 9 provide a comprehensive analysis of the network and density mapping of leading sources in WGP-based concrete literature. A network of interconnected dots representing different sources, with the largest dot indicating the highest density observed for the source Construction and Building Materials. This source exhibits extensive connections and collaborations with other sources in the network. Notable sources in the network, represented by dots in different colors, include Journal of Cleaner Production, Materials Today: Proceedings, IOP Conference Series: Materials Science and Engineering, and more, each with distinct roles and characteristics within the network. The analysis of the network and density provides insights into the interconnections and collaborations among these leading sources in the field. A density mapping is provided, with colors representing different levels of density. Red indicates the highest density, yellow represents the intermediate density, and blue represents the lowest density. The mapping reveals that “Construction and Building Materials” is the most densely connected source, demonstrating a high level of collaboration, citations, and interactions within the research community. On the other hand, “Cement and Concrete Research” is the least dense source, indicating a lower level of connectivity and collaboration compared to others. The density mapping helps visualize the varying levels of interconnectedness among the sources, with red indicating strong connectivity and blue indicating weaker connectivity. Figures 8 and 9 offer a comprehensive overview of the network of leading sources in WGP-based concrete literature. Figure 8 highlights the network’s structure and the prominent sources within it, while Figure 9 provides a density mapping that visually represents the levels of interconnectedness among the sources. This combined analysis provides valuable insights into the collaborations and interconnections among these leading sources in the field.

Network mapping of the sources of WGP-based concrete documents.

Density mapping of the sources of WGP-based concrete documents.

3.5 Articles

The scientometric method was used to analyze these articles in order to show the clarity of the overall literature sample, research keywords, publication source, most productive and influential scholars, most-cited articles, nations, and institutions actively involved in the concrete WGP research. Table 2 presents a collection of articles on WGP-based concrete, showcasing their document titles, total link strengths, and citation counts. Among the articles listed, the one titled “The Greening of the Concrete Industry” by Neyer C. in 2009 stands out with the highest number of citations, reaching 986. This article has garnered significant attention and recognition within the research community. On the other hand, the article titled “Microstructural Characterisation” by Torres-Carrasco M. and Puertas F. in 2015 has the lowest number of citations, with a count of 232. In terms of total link strength, the article titled “Waste Materials and By-Products in Concrete” by Siddique R. in 2008 holds the highest value at 25. This suggests a strong interconnection and referencing of this particular article within the field. Conversely, the lowest total link strength is associated with multiple papers, one of which is titled “Studies on Concrete Containing Ground Waste Glass” by Shao et al. in 2000. This indicates a relatively lower level of interconnection and referencing for this group of papers compared to others in the table. The citation counts mentioned in Table 2 for the articles on WGP-based concrete play a crucial role in advancing research in this field. Citations serve as an indicator of the impact and significance of a particular article within the academic community. A higher number of citations suggests that the article has been widely recognized and referenced by other researchers, indicating its influence and contribution to the existing body of knowledge. The information presented in Table 2 provides insights into the citation counts and link strengths of various articles in the field of WGP-based concrete, highlighting the articles that have garnered significant attention and influence within the research community.

Articles of WGP-based concrete

| S. no. | Document | Ref. | Citations | Total link strength |

|---|---|---|---|---|

| 1 | The greening of the concrete industry | [51] | 986 | 1 |

| 2 | Studies on concrete containing ground waste glass | [52] | 525 | 0 |

| 3 | Use of selected waste materials in concrete mixes | [53] | 492 | 0 |

| 4 | Value-added utilization of waste glass in concrete | [54] | 461 | 6 |

| 5 | Properties of concrete containing waste glass | [55] | 442 | 2 |

| 6 | A review on the use of waste glasses in the production of cement and concrete | [56] | 362 | 14 |

| 7 | Studies on mechanical properties of concrete containing waste glass aggregate | [57] | 343 | 0 |

| 8 | Performance of glass powder as a pozzolanic material in concrete: A field trial on concrete slabs | [58] | 324 | 6 |

| 9 | A review on the viable technology for construction waste recycling | [59] | 320 | 1 |

| 10 | Geotechnical and geoenvironmental properties of recycled construction and demolition materials in pavement subbase applications | [60] | 315 | 3 |

| 11 | Recycling of waste glass as a partial replacement for fine aggregate in concrete | [61] | 305 | 5 |

| 12 | A review of waste products utilized as supplements to Portland cement in concrete | [62] | 293 | 7 |

| 13 | Waste glass powder as partial replacement of cement for sustainable concrete practice | [63] | 279 | 4 |

| 14 | Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement | [64] | 266 | 11 |

| 15 | Use of glass waste as an activator in the preparation of alkali-activated slag. Mechanical strength and paste characterization | [65] | 259 | 5 |

| 16 | Utilization of waste glass powder in the production of cement and concrete | [3] | 257 | 0 |

| 17 | Waste glass in the production of cement and concrete – A review | [22] | 248 | 14 |

| 18 | Waste materials and by-products in concrete | [66] | 247 | 25 |

| 19 | Durability of mortar using waste glass powder as cement replacement | [67] | 244 | 12 |

| 20 | Waste glass in the geopolymer preparation. Mechanical and microstructural characterization | [68] | 232 | 5 |

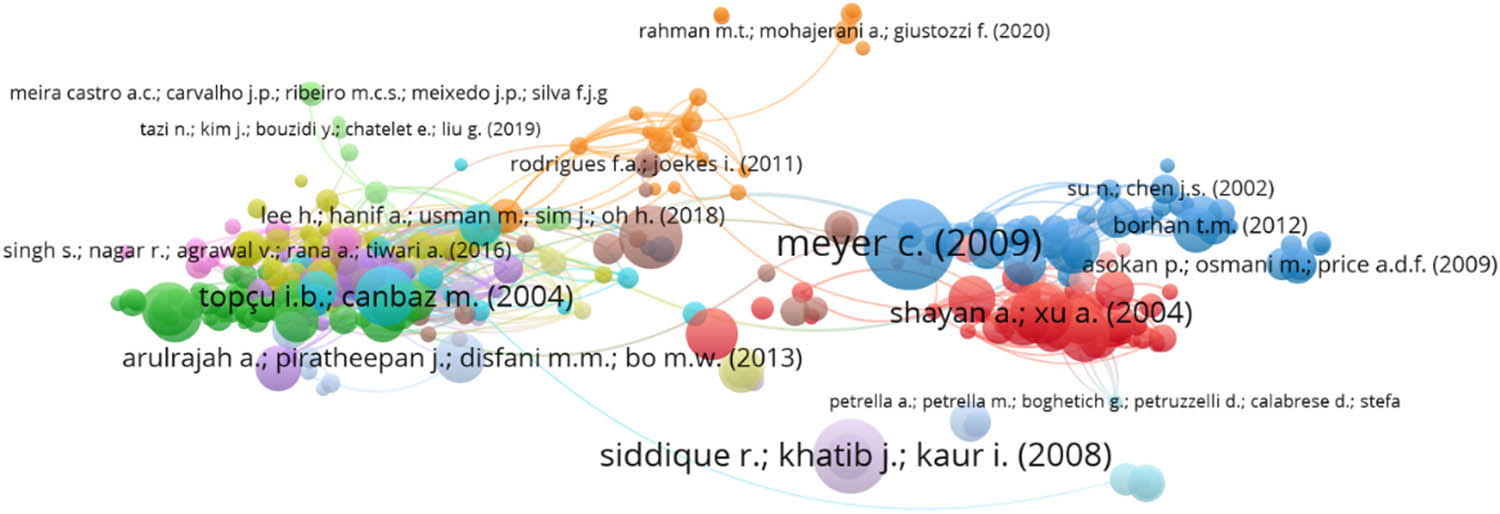

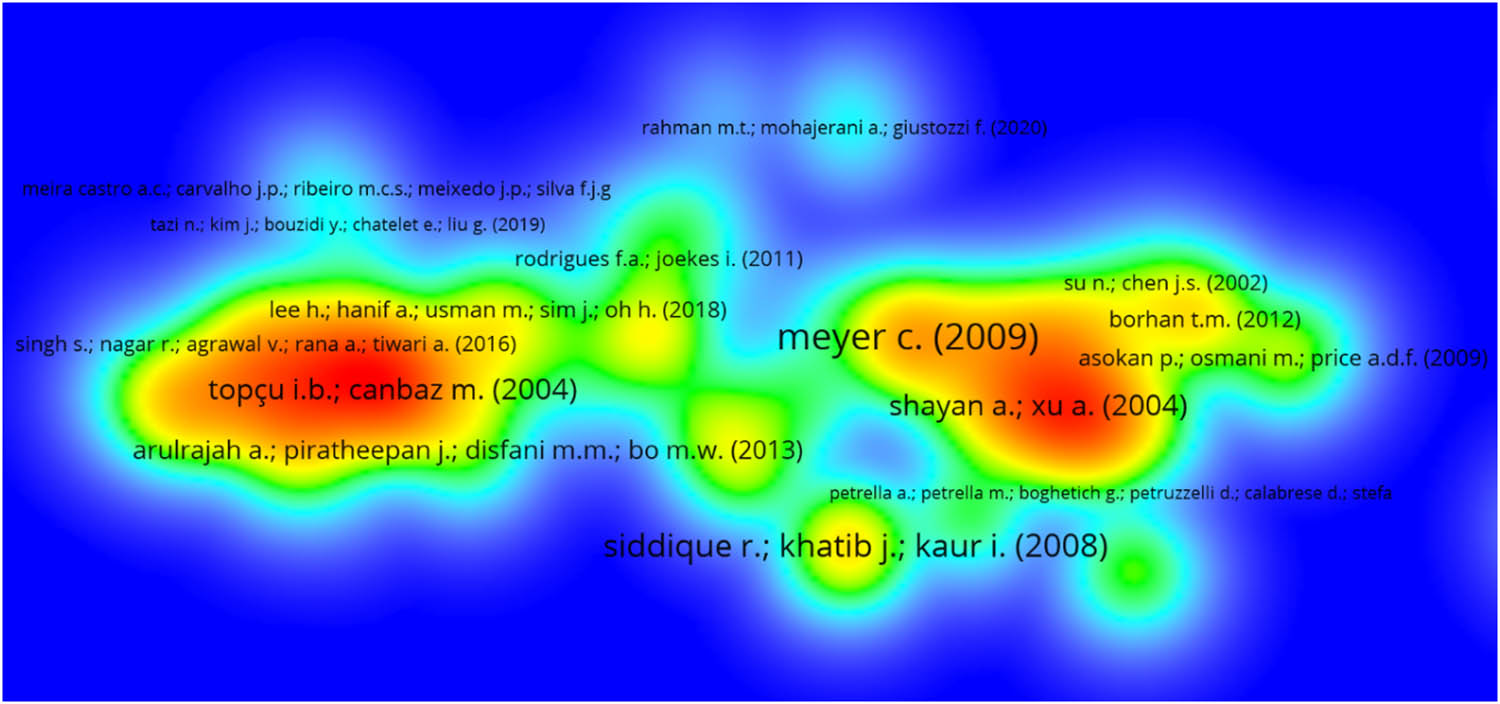

Figures 10 and 11 provide valuable insights into WGP-based concrete research. A network mapping that visually represents the connections and relationships between articles and authors. Each article is represented by a colored dot, indicating specific authors or groups of authors with common research focuses. The size of each dot corresponds to the number of citations received, reflecting the influence and impact of the articles within the research community. On the other hand, a density mapping showcases the citation impact of different authors in the field. The figure utilizes color coding to represent varying levels of citations, with red indicating high impact, yellow indicating moderate impact, and light blue representing lower impact. This visualization allows researchers to identify influential authors and understand the varying levels of impact associated with different articles. Figures 10 and 11 provide a comprehensive understanding of the network mapping and citation impact in WGP-based concrete research, enabling researchers to navigate the research landscape, identify key contributors, and gain insights into the field’s trends and connections.

Network mapping of the WGP-based concrete documents.

Density mapping of the WGP-based concrete documents.

3.6 Keywords

The search term used to find relevant publications and data in the Scopus database was WGP concrete. Table 3 provides a comprehensive overview of the keywords associated with WGP-based concrete. The table includes columns such as occurrences, keywords, and total link power. The keywords listed in the table highlight the important concepts and aspects related to this field of research. The keyword “Glass” appears most frequently, with 971 occurrences and overall link strength of 5,847, indicating its significance in WGP-based concrete studies. Other prominent keywords include “Compressive Strength” with 689 occurrences and a total link strength of 4,288, “Recycling” with 524 occurrences and a total link strength of 3,058, and “Concretes” with 494 occurrences and a total link strength of 3,026. These keywords reflect the key focus areas within the research, covering aspects such as glass being used as a material, the strength properties of the concrete, recycling practices, and the overall durability and sustainability of concrete made using leftover GP. The table provides the list of researchers with valuable insights into the prevalent themes and areas of interest in this field, allowing us to identify relevant keywords and explore specific aspects of WGP-based concrete more effectively.

Keywords of WGP-based concrete documents

| S. no. | Keyword | Occurrences | Total link strength |

|---|---|---|---|

| 1 | Glass | 971 | 5,847 |

| 2 | Compressive strength | 689 | 4,288 |

| 3 | Recycling | 524 | 3,058 |

| 4 | Concretes | 494 | 3,026 |

| 5 | Concrete aggregates | 448 | 2,918 |

| 6 | Aggregates | 347 | 2,304 |

| 7 | Concrete | 334 | 1,844 |

| 8 | Waste glass | 322 | 2,031 |

| 9 | Cements | 312 | 2,108 |

| 10 | Fly ash | 284 | 1,796 |

| 11 | Durability | 211 | 1,478 |

| 12 | Silica | 208 | 1,509 |

| 13 | Sustainable development | 203 | 1,418 |

| 14 | Slags | 201 | 1,410 |

| 15 | Mechanical properties | 195 | 1,176 |

| 16 | Tensile strength | 195 | 1,398 |

| 17 | Concrete mixtures | 179 | 1,284 |

| 18 | Portland cement | 178 | 1,263 |

| 19 | Glass powder | 177 | 1,103 |

| 20 | Mortar | 174 | 1,223 |

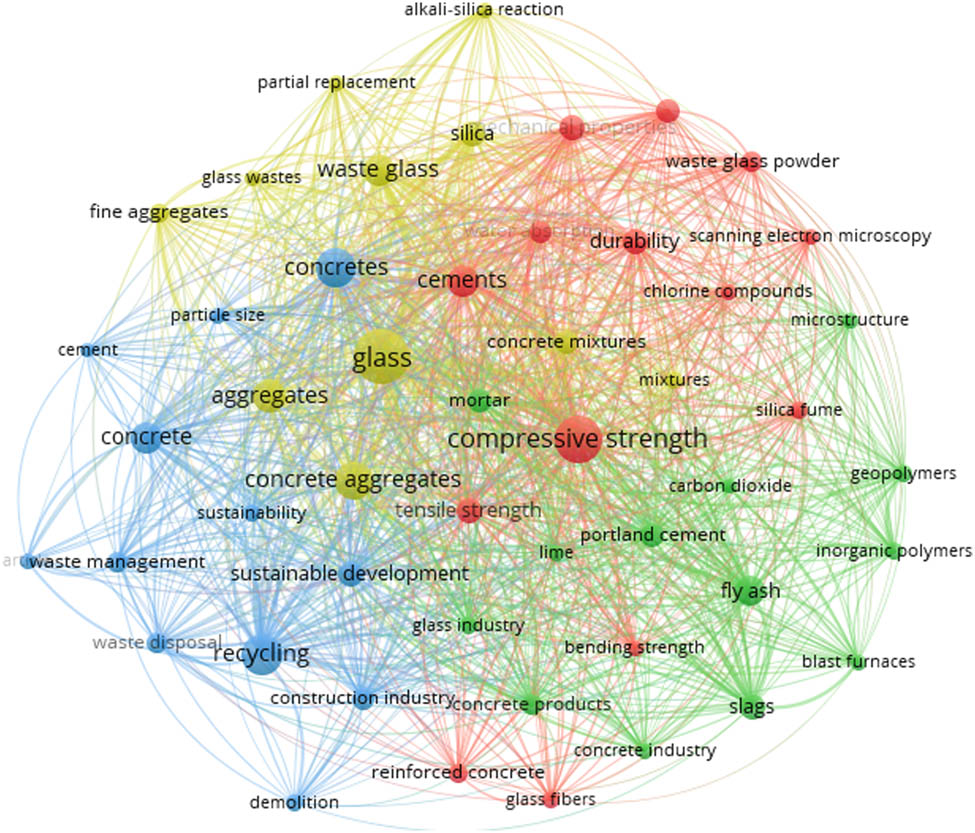

Figures 12 and 13 offer comprehensive insights into WGP-based concrete research. Figure 12 presents a network mapping of keywords associated with the field, representing them as dots with varying sizes. The size of each dot reflects the frequency of occurrence and the strength of links associated with the keyword. Different colors categorize specific groups of keywords, such as yellow for materials like glass and WG, red for properties like compressive strength and durability, green for supplementary cementitious materials, and blue for keywords related to concrete and sustainability. This mapping visually illustrates the interconnections and relationships between keywords, aiding researchers in identifying significant keywords and their associations for further exploration and analysis.

Network mapping of the keywords of WGP-based concrete documents.

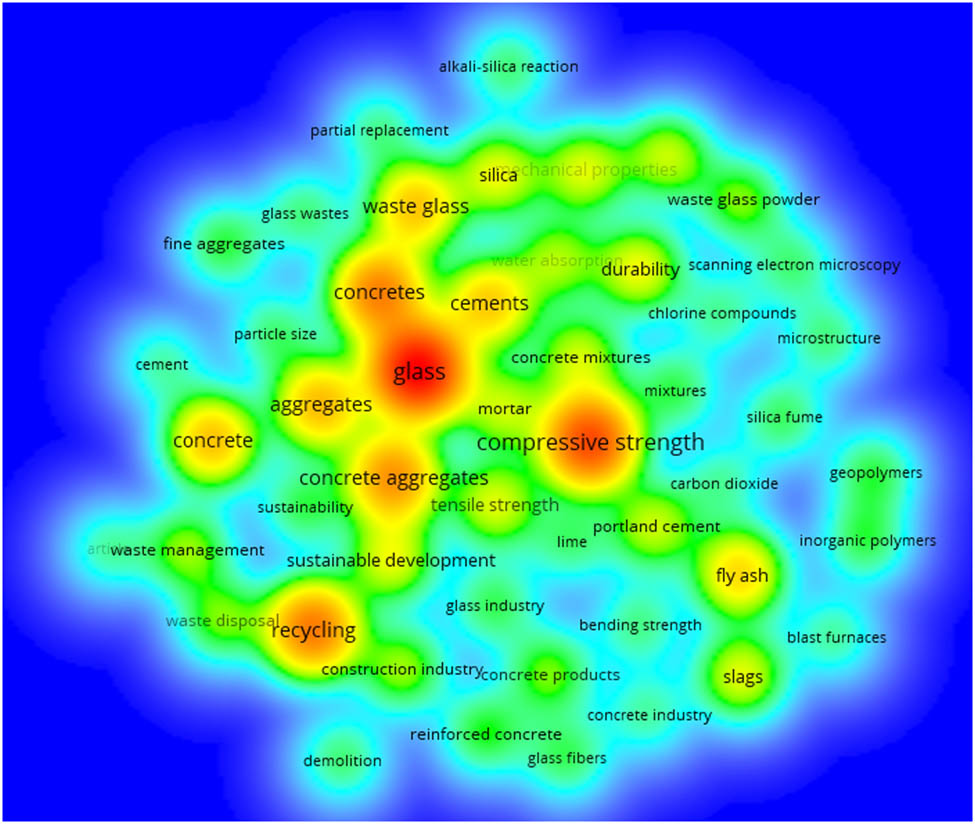

Density mapping of the keywords of WGP-based concrete documents.

In Figure 13, a density mapping focuses on the impact of different keywords in WGP-based concrete research. Colors indicate the frequency of occurrence for each keyword, with red representing high occurrence, yellow indicating moderate occurrence, and light blue representing minimum occurrence. The mapping allows researchers to understand the distribution and prominence of keywords within the research literature. It helps identify frequently studied and influential keywords, highlighting key areas of focus and enabling researchers to explore the relationships and connections between these keywords. Overall, Figures 12 and 13 provide researchers with a comprehensive visual representation of the network mapping and density of keywords in WGP-based concrete research, facilitating deeper understanding and analysis of the subject matter.

3.7 Authors

In scientometric reviews, the authors play a crucial role in conducting comprehensive analyses and providing valuable insights. Table 4 provides information on the researchers that developed WGP-based concrete, presenting data in columns such as author, citations, and total link strength. According to the most citations they have earned, the authors are presented in descending order. The table offers valuable insights into the prominent authors in this field and their research impact. Topping the list is author Poon C.S. with 1,285 citations and a total link strength of 40,199. Following closely is De Brito J. with 704 citations and 17,981 total link strength, and Tagnit-Hamou A. with 605 citations and 22,129 total link strength. Other notable authors include Shi C. with 592 citations and 19,630 total link strength, Ling T.C. with 487 citations and 16,362 total link strength, and Du H. and Tan K.H., both with 434 citations and total link strengths of 16,871 and 17,010, respectively. These data provide researchers with an overview of the leading contributors in the field of WGP-based concrete and allows for a deeper understanding of the research landscape and the authors who have made significant contributions to this area of study.

Authors of WGP-based concrete documents

| S. no. | Author | Citations | Total link strength |

|---|---|---|---|

| 1 | Poon C. S. | 1,285 | 40,199 |

| 2 | De Brito J. | 704 | 17,981 |

| 3 | Tagnit-Hamou A. | 605 | 22,129 |

| 4 | Shi C. | 592 | 19,630 |

| 5 | Ling T. C. | 487 | 16,362 |

| 6 | Du H. | 434 | 16,871 |

| 7 | Tan K. H. | 434 | 17,010 |

| 8 | Meyer C. | 413 | 9,880 |

| 9 | Arulrajah A. | 395 | 11,990 |

| 10 | Shayan A. | 343 | 10,171 |

| 11 | Xu A. | 309 | 9,478 |

| 12 | Siddique R. | 306 | 7,097 |

| 13 | Tayeh B. A. | 305 | 8,147 |

| 14 | Wang Y. | 302 | 8,308 |

| 15 | Dhir R. K. | 299 | 11,112 |

| 16 | Provis J. L. | 292 | 8,695 |

| 17 | Topcu I. B. | 281 | 8,468 |

| 18 | Wang H. | 279 | 8,732 |

| 19 | Li J. | 268 | 6,310 |

| 20 | Cyr M. | 263 | 10,362 |

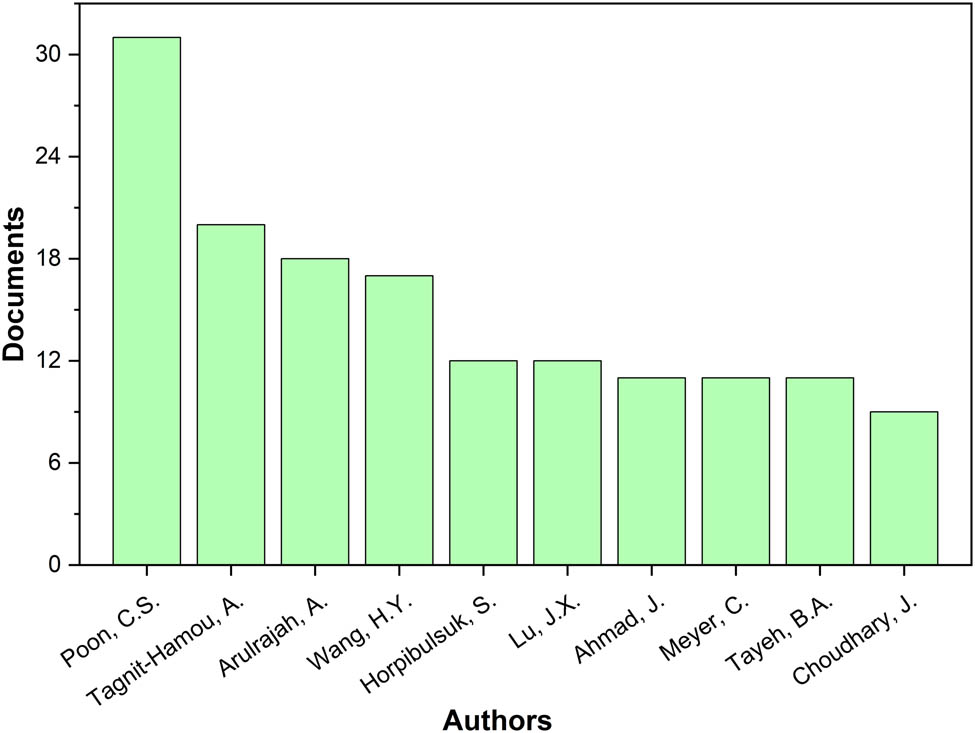

Figure 14 presents a vertical bar graph illustrating the distribution of authors and the number of documents related to WGP-based concrete. The accompanying table displays the authors in descending order, with Poon C.S. having the highest number of papers, exceeding 30 publications. On the other hand, Choudhary J. has the lowest number of papers, with approximately nine publications. This bar graph provides a visual representation of the distribution of research contributions among different authors in the use of concrete made using WGP. It highlights the varying levels of involvement and productivity among researchers, showcasing the extensive body of work produced by authors such as Poon C.S. while indicating the relatively lower number of publications by Choudhary J. This information can be useful in understanding the research landscape and identifying key contributors and their research output in this particular field.

Authors of WGP-based concrete documents.

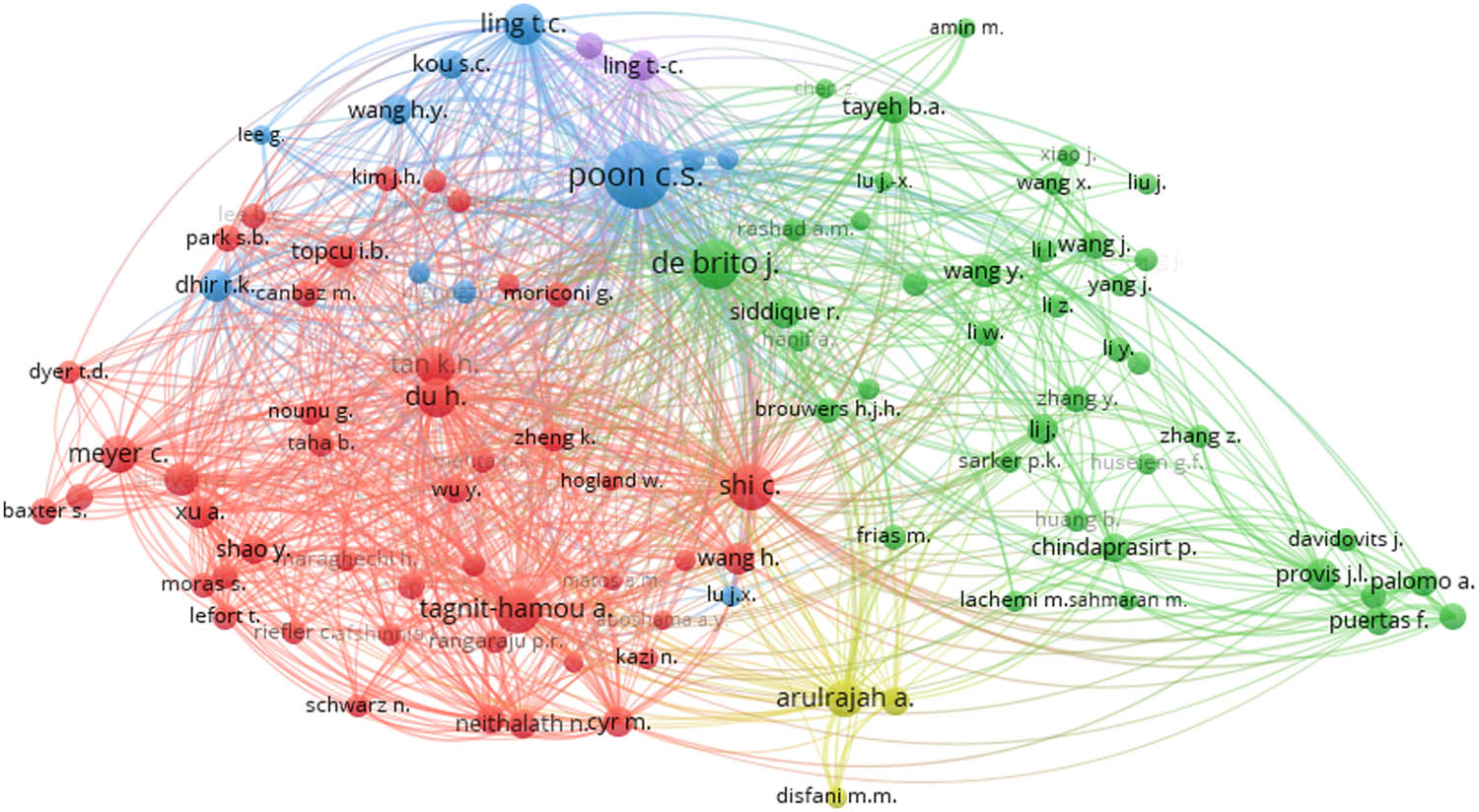

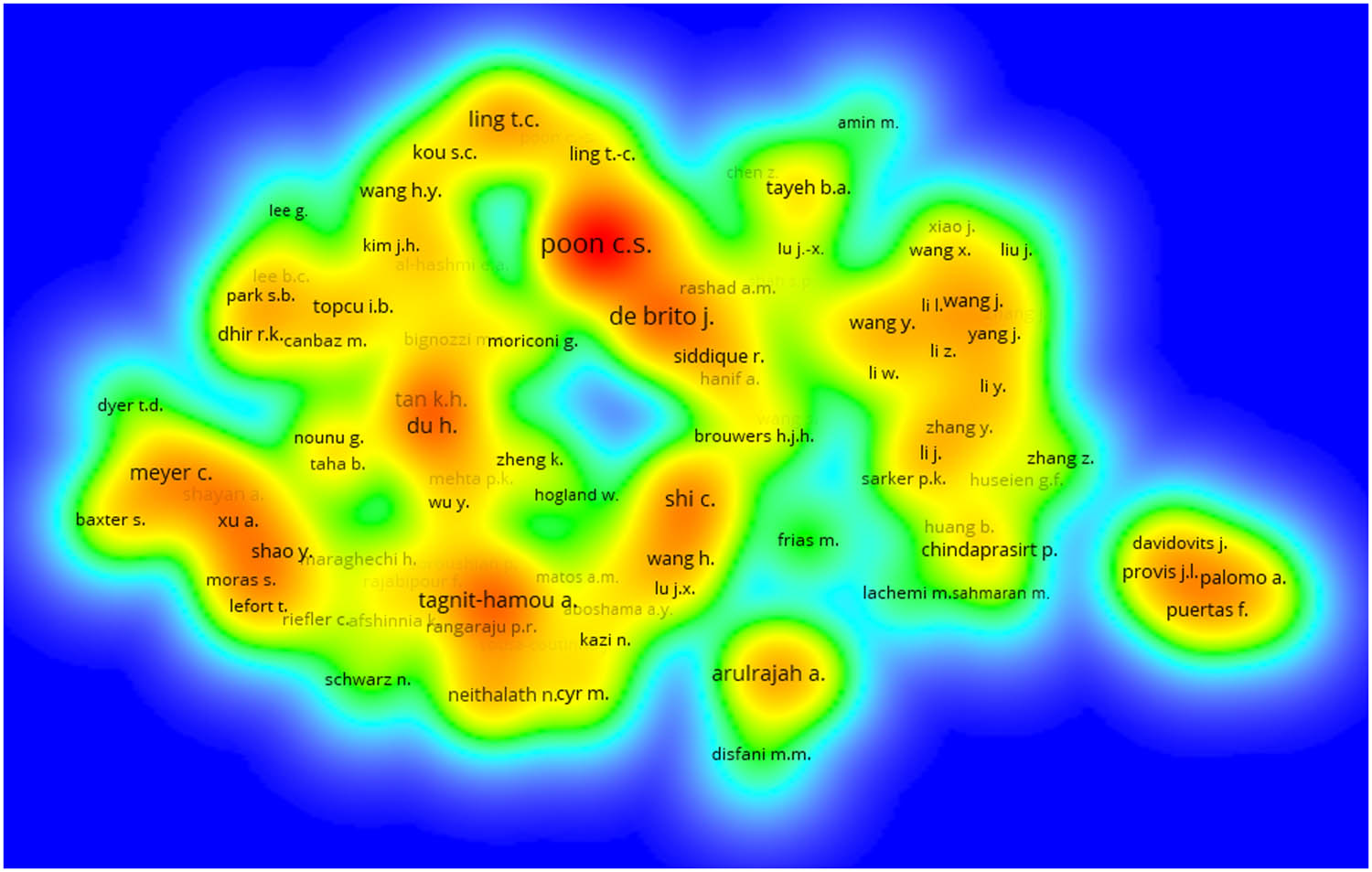

Figures 15 and 16 provide complete insights into the WGP-based concrete research landscape. Figure 15 presents a network mapping of authors involved in this research, with the size of each author’s dot representing their citation count. Larger dots indicate higher citation counts, showcasing the influence and impact of authors within the field. The mapping also illustrates the collaborative relationships and co-authorships among researchers. Additionally, the dot colors correspond to each author’s research focus, enabling viewers to identify authors with similar objectives based on their dot colors. This network mapping visually represents citation impact, collaborations, and research aims, facilitating a better understanding of influential authors and their areas of expertise. In Figure 16, a density mapping of authors in the area of WGP-based concrete research is shown. The mapping utilizes different colors to indicate the level of citation impact for each author. The authors with the most citations are shown in red, those with a moderate number of citations in yellow, and authors with the minimum number of citations in light blue. This density mapping allows for a quick visual assessment of citation distribution among authors, highlighting those who have made significant contributions to the research field and distinguishing them from those with fewer citations. By examining the density of colors across the mapping, viewers can easily identify authors who have garnered substantial attention and recognition for their work in WGP-based concrete research.

Network mapping of the authors of WGP-based concrete documents.

Density mapping of the authors of WGP-based concrete documents.

Together, Figures 15 and 16 provide a comprehensive visual representation of the network mapping, collaborative relationships, citation impact, and research focuses within the field of WGP-based concrete. These figures offer valuable insights into influential authors, their contributions, and the overall research landscape, aiding researchers in identifying key contributors, understanding research trends, and fostering further exploration and collaboration.

3.8 Organizations

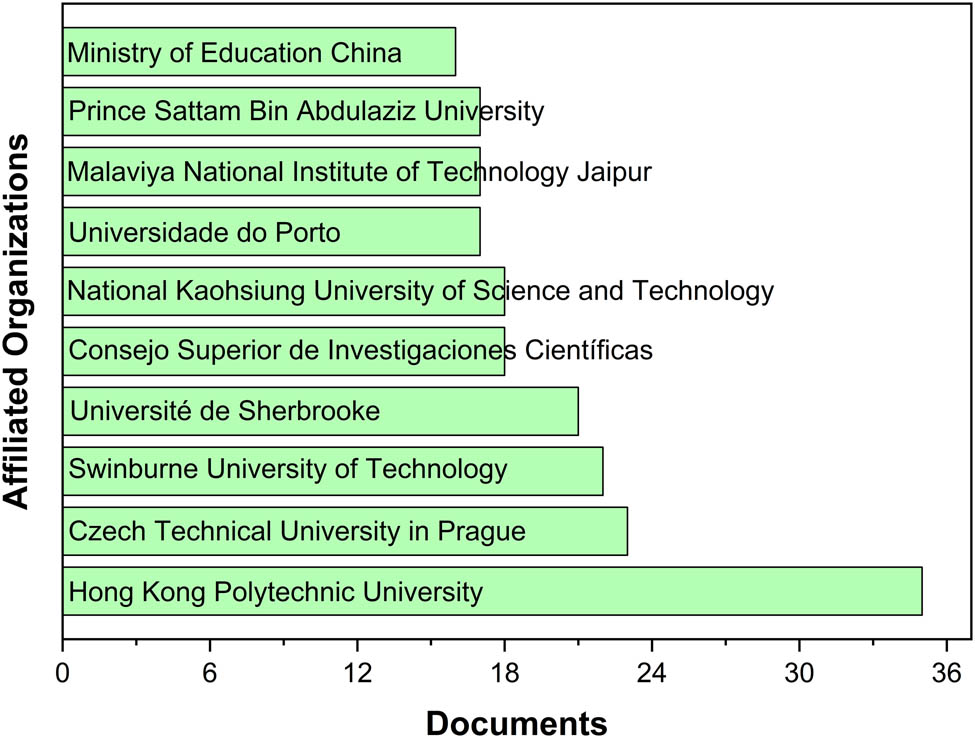

The organization provides the necessary resources and infrastructure to carry out the analysis of bibliometric data effectively. It may include academic institutions, research centers, or scientific organizations that have expertise in scientometrics and bibliometrics. Figure 17 presents a horizontal bar graph that depicts the connection between various organizations and their involvement in research on WGP-based concrete. The chart highlights several institutions, including Hong Kong Polytechnic University, Czech Technical University of Prague, University de Sherbrooke, Consejo Superior de Investigaciones Científicas, National Kaohsiung University of Science and Technology, Universidade do Porto, Malaviya National Institute of Technology Jaipur, Prince Sattam Bin Abdulaziz University, and the Ministry of Education China. Each organization is represented by a node within the bar graph, indicating their presence in this research field.

Organizations linked with WGP-based concrete documents.

Each node’s size indicates how many papers have been published by that organization, according to the nodes’ sizes, reflecting their research contributions. Hong Kong Polytechnic University holds the largest node with 35 papers, demonstrating their significant involvement in WGP-based concrete research. Czech Technical University of Prague follows with 23 papers, while University de Sherbrooke, Consejo Superior de Investigaciones Científicas, and National Kaohsiung University of Science and Technology have 22, 21, and 18 papers, respectively. Other institutions, including Universidade do Porto, Malaviya National Institute of Technology Jaipur, Prince Sattam Bin Abdulaziz University, and the Ministry of Education China, also show their presence in the field with varying numbers of published papers. Overall, this bar graph provides valuable insights into the collaboration and research output among different organizations engaged in studying WGP-based concrete.

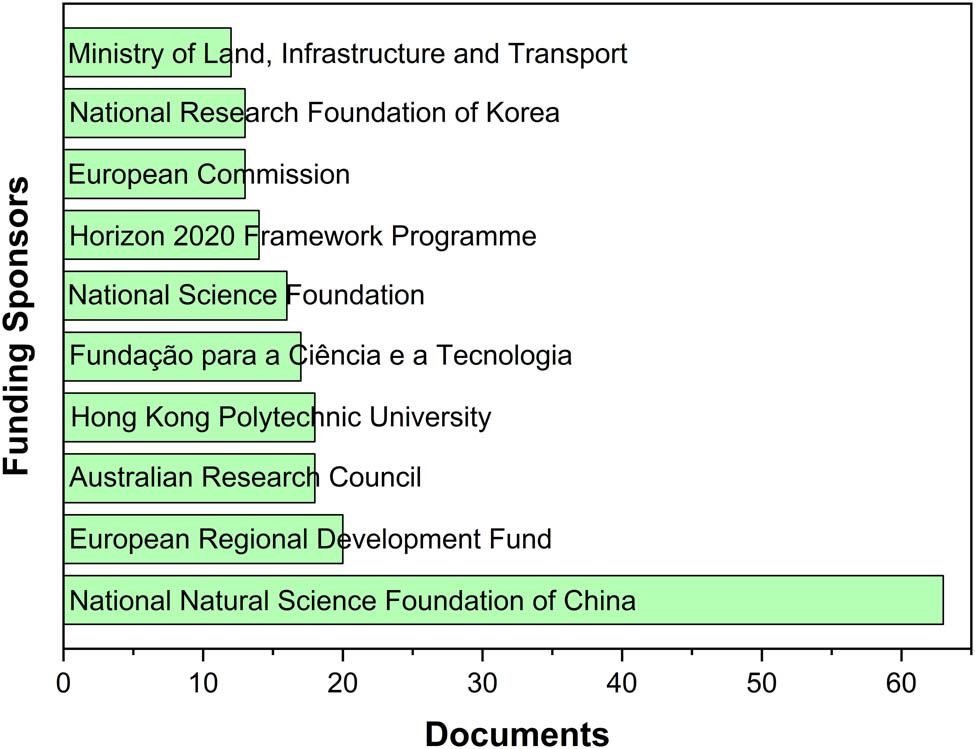

3.9 Funding sponsors

The sponsors can be governmental or non-governmental organizations, research foundations, or private entities that recognize the importance of scientometric analysis and its potential impact on scientific knowledge. Figure 18 presents a horizontal bar graph depicting the funding and sponsorship sources for research on concrete made with WGP. The majority of research funding is contributed by corporations through their research and development departments, as well as by government entities. Among the funding sources, the National Natural Science Foundation of China stands out with the highest number of papers supported, totaling approximately 63. On the other hand, the Ministry of Land, Infrastructure, and Transport has the lowest number of papers, with around 12. Other notable funding sponsors include the European Regional Development Fund, the Australian Research Council, the Hong Kong Polytechnic University, and the National Science Foundation, among others. These organizations play a crucial role in supporting research and development in the field of WGP-based concrete.

Funding sponsors of WGP-based concrete documents.

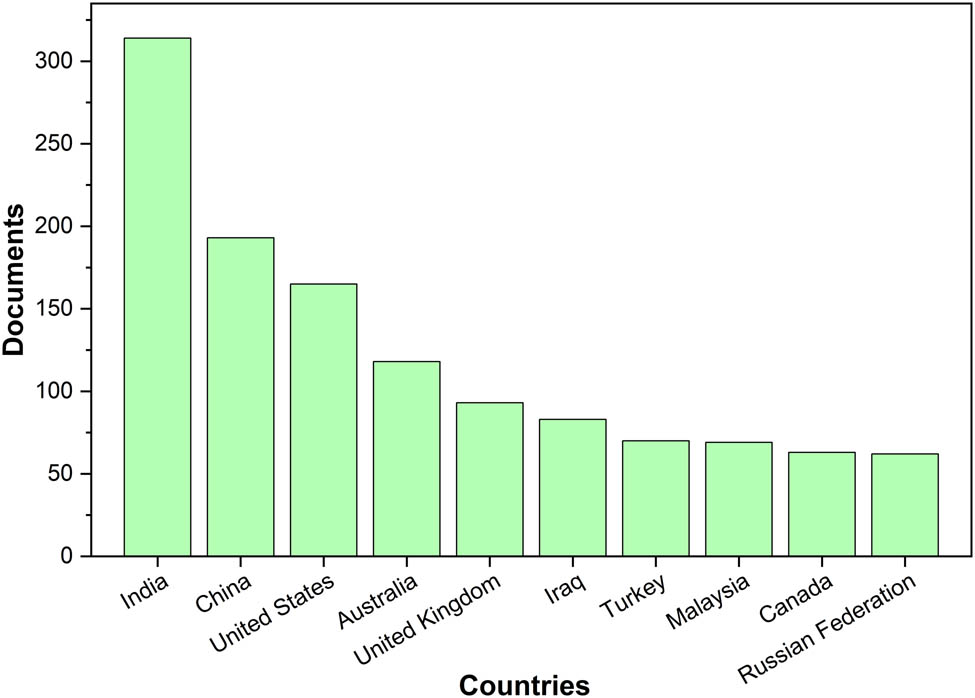

3.10 Countries

Countries play a significant role in scientometric reviews as they provide a geographical context for analyzing scientific output and collaboration patterns. Understanding the contribution of different countries to scientific research is essential for identifying global research trends, assessing scientific productivity, and promoting international collaborations. Table 5 provides information about the countries that are actively involved in research on WGP-based concrete. The table consists of five columns, including serial number, country, number of documents, citations, and total link strength. The data reveal the research output and impact of each country in this field. India occupies the top position with 315 documents, 5,036 citations, and a total link strength of 13,989. China follows closely with 192 documents, 4,101 citations, and a total link strength of 14,214. The United States ranks third with 166 documents, 6,332 citations, and a total link strength of 13,661. Australia, United Kingdom, Iraq, Turkey, Malaysia, Canada, and the Russian Federation also contribute significantly to the research on WGP-based concrete. Each country’s research output is measured by the number of documents, citations, and total link strength, providing valuable insights into their contributions to this field of study. The table highlights the global nature of research on WGP-based concrete, with diverse countries actively participating and making significant contributions. This international collaboration and knowledge exchange facilitate advancements in this area, leading to a more comprehensive understanding of WGP-based concrete applications and technologies.

Countries linked with WGP-based concrete documents

| S. no. | Country | Documents | Citations | Total link strength |

|---|---|---|---|---|

| 1 | India | 315 | 5,036 | 13,989 |

| 2 | China | 192 | 4,101 | 14,214 |

| 3 | United States | 166 | 6,332 | 13,661 |

| 4 | Australia | 118 | 4,613 | 14,026 |

| 5 | United Kingdom | 93 | 3,371 | 9,036 |

| 6 | Iraq | 83 | 1,339 | 11,966 |

| 7 | Turkey | 70 | 1,593 | 10,549 |

| 8 | Malaysia | 69 | 1,364 | 9,931 |

| 9 | Canada | 63 | 2,691 | 6,153 |

| 10 | Russian Federation | 62 | 292 | 6,350 |

| 11 | Egypt | 61 | 1,634 | 5,096 |

| 12 | Italy | 58 | 1,403 | 5,072 |

| 13 | Iran | 55 | 1,410 | 6,068 |

| 14 | South Korea | 55 | 1,297 | 4,296 |

| 15 | Saudi Arabia | 52 | 715 | 11,254 |

| 16 | Spain | 52 | 2,518 | 7,067 |

| 17 | Pakistan | 51 | 809 | 9,002 |

| 18 | Poland | 46 | 519 | 2,610 |

| 19 | Hong Kong | 44 | 2,830 | 4,464 |

| 20 | Portugal | 43 | 1,954 | 6,053 |

Figure 19 presents a vertical bar graph illustrating the countries that are actively engaged in research on WGP-based concrete. The graph provides a visual representation of the number of documents that each country has provided, enabling us to understand the level of research activity in different regions. According to the graph, India stands out as the leading country with the highest number of documents, recording a significant count of 315. On the other end of the spectrum, the Russian Federation has the lowest number of documents, with 62. Notable countries that contribute significantly to the research on WGP-based concrete include China, the United States, Australia, the United Kingdom, Iraq, Turkey, Malaysia, and Canada. The vertical bar graph offers a quick overview of the research landscape, allowing us to identify the countries with a substantial research presence in this field. By understanding which countries are actively researching WGP-based concrete, researchers, policymakers, and industry professionals can identify potential collaborators, gain insights into regional expertise, and foster international cooperation for further advancements in this area of study.

Countries linked with WGP-based concrete documents.

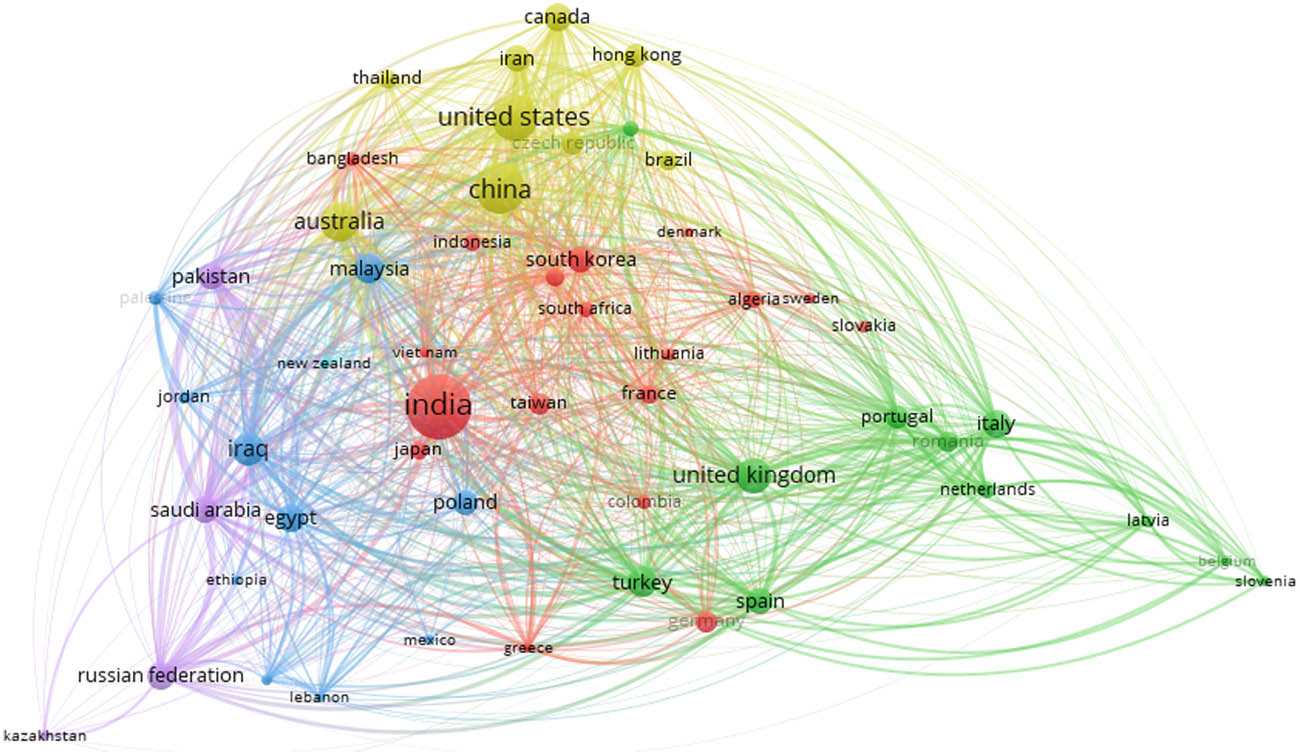

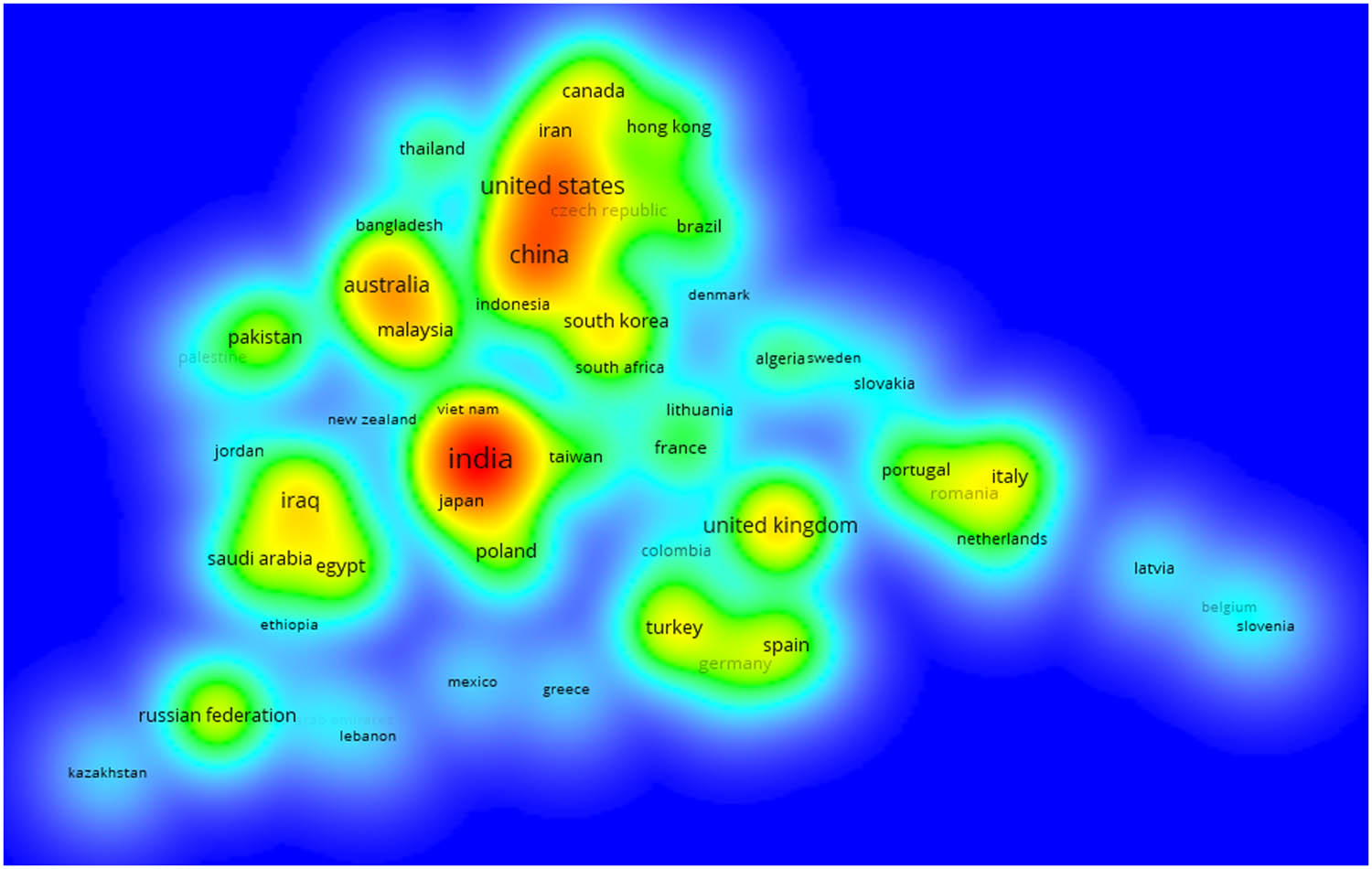

Figures 20 and 21 offer valuable insights into WGP-based concrete research at the global level. Figure 20 presents a network mapping of countries connected to this research, with dots representing individual countries and links indicating their interconnections and collaborations. The colors assigned to the dots signify regional associations and research interests. This network mapping visually depicts the relationships and connections among different countries, enabling researchers to identify clusters or groups with similar interests and collaborations. The visual representation emphasizes the global reach of research efforts in this field and facilitates the identification of potential opportunities for international cooperation and knowledge exchange. In Figure 21, a density mapping of countries linked to WGP-based concrete research is presented. The mapping illustrates the level of research contributions from different countries. The density of each country’s research output is represented by the color of the corresponding spot on the map. Red spots indicate countries with a higher number of research papers and substantial involvement in the field, while yellow spots represent countries with a moderate level of research activity. Light yellow spots signify countries with a relatively smaller research output in this area. This density mapping provides an overview of the distribution and intensity of research efforts across countries, allowing researchers, policymakers, and stakeholders to identify active contributors and those making significant contributions to the field. The visualization helps in understanding the global research landscape of WGP-based concrete, supporting collaboration, knowledge sharing, and targeted initiatives to further advance research and development.

Network mapping of the countries linked with WGP-based concrete documents.

Density mapping of the countries linked with WGP-based concrete documents.

Figures 20 and 21 provide a comprehensive visual representation of the network mapping, interconnections, collaborations, and research contributions at the country level in the field of WGP-based concrete. These figures facilitate a better understanding of the global landscape, foster international cooperation, and support strategic efforts to drive research and innovation in this domain.

4 Discussion

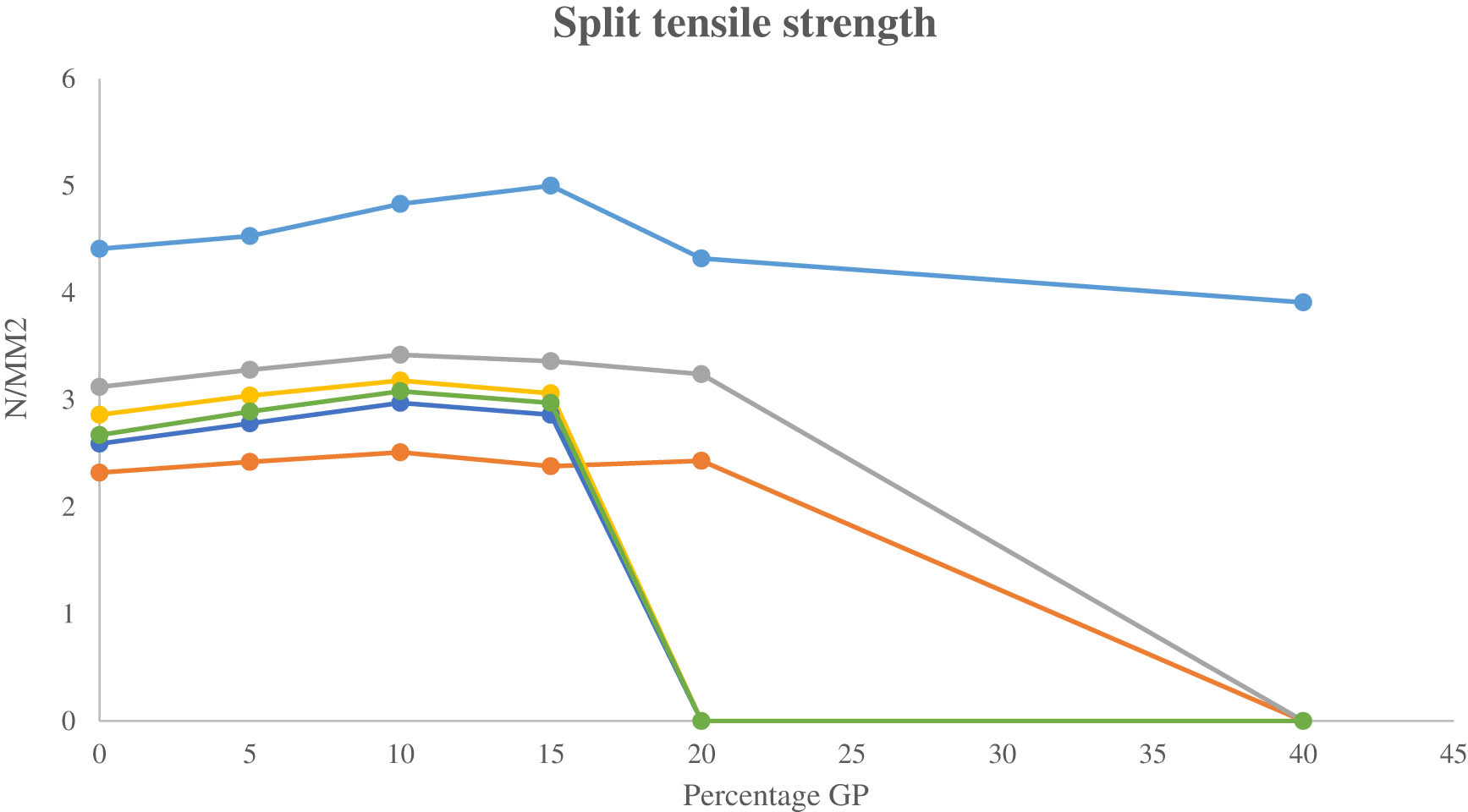

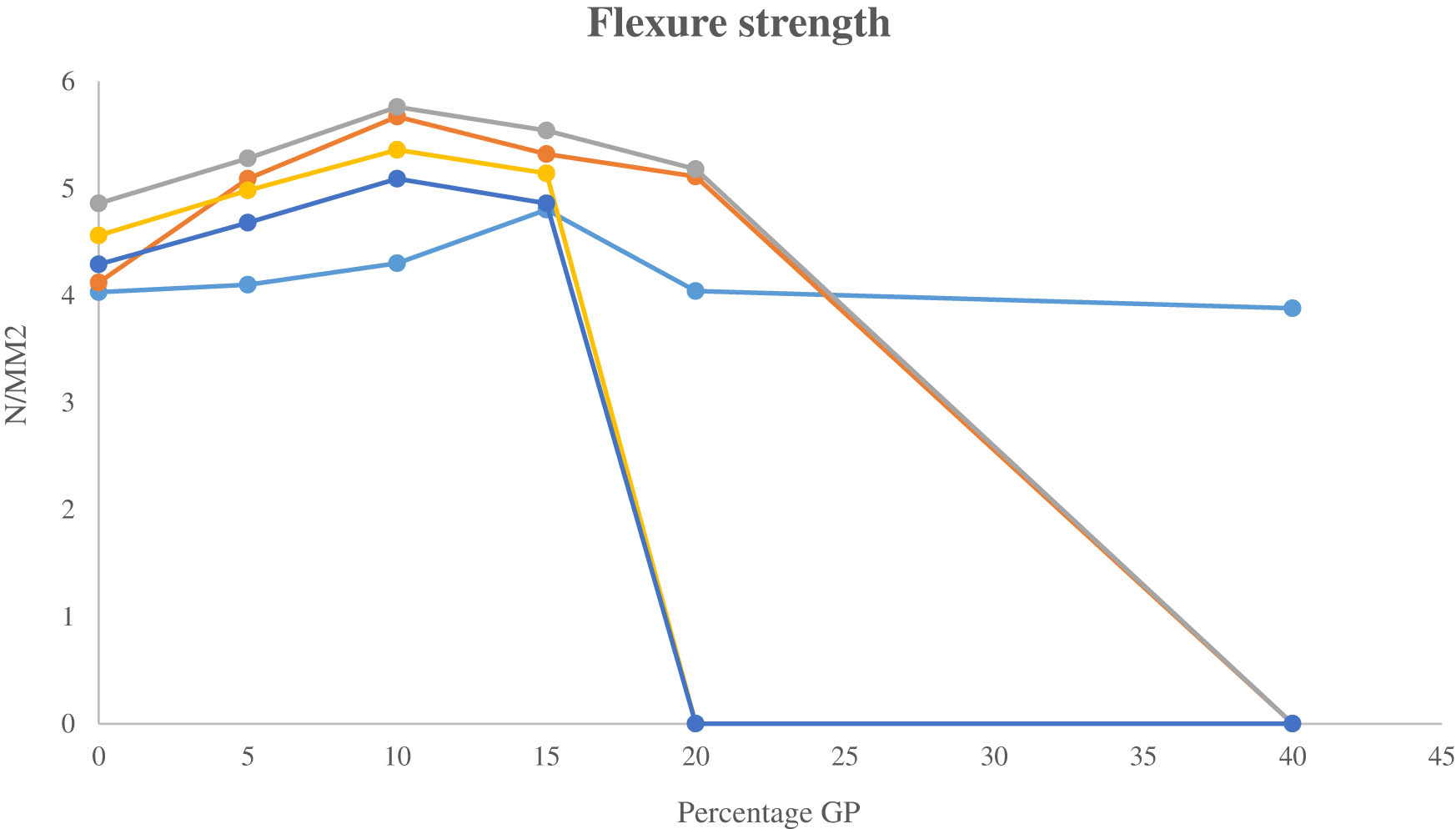

This research section delves into various parameters concerning WGP-based concrete. These parameters include the significance of WGP, limitations of WGP, environmental impact assessment of WGP, properties of WGP, role of WGP in concrete, fresh state properties of WGP-based concrete, and hardened state WGP-based concrete’s properties. The significance of WGP explores the importance and potential benefits associated with its usage in concrete applications. The limitations of WGP shed light on the challenges or constraints that may arise when incorporating WGP into concrete mixtures. The environmental impact assessment of WGP evaluates the ecological implications and sustainability aspects associated with its use. The properties of WGP focus on its physical and chemical characteristics, including particle size distribution, chemical composition, and pozzolanic reactivity. The role of WGP in concrete investigates impact on the strength and other qualities of concrete, durability, and workability. The fresh state properties of WGP-based concrete examine its behavior during mixing, placing, and early curing stages. Finally, the hardened state properties of WGP-based concrete assess its long-term performance, including mechanical strength, durability, and resistance to environmental factors. By addressing these parameters, the research aims to provide comprehensive insights into the utilization and potential using WGP in improving the sustainability and properties of concrete.

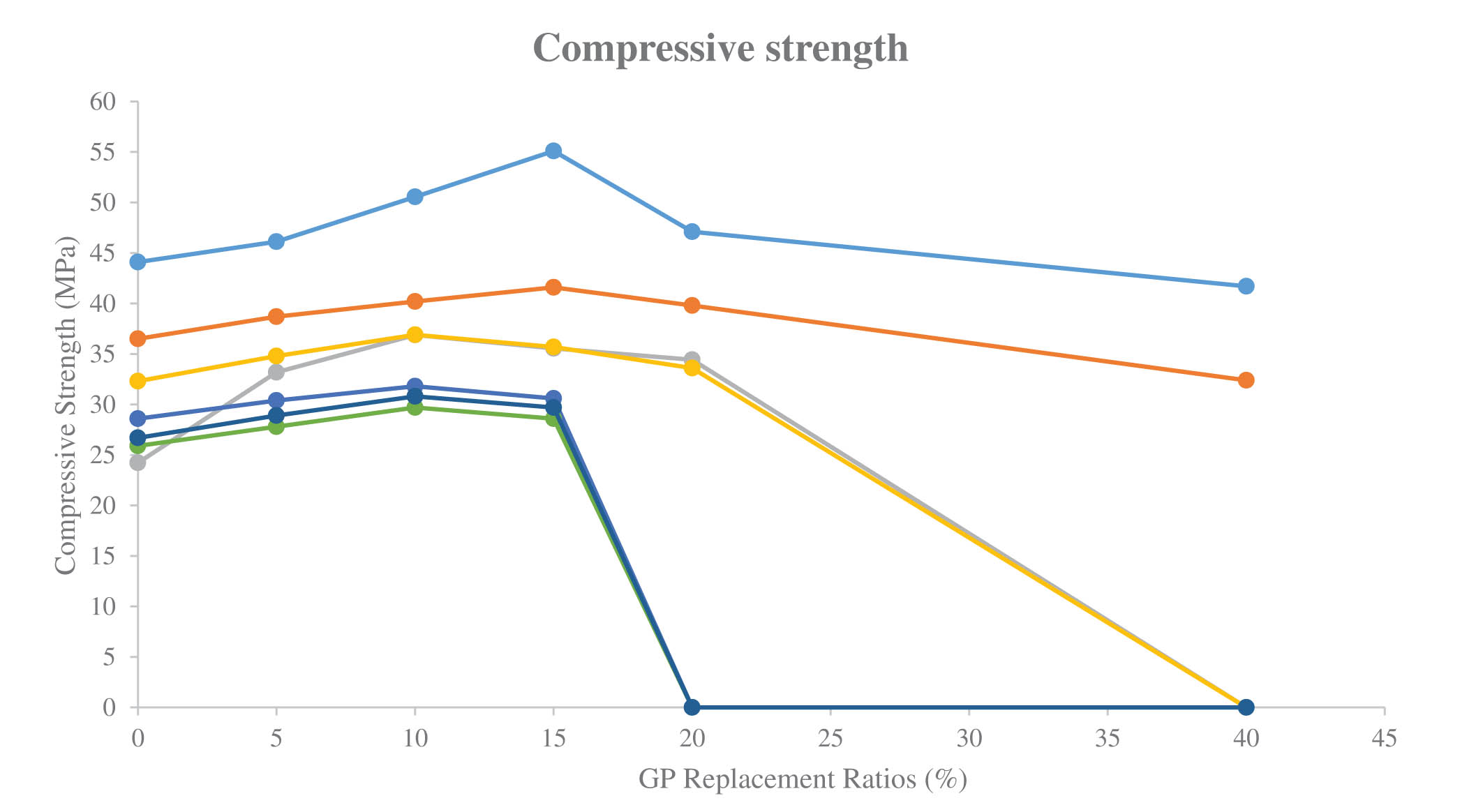

4.1 Significance of WGP

Concrete is a widely used construction material, but it presents various challenges related to both cement and aggregates. The usage of natural aggregates is one of the main issues, it harms the ecosystem and results in the depletion of natural resources. This poses a significant problem for future generations. According to Aliabdo et al. [3], an analysis of concrete that used WGP as a cement component revealed increased strength with 10% cement replacement and enhanced properties with up to 15% replacement or 15% addition. However, in this section, we will discuss several significant advantages of using WGP to make concrete. First, it helps reduce the volume of waste dumped in landfills, promoting waste management and sustainability. Second, the incorporation of WGP in concrete leads to a reduction in environmental pollution, as it provides an alternative use for glass waste that would otherwise contribute to pollution. Additionally, it offers improvements in concrete properties, increasing its durability and strength. Concrete made using WGP displays increased resistance against various deleterious effects, including sulfate attack [69], alkali–silica reaction (ASR) [70], and FT cycles [71]. Federico and Chidiac [72] conducted a study in which they concluded that cost-effective collection of WG in mixed colors is possible. Moreover, the utilization of WGP promotes better hydration, leading to improved concrete performance. By highlighting these significant benefits, this study area aims to highlight the benefits and potential of waste GP-based concrete as an environmentally responsible and long-lasting substitute for conventional concrete production techniques.

4.1.1 Reduction in landfills

One of the main waste sources in the globe is glass. Glass is a common substance in the world’s largest landfills and in the oceans, where it affects not just people but also marine life. Egypt produces over 3.45 million tons of glass waste per year, with 84% of it ending up in landfills [69]. Glass has a tremendous potential for use in concrete as a partial replacement for cement because of its pozzolanic qualities.

4.1.2 Reduction in environmental pollution

The large portion of the waste produced worldwide is made of glass. Basically, burning and melting glass to shape it into various jars and bottles will produce more pollution. According to Shekhawat and Aggarwal [73], environmental legislation is driving the increased availability supplementary aggregates for concrete made of WG. This is due to the impact of regulations governing containers, end-of-life vehicles, and waste electrical goods. When concrete contains GP in place of some of the cement, glass acts as pozzolan. In addition to increasing glass utilization, using glass in concrete will reduce pollution by preventing glass burning, which is good for the environment.

4.1.3 Improvement in basic properties of concrete

The WGP has a particle size that is smaller than cement. In comparison to regular cement concrete, smaller particles will help the concrete have less porosity, which will help the concrete have fewer cracks. Concrete’s mechanical strength will increase with the addition of GP with smaller particles. Khatib et al. [74] reported an increase in the compressive strength of concrete with a maximum observed enhancement of up to 10.0% while utilizing GP in place of cement. Concrete’s workability is also influenced by particle size; smaller particles will be more workable than typical cement concrete.

4.1.4 Resistance against sulfate attack

Concrete is significantly affected by sulfate attack. The sulfate attack can result in spalling, expansion, delayed ettringite formation, and cracking. According to Rashad [75], long-term chloride permeability performance was increased by the durability of concrete containing WG. However, concerns were raised regarding ASR. Over the course of the concrete’s existence, noxious chemical components like sulfides, sulfates, and alkalis provide a higher danger of ASR. It was noted that a suitable pozzolan can effectively mitigate ASR and consume lime, thereby significantly reducing efflorescence. GP can help concrete be more sulfate resistant than regular concrete by being used in the concrete-making process. The glass will withstand the sulfate attack because it is less permeable than cement and does not react with salt.

4.1.5 Resistance against ASR

When the mixture contains silica material that is reactive, an ASR occurs. ASR damages the structure and generates significant cracks. GP does not react with silica; hence it can help to keep the silica material from reacting with other substances. In a study by Du and Tan [76], a unique behavior of concrete was observed upon the addition of GP. When 60% of the cement was replaced with GP, the researcher discovered that the resistance to the ASR and water absorption dramatically increased.

4.1.6 Resistance against FT effect

When water is present in small voids in the concrete, a cycle of freezing and thawing causes the concrete to crack. Concrete cracks as a result of freezing and thawing’s expansion and contraction of the material. GP is very fine particle, which will absorb less water than cement. Concrete will be less vulnerable to the effects of freezing and thawing because of the smaller size of GP will lead to less voids. Furthermore, the study found that adding more WGP to concrete increases the FT resilience of plain concrete [77].

4.1.7 Improvement in hydration process

Concrete’s mechanical properties are crucial. The majority of researchers investigate a variety of approaches to enhance the concrete’s mechanical properties. Because it is smaller and absorbs less water than cement, the improved strength of the concrete will be aided by the use of GP in its manufacturing. As a result, there will be enough water available for the reaction to fully hydrate and develop its maximum strength. Based on hydration studies, investigations were made on the WGP’s pozzolanic reactivity through experimental analysis at different cement replacement levels (0, 15, 30, 45, and 60% by weight). The results demonstrated that up to 30% cement substitution, due to the pozzolanic reaction between glass particles and cement hydration products, the compressive strength of concrete was unchanged after 28 days [78].

4.2 Limitations of WGP

WGP-based concrete has a few limitations. The color of the glass used can affect not only the visual appearance but also the chemical properties of the concrete. Certain glass colors, such as amber or green, may contain additives or impurities that can react with the cementitious matrix and impact the concrete’s performance. According to the findings by Vandhiyan et al. [79], using GP in concrete adversely affected the workability. The GP, with an angular shape and passing through a 90 μm sieve, resulted in 50% retention on a 75 μm sieve [80]. Additionally, other factors like glass sources, availability, and the challenges associated with working with glass must be considered to maximize the benefits and minimize the limitations of WGP-based concrete. Ongoing research and innovation are crucial in addressing these limitations and optimizing the utilization of used glass in practical applications.

4.2.1 Glass color

Glass is available in a wide range of forms and originates from numerous sources. Glass comes in a variety of colors as well. It can often be very difficult to remove its color without the help of chemicals. Different chemicals are used to remove the color of glass, but they are also costly and dangerous [81]. The properties of glass are also changed by its color. It is quite hard to use colored glass in concrete since it also reacts with some materials when a reaction occurs. Jiang et al. [82] have discussed how the color of the glass affects pozzolanic and ASR reactivity [83], durability of alkali-activated materials (AAMs) with GP [84], performance of glass fume in ultra-high-performance concrete (UHPC) [85], and use of GP in phase change materials and sintering products [86].

4.2.2 Glass sources

Many different household and other products are made from glass. Glass is not obtained from a single source in landfills or other locations. The majority of WGP is sourced from landfills as the non-recyclable fraction, because it is difficult to achieve the standards for quality in remanufacturing glass. Consequently, usually, this portion is abandoned and dumped in landfills [87]. Glass is gathered from a variety of places. When glass from various sources is used in the preparation of concrete, the concrete’s strength will be impacted. In certain areas, the concrete’s strength will be higher, while in others, it will be lower, which is risky for important structures [88].

4.2.3 Difficulty to work with glass

Glass is a very sharp material that easily cuts through anything. When glass is used in concrete, it is done so in the form of powder. Due to the high percentage of amorphous silica (50–70%) in large particle size glass aggregates, the ASR poses a serious concern [89] and sodium (8–15%) [90] in soda-lime glass [91]. Glass is crushed down to a fine powder to use it in concrete. When someone comes into contact with the smaller glass, it can hurt both humans and animals since it is so sharp. The GP behaves sharply like crystal, and working with it can be challenging [92].

4.3 Environmental impact assessment of WGP

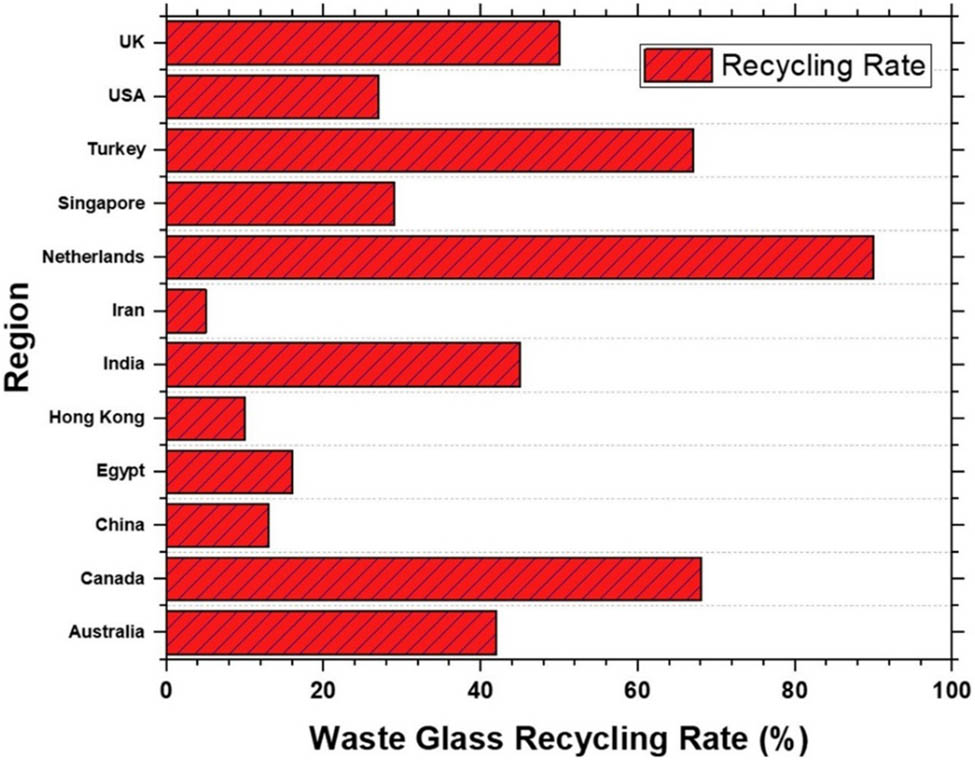

Almost all household items, including drinking glasses, plates, cups, tables, bottles, jars, mirrors, building partitions, windows, facades, TV, computer, and smartphone screens, are made of glass. Almost everyone comes in contact with glass more than once every day, and tones of glass waste are produced daily, increasing the amount of waste pollution from garbage and the amount of waste in landfills. Recycling WG reduces quantity of glass that have been dumped in landfills; however, using traditional recycling techniques causes more pollution in the air and water, whether the glass is recycled or new glass is manufactured, both causes increase in pollution. WGP needs to be recycled quickly and effectively because of its growing accumulation, which is taking up more space, pollutes the environment, and wastes valuable resources for its management [93]. The large amount of waste in landfills across the world is glass. Natural materials including sand, soda ash, cullet, and limestone are used to make glass. High heat energy is needed to melt and shape glass during manufacturing [94], for 1 kg glass, over 0.6 kWh is used. Glass can be recycled such that it uses less energy during recycling compared to manufacturing of new glass. Other advantages of recycling include reduced air and water pollution as well as a decrease in disposal in landfills. Given the final applications and volume of production, recycling WG in the production of cement and concrete can have a positive impact on the environment and the economy [56]. The recycling rate of glass waste remains considerably low worldwide, as depicted in Figure 22, which illustrates the percentage of recycled glass through a horizontal bar graph. The Netherlands stands out with the highest recycling rate of approximately 90%, while Iran demonstrates the lowest rate of recycling WG. This highlights the significant impact of WG on our environment and the urgent need for effective recycling practices. Furthermore, these findings indicate a vast potential to utilize WG in concrete production, providing a sustainable solution that improves the environmental performance of the building sector while also reducing waste. By harnessing the opportunities presented by WG, we can help promote a circular economy and lessen the environmental harm caused by the disposal of glass waste. According to Heriyanto and Pahlevani [95], with a recycling rate of 42%, Australia produced roughly 800,000 tons of glass garbage in 2015.

Percentage of WG in different countries.

Glass is made of silica, a naturally occurring material similar to sand. Nearly every year, 28 billion glass bottles are added to landfills. Despite growing public awareness of municipal garbage separate collection, less than 10% of used glass beverage bottles are recycled [96]. Glass pollutes the environment because of the chemicals it contains. When glass decomposes, sulfate is formed, and when it burns, nitrogen is created. Ocean acidification, land toxicity, and freshwater toxicity are all caused by glass waste. The effects of glass waste on people, animals, and plants extend to all other living things in the planet. Glass takes approximately 1 million years to break down. There are various phases for recycling of glass. The glass is initially collected from various landfills. After that, the glass is thoroughly cleaned by having all of the impurities removed from it, which requires a lot of water. The glass aggregate used in the study was sourced from building and car window panels, which were carefully washed and treated in a dedicated facility [91]. To remove the glass’s color, various chemicals are added, and water is then used to wash the glasses once more. Glass is placed in a big kiln in the last phase, and when it melts, it is then shaped into bottles, jars, and other objects. Recycling uses less energy than producing new glass, yet it still pollutes the air and water.

Glass has a significant amount of silica, which is what causes the pozzolanic reaction while concrete is being mixed. The creation of items for extra hydration, such as magnesium silicate hydrate (MSH) [97] and magnesium calcium silicate hydrate (MCSH) [98], can occur through the reaction between a magnesium source (such as MgO nanoparticles [99], Mg (OH)2, and MgCO3 hydrated phases) and an amorphous silica source (such as rice husk ash, silica fume [SF], and pulverized fuel ash). These recently developed phases (MSH and MCSH) improve the mechanical properties of composite cement matrices [100]. Glass recycling using the conventional approach uses a lot of energy and water. When glass is reduced to powder, it develops into a natural pozzolan that gives concrete its hardening and fresh properties. It will not consume a lot of energy or other processing to employ glass in concrete when it is ground into powder form. Glass can be used to make concrete more economically and since it does not need to be melted, there will be less water and air pollution. Due to rising population levels and the need for new homes and buildings, glass has a significant market [101]. GP is the most acceptable replacement for cement in the production of concrete due to its low cost of WG and pozzolanic activity.

4.4 Properties of WGP

In Table 6, the chemical composition of GP and cement is compared. The amount of Al2O3 in GP is about 0.4%, compared to 6.97% in cement, and it acts as the cement’s nuclei, accelerating the hydration reaction until the concrete’s initial setting time has passed. Al2O3 also improves the strength of concrete while reducing its porosity. The hydration reaction will be slowed down, there will be an increase in porosity, and the strength will also be compromised if GP is used to replace cement. This is so because GP has a lower Al2O3 content than cement does. Around 2–5% of cement contains magnesium oxide, which is essential for the reaction that creates concrete. The production of C3S and C4A3S is facilitated by MgO, which also helps in the absorption of additional lime. While MgO is present in GP in amounts between 2 and 5% of what is needed, it also helps concrete gain strength and speed up the setting time. When a reaction occurs, calcium oxide helps the concrete in expanding and overcoming past contraction. When there is more CaO in concrete, there are less cracks. GP contains less calcium oxide (9.7%) than cement (62.72%), which will result in more microscopic cracks in concrete. A slight decrease in compressive strength will occur, and Fe2O3 helps the concrete obtain additional flexure strength. GP contains 0.2% Fe2O3, which is less than cement, which has 3.34% Fe2O3. There will be no changes in compressive strength when GP is used; however, there will be a small increase in flexure strength. Due to SiO2’s pozzolanic nature, there will be an increase in shrinkage but a decrease in permeability when there is more SiO2 in concrete. SiO2 content in GP is higher than in cement, resulting in greater shrinkage but decreased permeability. Na2O should not exceed more than 0.6% while making concrete. When the amount of sodium oxide increases, it will damage the concrete. In GP, the amount is very high compared to cement which will cause damage. The alkaline metal found in cement is potassium oxide. When there is more K2O in concrete, the concrete will weaken. Less K2O is present in GP, which makes it more workable and aesthetically pleasing.

Comparison of chemical property of GP with cement

| Chemical composition | Al2O3 | MgO | CaO | Fe2O3 | SiO2 | Na2O | K2O |

|---|---|---|---|---|---|---|---|

| Percentage in GP | 0.40 | 3.30 | 9.70 | 0.20 | 72.50 | 13.7 | 0.10 |

| Percentage in cement | 6.97 | 2.36 | 62.72 | 3.34 | 21.24 | 0.13 | 0.81 |