Friction stir welding of dissimilar Al–Mg alloys for aerospace applications: Prospects and future potential

-

Santhosh Nagaraja

, Praveena Bindiganavile Anand

, Madhusudhan Mariswamy

, Meshel Q. Alkahtani

, Saiful Islam

, Mohammad Amir Khan

and Javed Khan Bhutto

Abstract

Friction stir welding (FSW) is increasingly utilized in aerospace for welding dissimilar Al–Mg alloys without melting, overcoming fusion welding challenges. This summary highlights FSW’s key aspects for dissimilar Al–Mg alloys and its aerospace relevance. These alloys are widely used in aerospace due to their beneficial properties, but fusion welding faces issues like brittle intermetallic compounds (IMC) and decreased mechanical properties. FSW addresses these challenges by using a rotating tool to generate frictional heat, plasticizing the material for solid-state joining without melting. This reduces IMC formation, enhancing joint strength and mechanical properties. Critical parameters like rotational speed, traverse speed, tool design, and process variables are emphasized for optimal FSW of dissimilar Al–Mg alloys. Joining these alloys is crucial in aerospace for applications such as aircraft structures, engine components, and fuel tanks. FSW offers advantages like weight reduction, improved fuel efficiency, and structural integrity enhancement. It allows welding dissimilar Al–Mg alloys with varying compositions for tailored material combinations meeting specific needs. In conclusion, FSW of dissimilar aluminum alloys is promising for aerospace, creating defect-free joints with improved mechanical properties. However, further research is needed to optimize parameters, explore tool designs, and validate long-term performance in aerospace environments.

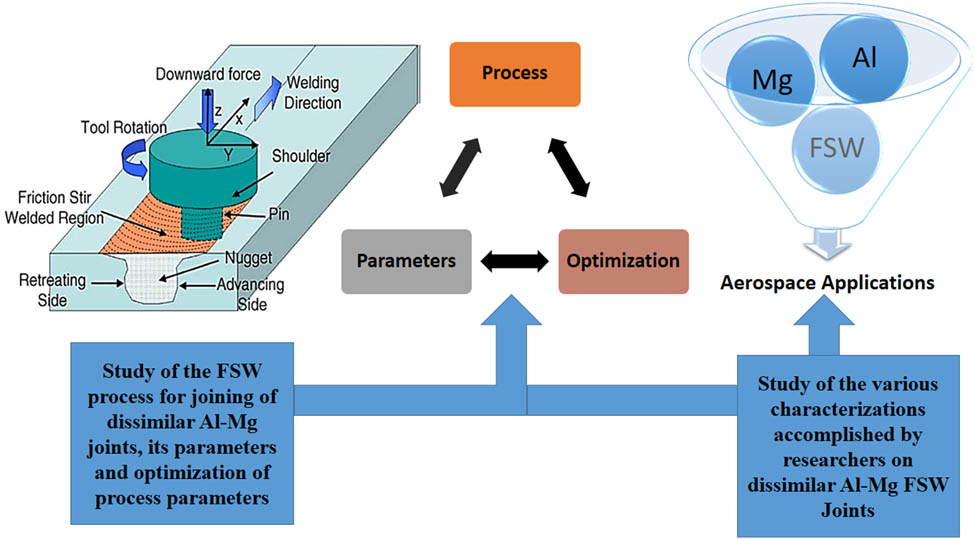

Graphical abstract

1 Introduction

Friction stir welding (FSW) has emerged as a promising solid-state joining technique for dissimilar aluminum (Al) alloys in the aerospace and other engineering industry [1]. FSW, a mature solid-state welding technique, involving temperature, mechanics, metallurgy, and interactions, has become a revolutionary welding technique because of its energy efficiency, environmental friendliness, and high-quality joints. And the state-of-the-art friction-based welding techniques are characterized by low peak temperature, severe plastic deformation, energy efficiency, which can simultaneously realize the mechanical and chemical bonding, improving mechanical performances. Furthermore, the introduction explores the potential applications of FSW in aerospace engineering and the benefits it offers, including reduced weight, improved fuel efficiency, and enhanced structural integrity. The unique properties of dissimilar Al–Mg alloys, make them attractive for various aerospace applications [2,3]. However, conventional fusion welding methods encounter challenges when joining dissimilar aluminum alloys, such as the formation of brittle intermetallic compounds (IMC) and reduction in the mechanical characteristics [4,5]. FSW offers a potential solution to overcome these challenges by utilizing a rotating non-consumable tool that generates frictional heat and plasticizes the material, enabling solid-state joining [6,7,8].

This introduction aims to explore the prospects and future potential of FSW for dissimilar aluminum alloys in aerospace applications. The section begins by providing an overview of FSW and its advantages over traditional fusion welding techniques. It then discusses the specific challenges associated with joining dissimilar aluminum alloys and highlights how FSW can address these challenges. Furthermore, the introduction explores the potential applications of FSW in aerospace engineering and the benefits it offers, including reduced weight, improved fuel efficiency, and enhanced structural integrity. Finally, the section concludes by emphasizing the need for further research and development efforts to optimize FSW parameters, explore new tool designs, and validate the long-term performance of FSW joints in aerospace environments.

Ahmed et al. accomplished an extensive examination of FSW, encompassing its principles, process parameters, microstructural changes, and mechanical properties [9]. To broaden the adoption of FSW in manufacturing fields, the inherent issues should be addressed to ensure the structural integrity, safety, and service life of the manufactured. The article discusses the application of FSW in diverse aluminum alloys, addressing both challenges and prospects. Additionally, Beygi et al. conducted a research review that delves into the use of FSW as a thermal-mechanical tool to enhance the properties of aluminum alloys. The focus lies on the modifications in microstructure achieved through friction stir processing and their impact on the alloys’ mechanical behavior [10]. In a separate study, Beygi et al. explored the microstructure and mechanical properties of dissimilar aluminum alloy welds produced via FSW. Their analysis investigates the effects of process parameters on defect formation, grain refinement, and joint strength, providing valuable insights for optimizing FSW in dissimilar alloys [11]. Beygi et al. have written a review article centered on the research and development of FSW in dissimilar aluminum alloys. They have addressed the challenges associated with welding dissimilar alloys, and explored process optimization strategies, and examined joint properties achieved through FSW [12]. Ding et al. provided an overview of the state-of-the-art research on FSW of dissimilar aluminum alloys. Their review encompasses discussions on microstructural characteristics, mechanical properties, joint performance, challenges, and future directions in the field [13]. Hassanifard et al. have conducted a comprehensive review that encompasses the advancements in FSW, including the process, weldment structure, and properties of friction stir welds. They have discussed microstructural evolution, defects, residual stresses, and mechanical behavior of FSW joints in aluminum alloys [14]. Hou, et al. focused their study on investigating the microstructural and mechanical properties of dissimilar FSW between aluminum alloys AA5083 and AA6061. Their examination includes an analysis of joint characteristics such as microstructural evolution, hardness distribution, and tensile properties [15]. Ribeiro et al. carried out research on the influence of pin profile on the microstructure and mechanical properties of dissimilar friction stir welds between aluminum alloys AA1050-H24 and AA2024-T3. They examined the joint characteristics such as grain refinement, intermetallic formation, and mechanical behavior [16]. Mehdi et al., accomplished the works on the influence of tool geometry and the factors on the FSW process of dissimilar aluminum sheets. The study focuses on welding four AZ91D and AA7075 alloy ultrathin sheets, each with a thickness of 0.3 mm, utilizing two convex tools with various edge radii. Their work evaluates elements including the coefficient of friction (CoF), microstructure, and mechanical properties evaluated using Vickers micro hardness testing and the tiny punch test in order to look into the effects of tool geometries and process parameters. To assess the quality of the welds, a scanning acoustic microscope is also used. According to the findings, raising tool radius from 15 to 22.5 mm dramatically decreases dwell time, increasing productivity. Due mostly to the prolonged stirring time, samples welded using a specific tool show no delamination and better mechanical qualities. Rotational speed is found to be the process parameter most important in shaping the weld, affecting CoF, microstructure, micro hardness, and weld effectiveness. For both of the instruments analyzed in this study, lower rotational speeds result in an increase in joint efficiency of 14.4 and 12.8% when compared to higher rotational speeds [17]. In contrast to the traditional FSW tool, which has a single shoulder and pin, bobbin tool friction stir welding (BTFSW) uses a novel tool design that has two shoulders joined by a pin. The mechanics of the welding process are made simpler by this design, especially when using the FSW arrangement, where the lower shoulder acts as the weld’s base without the need for a supporting plate. Additionally, the beginning downward and final upward movements generally seen in the FSW process are not necessary because the BTFSW tool enters the base metal from the side and rotates in a straight line. This study examines the shape and parameters of the BTFSW tool in relation to the development of wormhole defects and their effects on the mechanical properties of the Al-7Si/AZ91D alloys. According to the research, the geometry of the tool, which places more stress on the joint, significantly affects the heating process, just like how a faster rotating speed would. To avoid wormhole defects, it is crucial to get the best kinematic and geometric tool properties. The welds display ductile fracture behavior despite having significantly lower weld tensile strengths (varying from roughly 111–115 MPa) than the base metal (137 MPa). Additionally, compared to the base material (BM) (about 20.7–27.8 J), all welds exhibit higher impact strength values [18]. The FSW process offers numerous advantages over fusion welding. Given its crucial role in achieving robust welds, the design of FSW tools has become a focal point of interest. While there are various commercially available alternatives for FSW tools, they are not as versatile as consumables used in traditional fusion welding, as their applicability is limited to specific conditions. In this study, the research introduces formulas to serve as guidelines for designing FSW tools, specifically for the 2XXX, 5XXX, 6XXX, and 7XXX aluminum series and various thicknesses. These formulas aid in estimating key tool parameters, including pin length, pin diameter, and shoulder diameter [19]. Additionally, Çam et al. published a comprehensive review article that underscores recent advancements in FSW and their relevance in joining dissimilar aluminum alloys, particularly in structural applications for aircraft. The article provides an extensive examination of various aspects, including process variations, joint formation, microstructural characteristics, defects, and mechanical properties. It offers valuable insights that can guide future research endeavors in this field [20].

The need for optimization of the tool shoulder configuration, tool pin profile, and tool material is a key aspect in achieving better weld joints. In this regard, the review is more focused towards the choice of tool configuration, and the tool materials. In the study by Padmanaban and Balasubramanian, researchers have identified the optimal combination of tool pin profile, tool shoulder diameter, and tool material for FSW AZ31B magnesium (Mg) alloy. They tested five different tool pin profiles, five tool materials, and three tool shoulder diameters to create the joints. The tensile properties of the joints were examined and compared with the microstructure and hardness of the weld zone. The investigation revealed that the joints produced using a threaded pin profiled tool made of high carbon steel with an 18 mm shoulder diameter exhibited superior mechanical integrity and metallurgical quality compared to other configurations. The absence of defects in the weld region, the presence of very fine equiaxed grains within the weld region, and higher hardness in the weld region were identified as key factors contributing to the enhanced tensile properties of these joints [21].

Gopi and Mohan worked extensively on the aluminum alloy 6082-T6, which holds significant importance in crafting lightweight structures, particularly in the production of artillery, defense vehicles, and aircraft. Recognized for its robust strength-to-weight ratio and excellent resistance to corrosion even in harsh conditions, this alloy stands out as a preferred choice for structural applications. This research delved into the FSW process of aluminum alloy 6082-T6, considering three key process parameters (spindle speed, weld speed, and shoulder penetration) and two geometric tool parameters defining pin and shoulder profiles across five levels. Optimization was pursued through the Taguchi experimental design method, with FSW experiments executed using a conventional milling machine. The goal was to maximize tensile strength across varying plate thicknesses. Notably, the number of edges on the tool pin profile directly influences welding pulses. The findings revealed that maintaining a pulse range of 105–110 pulses per second proved optimal for achieving high-quality welds devoid of defects [22].

The increasing demand for lightweight materials in sectors such as automotive and aerospace has spurred investigations into the joining of dissimilar lightweight alloys, notably aluminum and magnesium alloys (Al/Mg). FSW emerges as a promising method for Al/Mg alloy joining due to its operation below the base metal’s melting point, resulting in refined microstructures, decreased porosity, and heightened productivity. The strength of Al/Mg friction stir welds hinges on the formed interface, primarily characterized by micromechanical interlocks and the distribution of IMCs. While various interfaces for butt joints have been explored in literature, a comprehensive review detailing interfacial interactions and methods for interface enhancement has been lacking. This review article addresses this gap by analyzing historical data on process parameters and mechanical properties, elucidating joining mechanisms, and examining the microstructural evolution of different interfaces. Additionally, strategies for enhancing interfaces to bolster mechanical properties are delineated [23]. By furnishing crucial insights into FSW techniques and Al/Mg weld interfaces, this review article lays the groundwork for refining FSW procedures for Al/Mg butt welds with a focus on augmenting strength and performance. It is anticipated that the current article is of significant interest to researchers and engineers in the FSW domain, especially for Al/Mg lightweight applications, offering a comprehensive overview of current knowledge and delineating avenues for future research.

2 Materials and methods

This section elucidates in detail, the findings of the existing literature available on the process, principle, and the factors influencing the process parameters and its effect on the quality of the FSW joints.

2.1 FSW – process and principle

The working principle of FSW involves the use of a rotating non-consumable tool that generates frictional heat and plasticizes the material to be joined, facilitating the formation of a strong and defect-free weld.

During the FSW process, the tool is plunged into the interface between the two workpieces and moved along the joint line, causing severe plastic deformation of the material. The frictional heat generated by the rotating tool softens the material without reaching its melting point, leading to a solid-state joining process. This aspect of FSW is crucial as it helps to minimize the formation of undesirable IMCs and retain the desirable properties of the BMs.

Several studies have investigated the working principle of FSW and its effects on the microstructural evolution and mechanical properties of the welded joints. To optimize the processing parameters, the entire-process simulation of FSW based on experiment validation was adopted for the prediction of tensile strength. This included the computational fluid dynamics model and computational solid mechanics model. High-throughput screening method, based on the marriage between massively parallel computational methods and existing database containing the calculated properties, is capable to explore hypothetical candidates, and the amelioration via the material flow model inhibits the welding defects and optimizes the parameter intervals, providing references to extracting process–structure–property linkages for FSW. The works of Taheri et al. provided a comprehensive improvements in the mechanical properties, viz., the tensile and fatigue strength, hardness, and wear resistance, achieved through FSW, discussing the principles, process parameters, and various applications [24]. Several researchers have focused on modeling the heat flow and material flow in FSW, highlighting the thermal and mechanical aspects of the process and the resulting improvement in the strength of the weld joints. In FSW, the material is subjected to severe plastic deformation due to the rotational motion of the tool, resulting in the mixing and redistribution of material across the weld zone. Di Lorenzo focused on the process of generating stronger joints by the frictional forces generated by the rotating tool plunged into the workpiece. In their works, the researchers have accomplished the FSW process with varying process parameters using a tempered tool steel shoulder pin configuration on dissimilar alloys of Al. The friction force generated by the rotating shoulder pin configurations enhances the strength of the joints, which can be attributed to severe plastic deformation brought about by the friction stirring of the tool against the workpiece [25]. Dias et al. developed a thermomechanical model for FSW of age-hardening aluminum alloys, elucidating the deformation behavior and microstructural changes during the process. They also proposed a model for predicting the temperature distribution, plastic flow, and residual stresses in FSW of 6061-T6 aluminum alloy [26]. Yang et al. provided an extensive review of the advancements in FSW process, including bobbin tool and stationary shoulder that enhanced the mechanical properties. They discussed the influence of these variants on joint formation, microstructural characteristics, defect formation, and mechanical properties. A rotating shoulder, a mechanical “stirring” device that mimics a drill bit, and two metals fastened on a rigid surface that serves as an anvil are generally used in the FSW process. During the FSW process, the anvil reacts to the plunge force, or downward pressure. Due to the high speeds and constant downward pressure of the spinning shoulder against the metal plates, a frictional force is created by driving it into the materials at the weld interface. A softened zone that is mechanically plasticized is produced at the joining place as a result of the frictional heating that results (Figure 1). The ingredients are mixed along the path as the welding instrument is simultaneously rotated and moved along the intended weld line [27].

![Figure 1

Working principle of FSW process. Adopted with permission from ref. [28]. Copyright 2021, SAGE.](/document/doi/10.1515/rams-2024-0033/asset/graphic/j_rams-2024-0033_fig_001.jpg)

Working principle of FSW process. Adopted with permission from ref. [28]. Copyright 2021, SAGE.

In summary, the working principle of FSW involves the generation of frictional heat and plastic deformation to achieve solid-state joining. Through a combination of experimental investigations and numerical modeling, researchers have gained insights into the thermal and mechanical behavior during the FSW process. These studies have contributed to the optimization of process parameters and the development of advanced process variants, making FSW a promising welding technique for a wide range of applications.

2.2 FSW of dissimilar Al–Mg alloys

FSW technique for welding Al–Mg alloys offers several advantages such as reduced defects, improved mechanical properties, and enhanced productivity [29,30]. In a comprehensive research study, Baghdadi et al. provided an overview of FSW, covering process parameters, microstructural evolution, and mechanical properties. Various aluminum alloys are considered, and the influence of welding parameters on weld quality is discussed [31]. Silva et al. focused on the early development of FSW for aluminum alloys, emphasizing the process concept, tool design, and welding parameters, along with examples of successful welds in different aluminum alloys [32]. Lee et al. highlighted the impact of process parameters (rotational speed, traverse speed, and tool geometry) on the mechanical properties of friction stir-welded aluminum alloys. They examined the microstructural changes and their correlation with resulting mechanical properties [33]. Esmaeili et al. conducted in-depth research on FSW of aluminum alloys, exploring tool materials, joint design, defects, and post-weld treatments. They discussed process optimization advancements and presented case studies on different aluminum alloy systems [34]. Sato et al. focused on the microstructural evolution and mechanical properties of friction stir-welded aluminum alloys, discussing factors influencing grain refinement, precipitate dissolution, and recrystallization during the welding process, as well as the impact of microstructure on mechanical properties [35]. Mofid et al. and Zettler et al. contributed valuable works that establish a foundation for understanding the principles and applications of FSW in aluminum alloys. Further examination of these studies and related research will provide additional insights into specific aluminum alloys, process parameters, and optimization techniques in FSW [36,37].

Moreover, FSW shows promise for joining dissimilar aluminum alloys, as it can produce high-quality welds with favorable mechanical properties [38,39]. Cao and Jahazi’s work focused on using FSW to join dissimilar aluminum alloys, specifically AA 2024-T3 to AZ31B-H24 alloys. The effects of tool geometry and welding parameters on weld quality are investigated, and the results demonstrate that FSW can generate defect-free welds in dissimilar aluminum alloys with satisfactory mechanical properties. The welds exhibit comparable tensile strength and fatigue strength to the base metal [40].

Similarly, Abachi et al. presented findings that support the potential of FSW for joining dissimilar aluminum alloys. Their study demonstrated that FSW can create high-quality welds with favorable mechanical properties, positioning it as a viable alternative to traditional welding methods [41].

Additionally, Dolatkhah et al. extensively examined the FSW of Al5052/SiC metal matrix composites, with key findings including the ability of FSW to produce defect-free welds in dissimilar aluminum alloys. The welds exhibited comparable tensile strength and fatigue strength to the base metal, further highlighting FSW as a promising technology for joining dissimilar aluminum alloys [42].

The growing demand for lightweight materials has created an urgent requirement to weld Mg/Al composite structures, which hold significant promise across various industries. However, welding dissimilar Mg/Al alloys often results in the undesirable formation of brittle IMCs, presenting challenges in achieving high-quality welded joints. Solid-state welding methods, characterized by their low energy input and high efficiency, offer a viable solution to mitigate the formation of these problematic compounds and address strength issues in Mg/Al dissimilar alloy welds for engineering applications. Drawing insights from recent research literature on techniques such as ultrasonic welding, friction welding, diffusion welding, explosive welding, magnetic pulse welding, and resistance spot welding of Al/Mg, this study presents a comprehensive overview and future outlook for solid-state welding in the context of Mg/Al dissimilar alloy welding. It encompasses areas such as the optimization of welding parameters, the incorporation of interlayers, and the exploration of hybrid welding processes [43]. In engineering sectors like automotive, marine, aerospace, and railway, the use of lightweight aluminum and magnesium alloys is vital for enhancing fuel efficiency, performance, and cost-effectiveness. FSW is favored over traditional fusion welding due to its metallurgical benefits when joining these dissimilar materials. This study specifically investigated the creation of dissimilar joints using AA6061 (A), AZ31B (B), and AZ91D (C) alloys, varying the advancing side (AS) and retreating side (RS). The joints, formed through FSW, underwent a battery of tests encompassing tensile, impact, corrosion, and fracture assessments, along with statistical and cost analyses. The results showcased notable achievements, such as the highest tensile strength in AZ91 and AZ31B, peak yield strength in AA6061 and AZ91, the hardest composition in AA6061 and AZ31B, and the lowest corrosion rate in AA6061 and AZ31B. These outcomes were validated by SEM analysis of fracture surfaces, and the dissimilar joints were further evaluated and ranked using statistical analysis and the TOPSIS method, considering their proximity to the ideal solution [44].

In conclusion, FSW has emerged as a promising technique for welding aluminum alloys, offering numerous advantages. It enables defect-free welds with favorable mechanical properties, positioning it as a viable alternative to traditional welding methods for joining both similar and dissimilar aluminum alloys.

2.2.1 Major challenges in dissimilar welding

Dissimilar welding, which involves joining two or more materials with different compositions, poses several challenges compared to welding similar materials. Some of the major problems encountered in dissimilar welding include:

Material compatibility: Dissimilar materials often have different melting points, thermal conductivities, and coefficients of thermal expansion, leading to issues such as cracking, distortion, and residual stresses during welding. Achieving proper fusion and metallurgical bonding between dissimilar materials requires careful control of welding parameters and techniques.

IMC formation: When dissimilar materials are welded together, IMCs may form at the interface, altering the mechanical properties and corrosion resistance of the joint. The formation of brittle IMCs can weaken the weld, leading to reduced joint strength and ductility. Minimizing IMC formation while maintaining a sound weld is a significant challenge in dissimilar welding.

Microstructural inhomogeneity: Dissimilar materials often have different microstructures, grain sizes, and phases, which can result in non-uniform mechanical properties across the weld joint. Inhomogeneous microstructures may lead to localized stress concentrations and susceptibility to cracking or failure under mechanical or thermal loads.

Thermal gradient effects: Dissimilar welding generates significant thermal gradients across the weld zone due to the different thermal conductivities and heat capacities of the materials being joined. Thermal gradients can result in distortion, warping, and residual stresses, particularly in thick or complex structures. Managing thermal gradients is crucial to prevent weld defects and ensure dimensional stability.

Corrosion susceptibility: Welding dissimilar materials can introduce galvanic corrosion potential due to the formation of bimetallic couples at the weld interface. The difference in electrochemical potentials between dissimilar materials can accelerate corrosion rates, compromising the long-term integrity of the joint. Proper selection of filler materials and post-weld treatments are essential to mitigate corrosion risks.

Weldability issues: Some dissimilar material combinations may exhibit poor weldability due to factors such as metallurgical incompatibility, chemical reactions, or the presence of surface contaminants. Ensuring adequate joint preparation, cleanliness, and compatibility testing is necessary to overcome weldability challenges and produce high-quality joints.

Complexity in process optimization: Welding dissimilar materials requires careful optimization of welding parameters, including heat input, travel speed, shielding gas composition, and interpass temperature control. The complex interaction between these parameters and their effects on weld quality and performance necessitates extensive experimentation and process validation.

Addressing these challenges in dissimilar welding requires a comprehensive understanding of material properties, welding processes, and joint design considerations. Innovative welding techniques, advanced materials characterization methods, and computational modeling approaches play a crucial role in overcoming these problems and advancing the state-of-the-art in dissimilar welding technology.

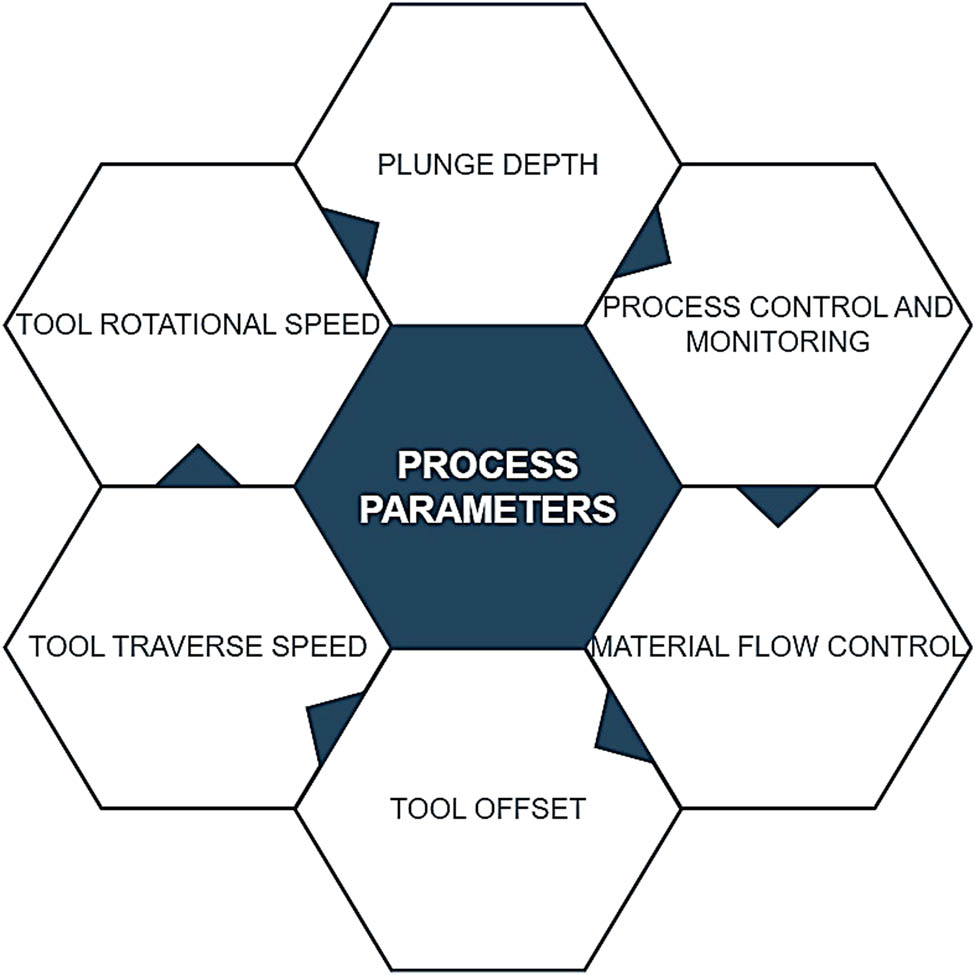

2.3 Process parameters influencing FSW of dissimilar Al–Mg alloys

Al–Mg alloys are widely utilized in the aerospace and automotive industries due to the numerous advantages they offer. However, their application in structural uses is often limited due to their poor weldability.

The dissimilar FSW of Al–Mg alloys presents significant challenges due to the contrasting properties of the two materials, including melting points, thermal conductivity, and wettability. While aluminum has a melting point of 660°C and a thermal conductivity of 240 W·m−1·K−1, magnesium’s melting point is 650°C, and its thermal conductivity is 150 W·m−1·K−1. Additionally, both aluminum and magnesium exhibit poor wettability [45].

In the research conducted by Luo and Sachdev, the focus was on dissimilar Al–Mg FSW, exploring the associated challenges. The study emphasized the discrepancies in material properties, such as melting points, thermal conductivity, and wettability, and proposed strategies to overcome these difficulties [46]. Yang et al. examined the microstructural evolution and mechanical properties of dissimilar Al–Mg FSW joints, investigating the influence of process parameters like rotational speed, traverse speed, and tool offset on the joint’s microstructure and mechanical performance. The study highlighted the significance of optimizing these parameters to achieve desirable joint properties [27].

Cao and Jahazi specifically investigated the impact of tool pin profiles on the quality of dissimilar Al–Mg FSW joints. They compared conventional cylindrical pins with specially designed tapered and concave pins, demonstrating the substantial influence of tool pin geometry on joint quality and mechanical properties [47]. Ke et al. delved into the microstructure and mechanical properties of dissimilar Al–Mg FSW joints, analyzing the effect of various FSW conditions on joint strength, hardness, and microstructural changes [48]. Siddesh Kumar et al. examined the corrosion behavior of dissimilar Al–Mg FSW joints, studying how FSW process parameters affected their corrosion resistance. The research emphasized the role of grain structure, IMCs, and microstructural defects in determining corrosion behavior [49].

Furthermore, Gulati et al. conducted mechanical and metallurgical characterization of dissimilar Al–Mg FSW joints using advanced techniques like electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM). Their study provided insights into grain structure, texture, and precipitate distribution in the joints, contributing to a better understanding of joint microstructure and mechanical behavior [50]. Lambrakos explored the influence of tool design on the mechanical properties of dissimilar Al–Mg FSW joints, comparing different geometries (cylindrical, threaded, and hexagonal pins) and evaluating their impact on joint strength and defect formation. The research emphasized the significance of optimizing tool design for achieving high-quality joints [51].

The key process parameters that significantly affect the quality of dissimilar FSW joints include tool rotational speed, tool traverse speed, tool offset, and plunge depth [52]. The tool rotational speed should generate sufficient heat to soften the BMs without overheating the tool itself [53]. The tool traverse speed should ensure proper joint formation while allowing for efficient tool movement through the workpiece [54]. The tool offset should strike a balance between maintaining contact with both BMs and avoiding pin breakage. The plunge depth should create a sound weld without causing excessive tool overheating [55]. Figure 2 provides a schematic illustrating the factors that influence the FSW process.

Process parameters influencing the quality of the joints in FSW process.

The effect of various process parameters on dissimilar FSW of different materials, such as Al–Mg, is crucial for achieving high-quality joints [56,57]. Here are some commonly investigated process parameters and their effects:

2.3.1 Tool rotational speed

Higher rotational speeds generally lead to increased heat input, resulting in improved material softening and better mixing between the BMs [58]. However, excessively high rotational speeds can cause tool wear, material overheating, or defects such as tunnel defects or voids [59].

In the study conducted by Sankar and Umamaheswarrao, the influence of tool rotational speed on the microstructure and mechanical properties of friction stir-welded joints in Al–Mg alloys was investigated. The researchers employed various characterization techniques such as optical microscopy, scanning electron microscopy (SEM), and TEM to examine the welds’ microstructure. Additionally, tensile tests were performed to evaluate the mechanical properties of the welds. The findings revealed that tool rotational speed played a significant role in determining the microstructure and mechanical properties of the Al–Mg alloy joints produced through FSW. At lower tool rotational speeds, the microstructure of the welds exhibited a larger number of equiaxed grains. This outcome can be attributed to the less effective stirring action of the tool at lower rotational speeds. Conversely, increasing the tool rotational speed led to a more refined microstructure in the welds. This improvement occurred due to the more efficient stirring action of the tool, which facilitated the breakdown of larger grains. Regarding the mechanical properties, the tensile tests demonstrated that the tensile strength of the welds increased as there was a substantial increase in the tool rotational speed. The refined microstructure of the welds exhibited enhanced resistance to deformation, thereby contributing to the higher tensile strength. However, an inverse relationship was observed between the ductility of the welds and the tool rotational speed. This reduction in ductility was attributed to the refined microstructure’s increased susceptibility to cracking [60].

2.3.2 Tool traverse speed

Increased traverse speeds in FSW have implications for material flow during the welding process [61,62]. When traverse speeds are higher, there is a potential for inadequate material mixing and compromised joint strength if sufficient time is not allowed for proper consolidation [63,64]. Extensive research has been conducted in the field of welding and materials science to explore the relationship between tool traverse speed and the strength of FSW joints. Numerous research papers and studies have investigated this relationship, considering various materials, welding conditions, and evaluation methods [65,66].

It should be noted that the impact of tool traverse speed on joint strength is intricate and influenced by multiple factors [67,68]. Here are some key observations from the literature:

Heat input and microstructure: The traverse speed affects the heat input during welding, which influences the thermal cycle experienced by the material. A higher traverse speed reduces the heat input, resulting in shorter heat exposure and reduced thermal diffusion. This can lead to a finer grain structure, improved microstructural homogeneity, and potentially higher joint strength [69,70].

Material flow and defect formation: The traverse speed influences the material flow patterns during FSW. Higher traverse speeds generally result in increased material flow rates, promoting better mixing and reducing defects such as voids and inclusions. However, excessively high traverse speeds can lead to insufficient material flow and incomplete consolidation, resulting in lower joint strength [71,72].

Weld zone geometry: The traverse speed affects the geometry of the weld zone, including the width and depth of the weld. Different traverse speeds can alter the thermal profile and the distribution of plastic deformation in the joint. Optimal weld zone geometry depends on the material being welded and can vary for different applications. In some cases, a moderate traverse speed has been found to produce joints with superior strength [73,74,75].

Mechanical properties and joint strength: The traverse speed can have a direct influence on the mechanical characteristics of FSW joints. Higher traverse speeds tend to result in joints with higher tensile strength but lower ductility, while lower traverse speeds can lead to increased joint toughness [76,77,78]. The optimal traverse speed for achieving the desired balance of mechanical properties depends on the specific material and application. It is important to note that the specific findings and optimal traverse speed ranges may vary depending on the materials being welded, joint configuration, welding parameters, and evaluation methods used in different studies. Additionally, ongoing research and advancements in FSW continue to contribute to the understanding of the influence of traverse speed on joint strength [79,80,81].

The results of these studies show that the FSW process gives good joint strength and toughness between the dissimilar weld joints of Al–Mg alloys. The FSW process is also a relatively clean and environmentally friendly process. However, the FSW process can be sensitive to process parameters, such as tool rotation speed and traverse speed [82]. The studies also reveal that the FSW process can be optimized by carefully controlling these process parameters. Slower traverse speeds may provide better mixing but can increase the overall welding time [83,84,85].

2.3.3 Tool offset

Tool offset in FSW refers to the lateral displacement of the rotating tool from the centerline of the joint. When welding dissimilar Al–Mg alloys, the tool offset can have a significant influence on the FSW process and the resulting joint properties [86,87].

The tool offset determines the penetration depth of the pin into the joint, affecting the interaction between the materials. A small offset ensures proper contact between the pin and both BMs, promoting effective mixing and joint formation [88,89]. If the offset is too large, excessive heat generation or pin breakage can occur, leading to defects or weakened joints [90,91].

Here is a review of the effect of tool offset on FSW of Al–Mg alloys

Material mixing: Tool offset affects the material mixing during FSW. When the tool is offset towards the aluminum side, it promotes better mixing and distribution of the magnesium-rich material into the aluminum matrix. This can enhance the metallurgical bonding and reduce the formation of IMCs that are typically brittle and weak [92,93].

Microstructure: The tool offset also affects the microstructural evolution in the weld zone. A proper tool offset can result in a more refined and uniform microstructure. It helps in breaking down the large grain structures and promoting grain refinement, leading to improved mechanical properties. An excessive offset, however, can lead to non-uniform microstructures, including uneven grain sizes and localized defects [94,95].

Mechanical properties: The choice of tool offset can significantly impact the mechanical properties of the joint. Proper offset selection can enhance the joint strength, ductility, and fatigue resistance. Studies have shown that an optimized tool offset can result in improved tensile strength and hardness, as well as enhanced fatigue life in aluminum-magnesium joints [96,97].

Intermetallic formation: Tool offset can influence the formation of IMCs at the weld interface. Excessive offset may lead to the formation of brittle intermetallic phases, such as Al–Mg and Al–Mg2, which can negatively affect the joint strength. However, a suitable tool offset can minimize the intermetallic thickness and maintain a favorable interfacial microstructure [98,99].

Process optimization: The choice of tool offset depends on several factors, including the specific aluminum and magnesium alloys being welded, the desired joint properties, and the welding conditions. Optimal tool offset values may vary depending on the material combinations and welding parameters. Process optimization through experimental investigations and parameter studies is crucial to determine the most suitable tool offset for achieving the desired joint quality and mechanical properties [100,101].

2.3.4 Plunge depth

The plunge depth determines the initial penetration of the tool into the workpiece before the traverse motion begins [102]. A suitable plunge depth ensures sufficient material supply for proper mixing and joint formation [103]. Too shallow plunge depths may result in incomplete material mixing, while excessive depths can lead to overheating or defects [104].

Here is a review of the effect of plunge depth on FSW of aluminum-magnesium joints:

Material mixing: The plunge depth affects the material mixing during FSW. By controlling the plunge depth, it is possible to regulate the extent of material intermixing between the aluminum and magnesium alloys. A deeper plunge depth typically leads to more extensive mixing, resulting in better metallurgical bonding between the two dissimilar materials [105,106].

Heat generation: The plunge depth affects the heat generation and dissipation in the weld zone. A deeper plunge depth generally results in increased heat generation due to greater contact between the tool and the workpiece. This increased heat can affect the thermal history, material flow, and microstructural evolution during the welding process [107,108].

Microstructure: The plunge depth can influence the microstructure of the weld zone. Deeper plunge depths tend to induce more severe plastic deformation and higher strain rates, leading to grain refinement and potential changes in the grain structure of both aluminum and magnesium alloys. This can affect the mechanical properties of the joint [109,110].

Defect formation: The plunge depth can impact defect formation during FSW. Excessive plunge depths can lead to excessive plastic deformation, which may result in the formation of defects such as voids, tunnel defects, or wormholes. It is important to select an appropriate plunge depth to minimize these defects and ensure sound joint formation [111,112].

Joint strength and properties: The choice of plunge depth can significantly influence the joint strength and properties of aluminum-magnesium FSW joints. Studies have shown that an optimized plunge depth can lead to improved joint strength, including higher tensile strength and better fatigue performance. The specific optimum plunge depth may vary depending on the alloy compositions, joint configuration, and desired joint properties [113,114].

It is worth noting that the effect of plunge depth on FSW of aluminum-magnesium joints may depend on various factors, such as the specific alloys being welded, welding parameters, tool geometry, and joint design. Optimal plunge depth selection should be determined through experimental investigations, parameter studies, and process optimization to achieve the desired joint quality and mechanical properties.

2.3.5 Material flow control

In dissimilar FSW, material flow control is crucial for achieving sound joints. Various factors, including pin geometry, shoulder design, and process parameters, influence material flow and mixing [115]. Optimization of these factors can help control material flow and enhance joint quality [116].

Material flow control is an important aspect in FSW of dissimilar Al–Mg alloys. Proper material flow during the FSW process is crucial for achieving sound welds and desirable joint properties [117]. Here is a review of the significance of material flow control in FSW process:

Mixing and homogenization: Material flow control ensures effective mixing and homogenization of the aluminum and magnesium alloys during the welding process. The rotating tool generates frictional heat and applies pressure, causing the materials to undergo plastic deformation and mix at the joint interface. Controlling material flow helps promote thorough mixing and the distribution of alloying elements, leading to a more uniform microstructure and improved joint properties [119,120].

Defect minimization: Proper material flow control helps minimize the formation of defects in FSW joints. Insufficient material flow can result in unfilled regions, voids, or incomplete consolidation, which can weaken the joint. On the other hand, excessive material flow can lead to tunnel defects or wormholes. By optimizing the material flow through proper tool design, process parameters, and welding conditions, defects can be minimized, enhancing the joint strength and integrity [120,121].

Grain refinement: Material flow control influences the grain refinement in the weld zone. During FSW, the stirring action of the tool breaks down the original grain structures and induces dynamic recrystallization, resulting in a refined grain structure. Effective material flow helps distribute the recrystallized grains evenly throughout the weld zone, contributing to improved characteristics, such as higher strength and enhanced ductility [122,123].

Intermetallic formation: Material flow control can also influence the formation of IMCs at the weld interface. In aluminum-magnesium joints, intermetallic phases can form due to diffusion and reaction between the two alloys. By controlling material flow, the intermetallic thickness and distribution can be managed, reducing the formation of brittle phases, and improving joint strength [124,125].

Tool design and parameters: Achieving proper material flow control requires careful consideration of tool design and process parameters. Factors such as tool geometry, rotational speed, traverse speed, axial force, and tool tilt angle (TTA) can all influence material flow patterns. Process optimization through experimentation and parameter studies is essential to determine the most suitable combination of parameters for achieving the desired material flow and resulting joint properties [126]. The tool is the key point to get sound joint. The material flow was affected by the temperature and the profile of tool. The design of tool can be considered for avoiding weld thinning. Flash defects were eliminated and weld thinning was avoided. For eliminating root kissing bond, the root-enhanced FSW, with an enlarged-tip pin and concave structure, was a good choice to enhance the root tolerance in thick plates [127]. The material flow was affected by the temperature and the profile of tool.

It is worth noting that material flow control in FSW is a complex phenomenon influenced by multiple factors. The specific requirements for material flow control may vary depending on the aluminum and magnesium alloys being welded, joint configuration, and application requirements [128]. Therefore, comprehensive process optimization and experimentation are necessary to achieve optimal material flow control and desired joint properties.

2.4 Process control and monitoring

Effective process control and monitoring, such as temperature monitoring, force monitoring, and in-process inspections, can ensure consistent and high-quality dissimilar FSW joints [129].

Real-time feedback systems can be used to adjust process parameters for improved weld quality and defect prevention. It is important to note that the effects of these process parameters can vary depending on the specific materials being joined and the welding conditions [130]. Therefore, thorough experimentation and parameter optimization are necessary for each dissimilar FSW application to achieve desired joint quality and mechanical properties.

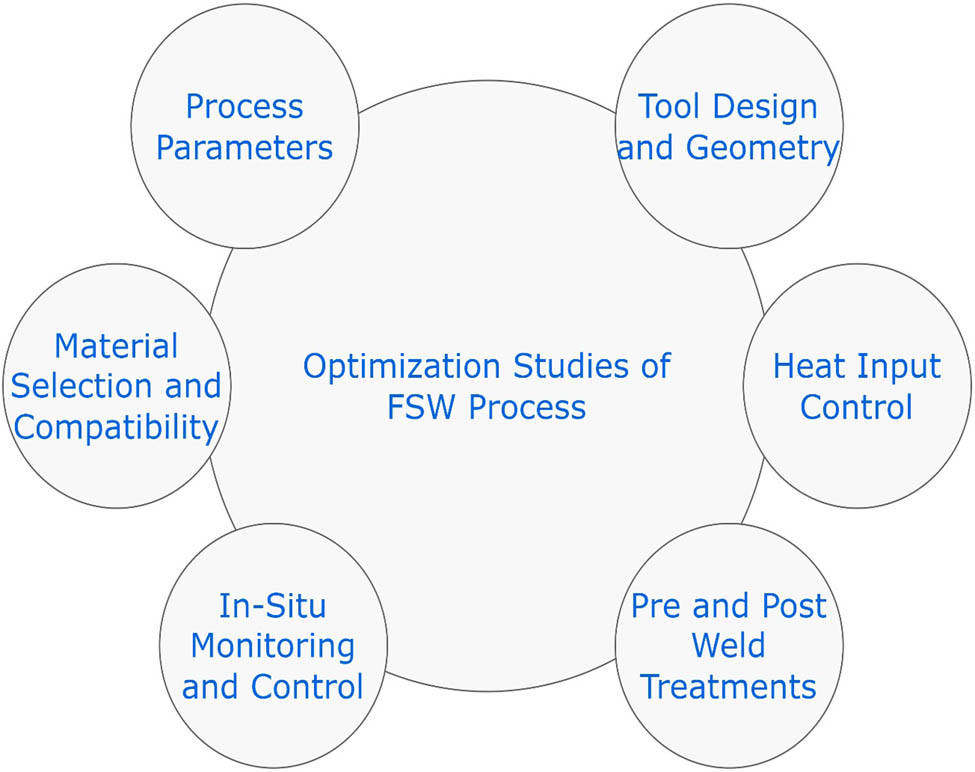

In addition to these process parameters, other factors such as tool design, material preparation, and post-weld heat treatment (PWHT) can also influence the quality of dissimilar FSW joints between aluminum and magnesium [131]. Therefore, careful optimization of these parameters, along with proper process control and monitoring, is essential to achieve reliable and high-quality welds in Al–Mg dissimilar FSW applications.

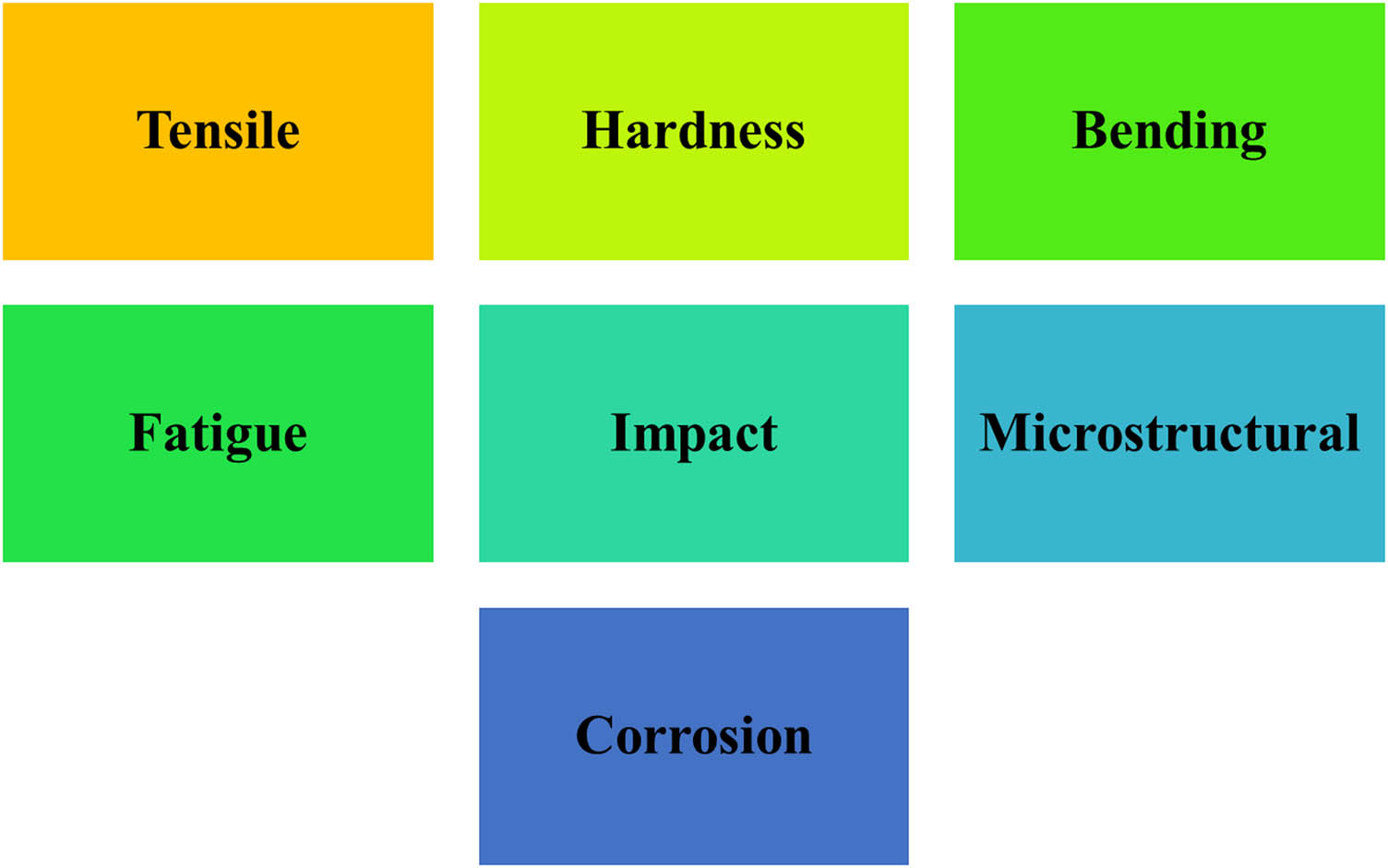

3 Experimental section

The experimental section encompasses the findings of the review related to the characterization of FSW joints evaluating the performance and properties of the welded joint to ensure its suitability for intended applications. Several mechanical tests are commonly conducted to assess the quality and integrity of FSW joints. Here are some key experimentations accomplished to characterize the FSW joints.

3.1 Tensile testing

Tensile testing is used to determine the tensile strength, elongation, and yield strength of FSW joints. Specimens are typically extracted from the welded region and subjected to axial loading until fracture. The test provides information about the joint’s load-carrying capacity and its resistance to deformation under tension [132].

The tensile testing of FSW joints is vital to identify the tenacity of the joints under tensile loading patterns. The specimens are subjected to varied loadings to critically evaluate the joint strength under the action of pulling forces. This type of tests are needed to understand the behavior of FSW joints, particularly for its use in aerospace applications.

Sameer and Birru conducted a study on FSW of dissimilar materials, specifically AA 6082-T6 aluminum alloy and AZ91 magnesium alloy. Their research focused on assessing the impact of process parameters on the tensile strength of the friction stir-welded joints, as well as analyzing the microstructural characteristics and mechanical properties of the joints. The experimental work involved performing FSW on the dissimilar combination of AZ91 magnesium alloy and AA 6082-T6 aluminum alloy, considering various process parameters such as rotational speed, traverse speed, and axial force. A cylindrical tool with a threaded profile was used for the welding process. The study findings indicated that the tensile strength of the dissimilar joints was influenced by the selected process parameters. The joints exhibited a mixture of IMCs with different sizes and distributions, which were formed during the FSW process. Microstructural analysis revealed grain refinement and the presence of a partially melted zone near the joint interface. A stress–strain curve for different weld joints is presented in Figure 3 [133].

![Figure 3

Stress–Strain diagram from tensile tests on FSW joints of Al–Mg alloys. Adopted with permission from ref. [133]. Copyright 2019 Elsevier.](/document/doi/10.1515/rams-2024-0033/asset/graphic/j_rams-2024-0033_fig_003.jpg)

Stress–Strain diagram from tensile tests on FSW joints of Al–Mg alloys. Adopted with permission from ref. [133]. Copyright 2019 Elsevier.

Figure 4 illustrates the comparative evaluation of the different welding processes and the corresponding tensile characteristics. When examining the different welding processes, it was observed that the tensile properties of FSW process has enhanced owing to coring and segregation at the stir zone (SZ) in the FSW weld joint. The FSW specimen exhibited a higher ultimate tensile strength (UTS) compared to the specimens from other welding process, and a similar trend was observed in the tensile strain (elongation). This difference can be attributed to the fact that the FSW specimen consists of the SZ material with uniform grain sizes, while the specimens from other welding processes include four distinct regions: the BM, heat-affected zone (HAZ), thermo-mechanically affected zone, and the SZ. Another contributing factor to the higher UTS in the longitudinal direction is the presence of positive residual stress, which is more significant in the longitudinal direction than in the transverse direction. As a result, when samples are cut along the longitudinal direction, they can release a greater amount of residual stress, likely contributing to the higher strength levels observed. Furthermore, in the longitudinal joint, the applied tensile load primarily follows the direction of the weld, leading to a more direct and uniform distribution of strain. This uniform strain distribution promotes better load sharing among grains, resulting in higher UTS and elongation compared to the transverse joint, where strain distribution is less uniform [134].

![Figure 4

Comparison of the specimens from FSW and other processes. Adopted with permission from ref. [134]. Copyright 2023 MDPI Materials.](/document/doi/10.1515/rams-2024-0033/asset/graphic/j_rams-2024-0033_fig_004.jpg)

Comparison of the specimens from FSW and other processes. Adopted with permission from ref. [134]. Copyright 2023 MDPI Materials.

Based on the results, the researchers have reached the conclusion that the tensile strength of the dissimilar joints can be enhanced by appropriately choosing the process parameters during FSW. Furthermore, the alterations in the microstructure and the development of IMCs have a notable impact on the mechanical properties of the joints. Tensile testing is a crucial method for evaluating the tensile strength and tensile modulus of the dissimilar weld joints between aluminum and magnesium alloys.

3.2 Hardness testing

Hardness testing measures the hardness profile across the FSW joint to assess its hardness distribution and potential variations. Hardness tests, such as Vickers or Rockwell hardness tests, are performed on specific locations within the joint, including the HAZ, weld nugget, and BMs. Hardness values can indicate the extent of material softening, phase transformations, and microstructural changes in the joint. Micro hardness measurements were conducted following the ASTM E92 standard, employing a 100 g load for 10 s on a Micro Vickers Hardness Testing Machine with a capability to apply forces ranging from 10 g to 1 kg. Figure 5 illustrates the impact of FSW at a rotational speed of 500 rpm on the hardness distribution across the welded samples. Hardness values were measured at various points, including the HAZ, center, and transverse cross-section of the friction stir-welded joints. Notably, the center zone of the friction stir-welded specimens (Specimen 1, Specimen 2, Specimen 3, and Specimen 4) exhibited the highest level of hardness due to the stirring action during welding. The hardness profiles within the weld zone were strongly influenced by several processing parameters, including heat input, fusion zone dilution, circulation of the molten pool, intermixing of dissimilar metals, and the subsequent formation and distribution of intermetallic phases within the interaction zones rich in Mg and Al. It is important to note that while Sample 5 did not undergo mechanical deformation (stirring), the peak temperature reached during welding was sufficient to soften the material near the SZ/nugget zone [135].

![Figure 5

Vickers micro hardness for different locations of FSW joint. Adopted with permission from ref. [134]. Copyright 2023 MDPI Crystals.](/document/doi/10.1515/rams-2024-0033/asset/graphic/j_rams-2024-0033_fig_005.jpg)

Vickers micro hardness for different locations of FSW joint. Adopted with permission from ref. [134]. Copyright 2023 MDPI Crystals.

3.3 Bend testing

Bend testing evaluates the ductility and resistance to cracking of FSW joints [136]. The test involves subjecting the FSW specimen to bending forces, typically using a three-point or four-point bend setup. Bend testing can detect any defects or discontinuities in the joint, such as cracks, lack of fusion, or incomplete penetration [137].

In their research, Das and Toppo conducted bend tests in accordance with ASTM E190 standards to assess the bending strength of friction stir-welded joints and investigate the impact of process parameters on mechanical properties. FSW was employed as the joining technique, involving a rotating tool that generates heat through friction and plasticizes the material to form the joint. The experimental setup involved butt joints of AA6101-T6 and AA6351-T6 aluminum alloys as the BMs. Various welding parameters, including tool rotational speed, welding speed (WS), and axial force, were modified to analyze their influence on the bending strength of the joints. A three-point bending test was performed to evaluate the load-bearing capacity of the joints. The study results indicate that the bending strength of the friction stir-welded butt joints is affected by the process parameters, leading to varying bending strength based on the chosen welding conditions. Microstructural analysis reveals a refined and homogeneous microstructure within the weld zone. Based on their findings, the authors conclude that selecting appropriate process parameters during FSW can optimize the bending strength of friction stir-welded butt joints. The study emphasizes the importance of process optimization in achieving desired mechanical properties in friction stir-welded joints of Al–Mg alloys [138].

3.4 Fatigue testing

Fatigue testing assesses the resistance of FSW joints to cyclic loading, simulating real-life service conditions. Specimens are subjected to repeated loading and unloading cycles until failure. Fatigue tests can determine the joint’s fatigue strength, fatigue life, and the initiation and propagation of fatigue cracks [139,140].

In a study conducted by Yan, the fatigue performance of dissimilar friction stir-welded joints between Al–Mg–Si and Al–Zn–Mg aluminum alloys is investigated. The objective of the study is to evaluate the fatigue behavior of these joints and understand the impact of the welding process on their fatigue strength. FSW is employed as the joining technique, utilizing a rotating tool to generate heat and mechanically mix the materials. The experimental work involves the creation of friction stir-welded joints using dissimilar Al–Mg-Si and Al–Zn–Mg aluminum alloy sheets. Fatigue testing is carried out on the joints to determine their endurance limit and fatigue life under cyclic loading conditions. The test specimens are subjected to varying stress levels, and the number of cycles until failure is recorded. The results of the study indicate that the fatigue behavior of the dissimilar friction stir-welded joints is influenced by the welding parameters and joint microstructure. The joints exhibit different fatigue strengths depending on the specific welding conditions employed. Microstructural analysis reveals the presence of fine grains and IMCs within the weld zone [141]. Figure 6 gives the fatigue life for dissimilar Al–Mg alloy FSW joints.

![Figure 6

Fatigue life curve for dissimilar Al–Mg alloy joints. Adopted with permission from ref. [141]. Copyright 2016, Springer Nature, Acta Metallurgica Sinica.](/document/doi/10.1515/rams-2024-0033/asset/graphic/j_rams-2024-0033_fig_006.jpg)

Fatigue life curve for dissimilar Al–Mg alloy joints. Adopted with permission from ref. [141]. Copyright 2016, Springer Nature, Acta Metallurgica Sinica.

Based on the findings, the authors conclude that the fatigue performance of dissimilar Al–Mg–Si/Al–Zn–Mg friction stir-welded joints can be optimized by selecting appropriate welding parameters. The study highlights the significance of understanding the microstructural changes and their impact on the fatigue behavior of such joints.

3.5 Impact testing

Impact testing evaluates the behavior of FSW joints under dynamic loading conditions [138]. Charpy or Izod impact tests are commonly performed to measure the impact toughness and energy absorption capacity of the joint. The test measures the resistance of the joint to sudden, high-energy impacts and provides insights into its fracture behavior [142].

In a study conducted by Sidhu et al., the impact energy absorbed by dissimilar friction stir-welded joints between dissimilar Al–Mg alloys is investigated. The main objective of the study is to evaluate the impact energy properties of these joints and examine the impact of process parameters on their mechanical behavior. Various welding parameters, including tool rotational speed, WS, and axial force, are adjusted to investigate their influence on the impact energy of the joints. Impact testing is performed using a Charpy impact test machine to measure the energy absorbed during fracture. The findings of the study indicate that the impact energy properties of the dissimilar friction stir-welded joints are significantly influenced by the welding parameters. The joints exhibit different impact energy absorption capacities based on the selected welding conditions. The microstructural analysis indicates the presence of a refined and homogeneous microstructure within the weld zone. Table 1 gives the impact energy absorbed by the FSW joints for dissimilar alloys of Al–Mg [43].

Results of impact tests on dissimilar alloys of Al and Mg

| Weld joint | Impact energy (J) | |||

|---|---|---|---|---|

| Trial 1 | Trial 2 | Trial 3 | Average | |

| AA 6061 and AZ31B | 8.1 | 8.5 | 8.3 | 8.3 |

| AZ31 and AA6061 | 7.6 | 8.5 | 7.9 | 8 |

| AZ31B and AZ91 | 5.3 | 5.5 | 5.7 | 5.5 |

| AZ91 and AZ31B | 5.4 | 5.6 | 5.8 | 5.6 |

| AA6061 and AZ91 | 7.1 | 7.9 | 7.5 | 7.5 |

| AZ91 and AA6061 | 7.8 | 8.5 | 7.7 | 8 |

Note: Compiled with permission from the findings of Sidhu et al. [43]. Copyright 2022 MDPI Materials.

Based on their findings, the authors of the study have drawn the conclusion that the impact energy properties of weld joints between dissimilar Al–Mg alloys can be enhanced by carefully selecting suitable welding parameters during the process. They have emphasized the significance of process optimization to achieve the desired mechanical properties, particularly in terms of impact energy, for dissimilar Al–Mg alloy joints.

3.6 Microstructural analysis

Microstructural analysis techniques, such as optical microscopy, SEM, and TEM, are employed to examine the weld microstructure, grain size, and distribution [143]. These analyses can help identify defects, such as voids, cracks, or inclusions, and assess the quality of the FSW joint, and understand the weld zone geometries, particularly the influence of HAZ, SZ, thermo–mechanically affected zone on the mechanical characteristics and integrity of the joints [144]. Figure 7 gives the different weld zones in a FSW joint.

![Figure 7

SEM Micrographs of the FSW (SS-SS) weld sub regions along crosssection: (a) SS-BM; (b) SS-HAZ; (c) Weld nugget/TMAZ and TMAZ/HAZ interface; (d) Weld nugget; (e) Weld nugget (at high magnifcation); (f) Plastic material fow pattern (onion rings), Adopted from ref. [147] with permission. Copyright 2021, Springer Nature.](/document/doi/10.1515/rams-2024-0033/asset/graphic/j_rams-2024-0033_fig_007.jpg)

SEM Micrographs of the FSW (SS-SS) weld sub regions along crosssection: (a) SS-BM; (b) SS-HAZ; (c) Weld nugget/TMAZ and TMAZ/HAZ interface; (d) Weld nugget; (e) Weld nugget (at high magnifcation); (f) Plastic material fow pattern (onion rings), Adopted from ref. [147] with permission. Copyright 2021, Springer Nature.

By conducting these mechanical and microstructural characterization tests, researchers and engineers can assess the strength, ductility, toughness, fatigue resistance, and overall structural integrity of FSW joints.

Figure 8 provides an overview of the diverse microstructures formed within the different weld zones created through FSW. Adjacent to the welded area is the HAZ. In this region, the temperature can rise to a level that induces certain structural modifications without affecting the grain structure. While the HAZ may experience alterations in strength and ductility, the metal is anticipated to largely retain its original properties, similar to those of the BM [145].

![Figure 8

SEM of different zones of weld joint. Adopted with permission from ref. [145]. Copyright 2016 Soldagem and Inspecao.](/document/doi/10.1515/rams-2024-0033/asset/graphic/j_rams-2024-0033_fig_008.jpg)

SEM of different zones of weld joint. Adopted with permission from ref. [145]. Copyright 2016 Soldagem and Inspecao.

This information is essential for evaluating the suitability of FSW joints in various applications and optimizing process parameters for improved joint performance. Figure 9 gives the schematic of different mechanical and microstructural characterizations carried out by several researchers on the friction stir-welded dissimilar Al–Mg alloy joints.

Schematic of different characterizations carried out on dissimilar Al–Mg FSW joints.

3.7 Surface roughness characterization

Surface roughness of friction stir-welded aluminum joints are also critical when analyzing their performance attributes. When dissimilar aluminum alloys undergo the process of FSW, the resulting characteristics of surface roughness can be significantly influenced by several critical factors. The design and geometry of the FSW tool emerge as pivotal determinants in shaping the surface roughness. The specific configuration of the tool, including its composition and shape, introduces variations in pressure, heat generation, and the movement of material during the welding process. These factors collectively contribute to the final texture of the welded surface.

The intricacies of process parameters within FSW, encompassing rotational speed, traverse speed, axial force, and tilt angle, hold utmost importance. These variables intricately dictate aspects such as heat input, material flow, and the mechanics at play during welding. Consequently, they exert a direct influence on the ultimate roughness observed on the surface.

The distinctive properties inherent to the dissimilar aluminum alloys being united, encompassing qualities like tensile strength, ductility, and thermal conductivity, interact with the FSW process in defining ways. These attributes bestow a unique response to the welding process for each alloy, leading to variations in flow behavior that manifest as disparities in surface appearance.

Amidst the environmental conditions under which welding takes place, such as ambient temperature, lies an influencing factor. Elevated temperatures, for instance, drive heightened material flow, yielding smoother surfaces as a result. Conversely, lower temperatures are more prone to generating coarser surface finishes.

The traverse speed at which the tool moves along the joint fundamentally governs material displacement and heat input. Accelerated feed rates can contribute to rougher surfaces due to reduced material flow and escalated frictional heat.

The wear experienced by the FSW tool during its interaction with the materials holds significance. Tool wear subtly shapes weld quality and, by extension, the final roughness of the surface. Tool wear, particularly when the tool is worn-out, can translate to an increased degree of surface roughness.

Subsequent treatments post-welding, like grinding, polishing, or shot peening, introduce an additional dimension. These interventions serve to mitigate surface roughness, concurrently enhancing the visual appeal of the weld.

Microstructure formation, intrinsic to the FSW process, further adds to the complexity. As microstructural changes occur, certain regions exhibit distinct grain structures that can influence the surface characteristics, in turn contributing to variations in roughness.

In the broader context, FSW stands out for its propensity to yield smoother surfaces when compared to conventional fusion welding methods. The absence of molten metal obviates the potential for surface irregularities that often arise during solidification. Nonetheless, it is crucial to acknowledge that variations in surface roughness are still plausible due to the interconnected factors outlined above. Parameters such as average roughness (Ra) and average maximum height (Rz) commonly serve as quantitative indicators of surface roughness. Wu et al. focused their work on the influence of stationary shoulder FSW (SSFSW) process on the surface characteristics of weld of the dissimilar aluminum alloys. They have reported that the stationary SSFSW process yield better surface finish in comparison with the conventional FSW process. Figure 10 gives the comparison of surface roughness values between FSW and SSFSW process. The Ra value for SSFSW process is relatively lesser in comparison with the FSW process [146].

![Figure 10

(a) Surface displacement maps for FSW, (b) surface displacement maps for SSFSW, (c) roughness vs transverse distance, and (d) distance from surface vs transverse distance. Adopted with permission from ref. [146]. Copyright 2015 Journal of Materials Processing Technology.](/document/doi/10.1515/rams-2024-0033/asset/graphic/j_rams-2024-0033_fig_010.jpg)

(a) Surface displacement maps for FSW, (b) surface displacement maps for SSFSW, (c) roughness vs transverse distance, and (d) distance from surface vs transverse distance. Adopted with permission from ref. [146]. Copyright 2015 Journal of Materials Processing Technology.

3.8 Relation between microstructure and mechanical characteristics

Several factors, such as material composition, process parameters, tool design, and PWHT, exert influence on the microstructural and mechanical behavior of FSW joints between dissimilar Al–Mg alloys. There are several noteworthy aspects to consider regarding the microstructural and mechanical behavior of these joints and are enlisted as follows [133].

3.8.1 IMC formation

During FSW, IMC formation occurs at the interface of Al and Mg alloys. The distribution, thickness, and type, of IMCs can significantly affect the mechanical properties and joint integrity. Common IMCs in Al–Mg FSW joints include Al3Mg2 and Al12Mg17, which can contribute to joint strength but may also cause brittleness if excessive [147]. Figure 11 gives the IMC formation as depicted in the works of Sameer and Birru [133].

![Figure 11

SEM image of intermetallic layer of Al–Mg FSW joints: (a) AZ91 AS–Al 6082 alloy RS and (b) Al 6082 AS–AZ91 RS. Adopted with permission from ref. [133]. Copyright 2019 Elsevier.](/document/doi/10.1515/rams-2024-0033/asset/graphic/j_rams-2024-0033_fig_011.jpg)

SEM image of intermetallic layer of Al–Mg FSW joints: (a) AZ91 AS–Al 6082 alloy RS and (b) Al 6082 AS–AZ91 RS. Adopted with permission from ref. [133]. Copyright 2019 Elsevier.

3.8.2 Grain structure

FSW can result in grain refinement and modification of the grain structure in the welded region.

The stirring action of the tool leads to dynamic recrystallization, resulting in smaller and more equiaxed grains compared to the BMs.

The grain structure and distribution play a role in influencing the strength and ductility, of the dissimilar joint [65].

The examination of the weld zones give a detailed analysis of the flow patterns, grain sizes, and the orientations in different regions as depicted in Figure 12. In Figure 12(a), the region near the AS of the shoulder pin in the weld zone exhibits finer grains oriented toward the shoulder-pin influenced regions. Figure 12(b) shows the dynamically recrystallized equiaxed grains structure at the center of the SZ. Figure 12(c) exhibited the interface microstructure in the shoulder influenced region near the RS, where grains were heavily deformed in the thermo-mechanically affected zone. Figure 12(d) exhibited the microstructure of the mid region of the interface in the SZ depicted with an increase in grain size. The regions in Figure 12(a) and (b) illustrates the lamellar flow of dissimilar materials in the pin influenced region, while the Figure 12(c) and (d) displays the grain structure of the pin influenced region, where grain sizes were relatively thin and elongated upwards in the direction of the SZs [23].

![Figure 12

(a) Al/Mg interface showing dual layers of IMC at 800 rpm and 50 mm/min, (b) diminishing of one layer of IMC due to ultrasonic vibrations (UV), (c) discontinued IMC in Mg matrix due to UV, (d) discontinued IMC at Al/Mg interface due to UV, Adopted from ref. [152] with permission. Copyright 2023 Elsevier. [Open Access under a Creative Commons License CC BY-NC 4.0 DEED].](/document/doi/10.1515/rams-2024-0033/asset/graphic/j_rams-2024-0033_fig_012.jpg)

(a) Al/Mg interface showing dual layers of IMC at 800 rpm and 50 mm/min, (b) diminishing of one layer of IMC due to ultrasonic vibrations (UV), (c) discontinued IMC in Mg matrix due to UV, (d) discontinued IMC at Al/Mg interface due to UV, Adopted from ref. [152] with permission. Copyright 2023 Elsevier. [Open Access under a Creative Commons License CC BY-NC 4.0 DEED].

3.8.3 Material mixing

FSW promotes extensive material mixing between the dissimilar Al–Mg alloys, leading to a gradual transition region.

The mixing of the materials can result in the redistribution of alloying elements, affecting the local composition and properties [148].

Proper material mixing is essential to achieve a sound joint with improved mechanical properties [149].

3.8.4 Mechanical behavior of Al–Mg FSW

The mechanical behavior of dissimilar Al–Mg FSW joints is influenced by various factors, including the microstructure, IMC formation, and residual stresses [64].

The joint strength, ductility, and fatigue performance can be evaluated through tensile testing, hardness testing, and fatigue testing.

The presence of IMCs can affect the joint strength, with the potential for a trade-off between strength and ductility [150].

PWHT or the addition of interlayers/fillers can be employed to modify the mechanical characteristics and enhance joint performance [151].

3.8.5 Residual stresses

FSW induces residual stresses in the welded joint, which can influence the mechanical behavior and susceptibility to cracking [152].

Residual stresses are influenced by factors such as thermal gradients, material flow, and phase transformations during the welding process [153].

Understanding and managing residual stresses are crucial to minimize the risk of distortion, cracking, and premature joint failure [154].

It is important to note that the specific microstructural and mechanical behavior in dissimilar Al–Mg FSW joints can vary depending on the alloy compositions, process parameters, and post-weld treatments employed. Therefore, comprehensive characterization techniques, including microscopy, X-ray diffraction, and mechanical testing, are typically used to assess the microstructure and mechanical characteristics of dissimilar Al–Mg FSW joints in research and development studies [155].

3.9 Corrosion characterization

In the context of the review of the corrosion of the dissimilar Al–Mg joints, the focus is on evaluating the corrosion of joints created by FSW in dissimilar aluminum alloys. The aim of this study is to investigate how the welding process influences the corrosion resistance of these alloys, particularly when different aluminum compositions are joined. The corrosion behavior of these welds is a critical aspect to examine, as it can impact the long-term durability and reliability of components in various applications, such as the aerospace industry and marine environments.

The research accomplished by several researchers involves conducting corrosion tests and analyses on FSW joints, which includes assessing factors like the type of corrosion (e.g., pitting, intergranular, or general corrosion), corrosion rate, and the microstructural features of the weld zone that may influence corrosion susceptibility. Understanding how FSW affects the corrosion properties of dissimilar aluminum alloys is essential for ensuring the integrity of structures and components in real-world conditions where exposure to corrosive environments is a concern. In Figure 13, there is a representation of the rate of weight loss observed in two different groups of FSW samples of Al 6022 and ZEK 100 Mg alloy joints over an 8 week testing period. These groups have varying cathode-to-anode area ratios. The findings revealed that during the first 2 weeks, having a larger cathode area led to a slightly higher corrosion rate compared to a smaller cathode area. This outcome aligns with the established understanding of the area effect in galvanic corrosion, which suggests that, in a given bimetallic corrosion system, a larger cathode or a smaller anode results in a higher current density on the anode, consequently causing a greater corrosion rate. However, after the initial 2 weeks, the influence of the cathode area gradually diminished due to the passivation behavior of the aluminum alloy. This passivation process eliminated the cathodic area effect. During the early stages of corrosion, it was observed that a thin film of Mg (OH)2, formed. Nonetheless, in the presence of Cl− ions, this protective film was rapidly corroded and penetrated, resulting in the formation of a porous structure, as depicted in the SEM image in Figure 14(a) and XRD graph in Figure 14(b) [156].

![Figure 13

Corrosion rate for two different cathode to anode (C/A) ratios. Adopted with permission from ref. [156]. Copyright 2023 MDPI Corrosion and Materials Degradation.](/document/doi/10.1515/rams-2024-0033/asset/graphic/j_rams-2024-0033_fig_013.jpg)

Corrosion rate for two different cathode to anode (C/A) ratios. Adopted with permission from ref. [156]. Copyright 2023 MDPI Corrosion and Materials Degradation.

![Figure 14

(a) SEM images of micro pits and (b) XRD of the corrosion product, in FSW joints of Al 6022 and ZEK 100Mg alloy joints. Adopted with permission from ref. [156]. Copyright 2023 MDPI Corrosion and Materials Degradation.](/document/doi/10.1515/rams-2024-0033/asset/graphic/j_rams-2024-0033_fig_014.jpg)

(a) SEM images of micro pits and (b) XRD of the corrosion product, in FSW joints of Al 6022 and ZEK 100Mg alloy joints. Adopted with permission from ref. [156]. Copyright 2023 MDPI Corrosion and Materials Degradation.

Typically, the initiation of pitting corrosion is attributed to the presence of aggressive anions, reaching a critical potential where the adsorption capacity of chloride ions is stronger than that of oxygen atoms or water molecules. Furthermore, these aggressive anions could penetrate into small pores, causing the breakdown potential to become even more negative.