Development and performance evaluation of green aluminium metal matrix composites reinforced with graphene nanopowder and marble dust

-

Rahul Chaurasia

und Marek Sadilek

Abstract

Sustainable and high-performance composites have gained sufficient attention in recent years. In this regard, an attempt is made to develop aluminium metal matrix composites reinforced with graphene nanopowder and marble dust using the stir casting technique. Marble dust powder was kept constant at 0.5% in all composite samples, while graphene varied between 0.5 and 2.5%. This unique synergic combination of reinforcement shows improvement in the mechanical and tribological properties of composites. The optimum properties of the composites are recorded at 0.5% marble dust and 2% graphene nanopowder-reinforced samples. A maximum drop of 41% in wear rate was observed at 60 N loading conditions at a 0.63 m/s speed within a range of 20–100 N loading and 0.63 and 1.89 m/s rotational speed conditions. The specific wear rate also shows the same trend. The coefficient of friction values also decreased in the composite samples compared to the as-cast aluminium alloy. Toughness values decreased sharply in composite samples; however, a slight increase was observed as reinforcement increased, reaching 9J in the 0.5% marble dust and 2% graphene samples, which was 25% lower than the as-cast alloy sample. Microhardness is improved by 56.9% and tensile strength by 32.5% in the 0.5% marble dust and 2% graphene-reinforced sample, and elongation decreased by 33.7% in the 2.5 % graphene-reinforced sample. SEM characterization of fractured tensile and toughness samples reveals the nature of the failure of composites. SEM of the wear surface shows the wear behaviour of the composites. The overall findings demonstrate that the marble dust and graphene powder hybrid reinforcement offer an optimal balance between the mechanical and tribological properties along with sustainability, paving the way for next-generation green metal matrix composites.

1 Introduction

Aluminium metal matrix composites (AMMCs) have emerged as a transformative class of materials, primarily driven by the need to overcome the inherent limitations of pure aluminium alloys. Pure aluminium, although known for its low density and good corrosion resistance, suffers from relatively low strength, poor wear resistance, and limited high-temperature performance. These deficiencies restrict its use in applications where higher mechanical performance is required. In contrast, AMMCs have shown excellent properties and minor weight gain while significantly enhancing the strength, stiffness, and wear resistance through the incorporation of reinforcing particles [1]. By embedding reinforcements into the ductile aluminium matrix, the composite exhibits a synergistic improvement in overall properties. Over the past decade, numerous reinforcements have been explored for use in AMMCs. Traditional ceramic reinforcements such as silicon carbide (SiC), alumina (Al2O3), boron carbide (B4C), and many others have been extensively studied due to their high hardness, chemical stability, and wear resistance. Al7075/TiO2/kaoline hybrid metal matrix composites (MMCs) with increasing kaoline content and sintering temperature increased the microhardness from 62.27 ± 2 to 75.83 ± 2 HV and lowered the friction coefficient from 0.82 ± 0.01 to 0.62 ± 0.01, with the wear rate reduced from 2.1 × 10⁻³ to 1.5 × 10⁻³ mm³ m⁻¹ [2]. Likewise, in other work, the Al–10Ni/TiO₂ composites achieved a maximum hardness up to 541 ± 20 HV1 at 20 h milling and 500°C sintering, and showed reduced mass loss as the grinding time and sintering temperature increased [3]. In hybrid Al2519–SiC/fly ash nanocomposites, reinforcement and aging improved the microhardness and compressive strength by 38.1 and 48% at the highest content, and decreased the wear rate by 58% relative to the base alloy after 4 h aging [4]. More recently, carbon-based reinforcements, notably graphene [5] and carbon nanotubes (CNTs) [6,7], have attracted significant attention owing to their extraordinary intrinsic mechanical properties. Graphene oxide (GO) has also shown good results when incorporated as reinforcements in the aluminium matrix. The authors reported that the Al–10Ni/GO composites fabricated via mechanical alloying exhibited significantly enhanced hardness up to 315 ± 10 HV1 with 1 wt% GO and reduced wear loss, with the coefficient of friction (COF) decreasing to 0.27 under optimized processing conditions [8]. Similarly, Dasari et al. demonstrated that the addition of GO into aluminium matrices improved hardness by 29% at 0.2 wt% GO reinforcement, confirming the potential of GO to strengthen aluminium while maintaining lightweight characteristics [9]. In addition, many industrial and agricultural wastes have also been used for making sustainable and green composites and materials that have also shown almost parallel improvement in mechanical and tribological properties [10,11,12,13,14,15]. Green and sustainable composites are advanced materials developed by incorporating eco-friendly or waste-derived reinforcements into metal or polymer matrices. They aim to reduce environmental impact, minimize resource consumption, and promote circular economy practices while still enhancing mechanical, tribological, and thermal properties [16]. Micro-sized particles were used previously, and have now shifted to nano reinforcements. As nano reinforcement delivers more promising results, they are in high demand nowadays [17,18]. Another critical aspect that has received increasing attention is the development of green and sustainable composites. With a growing emphasis on environmental stewardship and resource efficiency, researchers are turning toward materials that not only enhance performance but also reduce environmental impact [19,20]. This sustainable approach not only minimizes the environmental burden associated with waste disposal but also lowers production costs, making the composite more economically viable. Furthermore, green composites are designed with the aim of reducing carbon emissions and energy consumption during their manufacture, aligning with global sustainability goals. The drive toward sustainability is also influencing the selection of reinforcement materials. While advanced nano-reinforcements like graphene offer unmatched performance enhancements, their production can be energy-intensive and costly. On the other hand, sustainable reinforcements such as marble dust, derived from industrial byproducts, offer a more environmentally friendly alternative [21]. The hybridization of such reinforcements with high-performance materials like graphene is a promising strategy that seeks to balance performance with sustainability. By combining the exceptional properties of graphene with the marble dust, in the present research, we aim to develop composites that not only meet demanding technical specifications but also adhere to principles of green and sustainable composites. This approach contributes to responsible resource management and supports the global transition to more sustainable industrial practices.

Srivastava et al. [22] studied the effect of graphene in aluminium composites prepared using the stir casting technique. They found that 1.2% of graphene reinforcement improved yield strength (YS) and ultimate tensile strength (UTS) by 63 and 52 MPa, respectively. A similar trend was also observed in hardness; elongation percentage was found to decrease as the reinforcement percentage improved. Khoshghadam-Pireyousefan et al. [23] fabricated nanocomposites by combining high-energy ball milling and molecular-level mixing processes, followed by the spark plasma sintering method. The composites showed improvement in the YS, ultimate strength, and Vickers hardness, by 79, 49, and 44%, respectively, for only 1 wt% graphene-containing nanocomposite compared to the unreinforced Al–4Cu alloy. In graphene-reinforced AA7075 alloy using the stir casting method, Chaurasia and Sarangi [24] found the tensile strength to be improved to a maximum by 69.5% and microhardness by 76.67% in samples with 2% graphene; however, the wear rate reduced by 43% with 10 N loading and 40% with 20 N loading in samples with 1% graphene reinforced compared to base alloy in as-cast conditions. Several other studies demonstrate that graphene is an excellent reinforcement for aluminium alloys [25,26,27]. Kumar et al. [28] fabricated the AA7075 matrix composites using marble dust with 2, 4, and 6% reinforcement by stir casting and found the highest compressive strength for 2 wt% marble dust, and maximum flexural strength and maximum impact strength for 6 wt% marble dust reinforcement. Also, in tribological testing, they found that 6 wt% marble dust-reinforced composites had the highest wear resistant among all fabricated samples. Sharma et al. [29] used waste marble dust particles as reinforcements in the Al 6063 aluminium matrix by friction stir processing; first, they preheated the marble dust at 100 and 200°C and found that the samples that were preheated with marble dust at 200°C showed better properties. The improvement in the tensile strength and microhardness was 52 and 29%, respectively. An improvement in the specific wear rate by 25 and 23% in the COF was also observed. Tejyan et al. [30] studied waste marble dust reinforcement in AA6061 alloy by varying 3, 5, and 7% of reinforcement fabricated using the stir casting technique, using preheated reinforcement, and found that the composite samples with 5 wt% marble dust had good mechanical and sliding wear resistance properties compared to 3 and 7 wt% marble dust-reinforced composites. This literature review shows that marble dust can be an excellent reinforcement for aluminium matrix composites if it is preheated at 200°C and then used.

For hybrid composites, many studies are available using two different ceramic materials like silicon carbide, boron carbide [31], TiC/Gr [32], etc. For industrial and agricultural waste, authors have used fly ash [33], red mud [34], etc., and found these reinforcements useful. Several studies have examined the integration of industrial and agricultural byproducts with conventional reinforcements. For example, Chinnamahammad Bhasha and Balamurugan [35] combined rice husk with TiC; however, these hybrid approaches are limited. Notably, research articles focusing on the synergistic use of marble dust in conjunction with other ceramics or carbonaceous reinforcements in aluminium alloys are scarce, leaving this area largely unexploited. This research aims to fill that gap by evaluating the suitability of a novel reinforcement combination that leverages marble dust with graphene reinforcements in aluminium alloys, thereby advancing the development of green and sustainable composites without compromising mechanical and tribological performance.

2 Materials and methods

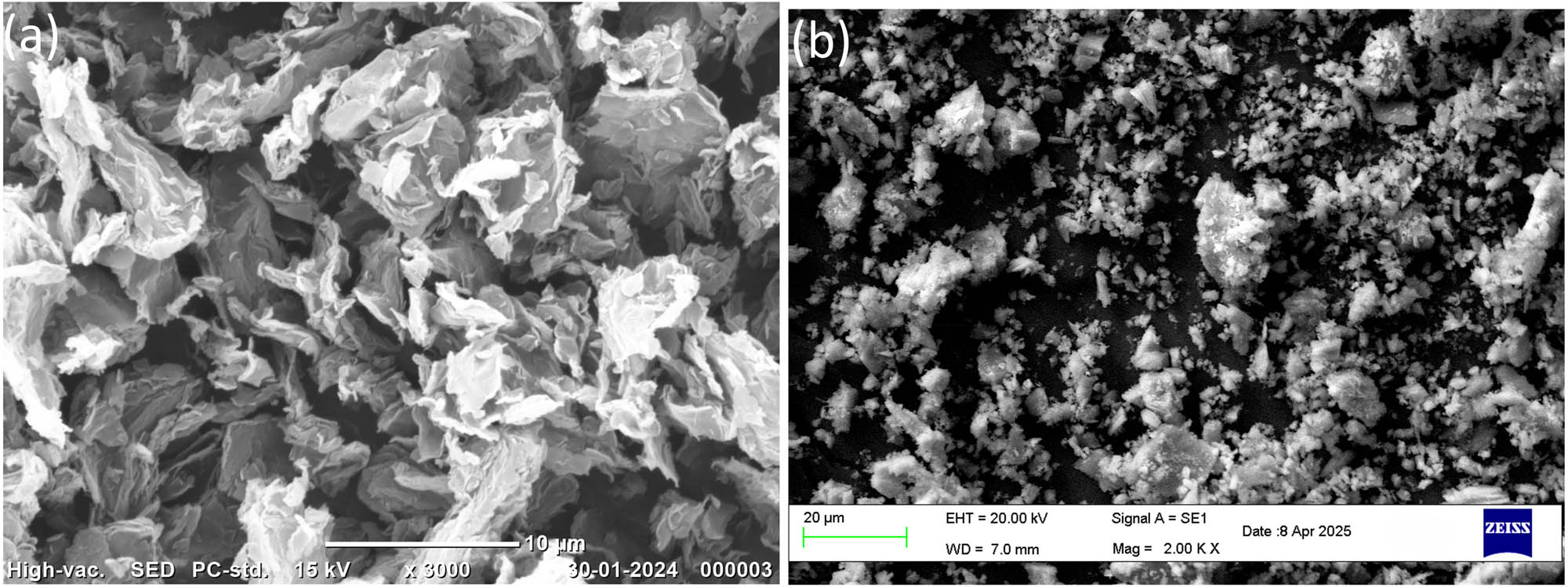

In the present study, aluminium was selected as the matrix material due to its excellent strength-to-weight ratio, corrosion resistance, and widespread availability, making it highly suitable for lightweight structural and tribological applications [36]. To reinforce the aluminium matrix, two different particulate reinforcements were employed, graphene nanopowder (GNP) and marble dust, selected with the objective of developing sustainable and performance-enhanced green composites. GNP was chosen for its extraordinary mechanical, thermal, and electrical properties. It contributes to the load-bearing capacity and enhances wear resistance due to its high surface area and intrinsic strength [37]. The graphene powder used in this research had an average particle size in the range of 3–8 nm and a density of approximately 2.2 g/cm³. Marble dust, a by-product of the marble processing industry, was selected as a secondary reinforcement with the intent to promote sustainability and reduce the environmental footprint of the composite. The marble dust consists predominantly of calcium carbonate (CaCO₃) particles and exhibits a density of approximately 2.74 g/cm³. The collected waste was initially dried in a furnace at 200°C for 2 h to eliminate any moisture content. To evaluate the morphology and microstructure of both reinforcements, scanning electron microscopy (SEM) characterization was performed before their incorporation into the matrix. Figure 1 shows the SEM images of both reinforcements, graphene nanopowder and marble dust powder. The SEM images of graphene nanopowder were done just after procurement, and for marble dust powder, SEM was conducted with the composite’s samples after testing. The SEM image of the GNP revealed layered and flaky structures, indicative of its high surface area and nanoscale thickness, while the SEM image of the marble dust showed irregular, angular particles with relatively rough surfaces, which are expected to contribute positively to the mechanical interlocking within the matrix during composite formation. The terms “irregular,” “angular,” and “rough surface” are qualitative but are commonly used in SEM-based morphological analyses for particle shape. Awad and Abdellatif [38] also describe marble dust particles in LDPE composites as “not uniform in size nor in shape,” relying on visual SEM interpretation to explain their behaviour. A compositional analysis of marble powder was carried out using energy dispersive spectroscopy (EDS). The results indicated that the powder predominantly consisted of carbon (43.40 wt%) and oxygen (42.28 wt%), confirming CaCO₃ as the primary constituent. Minor elements such as magnesium (4.32 wt%), silicon (2.83 wt%), calcium (6.87 wt%), and traces of iron (0.30 wt%) were also detected. Figure 2 shows the EDS results of the marble powder.

SEM of (a) graphene powder, and (b) marble dust powder reinforcements.

EDS of the marble powder.

The specific weight fractions of graphene and marble dust reinforcements were varied across six different samples, as detailed in the experimental design section, and are presented in Table 1. This allowed the investigation of the synergistic effects of carbonaceous and industrial waste reinforcements on the mechanical and tribological properties of the fabricated composites.

Composite with varying reinforcement percentages

| Sample no. | GNP (wt%) | Marble dust powder (wt%) | Aluminium (wt%) |

|---|---|---|---|

| 1 | 0 | 0 | 0 |

| 2 | 0.5 | 0.5 | 99 |

| 3 | 1 | 0.5 | 98.5 |

| 4 | 1.5 | 0.5 | 98 |

| 5 | 2 | 0.5 | 97.5 |

| 6 | 2.5 | 0.5 | 97 |

In MMCs with a base metal of aluminium, a low fraction of reinforcement is effective. Higher reinforcement percentage often results in agglomeration and porosity. In the case of nano reinforcements, it is even lower compared to microsized reinforcements for optimum properties. Graphene is a 2D nanoparticle with a high surface area and has a tendency to agglomerate more than 0D nanoparticles. Graphene is found to be more effective than marble dust in improving the properties. Based on all these factors and the literature review, collectively, total reinforcement is kept at a maximum of 3%. This proportion is similar to previous work, where authors used 1% GNP and 2% Al2O3 samples and showed optimum properties [39].

Aluminium ingots were cut into predetermined weights and placed in a graphite crucible, which was then loaded into an induction furnace set at 900°C for melting. GNP and sand dust, used as reinforcements, were preheated separately at 300°C for 15 min (graphene) and 200°C for 2 h (marble dust) to eliminate any moisture content and improve wettability. Once the aluminium was fully molten, the preheated reinforcements were gradually introduced into the melt using a controlled hopper setup when the moment of stirring began. The schematic diagram of stir casting is shown in Figure 3. A stainless-steel two-blade stirrer, operating at a constant speed of 400 rpm for 15 min, was employed to ensure homogeneous mixing. The stirring action generated a visible vortex in the melt, which facilitated the uniform distribution of reinforcement particles by creating pressure differentials within the molten matrix. Following thorough mixing, the melt was allowed to cool naturally in the crucible at room temperature. The solidified composite was then removed, sectioned using a power hacksaw, and machined to standard dimensions using a CNC machine and power hacksaw according to various ASTM specifications for mechanical and tribological testing. The density of the composite samples was determined using the Archimedes' principle by immersing the specimens in distilled water and calculating their weight-to-volume ratio. Each sample was cylindrical, with dimensions of 10 mm in diameter and 10 mm in height. For consistency and accuracy, three specimens per sample were tested following ASTM B962 standards. In terms of mechanical testing, tensile tests were carried out on a computerized universal testing machine with a maximum load capacity of 20 kN, and a constant crosshead speed of 1 mm/min was maintained during testing. Specimens were prepared in line with ASTM E8 standards, with a gauge diameter of 12.5 mm and a length of 50 mm. Microhardness assessments were conducted using the FMV1 model tester under a 0.1 kgf load, applied for a dwell time of 10 s. According to ASTM E384 procedures, three readings were taken from different regions of each sample, and the average was reported. To evaluate toughness, impact testing was performed using specimens in compliance with ASTM E23 guidelines, utilizing a pendulum-type impact testing machine. For the tribological evaluation of the composites using a pin-on-disc setup, cylindrical specimens with a diameter of 10 mm and a length of 30 mm were fabricated. The preparation of all samples strictly adhered to ASTM G99 guidelines, ensuring uniform dimensions across all test specimens. The wear tests were conducted on a DUCOM TR20 tribology testing system. Prior to testing, the sample surfaces were polished using silicon carbide abrasive paper conforming to FEPA standards (ISO 6344), in a sequential order of P400, P800, P1000, and P1200. This polishing process was essential to improve the accuracy of wear and friction measurements and to allow for a clearer examination of the worn surfaces. SEM characterization was conducted using an EVO-S Scanning Electron Microscope MA15/18 Carl Zeiss Microscopy Machine.

Schematic diagram of the stir-casting setup.

3 Results and discussion

3.1 Physical properties

The density measurements of the prepared composites provide insight into the effect of reinforcement on the material’s physical properties. The theoretical density was calculated based on the weight fraction and densities of the constituent materials, while the actual density was measured experimentally. As shown in Figure 4, the theoretical density of the composites gradually decreased from 2.7 g/cm³ in Sample 1 to 2.685 g/cm³ in Sample 6 due to the increasing addition of graphene, which has a lower density compared to aluminium. The actual density values follow a similar trend but are slightly lower than the theoretical values. Porosity, which represents the percentage difference between theoretical and actual density, is an important factor affecting mechanical performance. The porosity of Sample 1 is negligible (0%), indicating an ideal compaction of the base aluminium. However, with the addition of graphene and marble dust, a slight increase in porosity is observed, with Sample 2 exhibiting 0.48% porosity, Sample 3 at 0.41%, and Sample 4 at 0.63%. The porosity further increases for Sample 5 (0.70%) and Sample 6 (1.53%), suggesting that higher reinforcement content may contribute to increased void formation within the composite matrix. Higher reinforcement also increases the chances of agglomeration and segregation of reinforced particles, which may also be a major cause of porosity development within the composites. A similar trend was observed previously by different researchers [40,41]. However, these affect the material properties and have a negative impact [42]. Despite the increase, the overall porosity values remained relatively low, indicating effective dispersion and minimal defects in the prepared composites. These porosities can be minimized to a certain extent by improved process parameters.

Theoretical and actual densities of the fabricated composites with porosity percentages.

3.2 Tribological properties

Wear rate: The wear behaviour of the composites was evaluated under five different loads (20, 40, 60, 80, and 100 N) at two sliding velocities (0.63 and 1.89 m/s). The results reveal distinct trends that underline the influence of both load and sliding speed on the material wear. At a lower sliding velocity of 0.63 m/s, shown in Figure 5(a), all samples exhibited a progressive increase in the wear rate as the applied load increased. The wear rates ranged from 1.9–2.8 × 10−3 mm³/min at 20 N to 3.7–5.6 × 10−3 mm³/min at 100 N. This increase is a result of greater contact stresses and higher localized deformation, which intensify the material removal mechanisms such as abrasive and adhesive wear. This trend follows the law of Archard, which states that the wear rate is directly proportional to the applied load [43]. Notably, samples 5 and 6 demonstrated lower wear rates at each load compared to the other samples, with sample 5 having a minimum value, indicating that the optimum reinforcement percentage likely achieved a more uniform dispersion and stronger interfacial bonding, which effectively blocks dislocation motion and reduces plastic deformation at the contact surface. An increase in wear load also resists the wear rate on the surface of composites due to the work-hardening effect, which results in grain disintegration and dislocation buildup at the contact area [44]. At a higher sliding velocity of 1.89 m/s (Figure 5(b)), the wear rates were significantly higher across all load levels. Under identical loads, wear rates at 1.89 m/s were greater than those at 0.63 m/s, reflecting the impact of increased frictional heating and dynamic interactions at the sliding interface. For instance, at 20 N, the wear rates ranged from 3.23 to 4.76 × 10−3 mm³/min, and at 100 N, they increased to 6.2–8.9 × 10−3 mm³/min. The elevated velocity exacerbates the generation of heat, softens the matrix, and accelerates material removal. These results are in line with a previous study, where increasing sliding velocities increased the wear values [45]. However, the comparative advantage of samples 5 and 6 persisted even at this higher speed, as these samples consistently showed lower wear values. This suggests that the reinforcement present in these samples not only enhances the mechanical strength but also provides a more robust resistance to wear by minimizing the adhesion of wear debris and reducing friction through improved lubrication at the microlevel. The results clearly indicate that both load and sliding velocity have a profound effect on the wear performance of the composites. Increased load leads to higher contact pressures, which in turn enhance abrasive and adhesive wear mechanisms, while higher sliding speeds result in increased frictional heat that accelerates wear. The results are in agreement with those obtained previously [46,47]. The superior performance of samples 5 and 6 underscores the importance of optimal reinforcement distribution and strong interfacial bonding in mitigating wear. These findings not only align with fundamental tribological principles but also emphasize the potential of advanced reinforcement strategies in developing AMMCs with improved wear resistance for high-performance applications. The wear resistance of the composites is further quantified by calculating the specific wear rate, which consistently shows higher values for Sample 5 across all loading conditions. Figure 5(c) and (d) clearly illustrates these trends, confirming that the optimized reinforcement strategy significantly reduces both overall and specific wear, thereby enhancing the durability of the composite. Similarly, the specific wear, which measures the volume loss per unit load and sliding distance, is significantly lower for Sample 5, as shown in Figure 5(e) and (f).

Wear rates of composites: (a) 0.63 m/s and (b) 1.83 m/s; wear resistances of composite samples: (c) 0.63 m/s and (d) 1.83 m/s; and specific wear rates of the composites: (e) 0.63 m/s, (f) 1.83 m/s.

3.3 COF

The COF plays a critical role in evaluating the tribological performance of the MMCs. In this study, the average COF values of all samples were measured under two distinct sliding speeds – 0.63 and 1.83 m/s – across different loading conditions ranging from 20 to 100 N. The results are presented in Figure 6. Figure 6(a) displays the real-time COF variation of Sample 3 at 60 N load and 0.63 m/s speed, Figure 6(b) illustrates the average COF values for all samples at 0.63 m/s, and Figure 6(c) presents the COF data at 1.83 m/s. From the obtained results, it is evident that with the increment in the weight percentage of graphene nanopowder, the COF values consistently decrease for all loading conditions at both sliding speeds. This behaviour can be attributed to the solid lubricant nature of graphene, which provides a protective tribofilm on the sliding surface [39,48]. The addition of marble dust, a mineral-based filler, complements the lubricating action and contributes to the load-bearing capacity. Sample 1, composed of unreinforced aluminium alloy, exhibits the highest COF under all testing conditions, highlighting the poor lubrication of the base alloy. Conversely, Sample 6, reinforced with 2.5 wt% graphene and 0.5 wt% marble dust, recorded the lowest COF values among the samples. This underscores the positive synergy between carbon-based and ceramic reinforcements in reducing surface interactions and frictional resistances. A noticeable decrease in COF is observed with increasing load for all sample sets. This is primarily due to the development of a more stable and uniform contact interface under higher pressures, which suppresses stick-slip behaviour. Additionally, with increased load, the formation of a compacted transfer layer on the disc surface may also contribute to smoother sliding. The comparison between 0.63 and 1.83 m/s speeds reveals that the COF is lower at the higher speed for all samples and load combinations. At elevated speeds, the thermal softening of asperities and better smearing of graphene particles promote reduced shear stress at the contact surface, minimizing the friction coefficient. Similar results were also observed where reinforcing beyond 4% of TiO2 decreased COF at 40 N load [49]. The highest reduction was observed in Sample 6, which demonstrates the most stable tribological behaviour under both speed conditions. The real-time curve in Figure 6(a) for Sample 3 at 60 N and 0.63 m/s exhibits an initial transient increase in friction followed by a steady-state region. The early fluctuations can be linked to the bedding-in period of the sample, while the stabilized portion indicates the effectiveness of graphene in maintaining uniform contact. The presence of reinforcement ensures minimal wear debris and consistent contact conditions, leading to a stable COF response over the sliding duration. Table 2 presents numerical values of tribological properties of composites and the as-cast alloy.

COF values of Sample 3 at (a) 60 N and 0.63 m/s, (b) 0.63 m/s, and (c) 1.83 m/s.

Tribological properties of the composites

| Load (N) | Speed: 0.63 m/s | Speed: 1.83 m/s | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 40 | 60 | 80 | 100 | 20 | 40 | 60 | 80 | 100 | |

| COF | ||||||||||

| Sample 1 | 0.66 | 0.63 | 0.6 | 0.57 | 0.54 | 0.561 | 0.5355 | 0.51 | 0.4845 | 0.459 |

| Sample 2 | 0.561 | 0.5355 | 0.51 | 0.4845 | 0.459 | 0.477 | 0.4552 | 0.4335 | 0.4118 | 0.3902 |

| Sample 3 | 0.495 | 0.4725 | 0.45 | 0.4275 | 0.405 | 0.4208 | 0.4016 | 0.3825 | 0.3634 | 0.3443 |

| Sample 4 | 0.44 | 0.42 | 0.4 | 0.38 | 0.36 | 0.374 | 0.357 | 0.34 | 0.323 | 0.306 |

| Sample 5 | 0.385 | 0.3675 | 0.35 | 0.3325 | 0.315 | 0.3273 | 0.3124 | 0.2975 | 0.2826 | 0.2678 |

| Sample 6 | 0.363 | 0.3465 | 0.33 | 0.3135 | 0.297 | 0.3086 | 0.2945 | 0.2805 | 0.2665 | 0.2525 |

| Wear rate (× 10−3) mm3/m | ||||||||||

| Sample 1 | 2.8 | 3.5 | 4.4 | 5.1 | 5.6 | 4.76 | 6.1 | 7.48 | 8.3 | 8.9 |

| Sample 2 | 2.6 | 3.1 | 3.8 | 4.6 | 5.2 | 4.5 | 5.2 | 6.4 | 7.82 | 8.4 |

| Sample 3 | 2.3 | 2.7 | 3.5 | 4.2 | 4.7 | 3.9 | 4.5 | 5.8 | 6.9 | 7.9 |

| Sample 4 | 2.2 | 2.6 | 3 | 3.6 | 4.3 | 3.7 | 4.3 | 5.1 | 5.9 | 7.1 |

| Sample 5 | 1.9 | 2.3 | 2.6 | 3.1 | 3.7 | 3.23 | 3.9 | 4.5 | 5.3 | 6.2 |

| Sample 6 | 2 | 2.5 | 2.8 | 3.2 | 3.9 | 3.5 | 4.2 | 4.9 | 5.5 | 6.7 |

3.4 Mechanical properties

3.4.1 Microhardness

The microhardness values of the six samples are presented in Table 1, showing a clear trend of increasing hardness from Sample 1 to Sample 5, with a slight drop in Sample 6. Sample 1, presumed to be the baseline as it is an as-cast composite sample, has the lowest microhardness of 58 HV. In contrast, Sample 5 exhibits the highest microhardness at 91 HV, representing an increase of 57%. Sample 4, with 83 HV, demonstrates about 43% improvement, while Samples 3 and 2 show more modest gains of around 29 and 15%, respectively. Sample 6, though lower than Sample 5, shows 84 HV. These data suggest that the introduction or optimization of reinforcing fraction in the composite is highly effective at elevating hardness, likely through mechanisms such as grain refinement, load transfer, and the presence of hard ceramic or carbonaceous particles that impede dislocation motion. Similar improvements were observed in various studies [50,51]. These gains in microhardness indicate that incremental adjustments in reinforcement content can yield significant hardness improvements. Consequently, the enhanced microhardness observed across most samples underscores the potential of these composite formulations for applications requiring high surface durability and resistance to deformation.

3.4.2 Toughness

The toughness values for different samples, as shown in Figure 7, demonstrate a significant initial drop followed by a gradual recovery. Sample 1, which contains no reinforcement, exhibits the highest toughness at 12 J, serving as the baseline. Several research articles showed that toughness was reduced by reinforcing the particulate [52]. However, with the introduction of 0.5 wt% graphene and 0.5 wt% marble dust in Sample 2, the toughness experiences a sharp decline to 7.5 J, representing a 37.5% reduction compared to Sample 1. This significant drop can be attributed to the introduction of hard reinforcing particles, which act as stress concentrators, thereby reducing the material’s ability to absorb energy before fracture. As the graphene content increases in subsequent samples, the toughness shows a moderate improvement. As the nano reinforcement sample does not lead to a decrease in elongation as in comparison to microsize reinforcement, this improvement is expected. These results are in agreement with the findings of published studies where nano reinforcement improves toughness [53]. Sample 3, containing 1 wt% graphene, has a toughness of 8 J, marking a slight 6.7% increase over Sample 2. This trend continues, with Sample 4 (1.5 wt% graphene) reaching 8.5 J, Sample 5 (2 wt% graphene) improving further to 9 J, and Sample 6 (2.5 wt% graphene) maintaining a value of 8 J. The gradual enhancement in toughness beyond Sample 2 suggests that at higher graphene concentrations, the reinforcement begins to contribute positively by improving load transfer and crack deflection mechanisms. Despite this partial recovery, the toughness values remain lower than the unreinforced Sample 1, indicating that while graphene and marble dust improve other mechanical properties, they slightly compromise the material’s energy absorption capacity. The presence of hard reinforcements tends to embrittle the matrix, and although graphene contributes to strengthening mechanisms, its excessive content can limit plastic deformation. The observed trend suggests that while an optimal balance of reinforcements can mitigate the toughness loss to some extent, there is an inherent trade-off between hardness, wear resistance, and toughness in these composites.

Microhardness and toughness of the composite samples.

3.4.3 Tensile strength

The mechanical properties, including UTS, YS, and elongation, for different samples are presented in Figure 8. The results indicate a significant improvement in tensile properties with the addition of graphene and marble dust reinforcements, accompanied by a slight reduction in elongation. The UTS values exhibit a continuous increase up to Sample 5, indicating the strengthening effect of the reinforcements. The unreinforced sample (Sample 1) shows a UTS of 164.5 MPa, which increases to 173.1 MPa in Sample 2 with the addition of 0.5 wt% graphene and 0.5 wt% marble dust. A further increase is observed as the graphene content increases, with Sample 4 (1.5 wt% graphene) reaching 189.8 MPa. The highest UTS is recorded in Sample 5 at 217.9 MPa, marking a 32.5% improvement compared to the base alloy. This enhancement can be attributed to the uniform distribution of reinforcements, which improves load transfer, restricts dislocation movement, and strengthens the matrix. The Orowan strengthening mechanism and Hall–Petch relation are the majorly responsible mechanisms for this growth [54]. However, in Sample 6, the UTS decreases slightly to 194 MPa, suggesting that excessive graphene addition may lead to particle agglomeration, reducing the strengthening effect, which is common in highly reinforced samples. A similar trend is observed in the YS, where the base alloy (Sample 1) has a YS of 99 MPa, which increases steadily with reinforcement addition. Sample 3, containing 1 wt% graphene, achieves a YS of 107 MPa, while Sample 5 reaches 131 MPa, marking a 32.3% increase over the unreinforced alloy. The strengthening mechanisms primarily involve grain refinement, dispersion strengthening, and load transfer from the matrix to the harder reinforcement phases. Sample 6, however, exhibits a slight reduction in YS to 113 MPa, reinforcing the idea that excess graphene can negatively impact mechanical properties by promoting clustering and weakening matrix-reinforcement bonding. Contrary to the strength improvements, elongation (%) decreases with increasing reinforcement content, indicating a reduction in ductility. The base alloy (Sample 1) exhibits the highest elongation of 9.5%, which drops to 7.9% in Sample 2 and further reduces to 6.3% in Sample 6. This 33.7% reduction in elongation can be attributed to the rigid nature of ceramic and carbon-based reinforcements, which reduce the matrix’s ability to undergo plastic deformation. The sharpest decline is observed in Sample 5 (6.9% elongation) and Sample 6 (6.3% elongation), where higher reinforcement concentrations lead to increased brittleness. The results confirm that incorporating graphene and marble dust reinforcements enhances the strength properties (UTS and YS) at the cost of reduced ductility (elongation). Table 3 presents numerical values of the mechanical properties of the composites and the as-cast alloy.

(a) Stress–strain curve, (b) histogram representing tensile strength, YS, and strain of the composite samples.

Mechanical properties of the composites

| Sample | Microhardness | Toughness | UTS | Elongation | YS |

|---|---|---|---|---|---|

| 1 | 58 | 12 | 164.5 | 9.5 | 99 |

| 2 | 67 | 7.5 | 173.1 | 7.9 | 105 |

| 3 | 75 | 8 | 179.1 | 7.7 | 107 |

| 4 | 83 | 8.5 | 189.8 | 7.1 | 110 |

| 5 | 91 | 9 | 217.9 | 6.9 | 131 |

| 6 | 84 | 8 | 194 | 6.3 | 113 |

3.4.4 Surface morphology of the fractured and worn composite samples

To gain a better understanding of the failure mechanisms and surface characteristics of the fabricated green aluminium matrix composites, SEM analysis was carried out on fractured surfaces from tensile and impact tests, as well as worn surfaces after tribological evaluation.

Figure 9 displays the tensile fracture surfaces of both composite samples. In the sample with 0.5% graphene, a mixed-mode fracture is evident, where several shallow and deep dimples are observed, indicating ductile fracture behaviour. The presence of microvoids and necking features further supports plastic deformation prior to failure. Intergranular fracture regions are also noticeable, suggesting crack propagation along the grain boundaries. In contrast, the sample reinforced with 2.5% graphene shows finer and more uniformly distributed dimples along with transgranular fracture features. A dimple fracture was observed previously [55]. The enhanced graphene content seemed to have restricted grain boundary sliding and promoted crack deflection through grains, contributing to higher strength and moderate ductility. Such fracture morphology is typical in particle-reinforced MMCs, where strong particle–matrix bonding leads to void nucleation around reinforcement particles.

SEM morphology of the fractured tensile specimen: (a) 0.5% graphene and 0.5% marble dust reinforced composite sample, and (b) 2.5% graphene and 0.5% marble dust reinforced composite sample.

Figure 10 highlights the SEM micrographs of the fractured surfaces post-impact testing. The composite containing 0.5% graphene reveals a predominantly brittle fracture characterized by cleavage facets and the presence of sharp crack paths. These facets suggest limited energy absorption during crack propagation. Additionally, crack deflection can be seen around some reinforcement particles, implying an obstruction to crack growth due to the presence of hard ceramic particles. For the 2.5% graphene composite, the surface reveals more complex features such as multiple microcracks, evidence of particle–matrix debonding, and reduced cleavage compared to the first sample. The microcracks initiate and propagate around graphene clusters or particle agglomerates, which act as local stress concentrators. However, higher graphene content also contributes to enhanced energy dissipation through crack bridging and deflection, improving the material’s resistance to sudden fracture. These features are commonly associated with hybrid composites containing both ceramic and carbon-based reinforcements.

SEM morphology of the fractured toughness test specimen: (a) 0.5% graphene and 0.5% marble dust reinforced composite sample, and (b) 2.5% graphene and 0.5% marble dust reinforced composite sample.

Figure 11 shows the SEM analysis of wear tracks from the sliding wear tests for both composite compositions. The sample with 0.5% graphene displays prominent signs of ploughing and micro-grooves along the sliding direction. The accumulation of debris and detached particles is clearly visible, suggesting abrasive wear as the dominant mechanism. Some localized material delamination is also observed, indicating sub-surface cracking due to repeated sliding action. In the case of the 2.5% graphene composite, the worn surface appears relatively smoother with smaller and shallower grooves. Debris particles are still visible, but in reduced quantity and with finer morphology. This suggests that the higher graphene content contributed to a more stable tribo layer formation and better load distribution during sliding [56] and effectively distributed external stress [57]. Reduced wear marks and minimal ploughing confirm the role of graphene in enhancing wear resistance by lowering friction and minimizing material removal. Ploughing is common in wear of aluminium composites, as shown previously [58]. Debris is also common in the wear surface morphology of aluminium-based MMCs, as the same phenomenon was observed previously [46,59]. The direction of sliding is marked in both images, showing alignment of grooves consistent with unidirectional wear action. These surface features align with commonly reported observations in graphene-reinforced MMCs, where improved self-lubrication and hardness help reduce material degradation.

SEM morphology of the wear test specimen: (a) 0.5% graphene and 0.5% marble dust reinforced composite sample, and (b) 2.5% graphene and 0.5% marble dust reinforced composite sample.

4 Conclusion

In this study, aluminium-based green MMCs were successfully fabricated using the stir casting technique, incorporating graphene nanopowder and marble dust as hybrid reinforcements. The following conclusions can be drawn from the outcome of the present research:

Green AMMCs were successfully developed using GNP and marble dust as reinforcements using the stir casting method.

The mechanical testing revealed that increasing graphene content improved both the UTS and YS of the composites. A maximum UTS of 217.9 MPa was observed for the sample with 2.0 wt% graphene and 0.5 wt% marble dust.

A minor reduction in elongation with higher reinforcement levels indicated a trade-off between strength and ductility, confirming a tendency towards brittle behaviour.

Microhardness increased steadily with reinforcement, with the highest hardness reaching 91 HV, indicating enhanced resistance to localized plastic deformation.

Impact toughness initially dropped due to the presence of marble dust and then gradually improved with the inclusion of graphene, highlighting its role in improving energy absorption during fracture.

SEM analysis of tensile fracture surfaces exhibited features like dimples, microvoids, and intergranular fractures, supporting the mechanical test findings. Impact fracture surfaces showed evidence of crack deflection and particle–matrix debonding.

Density analysis showed a slight reduction in theoretical density with increasing graphene and marble dust contents. Actual density followed a similar trend, while porosity remained under control across all samples.

Tribological tests showed a consistent reduction in the COF and wear rate with increasing graphene content, suggesting improved surface stability and resistance to material loss.

The incorporation of graphene nanopowder and marble dust significantly reduced the COF in aluminium matrix composites, with the lowest values observed at higher reinforcement levels, increased loads, and elevated sliding speeds.

SEM examination of the worn surfaces confirmed the presence of ploughing and debris at lower graphene content, while smoother wear tracks and less material removal were observed in higher graphene samples.

The combination of graphene and industrial waste marble dust demonstrated an effective balance of strength, wear resistance, and sustainability, making the developed composites suitable for engineering applications where lightweight and durability are critical.

-

Funding information: The authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: All data generated or analysed during this study are included in this published article.

References

[1] Chaurasia R, Sarangi SK. Synergistic effect of graphene nanoplatelets and titanium dioxide nanopowder-reinforced aluminium nanohybrid composites on mechanical properties. Funct Compos Struct. 2024;6(2):025012.10.1088/2631-6331/ad5925Suche in Google Scholar

[2] Demir ME, Okumuş M. Investigation of microhardness, microstructural, tribological, and thermal properties of Al7075/TiO2/kaoline hybrid metal matrix composites produced by powder metallurgy process. Adv Eng Mater. 2024;26(24):2401343.10.1002/adem.202401343Suche in Google Scholar

[3] Bülbül B, Okumuş M. Microstructure, hardness, thermal and wear behaviours in Al–10Ni/TiO2 composites fabricated by mechanical alloying. Mater Chem Phys. 2022;281:125908.10.1016/j.matchemphys.2022.125908Suche in Google Scholar

[4] Bezzina S, Moustafa EB, Taha MA. Effects of metastable θ′ precipitates on the strengthening, wear and electrical behaviors of Al 2519-SiC/fly ash hybrid nanocomposites synthesized by powder metallurgy technique. Silicon. 2022;14(14):8381–95.10.1007/s12633-021-01641-zSuche in Google Scholar

[5] Chak V, Chattopadhyay H. Fabrication and heat treatment of graphene nanoplatelets reinforced aluminium nanocomposites. Mater Sci Eng: A. 2020;791:139657.10.1016/j.msea.2020.139657Suche in Google Scholar

[6] Esawi AMK, Morsi K, Sayed A, Taher M, Lanka S. The influence of carbon nanotube (CNT) morphology and diameter on the processing and properties of CNT-reinforced aluminium composites. Compos Part A: Appl Sci Manuf. 2011;42(3):234–43.10.1016/j.compositesa.2010.11.008Suche in Google Scholar

[7] Singla D, Amulya K, Murtaza Q. CNT reinforced aluminium matrix composite-a review. Mater Today: Proc. 2015;2(4):2886–95.10.1016/j.matpr.2015.07.248Suche in Google Scholar

[8] Okumuş M, Bülbül B. Study of microstructural, mechanical, thermal and tribological properties of graphene oxide reinforced Al–10Ni metal matrix composites prepared by mechanical alloying method. Wear. 2022;510–511:204511.10.1016/j.wear.2022.204511Suche in Google Scholar

[9] Dasari BL, Morshed M, Nouri JM, Brabazon D, Naher S. Mechanical properties of graphene oxide reinforced aluminium matrix composites. Composites, Part B. 2018;145:136–44.10.1016/j.compositesb.2018.03.022Suche in Google Scholar

[10] Singh A, Srivastava AK, Kumar A, Gautam P. Design for low thermal conductivity and low vibrational impact without efflorescence of the composite bricks developed by waste plastic resin/fly ash/glass powder/gypsum. Int J Interact Des Manuf. 2025;19(2):949–60.10.1007/s12008-023-01582-4Suche in Google Scholar

[11] Singh A, Srivastava AK, Kumar A, Bajaj R, Singh GK. Design and development of plentiful fly ash-based glass powder-reinforced plastic composite bricks for low water absorption and high compressive and flexural strength. Int J Interact Des Manuf. 2025;19(2):939–48.10.1007/s12008-023-01580-6Suche in Google Scholar

[12] Kumar Murmu S, Chattopadhayaya S, Cep R, Kumar A, Kumar A, Kumar Mahato S, et al. Exploring tribological properties in the design and manufacturing of metal matrix composites: an investigation into the AL6061-SiC-fly ASH alloy fabricated via stir casting process. Front Mater. 2024;11:1415907.10.3389/fmats.2024.1415907Suche in Google Scholar

[13] Kumar A, Kumar P, Srivastava AK, Saharan L. Manufacturing strategies and systems: technologies, processes, and machine tools. Boca Raton: CRC Press; 2025.10.1201/9781032725086Suche in Google Scholar

[14] Kumar A, Liu Y, Kumar R. Handbook of intelligent and sustainable manufacturing: tools, principles, and strategies. Boca Raton: CRC Press; 2024.10.1201/9781003405870Suche in Google Scholar

[15] Kumar A, Kumar P, Srivastava AK, Goyat V. Modeling, characterization, and processing of smart materials. IGI Global; 2023.10.4018/978-1-6684-9224-6Suche in Google Scholar

[16] Seetharaman S, Subramanian J, Singh RA, Wong WLE, Nai MLS, Gupta M. Mechanical properties of sustainable metal matrix composites: a review on the role of green reinforcements and processing methods. Technologies. 2022;10(1):32.10.3390/technologies10010032Suche in Google Scholar

[17] Harichandran R, Selvakumar N. Effect of nano/micro B4C particles on the mechanical properties of aluminium metal matrix composites fabricated by ultrasonic cavitation-assisted solidification process. Arch Civ Mech Eng. 2016;16(1):147–58.10.1016/j.acme.2015.07.001Suche in Google Scholar

[18] Ravikumar M, Reddappa HN, Suresh R, Babu ER, Nagaraja CR. Study on micro - nano sized Al2O3 particles on mechanical, wear and fracture behavior of Al7075 Metal matrix composites. Fract Struct Integr. 2021;15(58):166–78.10.3221/IGF-ESIS.58.12Suche in Google Scholar

[19] Wąsik A, Leszczyńska-Madej B, Madej M. Sustainability in the manufacturing of eco-friendly aluminum matrix composite materials. Sustainability. 2024;16(2):903.10.3390/su16020903Suche in Google Scholar

[20] Al-Alimi S, Yusuf NK, Ghaleb AM, Lajis MA, Shamsudin S, Zhou W, et al. Recycling aluminium for sustainable development: A review of different processing technologies in green manufacturing. Results Eng. 2024;23:102566.10.1016/j.rineng.2024.102566Suche in Google Scholar

[21] Ror CK, Tejyan S, Kumar N. Effect of marble dust reinforcement in composites for different applications: A review. Mater Today: Proc. 2022;60:1120–4.10.1016/j.matpr.2022.02.246Suche in Google Scholar

[22] Srivastava AK, Sharma B, Saju BR, Shukla A, Saxena A, Maurya NK. Effect of Graphene nanoparticles on microstructural and mechanical properties of aluminum based nanocomposites fabricated by stir casting. World J Eng. 2020;17(6):859–66.10.1108/WJE-04-2020-0128Suche in Google Scholar

[23] Khoshghadam-Pireyousefan M, Rahmanifard R, Orovcik L, Švec P, Klemm V. Application of a novel method for fabrication of graphene reinforced aluminum matrix nanocomposites: Synthesis, microstructure, and mechanical properties. Mater Sci Eng A. 2020;772:138820.10.1016/j.msea.2019.138820Suche in Google Scholar

[24] Chaurasia R, Sarangi SK. Tribological and mechanical properties of graphene nano platelets (GNP)-reinforced aluminium 7075 nano composites. Recent Pat Mech Eng. 2025;18(5):508–15.10.2174/0122127976305485240329053923Suche in Google Scholar

[25] Li D, Ye Y, Liao X, Qin QH. A novel method for preparing and characterizing graphene nanoplatelets/aluminum nanocomposites. Nano Res. 2018;11(3):1642–50.10.1007/s12274-017-1779-9Suche in Google Scholar

[26] Raj RR, Yoganandh J, Saravanan MSS, Kumar SS. Effect of graphene addition on the mechanical characteristics of AA7075 aluminium nanocomposites. Carbon Lett. 2021;31(1):125–36.10.1007/s42823-020-00157-7Suche in Google Scholar

[27] Khanna V, Kumar V, Bansal SA, Prakash C, Ubaidullah M, Shaikh SF, et al. Fabrication of efficient aluminium/graphene nanosheets (Al-GNP) composite by powder metallurgy for strength applications. J Mater Res Technol. 2023;22:3402–12.10.1016/j.jmrt.2022.12.161Suche in Google Scholar

[28] Kumar A, Kumar V, Kumar A, Nahak B, Singh R. Investigation of mechanical and tribological performance of marble dust 7075 aluminium alloy composites. Mater Today: Proc. 2021;44:4542–7.10.1016/j.matpr.2020.10.812Suche in Google Scholar

[29] Sharma VK, Chaudhary S, Singh RC, Sonia V, Goel V. Reusing marble dust as reinforcement material for better mechanical performance: studies on compositing aluminum matrix. Mater Res Express. 2019;6(12):1265f6.10.1088/2053-1591/ab6702Suche in Google Scholar

[30] Tejyan S, Lal C, Ror CK, Singh V. Influence of marble waste reinforcement on mechanical properties and sliding wear behavior of an aluminium alloy metal matrix composite. J Eng Res. 2025;13(1):131–41.10.1016/j.jer.2023.08.002Suche in Google Scholar

[31] Poovazhagan L, Kalaichelvan K, Rajadurai A, Senthilvelan V. Characterization of hybrid silicon carbide and boron carbide nanoparticles-reinforced aluminum alloy composites. Procedia Eng. 2013;64:681–9.10.1016/j.proeng.2013.09.143Suche in Google Scholar

[32] Sozhamannan GG, Mohamed Yusuf M, Aravind G, Kumaresan G, Velmurugan K, Venkatachalapathy VSK. Effect of applied load on the wear performance of 6061 Al/Nano Ticp/Gr hybrid composites. Mater Today: Proc. 2018;5(2, Part 1):6489–96.10.1016/j.matpr.2017.12.262Suche in Google Scholar

[33] Narasimha Murthy I, Venkata Rao D, Babu Rao J. Microstructure and mechanical properties of aluminum–fly ash nano composites made by ultrasonic method. Mater & Des. 2012;35:55–65.10.1016/j.matdes.2011.10.019Suche in Google Scholar

[34] Chinta ND, Selvaraj N, Mahesh V. Mechanical characterization of aluminium – red mud metal matrix composites. Mater Today: Proc. 2018;5(13, Part 3):26911–7.10.1016/j.matpr.2018.08.178Suche in Google Scholar

[35] Chinnamahammad Bhasha A, Balamurugan K. Studies on mechanical properties of Al6061/RHC/TiC hybrid composite. Int J Lightweight Mater Manuf. 2021;4(4):405–15.10.1016/j.ijlmm.2021.06.003Suche in Google Scholar

[36] Niemczewska-Wójcik M, Pethuraj M, Uthayakumar M, Abdul Majid MS. Characteristics of the surface topography and tribological properties of reinforced aluminum matrix composite. Materials. 2022;15(1):358.10.3390/ma15010358Suche in Google Scholar PubMed PubMed Central

[37] Dorri Moghadam A, Omrani E, Menezes PL, Rohatgi PK. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene – A review. Compos Part B: Eng. 2015;77:402–20.10.1016/j.compositesb.2015.03.014Suche in Google Scholar

[38] Awad AH, Abdellatif MH. Assessment of mechanical and physical properties of LDPE reinforced with marble dust. Compos Part B: Eng. 2019;173:106948.10.1016/j.compositesb.2019.106948Suche in Google Scholar

[39] Omrani E, Moghadam AD, Kasar AK, Rohatgi P, Menezes PL. Tribological performance of graphite nanoplatelets reinforced Al and Al/Al2O3 self-lubricating composites. Materials. 2021;14(5):1183.10.3390/ma14051183Suche in Google Scholar PubMed PubMed Central

[40] Vani VV, Chak SK. The effect of process parameters in aluminum metal matrix composites with powder metallurgy. Manuf Rev. 2018;5:7.10.1051/mfreview/2018001Suche in Google Scholar

[41] Bastwros MMH, Esawi AMK, Wifi A. Friction and wear behavior of Al–CNT composites. Wear. 2013;307(1):164–73.10.1016/j.wear.2013.08.021Suche in Google Scholar

[42] Malaki M, Xu W, Kasar AK, Menezes PL, Dieringa H, Varma RS, et al. Advanced metal matrix nanocomposites. Metals. 2019;9(3):330.10.3390/met9030330Suche in Google Scholar

[43] Archard J. Contact and rubbing of flat surfaces. J Appl Phys. 1953;24(8):981–8.10.1063/1.1721448Suche in Google Scholar

[44] Sekhar R, Singh TP. Mechanisms in turning of metal matrix composites: a review. J Mater Res Technol. 2015;4(2):197–207.10.1016/j.jmrt.2014.10.013Suche in Google Scholar

[45] Wilson S, Alpas AT. Wear mechanism maps for metal matrix composites. Wear. 1997;212(1):41–9.10.1016/S0043-1648(97)00142-7Suche in Google Scholar

[46] Chaurasia R, Sarangi SK, Srivastava AK, Saxena A. Tribological and corrosion properties of graphene nanoplatelets and titanium dioxide nanoparticles reinforced aluminium zinc magnesium alloy-based nanohybrid metal matrix composites. Russ J Non-Ferrous Met. 2025;66(1):1–16.10.1134/S1067821225600206Suche in Google Scholar

[47] Jayappa K, Anil KC, Khan ZA. Enhancing wear resistance in Al-7075 composites through conventional mixing and casting techniques. J Mater Res Technol. 2023;27:7935–45.10.1016/j.jmrt.2023.11.171Suche in Google Scholar

[48] Wozniak J, Kostecki M, Cygan T, Buczek M, Olszyna A. Self-lubricating aluminium matrix composites reinforced with 2D crystals. Compos Part B: Eng. 2017;111:1–9.10.1016/j.compositesb.2016.11.054Suche in Google Scholar

[49] Ahmad S, Tian Y, Hashmi AW, Singh RK, Iqbal F, Dangi S, et al. Experimental studies on mechanical properties of Al-7075/TiO2 metal matrix composite and its tribological behaviour. J Mater Res Technol. 2024;30:8539–52.10.1016/j.jmrt.2024.05.227Suche in Google Scholar

[50] Sankhla AM, Patel KM, Makhesana MA, Giasin K, Pimenov DY, Wojciechowski S, et al. Effect of mixing method and particle size on hardness and compressive strength of aluminium based metal matrix composite prepared through powder metallurgy route. J Mater Res Technol. 2022;18:282–92.10.1016/j.jmrt.2022.02.094Suche in Google Scholar

[51] Bhuvaneswari V, Rajeshkumar L, Nimel Sworna Ross K. Influence of bioceramic reinforcement on tribological behaviour of aluminium alloy metal matrix composites: experimental study and analysis. J Mater Res Technol. 2021;15:2802–19.10.1016/j.jmrt.2021.09.090Suche in Google Scholar

[52] Dwivedi SP, Srivastava AK, Maurya NK, Sahu R, Tyagi A, Maurya R. Microstructure and mechanical behaviour of Al/SiC/Al2O3 hybrid metal matrix composite. Mater Today: Proc. 2020;25:789–92.10.1016/j.matpr.2019.09.023Suche in Google Scholar

[53] Kannan C, Ramanujam R. Comparative study on the mechanical and microstructural characterisation of AA 7075 nano and hybrid nanocomposites produced by stir and squeeze casting. J Adv Res. 2017;8(4):309–19.10.1016/j.jare.2017.02.005Suche in Google Scholar PubMed PubMed Central

[54] Chaurasia R, Sarangi SK. Effect of titanium di oxide nano powder on mechanical and tribological properties of reinforced aluminium nano composites. Prog Eng Sci. 2025;2(1):100039.10.1016/j.pes.2024.100039Suche in Google Scholar

[55] Ali MA, Mufti NA, Ishfaq K, Naveed R, Saleem MQ, Qureshi AM. Development and characterization of hybrid aluminium matrix composites through stir-squeeze casting using distinct reinforcements for structural applications. Int J Adv Manuf Technol. 2024;133(11):5897–925.10.1007/s00170-024-14102-9Suche in Google Scholar

[56] Yu J, Sun W, Xie L, Huang Y, Huang H. Effect of graphene content on the tribological and corrosion behavior of high-speed-laser-clad high-entropy-alloy composite coatings. Tribol Int. 2025;201:110197.10.1016/j.triboint.2024.110197Suche in Google Scholar

[57] Saxena A, Gupta TK, Chaurasia R, Srivastava AK, Singh KP, Mishra N. Influence of graphene reinforcement particles on the mechanical and wear behavior of AlMgCuCrFeZn high entropy alloy composite material. ECS J Solid State Sci Technol. 2025;14(3):031006.10.1149/2162-8777/adbebdSuche in Google Scholar

[58] Pawar SY, Kharde YR. Effect of dual reinforced ceramic particles on elevated temperature tribological properties of hybrid aluminium matrix composites. Adv Mater Process Technol. 2022;8(1):1104–20.10.1080/2374068X.2020.1853495Suche in Google Scholar

[59] Valizade N, Farhat Z. A Review on abrasive wear of aluminum composites: mechanisms and influencing factors. J Compos Sci. 2024;8(4):149.10.3390/jcs8040149Suche in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- MHD radiative mixed convective flow of a sodium alginate-based hybrid nanofluid over a convectively heated extending sheet with Joule heating

- Experimental study of mortar incorporating nano-magnetite on engineering performance and radiation shielding

- Multicriteria-based optimization and multi-variable non-linear regression analysis of concrete containing blends of nano date palm ash and eggshell powder as cementitious materials

- A promising Ag2S/poly-2-amino-1-mercaptobenzene open-top spherical core–shell nanocomposite for optoelectronic devices: A one-pot technique

- Biogenic synthesized selenium nanoparticles combined chitosan nanoparticles controlled lung cancer growth via ROS generation and mitochondrial damage pathway

- Fabrication of PDMS nano-mold by deposition casting method

- Stimulus-responsive gradient hydrogel micro-actuators fabricated by two-photon polymerization-based 4D printing

- Physical aspects of radiative Carreau nanofluid flow with motile microorganisms movement under yield stress via oblique penetrable wedge

- Effect of polar functional groups on the hydrophobicity of carbon nanotubes-bacterial cellulose nanocomposite

- Review in green synthesis mechanisms, application, and future prospects for Garcinia mangostana L. (mangosteen)-derived nanoparticles

- Entropy generation and heat transfer in nonlinear Buoyancy–driven Darcy–Forchheimer hybrid nanofluids with activation energy

- Green synthesis of silver nanoparticles using Ginkgo biloba seed extract: Evaluation of antioxidant, anticancer, antifungal, and antibacterial activities

- A numerical analysis of heat and mass transfer in water-based hybrid nanofluid flow containing copper and alumina nanoparticles over an extending sheet

- Investigating the behaviour of electro-magneto-hydrodynamic Carreau nanofluid flow with slip effects over a stretching cylinder

- Electrospun thermoplastic polyurethane/nano-Ag-coated clear aligners for the inhibition of Streptococcus mutans and oral biofilm

- Investigation of the optoelectronic properties of a novel polypyrrole-multi-well carbon nanotubes/titanium oxide/aluminum oxide/p-silicon heterojunction

- Novel photothermal magnetic Janus membranes suitable for solar water desalination

- Green synthesis of silver nanoparticles using Ageratum conyzoides for activated carbon compositing to prepare antimicrobial cotton fabric

- Activation energy and Coriolis force impact on three-dimensional dusty nanofluid flow containing gyrotactic microorganisms: Machine learning and numerical approach

- Machine learning analysis of thermo-bioconvection in a micropolar hybrid nanofluid-filled square cavity with oxytactic microorganisms

- Research and improvement of mechanical properties of cement nanocomposites for well cementing

- Thermal and stability analysis of silver–water nanofluid flow over unsteady stretching sheet under the influence of heat generation/absorption at the boundary

- Cobalt iron oxide-infused silicone nanocomposites: Magnetoactive materials for remote actuation and sensing

- Magnesium-reinforced PMMA composite scaffolds: Synthesis, characterization, and 3D printing via stereolithography

- Bayesian inference-based physics-informed neural network for performance study of hybrid nanofluids

- Numerical simulation of non-Newtonian hybrid nanofluid flow subject to a heterogeneous/homogeneous chemical reaction over a Riga surface

- Enhancing the superhydrophobicity, UV-resistance, and antifungal properties of natural wood surfaces via in situ formation of ZnO, TiO2, and SiO2 particles

- Synthesis and electrochemical characterization of iron oxide/poly(2-methylaniline) nanohybrids for supercapacitor application

- Impacts of double stratification on thermally radiative third-grade nanofluid flow on elongating cylinder with homogeneous/heterogeneous reactions by implementing machine learning approach

- Synthesis of Cu4O3 nanoparticles using pumpkin seed extract: Optimization, antimicrobial, and cytotoxicity studies

- Cationic charge influence on the magnetic response of the Fe3O4–[Me2+ 1−y Me3+ y (OH2)] y+(Co3 2−) y/2·mH2O hydrotalcite system

- Pressure sensing intelligent martial arts short soldier combat protection system based on conjugated polymer nanocomposite materials

- Magnetohydrodynamics heat transfer rate under inclined buoyancy force for nano and dusty fluids: Response surface optimization for the thermal transport

- Fly ash and nano-graphene enhanced stabilization of engine oil-contaminated soils

- Enhancing natural fiber-reinforced biopolymer composites with graphene nanoplatelets: Mechanical, morphological, and thermal properties

- Performance evaluation of dual-scale strengthened co-bonded single-lap joints using carbon nanotubes and Z-pins with ANN

- Computational works of blood flow with dust particles and partially ionized containing tiny particles on a moving wedge: Applications of nanotechnology

- Hybridization of biocomposites with oil palm cellulose nanofibrils/graphene nanoplatelets reinforcement in green epoxy: A study of physical, thermal, mechanical, and morphological properties

- Design and preparation of micro-nano dual-scale particle-reinforced Cu–Al–V alloy: Research on the aluminothermic reduction process

- Spectral quasi-linearization and response optimization on magnetohydrodynamic flow via stenosed artery with hybrid and ternary solid nanoparticles: Support vector machine learning

- Ferrite/curcumin hybrid nanocomposite formulation: Physicochemical characterization, anticancer activity, and apoptotic and cell cycle analyses in skin cancer cells

- Enhanced therapeutic efficacy of Tamoxifen against breast cancer using extra virgin olive oil-based nanoemulsion delivery system

- A titanium oxide- and silver-based hybrid nanofluid flow between two Riga walls that converge and diverge through a machine-learning approach

- Enhancing convective heat transfer mechanisms through the rheological analysis of Casson nanofluid flow towards a stagnation point over an electro-magnetized surface

- Intrinsic self-sensing cementitious composites with hybrid nanofillers exhibiting excellent piezoresistivity

- Research on mechanical properties and sulfate erosion resistance of nano-reinforced coal gangue based geopolymer concrete

- Impact of surface and configurational features of chemically synthesized chains of Ni nanostars on the magnetization reversal process

- Porous sponge-like AsOI/poly(2-aminobenzene-1-thiol) nanocomposite photocathode for hydrogen production from artificial and natural seawater

- Multifaceted insights into WO3 nanoparticle-coupled antibiotics to modulate resistance in enteric pathogens of Houbara bustard birds

- Synthesis of sericin-coated silver nanoparticles and their applications for the anti-bacterial finishing of cotton fabric

- Enhancing chloride resistance of freeze–thaw affected concrete through innovative nanomaterial–polymer hybrid cementitious coating

- Development and performance evaluation of green aluminium metal matrix composites reinforced with graphene nanopowder and marble dust

- Morphological, physical, thermal, and mechanical properties of carbon nanotubes reinforced arrowroot starch composites

- Influence of the graphene oxide nanosheet on tensile behavior and failure characteristics of the cement composites after high-temperature treatment

- Central composite design modeling in optimizing heat transfer rate in the dissipative and reactive dynamics of viscoplastic nanomaterials deploying Joule and heat generation aspects

- Double diffusion of nano-enhanced phase change materials in connected porous channels: A hybrid ISPH-XGBoost approach

- Synergistic impacts of Thompson–Troian slip, Stefan blowing, and nonuniform heat generation on Casson nanofluid dynamics through a porous medium

- Optimization of abrasive water jet machining parameters for basalt fiber/SiO2 nanofiller reinforced composites

- Enhancing aesthetic durability of Zisha teapots via TiO2 nanoparticle surface modification: A study on self-cleaning, antimicrobial, and mechanical properties

- Nanocellulose solution based on iron(iii) sodium tartrate complexes

- Combating multidrug-resistant infections: Gold nanoparticles–chitosan–papain-integrated dual-action nanoplatform for enhanced antibacterial activity

- Novel royal jelly-mediated green synthesis of selenium nanoparticles and their multifunctional biological activities

- Direct bandgap transition for emission in GeSn nanowires

- Synthesis of ZnO nanoparticles with different morphologies using a microwave-based method and their antimicrobial activity

- Numerical investigation of convective heat and mass transfer in a trapezoidal cavity filled with ternary hybrid nanofluid and a central obstacle

- Halloysite nanotube enhanced polyurethane nanocomposites for advanced electroinsulating applications

- Low molar mass ionic liquid’s modified carbon nanotubes and its role in PVDF crystalline stress generation

- Green synthesis of polydopamine-functionalized silver nanoparticles conjugated with Ceftazidime: in silico and experimental approach for combating antibiotic-resistant bacteria and reducing toxicity

- Evaluating the influence of graphene nano powder inclusion on mechanical, vibrational and water absorption behaviour of ramie/abaca hybrid composites

- Dynamic-behavior of Casson-type hybrid nanofluids due to a stretching sheet under the coupled impacts of boundary slip and reaction-diffusion processes

- Influence of polyvinyl alcohol on the physicochemical and self-sensing properties of nano carbon black reinforced cement mortar

- Review Articles

- A comprehensive review on hybrid plasmonic waveguides: Structures, applications, challenges, and future perspectives

- Nanoparticles in low-temperature preservation of biological systems of animal origin

- Fluorescent sulfur quantum dots for environmental monitoring

- Nanoscience systematic review methodology standardization

- Nanotechnology revolutionizing osteosarcoma treatment: Advances in targeted kinase inhibitors

- AFM: An important enabling technology for 2D materials and devices

- Carbon and 2D nanomaterial smart hydrogels for therapeutic applications

- Principles, applications and future prospects in photodegradation systems

- Do gold nanoparticles consistently benefit crop plants under both non-stressed and abiotic stress conditions?

- An updated overview of nanoparticle-induced cardiovascular toxicity

- Arginine as a promising amino acid for functionalized nanosystems: Innovations, challenges, and future directions

- Advancements in the use of cancer nanovaccines: Comprehensive insights with focus on lung and colon cancer

- Membrane-based biomimetic delivery systems for glioblastoma multiforme therapy

- The drug delivery systems based on nanoparticles for spinal cord injury repair

- Green synthesis, biomedical effects, and future trends of Ag/ZnO bimetallic nanoparticles: An update

- Application of magnesium and its compounds in biomaterials for nerve injury repair

- Micro/nanomotors in biomedicine: Construction and applications

- Hydrothermal synthesis of biomass-derived CQDs: Advances and applications

- Research progress in 3D bioprinting of skin: Challenges and opportunities

- Review on bio-selenium nanoparticles: Synthesis, protocols, and applications in biomedical processes

- Gold nanocrystals and nanorods functionalized with protein and polymeric ligands for environmental, energy storage, and diagnostic applications: A review

- An in-depth analysis of rotational and non-rotational piezoelectric energy harvesting beams: A comprehensive review

- Advancements in perovskite/CIGS tandem solar cells: Material synergies, device configurations, and economic viability for sustainable energy

- Deep learning in-depth analysis of crystal graph convolutional neural networks: A new era in materials discovery and its applications

- Review of recent nano TiO2 film coating methods, assessment techniques, and key problems for scaleup

- Antioxidant quantum dots for spinal cord injuries: A review on advancing neuroprotection and regeneration in neurological disorders

- Rise of polycatecholamine ultrathin films: From synthesis to smart applications

- Advancing microencapsulation strategies for bioactive compounds: Enhancing stability, bioavailability, and controlled release in food applications

- Advances in the design and manipulation of self-assembling peptide and protein nanostructures for biomedical applications

- Photocatalytic pervious concrete systems: from classic photocatalysis to luminescent photocatalysis

- Corrigendum

- Corrigendum to “Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer”

- Special Issue on Advanced Nanomaterials for Carbon Capture, Environment and Utilization for Energy Sustainability - Part III

- Efficiency optimization of quantum dot photovoltaic cell by solar thermophotovoltaic system

- Exploring the diverse nanomaterials employed in dental prosthesis and implant techniques: An overview

- Electrochemical investigation of bismuth-doped anode materials for low‑temperature solid oxide fuel cells with boosted voltage using a DC-DC voltage converter

- Synthesis of HfSe2 and CuHfSe2 crystalline materials using the chemical vapor transport method and their applications in supercapacitor energy storage devices

- Special Issue on Green Nanotechnology and Nano-materials for Environment Sustainability

- Influence of nano-silica and nano-ferrite particles on mechanical and durability of sustainable concrete: A review

- Surfaces and interfaces analysis on different carboxymethylation reaction time of anionic cellulose nanoparticles derived from oil palm biomass

- Processing and effective utilization of lignocellulosic biomass: Nanocellulose, nanolignin, and nanoxylan for wastewater treatment

- Retraction

- Retraction of “Aging assessment of silicone rubber materials under corona discharge accompanied by humidity and UV radiation”

Artikel in diesem Heft

- Research Articles

- MHD radiative mixed convective flow of a sodium alginate-based hybrid nanofluid over a convectively heated extending sheet with Joule heating

- Experimental study of mortar incorporating nano-magnetite on engineering performance and radiation shielding

- Multicriteria-based optimization and multi-variable non-linear regression analysis of concrete containing blends of nano date palm ash and eggshell powder as cementitious materials

- A promising Ag2S/poly-2-amino-1-mercaptobenzene open-top spherical core–shell nanocomposite for optoelectronic devices: A one-pot technique

- Biogenic synthesized selenium nanoparticles combined chitosan nanoparticles controlled lung cancer growth via ROS generation and mitochondrial damage pathway

- Fabrication of PDMS nano-mold by deposition casting method

- Stimulus-responsive gradient hydrogel micro-actuators fabricated by two-photon polymerization-based 4D printing

- Physical aspects of radiative Carreau nanofluid flow with motile microorganisms movement under yield stress via oblique penetrable wedge

- Effect of polar functional groups on the hydrophobicity of carbon nanotubes-bacterial cellulose nanocomposite

- Review in green synthesis mechanisms, application, and future prospects for Garcinia mangostana L. (mangosteen)-derived nanoparticles

- Entropy generation and heat transfer in nonlinear Buoyancy–driven Darcy–Forchheimer hybrid nanofluids with activation energy

- Green synthesis of silver nanoparticles using Ginkgo biloba seed extract: Evaluation of antioxidant, anticancer, antifungal, and antibacterial activities

- A numerical analysis of heat and mass transfer in water-based hybrid nanofluid flow containing copper and alumina nanoparticles over an extending sheet

- Investigating the behaviour of electro-magneto-hydrodynamic Carreau nanofluid flow with slip effects over a stretching cylinder

- Electrospun thermoplastic polyurethane/nano-Ag-coated clear aligners for the inhibition of Streptococcus mutans and oral biofilm

- Investigation of the optoelectronic properties of a novel polypyrrole-multi-well carbon nanotubes/titanium oxide/aluminum oxide/p-silicon heterojunction

- Novel photothermal magnetic Janus membranes suitable for solar water desalination

- Green synthesis of silver nanoparticles using Ageratum conyzoides for activated carbon compositing to prepare antimicrobial cotton fabric

- Activation energy and Coriolis force impact on three-dimensional dusty nanofluid flow containing gyrotactic microorganisms: Machine learning and numerical approach

- Machine learning analysis of thermo-bioconvection in a micropolar hybrid nanofluid-filled square cavity with oxytactic microorganisms

- Research and improvement of mechanical properties of cement nanocomposites for well cementing

- Thermal and stability analysis of silver–water nanofluid flow over unsteady stretching sheet under the influence of heat generation/absorption at the boundary

- Cobalt iron oxide-infused silicone nanocomposites: Magnetoactive materials for remote actuation and sensing

- Magnesium-reinforced PMMA composite scaffolds: Synthesis, characterization, and 3D printing via stereolithography

- Bayesian inference-based physics-informed neural network for performance study of hybrid nanofluids

- Numerical simulation of non-Newtonian hybrid nanofluid flow subject to a heterogeneous/homogeneous chemical reaction over a Riga surface

- Enhancing the superhydrophobicity, UV-resistance, and antifungal properties of natural wood surfaces via in situ formation of ZnO, TiO2, and SiO2 particles

- Synthesis and electrochemical characterization of iron oxide/poly(2-methylaniline) nanohybrids for supercapacitor application

- Impacts of double stratification on thermally radiative third-grade nanofluid flow on elongating cylinder with homogeneous/heterogeneous reactions by implementing machine learning approach

- Synthesis of Cu4O3 nanoparticles using pumpkin seed extract: Optimization, antimicrobial, and cytotoxicity studies

- Cationic charge influence on the magnetic response of the Fe3O4–[Me2+ 1−y Me3+ y (OH2)] y+(Co3 2−) y/2·mH2O hydrotalcite system

- Pressure sensing intelligent martial arts short soldier combat protection system based on conjugated polymer nanocomposite materials

- Magnetohydrodynamics heat transfer rate under inclined buoyancy force for nano and dusty fluids: Response surface optimization for the thermal transport

- Fly ash and nano-graphene enhanced stabilization of engine oil-contaminated soils

- Enhancing natural fiber-reinforced biopolymer composites with graphene nanoplatelets: Mechanical, morphological, and thermal properties

- Performance evaluation of dual-scale strengthened co-bonded single-lap joints using carbon nanotubes and Z-pins with ANN

- Computational works of blood flow with dust particles and partially ionized containing tiny particles on a moving wedge: Applications of nanotechnology

- Hybridization of biocomposites with oil palm cellulose nanofibrils/graphene nanoplatelets reinforcement in green epoxy: A study of physical, thermal, mechanical, and morphological properties

- Design and preparation of micro-nano dual-scale particle-reinforced Cu–Al–V alloy: Research on the aluminothermic reduction process

- Spectral quasi-linearization and response optimization on magnetohydrodynamic flow via stenosed artery with hybrid and ternary solid nanoparticles: Support vector machine learning

- Ferrite/curcumin hybrid nanocomposite formulation: Physicochemical characterization, anticancer activity, and apoptotic and cell cycle analyses in skin cancer cells

- Enhanced therapeutic efficacy of Tamoxifen against breast cancer using extra virgin olive oil-based nanoemulsion delivery system

- A titanium oxide- and silver-based hybrid nanofluid flow between two Riga walls that converge and diverge through a machine-learning approach