Exploring the diverse nanomaterials employed in dental prosthesis and implant techniques: An overview

-

Natesan Thirumalaivasan

, Deepak Verma

, Ramyakrishna Pothu

, Ahmed Bahgat Radwan

Abstract

The landscape of prosthodontics and dental implantology is undergoing a transformative evolution, driven by remarkable advancements in materials science. This review explores the pivotal role of multifaceted materials, ceramics, polymers, metal alloys, and composites in revolutionizing dental restorative procedures. These materials are not only enhancing the mechanical properties and biocompatibility of dental prostheses and implants but also elevating aesthetic outcomes to meet patient expectations. Our discussion highlights how traditional materials like titanium (Ti) and cobalt-chromium (Co–Cr), alongside newer innovations such as zirconia and polymer-based composites, contribute to the restoration and enhancement of oral functions. Furthermore, this article delves into the integration of cutting-edge technologies such as 3D printing and computer-aided design/manufacturing, which synergize with these advanced materials to tailor dental solutions to individual patient needs, thereby improving both functional outcomes and patient satisfaction. As the field progresses, we anticipate future innovations to focus on increasing the sustainability of materials used, refining their properties through nanotechnology, and further personalizing dental care through digital workflows, setting a new standard in the interdisciplinary approach of modern dentistry.

Abbreviations

- 3D

-

three dimensional

- ABS

-

acrylonitrile butadiene styrene

- AP

-

adaptation process

- APW

-

assembled prosthetic works

- Au

-

gold

- CAD

-

computer-aided design

- CAL

-

clinical attachment level

- CAM

-

computer-aided manufacturing

- CM

-

collagen membrane

- Co

-

cobalt

- Co–Cr

-

cobalt–chromium

- CoM

-

casting over metal

- CPS

-

sterile saline

- Cr

-

chromium

- DC

-

direct construction

- DD

-

decontamination

- DRCs

-

dental resin composites

- ERL

-

Er:YAG laser

- NBM

-

natural bone mineral

- Ni

-

nickel

- Ni–Cr

-

nickel–chromium

- PC

-

polycarbonate

- PCL

-

poly(e-caprolactone)

- PDMS

-

polydimethylsiloxane

- PE

-

polyethylene

- PEd

-

partial edentulism

- PEEK

-

polyetheretherketone

- PEG

-

polyethylene glycol

- PGA

-

polyglycolic acid

- PLA

-

polylactic acid

- PME

-

permucosal healing element

- PMMA

-

polymethyl methacrylate

- PP

-

polypropylene

- PU

-

polyurethane

- RD

-

refractory duplicate

- RPD

-

removable partial dentures

- SiN

-

silicon nitride

- Ti

-

titanium

- Ti6Al4V

-

vanadium

- Ti–Al–V

-

titanium–aluminum–vanadium

- Ti-m

-

titanium

- Ti-p

-

etched titanium

- Y-TZP

-

tetragonal zirconia polycrystal

- ZrO2

-

zirconium dioxide

1 Introduction

Prosthodontics and dental implantology stand at the forefront of modern dentistry, offering patients innovative solutions for tooth replacement and oral rehabilitation. Over the past few decades, these fields have witnessed remarkable progress, largely propelled by advancements in materials science and technology. Among the key drivers of these advancements are the multifunctional materials that have emerged as critical components in the development of dental prostheses and implants [1,2]. This article explores innovative materials utilized in prosthodontics and dental implantology in depth, emphasizing their important role in transforming restorative dentistry. It underlines how these materials, which combine aesthetics, strength, and utility, are critical to the advancement and transformational impact of dental difficulties such as missing or broken teeth [3,4]. Continuous progress in materials science and technology contributes considerably to the creation of effective and better dental restorations and implants.

Structure of a dental implant: Dental implants differ from crowns in that they are a permanent solution, whereas crowns can be either temporary or permanent. Temporary crowns serve as placeholders until the implant has successfully integrated with the bone, after which a permanent crown is installed [5]. Dental implants are categorized based on their surgical phases, with the main types being one-stage and two-stage implants. In one-stage implants, the implant fixture is inserted in such a way that the implant’s prosthetic post protrudes into the oral cavity [6]. These implants are often supported by interimplant splints to mitigate the impact of excessive loading forces during the healing phase. After surgery, a permucosal healing element (PME) is attached to the implant body, which is typically positioned slightly above the bone crest [7]. Soft tissue is then arranged around the PME. Two-stage implants utilize a multicomponent system (osseointegration, Figure 1). The first stage involves embedding the implant body in the bone and covering it entirely with a mucoperiosteal flap. The fixture then undergoes a healing period with the bone through a process known as osseointegration [8–10]. Approximately 6 weeks later, the second stage is performed. During this stage, the implant fixture is exposed, allowing for the placement of the prosthetic component onto the implant.

Representation of dental prosthesis and implants. (a) Structure of a dental implant in comparison with a normal tooth, (b) elements of dental implant/name of the components or parts of dental implanting materials, and (c) steps involved in the dental implants.

The restoration of oral function and aesthetics following tooth loss or damage is a paramount goal in dentistry. Prosthodontics, a specialized branch of dentistry, focuses on the art and science of designing and fabricating dental prostheses that mimic the form and function of natural teeth [11]. Dental implantology, on the other hand, has revolutionized the field by offering a more permanent and stable solution for tooth replacement through the use of dental implants surgically anchored in the jawbone [12]. These remarkable advancements not only have enhanced the quality of life for countless individuals but have also opened new horizons for dental professionals. In this era of precision and patient-centric care, it is imperative to understand the dynamic interplay between materials and clinical outcomes. The foundation of this review lies in unraveling the fundamental requirements of materials used in prosthodontics and dental implantology, underscoring the nonnegotiable attributes of biocompatibility, mechanical robustness, and long-term stability [13,14,15]. As we navigate through the intricate terrain of multifunctional materials, encompassing ceramics, polymers, metals, and composite materials, their unique properties and applications will come into focus, offering insights into their suitability for various dental restorations, from crowns and bridges to dentures and implant-supported prostheses.

At the heart of these transformative developments are the materials utilized in prosthodontics and dental implantology. These materials play a multifaceted role, serving as the building blocks for dental restorations and implants, and influencing their aesthetics, durability, and functionality. The selection of appropriate materials is crucial, as it directly impacts the success of treatment outcomes, patient satisfaction, and long-term oral health [14]. Moreover, we will explore the ever-expanding realm of esthetic materials, exemplified by tooth-colored ceramics and resin-based composites [16], which play an instrumental role in achieving natural-looking dental restorations. The fusion of cutting-edge technologies, such as 3D printing and digital dentistry, with these multifaceted materials promises to redefine the boundaries of customization in dental prostheses and implants [17,18].

The demand for dental prostheses and implants that seamlessly blend with the natural dentition has propelled extensive research and innovation in materials science. Today, a plethora of materials, ranging from traditional metals and ceramics to cutting-edge polymers and composites, offer a wide array of options for clinicians and patients alike. These materials are meticulously engineered to exhibit properties such as biocompatibility, mechanical strength, esthetic appeal, and resistance to wear and degradation [19,20]. Moreover, we will explore the ever-expanding realm of esthetic materials, exemplified by tooth-colored ceramics and resin-based composites, which play an instrumental role in achieving natural-looking dental restorations. The fusion of cutting-edge technologies, such as 3D printing and digital dentistry, with these multifaceted materials promises to redefine the boundaries of customization in dental prostheses and implants. In this review article, we embark on a journey to explore the multifunctional materials that have transformed the landscape of prosthodontics and dental implantology. We will delve into the fundamental requirements of these materials, examine their unique properties, and elucidate their applications in various dental scenarios, including crowns, bridges, dentures, and implant-supported restorations. Furthermore, we will investigate the evolving role of emerging technologies, such as 3D printing and digital dentistry, in conjunction with these materials, and assess their impact on the field. As we navigate this multifaceted world of dental materials, we will also delve into the biomechanical aspects, emphasizing the importance of mechanical properties and load-bearing capabilities, as well as the role of bioactive and antibacterial materials in promoting the successful integration of implants and preventing complications [21,22].

Ultimately, this review article aims to underscore the indispensable role that multifunctional materials play in elevating the domains of prosthodontics and dental implantology. Through their integration with innovative techniques and technologies, these materials have redefined the standards of dental restorations and implant procedures, offering patients more durable, esthetically pleasing, and functional solutions for tooth replacement and oral rehabilitation [23,24]. In this rapidly evolving landscape, a deeper understanding of these materials becomes essential for dental professionals striving to provide the highest level of care and satisfaction to their patients. Our journey will not only traverse the aesthetic aspects but also delve into the biomechanical considerations that shape the success of dental implants and prostheses. We will illuminate the critical importance of materials’ mechanical properties, load-bearing capabilities, and resistance to fatigue, providing a comprehensive understanding of their role in the clinical context. Furthermore, we will explore the fascinating world of bioactive and antibacterial materials, uncovering their role in promoting osseointegration and safeguarding against peri-implantitis, thereby contributing to the long-term success of dental implants. In conclusion, this review article serves as an enlightening compass, guiding us through the multifaceted landscape of materials science as it converges with prosthodontics and dental implantology. The amalgamation of advanced materials, coupled with innovative techniques and technologies, has ushered in an era of heightened expectations, where patients can anticipate more enduring, aesthetically pleasing, and functionally superior solutions for tooth replacement and oral rehabilitation.

2 Historical overview

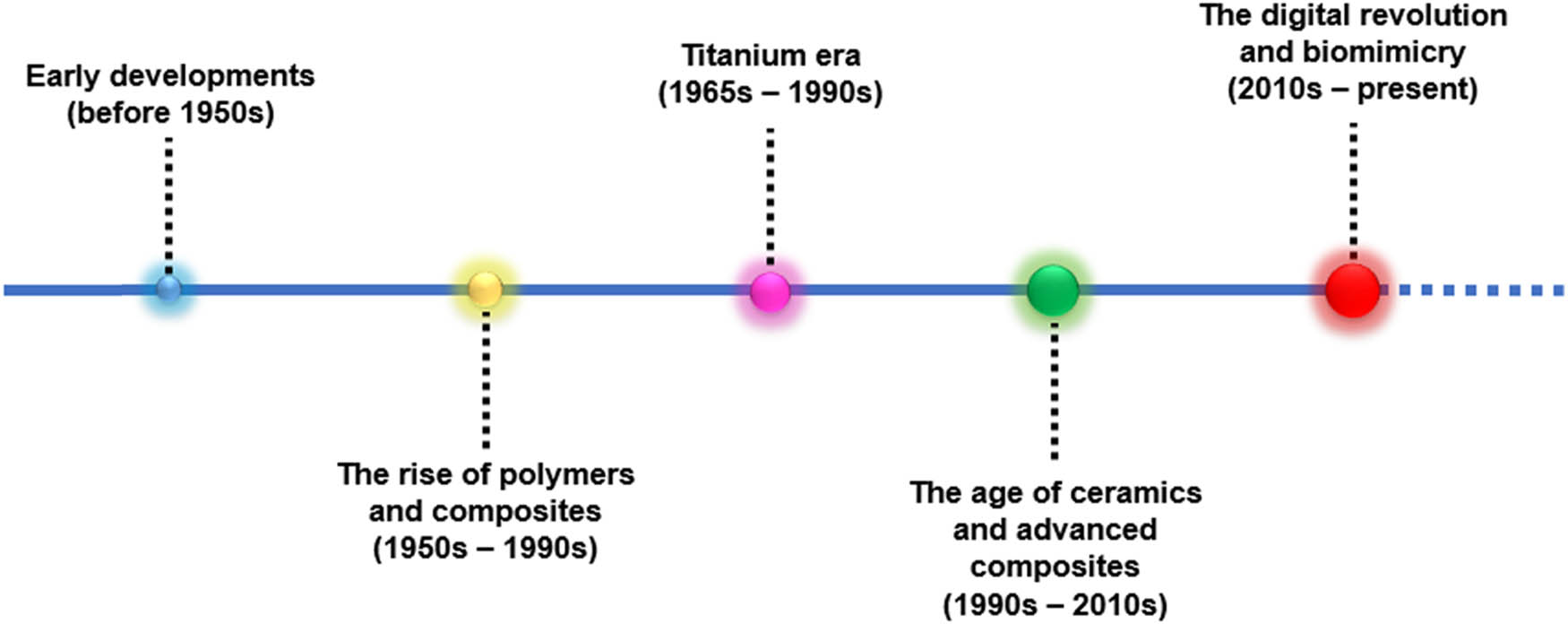

Prosthodontics and dental implantology are specialized branches of dentistry dedicated to the restoration and replacement of missing or damaged teeth [25,26,27]. Over the years, these fields have witnessed remarkable advancements in materials and techniques (Figure 2). These innovations aim to enhance patient satisfaction, improve esthetic outcomes, and bolster the mechanical properties of dental restorations and implants. As a result, a new category of materials, known as multifunctional materials, has emerged. These materials are specifically designed for use in prosthodontics and dental implantology, offering a diverse range of properties and functions to cater to the complex needs of patients in these disciplines. This review explores the historical development and current state of multifunctional materials in prosthodontics and dental implantology, shedding light on their pivotal role in modern dental practice.

Various materials employed in dental prosthesis and implant techniques over the years.

2.1 Early developments (before 1950s)

In ancient Egypt around 1500 BCE, dental prosthetics were crafted using gold (Au) wires that were affixed to teeth. Occasionally, teeth from human donors were utilized as replacements for missing ones. Fast forward to Ancient Rome in the first century CE, Au continued to be a popular material for dental works, especially for crowns and bridges. Interestingly, the Etruscans of that era employed a mix of animal teeth, bone, and Au to create dental bridges. Au, due to its malleability, resistance to corrosion, and biocompatibility, was one of the earliest materials used in the realm of dentistry [28]. However, despite these beneficial properties, its premium cost and limited strength rendered it less suitable for certain dental applications. By the eighteenth century, porcelain emerged as a choice material, offering esthetically pleasing results for crowns and other fixed prostheses. Nevertheless, its brittleness posed challenges in its application [29].

2.2 Rise of polymers and composites (1950s–1980s)

In the seventeenth century, dentures saw the introduction of materials like ivory and, subsequently, porcelain for their fabrication. However, these materials were not optimal, presenting aesthetic shortcomings along with issues of fit and retention. The following century, the eighteenth century, witnessed the evolution of denture technology with the advent of the first porcelain dentures, which were intricately held together using Au wires or springs. By the nineteenth century, a significant shift in materials occurred when vulcanite rubber, an early variant of hard rubber, emerged [30]. This material quickly gained preference over ivory for denture bases, mainly due to its enhanced comfort and cost-effectiveness. The mid-twentieth century brought another advancement with the introduction of polymethyl methacrylate (PMMA) during the 1940s and 1950s [31]. PMMA rapidly became the preferred material for dentures, given its easy processing and satisfactory aesthetic qualities. Moreover, by the late 1950s and into the 1960s, composite resins, consisting of organic polymer matrices combined with inorganic fillers, grew in popularity [32]. This was attributable to their superior mechanical properties and enhanced esthetic appeal.

2.3 Titanium (Ti) era (1965–1990s)

In the seventeenth century through the early 1900s, metals like cobalt–chromium (Co–Cr) alloys gained popularity for the fabrication of removable partial dentures (RPD). However, the landscape of dentistry underwent a significant transformation in the 1950s when Per-Ingvar Brånemark introduced Ti [33]. Renowned for its biocompatible properties, Ti set a new benchmark in dental implants, heralding a revolution in implantology. Further advancements were seen in the late twentieth century with the introduction of ceramics, such as zirconia and alumina. These materials offered an optimal combination of strength and aesthetics, particularly for crowns and fixed prostheses. A groundbreaking discovery that further shaped the realm of dental implantology was “osseointegration” [34,35]. This term, coined by Per-Ingvar Brånemark in the 1960s, refers to the bone’s unique ability to bond directly with Ti without forming a fibrous layer [35]. Owing to its exceptional biocompatibility, strength, and the proven benefits of osseointegration, Ti and its alloys swiftly became the Au standard for dental implant materials.

2.4 Age of ceramics and advanced composites (1990s–2010s)

Bioactive materials, including bioactive glasses (BAGs) and ceramics, have been introduced to bond with living tissues. These materials have the unique ability to release therapeutic ions that assist in tissue regeneration. Additionally, there has been significant advancement in the realm of polymeric materials. High-performance polymers have been developed that show improved aesthetic properties along with the increased resilience [36]. One of the key breakthroughs in ensuring the success of implants has been the introduction of surface modification techniques [37]. Processes like acid etching, sandblasting, and laser treatments have been utilized to bolster the osseointegration of implants, ensuring a tighter bond with the surrounding bone [38]. Zirconia has emerged as a prominent material in the dental industry, thanks to its natural white hue and impressive strength [39]. As an alternative to traditional metal, zirconia is now frequently used in prosthodontic frameworks and dental implants. Meanwhile, glass ceramics such as lithium disilicate (LD) have seen a surge in popularity [40]. Their unique blend of strength and esthetics makes them highly sought after. Finally, to enhance the durability and mechanical properties of resin-based materials, fiber-reinforced composites have been introduced.

2.5 Digital revolution and biomimicry (2010s–present)

In recent times, there have been notable advancements in dental technology, as highlighted in Table 1. One of the major breakthroughs in this field has been the widespread use of computer-aided design (CAD) and computer-aided manufacturing (CAM) technology, which has become increasingly common [41]. This has enabled the precise fabrication of dental prosthetics. Concurrently, there has been a surge in the application of nanotechnology in the dental field. Nanofilled and nanohybrid composites have been developed for restorations, boasting superior mechanical properties and enhanced aesthetics [42]. Another transformative innovation has been the adoption of 3D printing technologies [43]. These are now frequently employed in the creation of dental prostheses, surgical guides, and even in the bioprinting of tissues. Additionally, the development of smart materials, particularly those with the ability to change properties in response to external stimuli like shape-memory alloys, has opened up new avenues in dentistry [44]. The precision and speed of dental restorations have been further improved with the broader adoption of CAD/CAM systems, which provide a range of material options. Finally, there is a growing interest in bioactive and smart materials. The dental industry is exploring materials capable of stimulating tissue regeneration and those with self-healing properties [45]. Moreover, the integration of nanosized particles and fibers into dental materials not only boosts mechanical properties and aesthetics but also introduces potential antibacterial properties [46].

Succinct summary of various multifunctional materials commonly used in prosthodontics and dental implantology

| S. no | Materials | Applications | Limitations | Advantages | Mechanical/physical properties | Biocompatibility | Ref. |

|---|---|---|---|---|---|---|---|

| 1 | Ti (titanium) | Primary material for dental implants due to its excellent biocompatibility, strength, and ability to osseointegrate | Higher cost compared to other metals | Excellent strength and biocompatibility | High tensile strength and ductility | Highly biocompatible with human tissues, rarely causes allergic reactions | [47,48,49,50,51] |

| Used in making crowns, bridges, and dentures when combined with other prosthetic materials | Can be difficult to adjust or repair once placed | High corrosion resistance | Low density | ||||

| Ability to osseointegrate well with bone | Corrosion resistant | ||||||

| Common in substructures or frameworks of prosthetic devices due to its durability and lightweight nature | |||||||

| Frequently utilized in orthodontic appliances for its nontoxic and corrosion-resistant properties | |||||||

| 2 | Co–Cr alloys | Extensively used in making RPD due to their high corrosion resistance and mechanical strength | Potential for allergic reactions due to nickel content (in some alloys) | High mechanical strength | High elastic modulus | Generally biocompatible, but some individuals may react to nickel content | [52,53,54,55,56] |

| Excellent wear resistance | Good fatigue strength | ||||||

| Utilized for framework fabrication in fixed and removable prostheses | More difficult to polish than some other materials | Cost-effective compared to other high-end materials like titanium | Corrosion resistant | ||||

| Sometimes employed in full-cast crowns and bridges for their excellent wear resistance | |||||||

| Preferred in cases where strong, thin frameworks are needed, maximizing patient comfort | |||||||

| 3 | Ni–Cr alloy | Commonly used in fixed prosthodontics, particularly for porcelain-fused-to-metal crowns and bridges | Contains nickel, which can cause allergic reactions | Cost-effective | Moderate strength | Less biocompatible compared to titanium and Co–Cr alloys, potential for allergic reactions due to nickel | [57,58] |

| Good mechanical properties | High thermal conductivity | ||||||

| Valued for their thermal expansion compatibility with ceramics | Lower corrosion resistance compared to titanium and cobalt–chromium alloys | Thermal expansion compatibility with ceramics | Good resistance to thermal and mechanical fatigue | ||||

| 4 | Ceramics | Widely utilized for crowns, bridges, veneers, and inlays due to their aesthetic appeal and biocompatibility | Brittle nature can lead to fractures | Excellent aesthetic qualities | High hardness | Excellent biocompatibility, minimal risk of allergic reactions | [59,60] |

| Employed in prosthetics for their resemblance to natural tooth enamel | Higher cost than some metal alloys | High Biocompatibility | Low thermal conductivity | ||||

| Used in all-ceramic restorations for their translucency and color stability | Technique sensitive, requiring precise handling | Do not corrode | Good wear resistance | ||||

| 5 | Zirconia and alumina ceramics | Zirconia is popular for its high strength and aesthetic quality, making it suitable for crowns, bridges, and implant abutments | Higher cost than traditional ceramics | Exceptional strength and durability | Zirconia: High fracture toughness and flexural strength | Very high biocompatibility with negligible inflammatory response | [61,62] |

| Alumina ceramics are used for their translucency and strength, though less frequently than zirconia | Zirconia may require more tooth reduction during preparation | High aesthetic appeal with excellent color matching | Alumina: High hardness and stiffness | ||||

| Both materials are utilized for their excellent wear resistance and minimal abrasiveness to opposing natural teeth | Low wear to opposing teeth | ||||||

| 6 | Polymers | Employed in the fabrication of dentures, particularly the denture bases, due to their adaptability and comfort | Less durable than metal or ceramic materials, can wear out faster | Variable; generally lower strength compared to ceramics or metals but improved with reinforcement | Generally biocompatible; specifics depend on the polymer type | Denture bases, temporary prosthetics, orthodontic appliances | [63,64,65,66,67] |

| Used in temporary prosthetics and as part of certain orthodontic appliances | |||||||

| Recent advancements include reinforced polymers for increased strength in load bearing |

2.6 Future outlook and challenges

In terms of the future outlook and challenges in the field, there is a significant moment toward advancements in research. The primary aim is to develop materials that excel in biocompatibility, aesthetics, durability, and multifunctionality. The incorporation of cutting-edge smart materials, combined with the latest biotechnologies and AI-driven diagnostic and design tools, promises to usher in a new era of personalized and effective dental treatments. The field of prosthodontics and dental implantology has experienced a remarkable evolution, transitioning from the early days when Au and porcelain were predominantly used to the modern era dominated by smart materials, nanotechnology, and 3D printing. This journey underscores the relentless drive for innovation aimed at enhancing patient care. As material science and biotechnology push their boundaries further, the future is set to witness even more ground-breaking advancements. This progress, marked by the shift from materials like Au and ivory to contemporary smart materials, highlights the interdisciplinary nature of research that merges dentistry with material science. Such a fusion is paving the way for exhilarating innovations that will undoubtedly reshape patient-centric care in the coming years.

3 Material categories

Various types of materials have been utilized for dental implants, including metallic and metallic-alloy, ceramics, composites, and polymeric materials, among others. In the initial stages, metallic implants were predominantly used, as indicated in Figure 3.

Materials employed in dental prosthesis and implants.

3.1 Metal- and metallic alloy-based implants

3.1.1 Ti and its alloys in dental applications

In the ever-evolving realm of dentistry, materials play an indispensable role in determining the success of treatments, especially in restorative procedures and dental implants. Two significant materials, namely, Ti and its alloys, and Co–Cr alloys, have historically marked their territory in this domain due to their unparalleled properties. This article seeks to provide a brief overview of these materials, emphasizing their advantages, limitations, and potential future directions in dental applications. The multifaceted world of dentistry is perpetually in flux, with continuous advancements and innovations driving it forward. Central to this progression is the role of materials, serving as the very foundation upon which dental procedures are built. Their choice directly influences the outcomes, longevity, and overall efficacy of treatments, especially when it comes to restorative procedures and dental implants. Delving into this expansive material landscape, two metallic substances distinctly stand out due to their unique attributes: Ti and its alloys, along with Co–Cr alloys. This exposition offers a succinct insight into these materials, delineating their virtues, inherent challenges, and their potential trajectory in future dental applications.

3.1.1.1 Ti poisoning

Titanium implants are highly favored in dental applications due to their superior mechanical attributes and exceptional biocompatibility. However, there is a concern regarding the propensity of these implants to release titanium ions, which could pose localized and systemic risks. This ion emission has the potential to precipitate implant failure or exert deleterious effects on human physiological systems. It also discusses the possible health risks – such as inflammation, allergic reactions, and neurological disorders – that could result from titanium poisoning [68]. Challenges associated with titanium-based dental implants may stem from the release of titanium and titanium alloy particulates and ions into adjacent tissues due to corrosion and wear of the implant. This release can provoke inflammatory responses, culminating in osteolysis and potentially leading to the failure of the implant integration. Systemic deposition of these titanium ions and particles can incite adverse responses in distal tissues, exemplified by conditions such as yellow nail syndrome. In addition, hypersensitivity reactions may precipitate allergies and compromise implant functionality [69].

Titanium dioxide nanoparticles (TiO2 NPs) have been associated with cognitive deficits, evidenced by diminished expression of key blood–brain barrier transcripts in hippocampal tissues extracted from subjects following exposure protocols. This reduction corroborates with the paracellular permeability observed in our in vitro models. Entry of titanium particles into brain-mimetic endothelial cells is predominantly facilitated through caveolae-mediated endocytosis and macropinocytosis, instigating a pronounced proinflammatory cascade characterized by the upregulation of proinflammatory cytokines and proteins. This immune activation is partly regulated via the interleukin-1 receptor and interleukin-6 pathways. Moreover, elevated titanium concentrations have been detected in human tissues proximal to orthopedic implants, with both in vivo and in vitro analyses underscoring the potential neurotoxic implications of titanium exposure [70]. Titanium should not be thought of as an inert material because it can result in allergic reactions and is a potential cause of implant failure [71].

3.1.1.2 Mechanism of titanium toxicity

Titanium ions and titanium nanoparticles generate reactive oxygen species, which create cellular damage and inflammation surrounding tissues [72].

Titanium particles and ions can disrupt cellular signaling pathways, impairing cell growth and differentiation. This can cause cellular changes and contribute to the development of toxicity [73].

Increased concentrations of titanium ions and particles can cause necrosis or apoptosis in cells, which can cause direct damage and the release of proinflammatory mediators may result from this, leading to the inflammation and toxicity [74].

Ti and its alloys have revolutionized the field of dental applications, embodying the epitome of biocompatibility, strength, and resilience necessary for oral rehabilitations and prosthetics. Ti’s inherent properties, such as corrosion resistance and an affinity for osseointegration, make it an invaluable material in dentistry, primarily utilized in dental implants and prosthetic superstructures [75,76]. The light weight and remarkable biocompatibility of Ti allow for seamless integration into the bone structures, fostering stable and long-lasting dental restorations [77]. Various alloys of Ti have been developed and optimized to enhance specific mechanical properties, thus expanding the spectrum of dental applications. These alloys often amalgamate elements such as aluminum and vanadium, which bestow enhanced strength and durability, making them apt for the meticulous demands of the oral environment [78,79].

The adaptation of Ti and its alloys in dentistry is perpetually evolving, driven by incessant research and technological advancements. Innovative surface modifications and treatment processes have been introduced to improve the biological and mechanical interface between the dental implants and the surrounding bone, thus promoting better clinical outcomes [80]. The versatility of Ti allows it to be manipulated through contemporary fabrication techniques such as CAD/CAM, enabling precise customization and improving the overall efficacy and aesthetics of dental restorations [81]. Comprehensive studies and clinical trials underscore the significance of Ti in rendering reliable and effective solutions in restorative and implant dentistry. By capitalizing on Ti’s unique attributes and continual technological innovation, dental professionals can leverage this exceptional material to pave the way for advanced, sustainable, and patient-specific dental applications.

The role of Ti is indispensable in navigating the challenges encountered in dental rehabilitations, as it facilitates the confluence of functionality, durability, and biological harmony. In essence, Ti and its alloys have become the cornerstone in the realm of dental materials, holding a pivotal role in the pursuit of excellence in oral health and rehabilitation [82]. The literature vividly portrays the pivotal role of Ti, delineating its journey from being a novel material to an integral component in the odyssey of dental advancements. In conclusion, Ti and its alloys manifest as quintessential materials, shaping the future trajectory of innovative, resilient, and biocompatible solutions in dental applications.

3.1.2 Ti alloys: The Au standard in dental implants

Ti and its alloys have unequivocally become the Au standard in the realm of dental implants, revolutionizing the approach to mitigating tooth loss and revitalizing oral aesthetics and function. The inception of Ti as the cornerstone material for dental implants can be traced back to its exemplary biocompatibility, mechanical strength, and resistance to corrosion, characteristics that are instrumental in the realms of durability and long-term success. Diving into the heart of Ti’s biocompatibility, it becomes evident that this metallic element fosters an intimate relationship with human biology, particularly the bone tissue [83]. Ti implants remarkably encourage osseointegration, a natural process where the bone intimately binds with the implanted material, cultivating a robust foundation for the artificial tooth. This facilitates a symbiotic relationship where the implant not only replaces the lost tooth but also promotes the preservation and health of the jawbone, forestalling bone resorption and maintaining the structural integrity of the facial features.

Mechanical prowess is another accolade in Ti’s repository of attributes. The inherent strength and resilience of Ti and its alloys mimic the natural tenacity of a tooth root, ensuring that the implant can withstand the vicissitudes of masticatory pressures and diverse oral functionalities. This mechanical integrity is harmonized with a relative lightness, ensuring that the implant does not become a burdensome presence in the oral cavity but rather integrates seamlessly in terms of function and feel [84]. Corrosion resistance further elevates Ti’s stature in dental implantology. In the intricate environment of the mouth, where variables such as saliva, pH levels, and various biochemical interactions are constantly in flux, Ti demonstrates remarkable resilience. Its immunity to corrosive influences ensures that the integrity of the implant is steadfastly maintained, safeguarding both the aesthetics and the functional viability of the implanted structure over substantial periods.

3.1.2.1 Titanium–zirconium alloy (Straumann Roxolid)

Higher elongation and fatigue strength are two of the mechanical properties of titanium zirconium alloys containing 13–17% zirconium (TiZr1317) compared to pure titanium. Titanium and zirconium do not inhibit the growth of osteoblasts, which are necessary for osseointegration [85]. To meet the demands of dental implantologists, Straumann created Roxolid, which is 50% stronger than pure titanium [86]. The surface of TiZr1317 with a monophasic structure is topographically identical to that of pure titanium implants after sandblasting and acid etching [87]. Due to its exceptional mechanical qualities. Due to TiZr1317’s superior mechanical qualities, thin implants and implant components that can withstand high strains can be created, provided that the material exhibits a satisfactory level of biocompatibility comparable to that of pure titanium [88].

3.1.2.2 Titanium–aluminum–vanadium (Ti–Al–V)

Titanium forms alloys with various elements such as silver (Ag), aluminum (Al), argon (Ar), copper (Cu), iron (Fe), uranium (Ur), vanadium (V), and zinc (Zn). These alloys typically exist in three forms: alpha, beta, and alpha–beta (α-β) [89]. The specified morphologies are synthesized through the thermal treatment of pristine titanium in the presence of defined molarities of elements such as aluminum (Al) and vanadium (V), followed by the controlled cooling processes. These dopants act as phase-condition stabilizers. Specifically, aluminum is efficacious in stabilizing the alpha-phase microstructure of the alloy, concurrently augmenting its mechanical robustness while diminishing its overall mass. Conversely, vanadium serves to stabilize the beta-phase matrix. Incorporating either Al or V into the titanium matrix modifies the thermal boundaries at which the alpha to beta phase transformation occurs, thus facilitating the simultaneous presence of both phases within this modified thermal spectrum [90]. Desired forms can be obtained by quenching the alloy at room temperature. Heat treatment may be applied to increase the strength of these alloys. The most common alloys used for dental implants are of the alpha–beta variety, with the most common composition containing 6% Al and 4% V (Ti6Al4V).

Discussing the symphony of alloys in concert with titanium refines our understanding. Alloys such as Ti–Al–Va enhance the holistic performance of the implants. These concoctions of metallic synergy improve upon the already formidable characteristics of Ti, fine-tuning the balance between strength and weight and optimizing the adaptability and compatibility of the implants with the biological milieu. Exploring the innovative horizon, advancements in surface modifications and coatings of Ti implants further perpetuate their supremacy. Techniques such as sandblasting and acid etching enhance the surface topography of the implants, promoting improved cellular responses and accelerated osseointegration. Additionally, the exploration into nanotechnological enhancements and ceramic coatings broadens the spectrum of Ti’s applicability and performance, promising an evolving trajectory of excellence and adaptation to diverse patient needs and clinical scenarios.

Herrmann et al. investigated the microbial dynamics of commonly used implant/abutment materials at various biofilm maturity stages [91]. It highlights the complex relationship between surface texture and bacterial attachment. Examining a range of materials, from sand-blasted, acid-etched Ti to ZrO2 abutments, the study employs sophisticated methods such as reverse transcription-quantitative polymerase chain reaction and microarrays for an in-depth bacterial analysis. Interestingly, even though surface texture is a key factor in bacterial colonization, ZrO2 abutments, having a medium roughness, showed the most significant bacterial presence. This suggests other inherent material characteristics may impact bacterial growth. The consistent detection of periodontopathogens on every material, regardless of the observation period, emphasizes the importance of thorough postsurgical care. While the findings are informative, the study’s restricted sample size and its deviation from the clinical outcomes of bacterial colonization indicate the need for broader and varied future research.

These specimens were deliberately aligned at a precise, minimal distance, oriented toward the lingual surface of the incisors (highlighted by yellow arrows), to ensure the uninterrupted passage of saliva and to prevent the displacement of microbial biofilms. The schematic illustrates the strategic placement of materials as follows: zirconium dioxide (ZrO2) is allocated in the mesioincisal quadrant; pure, sand-blasted, acid-etched titanium (Ti-p) is deployed in the distoincisal quadrant; an alloy of titanium, 6% aluminum, and 4% vanadium with 1% trace elements (Ti6Al4V) is situated in the distocervical quadrant; and pure, mechanically processed titanium (Ti-m) is positioned in the mesiocervical quadrant.

Treatment of peri-implantitis was the subject of research by Schwarz et al. that compared two methods of surface debridement and decontamination [92]. This study compared the efficacy of an Er:YAG laser (ERL) with a more traditional method involving plastic curets, cotton pellets, and sterile saline (CPS). The comprehensive treatment plan included flap surgery, removal of granulation tissue, and implantoplasty, targeting both supra- and intra-bony defects. After a 6-month period, both the ERL and CPS methods [93] showed no substantial difference in their impact, achieving similar levels of bone fill as observed in radiographs. However, given the study’s short-term follow-up and the loss of two participants from a total of 32, the results require careful interpretation. While there were measurable differences in bleeding on probing and clinical attachment level values [94], these differences were not significant enough to favor one method over the other clinically. Consequently, the results mildly suggest a preference for the CPS method, considering its simplicity and cost-effectiveness, alongside comparable effectiveness to the ERL approach. Future studies with longer follow-up periods and larger sample sizes are necessary to gain more definitive insights.

The effectiveness of dental implants largely depends on their ability to integrate with bone (osseointegration) and their mechanical strength. The design details of implants, particularly their surface texture, play a key role in determining clinical success. Studies show that both commercially pure titanium and zirconia perform well yet implants with a roughened titanium surface generally achieve better osseointegration and greater longevity. On the other hand, zirconia implants are more prone to crack propagation, which can affect their resistance to wear and tear. In clinical settings where there are significant mechanical demands, rough titanium implants are often preferred because of their superior integration with bone. Despite this, zirconia implants still offer significant aesthetic benefits [95]. This research highlights the advantages of rough titanium implants, providing crucial insights for dental professionals and industry stakeholders.

In the broader schema of patient experiences and outcomes, titanium implants embody a narrative of reliability and quality of life improvement. The confidence instilled by a durable and naturally integrated implant enhances the psychological and social facets of the patient’s life, manifesting improvements that transcend the boundaries of oral health. Furthermore, the adaptability of titanium allows for a versatile range of applications, accommodating a multitude of dental rehabilitation needs, from single tooth replacements to comprehensive full-arch restorations. The environmental consciousness encapsulated in the choice of titanium and its alloys also reverberates with significance [96]. The sustainability of these materials, in terms of their long-lasting nature, minimizes the ecological footprint, embodying a conscientious approach to dental healthcare solutions. This echo of responsibility augments the ethical dimensions of titanium’s application in dental implants, reinforcing its position as an Au standard that resonates not only with technological prowess but also with a harmonious ethos of care, longevity, and respect for broader ecological considerations. In conclusion, titanium and its alloys have meticulously sculpted their legacy as the pinnacle in dental implant materials. Their orchestration of biocompatibility, mechanical strength, and corrosion resistance, along with a continual symphony of innovation and ethical resonance, underscores a narrative of excellence. This narrative is vibrantly alive, adapting and flourishing with each nuance of scientific advancement and each echo of human experience, reinforcing titanium’s unwavering stature as the Au standard in dental implants.

3.1.3 Co–Cr alloys: bridging strength and aesthetics

Co–Cr alloys have ascended to prominence within the dental sciences sector, serving as pivotal materials that harmonize robust mechanical attributes with aesthetic qualities. Historically, a diverse array of metals and alloys has been utilized for the fabrication of dental prostheses, including crowns and bridges, designed to mimic the functional and visual characteristics of natural dentition. The pursuit of an archetypal dental alloy, characterized by its exemplary mechanical strength, heightened biocompatibility, and superior aesthetic integration, has catalyzed the adoption and advancement of Co–Cr alloys in dental applications [97]. The selection of materials for dental prosthetics is paramount, as they must withstand the dynamically harsh conditions of the oral milieu, characterized by fluctuating temperatures, varying pH levels, and the substantial mechanical loads imparted during mastication. Co–Cr alloys are particularly notable in these rigorous environments due to their exceptional mechanical robustness and superior resistance to both wear and corrosion. Cobalt, an inherently strong and durable element, synergistically combines with chromium to forge alloys that manifest outstanding hardness and resilience. These properties are critical in coping with the considerable pressures and forces encountered within the oral cavity. Consequently, the enhanced mechanical stability of Co–Cr alloys contributes significantly to the longevity and reliability of dental restorations, rendering them an efficacious solution for dental prosthetic applications [98].

Aesthetics is another paramount concern in dental prosthetics [99]. People seek dental restorations that not only restore functionality but also blend seamlessly with their natural teeth, enhancing their appearance and confidence. Co–Cr alloys cater to this need by allowing for the creation of thin yet robust dental appliances, offering a more refined and less bulky appearance. The ability to fabricate thinner restorations also facilitates better gum health and easier cleaning, contributing to the overall aesthetic appeal and maintenance of the dental work. Moreover, Co–Cr alloys exhibit excellent biocompatibility, ensuring that they interact favorably with the biological tissues within the oral cavity. The absence of elements like nickel (Ni) [100], which could cause allergic reactions in some individuals, makes Co–Cr alloys safer and more comfortable for a broader spectrum of patients. This biocompatibility contributes to the overall success and acceptance of Co–Cr-based dental restorations, ensuring that patients can wear them with comfort and confidence over extended periods.

In Figure 4, oral rehabilitation for partial edentulism (PEd) involves the use of RPD or assembled prosthetic works (APWs). APWs consist of fixed (Pa) and removable (Pb) components, enhancing the ease of cleaning and chewing [101]. Typically, these prosthetics are crafted from Co–Cr alloys. To maintain research consistency, the design of the Pa framework was standardized across five Co–Cr alloys (0-A, 5-A, 10-A, 15-A, 16.4-A). The study examined three fabrication methods: refractory duplicate (RD, Pb), direct construction (DC, Pb−), and casting over metal (CoM, Pb+). Notably, the CoM method eliminated the need for Pa-Pb+ alignment and the adaptation process, resulting in a 91.7% improvement in component joining precision over RD and an 80.62% improvement over DC. The precision efficiency ranking of these methods is as follows: CoM, DC, and RD.

![Figure 4

Diagram of the transition from framework P (individual framework) to the series production of Pa frameworks by using the Ma framework wax model. Reproduced from the study of Uriciuc et al. [101], published by MDPI, 2021.](/document/doi/10.1515/ntrev-2025-0140/asset/graphic/j_ntrev-2025-0140_fig_004.jpg)

Diagram of the transition from framework P (individual framework) to the series production of Pa frameworks by using the Ma framework wax model. Reproduced from the study of Uriciuc et al. [101], published by MDPI, 2021.

Technological innovations have significantly contributed to the heightened utility of Co–Cr alloys within dental contexts. Contemporary fabrication methodologies, such as CAD/CAM, have transformed the production landscape for dental prosthetics, facilitating unprecedented precision and customization capabilities. These advancements permit the synthesis of Co–Cr alloy-based prosthetics that boast complex geometries and superior fit and finish, thereby enhancing both their aesthetic and functional attributes. In summation, Co–Cr alloys embody the requisite characteristics for advanced dental prosthetics, adeptly harmonizing robust mechanical properties with aesthetic finesse. Their outstanding durability, biocompatibility, and seamless integration with cutting-edge manufacturing technologies render them an essential component in the progressive development of dental restoration materials. Consequently, Co–Cr alloys epitomize the synthesis of scientific rigor and artistic precision in dental applications, marking a transformative phase in the materials and methodologies employed in dental prosthetics.

3.1.4 Co–Cr alloys in dental prosthetics

Co–Cr alloys have become indispensable in the field of dental prosthetics, merging functionality with biocompatibility to meet the diverse needs of patients and dental professionals alike. This composition of metals, primarily involving cobalt (Co) and chromium (Cr), is skillfully manipulated to create a variety of dental prosthetics, such as crowns, bridges, and partial dentures, due to their commendable mechanical properties, corrosion resistance, and affordability. Initially, the core tenet behind the utilization of Co–Cr alloys resides in their physical and mechanical properties. They possess a significant level of hardness and strength, which is instrumental in bearing the substantial masticatory forces exerted during chewing and biting. These alloys are resilient and offer exceptional durability and wear resistance, thereby ensuring the longevity of dental restorations. This is particularly crucial in the high-load bearing areas of the oral cavity, where the prosthetic materials are subjected to continuous stress and strain [102].

Co–Cr alloys are distinguished by their superior biocompatibility, an essential characteristic of materials used in dental prosthetics. They demonstrate exceptional affinity with the biological tissues of the oral cavity, ensuring minimal adverse biologic interactions and optimal tissue integration. The inherent corrosion resistance of Co–Cr alloys enhances their biocompatibility by reducing the release of metallic ions into the oral environment, which could potentially trigger toxic responses or hypersensitivity in susceptible individuals. These attributes render Co–Cr alloys a reliable choice for promoting oral health and safeguarding the integrity of dental tissues adjacent to prosthetic devices. Moreover, Co–Cr alloys excel in the aesthetic domain, a critical aspect of dental prosthetics. They facilitate the fabrication of slender, intricately detailed prosthetic structures that preserve a low profile while effectively restoring both the function and aesthetics of teeth. Furthermore, Co–Cr alloys can be skillfully employed as a framework over which ceramic or other visually appealing materials may be layered, thereby merging structural strength with aesthetic appeal. This combination ensures that the prosthetics not only meet functional requirements but also blend seamlessly with the natural dentition, enhancing the overall visual harmony.

In Figure 5, Co–Cr alloys, known for their robust mechanical properties, have transitioned from traditional casting to newer techniques like milling, laser melting, and presintered milling for dental and implant constructions [103]. This study explores these alloys’ hardness, yield strength, elastic modulus, and microstructure, categorized by manufacturing method, and examines the influence of heat treatment. Five Co–Cr alloys in various shapes are evaluated: cast, milled, laser melted, and presintered milled. Comparison is made with pure Ti grade 4 and Ti–6Al–4V (vanadium) ELI. Results show that laser-melted and presintered Co–Cr alloys have the highest mechanical properties and finer grain sizes. Ti–6Al–4V (vanadium) ELI exhibits superior hardness and yield strength over pure Ti grade 4. No significant differences are found after heat treatment. In summary, laser melting and presintered milling offer superior mechanical properties for Co–Cr alloys compared to casting and milling.

![Figure 5

The backscatter micrographs of heat-treated specimens: (a) Cast specimen with large grains, dendrites (darker gray), and white secondary phase particles (lighter gray), grain size >1 mm. (b) Milled specimen with secondary phase particles (white) along glide planes, possibly due to prior material deformation. (c) Laser melted specimens with ordered grain morphology typical for the process, grain size 20–100 mm, represented by channeling and/or strain contrast. (d) Presintered milled specimens showing many pores (black), grain size 10–100 mm, and twin boundaries with twinned grains (orange arrow) due to channeling contrast. Original magnification: ×1,000 ((a), (b), (d)), ×2,000 (c). Reproduced from the study of Kassapidou et al. [52], published by Elsevier, 2023.](/document/doi/10.1515/ntrev-2025-0140/asset/graphic/j_ntrev-2025-0140_fig_005.jpg)

The backscatter micrographs of heat-treated specimens: (a) Cast specimen with large grains, dendrites (darker gray), and white secondary phase particles (lighter gray), grain size >1 mm. (b) Milled specimen with secondary phase particles (white) along glide planes, possibly due to prior material deformation. (c) Laser melted specimens with ordered grain morphology typical for the process, grain size 20–100 mm, represented by channeling and/or strain contrast. (d) Presintered milled specimens showing many pores (black), grain size 10–100 mm, and twin boundaries with twinned grains (orange arrow) due to channeling contrast. Original magnification: ×1,000 ((a), (b), (d)), ×2,000 (c). Reproduced from the study of Kassapidou et al. [52], published by Elsevier, 2023.

Economic considerations further elevate the status of Co–Cr alloys in dental prosthetics. They offer a cost-effective alternative to other high-end materials such as Au and Ti, making dental restoration more accessible to a broader range of patients. This affordability does not compromise the quality and performance of the prosthetics, as Co–Cr alloys maintain a commendable standard of durability, functionality, and aesthetics. However, despite their numerous benefits, it is also essential to consider the challenges associated with the use of Co–Cr alloys. Allergic reactions, while rare, can still occur in some patients, necessitating careful consideration and patient history evaluation before opting for these materials [104]. In addition, the manipulation and casting of Co–Cr alloys require specialized knowledge and technical expertise, underscoring the need for dental professionals to be proficient in their use and handling to maximize their benefits and minimize potential complications.

In conclusion, Co–Cr alloys stand as a pillar in the landscape of dental prosthetics due to their multifaceted benefits ranging from exceptional mechanical properties to excellent biocompatibility. Their role in enhancing the durability, functionality, and aesthetic appeal of dental restorations is instrumental, providing a versatile and economical solution that caters to the diverse and dynamic needs of modern dentistry. Their thoughtful application, combined with a nuanced understanding of their properties and potential challenges, is crucial in leveraging their capabilities to foster optimal oral health outcomes in dental prosthetics.

3.1.5 Art of alloying: Enhancing utility with Ni–Cr alloy

The world of dental prosthetics has witnessed numerous advancements over the years, driven by a relentless quest for materials that combine strength, durability, and biocompatibility. In this intricate journey, the science of alloying emerges as an essential component. Alloying, the art of combining two or more metals to achieve enhanced properties, has led to the creation of a myriad of materials tailored to meet the diverse needs of various industries, including the medical and dental fields. Among these, the Ni–Cr alloy stands as a testament to the triumph of this science, particularly in the realm of dental prosthetics. Ni–Cr alloys are renowned for their outstanding mechanical properties, exemplary of the achievements possible through the meticulous manipulation of elements [105]. The amalgamation of Ni and Cr results in a material characterized by high tensile strength and a commendable level of hardness [106]. These attributes render it an excellent choice for dental prosthetics, where the need for a robust and durable material is not just preferred but is an absolute necessity. After all, the oral environment is a complex, dynamic system – a battlefield where materials are subjected to a variety of forces and elements, necessitating not only strength but resilience.

One of the defining characteristics of the Ni–Cr alloy is its extraordinary resistance to corrosion [107]. In the context of dental prosthetics, this is a golden attribute. The oral cavity is a highly corrosive environment, harboring a plethora of chemical substances, including acids and enzymes that can wage war against materials. Corrosion resistance is not just about maintaining the structural integrity of the prosthetic; it is intrinsically linked to the biocompatibility of the material. A corroded material can release ions into the oral environment, leading to toxic reactions and allergies [108]. Ni, when alloyed with Cr, exhibits an enhanced ability to withstand the corrosive influences of the oral environment. Cr, with its remarkable knack for forming a passive oxide layer on the surface of the alloy, acts as a shield. This invisible, yet potent, barrier is resistant to the corrosive substances found in the mouth, ensuring that the alloy remains unscathed, its structural integrity unimpaired, and its biocompatibility unchallenged.

The narrative surrounding Ni–Cr alloys in dental prosthetics encompasses a complex interplay of advanced materials science and biocompatibility issues. Nickel, recognized as a potent allergen, has elicited concerns from both dental professionals and patients. Although adverse reactions are uncommon, their occurrence necessitates a rigorous evaluation of the alloy’s use in clinical applications. This scenario epitomizes the delicate balance between leveraging the superior mechanical and corrosion-resistant properties of Ni–Cr alloys and mitigating allergenic risks, highlighting the critical role of tailored patient assessments and the relentless pursuit of alloy refinement. At the forefront of innovation within the domain of Ni–Cr alloys, research endeavors are robust, marked by a relentless drive to reduce the allergenic properties of nickel while enhancing the alloy’s intrinsic benefits. Advanced coating technologies, precision alloying techniques, and the investigation of novel substitute materials are at the cutting edge of strategies aiming to redefine Ni–Cr not merely as a viable option but as the premier choice for dental prosthetics. These scientific advancements underscore a broader commitment to optimizing material performance and patient safety in the field of dental materials science [109,110].

The evolution of Ni–Cr in dental prosthetics is a narrative of triumphant innovation, of the unyielding human spirit that seeks to conquer nature’s limitations. It is a journey characterized by the harmonious blend of art and science the art of alloying, where metals unite to form an entity greater than the sum of its parts, and the science of engineering, where every atom, every molecule, and every alloy is meticulously crafted to meet the stringent demands of the human body [111]. As we stand on the threshold of new discoveries, with technologies such as additive manufacturing and nanotechnology transforming the landscape, the story of Ni–Cr is still being written. Every challenge is an opportunity, and every limitation a stepping stone to new horizons. The art of alloying continues to evolve, not just in the quest for the perfect material but in the undying human aspiration for excellence – where science, art, and the human spirit unite to transform not just metals, but lives. In the world of dental prosthetics, Ni–Cr is not just an alloy; it is a symbol of human ingenuity, resilience, and the unyielding pursuit of perfection [111,112].

3.1.5.1 Fe–Cr–Ni-based alloys

Alloys made of stainless steel are utilized in implant and orthopedic devices. Stabilizer pins, ramus blades, ramus frames, and certain mucosal inserts are made of alloys based on iron [113]. Because nickel is a prominent constituent in this alloy, care must be taken while using it to preserve the passiviated (oxide) surface condition. The alloy is particularly susceptible to pitting corrosion. Patients with allergies should not use it. They are resistant to corrosion and have high galvanic potentials. Using titanium, cobalt, zirconium, or carbon implant biomaterials with it may cause galvanic coupling and biocorrosion.

3.1.6 Advanced coatings for enhanced biocompatibility and durability of magnesium implants

Magnesium alloys rank among the less toxic, one of the most biocompatible, and the most biodegradable biomaterials, thus making them strong candidates for use as orthopedic and dental implants. Nevertheless, their short maturation time in physiological samples questions their stability and efficiency. This is being addressed with advanced coating technologies which revolutionizes their use in medical and sports injury applications, improving their durability and functionality [114].

3.1.6.1 Innovative coating approaches

Current development concentrates on coating magnesium implants with reinforced nanocomposite nanoparticles, including magnetic nanoparticles, wollastonite, and hydroxyapatite (HAP). Moreover, this multifaceted coating approach not only protects the magnesium from premature degradation but also promotes bone cell attachment and proliferation, important for orthopedic healing and sports injury recovery. The use of the specialized combination form of these nanoparticles allows for their exploitation of tailored properties such as magnetic responsiveness, which can be advantageous for therapeutic applications [115].

The fabrication process of this membrane begins with careful and precise preparation of the magnesium alloy, and then on advanced coating such as electrophoretic deposition, plasma spraying, and soldering. The protective composites are layered systematically using these methods, which improve the interfacial bonding and crystallinity of the coatings. Fabrication to this level of precision results in robust, long-service life implants suitable for both athletic and medical applications [116].

3.1.6.2 Comprehensive characterization protocols

The advanced coatings are characterized by a combination of sophisticated techniques including electron microscopy and mechanical testing of coatings to reveal the nano-architecture and integrity of the coatings. Moreover, cytotoxicity and osteogenic assessment were performed to assess the implants’ ability to promote bone growth, without the corrosive risk, of incomparable consequences for their long-term in vivo effectiveness. The design process is exclusively dependent on finite element analysis (FEA) to simulate stress distribution and mechanical interactions between the implant and the device under physiological loads. This analysis then leads to refining implant designs to reduce common failure modes and enhance load-bearing capacity in the outline of the coating thickness and material composition [117].

At the same time, high rates of advancement in dental implantology employ FEA to find the optimal lengths and thread pitches of an implant. The validation of experimental assessments is carried out against this biomechanical modeling that feeds into design of dental implants that effectively disburse masticatory loads, providing longevity and safety of the implants. A synergistic approach combining FEA with experimental validations is beneficial to both orthopedic and dental implant designs by streamlining the development of new implants particularly designed for specific clinical needs. This approach pays off at once: it maximizes implant performance, and accelerates the path from concept to clinical, promising better patient outcomes in orthopedics and dentistry [118].

A change in the state of the art at the implant sciences level is the application of advanced coatings and innovative technologies in magnesium implant fabrication. In addition to broadening lifespans of implants, these improvements ensure integration and performance of implants in the body, establishing new milestones in the treatment and rehabilitation of patients in medical and athletic fields.

3.1.7 Aesthetic appeal through alloy fusion

In the dynamic world of dentistry, aesthetics often holds as much importance as functionality. As patients increasingly demand dental restorations that do not just serve their primary purpose but also look good, dental professionals are on a continual quest to find materials that meet both criteria. Among the myriad of options available, the fusion of Ni and Cr stands out. This alloy combination, often referred to as Ni–Cr, has proven to be both durable and aesthetically pleasing, making it a popular choice for various dental applications. The use of metals in dental restoration is not new. Au, for instance, has been used for centuries because of its durability and malleability. However, with the rising cost of Au and the demand for more cost-effective materials, dentists started exploring other metal alloys. By the twentieth century, the fusion of Ni and Cr emerged as a favorable choice. Its aesthetic silver-like appearance combined with its cost-effectiveness made it a compelling alternative to Au.

Ni–Cr alloys, commonly composed of approximately 80% nickel and 20% chromium – though variations in this ratio exist exhibit superior corrosion resistance, primarily attributable to the chromium content. Chromium contributes to the formation of a coherent oxide layer on the alloy’s surface upon exposure to oxygen. This oxide layer acts as a barrier, inhibiting oxidation and material degradation. The protective layer not only prolongs the functional lifespan of dental restorations but also preserves their aesthetic quality over extended periods. In addition, Ni–Cr alloys are noted for their high biocompatibility, a critical property in dental applications where materials are in persistent interaction with the oral environment. These materials must not elicit adverse biological responses or trigger allergic reactions. Through meticulous alloying and processing, Ni–Cr alloys minimize the likelihood of allergic responses or negative reactions in the majority of patients [119,120].

The aesthetic appeal of Ni–Cr is one of its standout features. Unlike some other metals that may discolor/decolorize or tarnish over time, Ni–Cr maintains its lustrous appearance [116]. Its natural silver-like hue closely resembles the color of natural teeth, especially when compared to the yellowish tint of Au. This makes it easier for dentists to achieve a natural look, especially when Ni–Cr is used in conjunction with porcelain or ceramic materials. Further, with advancements in dental technology, Ni–Cr can be manipulated to achieve varying degrees of translucency. This allows for even more accurate matching with the patient’s natural teeth, ensuring a seamless integration of the restoration into the oral environment.

Ni–Cr alloy finds application in various dental restorations, including crowns, bridges, and dentures. Crowns made of Ni–Cr alloy, often layered with porcelain, offer both strength and beauty. The underlying metal provides the necessary strength to withstand chewing forces, while the porcelain overlay imparts a lifelike appearance. Moreover, Ni–Cr’s ability to bond well with dental ceramics makes it an ideal choice for fixed dental bridges. These bridges are designed to replace missing teeth, and the aesthetic compatibility between Ni–Cr and ceramics ensures a natural-looking result. While Ni–Cr offers many advantages, it is essential to acknowledge its limitations. Some patients might have a Ni allergy, making it imperative for dental professionals to screen for such allergies before opting for Ni-Cr restorations. In addition, while Ni–Cr is resistant to corrosion, poor oral hygiene can still lead to issues like plaque accumulation around the restoration, which can compromise aesthetics over time.

In the domain of dental materials science, Ni–Cr alloys have emerged as a pivotal material due to their robust integration of mechanical strength, corrosion resistance, and aesthetic qualities. These properties render Ni–Cr alloys particularly advantageous for dental applications, aligning durability with visual harmony, thus garnering preference among dental professionals and patients. The intrinsic qualities of Ni–Cr, including its formidable structural integrity and excellent biocompatibility when alloyed, enable the creation of dental restorations that not only fulfill functional requisites but also aesthetically complement the patient’s dentition. Moreover, Ni–Cr alloys’ compatibility with advanced ceramic materials enhances their application in crafting prosthetic devices that are both efficacious and visually appealing. This synergy between metal and ceramic is instrumental in producing restorations that mimic the natural luster and translucency of tooth enamel, thereby elevating the overall aesthetic outcome.

In the broader context of dental technology, the strategic utilization of Ni–Cr alloys is integral to developing customized solutions that address individual patient profiles, particularly considering variability in oral biomechanics and potential metal sensitivities. Emphasizing a tailored approach in the deployment of these materials is crucial to optimizing therapeutic outcomes. Thus, the integration of Ni–Cr in dental restorative procedures not only marks a significant advancement in dental materials science but also enhances patient satisfaction through improved functional and aesthetic results, affirming its role as a transformative element in contemporary dental practice.

3.1.8 The revolution in dental aesthetics

The inclusion of Ni–Cr alloys in dentistry marked a turning point in the quest for natural-looking dental restorations. The fusion of this alloy with porcelain paved the way for dental work that was not only functional but also indistinguishable from natural teeth. As dental technologies continue to evolve, and patient expectations rise, materials like Ni–Cr will play an instrumental role in bridging the gap between functionality and aesthetics. In conclusion, the aesthetic appeal of Ni–Cr in dental applications has elevated the standard of dental restorations, offering a harmonious blend of strength, durability, and natural appearance. As dentistry continues its journey toward merging health, function, and beauty, the role of materials like Ni–Cr, with their intrinsic blend of science and art, becomes ever more critical.

3.2 Ceramics-based implants

Ceramic materials in the dental domain have emerged as a prominent solution, offering both aesthetic appeal and functional utility. Aesthetically, they mimic the natural appearance of teeth, blending seamlessly with the surrounding oral environment, thereby enhancing the patient’s smile and overall facial appearance. Functionally, they exhibit commendable strength, wear resistance, and biocompatibility, aligning with the body’s natural processes and tissues. Dental ceramics have demonstrated adaptability, catering to various applications, including crowns, bridges, veneers, inlays, and onlays [121,122]. Over the years, the evolution of dental ceramics has been influenced by advancements in material science and engineering. Traditional ceramics, although heralded for their aesthetic prowess, faced challenges regarding strength and durability. The introduction of contemporary ceramic materials, including zirconia and LD, has mitigated these challenges [123]. Zirconia, for instance, boasts remarkable strength and fracture resistance, making it a preferred choice for posterior restorations. Its ability to withstand masticatory forces without succumbing to cracks and wear is noteworthy.

LD, on the other hand, is celebrated for its optimal blend of strength and aesthetics [121]. Its translucent nature facilitates natural light transmission, bestowing a lifelike appearance to restorative works. In addition, the material’s resilient nature ensures longevity, even in environments subjected to intense mechanical forces. The process of crystallization augments its strength, rendering it a reliable solution for a myriad of dental applications. The incorporation of CAD/CAM technology in the fabrication of dental ceramics has revolutionized precision and customization. Dentists and technicians can design restorations with impeccable accuracy, ensuring a snug fit and optimal performance. The digital impressions and 3D modeling facilitate a streamlined workflow, reducing the turnaround time and enhancing patient comfort [124]. The precision intrinsic to this technology mitigates the risk of errors, ensuring that each restoration aligns with the specific contours and dimensions of the individual’s oral structure.

The biocompatibility of dental ceramics underscores their prominence in restorative dentistry. These materials exhibit an innate compatibility with the body’s tissues, reducing the risk of allergic reactions and sensitivities. Their inert nature curtails the likelihood of corrosion and degradation, promoting oral health and systemic wellness. Patients with metal sensitivities often gravitate toward ceramic restorations, finding solace in their hypoallergenic properties. Despite the accolades, dental ceramics are not immune to challenges. The material’s brittleness can be a concern, necessitating meticulous handling and installation. Advances in material science aim to augment the toughness and resilience of ceramics, integrating innovations like nano-ceramics, which amalgamate the benefits of composite materials and ceramics to offer enhanced performance.

Maintaining dental ceramics involves standard oral hygiene practices such as regular brushing, flossing, and professional cleanings, which are essential for the durability of ceramic restorations (Figure 6). The material’s inherent resistance to stains and discoloration further preserves its aesthetic quality over time. The future of dental ceramics is closely tied to continuous advancements in material science. Ongoing research into new ceramic formulations, powered by technological progress, heralds a future in which dental restorations are not only functional and visually pleasing but also enhance overall health. Innovations might include biointegration, tissue regeneration, and dynamic adaptation to the oral milieu, setting new standards for future dental ceramic materials. In summary, dental ceramics have established a significant presence in restorative dentistry through a seamless integration of beauty, functionality, and biocompatibility. Their development reflects the progress in material science and technology, with each breakthrough setting new standards for quality and performance [125]. As ongoing research opens new possibilities, dental ceramics are set to play a crucial role in the evolving field of restorative dentistry, offering solutions that go beyond repair to actively improve individual health. Ceramic-polymer hybrids combine the robustness of ceramics with the adaptability of polymers and are employed in various dental components like implant abutments and prostheses.

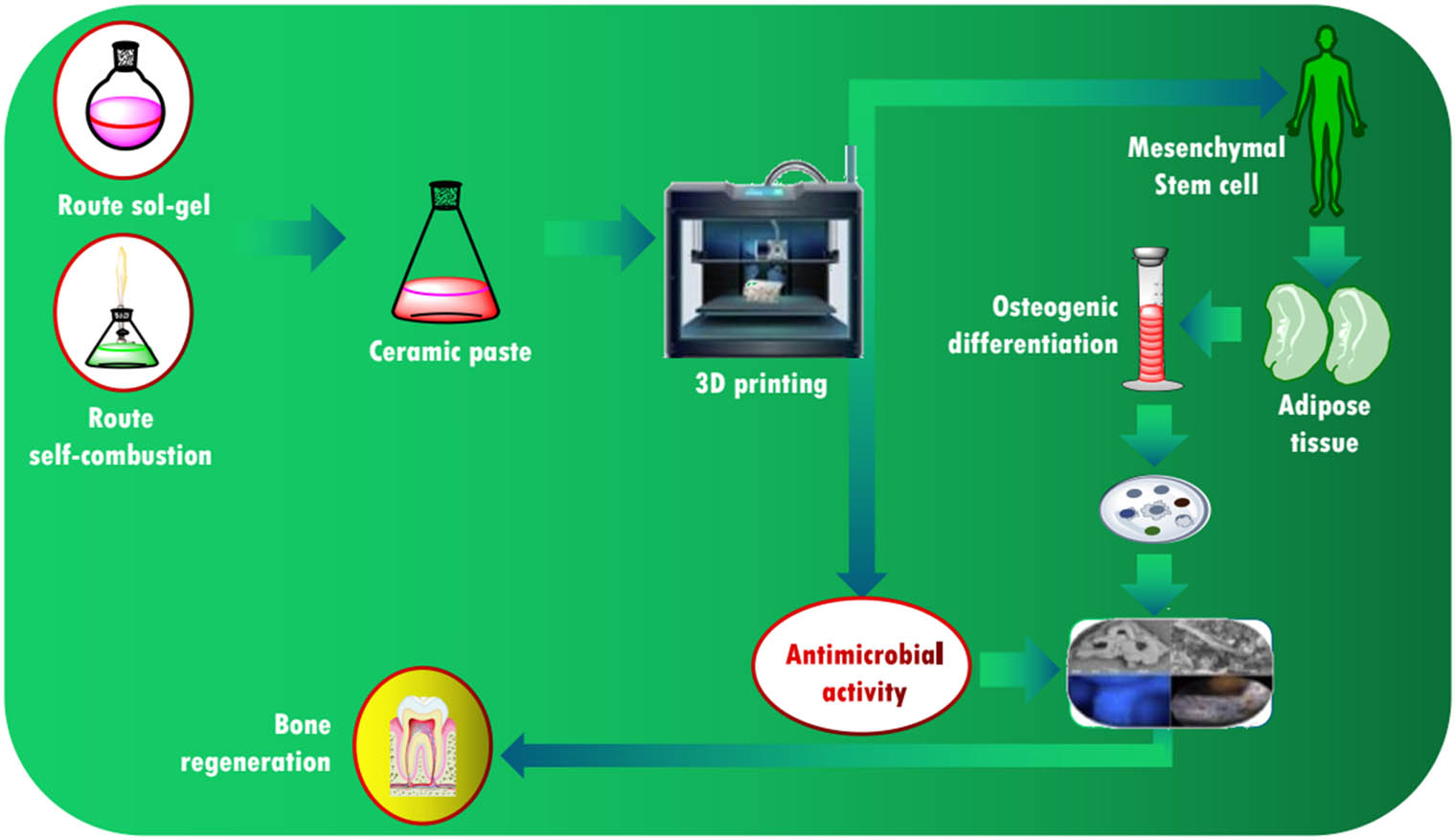

Effect of synthesis on the antimicrobial response of β-TCP/Mg with potential applications in the regeneration of dental tissue: 3D printing of ceramic paste in a β-TCP/Mg/bioglass system.

3.2.1 Zirconia and alumina ceramics

Zirconia and alumina ceramics have carved a significant niche in the dental domain, owing to their superior mechanical and aesthetic properties. Dentistry, a field that combines both the art of aesthetics and the robustness of mechanical engineering, has welcomed these materials as solutions for a myriad of applications, ranging from dental implants to crowns and bridges. Zirconia, scientifically known as zirconium dioxide (ZrO2), is renowned for its strength, durability, and biocompatibility. These characteristics make it an ideal choice for applications where strength is paramount, such as in the creation of dental implants and crowns. Zirconia’s color and translucency can be tailored to match the natural teeth, offering an aesthetic appeal that is often superior to other restorative materials.

Polymorphic zirconia structure is found in three different crystal forms: monoclinic (M), cubic (C), and tetragonal (T). At ambient temperature, zirconia takes on a monoclinic structure [126]. At 1,170°C, it transforms into a tetragonal phase, and at 2,370°C, it becomes a cubic phase. These phases are unstable at ambient temperature and fragment upon cooling. By adding CaO, MgO, and Y2O3 (Yttrium) to pure zirconia, the C-phase can be stabilized [127]. This produces a multiphase material known as partially stabilized zirconia, which combines the cubic, monoclinic, and tetragonal phases in the order of significance. Yttrium can be added to tetragonal zirconia polycrystals (TZP) at room temperature to produce a material that exclusively contains the tetragonal phase [128]. Yttria-stabilized titanium dioxide (TZP) exhibits favorable properties for biomedical applications, including low porosity, high density, strong bending, and compression strength.