Influence of the graphene oxide nanosheet on tensile behavior and failure characteristics of the cement composites after high-temperature treatment

Abstract

Graphene oxide (GO) has great potential in enhancing the strength and durability of cement-based materials due to its superior nano properties. While existing studies focus on ambient-condition enhancements, the thermal stability of GO enhanced systems remains unexplored. This investigation systematically evaluates the thermal performance and failure mechanisms of GO-modified cement composite under elevated temperatures. The results show that after high-temperature degradation, the tensile strength of cement-based materials optimized with GO can be increased by 6.5–46.8%. The nucleation and pore-infilling effects of GO nanosheets can be better demonstrated under the condition of high-temperature degradation. The acoustic emission and surface characterization results suggest that the addition of GO can transform a large-scale violent disruption into multiple small-scale disruptions and significantly reinforce the integrity of the hardened cement matrix. Microscopic tests have shown that GO nanosheets optimize the matrix of cement-based materials and suppress the propagation of microcracks during their fracture process. The fractal dimension value of the optimized GO sample is smaller than that of the unoptimized sample. The enhanced thermal stability and fracture integrity of GO-modified cement materials highlight their potential for improving fire resistance in high-temperature engineering applications.

1 Introduction

By virtue of their excellent compressive performance, high durability, low cost, and convenient production, cement composites have become the most consumed construction materials worldwide [1,2,3,4]. Nevertheless, as quasi-brittle materials, cement composites own drawbacks, such as easy cracking [5,6], poor toughness [7], and low tensile strength [8], make it highly susceptible to cracking in practical engineering applications [9,10,11]. As cracks appear, water, gas, and other corrosive substance will be able to penetrate the cracks and erode the interior of the composite materials, seriously affecting the bearing capacity and durability of the structure [12,13]. Particularly, when cement composites are exposed to extreme environments such as fire, their performance will rapidly deteriorate [14]. After high-temperature deterioration, it is generally believed that complex physical and chemical changes have occurred inside the cement composites [15,16]. From a macro perspective, the common deteriorated forms of cement composites after high temperature include expansion, cracking, stiffness dropping, and strength reduction [17,18]. In some cases, it can also cause the cement to peel off or burst [19]. For reinforced concrete components, once the concrete protective layer cracks or peels off due to high temperature, the steel bars directly exposed to the external environment will lose their original bearing capacity, bringing safety hazards to the buildings [20]. Therefore, investigating the high-temperature performance is significant for guiding the high-temperature resistance design of cement composites and mitigating the impact of fires [21].

In recent research, the utilization of nanomaterials to improve the properties of traditional cement has become a notable research avenue in construction materials science [22,23,24,25,26,27], with graphene oxide (GO) garnering significant attention [28,29,30,31]. Meanwhile, the application of GO-derived materials in cement-based composites – such as graphene nanoplatelets, graphene quantum dots (GQDs), and graphene quantum dot suprastructure (supra-GQDs) – has shown a rising trend [32,33,34]. Various studies have revealed that incorporating a minimal dosage of GO (0.01–0.05 wt% relative to cement mass) into cementitious materials can notably enhance the mechanical strength, impermeability, and durability of cement composites [35,36,37,38]. The superior reinforcing properties of GO in these composites are attributed to three key mechanisms. First, GO possesses an ultra-high specific surface area and a rich array of oxygen-containing functional groups, which induce nucleation effects to promote the hydration of binder materials and refine the microstructure of the cement matrix [39,40]. Second, GO exhibits outstanding physical-mechanical properties: the Young’s modulus and tensile strength of GO nanosheets are several orders of magnitude higher than those of cement-based materials, enabling them to enhance nano-friction within micro-units through “bridging” in hardened cement paste [41]. Third, as a cement additive, GO is used at extremely low dosages. Compared to fiber-reinforced cement modifiers, its impact on the workability of cement composites remains relatively minor [42].

Leveraging these advantages, GO demonstrates remarkable effectiveness in enhancing the tensile performance of cement composites. Lu et al. [43] reported that adding GO significantly improved the peak strength of strain-hardening cementitious composites. Under constant ultimate stress conditions, incorporating 0.08 wt% GO notably enhanced the mechanical properties: compressive strength increased by 24.8%, and tensile strength rose by 37.7%. Naseem et al. [44] observed that compared with polymer-modified cement, GO incorporation led to substantial tensile strength improvements in composites, with 7 and 28 days tensile strengths of graphene oxide polymer modified cement increasing by 73 and 59%, respectively. Lv et al. [45] found a positive correlation between GO content and increase in tensile and flexural strengths. When the GO content reached 0.03%, the reinforcement effect on cement-based materials was optimal, achieving 78.6 and 60.7% increase in 28 days tensile and flexural strengths, respectively, compared to the control sample without GO.

Nevertheless, the influence of GO on the tensile behavior and failure characteristics of the cement composites after high temperature deterioration are not very clear. Under the action of high temperature, the deterioration of the cementitious composites mainly comes from two aspects, one is from the steam pressure and temperature stress accumulated inside the cement matrix [46], and the other is from the decomposition of hydration products [47]. Hence, in this study, we mixed GO nanosheets in the cement composites to investigate the tensile behavior and failure characteristics of hardened matrix. After that, the hardened cement matrix was heat treated by using a resistance furnace. The tensile strength and elastic modulus of the nano-modified cement composites were tested. The acoustic emission (AE) monitoring system was applied in the test to characterize the failure characteristics during the mechanical test processes. Afterwards, the failure surfaces were characterized using three-dimension scanning and scanning electron microscope (SEM) technology to further reveal the reinforcing mechanisms of the GO on the cementitious composites after high-temperature treatment.

2 Experimental methods

2.1 Materials and instrumentation

In this research, ordinary Portland cement (OPC, type PO.32.5 [47,48,49]) was used. The chemical compositions are shown in Table 1. The industrial-grade GO was supplied by Nanjing XFNANO Materials Technology Co. (Nanjing, Jiangsu, China). The physical properties are shown in Table 2. To improve the dispersibility of GO in the solution, a polycarboxylate superplasticizer (PS) was incorporated as an external additive.

Chemical composition of OPC (%)

| CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | Loss | |

|---|---|---|---|---|---|---|---|

| OPC | 64.01 | 20.69 | 5.71 | 3.18 | 2.52 | 0.61 | 2.7 |

Physical properties of industrial GO

| Purity | Thickness | Carbon content | Oxygen content | Sulfur content | Diameter | Layers |

|---|---|---|---|---|---|---|

| 95% | ~1 nm | <50% | >42% | <4% | 10–50 μm | 1–2 |

2.2 Preparation of GO-reinforced cement composites

The preparation of GO-reinforced cement composites involves two steps: dispersing GO suspension and mixing with cement powder. As per prior research [35], GO and polycarboxylate superplasticizer were added to the suspension at 0.08 and 0.64 wt%, respectively. The detailed procedure is as follows: First, GO and PS powders were precisely weighed and dissolved in deionized water. The mixture was magnetically stirred for 180 s before ultrasonic treatment using a VCX-500W device (SONICS, USA). Following the authors’ previous protocol [48], ultrasonic dispersion was conducted at 60 W for 10 min with a 3s-on/3s-off pulse mode to avoid overheating. The dispersed GO suspension was mixed with cement (W/C = 0.4). The cementitious paste was mechanically mixed at 180 rpm for 3 min, poured into 50 mm × 100 mm cylindrical molds, and cured in a standard environment (20 ± 2°C, ≥95% relative humidity) for 28 days. After curing, each cylindrical specimen was cut into three Brazilian disk specimens (50 mm diameter, 25 mm thickness). A control group of pure cement pastes without GO was prepared simultaneously for comparative analysis (Table 3).

Group categorization and mixing proportions

| Item number | W/C | P/s (wt%) | GO/s (wt%) | Temperature (°C) |

|---|---|---|---|---|

| Ref-1 | 0.4 | 0.64 | 0 | 20 |

| Ref-2 | 0.4 | 0.64 | 0 | 200 |

| Ref-3 | 0.4 | 0.64 | 0 | 400 |

| Ref-4 | 0.4 | 0.64 | 0 | 600 |

| Ref-5 | 0.4 | 0.64 | 0 | 800 |

| GO-1 | 0.4 | 0.64 | 0.08 | 20 |

| GO-2 | 0.4 | 0.64 | 0.08 | 200 |

| GO-3 | 0.4 | 0.64 | 0.08 | 400 |

| GO-4 | 0.4 | 0.64 | 0.08 | 600 |

| GO-5 | 0.4 | 0.64 | 0.08 | 800 |

The cement composite specimens were subjected to high-temperature treatment using a SX2-8-10N box-type resistance furnace (dimensions: 250 mm × 400 mm× 160 mm, maximum working temperature: 1,200°C). Specimens were first preheated at 75 V for 10 min to prevent thermal shock, after which the voltage was increased to 100 V and the furnace was heated to target temperatures (200, 400, 600, and 800°C) at a rate of 10°C/min. Each target temperature was held isothermally for 120 min, followed by natural cooling to room temperature (25°C).

2.3 Experimental methods

2.3.1 Mechanical properties test

Brazilian splitting tests were performed on an MTS816 system under displacement-controlled loading (0.05 mm/min), with a pre-load of 0.1 kN. Stress–strain curves were recorded during the tests.

2.3.2 Thermogravimetric analysis (TGA)

Thermal decomposition behavior of pure cement and GO-modified cement samples was analyzed using a Netzsch STA449F5 analyzer. Samples were heated from 20 to 800°C at a rate of 10°C/min under a continuous argon flow atmosphere.

2.3.3 AE monitoring

AE signals during splitting tests were acquired using a Micro-II Express system. A 300 kHz sensor, coupled to the specimen with Vaseline, recorded signals at 1 MSPS with a 40 dB threshold and 40 dB amplification. Time parameters (HLT: 1,000 μs, HDT: 800 μs, PDT: 200 μs) were optimized for signal capture.

2.3.4 Digital image correlation (DIC)

Surface deformation was tracked via DIC. Specimens were coated with white paint and black speckles (0.5–1 mm diameter). A high-speed camera (1,000 fps) captured images, processed using Photoinfor software, and strain fields were generated via PostViewer.

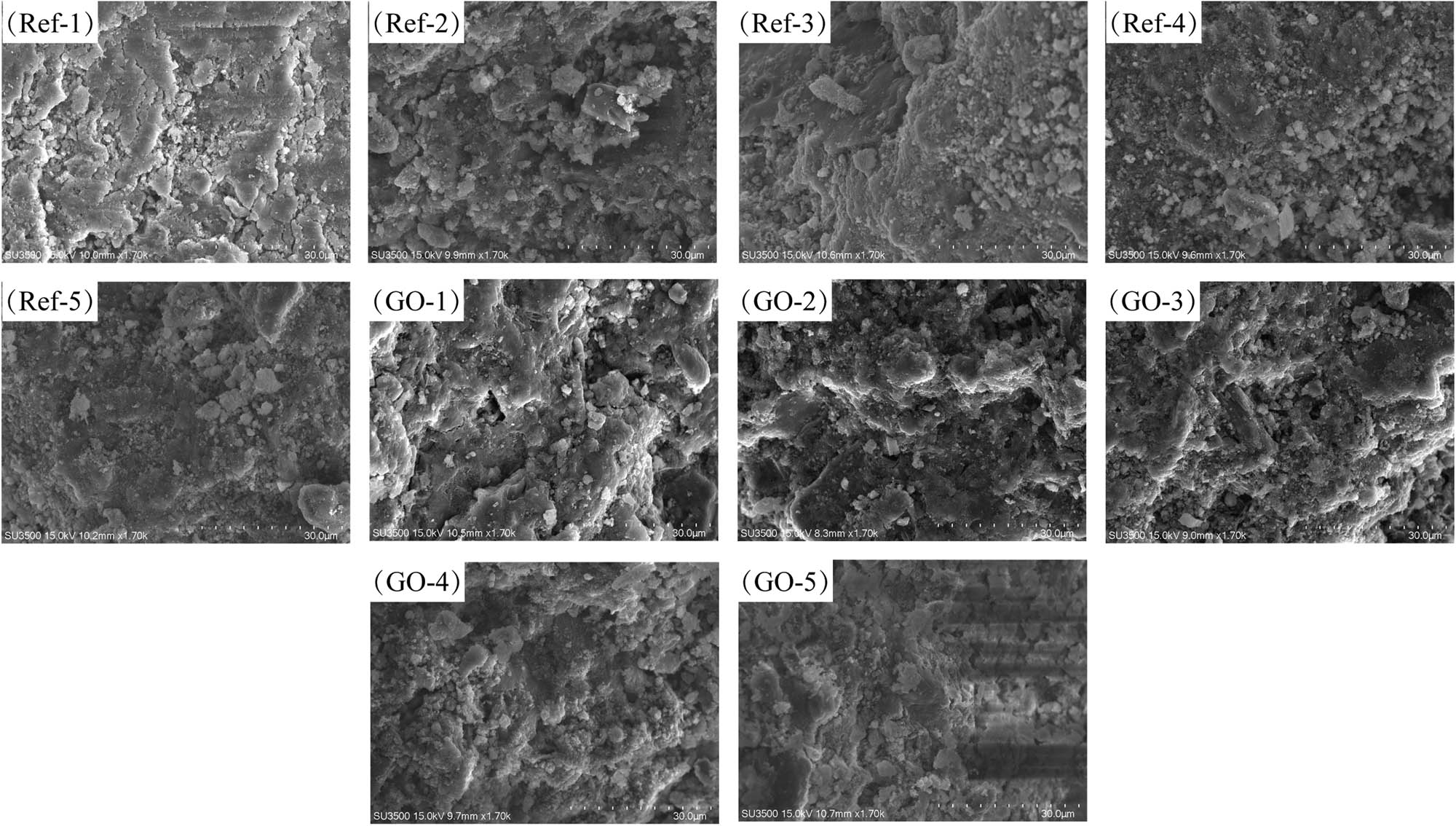

2.3.5 SEM

Fracture surfaces were sputter-coated with Au/Pd and imaged at 3,000× magnification. Fractal dimensions of SEM images were quantified using MATLAB-based box-counting analysis.

3 Results and discussion

3.1 Tensile properties of the GO-reinforced cement composites

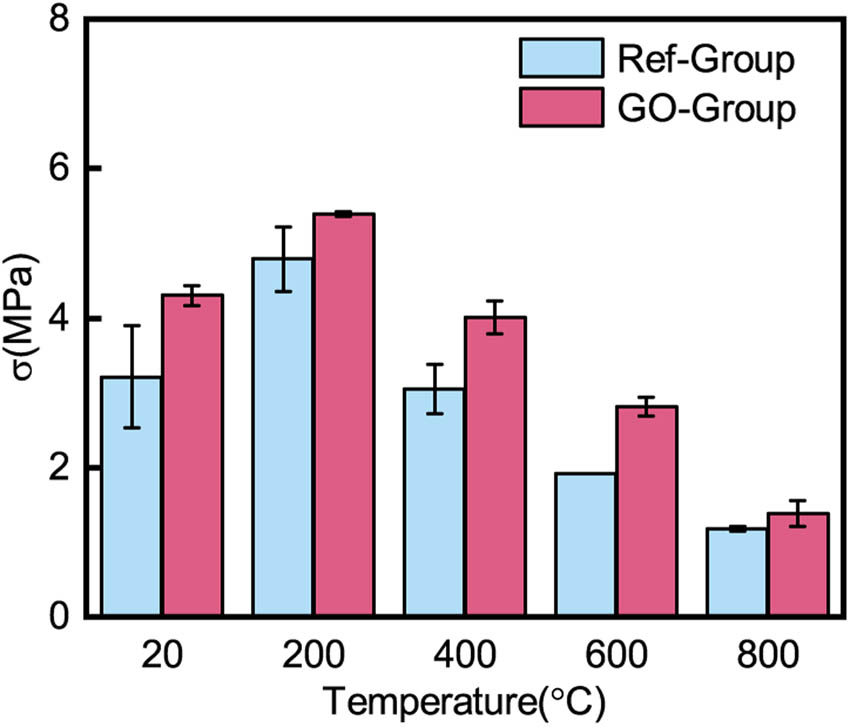

As shown in Figure 1, it can be found that the tensile strength of the hardened cement composite specimens after high-temperature treatment tends to rise first and reaches the maximum tensile strength of 4.78 MPa at 200°C. Nevertheless, as the temperature rises, the tensile strength decreases gradually and hits the lowest value of 1.18 MPa at 800°C. This is mainly due to the fact that at 200°C treatment, no obvious material changes occurred in the cement. Mainly, the evaporation of free water and some bound water took place, and the main hydration products of the cement material did not decompose. Meanwhile, the free water and physically bound water in the cement composites begin to evaporate, forming an autoclave environment within the matrix. In autoclaved environments, unhydrated cement particles in the composites produce additional hydration reactions, enhancing the tensile properties of the hardened specimens [49]. Elevated temperatures induced progressive dehydration of hydration products and decomposition of the C–S–H skeleton in cement composites, leading to continuous deterioration of mechanical properties [50]. This degradation culminated in minimal tensile strength and elastic modulus at 800°C.

Tensile strength of each sample at different temperatures.

With GO addition, the tensile properties of cement composites after high-temperature treatment were notably enhanced, as illustrated in Figure 1. Across all tested temperatures, both the tensile strength and elastic modulus of GO-reinforced specimens exceeded those of the control group. Similar to control specimens, the tensile strength of GO-modified samples reached its peak at 200°C and lowest value at 800°C. According to the test results, incorporating GO can increase the tensile strength of the cement composites from 6.5 to 46.8%. With the increase in temperature, the enhancement efficiency showed an increasing trend. When the temperature is 400°C, the increasing rate of the GO-reinforced specimen achieved about 31%. By contrast, for 600 and 800°C, the increasing rates were rising to approximately 44–45% compared with the control group. Studies demonstrate that GO enhances cement composites via dual mechanisms: nucleation sites promotion [51] and pore structure refinement [52]. The oxygen-rich functional groups on GO surfaces facilitate calcium ion adsorption, enabling denser C–S–H formation through localized hydration compared to plain cement [53]. Under thermal exposure, mobile GO nanosheets establish supplementary chemical bonds with C–S–H networks, elevating thermal stability by increasing the energy barrier for structural disintegration. Microstructurally, GO acts as both bridging reinforcement within hydrated phases and a template for creating “wall-like” dense configurations through inter-sheet interactions upon hardening [54]. During mechanical loading, this hierarchical architecture generates interfacial friction between GO and matrix, effectively delaying failure initiation [53,55].

3.2 TGA

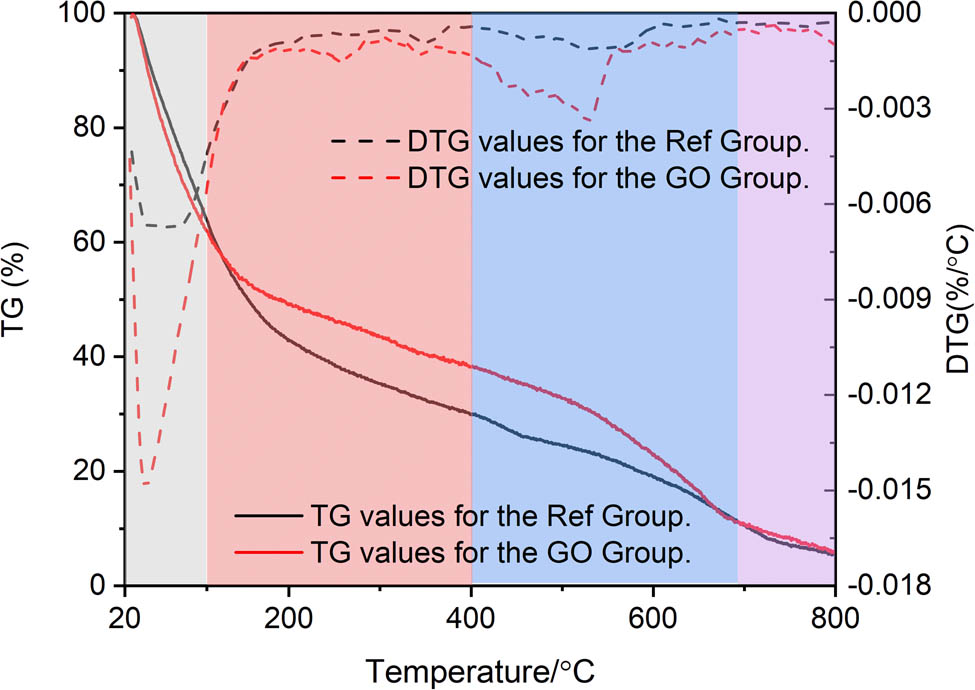

TGA in Figure 2 highlights the enhanced thermal stability of GO-modified cement composites. Three key degradation stages were observed. Below 200°C, both samples experienced approximately 50% mass loss primarily due to evaporation of capillary and bound water, with GO composites exhibiting slower dehydration rates compared to the reference group [11]. Between 200°C and 250°C, the decomposition of oxygen-containing groups in GO sample produces substances including carbon dioxide and water. This resulted in 23% less mass loss than that of plain cement, indicating structural stabilization through the selective elimination of labile components. At 650°C, a sharp increase in the DTG curve signaled accelerated C–S–H decomposition, yet GO-modified specimens demonstrated delayed degradation compared to carbon nanotube-reinforced systems that rapidly decomposed at 500–540°C [56]. This thermal resilience stems from GO’s dual mechanisms: chemically, the sacrificial release of oxygen groups strengthens residual graphene frameworks, while structurally, the reinforced GO-C–S–H interfaces require 18% higher energy for bond dissociation. Additionally, the preserved GO network physically inhibits crack propagation under thermal stress, synergistically improving high-temperature performance.

TG/DTG of sample.

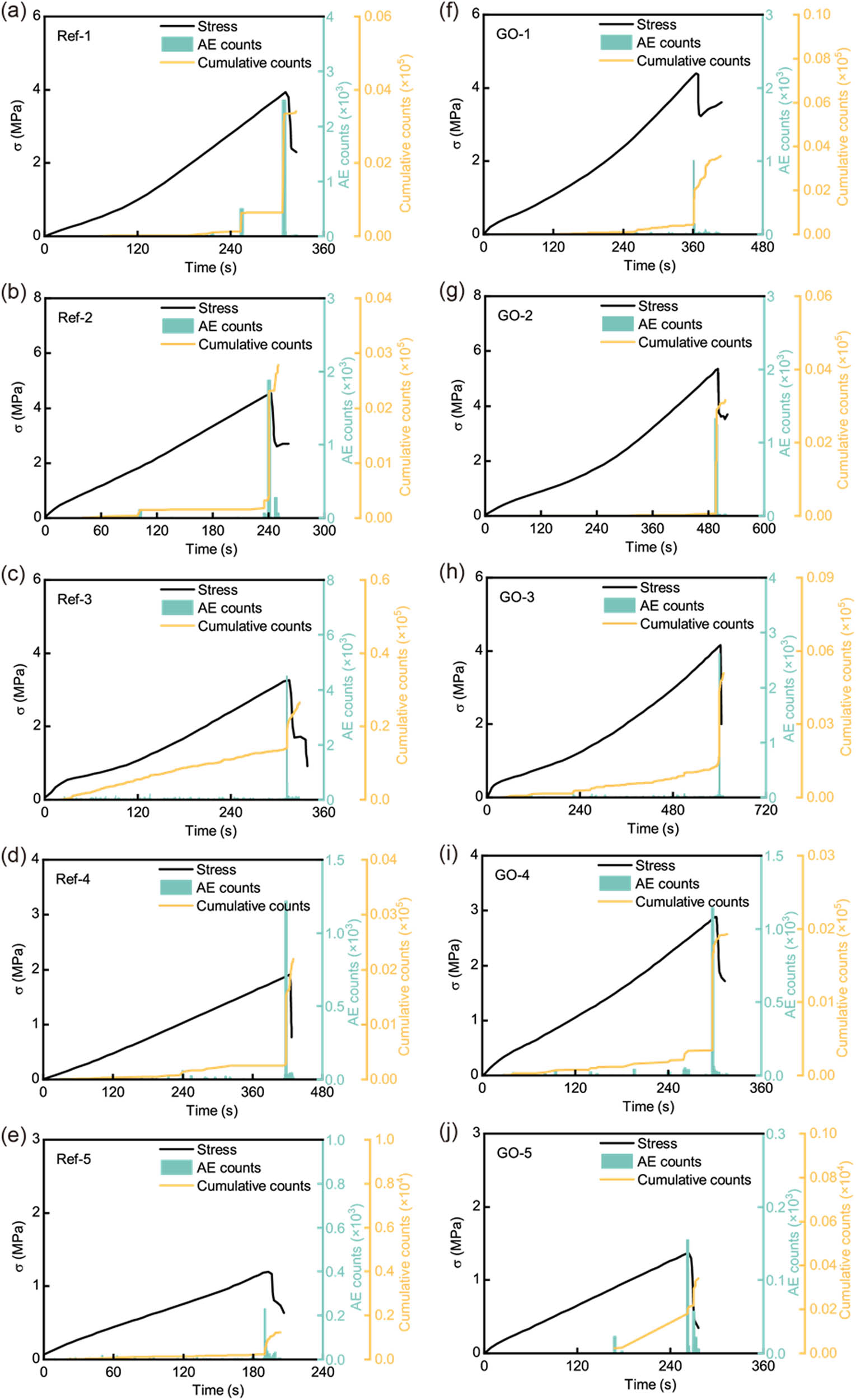

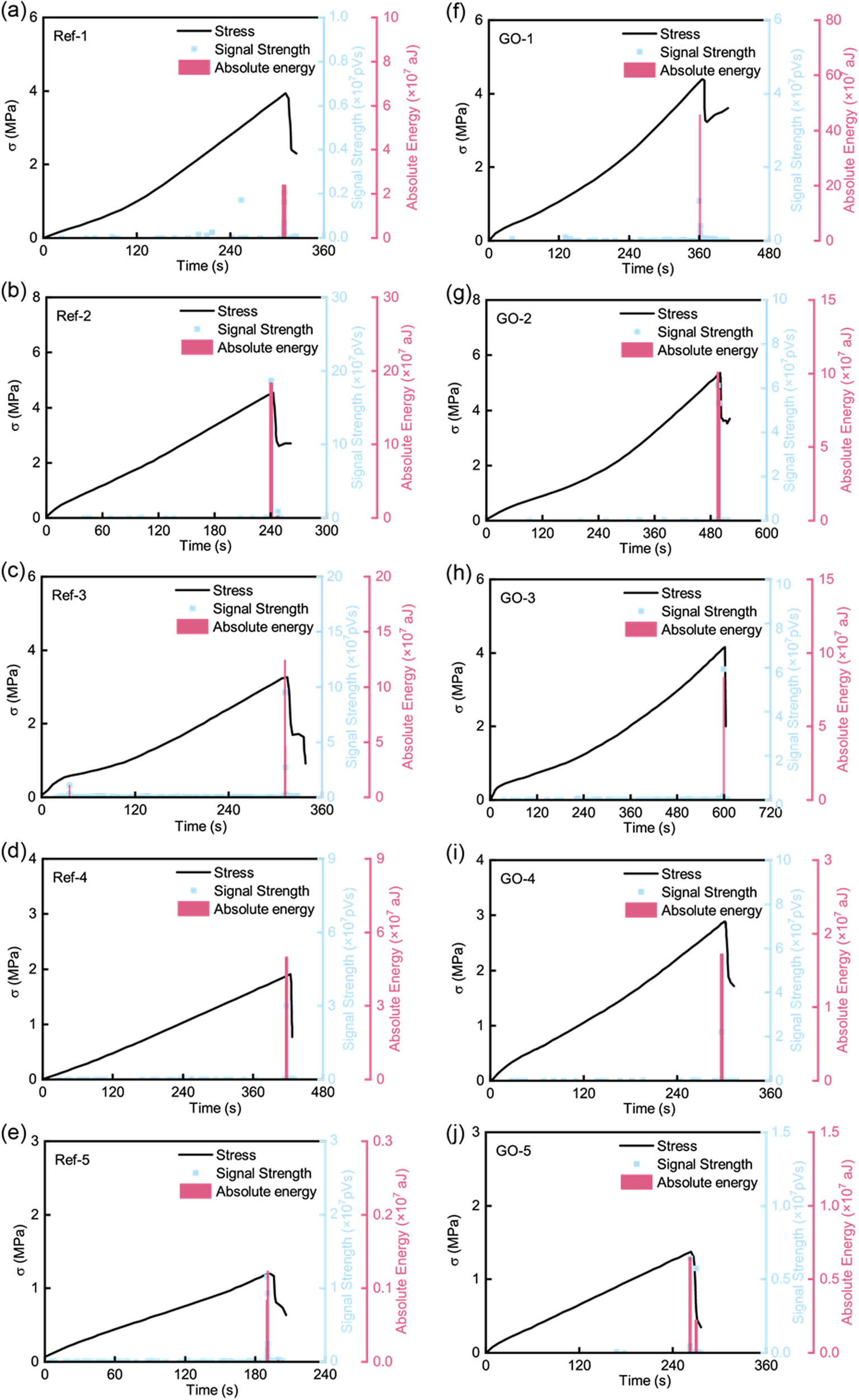

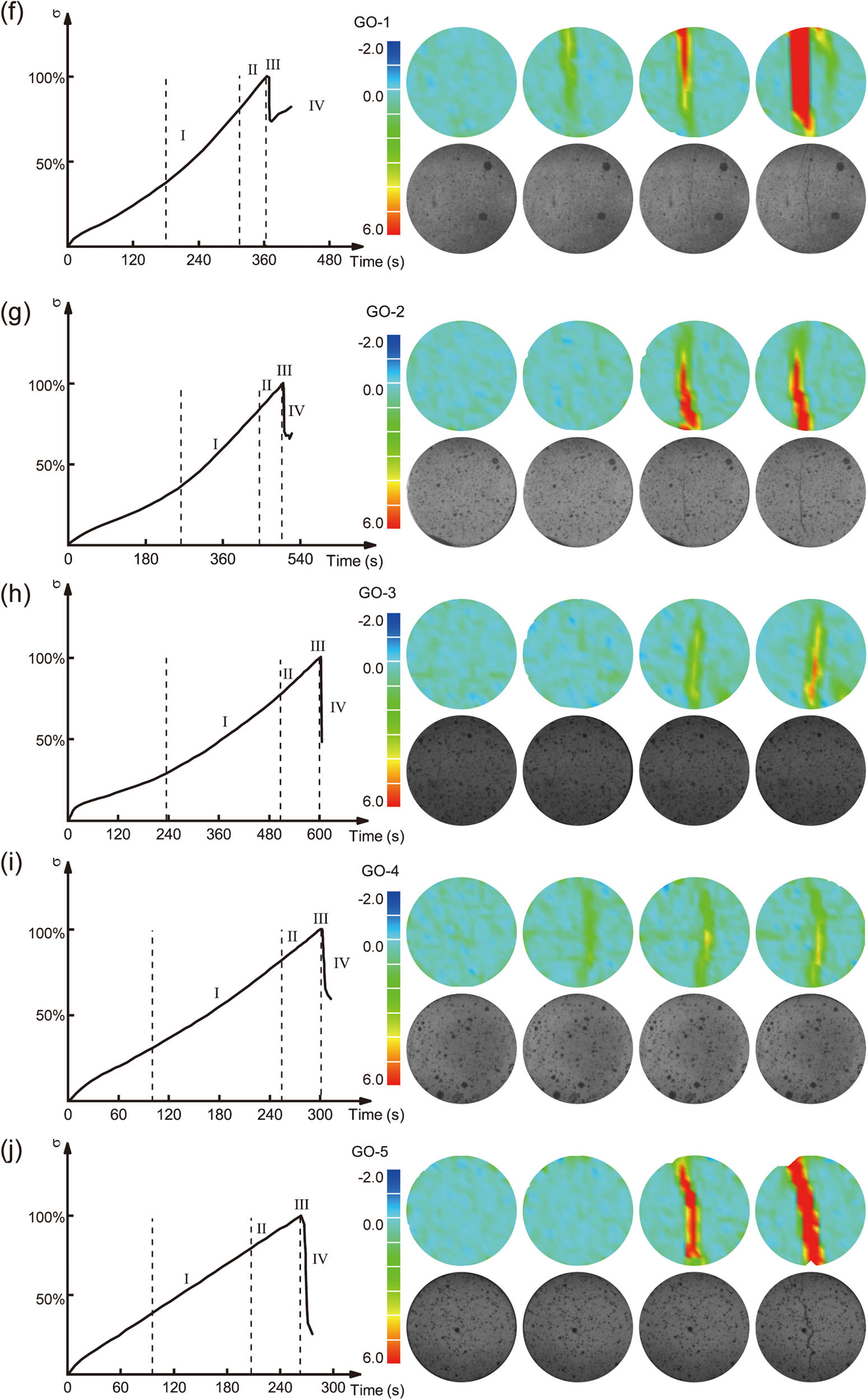

3.3 Failure event distribution of AE

To investigate the influence of internal crack evolution on the tensile fracture behavior of cement composites after high-temperature degradation, an AE system was employed for real-time monitoring of the entire Brazilian splitting test. During loading, internal cracking and damage generate elastic waves, which are captured by the AE equipment [57,58]. The sample with the smallest error from the average was selected for analysis, as shown in Figure 3. During the initial stage, AE event rates are predominantly at low levels. As loading increases, a higher event rate emerges near the peak stress. This phenomenon occurs because hardened cementitious specimens contain inherent primary pores: the compaction stage generates fewer AE events, while the abrupt failure after the elastic stage leads to a surge in event rates [59]. Regarding temperature effects, the number of AE events first increases and then decreases as the treatment temperature rises. Previous research indicates that when the temperature surpasses approximately 105°C, free water within cement composites start to evaporate [60,61]. Between 120 and 150°C, the C–S–H phase releases water [62]. This water loss creates more pores, resulting in a higher AE event count during loading. As the temperature increases to 350°C, the C–S–H phase begins to degrade. At 450–570°C, the decomposition of calcium hydroxide (CH) and C–S–H structures promotes the interconnection of pores and cracks in the matrix, reducing the frequency of AE events.

Acoustic emission counting during loading process. (a)–(e) The trend of changes in acoustic emission counts and cumulative counts in the Ref group. (f)–(j) The trend of changes in acoustic emission counts and cumulative counts in the GO group.

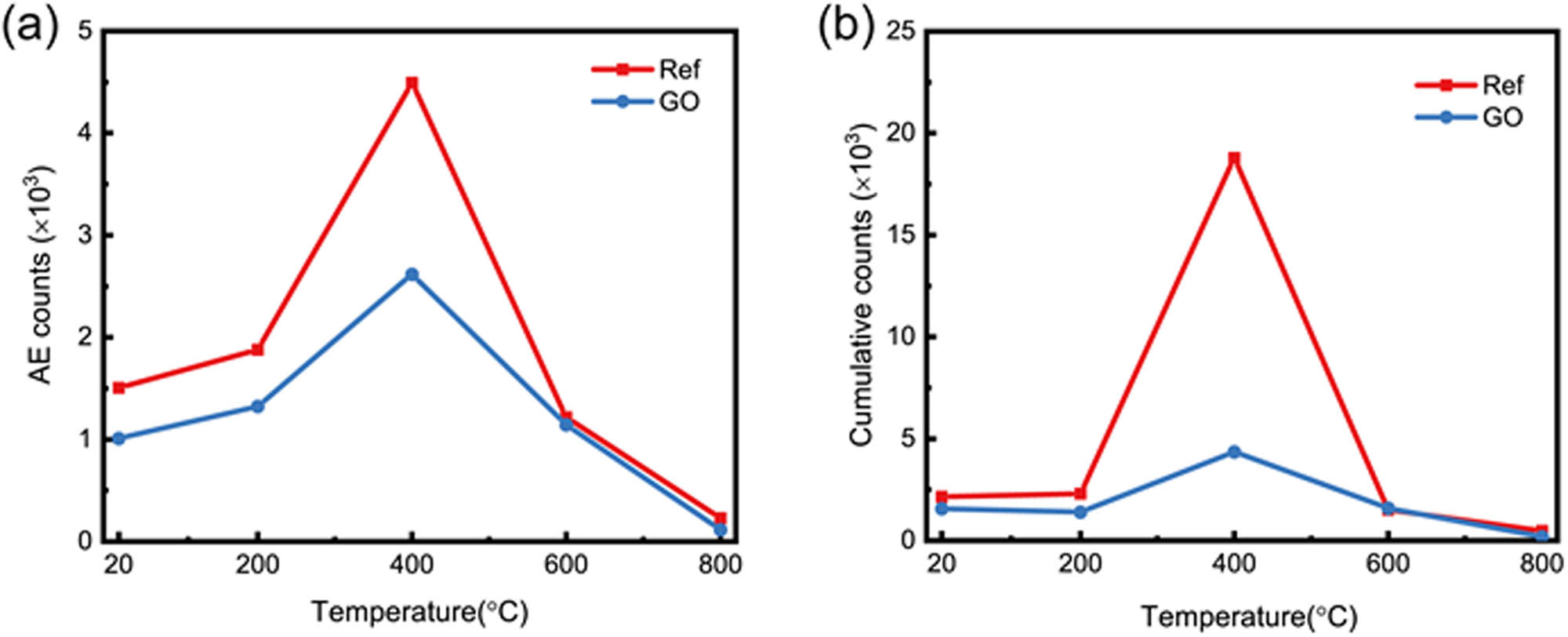

Furthermore, the addition of GO promoted the transformation of the failure mode of the cement sample from a violent failure mode to a large number of small-scale failures. This change directly affected the change in the distribution of AE event numbers during the entire loading process of the sample until failure. As demonstrated in Figure 3(a) and (f), after mixing GO nanosheets, several small amplitude AE signals are generated before the peak, while the number of AE events of the control group specimens is concentrated near the peak value. The AE event rate generated at the peak stage under different temperature conditions is calculated, as exhibited in Figure 4(a). By contrast, the event rate of the sample in the GO group is significantly lower, with a reduction range of 29–30%. The increase in temperature also leads to an increase in the rate of AE events before the peak phase, which can be attributed to the damage caused by high-temperature degradation. Taking GO-4 and Ref-4 as an example, both have a small range of damage before the peak stage, and the frequency of GO-4 is smaller than that of Ref-4. Figure 4(b) shows the statistics of the cumulative AE rate before the peak stage. Overall, the number of AE events in the GO group is smaller than that in the Ref. group, with a reduction in the range of 27–76%.

(a) AE count during peak phase. (b) Accumulated AE count before peak stage.

Experimental results indicate that the addition of GO contributes to the closure and reduction in pores and cracks in cement composites, thereby decreasing the number of AE events during their loading process. Such effects are primarily attributed to GO’s promotion of the hydration reaction, which generates more C–S–H gel and refines the pore structure. As temperature rises, GO alleviates thermal stress and hinders the initiation of thermal cracks [63]. The presence of GO nanosheets prevents the rapid propagation of single cracks at high temperatures [64], leading to a lower occurrence of AE event rates.

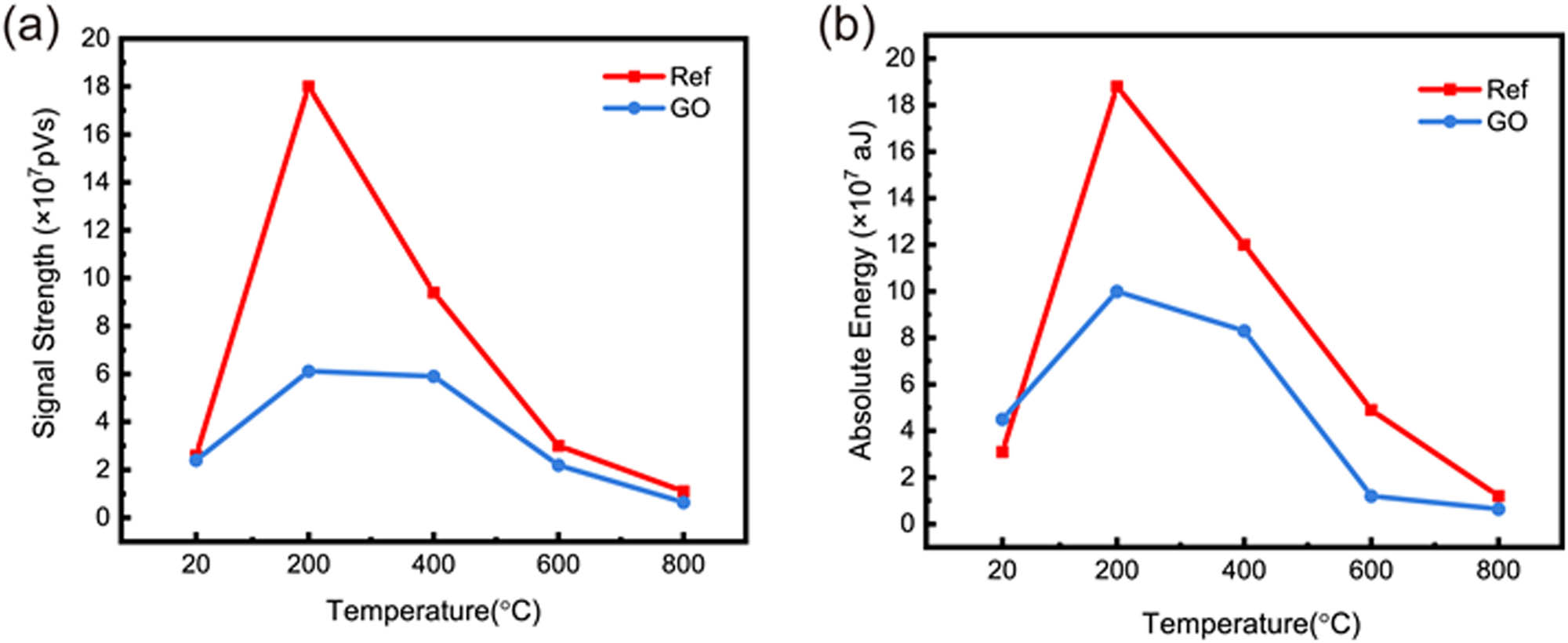

3.4 Energy dissipation of AE

When the sample is damaged, strain energy and dissipative energy are generated, and the signal strength and absolute energy could reflect the intensity of the failure inside the hardened cement composites. As shown in Figure 5, both signal strength and absolute energy values remain low, indicating minimal damage intensity during this period before the peak stage. As the load increases, internal energy in cement composites accumulates gradually, leading to sample cracking at peak strength. At this point, the material experiences high-intensity failure, causing a sudden surge in signal strength that reflects substantial energy release. After peak strength, the sample undergoes large-scale structural failure, resulting in a significant drop in overall strength. Subsequent failure events primarily involve small-scale crack propagation, requiring less energy and producing values lower than those released during peak-strength failure. As shown in Figure 6(a) and (b), the signal strength and absolute energy exhibit a trend of increasing first and then decreasing as temperature rises. In the Ref. group, the signal strength and absolute energy reached the maximum value at 200°C, which were 1.8 × 108 pVs and 1.9 × 108 aJ, respectively. This is due to the high-temperature sterilization environment formed inside the cement composites at this temperature condition, which promotes the additional hydration of cement particles and enhances the tensile strength of the hardened matrix [65]. When the temperature rises to 800°C, the signal intensity and absolute energy reach the minimum values, which are 1.1 × 107 pVs and 1.2 × 107 aJ, dropping by 93.9 and 93.6% compared with 200°C, respectively. This phenomenon indicates that the high-temperature degradation causes severe damage inside the cement composites and dramatically reduces the ability of the cement composites to resist the load.

The dissipation of energy in AE signals emission. (a)–(e) The trend of changes in acoustic emission Signal Strength and Absolute Energy in the Ref group. (f)–(j) The trend of changes in acoustic emission Signal Strength and Absolute Energy in the GO group.

(a) Signal strength during peak phase. (b) Absolute energy during peak phase.

As shown in Figure 6, the signal strength and absolute energy of the hardened cement composite specimens in the GO group are lower than those in the control group on the whole. This phenomenon indicates that the destruction of the sample after the incorporation of GO presents a pattern of multiple small-scale destruction, and the energy released in a certain period is reduced. At 200°C, the signal strength and absolute energy reach the maximum, achieving 6.1 × 107 pVs and 1.0 × 108 aJ, respectively. When the temperature rises to 800°C, the signal intensity and absolute energy reach the minimum values, hitting 6.4 × 106 pVs and 6.4 × 106 aJ and decreasing by 89.5 and 93.6% compared to that at 200°C. Compared with the Ref. group, the decline in signal strength was reduced, suggesting that GO reduced the damage of cement composites under high-temperature treatment.

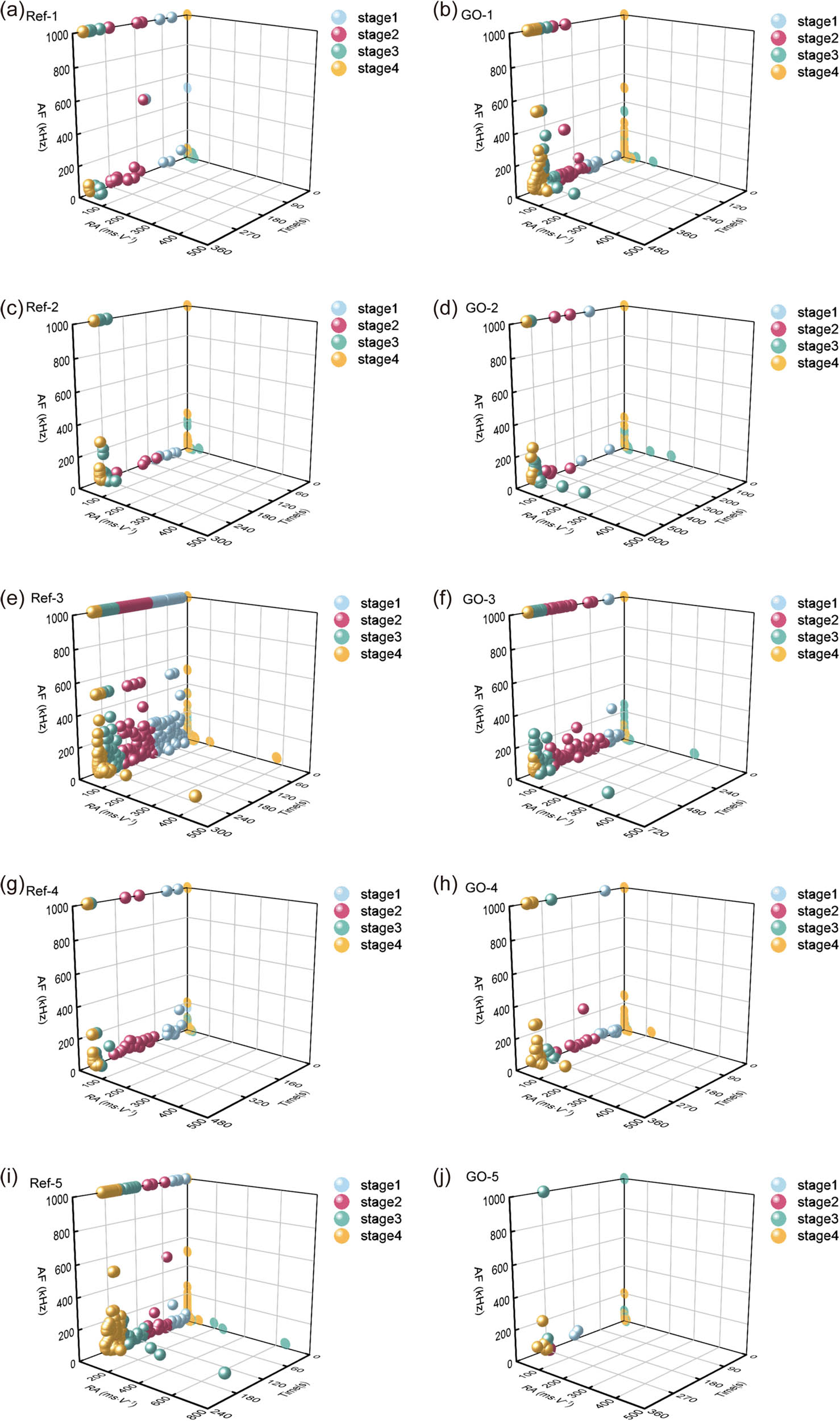

3.5 Analysis of destruction modes characterized by AE signals

Tensile and shear are the two primary forms of microcracks in the process of specimen failure [66]. In order to display the changes in ratio of rise time to amplitude-average frequency: ratio of AE count to signal duration in different loading stages, different colors are used to represent them, as shown in Figure 7. In the Ref. group, the damage of samples is mainly tensile. The number of tensile failures increases with the treated temperature until 400°C. This is because after high-temperature degradation, there are more hot cracks inside the sample. When the temperature rises to 600–800°C, the number of tensile failures decreases obviously, and the pattern of mixed failure increases. It can be seen that under these conditions, severe damage occurs inside the cement composites, and the microcracks extend and expand to form significant defects. Take Ref-3 and GO-3 as examples, as shown in Figure 7(e) and (f). At 400°C, cement composites will produce severe damage, at which point the C–S–H skeleton decomposes, significantly reduce the carrying capacity. The Ref. group produced more tension failure from the failure mode at this temperature. In contrast, the GO group significantly decreased the proportion of tension failure and was more inclined to mixed failure mode. This may be due to the bridge action of GO and the promotion of hydration, which inhibits the development of a single tensile fracture along the cement micropores and reduces tensile failure [35].

Distribution of AF and RA values of acoustic emission signals. (a, c, e, i, j) Distribution of AF and RA values of acoustic emission signals in Ref group. (b, d, f, h, j) Distribution of AF and RA values of acoustic emission signals in GO group.

The AE monitoring results show a high degree of consistency with the change in the tensile strength of cement paste. Overall, the AE event rate, signal intensity, and absolute energy reach their maximum values during the peak load stage, reflecting the failure process of crack cooperative propagation and concentrated energy release. At different temperatures, the AE response characteristics of the material are closely related to its tensile strength. Among them, the AE signal of the specimen under the treatment condition of 200°C is the strongest, the energy release is the largest, and at the same time, the tensile strength reaches its peak, indicating that the material has good load-bearing and energy accumulation capabilities. Cement paste exhibits the best mechanical properties at 200°C. This is mainly because this temperature can promote the secondary hydration of incompletely hydrated particles, generating more C–S–H gel, filling pores, and improving compactness. At the same time, the main cementing phase does not decompose, and the structure is stable. The corresponding AE parameters also show intense energy release, which is a direct manifestation of its enhanced performance. The introduction of GO changes the failure process from a single violent release to multiple small-energy releases. Although the signal intensity is relatively low at 200°C, the tensile strength is significantly improved. This indicates that GO improves the stability and toughness of the failure process, effectively delays the unstable propagation of cracks, and improves the structural integrity and load-bearing capacity of the material at high temperatures.

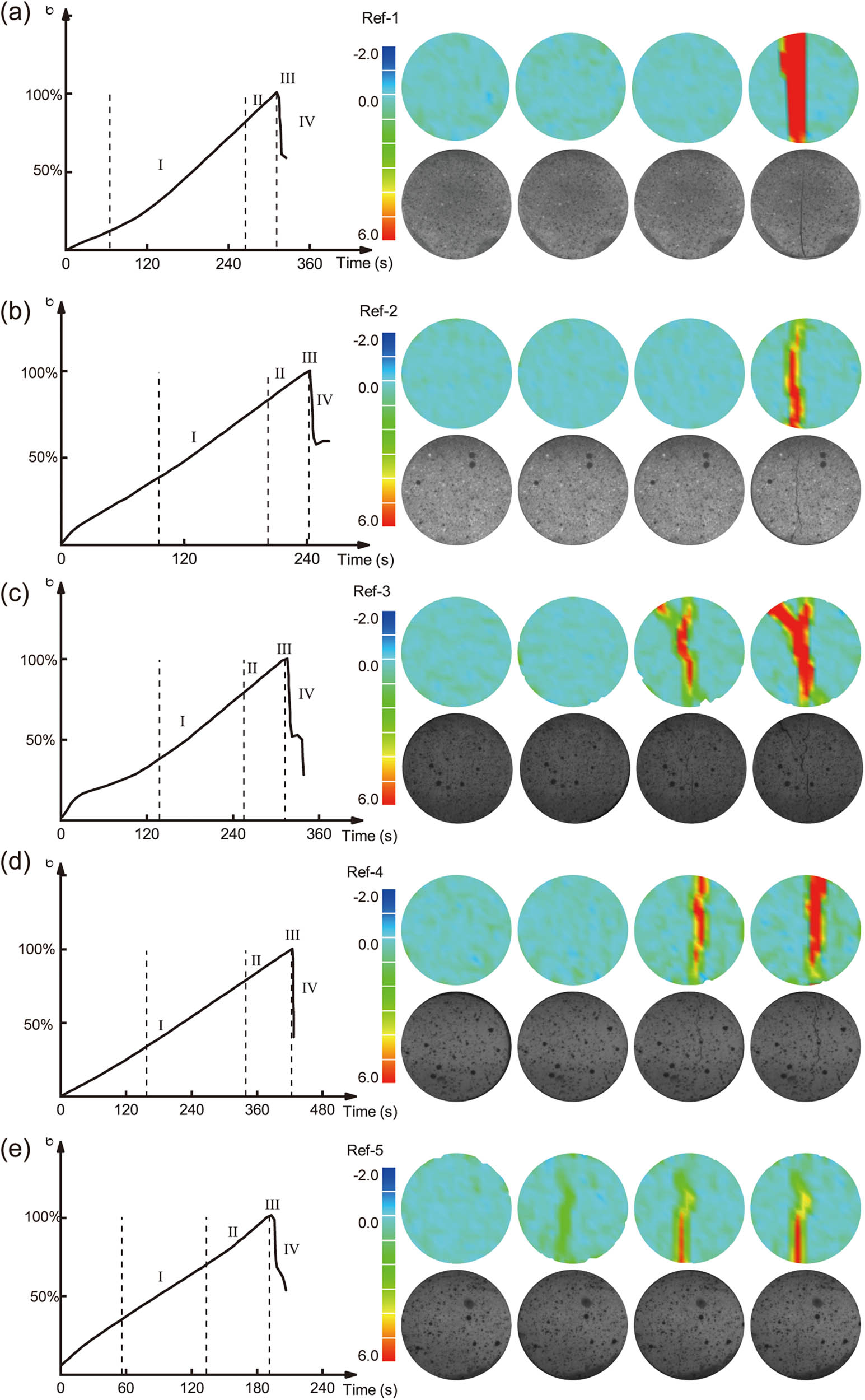

3.6 Crack development process

As shown in Figure 8, the stress curve for the tensile properties of cement composites are divided into four stages [67]. Stage I corresponds to the elastic strain phase, where stress distribution in hardened cement composites remains relatively uniform. Only minor strain areas appear at the periphery, indicating the sample is undergoing elastic deformation without permanent damage. Stage II represents the plastic stage. For instance, in Ref-1, as stress increases, a distinct strip-shaped tensile strain zone emerges. Green pixels denoting tensile strain show a dark, dense central region and lighter, thinner ends within this zone, reflecting localized deformation as the material transitions into plastic behavior. Stage III is the peak strain stage, during which crack propagation accelerates rapidly when the load reaches peak strength. The specimen loses its load-bearing capacity abruptly, causing a sharp stress drop as catastrophic failure occurs. Stage IV refers to the residual strain phase, where existing cracks continue to expand and damage accumulates progressively. The material’s carrying capacity diminishes until it is completely lost, marking the final stage of tensile failure.

(a)–(j) Destructive equivalent strain field cloud map.

For pure cement specimens, taking Ref-1 in Stage I as an example, the strain distribution of the sample is relatively uniform, indicating that the sample was in the stage of elastic deformation. At stage II, with the increase in load, tensile strain distribution appears in the local range of the sample. After that, the tensile strain expands to form cracks during stage III. In stage IV, the damage is further aggravated, the crack penetrates, and the specimen loses its bearing capacity. With the increased treated temperature, the area of tensile strain in a small range began to increase before stage II. By comparing Sample Ref-2 and Ref-3, it can be found that the strain in a small area began to appear at stage I due to the increase in micro-cracks and the intensification of regional damage in the sample caused by high temperature.

In the GO group, the overall failure mode of GO-reinforced specimens is similar to that of pure cement composite specimens. However, taking GO-4 as an example, more small-range tensile strain regions appeared and presented a network-like intermittent distribution in stages I and II. When the first major tensile strain zone appears, the presence of GO improves the performance of the weak zone and inhibits the continuous development of cracks along micro-cracks. At the same time, due to the better stress transfer of GO, the sample reached the failure critical state before the defects in other area were further developed into cracks, delaying the failure of the sample. In comparison to conventional reinforcement materials [68], GO serves as a more effective reinforcement material in cement composites due to its superior capability in regulating the initiation and expansion of cracks at the nanoscale [69].

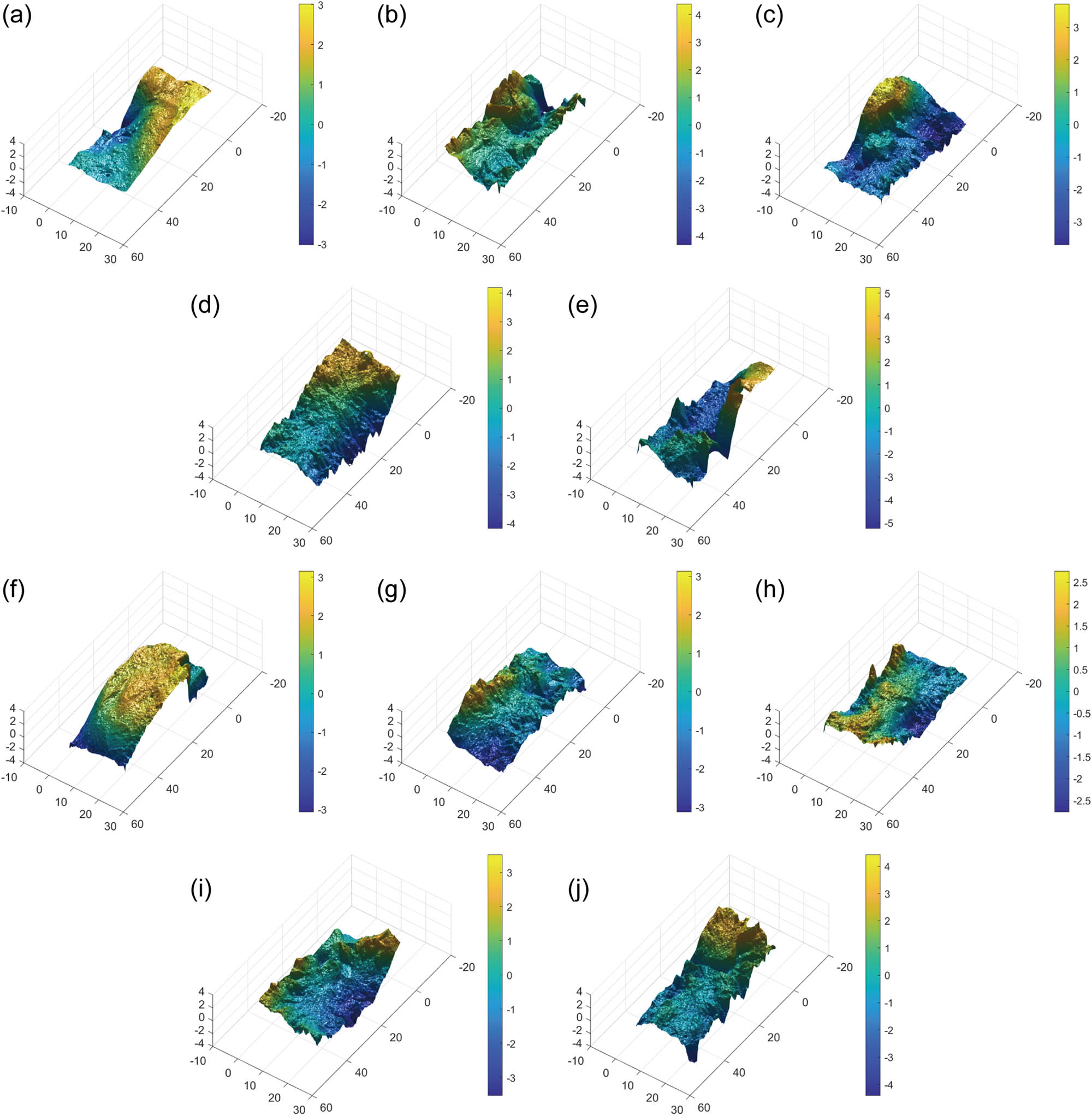

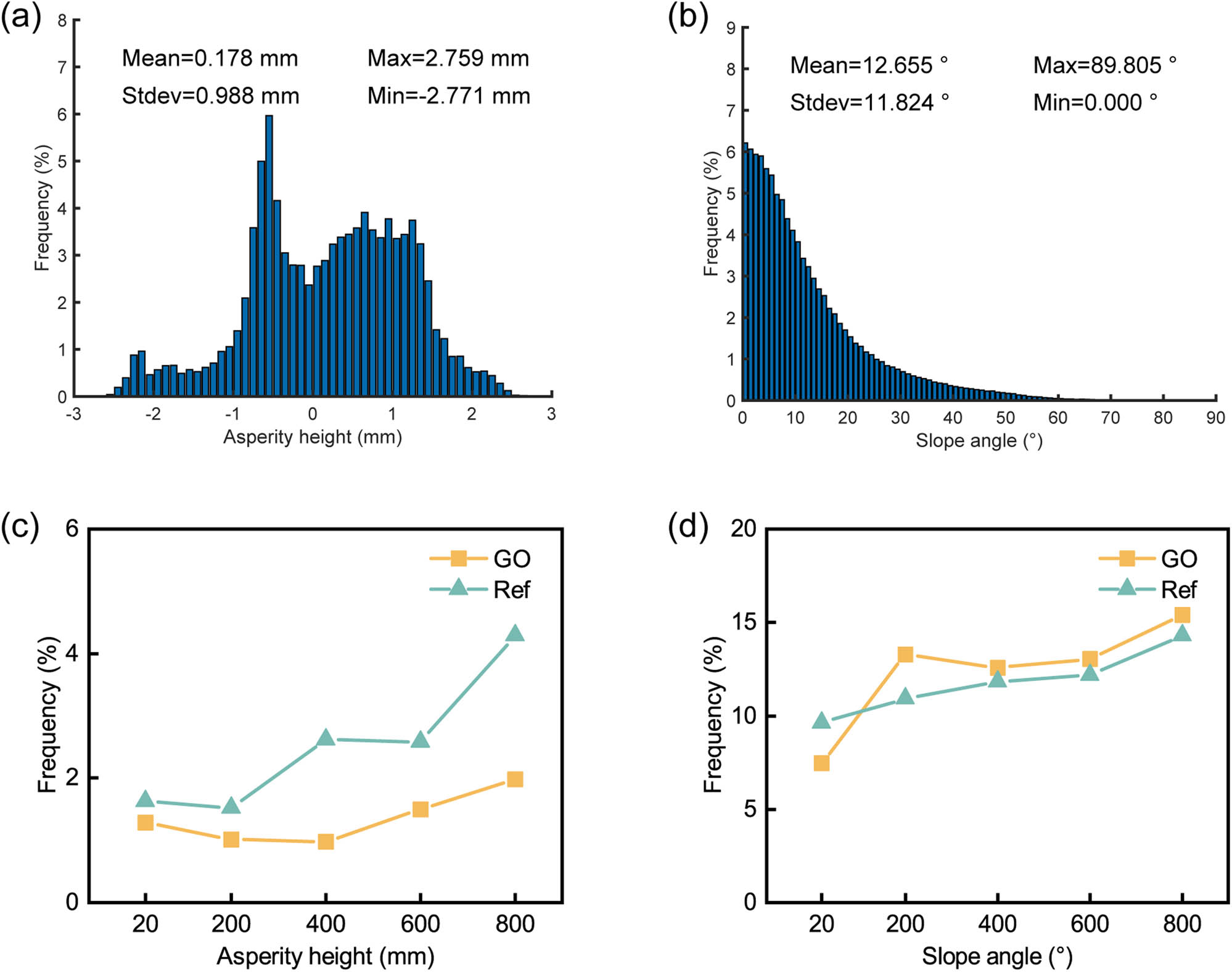

3.7 3D scanning

This study employs the microscopic morphology statistical method proposed by Belem et al. [70], which involves two key steps: (1) discretizing and meshing the 3D fracture surface scanning point cloud data into a series of meso-planes; (2) defining the local inclination angle (αij) of each meso-plane as the angle between the plane and the horizontal plane, followed by statistical calculations of the maximum, minimum, average values, standard deviation of αij, and the height of plane corners for meso-plane.

The fracture surface was reconstructed using MATLAB software, and the corresponding three-dimensional reconstruction rendering is shown in Figure 9. Then, the point cloud data obtained by three-dimensional scanning is discretized into a grid, and the meso-roughness height of each grid point is calculated. Figure 10 shows the mesoscopic roughness height distribution results of the fracture surface, with sample GO-4 taken as a typical example, and the corresponding standard deviation is calculated. Additionally, the standard deviation results of the roughness height for each specimen are plotted as a line chart following the aforementioned procedure. Figure 10(a) and (b) shows that across all temperatures, the standard deviation of fracture surface fluctuation height in the Ref. group is higher than that in the GO group. Therefore, the macro fracture surface fluctuation in the Ref. group is higher than that in the GO group, indicating that the formation of fracture surface in Ref group overcomes more surface energy and causes the crack expansion path to be more complex and tortuous.

(a)–(j) 3D reconstruction of fracture surface after tensile failure.

(a) Roughness height distribution of fracture surface in sample GO-4. (b) Local inclination angle of sample GO-4 fracture surface. (c) Standard deviation of fracture surface roughness height for each group of samples. (d) Standard deviation of local inclination angle of fracture surface of each group of samples.

Owing to the presence of micro-cracks and pores in Ref. group specimens, under constant loading, internal stored energy is released to stress-concentrated areas at micro-crack tips, causing cracks to propagate along preferential directions and forming more tortuous paths. In contrast, GO sheets in the GO group fill pores and enhance cement hydration, promoting additional C–S–H gel formation that effectively improves specimen integrity. Thus, the accumulated energy was too late to release under the action of load, resulting in smaller macro-fluctuation of the fracture surface. In addition, according to the research of Win et al. [32,33,71,72], GO plays a bridging role in the cement matrix. When subjected to tensile stress, the inhibitory effect of GO on crack propagation is more pronounced.

It can be seen from Figure 10(c) and (d) that the standard deviation of fluctuation height in the Ref. group increases significantly at 400 and 800°C, indicating that the fracture surfaces formed at these temperatures are more complex and irregular. This trend is closely related to the thermal degradation and phase transitions of cement hydration products within this temperature range. Specifically, around 400°C, the decomposition of C–S–H gel begins, and chemically bound water is gradually released, leading to the formation of microcracks and increased porosity. Under loading, these defects promote irregular crack propagation and result in a rougher fracture morphology. At 800°C, the degradation becomes much more severe. The C–S–H skeleton is almost completely decomposed, while CH has already undergone significant decomposition starting around 450–550°C. Additionally, calcium carbonate (CaCO3), which may be present as a secondary product, begins to decompose at temperatures above 700°C. These transformations result in a highly porous, structurally compromised matrix with poor cohesion, which explains the large fluctuations in fracture surface height at this stage. In contrast, the GO group exhibits more stable behavior across all temperatures. At 400°C, the fluctuation height remains relatively low, indicating a more uniform and less damaged fracture surface. From 600 to 800°C, only a gradual increase in roughness is observed. This improved thermal resistance can be attributed to the presence of GO nanosheets, which undergo partial thermal reduction above 200°C, forming nano-defects. These defects enable silicate species to interact with the GO structure, reducing the oxygen exchange rate between GO and C–S–H, and promoting the formation of thermally stable S–O–Si and C–O–Si bonds. These new chemical linkages contribute to enhancing the integrity of the C–S–H network and improving the thermal stability of the composite [73]. Although C–S–H begins to decompose at 400°C, due to the improved thermal stability, the samples in GO group can maintain a relatively complete C–S–H gel skeleton, and slow down the decomposition of C–S–H at 600 and 800°C. The mathematical statistical results of the meso-plane local inclination angle in fracture surface actually reflect the meso-plane roughness characteristics of the fracture surface. As shown in Figure 10(b), the standard deviation of the GO group is lower than Ref. group, indicating that the fracture surface is coarser.

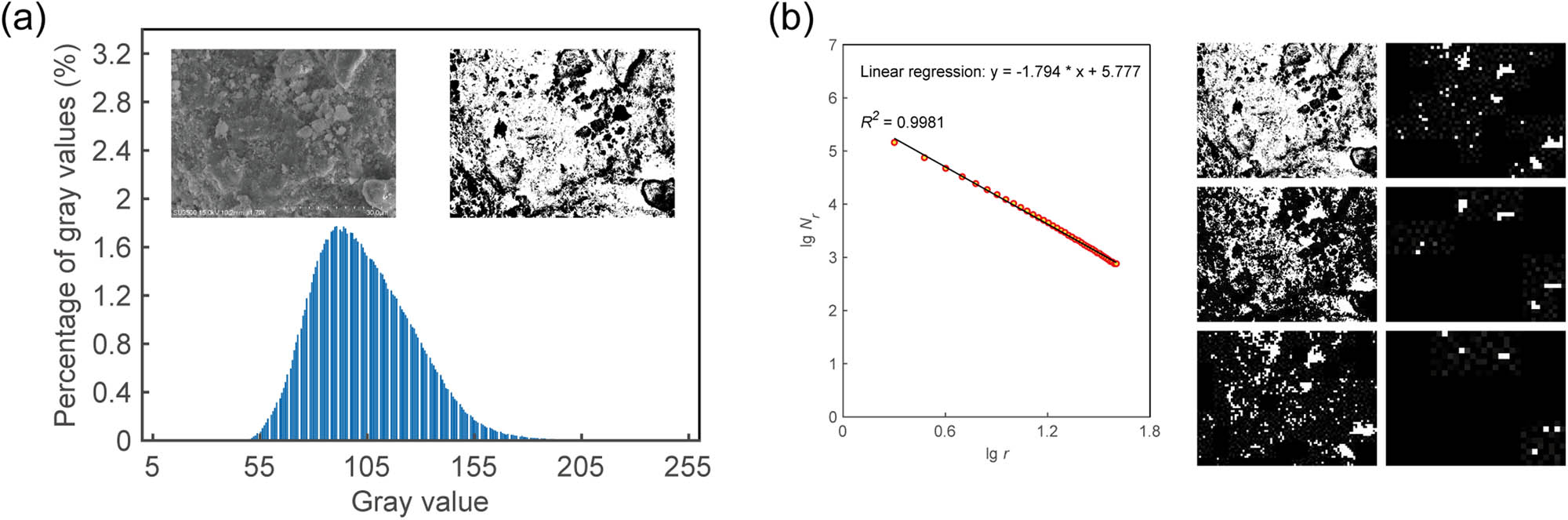

3.8 SEM simulation

In this study, SEM was used to examine the fracture surfaces of samples. Fractal theory is widely used in studying porous materials, as specimen failure under external load is essentially attributed to the nonlinear superposition of internal microstructural deformations – a statistically significant process. Employ the fractal box dimension to analyze the fracture surfaces. SEM images are processed using graythresh(I) function with Otsu method in MATLAB, which determines threshold T by minimizing within-class variance of grayscale pixels in image (I). As shown in Figure 11, the fractal process refers to the method proposed [31].

(a) Image binarization and grayscale values. (b) Calculation process of fractal dimension.

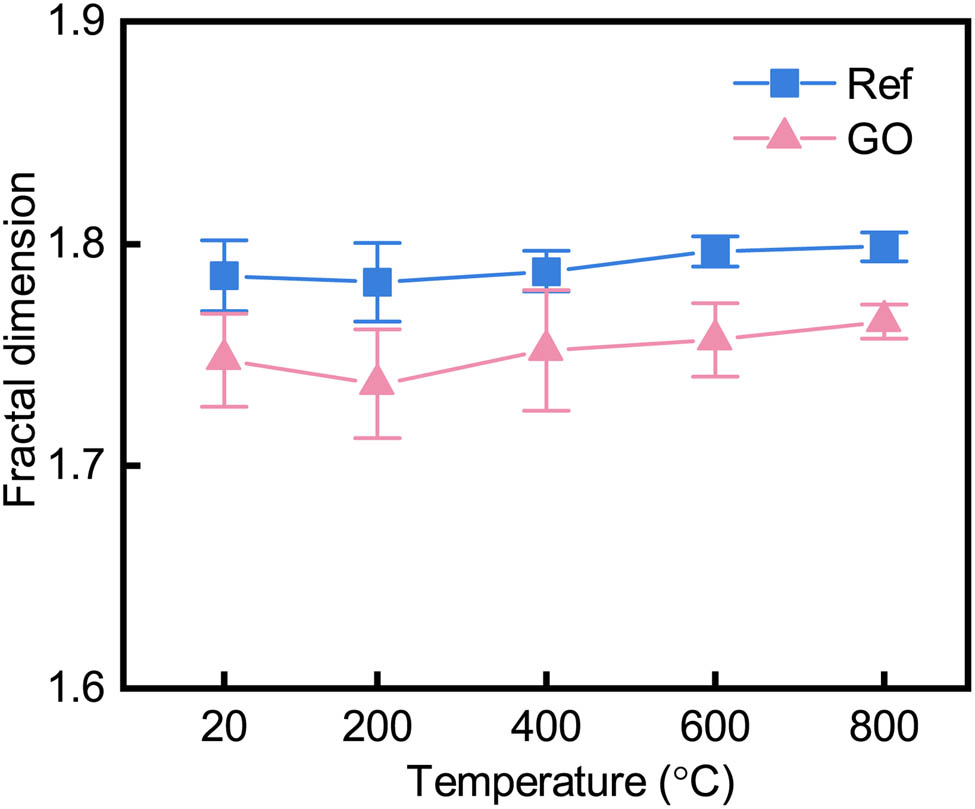

Figure 12 shows the microstructure of the fracture surfaces of the Ref. and GO groups. The calculated fractal dimension results are presented in Figure 13. Previous studies have shown that a larger fractal dimension indicates a higher degree of surface damage in the sample. The fracture surface analysis results closely align with the findings from mechanical testing and AE characterization. The fractal dimension values of GO-group samples remain consistently lower than those of the reference group. This indicates that the addition of GO enhances sample structural integrity and that GO maintains its reinforcing capability even under high-temperature conditions. Notably, between 20 and 200°C, a downward trend in the fractal dimension of GO-group samples was observed, which correlates with the improved tensile strength of these samples at 200°C discussed in Section 3. This behavior may be attributed to the further hydration of unreacted cement particles under internal autoclaving conditions, implying that GO promotes the hydration reaction of cement within the 20–200°C range, thereby enhancing the integrity and strength of GO-group samples. At 400°C, an increase in fractal dimension and intensified fracture surface damage were observed, likely due to partial decomposition of CH or C–S–H phases. The fractal dimension continued to rise at 600 and 800°C, indicating progressive sample damage. This is because C–S–H begins to decompose around 560°C, with significant decomposition occurring above 600°C, culminating in complete breakdown of C–S–H at 750°C.

SEM test image.

Typing dimension of each group of samples.

These results offer meaningful implications for real-world engineering applications involving fire exposure or high-temperature environments. The observed reduction in fractal dimension and improved fracture integrity at temperatures up to 200°C suggest that GO-modified cement materials may be particularly well-suited for structures subjected to moderate thermal loads – such as tunnel linings, underground facilities, and industrial floors where internal temperature rises may occur during service. The ability of GO to maintain structural continuity and suppress crack complexity even under severe thermal degradation (up to 800°C) indicates its potential for enhancing the fire resistance and post-fire mechanical recoverability of cementitious structures. This suggests a feasible pathway for developing high-performance, thermally durable concrete formulations for fire-prone infrastructures, offering enhanced resilience, safety, and service life in extreme conditions.

4 Conclusion

In this study, the effects of the GO nanosheets on the tensile behavior and failure characteristics of the cement composites after high-temperature treatment were investigated. The main findings are as follows.

The tensile strength and elastic modulus of the cement composites experienced first an increasing and then decreasing trend with the increase in the treated high temperature. After mixing GO nanosheets, the tensile strength of the cement composites degraded by high-temperature are significantly reinforced. The strength enhancement ratio ranges from 6.5 to 46.8%, hitting the highest reinforcing point under 200°C.

Due to the nucleation and pore-filling effects, the enhancement effect of GO-reinforced cement composites becomes more pronounced after high-temperature treatment. As temperature increases, GO nanosheets exhibit thermally induced mobility and form additional chemical bonds through interaction with C–S–H, thereby improving the thermal resistance and stability of the C–S–H structure. Furthermore, GO can act as bridging roles in cement composites, and the hydrated product after hardening will interact with the GO nanosheets to form a “wall-like” dense structure. Bridging GO can inhibit the expansion of microcracks in the thermal expansion of cement, thus ensuring that cement composites are not damaged.

The AE results indicate that with rising temperature, cement composites undergo dehydration to varying degrees, and the number of AE events first increases and then decreases. The inclusion of GO modifies the distribution pattern of AE events, converting single large-scale severe disruptions into multiple small-scale damage processes. Furthermore, GO incorporation notably alleviates the tensile failure of cement-based materials under high-temperature conditions.

The 3D scanning and SEM analysis reveal that the fracture surface roughness of GO-modified samples is lower than that of the control group. Across all temperature conditions, the fractal dimension of GO specimens is consistently lower than the reference group, indicating that GO improves specimen integrity and maintains its reinforcing effect even after high-temperature treatment.

-

Funding information: This study was supported by the National Natural Science Foundation of China (Nos 52204146, 42302353, 52304096) and the Natural Science Foundation of Jiangsu Province, China (No. BK20230615).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

References

[1] Shaikh FUA. Review of mechanical properties of short fibre reinforced geopolymer composites. Constr Build Mater. 2013;43:37–49. 10.1016/j.conbuildmat.2013.01.026.Search in Google Scholar

[2] Meyer C. The greening of the concrete industry. Cem Concr Compos. 2009;31:601–5. 10.1016/j.cemconcomp.2008.12.010.Search in Google Scholar

[3] Zhao Z, Qi T, Zhou W, Hui D, Xiao C, Qi J, et al. A review on the properties, reinforcing effects, and commercialization of nanomaterials for cement-based materials. Nanotechnol Rev. 2020;9:303–22. 10.1515/ntrev-2020-0023.Search in Google Scholar

[4] Du M, Jing H, Gao Y, Su H, Fang H. Carbon nanomaterials enhanced cement-based composites: advances and challenges. Nanotechnol Rev. 2020;9:115–35. 10.1515/ntrev-2020-0011.Search in Google Scholar

[5] Han B, Yu X, Ou J. Multifunctional and smart carbon nanotube reinforced cement-based materials. In: Gopalakrishnan K, Birgisson B, Taylor P, Attoh-Okine NO, editors. Nanotechnology in civil infrastructure. Berlin, Heidelberg: Springer Berlin Heidelberg; 2011. p. 1–47. 10.1007/978-3-642-16657-0_1.Search in Google Scholar

[6] Qian C, Ren L, Xue B, Cao T. Bio-mineralization on cement-based materials consuming CO2 from atmosphere. Constr Build Mater. 2016;106:126–32. 10.1016/j.conbuildmat.2015.10.105.Search in Google Scholar

[7] Xue G, Yilmaz E, Song W, Cao S. Mechanical, flexural and microstructural properties of cement-tailings matrix composites: Effects of fiber type and dosage. Compos Part B: Eng. 2019;172:131–42. 10.1016/j.compositesb.2019.05.039.Search in Google Scholar

[8] Chintalapudi K, Pannem RMR. Enhanced Strength, Microstructure, and Thermal properties of Portland Pozzolana Fly ash-based cement composites by reinforcing Graphene Oxide nanosheets. J Build Eng. 2021;42:102521. 10.1016/j.jobe.2021.102521.Search in Google Scholar

[9] Somarathna HMCC, Raman SN, Mohotti D, Mutalib AA, Badri KH. The use of polyurethane for structural and infrastructural engineering applications: A state-of-the-art review. Constr Build Mater. 2018;190:995–1014. 10.1016/j.conbuildmat.2018.09.166.Search in Google Scholar

[10] Wu J, Jing H, Yin Q, Yu L, Meng B, Li S. Strength prediction model considering material, ultrasonic and stress of cemented waste rock backfill for recycling gangue. J Clean Prod. 2020;276:123189. 10.1016/j.jclepro.2020.123189.Search in Google Scholar

[11] Wu J, Wong HS, Zhang H, Yin Q, Jing H, Ma D. Improvement of cemented rockfill by premixing low-alkalinity activator and fly ash for recycling gangue and partially replacing cement. Cem Concr Compos. 2024;145:105345. 10.1016/j.cemconcomp.2023.105345.Search in Google Scholar

[12] Zhang X, Du M, Fang H, Shi M, Zhang C, Wang F. Polymer-modified cement mortars: Their enhanced properties, applications, prospects, and challenges. Constr Build Mater. 2021;299:124290. 10.1016/j.conbuildmat.2021.124290.Search in Google Scholar

[13] Wu J, Jing H, Gao Y, Meng Q, Yin Q, Du Y. Effects of carbon nanotube dosage and aggregate size distribution on mechanical property and microstructure of cemented rockfill. Cem Concr Compos. 2022;127:104408. 10.1016/j.cemconcomp.2022.104408.Search in Google Scholar

[14] Feng G, Zhu D, Guo S, Rahman MZ, Jin Z, Shi C. A review on mechanical properties and deterioration mechanisms of FRP bars under severe environmental and loading conditions. Cem Concr Compos. 2022;134:104758. 10.1016/j.cemconcomp.2022.104758.Search in Google Scholar

[15] Babalola OE, Awoyera PO, Le D-H, Romero LB. A review of residual strength properties of normal and high strength concrete exposed to elevated temperatures: Impact of materials modification on behaviour of concrete composite. Constr Build Mater. 2021;296:123448. 10.1016/j.conbuildmat.2021.123448.Search in Google Scholar

[16] Ma Q, Guo R, Zhao Z, Lin Z, He K. Mechanical properties of concrete at high temperature – A review. Constr Build Mater. 2015;93:371–83. 10.1016/j.conbuildmat.2015.05.131.Search in Google Scholar

[17] Smarzewski P. Study of toughness and macro/micro-crack development of fibre-reinforced ultra-high performance concrete after exposure to elevated temperature. Materials. 2019;12:1210. 10.3390/ma12081210.Search in Google Scholar PubMed PubMed Central

[18] Fu YF, Wong YL, Poon CS, Tang CA, Lin P. Experimental study of micro/macro crack development and stress–strain relations of cement-based composite materials at elevated temperatures. Cem Concr Res. 2004;34:789–97. 10.1016/j.cemconres.2003.08.029.Search in Google Scholar

[19] Ju Y, Liu J, Liu H, Tian K, Ge Z. On the thermal spalling mechanism of reactive powder concrete exposed to high temperature: Numerical and experimental studies. Int J Heat Mass Transf. 2016;98:493–507. 10.1016/j.ijheatmasstransfer.2016.03.033.Search in Google Scholar

[20] Amran M, Huang S-S, Onaizi AM, Murali G, Abdelgader HS. Fire spalling behavior of high-strength concrete: A critical review. Constr Build Mater. 2022;341:127902. 10.1016/j.conbuildmat.2022.127902.Search in Google Scholar

[21] Zhang P, Kang L, Wang J, Guo J, Hu S, Ling Y. Mechanical properties and explosive spalling behavior of steel-fiber-reinforced concrete exposed to high temperature – a review. Appl Sci. 2020;10:2324. 10.3390/app10072324.Search in Google Scholar

[22] Wang H, Liu Z, Wang F, Zhang J, Guo L, Zhang Y, et al. Deciphering the influence of superabsorbent polymers on cement hydration and portlandite formation. Constr Build Mater. 2024;418:135455. 10.1016/j.conbuildmat.2024.135455.Search in Google Scholar

[23] Wang H, Wang L, Lin J, Li Y, Lu Z, Jiang J. Target dispersion of pozzolanic materials nearby hydration-released calcium hydrates to improve the pozzolanic reaction degree. Cem Concr Compos. 2024;153:105741. 10.1016/j.cemconcomp.2024.105741.Search in Google Scholar

[24] Wang H, Miao Y, Liu Z, Li Y, Lin J, Jiang J, et al. MOFs structure-inspired mesoporous composites to reinforce cementitious materials as internal curing agents. Cem Concr Compos. 2024;152:105628. 10.1016/j.cemconcomp.2024.105628.Search in Google Scholar

[25] Wang H, Lu Z, Wang F, Li Y, Ou Z, Jiang J. A novel strategy to reinforce double network hydrogels with enhanced mechanical strength and swelling ratio by nano cement hydrates. Polymer. 2023;269:125725. 10.1016/j.polymer.2023.125725.Search in Google Scholar

[26] Jiang J, Wang H, Lin J, Wang F, Liu Z, Wang L, et al. Nature-inspired hierarchical building materials with low CO2 emission and superior performance. Nat Commun. 2025;16:3018. 10.1038/s41467-025-58339-8.Search in Google Scholar PubMed PubMed Central

[27] Gao Y. Mechanical performance enhancement of UHPC via ITZ improvement using graphene oxide-coated steel fibers. Cem Concr Compos. 2025;157:105931. 10.1016/j.cemconcomp.2025.105931.Search in Google Scholar

[28] Aziz M, Hamza M, Rasool AM, Ali S, Ahmed T, Name Z, et al. Use of graphene oxide nanomaterial to improve mechanical properties of cement-treated silty soil. Arab J Sci Eng. 2022;48:5603–18. 10.1007/s13369-022-07530-w.Search in Google Scholar

[29] Lin J, Shamsaei E, Basquiroto de Souza F, Sagoe-Crentsil K, Duan WH. Dispersion of graphene oxide–silica nanohybrids in alkaline environment for improving ordinary Portland cement composites. Cem Concr Compos. 2020;106:103488. 10.1016/j.cemconcomp.2019.103488.Search in Google Scholar

[30] Liu C, He X, Deng X, Wu Y, Zheng Z, Liu J, et al. Application of nanomaterials in ultra-high performance concrete: A review. Nanotechnol Rev. 2020;9:1427–44. 10.1515/ntrev-2020-0107.Search in Google Scholar

[31] Huang K, Jing H, Gao Y, Yu Z, Chen M, Sun S. Study on the properties of graphene oxide reinforced cement-based materials at high temperature. Constr Build Mater. 2024;421:135704. 10.1016/j.conbuildmat.2024.135704.Search in Google Scholar

[32] Win TT, Raengthon N, Prasittisopin L. Advanced cement composites: Investigating the role of graphene quantum dots in improving thermal and mechanical performance. J Build Eng. 2024;96:110556. 10.1016/j.jobe.2024.110556.Search in Google Scholar

[33] Win TT, Prasittisopin L, Nganglumpoon R, Pinthong P, Watmanee S, Tolek W, et al. Innovative GQDs and supra-GQDs assemblies for developing high strength and conductive cement composites. Constr Build Mater. 2024;421:135693. 10.1016/j.conbuildmat.2024.135693.Search in Google Scholar

[34] Wang Z, Su M, Wang Y, Unluer C, Li S. X-ray computed tomography-based characterisation of graphene nanoplatelets re-agglomeration in hardened cement composites. Cem Concr Compos. 2025;158:105967. 10.1016/j.cemconcomp.2025.105967.Search in Google Scholar

[35] Gao Y, Yu Z, Cheng Z, Chen W, Zhang T, Wu J. Influence of industrial graphene oxide on tensile behavior of cemented waste rock backfill. Constr Build Mater. 2023;371:130787.10.1016/j.conbuildmat.2023.130787Search in Google Scholar

[36] Liu C, Huang X, Wu Y-Y, Deng X, Zheng Z. The effect of graphene oxide on the mechanical properties, impermeability and corrosion resistance of cement mortar containing mineral admixtures. Constr Build Mater. 2021;288:123059. 10.1016/j.conbuildmat.2021.123059.Search in Google Scholar

[37] Liu C, Huang X, Wu Y-Y, Deng X, Liu J, Zheng Z, et al. Review on the research progress of cement-based and geopolymer materials modified by graphene and graphene oxide. Nanotechnol Rev. 2020;9:155–69. 10.1515/ntrev-2020-0014.Search in Google Scholar

[38] Liu C, Chen F, Wu Y, Zheng Z, Yang J, Yang B, et al. Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials. Nanotechnol Rev. 2021;10:1208–35. 10.1515/ntrev-2021-0080.Search in Google Scholar

[39] Fu Q, Wang Z, Xue Y, Niu D. Catalysis and regulation of graphene oxide on hydration properties and microstructure of cement-based materials. ACS Sustain Chem Eng. 2023;11:5626–43. 10.1021/acssuschemeng.3c00109.Search in Google Scholar

[40] Liu C, Huang X, Wu Y-Y, Deng X, Zheng Z, Xu Z, et al. Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials. Nanotechnol Rev. 2021;10:34–49. 10.1515/ntrev-2021-0003.Search in Google Scholar

[41] Cheng Z, Liu Y, Wu J, Guo X, Chen W, Gao Y. Graphene oxide-coated fly ash for high performance and low-carbon cementitious composites. J Mater Res Technol. 2023;25:6710–24. 10.1016/j.jmrt.2023.07.141.Search in Google Scholar

[42] Lee S-J, Jeong S-H, Kim D-U, Won J-P. Effects of graphene oxide on pore structure and mechanical properties of cementitious composites. Compos Struct. 2020;234:111709. 10.1016/j.compstruct.2019.111709.Search in Google Scholar

[43] Lu C, Lu Z, Li Z, Leung CKY. Effect of graphene oxide on the mechanical behavior of strain hardening cementitious composites. Constr Build Mater. 2016;120:457–64. 10.1016/j.conbuildmat.2016.05.122.Search in Google Scholar

[44] Naseem Z, Shamsaei E, Sagoe-Crentsil K, Duan W. Antifoaming effect of graphene oxide nanosheets in polymer-modified cement composites for enhanced microstructure and mechanical performance. Cem Concr Res. 2022;158:106843. 10.1016/j.cemconres.2022.106843.Search in Google Scholar

[45] Lv S, Ma Y, Qiu C, Sun T, Liu J, Zhou Q. Effect of graphene oxide nanosheets of microstructure and mechanical properties of cement composites. Constr Build Mater. 2013;49:121–7. 10.1016/j.conbuildmat.2013.08.022.Search in Google Scholar

[46] Li Y, Pimienta P, Pinoteau N, Tan KH. Effect of aggregate size and inclusion of polypropylene and steel fibers on explosive spalling and pore pressure in ultra-high-performance concrete (UHPC) at elevated temperature. Cem Concr Compos. 2019;99:62–71. 10.1016/j.cemconcomp.2019.02.016.Search in Google Scholar

[47] Wei J, Meyer C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem Concr Res. 2015;73:1–16. 10.1016/j.cemconres.2015.02.019.Search in Google Scholar

[48] Gao Y, Jing H, Zhao Z, Shi X, Li L. Influence of ultrasonication energy on reinforcing-roles of CNTs to strengthen ITZ and corresponding anti-permeability properties of concrete. Constr Build Mater. 2021;303:124451. 10.1016/j.conbuildmat.2021.124451.Search in Google Scholar

[49] Yazıcı H, Yardımcı MY, Yiğiter H, Aydın S, Türkel S. Mechanical properties of reactive powder concrete containing high volumes of ground granulated blast furnace slag. Cem Concr Compos. 2010;32:639–48. 10.1016/j.cemconcomp.2010.07.005.Search in Google Scholar

[50] Chen Y, Li X, Du H. A review of high temperature properties of cement based composites: Effects of nano materials. Mater Today Commun. 2023;35:105954. 10.1016/j.mtcomm.2023.105954.Search in Google Scholar

[51] Li X, Liu YM, Li WG, Li CY, Sanjayan JG, Duan WH, et al. Effects of graphene oxide agglomerates on workability, hydration, microstructure and compressive strength of cement paste. Constr Build Mater. 2017;145:402–10. 10.1016/j.conbuildmat.2017.04.058.Search in Google Scholar

[52] Indukuri CSR, Nerella R. Enhanced transport properties of graphene oxide based cement composite material. J Build Eng. 2021;37:102174. 10.1016/j.jobe.2021.102174.Search in Google Scholar

[53] Hou D, Lu Z, Li X, Ma H, Li Z. Reactive molecular dynamics and experimental study of graphene-cement composites: Structure, dynamics and reinforcement mechanisms. Carbon. 2017;115:188–208. 10.1016/j.carbon.2017.01.013.Search in Google Scholar

[54] Gao Y, Jing H, Fu G, Zhao Z, Shi X. Studies on combined effects of graphene oxide-fly ash hybrid on the workability, mechanical performance and pore structures of cementitious grouting under high W/C ratio. Constr Build Mater. 2021;281:122578. 10.1016/j.conbuildmat.2021.122578.Search in Google Scholar

[55] Huang C-Y, Lin Y-C, Chung JHY, Chiu H-Y, Yeh N-L, Chang S-J, et al. Enhancing cementitious composites with functionalized graphene oxide-based materials: surface chemistry and mechanisms. Int J Mol Sci. 2023;24:10461. 10.3390/ijms241310461.Search in Google Scholar PubMed PubMed Central

[56] Suh H, Cho S, Im S, Moon J, Park J, Lim J, et al. Characterization of thermal resistance and mechanical strength recovery of carbon nanotubes incorporated Portland cement composites subjected to heating and rehydration: Visualization of pore structural evolutions via synchrotron 3D X-ray nanoimaging. Cem Concr Compos. 2024;146:105361. 10.1016/j.cemconcomp.2023.105361.Search in Google Scholar

[57] Rodríguez P, Arab PB, Celestino TB. Characterization of rock cracking patterns in diametral compression tests by acoustic emission and petrographic analysis. Int J Rock Mech Min Sci. 2016;83:73–85. 10.1016/j.ijrmms.2015.12.017.Search in Google Scholar

[58] Niu Y, Wang E, Li Z. A study on moment tensor inversion of acoustic emission response on damaging localization of gas-bearing coal under load. Sci Rep. 2022;12:16360. 10.1038/s41598-022-20603-y.Search in Google Scholar PubMed PubMed Central

[59] Wang X, Wang E, Liu X, Zhou X. Failure mechanism of fractured rock and associated acoustic behaviors under different loading rates. Eng Fract Mech. 2021;247:107674. 10.1016/j.engfracmech.2021.107674.Search in Google Scholar

[60] Zemri C, Bouiadjra MB. Comparison between physical–mechanical properties of mortar made with Portland cement (CEMI) and slag cement (CEMIII) subjected to elevated temperature. Case Stud Constr Mater. 2020;12:e00339. 10.1016/j.cscm.2020.e00339.Search in Google Scholar

[61] Abdi Moghadam M, Izadifard RA, Khalighi A. Microstructural and mechanical characteristics of fiber-reinforced cementitious composites under high-temperature exposure. J Mater Civ Eng. 2022;34:04022208. 10.1061/(ASCE)MT.1943-5533.0004337.Search in Google Scholar

[62] Lee NK, Koh KT, Park SH, Ryu GS. Microstructural investigation of calcium aluminate cement-based ultra-high performance concrete (UHPC) exposed to high temperatures. Cem Concr Res. 2017;102:109–18. 10.1016/j.cemconres.2017.09.004.Search in Google Scholar

[63] Xu J, Ding Y, Gao Y, Wang H, Hu Y, Zhang D. Grain refinement and crack inhibition of hard-to-weld Inconel 738 alloy by altering the scanning strategy during selective laser melting. Mater Des. 2021;209:109940. 10.1016/j.matdes.2021.109940.Search in Google Scholar

[64] Ahmad I, Islam M, Abdo HS, Subhani T, Khalil KA, Almajid AA, et al. Toughening mechanisms and mechanical properties of graphene nanosheet-reinforced alumina. Mater Des. 2015;88:1234–43. 10.1016/j.matdes.2015.09.125.Search in Google Scholar

[65] Zhang J, Liu W, Schnitzler V, Tancret F, Bouler J-M. Calcium phosphate cements for bone substitution: Chemistry, handling and mechanical properties. Acta Biomater. 2014;10:1035–49. 10.1016/j.actbio.2013.11.001.Search in Google Scholar PubMed

[66] Sun W, Hou K, Yang Z, Wen Y. X-ray CT three-dimensional reconstruction and discrete element analysis of the cement paste backfill pore structure under uniaxial compression. Constr Build Mater. 2017;138:69–78. 10.1016/j.conbuildmat.2017.01.088.Search in Google Scholar

[67] Liu B, Zhou J, Wen X, Hu X, Deng Z. Mechanical properties and constitutive model of carbon fiber reinforced coral concrete under uniaxial compression. Constr Build Mater. 2020;263:120649. 10.1016/j.conbuildmat.2020.120649.Search in Google Scholar

[68] Li P, Liu J, Suh H, Nezhad EZ, Bae S. Understanding the role of graphene oxide nanoribbons–functionalized carbon nanotubes–graphene oxide (GNFG) complex in enhancing the fire resistance of cementitious composites. Constr Build Mater. 2022;348:128637.10.1016/j.conbuildmat.2022.128637Search in Google Scholar

[69] Murali M, Alaloul WS, Mohammed BS, Musarat MA, Salaheen MA, Al-Sabaeei AM, et al. Utilizing graphene oxide in cementitious composites: A systematic review. Case Stud Constr Mater. 2022;17:e01359. 10.1016/j.cscm.2022.e01359.Search in Google Scholar

[70] Belem T, Homand-Etienne F, Souley M. Quantitative parameters for rock joint surface roughness. Rock Mech Rock Eng. 2000;33(4):217–42. 10.1007/s006030070001.Search in Google Scholar

[71] Win TT, Prasittisopin L, Nganglumpoon R, Pinthong P, Watmanee S, Tolek W, et al. Chemo-physical mechanisms of high-strength cement composites with suprastructure of graphene quantum dots. Clean Mater. 2024;11:100229. 10.1016/j.clema.2024.100229.Search in Google Scholar

[72] Win TT, Prasittisopin L, Jongvivatsakul P, Likitlersuang S. Investigating the synergistic effect of graphene nanoplatelets and fly ash on the mechanical properties and microstructure of calcium aluminate cement composites. J Build Eng. 2023;78:107710. 10.1016/j.jobe.2023.107710.Search in Google Scholar

[73] Lu L, Zhang Y, Yin B. Structure evolution of the interface between graphene oxide-reinforced calcium silicate hydrate gel particles exposed to high temperature. Comp Mater Sci. 2020;173:109440. 10.1016/j.commatsci.2019.109440.Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- MHD radiative mixed convective flow of a sodium alginate-based hybrid nanofluid over a convectively heated extending sheet with Joule heating

- Experimental study of mortar incorporating nano-magnetite on engineering performance and radiation shielding

- Multicriteria-based optimization and multi-variable non-linear regression analysis of concrete containing blends of nano date palm ash and eggshell powder as cementitious materials

- A promising Ag2S/poly-2-amino-1-mercaptobenzene open-top spherical core–shell nanocomposite for optoelectronic devices: A one-pot technique

- Biogenic synthesized selenium nanoparticles combined chitosan nanoparticles controlled lung cancer growth via ROS generation and mitochondrial damage pathway

- Fabrication of PDMS nano-mold by deposition casting method

- Stimulus-responsive gradient hydrogel micro-actuators fabricated by two-photon polymerization-based 4D printing

- Physical aspects of radiative Carreau nanofluid flow with motile microorganisms movement under yield stress via oblique penetrable wedge

- Effect of polar functional groups on the hydrophobicity of carbon nanotubes-bacterial cellulose nanocomposite

- Review in green synthesis mechanisms, application, and future prospects for Garcinia mangostana L. (mangosteen)-derived nanoparticles

- Entropy generation and heat transfer in nonlinear Buoyancy–driven Darcy–Forchheimer hybrid nanofluids with activation energy

- Green synthesis of silver nanoparticles using Ginkgo biloba seed extract: Evaluation of antioxidant, anticancer, antifungal, and antibacterial activities

- A numerical analysis of heat and mass transfer in water-based hybrid nanofluid flow containing copper and alumina nanoparticles over an extending sheet

- Investigating the behaviour of electro-magneto-hydrodynamic Carreau nanofluid flow with slip effects over a stretching cylinder

- Electrospun thermoplastic polyurethane/nano-Ag-coated clear aligners for the inhibition of Streptococcus mutans and oral biofilm

- Investigation of the optoelectronic properties of a novel polypyrrole-multi-well carbon nanotubes/titanium oxide/aluminum oxide/p-silicon heterojunction

- Novel photothermal magnetic Janus membranes suitable for solar water desalination

- Green synthesis of silver nanoparticles using Ageratum conyzoides for activated carbon compositing to prepare antimicrobial cotton fabric

- Activation energy and Coriolis force impact on three-dimensional dusty nanofluid flow containing gyrotactic microorganisms: Machine learning and numerical approach

- Machine learning analysis of thermo-bioconvection in a micropolar hybrid nanofluid-filled square cavity with oxytactic microorganisms

- Research and improvement of mechanical properties of cement nanocomposites for well cementing

- Thermal and stability analysis of silver–water nanofluid flow over unsteady stretching sheet under the influence of heat generation/absorption at the boundary

- Cobalt iron oxide-infused silicone nanocomposites: Magnetoactive materials for remote actuation and sensing

- Magnesium-reinforced PMMA composite scaffolds: Synthesis, characterization, and 3D printing via stereolithography

- Bayesian inference-based physics-informed neural network for performance study of hybrid nanofluids

- Numerical simulation of non-Newtonian hybrid nanofluid flow subject to a heterogeneous/homogeneous chemical reaction over a Riga surface

- Enhancing the superhydrophobicity, UV-resistance, and antifungal properties of natural wood surfaces via in situ formation of ZnO, TiO2, and SiO2 particles

- Synthesis and electrochemical characterization of iron oxide/poly(2-methylaniline) nanohybrids for supercapacitor application

- Impacts of double stratification on thermally radiative third-grade nanofluid flow on elongating cylinder with homogeneous/heterogeneous reactions by implementing machine learning approach

- Synthesis of Cu4O3 nanoparticles using pumpkin seed extract: Optimization, antimicrobial, and cytotoxicity studies

- Cationic charge influence on the magnetic response of the Fe3O4–[Me2+ 1−y Me3+ y (OH2)] y+(Co3 2−) y/2·mH2O hydrotalcite system

- Pressure sensing intelligent martial arts short soldier combat protection system based on conjugated polymer nanocomposite materials

- Magnetohydrodynamics heat transfer rate under inclined buoyancy force for nano and dusty fluids: Response surface optimization for the thermal transport

- Fly ash and nano-graphene enhanced stabilization of engine oil-contaminated soils

- Enhancing natural fiber-reinforced biopolymer composites with graphene nanoplatelets: Mechanical, morphological, and thermal properties

- Performance evaluation of dual-scale strengthened co-bonded single-lap joints using carbon nanotubes and Z-pins with ANN

- Computational works of blood flow with dust particles and partially ionized containing tiny particles on a moving wedge: Applications of nanotechnology

- Hybridization of biocomposites with oil palm cellulose nanofibrils/graphene nanoplatelets reinforcement in green epoxy: A study of physical, thermal, mechanical, and morphological properties

- Design and preparation of micro-nano dual-scale particle-reinforced Cu–Al–V alloy: Research on the aluminothermic reduction process

- Spectral quasi-linearization and response optimization on magnetohydrodynamic flow via stenosed artery with hybrid and ternary solid nanoparticles: Support vector machine learning

- Ferrite/curcumin hybrid nanocomposite formulation: Physicochemical characterization, anticancer activity, and apoptotic and cell cycle analyses in skin cancer cells

- Enhanced therapeutic efficacy of Tamoxifen against breast cancer using extra virgin olive oil-based nanoemulsion delivery system

- A titanium oxide- and silver-based hybrid nanofluid flow between two Riga walls that converge and diverge through a machine-learning approach

- Enhancing convective heat transfer mechanisms through the rheological analysis of Casson nanofluid flow towards a stagnation point over an electro-magnetized surface

- Intrinsic self-sensing cementitious composites with hybrid nanofillers exhibiting excellent piezoresistivity

- Research on mechanical properties and sulfate erosion resistance of nano-reinforced coal gangue based geopolymer concrete

- Impact of surface and configurational features of chemically synthesized chains of Ni nanostars on the magnetization reversal process

- Porous sponge-like AsOI/poly(2-aminobenzene-1-thiol) nanocomposite photocathode for hydrogen production from artificial and natural seawater

- Multifaceted insights into WO3 nanoparticle-coupled antibiotics to modulate resistance in enteric pathogens of Houbara bustard birds

- Synthesis of sericin-coated silver nanoparticles and their applications for the anti-bacterial finishing of cotton fabric

- Enhancing chloride resistance of freeze–thaw affected concrete through innovative nanomaterial–polymer hybrid cementitious coating

- Development and performance evaluation of green aluminium metal matrix composites reinforced with graphene nanopowder and marble dust

- Morphological, physical, thermal, and mechanical properties of carbon nanotubes reinforced arrowroot starch composites

- Influence of the graphene oxide nanosheet on tensile behavior and failure characteristics of the cement composites after high-temperature treatment

- Central composite design modeling in optimizing heat transfer rate in the dissipative and reactive dynamics of viscoplastic nanomaterials deploying Joule and heat generation aspects

- Double diffusion of nano-enhanced phase change materials in connected porous channels: A hybrid ISPH-XGBoost approach

- Review Articles

- A comprehensive review on hybrid plasmonic waveguides: Structures, applications, challenges, and future perspectives

- Nanoparticles in low-temperature preservation of biological systems of animal origin

- Fluorescent sulfur quantum dots for environmental monitoring

- Nanoscience systematic review methodology standardization

- Nanotechnology revolutionizing osteosarcoma treatment: Advances in targeted kinase inhibitors

- AFM: An important enabling technology for 2D materials and devices

- Carbon and 2D nanomaterial smart hydrogels for therapeutic applications

- Principles, applications and future prospects in photodegradation systems

- Do gold nanoparticles consistently benefit crop plants under both non-stressed and abiotic stress conditions?

- An updated overview of nanoparticle-induced cardiovascular toxicity

- Arginine as a promising amino acid for functionalized nanosystems: Innovations, challenges, and future directions

- Advancements in the use of cancer nanovaccines: Comprehensive insights with focus on lung and colon cancer

- Membrane-based biomimetic delivery systems for glioblastoma multiforme therapy

- The drug delivery systems based on nanoparticles for spinal cord injury repair

- Green synthesis, biomedical effects, and future trends of Ag/ZnO bimetallic nanoparticles: An update

- Application of magnesium and its compounds in biomaterials for nerve injury repair

- Micro/nanomotors in biomedicine: Construction and applications

- Hydrothermal synthesis of biomass-derived CQDs: Advances and applications

- Research progress in 3D bioprinting of skin: Challenges and opportunities

- Review on bio-selenium nanoparticles: Synthesis, protocols, and applications in biomedical processes

- Gold nanocrystals and nanorods functionalized with protein and polymeric ligands for environmental, energy storage, and diagnostic applications: A review

- An in-depth analysis of rotational and non-rotational piezoelectric energy harvesting beams: A comprehensive review

- Advancements in perovskite/CIGS tandem solar cells: Material synergies, device configurations, and economic viability for sustainable energy

- Deep learning in-depth analysis of crystal graph convolutional neural networks: A new era in materials discovery and its applications

- Review of recent nano TiO2 film coating methods, assessment techniques, and key problems for scaleup

- Antioxidant quantum dots for spinal cord injuries: A review on advancing neuroprotection and regeneration in neurological disorders

- Rise of polycatecholamine ultrathin films: From synthesis to smart applications

- Advancing microencapsulation strategies for bioactive compounds: Enhancing stability, bioavailability, and controlled release in food applications

- Corrigendum

- Corrigendum to “Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer”

- Special Issue on Advanced Nanomaterials for Carbon Capture, Environment and Utilization for Energy Sustainability - Part III

- Efficiency optimization of quantum dot photovoltaic cell by solar thermophotovoltaic system

- Exploring the diverse nanomaterials employed in dental prosthesis and implant techniques: An overview

- Electrochemical investigation of bismuth-doped anode materials for low‑temperature solid oxide fuel cells with boosted voltage using a DC-DC voltage converter

- Synthesis of HfSe2 and CuHfSe2 crystalline materials using the chemical vapor transport method and their applications in supercapacitor energy storage devices

- Special Issue on Green Nanotechnology and Nano-materials for Environment Sustainability

- Influence of nano-silica and nano-ferrite particles on mechanical and durability of sustainable concrete: A review

- Surfaces and interfaces analysis on different carboxymethylation reaction time of anionic cellulose nanoparticles derived from oil palm biomass

- Processing and effective utilization of lignocellulosic biomass: Nanocellulose, nanolignin, and nanoxylan for wastewater treatment

- Retraction

- Retraction of “Aging assessment of silicone rubber materials under corona discharge accompanied by humidity and UV radiation”

Articles in the same Issue

- Research Articles

- MHD radiative mixed convective flow of a sodium alginate-based hybrid nanofluid over a convectively heated extending sheet with Joule heating

- Experimental study of mortar incorporating nano-magnetite on engineering performance and radiation shielding

- Multicriteria-based optimization and multi-variable non-linear regression analysis of concrete containing blends of nano date palm ash and eggshell powder as cementitious materials

- A promising Ag2S/poly-2-amino-1-mercaptobenzene open-top spherical core–shell nanocomposite for optoelectronic devices: A one-pot technique

- Biogenic synthesized selenium nanoparticles combined chitosan nanoparticles controlled lung cancer growth via ROS generation and mitochondrial damage pathway

- Fabrication of PDMS nano-mold by deposition casting method

- Stimulus-responsive gradient hydrogel micro-actuators fabricated by two-photon polymerization-based 4D printing

- Physical aspects of radiative Carreau nanofluid flow with motile microorganisms movement under yield stress via oblique penetrable wedge

- Effect of polar functional groups on the hydrophobicity of carbon nanotubes-bacterial cellulose nanocomposite

- Review in green synthesis mechanisms, application, and future prospects for Garcinia mangostana L. (mangosteen)-derived nanoparticles

- Entropy generation and heat transfer in nonlinear Buoyancy–driven Darcy–Forchheimer hybrid nanofluids with activation energy

- Green synthesis of silver nanoparticles using Ginkgo biloba seed extract: Evaluation of antioxidant, anticancer, antifungal, and antibacterial activities

- A numerical analysis of heat and mass transfer in water-based hybrid nanofluid flow containing copper and alumina nanoparticles over an extending sheet

- Investigating the behaviour of electro-magneto-hydrodynamic Carreau nanofluid flow with slip effects over a stretching cylinder

- Electrospun thermoplastic polyurethane/nano-Ag-coated clear aligners for the inhibition of Streptococcus mutans and oral biofilm

- Investigation of the optoelectronic properties of a novel polypyrrole-multi-well carbon nanotubes/titanium oxide/aluminum oxide/p-silicon heterojunction

- Novel photothermal magnetic Janus membranes suitable for solar water desalination

- Green synthesis of silver nanoparticles using Ageratum conyzoides for activated carbon compositing to prepare antimicrobial cotton fabric

- Activation energy and Coriolis force impact on three-dimensional dusty nanofluid flow containing gyrotactic microorganisms: Machine learning and numerical approach

- Machine learning analysis of thermo-bioconvection in a micropolar hybrid nanofluid-filled square cavity with oxytactic microorganisms

- Research and improvement of mechanical properties of cement nanocomposites for well cementing

- Thermal and stability analysis of silver–water nanofluid flow over unsteady stretching sheet under the influence of heat generation/absorption at the boundary

- Cobalt iron oxide-infused silicone nanocomposites: Magnetoactive materials for remote actuation and sensing

- Magnesium-reinforced PMMA composite scaffolds: Synthesis, characterization, and 3D printing via stereolithography

- Bayesian inference-based physics-informed neural network for performance study of hybrid nanofluids

- Numerical simulation of non-Newtonian hybrid nanofluid flow subject to a heterogeneous/homogeneous chemical reaction over a Riga surface

- Enhancing the superhydrophobicity, UV-resistance, and antifungal properties of natural wood surfaces via in situ formation of ZnO, TiO2, and SiO2 particles

- Synthesis and electrochemical characterization of iron oxide/poly(2-methylaniline) nanohybrids for supercapacitor application

- Impacts of double stratification on thermally radiative third-grade nanofluid flow on elongating cylinder with homogeneous/heterogeneous reactions by implementing machine learning approach

- Synthesis of Cu4O3 nanoparticles using pumpkin seed extract: Optimization, antimicrobial, and cytotoxicity studies

- Cationic charge influence on the magnetic response of the Fe3O4–[Me2+ 1−y Me3+ y (OH2)] y+(Co3 2−) y/2·mH2O hydrotalcite system

- Pressure sensing intelligent martial arts short soldier combat protection system based on conjugated polymer nanocomposite materials

- Magnetohydrodynamics heat transfer rate under inclined buoyancy force for nano and dusty fluids: Response surface optimization for the thermal transport

- Fly ash and nano-graphene enhanced stabilization of engine oil-contaminated soils

- Enhancing natural fiber-reinforced biopolymer composites with graphene nanoplatelets: Mechanical, morphological, and thermal properties

- Performance evaluation of dual-scale strengthened co-bonded single-lap joints using carbon nanotubes and Z-pins with ANN

- Computational works of blood flow with dust particles and partially ionized containing tiny particles on a moving wedge: Applications of nanotechnology

- Hybridization of biocomposites with oil palm cellulose nanofibrils/graphene nanoplatelets reinforcement in green epoxy: A study of physical, thermal, mechanical, and morphological properties

- Design and preparation of micro-nano dual-scale particle-reinforced Cu–Al–V alloy: Research on the aluminothermic reduction process

- Spectral quasi-linearization and response optimization on magnetohydrodynamic flow via stenosed artery with hybrid and ternary solid nanoparticles: Support vector machine learning

- Ferrite/curcumin hybrid nanocomposite formulation: Physicochemical characterization, anticancer activity, and apoptotic and cell cycle analyses in skin cancer cells

- Enhanced therapeutic efficacy of Tamoxifen against breast cancer using extra virgin olive oil-based nanoemulsion delivery system

- A titanium oxide- and silver-based hybrid nanofluid flow between two Riga walls that converge and diverge through a machine-learning approach

- Enhancing convective heat transfer mechanisms through the rheological analysis of Casson nanofluid flow towards a stagnation point over an electro-magnetized surface

- Intrinsic self-sensing cementitious composites with hybrid nanofillers exhibiting excellent piezoresistivity

- Research on mechanical properties and sulfate erosion resistance of nano-reinforced coal gangue based geopolymer concrete

- Impact of surface and configurational features of chemically synthesized chains of Ni nanostars on the magnetization reversal process

- Porous sponge-like AsOI/poly(2-aminobenzene-1-thiol) nanocomposite photocathode for hydrogen production from artificial and natural seawater