Hybridization of biocomposites with oil palm cellulose nanofibrils/graphene nanoplatelets reinforcement in green epoxy: A study of physical, thermal, mechanical, and morphological properties

Abstract

With the rising demand for sustainable and high-performance materials, biobased nanocomposites have gained considerable attention as eco-friendly alternatives to conventional polymers. In this research, the effective incorporation of the oil palm cellulose nanofibrils (CNFs) and graphene nanoplatelets (GNPs) as nanofillers into biopolymer matrices made by biomass with 28% carbon content resulted in notable improvements in mechanical properties. The study aimed to fabricate green/bioepoxy hybrid nanocomposites by using acetone as the solvent in a solution blending procedure with varying CNF loadings (0.1, 0.25, and 0.5 wt%). The resulting nanocomposites were thoroughly analyzed and compared to unfilled green epoxy. The mechanical test results were consistent with previously published studies, demonstrating a 77% increase in tensile strength and 23.46% improvement in hardness when evaluated against unfilled green epoxy. However, the green epoxy hybrid nanocomposites' thermal degradation temperature (T d) revealed a drop in temperature between 0.1 wt% of CNF/GNP loading and unfilled green epoxy (neat). Overall, the results demonstrated a significant improvement in the mechanical performance of green epoxy hybrid nanocomposites and showed the potential of using low-loading nanofillers in green epoxy. The hybrid composites can be used in electronics, marine, and biomedical applications.

Graphical abstract

1 Introduction

Identifying effective, renewable, sustainable, and ecologically sound resources and materials exhibiting favorable properties represents a formidable challenge. It constitutes an essential pathway toward attaining sustainable advancement, particularly considering the precipitous depletion of non-renewable resources and the exacerbation of environmental degradation. These changes are driven by the rapidly developing social economy and accelerating industrialization [1,2]. Cellulose nanofibrils (CNFs) represent naturally occurring polymeric nanomaterials characterized by their superior biocompatibility and biodegradability, as well as possessing commendable mechanical properties, substantial strength, reduced density, extensive specific surface area, and adjustable chemical characteristics. Due to its biodegradable nature, sustainability, and biosafety features, cellulose is becoming popular. Cellulose, a biodegradable polymer derived from renewable sources like plants and algae, has applications in biomedical fields, paper production, textiles, and packaging [3,4]. However, issues like moisture absorption and poor mechanical properties for natural fiber-reinforced composites (NFRCs) pose a challenge to utilize on a large scale [5]. The problems result in fungal growth, poor bonding, and swelling. They are vulnerable to biological threats, ultraviolet (UV) deterioration [6], and limited thermal stability [7]. Low fatigue resistance and creep deformation also restrict long-term performance. Fiber hybridization, matrix modification, UV/fire retardants, hydrophobic coatings, and chemical treatments can all increase the durability of NFRCs [8].

It has been shown that CNF combined with other nanomaterials, such as graphene derivatives and graphene nanoplatelets (GNPs), is useful for developing hybrids with exceptional physicochemical features, high performance, and configurable functionality [9].

Recently, there has emerged significant scholarly interest in hybrid organic–inorganic nanocomposites synthesized via environmentally sustainable methods that utilize renewable intelligent materials. This increasing attention is attributable to their numerous advantages and unique properties. Given the dependence on limited and exhaustible non-renewable resources, the emphasis has transitioned toward the fabrication and optimization of hybrid composite materials [10]. Numerous scholars have utilized a diverse array of methodologies to synthesize graphene nanocellulose-reinforced hybrids, encompassing techniques such as layer-by-layer assembly, ultrasonication, ambient pressure drying, ball milling, and liquid-phase exfoliation [11]. The most common method is solution blending along with ultrasonication. Mohammadsalih et al. [12] used solution blending along with sonication for dispersing graphene nanosheets in a thermoplastic matrix. The resultant polystyrene/graphene oxide nanocomposites exhibited better dispersion and enhanced thermal properties.

Liu et al. [13] produced cellulose nanowhisker/GNP composite films using sonication mixing and solution casting. The composite films showed enhanced melting and decomposition temperatures, electrical conductivity, and tensile strength, making them suitable for bio-anti-static and electronic packaging applications. Many other researchers have also worked on the CNF/GNP, as shown in Table 1.

Various fillers in the polymer matrix

| Polymer matrix | Hybrid filler | Preparation technique | Findings | Applications | Ref. |

|---|---|---|---|---|---|

| Glass/Epoxy | Multiwall carbon nanotubes (MWCNTs), nano-silica (NS), and nano-iron oxide (NFe) | Sonication | Significant improvement to the polymer cross-linking web | Automotive, aviation, and defense industries | [14] |

| Epoxy | Alumina nanoparticles, nylon-6 fibers, glass fibers | Solution blend technique | Reduces the wear loss of epoxy hybrid nanocomposites | Biomedical domains | [15] |

| Bisglycidyl dimethacrylate (Bis-GMA)/triethylene glycol dimethacrylate (TEGDMA) | Silica/poly(methylmethacrylate) (PMMA) | Emulsion polymerization, sonication | A higher content of PMMA in the hybrid particles results in a lower modulus owing to the lower amount of crosslinking in the matrix | Dental restoration | [16] |

| GNP paper | CNF | Vacuum-assisted self-assembly | CNF efficiently links the neighboring GNP sheets, thus reinforcing the structural integrity of the GNP papers | Gas barrier | [17] |

| PVA (polyvinyl alcohol) | Cellulose nanocrystals (CNCs) and graphene oxide (GO) | Sonication | The synergistic effect of hybrid nanofillers improved dispersion, leading to nanocomposites with superior performance compared to those with single nanofillers | Food packaging | [18] |

Epoxy is widely used for its mechanical properties and chemical resistance. However, it faces an environmental concern due to the toxic behavior of bisphenol A (BPA), resulting in endangering human and animals [19]. This is vital in the context of increasing concerns regarding environmental contamination and the discharge of hazardous substances into aquatic ecosystems attributable to synthetic polymers [20]. Thus, efforts are made to develop biopolymers from renewable resources like vegetable oils and lignin, which are aimed to replace BPA along with an added value [21] (Figure 1). Green epoxy resin is another alternative in a green matrix for producing NFRC. Green epoxy is produced from many renewable resources such as Nahar seed plant oil and bio tea leaf phenolic extract [21]. To be labeled as green epoxy, the resin needs at least 25% biocontent as per United States Department of Agriculture (USDA) standards. Researchers claim that green epoxy significantly reduces biohouse gas emissions at 30% biocontent.

![Figure 1

Transformation from green platform compounds to green epoxy resins [22].](/document/doi/10.1515/ntrev-2025-0197/asset/graphic/j_ntrev-2025-0197_fig_001.jpg)

Transformation from green platform compounds to green epoxy resins [22].

Borah and Karak [23] developed bio-derived green epoxy composites using functionalized waste tea fibers. The results showed enhanced mechanical and thermal properties. The composites demonstrated high durability under harsh conditions, including UV exposure and extreme temperatures. Kumar et al. [24] used novel lignin-derived vanillyl alcohol epoxy (m&dVAE) thermoset to develop a unique mono- and diepoxy cross-linking structure, offering a sustainable alternative to petroleum-based epoxies. When cured with 4,4′-diaminodiphenyl methane (DDM), it outperformed commercial diglycidyl ether bisphenol A (DGEBA) in tensile strength, modulus, and adhesion with cellulose nanofibers. Zindani et al. [25] developed green biocomposites using short Punica granatum fibers (SPGF) reinforced in bioepoxy derived from cashew-nut shell oil. SPGFs were treated with sodium bicarbonate for varying durations to enhance the composite performance. While chemical treatment did not alter the cellulose structure, it improved physical and mechanical properties, especially after 5 days of treatment. The eco-friendly process supports sustainable composite fabrication with reduced environmental impact.

Through a synergistic interaction between the high surface area of nanocellulose and the remarkable strength of graphene, hybridizing nanocellulose with GNPs in a green epoxy matrix greatly enhances load transfer, crack resistance, and thermal conductivity [26]. The hybrid composite becomes suitable for sophisticated structural and functional applications while preserving biodegradability and sustainability due to this combination, which also strengthens the matrix at the nanoscale and improves barrier qualities, durability, and multifunctionality.

While a considerable volume of research has been conducted previously regarding nanoparticles and epoxy composites, encompassing an extensive range of scientific explorations and analyses. Nonetheless, there exists a gap in research aimed at investigating the implications of incorporating minimal concentrations of nanoparticles with bio-derived green epoxy in composite fabrication.

This research seeks to investigate the influence of low loading levels on CNF/GNP-reinforced green epoxy nanocomposites. The present investigation incorporates low-loading fillers of GNPs to address the mechanical deficiencies observed. The methodology employed for the fabrication of the nanocomposites was solution blending, followed by a thorough examination of their properties. In terms of mechanical evaluation, tensile, flexural, impact, and hardness tests were carried out. The composition of the nanocomposites was interpreted through the analysis of the Fourier-transform infrared (FTIR) spectrum. Furthermore, thermogravimetric analysis (TGA) was conducted to assess the thermal properties. In addition, field emission scanning electron microscopy (FE-SEM) was utilized to analyze the morphological attributes.

2 Experimental

2.1 Materials

The commercially available green epoxy resin, designated as SR Bio Poxy 28 (Part A), was provided by Mecha Solve Engineering (Kuala Lumpur, Malaysia) with its corresponding hardener SD 3304 (Part B). The density of the green epoxy resin was determined to be 1.17 ± 0.01, while its viscosity at a temperature of 30°C was measured at 4,500 mPa s, and the gel time at the same temperature was 3.45 h. GNP was sourced from GO Advanced Solutions Sdn. Bhd. (Malaysia). GNP presented as a black/gray powder, exhibiting a specific surface area in the range of 20–40 m2/g, a carbon content exceeding 99%, an apparent density between 0.06 and 0.09 g/mL, a water content below 2 wt%, and residual impurities less than 1 wt%. The spray-dried CNF derived from oil palm was obtained from Zoepnano Sdn. Bhd., Putra Science Park, Serdang, Selangor, Malaysia. The physical characteristics of the CNF were described as white and opaque. The nanocellulose content was found to be 99%, the pH level was neutral, the diameter was less than 50 nm, dynamic light scattering (DLS) measurements ranged from 40 to 25 nm, and the onset temperature was approximately 300°C, with the complete deposition temperature reaching around 600°C. Acetone served as a solvent agent, facilitating the dispersion process.

2.2 Methods

The GNP/CNF-reinforced green epoxy hybrid green nanocomposites were synthesized through a solution blending methodology encompassing four fundamental steps: the dissolution of nanoparticles in a solvent utilizing sonication (Digital Pro+, Malaysia), the incorporation of the polymer solution, subsequent mixing, and ultimately, the removal of the solvent via evaporation (Faithful Instrument, China). The combined GNP/CNF was prepared in varying weight percentages, such as (0.1, 0.25, and 0.5) wt%, which were precisely measured using a digital balance (AND GF-1000, Japan) with a readability of 0.01 mg. These materials were then dispersed in acetone within a glass beaker and subjected to sonication with an ice bath employed to maintain a lower water temperature; after sonication, the suspension was permitted to remain undisturbed for a period to observe sedimentation characteristics.

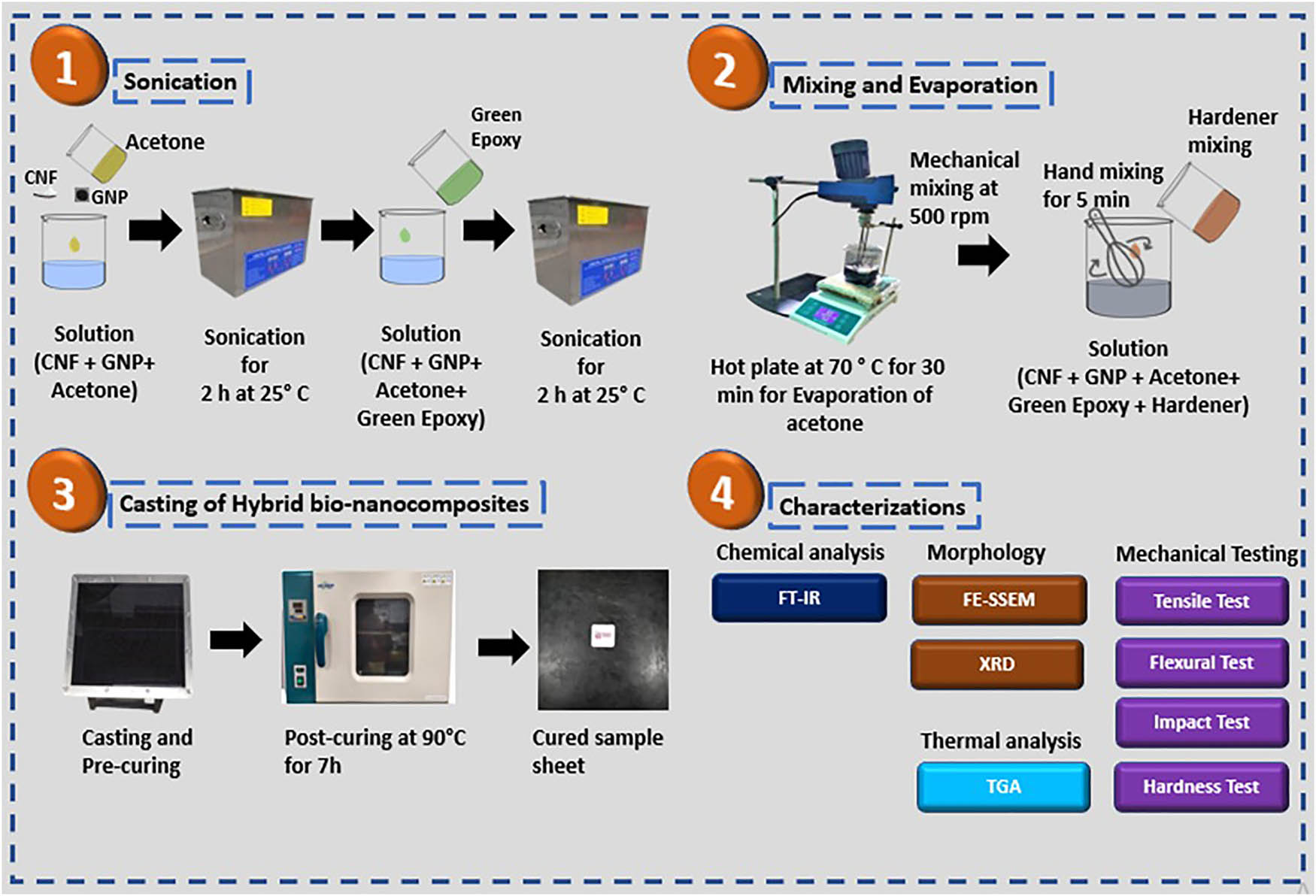

Figure 2 illustrates the primary procedures involved in the synthesis of GNP/CNF-reinforced green epoxy hybrid nanocomposites. Green epoxy was subsequently incorporated in acetone and GNP/CNF, followed by sonication for a duration of 2 h. Acetone was subsequently eliminated through the utilization of a laboratory hot plate, with the mixture maintained at a temperature of 75°C for a period of 2.5 h. Continuous agitation was performed to ensure homogenous mixing of the green epoxy with GNP/CNF, facilitated by a mechanical stirrer (IKA RW 20, Malaysia) operating at 500 rpm. A curing hardener, designated as part B of the epoxy, was combined in a ratio of 8:2 and manually blended for 5 min. Steel mold with dimensions of (200 mm × 200 mm × 3.0 mm) was pre-prepared by applying mold release wax (Meigura’s mirror glase) in three successive applications at 30 min intervals. The resulting mixture was then introduced into the steel mold and subjected to pre-curing for a duration of 16 h at ambient temperature. The mold was post-cured for 7 h at 90°C in an oven (Lichen Technology, China). After the sheet was taken out of the mold, samples were made for testing using a vertical bandsaw (Makita LB1200F, Japan).

Methodology for the preparation of GNP/CNF-reinforced green epoxy hybrid nanocomposites.

2.3 Characterization

2.3.1 Chemical analysis

The functional groups present in GNP/CNF-reinforced green epoxy hybrid green nanocomposites were analyzed utilizing a Thermo-Fisher Nicolet iS10 spectrophotometer through FTIR spectroscopy, conducted within the frequency range of 400–4,000 cm−1. To acquire the spectra for the FTIR analysis, 16 scans were performed at a velocity of 0.47 cm/s, which aimed to accurately explain the functional groups associated with the CNF/GNP component and to delineate the characteristics of the hybrid nanocomposites.

2.3.2 Morphological analysis

The microstructure analysis of the broken surface of hybrid green nanocomposites, which was the outcome of a tensile test, was done using a 5.0 kV field-emission scanning electron microscope (JEOL JSM-7600F FESEM, Japan). The vacuum suction source runs the FESEM at discrete magnifications ranging from 5,000 to 50,000. To improve the observation of fragmented surface morphology, the sample was coated with platinum using a sputter (Model: K575X, UK) for a duration of 50 s.

2.3.3 X-ray diffraction (XRD)

The dispersion state of the nanoparticles in each epoxy nanocomposite sample was analyzed using the XRD technique. XRD testing was performed using Rigaku SmartLab (2), MiniFlex 600 (Rigaku Corporation, Japan) at 25°C, 40 kV, and 30 mA. The samples (20 mm × 20 mm × 3 mm) were scanned from 2θ = 5° to 60°.

2.3.4 Thermogravimetric analysis

Thermogravimetric analysis (TGA Mettler Toledo, Malaysia) serves to ascertain the temperature at which thermal degradation occurs, denoted as T d. A sample mass of 10 mg was employed during this investigation. The sample holder is constructed from alumina and ceramics, possessing a volume of 70 μL. The experimental procedure is executed by directing 50 mL of N2 gas through the apparatus while maintaining a temperature increment of 10°C/min. The temperature was maintained within the range of 25°C.

2.4 Mechanical testing

Tensile, flexural, and impact strength, along with Rockwell hardness, were measured for the mechanical properties of the nanocomposites. Every test was conducted on five samples, and the standard deviation and average value were calculated.

2.4.1 Tensile test

The tensile testing of hybrid nanocomposites was conducted by the ASTM D638–10 standard [27] utilizing a Universal Testing Machine (UTM) INSTRON 3366 (Instron, USA) under ambient temperature conditions. The dimensions of the specimens were maintained at (150 mm × 25 mm × 3.0 mm), adhering to the specified standards. During the execution of the tensile test, the crosshead velocity was set at 2.0 mm/min.

2.4.2 Flexural test

Samples of hybrid nanocomposites were tested on an INSTRON 3366 (Instron, USA) using a three-point loading method by ASTM D 790 standard [28]. According to the standard, the specimen’s dimensions were (127 mm × 12.7 mm × 3.0 mm). During the flexural test, the span length was 50 mm, and the crosshead velocity was 12 mm/min. A test was run to determine the modulus of elasticity.

2.4.3 Rockwell hardness test

To measure the hardness of the hybrid nanocomposites, the Rockwell F hardness test was used on a digital hardness tester. The testing samples are 25 mm × 25 mm in accordance with ASTM D 785 [29]. A 1/16-inch-diameter steel ball was employed for 5 s at 490 N.

2.4.4 Impact test

The amount of energy absorbed prior to the rupture of the hybrid nanocomposites was measured using the Charpy test. Impact strength was computed using the device (Gunt Hamberg, Germany). Polymer nanocomposites were tested for impact strength using the ASTM D256 standard [30]. The samples were notched prior to the test and had dimensions of 65 mm × 15 mm × 3 mm.

3 Results and discussion

3.1 Chemical analysis

The FTIR spectral analysis was employed to identify the functional groups present within the hybrid composite and to explain the interactions among GNPs, CNF, and green epoxy molecules, as illustrated in Figure 2. The FTIR spectra reveal absorption peaks corresponding to both the pure green epoxy polymer, GNP, and CNF. The FTIR spectra of the pure polymer exhibit O–H stretching vibrations occurring in the range of 3,000–3,600 cm−1, indicating the presence of hydroxyl groups as evidenced by the FTIR data, which contributes to the existence of a free hydroxyl group (moisture).

The spectral peaks observed at 2,916 and 2,848 cm−1 are associated with the valence vibrations of the –CH bonds within the epoxy ring and the stretching vibrations of the –CH2 groups present in aromatic rings, respectively, which are categorized under alkanes, as the characteristic range for this group spans from 3,000 to 2,840 cm−1, as depicted in Figure 3. The symmetrical stretching vibrations of the –CH3 functional group are discerned at the peak near 2,868 cm−1. The infrared spectra of pure epoxy demonstrate distinct peaks at 1,608, 1,508, and 1,454 cm−1, which correspond to the C–C stretching vibrations of aromatic rings. The peak observed at 1,237 cm−1 is indicative of the C–O stretching vibrations characteristic of alkyl aryl ethers. The pronounced vibrational frequencies identified at 1,107 and 1,180 cm−1 are ascribed to the robust C–O stretching associated with tertiary alcohols [31]. The spectral peaks observed at 3,445 cm−1 are indicative of the stretching vibrations associated with N–H functional groups. With the incremental loading of GNPs and CNF, the peaks corresponding to NH and OH groups (which are overlapping) exhibited a shift toward higher wavenumbers, concurrently with an increase in the peak intensities of hydrogen-bonded carbonyl groups. This visible peak can be attributed to the presence of hydroxyl and carbonyl functional groups located at the periphery of the GNP [32]. The spectrum analysis revealed that the functional groups present within the green epoxy composites exert an influence on the remaining nanocomposites, as evidenced by the absence of newly formed peaks within the nanocomposites [33]. The significant peak detected at approximately 1,500 cm−1 is likely a consequence of the incorporation of carboxylic groups onto the primary alcoholic groups present at the surface of CNF, which are consistently observed across all epoxy nanocomposites. This observation substantiates the effective incorporation of these components into the green epoxy matrix [34]. While observing FTIR spectra closely, it can be seen that all the peak values were nearly identical. This implies that there was no new chemical bonding between the polymer and loadings [35].

FTIR spectra of different neat and CNF/GNP loadings.

3.2 Morphological analysis

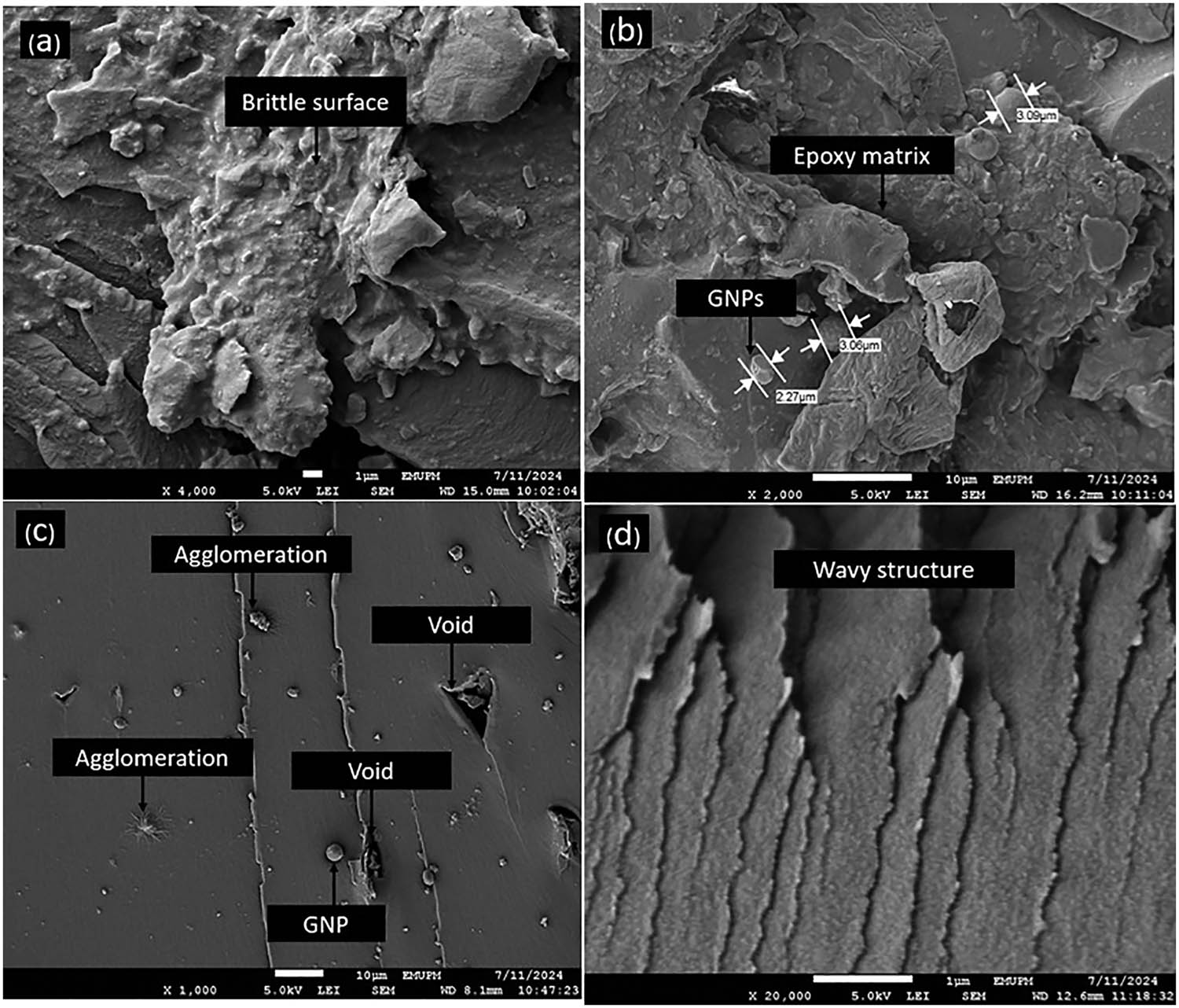

The micrographs of fractured surfaces of hybrid nanocomposites obtained by FE-SEM [36] are displayed in Figure 4. The neat epoxy image is displayed in Figure 4a, whereas the remaining micrographs (Figure 4(b)–(d)) depict the hybrid nanocomposite materials with varying loadings of CNF/GNP. The morphology of the fractured surface in Figure 4(a) demonstrated the neat epoxy composite’s brittle traits. This was due to the material’s weak resistance to crack induction and transmission under load, which resulted in low fracture toughness [37]. When 0.1 wt% CNF and 0.1 wt% GNP were loaded as the hybrid nanofillers, there was no restacking of GNP or agglomeration of CNF in the micrographs of the green epoxy composites. Consequently, void forms were eliminated since the evenly distributed CNF restricts the stacking of GNP (Figure 4(b)). An increase in CNF loads also increases the interconnectivity of nanofillers in the matrix. This can be due to the process by which loading quantity modifies the connection of the nanoparticles, leading to improved mechanical characteristics. The fracture surface of 0.1 wt% cracks took additional complicated paths on the well-dispersed fillers on the composites [38]. Thus, no river line marking was perceived, which makes the surface coarser. Hence, the loading of CNF impacts the dispersing ability of GNP into the green epoxy polymer matrix, which has been justified by the synergistic effect of CNF and GNP.

FE-SEM images depicting the fractured surfaces of both neat and nanocomposite materials resulting from tensile testing at varying loadings of GNP/CNF: (a) the neat epoxy composite, (b) a composition containing 0.1 wt% CNF/GNP, (c) a composition with 0.25 wt% CNF/GNP, and (d) a composition exhibiting 0.5 wt% CNF/GNP.

The micrographs of the hybrid green epoxy sample reinforced with 0.25 and 0.5 wt% CNF/GNP demonstrate that GNP restacks into the epoxy polymer matrix due to van der Waals forces, which are caused by the plane-to-plane contact of adjacent GNP [39] (voids are indicated by the arrow in Figure 4(c)). This could be because the use of 0.25 and 0.5% GNP as a reinforcing agent with the same quantity of CNF loading is high. Therefore, the micrographs of both the loadings of green epoxy composites show the formation of agglomerates of CNF and GNP, resulting in stress concentration [40]. These agglomerations generate voids and cavities between the GNP and the green epoxy polymer matrix as well as limit the flow of matrix into the agglomerated GNP, which leads to the formation of waves and other deformations (Figure 4(d)). Poor mechanical and thermal qualities are the outcome of the filler’s poor adherence and compatibility with the matrix at high loadings.

3.3 Structural analysis

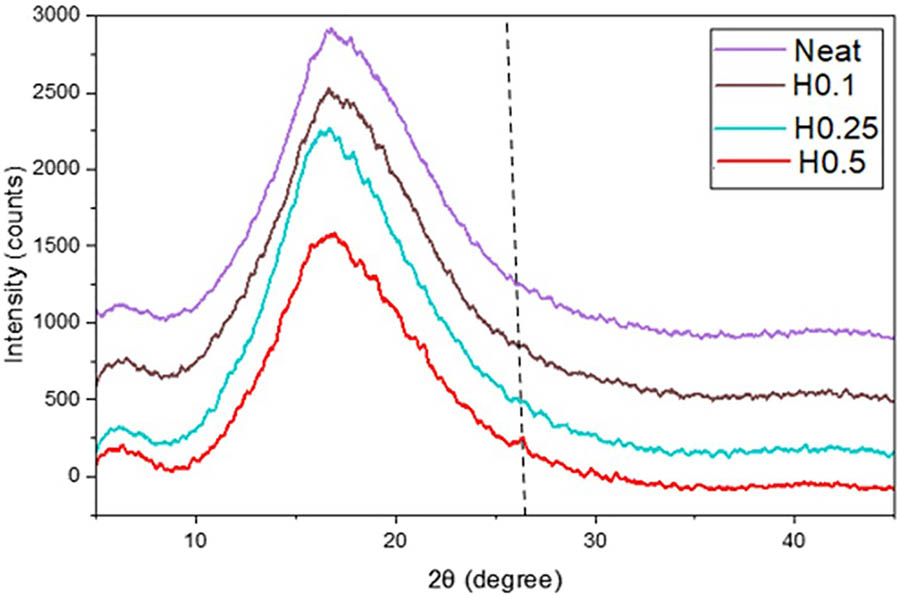

XRD was used to characterize the amorphous structures of neat and GNP/CNF hybrid nanocomposites. The van der Waals forces of contact between the layers are weakened by the sonication of GNP and CNF, which permits green epoxy molecules to intercalate. Similarly, nanoparticles with an intense tendency to aggregate in epoxy were intercalated with the aid of sonication and magnetic stirring [41]. It is assumed that in nanocomposites, the extremely thin nature of GNP allows them to easily slide and move within the larger spaces between the epoxy polymer chains, essentially “filling in” the gaps due to their small thickness compared to the overall epoxy matrix structure [42]. Figure 5 shows an XRD graph for a neat sample and varying loadings of GNP/CNF-reinforced composites. There is no evident diffraction of GNP seen in the figure in the nanocomposite at GNP contents of 0.1 and 0.25 wt%, which is believed to be associated with a small amount of consistently dispersed GNP embedded in epoxy matrices [43]. A small peak positioned at 26.3° can be observed on the XRD pattern of 0.5 wt% CNF/GNP nanocomposites when the GNP content is 0.5 wt%.

XRD patterns of neat and GNP/CNF hybrid nanocomposites.

Figure 5 also shows that during sonication, the nanosheets in the green epoxy matrix separated. Two broader peaks with lower intensities were visible in the nanocomposite results. The two nanoparticle interactions with epoxy molecules, which permit the molecules to migrate between the layers, are responsible for these peaks. The two unique peaks can be explained by the presence of individual nanoparticles in different places across the system, while lower peak intensities indicate a major disruption in the nanoparticle arrangements. As a result, XRD data results indicate that each nanoparticle is sufficiently dispersed throughout the epoxy system. The vertical dashed line near 2θ ≈ 26.5° indicates the (002) plane of graphene. The calculated interlayer spacing (d₀₀₂) is approximately 0.336 nm, which is typical for few-layer or graphitic structures.

As CNF/GNP content increases (from H0.1 to H0.5), the peak intensity decreases and broadens and shows disruption in crystalline order, lower stacking regularity of graphene layers, and better dispersion or exfoliation of graphene in the epoxy matrix. All nanocomposites XRD graphs show the relative intensity of wider peaks that indicate how the matching nanoparticles are distributed throughout the epoxy system [33].

3.4 Thermogravimetric analysis

It is apparent that the homogeneous dispersion of nanoparticles in hybrid nanocomposites and the quality of interface interactions between nanoparticles, along with the matrix, determine the thermal and mechanical properties of polymer composites. However, in the hybrid green epoxy nanocomposites, this was not the case, as shown in Figure 6. In the previous published research by Yusuf et al. [44], the thermal degradation temperature (T d) of GNP-reinforced green epoxy nanocomposites was increased as compared to the neat sample. However, the results were not the same in the case of CNF/GNP hybrid green epoxy nanocomposites. A major possible reason is the addition of CNF. CNF caused the agglomeration of CNF, which led to limited compatibility of GNP and CNF particles in green epoxy. Due to the stronger links between the clumping nanoparticles and the green epoxy resin, particle-to-particle interactions become high. As a result, molecular mobility is not restricted, which lowers the decomposition temperature [38].

TGA curves for neat and nanocomposites with varying CNF/GNP loadings.

While neat epoxy composites were stable up to 334°C, hybrid green nanocomposites with 0.1 wt% CNF/GNP filler loading exhibit a lower temperature of 322°C and a decreasing trend with increasing filler loading (Figure 5). The neat epoxy composite’s increased thermal stability can be attributed to the green epoxy resin’s increased cross-linking [45]. However, out of three loaded samples, a sizable amount of thermal stability improvement occurred at 0.1 wt% CNF/GNP compared to different loadings that were caused by the evenly distributed GNP. Adding CNF along with GNP, which showed a decreasing trend for the degradation temperature, is because of the CNF’s susceptibility to trapping moisture, which can accelerate thermal degradation and reduce the composite’s thermal stability [46]. Overall, it can be concluded that the decrease in the thermal properties at 0.1, 0.25, and 0.5 wt% CNF/GNP loading, in contrast to the neat sample, may be caused by the addition of CNF [47].

The primary reasons for the decrease in thermal stability are the susceptibility of CNF to trap moisture. This moisture can accelerate thermal degradation, leading to a reduction in the overall thermal stability of the composite [48]. The presence of moisture can create pathways for thermal degradation to occur at lower temperatures, which negatively impacts the thermal performance of the material. The higher loading levels of CNF and GNP can lead to non-uniform dispersion and agglomeration within the composite. This agglomeration can create voids and weak points in the material, which may facilitate thermal degradation. As the filler loading increases, the effectiveness of the reinforcement diminishes, resulting in a decrease in thermal stability. While the neat epoxy composite exhibits increased thermal stability due to enhanced cross-linking, the addition of CNF and GNP at certain loading levels can disrupt this cross-linking network. The study explores that the hybrid green nanocomposites with 0.1 wt% CNF/GNP showed a lower thermal degradation temperature compared to neat epoxy, suggesting that the addition of these fillers may interfere with the optimal cross-linking required for maintaining thermal stability. As the loading of CNF/GNP increases, there is a corresponding decrease in thermal properties. Specifically, the thermal degradation temperature (T d) of the composites decreases with higher filler loading, which suggests that the composite’s ability to withstand heat diminishes as more filler is added [49].

3.5 Mechanical testing

The hybrid nanocomposite’s tensile strength was influenced by a number of variables, including the filler’s form, availability of functional groups, loading in the matrix, state of dispersion, aspect ratio, and interaction with the matrix [50]. A key component in the fabrication of polymer composites was the filler’s homogeneous dispersion (GNP and CNF). The characteristics of the green nanocomposite were negatively impacted by the high loading of GNP and CNF. To prevent agglomeration and the formation of GNP and CNF lumps, which were the cause for the decline of the tensile strength, an effective dispersion state of the fillers in epoxy was required. The load transfer capability between the fillers and the polymer matrix is reduced because of these lumps acting as stress concentration spots, which also limit and diminish the interfacial bonding of GNP/CNF and epoxy [51].

Figure 7(a) shows the behavior of CNF/GNP green epoxy hybrid nanocomposites and neat green epoxy. At 0.1 wt%, the maximum tensile strength of 81 MPa was observed. This is because the filler’s loading of 0.1 wt% is very small and does not exceed the percolation threshold, indicating no excess loading. As a mechanical support inside the polymer, CNF offers a linked cellulosic network. The presence of amorphous domains along nanofibrils and the high aspect ratio of CNF contributed to its flexibility in forming the network [32].

Mechanical testing of different CNF/GNP loadings: (a) tensile test, (b) flexural test, (c) hardness test, and (d) impact test.

When compared to the neat sample of 62 MPa, tensile strength improved to 23.46% at 0.1 wt% CNF addition. As the loading increased to 0.25 and 0.5 wt%, the value decreased from 35 to 25 MPa. A strong filler–epoxy interaction can efficiently produce fibrillar interphase areas. There might be a higher volume fraction of fibrils because of improved stress in the interphase area as compared to clean epoxy, which would improve the mechanical properties [52].

As fillers were loaded above 0.1 wt% loadings in the matrix, the tensile strength was further reduced; this was most likely due to the potential for accumulation to occur. Agglomerated areas and fillers' hydrophilic nature would operate as stress concentration points, causing failure or early break and lowering tensile strength [53].

Flexural strength was initially increased by the loading of GNP/CNF from 141 to 215 MPa in the matrix, but when the loading of GNP/CNF exceeded 0.1 wt%, a sharp decrement in flexural strength was recorded at 0.25 and 0.5 wt% from 70 to 60 MPa, as shown in Figure 7(b). The interphase that forms between the fiber and the matrix, which is anticipated to be stiffer than the epoxy, is responsible for the increase in flexural strength. This results from the uniform dispersion of hard GNP, which stiffens it [54]. At the same time, CNF also acted as an effective hardening mechanism, acting as bridges that increase the energy required for crack propagation [55]. However, a further increase in GNP/CNF loading led to a sharp reduction in flexural properties. It was due to the agglomeration of GNP/CNF in the hybrid composite. These clusters may serve as stress concentrators, hastening the propagation of interface-generated faults. These flaws may enlarge beyond the threshold crack size, leading to the failure of hybrid green nanocomposites [56].

It was significant to note that the reduction in strength properties relied on the hybrid CNF/GNP composition, in which the higher the GNP amount, the lower the strength [57,58]. Due to this reason, the reduction in flexural properties was observed. The large surface area and stiffness of GNP have been linked to a predicted decrease in strength, particularly at higher loads, which increases the stiffness in the sample [59]. Another possibility is that GNP aggregation would serve as a steric barrier, obstructing the flow of the polymer into them and causing gaps and holes to emerge between the GNP and epoxy [60]. Hence, it can be concluded that, due to the significant void content and nonuniform dispersion of GNP/CNF, flexural characteristics decreased as the GNP loading increased. When force was applied, the densely packed layer of GNP generated enhanced internal delamination, resulting in low flexural strength [61].

The hardness increased as GNP/CNF was loaded into the matrix, as shown in the hardness of the neat sample was noted as 12.6, which increased to 22.4 when 0.1 wt% of CNF was loaded, and approximately 77% of the total increment was recorded. The maximum hardness value of 0.1 wt% loading of GNP/CNF was recorded because of uniform dispersion and increased surface area of GNP/CNF in the matrix (Figure 7(c)). Proper distribution of fibrils in the matrix produces this effect, which is due to stronger interfacial bonds between the CNF and polymer matrix, which tend to decrease void contents [62]. Additionally, the toughening mechanisms that lead to the gain in hardness are induced by the presence of GNP in the epoxy matrix. GNP functions as a hard nanofiller, which is evenly dispersed throughout the epoxy matrix, giving the nanocomposite materials their excellent hardness and favorably affecting other mechanical properties as well [63].

Nevertheless, as the loading is further increased, from 0.25 to 0.5 wt% of GNP/CNF, a decrease in hardness is noticed. Poor dispersion is the main cause of the hardness loss, which causes voids and porosity to form within the nanocomposite, which in turn causes a site of stress concentration and overlapped GNP slippage [64]. The addition of CNF lowers the mechanical properties because the intrinsic van der Waals forces between the polymer matrix and CNF are weaker, which lowers the hardness of the composite overall [65].

The impact strength of the composite material is characterized by the polymer’s capacity to absorb energy when subjected to fracture propagation and dynamic impact loading within the matrix [66]. The impact strength value was lower for the neat sample than for the neat epoxy composites because the neat sample was brittle (Figure 7(d)). When GNP/CNF was added, the impact strength of nanocomposites increased, and the recorded impact strength was maximum at 0.1% GNP/CNF loading. The 0.1 wt% loading of GNP/CNF produced the highest impact strength value at 8 J, which was 35.5% greater than the neat sample. The uniform distribution of GNP/CNF throughout the matrix was identified as the cause of the impact test’s high value. An important factor in raising the nanocomposite’s fracture toughness is the interfacial contact. The nanocomposite’s fracture toughness is further enhanced by the large surface [67]. Rapid fracture propagation starts when an impact occurs on a composite material. When the CNF/GNP and epoxy matrix have significant interfacial contacts, CNF in the composite absorbs impact energy and prevents fracture from spreading [38]. On the other hand, if the loading exceeds 0.1 wt% GNP/CNF, the matrix will not be distributed evenly. A larger weight percentage of GNP is linked to a decrease in fracture toughness due to the non-uniform dispersion of CNF/GNP in the matrix [68]. In a nutshell, the mechanical properties of nanocomposites are not exclusively dictated by the weight proportion of GNP/CNF. The dispersion technique, dispersant use, and functionalization can be further influential factors if applied. Utilizing an organic solvent is a vital factor in determining the improvement in mechanical properties.

4 Conclusions

This study examines the effects of low loading of CNF and GNP reinforcement within hybrid green epoxy nanocomposites, wherein the green epoxy resin comprises 28% carbon content sourced from biomass. The significant peak identified in the FTIR spectra at approximately 1,500 cm−1 may be ascribed to the effective incorporation into the green epoxy matrix. Various loading profiles were observed by TGA. The thermal degradation temperature (T d) of the CNF/GNP curve with 0.1 wt% loading displayed a slight increase toward elevated temperatures, suggesting that the lower loading of CNF/GNP conferred enhanced thermal stability. An improvement in mechanical properties was observed at the 0.1 wt% CNF/GNP addition in comparison to the unmodified green epoxy. An increase in mechanical characteristics was observed at the 0.1 wt% CNF/GNP addition relative to the standard green epoxy sample. Conversely, elevated loadings of CNF/GNP resulted in a subsequent reduction in the measured values, a phenomenon corroborated by FE-SEM analysis and attributed to the presence of non-uniform dispersion, void formation, and the agglomeration of CNF/GNP. The specimen exhibiting the maximum tensile strength, which surpassed the control sample by 77% and demonstrated a 23.46% enhancement in hardness, was incorporated with 0.1 wt% CNF/GNP.

While this investigation reveals encouraging advancements in the domain of hybrid green nanocomposites, it is imperative to acknowledge that the scope of this research was confined to a limited spectrum of CNF/GNP loadings in green epoxy and that the primary focus was on the thermal, mechanical, and morphological properties. Future research could explore the broader applicability of these findings to various green polymer matrices and emphasize areas such as electrical properties, chemical resistance, environmental implications, and the potential industrial applications of green hybrid nanocomposites.

Acknowledgments

The authors wish to thank Puncak RM Sdn. Bhd. Terengganu, Malaysia, for the research grant, under project number V26000. The authors are also thankful to Universiti Putra Malaysia (UPM) for providing Putra IPS vote number 9742900. The authors are grateful for the financial support given by The Ministry of Higher Education Malaysia (MOHE) under the Higher Institution Centre of Excellence (HICoE2.0/6369123) at the Institute of Tropical Forestry and Forest Products. The authors also thank MOHE for providing the financial support through the Malaysia International Scholarship (MIS).

-

Funding information: The authors are grateful for the financial support given by The Ministry of Higher Education Malaysia (MOHE) under the Higher Institution Centre of Excellence (HICoE2.0/6369123) with vote number 5210003 at the Institute of Tropical Forestry and Forest Products.

-

Author contributions: J. Yusuf: writing – original draft. S. M. Sapuan: supervision. U. Rashid: supervision. R. A. Ilyas: supervision. M. R. Hassan: supervision. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Li F, Zhang J, Li X. Research on supporting developing countries to achieve green development transition: Based on the perspective of renewable energy and foreign direct investment. J Clean Prod. 2022;372:133726.10.1016/j.jclepro.2022.133726Suche in Google Scholar

[2] Nurnadia A, Roshafima RA, Nur Shazwani AL, Hafizah A, Yunus WMZW, Fatehah R. Effect of silane treatment on rise straw/high density polyethylene biocomposites. J Nat Fibre Polym Compos. 2023;2:2821–3289.Suche in Google Scholar

[3] Yusuf J, Sapuan SM, Ansari MA, Siddiqui VU, Jamal T, Ilyas RA, et al. Exploring nanocellulose frontiers: A comprehensive review of its extraction, properties, and pioneering applications in the automotive and biomedical industries. Int J Biol Macromol. 2024;255:128121. 10.1016/j.ijbiomac.2023.128121.Suche in Google Scholar PubMed

[4] F Norrrahim MN, S M Shakrin NN, A Shukor MF, Shukor NN, S A Junaidi NS, Knight VF, et al. Advancements in functionalized nanocellulose and its composites for biomedical applications. J Nat Fibre Polym Compos. 2023;2:2821–3289.10.1201/9781003400998-20Suche in Google Scholar

[5] Al-Maharma AY, Al-Huniti N. Critical review of the parameters affecting the effectiveness of moisture absorption treatments used for natural composites. J Compos Sci. 2019;3:27.10.3390/jcs3010027Suche in Google Scholar

[6] Mohammed M, Jawad AJM, Mohammed AM, Oleiwi JK, Adam T, Osman AF, et al. Challenges and advancement in water absorption of natural fiber-reinforced polymer composites. Polym Test. 2023;124:108083.10.1016/j.polymertesting.2023.108083Suche in Google Scholar

[7] Jagadeesh P, Puttegowda M, Boonyasopon P, Rangappa SM, Khan A, Siengchin S. Recent developments and challenges in natural fiber composites: A review. Polym Compos. 2022;43:2545–61.10.1002/pc.26619Suche in Google Scholar

[8] Prem Kumar R, Muthukrishnan M, Felix Sahayaraj A. Effect of hybridization on natural fiber reinforced polymer composite materials–A review. Polym Compos. 2023;44:4459–79.10.1002/pc.27489Suche in Google Scholar

[9] Trache D, Tarchoun AF, Abdelaziz A, Bessa W, Hussin MH, Brosse N, et al. Cellulose nanofibrils–graphene hybrids: Recent advances in fabrication, properties, and applications. Nanoscale. 2022;14:12515–46. 10.1039/D2NR01967A.Suche in Google Scholar

[10] Brakat A, Zhu H. Nanocellulose-graphene hybrids: Advanced functional materials as multifunctional sensing platform. Nano-Micro Lett. 2021;13:94. 10.1007/s40820-021-00627-1.Suche in Google Scholar PubMed PubMed Central

[11] Samantara AK, Tripathy RK, Behera JN. Hybrid nanocomposites based on graphene and gold nanoparticles: From preparation to applications. Singapore: Springer; 2021. p. 197–211. 10.1007/978-981-33-4988-9_7.Suche in Google Scholar

[12] Mohammadsalih ZG, Inkson BJ, Chen B. The effect of dispersion condition on the structure and properties of polystyrene/graphene oxide nanocomposites. Polym Compos. 2021;42:320–8. 10.1002/pc.25827.Suche in Google Scholar

[13] Liu D, Dong Y, Liu Y, Ma N, Sui G. Cellulose nanowhisker (CNW)/graphene nanoplatelet (GN) composite films with simultaneously enhanced thermal, electrical and mechanical properties. Front Mater. 2019;6:1–11. 10.3389/fmats.2019.00235.Suche in Google Scholar

[14] Rajhi AA. Mechanical characterization of hybrid nano-filled glass/epoxy composites. Polymers (Basel). 2022;14:4852. 10.3390/polym14224852.Suche in Google Scholar PubMed PubMed Central

[15] Dilip Kumar K, Shantharaja M, Kiran MD, Rajesh M, Kumar N, Lenin H. Tribological characterization of epoxy hybrid composites reinforced with Al2O3 nanofiller. Adv Mater Sci Eng. 2023;2023:8196933. 10.1155/2023/8196933.Suche in Google Scholar

[16] Canché-Escamilla G, Duarte-Aranda S, Toledano M. Synthesis and characterization of hybrid silica/PMMA nanoparticles and their use as filler in dental composites. Mater Sci Eng C. 2014;42:161–7. 10.1016/j.msec.2014.05.016.Suche in Google Scholar PubMed

[17] Wang F, Drzal LT. The use of cellulose nanofibrils to enhance the mechanical properties of graphene nanoplatelets papers with high electrical conductivity. Ind Crop Prod. 2018;124:519–29. 10.1016/j.indcrop.2018.08.019.Suche in Google Scholar

[18] El Miri N, El Achaby M, Fihri A, Larzek M, Zahouily M, Abdelouahdi K, et al. Synergistic effect of cellulose nanocrystals/graphene oxide nanosheets as functional hybrid nanofiller for enhancing properties of PVA nanocomposites. Carbohydr Polym. 2016;137:239–48. 10.1016/j.carbpol.2015.10.072.Suche in Google Scholar PubMed

[19] Neves RM, Ornaghi HL, Zattera AJ, Amico SC. Recent studies on modified cellulose/nanocellulose epoxy composites: A systematic review. Carbohydr Polym. 2021;255:117366. 10.1016/j.carbpol.2020.117366.Suche in Google Scholar PubMed

[20] Razzak A, Mannai F, Khiari R, Moussaoui Y, Belgacem MN. Cellulose fibre from Schinus molle and its characterization. J Renew Mater. 2022;10:2593–606. 10.32604/jrm.2022.021706.Suche in Google Scholar

[21] Zainudin MZ, Mansor MR, Ali MB, Jameel Y, Sapuan SM, Basori. Effect of varying fibre loadings on the impact performance of kenaf and coir effect of varying fibre loadings on the impact performance of kenaf and coir reinforced bioepoxy composites. J Nat Fibre Polym Compos. 2023;2:2821–3289.Suche in Google Scholar

[22] Zhang Y, Liu X, Wan M, Zhu Y, Zhang K. Recent development of functional bio-based epoxy resins. Molecules. 2024;29:4428. 10.3390/molecules29184428.Suche in Google Scholar PubMed PubMed Central

[23] Borah N, Karak N. Green composites of bio-based epoxy and waste tea fiber as environmentally friendly structural materials. J Macromol Sci Part A. 2023;60:217–9.10.1080/10601325.2023.2177171Suche in Google Scholar

[24] Kumar B, Adil S, Kim J. Bio-based vanillyl alcohol epoxy thermoset with high mechanical properties and its applications for high-performance natural fiber-reinforced composites. Res Sq. 2023;1:3132839.10.21203/rs.3.rs-3132839/v1Suche in Google Scholar

[25] Zindani D, Kumar S, Maity SR, Bhowmik S. Mechanical characterization of bio-epoxy green composites derived from sodium bicarbonate treated Punica granatum short fiber agro-waste. J Polym Environ. 2021;29:143–55. 10.1007/s10924-020-01868-8.Suche in Google Scholar

[26] Afolabi OA, Ndou N. Synergy of hybrid fillers for emerging composite and nanocomposite materials—A review. Polymers (Basel). 2024;16:1907.10.3390/polym16131907Suche in Google Scholar PubMed PubMed Central

[27] Junaedi H, Albahkali E, Baig M, Dawood A, Almajid A. Ductile to brittle transition of short carbon fiber-reinforced polypropylene composites. Adv Polym Technol. 2020;2020:1–10. 10.1155/2020/6714097.Suche in Google Scholar

[28] Saharudin MS, Hasbi S, Zulkifli A, Zailani NF. The processing of epoxy/1 wt%-graphene nanocomposites: Effects of ethanol on flexural properties. Int J Innov Technol Explor Eng. 2019;9:5440–4. 10.35940/ijitee.A8105.119119.Suche in Google Scholar

[29] Talib AAA, Jumahat A, Jawaid M, Sapiai N, Leao AL. Effect of wear conditions, parameters and sliding motions on tribological characteristics of basalt and glass fibre reinforced epoxy composites. Materials (Basel). 2021;14:1–18. 10.3390/ma14030701.Suche in Google Scholar PubMed PubMed Central

[30] Vijaya Ramnath B, Rajesh S, Elanchezhian C, Santosh Shankar A, Pithchai Pandian S, Vickneshwaran S, et al. Investigation on mechanical behaviour of twisted natural fiber hybrid composite fabricated by vacuum assisted compression molding technique. Fibers Polym. 2016;17:80–7. 10.1007/s12221-016-5276-7.Suche in Google Scholar

[31] Zaccone A. Thermal properties. Polymers (Basel). 2023;16:213–20. 10.1007/978-3-031-24706-4_6.Suche in Google Scholar

[32] Amri MR, Yasin FM, Abdullah LC, Al-Edrus SSO, Mohamad SF. Ternary nanocomposite system composing of graphene nanoplatelet, cellulose nanofiber and jatropha oil based waterborne polyurethane: Characterizations, mechanical, thermal properties and conductivity. Polymers (Basel). 2021;13:1–17. 10.3390/polym13213740.Suche in Google Scholar PubMed PubMed Central

[33] Mohammed Z, Tcherbi-Narteh A, Jeelani S. Effect of graphene nanoplatelets and montmorillonite nanoclay on mechanical and thermal properties of polymer nanocomposites and carbon fiber reinforced composites. SN Appl Sci. 2020;2:1959. 10.1007/s42452-020-03780-1.Suche in Google Scholar

[34] Oun AA, Rhim JW. Characterization of nanocelluloses isolated from Ushar (Calotropis procera) seed fiber: Effect of isolation method. Mater Lett. 2016;168:146–50. 10.1016/j.matlet.2016.01.052.Suche in Google Scholar

[35] Nuruddin M, Hosur M, Gupta R, Hosur G, Tcherbi-Narteh A, Jeelani S. Cellulose nanofibers-graphene nanoplatelets hybrids nanofillers as high-performance multifunctional reinforcements in epoxy composites. Polym Polym Compos. 2017;25:273–84. 10.1177/096739111702500404.Suche in Google Scholar

[36] Yadav PS, Purohit R, Namdev A. Physical and mechanical properties of hybrid composites using Kevlar fibre and nano-SiO2. Adv Mater Process Technol. 2022;8:2057–69.10.1080/2374068X.2022.2034312Suche in Google Scholar

[37] Zakaria MR, Abdul Kudus MH, Akil HM, Zamri MH. Improvement of fracture toughness in epoxy nanocomposites through chemical hybridization of carbon nanotubes and alumina. Materials (Basel). 2017;10:301. 10.3390/ma10030301.Suche in Google Scholar PubMed PubMed Central

[38] Abdul Khalil HPS, Fizree HM, Bhat AH, Jawaid M, Abdullah CK. Development and characterization of epoxy nanocomposites based on nano-structured oil palm ash. Compos Part B Eng. 2013;53:324–33. 10.1016/j.compositesb.2013.04.013.Suche in Google Scholar

[39] Li W, Dichiara A, Bai J. Carbon nanotube–graphene nanoplatelet hybrids as high-performance multifunctional reinforcements in epoxy composites. Compos Sci Technol. 2013;74:221–7. 10.1016/j.compscitech.2012.11.015.Suche in Google Scholar

[40] Safdari M, Al-Haik MS. A review on polymeric nanocomposites. Carbon-based polymer nanocomposites for environmental and energy applications. Amsterdam, Netherlands: Elsevier; 2018. p. 113–46. 10.1016/B978-0-12-813574-7.00005-8.Suche in Google Scholar

[41] Zainuddin S, Hosur MV, Zhou Y, Narteh AT, Kumar A, Jeelani S. Experimental and numerical investigations on flexural and thermal properties of nanoclay–epoxy nanocomposites. Mater Sci Eng A. 2010;527:7920–6. 10.1016/j.msea.2010.08.078.Suche in Google Scholar

[42] Zuo L, Fan W, Zhang Y, Zhang L, Gao W, Huang Y, et al. Graphene/montmorillonite hybrid synergistically reinforced polyimide composite aerogels with enhanced flame-retardant performance. Compos Sci Technol. 2017;139:57–63. 10.1016/j.compscitech.2016.12.008.Suche in Google Scholar

[43] Son Y-R, Park S-J. Green preparation and characterization of graphene oxide/carbon nanotubes-loaded carboxymethyl cellulose nanocomposites. Sci Rep. 2018;8:17601. 10.1038/s41598-018-35984-2.Suche in Google Scholar PubMed PubMed Central

[44] Yusuf J, Sapuan SM, Rashid U, Ilyas RA, Hassan MR. Thermal, mechanical, thermo-mechanical and morphological properties of graphene nanoplatelets reinforced green epoxy nanocomposites. Polym Compos. 2024;45:1998–2011. 10.1002/pc.27900.Suche in Google Scholar

[45] He H, Li K, Wang J, Sun G, Li Y, Wang J. Study on thermal and mechanical properties of nano-calcium carbonate/epoxy composites. Mater Des. 2011;32:4521–7. 10.1016/j.matdes.2011.03.026.Suche in Google Scholar

[46] Poveda RL, Gupta N, Poveda RL, Gupta N. Environmental effects on CNF/polymer composites. Carbon nanofiber reinforced polymer composites. Cham, Switzerland: Springer Cham; 2016. p. 43–51.10.1007/978-3-319-23787-9_4Suche in Google Scholar

[47] Pandurangan MT, Kanny K. Study of curing characteristics of cellulose nanofiber-filled epoxy nanocomposites. Catalysts. 2020;10:831. 10.3390/catal10080831.Suche in Google Scholar

[48] Mianehrow H, Li L, Olsén P, Berglund L. Moisture effects on mechanical behavior of CNF-RGO nanocomposites showing electrical conductivity. Compos Part A Appl Sci Manuf. 2022;163:107235. 10.1016/j.compositesa.2022.107235.Suche in Google Scholar

[49] Jasmee S, Omar G, Othaman SSC, Masripan NA, A, Hamid H. Interface thermal resistance and thermal conductivity of polymer composites at different types, shapes, and sizes of fillers: A review. Polym Compos. 2021;42:2629–52. 10.1002/pc.26029.Suche in Google Scholar

[50] Hashim UR, Jumahat A. Improved tensile and fracture toughness properties of graphene nanoplatelets filled epoxy polymer via solvent compounding shear milling method. Mater Res Express. 2018;6:025303. 10.1088/2053-1591/aaeaf0.Suche in Google Scholar

[51] Ghaleb ZA, Mariatti M, Ariff ZM. Graphene nanoparticle dispersion in epoxy thin film composites for electronic applications: effect on tensile, electrical and thermal properties. J Mater Sci Mater Electron. 2017;28:808–17. 10.1007/s10854-016-5594-y.Suche in Google Scholar

[52] Nair SS, Wang S, Hurley DC. Nanoscale characterization of natural fibers and their composites using contact-resonance force microscopy. Compos Part A Appl Sci Manuf. 2010;41:624–31. 10.1016/j.compositesa.2010.01.009.Suche in Google Scholar

[53] Saba N, Tahir PM, Abdan K, Ibrahim NA. Fabrication of epoxy nanocomposites from oil palm nano filler: Mechanical and morphological properties. BioResources. 2016;11:7721–36. 10.15376/biores.11.3.7721-7736.Suche in Google Scholar

[54] Srivastava AK, Gupta V, Yerramalli CS, Singh A. Flexural strength enhancement in carbon-fiber epoxy composites through graphene nano-platelets coating on fibers. Compos Part B Eng. 2019;179:107539. 10.1016/j.compositesb.2019.107539.Suche in Google Scholar

[55] Aquino Rocha JH, Farias L, do N, Siqueira TPL. Nanofibras de celulose (NFC) como reforço de matrizes cimentícias: revisão sistemática da literatura. Rev ALCONPAT. 2022;12:311–27. 10.21041/ra.v12i3.594.Suche in Google Scholar

[56] Orellana JL, Wichhart D, Kitchens CL. Mechanical and optical properties of polylactic acid films containing surfactant-modified cellulose nanocrystals. J Nanomater. 2018;2018:1–12. 10.1155/2018/7124260.Suche in Google Scholar

[57] Namdev A, Telang A, Purohit R. Synthesis and mechanical characterization of epoxy hybrid composites containing graphene nanoplatelets. Proc Inst Mech Eng Part C. 2022;236:7984–98. 10.1177/09544062221081286.Suche in Google Scholar

[58] Mohd SH, Rosdi NAM, Bakar MBA, Mohamed M, Md Akil H, Thirmirzir MZA. Cellulose nano crystal/graphene nano platelets hybrid nanofillers reinforced polylactic acid biocomposites: Mechanical and morphological properties. IOP Conf Ser Earth Environ Sci. 2022;1102:1–8. 10.1088/1755-1315/1102/1/012005.Suche in Google Scholar

[59] Mármol G, Gauss C, Fangueiro R. Potential of cellulose microfibers for PHA and PLA biopolymers reinforcement. Molecules. 2020;25:4653. 10.3390/molecules25204653.Suche in Google Scholar PubMed PubMed Central

[60] Michael FM, Khalid M, Chantara Thevy R, Raju G, Shahabuddin S, Walvekar R, et al. Graphene/nanohydroxyapatite hybrid reinforced polylactic acid nanocomposite for load-bearing applications. Polym Technol Mater. 2022;61:803–15. 10.1080/25740881.2022.2029885.Suche in Google Scholar

[61] Umer R. Manufacturing and mechanical properties of graphene coated glass fabric and epoxy composites. J Compos Sci. 2018;2:17. 10.3390/jcs2020017.Suche in Google Scholar

[62] Vijaya Ramnath B, Manickavasagam VM, Elanchezhian C, Vinodh Krishna C, Karthik S, Saravanan K. Determination of mechanical properties of intra-layer abaca-jute-glass fiber reinforced composite. Mater Des. 2014;60:643–52. 10.1016/j.matdes.2014.03.061.Suche in Google Scholar

[63] Dlouhy I, Tatarko P, Bertolla L, Chlup Z. Nano-fillers (nanotubes, nanosheets): Do they toughen brittle matrices? Procedia Struct Integr. 2019;23:431–8. 10.1016/j.prostr.2020.01.125.Suche in Google Scholar

[64] Jarosinski L, Rybak A, Gaska K, Kmita G, Porebska R, Kapusta C. Enhanced thermal conductivity of graphene nanoplatelets epoxy composites. Mater Sci Pol. 2017;35:382–9. 10.1515/msp-2017-0028.Suche in Google Scholar

[65] Ashenai Ghasemi F, Ghasemi I, Menbari S, Ayaz M, Ashori A. Optimization of mechanical properties of polypropylene/talc/graphene composites using response surface methodology. Polym Test. 2016;53:283–92. 10.1016/j.polymertesting.2016.06.012.Suche in Google Scholar

[66] Al-Maharma AY, Sendur P. Review of the main factors controlling the fracture toughness and impact strength properties of natural composites. Mater Res Express. 2018;6:022001. 10.1088/2053-1591/aaec28.Suche in Google Scholar

[67] Sarwar A, Mahboob Z, Zdero R, Bougherara H. Mechanical characterization of a new Kevlar/Flax/epoxy hybrid composite in a sandwich structure. Polym Test. 2020;90:106680. 10.1016/j.polymertesting.2020.106680.Suche in Google Scholar

[68] Ma J, Meng Q, Zaman I, Zhu S, Michelmore A, Kawashima N, et al. Development of polymer composites using modified, high-structural integrity graphene platelets. Compos Sci Technol. 2014;91:82–90. 10.1016/j.compscitech.2013.11.017.Suche in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- MHD radiative mixed convective flow of a sodium alginate-based hybrid nanofluid over a convectively heated extending sheet with Joule heating

- Experimental study of mortar incorporating nano-magnetite on engineering performance and radiation shielding

- Multicriteria-based optimization and multi-variable non-linear regression analysis of concrete containing blends of nano date palm ash and eggshell powder as cementitious materials

- A promising Ag2S/poly-2-amino-1-mercaptobenzene open-top spherical core–shell nanocomposite for optoelectronic devices: A one-pot technique

- Biogenic synthesized selenium nanoparticles combined chitosan nanoparticles controlled lung cancer growth via ROS generation and mitochondrial damage pathway

- Fabrication of PDMS nano-mold by deposition casting method

- Stimulus-responsive gradient hydrogel micro-actuators fabricated by two-photon polymerization-based 4D printing

- Physical aspects of radiative Carreau nanofluid flow with motile microorganisms movement under yield stress via oblique penetrable wedge

- Effect of polar functional groups on the hydrophobicity of carbon nanotubes-bacterial cellulose nanocomposite

- Review in green synthesis mechanisms, application, and future prospects for Garcinia mangostana L. (mangosteen)-derived nanoparticles

- Entropy generation and heat transfer in nonlinear Buoyancy–driven Darcy–Forchheimer hybrid nanofluids with activation energy

- Green synthesis of silver nanoparticles using Ginkgo biloba seed extract: Evaluation of antioxidant, anticancer, antifungal, and antibacterial activities

- A numerical analysis of heat and mass transfer in water-based hybrid nanofluid flow containing copper and alumina nanoparticles over an extending sheet

- Investigating the behaviour of electro-magneto-hydrodynamic Carreau nanofluid flow with slip effects over a stretching cylinder

- Electrospun thermoplastic polyurethane/nano-Ag-coated clear aligners for the inhibition of Streptococcus mutans and oral biofilm

- Investigation of the optoelectronic properties of a novel polypyrrole-multi-well carbon nanotubes/titanium oxide/aluminum oxide/p-silicon heterojunction

- Novel photothermal magnetic Janus membranes suitable for solar water desalination

- Green synthesis of silver nanoparticles using Ageratum conyzoides for activated carbon compositing to prepare antimicrobial cotton fabric

- Activation energy and Coriolis force impact on three-dimensional dusty nanofluid flow containing gyrotactic microorganisms: Machine learning and numerical approach

- Machine learning analysis of thermo-bioconvection in a micropolar hybrid nanofluid-filled square cavity with oxytactic microorganisms

- Research and improvement of mechanical properties of cement nanocomposites for well cementing

- Thermal and stability analysis of silver–water nanofluid flow over unsteady stretching sheet under the influence of heat generation/absorption at the boundary

- Cobalt iron oxide-infused silicone nanocomposites: Magnetoactive materials for remote actuation and sensing

- Magnesium-reinforced PMMA composite scaffolds: Synthesis, characterization, and 3D printing via stereolithography

- Bayesian inference-based physics-informed neural network for performance study of hybrid nanofluids

- Numerical simulation of non-Newtonian hybrid nanofluid flow subject to a heterogeneous/homogeneous chemical reaction over a Riga surface

- Enhancing the superhydrophobicity, UV-resistance, and antifungal properties of natural wood surfaces via in situ formation of ZnO, TiO2, and SiO2 particles

- Synthesis and electrochemical characterization of iron oxide/poly(2-methylaniline) nanohybrids for supercapacitor application

- Impacts of double stratification on thermally radiative third-grade nanofluid flow on elongating cylinder with homogeneous/heterogeneous reactions by implementing machine learning approach

- Synthesis of Cu4O3 nanoparticles using pumpkin seed extract: Optimization, antimicrobial, and cytotoxicity studies

- Cationic charge influence on the magnetic response of the Fe3O4–[Me2+ 1−y Me3+ y (OH2)] y+(Co3 2−) y/2·mH2O hydrotalcite system

- Pressure sensing intelligent martial arts short soldier combat protection system based on conjugated polymer nanocomposite materials

- Magnetohydrodynamics heat transfer rate under inclined buoyancy force for nano and dusty fluids: Response surface optimization for the thermal transport

- Fly ash and nano-graphene enhanced stabilization of engine oil-contaminated soils

- Enhancing natural fiber-reinforced biopolymer composites with graphene nanoplatelets: Mechanical, morphological, and thermal properties

- Performance evaluation of dual-scale strengthened co-bonded single-lap joints using carbon nanotubes and Z-pins with ANN

- Computational works of blood flow with dust particles and partially ionized containing tiny particles on a moving wedge: Applications of nanotechnology

- Hybridization of biocomposites with oil palm cellulose nanofibrils/graphene nanoplatelets reinforcement in green epoxy: A study of physical, thermal, mechanical, and morphological properties

- Design and preparation of micro-nano dual-scale particle-reinforced Cu–Al–V alloy: Research on the aluminothermic reduction process

- Spectral quasi-linearization and response optimization on magnetohydrodynamic flow via stenosed artery with hybrid and ternary solid nanoparticles: Support vector machine learning

- Ferrite/curcumin hybrid nanocomposite formulation: Physicochemical characterization, anticancer activity, and apoptotic and cell cycle analyses in skin cancer cells

- Enhanced therapeutic efficacy of Tamoxifen against breast cancer using extra virgin olive oil-based nanoemulsion delivery system

- A titanium oxide- and silver-based hybrid nanofluid flow between two Riga walls that converge and diverge through a machine-learning approach

- Enhancing convective heat transfer mechanisms through the rheological analysis of Casson nanofluid flow towards a stagnation point over an electro-magnetized surface

- Intrinsic self-sensing cementitious composites with hybrid nanofillers exhibiting excellent piezoresistivity

- Research on mechanical properties and sulfate erosion resistance of nano-reinforced coal gangue based geopolymer concrete

- Impact of surface and configurational features of chemically synthesized chains of Ni nanostars on the magnetization reversal process

- Porous sponge-like AsOI/poly(2-aminobenzene-1-thiol) nanocomposite photocathode for hydrogen production from artificial and natural seawater

- Multifaceted insights into WO3 nanoparticle-coupled antibiotics to modulate resistance in enteric pathogens of Houbara bustard birds

- Synthesis of sericin-coated silver nanoparticles and their applications for the anti-bacterial finishing of cotton fabric

- Enhancing chloride resistance of freeze–thaw affected concrete through innovative nanomaterial–polymer hybrid cementitious coating

- Development and performance evaluation of green aluminium metal matrix composites reinforced with graphene nanopowder and marble dust

- Morphological, physical, thermal, and mechanical properties of carbon nanotubes reinforced arrowroot starch composites

- Influence of the graphene oxide nanosheet on tensile behavior and failure characteristics of the cement composites after high-temperature treatment

- Central composite design modeling in optimizing heat transfer rate in the dissipative and reactive dynamics of viscoplastic nanomaterials deploying Joule and heat generation aspects

- Double diffusion of nano-enhanced phase change materials in connected porous channels: A hybrid ISPH-XGBoost approach

- Synergistic impacts of Thompson–Troian slip, Stefan blowing, and nonuniform heat generation on Casson nanofluid dynamics through a porous medium

- Optimization of abrasive water jet machining parameters for basalt fiber/SiO2 nanofiller reinforced composites

- Enhancing aesthetic durability of Zisha teapots via TiO2 nanoparticle surface modification: A study on self-cleaning, antimicrobial, and mechanical properties

- Nanocellulose solution based on iron(iii) sodium tartrate complexes

- Combating multidrug-resistant infections: Gold nanoparticles–chitosan–papain-integrated dual-action nanoplatform for enhanced antibacterial activity

- Novel royal jelly-mediated green synthesis of selenium nanoparticles and their multifunctional biological activities

- Direct bandgap transition for emission in GeSn nanowires

- Synthesis of ZnO nanoparticles with different morphologies using a microwave-based method and their antimicrobial activity

- Numerical investigation of convective heat and mass transfer in a trapezoidal cavity filled with ternary hybrid nanofluid and a central obstacle

- Halloysite nanotube enhanced polyurethane nanocomposites for advanced electroinsulating applications

- Low molar mass ionic liquid’s modified carbon nanotubes and its role in PVDF crystalline stress generation

- Green synthesis of polydopamine-functionalized silver nanoparticles conjugated with Ceftazidime: in silico and experimental approach for combating antibiotic-resistant bacteria and reducing toxicity

- Evaluating the influence of graphene nano powder inclusion on mechanical, vibrational and water absorption behaviour of ramie/abaca hybrid composites

- Dynamic-behavior of Casson-type hybrid nanofluids due to a stretching sheet under the coupled impacts of boundary slip and reaction-diffusion processes

- Influence of polyvinyl alcohol on the physicochemical and self-sensing properties of nano carbon black reinforced cement mortar

- Advanced machine learning approaches for predicting compressive and flexural strength of carbon nanotube–reinforced cement composites: a comparative study and model interpretability analysis

- Review Articles

- A comprehensive review on hybrid plasmonic waveguides: Structures, applications, challenges, and future perspectives

- Nanoparticles in low-temperature preservation of biological systems of animal origin

- Fluorescent sulfur quantum dots for environmental monitoring

- Nanoscience systematic review methodology standardization

- Nanotechnology revolutionizing osteosarcoma treatment: Advances in targeted kinase inhibitors

- AFM: An important enabling technology for 2D materials and devices

- Carbon and 2D nanomaterial smart hydrogels for therapeutic applications

- Principles, applications and future prospects in photodegradation systems

- Do gold nanoparticles consistently benefit crop plants under both non-stressed and abiotic stress conditions?

- An updated overview of nanoparticle-induced cardiovascular toxicity

- Arginine as a promising amino acid for functionalized nanosystems: Innovations, challenges, and future directions

- Advancements in the use of cancer nanovaccines: Comprehensive insights with focus on lung and colon cancer

- Membrane-based biomimetic delivery systems for glioblastoma multiforme therapy

- The drug delivery systems based on nanoparticles for spinal cord injury repair

- Green synthesis, biomedical effects, and future trends of Ag/ZnO bimetallic nanoparticles: An update

- Application of magnesium and its compounds in biomaterials for nerve injury repair

- Micro/nanomotors in biomedicine: Construction and applications

- Hydrothermal synthesis of biomass-derived CQDs: Advances and applications

- Research progress in 3D bioprinting of skin: Challenges and opportunities

- Review on bio-selenium nanoparticles: Synthesis, protocols, and applications in biomedical processes

- Gold nanocrystals and nanorods functionalized with protein and polymeric ligands for environmental, energy storage, and diagnostic applications: A review

- An in-depth analysis of rotational and non-rotational piezoelectric energy harvesting beams: A comprehensive review

- Advancements in perovskite/CIGS tandem solar cells: Material synergies, device configurations, and economic viability for sustainable energy

- Deep learning in-depth analysis of crystal graph convolutional neural networks: A new era in materials discovery and its applications

- Review of recent nano TiO2 film coating methods, assessment techniques, and key problems for scaleup

- Antioxidant quantum dots for spinal cord injuries: A review on advancing neuroprotection and regeneration in neurological disorders

- Rise of polycatecholamine ultrathin films: From synthesis to smart applications

- Advancing microencapsulation strategies for bioactive compounds: Enhancing stability, bioavailability, and controlled release in food applications

- Advances in the design and manipulation of self-assembling peptide and protein nanostructures for biomedical applications

- Photocatalytic pervious concrete systems: from classic photocatalysis to luminescent photocatalysis

- Corrigendum

- Corrigendum to “Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer”

- Special Issue on Advanced Nanomaterials for Carbon Capture, Environment and Utilization for Energy Sustainability - Part III

- Efficiency optimization of quantum dot photovoltaic cell by solar thermophotovoltaic system

- Exploring the diverse nanomaterials employed in dental prosthesis and implant techniques: An overview

- Electrochemical investigation of bismuth-doped anode materials for low‑temperature solid oxide fuel cells with boosted voltage using a DC-DC voltage converter

- Synthesis of HfSe2 and CuHfSe2 crystalline materials using the chemical vapor transport method and their applications in supercapacitor energy storage devices

- Special Issue on Green Nanotechnology and Nano-materials for Environment Sustainability

- Influence of nano-silica and nano-ferrite particles on mechanical and durability of sustainable concrete: A review

- Surfaces and interfaces analysis on different carboxymethylation reaction time of anionic cellulose nanoparticles derived from oil palm biomass

- Processing and effective utilization of lignocellulosic biomass: Nanocellulose, nanolignin, and nanoxylan for wastewater treatment

- Retraction

- Retraction of “Aging assessment of silicone rubber materials under corona discharge accompanied by humidity and UV radiation”

Artikel in diesem Heft

- Research Articles

- MHD radiative mixed convective flow of a sodium alginate-based hybrid nanofluid over a convectively heated extending sheet with Joule heating

- Experimental study of mortar incorporating nano-magnetite on engineering performance and radiation shielding

- Multicriteria-based optimization and multi-variable non-linear regression analysis of concrete containing blends of nano date palm ash and eggshell powder as cementitious materials

- A promising Ag2S/poly-2-amino-1-mercaptobenzene open-top spherical core–shell nanocomposite for optoelectronic devices: A one-pot technique

- Biogenic synthesized selenium nanoparticles combined chitosan nanoparticles controlled lung cancer growth via ROS generation and mitochondrial damage pathway

- Fabrication of PDMS nano-mold by deposition casting method

- Stimulus-responsive gradient hydrogel micro-actuators fabricated by two-photon polymerization-based 4D printing

- Physical aspects of radiative Carreau nanofluid flow with motile microorganisms movement under yield stress via oblique penetrable wedge

- Effect of polar functional groups on the hydrophobicity of carbon nanotubes-bacterial cellulose nanocomposite

- Review in green synthesis mechanisms, application, and future prospects for Garcinia mangostana L. (mangosteen)-derived nanoparticles

- Entropy generation and heat transfer in nonlinear Buoyancy–driven Darcy–Forchheimer hybrid nanofluids with activation energy

- Green synthesis of silver nanoparticles using Ginkgo biloba seed extract: Evaluation of antioxidant, anticancer, antifungal, and antibacterial activities

- A numerical analysis of heat and mass transfer in water-based hybrid nanofluid flow containing copper and alumina nanoparticles over an extending sheet

- Investigating the behaviour of electro-magneto-hydrodynamic Carreau nanofluid flow with slip effects over a stretching cylinder

- Electrospun thermoplastic polyurethane/nano-Ag-coated clear aligners for the inhibition of Streptococcus mutans and oral biofilm

- Investigation of the optoelectronic properties of a novel polypyrrole-multi-well carbon nanotubes/titanium oxide/aluminum oxide/p-silicon heterojunction

- Novel photothermal magnetic Janus membranes suitable for solar water desalination

- Green synthesis of silver nanoparticles using Ageratum conyzoides for activated carbon compositing to prepare antimicrobial cotton fabric

- Activation energy and Coriolis force impact on three-dimensional dusty nanofluid flow containing gyrotactic microorganisms: Machine learning and numerical approach

- Machine learning analysis of thermo-bioconvection in a micropolar hybrid nanofluid-filled square cavity with oxytactic microorganisms

- Research and improvement of mechanical properties of cement nanocomposites for well cementing

- Thermal and stability analysis of silver–water nanofluid flow over unsteady stretching sheet under the influence of heat generation/absorption at the boundary

- Cobalt iron oxide-infused silicone nanocomposites: Magnetoactive materials for remote actuation and sensing

- Magnesium-reinforced PMMA composite scaffolds: Synthesis, characterization, and 3D printing via stereolithography

- Bayesian inference-based physics-informed neural network for performance study of hybrid nanofluids

- Numerical simulation of non-Newtonian hybrid nanofluid flow subject to a heterogeneous/homogeneous chemical reaction over a Riga surface

- Enhancing the superhydrophobicity, UV-resistance, and antifungal properties of natural wood surfaces via in situ formation of ZnO, TiO2, and SiO2 particles

- Synthesis and electrochemical characterization of iron oxide/poly(2-methylaniline) nanohybrids for supercapacitor application

- Impacts of double stratification on thermally radiative third-grade nanofluid flow on elongating cylinder with homogeneous/heterogeneous reactions by implementing machine learning approach

- Synthesis of Cu4O3 nanoparticles using pumpkin seed extract: Optimization, antimicrobial, and cytotoxicity studies

- Cationic charge influence on the magnetic response of the Fe3O4–[Me2+ 1−y Me3+ y (OH2)] y+(Co3 2−) y/2·mH2O hydrotalcite system

- Pressure sensing intelligent martial arts short soldier combat protection system based on conjugated polymer nanocomposite materials

- Magnetohydrodynamics heat transfer rate under inclined buoyancy force for nano and dusty fluids: Response surface optimization for the thermal transport

- Fly ash and nano-graphene enhanced stabilization of engine oil-contaminated soils

- Enhancing natural fiber-reinforced biopolymer composites with graphene nanoplatelets: Mechanical, morphological, and thermal properties

- Performance evaluation of dual-scale strengthened co-bonded single-lap joints using carbon nanotubes and Z-pins with ANN

- Computational works of blood flow with dust particles and partially ionized containing tiny particles on a moving wedge: Applications of nanotechnology

- Hybridization of biocomposites with oil palm cellulose nanofibrils/graphene nanoplatelets reinforcement in green epoxy: A study of physical, thermal, mechanical, and morphological properties

- Design and preparation of micro-nano dual-scale particle-reinforced Cu–Al–V alloy: Research on the aluminothermic reduction process

- Spectral quasi-linearization and response optimization on magnetohydrodynamic flow via stenosed artery with hybrid and ternary solid nanoparticles: Support vector machine learning

- Ferrite/curcumin hybrid nanocomposite formulation: Physicochemical characterization, anticancer activity, and apoptotic and cell cycle analyses in skin cancer cells

- Enhanced therapeutic efficacy of Tamoxifen against breast cancer using extra virgin olive oil-based nanoemulsion delivery system

- A titanium oxide- and silver-based hybrid nanofluid flow between two Riga walls that converge and diverge through a machine-learning approach

- Enhancing convective heat transfer mechanisms through the rheological analysis of Casson nanofluid flow towards a stagnation point over an electro-magnetized surface

- Intrinsic self-sensing cementitious composites with hybrid nanofillers exhibiting excellent piezoresistivity