Abstract

In the current scenario, a green product is designed to have a minimal impact on the environment as it is made from recycled materials. In the highly energy-intensive industry, green production has a significant influence on business sustainability. The intelligent environment around us created an unavoidable problem, because of the uncontrolled growth in waste materials like plastic and electrical trash. Both seriously endanger the environment, wildlife, and human health, trash has an impact on societal structures and financial systems in future generations. Industrial and domestic plastic wastes, which are dumped in landfills or the environment, are mostly made of polyethylene (PE) polymers. These wastes’ polymeric nature makes them difficult for microorganisms to degrade. Incorporating biological and chemical processes together is facilitated by pyrolysis and the biodegradation of alkenes to achieve the maximum biodegradation of PE plastics, as proposed in this study, to reduce plastic waste. This research outcome demonstrates that the Waste plastic recycling plant dataset is taken to show the decomposition of high-density PE plastic to simpler alkene with microbial-assisted degradation of alkene to biomass through bacterial communities. Communities of microbes from three different environments inoculating at three nutrient levels are monitored for their ability to degrade model alkenes (with several carbon atoms) within 5 days. There is Plenty of evidence indicating that the nutritional content significantly influences the rates at which hydrocarbons are broken down. These findings imply that the microorganisms required for alkene breakdown are present in a wide range of ambient microbial communities and are significantly chosen under optimized environments such as nutrient enrichment.

1 Introduction

The world is realizing that it is time to address the issue of plastic trash because it spoils the soil’s fertility. In addition, it is a hotspot for disease- and death-spreading insects of all shapes and sizes. Plastic trash is the primary threat to marine life. Plastic trash in the water can fool animals into thinking it is food [1]. To sidestep such problems, some common waste management practices, include recycling, composting, trash collection, trash burning, incineration, and sewage treatment and removal. The disease can be spread through water supply if hazardous waste is placed in unregulated places. These health problems are exacerbated by the release of excess gases into the atmosphere from poor waste management. The decomposition of waste releases greenhouse gases like methane that have a considerable impact on global warming. To counteract climate change on a worldwide scale, it is necessary for better waste management practices. Plastic trash is a major contributor to many environmental problems. Even if only a fraction of it is turned into micro- and nano-plastics, it can still harm aquatic species in rivers, lakes, and seas [2]. However trash made of plastic is burned or buried, it releases heat and carbon dioxide. Upcycling processes that convert it into higher value chemical compounds, however, can greatly increase its monetary value [3]. Plastic garbage presents huge prospects of polyethylene (PE), often spelled polythene and polyethene, which is one of the most popular polymers in the globe. The linear molecular structure of PE gives them their name as an addition polymer [4].

High-density polyethylene (HDPE) plastic is widely utilized because of its strength and versatility; it is commonly found in products such as water bottles, packaging, pipes, and plastic bags. Due to their intricate molecular structure, PE polymers are extremely difficult to break down in the environment. The plastic items are first shrunk in size using a rudimentary shredder [5]. After being shredded, the material is sent down a conveyor belt to be washed for the first time. For instance, in this rotating drum washer, heavy materials like stones, metallic materials, and glasses are separated by gravity simultaneously being cleaned by a stream of water [6]. HDPE plastics are extensively used in items like water bottles, packaging, pipes, and plastic bags due to their strength and adaptability. PE polymers are notoriously difficult to degrade in nature due to their complex molecular structure. The plastic is initially reduced in size with a crude shredder [7]. A crude shredder is powered by an electric motor that spins a rotor with attached blades in a sealed housing. It can be found in a huge array of forms and dimensions. The chamber is there and the rotor’s blades work to reduce the material to useable granules. The plastic pieces are now introduced to a miller to further reduce their size. The plastic pieces then move on to the float-sink apparatus, where the polymers are density-separated. Polymers with concentrations below 1 kg·L−1 (such as PE and PP) float, and polymers with concentrations above 1 kg·L−1 (such as PET, PS, and PVC) sink [8]. Wet processing necessitates a second round of washing for the flakes. Once the flakes have been separated using the float-sink method, they are dried using a mechanical and/or thermal dryer. The materials of wood, paper goods, old particles of rubber, and higher-melting monomers (things like PET in Polypropylene heated at 220°C) are only some of the contaminants that can be removed from plastics during the melting and extruding processes [9]. Plastics can be pyrolyzed, or decomposed thermally between 400 and 900°C, resulting in the breakdown of hydrocarbons with lengthy chains and polymers. Alkane molecules with straight confinement, like those used to make PE, can be found in crude oil mixtures. However PE is heated, and it breaks down into long-chain alkene compounds [10]. Straight-chain alkane molecules, like those found in crude oil mixes, are the building blocks of PE. PE decomposes into long-chain alkenes by heating [11]. Considering oil-degrading bacteria are prevalent in the environment, they could be used as inocula to seed consortiums for the biological degradation of polyethene plastic components and pyrolysis-treated HDPE.

Oil contamination in the environment provides a carbon source for microbial communities in a wide range of environments [12]. Bacteria are known to metabolize hydrocarbon compounds in both marine and freshwater aquatic systems, as well as in sediments. Hydrocarbon contamination in the environment contains a mixture of a broad range of compounds, including alkanes, alkenes, and aromatic hydrocarbons of varying sizes and complexities. PE plastic monomers and pyrolysis-treated PE could be biodegraded using inoculation from the environment because oil-degrading microorganisms are very prevalent in the environment [13]. The biodegradation of alkanes is well-characterized in aquatic systems and soils regarding both the rate of biodegradation and the composition of the associated microbial community [14]. Potential for improved biodegradation and application in biological recycling and upcycling of plastics may be realized through the development of enrichment cultures of oil-degrading microorganisms functioning under optimal conditions in a laboratory setting [15,16,17,18,19]. The goal of this study is to show that, under three different nutritional conditions, alkene biodegradation can occur using inoculums collected from a variety of environmental sources with varying beginning microbial communities.

The main contribution of this work is as follows:

Bacterial isolates and microbial communities can break down the long-chain alkene compounds produced during the pyrolysis of HDPE plastic wastes.

The pyrolysis process yields alkenes as water-in-oil (w/o) emulsion.

Biodegradation of oil in the kind of long-chain alkene takes place for five consecutive days according to three nutritional treatments, generating protein and carbon dioxide from microbial communities isolated from farming compost, sediment from the Caspian Sea’s bottom, and iron-rich sand.

The remaining parts of this research are organized as follows: Previous studies on plastic waste recycling and its use in chemical production are reviewed in Section 2. The third section examines the pyrolysis and biodegradation techniques used in the HDPE plastic waste recycling process. Section 4 presents the results of alkene biodegradation under three distinct nutrient regimes. Section 5 offers the final thoughts.

2 Related works

Ncube et al. [20] proposed circular economy (CE) and Green Chemistry (GC): New product development must use radical, innovative approaches that prioritize efficiency, resource conservation, and pollution prevention without sacrificing profitability. Using a wide range of research, this study attempts to sum up the critical problems with the current CE and GC paradigms along with sustainable business models and novel materials. This amalgamation considers both environmental sustainability and economic viability by prioritizing waste reduction, resource conservation, and pollution prevention. Investment, environmental education, and law are some of the challenges in ensuring the application of the principles of the CE and GC.

The behavioral shift toward the CE was hypothesized by Parajuly et al. [21]. Possibilities for behavioral measures to improve the management of electronic waste and move toward a more circular economic model were discovered through a policy study with a focus on the European Union. Implementing behavioral measures in the context of an environmentally friendly economy and electronic products without first learning about the relevant technological and economic background may backfire. The factors (such as morals and environmental views) underlying garbage reduction and reuse behaviors could vary from those driving the performance of organized recycling systems, a feature that may not be accounted for by techno-economic models. Unfortunately, our knowledge of human nature is lacking when it comes to the technological domain of a product’s lifespan. Making people change their habits to promote a CE for electronic goods is a difficult problem to solve.

To emphasize the importance of GC and sustainable chemistry (SC) in transforming human resource, organizational, and architectural contexts across all industries, Zuin et al. [22] advocated education in GC and SC: approaches towards sustainability. Increasing collaboration, particularly through preexisting GC and SC networks is used to advance GC education and SC education everywhere, but especially in developed, emerging, and transition economies. In an ever-changing and unpredictable environment, companies need to develop cutting-edge knowledge that can be put into practice to create greener, more sustainable goods and processes. Their histories and the development of their unique traits remain mostly unknown.

In a recent paper by Ghatge et al. [23] decomposition of PE: Recent discoveries about the enzymes produced by microorganisms and their possible role in the degradation of PE were summarized. It has been shown through research and experimentation that biodegradation of PE is preferable to additive degradation in terms of reducing the resulting abnormalities. Furthermore, using isotope-labeled PE to assess its metabolism into end products confirmed the accurate deployment of cutting-edge technology for evaluating PE degradation. More study of the enzymatic degradation process will reveal the molecular pathway for efficient biodegradation of PE.

Studies on the depolymerization of waste plastics in sub- and hyper toluene have demonstrated increases in reaction temperature and time, lending credence to the proposal by Saha et al. [24] toward the solvothermal recycling of combined plastic wastes. Sub and supercritical toluene are used to depolymerize plastic waste. The STL conversion was aided by increasing the reaction temperature and lengthening the residence time, although supercritical toluene was superior for depolymerizing tough polymers like PP. The severity of the reaction had a substantial effect on the amount of lower hydrocarbons (C8-C20) produced. The scientific community may benefit in the future from a more in-depth examination of gas and liquid products in addition to the residual solid.

Legal rules restricting waste disposal have increased the significance of initiatives like the one presented by Kijo-Kleczkowska et al. [25]: Plastics reusing, with an accent on heating technologies of plastics recycling. Plastic recycling has many benefits, including preventing pollution from plastics that have been stored, reusing materials, and recovering energy. Legal requirements enacted to eradicate trash storage are conducive to the growth of the recycling business sector. Future efforts would center on developing an ecosystem to reuse alternatives to single-use items and packaging is the norm.

Chew et al. [26] suggested turning bio-waste into organic fertilizer as a way to highlight the advantages of utilizing organic fertilizer over chemical fertilizer and the potential management of bio-waste that might be transformed into organic fertilizer. One method for understanding the environmental and financial impacts of commercializing bio-fertilizer production is to conduct a life cycle analysis of the organic fertilizer production process. Uncertainties in nutrient content and soil appropriateness are likely the major obstacles for adopting organic fertilizer. Organic fertilizer may have a lower agronomic output than standard mineral fertilizer management, but it helps reduce greenhouse gases because it is a win all around.

A plan for materials science to ensure proper management of these wastes and innovative concepts for new sustainable technologies were proposed by Nandy et al. [27]. The current environmental pollution can be remedied by combining green technology with circular economic practices (green economy). Due to the lack of precautions taken at illegal disposal sites, hazardous materials, primarily from electronic waste, are recycled and there is a lack of attention toward recycling standards. As a result, the recycling process and any subsequent disassembly or reassembly of the used consumables must be handled with the utmost caution to prevent any potential harm to the end-users or the environment.

Analysis of gas chromatography and mass spectrometry data demonstrates the efficacy of different washing media in eliminating odors from different polymers, as proposed by Roosen et al. [28]. This shows how effective certain washing mediums are at removing odors. Water and NaOH achieved greater deodorization efficiency (70–80%) for PET bottles than water and ethyl acetate (60%). Deodorization is most effective when washing techniques are tailored to the specifics of the packaging type, as well as the physicochemical qualities of the washing material and fragrance components. This has the potential to broaden the applications of the material.

In the article entitled “Conversion of PE to High-Yield Combustion Oil at Low Heating and Environmental Starting Pressure,” Zhang et al. [29] described a process for reusing plastics utilizing lower-energy pyrolysis. Heat input, material costs, energy consumption, and the price of introducing lighter hydrocarbons and high-pressure region gases can all be minimized. The microscopic basis of phase transition, including conformational energetics and harmonic lattice dynamics, is still not established with certainty, despite the abovementioned tests being conducted from different perspectives.

Innovations for sustainable chemical manufacturing and waste minimization through green production practices are discussed through various technological research. Here the proposed method is used to minimize the plastic waste through pyrolysis with biodegradation by microorganisms. The goal of GC is to reduce the use of hazardous compounds, eliminate waste, and promote energy efficiency in chemical processes and products to minimize their negative effects on the environment. It gives ecologically friendly and sustainable solutions top priority across all industries. Resource efficiency and sustainability are given top priority in a green economy. In terms of waste management, this entails reducing trash, promoting recycling, implementing eco-friendly technologies, and adhering to ecologically conscious activities.

3 The proposed system

Plastics’ widespread use in agriculture, construction, healthcare, and consumer products has a significant global economic impact. Plastic is a necessary element in daily life, and because of its versatility, it is used in many different consumer products, including construction materials, electronics, and packaging. Convenient as it is, its widespread use creates environmental issues that motivate recycling and sustainable alternatives as a means of contributing to a more sustainable and responsible future. The usage of plastic has raised issues about pollution, resource depletion, and ecological damage from gradual deterioration. These concerns caused efforts to increase recycling and sustainable alternatives. Recycling conserves resources by reducing the need for new plastic manufacturing, whereas a CE promotes material reuse and waste reduction. The long-term environmental effect of conventional plastics is intended to be reduced by using biodegradable and compostable polymers. Initiatives concentrate on reducing dependency on single-use plastics and supporting the development of sustainable materials to solve environmental challenges and promote appropriate waste management. Plastics serve as the backbone of various businesses due to their widespread application in the production of anything from defense components to bathroom fixtures to plastic bottles to artificial leather and countless other consumer goods. Foods, drugs, detergents, and cosmetics are just some of the products that come in plastic containers. The overuse of plastics is dangerous for the environment and for human survival. Overuse of plastic has detrimental effects on the environment, human survival, and ecosystems. It can also harm wildlife, contaminate soil, and pose health risks to humans if inhaled. Interest in finding ways to break down plastics has been sparked by their accumulation on land and sea. To lessen the environmental impact of plastics, it is important to employ effective biodegradable techniques. Biodegradable techniques have many uses and provide environmentally appropriate substitutes for single-use items, packaging, agriculture, textiles, medical products, wastewater treatment, and building materials. They support a CE by lowering pollution and advancing sustainability in a range of sectors. It is essential to comprehend the connection between bacteria and polymers to find solutions to the environmental concerns caused by plastics using the suggested HDPE biodegradation via the pyrolysis Method. Many types of life, especially microbes, have adapted mechanisms to live in and break down plastics. Plastics can be converted into valuable compounds through a thermochemical process called pyrolysis. In general, variables including efficiency, environmental impact, economic feasibility, and scalability determine the success of plastic waste treatment techniques, including pyrolysis. To evaluate sustainability, a thorough life cycle analysis is essential. Efficiency, environmental impact, resource utilization, economic viability, technological advancements, regulatory compliance, and societal acceptance are all important factors in the success of plastic waste treatment methods like pyrolysis. The primary objectives are to convert plastic waste into valuable products as efficiently as possible while minimizing emissions and energy consumption and ensuring sustainability by considering available feedstock and adhering to environmental regulations. Economic feasibility is required for widespread adoption, which includes competitive costs and market demand. The success of these methods is also affected by ongoing research, technological advancements, and public perception. A comprehensive life cycle analysis is critical for evaluating sustainability, providing insights into environmental and social impacts throughout the treatment process, and assisting decision-makers in minimizing overall environmental effects.

Plastic bags, containers, pipelines, and water bottles are all common places to find HDPE due to their durability and adaptability. PE plastics are particularly stubborn pollutants due to their complicated molecular structure. To speed up the biodegradation process, plastic might be pretreated to make it a more digestible substrate for microorganisms. Pretreating plastic increases the surface area available for microbial action, which accelerates the biodegradation process and makes it a more digestible substrate for microorganisms. Microorganisms can degrade plastic more quickly due to its increased accessibility, accelerating the process of biodegradation. Proprietary solvents, typically based on ethyl alcohol, are highly versatile solvents due to their superior solvent properties. Solvents with most ethyl alcohol have inconceivable solvent properties and an immense amount of flexibility. These polar solvents are commonly derived from ethyl alcohol since they can dissolve enormous molecules in both polar and non polar solvents. Also, these solvents find widespread use in laboratory procedures, pharmaceutical manufacturing, the formulation of inks and coatings, as well as various industrial cleaning applications, among numerous other uses. Even with its flexibility, the flammability of ethyl alcohol requires safety precautions. However, users need to conform to the regulatory standards to ensure the safe and responsible use of a variety of applications. Here a batch-type pyrolyzer reactor was used to convert recycled HDPE pellets into pyrolysis oil using thermochemical processes as shown in Figure 1. The sealed system known as a batch-type pyrolyzer reactor is utilized for oxygen-free thermal degradation. It entails filling the reactor with a predetermined volume of feedstock, heating it to the appropriate temperature, and using a cooling mechanism. Controlling the temperature and having methods for gathering the products of pyrolysis are essential elements that help optimize the process for a variety of uses. An externally heated pyrolyzer made of 316 stainless steel with a 3 capacity is subjected to the cascade heating phases. Before each run, the pyrolyzer was purged of air with a stream of industrial-grade nitrogen gas. Air purging with industrial-grade nitrogen gas before each run in the pyrolyzer process is essential for multiple reasons. First, it removes oxygen from the system, preventing interference with the pyrolysis reactions that occur in the absence of oxygen. This is crucial for achieving desired and complete products. Additionally, replacing air with inert nitrogen reduces the possibility of combustion and increases safety, especially in areas where combustible materials are prevalent. By reducing oxidation and corrosion, this process also protects the equipment and eventually increases the usefulness of the pyrolyzer and its associated parts. Nitrogen purging is critical for ensuring product purity by preventing the formation of unwanted by-products or contaminants that may result from interactions with oxygen. Furthermore, nitrogen’s inert properties help to control the pyrolyzer’s temperature by removing reactive gases from the system. The pressure release line can be attached securely to the dissolving water tank. After passing through a water-cool condenser kept at around 15°C, the pyrolysis oil was collected from the main line. 80% output can be expected from the fast pyrolysis process using recycled HDPE pellets as the feed. Plastic polymers are partially decomposed into shorter-chain hydrocarbons and molecules during pyrolysis at extreme temperatures (between 400 and 900°C). For best outcomes, the pyrolysis of PE must be conducted within a particular temperature range of 400 to 900°C. By ensuring the effectiveness of the pyrolysis process and facilitating the breakdown of PE into valuable goods like liquid fuels, this regulated heating improves the overall conversion of plastic waste into useful substances. Straight-chain alkane molecules in crude oil serve as the basis for PE polymers. The pyrolysis of PE results in the formation of long-chain alkene by-products. Oil in the environment can serve as a carbon source for bacteria in a variety of settings. Sediment, ocean, and lake bacteria all play a role in hydrocarbon metabolism. These bacteria include Pseudomonas, Acinetobacter, and Desulfobacteraceae in sediments, and Alcanivorax and Marinobacter in seas. In a variety of aquatic habitats, they are essential for cleanup and natural attenuation. One hundred and seventy-five different microbiological taxonomic families have been identified as oil degraders in different ecosystems. Both aerobic and anaerobic oil-utilizing metabolisms are prevalent in microbial communities, thereby likely explaining the extensive distribution of these bacteria. Hydrocarbon breakdown is facilitated by the use of both aerobic and anaerobic oil-utilizing metabolisms, which were previously common in microbial populations. Anaerobic metabolism is essential in low-oxygen situations, but aerobic metabolism works well in oxygen-rich environments, offering quick breakdown and large energy returns. Microbial communities’ ability to adjust to changing oxygen concentrations improves overall oil breakdown efficiency in a variety of settings. A key component of optimizing oil breakdown efficiency is the capacity of microbial populations to adapt to varying oxygen concentrations. The main energy source for microorganisms like bacteria and fungi that decompose complex hydrocarbons in oil is aerobic respiration. However, oil spills can cause changes in oxygen levels. Oil deterioration in low-oxygen conditions depends on microbes that may convert to other metabolic pathways, such as anaerobic respiration or fermentation. This flexibility protects the survival of microbial communities and improves their capacity to efficiently decompose oil elements in a variety of environmental circumstances. Some bacteria and algae produce natural hydrocarbons, which could provide a substrate for hydrocarbon-metabolizing microorganisms. Oil-degrading microbial taxa can rapidly expand to outcompete other bacteria, taking over as much as 90% of the population within 72 h of an oil spill. Bacteria and fungi are crucial contributors to environmental recovery, particularly in addressing oil spills. These microorganisms demonstrate a pivotal role in decomposing hydrocarbons, possessing distinctive enzymes and genetic adaptations that significantly boost their efficiency in breaking down complex hydrocarbons. This capability plays a pivotal role in mitigating the adverse environmental impacts of oil pollution. Their rapid proliferation after a spill, influenced by factors such as enzymatic activity, microbial competition, and environmental conditions, allows them to outperform other species in the ecosystem. Through collaboration and specific adaptations, these microbes significantly contribute to the natural remediation of oil-contaminated areas, underscoring their indispensable role in ecological restoration. Hydrocarbon pollution in the environment often contains a wide variety of chemicals, from simple alkenes to complex aromatic hydrocarbons. Biodegradation of alkene compounds is significant because alkenes are harmful to the environment and because it has potential applications in the treatment of solid industrial waste. Due to their role in the creation of ground-level ozone, a primary contributor to smog, alkenes are regarded as being extremely damaging to the environment. This may harm ecosystems, worsen human health, and exacerbate air pollution problems. Alkenes may be used in the degradation and polymerization processes for the treatment of solid industrial waste. They can be used to generate binders or protective coatings for solid waste materials, as well as polymers for waste encapsulation. Alkene-based degradation processes can also help break down some waste components, which makes solid waste treatment techniques more effective and eco-friendly. Alkene-based degradation processes significantly improve solid waste treatment by providing increased reactivity and specificity, faster pollutant degradation, and reduced environmental impact through biodegradability. Their adaptability to a variety of conditions, integration with biological systems, and potential for energy recovery all contribute to overall sustainability. These processes also reduce residue formation and chemical dependency, resulting in a more environmentally friendly approach to solid waste management. However, careful consideration of waste composition and environmental factors is required for successful implementation. The rate at which hydrocarbons are broken down by microbes and other environmental factors, like temperature and availability of nutrients, varies depending on the location you live. Even if environmental circumstances are less than ideal, hydrocarbon biodegradation is frequently still possible. However, it could be able to improve biodegradation and use oil-degrading microorganisms in experimental enrichment cultures for biological reuse and reusing of plastics. To further examine the biodegradation process and answer specific concerns about hydrocarbon-degrading microorganisms, enhanced microbial consortia can be used to create a simpler community. Microbial consortia are essential for studying the hydrocarbon biodegradation process. They answer worries about restrictions on the breakdown of particular hydrocarbons by offering insights into the synergistic interactions among various bacteria. Researching consortiums increases the predictability and efficiency of biodegradation processes while deepening our knowledge of intricate degradation pathways. The purpose of this study was to show that three different nutrient treatments can bring about alkene biodegradation using distinct environmental inoculum sources harboring different starting microbial populations. Trace metal supplementation, carbon source addition, and nitrogen and phosphorus enrichment are the three nutrient treatments that promote alkene biodegradation. By supplying necessary nutrients and co-factors, these treatments boost the microbial activity that breaks down alkenes, facilitating rapid and successful biodegradation processes. Alkene biodegradation necessitates enhanced nutrient treatments, such as trace metal supplementation and carbon source addition. This includes increasing enzyme activity with trace metal cofactors and facilitating uptake with improved metal transporters. Degradation of alkenes and secondary carbon sources can occur simultaneously when a suitable carbon source increases microbial growth and metabolism. Nutrient optimization is improved by maintaining a balanced nutrient composition, real-time monitoring, and feedback control systems. Increasing the variety of metabolic processes improves the efficiency of biodegradation. These alkene chemicals are typical pyrolysis by-products of HDPE. Learning about the optimal nutritional conditions for alkene biodegradation is essential. The rate and extent of biodegradation will be dependent on the chain length of the alkene, with the catabolism of carbon sources with longer chains needing potentially longer lag phases in cultures. Based on the available inoculum, several communities of bacteria will be chosen for enrichment cultures, each of which will have a unique response to alkene biological degradation. Changing the nutrient concentrations in our cultures under controlled laboratory conditions will significantly affect the microbial community composition and alkene breakdown rates because in situ microbial community dynamics are generally responsive to changes in heat, vitamins and minerals, pH value, and other external variables.

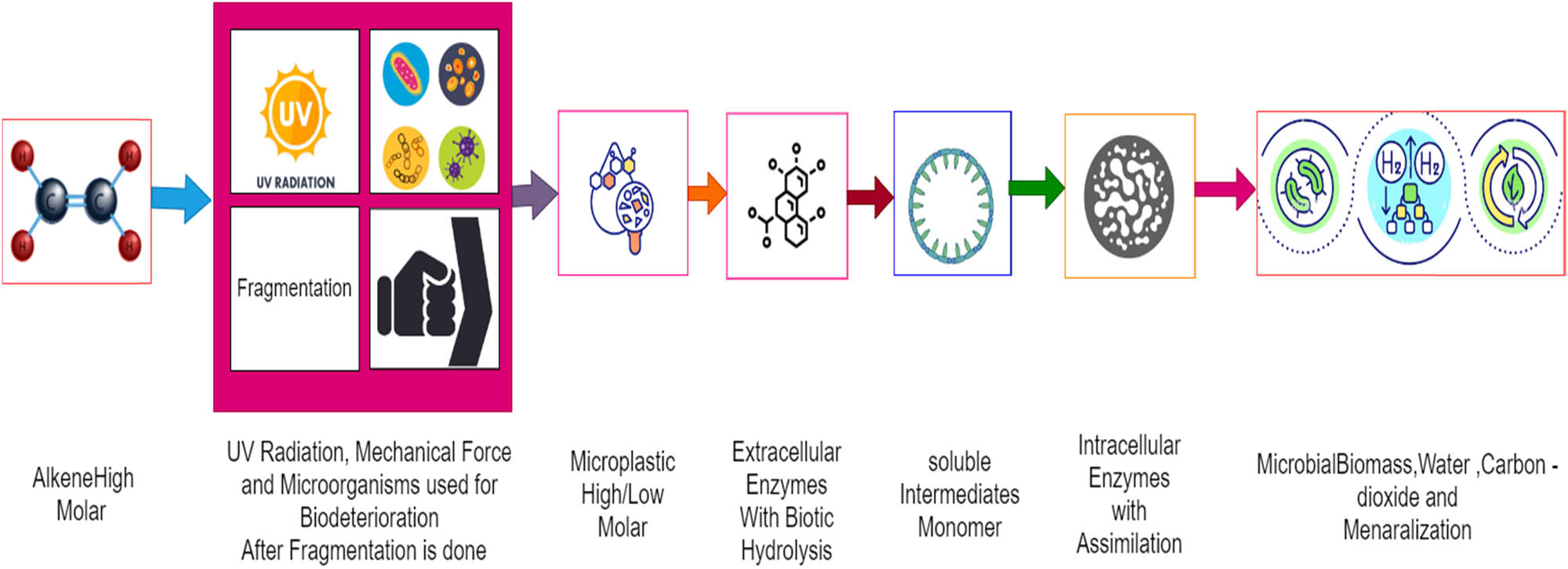

Proposed HDPE biodegradation through pyrolysis method block diagram.

3.1 Laboratory pyrolysis for liquid oil from condenser 2

In the process of pyrolysis, which uses heat to break down plastics into smaller molecules, condensers are essential. To condense various chemicals selectively, specific temperatures in each condenser are essential. This accuracy makes it possible to produce liquid goods with different qualities on purpose, such as chemical feedstocks or fuels. Pyrolysis is an efficient and versatile process because temperature control maximizes yield and product quality. The output of oil from the pyrolysis process is explained in Figure 2. Heating tape from BriskHeat Corporation was used to heat the dissolving tank and pyrolysis reactor. BriskHeat Corporation introduced heating tape or heat trace, a dynamic heating solution. This semi-flexible, self-regulating cable automatically adjusts its heat output based on ambient conditions and surface temperature. BriskHeat’s silicone rubber heating tape (BS0) is flexible and adaptable for a wide range of applications, including wrapping pipes, tanks, vessels, and roofing. It is also suitable for use on glass and electrically conductive metal surfaces. This heating tape is especially useful for heating laboratory apparatus, gas tubing, and valves, and providing temporary heat. Regulation of the pyrolysis temperature in steps was tracked and modified by Table 1. The length of the reactor using an Omega Multi-Zone Controller. To create the liquid feed, HDPE was melted in the dissolving tank and then mixed with a proprietary solvent in a ratio of 1:1. The carrier gas in the pyrolysis reactor was 99.9% pure nitrogen (N2) gas, and it was employed to keep the tank pressure at 10.5 psig. The plug-flow pyrolysis processor received a plastic/solvent feeding solution at a rate of 0.12 kg·h−1 through a pressure-driven, regulated nozzle. The carrier gas flow rate allowed us to estimate the vapor residence period at around 4.1 s. The pyrolysis reactor was maintained at a constant temperature of 575°C. In a pyrolysis reactor, maintaining a constant temperature of 575°C has a major impact on how HDPE plastic breaks down. It improves decomposition efficiency, speeds up reaction rates, and increases product yield. The controlled temperature ensures uniform heating, preventing cold spots and reducing the formation of undesirable by-products. This method not only reduces energy input but also maintains consistent product quality throughout the pyrolysis process. After passing through a pair of condensers, the by-products of pyrolysis are separated into their respective liquid, gaseous, and solid states, with the waxy by-product (>C15) being the heaviest. Employing the heating strip and the control unit, we succeeded in managing to maintain a steady temperature of 200°C in condenser 1. The integration of a heating strip and a control unit enables Condenser 1 to consistently uphold a temperature of 200°C. The control device is responsible for overseeing the condenser’s temperature and activating the heating strip as necessary to sustain it above the specified temperature. The heating strip, composed of a high-resistance alloy such as nichrome, heats up due to the electric current passing through it. The control unit precisely adjusts the electric current in the heating strip to regulate heat production and ensure the temperature remains within the desired range. This amalgamation of a heating strip and control unit finds application in diverse fields, including medical devices, scientific research, and industrial processes, where precise temperature control is critical. Condenser 2 was cooled to ambient temperature (about 30°C) by soaking it in water. Condenser 1 produced N2-suspended aerosols of products from pyrolysis, and Condenser 2 yielded an insoluble substrate for the microbial cultures. The biodegradation of alkene high molar output is described in Section 3.2.

Laboratory pyrolysis for liquid oil from condenser 2 using heating tape.

Regulation of the pyrolysis temperature in steps

| Time (h) | Temperature (°C) |

|---|---|

| 0.37 | 30–400 |

| 1 | 400–500 |

| 1 | 500 |

| 1.4 | 500–600 |

| 1 | 600 |

3.2 Biodegradation of alkene to produce protein and carbon dioxide

Figure 3 shows that biodegradation of alkene from the pyrolysis process results in high-molar alkene. Large quantities of polymeric waste are produced as a result of the widespread use of plastic bags. PE is the material of choice for shopping bags. Micrococcus sp., Staphylococcus sp., Mucor sp., and Rhizopus sp. are all examples of bacteria and fungi that manufacture PE-degrading enzymes and exude them into the environment. The digestive enzymes that degrade PE, i.e., depolymerizes, can fragment the polymer into macromers and can be further degraded into ethylene monomers. Microbes may use these monomers (ethylene) as a carbon and energy source by metabolizing them via aerobic or anaerobic pathways. This energy is used by microbes during reproduction, leading to an increase in microbial biomass.

Biodegradation of alkene to produce protein and carbon dioxide.

3.2.1 Mechanism of biodegradation

Big-bite plastics are a group of naturally occurring or synthetically produced compounds characterized by the presence of very large molecules (macromolecules), these are aggregates of monomer units. Polymers are the building blocks of many natural and synthetic substances, including those found in living creatures. There are three stages involved in the biodegradation of polymers: (a) microbes affixing to the polymer surface, (b) polymer decomposition, and (c) microorganisms using the polymer as a carbon source. The rate of hydrocarbon biodegradation by microbes is influenced by factors such as temperature, nutrient availability, oxygen levels, and the type of hydrocarbon. The dilution threshold theory suggests that as the concentration of hydrocarbons in an emulsion decreases, the viscosity also decreases, making it more accessible to microbial degradation. Since there is less viscosity at lower concentrations, microbial breakdown is facilitated more effectively, improving the biodegradation process. Indeed, modifications to a polymer’s environment can cause changes in its characteristics, which may affect the way it performs and whether it is appropriate for a certain use. To get the nutrients that need to develop, microorganisms adhere to polymers and release enzymes that break down the polymers. Low-molecular-weight compounds like monomers and oligomers formed as large polymers break down. After diffusing inside microorganisms, some oligomers may be absorbed into their internal environment. The first step in biodegradation is biodeterioration, in which an object’s mechanical structure weakens; the second is bio fragmentation, in which materials are broken down by microorganisms; and the third is assimilation, in which the old material is incorporated into new cells. In a lack of oxygen consumption, microorganisms decompose organic matter in a process known as anaerobic biological degradation. Oxygen is crucial for the natural cleaning of hazardous waste sites. Nitrate, iron, sulfate, manganese, and carbon dioxide (CO2) serve as electron acceptors for anaerobic bacteria in place of oxygen, allowing them to metabolize big organic compounds into smaller ones like methane, carbon dioxide (CO2), water, and carbon residue. Not all polymers can be absorbed by bacteria via their cell walls because of their large size and insolubility in water. Extracellular enzymes secreted by microorganisms convert these polymers into energy. The goal of the research is to create effective processes for converting these materials into useful energy sources by converting polymers into energy. The goal of this research is to maximize the energy potential of polymers while managing waste by developing sustainable solutions. The specificity of the enzyme, substrate accessibility, pH and temperature fluctuations, microbial diversity, and cofactor presence are some of the elements that affect extracellular enzymes’ ability to convert polymers into energy. For polymer degradation processes to be as efficient as possible in producing energy, it is essential to comprehend these elements. These enzymes operate outside the cells of bacteria, depolymerizing polymers. Both intracellular and extracellular enzymes contribute to the biodegradation of polymers. Polymer degradation relies on the collaborative function of enzymes, which operate both outside and inside cells. Microorganisms produce extracellular enzymes that commence the hydrolysis of large polymers into smaller fragments in the external environment. Subsequently, these fragments are transported into microbial cells, where intracellular enzymes play a role in further breaking them down within specific metabolic pathways. This interaction is intricately regulated by feedback mechanisms that respond to substrate availability and environmental conditions. Enzymes both intracellular and extracellular work together to facilitate the effective breakdown of polymers, which gives microorganisms energy and supports cellular functions. The biological deterioration of plastic polymers includes depolymerization and mineralization. Extracellularly released enzymes known as exoenzymes degrade the big polymers into molecules small enough to be soluble in water. These compounds can enter bacteria through their semipermeable membrane and be used as fuel. Depolymerization refers to the breakdown of big polymers; however, mineralization refers to the breakdown of large polymers into inorganic species such as water, alkenes, and carbon dioxide. The polymer’s end products were water, carbon dioxide, and microbial mass in an aerobic environment, while alkenes and H2S in an anaerobic/methanogenic and sulfidogenic one.

3.2.2 Polymer degradation by microorganisms

The flow chart represents the degradation of polymers by microorganisms in the main four steps biodeterioration, biofragmentation, mineralization, and assimilation as shown in Figure 4.

The process of polymers degradation by microorganisms.

Degradation of polymers by microorganisms can occur in several different ways, as depicted in Figure 4: biodeterioration, bio-fragmentation, mineralization, and assimilation. The physical, chemical, and mechanical qualities of monomers undergo an individualized modification during biological degradation. Depending on their makeup and structure, polymers undergo significant biochemical and structural transformations. The properties of polymers can change in response to their conditions. A phenomenon known as stimuli-responsive behavior occurs when the properties of polymers can alter in response to changing circumstances. Response to many stimuli, including light, pH, temperature, and the presence of particular compounds, is one of these attributes. Smart or intelligent polymers, also referred to as stimulus-responsive polymers, respond to external stimuli by undergoing reversible changes in their solubility, shape, or structure. A substrate forms inside the plastic, and a biofilm forms on its surface, as a result of the degradation process. Following biodeterioration, bio-fragmentation occurs whenever plastic polymers are broken down by enzymes. Bacterial oxidases can break apart oxygen molecules bonded to carbon chains, transforming them into safer alcohols and peroxyl compounds. Carboxyl group transitions are also catalyzed by enzymes such as lipases, esterases, and endopeptidases for amide groups. In the bio-fragmentation process, mineralization creates plastic polymers that can cross bacterial cell membranes. In bacterial cell membranes, mineralization and plastic polymers interact to break down plastic into mineral components that are then integrated into cellular structures. Numerous factors, including microbial activity, ambient conditions, and polymer properties, have an impact on this process. Large monomers are unable to penetrate the cell membrane and must remain on the outside. Due to size constraints, large monomers cannot pass through the cell membrane effectively. Only ions, tiny molecules, and specific gasses can readily pass through the cell membrane due to its selective permeability. Bigger molecules find it more difficult to get through the membrane barrier, especially if their size exceeds the membrane’s capacity for transport, which restricts their ability to enter the cell. The energy in your body comes from the oxidation of tiny monomers that have migrated around inside the cells. Biomass generation ultimately makes use of this energy. Atoms are assimilated into microbial cells during the decomposition process. During decomposition, atoms are taken up by microbial cells to carry out vital metabolic tasks and produce biomass. Microorganisms’ life cycle is sustained by this process, which gives them the nutrients they need for growth and energy production. Secondary metabolites are either exported from the cell or transferred to other microorganisms that degrade and utilize them further. When organic matter degrades, secondary metabolites frequently go through further changes that aid in the disintegration of the material as a whole. These metabolites can operate as signaling molecules, supply energy to bacteria, or affect ecological interactions, among other functions. Secondary metabolites participate in microbial interactions and affect when degradation pathways affect the environment, all of which are important aspects of the entire degradation process. Once metabolites break down, oxidized products such as carbon dioxide (CO2), water (H2O), and alkenes are released.

4 Results and analysis

The waste plastic recycling plant (WaRP) dataset consists of captioned photos of an industrial waste sorting factory, it is used in the pyrolysis process. WaRP dataset emphasizes data gathering and analysis linked to recycling processes, resource recovery, and waste management techniques. It functions based on fundamental principles of waste recycling. It seeks to shed light on effective recycling practices, sustainable waste management, and the effects of trash recycling programs on the environment. This is settled on 28 types of recyclable trash [29]. There are 17 varieties of plastic bottles in the dataset (class names beginning with the bottle prefix), 3 types of glass bottles (class names beginning with the glass prefix), 2 types of cardboard, 4 types of detergents, and 2 types of canisters and cans. Models for detection, classification, and segmentation can all be learned using the WaRP dataset. On the other hand, analyzing the way pyrolysis contributes to waste-to-energy conversion and highlighting the potential for energy recovery and environmental impact mitigation based on data from the waste and resources program (WaRP) are part of analyzing the significance of the pyrolysis process about the WaRP dataset. Biodegradation of the alkene by-product of the pyrolysis process is carried out by microbial populations isolated from the environment at three distinct nutrient concentrations [30,31]. Alkene by-products are broken down by microorganisms using enzymes into less complex, environmentally safe compounds. By encouraging the breakdown of leftover alkene molecules, this microbial activity is essential in lowering the environmental impact of pyrolysis. Indeed, there are difficulties in the microbial biodegradation of alkene by-products. These include the toxicity of some alkenes to bacteria, the requirement for particular microbial strains capable of breaking down these chemicals, and the possibility of slow degradation rates. These variables may impact the biodegradation process’s effectiveness and need the use of optimization techniques for the successful removal of alkene by-products.

4.1 Pyrolysis method to produce water-in-oil (w/o) emulsion

Using sorbitan monooleate (Span 80), a commercial emulsifier, an oil-in-water (w/o) combination has been created for pyrolysis. To make the w/o emulsion, pyrolysis oil, and Span80 were combined beforehand, and then distilled water was added gradually. The ideal concentration range for the surfactant was followed by maintaining the concentration at 2% by volume. Both a 20 kHz (176 W) ultrasonic mixer (Bandelin Sonopuls) and a 4,000 rpm (440 W) homogenizer (IKA-Ultra-Turrex T50) were used to emulsify at the room temperature of oil-and-water emulsion. The 15-min mixing period remained unchanged. Emulsions were visually characterized according to the average droplet size and dispersion. The kind and quantity of emulsifying agents, shear forces during mixing, temperature, phase volume ratios, agitation speed, equipment design, viscosity of phases, and pH all affect the average droplet size and dispersion in emulsions. Water concentration has a significant impact on emulsion viscosity. The concentration of water greatly affects the viscosity of emulsions. Higher water concentrations tend to increase viscosity, giving the emulsion a thicker consistency, whereas lower water concentrations tend to decrease viscosity, making the emulsion more fluid. For regulating and maximizing the physical properties of emulsions in a variety of industrial applications, the link between water content and emulsion viscosity is essential. The ratio of the oil to water phases, as well as the presence of emulsifiers, affects viscosity in industries such as food and cosmetics. For formulations to be optimized and for emulsions to have the intended rheological characteristics, this information is essential. Using measurements of shear stress of pyrolysis oil at varying shear rates, construct a viscosity flow curve. The flow curve’s linear correlation is further evidence of Newtonian behavior. Shear viscosity at room temperature is 150 centipoise and 154 centipoise is recorded using a capillary viscometer. The proportion of water in an emulsion can have a major impact on its viscosity. Here the capillary viscometer measures the emulsion’s viscosity and reports it as a relative viscosity (η r), it is the emulsion’s viscosity divided by the viscosity of the pyrolysis oil. Equation (1) gives the mathematical Einstein solution for comparative viscosity, and it is compared to the practical finding.

where the volume fraction of the disperse phase (water) is denoted by ɸ, the emulsion viscosity by

Coefficient of heat transfer about water volume fraction.

Emulsion relative viscosity as a function of water concentration.

4.2 Quantifying CO2 in biodegradation

In this case, the alkene biodegradation is indirectly measured by measuring the amount of CO2) produced. CO2 generation was determined for each sample 5 days after inoculation as shown in Figure 7. When comparing treatments for total CO2, the Kruskal–Wallis test found no statistically significant differences to give a nonparametric test value (P = 0.1710). Analysis of microbiome data is better suited to the Kruskal–Wallis test. It is preferable to utilize rankings rather than actual values in tests when analyzing post-sequencing microbiome data because these data are rarely normally distributed and frequently contain some strong outliers. When assessing post-sequencing microbiome data, using rankings rather than actual values has several benefits, including improved focus on the relative abundance and distribution of microbial taxa, decreased sensitivity to differences in sequencing depth, and increased robustness to outliers. When comparing samples, rankings offer a more reliable and comparable foundation, particularly in datasets with changing microbial compositions. Therefore, it is reasoned that different ecosystems would produce biodegradation rates that are strikingly different from one another, thus need to set out to verify this hypothesis. The examined linear regression slopes between various combinations of nutrient levels and inoculum sources are shown in Table 2. No statistically significant differences were found using the Kruskal–Wallis test to compare the sloping patterns of CO2 generation in the log phase of growth across different inoculum sources and nutrient concentrations (P = 0.432). The log phase (exponential phase) is one of the phases observed in a bacterial growth curve. The estimation of CO2 production takes mean control production into account. The aim is to quantify the potential contribution of alkene biodegradation to total CO2 emissions as contrasted to other fundamental processes. The values in Table 2 are inoculum source values mentioned as standard deviation ± slope.

The metabolic reaction to model alkene molecules as measured by total carbon dioxide production during 5 days of cultivation in the lab at high, standard, and low nutrient levels.

Linear regression slopes for daily CO2 production in milligrams as bacteria are in their exponential growth phase, the nutrient density of inoculum

| Inoculation’s origin | |||

|---|---|---|---|

| Intake of nutrients | Sediment from the Caspian Sea’s bottom origin | Iron-rich sand origin | Farming compost origin |

| High | 1.70 ± 1.42 | 2.98 ± 1.69 | 2.30 ± 2.66 |

| Standard | 0.91 ± 0.07 | 4.58 ± 0.14 | 3.16 ± 1.24 |

| Low | 1.58 ± 1.47 | 2.54 ± 1.00 | 3.30 ± 1.06 |

4.3 Quantifying proteins in biodegradation

Protein levels in cultured cells are evaluated to determine how much of our original alkene intake is devoted to assimilatory metabolism. Protein concentrations in iron-rich sediment cultures averaged 1.47 mg·mL−1 after 5 days in the lab, while those in compost samples averaged near 0 mg·mL−1 (Figure 8). Protein content increased during the 5 days of incubation, suggesting that some of the alkenes have been incorporated into the biological mass as proteins. Proteins account for only a small percentage of a cell’s total mass. This allows for trends to be analyzed using protein measurements; however, these data are likely to underestimate the biomass produced by these cultures.

Protein concentrations.

4.3.1 Proportional mass balance

Given the information at hand, an approximation of the mass balance (Table 3), is used to track the passage of carbon from alkenes through the system. The amount of alkenes introduced to each flask was calculated by weighing the alkenes before and after addition. Each flask’s alkene introduction quantity is determined by accounting for variables such as reaction stoichiometry, goal concentration, and experimental needs. Controlled and repeatable conditions are ensured by precise measurements and computations. After 5 days incubation period in sediment cultures enriched with high nutrients and iron, the analysis revealed an unaccounted mass of 0.193 ± 0.05 g. Conversely, among compost samples characterized by low nutrient levels, the average weight was recorded as 0.319 ± 0.0029 g (Table 3). This indicates that a considerable amount of carbon may be overlooked in our current estimations. Protein production is roughly 50% lower than calculated since total biomass production is not taken into consideration. When calculating protein production, total biomass production must be taken into account because it offers an accurate representation of all biological output, including protein production. This method makes it possible to evaluate resource usage, sustainability, and efficiency in protein synthesis processes more precisely. It is essential to comprehend the connection between total biomass and protein content to be able to maximize productivity and make wise resource selections. Values are presented as means of standard deviations for fairness.

Establishing enrichment cultures from different inoculum sources for the production of alkene liquid products and mass balances

| Mass (g) | |||

|---|---|---|---|

| Group of inoculum and nutrient concentration | Alkene (g) is the initial input | Caused by protein synthesis | Unaccounted for (mass balance) |

| Farm compost | |||

| High | 0.372 | 0.029 ± 0.018 | 0.276 ± 0.02 |

| Standard | 0.372 | 0.02 ± 0.027 | 0.312 ± 0.03 |

| Low | 0.372 | 0.0029 ± 0.004 | 0.319 ± 0.0029 |

| Iron-rich sediment | |||

| High | 0.372 | 0.07 ± 0.049 | 0.193 ± 0.05 |

| Standard | 0.372 | 0.01 ± −0.002 | 0.312 ± 0.006 |

| Low | 0.372 | 0.009 ± 0.0029 | 0.302 ± 0.010 |

| Caspian Sea sediment | |||

| High | 0.372 | 0.01 ± 0.030 | 0.217 ± 0.07 |

| Standard | 0.372 | 0.0003 ± 0.0005 | 0.236 ± 0.019 |

| Low | 0.372 | 0.003 ± 0.014 | 0.255 ± 0.05 |

After 5 days of cultivation period in a laboratory setting utilizing diverse sources of environmental inoculum, the results were presented in the form of a box plot. These results were attained by employing a protein extraction kit from Thermo Fisher Scientific and constructing a calibration curve with albumin protein standards. These disparities can be explained by the depletion of alkenes caused by abiotic variable processes involving evaporation that have not been taken into consideration in this mass balancing.

5 Conclusion

The purpose of this study is to demonstrate that PE gets degraded and converted to biomass by microbial consortiums more quickly if chemical and biological processes are coordinated. Here researchers tested the efficiency of enriched consortia for alkene breakdown over 5 days using different nutritional treatments and from microbial inoculum communities isolated from farming compost, sediment from the Caspian Sea’s bottom, and iron-rich sand. Extensive biodegradation was observed in every one of the sample types, with the majority of samples achieving biodegradation between 60 and 95% across all examined components. These results show that HDPE that has been pyrolyzed is biodegradable and that hydrocarbon-degrading bacteria that can metabolize pyrolysis products are abundant in the natural world. These results pave the way for further research into the thermochemical and biological coupling mechanisms that could be used to convert and upcycle HDPE waste. The inorganic contaminants in a medium cannot be destroyed by pyrolysis, and the inorganic contaminants cannot be physically separated by pyrolysis. Higher temperatures during the process may lead to the removal of volatile metals without destroying them. In future work removal of volatile metal can be destroyed using advancement in the system.

Acknowledgment

Not applicable.

-

Funding information: No funds or grants were received by any of the authors.

-

Author contributions: Lu Mei and Zhang Fa Min contributed to the design and methodology of this study, the assessment of the outcomes, and the writing of the manuscript.

-

Conflict of interest: The authors state no conflict of interest.

-

Code availability: Not applicable.

-

Data availability statement: All data generated or analyzed during this study are included in the manuscript.

References

[1] Shekhar, S., M. E. Hoque, P. K. Bajpai, H. Islam, and B. Sharma. Chemical upcycling of plastics as a solution to the plastic trash problem for an ideal, circular polymer economy and energy recovery. Environment, Development and Sustainability, Vol. 26, 2023, pp. 1–36.10.1007/s10668-023-03003-8Search in Google Scholar

[2] Peng, L., D. Fu, H. Qi, C. Q. Lan, H. Yu, and C. Ge. Micro- and nano-plastics in the marine environment: Source, distribution, and threats — A review. Science of the Total Environment, Vol. 698, 2020, id. 134254.10.1016/j.scitotenv.2019.134254Search in Google Scholar PubMed

[3] Saeaung, K., N. Phusunti, W. Phetwarotai, S. Assabumrungrat, and B. Cheirsilp. Catalytic pyrolysis of petroleum-based and biodegradable plastic waste to obtain high-value chemicals. Waste Management, Vol. 127, 2021, pp. 101–111.10.1016/j.wasman.2021.04.024Search in Google Scholar PubMed

[4] Xu, D., G. Huang, L. Guo, Y. Chen, C. Ding, and C. Liu. Enhancement of catalytic combustion and thermolysis for treating polyethylene plastic waste. Advanced Composites and Hybrid Materials, Vol. 5, 2022, pp. 1–17.10.1007/s42114-021-00317-xSearch in Google Scholar

[5] Samak, N. A., Y. Jia, M. M. Sharshar, T. Mu, M. Yang, S. Peh, et al. Recent advances in biocatalysts engineering for polyethylene terephthalate plastic waste green recycling. Environment International, Vol. 145, 2020, id. 106144.10.1016/j.envint.2020.106144Search in Google Scholar PubMed

[6] Curtis, A. and R. Sarc. Real-time monitoring of volume flow, mass flow, and shredder power consumption in mixed solid waste processing. Waste Management, Vol. 131, 2021, pp. 41–49.10.1016/j.wasman.2021.05.024Search in Google Scholar PubMed

[7] Bertin, S. and J. J. Robin. Study and characterization of virgin and recycled LDPE/PP blends. European Polymer Journal, Vol. 38, No. 11, 2002, pp. 2255–2264.10.1016/S0014-3057(02)00111-8Search in Google Scholar

[8] Cho, S. J., H. N. Jang, S. J. Cho, Y. S. Yoon, and H. M. Yoo. Material recycling for manufacturing aggregates using melting slag of automobile shredder residues. Materials, Vol. 16, No. 7, 2023, id. 2664.10.3390/ma16072664Search in Google Scholar PubMed PubMed Central

[9] Nukala, S. G., I. Kong, A. B. Kakarla, W. Kong, and W. Kong. Development of wood polymer composites from recycled wood and plastic waste: Thermal and mechanical properties. Journal of Composites Science, Vol. 6, No. 7, 2022, id. 194.10.3390/jcs6070194Search in Google Scholar

[10] Chen, Z., X. Zhang, L. Che, H. Peng, S. Zhu, F. Yang, et al. Effect of volatile reactions on oil production and composition in thermal and catalytic pyrolysis of polyethylene. Fuel, Vol. 271, 2020, id. 117308.10.1016/j.fuel.2020.117308Search in Google Scholar

[11] Byrne, E., L. G. Schaerer, D. G. Kulas, S. K. Ankathi, L. I. Putman, K. R. Codere, et al. Pyrolysis-aided microbial biodegradation of high-density polyethylene plastic by environmental inocula enrichment cultures. ACS Sustainable Chemistry & Engineering, Vol. 10, No. 6, 2022, pp. 2022–2033.10.1021/acssuschemeng.1c05318Search in Google Scholar

[12] Nasution, F., H. Husin, F. Abnisa, F. T. Yani, and L. Maulinda. Conversion of pyrolysis vapors derived from non-biodegradable waste plastics (PET) into valuable fuels using nickel-impregnated HZSM5-70 catalysts. Energy Conversion and Management, Vol. 273, 2022, id. 116440.10.1016/j.enconman.2022.116440Search in Google Scholar

[13] Sun, X., Z. Chen, T. Kong, Z. Chen, Y. Dong, M. Kolton, et al. Mycobacteriaceae Mineralizes Micropolyethylene in Riverine Ecosystems. Environmental Science & Technology, Vol. 56, No. 22, 2022, pp. 15705–15717.10.1021/acs.est.2c05346Search in Google Scholar PubMed

[14] Ke, H., J. Li, X. Zhang, and J. Hu. Bacterial community structure and predicted metabolic function of landfilled municipal solid waste in China. Sustainability, Vol. 14, No. 6, 2022, id. 3144.10.3390/su14063144Search in Google Scholar

[15] Pellis, A., G. M. Guebitz, and D. Ribitsch. Bio-upcycling of multilayer materials and blends: Closing the plastics loop. Current Opinion in Biotechnology, Vol. 81, 2023, id. 102938.10.1016/j.copbio.2023.102938Search in Google Scholar PubMed

[16] Aggarwal, K., B. T. Khoa, K. D. Sagar, R. Agrawal, M. Dhingra, and J. Dhingra. Marketing information system based on unsupervised visual data to manage transportation industry using signal processing. Expert Systems, 2023, id. e13384.10.1111/exsy.13384Search in Google Scholar

[17] Chen, Z., C. B. Sivaparthipan, and B. Muthu. IoT based smart and intelligent smart city energy optimization. Sustainable Energy Technologies and Assessments, Vol. 49, 2022, id. 101724.10.1016/j.seta.2021.101724Search in Google Scholar

[18] Yue, W., C. Yu, A. Antonidoss, and M. Anbarasan. Deep learning–based monitoring sustainable decision support system for energy building to smart cities with remote sensing techniques. Photogrammetric Engineering & Remote Sensing, Vol. 88, No. 9, 2022, pp. 593–601.10.14358/PERS.22-00010R2Search in Google Scholar

[19] Rajesh, K., I. Emerson, A. Ramkumar, R. Jenitha, and B. Baranitharan. Smart power-sharing system for dormant domestic consumers using green energy using wireless networks. In 2023 Fifth International Conference on Electrical, Computer and Communication Technologies (ICECCT), IEEE, 2023, February, pp. 1–6.10.1109/ICECCT56650.2023.10179632Search in Google Scholar

[20] Ncube, A., S. Mtetwa, M. Bukhari, G. Fiorentino, and R. Passaro. Circular economy and green chemistry: The need for radical innovative approaches in the design for new products. Energies, Vol. 16, No. 4, 2023, id. 1752.10.3390/en16041752Search in Google Scholar

[21] Parajuly, K., C. Fitzpatrick, O. Muldoon, and R. Kuehr. Behavioral change for the circular economy: A review with a focus on electronic waste management in the EU. Resources, Conservation & Recycling: X, Vol. 6, 2020, id. 100035.10.1016/j.rcrx.2020.100035Search in Google Scholar

[22] Zuin, V. G., I. Eilks, M. Elschami, and K. Kümmerer. Education in green chemistry and sustainable chemistry: perspectives towards sustainability. Green Chemistry, Vol. 23, No. 4, 2021, pp. 1594–1608.10.1039/D0GC03313HSearch in Google Scholar

[23] Ghatge, S., Y. Yang, J. H. Ahn, and H. G. Hur. Biodegradation of polyethylene: A brief review. Applied Biological Chemistry, Vol. 63, No. 1, 2020, pp. 1–14.10.1186/s13765-020-00511-3Search in Google Scholar

[24] Saha, N., S. Banivaheb, and M. T. Reza. Towards solvothermal upcycling of mixed plastic wastes: Depolymerization pathways of waste plastics in sub- and supercritical toluene. Energy Conversion and Management: X, Vol. 13, 2022, id. 100158.10.1016/j.ecmx.2021.100158Search in Google Scholar

[25] Kijo-Kleczkowska, A. and A. Gnatowski. Recycling of plastic waste, with particular emphasis on thermal methods. Energies, Vol. 15, No. 6, 2022, id. 2114.10.3390/en15062114Search in Google Scholar

[26] Chew, K. W., S. R. Chia, H. W. Yen, S. Nomanbhay, Y. C. Ho, and P. L. Show. Transformation of biomass waste into sustainable organic fertilizers. Sustainability, Vol. 11, No. 8, 2019, id. 2266.10.3390/su11082266Search in Google Scholar

[27] Nandy, S., E. Fortunato, and R. Martins. Green economy and waste management: An inevitable plan for materials science. Progress in Natural Science: Materials International, Vol. 32, No. 1, 2022, pp. 1–9.10.1016/j.pnsc.2022.01.001Search in Google Scholar

[28] Roosen, M., L. Harinck, S. Ügdüler, T. De Somer, A. G. Hucks, T. G. Belé, et al. Deodorization of post-consumer plastic waste fractions: A comparison of different washing media. Science of the Total Environment, Vol. 812, 2022, id. 152467.10.1016/j.scitotenv.2021.152467Search in Google Scholar PubMed

[29] Zhang, Y., X. Chen, L. Cheng, J. Gu, and Y. Xu. Conversion of Polyethylene to High-Yield Fuel Oil at Low Temperatures and Atmospheric Initial Pressure. International Journal of Environmental Research and Public Health, Vol. 20, No. 5, 2023, id. 4048.10.3390/ijerph20054048Search in Google Scholar PubMed PubMed Central

[30] Waskow, R., V. G. Maciel, R. Tubino, and A. Passuello. Environmental performance of construction and demolition waste management strategies for valorization of recycled coarse aggregate. Journal of Environmental Management, Vol. 295, 2021, id. 113094.10.1016/j.jenvman.2021.113094Search in Google Scholar PubMed

[31] Cortes-Tolalpa, L., D. J. Jiménez, M. J. de Lima Brossi, J. F. Salles, and J. D. van Elsas. Different inocula produce distinctive microbial consortia with similar lignocellulose degradation capacity. Appl Microbiol Biotechnol, Vol. 100, 2016, pp. 7713–7725.10.1007/s00253-016-7516-6Search in Google Scholar PubMed PubMed Central

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- De-chlorination of poly(vinyl) chloride using Fe2O3 and the improvement of chlorine fixing ratio in FeCl2 by SiO2 addition

- Reductive behavior of nickel and iron metallization in magnesian siliceous nickel laterite ores under the action of sulfur-bearing natural gas

- Study on properties of CaF2–CaO–Al2O3–MgO–B2O3 electroslag remelting slag for rack plate steel

- The origin of {113}<361> grains and their impact on secondary recrystallization in producing ultra-thin grain-oriented electrical steel

- Channel parameter optimization of one-strand slab induction heating tundish with double channels

- Effect of rare-earth Ce on the texture of non-oriented silicon steels

- Performance optimization of PERC solar cells based on laser ablation forming local contact on the rear

- Effect of ladle-lining materials on inclusion evolution in Al-killed steel during LF refining

- Analysis of metallurgical defects in enamel steel castings

- Effect of cooling rate and Nb synergistic strengthening on microstructure and mechanical properties of high-strength rebar

- Effect of grain size on fatigue strength of 304 stainless steel

- Analysis and control of surface cracks in a B-bearing continuous casting blooms

- Application of laser surface detection technology in blast furnace gas flow control and optimization

- Preparation of MoO3 powder by hydrothermal method

- The comparative study of Ti-bearing oxides introduced by different methods

- Application of MgO/ZrO2 coating on 309 stainless steel to increase resistance to corrosion at high temperatures and oxidation by an electrochemical method

- Effect of applying a full oxygen blast furnace on carbon emissions based on a carbon metabolism calculation model

- Characterization of low-damage cutting of alfalfa stalks by self-sharpening cutters made of gradient materials

- Thermo-mechanical effects and microstructural evolution-coupled numerical simulation on the hot forming processes of superalloy turbine disk

- Endpoint prediction of BOF steelmaking based on state-of-the-art machine learning and deep learning algorithms

- Effect of calcium treatment on inclusions in 38CrMoAl high aluminum steel

- Effect of isothermal transformation temperature on the microstructure, precipitation behavior, and mechanical properties of anti-seismic rebar

- Evolution of residual stress and microstructure of 2205 duplex stainless steel welded joints during different post-weld heat treatment

- Effect of heating process on the corrosion resistance of zinc iron alloy coatings

- BOF steelmaking endpoint carbon content and temperature soft sensor model based on supervised weighted local structure preserving projection

- Innovative approaches to enhancing crack repair: Performance optimization of biopolymer-infused CXT

- Structural and electrochromic property control of WO3 films through fine-tuning of film-forming parameters

- Influence of non-linear thermal radiation on the dynamics of homogeneous and heterogeneous chemical reactions between the cone and the disk

- Thermodynamic modeling of stacking fault energy in Fe–Mn–C austenitic steels

- Research on the influence of cemented carbide micro-textured structure on tribological properties

- Performance evaluation of fly ash-lime-gypsum-quarry dust (FALGQ) bricks for sustainable construction

- First-principles study on the interfacial interactions between h-BN and Si3N4

- Analysis of carbon emission reduction capacity of hydrogen-rich oxygen blast furnace based on renewable energy hydrogen production

- Just-in-time updated DBN BOF steel-making soft sensor model based on dense connectivity of key features

- Effect of tempering temperature on the microstructure and mechanical properties of Q125 shale gas casing steel

- Review Articles

- A review of emerging trends in Laves phase research: Bibliometric analysis and visualization

- Effect of bottom stirring on bath mixing and transfer behavior during scrap melting in BOF steelmaking: A review

- High-temperature antioxidant silicate coating of low-density Nb–Ti–Al alloy: A review

- Communications

- Experimental investigation on the deterioration of the physical and mechanical properties of autoclaved aerated concrete at elevated temperatures

- Damage evaluation of the austenitic heat-resistance steel subjected to creep by using Kikuchi pattern parameters

- Topical Issue on Focus of Hot Deformation of Metaland High Entropy Alloys - Part II

- Synthesis of aluminium (Al) and alumina (Al2O3)-based graded material by gravity casting

- Experimental investigation into machining performance of magnesium alloy AZ91D under dry, minimum quantity lubrication, and nano minimum quantity lubrication environments

- Numerical simulation of temperature distribution and residual stress in TIG welding of stainless-steel single-pass flange butt joint using finite element analysis

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part I

- Electro-thermal performance evaluation of a prismatic battery pack for an electric vehicle

- Experimental analysis and optimization of machining parameters for Nitinol alloy: A Taguchi and multi-attribute decision-making approach

- Experimental and numerical analysis of temperature distributions in SA 387 pressure vessel steel during submerged arc welding

- Optimization of process parameters in plasma arc cutting of commercial-grade aluminium plate

- Multi-response optimization of friction stir welding using fuzzy-grey system

- Mechanical and micro-structural studies of pulsed and constant current TIG weldments of super duplex stainless steels and Austenitic stainless steels

- Stretch-forming characteristics of austenitic material stainless steel 304 at hot working temperatures

- Work hardening and X-ray diffraction studies on ASS 304 at high temperatures

- Study of phase equilibrium of refractory high-entropy alloys using the atomic size difference concept for turbine blade applications

- A novel intelligent tool wear monitoring system in ball end milling of Ti6Al4V alloy using artificial neural network

- A hybrid approach for the machinability analysis of Incoloy 825 using the entropy-MOORA method

- Special Issue on Recent Developments in 3D Printed Carbon Materials - Part II

- Innovations for sustainable chemical manufacturing and waste minimization through green production practices

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part I

- Characterization of Co–Ni–TiO2 coatings prepared by combined sol-enhanced and pulse current electrodeposition methods

- Hot deformation behaviors and microstructure characteristics of Cr–Mo–Ni–V steel with a banded structure

- Effects of normalizing and tempering temperature on the bainite microstructure and properties of low alloy fire-resistant steel bars

- Dynamic evolution of residual stress upon manufacturing Al-based diesel engine diaphragm

- Study on impact resistance of steel fiber reinforced concrete after exposure to fire

- Bonding behaviour between steel fibre and concrete matrix after experiencing elevated temperature at various loading rates

- Diffusion law of sulfate ions in coral aggregate seawater concrete in the marine environment

- Microstructure evolution and grain refinement mechanism of 316LN steel

- Investigation of the interface and physical properties of a Kovar alloy/Cu composite wire processed by multi-pass drawing

- The investigation of peritectic solidification of high nitrogen stainless steels by in-situ observation

- Microstructure and mechanical properties of submerged arc welded medium-thickness Q690qE high-strength steel plate joints

- Experimental study on the effect of the riveting process on the bending resistance of beams composed of galvanized Q235 steel

- Density functional theory study of Mg–Ho intermetallic phases

- Investigation of electrical properties and PTCR effect in double-donor doping BaTiO3 lead-free ceramics

- Special Issue on Thermal Management and Heat Transfer

- On the thermal performance of a three-dimensional cross-ternary hybrid nanofluid over a wedge using a Bayesian regularization neural network approach

- Time dependent model to analyze the magnetic refrigeration performance of gadolinium near the room temperature

- Heat transfer characteristics in a non-Newtonian (Williamson) hybrid nanofluid with Hall and convective boundary effects

- Computational role of homogeneous–heterogeneous chemical reactions and a mixed convective ternary hybrid nanofluid in a vertical porous microchannel

- Thermal conductivity evaluation of magnetized non-Newtonian nanofluid and dusty particles with thermal radiation

Articles in the same Issue

- Research Articles

- De-chlorination of poly(vinyl) chloride using Fe2O3 and the improvement of chlorine fixing ratio in FeCl2 by SiO2 addition

- Reductive behavior of nickel and iron metallization in magnesian siliceous nickel laterite ores under the action of sulfur-bearing natural gas

- Study on properties of CaF2–CaO–Al2O3–MgO–B2O3 electroslag remelting slag for rack plate steel

- The origin of {113}<361> grains and their impact on secondary recrystallization in producing ultra-thin grain-oriented electrical steel

- Channel parameter optimization of one-strand slab induction heating tundish with double channels

- Effect of rare-earth Ce on the texture of non-oriented silicon steels

- Performance optimization of PERC solar cells based on laser ablation forming local contact on the rear

- Effect of ladle-lining materials on inclusion evolution in Al-killed steel during LF refining

- Analysis of metallurgical defects in enamel steel castings

- Effect of cooling rate and Nb synergistic strengthening on microstructure and mechanical properties of high-strength rebar

- Effect of grain size on fatigue strength of 304 stainless steel

- Analysis and control of surface cracks in a B-bearing continuous casting blooms

- Application of laser surface detection technology in blast furnace gas flow control and optimization

- Preparation of MoO3 powder by hydrothermal method

- The comparative study of Ti-bearing oxides introduced by different methods

- Application of MgO/ZrO2 coating on 309 stainless steel to increase resistance to corrosion at high temperatures and oxidation by an electrochemical method

- Effect of applying a full oxygen blast furnace on carbon emissions based on a carbon metabolism calculation model

- Characterization of low-damage cutting of alfalfa stalks by self-sharpening cutters made of gradient materials

- Thermo-mechanical effects and microstructural evolution-coupled numerical simulation on the hot forming processes of superalloy turbine disk