Abstract

The conversion of palm oil into biofuel is continuing interest in a green alternative fuel. Catalytic hydrocracking palm oil into biofuels was carried out by NiMoO4/activated carbon catalyst. The catalyst was first designed from nanoparticle NiO–MoO3 supported by activated carbon from palm kernel shell and characterized using X-ray crystallography, Fourier transform infrared, and scanning electron microscope with energy dispersive X-ray. The efficiency of the catalyst was evaluated for the conversion of palm oil into biogasoline and kerosene using the hydrocracking process at different temperatures (150, 250, and 350°C). The resulting catalytic hydrocracking is liquid biofuels, which is analyzed using GC–MC to determine its fractions: biogasoline (C5–C10) and kerosine (C11–C16). The optimum condition of catalytic hydrocracking was obtained at a temperature of 150°C resulting in two primary fractions classified into biogasoline (37.83%) consisting of n-nonane (C9) and 1-heptene (C7) and kerosine (61.34%) consisting of three primary fractions, n-pentadecane (C15), hexadecene (C16), and 1-undecene (C11). The result of this study proved that the NiMoO4/activated carbon catalyst plays an important role in catalytic hydrocracking and becomes a promising alternative catalyst for the preparation of biofuels.

1 Introduction

In the recent decade, researchers have selected biomass as an important alternative fuel for the requirement of energy and transportation [1]. Indonesia has abundant biomass sources available in Sumatera, Kalimantan, and Irian Jaya islands. Palm oil derivates are glycerol, fatty acid, or fatty alcohol that are potential compounds for raw materials of food products, cosmetics, perfumes, and detergents [2–4]. Nevertheless, these compounds have made palm oil to become a sustainable replacement for the fossil fuels. The extensive use and depletion of fossil fuel resources have increased the research level to replace fossil oil with palm oil, which is low energy, renewable resources, and environmentally friendly [5,6]. Palm oil consists of predominantly paraffin and aromatic that can be converted into biofuel. However, the characteristics, utilizations, and environmental impacts of the palm oil industry should be further investigated.

Activated carbon has been extensively studied and used as a catalyst and supporting catalyst. Previous research showed that activated carbon is widely used as catalyst for the conversion of palm oil into biodiesel due to its low-cost material, rich in functional groups, and porous material [7,8]. The application of activated carbon has been developed for supporting of the heterogeneous catalyst. Therefore, it is necessary to modify the naturally activated carbon to improve its characterization and structure such as thermal stability, porous structure, and acidity. The incorporation of the activated carbon with metallic ions and metallic oxides such as nickel, iron, cobalt, platinum, and molybdenum has been widely published [9,10]. Molybdenum nitride-zeolite was used as a catalyst and successfully prepared for the hydrocracking process [11]. Ni–Fe/HZSM-5 a catalyst was prepared for the hydrocracking of coconut oil [12,13]. Ni–Cu/bentonite was used as a catalyst to convert palm oil into gasoline production [14]. Based on the porous structure of activated carbon, the dispersion of metals and metal oxides on the surface through the physical and chemical interaction can increase the active sites and be used as a heterogeneous catalyst. Increasing the active site of catalysts such as metallic active sites and acidity may support the catalytic activity through hydrocracking, isomerization, and cyclization process [15,16]. In this research, the modification of activated carbon as a porous material doped with the bimetallic nanoparticle NiO and MoO3 is a promising material for hydrocracking catalysts. The catalyst of NiMoO4/activated carbon was prepared and will test its performance for the conversion of palm oil to produce biofuels consisting of biogasoline (C5–C10) and kerosine (C11–C16) fractions at different temperatures.

2 Materials and methods

2.1 Materials

The waste of palm kernel shell (PKS) was collected from an open area around the palm oil industry in East Kalimantan, Indonesia. The PKS was found in large quantities and used as a source of energy in the steam boiler. All chemicals and reagent such as potassium hydroxide, nitrate acid, nickel nitrate hexahydrate (Ni(NO3)2·6H2O), ammonium hepta-molybdate tetrahydrate ((NH4)6Mo7O24·4H2O), chloride acid, and sodium hydroxide were of analytical grade from Merck and used without any further purification. Hydrogen and nitrogen gas were of high purity from Samator distributor gas industry, in Indonesia.

2.2 Methods

2.2.1 Catalyst preparation

The bimetallic nickel and molybdenum oxides supported by activated carbon or NiMoO4/activated carbon catalyst was obtained by the calcination process at 400°C. The activated carbon used in this study was prepared using the previous work with the modification of a pyrolysis temperature of 700°C [17]. About 5 g of the activated carbon was impregnated with 100 mL aqueous solution of 7.2 g Ni(NO3)2·6H2O and 1.8 g (NH4)6Mo7O24·4H2O and strongly stirred for 1 h. The mixture was continuously stirred at temperature of 60–70°C for 5 h followed by gradually dripped 2 M sodium hydroxide solution to control the pH in the range of 8–9. The mixture was filtered and dried in an oven at 110°C. The dried mixture was calcinated at a temperature of 400°C for 5 h and finally reduced by gas hydrogen. The NiMo4/activated catalyst was kept for further analysis.

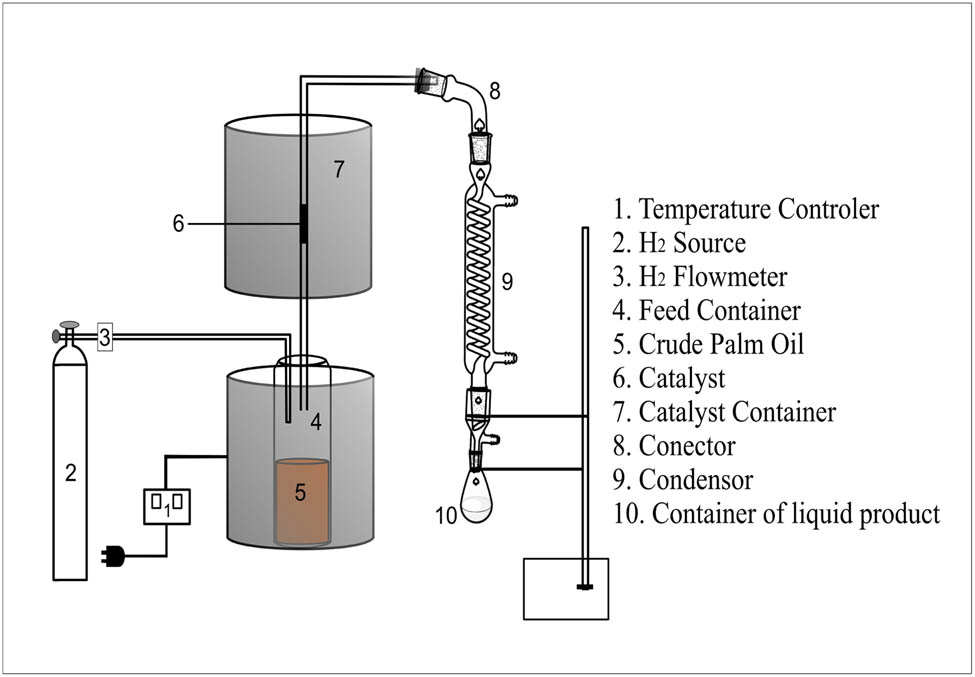

2.2.2 Hydrocracking process

The hydrocracking process was carried out as shown in Figure 1 [18]. Approximately, 1.0 g of NiMoO4/activated carbon was placed into the catalyst chamber and 100 g of palm oil as a feedstock was injected into the feedstock reactor. The reactor was gradually heated to the temperature of 350°C and kept for 30 min as a contact time. During the catalytic process, gas hydrogen was injected with a flow rate of 20 mL/min. The palm oil slowly evaporates as the lightest gas and passes through the catalyst chamber which was set up at a temperature of 150°C. The interaction between gas particles and catalyst occurred in the catalyst chamber as a catalytic hydrocracking process. The result is a gas product and then it was condensed to form a liquid yield which was collected into a vial as the primary product. The experiment for each hydrocracking process was continued with a similar method at different temperatures (450 and 550°C) and the temperature catalyst was set up at 250 and 350°C. The result of the hydrocracking process yields three liquid products, which were obtained at the temperatures of 150, 250, and 350°C as the main product. However, some gas products cannot be collected because of disappearance during the catalytic process.

Diagram of hydrocracking process.

2.2.3 Characterization of the catalyst

The characterization of NiMoO4/activated carbon catalyst was carried out using Fourier transform infrared spectroscopy (FTIR, PerkinElmer Spectrum Version), X-ray crystallography (XRD, Bruker D2 Phaser Gen), and scanning electron microscope with energy dispersive X-ray analysis mapping (SEM-EDX/mapping, JEOL JED-2300). The effectivity of the catalyst was tested for the conversion of palm oil into biofuel at different temperatures. The liquid product was separated into biogasoline and kerosene. The percentage fraction and composition of biogasoline and kerosine were evaluated by the gas chromatography-mass spectrometer (GC-MS, Shimadzu QP2010 SE).

3 Results and discussion

3.1 Characterization of catalyst

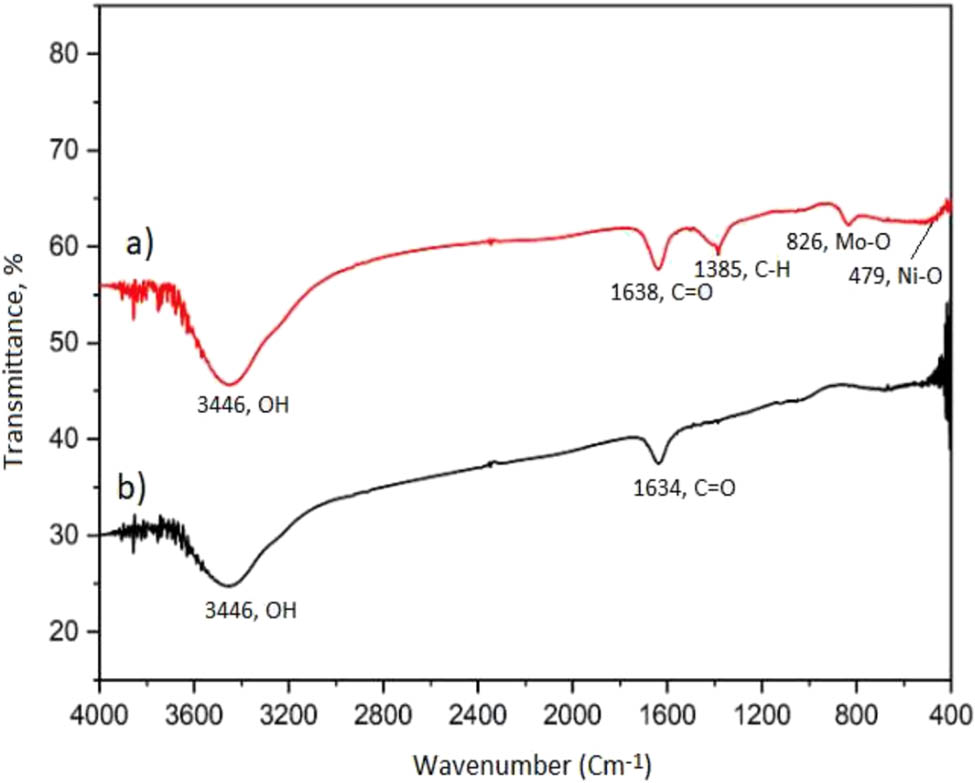

The determination of functional groups on the activated carbon and the catalyst is analyzed using FTIR as shown in Figure 2. A broad peak around 3,446 cm−1 is assigned to the −OH stretching vibration of hydroxyl groups. Both peaks at 1,634 and 1,638 cm−1 are attributed to the C═O stretching vibration of carboxylate and carbonyl groups. The peak at around 1,385 cm−1 is the characteristic of C–H in the −CH2 and −CH3 deformation. The peaks at 826 and 479 cm−1 are assigned to the presence of metal–oxygen bonding in the form of Ni–O or Mo–O on the surface of activated carbon [19]. The presence of an oxygen-containing functional group leads to strong bonding between oxygen and nitrogen–molybdenum during the impregnation process. This interaction is essential for achieving and preserving high nickel and molybdenum dispersion on the surface of activated carbon. This effect on the Ni–O and Mo–O dispersion on the surface of activated carbon might increase the catalyst activity [20,21].

FTIR spectra of (a) activated carbon and (b) NiMoO4/activated carbon.

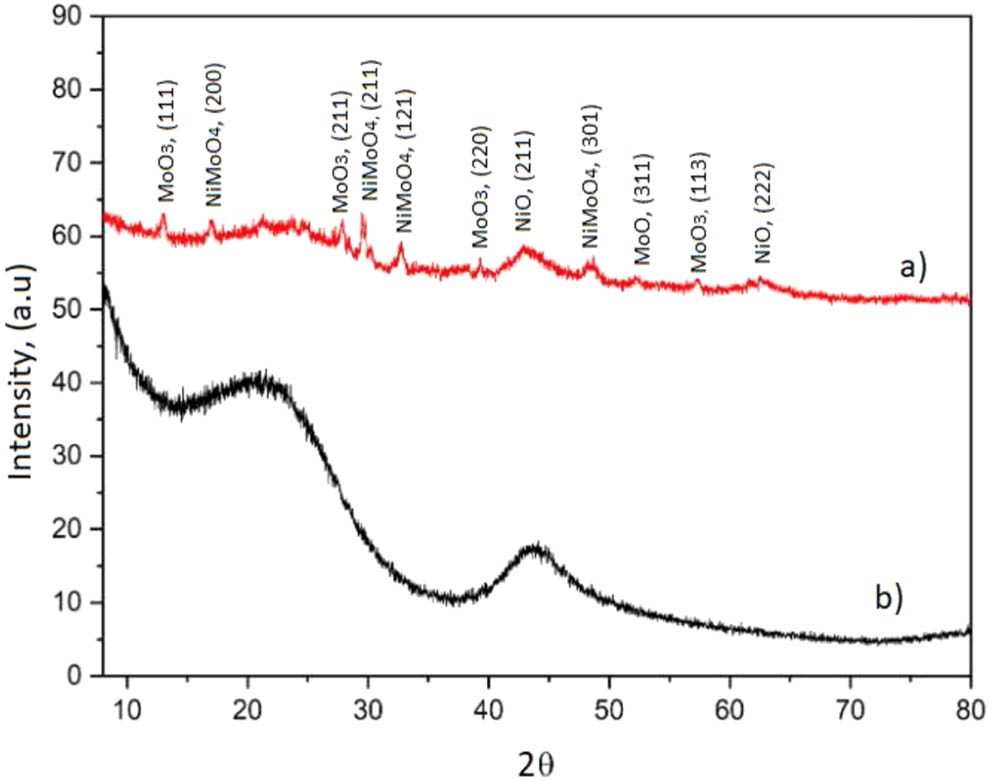

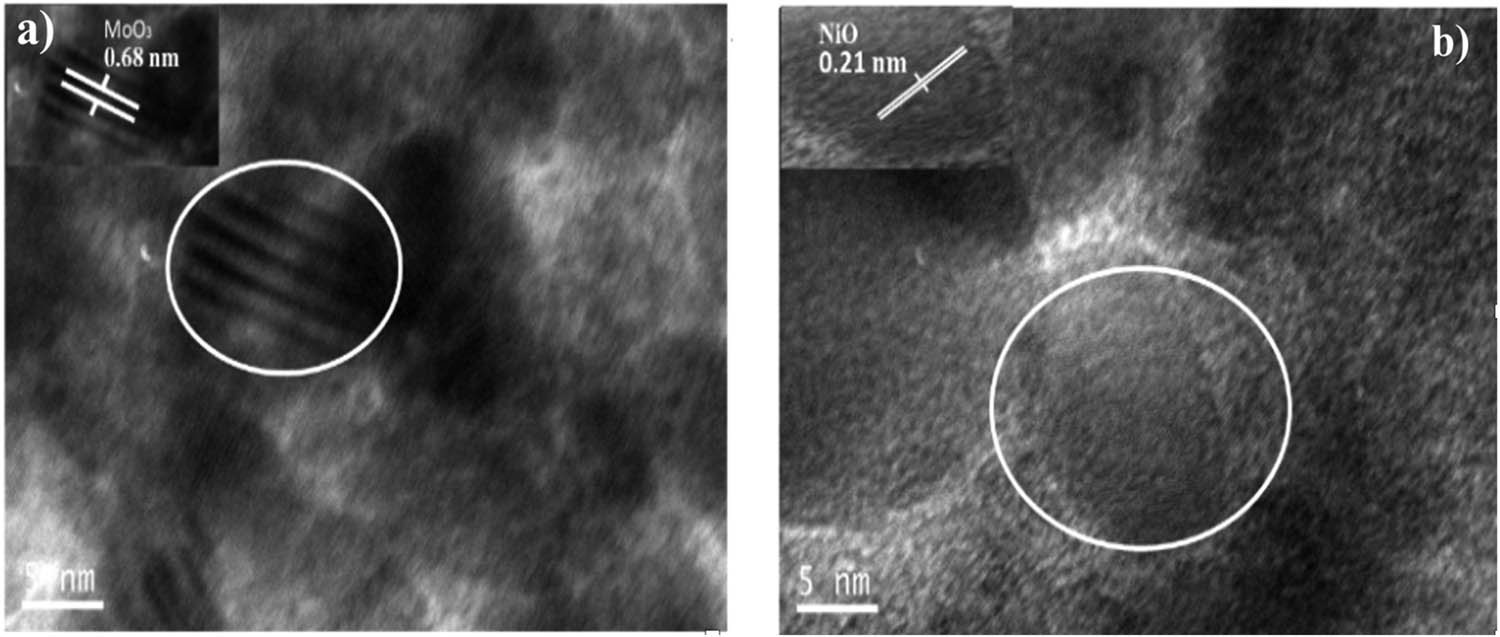

The crystallinity of the catalyst was carried out using XRD and is shown in Figure 3. The diffraction pattern of activated carbon showed a wide peak found at 2θ = 23.58° and 44.11°, which indicates an amorphous structure with the disorderly stacked up carbon rings. Metal oxide of MoO3 was detected at 2θ = 13.01° (111), 27.84° (211), 39.28° (220), 52.23° (311), and 57.30° (113), which was confirmed with JCPDS 00-005-0506. The d-spacing of MoO3 is 0.68, 0.32, 0.23, 0.16, and 0.16 nm. The NiO shows well diffraction at 2θ = 42. 93° (211) and 62.75° (222) with the average of d-spacing of 0.21 and 0.15 nm, respectively, confirmed with JCPDS 00-004-0835. The peaks at 2θ = 16.88° (200), 29.51° (211), 32.77° (121), and 48.69° (301) are the indication of NiMoO4 with the d-spacing of 0.52, 0.30, 0.27, and 0.19 nm, based on the JCPDS 00-031-0902 [22,23]. The crystallized size of the catalyst was calculated by Scherer’s equation using D (crystallize size) and full width at half maxima (FWHM) parameters. The NiMoO4/activated carbon had a crystalized size of about 14.4 nm as the crystal of nickel–molybdenum attached to the surface activated carbon.

XRD patterns of (a) activated carbon and (b) NiMoO4/activated carbon.

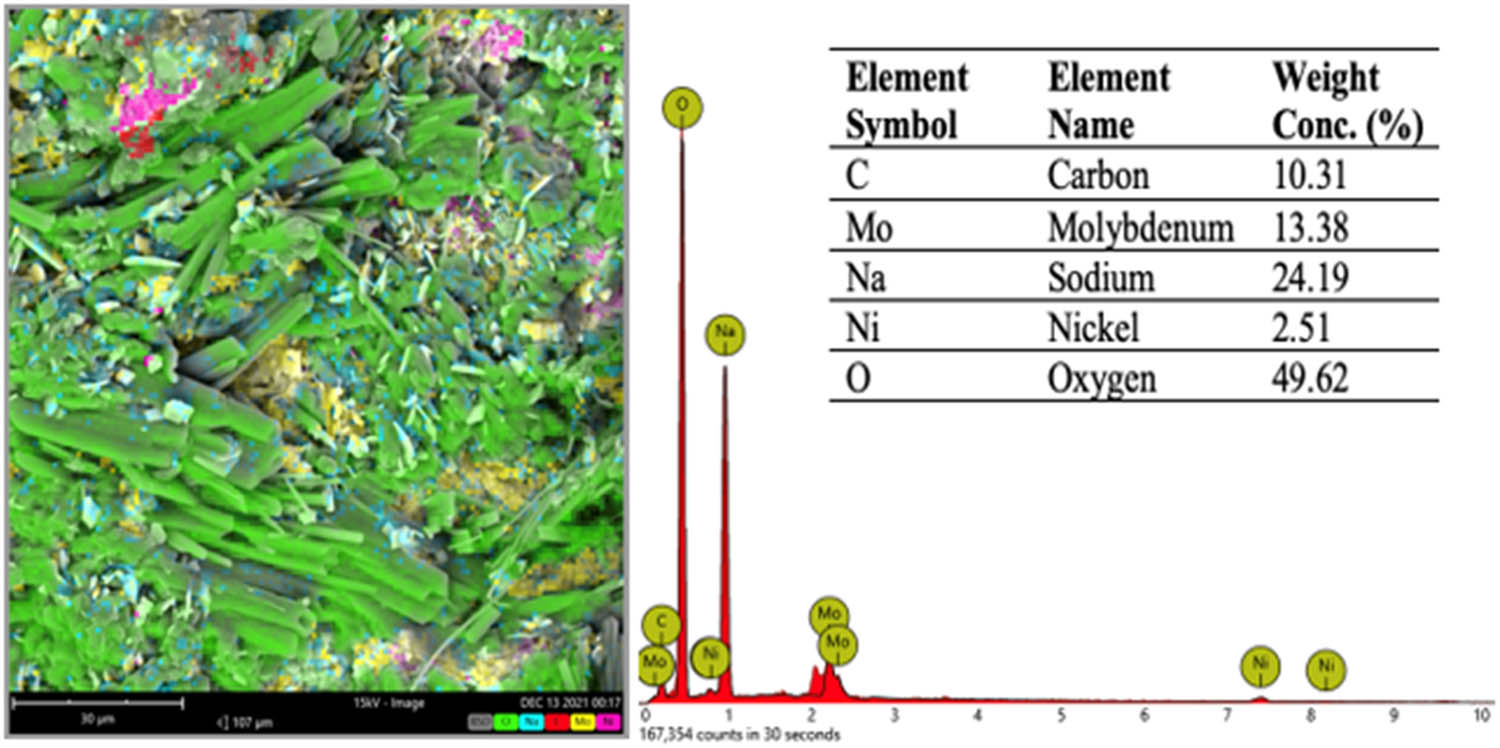

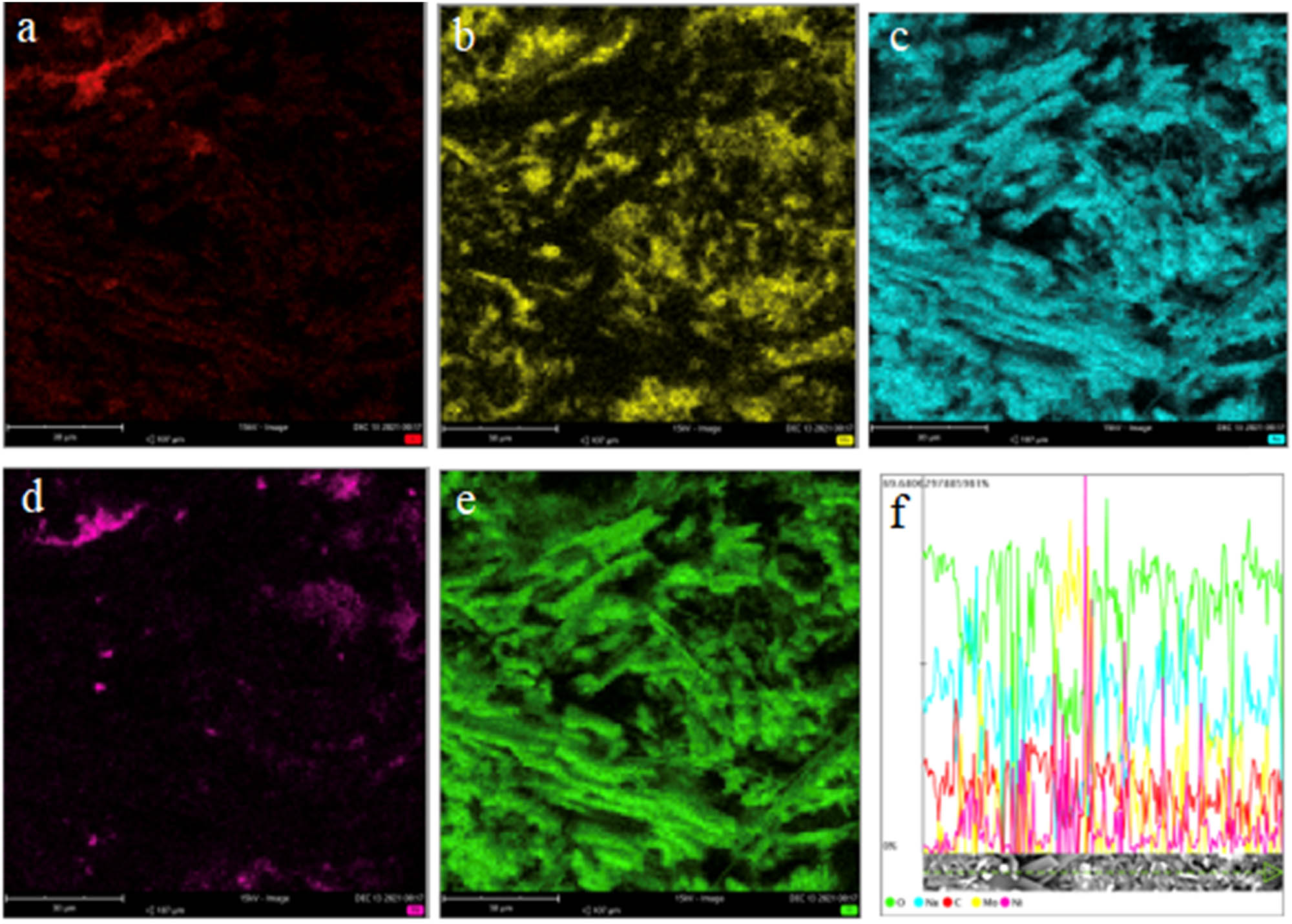

Figure 4 shows the SEM image and EDX elemental mapping of NiMoO4/activated carbon. The microstructure image shows that the surface morphology catalyst is an irregular tubular structure with unsmooth surface. The elemental analysis proved that molybdenum and nickel were found at about 13.38 and 250%, respectively, and distributed on the surface of the catalyst as shown in the table in Figure 4. Figure 5(a–e) shows the EDX elemental mapping as a distribution of elements on the surface of activated carbon assigned with different colors. The incorporation of metal NiO and MoO3 on the surface of activated carbon caused an increase in the thickness of the surface through the overlap among the metal elements. The thickness of NiMoO4/activated can be shown from the scanline analysis as shown in Figure 5(f). The highest element content is oxygen presented with a green color on the top of the activated carbon surface. Metal nickel and molybdenum are attached to the surface of activated carbon.

SEM-EDX of the catalyst of NiMoO4/activated carbon.

SEM-EDX/mapping of the distribution of elements on the surface of activated carbon: (a) carbon, (b) molybdenum, (c) sodium, (d) nickel, (e) oxygen, and (f) scanline.

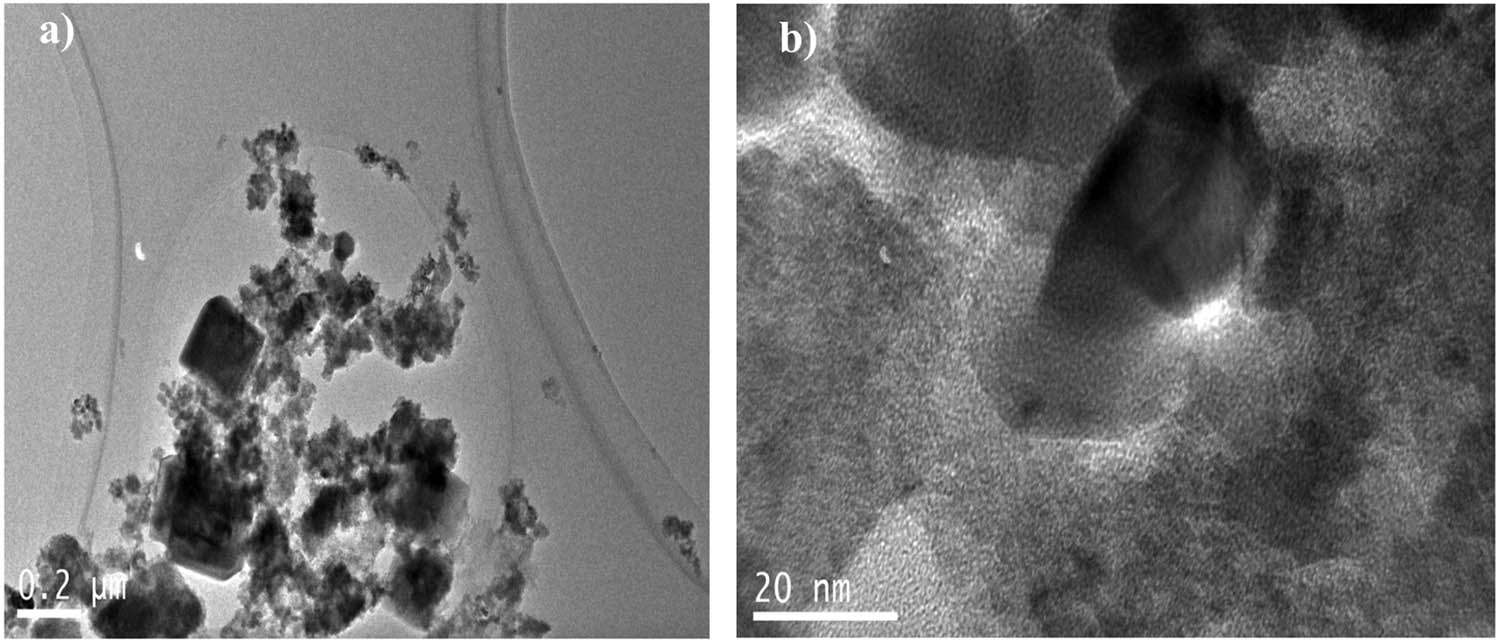

Characterization of NiMoO4/activated carbon was determined using high-resolution transmission electron microscopy (HRTEM) as shown in Figure 6. The HRTEM image shows that the spherical feature with a bright color is indication of the surface of activated carbon and a cubical dark particle is a crystal of Ni and Mo. It is difficult to differentiate the particles of metal Ni and Mo due to their appearing in similar dark cubical particles. The distribution of nanoparticles shows a relatively uniform structure with irregular size. The particles are agglomerated to create a dark spot representing the overlap particles with more layer formations [24]. This observation reveals that the particles NiO and MoO3 are successfully immobilized on the surface of activated carbon as the catalyst of NiMoO4/activated carbon. The EDX mapping shows that the particle Mo leads the formation of metals in the catalyst.

The HRTEM of (a) MoO3 and (b) NiO.

Figure 7 shows that the high-resolution TEM of the catalyst displays a crystal lattice structure of Mo–O and an agglomeration of Ni–O crystal that are immobilized on the activated carbon. The inter-planar distance of the fringes was obtained at 0.68 and 0.21 nm for the MoO3 and NiO, respectively. This result is also confirmed from the XRD data. A different d spacing is caused by the different ionic radii of metals NiO and MoO3 [25].

TEM image of NiMoO4/activated carbon at different sizes: (a) 0.2 µm and (b) 20 nm.

3.2 Conversion of palm oil by catalytic reaction

The optimizing hydrocracking of palm oil to biofuel was carried out using the NiMoO4/activated carbon catalyst. The hydrocracking process was conducted at different temperatures of 150, 250, and 350°C with a hydrogen flow rate of 20 mL/min. The hydrogen gas is passed in flow over the catalyst bed at a certain temperature. The main product of the hydrocracking process is liquid and then analyzed using GC–MC to determine the hydrocarbon fuel product. The liquid product is light hydrocarbon fuel that was separated into biogasoline (C5–C10), kerosine (C11–C16), and a heavy product (>C18). The side product of the hydrocracking process is coke, residue, and gas. The determination of total percentage of the side product and liquid is written as follows:

Here L is the liquid conversion obtained from the catalytic process (wt%), C is the coke formation on the catalyst (wt%), R is the residue in the reactor (wt%), G is the gas conversion (wt%), w l is the weight of liquid obtained after treatment, w r is the residue weight after treatment, w f is the weight of crude palm oil, w cat is the weight of catalyst after treatment, and w cbt is the weight of catalyst before treatment.

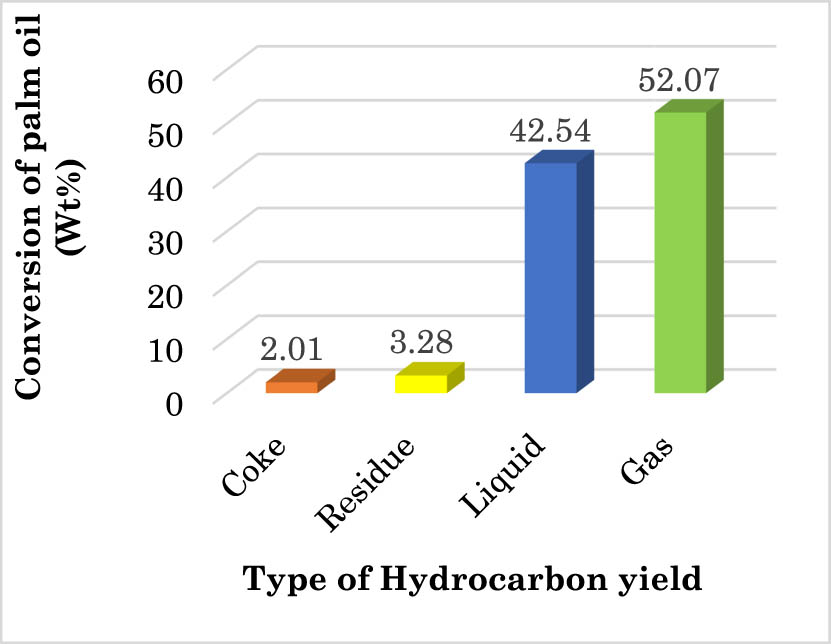

Figure 8 shows the total percentage conversion of the coke, liquid, residue, and gas resulted from the hydrocracking process. Coke occurs due to the clumping of residual oil on the surface that can inhibit the interaction between the active site of the catalyst and oil. The percentage yield of coke was calculated according to equation (1). The amount of coke found is about 2.01 wt% as a solid compound that strongly attaches to the catalyst surface. The residue was obtained inside the reactor in form of a thick oil as a residual feedstock in the combustion reaction. The percentage residue was obtained as per equation (2). The yield of residue is about 3.28 wt%. Liquid is a main product resulting from the condensation of the lightest gas product and it is calculated according to equation (3). The yield of liquid is found to be about 42.54 wt%. The resulted liquid was analyzed with the GC-MS to determine their fractions such as biogasoline, kerosine, and heavy hydrocarbon fuel. The largest side yield is the gas that disappeared during the catalytic activation. The determination of percentage gas is calculated as in equation (4). The amount of gas yield is 52.07 wt%. All the side products such as coke, residue, and gas are difficult to collect and hence cannot determine their fractions and compositions.

Total products resulted from the hydrocracking process.

3.3 Conversion of liquid to biofuel

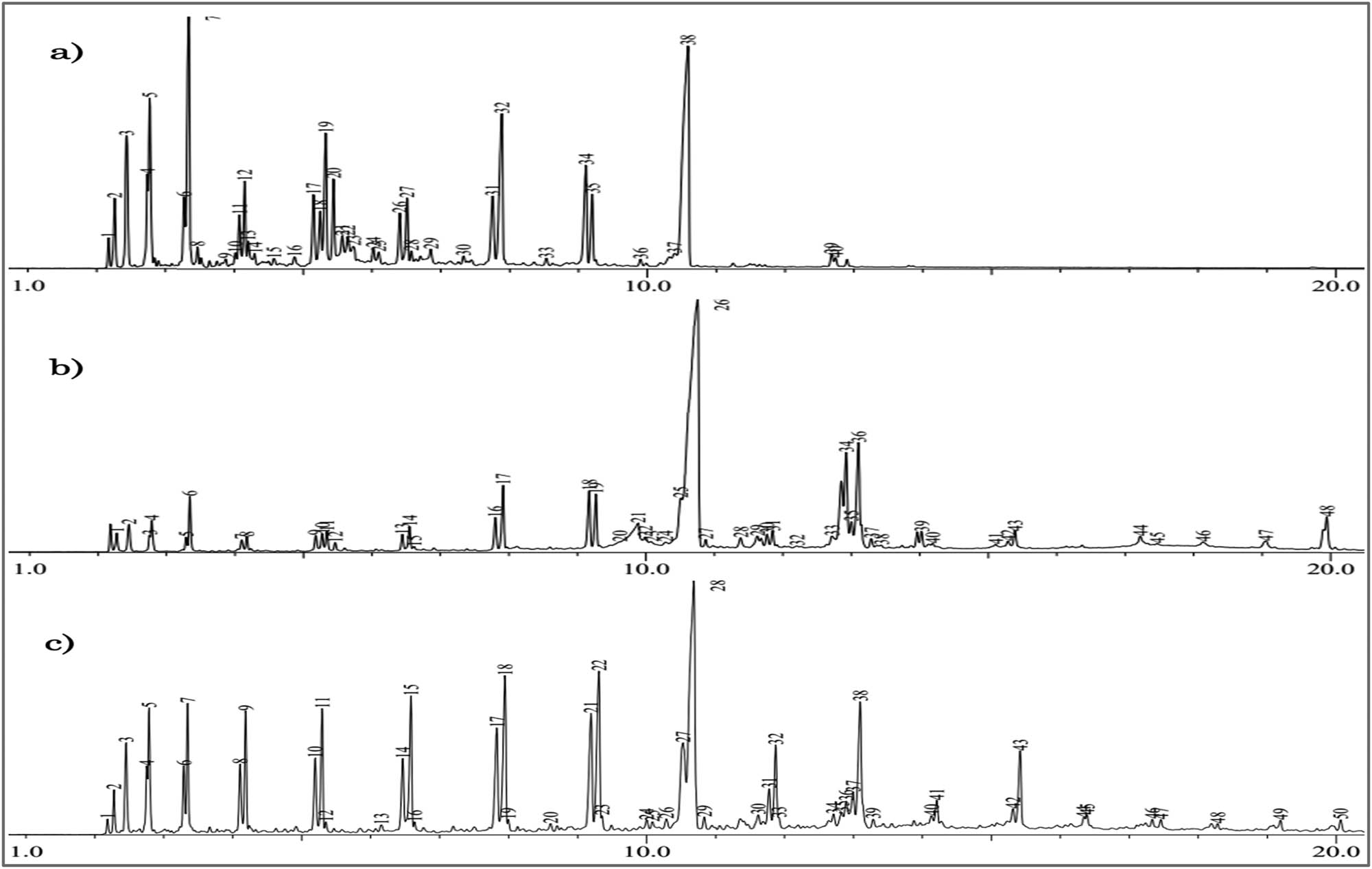

The ability of NiMoO4/activated carbon catalyst in the conversion of palm oil into biofuel is an indication of the successful catalytic process. Many numbers of peaks present in the figure show the effectivity of the catalyst in the catalytic hydrocracking. Figure 9 shows the GC spectra of the liquid product obtained at different temperatures. Figure 9(a–c) describes the distribution of peaks at the temperatures of 150, 250, and 350°C, respectively. Different number of peaks are shown in each of the temperature. At a temperature of 150°C, the number of the peak at low retention time in the range of 2–10 min is more dominant compared to other hydrocracking temperatures. This result proves that the hydrocracking temperature of 150°C is predominantly biogasoline. However, Figure 9(a) and (b) shows the reduction in the number of peaks at low retention time and shifts to higher retention time in the range of 10–20 min. The reason is that the increase in temperature to 250 and 350°C increases the kerosine (C11–C16) and heavy hydrocarbon fraction (>C17) product. The effectiveness of the catalyst of NiMoO4/activated carbon in the conversion of palm oil to biofuel was influenced by the temperature which was supported with hydrogen gas and an active site of the catalyst. Temperature of the hydrocracking may initiate the breakdown of carbon–carbon to form free radicals resulting in an increasing gas and light oil product.

GC-MS spectra of liquid product resulted at different temperatures of (a) 150°C, (b) 250°C, and (c) 350°C.

The presence of hydrogen in the catalytic process is very important to support the formation of the product. At high temperatures, the hydrogen is easily split into free radicals, which are dispersed on the active site of the catalyst. However, the active site of a catalyst consisting of metallic NiMoO4 and a porous structure of activated carbon has a dual function as an acidic site for an increase of the cracking process and as metal sites for the hydrogenation process. The combination of free radicals resulted from hydrogen and carbon inhibits serious cracking and facilitates the condensation of free radicals. This process suggested that temperature of 150°C is the optimum condition for producing of a shorter-chain-hydrocarbon compound as a biofuel product. However, at a higher temperature, the yield of the catalytic hydrocracking is a heavy fraction such as kerosene and coke.

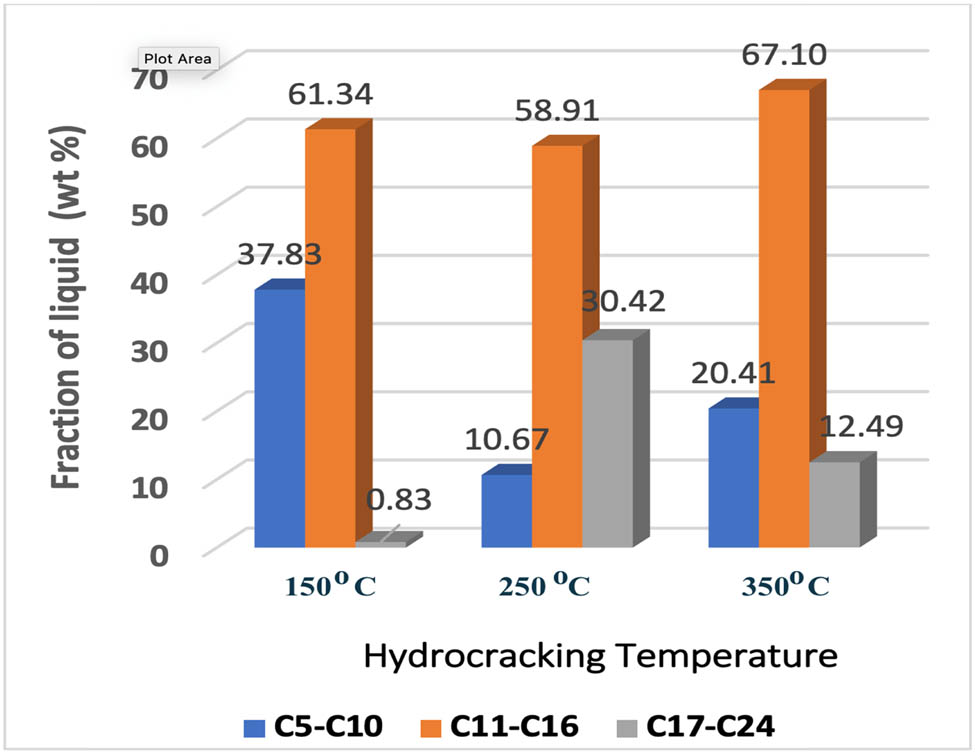

Figure 10 shows the percentage of the liquid product determined from the GC data. The result was classified according to carbon contents such as biogasoline (C5–C10), kerosine (C11–C16), and heavy product (>C18). The highest conversion was obtained at a temperature of 150°C consisting of biogasoline (37.83 wt%), kerosine (61.33 wt%), and heavier hydrocarbon (0.83 wt%). A temperature of 250°C shows decrease in biogasoline and kerosene products to 10.67and 58.91 wt%, respectively, and an increase in the heavy product (30.42 wt%). However, at the temperature of 350°C, the product of biogasoline increases to 20.41 wt% followed by decrease in kerosene (67.10 wt%) and heavier products (12.49 wt%). This study suggests that the optimum condition of the hydrocracking process is obtained at a temperature of 150°C. Increasing the temperature from 250 to 350°C may accelerate the formation of free radicals from hydrogen and carbon. Incorporation of free radicals through isomerization might create a new hydrocarbon fuel with smaller carbon content. The condensation of free radicals may form hydrocarbon fuels such as biogasoline and kerosene. However, the formation of a heavy hydrocarbon fuel such as coke is due to the ineffective catalyst to facilitate the isomerization process. This result was compared with the previous study [18] and shows a similar optimum temperature (150°C) with the highest gasoline products. This result can be assumed that the conversion of palm oil into biogasoline can be recommended at a temperature of 150°C.

Types of liquid fractions at different temperatures: biogasoline (C5–C10), kerosine (C11–C16), and heavy hydrocarbon fuel (C17–C24).

3.4 Conversion of biofuel to hydrocarbon fraction

The liquid fraction of the hydrocracking process can be separated into biogasoline (C5–C10), kerosine (C11–C16), and heavy hydrocarbon fuel (C17–C24). The prediction of fraction compounds was determined by GC-MS supported with the Similarity Index. Table 1 shows the distribution of liquid fractions at different temperatures. At the temperature of 150°C, the primary products in the biogasoline are n-nonane (C9) and 1-heptene (C7). This result was confirmed from a previous study that biogasoline consists of alkanes and alkenes compounds [26]. Based on the GC-MS analysis, the kerosine fraction primarily consists of n-pentadecane (C15) and 2-undecene (C10). This result is assumed from the conversion of unsaturated fatty acid into fatty acid and followed by the conversion into shorten-chain-hydrocarbon using decarboxylation and hydrodeoxygenation process [27]. The increase in the temperature to 250°C decreased the biogasoline and kerosine yield to 10.67 and 58.91%, respectively. At the hydrocracking temperature of 350°C, the percentage fraction of the biogasoline is 20.41% with a large number of n-decane (C10) compounds. Meanwhile, the kerosine fraction increases to 67.1% consisting of a high n-pentadecane (C15). The percentage of heavy products is 12.49 wt% as a side product of catalytic hydrocarbon. The reduction of fraction yield is assumed that an increasing temperature caused an overheating of the catalytic process and continued splitting of hydrogen and carbon–carbon bond to form free radicals. The formation of the incorporation of free radicals may create new heavy hydrocarbon product but then it continued to block the active site of the catalyst by the coke formation. Therefore, the yield of palm oil conversion is strongly influenced by the temperature of hydrocracking.

Experiment result of biogasoline and kerosine fractions

| Biogasoline (C5–C10) | Kerosine (C11–C16) | Heavier hydrocarbon (C17–C24) | |||

|---|---|---|---|---|---|

| Compound | Relative content (%) | Compound | Relative content (%) | Compound | Relative content (%) |

| Hydrocracking temperature 150°C | |||||

| 1-Hexanol (C6) | 3.13 | 1-Undecene (C11) | 12.90 | C17–C24 | 0.83 |

| 1-Heptene (C7) | 8.78 | 4-Dodecen (C12) | 7.36 | ||

| Octane (C8) | 5.36 | Tridecane (C13) | 1.69 | ||

| n-Nonane (C9) | 12.88 | Dodecenylacetate (C14) | 3.57 | ||

| Decane (C10) | 7.68 | Pentadecane (C15) | 21.01 | ||

| Hexadecene (C16) | 14.81 | ||||

| 37.83 | 61.34 | 0.83 | |||

| Hydrocracking temperature 250°C | |||||

| 1-Hexanol (C6) | 0.75 | 1-Undecene (C11) | 2.26 | (C17–C24) | 30.42 |

| 1-Heptene (C7) | 1.23 | 4-Dodecen (C12) | 1.82 | ||

| Octane (C8) | 1.46 | Tridecane (C13) | 6.82 | ||

| Nonane (C9) | 2.65 | Tetradecane (C14) | 3.16 | ||

| Decane (C10) | 4.58 | Pentadecane (C15) | 41.58 | ||

| Hexadecane (C16) | 3.27 | ||||

| 10.67 | 58.91 | 30.42 | |||

| Hydrocracking temperature 350°C | |||||

| Pentane (C5) | 0.33 | 1-Undecene (C11) | 2.87 | (C17–C24) | 12.49 |

| Hexane (C6) | 1.04 | 1-Dodecene (C12) | 13.94 | ||

| Heptane (C7) | 2.62 | Tridecane (C13) | 10.18 | ||

| Octane (C8) | 4.46 | Tetradecane (C14) | 12.15 | ||

| Nonane (C9) | 5.37 | Pentadecane (C15) | 18.46 | ||

| Decane (C10) | 6.59 | Hexadecane (C16) | 9.50 | ||

| 20.41 | 67.10 | 12.49 | |||

4 Conclusion

Characterization of NiMoO4/activated carbon was carried out using XRD, FTIR, and SEM-EDX mapping and shows that the catalyst has favorable properties for the hydrocracking process. The application was used for the conversion of palm oil shells into biofuel at different hydrocracking temperatures. The optimum condition of the reaction was obtained at a temperature of 150°C resulting in 37.83% of biogasoline and 67.34% of kerosine. The primary fractions for biogasoline are n-nonane (C9) and 1-neptene (C7), and for kerosene are pentadecane (C15) and hexadecene (C16). However, an increase in the reaction temperature to 250 and 350°C decreases the percentage of biogasoline and kerosine products. Most of the heavy hydrocarbon fraction has a low percentage due to the ineffective active site of the catalyst. The result of these studies can be concluded that the NiMoO4/activated carbon performs an important role and is a promising catalyst for heterogeneous catalyst.

-

Funding information: The authors would like to thank The Ministry of Education, Culture, Research, and Technology (Kemdikbudristek) for research funding through The Higher Education Leading Basic Research Scheme (PDUPT) 2021: No. 003/DirDPPM/70/DPPM/PDUPT-Kemendikbudristek/VII/2021.

-

Author contributions: A. Allwar: conceived and designed the experiments, analyzed and interpreted the data, and wrote the article; N. Indriyani: interpreted the data and reviewed the article; R. Maulina and F. Rahmawati: conducted the experiment and analyzed the results.

-

Conflict of interest: The authors declare no conflict of interest regarding this publication.

-

Ethical approval: The conducted research is not related to either human or animal use.

References

[1] Suganuma S, Katada N. Innovation of catalytic technology for upgrading of crude oil in petroleum refinery. Fuel Process Technol. 2020;208:106518.10.1016/j.fuproc.2020.106518Search in Google Scholar

[2] Henindar D, Sari DW. Output of Indonesian crude palm oil (CPO) industry: a review – running head: output of CPO in Indonesia. Int J Manag. 2020;1(6):2011–22.Search in Google Scholar

[3] Trieu TQ, Guan G, Liu G, Tsubaki N, Samart C, Reubroycharoeu P. Direct synthesis of ISO-paraffin fuel from palm oil on mixed heterogeneous acid and base catalysts. Monatshefte Chem Chem Mon. 2017;148(7):1235–43. 10.1007/s00706-017-1963-3.Search in Google Scholar

[4] Bezergianni S, Kalogianni A. Hydrocracking of used cooking oil for biofuels production. Bioresour Technol. 2009 Sep;100(17):3927–32. https://www.sciencedirect.com/journal/bioresource-technology.10.1016/j.biortech.2009.03.039Search in Google Scholar PubMed

[5] Naimaha K, Mardaniea BR, Dwia LM, Adia SN. A review of technology assessment of green gasoline processing. Energy Rep. 2020;6(9):1641–9.10.1016/j.egyr.2019.11.030Search in Google Scholar

[6] Awogbemi O, Kallon DV, Onuh EI, Aigbodion VS. An overview of the classification, production and utilization of biofuelsfor internal combustion engine applications. Energies. 2021;14(18):5687.10.3390/en14185687Search in Google Scholar

[7] Rechnia-Goracy P, Malaika A, Kozlowski M. Acidic activated carbons as catalysts of biodiesel formation. Diam Relat Mater. 2018;87:124–33. 10.1016/j.diamond.2018.05.015.Search in Google Scholar

[8] Ramirez-Arias AM, Giraldo L, Moreno-Pirajan JC. Biodiesel synthesis: use of activated carbon as support of the catalysts. In: Kumar S, Sani R, editors. Biorefining of Biomass to Biofuels. Biofuel and Biorefinery Technologies. India: Springer; Vol. 4. 2018. 10.1007/978-3-319-67678-4_5.Search in Google Scholar

[9] Lam-Maldonado M, Melo-Banda JA, Macias-Ferrer D, Schacht P, Mata-Padilla JM, de la Trre AI, et al. NiFe nanocatalysts for the hydrocracking heavy crude oil. Catal Today. 2020;349:17–25.10.1016/j.cattod.2018.08.005Search in Google Scholar

[10] Li J, Xia H, Wu Q, Hu Z, Hao Z, Zhu Z. Hydrocracking of the crude oil from thermal pyrolysis of municipal wastes over bi-functional Mo–Ni catalyst. Catal Today. 2016;27:172–8. S0920586115005143. 10.1016/j.cattod.2015.08.034.Search in Google Scholar

[11] Hasanudin H, Asri WR, Said M, Hidayati PT, Purwaningrum W, Novia N, et al. Hydrocracking optimization of palm oil to bio-gasoline and bio-aviation fuels using molybdenum nitride–bentonite catalyst. RSC Adv. 2022 Jun;12(26):16431–43.10.1039/D2RA02438ASearch in Google Scholar

[12] Al Muttaqii M, Kurniawansyah F, Prajitno DH, Roesyadi A. Hydrocracking of coconut oil over Ni–Fe/HZSM-5 catalyst to produce hydrocarbon biofuel, Indones. J Chem. 2019;19(2):319–27.10.22146/ijc.33590Search in Google Scholar

[13] Al Muttaqii M, Kurniawansyah F, Prajitno DH, Roesyadi A. Bio-kerosene and bio-gasoil from coconut oils via hydrocracking process over Ni–Fe/HZSM-5 catalyst. Bull Chem React Eng Catal. 2019;14(2):309–19.10.9767/bcrec.14.2.2669.309-319Search in Google Scholar

[14] Suseno A. Hydrocracking of palm oil to gasoline on bimetallic Ni–Cu/zirconia pillared bentonite. IOP Conf. Series: Mater Sci Eng. 509, 2019. p. 012005. 10.1088/1757-899X/509/1/012005.Search in Google Scholar

[15] Kostyniuk A, Bajec D, Likozar B. Hydrocracking, hydrogenation, and isomerization of model biomass tar in a packed bed reactor over bimetallic NiMo zeolite catalysts: tailoring structure/acidity. Appl Catal A Gen. 2021;612:118004.10.1016/j.apcata.2021.118004Search in Google Scholar

[16] Echaroj S, Pannucharoenwong N, Rattanadecho P, Benjapiyaporn C, Benjapiyaporn J. Investigation of palm fibre pyrolysis over acidic catalyst for bio-fuel production. Energy Rep. 2021;7(5):599–607.10.1016/j.egyr.2021.07.093Search in Google Scholar

[17] Allwar A, Setyani A, Fauzani KA. Physical–chemical characterization of nano-zinc oxide/activated carbon composite for phenol removal from aqueous solution. Bull Chem React Eng Catal. 2021;16(1):136–47.10.9767/bcrec.16.1.10282.136-147Search in Google Scholar

[18] Allwar A, Maulina R, Julianto TS, Widyaningsih AA. Hydrocracking of crude palm oil over bimetallic oxide NiO–CdO/biochar catalyst. Bull Chem React Eng Catal. 2022;17(2):476–85.10.9767/bcrec.17.2.14074.476-485Search in Google Scholar

[19] Torre-Luna JA, Moreno S, Molina R, Carriazo JG. Comparison of the catalytic performance of Ni, Mo, and Ni−Mo impregnated on acid halloysite nanotubes in the n‑decane hydroconversion. Energy Fuels. 2019;33(12):12647–55.10.1021/acs.energyfuels.9b02211Search in Google Scholar

[20] Calafat A, Laiane J, Lopez-Agudo A, Palacios JM. Effect of surface oxidation of the support on the thiophene hydrodesulfurization activity of Mo, Ni, and NiMo catalysts supported on activated carbon. J Catal. 1996;162(1):20–30.10.1006/jcat.1996.0256Search in Google Scholar

[21] Rammal MB, Omanovic S. Synthesis and characterization of NiO, MoO3, and NiMoO4 nanostructures through a green, facile method and their potential use as electrocatalysts for water splitting. Mater Chem Phys. 2020;255:123570.10.1016/j.matchemphys.2020.123570Search in Google Scholar

[22] Feste PD, Crisci M, Barbon F, Tajoli F, Salerno M, Drago F, et al. Work function tuning in hydrothermally synthesized vanadium-doped MoO3 and Co3O4 mesostructures for energy conversion devices. Appl Sci (Basel). 2021;11(5):2016.10.3390/app11052016Search in Google Scholar

[23] Wang J, Wei X, Wangyang P. Gas-sensing devices based on Zn-doped NiO two-dimensional grainy films with fast response and recovery for ammonia molecule detection. Nanoscale Res Lett. 2015 Dec;10(1):461.10.1186/s11671-015-1170-2Search in Google Scholar PubMed PubMed Central

[24] Lobiak E, Shlyakhova E, Bulusheva L, Okotrub A. Ni–Mo and Co–Mo alloy nanoparticles for catalytic chemical vapor deposition synthesis of carbon nanotubes. J Alloy Compd. 2015;621:351–6.10.1016/j.jallcom.2014.09.220Search in Google Scholar

[25] Rakshit S, Ghosh S, Chall S, Sundar Mati S, Moulikac SP, Bhattacharya SC. Controlled synthesis of spin glass nickel oxide nanoparticles and evaluation of their potential antimicrobial activity: a cost effective and eco friendly approach. RSC Adv. 2013;3(42):19348–56, https://www.researchgate.net/publication/271380243.10.1039/c3ra42628aSearch in Google Scholar

[26] Shamsul NS, Kamarudin SK, Rahman NA. Conversion of bio-oil to bio-gasoline via pyrolysis and hydrothermal: a review. Renew Sustain Energy Rev. 2017;80:538–49.10.1016/j.rser.2017.05.245Search in Google Scholar

[27] Srihanun N, Dujjanutat P, Muanruksa P, Kaewkannetra P. Biofuels of green diesel–kerosene–gasoline production from palm oil: effect of palladium cooperated with second metal on hydrocracking reaction. Catalysts. 2020;10(241):241.10.3390/catal10020241Search in Google Scholar

© 2022 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Photocatalytic degradation of Rhodamine B in aqueous phase by bimetallic metal-organic framework M/Fe-MOF (M = Co, Cu, and Mg)

- Assessment of using electronic portal imaging device for analysing bolus material utilised in radiation therapy

- A detailed investigation on highly dense CuZr bulk metallic glasses for shielding purposes

- Simulation of gamma-ray shielding properties for materials of medical interest

- Environmental impact assesment regulation applications and their analysis in Turkey

- Sample age effect on parameters of dynamic nuclear polarization in certain difluorobenzen isomers/MC800 asphaltene suspensions

- Passenger demand forecasting for railway systems

- Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach

- Gamma, neutron, and heavy charged ion shielding properties of Er3+-doped and Sm3+-doped zinc borate glasses

- Bridging chiral de-tert-butylcalix[4]arenes: Optical resolution based on column chromatography and structural characterization

- Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt

- Comparison of the yield and purity of plasma exosomes extracted by ultracentrifugation, precipitation, and membrane-based approaches

- Bioactive triterpenoids from Indonesian medicinal plant Syzygium aqueum

- Investigation of the effects of machining parameters on surface integrity in micromachining

- The mesoporous aluminosilicate application as support for bifunctional catalysts for n-hexadecane hydroconversion

- Gamma-ray shielding properties of Nd2O3-added iron–boron–phosphate-based composites

- Numerical investigation on perforated sheet metals under tension loading

- Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt

- Two new polypodane-type bicyclic triterpenoids from mastic

- Structural, physical, and mechanical properties of the TiO2 added hydroxyapatite composites

- Tribological properties and characterization of borided Co–Mg alloys

- Studies on Anemone nemorosa L. extracts; polyphenols profile, antioxidant activity, and effects on Caco-2 cells by in vitro and in silico studies

- Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system

- Cyclic connectivity index of bipolar fuzzy incidence graph

- The role of passage numbers of donor cells in the development of Arabian Oryx – Cow interspecific somatic cell nuclear transfer embryos

- Mechanical property evaluation of tellurite–germanate glasses and comparison of their radiation-shielding characteristics using EPICS2017 to other glass systems

- Molecular screening of ionic liquids for CO2 absorption and molecular dynamic simulation

- Microwave-assisted preparation of Ag/Fe magnetic biochar from clivia leaves for adsorbing daptomycin antibiotics

- Iminodisuccinic acid enhances antioxidant and mineral element accumulation in young leaves of Ziziphus jujuba

- Cytotoxic activity of guaiane-type sesquiterpene lactone (deoxycynaropicrin) isolated from the leaves of Centaurothamnus maximus

- Effects of welding parameters on the angular distortion of welded steel plates

- Simulation of a reactor considering the Stamicarbon, Snamprogetti, and Toyo patents for obtaining urea

- Effect of different ramie (Boehmeria nivea L. Gaud) cultivars on the adsorption of heavy metal ions cadmium and lead in the remediation of contaminated farmland soils

- Impact of a live bacterial-based direct-fed microbial (DFM) postpartum and weaning system on performance, mortality, and health of Najdi lambs

- Anti-tumor effect of liposomes containing extracted Murrayafoline A against liver cancer cells in 2D and 3D cultured models

- Physicochemical properties and some mineral concentration of milk samples from different animals and altitudes

- Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies

- Diagnostic and therapeutic radioisotopes in nuclear medicine: Determination of gamma-ray transmission factors and safety competencies of high-dense and transparent glassy shields

- Calculation of NaI(Tl) detector efficiency using 226Ra, 232Th, and 40K radioisotopes: Three-phase Monte Carlo simulation study

- Isolation and identification of unstable components from Caesalpinia sappan by high-speed counter-current chromatography combined with preparative high-performance liquid chromatography

- Quantification of biomarkers and evaluation of antioxidant, anti-inflammatory, and cytotoxicity properties of Dodonaea viscosa grown in Saudi Arabia using HPTLC technique

- Characterization of the elastic modulus of ceramic–metal composites with physical and mechanical properties by ultrasonic technique

- GC-MS analysis of Vespa velutina auraria Smith and its anti-inflammatory and antioxidant activities in vitro

- Texturing of nanocoatings for surface acoustic wave-based sensors for volatile organic compounds

- Insights into the molecular basis of some chalcone analogues as potential inhibitors of Leishmania donovani: An integrated in silico and in vitro study

- (1R,2S,5R)-5-Methyl-2-(propan-2-yl)cyclohexyl 4-amino-3-phenylbutanoate hydrochloride: Synthesis and anticonvulsant activity

- On the relative extraction rates of colour compounds and caffeine during brewing, an investigation of tea over time and temperature

- Characterization of egg shell powder-doped ceramic–metal composites

- Rapeseed oil-based hippurate amide nanocomposite coating material for anticorrosive and antibacterial applications

- Chemically modified Teucrium polium (Lamiaceae) plant act as an effective adsorbent tool for potassium permanganate (KMnO4) in wastewater remediation

- Efficiency analysis of photovoltaic systems installed in different geographical locations

- Risk prioritization model driven by success factor in the light of multicriteria decision making

- Theoretical investigations on the excited-state intramolecular proton transfer in the solvated 2-hydroxy-1-naphthaldehyde carbohydrazone

- Mechanical and gamma-ray shielding examinations of Bi2O3–PbO–CdO–B2O3 glass system

- Machine learning-based forecasting of potability of drinking water through adaptive boosting model

- The potential effect of the Rumex vesicarius water seeds extract treatment on mice before and during pregnancy on the serum enzymes and the histology of kidney and liver

- Impact of benzimidazole functional groups on the n-doping properties of benzimidazole derivatives

- Extraction of red pigment from Chinese jujube peel and the antioxidant activity of the pigment extracts

- Flexural strength and thermal properties of carbon black nanoparticle reinforced epoxy composites obtained from waste tires

- A focusing study on radioprotective and antioxidant effects of Annona muricata leaf extract in the circulation and liver tissue: Clinical and experimental studies

- Clinical comprehensive and experimental assessment of the radioprotective effect of Annona muricata leaf extract to prevent cellular damage in the ileum tissue

- Effect of WC content on ultrasonic properties, thermal and electrical conductivity of WC–Co–Ni–Cr composites

- Influence of various class cleaning agents for prosthesis on Co–Cr alloy surface

- The synthesis of nanocellulose-based nanocomposites for the effective removal of hexavalent chromium ions from aqueous solution

- Study on the influence of physical interlayers on the remaining oil production under different development modes

- Optimized linear regression control of DC motor under various disturbances

- Influence of different sample preparation strategies on hypothesis-driven shotgun proteomic analysis of human saliva

- Determination of flow distance of the fluid metal due to fluidity in ductile iron casting by artificial neural networks approach

- Investigation of mechanical activation effect on high-volume natural pozzolanic cements

- In vitro: Anti-coccidia activity of Calotropis procera leaf extract on Eimeria papillata oocysts sporulation and sporozoite

- Determination of oil composition of cowpea (Vigna unguiculata L.) seeds under influence of organic fertilizer forms

- Activated partial thromboplastin time maybe associated with the prognosis of papillary thyroid carcinoma

- Treatment of rat brain ischemia model by NSCs-polymer scaffold transplantation

- Lead and cadmium removal with native yeast from coastal wetlands

- Characterization of electroless Ni-coated Fe–Co composite using powder metallurgy

- Ferrate synthesis using NaOCl and its application for dye removal

- Antioxidant, antidiabetic, and anticholinesterase potential of Chenopodium murale L. extracts using in vitro and in vivo approaches

- Study on essential oil, antioxidant activity, anti-human prostate cancer effects, and induction of apoptosis by Equisetum arvense

- Experimental study on turning machine with permanent magnetic cutting tool

- Numerical simulation and mathematical modeling of the casting process for pearlitic spheroidal graphite cast iron

- Design, synthesis, and cytotoxicity evaluation of novel thiophene, pyrimidine, pyridazine, and pyridine: Griseofulvin heterocyclic extension derivatives

- Isolation and identification of promising antibiotic-producing bacteria

- Ultrasonic-induced reversible blood–brain barrier opening: Safety evaluation into the cellular level

- Evaluation of phytochemical and antioxidant potential of various extracts from traditionally used medicinal plants of Pakistan

- Effect of calcium lactate in standard diet on selected markers of oxidative stress and inflammation in ovariectomized rats

- Identification of crucial salivary proteins/genes and pathways involved in pathogenesis of temporomandibular disorders

- Zirconium-modified attapulgite was used for removing of Cr(vi) in aqueous solution

- The stress distribution of different types of restorative materials in primary molar

- Reducing surface heat loss in steam boilers

- Deformation behavior and formability of friction stir processed DP600 steel

- Synthesis and characterization of bismuth oxide/commercial activated carbon composite for battery anode

- Phytochemical analysis of Ziziphus jujube leaf at different foliar ages based on widely targeted metabolomics

- Effects of in ovo injection of black cumin (Nigella sativa) extract on hatching performance of broiler eggs

- Separation and evaluation of potential antioxidant, analgesic, and anti-inflammatory activities of limonene-rich essential oils from Citrus sinensis (L.)

- Bioactivity of a polyhydroxy gorgostane steroid from Xenia umbellata

- BiCAM-based automated scoring system for digital logic circuit diagrams

- Analysis of standard systems with solar monitoring systems

- Structural and spectroscopic properties of voriconazole and fluconazole – Experimental and theoretical studies

- New plant resistance inducers based on polyamines

- Experimental investigation of single-lap bolted and bolted/bonded (hybrid) joints of polymeric plates

- Investigation of inlet air pressure and evaporative cooling of four different cogeneration cycles

- Review Articles

- Comprehensive review on synthesis, physicochemical properties, and application of activated carbon from the Arecaceae plants for enhanced wastewater treatment

- Research progress on speciation analysis of arsenic in traditional Chinese medicine

- Recent modified air-assisted liquid–liquid microextraction applications for medicines and organic compounds in various samples: A review

- An insight on Vietnamese bio-waste materials as activated carbon precursors for multiple applications in environmental protection

- Antimicrobial activities of the extracts and secondary metabolites from Clausena genus – A review

- Bioremediation of organic/heavy metal contaminants by mixed cultures of microorganisms: A review

- Sonodynamic therapy for breast cancer: A literature review

- Recent progress of amino acid transporters as a novel antitumor target

- Aconitum coreanum Rapaics: Botany, traditional uses, phytochemistry, pharmacology, and toxicology

- Corrigendum

- Corrigendum to “Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt”

- Corrigendum to “Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach”

- Corrigendum to “Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt”

- Corrigendum to “Aroma components of tobacco powder from different producing areas based on gas chromatography ion mobility spectrometry”

- Corrigendum to “Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system”

- Erratum

- Erratum to “Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies”

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2021)

- Study of solidification and stabilization of heavy metals by passivators in heavy metal-contaminated soil

- Human health risk assessment and distribution of VOCs in a chemical site, Weinan, China

- Preparation and characterization of Sparassis latifolia β-glucan microcapsules

- Special Issue on the Conference of Energy, Fuels, Environment 2020

- Improving the thermal performance of existing buildings in light of the requirements of the EU directive 2010/31/EU in Poland

- Special Issue on Ethnobotanical, Phytochemical and Biological Investigation of Medicinal Plants

- Study of plant resources with ethnomedicinal relevance from district Bagh, Azad Jammu and Kashmir, Pakistan

- Studies on the chemical composition of plants used in traditional medicine in Congo

- Special Issue on Applied Chemistry in Agriculture and Food Science

- Strip spraying technology for precise herbicide application in carrot fields

- Special Issue on Pharmacology and Metabolomics of Ethnobotanical and Herbal Medicine

- Phytochemical profiling, antibacterial and antioxidant properties of Crocus sativus flower: A comparison between tepals and stigmas

- Antioxidant and antimicrobial properties of polyphenolics from Withania adpressa (Coss.) Batt. against selected drug-resistant bacterial strains

- Integrating network pharmacology and molecular docking to explore the potential mechanism of Xinguan No. 3 in the treatment of COVID-19

- Chemical composition and in vitro and in vivo biological assortment of fixed oil extracted from Ficus benghalensis L.

- A review of the pharmacological activities and protective effects of Inonotus obliquus triterpenoids in kidney diseases

- Ethnopharmacological study of medicinal plants in Kastamonu province (Türkiye)

- Protective effects of asperuloside against cyclophosphamide-induced urotoxicity and hematotoxicity in rats

- Special Issue on Essential Oil, Extraction, Phytochemistry, Advances, and Application

- Identification of volatile compounds and antioxidant, antibacterial, and antifungal properties against drug-resistant microbes of essential oils from the leaves of Mentha rotundifolia var. apodysa Briq. (Lamiaceae)

- Phenolic contents, anticancer, antioxidant, and antimicrobial capacities of MeOH extract from the aerial parts of Trema orientalis plant

- Chemical composition and antimicrobial activity of essential oils from Mentha pulegium and Rosmarinus officinalis against multidrug-resistant microbes and their acute toxicity study

- Special Issue on Marine Environmental Sciences and Significance of the Multidisciplinary Approaches

- An insightful overview of the distribution pattern of polycyclic aromatic hydrocarbon in the marine sediments of the Red Sea

- Antifungal–antiproliferative norcycloartane-type triterpenes from the Red Sea green alga Tydemania expeditionis

- Solvent effect, dipole moment, and DFT studies of multi donor–acceptor type pyridine derivative

- An extensive assessment on the distribution pattern of organic contaminants in the aerosols samples in the Middle East

- Special Issue on 4th IC3PE

- Energetics of carboxylic acid–pyridine heterosynthon revisited: A computational study of intermolecular hydrogen bond domination on phenylacetic acid–nicotinamide cocrystals

- A review: Silver–zinc oxide nanoparticles – organoclay-reinforced chitosan bionanocomposites for food packaging

- Green synthesis of magnetic activated carbon from peanut shells functionalized with TiO2 photocatalyst for Batik liquid waste treatment

- Coagulation activity of liquid extraction of Leucaena leucocephala and Sesbania grandiflora on the removal of turbidity

- Hydrocracking optimization of palm oil over NiMoO4/activated carbon catalyst to produce biogasoline and kerosine

- Special Issue on Pharmacology and metabolomics of ethnobotanical and herbal medicine

- Cynarin inhibits PDGF-BB-induced proliferation and activation in hepatic stellate cells through PPARγ

- Special Issue on The 1st Malaysia International Conference on Nanotechnology & Catalysis (MICNC2021)

- Surfactant evaluation for enhanced oil recovery: Phase behavior and interfacial tension

- Topical Issue on phytochemicals, biological and toxicological analysis of aromatic medicinal plants

- Phytochemical analysis of leaves and stems of Physalis alkekengi L. (Solanaceae)

- Phytochemical and pharmacological profiling of Trewia nudiflora Linn. leaf extract deciphers therapeutic potentials against thrombosis, arthritis, helminths, and insects

- Pergularia tomentosa coupled with selenium nanoparticles salvaged lead acetate-induced redox imbalance, inflammation, apoptosis, and disruption of neurotransmission in rats’ brain

- Protective effect of Allium atroviolaceum-synthesized SeNPs on aluminum-induced brain damage in mice

- Mechanism study of Cordyceps sinensis alleviates renal ischemia–reperfusion injury

- Plant-derived bisbenzylisoquinoline alkaloid tetrandrine prevents human podocyte injury by regulating the miR-150-5p/NPHS1 axis

- Network pharmacology combined with molecular docking to explore the anti-osteoporosis mechanisms of β-ecdysone derived from medicinal plants

- Chinese medicinal plant Polygonum cuspidatum ameliorates silicosis via suppressing the Wnt/β-catenin pathway

- Special Issue on Advanced Nanomaterials for Energy, Environmental and Biological Applications - Part I

- Investigation of improved optical and conductivity properties of poly(methyl methacrylate)–MXenes (PMMA–MXenes) nanocomposite thin films for optoelectronic applications

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2022)

- Model predictive control for precision irrigation of a Quinoa crop

Articles in the same Issue

- Regular Articles

- Photocatalytic degradation of Rhodamine B in aqueous phase by bimetallic metal-organic framework M/Fe-MOF (M = Co, Cu, and Mg)

- Assessment of using electronic portal imaging device for analysing bolus material utilised in radiation therapy

- A detailed investigation on highly dense CuZr bulk metallic glasses for shielding purposes

- Simulation of gamma-ray shielding properties for materials of medical interest

- Environmental impact assesment regulation applications and their analysis in Turkey

- Sample age effect on parameters of dynamic nuclear polarization in certain difluorobenzen isomers/MC800 asphaltene suspensions

- Passenger demand forecasting for railway systems

- Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach

- Gamma, neutron, and heavy charged ion shielding properties of Er3+-doped and Sm3+-doped zinc borate glasses

- Bridging chiral de-tert-butylcalix[4]arenes: Optical resolution based on column chromatography and structural characterization

- Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt

- Comparison of the yield and purity of plasma exosomes extracted by ultracentrifugation, precipitation, and membrane-based approaches

- Bioactive triterpenoids from Indonesian medicinal plant Syzygium aqueum

- Investigation of the effects of machining parameters on surface integrity in micromachining

- The mesoporous aluminosilicate application as support for bifunctional catalysts for n-hexadecane hydroconversion

- Gamma-ray shielding properties of Nd2O3-added iron–boron–phosphate-based composites

- Numerical investigation on perforated sheet metals under tension loading

- Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt

- Two new polypodane-type bicyclic triterpenoids from mastic

- Structural, physical, and mechanical properties of the TiO2 added hydroxyapatite composites

- Tribological properties and characterization of borided Co–Mg alloys

- Studies on Anemone nemorosa L. extracts; polyphenols profile, antioxidant activity, and effects on Caco-2 cells by in vitro and in silico studies

- Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system

- Cyclic connectivity index of bipolar fuzzy incidence graph

- The role of passage numbers of donor cells in the development of Arabian Oryx – Cow interspecific somatic cell nuclear transfer embryos

- Mechanical property evaluation of tellurite–germanate glasses and comparison of their radiation-shielding characteristics using EPICS2017 to other glass systems

- Molecular screening of ionic liquids for CO2 absorption and molecular dynamic simulation

- Microwave-assisted preparation of Ag/Fe magnetic biochar from clivia leaves for adsorbing daptomycin antibiotics

- Iminodisuccinic acid enhances antioxidant and mineral element accumulation in young leaves of Ziziphus jujuba

- Cytotoxic activity of guaiane-type sesquiterpene lactone (deoxycynaropicrin) isolated from the leaves of Centaurothamnus maximus

- Effects of welding parameters on the angular distortion of welded steel plates

- Simulation of a reactor considering the Stamicarbon, Snamprogetti, and Toyo patents for obtaining urea

- Effect of different ramie (Boehmeria nivea L. Gaud) cultivars on the adsorption of heavy metal ions cadmium and lead in the remediation of contaminated farmland soils

- Impact of a live bacterial-based direct-fed microbial (DFM) postpartum and weaning system on performance, mortality, and health of Najdi lambs

- Anti-tumor effect of liposomes containing extracted Murrayafoline A against liver cancer cells in 2D and 3D cultured models

- Physicochemical properties and some mineral concentration of milk samples from different animals and altitudes

- Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies

- Diagnostic and therapeutic radioisotopes in nuclear medicine: Determination of gamma-ray transmission factors and safety competencies of high-dense and transparent glassy shields

- Calculation of NaI(Tl) detector efficiency using 226Ra, 232Th, and 40K radioisotopes: Three-phase Monte Carlo simulation study

- Isolation and identification of unstable components from Caesalpinia sappan by high-speed counter-current chromatography combined with preparative high-performance liquid chromatography

- Quantification of biomarkers and evaluation of antioxidant, anti-inflammatory, and cytotoxicity properties of Dodonaea viscosa grown in Saudi Arabia using HPTLC technique

- Characterization of the elastic modulus of ceramic–metal composites with physical and mechanical properties by ultrasonic technique

- GC-MS analysis of Vespa velutina auraria Smith and its anti-inflammatory and antioxidant activities in vitro

- Texturing of nanocoatings for surface acoustic wave-based sensors for volatile organic compounds

- Insights into the molecular basis of some chalcone analogues as potential inhibitors of Leishmania donovani: An integrated in silico and in vitro study

- (1R,2S,5R)-5-Methyl-2-(propan-2-yl)cyclohexyl 4-amino-3-phenylbutanoate hydrochloride: Synthesis and anticonvulsant activity

- On the relative extraction rates of colour compounds and caffeine during brewing, an investigation of tea over time and temperature

- Characterization of egg shell powder-doped ceramic–metal composites

- Rapeseed oil-based hippurate amide nanocomposite coating material for anticorrosive and antibacterial applications

- Chemically modified Teucrium polium (Lamiaceae) plant act as an effective adsorbent tool for potassium permanganate (KMnO4) in wastewater remediation

- Efficiency analysis of photovoltaic systems installed in different geographical locations

- Risk prioritization model driven by success factor in the light of multicriteria decision making

- Theoretical investigations on the excited-state intramolecular proton transfer in the solvated 2-hydroxy-1-naphthaldehyde carbohydrazone

- Mechanical and gamma-ray shielding examinations of Bi2O3–PbO–CdO–B2O3 glass system

- Machine learning-based forecasting of potability of drinking water through adaptive boosting model

- The potential effect of the Rumex vesicarius water seeds extract treatment on mice before and during pregnancy on the serum enzymes and the histology of kidney and liver

- Impact of benzimidazole functional groups on the n-doping properties of benzimidazole derivatives

- Extraction of red pigment from Chinese jujube peel and the antioxidant activity of the pigment extracts

- Flexural strength and thermal properties of carbon black nanoparticle reinforced epoxy composites obtained from waste tires

- A focusing study on radioprotective and antioxidant effects of Annona muricata leaf extract in the circulation and liver tissue: Clinical and experimental studies

- Clinical comprehensive and experimental assessment of the radioprotective effect of Annona muricata leaf extract to prevent cellular damage in the ileum tissue

- Effect of WC content on ultrasonic properties, thermal and electrical conductivity of WC–Co–Ni–Cr composites

- Influence of various class cleaning agents for prosthesis on Co–Cr alloy surface

- The synthesis of nanocellulose-based nanocomposites for the effective removal of hexavalent chromium ions from aqueous solution

- Study on the influence of physical interlayers on the remaining oil production under different development modes

- Optimized linear regression control of DC motor under various disturbances

- Influence of different sample preparation strategies on hypothesis-driven shotgun proteomic analysis of human saliva

- Determination of flow distance of the fluid metal due to fluidity in ductile iron casting by artificial neural networks approach

- Investigation of mechanical activation effect on high-volume natural pozzolanic cements

- In vitro: Anti-coccidia activity of Calotropis procera leaf extract on Eimeria papillata oocysts sporulation and sporozoite

- Determination of oil composition of cowpea (Vigna unguiculata L.) seeds under influence of organic fertilizer forms

- Activated partial thromboplastin time maybe associated with the prognosis of papillary thyroid carcinoma

- Treatment of rat brain ischemia model by NSCs-polymer scaffold transplantation

- Lead and cadmium removal with native yeast from coastal wetlands

- Characterization of electroless Ni-coated Fe–Co composite using powder metallurgy

- Ferrate synthesis using NaOCl and its application for dye removal

- Antioxidant, antidiabetic, and anticholinesterase potential of Chenopodium murale L. extracts using in vitro and in vivo approaches

- Study on essential oil, antioxidant activity, anti-human prostate cancer effects, and induction of apoptosis by Equisetum arvense

- Experimental study on turning machine with permanent magnetic cutting tool

- Numerical simulation and mathematical modeling of the casting process for pearlitic spheroidal graphite cast iron

- Design, synthesis, and cytotoxicity evaluation of novel thiophene, pyrimidine, pyridazine, and pyridine: Griseofulvin heterocyclic extension derivatives

- Isolation and identification of promising antibiotic-producing bacteria

- Ultrasonic-induced reversible blood–brain barrier opening: Safety evaluation into the cellular level

- Evaluation of phytochemical and antioxidant potential of various extracts from traditionally used medicinal plants of Pakistan

- Effect of calcium lactate in standard diet on selected markers of oxidative stress and inflammation in ovariectomized rats

- Identification of crucial salivary proteins/genes and pathways involved in pathogenesis of temporomandibular disorders

- Zirconium-modified attapulgite was used for removing of Cr(vi) in aqueous solution

- The stress distribution of different types of restorative materials in primary molar

- Reducing surface heat loss in steam boilers

- Deformation behavior and formability of friction stir processed DP600 steel

- Synthesis and characterization of bismuth oxide/commercial activated carbon composite for battery anode

- Phytochemical analysis of Ziziphus jujube leaf at different foliar ages based on widely targeted metabolomics

- Effects of in ovo injection of black cumin (Nigella sativa) extract on hatching performance of broiler eggs

- Separation and evaluation of potential antioxidant, analgesic, and anti-inflammatory activities of limonene-rich essential oils from Citrus sinensis (L.)

- Bioactivity of a polyhydroxy gorgostane steroid from Xenia umbellata

- BiCAM-based automated scoring system for digital logic circuit diagrams

- Analysis of standard systems with solar monitoring systems

- Structural and spectroscopic properties of voriconazole and fluconazole – Experimental and theoretical studies

- New plant resistance inducers based on polyamines

- Experimental investigation of single-lap bolted and bolted/bonded (hybrid) joints of polymeric plates

- Investigation of inlet air pressure and evaporative cooling of four different cogeneration cycles

- Review Articles

- Comprehensive review on synthesis, physicochemical properties, and application of activated carbon from the Arecaceae plants for enhanced wastewater treatment

- Research progress on speciation analysis of arsenic in traditional Chinese medicine

- Recent modified air-assisted liquid–liquid microextraction applications for medicines and organic compounds in various samples: A review

- An insight on Vietnamese bio-waste materials as activated carbon precursors for multiple applications in environmental protection

- Antimicrobial activities of the extracts and secondary metabolites from Clausena genus – A review

- Bioremediation of organic/heavy metal contaminants by mixed cultures of microorganisms: A review

- Sonodynamic therapy for breast cancer: A literature review

- Recent progress of amino acid transporters as a novel antitumor target

- Aconitum coreanum Rapaics: Botany, traditional uses, phytochemistry, pharmacology, and toxicology

- Corrigendum

- Corrigendum to “Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt”

- Corrigendum to “Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach”

- Corrigendum to “Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt”

- Corrigendum to “Aroma components of tobacco powder from different producing areas based on gas chromatography ion mobility spectrometry”

- Corrigendum to “Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system”

- Erratum

- Erratum to “Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies”

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2021)

- Study of solidification and stabilization of heavy metals by passivators in heavy metal-contaminated soil

- Human health risk assessment and distribution of VOCs in a chemical site, Weinan, China

- Preparation and characterization of Sparassis latifolia β-glucan microcapsules

- Special Issue on the Conference of Energy, Fuels, Environment 2020

- Improving the thermal performance of existing buildings in light of the requirements of the EU directive 2010/31/EU in Poland

- Special Issue on Ethnobotanical, Phytochemical and Biological Investigation of Medicinal Plants

- Study of plant resources with ethnomedicinal relevance from district Bagh, Azad Jammu and Kashmir, Pakistan

- Studies on the chemical composition of plants used in traditional medicine in Congo

- Special Issue on Applied Chemistry in Agriculture and Food Science

- Strip spraying technology for precise herbicide application in carrot fields

- Special Issue on Pharmacology and Metabolomics of Ethnobotanical and Herbal Medicine

- Phytochemical profiling, antibacterial and antioxidant properties of Crocus sativus flower: A comparison between tepals and stigmas

- Antioxidant and antimicrobial properties of polyphenolics from Withania adpressa (Coss.) Batt. against selected drug-resistant bacterial strains

- Integrating network pharmacology and molecular docking to explore the potential mechanism of Xinguan No. 3 in the treatment of COVID-19

- Chemical composition and in vitro and in vivo biological assortment of fixed oil extracted from Ficus benghalensis L.

- A review of the pharmacological activities and protective effects of Inonotus obliquus triterpenoids in kidney diseases

- Ethnopharmacological study of medicinal plants in Kastamonu province (Türkiye)

- Protective effects of asperuloside against cyclophosphamide-induced urotoxicity and hematotoxicity in rats

- Special Issue on Essential Oil, Extraction, Phytochemistry, Advances, and Application

- Identification of volatile compounds and antioxidant, antibacterial, and antifungal properties against drug-resistant microbes of essential oils from the leaves of Mentha rotundifolia var. apodysa Briq. (Lamiaceae)

- Phenolic contents, anticancer, antioxidant, and antimicrobial capacities of MeOH extract from the aerial parts of Trema orientalis plant

- Chemical composition and antimicrobial activity of essential oils from Mentha pulegium and Rosmarinus officinalis against multidrug-resistant microbes and their acute toxicity study

- Special Issue on Marine Environmental Sciences and Significance of the Multidisciplinary Approaches

- An insightful overview of the distribution pattern of polycyclic aromatic hydrocarbon in the marine sediments of the Red Sea

- Antifungal–antiproliferative norcycloartane-type triterpenes from the Red Sea green alga Tydemania expeditionis

- Solvent effect, dipole moment, and DFT studies of multi donor–acceptor type pyridine derivative

- An extensive assessment on the distribution pattern of organic contaminants in the aerosols samples in the Middle East

- Special Issue on 4th IC3PE

- Energetics of carboxylic acid–pyridine heterosynthon revisited: A computational study of intermolecular hydrogen bond domination on phenylacetic acid–nicotinamide cocrystals

- A review: Silver–zinc oxide nanoparticles – organoclay-reinforced chitosan bionanocomposites for food packaging

- Green synthesis of magnetic activated carbon from peanut shells functionalized with TiO2 photocatalyst for Batik liquid waste treatment

- Coagulation activity of liquid extraction of Leucaena leucocephala and Sesbania grandiflora on the removal of turbidity

- Hydrocracking optimization of palm oil over NiMoO4/activated carbon catalyst to produce biogasoline and kerosine

- Special Issue on Pharmacology and metabolomics of ethnobotanical and herbal medicine

- Cynarin inhibits PDGF-BB-induced proliferation and activation in hepatic stellate cells through PPARγ

- Special Issue on The 1st Malaysia International Conference on Nanotechnology & Catalysis (MICNC2021)

- Surfactant evaluation for enhanced oil recovery: Phase behavior and interfacial tension

- Topical Issue on phytochemicals, biological and toxicological analysis of aromatic medicinal plants

- Phytochemical analysis of leaves and stems of Physalis alkekengi L. (Solanaceae)

- Phytochemical and pharmacological profiling of Trewia nudiflora Linn. leaf extract deciphers therapeutic potentials against thrombosis, arthritis, helminths, and insects

- Pergularia tomentosa coupled with selenium nanoparticles salvaged lead acetate-induced redox imbalance, inflammation, apoptosis, and disruption of neurotransmission in rats’ brain

- Protective effect of Allium atroviolaceum-synthesized SeNPs on aluminum-induced brain damage in mice

- Mechanism study of Cordyceps sinensis alleviates renal ischemia–reperfusion injury

- Plant-derived bisbenzylisoquinoline alkaloid tetrandrine prevents human podocyte injury by regulating the miR-150-5p/NPHS1 axis

- Network pharmacology combined with molecular docking to explore the anti-osteoporosis mechanisms of β-ecdysone derived from medicinal plants

- Chinese medicinal plant Polygonum cuspidatum ameliorates silicosis via suppressing the Wnt/β-catenin pathway

- Special Issue on Advanced Nanomaterials for Energy, Environmental and Biological Applications - Part I

- Investigation of improved optical and conductivity properties of poly(methyl methacrylate)–MXenes (PMMA–MXenes) nanocomposite thin films for optoelectronic applications

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2022)

- Model predictive control for precision irrigation of a Quinoa crop