Abstract

In this study, the effect of cutting conditions on surface integrity was investigated in micromilling of magnesium alloy (AZ91). Microtool diameter, cutting speed, feed rate, and depth of cut parameters are used. These variables were investigated at three different levels with the Taguchi L9 experimental design method. The least-best objective function was used. As a result of the experiments, surface roughness values were obtained. It has been determined that surface roughness values and depth of cut are effective parameters. After evaluating the results obtained, variance and regression analyses were performed. Based on the analysis of variance, 58.73% feed rate was found for the 1.0 mm diameter tool, on the other hand, for the 0.8 mm diameter tool, the depth of cut was found to be an effective parameter with 53.6%.

1 Introduction

Magnesium is an alkaline earth metal in group IIA of the periodic table. Magnesium has an atomic number of 12, an atomic weight of 24.3 g/mol, and a melting point of 651°C. Magnesium has the distinction of being the sixth most abundant metal and the eighth element, with a density of just 1.74 g/cm3. Due to its lightness, its usage areas are quite high [1]. Magnesium is a silver-colored and shiny metal. When in contact with air, an oxide layer is formed on its surface. It is a refractory and easily formable material. It is 36% lighter than aluminum and 78% lighter than steel [2].

The use of magnesium continues to increase due to its properties in many sectors such as automotive, aerospace, defense, and machinery [3]. In the aviation industry, magnesium alloys are successfully used in aircraft skeleton, engine, gearbox, wheels, landing gear, interior furniture, cargo accessory products, ventilation, and pressurization systems [4]. Machining methods are used in the manufacture of magnesium alloys.

Machining is used extensively in aerospace, defense, electronics, medical, and automotive sectors. Miniaturization is frequently observed in the products of these sectors as well. Accordingly, machining started to be used on a microscale. With miniaturization, lightness, economy, superior surface quality, and precision are the desired features.

Micromachining is the name given to the process that enables miniaturization. Micromilling is the production of complex shaped parts with 1 mm or smaller tools with limited tolerances and high surface integrity. Ozel et al. modeled and simulated the micromilling process on Al 2024-T6 aluminum alloy and AISI 4340 steel. The diameter of the tool used in the research is 0.635 mm. Spindle speed is max 80,000 rpm. The impacts of spindle speed and feed ratio on the forces were investigated. A large fluctuation in cutting forces was observed due to process dynamics and continuous slip. The edge radius ratio of the minimum chip thickness was found to be between 42 and 45% for Al 2024-T6 aluminum alloy, and 30–35% for AISI 4340 steel [5]. The mechanistic force model presented by Mamedov and Lazoglu for micromilling gave more accurate results than the conventional force model. In the research, experiments were carried out on Al 7050 material. As a conclusion of the research, it was stated that the correct determination of the cutting forces is significant in terms of tool wear, product precision, and surface quality [6]. In a study conducted by Mamedov and Lazoglu), they examined the techniques of measuring cutting force, tool elastic deformation, and speed of rotating tool. They stated the noisy force signal and the small band gap of the dynamometer as problems encountered when measuring cutting forces. They stated that in order to calculate the rotational speed of the tool, the laser beam is sent to the double-edged tool and the rotational speed of the tool can be calculated from the period of the displacement signal [7]. Oliaeia and Karpat conducted a micromilling study on Stavax stainless steel. In the experiments, the parameters of cutting speed, depth of cut, feed ratio, radial immersion percentage, and plunging method were investigated. Tool wear, machining forces, and surface roughness were analyzed. As a result of the experiments, the immersion method significantly affects the tool wear. Accordingly, surface quality and cutting forces are also affected. It has been demonstrated that the relationship between radial plunge and feed ratio is significant in terms of tool wear and surface roughness [8]. Gunaydin developed tool path geometry, machining strategy, and optimized cutting parameters in order to obtain maximum efficiency in the micro-groove milling process [9]. In the research, the values of cutting forces, surface roughness, and tool wear were not created by analytical calculation, but by mathematical models using an experimental design table. 2738 plastic die steel is used. With the aim of minimizing the manufacturing cost, the cutting parameters were optimized around this purpose. Cutter feed, cutting speed, and cutter diameter/groove width ratio are the parameters used. Models based on tool path geometry, which contain the response of the control unit to cutting conditions, have been developed [9]. Pratap et al. modeled cutting forces on Ti-6Al-4V alloy using ABAQUS program with finite element analysis. In the research, stress distribution, temperature distribution, and forces were simulated by using tool edge radius, uncut chip thickness, cutting speed, and feed ratio parameters. Maximum Von-Mises stress and cutting temperature are higher than that in macromilling of Ti-6Al-4V alloy. The reason for this is the tool edge radius and low feed values. The simulated cutting forces have been proven as a result of experiments [10]. Karpat et al. developed a mechanistic model based on the mean force model in which the tool axis deviation is included. In the study, it was stated that the cutting forces were not linear compared to milling at the macroscale. As a result of the studies on the Ti-6Al-4V alloy, it was observed that the force values obtained from the model revealed were compatible with the measured values [11].

Yucel and Cicek examined micromachining techniques commonly used in manufacturing. They have broadly classified micromachining techniques into two categories: micromachining and micro-abrasive machining. In the research, AISI H13 hardened (45 HRC) hot work tool steel was investigated by micromilling. It has been indicated that a better surface roughness can be obtained by optimizing parameters such as speed, axial depth, and the use of appropriate tool coatings in the micromilling process [12]. Aslantas et al. searched the effect of tool wear on groove geometry, surface quality, and burr formation in micromilling of Inconel 718 alloy. The experiments were carried out with constant cutting parameters and dry cutting conditions. In the research, the dimensional change, burr formation, and cutting forces in the groove obtained by micromachining were investigated. As a result of the experiments, it was observed that the cutting tool was worn axially and circumferentially [13]. Lu et al. investigated the effect of cutting parameters on microhardness and estimation of Vickers hardness based on reaction surfaces methodology in micromilling of Inconel 718 material. In the research, spindle speed, feed ratio, and axial depth parameters were used. As a result of the research, spindle speed affected Vickers hardness the most. Axial depth, on the other hand, affected more than the amount of feed. Microhardness decreases with increase in the spindle speed, and it increases with increase in the axial depth [14]. Aslantas and Kaynak examined the shape memory NiTi alloy with micromilling. Feed per tooth and depth of cut parameters were used in the research. Critical chip thickness was tried to be found. Burr width, cutting forces, and surface roughness are the outputs of the research. The critical chip thickness was obtained as 0.5 µm, as a result of the research. The critical chip thickness is 33% of the cutting-edge radius. As the cutting speed increases, the cutting force and burr widths also increase [15]. Kuram and Kesici researched the effects of cutting tool clamping length on tool wear, forces, and burr size in micromilling of Inconel 718 super alloy. Diameter reduction in the cutter was evaluated in determining tool wear. As a result of the research, it was determined that the measured Fx and Fy forces and burr width values of tool wear were proportional to the clamping length and increased with the increment in the clamping length. The lowest burr width was measured when the cutting tool clamping length was 10 mm [16]. Nahata et al. created a mathematical model of radial oscillation in the micromachining process, and then examined the radial oscillation with independent experiments and compared it with the mathematical model [17]. Yu et al. investigated the impact of microstructure on surface integrity and chip form in the micromachining process. Copper material with two different grain sizes and a single diamond cutting tool were used in the research. Based on the research results, decreasing the grain size will reduce the effect of the microstructure on the surface integrity in the microcutting process. Moreover, it has been observed that the resulting chip shape loses continuity and becomes intermittent with the decrease in the feed rate for annealed and blister copper, which is the subject of the research. This observation was made for the same depth of cut [18]. Aslantas et al. examined the surface quality and burr width in micromilling in their study on Ti-6Al-4V alloy. Cutting parameters were optimized with the Taguchi method in the aim of minimum burr width and surface roughness. In the research, spindle speed, feed ratio, and depth of cut were used as parameters. As a result of the research, the feed was measured as 0.25 μm/step for the best surface quality. It was observed that ploughing occurred at a lower feed rate. Low feed and high depth of cut increase burr width. Furthermore, the increase in spindle speed causes rapid tool wear, resulting in an increase in burr width [19]. Sun et al. modeled micromilling on aluminum Al 7075-T6 material with finite element analysis. Cutting forces and chip formation were investigated with the change in feed rate in the research. It has been observed that as the radial depth of cut increases, the cutting forces increase [20]. Kuram and Ozcelik performed the optimization of spindle speed, feed rate, and depth of cut parameters using Taguchi experimental design method on Ti-6Al-4V and Inconel 718 materials [21]. Tool wear, surface roughness, and cutting forces were measured and then optimization was performed according to the signal/noise ratio. As a conclusion of the research, the spindle speed was determined as 12,000 rpm and the depth of cut was 75 µm for optimum surface roughness in Ti-6Al-4V titanium alloy. For Inconel 718 Nickel alloy, the spindle speed is determined as 10,000 rpm and the depth of cut is 75 µm. The feed rate for both materials was determined as 50 mm/min. The most significant parameter affecting tool wear is the depth of cut for Ti-6Al-4V and the spindle speed for Inconel 718 [21]. There are also few other studies done on this topics for different purposes [22,23,24,25,26].

In this study, the impact of cutting conditions on the surface integrity was investigated in the micro milling of magnesium alloy (AZ91). Microtool diameter, cutting speed, feed rate, and depth of cut parameters are used. These variables were investigated at three different levels with the Taguchi L9 experimental design method. The least-best objective function was used. As a result of the experiments, the cutting force and surface roughness values were obtained. After evaluating the obtained results, variance analysis was performed. Lastly, the conclusion is conveyed.

2 Materials and methods

2.1 Materials

The material used in the research is the AZ91 series, which is a magnesium alloy. The components of the material are shown in Table 1 where the dimensions of the magnesium alloy used are 150 mm × 150 mm × 10 mm.

AZ91 magnesium alloy and its chemical composition (wt%) [27]

| Alloy element | Al% | Zn% | Mn% | Si% (max) | Fe% (max) | Cu% | Ni% (max) | Be% | Others% | Mg% |

|---|---|---|---|---|---|---|---|---|---|---|

| AZ91 | 8.5–9.5 | 0.45 | 0.17 | 0.05 | 0.004 | 0.025 | 0.001 | — | 0.01 | Remaining |

2.2 Experimental setup

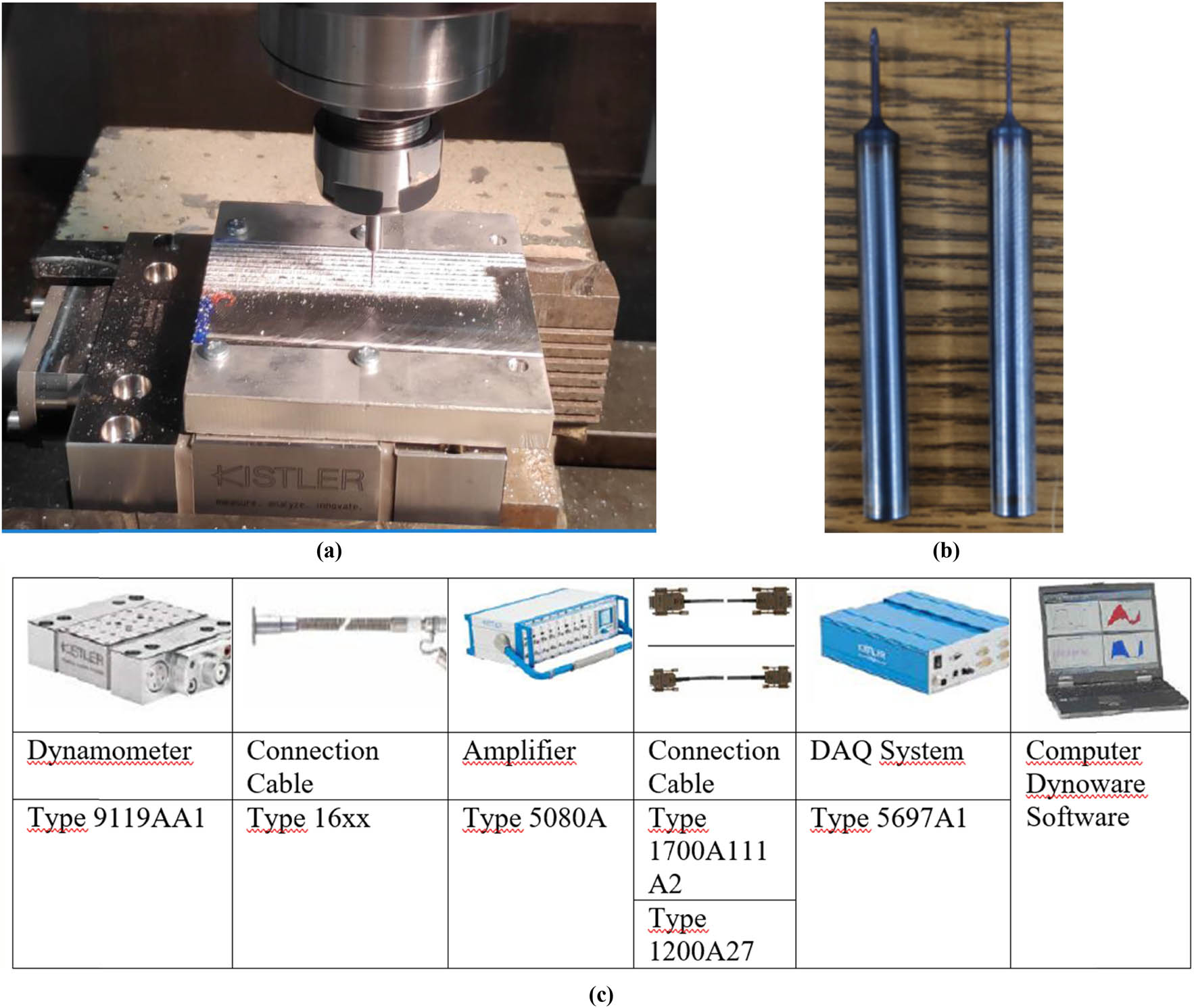

For micromilling, it is necessary for the microcutting tools to work at high speeds. In the experiments, the Nikken brand spindle speeder was adapted for the CNC machining center as a high-speed rotation provider on the JOHNFORD VMC-850/550 + APC CNC Fanuc 0T x–y–z axis milling machine. The inner taper of the spindle speeder is in the norm of SK10. Collet in SK10 norm was used in order to use micro tools. 0.8 and 1 mm microtools were used in the experiments (Figure 1).

Experimental setup: (a) experiment set, (b) cutting tool, and (c) cutting force measurement and evaluation set.

Kistler 9119AA1 dynamometer, Kistler 5080A type load amplifier, and DynoWare software program were used for the measurement of cutting force in the micromilling process of magnesium alloy. Surface roughness was measured with a Keyence digital microscope.

2.3 Experimental design

Parameters such as revs per minute, feed rate, and depth of cut constitute the cutting conditions. The Taguchi method reduces the number of experiments and provides a decrease in testing and production costs [28]. Experiments were designed using the Taguchi method. First, the control factor and levels were determined. Following this, matrix selection was made and the levels were transferred to the matrix. There are three different levels of variables according to the L9 index used. A total of nine different experiments were conducted.

The variables and levels in this study are given in Table 2.

Variables and levels

| Variables | Symbol | Units | Code | Levels | ||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| Rev | n | m/min | A | 10,000 | 11,000 | 12,000 |

| Feed rate | f | mm/min | B | 170 | 200 | 230 |

| Depth of cut | d | mm | C | 0.1 | 0.2 | 0.3 |

The list of experiments designed according to the Taguchi method is given in Table 3 below. The total number of experiments performed was nine.

Experimental design

| Experiment number | Variables | Cutting speed (m/min) | Feed rate (mm/rev.) | Depth of cut (mm) |

|---|---|---|---|---|

| 1 | A1B1C1 | 1 | 1 | 1 |

| 2 | A1B2C2 | 1 | 2 | 2 |

| 3 | A1B3C3 | 1 | 3 | 3 |

| 4 | A2B1C2 | 2 | 1 | 2 |

| 5 | A2B2C3 | 2 | 2 | 3 |

| 6 | A2B3C1 | 2 | 3 | 1 |

| 7 | A3B1C3 | 3 | 1 | 3 |

| 8 | A3B2C1 | 3 | 2 | 1 |

| 9 | A3B3C2 | 3 | 3 | 2 |

3 Results and discussion

3.1 Surface roughness results

The surface roughness values obtained as a result of the milling process on the magnesium AZ91 alloy according to the L9 index and the S/N values calculated with the Taguchi least-best approach are given in Table 4.

Surface roughness and S/N values

| Experiment number | Levels | 1.0 mm tool | 0.8 mm tool | ||

|---|---|---|---|---|---|

| R a (µm) | S/N (dB) | R a (µm) | S/N (dB) | ||

| 1 | A1B1C1 | 0.374 | 8.5426 | 0.407 | 7.8152 |

| 2 | A1B2C2 | 0.370 | 8.6360 | 0.536 | 5.4167 |

| 3 | A1B3C3 | 0.562 | 5.0053 | 0.256 | 11.8352 |

| 4 | A2B1C2 | 0.227 | 12.8604 | 0.450 | 6.9357 |

| 5 | A2B2C3 | 0.332 | 9.5772 | 0.455 | 6.8398 |

| 6 | A2B3C1 | 0.440 | 7.1309 | 0.648 | 3.7752 |

| 7 | A3B1C3 | 0.466 | 6.6323 | 0.332 | 9.5772 |

| 8 | A3B2C1 | 0.310 | 10.1728 | 0.684 | 3.2989 |

| 9 | A3B3C2 | 0.495 | 6.1079 | 0.310 | 10.1728 |

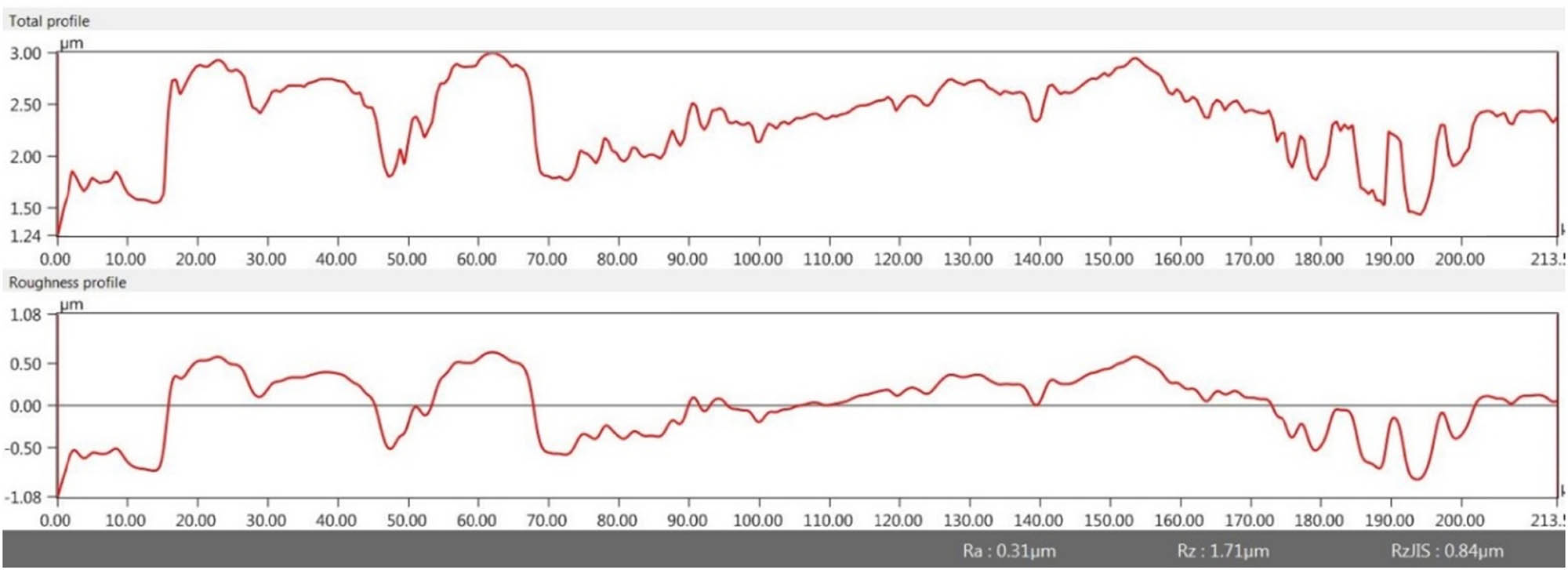

In the measurements made with the Keyence device, five samples were taken for each experiment. The mean value of these samples was calculated and the results were conveyed. An image of the sample is given in Figure 2.

Surface roughness measurement.

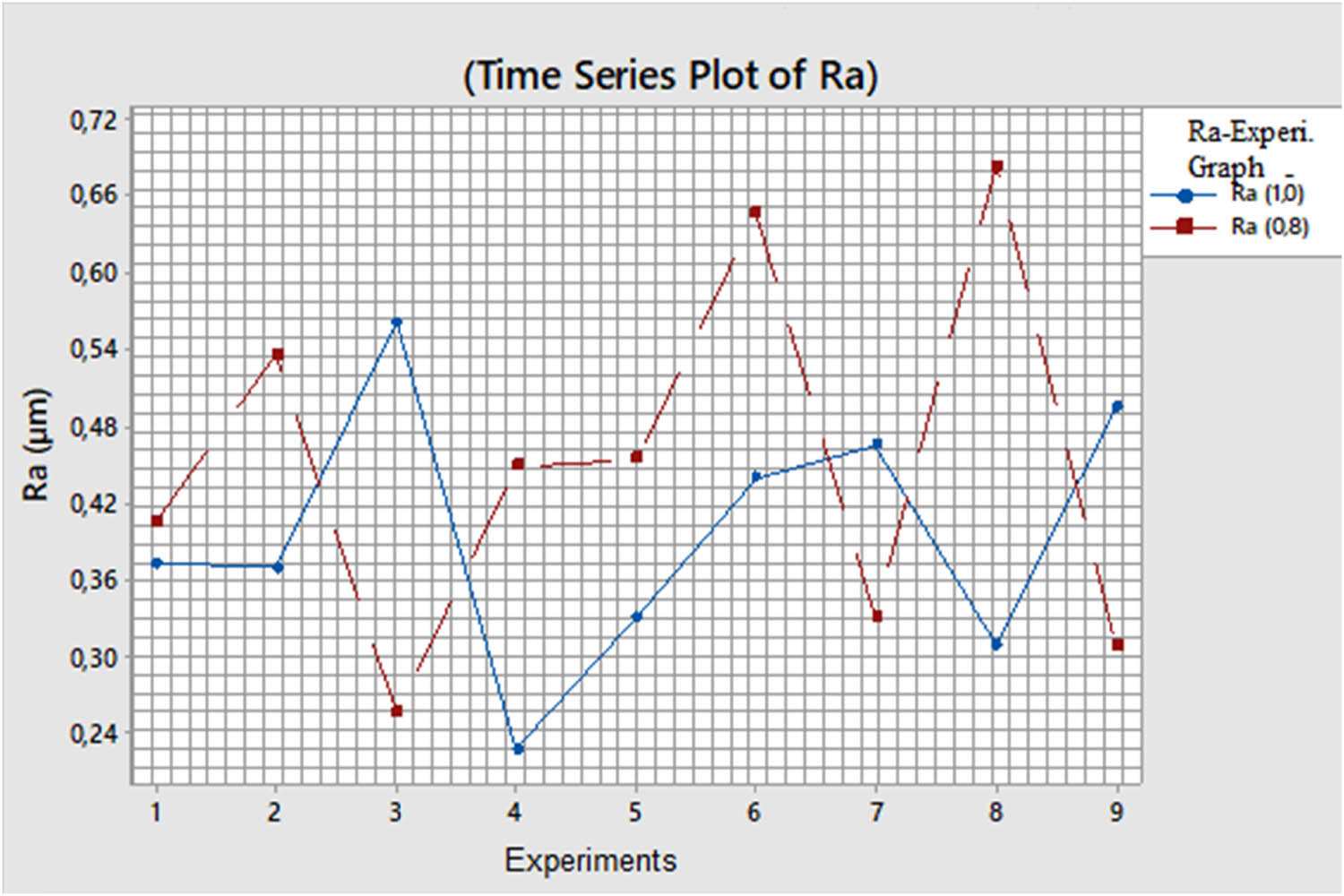

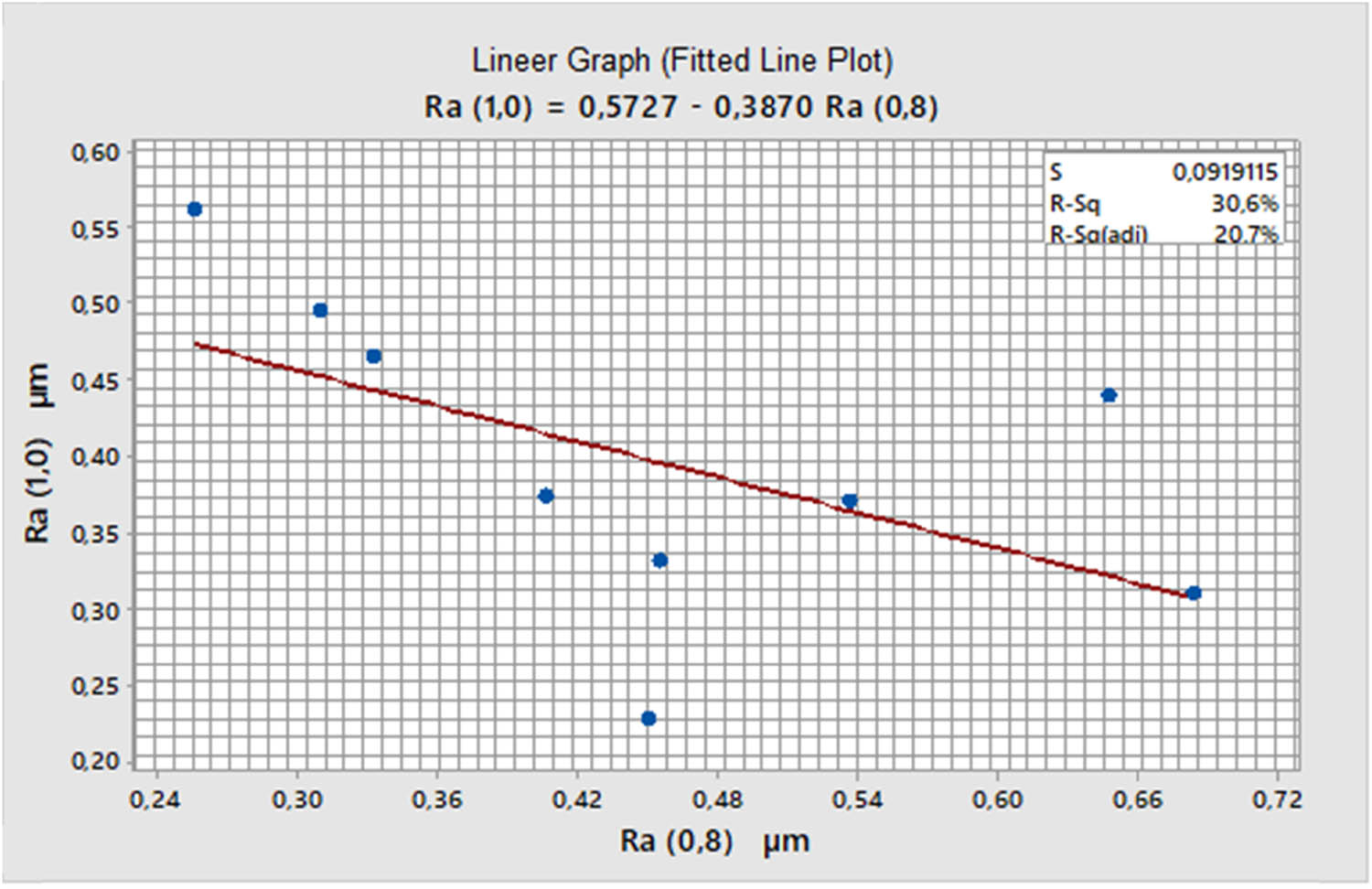

In Figure 3, the comparison of the surface roughness of the experiments with the 0.8 and 1.0 mm tools (time series plot of R a) is given. It is observed that there is a similarity between the surface roughness values of the 4th, 5th, and 6th, 7th experiments. In Figure 4, a linear equation (fitted line plot) was obtained between the surface roughness values.

Comparison of surface roughness.

Comparison of surface roughness.

3.2 Surface roughness analysis

3.2.1 Main effects

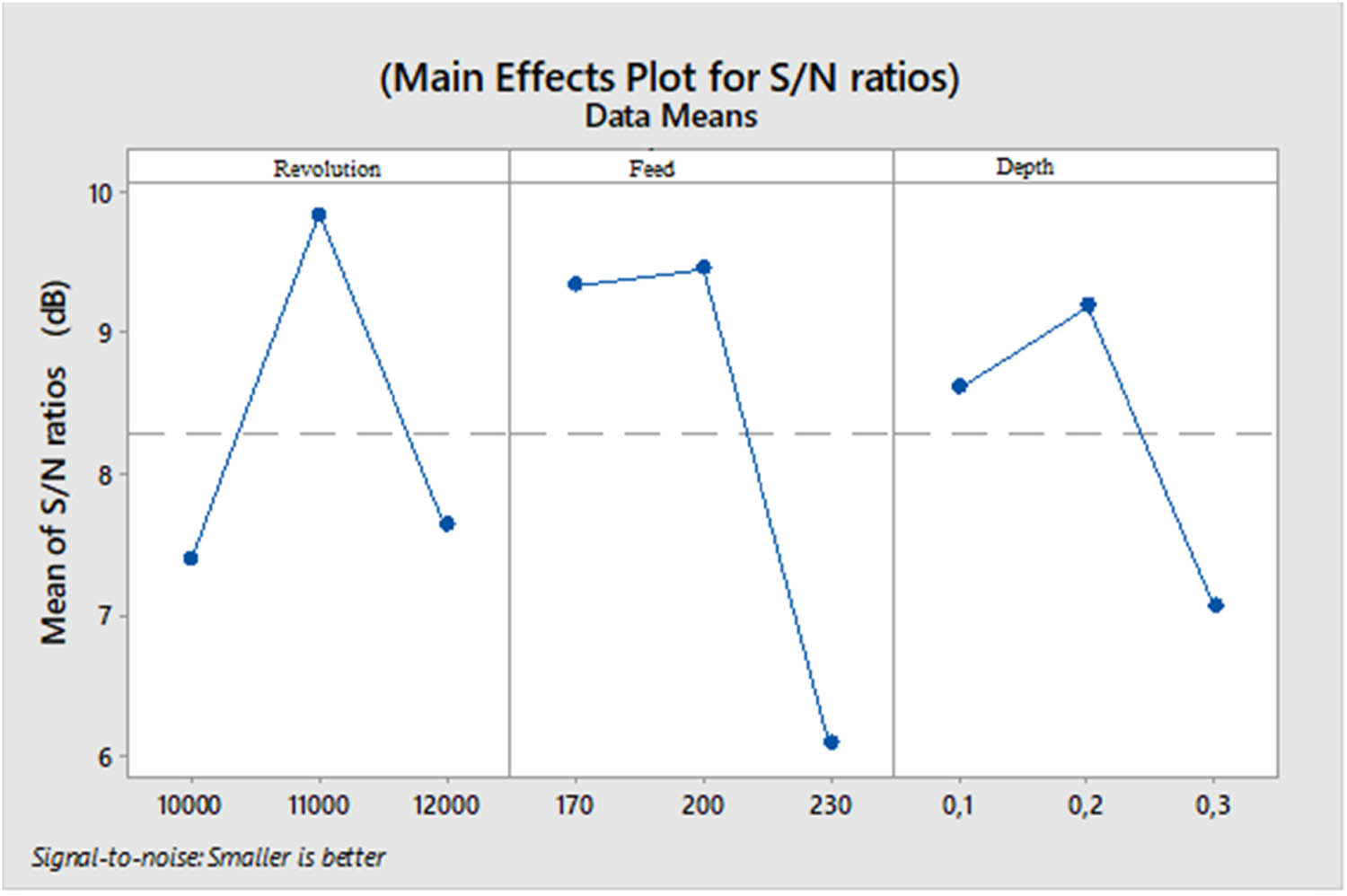

When the experiments with the 1.0 mm tool were examined, the mean values of the obtained surface roughness values were between 0.22 and 0.56 µm. The S/N ratios of the surface roughness values according to the machining parameters are presented in Table 5 and Figure 5.

S/N ratios of surface roughness values

| Level | A rev (n) (rpm) | B feed rate (f) (mm/min) | C depth of cut (d) (mm) |

|---|---|---|---|

| 1 | 7.395 | 9.345 | 8.615 |

| 2 | 9.856 | 9.456 | 9.201 |

| 3 | 7.638 | 6.081 | 7.072 |

| Difference | 2.462 | 3.381 | 2.13 |

| Rank | 2 | 1 | 3 |

Main effect plot (1.0 mm).

As seen in Table 5 and Figure 5, when the effects of machining parameters on the surface roughness are examined according to the obtained S/N ratio, it is seen that the lowest surface roughness value is obtained when the rev is 11,000 rpm, the feed rate is 170 mm/min, and the depth of cut is 0.3 mm (A2B1C3). Validation experiments were carried out for this. The obtained values are consistent with the literature [21,27,29].

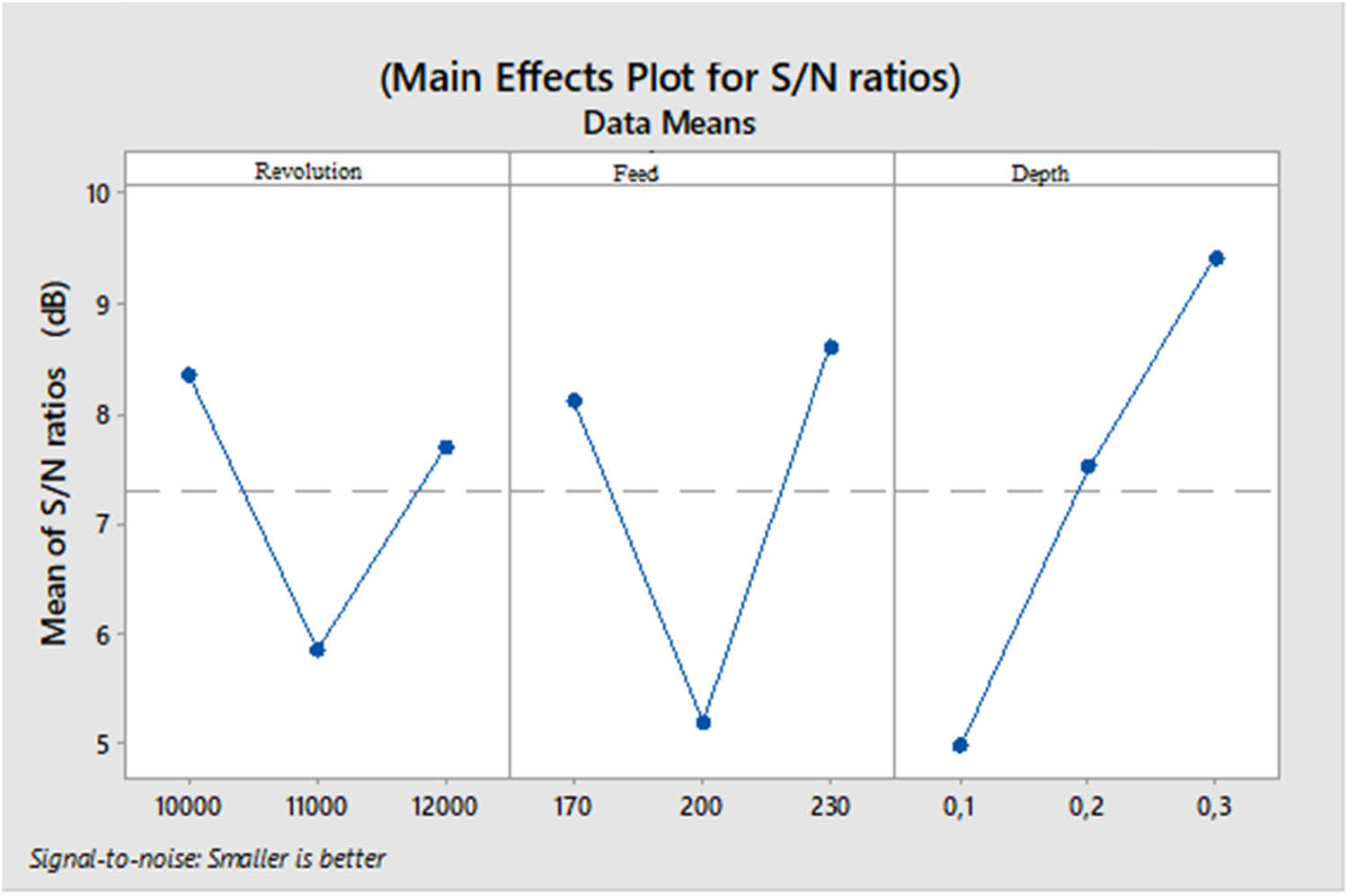

When the experiments with the 0.8 mm tool were examined, the mean values of the obtained surface roughness values were between 0.25 and 0.69 µm. S/N ratios of surface roughness values according to machining parameters are given in Table 6 and Figure 6.

S/N ratios of surface roughness values

| Level | A rev (n) (rpm) | B feed rate (f) (mm/min) | C depth of cut (d) (mm) |

|---|---|---|---|

| 1 | 8.356 | 8.109 | 4.963 |

| 2 | 5.85 | 5.185 | 7.508 |

| 3 | 7.683 | 8.594 | 9.417 |

| Difference | 2.505 | 3.409 | 4.454 |

| Rank | 3 | 2 | 1 |

Main effect plot (for 0.8 mm tool).

The effects of machining parameters on the surface roughness are examined according to the S/N ratio obtained in the nine experiments performed with 0.8 mm tool, as seen in Table 6.

It is understood that the lowest surface roughness value is obtained when the rev is 12,000 rpm, the feed rate is 200 mm/min, and the depth of cut is 0.3 mm (A3B2C1). Validation experiments were carried out for this.

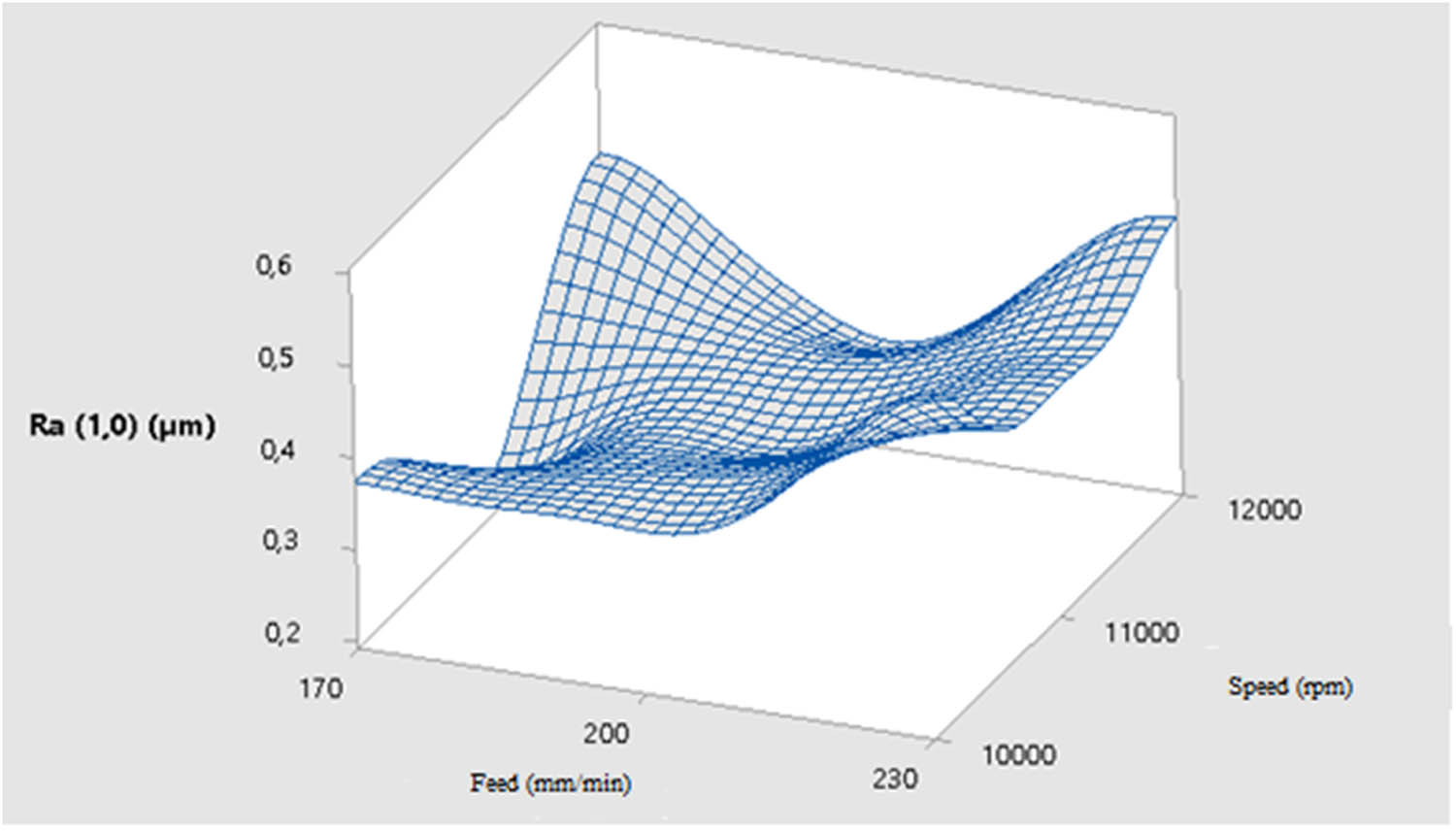

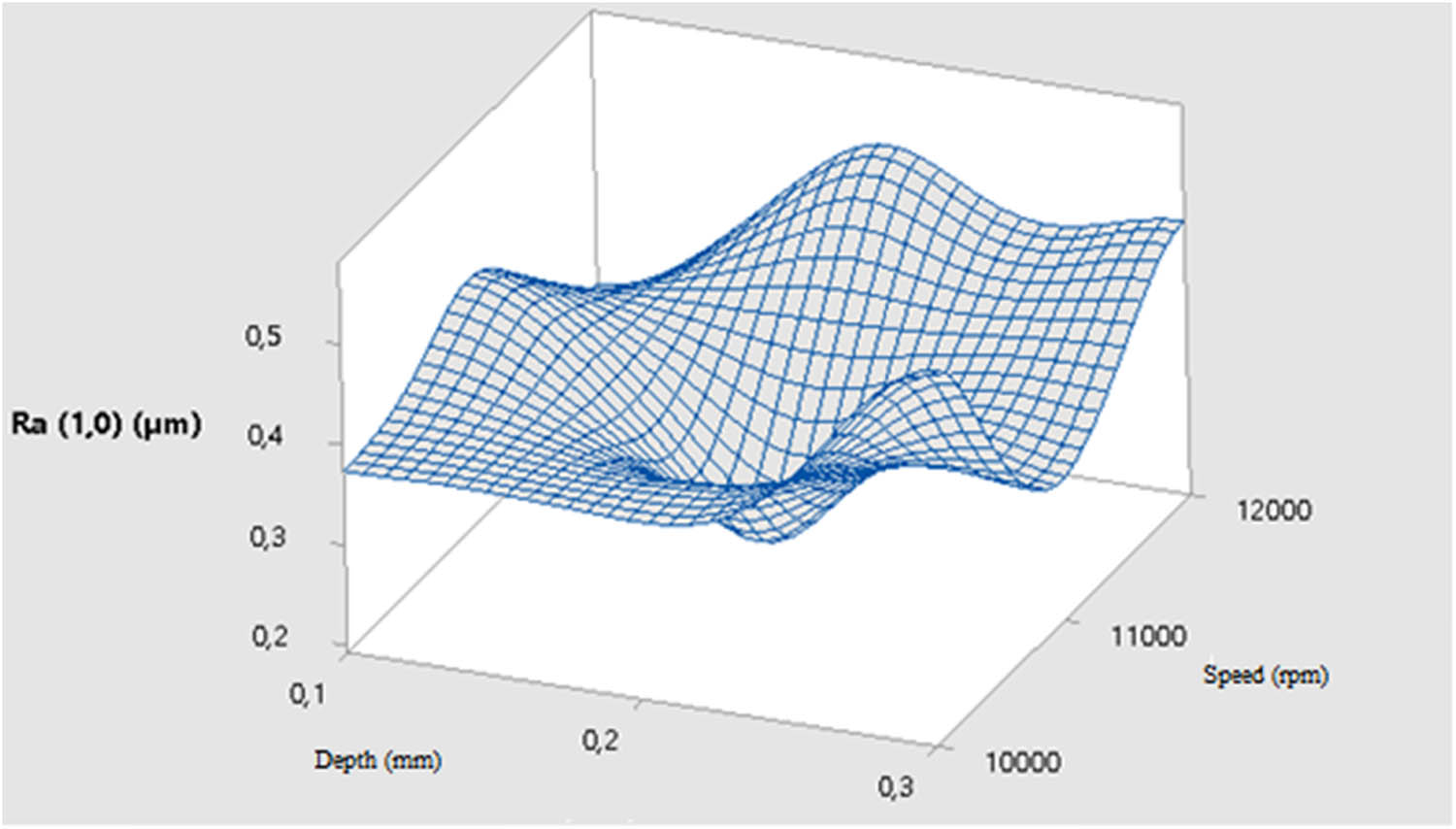

3.2.2 Effect plots

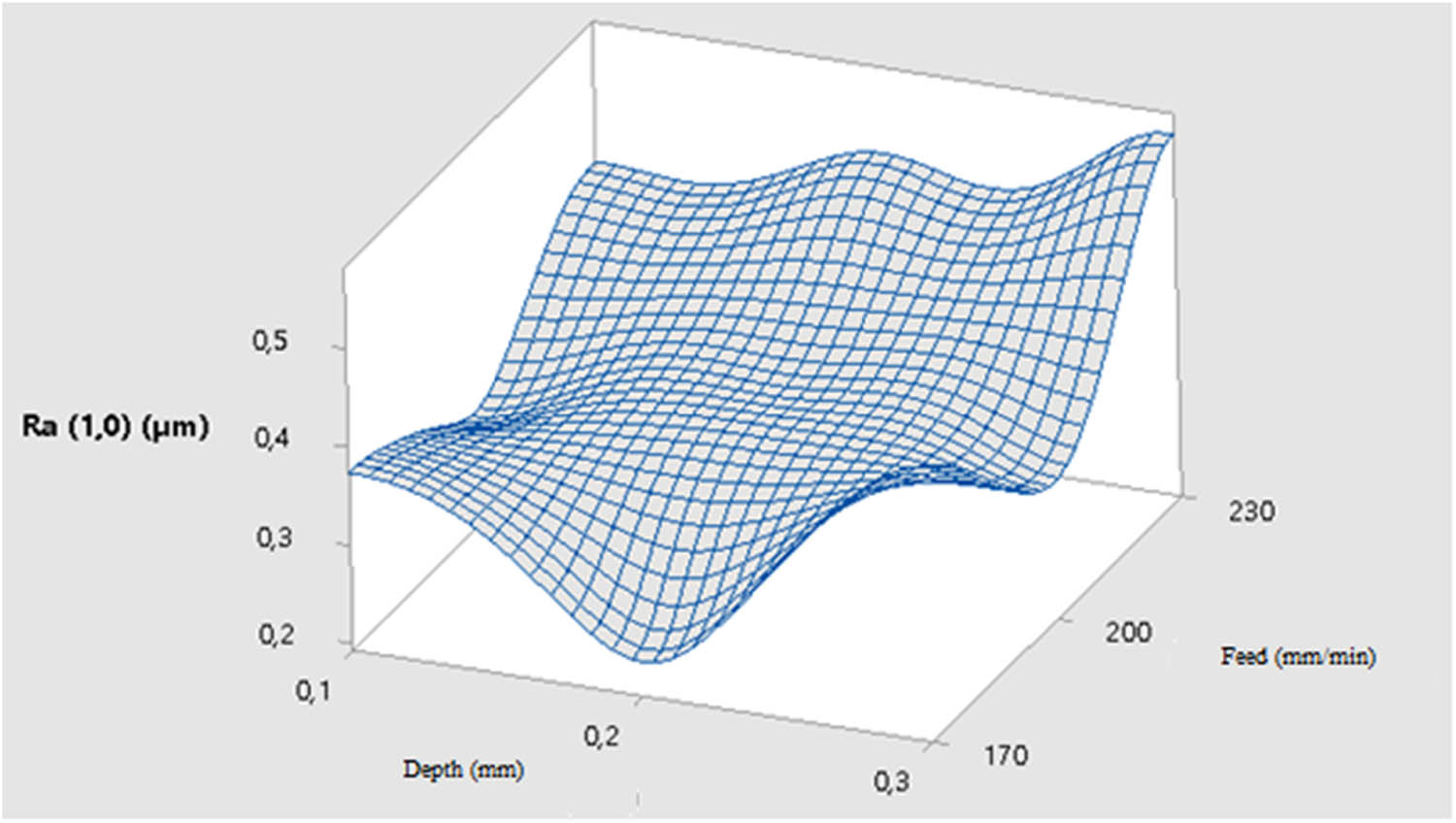

As seen in Table 5, in the experiments performed with the 1.0 mm tool, the feed parameter has the greatest effect on the cutting force. Thereafter, rev and depth of cut are significant. The effects of the parameters used in the experimental studies on the cutting forces are given in Figures 7–9.

Effects of feed rate and rev on surface roughness.

Effects of depth of cut and rev on surface roughness.

Effects of the depth of cut and feed rate on surface roughness.

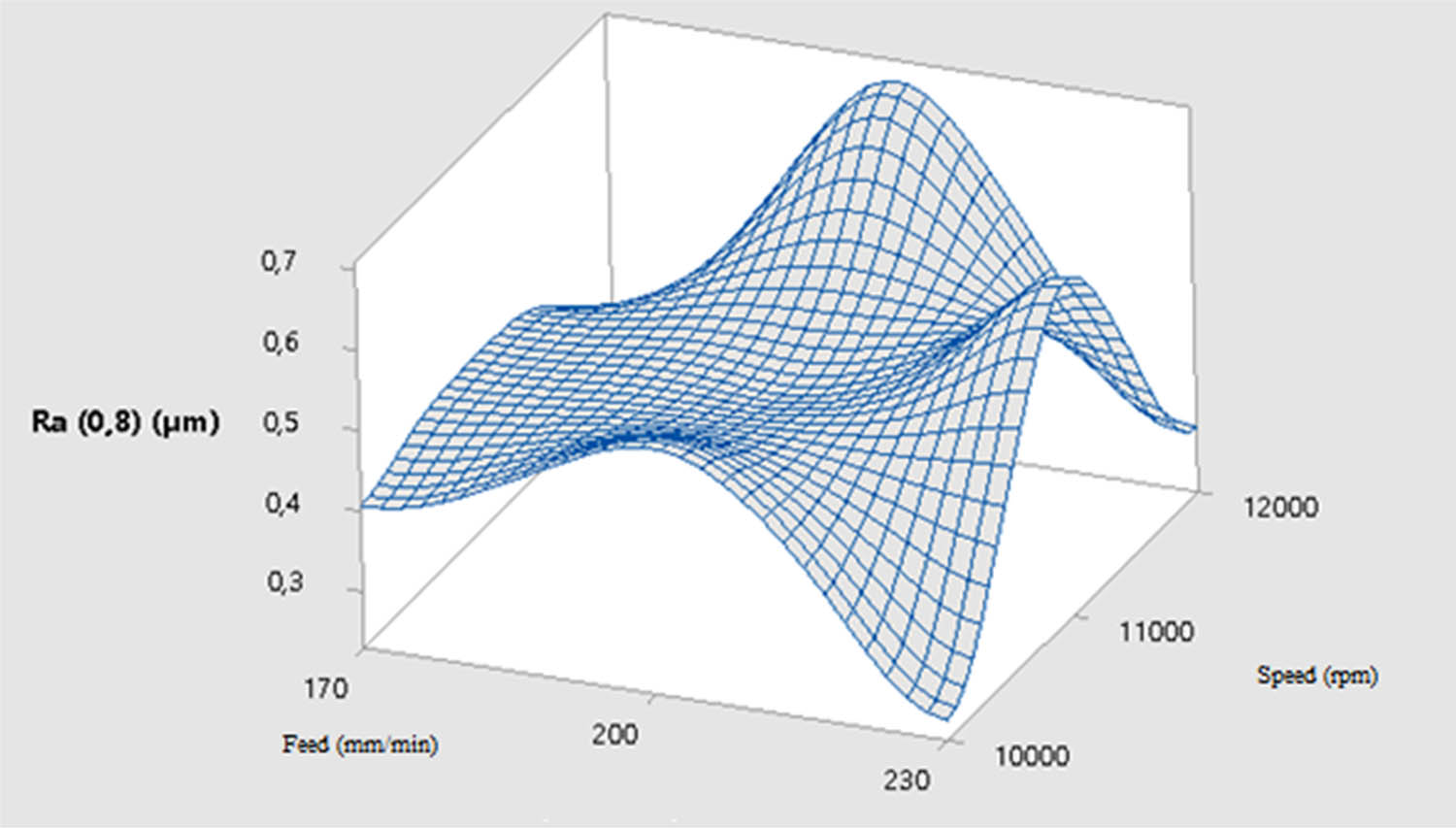

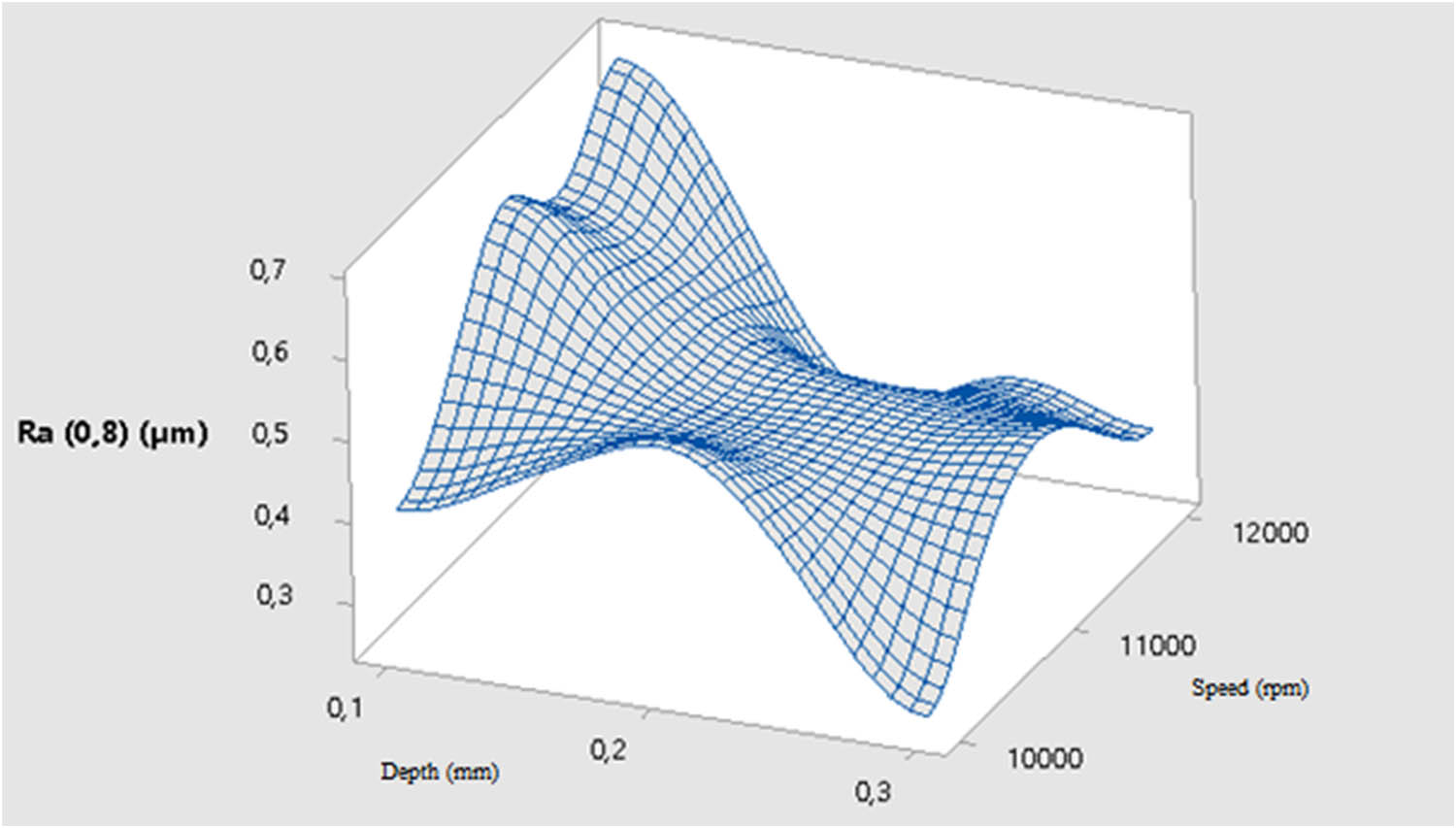

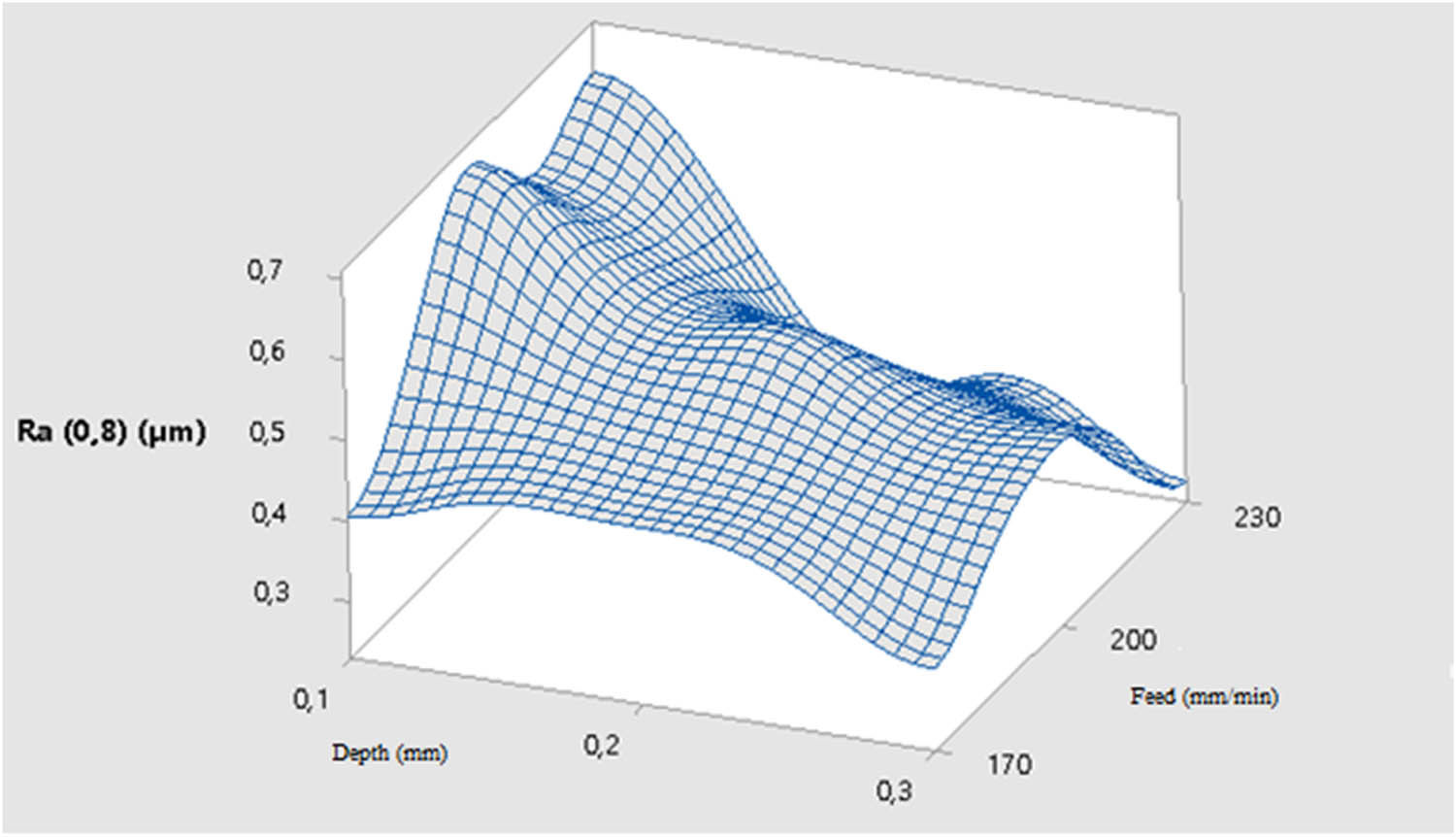

As seen in Table 6, the effect of the cutting depth parameter on the cutting force is the highest in the experiments performed with the 0.8 mm tool. Following this, feed and rev are important. The effects of the parameters used in the experimental studies on the cutting forces are given in Figures 10–12.

Effects of feed and rev on surface roughness.

Effects of depth of cut and rev on surface roughness.

Effects of depth of cut and feed rate on surface roughness.

3.2.3 Variance analysis

The results of the variance analysis of the mean surface roughness values in the experiments performed with the 1.0 mm tool are shown in Table 7. As can be interpreted from the table, the most effective factor in the formation of roughness on the machined surface as a result of machining AZ91 magnesium alloy material with microcutting tools is the feed with 58.73%.

Surface roughness ANOVA results 1 mm tool

| Parameter | Degree of freedom | Sum of squares | Mean of squares | F value | % |

|---|---|---|---|---|---|

| Rev (n) | 2 | 0.018764 | 0.009382 | 3.59 | 23.48 |

| Feed (f) | 2 | 0.046975 | 0.023488 | 8.98 | 58.73 |

| Depth (d) | 2 | 0.014249 | 0.007125 | 2.72 | 17.79 |

| Error | 2 | 0.005231 | 0.002616 | ||

| Total | 8 | 0.08522 |

The results of the mean surface roughness variance analysis of the experiments performed with a 0.8 mm tool are shown in Table 8. As can be seen from the table, unlike the experiment results processed with 0.8 mm, the most effective factor is the depth of cut with 53.60%.

Surface roughness ANOVA results of 0.8 mm tool

| Parameter | Degree of freedom | Sum of squares | Mean of squares | F value | % |

|---|---|---|---|---|---|

| Rev (n) | 2 | 0.02141 | 0.01071 | 1.06 | 13.90 |

| Feed (f) | 2 | 0.05001 | 0.02501 | 2.48 | 32.50 |

| Depth (d) | 2 | 0.08253 | 0.04127 | 4.09 | 53.60 |

| Error | 2 | 0.02018 | 0.01009 | ||

| Total | 8 | 0.17414 |

As a result of the experiments, feed rate is a parameter that affects the surface roughness. It is observed that the depth of cut for the 0.8 mm tool affects the surface roughness.

3.2.4 Optimization

Optimum levels of surface roughness are given in Table 9 for 1.0 mm tool and 0.8 mm tool. These levels were obtained from Tables 5 and 6. A2B1C3 is the optimum level for a 1.0 mm tool. For a 0.8 mm tool, on the other hand, A3B2C1 is the optimum level.

Optimum levels for surface roughness

| Parameters | Symbol | Units | Code | For 1.0 mm tool | For 0.8 mm tool | ||

|---|---|---|---|---|---|---|---|

| Optimum level | Optimum value | Optimum level | Optimum value | ||||

| Rev | n | rpm | A | 2 | 11,000 | 1 | 12,000 |

| Feed | f | mm/min | B | 2 | 170 | 1 | 200 |

| Depth | d | mm | C | 2 | 0.3 | 3 | 0.1 |

3.2.5 Validation experiments

The value validation experiments were carried out in which the roughness value was estimated by Minitab linear regression under optimum conditions. As a result of the regression estimation at the A2B1C3 level for the 1.0 mm tool, the surface roughness value of 0.240 µm was obtained, and for the 0.8 mm tool, surface roughness value of 0.237 µm at the A3B2C1 level was obtained. As a result of the validation experiments, the surface roughness values were found as 0.256 µm for the 1.0 mm tool and 0.262 µm for the 0.8 mm tool. The obtained values are consistent with the literature. [21,29]. The results are presented in Table 10.

Validation experiments

| A3B1C1 level | For 1.0 mm tool | For 0.8 mm tool | ||

|---|---|---|---|---|

| R a (µm) | S/N (dB) | R a (µm) | S/N (dB) | |

| Calculated value | 0.240 | 11.927 | 0.237 | 11.290 |

| Validation experiments results | 0.256 | 11.836 | 0.262 | 11.634 |

| Differences | 0.016 | 0.091 | 0.025 | 0.344 |

Estimates for the 1.0 mm tool have an error of 6.70% according to the validation experiment. This value is 9.5% for a 0.8 mm tool.

3.2.6 Regression analysis

The equations obtained for the surface roughness values as a result of the linear regression analysis are given below. The equations stated in 1 and 2 were obtained with three unknowns with the rev feed and depth parameters. The equations specified in 3 and 4 represent a quadratic equation and also include the relationship of the parameters with each other.

For experiments with a 1.0 mm tool:

For experiments with 0.8 mm tool:

The obtained values are consistent with the literature [28].

4 Conclusion

In this study, Taguchi (L9) experimental design was made for three different levels of rev, feed, and depth of cut parameters. A total of 18 experiments were conducted at three different levels for two different tools. As the surface roughness value is desired to be minimum, the smallest best objective function is used [19,21]. The results for both tools were examined and analyzed separately.

When the mean surface roughness values of the experiments performed with the 1.0 mm tool were examined, the maximum surface roughness of 0.56 µm was obtained in the third experiment, and the minimum surface roughness of 0.22 µm was obtained in the fourth experiment. The mean surface roughness in the experiments is 0.40 µm.

When the mean surface roughness values of the experiments performed with a 0.8 mm tool were examined, the maximum surface roughness of 0.68 µm was obtained in the eighth experiment and a minimum surface roughness of 0.25 µm was obtained in the third experiment. The mean surface roughness in the experiments is 0.45 µm.

When the mean values of the surface roughness are compared, higher roughness values were observed in the experiments performed with the 0.8 mm tool. One reason for this may be the vibration during machining caused by the increased rev parameter.

It is observed that there is a similarity between the surface roughness values of the 4th, 5th, and 6th, 7th experiments. The equation specified in (equation (5)) was obtained linearly between the surface roughness values.

When the research is evaluated in terms of surface roughness, the most effective factor for the 1.0 mm tool is feed rate with 58.73%. The effect of feed on the surface roughness is expected and is a situation in the literature [27,28]. Thereafter, rev and depth are significant. The most effective factor for the 0.8 mm tool is the depth of cut with 53.60%, followed by feed and rev. As can be understood, the depth parameter has a great effect on the tool surface roughness of 0.8 mm.

In experiments (A2B1C3) using 1.0 mm tool, it has been observed that minimum surface roughness can be obtained with 11,000 rpm, 170 mm/min feed, and 0.3 mm depth of cut. On the other hand, in experiments using 0.8 mm tool (A3B2C1), it was observed that minimum surface roughness could be obtained with 12,000 rpm, 200 mm/min feed, and 0.1 mm depth of cut. Unlike the literature, an increase in surface roughness values was observed at low depth of cuts due to scraping and friction.

It is demonstrated in the study that the Taguchi optimization technique is an effective technique in the machinability of AZ91 magnesium alloy material, in the experimental design, and in the optimization of the parameters and the response values in the desired ratios [19,21,29,30,31].

Acknowledgements

There is no body or organization to be acknowledged.

-

Funding information: There are no funding sources for this study.

-

Author contributions: All data were obtained by authors equally.

-

Conflict of interest: The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this article.

-

Ethical approval: The conducted research is not related to either human or animal use.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

References

[1] Kaçar İ, Öztürk F. Magnezyum alaşimlarinin şekillendirilmesindeki son gelişmeler. TİMAK-Tasarım İmalat Anal Kongresi. 2006. p. 354–61 (Turkish).Search in Google Scholar

[2] Gözüaçık NK. AZ91 magnezyum alaşiminin mikro ark oksidasyonunda elektrolit bileşiminin etkileri. Yüksek lisans tezi. İstanbul: İstanbul Teknik Üniversitesi, Fen Bilimleri Enstitüsü, Metalürji ve Malzeme Mühendisliği Anabilim Dalı; 2012 (Turkish).Search in Google Scholar

[3] Atalay O. Magnezyum ve alaşimlarinin konstrüksiyon malzemesi olarak otomotivde kullanimi. Yüksek lisans tezi. Istanbul: İstanbul Teknik Üniversitesi, Fen Bilimleri Enstitüsü, Makine Mühendisliği Anabilim Dalı, İstanbul Türkiye; 2006 (Turkish).Search in Google Scholar

[4] Güler KA. Uçak Yapımında Kullanılan Malzemeler ve Özelliklerinin İncelenmesi. Bitirme Tezi, Yıldız Teknik Üniversitesi, Kimya-Metalürji Fakültesi, Metalürji ve Malzeme Mühendisliği Bölümü. İstanbul: Türkiye; 2003 (Turkish).Search in Google Scholar

[5] Özel T, Liu X, Dhanorker A. Modelling and simulation of micro-milling process. Mater Manuf Process. 2009;24(12):1–8.10.1080/10426910903130008Search in Google Scholar

[6] Mamedov A, Lazoğlu İ. Mikro Frezeleme İçin Mekanistik Kuvvet Modeli. 3. Ulusal Tasarım İmalat ve Analiz Kongresi. Balıkesir: Türkiye; 2012;29–30 Kasım 2012, Turkish.Search in Google Scholar

[7] Mamedov A, Lazoğlu İ. CNC ile Talaşlı İşlemede Kuvvet ve Titreşim Ölçümü. VIII. Ulusal Ölçümbilim Kongresi. Gebze/Kocaeli; 2013;26–28. Kocaeli: Eylül 2013, Turkish.Search in Google Scholar

[8] Oliaeia SN, Karpat Y. Experimental investigations on micro milling of Stavax stainless steel. Procedia CIRP. 2014;14:14377–82. 10.1016/j.procir.2014.03.006.Search in Google Scholar

[9] Günaydın E. Mikro frezeleme uygulamalarinda. uygun takim yolunun ve kesme parametrelerinin belirlenmesi. Kocaeli, Türkiye: Yüksek Lisans Tezi, Gebze Yüksek Teknoloji Enstitüsü, Makine Mühendisliği Anabilim Dalı; 2014 (Turkish).Search in Google Scholar

[10] Pratap T, Patraa K, Aleksandr D. Modeling cutting force in micro-milling of Ti-6Al-4V titanium alloy. Procedia Eng. 2015;129:134–9. 10.1016/j.proeng.2015.12.021.Search in Google Scholar

[11] Karpat Y, Kanlı M, Oliaer SN. Mikro frezeleme işleminin takım eksen sapması göz önüne alınarak mekanistik modellemesi. J Faculty Eng Architecture Gazi Univ. 2018;3(2):771–81 (Turkish).10.17341/gazimmfd.416407Search in Google Scholar

[12] Yücel E, Çiçek A. İmalat alaninda yaygin olarak kullanilan mikro işleme teknikleri. Sakarya Üniversitesi Fen Bilimleri Derg. 2011;15(1):46–59 (Turkish).Search in Google Scholar

[13] Aslantaş K, Çiçek A, Çelik SG. Mikro işlemede takim aşinmasi-kanal geometrisi ilişkisi üzerine deneysel bir çalişma. J Faculty Eng Architecture Gazi Univ. 2018;33(4):1285–98.10.17341/gazimmfd.416425Search in Google Scholar

[14] Lu A, Jia Z, Wanga H, Feng Y, Liang SY. The effect of cutting parameters on micro-hardness and the prediction of Vickers hardness based on a response surface methodology for micro-milling Inconel 718. Measurement. 2019;140:56–62. 10.1016/j.measurement.2019.03.037.Search in Google Scholar

[15] Aslantaş K, Kaynak Y. Şekil hafızalı NiTi alaşımının mikro frezelenmesi ve kritik talaş kalınlığının belirlenmesi. J Faculty Eng Architecture Gazi Univ. 2019;34(3):1201–11 (Turkish).10.17341/gazimmfd.460515Search in Google Scholar

[16] Kuram E. Kesici takim bağlama uzunluğunun mikro frezelemede takim aşinmasi. Kuvvetler ve Çapak Boyutu Üzerindeki Etkileri Dokuz Eylül Üniversitesi Mühendislik Fakültesi Fen ve Mühendislik Derg. 2017;19(55):229–37 (Turkish).10.21205/deufmd.2017195518Search in Google Scholar

[17] Nahata S, Onler R, Korkmaz E, Ozdoganlar OB. Radial throw at the cutting edges of micro-tools when using ultra-high-speed micro machining spindles. Proc Manuf. 2018;26:1517–26. 10.1016/j.promfg.2018.07.085.Search in Google Scholar

[18] Yu J, Wang G, Rong Y. Experimental study on the surface integrity and chip formation in the micro cutting process. Proc Manuf. 2015;1:655–62. 10.1016/j/promfg.2015.09.063.Search in Google Scholar

[19] Aslantaş K, Ekici E, Çiçek A. Optimization of process parameters for micro milling of Ti-6Al-4V alloy using Taguchi-based gray relational analysis. Measurement. 2018;128:419–27. 10.1016/j.measurement.2018.06.066Get.Search in Google Scholar

[20] Sun Q, Cheng X, Liu Y, Yang X, Li Y. Modelling and simulation for micromilling mechanisms. Procedia Eng. 2017;174:760–6. 10.1016/j.proeng.2017.01.219.Search in Google Scholar

[21] Kuram E, Ozçelik B. Optimization of machining parameters during micro-milling of Ti6Al4V titanium alloy and Inconel 718 materials using Taguchi method. Proc Inst Mech Eng, Part B: J Eng Manuf. 2015;231(2):228–42. 10.1177/0954405415572662.Search in Google Scholar

[22] Singh SK, Panda SK, Singh SK, Panda SK. An analytical approach to evaluate the effective coefficients of piezoelectric composites. Emerg Mater Res. 2021;10(2):178–93. 10.1680/jemmr.19.00167.Search in Google Scholar

[23] Dindar B, Ağir İ, Dindar B, Ağir İ. Tensile and buckling properties of notched 6063 aluminum repaired with composite patches. Emerg Mater Res. 2021;10(2):139–44. 10.1680/jemmr.20.00306.Search in Google Scholar

[24] Kurtulmuş M, Doğan E;, Kurtulmuş M, Doğan E. The effects of undercut geometry on the static stress concentration factor of welds. Emerg Mater Res. 2021;10(3):272–7. 10.1680/jemmr.20.00100.Search in Google Scholar

[25] Yusuf D, Bekir G, Adem Ö, Ali Ö. Microstructure and wear properties of WC–10Co–4Cr coating to cultivator blades by DJ-HVOF. Emerg Mater Res. 2021;10(3):278–88. 10.1680/jemmr.20.00324.Search in Google Scholar

[26] Berkant D, İnan A, Behlül BN. Low-velocity impact response of Kevlar/epoxy aluminum laminates. Emerg Mater Res. 2021;10(3):295–9. 10.1680/jemmr.20.00302.Search in Google Scholar

[27] Aydın U, Ay M, Etyemez A. Milling of magnesium alloy with micro cutting tools. Int J Innovative Res Rev. 2019;3(1):30–4.Search in Google Scholar

[28] Ay M, Ay İ. The prediction and optimization of the effects of abrasive waterjet cutting parameters on kerf. Acta Phys Pol A. 2016;129(4):762–6. 10.12693/APhysPolA.129.762.Search in Google Scholar

[29] Akgün M, Özger G, Ulaş HB. Döküm yöntemiyle üretilmiş AZ91 magnezyum alaşiminin işlenebilirliğinin yüzey pürüzlülüğü açisindan değerlendirilmesi. Erciyes Üniversitesi Fen Bilimleri Enstitüsü Derg. 2014;30(5):323–8 (Turkish).Search in Google Scholar

[30] Basmacı G, Taskin A, Koklu U. Effect of tool path strategies and cooling conditions in pocket machining of AZ91 magnesium alloy. Indian J Chem Technol. 2019;26(2):139–45.Search in Google Scholar

[31] Basmaci G. Optimization of processing parameters of AISI 316 Ti stainless steels. Academic Platf J Eng Sci. 2018;6(3–6):1–7. 10.21541/apjes.422606.Search in Google Scholar

© 2022 Ayhan Etyemez et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Photocatalytic degradation of Rhodamine B in aqueous phase by bimetallic metal-organic framework M/Fe-MOF (M = Co, Cu, and Mg)

- Assessment of using electronic portal imaging device for analysing bolus material utilised in radiation therapy

- A detailed investigation on highly dense CuZr bulk metallic glasses for shielding purposes

- Simulation of gamma-ray shielding properties for materials of medical interest

- Environmental impact assesment regulation applications and their analysis in Turkey

- Sample age effect on parameters of dynamic nuclear polarization in certain difluorobenzen isomers/MC800 asphaltene suspensions

- Passenger demand forecasting for railway systems

- Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach

- Gamma, neutron, and heavy charged ion shielding properties of Er3+-doped and Sm3+-doped zinc borate glasses

- Bridging chiral de-tert-butylcalix[4]arenes: Optical resolution based on column chromatography and structural characterization

- Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt

- Comparison of the yield and purity of plasma exosomes extracted by ultracentrifugation, precipitation, and membrane-based approaches

- Bioactive triterpenoids from Indonesian medicinal plant Syzygium aqueum

- Investigation of the effects of machining parameters on surface integrity in micromachining

- The mesoporous aluminosilicate application as support for bifunctional catalysts for n-hexadecane hydroconversion

- Gamma-ray shielding properties of Nd2O3-added iron–boron–phosphate-based composites

- Numerical investigation on perforated sheet metals under tension loading

- Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt

- Two new polypodane-type bicyclic triterpenoids from mastic

- Structural, physical, and mechanical properties of the TiO2 added hydroxyapatite composites

- Tribological properties and characterization of borided Co–Mg alloys

- Studies on Anemone nemorosa L. extracts; polyphenols profile, antioxidant activity, and effects on Caco-2 cells by in vitro and in silico studies

- Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system

- Cyclic connectivity index of bipolar fuzzy incidence graph

- The role of passage numbers of donor cells in the development of Arabian Oryx – Cow interspecific somatic cell nuclear transfer embryos

- Mechanical property evaluation of tellurite–germanate glasses and comparison of their radiation-shielding characteristics using EPICS2017 to other glass systems

- Molecular screening of ionic liquids for CO2 absorption and molecular dynamic simulation

- Microwave-assisted preparation of Ag/Fe magnetic biochar from clivia leaves for adsorbing daptomycin antibiotics

- Iminodisuccinic acid enhances antioxidant and mineral element accumulation in young leaves of Ziziphus jujuba

- Cytotoxic activity of guaiane-type sesquiterpene lactone (deoxycynaropicrin) isolated from the leaves of Centaurothamnus maximus

- Effects of welding parameters on the angular distortion of welded steel plates

- Simulation of a reactor considering the Stamicarbon, Snamprogetti, and Toyo patents for obtaining urea

- Effect of different ramie (Boehmeria nivea L. Gaud) cultivars on the adsorption of heavy metal ions cadmium and lead in the remediation of contaminated farmland soils

- Impact of a live bacterial-based direct-fed microbial (DFM) postpartum and weaning system on performance, mortality, and health of Najdi lambs

- Anti-tumor effect of liposomes containing extracted Murrayafoline A against liver cancer cells in 2D and 3D cultured models

- Physicochemical properties and some mineral concentration of milk samples from different animals and altitudes

- Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies

- Diagnostic and therapeutic radioisotopes in nuclear medicine: Determination of gamma-ray transmission factors and safety competencies of high-dense and transparent glassy shields

- Calculation of NaI(Tl) detector efficiency using 226Ra, 232Th, and 40K radioisotopes: Three-phase Monte Carlo simulation study

- Isolation and identification of unstable components from Caesalpinia sappan by high-speed counter-current chromatography combined with preparative high-performance liquid chromatography

- Quantification of biomarkers and evaluation of antioxidant, anti-inflammatory, and cytotoxicity properties of Dodonaea viscosa grown in Saudi Arabia using HPTLC technique

- Characterization of the elastic modulus of ceramic–metal composites with physical and mechanical properties by ultrasonic technique

- GC-MS analysis of Vespa velutina auraria Smith and its anti-inflammatory and antioxidant activities in vitro

- Texturing of nanocoatings for surface acoustic wave-based sensors for volatile organic compounds

- Insights into the molecular basis of some chalcone analogues as potential inhibitors of Leishmania donovani: An integrated in silico and in vitro study

- (1R,2S,5R)-5-Methyl-2-(propan-2-yl)cyclohexyl 4-amino-3-phenylbutanoate hydrochloride: Synthesis and anticonvulsant activity

- On the relative extraction rates of colour compounds and caffeine during brewing, an investigation of tea over time and temperature

- Characterization of egg shell powder-doped ceramic–metal composites

- Rapeseed oil-based hippurate amide nanocomposite coating material for anticorrosive and antibacterial applications

- Chemically modified Teucrium polium (Lamiaceae) plant act as an effective adsorbent tool for potassium permanganate (KMnO4) in wastewater remediation

- Efficiency analysis of photovoltaic systems installed in different geographical locations

- Risk prioritization model driven by success factor in the light of multicriteria decision making

- Theoretical investigations on the excited-state intramolecular proton transfer in the solvated 2-hydroxy-1-naphthaldehyde carbohydrazone

- Mechanical and gamma-ray shielding examinations of Bi2O3–PbO–CdO–B2O3 glass system

- Machine learning-based forecasting of potability of drinking water through adaptive boosting model

- The potential effect of the Rumex vesicarius water seeds extract treatment on mice before and during pregnancy on the serum enzymes and the histology of kidney and liver

- Impact of benzimidazole functional groups on the n-doping properties of benzimidazole derivatives

- Extraction of red pigment from Chinese jujube peel and the antioxidant activity of the pigment extracts

- Flexural strength and thermal properties of carbon black nanoparticle reinforced epoxy composites obtained from waste tires

- A focusing study on radioprotective and antioxidant effects of Annona muricata leaf extract in the circulation and liver tissue: Clinical and experimental studies

- Clinical comprehensive and experimental assessment of the radioprotective effect of Annona muricata leaf extract to prevent cellular damage in the ileum tissue

- Effect of WC content on ultrasonic properties, thermal and electrical conductivity of WC–Co–Ni–Cr composites

- Influence of various class cleaning agents for prosthesis on Co–Cr alloy surface

- The synthesis of nanocellulose-based nanocomposites for the effective removal of hexavalent chromium ions from aqueous solution

- Study on the influence of physical interlayers on the remaining oil production under different development modes

- Optimized linear regression control of DC motor under various disturbances

- Influence of different sample preparation strategies on hypothesis-driven shotgun proteomic analysis of human saliva

- Determination of flow distance of the fluid metal due to fluidity in ductile iron casting by artificial neural networks approach

- Investigation of mechanical activation effect on high-volume natural pozzolanic cements

- In vitro: Anti-coccidia activity of Calotropis procera leaf extract on Eimeria papillata oocysts sporulation and sporozoite

- Determination of oil composition of cowpea (Vigna unguiculata L.) seeds under influence of organic fertilizer forms

- Activated partial thromboplastin time maybe associated with the prognosis of papillary thyroid carcinoma

- Treatment of rat brain ischemia model by NSCs-polymer scaffold transplantation

- Lead and cadmium removal with native yeast from coastal wetlands

- Characterization of electroless Ni-coated Fe–Co composite using powder metallurgy

- Ferrate synthesis using NaOCl and its application for dye removal

- Antioxidant, antidiabetic, and anticholinesterase potential of Chenopodium murale L. extracts using in vitro and in vivo approaches

- Study on essential oil, antioxidant activity, anti-human prostate cancer effects, and induction of apoptosis by Equisetum arvense

- Experimental study on turning machine with permanent magnetic cutting tool

- Numerical simulation and mathematical modeling of the casting process for pearlitic spheroidal graphite cast iron

- Design, synthesis, and cytotoxicity evaluation of novel thiophene, pyrimidine, pyridazine, and pyridine: Griseofulvin heterocyclic extension derivatives

- Isolation and identification of promising antibiotic-producing bacteria

- Ultrasonic-induced reversible blood–brain barrier opening: Safety evaluation into the cellular level

- Evaluation of phytochemical and antioxidant potential of various extracts from traditionally used medicinal plants of Pakistan

- Effect of calcium lactate in standard diet on selected markers of oxidative stress and inflammation in ovariectomized rats

- Identification of crucial salivary proteins/genes and pathways involved in pathogenesis of temporomandibular disorders

- Zirconium-modified attapulgite was used for removing of Cr(vi) in aqueous solution

- The stress distribution of different types of restorative materials in primary molar

- Reducing surface heat loss in steam boilers

- Deformation behavior and formability of friction stir processed DP600 steel

- Synthesis and characterization of bismuth oxide/commercial activated carbon composite for battery anode

- Phytochemical analysis of Ziziphus jujube leaf at different foliar ages based on widely targeted metabolomics

- Effects of in ovo injection of black cumin (Nigella sativa) extract on hatching performance of broiler eggs

- Separation and evaluation of potential antioxidant, analgesic, and anti-inflammatory activities of limonene-rich essential oils from Citrus sinensis (L.)

- Bioactivity of a polyhydroxy gorgostane steroid from Xenia umbellata

- BiCAM-based automated scoring system for digital logic circuit diagrams

- Analysis of standard systems with solar monitoring systems

- Structural and spectroscopic properties of voriconazole and fluconazole – Experimental and theoretical studies

- New plant resistance inducers based on polyamines

- Experimental investigation of single-lap bolted and bolted/bonded (hybrid) joints of polymeric plates

- Investigation of inlet air pressure and evaporative cooling of four different cogeneration cycles

- Review Articles

- Comprehensive review on synthesis, physicochemical properties, and application of activated carbon from the Arecaceae plants for enhanced wastewater treatment

- Research progress on speciation analysis of arsenic in traditional Chinese medicine

- Recent modified air-assisted liquid–liquid microextraction applications for medicines and organic compounds in various samples: A review

- An insight on Vietnamese bio-waste materials as activated carbon precursors for multiple applications in environmental protection

- Antimicrobial activities of the extracts and secondary metabolites from Clausena genus – A review

- Bioremediation of organic/heavy metal contaminants by mixed cultures of microorganisms: A review

- Sonodynamic therapy for breast cancer: A literature review

- Recent progress of amino acid transporters as a novel antitumor target

- Aconitum coreanum Rapaics: Botany, traditional uses, phytochemistry, pharmacology, and toxicology

- Corrigendum

- Corrigendum to “Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt”

- Corrigendum to “Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach”

- Corrigendum to “Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt”

- Corrigendum to “Aroma components of tobacco powder from different producing areas based on gas chromatography ion mobility spectrometry”

- Corrigendum to “Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system”

- Erratum

- Erratum to “Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies”

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2021)

- Study of solidification and stabilization of heavy metals by passivators in heavy metal-contaminated soil

- Human health risk assessment and distribution of VOCs in a chemical site, Weinan, China

- Preparation and characterization of Sparassis latifolia β-glucan microcapsules

- Special Issue on the Conference of Energy, Fuels, Environment 2020

- Improving the thermal performance of existing buildings in light of the requirements of the EU directive 2010/31/EU in Poland

- Special Issue on Ethnobotanical, Phytochemical and Biological Investigation of Medicinal Plants

- Study of plant resources with ethnomedicinal relevance from district Bagh, Azad Jammu and Kashmir, Pakistan

- Studies on the chemical composition of plants used in traditional medicine in Congo

- Special Issue on Applied Chemistry in Agriculture and Food Science

- Strip spraying technology for precise herbicide application in carrot fields

- Special Issue on Pharmacology and Metabolomics of Ethnobotanical and Herbal Medicine

- Phytochemical profiling, antibacterial and antioxidant properties of Crocus sativus flower: A comparison between tepals and stigmas

- Antioxidant and antimicrobial properties of polyphenolics from Withania adpressa (Coss.) Batt. against selected drug-resistant bacterial strains

- Integrating network pharmacology and molecular docking to explore the potential mechanism of Xinguan No. 3 in the treatment of COVID-19

- Chemical composition and in vitro and in vivo biological assortment of fixed oil extracted from Ficus benghalensis L.

- A review of the pharmacological activities and protective effects of Inonotus obliquus triterpenoids in kidney diseases

- Ethnopharmacological study of medicinal plants in Kastamonu province (Türkiye)

- Protective effects of asperuloside against cyclophosphamide-induced urotoxicity and hematotoxicity in rats

- Special Issue on Essential Oil, Extraction, Phytochemistry, Advances, and Application

- Identification of volatile compounds and antioxidant, antibacterial, and antifungal properties against drug-resistant microbes of essential oils from the leaves of Mentha rotundifolia var. apodysa Briq. (Lamiaceae)

- Phenolic contents, anticancer, antioxidant, and antimicrobial capacities of MeOH extract from the aerial parts of Trema orientalis plant

- Chemical composition and antimicrobial activity of essential oils from Mentha pulegium and Rosmarinus officinalis against multidrug-resistant microbes and their acute toxicity study

- Special Issue on Marine Environmental Sciences and Significance of the Multidisciplinary Approaches

- An insightful overview of the distribution pattern of polycyclic aromatic hydrocarbon in the marine sediments of the Red Sea

- Antifungal–antiproliferative norcycloartane-type triterpenes from the Red Sea green alga Tydemania expeditionis

- Solvent effect, dipole moment, and DFT studies of multi donor–acceptor type pyridine derivative

- An extensive assessment on the distribution pattern of organic contaminants in the aerosols samples in the Middle East

- Special Issue on 4th IC3PE

- Energetics of carboxylic acid–pyridine heterosynthon revisited: A computational study of intermolecular hydrogen bond domination on phenylacetic acid–nicotinamide cocrystals

- A review: Silver–zinc oxide nanoparticles – organoclay-reinforced chitosan bionanocomposites for food packaging

- Green synthesis of magnetic activated carbon from peanut shells functionalized with TiO2 photocatalyst for Batik liquid waste treatment

- Coagulation activity of liquid extraction of Leucaena leucocephala and Sesbania grandiflora on the removal of turbidity

- Hydrocracking optimization of palm oil over NiMoO4/activated carbon catalyst to produce biogasoline and kerosine

- Special Issue on Pharmacology and metabolomics of ethnobotanical and herbal medicine

- Cynarin inhibits PDGF-BB-induced proliferation and activation in hepatic stellate cells through PPARγ

- Special Issue on The 1st Malaysia International Conference on Nanotechnology & Catalysis (MICNC2021)

- Surfactant evaluation for enhanced oil recovery: Phase behavior and interfacial tension

- Topical Issue on phytochemicals, biological and toxicological analysis of aromatic medicinal plants

- Phytochemical analysis of leaves and stems of Physalis alkekengi L. (Solanaceae)

- Phytochemical and pharmacological profiling of Trewia nudiflora Linn. leaf extract deciphers therapeutic potentials against thrombosis, arthritis, helminths, and insects

- Pergularia tomentosa coupled with selenium nanoparticles salvaged lead acetate-induced redox imbalance, inflammation, apoptosis, and disruption of neurotransmission in rats’ brain

- Protective effect of Allium atroviolaceum-synthesized SeNPs on aluminum-induced brain damage in mice

- Mechanism study of Cordyceps sinensis alleviates renal ischemia–reperfusion injury

- Plant-derived bisbenzylisoquinoline alkaloid tetrandrine prevents human podocyte injury by regulating the miR-150-5p/NPHS1 axis

- Network pharmacology combined with molecular docking to explore the anti-osteoporosis mechanisms of β-ecdysone derived from medicinal plants

- Chinese medicinal plant Polygonum cuspidatum ameliorates silicosis via suppressing the Wnt/β-catenin pathway

- Special Issue on Advanced Nanomaterials for Energy, Environmental and Biological Applications - Part I

- Investigation of improved optical and conductivity properties of poly(methyl methacrylate)–MXenes (PMMA–MXenes) nanocomposite thin films for optoelectronic applications

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2022)

- Model predictive control for precision irrigation of a Quinoa crop

Articles in the same Issue

- Regular Articles

- Photocatalytic degradation of Rhodamine B in aqueous phase by bimetallic metal-organic framework M/Fe-MOF (M = Co, Cu, and Mg)

- Assessment of using electronic portal imaging device for analysing bolus material utilised in radiation therapy

- A detailed investigation on highly dense CuZr bulk metallic glasses for shielding purposes

- Simulation of gamma-ray shielding properties for materials of medical interest

- Environmental impact assesment regulation applications and their analysis in Turkey

- Sample age effect on parameters of dynamic nuclear polarization in certain difluorobenzen isomers/MC800 asphaltene suspensions

- Passenger demand forecasting for railway systems

- Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach

- Gamma, neutron, and heavy charged ion shielding properties of Er3+-doped and Sm3+-doped zinc borate glasses

- Bridging chiral de-tert-butylcalix[4]arenes: Optical resolution based on column chromatography and structural characterization

- Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt

- Comparison of the yield and purity of plasma exosomes extracted by ultracentrifugation, precipitation, and membrane-based approaches

- Bioactive triterpenoids from Indonesian medicinal plant Syzygium aqueum

- Investigation of the effects of machining parameters on surface integrity in micromachining

- The mesoporous aluminosilicate application as support for bifunctional catalysts for n-hexadecane hydroconversion

- Gamma-ray shielding properties of Nd2O3-added iron–boron–phosphate-based composites

- Numerical investigation on perforated sheet metals under tension loading

- Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt

- Two new polypodane-type bicyclic triterpenoids from mastic

- Structural, physical, and mechanical properties of the TiO2 added hydroxyapatite composites

- Tribological properties and characterization of borided Co–Mg alloys

- Studies on Anemone nemorosa L. extracts; polyphenols profile, antioxidant activity, and effects on Caco-2 cells by in vitro and in silico studies

- Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system

- Cyclic connectivity index of bipolar fuzzy incidence graph

- The role of passage numbers of donor cells in the development of Arabian Oryx – Cow interspecific somatic cell nuclear transfer embryos

- Mechanical property evaluation of tellurite–germanate glasses and comparison of their radiation-shielding characteristics using EPICS2017 to other glass systems

- Molecular screening of ionic liquids for CO2 absorption and molecular dynamic simulation

- Microwave-assisted preparation of Ag/Fe magnetic biochar from clivia leaves for adsorbing daptomycin antibiotics

- Iminodisuccinic acid enhances antioxidant and mineral element accumulation in young leaves of Ziziphus jujuba

- Cytotoxic activity of guaiane-type sesquiterpene lactone (deoxycynaropicrin) isolated from the leaves of Centaurothamnus maximus

- Effects of welding parameters on the angular distortion of welded steel plates

- Simulation of a reactor considering the Stamicarbon, Snamprogetti, and Toyo patents for obtaining urea

- Effect of different ramie (Boehmeria nivea L. Gaud) cultivars on the adsorption of heavy metal ions cadmium and lead in the remediation of contaminated farmland soils

- Impact of a live bacterial-based direct-fed microbial (DFM) postpartum and weaning system on performance, mortality, and health of Najdi lambs

- Anti-tumor effect of liposomes containing extracted Murrayafoline A against liver cancer cells in 2D and 3D cultured models

- Physicochemical properties and some mineral concentration of milk samples from different animals and altitudes

- Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies

- Diagnostic and therapeutic radioisotopes in nuclear medicine: Determination of gamma-ray transmission factors and safety competencies of high-dense and transparent glassy shields

- Calculation of NaI(Tl) detector efficiency using 226Ra, 232Th, and 40K radioisotopes: Three-phase Monte Carlo simulation study

- Isolation and identification of unstable components from Caesalpinia sappan by high-speed counter-current chromatography combined with preparative high-performance liquid chromatography

- Quantification of biomarkers and evaluation of antioxidant, anti-inflammatory, and cytotoxicity properties of Dodonaea viscosa grown in Saudi Arabia using HPTLC technique

- Characterization of the elastic modulus of ceramic–metal composites with physical and mechanical properties by ultrasonic technique

- GC-MS analysis of Vespa velutina auraria Smith and its anti-inflammatory and antioxidant activities in vitro

- Texturing of nanocoatings for surface acoustic wave-based sensors for volatile organic compounds

- Insights into the molecular basis of some chalcone analogues as potential inhibitors of Leishmania donovani: An integrated in silico and in vitro study

- (1R,2S,5R)-5-Methyl-2-(propan-2-yl)cyclohexyl 4-amino-3-phenylbutanoate hydrochloride: Synthesis and anticonvulsant activity

- On the relative extraction rates of colour compounds and caffeine during brewing, an investigation of tea over time and temperature

- Characterization of egg shell powder-doped ceramic–metal composites

- Rapeseed oil-based hippurate amide nanocomposite coating material for anticorrosive and antibacterial applications

- Chemically modified Teucrium polium (Lamiaceae) plant act as an effective adsorbent tool for potassium permanganate (KMnO4) in wastewater remediation

- Efficiency analysis of photovoltaic systems installed in different geographical locations

- Risk prioritization model driven by success factor in the light of multicriteria decision making

- Theoretical investigations on the excited-state intramolecular proton transfer in the solvated 2-hydroxy-1-naphthaldehyde carbohydrazone

- Mechanical and gamma-ray shielding examinations of Bi2O3–PbO–CdO–B2O3 glass system

- Machine learning-based forecasting of potability of drinking water through adaptive boosting model

- The potential effect of the Rumex vesicarius water seeds extract treatment on mice before and during pregnancy on the serum enzymes and the histology of kidney and liver

- Impact of benzimidazole functional groups on the n-doping properties of benzimidazole derivatives

- Extraction of red pigment from Chinese jujube peel and the antioxidant activity of the pigment extracts

- Flexural strength and thermal properties of carbon black nanoparticle reinforced epoxy composites obtained from waste tires

- A focusing study on radioprotective and antioxidant effects of Annona muricata leaf extract in the circulation and liver tissue: Clinical and experimental studies

- Clinical comprehensive and experimental assessment of the radioprotective effect of Annona muricata leaf extract to prevent cellular damage in the ileum tissue

- Effect of WC content on ultrasonic properties, thermal and electrical conductivity of WC–Co–Ni–Cr composites

- Influence of various class cleaning agents for prosthesis on Co–Cr alloy surface

- The synthesis of nanocellulose-based nanocomposites for the effective removal of hexavalent chromium ions from aqueous solution

- Study on the influence of physical interlayers on the remaining oil production under different development modes

- Optimized linear regression control of DC motor under various disturbances

- Influence of different sample preparation strategies on hypothesis-driven shotgun proteomic analysis of human saliva

- Determination of flow distance of the fluid metal due to fluidity in ductile iron casting by artificial neural networks approach

- Investigation of mechanical activation effect on high-volume natural pozzolanic cements

- In vitro: Anti-coccidia activity of Calotropis procera leaf extract on Eimeria papillata oocysts sporulation and sporozoite

- Determination of oil composition of cowpea (Vigna unguiculata L.) seeds under influence of organic fertilizer forms

- Activated partial thromboplastin time maybe associated with the prognosis of papillary thyroid carcinoma

- Treatment of rat brain ischemia model by NSCs-polymer scaffold transplantation

- Lead and cadmium removal with native yeast from coastal wetlands

- Characterization of electroless Ni-coated Fe–Co composite using powder metallurgy

- Ferrate synthesis using NaOCl and its application for dye removal

- Antioxidant, antidiabetic, and anticholinesterase potential of Chenopodium murale L. extracts using in vitro and in vivo approaches

- Study on essential oil, antioxidant activity, anti-human prostate cancer effects, and induction of apoptosis by Equisetum arvense

- Experimental study on turning machine with permanent magnetic cutting tool

- Numerical simulation and mathematical modeling of the casting process for pearlitic spheroidal graphite cast iron

- Design, synthesis, and cytotoxicity evaluation of novel thiophene, pyrimidine, pyridazine, and pyridine: Griseofulvin heterocyclic extension derivatives

- Isolation and identification of promising antibiotic-producing bacteria

- Ultrasonic-induced reversible blood–brain barrier opening: Safety evaluation into the cellular level

- Evaluation of phytochemical and antioxidant potential of various extracts from traditionally used medicinal plants of Pakistan

- Effect of calcium lactate in standard diet on selected markers of oxidative stress and inflammation in ovariectomized rats

- Identification of crucial salivary proteins/genes and pathways involved in pathogenesis of temporomandibular disorders

- Zirconium-modified attapulgite was used for removing of Cr(vi) in aqueous solution

- The stress distribution of different types of restorative materials in primary molar

- Reducing surface heat loss in steam boilers

- Deformation behavior and formability of friction stir processed DP600 steel

- Synthesis and characterization of bismuth oxide/commercial activated carbon composite for battery anode

- Phytochemical analysis of Ziziphus jujube leaf at different foliar ages based on widely targeted metabolomics

- Effects of in ovo injection of black cumin (Nigella sativa) extract on hatching performance of broiler eggs

- Separation and evaluation of potential antioxidant, analgesic, and anti-inflammatory activities of limonene-rich essential oils from Citrus sinensis (L.)

- Bioactivity of a polyhydroxy gorgostane steroid from Xenia umbellata

- BiCAM-based automated scoring system for digital logic circuit diagrams

- Analysis of standard systems with solar monitoring systems

- Structural and spectroscopic properties of voriconazole and fluconazole – Experimental and theoretical studies

- New plant resistance inducers based on polyamines

- Experimental investigation of single-lap bolted and bolted/bonded (hybrid) joints of polymeric plates

- Investigation of inlet air pressure and evaporative cooling of four different cogeneration cycles

- Review Articles

- Comprehensive review on synthesis, physicochemical properties, and application of activated carbon from the Arecaceae plants for enhanced wastewater treatment

- Research progress on speciation analysis of arsenic in traditional Chinese medicine

- Recent modified air-assisted liquid–liquid microextraction applications for medicines and organic compounds in various samples: A review

- An insight on Vietnamese bio-waste materials as activated carbon precursors for multiple applications in environmental protection

- Antimicrobial activities of the extracts and secondary metabolites from Clausena genus – A review

- Bioremediation of organic/heavy metal contaminants by mixed cultures of microorganisms: A review

- Sonodynamic therapy for breast cancer: A literature review

- Recent progress of amino acid transporters as a novel antitumor target

- Aconitum coreanum Rapaics: Botany, traditional uses, phytochemistry, pharmacology, and toxicology

- Corrigendum

- Corrigendum to “Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt”

- Corrigendum to “Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach”

- Corrigendum to “Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt”

- Corrigendum to “Aroma components of tobacco powder from different producing areas based on gas chromatography ion mobility spectrometry”

- Corrigendum to “Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system”

- Erratum

- Erratum to “Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies”

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2021)

- Study of solidification and stabilization of heavy metals by passivators in heavy metal-contaminated soil

- Human health risk assessment and distribution of VOCs in a chemical site, Weinan, China

- Preparation and characterization of Sparassis latifolia β-glucan microcapsules

- Special Issue on the Conference of Energy, Fuels, Environment 2020

- Improving the thermal performance of existing buildings in light of the requirements of the EU directive 2010/31/EU in Poland

- Special Issue on Ethnobotanical, Phytochemical and Biological Investigation of Medicinal Plants

- Study of plant resources with ethnomedicinal relevance from district Bagh, Azad Jammu and Kashmir, Pakistan

- Studies on the chemical composition of plants used in traditional medicine in Congo

- Special Issue on Applied Chemistry in Agriculture and Food Science

- Strip spraying technology for precise herbicide application in carrot fields

- Special Issue on Pharmacology and Metabolomics of Ethnobotanical and Herbal Medicine

- Phytochemical profiling, antibacterial and antioxidant properties of Crocus sativus flower: A comparison between tepals and stigmas

- Antioxidant and antimicrobial properties of polyphenolics from Withania adpressa (Coss.) Batt. against selected drug-resistant bacterial strains

- Integrating network pharmacology and molecular docking to explore the potential mechanism of Xinguan No. 3 in the treatment of COVID-19

- Chemical composition and in vitro and in vivo biological assortment of fixed oil extracted from Ficus benghalensis L.

- A review of the pharmacological activities and protective effects of Inonotus obliquus triterpenoids in kidney diseases

- Ethnopharmacological study of medicinal plants in Kastamonu province (Türkiye)

- Protective effects of asperuloside against cyclophosphamide-induced urotoxicity and hematotoxicity in rats

- Special Issue on Essential Oil, Extraction, Phytochemistry, Advances, and Application

- Identification of volatile compounds and antioxidant, antibacterial, and antifungal properties against drug-resistant microbes of essential oils from the leaves of Mentha rotundifolia var. apodysa Briq. (Lamiaceae)

- Phenolic contents, anticancer, antioxidant, and antimicrobial capacities of MeOH extract from the aerial parts of Trema orientalis plant

- Chemical composition and antimicrobial activity of essential oils from Mentha pulegium and Rosmarinus officinalis against multidrug-resistant microbes and their acute toxicity study

- Special Issue on Marine Environmental Sciences and Significance of the Multidisciplinary Approaches

- An insightful overview of the distribution pattern of polycyclic aromatic hydrocarbon in the marine sediments of the Red Sea

- Antifungal–antiproliferative norcycloartane-type triterpenes from the Red Sea green alga Tydemania expeditionis

- Solvent effect, dipole moment, and DFT studies of multi donor–acceptor type pyridine derivative

- An extensive assessment on the distribution pattern of organic contaminants in the aerosols samples in the Middle East

- Special Issue on 4th IC3PE

- Energetics of carboxylic acid–pyridine heterosynthon revisited: A computational study of intermolecular hydrogen bond domination on phenylacetic acid–nicotinamide cocrystals

- A review: Silver–zinc oxide nanoparticles – organoclay-reinforced chitosan bionanocomposites for food packaging

- Green synthesis of magnetic activated carbon from peanut shells functionalized with TiO2 photocatalyst for Batik liquid waste treatment

- Coagulation activity of liquid extraction of Leucaena leucocephala and Sesbania grandiflora on the removal of turbidity

- Hydrocracking optimization of palm oil over NiMoO4/activated carbon catalyst to produce biogasoline and kerosine

- Special Issue on Pharmacology and metabolomics of ethnobotanical and herbal medicine

- Cynarin inhibits PDGF-BB-induced proliferation and activation in hepatic stellate cells through PPARγ

- Special Issue on The 1st Malaysia International Conference on Nanotechnology & Catalysis (MICNC2021)

- Surfactant evaluation for enhanced oil recovery: Phase behavior and interfacial tension

- Topical Issue on phytochemicals, biological and toxicological analysis of aromatic medicinal plants

- Phytochemical analysis of leaves and stems of Physalis alkekengi L. (Solanaceae)

- Phytochemical and pharmacological profiling of Trewia nudiflora Linn. leaf extract deciphers therapeutic potentials against thrombosis, arthritis, helminths, and insects

- Pergularia tomentosa coupled with selenium nanoparticles salvaged lead acetate-induced redox imbalance, inflammation, apoptosis, and disruption of neurotransmission in rats’ brain

- Protective effect of Allium atroviolaceum-synthesized SeNPs on aluminum-induced brain damage in mice

- Mechanism study of Cordyceps sinensis alleviates renal ischemia–reperfusion injury

- Plant-derived bisbenzylisoquinoline alkaloid tetrandrine prevents human podocyte injury by regulating the miR-150-5p/NPHS1 axis

- Network pharmacology combined with molecular docking to explore the anti-osteoporosis mechanisms of β-ecdysone derived from medicinal plants

- Chinese medicinal plant Polygonum cuspidatum ameliorates silicosis via suppressing the Wnt/β-catenin pathway

- Special Issue on Advanced Nanomaterials for Energy, Environmental and Biological Applications - Part I

- Investigation of improved optical and conductivity properties of poly(methyl methacrylate)–MXenes (PMMA–MXenes) nanocomposite thin films for optoelectronic applications

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2022)

- Model predictive control for precision irrigation of a Quinoa crop