Abstract

In a welding process, distortion is inevitable and causes a significant problem. Distortion could be minimized up to a specific limit by controlling the welding parameters. The expansion and contraction of the welding metal and the adjacent base metal during the heating and cooling cycles of the welding process create thermal stresses and angular distortion in a welding joint. The welding parameters determine the geometry of a weld bead. The form of the weld bead is vital in the angular distortion of butt welded plates. This article discusses the influence of some flux-cored arc welding process parameters such as shielding gas flow rate, weaving motion of welding electrodes, and torch angle on bead profile and angular distortion of St 37 steel plates of 10 mm thickness. The angular distortion decreases with the torch angle, but it increases with the gas flow rate. The electrode weaving motion consists of three components: the designed weld width, the vertical motion period in the welding direction, and the lateral motion speed normal to the welding direction. The angular distortion decreases with the weld width and the vertical motion period but decreases with the lateral speed.

1 Introduction

In every welding process, the weld metal and adjacent base metal heterogeneity heat and cool. Meanwhile, heterogeneous expansion and contraction occur in the weld area, producing thermal stresses in the weld zone [1]. The weld metal size is maximum at the solidification temperature. On cooling, the weld metal contracts, but it is restrained from doing by the adjacent base metal. Because of this, stresses develop within the weld and the adjacent base metal. Six types of distortions happen in weldments because of the weld shrinkage stresses [2]. The transverse and longitudinal shrinkage types occur when the shrinkage forces are perpendicular and parallel to the weld bead. The angular distortion occurs when the non-uniform shrinkage forces are produced through the thickness, generating a resultant force in the weld metal’s centroid [3]. When this centroid differs from the centroid of the base metal’s transverse cross section, a bending moment occurs and warps the plate [4]. Angular distortion is a widespread welding defect that leads to expensive repairs in steel constructions [5].

The weld bead geometry is critical because it determines the shrinkage amount and the created internal shrinkage stresses. The magnitude and the direction of the angular distortion depend on the contraction stresses [6]. Two different full penetration and butt weld joint beads are produced using laser welding [7]. Multiplying the contraction force of each weld metal point and the distance between this point and the centroid of the plate gives the bending moment that occurred at that point. The resultant bending moment of all weld metal points gives the resultant bending moment of the weld. Each weld has a different weld bead so that different contraction stresses and bending moments could be produced after the welding process. When the distance between the centroid of the weld bead and the plate is short, a small resultant bending moment and a tiny angular distortion are obtained. Welding parameters influence the bead geometry. The welding parameters can be classified as primary and secondary parameters [8]. The primary parameters are the welding current, the arc voltage, and the welding speed, which directly determine the profile of the weld pool and the weld form [9]. The secondary parameters indirectly affect the weld bead geometry. They make changes to primary parameters and hence affect the weld form. These parameters are arc distance, torch angle, the chemical composition of the shielding gas, gas flow rate, electrode polarity, etc. [10]. The objective of the present study involves studying the effect of shielding gas flow rate, weaving motion of welding electrodes, and torch angle on bead profile and angular distortion of mild steel plates. These three parameters are all-electric arc welding secondary parameters.

From the gas flow rate effect and the torch angle effect experiments, the researchers got conflicting results. Sudhakaran et al. found that the angular distortion decreased between the 50o and 60o torch angle. They also found that the angular distortion remained constant between 60o and 80o and increased when the torch angle was above 80o [11]. Aggarwal et al. found that the angular distortion increased when the torch angle varied from 50o to 70o. The angular distortion was maximum at 70o and then decreased with the torch angle increase [12]. In his experiments, Pandit determined that the angular distortion decreases linearly when the torch angle is increased from 70o to 100o [13]. Ramani et al. found that the angular distortion increased continuously as the torch angle increased between 70o and 100o [14]. The results of Ramani and Pandit have been entirely opposite to each other. Upreti et al., on the other hand, found that the angular distortion remained constant when the torch angle was between 45o and 55o, and it increased continuously after 55o [15]. Since the researchers’ experiments showed contradictory results, exactly how the torch angle affected the angular distortion could not be determined.

In a study, the effects of shielding gas flow rate on welding angular distortion in Tungsten Inert Gas welding of stainless steels were investigated. It was observed that when the gas flow rate was increased from 5 to 15 L/min, the angular distortion decreased and then distortion increased with higher gas flow rates [11]. Three different researchers found that the angular distortion increases with the torch angle [4,16,17,18]. Akella’s tests indicated that the angular distortion decreased with the torch angle [19]. During the welding process, the electrode weaving movement causes a change in the geometry of the liquid weld pool and thus the center of gravity of the weld, which affects the angular distortion [20]. The electrode weaving movement determines the weld thermal stresses and hence affects the welding distortion [21]. There are not enough articles describing the effect of electrode weaving movement on the welding angular distortion. In these studies, which were examined in the literature, it was seen that contradictory results were obtained with regard to the torch angle, shielding gas flow rate, and electrode weaving motion, which are among the factors affecting the weld distortion. The aim of this study is to conduct an experimental study in order to clarify the contradiction in the relevant factors.

2 Materials and methods

A 10 mm thick mild steel plate-type St 37 with chemical composition listed in Table 1 was used in this study. The C% describes the carbon content of the material which is used in the experiments. The mechanical properties of the plate are shown in Table 2; 100X250 mm test specimens were cut from the plates.

Chemical analysis of the test plate

| C% | Mn% | Cu% | S% | P% | Balance (Fe)% |

|---|---|---|---|---|---|

| 0.15 | 1.24 | 0.36 | 0.03 | 0.02 | 98.2 |

Mechanical properties of the test plate

| Yield strength (MPa) | Tensile strength (MPa) | Elongation (%) |

|---|---|---|

| 229 | 387 | 18.4 |

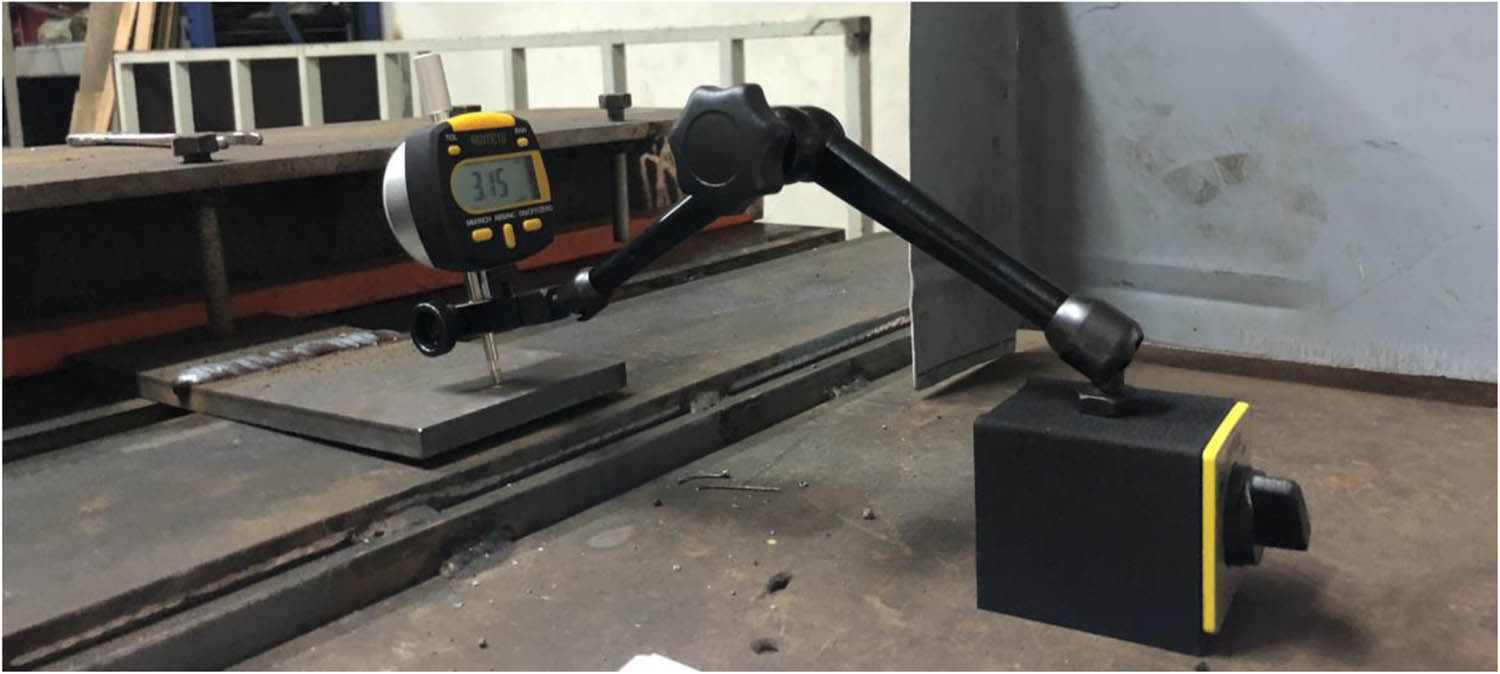

ESAB Aristo Mig U5000i metal inert gas welding machine and ESAB Railtrac B42V welding robot was used in welding operations. ESAB OK Tubrod 15.17 flux-cored arc welding (FCAW) wire of 1.2 mm diameter has been used in welding operations. The welding operations were carried out on a specially prepared table. Before welding, one end of the test piece was tightened with a screw. Bead on plate welding was done on the test piece. The length of each weld was 100 mm. The vertical movement of the plate over the free end of the test piece was measured with a dial indicator. This vertical movement gave the measurement of the angular distortion of the weld. The working table, the workpiece, the weld, and the dial indicator are shown in Figure 1. The dial indicator was protected from welding spatters by placing a sheet metal curtain between the device and the welding torch during welding.

The welded workpiece and the dial indicator.

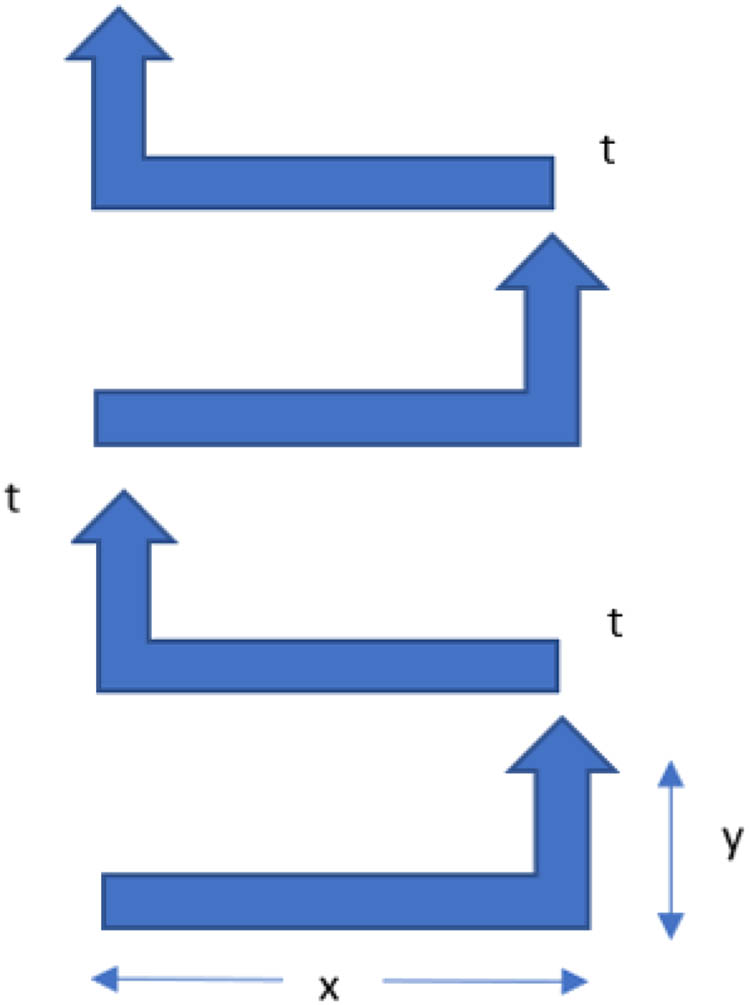

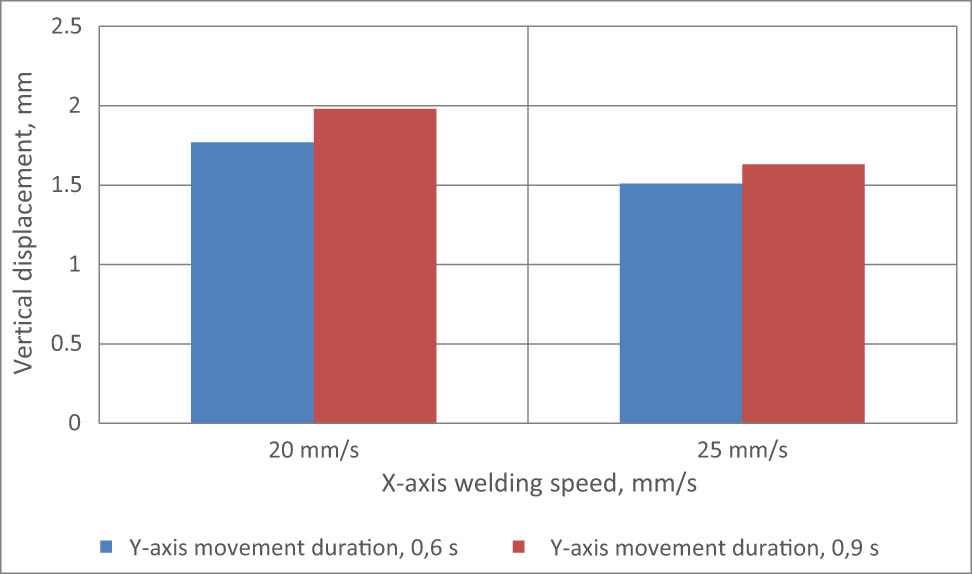

The weaving motion is described in Figure 2. The x sign describes the movement length of the electrode perpendicular to the welding direction. The letter y identifies the electrode movement in the direction of welding progress. The letter t defines the moving duration in the y direction. Welding was done with only two different values of each of the electrode weaving motion parameters. The x value was 10 or 20 mm, the y parameter was 0.6 or 0.9 s, and the t parameter was 20 or 25 mm/s.

The weaving motion of the welding electrode.

An optical microscope was used to measure the dimensions of the weld bead depth and bead width. All metallographic specimens were obtained by cutting the weldments normal to the welding direction. Then, microscope specimens were prepared by conventional grinding, polishing, and etching technics. The etching reagent was a 2 mL HNO3 + 98 mL ethyl alcohol solution.

3 Results and discussions

3.1 Effects of torch angle on welding angular distortion

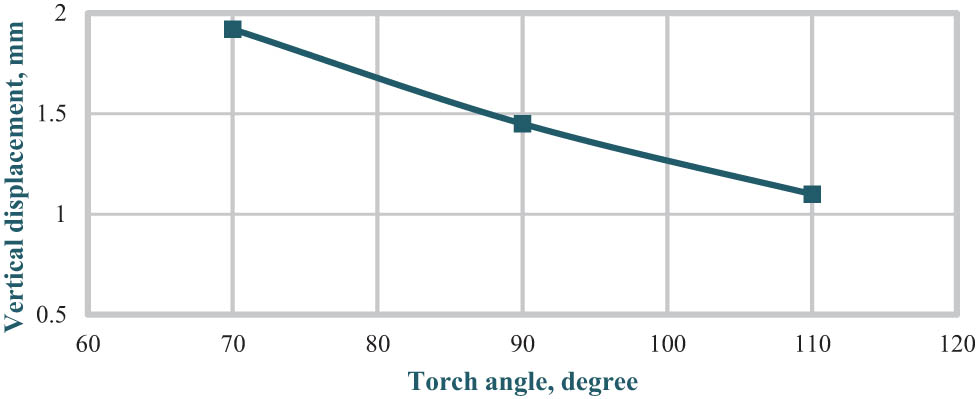

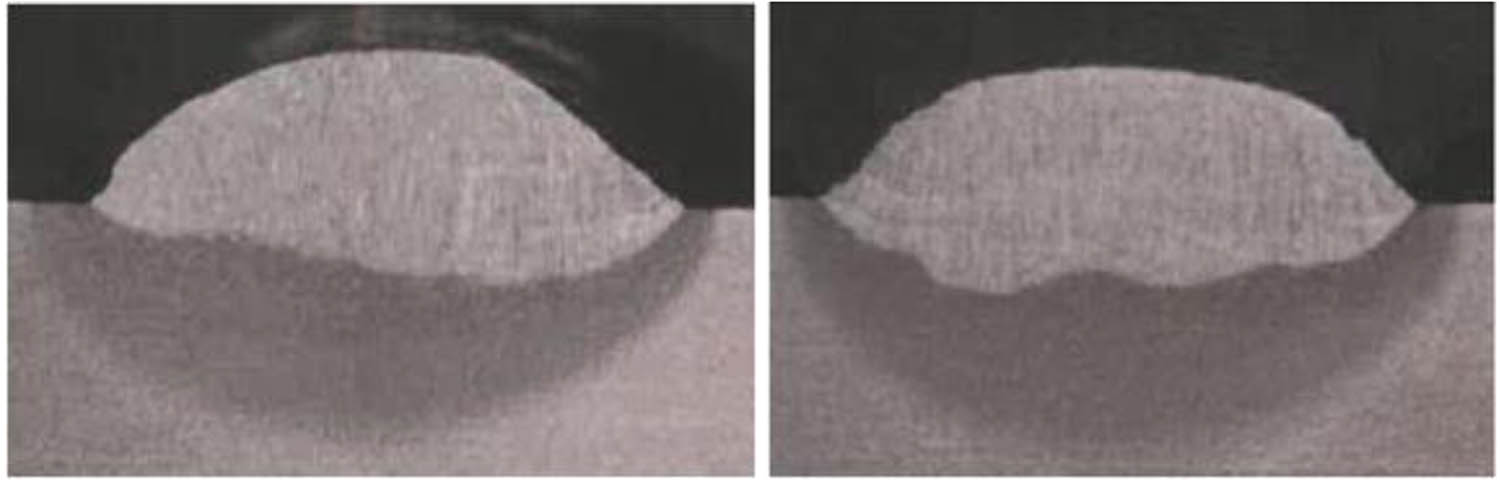

The effect of the welding torch angle on the angular distortion is shown in Figure 3. The welds were produced with a constant 6.5 m/min wire feeding rate, 26 volts arc voltage, 5.5 mm/s welding speed, and 12 L/min gas flow rate. The angular distortion decreased linearly with the torch angle. The cross-sections of weld bead geometries are indicated in Figure 4. The weld on the left belongs to the 70° weld angle welding operation. The other weld was produced with the 110o torch angle. The size of the welds is given in Table 3. At the 70o torch angle, there was less weld depth, but bigger weld width, higher reinforcement height, and more distortion were obtained. The increment of the torch angle caused a change in the weld geometry and the distortion magnitude as shown in Table 3. The weld depth increased, and the reinforcement and the width decreased. The distance between the weld metal centroid and the plate center decreased. The increase in the torch angle changed the weld geometry, which caused a drastic decrease in distortion, as shown in Figure 3.

The variation of the angular distortion with the torch angle.

The welds’ microstructures were produced with 70o torch angle shown in the picture on the left and 110o torch angle shown in the picture on the right.

Weld bead geometry sizes and distortion of the welds as shown in Figure 6

| Torch angle (°) | Weld depth (mm) | Weld width (mm) | Height of reinforcement (mm) | Vertical displacement (mm) |

|---|---|---|---|---|

| 70 | 0.78 | 11.07 | 2.64 | 1.92 |

| 110 | 0.89 | 10.67 | 1.82 | 1.11 |

The torch angle is effective in the transfer of welding energy to the workpiece. Larger torch angles have been reported to introduce an entire arc on the weld zone resulting in a higher penetration in the base metal [22]. The photographs in Figure 4 and the results in Table 4 are compatible with the published literature. In the 70o torch angle, a wide weld bead caused higher shrinkage stress in the weld [6]. The distance between the centroid of the weld metal and the center of the plate was considerable because the reinforcement was high. The long distance caused a high bending moment and a significant distortion in the weld [11]. The bending moment produced in the 70o torch angle was huge. The high reinforcement was the main reason for the high bending moment. The high bending moment resulted in high distortion. The variations in the weld bead geometry of the 100o torch angle produced a smaller bending moment and hence a more minor distortion than the 70o torch angle.

Weld bead geometry sizes and distortion of the welds as shown in Figure 6

| Shielding gas flow rate (L/min) | Weld depth (mm) | Weld width (mm) | Height of reinforcement (mm) | Vertical displacement (mm) |

|---|---|---|---|---|

| 9 | 1.32 | 12.51 | 2.81 | 0.80 |

| 18 | 1.01 | 13.00 | 3.17 | 2.04 |

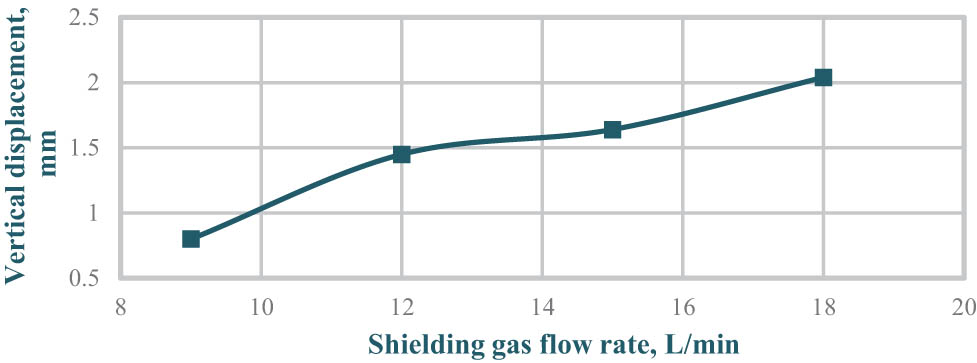

3.2 Effects of shielding gas flow rate on welding angular distortion

In the welding process, the amount of gas flowing per unit time is known as the gas flow rate. The gas flow rate will determine the amount of depth of melting, and thus, it will affect the dilution. The effect of shielding gas flow rate on angular distortion is shown in Figure 5. In this test, all welds were produced with a constant 6.5 m/min wire feeding rate, 26 volts arc voltage, 5.5 mm/s welding speed, and 90o torch angle. The angular distortion increased with the gas flow rate. It has been determined that in electric arc welding operations, the net weld energy increases with the gas flow rate, regardless of the chemical composition of the shielding gas [23]. It has been experimentally proven that when CO2 is used as a shielding gas, the disintegrated carbon and oxygen atoms in the arc region recombine and increase the number of CO2 molecules in the arc [23]. As the gas flow rate increases, this event occurs more. The combination of these atoms causes more energy input in the weld pool [24]. The increase in the energy transfer to the workpiece leads to the pool’s high amount of metal deposition. As a consequence of higher metal deposition in the weld pool, more shrinkage and shrinkage stress occurs. Therefore, the angular distortion increases with the gas flow rate.

The variation of the angular distortion with the shielding gas flow rate.

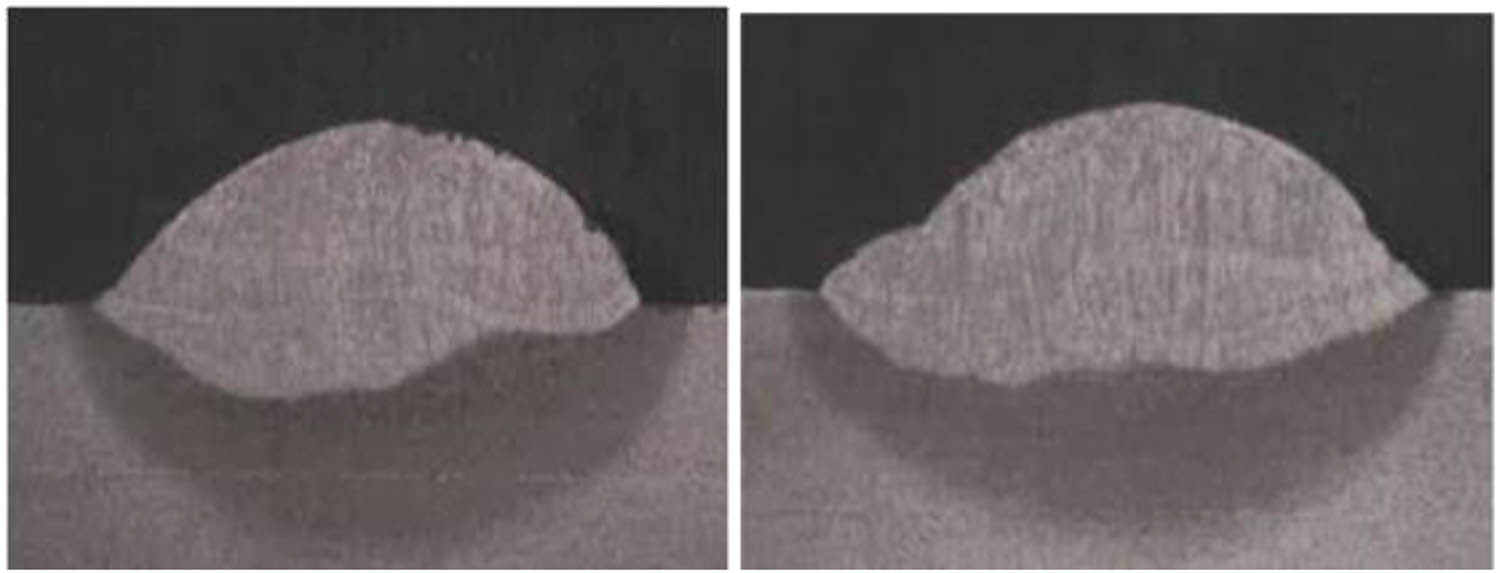

The effect of gas flow rate on weld bead formation is shown in Figure 6. The welds were produced with a constant 6.5 m/min wire feeding rate, 26 volts arc voltage, 5.5 mm/s welding speed, and 90o torch angle. The gas flow rate was 9 L/min on the left weld and 18 L/min on the proper weld. The weld bead parameter sizes of these two welds are given in Table 4. The increase in the gas flow rate increased the cross-sectional area of the weld. The weld produced with 18 L/min gas flow has a bigger weld width and a reinforcement height than the other weld. The weld depth decreased as the gas flow rate increased, while the weld width and reinforcement height increased [25]. The increase in the width increased the amount of shrinkage during solidification and, accordingly, the shrinkage stress. The changes in weld bead geometry also made a difference in the location of the weld center point. As the gas flow rate increases, the center of gravity of the weld shifts upward and the distance between the centroid of gravity of the workpiece increases. As the shrinkage force and the distance between the center of gravity increased, the bending moment in the welded part increased. The amount of angular distortion grew with the bending moment. Figure 6 shows that the angular distortion increases almost linearly with the gas flow rate.

The welds’ microstructures were produced by 9 L/min gas flow rate shown in the picture on the left and 18 L/min gas flow rate shown in the picture on the right.

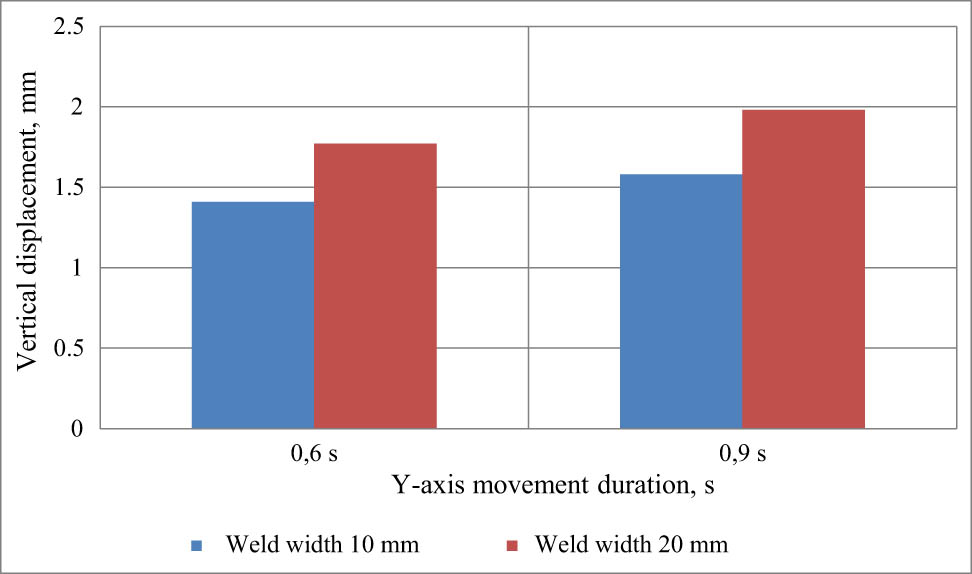

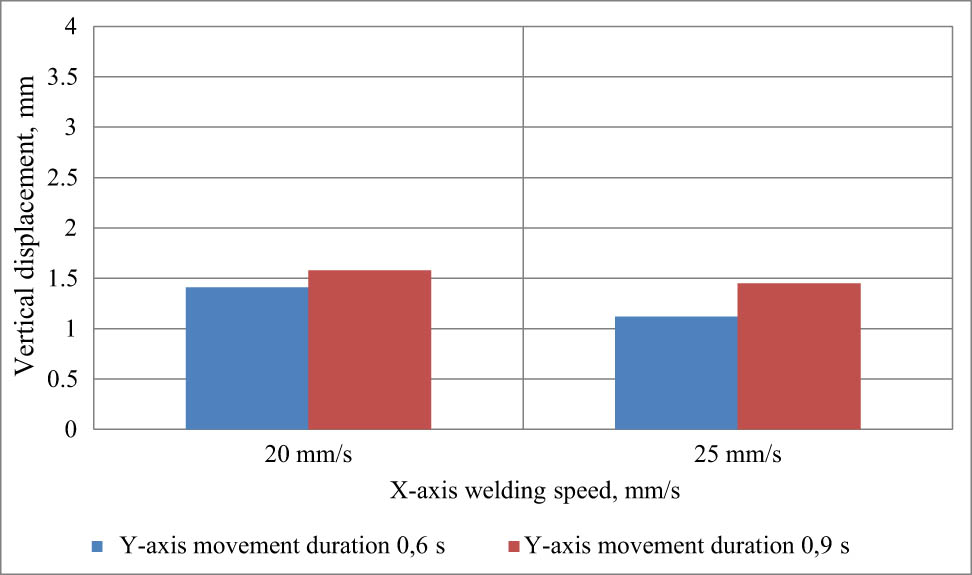

3.3 Effects of electrode weaving motion on welding angular distortion

Table 5 shows the varying parameters used in the weaving motion experiments and the obtained angular distortion values. In these experiments, the wire feed speed was 6 m/min, the arc voltage was 25 volts, the welding speed was 6 mm/s, the gas flow rate was 12 L/min, and the torch angle was kept constant 90o. In the experiments, the weld width was either 10 mm or 20 mm, the x-axis welding speed was 20 or 25 mm/s, and the travel time on the y-axis was changed to 0.6–0.9 s. The obtained angular distortion test results are shown in Table 5. Figures 7–9 are drawn by using the results of Table 5.

Electrode weaving movement parameters and angular distortions

| Weld width (x) (mm) | Movement duration in y-axis (s) | Movement speed in x-axis (mm/s) | Vertical displacement (mm) |

|---|---|---|---|

| 10 | 0.6 | 20 | 1.41 |

| 10 | 0.9 | 20 | 1.58 |

| 20 | 0.6 | 20 | 1.77 |

| 20 | 0.9 | 20 | 1.98 |

| 10 | 0.6 | 25 | 1.12 |

| 10 | 0.9 | 25 | 1.45 |

| 20 | 0.6 | 25 | 1.51 |

| 20 | 0.9 | 25 | 1.63 |

The effect of weld width and y-axis movement duration on the angular distortion of plates welded with 20 mm/s x-axis welding speed.

The effect of y-axis movement duration and x-axis welding speed on the angular distortion of 10 mm wide weld plates.

The effect of y-axis movement duration and x-axis welding speed on the angular distortion of 20 mm wide weld plates.

The angular distortion increased when the weld bead width was increased from 10 to 20 mm under all test conditions (Table 5). As the weld bead width increased, the amount of shrinkage and the shrinkage force grew, increasing the angular distortion. This situation tells us that the weld should not be wider than the optimum size. Another point that draws our attention in Table 5 is that the angular distortion enlarged in each experimental group as the electrode movement duration in the y-axis increased. For example, when the travel time in the y-axis is increased from 0.6 to 0.9 s at the moving speed of 20 mm/s with the 10 mm weld width, the amount of angular distortion enlarged from 1.41 to 1.58 mm. Because high welding time causes an increase in the amount of metal deposited in the weld and the shrinkage force increased in the weld. This situation occurred in each experimental group, as indicated in Figure 7. The distortion is more significant in the 20 mm wide weld than the 10 mm wide weld. Increasing the weld time caused a significant growth in distortion in 20 mm wide welds. The enlargement of distortion in 10 mm weld is much smaller.

The angular distortion decreased when the x-axis movement speed was increased from 20 to 25 mm/s (Figures 8 and 9). For example, in the 10 mm wide welds, the plate displaced 1.41 mm at the moving speed of 20 mm/s, but the plate displaced 1.12 mm at the 25 mm/s speed (Figure 8). Figure 9 indicates similar results for 20 mm wide welds.

4 Conclusions

The following results were obtained from the FCAW process on-plate welding of St 37 steel plate tests:

The angular distortion increases with the shielding gas flow rate.

The angular distortion decreases with increase in the torch angle.

The weaving motion of electrodes affects the angular distortion.

In this study, it is found that the lowest angular distortion was obtained with a 100o torch angle of 1.11 mm. With a 9 L/min shielding gas flow rate, the minimum vertical displacement was acquired.

-

Funding information: The author declares that there is no funding to be acknowledged.

-

Author contributions: ED: writing – original draft and visualization (Master Student); MA: supervision and project administration (First Student Advisor); MK: supervision, validation and resources (Second Student Advisor); AIY: conceptualization, data curation and methodology; AE: conceptualization and validation.

-

Conflict of interest: The author declares that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

-

Ethical approval: The conducted research is not related to either human or animal use.

-

Data availability statement: The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.

References

[1] James F. Lincoln Arc Welding Foundation. The procedure handbook of arc welding. 13th edn. Cleveland: The Lincoln Electric Company; 1994.Suche in Google Scholar

[2] Pazooki A, Hermans M, Richardson I. Control of welding distortion during gas metal arc welding of AH36 plates by stress engineering. Int J Adv Manf Tech. 2017;88:1439–57.10.1007/s00170-016-8869-9Suche in Google Scholar

[3] Cordeiro F. A critical analysis on weld’s distortion. Portugal: University of Coimbra; 2015.Suche in Google Scholar

[4] Narwadkar A, Bhosle S. Optimization of MIG welding parameters to control the angular distortion in FE410WA steel. Mat Manf Prc. 2017;31:2158–64.10.1080/10426914.2015.1127939Suche in Google Scholar

[5] Shen C. Low distortion welding for shipbuilding industry. Australia: University of Wollongong; 2013.Suche in Google Scholar

[6] Tseng K, Hsu C. Performance of activated TIG process in austenitic stainless steel welds. J Mat Prc Tech. 2011;211:503–12.10.1016/j.jmatprotec.2010.11.003Suche in Google Scholar

[7] Xie D. Cause of angular distortion in fusion welding: Asymmetric cross-sectional profile along the thickness. Mat. 2019;12:58–72.10.3390/ma12010058Suche in Google Scholar

[8] Koli Y, Yuvaraj N, Aravindan S. Multi-response mathematical modeling for prediction of weld bead geometry of AA6061-T6 using response surface methodology. Trs Ind Ins Met. 2020;73:645–66.10.1007/s12666-020-01883-2Suche in Google Scholar

[9] Kurtulmus M, Yukler AI, Bilici MK, Catalgol Z. Effects of welding current and arc voltage on FCAW weld bead geometry. Int J Res Eng Tech. 2015;4(9):23–8.10.15623/ijret.2015.0409004Suche in Google Scholar

[10] Ozhan Dogan S, Ozden T. Optimization of welding application parameters of thin sheet blocks used in the ship hull. Em Mat Res. 2021;11(1):1–9.10.1680/jemmr.20.00330Suche in Google Scholar

[11] Sudhakaran R, Murugan V, Sakthivel P. Optimization of process parameters to minimize angular distortion in gas tungsten arc welded stainless steel 202 grade plates using genetic algorithms. Int J Eng Sci Tech. 2012;7(2):195–208.Suche in Google Scholar

[12] Aggarwal I, Faujdar N, Das A, Khanna P. Mathematical modeling for predicting angular distortion in TIG welding of stainless steel 409L butt welds. Int J Res Eng Tech. 2018;7:92–7.10.15623/ijret.2018.0706013Suche in Google Scholar

[13] Pandit M, Sood S, Mishra P, Khanna P. Mathematical analysis of the effect of process parameters on angular distortion of MIG welded stainless steel 202 plates by using the technique of response surface methodology. Mat Today. 2021;41:1045–54.10.1016/j.matpr.2020.06.570Suche in Google Scholar

[14] Ramani S, Velmurugan V. Effect of process parameters on angular distortion of MIG welded Al6061 plates. 5th International & 26th All India Manufacturing Technology, Design and Research Conference; 2014 Dec 12–14; Guwahati, Assam, India.Suche in Google Scholar

[15] Upreti M, Singh A, Malik A, Khanna P. Prediction of angular distortion in TIG welded stainless steel 202 sheets by using mathematical modeling. Int Res J Eng Tech. 2019;6:4540–5.Suche in Google Scholar

[16] Sudhakaran R, Murugan VV, Sivasakthivel PS. Optimization of process parameters to minimize angular distortion in gas tungsten arc welded stainless steel 202 grade plates using particle swarm optimization. J Eng Sci Tech. 2012;7:195–208.Suche in Google Scholar

[17] Venkatesan MV, Murugan N, Prasad BM, Manickavasagam A. Influence of FCA welding process parameters on distortion of 409M stainless steel for rail coach building. Int J Ir St Res. 2013;20(1):71–8.10.1016/S1006-706X(13)60047-3Suche in Google Scholar

[18] Kumar R, Walia T, Kaushik V. Welding distortion in joining of thin plate of dissimilar metal of AISI 304 and duplex 2205 using GMAW. Intl J Eng Manf Res. 2016;6(3):150–5.Suche in Google Scholar

[19] Akella S, Ramesh Kumar B. Distortion control in TIG welding process with Taguchi approach. Adv Mat Manf Chr. 2013;3:199–205.10.1504/IJPTECH.2013.053305Suche in Google Scholar

[20] Tasalloti H, Kah P, Martikainen J. Effects of welding wire and torch weaving on GMAW of S355MC and AISI 304L dissimilar welds. Int J Adv Manf Tech. 2014;71:197–205.10.1007/s00170-013-5484-xSuche in Google Scholar

[21] Mikami Y, Nakamura T, Mochizuki M. Numerical investigation of the influence of heat source modeling on simulated residual stress distribution in weaving welds. Weld W. 2016;60:41–9.10.1007/s40194-015-0274-8Suche in Google Scholar

[22] Torbati AM, Miranda RM, Quintino L, Williams S. Welding bimetal pipes in duplex stainless steel. Int J Adv Manf Tech. 2011;53:1039–47.10.1007/s00170-010-2889-7Suche in Google Scholar

[23] Norio K, Shogo T, Kunimasa T. Effect of shielding gas on welding distortion of laser welded aluminum alloy sheet. Fukui Uni Mem Fac Eng. 2004;52:217–22.Suche in Google Scholar

[24] Banerjee R. The role of gases in welding and cutting processes. Ind Weld J. 2005;38(3):13–22.10.22486/iwj.v38i3.178891Suche in Google Scholar

[25] Sakthivel R, Venkadeshwaran P, Sridevi R, Meeran R, Chandrasekaran K. Effect of welding current, arc voltage and gas flow rate on depth of penetration during MIG welding of AA2014 plate. Int J Adv Res Tech Eng Sci. 2015;2(2):1–7.Suche in Google Scholar

© 2022 Ezgi Dogan et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Photocatalytic degradation of Rhodamine B in aqueous phase by bimetallic metal-organic framework M/Fe-MOF (M = Co, Cu, and Mg)

- Assessment of using electronic portal imaging device for analysing bolus material utilised in radiation therapy

- A detailed investigation on highly dense CuZr bulk metallic glasses for shielding purposes

- Simulation of gamma-ray shielding properties for materials of medical interest

- Environmental impact assesment regulation applications and their analysis in Turkey

- Sample age effect on parameters of dynamic nuclear polarization in certain difluorobenzen isomers/MC800 asphaltene suspensions

- Passenger demand forecasting for railway systems

- Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach

- Gamma, neutron, and heavy charged ion shielding properties of Er3+-doped and Sm3+-doped zinc borate glasses

- Bridging chiral de-tert-butylcalix[4]arenes: Optical resolution based on column chromatography and structural characterization

- Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt

- Comparison of the yield and purity of plasma exosomes extracted by ultracentrifugation, precipitation, and membrane-based approaches

- Bioactive triterpenoids from Indonesian medicinal plant Syzygium aqueum

- Investigation of the effects of machining parameters on surface integrity in micromachining

- The mesoporous aluminosilicate application as support for bifunctional catalysts for n-hexadecane hydroconversion

- Gamma-ray shielding properties of Nd2O3-added iron–boron–phosphate-based composites

- Numerical investigation on perforated sheet metals under tension loading

- Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt

- Two new polypodane-type bicyclic triterpenoids from mastic

- Structural, physical, and mechanical properties of the TiO2 added hydroxyapatite composites

- Tribological properties and characterization of borided Co–Mg alloys

- Studies on Anemone nemorosa L. extracts; polyphenols profile, antioxidant activity, and effects on Caco-2 cells by in vitro and in silico studies

- Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system

- Cyclic connectivity index of bipolar fuzzy incidence graph

- The role of passage numbers of donor cells in the development of Arabian Oryx – Cow interspecific somatic cell nuclear transfer embryos

- Mechanical property evaluation of tellurite–germanate glasses and comparison of their radiation-shielding characteristics using EPICS2017 to other glass systems

- Molecular screening of ionic liquids for CO2 absorption and molecular dynamic simulation

- Microwave-assisted preparation of Ag/Fe magnetic biochar from clivia leaves for adsorbing daptomycin antibiotics

- Iminodisuccinic acid enhances antioxidant and mineral element accumulation in young leaves of Ziziphus jujuba

- Cytotoxic activity of guaiane-type sesquiterpene lactone (deoxycynaropicrin) isolated from the leaves of Centaurothamnus maximus

- Effects of welding parameters on the angular distortion of welded steel plates

- Simulation of a reactor considering the Stamicarbon, Snamprogetti, and Toyo patents for obtaining urea

- Effect of different ramie (Boehmeria nivea L. Gaud) cultivars on the adsorption of heavy metal ions cadmium and lead in the remediation of contaminated farmland soils

- Impact of a live bacterial-based direct-fed microbial (DFM) postpartum and weaning system on performance, mortality, and health of Najdi lambs

- Anti-tumor effect of liposomes containing extracted Murrayafoline A against liver cancer cells in 2D and 3D cultured models

- Physicochemical properties and some mineral concentration of milk samples from different animals and altitudes

- Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies

- Diagnostic and therapeutic radioisotopes in nuclear medicine: Determination of gamma-ray transmission factors and safety competencies of high-dense and transparent glassy shields

- Calculation of NaI(Tl) detector efficiency using 226Ra, 232Th, and 40K radioisotopes: Three-phase Monte Carlo simulation study

- Isolation and identification of unstable components from Caesalpinia sappan by high-speed counter-current chromatography combined with preparative high-performance liquid chromatography

- Quantification of biomarkers and evaluation of antioxidant, anti-inflammatory, and cytotoxicity properties of Dodonaea viscosa grown in Saudi Arabia using HPTLC technique

- Characterization of the elastic modulus of ceramic–metal composites with physical and mechanical properties by ultrasonic technique

- GC-MS analysis of Vespa velutina auraria Smith and its anti-inflammatory and antioxidant activities in vitro

- Texturing of nanocoatings for surface acoustic wave-based sensors for volatile organic compounds

- Insights into the molecular basis of some chalcone analogues as potential inhibitors of Leishmania donovani: An integrated in silico and in vitro study

- (1R,2S,5R)-5-Methyl-2-(propan-2-yl)cyclohexyl 4-amino-3-phenylbutanoate hydrochloride: Synthesis and anticonvulsant activity

- On the relative extraction rates of colour compounds and caffeine during brewing, an investigation of tea over time and temperature

- Characterization of egg shell powder-doped ceramic–metal composites

- Rapeseed oil-based hippurate amide nanocomposite coating material for anticorrosive and antibacterial applications

- Chemically modified Teucrium polium (Lamiaceae) plant act as an effective adsorbent tool for potassium permanganate (KMnO4) in wastewater remediation

- Efficiency analysis of photovoltaic systems installed in different geographical locations

- Risk prioritization model driven by success factor in the light of multicriteria decision making

- Theoretical investigations on the excited-state intramolecular proton transfer in the solvated 2-hydroxy-1-naphthaldehyde carbohydrazone

- Mechanical and gamma-ray shielding examinations of Bi2O3–PbO–CdO–B2O3 glass system

- Machine learning-based forecasting of potability of drinking water through adaptive boosting model

- The potential effect of the Rumex vesicarius water seeds extract treatment on mice before and during pregnancy on the serum enzymes and the histology of kidney and liver

- Impact of benzimidazole functional groups on the n-doping properties of benzimidazole derivatives

- Extraction of red pigment from Chinese jujube peel and the antioxidant activity of the pigment extracts

- Flexural strength and thermal properties of carbon black nanoparticle reinforced epoxy composites obtained from waste tires

- A focusing study on radioprotective and antioxidant effects of Annona muricata leaf extract in the circulation and liver tissue: Clinical and experimental studies

- Clinical comprehensive and experimental assessment of the radioprotective effect of Annona muricata leaf extract to prevent cellular damage in the ileum tissue

- Effect of WC content on ultrasonic properties, thermal and electrical conductivity of WC–Co–Ni–Cr composites

- Influence of various class cleaning agents for prosthesis on Co–Cr alloy surface

- The synthesis of nanocellulose-based nanocomposites for the effective removal of hexavalent chromium ions from aqueous solution

- Study on the influence of physical interlayers on the remaining oil production under different development modes

- Optimized linear regression control of DC motor under various disturbances

- Influence of different sample preparation strategies on hypothesis-driven shotgun proteomic analysis of human saliva

- Determination of flow distance of the fluid metal due to fluidity in ductile iron casting by artificial neural networks approach

- Investigation of mechanical activation effect on high-volume natural pozzolanic cements

- In vitro: Anti-coccidia activity of Calotropis procera leaf extract on Eimeria papillata oocysts sporulation and sporozoite

- Determination of oil composition of cowpea (Vigna unguiculata L.) seeds under influence of organic fertilizer forms

- Activated partial thromboplastin time maybe associated with the prognosis of papillary thyroid carcinoma

- Treatment of rat brain ischemia model by NSCs-polymer scaffold transplantation

- Lead and cadmium removal with native yeast from coastal wetlands

- Characterization of electroless Ni-coated Fe–Co composite using powder metallurgy

- Ferrate synthesis using NaOCl and its application for dye removal

- Antioxidant, antidiabetic, and anticholinesterase potential of Chenopodium murale L. extracts using in vitro and in vivo approaches

- Study on essential oil, antioxidant activity, anti-human prostate cancer effects, and induction of apoptosis by Equisetum arvense

- Experimental study on turning machine with permanent magnetic cutting tool

- Numerical simulation and mathematical modeling of the casting process for pearlitic spheroidal graphite cast iron

- Design, synthesis, and cytotoxicity evaluation of novel thiophene, pyrimidine, pyridazine, and pyridine: Griseofulvin heterocyclic extension derivatives

- Isolation and identification of promising antibiotic-producing bacteria

- Ultrasonic-induced reversible blood–brain barrier opening: Safety evaluation into the cellular level

- Evaluation of phytochemical and antioxidant potential of various extracts from traditionally used medicinal plants of Pakistan

- Effect of calcium lactate in standard diet on selected markers of oxidative stress and inflammation in ovariectomized rats

- Identification of crucial salivary proteins/genes and pathways involved in pathogenesis of temporomandibular disorders

- Zirconium-modified attapulgite was used for removing of Cr(vi) in aqueous solution

- The stress distribution of different types of restorative materials in primary molar

- Reducing surface heat loss in steam boilers

- Deformation behavior and formability of friction stir processed DP600 steel

- Synthesis and characterization of bismuth oxide/commercial activated carbon composite for battery anode

- Phytochemical analysis of Ziziphus jujube leaf at different foliar ages based on widely targeted metabolomics

- Effects of in ovo injection of black cumin (Nigella sativa) extract on hatching performance of broiler eggs

- Separation and evaluation of potential antioxidant, analgesic, and anti-inflammatory activities of limonene-rich essential oils from Citrus sinensis (L.)

- Bioactivity of a polyhydroxy gorgostane steroid from Xenia umbellata

- BiCAM-based automated scoring system for digital logic circuit diagrams

- Analysis of standard systems with solar monitoring systems

- Structural and spectroscopic properties of voriconazole and fluconazole – Experimental and theoretical studies

- New plant resistance inducers based on polyamines

- Experimental investigation of single-lap bolted and bolted/bonded (hybrid) joints of polymeric plates

- Investigation of inlet air pressure and evaporative cooling of four different cogeneration cycles

- Review Articles

- Comprehensive review on synthesis, physicochemical properties, and application of activated carbon from the Arecaceae plants for enhanced wastewater treatment

- Research progress on speciation analysis of arsenic in traditional Chinese medicine

- Recent modified air-assisted liquid–liquid microextraction applications for medicines and organic compounds in various samples: A review

- An insight on Vietnamese bio-waste materials as activated carbon precursors for multiple applications in environmental protection

- Antimicrobial activities of the extracts and secondary metabolites from Clausena genus – A review

- Bioremediation of organic/heavy metal contaminants by mixed cultures of microorganisms: A review

- Sonodynamic therapy for breast cancer: A literature review

- Recent progress of amino acid transporters as a novel antitumor target

- Aconitum coreanum Rapaics: Botany, traditional uses, phytochemistry, pharmacology, and toxicology

- Corrigendum

- Corrigendum to “Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt”

- Corrigendum to “Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach”

- Corrigendum to “Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt”

- Corrigendum to “Aroma components of tobacco powder from different producing areas based on gas chromatography ion mobility spectrometry”

- Corrigendum to “Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system”

- Erratum

- Erratum to “Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies”

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2021)

- Study of solidification and stabilization of heavy metals by passivators in heavy metal-contaminated soil

- Human health risk assessment and distribution of VOCs in a chemical site, Weinan, China

- Preparation and characterization of Sparassis latifolia β-glucan microcapsules

- Special Issue on the Conference of Energy, Fuels, Environment 2020

- Improving the thermal performance of existing buildings in light of the requirements of the EU directive 2010/31/EU in Poland

- Special Issue on Ethnobotanical, Phytochemical and Biological Investigation of Medicinal Plants

- Study of plant resources with ethnomedicinal relevance from district Bagh, Azad Jammu and Kashmir, Pakistan

- Studies on the chemical composition of plants used in traditional medicine in Congo

- Special Issue on Applied Chemistry in Agriculture and Food Science

- Strip spraying technology for precise herbicide application in carrot fields

- Special Issue on Pharmacology and Metabolomics of Ethnobotanical and Herbal Medicine

- Phytochemical profiling, antibacterial and antioxidant properties of Crocus sativus flower: A comparison between tepals and stigmas

- Antioxidant and antimicrobial properties of polyphenolics from Withania adpressa (Coss.) Batt. against selected drug-resistant bacterial strains

- Integrating network pharmacology and molecular docking to explore the potential mechanism of Xinguan No. 3 in the treatment of COVID-19

- Chemical composition and in vitro and in vivo biological assortment of fixed oil extracted from Ficus benghalensis L.

- A review of the pharmacological activities and protective effects of Inonotus obliquus triterpenoids in kidney diseases

- Ethnopharmacological study of medicinal plants in Kastamonu province (Türkiye)

- Protective effects of asperuloside against cyclophosphamide-induced urotoxicity and hematotoxicity in rats

- Special Issue on Essential Oil, Extraction, Phytochemistry, Advances, and Application

- Identification of volatile compounds and antioxidant, antibacterial, and antifungal properties against drug-resistant microbes of essential oils from the leaves of Mentha rotundifolia var. apodysa Briq. (Lamiaceae)

- Phenolic contents, anticancer, antioxidant, and antimicrobial capacities of MeOH extract from the aerial parts of Trema orientalis plant

- Chemical composition and antimicrobial activity of essential oils from Mentha pulegium and Rosmarinus officinalis against multidrug-resistant microbes and their acute toxicity study

- Special Issue on Marine Environmental Sciences and Significance of the Multidisciplinary Approaches

- An insightful overview of the distribution pattern of polycyclic aromatic hydrocarbon in the marine sediments of the Red Sea

- Antifungal–antiproliferative norcycloartane-type triterpenes from the Red Sea green alga Tydemania expeditionis

- Solvent effect, dipole moment, and DFT studies of multi donor–acceptor type pyridine derivative

- An extensive assessment on the distribution pattern of organic contaminants in the aerosols samples in the Middle East

- Special Issue on 4th IC3PE

- Energetics of carboxylic acid–pyridine heterosynthon revisited: A computational study of intermolecular hydrogen bond domination on phenylacetic acid–nicotinamide cocrystals

- A review: Silver–zinc oxide nanoparticles – organoclay-reinforced chitosan bionanocomposites for food packaging

- Green synthesis of magnetic activated carbon from peanut shells functionalized with TiO2 photocatalyst for Batik liquid waste treatment

- Coagulation activity of liquid extraction of Leucaena leucocephala and Sesbania grandiflora on the removal of turbidity

- Hydrocracking optimization of palm oil over NiMoO4/activated carbon catalyst to produce biogasoline and kerosine

- Special Issue on Pharmacology and metabolomics of ethnobotanical and herbal medicine

- Cynarin inhibits PDGF-BB-induced proliferation and activation in hepatic stellate cells through PPARγ

- Special Issue on The 1st Malaysia International Conference on Nanotechnology & Catalysis (MICNC2021)

- Surfactant evaluation for enhanced oil recovery: Phase behavior and interfacial tension

- Topical Issue on phytochemicals, biological and toxicological analysis of aromatic medicinal plants

- Phytochemical analysis of leaves and stems of Physalis alkekengi L. (Solanaceae)

- Phytochemical and pharmacological profiling of Trewia nudiflora Linn. leaf extract deciphers therapeutic potentials against thrombosis, arthritis, helminths, and insects

- Pergularia tomentosa coupled with selenium nanoparticles salvaged lead acetate-induced redox imbalance, inflammation, apoptosis, and disruption of neurotransmission in rats’ brain

- Protective effect of Allium atroviolaceum-synthesized SeNPs on aluminum-induced brain damage in mice

- Mechanism study of Cordyceps sinensis alleviates renal ischemia–reperfusion injury

- Plant-derived bisbenzylisoquinoline alkaloid tetrandrine prevents human podocyte injury by regulating the miR-150-5p/NPHS1 axis

- Network pharmacology combined with molecular docking to explore the anti-osteoporosis mechanisms of β-ecdysone derived from medicinal plants

- Chinese medicinal plant Polygonum cuspidatum ameliorates silicosis via suppressing the Wnt/β-catenin pathway

- Special Issue on Advanced Nanomaterials for Energy, Environmental and Biological Applications - Part I

- Investigation of improved optical and conductivity properties of poly(methyl methacrylate)–MXenes (PMMA–MXenes) nanocomposite thin films for optoelectronic applications

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2022)

- Model predictive control for precision irrigation of a Quinoa crop

Artikel in diesem Heft

- Regular Articles

- Photocatalytic degradation of Rhodamine B in aqueous phase by bimetallic metal-organic framework M/Fe-MOF (M = Co, Cu, and Mg)

- Assessment of using electronic portal imaging device for analysing bolus material utilised in radiation therapy

- A detailed investigation on highly dense CuZr bulk metallic glasses for shielding purposes

- Simulation of gamma-ray shielding properties for materials of medical interest

- Environmental impact assesment regulation applications and their analysis in Turkey

- Sample age effect on parameters of dynamic nuclear polarization in certain difluorobenzen isomers/MC800 asphaltene suspensions

- Passenger demand forecasting for railway systems

- Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach

- Gamma, neutron, and heavy charged ion shielding properties of Er3+-doped and Sm3+-doped zinc borate glasses

- Bridging chiral de-tert-butylcalix[4]arenes: Optical resolution based on column chromatography and structural characterization

- Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt

- Comparison of the yield and purity of plasma exosomes extracted by ultracentrifugation, precipitation, and membrane-based approaches

- Bioactive triterpenoids from Indonesian medicinal plant Syzygium aqueum

- Investigation of the effects of machining parameters on surface integrity in micromachining

- The mesoporous aluminosilicate application as support for bifunctional catalysts for n-hexadecane hydroconversion

- Gamma-ray shielding properties of Nd2O3-added iron–boron–phosphate-based composites

- Numerical investigation on perforated sheet metals under tension loading

- Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt

- Two new polypodane-type bicyclic triterpenoids from mastic

- Structural, physical, and mechanical properties of the TiO2 added hydroxyapatite composites

- Tribological properties and characterization of borided Co–Mg alloys

- Studies on Anemone nemorosa L. extracts; polyphenols profile, antioxidant activity, and effects on Caco-2 cells by in vitro and in silico studies

- Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system

- Cyclic connectivity index of bipolar fuzzy incidence graph

- The role of passage numbers of donor cells in the development of Arabian Oryx – Cow interspecific somatic cell nuclear transfer embryos

- Mechanical property evaluation of tellurite–germanate glasses and comparison of their radiation-shielding characteristics using EPICS2017 to other glass systems

- Molecular screening of ionic liquids for CO2 absorption and molecular dynamic simulation

- Microwave-assisted preparation of Ag/Fe magnetic biochar from clivia leaves for adsorbing daptomycin antibiotics

- Iminodisuccinic acid enhances antioxidant and mineral element accumulation in young leaves of Ziziphus jujuba

- Cytotoxic activity of guaiane-type sesquiterpene lactone (deoxycynaropicrin) isolated from the leaves of Centaurothamnus maximus

- Effects of welding parameters on the angular distortion of welded steel plates

- Simulation of a reactor considering the Stamicarbon, Snamprogetti, and Toyo patents for obtaining urea

- Effect of different ramie (Boehmeria nivea L. Gaud) cultivars on the adsorption of heavy metal ions cadmium and lead in the remediation of contaminated farmland soils

- Impact of a live bacterial-based direct-fed microbial (DFM) postpartum and weaning system on performance, mortality, and health of Najdi lambs

- Anti-tumor effect of liposomes containing extracted Murrayafoline A against liver cancer cells in 2D and 3D cultured models

- Physicochemical properties and some mineral concentration of milk samples from different animals and altitudes

- Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies

- Diagnostic and therapeutic radioisotopes in nuclear medicine: Determination of gamma-ray transmission factors and safety competencies of high-dense and transparent glassy shields

- Calculation of NaI(Tl) detector efficiency using 226Ra, 232Th, and 40K radioisotopes: Three-phase Monte Carlo simulation study

- Isolation and identification of unstable components from Caesalpinia sappan by high-speed counter-current chromatography combined with preparative high-performance liquid chromatography

- Quantification of biomarkers and evaluation of antioxidant, anti-inflammatory, and cytotoxicity properties of Dodonaea viscosa grown in Saudi Arabia using HPTLC technique

- Characterization of the elastic modulus of ceramic–metal composites with physical and mechanical properties by ultrasonic technique

- GC-MS analysis of Vespa velutina auraria Smith and its anti-inflammatory and antioxidant activities in vitro

- Texturing of nanocoatings for surface acoustic wave-based sensors for volatile organic compounds

- Insights into the molecular basis of some chalcone analogues as potential inhibitors of Leishmania donovani: An integrated in silico and in vitro study

- (1R,2S,5R)-5-Methyl-2-(propan-2-yl)cyclohexyl 4-amino-3-phenylbutanoate hydrochloride: Synthesis and anticonvulsant activity

- On the relative extraction rates of colour compounds and caffeine during brewing, an investigation of tea over time and temperature

- Characterization of egg shell powder-doped ceramic–metal composites

- Rapeseed oil-based hippurate amide nanocomposite coating material for anticorrosive and antibacterial applications

- Chemically modified Teucrium polium (Lamiaceae) plant act as an effective adsorbent tool for potassium permanganate (KMnO4) in wastewater remediation

- Efficiency analysis of photovoltaic systems installed in different geographical locations

- Risk prioritization model driven by success factor in the light of multicriteria decision making

- Theoretical investigations on the excited-state intramolecular proton transfer in the solvated 2-hydroxy-1-naphthaldehyde carbohydrazone

- Mechanical and gamma-ray shielding examinations of Bi2O3–PbO–CdO–B2O3 glass system

- Machine learning-based forecasting of potability of drinking water through adaptive boosting model

- The potential effect of the Rumex vesicarius water seeds extract treatment on mice before and during pregnancy on the serum enzymes and the histology of kidney and liver

- Impact of benzimidazole functional groups on the n-doping properties of benzimidazole derivatives

- Extraction of red pigment from Chinese jujube peel and the antioxidant activity of the pigment extracts

- Flexural strength and thermal properties of carbon black nanoparticle reinforced epoxy composites obtained from waste tires

- A focusing study on radioprotective and antioxidant effects of Annona muricata leaf extract in the circulation and liver tissue: Clinical and experimental studies

- Clinical comprehensive and experimental assessment of the radioprotective effect of Annona muricata leaf extract to prevent cellular damage in the ileum tissue

- Effect of WC content on ultrasonic properties, thermal and electrical conductivity of WC–Co–Ni–Cr composites

- Influence of various class cleaning agents for prosthesis on Co–Cr alloy surface

- The synthesis of nanocellulose-based nanocomposites for the effective removal of hexavalent chromium ions from aqueous solution

- Study on the influence of physical interlayers on the remaining oil production under different development modes

- Optimized linear regression control of DC motor under various disturbances

- Influence of different sample preparation strategies on hypothesis-driven shotgun proteomic analysis of human saliva

- Determination of flow distance of the fluid metal due to fluidity in ductile iron casting by artificial neural networks approach

- Investigation of mechanical activation effect on high-volume natural pozzolanic cements

- In vitro: Anti-coccidia activity of Calotropis procera leaf extract on Eimeria papillata oocysts sporulation and sporozoite

- Determination of oil composition of cowpea (Vigna unguiculata L.) seeds under influence of organic fertilizer forms

- Activated partial thromboplastin time maybe associated with the prognosis of papillary thyroid carcinoma

- Treatment of rat brain ischemia model by NSCs-polymer scaffold transplantation

- Lead and cadmium removal with native yeast from coastal wetlands

- Characterization of electroless Ni-coated Fe–Co composite using powder metallurgy

- Ferrate synthesis using NaOCl and its application for dye removal

- Antioxidant, antidiabetic, and anticholinesterase potential of Chenopodium murale L. extracts using in vitro and in vivo approaches

- Study on essential oil, antioxidant activity, anti-human prostate cancer effects, and induction of apoptosis by Equisetum arvense

- Experimental study on turning machine with permanent magnetic cutting tool

- Numerical simulation and mathematical modeling of the casting process for pearlitic spheroidal graphite cast iron

- Design, synthesis, and cytotoxicity evaluation of novel thiophene, pyrimidine, pyridazine, and pyridine: Griseofulvin heterocyclic extension derivatives

- Isolation and identification of promising antibiotic-producing bacteria

- Ultrasonic-induced reversible blood–brain barrier opening: Safety evaluation into the cellular level

- Evaluation of phytochemical and antioxidant potential of various extracts from traditionally used medicinal plants of Pakistan

- Effect of calcium lactate in standard diet on selected markers of oxidative stress and inflammation in ovariectomized rats

- Identification of crucial salivary proteins/genes and pathways involved in pathogenesis of temporomandibular disorders

- Zirconium-modified attapulgite was used for removing of Cr(vi) in aqueous solution

- The stress distribution of different types of restorative materials in primary molar

- Reducing surface heat loss in steam boilers

- Deformation behavior and formability of friction stir processed DP600 steel

- Synthesis and characterization of bismuth oxide/commercial activated carbon composite for battery anode

- Phytochemical analysis of Ziziphus jujube leaf at different foliar ages based on widely targeted metabolomics

- Effects of in ovo injection of black cumin (Nigella sativa) extract on hatching performance of broiler eggs

- Separation and evaluation of potential antioxidant, analgesic, and anti-inflammatory activities of limonene-rich essential oils from Citrus sinensis (L.)

- Bioactivity of a polyhydroxy gorgostane steroid from Xenia umbellata

- BiCAM-based automated scoring system for digital logic circuit diagrams

- Analysis of standard systems with solar monitoring systems

- Structural and spectroscopic properties of voriconazole and fluconazole – Experimental and theoretical studies

- New plant resistance inducers based on polyamines

- Experimental investigation of single-lap bolted and bolted/bonded (hybrid) joints of polymeric plates

- Investigation of inlet air pressure and evaporative cooling of four different cogeneration cycles

- Review Articles

- Comprehensive review on synthesis, physicochemical properties, and application of activated carbon from the Arecaceae plants for enhanced wastewater treatment

- Research progress on speciation analysis of arsenic in traditional Chinese medicine

- Recent modified air-assisted liquid–liquid microextraction applications for medicines and organic compounds in various samples: A review

- An insight on Vietnamese bio-waste materials as activated carbon precursors for multiple applications in environmental protection

- Antimicrobial activities of the extracts and secondary metabolites from Clausena genus – A review

- Bioremediation of organic/heavy metal contaminants by mixed cultures of microorganisms: A review

- Sonodynamic therapy for breast cancer: A literature review

- Recent progress of amino acid transporters as a novel antitumor target

- Aconitum coreanum Rapaics: Botany, traditional uses, phytochemistry, pharmacology, and toxicology

- Corrigendum

- Corrigendum to “Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt”

- Corrigendum to “Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach”

- Corrigendum to “Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt”

- Corrigendum to “Aroma components of tobacco powder from different producing areas based on gas chromatography ion mobility spectrometry”

- Corrigendum to “Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system”

- Erratum

- Erratum to “Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies”

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2021)

- Study of solidification and stabilization of heavy metals by passivators in heavy metal-contaminated soil

- Human health risk assessment and distribution of VOCs in a chemical site, Weinan, China

- Preparation and characterization of Sparassis latifolia β-glucan microcapsules

- Special Issue on the Conference of Energy, Fuels, Environment 2020

- Improving the thermal performance of existing buildings in light of the requirements of the EU directive 2010/31/EU in Poland

- Special Issue on Ethnobotanical, Phytochemical and Biological Investigation of Medicinal Plants

- Study of plant resources with ethnomedicinal relevance from district Bagh, Azad Jammu and Kashmir, Pakistan

- Studies on the chemical composition of plants used in traditional medicine in Congo

- Special Issue on Applied Chemistry in Agriculture and Food Science

- Strip spraying technology for precise herbicide application in carrot fields

- Special Issue on Pharmacology and Metabolomics of Ethnobotanical and Herbal Medicine

- Phytochemical profiling, antibacterial and antioxidant properties of Crocus sativus flower: A comparison between tepals and stigmas

- Antioxidant and antimicrobial properties of polyphenolics from Withania adpressa (Coss.) Batt. against selected drug-resistant bacterial strains

- Integrating network pharmacology and molecular docking to explore the potential mechanism of Xinguan No. 3 in the treatment of COVID-19

- Chemical composition and in vitro and in vivo biological assortment of fixed oil extracted from Ficus benghalensis L.

- A review of the pharmacological activities and protective effects of Inonotus obliquus triterpenoids in kidney diseases

- Ethnopharmacological study of medicinal plants in Kastamonu province (Türkiye)

- Protective effects of asperuloside against cyclophosphamide-induced urotoxicity and hematotoxicity in rats

- Special Issue on Essential Oil, Extraction, Phytochemistry, Advances, and Application

- Identification of volatile compounds and antioxidant, antibacterial, and antifungal properties against drug-resistant microbes of essential oils from the leaves of Mentha rotundifolia var. apodysa Briq. (Lamiaceae)

- Phenolic contents, anticancer, antioxidant, and antimicrobial capacities of MeOH extract from the aerial parts of Trema orientalis plant

- Chemical composition and antimicrobial activity of essential oils from Mentha pulegium and Rosmarinus officinalis against multidrug-resistant microbes and their acute toxicity study

- Special Issue on Marine Environmental Sciences and Significance of the Multidisciplinary Approaches

- An insightful overview of the distribution pattern of polycyclic aromatic hydrocarbon in the marine sediments of the Red Sea

- Antifungal–antiproliferative norcycloartane-type triterpenes from the Red Sea green alga Tydemania expeditionis

- Solvent effect, dipole moment, and DFT studies of multi donor–acceptor type pyridine derivative

- An extensive assessment on the distribution pattern of organic contaminants in the aerosols samples in the Middle East

- Special Issue on 4th IC3PE

- Energetics of carboxylic acid–pyridine heterosynthon revisited: A computational study of intermolecular hydrogen bond domination on phenylacetic acid–nicotinamide cocrystals

- A review: Silver–zinc oxide nanoparticles – organoclay-reinforced chitosan bionanocomposites for food packaging

- Green synthesis of magnetic activated carbon from peanut shells functionalized with TiO2 photocatalyst for Batik liquid waste treatment

- Coagulation activity of liquid extraction of Leucaena leucocephala and Sesbania grandiflora on the removal of turbidity

- Hydrocracking optimization of palm oil over NiMoO4/activated carbon catalyst to produce biogasoline and kerosine

- Special Issue on Pharmacology and metabolomics of ethnobotanical and herbal medicine

- Cynarin inhibits PDGF-BB-induced proliferation and activation in hepatic stellate cells through PPARγ

- Special Issue on The 1st Malaysia International Conference on Nanotechnology & Catalysis (MICNC2021)

- Surfactant evaluation for enhanced oil recovery: Phase behavior and interfacial tension

- Topical Issue on phytochemicals, biological and toxicological analysis of aromatic medicinal plants

- Phytochemical analysis of leaves and stems of Physalis alkekengi L. (Solanaceae)

- Phytochemical and pharmacological profiling of Trewia nudiflora Linn. leaf extract deciphers therapeutic potentials against thrombosis, arthritis, helminths, and insects

- Pergularia tomentosa coupled with selenium nanoparticles salvaged lead acetate-induced redox imbalance, inflammation, apoptosis, and disruption of neurotransmission in rats’ brain

- Protective effect of Allium atroviolaceum-synthesized SeNPs on aluminum-induced brain damage in mice

- Mechanism study of Cordyceps sinensis alleviates renal ischemia–reperfusion injury

- Plant-derived bisbenzylisoquinoline alkaloid tetrandrine prevents human podocyte injury by regulating the miR-150-5p/NPHS1 axis

- Network pharmacology combined with molecular docking to explore the anti-osteoporosis mechanisms of β-ecdysone derived from medicinal plants

- Chinese medicinal plant Polygonum cuspidatum ameliorates silicosis via suppressing the Wnt/β-catenin pathway

- Special Issue on Advanced Nanomaterials for Energy, Environmental and Biological Applications - Part I

- Investigation of improved optical and conductivity properties of poly(methyl methacrylate)–MXenes (PMMA–MXenes) nanocomposite thin films for optoelectronic applications

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2022)

- Model predictive control for precision irrigation of a Quinoa crop