Abstract

In the modern fashion industry, computer-aided systems are essential for planning, design, and marketing. Three-dimensional (3D) virtual simulation technology allows designers to style virtual models and create distinct looks. However, accurately simulating real fabrics requires more than just color, fiber type, mass, and thickness. This research aimed to evaluate the color uniformity and accuracy of 3D virtual simulations of knitted fabrics compared to real ones. Color uniformity ensures that cloth is observed as it is throughout the model until we observe it from different angles. Without this, the fabric would have a different color impression, which may impart our study towards different sides. Focusing on 80 knitted fabric samples, the study analyzed yarn types, stitch patterns, and colors. A seven-point Likert scale was used to assess the product quality through sensory evaluation of real and simulated garments. The results demonstrated that 3D simulations can accurately replicate the color characteristics of knitted fabrics, producing outcomes comparable to real ones. This study highlights the potential of 3D simulation as a valuable tool in the textile industry, improving efficiency and innovation in fabric design and manufacturing. The outcomes demonstrate that 3D virtual simulations can accurately replicate the color characteristics of knitted fabrics, producing outcomes that are comparable to those of actual knitted fabric. This study advances the use of digital tools in the fashion industry while encouraging efficiency and innovation in fabric creation.

1 Introduction

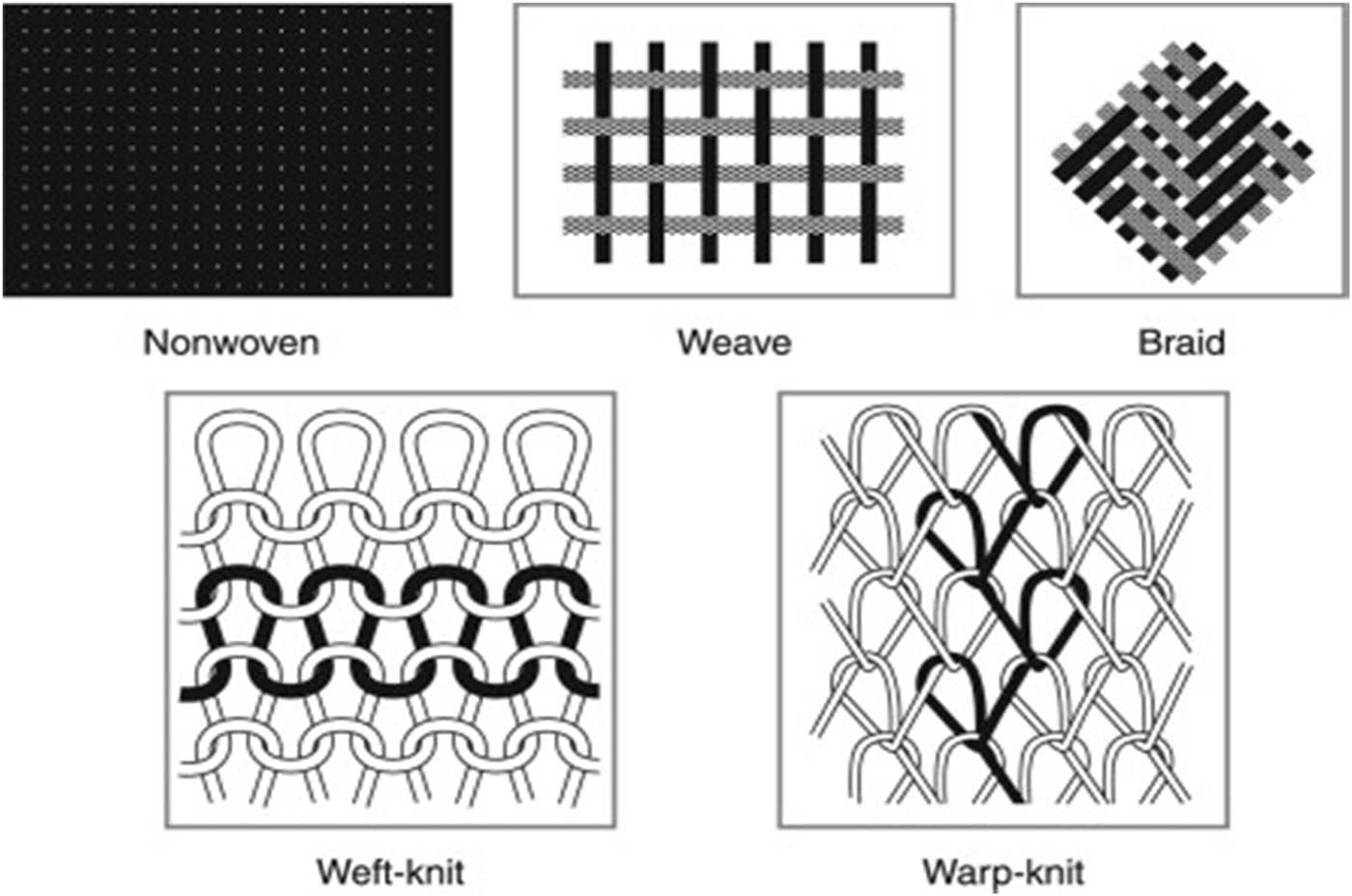

With the advent of cutting edge technologies, the downstream supply chain of every industry has improved [1]. The garment industry began sending technical specification sheets to producers via email in the 1990s once the Internet and Hotmail were established [2]. It reduced the cost and waiting time associated with the once labor-intensive and time-consuming process of garment prototypes. Textile engineers have been able to create novel, intricate, and complicated textile fabric structures that can be employed in no textile applications, manufacturing techniques, and exotic materials [3]. Technical fabrics are the ones that are employed in engineering applications to carry out technological tasks. Several other researchers have developed and updated the model to simulate knitted materials. The clothing industry uses knit materials extensively because of their excellent formability, comfort, flexibility, and elasticity [4].

Various factors, including fiber fineness, cross-section, yarn type, coarse hair, twist level, texturing technique, knitting and weaving structure, porosity, roughness, and finishing techniques [5], influence how a fabric is perceived to be colored [6]. A portion of light is absorbed and a portion is reflected when it strikes a textile surface. The ratio of absorbed to reflected light determines the material’s color. Many fine fibers are combined to produce a textile product [7]. A textile product’s structure is comparable to a cluster made up of several glass sticks. The comparison aids in the explanation of the textile material’s physical characteristics. A portion of the light that strikes each fiber’s upper surface is reflected as an optical needle [8]. A textile product’s numerous white fibers are arranged progressively, which causes almost all light to be reflected off of the surface. Despite glass, the surface of the textile has oriented fibers in different shapes, which causes light to reflect in different directions [9].

Concurrent engineering, which allows for the parallel production of design and manufacturing [10], is one of the primary strategies recommended for reducing the time required from product planning to design and manufacture. Additionally, computer-aided engineering has gained popularity as a means of employing computers to evaluate goods or to ascertain whether their parts are truly usable [11]. Traditionally, two-dimensional (2D) data media (drawings) are used for product design and manufacturing. However, media based on computer-processed three-dimensional (3D) data are currently replacing drawings. It would not be a stretch to suggest that employing 3D software and its application methods could be the difference between winning and losing in the race to design new items [12].

The purpose of this analysis is to assess the color correctness with the consistency of 3D virtual simulation knitted fabrics against real knit fabrics. To maximize the performance of virtual simulations, it aims to improve the portrayal of hue, saturation, and lightness of color [13]. Its goal is to make 3D simulations for textile design and production more realistic and effective. Let us dive into some of the past contributions in this area, starting with inversely simulating the yarn-level dynamics of fabric grounded in the actual mechanical behavior of materials [14]. Hakeem et al. [15] offered a way to generate woven patterned materials with centimeter and micrometer-level 3D structures using parametric simulation. With these technologies, the naturally iterative process of fabric design can be transferred to the digital realm, and the structure of different woven fabrics can be designed without the need to analyze the minutiae of the fabric architecture. Shen et al. [16] produced a transparent design procedure with outcomes visualized, making it easy for designers to alter knitting factors, such as quilted patterns and knitting knowledge before the object was knitted. By using the simulation approach, the warp-knitted boa could be quickly designed, reducing the need for duplicate samples, speeding up the design management, and saving money on raw materials. Huo et al. [17] developed a mesh-loop modeling with movement vectors according to the basic components of four stitching types: loop advancement, tuck, and floating. Hu et al. [18] presented an image-based approach that compares morphological characteristics from simulation results and real fabric images to quantitatively resolve accuracy.

2 Methodology

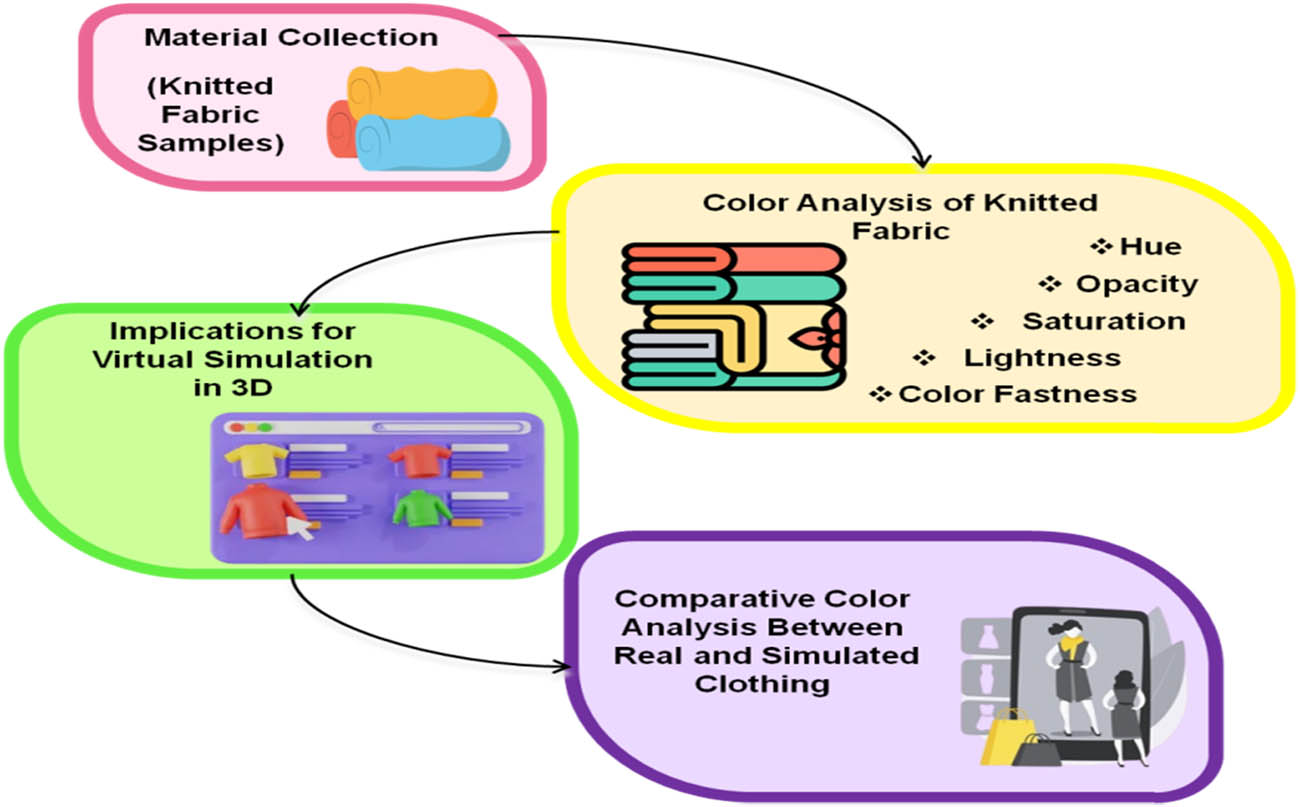

To proceed with color analysis and performance optimization, 80 knitted fabric samples of different categories were chosen, including different yarn varieties, stitch patterns, and color attributes. By incorporating dying processes and color evaluation techniques, 3D fabric representation in a virtual fabric space is designed as a platform where color characteristics can be gauged, and fabric behavior can be modeled [19]. To establish quality control as well as improve the efficiency of the designer clothes, a sensory test on the real and fake clothes is conducted using the seven-point Likert scale. This test enables analysis of many specifications, including smoothness, drape, texture, and many others. This evaluation helps developers validate the accuracy of 3D models by comparing simulated fabric behavior with real-world observations. Figure 1 represents the method flow.

Methodology flow.

2.1 Material selection

Eighty samples of the knitted fabric components were used in this study, focusing on their color, stitch, and yarn types. The study includes a wide array of knitted fabrics where the researcher should be in a position to acquire adequate materials for color analysis as well as to optimize the performance of the fabrics. The five knitted textiles chosen are defined in Table 1, where various features are relevant to the investigation. These yarn kinds provide a range of materials that are displayed that consist of cotton, polyester, wool, nylon, and acrylic. Concerning the stitch designs, jersey and rib, among others, are parameters that provide each cloth texture and usefulness. The variations that make up the color version consist of red, blue, green, yellow, and white. This means that the textiles also differed in the aspects of wear and tear, porosity, flexibility, and density, which all have significant importance when determining the extent to which textiles are fit for performance in imitation of virtual environments.

Material selection

| Material ID | Yarn type | Stitch pattern | Color | Weight (g/m2) | Stretchability (%) | Breathability | Durability (cycles) |

|---|---|---|---|---|---|---|---|

| Type 1 | Cotton | Jersey | Red | 180 | 10 | Moderate | 20 |

| Type 2 | Polyester | Rib | Blue | 220 | 15 | High | 50 |

| Type 3 | Wool | Purl | Green | 200 | 12 | Low | 30 |

| Type 4 | Nylon | Flat knit | Yellow | 250 | 20 | High | 60 |

| Type 5 | Acrylic | Double knit | White | 210 | 22 | Moderate | 35 |

To determine how these 80 specimens came into action, there are several ways to obtain this figure and to proceed with this study, varying fabric proportions techniques were implied. For instance:

Specimen 1: 50% Fabric A, 25% Fabric B, 15% Fabric C, 10% Fabric D, 5% Fabric E

Specimen 2: 30% Fabric A, 30% Fabric B, 20% Fabric C, 10% Fabric D, 10% Fabric E and so on.

This is the easiest way to obtain the desired number and can be exceeded too (Figure 2 and Table 2).

Varying fabric patterns.

Varying fabric proportions

| Specimen | Type 1 (%) | Type 2 (%) | Type 3 (%) | Type 4 (%) | Type 5 (%) |

|---|---|---|---|---|---|

| 1 | 20 | 20 | 20 | 20 | 20 |

| 2 | 25 | 15 | 20 | 20 | 20 |

| 3 | 30 | 10 | 20 | 20 | 20 |

| 4 | 35 | 5 | 20 | 20 | 20 |

| … | … | … | … | … | … |

| 76 | 20 | 20 | 20 | 20 | 20 |

| 77 | 20 | 20 | 25 | 15 | 20 |

| 78 | 20 | 20 | 30 | 10 | 20 |

| 79 | 20 | 20 | 35 | 5 | 20 |

| 80 | 20 | 20 | 40 | 0 | 20 |

2.2 Color analysis and the dying process components in 3D virtual knitted fabric simulation

There are technical factors related to how the colors of knitted fabrics are manufactured and used, along with the areas of color analysis, how they are perceived or interpreted, how effective they are, and how customers respond to them about the manufacturing and use of knitted fabrics. The understanding of color characteristics, such as tint, saturation, and brightness, allows the creation of effective materials that are at once highly desirable as well as functional [20]. Color determining enables the selection of the right dying agents and methods to ensure the right color on all fabrics. Interactions between dying agents and color are important determinants of the final look of knitted materials, especially in simulated dying. Owing to color analysis and dying chemicals, know-how designers are in a better position to estimate, based on the apparel knitted structure, how a certain color or tone will appear [21].

2.2.1 Dying process

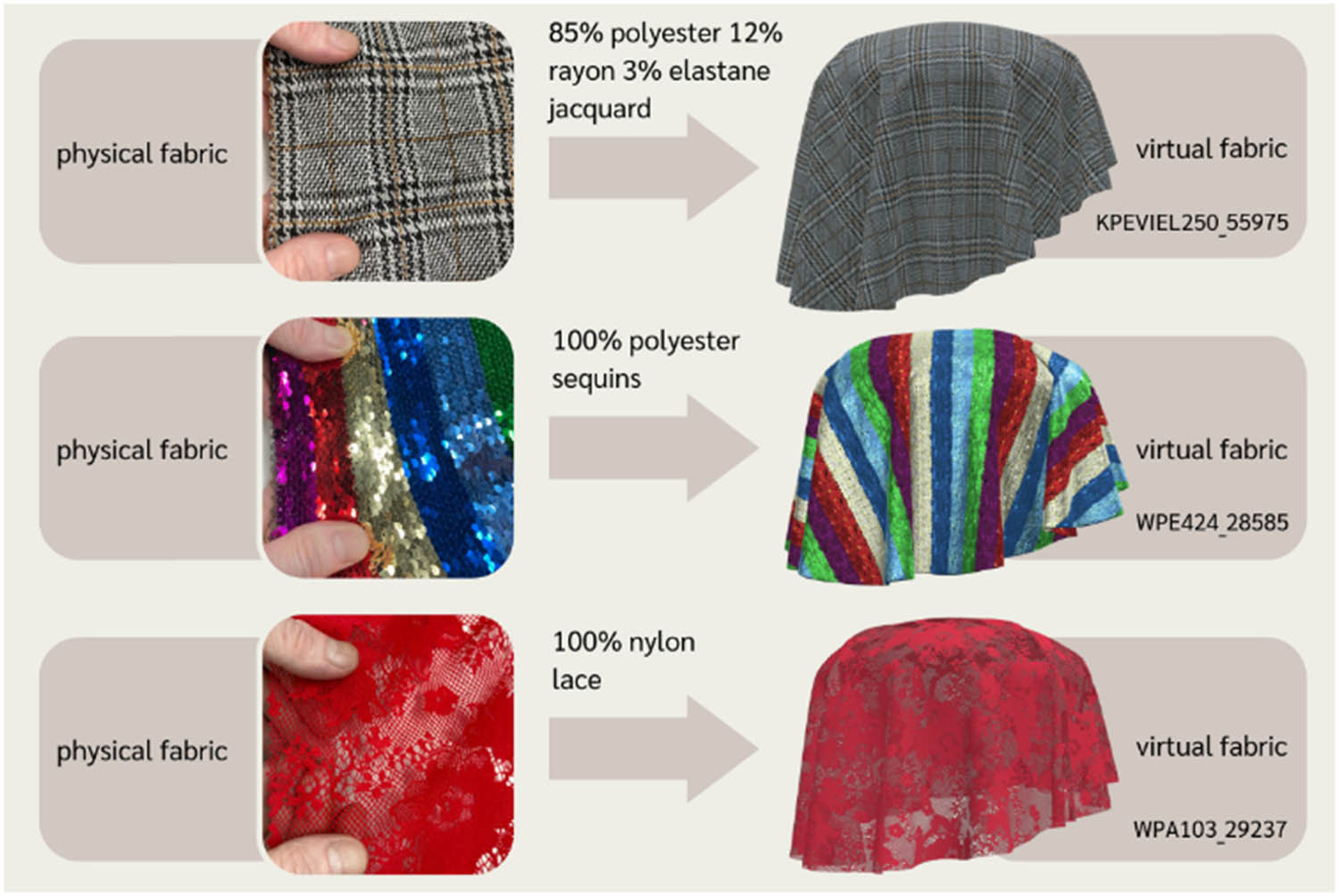

To obtain higher-quality knitted fabrics and to develop the color properties of some materials, the application of dying chemicals is inevitable. The following substances are used in this investigation. In dying, other substances, which are called auxiliary chemicals, are used to assist and/or extend the function of the dying process [22]. It helps to determine stable color scatter and enhance durability, simultaneously maintaining the fibers (Figure 3).

Virtual results.

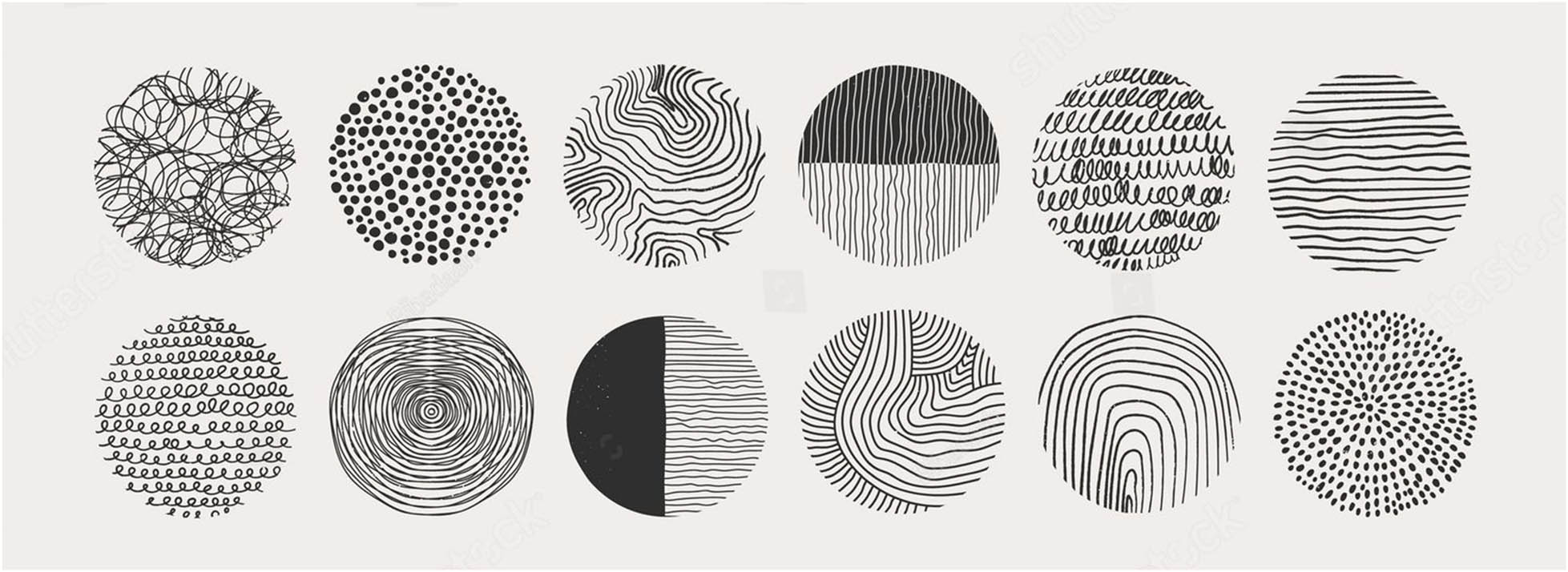

2.2.2 Development of 3D virtual fabric

It is always crucial to mark straight fabric digitalization prior to the design. First, the fabric was passed with two different gadgets: Browzwear’s fabric analyzer (FAB), which helps to demonstrate the cloth physics like thickness and bend, and the second was a Vizoo machine, which produces cloth texture in digital form. The following fabric metrics were chosen to evaluate visual similarity: stretch, shear, bending, thickness, weight, damping, reflection, and transparency. The images of fabric patterns obtained by digital equipment were matched with circular patterns (which are circular rings basically just to describe the diameter and a few other properties in software, as shown in Figure 4) based on the digital capture and the 3D virtual fabric simulation environment was embedded into a circular table with diameter. The decoding of the garments’ primary color analysis based on the clothing lifecycle optimization (CLO) 3D virtual clothing design program is shown in Table 3.

Circular patterns.

Color analysis parameters

| Parameters | Description |

|---|---|

| Colorfastness | The ability of a fabric to retain its color in the face of fading or rubbing off light or water |

| Hue | A color’s characteristic indicates where it falls on the color spectrum (e.g., red, blue, and green) |

| Saturation | Higher saturation denotes more vibrant hues; the intensity or purity of the color |

| Lightness | The color’s brightness or darkness, which reflects light off the fabric, is measured |

| Opacity | The degree to which light can flow through a material and alter one’s perception of color |

| Dye absorption rate | The rate at which the fabric absorbs dye throughout the dying process |

Each parameter is vital for understanding and controlling the characteristics of shade, chroma, and luminosity, affecting the positive appeal of styles of knitted fabrics. It allows designers to observe how pigments react to light and substrate through the functions of simulating color fastness and changing the level of transparency. By incorporating these capabilities, textile designers can achieve the right color choices and avoid compromising on the quality of production, hence enhanced designs.

2.3 Advantages of color analysis integration with 3D virtual simulations for knitted fabric design

The following are some advantages of designing and developing knitted fabrics by putting effect to color analysis and dying agents in 3D virtual simulations. The purpose of this integration is to ensure high-quality and realistic design outcomes while at the same time ensuring the optimality of the design process. This strategy is important because it addresses the textile industry’s demand for flexibility and creativity that has emerged.

Visual representation: Designers can understand how various dying chemicals impact color uptake and fabric expectation in real time from the real-time representation presented in the simulations. This helps in making design decisions, which are often based on knowledge that is not easily accessible.

Interactive exploration: When designers allow themselves to experiment with color schemes and numerous finishes on a particular fabric, then their creativity and creativity regarding the production of new fabrics can be boosted.

Performance prediction: The simulations rely on the impact of the dying chemicals to approximate the behavior of dyed materials under specific conditions, such as wearing off with time. This extends the understanding of the durability or weather resistance in the longer term and appearance or color too.

Enhanced design process: One of the advantages of the design process is the possibility of performance prediction and visualization that will also help eliminate the expensive physical prototypes.

Customization: It is thus possible to examine the basic color shades of light, medium, dark, and very dark and facilitate dying procedures with the help of the simulation. As a result, designers are able to make textiles in a way that best suits some consumer tastes and commercial needs.

The process is quite simple: colored clothes are run with the software by putting them in machines like FAB and Vizoo.

2.4 Procedure for comparative assessment of real and simulated clothing-wearing color analysis

To expedite the investigation of the examiners and to help them effectively compare the images of real and virtual apparel, an evaluation table was constructed, which included all types of knitted fabric samples used in the images. The type of assessment used was the seven-point Likert-Test Scale, and any result that was around 5 points was considered a favorable result. The Commission International de l’ Éclairage (CIE) color system is a standard means of accurately describing and quantifying color in diverse industries, including textiles, for design and production. In its primary color space, CIE, lightness (L*), and the color-opponent variables green-red (a*) and blue-yellow (b*) facilitate perceptually meaningful color comparisons. From this method, it is easy to identify color differences, as well as ensure that the color of the product and textile conforms to fixed standards. Due to the penetration depth and description of color attributes, designers can create visually realistic representations of fabrics when simulating some context in 3D space. The results of the analysis were discussed concerning additional points of view. In total, ten persons were selected as evaluators: four graduate students or recent graduates who focused on apparel and textiles, three professional fashion designers with more than 5 years of experience, and three who specialized in creating 3D virtual clothing simulations.

3 Results and discussion

This study proposes to compare the color constancy and accuracy of 3D virtual simulation knitted fabrics to the original fabrics. It aims to improve the modeling of the color attributes, particularly hue, saturation, and lightness, to optimize the functioning of virtual replicas. Color analysis parameters of five different fabric samples, such as cotton, polyester, wool, nylon, and acrylic, are presented in Table 4. The rating of each parameter is done using standard numerical scales of color fastness (1–5), hue (0°–360°), saturation (0–100), brightness (0–100), and opacity (0–100). These are the relative values exhibited by the fabrics as to their brightness, light transmittance, pigmentation, hue characteristics, and color fastness. It helps understand the utilitarian and perceptive traits of each sort of material, which guides the selection of fabrics for its creation and appearance.

Fabric samples

| Samples | Parameter values | ||||

|---|---|---|---|---|---|

| Colorfastness (1–5) | Hue (0°–360°) | Saturation (0–100) | Lightness (0–100) | Opacity (0–100) | |

| Type 1 (cotton) | 3 | 0 | 85 | 50 | 90 |

| Type 2 (polyester) | 5 | 210 | 90 | 55 | 85 |

| Type 3 (wool) | 3 | 120 | 65 | 30 | 40 |

| Type 4 (nylon) | 4 | 60 | 95 | 70 | 90 |

| Type 5 (acrylic) | 3 | 0 | 55 | 80 | 70 |

Table 5 examines the values of the CIE color system’s constituent parts with those of CLO 3D for five distinct knitted fabric samples: acrylic, cotton, polyester, wool, and nylon. Hue, saturation, brightness, opacity, and color fastness are all measured on a relevant scale to allow for the evaluation of the color attributes of the fabrics. For instance, when using cotton, one gets a very strong saturation and excellent color fastness, while with wool, the garments show reduced opacity and lightness. Thus, this analysis aids designers in creating substantial textile representations by establishing how these knitted materials perform in virtual applications.

Comparing the CLO 3D and CIE color system components for fabric samples

| CIE components | CLO 3D components (scale) | Type 1 (cotton) | Type 2 (polyester) | Type 3 (wool) | Type 4 (nylon) | Type 5 (acrylic) |

|---|---|---|---|---|---|---|

| Colorfastness | 1–5 | 4 | 5 | 3 | 4 | 3 |

| Hue | 0°–360° | 0 (red) | 210 (blue) | 120 (green) | 60 (yellow) | 0 (white) |

| Saturation | 0–100 | 85 | 90 | 65 | 95 | 55 |

| Lightness | 0–100 | 70 | 80 | 40 | 90 | 80 |

| Opacity | 0–100 | 90 | 85 | 40 | 90 | 70 |

In this regard, eight primary questions are presented in Table 6 that compare in-person/3D virtual observable between observation and simulation in knit color analysis. Different questions are as follows: The degrees of texture realism, product vibrancy, products’ consistency, and color correctness are specific criteria to be asked. Participants will provide more elaborated opinions on a descriptive scale ranging from strongly disagree to strongly agree. This technique allows assessing the usability of 3D simulations that try to mimic the color characteristics of real fabrics. As such, the study will serve to improve the ways and models within the simulation and designing of virtual fabrics.

Parameters and corresponding questions for color analysis

| Color analysis field | Questions |

|---|---|

| Accuracy | How accurately does the 3D virtual simulation represent the color of the real fabric? |

| Vibrancy | How would you rate the vibrancy of the colors in the 3D simulation compared to the real fabric? |

| Consistency | How consistent is the color across different lighting conditions in the 3D simulation? |

| Shade matching | How closely do the shades in the 3D simulation match the actual shades of the fabric? |

| Variation display | How well does the 3D virtual fabric show variations in color that occur in the real fabric? |

| Texture realism | How realistic is the texture representation of the knitted fabric in the 3D simulation? |

| Color adjustment capability | How well does the 3D simulation allow for color adjustments compared to physical fabric? |

| Overall satisfaction | Overall, how satisfied are you with the color representation of the 3D simulation compared to the actual fabric? |

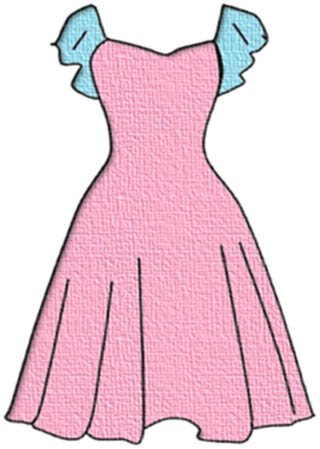

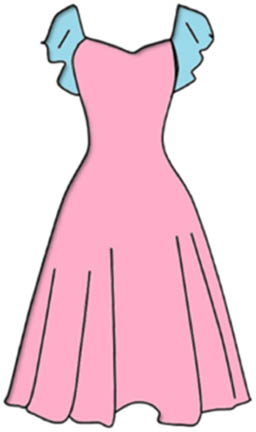

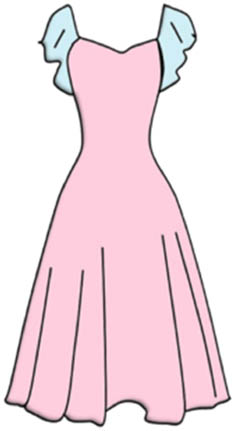

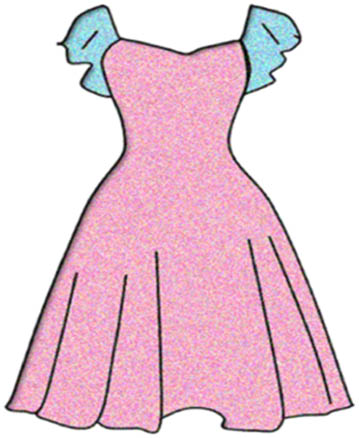

A comparison of color features of real knitted fabric clothes with 3D virtual apparel is presented in Table 7, which reveals that both possess the closest color properties. This comparison indicates how effectively the 3D virtual simulation imitates real fabric by parameters such as hue, saturation, brightness, and color fastness. The high correlation coefficient of color analysis data proves virtual simulations can be useful in design and production because the images have similar visual qualities to the real textile samples. The fashion industry is relying more and more on 3D virtual apparel and this consistency in color representation ensures that designers make judgments predicated on visual accuracy rather than reliance on appearance alone. Figure 5 shows the samples that were collected before dying.

Color analysis of images using 3D virtual clothes and actual clothes

| Knitted fabric samples | 3D virtual knitted cloth | Real knitted cloth |

|---|---|---|

| Type 1 (cotton) |

|

|

| Type 2 (polyester) |

|

|

| Type 3 (wool) |

|

|

| Type 4 (nylon) |

|

|

| Type 5 (acrylic) |

|

|

Samples of cloth collected.

This analysis demonstrates a strong correlation between the color characteristics of real knitted fabrics and their 3D virtual simulations. By comparing key parameters like hue, saturation, lightness, opacity, and color fastness, it is evident that CLO 3D accurately replicates the color properties of real fabrics.

Furthermore, the survey results, using a seven-point scale, support these findings. Respondents consistently noted high levels of accuracy, vibrancy, and textural realism in the 3D simulations. This indicates that the virtual models effectively capture the subtle color variations and microtextural nuances present in real textiles.

4 Conclusion

This study has accessed all the attributes to evaluate the color combinations that play a mindful game in the 3D virtual simulations of fabrics. Parameters like hue, saturation, brightness, and color fastness with regard to collected five samples (cotton, polyester, wool, nylon, and acrylic), the proportion between the computers generated colors, and the items that are in real life need to be discussed. Later implied a strategy of varying fabric proportions to obtain 80 different specimens just to make deeper evaluations. The dying process also helped to determine the real picture. The findings indicate that 3D simulation technology can effectively replicate the color characteristics of knitted fabrics, producing visually accurate representations. This capability has significant implications for the fashion industry, enabling designers to make informed decisions based on realistic virtual prototypes. By minimizing the need for physical samples and accelerating the design process, 3D simulation technology can contribute to increased efficiency, reduced material waste, and, ultimately, a more sustainable and innovative approach to fabric design and manufacturing.

Further research could explore the impact of different lighting conditions and viewing angles on color perception in both virtual and real-world scenarios, as well as investigate the potential for incorporating advanced color management systems to further enhance the accuracy and realism of 3D fabric simulations.

-

Funding information: Joint research by universities and enterprises (F horizontal project) Historical costume modeling design and 3D data scanning technology service contract. Project number: [220220098].

-

Author contributions: The author confirms the sole responsibility for the conception of the study, presented results and manuscript preparation.

-

Conflict of interest: The author has no conflicts of interest to declare.

-

Ethical approval: The conducted research is not related to either human or animals use.

-

Data availability statement: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Turgut, E., Değirmenci, Z. (2023). Investigation of the effect of colour variation and pattern change on performance and thermal properties of acrylic knitted fabrics. Afyon Kocatepe Üniversitesi Uluslararası Mühendislik Teknolojilerive Uygulamalı Bilimler Dergisi, 6(1), 14–24. 10.53448/akuumubd.1187051.Search in Google Scholar

[2] Dash, A. K., Nayak, R., Sahoo, S. K. (2022). Testing and evaluation of knitted fabrics. In: Maity, S. Rana, S. Pandit P, & Singha K. (Eds.) Advanced knitting technology (pp. 623–656). Woodhead Publishing. 10.1016/B978-0-323-85534-1.00017-9.Search in Google Scholar

[3] Kumpikaitė, E., Tautkutė-Stankuvienė, I., Milašienė, D., Petraitienė, S. (2022). Analysis of color fastness and shrinkage of dyed and printed linen/silk fabrics. Coatings, 12(3), 408. 10.3390/coatings12030408.Search in Google Scholar

[4] Maiti, S., Maity, S., Pandit, P., Maulik, S. R., Singha, K. (2022). Sustainability analysis for knitting process and products. In: Maity, S. Rana, S. Pandit P, & Singha K. (Eds.) Advanced knitting technology (pp. 657–671). Woodhead Publishing. 10.1016/B978-0-323-85534-1.00001-5.Search in Google Scholar

[5] El-Newashy, R., Zakaria El-Sayed, H. E. D. (2022). Evaluation and CLO3D simulation of some characteristics of bio-treated knitted polyester/Lycra fabrics. Egyptian Journal of Chemistry, 65(8), 779–789. 10.21608/ejchem.2022.150365.6512.Search in Google Scholar

[6] Wilson, S. A., Laing, R. M., Tan, E., Wilson, C. A., Arachchige, P. S. G., Gordon, K. C., et al. (2024). Determining deposits on knit fabrics, yarns, and fibers, from sensor-related treatments. The Journal of The Textile Institute, 115(8), 1229–1241. 10.1080/00405000.2023.2221427.Search in Google Scholar

[7] Ferdusha, J., Jahana, N., Ahmeda, S., Ferdousa, M. J. (2022). Colorimetric analysis and fastness rating of natural yellow color dyes on cotton fabric. Journal of Natural Science and Textile Technology, 1, 1.Search in Google Scholar

[8] Elsehrawy, F., Blomstedt, B., Ilén, E., Palovuori, E., Halme, J. (2023). Optimization of knitted fabrics as visually concealing covers for textile-integrated photovoltaics. Solar Energy Materials and Solar Cells, 252, 112205. 10.1016/j.solmat.2023.112205.Search in Google Scholar

[9] Sperl, G., Sánchez-Banderas, R. M., Li, M., Wojtan, C., Otaduy, M. A. (2022). Estimation of yarn-level simulation models for production fabrics. ACM Transactions on Graphics (TOG), 41(4), 1–15. 10.1145/3528223.3530167.Search in Google Scholar

[10] Zheng, P., Jiang, G., Cong, H. (2023). Texture mapping-based virtual simulation of striped jacquard fabrics. Textile Research Journal, 93(19–20), 4345–4357. 10.1177/00405175231169046.Search in Google Scholar

[11] Deng, W., Ke, W., Deng, Z., Wang, X. (2024). Virtual design of woven fabrics based on parametric modelling and physically based rendering. Computer-Aided Design, 173, 103717. 10.1016/j.cad.2024.103717.Search in Google Scholar

[12] Dong, Z., Liu, H., Jiang, G., Ma, P. (2024). 3D simulation of warp knitted boa for visual and quicker design. Textile Research Journal, 94(23–24), 2616–2628. 10.1177/00405175241249457.Search in Google Scholar

[13] Ru, X., Zheng, S., Peng, L., Wang, J. (2024). Yarn-level modelling and simulation of fancy weft-knitted fabric. Textile Research Journal, 94(17–18):2063–2078. 10.1177/00405175241235950.Search in Google Scholar

[14] Li, X., Tian, M., He, J., Di, J., Zhang, A., Qin, X. (2022). Simulation evaluation of knitted mesh structure using morphological operations. Journal of Engineered Fibers and Fabrics, 17, 15589250221117215. 10.1177/15589250221117215.Search in Google Scholar

[15] Hakeem, F., Xia, S., Stannard, C. (2024). Evaluating 3D apparel simulation technology’s performance of creative pattern-cutting techniques with the assist of ASVT. Clothing and Textiles Research Journal, 0887302X241278929. 10.1177/0887302X241278929.Search in Google Scholar

[16] Shen, Y., Dong, Z., Cong, H. (2022). Structure modelling in the three-dimensional simulation of weft-knitted seamless kneepads. Textile Research Journal, 92(3–4), 608–617. 10.1177/00405175211040872.Search in Google Scholar

[17] Huo, D., Yuan, L., Gu, Q., Xiong, Y., Wang, D. (2023). Computer simulation of colored spun knitted fabric based on Dual-Tree complex wavelet transform. The Journal of The Textile Institute, 114(4), 682–691. 10.1080/00405000.2022.2063474.Search in Google Scholar

[18] Hu, H., Li, T., Ke, W., Wang, L., Deng, Z. (2023). Simulation of weft knitted fabric using three-dimensional yarn loops and grid and spring mass models. Advances in Materials Science and Engineering, 2023(1), 9757748. 10.1155/2023/9757748.Search in Google Scholar

[19] Tan, J., Jiang, G., Gao, Z., Ma, P., Zheng, P. (2022). Development and mechanical properties of three-dimensional flat-knitted fabrics with reinforcement yarns. Journal of Industrial Textiles, 51(2_suppl), 2071S–2088S. 10.1177/15280837211046061.Search in Google Scholar

[20] Khalil, A., Eldeeb, M., Těšinová, P., Fouda, A. (2023). Theoretical porosity of elastic single jersey knitted fabric based on 3D geometrical model of stitch overlapping. Journal of Natural Fibers, 20(1), 2181274. 10.1080/15440478.2023.2181274.Search in Google Scholar

[21] Huang, Y., Zhao, W., Ren, H., Jiang, L., Ouyang, Y., Xu, W., et al. (2024). Enhanced shape memory performance and numerical simulation of knitted‐fabric reinforced polymer composites with weft yarns. Polymer Composites, 45(18), 16916–16928. 10.1002/pc.28940.Search in Google Scholar

[22] Pham, M. Q., Wendt, E., Häntzsche, E., Gereke, T., Cherif, C. (2022). Numerical modelling of the mechanical behavior of textile structures on the mesoscale for forming process simulations of composite 3D preforms. Engineering Reports, 4(7–8), e12348. 10.1002/eng2.12348.Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Study and restoration of the costume of the HuoLang (Peddler) in the Ming Dynasty of China

- Texture mapping of warp knitted shoe upper based on ARAP parameterization method

- Extraction and characterization of natural fibre from Ethiopian Typha latifolia leaf plant

- The effect of the difference in female body shapes on clothing fitting

- Structure and physical properties of BioPBS melt-blown nonwovens

- Optimized model formulation through product mix scheduling for profit maximization in the apparel industry

- Fabric pattern recognition using image processing and AHP method

- Optimal dimension design of high-temperature superconducting levitation weft insertion guideway

- Color analysis and performance optimization of 3D virtual simulation knitted fabrics

- Analyzing the effects of Covid-19 pandemic on Turkish women workers in clothing sector

- Closed-loop supply chain for recycling of waste clothing: A comparison of two different modes

- Personalized design of clothing pattern based on KE and IPSO-BP neural network

- 3D modeling of transport properties on the surface of a textronic structure produced using a physical vapor deposition process

- Optimization of particle swarm for force uniformity of personalized 3D printed insoles

- Development of auxetic shoulder straps for sport backpacks with improved thermal comfort

- Image recognition method of cashmere and wool based on SVM-RFE selection with three types of features

- Construction and analysis of yarn tension model in the process of electromagnetic weft insertion

- Influence of spacer fabric on functionality of laminates

- Design and development of a fibrous structure for the potential treatment of spinal cord injury using parametric modelling in Rhinoceros 3D®

- The effect of the process conditions and lubricant application on the quality of yarns produced by mechanical recycling of denim-like fabrics

- Textile fabrics abrasion resistance – The instrumental method for end point assessment

- CFD modeling of heat transfer through composites for protective gloves containing aerogel and Parylene C coatings supported by micro-CT and thermography

- Comparative study on the compressive performance of honeycomb structures fabricated by stereo lithography apparatus

- Effect of cyclic fastening–unfastening and interruption of current flowing through a snap fastener electrical connector on its resistance

- NIRS identification of cashmere and wool fibers based on spare representation and improved AdaBoost algorithm

- Biο-based surfactants derived frοm Mesembryanthemum crystallinum and Salsοla vermiculata: Pοtential applicatiοns in textile prοductiοn

- Predicted sewing thread consumption using neural network method based on the physical and structural parameters of knitted fabrics

- Research on user behavior of traditional Chinese medicine therapeutic smart clothing

- Effect of construction parameters on faux fur knitted fabric properties

- The use of innovative sewing machines to produce two prototypes of women’s skirts

- Numerical simulation of upper garment pieces-body under different ease allowances based on the finite element contact model

- The phenomenon of celebrity fashion Businesses and Their impact on mainstream fashion

- Marketing traditional textile dyeing in China: A dual-method approach of tie-dye using grounded theory and the Kano model

- Contamination of firefighter protective clothing by phthalates

- Sustainability and fast fashion: Understanding Turkish generation Z for developing strategy

- Digital tax systems and innovation in textile manufacturing

- Applying Ant Colony Algorithm for transport optimization in textile industry supply chain

- Innovative elastomeric yarns obtained from poly(ether-ester) staple fiber and its blends with other fibers by ring and compact spinning: Fabrication and mechanical properties

- Design and 3D simulation of open topping-on structured crochet fabric

- The impact of thermal‒moisture comfort and material properties of calf compression sleeves on individuals jogging performance

- Calculation and prediction of thread consumption in technical textile products using the neural network method

Articles in the same Issue

- Study and restoration of the costume of the HuoLang (Peddler) in the Ming Dynasty of China

- Texture mapping of warp knitted shoe upper based on ARAP parameterization method

- Extraction and characterization of natural fibre from Ethiopian Typha latifolia leaf plant

- The effect of the difference in female body shapes on clothing fitting

- Structure and physical properties of BioPBS melt-blown nonwovens

- Optimized model formulation through product mix scheduling for profit maximization in the apparel industry

- Fabric pattern recognition using image processing and AHP method

- Optimal dimension design of high-temperature superconducting levitation weft insertion guideway

- Color analysis and performance optimization of 3D virtual simulation knitted fabrics

- Analyzing the effects of Covid-19 pandemic on Turkish women workers in clothing sector

- Closed-loop supply chain for recycling of waste clothing: A comparison of two different modes

- Personalized design of clothing pattern based on KE and IPSO-BP neural network

- 3D modeling of transport properties on the surface of a textronic structure produced using a physical vapor deposition process

- Optimization of particle swarm for force uniformity of personalized 3D printed insoles

- Development of auxetic shoulder straps for sport backpacks with improved thermal comfort

- Image recognition method of cashmere and wool based on SVM-RFE selection with three types of features

- Construction and analysis of yarn tension model in the process of electromagnetic weft insertion

- Influence of spacer fabric on functionality of laminates

- Design and development of a fibrous structure for the potential treatment of spinal cord injury using parametric modelling in Rhinoceros 3D®

- The effect of the process conditions and lubricant application on the quality of yarns produced by mechanical recycling of denim-like fabrics

- Textile fabrics abrasion resistance – The instrumental method for end point assessment

- CFD modeling of heat transfer through composites for protective gloves containing aerogel and Parylene C coatings supported by micro-CT and thermography

- Comparative study on the compressive performance of honeycomb structures fabricated by stereo lithography apparatus

- Effect of cyclic fastening–unfastening and interruption of current flowing through a snap fastener electrical connector on its resistance

- NIRS identification of cashmere and wool fibers based on spare representation and improved AdaBoost algorithm

- Biο-based surfactants derived frοm Mesembryanthemum crystallinum and Salsοla vermiculata: Pοtential applicatiοns in textile prοductiοn

- Predicted sewing thread consumption using neural network method based on the physical and structural parameters of knitted fabrics

- Research on user behavior of traditional Chinese medicine therapeutic smart clothing

- Effect of construction parameters on faux fur knitted fabric properties

- The use of innovative sewing machines to produce two prototypes of women’s skirts

- Numerical simulation of upper garment pieces-body under different ease allowances based on the finite element contact model

- The phenomenon of celebrity fashion Businesses and Their impact on mainstream fashion

- Marketing traditional textile dyeing in China: A dual-method approach of tie-dye using grounded theory and the Kano model

- Contamination of firefighter protective clothing by phthalates

- Sustainability and fast fashion: Understanding Turkish generation Z for developing strategy

- Digital tax systems and innovation in textile manufacturing

- Applying Ant Colony Algorithm for transport optimization in textile industry supply chain

- Innovative elastomeric yarns obtained from poly(ether-ester) staple fiber and its blends with other fibers by ring and compact spinning: Fabrication and mechanical properties

- Design and 3D simulation of open topping-on structured crochet fabric

- The impact of thermal‒moisture comfort and material properties of calf compression sleeves on individuals jogging performance

- Calculation and prediction of thread consumption in technical textile products using the neural network method