Abstract

Nowadays modern apparel industry encounters numerous challenges, including the dynamic nature of the market and the increasing customer demand for product variety. This drives fashion industries to diversify their product range, intensifying competition and leading to the production of a wide range of products in a single factory. Hence, implementing a systematic method and/or model to ascertain optimal product mix combinations within a garment factory becomes pivotal for informed decision-making. The current research aims to formulate a model to manage the available resources and improve overall operational efficiency through optimal product mix and production scheduling. The case study took place at CBA Garments Factory PLC in Ethiopia, which aimed to produce multiple garments but ultimately manufactured only one product at a time. The research employed quantitative research through analyzing data, general sewing data system, utilizing sequencing and scheduling approaches, and employing simple integer linear programming modeling tools. Based on the result, the newly developed optimized model enabled the case company to produce an average of four product types to fulfil multiple orders and increase resource utilization from 19.6% to an average of 73%.

1 Introduction

The Garment industry’s strategic development is mainly characterized by the efficient use of resources through different technical and managerial methods at every production stage. Such efficient utilization of resources is sustained through the implementation of different effective management decision-making techniques [1,2]. The Ethiopian apparel and leather sector has gotten significant attention than any other industry due to its rapid growth, attracting international investors, and substantial contribution to foreign exchange earnings [3,4]. Different researchers have also studied its comparative advantages within different products and among different countries [5,6,7]. However, the Ethiopian apparel industry presently faces considerable challenges. For instance, the recent termination of Ethiopia from the trade preference program called the African Growth and Opportunity Act (AGOA) trade preference program by the United States due to the violation of the AGOA Statute has discouraged investors, compelling them to seek opportunities elsewhere [8]. Consequently, local market exploration has become a focus for this industry. However, the quantity of orders received from the local market is insufficient, which imposes a shift in product focus as prolonged production of the same kind of product is not feasible due to the limited variety of local demand. Besides, garment industries are presently experiencing a similar or increased number of orders and volumes, yet the variety of styles they must manage has risen significantly. Previously, industries dealt with bulk orders, alleviating concerns as production lines could operate continuously for extended periods [9]. However, the dynamic nature of demand in the Ethiopian garment industry has become highly volatile. Failure to fulfill orders on time poses a genuine risk of losing business [10]. Therefore, the shift toward the local market exposes industries to the unpredictable and unstable needs of the buyers, which demands efficient and effective production planning and scheduling strategies. To thrive in this situation, companies must optimize their product mix scheduling to meet customer demands, minimize costs, and maximize profitability. However, many Ethiopian apparel industries, including CBA, face challenges related to inefficient resource utilization and managing multiple products with varying production requirements. This inefficiency brings difficulties in achieving the optimal product mix to maximize profits while meeting customer needs. To address these issues and modernize the apparel sector, merely improving performance is not enough but industries must adopt operations research and other techniques to enhance their resource utilization effectively [11,12,13,14,15,16].

The primary objective of the current study is to introduce a model designed for the apparel industry, specifically focusing on CBA Garment Factory PLC for optimized product mix scheduling. This enables the production planner at CBA Garment Factory PLC to efficiently decide on multiple products that can be produced simultaneously. To achieve this, the current research started by outlining the general background and problems of product mix optimization in the garment industry. State of the art is followed by analyzing various scientific research works on product mix and scheduling, manufacturing capacity, and different program modeling systems to improve the overall operational efficiency. Then, the employed methodologies and model formulation process will be outlined. Subsequently, data were collected and analyzed to determine the standard minute value (SMV) for each operation, target efficiency, existing target output, and machine and manpower requirements. Based on these data, appropriate models using Excel Solver and integer programming were formulated to generate possible product mix combinations. Finally, the article will conclude by providing findings and final recommendations.

2 Literature review

Resources utilization is the major concern in the overall efficiency of the apparel industry and could be affected by various factors. For instance, the industry is known for being labor-intensive and is defined by several key challenges, including short product life spans, unpredictable customer demand, increasing labor expenses, extensive product diversity, and lengthy supply chain processes. Therefore, greater focus is required to address the challenges posed by complex scheduling problems effectively [17]. This is due to a variety of product types being considered through product mix, which represents the complete assortment of products offered by a firm. A product mix is composed of several product lines, which refer to collections of items related to the life cycle and usage or which customers perceive as being related by function and purpose [18,19]. Another problem is the inability to achieve proper scheduling of different products in the line. The critical issue in scheduling is the complexity of the problem due to the apparel companies possessing a high rate of product mix in scheduling and being difficult to solve in a real-life scenario [20]. Then, proper production scheduling in apparel firms pursuits to maximize the performance of the operation and decrease the different charges [21]. Additionally, the daily production line capacity encompasses various factors, including contingency allowances along with SMV, fatigue, and machine delay allowances [22]. Therefore, methods analysis and related techniques could play a crucial role by involving and analyzing machine activities, material movements, and individual body movements, particularly arms and hands [23]. For example, optimization is one of the most notable fields used to maximize resource utilization in very diverse labor-intensive industries, like apparel manufacturing [24]. The approach is directed at finding the best solution(s) according to predefined criteria within a feasible domain defined by a set of constraints [25]. Determining the facility size is also equally critical to achieving high levels of utilization and a substantial return on investment [26]. Employing mass customization, aiming to provide products and services that efficiently meet individual customers’ needs, and approaching the efficiency of mass production is also another approach for optimizations [27].

The development of linear programming is another product mix optimization tool which recognized as one of the most significant scientific advances and standing as a standard tool that has saved substantial amounts of dollars for numerous companies [28]. The most powerful applications of integer programming involve 0–1 variable, wherein each variable corresponds to the choice of an item or an activity. Choice of one means selection and zero means not selected [29]. Based on this, a research study [30] employed linear programming to resolve the product mix problem within an ice-cream manufacturing company that encompassed three products. By allowing non-integer solutions, the study identified a product mix that ensured a minimum of 75% of the study while limiting total waste to below 30% of the optimum amount. Another study also highlights the role of linear programming in optimizing product mix for effective decision-making in industry [31]. It emphasizes the importance of understanding optimization to meet customer needs, with manufacturing profits relying on efficient distribution of materials and use of production resources. Findings suggest that company profit is closely tied to product demand. The research by Chen et al. [32] addressed short-term capacity planning for the product mix problem by developing a mathematical model to help managers select a set of orders to complete before their due dates, with the goal of maximizing overall profit. Similarly, Lee [33] introduced three heuristic algorithms to tackle the problems of order scheduling, focusing on minimizing total tardiness. The study proposed a system involving multiple identical machines, where orders comprising multiple components were processed on separate dedicated machines. A novel approach has been proposed to obtain scheduling rules in the study of Yamaba et al. [34] for a decentralized production environment. An earlier behavioral modeling of scheduling activities, extended by reinforcement learning methods, constituted the basis. Along this same line, Novas and Henning [35] also developed a reactive scheduling based on domain knowledge and constraint programming. Their method generated the revised schedules according to the disruption response; this facilitated adaptability with efficiency in a dynamic production environment. Another study also developed an interactive decision support system (DSS) designed to assist decision-makers in analyzing and evaluating trade-offs among solutions generated through integer programming [36].

Various researchers have also used a linear programming model for specific applications within different departments of the textile and apparel industry. For example, taking a case study in an apparel industrial unit in Ethiopia, a linear programming model was developed for product mix optimization [37]. This research examined the monthly available resources, production volumes, and the resource requirements for producing each unit of the product. Other research proposed a model-driven DSS specific to the textile industry that could choose orders to be processed in a production line using two greedy algorithms for scheduling [38]. In tests with real-world scenarios, the algorithm achieved a result 4.5% distant from the maximum revenue. Another study used enumerative methods to find an optimal cutting schedule in garment manufacturing with a minimum number of lays of fabric. Their method was able to solve standard test problems from the literature and difficult real-world scenarios provided by a global apparel manufacturer [39]. Similarly, a researcher tried to optimize the profit by employing a linear programming model considering a case study in Bangladesh's apparel industries [40]. This study exhibits limitations, especially when considering a pull production system since it relies on specific assumptions that hinder its realism. For example, the study assumes static objectives and constraints do not change over time. However, in our dynamic world, changes occur daily, making it uncertain that all conditions will remain constant. Recent work proposed a DSS with scheduling and rescheduling, emphasizing the addition of constraints sequentially after resolving the previous ones. They evaluated their model using the Monte-Carlo random number simulation system [41]. However, a limitation arises as they do not account for all possible affecting constraints at the initial stage, potentially resulting in a misallocation of the company’s budget. Another research by Bowers and Agrawal [42] also describes hierarchical production planning and scheduling in the apparel industry. Even though the research incorporates long-term, short-term, and daily plans, it solely focuses on the actual production output without exploring decision-making opportunities for product mix combinations and lacks a description Concerning the arrangement of orders within the production line.

The current research work varies from the previously discussed literature in several ways. The primary objective is to maximize profit by identifying the optimal product mix combination while incorporating sequencing techniques. Unlike many existing literature that solely focus on scheduling or consider a limited variety of products, this research investigates optimizing product mix combinations alongside scheduling. Additionally, it goes beyond considering only raw materials for profitability, incorporating factors like capacity, customer needs, and market scenarios, including the handling of unexpected order arrivals.

3 Methodology and model formulation

3.1 Problem identification

This research focuses on the Ethiopian garment industry, specifically on CBA Garments Factory PLC. The company faces multiple challenges, but the primary issue lies in its struggle with single product selection. Despite receiving multiple orders, CBA Garments Factory PLC processes only one order at a time, leading to a slow working pace and an unclear commitment to meeting order deadlines. This practice results in significant idle time, as rejected orders are not held until the current order is completed. Consequently, potential buyers may turn to other suppliers, reducing the likelihood of securing future orders in a timely manner. As a result, the company often experiences idle periods between orders, with less than 25% of available orders being received in the current scenario. Another major challenge is resource utilization, with the factory using only 19.6% of its available resources. For example, out of the 126 available machines, an average of just 25 are in use at any given time, leaving the majority idle. To address these inefficiencies, the current research proposes and formulates a model aimed at optimizing resource utilization, maximizing profit, and enhancing customer satisfaction by ensuring that order deadlines are consistently met.

3.2 Methodology

The research is grounded in the SMV system, derived from the general sewing data (GSD) framework, which involves motion analysis of each operation across various product styles. Every motion is assigned a unique code with a corresponding time measurement unit (TMU) value. These TMU values are summed and converted into minutes, incorporating allowances, to establish the SMV for each style. This SMV then informs the manpower and machine requirements for production. A quantitative methodology was employed, gathering data from both primary and secondary sources. Primary data collection began with interviews of key management personnel and direct work measurements for various product styles. The study also relied on the predetermined motion time study to establish the GSD system and determine the SMV for each product. Key steps were followed to address the challenges faced by CBA Garments Factory PLC. Additionally, quantitative data related to order quantities, accessory prices, lead times, operator turnover rates, power downtimes, and customer plan changes were collected. To optimize product combinations, Excel Solver and POM QM software were utilized in modeling. However, Excel Solver was chosen for its accessibility to a wider audience in this research.

3.3 Optimization model development and description

This model is designed to optimize production at CBA Garments Factory PLC by balancing factory capacity constraints and the need to remain competitive. Using integer linear programming, it accounts for uncertainty and stochastic conditions to allocate orders efficiently, with a focus on minimizing tardiness costs. The model is based on detailed data, including machinery requirements and SMVs for each product style. Through this approach, the factory can estimate optimal production capacity, manpower, and resource needs, ensuring efficient order prioritization and scheduling to meet customer demands. The ultimate goal is to maximize profit per piece while maintaining production efficiency. The following section will explain in detail the different steps of the overall model description and optimizations.

3.3.1 Optimization model development

This research develops an integer linear programming model tailored to CBA Garments Factory PLC, designed to enhance competitiveness by minimizing total tardiness costs through optimal order allocation. The model integrates stochastic constraints reflective of the factory’s operational uncertainties. Detailed and accurate data collection, particularly concerning machinery requirements and SMVs for each style, ensures model validity and reliability. A comprehensive quantitative approach is adopted, analyzing direct and indirect production costs, resource utilization, and contingency costs. The study emphasizes the importance of accurately defining constraints and variables to achieve an optimal solution amidst operational uncertainties. The study, utilizing historical data from 2022 at CBA Garment Factory PLC, analyzed 15 distinct garment styles. Of these, ten styles were selected for constructing the model, while the remaining styles contributed to the development of SMVs, cost calculations, and profit analysis during the data collection phase. The integer linear programming model formulated in this study focuses on maximizing the profit per garment piece. The objective function is defined as follows:

Notations:

x is the profit for every piece of product.

The product mix combinations feasible for simultaneous production at CBA Garment Factory PLC are formulated through the application of an integer linear programming model, represented in the following formula. The objective function calculates the profit generated from each product manufactured at CBA Garment Factory PLC. To compute the profit for each product on a per-piece basis, the following calculation formulas are employed:

In determining the actual capacity of CBA Garment Factory PLC, the SMV of each of the ten styles is employed. However, due to the labor-intensive nature of the garment sector, achieving 100% efficiency is unattainable because of unforeseen contingencies. Therefore, it is crucial for planners to include contingency allowances when establishing the target efficiency. The following formula is utilized to calculate the target efficiency of CBA Garment Factory PLC:

Therefore, by deducting the contingency allowance, the factory can determine the actual anticipated efficiency. Next, we calculate the number of machines required in each operation of the style.

After determining the taken time, we substitute this result into the machine calculation formula and then divide it by the SMV of that specific operation.

Now, it is possible for us to determine the number of manpower needed for a specific style or product; from that it is known that the capacity output is driven.

From equation (6), we can drive the equation for the actual output as follows:

Subsequently, the calculation determines the number of pieces that can be produced at the expected efficiency level. By incorporating the contingency percentage, CBA Garment Factory PLC can accurately assess its available production capacity, signifying the maximum achievable output. Prioritizing production orders involves a comprehensive assessment of several factors, including the number of orders received, the quantity specified in each order, and the respective due dates for these orders. This systematic approach ensures that the factory optimally allocates its resources and meets customer demands efficiently.

3.3.2 Model description

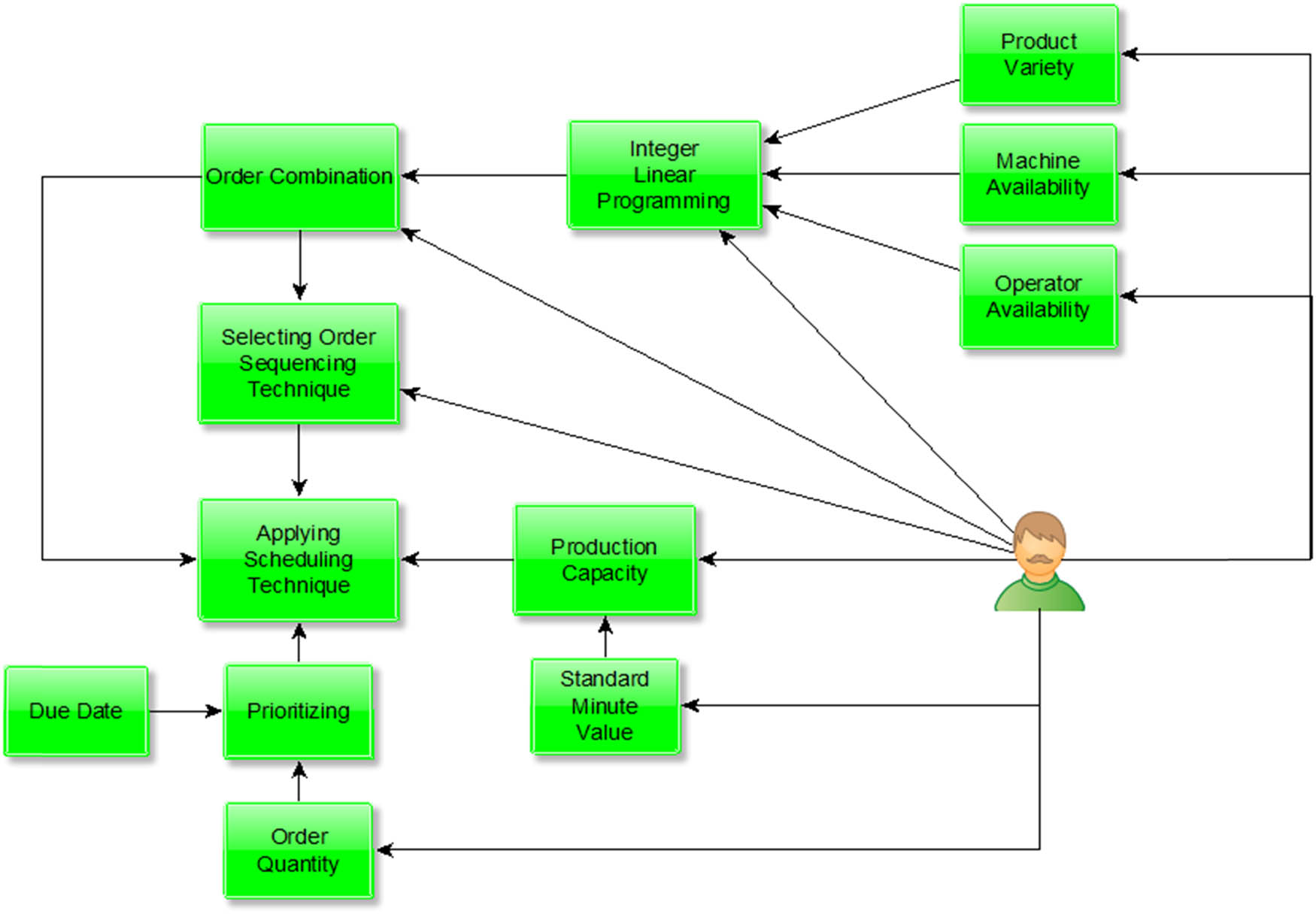

The process of optimizing product combinations at CBA Garment Factory PLC requires identifying feasible product mixes that can be produced simultaneously. The model for optimizing product mix scheduling is shown in Figure 1. Once these combinations are established, the sequencing technique is implemented to ensure alignment with customer needs and expectations. Factors such as customer quality requirements, due dates, order quantities, delivery expectations, and the internal capabilities of the factory are all considered when selecting the most appropriate sequencing method. The research begins with a thorough evaluation of CBA Garment Factory PLC’s capacity, starting with an analysis of SMV to estimate efficiency and manpower requirements. This evaluation determines the factory’s capacity for each producible product type, which then informs the scheduling process. Scheduling is driven by factors such as calculated capacity, order quantities, and customer due dates, allowing for the prioritization of sequential orders. With a clear understanding of both customer requirements and factory capacity, the research prioritizes product combinations that can be produced simultaneously, followed by a strategic sequencing of subsequent products once each order is completed. This approach ensures optimal resource utilization, on-time delivery, and customer satisfaction.

A diagrammatical representation of the model for optimized product mix scheduling.

Using the initially computed product mix combinations, an optimized order combination is selected, acknowledging that the finishing dates for all potential product combinations differ. To refine this process, we return to the integer linear programming optimization technique, where orders that are complete are set to zero and those in progress are set to one within the constraints. For instance, at CBA Garment Factory PLC, completing two products, sportswear trousers and T-shirts, precedes the selected scenario involving a combination of four product types. As some orders may be completed earlier or later than anticipated, planners must recalculate order combinations using prior techniques while considering both ongoing and upcoming orders to achieve an optimal solution. This methodology allows planners to ascertain the number of orders to initiate from the start. The accompanying diagram illustrates the entire workflow, from resource evaluation to the application of scheduling techniques. It visually represents how the model operates, highlighting the process of determining order combinations based on the status of running orders and the additional orders required to attain an optimal outcome. This structured approach ultimately enhances the factory’s operational efficiency and resource management.

4 Results and discussion

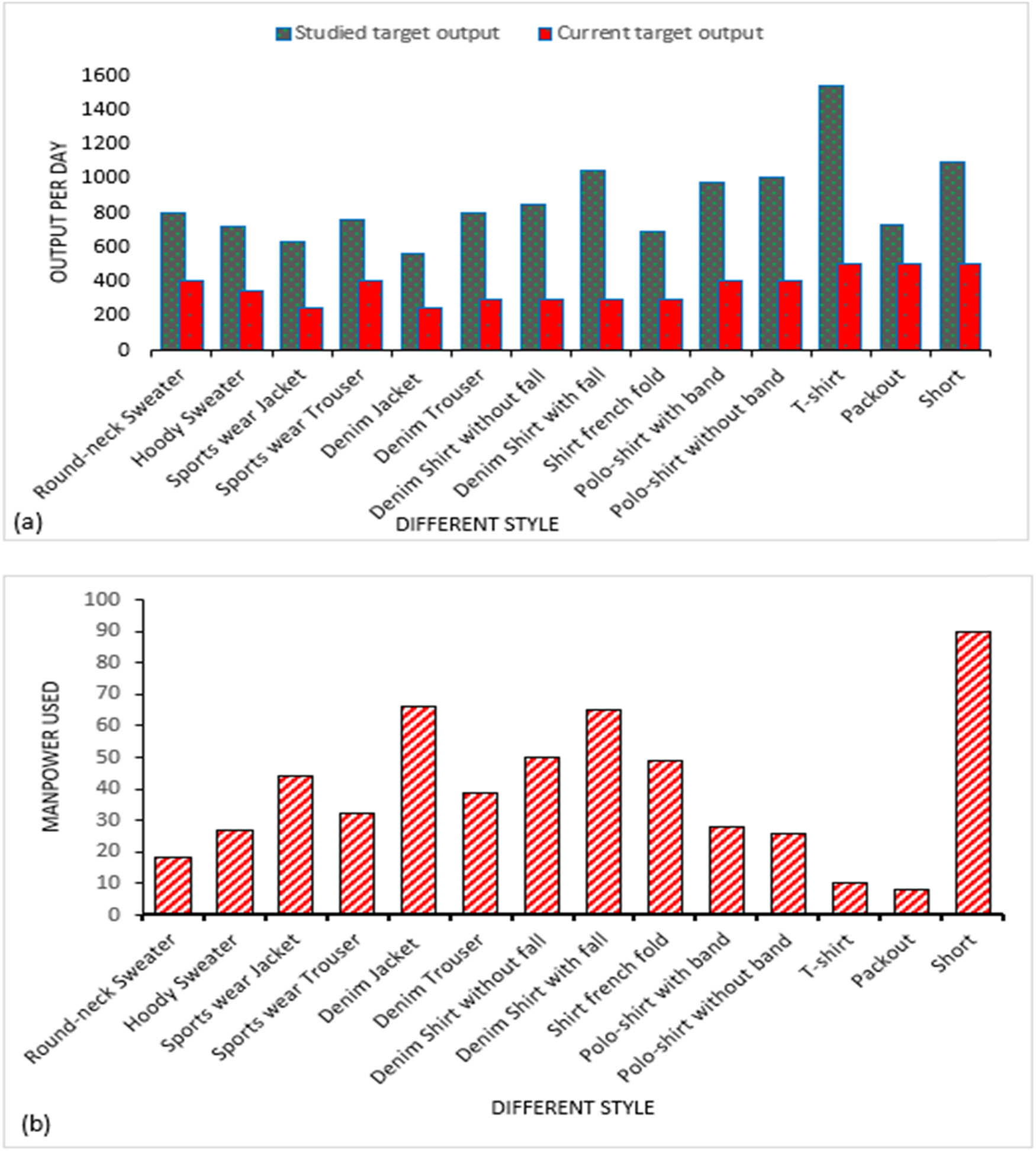

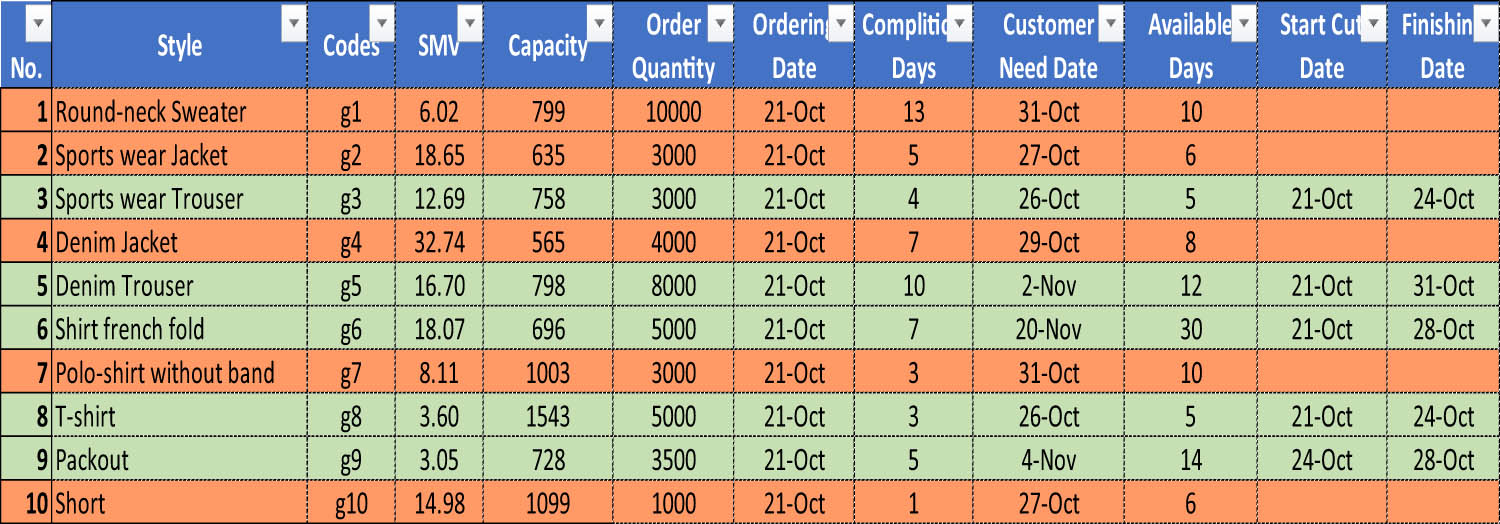

In this section, two main categories have been discussed: the research parameters and the research output. The product varieties feasible for production at CBA Garment Factory PLC are detailed in Figure 2. The target efficiency and the existing target outputs are calculated, and the SMVs for each product style are determined using the GSD system and the predetermined motion time study. Besides, all the machine and manpower requirements are calculated, along with the cost analysis for each product type based on the current local market scenario. Additionally, the single-piece profit is determined and established for each style based on the model. Figure 3(b) illustrates the single-piece profit for each style viable for production at CBA Garment PLC.

(a) Comparison between current target output and studied output capacity per day and (b) the manpower requirement to produce the different styles at CBA Garments Factory PLC.

![Figure 3

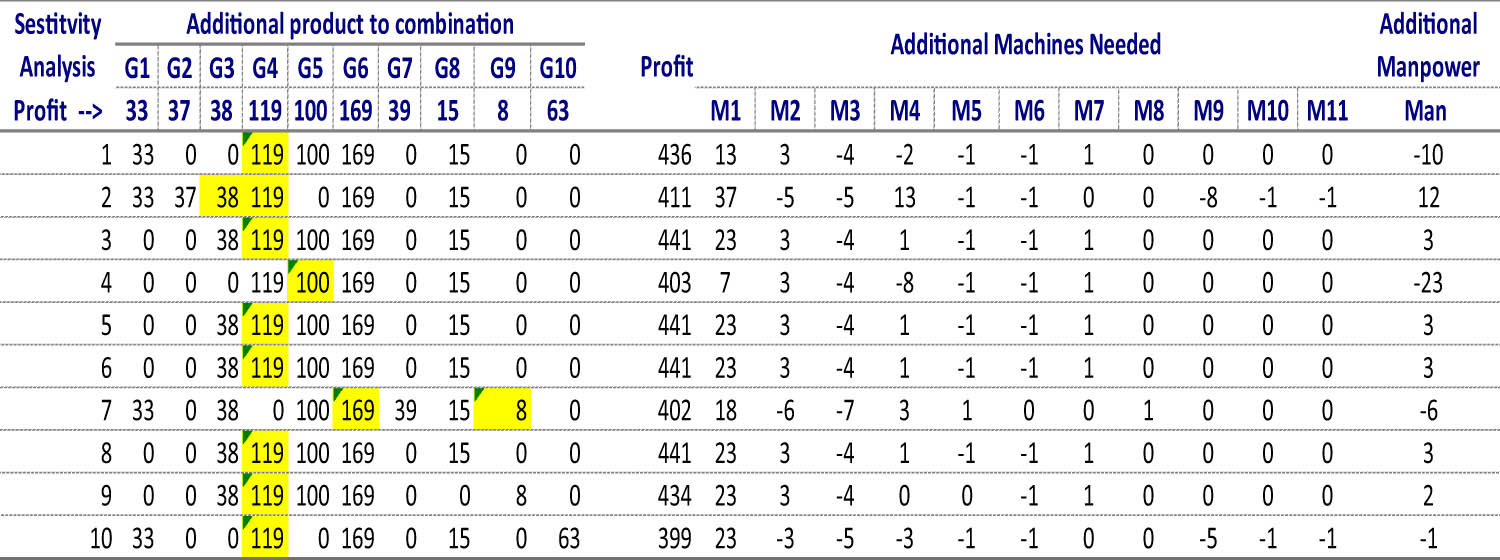

Variable and constraints table for CBA Garment Factory PLC: (a) the different number of machines required (SNLS m/c [M1], DNLS m/c [M2], feed of the arm m/c [M3], overlock m/c [M4], piping m/c [M5], button hole m/c [M6], eyelet button hole m/c [M7], button sew m/c [M8], bar tack m/c [M9], auto pocket setter m/c [M10], decoration m/c [M11]) to produce different styles (sweater [G1], jacket sportswear [G2], trouser sportswear [G3], denim jacket [G4], denim trouser [G5], shirt French fold [G6], Polo-shirt [G7], T-shirt [G8], singlet undervest [G9], and shorts [G10]), and (b) the required time and manpower to produce one product style and its profit per styles.](/document/doi/10.1515/aut-2024-0027/asset/graphic/j_aut-2024-0027_fig_003.jpg)

Variable and constraints table for CBA Garment Factory PLC: (a) the different number of machines required (SNLS m/c [M1], DNLS m/c [M2], feed of the arm m/c [M3], overlock m/c [M4], piping m/c [M5], button hole m/c [M6], eyelet button hole m/c [M7], button sew m/c [M8], bar tack m/c [M9], auto pocket setter m/c [M10], decoration m/c [M11]) to produce different styles (sweater [G1], jacket sportswear [G2], trouser sportswear [G3], denim jacket [G4], denim trouser [G5], shirt French fold [G6], Polo-shirt [G7], T-shirt [G8], singlet undervest [G9], and shorts [G10]), and (b) the required time and manpower to produce one product style and its profit per styles.

In the studied target capacity per day, the calculation includes a contingency allowance. Based on the calculated values and current trends, the company is not focusing on productivity or continuous improvement. Percentage-wise, when comparing the current production trend with the studied one, there is a 45% difference. This implies that the case company allocates only 32% of its target to production. For example, for sweaters, the initial target was set at 400 pieces per day; however, there is potential to produce up to 799 pieces at CBA Garment Factory PLC. The case company was purchased from Turkish investors and is currently owned by a local investor; the company has operated traditionally.

For instance, they only seek and accept the order for the next production once completing the product which is set for production. Therefore, while formulating and generating our optimization model, three key assumptions were considered. First, sequencing techniques were chosen based on the assumption that customers highly prioritize production deadlines. Second, assuming raw materials are supplied by buyers, removing potential shortages if CBA decides to purchase. Third, the model assumes that the company’s indirect costs can be covered by its profits, significantly boosting the company’s profit margin from an average of 7–77%.

Based on the above assumptions, Figure 3(a) outlines the machine requirements for each product type, ranging from G1 to G2. This indicates the specific machine types and quantities required for the production process of each product style. For example, the production of a sweater (G1) necessitates 6 single needle lock stitch machines (SNLS) (M1) and 6 overlock machines (M4), whereas Denim jacket (G4) required 24 SNLS machines (M1), 9 double needle lockstitch (DNLS) (M2), 3 feed of the arm machines (M3), 12 overlock machines (M4), and 1 eyelet buttonhole machine (M7). Figure 4(b) provides essential parameters for manufacturing all available product varieties within CBA Garment Factory PLC. This includes details such as the time required to complete a single product, the profit generated per unit, and the necessary manpower for each item. For instance, in the case of producing a sweater (notated as G1), the time per piece or SMV required is 6.02 min, and the company’s profit from each sweater is estimated at 33 Birr (1 USD = 56.32 birrs as of 12/30/2023). Similarly, detailed information for all the ten products has been thoroughly assessed and organized. The objective function of our model encompasses multiple scenarios derived from the consideration that various product orders arrive at different times and possess different selection probabilities. A linear programming model has been formulated accordingly.

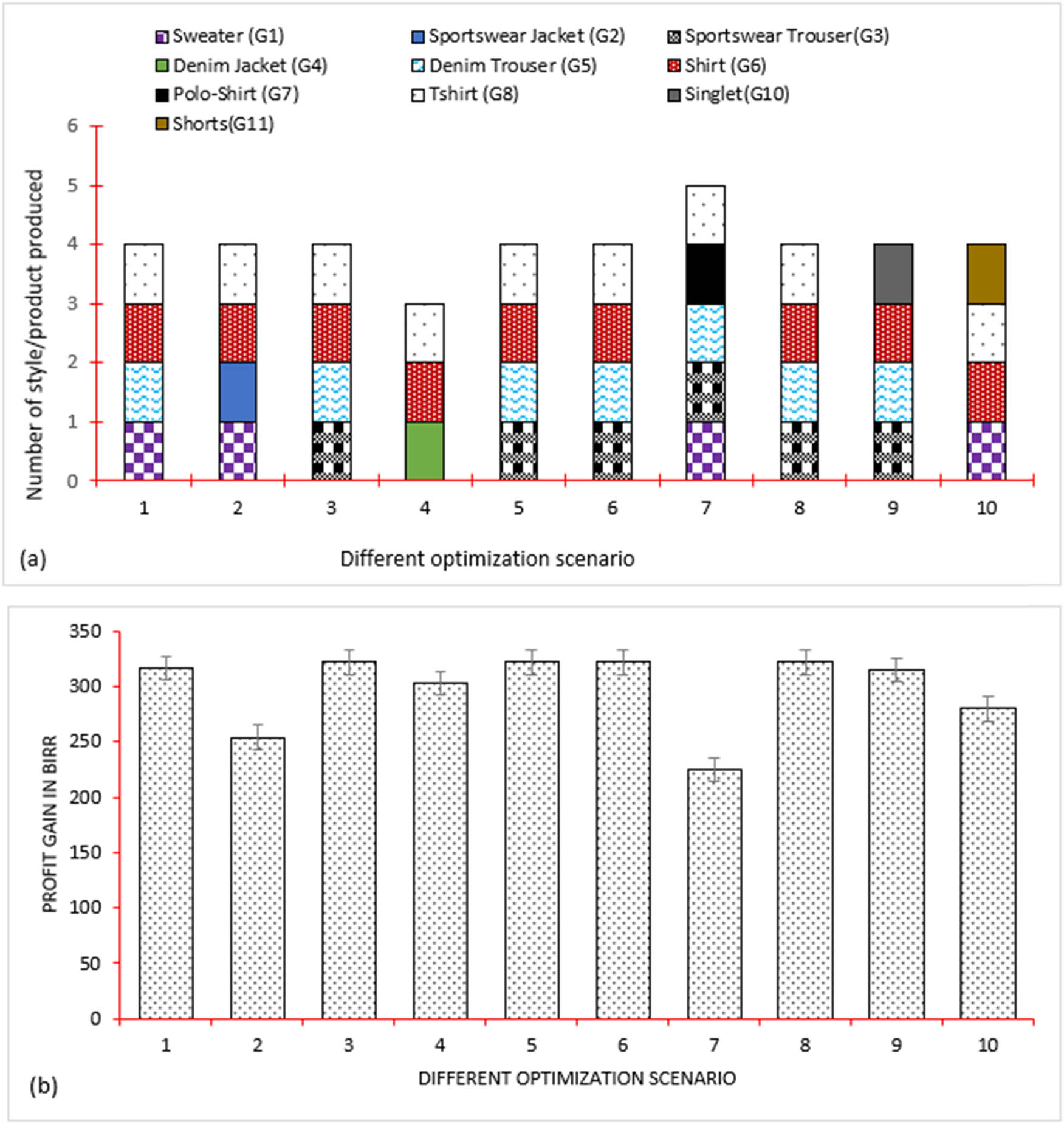

Product mix combination (a) different optimization scenario of the product mix of different style and (b) the respective profit gain per each optimization scenario.

A linear programming model is formulated as follows:

where MaxZ is the maximizing profit and G1 to G10 is the different product style.

Subjective function of the model is constructed as follows:

Manpower constraints

SNLS machine constraints

DNLS machine constraints

FOA machine constraints

Overlock machine constraints

Piping machine constraints

Buttonhole machine constraints

Eyelet buttonhole machine constraints

Bar tack machine constraints

Auto pocket setter machine constraints

Button sew machine constraints

Decor machine constraints

This section outlines the constraints for the scenario case, denoted from (m) to (v), where one will be selected within the model. Setting the equality sign, “=” to 1 indicates to the software that G1, or any other product, is actively being processed on the line. Consequently, the model considers this information during computation to provide an optimal solution

The linear programming model presented above is explained as follows: equation (8) represents the manpower constraint, where CBA Garment possesses a total of 150 manpower units, and each product type requires varying levels of labor. Specifically, G1 (sweater) requires 13 manpower units, G2 (sportswear jacket) requires 32, G3 (sportswear trouser) requires 26, G4 (denim jacket) requires 50, G5 (denim trouser) requires 36, G6 (shirt) requires 34, G7 (polo shirt) requires 22, G8 (T-shirt) requires 7, G9 (singlet) requires 6, and G10 (short) requires 45. The total sum of these labor requirements must not exceed 150, aligning with the company’s current manpower limit. Equations (9)–(19) cover the machine constraints. Notably, 0Gi in the equations indicates that the specific product does not require that machine. On the right side of the inequality sign, the total quantity of available machines within the factory is shown. Therefore, the cumulative usage of each machine type must not exceed the quantity available in the factory. Equations (20)–(29) elaborate on the scenario constraints. These constraints imply that when one or more products are in production, they are assigned a value of “1.” The software then generates the optimal combination of products for scheduling. For each product, ten scenarios are discussed, highlighting their respective optimal combinations. The model also allows for the examination of additional scenarios. For example, by setting two products as binary “1” in Excel Solver, it runs integer programming to determine feasible product mix combinations.

In this case, ten scenarios have been calculated using the Excel Solver function, and the optimal solution for each scenario is summarized in Figure 4. In terms of efficient resource utilization, it is recommended to consider Scenario 10. In this scenario, there are 53 available single needle lockstitch machines, but the linear programming model indicates the use of 52 machines in this scenario. This leaves a redundancy option, allowing for potential deployment of the remaining machine in bottleneck operations. Figure 4(a) presents a summary of the optimal solutions for potential product mix combinations feasible to be processed simultaneously within the factory. For instance, in Scenario 1, the focus is on the G1 (Sweater) product, prioritizing its processing ahead of the other nine products. Consequently, considering available machinery and manpower, the additional products feasible to be processed alongside G1 include G5 (Denim trousers), G6 (Shirt), and G8 (T-shirt). Similarly, Scenario 2 involves G2 as the primary product, accompanied by G1, G2, G6, and G8 in simultaneous production. Similarly, Figure 4(a) elaborates on the ten different scenarios, systematically evaluating each product type’s processing as the primary focus, allowing for different combinations with other products.

Additionally, Figure 4(b) details the optimal profit for each combination of products per piece. For example, in Scenario 1, the optimal solution generates a profit of 317 Birr, derived from the sum of the profits of one piece each of G1, G5, G6, and G8. This pattern continues for the remaining ten scenarios, with the software computing the optimal profits based on the combinations achieved. The subsequent segment of the model involves the application of scheduling techniques, outlined as follows. For example, if all the ten product styles arrive simultaneously, the model selects the worst-case scenario, which is Scenario 3. This phase entails utilizing the SMV for all the ten product types obtained from the preceding analysis, along with the calculated capacity. The planning process commences by considering factors such as order quantity, order delivery date, and ordering date. The CBA Garment Factory PLC is expected to receive five orders from the available ten. These orders are to be scheduled in the following manner.

Referring to Figure 5, the green-colored rows represent products selected upon receiving orders from various customers. Conversely, the red/orange rows signify rejected orders attributed to resource constraints. Subsequently, the scheduling process is overseen and monitored through the utilization of a Gantt chart. Furthermore, the model’s sensitivity analysis has been computed and deliberated upon within various “what

Accepted and declined order with scheduling based on CBA Garment PLC capacity.

Sensitivity analysis of product mix scheduling for CBA Garment Factory PLC.

As illustrated in Figure 6, the sensitivity analysis examines different scenarios (1–10) based on additional products integrated into the previous combinations, assessing machine requirements and manpower. In the interest of enhancing the company’s profit margin, let us consider the initial scenario (1) where the profit stood at 317 birrs. If we include G4 (Denim jacket) within the optimized combination, the profit will surge by 119 birrs. However, this enhancement requires additional investments, such as acquiring 13 and 3 more SNLS and DNLS machines, respectively.

Unusually, this augmentation does not demand further manpower, given the availability of ten more operators. Now, exploring the rationale behind the fourth scenario (4), initially yielding a profit of 303 birrs. However, incorporating G5 (Denim trouser) into the optimized combination could bolster the profit by 100 birrs. Achieving this enhancement would require supplementary investments, including 7 SNLS, 3 DNLS, and 1 eyelet buttonhole machine. Encouragingly, this augmentation does not necessitate additional manpower, thanks to the availability of twenty-three more operators.

5 Conclusions and recommendations

The modern apparel industry encounters numerous challenges, including the increasing demand for product variety from customers. Meeting these evolving demands requires satisfying a diverse customer base. Hence, implementing a systematic method or model to ascertain optimal product mix combinations concurrently within a garment factory becomes pivotal for informed decision-making. Considering the case study of CBA Garment Factory PLC, the formulated optimization model for product mix scheduling in the apparel industry provides indispensable insights that bolster profitability, efficiency, and productivity. This study presents a methodical approach utilizing an Integer Linear Programming model to optimize product mix scheduling. The outcomes revealed a significant enhancement in profitability, exhibiting a substantial 70% increase, translating from an average daily profit of 20,801–234,483 Ethiopian Birr. Furthermore, resource utilization at CBA Garment Factory PLC saw a significant improvement. Formerly averaging 25 machines, resource utilization ascended to an optimized usage of 93 machines, marking an impressive rise from 19.6 to 73% in machine utilization. The model’s capability to determine concurrent product options prompted CBA Garment Factory PLC’s management to contemplate expanding into retail shops. This strategic move allows them to leverage company resources efficiently by producing the optimal product mix for retail outlets during periods lacking customer orders. Consequently, this transformation substantially increased the company’s productivity and profitability. In the future, acknowledging the model’s significance within the apparel sector, there exists potential for its automation using robust programming languages. This initiative aims to develop a user-friendly system, enhancing model’s accessibility and usability across diverse setups in the apparel industry.

Acknowledgments

The authors extend their gratitude to the owner, management, and technical teams of CBA Garment Factory PLC, Ethiopia, for permitting us to conduct this research within their organization. Their generosity in sharing knowledge, resources, and time has been invaluable in collecting relevant data and gaining insights into the complexities of the apparel industry.

-

Funding information: Authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and consented to its submission to the journal, reviewed all the results and approved the final version of the manuscript. AAA, FMK, and BAS designed the experiments, FMK and BAS supervised the research, and AAA developed the model code, collected the data. AAA, FMK, MAA and BAS make the analysis, FMK and MAA cured the data formulation, modelling and the analysis. AAA, FMK, and BAS performed the model simulations, AAA and MAA prepared the draft manuscript, and FMK and MAA revised the manuscript.

-

Conflict of interest: Authors state no conflict of interest.

-

Ethical approval: The conducted research is not related to either human or animal use.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Bizuneh, B., Tadesse, R. (2022). Investigation of Ethiopian apparel industry’s fabric waste and its management strategies. Journal of the Textile Institute, 113, 141–150.10.1080/00405000.2020.1865509Search in Google Scholar

[2] Abtew, M. A., Kropi, S., Hong, Y., Pu, L. (2018). Implementation of statistical process control (SPC) in the sewing section of garment industry for quality improvement. Autex Research Journal, 18, 160–172.10.1515/aut-2017-0034Search in Google Scholar

[3] ETIDI. (2017). Ethiopia textile sector profile. September 2017. Ethiopian Institute, Textile Industry Development, Addis Ababa, Ethiopia.Search in Google Scholar

[4] Oqubay, A. (2018). Industrial policy and late industrialisation in Ethiopia, Oxford Handbooks, Abidjan, Côte d’Ivoire.10.1093/oxfordhb/9780198814986.013.31Search in Google Scholar

[5] Alubel Abtew, M. (2015). Revealed comparative advantage of Ethiopian leather industry with selected African economies. International Journal of Business and Economics Research, 4, 229.10.11648/j.ijber.20150405.11Search in Google Scholar

[6] Rundassa, M. W., Azene, D. K., Berhan, E. (2019). Comparative advantage of Ethiopian textile and apparel industry. Research Journal of Textile and Apparel, 23, 244–256.10.1108/RJTA-08-2018-0049Search in Google Scholar

[7] Abtew, M. A., Kumari, A., Moorthy, S. (2017). Export performance and revealed comparative advantage of developing and developed economies for textile fibers or fabrics. Journal of Global Economics, 5(3), 1–9. 10.4172/2375-4389.1000256.Search in Google Scholar

[8] U.S. cuts off Ethiopia, Mali, Guinea from Africa duty-free trade program (2022). Reuters, https://www.reuters.com/world/africa/us-cuts-off-ethiopia-mali-guinea-africa-duty-free-trade-program-2022-01-01.Search in Google Scholar

[9] Kitaw, D., Matebu, A. (2010). Competitiveness for Ethiopian textile and garment industries: A way forward. Paper presented at 2nd national workshop on future prospects and the role of textile and garment sectors in achieving the millennium development goals of Ethiopia.Search in Google Scholar

[10] Mahmood, K., Shevtshenko, E. (2015-Jan). Productivity improvement by implementing lean production approach. Proc Int Conf DAAAM Balt 2015, pp. 45–51.Search in Google Scholar

[11] Ewnetu, M., Gzate, Y. (2023). Assembly operation productivity improvement for garment production industry through the integration of lean and work-study, a case study on Bahir Dar textile share company in garment, Bahir Dar, Ethiopia. Heliyon, 9, e17917.10.1016/j.heliyon.2023.e17917Search in Google Scholar PubMed PubMed Central

[12] Bongomin, O., Mwasiagi, J. I., Nganyi, E. O., Nibikora, I. (2020). Improvement of garment assembly line efficiency using line balancing technique. Engineering Reports, 2, 1–18.10.1002/eng2.12157Search in Google Scholar

[13] Patil, U., Kolte, P. P., Chandurkar, P., Rajkumar, S. S. (2018). Performance improvement in apparel industry by reducing DHU%. International Journal on Textile Engineering and Processes, 4(2), 24–30.Search in Google Scholar

[14] Mekala, N., Sanju, S. D., Thamaraiselvan, V., Kavya, M. (2021). Implementation of industrial engineering concepts in apparel industry to improving productivity and it’s cost reduction. IOP Conference Series: Materials Science and Engineering, 1059.10.1088/1757-899X/1059/1/012027Search in Google Scholar

[15] Rajput, D., Kakde, M., Chandurkar, P., Raichurkar, P. P. (2018). Enhancing efficiency and productivity of garment industry by using different techniques. International Journal on Textile Engineering and Processes, 4(1), 5–8.Search in Google Scholar

[16] Fatima, A., Tufail, M. (2023). Improving efficiency of apparel manufacturing through the principles of resource management. Clothing and Textiles Research Journal, 41, 225–235.10.1177/0887302X211005432Search in Google Scholar

[17] Du, W., Tang, Y., Leung, S. Y. S., Tong, L., Vasilakos, A. V., Qian, F. (2018). Robust order scheduling in the discrete manufacturing industry: A multiobjective optimization approach. IEEE Transactions on Industrial Informatics, 14, 253–264.10.1109/TII.2017.2664080Search in Google Scholar

[18] Bagalagel, S., ElMaraghy, W. (2020). Product mix optimization model for an industry 4.0-enabled manufacturing-remanufacturing system. Procedia CIRP, 93, 204–209.10.1016/j.procir.2020.03.029Search in Google Scholar

[19] Aghazadeh, S.-M. (1998). Determination of optimal product mix and maximizing profit by linear programming. Southern Business Review, 24(1), 3.Search in Google Scholar

[20] Brucker, P., Knust, S. Complex scheduling. two. Heidelberg: Springer, 2006.Search in Google Scholar

[21] Tomastik, R. N., Luh, P. B., Liu, G. (1996). Scheduling flexible manufacturing systems for apparel production. IEEE Transactions on Robotics and Automation, 12, 789–799.10.1109/70.538983Search in Google Scholar

[22] Abtew, M. A., Kumari, A., Babu, A., Hong, Y. (2020). Statistical analysis of standard allowed minute on sewing efficiency in apparel industry. Autex Research Journal, 20, 359–365.10.2478/aut-2019-0045Search in Google Scholar

[23] Heizer, J., Render, B., Munson, C. (2023). Operations management: Sustainability and supply chain management. 14th ed. Pearson, New York, NY.Search in Google Scholar

[24] Hiller, F. S., Lieberman, G. J. (2021). Introduction to operation research. 11th ed. McGrew Hill, New York.Search in Google Scholar

[25] Kacem, I. (2017). Applications of optimization methods to industrial engineering problems. Computers & Industrial Engineering, 112, 467–468.10.1016/j.cie.2017.08.034Search in Google Scholar

[26] Stevenson, W. J. (2021). Operation management. 14th ed. McGrawHill, New York.Search in Google Scholar

[27] Yao, J., Liu, L. (2009). Optimization analysis of supply chain scheduling in mass customization. International Journal of Production Economics, 117, 197–211.10.1016/j.ijpe.2008.10.008Search in Google Scholar

[28] Akpan, N. P., Iwok, I. A. (2016). Application of linear programming for optimal use of raw materials in bakery. International Journal of Mathematics and Statistics Invention, 4, 51–57.Search in Google Scholar

[29] Anderson, D. R., Sweeney, D. J., Williams, T. A. (2014). An introduction to management science: Quantitative approaches to decision making, 4th edn., pp. 1–578.Search in Google Scholar

[30] Suharto, I., Susanto, S., Rosmiyanti, N. T., Bhattacharya, A. (2008). Fuzzy multi-objective linear programming having probabilistic constraints: Application in product-mix decision-making. Proc - 5th Int Conf Fuzzy Syst Knowl Discov FSKD 2008, Vol. 4, pp. 652–656.10.1109/FSKD.2008.681Search in Google Scholar

[31] Rathi, V., Gupta, S., Srivastav, S. (2021). Case study: Application for optimizing the product mix problem of linear programming in the Apparel Industry. Journal of University of Shanghai for Science and Technology, 23, 1091–1098.10.51201/JUSST/21/07240Search in Google Scholar

[32] Chen, C. S., Mestry, S., Damodaran, P., Wang, C. (2009). The capacity planning problem in make-to-order enterprises. Mathematical and Computer Modelling, 50, 1461–1473.10.1016/j.mcm.2009.07.010Search in Google Scholar

[33] Lee, I. S. (2013). Minimizing total tardiness for the order scheduling problem. International Journal of Production Economics, 144, 128–134.10.1016/j.ijpe.2013.01.025Search in Google Scholar

[34] Yamaba, H., Matsumoto, S., Tomita, S. (2008). An attempt to obtain scheduling rules of network-based support system for decentralized scheduling of distributed production systems. IEEE Int Conf Ind Informatics, pp. 506–511.10.1109/INDIN.2008.4618153Search in Google Scholar

[35] Novas, J. M., Henning, G. P. (2009). A reactive scheduling approach based on domain-knowledge. Elsevier Inc.10.1016/S1570-7946(09)70348-7Search in Google Scholar

[36] Makarouni, I., Psarras, J., Siskos, E. (2015). Interactive bicriterion decision support for a large scale industrial scheduling system. Annals of Operations Research, 227, 45–61.10.1007/s10479-013-1406-4Search in Google Scholar

[37] Woubante, G. W. (2017). The optimization problem of product mix and linear programming applications: Case study in the apparel industry. Open Science Journal, 2(2).10.23954/osj.v2i2.853Search in Google Scholar

[38] Stern, H. I., Avivi, Z. (1990). The selection and scheduling of textile orders with due dates. European Journal of Operational Research, 44, 11–16.10.1016/0377-2217(90)90309-YSearch in Google Scholar

[39] Rose, D. M., Shier, D. R. (2007). Cut scheduling in the apparel industry. Computers & Operations Research, 34, 3209–3228.10.1016/j.cor.2005.12.001Search in Google Scholar

[40] Shakirullah F. M., Uddin Ahammad M., Forhad Uddin, M. (2020). Profit optimization of an apparel industry in Bangladesh by linear programming model. American Journal of Applied Mathematics, 8, 182.10.11648/j.ajam.20200804.13Search in Google Scholar

[41] Ardjmand, E., Young, W. A. II, Ghalehkhondabi, I., Weckman, G. R. (2021). A scheduling and rescheduling decision support system for apparel manufacturing. International Journal of Operations Research and Information Systems, 12, 1–19.10.4018/IJORIS.20211001.oa4Search in Google Scholar

[42] Bowers, M. R., Agarwal, A. (1993). Hierarchical production planning. International Journal of Clothing Science and Technology, 5, 36–43.10.1108/eb003018Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Study and restoration of the costume of the HuoLang (Peddler) in the Ming Dynasty of China

- Texture mapping of warp knitted shoe upper based on ARAP parameterization method

- Extraction and characterization of natural fibre from Ethiopian Typha latifolia leaf plant

- The effect of the difference in female body shapes on clothing fitting

- Structure and physical properties of BioPBS melt-blown nonwovens

- Optimized model formulation through product mix scheduling for profit maximization in the apparel industry

- Fabric pattern recognition using image processing and AHP method

- Optimal dimension design of high-temperature superconducting levitation weft insertion guideway

- Color analysis and performance optimization of 3D virtual simulation knitted fabrics

- Analyzing the effects of Covid-19 pandemic on Turkish women workers in clothing sector

- Closed-loop supply chain for recycling of waste clothing: A comparison of two different modes

- Personalized design of clothing pattern based on KE and IPSO-BP neural network

- 3D modeling of transport properties on the surface of a textronic structure produced using a physical vapor deposition process

- Optimization of particle swarm for force uniformity of personalized 3D printed insoles

- Development of auxetic shoulder straps for sport backpacks with improved thermal comfort

- Image recognition method of cashmere and wool based on SVM-RFE selection with three types of features

- Construction and analysis of yarn tension model in the process of electromagnetic weft insertion

- Influence of spacer fabric on functionality of laminates

- Design and development of a fibrous structure for the potential treatment of spinal cord injury using parametric modelling in Rhinoceros 3D®

- The effect of the process conditions and lubricant application on the quality of yarns produced by mechanical recycling of denim-like fabrics

- Textile fabrics abrasion resistance – The instrumental method for end point assessment

- CFD modeling of heat transfer through composites for protective gloves containing aerogel and Parylene C coatings supported by micro-CT and thermography

- Comparative study on the compressive performance of honeycomb structures fabricated by stereo lithography apparatus

- Effect of cyclic fastening–unfastening and interruption of current flowing through a snap fastener electrical connector on its resistance

- NIRS identification of cashmere and wool fibers based on spare representation and improved AdaBoost algorithm

- Biο-based surfactants derived frοm Mesembryanthemum crystallinum and Salsοla vermiculata: Pοtential applicatiοns in textile prοductiοn

- Predicted sewing thread consumption using neural network method based on the physical and structural parameters of knitted fabrics

- Research on user behavior of traditional Chinese medicine therapeutic smart clothing

- Effect of construction parameters on faux fur knitted fabric properties

- The use of innovative sewing machines to produce two prototypes of women’s skirts

- Numerical simulation of upper garment pieces-body under different ease allowances based on the finite element contact model

- The phenomenon of celebrity fashion Businesses and Their impact on mainstream fashion

- Marketing traditional textile dyeing in China: A dual-method approach of tie-dye using grounded theory and the Kano model

- Contamination of firefighter protective clothing by phthalates

- Sustainability and fast fashion: Understanding Turkish generation Z for developing strategy

- Digital tax systems and innovation in textile manufacturing

- Applying Ant Colony Algorithm for transport optimization in textile industry supply chain

- Innovative elastomeric yarns obtained from poly(ether-ester) staple fiber and its blends with other fibers by ring and compact spinning: Fabrication and mechanical properties

- Design and 3D simulation of open topping-on structured crochet fabric

- The impact of thermal‒moisture comfort and material properties of calf compression sleeves on individuals jogging performance

- Calculation and prediction of thread consumption in technical textile products using the neural network method

Articles in the same Issue

- Study and restoration of the costume of the HuoLang (Peddler) in the Ming Dynasty of China

- Texture mapping of warp knitted shoe upper based on ARAP parameterization method

- Extraction and characterization of natural fibre from Ethiopian Typha latifolia leaf plant

- The effect of the difference in female body shapes on clothing fitting

- Structure and physical properties of BioPBS melt-blown nonwovens

- Optimized model formulation through product mix scheduling for profit maximization in the apparel industry

- Fabric pattern recognition using image processing and AHP method

- Optimal dimension design of high-temperature superconducting levitation weft insertion guideway

- Color analysis and performance optimization of 3D virtual simulation knitted fabrics

- Analyzing the effects of Covid-19 pandemic on Turkish women workers in clothing sector

- Closed-loop supply chain for recycling of waste clothing: A comparison of two different modes

- Personalized design of clothing pattern based on KE and IPSO-BP neural network

- 3D modeling of transport properties on the surface of a textronic structure produced using a physical vapor deposition process

- Optimization of particle swarm for force uniformity of personalized 3D printed insoles

- Development of auxetic shoulder straps for sport backpacks with improved thermal comfort

- Image recognition method of cashmere and wool based on SVM-RFE selection with three types of features

- Construction and analysis of yarn tension model in the process of electromagnetic weft insertion

- Influence of spacer fabric on functionality of laminates

- Design and development of a fibrous structure for the potential treatment of spinal cord injury using parametric modelling in Rhinoceros 3D®

- The effect of the process conditions and lubricant application on the quality of yarns produced by mechanical recycling of denim-like fabrics

- Textile fabrics abrasion resistance – The instrumental method for end point assessment

- CFD modeling of heat transfer through composites for protective gloves containing aerogel and Parylene C coatings supported by micro-CT and thermography

- Comparative study on the compressive performance of honeycomb structures fabricated by stereo lithography apparatus

- Effect of cyclic fastening–unfastening and interruption of current flowing through a snap fastener electrical connector on its resistance

- NIRS identification of cashmere and wool fibers based on spare representation and improved AdaBoost algorithm

- Biο-based surfactants derived frοm Mesembryanthemum crystallinum and Salsοla vermiculata: Pοtential applicatiοns in textile prοductiοn

- Predicted sewing thread consumption using neural network method based on the physical and structural parameters of knitted fabrics

- Research on user behavior of traditional Chinese medicine therapeutic smart clothing

- Effect of construction parameters on faux fur knitted fabric properties

- The use of innovative sewing machines to produce two prototypes of women’s skirts

- Numerical simulation of upper garment pieces-body under different ease allowances based on the finite element contact model

- The phenomenon of celebrity fashion Businesses and Their impact on mainstream fashion

- Marketing traditional textile dyeing in China: A dual-method approach of tie-dye using grounded theory and the Kano model

- Contamination of firefighter protective clothing by phthalates

- Sustainability and fast fashion: Understanding Turkish generation Z for developing strategy

- Digital tax systems and innovation in textile manufacturing

- Applying Ant Colony Algorithm for transport optimization in textile industry supply chain

- Innovative elastomeric yarns obtained from poly(ether-ester) staple fiber and its blends with other fibers by ring and compact spinning: Fabrication and mechanical properties

- Design and 3D simulation of open topping-on structured crochet fabric

- The impact of thermal‒moisture comfort and material properties of calf compression sleeves on individuals jogging performance

- Calculation and prediction of thread consumption in technical textile products using the neural network method