Abstract

The objective of this study was to search the effects of the inlet air compressor pressure and evaporative cooling of four different cogeneration plants that are absorption cooling (ab), basic (bsc), air heating (airh), and air fuel heating (airfh) cogeneration systems by using the first law and the second law of thermodynamics, and the exergy analysis methods. For analysis, a program is written by the author in the FORTRAN programming language. Decreasing the atmospheric pressure or increasing the installation altitude of the plants increases the Z factor (ratio of lost exergy to useful exergy) of the four cycles about 10–13%. Also, decreasing inlet air pressure decreases the specific work about 25–28%, and the fuel energy saving ratio of the four cycles decreases about 29–30%. The method of water spray cooling of the compressor inlet air especially in the summer months, the humidity increases and the evaporative cooling can be obtained. By using this method, the ratio of lost exergy to useful exergy can be decreased for the four cycles about 0.5–2%. Also, the specific work of the four cycles can be increased about 1.2–6%.

1 Introduction

In the conventional system, heat is produced in two separate systems in order to produce power and heat. However, in cogeneration systems, power and heat are produced in one system. In that situation, while the total energy efficiency of conventional systems is around 60%, the energy efficiency of a cogeneration plant can reach up to 90%. In other words, it is seen that there is about 30% more benefit from the energy of the fuel in the cogeneration plant. Furthermore, when a cogeneration plant is installed in systems that require heat and electrical energy at the same time, the costs of the system can be significantly reduced [1,2]. The operating method, efficiency, and other properties of the gas turbine identify the characteristics, the operating style, and the efficiency of the whole plant. Cogeneration systems can be classified as steam turbine cogeneration, gas turbine cogeneration, gas–steam turbine combined cogeneration, fuel cells, and motor cogeneration [3,4]. Energy efficiency in cogeneration plants varies between 50 and 90%. In the hot exhaust gases of the turbine outlet, there are around 1.5–3 kW of usable heat energy for each kW of electricity output. It is desired that the minimum flue gas temperature is around 150°C so that the condensation of the steam in the exhaust (corrosion formation) can be prevented [5,6,7].

Compressor inlet air pressure has serious effects on the heat and electrical energy power of the cogeneration plants. It is imperative to know the effects of the height of the chosen place or the choice of location in the installation of the facilities. As the altitude increases, the pressure of the air decreases. There are also advantages and disadvantages in working conditions. The gas turbine performance and the efficiency depend on the ambient and turbine pressures and ambient temperature. For 1 K increase in the inlet temperature, the electrical power is decreased about 0.9%. An increase of 100 m on altitude decreases the electrical power about 1.2%. For every kPa pressure, a decrease of the inlet air pressure in elements, filters, ducts, and components decreases the electrical power by around 1.2–2%. Kehlhofet et al. studied the effect of altitude above sea level on obtained work. They have drawn curves showing decreases as the height increases, and this decrease is from 10 to 75%. They have reported that these results are in agreement with the literature [8].

The inlet air temperatures affect the heat and electrical energy power of the plants. Water particles are injected into the inlet air, and then, this air is compressed in the summer months by this method to increase the humidity, as well as evaporative cooling in this way; it is possible to easily connect the electrical power to the temperature of the surrounding air. Depending on the evaporative humidity, it is possible to increase the electrical power between 2 and 7%. In the literature, it is found that the decrease in inlet air temperatures increases the mechanical power; for instance, a decrease from 25 to 0°C means an increase in the mechanical power about 14%; however, the heat energy decreases about 10–15% [7,8,9,10].

Ashraf in his study on this subject examined the evaporative effect of cooling on power and found similar results [11]. Al-Fahed et al. reported in their research that the influence of ambient temperature on the performance of a simple cycle varies. The decrease in the air temperature increases the density, so less energy is required for the compression of the same mass of flow. For some regions especially in the Middle East, the difference between daytime–nighttime temperatures is large, which changes the cost greatly. In the study of Al-Fahed et al. and in the literature studies, it was reported that an increasing 1°C on the compressor inlet air temperature decreases electricity production about 0.7%. In the literature, it can be seen that the work efficiency increases about 0.7–2%, if the compressor inlet air could be cooled to 5°C [10,12,13].

Basrawi et al. have obtained the results that increasing ambient temperature decreases the mechanical efficiency; however, heat energy of exhaust gas recovery increased. They also obtained that an increase in the ambient temperature increases the heat of the exhaust gases and also the heat recovery. They also obtained that this exhaust energy to power energy ratio had the same properties with the exhaust heat energy recovery to power energy ratio [14].

Fernandez et al. have found in their study that an increase in the ambient temperature decreases the electrical power about 22%. They also found that for each 1°C increasing above ISO conditions, the heat efficiency of the systems decreases about 0.06%. The results showed an insight into the cogeneration systems of the tropical climate [15]. In addition to some other works done [16,17,18,19,20,21,22,23,24,25,26,27,28,29], there are still some open questions in this field. Thus, the objective of this study is to search the effects of the inlet air compressor pressure and evaporative cooling of four different cogeneration plants that are absorption cooling (ab), basic (bsc), air heating (airh), and air fuel heating (airfh) cogeneration systems by using the first law and the second law of thermodynamics, and the exergy analysis methods.

2 Materials and methods

Cogeneration plants consist of some apparatus, and in chemical compositions, on pressures, and in temperatures changes occur in those apparatus; in addition, a chemical reaction takes place in a combustion chamber. The assumptions made in the calculations of the cycles are as follows [30]: the ideal gas mixture laws have been applied to air and exhaust, the cogeneration plant works in a continuous regime, combustion is completed, there is no NOx formation, methane was chosen as the fuel and accepted as an ideal gas, and the combustion chamber heat loss is about 2% of the upper heating value of the fuel. The heat loss is zero in other apparatus, and the kinetic–potential energies are accepted as zero.

The compressor compresses air to high pressure. The three types of compressors are piston compressors for high-pressure (P 2/P 1 = r > 30) low-flow, centrifugal compressors for medium-pressure (r = 5–25) medium-flow, axial compressors for low pressure (less than r = 20) high flow. The gas turbine cogeneration systems mostly use axial and centrifugal compressors and their efficiencies are approximately 90 and 85%, respectively [9]. A part of the heat of the exhaust transfers by a recuperator to the gases of the outlet of the compressor. Recuperators are generally produced in sheet type. The combustion chamber’s main function is to maintain a good combustion reaction. The combustion chambers used in gas turbines have three characteristics: mixing zone, combustion zone, and dilution zone. Gas turbine combustion chambers have the feature of producing low NOx called dry low emission. Combustion chambers with catalytic combustion, where the combustion is close to the surface of the catalyst, provide near-zero NOx emissions, and its use is becoming more widespread [30]. There are two types of gas turbines: axial flow and radial turbines. Gas turbines are classified as reaction and impulse turbines. The 95% of applications have axial flow turbines. A part of the energy of the exhaust gases is transformed into mechanical energy in a gas turbine. Heat recovery steam generator (HRSG) passes a part of the energy of the exhaust gases to steam production. The pressure of the remaining exhaust gases is higher than the atmospheric pressure [31,32].

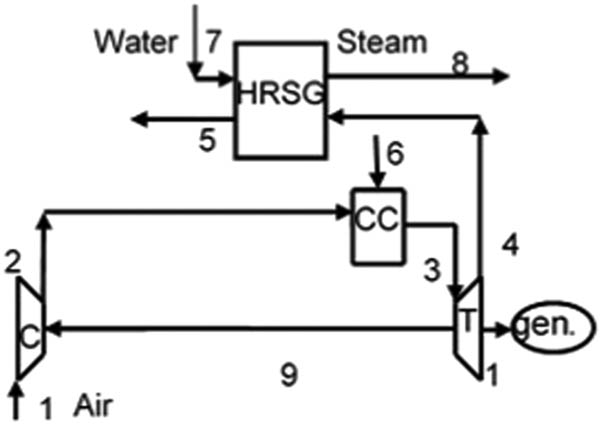

As can be seen in Figure 1, the compressed air at the exit of the compressor is burned in a combustion chamber with natural gas. Some of the exhaust energy is obtained as mechanical energy in a gas turbine, and the remaining energy of the exhaust is used in an HRSG device to obtain steam.

Diagram of a bsc cogeneration cycle.

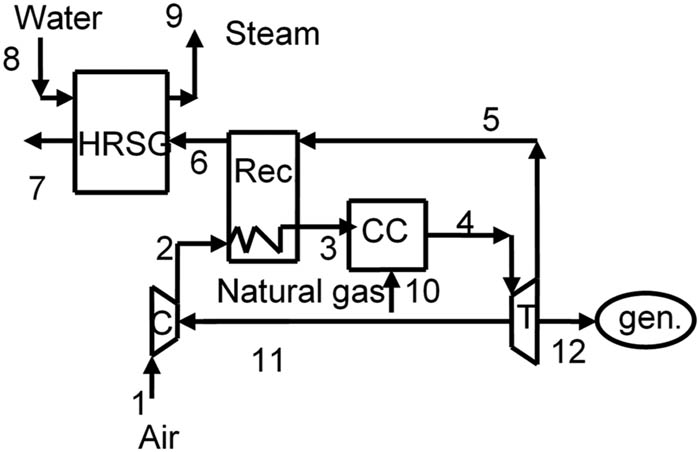

In Figure 2, the diagram of an airh cogeneration cycle is given. As can be seen, the air of the outlet of the compressor is heated by using the exhaust energy with a recuperator before entering the combustion chamber.

Diagram of an airh cogeneration cycle.

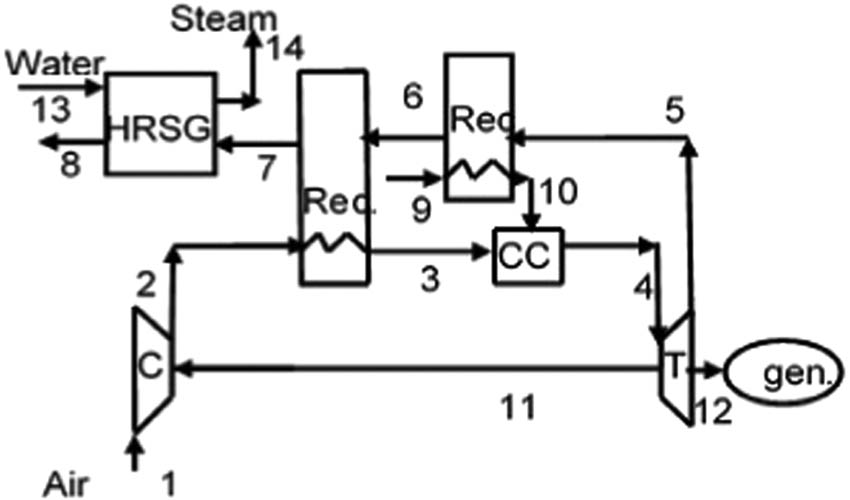

In Figure 3, the diagram of an airfh cogeneration cycle is given. The fuel and the compressed air, before entering into the combustion chamber, are heated with recuperators.

Diagram of an airfh cogeneration cycle.

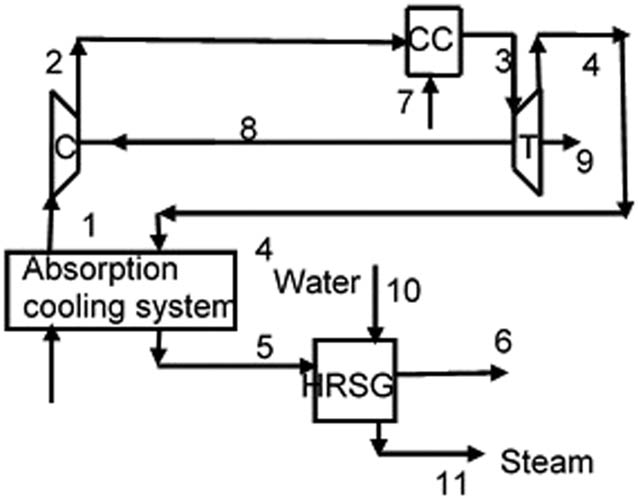

In Figure 4, the diagram of a cogeneration cycle added ab that the air before entering into the compressor is cooled by an absorption component that uses the heat energy of the exhaust is shown. Some of the remaining heat energy of the exhaust energy is passed to steam production.

Diagram of an ab cogeneration cycle.

For an open system and steady state, the first law of thermodynamics is as follows:

In the steady state, the law of conservation mass is as follows:

Chemical energy is converted into thermal energy by combustion. In this study, it is accepted that the combustion reaction happens ideally and completely. It is also assumed that the natural gases are taken as methane gas for simplifying the calculations. The following chemical reaction is taken as a basis:

For completing the theoretical combustion, the required minimum amount of air is called the stoichiometric amount of air. However, for complete combustion, more air than the theoretical amount of air is always used. The excess air coefficient is the ratio of the real amount of air to the theoretical amount of air [30]. Exergy or availability is the theoretical maximum amount of available work, which is obtained if equilibrium with the environment is achieved at the end of a reversible process. It has two components: chemical and physical. The perfect gas mixture of physical exergy can be written in molar terms for mixed substances

Chemical exergy is the maximum useful work, which is achieved when a substance in the reference state (T 0, P 0) becomes thermodynamic equilibrium in terms of chemical composition with its surroundings [32]. The chemical exergy of gas mixtures is calculated as follows:

Thus, the total exergy of a flow or control volume is as follows:

The exergy equation for open systems (input and output mass quantities are equal to each other) is as follows:

In Table 1, energy, entropy, and mass equations of the apparatus of the ab system are given.

| Devices | Mass equation | Energy equation | Entropy equation |

|---|---|---|---|

| Compressor |

|

|

|

| Turbine |

|

|

|

| HRSG |

|

|

|

|

|

|||

| Combustion chamber |

|

|

|

| Overall cycle |

|

||

|

|

|||

|

|

|||

|

|

|||

In Table 2, exergy, evaluation criteria, and exergy efficiency equations of the apparatus of the ab system are given.

Exergy, evaluation criteria, and exergy efficiency equations of the apparatus of the ab system [5,7,30,32]

| Devices | Exergy equation | Exergy efficiency |

|---|---|---|

| Compressor |

|

|

| Turbine |

|

|

| HRSG |

|

|

| Combustion chamber |

|

|

| Overall cycle | Electrical heat ratio |

|

| Exergy efficiency |

|

|

|

|

||

|

|

||

|

|

||

| ATE |

|

|

| SFC |

|

|

| IHR |

|

|

| Z factor (ratio of lost exergy to useful exergy) |

|

|

| FESR |

|

3 Results and discussion

In this research, ambient pressure and temperature are taken as 101.3 kPa and 298.15 K, respectively. For the calculations, the inlet fuel mass m fuel = 1.64 kg/s, the inlet compressor air mass flow m air = 91.3 kg/s, the turbine and the compressor isentropic efficiency η izC = η izT = 0.86, the compressor compression ratio r = 10, recuperator outlet temperature T recout = 850 K, steam temperature T steam = 485.57 K, and exhaust outlet temperature T exh = 426 K are taken.

In this study, compressor inlet air or ambient pressure depends on the installation altitude of the cogeneration system, and evaporative cooling is carried out by spraying water particles in the inlet air up to the saturation point on the 1.9% molar water vapor under normal conditions (at 25°C and 1 atm). Accordingly, the new temperature of the air was found from the amount of water injected using the psychrometric diagram and used in the calculation. Increasing the specific humidity affects the density of the air, thus the variation of specific heat with temperature. When the specific humidity is increased, it also increases the specific gas and heat constant values at a specific pressure.

In Figure 5, variation of the Z factor (ratio of lost exergy to useful exergy) with inlet air (atmospheric) pressure for ab, bsc, airh, and airfh cogeneration systems is given. It can be seen that increasing atmospheric pressure (or decreasing altitudes) decreases the Z factor (ratio of lost exergy to useful exergy) of the four cycles. Upon decreasing the inlet air (atmospheric) pressure of the four cycles from 101.3 to 70 kPa, the Z factors of the cycles increase about 10% for ab and bsc cycles and about 13% for airh and airfh cycles, which is important. Increasing inlet air (atmospheric) pressure decreases the lost exergy, which is unignorable, and should be taken into account.

Variation of the Z factor (ratio of lost exergy to useful exergy) with inlet air (atmospheric) pressure for ab, bsc, airh, and airfh cogeneration systems.

In Figure 6, variation of the specific work with inlet air (atmospheric) pressure for ab, bsc, airh, and airfh cogeneration systems is given. It can be shown that decreasing inlet air pressure decreases the specific work about 28% for airh and airfh cogeneration systems. Upon decreasing the inlet air pressure, for ab and bsc cycles, the decrease in specific work is about 25%.

Variation of the specific work with inlet air (atmospheric) pressure for ab, bsc, airh, and airfh cogeneration systems.

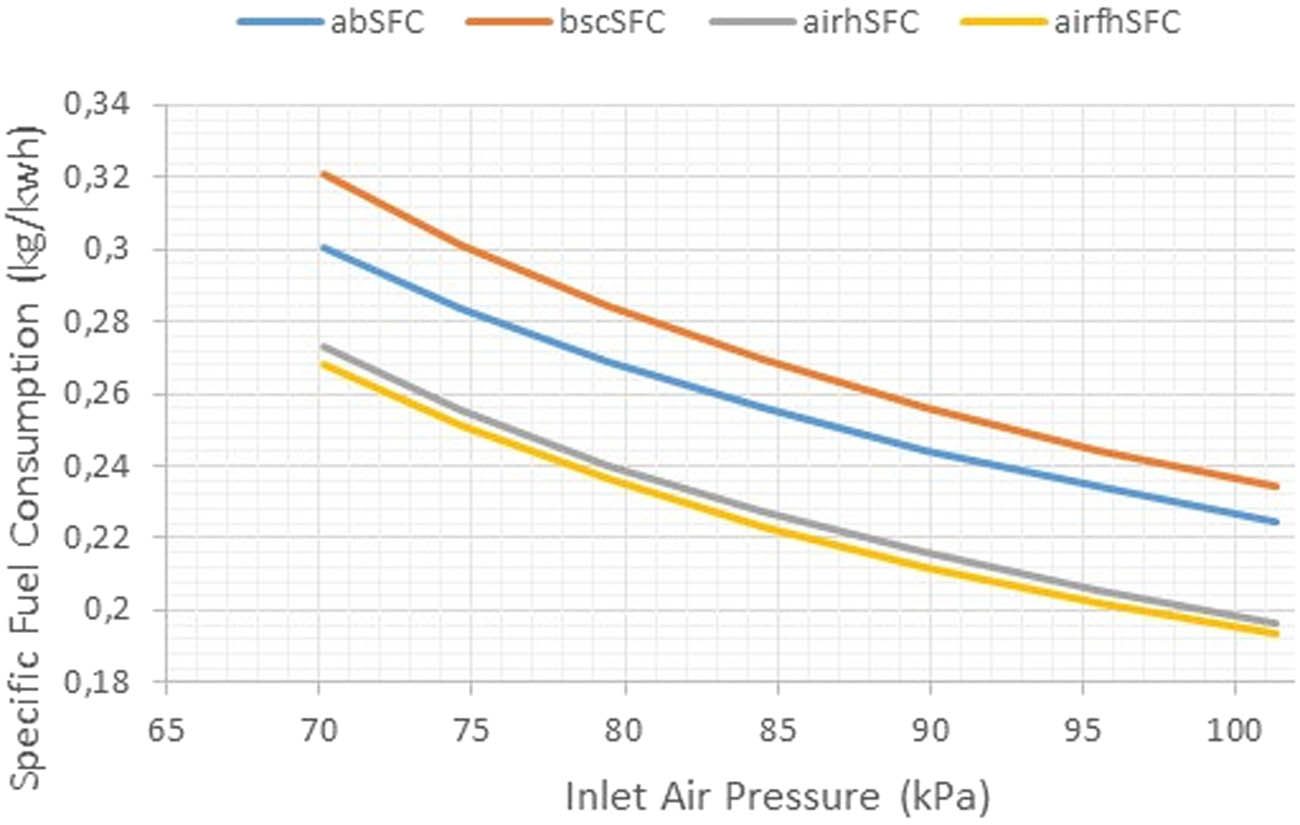

In Figure 7, variation of the specific fuel consumption (SFC) with atmospheric pressure for bsc, ab, airh, and airfh cogeneration systems is given. In Figure 7, it can be seen that increase in altitude or decrease in atmospheric pressure of the inlet air of the compressor increases the SFC of the four cycles. Decrease in atmospheric pressure of the inlet air of the compressor increases the SFC of bsc cycle about 27%, airh and airfh cycle about 28%, and the ab cycle about 25%.

Variation of the SFC with inlet air (atmospheric) pressure for ab, bsc, airh, and airfh cogeneration systems.

In Figure 8, variation of the fuel energy saving ratio (FESR) with altitude and atmospheric pressure for ab, bsc, airh, and airfh cogeneration systems is given. Figure 9 shows that decreasing the pressure of the inlet air decreases the FESR of the four cycles. The FESR decreases about 29% with decrease in the atmospheric pressure for airh and airfh cogeneration systems. For ab and bsc systems, FESR decreases about 30% with decrease in atmospheric pressure.

Variation of the FESR with atmospheric pressure for ab, bsc, airh, and airfh cogeneration systems.

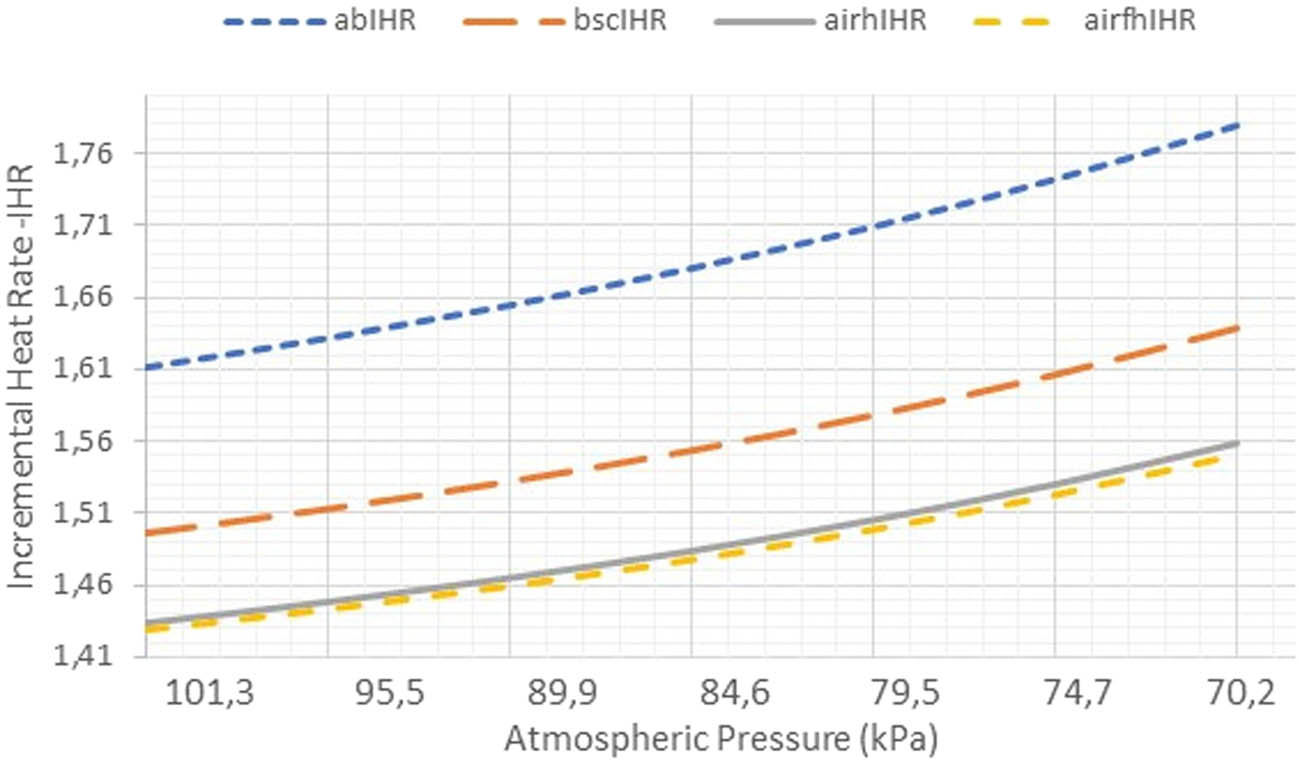

Variation of the IHR with atmospheric pressure for ab, bsc, airh, and airfh cogeneration systems.

In Figure 9, variation of the incremental heat rate (IHR) with atmospheric pressure for ab, bsc, airh, and airfh cogeneration systems is given. It can be concluded that decreasing the pressure of the inlet air increases the IHR of the four cycles. The IHRs of the ab, bsc, airh, and airfh cogeneration systems are increasing about 10% with decreasing compressor inlet air pressure.

In the summer months, the method of spraying water in the inlet air increases the humidity, so the evaporative cooling can be obtained. It is possible to connect the electrical power to the temperature of the ambient in this way. Increasing the electrical power between 2 and 6% depends on the ambient humidity. Reducing the inlet air temperature by spraying water particles into the compressor inlet air also reduces the combustion chamber outlet temperature.

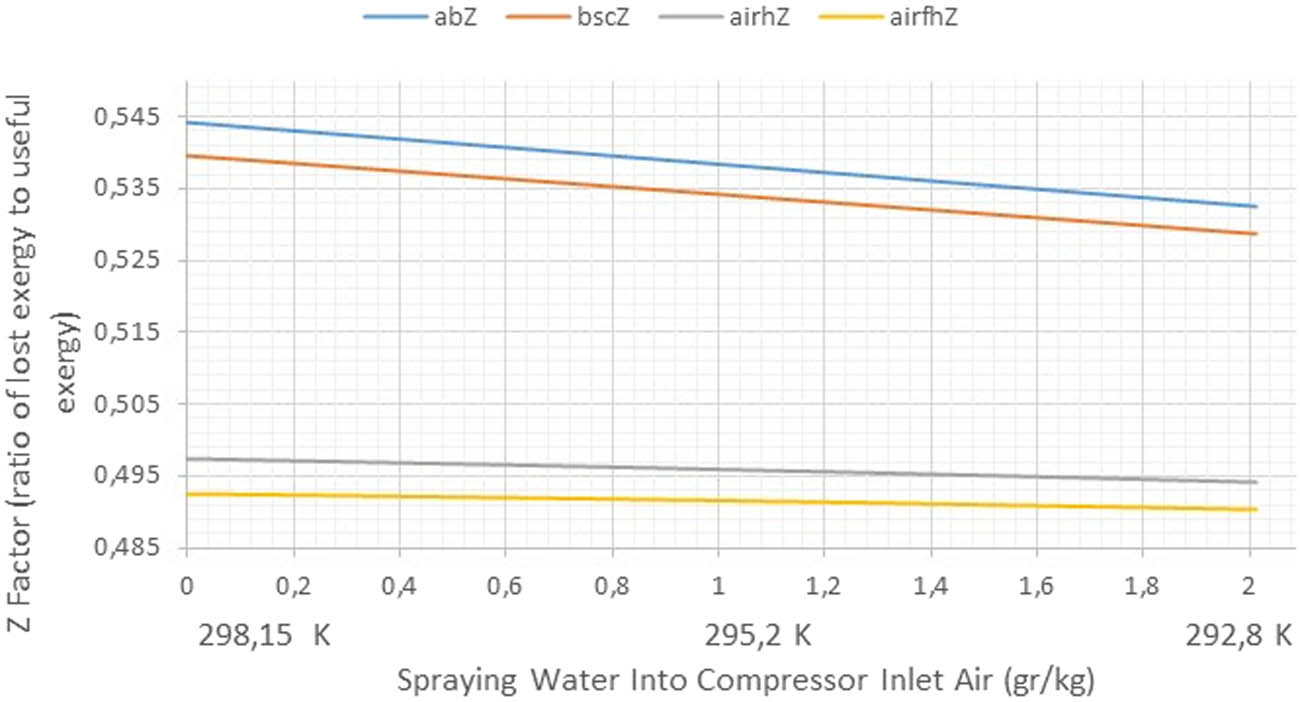

In Figure 10, variation of the Z factor (ratio of lost exergy to useful exergy) with spraying water into compressor inlet air (g/kg) for ab, bsc, airh, and airfh cogeneration systems is given. As can be seen in Figure 10, the Z factor (ratio of lost exergy to useful exergy) decreases with increasing (evaporative) compressor inlet air humidity ratio for ab, bsc, airh, and airfh cogeneration systems. The ratio of lost exergy to useful exergy decreases for ab and bsc cycles about 2%, and for airh and airfh plants it is about 0.5%.

Variation of Z factor (ratio of lost exergy to useful exergy) with spraying water into compressor inlet air (g/kg) for ab, bsc, airh, and airfh cogeneration systems.

In Figure 11, variation of the specific work with compressor inlet air humidity ratio for ab, bsc, airh, and airfh cogeneration systems is given. As shown in Figure 11, this increase in evaporative inlet air humidity increases the specific work of the ab, bsc, airh, and airfh cogeneration systems. Increasing spraying water in compressor inlet air (g/kg) increases the specific work of ab and bsc cycles about 6%, and for the airh and the airfh cycles it is about 1.2%.

![Figure 11

Variation of the specific work with spraying water into compressor inlet air (g/kg) for ab, bsc, airh, and airfh cogeneration systems [10].](/document/doi/10.1515/chem-2022-0263/asset/graphic/j_chem-2022-0263_fig_011.jpg)

Variation of the specific work with spraying water into compressor inlet air (g/kg) for ab, bsc, airh, and airfh cogeneration systems [10].

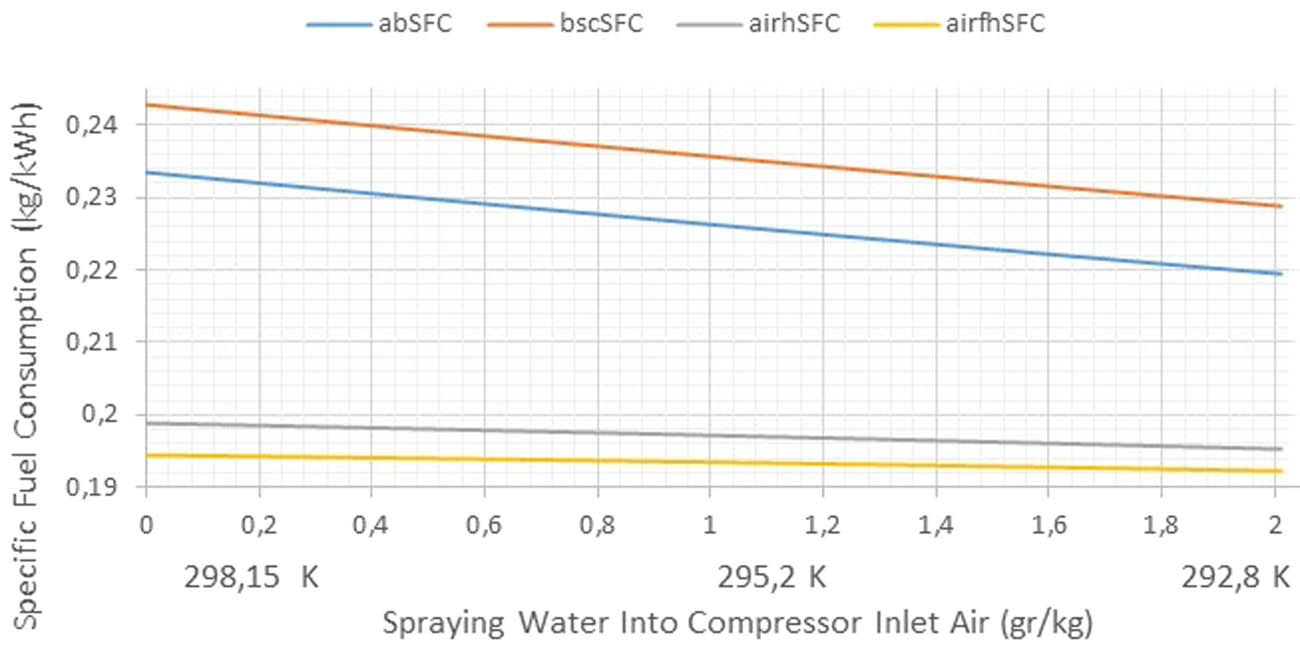

In Figure 12, variation of the SFC with spraying water into compressor inlet air (g/kg) for ab, bsc, airh, and airfh cogeneration systems is given. It is shown in Figure 12 that increasing spraying water into inlet air (g/kg) decreases the SFC of ab, bsc, airh, and airfh cogeneration systems. Increasing evaporative air humidity decreases the SFC of the ab and the bsc plants about 6% and decreases the airh cycle about 1.9% and the airfh plants about 1.1%.

Variation of the SFC with spraying water into compressor inlet air (g/kg) for ab, bsc, airh, and airfh cogeneration systems.

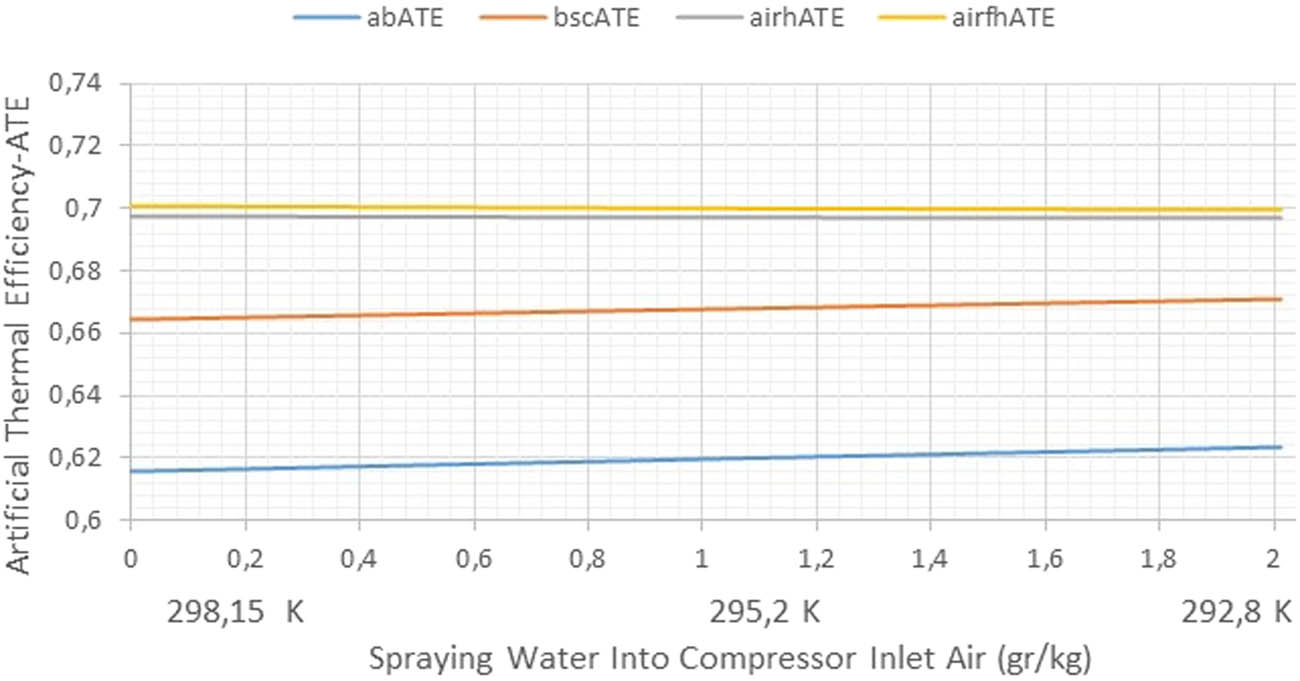

In Figure 13, variation of the artificial thermal efficiency (ATE) with spraying water into compressor inlet air (g/kg) for ab, bsc, airh, and airfh cogeneration systems is given. As can be seen in Figure 13, increasing spraying water into compressor inlet air (g/kg) increases the ATE of ab and bsc plants about 1%, and for the airh and the airfh plants it stays almost the same.

Variation of the ATE with spraying water into compressor inlet air (g/kg) for ab, bsc, airh, and airfh cogeneration systems.

In Figure 14, variation of the FESR with spraying water into compressor inlet air (g/kg) for ab, bsc, airh, and airfh cogeneration systems is given. It is shown in Figure 14 that increasing evaporative inlet air humidity ratio increases the FESR of the ab and the bsc plants about 6%. However, the increase for the airh plant and for the airfh plant is about 0.5%.

Variation of the FESR with spraying water into compressor inlet air (g/kg) for ab, bsc, airh, and airfh cogeneration systems.

In Figure 15, variation of the IHR with spraying water into compressor inlet air (g/kg) for ab, bsc, airh, and airfh cogeneration systems is given. As it is shown in Figure 15, increasing spraying water into inlet air (g/kg) decreases the IHR of the bsc and ab cycles about 1%. However, for the airh and the airfh cycles, it stays almost the same.

Variation of the IHR with spraying water into compressor inlet air (g/kg) for ab, bsc, airh, and airfh cogeneration systems.

4 Conclusions

In this study, compressor inlet air pressure and evaporative cooling effects on the performances is investigated. It is found that increasing atmospheric pressure (or decreasing installation altitudes) decreases the Z factor (ratio of lost exergy to useful exergy) of the four cycles. Upon decreasing the inlet air (atmospheric) pressure of the four cycles from 101.3 to 70 kPa, the Z factors of the cycles increase about 10% for ab and bsc cycles and about 13% for airh and airfh cycles. Increasing inlet air (atmospheric) pressure decreases the lost exergy, which is unignorable, and should be taken into account. Also, decreasing inlet air pressure decreases the specific work about 28% for the airh and airfh cycles, and for ab and bsc cycles, it is about 25%. In addition, decreasing the atmospheric pressure of the inlet air increases the SFC about 25–28% and decreases the FESR of the four cycles about 29–30%.

By spraying water into the compressor inlet air especially in the summer months, the humidity increases and evaporative cooling can be obtained. By using this method, the ratio of lost exergy to useful exergy can be decreased for the four cycles about 0.5–2%. Also, by increasing evaporative inlet air humidity the specific work of the four cycles can be increased about 1.2–6%, and the SFC can be decreased about 1.2–6%. In addition, increasing spraying water into inlet air, the FESR can be increased about 0.5–6%.

Acknowledgement

There is no acknowledgement.

-

Funding information: There is no funding for his work.

-

Author contributions: The author has equal rights on the preparation of this study.

-

Conflict of interest: The author declares that there is no conflict of interest.

-

Ethical approval: Ethical approval is not required, as the study was not performed in vivo.

-

Data availability statement: The processed data necessary to reproduce these findings are available upon request with permission.

References

[1] Taner T, Sivrioglu M. A techno-economic and cost analysis of a turbine power plant: A case study for sugar plant. Renew Sustain Energy Rev. 2017;78:722–30.10.1016/j.rser.2017.04.104Search in Google Scholar

[2] Taner T, and Sivrioglu M. Energy-exergy analysis and optimisation of a model sugar factory in Turkey. Energy. 2015;93:641–54.10.1016/j.energy.2015.09.007Search in Google Scholar

[3] Özahi E, Tozlu A, Abusoglu A. Thermodynamic performance assessment of different fluids in a typical organic Rankine cycle for usage in municipal solid waste power plant. Acta Phys Polonica A. 2017;132(3-II):807–12.10.12693/APhysPolA.132.807Search in Google Scholar

[4] Karaali R. Thermoeconomic optimization of cogeneration power Plants [dissertation]. Kocaeli Univ; 2010.Search in Google Scholar

[5] Horlock JH. Cogeneration combined heat and power. Florida: CRİEGER Pub; 1997.Search in Google Scholar

[6] ASHRAE. Cogeneration systems and engine and turbine drives. ASHRAE systems and equipment handbook. American society of heating, refrigerating and air conditioning engineers. New York: 2000.Search in Google Scholar

[7] Tozlu A, Abusoglu A, Özahi E. Thermoeconomic analysis and assessment of Gaziantep municipal solid waste power plant. Acta Phys Pol A. 2017;132(3):513–7.10.12693/APhysPolA.132.513Search in Google Scholar

[8] Kehlhofet R, Warner J, Nielsen H, Bachmann R. Combined cycle gas steam turbine power plants. Nashville, Tennessee, USA: Pennwell Corp; 1999.Search in Google Scholar

[9] Boyce MP. Handbook for cogeneration and combined cycle power plants. New York: Asme Press; 2002. p. 42–220.Search in Google Scholar

[10] Karaali R, Öztürk İT. Efficiency improvement of gas turbine cogeneration systems. Tehnički Vjesn. 2017;24(Suppl.1):21–7. 10.17559/TV-20140509154652.Search in Google Scholar

[11] Ashraf MB. Effects of evaporative inlet and after cooling on the recuperated gas turbine cycle. Appl Therm Eng. 2001;21(18):1875.10.1016/S1359-4311(01)00054-0Search in Google Scholar

[12] Al-Fahed SF, Alasfour FN, Abdulrahim HK. The effect of elevated inlet air temperature and relative humidity on cogeneration systems. Int J Energy Res. 2009;33:1384–94.10.1002/er.1552Search in Google Scholar

[13] Amel AA, Cadavid FJ. Influence of the relative humidity on the air cooling thermal load in gas turbine power plant. Appl Therm Eng. 2002;22:1529–33.10.1016/S1359-4311(02)00063-7Search in Google Scholar

[14] Basrawi F, Yamada T, Nakanishi K, Naing S. Effect of ambient temperature on the performance of micro gas turbine with cogeneration system in cold region. Appl Therm Eng. 2011;31:1058–67.10.1016/j.applthermaleng.2010.10.033Search in Google Scholar

[15] Fernandez DAP, Foliaco B, Padilla RV, Bula A, Quiroga AG. High ambient temperature effects on the performance of a gas turbine-based cogeneration system with supplementary fire in a tropical climate. Case Stud Therm Eng. 2021;26:1–13. 10.1016/j.csite.2021.101206.Search in Google Scholar

[16] Ural A, Kilimci ZH. The prediction of chiral metamaterial resonance using convolutional neural networks and conventional machine learning algorithms. Int J Comput Exp Sci Eng. 2021;7(3):156–63. 10.22399/ijcesen.973726.Search in Google Scholar

[17] Zarkooshi A, Latıf KH, Hawı F. Estimating the concentrations of natural isotopes of 238 U and 232Th and radiation dose rates for Wasit province-Iraq by Gr-460 system. Int J Comput Exp Sci Eng. 2021;7(3):128–32. 10.22399/ijcesen.891935.Search in Google Scholar

[18] Caymaz T, Çalışkan S, Botsalı AR. Evaluation of ergonomic conditions using fuzzy logic in a metal processing plant. Int J Comput Exp Sci Eng. 2022;8(1):19–24. 10.22399/ijcesen.932994.Search in Google Scholar

[19] Arbouz H. Modeling of a tandem solar cell structure based on CZTS and CZTSe absorber materials. Int J Comput Exp Sci Eng. 2022;8(1):14–8. 10.22399/ijcesen.843038.Search in Google Scholar

[20] Etyemez A. Structural, physical, and mechanical properties of the TiO2 added hydroxyapatite composites. Open Chem. 2022;20(1):272–6. 10.1515/chem-2022-0140.Search in Google Scholar

[21] Çilli A, Beken M, Kurt N. Determination of theoretical fracture criteria of layered elastic composite material by ANFIS method from artificial intelligence. Int J Comput Exp Sci Eng. 2022;8(2):32–9. 10.22399/ijcesen.1077328.Search in Google Scholar

[22] Özseven A. Assessment of using electronic portal imaging device for analysing bolus material utilised in radiation therapy. Open Chem. 2022;20(1):61–8. 10.1515/chem-2022-0126.Search in Google Scholar

[23] Waheed F, İmamoğlu M, Karpuz N, Ovalıoğlu H. Simulation of neutrons shielding properties for some medical materials. Int J Comput Exp Sci Eng. 2022;8(1):5–8. 10.22399/ijcesen.1032359.Search in Google Scholar

[24] Ovalioglu H. Sample age effect on parameters of dynamic nuclear polarization in certain difluorobenzene isomers/mc800 asphaltene suspensions. Open Chem. 2022;20(1):97–104. 10.1515/chem-2021-0114.Search in Google Scholar

[25] Kamar MS, Salem IA, El-Aassy IE, El-Sayed AA, Awad HA, Tekin HO, et al. Petrology and geochemistry of multiphase post-granitic dikes: A case study from Gabal Serbal area, Southwestern sinai, Egypt. Open Chem. 2022;20(1):169–81. 10.1515/chem-2022-0136.Search in Google Scholar

[26] Şen Baykal D, Tekin H, Çakırlı Mutlu R. An investigation on radiation shielding properties of borosilicate glass systems. Int J Comput Exp Sci Eng. 2021;7(2):99–108. 10.22399/ijcesen.960151.Search in Google Scholar

[27] Tekin HO, Cavli B, Altunsoy EE, Manici T, Ozturk C, Karakas HM. An investigation on radiation protection and shielding properties of 16 slice computed tomography (CT) facilities. Int J Comput Exp Sci Eng. 2018;4(2):37–40. 10.22399/ijcesen.408231.Search in Google Scholar

[28] Arslankaya S, Çelik MT. Prediction of heart attack using fuzzy logic method and determination of factors affecting heart attacks. Int J Comput Exp Sci Eng. 2021;7(1):1–8. 10.22399/ijcesen.837731.Search in Google Scholar

[29] Nar M, Arslankaya S. Passenger demand forecasting for railway systems. Open Chem. 2022;20(1):105–19. 10.1515/chem-2022-0124.Search in Google Scholar

[30] Bejan A, Tsatsaronis G, Moran M. Thermal design and optimization. New York: Wiley Pub; 1996.Search in Google Scholar

[31] Moran JM, Tsatsaronis G. The CRC handbook of thermal engineering. Florida: CRC Press LLC; 2000. p. 15–109.Search in Google Scholar

[32] Jaluria Y. Design and optimization of thermal systems. 2nd ed. New York: CRC Press; 2008.10.1201/9781420019483Search in Google Scholar

© 2022 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Photocatalytic degradation of Rhodamine B in aqueous phase by bimetallic metal-organic framework M/Fe-MOF (M = Co, Cu, and Mg)

- Assessment of using electronic portal imaging device for analysing bolus material utilised in radiation therapy

- A detailed investigation on highly dense CuZr bulk metallic glasses for shielding purposes

- Simulation of gamma-ray shielding properties for materials of medical interest

- Environmental impact assesment regulation applications and their analysis in Turkey

- Sample age effect on parameters of dynamic nuclear polarization in certain difluorobenzen isomers/MC800 asphaltene suspensions

- Passenger demand forecasting for railway systems

- Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach

- Gamma, neutron, and heavy charged ion shielding properties of Er3+-doped and Sm3+-doped zinc borate glasses

- Bridging chiral de-tert-butylcalix[4]arenes: Optical resolution based on column chromatography and structural characterization

- Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt

- Comparison of the yield and purity of plasma exosomes extracted by ultracentrifugation, precipitation, and membrane-based approaches

- Bioactive triterpenoids from Indonesian medicinal plant Syzygium aqueum

- Investigation of the effects of machining parameters on surface integrity in micromachining

- The mesoporous aluminosilicate application as support for bifunctional catalysts for n-hexadecane hydroconversion

- Gamma-ray shielding properties of Nd2O3-added iron–boron–phosphate-based composites

- Numerical investigation on perforated sheet metals under tension loading

- Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt

- Two new polypodane-type bicyclic triterpenoids from mastic

- Structural, physical, and mechanical properties of the TiO2 added hydroxyapatite composites

- Tribological properties and characterization of borided Co–Mg alloys

- Studies on Anemone nemorosa L. extracts; polyphenols profile, antioxidant activity, and effects on Caco-2 cells by in vitro and in silico studies

- Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system

- Cyclic connectivity index of bipolar fuzzy incidence graph

- The role of passage numbers of donor cells in the development of Arabian Oryx – Cow interspecific somatic cell nuclear transfer embryos

- Mechanical property evaluation of tellurite–germanate glasses and comparison of their radiation-shielding characteristics using EPICS2017 to other glass systems

- Molecular screening of ionic liquids for CO2 absorption and molecular dynamic simulation

- Microwave-assisted preparation of Ag/Fe magnetic biochar from clivia leaves for adsorbing daptomycin antibiotics

- Iminodisuccinic acid enhances antioxidant and mineral element accumulation in young leaves of Ziziphus jujuba

- Cytotoxic activity of guaiane-type sesquiterpene lactone (deoxycynaropicrin) isolated from the leaves of Centaurothamnus maximus

- Effects of welding parameters on the angular distortion of welded steel plates

- Simulation of a reactor considering the Stamicarbon, Snamprogetti, and Toyo patents for obtaining urea

- Effect of different ramie (Boehmeria nivea L. Gaud) cultivars on the adsorption of heavy metal ions cadmium and lead in the remediation of contaminated farmland soils

- Impact of a live bacterial-based direct-fed microbial (DFM) postpartum and weaning system on performance, mortality, and health of Najdi lambs

- Anti-tumor effect of liposomes containing extracted Murrayafoline A against liver cancer cells in 2D and 3D cultured models

- Physicochemical properties and some mineral concentration of milk samples from different animals and altitudes

- Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies

- Diagnostic and therapeutic radioisotopes in nuclear medicine: Determination of gamma-ray transmission factors and safety competencies of high-dense and transparent glassy shields

- Calculation of NaI(Tl) detector efficiency using 226Ra, 232Th, and 40K radioisotopes: Three-phase Monte Carlo simulation study

- Isolation and identification of unstable components from Caesalpinia sappan by high-speed counter-current chromatography combined with preparative high-performance liquid chromatography

- Quantification of biomarkers and evaluation of antioxidant, anti-inflammatory, and cytotoxicity properties of Dodonaea viscosa grown in Saudi Arabia using HPTLC technique

- Characterization of the elastic modulus of ceramic–metal composites with physical and mechanical properties by ultrasonic technique

- GC-MS analysis of Vespa velutina auraria Smith and its anti-inflammatory and antioxidant activities in vitro

- Texturing of nanocoatings for surface acoustic wave-based sensors for volatile organic compounds

- Insights into the molecular basis of some chalcone analogues as potential inhibitors of Leishmania donovani: An integrated in silico and in vitro study

- (1R,2S,5R)-5-Methyl-2-(propan-2-yl)cyclohexyl 4-amino-3-phenylbutanoate hydrochloride: Synthesis and anticonvulsant activity

- On the relative extraction rates of colour compounds and caffeine during brewing, an investigation of tea over time and temperature

- Characterization of egg shell powder-doped ceramic–metal composites

- Rapeseed oil-based hippurate amide nanocomposite coating material for anticorrosive and antibacterial applications

- Chemically modified Teucrium polium (Lamiaceae) plant act as an effective adsorbent tool for potassium permanganate (KMnO4) in wastewater remediation

- Efficiency analysis of photovoltaic systems installed in different geographical locations

- Risk prioritization model driven by success factor in the light of multicriteria decision making

- Theoretical investigations on the excited-state intramolecular proton transfer in the solvated 2-hydroxy-1-naphthaldehyde carbohydrazone

- Mechanical and gamma-ray shielding examinations of Bi2O3–PbO–CdO–B2O3 glass system

- Machine learning-based forecasting of potability of drinking water through adaptive boosting model

- The potential effect of the Rumex vesicarius water seeds extract treatment on mice before and during pregnancy on the serum enzymes and the histology of kidney and liver

- Impact of benzimidazole functional groups on the n-doping properties of benzimidazole derivatives

- Extraction of red pigment from Chinese jujube peel and the antioxidant activity of the pigment extracts

- Flexural strength and thermal properties of carbon black nanoparticle reinforced epoxy composites obtained from waste tires

- A focusing study on radioprotective and antioxidant effects of Annona muricata leaf extract in the circulation and liver tissue: Clinical and experimental studies

- Clinical comprehensive and experimental assessment of the radioprotective effect of Annona muricata leaf extract to prevent cellular damage in the ileum tissue

- Effect of WC content on ultrasonic properties, thermal and electrical conductivity of WC–Co–Ni–Cr composites

- Influence of various class cleaning agents for prosthesis on Co–Cr alloy surface

- The synthesis of nanocellulose-based nanocomposites for the effective removal of hexavalent chromium ions from aqueous solution

- Study on the influence of physical interlayers on the remaining oil production under different development modes

- Optimized linear regression control of DC motor under various disturbances

- Influence of different sample preparation strategies on hypothesis-driven shotgun proteomic analysis of human saliva

- Determination of flow distance of the fluid metal due to fluidity in ductile iron casting by artificial neural networks approach

- Investigation of mechanical activation effect on high-volume natural pozzolanic cements

- In vitro: Anti-coccidia activity of Calotropis procera leaf extract on Eimeria papillata oocysts sporulation and sporozoite

- Determination of oil composition of cowpea (Vigna unguiculata L.) seeds under influence of organic fertilizer forms

- Activated partial thromboplastin time maybe associated with the prognosis of papillary thyroid carcinoma

- Treatment of rat brain ischemia model by NSCs-polymer scaffold transplantation

- Lead and cadmium removal with native yeast from coastal wetlands

- Characterization of electroless Ni-coated Fe–Co composite using powder metallurgy

- Ferrate synthesis using NaOCl and its application for dye removal

- Antioxidant, antidiabetic, and anticholinesterase potential of Chenopodium murale L. extracts using in vitro and in vivo approaches

- Study on essential oil, antioxidant activity, anti-human prostate cancer effects, and induction of apoptosis by Equisetum arvense

- Experimental study on turning machine with permanent magnetic cutting tool

- Numerical simulation and mathematical modeling of the casting process for pearlitic spheroidal graphite cast iron

- Design, synthesis, and cytotoxicity evaluation of novel thiophene, pyrimidine, pyridazine, and pyridine: Griseofulvin heterocyclic extension derivatives

- Isolation and identification of promising antibiotic-producing bacteria

- Ultrasonic-induced reversible blood–brain barrier opening: Safety evaluation into the cellular level

- Evaluation of phytochemical and antioxidant potential of various extracts from traditionally used medicinal plants of Pakistan

- Effect of calcium lactate in standard diet on selected markers of oxidative stress and inflammation in ovariectomized rats

- Identification of crucial salivary proteins/genes and pathways involved in pathogenesis of temporomandibular disorders

- Zirconium-modified attapulgite was used for removing of Cr(vi) in aqueous solution

- The stress distribution of different types of restorative materials in primary molar

- Reducing surface heat loss in steam boilers

- Deformation behavior and formability of friction stir processed DP600 steel

- Synthesis and characterization of bismuth oxide/commercial activated carbon composite for battery anode

- Phytochemical analysis of Ziziphus jujube leaf at different foliar ages based on widely targeted metabolomics

- Effects of in ovo injection of black cumin (Nigella sativa) extract on hatching performance of broiler eggs

- Separation and evaluation of potential antioxidant, analgesic, and anti-inflammatory activities of limonene-rich essential oils from Citrus sinensis (L.)

- Bioactivity of a polyhydroxy gorgostane steroid from Xenia umbellata

- BiCAM-based automated scoring system for digital logic circuit diagrams

- Analysis of standard systems with solar monitoring systems

- Structural and spectroscopic properties of voriconazole and fluconazole – Experimental and theoretical studies

- New plant resistance inducers based on polyamines

- Experimental investigation of single-lap bolted and bolted/bonded (hybrid) joints of polymeric plates

- Investigation of inlet air pressure and evaporative cooling of four different cogeneration cycles

- Review Articles

- Comprehensive review on synthesis, physicochemical properties, and application of activated carbon from the Arecaceae plants for enhanced wastewater treatment

- Research progress on speciation analysis of arsenic in traditional Chinese medicine

- Recent modified air-assisted liquid–liquid microextraction applications for medicines and organic compounds in various samples: A review

- An insight on Vietnamese bio-waste materials as activated carbon precursors for multiple applications in environmental protection

- Antimicrobial activities of the extracts and secondary metabolites from Clausena genus – A review

- Bioremediation of organic/heavy metal contaminants by mixed cultures of microorganisms: A review

- Sonodynamic therapy for breast cancer: A literature review

- Recent progress of amino acid transporters as a novel antitumor target

- Aconitum coreanum Rapaics: Botany, traditional uses, phytochemistry, pharmacology, and toxicology

- Corrigendum

- Corrigendum to “Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt”

- Corrigendum to “Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach”

- Corrigendum to “Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt”

- Corrigendum to “Aroma components of tobacco powder from different producing areas based on gas chromatography ion mobility spectrometry”

- Corrigendum to “Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system”

- Erratum

- Erratum to “Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies”

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2021)

- Study of solidification and stabilization of heavy metals by passivators in heavy metal-contaminated soil

- Human health risk assessment and distribution of VOCs in a chemical site, Weinan, China

- Preparation and characterization of Sparassis latifolia β-glucan microcapsules

- Special Issue on the Conference of Energy, Fuels, Environment 2020

- Improving the thermal performance of existing buildings in light of the requirements of the EU directive 2010/31/EU in Poland

- Special Issue on Ethnobotanical, Phytochemical and Biological Investigation of Medicinal Plants

- Study of plant resources with ethnomedicinal relevance from district Bagh, Azad Jammu and Kashmir, Pakistan

- Studies on the chemical composition of plants used in traditional medicine in Congo

- Special Issue on Applied Chemistry in Agriculture and Food Science

- Strip spraying technology for precise herbicide application in carrot fields

- Special Issue on Pharmacology and Metabolomics of Ethnobotanical and Herbal Medicine

- Phytochemical profiling, antibacterial and antioxidant properties of Crocus sativus flower: A comparison between tepals and stigmas

- Antioxidant and antimicrobial properties of polyphenolics from Withania adpressa (Coss.) Batt. against selected drug-resistant bacterial strains

- Integrating network pharmacology and molecular docking to explore the potential mechanism of Xinguan No. 3 in the treatment of COVID-19

- Chemical composition and in vitro and in vivo biological assortment of fixed oil extracted from Ficus benghalensis L.

- A review of the pharmacological activities and protective effects of Inonotus obliquus triterpenoids in kidney diseases

- Ethnopharmacological study of medicinal plants in Kastamonu province (Türkiye)

- Protective effects of asperuloside against cyclophosphamide-induced urotoxicity and hematotoxicity in rats

- Special Issue on Essential Oil, Extraction, Phytochemistry, Advances, and Application

- Identification of volatile compounds and antioxidant, antibacterial, and antifungal properties against drug-resistant microbes of essential oils from the leaves of Mentha rotundifolia var. apodysa Briq. (Lamiaceae)

- Phenolic contents, anticancer, antioxidant, and antimicrobial capacities of MeOH extract from the aerial parts of Trema orientalis plant

- Chemical composition and antimicrobial activity of essential oils from Mentha pulegium and Rosmarinus officinalis against multidrug-resistant microbes and their acute toxicity study

- Special Issue on Marine Environmental Sciences and Significance of the Multidisciplinary Approaches

- An insightful overview of the distribution pattern of polycyclic aromatic hydrocarbon in the marine sediments of the Red Sea

- Antifungal–antiproliferative norcycloartane-type triterpenes from the Red Sea green alga Tydemania expeditionis

- Solvent effect, dipole moment, and DFT studies of multi donor–acceptor type pyridine derivative

- An extensive assessment on the distribution pattern of organic contaminants in the aerosols samples in the Middle East

- Special Issue on 4th IC3PE

- Energetics of carboxylic acid–pyridine heterosynthon revisited: A computational study of intermolecular hydrogen bond domination on phenylacetic acid–nicotinamide cocrystals

- A review: Silver–zinc oxide nanoparticles – organoclay-reinforced chitosan bionanocomposites for food packaging

- Green synthesis of magnetic activated carbon from peanut shells functionalized with TiO2 photocatalyst for Batik liquid waste treatment

- Coagulation activity of liquid extraction of Leucaena leucocephala and Sesbania grandiflora on the removal of turbidity

- Hydrocracking optimization of palm oil over NiMoO4/activated carbon catalyst to produce biogasoline and kerosine

- Special Issue on Pharmacology and metabolomics of ethnobotanical and herbal medicine

- Cynarin inhibits PDGF-BB-induced proliferation and activation in hepatic stellate cells through PPARγ

- Special Issue on The 1st Malaysia International Conference on Nanotechnology & Catalysis (MICNC2021)

- Surfactant evaluation for enhanced oil recovery: Phase behavior and interfacial tension

- Topical Issue on phytochemicals, biological and toxicological analysis of aromatic medicinal plants

- Phytochemical analysis of leaves and stems of Physalis alkekengi L. (Solanaceae)

- Phytochemical and pharmacological profiling of Trewia nudiflora Linn. leaf extract deciphers therapeutic potentials against thrombosis, arthritis, helminths, and insects

- Pergularia tomentosa coupled with selenium nanoparticles salvaged lead acetate-induced redox imbalance, inflammation, apoptosis, and disruption of neurotransmission in rats’ brain

- Protective effect of Allium atroviolaceum-synthesized SeNPs on aluminum-induced brain damage in mice

- Mechanism study of Cordyceps sinensis alleviates renal ischemia–reperfusion injury

- Plant-derived bisbenzylisoquinoline alkaloid tetrandrine prevents human podocyte injury by regulating the miR-150-5p/NPHS1 axis

- Network pharmacology combined with molecular docking to explore the anti-osteoporosis mechanisms of β-ecdysone derived from medicinal plants

- Chinese medicinal plant Polygonum cuspidatum ameliorates silicosis via suppressing the Wnt/β-catenin pathway

- Special Issue on Advanced Nanomaterials for Energy, Environmental and Biological Applications - Part I

- Investigation of improved optical and conductivity properties of poly(methyl methacrylate)–MXenes (PMMA–MXenes) nanocomposite thin films for optoelectronic applications

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2022)

- Model predictive control for precision irrigation of a Quinoa crop

Articles in the same Issue

- Regular Articles

- Photocatalytic degradation of Rhodamine B in aqueous phase by bimetallic metal-organic framework M/Fe-MOF (M = Co, Cu, and Mg)

- Assessment of using electronic portal imaging device for analysing bolus material utilised in radiation therapy

- A detailed investigation on highly dense CuZr bulk metallic glasses for shielding purposes

- Simulation of gamma-ray shielding properties for materials of medical interest

- Environmental impact assesment regulation applications and their analysis in Turkey

- Sample age effect on parameters of dynamic nuclear polarization in certain difluorobenzen isomers/MC800 asphaltene suspensions

- Passenger demand forecasting for railway systems

- Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach

- Gamma, neutron, and heavy charged ion shielding properties of Er3+-doped and Sm3+-doped zinc borate glasses

- Bridging chiral de-tert-butylcalix[4]arenes: Optical resolution based on column chromatography and structural characterization

- Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt

- Comparison of the yield and purity of plasma exosomes extracted by ultracentrifugation, precipitation, and membrane-based approaches

- Bioactive triterpenoids from Indonesian medicinal plant Syzygium aqueum

- Investigation of the effects of machining parameters on surface integrity in micromachining

- The mesoporous aluminosilicate application as support for bifunctional catalysts for n-hexadecane hydroconversion

- Gamma-ray shielding properties of Nd2O3-added iron–boron–phosphate-based composites

- Numerical investigation on perforated sheet metals under tension loading

- Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt

- Two new polypodane-type bicyclic triterpenoids from mastic

- Structural, physical, and mechanical properties of the TiO2 added hydroxyapatite composites

- Tribological properties and characterization of borided Co–Mg alloys

- Studies on Anemone nemorosa L. extracts; polyphenols profile, antioxidant activity, and effects on Caco-2 cells by in vitro and in silico studies

- Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system

- Cyclic connectivity index of bipolar fuzzy incidence graph

- The role of passage numbers of donor cells in the development of Arabian Oryx – Cow interspecific somatic cell nuclear transfer embryos

- Mechanical property evaluation of tellurite–germanate glasses and comparison of their radiation-shielding characteristics using EPICS2017 to other glass systems

- Molecular screening of ionic liquids for CO2 absorption and molecular dynamic simulation

- Microwave-assisted preparation of Ag/Fe magnetic biochar from clivia leaves for adsorbing daptomycin antibiotics

- Iminodisuccinic acid enhances antioxidant and mineral element accumulation in young leaves of Ziziphus jujuba

- Cytotoxic activity of guaiane-type sesquiterpene lactone (deoxycynaropicrin) isolated from the leaves of Centaurothamnus maximus

- Effects of welding parameters on the angular distortion of welded steel plates

- Simulation of a reactor considering the Stamicarbon, Snamprogetti, and Toyo patents for obtaining urea

- Effect of different ramie (Boehmeria nivea L. Gaud) cultivars on the adsorption of heavy metal ions cadmium and lead in the remediation of contaminated farmland soils

- Impact of a live bacterial-based direct-fed microbial (DFM) postpartum and weaning system on performance, mortality, and health of Najdi lambs

- Anti-tumor effect of liposomes containing extracted Murrayafoline A against liver cancer cells in 2D and 3D cultured models

- Physicochemical properties and some mineral concentration of milk samples from different animals and altitudes

- Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies

- Diagnostic and therapeutic radioisotopes in nuclear medicine: Determination of gamma-ray transmission factors and safety competencies of high-dense and transparent glassy shields

- Calculation of NaI(Tl) detector efficiency using 226Ra, 232Th, and 40K radioisotopes: Three-phase Monte Carlo simulation study

- Isolation and identification of unstable components from Caesalpinia sappan by high-speed counter-current chromatography combined with preparative high-performance liquid chromatography

- Quantification of biomarkers and evaluation of antioxidant, anti-inflammatory, and cytotoxicity properties of Dodonaea viscosa grown in Saudi Arabia using HPTLC technique

- Characterization of the elastic modulus of ceramic–metal composites with physical and mechanical properties by ultrasonic technique

- GC-MS analysis of Vespa velutina auraria Smith and its anti-inflammatory and antioxidant activities in vitro

- Texturing of nanocoatings for surface acoustic wave-based sensors for volatile organic compounds

- Insights into the molecular basis of some chalcone analogues as potential inhibitors of Leishmania donovani: An integrated in silico and in vitro study

- (1R,2S,5R)-5-Methyl-2-(propan-2-yl)cyclohexyl 4-amino-3-phenylbutanoate hydrochloride: Synthesis and anticonvulsant activity

- On the relative extraction rates of colour compounds and caffeine during brewing, an investigation of tea over time and temperature

- Characterization of egg shell powder-doped ceramic–metal composites

- Rapeseed oil-based hippurate amide nanocomposite coating material for anticorrosive and antibacterial applications

- Chemically modified Teucrium polium (Lamiaceae) plant act as an effective adsorbent tool for potassium permanganate (KMnO4) in wastewater remediation

- Efficiency analysis of photovoltaic systems installed in different geographical locations

- Risk prioritization model driven by success factor in the light of multicriteria decision making

- Theoretical investigations on the excited-state intramolecular proton transfer in the solvated 2-hydroxy-1-naphthaldehyde carbohydrazone

- Mechanical and gamma-ray shielding examinations of Bi2O3–PbO–CdO–B2O3 glass system

- Machine learning-based forecasting of potability of drinking water through adaptive boosting model

- The potential effect of the Rumex vesicarius water seeds extract treatment on mice before and during pregnancy on the serum enzymes and the histology of kidney and liver

- Impact of benzimidazole functional groups on the n-doping properties of benzimidazole derivatives

- Extraction of red pigment from Chinese jujube peel and the antioxidant activity of the pigment extracts

- Flexural strength and thermal properties of carbon black nanoparticle reinforced epoxy composites obtained from waste tires

- A focusing study on radioprotective and antioxidant effects of Annona muricata leaf extract in the circulation and liver tissue: Clinical and experimental studies

- Clinical comprehensive and experimental assessment of the radioprotective effect of Annona muricata leaf extract to prevent cellular damage in the ileum tissue

- Effect of WC content on ultrasonic properties, thermal and electrical conductivity of WC–Co–Ni–Cr composites

- Influence of various class cleaning agents for prosthesis on Co–Cr alloy surface

- The synthesis of nanocellulose-based nanocomposites for the effective removal of hexavalent chromium ions from aqueous solution

- Study on the influence of physical interlayers on the remaining oil production under different development modes

- Optimized linear regression control of DC motor under various disturbances

- Influence of different sample preparation strategies on hypothesis-driven shotgun proteomic analysis of human saliva

- Determination of flow distance of the fluid metal due to fluidity in ductile iron casting by artificial neural networks approach

- Investigation of mechanical activation effect on high-volume natural pozzolanic cements

- In vitro: Anti-coccidia activity of Calotropis procera leaf extract on Eimeria papillata oocysts sporulation and sporozoite

- Determination of oil composition of cowpea (Vigna unguiculata L.) seeds under influence of organic fertilizer forms

- Activated partial thromboplastin time maybe associated with the prognosis of papillary thyroid carcinoma

- Treatment of rat brain ischemia model by NSCs-polymer scaffold transplantation

- Lead and cadmium removal with native yeast from coastal wetlands

- Characterization of electroless Ni-coated Fe–Co composite using powder metallurgy

- Ferrate synthesis using NaOCl and its application for dye removal

- Antioxidant, antidiabetic, and anticholinesterase potential of Chenopodium murale L. extracts using in vitro and in vivo approaches

- Study on essential oil, antioxidant activity, anti-human prostate cancer effects, and induction of apoptosis by Equisetum arvense

- Experimental study on turning machine with permanent magnetic cutting tool

- Numerical simulation and mathematical modeling of the casting process for pearlitic spheroidal graphite cast iron

- Design, synthesis, and cytotoxicity evaluation of novel thiophene, pyrimidine, pyridazine, and pyridine: Griseofulvin heterocyclic extension derivatives

- Isolation and identification of promising antibiotic-producing bacteria

- Ultrasonic-induced reversible blood–brain barrier opening: Safety evaluation into the cellular level

- Evaluation of phytochemical and antioxidant potential of various extracts from traditionally used medicinal plants of Pakistan

- Effect of calcium lactate in standard diet on selected markers of oxidative stress and inflammation in ovariectomized rats

- Identification of crucial salivary proteins/genes and pathways involved in pathogenesis of temporomandibular disorders

- Zirconium-modified attapulgite was used for removing of Cr(vi) in aqueous solution

- The stress distribution of different types of restorative materials in primary molar

- Reducing surface heat loss in steam boilers

- Deformation behavior and formability of friction stir processed DP600 steel

- Synthesis and characterization of bismuth oxide/commercial activated carbon composite for battery anode

- Phytochemical analysis of Ziziphus jujube leaf at different foliar ages based on widely targeted metabolomics

- Effects of in ovo injection of black cumin (Nigella sativa) extract on hatching performance of broiler eggs

- Separation and evaluation of potential antioxidant, analgesic, and anti-inflammatory activities of limonene-rich essential oils from Citrus sinensis (L.)

- Bioactivity of a polyhydroxy gorgostane steroid from Xenia umbellata

- BiCAM-based automated scoring system for digital logic circuit diagrams

- Analysis of standard systems with solar monitoring systems

- Structural and spectroscopic properties of voriconazole and fluconazole – Experimental and theoretical studies

- New plant resistance inducers based on polyamines

- Experimental investigation of single-lap bolted and bolted/bonded (hybrid) joints of polymeric plates

- Investigation of inlet air pressure and evaporative cooling of four different cogeneration cycles

- Review Articles

- Comprehensive review on synthesis, physicochemical properties, and application of activated carbon from the Arecaceae plants for enhanced wastewater treatment

- Research progress on speciation analysis of arsenic in traditional Chinese medicine

- Recent modified air-assisted liquid–liquid microextraction applications for medicines and organic compounds in various samples: A review

- An insight on Vietnamese bio-waste materials as activated carbon precursors for multiple applications in environmental protection

- Antimicrobial activities of the extracts and secondary metabolites from Clausena genus – A review

- Bioremediation of organic/heavy metal contaminants by mixed cultures of microorganisms: A review

- Sonodynamic therapy for breast cancer: A literature review

- Recent progress of amino acid transporters as a novel antitumor target

- Aconitum coreanum Rapaics: Botany, traditional uses, phytochemistry, pharmacology, and toxicology

- Corrigendum

- Corrigendum to “Petrology and geochemistry of multiphase post-granitic dikes: A case study from the Gabal Serbal area, Southwestern Sinai, Egypt”

- Corrigendum to “Design of a Robust sliding mode controller for bioreactor cultures in overflow metabolism via an interdisciplinary approach”

- Corrigendum to “Statistical analysis on the radiological assessment and geochemical studies of granite rocks in the north of Um Taghir area, Eastern Desert, Egypt”

- Corrigendum to “Aroma components of tobacco powder from different producing areas based on gas chromatography ion mobility spectrometry”

- Corrigendum to “Mechanical properties, elastic moduli, transmission factors, and gamma-ray-shielding performances of Bi2O3–P2O5–B2O3–V2O5 quaternary glass system”

- Erratum

- Erratum to “Copper(ii) complexes supported by modified azo-based ligands: Nucleic acid binding and molecular docking studies”

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2021)

- Study of solidification and stabilization of heavy metals by passivators in heavy metal-contaminated soil

- Human health risk assessment and distribution of VOCs in a chemical site, Weinan, China

- Preparation and characterization of Sparassis latifolia β-glucan microcapsules

- Special Issue on the Conference of Energy, Fuels, Environment 2020

- Improving the thermal performance of existing buildings in light of the requirements of the EU directive 2010/31/EU in Poland

- Special Issue on Ethnobotanical, Phytochemical and Biological Investigation of Medicinal Plants

- Study of plant resources with ethnomedicinal relevance from district Bagh, Azad Jammu and Kashmir, Pakistan

- Studies on the chemical composition of plants used in traditional medicine in Congo

- Special Issue on Applied Chemistry in Agriculture and Food Science

- Strip spraying technology for precise herbicide application in carrot fields

- Special Issue on Pharmacology and Metabolomics of Ethnobotanical and Herbal Medicine

- Phytochemical profiling, antibacterial and antioxidant properties of Crocus sativus flower: A comparison between tepals and stigmas

- Antioxidant and antimicrobial properties of polyphenolics from Withania adpressa (Coss.) Batt. against selected drug-resistant bacterial strains

- Integrating network pharmacology and molecular docking to explore the potential mechanism of Xinguan No. 3 in the treatment of COVID-19

- Chemical composition and in vitro and in vivo biological assortment of fixed oil extracted from Ficus benghalensis L.

- A review of the pharmacological activities and protective effects of Inonotus obliquus triterpenoids in kidney diseases

- Ethnopharmacological study of medicinal plants in Kastamonu province (Türkiye)

- Protective effects of asperuloside against cyclophosphamide-induced urotoxicity and hematotoxicity in rats

- Special Issue on Essential Oil, Extraction, Phytochemistry, Advances, and Application

- Identification of volatile compounds and antioxidant, antibacterial, and antifungal properties against drug-resistant microbes of essential oils from the leaves of Mentha rotundifolia var. apodysa Briq. (Lamiaceae)

- Phenolic contents, anticancer, antioxidant, and antimicrobial capacities of MeOH extract from the aerial parts of Trema orientalis plant

- Chemical composition and antimicrobial activity of essential oils from Mentha pulegium and Rosmarinus officinalis against multidrug-resistant microbes and their acute toxicity study

- Special Issue on Marine Environmental Sciences and Significance of the Multidisciplinary Approaches

- An insightful overview of the distribution pattern of polycyclic aromatic hydrocarbon in the marine sediments of the Red Sea

- Antifungal–antiproliferative norcycloartane-type triterpenes from the Red Sea green alga Tydemania expeditionis

- Solvent effect, dipole moment, and DFT studies of multi donor–acceptor type pyridine derivative

- An extensive assessment on the distribution pattern of organic contaminants in the aerosols samples in the Middle East

- Special Issue on 4th IC3PE

- Energetics of carboxylic acid–pyridine heterosynthon revisited: A computational study of intermolecular hydrogen bond domination on phenylacetic acid–nicotinamide cocrystals

- A review: Silver–zinc oxide nanoparticles – organoclay-reinforced chitosan bionanocomposites for food packaging

- Green synthesis of magnetic activated carbon from peanut shells functionalized with TiO2 photocatalyst for Batik liquid waste treatment

- Coagulation activity of liquid extraction of Leucaena leucocephala and Sesbania grandiflora on the removal of turbidity

- Hydrocracking optimization of palm oil over NiMoO4/activated carbon catalyst to produce biogasoline and kerosine

- Special Issue on Pharmacology and metabolomics of ethnobotanical and herbal medicine

- Cynarin inhibits PDGF-BB-induced proliferation and activation in hepatic stellate cells through PPARγ

- Special Issue on The 1st Malaysia International Conference on Nanotechnology & Catalysis (MICNC2021)

- Surfactant evaluation for enhanced oil recovery: Phase behavior and interfacial tension

- Topical Issue on phytochemicals, biological and toxicological analysis of aromatic medicinal plants

- Phytochemical analysis of leaves and stems of Physalis alkekengi L. (Solanaceae)

- Phytochemical and pharmacological profiling of Trewia nudiflora Linn. leaf extract deciphers therapeutic potentials against thrombosis, arthritis, helminths, and insects

- Pergularia tomentosa coupled with selenium nanoparticles salvaged lead acetate-induced redox imbalance, inflammation, apoptosis, and disruption of neurotransmission in rats’ brain

- Protective effect of Allium atroviolaceum-synthesized SeNPs on aluminum-induced brain damage in mice

- Mechanism study of Cordyceps sinensis alleviates renal ischemia–reperfusion injury

- Plant-derived bisbenzylisoquinoline alkaloid tetrandrine prevents human podocyte injury by regulating the miR-150-5p/NPHS1 axis

- Network pharmacology combined with molecular docking to explore the anti-osteoporosis mechanisms of β-ecdysone derived from medicinal plants

- Chinese medicinal plant Polygonum cuspidatum ameliorates silicosis via suppressing the Wnt/β-catenin pathway

- Special Issue on Advanced Nanomaterials for Energy, Environmental and Biological Applications - Part I

- Investigation of improved optical and conductivity properties of poly(methyl methacrylate)–MXenes (PMMA–MXenes) nanocomposite thin films for optoelectronic applications

- Special Issue on Applied Biochemistry and Biotechnology (ABB 2022)

- Model predictive control for precision irrigation of a Quinoa crop